Pressurized blade dryer

A paddle dryer and paddle technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of limited drying capacity, restricting the drying effect of equipment, increasing production costs, etc., and achieve structural Simple, easy to design and manufacture, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

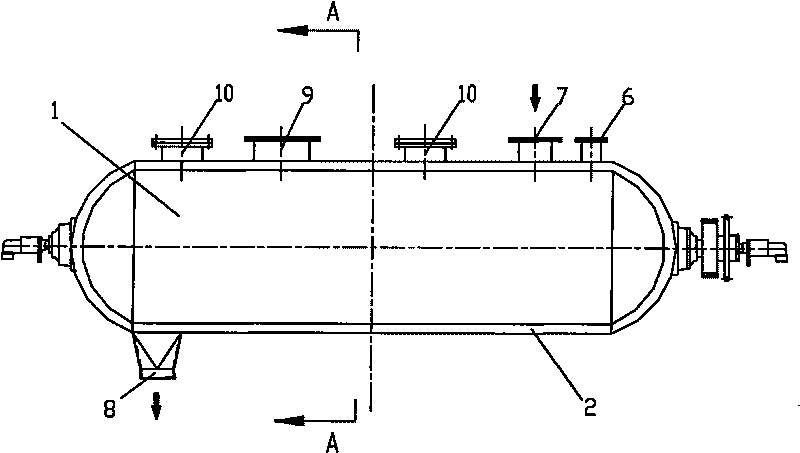

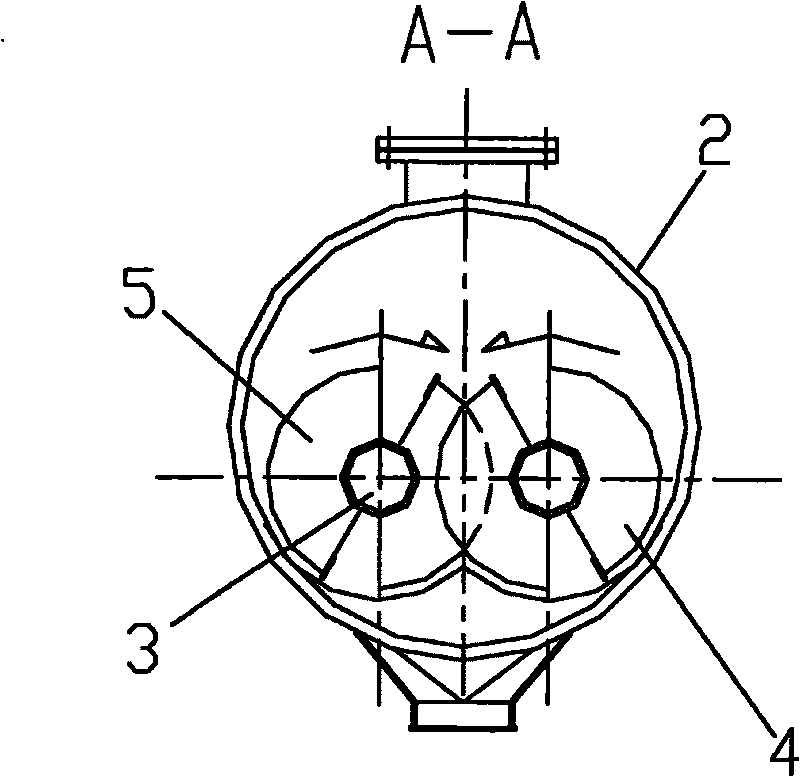

[0016] figure 1 , figure 2 Among them, the pressurized paddle dryer is mainly composed of a hollow paddle, a rotary shaft, a jacketed cylinder, a driving device and a heat source. Depend on figure 1 It can be seen that the machine has two parallel rotary shafts 3 inlaid with interlaced hollow paddles in the cylinder body 1 of the jacket 2, and each rotary shaft 3 is inlaid with two kinds of hollow fan-shaped staggered at a certain interval. Paddle: the hollow fan-shaped paddle 4 on the feeding cutting surface and the hollow fan-shaped paddle on the returning cutting surface, and the rotary shaft 3 rotates at a low speed. The heat source enters the hollow rotary shaft 3 through the universal coupling installed at the end of the rotary shaft 3 and after the two paddles are heat-conducted and dried, they are discharged out of the machine through the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com