Preparation method for reinforcing Ti2AlNb composite material by using graphene

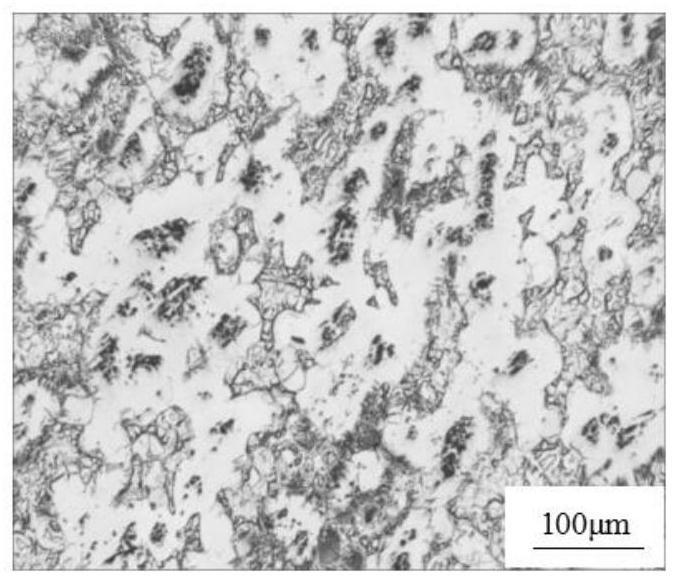

A composite material and graphene technology, which is applied in the field of preparation of graphene-reinforced Ti2AlNb composite materials, can solve the problems of poor thermal deformation ability, low temperature plasticity and toughness of AlNb alloys, etc., to reduce stress concentration effect and improve strength and toughness , the effect of optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

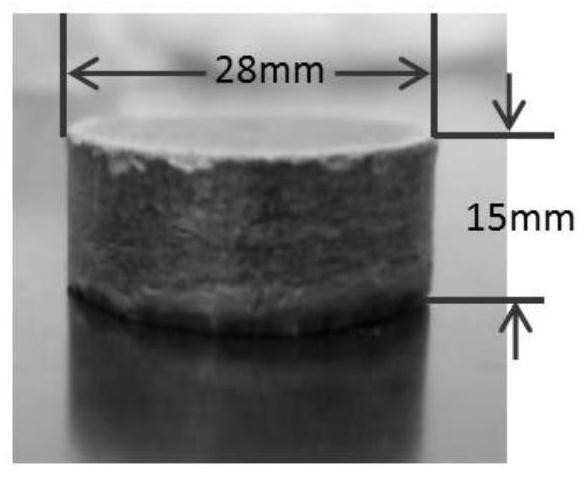

Embodiment 1

[0016] Step 1. Add graphene or graphene oxide in proportion to absolute ethanol and carry out ultrasonic dispersion treatment for 30min to 10h to obtain a uniformly dispersed graphene or graphene oxide ethanol dispersion; wherein graphene or graphene oxide is mixed with no The ratio of water to ethanol is 0.1(g):50(ml), adding 0.5wt% of graphene or graphene oxide reinforcement phase, ultrasonic treatment time is 60min, and ultrasonic power is 800W.

[0017] Step 2. Ti powder, Al powder and Nb powder are packed in the ball mill tank according to the atomic ratio of 53:22:25;

[0018] Step 3. Evenly disperse and drop the dispersion prepared in step 1 into the ball mill tank prepared in step 2, then add steel balls into the ball mill tank according to a certain ball-to-material ratio of 10:1, and "pump the ball mill tank" Vacuum-filling with argon” was repeated 4 times, the vacuum degree was -0.09~-0.1MPa, the purity of argon gas was ≥99.5 vol.%, and ball milling was carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com