Polycarbonate/polyamide alloy and preparation method thereof

A technology of polycarbonate and polyamide, which is applied in the field of polycarbonate/polyamide alloy and its preparation, can solve the problems of unsatisfactory physical and mechanical properties of the alloy, and the improvement effect is not obvious, so as to achieve good coating performance and improve comprehensive performance , Expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 9

[0061] A kind of preparation method of polycarbonate / polyamide alloy, this method comprises the following steps:

[0062] (1) Prepare materials according to the components and content listed in Embodiment 1 to Embodiment 9 in Table 1;

[0063] (2) Put the above raw materials into a high-speed mixer and mix at high speed (1500-3000rpm) for 1-3 minutes;

[0064] (3) Low-speed (500-1000rpm) discharge;

[0065] (4) Put the mixed raw materials into a twin-screw machine to extrude and granulate. The rotating speed of the extruder is 180-600 rpm and the temperature is 190-260° C. to obtain a polycarbonate / polyamide alloy.

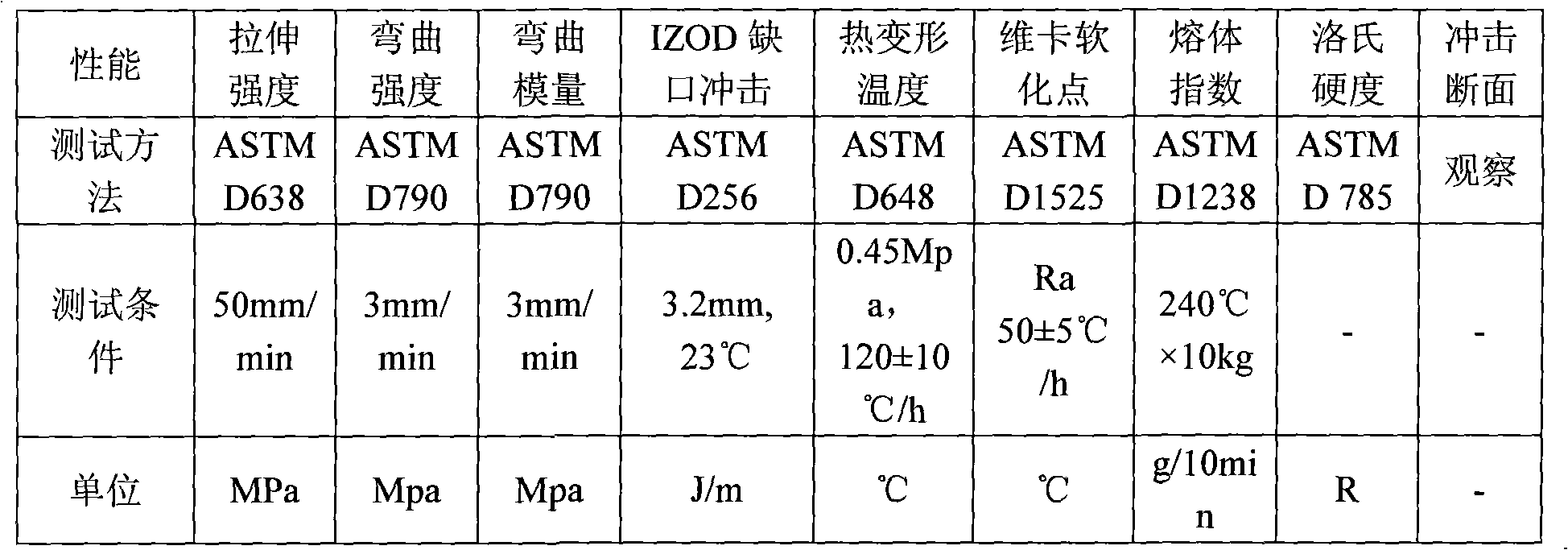

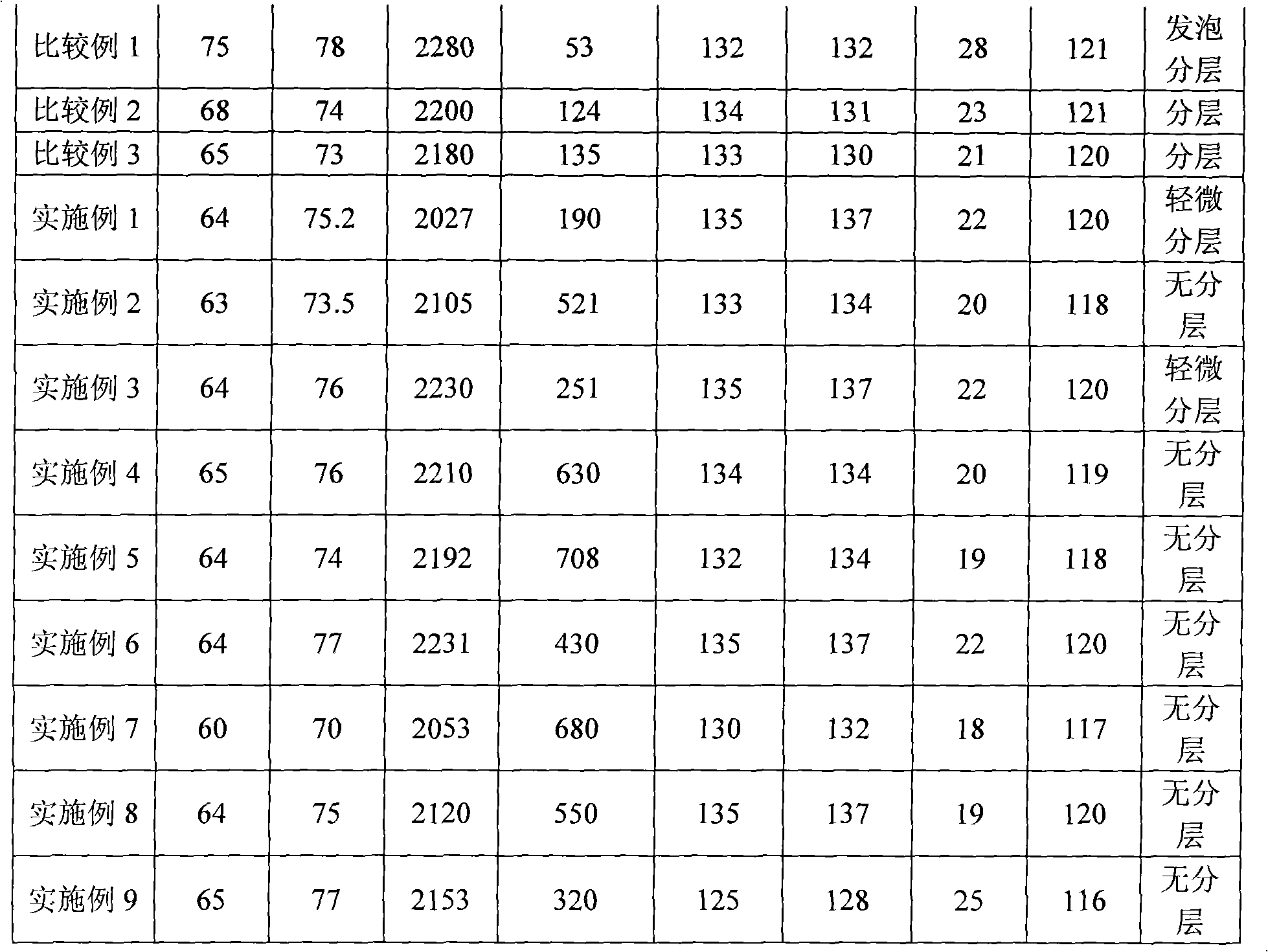

[0066] The polycarbonate / polyamide alloys prepared in Examples 1 to 9 were tested for performance, and the results are shown in Table 2.

[0067] The formula table (unit: kilogram) of table 1 comparative example 1~3 and embodiment 1~9

[0068] project

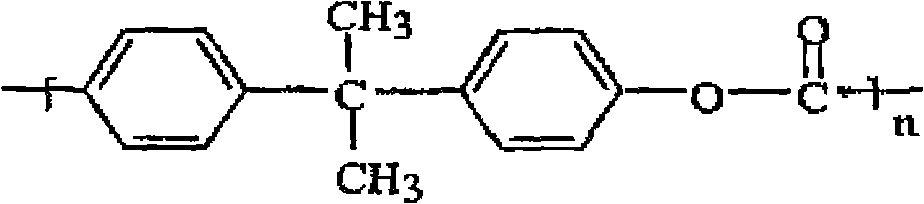

PC

PA

ABS resin

Compatibilizer 1

Compatibilizer 2

Compatibilizer 3

Antioxi...

Embodiment 10

[0088] A kind of preparation method of polycarbonate / polyamide alloy, this method comprises the following steps:

[0089] (1) Prepare materials according to the following components and contents:

[0090] Polycarbonate 40 kg

[0091] Polyamide 60kg

[0092] Toughener 15kg

[0093] Compatibilizer 1 3.3 kg

[0094] Compatibilizer 2 6.7 kg

[0095] Antioxidant 1076 0.05 kg

[0096] Antioxidant 168 0.05 kg

[0097] EBS 0.1 kg

[0098] Described polycarbonate is 201-10 of aliphatic polycarbonate DOW company; Described polyamide is PA66; Described toughening agent is granular ABS resin, and its glue content is 15%; Described Compatibilizer 1 is monofunctional styrene-maleic anhydride binary polymer (monomer ratio is ST: MAH=70:30 (weight ratio)); described compatibilizer 2 is monofunctional Reactively extruded ABS-g-GMA (ABS:GMA (glycidyl methacrylate)=95:5 (weight ratio));

[0099] (2) Put the above-mentioned raw materials into a high-speed mixer, and mix at a high speed o...

Embodiment 11

[0103] A kind of preparation method of polycarbonate / polyamide alloy, this method comprises the following steps:

[0104] (1) Prepare materials according to the following components and contents:

[0105] Polycarbonate 50kg

[0106] Polyamide 50kg

[0107] Toughener 20kg

[0108] Compatibilizer 3 8 kg

[0109] Antioxidant 1076 0.2 kg

[0110] Antioxidant 168 0.2 kg

[0111] EBS 2.5 kg;

[0112] The polycarbonate is aromatic polycarbonate Bayer 1805; the polyamide is PA6; the toughening agent is granular ABS resin with a glue content of 50%; the compatibilizer 3 is bismuth Functional styrene terpolymer containing glycidyl methacrylate (GMA) and maleic anhydride (MAH) bifunctional monomer (monomer ratio is GMA: ST: MAH=10: 80: 10 (weight Compare));

[0113] (2) Put the above raw materials into a high-speed mixer, and mix at a high speed of 150rpm for 3 minutes;

[0114] (3) Low speed 500rpm discharge;

[0115](4) Put the mixed raw materials into a twin-screw machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com