Blow molding grade halogen-free flame-retardant polypropylene material and preparation method thereof

A flame retardant polypropylene and polypropylene material technology, applied in the manufacture of automobile air ducts, blow molding grade halogen-free flame retardant polypropylene materials and their preparation fields, can solve problems such as poor flame retardant performance, and easily guarantee material performance , the process control is simple, the effect of high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 80.6 kg of polypropylene (grade SM256), 0.2 kg of phenolic heat stabilizer Irganox 1010 (CIBA company), 0.2 kg of lubricant EBS (that is, N, N-ethylene bis stearamide), 2 kg of compatibilizer methyl Glycidyl acrylate grafted polypropylene (GMA-PP), 2 kg of toughening agent ethylene-propylene-butadiene terpolymer, 10 kg of intumescent flame retardant FP2200 (a kind suitable for thermoplastic PP, PE, etc. Phosphorus-nitrogen series intumescent flame retardant for polyolefin plastics (produced in Japan) and 5 kg of talcum powder were melt-mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated to obtain this example Blow molding grade halogen-free flame retardant polypropylene material. The intumescent flame retardant is fed into the twin-screw extruder by side feeding, and the processing temperature is 200°C.

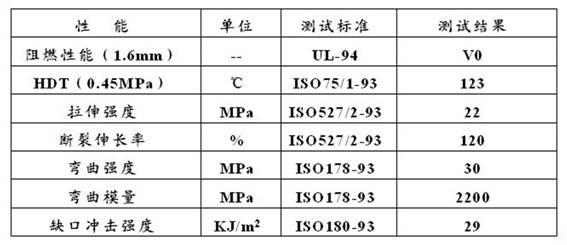

[0031] The performance of present embodiment gained polypropylene material is as follows:

[0032]

Embodiment 2

[0034] 67.5 kg of polypropylene (grade SM256), 0.3 kg of phenolic heat stabilizer Irganox 1010 (CIBA company), 0.2 kg of lubricant EBS (that is, N, N-ethylene bisstearamide), 3 kg of compatibilizer Malay Anhydride-grafted polypropylene (MAH-PP), 4 kg of toughening agent ethylene-octene copolymer, 15 kg of intumescent flame retardant FP2200 (an intumescent phosphorus-nitrogen system suitable for thermoplastic PP, PE and other polyolefin plastics) Flame retardant, produced in Japan) and 10 kg of wollastonite were melted, mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1, extruded and granulated to obtain the blow molding grade halogen-free flame-retardant Polypropylene material. The intumescent flame retardant is fed into the twin-screw extruder by side feeding, and the processing temperature is 200°C.

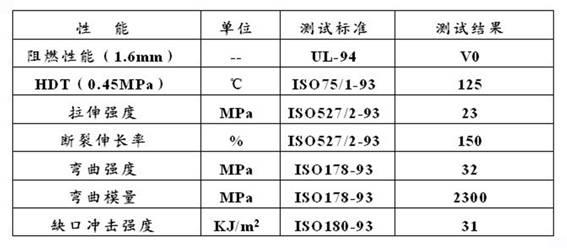

[0035] The performance of present embodiment gained polypropylene material is as follows:

[0036]

Embodiment 3

[0038] 54 kg of polypropylene (grade SM256), 0.5 kg of phenolic heat stabilizer Irganox 1010 (CIBA company), 0.5 kg of lubricant calcium stearate, 4 kg of compatibilizer maleic anhydride grafted polypropylene (MAH-PP) , 6 kg of toughening agent hydrogenated styrene-butadiene-styrene triblock copolymer (SEBS), 20 kg of intumescent flame retardant FP2200 (a phosphorus nitrogen system suitable for thermoplastic PP, PE and other polyolefin plastics) Intumescent flame retardant, produced in Japan) and 15 kg of kaolin were melted, mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1, extruded and granulated to obtain the blow molding grade halogen-free flame retardant of this embodiment Polypropylene material. The intumescent flame retardant is fed into the twin-screw extruder by side feeding, and the processing temperature is 200°C.

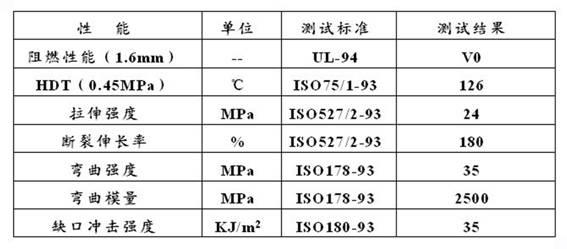

[0039] The performance of present embodiment gained polypropylene material is as follows:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com