Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

A technology of diffusion cladding and cladding sheet, which is applied in the direction of metal rolling, metal rolling, rolling mill control device, etc., can solve the problems of unobtainable size and thin thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

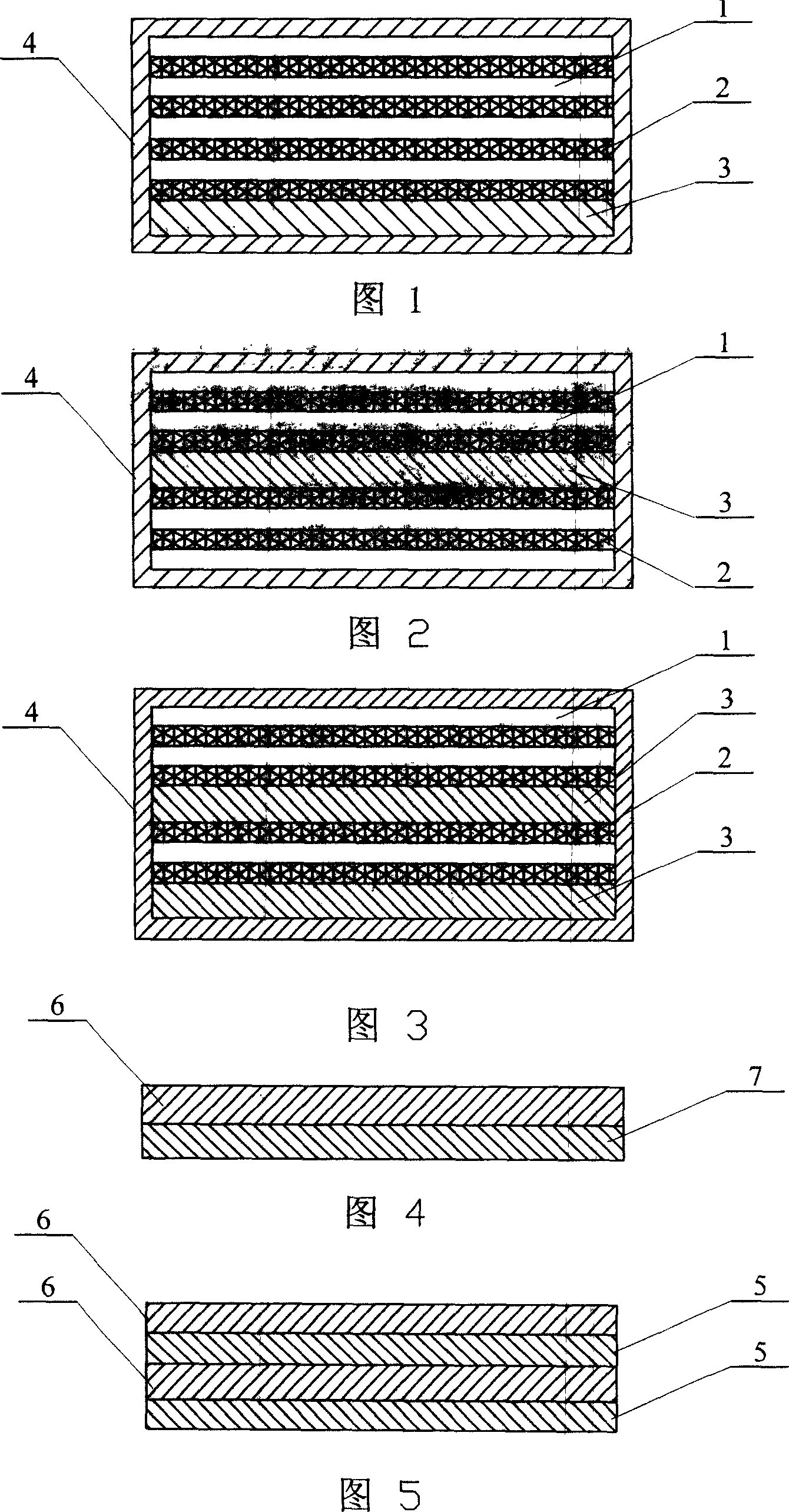

[0005] Specific embodiment one: (referring to Fig. 1, Fig. 2, Fig. 3) the technical scheme of the present embodiment is realized according to the following steps: 1, prepare original material: original material is titanium foil (hereinafter referred to as A), titanium (or titanium Alloy) foil or plate (hereinafter referred to as B), aluminum foil (hereinafter referred to as C), the thickness of A is 0.02-0.3mm, the thickness of B is 0.31-3mm, and the thickness of C is 0.02-0.3mm; 2. Lamination: A Placed in a stack with C, at least one layer of B in the stack, B is either on the upper and lower surfaces of the stack, or placed in the middle of the stack; in the stack, the adjacent layer of B is C, and the outermost layer is A or B, A, B, and C are stacked with 3 or more layers; 3. Cover: the outside of the stack is covered with stainless steel, pure titanium or titanium alloy, and the stack is placed in a layer made of stainless steel, pure titanium or titanium. In the cubic co...

specific Embodiment approach 2

[0006] Specific embodiment two: (referring to Fig. 1, Fig. 4) the technical scheme of present embodiment is realized like this: prepare original material: original material is titanium foil (abbreviated A), titanium plate material (abbreviated B), aluminum foil (abbreviated C) . The thickness of A is 0.05mm, the thickness of B is 1mm, and the thickness of C is 0.05mm. Lamination: A and C are stacked, and A and C are 5 layers respectively. B is a layer, and B is placed on the lower surface of A and C stacks. In the laminate, the adjacent layer of B is C, and the upper surface of the outermost layer is A. The above structure is similar to the laminated structure shown in FIG. 1 . Sheath: Stainless steel sheath is used outside the laminate, the thickness of the sheath is 2mm. Put the laminated structure into a cubic container welded by stainless steel plates, vacuumize it to less than 0.2Pa, and then weld it tightly. Rolling: The overall material that has been wrapped is fir...

specific Embodiment approach 3

[0007] Specific embodiment three: (referring to Fig. 3, Fig. 5) the technical scheme of present embodiment is realized like this: prepare original material: original material is titanium foil (abbreviation A), titanium alloy (Ti-6Al-4V) sheet material (abbreviation B), aluminum foil (referred to as C). The thickness of A is 0.07mm, the thickness of B is 1.5mm, and the thickness of C is 0.07mm. Lamination: A and C are stacked, A and C are 8 layers and 7 layers respectively. B is 2 layers, one layer B is placed on the lower surface of A and C stacks, and the other layer is placed in the middle of A and C stacks. In the laminate, the adjacent layer of B is C, and the upper surface of the outermost layer is A. The above structure is similar to the stacked structure shown in FIG. 3 . Sheath: Pure titanium sheath is used outside the lamination, the thickness of the sheath is 2.5mm. Put the stack into a cubic container welded by pure titanium plates, vacuumize it to less than 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com