Patents

Literature

869results about How to "Simple process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

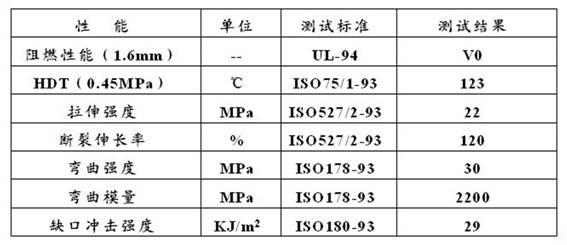

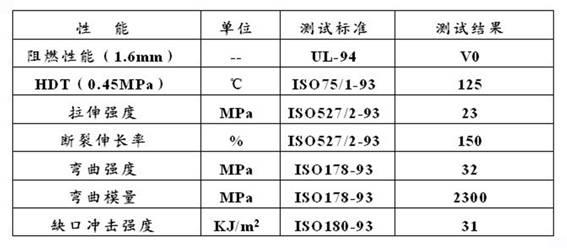

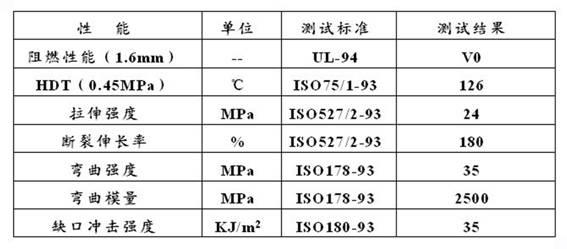

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Superhigh strength steel plate with yield strength more than 960Mpa and method for producing same

ActiveCN1840724AEasy to implementEasy to controlFurnace typesHeat treatment furnacesAusteniteForeign substance

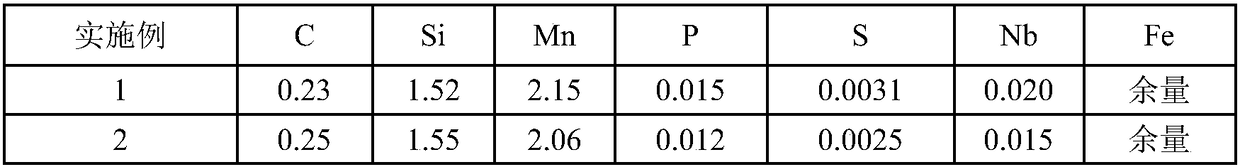

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.08-0.18%, Si<=0.6%, Mn 0.5-2.0%, Al <=0.018%, N<=0.008%, B<=0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni <=1.0%, Cr<=0.8%, Cu<=0.5%, Mo<=0.6%, Ti 0.01-0.03%, V<=0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance. The invention also provides the preparing process.

Owner:BAOSHAN IRON & STEEL CO LTD

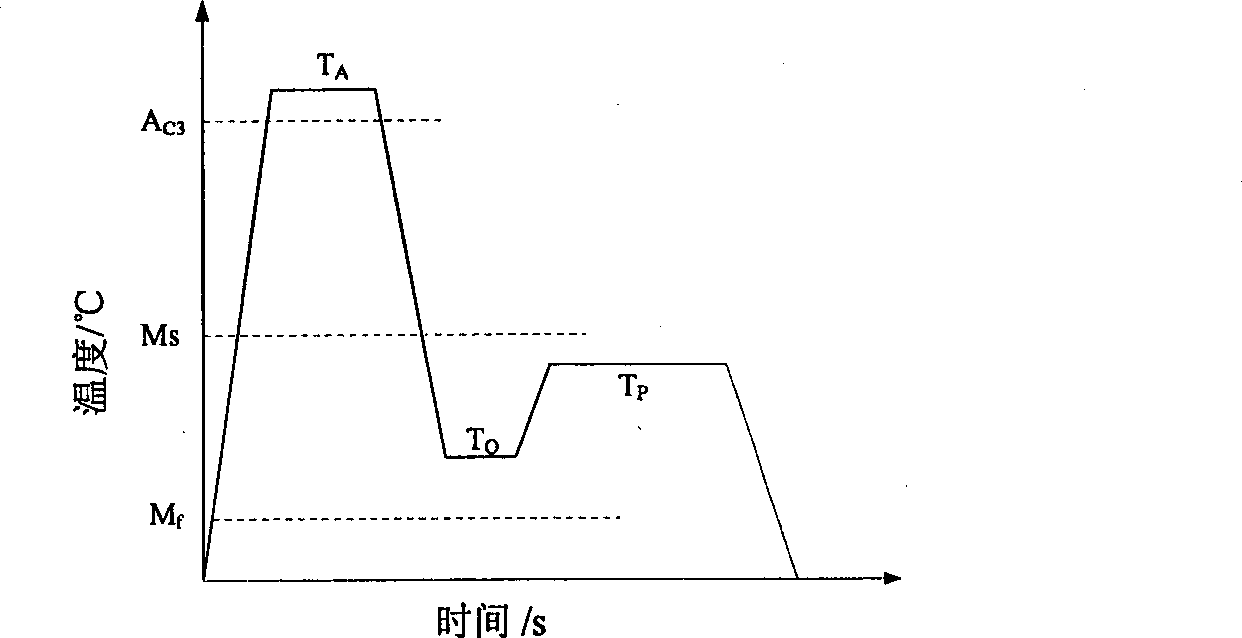

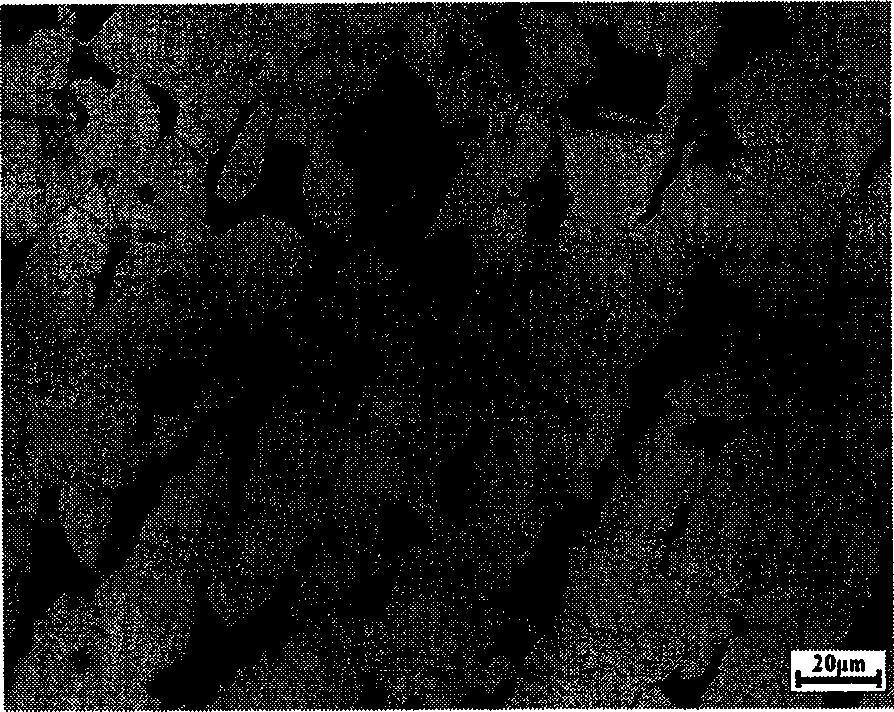

Low-alloy high-strength C-Mn-Al Q & P steel and method of manufacturing the same

The invention relates to a low-alloyed and high-strength Q and amp of a C-Mn-Al system; P steel; and a manufacturing method thereof, which belong to the technical field of metal materials. The method comprises the following processing steps of: (1) smelting and cast blocking: the mass percentages of the components are as follows: 0.16 percent to 0.25 percent of C, less than or equal to 0.40 percent of Si, 1.20 percent to 1.60 percent of Mn, 1.0 percent to 1.5 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.008 percent of S and the balance of ferrite. (2) rolling: after the multi-pass hot-rolling of rough rolling and finish rolling, wherein, the deformation of roughing pass is 10 percent to 30 percent, the total deformation of the finish rolling is more than 60 percent, a hot rolled plate is subjected to multi-pass cold rolling, the deformation is 5 percent to 50 percent, and the plate is rolled to be a thin plate with the thickness being 0.6 to 2.0mm. (3) heat treating: firstly, austenitizing of 850 to 930 DEG C is carried out in a heating furnace, temperature is kept for 100 to 200 seconds and then rapid quenching is carried out to reach 230 to 250 DEG C, the temperature is kept for 20 to 40 seconds, after that the temperature is kept in 300 to 400 DEG C for 120 to 3600 seconds, at last fast cooling is carried out to room temperature (the speed of the cooling is not less than 10 DEG C / s). The Q and amp and the P steel have economic components, good quality of the surface, high strength and good shaping resistance. The strength and ductility product can reach over 37000MPa question mark percent.

Owner:UNIV OF SCI & TECH BEIJING

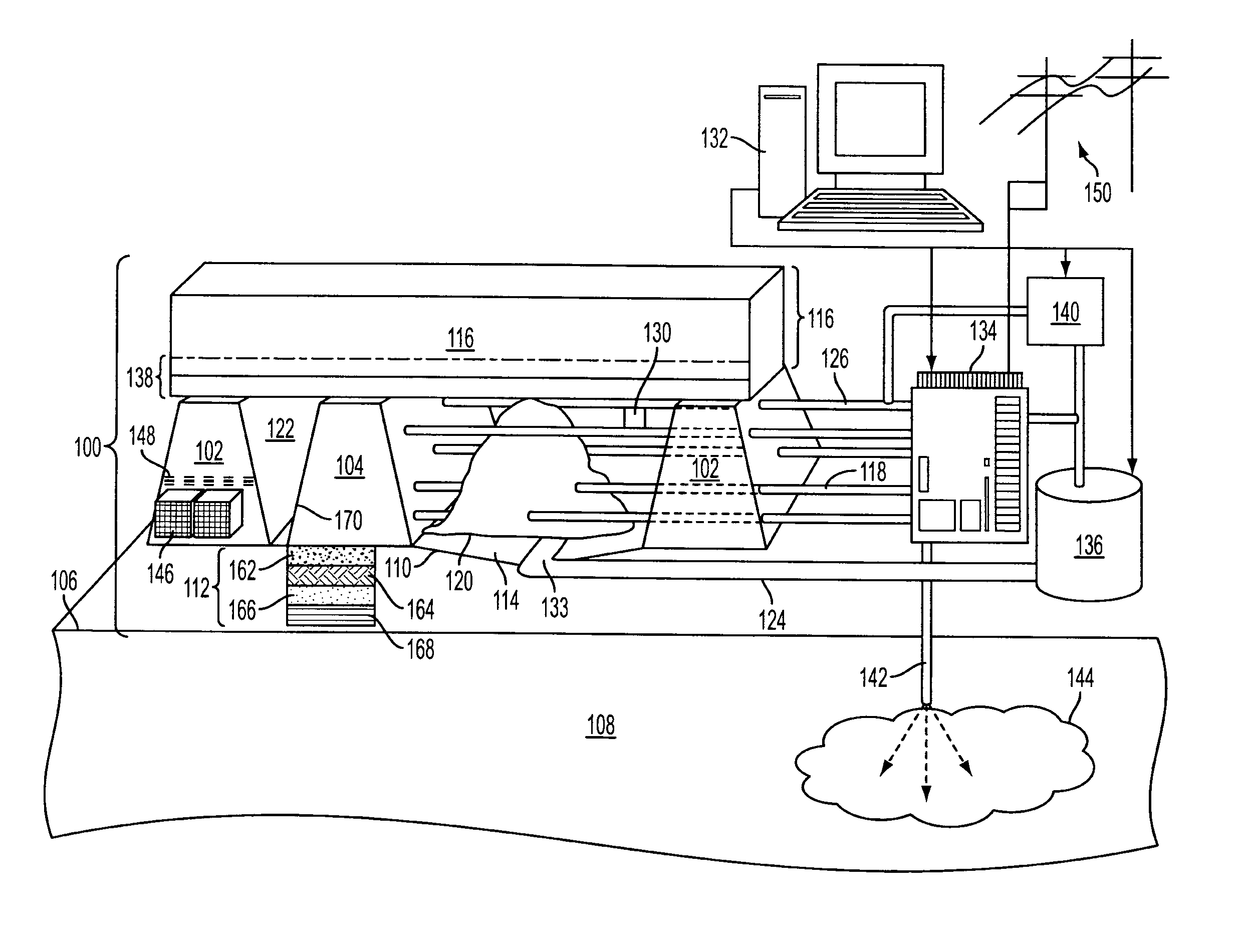

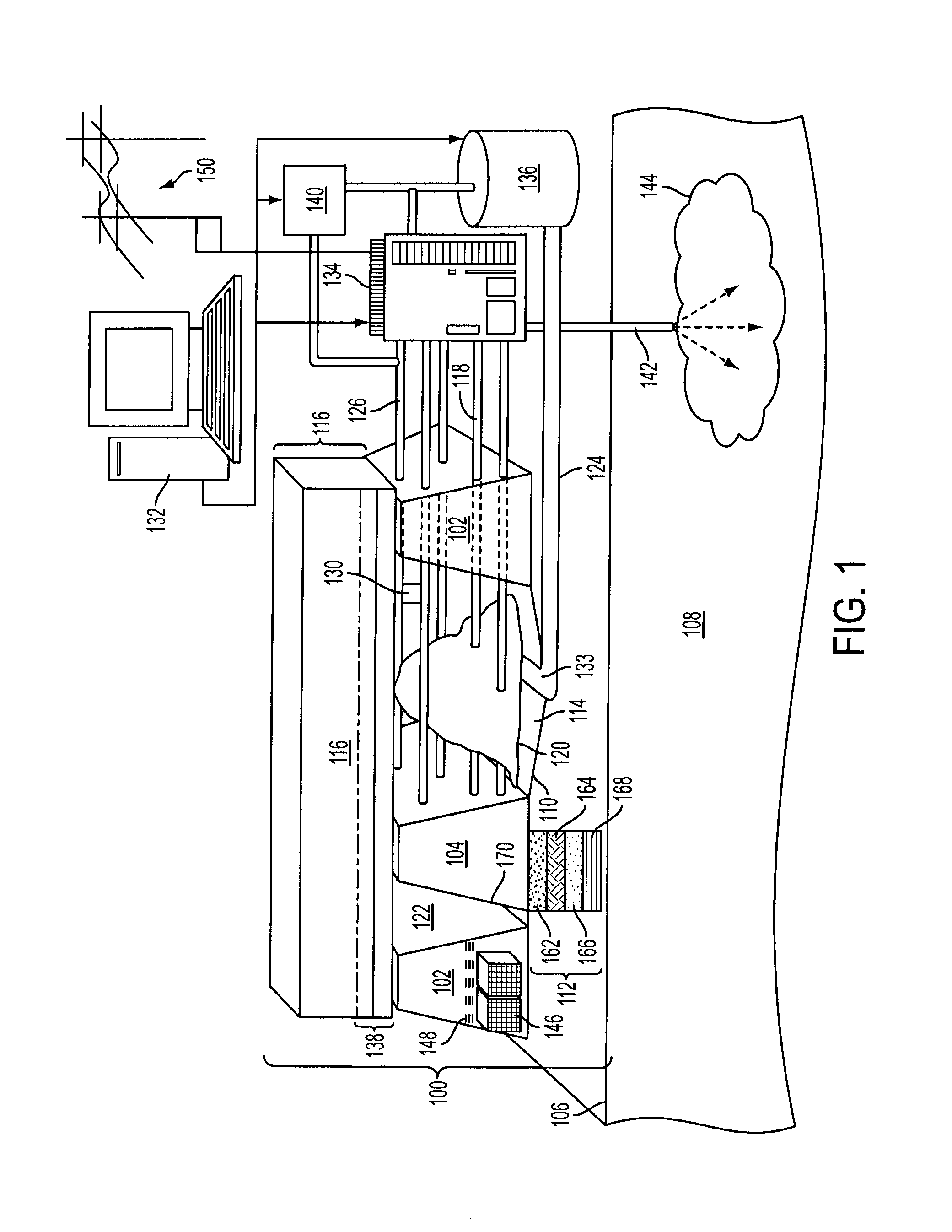

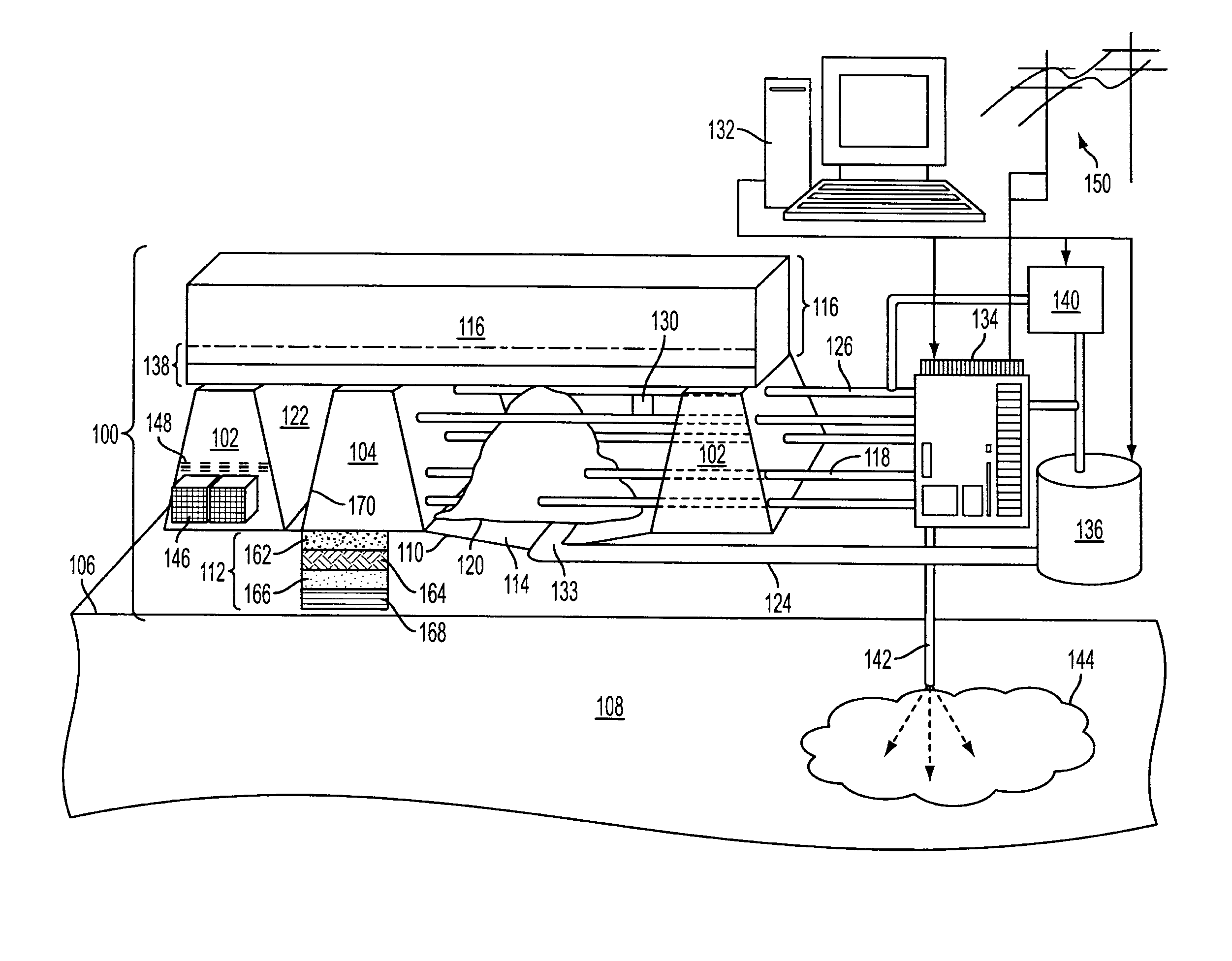

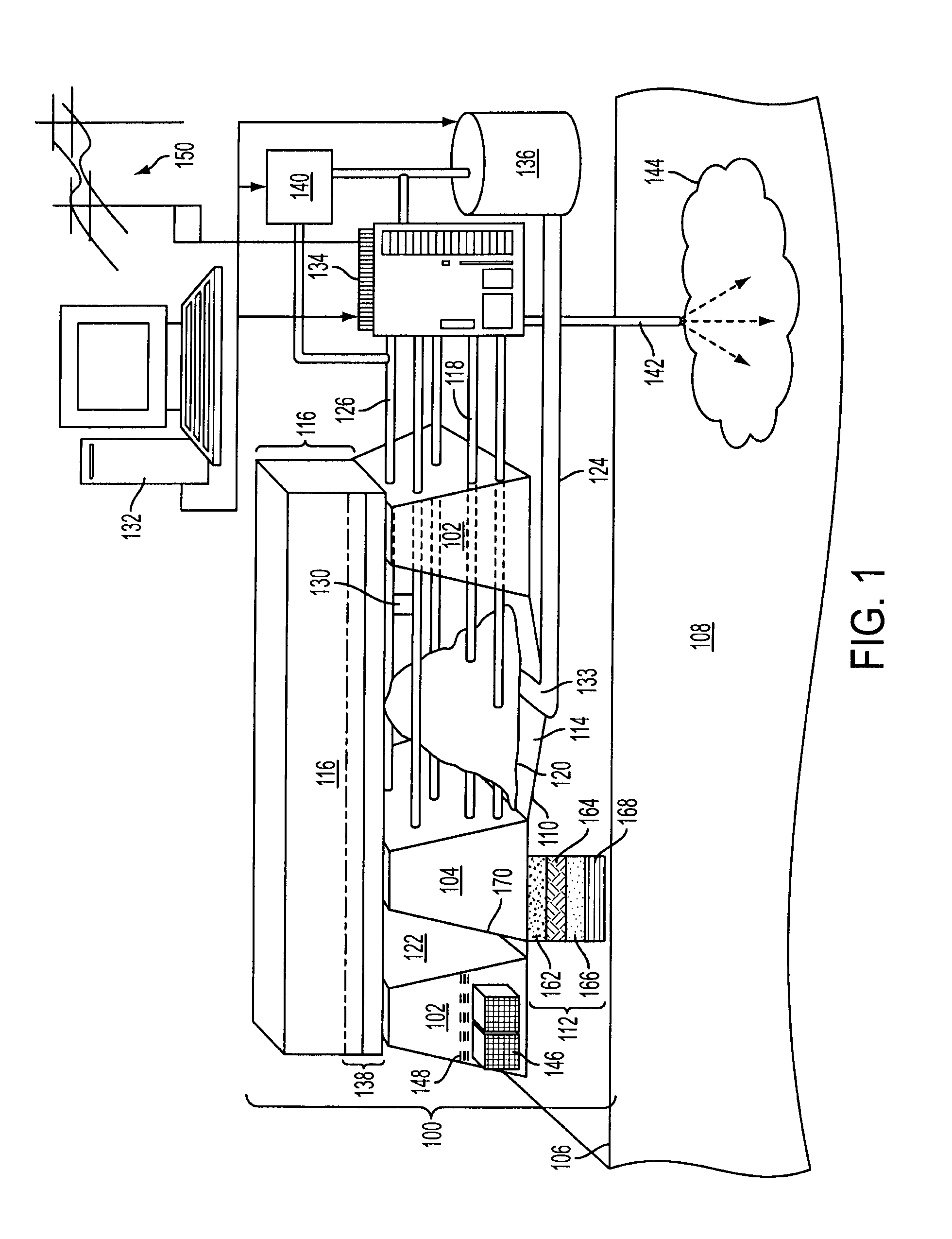

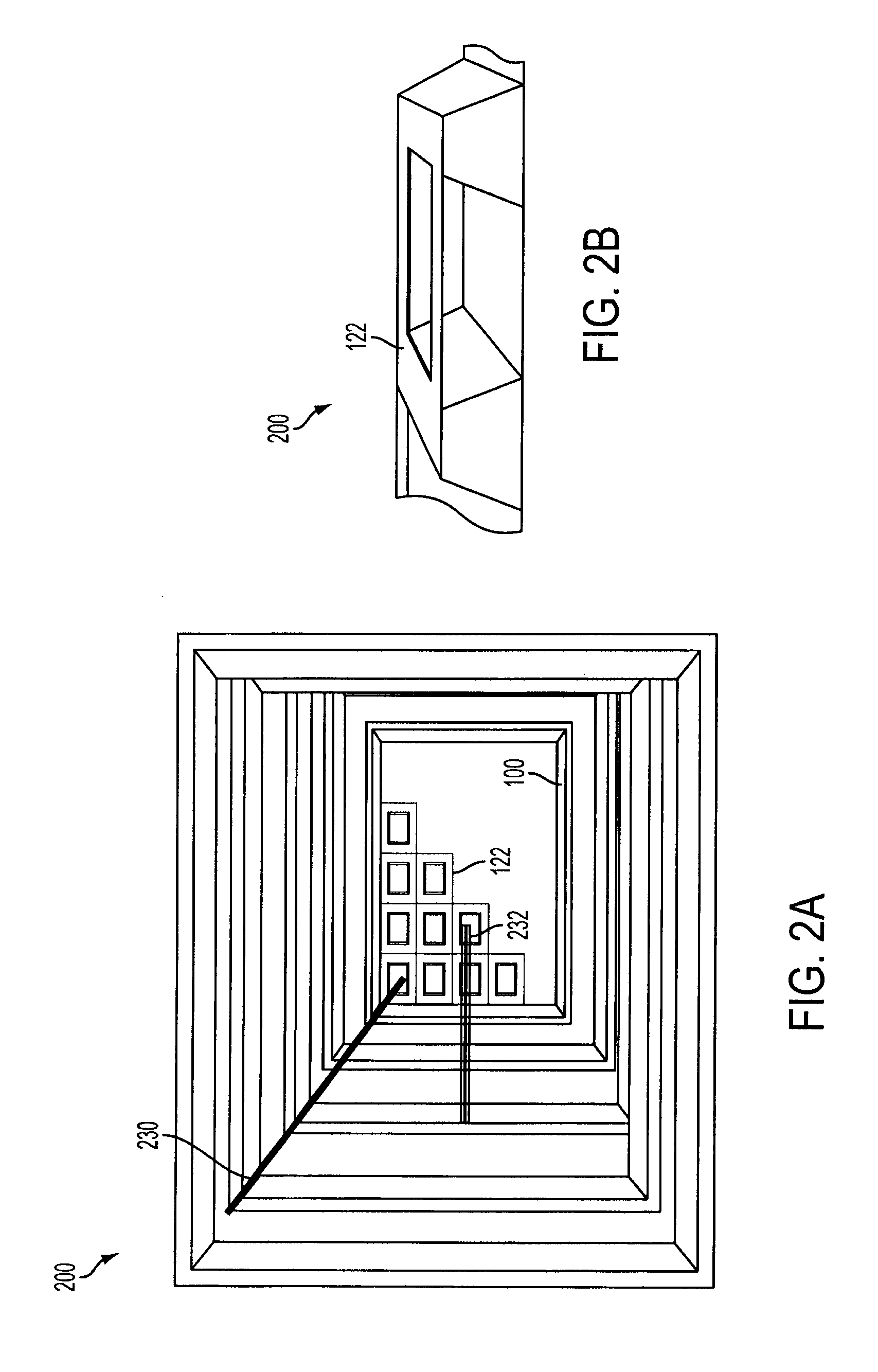

Methods of recovering hydrocarbons from hydrocarbonaceous material with reduced non-carbonaceous leachate and co2 and associated systems

ActiveUS20080190816A1Avoid insufficient heatingInhibition formationThermal non-catalytic crackingUnderground chambersLeachateMaterials science

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a stationary permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom within a temperature range which is sufficient to substantially avoid formation of carbon dioxide or non-hydrocarbon leachates. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

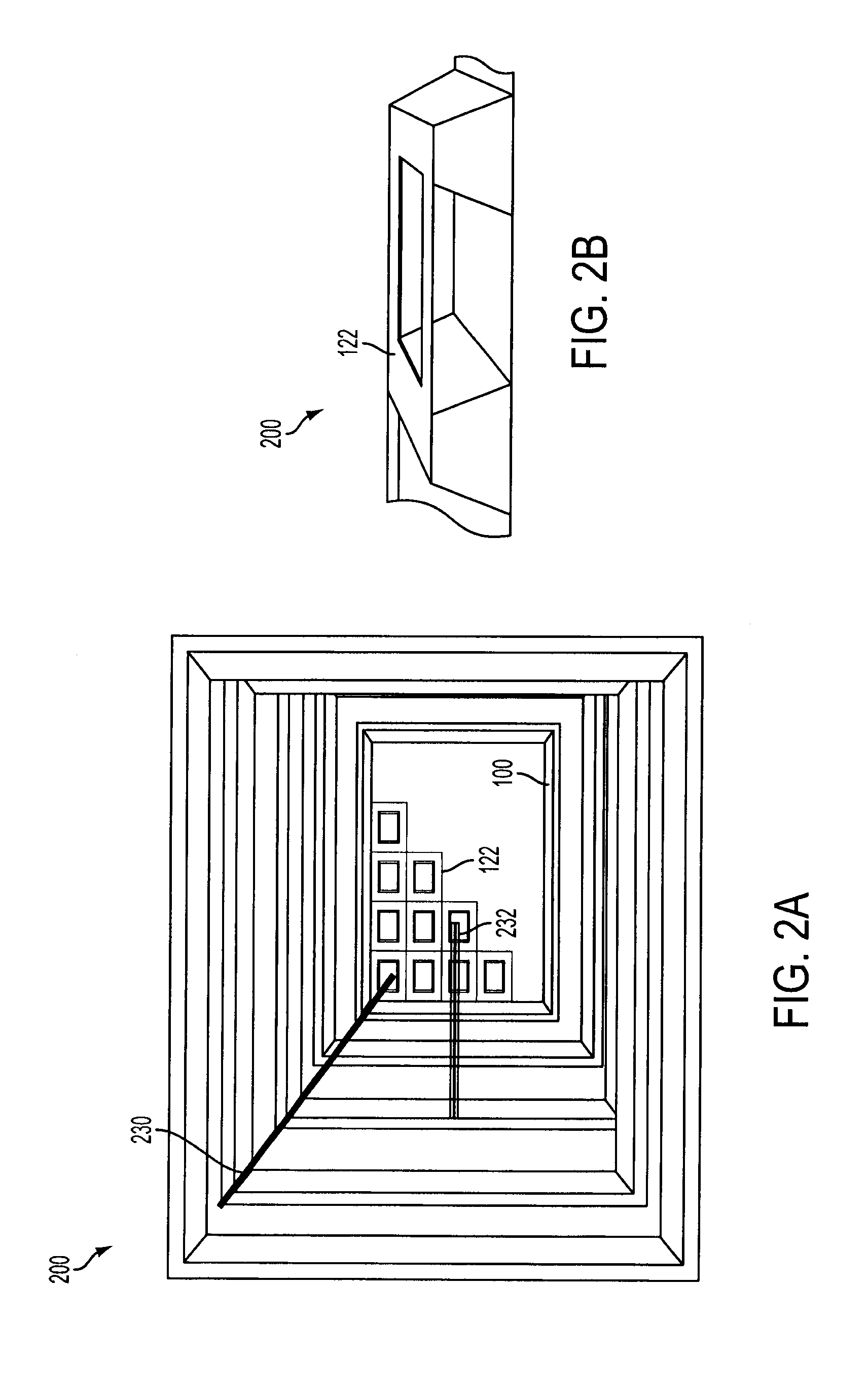

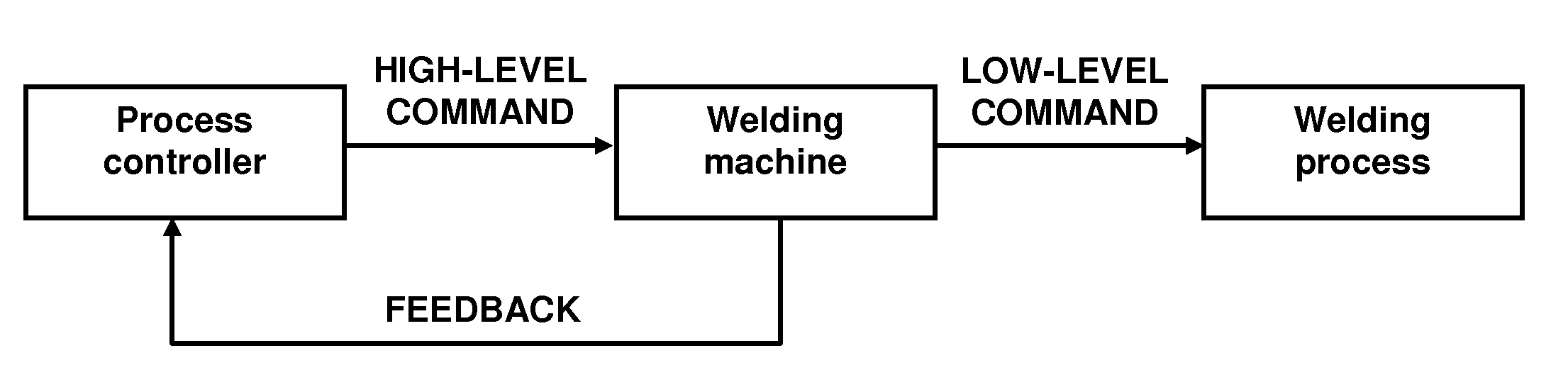

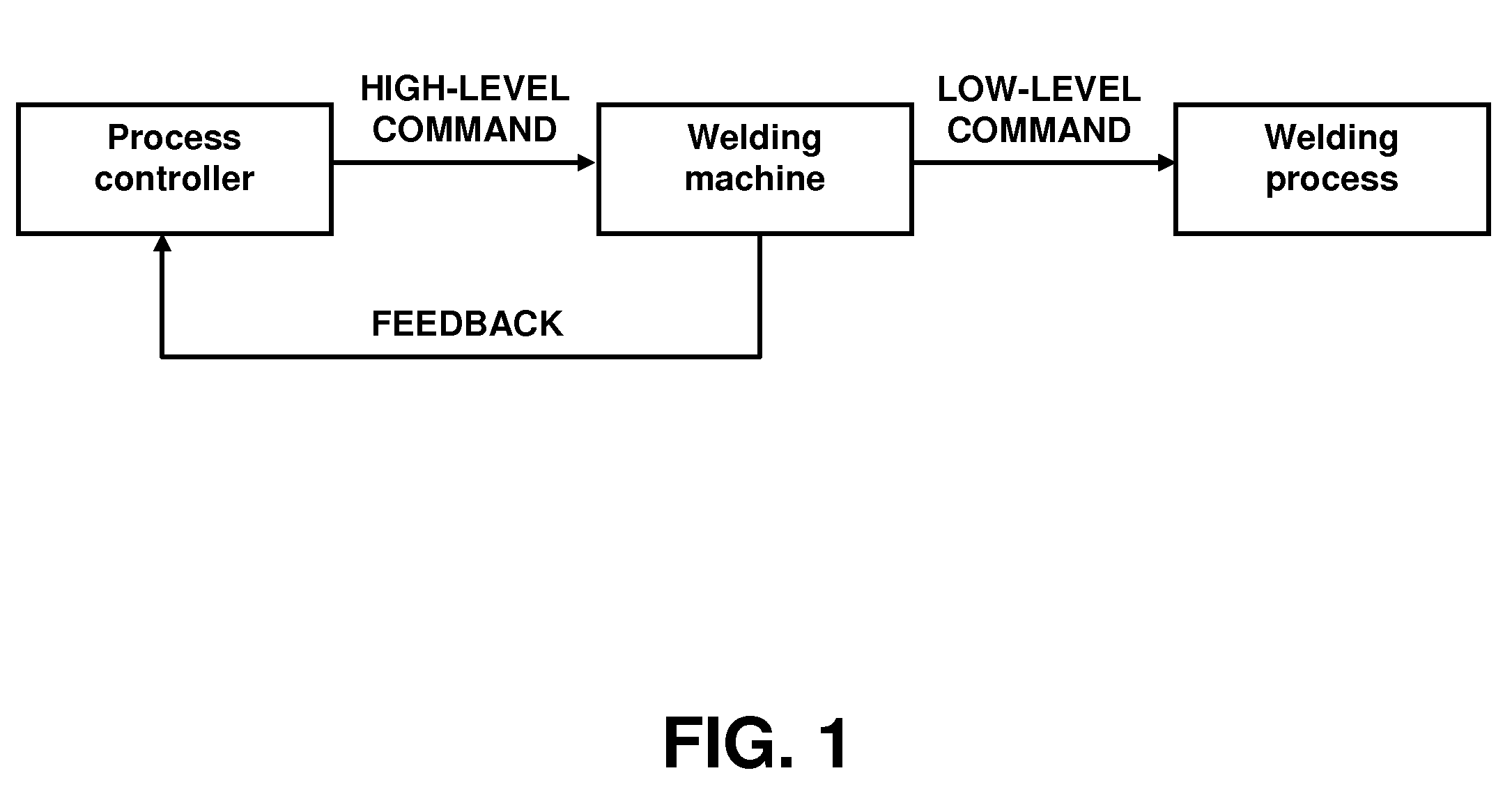

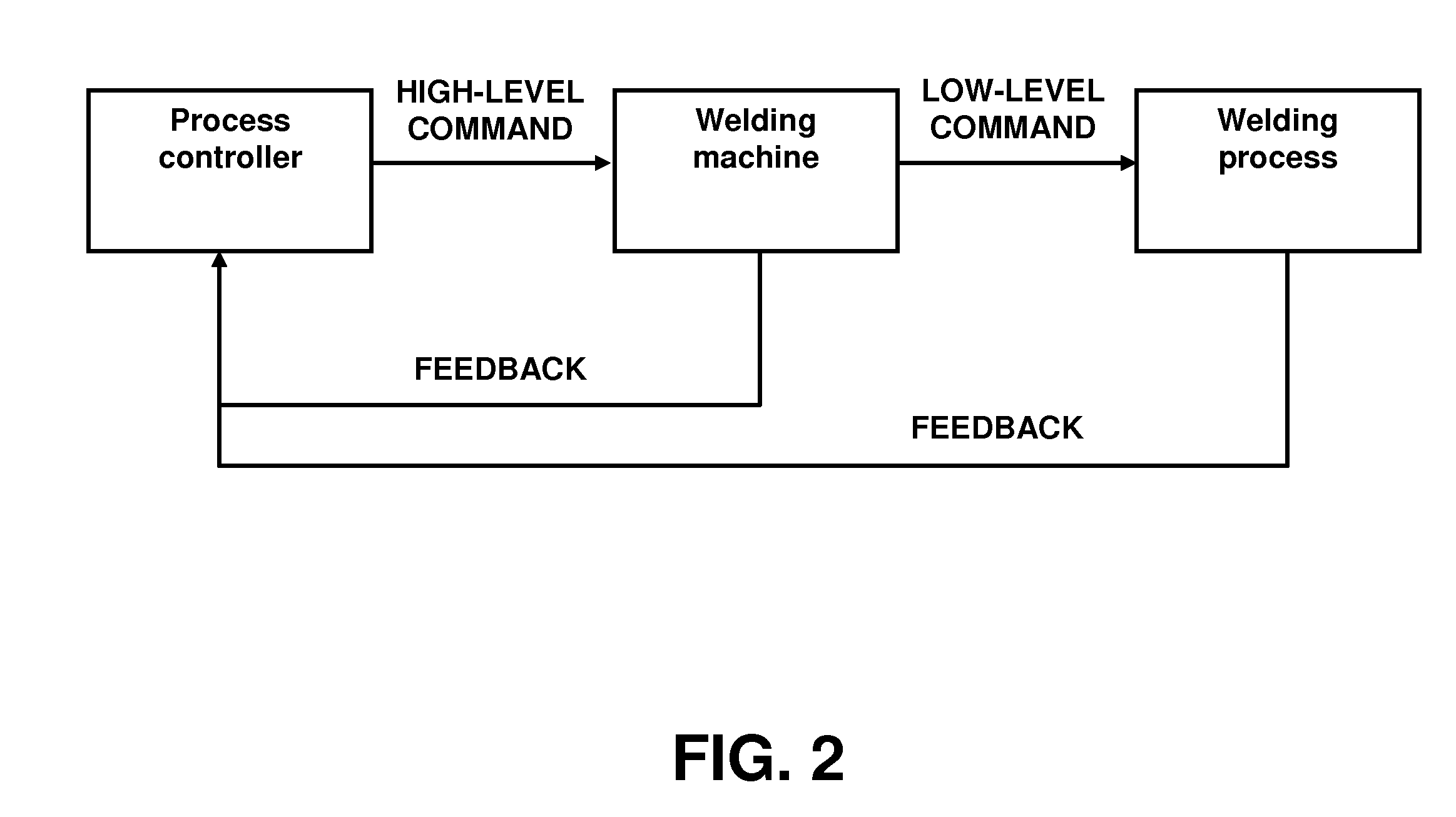

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

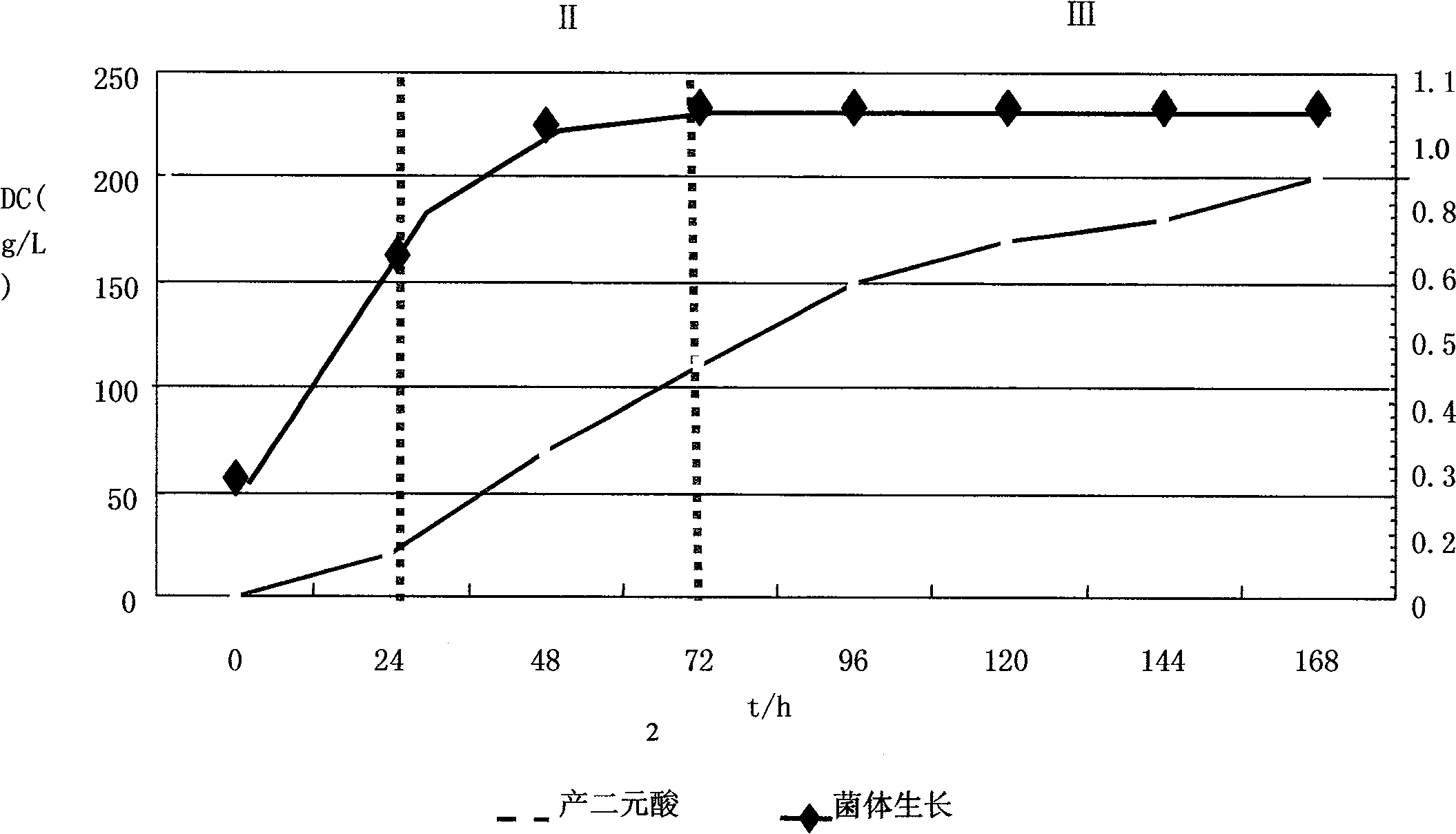

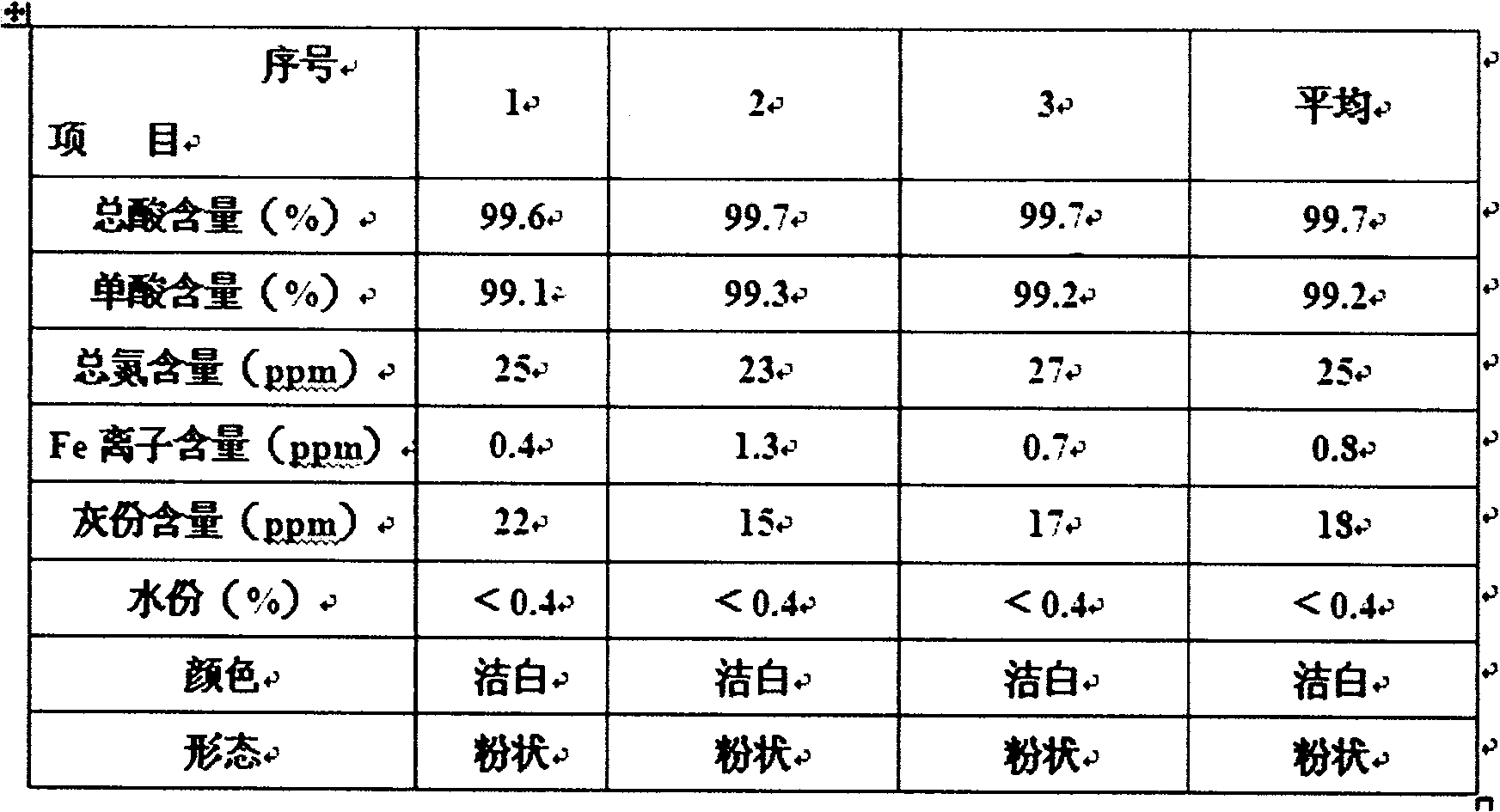

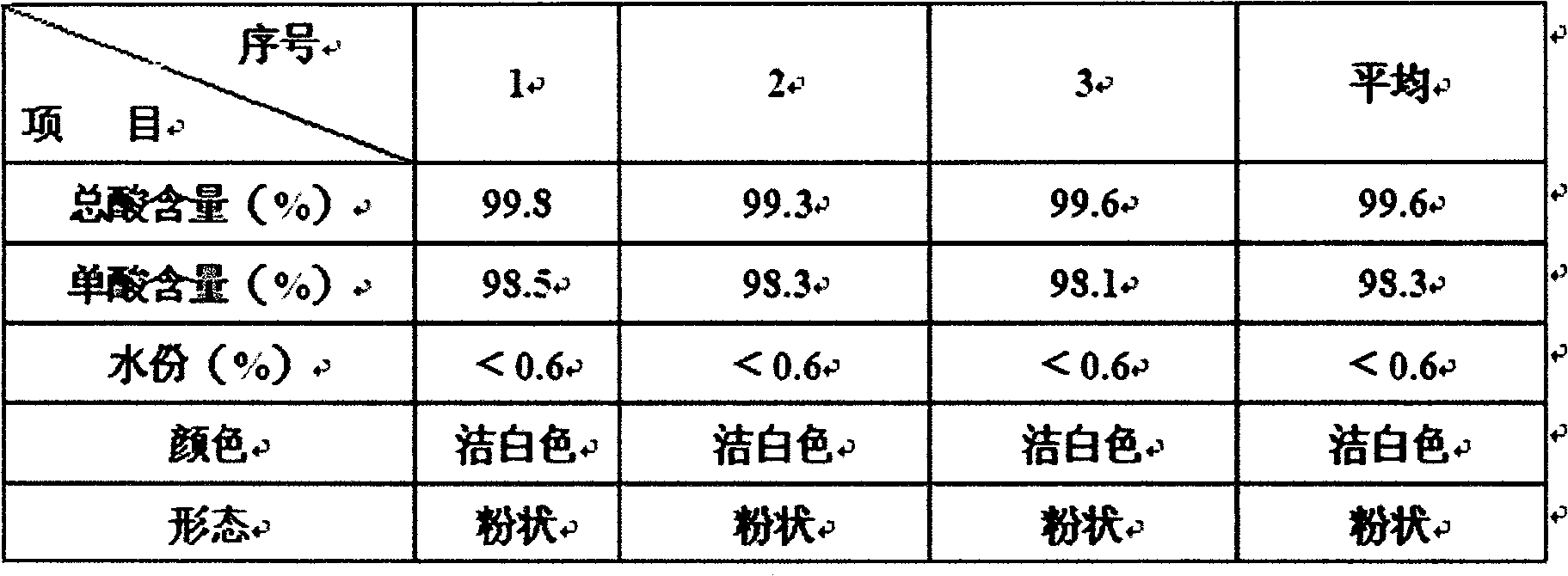

Preparation method of long carbon chain dibasic acid

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure having permeable walls and associated systems

ActiveUS20080190815A1Easy to produceLarge movementThermal non-catalytic crackingUnderground chambersHydrocotyle bowlesioidesEngineering

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume having substantially permeable side walls and a substantially impermeable cap. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom without contamination or substantial leaching of materials outside of the impoundment. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

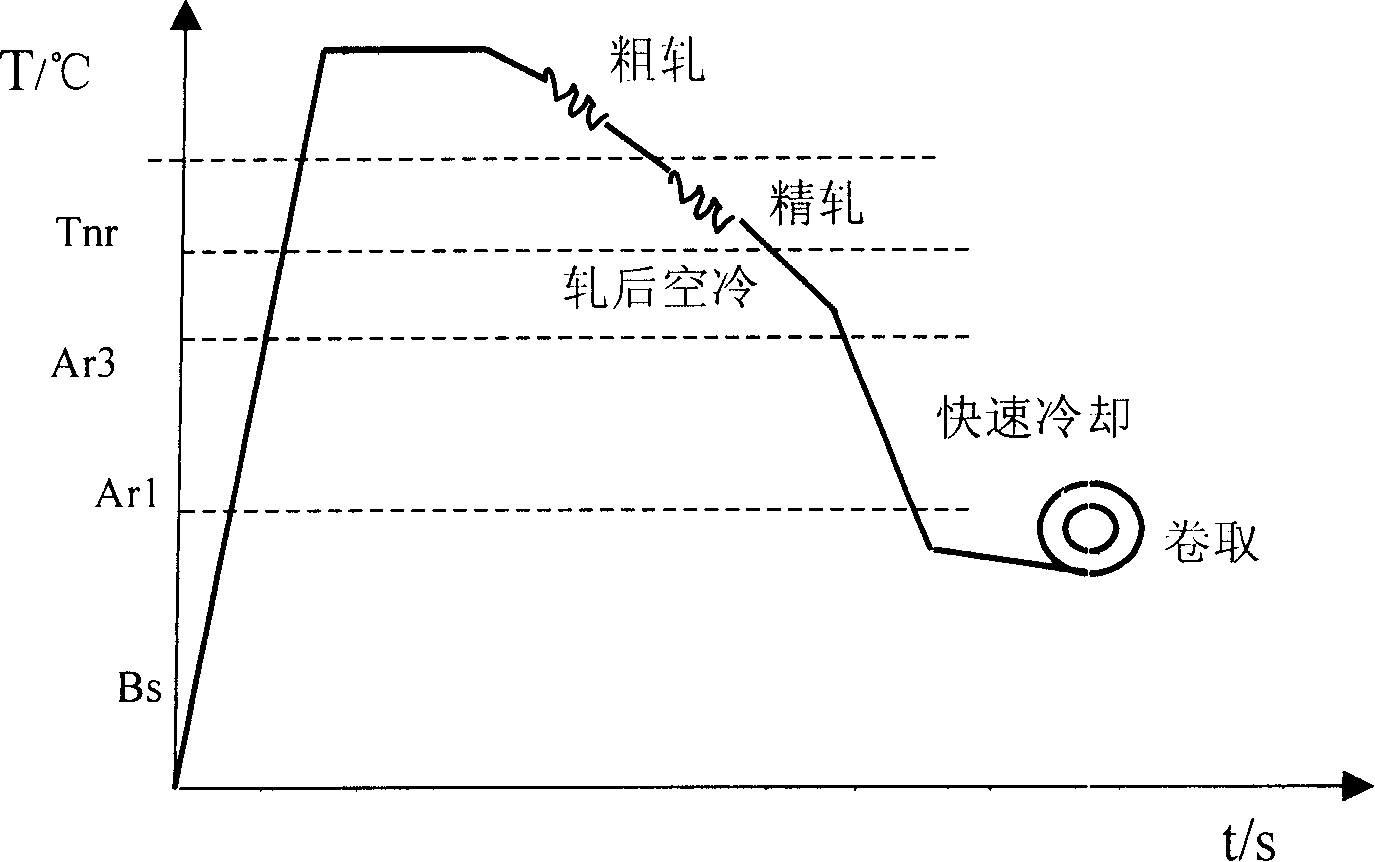

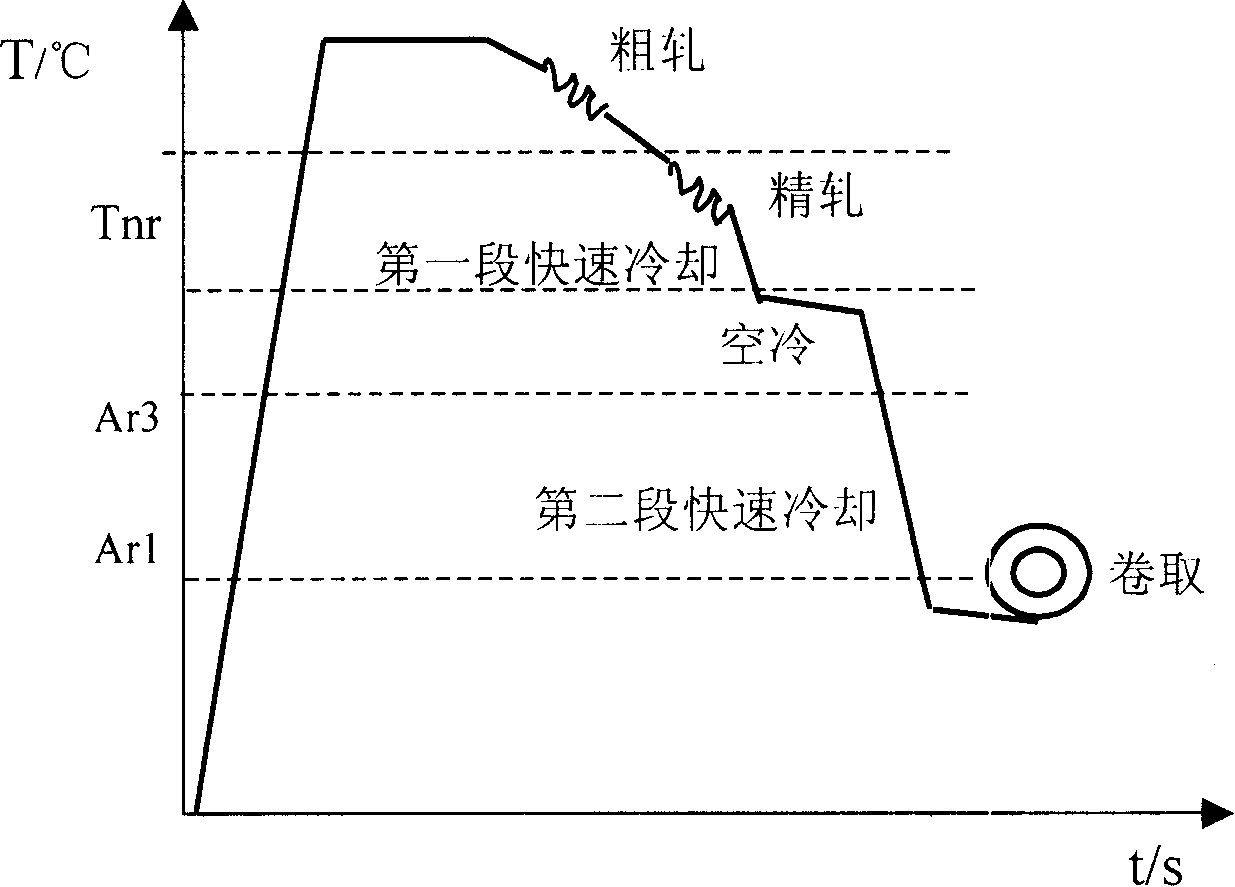

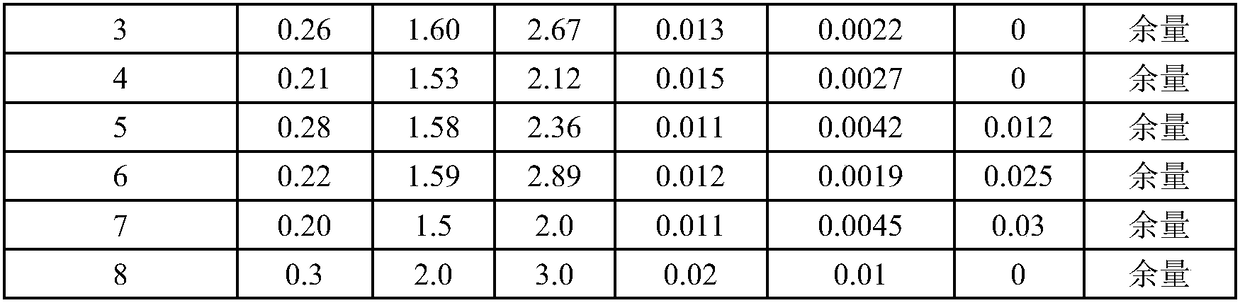

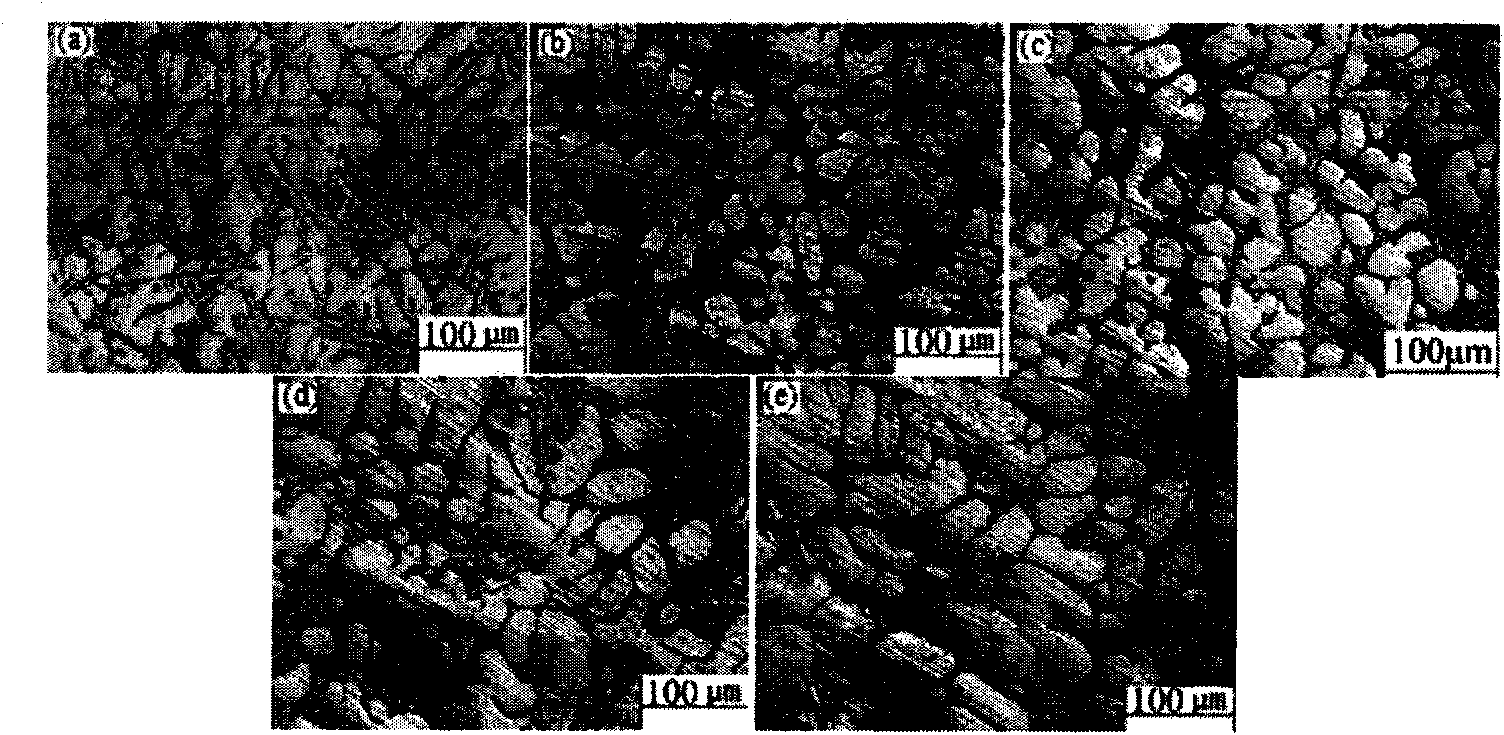

Hot-rolling phase change induction plasticity steel with 750MPa-level extension strength and preparation method thereof

ActiveCN101191174ARaise the intensity levelEasy to operateTemperature control deviceHeat treatment process controlSheet steelPhase change

The invention discloses a hot rolled transformation induced plasticity steel of 750MPa in tensile strength and the manufacture method which comprises the following procedures of 1) smelting, casting and blocking, the mass percentage compositions are: 0.08 to 0.20 percent of C, no more than 0.8 percent of Si, 0.5 to 2.0 percent of Mn, 0.8 to 2.5 percent of Al, no more than 0.03 percent of Nb, no more than 0.010 percent of N, no more than 0.020 percent of P, no more than 0.008 percent of S, 0.001 to 0.005 percent of Ca and the balance iron. 2) The blooms are heated to between 1150 and 1250 DEG C; keep the temperature and the holding time is in proportion to thickness 1 to 1.5min / mm; 3) Rolling: deformation occurs between the temperature ranges for austenite recrystallization, one pass or multi passes are adopted and the blooms are rolled into inner slabs. When deformation occurs between the temperature ranges lower than the Tnr temperature without austenite recrystallization but higher than Ar3 transformation point, blooms are rolled into steel plates of final thickness, and the finishing rolling temperature 800 to 880 DEG C.4) cooling. The invention has economical components, lower silicon contents, no Cr, Ni, Mo or other noble metal alloy elements, simple and applicable hot rolling technique, and steel slates of good surface quality, high strength and good plasticity.

Owner:BAOSHAN IRON & STEEL CO LTD

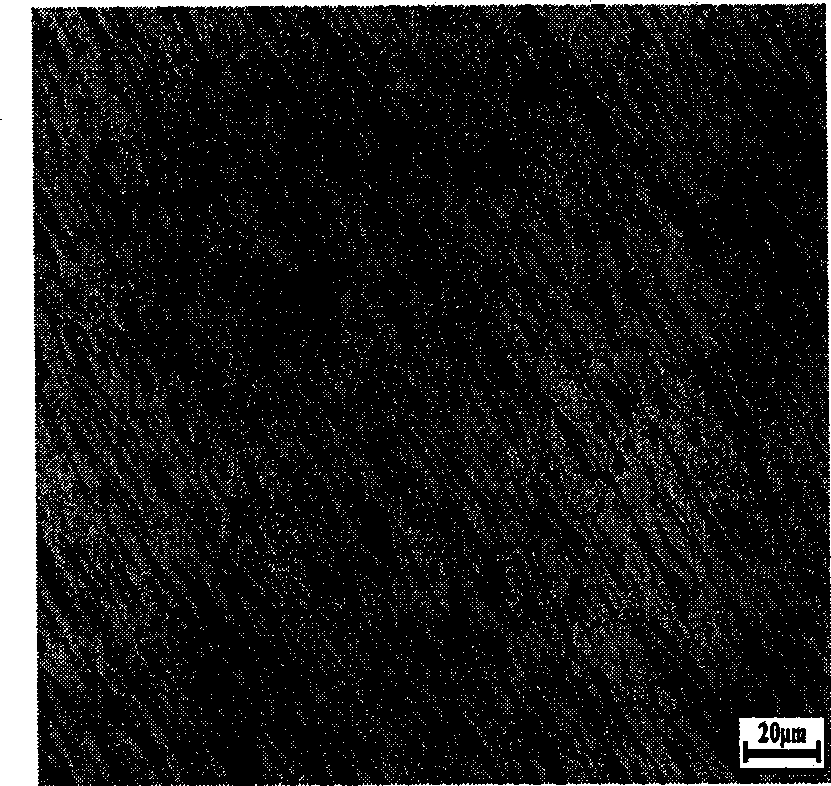

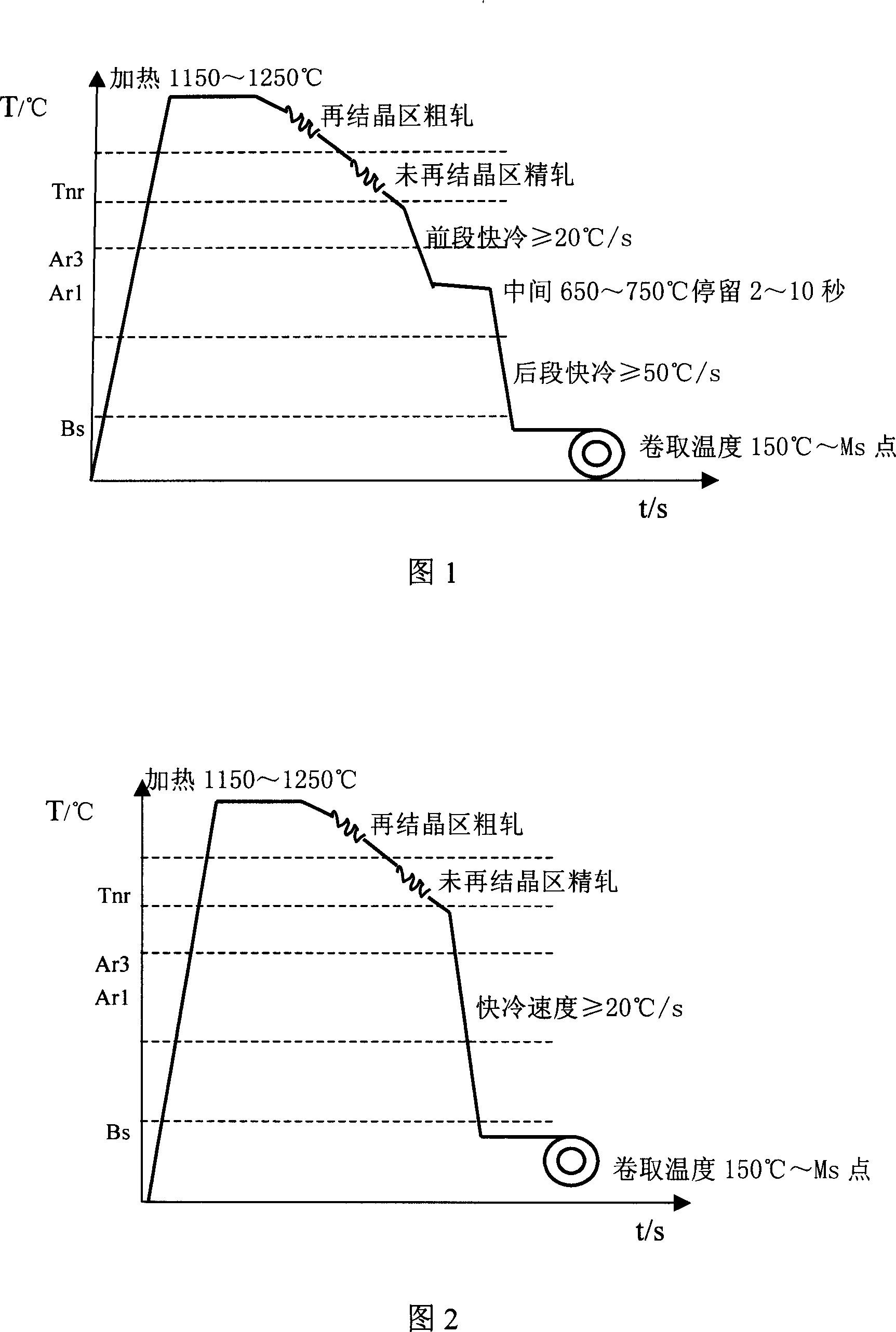

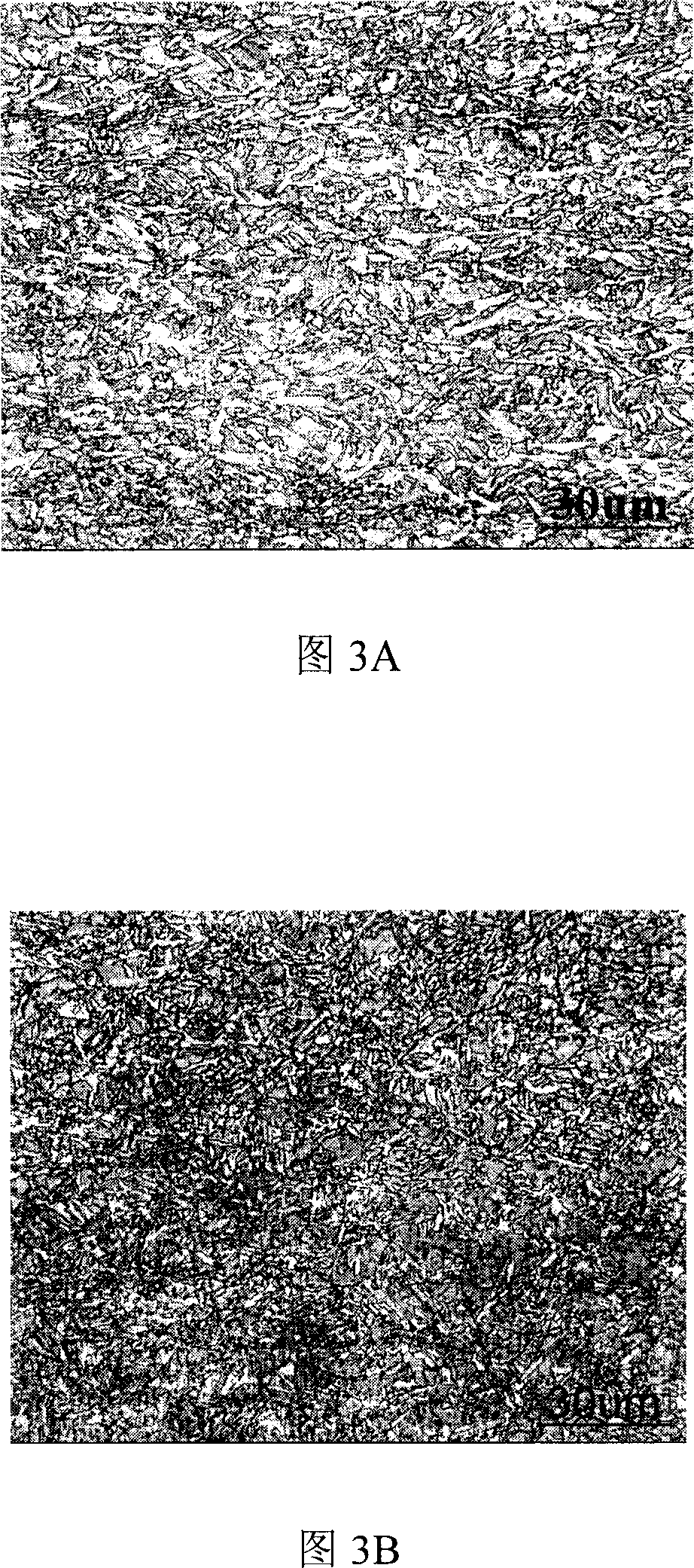

Hot rolling martensite steel plate with tensile strength higher than 1000Mpa and its production method

ActiveCN101008066AHigh strengthRequirements to ensure welding performanceHeat treatment process controlMartensiteHot rolled

The invention relates to a hot- roled martensite steel with strength for extension higher than 1000 Mpa, the component (with percent by weight) comprises: C 0.08-0.20, Si<=0.8, Mn 0.5-2.0, Al 0.010-0.060, N<=0.008, P<= 0.020, S<=0.005, one or more than one of Ti 0.01-0.03, V<=0.10 and Nb 0.01-0.05; Ca 0.001%-0.005%, added when sulfur content >=0.003; left is Fe and inavoidable foreigh matter. The main process parameters are as follows: cooling said steel with speed not less than 20 degree / s to cooling temeprature between 150 Deg. C to Ms, stopping cooling and batching to make metallic band; or cooling with speed not less than 20 degree / s to 650- 750 Deg. C, setting for 2- 10 seconds, and cooling with speed not less than 50 degree / s to cooling stop temperature of 150 Deg. C- Ms, and batching to make metallic band.

Owner:BAOSHAN IRON & STEEL CO LTD

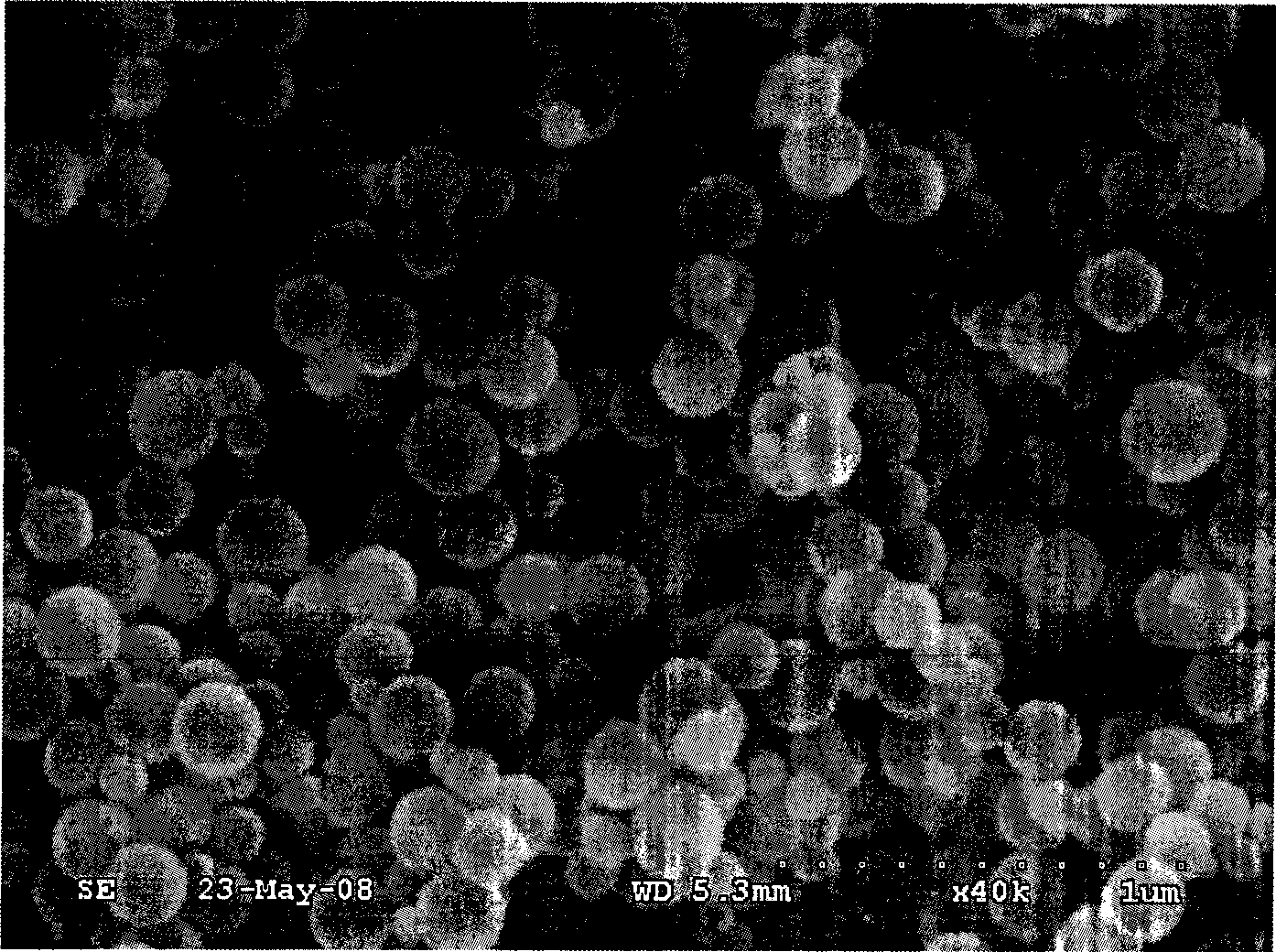

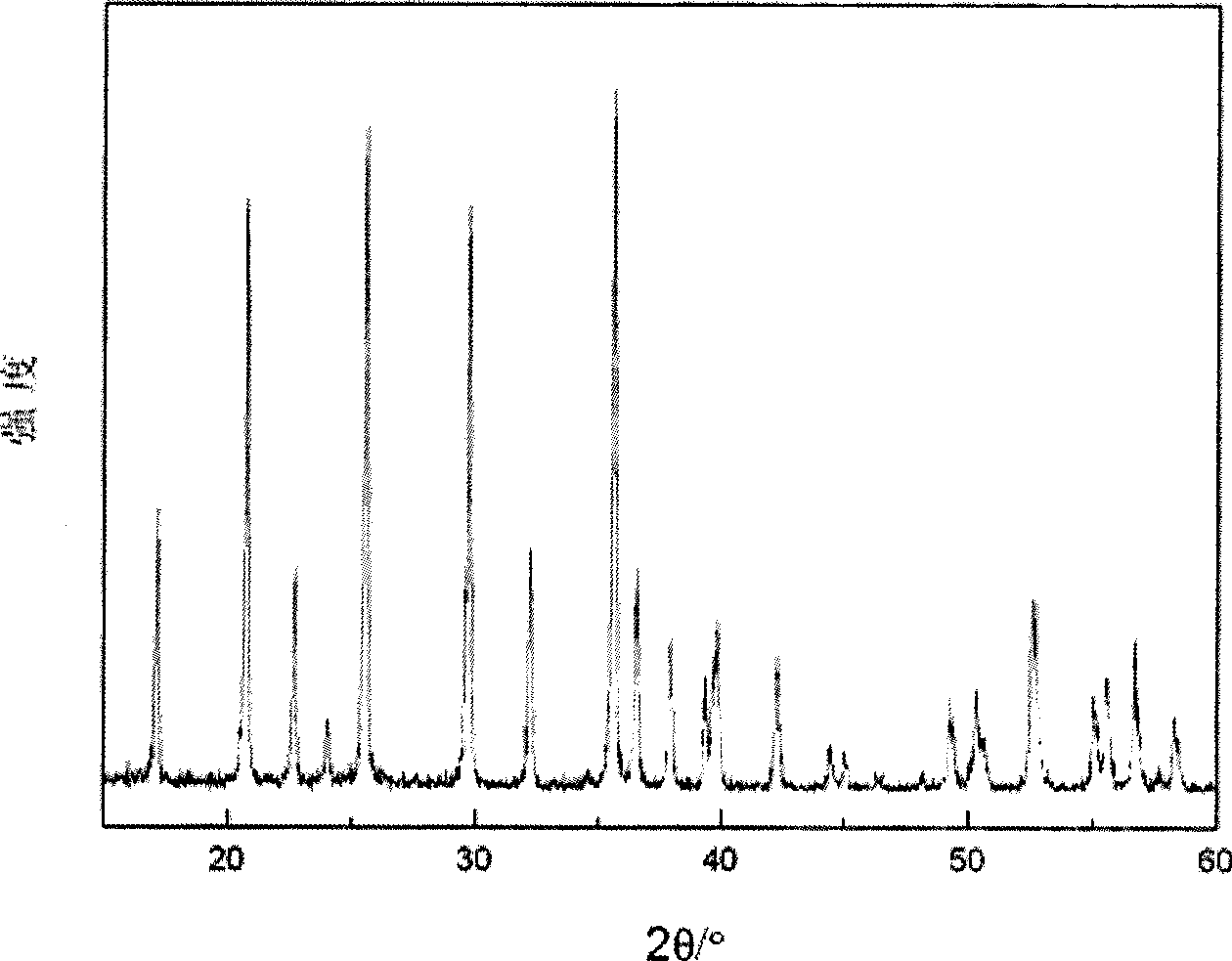

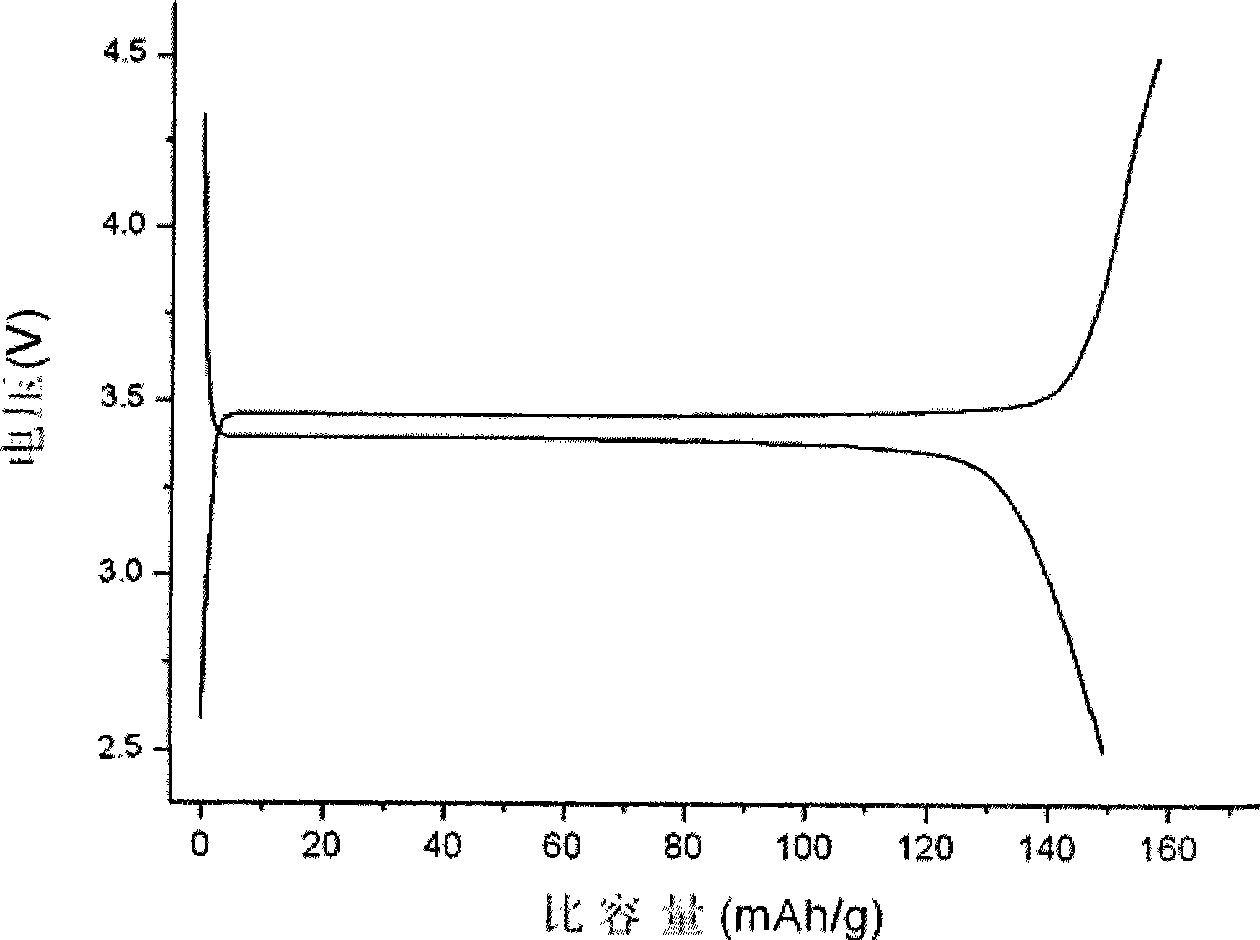

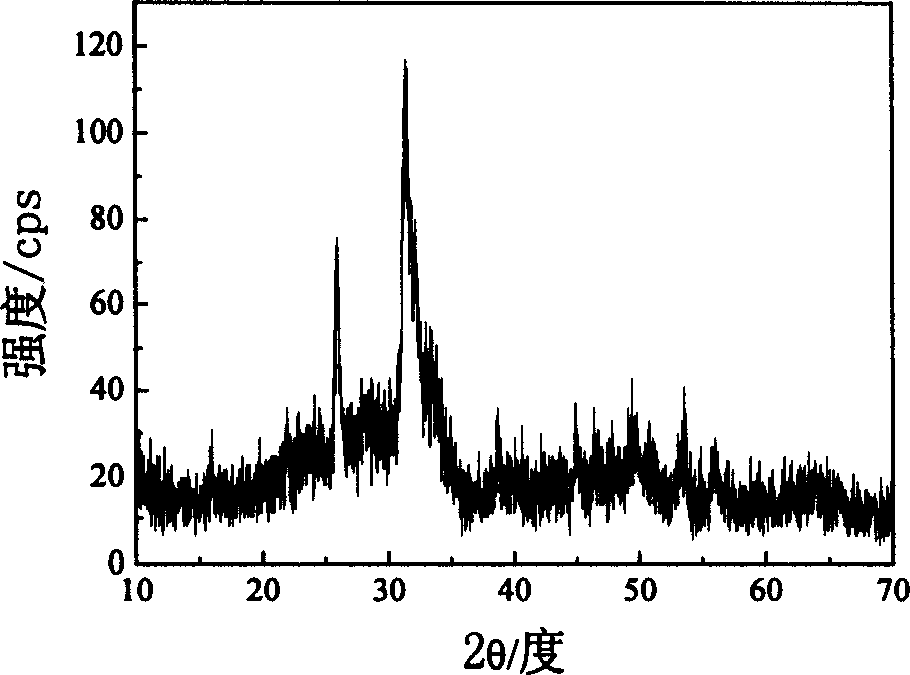

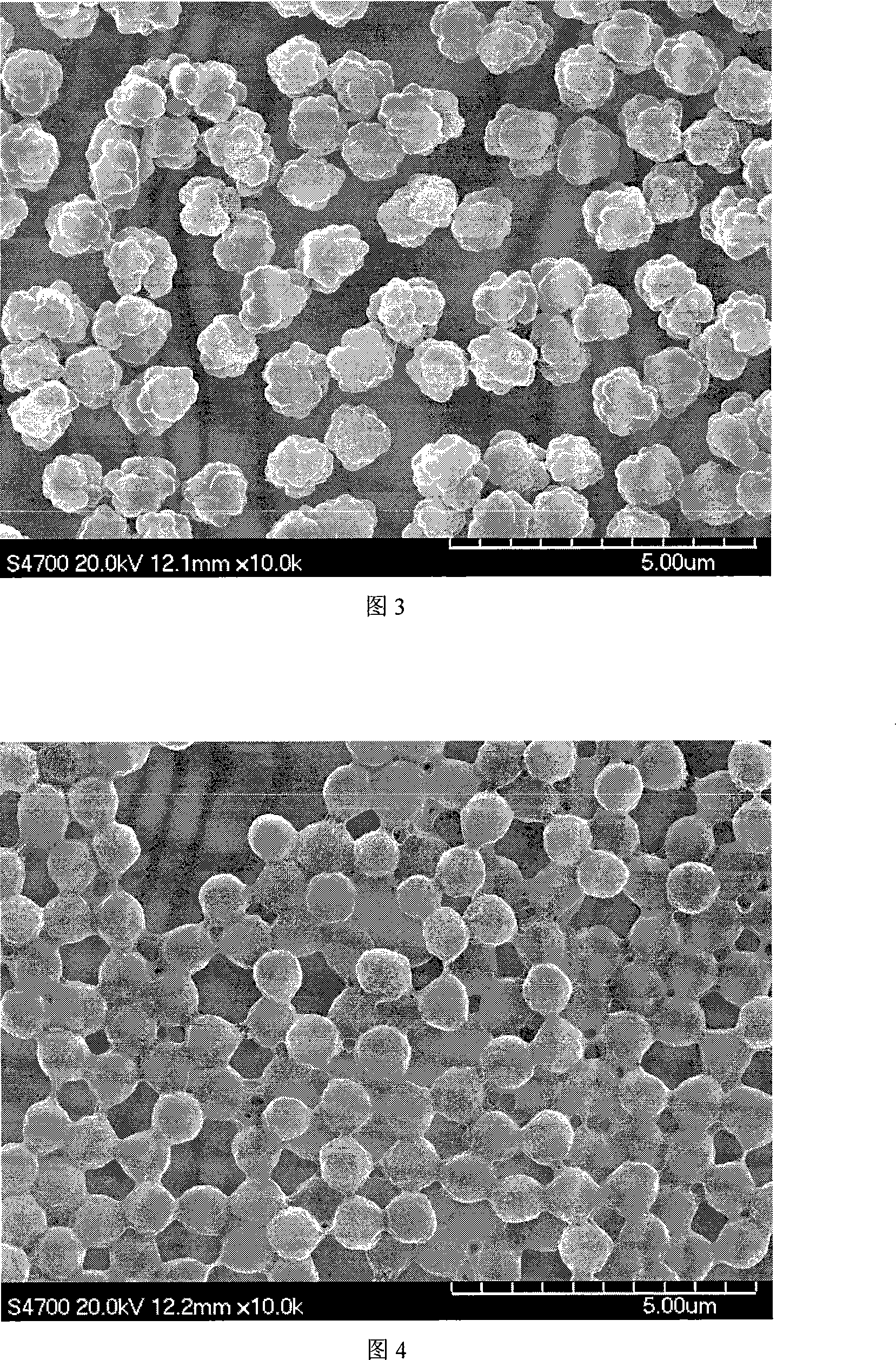

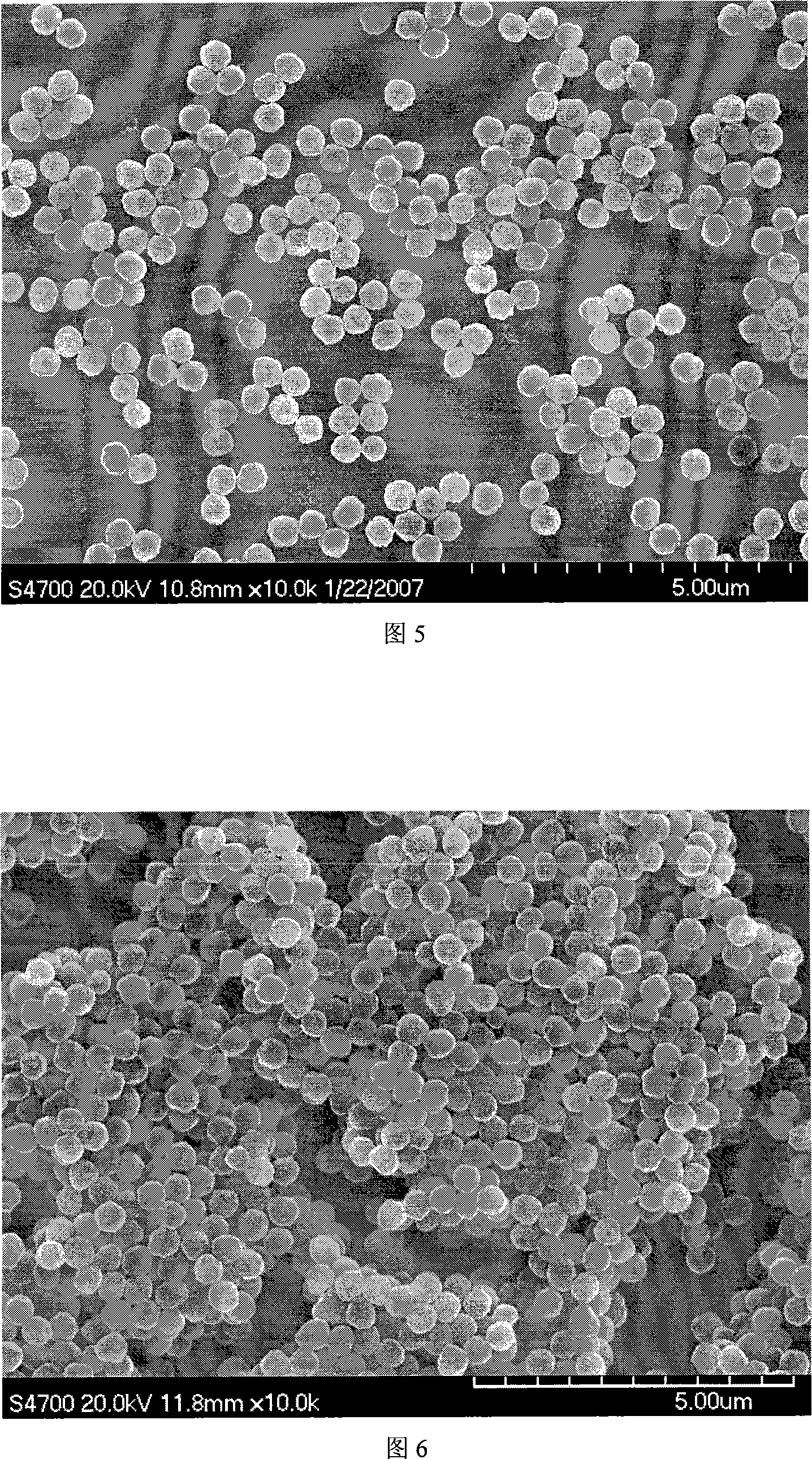

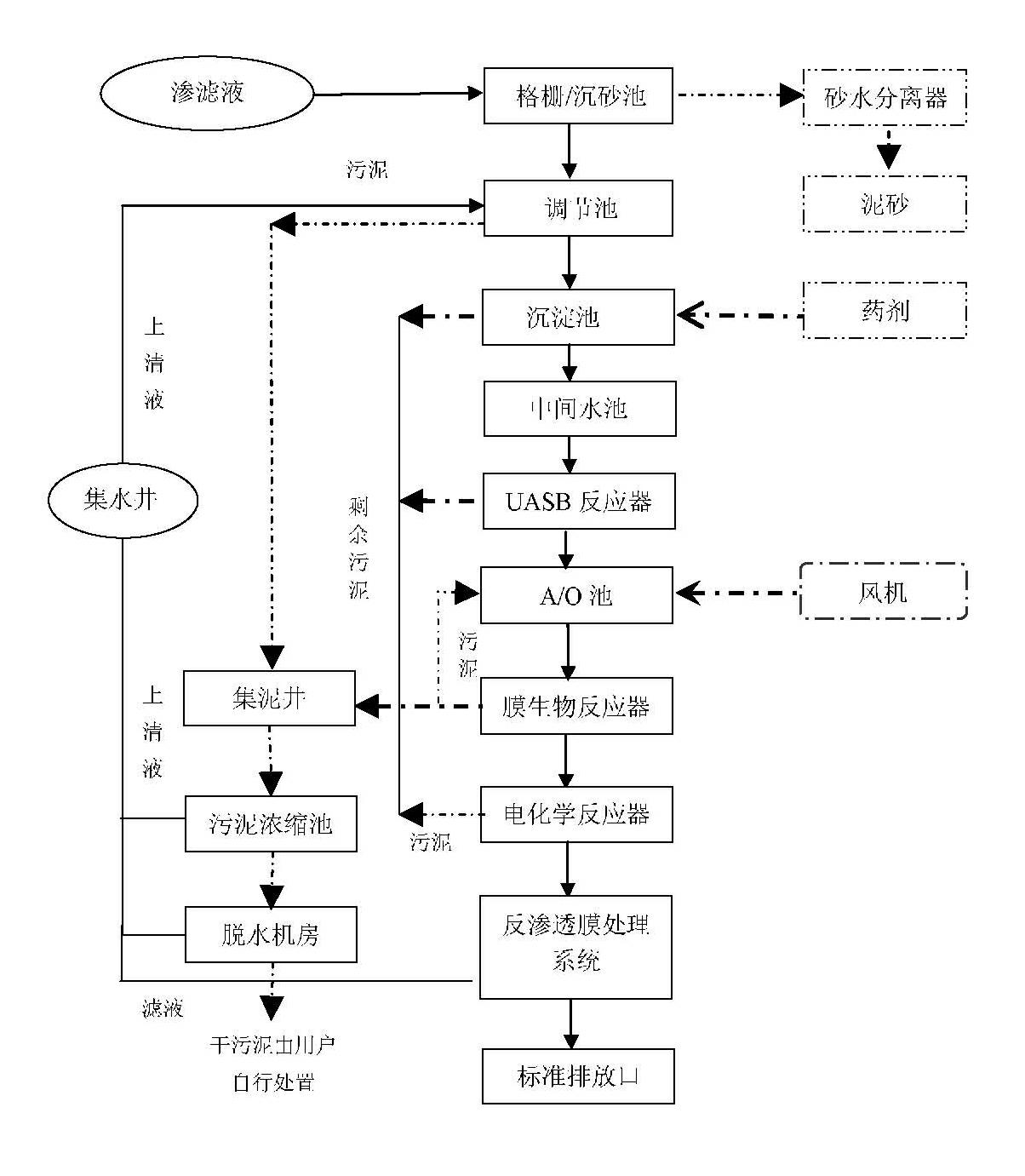

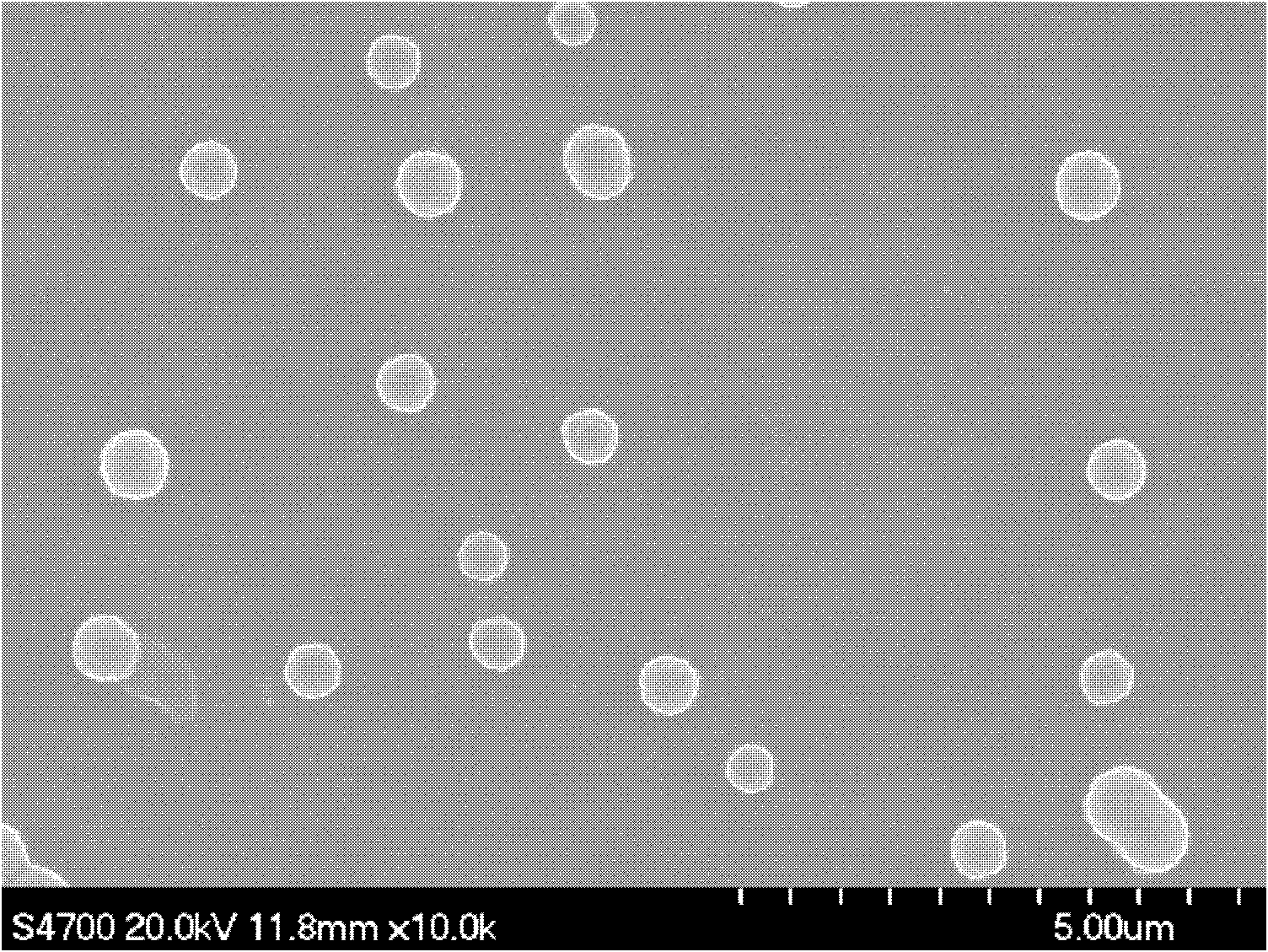

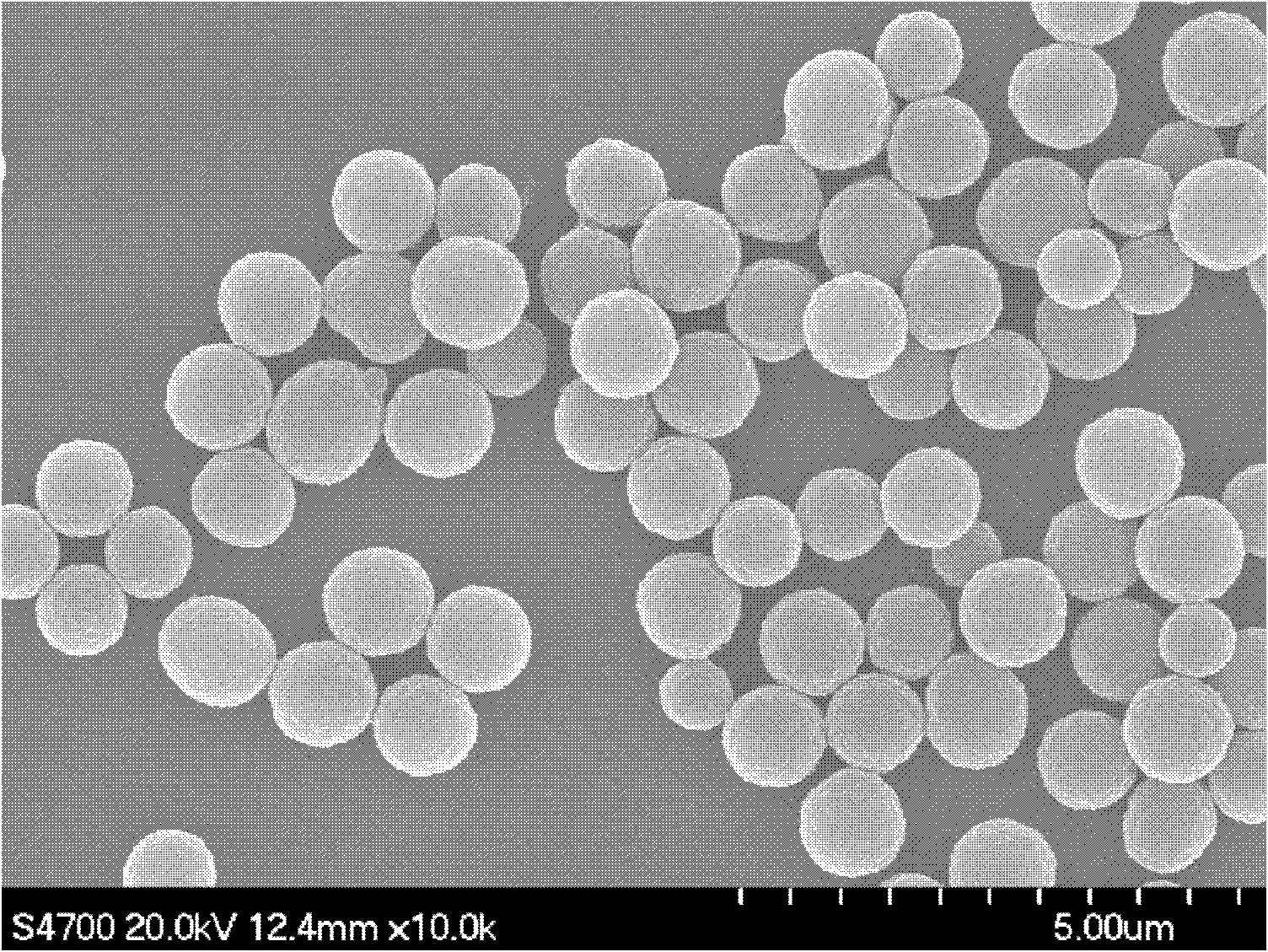

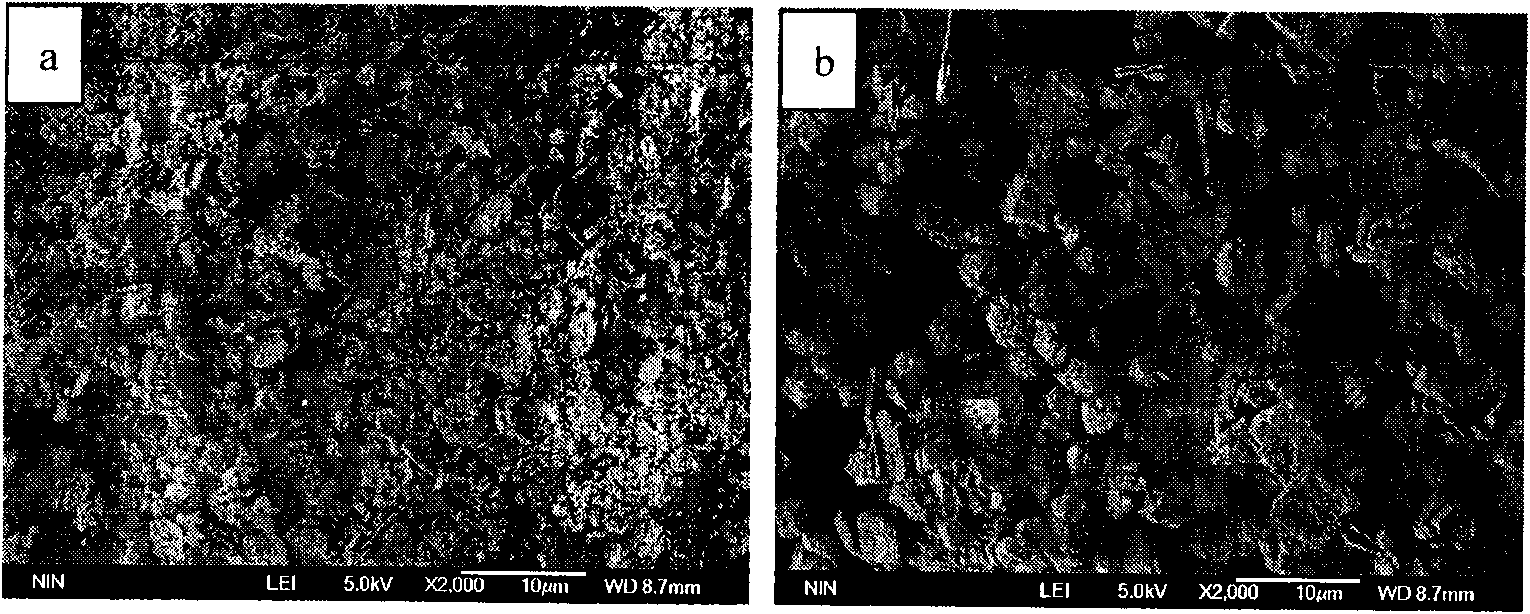

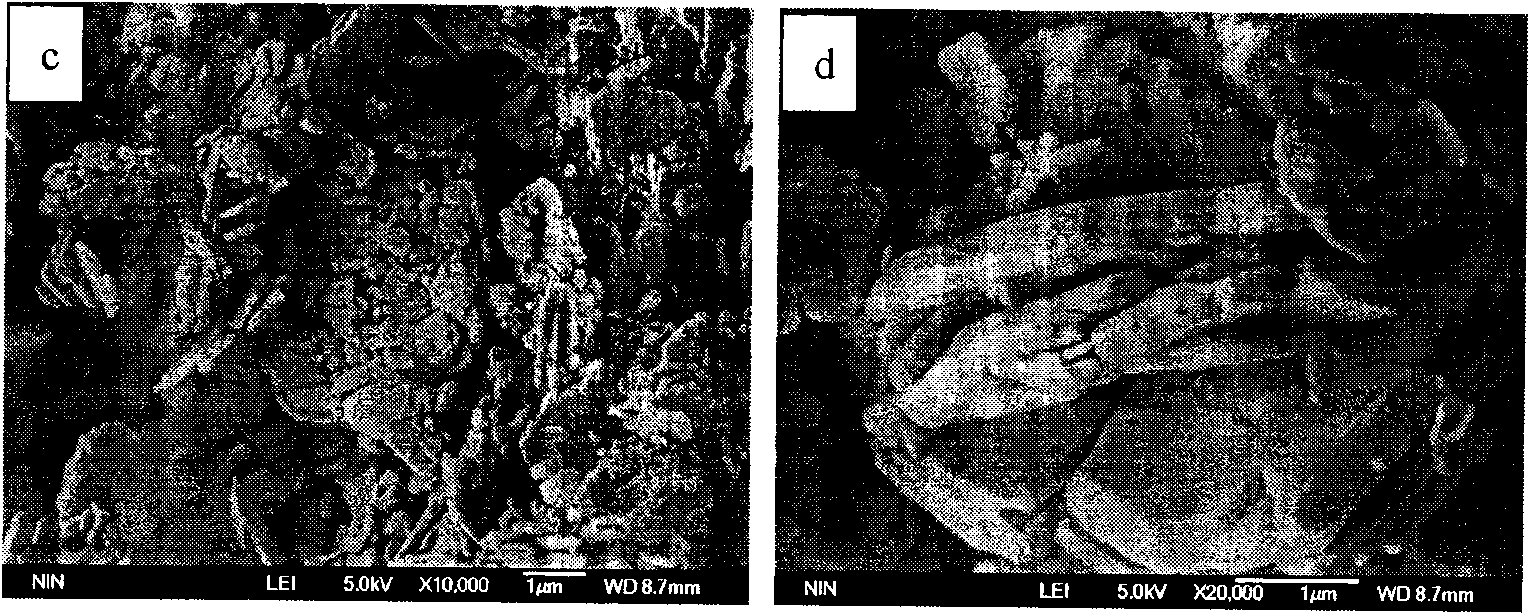

Process for producing homodisperse spherical iron lithium phosphate

InactiveCN101508431ALow costSimple process controlCell electrodesPhosphorus compoundsLithium iron phosphateRoom temperature

The invention relates to a method for preparing uniformly dispersed spherical lithium iron phosphate-an anode material for a lithium ion battery, and belongs to the field of green energy materials. The method comprises the following steps: firstly, preparing a spherical iron phosphate precursor through liquid-phase homogeneous precipitation; secondly, performing predecomposition on the spherical iron phosphate precursor at a temperature of between 350 and 450 DEG C for 2 to 8 hours under the protection of inert gas; and thirdly, performing reaction at the temperature of between 550 and 800 DEG C for 2 to 24 hours to obtain the uniformly dispersed spherical lithium iron phosphate. The particle diameter of the product is between 100 and 200 nanometers, the tap density is between 1.6 and 2.0 g / cm, and the specific capacity of initial discharge at the room temperature reaches 140 to 160 mAh / g. The method utilizes a liquid-phase spheroidization process to prepare the uniformly dispersed spherical lithium iron phosphate, has simple process, and is easy to realize industrialized production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nanometer hydroxyapatite powder preparation method

InactiveCN1544318AGood crystallizationSmall granularityEnergy based chemical/physical/physico-chemical processesPhosphorus compoundsCalcium nitrate tetrahydrateApatite

A process for preparing nano hydroxyapatite powder comprises the steps of, mixing Ca(NO3)-2-4H20 and NH4-2HPO-4 according to the mol ratio of Ca:P = 1.67-2.5:1, dissolving by charging distilled water, making the concentration of the Ca2++ ion to be 0.01-0.1 mol / L, charging aquadrate powder into the solution according the ratio of Ca(NO3)-2-4H2O : NH4-2HPO-4 = 1:5-12, conducting sound chemo synthesis through multiple frequency phonochemical generator, filtrating and washing the suspending liquid, placing the filtered material into vacuum drying oven for drying at the temperature of 80-100 deg. C, thus the nano hydroxyapatite powder can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

Comprehensive utilization method for bittern

InactiveCN101691239ARealize closed loopSimple process controlCalcium/strontium/barium carbonatesIodineSimple componentChemistry

The invention relates to a comprehensive utilization method for bittern, which belongs to the technical field of salt chemical engineering. The bittern is a liquid mineral product, and is rich in multiple elements such as potassium, sodium, lithium, boron, bromine, iodine and the like; and at present, in the prior domestic bittern development and utilization, some simple components or components with high additional value in the elements are extracted, and the un-extracted components are discharged along with old bittern to be abandoned so as to cause serious waste of resources and pollute the environment. Through reasonable combination of processes of removing H2S from the bittern, settling magnesium, settling calcium and preparing calcium carbonate, preparing potassium-sodium mixed saltthrough primary salt preparation and secondary salt preparation, extracting potassium chloride through flotation, extracting boron, iodine, bromine, rubidium and cesium through acidification, preparing rubidium chloride and cesium chloride, extracting lithium and the like, the method implements step-by-step ordered extraction of main components; the toil yield of several main components reaches over 95 percent; and the method has the advantages of mutually exclusive loss in component extraction, implementation of closed cycle of processes, no mother liquor discharge, simple process control, low cost, high yield, environmental protection and the like.

Owner:DAZHOU HENGCHENG ENERGY GROUP

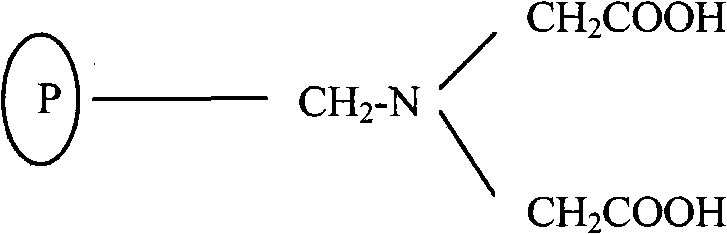

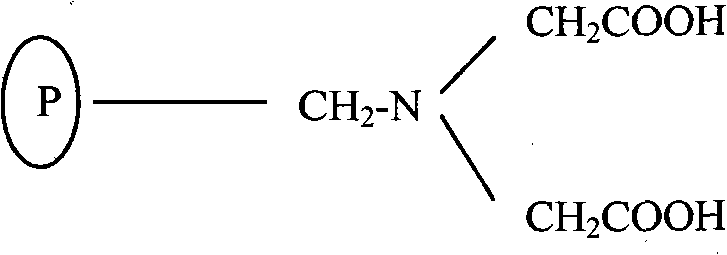

Novel chelate resin and production method and application thereof

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

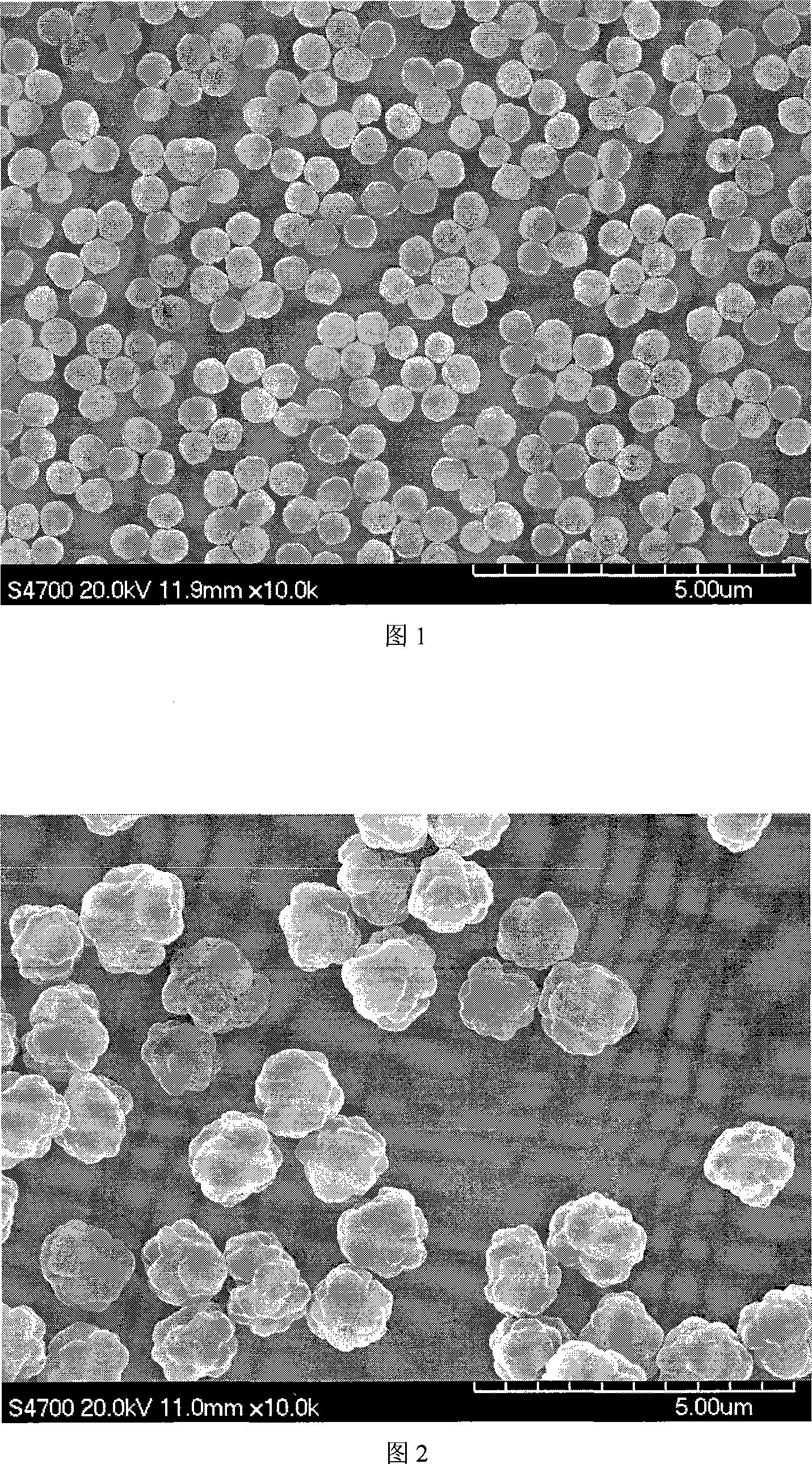

Copolymerization reaction method for styrene/maleic anhydride

A copolymerization method of phenylethene / maleic anhydride belongs to polymer preparation technical field, for resolving the defect caused by stabilizer in traditional disperse polymerization system, which comprises under nitrogen gas protection, dissolving monomer Man and St, inducer organic hyperoxide or azocompound of suitable ratio in organic acid alkyl ester, the mixture of aromatics and organic acid alkyl ester or the mixture of ketone and alkane to react for 1 / 4-12h at 60-90 DEG C to obtain the disperse system of polymer microballoon, wherein the average particle diameter of microballoon in the disperse system is 90-1715mm, the disperse factor is 1.04-1.004 and the number average molecular weight is 80000-300000g / mol. The invention has the advantages of eliminated stabilizer, simple process, low cost, clean polymer microballoon or particle surface, controllable particle diameter, controllable shape and narrow granularity distribution.

Owner:BEIJING UNIV OF CHEM TECH

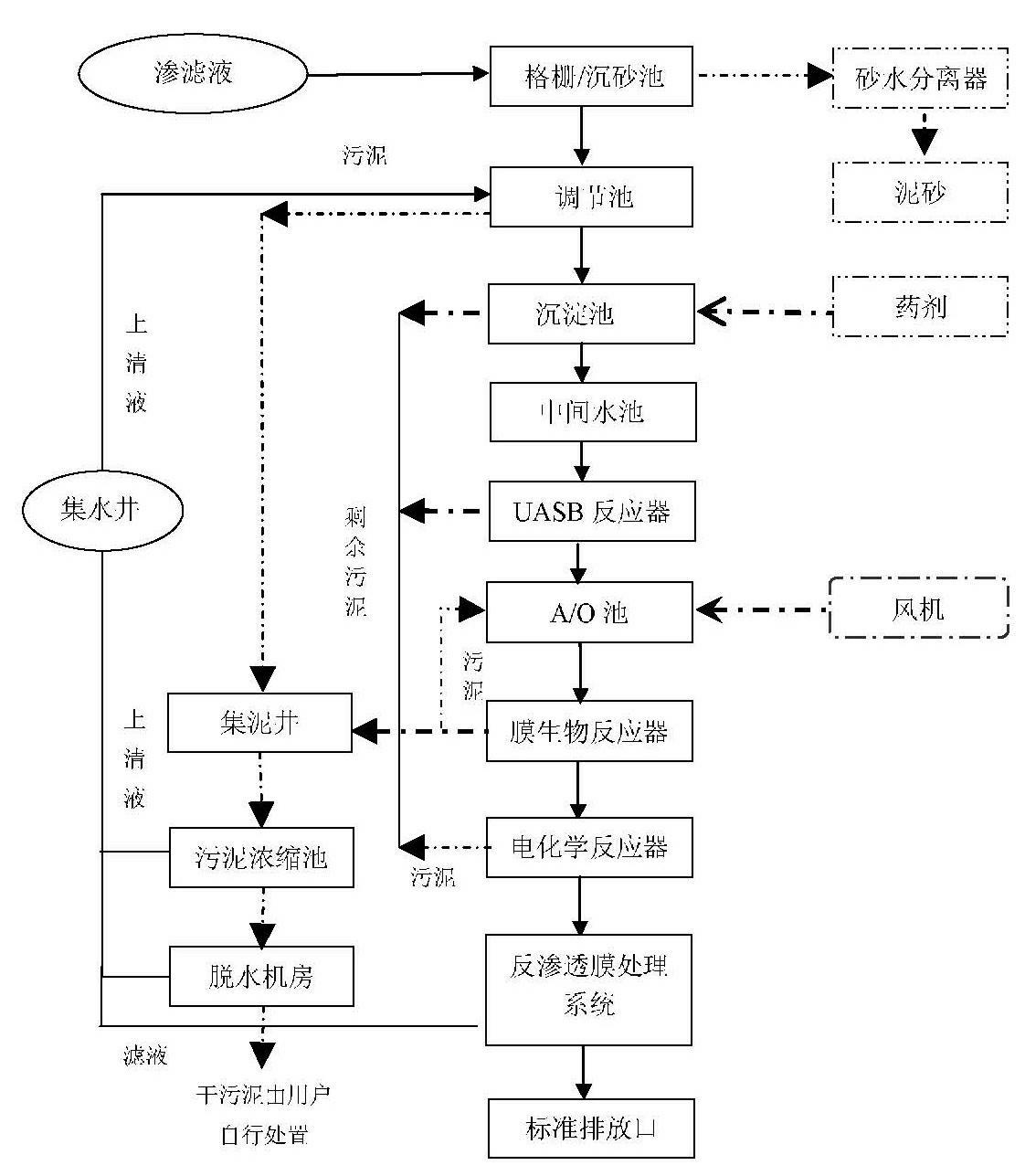

Treatment method and treatment system for percolate in garbage-burning plant

ActiveCN102153233AExtended cleaning cycleReduce loadMultistage water/sewage treatmentActivated sludgeGrating

The invention relates to a treatment method and a treatment system for percolate in a garbage-burning plant. The treatment method for garbage-burning percolate includes the steps as follows: the percolate is collected by a pipeline and then enters a coarse grating, a fine grating and a sand setting tank to be subjected to sand setting, and then flows into an adjusting tank for mixing and stirring; effluent of the adjusting tank is lifted to a settling tank by a lift pump of the adjusting tank; by adjusting pH value and adding coagulant, the effluent of the adjusting tank is coagulated and settled so as to remove most water suspended matters and part of insoluble organic matters; the effluent of the settling tank flows into a middle water tank and is heated by a steam-jet heating system to 35 DEG C; and the heated effluent of the middle water tank is subjected to biochemical treatment. In the invention, a pre-treatment unit is arranged in front of the adjusting tank, thus reducing the load of follow-up units and simultaneously prolonging the cleaning period of the adjusting tank; and an MBR (Meane Biological Reactor) system is adopted for effectively intercepting activated sludge to further improve the effect of a biochemical treatment unit, and simultaneously a secondary settling tank in a traditional biochemical treatment technology is replaced and the operation is simplified.

Owner:浙江博世华环保科技有限公司

Blow molding grade halogen-free flame-retardant polypropylene material and preparation method thereof

InactiveCN102532727AImprove flame retardant performanceHigh heat distortion temperatureBlow moldingHeat deflection temperature

The invention relates to a blow molding grade halogen-free flame-retardant polypropylene material. A raw material formula of the polypropylene material comprises the following components in percentage by weight: 32-81 percent of polypropylene, 0-1 percent of a thermal stabilizer, 0-1 percent of a lubricant, 2-10 percent of a toughening agent, 10-30 percent of a flame retardant, 2-6 percent of a compatilizer and 5-20 percent of an inorganic filler, wherein the polypropylene is ethylene propylene random copolymerized polypropylene of which the melt flowing rate is 0.01-10 g / 10min and the ethylene mole content is less than or equal to 10 percent; and the flame retardant is a halogen-free phosphorus-nitrogen expandable flame retardant. The polypropylene material disclosed by the invention has excellent flame retardance, high thermal deformation temperature and high comprehensive physical property, and is particularly suitable for blow molding of automobile air channels.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

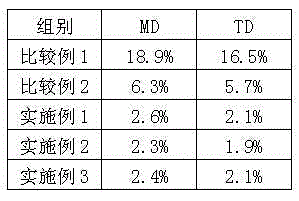

Quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and production method thereof

The invention relates to a quenched partitioned cold-rolled steel sheet with tensile strength of greater than 1180 MPa, and a production method thereof. During annealing heating, a steel plate is partially austenitized, so the enrichment of carbon in an austenite structure is realized; the two-phase-region slow cooling is employed for adjusting the volume fractions of an austenite phase and a ferrite phase, carbon is further enriched in the austenite; then rapid cooling at a cooling rate of 30-40 DEG C / s is carried out to partially convert the austenite into martensite; then heating and heat preservation are carried out; and finally, air-cooling to room temperature is carried out to obtain a multi-phase structure of ferrite, martensite and metastable austenite. The invention has the advantages that the production method is used for batch production of the quenched partitioned cold-rolled steel sheet with the tensile strength of greater than 1180 MPa; the quenched partitioned cold-rolled steel sheet has simple chemical components, no elemental Nb or only a small amount of elemental Nb is added except C, Si and Mn, so smelting cost is low, and process control is simple; two-phase-region heating is employed for continuous annealing; rapid cooling requires a low cooling speed and has low requirements on the equipment capacity of a continuous-annealing unit is low; and the production method is simple.

Owner:ANGANG STEEL CO LTD

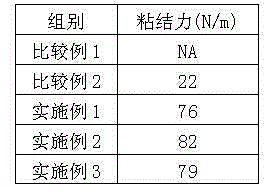

Ceramic membrane, preparation method of lithium ion secondary battery and battery

ActiveCN104064709AGood thermal stabilitySimple process controlFinal product manufactureSecondary cellsCeramic particleCeramic coating

The invention discloses a ceramic membrane. The ceramic membrane is formed by the following steps: synthesizing dendriform grafted copolymers by acrylate monomers and enol monomers in the presence of an initiator, then adding inorganic ceramic particles, uniformly dispersing to form a mixture, and then coating a single surface or two surfaces of a membrane base material with the mixture. The inorganic ceramic particles are adsorbed onto the copolymers and mutually bonded, so as to form compact ceramic coatings with three-dimensional network structures between the inorganic ceramic particles and between the copolymers, and the ceramic coatings are adsorbed together with the membrane base material by virtue of the copolymers, so that the three-dimensional network structure is formed by the inorganic ceramic particles, the copolymers and the membrane base material. The invention further discloses a preparation method of a lithium ion secondary battery and the battery. The ceramic membrane has the advantages of good thermostability, simplicity in process control and easiness in industrial production, in the process of using the lithium ion battery, the stability of the assembly process is kept, the safety performance of the battery is guaranteed, and the effects of environmental friendliness and energy conservation are achieved.

Owner:东莞市魔方新能源科技有限公司

Novel method for performing copolymerization reaction of dicyclopentadiene and maleic anhydride

The invention discloses a novel method for performing a copolymerization reaction of dicyclopentadiene and maleic anhydride, and belongs to the technical field of copolymers. The method comprises the following steps of: under the protection of nitrogen, adding monomers and an initiator into an organic medium and dissolving, reacting for 2 to 12h at the temperature of between 60 and 90 DEG C to obtain a self-stabilizing dispersion system of monodisperse microspheres of an alternating copolymer, and performing centrifugal separation, and drying to obtain a white solid of the dicyclopentadiene / maleic anhydride alternating copolymer, wherein the reaction monomers are the dicyclopentadiene and the maleic anhydride, and the molar ratio of the two monomers is 5:1-1:5; the medium is a mixed solvent of organic acid alkyl ester and organic alkane, and the organic acid alkyl ester accounts for 30 to 70 volume percent of the mixed solvent; and a chemical structure is that: R1 is a hydrogen atom, C1-C5 alkyl, phenyl or benzyl, and R2 is C1-C5 alkyl. A stabilizer and a costabilizer are not required to be added, the reaction system is simple, and a product is easy to separate; and polymer microspheres have smooth and clean surfaces, uniform particle sizes, controllable appearances, and high dispersibility.

Owner:BEIJING UNIV OF CHEM TECH

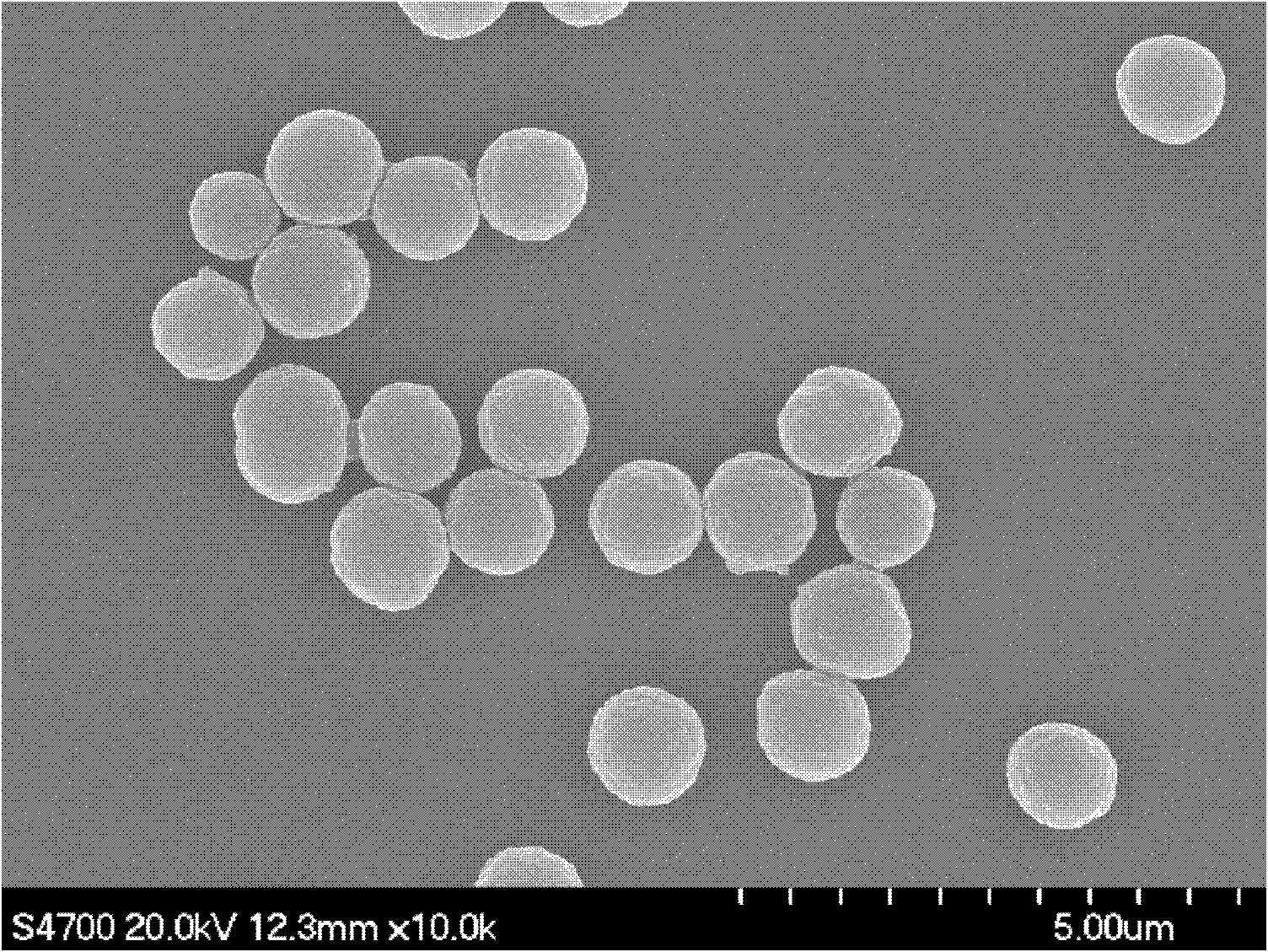

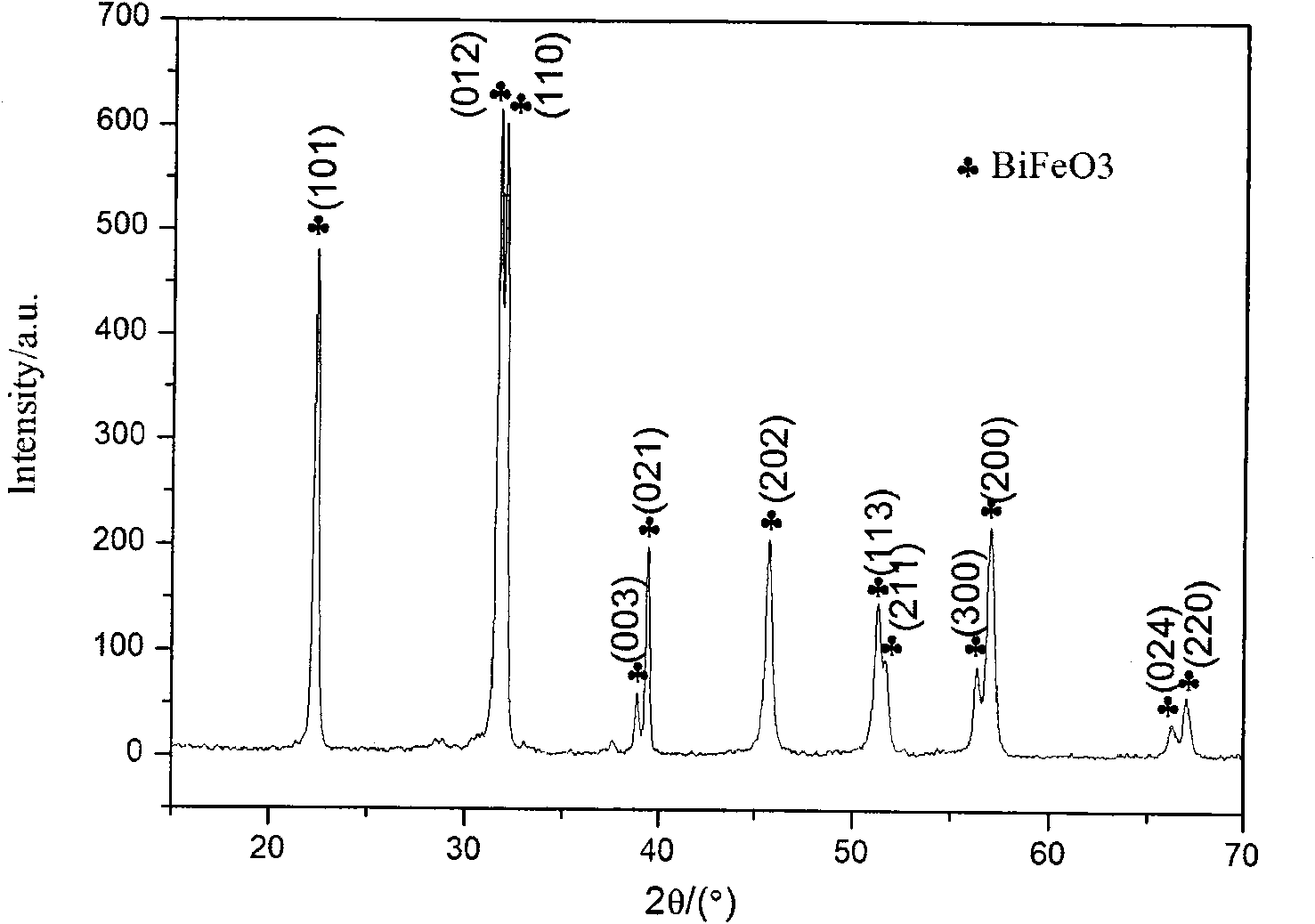

Method for preparing bismuth ferrite powder by microwave hydrothermal method

The invention discloses a method for preparing bismuth ferrite powder by microwave hydrothermal method, comprising: (1) dissolving FeCl3.6H2O and Bi(NO3)3.5H2O in proper amount of glycol to prepare into a parent salt solution; (2) dripping the parent salt solution into an aqueous ammonia solution with the concentration being 0.1-0.5mol / l and dripping speed being less than 2ml / min, and after finishing dripping, continuing to stir for 0.4-1h to obtain a deposit; (3) washing the deposit with de-ionized water repeatedly, ageing, and preparing a hydrothermal reaction precursor; and (4) adding the precursor solution into a microwave hydrothermal reaction kettle with the filling ratio being 60-75%, adding a mineralizer into the reaction kettle, placing the reaction kettle into a microwave assistant hydrothermal synthesizer to react for certain period, taking out a product in the reaction kettle, washing with de-ionized water to obtain a neutral product, washing the neutral product with absolute ethanol, and drying at room temperature to obtain the bismuth ferrite powder. The invention has the advantages of complete crystallization of BiFeO3, uniform grain fineness distribution, simple technical control, short technical cycle and energy saving.

Owner:SHAANXI UNIV OF SCI & TECH

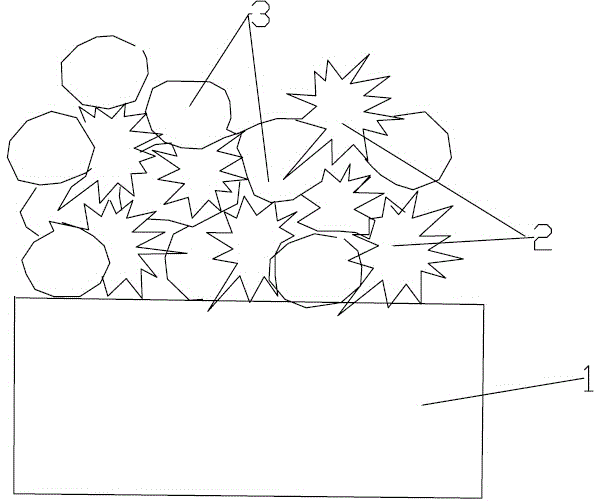

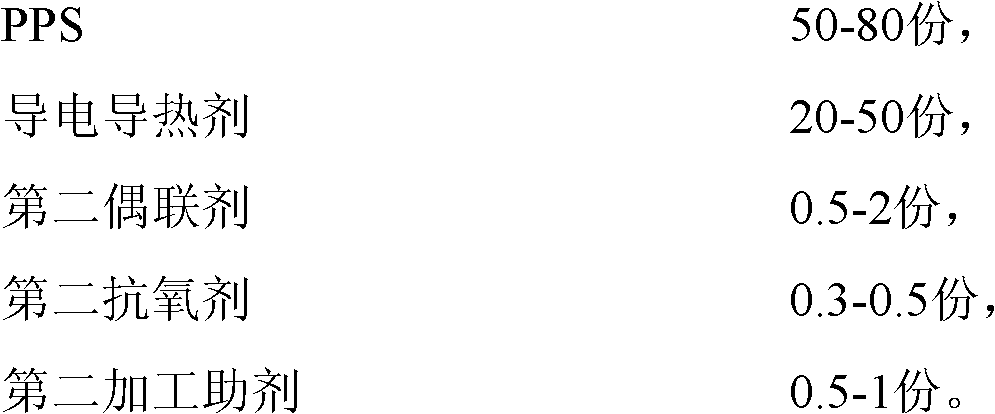

Long carbon fiber enhanced high-heat-conductivity polymer composite and preparation method thereof

ActiveCN102477182AEnhancement effect is goodImprove continuityHeat-exchange elementsMasterbatchCarbon fibers

The invention discloses a long carbon fiber enhanced high-heat-conductivity polymer composite, which is made of, by weight, from 10 to 80 parts of long carbon fiber enhanced thermoplastic resin masterbatch and from 20 to 90 parts of heat-conducting masterbatch by means of mixing. The long carbon fiber enhanced thermoplastic resin masterbatch is made of from 30 to 80 parts of first thermoplastic resin, from 20 to 70 parts of continuous long carbon fibers, from 0.5 to 2 parts of first coupling agent, from 0.3 to 0.5 part of first antioxidant and from 0.5 to 1 part of first processing aid by means of pultrusion. The heat-conducting masterbatch is made of from 30 to 80 parts of second thermoplastic resin, from 20 to 70 parts of heat-conducting agent, from 0.5 to 2 parts of second coupling agent, from 0.3 to 0.5 part of second antioxidant and from 0.5 to 1 part of second processing aid by means of traditional extrusion process. The long carbon fiber enhanced high-heat-conductivity polymer composite has excellent heat conductivity and mechanical property, and continuity of a heat-conducting network can be effectively improved by means of the long carbon fibers.

Owner:上海事升新材料有限公司

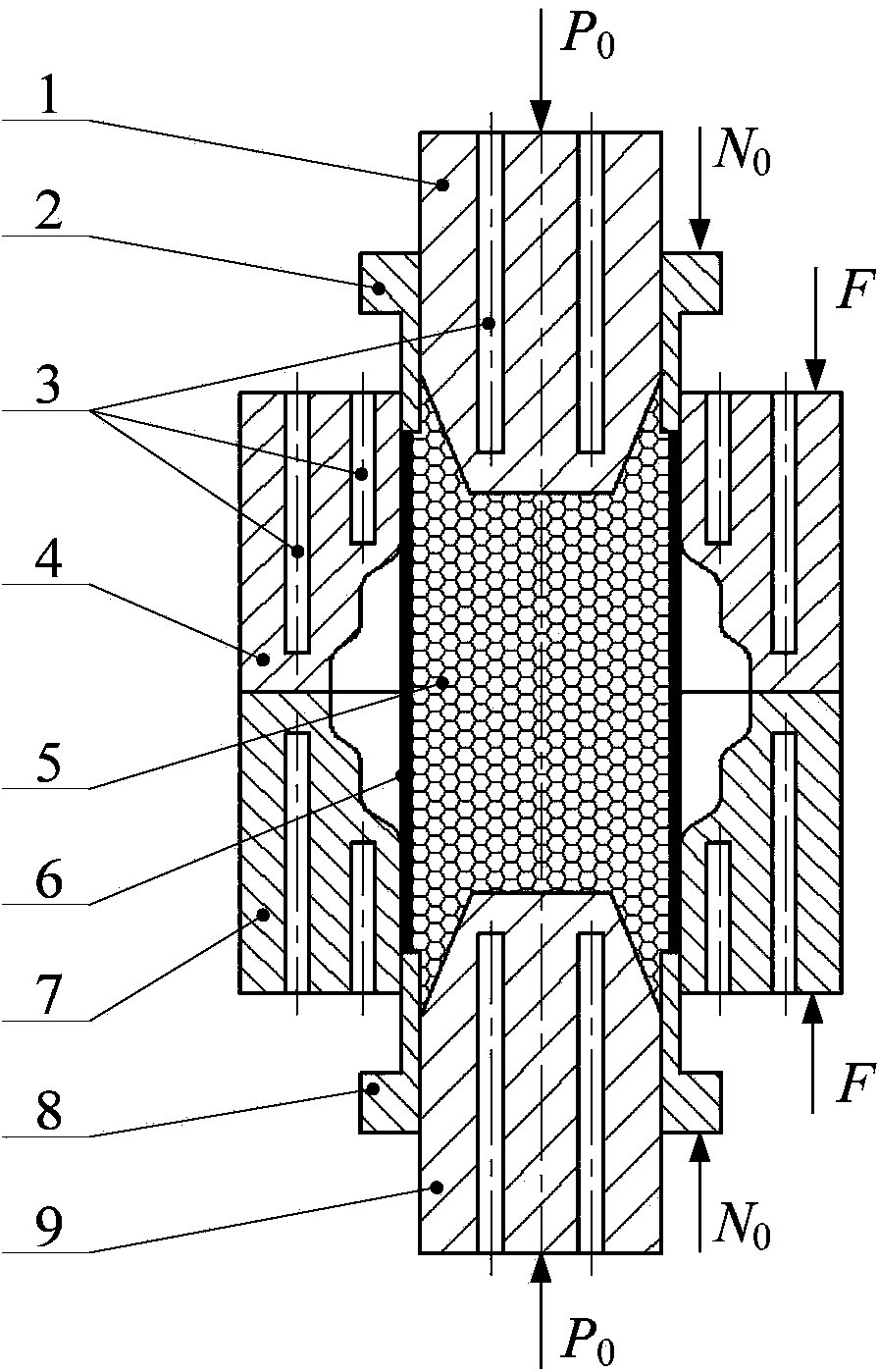

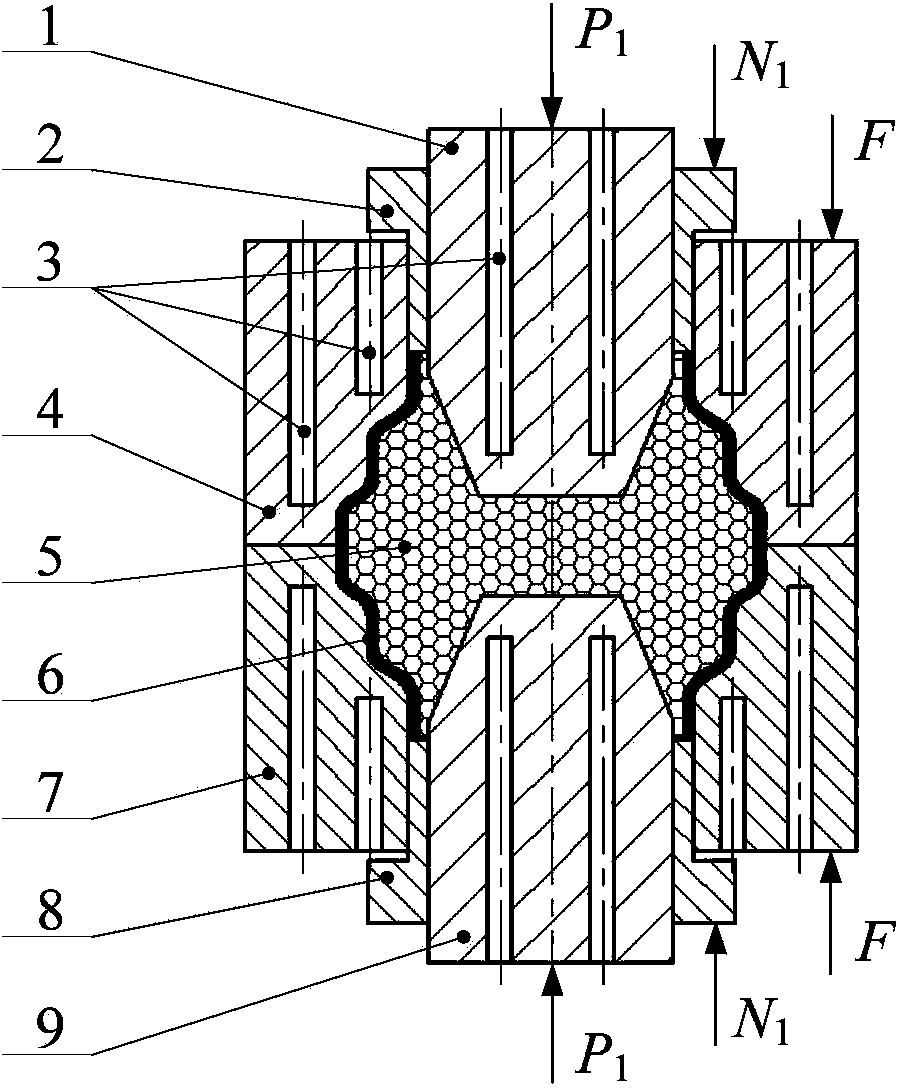

Solid particle medium thermal expansion forming method for light alloy tubular component

InactiveCN103894469ASimple process controlLow input costShaping toolsEnvironmental resistanceThermal expansion

Owner:YANSHAN UNIV

Method for preparing high impact modified material with waste and old polystyrene plastics

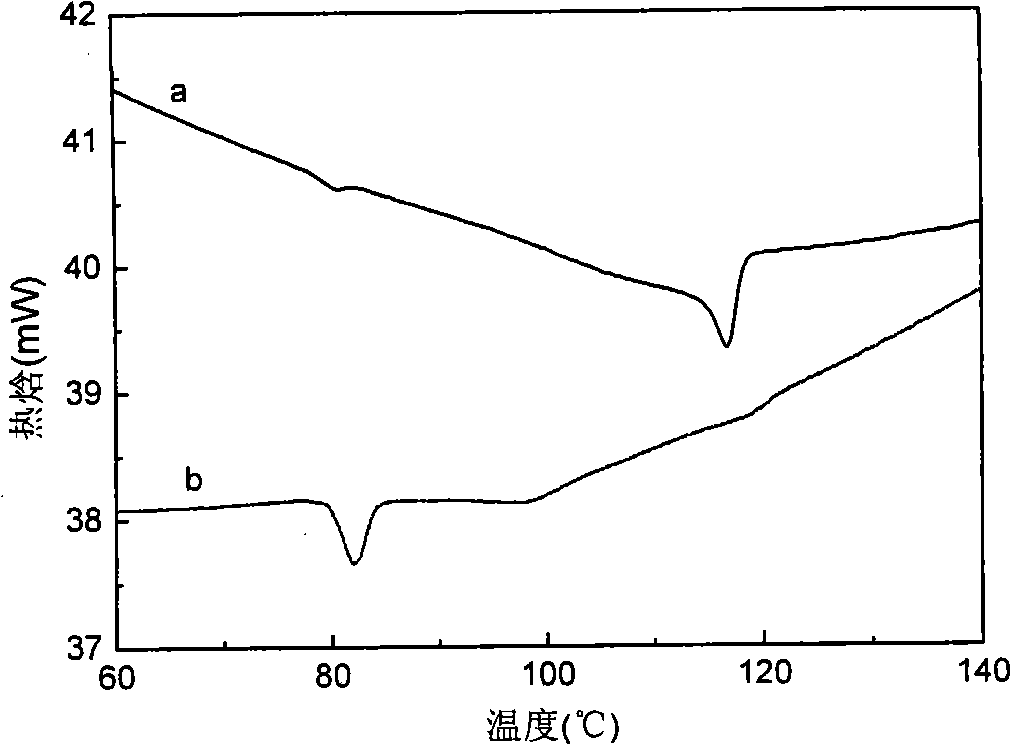

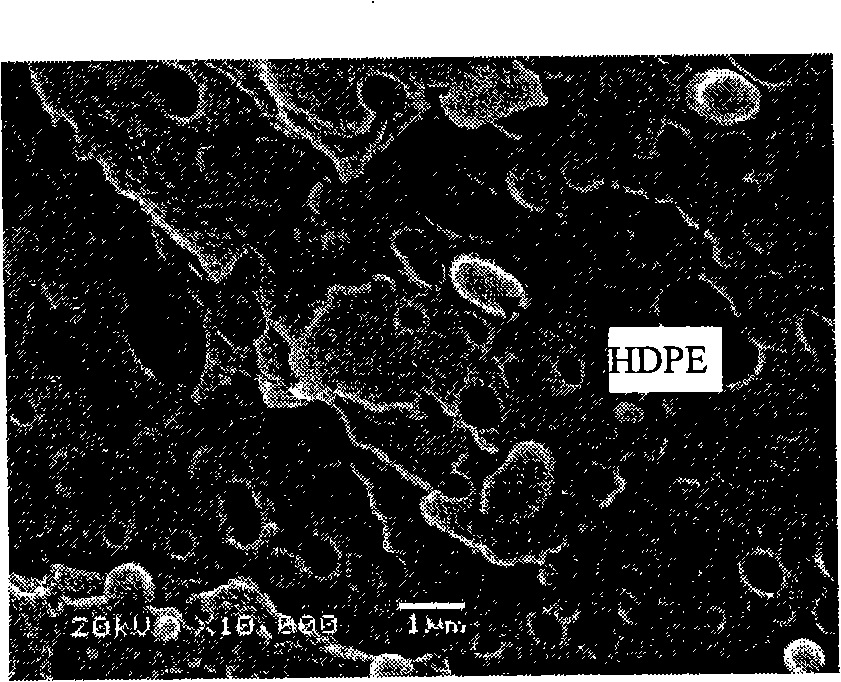

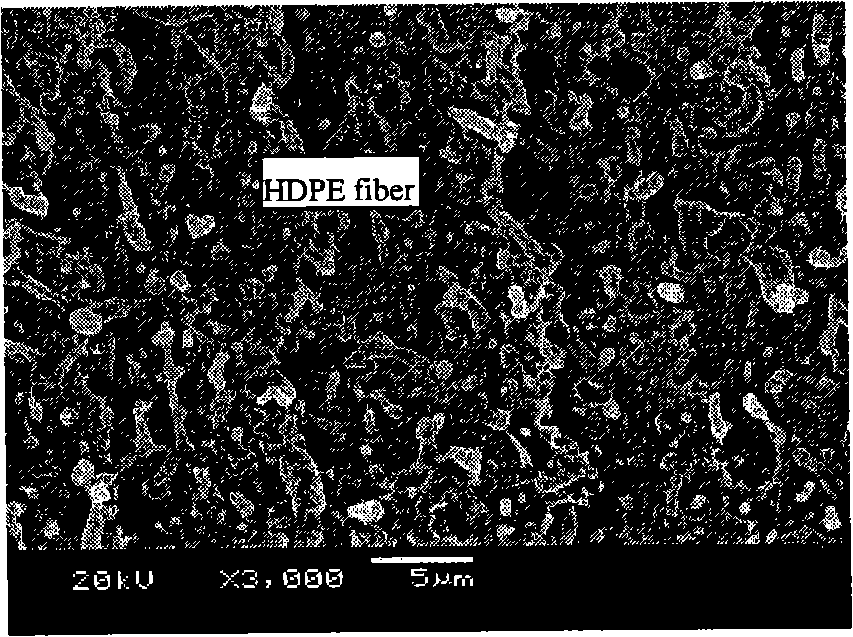

The invention discloses a method for preparing high-impact modified material from waste polystyrene plastic, which comprises the following steps: uniformly mixing 60 to 80 parts of waste polystyrene, 5 to 10 parts of polyethylene, 10 to 30 parts of elastomer, compatibilizer, etc. by stirring, adding to a screw extruder, and melting and blending at 150 to 210 DEG C, wherein the melt index ratio of polyethylene to polystyrene is equal to or less than 0.5. Due to the addition of small amount of polyethylene, the viscosity ratio of polyethylene to polystyrene and the crystallization behavior and the phase size of polyethylene can be controlled by restricting the melt index of waste polystyrene and polyethylene, so that the obtained modified material has a notched impact strength 8 to 10 times as high as that of original waste polystyrene and can maintain or even improve the tensile strength of polystyrene. The prepared modified polystyrene can be used for producing parts of middle- and high-level household appliances such as computer and air conditioner as the substitute of high-impact polystyrene new material, thus achieving remarkable social and economic benefits.

Owner:SICHUAN UNIV

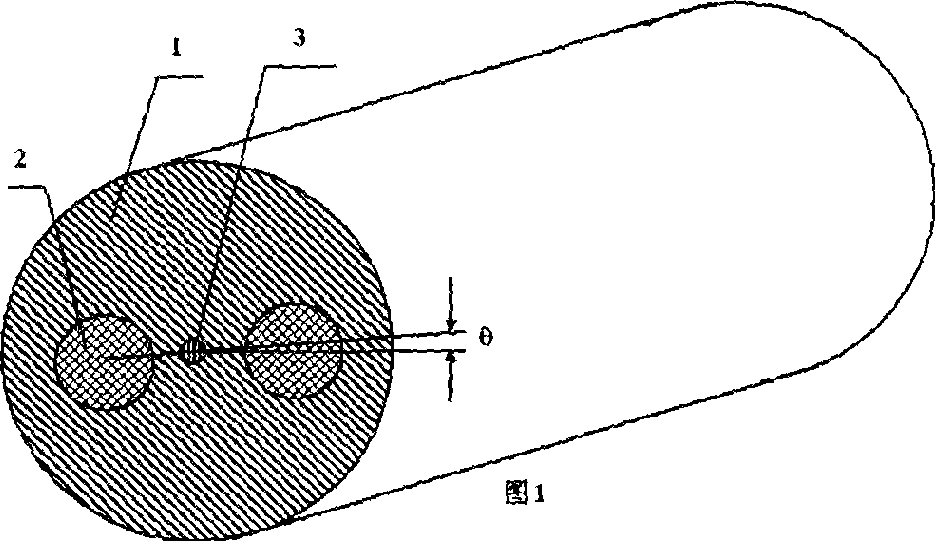

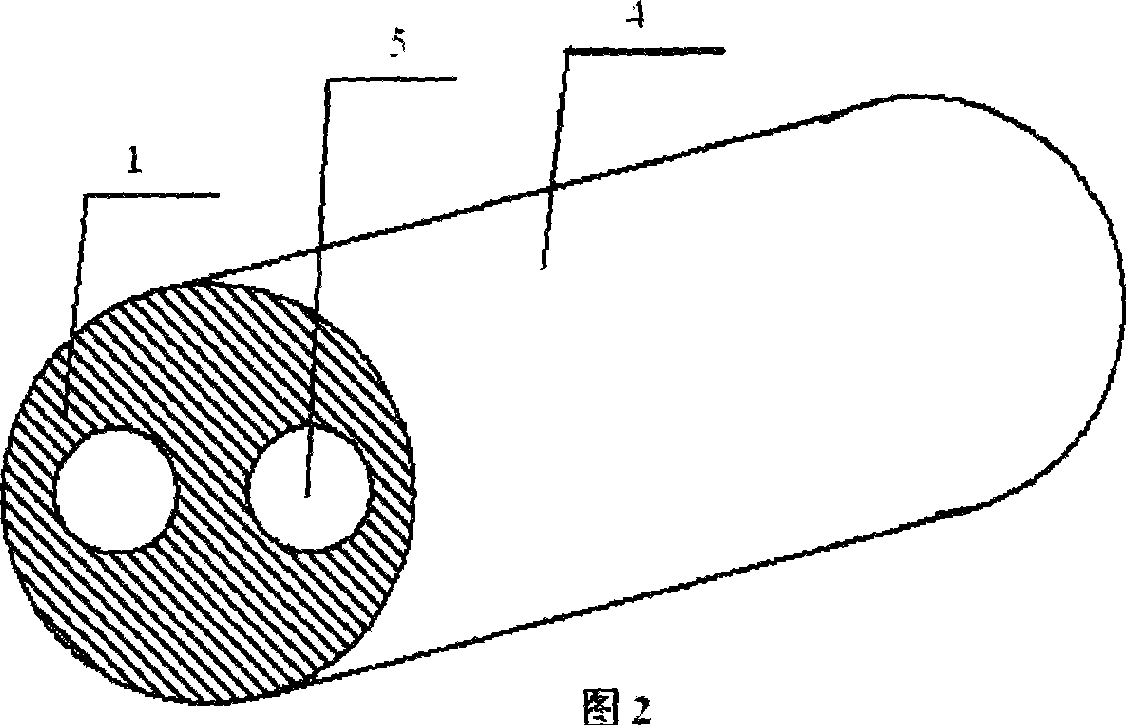

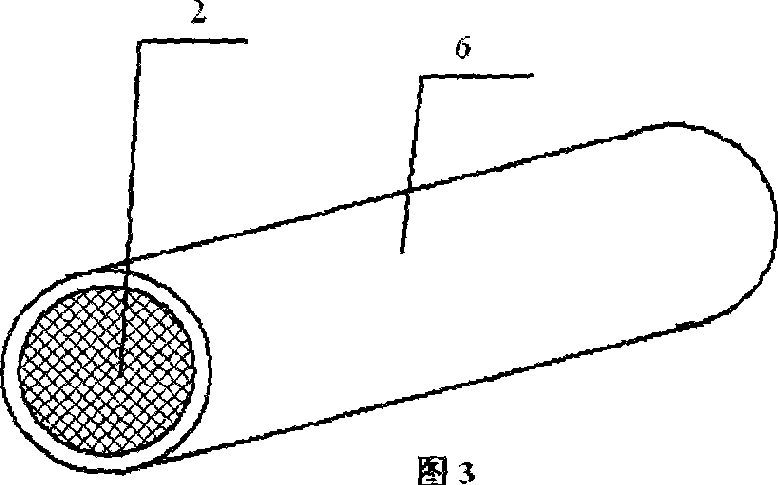

Large size combined optical fibre perform of polarization maintaining fiber and production method thereof

ActiveCN101391861AEasy to moveEvenly heatedGlass making apparatusGlass fibre productsStructural symmetryPolarization-maintaining optical fiber

The invention relates to a polarization maintaining optical fibre large-size composite optical fibre preform and a preparation technological method, and comprises the optical fibre preform with a fibre core and cladding layers; the areas of the cladding layers of the two sides of the fibre core of the optical fibre perform are provided with two holes which run through lengthways and are parallel to the fibre core; the two holes are provided with stress rods so as to form the composite optical fibre preform; the invention is characterized in that the optical fibre preform has the diameter of 30 to 80mm and the length of 200 to 800mm, the diameter range of the two side holes is 12 to 27mm and the diameter range of the stress area of the stress rod is 10 to 25mm. The polarization maintaining optical fibre large-size composite optical fibre preform and the preparation technological method lead the wire-drawing condition to be stable and controllable, and the drawn polarization maintaining optical fibre has excellent mechanical property and can pass the tension screening of 1 percent, even 2 percent; the preform with large diameter and large length is used for producing the polarization maintaining optical fibre; the wire-drawing length of a single preform reaches to be more than 200km, even more than 100km; and the production efficiency of the optical fibre is high. The drawn optical fibre structure has good symmetry and lengthwise uniformity and is easy to control.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

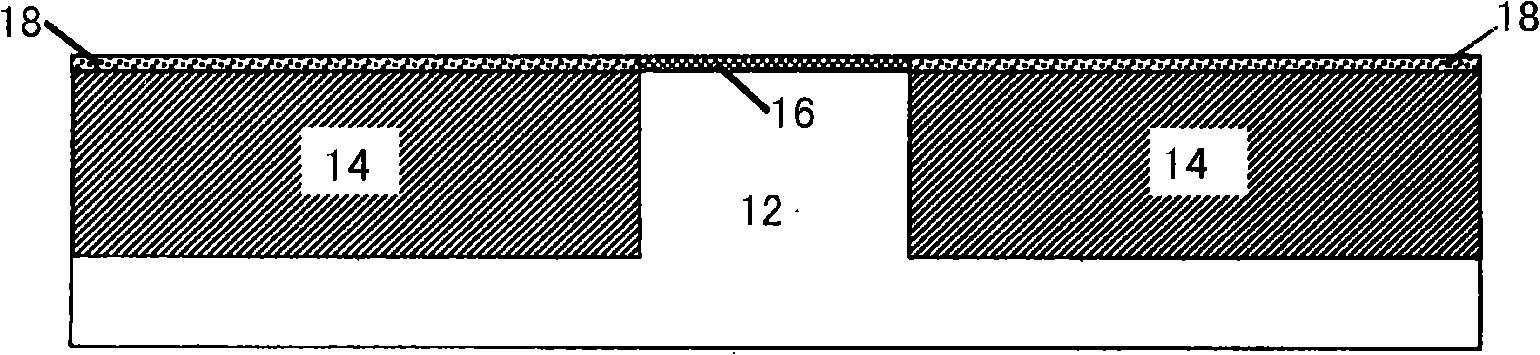

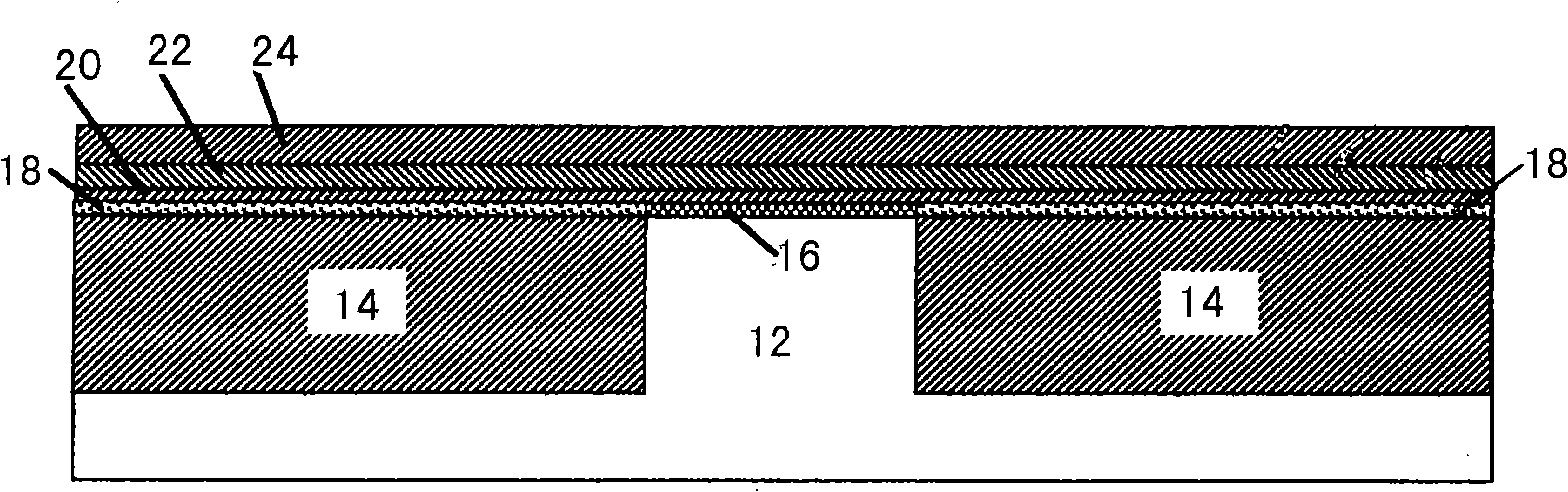

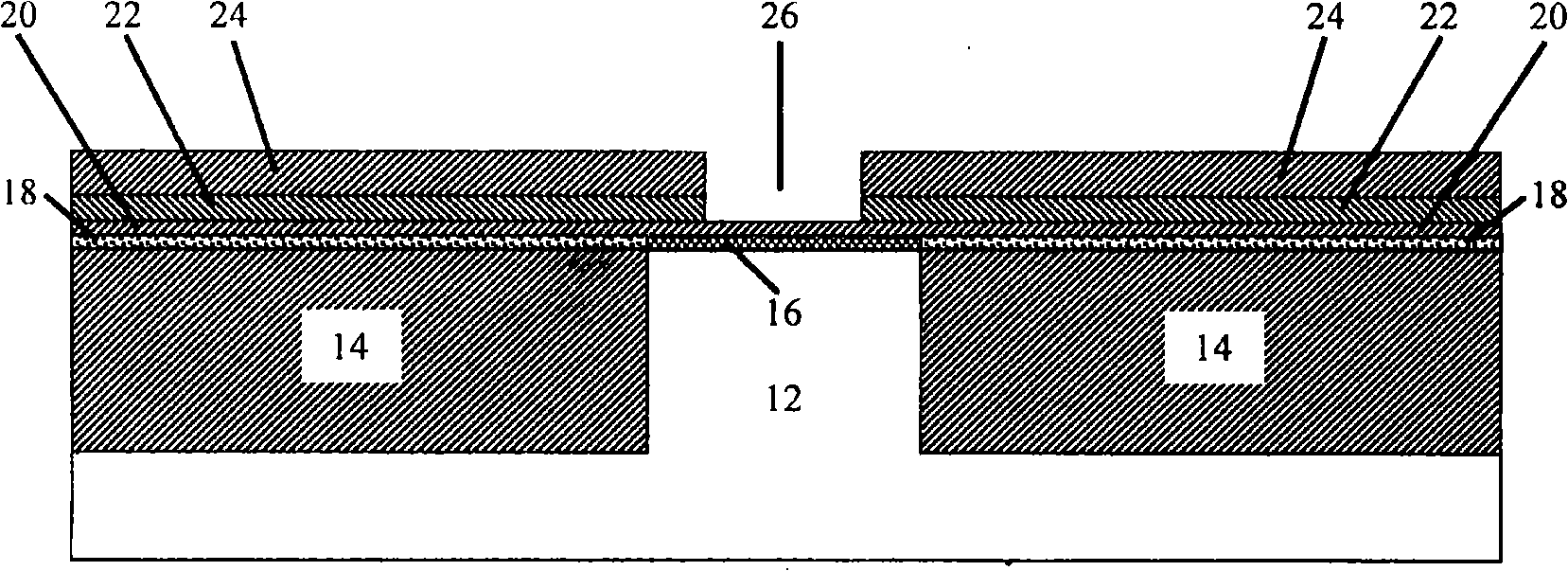

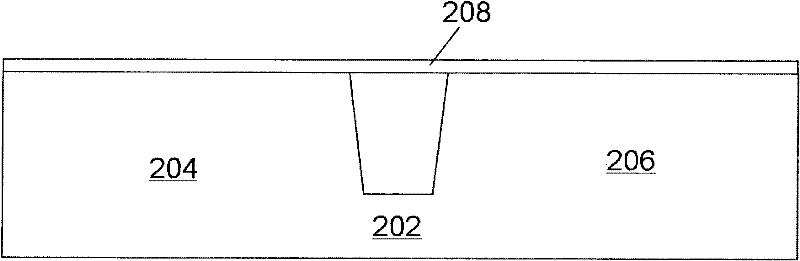

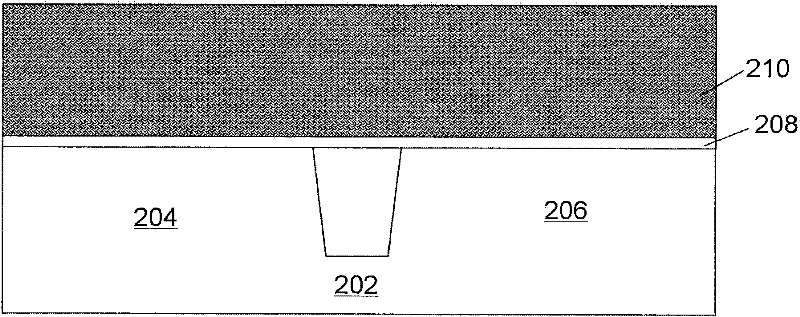

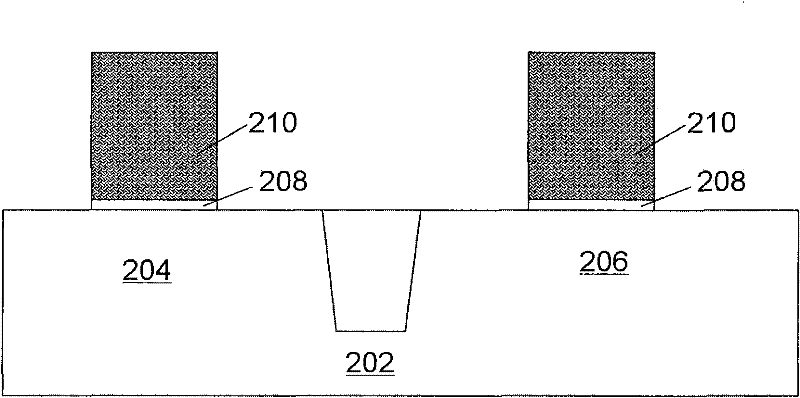

Self-alignment elevated external base area or heterojunction bipolar transistor and manufacturing method thereof

InactiveCN101359682AHigh speedHigh frequencyTransistorSemiconductor/solid-state device manufacturingSelective leachingMedia layer

The invention discloses a self-aligning bipolar transistor with an uplifted extrinsic base region or a heterojunction bipolar transistor and a fabrication method thereof, belonging to the technical field of semiconductor device fabrication. Firstly, a plurality of medium layers are deposited on a base; an emitter region window is formed through etching, then a medium inner wall is formed in the window; the medium layers (a plurality of) are selectively eroded on the basis of forming emitter region material through deposition or growing and etching, and then an uplifted extrinsic base region is formed through selective epitaxy method at the place vacated by the medium layers which are selectively eroded; and self-alignment of the uplifted extrinsic base region and the emitter region is realized due to the isolation action of the medium inner wall in the emitter region window, thus effectively reducing the base resistance of the device and thereby improving the speed, the frequency and the noise performance of the device.

Owner:TSINGHUA UNIV

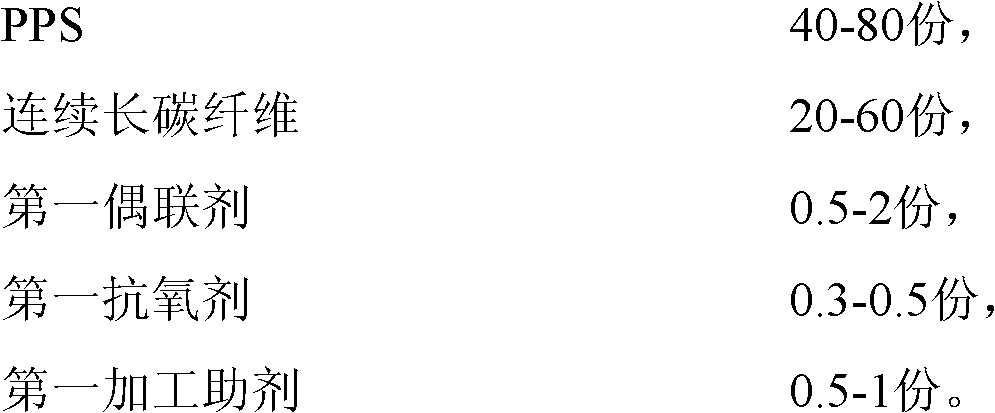

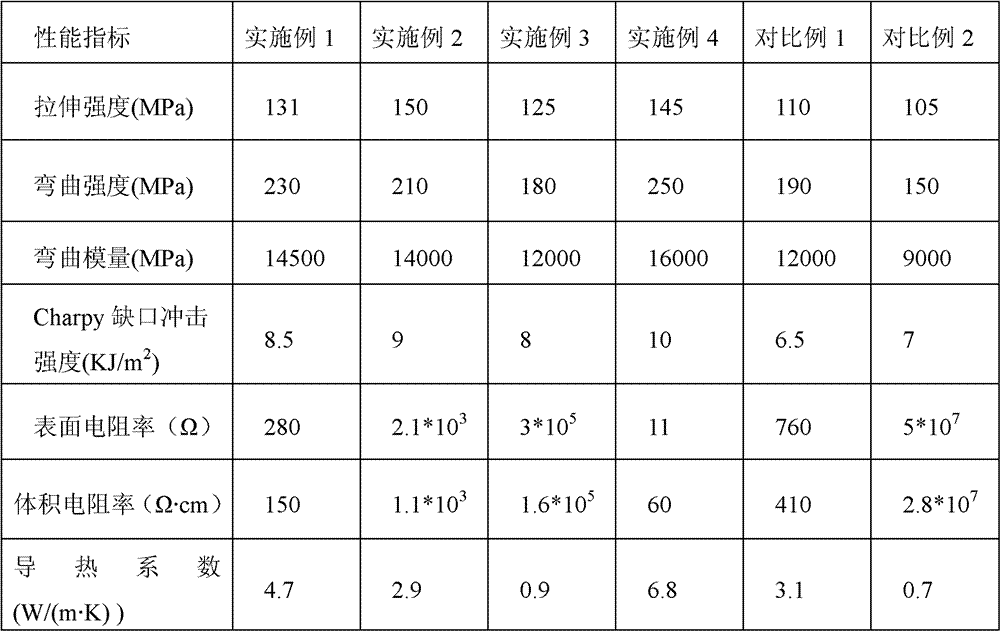

Long glass fiber reinforced electrically and thermally conductive polyphenylene sulfide composite material and preparation method thereof

The invention, belonging to the technical field of polyphenylene sulfide (PPS) composite material, discloses a long glass fiber reinforced electrically and thermally conductive polyphenylene sulfide composite material and a preparation method thereof. The composite material disclosed herein comprises the following ingredients: 30-80 weight parts of long glass fiber reinforced PPS masterbatch, and 20-70 weight parts of electrically and thermally conductive masterbatch, wherein the long glass fiber reinforced PPS masterbatch comprises 40-80 weight parts of PPS, 20-60 weight parts of continuous long glass fiber, 0.5-2 weight parts of first coupling agent, 0.3-0.5weight parts of first antioxidant, and 0.5-1 weight parts of first processing aid; and the electrically and thermally conductive masterbatch comprises 50-80 weight parts of PPS, 20-50 weight parts of electrically and thermally conductive agent, 0.5-2 weight parts of second coupling agent, 0.3-0.5 weight parts of second antioxidant, and 0.5-1 weight parts of processing aid. The preparation method disclosed herein comprises the following steps: mixing 30-80 weight parts of long glass fiber reinforced PPS masterbatch and 20-70 weight parts of electrically and thermally conductive masterbatch to prepare the long glass fiber reinforced thermal insulation polyphenylene sulfide composite material. The composite material disclosed herein has excellent thermal conducting property and mechanical property.

Owner:上海事升新材料有限公司

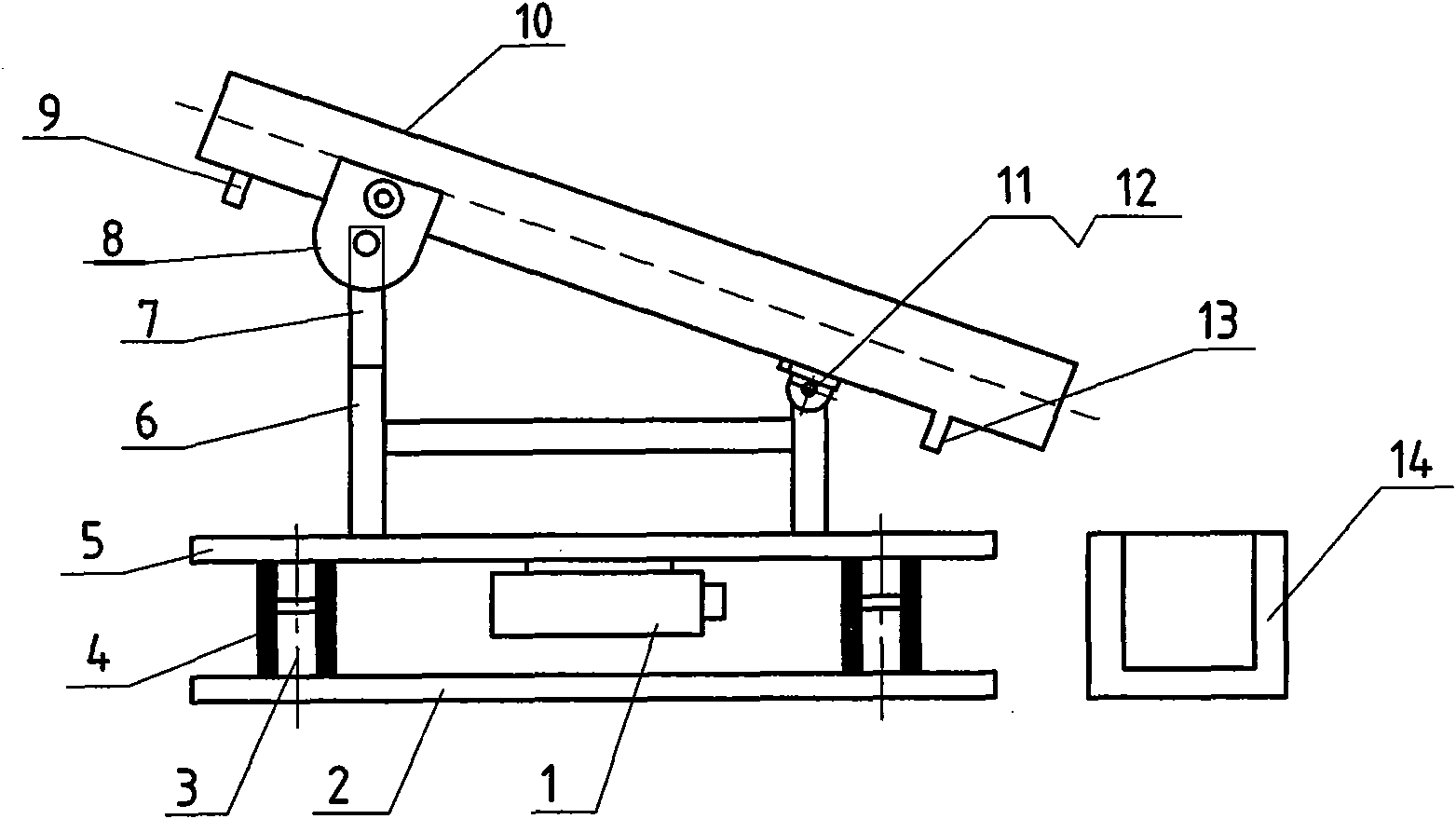

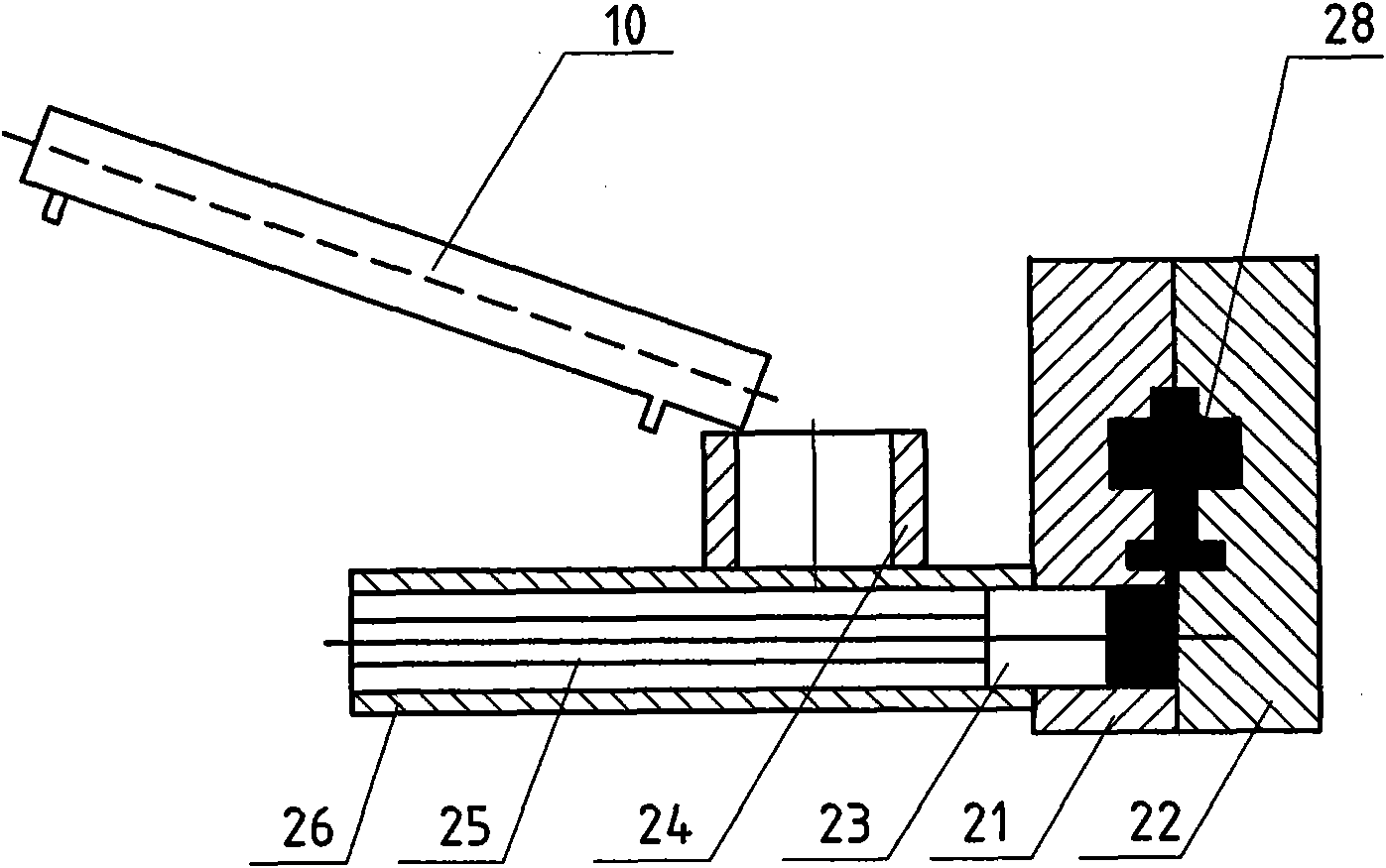

Device for preparing semi-solid alloy melt and process for preparing AlSi9Mg semi-solid alloy

The invention discloses a device for preparing semi-solid alloy melt and a process for preparing AlSi9Mg semi-solid alloy. The device comprises a vibrating device which comprises a base and a table top that are connected by a pillar and a rubber spring, the vibrating device is connected with a cooling groove in an inclined way by a supporting frame which can regulate an angle, the table top is provided with a three dimensional vibrating motor, the vibrating acceleration speed is 1 to 2g, the vibrating range is 0.5 to 1mm, the vibrating frequency is 10 to 60 Hz, and a liquid outlet end of the cooling groove corresponds to a forming device. The angle of the cooling groove is 40 to 60 degrees, and the pouring length is 600 to 800mm. The forming device comprises an injection chamber of a die-casting machine, an injection rod, an injection head, a material receiving port and a mold. The rheological forming process for preparing the semi-solid AlSi9Mg alloy melt comprises the steps of alloymelting, gas and slag removing, refining, modifying, inclined vibrating and pouring, rheological die-casting and the like. The device and the process can improve the texture and performance of the semi-solid alloy and solve the problem of solidification and crusting on the surface of an inclined plate in the preparing process.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of dried poultry egg

InactiveCN102461918ARealize industrial productionPlay a role in promotingFood preparationMonosodium glutamateAnimal science

The invention relates to a preparation method of a dried poultry egg. The preparation method is characterized by comprising the following steps of: mixing 70-100 parts by weight of a poultry egg mixed solution, 0.1-2.5 parts by weight of common salt, 0.1-1.5 parts by weight of chicken essence and 0.1-2.3 parts of monosodium glutamate according to a proportion, stirring for 10-15 minutes for uniformly stirring, standing under an environment at the temperature of 0-25 DEG C for 10-30 minutes, then filling into an edible non-sticky plastic mold, placing into a steam cooker, closing the steam cooker, raising the temperature of steam in the steam cooker to 60-90 DEG C within 0-20 minutes by adjusting atmospheric pressure (1.5-2atm) in the cooker, performing heat insulation for 20-30 minutes to form the dried poultry egg of egg white gel with better elasticity and hardness, further performing demolding, marinating and baking on the well formed dried poultry egg, then cutting into small pieces in different shapes and different sizes according to requirements, seasoning, and packaging the well seasoned dried poultry egg with a compound plastic bag. A well packaged product is sterilized through a heat exchange type sterilizer, and then cleaned, cooled, air-dried, boxed and code-printed so as to prepare a final product.

Owner:YANAN LAOSHAN CHICKEN IND

A kind of semiconductor device and its manufacturing method

ActiveCN102299156ARelieve stressEase of selective etchingTransistorSemiconductor/solid-state device manufacturingDielectricCMOS

The invention has the following beneficial effects: in the process of preparing CMOS (complementary metal-oxide-semiconductor) transistors by adopting the replacement gate or gate last, after high-k gate dielectric layers are formed in the NMOS device region and the PMOS device region, a first work function adjustment dielectric layer belonging to the NMOS region and a second work function adjustment dielectric layer belonging to the PMOS region are respectively formed to adjust the threshold voltages of the NMOS device and the PMOS device respectively, and formed by dielectric materials, the work function adjustment dielectric layers are easier to selectively etch and beneficial to process control and also relieve the pressure on research on dual metal gate materials.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

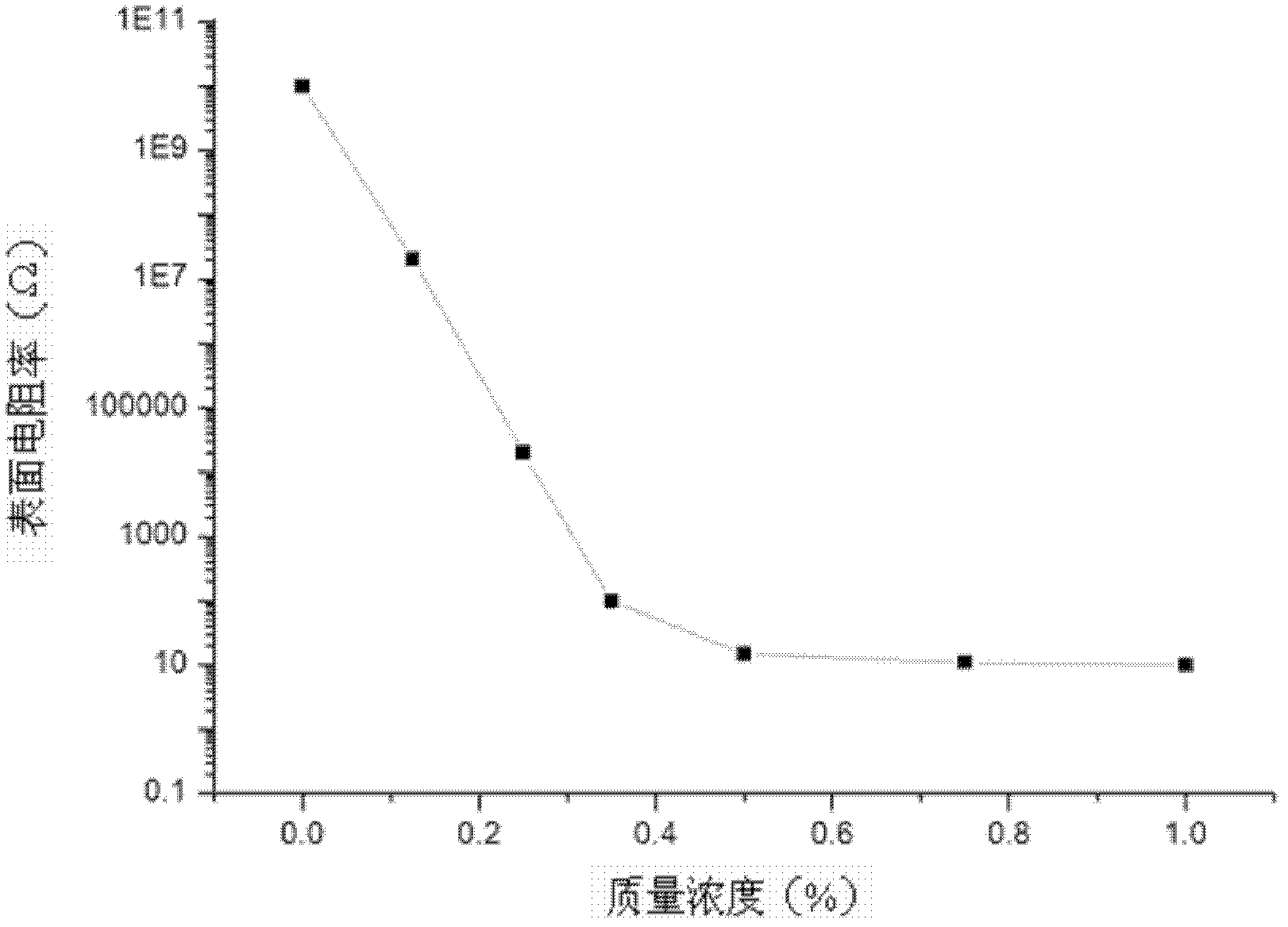

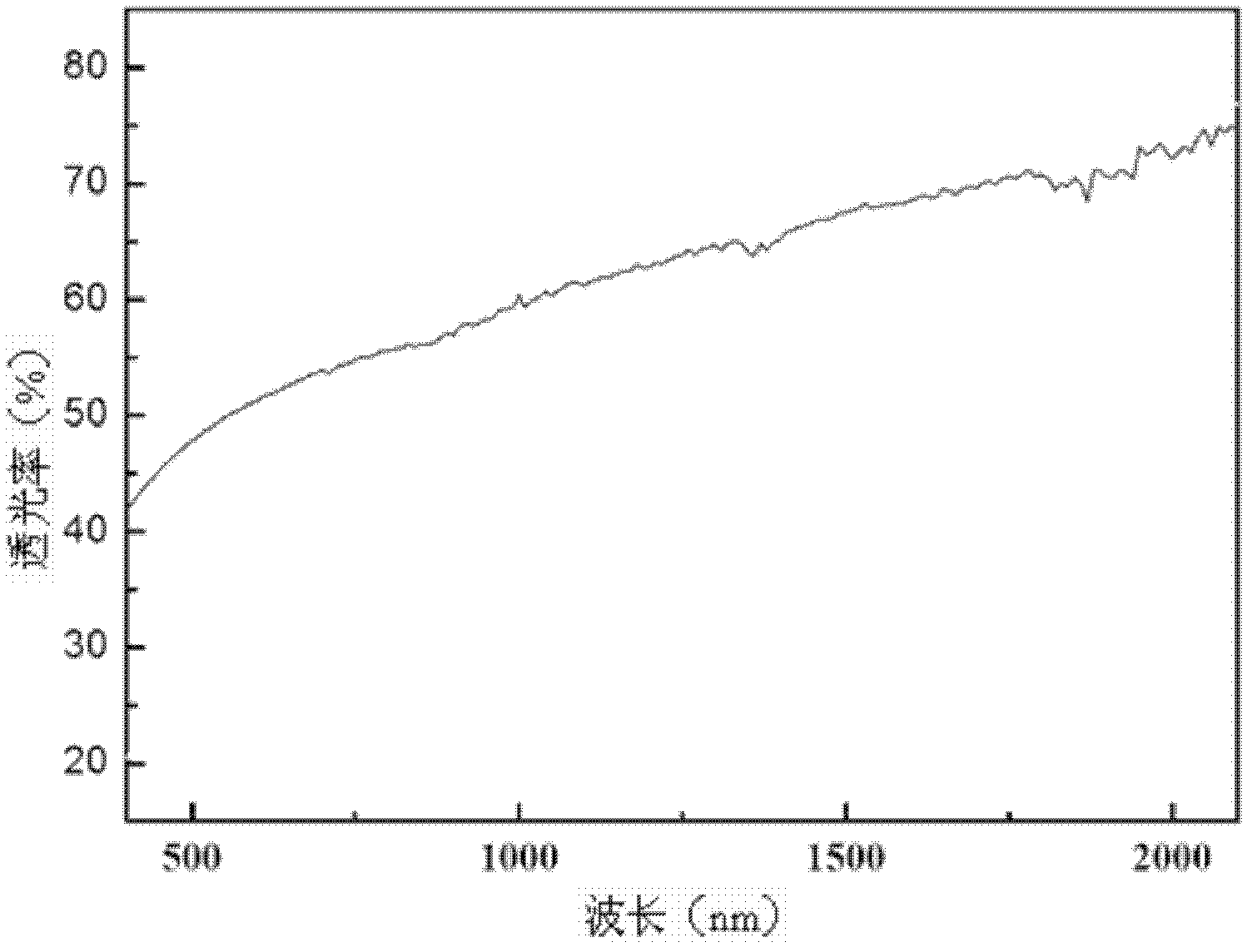

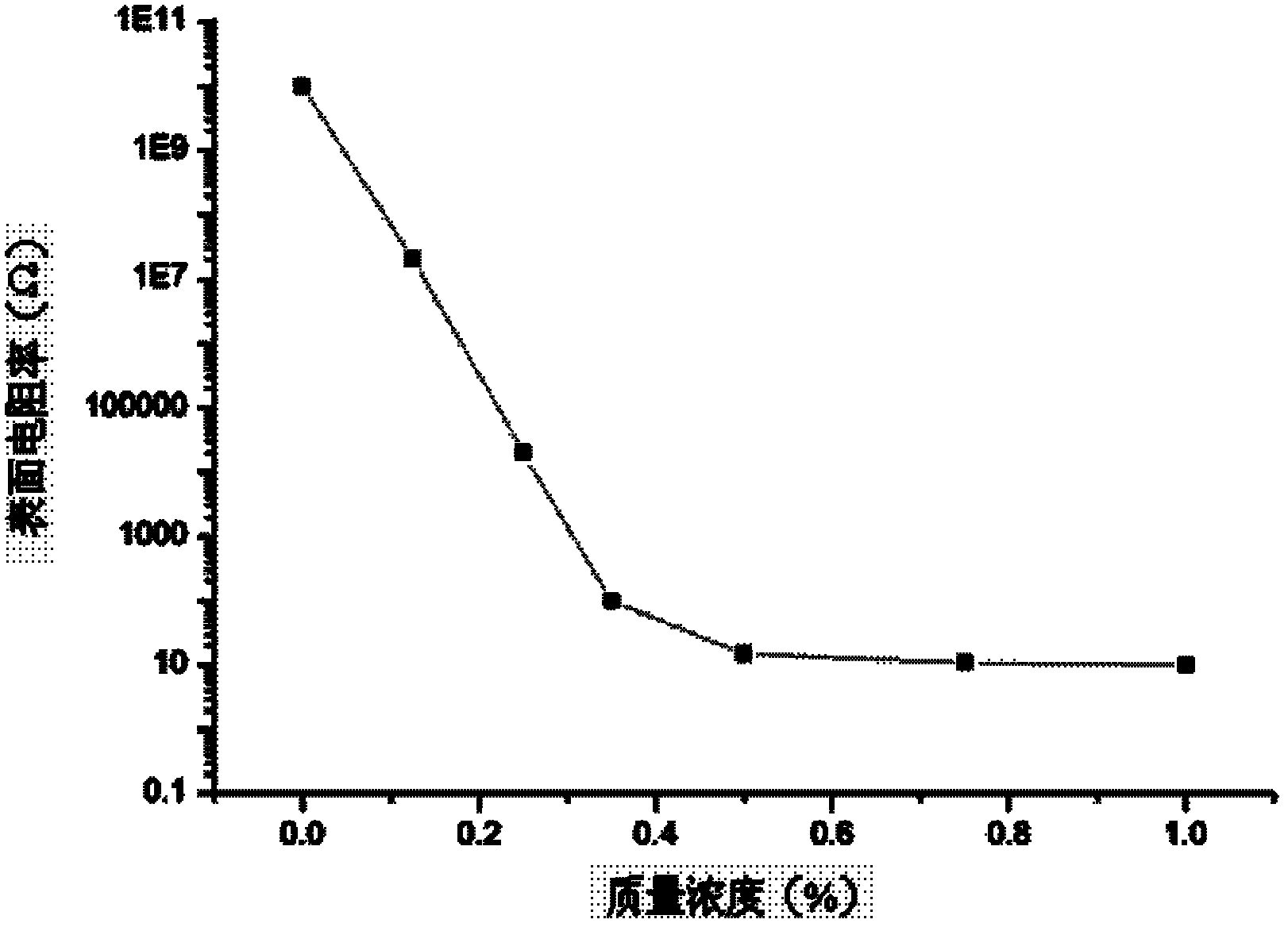

Method of surface self-assembly of graphene/polyimide transparent electric conduction film

ActiveCN102592749AImprove incompatibilitySimple processConductive layers on insulating-supportsCable/conductor manufactureOmegaUltrasonic dispersion

The invention relates to a method of surface self-assembly of graphene / polyimide transparent electric conduction film, and relates to a preparation method of the graphene / polyimide transparent electric conduction film. The invention aims to solve the technical problems that the adhesive force of a flexible substrate and a settled layer in the existing flexible electric conduction film is weak, and an inorganic electric conduction layer and an organic base are incompatible. The method comprises the following steps: firstly, placing graphite oxide respectively in N,N-dimethyl acetamide or N-methyl pyrrolidone, carrying out ultrasonic dispersion, adding a reducing agent, and carrying out reduction reaction, thereby obtaining a graphene organic solution system; secondly, adding a dianhydride monomer and a diamine monomer in N, N-dimethyl acetamide, and stirring in an inert atmosphere, thereby obtaining a PAA (poly acrylic acid) solution; and thirdly, mixing and stirring the graphene organic solution system and the PAA solution, then coating on a clean and dry glass plate, volatilizing the solvent and curing. The surface resistance of the graphene / polyimide transparent electric conduction film prepared by the method provided by the invention is 10-20 omega, and the graphene / polyimide transparent electric conduction film has favorable light transmissivity at the visible light wave band and the near-infrared wave band.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com