Carbon/graphene flexibility strain sensor and preparation method thereof

A strain sensor and graphene technology, applied in the field of sensors, can solve the problems of high stability and high sensitivity of the sensor cannot be obtained at the same time, the preparation process of the strain sensor is complicated, and the preparation process of the sensor is unstable, etc., and achieves good industrial promotion value. Wide range of applications, size-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

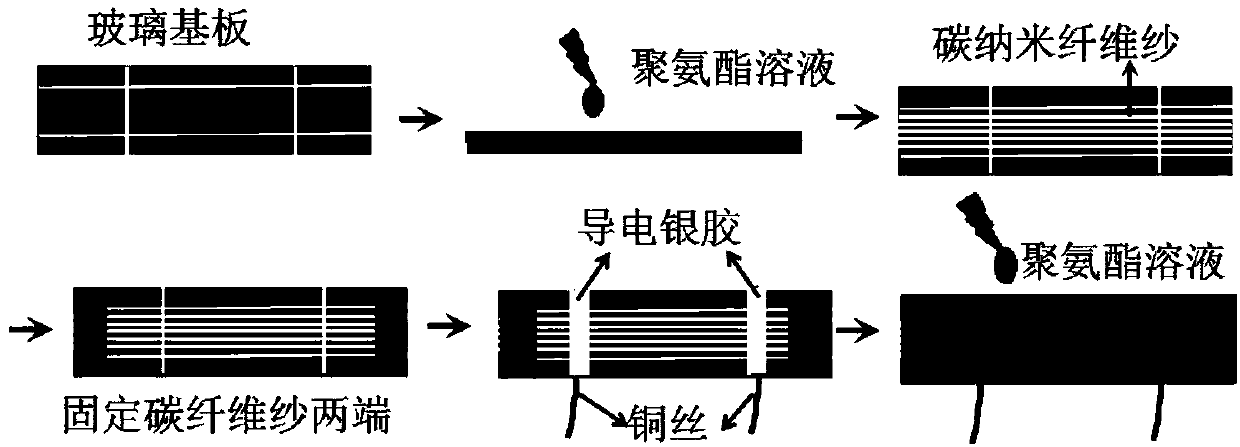

[0043] A kind of preparation method of carbon / graphene flexible strain sensor such as figure 2 As shown, the steps are as follows:

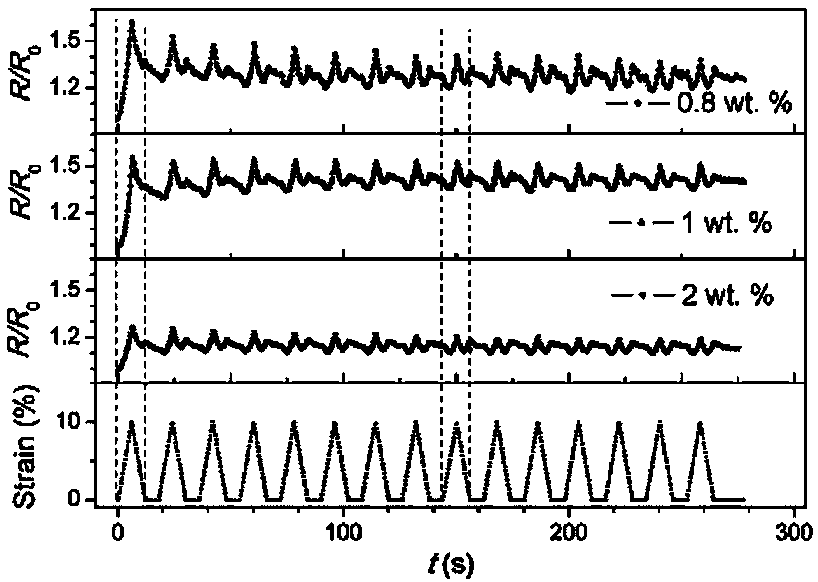

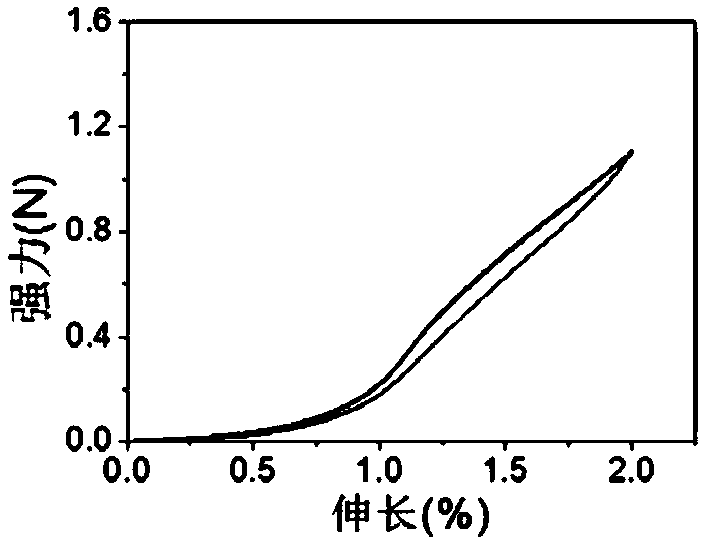

[0044] (1) First, the polyacrylonitrile / graphene composite nanofiber yarn with a graphene content of 1wt% is heated up to 270°C in the air at a rate of 2°C / min for pre-oxidation, and the pre-oxidation time is 1.5h, and then in an inert In the gas environment, the temperature was raised to 1100°C at a rate of 5°C / min for carbonization treatment. After carbonization for 3 hours, a carbon / graphene composite nanofiber yarn was obtained, wherein the yarn diameter of the polyacrylonitrile / graphene composite nanofiber yarn was 200um, and the twist 1500 twist / m, carbon / graphene composite nanofiber yarn diameter is 100um, carbon / graphene composite nanofiber yarn is brittle, its breaking strength is 50MPa, Young's modulus is 15GPa, conductivity is 81S / cm;

[0045] (2) Paste grid paper on one side of the glass substrate, and mark on the grid, evenly coat ...

Embodiment 2

[0059] A method for preparing a carbon / graphene flexible strain sensor, the steps are as follows:

[0060] (1) First, the polyacrylonitrile / graphene composite nanofiber yarn with a graphene content of 10wt% is heated up to 280° C. in the air at a rate of 1° C. / min for pre-oxidation. The pre-oxidation time is 1 h, and then in an inert gas In the environment, the temperature was raised to 800°C at a rate of 10°C / min for carbonization treatment. After carbonization for 1 hour, a carbon / graphene composite nanofiber yarn was obtained, in which the polyacrylonitrile / graphene composite nanofiber yarn had a yarn diameter of 420um and a twist of 2000 twist / m, the carbon / graphene composite nanofiber yarn diameter is 280um, the carbon / graphene composite nanofiber yarn is brittle, the breaking strength is 10MPa, the Young's modulus is 5GPa, and the conductivity is 2S / cm;

[0061] (2) Paste grid paper on one side of the glass substrate, and mark on the grid, uniformly coat the elastic rubb...

Embodiment 3

[0066] A method for preparing a carbon / graphene flexible strain sensor, the steps are as follows:

[0067] (1) First, the polyacrylonitrile / graphene composite nanofiber yarn with a graphene content of 5wt% is heated up to 270°C in the air at a rate of 1.5°C / min for pre-oxidation. The pre-oxidation time is 1h, and then in an inert gas In the environment, the temperature was raised to 1300°C at a rate of 6°C / min for carbonization treatment. After carbonization for 1.5 hours, a carbon / graphene composite nanofiber yarn was obtained, wherein the yarn diameter of the polyacrylonitrile / graphene composite nanofiber yarn was 525um, and the twist 1000 twist / m, carbon / graphene composite nanofiber yarn diameter is 225um, carbon / graphene composite nanofiber yarn is brittle, breaking strength is 15MPa, Young's modulus is 18GPa, electrical conductivity is 19S / cm;

[0068] (2) Paste grid paper on one side of the glass substrate, and mark on the grid, uniformly coat a polypropylene solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com