Patents

Literature

5168results about "Temperature control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving performance of 700MPa grade V-N micro-alloying high-strength weathering steel

InactiveCN101161849AImprove low temperature impact toughnessGood formabilityTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

The invention discloses a method for improving the performance of 700 MPa grade V-N microalloyed high strength weathering steel. The method is specific to the characteristics of the sheet billet continuous casting and tandem rolling technology and metallurgy component, and adopts an electric furnace or a revolving furnace to smelt, refine, continuously cast sheet billet which directly enters into a roller hearth to heat after a casting blank concretes, or soaking furnace, hot rolling, laminar flow cooling and wind-up process flow. The chemical composition of molten steel is :C occupies less than or equal to 0.08Wt. percent, Si occupies from 0.25 to 0.75Wt. percent, Mn occupies from 0.2 to 2.0Wt.percent, P occupies less than or equal to 0.025Wt. percent, S occupies less than or equal to 0.040Wt. percent, Cu occupies from 0.25 to 0.60Wt. percent, Cr occupies from 0.30 to 1.25 Wt.percent, Ni occupies less than or equal to 0.65Wt. percent, V occupies from 0.02 to 0.20Wt. percent and N occupies from 0.015 to 0.030 Wt. percent. The invention takes full advantages of the characteristics of the sheet billet continuous casting and tandem rolling short flow process and adopts the V-N microalloyed technique to produce 700 MPa grade high strength weathering steel under the thinning function of VN and V (C, N) nanometer scale precipitate on crystal grain in casting blank of the sheet billet continuous casting and tandem rolling flow and the theory of precipitation strength. By the optimization design of the metallurgy component of V-N microalloyed 700MPa grade high strength weathering steel, the invention increases the low temperature impact ductility of coil of strip and improves the shaping property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

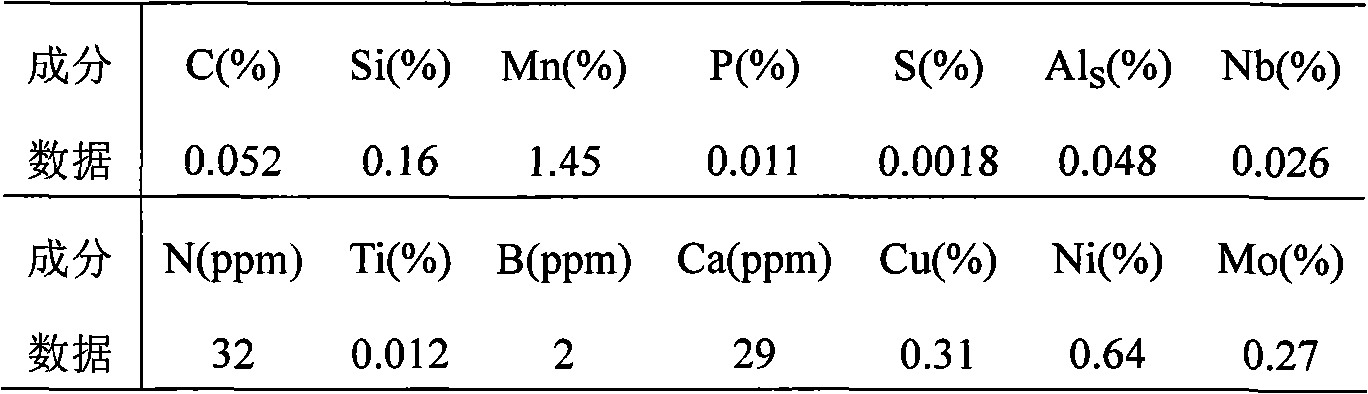

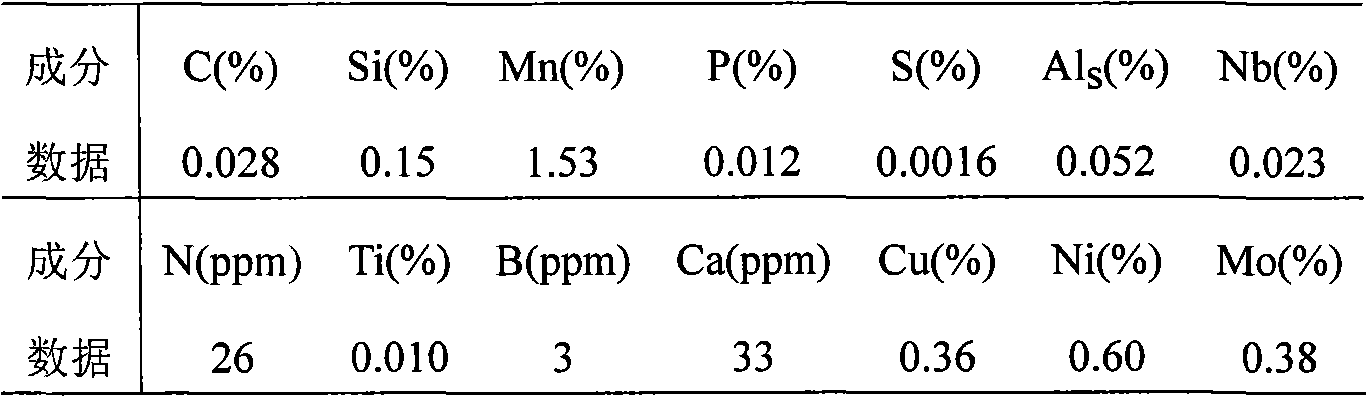

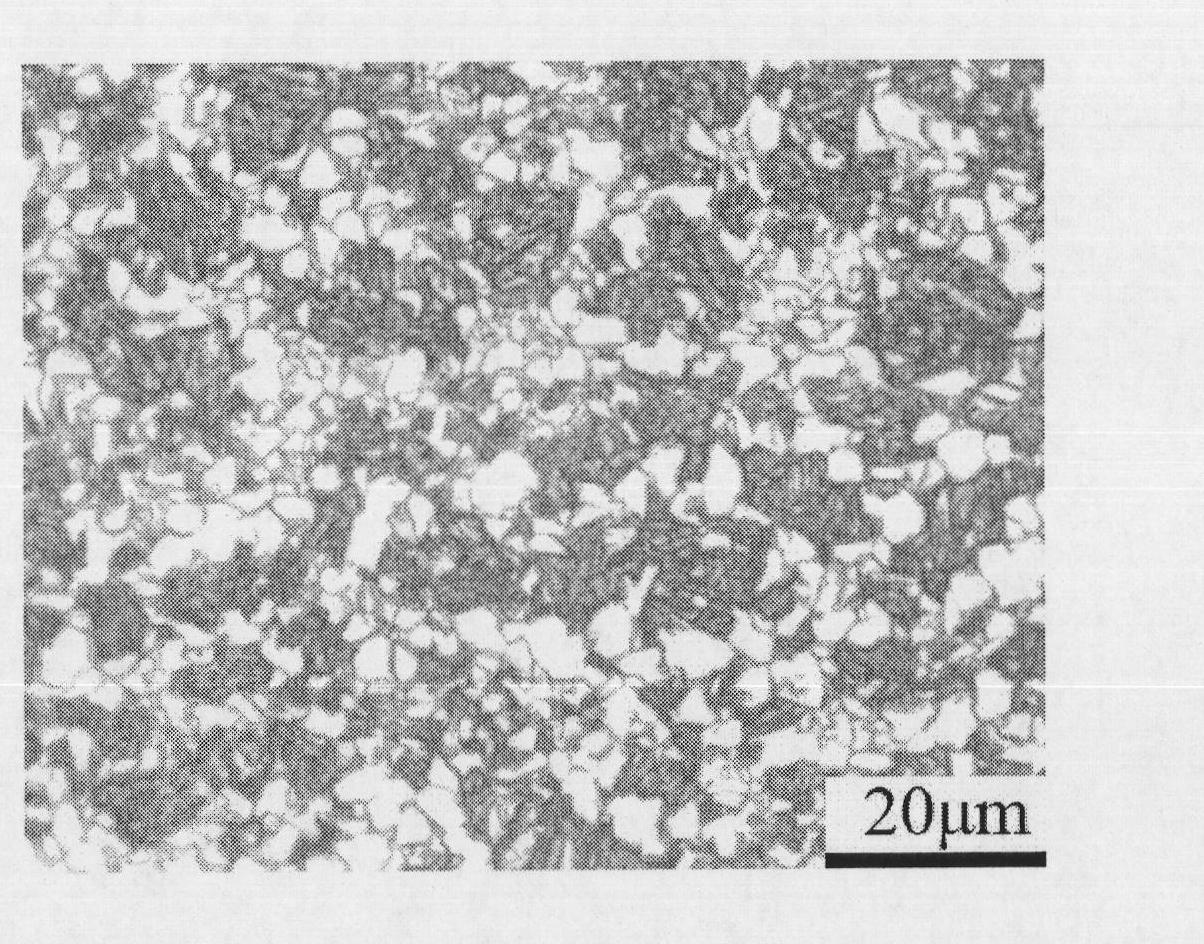

Automobile steel with low cost and high strength ductility balance and preparation method thereof

The invention provides automobile steel with low cost and high strength ductility balance and a preparation method thereof, belonging to the technical field of automobile steel. A multiphase, metastable and multiscale M<3> type organization structure is obtained based on reasonable design of chemical composition and partition of alloy elements and crucially based on the control of martensite phasetransformation, the repartition of solute such as C / Mn and the like and the austenite inverse phase transformation. The invention is characterized in that the martensite structure is obtained by using 0.02-0.50 wt%C and 3.50-9.00 wt%Mn in the cooling process of the inductrial production of steel plates and steel coils and the like; and superfine adverse transformation austenite and alpha phase substrate can be obtained through the partition of Mn and C in the heat preserving process between 100 DEG C below Acl and Acl, thus realizing the industrial production of hot rolled sheets and cold rolled sheets with high strength ductility balance used in automobiles. The invention has the advantages that the intensity is 0.7-1.3 GPa, the extension rate is 55-30% and the strength ductility balanceis 35-55 GPa%.

Owner:CENT IRON & STEEL RES INST

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

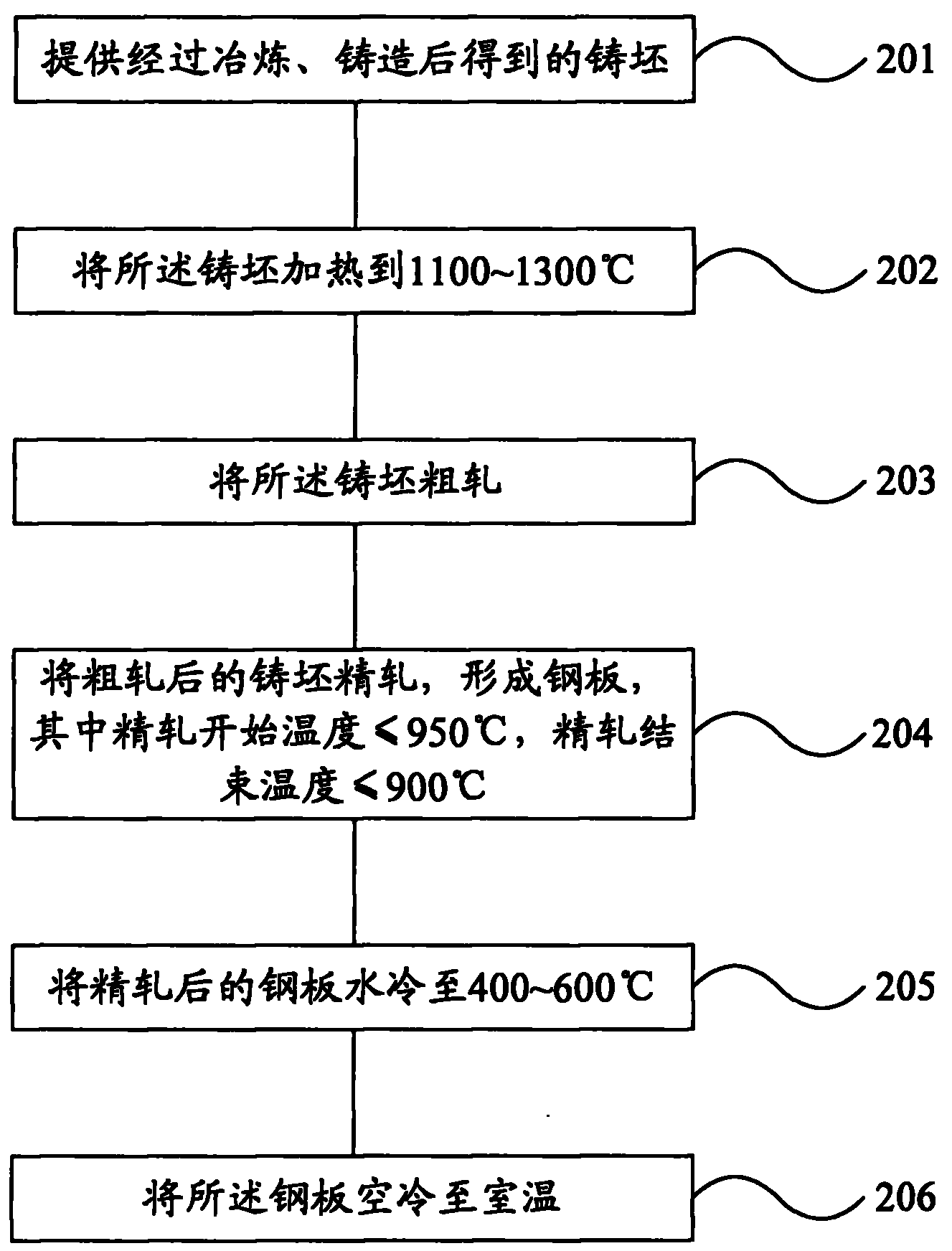

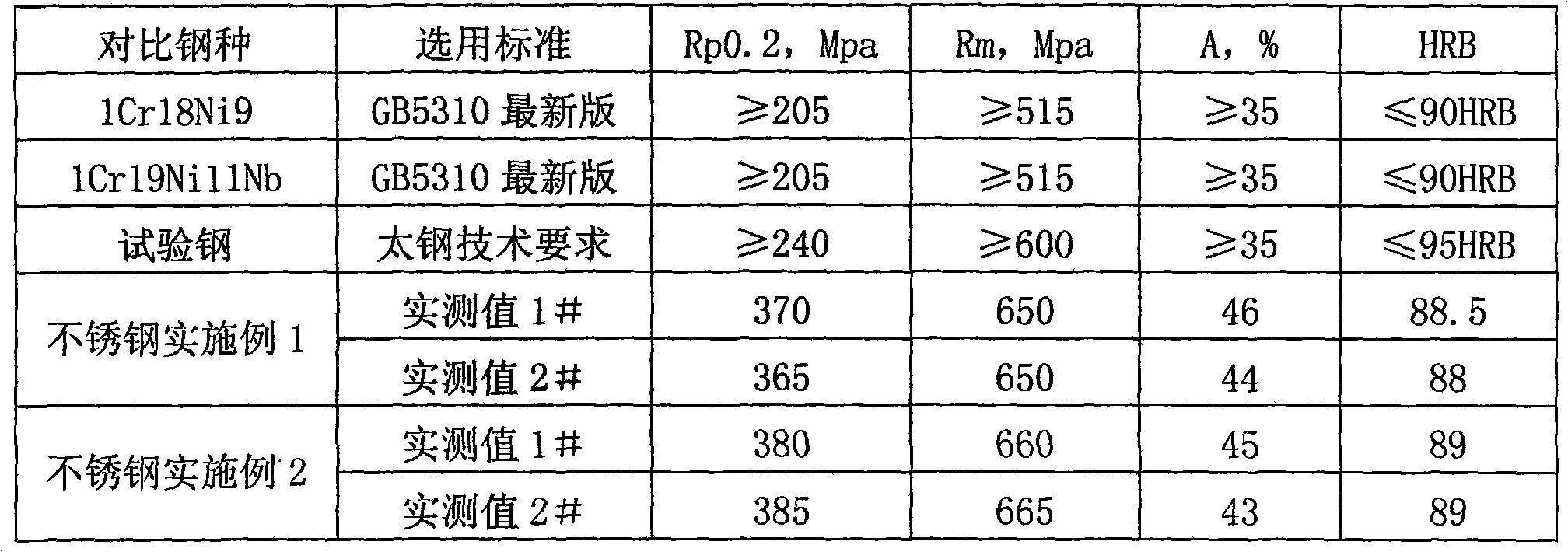

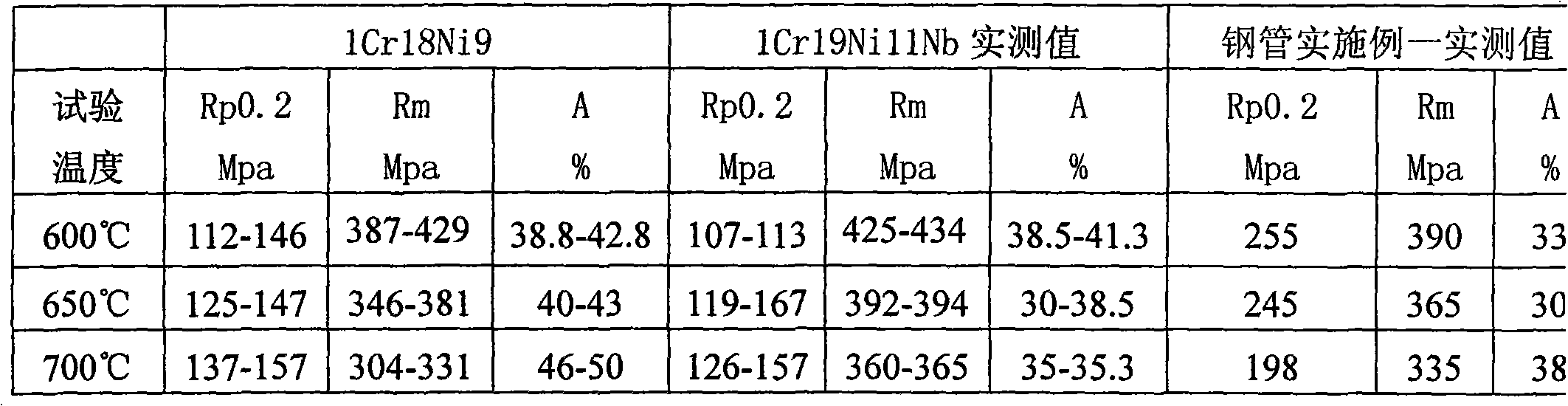

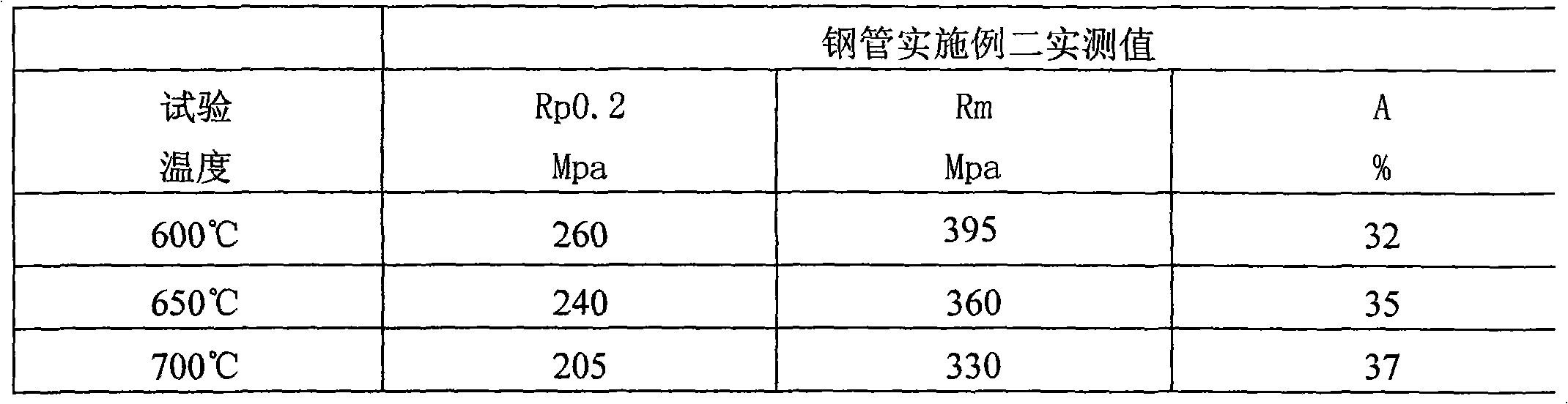

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

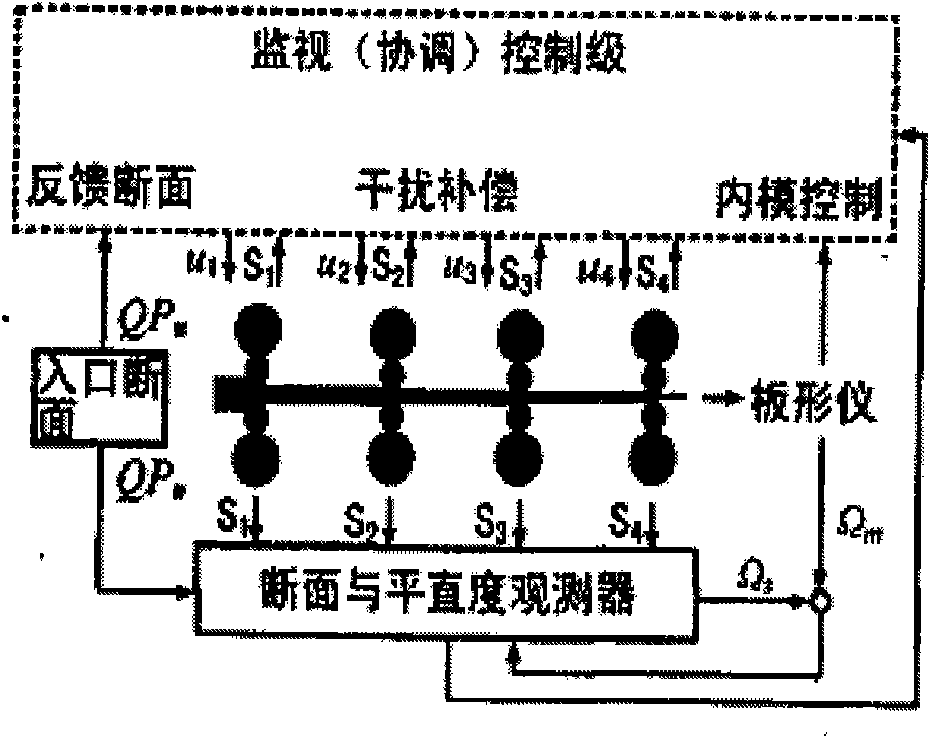

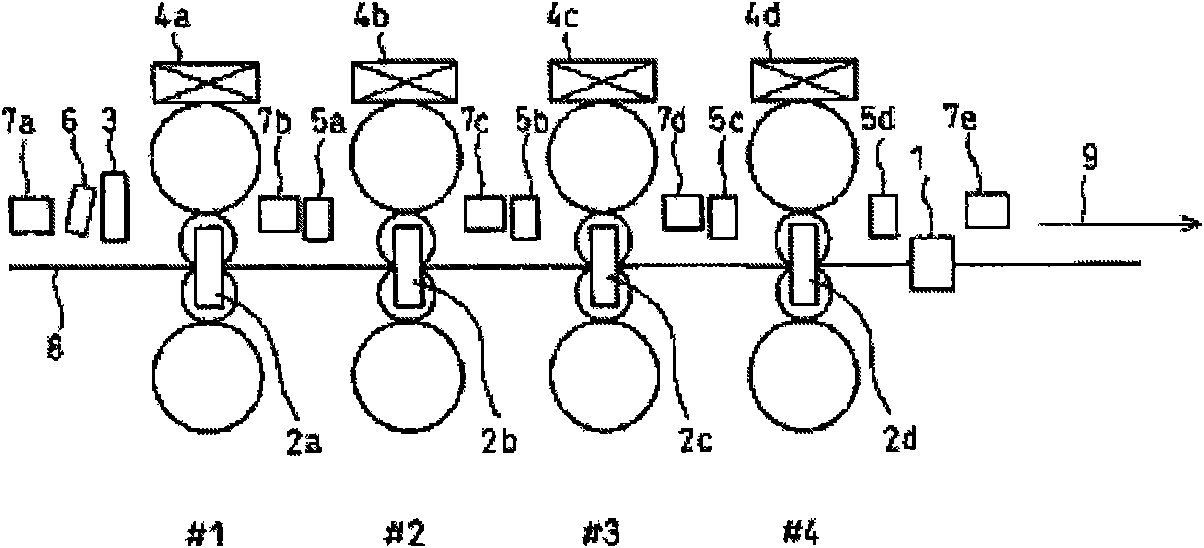

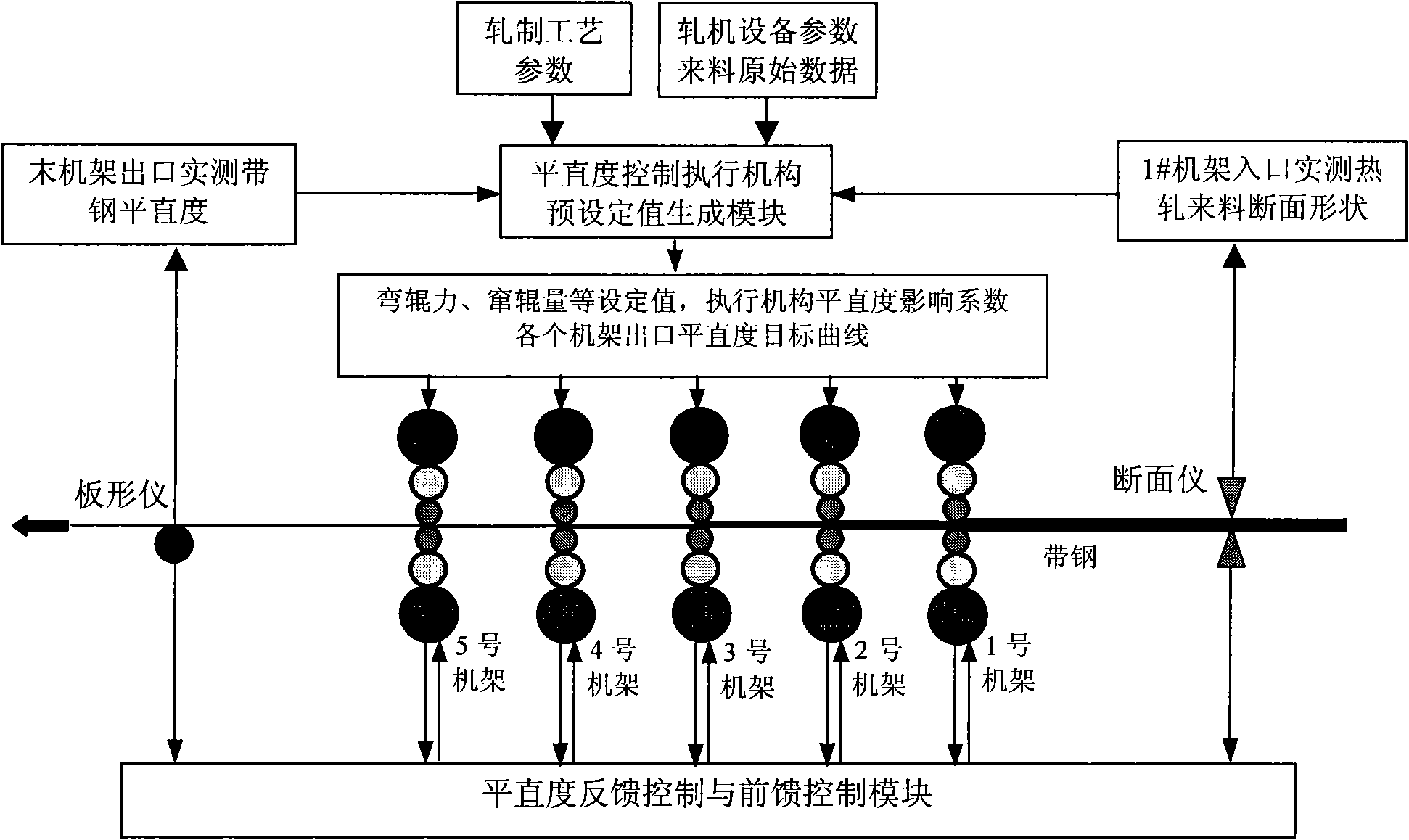

Method for controlling planeness of cold-rolling strip steel

ActiveCN101618402ARealize coordinated controlAccurate detectionRare end control deviceTemperature control deviceAutomatic controlEngineering

The invention discloses a method for controlling the planeness of cold-rolling strip steel, which comprises the following steps of: carrying out planeness feed-forward control, planeness feedback control and coordination control between both; detecting the cross-section shape and the planeness of a hot rolling incoming material, and actually-measured rolling technological parameters of each frame in real time based on a profiler configured on a No. 1 frame inlet, wherein the parameters comprise rolling force actually-measured values and plate shape adjusting mechanism actually-measured values, and carrying out the feed-forward control on the planeness of each frame outlet; and actually measuring the planeness of the cold-rolling strip steel based on a plate shape roller configured on an outlet of a cold rolling mill, and intensively carrying out the feedback control on the planeness of a final frame outlet. The method can eliminate the influences of the cross-section shape and the planeness of the hot rolling incoming material and fluctuations of the rolling technological parameters on the planeness of the final frame outlet to improve the planeness quality of the cold-rolling strip steel on the one hand, and can automatically control the planeness of each frame outlet, reduce incidence of abnormal conditions, such as fracture surfaces, deviation and the like, and improve the stability in the production process of tandem cold strip rolling on the other hand.

Owner:BAOSHAN IRON & STEEL CO LTD

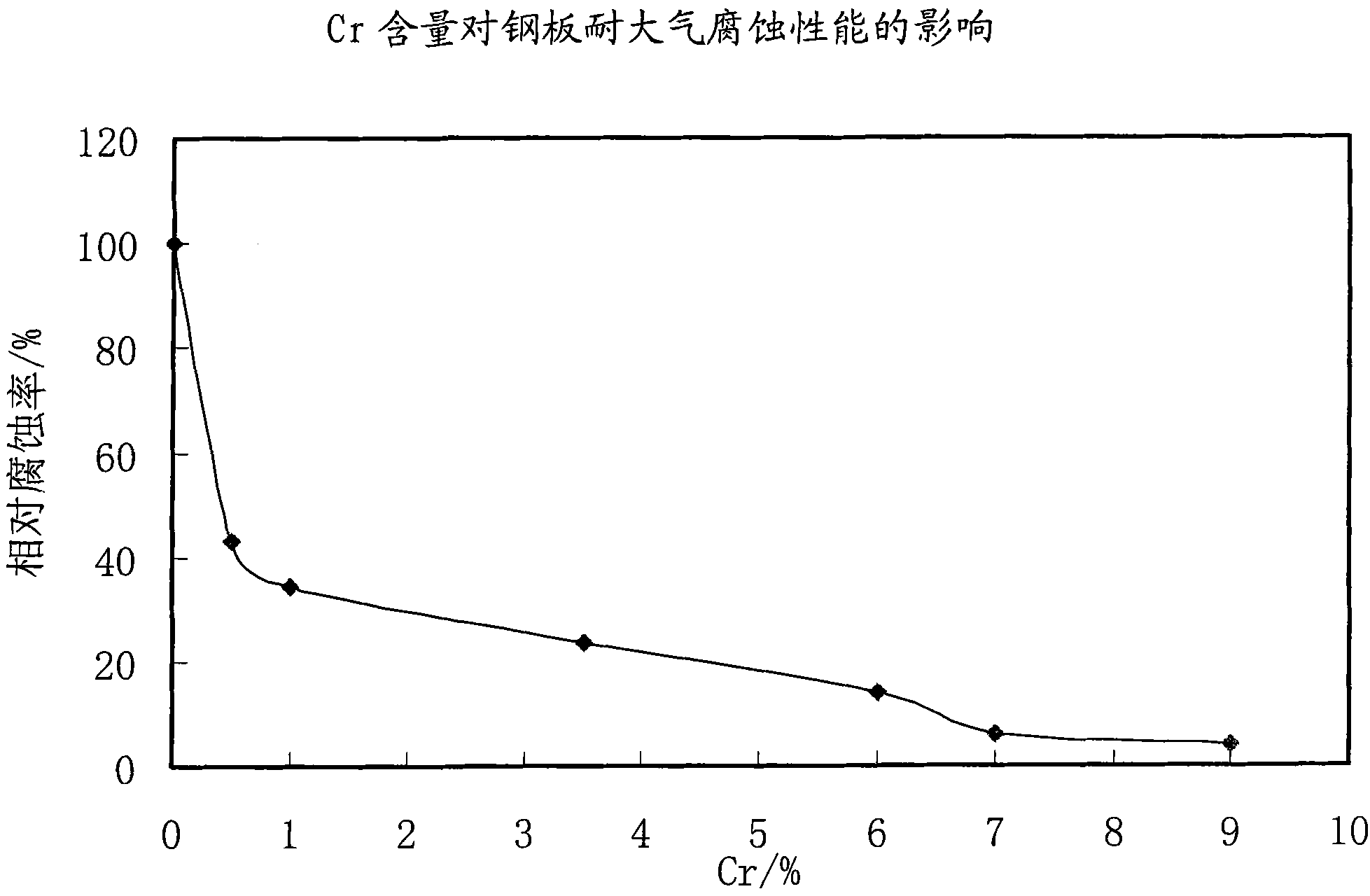

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

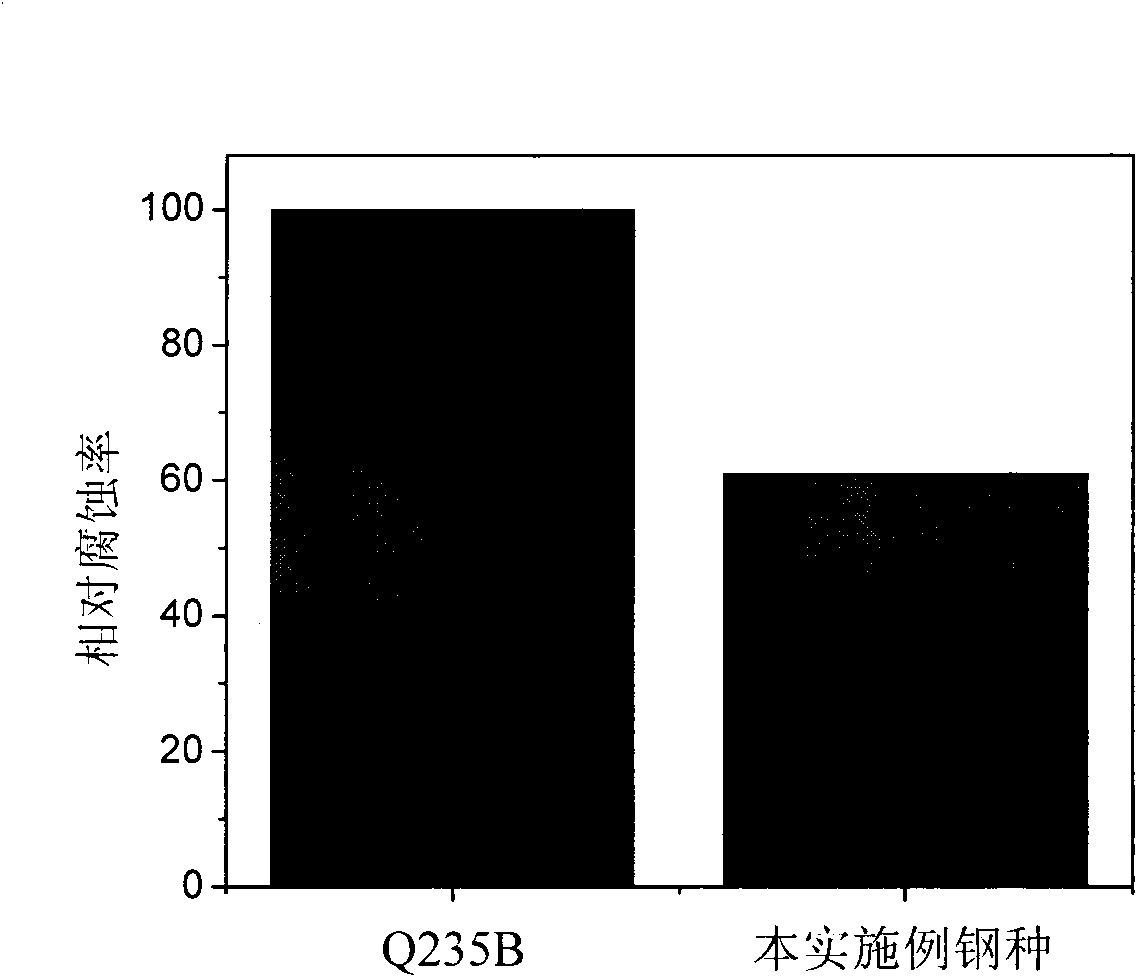

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

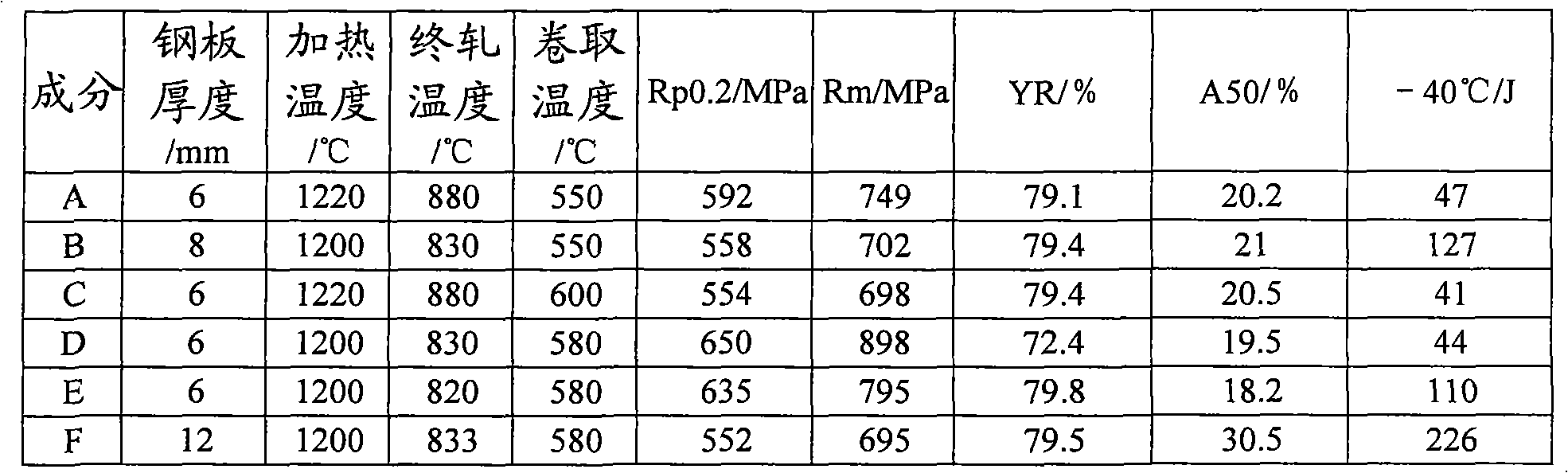

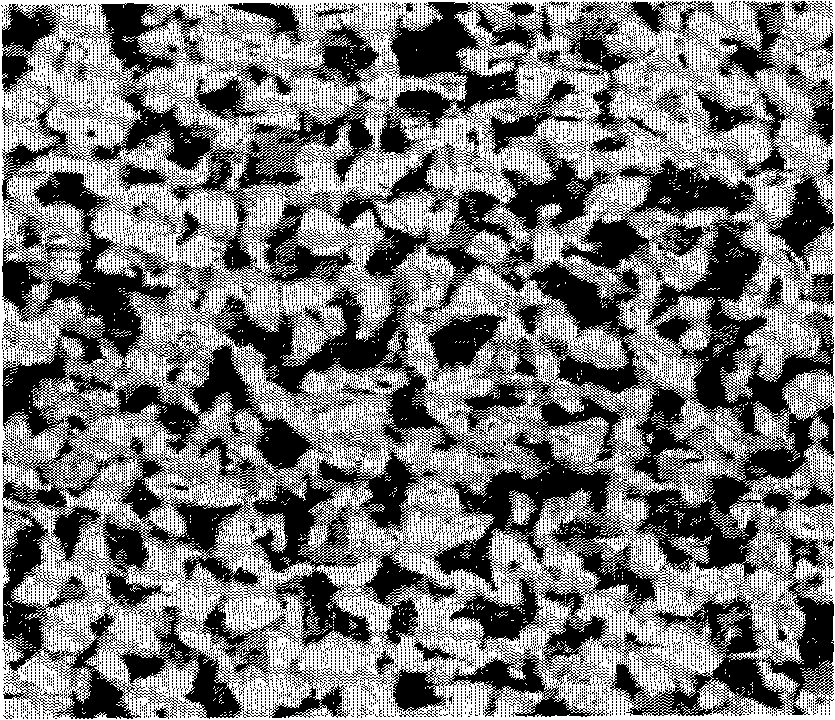

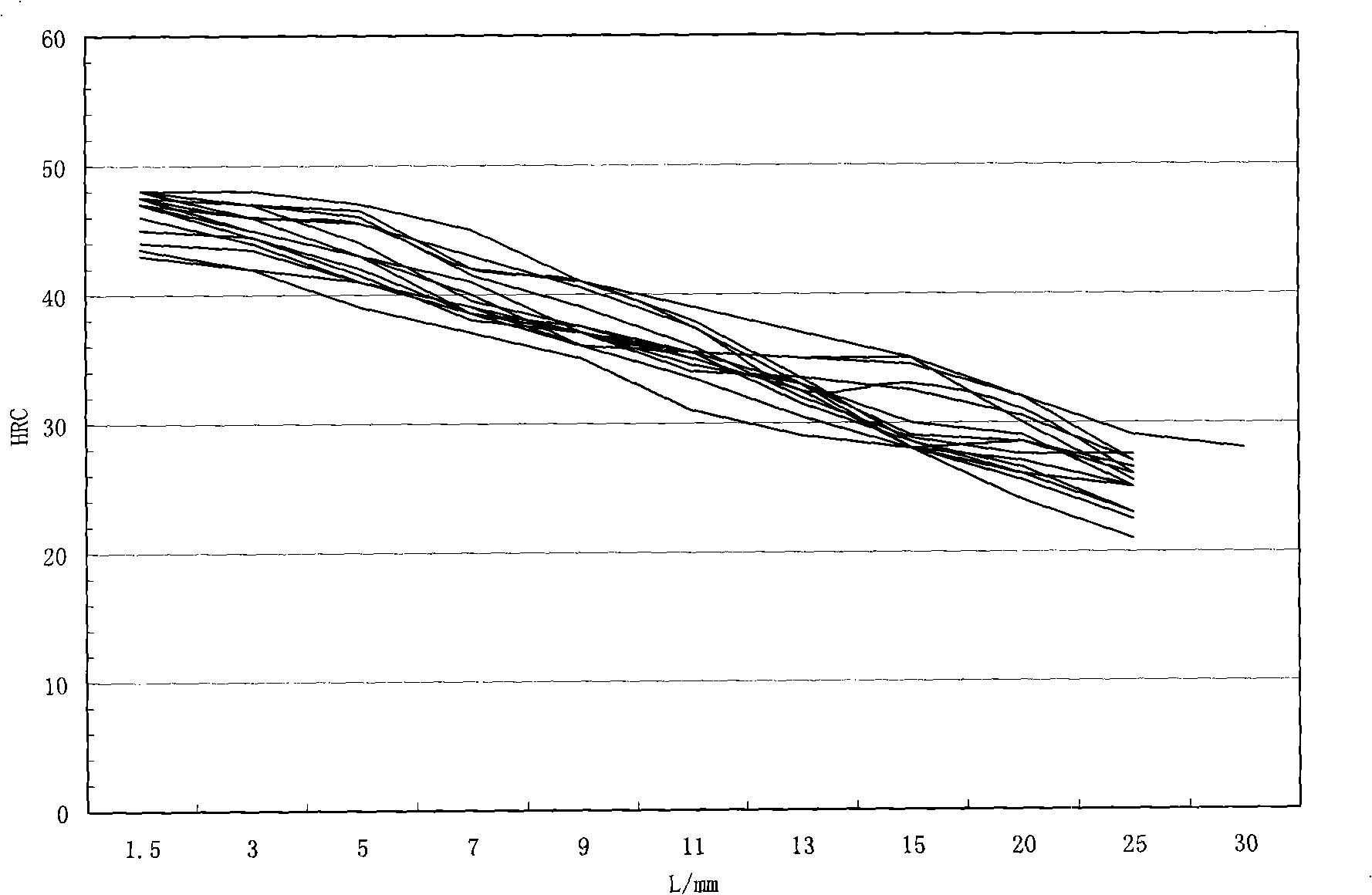

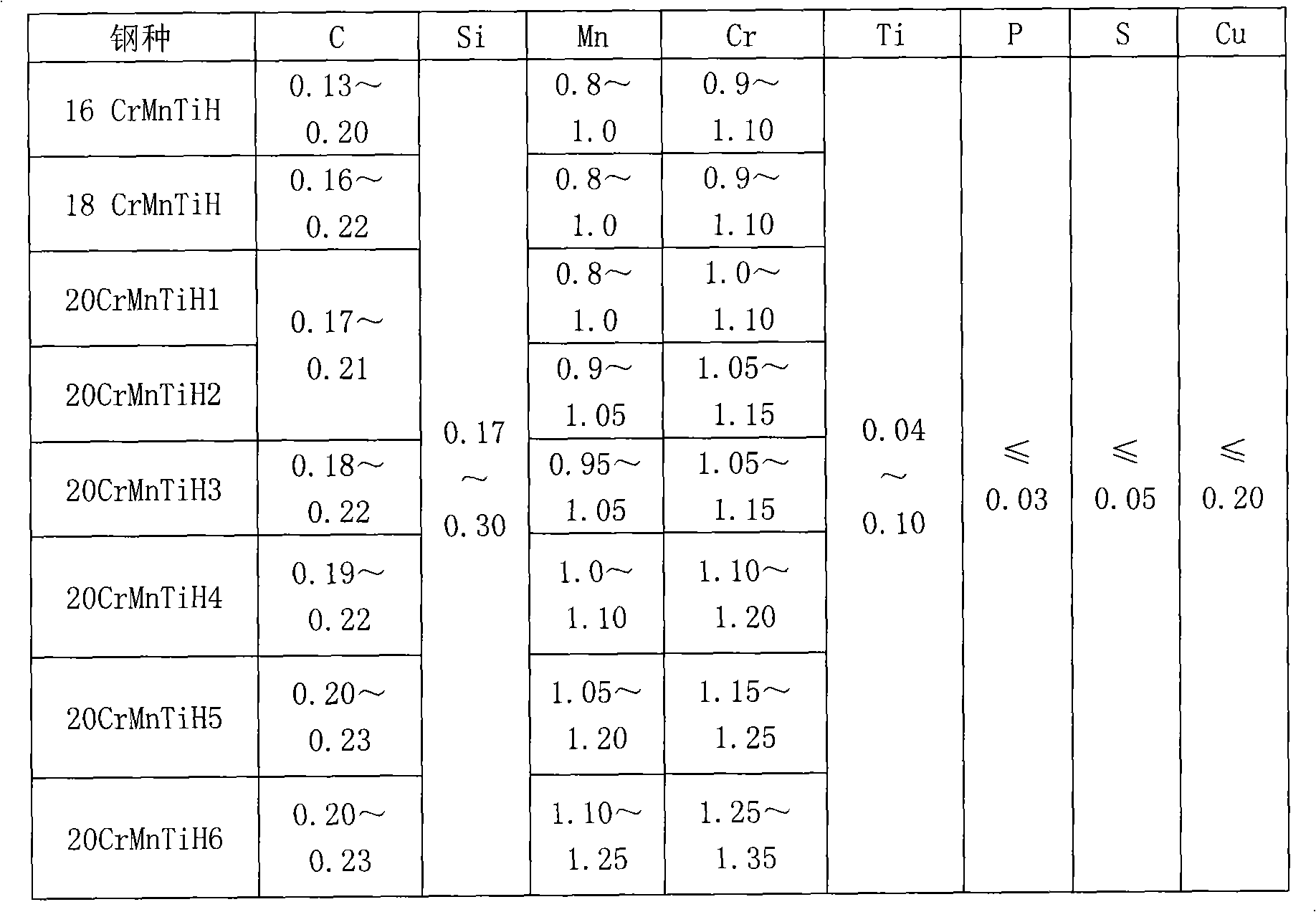

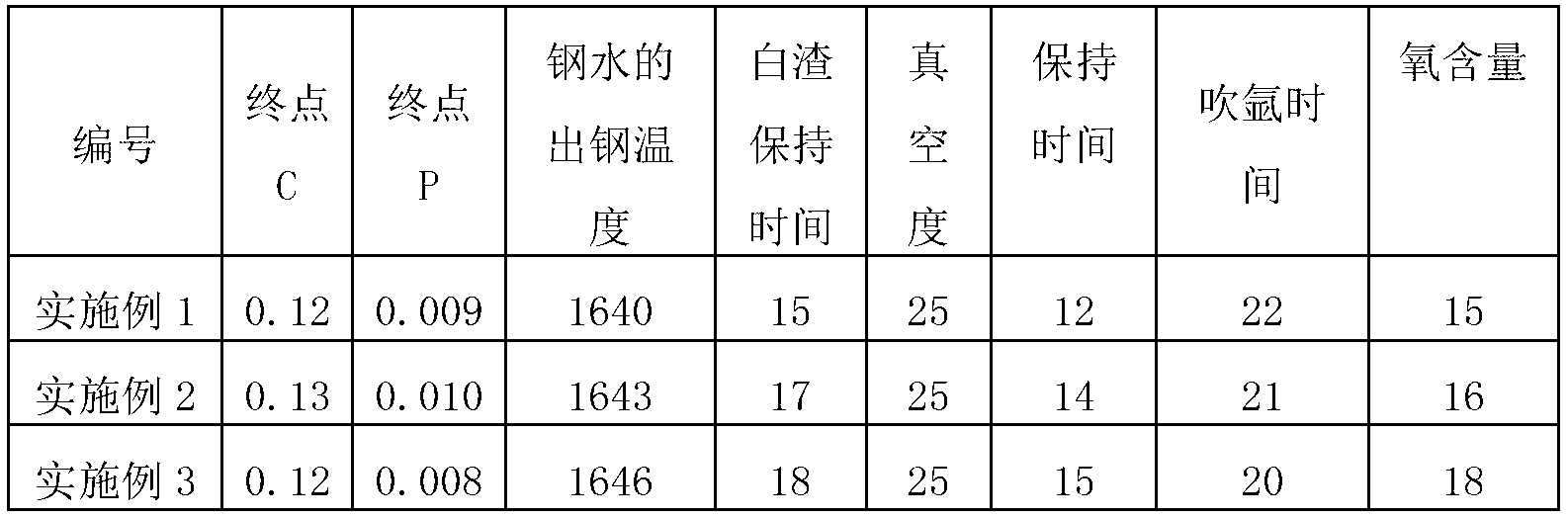

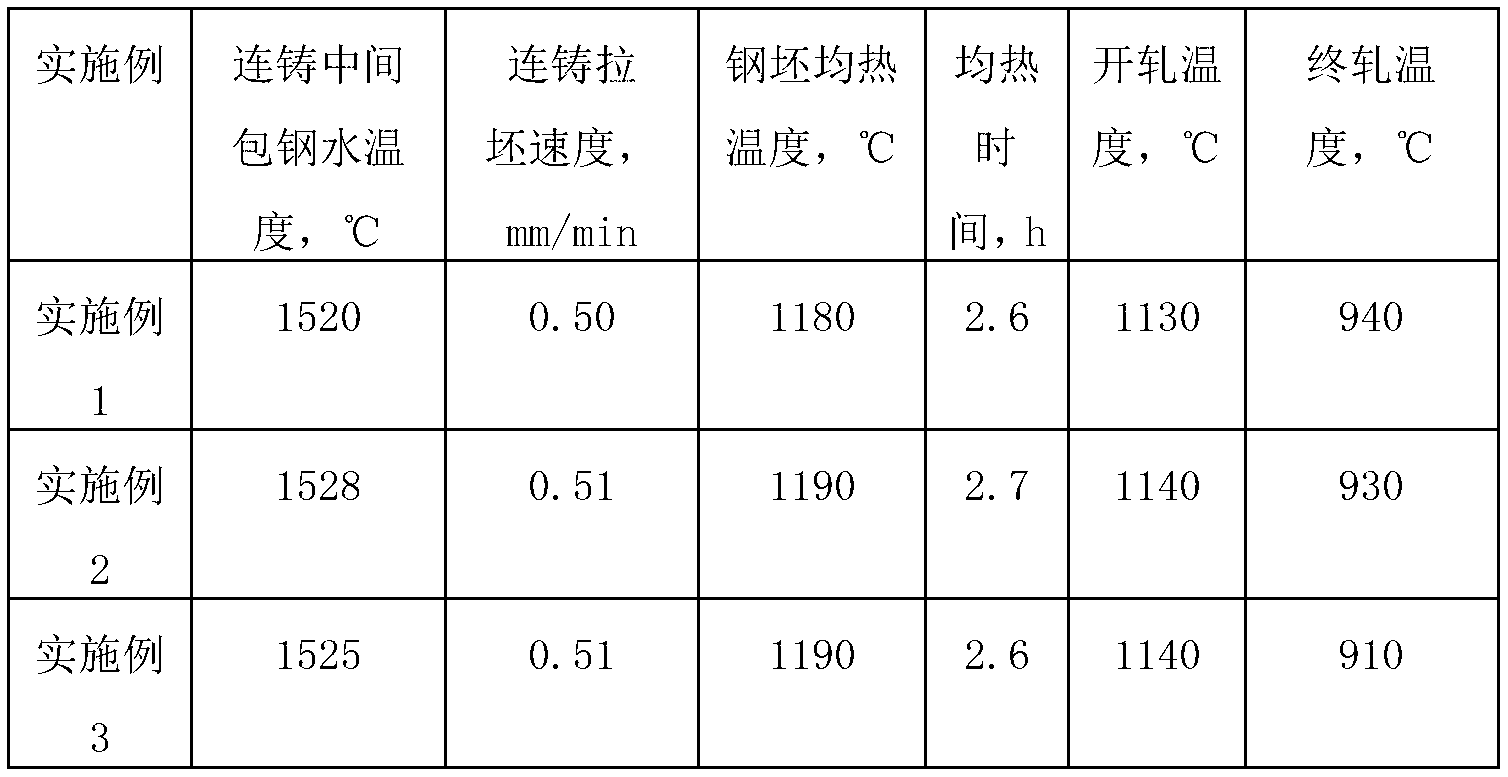

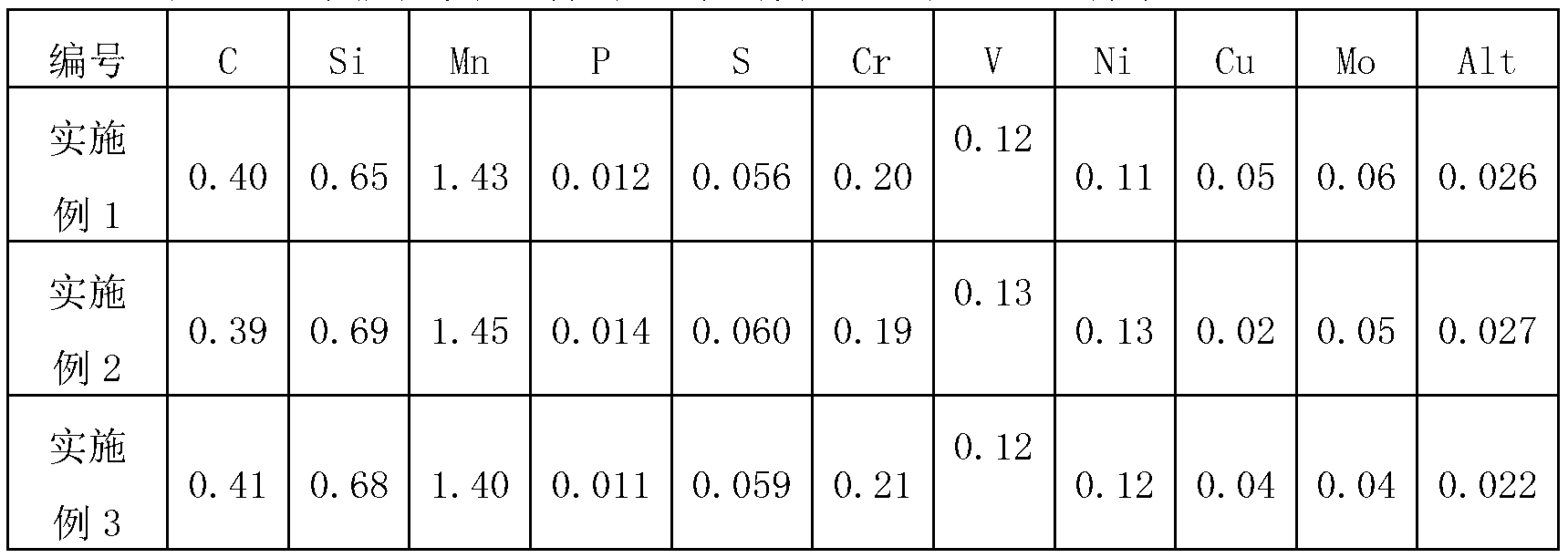

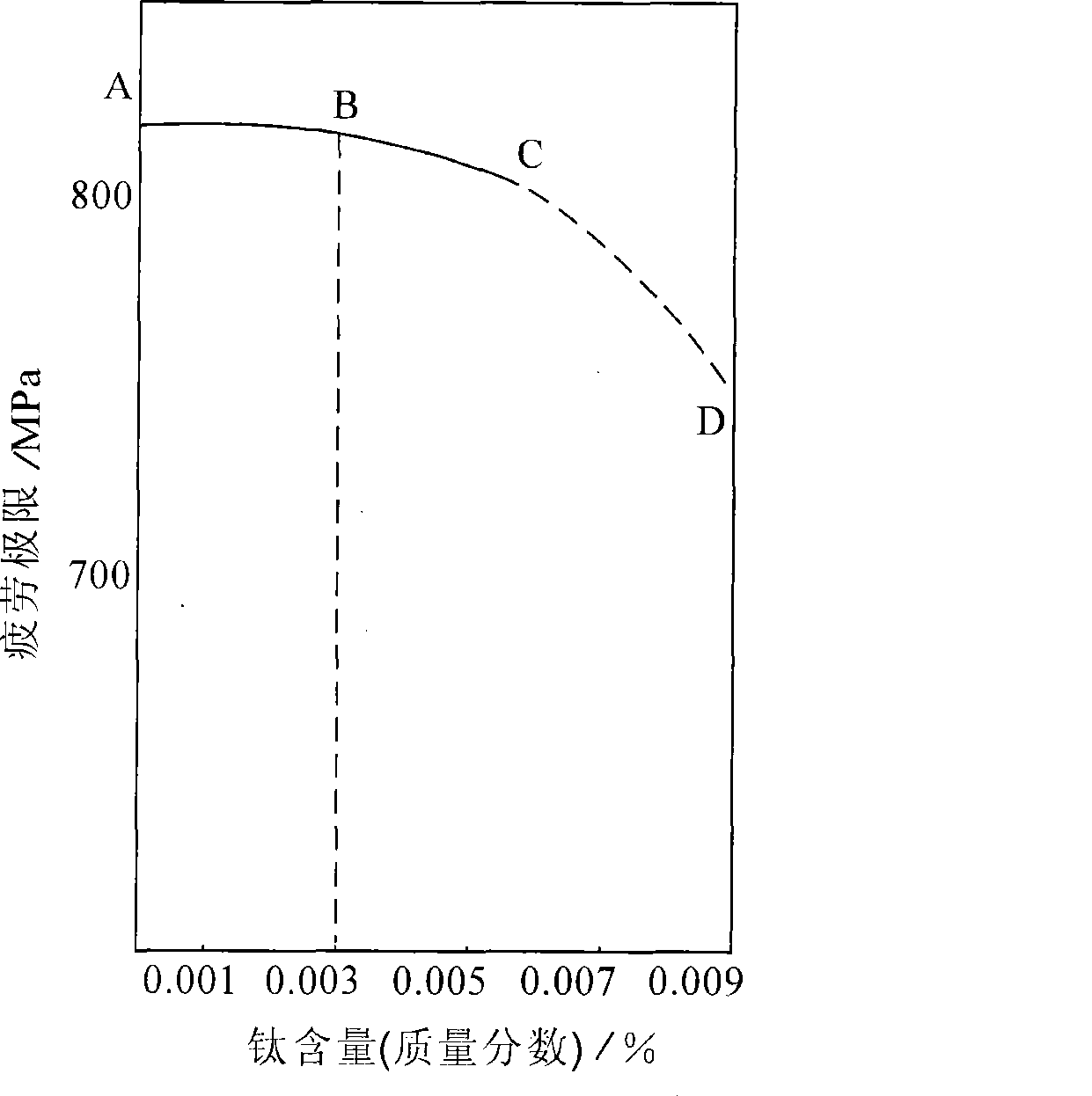

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

High carbon steel wire rod and preparation method thereof

ActiveCN101649416AImprove mechanical propertiesLess alloying elementsTemperature control deviceManufacturing convertersWire rodTemperature control

The invention relates to a high carbon steel wire rod with tensile strength of more than 1,200 MPa and surface shrinkage of more than 35 percent and a preparation method thereof. The high carbon steelwire rod comprises the base components of C, Si, Mn, Cr and the like, selective components of Ni, Cu, Al, B, Ti, Nb, Mo and the like, and the balance of Fe and impurities. The preparation method comprises the following procedures of smelting, casting, rolling and cooling control sequentially, wherein the rolling-starting temperature of the rolling procedure is controlled between 1,000 DEG C and 1,100 DEG C, the spinning temperature is 870-930 DEG C, the cooling controlling procedure is carried out by adopting Steyr cooling control, rapid cooling is adopted before the phase change and at the earlier stage of the phase change, and the slow cooling is adopted at the later stage of the phase change. The high carbon steel wire rod has excellent mechanical performance, less alloy elements and low cost; and meanwhile, the preparation method is realized by only less adjusting the prior production process of the high carbon steel wire rod without nearly adding any production cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

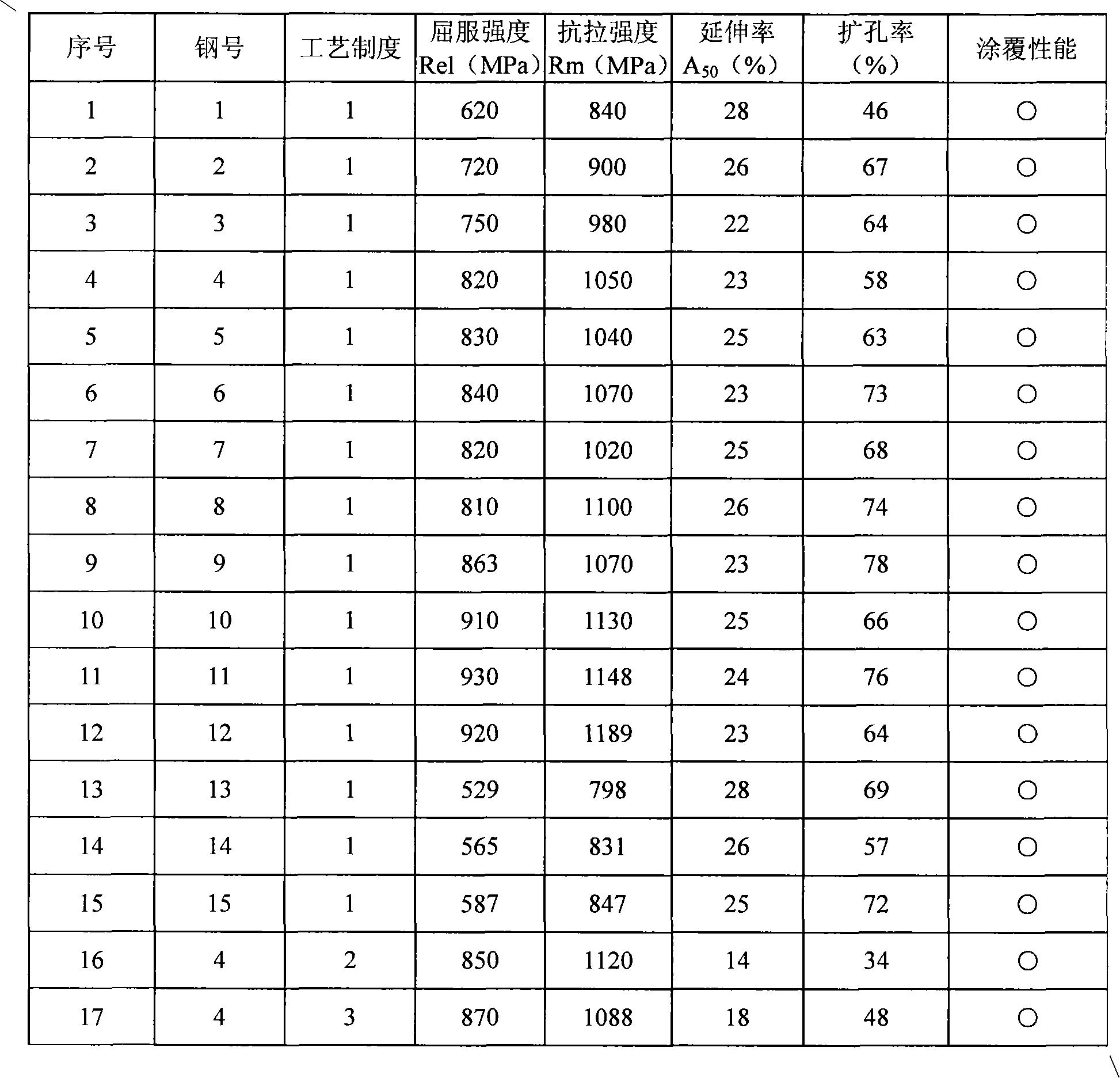

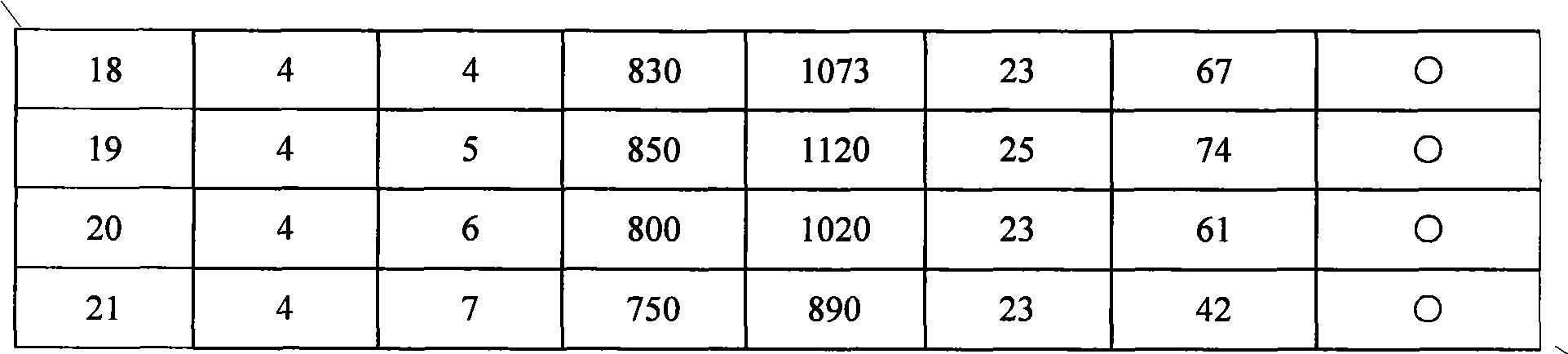

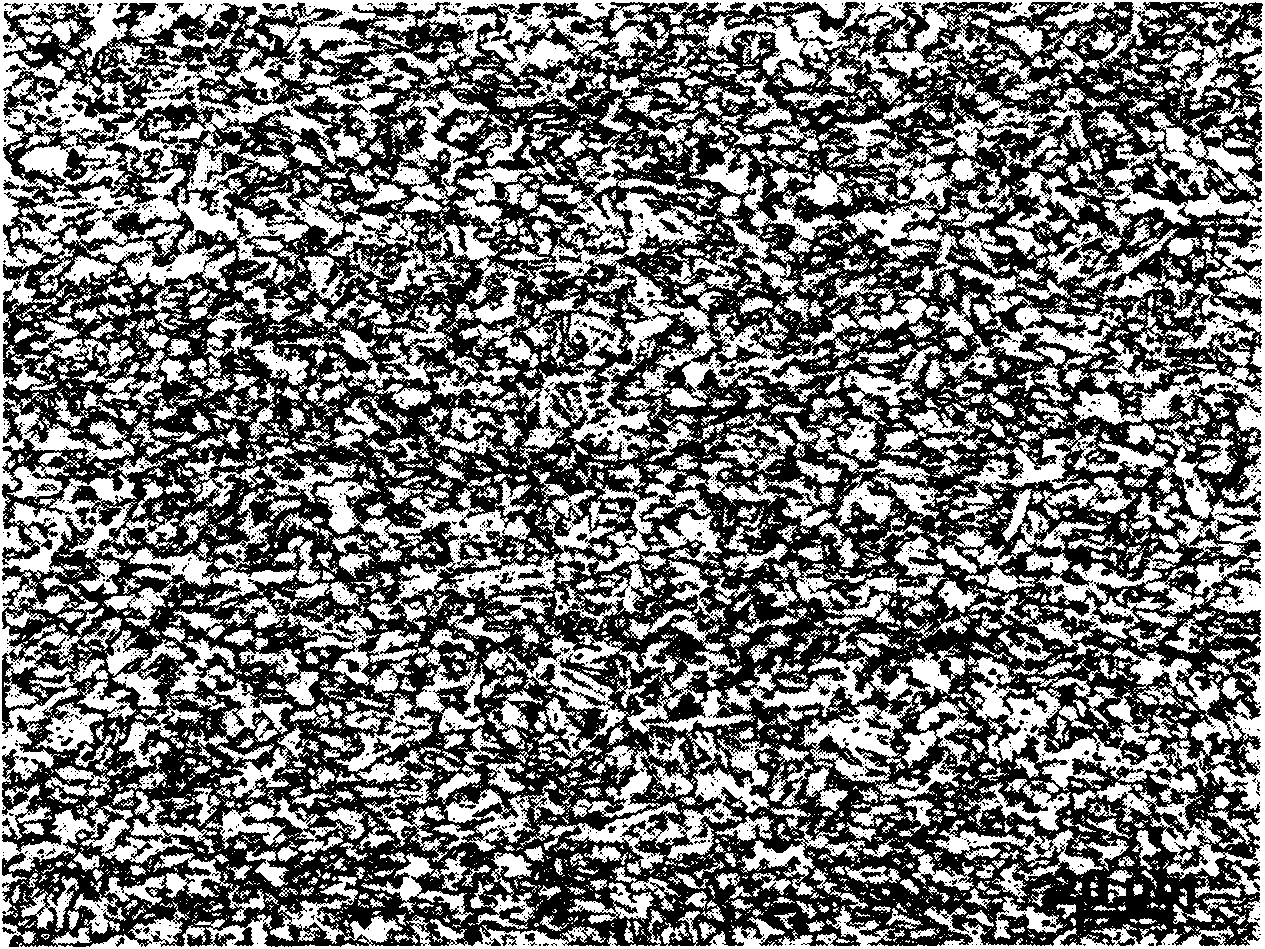

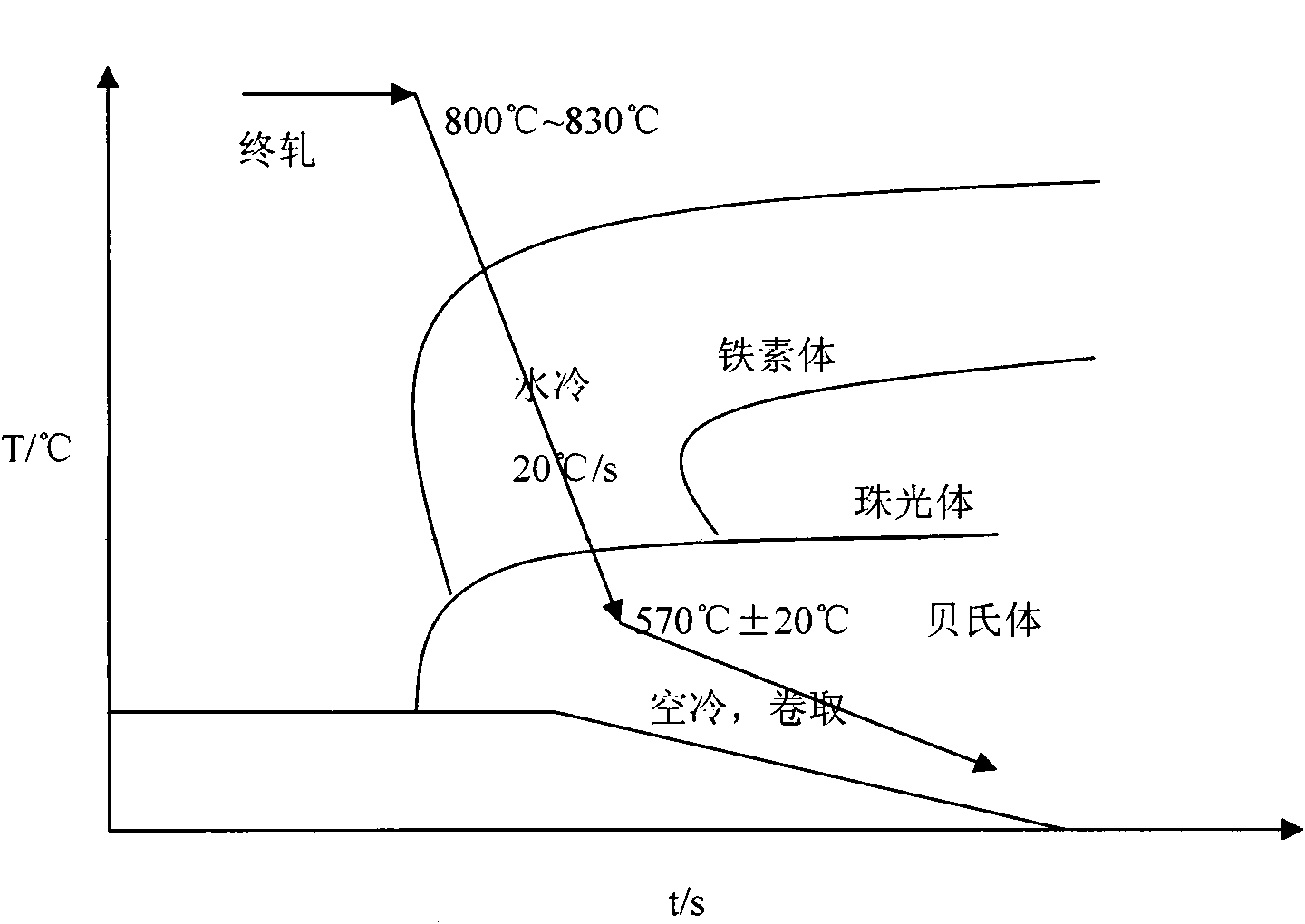

High-strength cold-rolled plate with favorable forming property and preparation method thereof

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

High strength low alloy hot rolling ferrite bainite weathering resistant steel and production method thereof

ActiveCN101660099AHigh strengthImprove toughnessTemperature control deviceManufacturing convertersNiobiumManganese

The invention relates to a high strength low alloy hot rolling ferrite bainite weathering resistant steel and a production method thereof. The steel comprises the components by weight percent: 0.05-0.10% of C, 0.30-0.45% of Si, 1.00-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.50-0.70% of Cr, 0.20-0.30% of Ni, 0.20-0.40% of Cu, less than or equal to 0.05% ofAl, 0.01-0.025% of Ti, 0.03-0.05% of Nb and the rest of Fe and impurities; and the yield strength is more than or equal to 450MPa, and the welding cold crack susceptibility coefficient is less than orequal to 0.2. The invention has the advantages of low cost, high strength, low yield ratio, high weatherability, excellent weldability and low temperature toughness, simple process flow of the preparation technique and easy operation. Therefore, the invention can be widely applied to the fields such as bridges, buildings, containers, railway coaches, etc.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

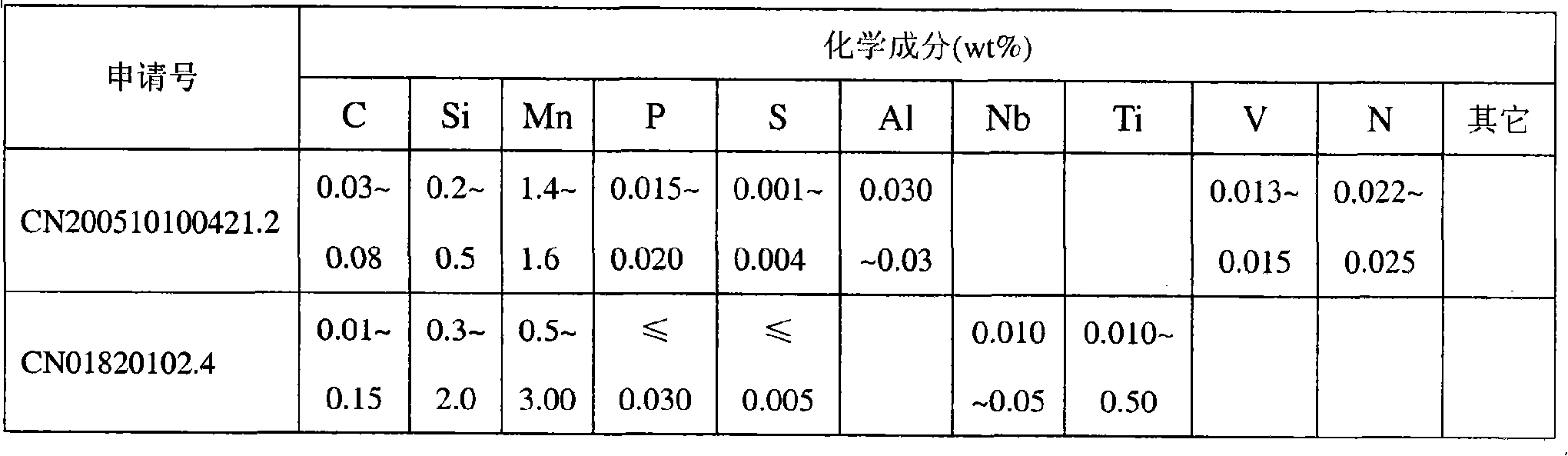

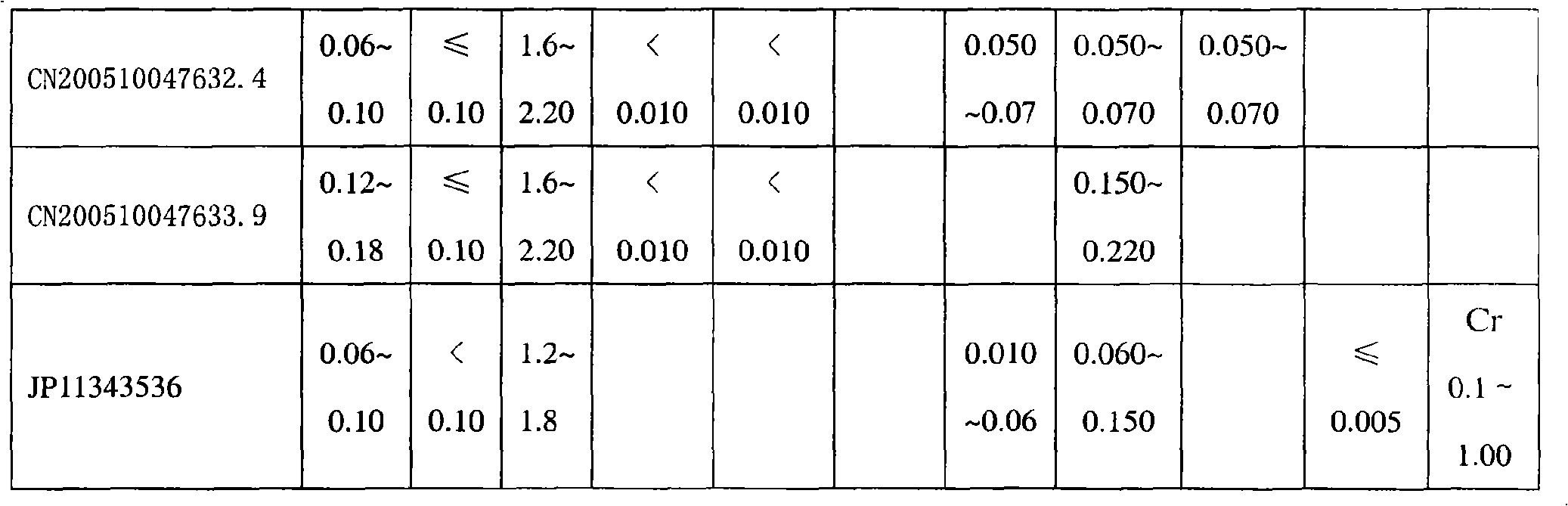

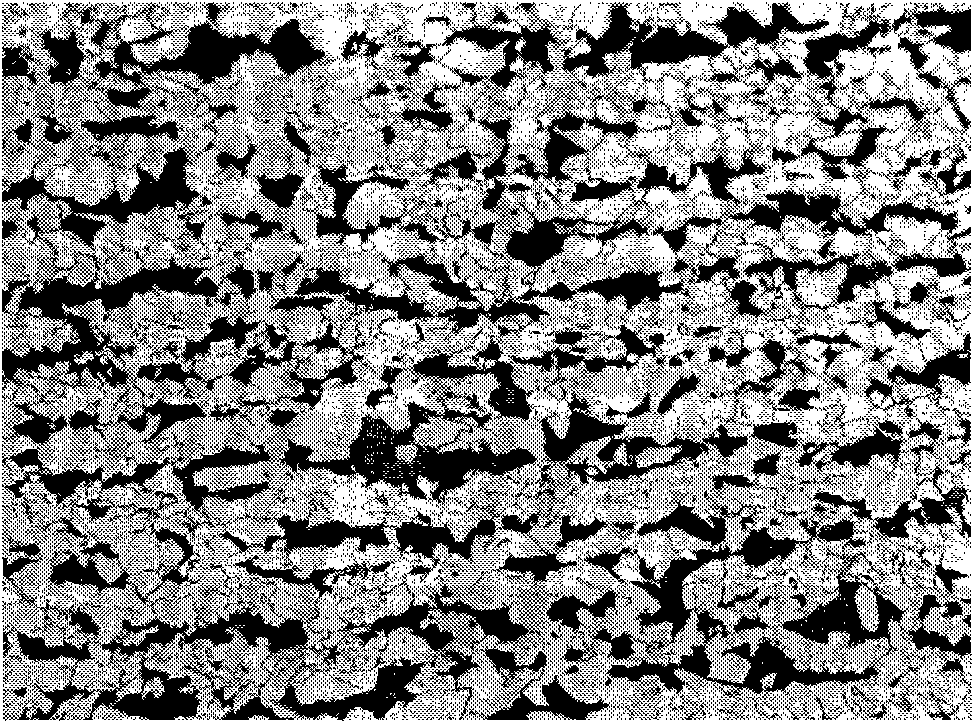

Q345q-series super-thick bridge steel plate and production method thereof

ActiveCN101880824AHigh standardRoll force/gap control deviceTemperature control deviceProduction lineChemical composition

The invention discloses a Q345q-series super-thick guaranteed performance and flaw detection bridge steel plate comprising the following chemical components in percentage by mass: 0.08-0.16 percent of C, 0.20-0.50 percent of Si, 1.15-1.60 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, not more than 0.12 percent of microalloyed element (V+Nb+Ti+Ni), 0.010-0.050 percent of AlS and the balance of Fe and residual elements; and carbon equivalent is not more than 0.43. The invention also discloses a production method of the steel plate, comprising the steps of rolling, cooling, straightening, cooling in pile and thermal treatment. In the rolling, the cooling and the straightening, the 130 mm super-thick Q345qD(E) steel plate is successfully developed in the production line of a converter, die casting, mill rolling and normalization thermal treatment through carrying out reasonable composition design, die casting, TMCP (Thermal Mechanical Control Process) rolling and thermal treatment; the secondary flaw detection qualification rate reaches 90 percent, the performance initial test qualification rate reaches 100 percent, and the Z-direction performance of the entity of the steel plate can reach Z15 level. The development of the super-thick steel plate satisfies the higher requirements on bridge industry.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Medium-carbon ferrite-pearlite non-quenched and tempered steel and manufacturing method thereof

ActiveCN103266287AHigh strengthImprove toughnessTemperature control deviceProcess efficiency improvementQuenchingToughness

The invention relates to a medium-carbon ferrite-pearlite non-quenched and tempered steel which comprises the following components in percentage by weight: 0.35-0.43% of C, 0.30-0.80% of Si, 1.00-1.60% of Mn, 0.10-0.30% of Cr, 0.06-0.20% of V, 0.10-0.30% of Ni, at most 0.035% of P, 0.040-0.075% of S, 0.010-0.060% of Alt, 100-200*10<-4>% of N, and the balance of Fe and inevitable impurities. The medium-carbon ferrite-pearlite non-quenched and tempered steel has the characteristics of high strength and high toughness, and the plasticity of the hot rolled steel can still achieve the level of 40Cr or 40MnB quenched and tempered steel under the condition of no quenching and tempering treatment. The invention also relates to a manufacturing method of the medium-carbon ferrite-pearlite non-quenched and tempered steel.

Owner:LAIWU IRON & STEEL GRP

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

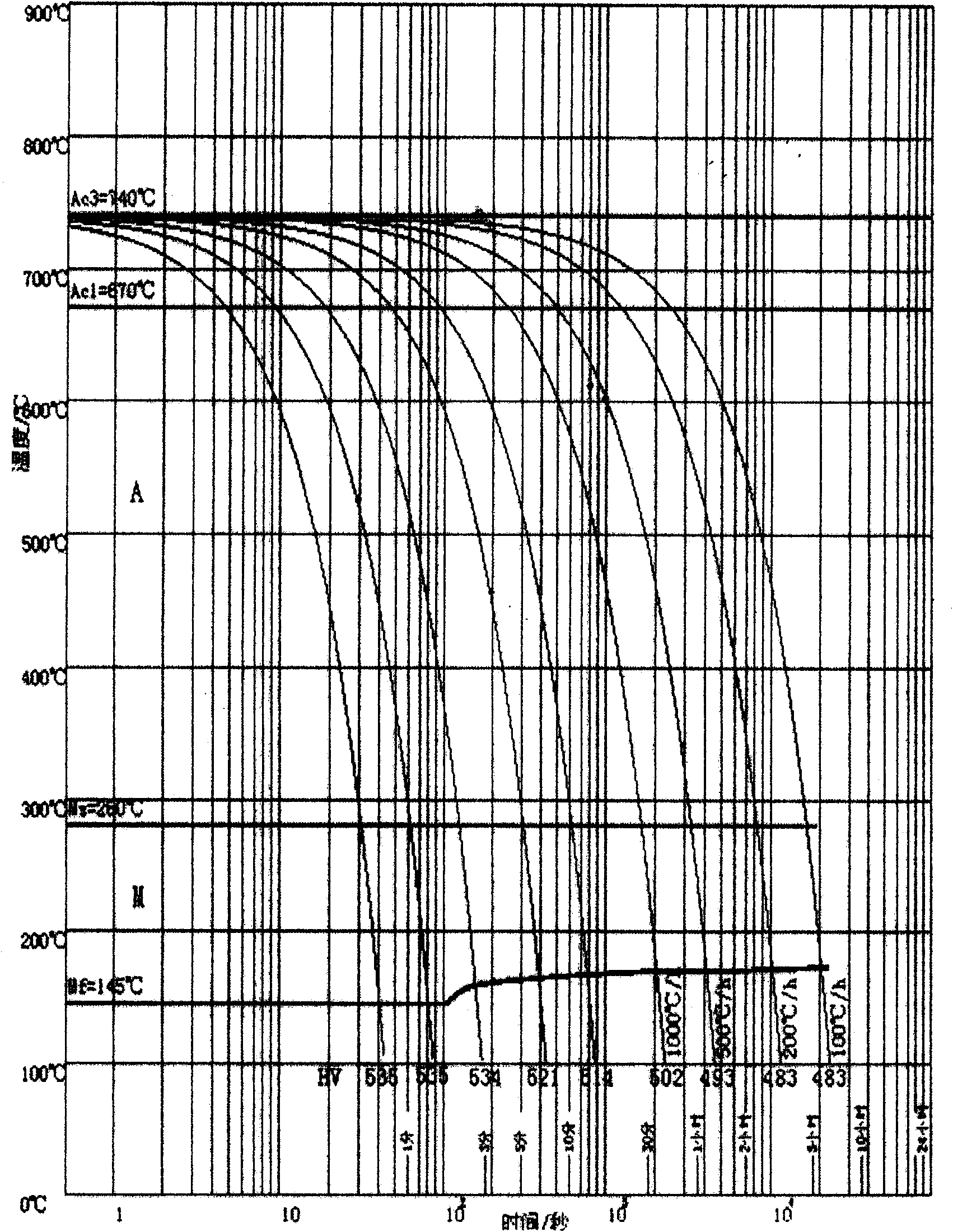

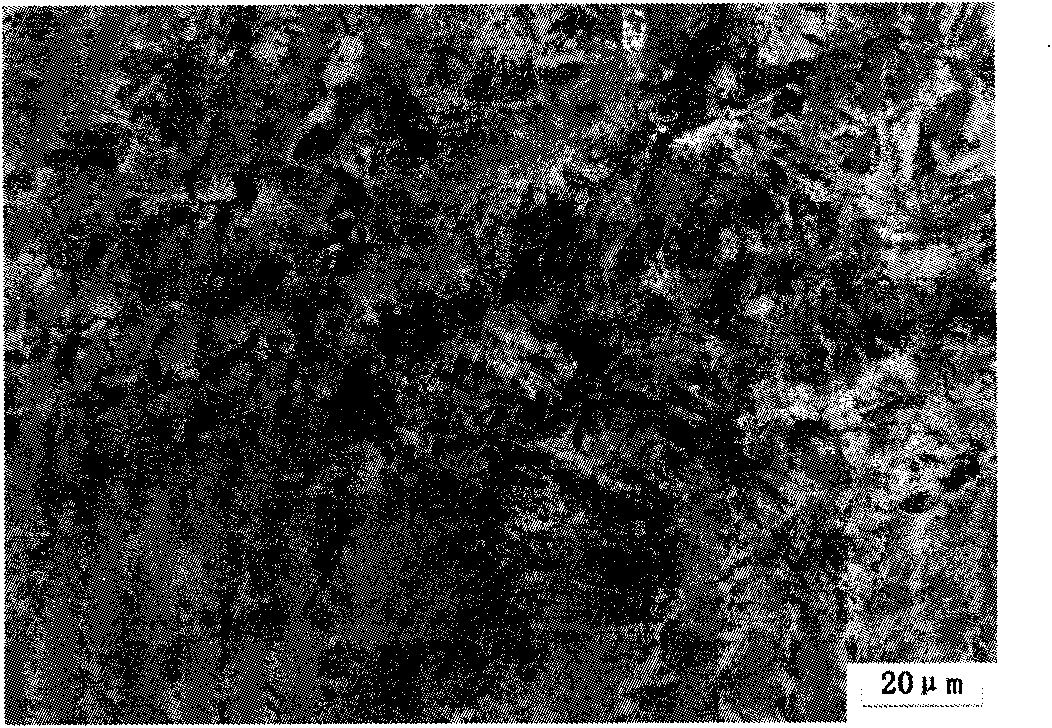

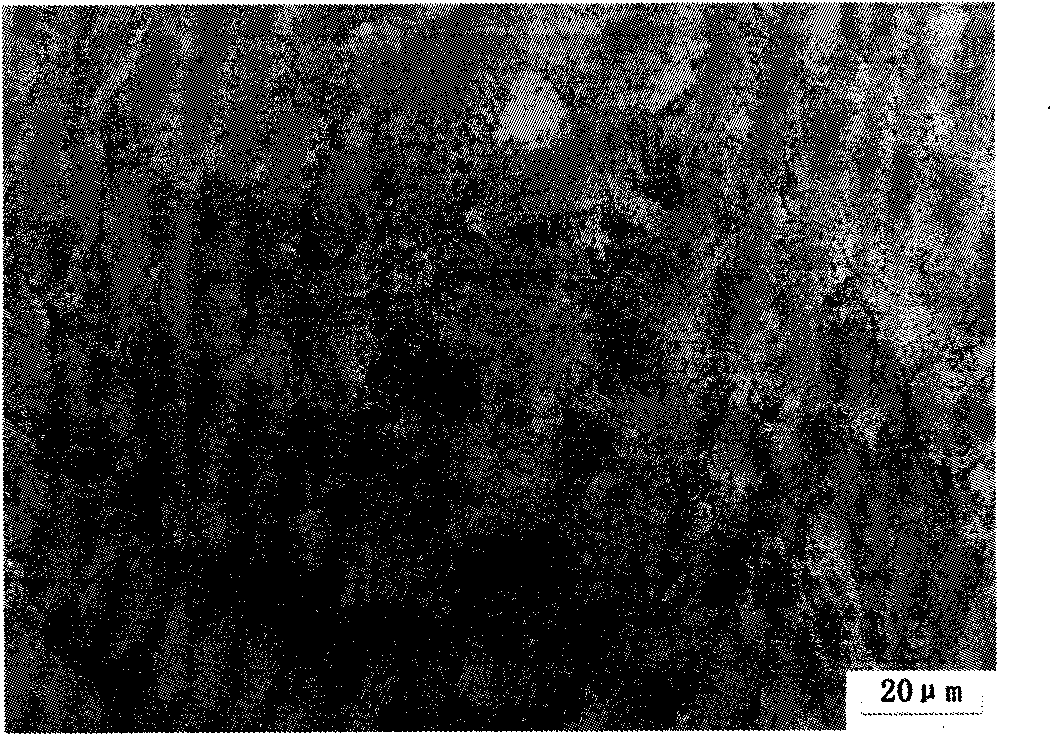

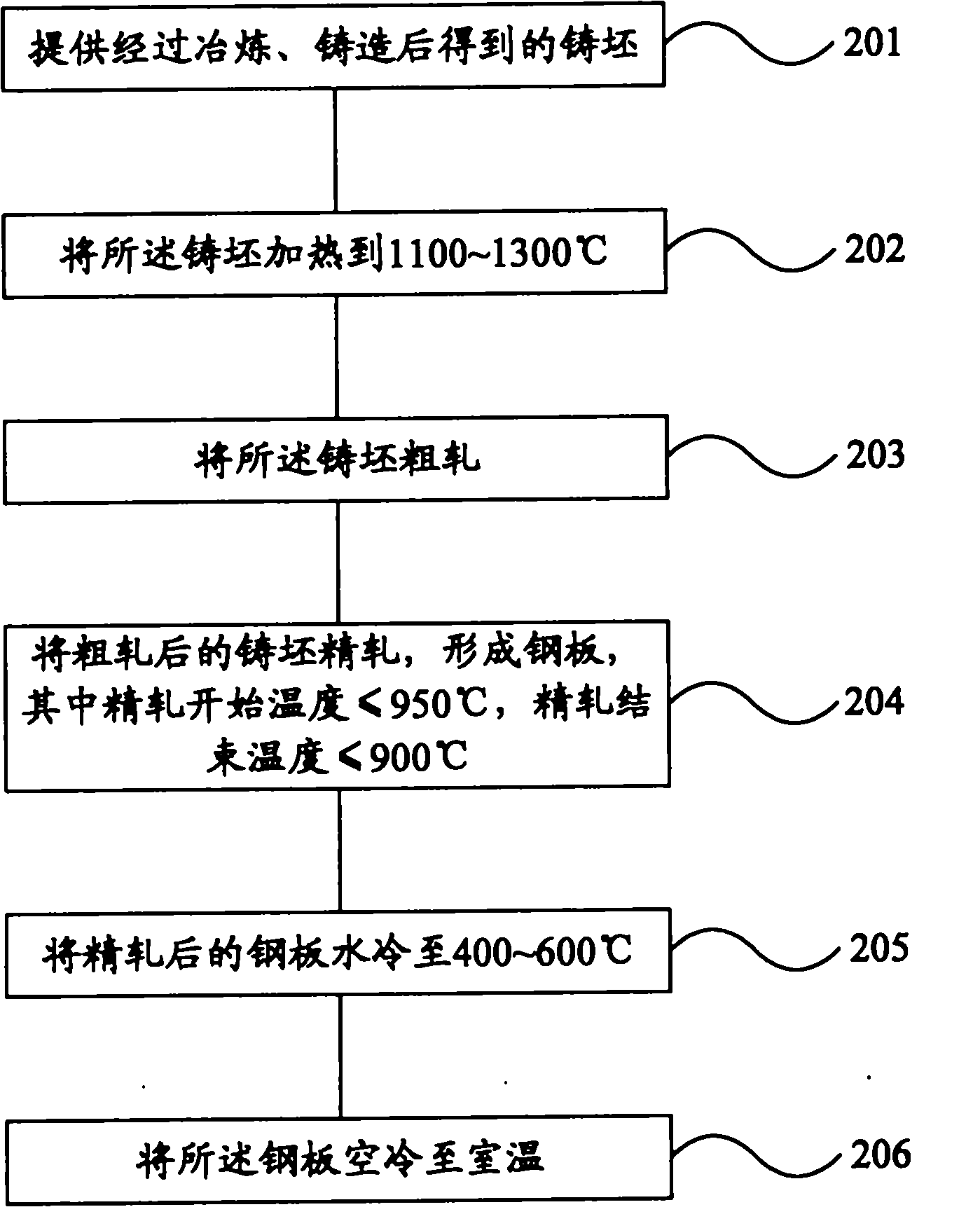

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength cold rolling transformation induced plasticity steel plate and preparation method thereof

InactiveCN102409235ASolve Surface Quality IssuesSolve the blockageTemperature control deviceFurnace typesSheet steelRoom temperature

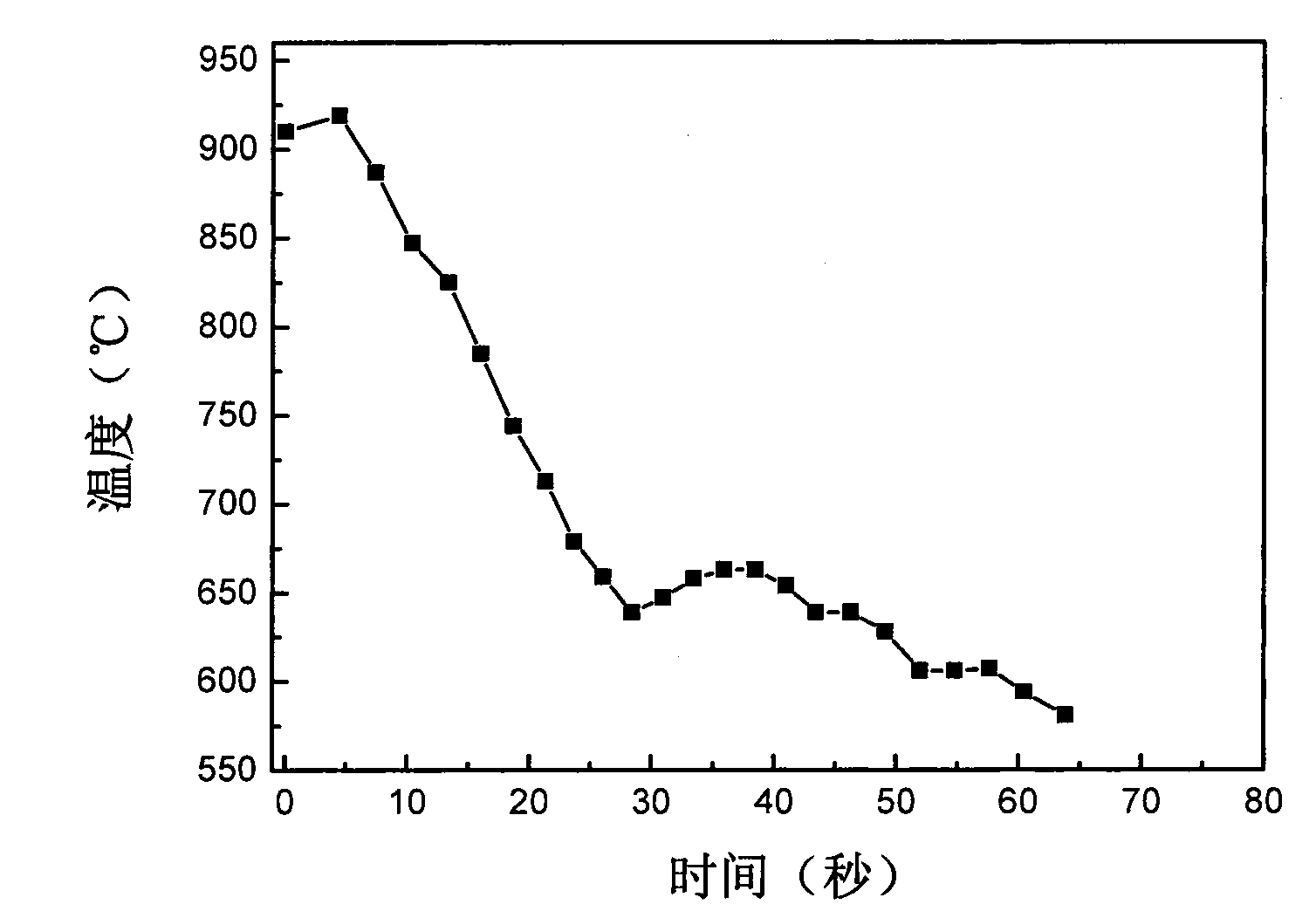

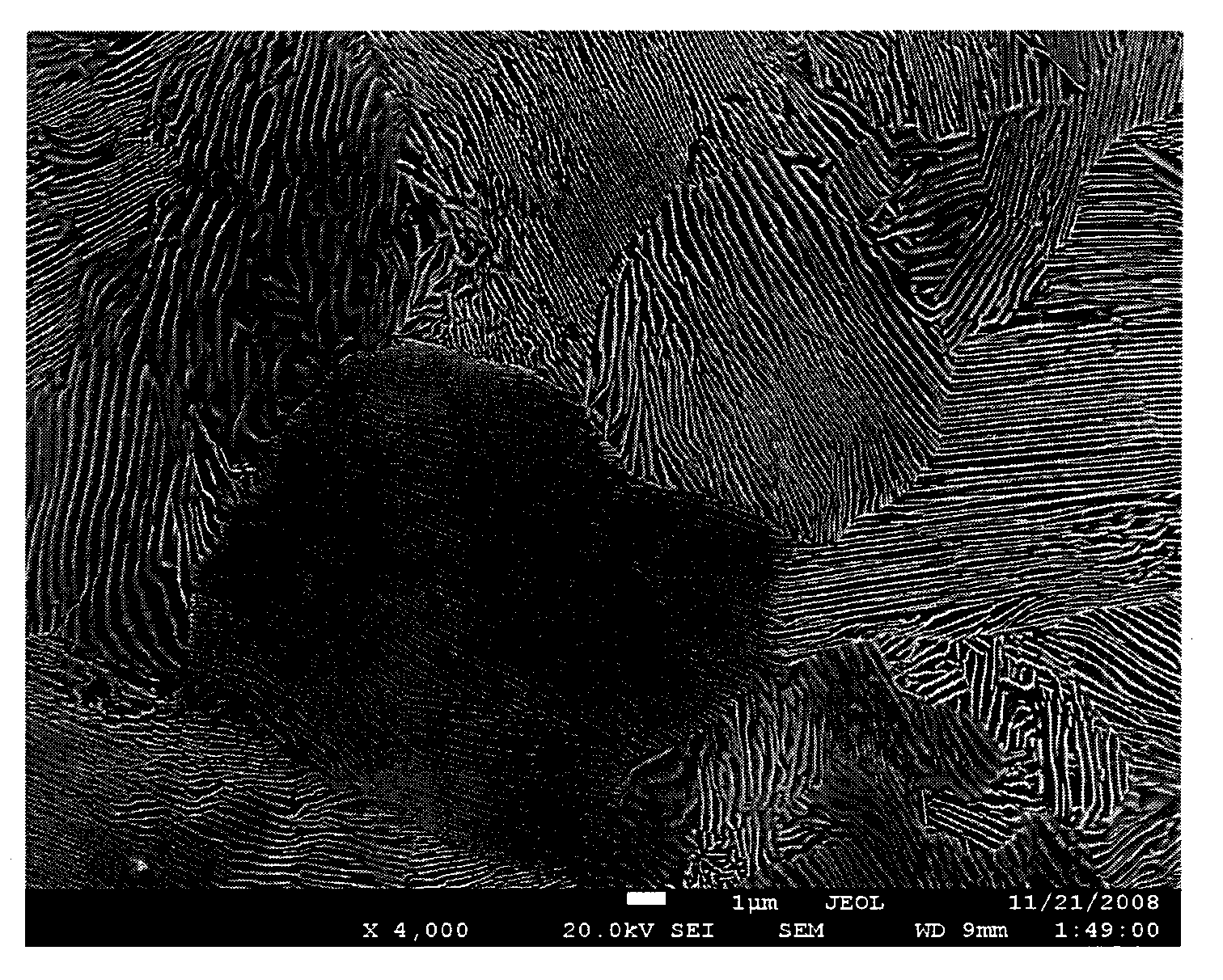

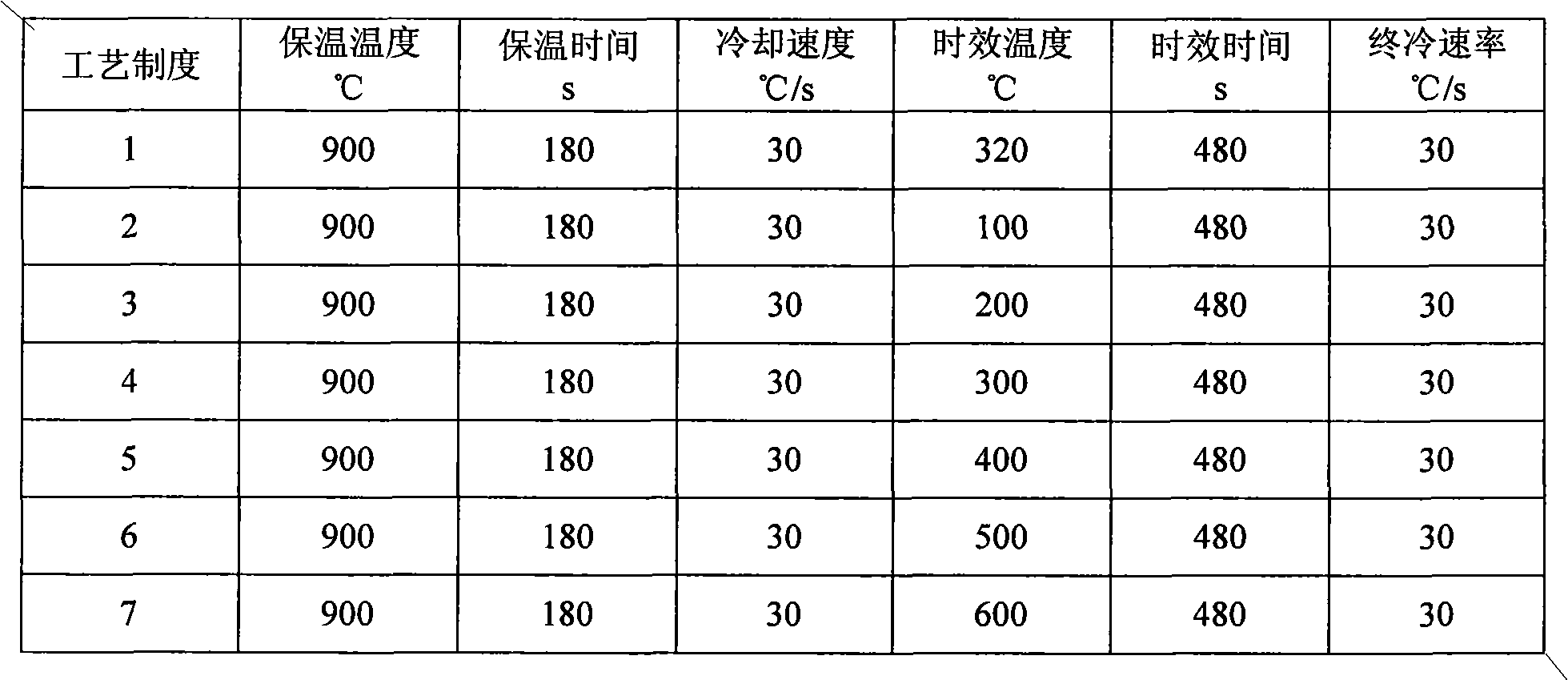

The invention provides a high-strength cold rolling transformation induced plasticity steel plate and a preparation method thereof. The high-strength cold rolling transformation induced plasticity steel plate comprises the following components by weight percentage: 0.1%-0.5% of C, 0.1%-0.6% of Si, 0.5%-2.5% of Mn, 0.02%-0.12% of P, less than or equal to 0.02% of S, 0.02%-0.5% of Al, less than or equal to 0.01% of N, 0.1%-1.0% of Cu and the rest Fe. The preparation method comprises the following steps of: (a) refining molten steel meeting a component condition, and casting into a blank; (b) rolling, wherein the heating temperature is 1,100-1,250 DEG C, the heat preservation time is 1-4h, the initial rolling temperature is 1,100 DEG C, the final rolling temperature is 750-900 DEG C, the coiling temperature is less than 700 DEG C, the thickness of a hot rolled steel plate is 2-4mm, and the cold rolling accumulated pressing amount is 40-80%; and (c) continuous annealing, wherein the annealing temperature is 700-Ac3+50 DEG C, the heat preservation time is 30-360s, the cooling speed is 10-150 DEG C / s, the aging temperature is 250-600 DEG C, the aging time is 30-1,200s, and the hot roller steel plate is cooled at the speed of 5-100DEG C / s to be at the room temperature. The steel plate disclosed by the invention has the bending strength of 380-1,000 MPa, tensile strength of 680-1,280 MPa and elongation of 15-30%.

Owner:ANGANG STEEL CO LTD

Low-yield ratio, high heat input welding, high-strength and high ductility steel plate and method of manufacture

ActiveCN101289728AIncrease contentSimple processTemperature control deviceAlloy elementOil production

The invention provides a steel plate having low-temperature toughness, high tensile strength and low yield ratio, as well as a method for making the same. By combining simple combination design of alloying elements with optimized TMCP process, the method successfully solves the problem that low-temperature impact toughness and low yield ratio are in mutual conflict and difficult to reconcile in composition design and process design, which reduces the amount of steel material, saves cost, lightens the dead weight of a steel structure, increases stability and safety, and more importantly, improves the safety, stability and seismic damage resistance of the steel structure. The steel plate can be widely applied to large-scale high-rise building structures, bridge structures, offshore oil production platform structures, low temperature pressure vessels and large-scale ship structures.

Owner:BAOSHAN IRON & STEEL CO LTD

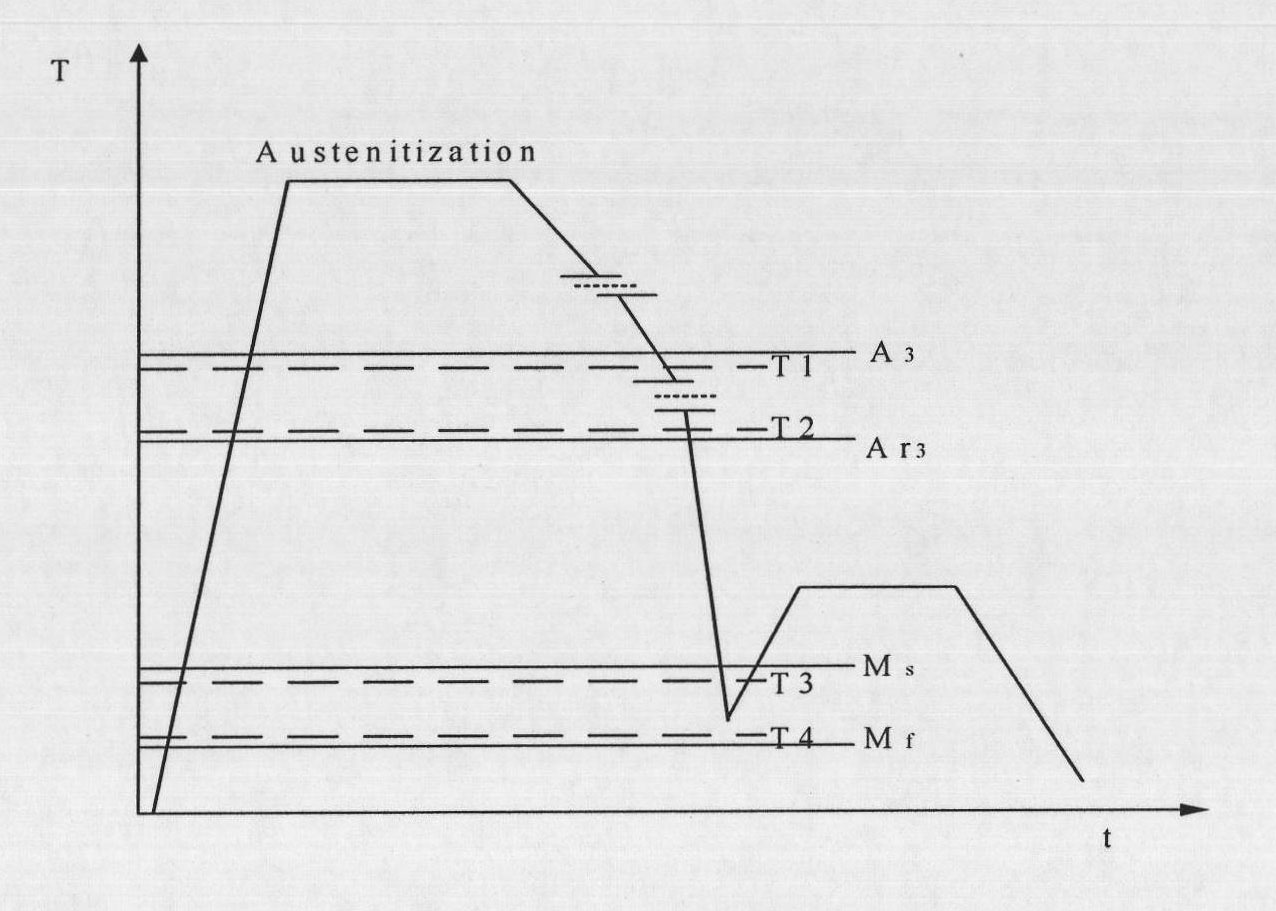

Production method of low-alloy complex-phase (Q and P) steel

InactiveCN101775470AImprove plasticityHigh strengthTemperature control deviceMetal rolling arrangementsRoom temperatureManganese

The invention discloses a production method of low-alloy complex-phase (Q and P) steel. In the method, low-carbon manganese silicon steel or low-carbon manganese silicon aluminium steel is used as raw materials, and the method comprises the following steps of: heating a steel blank to 1100-1250 DEG C; keeping the temperature for 5-120 minutes, and then cooling to 1000-1100 DEG C at the speed of 5-20 DEG C / s; then roughly rolling at the strain rate of 1-50 s<-1>; then cooling to a temperature ranging from T1 to T2 at the speed of 5-50 DEG C / s, wherein T1=A3-(A3-30) DEG C, and T2=Ar3-(Ar3+10) DEG C; then finely rolling at the strain rate of 1-50 s<-1>; after the fine rolling, cooling to the temperature ranging from T3 to T4 at the speed of 40-100 DEG C / s, wherein T3 is lower than a Ms point, and T4 is higher than a Mf point; then heating to 250-450 DEG C; keeping the temperature unchanged for 3-30 minutes, and then cooling to room temperature. Experiences prove that the low-alloy complex-phase (Q and P) steel produced by using the method has higher strength, good plasticity and comprehensive mechanical property better than that of the conventional complex-phase (Q and P) steel.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

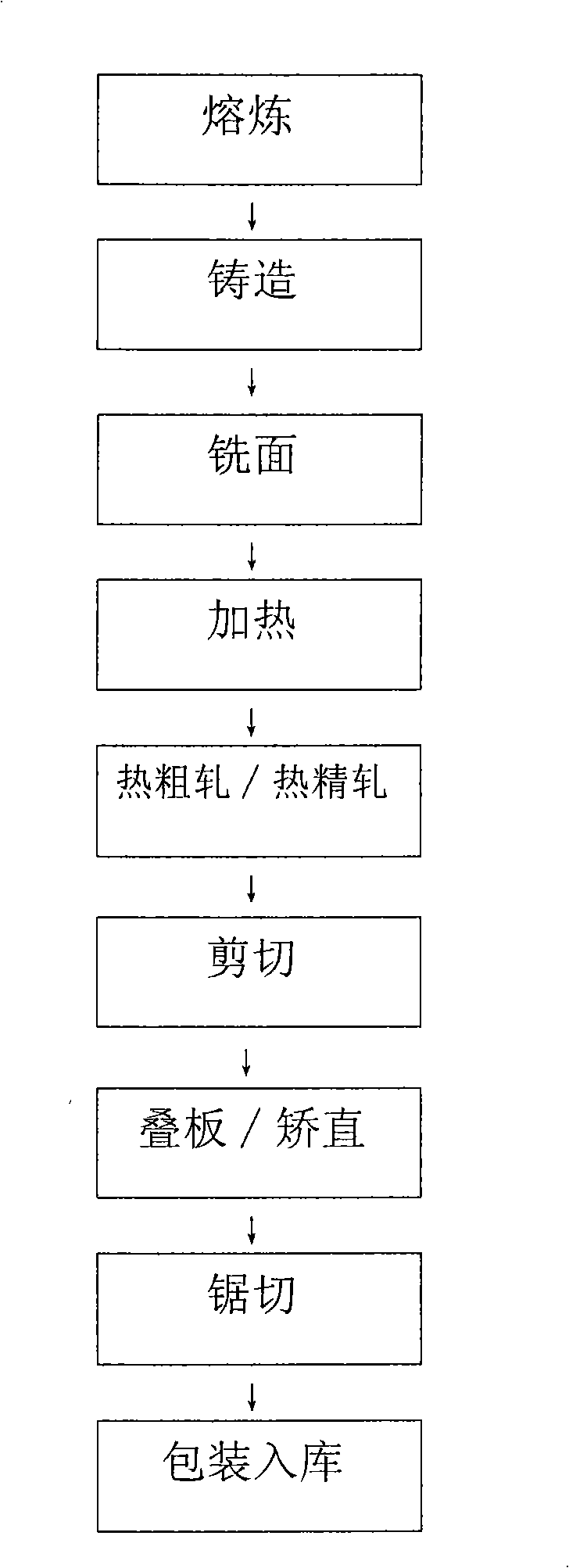

Production process of aluminum alloy hot rolling medium plate

The invention relates to a production process for hot-rolling medium plate by adopting aluminum alloy. The aluminum alloy materials are as follows according to the weight percentage: Fe is less than or equal to 0.35, Si is less than or equal to 0.25, Cu is less than or equal to 0.10, Mn is 0.70-0.90, Mg is 4.50-4.80, Cr is 0.10-0.20, Zn is less than or equal to 0.20, Ti is less than or equal to 0.10, other impurities are less than or equal to 0.15 in total, Na is less than or equal to 5pp,, Ca is less than or equal to 5ppm, and Al is the balance; and the sum of all components is 100. The main process comprises the following steps of melting, milling, heating, hot rough rolling or fine rolling. The invention adopts a soaking process during the processing of the aluminum alloy, mainly adopts two measures of milling sides and rolling the sides to solve the edge crack problem, controls the thickness difference and the plate form as well as oil spot and scuffing, and develops the production process for hot-rolling the medium plate by adopting the 5083 aluminum alloy.

Owner:中铝河南铝业有限公司

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

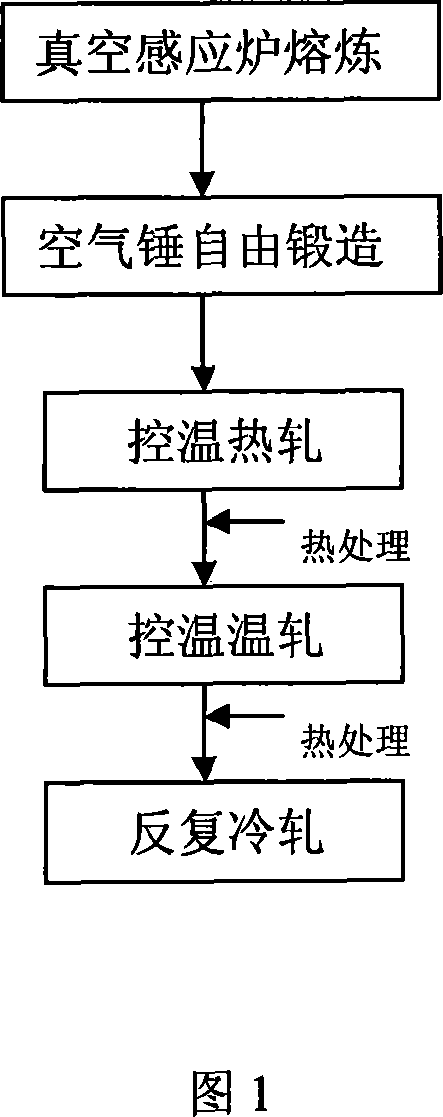

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

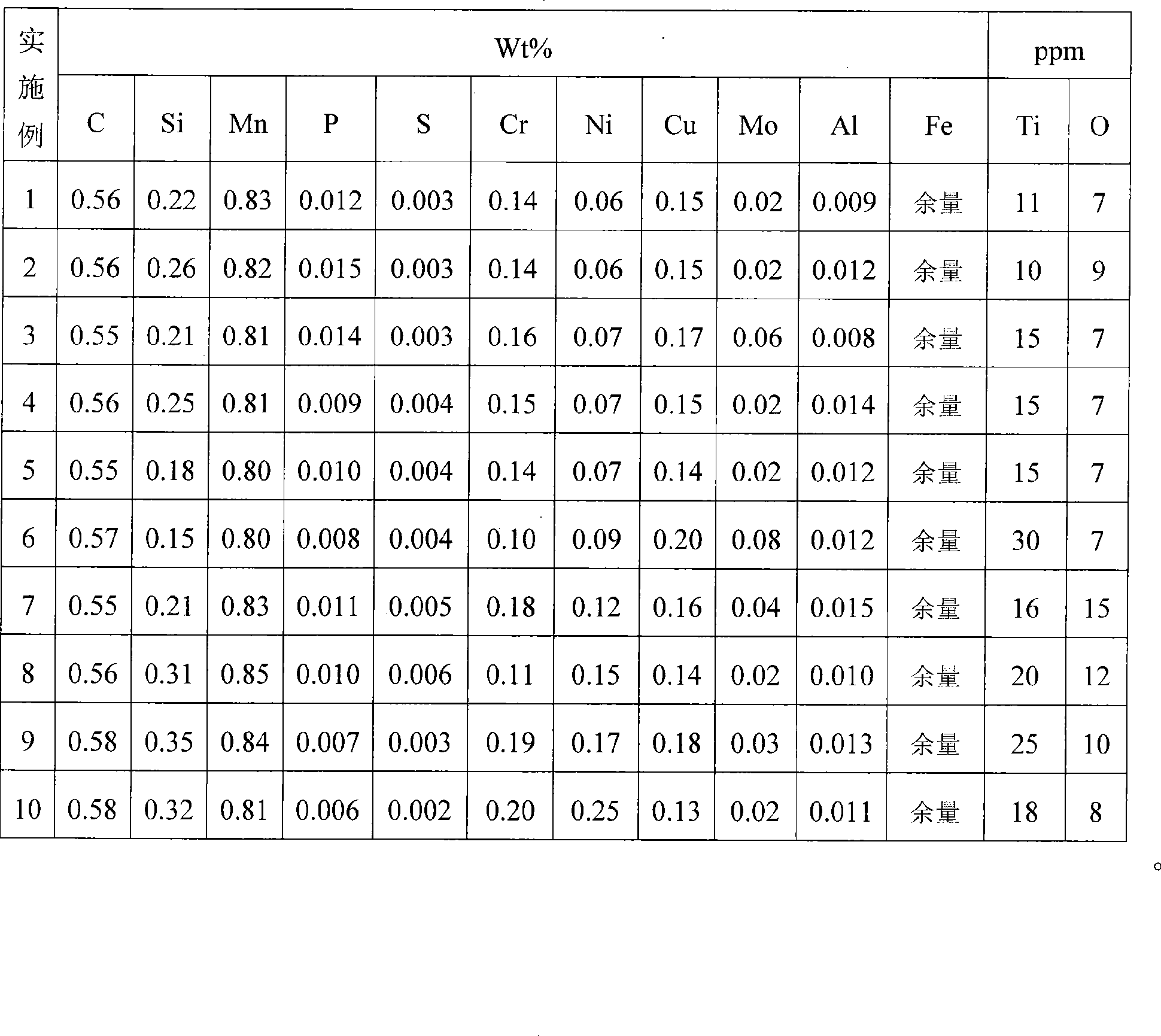

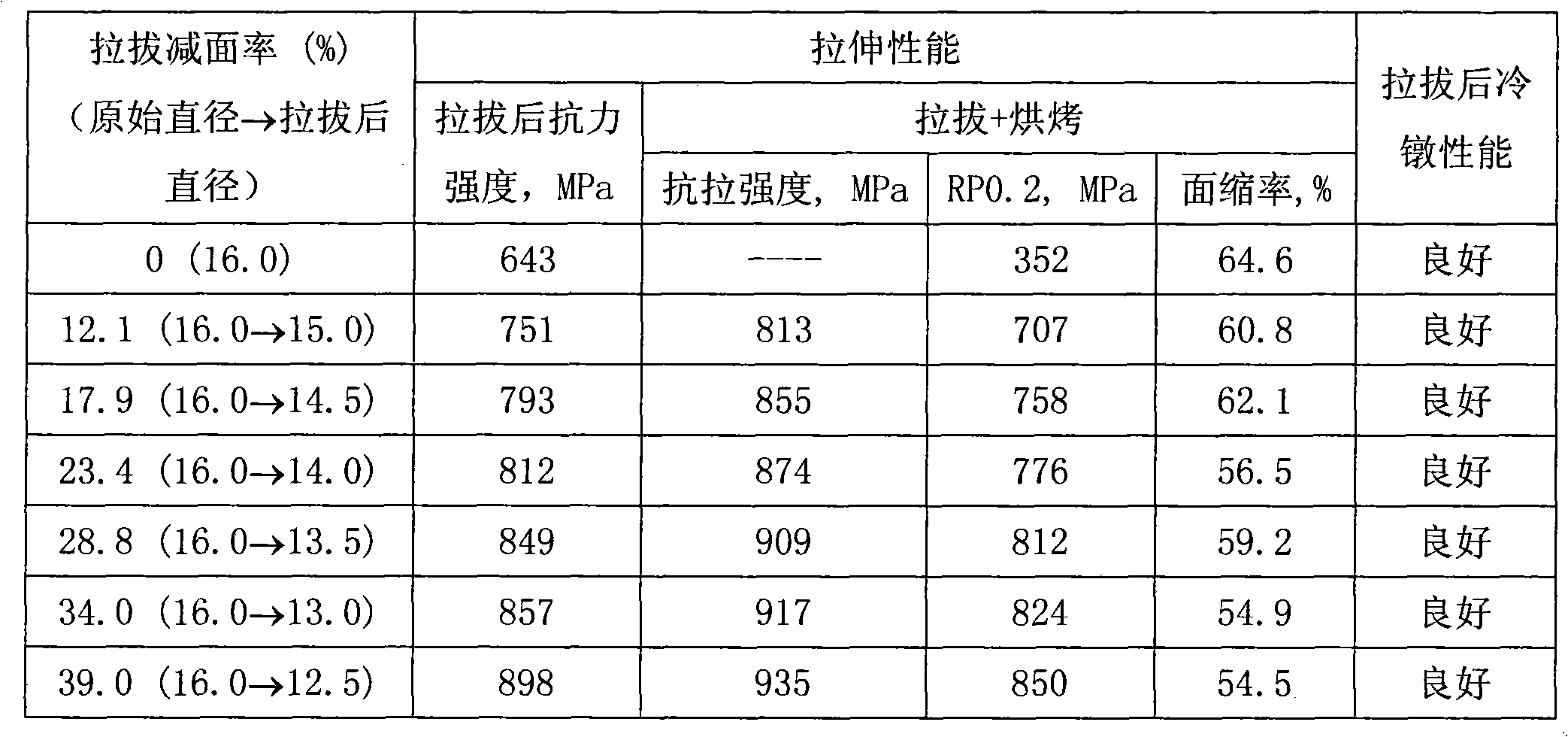

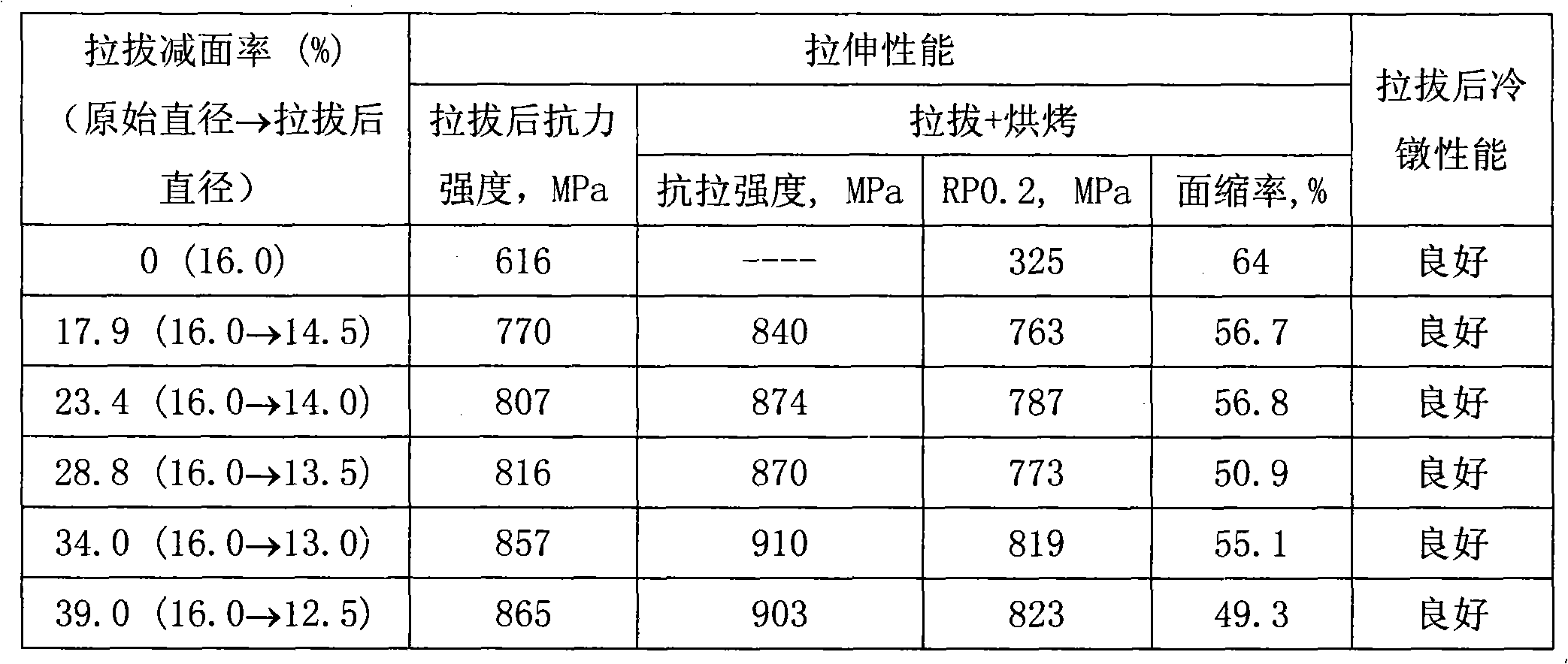

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Non-quenched cold heading steel for high-strength fasteners and manufacturing method thereof

InactiveCN101812644AModerate intensityImprove plasticityTemperature control deviceHigh intensityUltimate tensile strength

The invention relates to non-quenched cold heading steel for high-strength fasteners and a preparation process thereof. The non-quenched cold heading steel comprises the following components in percentage by weight: 0.15-0.35% of C, not more than 0.30% of Si, 0.8-1.80% of Mn, 0.20-0.80% of Cr, 0.01-0.10% of Al, not more than 0.035% of P, not more than 0.035% of S and the balance of iron and impurities. The process comprises the following steps of: preparing a casting blank having the same components with the non-quenched cold heading steel, heating the casting blank, and carrying out controlling rolling, coil collecting and controlling cooling treatment to form rod bundles as finished products. The non-quenched cold heading steel for high-strength fasteners has moderate strength, good plasticity, low deformation resistance in the cold heading and shaping of the fasteners, simple manufacturing process, effective saving of energy resources, environment pollution reduction and cost reduction, and is suitable for industrial production on a large scale.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

High-elongation aluminum alloy material and preparation method thereof

ActiveCN101525709AHigh strengthImprove creep resistanceTemperature control deviceMetal rolling arrangementsRare-earth elementElectrical conductor

The invention relates to a high-elongation aluminum alloy material and a preparation method thereof. The high-elongation aluminum alloy material contains 0.30-1.20% of iron, 0.03-0.10% of silicon, 0.01-0.30% of rare earth elements, and aluminum and inevitable impurities in weight percentage. The aluminum alloy is made from materials according to a fusion casting process and half-annealing treatment. An aluminum alloy conductor made by the method has high elongation and good safety and stability in use.

Owner:ANHUI JOY SENSE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com