PVC/ABS alloy material with high anti-impact strength and preparation method thereof

An alloy material, high impact resistance technology, applied in the field of high impact strength PVC/ABS alloy material and its manufacturing method, can solve problems such as poor impact strength, achieve good flame retardant performance, improve flexural modulus, improve The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

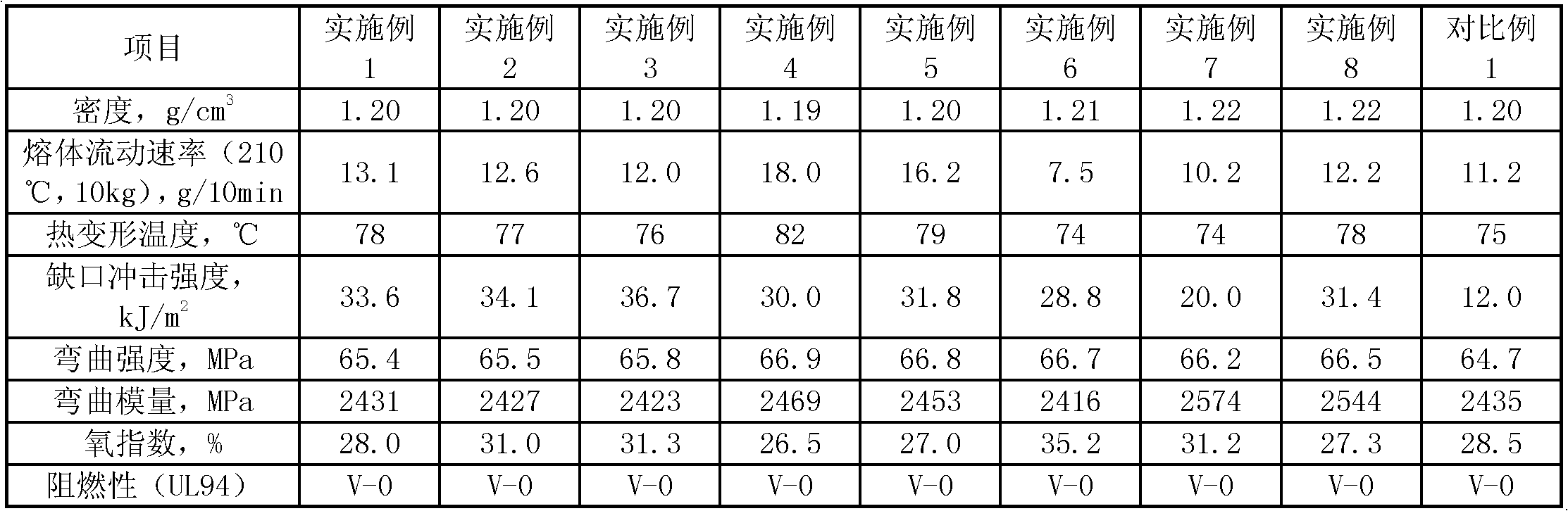

Examples

Embodiment 1

[0046] Step 1, in parts by weight, according to 100 parts of PVC resin with the brand name S-700 produced by Sinopec Qilu Branch, 3 parts of mercaptan organotin with the brand name 17MOK, and the brand produced by Wuxi Xilong Plastic Chemical Co., Ltd. It is 0.5 parts of phosphite ester of JH-1500, 1.2 parts of calcium stearate produced by Zibo Xinplastic Chemical Co., Ltd., 0.5 parts of lubricant of ZB-70Y produced by Zibo Huaxing Auxiliary Co., Ltd., produced by Shanghai Huaxing The grade produced by Yi Plastic Additives Factory is 2 parts of CH-4A polyethylene wax, 8 parts of 135A chlorinated polyethylene produced by Weifang Yaxing Chemical Co., Ltd., and the grade produced by Tianjin Chenguang Chemical Co., Ltd. is 0.8 parts of BC-1076 antioxidant, 5 parts of antimony trioxide flame retardant produced by Jinan Taixing Fine Chemical Co., Ltd., 10 parts of active nano calcium carbonate produced by Shaanxi Haize Nano Material Co., Ltd. Each component of the PVC composite mate...

Embodiment 2

[0050] Step 1, in parts by weight, according to 100 parts of PVC resin with the brand name S-700 produced by Sinopec Qilu Branch, 3 parts of mercaptan organotin with the brand name 17MOK, and the brand produced by Wuxi Xilong Plastic Chemical Co., Ltd. It is 0.5 parts of phosphite ester of JH-1500, 1.2 parts of calcium stearate produced by Zibo Xinplastic Chemical Co., Ltd., 0.5 parts of lubricant of ZB-70Y produced by Zibo Huaxing Auxiliary Co., Ltd., produced by Shanghai Huaxing The grade produced by Yi Plastic Additives Factory is 2 parts of CH-4A polyethylene wax, 8 parts of 135A chlorinated polyethylene produced by Weifang Yaxing Chemical Co., Ltd., and the grade produced by Tianjin Chenguang Chemical Co., Ltd. is 0.8 parts of BC-1076 antioxidant, 5 parts of antimony trioxide flame retardant produced by Jinan Taixing Fine Chemical Co., Ltd., 10 parts of active nano calcium carbonate produced by Shaanxi Haize Nano Material Co., Ltd. Each component of the PVC composite mate...

Embodiment 3

[0054] Step 1, in parts by weight, according to 100 parts of PVC resin with the brand name S-700 produced by Sinopec Qilu Branch, 3 parts of mercaptan organotin with the brand name 17MOK, and the brand produced by Wuxi Xilong Plastic Chemical Co., Ltd. It is 0.5 parts of phosphite ester of JH-1500, 1.2 parts of calcium stearate produced by Zibo Xinplastic Chemical Co., Ltd., 0.5 parts of lubricant of ZB-70Y produced by Zibo Huaxing Auxiliary Co., Ltd., produced by Shanghai Huaxing The grade produced by Yi Plastic Additives Factory is 2 parts of CH-4A polyethylene wax, 8 parts of 135A chlorinated polyethylene produced by Weifang Yaxing Chemical Co., Ltd., and the grade produced by Tianjin Chenguang Chemical Co., Ltd. is The ratio of 0.8 parts of BC-1076 antioxidant, 4 parts of antimony trioxide flame retardant produced by Jinan Taixing Fine Chemical Co., Ltd., and 10 parts of active nano calcium carbonate produced by Shaanxi Haize Nano Materials Co., Ltd. Each component of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| izod impact strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com