Patents

Literature

866results about How to "Increased flexural modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite polypropylene material and its preparing method

The composite polypropylene material is prepared with polypropylene 10-100 weight portions, polyethylene 1-50 weight portions, inorganic rigid grain 1-50 weight portions, toughener 1-50 weight portions, coupling agent 0.01-10 weight portions and grafting compatilizer 1-50 weight portions. The composite polypropylene material has high rigidity, high impact strength and balanced rigidity and toughness, and compared with common automobile bumper material, it has 15-30 % higher bending modulus.

Owner:吴永刚

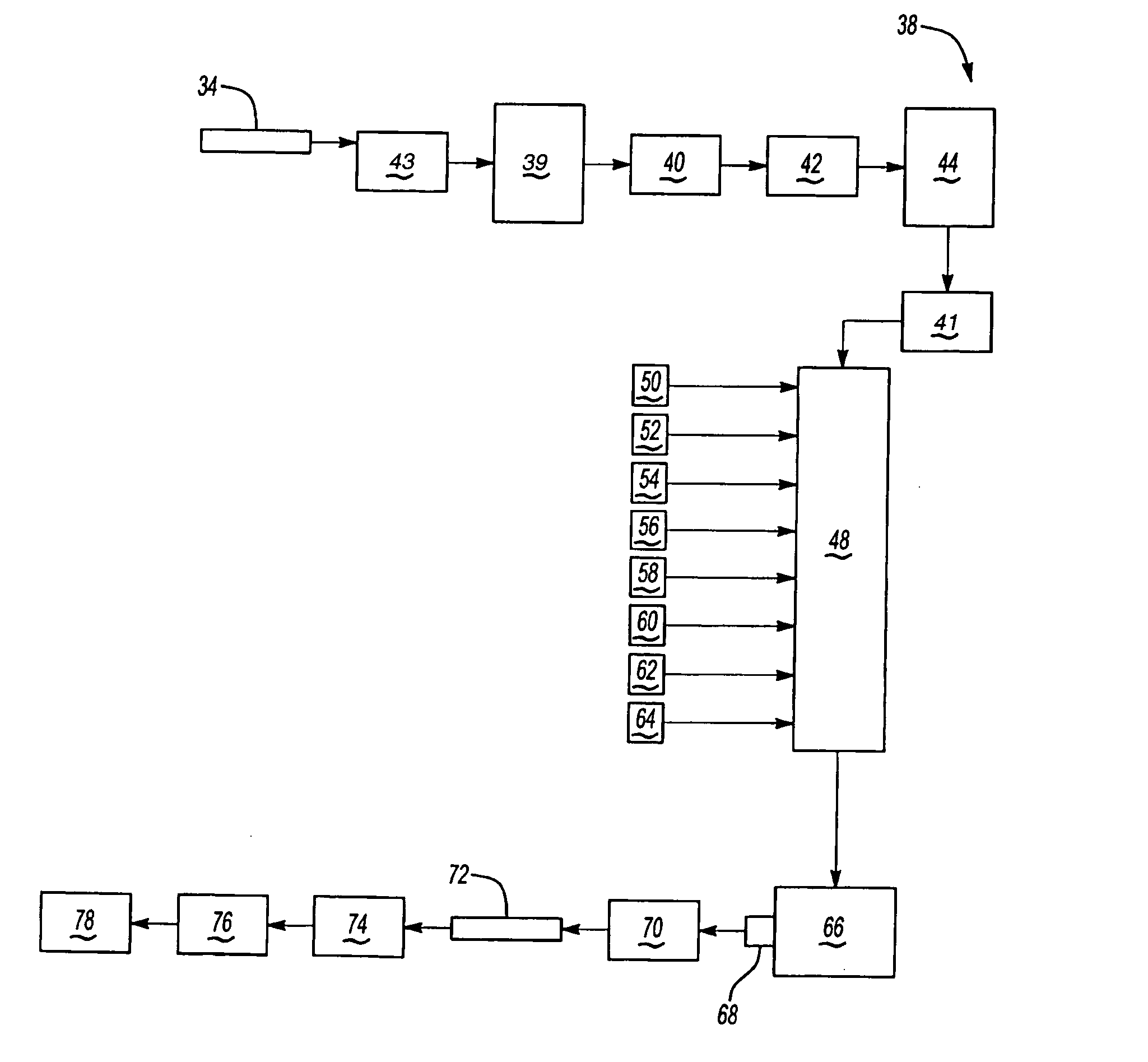

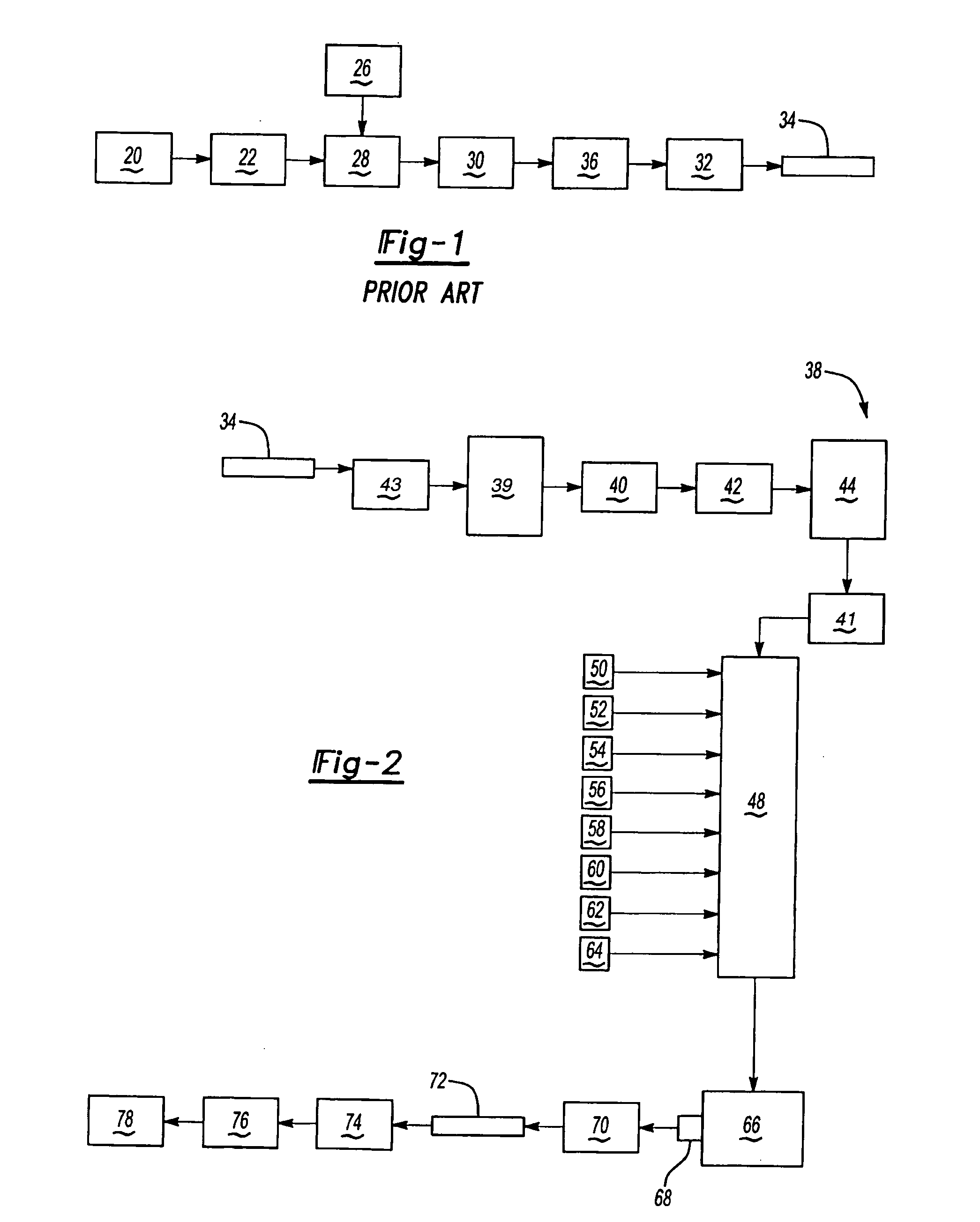

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

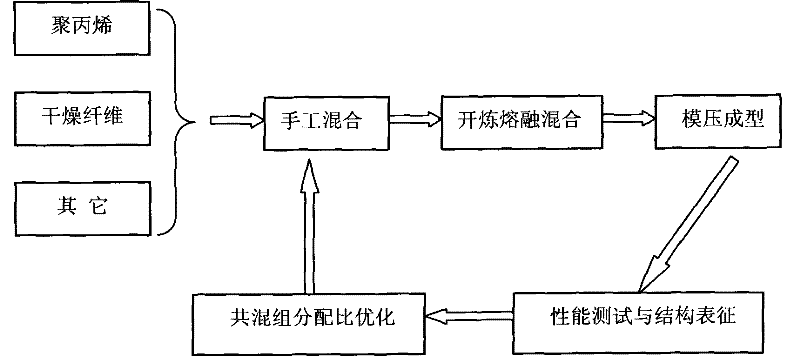

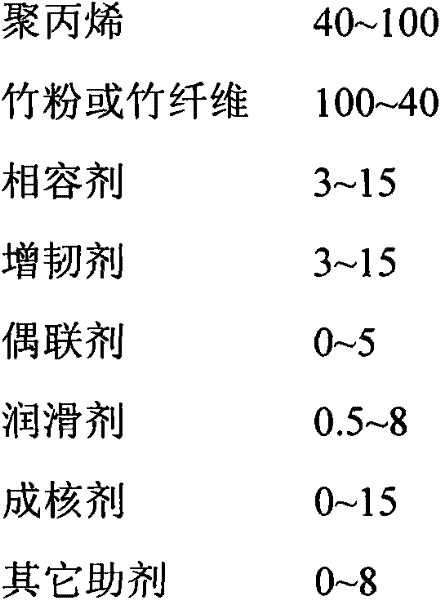

Novel bamboo-plastic composite material

The invention relates to a preparation method of a novel bamboo-plastic composite material, in particular to a bamboo-plastic composite material which has excellent mechanical property and is prepared by the step of adding reinforcing material bamboo powder (or bamboo fabric), a flexibilizer and other assistants to polypropylene used as a substrate resin, wherein the bamboo-plastic composite material comprises the following components in parts by mass: 40-100 parts of polypropylene, 40-100 parts of bamboo powder or bamboo fabric, 3-15 parts of compatilizer, 3-15 parts of flexibilizer, 0-5 parts of coupling agent, 0.5-8 parts of lubricant, 0-15 parts of nucleator and 0-8 parts of other assistants. According to the invention, by selecting proper types and proportions of flexibilizer, compatilizer and other assistants, the defect that the impact strength of the composite material is reduced greatly due to the addition of fiber is overcome.

Owner:EAST CHINA UNIV OF SCI & TECH

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

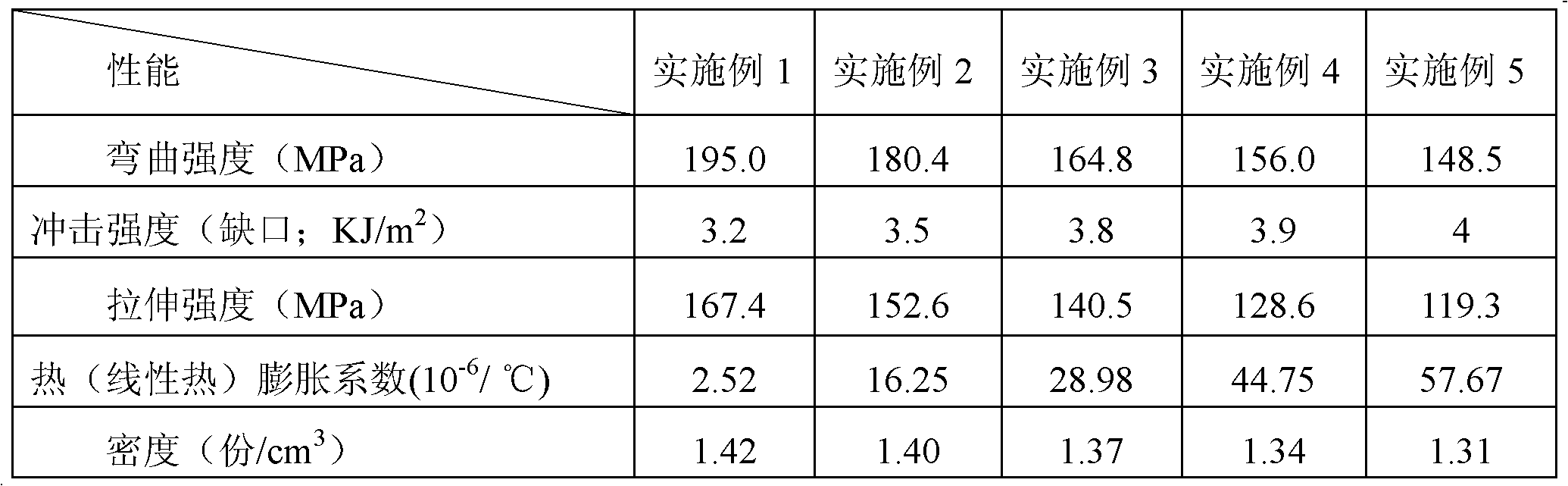

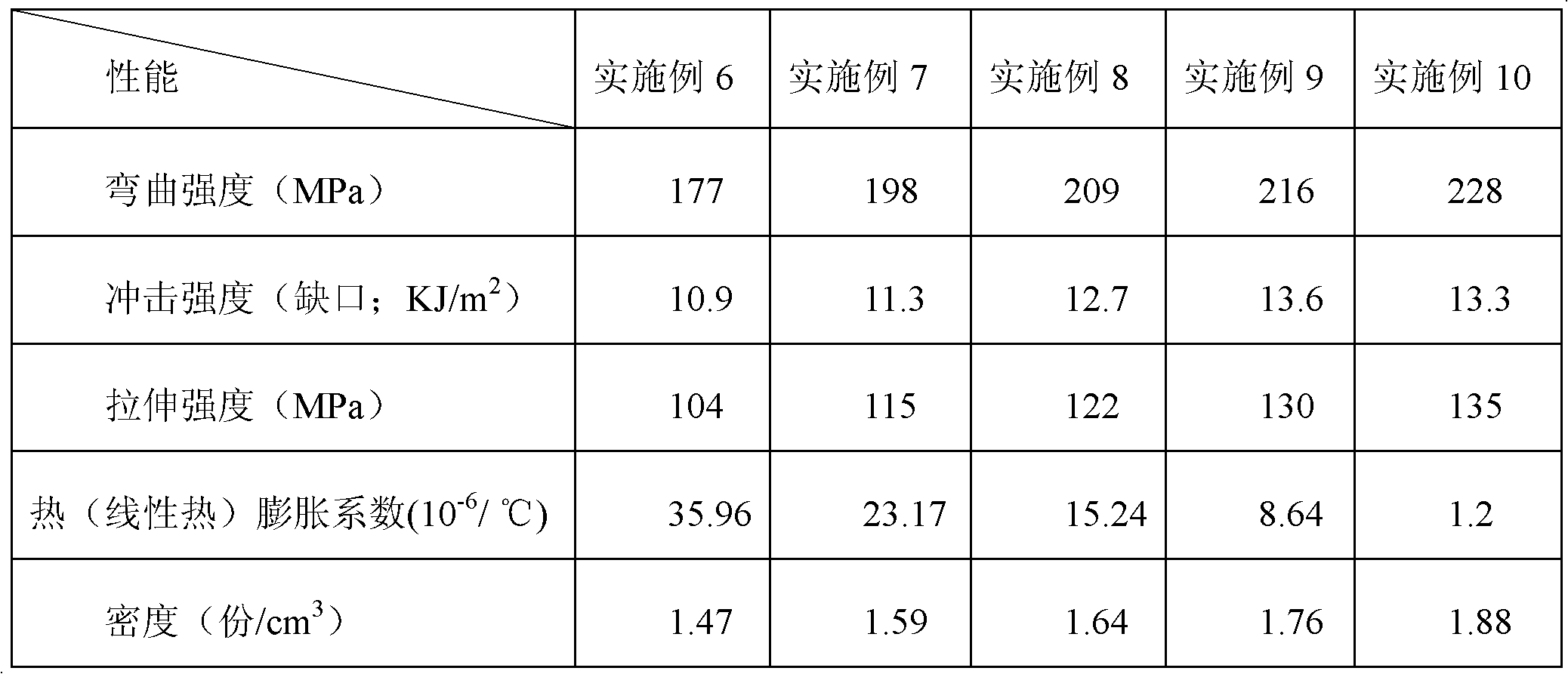

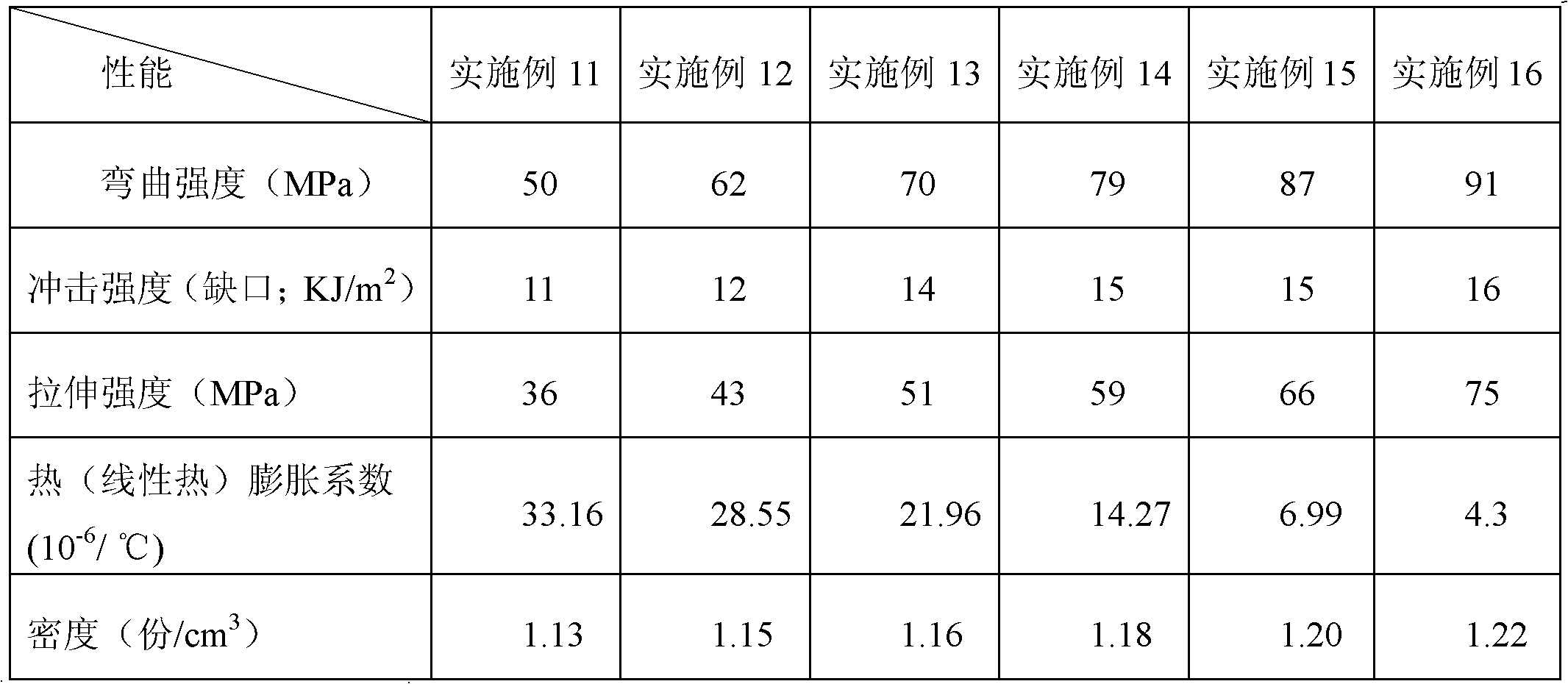

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

Dental materials with a high flexural modulus

InactiveUS20100068679A1Increased flexural modulusImprove liquidityImpression capsTeeth fillingFlexural modulusViscosity

Low viscosity composites, with a flexural modulus of at least 18 GPa and a flexural strength of at least 90 MPa for filling dental root canals for fixing post or as a build-up material on post, are composed of aluminum oxide with a mean particle size of 1 to 50 μm in combination with at least one additional filler with a mean particle size of 0.5 to 5 μm and a monomer mixture. Also disclosed is a method for the preparation of tooth restorations.

Owner:IVOCLAR VIVADENT AG

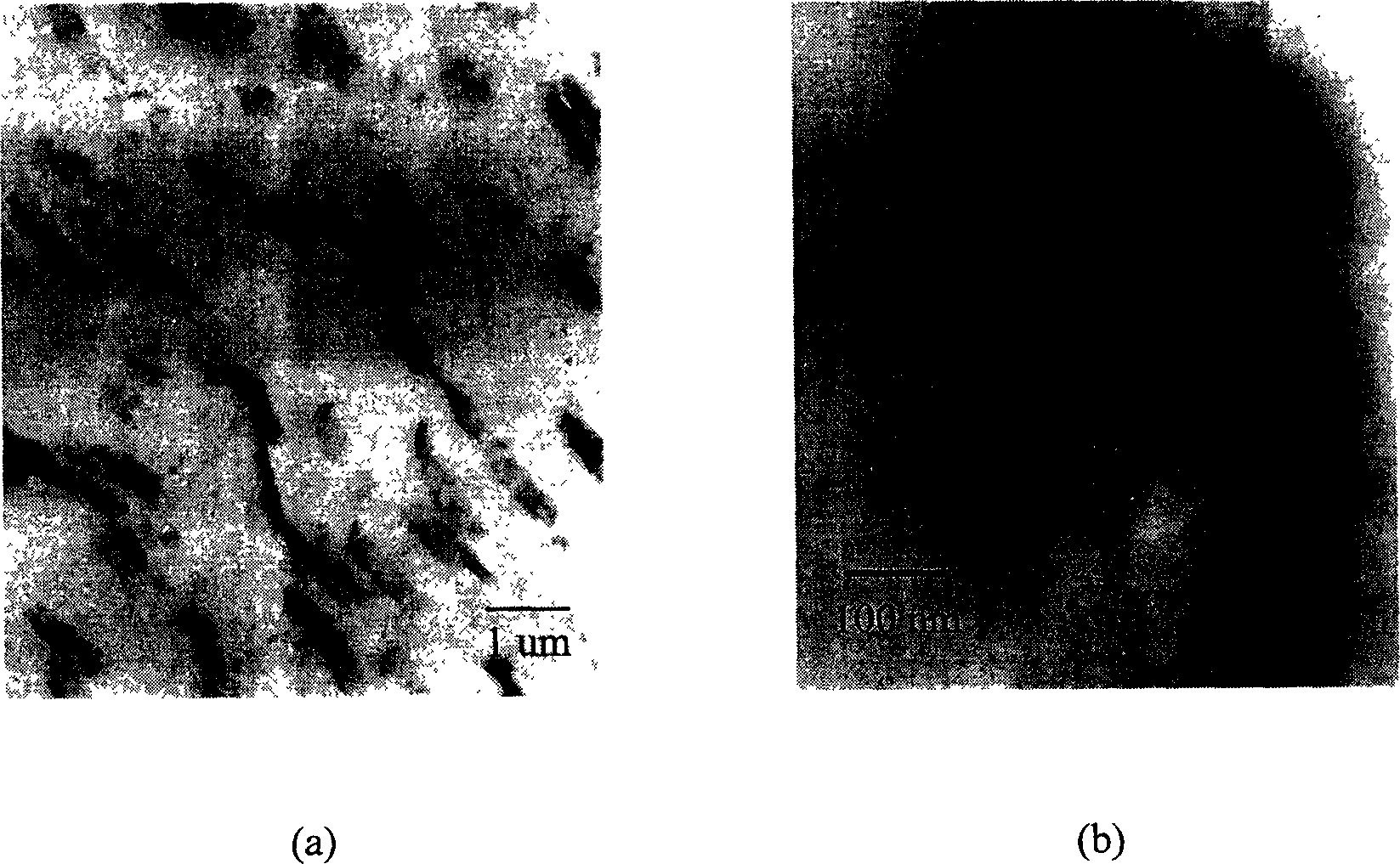

Method for preparing Nano-composite material of poly lactic acid/montmorillonite

A nano-class polylactic acid-montmorillonie composition is prepared from polylactic acid, organically modified montmorillonite with different interlayer gaps, compatibilizer and antioxidizing agent through fusing and mixing polylactic acid with said montmorillonite to obtain mother material, and fusing and mixing the mother material with polylactic acid. Its advantages are high mechanical performance, resistance to high temp and biodegradability.

Owner:TONGJI UNIV

Polymer filled with solid particles

InactiveUS6239196B1Increased flexural modulusHigh impact strengthMixing methodsOrganic dyesFlexural modulusSolid particle

The invention relates to a process for the preparation of a composition to be extruded comprising a polymer and a filler of solid particles comprising a stage of mixing the filler of solid particles with particles or granules of the said polymer, if appropriate in the form of an aqueous suspension.The invention is particularly simple, and the final material is in better mechanical properties than those obtained by direct incorporation of the solid filler in the polymer or copolymer. This improvement is very substantial, in particular with regard to the impact strength of the final material. The invention also relates to a polypropylene-based composition comprising a filler of solid particles, such as kaolin, exhibiting a high flexural modulus and a good impact strength.

Owner:APPRYL

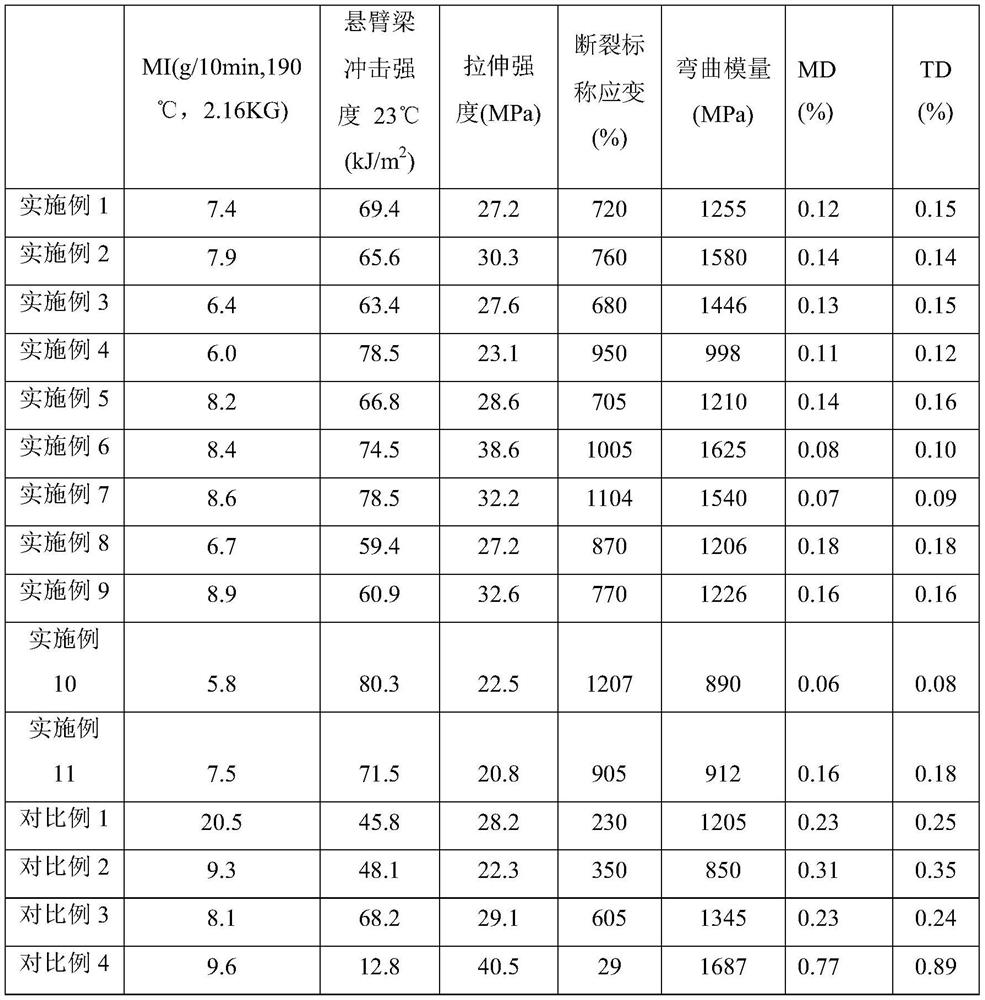

Lightweight, high-toughness, high-rigidity polypropylene composition and manufacturing method thereof

InactiveUS20200216651A1Enhanced interface bindingImprove impact resistanceMasterbatchPolymer science

A polypropylene composition provided with lightweight, highly tough and highly rigid as well as having a specific weight of 1.0-1.05 is made of a polypropylene resin, inorganic powder, a toughener, a coupling agent, a compatibilizer and an anti-oxidant; a method of manufacturing the composition involves grafting the inorganic powder onto the polypropylene resin and the coupling agent to form a masterbatch, and mixing the masterbatch with the other additives to enhance bonding ability of the inorganic powder inside the polypropylene composition to endow the composite with good toughness, rigidity and mobility, and reducing undesirable dust.

Owner:NANYA PLASTICS CORP

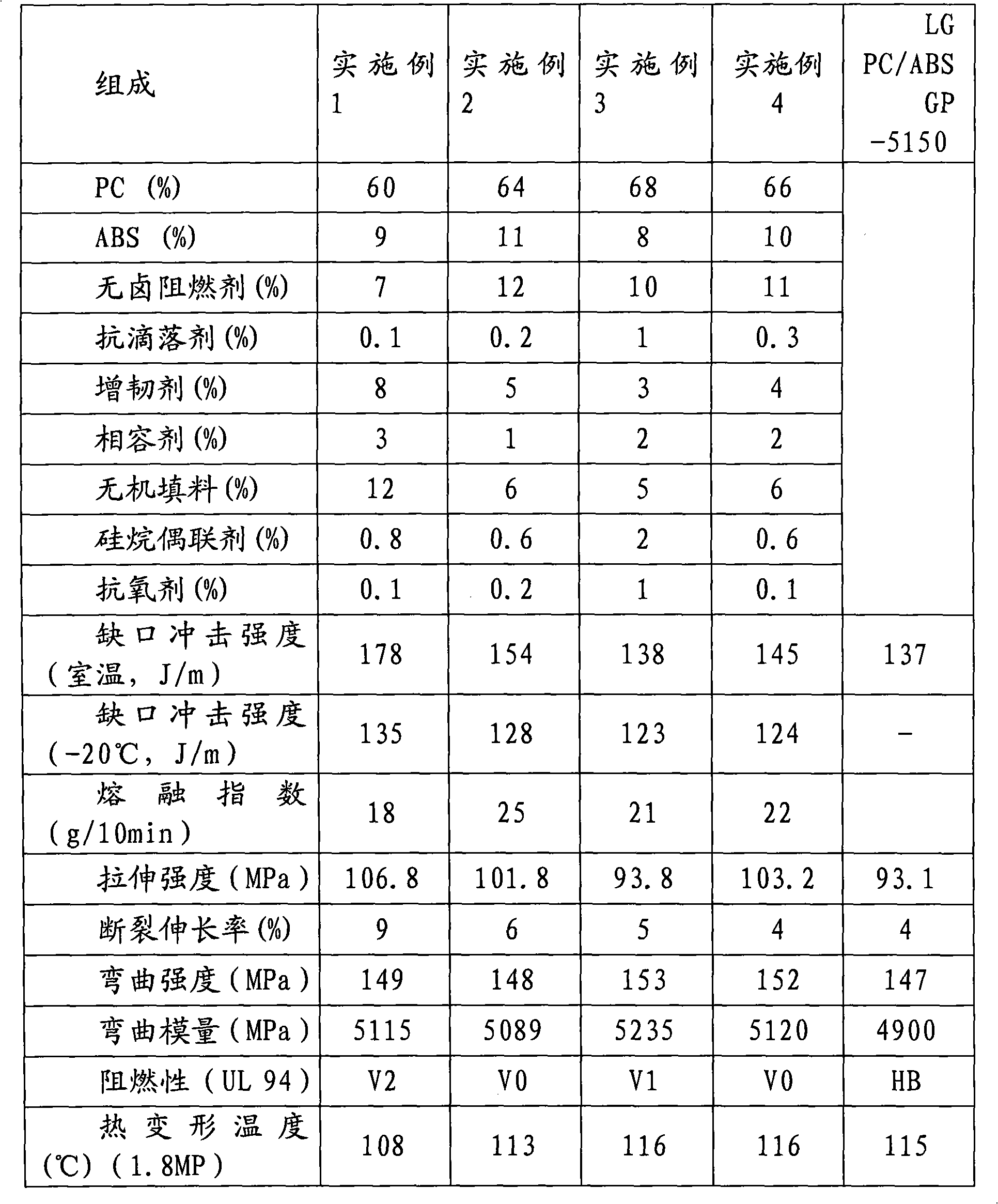

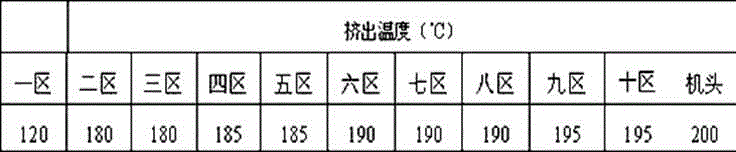

Environmentally-friendly halogen-free PC/ABS alloy and preparation method thereof

The invention discloses an environmentally-friendly halogen-free polycarbonate / acrylonitrile butadiene styrene (PC / ABS) alloy and a preparation method thereof. The environmentally-friendly halogen-free PC / ABS alloy consists of the following components in percentage by weight: 60 to 68 percent of PC, 6 to 14 percent of ABS, 7 to 12 percent of halogen-free flame retardant, 5 to 12 percent of inorganic filler and 4 to 16 percent of auxiliary agent. The environmentally-friendly halogen-free PC / ABS alloy has the advantages of high fill fluidity, processability, high bending strength and bending modulus, little surface warpage and deformation when an in-mold decoration (IMD) process is used for decorating the surface and good application prospect in high-end laptop computer casings, automotive instrument panels and electrical appliance shells.

Owner:SHENZHEN KEJU NEW MATERIAL

Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

The present invention relates to a glass fiber reinforced flame retardant polypropylene material for household appliance products, and belongs to the field of modified polypropylene plastic. The material comprises the following raw materials, by weight: a high-impact-resistance copolymer polypropylene resin, a bromine-based flame retardant agent, antimony trioxide, a flame retardant synergist, alkali-free continuous long glass fibers, a compatibility agent, a toughening agent, a lubricant, a UV absorber and an antioxidant. The present invention provides the glass fiber reinforced flame retardant polypropylene material with higher tensile strength, bending modulus and hardness as well as high impact-resistance, low molding shrinkage, aging resistance and the like. The glass fiber reinforced flame retardant polypropylene material has a high heat deformation temperature, good oxidation resistance at high temperature, and the flame retardant performance up to the level of UL94 V-2, and passes the glow wire test of GWIT: 700 / 3.0. The glass fiber reinforced flame retardant polypropylene material has a low cost and a light weight, and can be used instead of metal or plastic material to produce the household appliance products which need flame retardation and high temperature resistance.

Owner:GUANGDONG JUSHI CHEM CO LTD

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

High-strength high-toughness flame-retardant polypropylene material, and preparation method and application thereof

The invention belongs to the technical fields of high molecular material modification and processing, and discloses a high-strength high-toughness flame-retardant polypropylene material, and a preparation method and application thereof. The polypropylene material disclosed by the invention comprises the following components in parts by weight: 20-50 parts of polypropylene, 0.1-10 parts of toughener, 1-10 parts of compatilizer, 16-22 parts of compound flame retardant, 0.2-0.4 parts of antioxidant, 0.1-0.4 parts of light stabilizer and 30-50 parts of glass fiber. The preparation method of the polypropylene material comprises the following steps: mixing 20-50 parts of polypropylene, 0.1-10 parts of toughener, 1-10 parts of compatilizer, 16-22 parts of compound flame retardant, 0.2-0.4 part of antioxidant, 0.1-0.4 part of light stabilizer and 30-50 parts of glass fiber in a high-speed mixer for 3-5 minutes, adding the mixture into an extruding machine, extruding and granulating to obtain the required high-strength high-toughness flame-retardant polypropylene material. The polypropylene material disclosed by the invention has the advantages of high tensile strength, high flexural modulus, high impact strength and favorable flame retardancy, and is an optimal material for engineering plastic building templets.

Owner:HEFEI GENIUS NEW MATERIALS

PVC/ABS alloy material with high anti-impact strength and preparation method thereof

The invention provides a PVC / ABS alloy material with high anti-impact strength and a preparation method thereof. The alloy material comprises, by weight, 30 to 80% of a PVC composite material modified by filled active nanometer calcium carbonate and 20 to 70% of injection molding grade ABS resin. The PVC composite material comprises PVC resin, a heat stabilizer, a lubricant, an anti-impact modifier, an anti-oxidant, a fire retardant and the filler active nanometer calcium carbonate, and the weight ratio of the above-mentioned components is as follows: PVC resin: the heat stabilizer: the anti-impact modifier: the lubricant: the anti-oxidant: the fire retardant: the filler active nanometer calcium carbonate = 100 parts: 4.7-5.5 parts: 5-15 parts: 0.1-6 parts: 0.1-2 parts: 3-6 parts: 5-20 parts. The preparation method is as follows: all the materials are weighed according to a formula for the PVC composite material and placed in a high speed mixer with a rotate speed of 680 to 1400 r / min for high speed stirring, when the temperature of an obtained mixture rises to 100 to 120 DEG C, the high speed mixture is put in a low speed mixer with a rotate speed of 85 r / min for stirring and cooling, after the temperature of the mixture drops to 40 to 50 DEG C, a desired amount of the dried ABS resin is added into the mixture, low speed mixing at a rotate speed of 85 r / min is carried out for 2 to 8 min, and a discharged material is a dry blend for the alloy material; the dry blend is added into a double screw extruder or a double / single screw two-stage extruder for melt blending and extruding at a temperature of 110 to 170 DEG C, and an obtained material is cut into granular materials by using a plastic grain cutting machine.

Owner:CHINA PETROLEUM & CHEM CORP

Absorbable medical suture line and preparation method thereof

InactiveCN104800883ANo stimulationNo side effectsSuture equipmentsConjugated cellulose/protein artificial filamentsWater bathsWound healing

The invention discloses an absorbable medical suture line. The absorbable medical suture line comprises the following components in parts by weight: 30-50 parts of polyglycolic acid, 16-20 parts of collagen, 2.5-3 parts of chitosan, 1-2 parts of a bacteriostatic agent, 1-4 parts of a stabilizer, and 2-6 parts of a biological cross-linking agent. A preparation method for the absorbable medical suture line comprises the following steps: co-mixing the required components under a certain condition, extruding, performing water-cooling, drying in the air, pelletizing, spinning, stretching in a water bath and the like. All raw materials of the obtained suture line can be absorbed and degraded in vivo, free of stimulus on tissue, and are free of toxic or side effects, and a wound is free of obvious stitching marks after being healed. The formula of the composition is reasonably designed, so that the prepared product has excellent mechanical performances of high tensile strength, high bending modulus, and the like, and has the characteristic of easiness machining and shaping without obvious individual difference, and the pains of a patient are relieved.

Owner:WUJIANG ZHENYU SEWING EQUIP

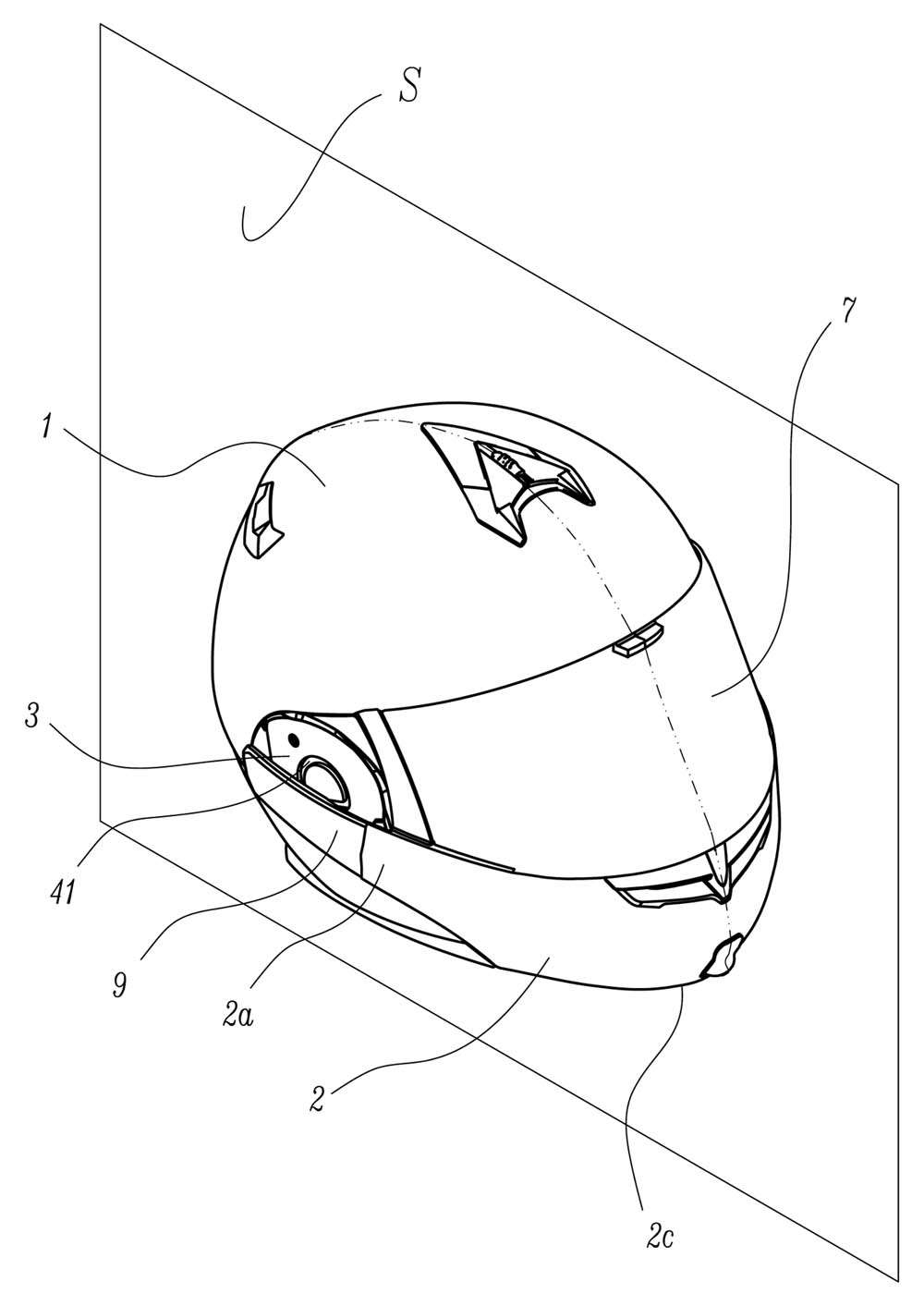

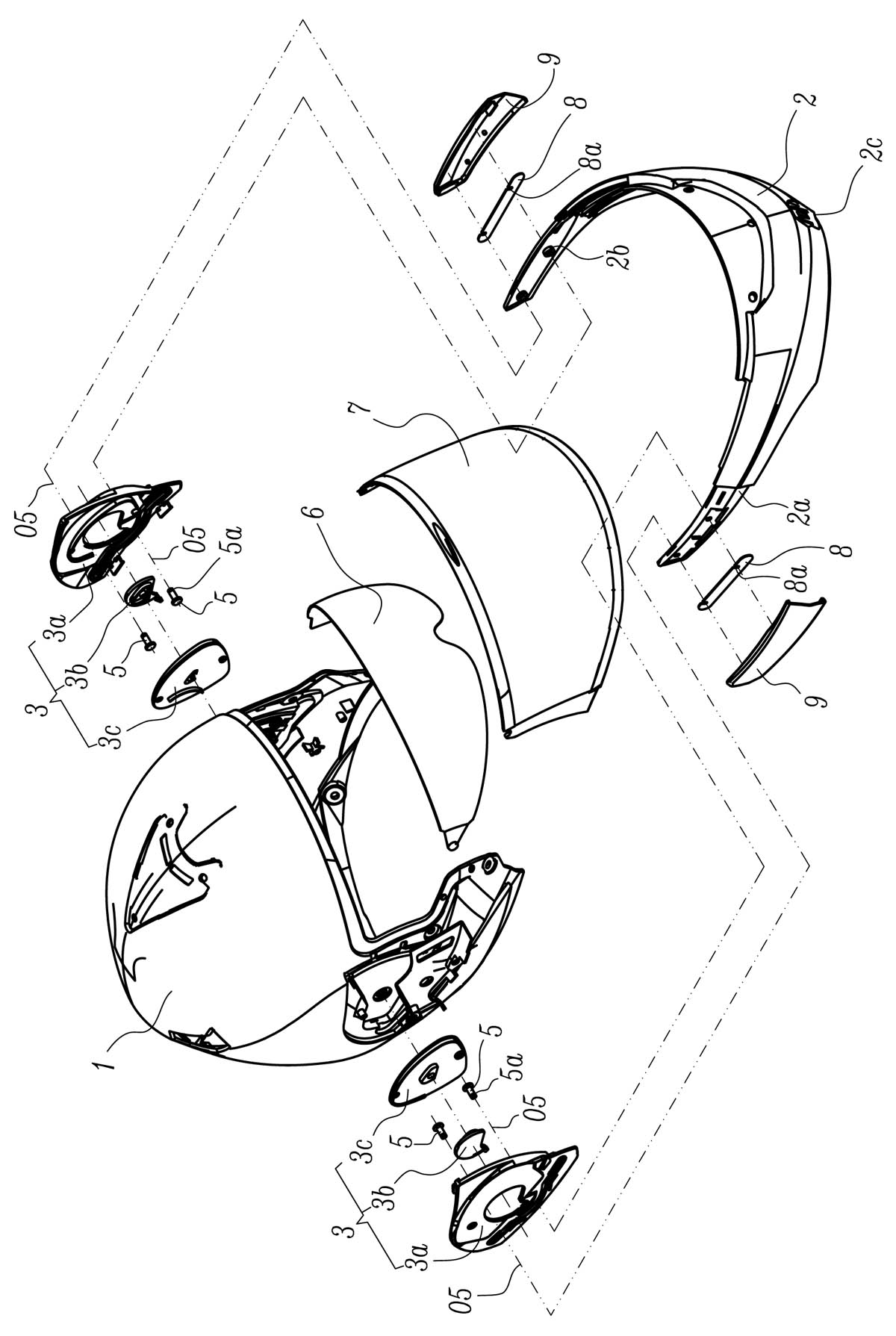

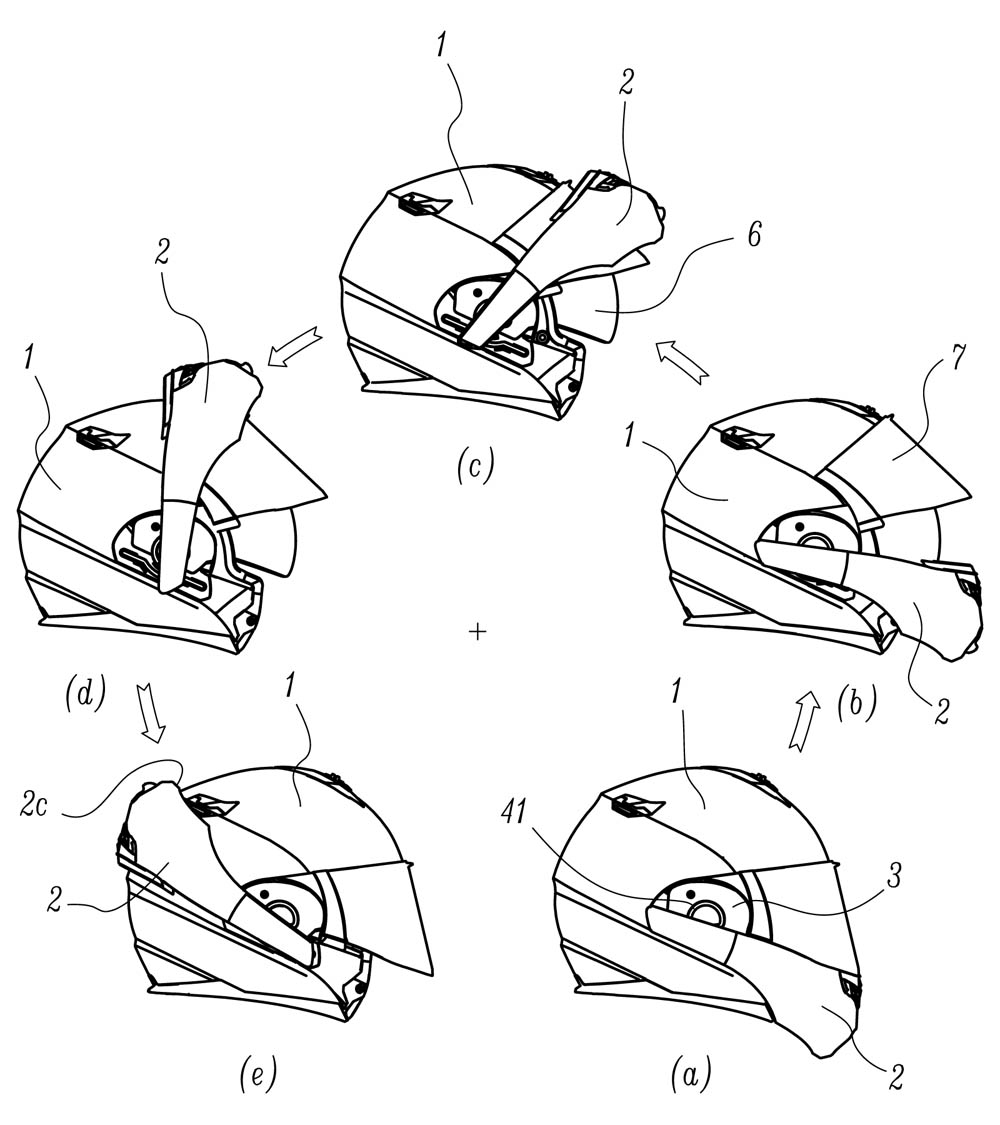

Variable jaw structure protecting helmet

The invention belongs to the technical field of helmet, relating to a variable jaw structure protecting helmet. The helmet comprises a helmet main body, a jaw guard and two mould boards; wherein the jaw guard is provided with two fork handles, the two mould boards are respectively arranged at the two sides of the helmet case main body, the mould board is fastened and connected with the helmet case main body or the mould boards are connected with the helmet main body into a whole, each mould board is opened with two groove-shaped guide rails and is additionally provided with four movable pins, one end of each movable pin is inserted into the four guide rails on the two mould boards, each fork handle is respectively connected with the two movable pins, the jaw guard drives the movable pin by virtue of the fork handle, each movable pin moves along respective corresponding guide rail, and the position of the jaw guard can be changed under the constraints of the movable pin and the guide rail. Compared with the prior art, the invention has the advantages that no guide rail is arranged on the jaw guard, bending strength of fork handle is improved, fracture resistance of the fork handle of the jaw guard is improved, besides, stress concentration hidden danger can be effectively eliminated by abandoning the chute of the fork handle, and meanwhile strength of jaw guard is improved.

Owner:JIANGMEN PENGCHENG HELMETS

Degradable plastic composition as well as preparation method and application thereof

ActiveCN111995848ASolve rigid problemsImprove mechanical propertiesBio-packagingPolymer scienceUltimate tensile strength

The invention discloses a degradable plastic composition as well as a preparation method and application thereof. The degradable plastic composition comprises the following components in parts by weight: 70-99 parts of at least two degradable resins, 0-6 parts of a toughening agent, 0.5-5 parts of a compatilizer, 0.05-3 parts of a chain extender, 0.05-5 parts of an anti-hydrolysis agent, 0.05-5 parts of a nucleating agent and 0.05-3 parts of a slipping agent. By matching two or more degradable resins, the problem of poor toughness or rigidity of the existing single degradable resin is solved,so that the product has excellent comprehensive mechanical properties, excellent rigidity and toughness, high impact property, high nominal strain at break and higher flexural modulus and tensile strength.

Owner:联泓(江苏)新材料研究院有限公司

Cross blend material based on polycarbonate and its prepn. method

InactiveCN1415661AImprove heat resistanceImproved boiling water aging resistanceHeat resistanceEngineering plastic

A polycarbonate-base mixture suitable for the engineering plastics in wet or hot water environment is prepared through mixing polyethene with maleic acid anhydride modified polyolefine or ionic polymer, kneading, granulating, mixing with polycarbonate and acrylonitrile-butadiene-styrene copolymer, and extruding out. Its advantages are high mechanical performance, size stability and refractory nature, and high antiageing nature in boiling water.

Owner:上海天原集团胜德塑料有限公司

Heat-conducting antistatic carbon fiber modified polyamide composite material and preparation method thereof

The invention belongs to the technical field of heat-conducting composite materials and relates to a heat-conducting antistatic carbon fiber modified polyamide composite material. The composite material disclosed by the invention comprises the following components by weight percent: 5-40% of asphalt-based carbon fiber, 50-85% of polyamide resin, 1-10% of compatilizer, 5-15% of graphite micropowder and 0.1-1% of processing aid. The asphalt-based carbon fiber is subjected to surface treatments as follows: (1), oxidizing the surface of the asphalt-based carbon fiber for 2-24 hours at the temperature of 60-120 DEG C by using an oxidant; and (2) filtering out the asphalt-based carbon fiber treated in the step (1), washing the asphalt-based carbon fiber with distilled water until the distilled water is neutral, and drying the asphalt-based carbon fiber at the temperature of 80-150 DEG C; and carrying out seal standing for 2-5 hours in a treatment liquid at room temperature and then drying. The composite material disclosed by the invention is less in addition amount and simple in processing step and has a heat-conducting function, and simultaneously, the mechanical and antistatic properties of the material are improved.

Owner:NANJING JULONG SCI&TECH CO LTD

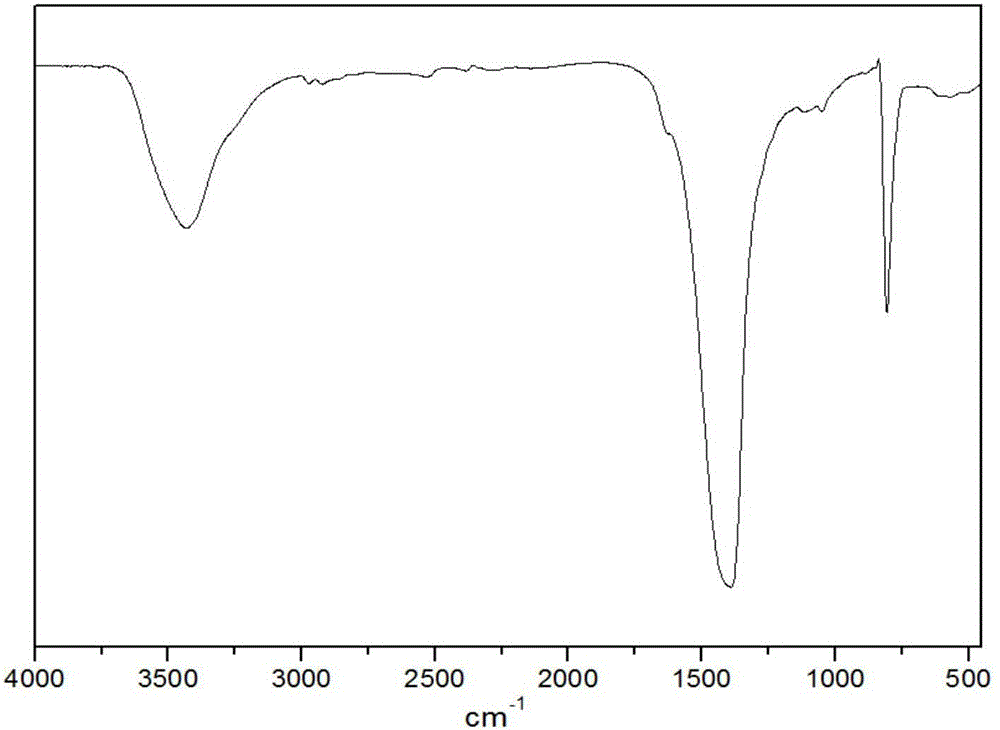

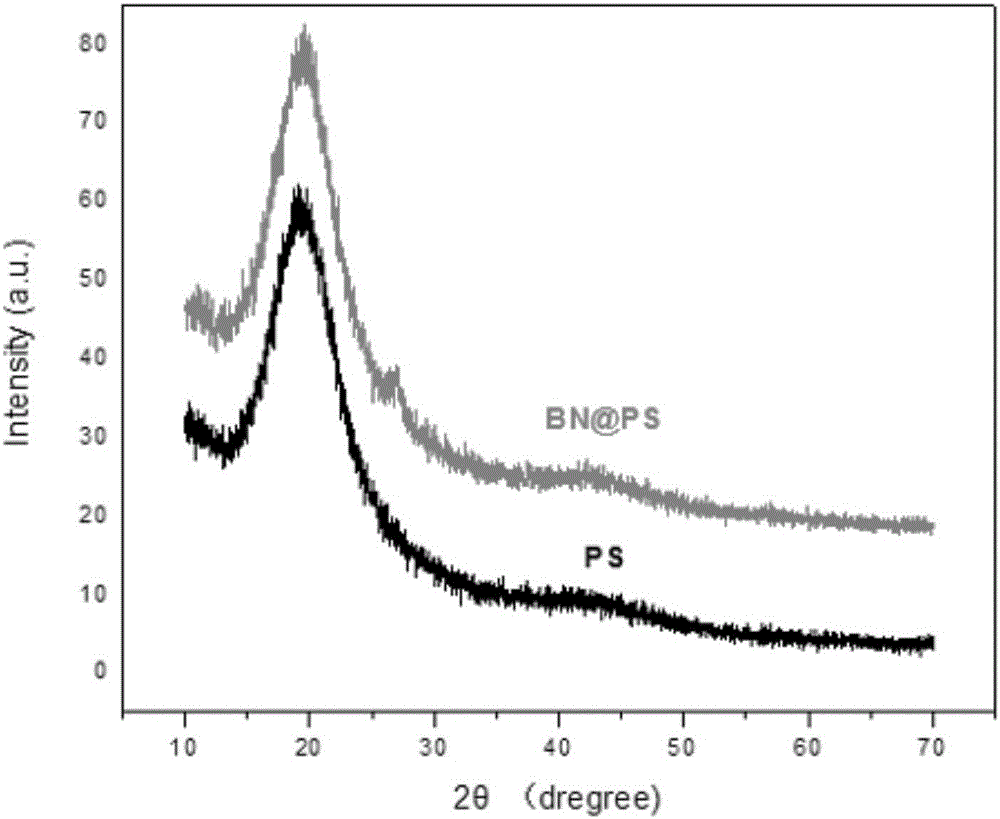

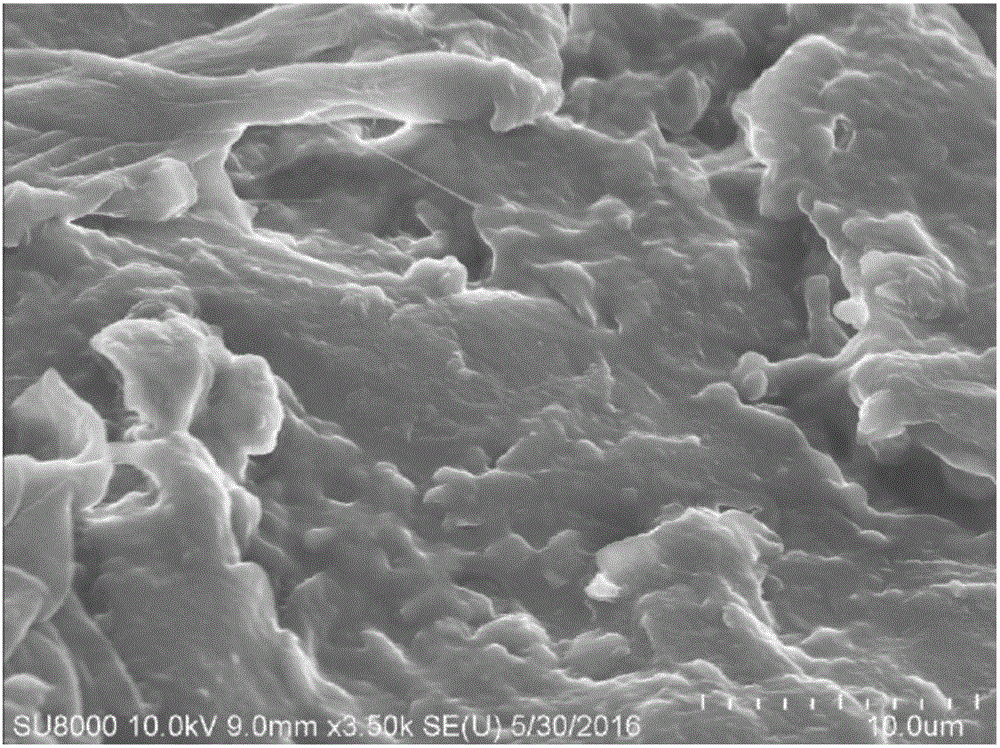

Preparing method of hexagonal boron nitride/polystyrene composite

ActiveCN105860315AImprove mechanical propertiesImprove thermal conductivityHeat-exchange elementsMasterbatchHexagonal boron nitride

The invention discloses a preparing method for a hexagonal boron nitride / polystyrene composite and belongs to the technical field of high polymer material modification and the technical field of processing. The preparing method comprises the steps that firstly, a suspension polymerization method is adopted, and h-BN@PS masterbatch is prepared from boron nitride, styrene, a coupling agent, an initiator and a dispersing agent, wherein the mass ratio of the h-BN@PS masterbatch to polystyrene is 1:(3-5); the h-BN@PS masterbatch and a polystyrene base material are mixed, and the hexagonal boron nitride / polystyrene composite is prepared, wherein the mechanical performance of polystyrene is enhanced, and the heat conductivity coefficient can be increased. The preparing process of the composite is advanced, the compatibility of hexagonal boron nitride and polystyrene can be improved, and operation is simple and environmentally friendly; the composite can obtain high mechanical performance and a high heat conductivity coefficient under a low filler doping amount, and significant application value is achieved.

Owner:LIAONING UNIVERSITY

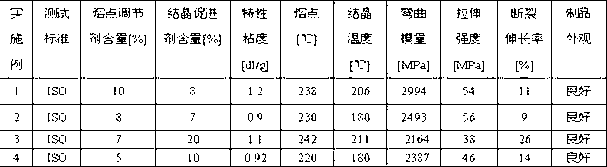

Low-melting point and high-crystallization temperature PET copolyester, its preparation method and application

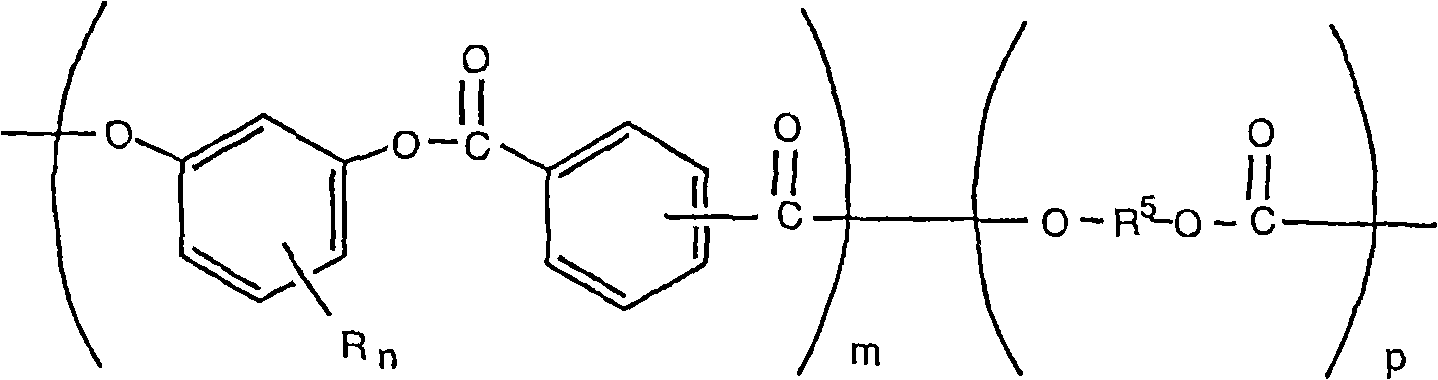

InactiveCN103102646AImprove processing and forming performanceGood flexural modulusCopolyesterPolyethylene terephtalate

The invention discloses a low-melting point and high-crystallization temperature PET (polyethylene terephthalate) copolyester, its preparation method and application. The PET copolyester comprises, by mass: 70%-88% of PET, 5%-10% of a melting point adjusting agent, and 7%-20% of a crystallization accelerating agent. According to the preparation method, in a synthesis process of PET, based on p-phthalic acid (PTA) and ethylene glycol (EG), the melting point adjusting agent and the crystallization accelerating agent are added to undergo a chemical reaction together, thus obtaining the low-melting point and high-crystallization temperature PET copolyester. The PET copolyester provided by the invention has a low melting point and a high crystallization temperature, and has improved processing molding performance, thus being widely applicable in injection molding products.

Owner:KINGFA SCI & TECH CO LTD +2

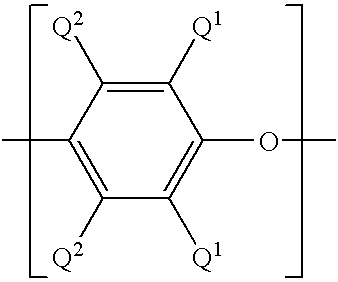

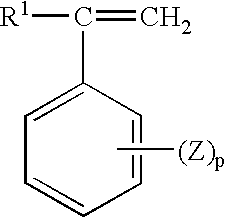

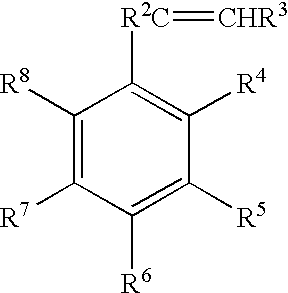

Poly(arylene ether)-polyolefin compositions and articles derived therefrom

A thermoplastic composition includes specified amounts of a poly(arylene ether), a homopolymer of an alkenyl aromatic monomer, a polyolefin, a hydrogenated block copolymer, and an unhydrogenated block copolymer, but the composition is substantially free of any rubber-modified poly(alkenyl aromatic) resin. The composition provides high stiffness and high impact strength and is suitable for molding a variety of articles, including automotive underhood components.

Owner:SHPP GLOBAL TECH BV

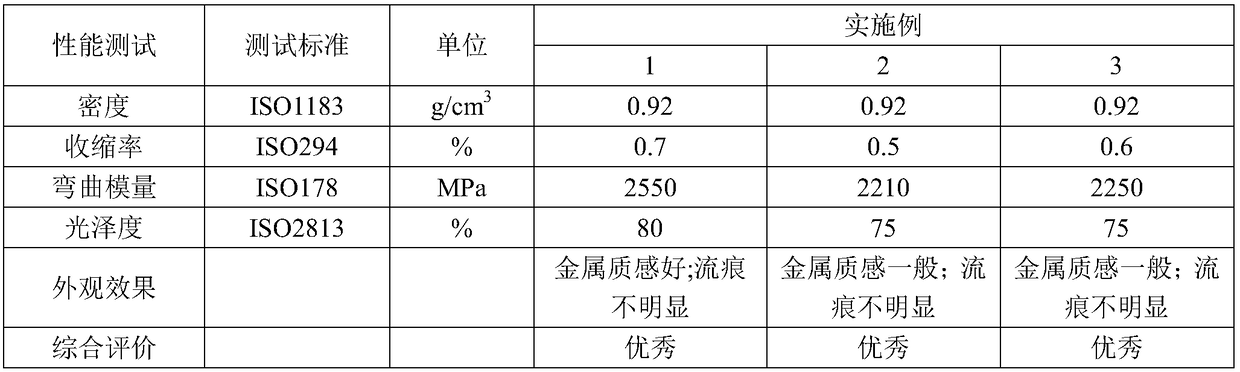

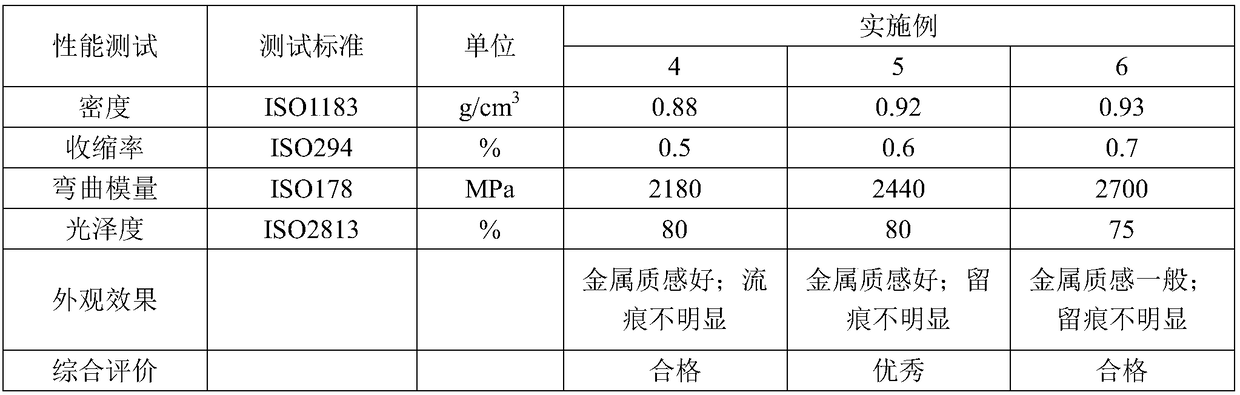

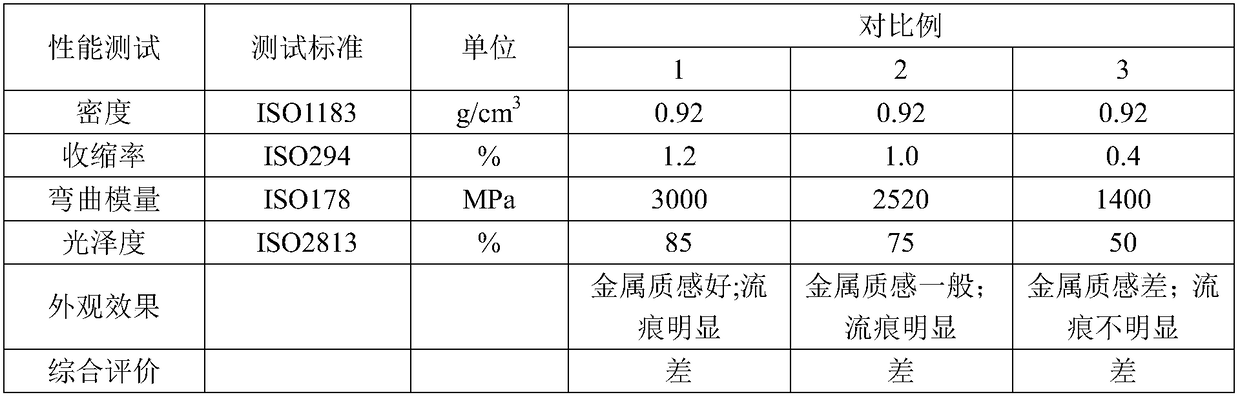

Low-density and low-shrinkage-rate silver metal texture polypropylene composite material and preparation method thereof

The invention discloses a low-density and low-shrinkage-rate silver metal texture polypropylene composite material and a preparation method thereof. The polypropylene composite material comprises high-crystallized polypropylene, high-melt-value polypropylene, low low-shrinkage-rate polypropylene, hollow glass beads, ultra-white and ultra-fine talcum powder, toughening fillers, metal pigments, nano-zinc sulfide, hyperbranched resin, antioxidants and scratch-resistant agents. In the injection molding process of the free-spraying polypropylene composite material, obvious welding marks on the surface of the material are omitted, the appearance of the material approaches to spraying effects, components can be directly used, later spraying treatment is omitted, cost is saved, the material is green and environmentally friendly, the density of the material is much lower than that of common modified polypropylene, lightweight requirements of clients are met, the shrinkage rate of the material is lower than 0.5, the material can directly replace ABS (acrylonitrile butadiene styrene) in the field such as household electric appliance shells, secondary mold opening is omitted, and cost is saved.

Owner:WANHUA CHEM GRP CO LTD +1

Flame retardant polymer blends

Owner:SHPP GLOBAL TECH BV

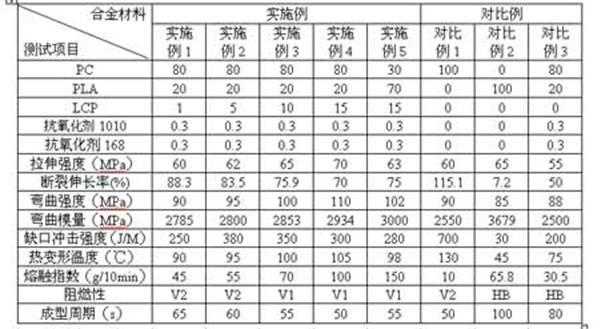

Polyactic acid/polycarbonate alloy material, and preparation method and application thereof

The invention discloses a polyactic acid / polycarbonate alloy material, and a preparation method and application thereof. The polyactic acid / polycarbonate alloy material comprises the following raw materials in part by weight: 10 to 90 parts of polycarbonate, 10 to 90 parts of polyactic acid, 1 to 20 parts of liquid crystal high polymer and 1 to 25 parts of flexibilizer. The polyactic acid / polycarbonate alloy material is prepared by adding the raw materials into a double-screw extruder to be melted and blended. The polyactic acid / polycarbonate alloy material provided by the invention has environmentally-friendly characteristics and excellent physical and mechanical properties, and greatly improves impact strength, bending modulus and heat distortion temperature. The liquid crystal high polymer is added to promote the quick crystallization of the polyactic acid, so that the prepared polyactic acid / polycarbonate alloy can be formed quickly, the forming cycle is reduced from 80 seconds to50 seconds, processing cost is reduced, flowability and fire resistance are improved, and the polyactic acid / polycarbonate alloy material is applicable in the fields of office automation (OA) equipment, communication equipment, automobile parts, domestic appliances and the like.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

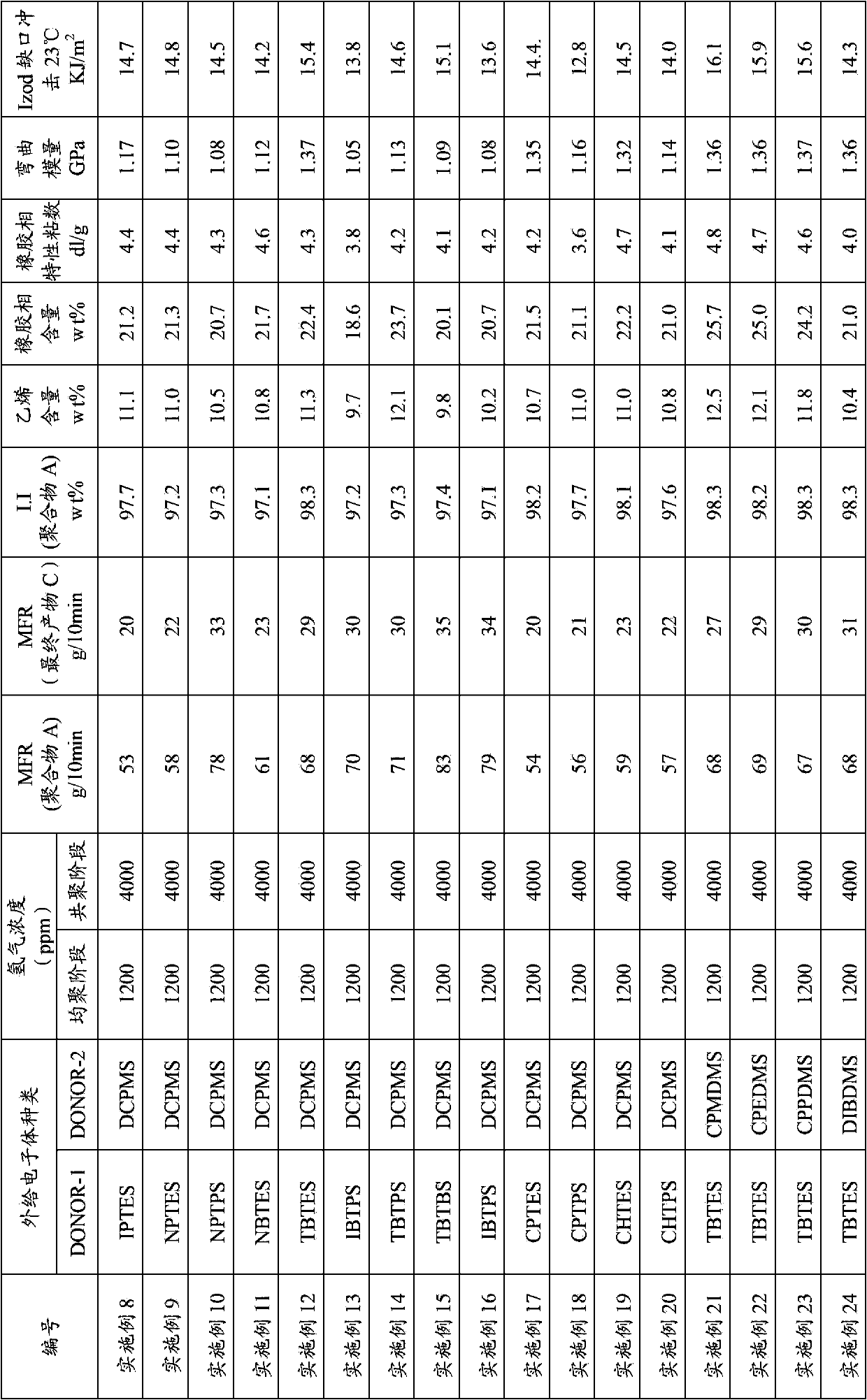

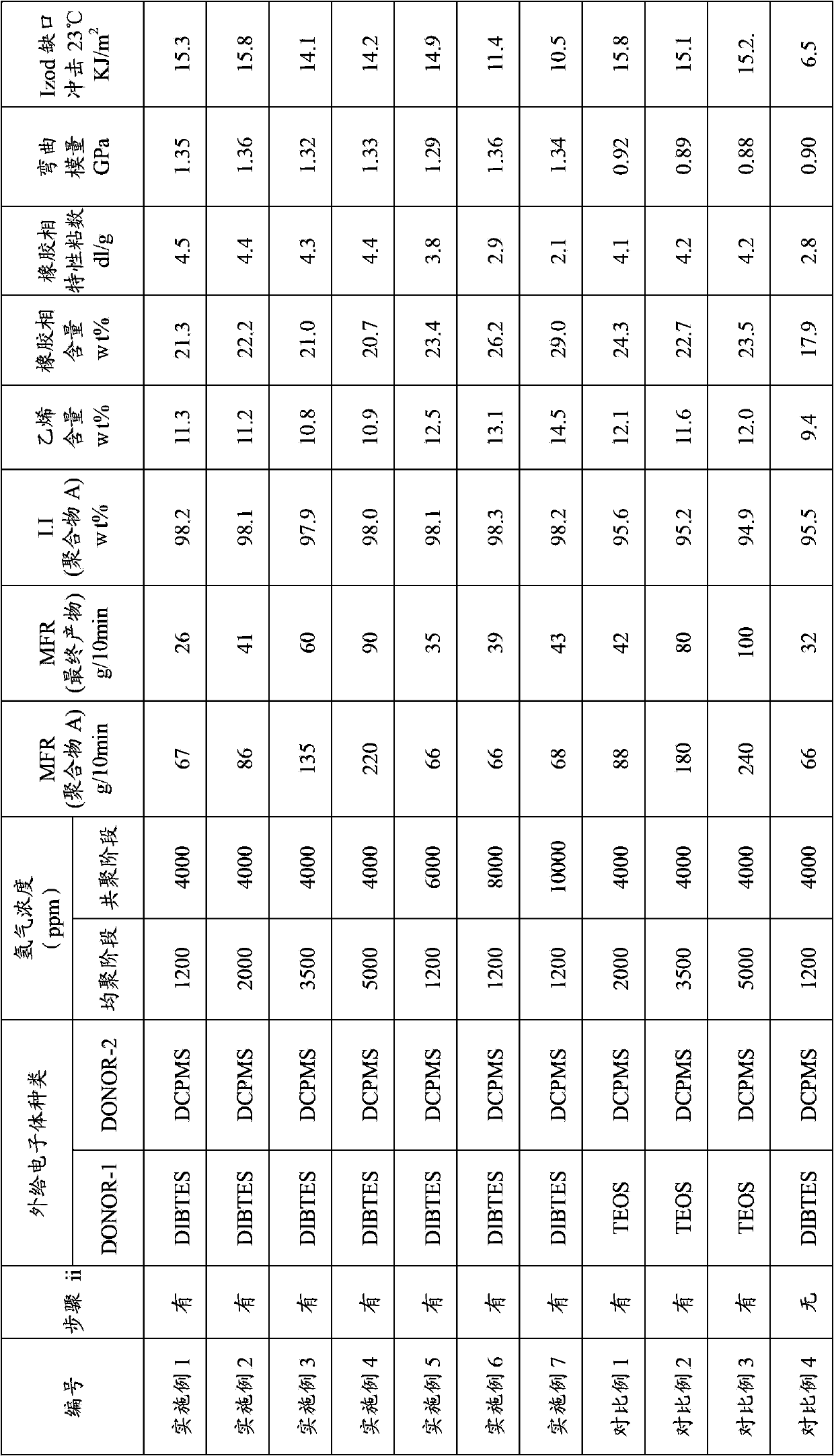

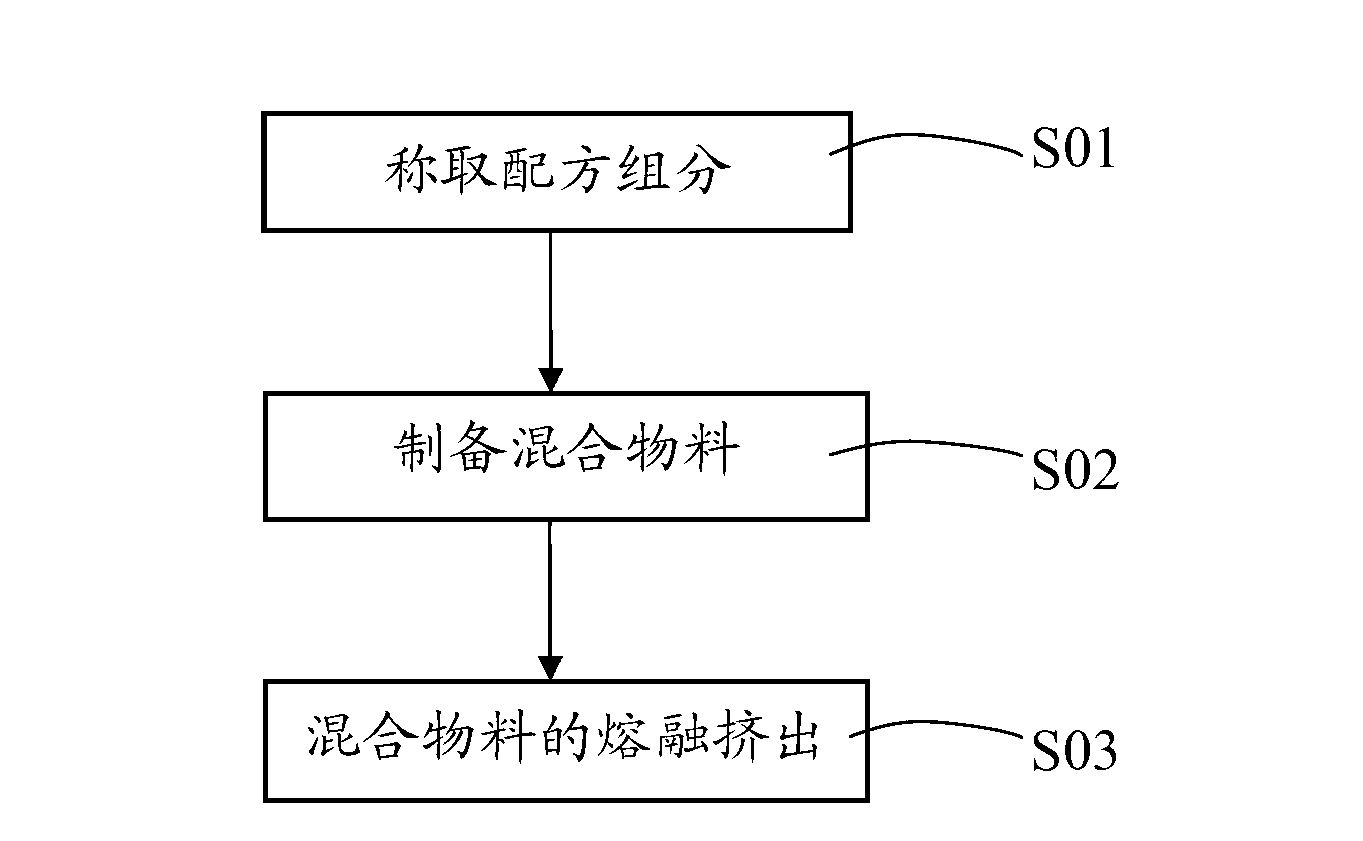

Preparation method of high-melt fluidity high-rigidity antishock polypropylene

The invention discloses a method of high-melt fluidity high-rigidity antishock polypropylene. The method is characterized by comprising the following steps: 1) under the effect of hydrogen and a Ziegler-Natta catalyst of a trialkoxyl silicane-containing compounds external electron donor, propylene or propylene and alpha-alkene are polymerized to obtain a polymer A; 2) a dialkoxysilanes compound external electron donor is added for premixing with the polymer A; 3)under the premixed material in the step 2) and hydrogen, propylene and alpha-alkene are polymerized to obtain a polymer B with melt mass flux rate of 0.01-30g / min; the antishock polypropylene comprising the polymer A and the polymer B can be finally obtained, the melt mass flux rate is 20-1000g / 10min, and preferably is 20-100g / 10min. The provided method has the advantages of easy operation, convenient operation and easy industrial production, so that high performance polypropylene with high melt mass flux rate, high rigidity and high antishock strength is prepared, and the high-melt fluidity high-rigidity antishock polypropylene has wide application and prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

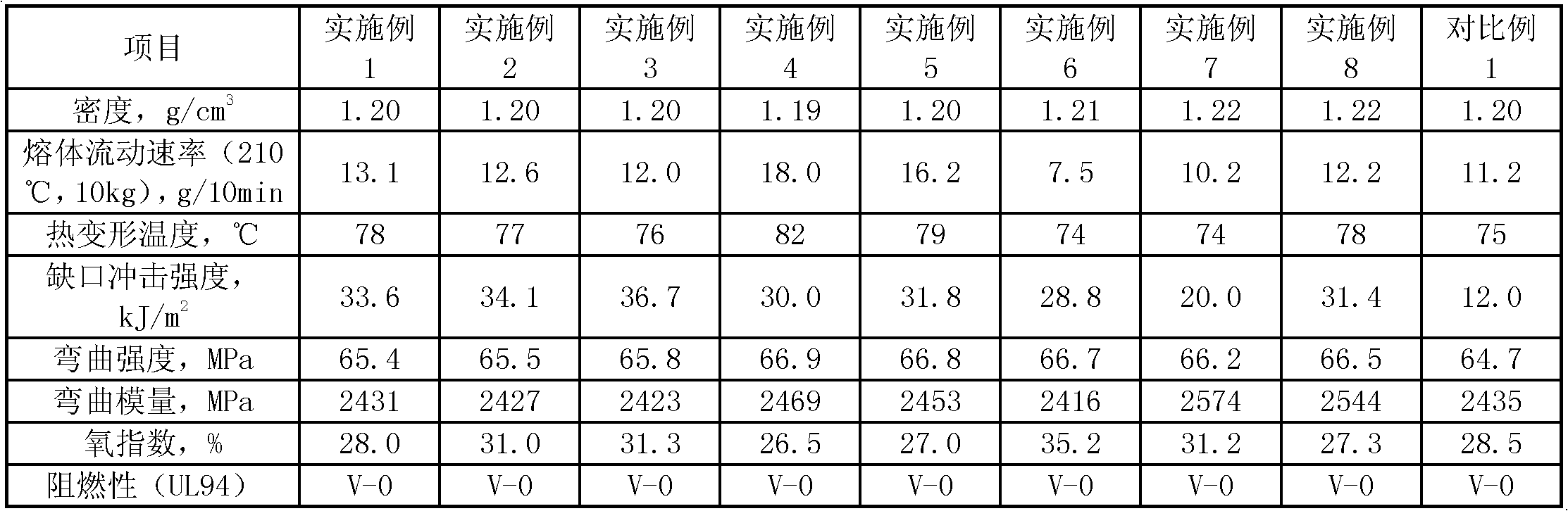

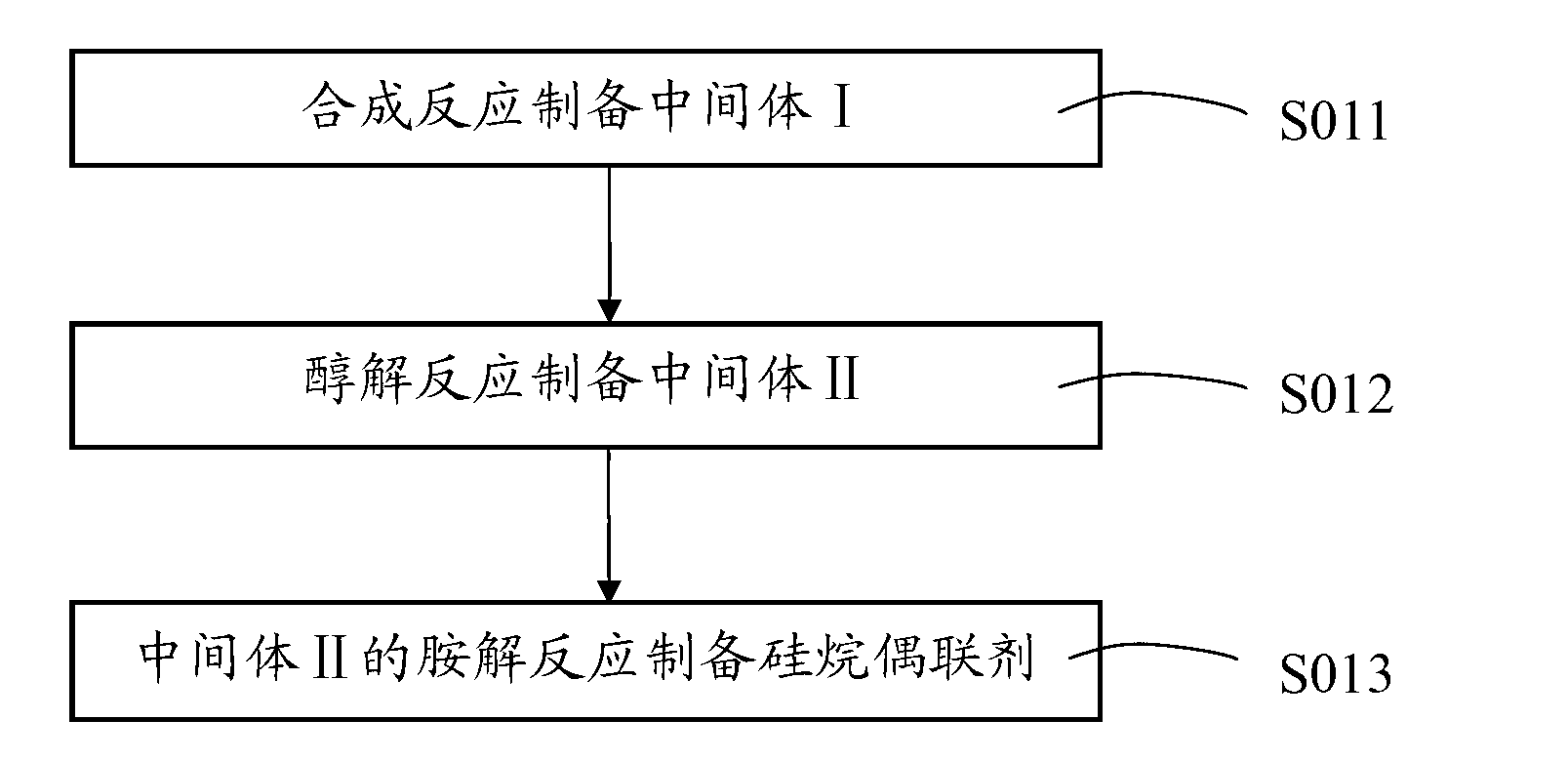

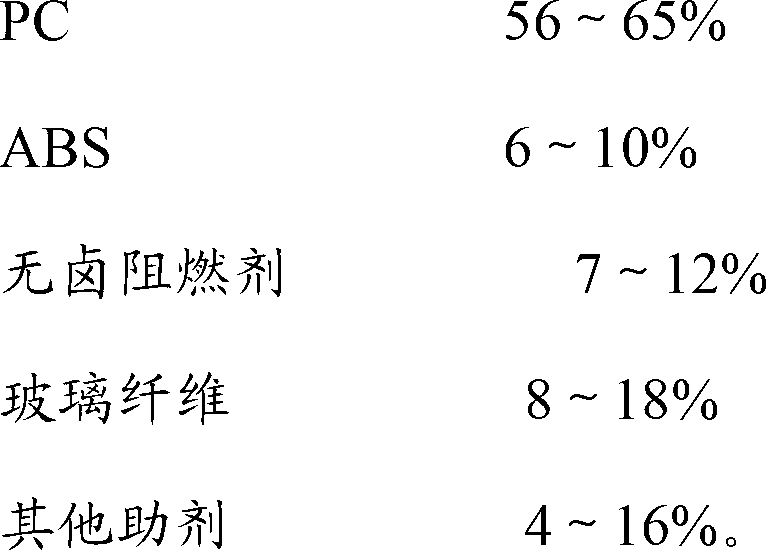

PC (Poly Carbonate)/ABS (Acrylonitrile Butadiene S) alloy material and preparation method thereof

InactiveCN103059540AHigh strengthImprove bending strengthGroup 4/14 element organic compoundsGlass fiberAcrylonitrile

The invention discloses a PC (Poly Carbonate) / ABS (Acrylonitrile Butadiene S) alloy material and a preparation method thereof. The PC / ABS alloy material comprises the following formulation components in weight percentage: 56-65 percent of PC, 6-10 percent of ABS, 7-12 percent of halogen-free flame retardant, 8-18 percent of glass fiber and 4-16 percent of other additives. The PC / ABS alloy material takes the PC and the ABS as the base materials, the synergic action is caused during the melt extrusion of the glass fiber and other components, the PC / ABS alloy material is endowed with high strength, and meanwhile, the PC / ABS alloy material has excellent processability and thermal properties, and meets the environmental protection requirement. The preparation method is simple in process, easy to control in conditions, low in cost and equipment requirement, and suitable for industrial production.

Owner:ANHUI KEJU NEW MATERIALS

Light free-spraying nylon material and preparation method thereof

The invention relates to a nylon material and a preparation method thereof, in particular to a light free-spraying nylon material and a preparation method thereof and belongs to the technical field of high polymer materials. The light free-spraying nylon material is prepared from, by weight, 50-70 parts of nylon, 20-40 parts of a reinforcing agent, 1-5 parts of compatilizer, 1-5 parts of foaming agent masterbatch, 1-5 parts of metallic pigment masterbatch, 0.3-2 parts of a lubricating agent and 0.2-1 part of an anti-oxidization agent. Due to the fact that the metallic pigment masterbatch of different colors is added in the reinforced nylon, the modified nylon material has metallic luster, tedious operation of traditional paint spraying, electroplating and the like is omitted, procedures are greatly simplified, and the nylon material is more environmentally friendly; meanwhile, the micro foaming technology is adopted, and therefore the weight of a manufactured piece can be remarkably reduced, the maximum weight reducing range is 20% or above, the equipment requirement is low, the product yield is high, and benefits are increased.

Owner:NANJING JULONG SCI&TECH CO LTD

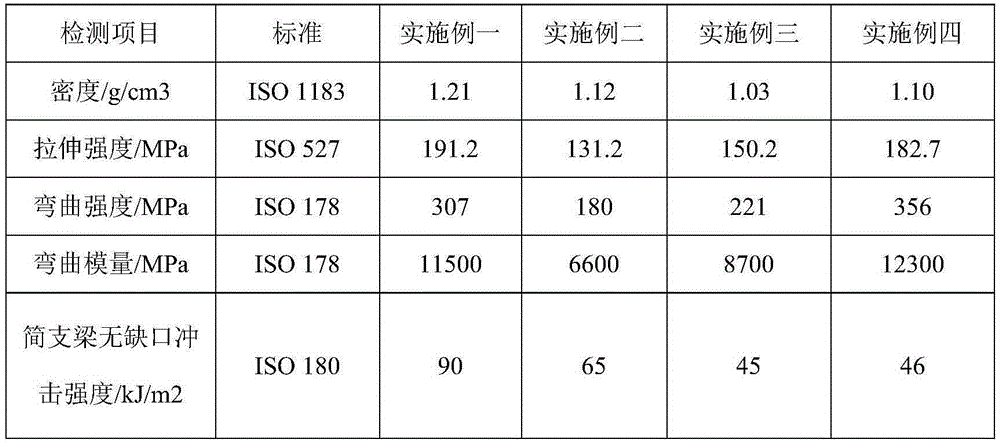

Polypropylene composition with excellent anti-impulsion, bend modulus and transparence and its product

The present invention relates to a polypropylene composition having excellent impact resistance, flexural modulus and transparency, and articles made therefrom. More particularly, it relates to a polypropylene composition having excellent impact resistance, flexural modulus, and transparency, which comprises: (a) 80-95 wt% of at least one highly crystalline random copolymer selected from an ethylene-propylene random copolymer containing 1-5 wt% ethylene and a propylene-butene-1 random copolymer containing 2-12 wt% butene-1; and (b) 5-20 wt% of an ethylene-propylene elastomeric copolymer containing 30-50 wt% ethylene, in which the ratio of the melt index of the component (b) to that of the component (a) is 1.5-35, as well as articles made therefrom. The inventive polypropylene composition is excellent not only with respect to impact resistance and flexural modulus, but also with respect to transparency, and is thus suitable for the production of refrigerating containers, freezing containers, food packaging containers, extrusion-molded articles, blow molded articles, films, sheets, bottle stoppers, etc.

Owner:SK INNOVATION CO LTD +1

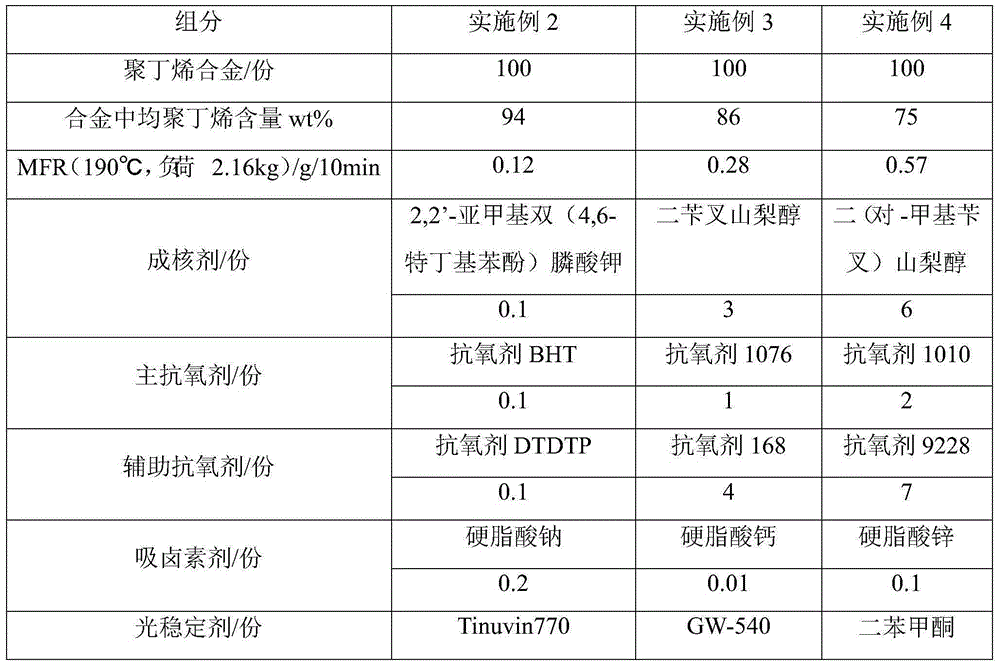

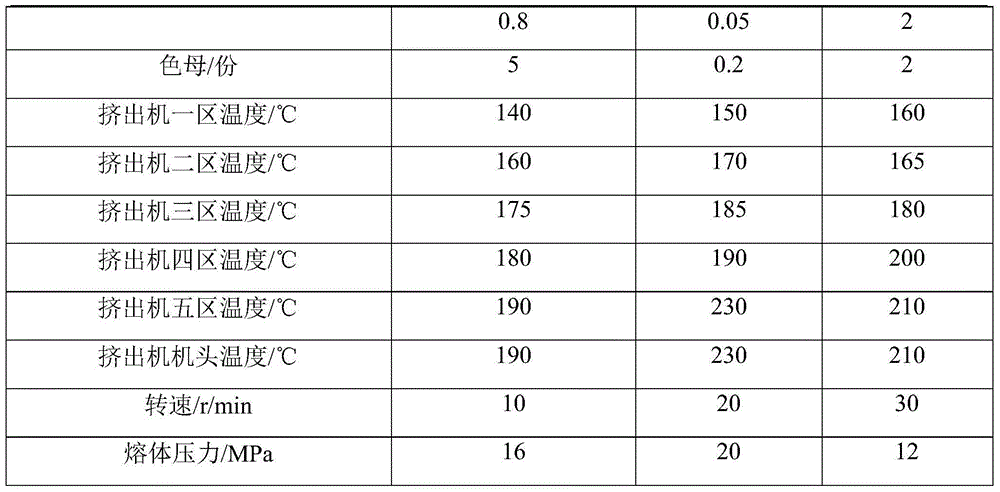

Special polybutylene alloy pipe material for cold/hot water pipe and preparation method of special polybutylene alloy pipe material

The invention relates to a special polybutylene alloy pipe material for a cold / hot water pipe and a preparation method of the special polybutylene alloy pipe material, belonging to the field of high polymer materials. The special polybutylene alloy pipe material comprises the following components: polybutylene alloy, an antioxidant, a halogen absorber, a light stabilizer, a color masterbatch and a nucleating agent. The preparation method comprises the steps of uniformly mixing the polybutylene alloy, the antioxidant, the halogen absorber, the light stabilizer, the nucleating agent and the color masterbatch by using a high-speed mixer; and extruding and pelleting to obtain the special polybutylene alloy pipe material for the cold / hot water pipe. The tensile strength and bending modulus of the special polybutylene alloy pipe material are greatly improved on the basis that the impact resistance, excellent environment stress crack resistance and thermal creep resistance of polybutylene are kept, and the special polybutylene alloy pipe material can be used as a cold / hot water pipe and pipe fitting material.

Owner:QINGDAO UNIV OF SCI & TECH +2

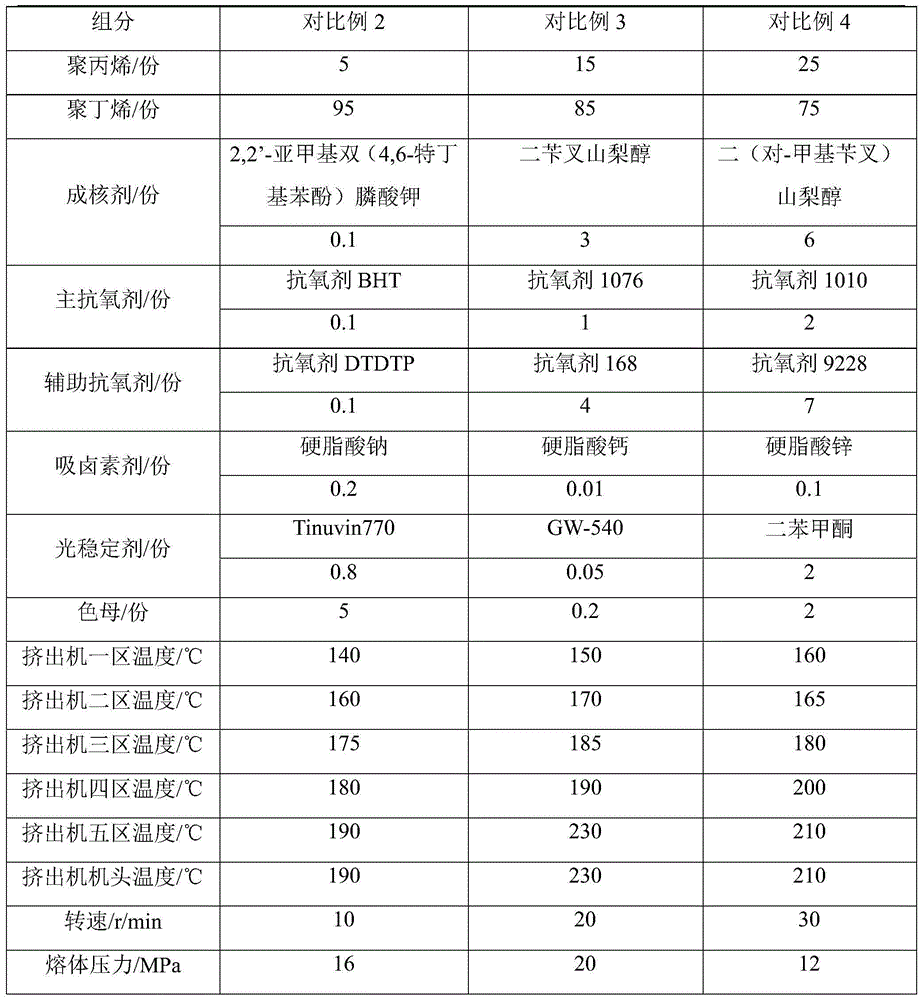

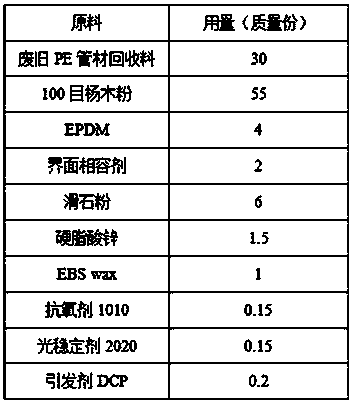

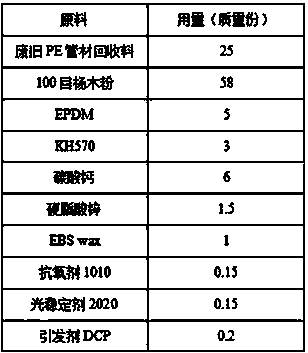

High-strength PE (polyethylene) wood-plastic composite material and preparation method thereof

The invention discloses a high-strength PE (polyethylene) wood-plastic composite material which is prepared from the following raw materials in parts by mass: 20-50 parts of waste PE plastic, 40-70 parts of plant fiber powder, 0-15 parts of thermoplastic elastomer, 2-6 parts of interfacial compatilizer, 0-20 parts of reinforcing filler, 1-6 parts of lubricant, 0.4-0.6 part of anti-aging assistant and 0.1-0.5 part of initiator. The invention also discloses a preparation method of the PE wood-plastic composite material, which comprises the following steps: 1) uniformly mixing the raw materials, and carrying out extrusion and granulation in an extruder; and 2) carrying out extrusion forming on the granules to obtain a plate. The wood-plastic composite material has excellent properties, such as favorable tensile strength, bending strength, bending modulus and the like. The interfacial compatilizer can effectively promote the interfacial properties of the substrate with other components, thereby enhancing the related properties of the composite material. The composite material has excellent workability, and can be sawed, nailed or shaven.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com