Patents

Literature

73results about How to "Reduce stress concentration effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

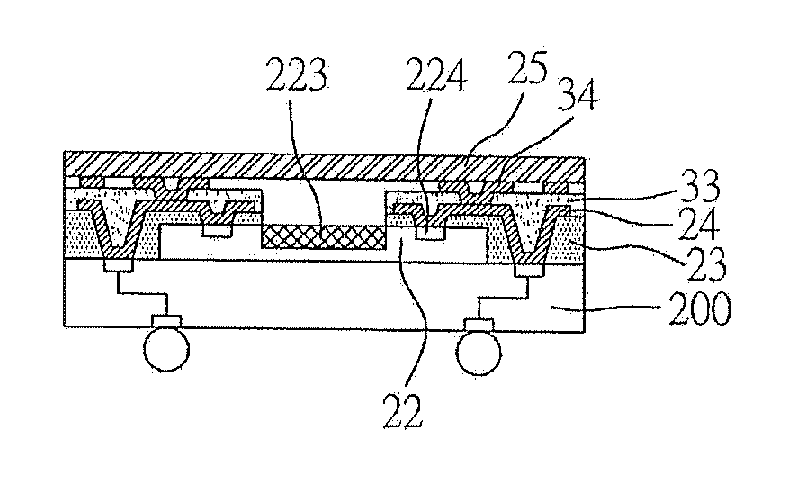

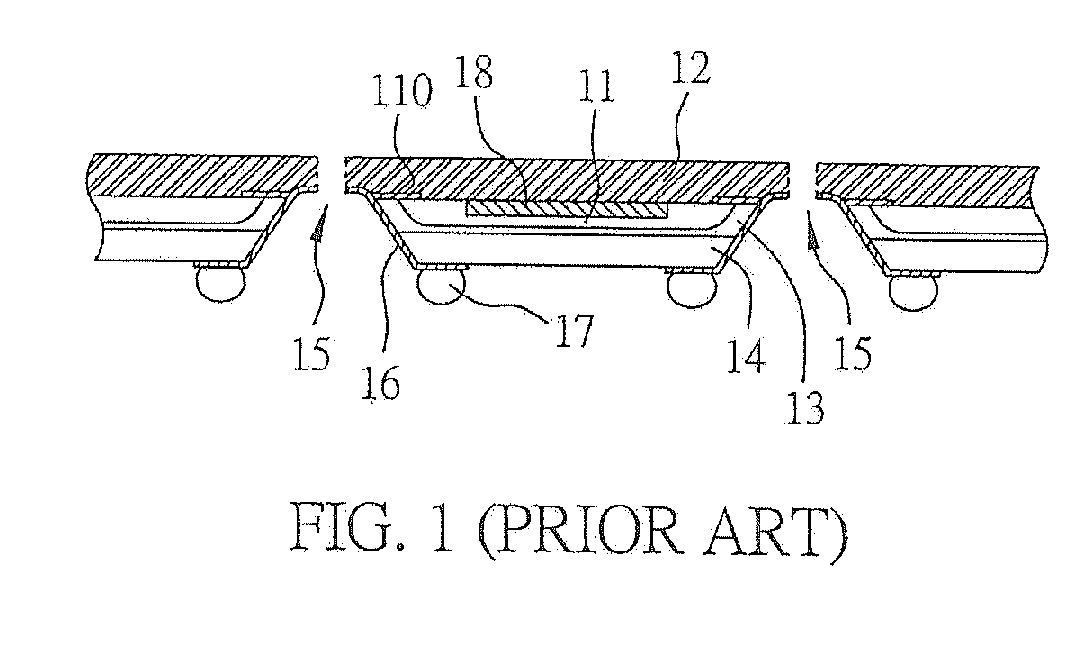

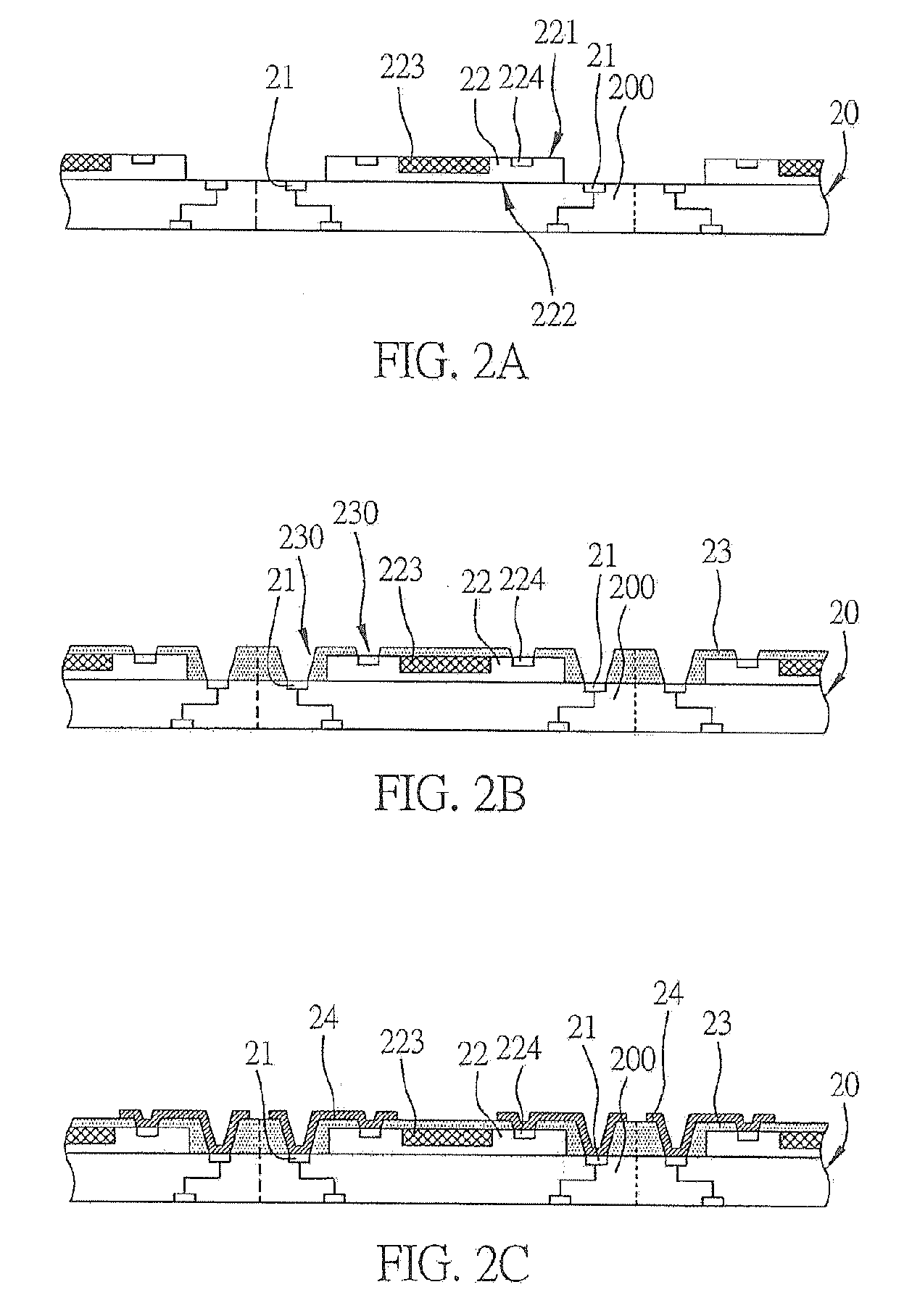

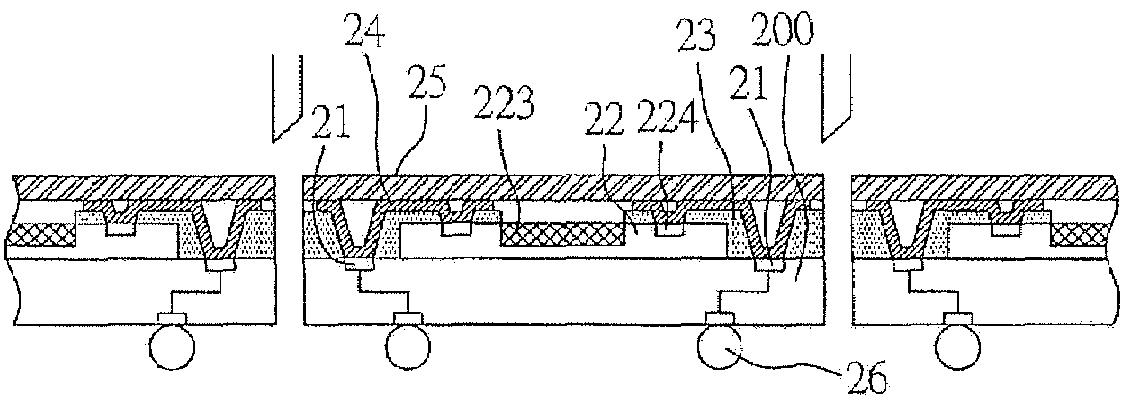

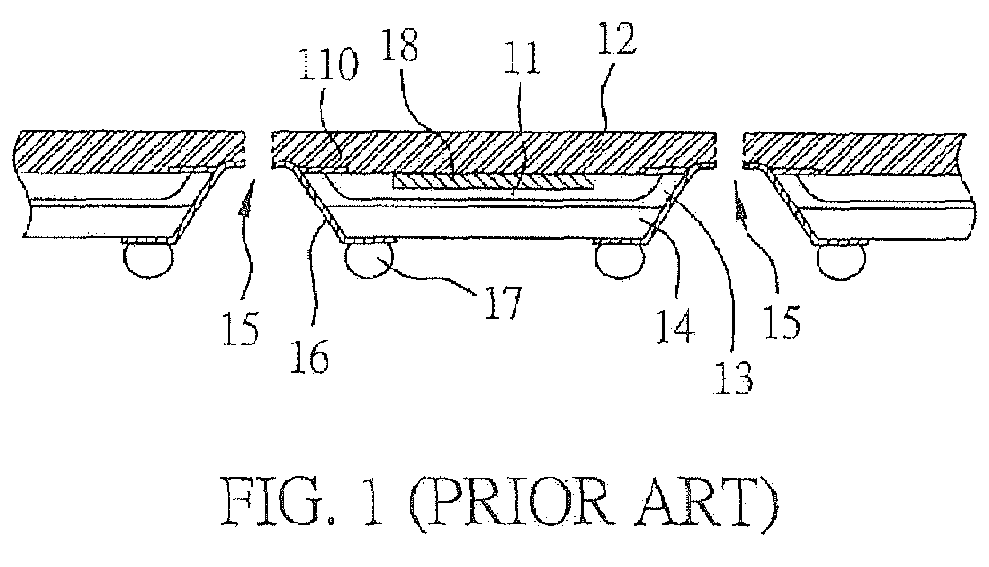

Sensor semiconductor device and method for fabricating the same

InactiveUS20060267125A1Easy to makeReduce thicknessSolid-state devicesSemiconductor devicesDevice materialSolder ball

A sensor semiconductor device and a method for fabricating the same are proposed. A sensor chip is mounted on a substrate, and a dielectric layer and a circuit layer are formed on the substrate, wherein the circuit layer is electrically connected to the substrate and the sensor chip. The dielectric layer is formed with an opening for exposing a sensor region of the sensor chip. A light-penetrable lid covers the opening of the dielectric layer, such that light is able to penetrate the light-penetrable lid to reach the sensor region and activate the sensor chip. The sensor chip can be electrically connected to an external device via a plurality of solder balls implanted on a surface of the substrate not for mounting the sensor chip. Therefore, the sensor semiconductor device is fabricated in a cost-effective manner, and circuit cracking and a know good die (KGD) problem are prevented.

Owner:SILICONWARE PRECISION IND CO LTD

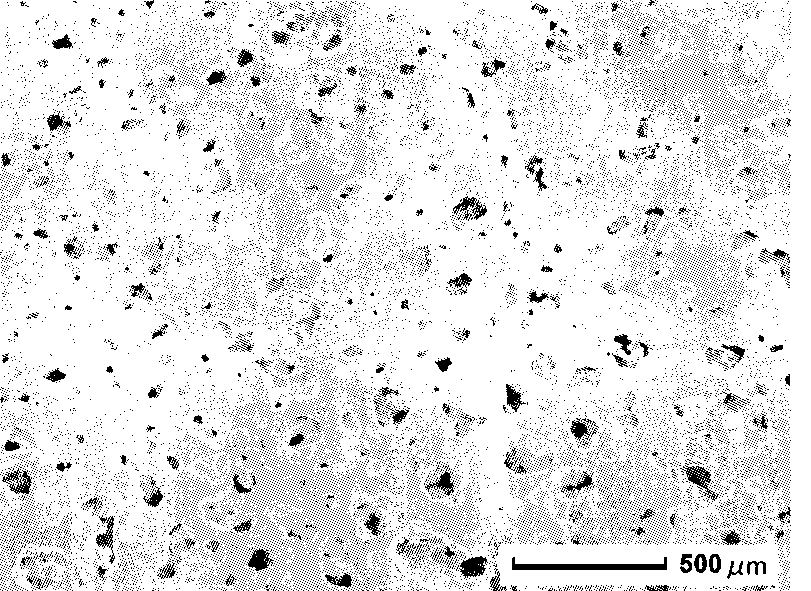

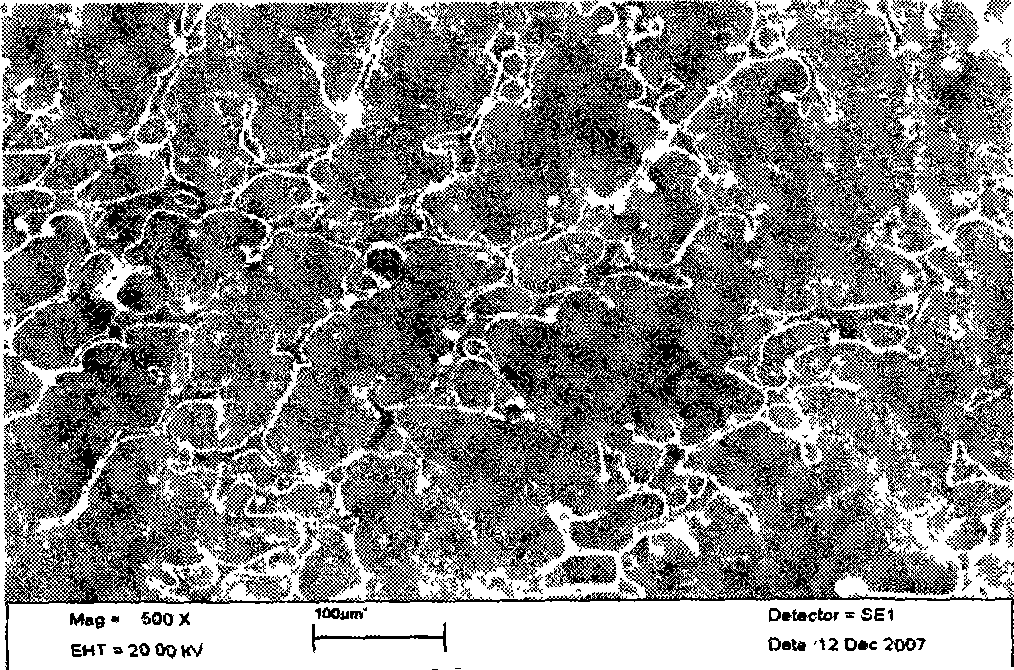

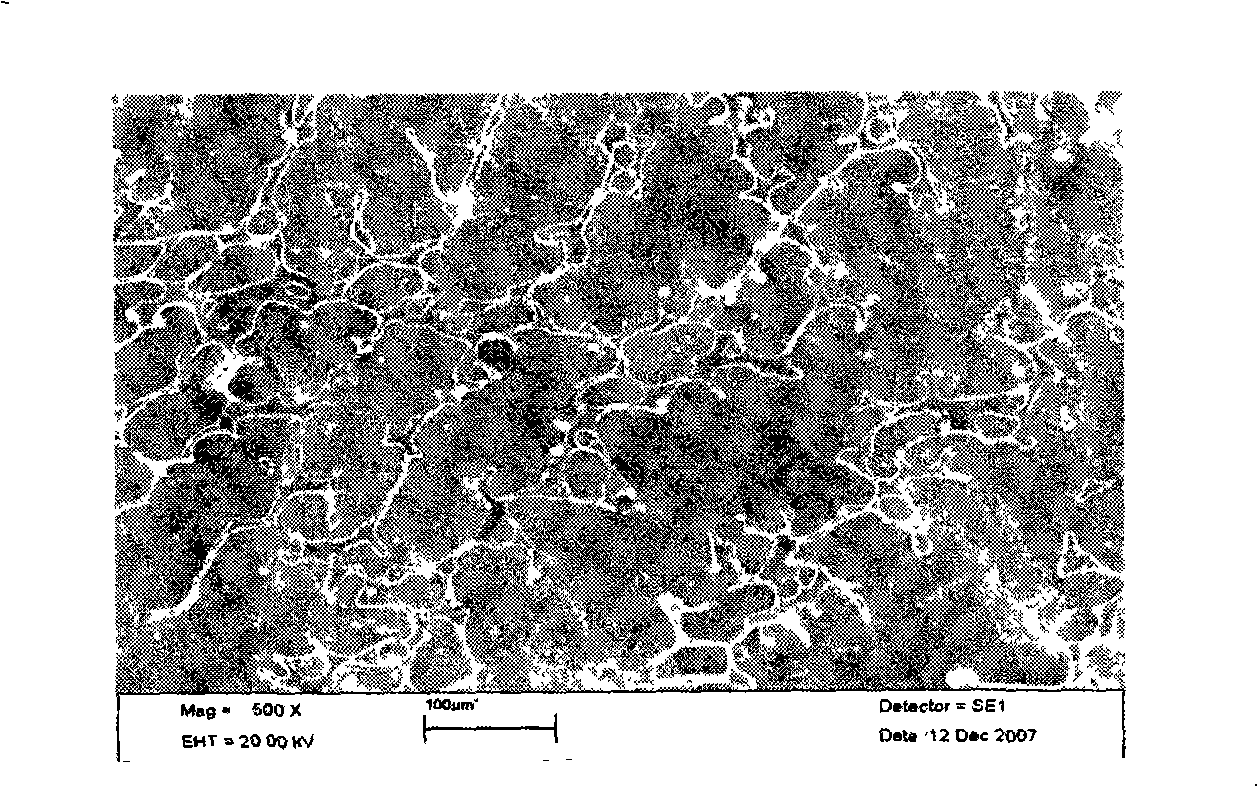

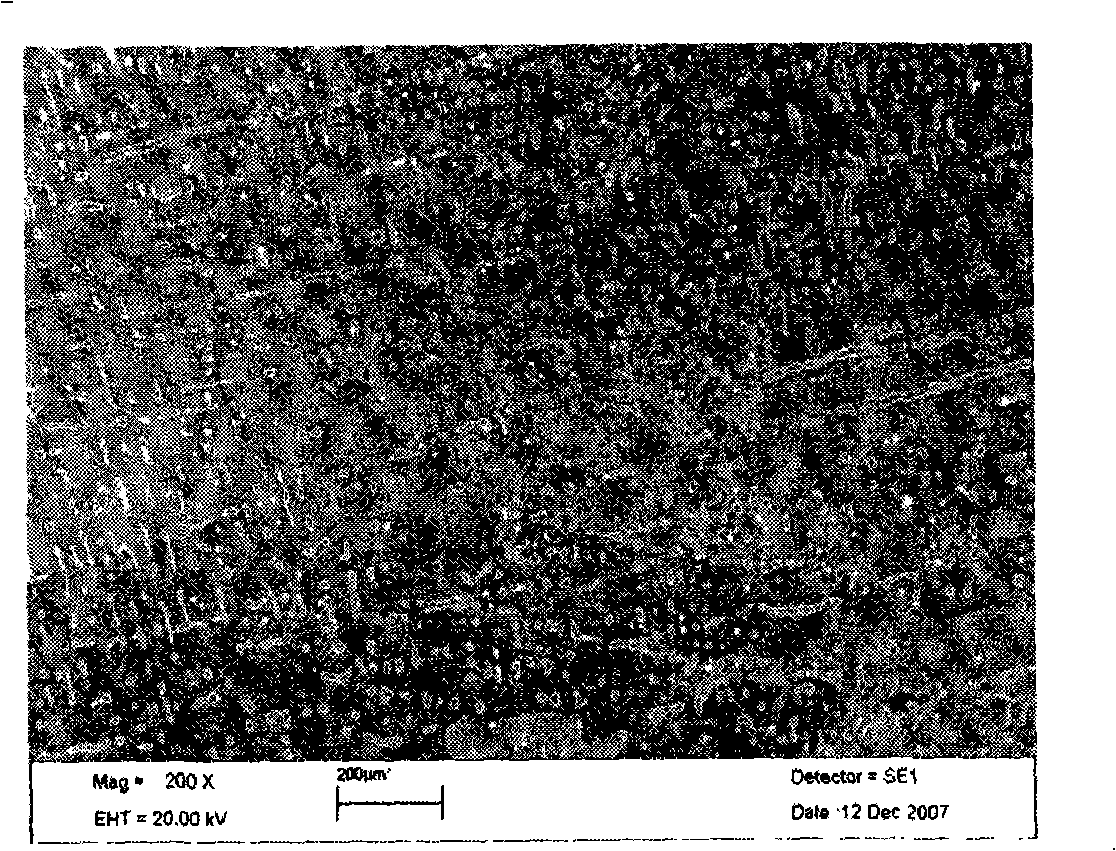

Bio-medical porous titanium products and preparation method thereof

InactiveCN101418392AReduce stress concentration effectsGood obedienceSurgeryProsthesisPowder metallurgyArtificial joints

The invention relates to a biological medical porous titanium material and a preparation method thereof. The preparation method, namely a method adopting powder metallurgy, is to add spherical particles of novel polymethyl methacrylate pore-forming agent to prepare a structure provided with a rough surface and three-dimensionally communicated open pores, wherein the number, the shape and the size of the pores can be controlled, namely, the porosity degree is less than 70vol. percent, the open porosity factor is more than 60 percent, the average pore diameter is less than 500 mums, the Young's modulus in compression is more than 0.3 GPa, the compressive strength is more than 40MPa, and the bending strength is more than 50MPa. The biological medical porous titanium material can be widely applied in the field of biological medical implants such as dental implants, artificial joints, spinal orthopaedic internal fixed systems, medullary internal nails and orthopaedic armor plates.

Owner:DALIAN JIAOTONG UNIVERSITY

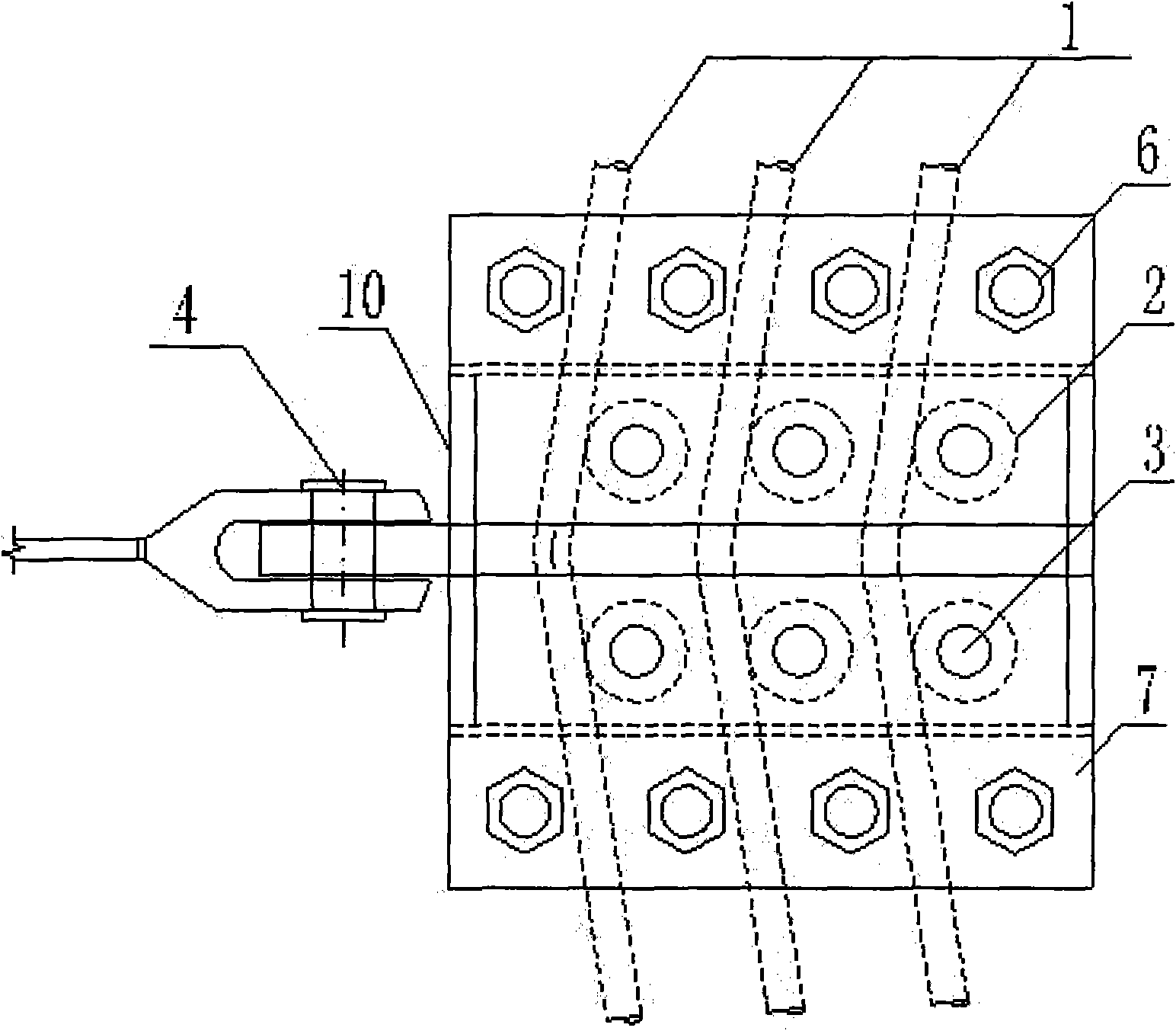

Cable support node connecting device

InactiveCN101881050ASmall turning angleReduce the adverse effects of bending stiffnessBuilding reinforcementsUltimate tensile strengthMotherboard

The invention relates to a cable support node connecting device. The device comprises a cable body and a connecting device, wherein the connecting device comprises a node main plate, node upper plates, a vertical connecting plate, a node lower cover plate, clamping plates and a lug plate; the node upper plates, the vertical connecting plate and the node lower cover plate are connected into a cavity through a centre shaft; a bearing is sleeved on the centre shaft; both ends of the node main plate are provided with the node upper plates; both sides of the node lower cover plate are provided with the clamping plates; the cable body passes through the internal space of the connecting device and is tangent to the bearing; the centre shaft fixes the bearing and the cable body inside the connecting device through pre-tightening force of bolts; and the clamping plates are fixedly connected with the node upper plates through the bolts and are used for clamping or fixing the cable body passing through from the middle part. The node connecting device has the characteristics of simple structure, clear force transmission, reasonable stress, strong bearing capacity and the like. The device can fully exert material strength, effectively transmit steel cable force, reduce stress amplitudes, reduce prestress loss caused by friction and improve integral bearing capacity and stability of the structure.

Owner:BEIJING UNIV OF TECH

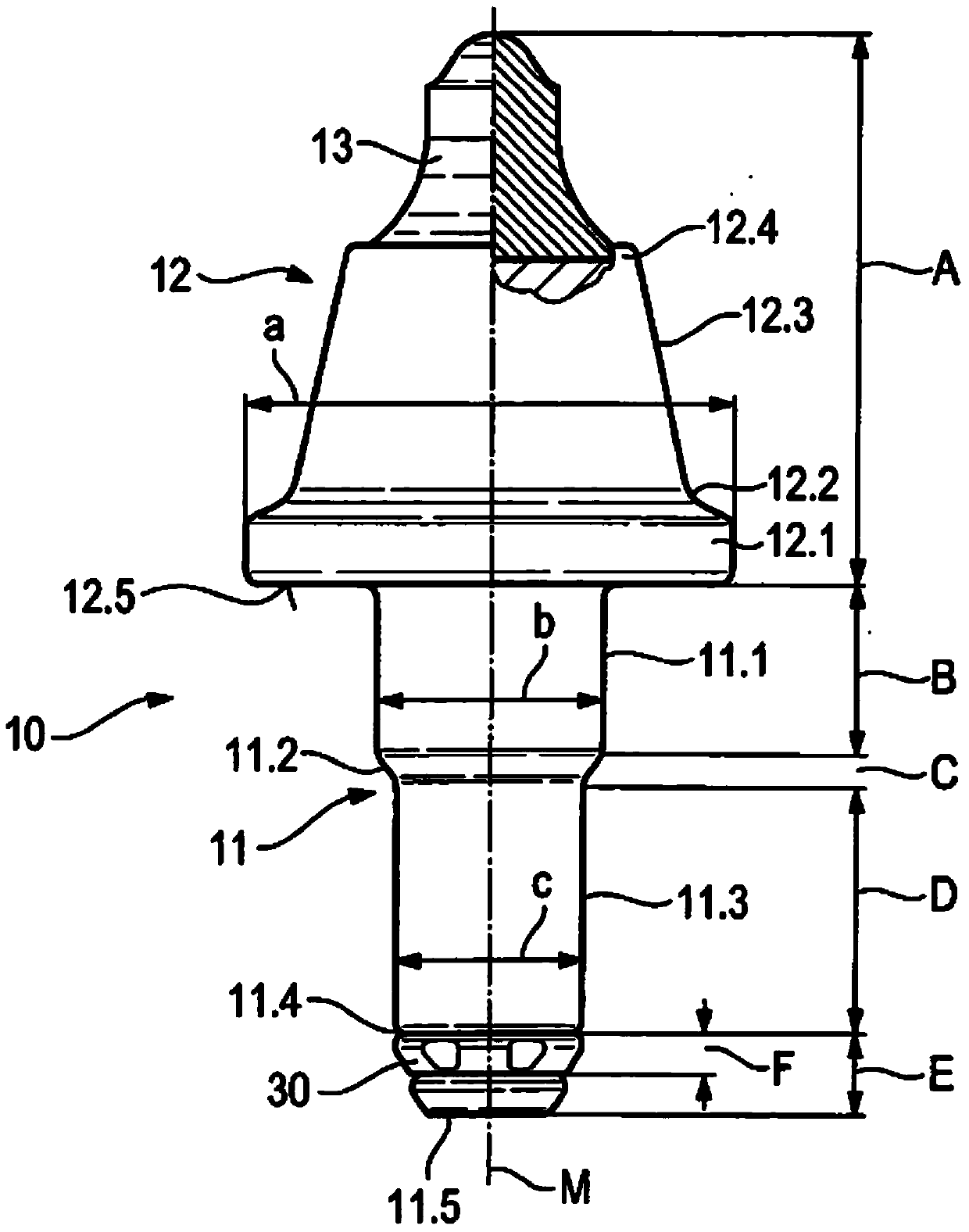

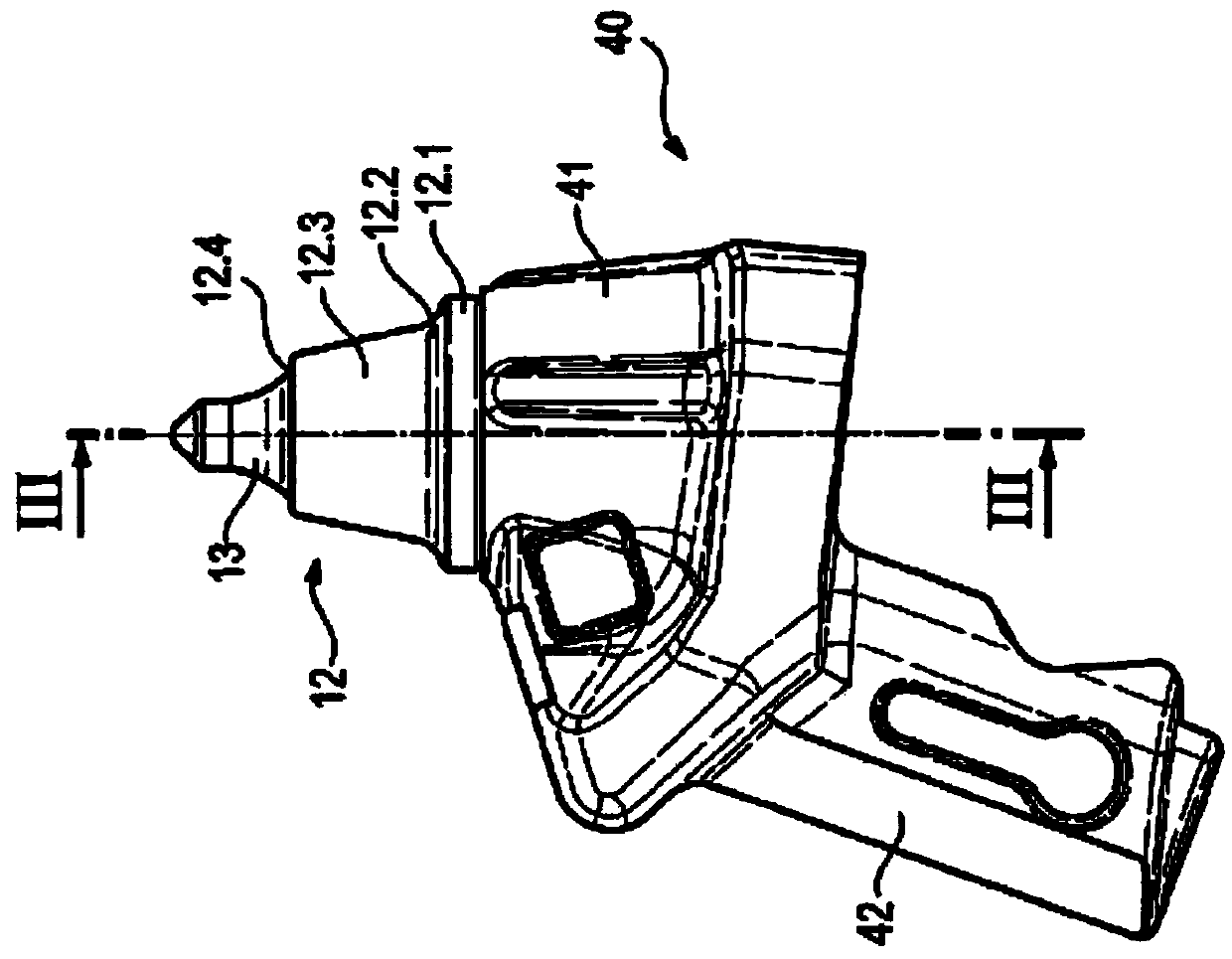

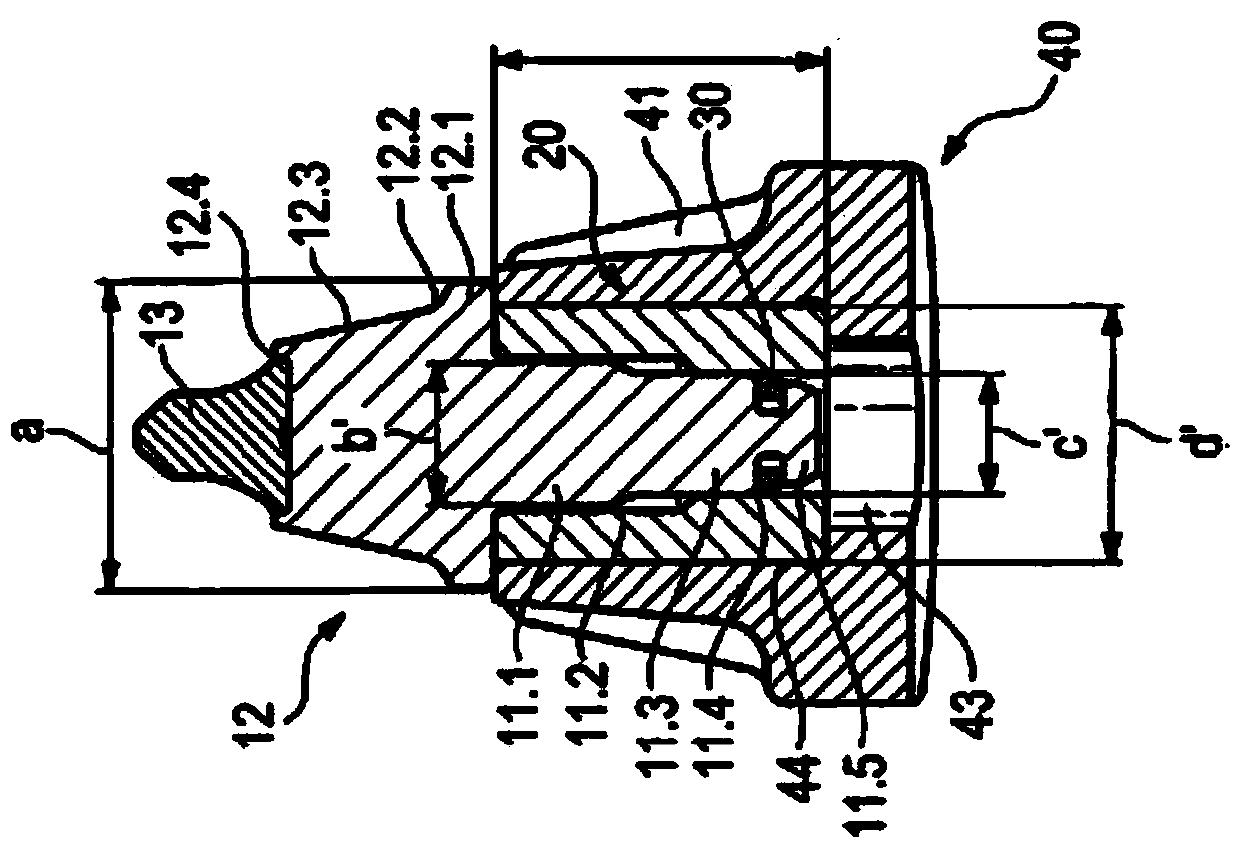

Shank tool

InactiveCN104024575AStable wearStable bootSlitting machinesRoads maintainenceKnife handlesEngineering

The invention relates to a shank tool for a road milling machine or the like, having a tool head (12) and a tool shank (11), wherein the tool shank (11) has a first cylindrical section (11.1) which indirectly or directly adjoins the tool head (12), and wherein the tool shank (11) has a second cylindrical section (11.3) which is remote from the tool head (12) and indirectly or directly adjoins the first cylindrical section (11.1), and wherein the diameter (c) of the second cylindrical section (11.3) differs from the diameter (b) of the first cylindrical section (11.1). With such a shank tool, improved use properties arise in that the first cylindrical section (11.1) has a diameter (b) in the range between 18 mm and 30 mm and an extent (B) in the direction of the centre longitudinal axis of the tool shank of less than 30 mm.

Owner:BETEK +1

Sensor semiconductor device with sensor chip

InactiveUS7365364B2Easy to makeReduce thicknessSolid-state devicesSemiconductor devicesSolder ballDielectric layer

A sensor semiconductor device and a method for fabricating the same are proposed. A sensor chip is mounted on a substrate, and a dielectric layer and a circuit layer are formed on the substrate, wherein the circuit layer is electrically connected to the substrate and the sensor chip. The dielectric layer is formed with an opening for exposing a sensor region of the sensor chip. A light-penetrable lid covers the opening of the dielectric layer, such that light is able to penetrate the light-penetrable lid to reach the sensor region and activate the sensor chip. The sensor chip can be electrically connected to an external device via a plurality of solder balls implanted on a surface of the substrate not for mounting the sensor chip. Therefore, the sensor semiconductor device is fabricated in a cost-effective manner, and circuit cracking and a know good die (KGD) problem are prevented.

Owner:SILICONWARE PRECISION IND CO LTD

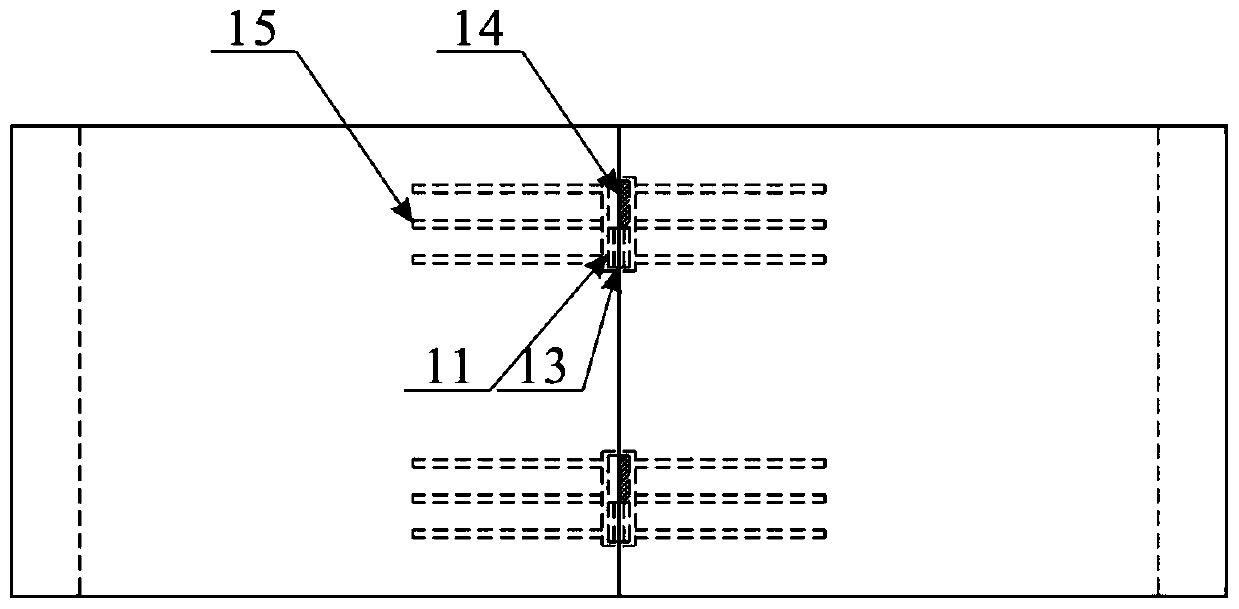

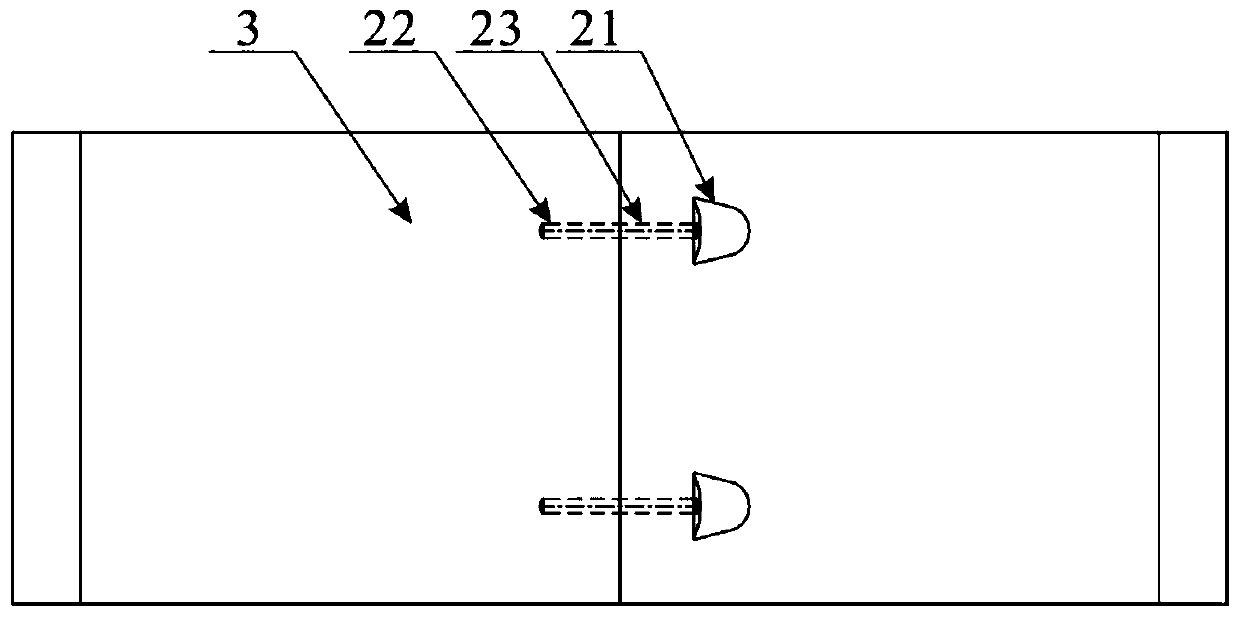

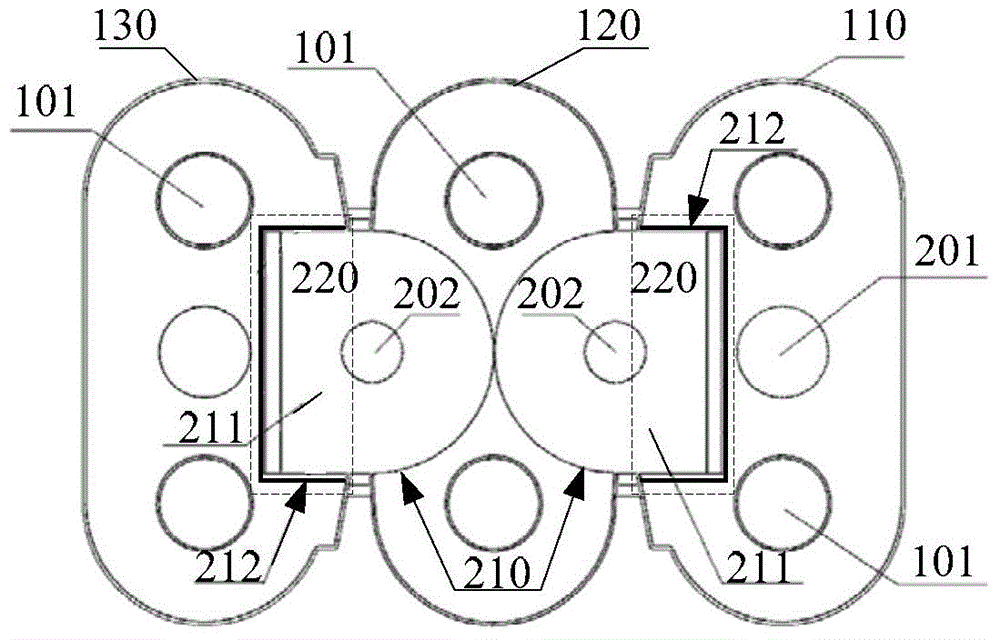

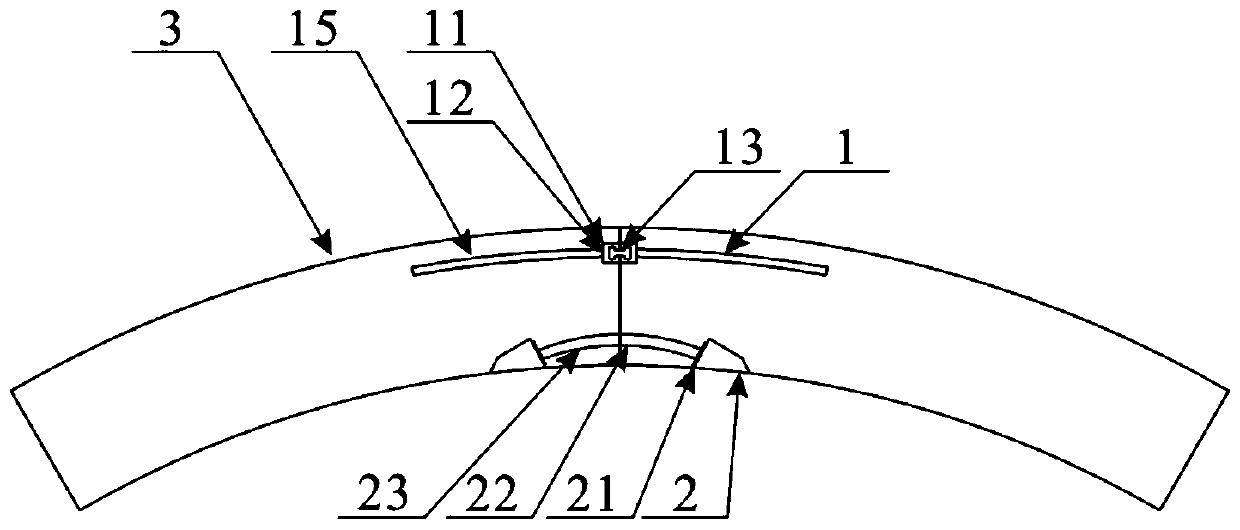

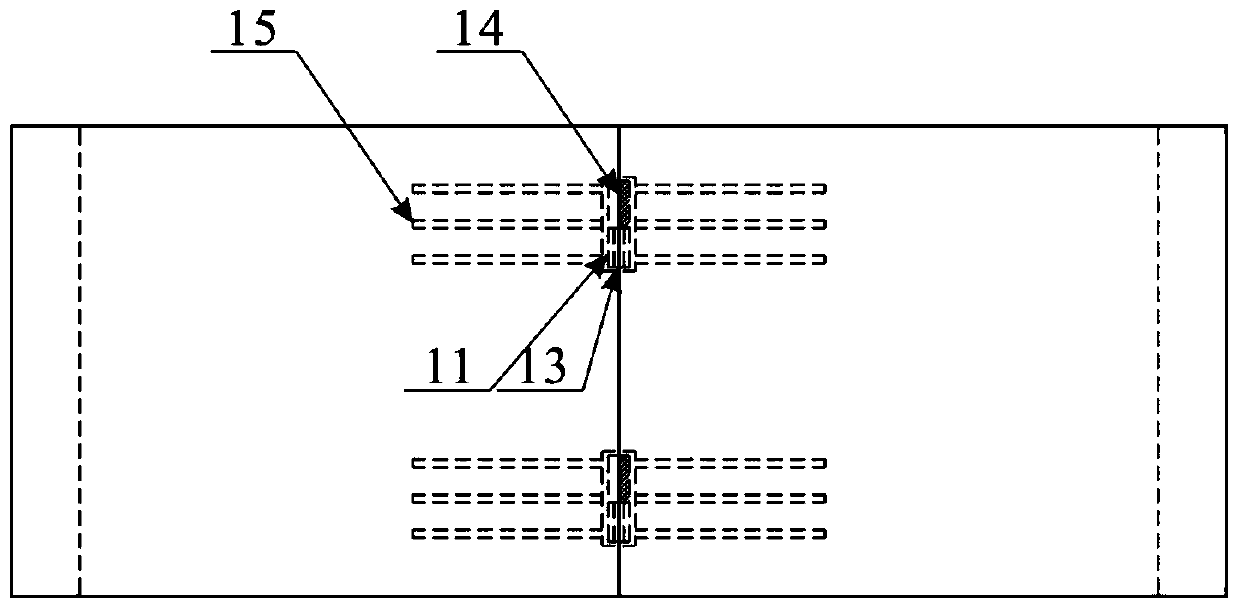

Combined joint for secondary lining reinforcement of mine method construction tunnel and mounting method

InactiveCN111022072AIncrease the areaReduce risk of frackingUnderground chambersTunnel liningStress concentrationArchitectural engineering

The invention discloses a combined joint for secondary lining reinforcement of a mine method construction tunnel and a mounting method. The combined joint comprises an outer arc surface joint and an inner arc surface joint. The outer arc surface joint comprises connecting grooves arranged on the end portions of two opposite secondary lining segments correspondingly. C-shaped members are arranged on one sides of the connecting grooves correspondingly, bolt holes are formed in the bottom surfaces of the C-shaped members, anchor ribs are arranged in the bolt holes in a penetrating mode, and the C-shaped members are connected through H-shaped members. One ends of the H-shaped members abut against supporting members. The mounting method comprises the steps that the connecting grooves, the C-shaped members, an annular joint hand hole and a straight bolt hole are preset in the two secondary lining segments. The combined joint for secondary lining reinforcement of the mine method constructiontunnel and the mounting method can solve the problem that secondary lining reinforcement is insufficient in bending moment resistance in the prior art, the structure is simple, the reliability is high, the stress concentration effect of segment joints can be remarkably weakened, and the concrete fracturing risk of the segment joints is reduced.

Owner:云南功东高速公路建设指挥部

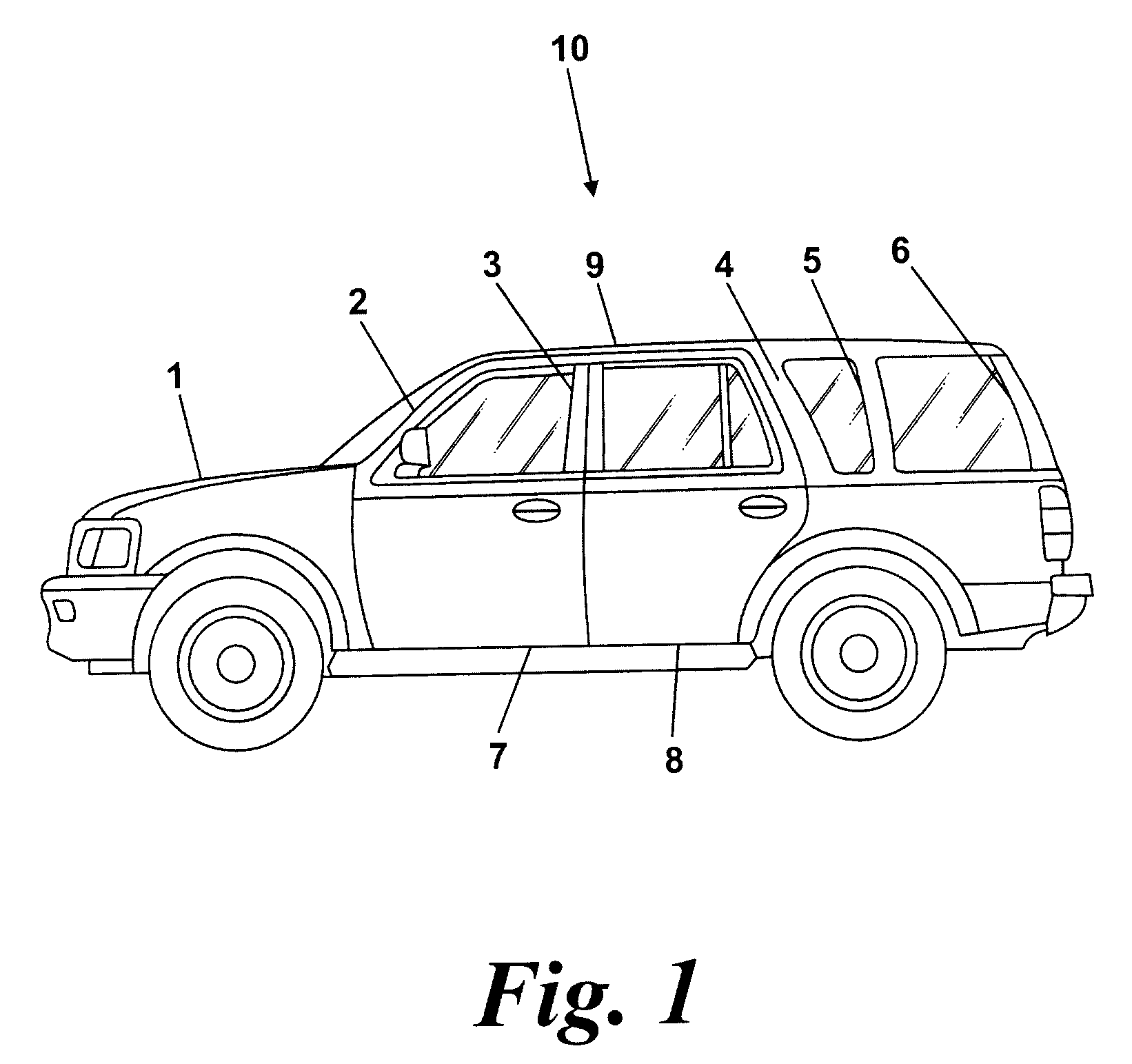

Structural member for a motor vehicle

ActiveUS7762622B2Reduce stress concentration effectsVehicle seatsMetal-working apparatusMobile vehicleMotor vehicle part

A structural member of a motor vehicle, e.g., a “B” pillar, comprises a reinforcing member having an elongate core of ultra high strength steel and a casing of aluminum alloy, the casing having a constant section profile with a closed section cavity. The core is encased within the casing and the core and the casing bonded together by co-drawing the core and the casing through a die. The casing has a pair of spaced flanges which connect the reinforcing member to aluminum alloy pressings to form the structural member. The reinforcing member has considerable yield strength from the use of the ultra high strength steel in the core while the flanges, being of aluminum alloy, are readily joined by self-piercing rivets.

Owner:FORD GLOBAL TECH LLC +1

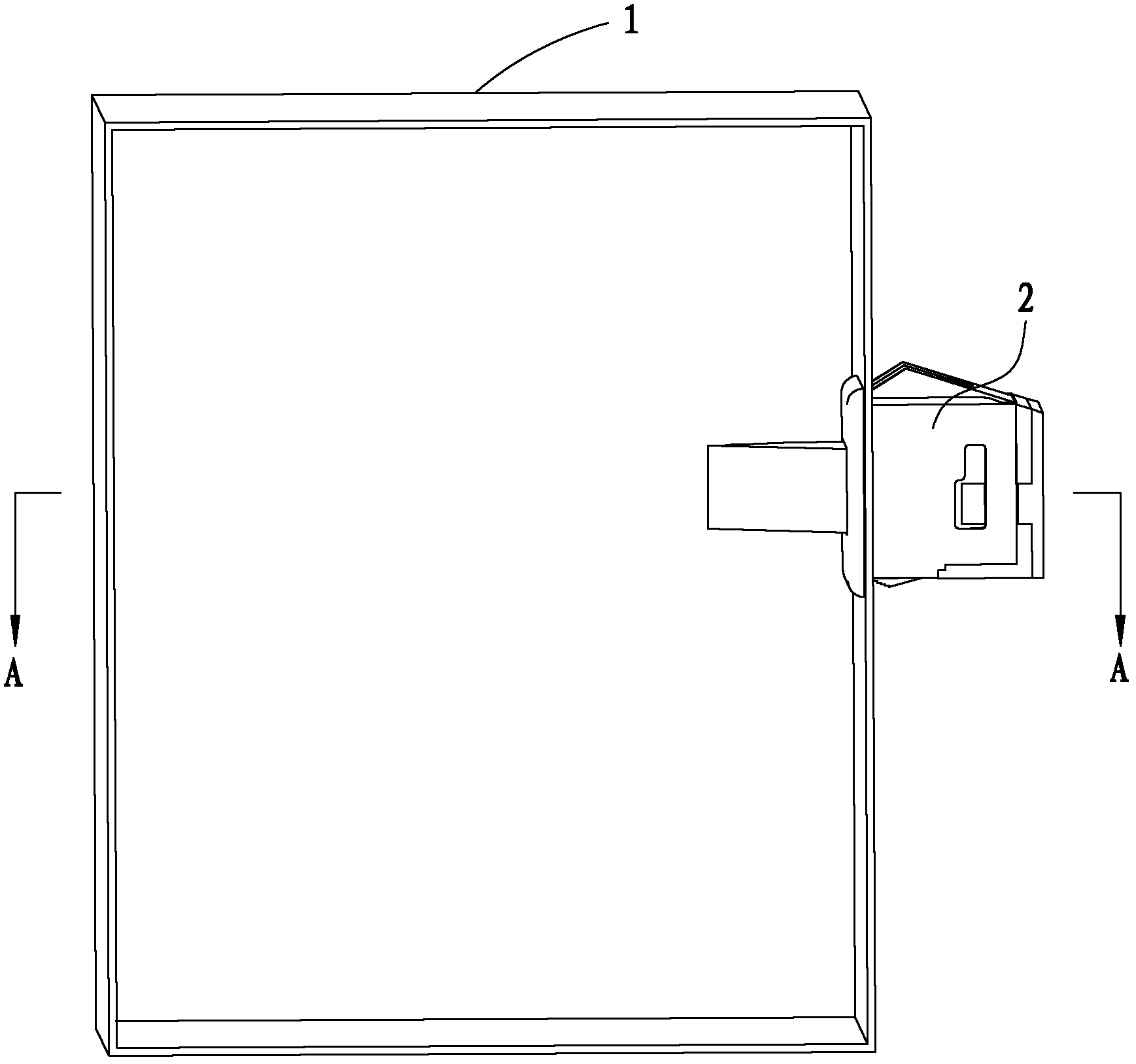

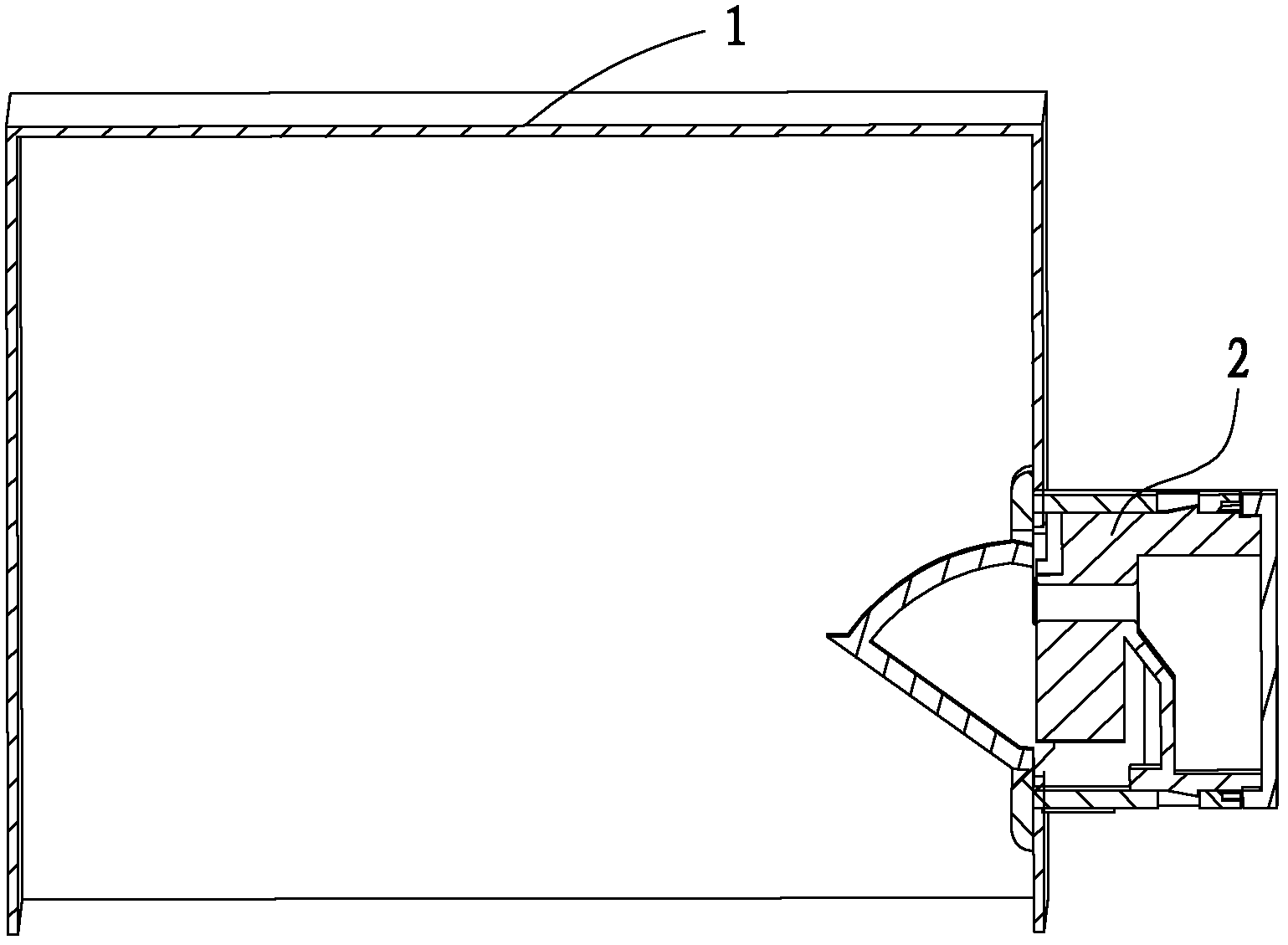

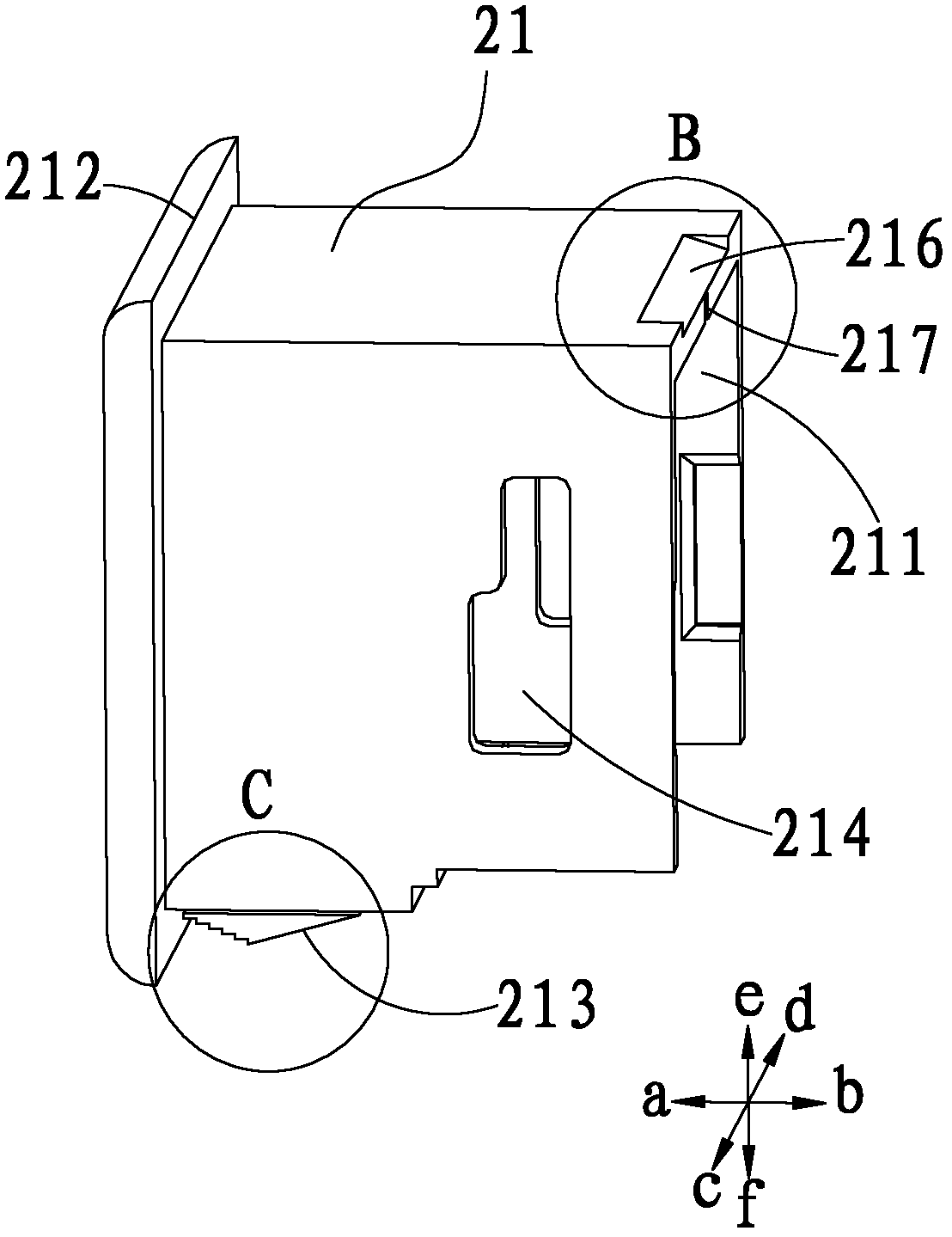

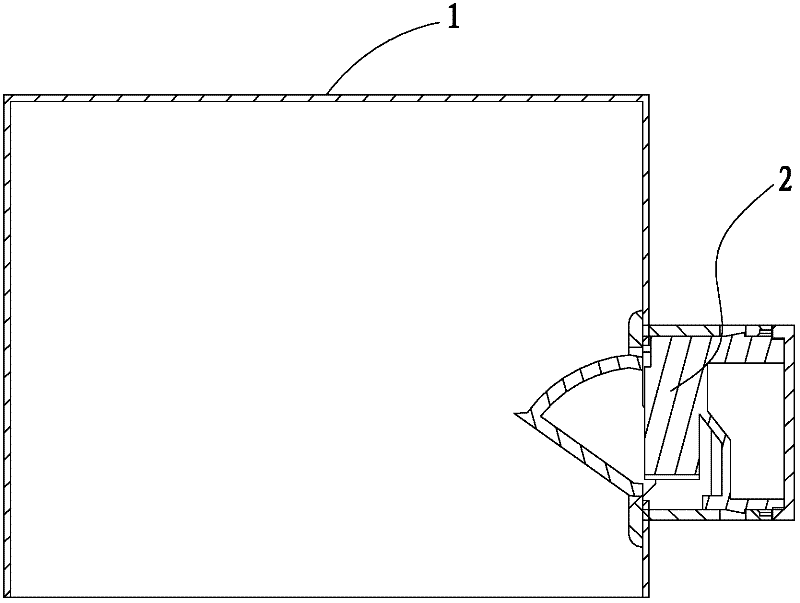

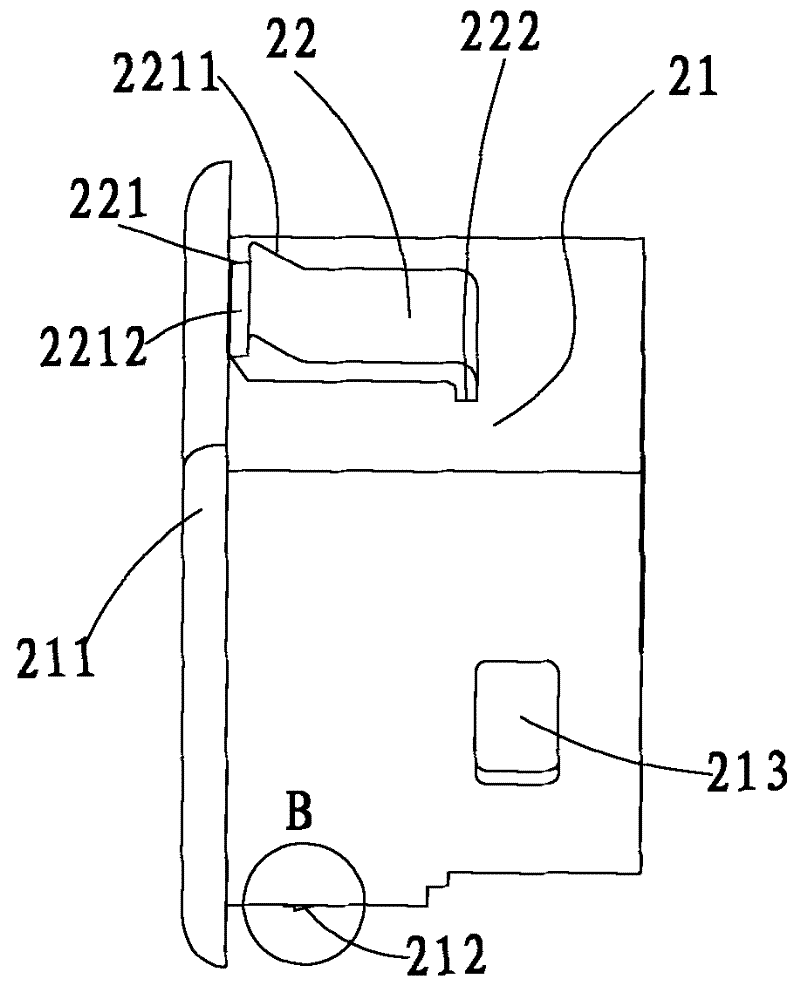

Refrigerator

ActiveCN102313422AReduce stress concentration effectsSimple structureLighting and heating apparatusDomestic refrigeratorsStress concentrationRefrigerator car

The invention discloses a refrigerator, which comprises a refrigerator body. The refrigerator body comprises a refrigerator container and a normally closed lamp switch connected with the refrigerator container; the normally closed lamp switch comprises a shell, a wiring terminal subassembly, a jack catch, a tongue block and a sealing gasket, wherein a preset hole adapting to the shell is formed on the refrigerator container; the shell penetrates through the preset hole; further, a first flange leans against the inner surface of the refrigerator container; a first convex rib further leans against the outer surface of the refrigerator container; and a free end of the jack catch is inserted into the preset hole. According to the refrigerator provided by the embodiment of the invention, the influence of the stress concentration of the jack catch is decreased; the free end of the jack catch is hidden in the preset hole of the refrigerator container; the interference fit of an inelastic part and the preset hole is avoided; the container can be effectively prevented from cracking; the production efficiency is improved; and the production cost is decreased.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

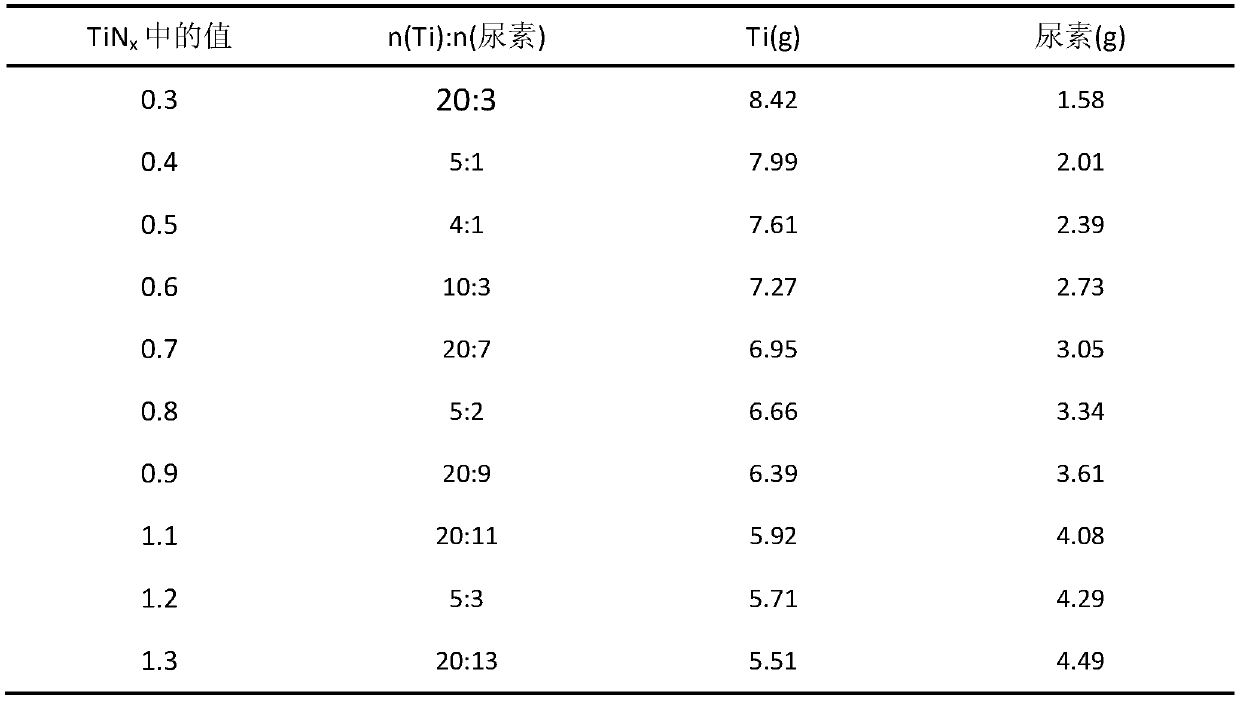

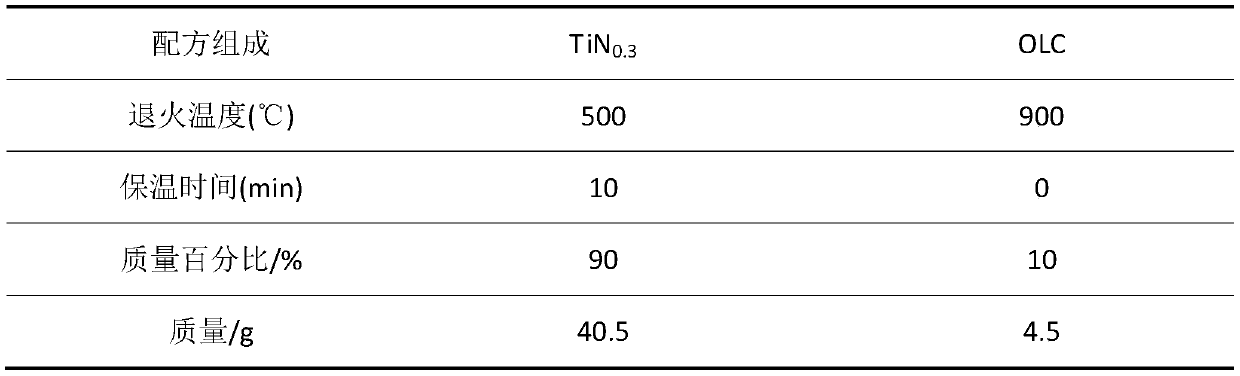

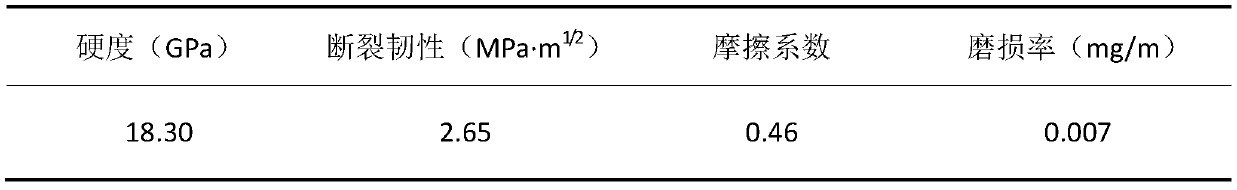

Carbon nano onion lubricating phase Ti (C,N) base self-lubricating composite material and preparing method thereof

ActiveCN110760729AStable structureExcellent intrinsic propertiesFracture toughnessMaterial technology

The invention provides a carbon nano onion lubricating phase Ti (C,N) base self-lubricating composite material and a preparing method thereof, and belongs to the technical field of composite materials. The composite material comprises, by weight percent, 10%-20% of OLC and 80%-90% of TiNx, wherein X in TiCx is larger than or equal to 0.4 and smaller than or equal to 0.9 or is equal to 1.1-1.3. According to the self-lubricating composite material, TiNx and OLC powder which are prepared through a mechanical alloying method and are in a non-stoichiometric ratio are mixed, hot pressing sintering is adopted for preparing the OLC lubricating phase Ti (C,N) base self-lubricating composite material, by utilization of the vacancy in TiNx, the sintering temperature can be reduced, and sintering is promoted. On the basis, the OLC lubricating phase Ti (C,N) base self-lubricating composite material is formed through composite sintering with OLC, the defect of lubricating failures of a traditional lubricating material in the extreme condition is overcome, and meanwhile hardness and fracture toughness of the OLC lubricating phase Ti (C,N) base self-lubricating composite material are improved.

Owner:YANSHAN UNIV

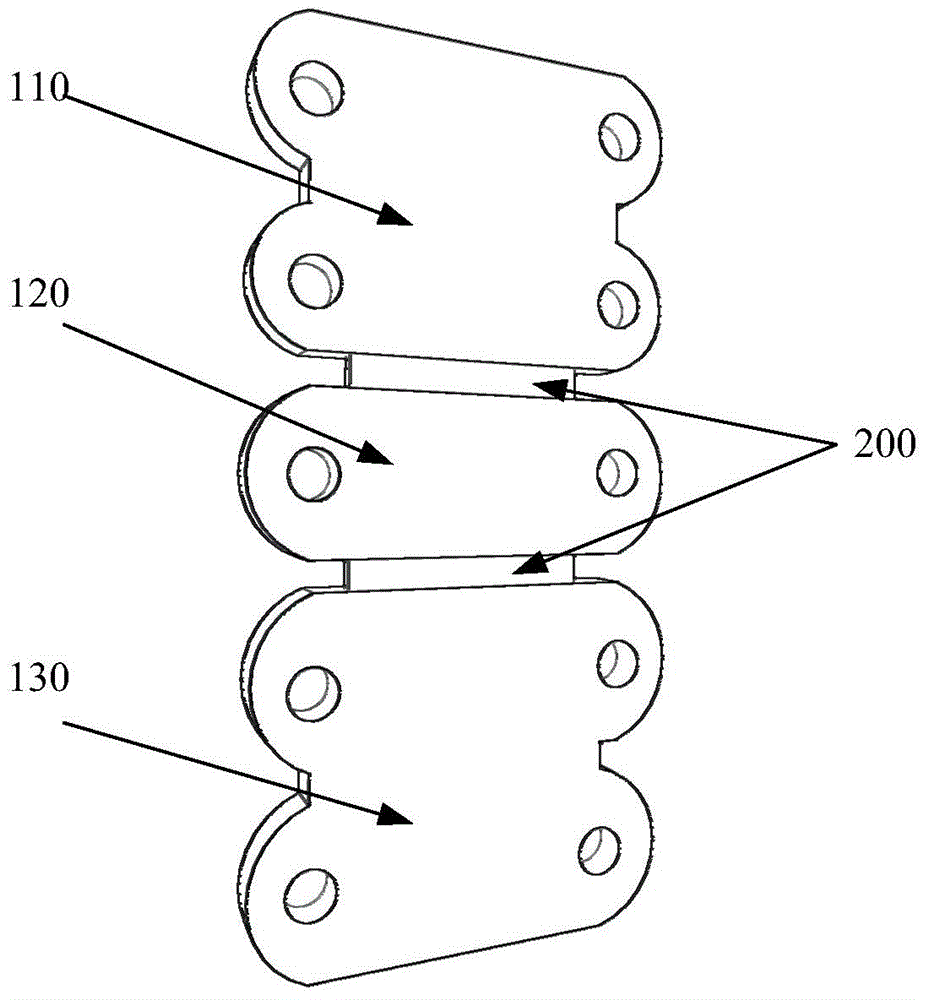

Dynamic cervical vertebra fixing steel plate

ActiveCN104546097AReserved activityReduce stress concentration effectsInternal osteosythesisBone platesStress concentrationMetallurgy

The invention discloses a dynamic cervical vertebra fixing steel plate, and relates to a device for treating bones or joints, in particular to a dynamic fixing steel plate used for cervical vertebra internal fixation. The dynamic cervical vertebra fixing steel plate comprises an upper locking steel plate, a middle locking steel plate and a lower locking steel plate; the two sides of the middle locking steel plate are each connected with a dynamic connecting plate to form two pendulum joint mechanisms; sliding grooves are formed in the inner side of the upper locking steel plate and the inner side of the lower locking steel plate; the dynamic connecting plates are in sliding fit with the sliding grooves to form two straight line sliding groove mechanisms; and the middle locking steel plate is dynamically connected with the upper locking steel plate and the lower locking steel plate through the pendulum joint mechanisms and the straight line sliding groove mechanisms on the two sides to form the stretchable and laterally-bendable dynamic cervical vertebra fixing steel plate. The problem that in an existing cervical vertebra steel plate, part or all vertebral body motion functions are lost after an operation is performed is solved; the activity of a target vertebral body section can be retained to the maximum degree; the stress concentration effect of adjacent vertebral body sections can be effectively reduced; and the long-term operative complications of the adjacent vertebral body sections is accordingly reduced.

Owner:SHANGHAI TONGJI HOSPITAL

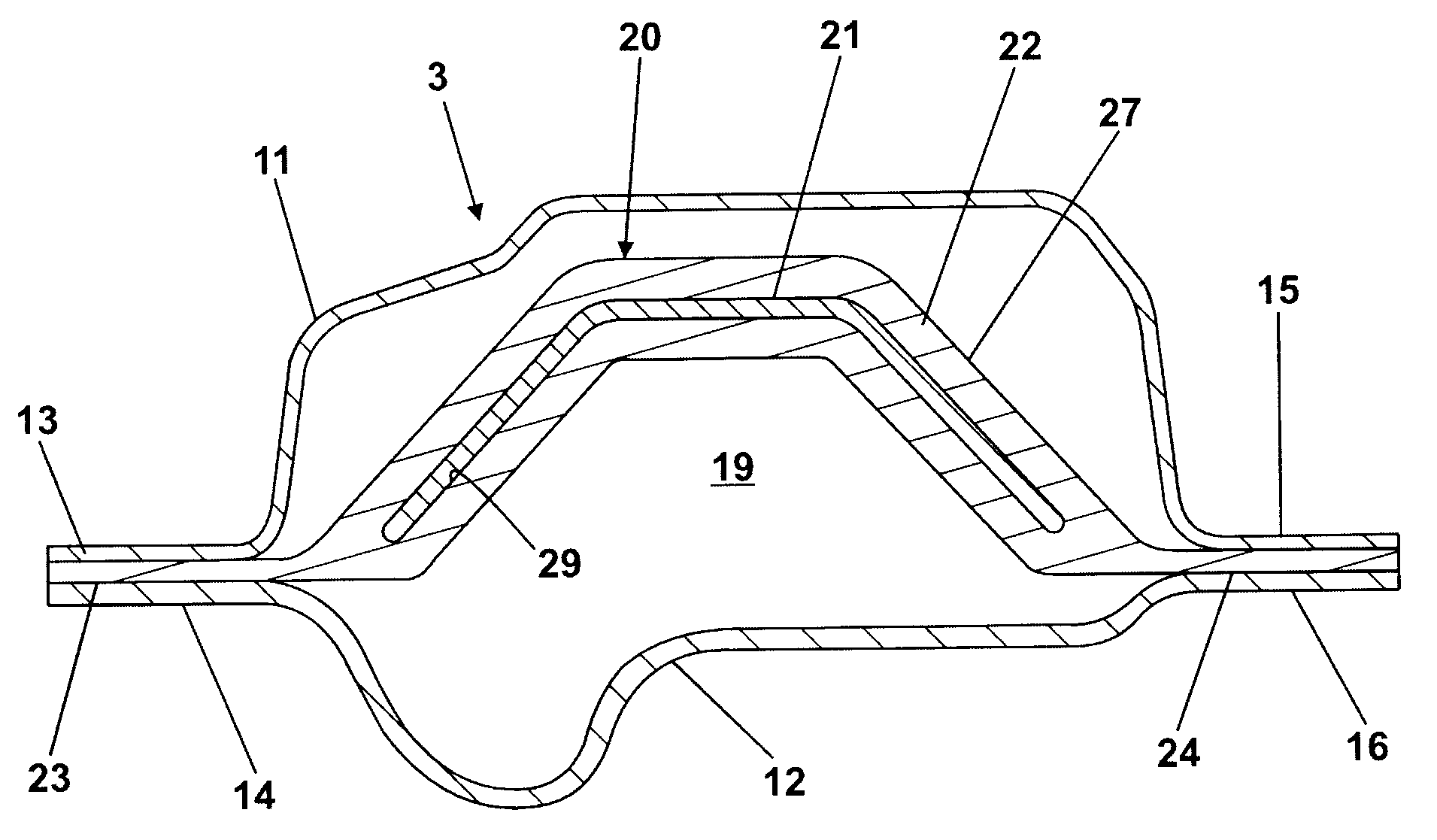

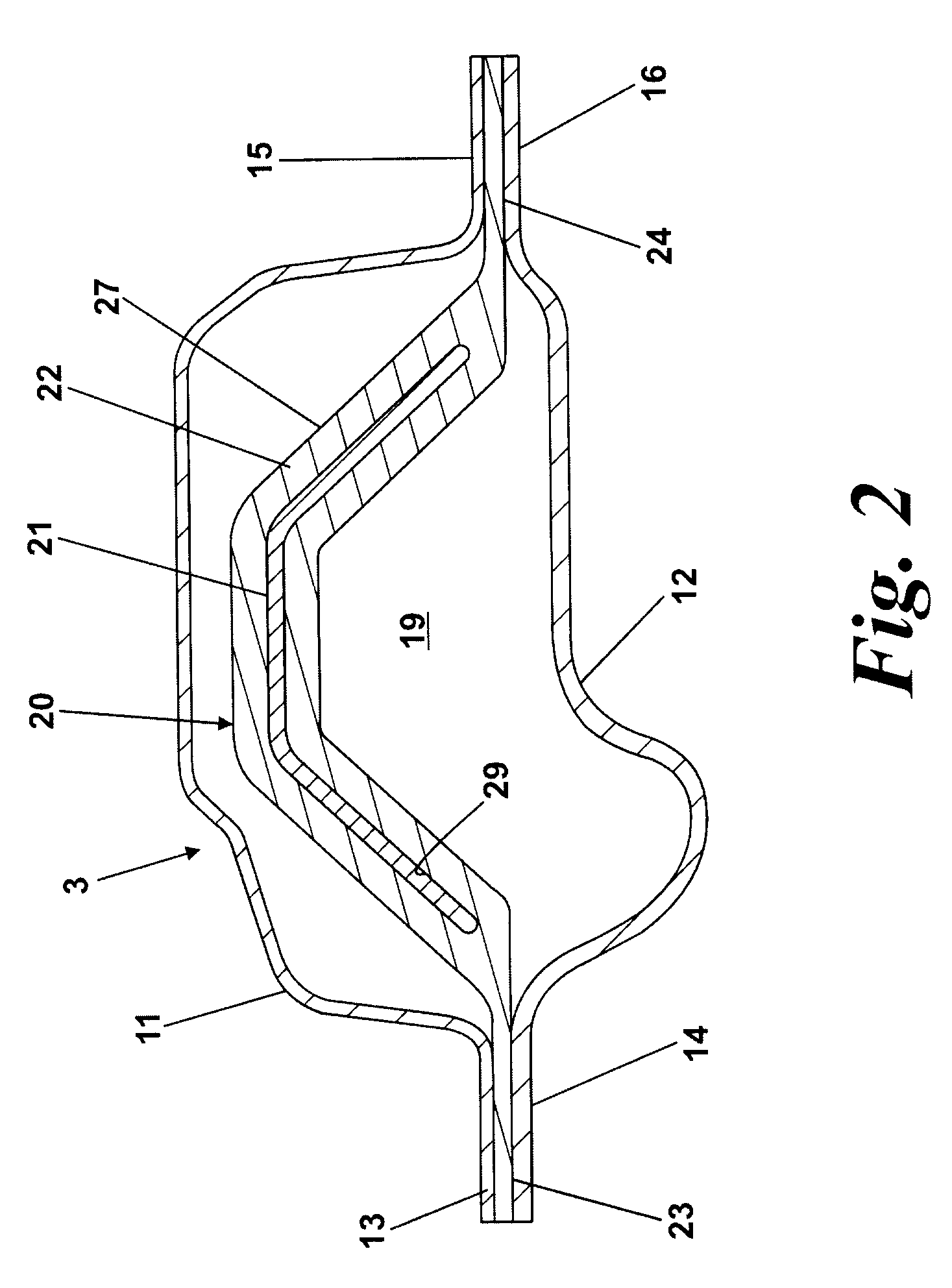

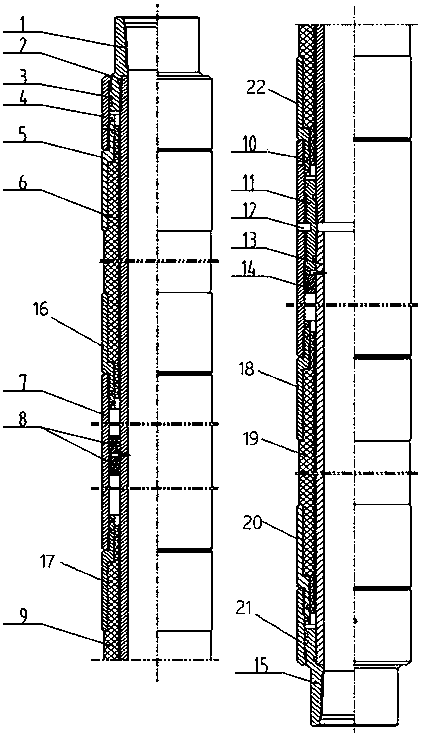

Double-medium multi-stage expansion packer and clamping and plugging method

PendingCN109681146AImprove tear resistanceReduce stress concentration effectsFluid removalSealing/packingStress concentrationPressure transmission

The invention discloses a double-medium multi-stage expansion packer and a clamping and plugging method. The packer comprises a central pipe and a rubber sleeves which sleeve the outer wall of the central pipe, the rubber sleeves comprise an upper shoulder short rubber sleeve, a middle long rubber sleeve and a lower shoulder short rubber sleeve, the upper end of the middle long rubber sleeve is connected to the upper shoulder part short rubber sleeve through an upper double-medium indirect pressure transmission mechanism, the lower end of the middle long rubber sleeve is connected to the lowershoulder part short rubber sleeve through a lower pressure transmission mechanism, and the upper end of the upper shoulder part short rubber sleeve and the lower end of the lower shoulder part shortrubber sleeve are connected to corresponding longitudinal self-adaptive adjusting mechanisms. The packer and the method have the advantages that the multiple rubber sleeves are flexibly combined so asto meet the longer-section clamping and plugging field requirement, so that the problem of sticking caused by a single long-section rubber sleeve can be solved; the rubber sleeves with different lengths and performances are combined so as to meet the requirements for different clamping and plugging strength; by means of the upper shoulder part longitudinal self-adaptive adjusting mechanism and the lower shoulder part longitudinal self-adaptive adjusting mechanism, the shoulder part stress concentration effect is reduced, and reasonable setting pressure is guaranteed; and by means of the double-medium indirect pressure transmission mechanisms, the problem that a whole pipe column loses efficacy due to the fact that a single rubber sleeve is broken can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

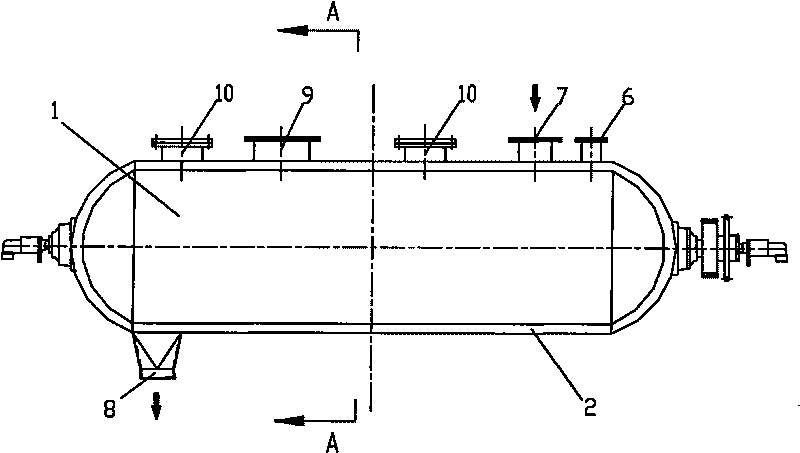

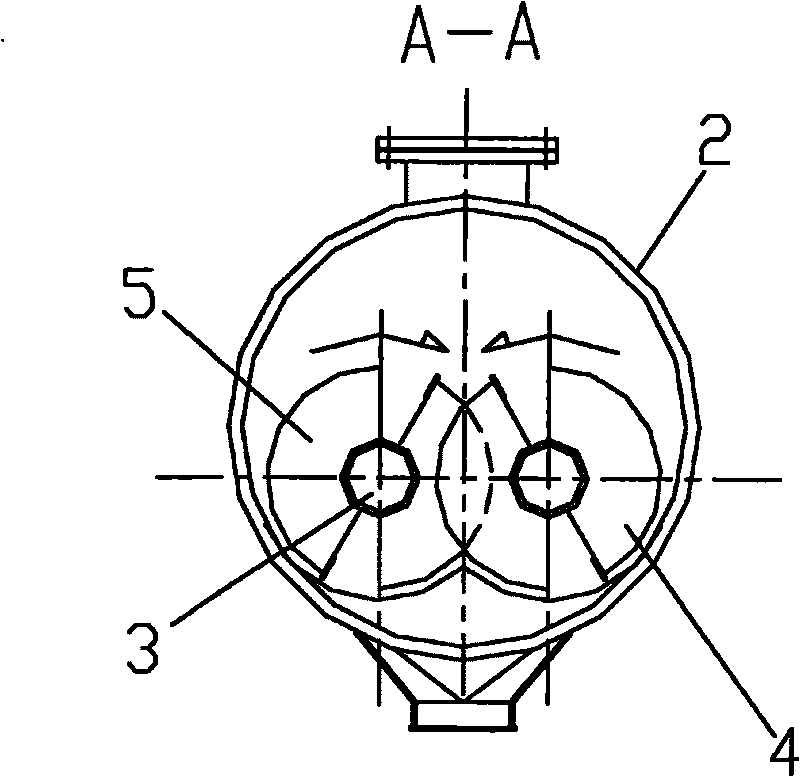

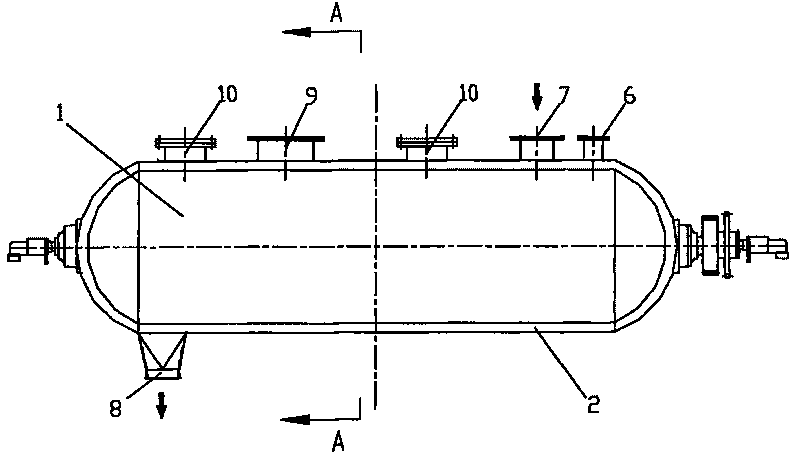

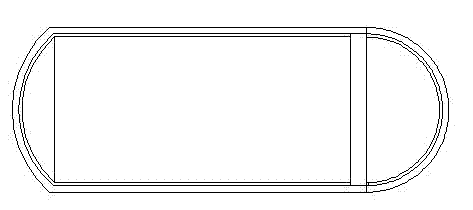

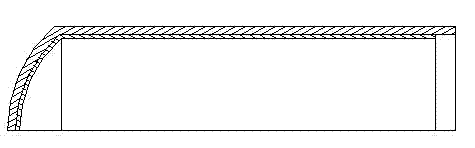

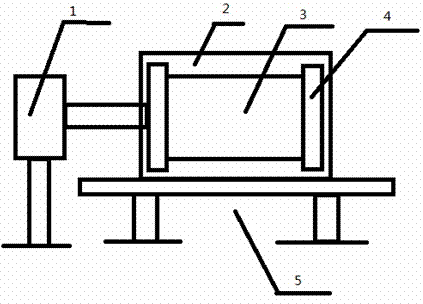

Pressurized blade dryer

ActiveCN101706194ALess investmentImprove heat transfer efficiencyDrying solid materialsDrying machines with non-progressive movementsEngineeringHeat transfer

The invention provides a pressurized blade dryer. The dryer mainly comprises a blade device, a cylinder with a sleeve, a drive device and a heat source, wherein the cylinder is provided with a charging hole and a discharging hole, and the dryer is characterized in that the charging hole is provided with a steam inlet; the section of the cylinder is circle and the outside of the cylinder is covered with the circular sleeve, and the two ends of the cylinder are semicircular shells. The dryer of the invention changes the unidirectional conduction type indirect heat transfer working condition of the common blade dryer, and the pressurized steam is introduced when the material is placed in the dryer so as to realize the pressurized working condition by mixing the material with the pressurized steam in the dryer. The whole device has both effects of direct heat transfer and indirect heat transfer so as to greatly increase the efficiency of heat transfer and have ideal effect of ensuring the product yield and the quality. Meanwhile, the dryer adopts the design of circular section and semicircular shells so as to ensure that the device can run safely and steadily; in addition, the structure of the dryer is simple, the dryer is easy to design and manufacture, the investments of equipment and energy can be saved, and the production cost is reduced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

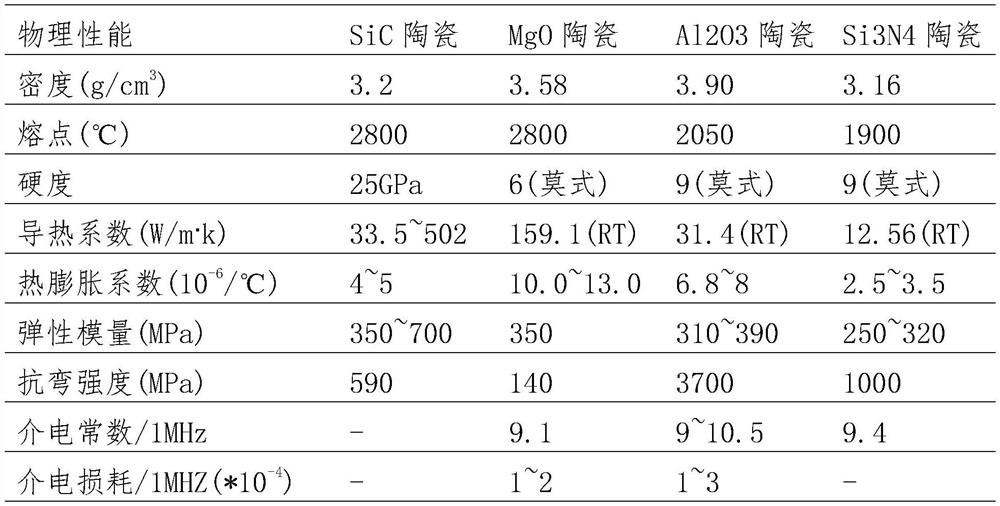

Silicon carbide ceramic sealing ring and preparation method thereof

PendingCN112266250AImprove mechanical propertiesIncrease the probability of contactEngine sealsCarbide siliconWater reducer

The invention relates to a preparation method of a silicon carbide ceramic sealing ring, which is characterized by at least comprising one or more of the following steps of by using silicon carbide asa main raw material, introducing one or more of a first sintering aid, a second sintering aid, a water reducing agent and other aids according to a preset mass ratio, carrying out pulverization mixing, and granulating and sintering the premixed slurry obtained after mixingto obtain the silicon carbide ceramic sealing ring. The premixed slurry comprises first premixed slurry and second premixed slurry which are obtained in the mode that silicon carbide and a second sintering aid are powdered and mixed with a first sintering aid and / or the water reducing agent which are / is added at least twicerespectively.

Owner:HENAN ARYAN SPEICAL CERAMICS

Bent bolt combination joint for secondary lining of mining method construction tunnel and reinforcing method

InactiveCN110952994AIncrease the areaReduce the waterproof effectUnderground chambersTunnel liningStress concentrationArchitectural engineering

The invention discloses a bent bolt combination joint for a secondary lining of a mining method construction tunnel and a reinforcing method. The combination joint comprises an outer arc surface jointand an inner arc surface joint, wherein the outer arc surface joint comprises connecting grooves which are correspondingly formed in the end parts of two opposite secondary lining segments, one sideof each connecting groove is provided with a C-shaped component, a bolt hole is formed in the bottom surface of each C-shaped component, an anchor bar is arranged in each bolt hole in a penetrating manner, and the C-shaped components are connected through H-shaped components; one end of each H-shaped component is abutted against a supporting component; the inner arc surface joint comprises two annular joint hand holes which are symmetrically formed relative to the end parts of the secondary lining segments; and the reinforcing method comprises the step of presetting the connecting grooves, theC-shaped components, the annular joint hand holes and bent bolt holes in the two secondary lining segments. According to the bent bolt combination joint and the reinforcing method, the problems thatthe rigidity of the secondary lining is insufficient and the joint is easy to fracture in the prior art can be solved, the structure is simple, the reliability is high, the stress concentration effectof the segment joint can be remarkably weakened, and the concrete fracturing risk of the segment joint is reduced.

Owner:云南功东高速公路建设指挥部

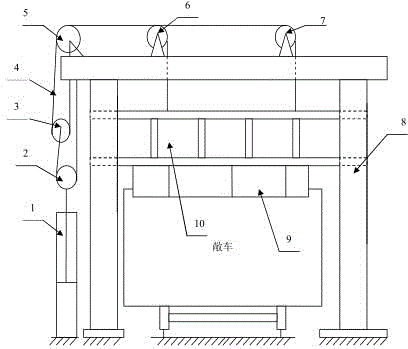

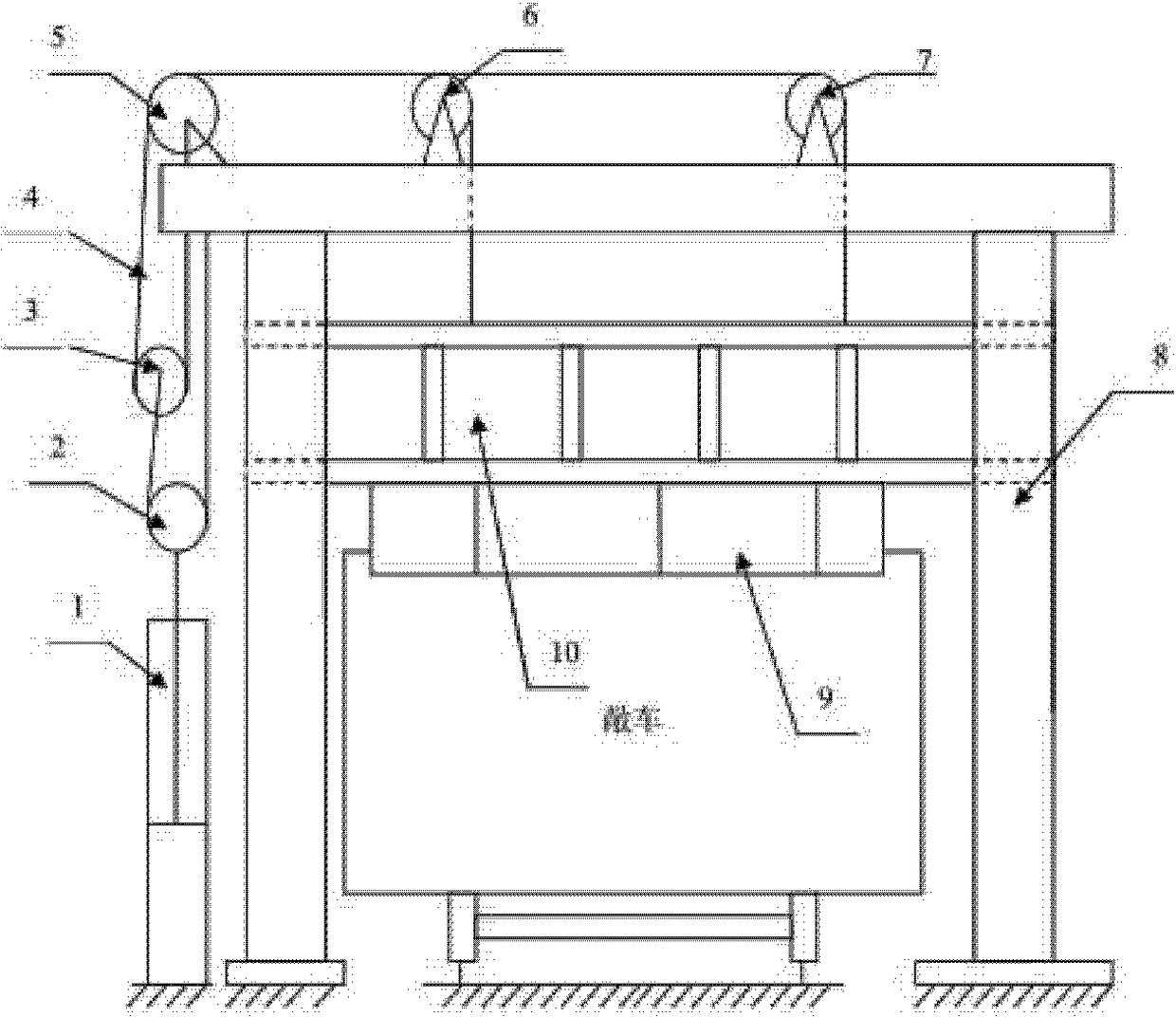

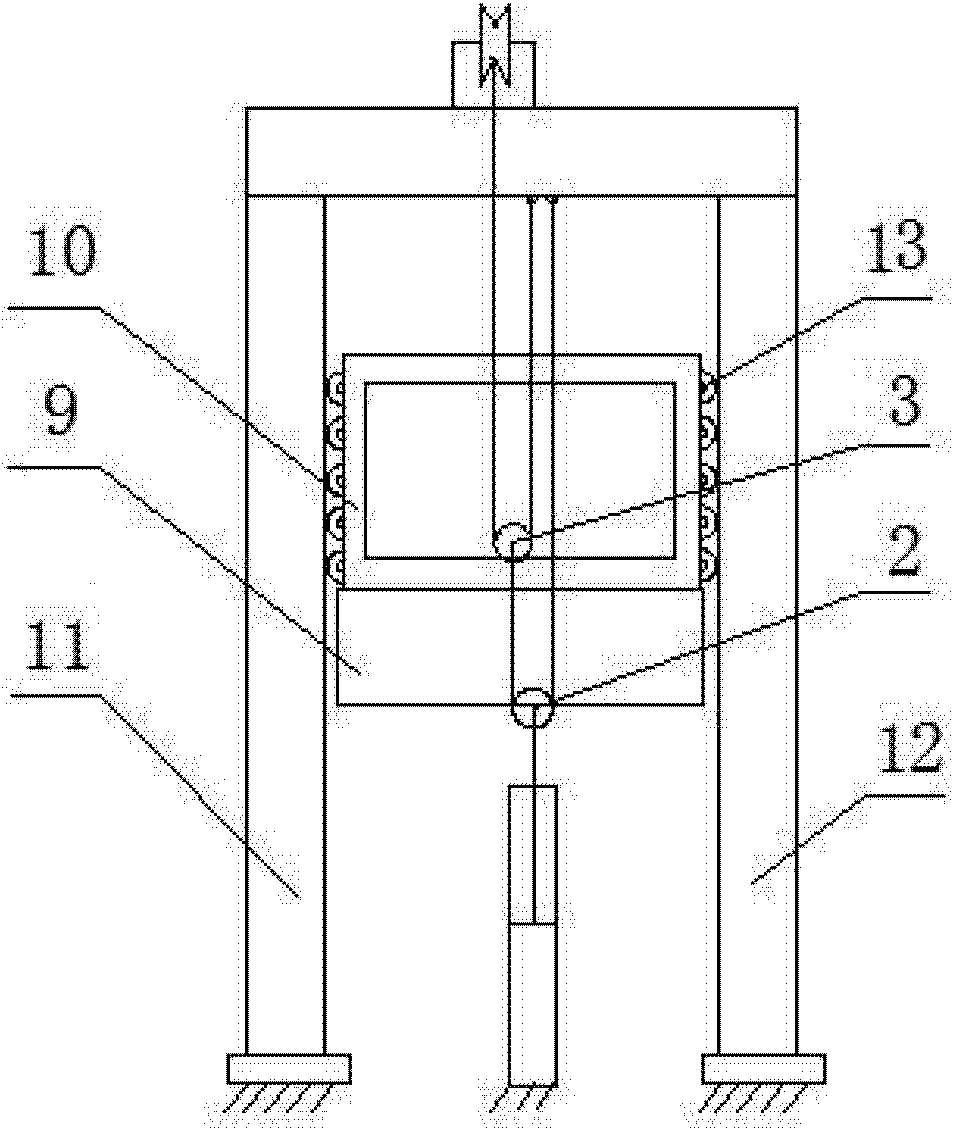

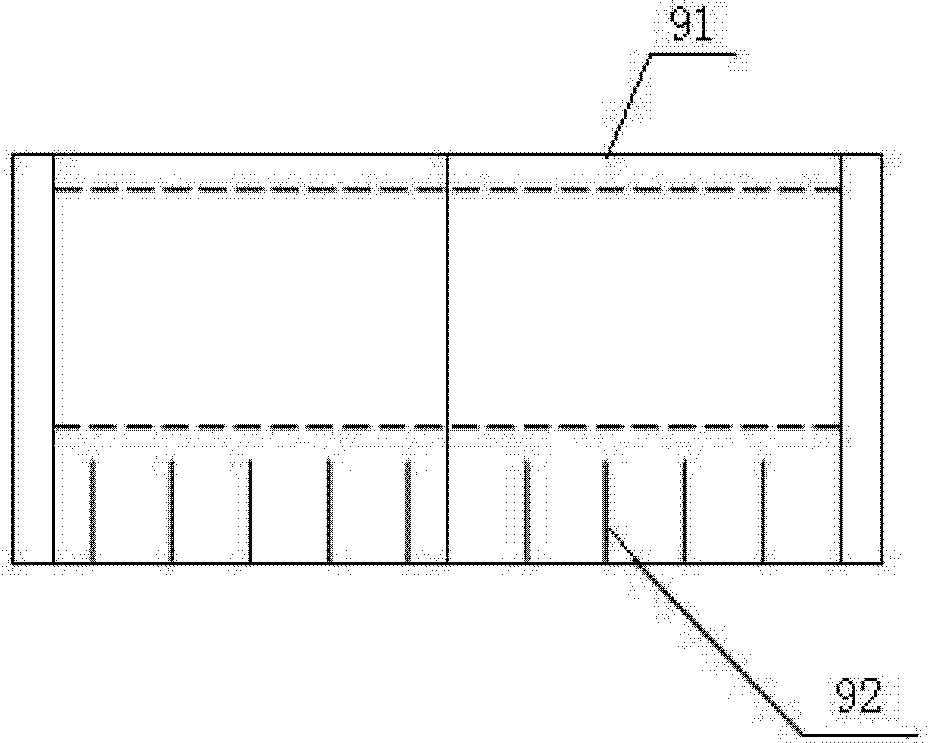

Coal leveling machine

InactiveCN104085708AImprove stabilityMove up and down freelyLoading/unloadingEngineeringUltimate tensile strength

The invention relates to a coal railway transportation loading auxiliary device, in particular to a coal leveling machine. The coal leveling machine comprises a gantry and a coal scraping plate assembly and further comprises a lifting frame. The left end and the right end of the lifting frame are clamped between a front frame and a rear frame of the gantry, and the side faces, opposite to the gantry, of the left end and the right end of the lifting frame are provided with rolling rollers. The coal scraping plate assembly is fixed to the lower end of the lifting frame, and the upper end of the lifting frame is connected with a lifting device through a steel wire rope. The coal leveling machine is simple in structure and low in using and maintaining cost, by means of the coal leveling machine, manual coal leveling intensity can be lowered, human cost is saved, coal leveling time is shortened, coal leveling efficiency is improved, on-schedule dispatching of various coal transportation vehicles is ensured, and safe production is achieved.

Owner:KAILUAN ENERGY CHEM

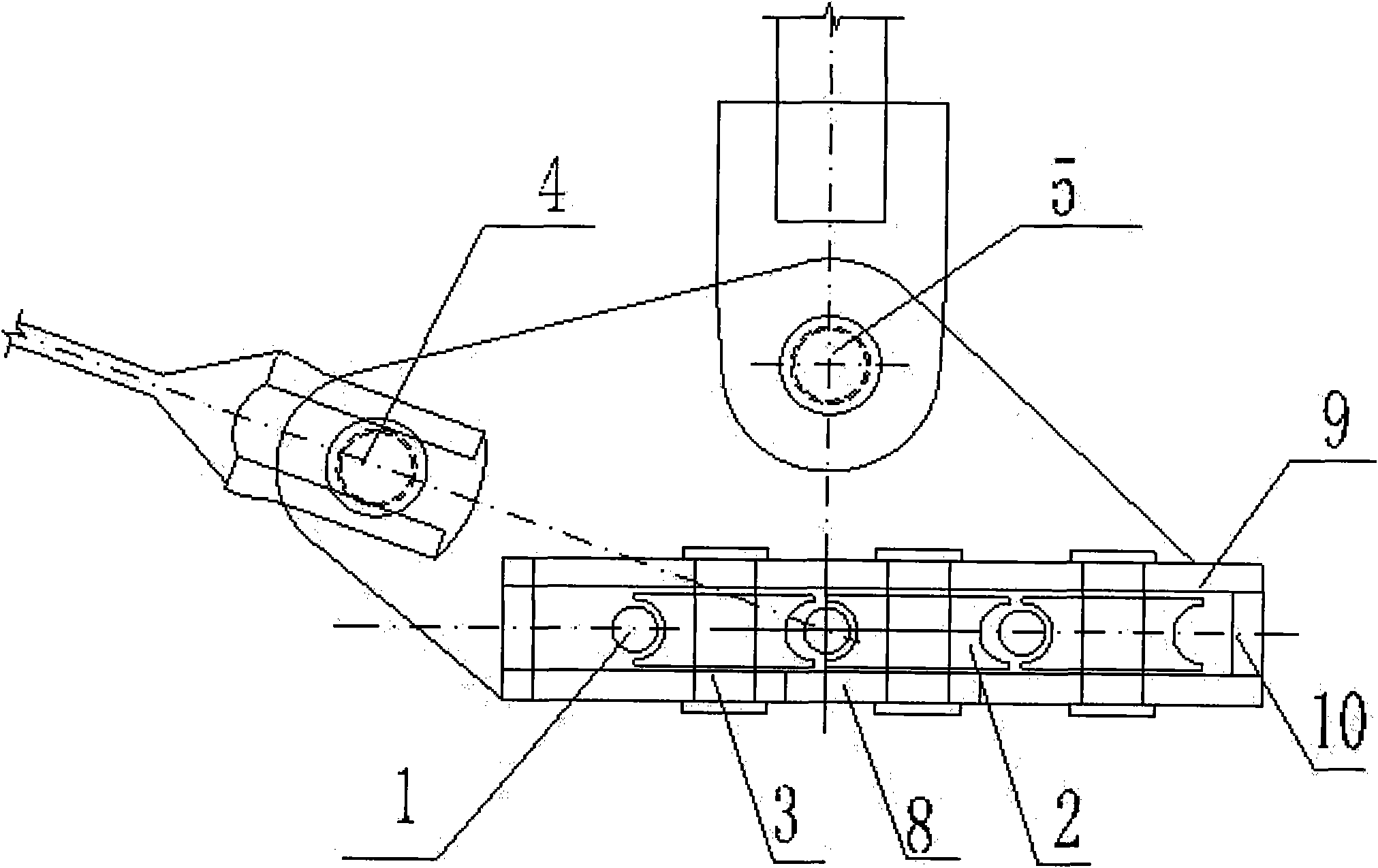

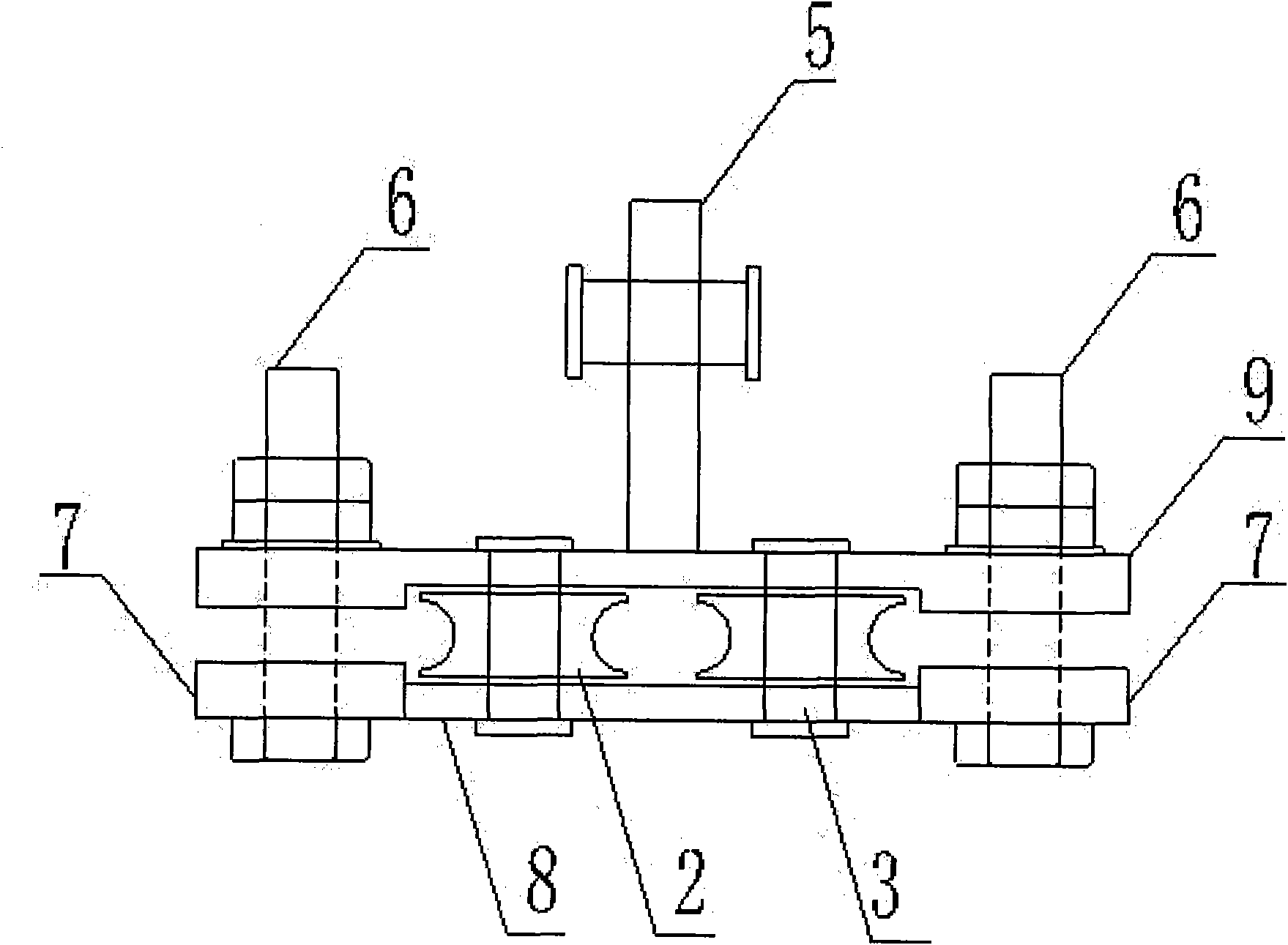

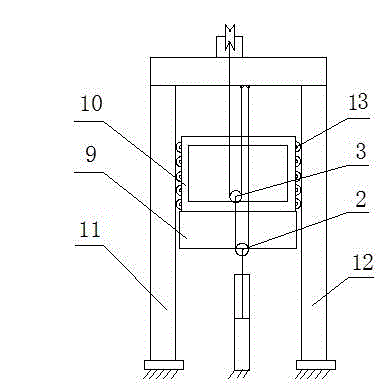

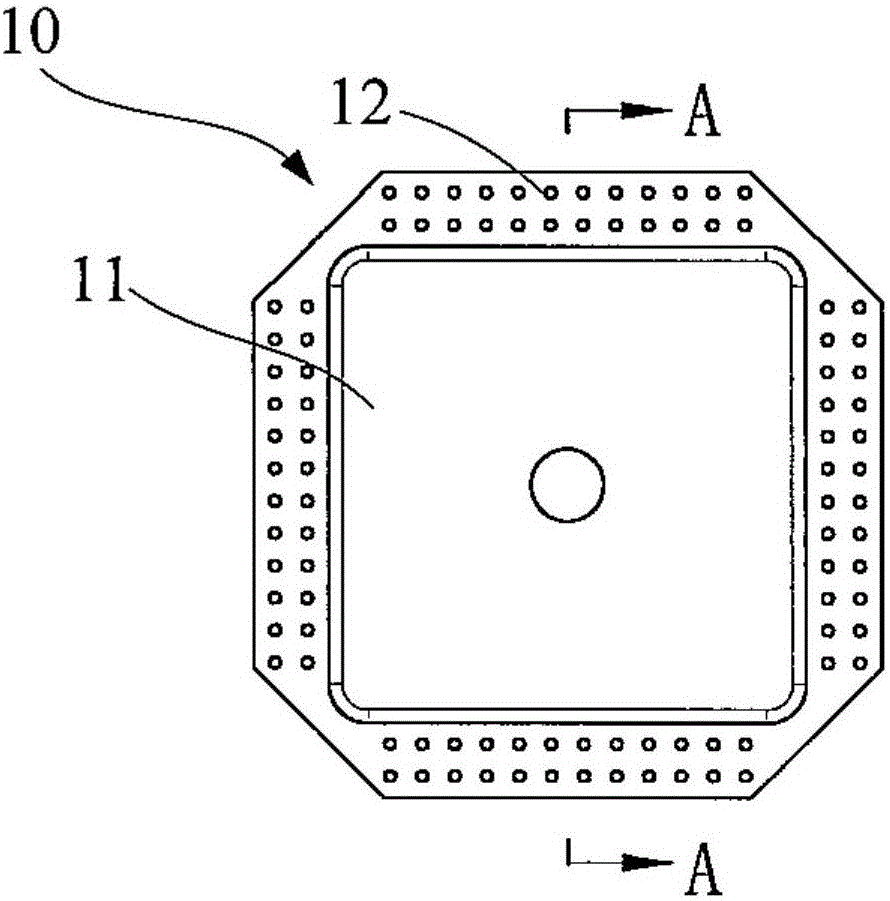

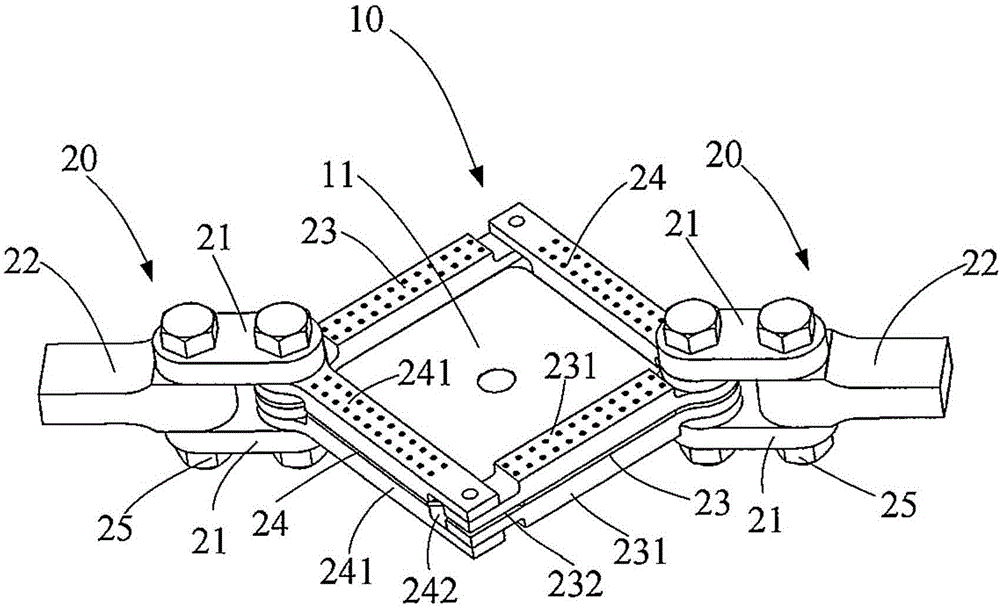

Pure shear fatigue test device for metal web plate

ActiveCN106442167AReduce stress concentration effectsAvoid destructionMaterial strength using steady shearing forcesEngineeringPure shear

The invention provides a pure shear fatigue test device for a metal web plate, comprising a square metal web plate provided with four chamfer parts and a clamp assebly, wherein the metal web plate comprises a central region and a peripheral region, and the thickness of the peripheral region is greater than the thickness of the central region; and the clamp assembly comprises two clamps for clamping the metal web plate, and each clamp comprises two draw plates arranged mutually in parallel along the horizontal direction, a loading single ear arranged between the two draw plates and fixed to one side of the two draw plates, and a first clamp plate and a second clamp plate arranged between the two draw plates and fixed to the other side of the two draw plates. The device can reduce the damaged probability of a non-fatigue examined detailed part, and completely meets the design requirements of a test for allowable values of a fatigue sheared plate.

Owner:COMAC +1

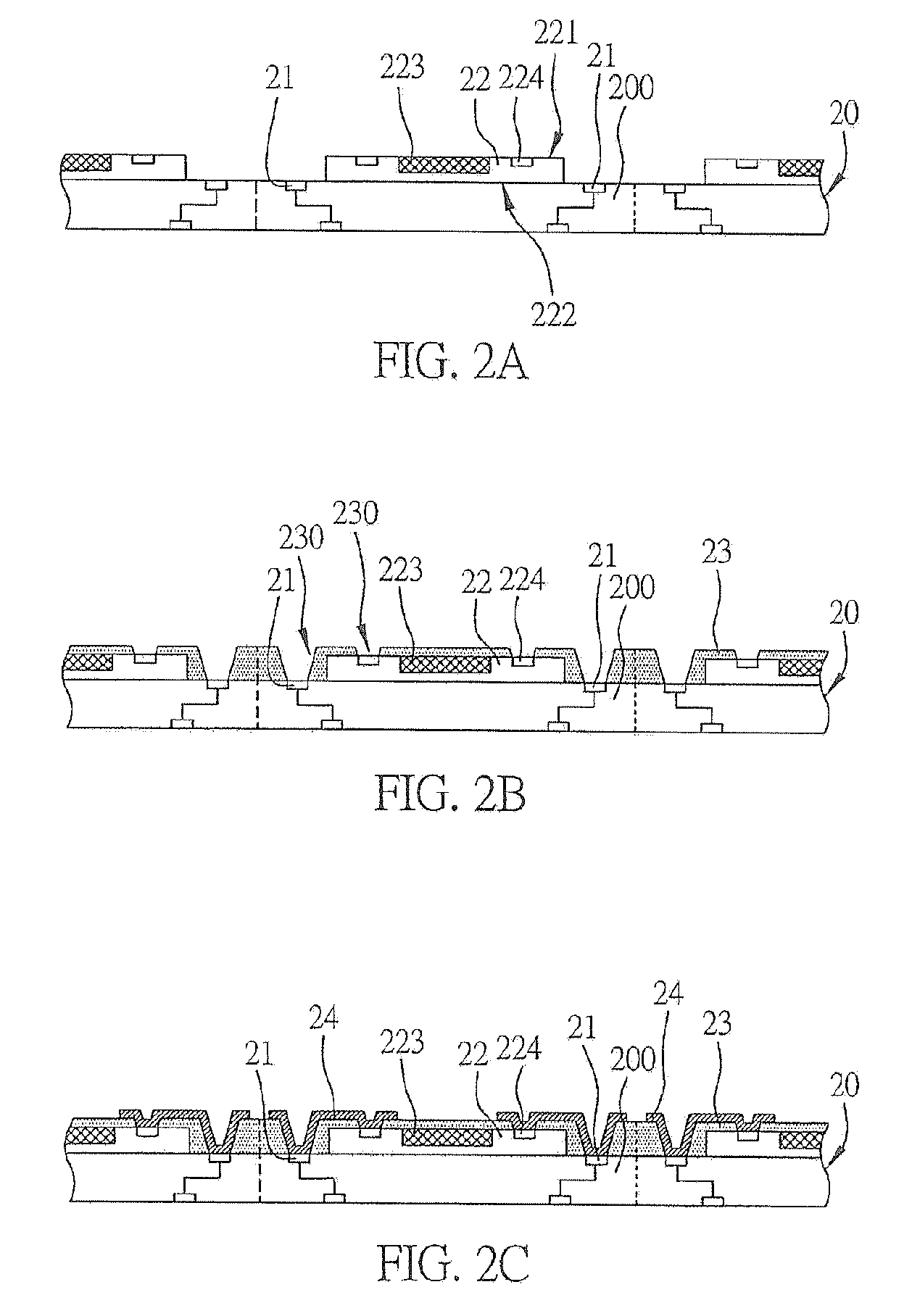

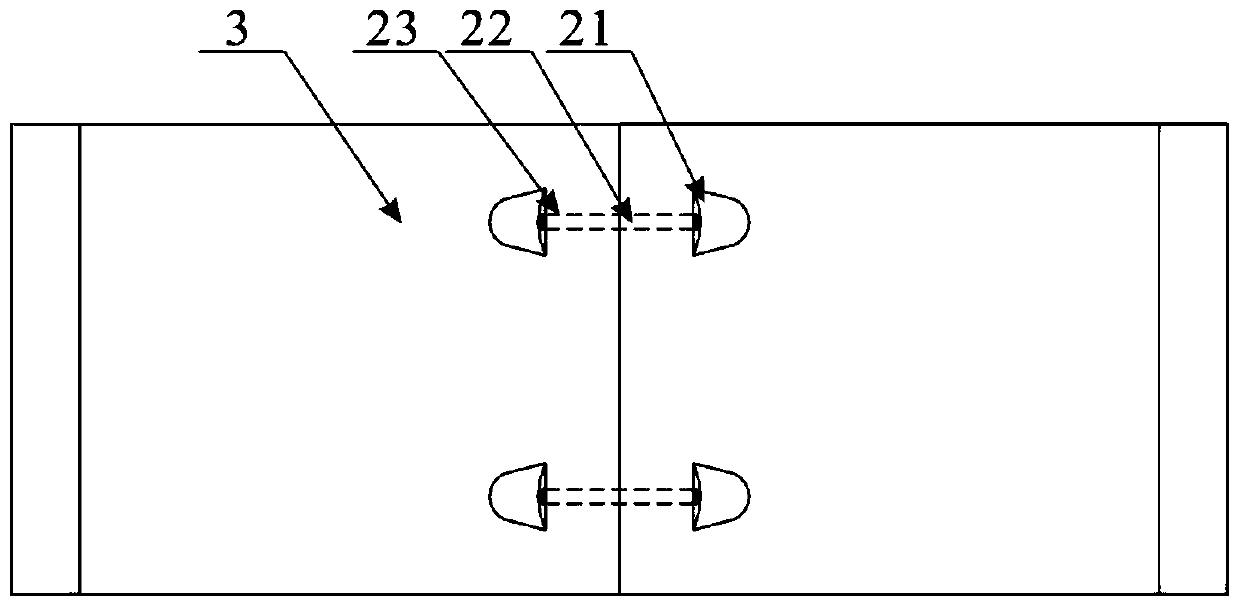

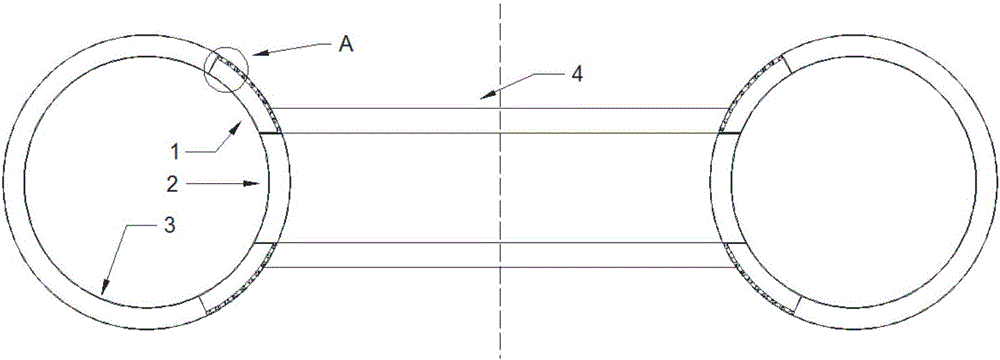

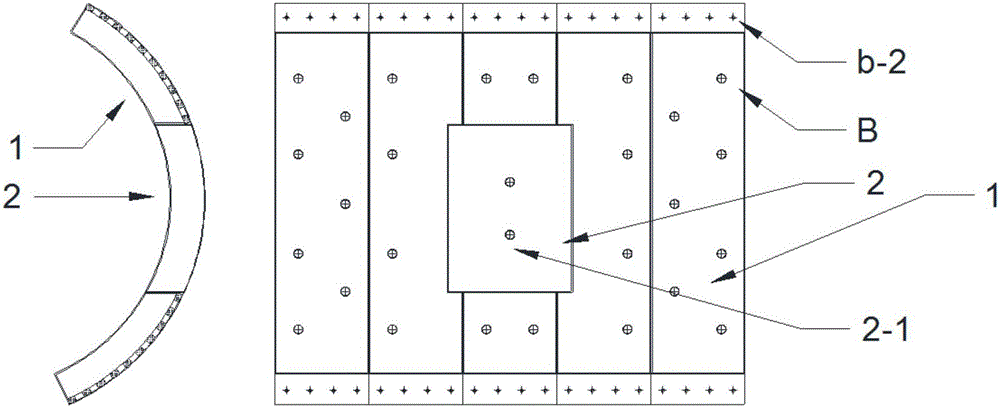

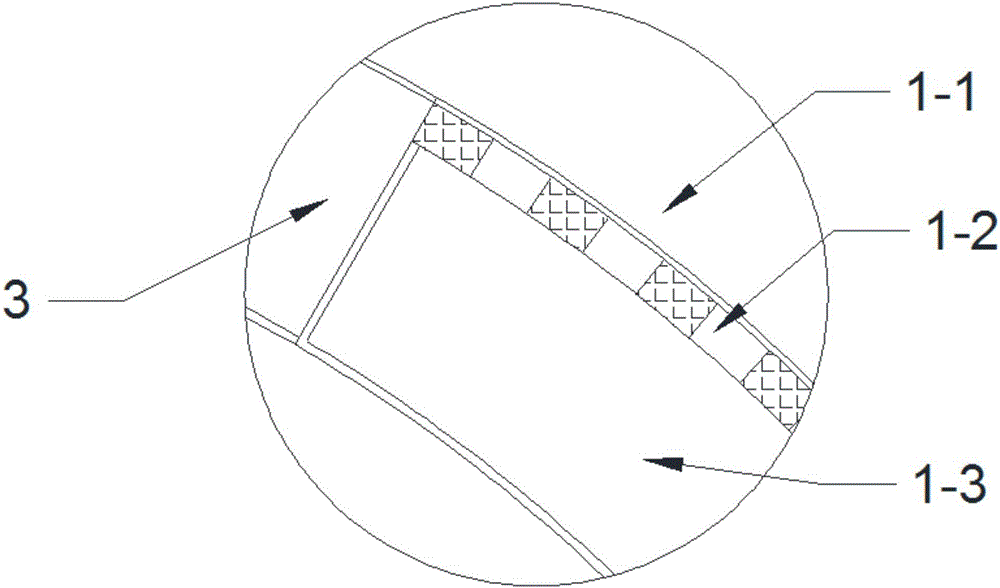

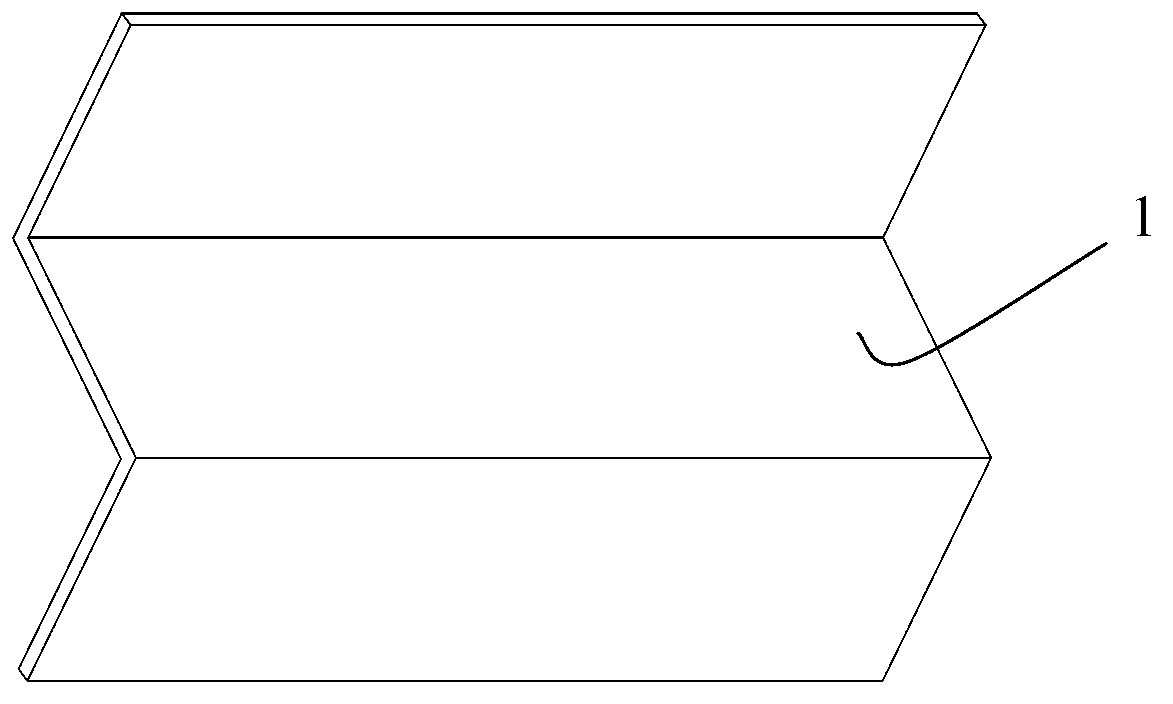

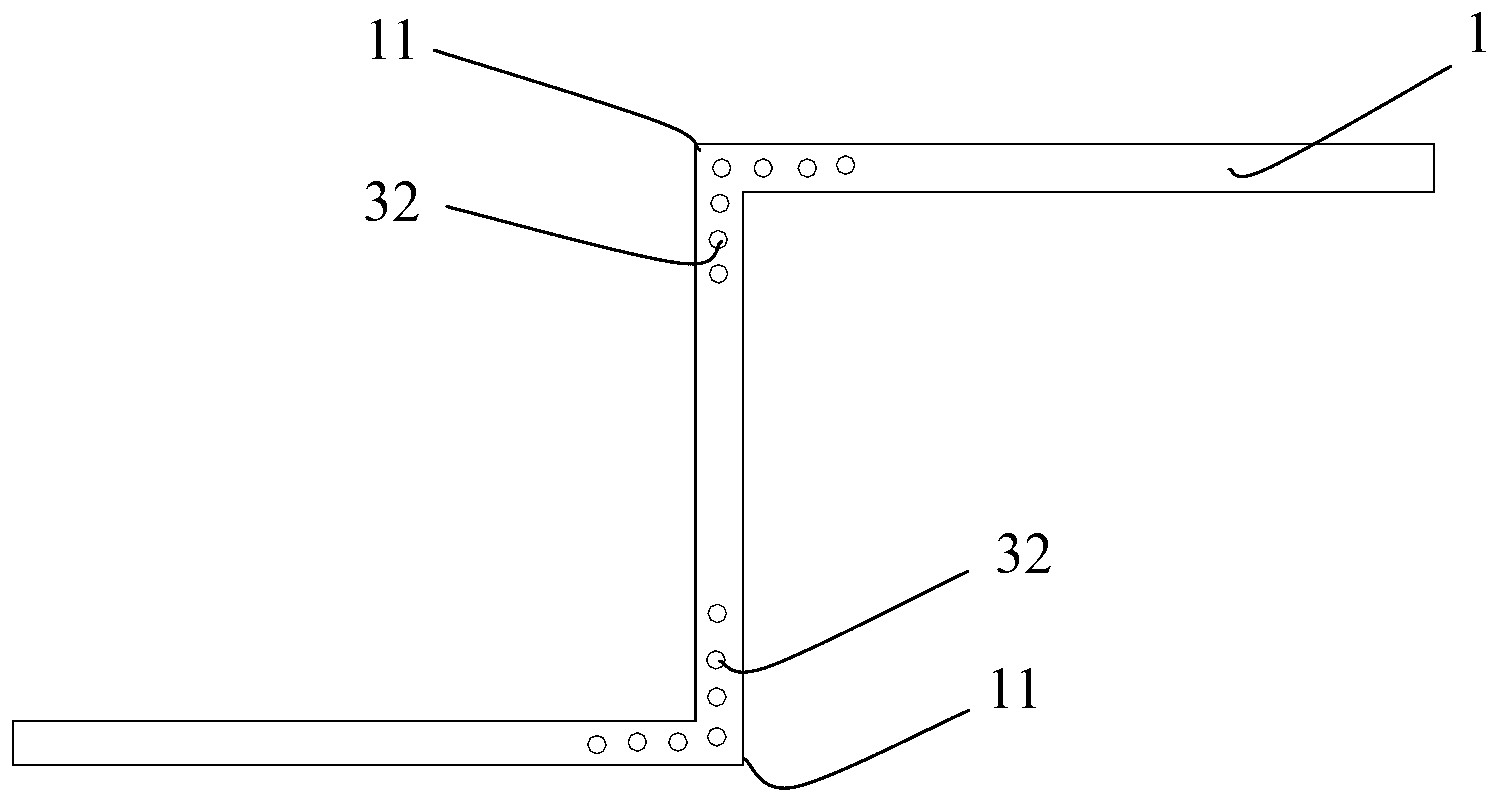

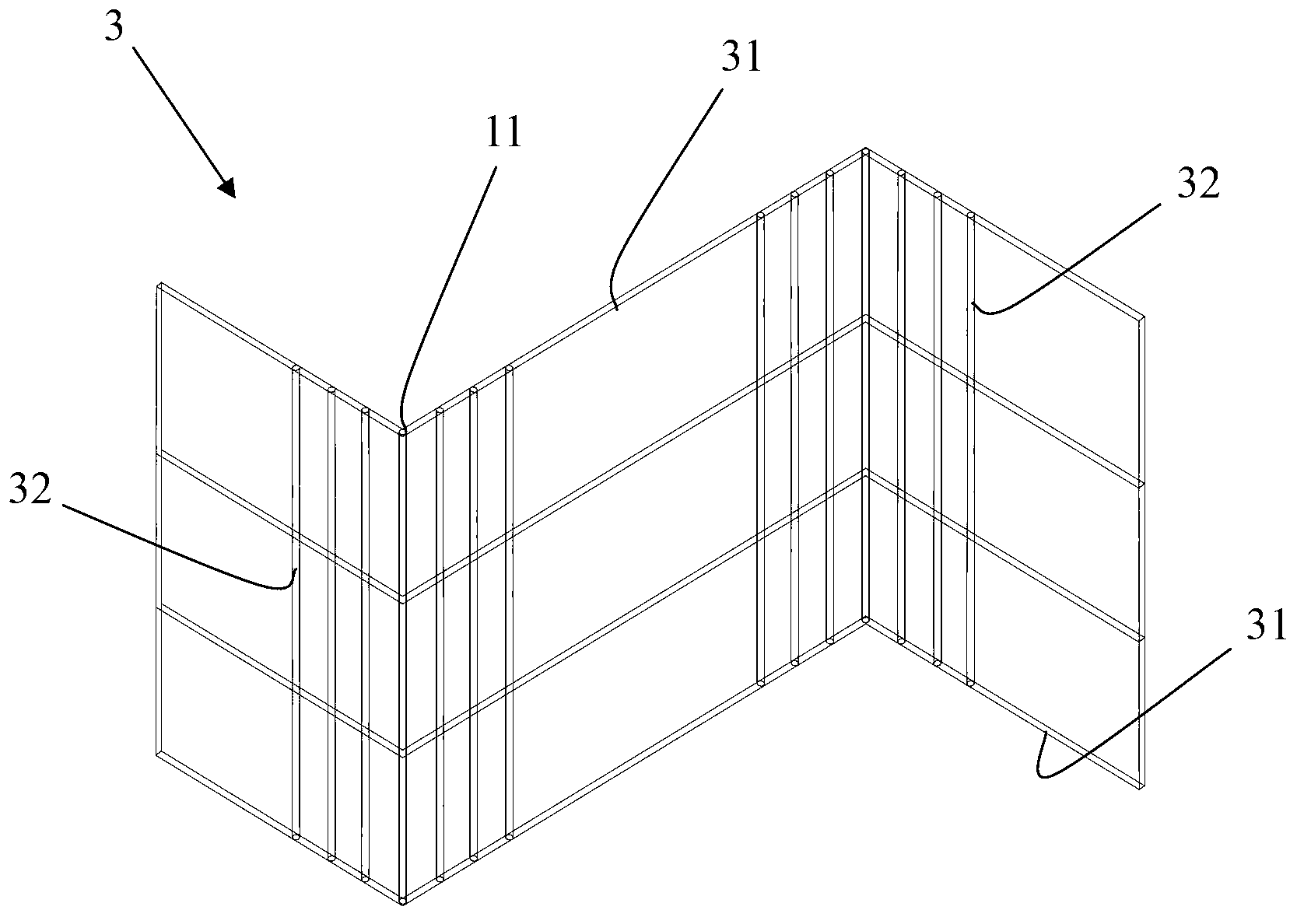

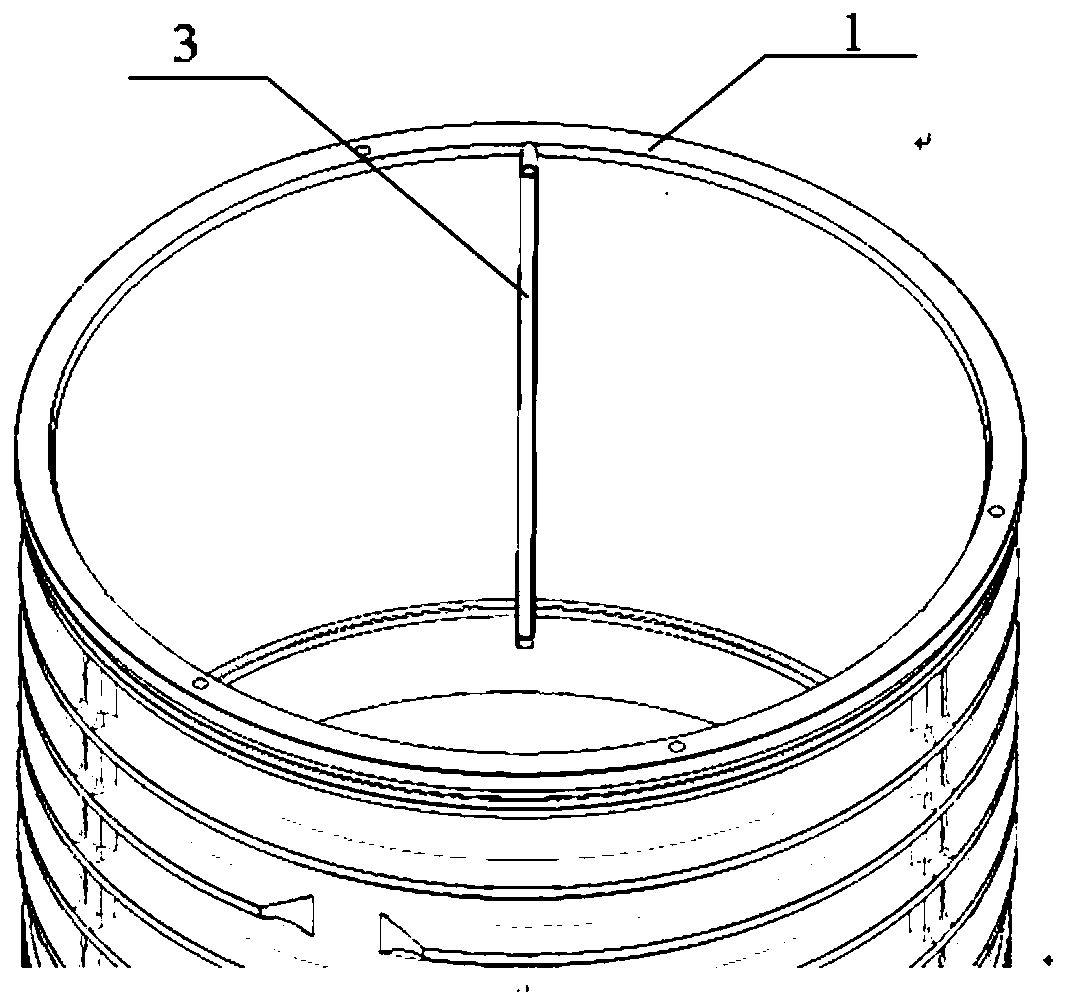

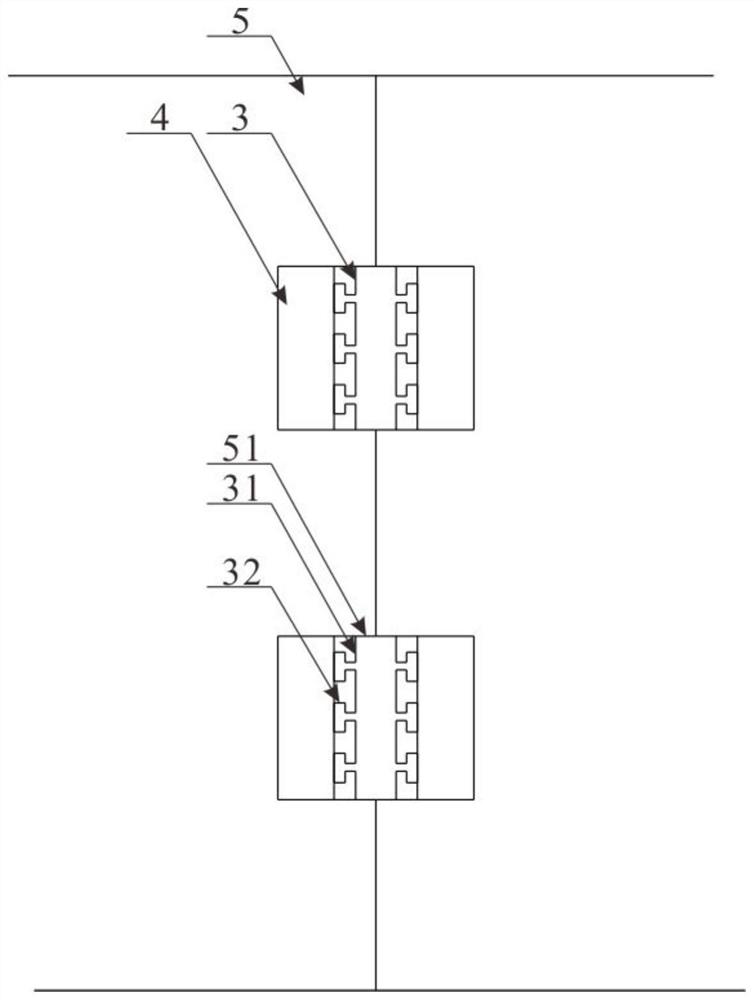

Detachable steel tube section construction method used for freezing method construction in tunnel contact channel

ActiveCN106593487AIncreased durabilityImprove securityUnderground chambersTunnel liningInter layerSheet steel

The invention relates to a detachable steel tube section construction method used for freezing method construction in a tunnel contact channel. According to the method, apart from common tunnel segment parts 3, non-detachable parts 1 and detachable parts 2 are further adopted. The detachable parts 2 are arranged in the tunnel contact channel, the non-detachable parts 1 are arranged in the peripheries of the detachable parts 2, the detachable parts 2 are connected with the common tunnel segment parts 3 through the non-detachable parts 1, and accordingly, a whole detachable steel tube section is formed, wherein each non-detachable part 1 is sequentially provided with three layers, namely, a thin steel plate outer layer, a flexible transition layer and a steel structure segment inter layer from outside to inside. The construction method comprises the following steps that the detachable steel tube section is mounted according to the description; freezing holes and pressure released holes are constructed; the freezing method construction is carried out to form a freezing curtain; and the detachable parts 2 are dissembled, and contact channel construction through a mining method is carried out.

Owner:TIANJIN UNIV

Rolling heating process for stainless steel for soldering

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Precast pavement structure and Z-shaped rubber insert applied to structure

ActiveCN103061228AAvoid wrinklesAchieve wholenessSingle unit pavingsPaving detailsStress concentrationRotational deformation

The invention provides a precast pavement structure and a Z-shaped rubber insert applied to the structure. The pavement structure is formed by a plurality of T-shaped precast block pavement spliced and clamped together, and the Z-shaped rubber insert is arranged between the splicing faces of the adjacent T-shaped precast blocks in a clamping way. The rubber insert comprises an insert framework and rubber at the outer layer of the insert framework, the insert framework is provided with transverse reinforcing steel wires along two vertical bending directions starting from the corner center, and the framework is provided with a plurality of longitudinal reinforcing steel wires in the longitudinal direction. Under the action of the insert, the tiny rotational deformation of the T-shaped precast blocks under the action of wheels can be achieved so as to reduce the rotational displacement, so that the smoothness in the traveling of construction vehicles is improved, meanwhile, the stress-focusing effect at the internal corners of the precast blocks in the traveling process is weakened, and the integrity and the continuousness of the interlock effect of the pavement structure are achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

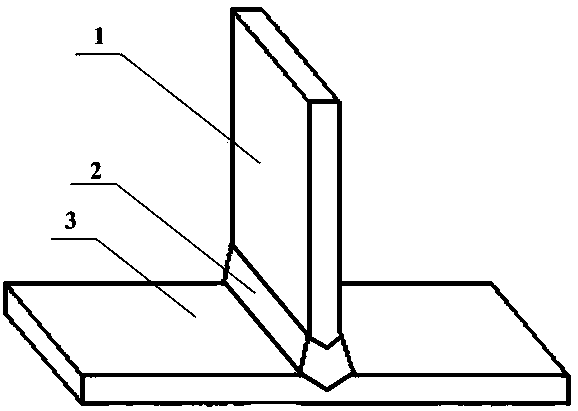

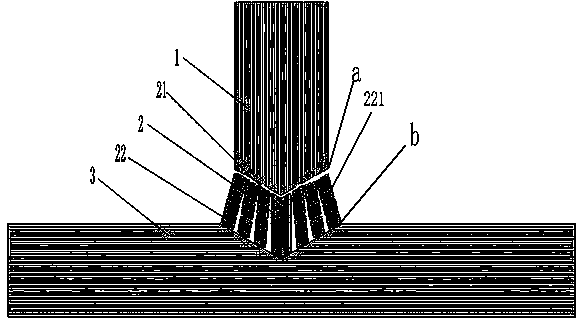

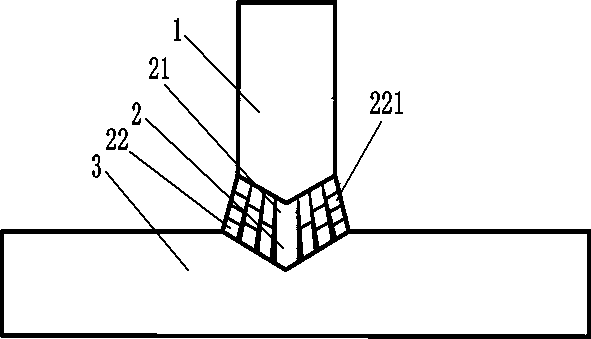

A kind of fiber-reinforced polymer-based composite material T-joint and its manufacturing method

ActiveCN105538747BImprove tensile propertiesImprove bending abilityDomestic articlesStress concentrationDamage tolerance

The invention discloses a fiber-reinforced polymer matrix composite T-joint and a making method thereof. The T-joint is formed by a vertical web plate, a bionic knuckle area and a lower wall panel, wherein two ends of the bionic knuckle area are respectively fixedly connected with the vertical web plate and the lower wall panel. According to the invention, the vertical web plate is connected with the lower wall panel by the bionic knuckle area with multiple functions, so that the tensile property and the bending resistance of the T-joint can be improved, the T-joint has good toughness and damage tolerance, and a stress concentration effect is relieved; and a malposition structure formed by a composite unit section in the knuckle area can effectively obstruct propagation of cracks, and therefore, the damage tolerance of a connecting part is improved, and the risk of disastrous structural damage of the T-joint can be reduced.

Owner:JILIN UNIV

Refrigerator

ActiveCN102374752ASimple structureEasy to manufactureDomestic cooling apparatusLighting and heating apparatusRefrigerator carEngineering

The invention discloses a refrigerator, comprising a refrigerator body which includes a refrigerator tank; and a normally-closed lamp switch connected with the refrigerator tank. The normally-closed lamp switch comprises a shell, a jaw, a wiring terminal, a tongue block and a sealing cushion, wherein the refrigerator tank is provided with a preset hole matched with the shell, the shell passes through the preset hole, the first flange of the shell is resisted against the inner surface of the refrigerator tank, the first ridge of the shell is resisted against the outer surface of the refrigerator tank, and the free end of the jaw is inserted into the preset hole. According to the refrigerator provided by the invention, when in assembly, the process is simple, the influence of stress concentration of the jaw is reduced, and the free end of the jaw is hidden in the preset hole of the refrigerator tank, therefore, the interference fit of the nonelastic part and the preset hole is avoided, the tank can be effectively prevented from cracking, the production efficiency is enhanced, and the production cost is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Rolling heating process for stainless steel for soldering

The invention relates to a rolling and heating method for stainless steel used for welding, in particular to a rolling and heating method for 309 L stainless steel. The rolling and heating method comprises the following steps sequentially that firstly, the first heating is performed, the stainless steel casting billet used for welding is heated in a step-by-step type continuous heating furnace, the continuous casting billet is heated to DEG C 1100 to 1150 DEG C, the heating time is between 180 minutes and 220 minutes, and the stainless steel casting billet used for welding is cooled down to the room temperature after being taken out of the heating furnace; secondly, the second heating is performed, the continuous casting billet after being cooled is positioned into the continuous heating furnace again, to heat the casting billet to 1200 DEG C to 1250 DEG C, and the casting billet is taken out of the heating furnace after the heating time of 180 minutes to 220 minutes. The casting billet is rolled into steel bands or wire rods after being taken out of the heating furnace. By adopting the rolling and heating method for stainless steel used for welding, the rolling cracking during rolling is obviously reduced, and the yield of good steels is enhanced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

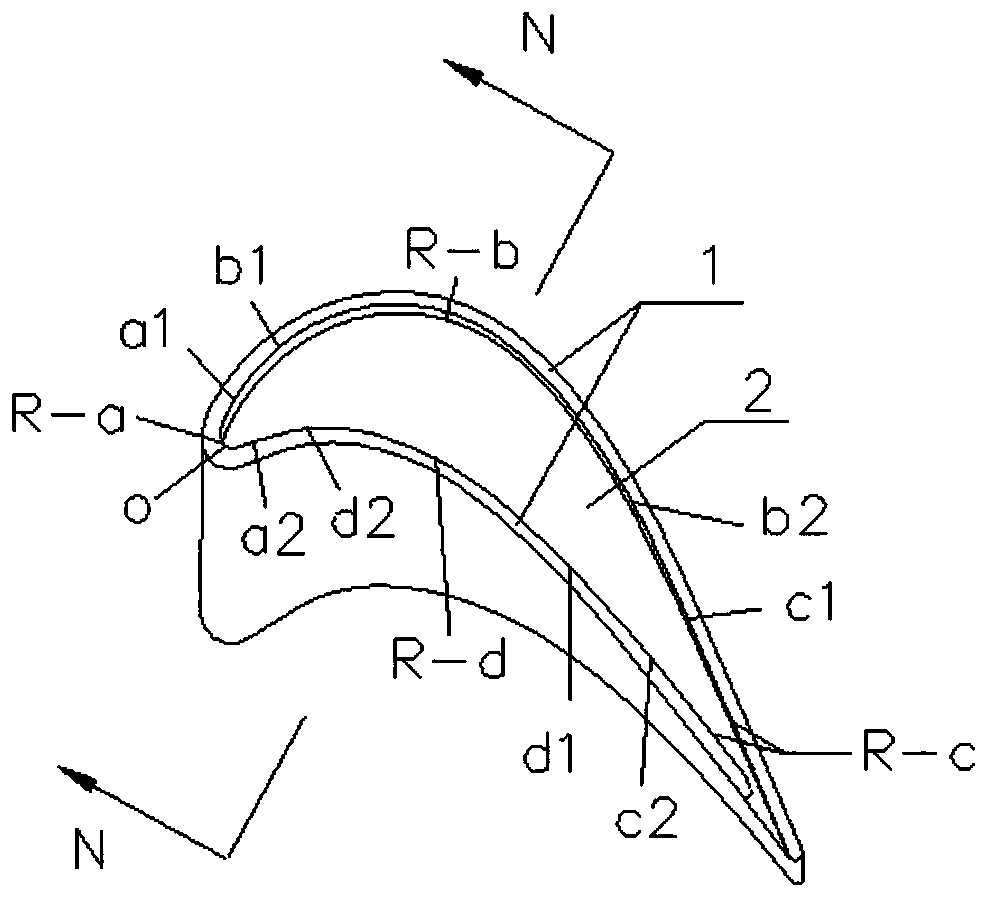

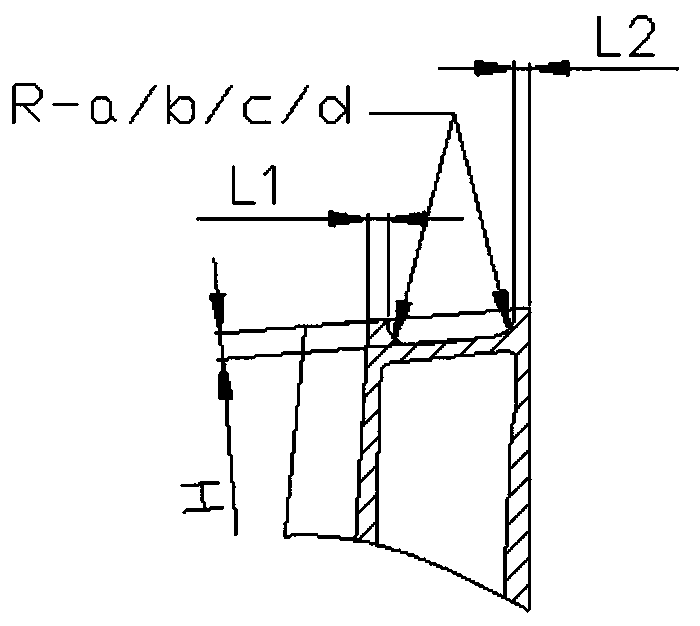

Turbine rotor blade groove-type blade tip structure and design method thereof

ActiveCN111379594AExtended service lifeHigh strengthBlade accessoriesMachines/enginesSuction forceClassical mechanics

The invention belongs to the field of aero-engine blades, and particularly relates to a turbine rotor blade groove-type blade tip structure and a design method thereof. The turbine rotor blade groove-type blade tip structure comprises a top cover (2) and a blade tip fence (1), wherein the top cover (2) is arranged at the top of a turbine rotor blade, and the blade tip fence (1) is arranged aroundthe top cover (2); the blade tip fence (1) comprises a pressure surface blade tip fence and a suction surface blade tip fence, and the wall thickness L1 of the pressure surface blade tip fence is larger than the wall thickness L2 of the suction surface blade tip fence; the top cover (2) and the blade tip fence (1) form a blade tip groove; and a variable radius fillet is arranged between the bladetip fence (1) and the top cover (2). According to the turbine rotor blade groove-type blade tip structure, the strength of the blade tip fence is improved, and the oversized cantilever size of the blade tip fence is avoided, so that the strength margin of the corresponding position is improved, a stress concentration effect is relieved, the service life of a blade is prolonged, the cost caused byparts replacement is reduced, and the design reliability is improved.

Owner:AECC SHENYANG ENGINE RES INST

Corrosion-resisting fuel tank with double-layer structure

InactiveCN102788245AImprove corrosion resistanceReduces the effects of corrosion damageContainer filling methodsNon-pressured vesselsFuel tankHigh intensity

The invention relates to a corrosion-resisting fuel tank with a double-layer structure, belonging to the field of astronavigation and aircrafts or equipment used in astronavigation. The fuel tank comprises an inner layer tank and an outer layer tank, wherein the inner layer tank is made from anti-corrosion materials, the outer layer tank is made from high strength materials, and the inner layer tank is uniformly adhered on the inner wall of the outer layer tank. According to the invention, the inner structure is made from anti-corrosion materials, and the outer structure is made from high strength materials; the inner structure has high corrosion resistance but bears small load, the outer structure is used for bearing most loads and is separated from fuels, thus the outer structure can not be corroded, and the influence caused by fuel corrosion and damage can be effectively reduced, thus the service life of the fuel tank is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

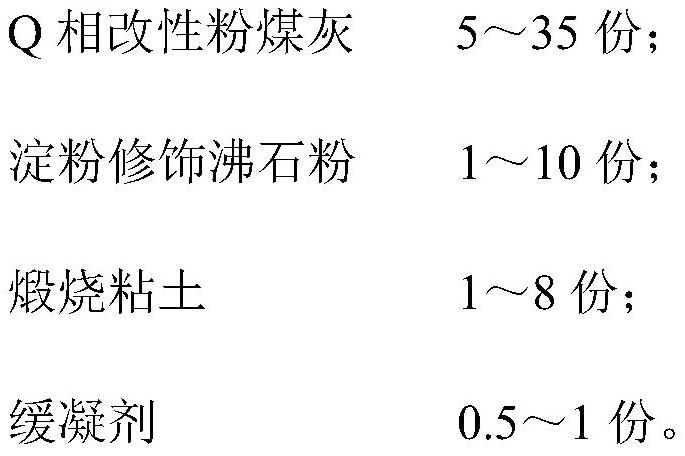

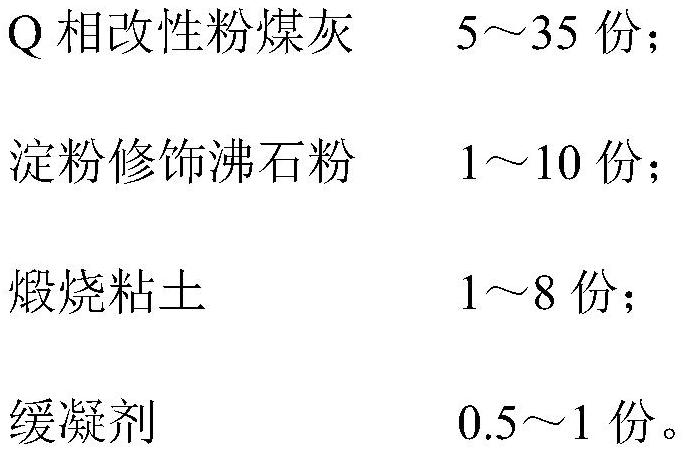

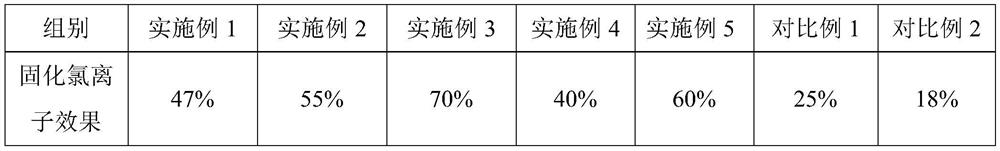

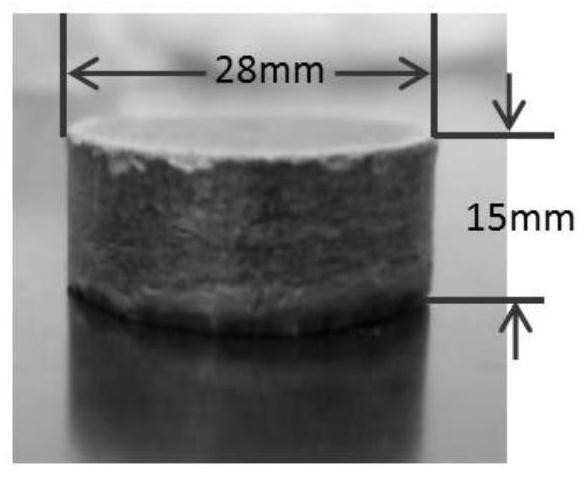

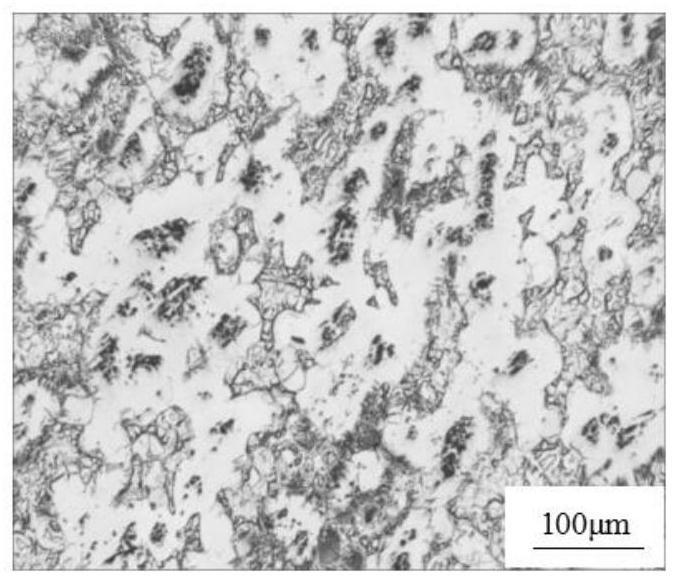

Functional admixture for treating desulfurized gypsum with high chloride ion content as well as preparation method and application of functional admixture

ActiveCN113979665ALow alkalinity propertiesEfficient physical adsorption capacityPhysical chemistryChloride

The invention relates to a functional admixture for treating desulfurized gypsum with high chloride ion content and a preparation method and application of the functional admixture, and the functional admixture comprises the following components in parts by mass: 5-35 parts of Q-phase modified fly ash, 1-10 parts of starch modified zeolite powder, 1-8 parts of calcined clay and 0.5-1 part of a retarder. A composite mineral admixture formed by the Q-phase modified fly ash, the starch modified zeolite powder, the calcined clay and the retarder is doped into the desulfurized gypsum to form a close packing effect, a low alkalinity characteristic and a synergetic hydration characteristic, a hydration product with the low alkalinity characteristic and efficient physical adsorption capacity is formed, migration and diffusion of chloride ions can be effectively limited, the chloride ion curing efficiency of the desulfurized gypsum is greatly improved, and the problems that the overall porosity and fracture toughness of a gypsum-based material are insufficient are solved.

Owner:WUHAN UNIV OF TECH

Preparation method for reinforcing Ti2AlNb composite material by using graphene

The invention belongs to the technical field of metal matrix composite materials and preparation thereof, and particularly relates to a preparation method for reinforcing a Ti2AlNb composite materialby using graphene. The preparation method adopts the graphene to reinforce a Ti2AlNb alloy, optimizes the properties of the Ti2AlNb alloy, and adopts the graphene to reinforce the Ti2AlNb composite material prepared by spark plasma sintering, it is found that the graphene is evenly distributed in the composite material, the relative density of the composite material reaches 98% or above, and whenthe content of the graphene is 0.5 wt.%, the fracture toughness and elongation of the composite material are improved by 70% and 51% correspondingly; the preparation method fully shows that the graphene has very remarkable toughening and plasticizing effects on the Ti2AlNb alloy, and when the the Ti2AlNb alloy is applied to the field of aviation starting, the combat performance of an aircraft canbe greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

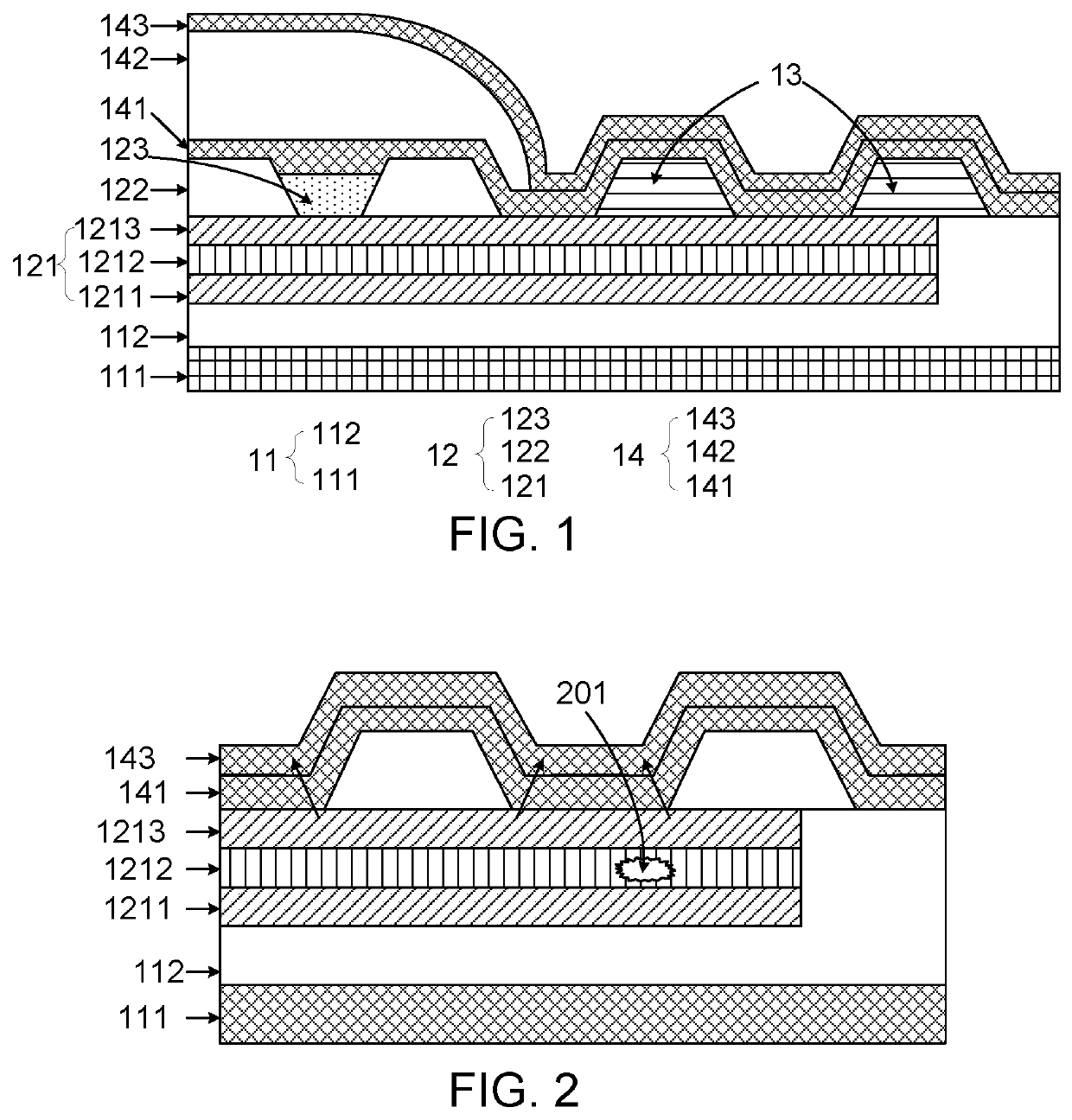

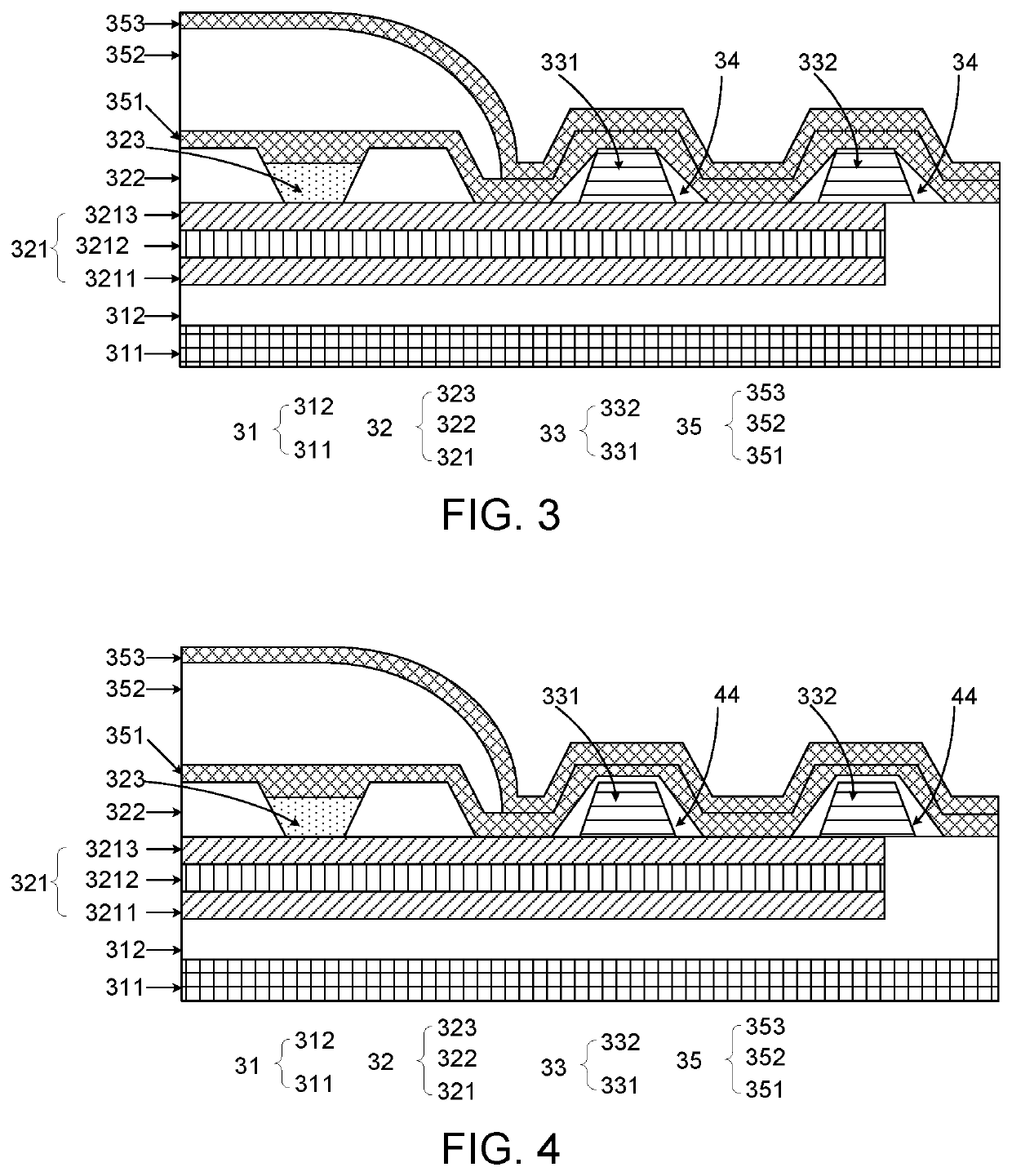

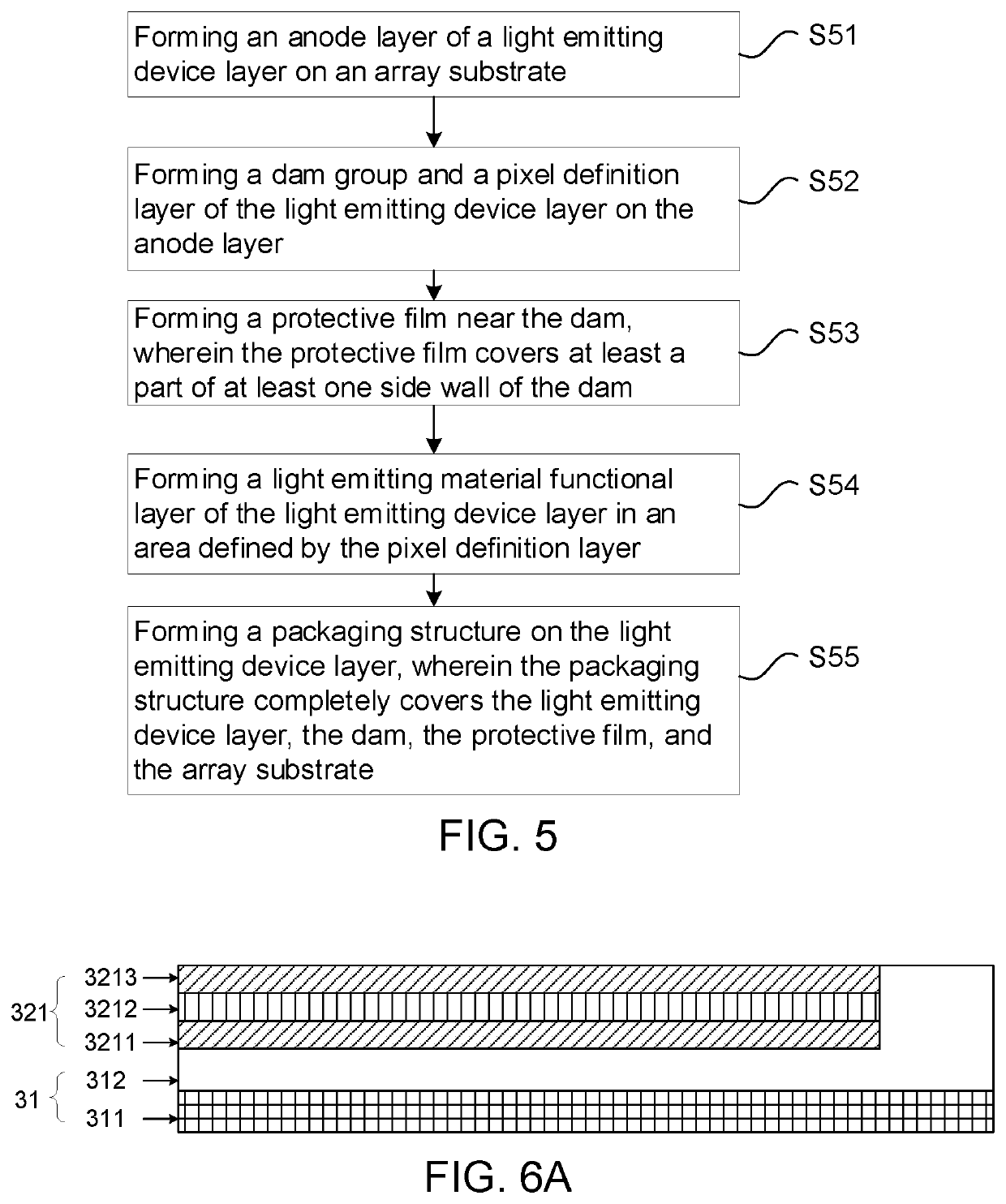

Flexible display panel and manufacturing method thereof

ActiveUS20210408460A1Slow down slopeReduce stress concentration effectsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayMechanical engineering

A flexible display panel and a manufacturing method thereof are provided. By filling a protective film in a stress concentration area of an inorganic film layer at a corner of a dam, a slope of a side wall of the dam can be effectively reduced, and stress concentration effect of the inorganic film layer in an upper packaging structure is reduced to a certain extent. When the protective film is subjected to stress, it can effectively relieve the stress and weaken or even eliminate stress effect of the packaging structure on an anode layer at a corner of the dam.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

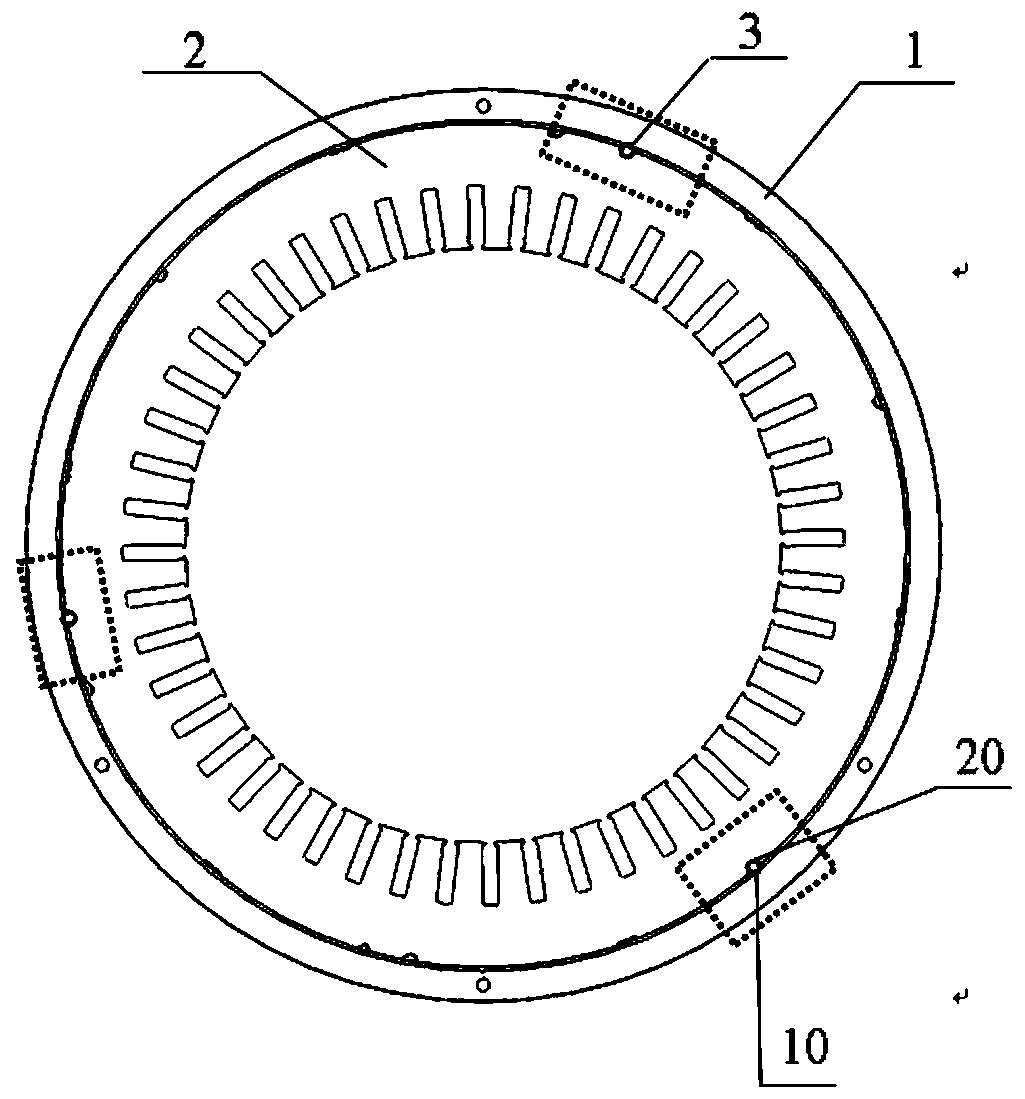

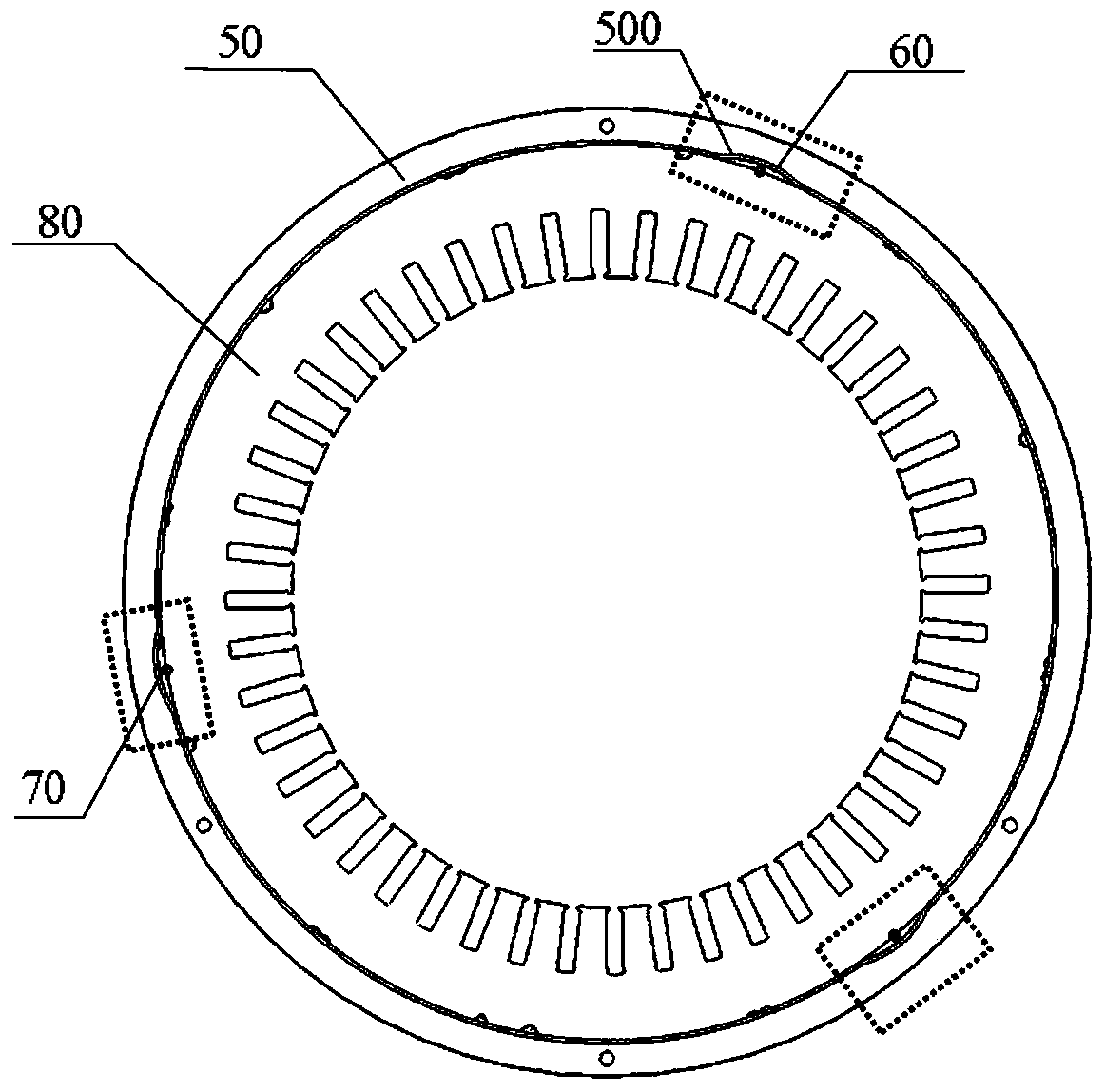

Motor and motor stator cooling structure

InactiveCN109768639AReduce stress concentration effectsGuaranteed normal deliveryMagnetic circuit stationary partsCooling/ventillation arrangementStatorEngineering

The invention relates a motor and a motor stator cooling structure. The motor stator cooling structure comprises a water sleeve and an elastic pin, wherein the water sleeve sleeves an outer ring surface of a motor stator and is in interference fit with the motor stator, a water sleeve groove is formed in an inner ring surface of the water sleeve and extends axially, an intermediate medium is arranged in the water sleeve groove, a positioning hole is formed in the intermediate medium and the outer ring surface of the motor stator, the elastic pin is integrally of an annular structure and is fixed in the positioning hole, the shape of the positioning hole is matched with the shape of the elastic pin, a radial opening is formed in the elastic pin and communicates with the inner ring surface of the elastic pin, and an axial end, along the elastic pin, of the radial opening extends to the other axial end. With the motor and the motor stator cooling structure, provided by the embodiment of the invention, the stress concentrated effect of the water sleeve groove can be reduced, the situation that the water sleeve is deformed caused by the stress at the water sleeve groove exceeds extremeyield strength is prevented, and normal transferring of torque between the motor stator and the water sleeve under a low-temperature environment is favorably ensured.

Owner:SCHAEFFLER TECH AG & CO KG

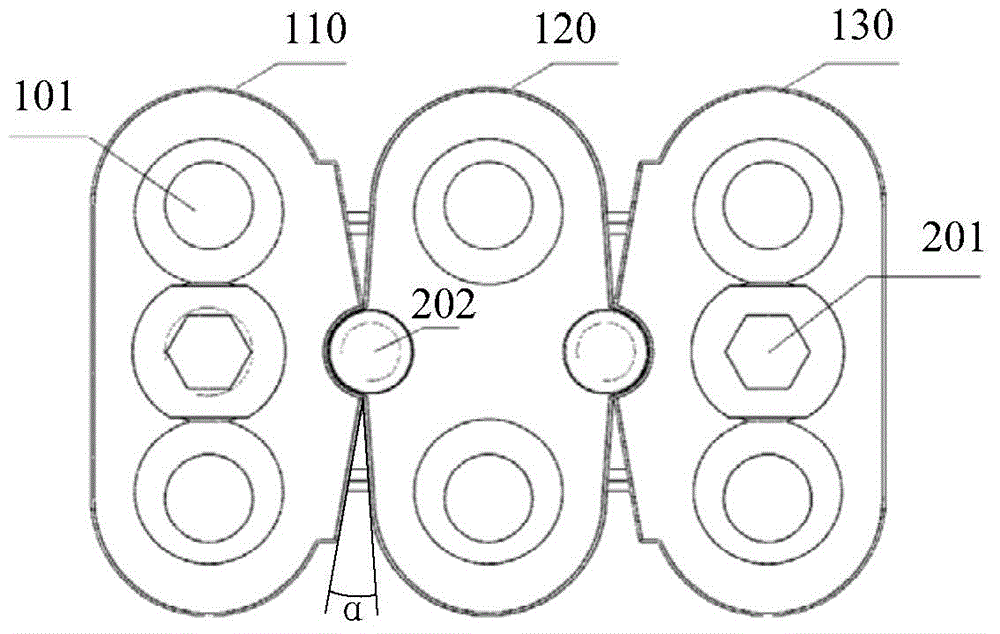

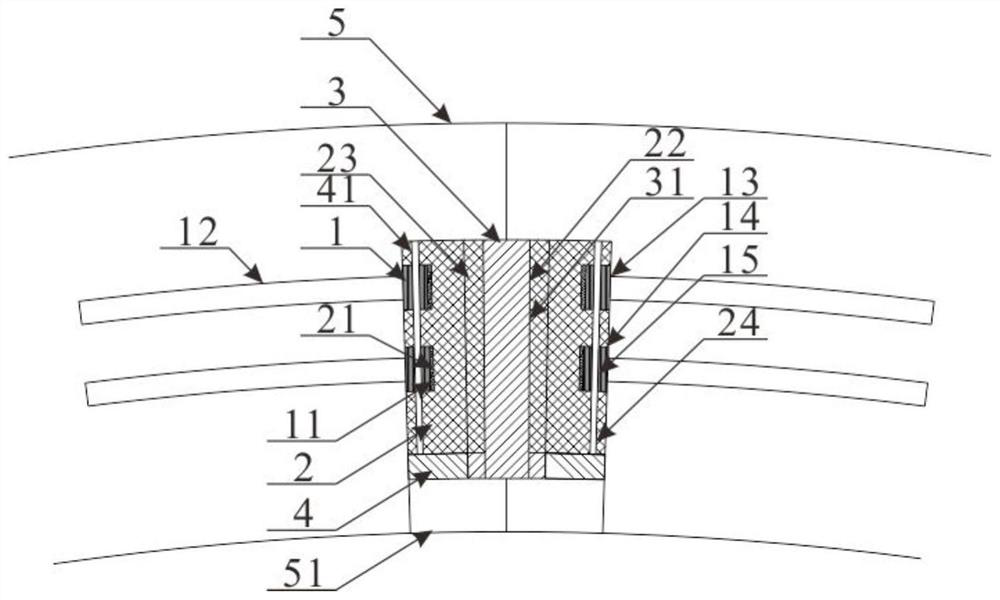

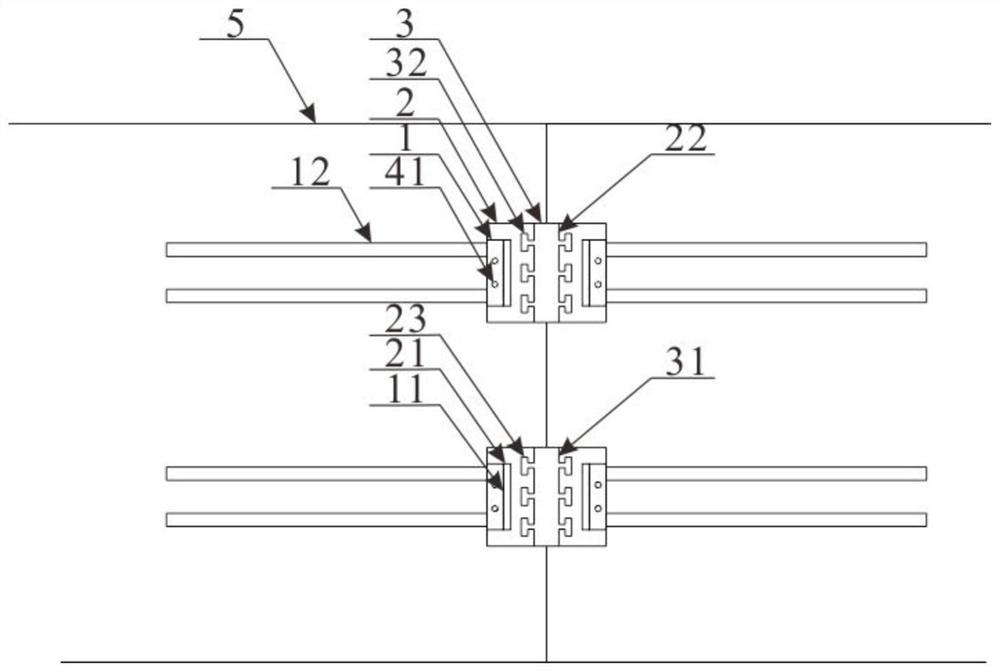

Radial pushing and pressing fastening type shield segment joint and construction method

ActiveCN112483123AEasy maintenance and replacementIncrease the areaUnderground chambersTunnel liningRubber matStress concentration

The invention discloses a radial pushing and pressing fastening type shield segment joint and a construction method. The segment joint comprises a plurality of connecting grooves which are symmetrically formed relative to the end of a secondary lining segment, and the connecting grooves communicate with the faces, connected with each other, of the inner sides of a tunnel; an outer cambered surfacejoint and an inner cambered surface joint which are parallel to each other are installed in the connecting grooves respectively, each of the outer cambered surface joint and the inner cambered surface joint comprises fixing blocks which are symmetrically arranged, anchor bars are arranged on the fixing blocks in the direction perpendicular to the end face of the secondary lining segment in a penetrating mode, and penetrating holes are formed in the fixing blocks in the direction parallel to the end face of the secondary lining segment; and rubber pads are arranged on the opposite end faces ofthe fixing blocks. The construction method comprises the steps of prefabricating the fixing blocks, base plates, bottom plates and inserting plates, and assembling the rubber pads, the anchor bars and the fixing blocks. The problems that in the prior art, under the action of external loads, a segment joint is prone to failure and inconvenient to install can be solved, the structure is simple, reliability is high, the stress concentration effect of the segment joint can be remarkably weakened, and the concrete fracturing risk of the segment joint is reduced.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

Coal leveling machine

InactiveCN109305576AImprove stabilityMove up and down freelyLoading/unloadingEngineeringUltimate tensile strength

The invention relates to coal railway transporting and loading auxiliary equipment, in particular to a coal leveling machine. The coal leveling machine comprises a gantry, a coal scraping plate assembly and a lifting frame, wherein the left end head and the right end head of the lifting frame are clamped between a front framework and a rear framework of the gantry; rolling rollers are arranged onthe side surfaces opposite to the gantry, of the left end head and the right end head of the lifting frame; the coal scraping plate assembly is fixed at the lower end of the lifting frame; and the upper end of the lifting frame is connected with the lifting device through steel ropes. The coal leveling machine disclosed by the invention is simple in structure, and low in using and maintenance cost; and when the coal leveling machine is applied the intensity of manual coal leveling can be reduced, labor cost is saved, coal leveling time is reduced, coal leveling efficiency is improved, departing of all kinds of coal transporting at the right time can be guaranteed, and safe production is realized.

Owner:湖北汇欣智能化系统工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com