Polypropylene composition with excellent anti-impulsion, bend modulus and transparence and its product

A polypropylene composition and impact resistance technology, used in the field of products, can solve the problems of limited methods for particle size and refractive index differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Ethylene, propylene, triethylaluminum, highly active Ziegler-Natta catalyst and silane electron donor are mixed in a reactor, and the slurry is kept at a reaction temperature of 60-80°C and a pressure of 30-35 atmospheres Bulk polymerization was carried out at 0°C to obtain an ethylene-propylene random copolymer (component a) with a propylene content of 96.7% by weight and an ethylene content of 3.3% by weight. The melt index of random copolymers is controlled by the amount of hydrogen.

[0034] After the polymerization of the ethylene-propylene random copolymer was completed, unreacted propylene was removed, and the pressure in the reactor was reduced to normal pressure. Then, introduce ethylene and propylene as monomers, and hydrogen as a melt index control agent into the reactor, keep the reaction temperature at 70-80° C., and the pressure at 10-15 atmospheres, and carry out continuous polymerization in a gaseous state. An ethylene-propylene elastomeric copolymer (com...

Embodiment 2-5 and 7-10 and comparative example 1-5

[0038] The polypropylene composition was prepared according to the method of Example 1, except that the components and contents were changed as shown in Table 1 and Table 2.

Embodiment 6

[0040] The polypropylene composition was prepared according to the method of Example 1, except that, as shown in Table 1 below, component (a) was prepared using propylene and 1-butene as monomers.

[0041] As can be seen from Table 1 below, by controlling the melt index ratio of component (b) and component (a), the prepared polypropylene composition is excellent not only in transparency but also in impact resistance and flexural modulus performance.

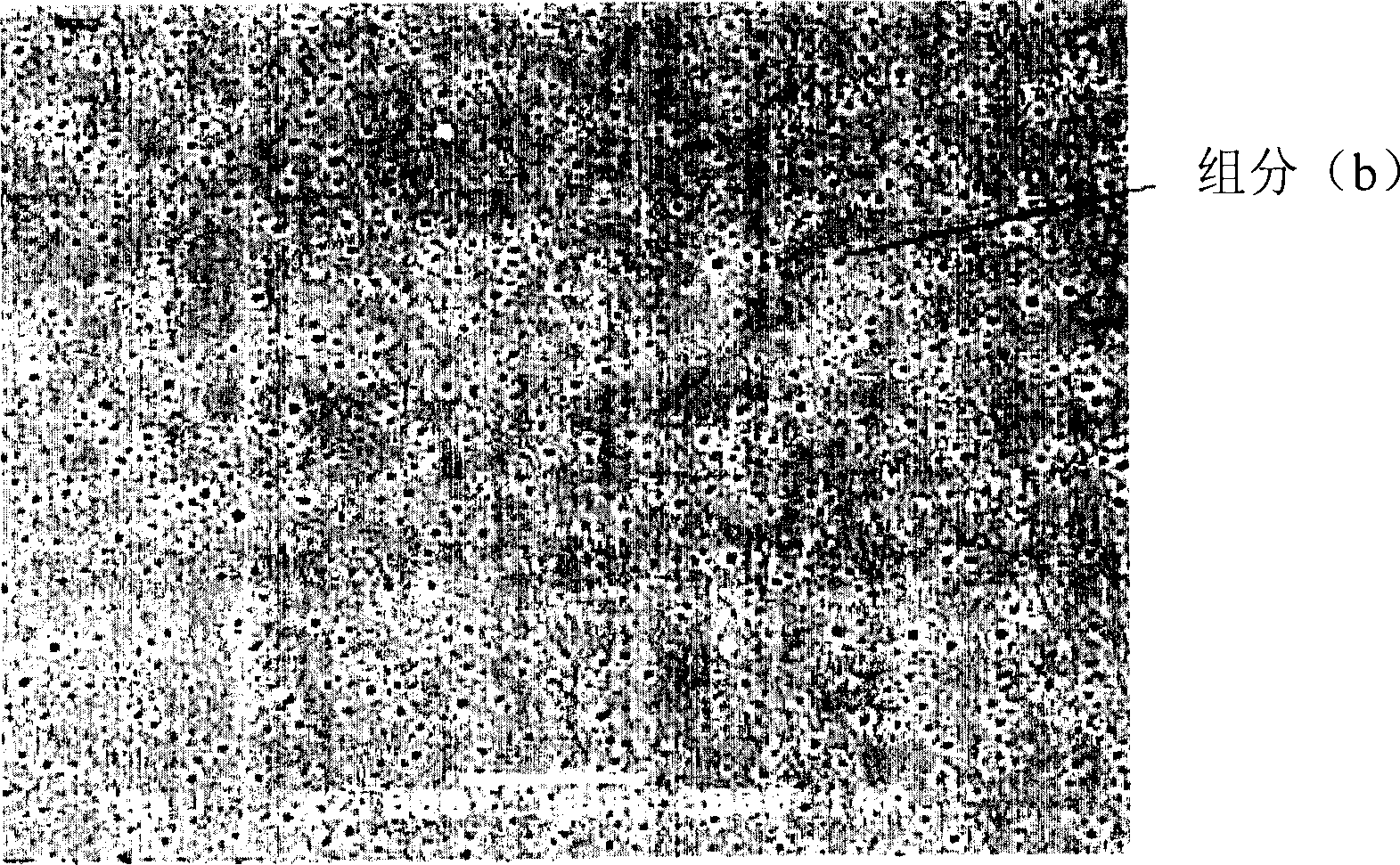

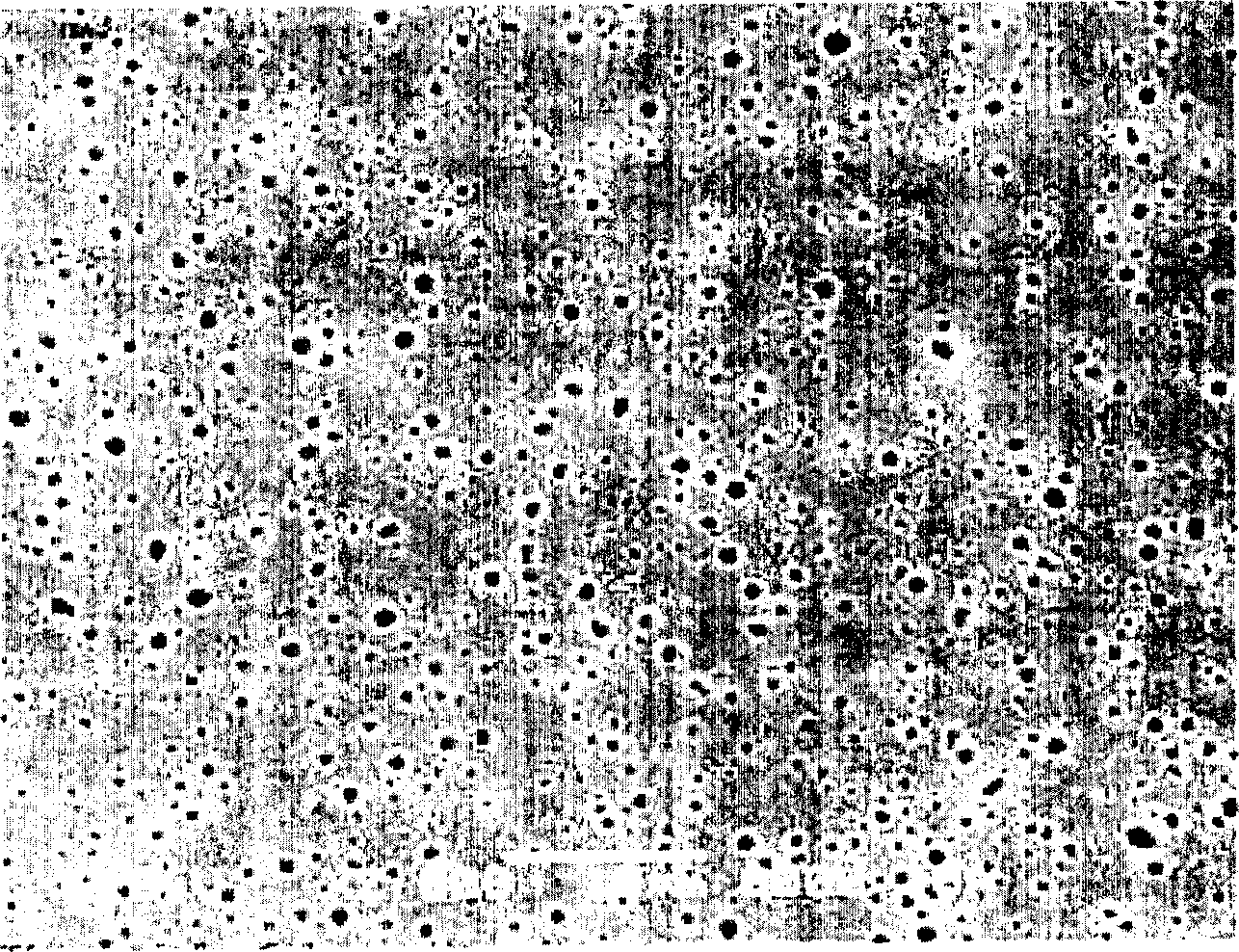

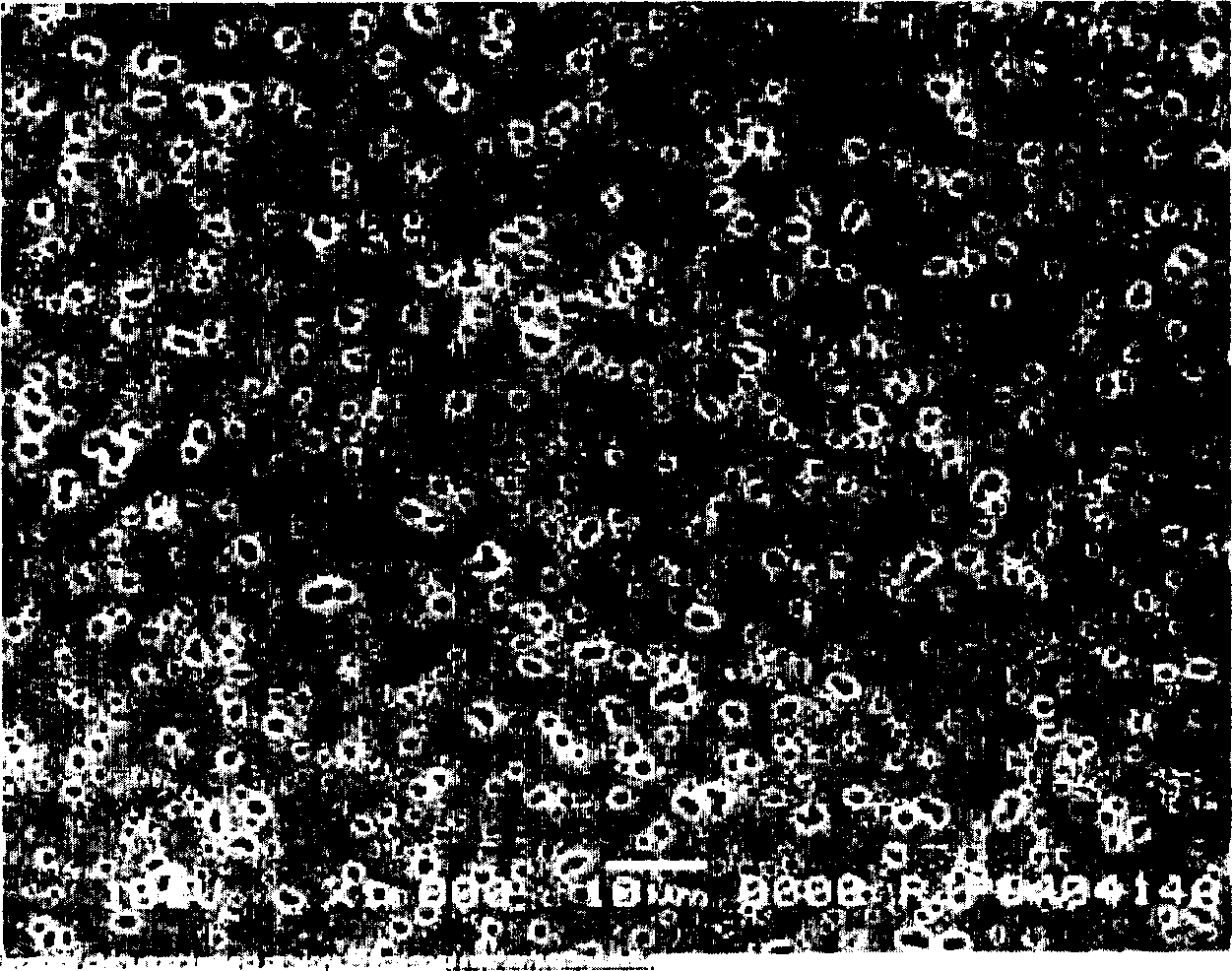

[0042] From Figure 1 to Figure 3 It can also be seen that, compared with Comparative Example 2 ( image 3 ) and Comparative Example 3 ( figure 2 ) compared to that in Example 2 ( figure 1 ), the ethylene-propylene elastomeric copolymer (component b) was dispersed with a smaller particle size, indicating a significant increase in transparency. That is, in the composition of the present invention, the melt index ratio of component (b) and component (a) is controlled, so that the particle diameter of component (b) is preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com