Cold rolling titanium foil process

A titanium foil and process technology, applied in the field of rare metal foil processing, can solve the problems of unsuitable foil processing, etc., and achieve the effects of excellent tensile strength, good ductility, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

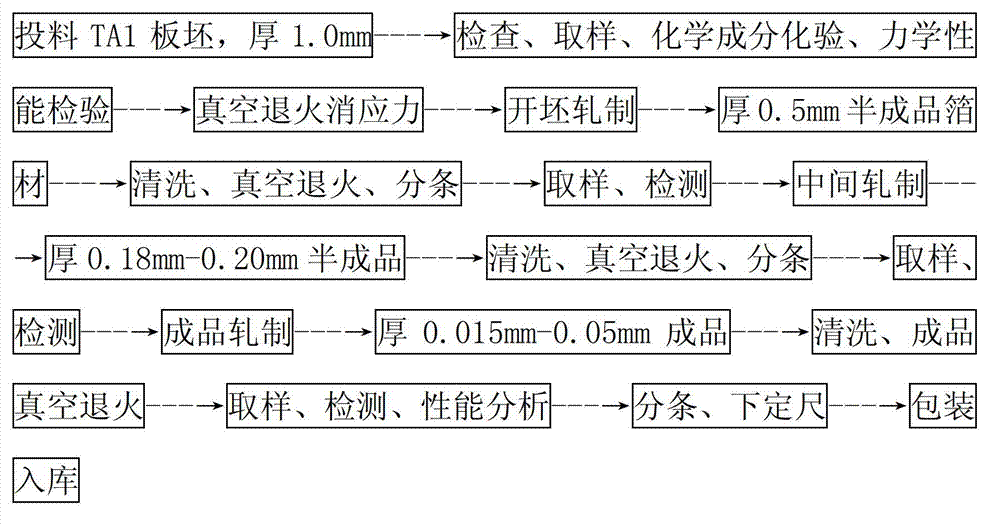

[0009] The cold-rolled titanium foil process is implemented according to the following process: (1) rough material selection treatment: select TA1 rough material with hydrogen content -3 In a vacuum furnace of Pa, anneal at 490°C-510°C, keep warm for 1-2 hours, and then cool down to room temperature to be the finished product.

[0010] Preliminary rolling includes: (1) Billet rolling: the billet is repeatedly cold-rolled to 0.5mm foil in a multi-roller foil mill, cleaned, vacuum annealed, cut into strips, and then sampled for inspection; (2 ) Intermediate rolling: through multi-roller foil rolling mills, reverse crossing and repeated cold rolling of 0.5mm foil to 0.18-0.20mm is a semi-finished product. After cleaning, vacuum annealing, cutting and slitting, sampling and testing are carried out before rolling into finished products. The reversing and cross-repetitive cold rolling means that after the foil is rolled once in one direction, the foil sheet is immediately turned by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com