Method for preparing B-doped g-C3N4 photocatalyst through nonmetal liquid-phase doping

A photocatalyst, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of limited activity and high recombination rate, and achieve novel Tissue structure morphology, the effect of high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

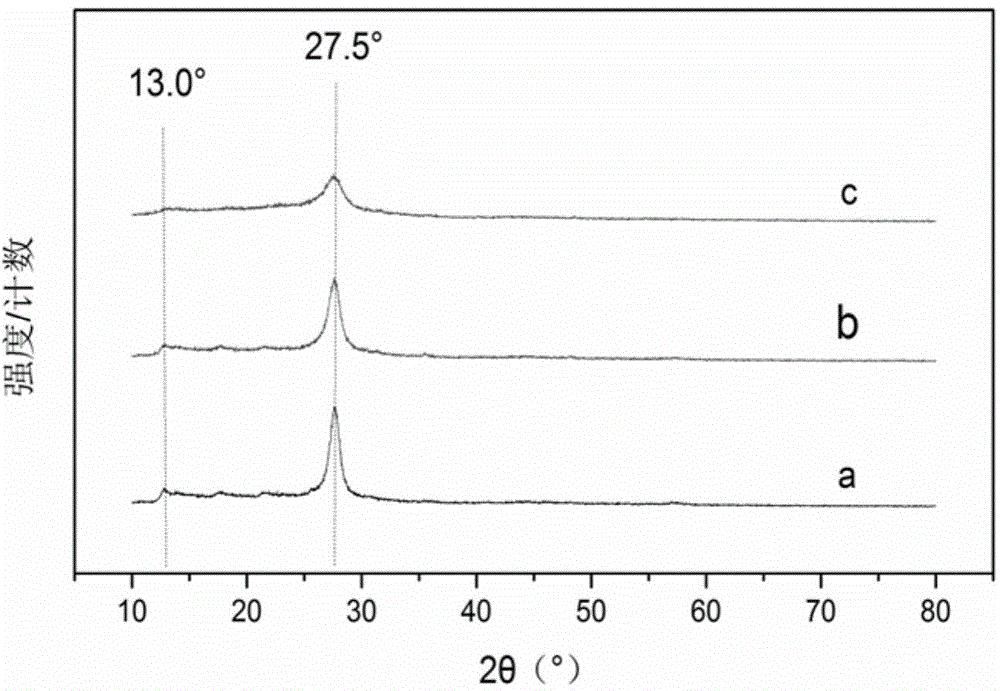

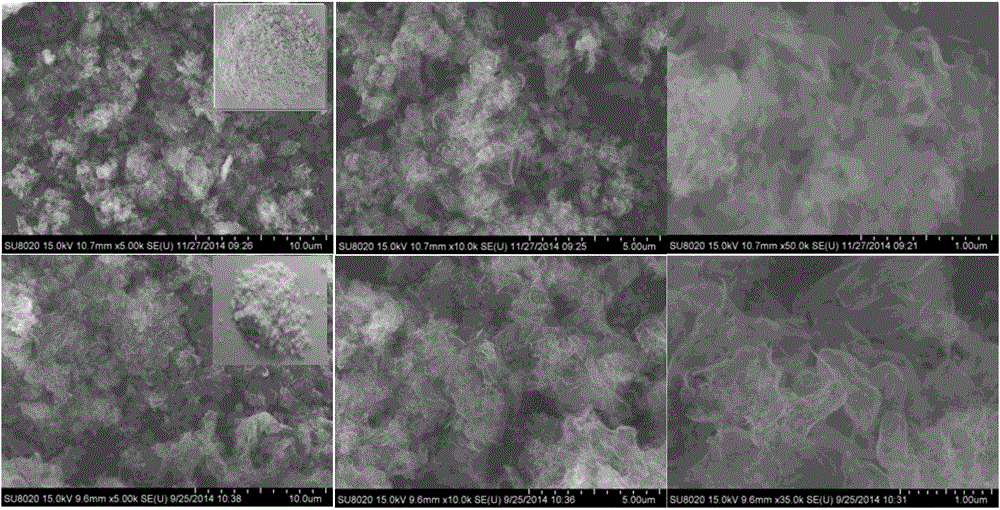

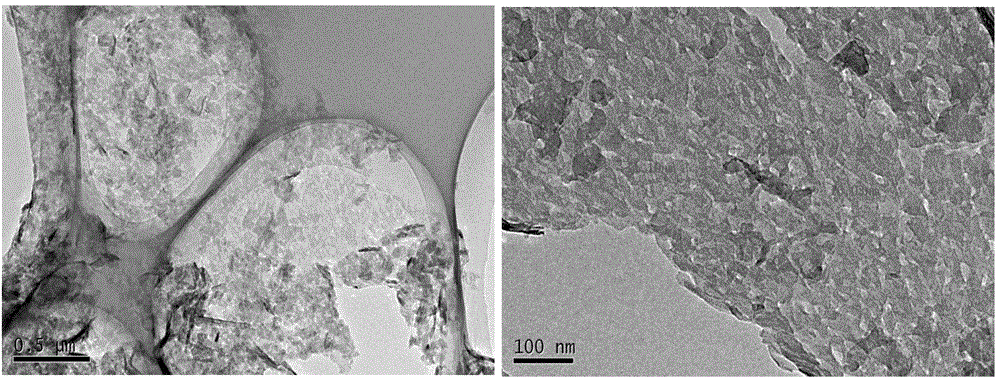

[0028] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water and ultrasonically for 0.5h, then continue stirring for 12h to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 1 hour, centrifuge and pour the supernatant, add a certain amount of water to 200ml, and stir well to obtain the CNP solution. Take 20ml of CNP solution, drop 20ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 1h, and dry the obtained solid at 60°C for 8 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 500°C, and the heating rate is 5°C / min. After 4 hours of heat preservation, it is naturally cooled, and the obtained powder is g-C modified by doping for non-metallic liquid phase...

Embodiment 2

[0030] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water for 1 hour, then continue to stir for 12 hours to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 2 hours, centrifuge and pour the supernatant, add a certain amount of water to 200ml, and stir well to obtain the CNP solution. Take 20ml of CNP solution, drop 50ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 2h, and dry the obtained solid at 60°C for 12 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 520°C, and the heating rate is 1°C / min. After 4 hours of heat preservation, it is naturally cooled to obtain a powder That is, non-metallic liquid phase B doped modified g-C 3 N 4 The phot...

Embodiment 3

[0032] Accurately weigh 2g of g-C 3 N 4 Place in 200ml of distilled water for 2 hours, then continue to stir for 24 hours to make it fully mixed to obtain g-C 3 N 4 suspension. Accurately weigh 0.2g of PEI and add to the above g-C 3 N 4 In the suspension, stir for 3h, centrifuge and pour a certain amount of water to 200ml after pouring the supernatant, and fully stir to obtain the CNP solution. Take 20ml of CNP solution, drop 70ml of prepared 1mg / ml sodium tetraphenylborate solution dropwise into the above-mentioned solution, centrifuge after stirring for 2h, and dry the obtained solid at 80°C for 8 hours to obtain Precursor. Grind the dried precursor evenly, place it in a crucible, and then place it in a muffle furnace for calcination in an air atmosphere. The calcination temperature is 500°C, and the heating rate is 1°C / min. After 4 hours of heat preservation, it is naturally cooled to obtain a powder That is, non-metallic liquid phase B doped modified g-C 3 N 4 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com