Patents

Literature

524results about How to "Reasonable preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

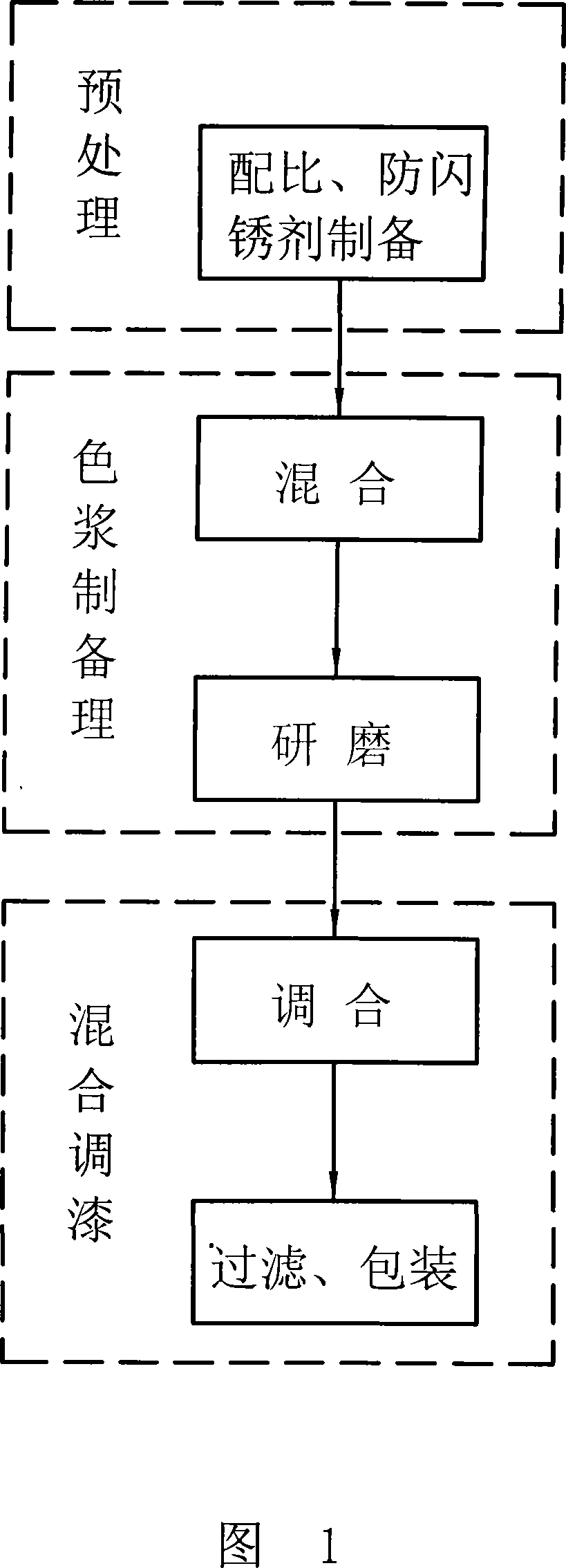

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

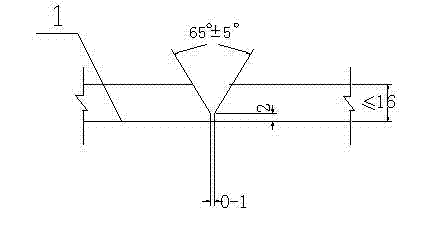

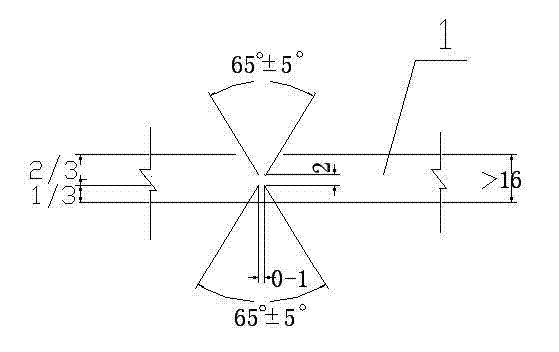

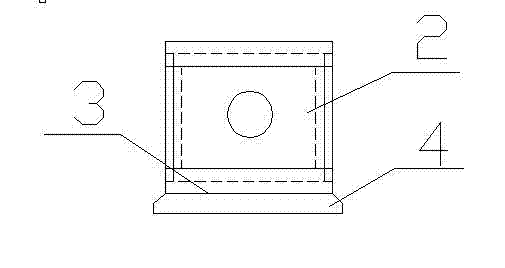

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

Ultrasonic process of preparing theasaponin

The present invention is ultrasonic process of preparing theasaponin and belongs to the field of agricultural side product processing technology. The technological scheme is that tea seed cake residue after extracting oil is processed through crushing, mixing with organic solvent, ultrasonic leaching, separating, recovering solvent, ultrafiltering to purify and to obtain theasaponin concentrate, decolorizing and drying to obtain theasaponin product. The present invention has the beneficial effects of physical extraction process caused high theasaponin extracting rate, high product purity and quality, simple technological process with low power consumption and low production cost, less pollution, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Polyvinyl chloride/chlorinated polyvinyl chloride skin foamed sheet and preparation method thereof

InactiveCN102040785AHigh surface hardnessIncrease productivityAntioxidantChlorinated polyvinyl chloride

The invention relates to a polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet and a preparation method thereof, and the polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet comprises the following materials in parts by weight: 60-90 parts of polyvinyl chloride, 10-40 parts of chlorinated polyvinyl chloride, 2.8-7 parts of stabilizer, 3-5 parts of foam regulator, 1-3 parts of foam nucleating agent, 0.5-2 parts of foaming agent, 0.6-1.5 parts of external lubricant, 0.5-1 part of internal lubricant, 0.5-2 parts of processing aids, 0.05-0.5 part of antioxidant and no more than 30 parts of filler. The preparation method is as follows: adding all the materials into a high-speed stirring machine, and mixing uniformly; heating to 90-120 DEG C, and carrying out heat preservation for more than 10 minutes; placing into a cold mixing machine, cooling down to 25-45 DEG C, tapping into a storage bin, extruding a foaming material through an extruder, and further carrying out vacuum shaping, cooling molding and edge trimming and finishing; and finally carrying out cutting and packaging according to the required length. The product has high surface hardness and great strength, is less prone to deformation, easy for processing, reasonable in manufacturing process, low in cost, good in quality and high in efficiency and has extensive popularization value and good economic and social benefits.

Owner:杜文军

Polycarbonate/polyamide alloy and preparation method thereof

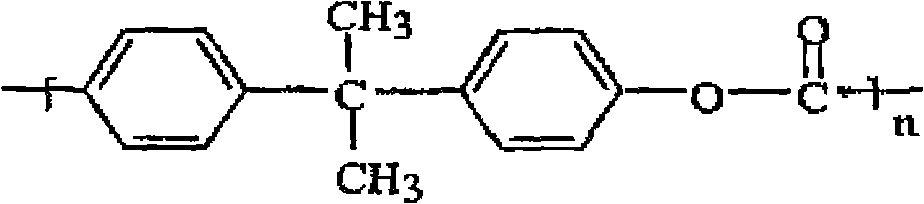

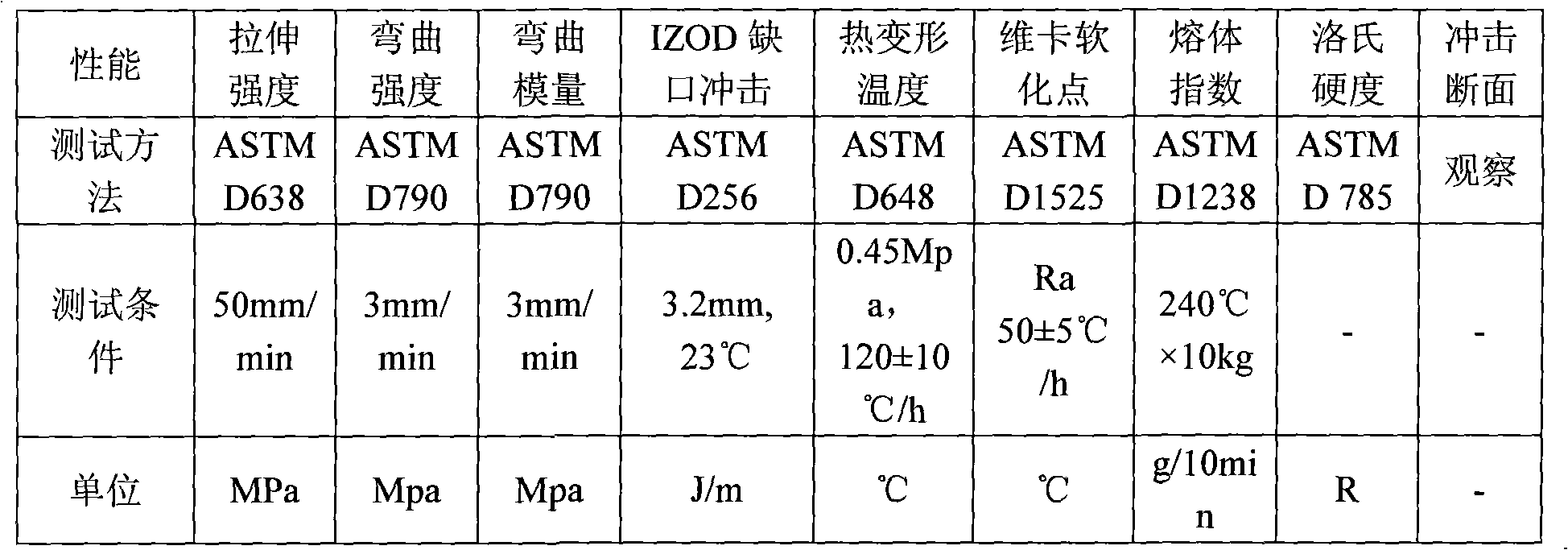

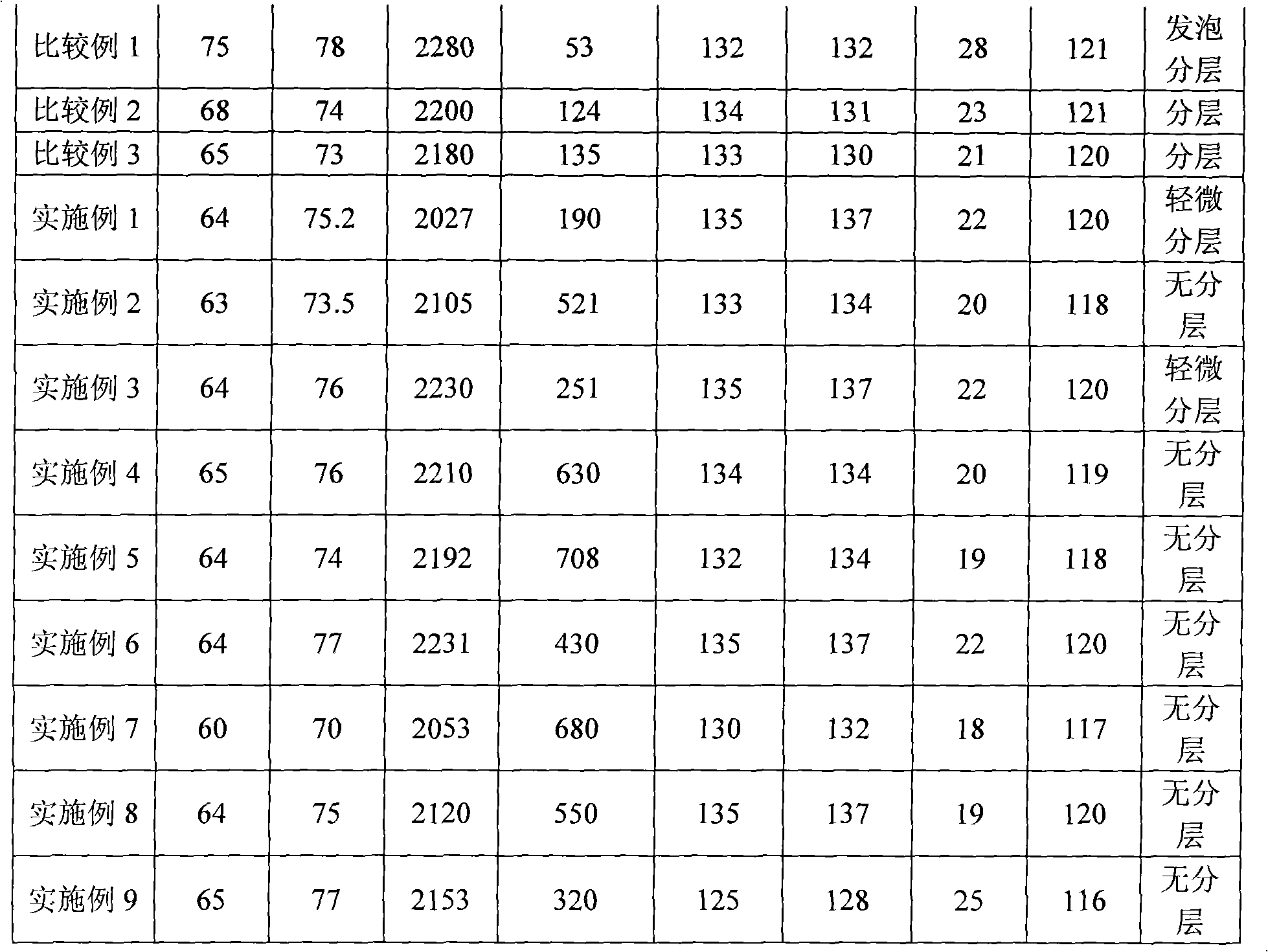

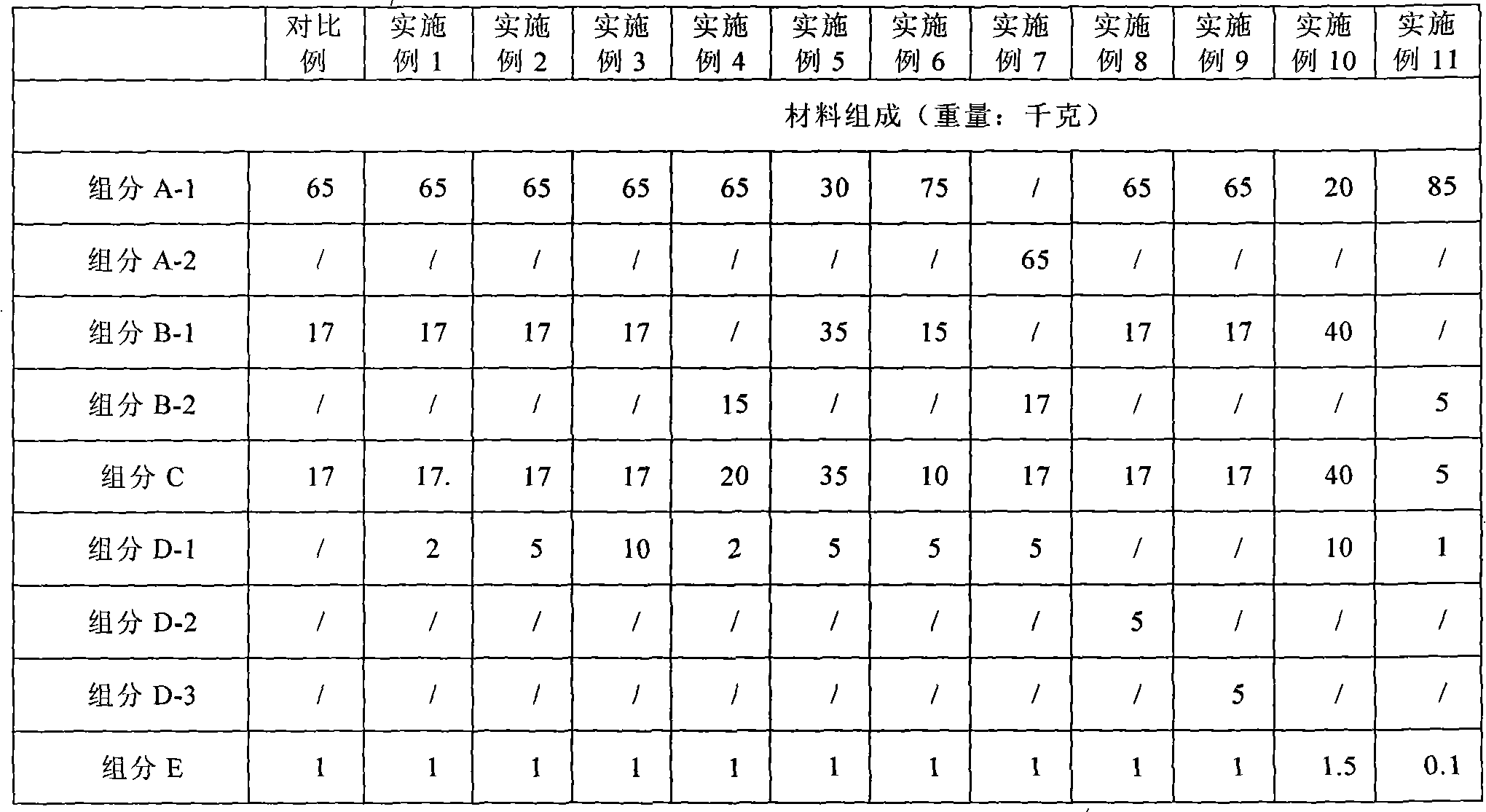

The invention relates to a polycarbonate / polyamide alloy and a preparation method thereof. The alloy contains the following components by weight percentage: 30-80 of polycarbonate, 20-70 of polyamide, 5-30 of toughening agent, 1.5-15 of compatibilizer and 0.2-3 of assistant; wherein the contents of the toughening agent, the compatibilizer and the assistant are based on the total weight of the polycarbonate and the polyamide. Compared with the prior art, due to the blending of the polycarbonate and the polyamide with the excellent compatibilizer in the preparation method, the preparation process is reasonable, the prepared polymer has good paint adhesion, solvent resistance and impact resistance and simultaneously combines the low moisture absorption, heat resistance, wear resistance and self-lubricity of the polycarbonate, and the polycarbonate / polyamide alloy can be widely applied in automobiles (front and rear baffles, column covers, wheel covers and instrument covers), electronic appliances (electric tool housings, wiring devices and relays) and other fields.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Low-gloss polycarbonate styreneresin composite and preparation method thereof

InactiveCN101787192AReasonable preparation processSolve technical problems with severe performance degradationStyrene-acrylonitrile resinAcrylonitrile-butadiene-styrene resin

The invention relates to a low-gloss polycarbonate styreneresin composite and a preparation method thereof. The composite comprises the following components (by weight percent): 20-85wt% of polycarbonate resin, 5-50wt% of styrene flexibilizer, 5-40wt% of styrene-acrylonitrile resin,1-10wt% of specific matting agent, and 0.1-1.5wt% of processing agent; the materials are premixed for 3-10 minutes in a high speed mixer, then premix compound is subject to melt extrusion at 230-300 DEG C by a double screw extruding machine, and cooling and pelletizing are carried out, thus obtaining the low-gloss polycarbonate (PC) / styreneresin composite. Compared with the prior art, the invention has the advantages that preparation technology is reasonable and the technical problem of degradation of performance of products as matting efficiency of polycarbonate (PC) / styreneresin composite is low is solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

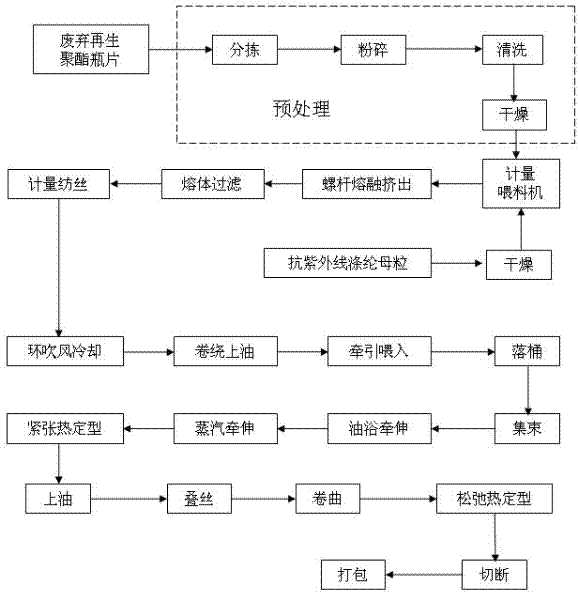

Method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips

InactiveCN102505182APromote environmental protectionReduce manufacturing costFilament forming substance formingPlastic recyclingPolyesterFiber

The invention discloses a method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips. The method comprises the following steps of: pre-treating and drying recovered waste renewable polyester bottle chips; drying ultraviolet-resistant polyester master batch; conveying the dried polyester bottle chips and ultraviolet-resistant polyester master batch into a special metering feeder to quantitatively feed and mix the polyester bottle chips and the ultraviolet-resistant polyester master batch to obtain a mixture; performing screw fusion extrusion on the mixed mixture with a certain concentration to obtain melt; filtering the melt, metering and spinning, cooling through circular blowing, winding and oiling, drawing and feeding, and holding filaments and falling into a barrel; bundling the filaments in the barrel; and performing oil water bath drawing and steam drawing, tense thermal forming, oiling, filament lamination, curling, loose thermal forming, cutting and packing to obtain an ultraviolet-resistant polyester staple fiber product. The method has the advantages of rational preparation process and high operability; and the product has lower cost than a new material and has good economic benefit and social benefit.

Owner:东莞市粤盛纤维制品有限公司

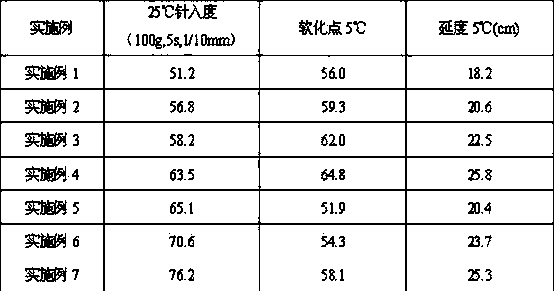

High-toughness waste rubber asphalt and preparation method thereof

InactiveCN103756341AIncreased viscosity and toughnessReduce pollutionBuilding insulationsRubberized asphaltColloid mill

The invention discloses high-toughness waste rubber asphalt. The high-toughness waste rubber asphalt comprises substrate asphalt, waste rubber powder, an activating agent, a nanometer toughening agent and a crosslinking agent. A preparation method of the high-toughness waste rubber asphalt comprises the following steps: heating the substrate asphalt for melting, adding the waste rubber powder, the activating agent, the nanometer toughening agent and the crosslinking agent in sequence, mixing and uniformly stirring to obtain an asphalt mixture; and performing the process treatment of high-speed colloid milling, high-speed shearing, crosslinking reaction, stability development and the like on the asphalt mixture in sequence to obtain the high-toughness waste rubber asphalt. The high-toughness waste rubber asphalt has the advantages of reasonable preparation process, low product price, lower storage temperature than products of the same type, aging resistance, high bonding performance and high low-temperature crack resistance, and the defect of limitation on the toughness of conventional modified asphalt used in a low-temperature environment is overcome.

Owner:HENAN PROVINCE ZHONGYUANDETONG NEW ENERGY TECH

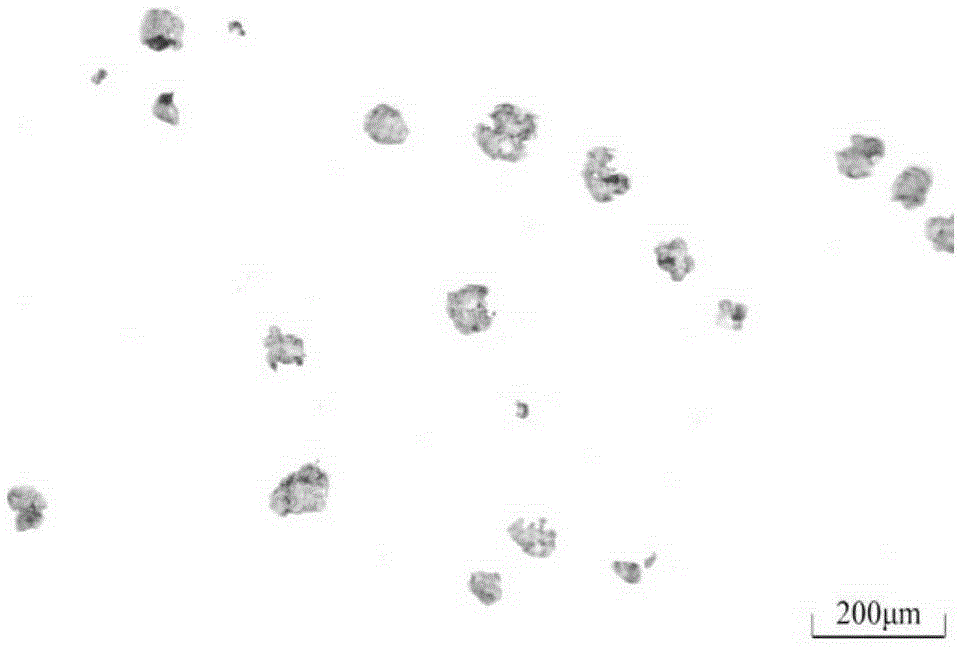

Dispersed copper composite material and preparation method thereof

The invention discloses a dispersed copper composite material and a preparation method thereof, belonging to the technical field of dispersed copper processing. The dispersed copper composite material is composed of the following components in percentage by mass: 0.24-3.74% of Al2O3, 0.03-1.27% of Y2O3 and the balance of Cu and unavoidable impurities. The dispersed copper composite material is prepared from Cu2O powder and Cu-Al-Y alloy powder through the steps of mixing, pressing, sintering and internal oxidation, extruding and forging; the composite material has the high strength of 500Pa or above and the high conductivity of 80% IACS or above and overcomes the defect that the high strength and high conductivity of other composite materials cannot simultaneously exist; and meanwhile the composite material is favorable in softening resistance, high in high-temperature strength and good in plasticity, and the softening temperature is 800 DEG C or higher.

Owner:HENAN UNIV OF SCI & TECH

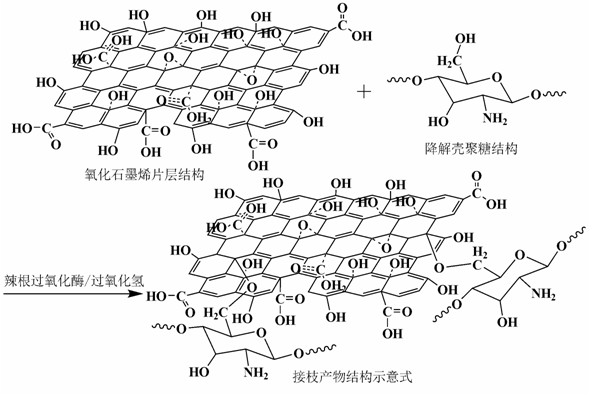

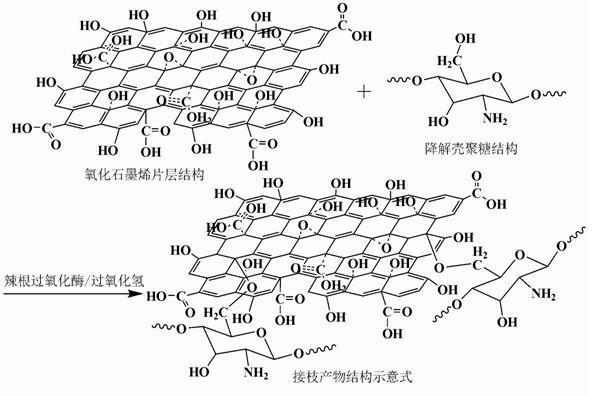

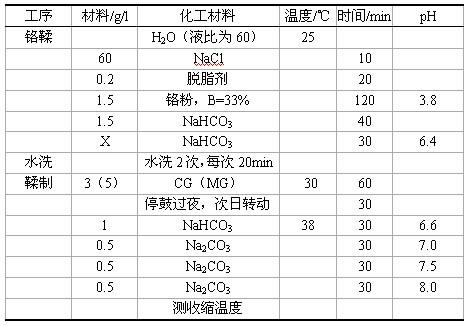

Preparation method of chitosan modified graphite oxide functional leather tanning agent

The invention relates to a preparation method of a chitosan modified graphite oxide functional leather tanning agent. Currently, the common leather tanning agents are chroming tanning agent, aluminum tanning agent, vegetable tanning agent, aldehyde tanning agent and synthetic tanning agent and the like, but the leather tanning agents can generate pollution problems hard to treat. The preparation method provided by the invention has the following steps of: mixing crystalline flake graphite powder, sodium nitrate and concentrated sulfuric acid and stirring uniformly, slowly adding potassium permanganate for oxygenation, and preparing a suspending liquid through washing, pH adjustment and ultrasonic treatment; and degrading chitosan with high-temperature alpha-amylase so as to obtain a degraded chitosan solution, modifying graphite oxide with the degraded chitosan under a horseradish peroxidase-hydrogen peroxide catalysis system, thus obtaining the chitosan modified graphite oxide functional leather tanning agent. The preparation method provided by the invention has the advantages of unique synthetizing preparation process and good tanning property, is suitable for main tanning and retanning; and the leather has excellent intensity and flexibility after main tanning.

Owner:JIANGSU BESCON PHARMA

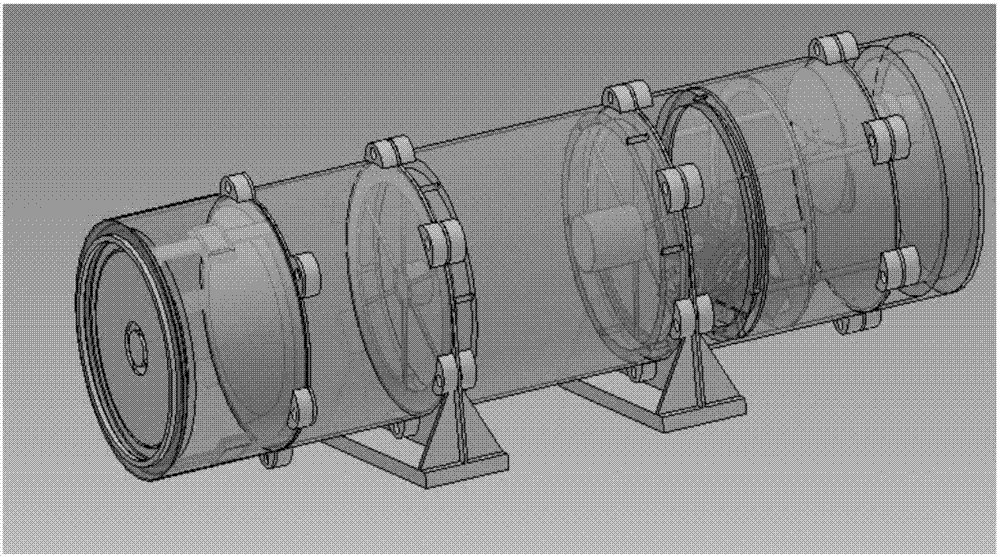

Manufacturing method of artificial core with crevices for simulated leaking stoppage experiment

InactiveCN102350724AWith strengthAvoid breakingCeramic shaping apparatusSealing/packingFine lineRock core

The invention provides a manufacturing method of an artificial core with crevices for a simulated leaking stoppage experiment, which relates to the technical field of oil well operation, in particular to the technical field of leaking prevention during well drilling. A paraffin plate of which two reinforced surfaces are both curved surfaces is firstly manufactured; then a concrete core column of the paraffin plate, of which two clamping surfaces are both curved surfaces, are manufactured; and finally, the paraffin plate in the concrete core column is melted. The manufacturing process disclosed by the invention is simple and reasonable; through designing curved surface shapes of an upper curved surface plate and a lower curved surface plate, the lifelike concrete core column provided with inner irregular crevices can be acquired; through using paraffin, inner crevices can be conveniently formed; and through arranging fine lines in the paraffin plate, the paraffin plate has certain strength and is difficult to crack, and the fine lines can be conveniently drawn out of the concrete core column after the paraffin is melted. The concrete core column manufactured by adopting the method disclosed by the invention is used in a simulator for conducting the loss and leaking stoppage experiment, the acquired data is close to the actual situation, and oil well mining operation is facilitated.

Owner:张逸群 +6

Novel technique for producing mandrel bar

InactiveCN101352796AReasonable preparation processQuality improvementTemperature control deviceMandrelsSocial benefitsIngot

The invention relates to a technique for manufacturing a tube rolling tool of hot rolling seamless steel tube, in particular to a technique for manufacturing a rolling machine mandril of a PQF which belongs to the processing technique of workpiece. The invention provides a novel technique for manufacturing the mandril of a tube rolling; the technical scheme adopted by the technical problem of the invention is as follows: refining a steel ingot-forging and blooming-rolling and shaping-surface rough machining-hardening and tempering processing-fine machining and polishing-surface plating. The technique is characterized in that the rolled mandril has the advantages of smoother surface, less bending degree of a blank as well as a small size tolerance. The technique is characterized in that the basic body of the mandril has a high temperature obdurability and the surface of the mandril has excellent wear-resistance. The technique has the beneficial effects that: the manufacturing technique of the mandril is more reasonable; the potential of a device is fully exerted; the yield rate and the production efficiency are high; the cost is low; the quality of the mandril is excellent; the social benefit is remarkable; besides, the manufacture technique brings broad prospects for manufacturing the mandril of the tube mill.

Owner:赵金发

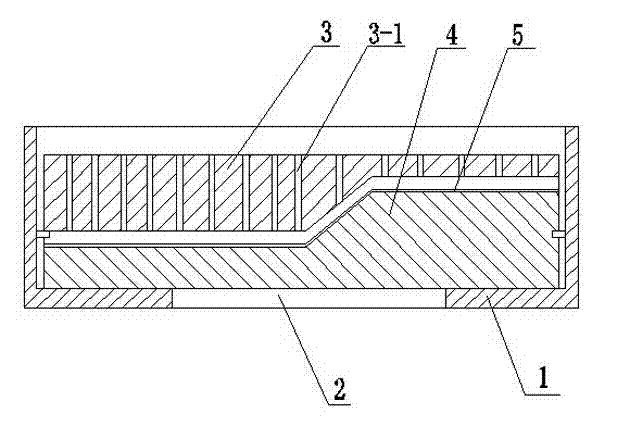

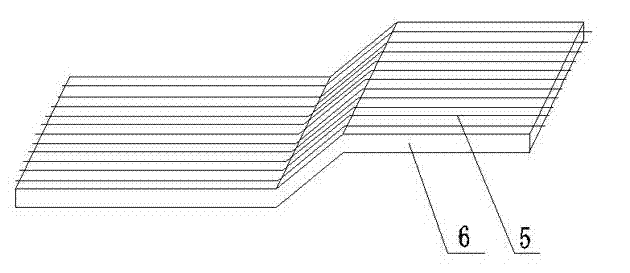

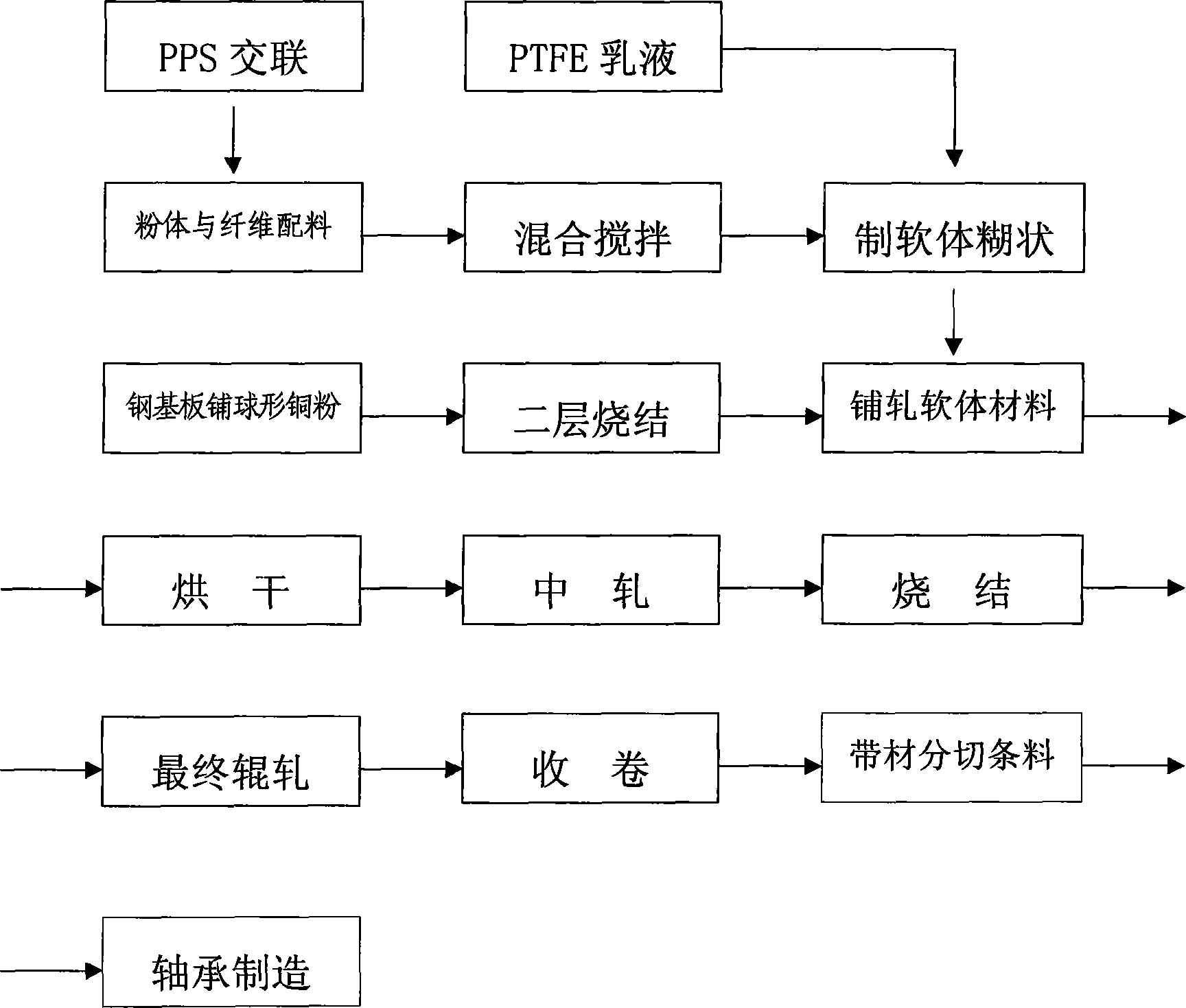

Lead-free self-lubricating bearing and its production

The invention relates to a mechanical components industry regulation hole coaxial between the methodology and regulation components, in particular the aviation, aerospace, civil and other mechanical structure of the multi-hinge assembly point. Double eccentric bushing from the eccentric bushing and the eccentric bushing composition, the eccentric bushing diameter and the outer diameter of a round circle of eccentric and the eccentric bushing diameter and the outer diameter of a round of the same circle of eccentric, and, Bushing end of the shaft is the first shoulder. Double eccentric bushing used in the eccentric bushing and the eccentric bushing with a certain amount of tolerance, through the inner and outer sleeve of repeated eccentric rotation adjustment can be realized coaxial connection points more than the match, and for each hub Heart of the biggest angle adjustment of not more than 360 degrees, adjust volume small. This greatly reduces the difficulty of assembling and because of the internal and external sleeve with tolerance, as well as components and assembly hub between the matching hole in the machining tolerances can be very good at that in the assembly, so there is no need to conduct a follow-up processing, reducing assembly time.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

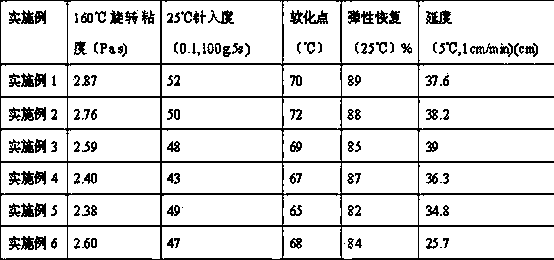

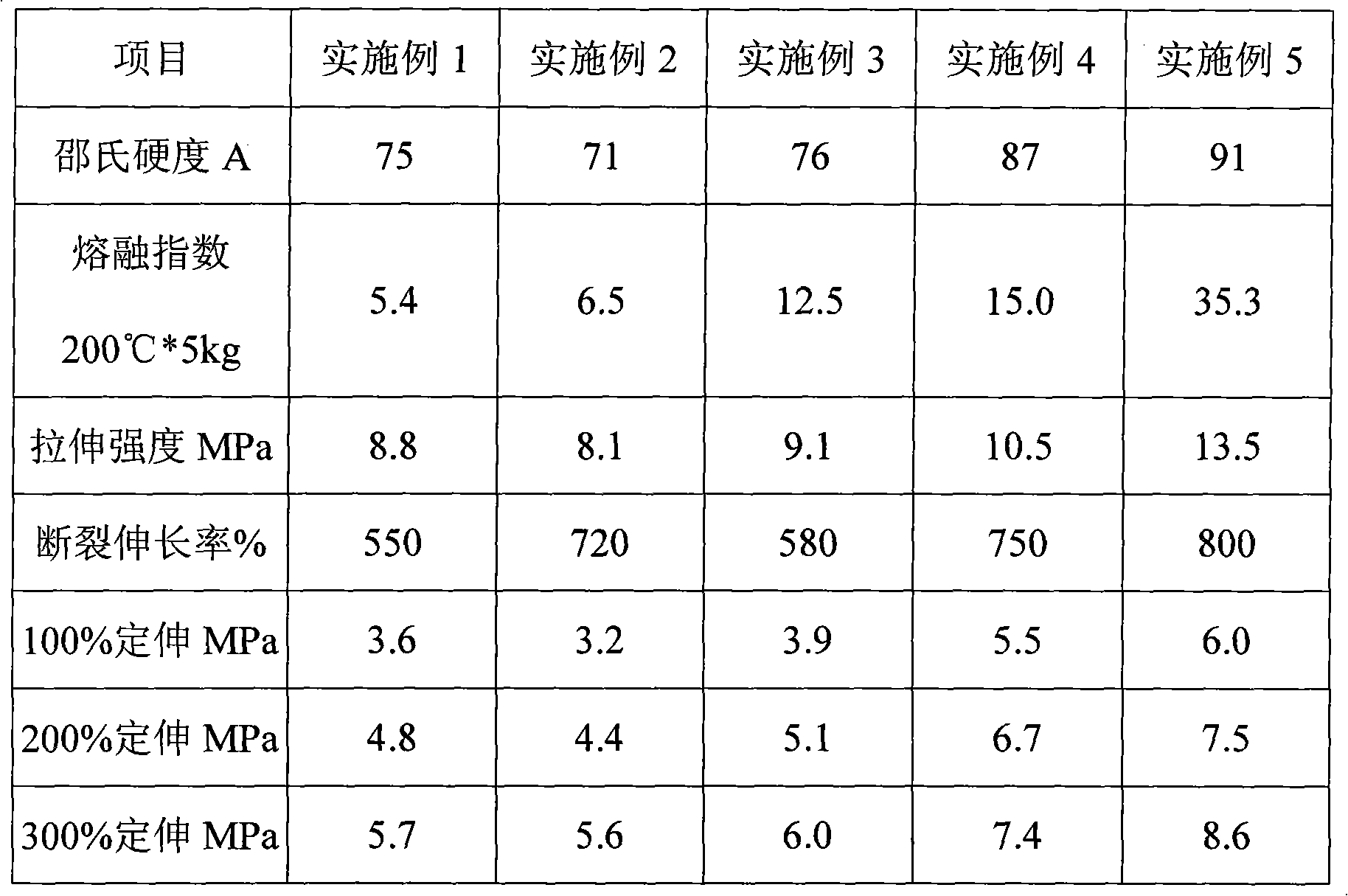

Dynamically vulcanized styrene thermoplastic elastomer and preparation method thereof

The invention relates to a dynamically vulcanized styrene thermoplastic elastomer and a preparation method thereof. The elastomer consists of the following components in percentage by weight: 20 to 70 percent of styrene segmented copolymer, 10 to 60 percent of rubber processing oil, 5 to 60 percent of polyolefin, 0 to 35 percent of inorganic mineral filler, 0.1 to 0.3 percent of antioxidant, 0.1 to 1 percent of crosslinking agent and 0.05 to 0.5 percent of auxiliary crosslinking agent. Compared with the prior art, the preparation technique of the invention is reasonable, the prepared elastomer has excellent comprehensive properties, the mechanical property, compression set resistance, abrasive resistance and the like of the elastomer are remarkably enhanced, meanwhile, the elastomer almost does not have residual smell, use is safe and environment-friendly, and the elastomer can be widely applied to the interior and the exterior decorations and other parts of automobiles and other more fields.

Owner:SHANGHAI SUNNY +1

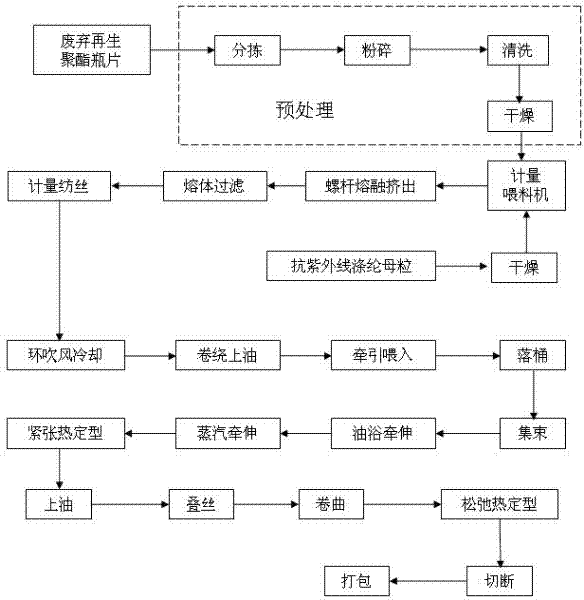

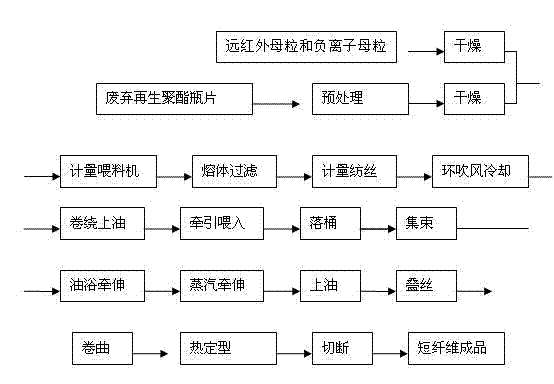

Method for preparing anion far-infrared short fibers employing waste renewable polyester bottle flakes

InactiveCN103484971AExcellent radiation protectionReasonable preparation processPlastic recyclingMelt spinning methodsPolyesterFiber

The invention discloses a method for preparing anion far-infrared short fibers employing waste renewable polyester bottle flakes. The method comprises the following steps: pretreating and drying the recycled waste renewable polyester bottle flakes; carrying out drying treatment on far-infrared masterbatch and anion masterbatch; feeding the dried polyester bottle flakes, the far-infrared masterbatch and the anion masterbatch to a special metering feeder for mixing, so as to obtain a mixture; carrying out melted extrusion on the mixed mixture by a screw to obtain a melt; filtering the melt, metering and spinning, cooling by cross blowing, winding and oiling, feeding by traction, filling fibers and doffing; carrying out bundling treatment on the fibers inside a barrel, and carrying out the procedures such as drafting, oiling, fiber folding, curling, thermoforming, cutting off and the like by oil bath, so as to obtain the anion far-infrared short fibers. The method disclosed by the invention is reasonable in preparation technology, and strong in maneuverability. The product prepared by the method disclosed by the invention is lower in selling price than the product prepared from native polyester. Therefore, the method has good economic benefits and social benefits.

Owner:JIANGSU FEILIN FIBER TECH

Polycarbonate/polyethylene terephthalate resin composition and preparation method

The invention relates to a polycarbonate / polyethylene terephthalate resin composition and a preparation method, the composition comprises the following components by weight percent (wt%): 60-75% of waste polycarbonate resin (PC), 20-30% of waste polyethylene terephthalate (PET), 4-15% of impact modifier, 0.5-1.5% of chain extender and 0.1-1.5% of processing aids, the chain extender is used for carrying out chain extension and granulation on the waste PC and the waste PET, then the PC and the PET after the chain extension, the impact modifier and the processing aids are pre-mixed in a high-speed mixer and then melted and extruded through a twin-screw extruder, and cooling and granulation are finally carried out for obtaining a product. The preparation process is reasonable, the chain extension is carried out on the waste PC material and the waste PET material, and then the alloying technology is further used for modification, thereby having excellent performances and simultaneously having short production cycle and low cost; furthermore, the whole process is more environment-friendly and has better economic benefits and social benefits.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

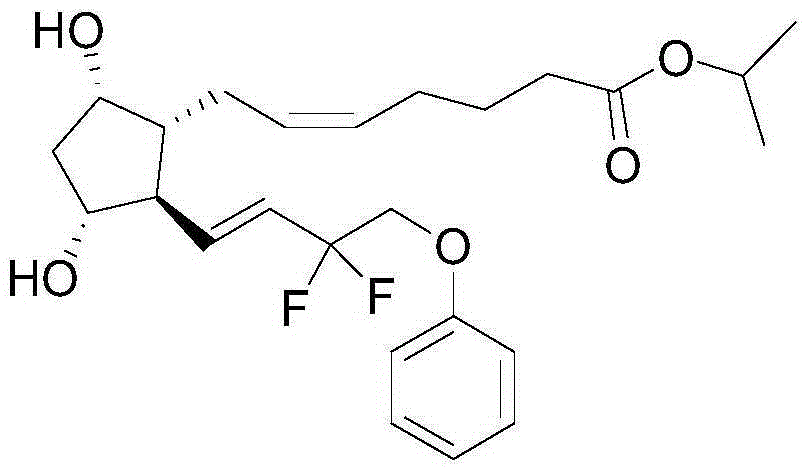

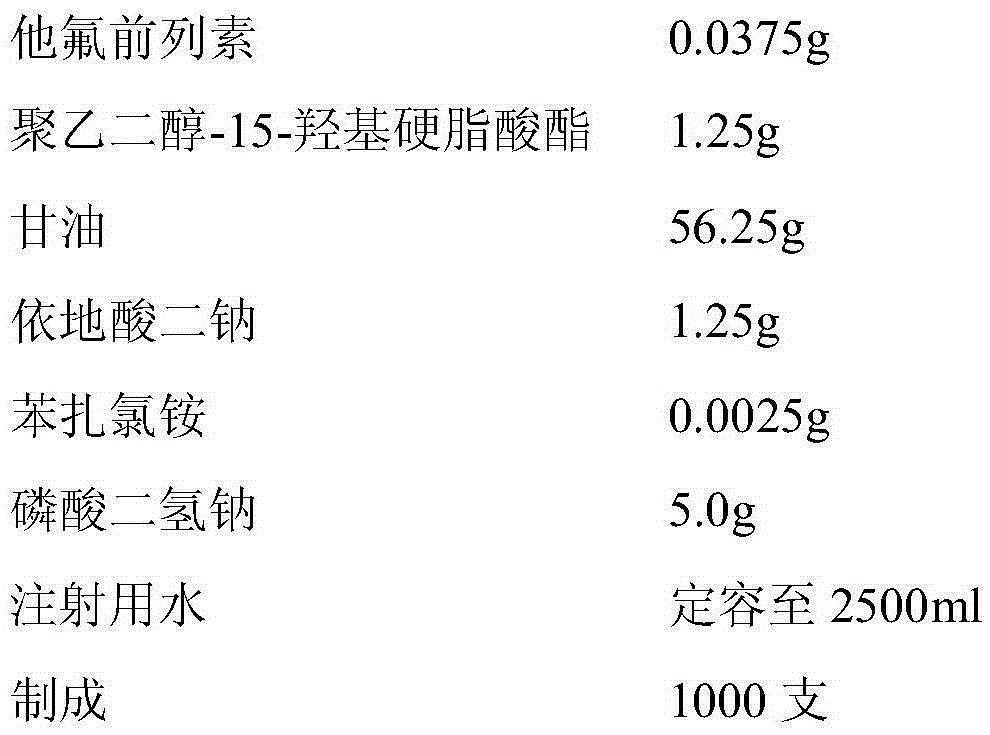

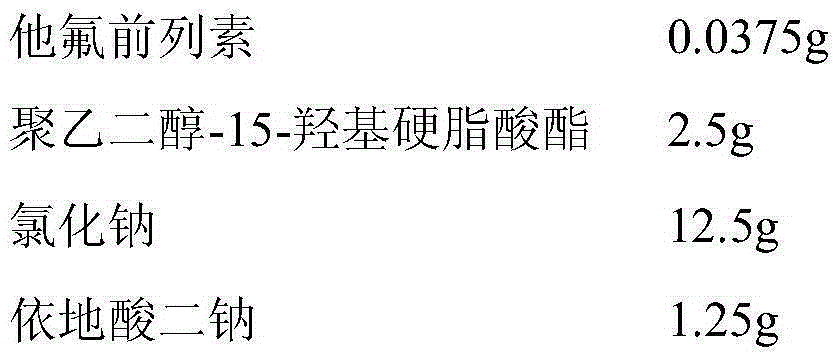

Tafluprost eye drop and preparation method thereof

ActiveCN105380901AReasonable preparation processEasy to operateOrganic active ingredientsSenses disorderSolubilityPolyethylene glycol

The invention relates to a tafluprost eye drop and a preparation method thereof. The eye drop takes tafluprost as an active ingredient and also contains a non-ionic solubilizer and a pharmaceutically acceptable carrier, wherein the non-ionic solubilizer is polyethylene glycol-15-hydroxyl stearate. According to the invention, the problem of low solubility of tafluprost in the preparation process can be solved, the stability of tafluprost in an aqueous solution can be increased, and formation of related substances is reduced.

Owner:苏州工业园区天龙制药有限公司

Kelp sauce and making method thereof

The invention relates to an edible kelp food, namely a kelp sauce, and a making method thereof. The kelp sauce is made by taking pretreated kelp as base material, making the base material into kelp paste, mixing the kelp paste with flour paste, minced meat, chili powder and seasoning and stir-frying the mixture with hot oil, wherein the weight percentages of the components are: 70 to 80 percent of kelp paste, 2 to 5 percent of flour paste, 6 to 10 percent of minced meat, 0.8 to 2 percent of chili powder, 5 to 12 percent of seasoning, and 3 to 5 percent of oil. The kelp sauce is reddish brown in color, spicy in taste, rich in nutrition, high in iodine content and convenient to eat, and has certain efficacy in preventing renal failure, arteriosclerosis, hypertension, diabetes and the like. The kelp sauce has the advantages of reasonable making process, readily available raw material, making convenience, low cost and strong operability.

Owner:TAIXIANG GRP TECH DEV

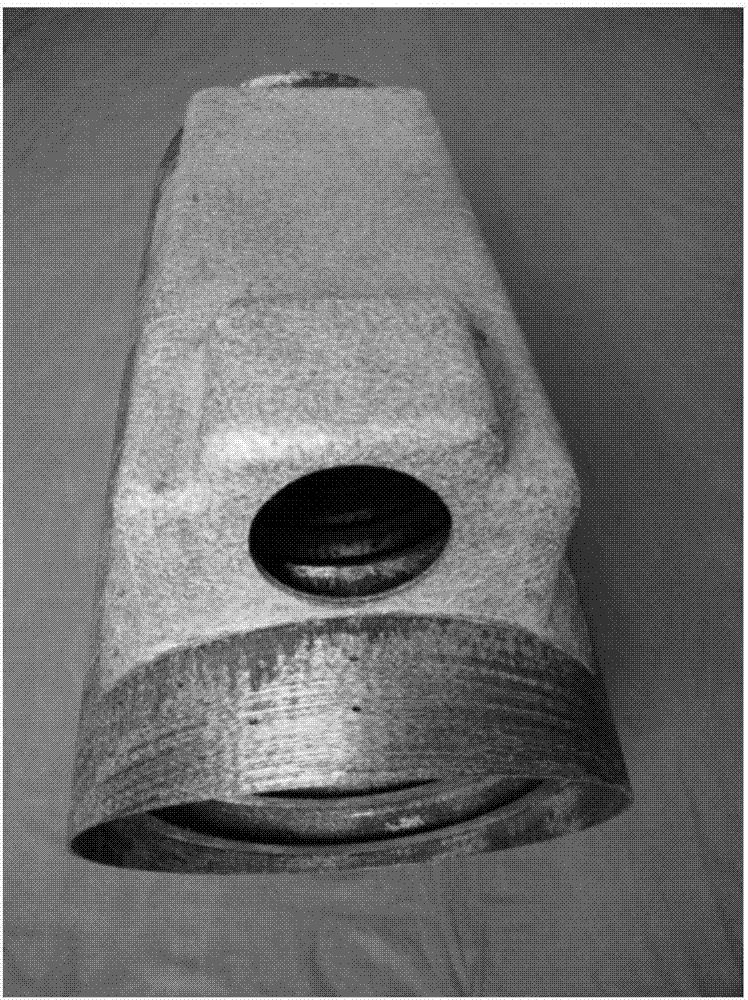

A high-size special-shape carbon-based composite material member and a preparing method thereof

The invention relates to a high-size special-shape carbon-based composite material member and a preparing method thereof. The member includes, by mass, 20-35% of carbon fibers, 35-75% of pyrolytic carbon and 5-15% of SiC. The preparing method includes needling the continuous carbon fibers into a prefabricated blank the density of which is 0.4-0.55 g / cm<3> according to a required shape of the member; then fixing the inner and outer surfaces of the prefabricated blank by adopting a graphite mold; and then performing high-temperature thermal treatment, a first time of carbon deposition, demolding, coarse machining, a second time of carbon deposition, graphite processing, silicon vapor bathing and finish machining in order to obtain a finished product. According to the member and the method, a problem that high-size special-shape carbon-based composite material members are liable to deform in long-time standing processes and preparing processes is overcome, and the obtained product has advantages of good mechanical performance, a low thermal expansion coefficient, high thermal conductivity, good chemical stability, and the like, is suitable for industrial production, and can be applied in the field of aviation and aerospace, the field of communication and transportation, the field of biomedicine, and the like.

Owner:CENT SOUTH UNIV

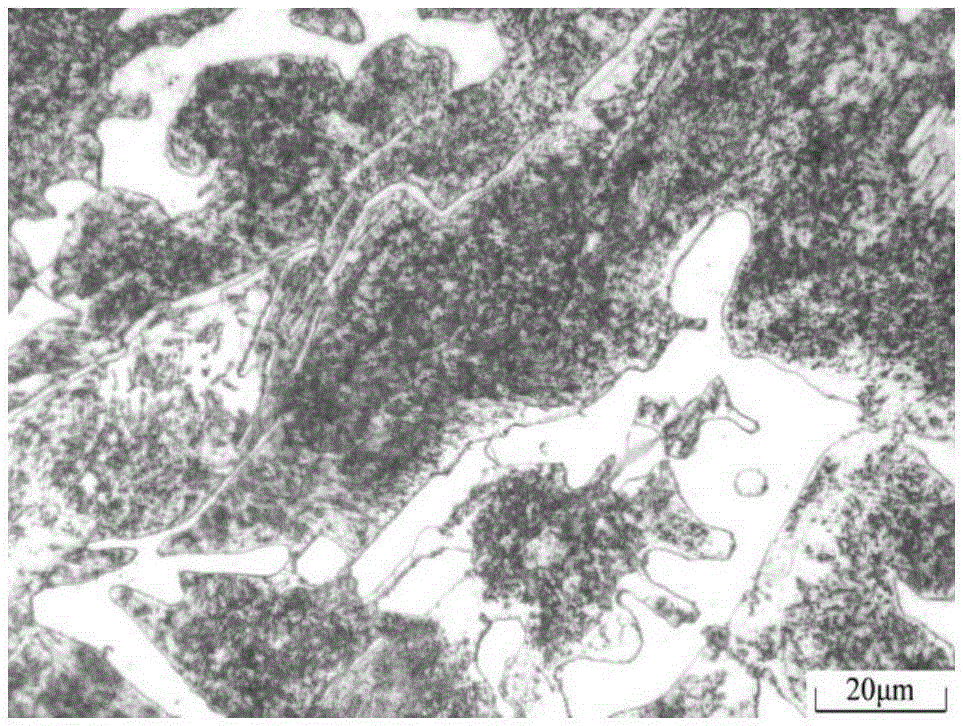

Universal type steel ball unthreaded ball iron roller ring and manufacturing method thereof

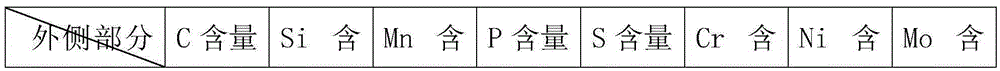

The invention discloses a universal type steel ball unthreaded ball iron roller ring which comprises an outer layer and an inner core. The proportion between the outer layer and the inner core is 2:1. The alloy component of the outer layer comprises, by weight, 3.0-3.5% of C, 1.2-2.0% of Si, 0.5-1.2% of Mn, 0.1% or less of P, 0.02% or less of S, 0.2-1.0% of Cr, 0.5-1.5% of Ni, 0.2-1.0% of Mo, and the balance Fe and inevitable impurities. The alloy component of the inner core comprises, by weight, 1.0-1.5% of C, 1.3-1.7% of Si, 0.5-1.0% of Mn, 0.08% or less of P, 0.03% or less of S, 0.5% or less of Cr, 0.3% or less of Ni, 0.13% or less of Mo, and the balance Fe and inevitable impurities. A manufacturing method comprises the steps of A, smelting, B, inoculation and spheroidizing, and C, casting. By means of the universal type steel ball unthreaded ball iron roller ring and the manufacturing method thereof, the hardness fall of rollers can become small, the steel adhesion tendency is relieved, and the comprehensive using performance of the roller ring is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Sea tangle catsup and preparation method thereof

The invention relates to kelp sauce and a preparation method thereof. The preparation method comprises the following steps: firstly cleaning and soaking kelp, adding 15 to 25 percent of edible salt and 200 to 400 percent of water of the weight of the kelp to the kelp, placing the kelp in a heater for heating, when heating to between 40 and 45 DEG C, adding 2 to 10 percent of edible alkali of the weight of the kelp, continuously heating until the kelp becomes pasty, cooling the kelp to below 30 DEG C, and grinding the kelp into kelp paste; after mixing the kelp paste with flour paste, garlic sauce, chilli sauce, salt, sugar and vinegar evenly, heating the mixture to prepare kelp sauce, bottling the kelp sauce after the kelp sauce is cooled, and then exhausting, sealing and sterilizing the kelp sauce, wherein the kelp sauce comprises the following components in weight percentage: 50 to 70 percent of the kelp paste, 10 to 20 percent of the flour paste,1 to 3 percent of the garlic sauce, 5 to 12 percent of the chilli sauce, 1to 5 percent of the salt, 5 to 12 percent of the sugar and 1 to 3 percent of the vinegar. The kelp sauce has the advantages of reddish brown color, delicious hot flavor, enough garlic fragrance, fresh taste and rich nutrition. The preparation method has the advantages of reasonable preparing technique, simple and convenient preparation, and strong operability, and is easy to achieve large-scale production.

Owner:山东俚岛海洋科技股份有限公司

Non-radiation ceramic tile with high whiteness and manufacturing technique thereof

The invention discloses a ceramic tile with a high whiteness and no radiation as well as the manufacturing method thereof. The weight percents of the main raw materials of the ceramic tile is: 15-60 wt.% of burning talcum, 15-30 wt.% of feldspar, 5-30 wt.% of porcelain sand, 20-28 wt.% of black mud. The steps of manufacturing method is as follows: (1) calcining the talcum; (2) the manufacturing process is: raw materialsbatchingball millingremoving zirconiumspraying and millingmouldingdryingpenetratingburningpolishing; (3) doing a strict anti-pollution treatment after polishing. The calcining temperature of the talcum is: 1200 DEG C; the calcining temperature of the ceramic tile is 1210-1230 DEG C; burning period is: 60-80 minutes; whiteness is: about 80 DEG. The invention firstly does a pre-burning treatment to the talcum material in 1200 DEG C, thus it manages its sheet structure and removes volatile with a high temperature. The disposed material is without greasy texture and the dosage will not influence the products molding.

Owner:GUANGDONG WINTO CERAMICS

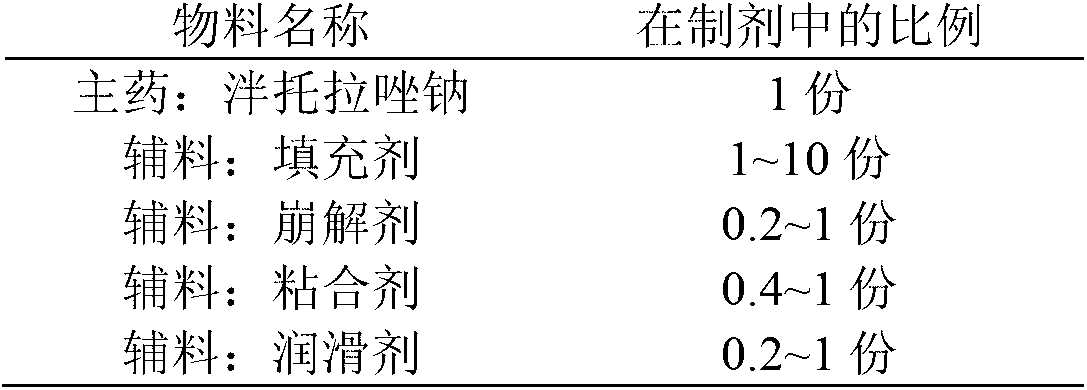

Pantoprazole sodium enteric-coated tablet and preparation method thereof

ActiveCN103006613AImprove stabilityReduced stabilityOrganic active ingredientsDigestive systemAdhesivePantoprazole Sodium

The invention provides a pantoprazole sodium enteric-coated tablet and a preparation method thereof. The pantoprazole sodium enteric-coated tablet comprises a pantoprazole sodium tablet, an isolated layer and an enteric-coated layer, wherein the pantoprazole sodium tablet comprises main drug pantoprazole sodium and auxiliaries; and the auxiliaries include a filler, a disintegrant, a lubricating agent, an adhesive, a pH regulating agent, and the like. The pantoprazole sodium enteric-coated tablet accelerates the disintegration time of the pantoprazole sodium enteric-coated tablet and solves the problem of drug instability during a storage period.

Owner:SHIJIAZHUANG HUAXIN PHARMA

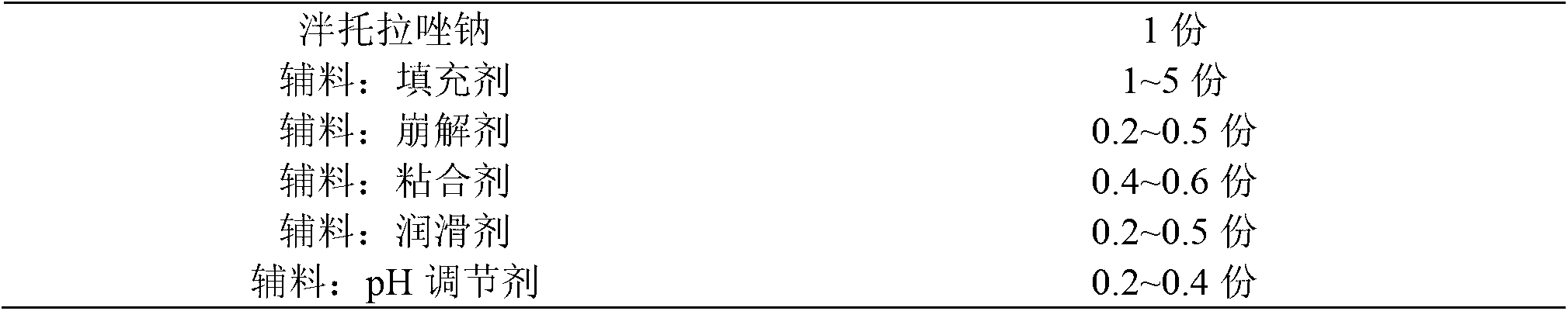

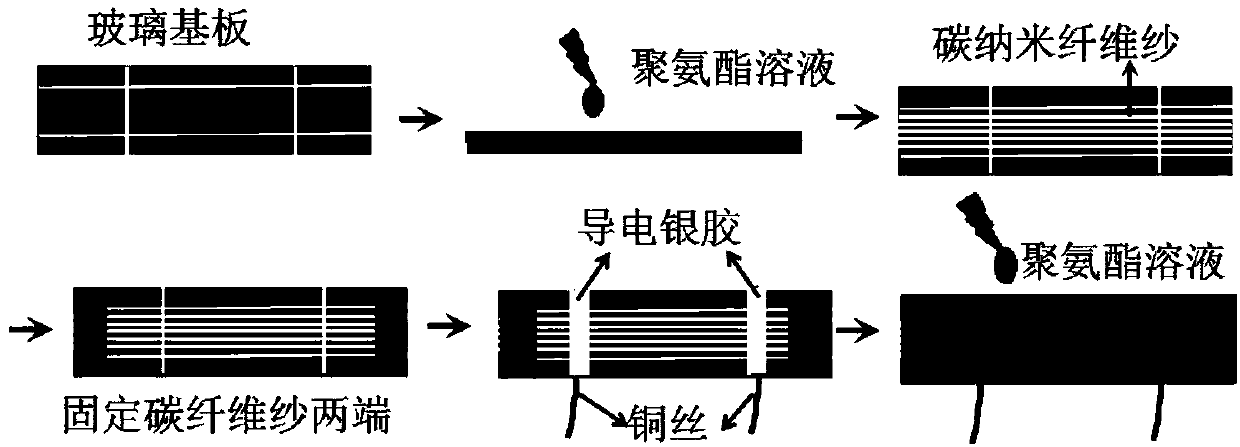

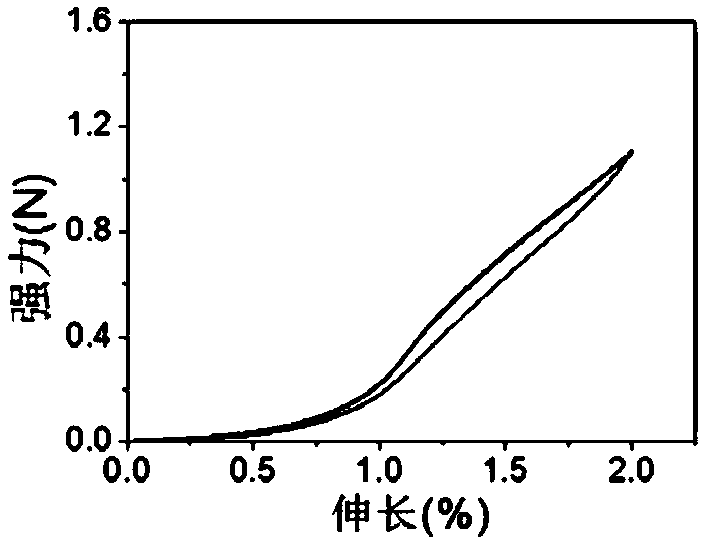

Carbon/graphene flexibility strain sensor and preparation method thereof

ActiveCN107720685AGood size controlEasy to carryElectrical/magnetic solid deformation measurementPiezoelectric/electrostrictive devicesYarnAdhesive

The invention relates to a carbon / graphene flexibility strain sensor and a preparation method thereof. The preparation method comprises the steps of firstly preoxidizing and carbonizing polyacrylonitrile / graphene composite nanometer fiber yarns to obtain carbon / graphene composite nanometer fiber yarns; and then compounding the carbon / graphene composite nanometer fiber yarns with an elastic film prepared from thermoplastics polymer, a lead and a conductive adhesive to obtain the carbon / graphene flexibility strain sensor. The preparation method is reasonable in preparation process; the sensor issteady in performance in the preparation process and the dimension of the sensor can be adjusted based on demands; the sensitivity coefficient of the obtain carbon / graphene flexibility strain sensoris 400-2500 when the sensitivity coefficient is A; and when the circular stretching is carried out in the presence of the elongation from 0 to A, the total test time is 2000s and the cycle index is 28, the standard deviation of the sensitivity coefficient is 0.5% to 4%; and A is equal to 1.5% t 2.3%.

Owner:SUZHOU UNIV

Shredded fish food and making method thereof

The invention relates to a marine fish food product, in particular to a shredded fish food and a making method thereof. The method comprises the following steps: steaming fish, cooling, making shredded fish, and dehydrating the shredded fish until the water content is 35-40%; weighing oyster polypeptides and fish head polypeptides, dissolving with water, evenly mixing with the dehydrated shreddedfish, weighting flavorings and adding the flavorings to obtain the wet shredded fish food; or baking the wet shredded fish food until the water content is 15-20% so as to obtain the dry shredded fishfood; and packaging, sterilizing and cooling to obtain the finished product. The shredded fish food comprises 50-75% of dehydrated shredded fish, 5-15% of oyster polypeptides, 1-10% of fish head polypeptides, 3-10% of water and 10-20% of flavorings. The shredded fish food is light orange or golden in color, has thick fish fragrance and has the advantages of favorable mouth feel, convenience and sanitation for eating, rich and comprehensive nutrients, quick absorption of nutrients, and high bioavailability. The method has the advantages of reasonable technique and easy operation, and is suitable for industrial production.

Owner:TAIXIANG GRP TECH DEV

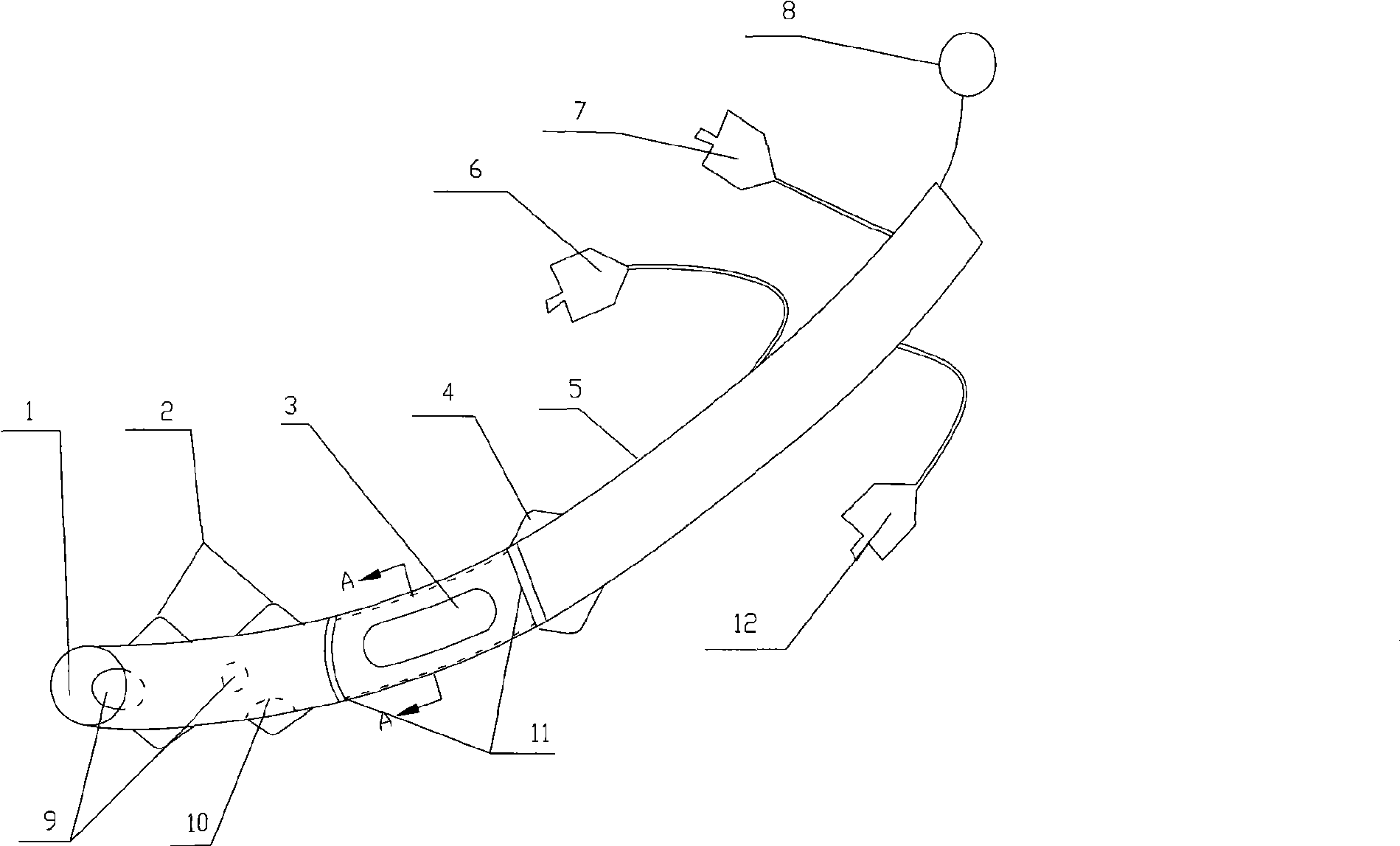

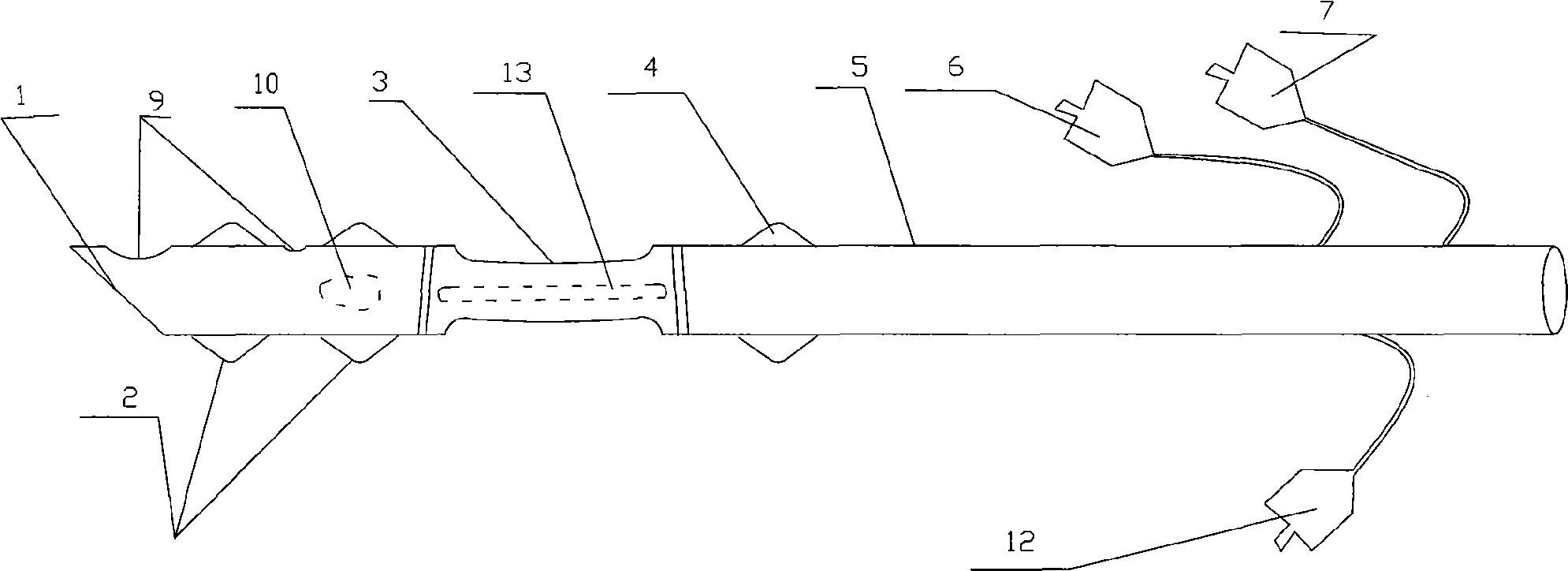

Tracheal cannula

The invention discloses a tracheal intubation. A plurality of outer casing sacs are arranged at the front end of the intubation. Each outer casing sac is communicated with an injection interface which is arranged at the external side of the tracheal intubation by fine airways. The tracheal intubation is also provided with an inner tube. One end of the inner tube is provided with an interface end used for connecting to machines. An external tube is longer than the inner tube. The outer casing sac is arranged on the external wall of the external tube. The inner wall of the external tube near the interface end is also provided with an inner casing sac. An injection interface of the inner casing sac is arranged at the other end of the external tube. The inner tube can be twitched in the external tube, and the twitching stroke is longer than the length of a long-kidney-shaped stoma arranged on the two ends of the external tube but shorter than the space between two outer casing sacs. The tracheal intubation has the characteristics of reasonable structure, simple process, convenient operation, etc.

Owner:张晓明

Clean modified briquette and method for preparing same

The invention relates to a clean modified briquette and method for preparing same, wherein the briquette is prepared from (by weight ratio) the following raw materials, super fine coal powder 10-20%, coal gangue or stone coal or kerosene shale or mushy coal 30-70%, purification powder 1-5%, complexing agent 1-5%, adhesive 8-10%, water 0-15, and balancing glance coal. The invention can be applied for diminishing pollution discharge.

Owner:KUNMING JUJIE SCI & TECH

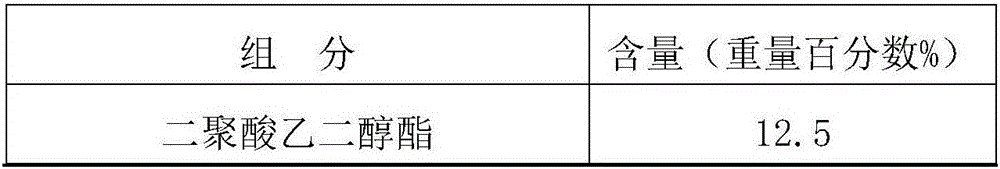

High-intensity brass plating wire drawing lubricant and preparation method thereof

ActiveCN106350190AImprove the lubrication effectReduce lossLubricant compositionWater basedOperability

The invention relates to a high-intensity brass plating wire drawing lubricant and a preparation method of the high-intensity brass plating wire drawing lubricant. The high-intensity brass plating wire drawing lubricant is prepared by heating oiliness agent, phosphorus-containing extreme pressure agent and emulsifying agent to 100-120 DEG C; adding water at 90-100 DEG C under the continuously stirring, and then cooling to 40 DEG C below; adding antiseptic antirust agent, mildew preventive, and antifoaming agent; evenly stirring and obtaining the product. The invention has the beneficial effects that (1) the water-based lubricant provided by the invention is good in lubricating performance, and used for drawing the high-intensity brass plating wire; the drawing speed is high, the mould loss is low, the fracture rate is low, surface of the steel wire is clean and smooth; besides, the drawing residue is few; the lubricant is highly and stably bonded with rubber, and can replace import product, thus the domestication progress of the metal product industry is promoted, the economic benefit and social benefit are significant. (2) The preparation technique of the water-based lubricant is reasonable, operability is strong, and production environment fits for the national environmental protection requirements.

Owner:湖北省化学工业研究设计院 +1

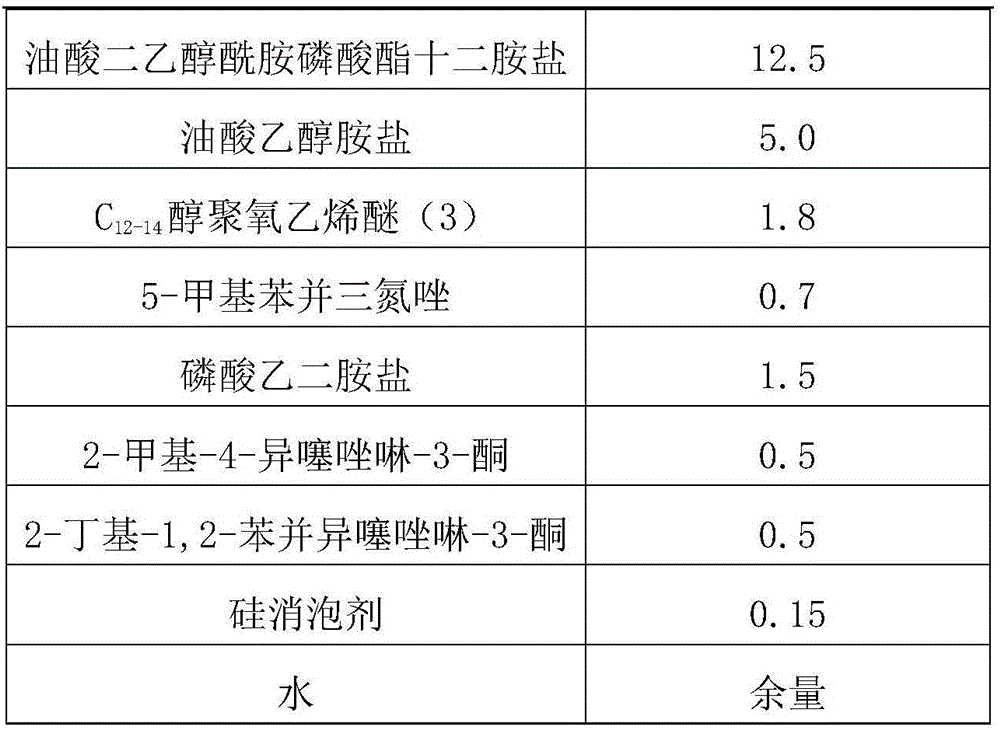

Chineses medicine prepn with several treating functions and its prepn proces and application

ActiveCN101066402AGood curative effectSimple preparation processPill deliveryUrinary disorderUrologyDiuresis

The present invention provides one kind of Chinese medicine preparation for treating urinary system calculus and urinary tract infection and its preparation process. The Chinese medicine preparation has functions of clearing away heat, promoting diuresis, treating stranguria, diminishing inflammation, relieving pain and removing urinary calculus. It is used in treating urinary calculus, renal colic, urinary tract infection and other urinary tract diseases.

Owner:GUAGNXI WANTONG PHARMA

Preparation of lead zirconate titanate nanometer powder

Production for Pb(ZrxTi(1-x)O3) nanometer powder is disclosed. It is carried out by: taking Ti(O-C4H9)4, Zr(NO3)4íñ5H2O, Pb(CH3COO)2íñ3 H2O as raw material, C2H6O2 as solvent, mixing C2H6O2 solution of Zr(NO3)4íñ5H2O with C2H6O2 solution of Ti(O-C4H9)4, back-flowing at temperature 60-70deg.C for 30mins, dripping C2H6O2 solution of Pb(CH3COO)2.3 H2O into system, back-flowing at 60-70deg.C for 3hrs, thermostatic drying for 10hrs in 100deg.C fan drying case, and dried gel powder sintering at temperature 400deg.C and 600deg.C in crucible to obtain yellow nanometer Pb(ZrxTi(1-x)O3) powder. It costs low and is simple.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com