Patents

Literature

275 results about "Titanium foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

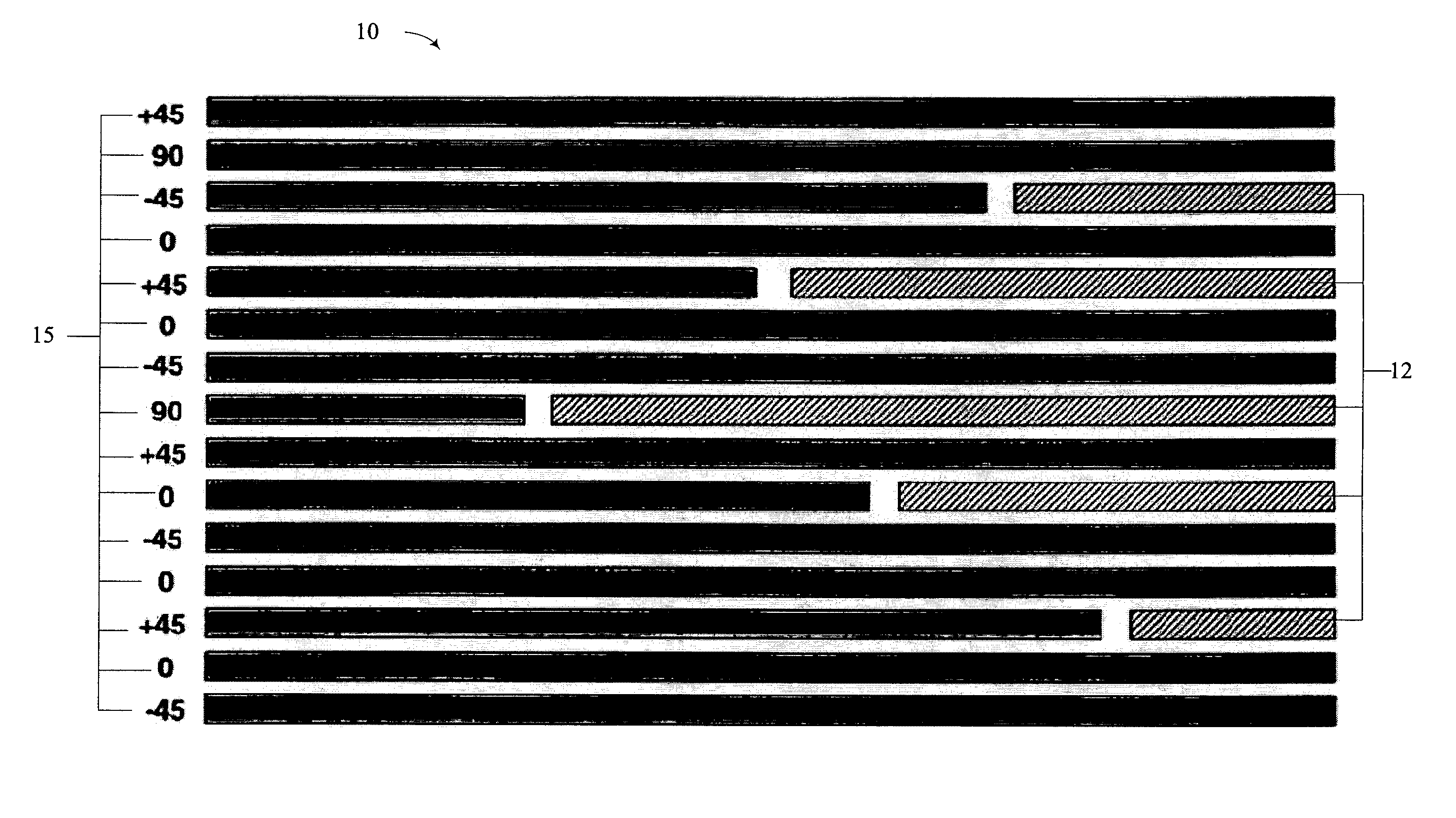

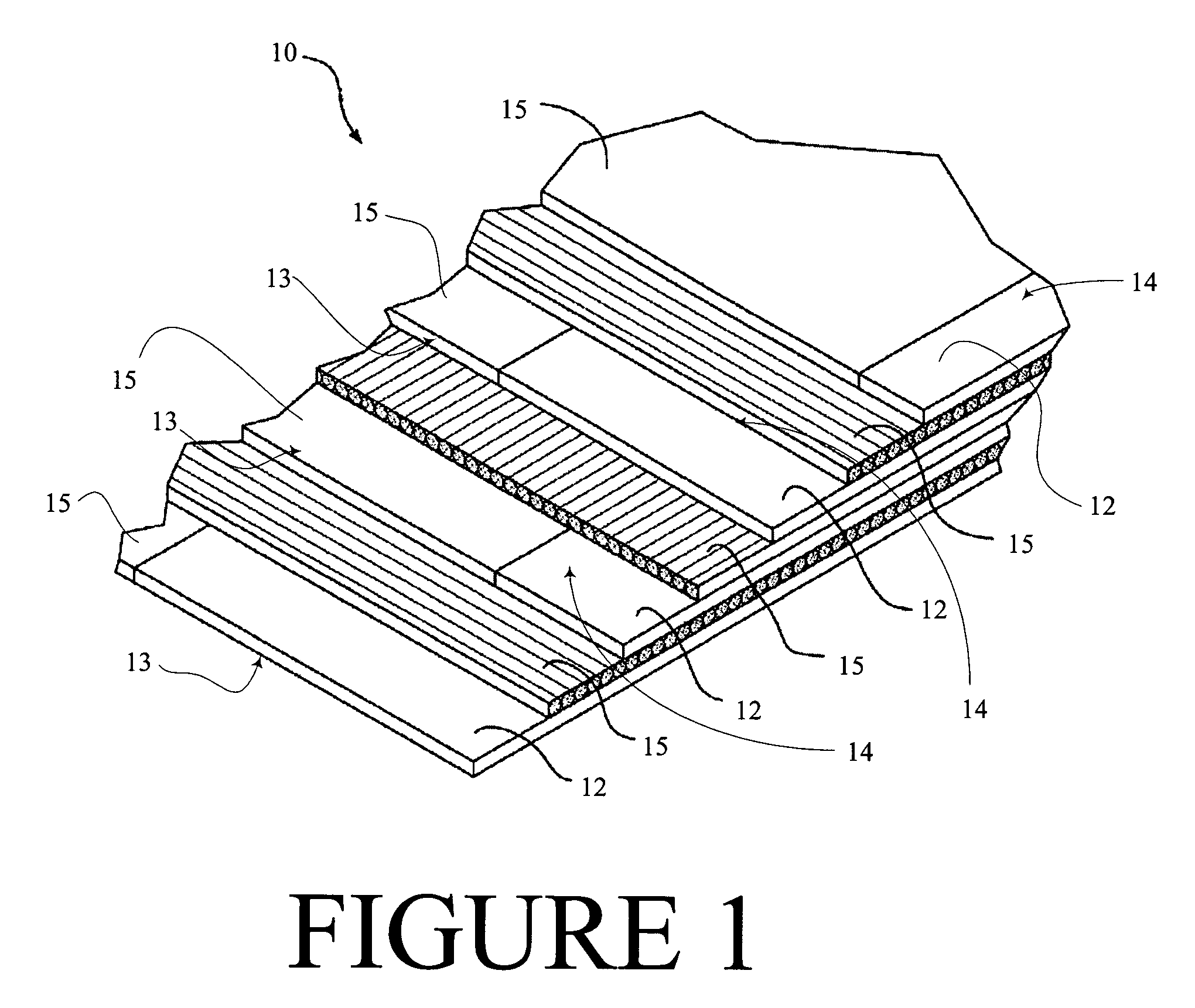

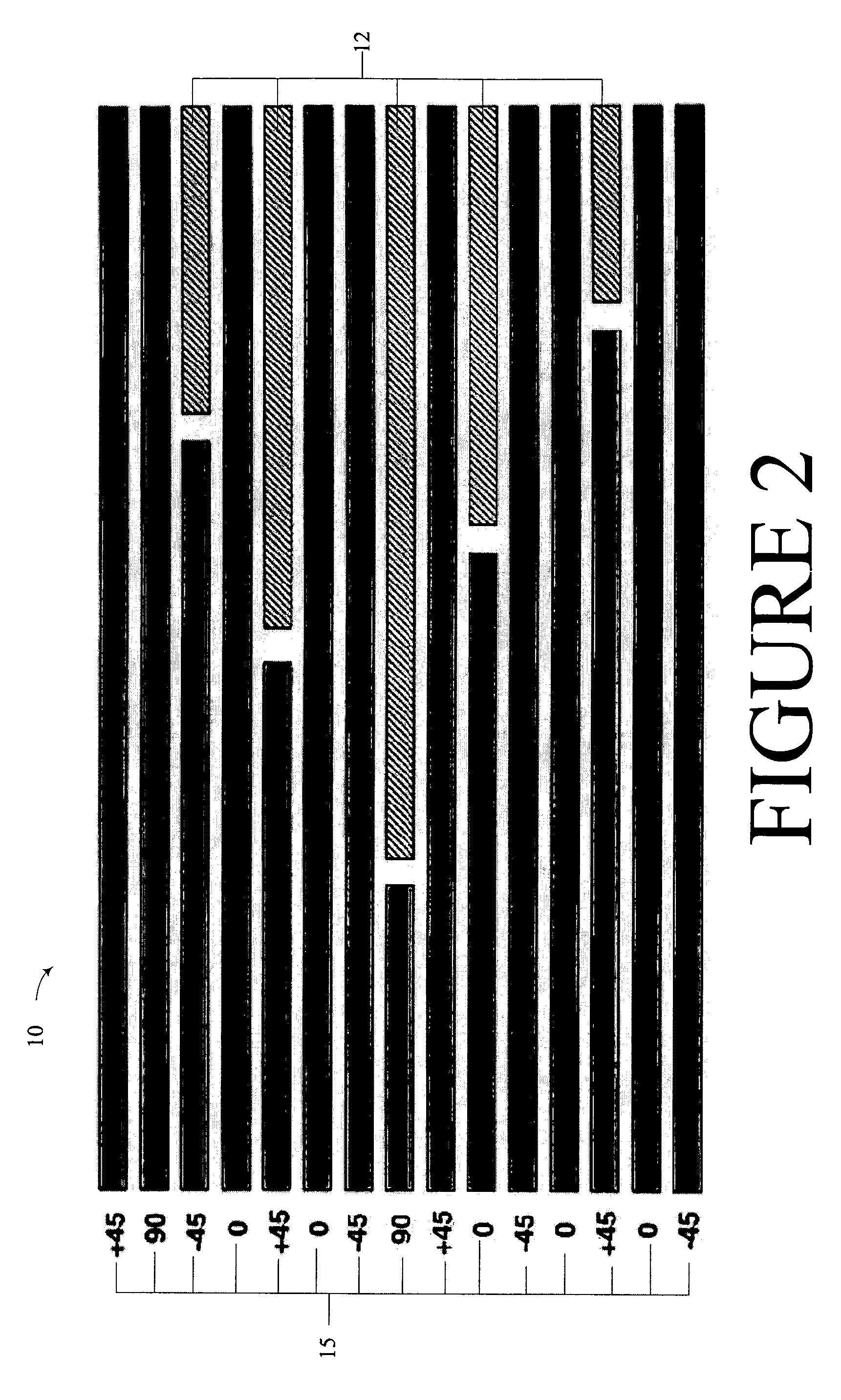

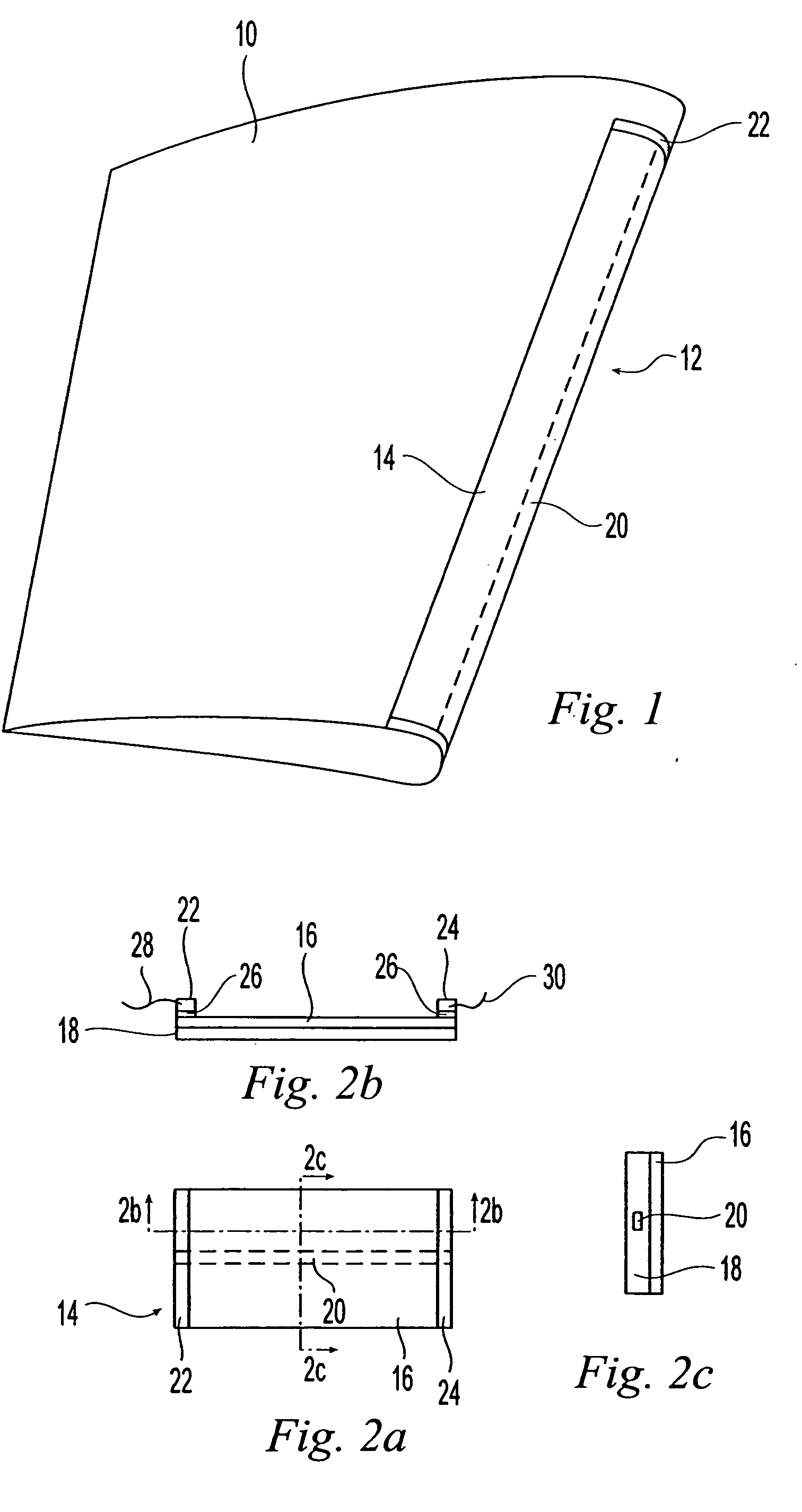

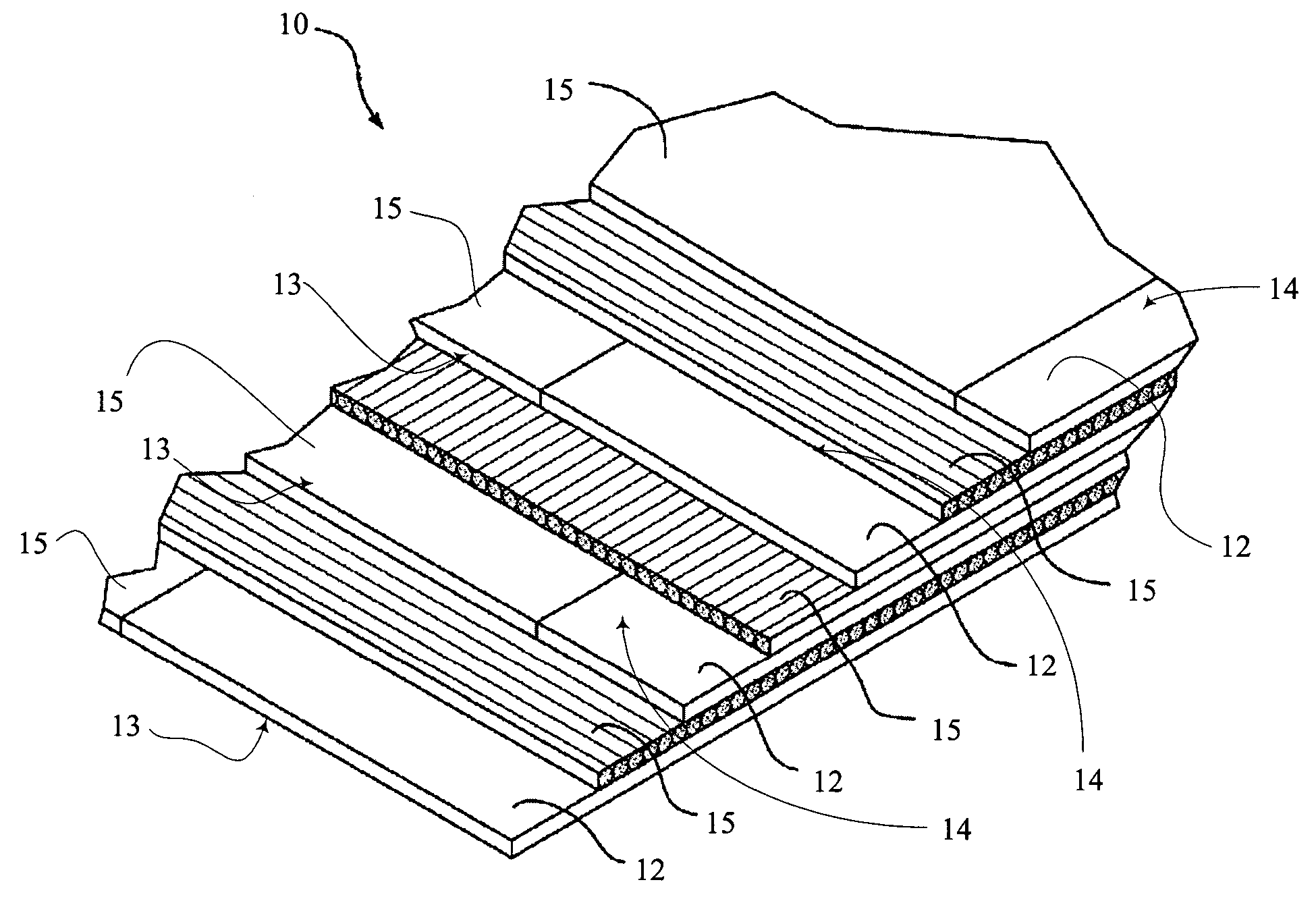

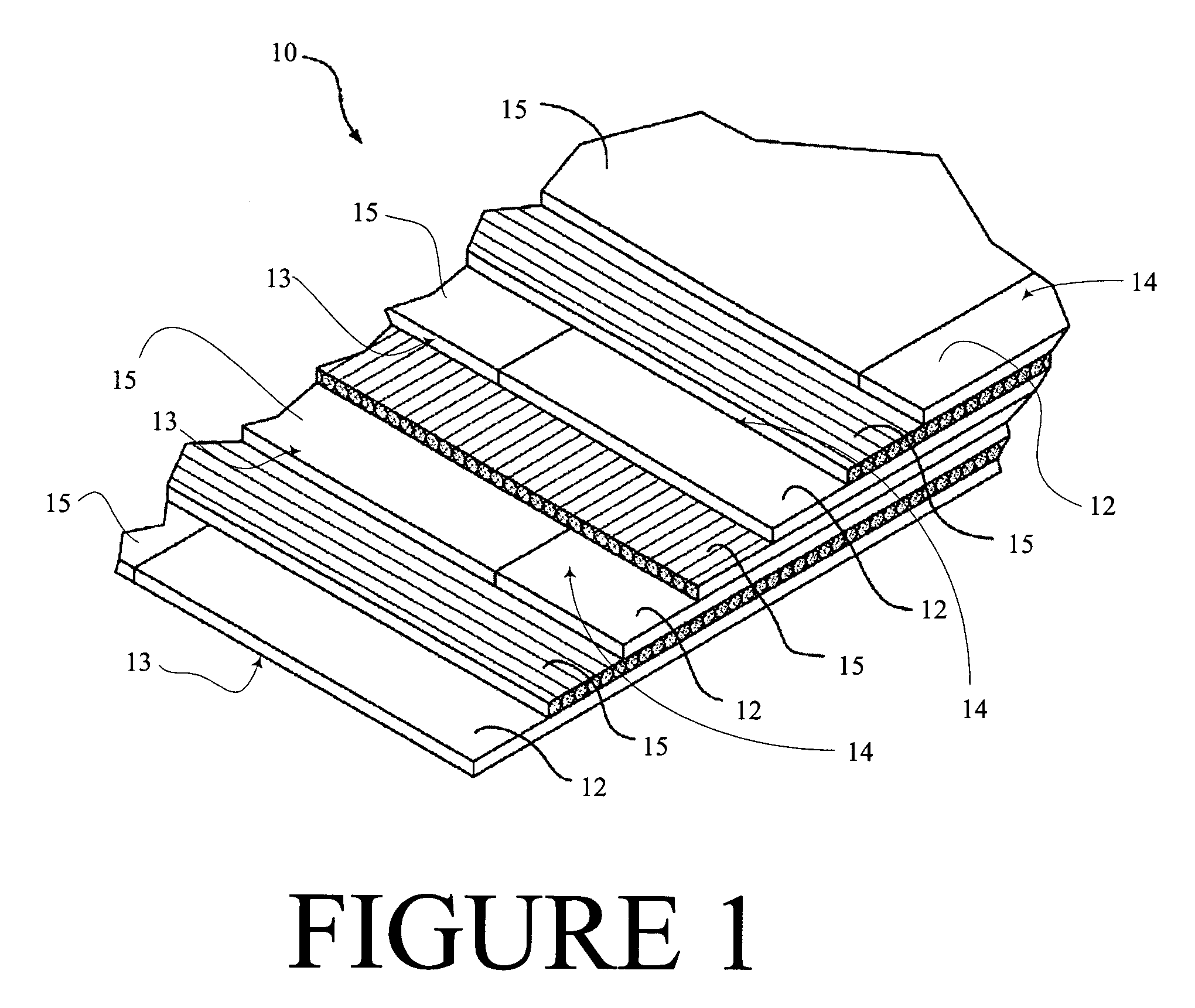

Titanium foil ply replacement in layup of composite skin

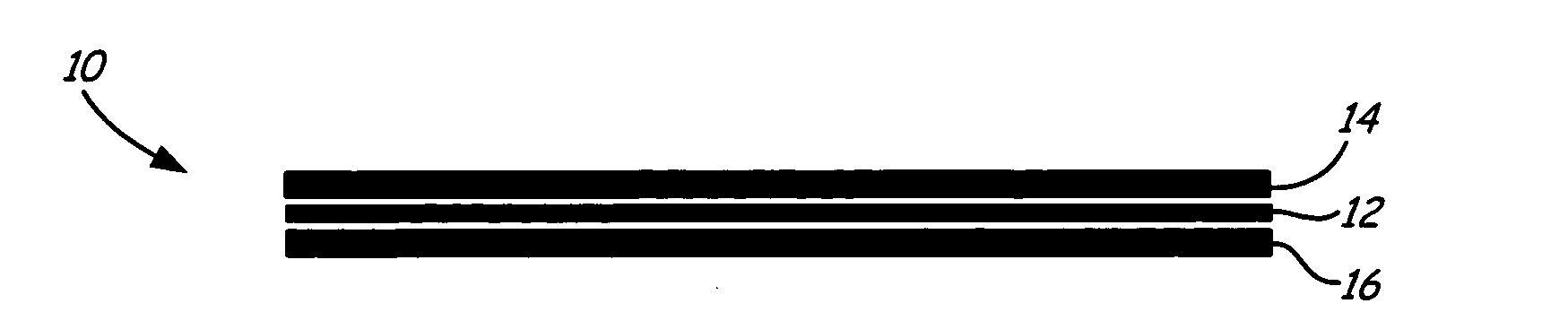

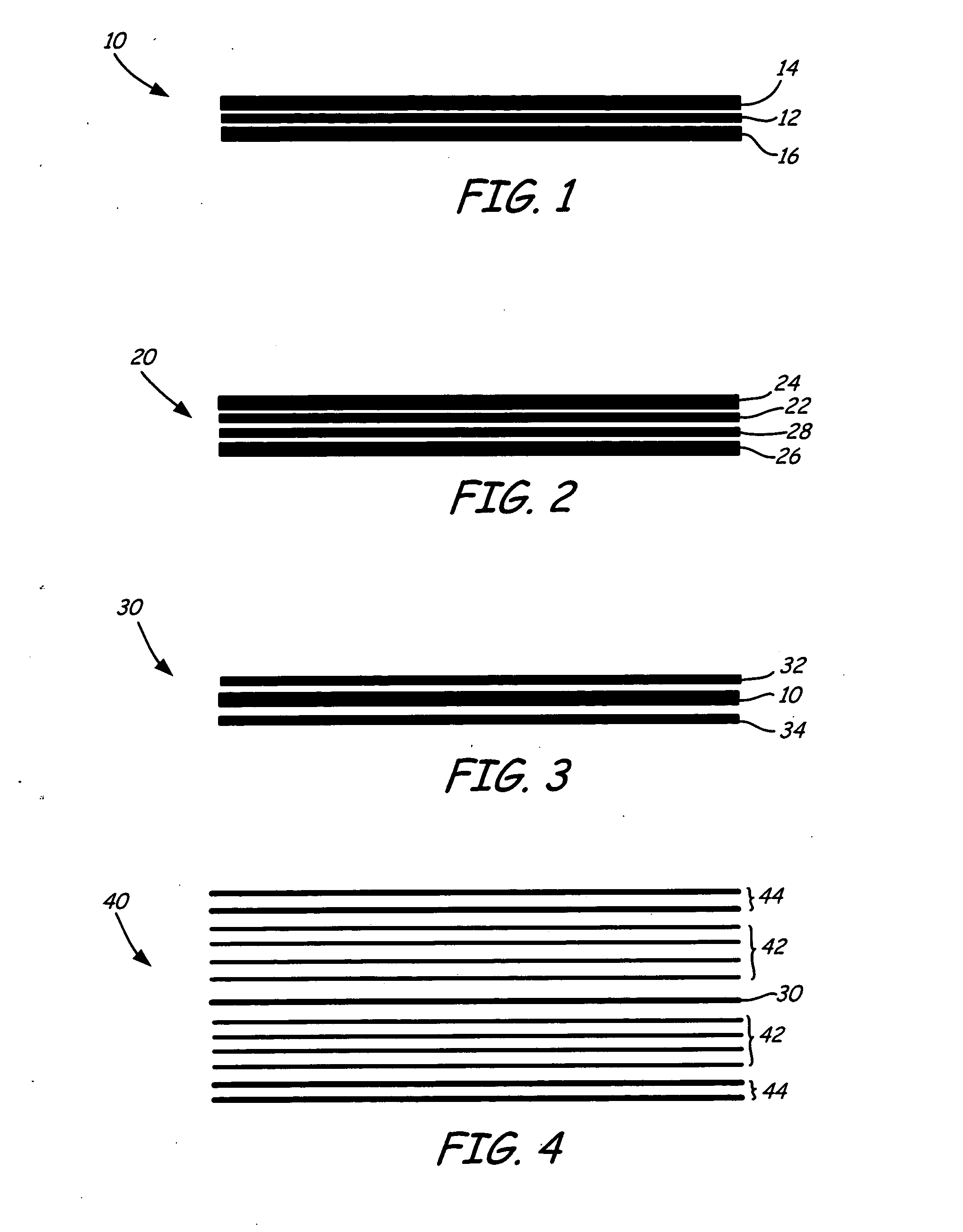

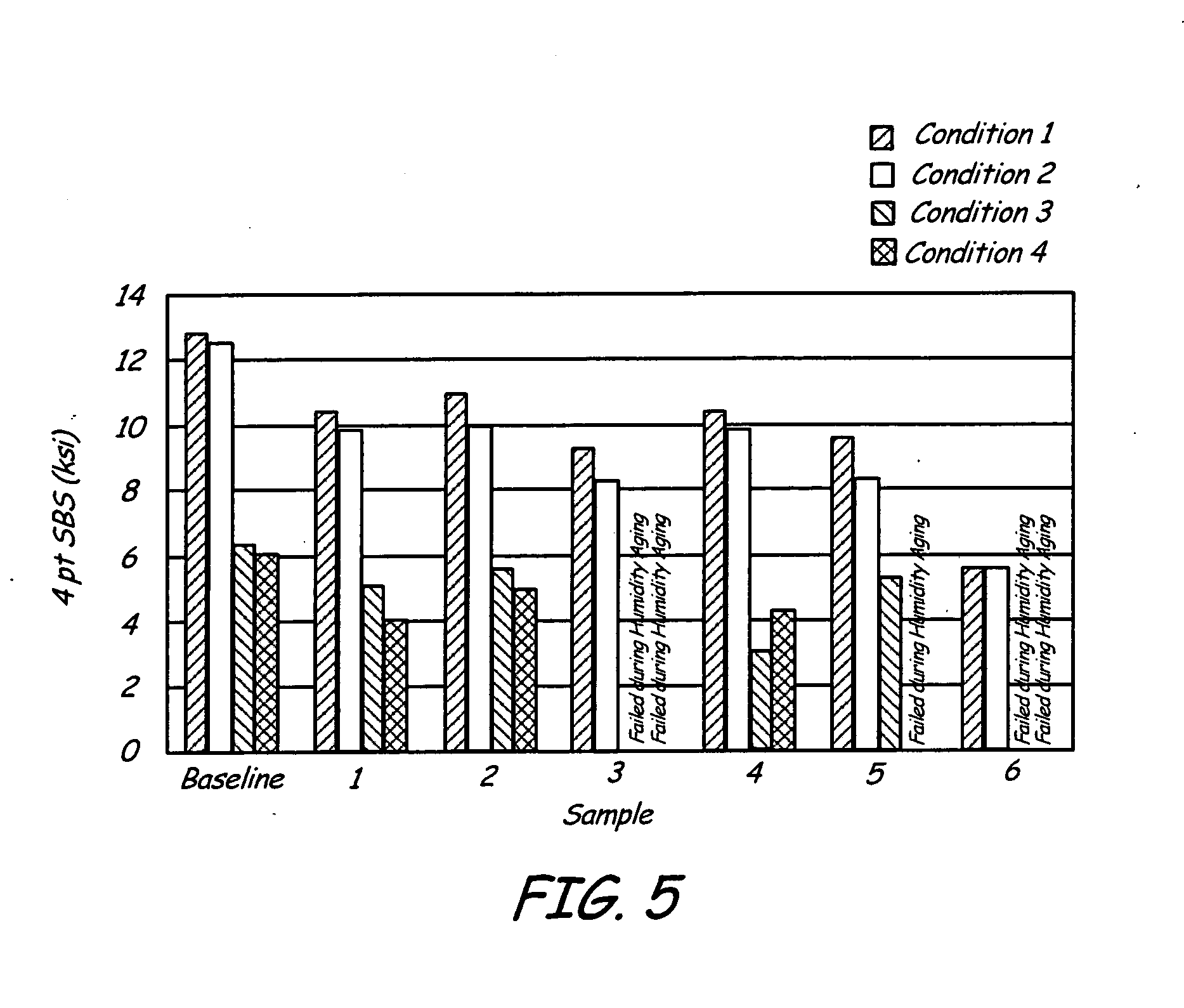

Laminate structures and methods for forming same are disclosed. In one embodiment, a laminate structure includes a metal-polymer composite lamina. The metal-polymer composite lamina has a first face and a second face spaced apart, and extends to a terminal edge. The lamina includes a ply of fiber-reinforced polymer that extends between the first face and the second face and has an interior edge. The interior edge defines at least one cutout. A ply of metal foil extends between the first face and the second face substantially from the interior edge filling the at least one cutout.

Owner:THE BOEING CO

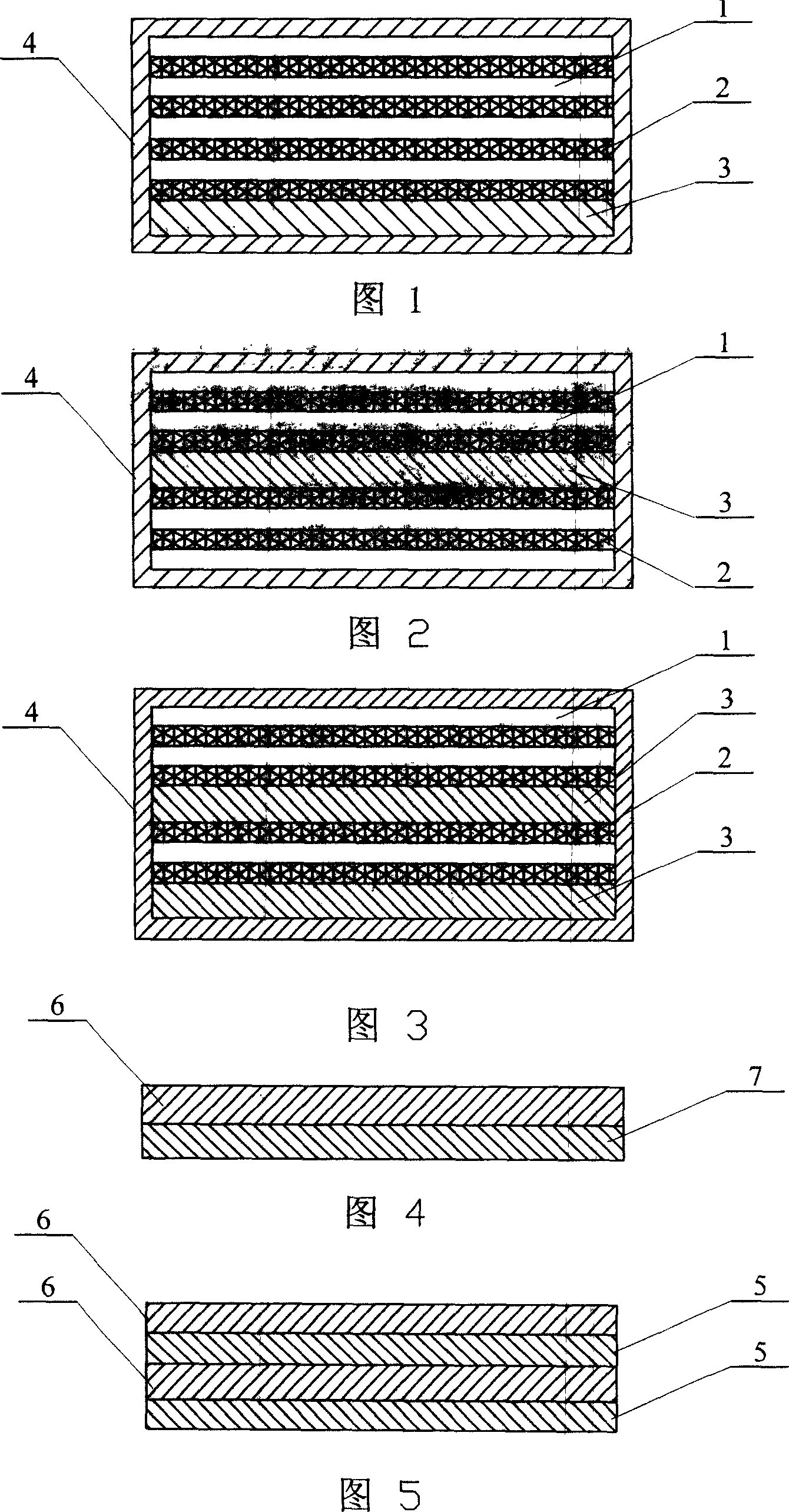

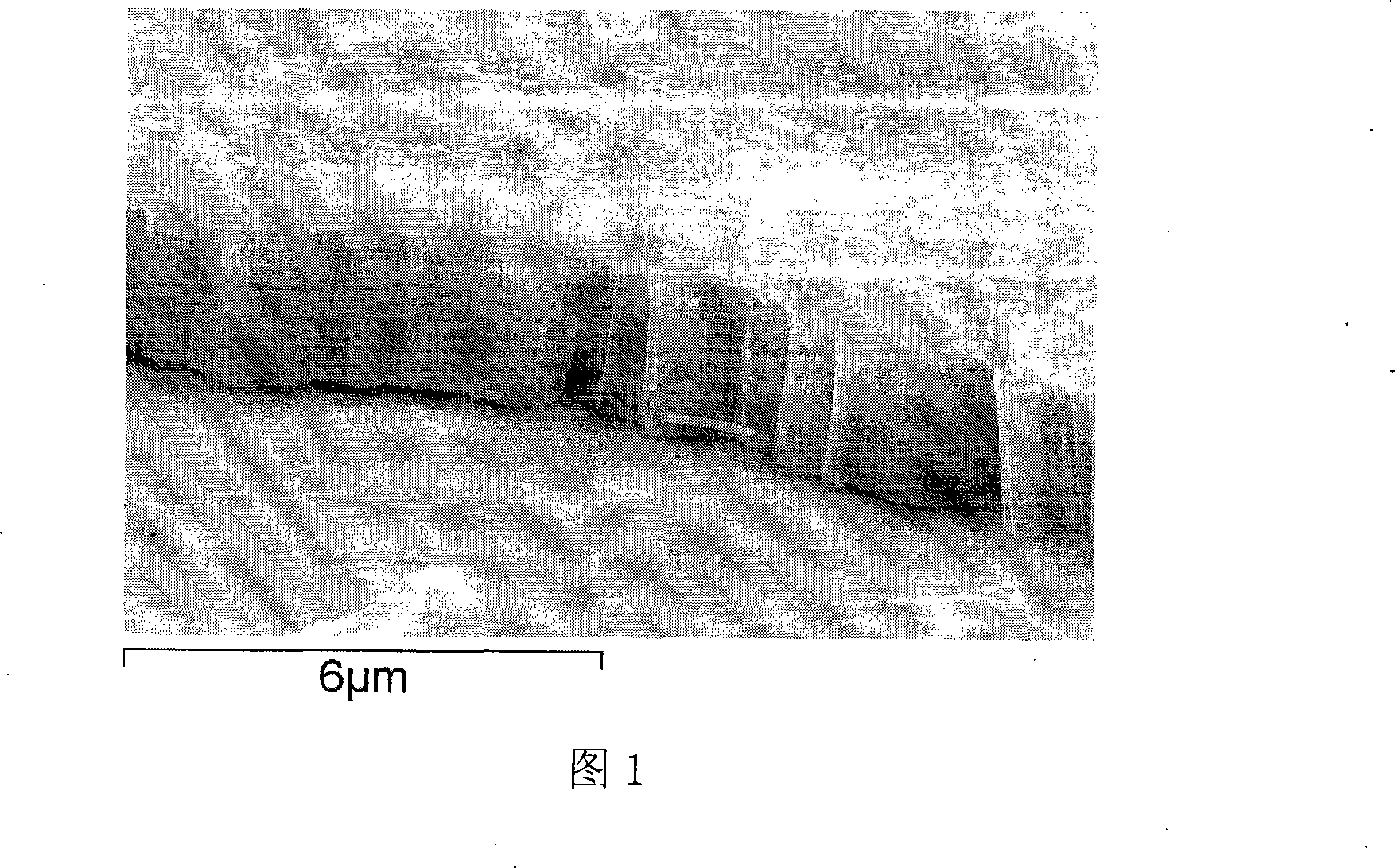

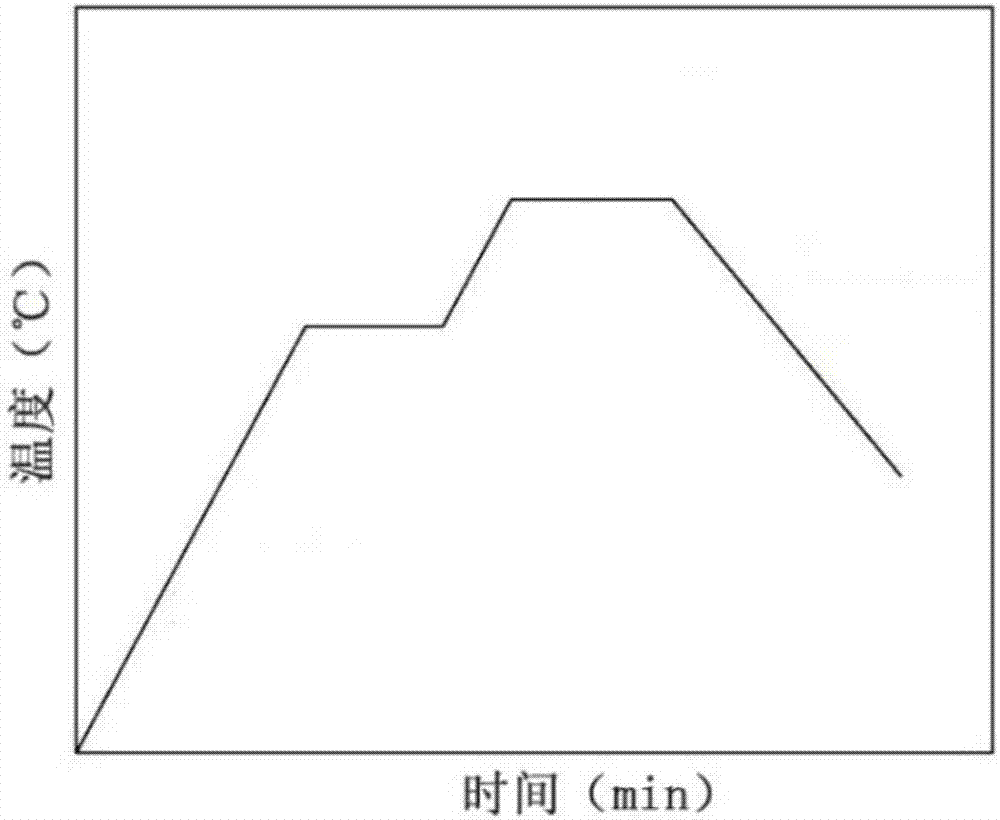

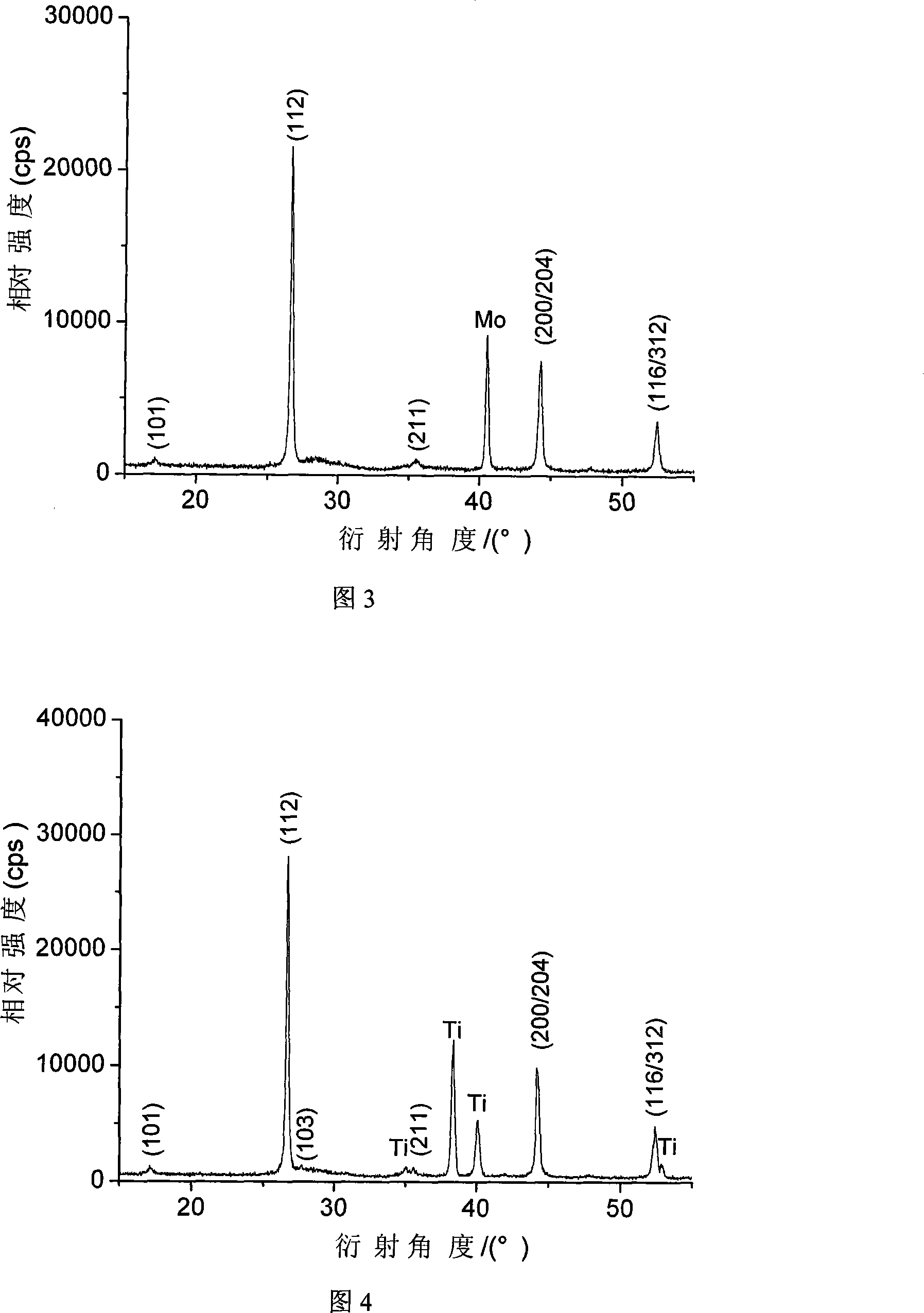

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

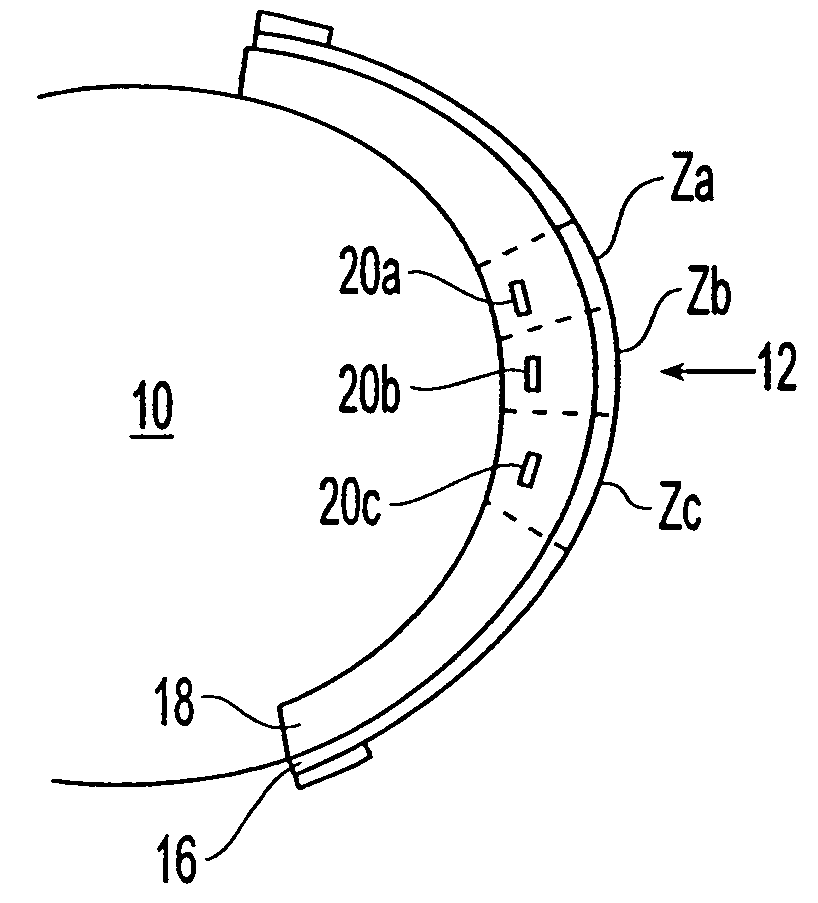

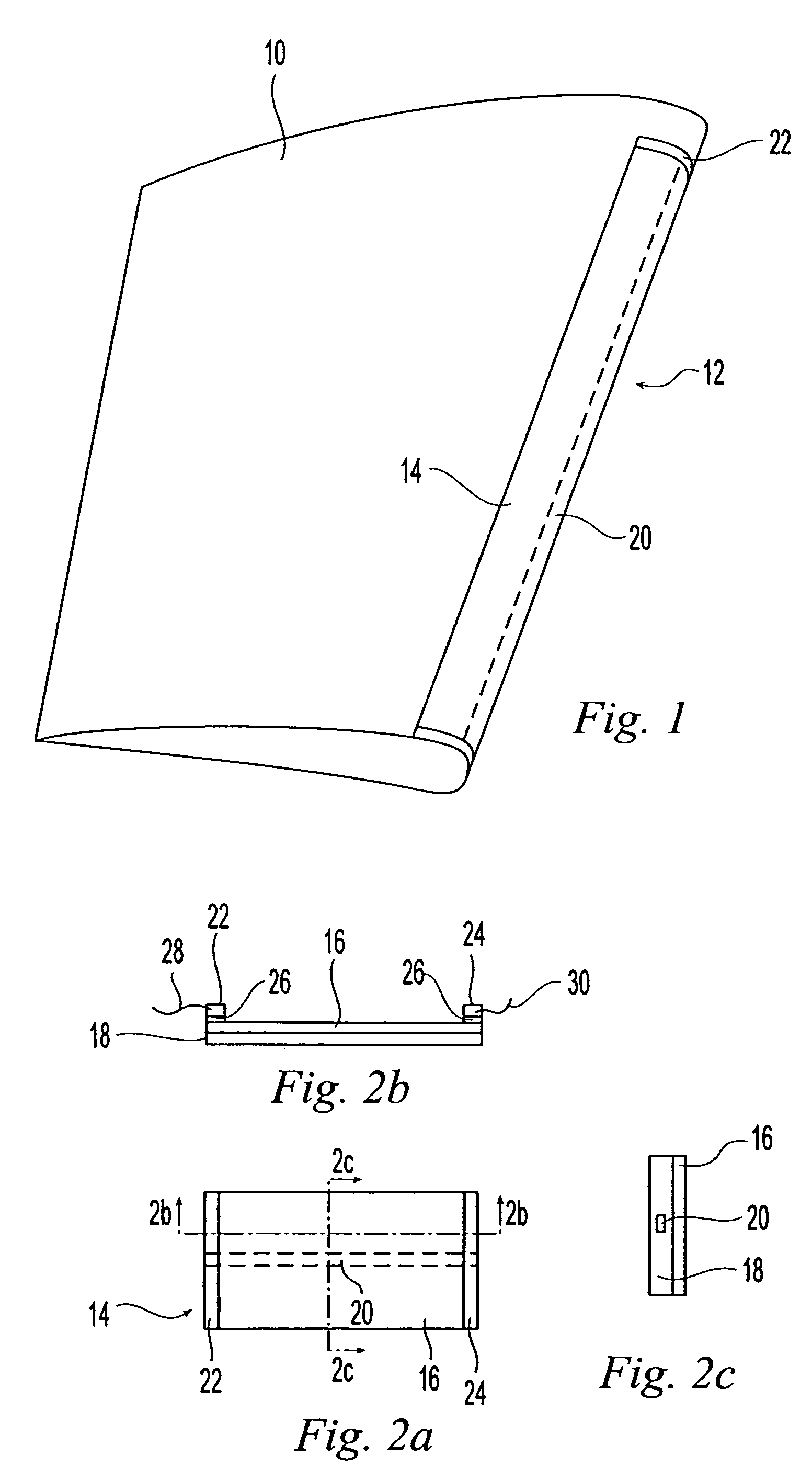

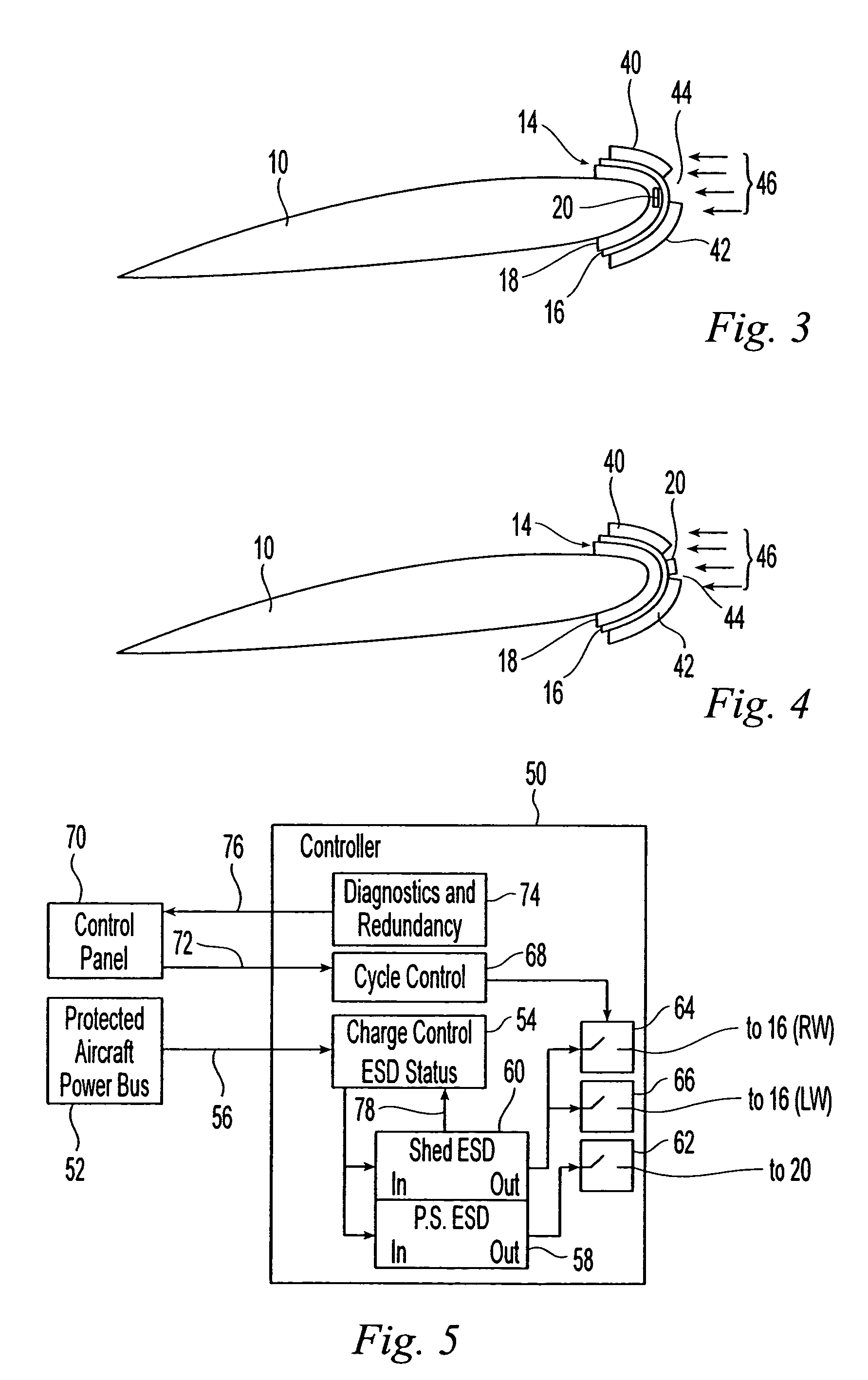

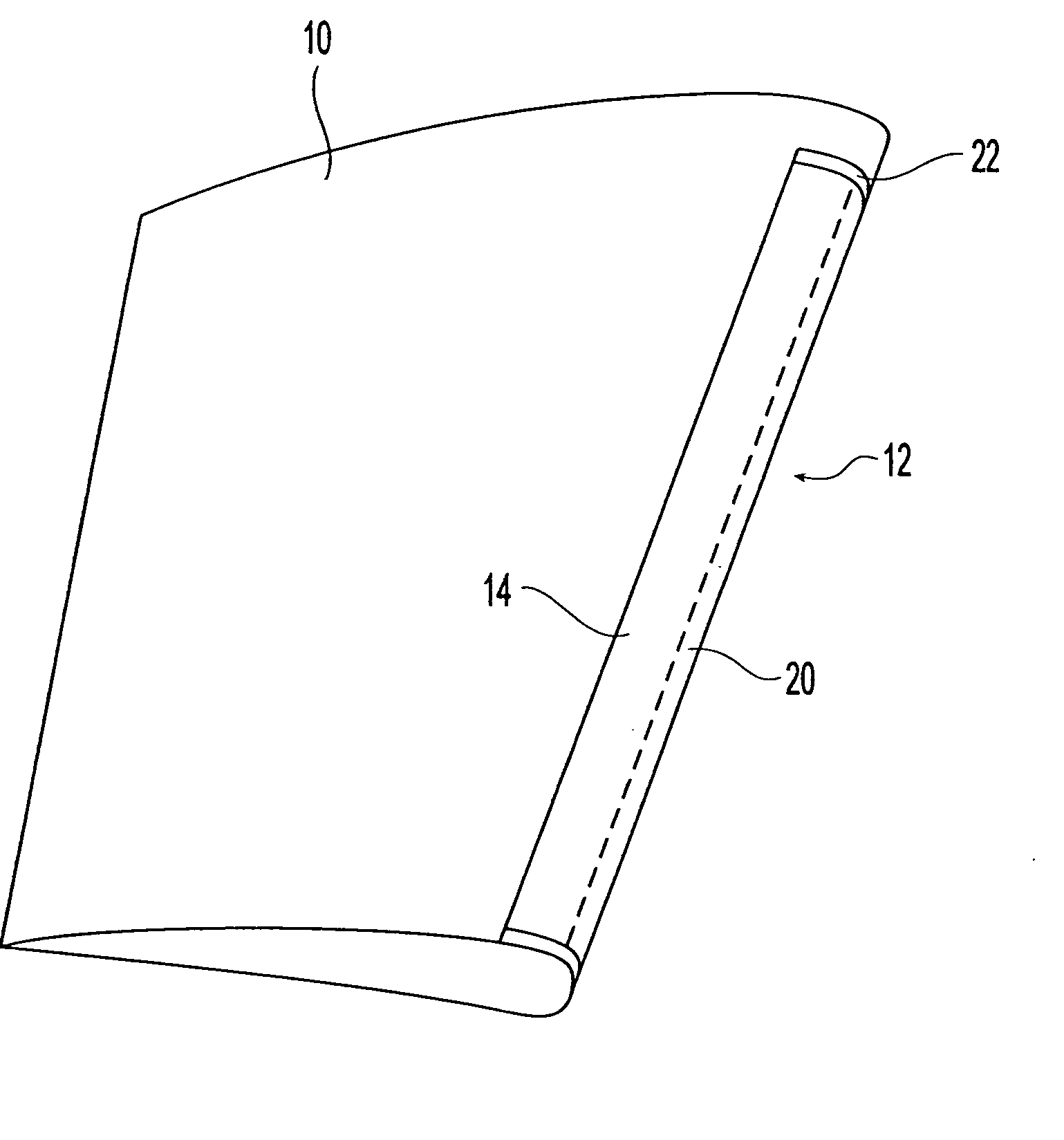

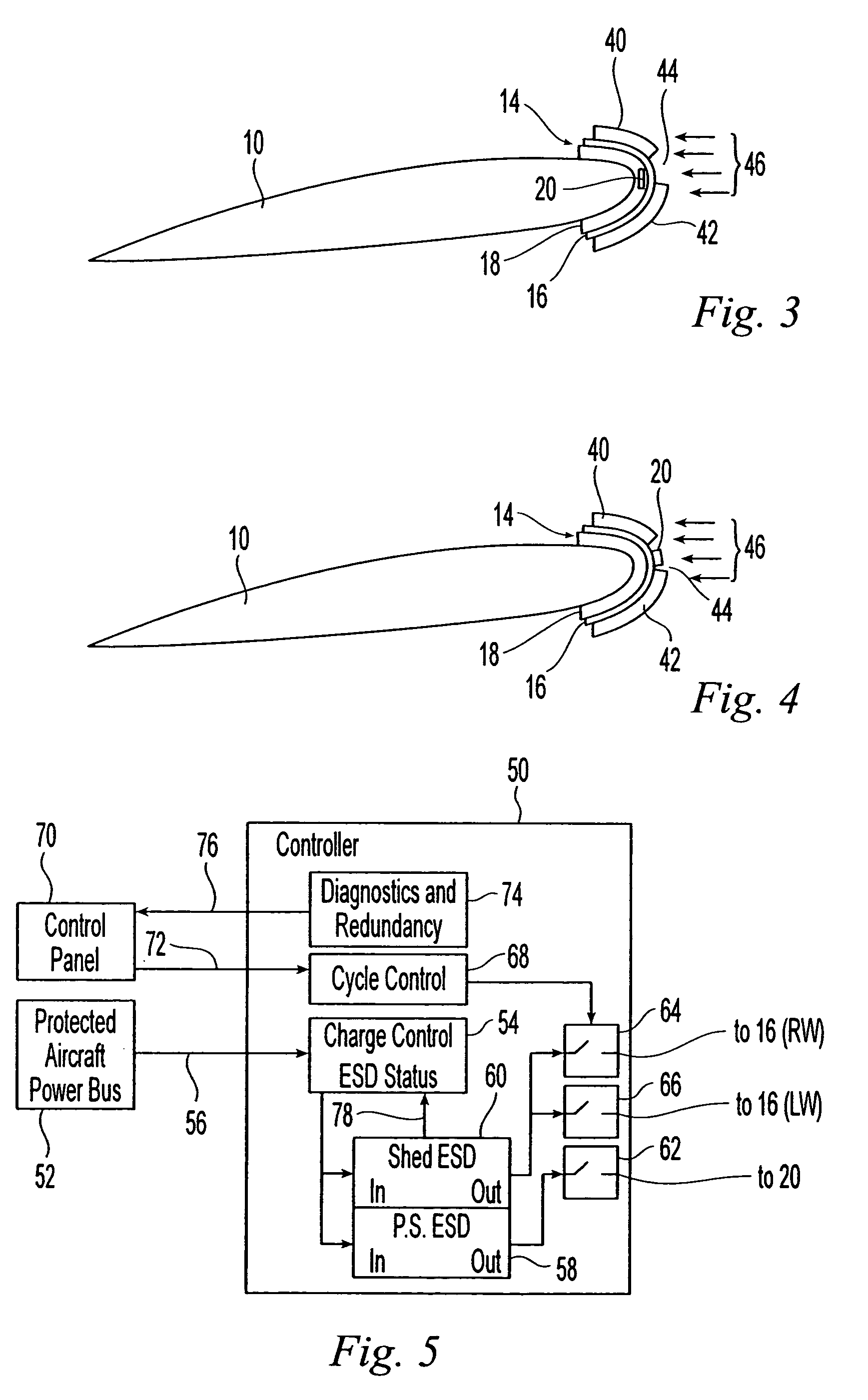

Low power, pulsed, electro-thermal ice protection system

ActiveUS7246773B2Avoid conductionDe-icing equipmentsEfficient propulsion technologiesMetal foilEngineering

An electro-thermal ice protection system for an airfoil comprises: a metal foil heater including an integral parting strip, the metal foil heater configurable to cover at least a portion of a leading edge of the airfoil with the integral parting strip disposed along an air-stagnation zone of the leading edge; and a controller coupled electrically to the metal foil heater for controlling electrical energy from a power source to the metal foil of the heater in accordance with a pulse duty-cycle and for controlling power to the parting strip of the heater to maintain the air-stagnation zone virtually free of ice formation. A method of making an exemplary metal foil heater for use in ice protection of an airfoil comprises the steps of: preparing a sheet of Titanium foil in a rectangular shape having a length substantially greater than a width thereof for covering at least a portion of the leading edge of the airfoil; applying a layer of Nickel material over an area along each width edge of the Titanium foil; applying a layer of Copper material over the Nickel layer along each width edge of the Titanium foil; and attaching conductor wires to the Copper layers at each width edge.

Owner:THE BF GOODRICH CO

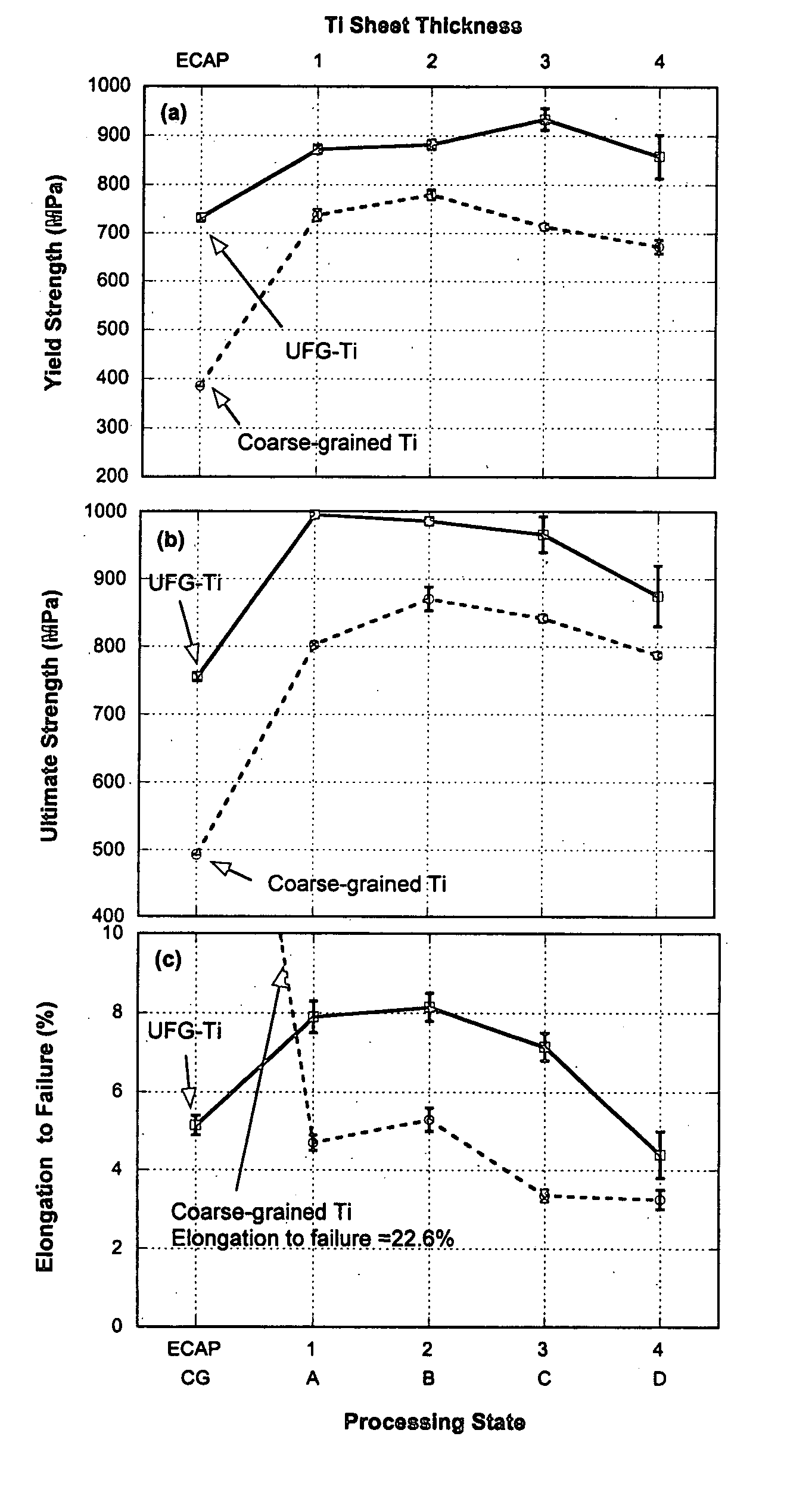

Method for preparing ultrafine-grained metallic foil

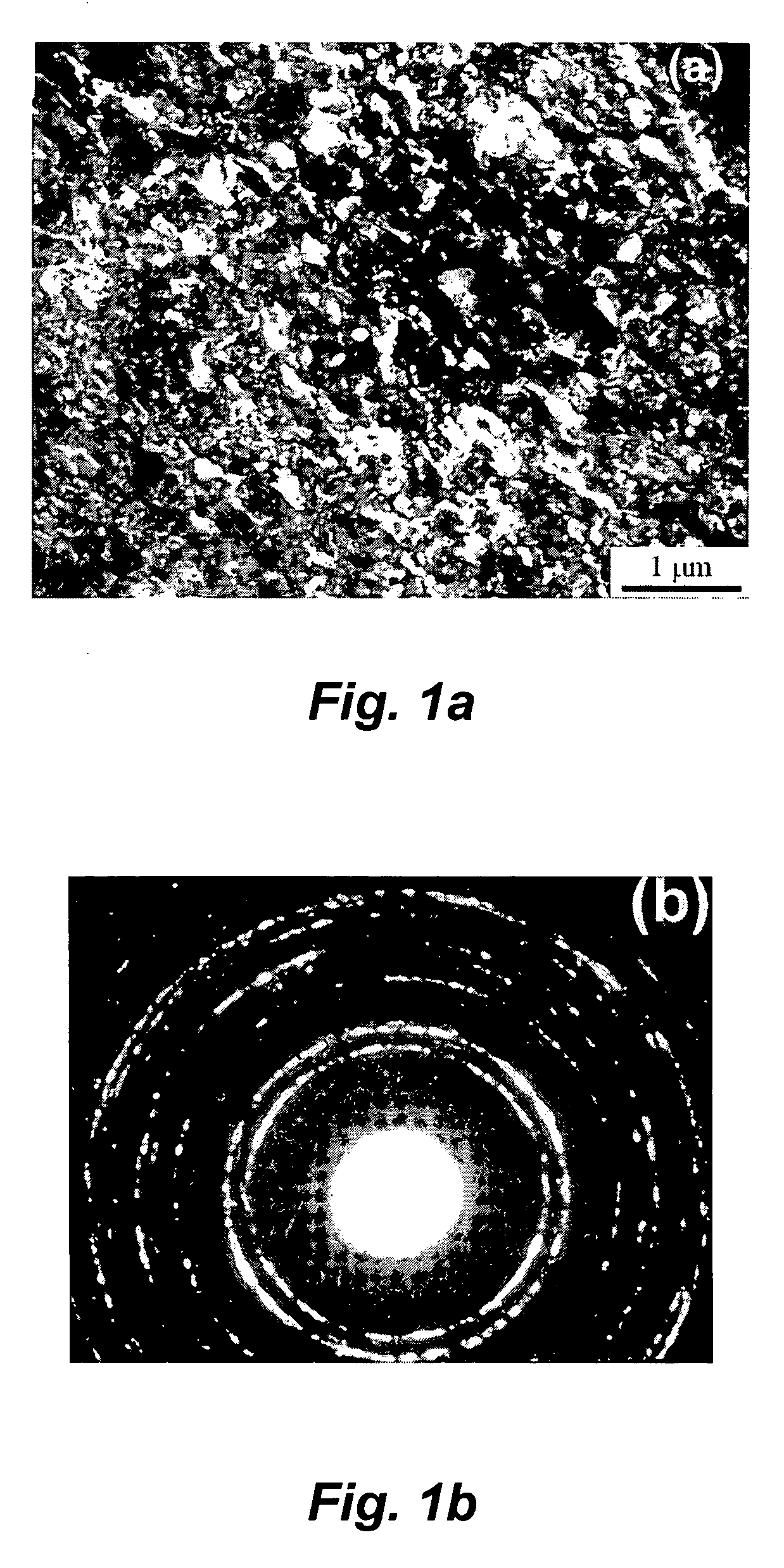

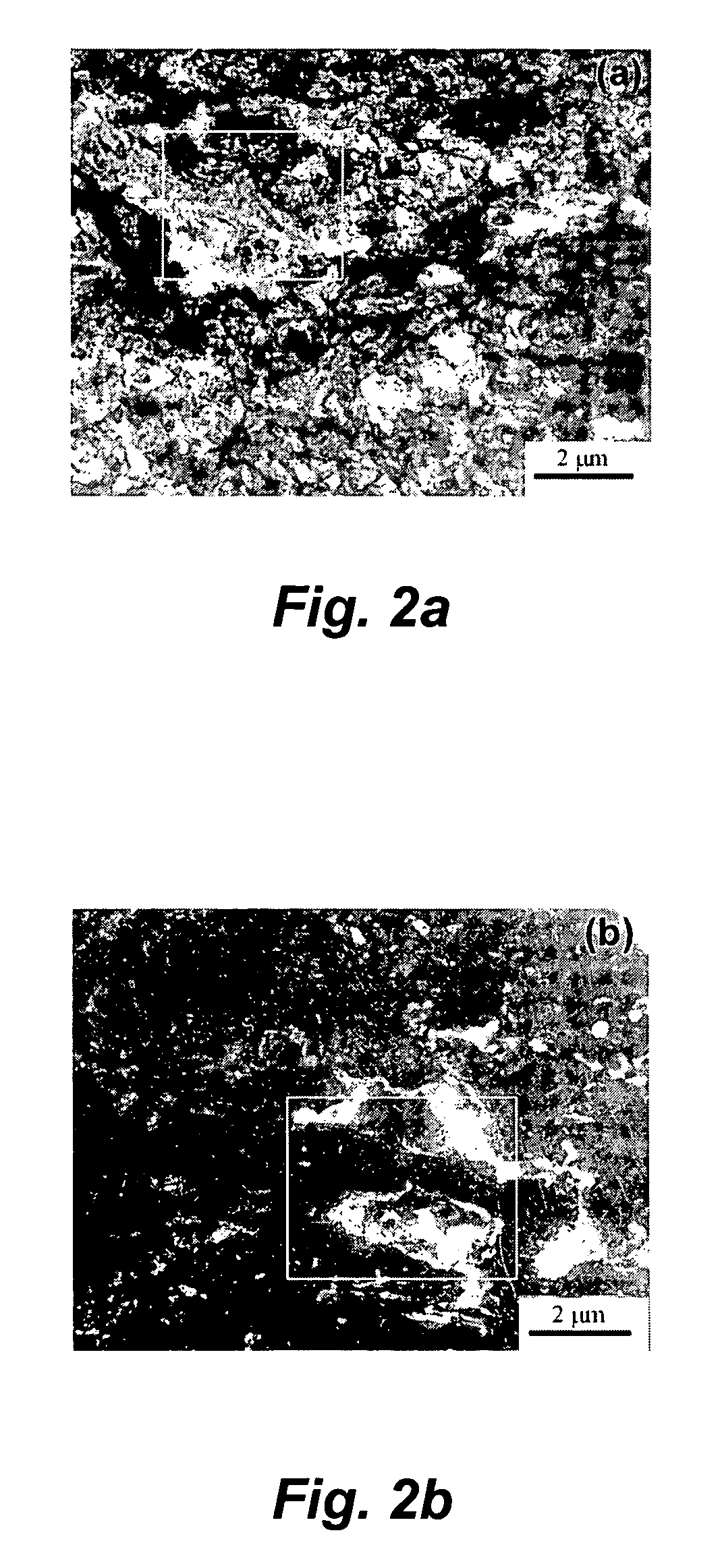

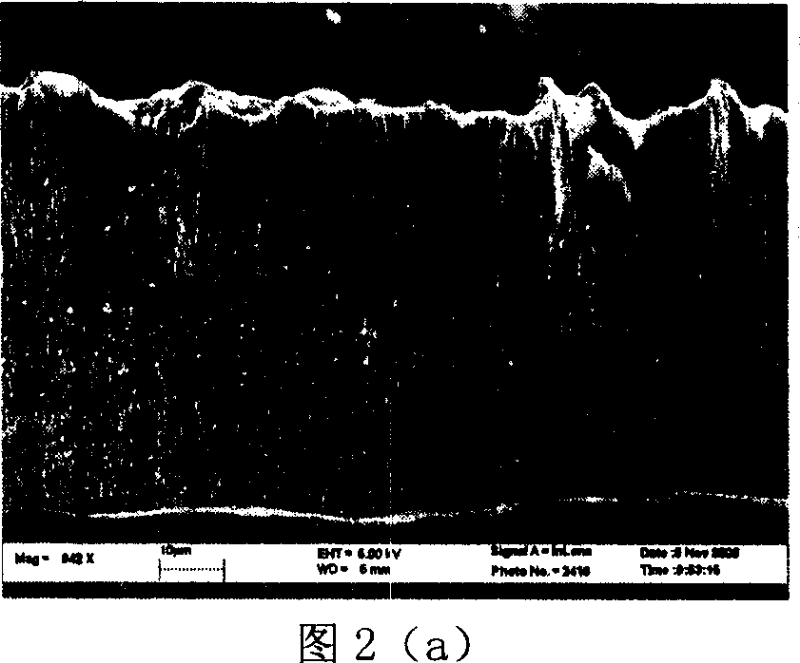

Coarse-grained titanium and ultrafine-grained (UFG) titanium billets were processed into titanium foil cold rolling and intermediate annealing. The foil produced from the UFG titanium billet exhibits a homogeneous nanostructure. By contrast, foil produced by cold rolling the coarse-grained titanium billet exhibits a heterogeneous structure with both nanostructured and coarser-grained regions. The foil produced from UFG billets has higher strength, higher ductility, and exhibits uniform deformation over a larger strain range at room temperature than foil produced from coarse-grained billets.

Owner:LOS ALAMOS NATIONAL SECURITY

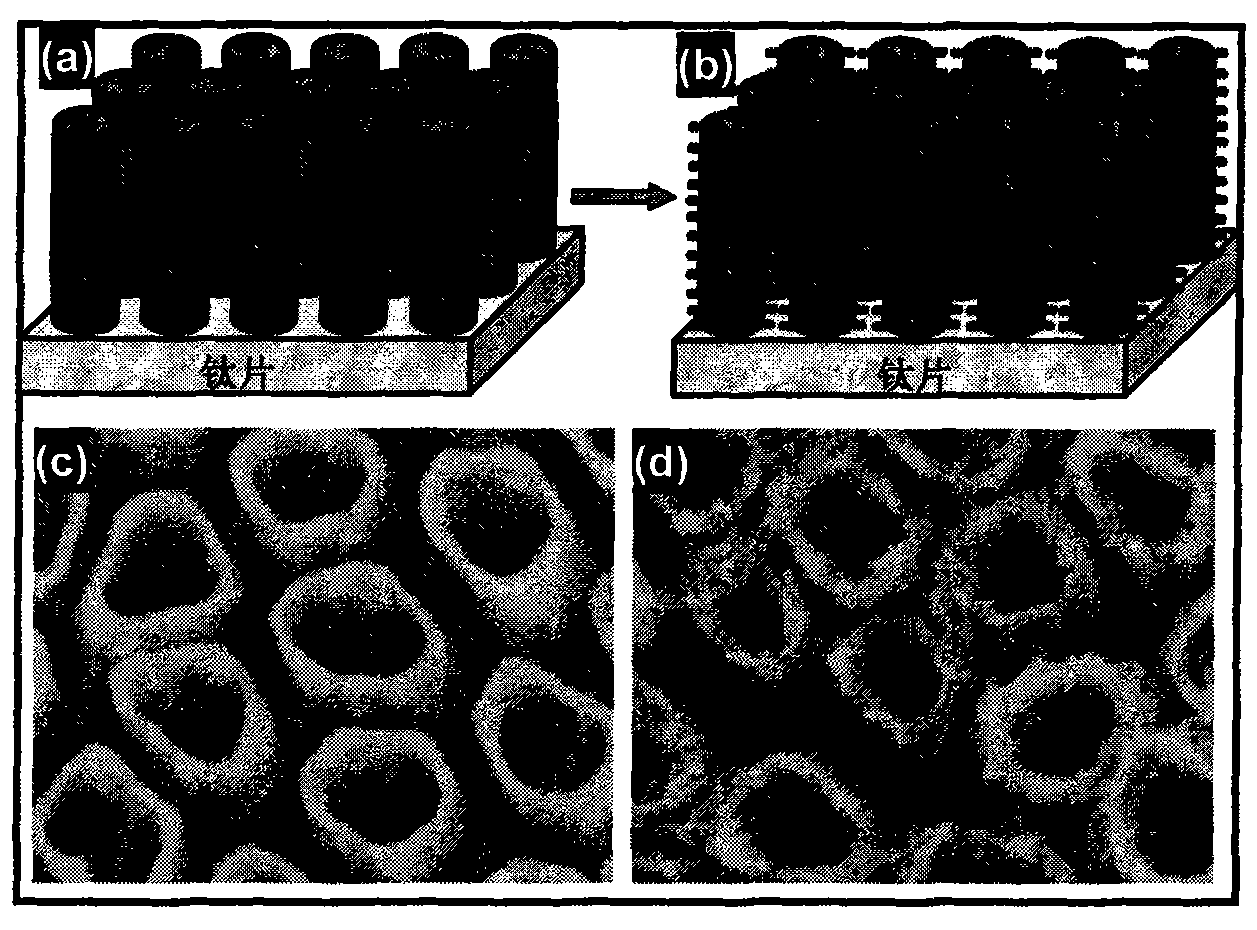

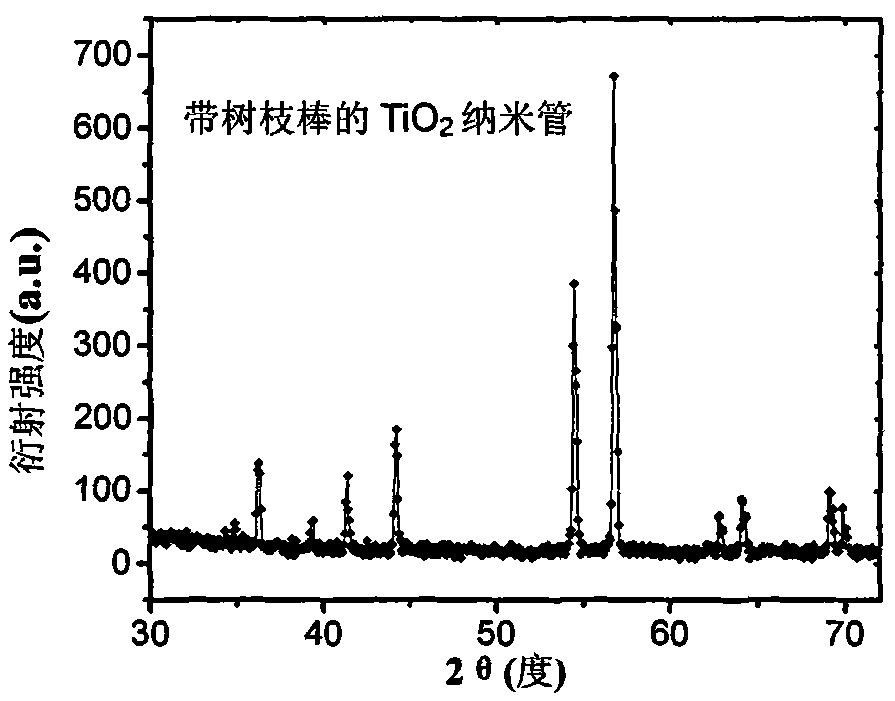

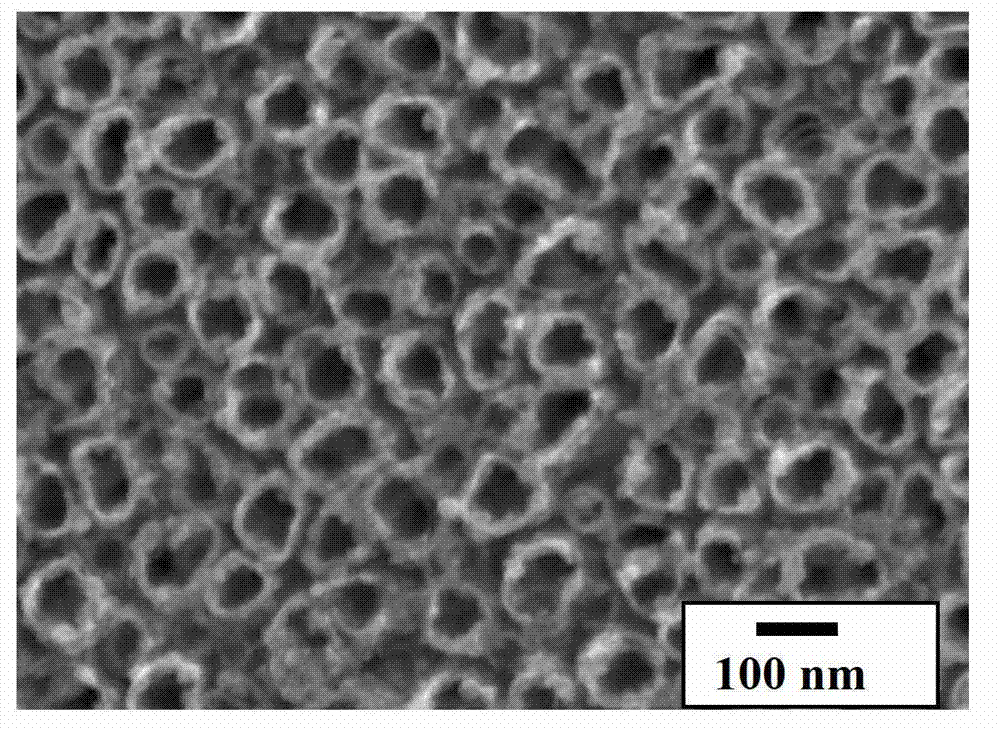

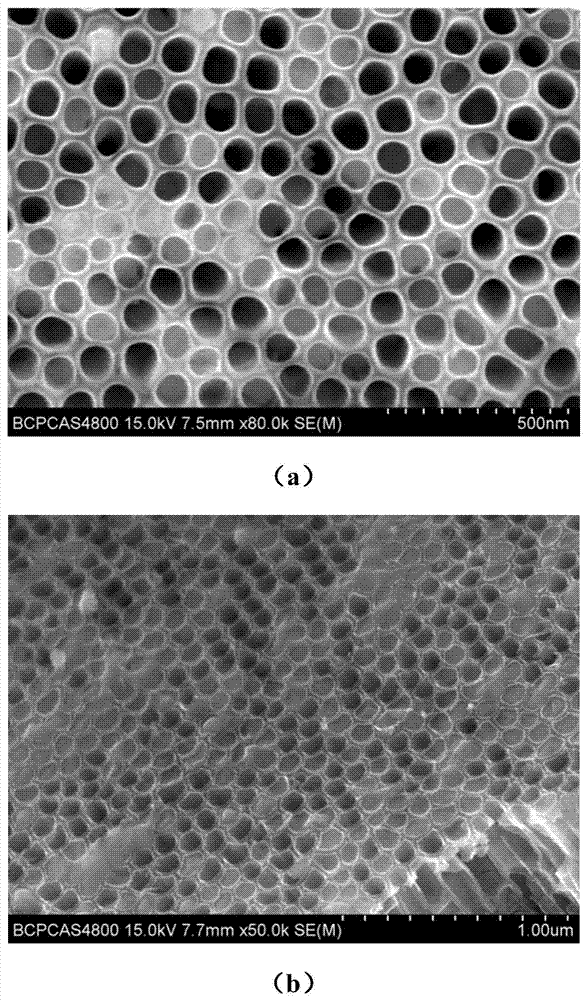

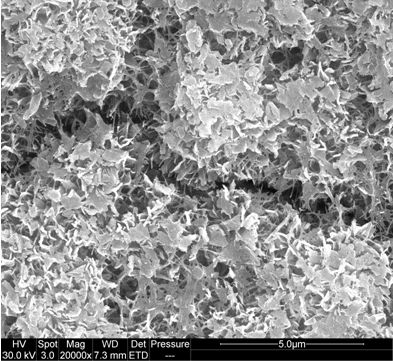

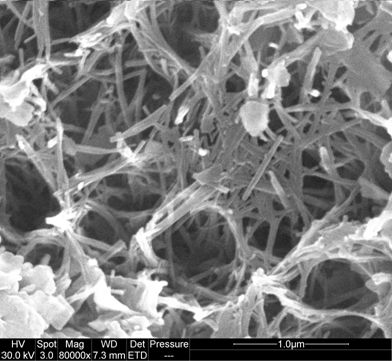

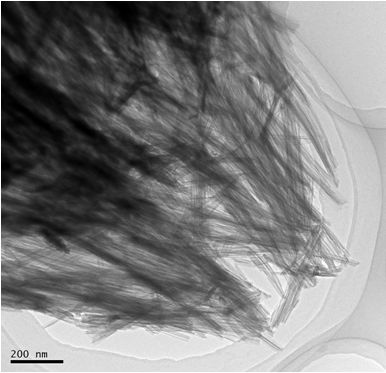

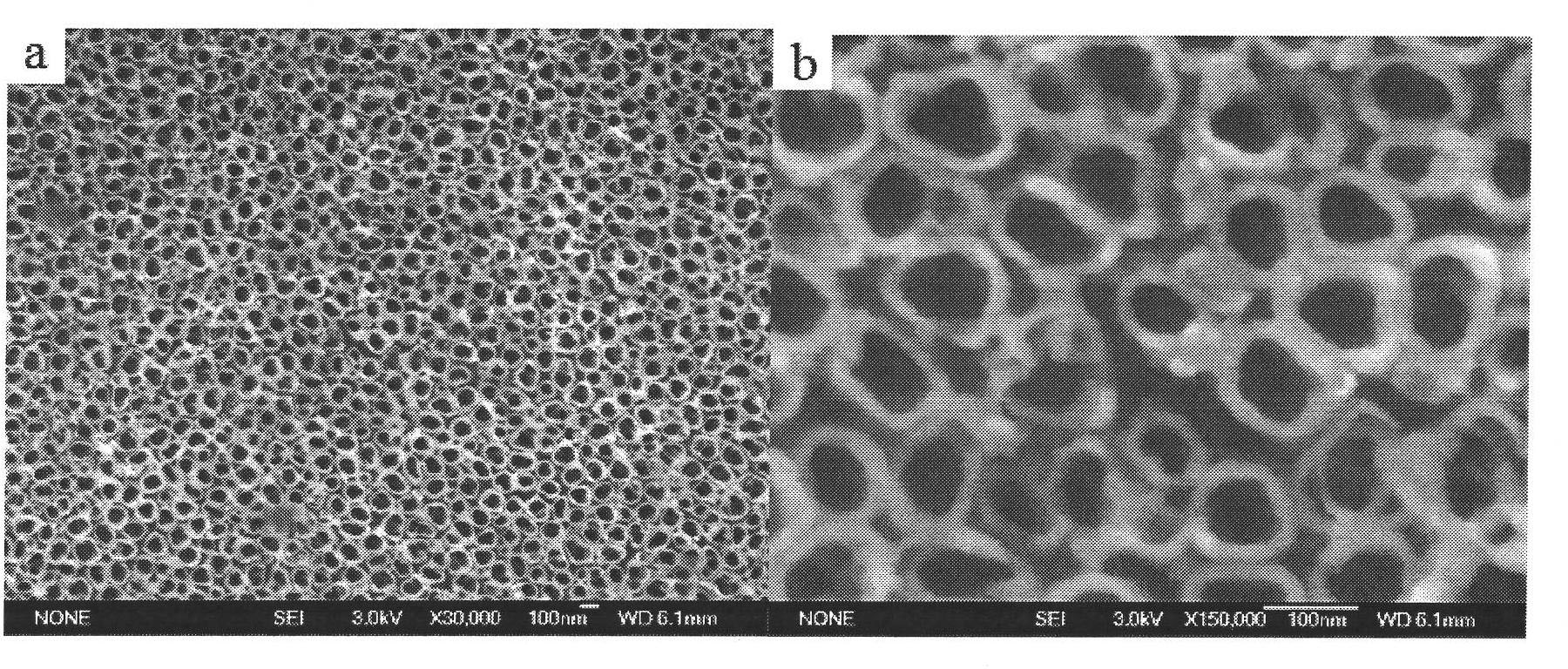

Titanium dioxide nano thread, belt and tube block array and preparation method thereof

InactiveCN101037225AEasy to controlGood process repeatabilityIndividual molecule manipulationTitanium dioxideSolar cellPt element

The present invention provides a titanium dioxide nanometer thread, strip and tube block array, and a preparation method of the same, which relates to a nanometer material and a preparation method of the same. A high purity titanium foil serves as a substrate; a mixture solution of ethylene glycol and fluorination ammonification with a content of 0.1~0.5 wt%; a titanium dioxide nanometer thread, strip and pipe block array, which has a nanometer thread, strip blended fasciculation substance of 1~20 micron at the upper end and a regular nanometer tube array at the lower part, is formed vertically at the substrate by constant pressure anodisation. The preparation method comprises the steps of that: the substrate serves as the anode, the platinum serves as the cathode, the distance between the anode and the cathode is 10~50 mm, the voltage is 10~60 V, the reaction time is 30~3000 min; the obtained product is roasted for 1~3 hours at 240~600 DEG C, and is cooled in the furnace, thereby the titanium dioxide nanometer thread, strip and tube block array is obtained. The method has a simple equipment, an excellent repetitiveness for technology, a steady quality of product, and can be used for the fields of photocatalysis, photolysis water, solar cell and spinning electron.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing gradient TiO2 nano-tube arrry thin film by using multistep anodic oxidation process

InactiveCN101230479AReduce energy consumptionSimple processPolycrystalline material growthSurface reaction electrolytic coatingWater basedTio2 nanotube

The invention relates to a method of preparing a gradient TiO2 nanotube array film by utilizing the method of multi-step anodic oxidation. Firstly, phosphoric acid, hydrofluoric acid, ammonium fluoride, glycerin and deionized water are adopted as raw materials and prepared into a water-base electrolyte and an organic electrolyte respectively; secondly, the two electrode systems composed of a titanium foil sheet and a platinum sheet are placed into the water-base electrolyte and the organic electrolyte for a repeated anodic oxidation; and finally, the TiO2 nanotube array film material with a gradient structure is generated on the titanium foil sheet. The method is fit for manufacturing photoelectrochemical apparatuses of various types and has a far-ranging application prospect in the industrial fields of light energy utilization, green energy development, sewage disposal and so on.

Owner:TSINGHUA UNIV

Low power, pulsed, electro-thermal ice protection system

ActiveUS20070075188A1Avoid conductionDe-icing equipmentsEfficient propulsion technologiesMetal foilEngineering

An electro-thermal ice protection system for an airfoil comprises: a metal foil heater including an integral parting strip, the metal foil heater configurable to cover at least a portion of a leading edge of the airfoil with the integral parting strip disposed along an air-stagnation zone of the leading edge; and a controller coupled electrically to the metal foil heater for controlling electrical energy from a power source to the metal foil of the heater in accordance with a pulse duty-cycle and for controlling power to the parting strip of the heater to maintain the air-stagnation zone virtually free of ice formation. A method of making an exemplary metal foil heater for use in ice protection of an airfoil comprises the steps of: preparing a sheet of Titanium foil in a rectangular shape having a length substantially greater than a width thereof for covering at least a portion of the leading edge of the airfoil; applying a layer of Nickel material over an area along each width edge of the Titanium foil; applying a layer of Copper material over the Nickel layer along each width edge of the Titanium foil; and attaching conductor wires to the Copper layers at each width edge.

Owner:THE BF GOODRICH CO

SPS diffusion welding method for molybdenum alloy and tungsten alloy

InactiveCN107175398AEfficient connectionFacilitated DiffusionWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureUltimate tensile strength

The invention provides an SPS diffusion welding method for a molybdenum alloy and a tungsten alloy. According to the method, titanium foil is used as an intermediate transition layer, solid phase diffusion welding is conducted on the molybdenum alloy and the tungsten alloy through an SPS technology, and a connecting piece of the molybdenum alloy and the tungsten alloy is obtained. By means of the welding method, a molybdenum alloy and tungsten alloy welding piece with the high strength and the good forming is obtained while it can be guaranteed that recrystallization of a base material is avoided, and the joint room temperature shear strength can reach 296 MPa.

Owner:HEFEI UNIV OF TECH

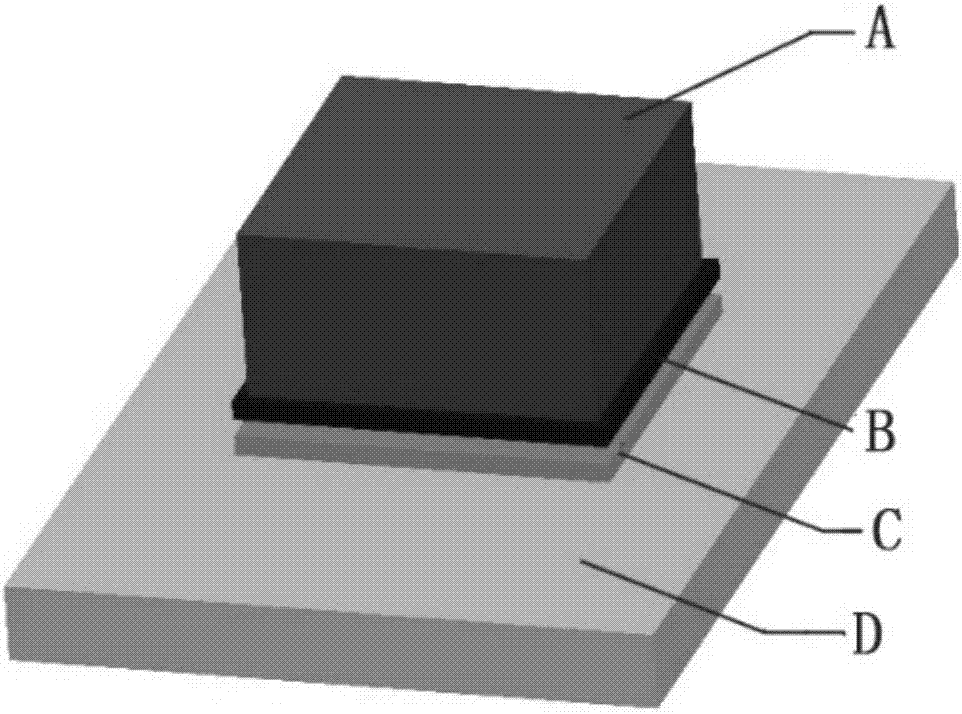

Method for brazing ceramic and metal by adopting composite high-entropy alloy solder

The invention relates to a method for brazing ceramic and metal by adopting a composite high-entropy alloy solder, and solves the problem of poor joint performance due to that a lot of brittle intermetallic compounds are generated on the joint surface during the ceramic and metal brazing process. The composite high-entropy alloy solder comprises an upper layer and a lower layer, wherein the upper layer is a high-entropy alloy foil band close to one side of the metal, and the lower layer is titanium foil close to one side of the ceramic. The method comprises the following steps: cleaning a substrate to be welded and the solder foil band, assembling a sandwich structure, applying a pressure of 0.01-0.03 MPa on the sandwich structure to ensure that the substrate can be in full contact with the solder layer, and placing the assembled part in a vacuum diffusion furnace for brazing after the completion of assembly. The method for brazing ceramic and metal by adopting the composite high-entropy alloy solder has the benefits as follows: the operation is simple, the high-entropy effect of the high-entropy alloy is utilized, an FCC and BCC solid solution structure is formed in the brazing seam, no brittle intermetallic compound is generated in the joint, that is, the generation of brittle intermetallic compounds in the joint is effectively suppressed, the reaction between active element Ti and ceramic in titanium foil is utilized, and tough compounds are generated on the joint surface so as to realize the effective metallurgical bonding of ceramic and metal.

Owner:BEIJING UNIV OF TECH

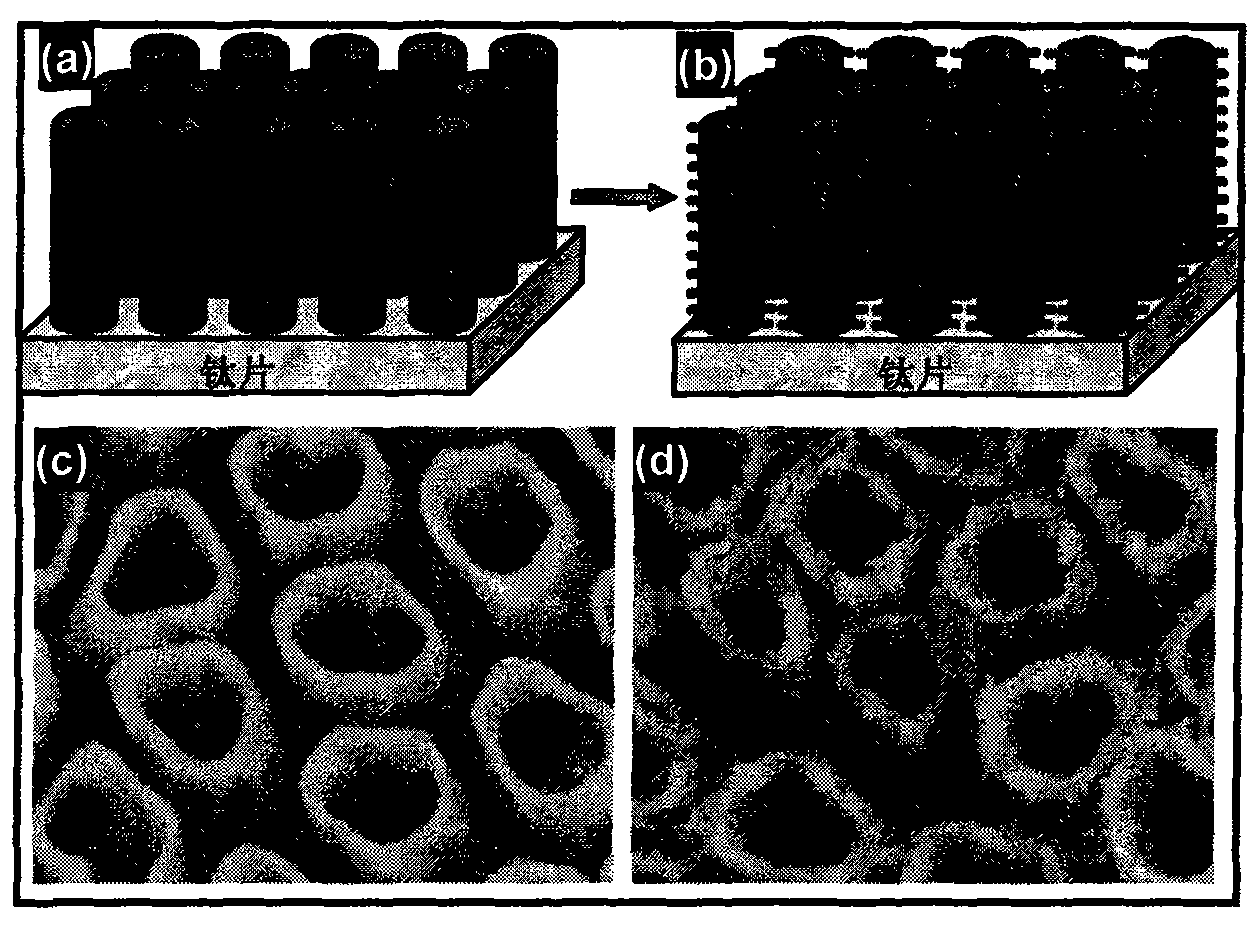

Preparation process of dendritic titanium dioxide nanotube array electrode

InactiveCN101969109ALarge specific surface areaLow manufacturing process costNanostructure manufactureLight-sensitive devicesTio2 nanotubeSolar cell

The invention provides a preparation process of a dendritic titanium dioxide nanotube array electrode, which comprises: firstly, pre-preparing a titanium dioxide nanotube array by using an anodizing method and by using pure titanium foil as an anode and mixed solution of ammonium fluoride, lactic acid and dimethyl sulphoxide as electrolyte; secondly, growing nanorods with dendritic titanium dioxide on the pre-prepared titanium dioxide nanotubes serving as a host skeleton by using a low-temperature liquid-phase method and by using aqueous solution of hydrochloric acid and TTIP as growing solution, and thus obtaining the required dendritic titanium dioxide nanotube array; and finally, using the dendritic titanium dioxide nanotube array as a material to assemble the working electrodes of dye-sensitized solar cells, photoelectrochemical cells, photocatalysis devices and the like. The dendritic titanium dioxide nanotube array can improve the conversion efficiency of the cells and the efficiency of the photocatalytic pollutant degradation considerably; and the preparation process is low in cost, simple in process and easy in production.

Owner:XIANGFAN UNIVERSITY

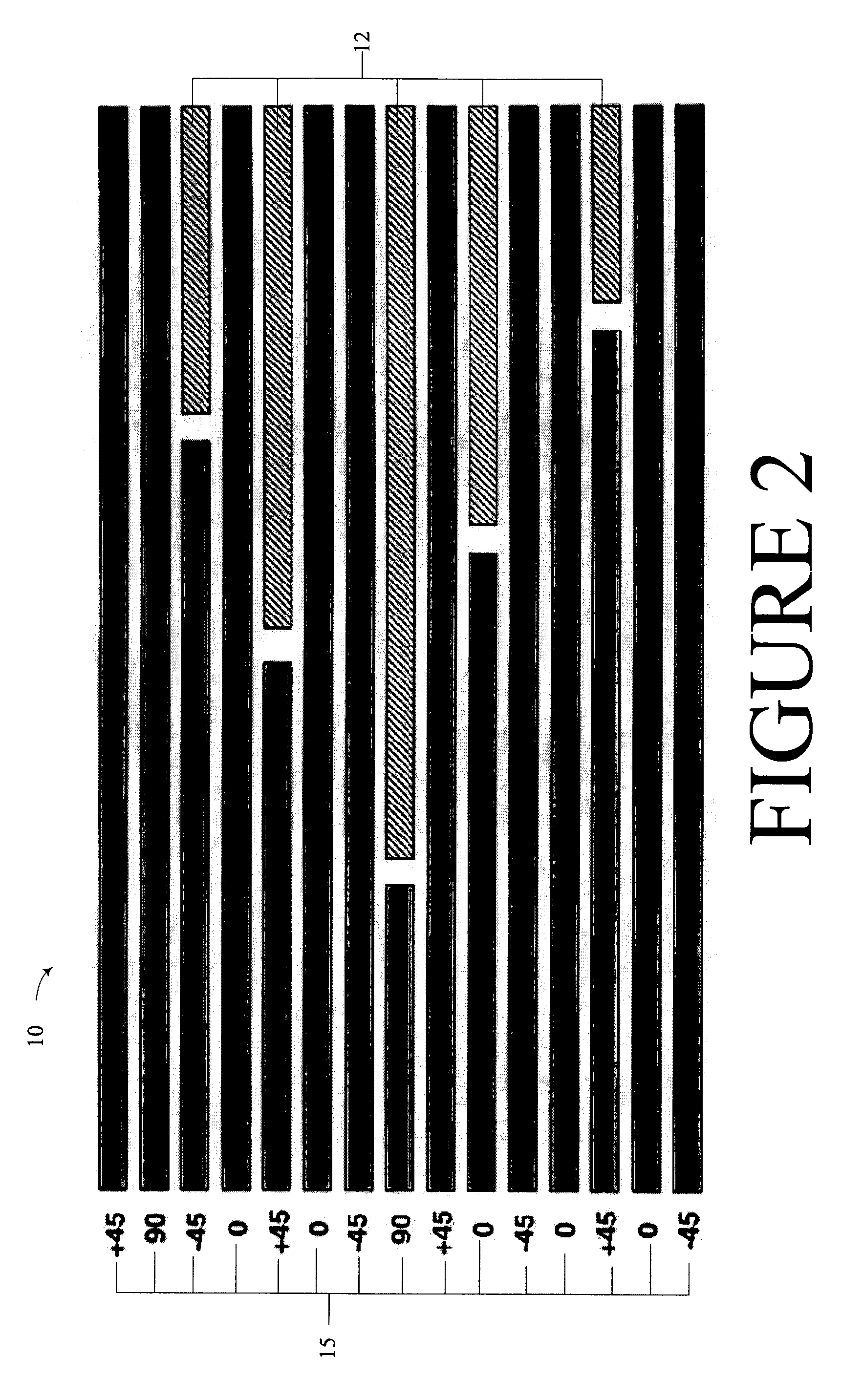

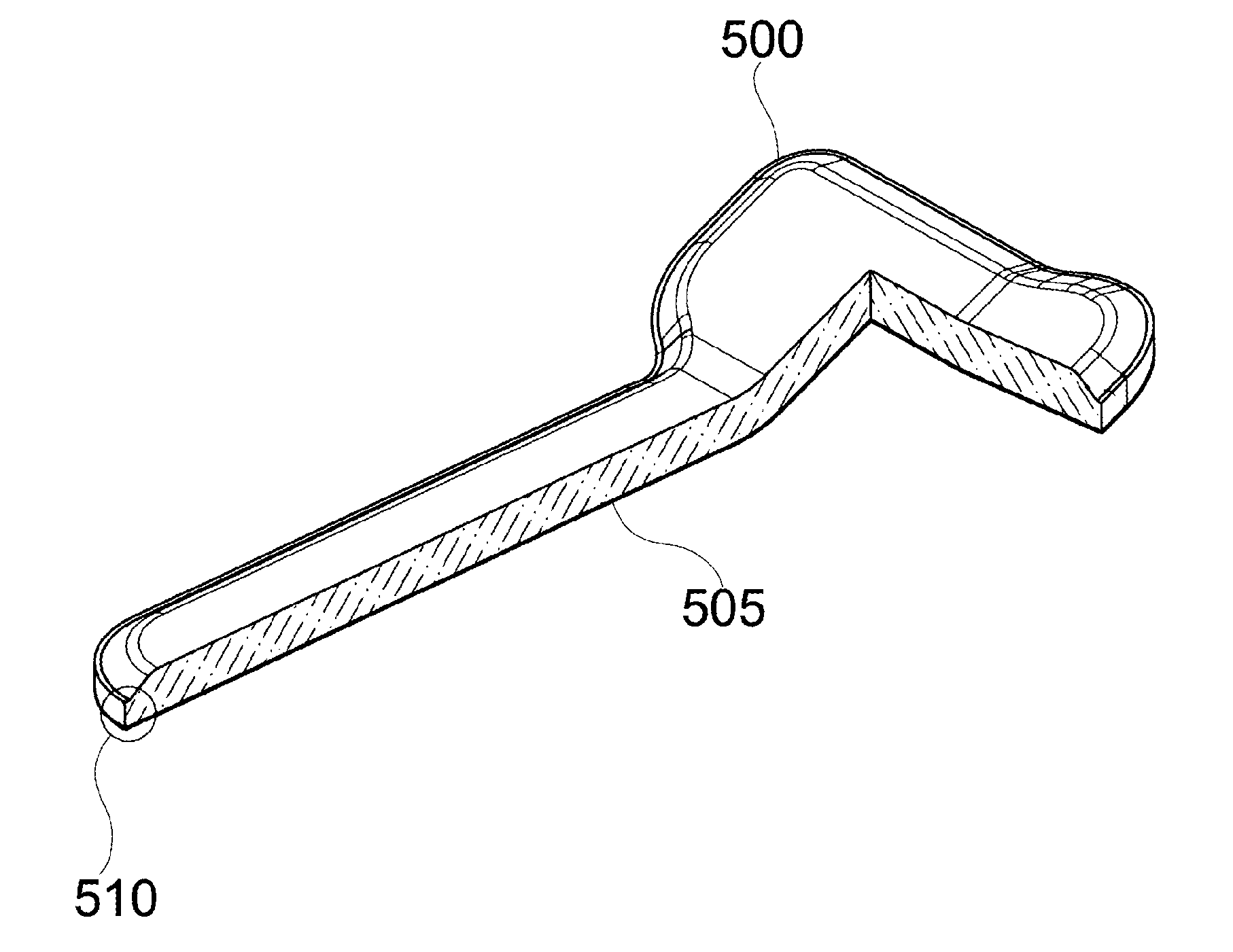

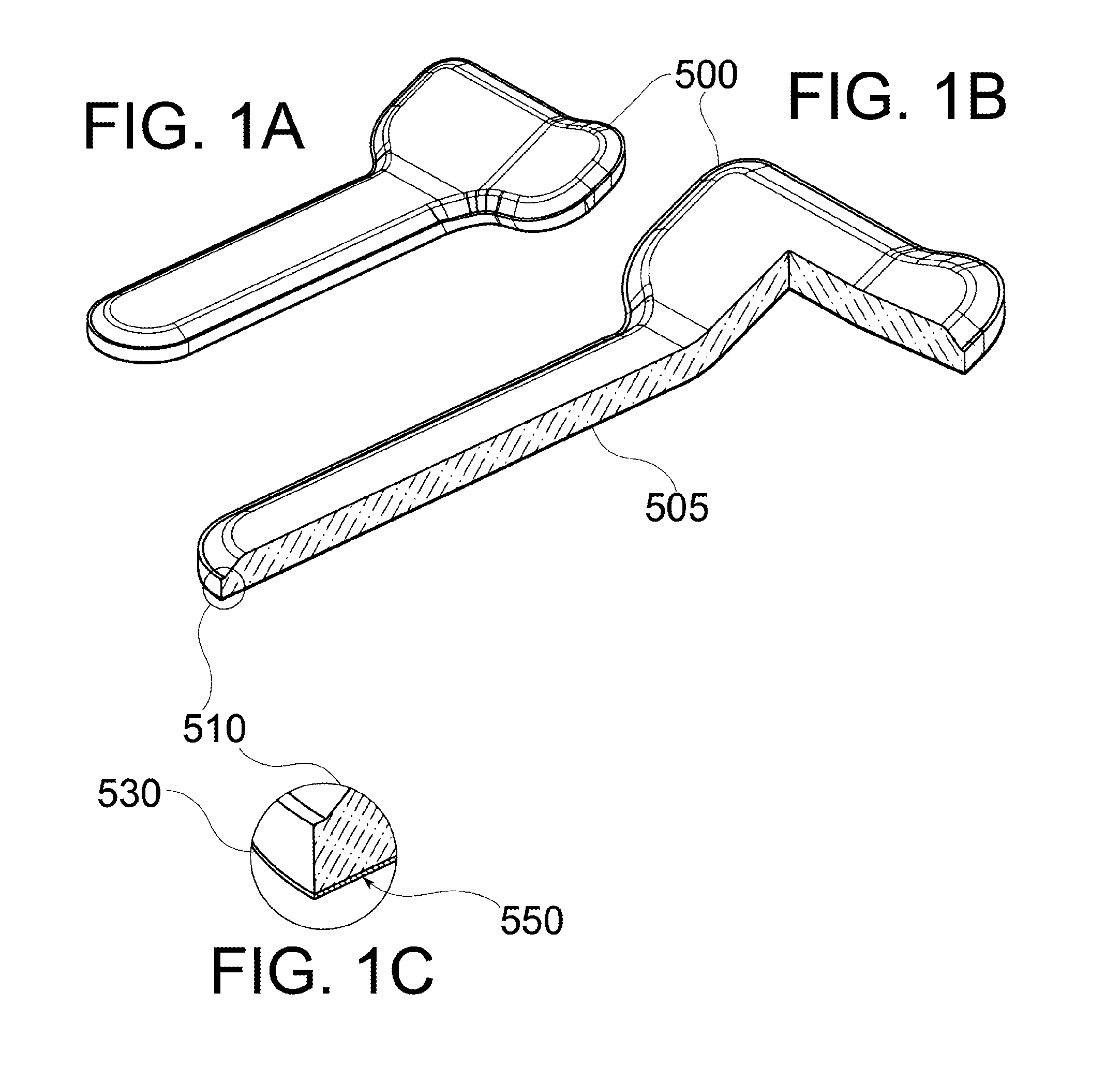

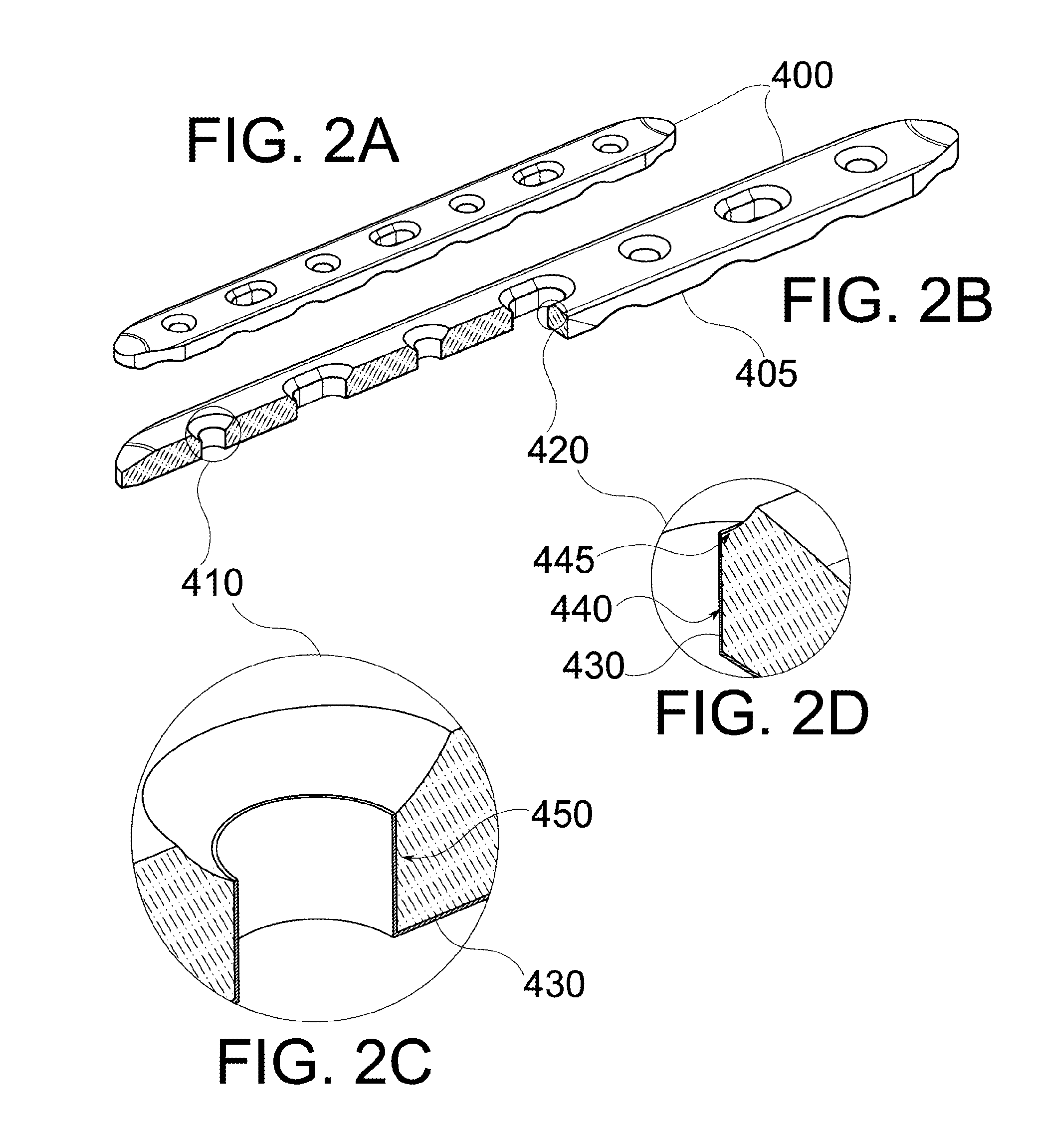

Titanium foil ply replacement in layup of composite skin

Laminate structures and methods for forming same are disclosed. In one embodiment, a laminate structure includes a metal-polymer composite lamina. The metal-polymer composite lamina has a first face and a second face spaced apart, and extends to a terminal edge. The lamina includes a ply of fiber-reinforced polymer that extends between the first face and the second face and has an interior edge. The interior edge defines at least one cutout. A ply of metal foil extends between the first face and the second face substantially from the interior edge filling the at least one cutout.

Owner:THE BOEING CO

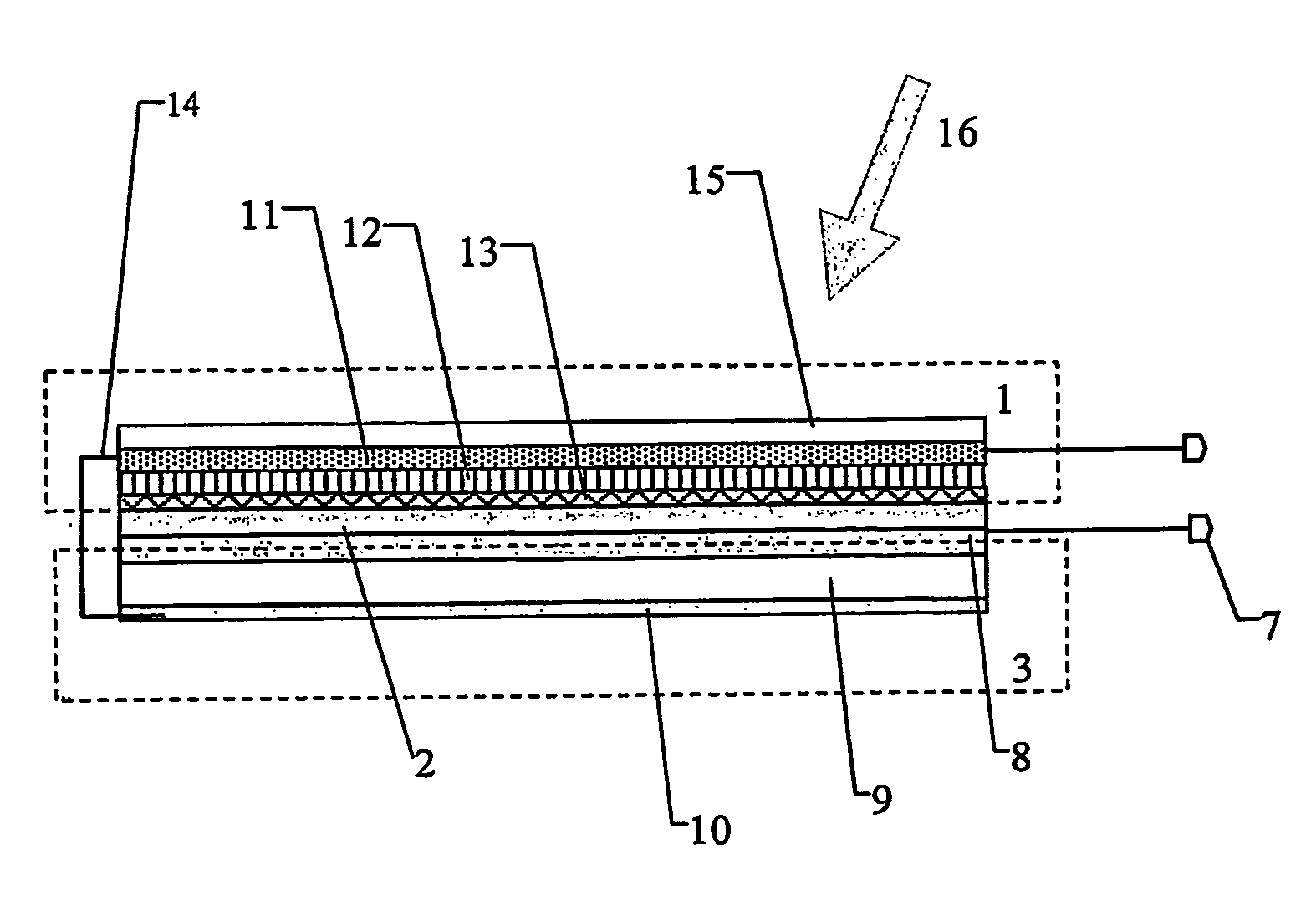

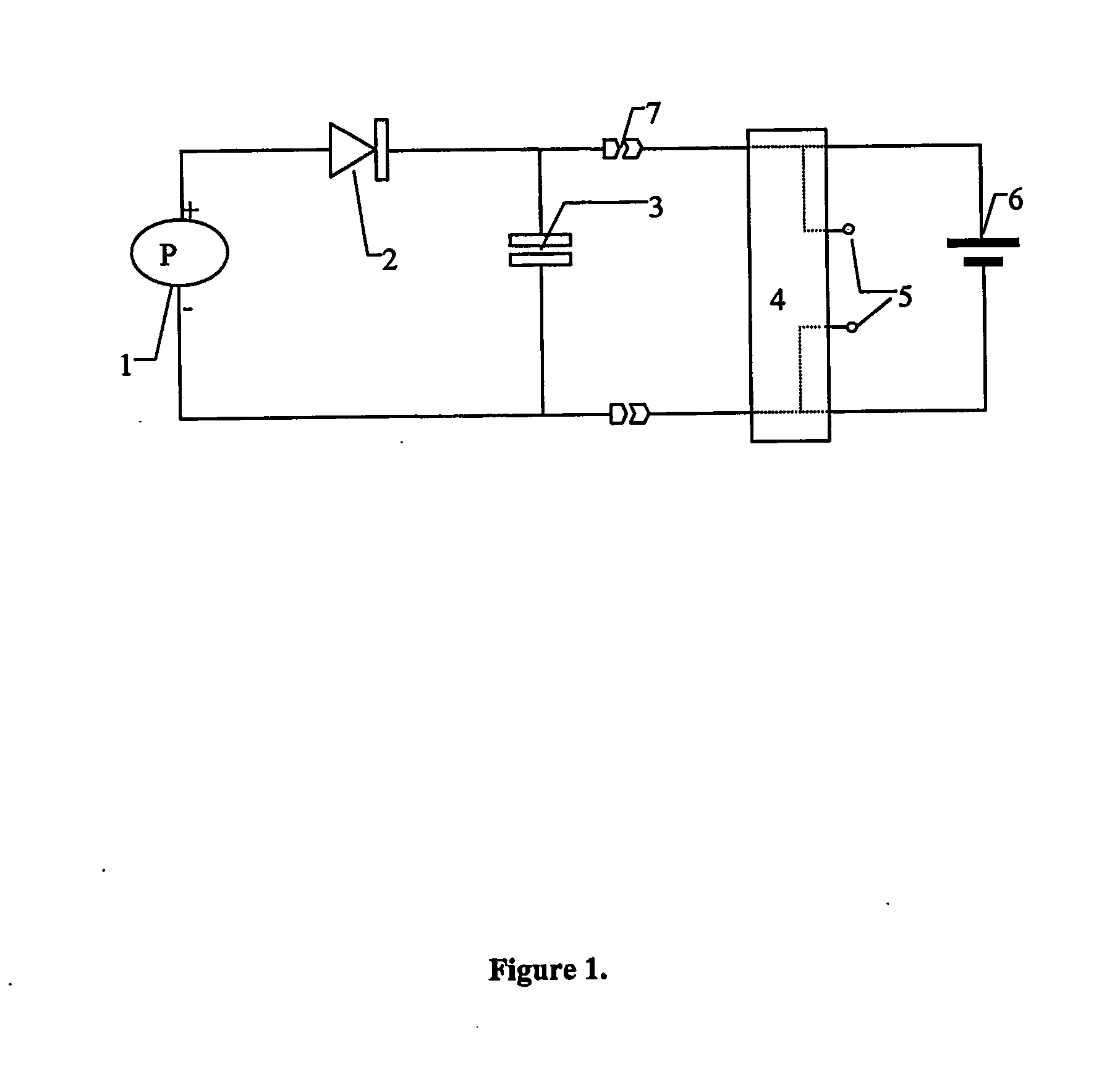

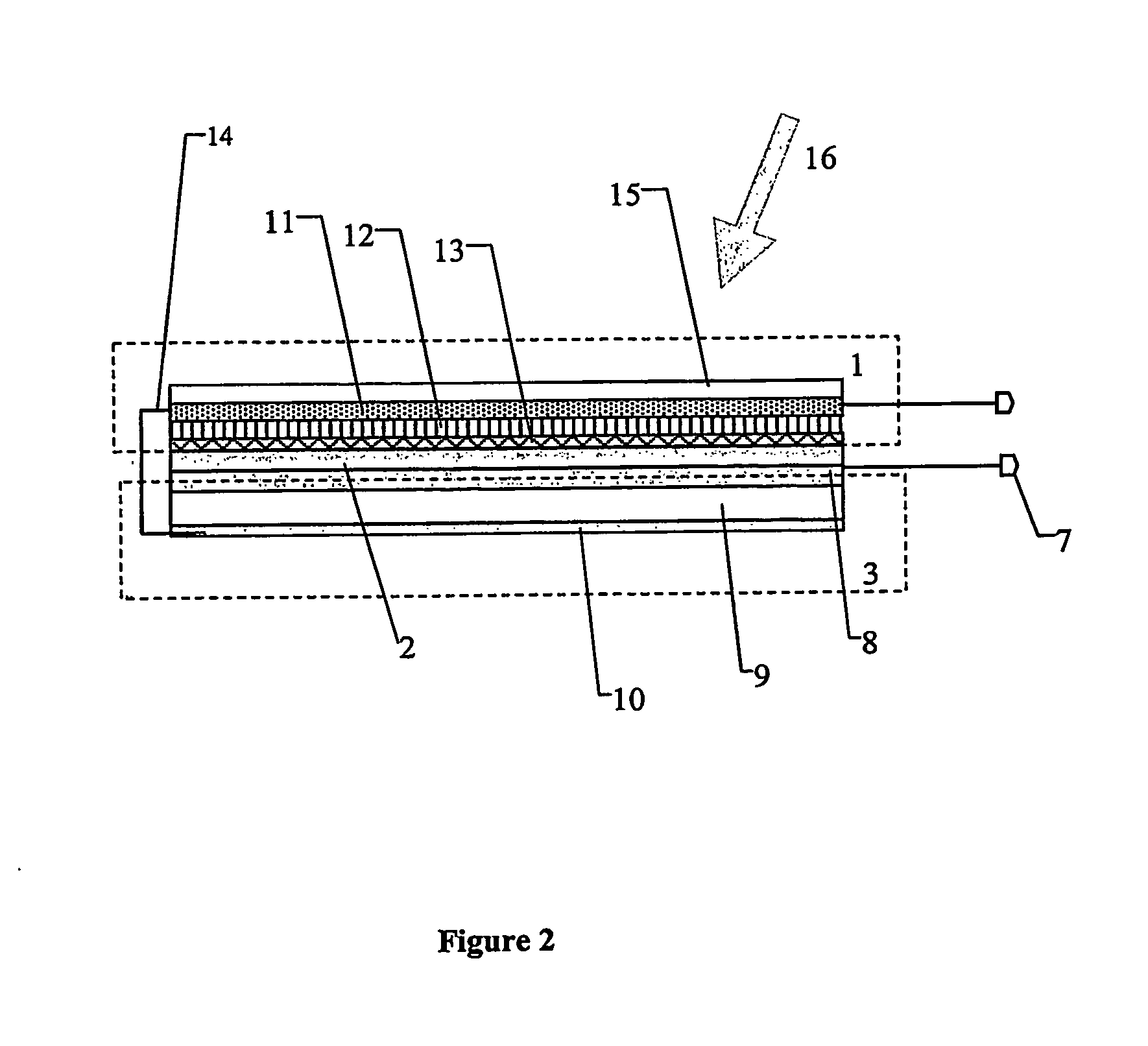

Combined photoelectrochemical cell and capacitor

A nanophotocapacitive device wherein: a photovoltaic element (1) extends over substantially the whole area of the device, a charge storage element (3) also extends over substantially the whole area of the device, connection mechanism (14) are provided for interconnecting the photovoltaic and charge storage elements, the photovoltaic element comprises a nanoparticulate dye sensitized layer (11) of wide band gap semiconductor, a catalytic layer (13) and an electrolyte (12) placed between the semiconductor and the catalytic layers. The photovoltaic (photoelectrochemical) element and charge storage element (capacitor) are formed on opposite sides of a titanium foil substrate (8). Light (16) is incident on the transparent electrode (15). A diode (2) may be integral with the device to prevent the charge storage element discharging when there is no solar energy input to the photovoltaic element.

Owner:DYESOL IND

Composite implant coating

A coating layer, for example PEEK or titanium foil, shields a bone implant surface from wearing interactions with surfaces of bone and / or other implants. The coating prevents shedding particles which are difficult to distinguish from evidence of potentially dangerous conditions, for example, microorganism contamination and / or degenerating tissue. Methods and structures for securing a coating layer are described. Other uses and implementations of coating layers are described.

Owner:CARBOFIX SPINE INC

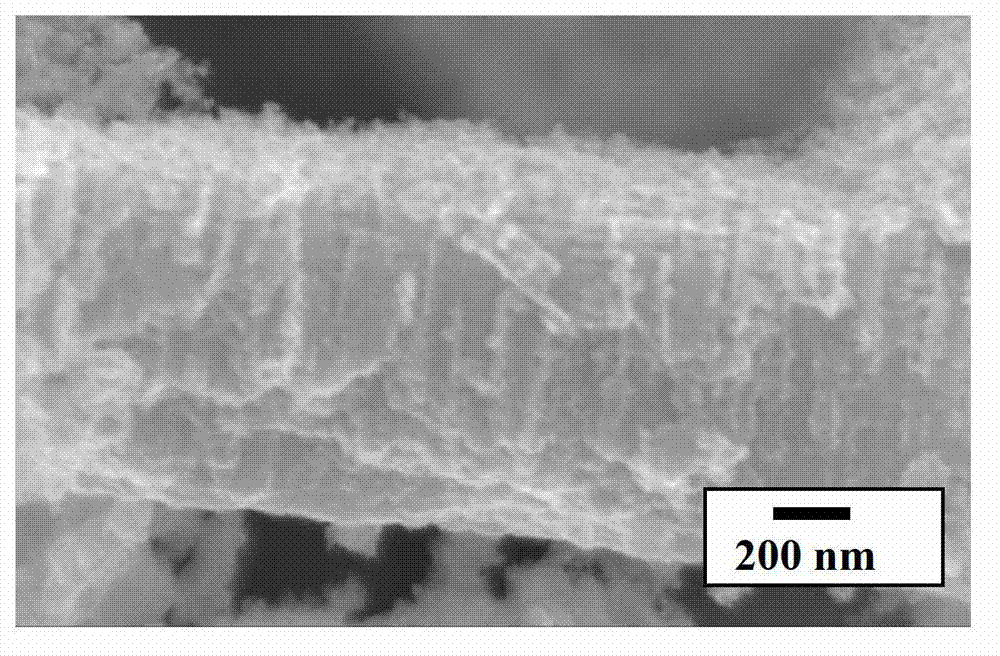

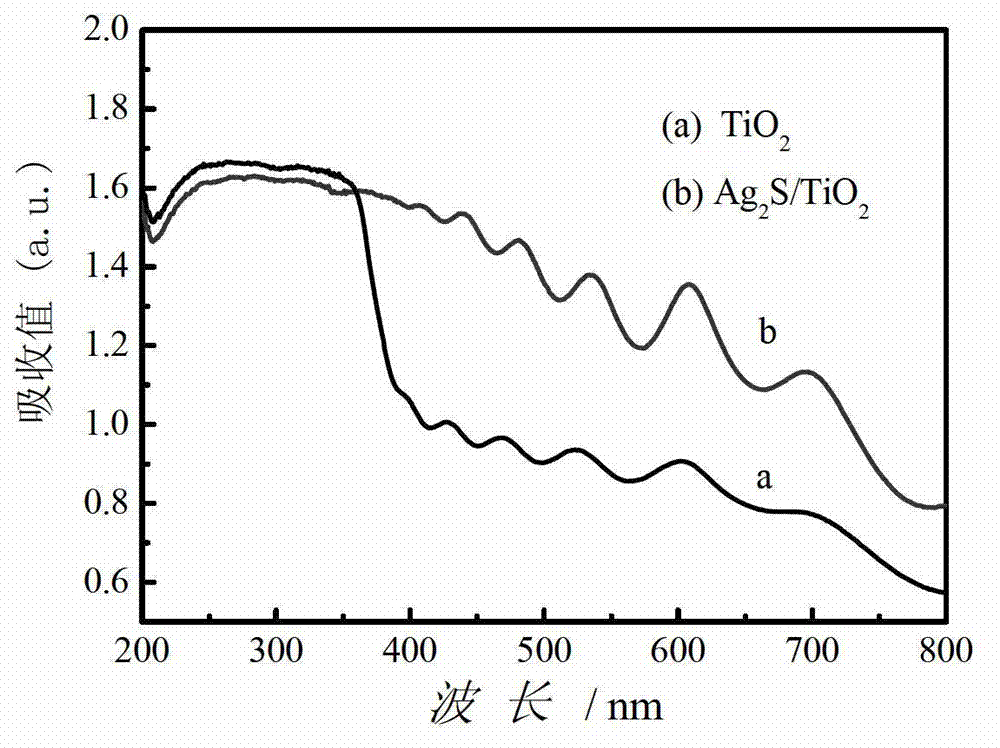

Preparation method of Ag2S/TiO2 composite film photo-anode for photoproduction cathode protection

InactiveCN103205760AUniform and complete coatingLower electrode potentialLiquid surface applicatorsSurface reaction electrolytic coatingComposite filmTio2 nanotube

The invention provides a preparation method of an Ag2S / TiO2 composite film photo-anode for photoproduction cathode protection and relates to a composite film anode. The preparation method of the Ag2S / TiO2 composite film photo-anode for photoproduction cathode protection provided by the invention has high efficiency and low toxicity. The preparation method comprises the following steps of: (1) preparing a titanium substrate sample, namely with a titanium foil as a substrate, sequentially carrying out ultrasonic washing on the titanium foil in acetone, absolute ethyl alcohol and deionized water to obtain the titanium substrate sample; (2) preparing a TiO2 nanotube array film on the surface of titanium, namely dissolving NH4F in the ionized water, adding glycerol to uniformly mix, carrying out anode oxidation by using platinum as a counter electrode, calcining the sample, and cooling the sample along with a furnace to room temperature, and therefore, the TiO2 nanotube array film is prepared on the surface of the titanium; and (3) preparing an Ag2s / TiO2 composite film, namely preparing Ag2S nanoparticles on the surface of the TiO2 nanotube array film to prepare the Ag2S / TiO2 composite film photo-anode for photoproduction cathode protection.

Owner:XIAMEN UNIV

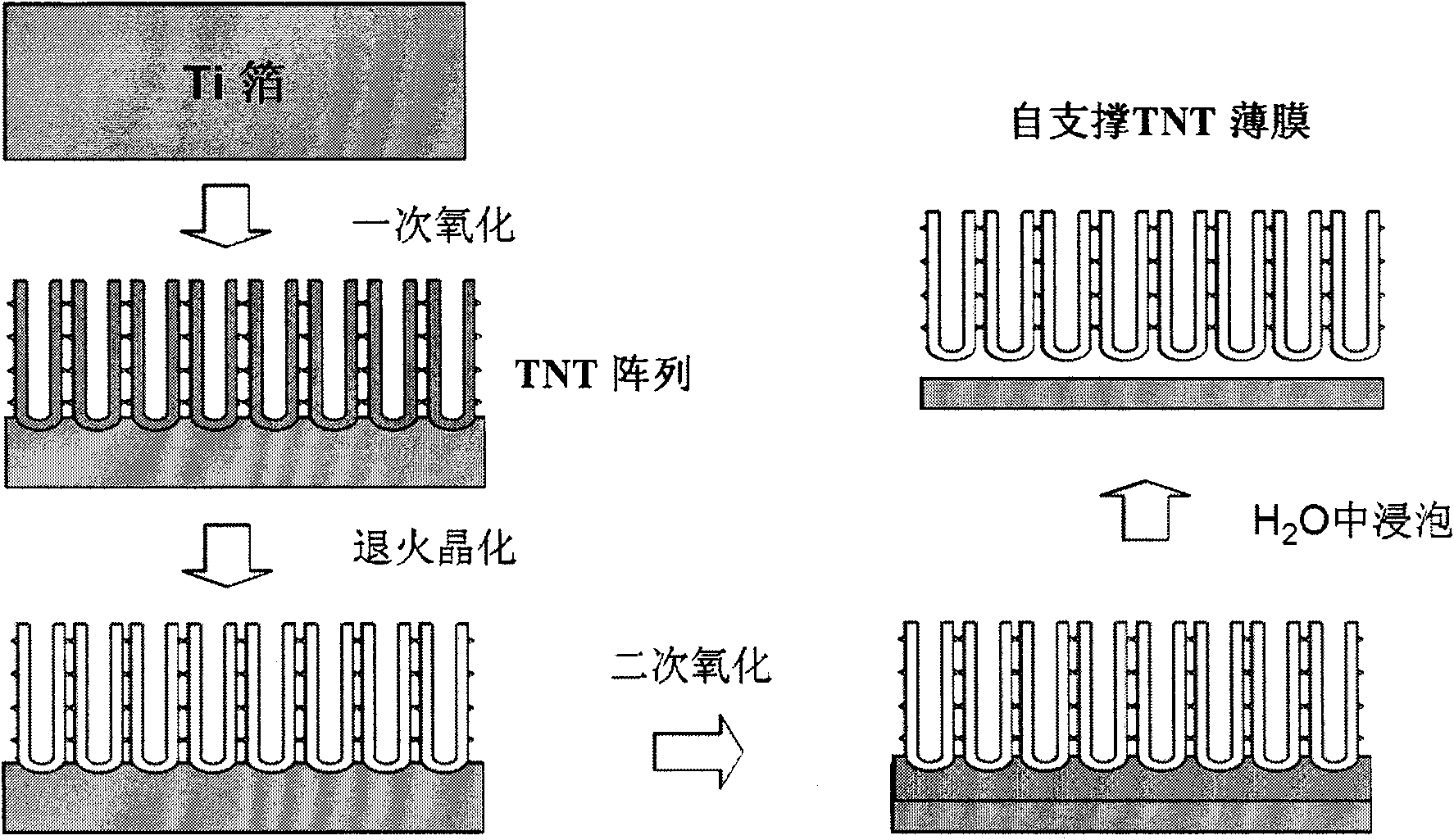

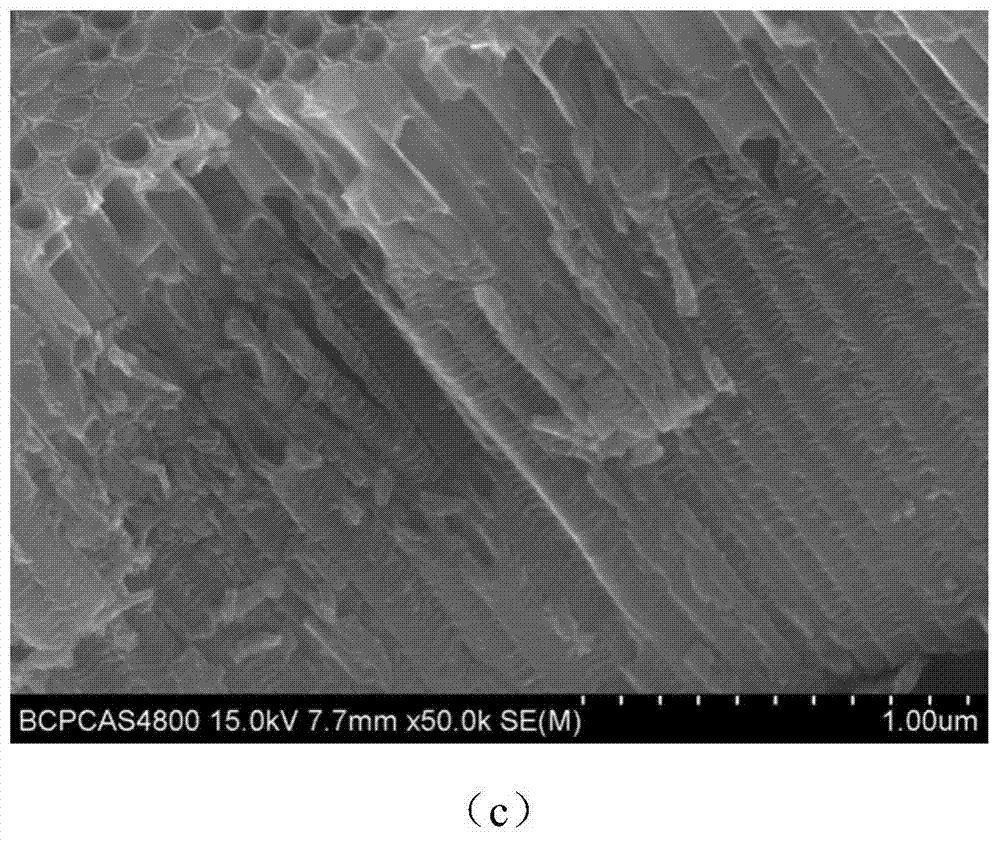

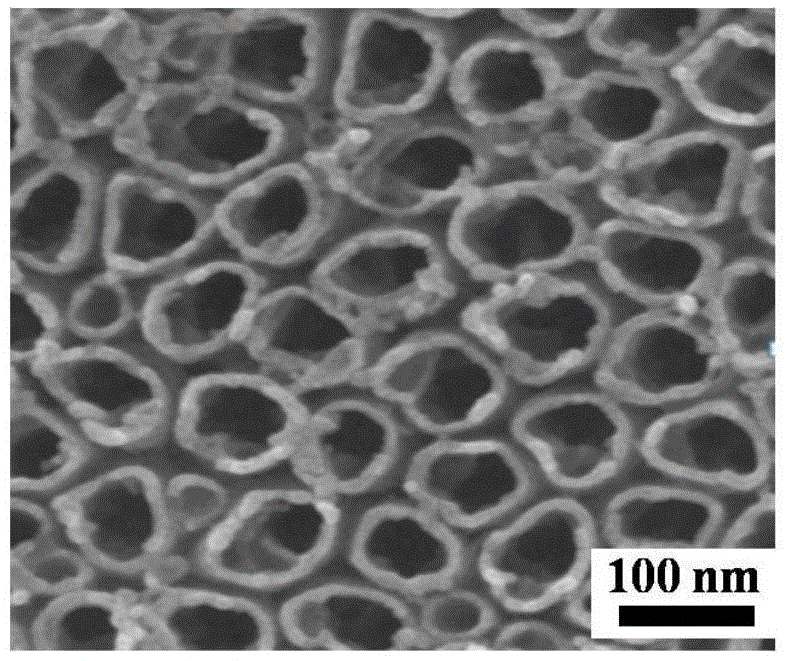

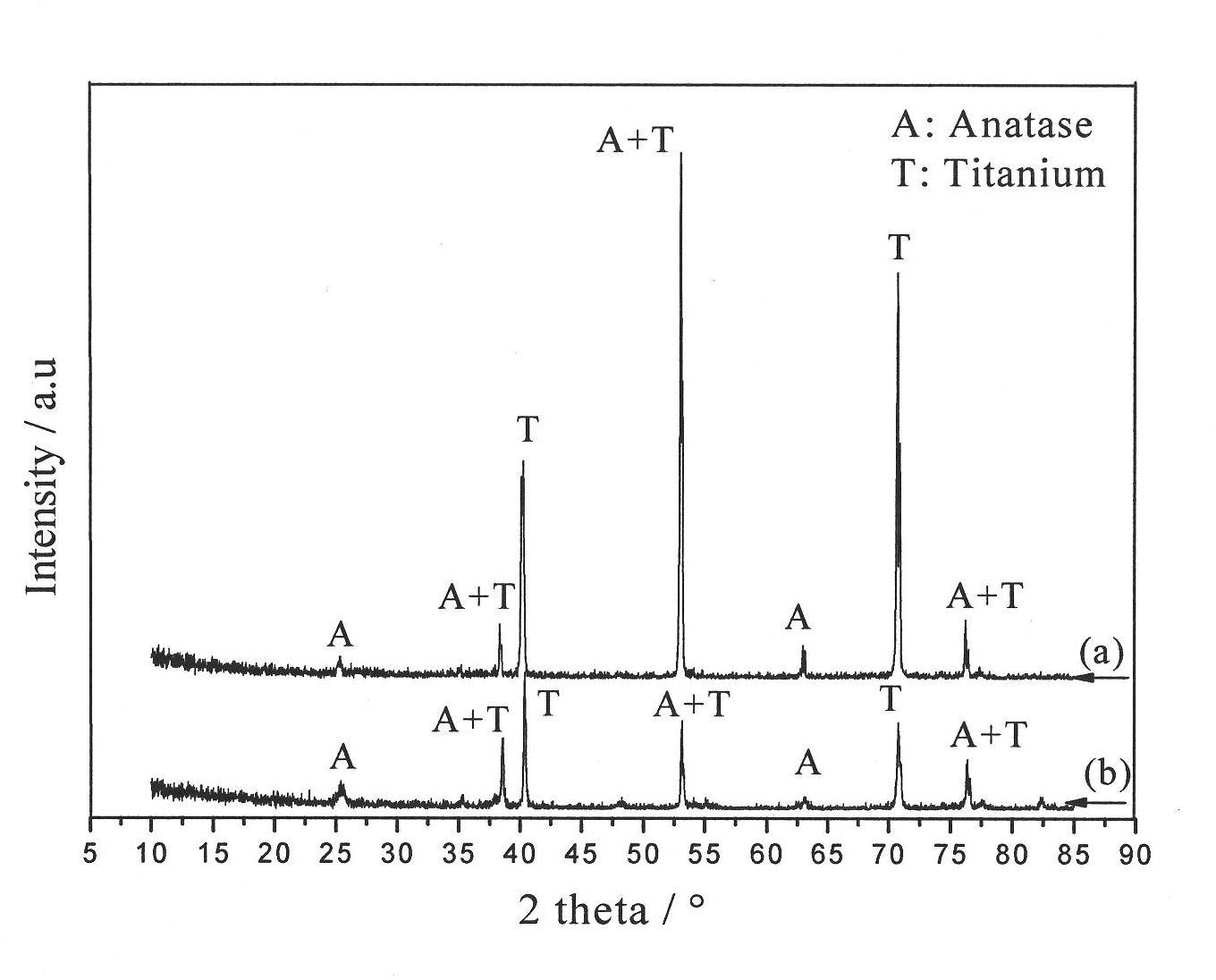

Self-standing TiO2 nanotube array membrane and preparation method thereof

InactiveCN101857966AHighly crystallineSimple structureLight-sensitive devicesSolid-state devicesTio2 nanotubeAnodic oxidation

The invention relates to a self-standing TiO2 nanotube array membrane and a preparation method thereof. The preparation method comprises: a), performing the primary anodic oxidation of a titanium foil, and forming a TiO2 nanotube array membrane on the titanium foil; b), annealing and crystallizing the titanium foil obtained by the processing of the step a); c) performing the secondary anodic oxidation of the processed titanium foil, and forming an amorphous oxide layer with a certain thickness between the titanium foil and the TiO2 nanotube array membrane; and d) stripping the TiO2 nanotube array membrane from the amorphous oxide layer. Meanwhile, the invention also provides a preparation method of the self-standing TiO2 nanotube array membrane and a dye-sensitized solar cell prepared by using the membrane. The self-standing TiO2 nanotube array membrane of the invention is flat in a large area and can be used for constructing an element such as the dye-sensitized solar cell based on the TiO2 nanotube array membrane conveniently.

Owner:PEKING UNIV

Process for producing intermetallic compound

InactiveCN101219433ASimple designImprove performanceRoll force/gap control deviceFurnace typesBiological activationHeating temperature

The invention relates to a preparation method of intermetallic compound, which is characterized in that iron foil, nickel foil or titanium foil and aluminum foil are adopted as raw materials; the preparation method comprises the steps are that: selecting raw foil material with consideration of the thickness of the raw foil material; defatting, degreasing and surface activation treating; alternative lapping of the treated foil; making rolling blank; warm rolling under heating temperature of 100-180 DEG C and 40-70 percent of rolling draft; edge cutting and cold rolling with 10-20 percent of rolling draft; heat treating of solid-phase alloying under temperature of 400-680 DEG C for 1-5 hours. The invention has the advantages that: the prepared intermetallic compound has uniform fine texture; average grain size is 2-20 Mum; room temperature brittleness and high temperature obdurability of the intermetallic compounds have been greatly improved. The invention overcomes the problem that intermetallic compound is difficult formed and has extensive industrial application value.

Owner:NORTHEASTERN UNIV LIAONING

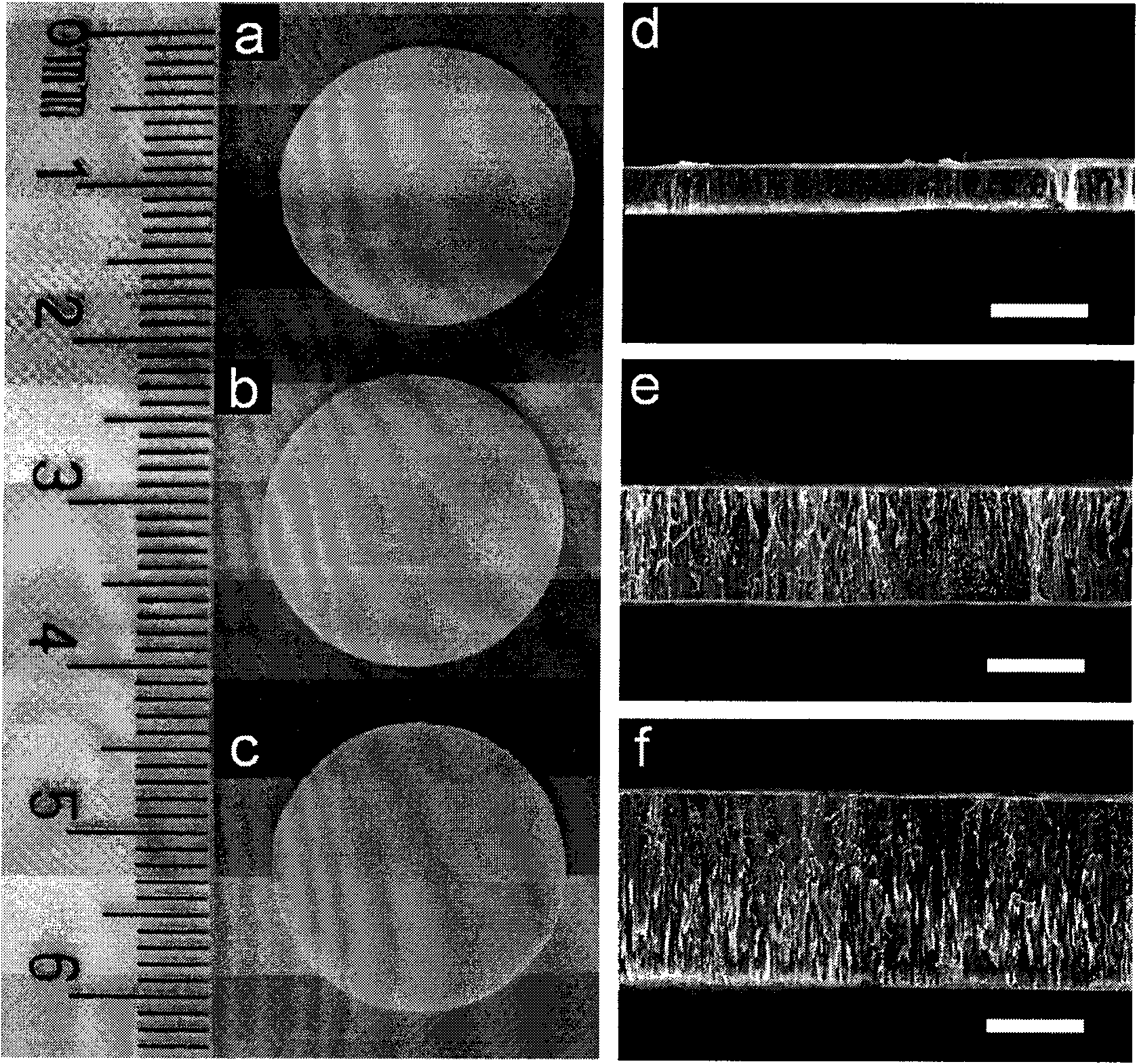

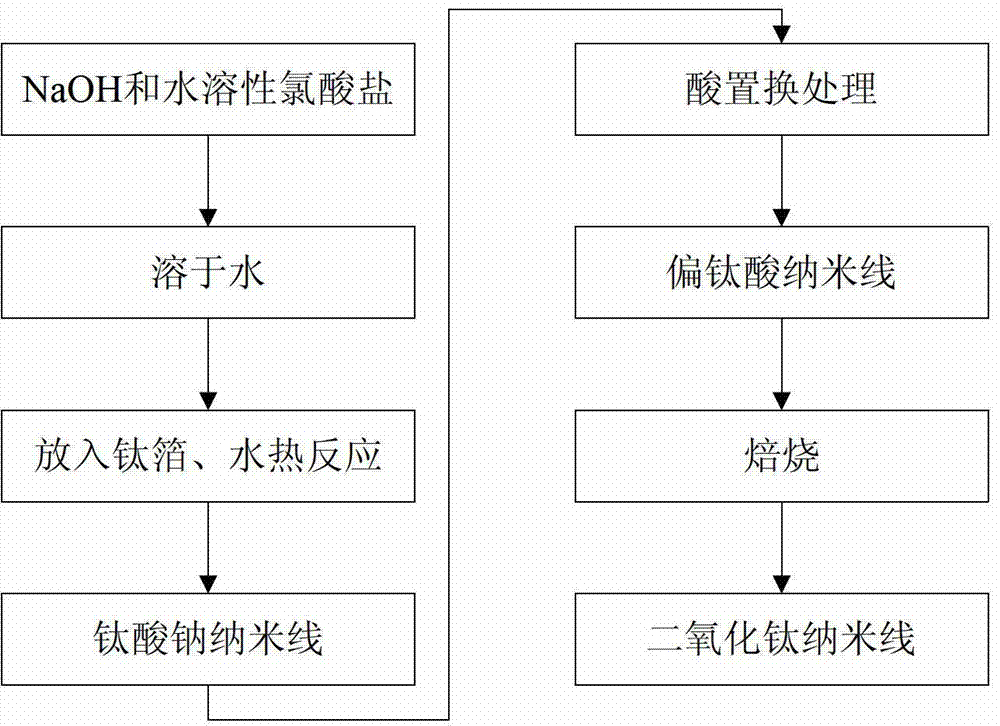

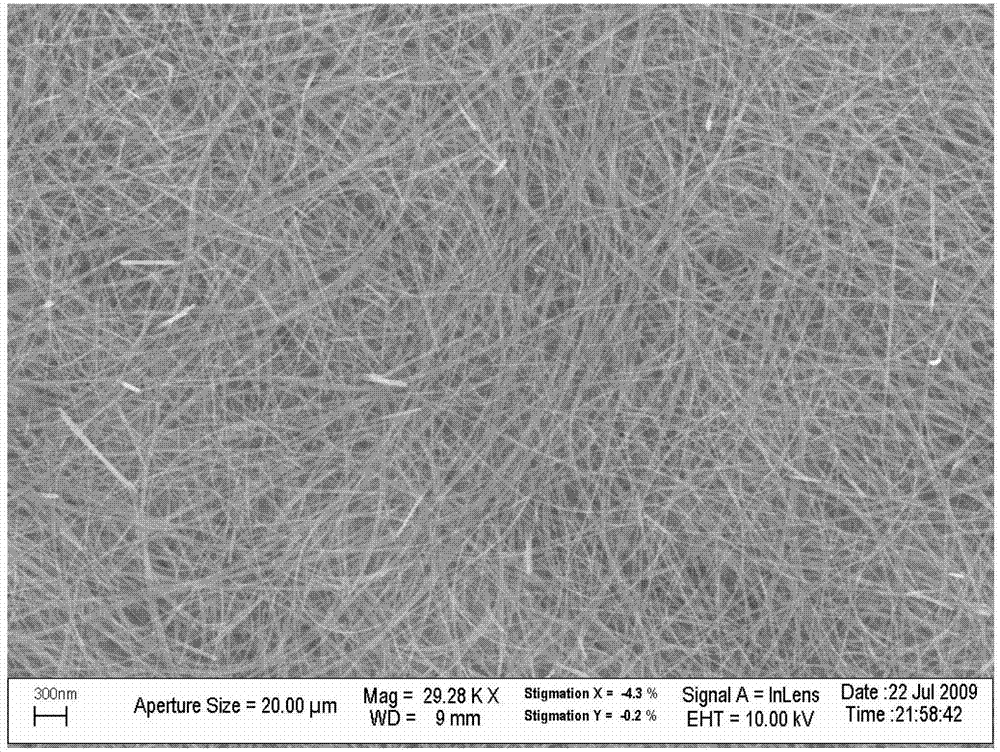

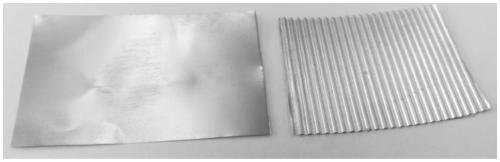

Method for preparing titanium dioxide nanowire

InactiveCN102826600ARegular size arrangementHigh crystallinityMaterial nanotechnologyTitanium dioxideNanowireSodium titanate

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

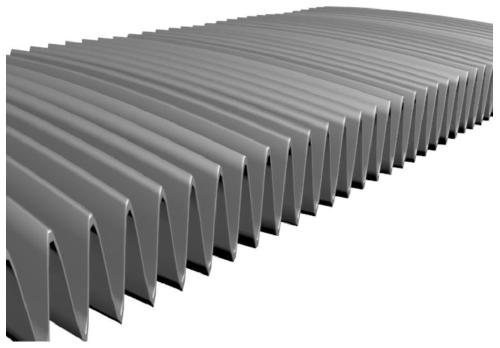

Heat conduction electromagnetic shielding composite material and preparation method thereof

ActiveCN109881038AImproved vertical thermal conductivityFlexibleMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic shieldingCopper foil

The invention discloses a heat conduction electromagnetic shielding composite material. The heat conduction electromagnetic shielding composite material is characterized by comprising a polymer matrixcomposite material and a heat conduction electromagnetic shielding membrane framework with a vertical orientation structure inlaid in the polymer matrix composite material; the heat conduction electromagnetic shielding membrane framework is parallel to the extension direction of the polymer matrix composite material; the heat conduction electromagnetic shielding membrane framework is made of oneor more composite membrane of gold foil, silver foil, copper foil, nickel foil, aluminum foil, iron foil, titanium foil, zinc foil, chromium foil, cobalt foil, a stainless steel plate and metal alloy;and the thickness of the heat conduction electromagnetic shielding membrane framework is 0.01mm to 0.2mm. The heat conduction electromagnetic shielding composite material is low in cost, simple in structure, simple and convenient to manufacture, easy to produce and capable of being used as a thermal interface material and an electromagnetic shielding material of an electronic device.

Owner:SHENZHEN INST OF ADVANCED TECH

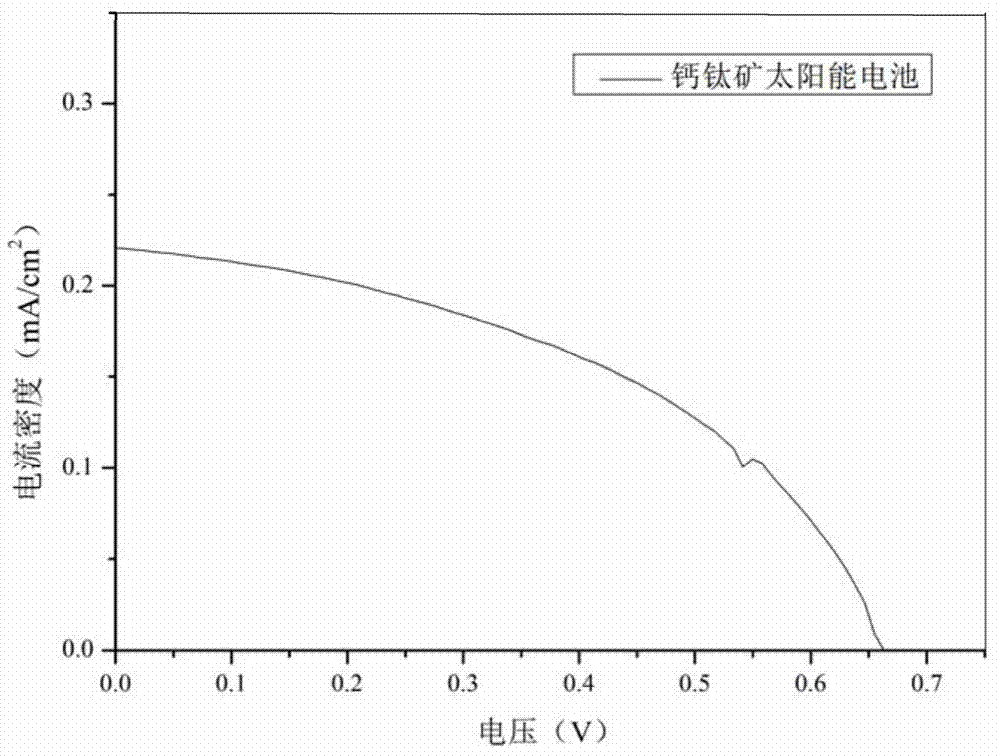

Manufacturing method of flexible all-solid-state array type perovskite solar battery

ActiveCN103928570AFinal product manufacturePhotovoltaic energy generationAll solid stateComposite film

The invention relates to a manufacturing method of a flexible all-solid-state array type perovskite solar battery, and belongs to the technical field of nano-thin film preparation and photo-electrochemical characteristics. By means of the pulse anodic oxidation technology, a titanium dioxide nanotube array with the controllable structure and the sequential arrangement heights is prepared on a flexible substrate made of titanium foil and the like, and the solution method is adopted for implanting perovskite sensitizers and solid electrolytes in titanium dioxide nanotubes to form a coaxial array; on the basis, the perovskite solar battery is assembled on the flexible substrate. The composite thin film prepared with the method is used for the perovskite solar battery, and photoelectric conversion efficiency of the perovskite solar battery reaches 0.64%.

Owner:BEIJING UNIV OF TECH

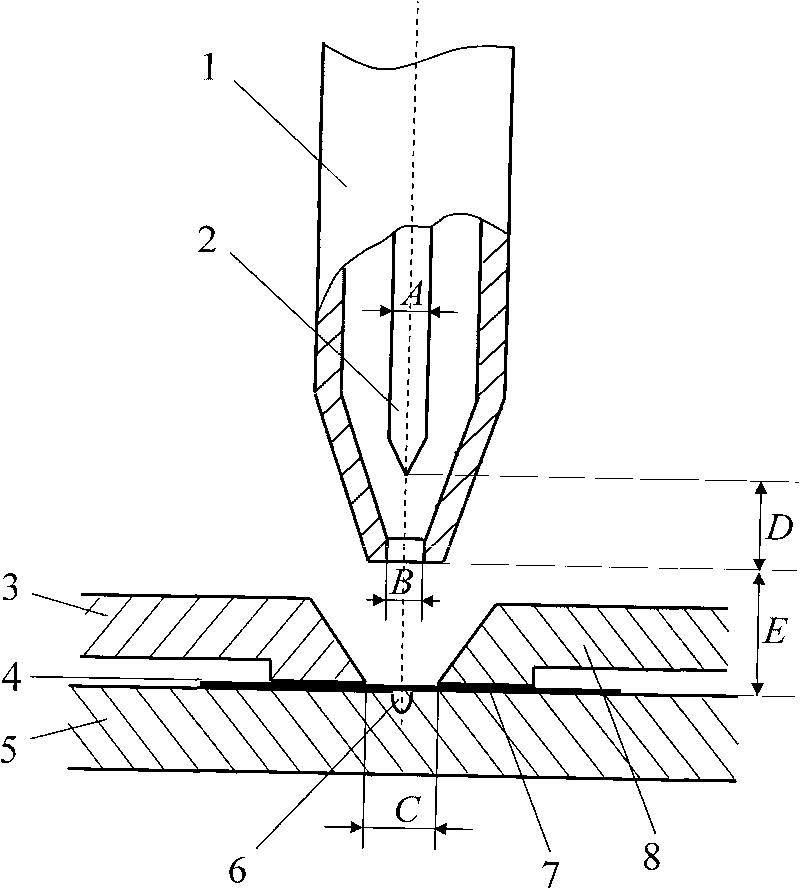

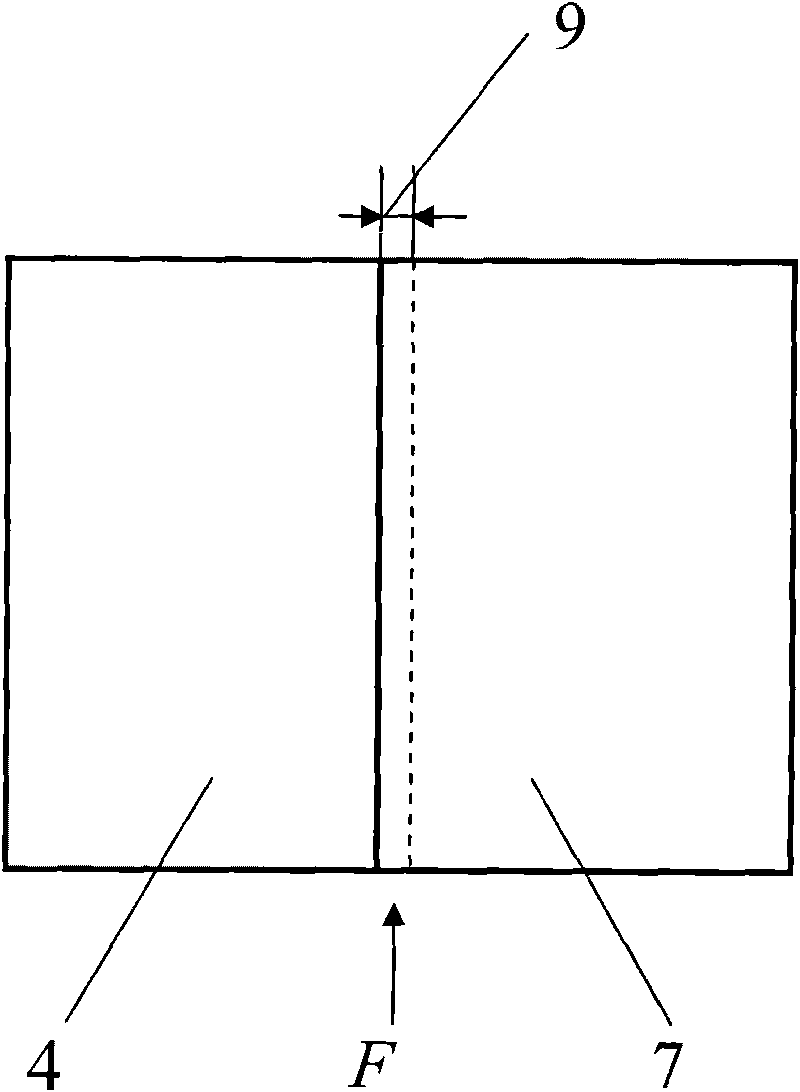

Welding method for micro-plasma arc welding of pure titanium foil

InactiveCN101722353ASolve the deformationSolve the burn-through problemPlasma welding apparatusWelding/soldering/cutting articlesButt weldingWeld seam

The invention discloses a welding method for micro-plasma arc welding of a pure titanium foil, in particular the welding of the pure titanium foil of which the titanium content is over 99 percent and the thickness is of 0.05 mm, and relates to the technical field of welding. The method comprises the following steps of: cutting the pure titanium foil to be welded into required sizes; selecting two pure titanium foils (4) and (7), and removing oil stains at the peripheries of the sides to be welded thereof; assembling the two pure titanium foils between fixtures of a tooling system; lapping the sides to be welded for about 0.1 to 0.2 mm so as to ensure a welding seam on grooves (6) of base plates of the fixtures; driving a welding torch to move along the welding seam (9) above the welding seam by a motor on the tooling system; and adopting a pulse current for welding. The welding method for the micro-plasma arc welding of the pure titanium foil realizes the butt welding of the micro-plasma arc welding of the pure titanium foil of 0.05 mm, solves the problems of the deformation and burning of the welding of the pure titanium, saves welding cost without adding a filling metal in the welding seam, is favorable for industrial popularization, and fills the blank of the micro-plasma arc welding in the field of pure titanium foils.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of titanium dioxide nanotube film

InactiveCN102115913AImprove integrityEasy to makePolycrystalline material growthFrom normal temperature solutionsChemical treatmentTio2 nanotube

The invention belongs to the technical fields of the preparations of the nanometer material and optoelectronic information material, and in particular relates to a method for preparing a titanium dioxide nanotube film by combining an interfacial chemical reaction with a hydrothermal reaction. In the method, a pure titanium foil is used as a raw material; and the raw material is placed in a high-pressure reaction kettle after chemical treatment to perform hydrothermal treatment and finally obtain the product. The titanium dioxide nanotube film prepared by the method has a three-dimensional ordered network structure and has better integrity; and compared with the existing template method and anodic oxidation method, the method in the invention has simple preparation steps and low cost and is easy to perform large-area preparation.

Owner:NORTHWEST UNIV

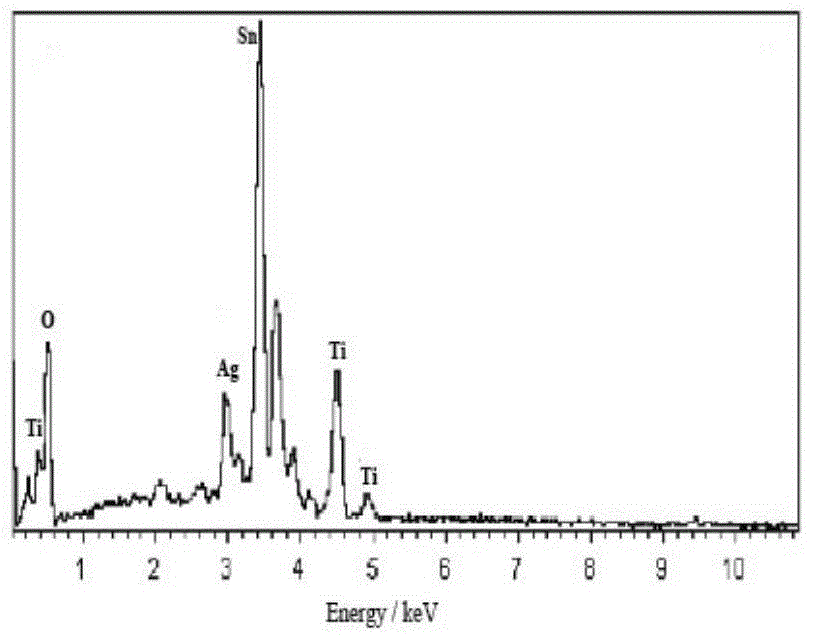

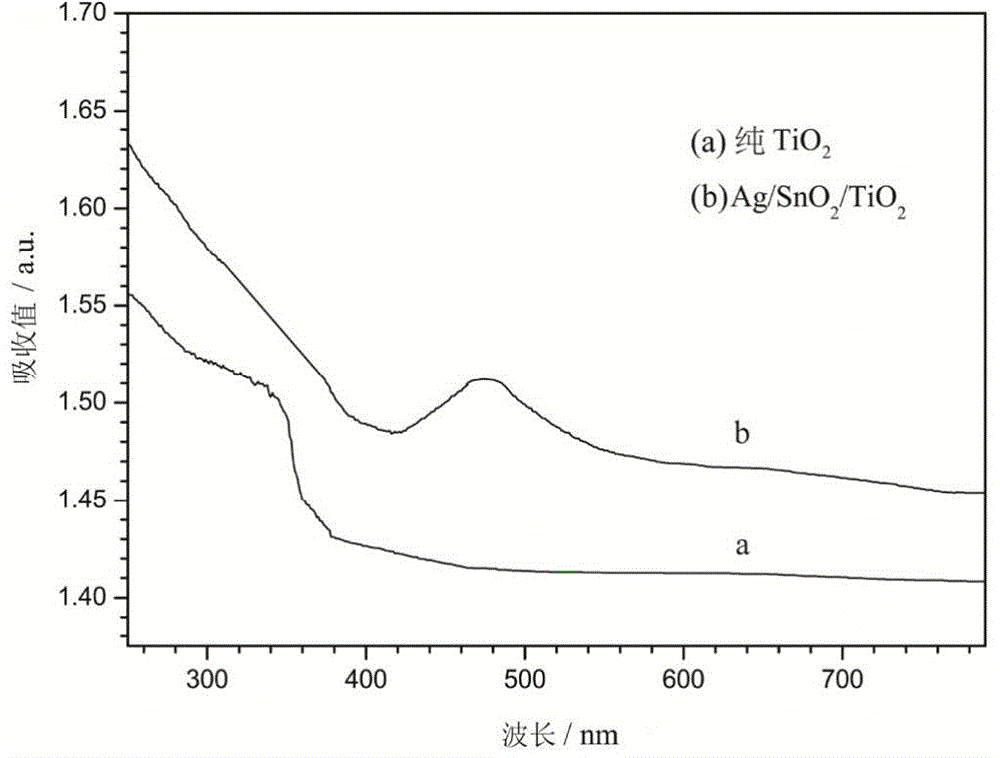

Preparation method for Ag/SnO2/TiO2 composite membrane photoanode used for photogenerated cathodic protection

ActiveCN103952708AUniform and complete coatingLower electrode potentialSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingTio2 nanotubeAcetone

The invention relates to preparation methods for an Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection, and relates to a composite membrane photoanode, and provides a preparation method for the efficient stable Ag / SnO2 / TiO2 composite membrane photoanode used for photogenerated cathodic protection. The preparation method comprises: 1) preparing a titanium substrate sample, specifically taking titanium foil as a substrate, and performing ultrasonic cleaning successively in acetone, absolute ethanol and deionized water to obtain a titanium substrate sample; 2) preparing a titanium-surface TiO2 nanotube array membrane, specifically dissolving NH4 in deionized water, adding glycol, mixing uniformly, taking platinum as a counter electrode, performing anodization, calcining the titanium substrate sample, and cooling to room temperature along the furnace, so as to obtain the TiO2 nanotube array membrane on the surface of titanium; and 3) preparing the Ag / SnO2 / TiO2 composite membrane, specifically preparing Ag and SnO2 nanometer particles on the surface of the TiO2 nanotube array membrane, so as to obtain the Ag / SnO2 / TiO2 photoanode used for photogenerated cathodic protection.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method of AgCuTi alloy, preparation method of foil strip brazing filler of AgCuTi alloy, and products of AgCuTi alloy

ActiveCN106521203AGood mechanical propertiesTo meet sealing needsWelding/cutting media/materialsSoldering mediaHigh densityOxygen content

The invention discloses a preparation method of an AgCuTi alloy, a preparation method of a foil strip brazing filler of the AgCuTi alloy, and products of the AgCuTi alloy. The preparation method is used for solving problems in the prior art that segregation of conventional AgCuTi alloy is easily caused, element Ti is combined with oxygen, activity reducing of brazing filler may be caused in sealing, and in full alloying process, microdefects such as easily caused increasing of grain size and holes are difficult to eliminate, Ag-Ti and Cu-Ti brittle phases are formed from Ti element, and Ag and Cu, and high quality foil strips are difficult to form via rolling. According to the preparation method, vacuum presintering of a powder billet at low temperature is carried out, segregation is inhibited, and hot isostatic pressure medium temperature sintering is adopted, so that grain size and oxygen content are controlled effectively, high density alloy with excellent mechanical properties is obtained, and finally foil strip brazing filler is formed via a plurality of times of direct cold rolling. The preparation method is capable of satisfying requirements on high performance silver copper titanium foil strip brazing filler used in dissimilar material component sealing, is promising in application prospect, and is worthy of large scale popularization and application.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

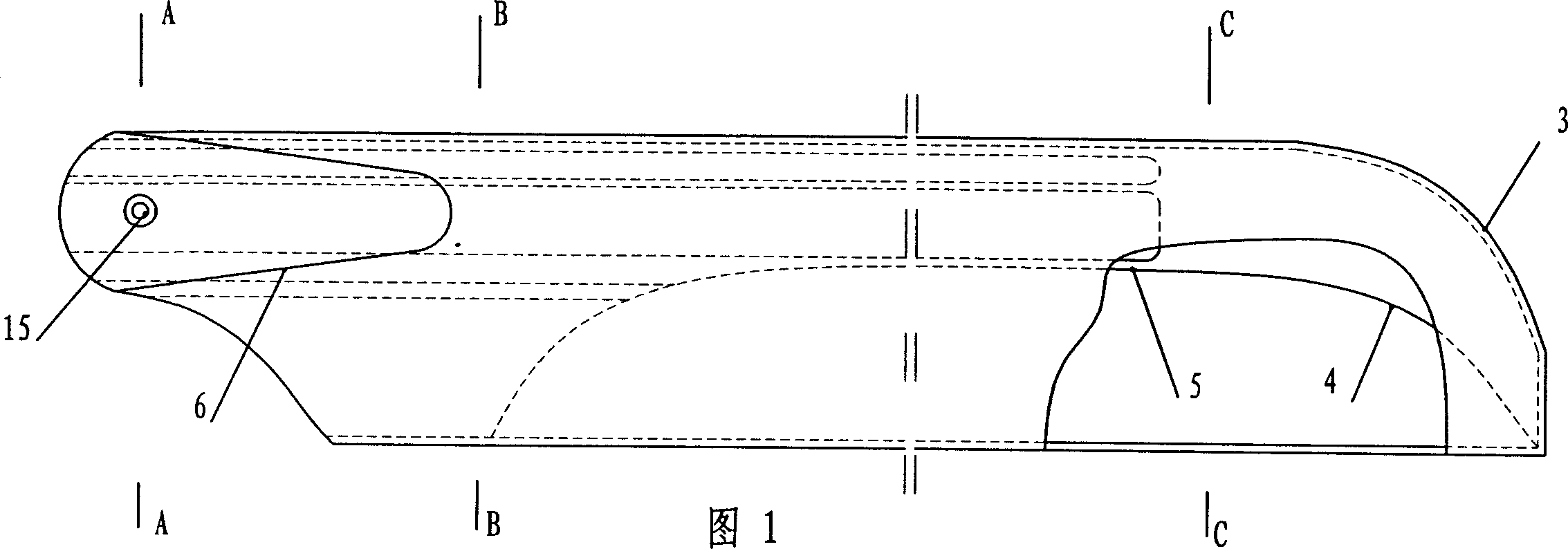

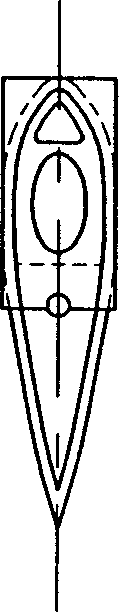

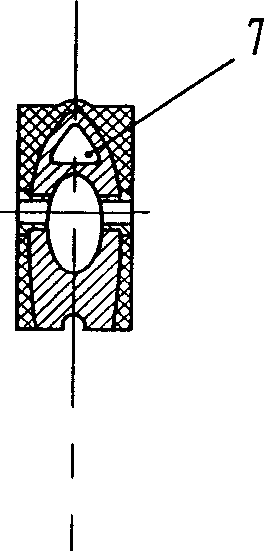

Rotary wing of simulation helicopter and its making process and curing mold

InactiveCN1846824AImprove residual strengthGood damage toleranceToy aircraftsGlass fiberCarbon fibers

The present invention relates to rotary wing of simulation helicopter and its making process and curing mold. The rotary wing includes carcass and covering, and the covering includes at least one closed reinforcing layer of reinforcing material carbon fiber, aramid fiber, polyethylene fiber, titanium foil and / or glass fiber. The making process includes making carcass, making covering and pressing to integrate the carcass the covering. The curing mold is one combined mold including upper mold and lower mold and with notch, positioning lobe and dovetail groove. The technology of the present invention may be used in making various kinds of simulation flyers.

Owner:王云松

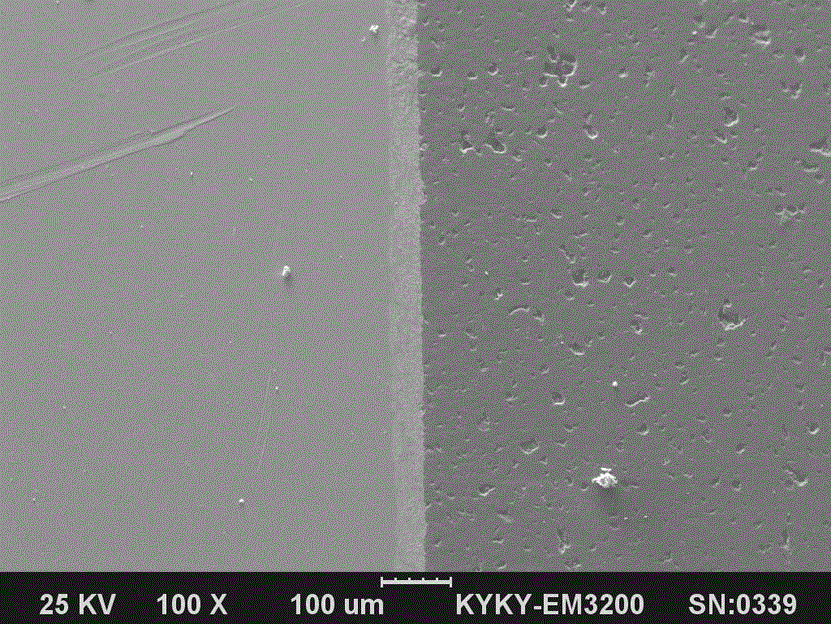

Surface treatment for a thin titanium foil

InactiveUS20080102292A1Promote full integrationBlade accessoriesElectrostatic cleaningAdhesiveWater treatment

A method of surface treating a thin titanium foil having a thickness of less than about 3 mils is used to facilitate adequate bonding of the foil with an adhesive. The method includes cleaning the foil with an acid solution and further cleaning the foil using an ultrasonic water treatment. Additional steps that may optionally be performed in between the acid solution and the ultrasonic water treatment include cleaning the foil with a first alkaline cleaner, followed by etching and desmuting the foil.

Owner:UNITED TECH CORP

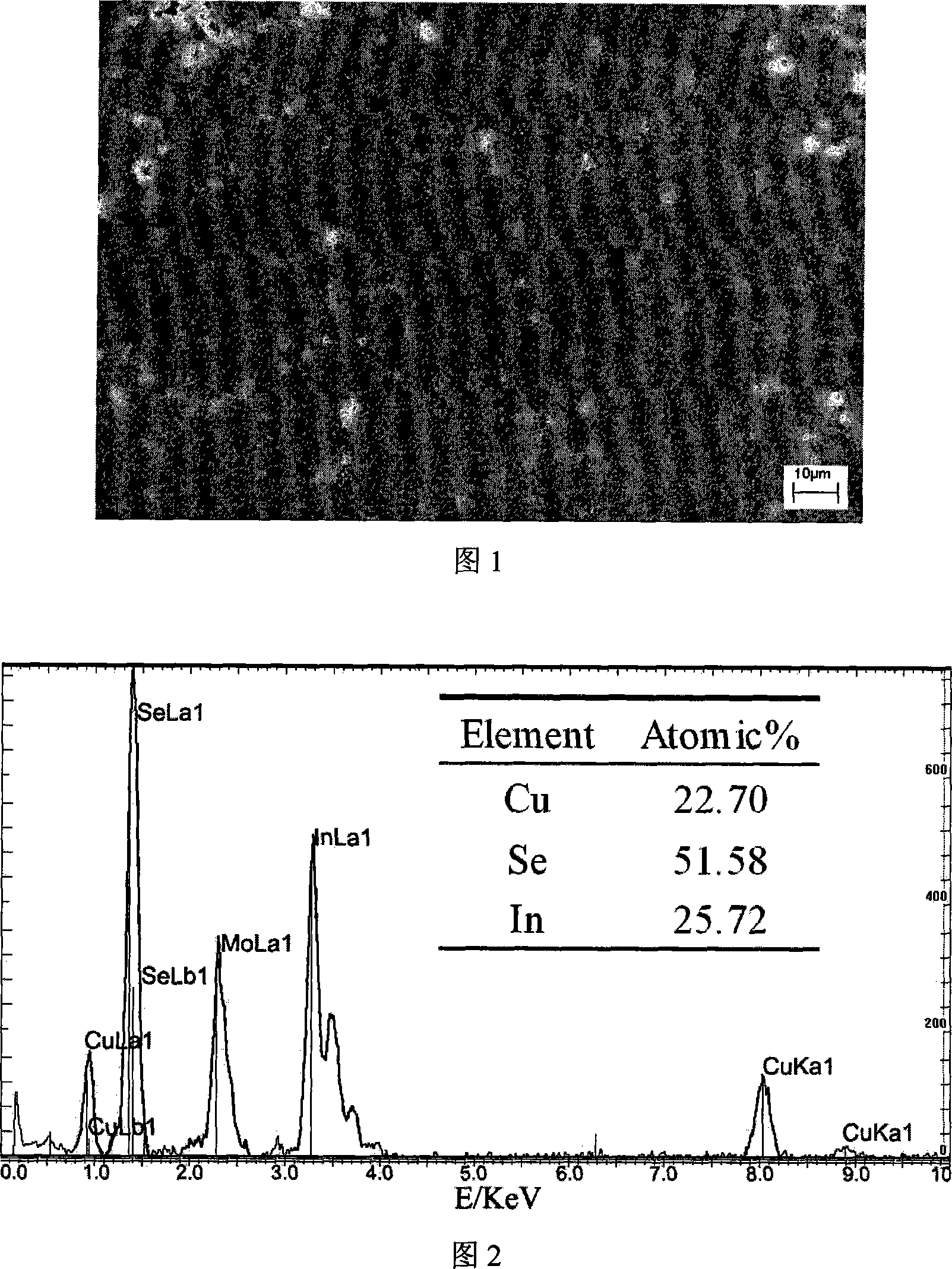

Method for producing copper-indium-selenium thin-film solar cell wealthy-indium optical absorption layer

InactiveCN101159298APrecise Control of Chemical CompositionLower sintering temperatureFinal product manufactureSemiconductor devicesIndiumAlloy

The invention provides a method of preparing an In-enriched light absorption layer for a CuInSe2 thin-film solar battery, belonging to the preparation of CuInSe2 semiconductor thin films. The method adopts coating-sintering process, and uses Cu-In alloy, Cu-In alloy and Se powder as raw material. The method comprises mixing Cu-In alloy, Cu-In alloy and Se powder with a molar ratio of 1:(1.1-1.25):2:(2-2.2), ball milling the mixture for 36-72 hr to form a black precursor slurry; coating the slurry on a molybdenum foil substrate or a titanium foil substrate to form a precursor thin-film, and drying at low temperature; densifying the precursor thin-film by exerting 10-300 MPa pressure, and subjecting the precursor thin-film to heat treatment under H2 atmosphere, N2 atmosphere or vacuum. The method can accurately control the chemical composition in the precursor thin-film, can ensure the preparation of the In-enriched CuInSe2 semiconductor thin-film solar battery, and is more suitable for forming the absorption layer with uniform composition, compact structure, and flat surface. And, the sintering process is performed under innoxious atmosphere, so as to be safe and practice in operation.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of zinc-doped titanium dioxide nano-tube array

InactiveCN102485968AEvenly distributedOrderly rowsSurface reaction electrolytic coatingTio2 nanotubeElectrochemical anodization

The invention belongs to the technical field of photoelectric materials and specially, relates to a preparation method of a zinc-doped titanium dioxide nano-tube array. The preparation method comprises the following steps that 1, an electrolyte of a HF aqueous solution having HF content of 0.3 to 1.0 wt%, an anode of pure titanium foil subjected to surface pretreatment and a cathode of a Pt sheet undergo an electrochemical anodization reaction under direct voltage of 10 to 50V to produce a titanium dioxide nano-tube array; and the titanium dioxide nano-tube array as a cathode, an anode of a platinum sheet and an electrolyte of a Zn(NO3) solution having concentration of 0.1 to 0.5mol / L undergo an electrochemical deposition reaction under direct voltage of 0.3 to 1.0V so that zinc is added into titanium dioxide nano-tube layers and the zinc-doped titanium dioxide nano-tube array is obtained. The preparation method provided by the invention has the advantages that ion implantation time is short; and doped ions Zn<2+> can enter into a titanium dioxide nano-tube under a electric field force and capillary action so that the zinc-doped titanium dioxide nano-tube array having good photoelectric properties and a light absorption range widen to a visible light range is prepared.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

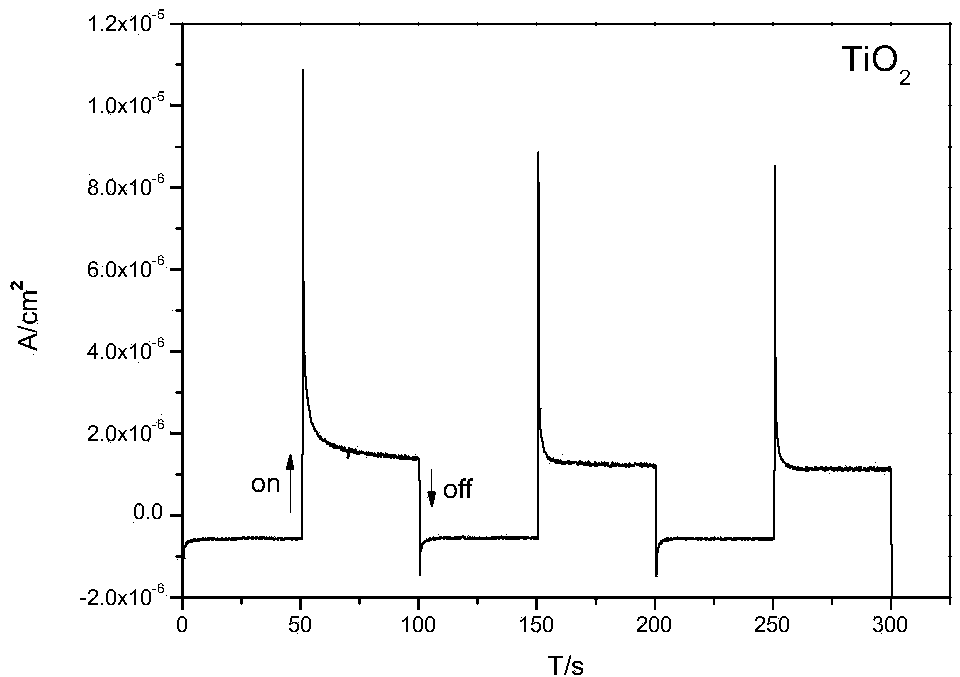

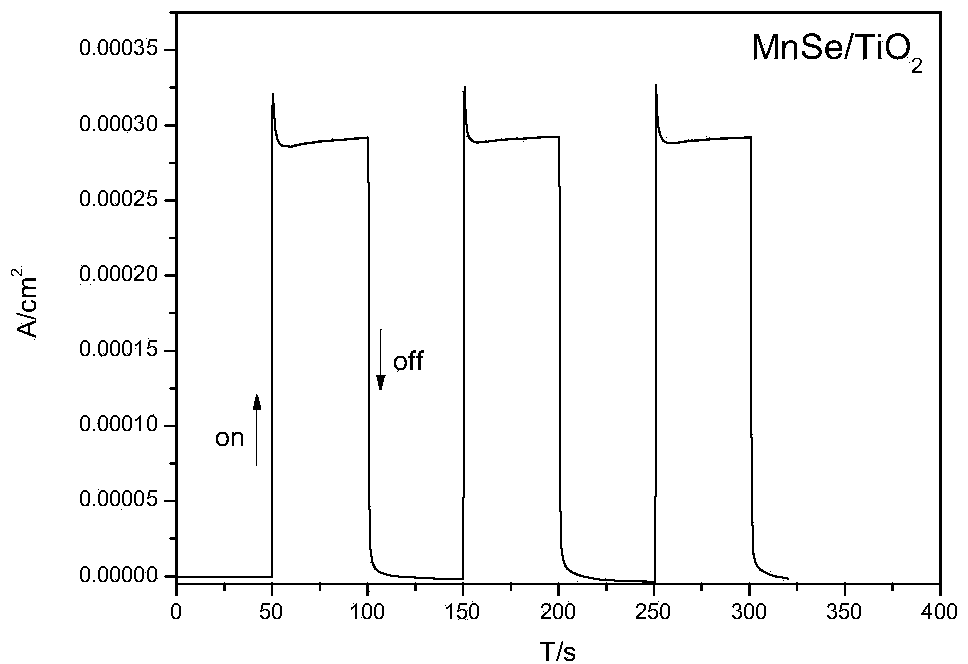

MnSe/TiO2 composite film for photogenerated cathode protection as well as preparation and application thereof

ActiveCN104357852AUniform and complete coatingLower electrode potentialSurface reaction electrolytic coatingSuperimposed coating processComposite filmTio2 nanotube

The invention relates to a composite film photoanode, in particular to a MnSe / TiO2 composite film for photogenerated cathode protection as well as preparation and application thereof. A TiO2 nanotube array film is calcined and loaded on the surface of a titanium substrate; the nanotube array film is alternately immersed in a solution containing Mn<2+> and a solution containing Se<2-> to obtain the MnSe / TiO2 composite film. The TiO2 nanotube array film is prepared on the surface of titanium foil by an anodic oxidation method firstly and then the MnSe / TiO2 composite film is obtained through continuous ion layer adsorption reaction; the composite film used as a photoanode, has an excellent photogenerated cathode protection effect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

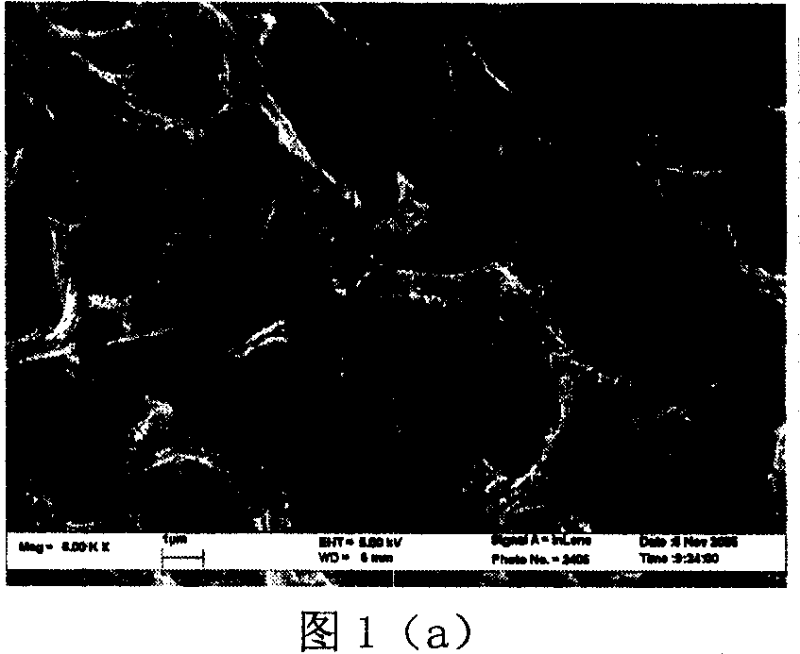

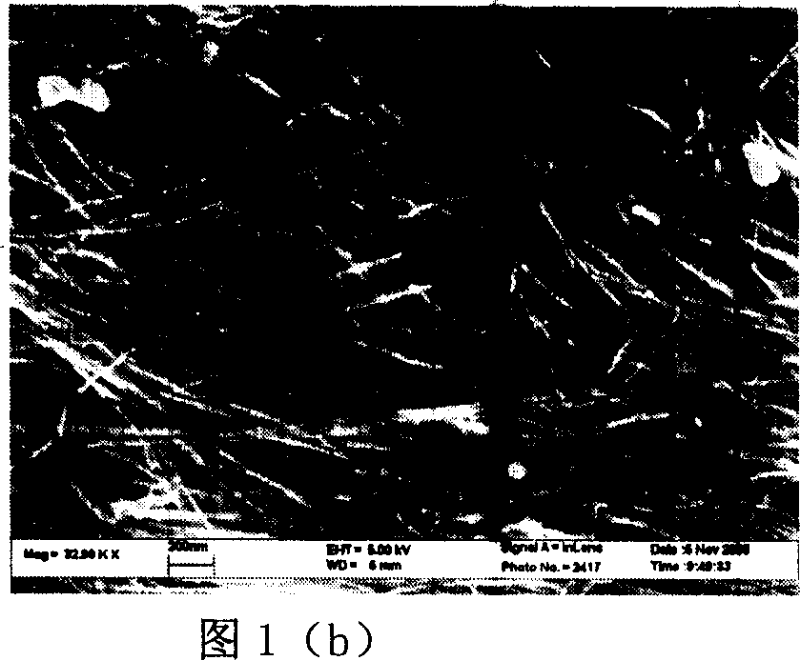

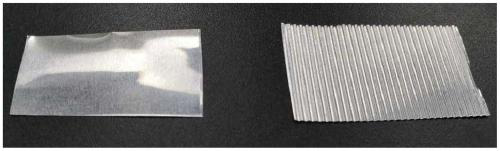

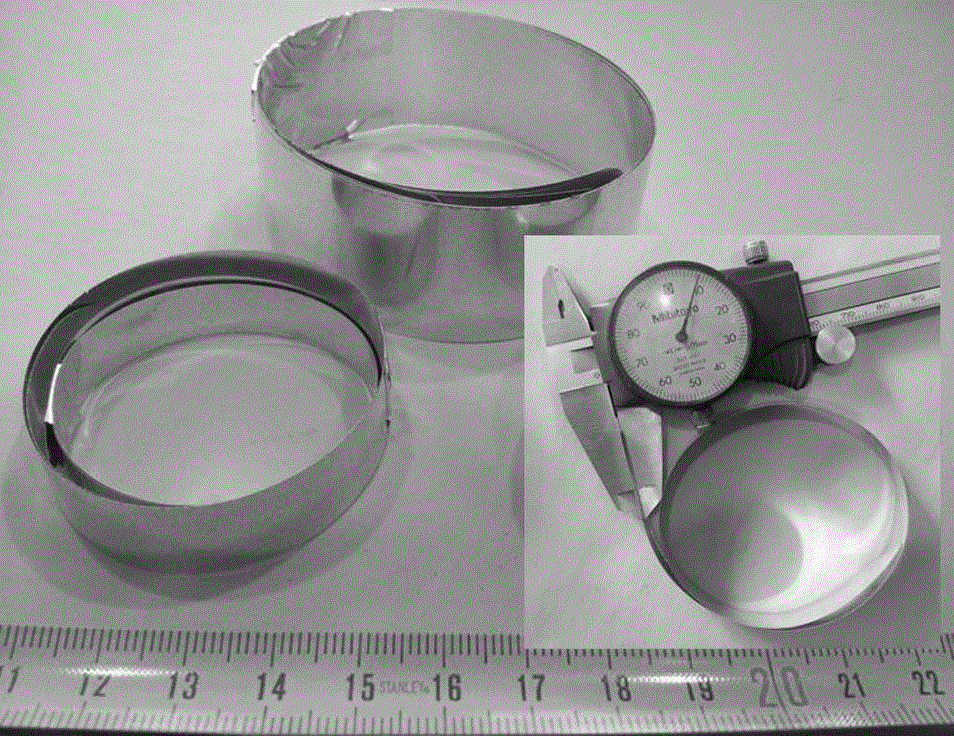

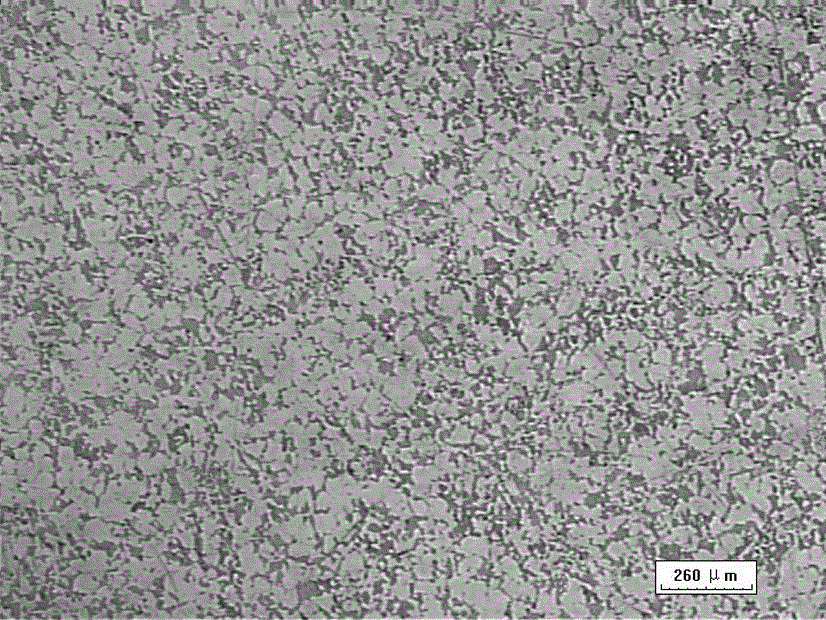

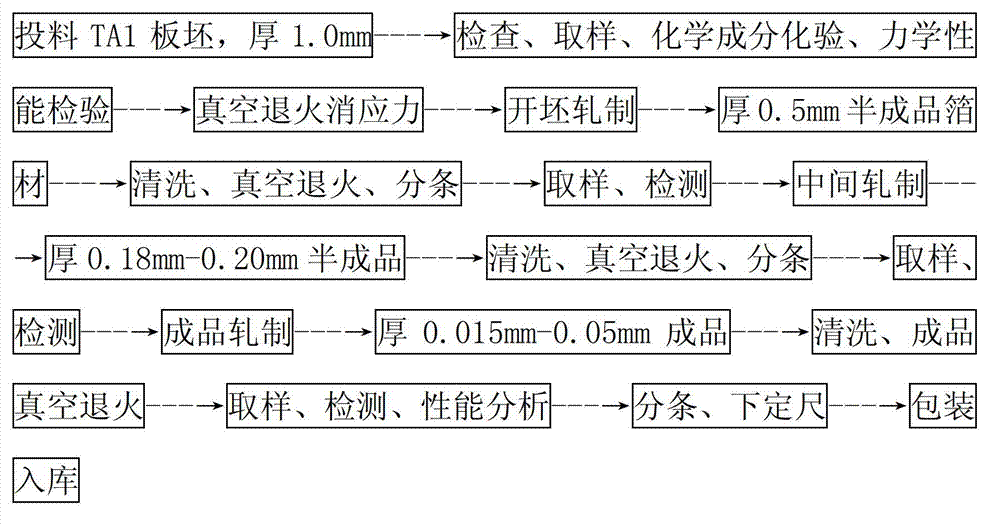

Cold rolling titanium foil process

ActiveCN103084389AImprove ductilityHigh specific strengthMetal rolling arrangementsHydrogenRoom temperature

The invention provides a cold rolling titanium foil process to meet requirements of ultrathin titanium foil machining. The cold rolling titanium foil process is carried out according to the following procedures that (1) blank materials are chosen and processed: hydrogen aluminum blank materials are chosen to be processed in a polished mode; (2) primary rolling is achieved: the blank materials are polished, the materials are reversed, intersected and repeatedly rolled through a multi-roll foil rolling machine for a plurality of times to achieve the fact that the thickness of the materials reaches 0.18mm-0.22mm; (3) end products are rolled: foil materials after primary rolling are rolled to the foil materials with the thickness of 0.05mm-0.003mm, and fatting, cleaning and lapping are achieved; and (4) packaging and annealing are achieved: under the state that titanium foil is naturally relaxed, the titanium foil is packaged through metal zirconium foil good at hydrogen absorption and oxygen absorption, and after the annealing is achieved in a vacuum furnace, the materials out of the furnace are cooled to be in the room temperature to become end products. The prepared foil materials have the advantages of being good in malleability, high in specific strength, excellent in strength of extension and rigidity, and the like.

Owner:宝鸡市星宏昌金属科技有限公司

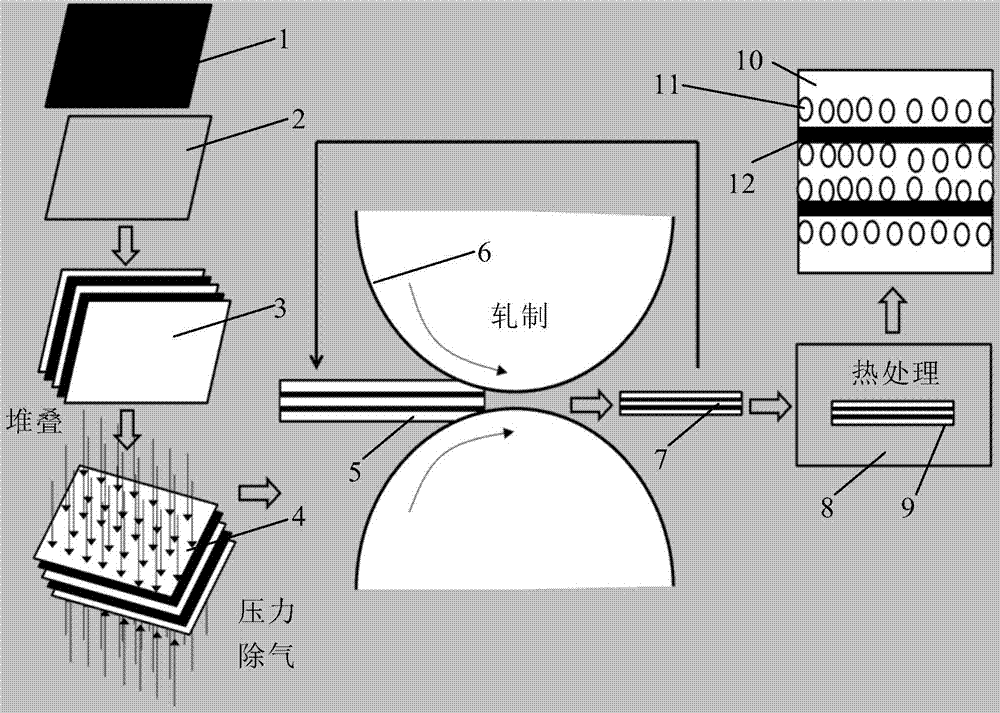

Method for preparing multi-component composite strip

The invention discloses a method for preparing a multi-component composite strip. Titanium foils and aluminum plate strips are machined as sheets with the same size; the aluminum plate strip, the titanium foil, the aluminum plate strip, the titanium foil, ...the aluminum plate strip are stacked; the front ends are welded through electric welding; the compressive stress deaeration is performed by adopting a forging machine; then, the pack rolling is performed; the further rolling is performed; the rolling is repeated until the requested strip thickness is reached; and rolled composite metal strips are heated to obtain aluminum / titanium aluminum intermetallic compound particle / titanium / titanium aluminum intermetallic compound particle / aluminum / titanium aluminum intermetallic compound / titanium / ... / titanium aluminum intermetallic compound particle / aluminum laminar composite strip. A ultrafine crystal metal composite strip is prepared by using the pack rolling mode; the intermetallic compound size, distribution and morphology of a metal interface are controlled by using the heat treatment process; the multi-component laminar composite strip is finally obtained; and the laminar composite strip achieves broad prospect in such fields as aerospace, acoustic insulation, noise reduction and vehicle lightness.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com