Patents

Literature

653 results about "Hydrogen absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The absorption spectrum for Hydrogen, arises when we view white light coming through hydrogen gas, as is typically observed by astronomers when they analyse the light coming from distant stars; the light from those stars passing through clouds of cold hydrogen gas.

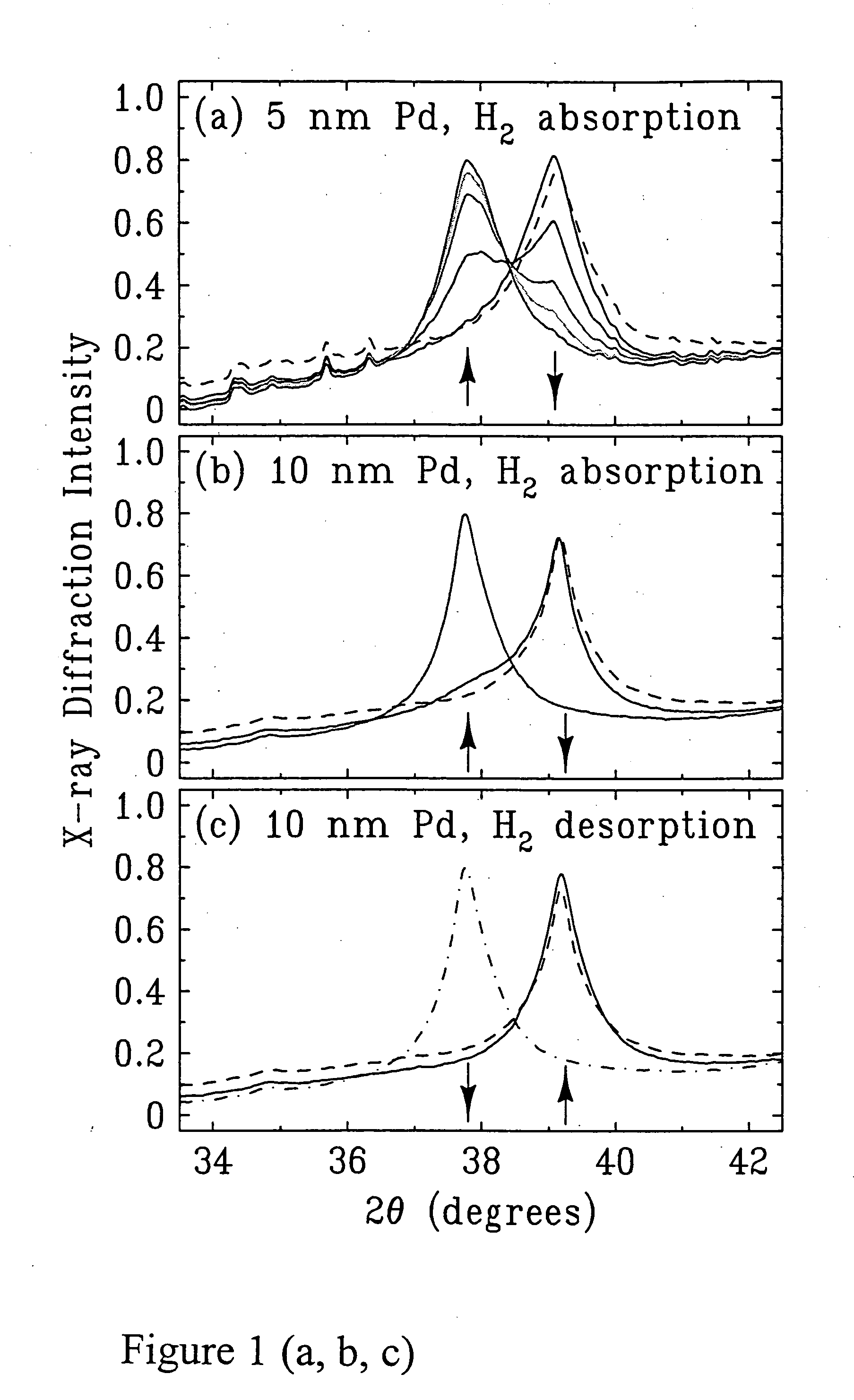

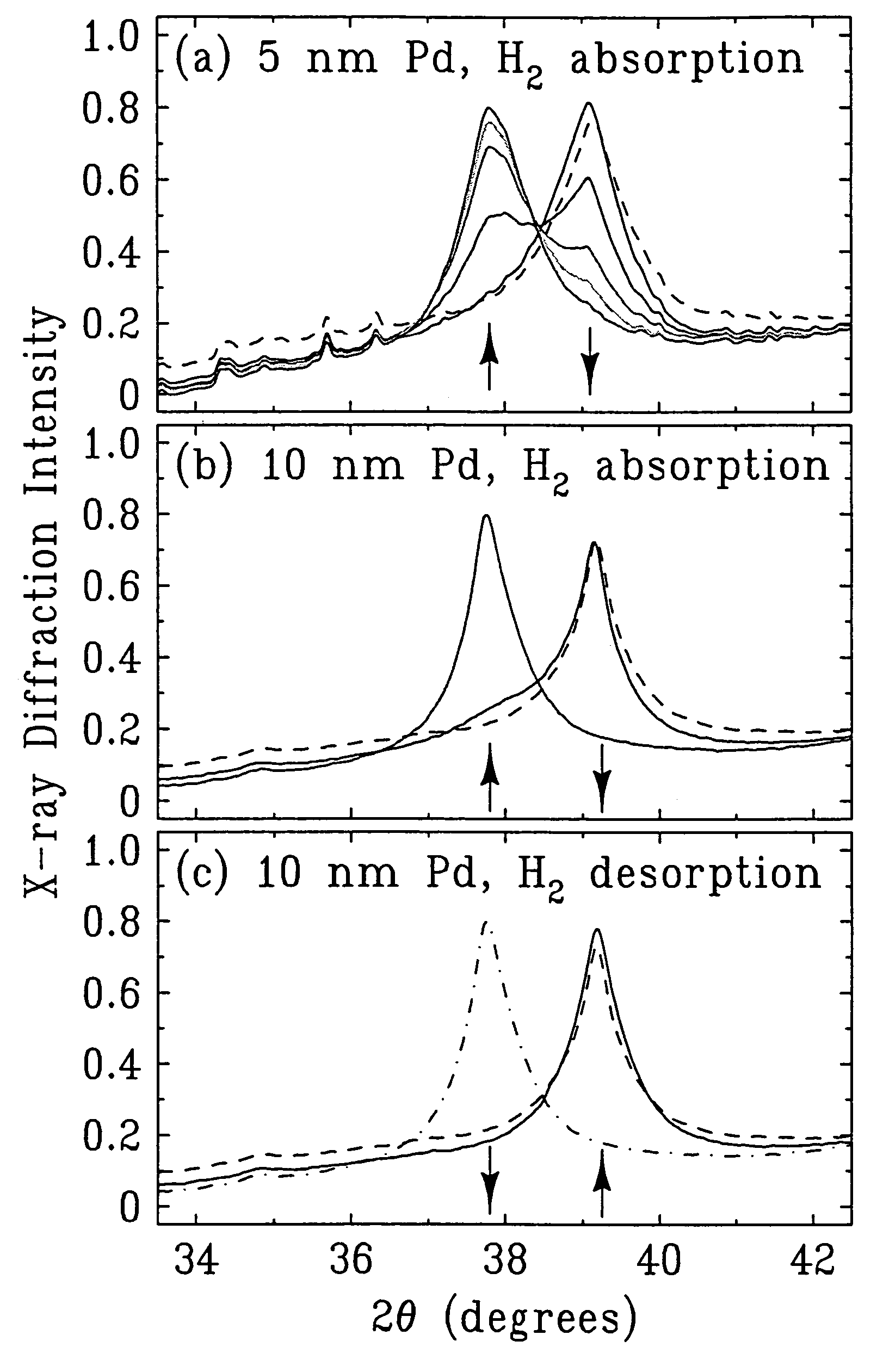

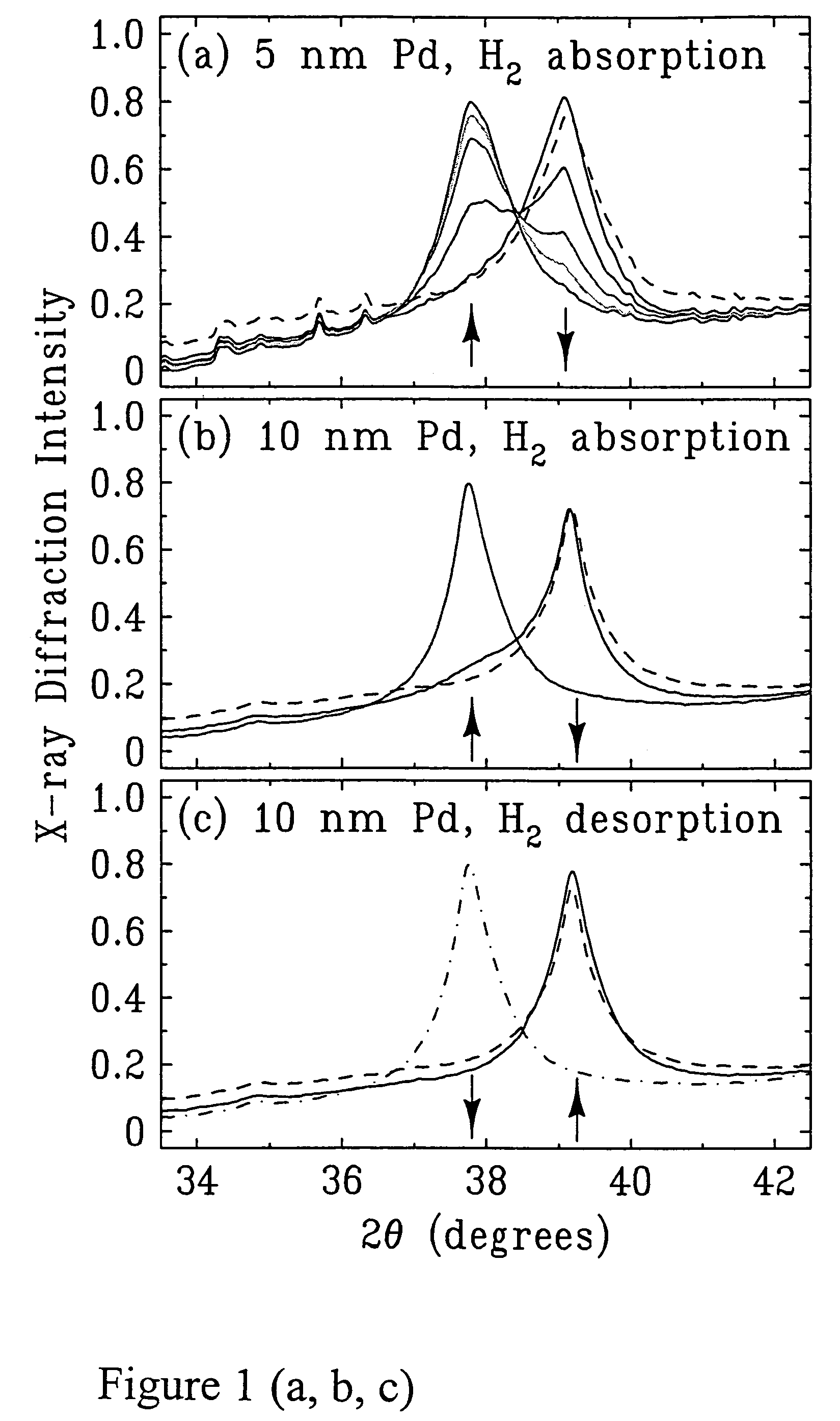

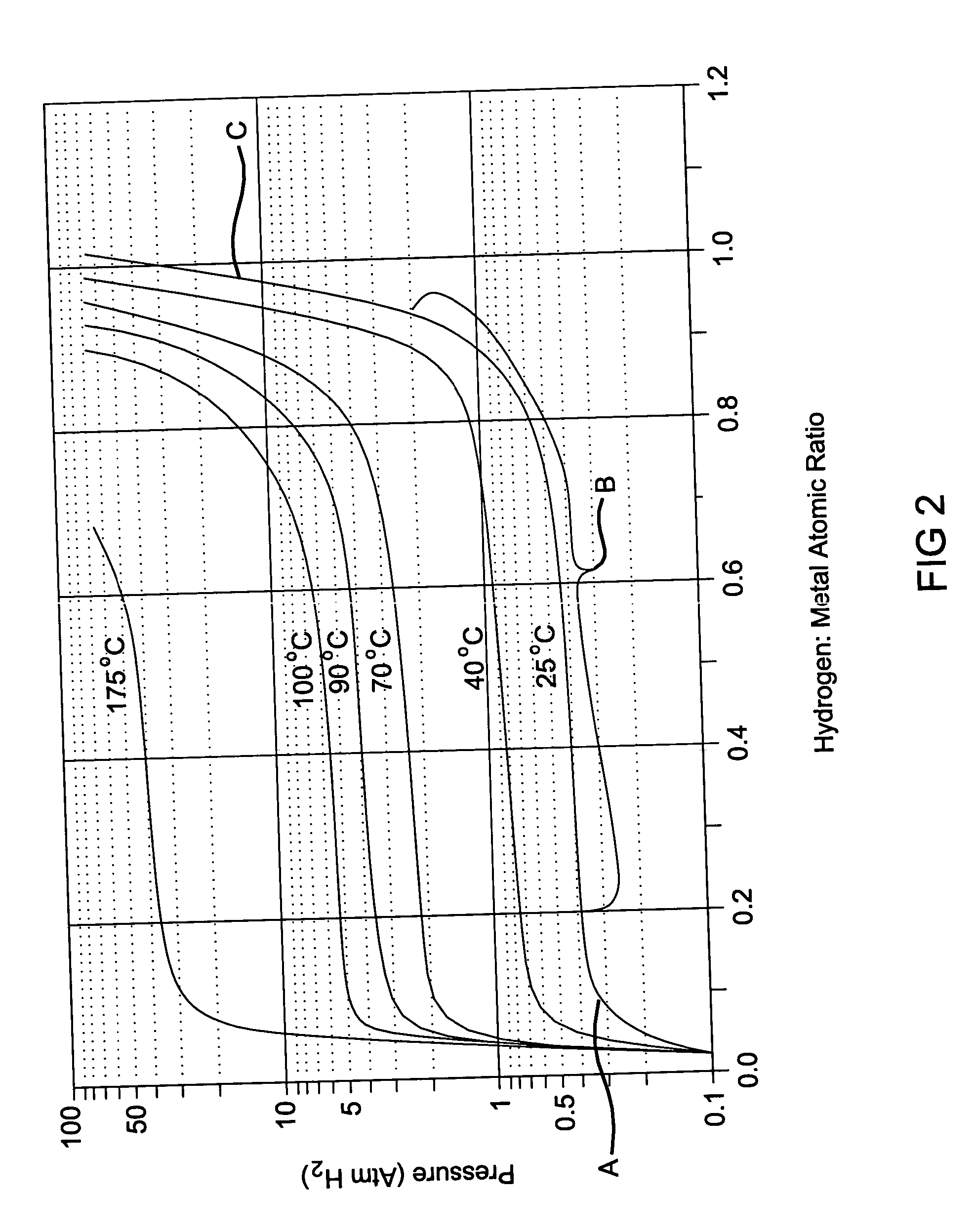

Hydrogen absorption induced metal deposition on palladium and palladium-alloy particles

The present invention relates to methods for producing metal-coated palladium or palladium-alloy particles. The method includes contacting hydrogen-absorbed palladium or palladium-alloy particles with one or more metal salts to produce a sub-monoatomic or monoatomic metal- or metal-alloy coating on the surface of the hydrogen-absorbed palladium or palladium-alloy particles. The invention also relates to methods for producing catalysts and methods for producing electrical energy using the metal-coated palladium or palladium-alloy particles of the present invention.

Owner:BROOKHAVEN SCI ASSOCS

Hydrogen absorption induced metal deposition on palladium and palladium-alloy particles

Owner:BROOKHAVEN SCI ASSOCS

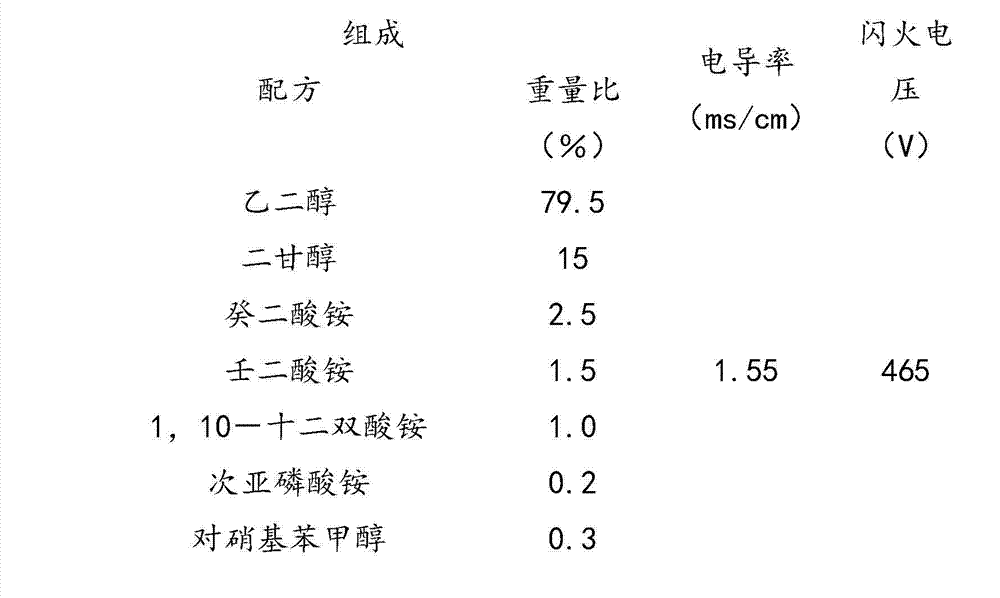

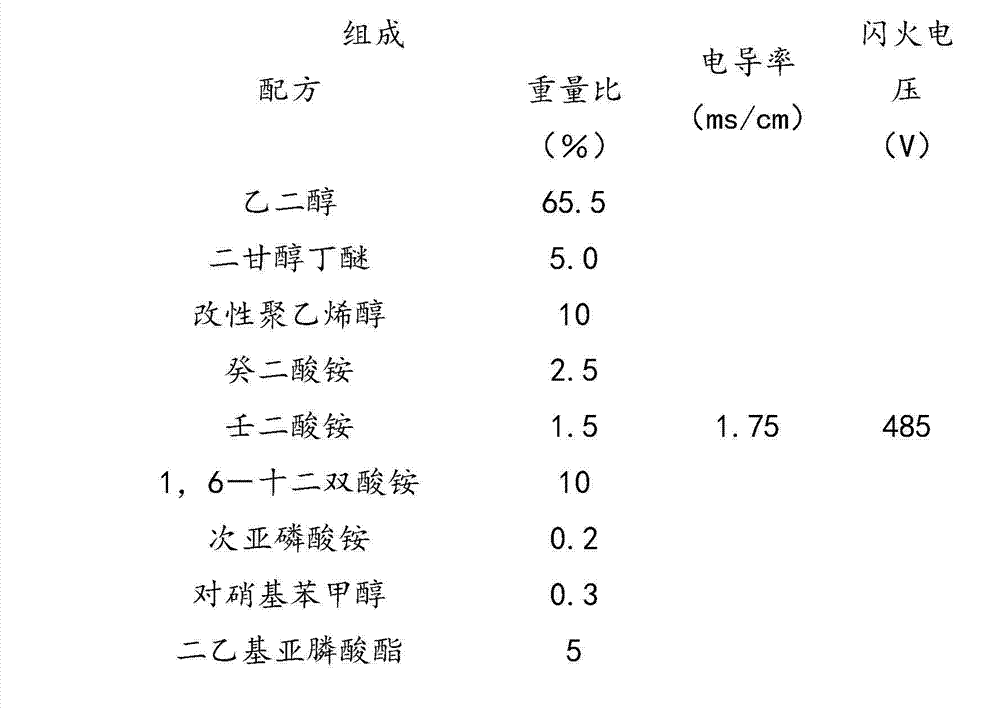

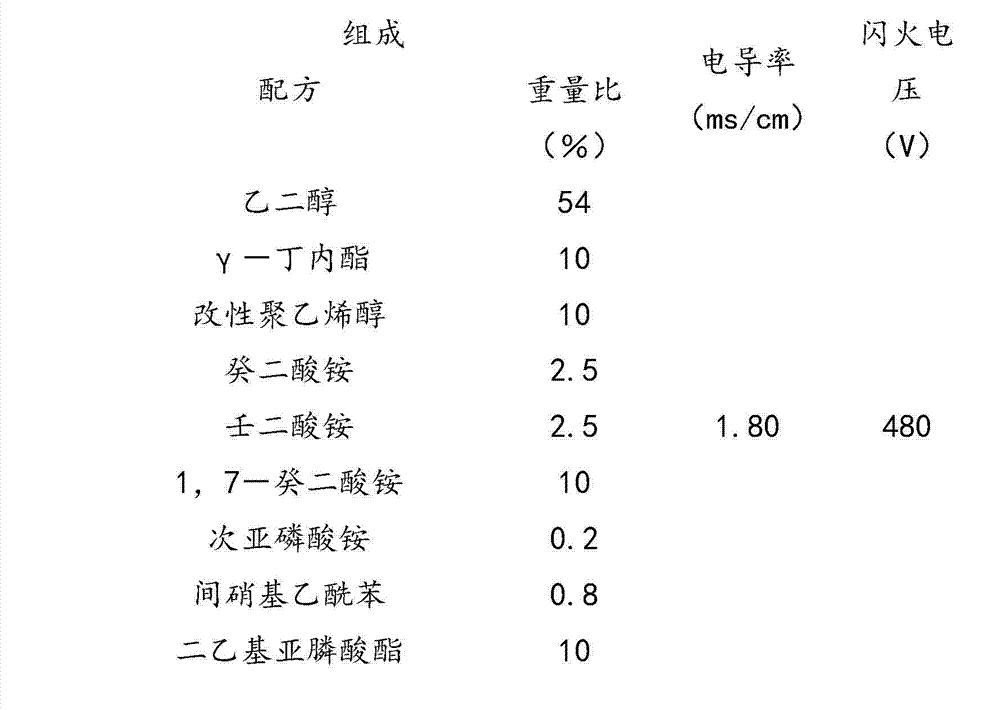

Electrolyte for flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor and preparation method thereof

ActiveCN102779644AWide temperature rangeGuaranteed stabilityElectrolytic capacitorsCapacitanceCarboxylic salt

The invention provides a working electrolyte for a flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor, which comprises the following components in percentage by weight: 45-80% of main solvent, 0.1-5% of oxidation film stabilizer, 5-15% of secondary solvent, 0.2-3% of hydrogen absorption agent, 5-10% of solute, 5-15% of flame retardant and 5-15% of spark voltage increasing agent. The invention also provides a preparation method of the electrolyte and application of the electrolyte in preparation of a high-voltage electrolytic capacitor. In the electrolyte, appropriate solvent combination is adopted, thus the wide temperature from -40 DEG C to 105 DEG C is realized; a composite solute of an organic carboxylate with a branched chain and a straight-chain carboxylate with a long carbon chain is adopted, thus the stability is ensured, and the cost is controlled; the appropriate spark voltage increasing agent, oxidation film stabilizer and hydrogen absorption agent are added, thus the spark voltage of the electrolyte is increased, and the characteristic parameters of the aluminum electrolytic capacitor are not deteriorated after the aluminum electrolytic capacitor is used for a long time; and the flame retardant is added, thus the aluminum electrolytic capacitor is difficult to burn after striking fire.

Owner:SHENZHEN ZHONGYUAN ELECTRONICS

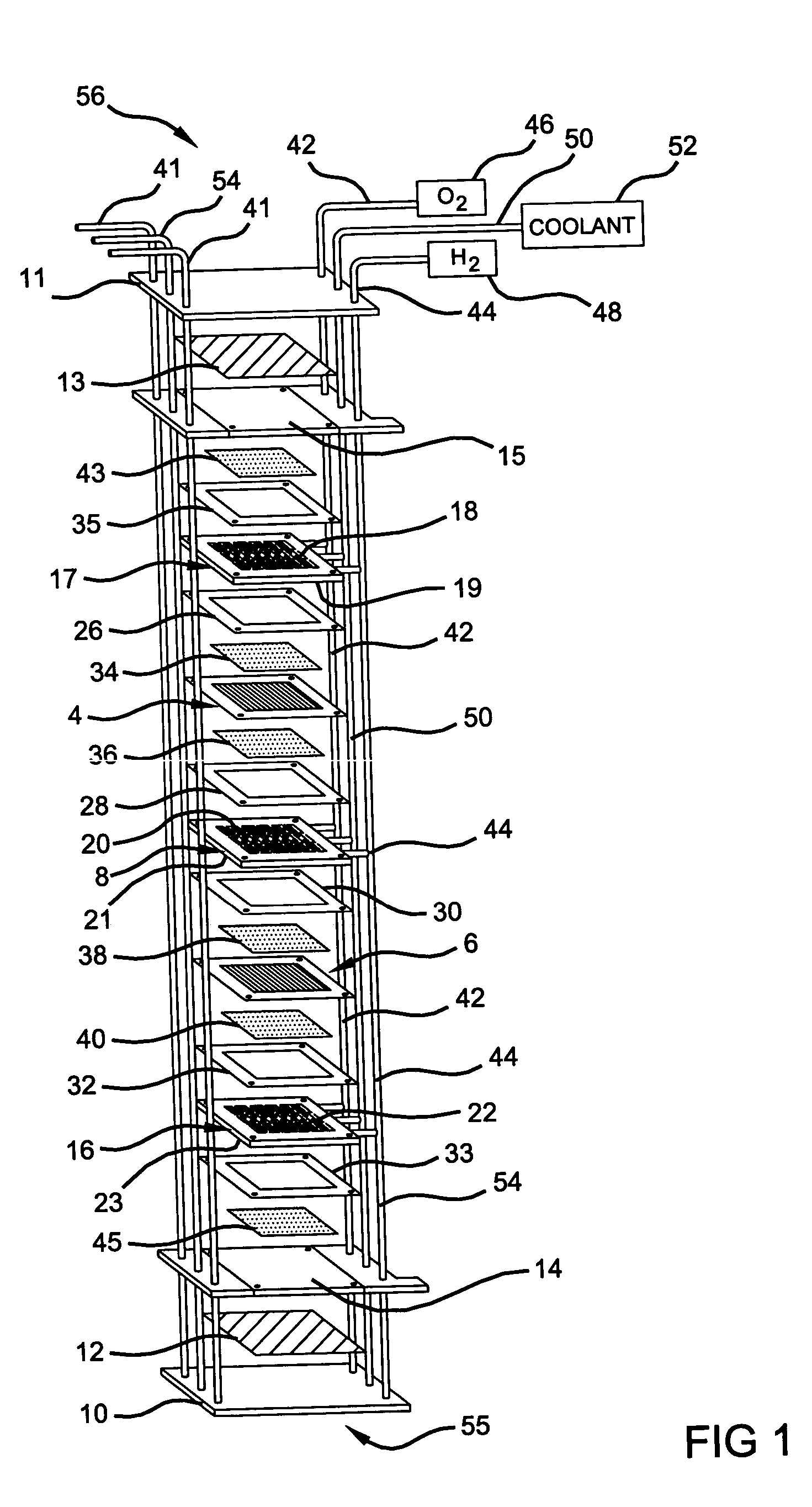

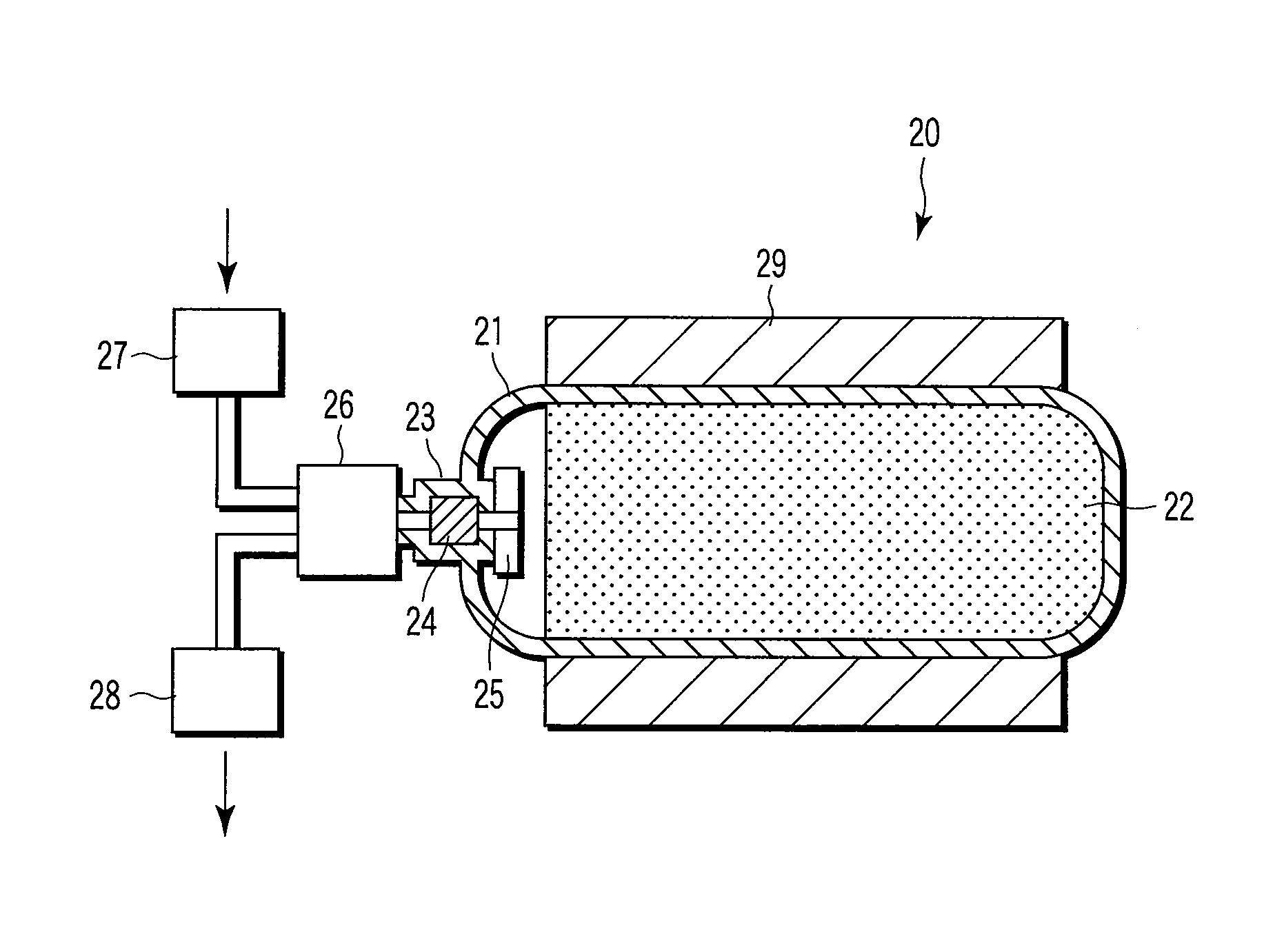

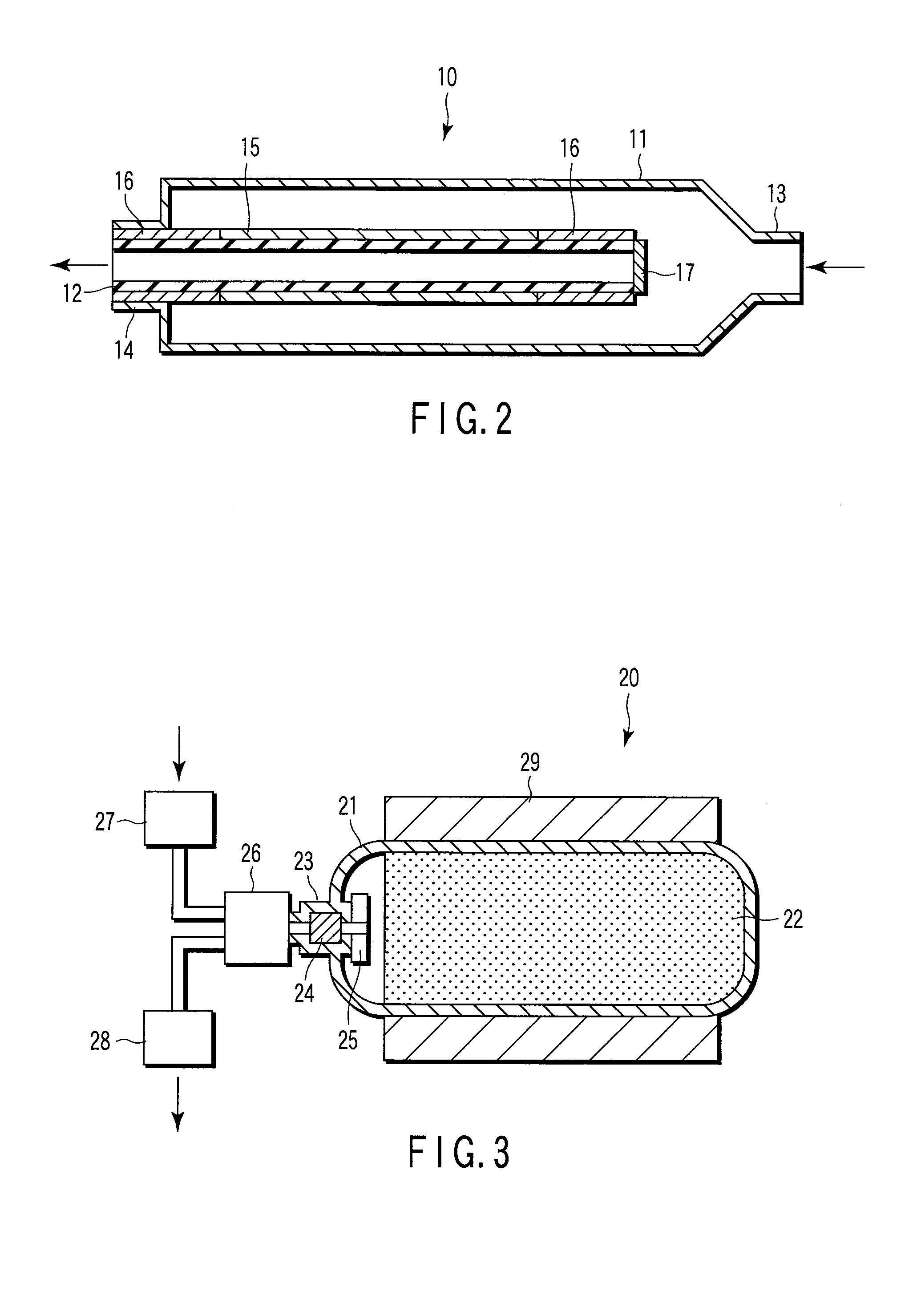

Hydrogen storage tank

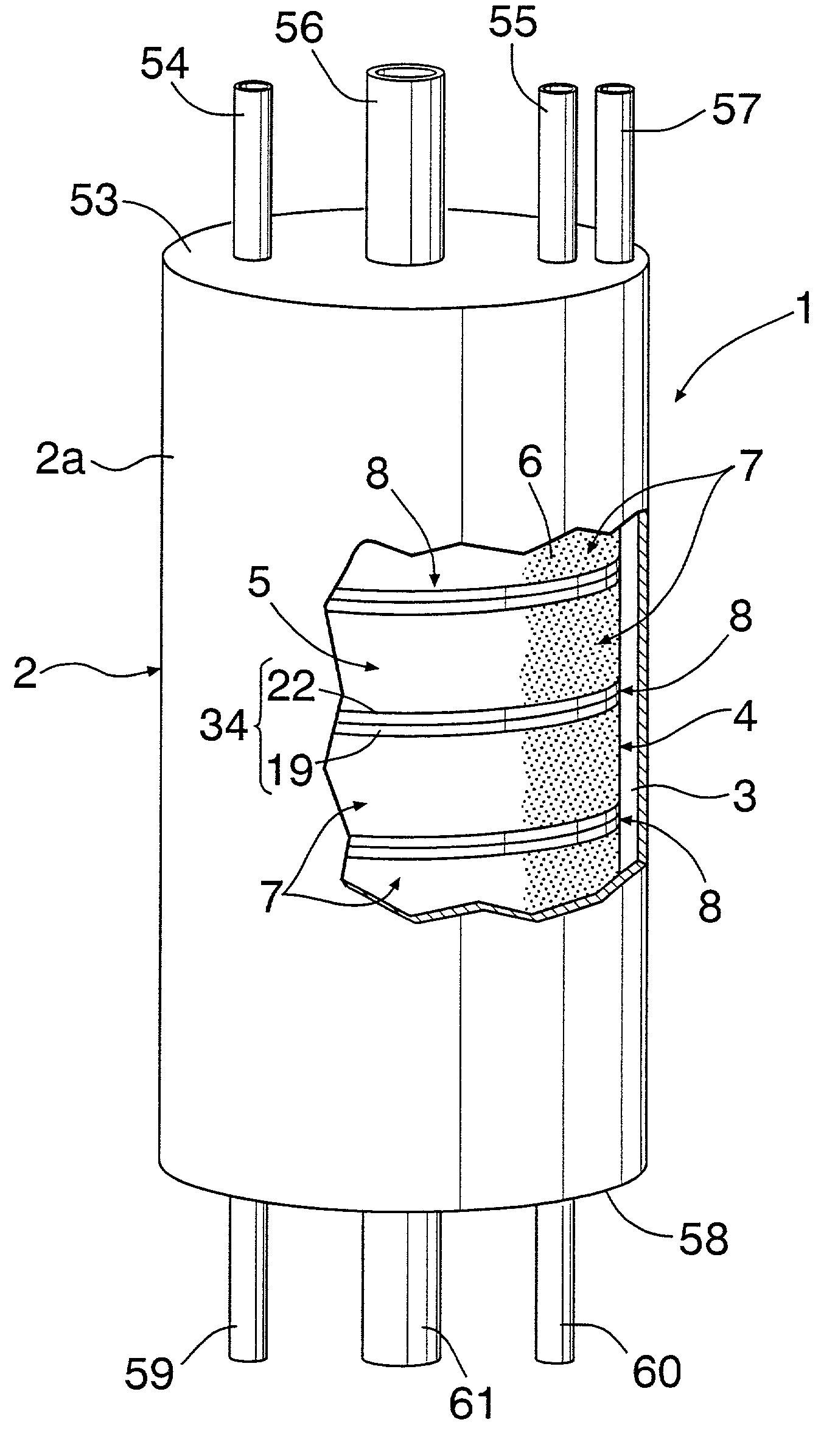

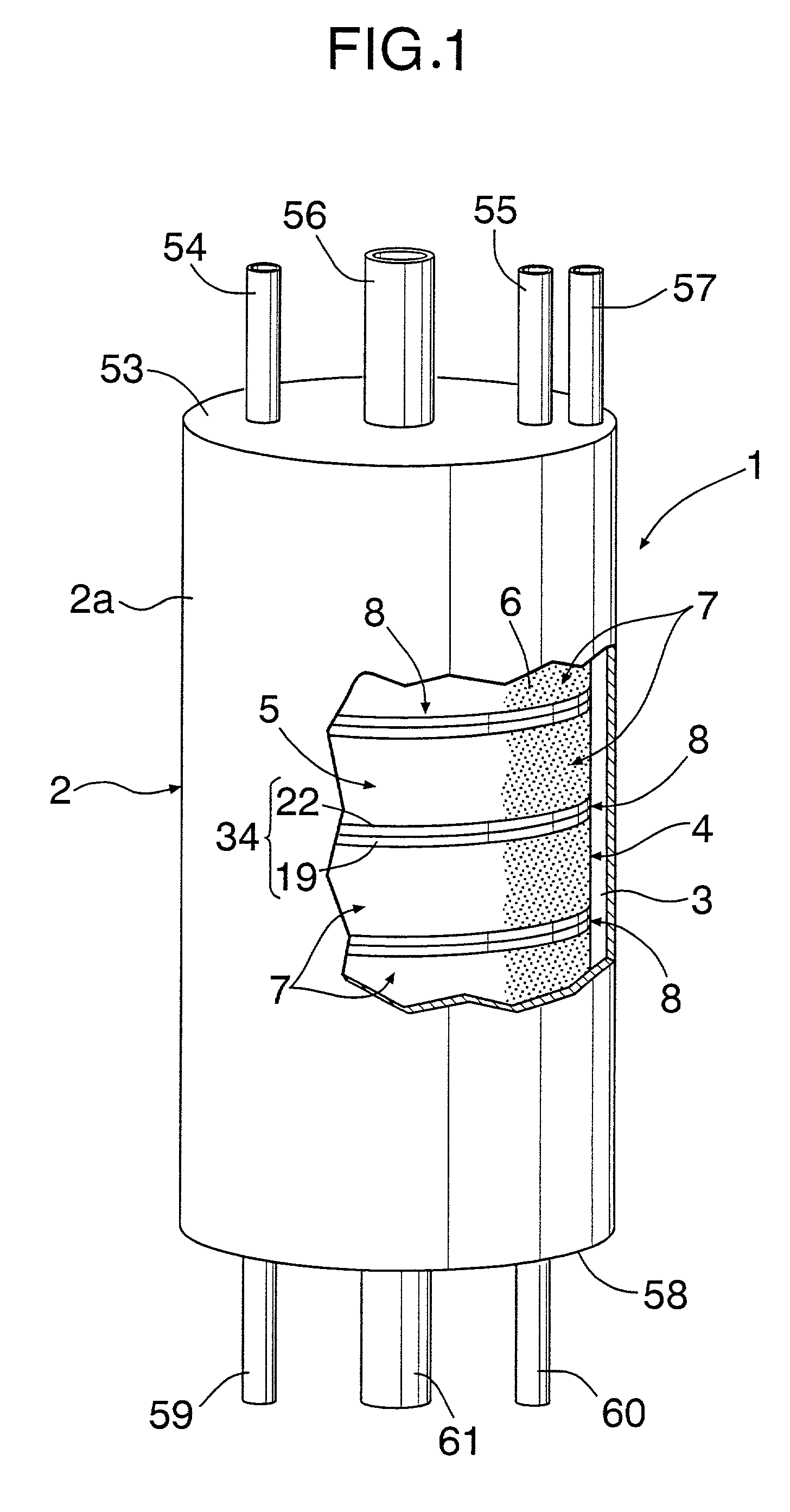

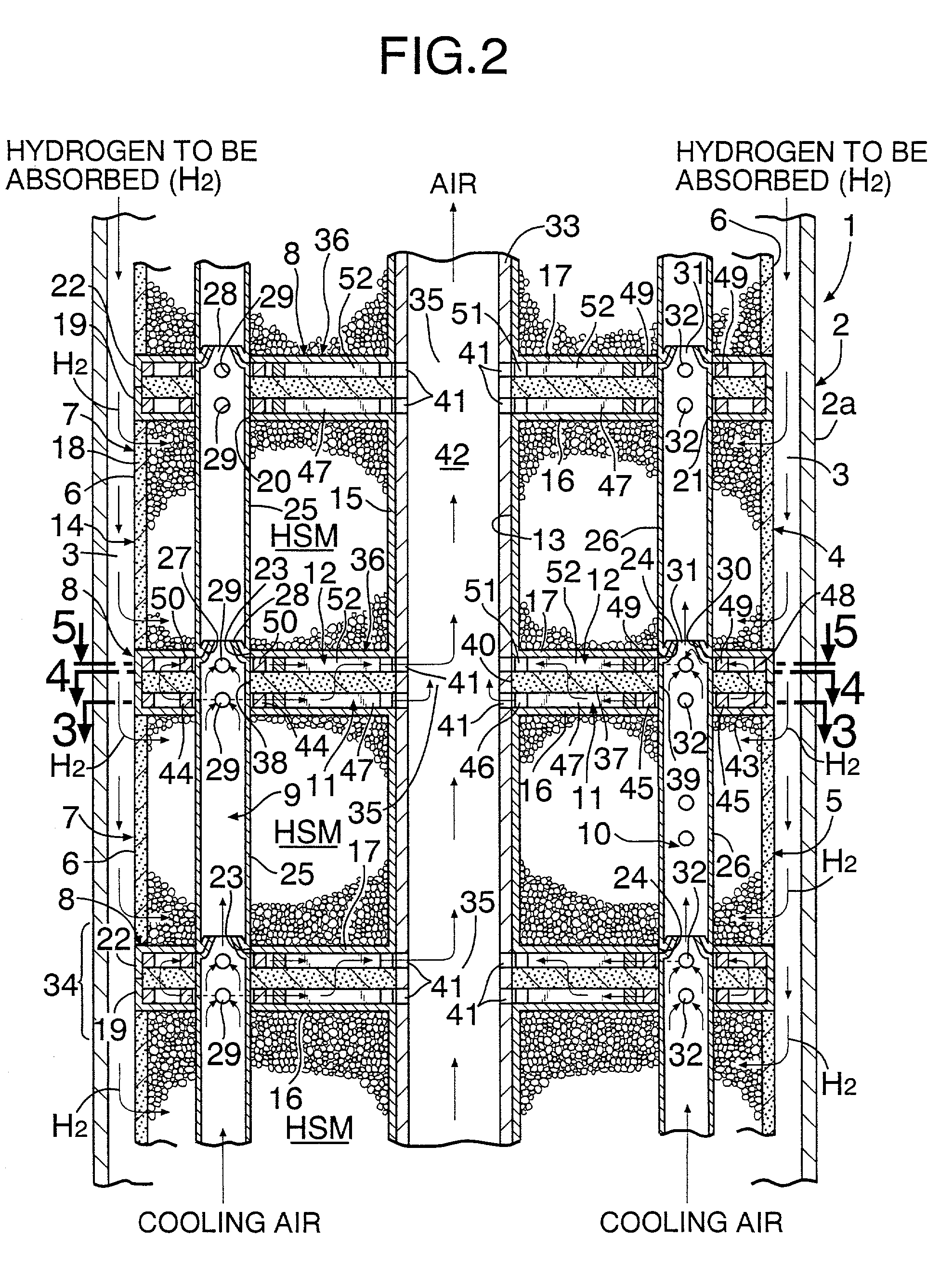

InactiveUS6991770B2Increase volumeIncrease the areaCombination devicesGas treatmentEngineeringCooling fluid

A hydrogen storage tank has an outer cylinder and a cylindrical hydrogen storage module within the outer cylinder spaced apart from an inner peripheral surface of the outer cylinder to provide a hydrogen passage therebetween. The cylindrical hydrogen storage module includes a lamination having a plurality of hydrogen storage units filled with powdery hydrogen absorption material and a hydrogen absorption and desorption surface on an entire outer peripheral surface, while interposing a heating / cooling element between ones of adjacent units. First and second main passages penetrate the lamination in a lamination direction of the units, and permit heating fluid and cooling fluid to flow therethrough. Sub passages branch from the main passages and extend over within each of the heating / cooling elements.

Owner:HONDA GIEKN IND

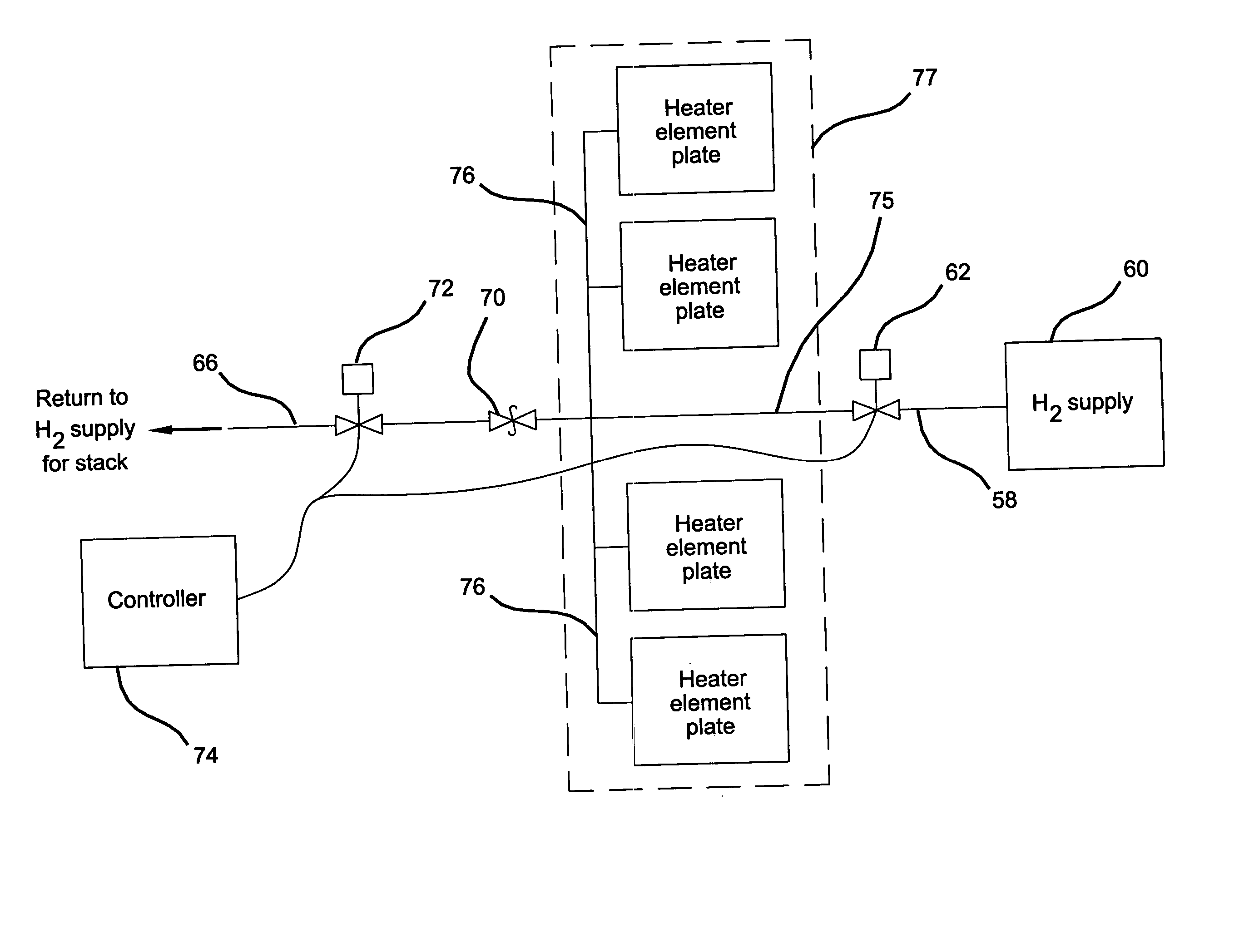

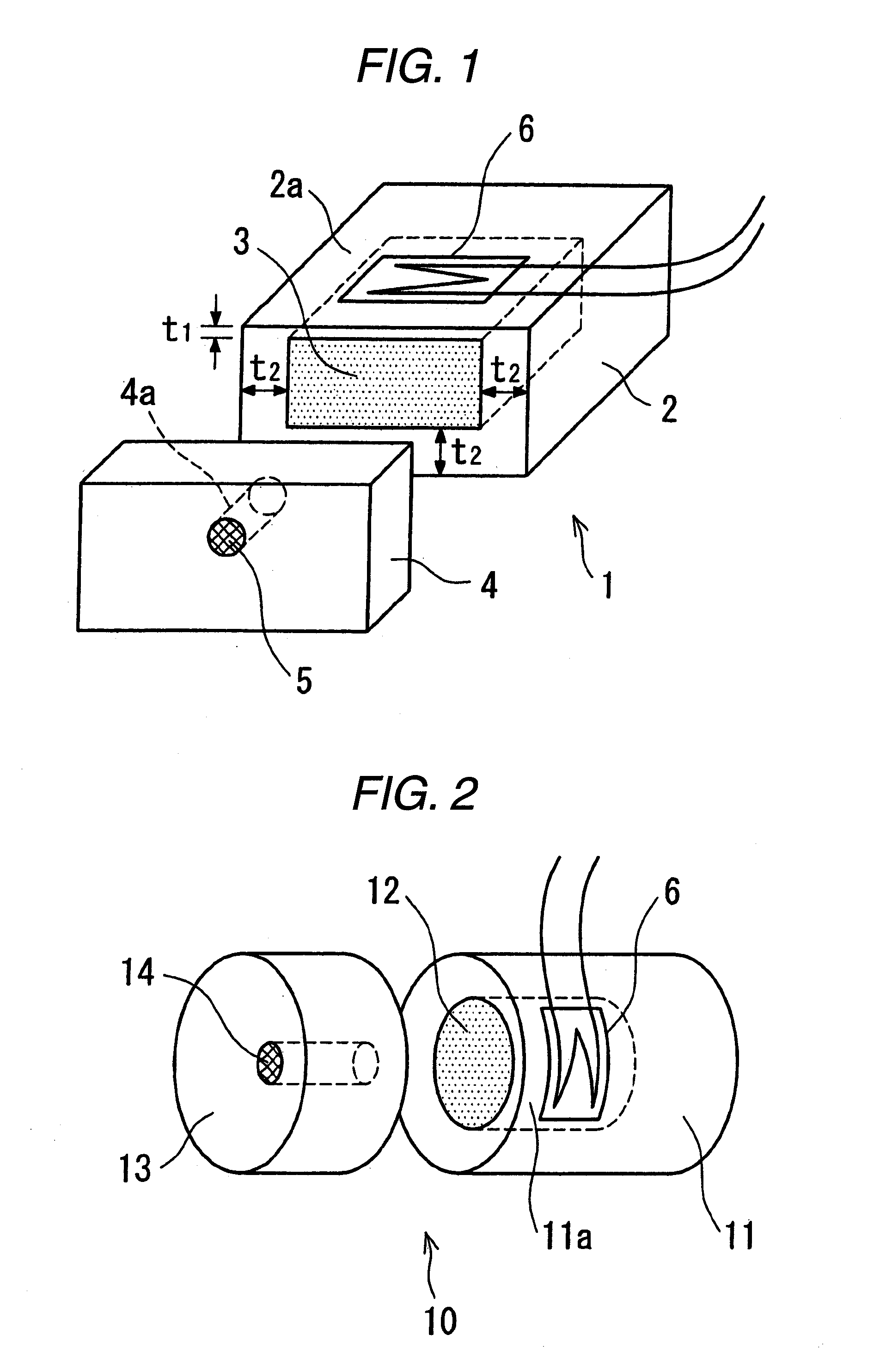

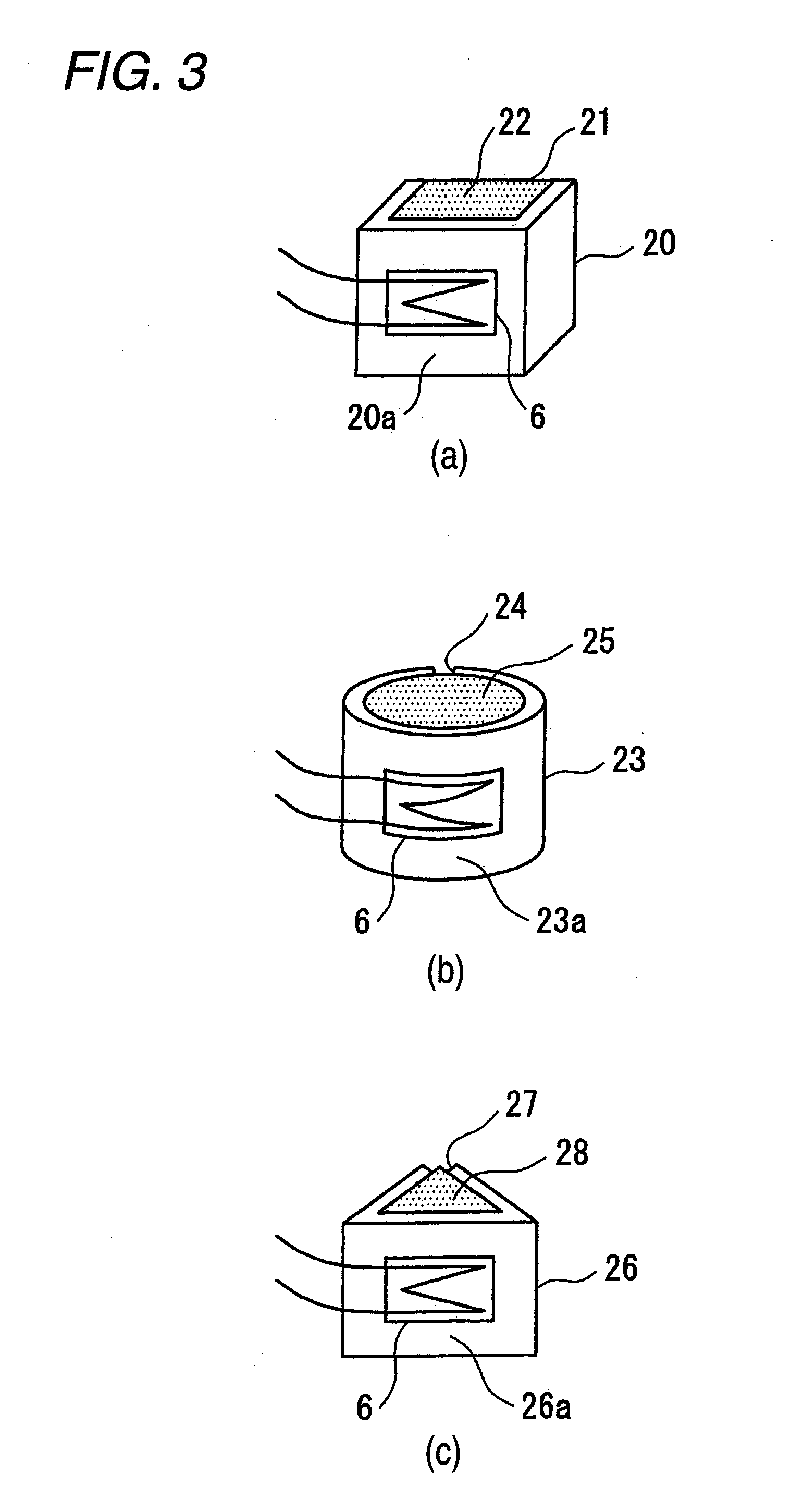

Metal hydride heating element

InactiveUS20050079397A1Fuel cell heat exchangeReactant parameters controlFuel cellsReversible reaction

A heating element for a fuel cell system comprising a body constructed of a thermally conductive material. The interior of the body has a plurality of fluid flow channels formed therein. A hydrogen absorption material capable of absorbing hydrogen in an exothermic reaction to form a metal hydride in a reversible reaction is disposed within the channels. A conduit provides fluid communication to and from the channels and the exterior of the body which is in the form of a storage vessel. Hydrogen is supplied via the conduit to the flow channels and is absorbed by the hydrogen absorption material which generates heat that is transferred through the thermally conductive material to regions surrounding the storage vessel. Methods of heating a fuel cell with a device storing material capable of an exothermic reaction that generates heat are also provided.

Owner:GENERAL MOTORS COMPANY

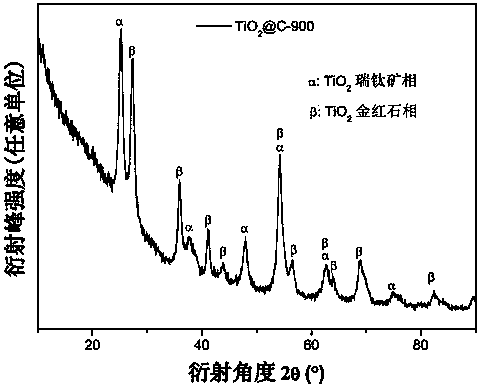

Porous carbon loaded nano metal oxide catalyst, preparation method of catalyst, and hydrogen storage material

ActiveCN104069842ARealize controllable modulationEasy to prepareCatalyst carriersHydrogen productionAlcoholMetal framework

The invention discloses a porous carbon loaded nano metal oxide catalyst, a preparation method of catalyst, and a hydrogen storage material applying the catalyst. The preparation method comprises the following steps: (1) immersing an organic metal framework into a mixed solution of furfuryl alcohol and alcohol, and stirring for 12-60 hours under a sealed condition; (2) filtering a product obtained from the step (1) to obtain solid powder, and rising the temperature to 140-165 DEG C under inert atmosphere protection; (3) rising the temperature of the product obtained from the step (1) to 700-1000 DEG C under inert gas flow protection; and keeping the temperature and cooling so as to obtain the porous carbon loaded nano metal oxide catalyst. The preparation method of the catalyst provided by the invention is simple and convenient; the hydrogen storage material in which the catalyst is added has the advantages of low hydrogen discharge temperature, high hydrogen discharge velocity, good hydrogen absorption and discharge reversibility and long circulation service life.

Owner:ZHEJIANG UNIV

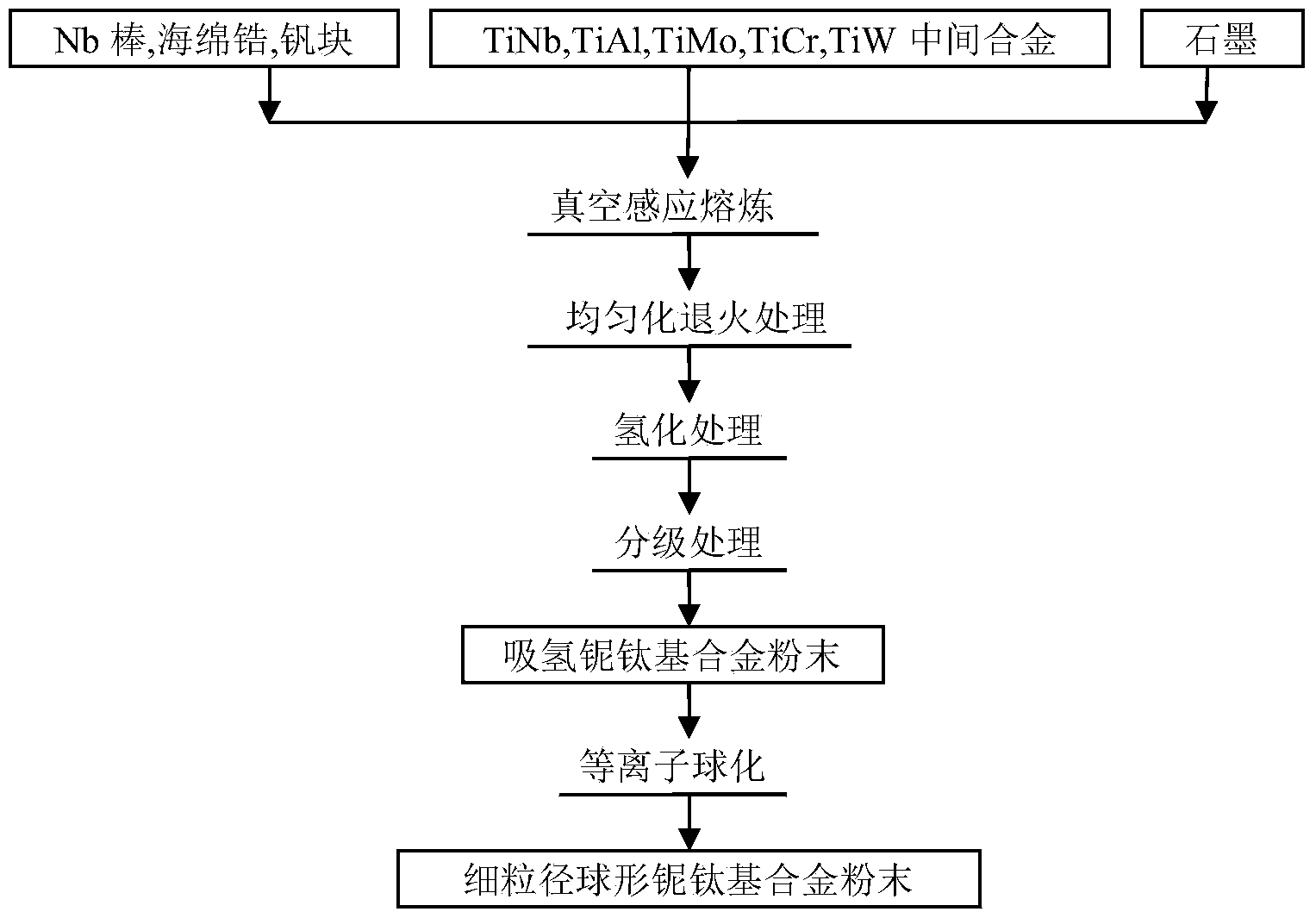

Method for manufacturing spherical niobium and titanium-based alloy powder with small particle size

The invention discloses a method for manufacturing spherical niobium and titanium-based alloy powder with a small particle size. The spherical niobium and titanium-based alloy powder is manufactured by the aid of vacuum induction melting, hydrogen treatment and plasma spheroidization technologies. The method includes firstly, manufacturing niobium and titanium-based spherical alloy ingots by the aid of the vacuum induction melting technology to realize a purification melting effect, reducing the quantity and the size of non-metallic inclusion to the greatest extent and performing homogenization thermal treatment on the niobium and titanium-based spherical alloy ingots to obtain ingots with uniform alloy contents; secondly, performing hydrogen treatment on the ingots to acquire hydrogen absorption niobium and titanium alloy powder; thirdly, sieving the hydrogen absorption niobium and titanium alloy powder, and then performing plasma spheroidization on the hydrogen absorption niobium and titanium alloy powder. The method has the advantages that output power, the powder feeding rate and the airflow rate are optimized in spheroidization procedures, accordingly, hollow powder can be prevented, and the fine powder yield can be increased; the spherical powder obtained by the method is excellent in dispersibility and flowability and uniform in particle size; the niobium and titanium-based alloy powder finally manufactured by the method is small in particle size, uniform in composition, good in flowability, high in spheroidization rate and low in oxygen content and is applicable to the technical field of injection molding, quick molding and thermal spraying.

Owner:UNIV OF SCI & TECH BEIJING

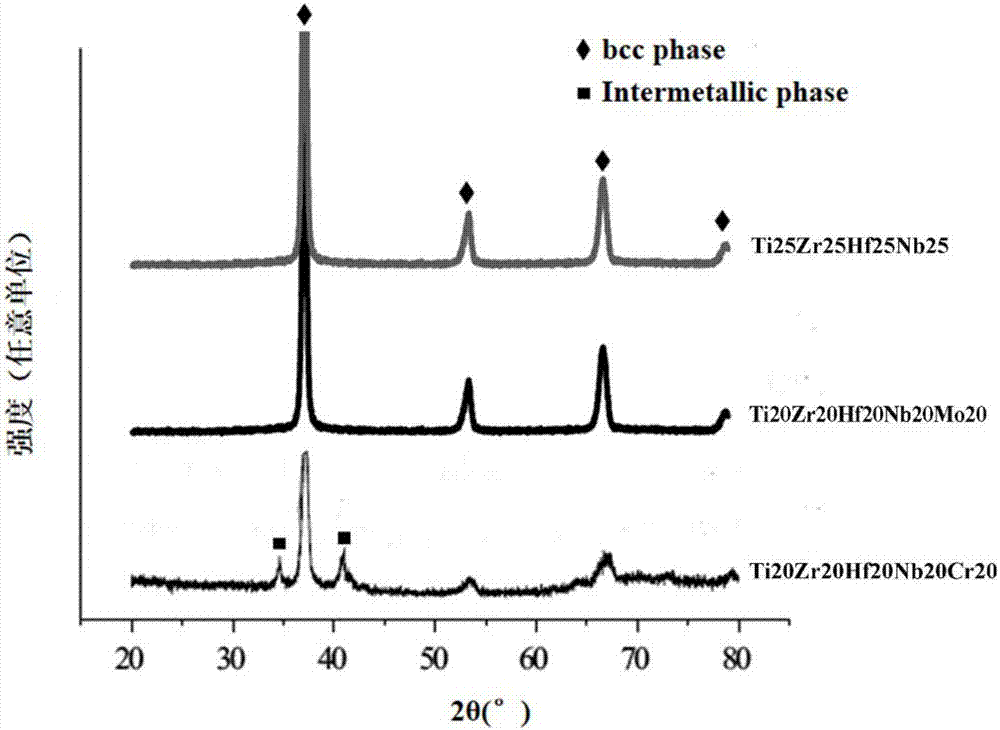

Hydrogen storage high-entropy alloy taking body-centered cubic structure as principal thing and preparation method for hydrogen storage high-entropy alloy

ActiveCN107338385AHigh hydrogen storage capacityFast hydrogen absorption and desorptionElectric arc furnaceHigh entropy alloys

The invention belongs to the field of hydrogen storage materials, and relates to a hydrogen storage high-entropy alloy taking a body-centered cubic structure as the principal thing and a preparation method for the hydrogen storage high-entropy alloy. A component expression formula of high-entropy alloy is as follows: (TiaZrbNbc)xMy, wherein a is greater than or equal to 5at% and smaller than or equal to 35at%, b is greater than or equal to at5% and smaller than or equal to 35at%, c is greater than or equal to 5at% and smaller than or equal to 35at%, a+b+c is equal to x, x is greater than or equal to 15at% and smaller than or equal to 100at%, M is any one or more of Hf, Fe, Co, Cr, Mn, Ni, Mo and W; and atomic percent of each M is 0-35%, and x+y is equal to 100. The preparation method for the hydrogen storage high-entropy alloy comprises the following steps of: adopting a non-consumable vacuum electric-arc furnace to smelt to prepare alloy; and adopting suction casting to sucking alloy into a water-cooling cooper mould, thereby obtaining a high-entropy alloy rod. The high-entropy alloy has high hydrogen storage capacity (3 mass% or more) and excellent hydrogen absorption and desorption dynamic performances; when hydrogen absorption and desorption amount is great, the high-entropy alloy, in comparison with a pure element, does not need to completely purify, so that cost can be saved to a great extent. The hydrogen storage high-entropy alloy taking the body-centered cubic structure as the principal thing has the characteristics of the high-entropy alloy, and has a wide application prospect in the fields of new energy resources and transportation.

Owner:UNIV OF SCI & TECH BEIJING

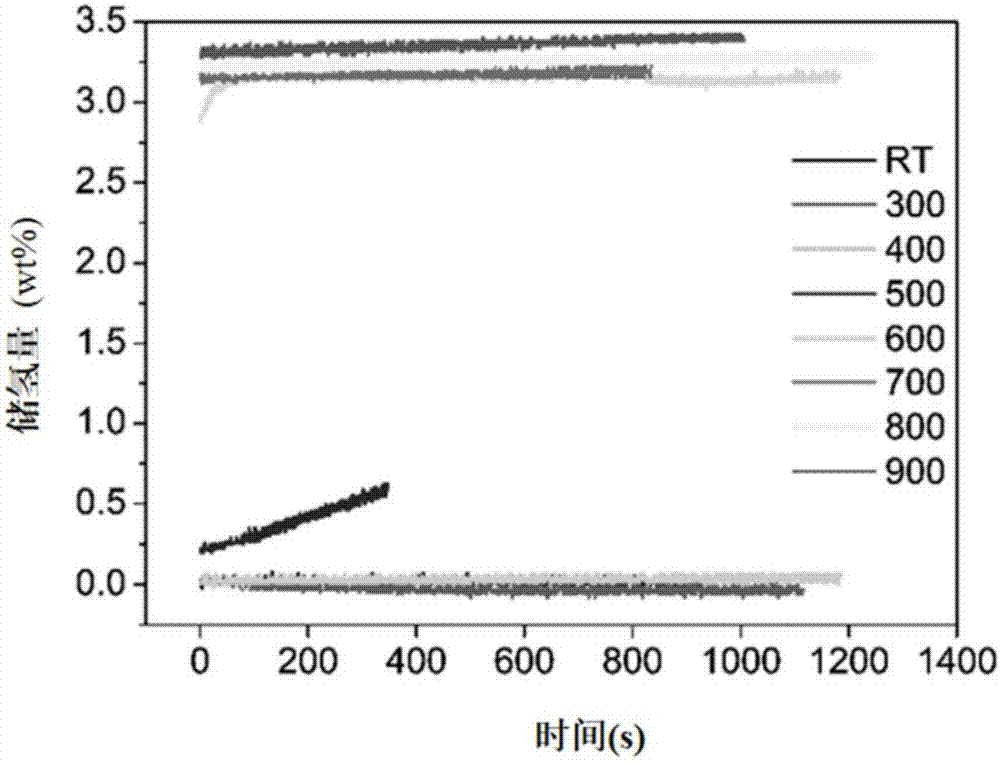

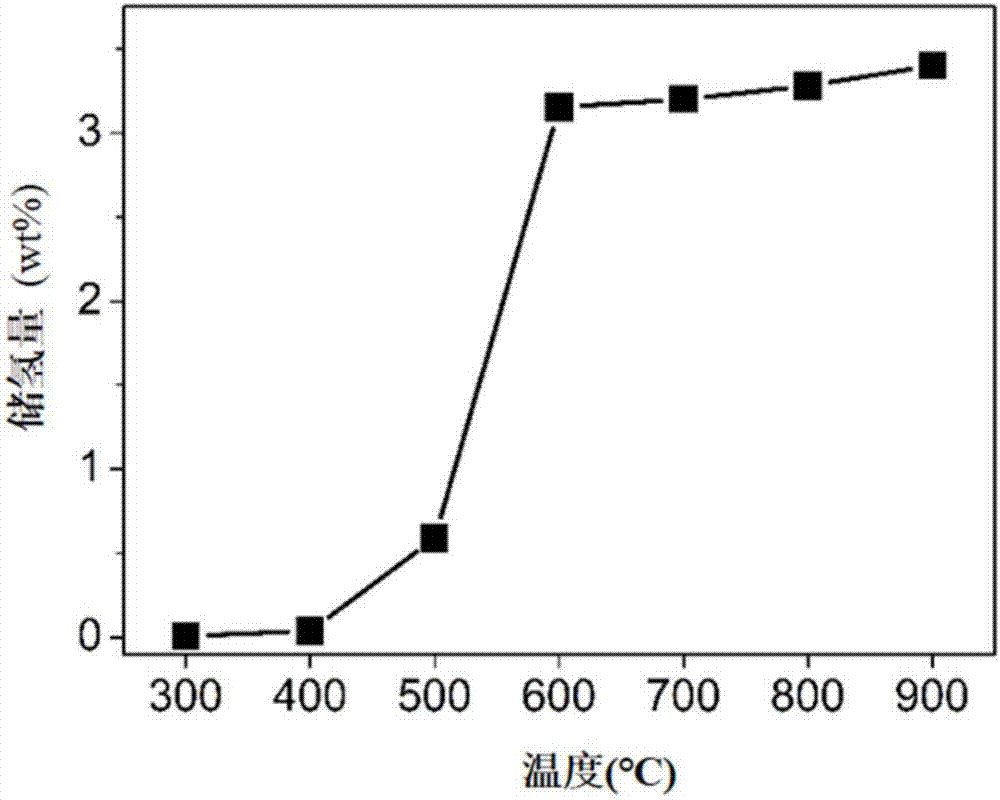

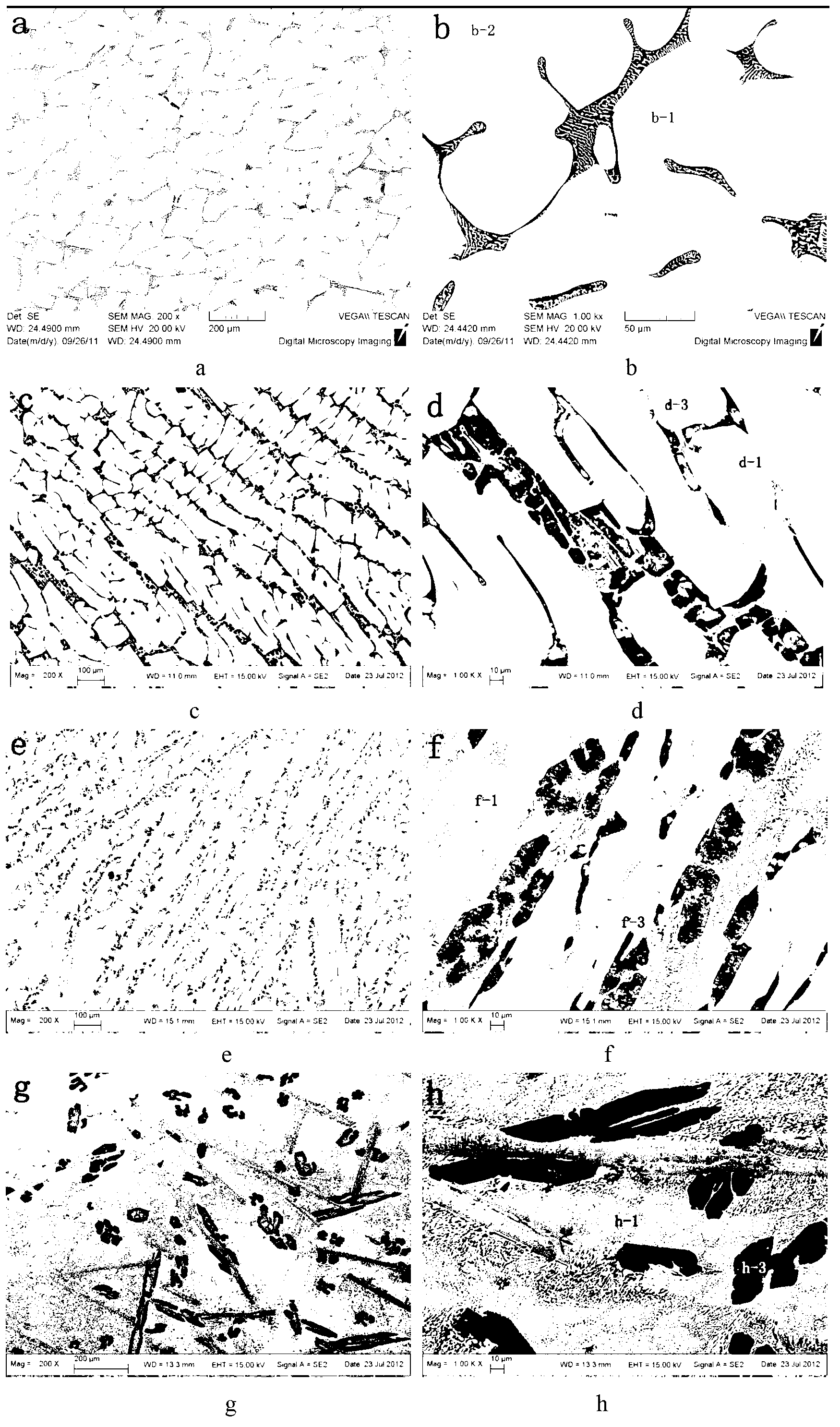

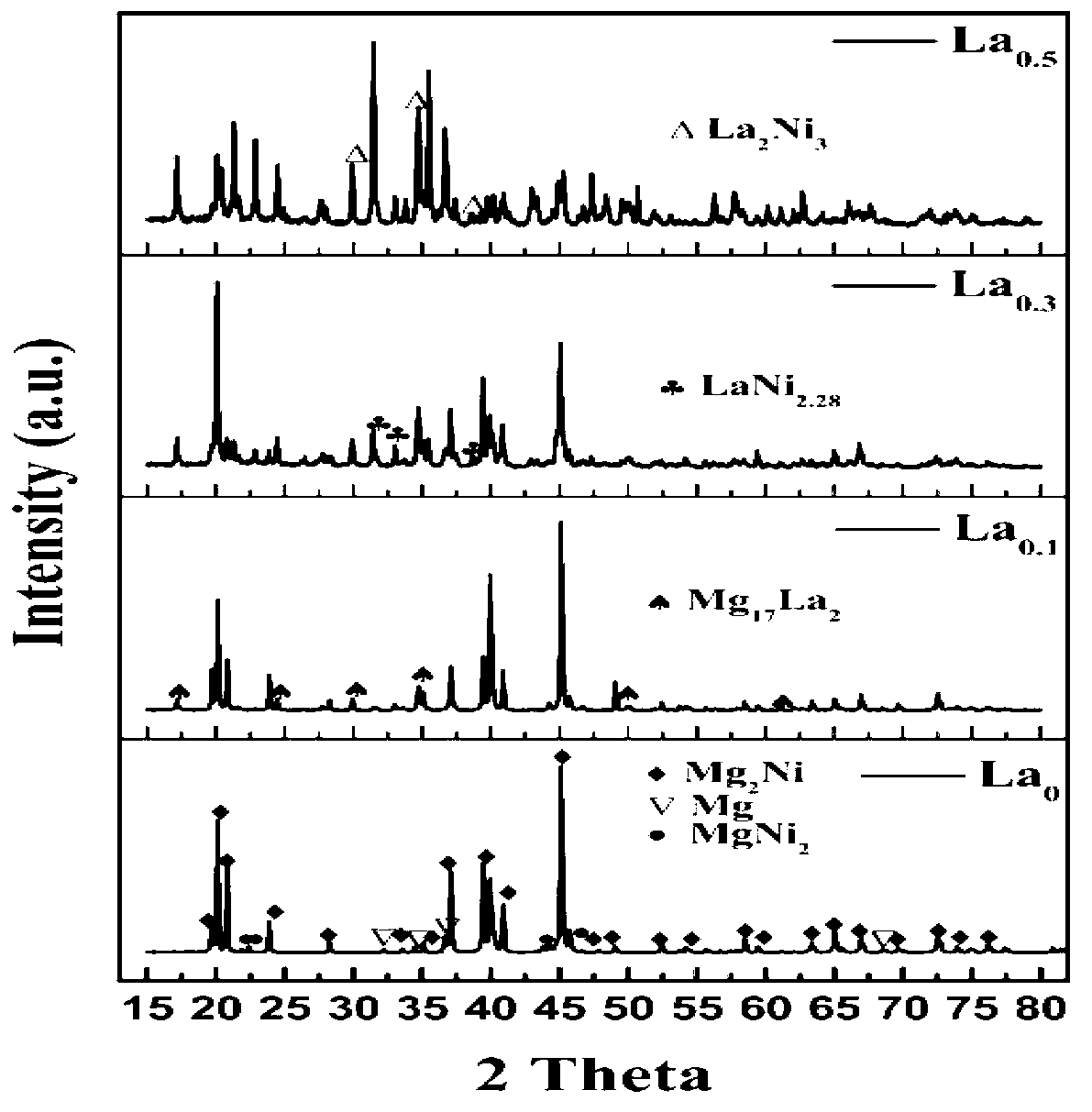

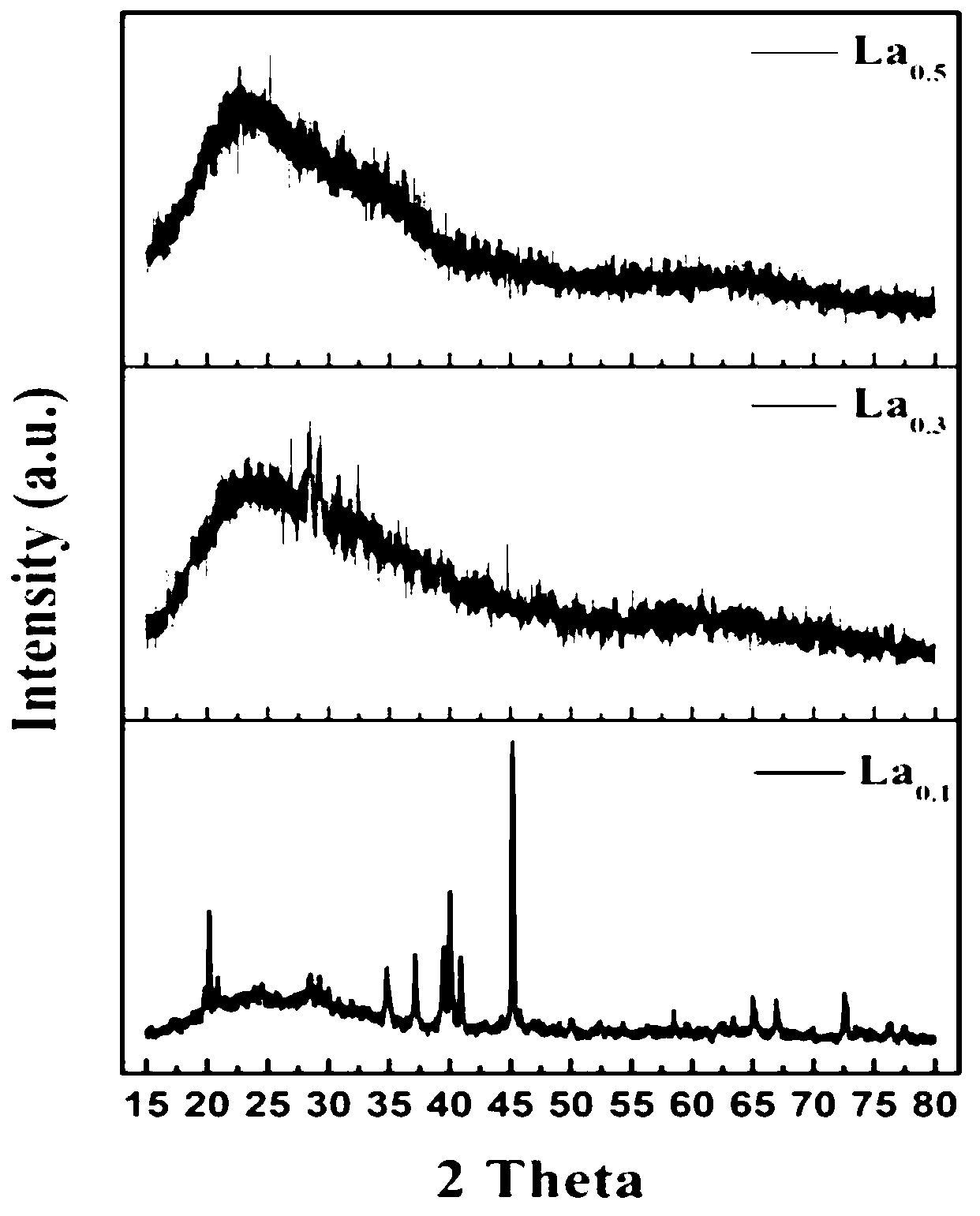

Mg-Ni-La based composite hydrogen-storage alloy powder and preparation process thereof

The invention discloses Mg-Ni-La based composite hydrogen-storage alloy powder and a preparation process thereof. The Mg-Ni-La based composite hydrogen-storage alloy powder is composed of Mg-Ni-La alloy strips and multi-walled carbon nanotubes (MWCNTs) and TiF3 catalysts. According to the Mg-Ni-La based composite hydrogen-storage alloy powder and the preparation process thereof, a melt rapid-quenching technology is used, a melt is ejected by the aid of the argon gas pressure and sprayed on surfaces of rotating smooth copper rods, by the aid of the quenching effect produced by the rotating copper rods, alloy structures are refined, and channels such as grain boundaries / phase boundaries, which are beneficial to diffusion of H atoms, are increased, so that amorphous / nano crystalline alloys are prepared. According to the Mg-Ni-La based composite hydrogen-storage alloy powder, the MWCNTs and the TiF3 catalysts are added simultaneously, rare earth La is added to improve the phase composition of Mg-Ni alloys, the formation of a new phase is beneficial to decomposition of H2 molecules on material surfaces and diffusion of the H atoms in materials, and the hydrogen absorption and desorption dynamic performance of Mg2Ni alloys is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

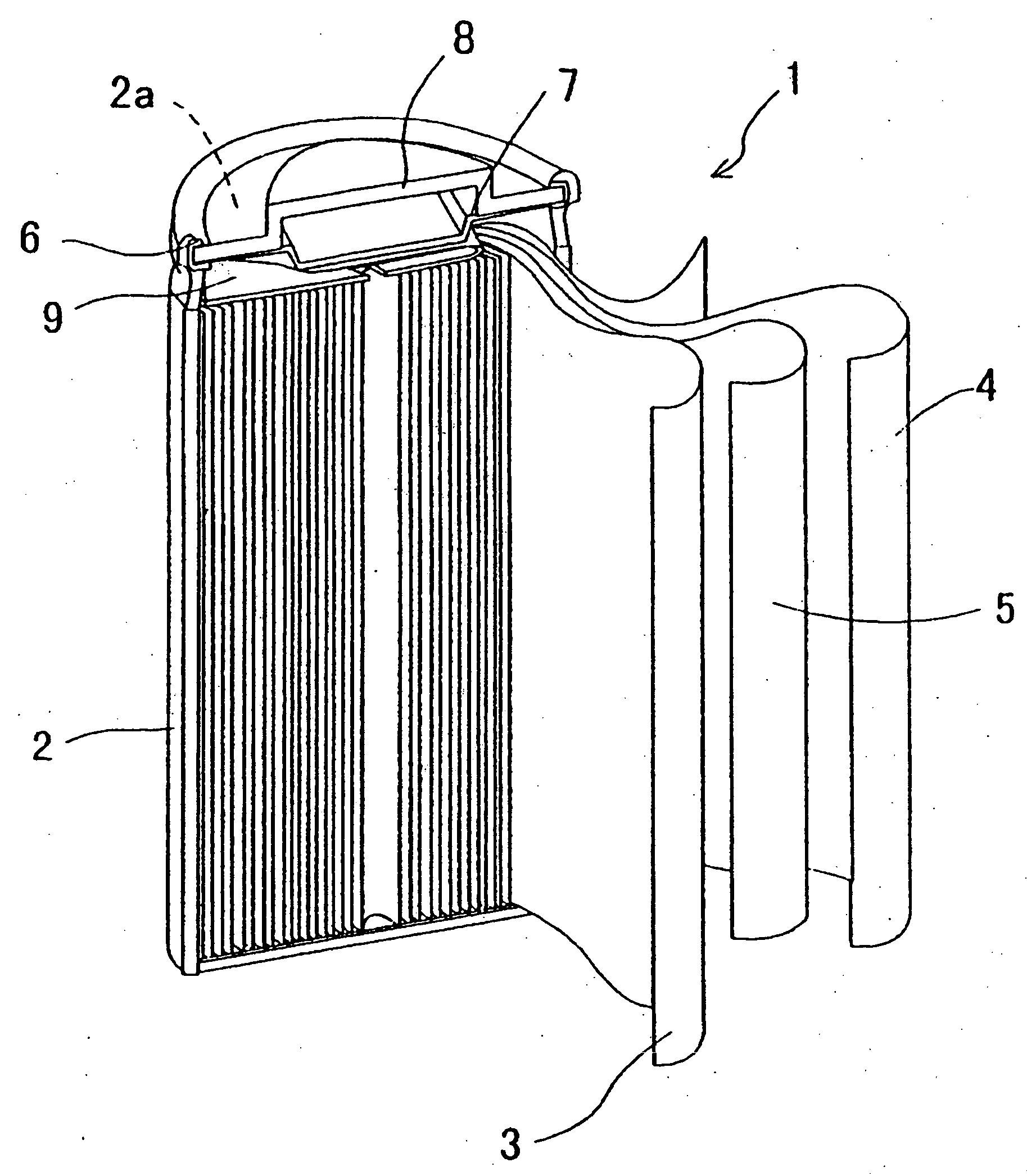

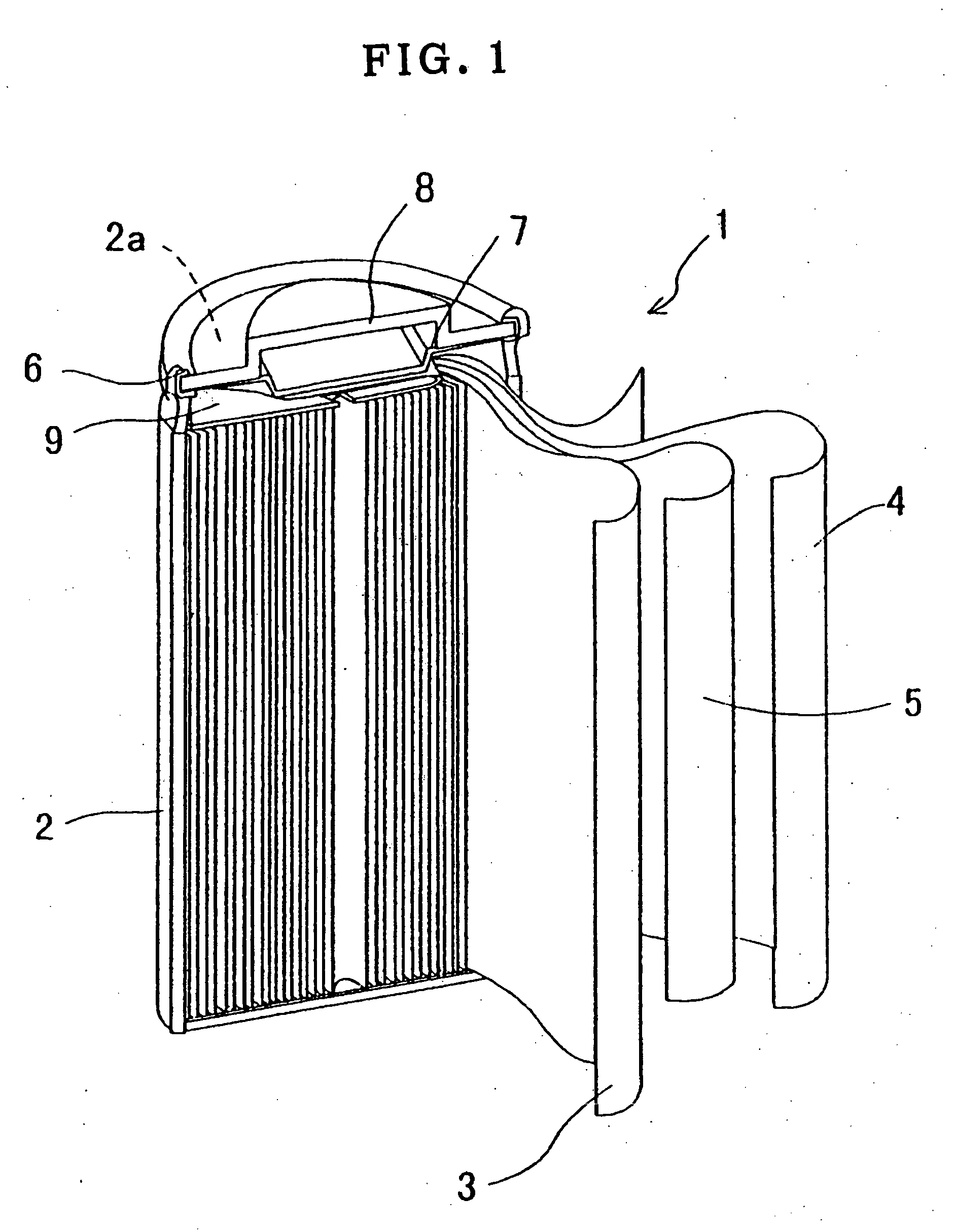

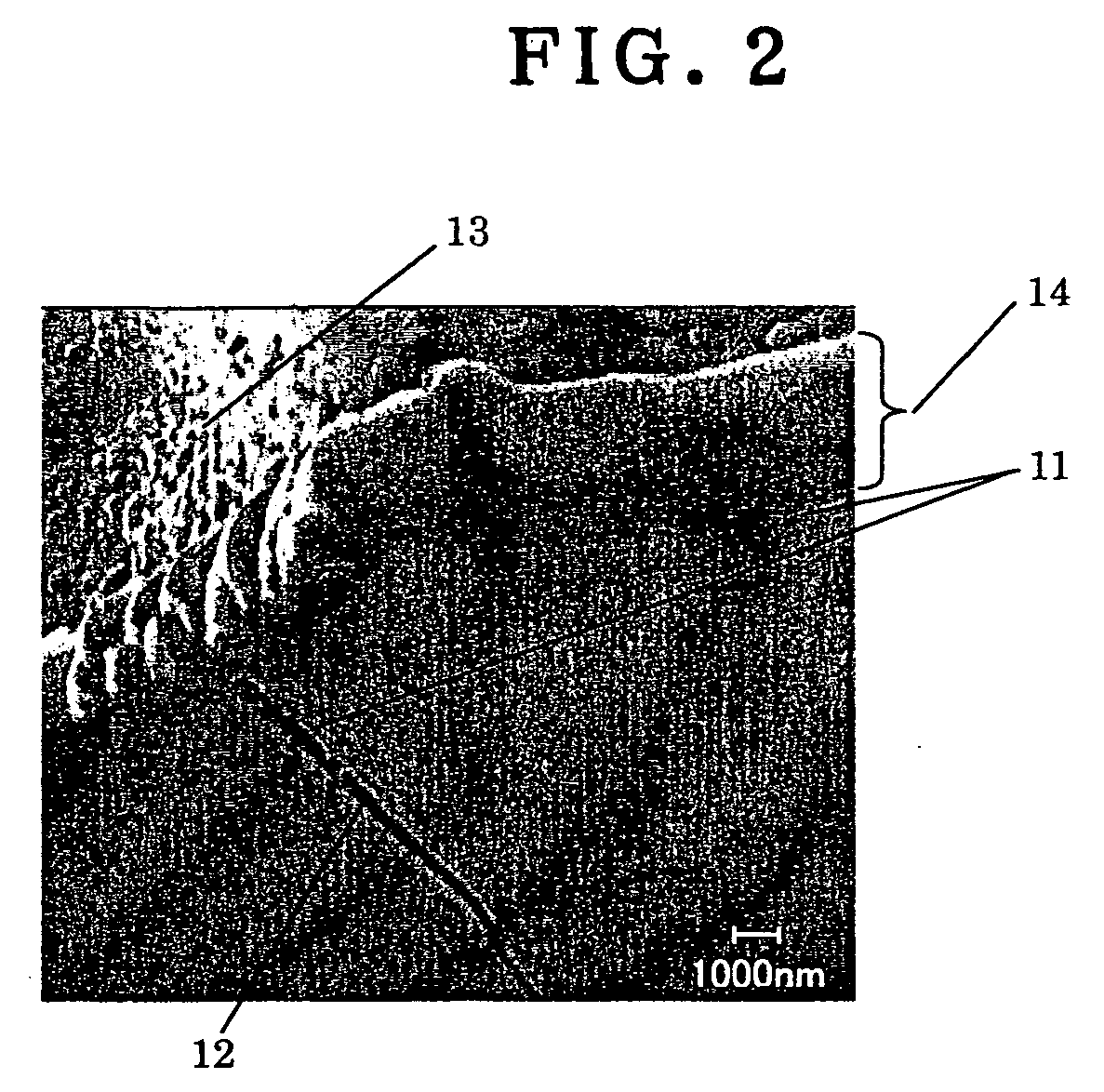

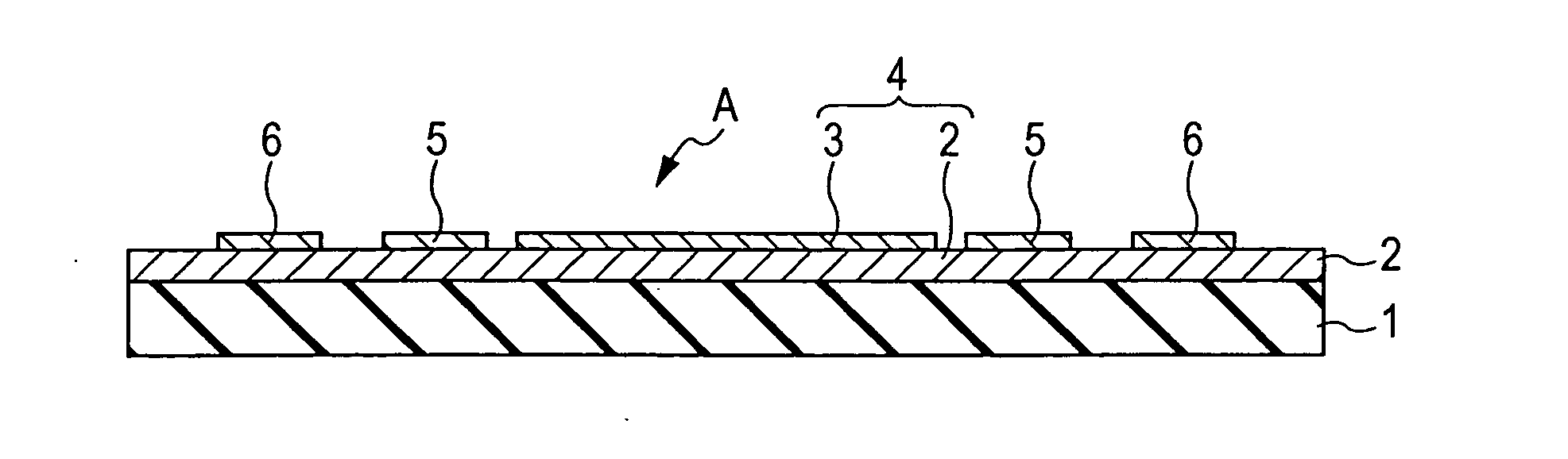

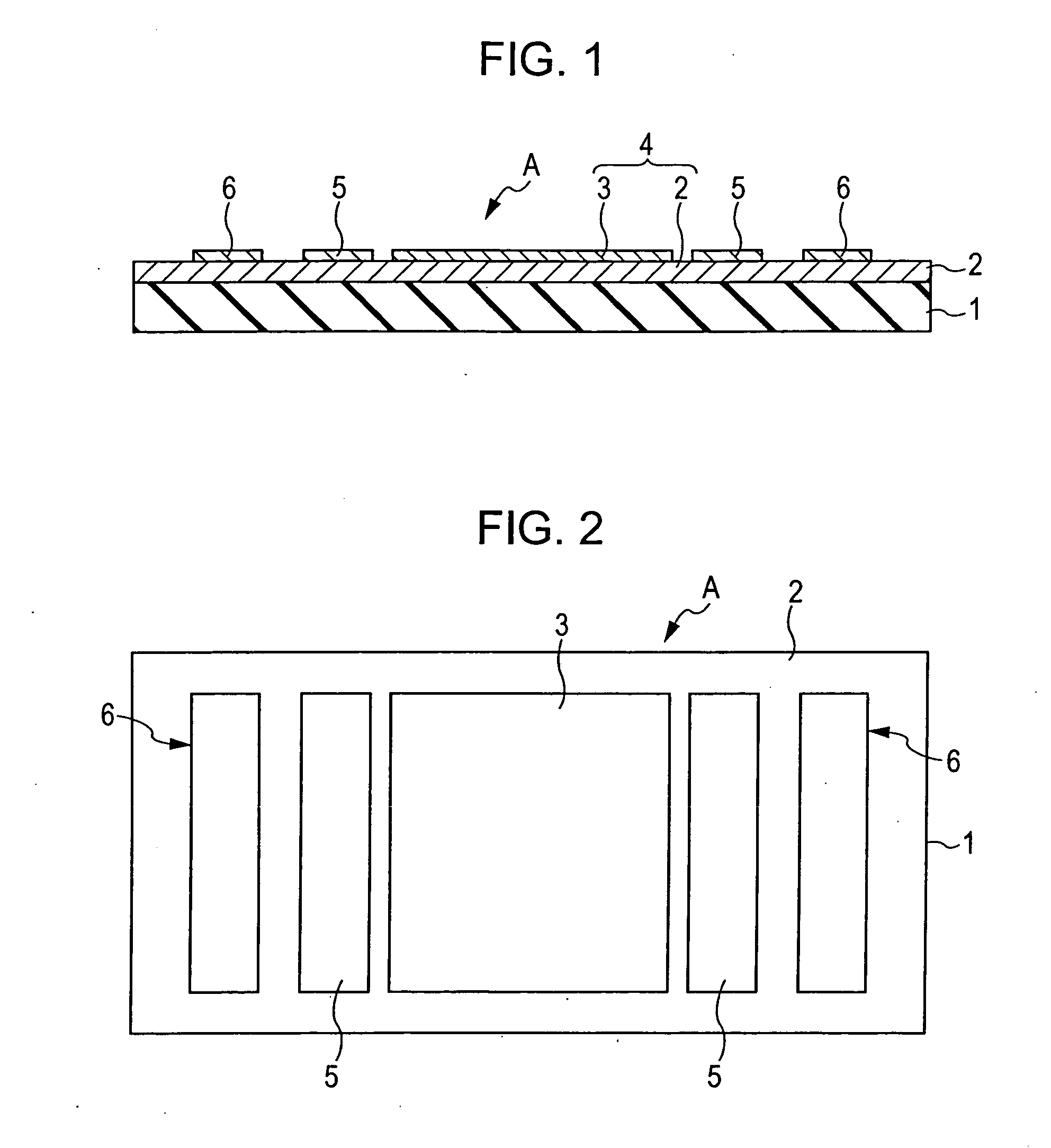

Closed nickel-hydrogen storage battery and its production method

One problem with a sealed type nickel-metal hydride battery is that the high-rate discharge capability is inferior to that of a nickel-cadmium storage battery, because of a slow transfer rate of charges to the surface of a hydrogen storing alloy that is a negative electrode. Another problem is that the use of an alloy having excellent life characteristics takes much time for initial activation of battery characteristics. The invention provides a solution to the aforesaid problems by the provision of a sealed type nickel-metal hydride battery (1) improved in high-rate discharge capability and charge-discharge cycle characteristics. To this end, the invention is characterized by locating a 50 nm to 400 nm thick nickel-rich layer (11) on the surface of a hydrogen storing alloy powder, and locating the nickel-rich layer (11) as well on the surface of cracks (12) that open at the surface of alloy, and more preferably setting the mass saturation magnetization of the alloy powder at 2.5 to 9 emu / g and the content of magnetic nickel at 0.5 to 1.9 mmol per gram of the hydrogen storing alloy powder. A succession of hydrogen absorption step, alkali treatment step, product removal step, hydrogen desorption step and partial oxidization step by air are applied to the hydrogen storing alloy powder to obtain alloy powder, which is then used to obtain a battery having the aforesaid features. The invention is effectively applied to corrosion-resistant hydrogen storing alloys containing Er, Y and Yb.

Owner:GS YUASA INT LTD

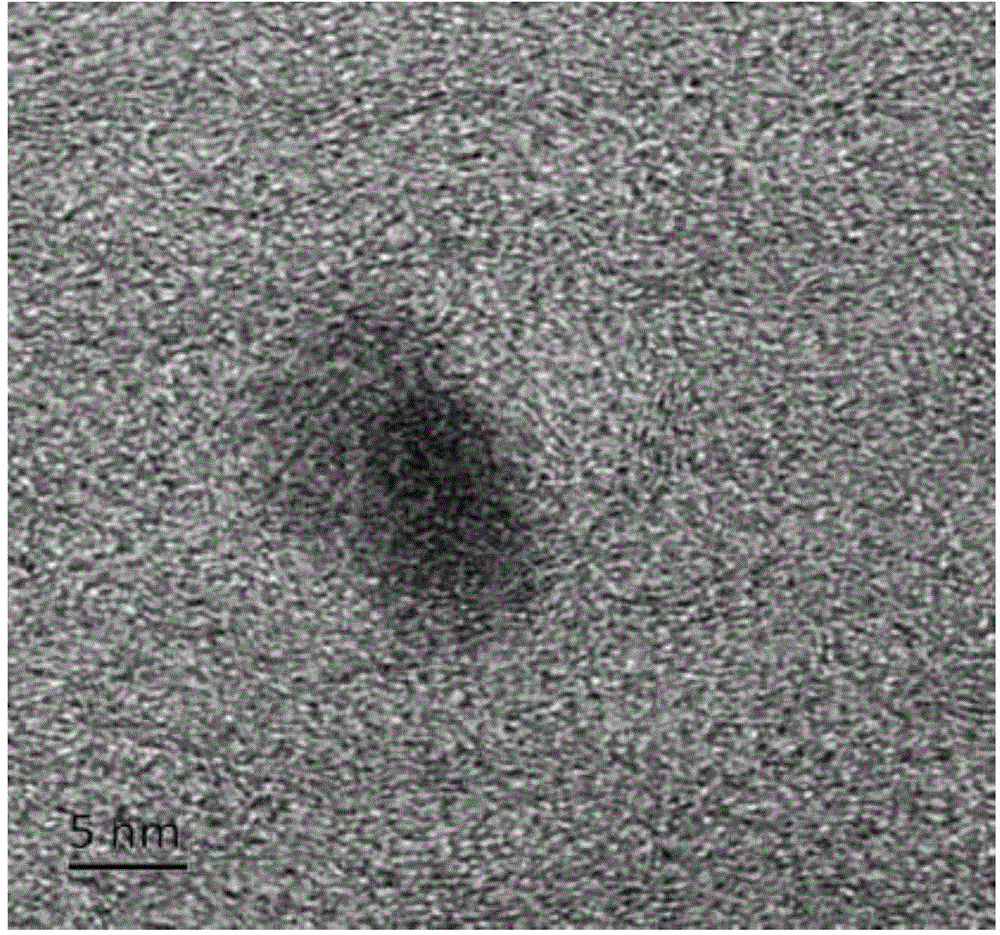

Magnesium hydride nano particle and preparation method and application thereof

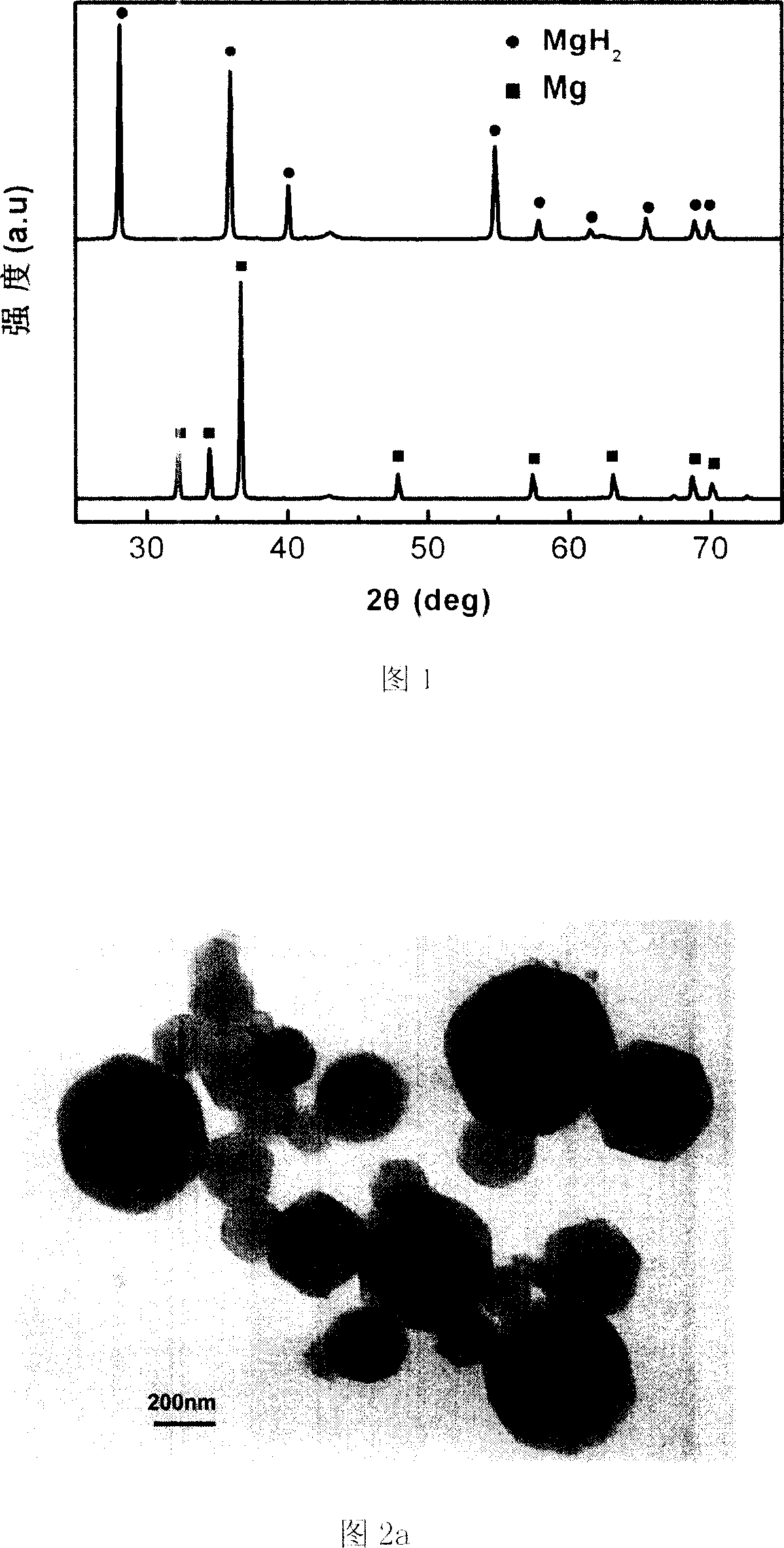

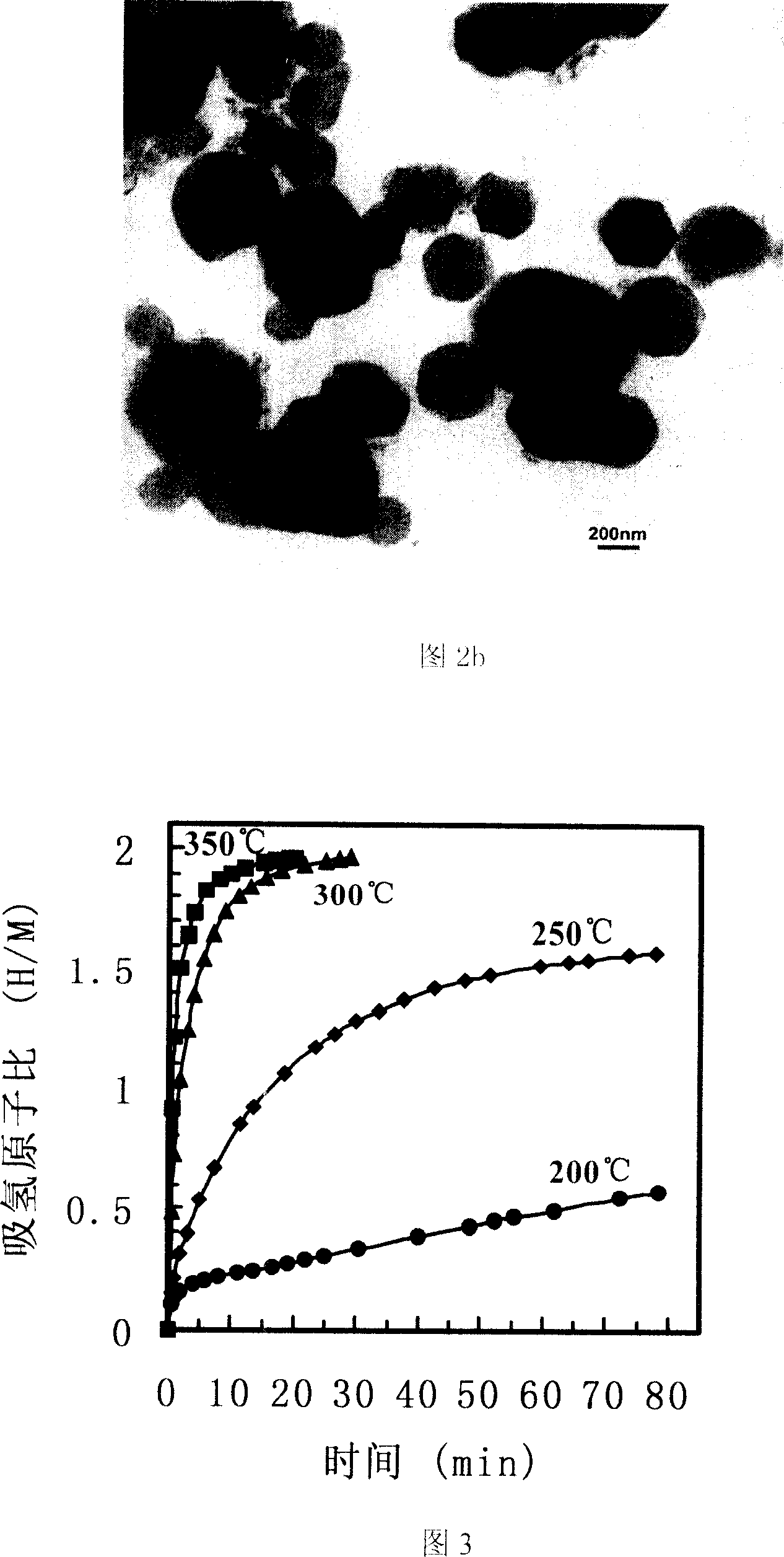

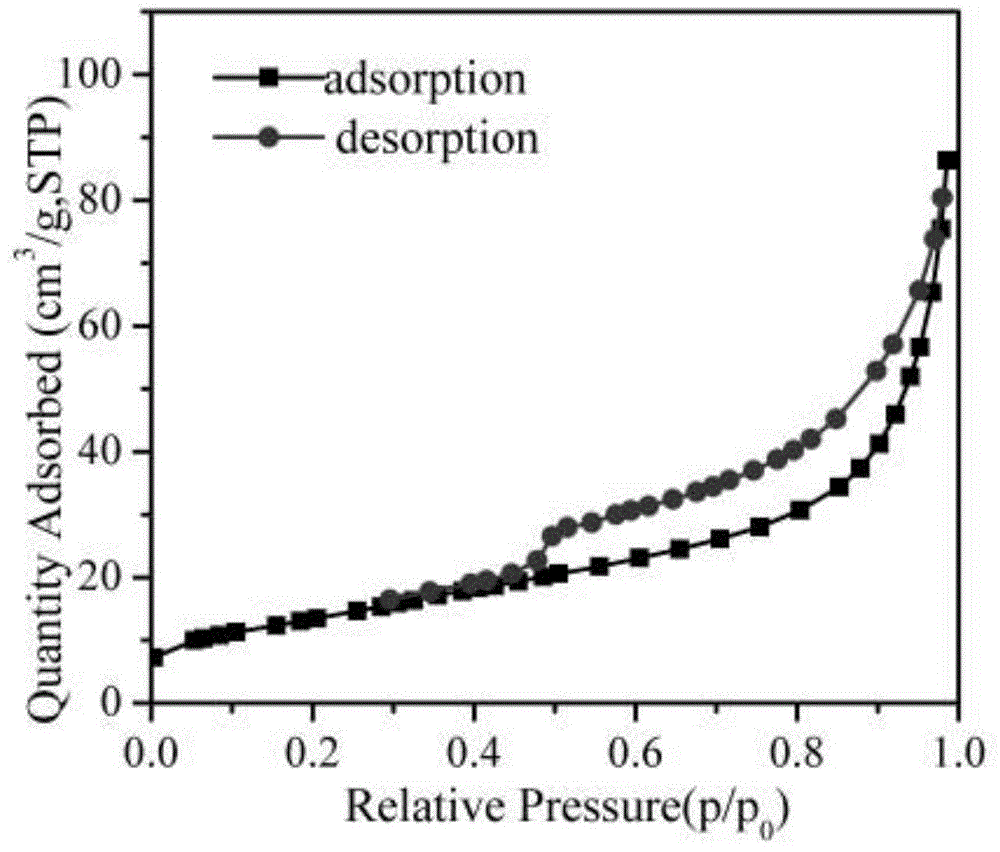

InactiveCN101117211ALarge specific surface areaShorten the diffusion distanceAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen absorptionNanotechnology

The invention discloses a magnesium hydride nanometer granular material and the preparing method and application, wherein nanometer magnesium powder is prepared through adopting arc heating method and then the magnesium powder is hydrogenated to obtain MgH2 granular product with the grain diameter being 50 nm to 600 nm. The nanometer MgH2 grain possesses high purity and outstanding kinetics property of hydrogen absorption and desorption during being used as hydrogen storage material, thereby possessing extremely important application value and extensive application potential in the hydrogen storage technical field.

Owner:PEKING UNIV

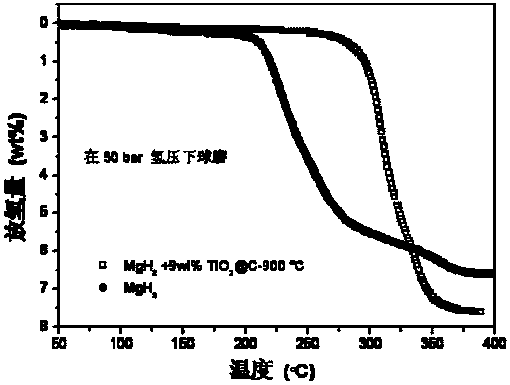

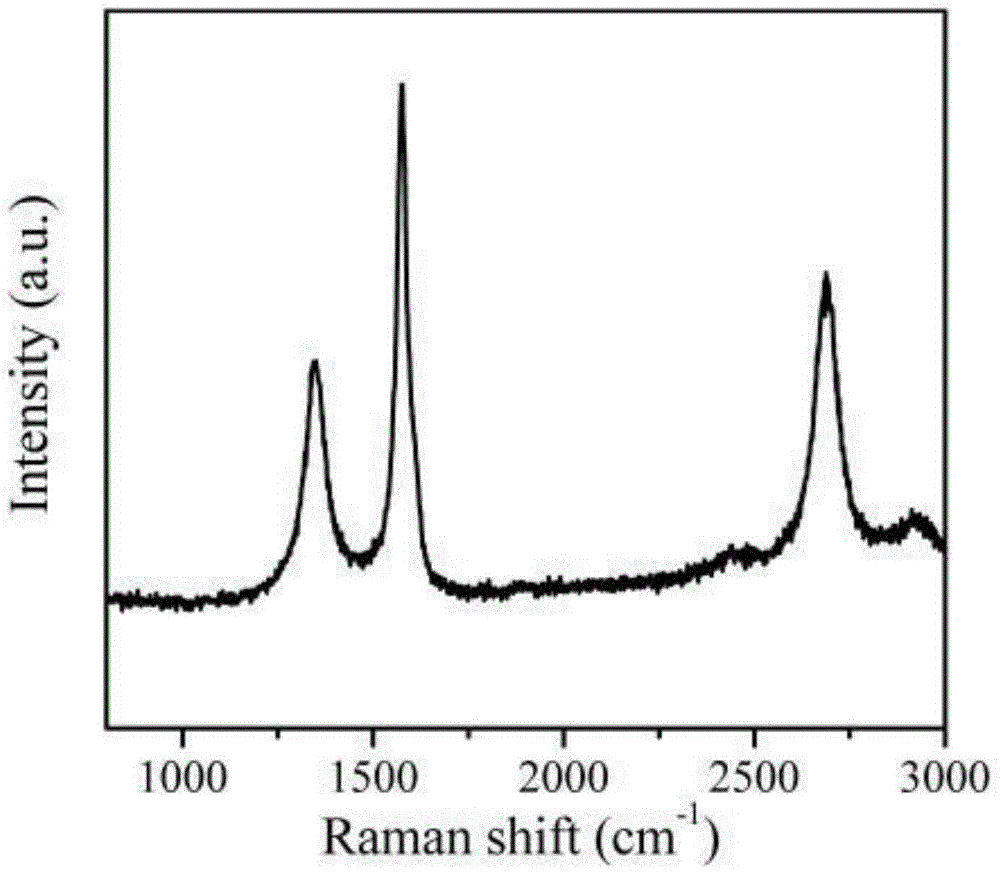

Method for nanocrystallization of magnesium-based hydrogen storage material

The invention relates to a method for the nanocrystallization of a magnesium-based hydrogen storage material, which utilizes a nanocrystallization process for a nano-carbon material to prepare the magnesium-based hydrogen storage material to form monocrystal or polycrystal nano-particles so as to improve a specific surface area greatly and increase diffusion channels of hydrogen atoms in the hydrogen storage material. Therefore, the method can improve the effective hydrogen capacity of the hydrogen storage material, accelerate the hydrogen absorption and desorption of the hydrogen storage material, and reduce the temperature of the hydrogen absorption and desorption of the hydrogen storage material.

Owner:IND TECH RES INST

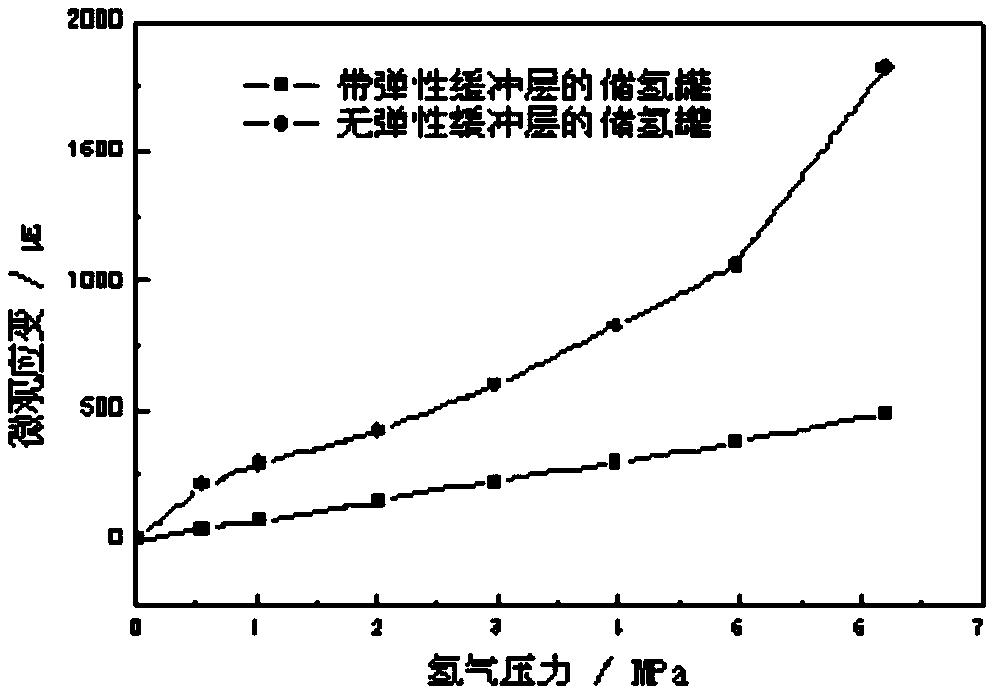

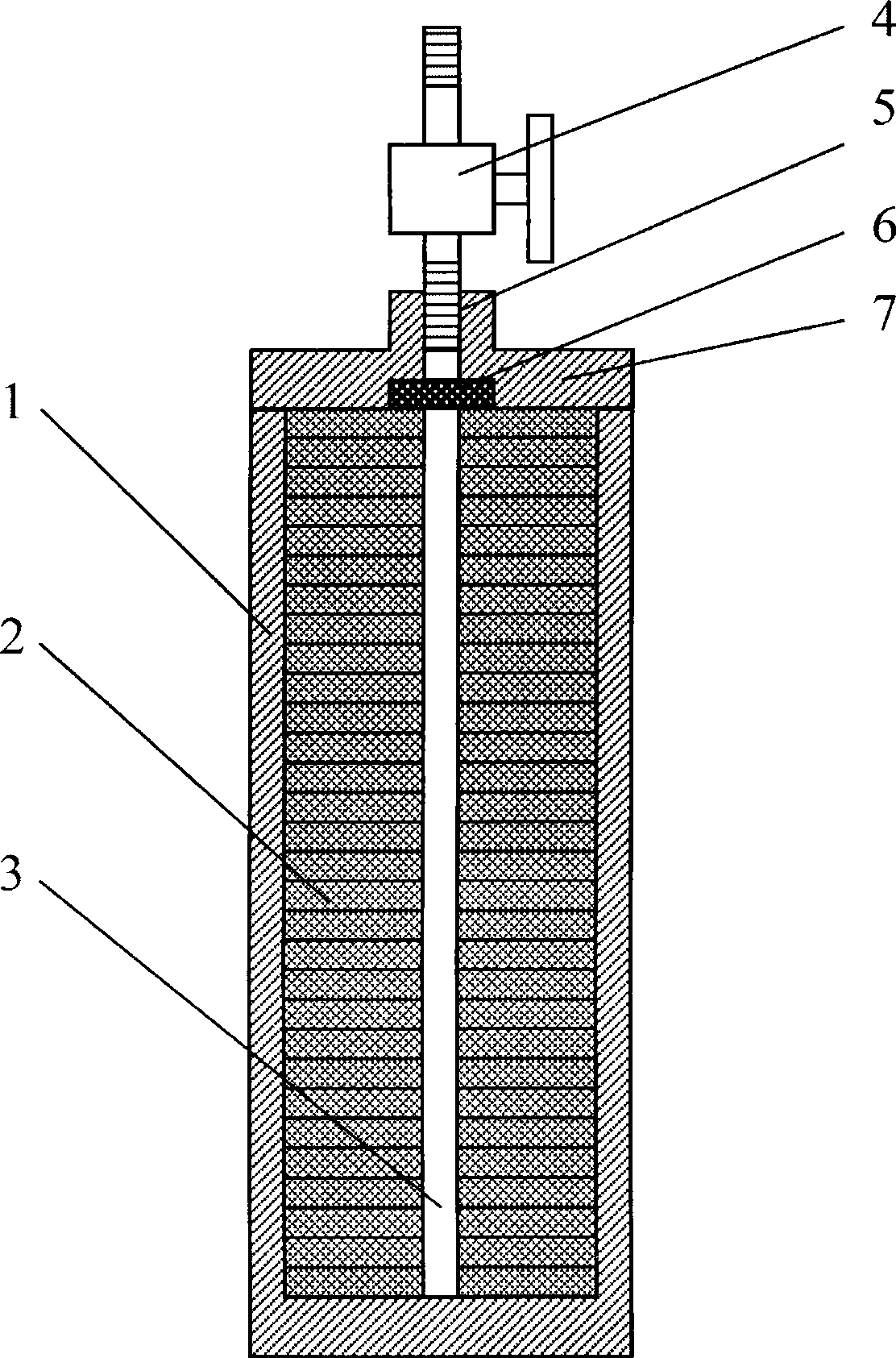

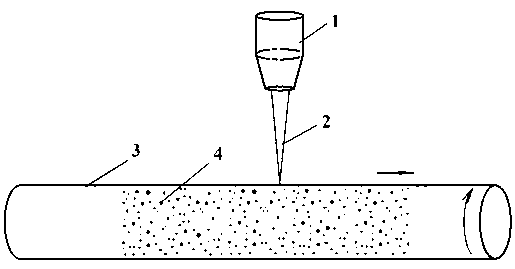

Hydrogen-absorption low-strain metal hydride hydrogen storage tank

ActiveCN105371105ASimple structureEasy to implementContainer filling methodsFixed capacity gas holdersHydrogen valveHydrogen absorption

The invention belongs to the hydrogen storage technology in the hydrogen energy field and particularly relates to a hydrogen-absorption low-strain metal hydride hydrogen storage tank. The hydrogen storage tank mainly comprises a tank body, a metal hydride hydrogen storage alloy bed body and an elastic buffer layer. The elastic buffer layer is arranged between the tank body and the metal hydride hydrogen storage alloy bed body. A heat exchange pipe is communicated with the interior of the metal hydride hydrogen storage alloy bed body and used for guiding heat generated in the hydrogen absorption and release processes of the metal hydride hydrogen storage alloy bed body out. A hydrogen valve is installed on an outlet of the tank body and meanwhile a hydrogen filter is welded to the outlet end of the tank body. The hydrogen-absorption low-strain metal hydride hydrogen storage tank is simple in structure and easy to obtain, the destructive effect on the tank body due to the fact that the metal hydride hydrogen storage alloy bed body expands after absorbing hydrogen can be relieved effectively, and the use safety of the hydrogen storage tank is improved.

Owner:GRIMAT ENG INST CO LTD

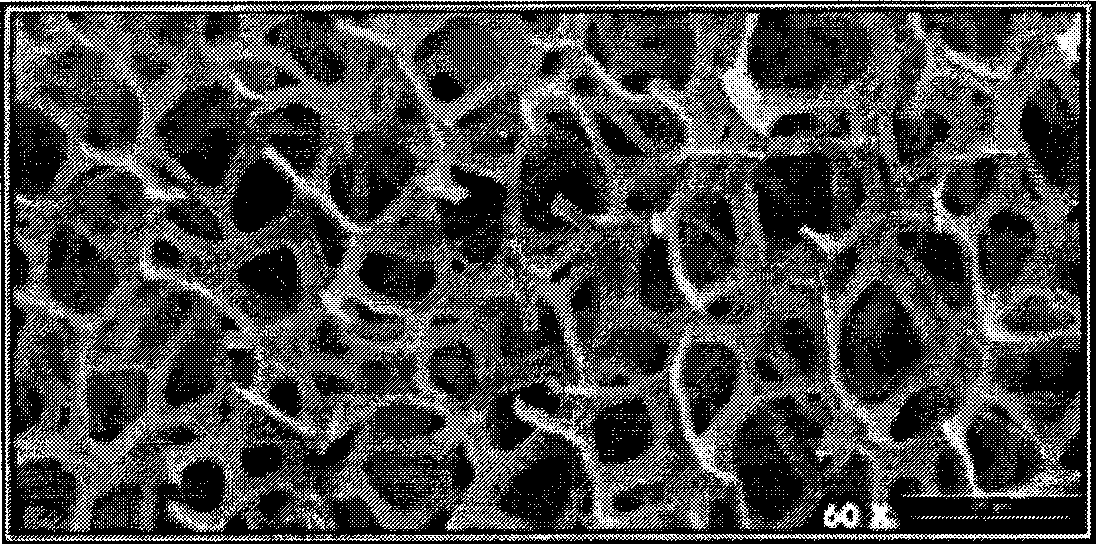

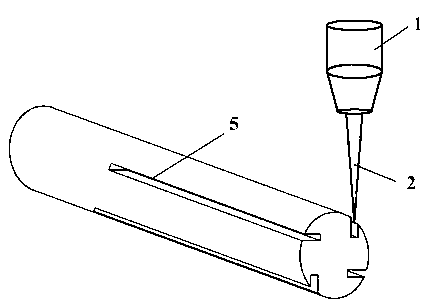

Hydrogen storing apparatus of metal hydrides and manufacturing method thereof

ActiveCN101413624AAvoid deformationAvoid destructionFixed capacity gas holdersHeat transmissionAdhesive

The invention relates to a metal hydride hydrogen storage device and a preparation method thereof; wherein, the device comprises a shell which is filled in superposed hydrogen-storage material sheet which consists of a spumescent metal substrate which absorbs no hydrogen and mixture of hydrogen-storage alloy powder and adhesive which are filled in the gap of the spumescent metal substrate; the hydrogen-storage material sheet is provided with a central hole which is coincident to the central hole of the shell head and is connected with the central hole of the head by a filter sheet which is embedded in the head; the central hole of the head is fixed with a joint pipe which is provided with a valve. The hydrogen storage device can effectively improve the heat transmission performance of the hydrogen storage alloy and hydride powder, effectively prevents the flowing and accumulating of the hydrogen-storage alloy and the hydride, solves the hydrogen absorption expansion problem of the hydrogen storage alloy powder, thus having the advantages of high-efficiency running, safety and reliability and being suitable for the production of meta hydride hydrogen-storage devices applied to various sites.

Owner:ZHEJIANG UNIV

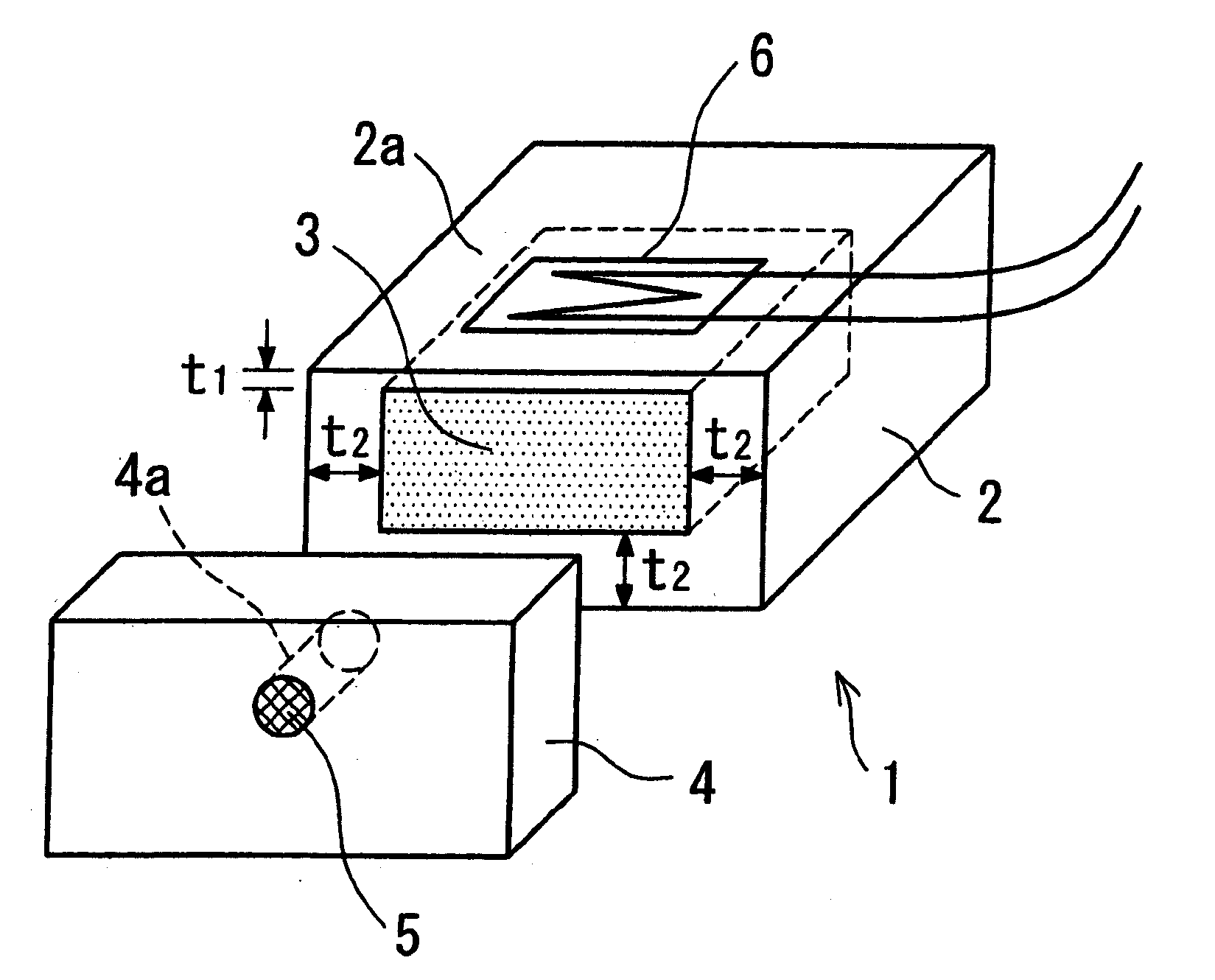

Hydrogen remaining sensor

InactiveUS20100050734A1Easily causedThe right amountTesting waterElectrical/magnetic solid deformation measurementStrain gaugeHydrogen absorption

In the hydrogen remaining sensor of the present invention, the hydrogen remaining sensor is arranged in a space in which the hydrogen is absorbed / released by the main hydrogen storage alloy, and is equipped with the vessel-like sensor main body in which the sensor hydrogen storage alloy is filled and through which the hydrogen is moved. Also, the easy-to-deform portion in which the strain is caused easily due to the hydrogen absorption / release of the sensor hydrogen storage alloy is provided to a part of the sensor main body, and the strain gauge for measuring the strain of the easy-to-deform portion is provided. As a result, according to the hydrogen remaining sensor of the present invention can contribute to sense precisely a remaining amount of hydrogen in the main hydrogen storage alloy.

Owner:JAPAN STEEL WORKS LTD

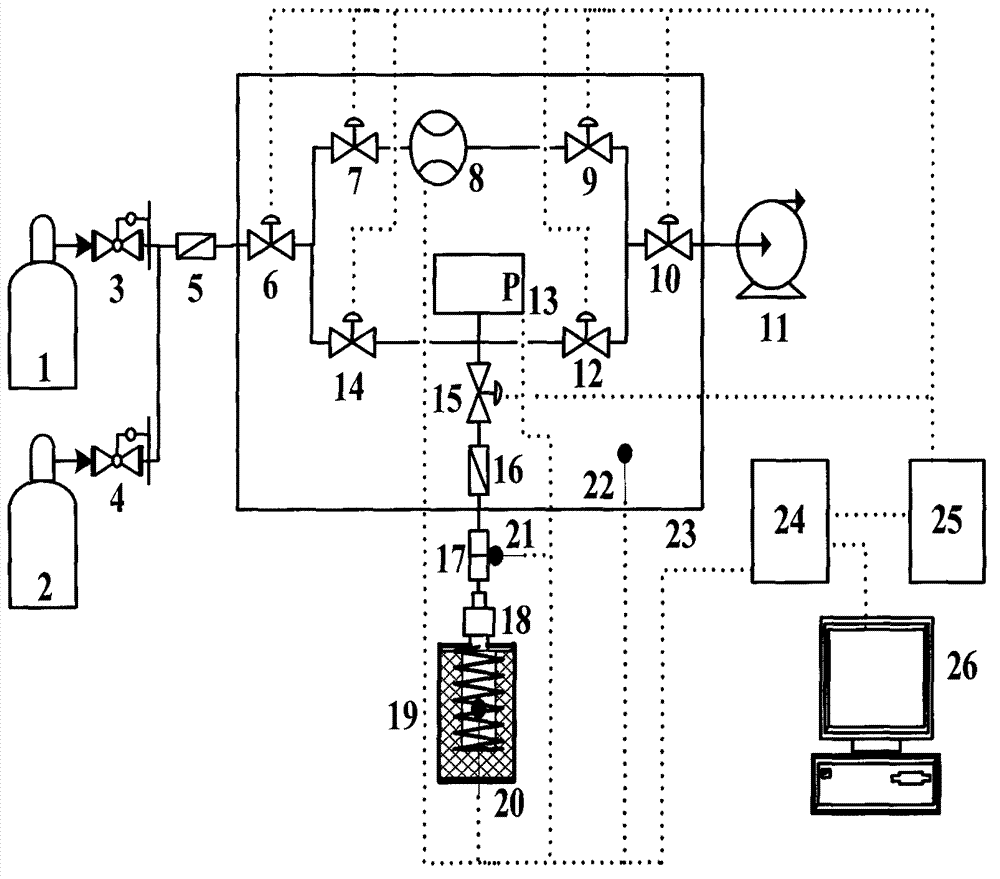

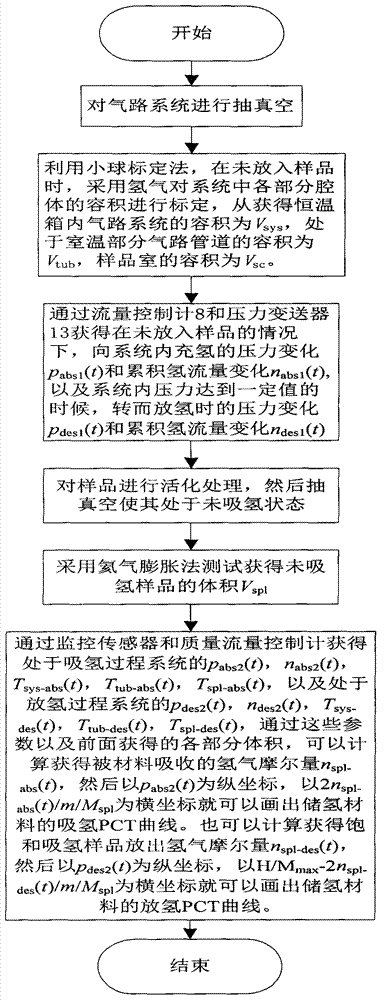

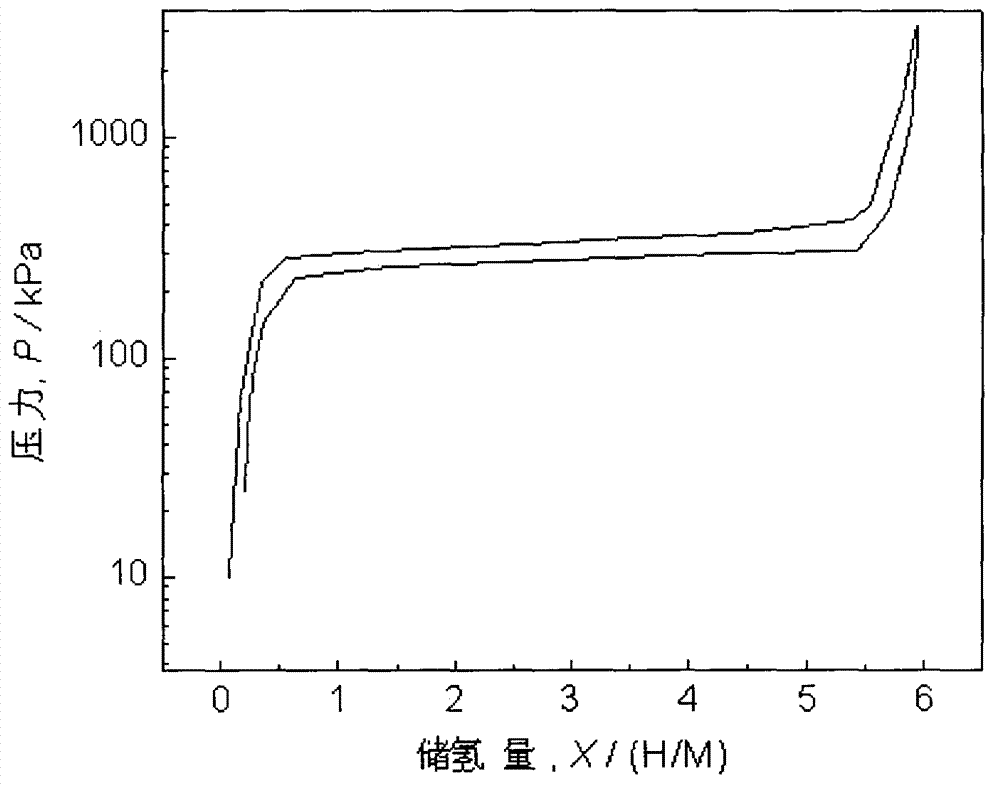

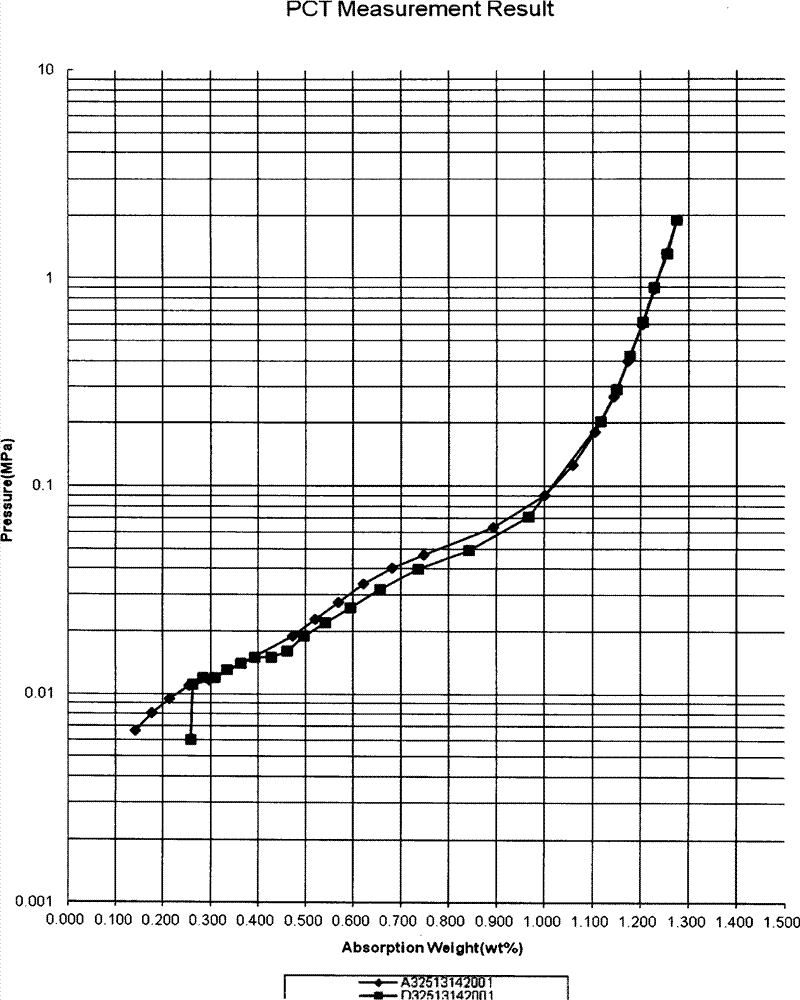

New method and testing device for characterizing PCT curve of hydrogen absorption and desorption of hydrogen storage material

InactiveCN102928315APractical structureNo complicated control operationMaterial analysisHigh pressure hydrogenData acquisition

The invention relates to a new method and a testing device for characterizing a PCT (percent) curve of hydrogen absorption and desorption of a hydrogen storage material. The testing device adopts the technical scheme that a high-pressure hydrogen cylinder and a high-pressure helium cylinder are connected with a filter by a reducing valve (3) and a reducing valve (4) and are connected with a valve (7) and a valve (14) by a valve (6) respectively; the valve (7) is connected with a mass flow control meter (8) and a valve (9); the valve (14) is connected with a pressure sensor (13) and a valve (12), is connected with a valve (10) in parallel, and is connected with a vacuum pump (11); a sample room (18) is connected with a filter (16) and a valve (15) and is connected with a gas circuit between the valve (14) and the valve (12) by a cross joint; a main body part of a testing system is placed in a thermostat (23); the sample room (18) is sheathed and connected with a heating jacket (19); a photoelectric isolation driver module (25) is connected with a data acquisition card (24); and the data acquisition card (24) is connected with a computer (26). With the adoption of the new method and the testing device, the defects such as errors, unbalance and low precision are overcome. The new method and the testing device are accurate and convenient to operate.

Owner:YANGZHOU UNIV

Filling oil-containing semi-solid composition for fibre-otpical composite overhead earth wire

A filling grease for composite fibre-optical overhead earth wire is prepared by mixing 36®|hydrogenated white oil and PAO-8 synthesized oil with PriCO-3002 polybasic alcohol ester and viscosity exponential improver Lc-212, adding into additive OB fluorescent brightening agent, grease-separating inhibitor BP2400 and G1702, raising temperature, stirring, adding into organic thickening agent gas-phase carbon white H20, raising temperature, thickening, adding into antioxidant AT-215 and inorganic thickening agent SEP1650, raising temperature, thickening, shearing, circulation feeding back, cooling to normal temperature, homogenizing, degassing, filtering and obtaining the grease. It achieves good hydrogen absorption and stable fibre-optical transmitting performance.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

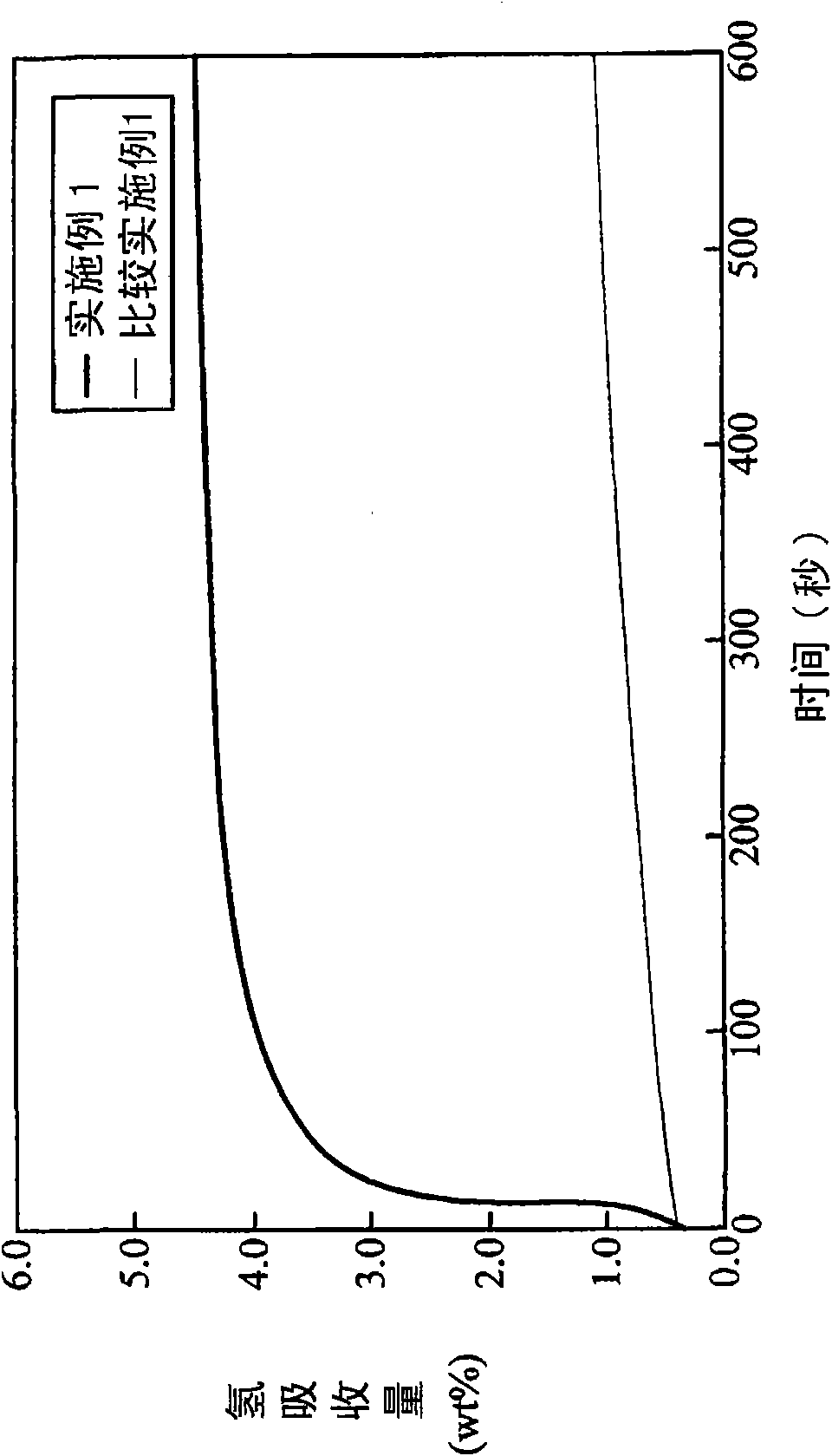

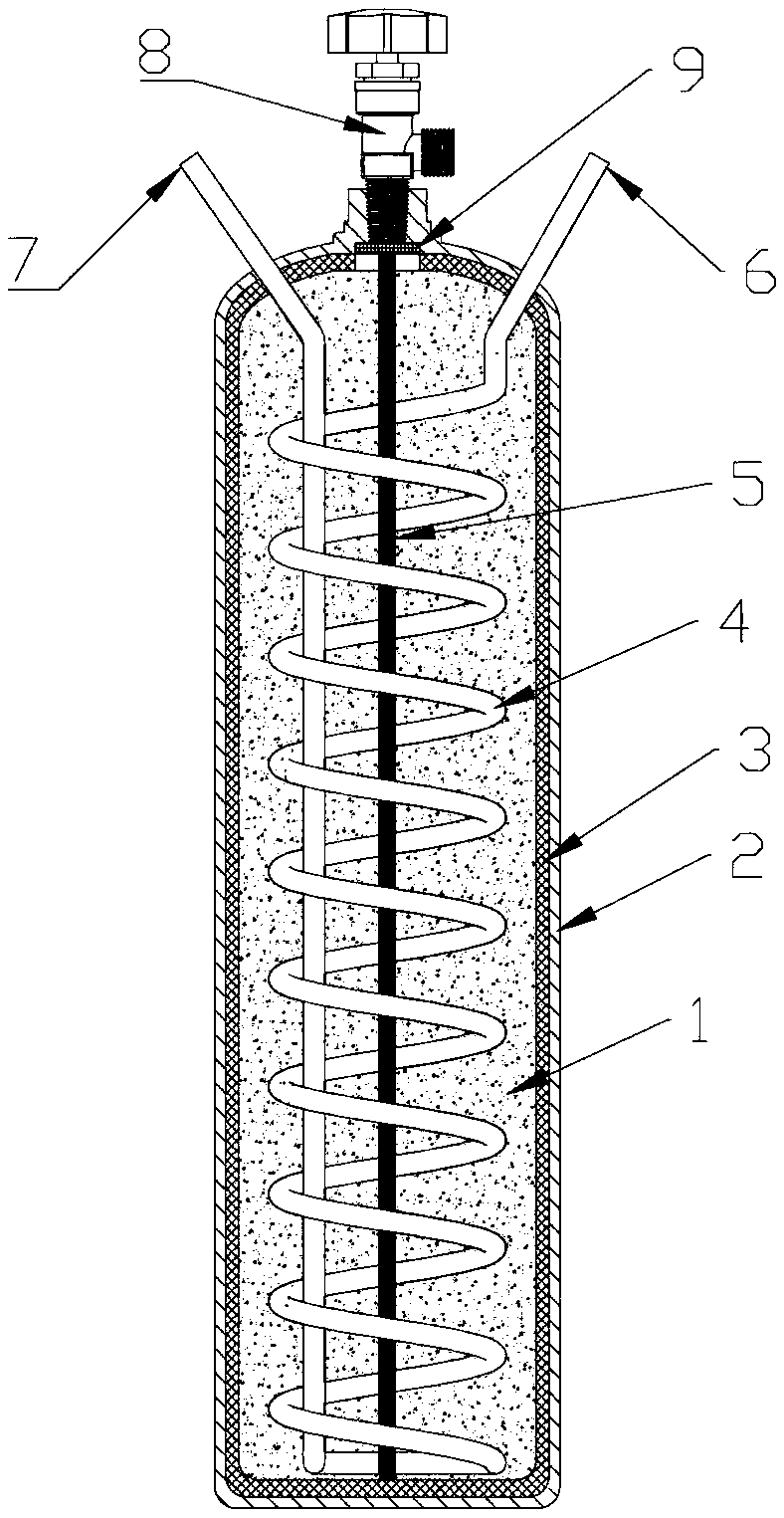

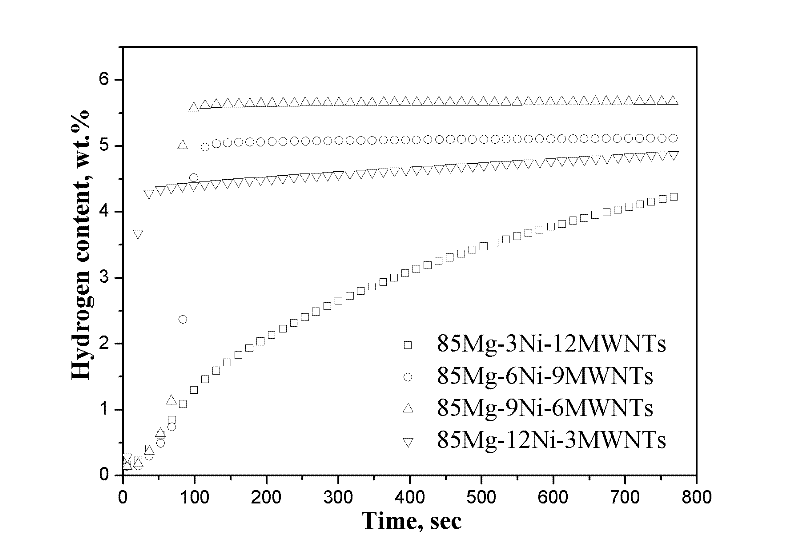

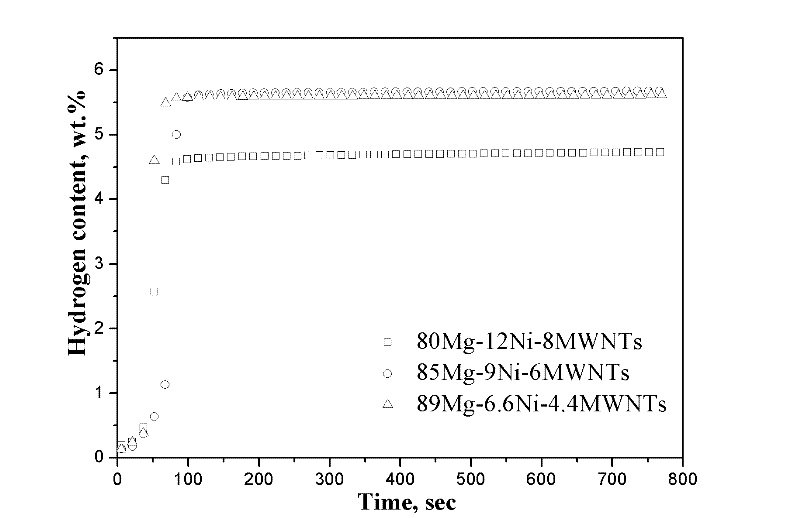

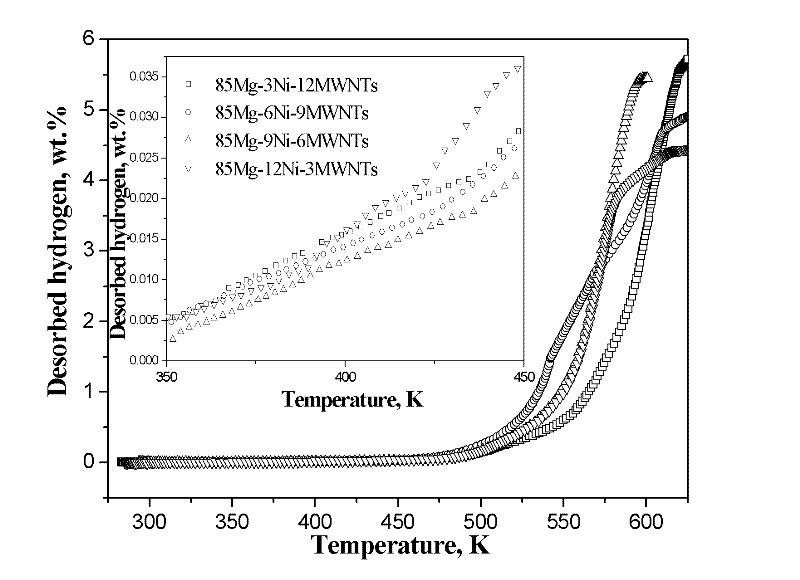

Nano-magnesium-based hydrogen storage material and preparation method thereof

The invention discloses a nano-magnesium-based hydrogen storage material and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing by adopting a chemical method to obtain various nickel-carried carbon powder; uniformly mixing magnesium powder and the nickel-carried carbon powder by using ultrasound and drying to obtain magnesium / nickel-carried carbon powder; secondly, preparing a magnesium-based hydrogen storage material from the magnesium / nickel-carried carbon powder by adopting a hydriding combustion synthesis process; and ball milling theobtained magnesium-based hydrogen storage material under the protection of hydrogen gas or argon gas atmosphere to finally obtain the nano-magnesium-based hydrogen storage material. The hydrogen absorption amount of the prepared nano-magnesium-based hydrogen storage material at the temperature of 373K within 100s reaches 5.62 percent by weight; and the initial dehydration temperature of samples is reduced below 400K. The nano-magnesium-based hydrogen storage material has excellent low-temperature hydrogen storage performance; and according to the nano-magnesium-based hydrogen storage material, the hydrogen absorption performance at low temperature is improved, the initial dehydration temperature is effectively reduced and the practical development of the magnesium-based hydrogen storage material is promoted.

Owner:NANJING UNIV OF TECH

Hydrogen sensor and method for detecting hydrogen

ActiveUS20050258051A1Reliable detectionAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationElectricityHydrogen sensor

The present invention has a hydrogen detection portion composed of a semiconductor and a hydrogen absorber provided at at least a part of a surface thereof, and pairs of electrodes provided at the semiconductor so as to sandwich the place at which the hydrogen absorber is provided and so as not to be electrically connected to each other with the hydrogen absorber, wherein the presence of hydrogen can be detected by the change in resistance of the semiconductor in response to hydrogen absorption into the hydrogen absorber, the change in resistance being measured between said pairs of electrodes.

Owner:ALPS ALPINE CO LTD +1

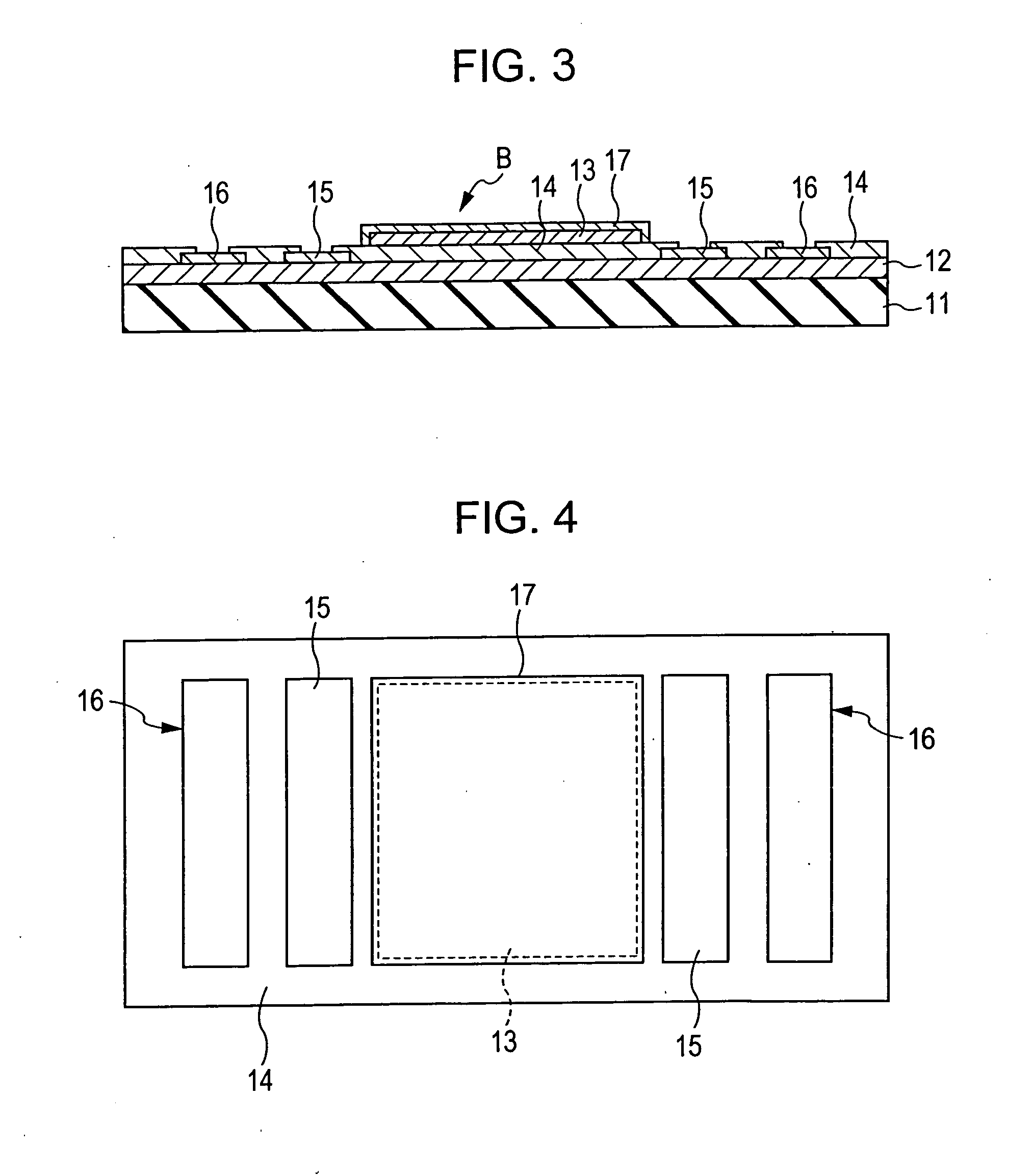

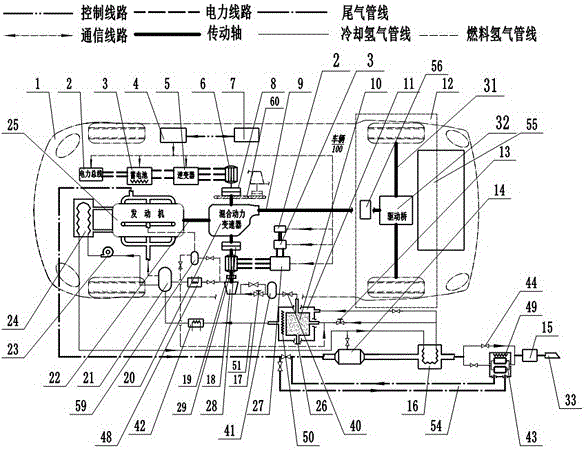

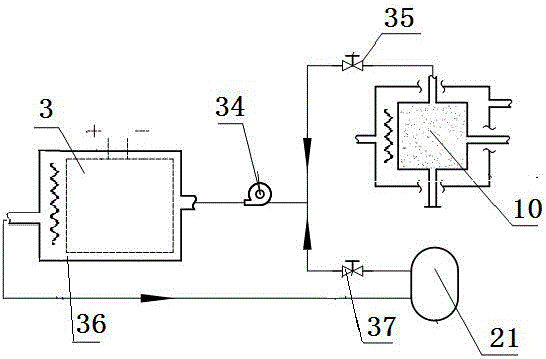

Hybrid power system with waste heat recovery function and environment air purification function and for hydrogen vehicle

ActiveCN106627090AImprove efficiencyFunction increaseHybrid vehiclesAir-treating devicesAtmospheric pollutionRecovery function

The invention relates to a hybrid power system with a waste heat recovery function and an environment air purification function and for a hydrogen vehicle. The hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle comprises a vehicle body, a transmission system, a hydrogen fuel engine, a hybrid power transmission, a metal hydride storage tank, a turbine, a catalyst, a high-pressure surge tank, a hydrogen buffering tank and the like. The metal hydride storage tank is connected to an inlet of the turbine through the high-pressure surge tank. An outlet of the turbine is connected to an inlet of the hydrogen fuel engine through the hydrogen buffering tank or a high-pressure hydrogen buffering tank. An outlet of the hydrogen fuel engine is connected to a discharge outlet through the catalyst, a tail gas heat exchanger, a residual hydrogen absorption unit and a tail gas zero-stage purifier. The hydrogen fuel engine is connected with the hybrid power transmission through a power output shaft. According to the hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle, the hydrogen fuel engine, the turbine and an exhaust gas waste heat recovery and purification system are combined to form the hybrid power system for the automobile, chemical energy of hydrogen is sufficiently used, various kinds of heat energy in the process is recovered, and the working efficiency of the power system is improved; and atmospheric pollution is avoided, the environment air is purified, and protection of the natural environment is facilitated.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Hydrogen storage alloy, hydrogen separation membrane, hydrogen storage tank, and hydrogen absorption and desorption method

A hydrogen storage alloy includes a composition defined by the following formula (Ca1-XLX)(Li1-Y-ZMYNiZ)m, wherein the L denotes one or more elements selected from the group consisting of Na, K, Rb, Cs, Mg, Sr, Ba, Sc, Ti, Zr, Hf, V, Nb, Ta, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu, the M denotes one or more elements selected from the group consisting of Cr, Mo, W, Mn, Fe, Ru, Co, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, B, Al, Ga, In, Si, Ge, Sn, Pb, Sb, Bi, and S, and the mole ratios X, Y, Z, and m respectively satisfy the following 0<X≦0.4, 0≦Y≦0.4, 0.1≦Z≦0.4, and 1.8≦m≦2.2.

Owner:KK TOSHIBA

Rare earth permanent magnetic powder and preparation method thereof

ActiveCN101552060AEasy to oxidizeImprove performanceInorganic material magnetismDehydrogenationRare earth

The invention discloses a rare earth permanent magnetic powder and a preparation method thereof. The magnetic powder is a multi-crystal powder containing columnar crystal and comprises the following component of R-T-B, wherein the R represents at least one kind of 17 kinds of elements including Sc and Y and accounts for 26.1-37.0 wt percent, the B represents at least boron or hydrogen and accounts for 0.8-1.5 wt percent, and the balance is T, and the T represents Fe and at least one kind of other transitional elements including Al, Ga, Si, Ge, Sn, Pb, Mg and Ca. The magnetic powder has high proportion of the column crystal, uniform particle size distribution and low oxygen content, and the prepared sintered permanent neodymium-iron-boron magnet has large coercive force and high magnetic energy product. The preparation method of the rare earth permanent magnetic powder comprises the following steps of precursor alloy preparation, hydrogen absorption or precursor alloy preparation, hydrogen absorption and dehydrogenation.

Owner:GRIREM ADVANCED MATERIALS CO LTD

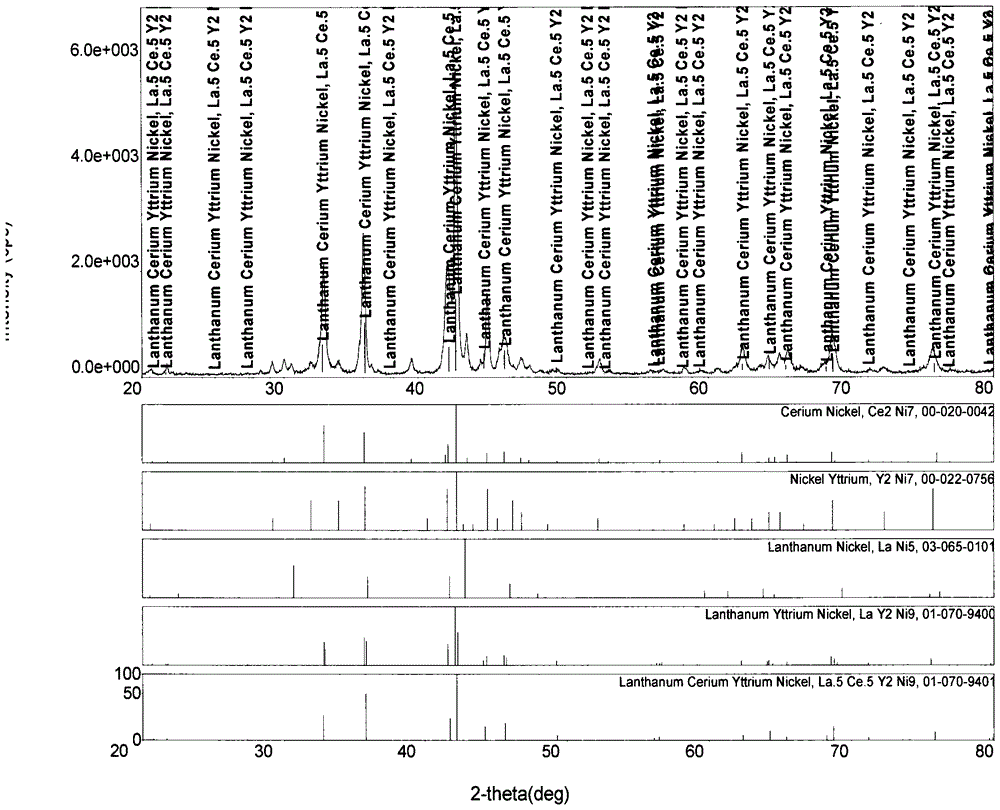

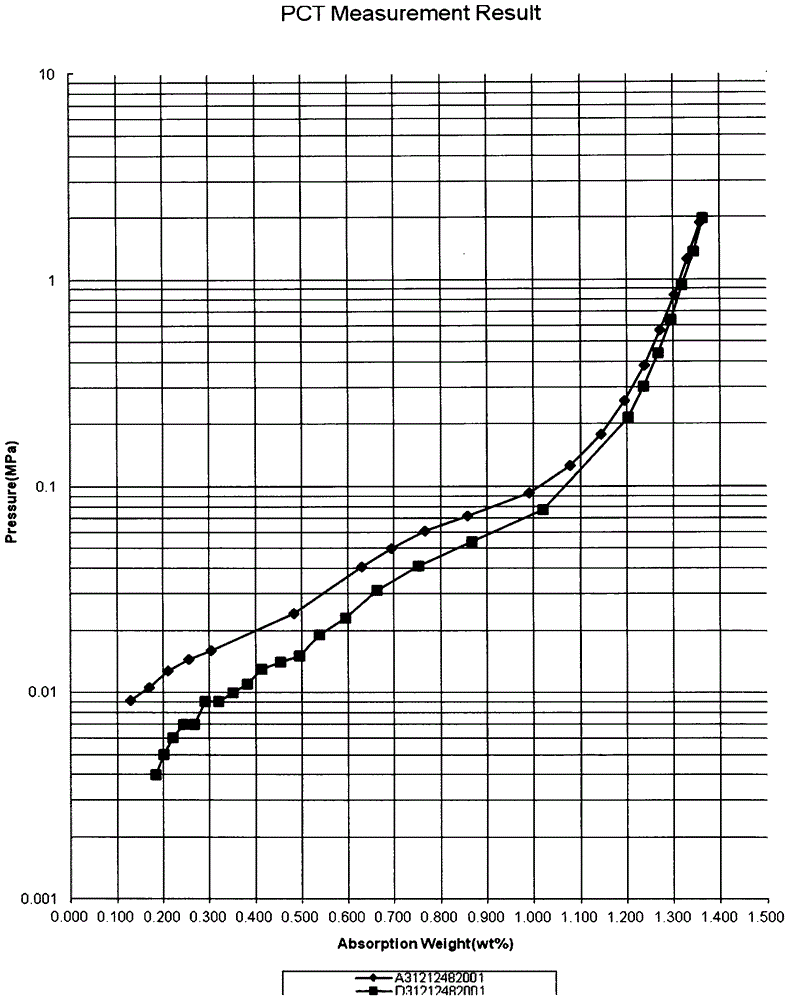

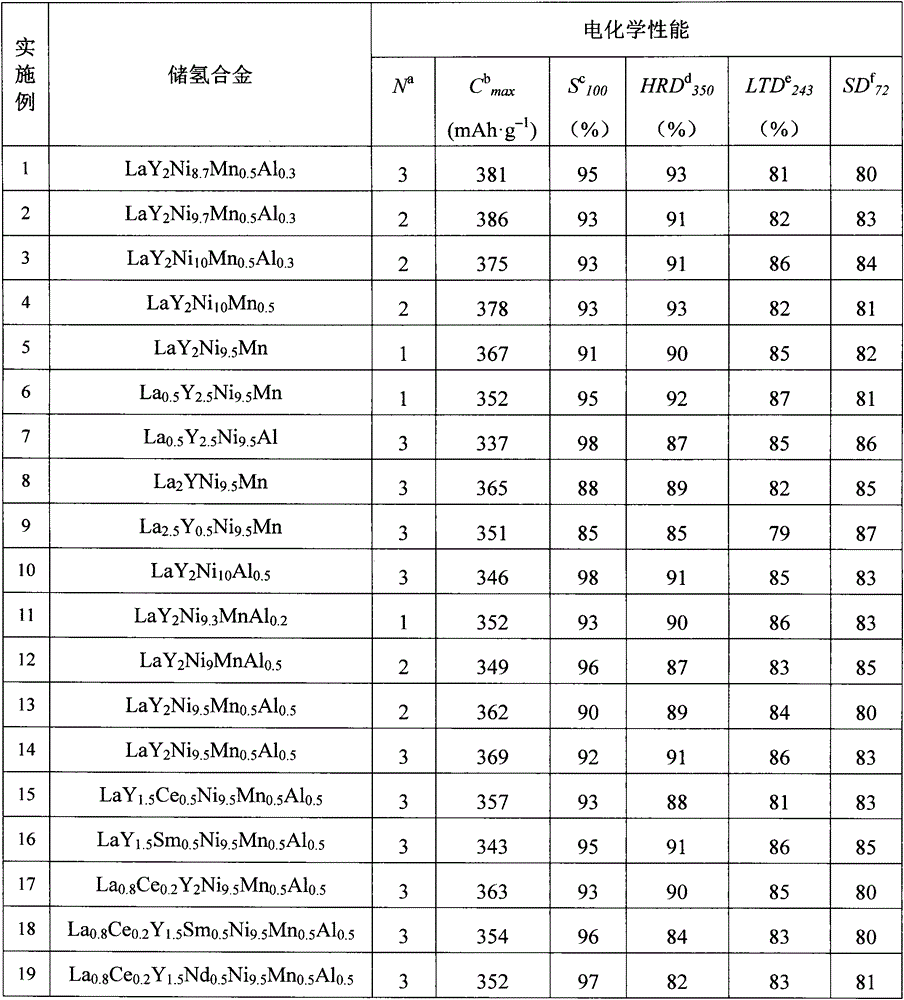

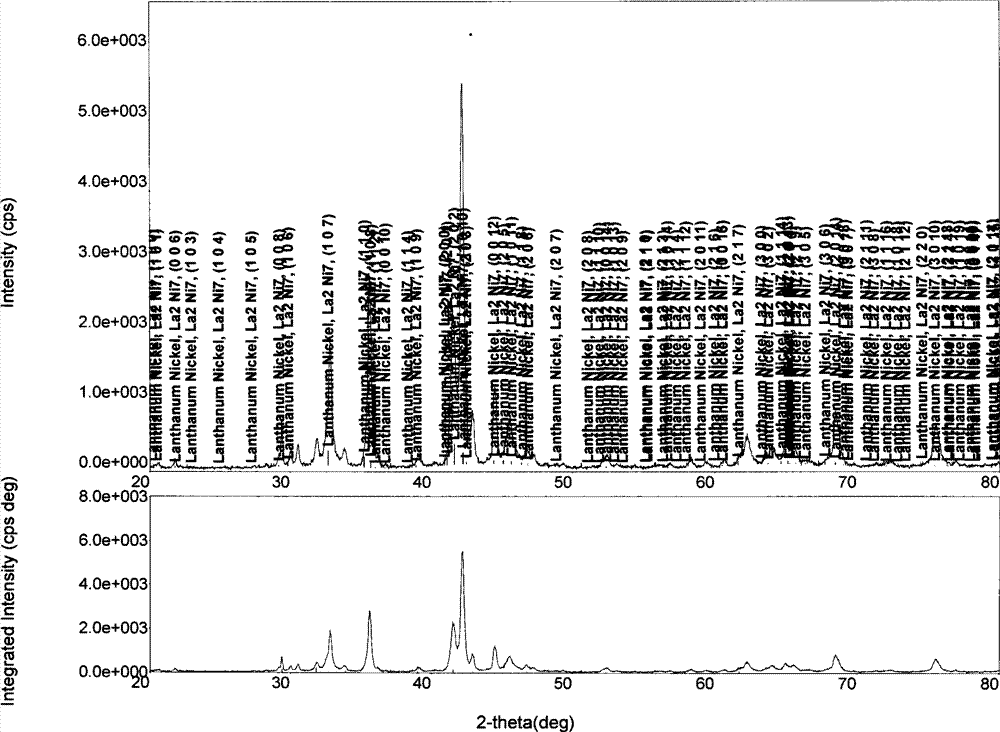

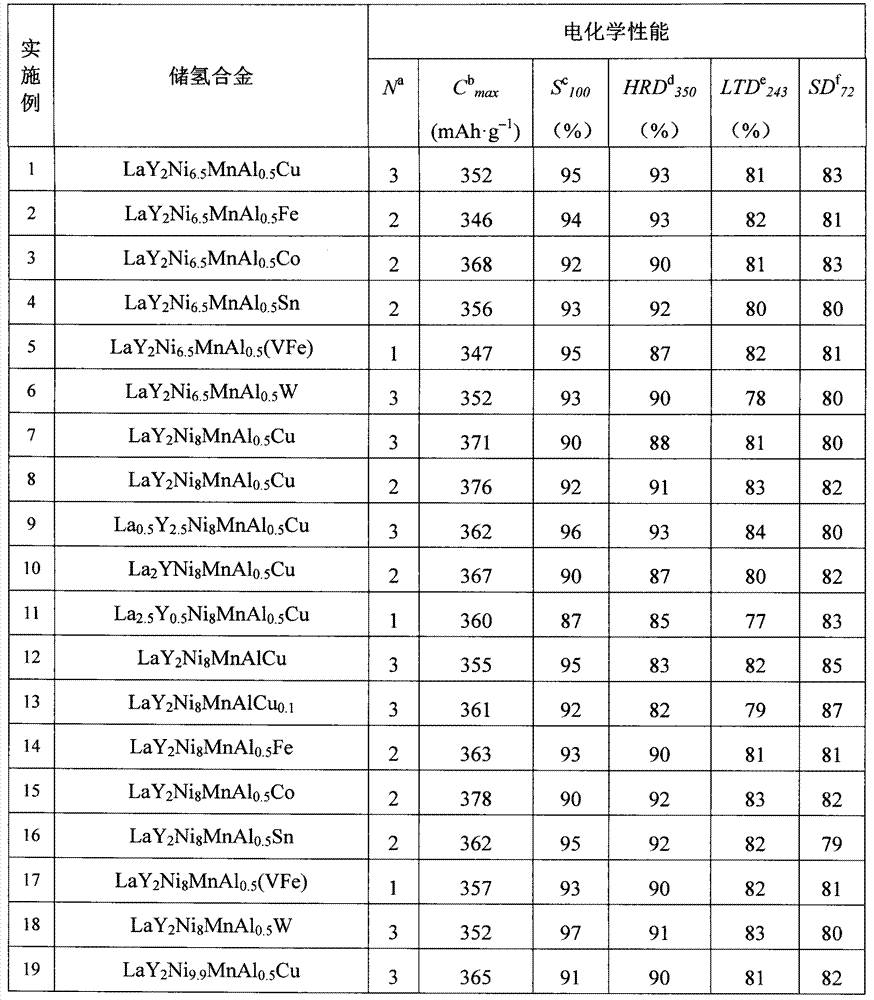

Yttrium-nickel rare earth-based hydrogen storage alloy

ActiveCN104532095AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesGas phaseRare earth

The invention relates to A2B7 type RExYnNiz-a-bMnaAlb hydrogen storage alloy. The alloy is good in pressure-composition-isothermality, and has a maximum hydrogen storage amount of up to more than 1.36 wt.% under usual conditions. The alloy of the invention has better electrochemical performance as a hydrogen storage electrode and better gas-phase hydrogen absorption and desorption performance as a hydrogen storage material than traditional LaNi5 type hydrogen storage alloy; the alloy contains no magnesium element in the composition, so the preparation method of the alloy is simple and safe when compared with that of traditional rare earth-magnesium-nickel-based A2B7 type hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

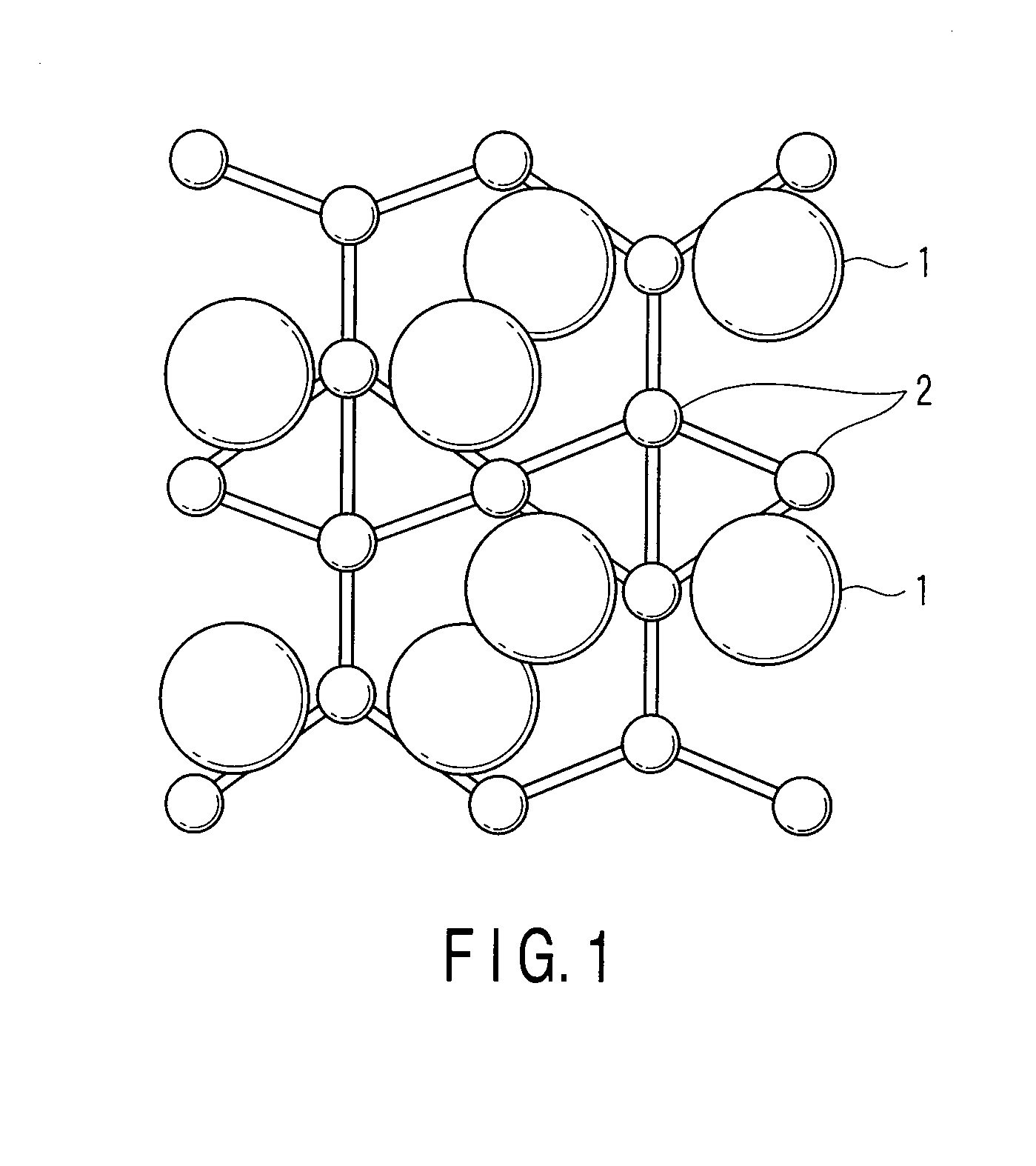

Hydrogen-absorbing alloy

InactiveUS6258184B1Excellent hydrogen absorptionExcellent desorption characteristicHydrogenCell electrodesFine structureLattice constant

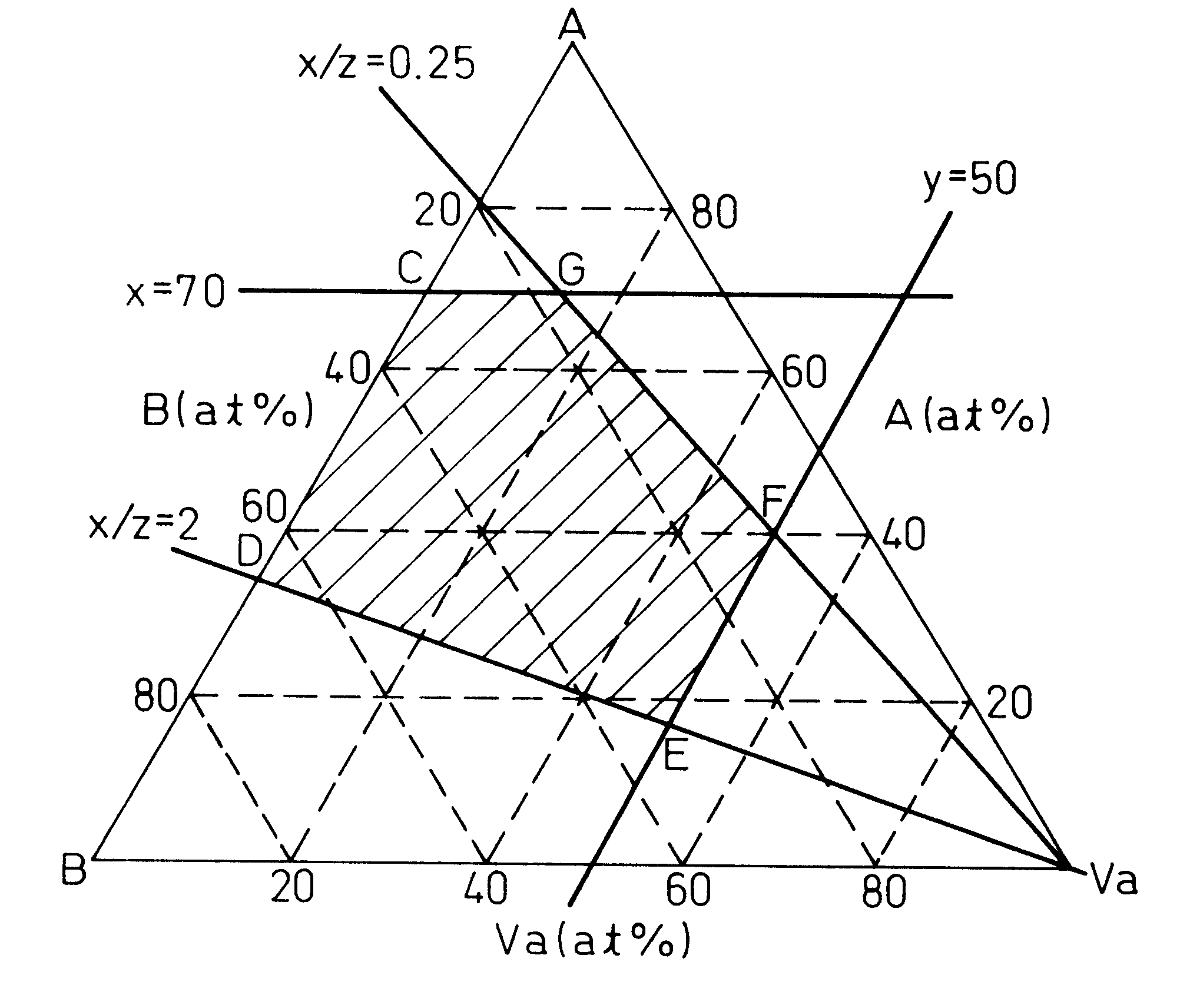

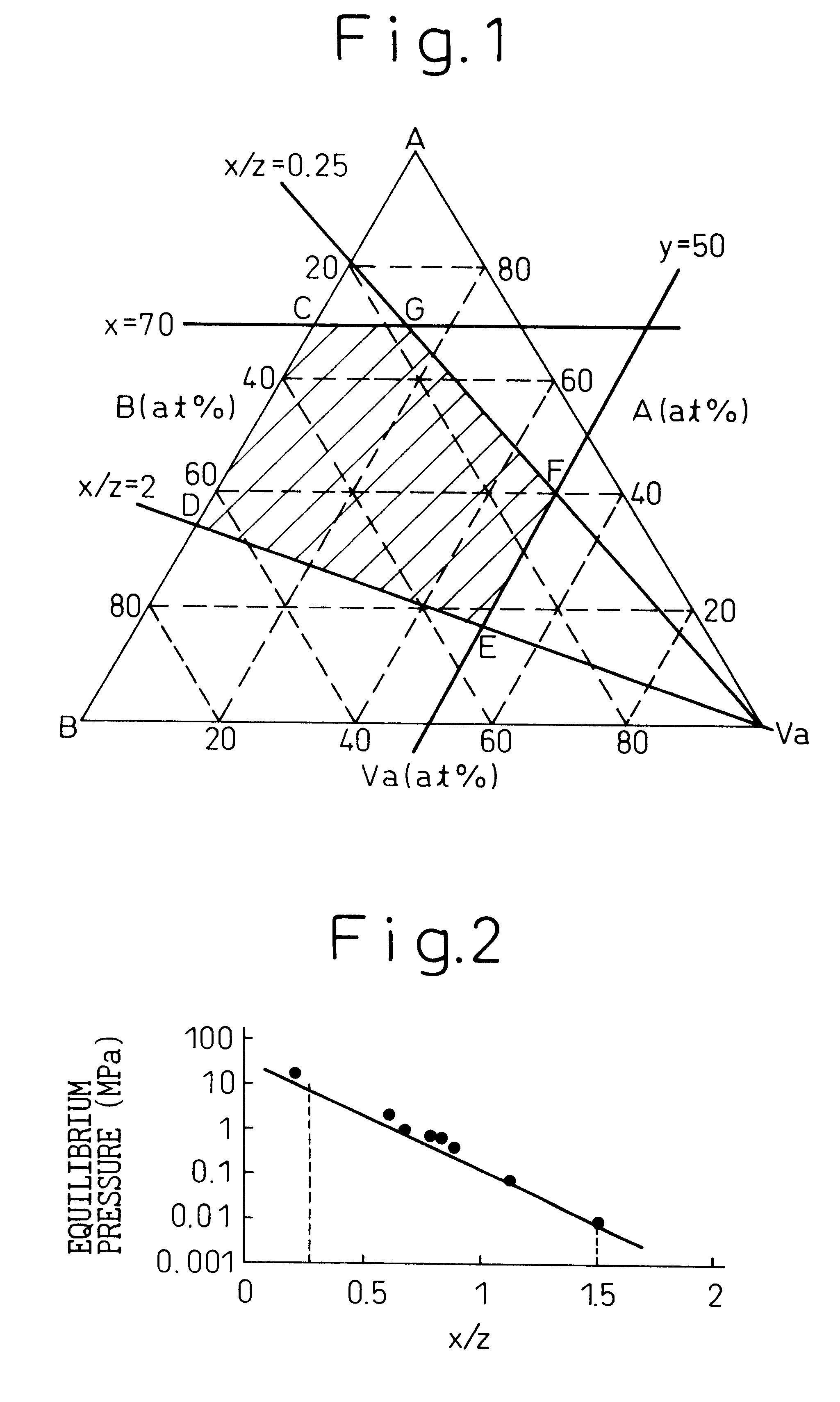

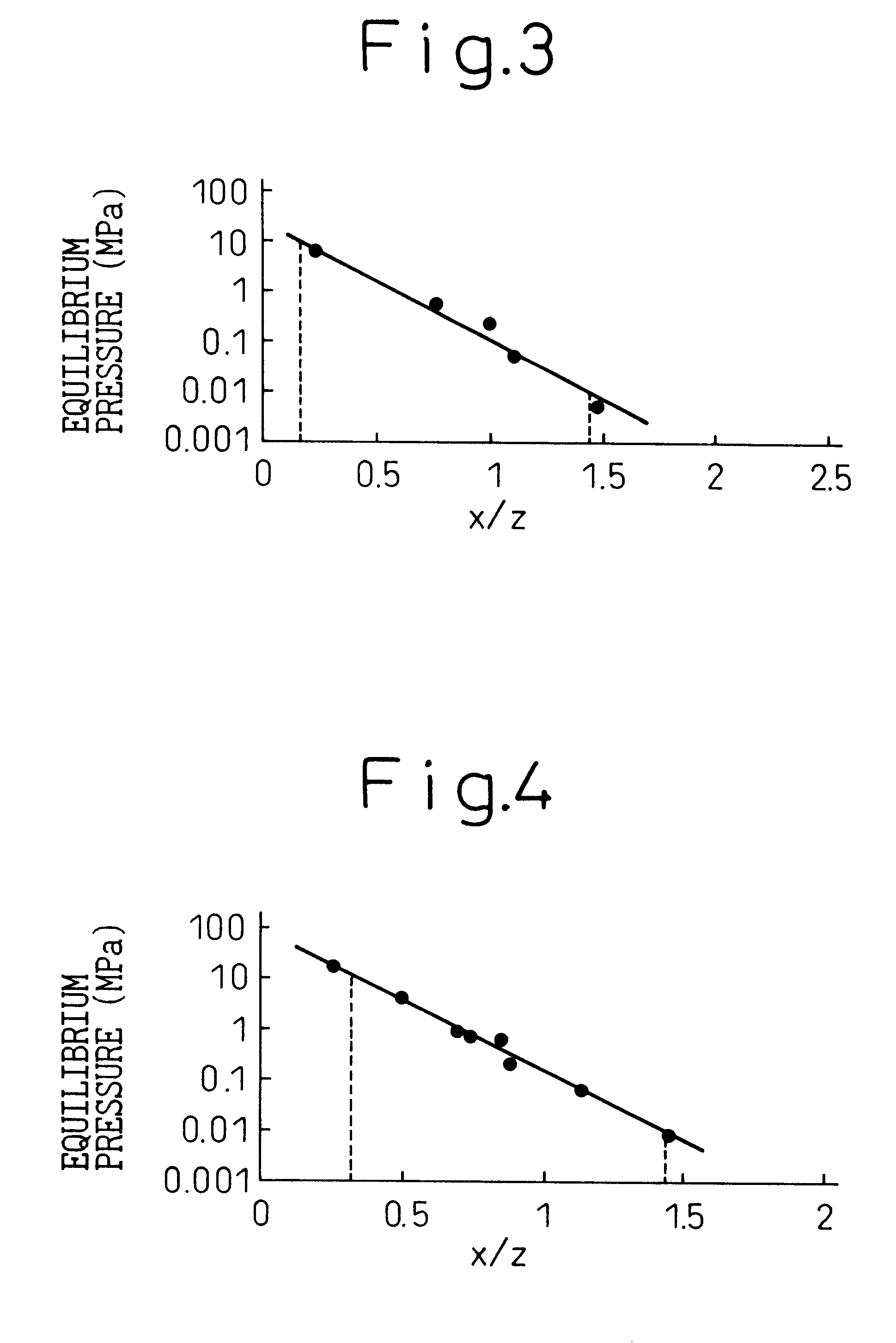

A BCC type hydrogen-absorbing alloy, which uses a ferroalloy, is advantageous from the aspect of the production cost and exhibits excellent hydrogen absorption and desorption characteristics due to a fine structure constituted by spinodal decomposition even when the iron component is increased. The hydrogen-absorbing alloy is expressed by the general formula AxVayBz, where A is at least one of Ti and Zr, Va is at least one member of the Group Va elements of the Periodic Table consisting of V, Nb and Ta, and B contains at least Fe and is at least one member selected from the group consisting of Cr, Mn, Co, Ni, Cu, Al, Mo and W, each of x, y and z satisfies the relation, in terms of of the atomic number ratio, 0<=x<=70, 0<=y<=50, x+y+z=100, and x / z=0.25 to 2.0, the phase of the body-centered cubic structure is at least 50% in terms of the phase fraction and its lattice constant is at least 0.2950 nm but not greater than 0.3100 nm.

Owner:TOYOTA JIDOSHA KK

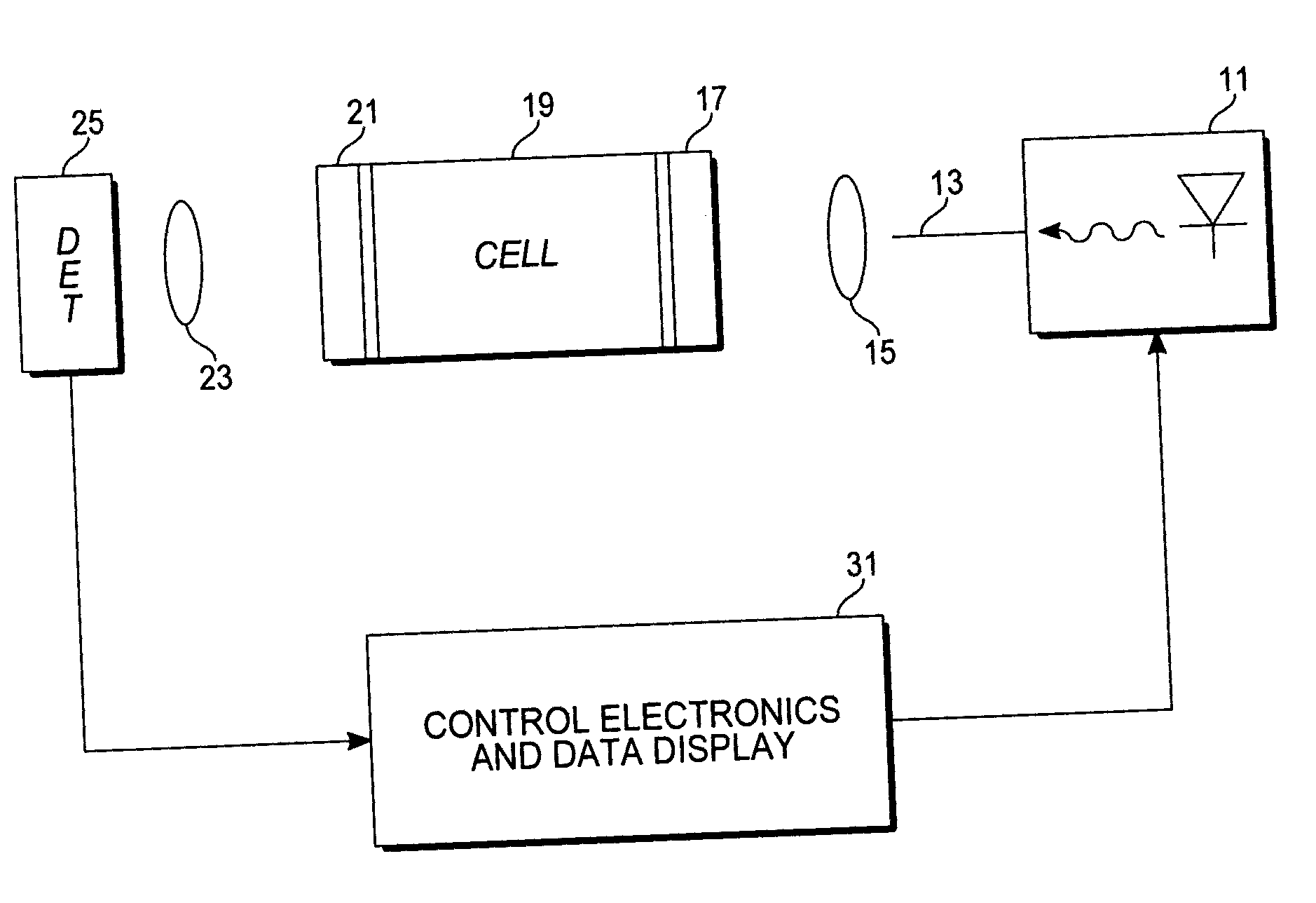

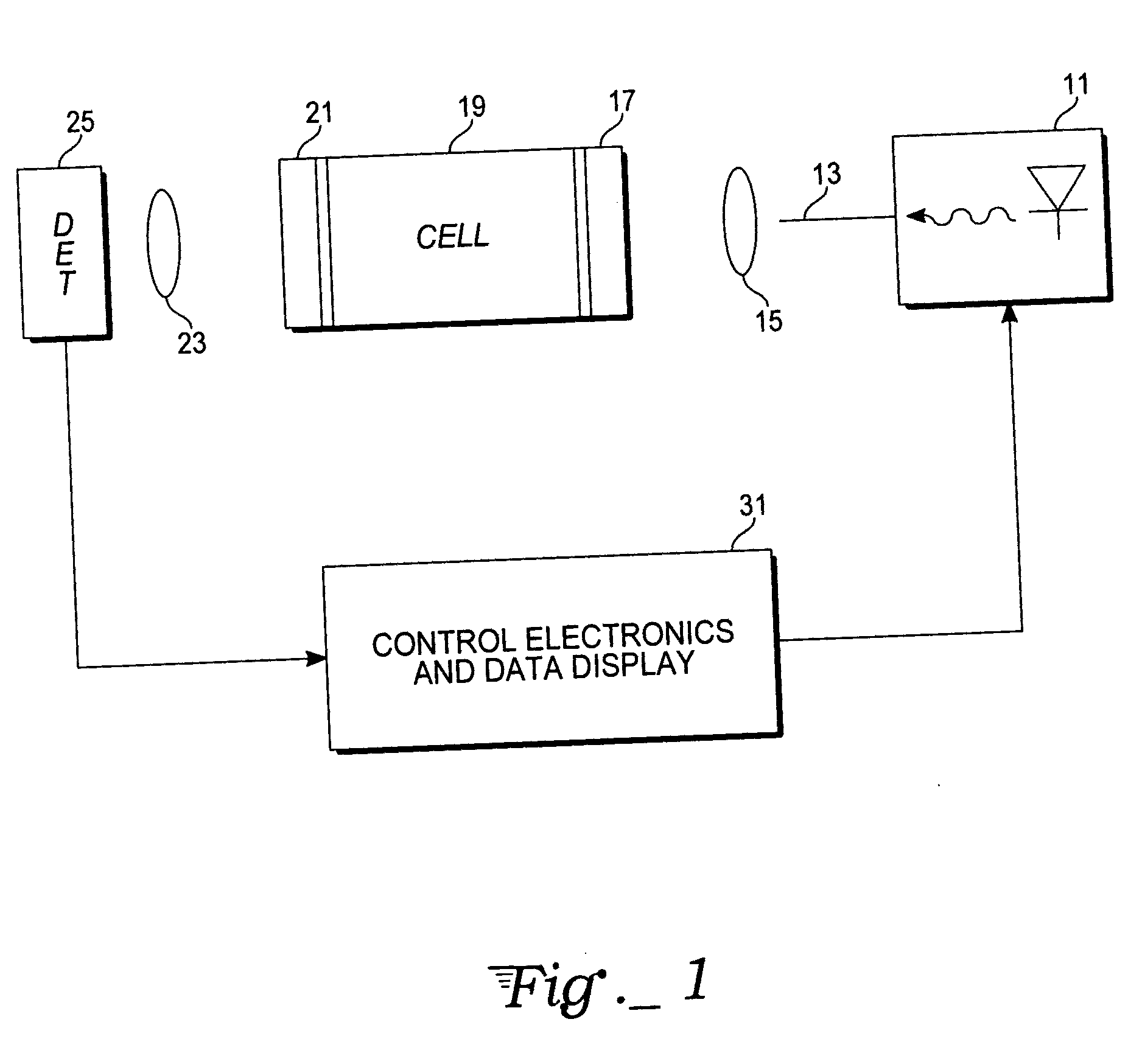

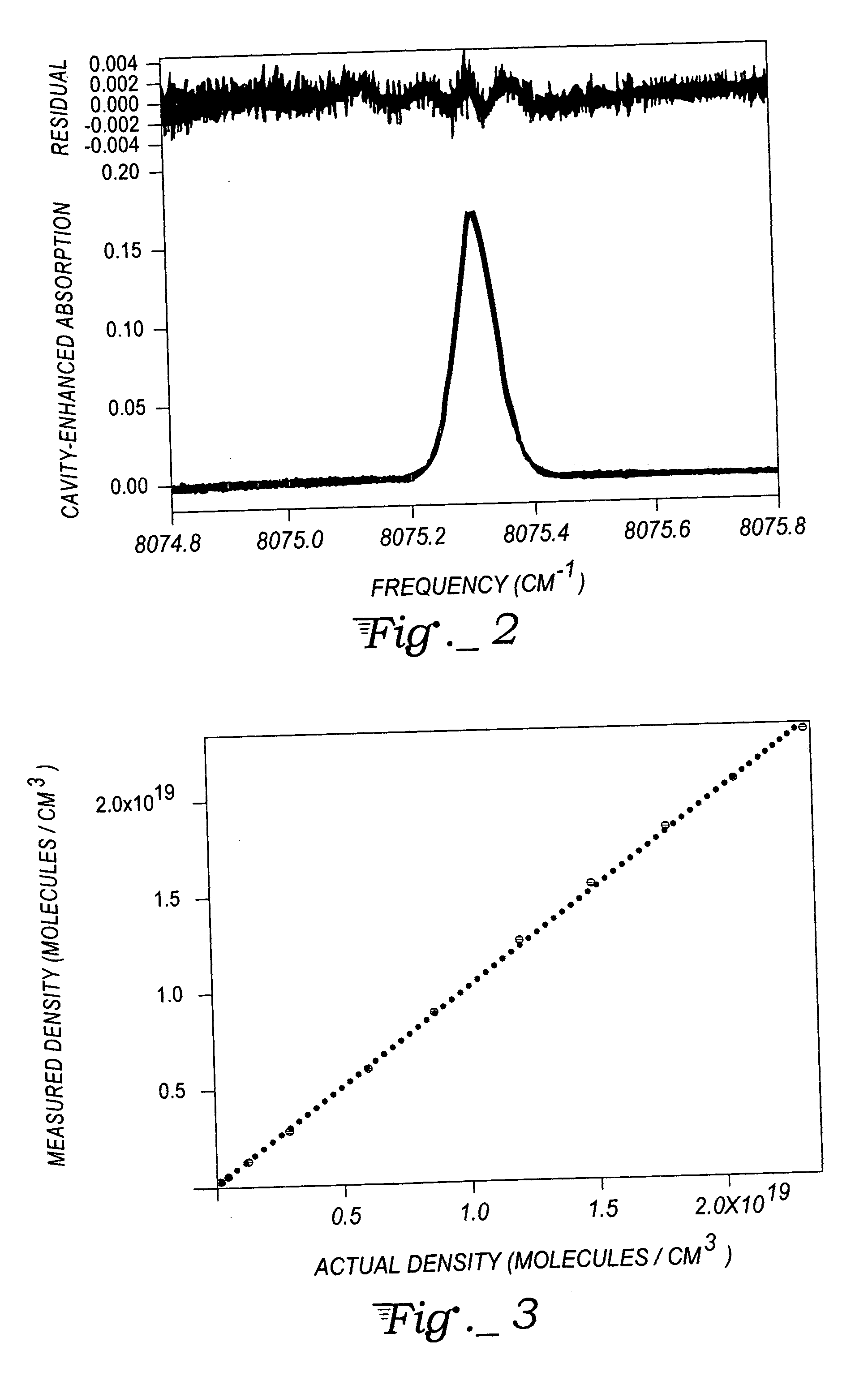

Hydrogen sensor based upon quadrupole absorption spectroscopy

ActiveUS20070076209A1Increasing effective path lengthIncrease the lengthRadiation pyrometryInterferometric spectrometryCavity resonanceHydrogen molecule

The disclosure describes an absorption spectroscopy method for sensing hydrogen gas in a sample atmosphere and an associated hydrogen sensor. A light beam, having a wavelength corresponding to a vibrational transition of hydrogen molecules from a ground vibration state to any excited rotational vibration state via a quadrupole interaction, is introduced into an optical cavity adapted to receive a sample atmosphere to be tested for the presence of hydrogen gas. The light is introduced into the cavity in an off-axis alignment to systematically eliminate cavity resonances, while preserving the absorption signal amplifying properties of such cavities. Hydrogen absorption is measured is terms of cavity output, as in the ICOS technique.

Owner:LOS GATOS RES

Method for preparing lignin-based carbon fiber hydrogen storage material by electrostatic spinning process

ActiveCN104947246AWide variety of sourcesLow priceFilament/thread formingFibre chemical featuresAir atmosphereMicro nano

The invention relates to a method for preparing a hydrogen storage material, and particularly relates to a method for preparing a lignin-based carbon fiber hydrogen storage material by electrostatic spinning. The method comprises the following steps: preparing a sodium lignin sulfonate / polyacrylonitrile / nickel acetate / boric acid spinning solution; preparing sodium lignin sulfonate / polyacrylonitrile composite micro-nano fiber through electrostatic spinning; drying in a vacuum drying oven and pre-oxidizing in an air atmosphere in a muffle furnace; and gradually heating and calcining in a condition of continuously introducing an inert gas into the tubular furnace to obtain sodium lignin sulfonate / polyacrylonitrile composite carbon fiber containing a Ni-B catalyst, wherein Ni-B realizes an effect of catalytic graphitization. The prepared sodium lignin sulfonate / polyacrylonitrile composite carbon fiber has relatively high graphitization degree, and the hydrogen absorption capacity under the conditions of 298K and 95bar reaches 0.92wt% within 60s.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

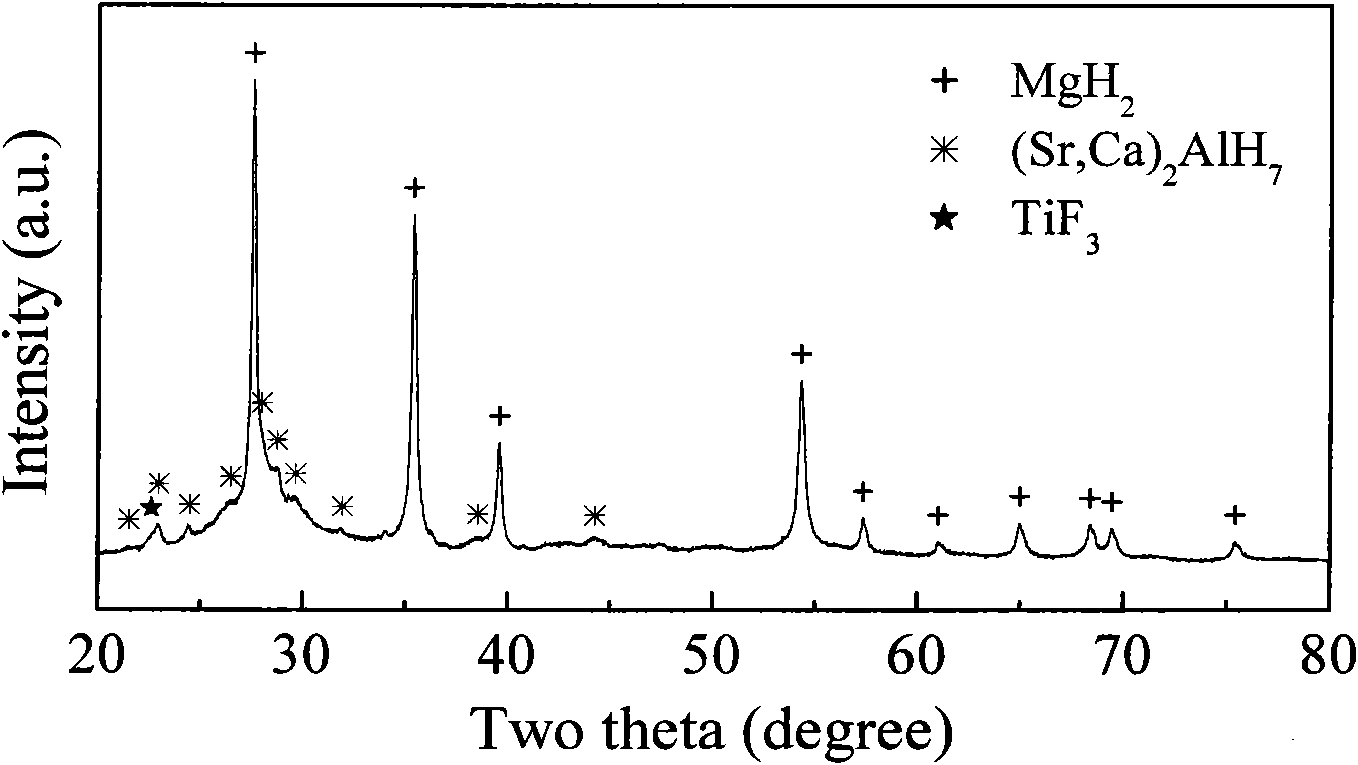

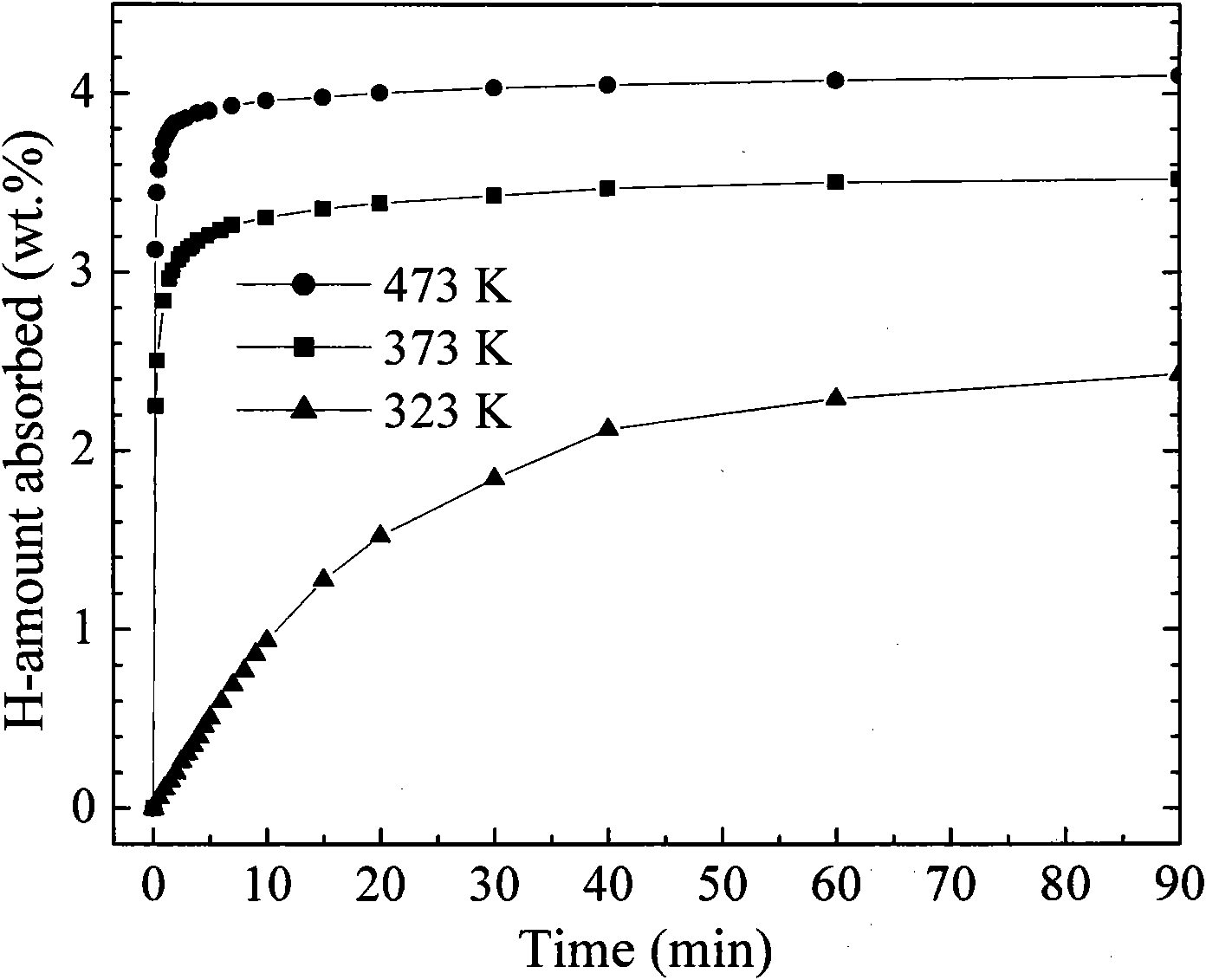

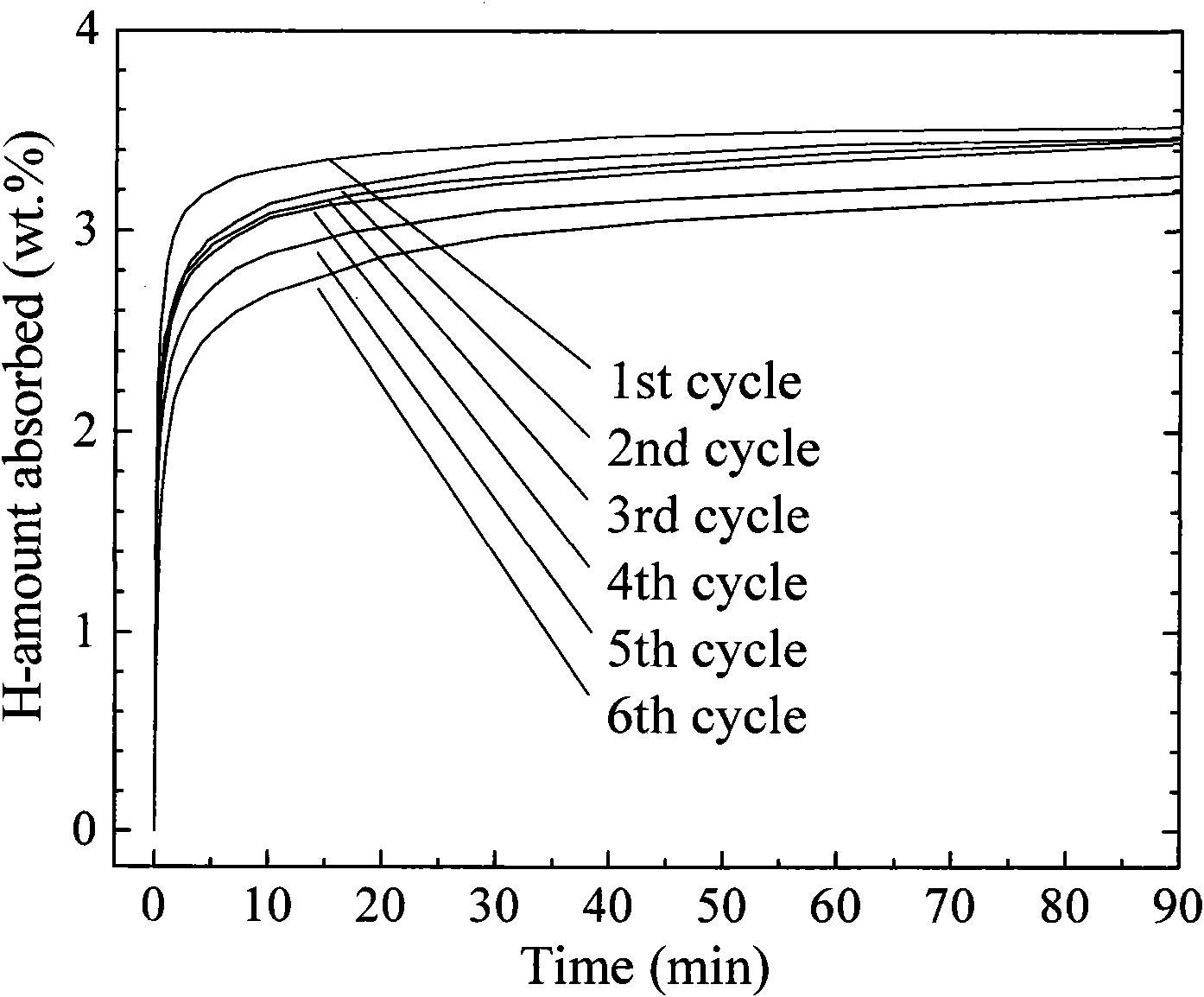

Mg-based composite hydrogen storage material containing alkaline earth metals-aluminum hydride and preparation method thereof

InactiveCN101549854AImprove hydrogen storage performanceHigh hydrogen storage capacityHydrogen productionAlkaline earth metalHydrogen fuel cell

The invention provides an Mg-based composite hydrogen storage material containing alkaline earth metals-aluminum hydride and a preparation method thereof, which belongs to the technical field of hydrogen storage material. The chemical general formula of the hydrogen storage material is MgH2+x wt.%(Sr1-yCay)2AlH7+z wt.%TiF3, wherein x is more than or equal to 30 and less than or equal to 50, y is more than or equal to 0 and less than or equal to 0.5, and z is more than or equal to 2 and less than or equal to 10. The hydrogen storage material is gained by mechanically ball milling three materials powder of MgH2, (Sr, Ca)2AlH7 and TiF3, a planetary ball mill is adopted when ball milling, the ball material ratio is 15:1 to 20:1, the rotational speed is 350 to 400rpm, the ball milling time is 10 to 20h, the ball milling protecting atmosphere is argon gas or hydrogen gas, and the atmosphere pressure is 1 to 5atm. The invention has the advantages that: the preparation technique is simple, the provided composite hydrogen storage materials do not need to be activated, and have high hydrogen storage capacity, simultaneously have good low temperature hydrogen absorption dynamic performance and high hydrogen absorption and desorption cycling stability. The invention is applicable to the safe and efficient storage and transportation of the hydrogen, especially the hydrogen fuel cells and other fields.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

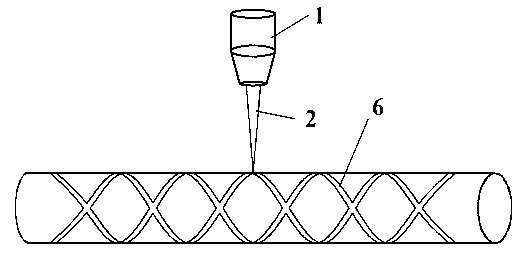

Fiber bragg grating hydrogen sensor based on femtosecond laser micromachining and preparation method for fiber bragg grating hydrogen sensor

InactiveCN103175784AImprove the pulling effectImprove bindingCladded optical fibreMaterial analysis by optical meansMicro structureFiber

The invention discloses a fiber bragg grating hydrogen sensor based on femtosecond laser micromachining and a preparation method for the fiber bragg grating hydrogen sensor. The method comprises the following steps of: preparing a straight slot array or an intersected helical slot three-dimensional micro structure on a fiber bragg grating wrapping layer through femtosecond laser, and plating a palladium alloy film, wherein the sensitivity of the sensor is greatly improved, and the service life of a thin film is prolonged. The fiber bragg grating hydrogen sensor is characterized in that a femtosecond laser micromachining technology is introduced; by a clamp, irregular micro pits are obtained by quickly scanning the wrapping layer; and the three-dimensional micro structure is prepared inside the grating wrapping layer. After the fiber bragg grating with the micro structure is plated with the film, a hydrogen absorption surface area is enlarged, and the axial direction of an optical fiber is softened; the grating wavelength drift is greatly improved by hydrogen absorption expanding strain; and therefore, the measuring precision is improved, and the measuring range is expanded. By the grating wrapping layer plated film with the surface micro pits and the bent three-dimensional micro structure, the adhesive force of the thin film can be greatly improved, and the service life of the thin film is prolonged. The sensor has the advantages of high sensitivity, wide measuring range, long service life and the like, and is suitable for remote monitoring.

Owner:WUHAN UNIV OF TECH

Rare earth-yttrium-nickel family hydrogen storage alloy, and secondary battery containing hydrogen storage alloy

ActiveCN104518204AIncrease capacityThe manufacturing method is simple and safeAlkaline accumulator electrodesNickel accumulatorsAlkaline earth metalRare earth

The invention relates to a rare earth family hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMc. The alloy treats the rare earth Y as one of main components, contains Mn and Al elements or one of Mn and Al, also contains one or more of Cu, Fe, Co, Sn, V and W, contains no alkali earth metals, and is simple and safe to produce. The hydrogen storage alloy has a good compression-composition-isothermal characteristic and a large hydrogen storage amount reaching above 1.28wt% under usual conditions; the highest capacity of the above hydrogen storage alloy electrode is higher than that of LaNi5 type hydrogen storage alloy; and the rare earth family hydrogen storage alloy has good activation performances, rate discharge ability, and charge and discharge or hydrogen absorption and desorption cycle stability, can be used in a wide temperature range, and has small self discharge.

Owner:BAOTOU RES INST OF RARE EARTHS +2

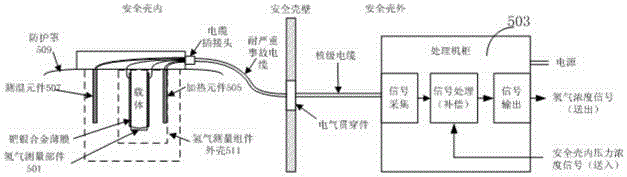

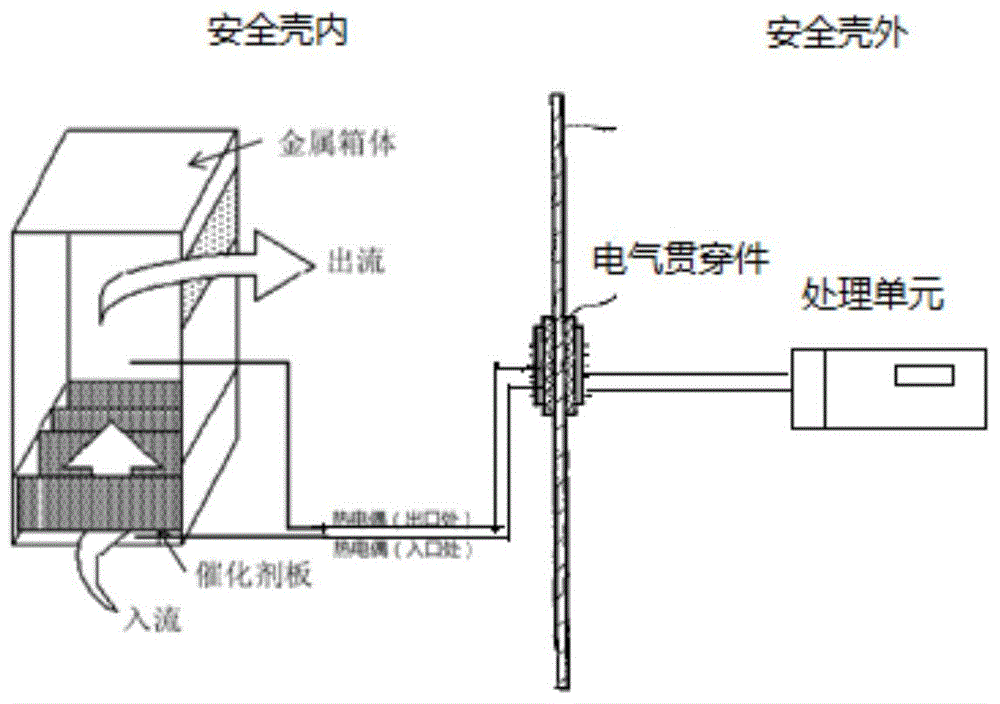

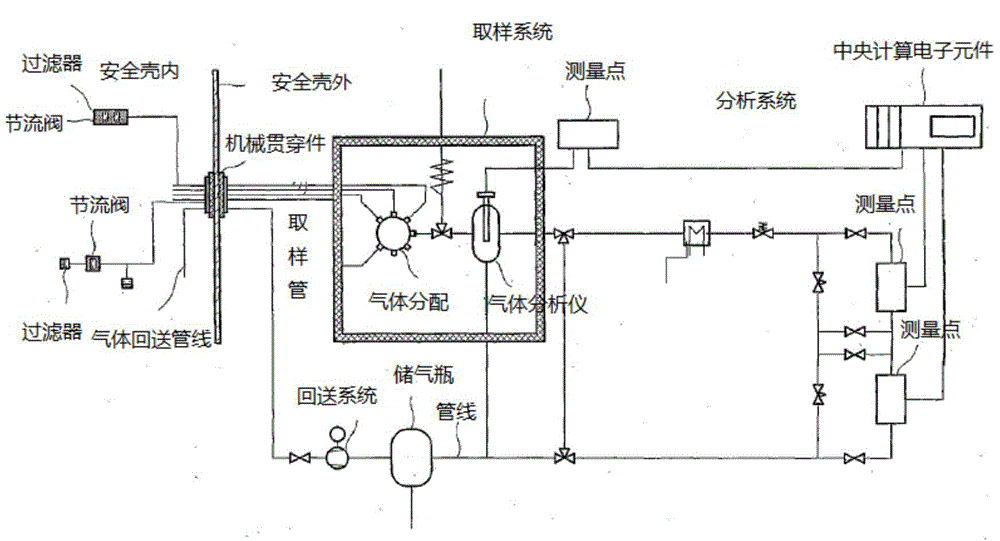

Method, device and system for measuring concentration of hydrogen in nuclear power station containment vessel

InactiveCN104538070ARealize measurementAvoid influenceNuclear energy generationNuclear monitoringNuclear powerNuclear engineering

The invention discloses a method for measuring a concentration of hydrogen in a nuclear power station containment vessel. The method comprises that a hydrogen measurement part plated with a palladium-silver alloy membrane is arranged in a nuclear power station containment vessel, a processor cabinet acquires a conductivity signal of the hydrogen measurement part after hydrogen absorption and release, and the processor cabinet determines a concentration of hydrogen in the nuclear power station containment vessel according the acquired conductivity signal and a signal of pressure in the nuclear power station containment vessel. The method for measuring a concentration of hydrogen in a nuclear power station containment vessel can realize safe and accurate measurement of a concentration of hydrogen in the nuclear power station containment vessel. The invention also discloses a device and system for measuring a concentration of hydrogen in a nuclear power station containment vessel.

Owner:中广核工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com