Sodium borosilicate glass doped with In2S3 quantum dots and preparation method thereof

A technology of sodium borosilicate glass and quantum dots, which is applied in the field of inorganic materials, can solve the problems of non-compliance with energy conservation and environmental protection, poor glass uniformity, and less preparation research, and achieve good third-order nonlinear optical properties, easy control, and good thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

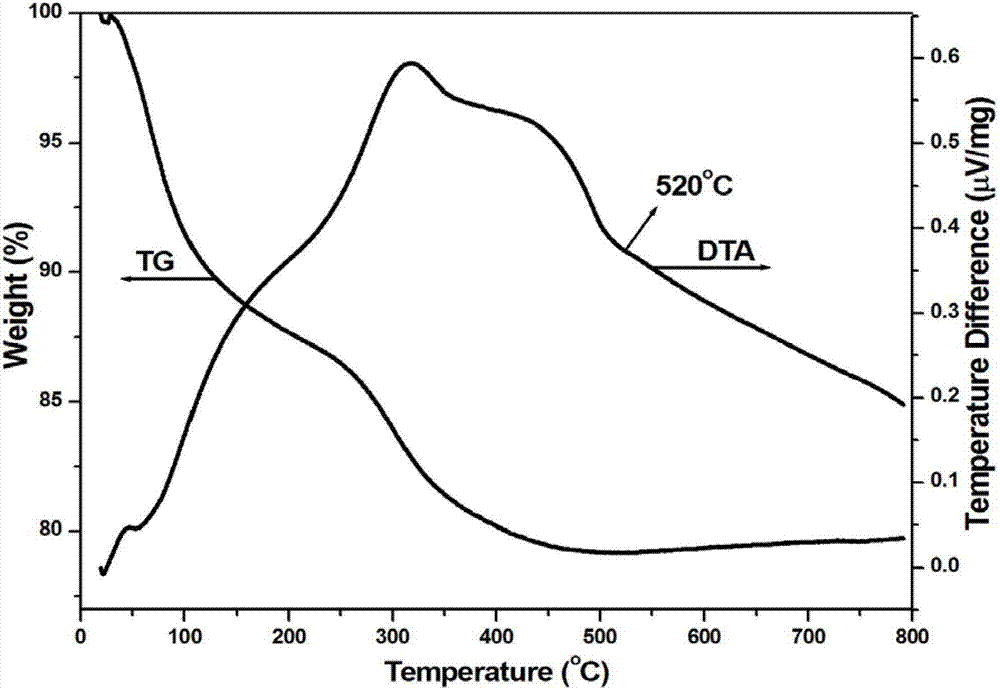

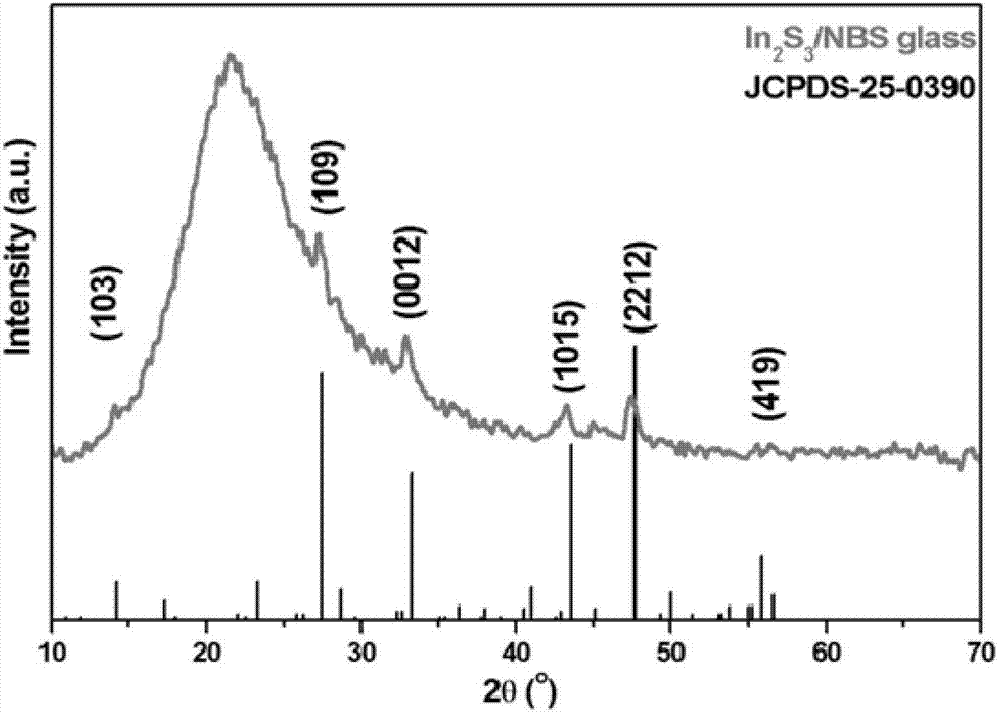

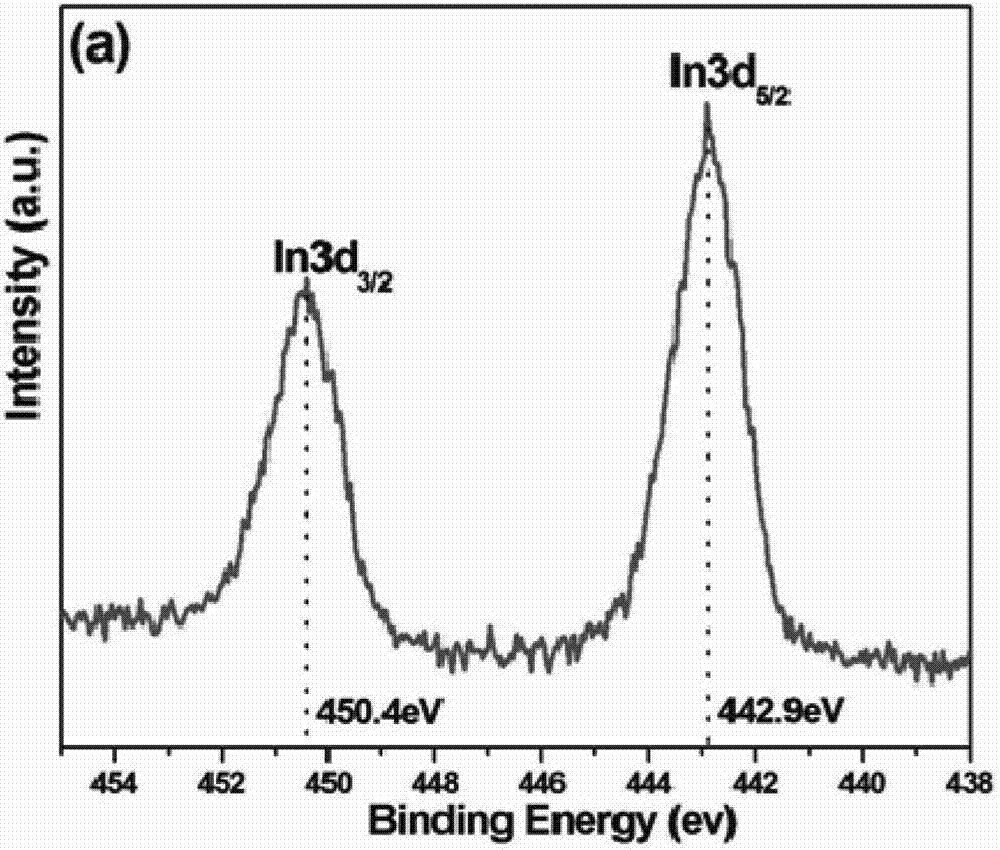

[0032] Embodiment 1: the preparation mass percentage is 1.5% In 2 S 3 Quantum dot soda borosilicate glass (base glass composition 5.74%Na 2 O-21.38%B 2 o 3 -72.88%SiO2 2 )

[0033]Dissolve 25ml of tetraethyl orthosilicate in absolute ethanol according to the volume ratio: 1:1, and stir at room temperature for 0.5 hours to form a silica precursor solution; weigh 4.26g of boric acid and dissolve it in 30ml of ethylene glycol methyl ether, Stir at 30°C for 0.5 hours to obtain a boron oxide precursor solution; weigh 0.47g of sodium and dissolve it in 15ml of absolute ethanol to form a sodium oxide precursor solution; prepare the silica precursor solution and boron oxide precursor solution Mix with the sodium oxide precursor solution, stir at room temperature for 0.5 to 1 hour to obtain a sol; weigh 0.35g In(NO 3 ) 3 Dissolve in 15ml of ethanol, after completely dissolved, add dropwise to the above sol, stir for 0.5 to 1 hour, place the sol at room temperature for 5 days, an...

Embodiment 2

[0034] Embodiment 2: preparation mass percentage is 1.5% In 2 S 3 Quantum dot soda borosilicate glass (base glass composition 5.74%Na 2 O-21.38%B 2 o 3 -72.88%SiO2 2 )

[0035] Dissolve 25ml of tetraethyl orthosilicate in absolute ethanol according to the volume ratio: 1:1, and stir at room temperature for 0.5 hours to form a silica precursor solution; weigh 4.26g of boric acid and dissolve it in 30ml of ethylene glycol methyl ether, Stir at 50°C for 0.5 hours to obtain a boron oxide precursor solution; weigh 0.47g of sodium and dissolve it in 15ml of absolute ethanol to form a sodium oxide precursor solution; prepare the silica precursor solution and boron oxide precursor solution Mix with the sodium oxide precursor solution, stir at room temperature for 0.5 to 1 hour to obtain a sol; weigh 0.35g In(NO 3 ) 3 Dissolve in 15ml of ethanol, after completely dissolved, add dropwise to the above sol, stir for 0.5 to 1 hour, place the sol at room temperature for 7 days, and t...

Embodiment 3

[0036] Embodiment 3: preparation mass percentage is 1.5% In 2 S 3 Quantum dot soda borosilicate glass (base glass composition 5.74%Na 2 O-21.38%B 2 o 3 -72.88%SiO2 2 )

[0037] Dissolve 25ml of tetraethyl orthosilicate in absolute ethanol at a volume ratio of 1:1, and stir at room temperature for 0.5 hours to form a silicon dioxide precursor solution; weigh 4.26g of boric acid and dissolve it in 30ml of ethylene glycol methyl ether. Stir at 80°C for 0.5 hours to obtain a boron oxide precursor solution; weigh 0.47g of sodium ethoxide and dissolve it in 15ml of absolute ethanol to form a sodium oxide precursor solution; prepare the silica precursor solution and boron oxide precursor solution Mix with sodium oxide precursor solution, stir at normal temperature for 0.5 hour, obtain sol; Weigh 0.35g In(NO 3 ) 3 Dissolve in 15ml of ethanol, after complete dissolution, add dropwise to the above sol, stir for 0.5 hours, place the sol at room temperature for 10 days, and then dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com