Patents

Literature

109 results about "Molding grade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

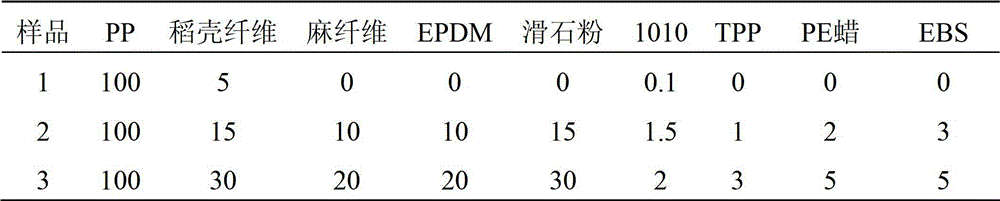

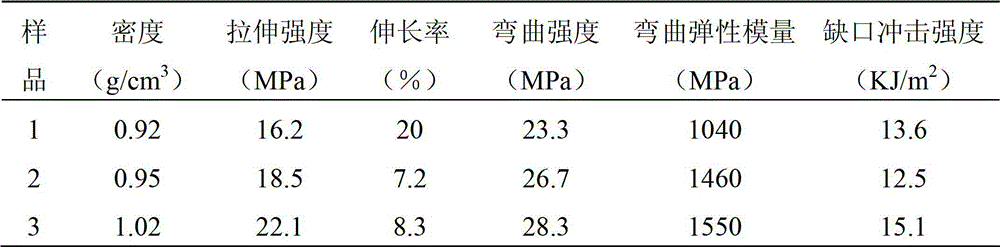

Injecting molding grade natural fiber composite material and preparation method thereof

The invention relates to a natural fiber composite material and a preparation method of the composite material. The composite material comprises the following components in parts by weight: 100 parts of thermoplastic resin, 5-50 parts of natural fiber, 0-20 parts of impact modifier, 0-30 parts of inorganic filler, 0.1-5 parts of anti-aging agent, and 0-10 parts of processing aid. The preparation method of the composite material comprises the steps of adding the natural fiber into an aqueous solution of a saline coupling agent to soak, then drying the natural fiber, mixing the natural fiber with the other processing aids, feeding the mixed material into a double-screw extruder to subject to the melting extrusion, and granulating to obtain the composite material. Compared with the prior art, the preparation method is simple in process and environment-friendly. More importantly, the problems that the composite material, into which a large amount of natural fiber is added, is poor in material mobility, low in intensity of parts, and poor in appearance quality, are solved. The current situation that the natural fiber composite material cannot adapt to the injection moldings of complex structures is changed.

Owner:CHERY AUTOMOBILE CO LTD

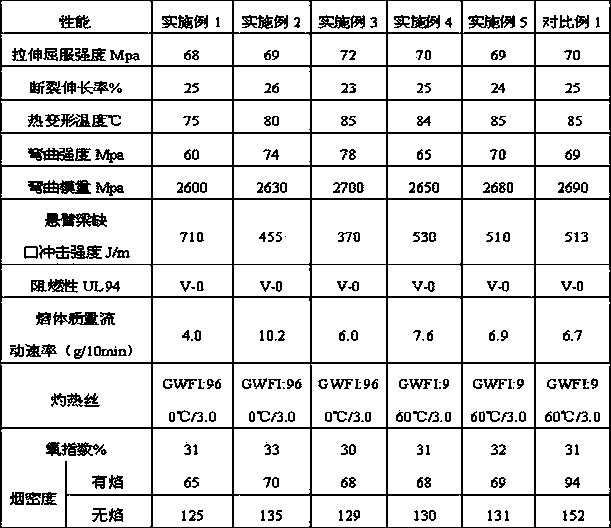

Injection molding grade flame retardant PVC/ABS alloy material and preparation method thereof

ActiveCN103509289AImprove mechanical propertiesImprove processing fluidityPlasticizerHeat resistance

The invention discloses an injection molding grade flame retardant PVC / ABS alloy material and a preparation method thereof. The alloy material comprises the following components in parts by weight: 30-80 parts of PVC resin, 35-70 parts of ABS resin, 1-6 parts of a heat stabilizer, 2-5 parts of a processing agent, 2-15 parts of an impact modifier, 1-10 parts of a heat resistant modifier, 2-5 parts of a plasticizer, 2-8 parts of a fire retardant, 3-10 parts of a smoke suppression agent and 3-15 parts of other accessory ingredients. The PVC / ABS alloy material disclosed by the invention adopts the high-fluidity PVC resin and the heat-resistance, high-toughness and high-fluidity ABS resin, so that the PVC / ABS alloy material has excellent mechanical performance and processing fluidity; on the premise of guaranteeing excellent physical performance of the material, the obtained PVC / ABS alloy material further improves the processing fluidity, the heat stability, the flame resistance and the heat resistance of products, and reduces the smoke density.

Owner:GUANGDONG JUSHI CHEM CO LTD

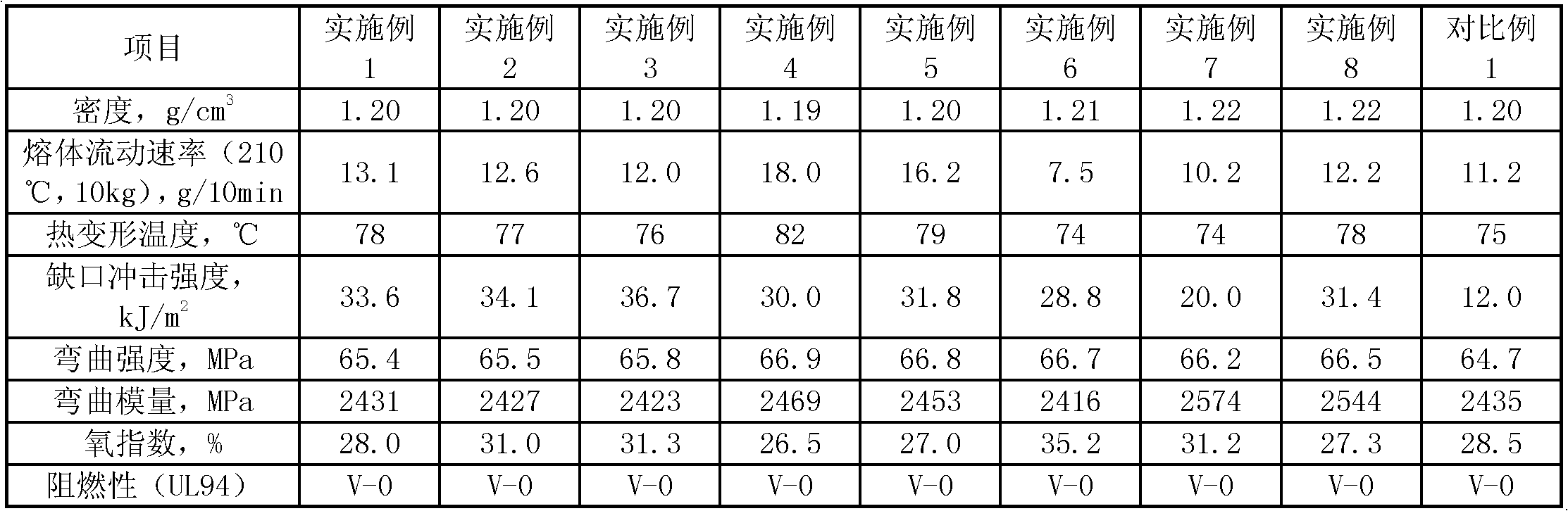

PVC/ABS alloy material with high anti-impact strength and preparation method thereof

The invention provides a PVC / ABS alloy material with high anti-impact strength and a preparation method thereof. The alloy material comprises, by weight, 30 to 80% of a PVC composite material modified by filled active nanometer calcium carbonate and 20 to 70% of injection molding grade ABS resin. The PVC composite material comprises PVC resin, a heat stabilizer, a lubricant, an anti-impact modifier, an anti-oxidant, a fire retardant and the filler active nanometer calcium carbonate, and the weight ratio of the above-mentioned components is as follows: PVC resin: the heat stabilizer: the anti-impact modifier: the lubricant: the anti-oxidant: the fire retardant: the filler active nanometer calcium carbonate = 100 parts: 4.7-5.5 parts: 5-15 parts: 0.1-6 parts: 0.1-2 parts: 3-6 parts: 5-20 parts. The preparation method is as follows: all the materials are weighed according to a formula for the PVC composite material and placed in a high speed mixer with a rotate speed of 680 to 1400 r / min for high speed stirring, when the temperature of an obtained mixture rises to 100 to 120 DEG C, the high speed mixture is put in a low speed mixer with a rotate speed of 85 r / min for stirring and cooling, after the temperature of the mixture drops to 40 to 50 DEG C, a desired amount of the dried ABS resin is added into the mixture, low speed mixing at a rotate speed of 85 r / min is carried out for 2 to 8 min, and a discharged material is a dry blend for the alloy material; the dry blend is added into a double screw extruder or a double / single screw two-stage extruder for melt blending and extruding at a temperature of 110 to 170 DEG C, and an obtained material is cut into granular materials by using a plastic grain cutting machine.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene)

The invention relates to a preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene). The preparation method comprises the following steps: adding a certain amount of solvent oil in a dispersion medium, and polymerizing, thus obtaining UHMWPE containing the solvent oil; extruding through a screw extruder after mixing a flow modifier, a function additive processed by a coupling agent, an antioxidant and the UHMWPE containing the solvent oil at high speed, thus obtaining the injection molding grade UHMWPE. Compared with the prior art, the injection molding grade UHMWPE prepared by the method has good liquidity and good mechanical performance, can be machined and formed on a common injection molding and extrusion device, the machining efficiency is increased, and the injection molding grade UHMWPE can be widely applied to many fields of spaceflight, military industry, automobiles, high-speed rails, rail transit, spinner accessories and the like.

Owner:SHANGHAI RES INST OF CHEM IND

Nylon-based nano composite material and preparation method thereof

The invention discloses a nylon-based nano composite material and a preparation method thereof. The nylon-based nano composite material consists of the following components in percentage by weight: 25 to 96.7 percent of polyamide resin, 0.5 to 30 percent of blocking macromolecular filler, 0.5 to 10 percent of blocking inorganic nano filler, 2 to 30 percent of toughening agent, and 0.3 to 5.0 percent of aid. The nylon-based nano composite material has wide raw material source, can be prepared into injection molding grade and blow molding grade products, has high blocking performance for polar and non-polar volatile small molecular substances such as fuel oil, ethanol, oxygen and carbon dioxide, and has excellent high and low temperature comprehensive performance; and the products can be applied to the occasions with high requirement for the blocking performance such as fuel tanks, lubricating oil pots, fuel pipelines and packing materials.

Owner:徐东

Injection molding-grade high-performance polypropylene composite material with good appearance and preparation method of injection molding-grade high-performance polypropylene composite material

InactiveCN104558834AHigh Molecular Weight DistributionImprove the appearance of injection moldingElastomerPolypropylene composites

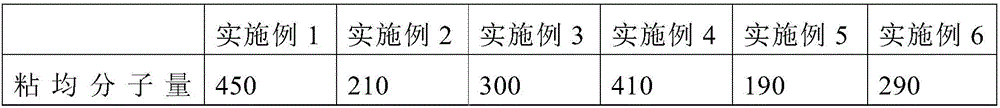

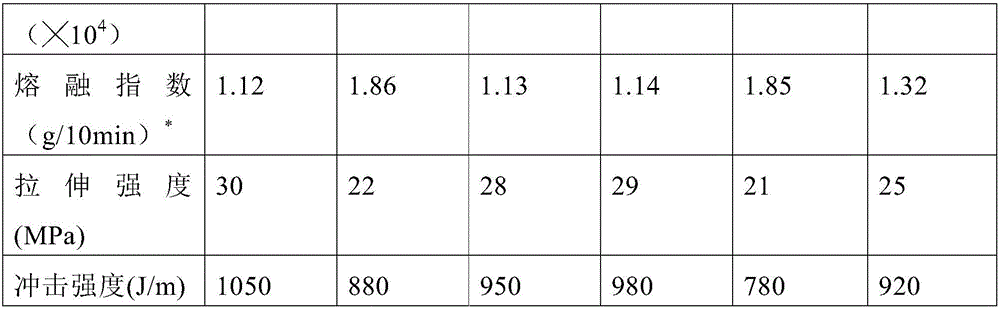

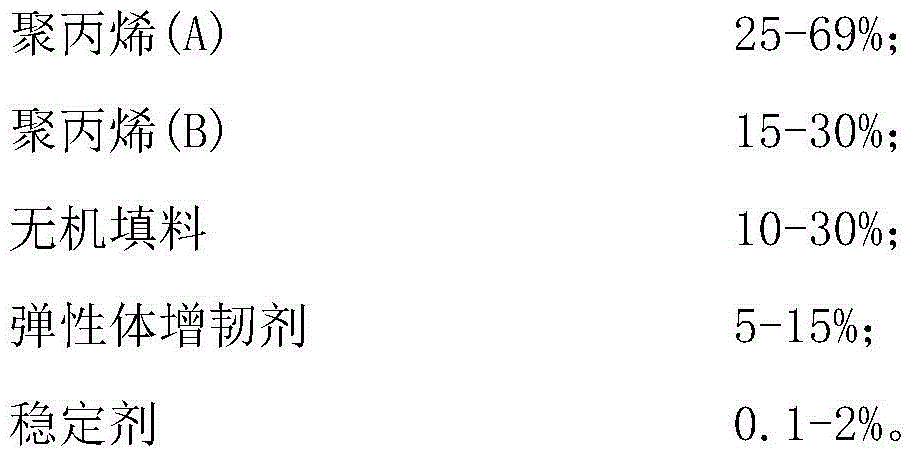

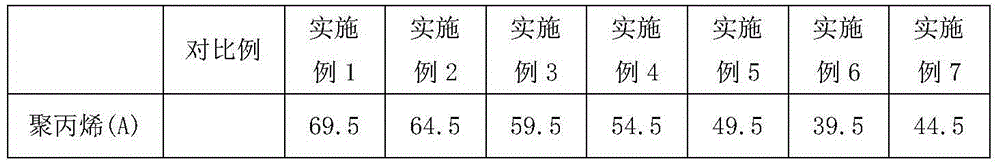

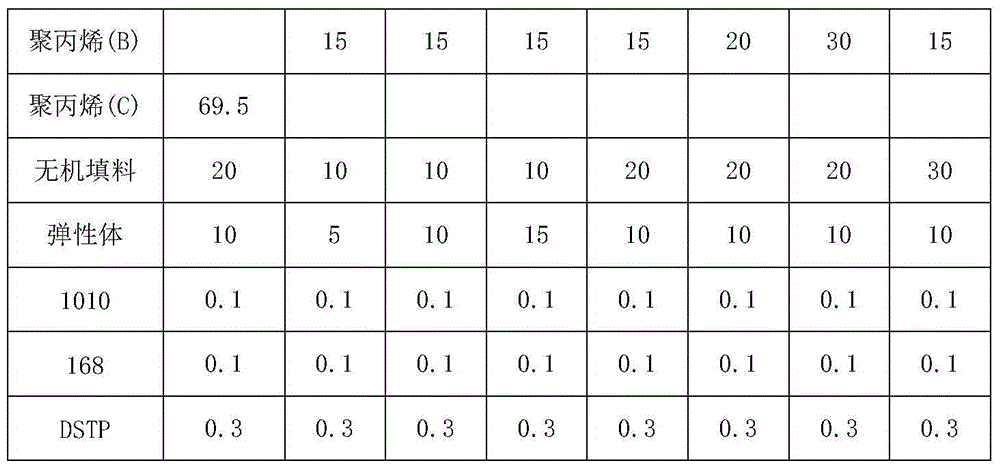

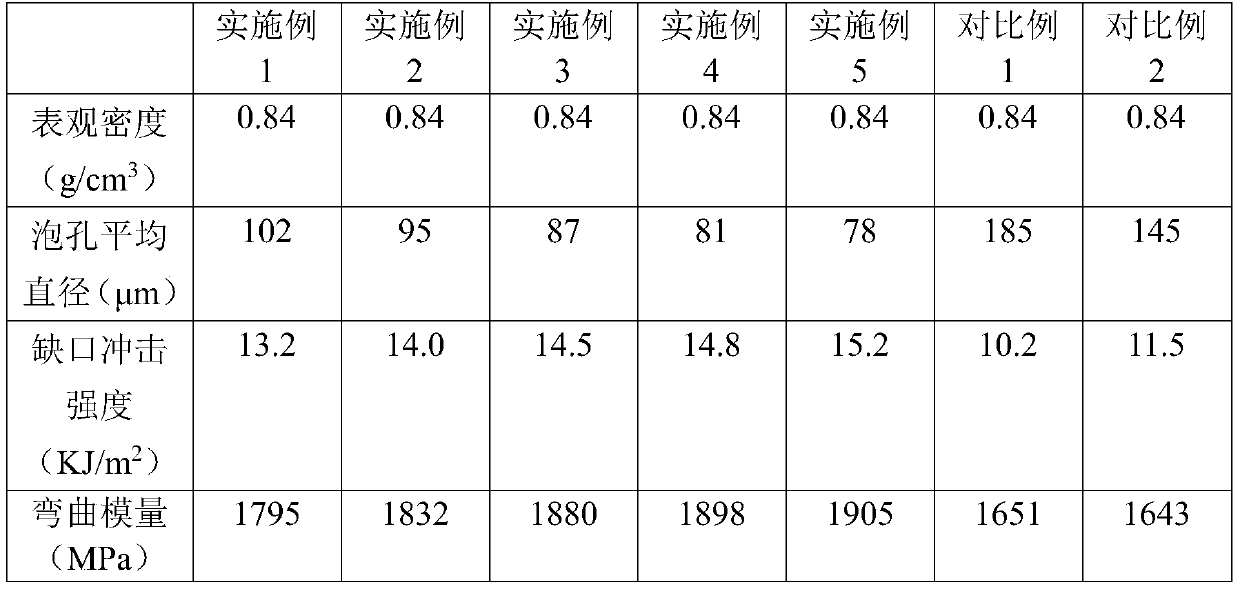

The invention discloses an injection molding-grade high-performance polypropylene composite material with a good appearance and a preparation method of the injection molding-grade high-performance polypropylene composite material. The polypropylene composite material comprises the following raw materials in percent by weight: 25-69 percent of polypropylene (A), 15-30 percent of polypropylene (B), 10-30 percent of an inorganic filler, 5-15 percent of an elastomer flexibilizer, 0.1-2 percent of a stabilizer, and 0-5 percent of other additives. The polypropylene composite material and the preparation method have the advantages that 1, the molecular weight distribution of a PP matrix is improved to achieve the effect of improving the appearance of the injection molded polypropylene composite material through synergistic effect of polypropylene resin with high molecular weight and polypropylene resin with low molecular weight; 2, the original optimum proportion of the inorganic filler to the elastomer flexibilizer is not changed, and an excellent mechanical property is still kept while the injection molded polypropylene composite material has a good appearance; 3, the component kinds of an original modified material are not changed, the material performance is not influenced, and at the same time, the cost is not remarkably increased.

Owner:SHANGHAI PRET COMPOSITES +2

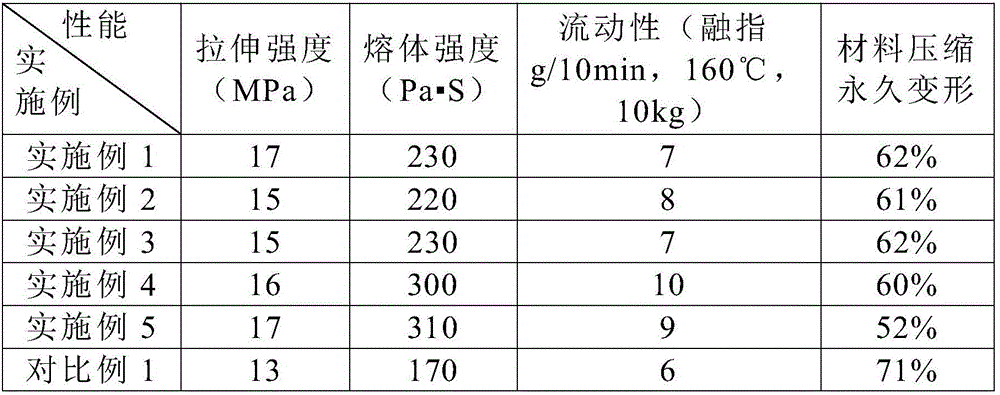

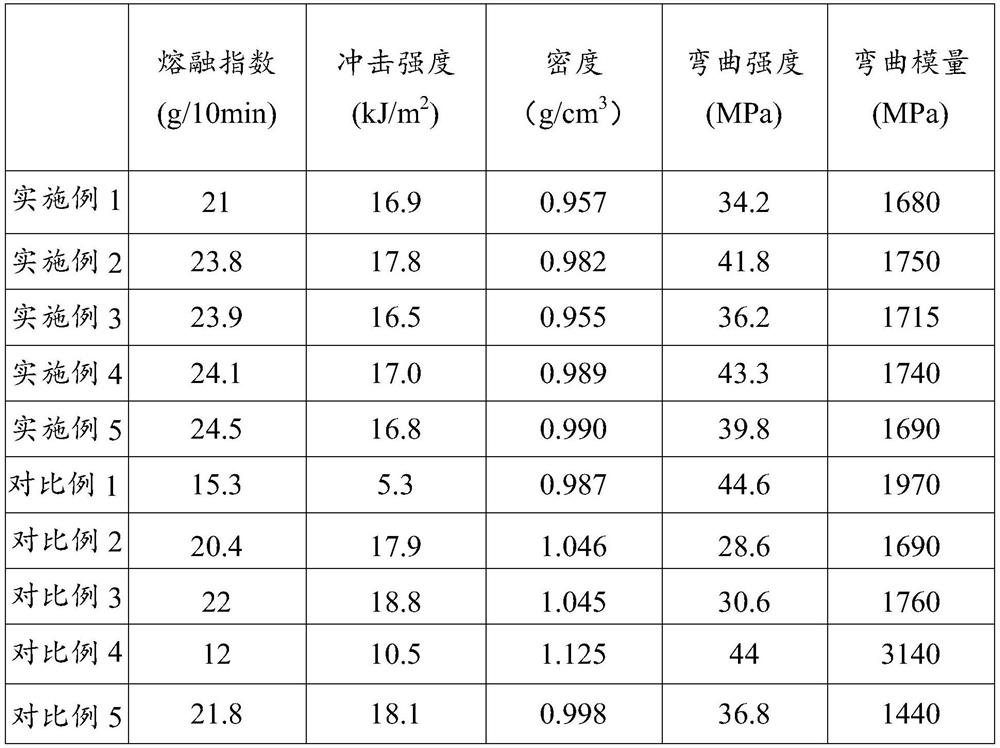

Injection molding grade physical foamed polypropylene material and preparation method thereof

The invention provides an injection molding grade physical foamed polypropylene material and a preparation thereof. The polypropylene material is prepared by mixing, extruding, foaming and injection-molding 55-93 parts of polypropylene, 5-30 parts of high melt strength polyethylene, 2-15 parts of a compatilizer, 0-1 part of a main antioxidant, 0-1 part of an auxiliary antioxidant, 0-1 part of a light stabilizer and 0.5-1 part of a dispersing agent. By modifying the polypropylene through a certain amount of the high melt strength polyethylene, the polypropylene material disclosed by the invention improves low temperature performance and mobility; moreover, the material is foamed through supercritical nitrogen, so as to protect the melt from being broken and reduce density of a final finished product; requirements of reducing weight and guaranteeing rigidity and beautiful appearance are met.

Owner:HEFEI GENIUS NEW MATERIALS

Injection molding grade polypropylene microcellular foam composite material and preparation method thereof

ActiveCN105504498AImprove melt strengthGood foaming effectSodium bicarbonatePolypropylene composites

The invention discloses an injection molding grade polypropylene microcellular foam composite material and a preparation method thereof. The preparation method comprises the step of carrying out microcellular injection molding foaming with an injection molding machine after uniformly mixing 90-99.9wt% of polypropylene composite material with 0.1-10wt% of foaming agent, wherein the polypropylene composite material is prepared from the following raw materials by weight percent: 42-95% of conventional polypropylene, 0.1-15% of micro-crosslinked polypropylene, 0.1-10% of polyethylene, 0.1-25% of talcum powder filler, 0.1-15% of toughening agent, 0.1-5% of antioxidant and 0-3% of other aids; the foaming agent is modified sodium bicarbonate. The polypropylene composite material has higher melt strength. The polypropylene microcellular foam material prepared from the polypropylene composite material is fine and uniform in pores, well maintains the original mechanical properties of the materials and also takes modified sodium bicarbonate as the foaming agent, thus preventing the obtained product from producing unpleasant odor.

Owner:SHANGHAI PRET COMPOSITES

Expanded graphite modified injection molding grade ultra-high molecular weight polyethylene and preparation method thereof

The invention discloses an expanded graphite modified injection molding grade ultra-high molecular weight polyethylene and a preparation method thereof. The polyethylene comprises ultra-high molecular weight polyethylene, high density polyethylene and expanded graphite with the weight ratio of (60-100):(5-50):(1-10). The preparation method comprises steps of adding the ultra-high molecular weight polyethylene, high density polyethylene and expanded graphite into a rubber and plastic internal mixer for internal mixing, then crushing by a crusher, finally extruding and pelletizing. As the expanded graphite is stripped at high load and high shearing speed, nano dispersing expanded graphite can be obtained and can form a continuous, uniform and stable lubricant membrane with a matrix, so as to play a lubricant role in ultra-high molecular weight polyethylene composite, energy transfer between polyethylene chains can be improved, the ultra-high molecular weight polyethylene chains relatively slide easily, and the fluidity of the ultra-high molecular weight polyethylene is improved. Furthermore, the expanded graphite is beneficial to lowering the friction coefficient and improving the abrasive resistance of the composite.

Owner:HEFEI UNIV OF TECH

Injection molding grade degradable polylactic acid wood plastic micro-foaming composite material and preparation method thereof

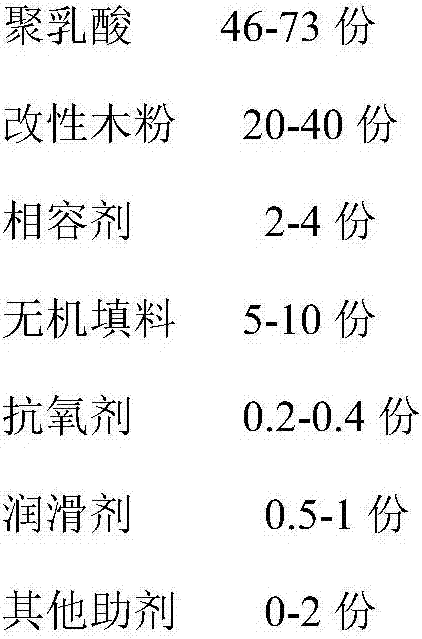

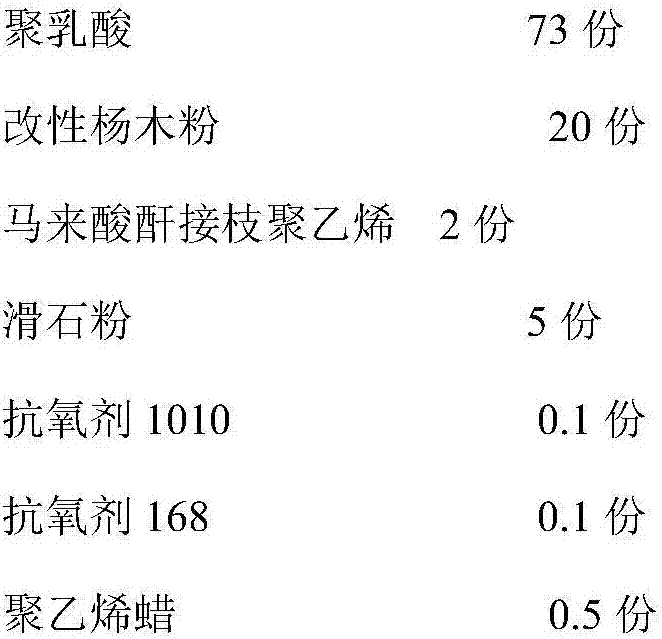

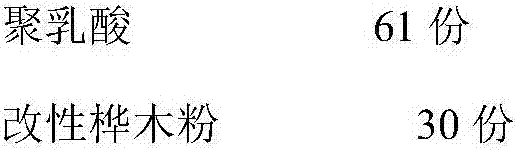

The invention provides an injection molding grade degradable polylactic acid wood plastic micro-foaming composite material and a preparation method thereof. A polylactic acid wood plastic composite material and a chemical foaming agent are mixed uniformly according to a certain proportion, and a polylactic acid wood plastic micro-foaming composite material product is prepared by an injection molding micro-foaming technology under the condition of secondary mold opening, wherein the polylactic acid wood plastic composite material is prepared from 46 to 73 parts of polylactic acid, 20 to 40 parts of modified wood powder, 2 to 4 parts of a compatibilizer, 5 to 10 parts of an inorganic filler, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricating agent and 0 to 2 parts of other aids. The polylactic acid wood plastic micro-foaming composite material provided by the invention has the characteristics of low density, capability of being degraded completely, high mechanical strength, low cost and the like, is an excellent environment-friendly material and can be widely applied to products such as floors, guard bars, furniture and automotive interior decoration.

Owner:ORINKO NEW MATERIAL CO LTD

Raw material treatment method for injection molding grade micro-foaming wood-plastic composite material

The invention relates to a raw material treatment method for an injection molding grade micro-foaming wood-plastic composite material, which comprises the following steps: pulverizing bamboo and wood waste into 40-200 meshes, then screening to obtain powder having different finenesses, and blending the coarse and fine powder with bamboo and wood powder according to a certain ratio; under a nitrogen gas protective atmosphere, performing heat treatment on the blended bamboo and wood powder at 160-280 DEG C for 0.5-12 hours; under the condition of stirring at a high speed of 300-2800r / min, uniformly mixing the modified bamboo and wood powder with adsorbent, plastic, coupling agent, foaming agent, foaming promoter, pigment, compatilizer, lubricant, plasticizer and enhanced filler to prepare a mixture; and extruding and granulating the mixture through an extruder, thus obtaining the injection molding grade micro-foaming wood-plastic composite material. The wood-plastic composite material has the characteristics of high surface gloss, high strength and toughness, low cost and the like, and is suitable for various injection molding products of which the molding shape is relatively complex.

Owner:江西省大余章源竹木制品有限公司

PVC alloy material

The invention provides a PVC (polyvinyl chloride) alloy material which comprises a modified PVC composite material filled with active nano calcium carbonate and injection molding grade ABS (acrylonitrile-butadiene-styrene) resin. The PVC alloy material is characterized in that the PVC modified alloy material comprising the following components in percentage by weight: 40-80% of the PVC composite material and 20-60% of the ABS resin, wherein the PVC composite material comprises PVC resin, a thermal stabilizer, a lubricant, an impact modifier, an antioxidant, a flame retardant, and a filling agent namely active anno calcium carbonate. The filling agent, namely active anno calcium carbonate, is added into the components of the PVC alloy material provided by the invention, so that the raw material cost is reduced, and the flexural modulus of the alloy material is improved. ABS greatly improves the fluidity of the alloy material and improves the alloy processability.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

Hydrolysis-resistant polyamide composite and preparation method thereof

PendingCN105885398AImprove hydrolysis resistanceImprove mechanical propertiesThermoplasticAntioxidant

The invention discloses a hydrolysis-resistant polyamide composite and a preparation method thereof. The composite is prepared from, by weight, 60-70 parts of injection molding grade PA66 resin, 5-10 parts of POK resin, 3-5 parts of grafting type compatilizer, 27-33 parts of thermoplastic plastic roving, 0.5-1 part of hydrolysis-resistant agent, 0-1 part of complex antioxidant and 0-1 part of lubricant. By weight, the injection molding type PA66 resin A66, the POK resin and the grafting type compatilizer are weighed firstly and added into a high-speed mixer to be mixed to be uniform; by weight, the hydrolysis-resistant agent, the antioxidant and the lubricant are weighed, mixed and then poured into a mixer, and the mixture and the mixture obtained after uniform mixing are stirred together and fully mixed to be uniform; final uniformly-mixed liquid is put in a two-screw extruder to be extruded and then subjected to injection molding through an injection molding machine, and the composite is obtained. The hydrolysis resistance of the composite can be improved, the mechanical performance of the composite is excellent, and the service life of products is greatly prolonged.

Owner:NANJING DELLON ENG PLASTICS

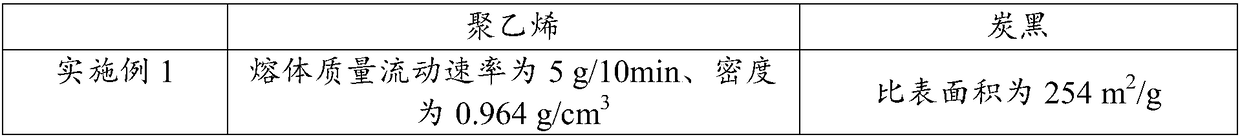

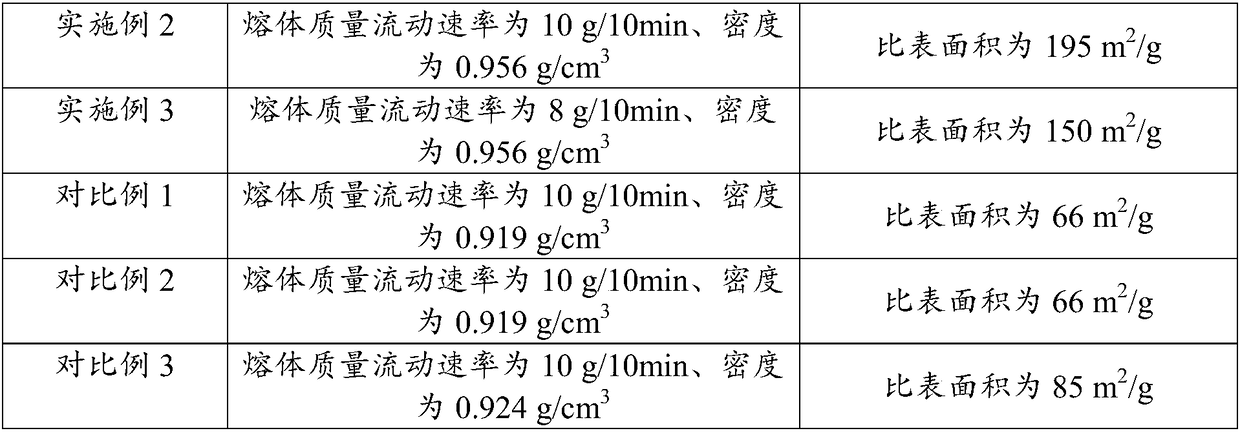

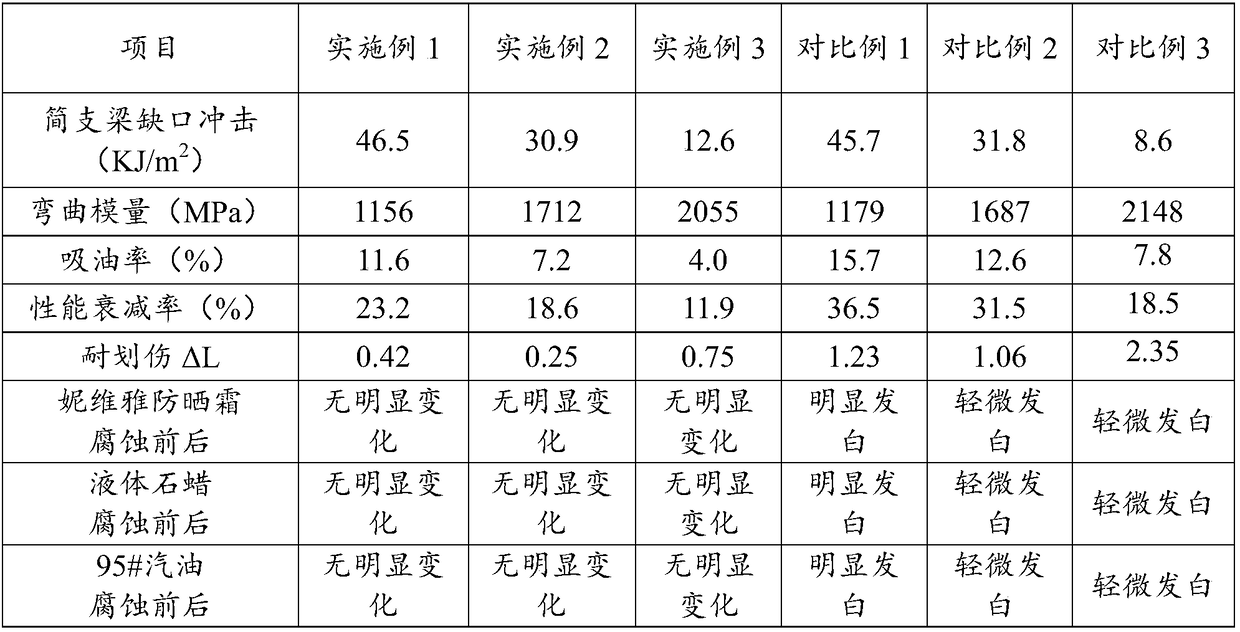

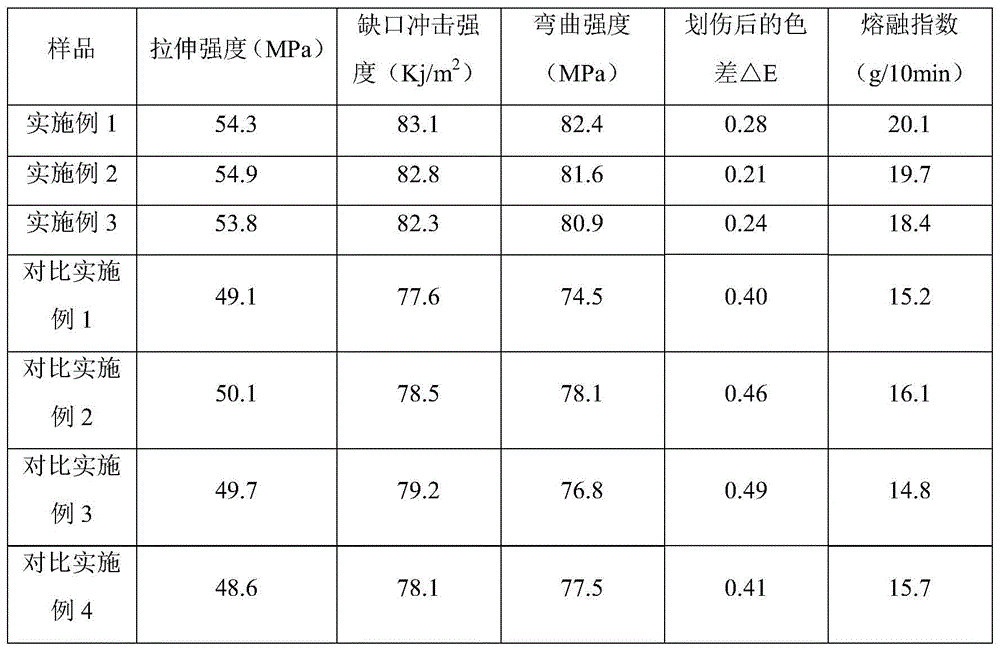

Chemical-resistant and scratch-resistant polypropylene composite material and preparation method thereof

ActiveCN108373565AGood chemical resistanceImprove scratch resistancePolypropylene compositesPolymer science

The invention discloses a chemical-resistant and scratch-resistant polypropylene composite material which is prepared from the following ingredients in parts by weight: 55 to 80 parts of polypropylene, 8 to 12 parts of polyethylene and 0.5 to 2 parts of carbon black, wherein the polyethylene is at least one of extrusion-grade high-density polyethylene and injection-molding-grade high-density polyethylene, the density of the polyethylene is 0.948 to 0.965g / cm<3>, and the melt mass flow rate of the polyethylene is 0.1 to 12g / 10min. In the polypropylene composite material disclosed by the invention, all the ingredients and contents interact with each other; meanwhile, the polyethylene and the carbon black are reasonably chosen, so that the polypropylene composite material has good comprehensive performance of chemical resistance and scratch resistance, keeps very good mechanical property at the same time and is especially suitable for being applied to automotive upholsteries. Meanwhile, the invention further discloses a preparation method of the chemical-resistant and scratch-resistant polypropylene composite material.

Owner:KINGFA SCI & TECH CO LTD

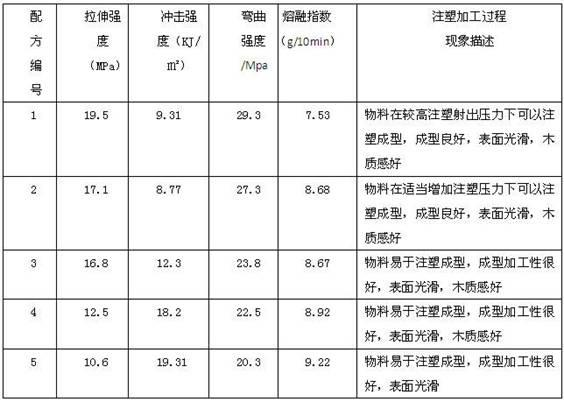

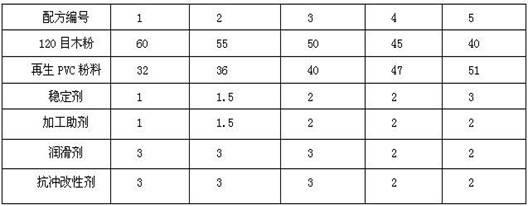

Polyvinyl chloride-based wood plastic composite and preparation method thereof

InactiveCN101974244AImprove physical and chemical propertiesHigh wood flour contentPolyvinyl chlorideMolding grade

The invention provides a polyvinyl chloride (PVC)-based wood plastic composite and a preparation method thereof. The PVC-based wood plastic composite is mixed by the following raw materials by weight percent: 32-51% of PVC, 1-3% of stabilizer, 1-2% of processing additive, 2-3% of impact modifier, 2-3% of lubricant and 40-60% of wood flour. The preparation method comprises the following steps: mixing the raw materials according to the formula ratio, using a conical twin-screw for mixing, cooling and solidifying, and cutting to obtain the finished product. Compared with the common wood plastic material, the prepared molding-grade PVC-based wood plastic composite has the advantages of high wood flour filling volume, good high temperature fluidity and the like and can be directly used for molding production; and the formed wood plastic product has good comprehensive physical-mechanical performance and appearance, strong wood feeling and obvious cost advantage.

Owner:杨大可

Injection molding grade natural straw plastic and its preparation method and application

The invention provides an injection molding grade natural straw plastic and its preparation method and application. The injection molding grade natural straw plastic is prepared from, by weight, 25-65parts of nature straw, 0-12 parts of filling agent, 25-63 parts of macromolecular resin, and 4-5 parts of macromolecular assistant. The preparation method includes steps of mixing nature straw with granularity of 250-350 meshes with diatomite, macromolecular resin and macromolecular assistant to form a raw material; extruding and pelleting by a dual-screw mixing extruder to obtain the injection molding grade natural straw plastic. The injection molding grade natural straw plastic can replace the application of a traditional thermal plastic resin on daily goods; the injection molding grade natural straw plastic passes through the national food hygienic index and can directly contact food. The injection molding grade natural straw plastic has straw smell, and its smell is durable, fragrantand nature; the product is easy to shape and has straw texture; the injection molding grade natural straw plastic can be applied to food packaging, and is wide in application and not easy to wet and go mouldy.

Owner:JIANGSU JINHE HI TECH

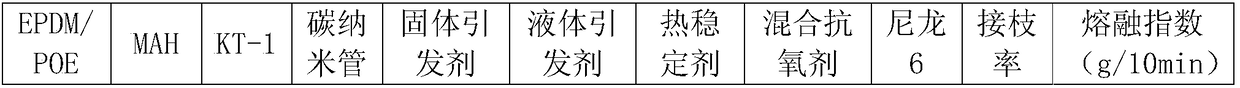

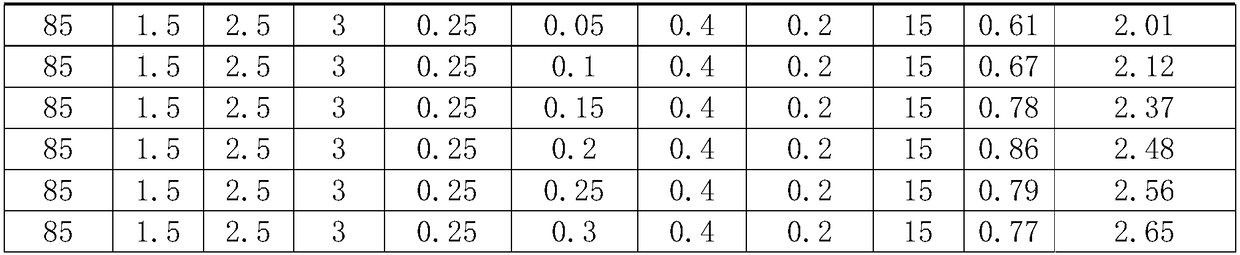

Ultra-low temperature-resistant toughening material for injection molding-grade nylon and preparation method of toughening material

ActiveCN108129757AImprove low temperature resistanceImprove notched impact strengthNylon 6-10Antioxidant

The invention belongs to the field of polymer materials, and particularly relates to an ultra-low temperature-resistant toughening material for injection molding-grade nylon and a preparation method of the toughening material. Raw materials of the ultra-low temperature-resistant toughening material comprise: in parts by weight, 70-80 parts of ethylene-propylene-diene monomer rubber, 20-30 parts ofethylene-octene copolymer, 5-10 parts of dibenzoyl peroxide, 0.5-2 parts of maleic anhydride, 1-5 parts of KT-1, 1-5 parts of carbon nanotubes, 0.05-0.3 part of solid initiator, 0.05-0.3 part of liquid initiator, 0.1-0.5 part of thermal stabilizer, 0.1-0.3 part of antioxidant and 10-20 parts of nylon 6. The prepared nylon toughening agent belongs to injection molding-grade toughening agents, anda step of reaction-extrusion of nylon toughened by a toughening agent is omitted, so that the production cost is saved effectively; secondly, the toughening material can be used in an environment withan ambient temperature of 50 DEG C below zero, so that low-temperature resistance of the toughened nylon is improved effectively, and the notched impact strength of the toughened nylon is improved.

Owner:SHENYANG KETONG PLASTIC

Heat-conducting silicone rubber composite material and preparation method thereof

ActiveCN106810869AImprove dispersion efficiencyEffective dispersionHeat-exchange elementsAviationCross-link

The invention relates to a heat-conducting silicone rubber composite material and a preparation method thereof. The heat-conducting silicone rubber composite material comprises, by weight, 20-80 parts of silicone rubber matrix, 20-80 parts of inorganic heat-conducting powder, 0.5-5 parts of silicone oil, 0.2-2 parts of cross-linking agent and 0.2-2 parts of coupling agent. The preparation method includes: 1, premixing: adding the silicone rubber matrix, the inorganic heat-conducting powder after being pretreated and auxiliaries like the cross-linking agent into a highly-mixing machine for premixing; 2, extruding and granulating: adding premixed materials into extensional rheological plasticizing and extruding equipment for extruding and granulating, wherein temperature of the extensional rheological plasticizing and extruding equipment at each stage of extrusion is 150-250 DEG C, rotating speed of a rotor is 10-150rpm, and rotating speed of a feeder is 10-100rpm. By the preparation method, the injection-molding-grade heat-conducting silicone rubber composite material which is high in heat conductivity and excellent in mechanical performance can be prepared to be widely applied in the heat-radiating field of electronic appliances, space flight and aviation and military industry.

Owner:SIIICO TECH CO LTD

Injection molding grade polypropylene wood-plastic micro-foaming composite material and preparation method thereof

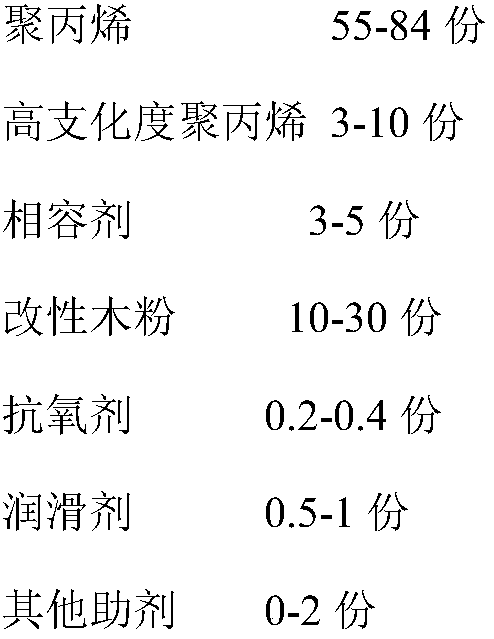

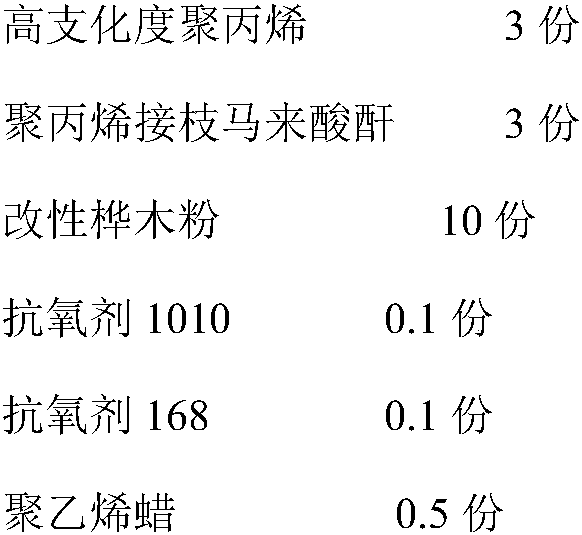

The invention provides an injection molding grade polypropylene wood-plastic micro-foaming composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a polypropylene wood-plastic composite material and a chemical foaming agent according to a proper ratio and adding into an injection molding machine; carrying out injection molding byadopting secondary mold opening to prepare the polypropylene wood-plastic micro-foaming composite material, wherein the polypropylene wood-plastic composite material is prepared from 55 to 84 parts ofpolypropylene, 3 to 10 parts of high-branching-degree polypropylene, 3 to 5 parts of a compatilizer, 10 to 30 parts of modified wood flour, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 2 parts of other auxiliary agents. The polypropylene wood-plastic micro-foaming composite material provided by the invention has the characteristics of small density, high mechanical strength, low cost and the like; the polypropylene wood-plastic micro-foaming composite material is used as a novel environment-friendly material and can be used for replacing wood, and has wide application in the fields including building materials, packaging and transportation, an automobile industry and the like.

Owner:ORINKO NEW MATERIAL CO LTD

Injection molding grade PVC composite material high in mobility and melt strength

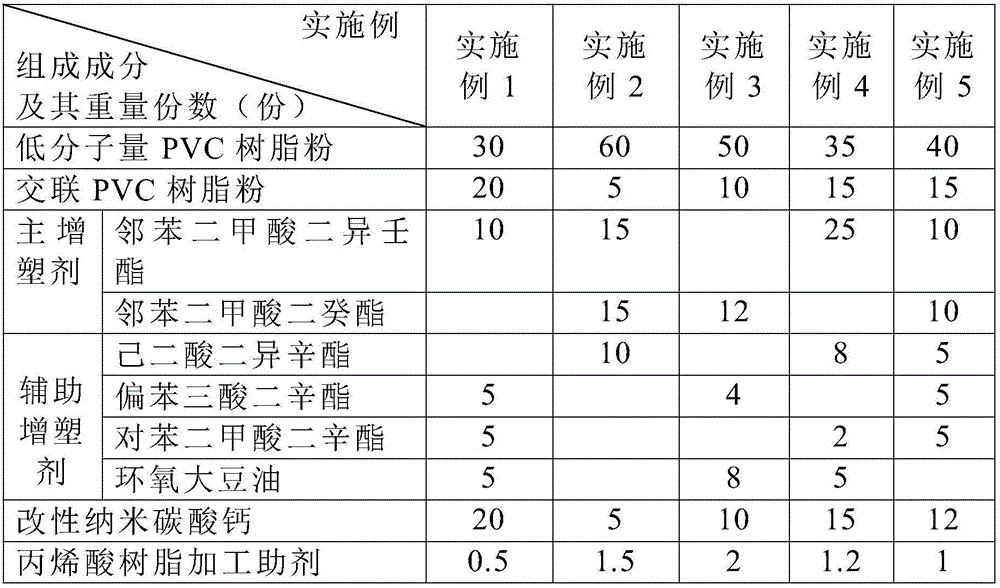

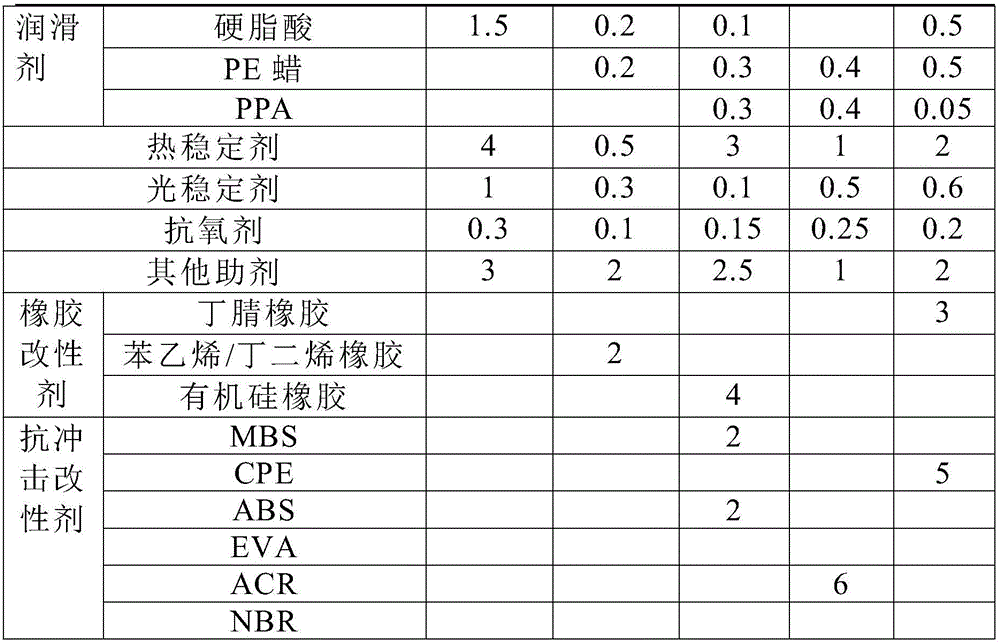

The invention relates to an injection molding grade PVC composite material high in mobility and melt strength and belongs to the technical field of macromolecules. The composite material comprises, by weight parts, 30-60 parts of low molecular weight PVC resin powder, 5-20 parts of crosslinking PVC resin powder, 10-30 parts of main plasticizer, 10-20 parts of secondary plasticizer, 0.5-20 parts of nano calcium carbonate, 0.5-2 parts of high melt strength processing agent, 0.4-1.5 parts of lubricant, 0.5-4 parts of heat stabilizer, 0.1-1 part of light stabilizer, 0.1-0.3 part of antioxidant and 1-3 parts of other auxiliaries. Melt strength and mechanical properties of the PVC composite material are improved while high mobility is guaranteed. The injection molding grade PVC composite material can adapt to injection molding products of various sizes and shapes and can meet requirements of low plastic temperature and short plastic cycle.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Injection molding grade graphite-filled high-temperature nylon and production process thereof

The invention relates to an organic polymer composite material, in particular to injection molding grade graphite-filled high-temperature nylon and a production process thereof. The injecting molding grade graphite-filled high-temperature nylon consists of the following compositions in percentage by weight: 68 to 97 percent of high-temperature nylon, 0.1 to 2.5 percent of high molecular weight silicone oil, 3 to 35 percent of conductive graphite powder, 0.3 to 1.5 percent of the antioxidant, 0.1 to 2.0 percent of coupling agent and 0.3 to 5.5 percent of other aids. The injection molding grade graphite-filled high-temperature nylon preserves the comprehensive performances of the original high-temperature nylon and has a good self-lubricating property and good abrasion resistance, automatic demolding is realized during injection molding or extrusion of a finished product, and release agent is not required, the procurement and the production of raw materials are convenient, raw and auxiliary materials and production equipment are made in China, and the costs of production and raw materials are greatly reduced, so that the comprehensive competitiveness of the product is improved.

Owner:KECHUANG POLYMER SUZHOU

Modified PP (polypropylene) regenerated material for automobiles and preparation method of modified PP regenerated material for automobiles

InactiveCN108410063AImprove performanceExcellent impact strengthMasterbatchUltimate tensile strength

The invention provides a modified PP (polypropylene) regenerated material for automobiles and a preparation method of the modified PP regenerated material for the automobiles. The modified PP regenerated material is prepared from a PP homopolymerized drawing-grade crushed material, a PP homopolymerized injection-molding-grade crushed material, a PP copolymerized washing machine drum crushed material, a PP copolymerized high-impact sheet-grade crushed material and color masterbatch. By adoption of the preparation method, the modified PP regenerated material for the automobiles is stable in performance and superior to other single PP materials in physical properties such as impact strength and melt index. The modified PP regenerated material not only can be used for manufacturing of moderate-impact-resistant parts such as automobile door panels but also can be used for manufacturing of high-impact-resistant parts such as bumpers through further modification. In adoption of the material and method for automobile modification, simplicity in operation and low cost are realized.

Owner:连云港益众再生资源有限公司

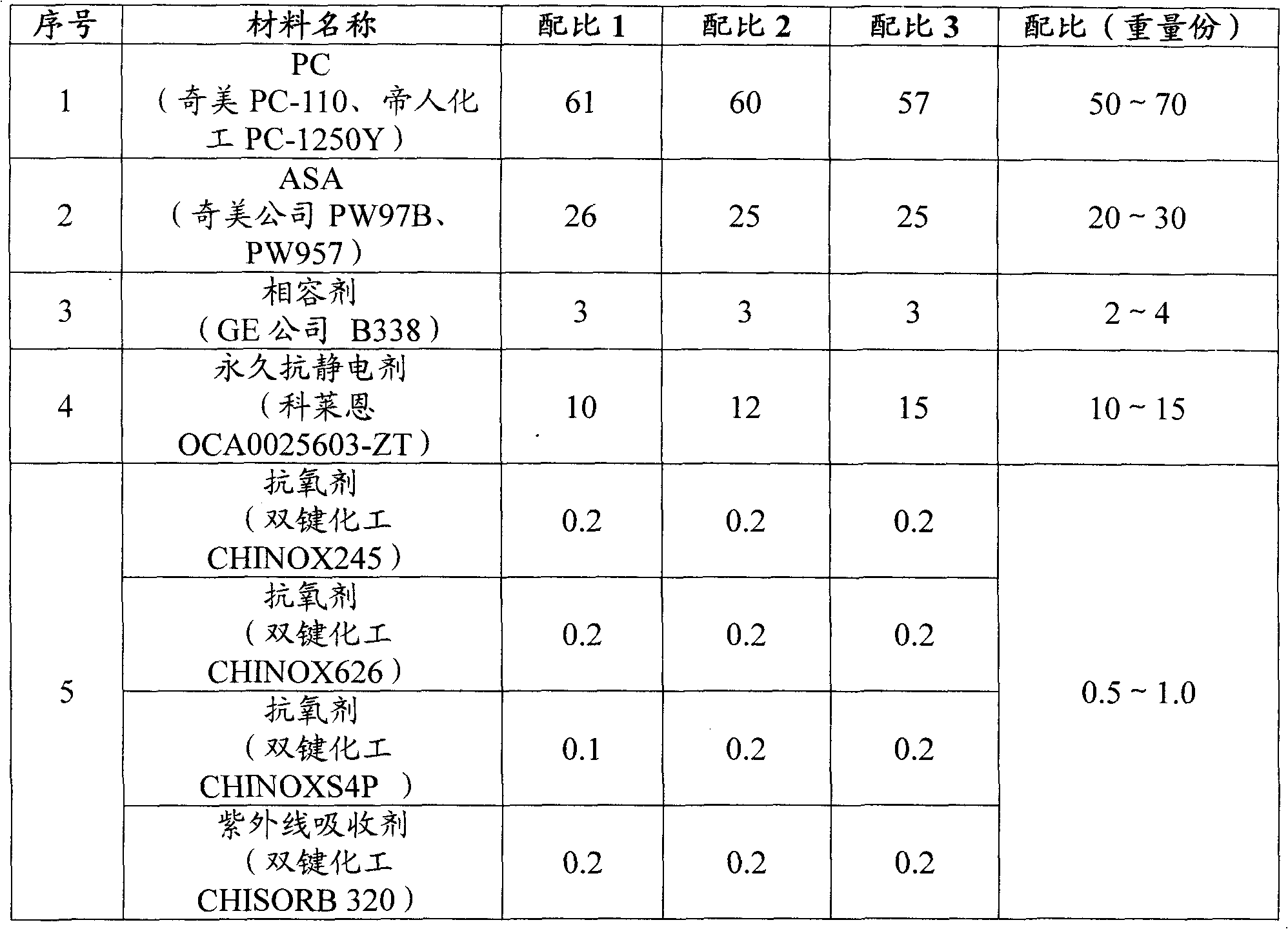

Permanently antistatic PC/ASA material

The invention relates to a permanently antistatic PC / ASA material, which comprises the following components by weight part: 50-70 parts of PC, 20-30 parts of ASA, 10-15 parts of permanent antistatic agent, 2-4 parts of compatibilizer and 0.5-1.0 part of additive, 0.4-0.7 part of antioxidant and 0.1-0.3 part of ultraviolet absorbent, wherein the additive comprises the antioxidant and the ultraviolet absorbent, and the permanent antistatic agent is synthesized based on polyamide and hindered amine polyether; the compatibilizer is of a PC / ASA special alloy modifier, and the PC comprises one or more of high-melting injection molding grade PC; and the ASA comprises one or more of high-gloss and high-mobility ASA. The invention has high gloss, good heat and light resistant performances, permanent anti-static property and wash resistance, thereby prolonging service life, reducing use cost, and being suitable for industrial scale production and large-scale popularization and application.

Owner:SHANGHAI JINCHANG ENG PLASTICS CO LTD

Wear-resistant and scraping-resistant injection-molding-grade PC/ABS alloy material and preparing method thereof

The invention discloses a wear-resistant and scraping-resistant injection-molding-grade PC / ABS alloy material. The wear-resistant and scraping-resistant injection-molding-grade PC / ABS alloy material is characterized by being prepared from, by weight, 35%-75% of PC, 15%-60% of ABS, 2%-5% of compound compatilizer, 1%-3% of compound toughening agent, 1%-3% of lubricating agent, 0.5%-1% of antioxidant and 0.5%-1% of anti-ultraviolet agent; a compound compatilizer is an interface compatilizer compounded by polyolefin elastomer (POE) and modified polyolefin in the compounding ratio of 1:1-1:3, the modified polyolefin is maleic-anhydride-grafted polypropylene (PP-g-MAH), and the grafting ratio ranges from 3% to 5%; a compound toughening agent is compounded by thermoplastic rubber, polyolefin and modified nanometer calcium carbonate. According to the wear-resistant and scraping-resistant injection-molding-grade PC / ABS alloy material, as the compound compatilizer is adopted, the compatibility between a PC interface and an ABS interface is greatly improved; as the compound toughening agent is adopted, the mechanical performance, the wear resistance and the scraping resistance of the alloy material are greatly improved. The wear-resistant and scraping-resistant injection-molding-grade PC / ABS alloy material can be widely applied to the field of the furniture appliance industry, the communication equipment industry, the electron industry and the like.

Owner:ZHEJIANG SENCHUAN FURNITURE

Recyclable nanocellulose reinforced polypropylene material and preparation method and application thereof

The invention provides a recyclable nanocellulose reinforced polypropylene material and a preparation method and application thereof, and belongs to the technical field of materials. The green low-carbon recyclable injection molding grade nano plant cellulose polypropylene automotive interior material is prepared from the following raw materials in percentage by mass: 49.5 to 73.5 parts of co-polypropylene, 15 to 35 parts of nano plant cellulose, 10 to 15 parts of ethylene-octylene copolymer elastomer, 0.5 to 1.5 parts of processing aid and 1.5 to 3 parts of polypropylene maleic anhydride graft. Through cooperation of the components, the obtained material has high rigidity and low-density performance, can replace a traditional PP + EPDM-TD20 material to be used as an automotive interior material, and has more excellent performance and a low carbon emission value compared with an existing material.

Owner:克林斯曼新材料有限公司

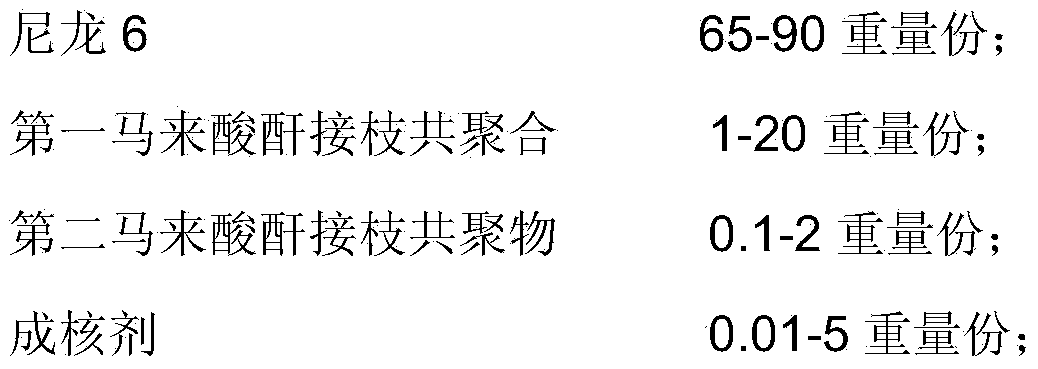

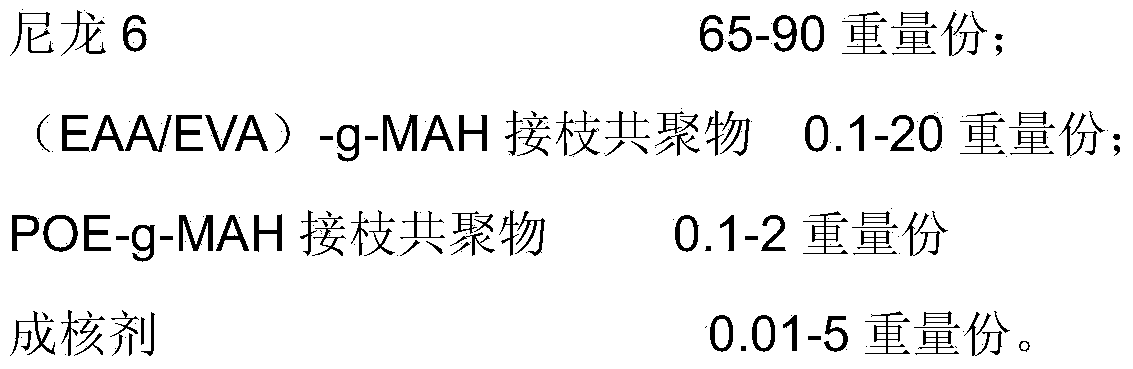

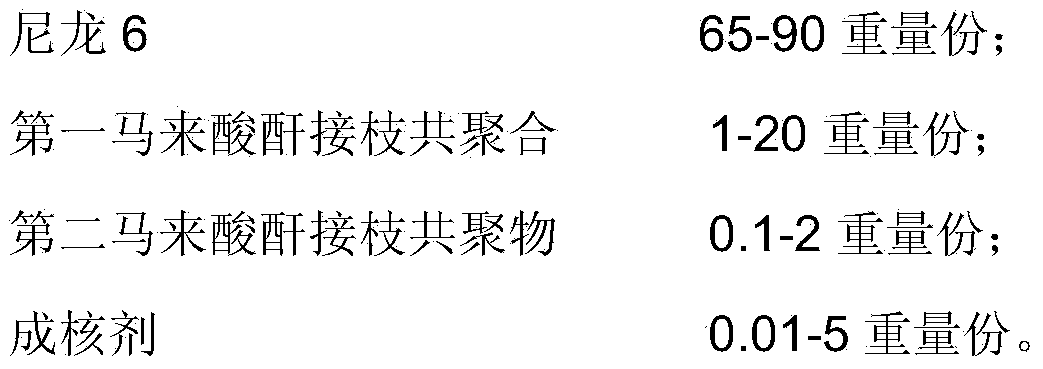

Injection-molding-grade nylon 6 composite material and application thereof

InactiveCN104177822ARapid heterogeneous crystallizationQuick releaseCoatingsNylon 6Injection molding process

The invention provides an injection-molding-grade nylon 6 composite material which comprises the following components in parts by weight: 65-90 parts of nylon 6 resin, 1-20 parts of first maleic anhydride graft copolymer, 0.1-10 parts of second maleic anhydride graft copolymer and 0.01-5 parts of nucleating agent. The injection-molding-grade nylon 6 composite material fills the blank in the injection-molding-grade nylon for special-function pieces, has favorable bonding property with zinc-base alloy materials, and can implement quick stripping in the injection molding process; and the prepared part has stable size, keeps stable in the alternating temperature experiment of 90 DEG C (2 hours) to 30 DEG C (2 hours), and widens the application range of the nylon 6.

Owner:上海日晶工程塑料科技有限公司

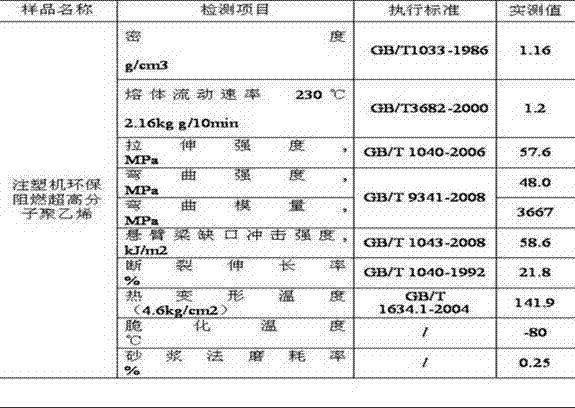

Injection molding grade environment-friendly anti-flaming ultra-high molecular weight polyethylene and preparation method thereof

The invention discloses injection molding grade environment-friendly anti-flaming ultra-high molecular weight polyethylene and a preparation method thereof. The injection molding grade environment-friendly anti-flaming ultra-high molecular weight polyethylene comprises 45 to 80 parts of ultra-high molecular weight polyethylene powder, 5 to 20 parts of fire retardant, 8 to 20 parts of liquid crystal polymer, 2 to 5 parts of heat stabilizer, 5 to 10 parts of compatilizer, which are all mixed at high speed for fifteen to twenty minutes by a high-speed kneading machine at the temperature ranging from 90 DEG C to 120 DEG C, extruded for being pelleted by double-screw extruding pelletizer at the temperature ranging from 190 DEG C to 220 DEG C. The injection molding grade environment-friendly anti-flaming ultra-high molecular weight polyethylene has the advantages of fine liquidity, high abrasion resistance, high modulus, low contractibility rate, fine self-lubricity, wide service temperature range and can be used at the temperature ranging from minus 70 DEG C to 130 DEG C as compared with existing common ultra-high molecular weight polyethylene. Besides, inflaming retarding coefficient can reach grades of UL(underwriters' laboratories) to V0, has higher impact mechanical performance, accords with European GSG standards and the UL standards of the United States, and is non-toxic, low-carbon and environment-friendly in concept.

Owner:重庆可益荧新材料有限公司

Heat-conducting nylon composite special for injection molding-grade LED lamps and preparation method thereof

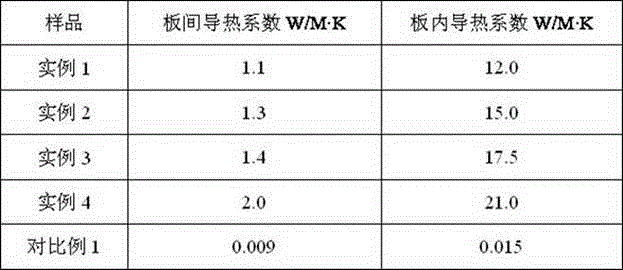

ActiveCN106479164AReduce usageImprove thermal conductivityHeat-exchange elementsHeat conductingAluminum composites

The invention discloses heat-conducting nylon composite special for injection molding-grade LED lamps and a preparation method thereof. The preparation method comprises the following steps: carrying out twin-screw extrusion on 5-50 parts by weight of attapulgite / aluminum oxide composite, 5-10 parts by weight of a dispersant, 0.5-5 parts by weight of a dispersant, 0-3 parts by weight of other aids and 75-85 parts by weight of matrix PA6; and granulating to obtain the heat-conducting nylon composite special for injection molding-grade LED lamps. The composite has excellent heat conductivity, is up to 1.0-2.2 W / M.K in inter-board heat conductivity coefficient, and is up to 10-25 W / M.K in inter-board heat conduction rate coefficient.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Self-lubricating abrasion-resistant injection-molding grade nylon 66 and preparation technology thereof

The invention relates to an organic polymer composite material, more specifically, in particular to self-lubricating abrasion-resistant injection-molding grade nylon 66 and a preparation technology thereof. The self-lubricating abrasion-resistant injection-molding grade nylon 66 comprises the following components according to weight ratio: 49.5-90% of nylon 66, 1-35% of graphite powder, 0.3-1.5% of antioxidant, 0.1-3.0% of heat stabilizer, 0.1-2.8% of coupling reagent, 0.1-3.0% of HMW (high molecular weight) silicone oil and 0.3-5.5% of other auxiliaries. The self-lubricating abrasion-resistant injection-molding grade nylon 66 provided by the invention has the characteristics of environment friendliness and freeness from halogen; better self-lubrication and abrasion resistance are obtained on a basis of keeping the comprehensive properties of original filled nylon 66; meanwhile, a mold releasing operation is automatically carried out in the process of injection-molding or extruding finished products, so that a releasing agent is unnecessary; and the raw and auxiliary materials as well as production equipment are all domestic, so that the production cost and raw material cost are largely lowered, therefore the comprehensive competitive power of products is well improved.

Owner:KECHUANG POLYMER SUZHOU

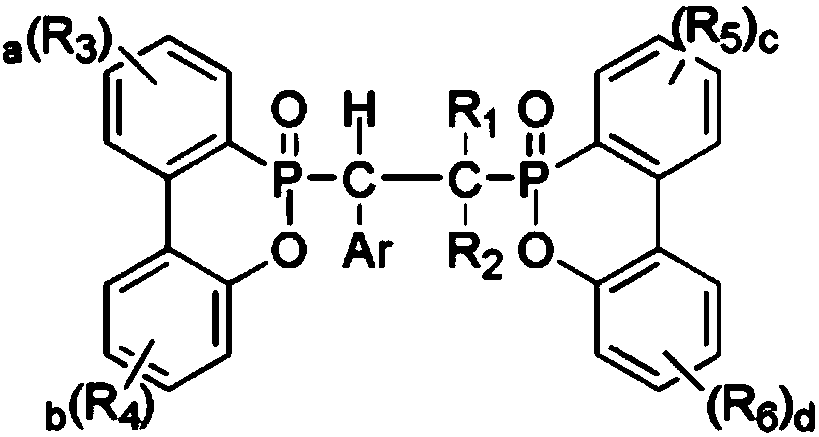

Transparent flame-retardant high-temperature nylon and preparation method thereof

ActiveCN108059824AHigh flame retardant efficiencyLow flame retardant efficiencyPolymer scienceElectronic component

The invention provides transparent flame-retardant high-temperature nylon and a preparation method thereof, and relates to the field of a halogen-free flame-retardant macromolecular material. The transparent flame-retardant high-temperature nylon comprises the following components in parts by weight: 85 to 95 parts of high-temperature nylon, 5 to 15 parts of bridge chain DOPO derivative and 0.1 to0.5 part of nano-silicon dioxide. The preparation method comprises the following steps: mixing the dried high-temperature nylon, bridge chain DOPO derivative and nano-silicon dioxide according to theparts by weight to obtain a mixed base material; and melting and blending the mixed base material at 280 to 330 DEG C and performing extrusion granulation. The transparent flame-retardant high-temperature nylon has high flame resistance and mechanical property, has the advantages of transparency, low price, environmental friendliness, high efficiency and the like, and can serve as injection molding-grade electronic components, communication equipment and the like.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com