Bio-medical porous titanium products and preparation method thereof

A biomedical, porous titanium technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of reduced strength, pungent ammonia gas, and low strength of molded products, reduce stress concentration effects, meet mechanical performance requirements, Reduces the effect of stress shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

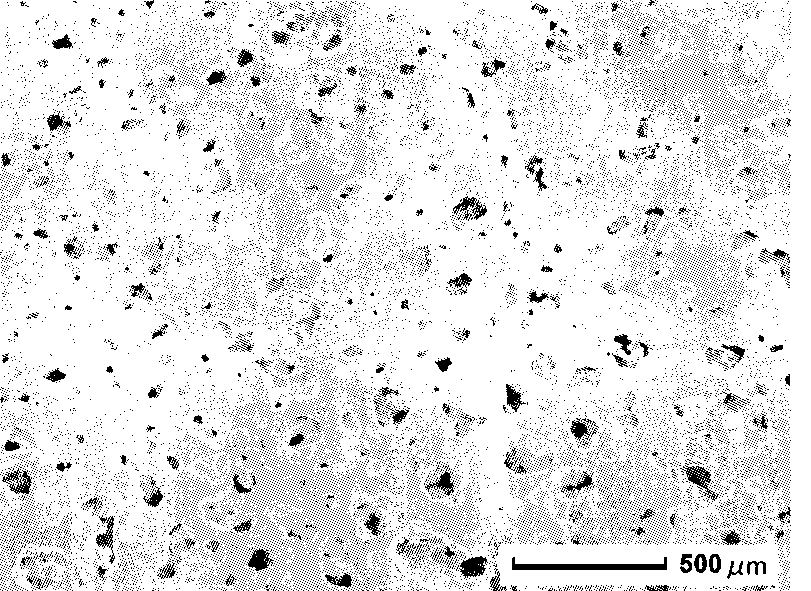

[0044] Titanium powder with a particle size of ≤45 μm and a purity of >99.3% is used as a base material, and spherical polymethyl methacrylate particles are added as a pore-forming agent. The particle sizes are: 71-100 μm, 100-154 μm, 154-200 μm, 200-315 μm, 315~400μm, 400~630μm. The volume fraction of the pore-forming agent is set to be 10vol.%, 25vol.%, 30vol.%, 40vol.%, 50vol.%, 55vol.%, 60vol.% and 65vol.%. Weigh the material according to the proportion, mix the weighed titanium powder and pore-forming agent evenly, take an appropriate amount and pour it into the mold, and press it on a hydraulic universal testing machine with a pressure of 500MPa in one direction, and the dwell time is 15 seconds. Place the compact in a vacuum sintering furnace at 5×10 -3 Under the vacuum degree of Pa, heat up to 250°C at a speed of 10°C / min, and after holding for 30 minutes, gradually heat at a speed of 3°C / min to 300°C, 350°C, 400°C, hold for 40 minutes each, and then gradually heat A...

Embodiment 2

[0048] This example aims at preparing a gradient biomedical porous titanium material. The particle size, purity and volume fraction of the base material titanium powder and the added pore-forming agent polymethyl methacrylate spherical particles are the same as those in Example 1.

[0049] Pour the titanium powder into the mold, after paving, mix the weighed titanium powder and pore-forming agent evenly, take an appropriate amount and pour it into the mold, after paving, then pour an appropriate amount of titanium powder into the mold, and then spread another The mixed powder of titanium powder and pore forming agent is added in increments. The number of layers and the pore characteristics of each layer of porous titanium are set according to requirements. Then use 500MPa pressure unidirectional pressing on the hydraulic universal testing machine, the dwell time is 15 seconds, take out the green compact, place it in the vacuum sintering furnace, in 2×10 -3 Under the vacuum de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com