Motor and motor stator cooling structure

A technology of motor stator and cooling structure, applied in cooling/ventilation device, magnetic circuit shape/pattern/structure, electrical components, etc., can solve the problems of water jacket unable to transmit torque, water jacket deformation, etc., to ensure normal transmission , the effect of reducing the stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It can be seen from the background art that in a low temperature environment (for example, -40° C.), the introduction of the elastic pin will cause deformation of the water jacket, and even cause the water jacket to fail to transmit torque.

[0031] The reason is analyzed in conjunction with a motor stator cooling structure.

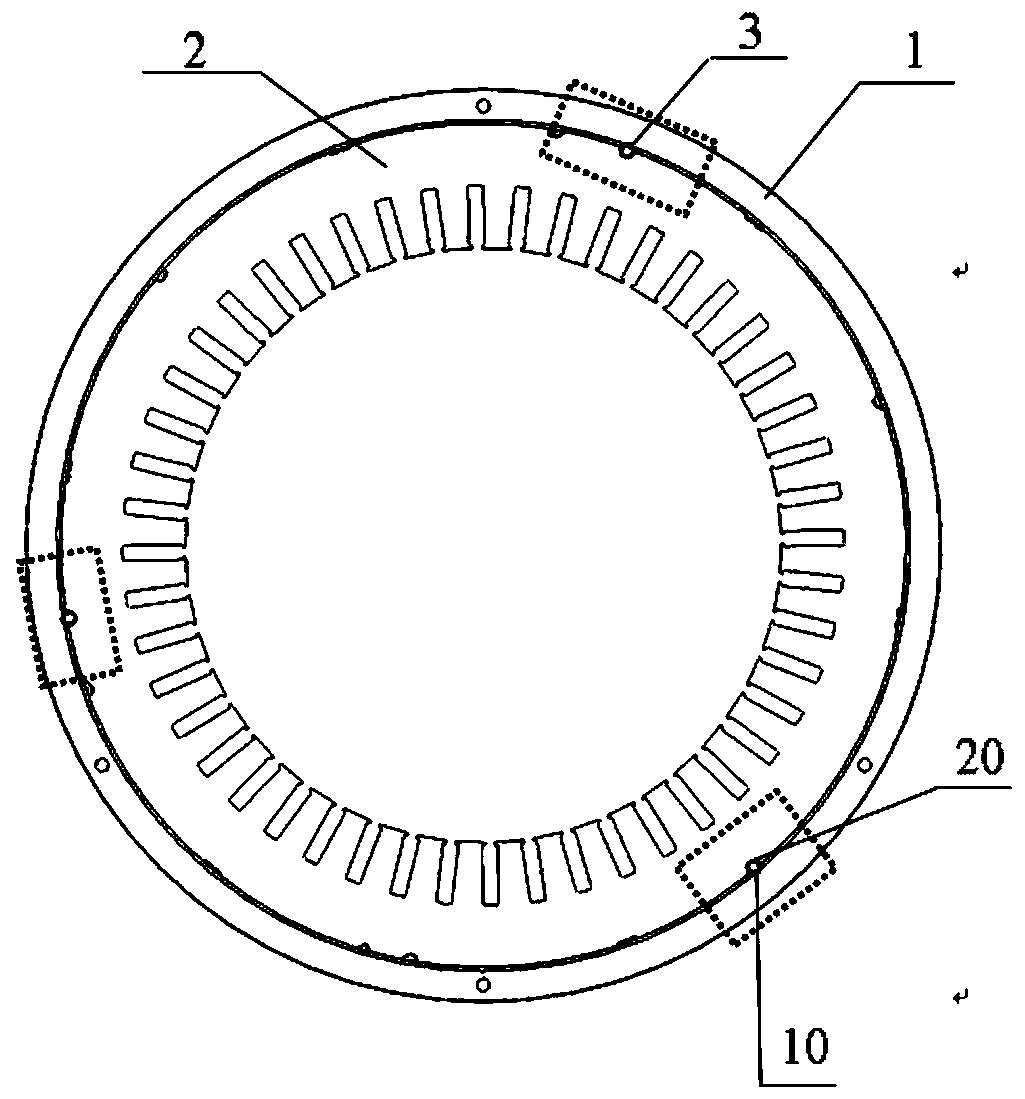

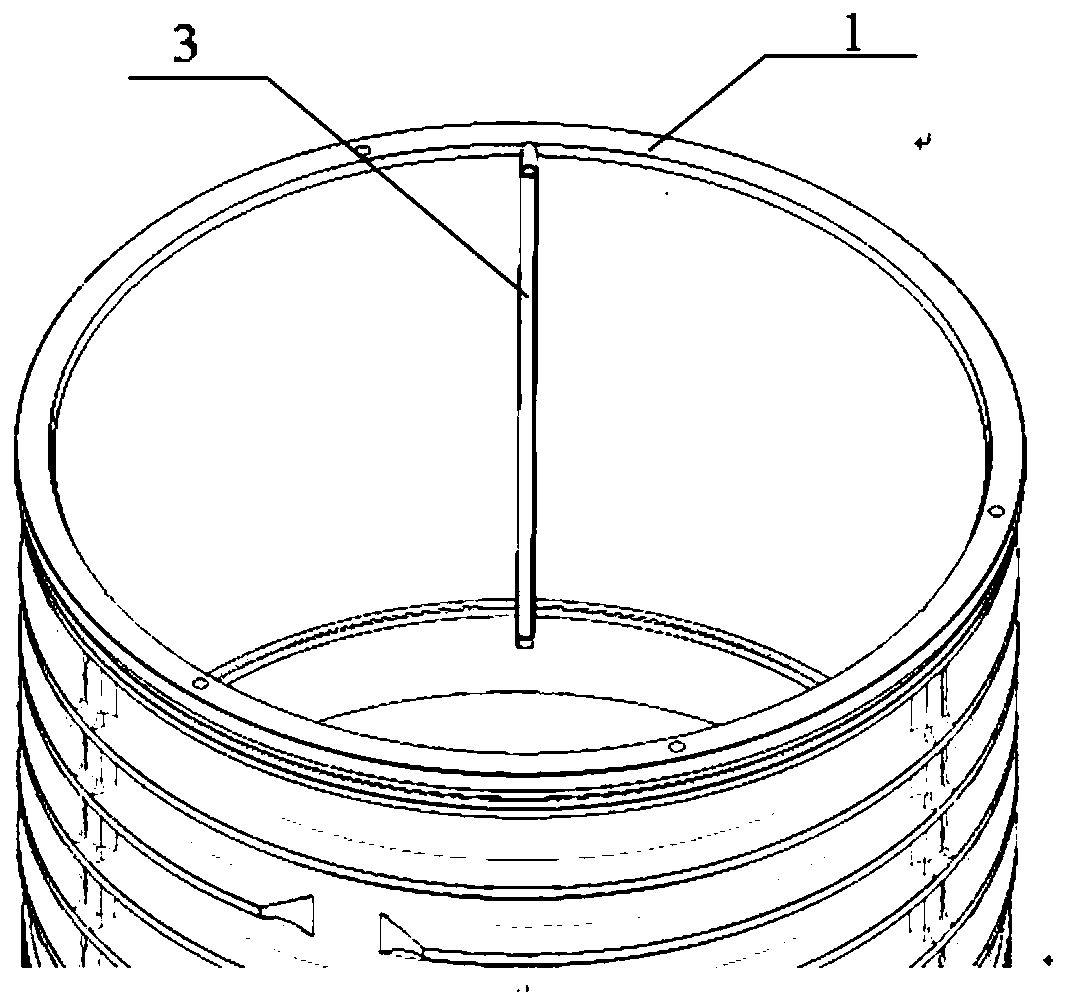

[0032] Please refer to figure 1 and figure 2 , figure 1 is a top view of a motor stator cooling structure; figure 2 yes figure 1 Schematic diagram of the water jacket and spring pin in .

[0033] to combine figure 1 and figure 2 , the water jacket 1 is set on the outer ring surface of the motor stator 2, and the elastic pin 3 is fixed between the water jacket 1 and the motor stator 2. By opening the first groove 10 on the inner ring surface of the water jacket 1, the outer ring of the motor A second groove 20 is opened on the surface, and the space size enclosed by the first groove 10 and the second groove 20 is smaller than the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com