Patents

Literature

247results about How to "Improve hydrogen storage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen storage in carbon material

InactiveUS6290753B1Reduce weightEasy to useMaterial nanotechnologyHydrogenPhysical chemistryProduct gas

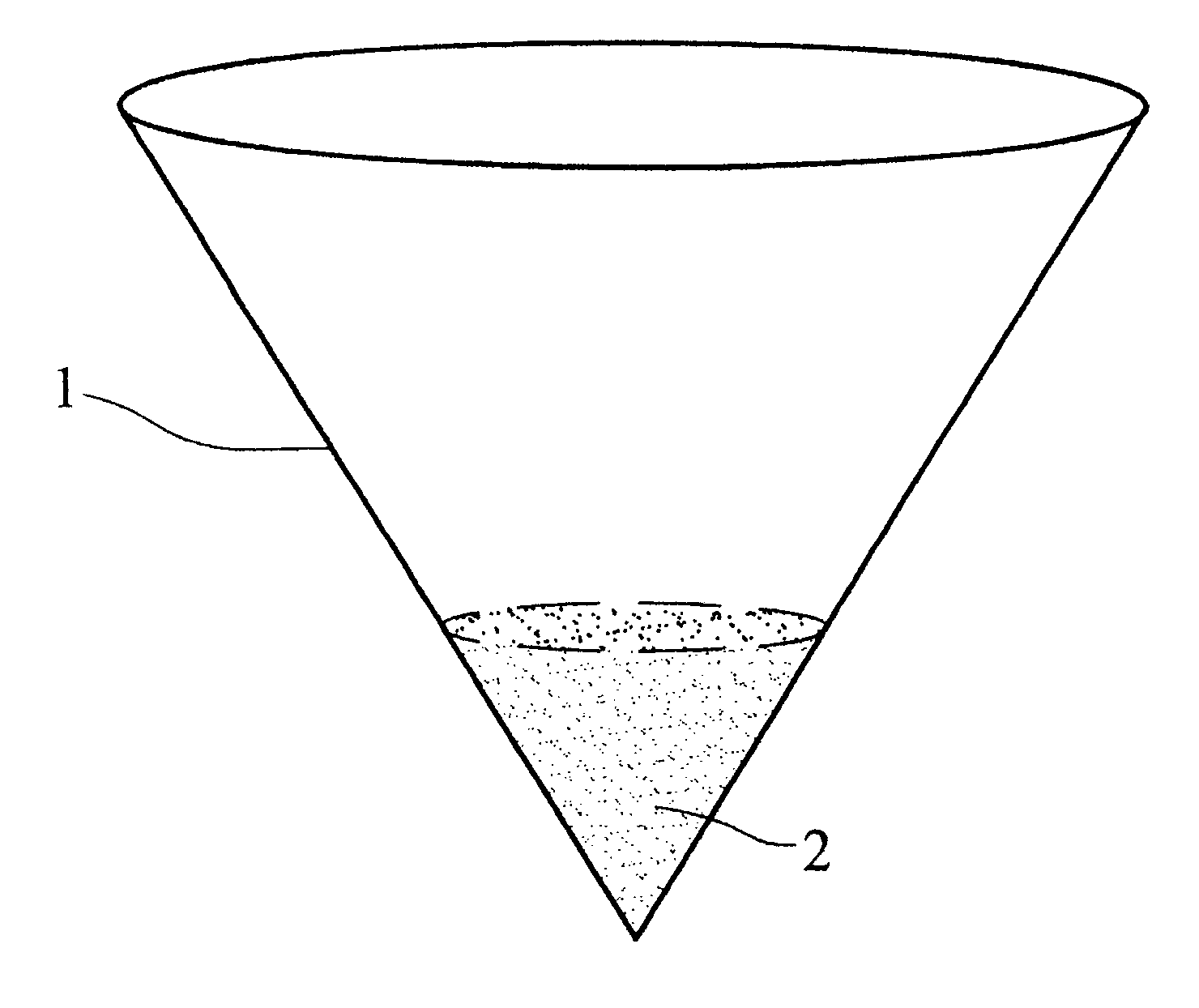

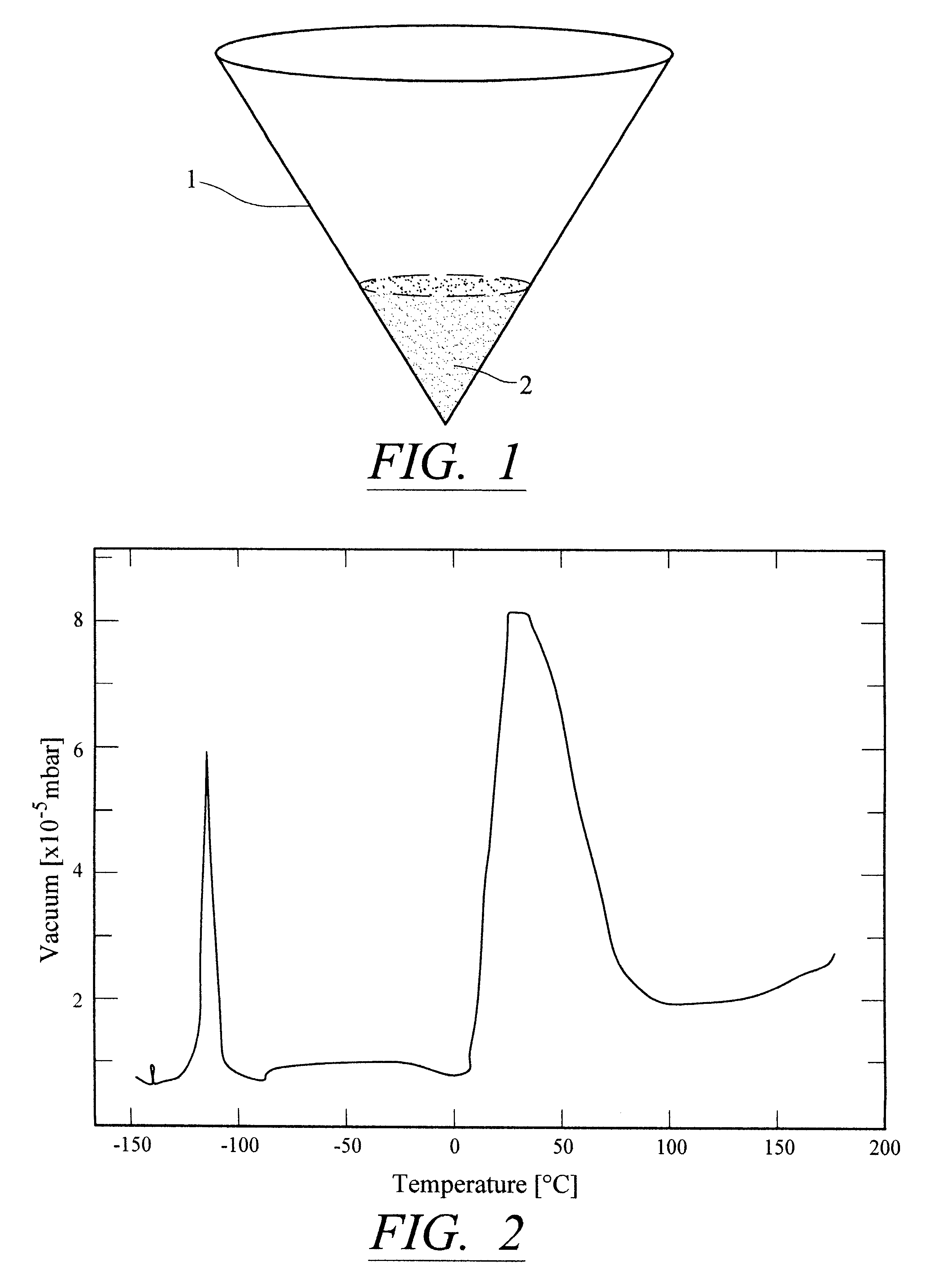

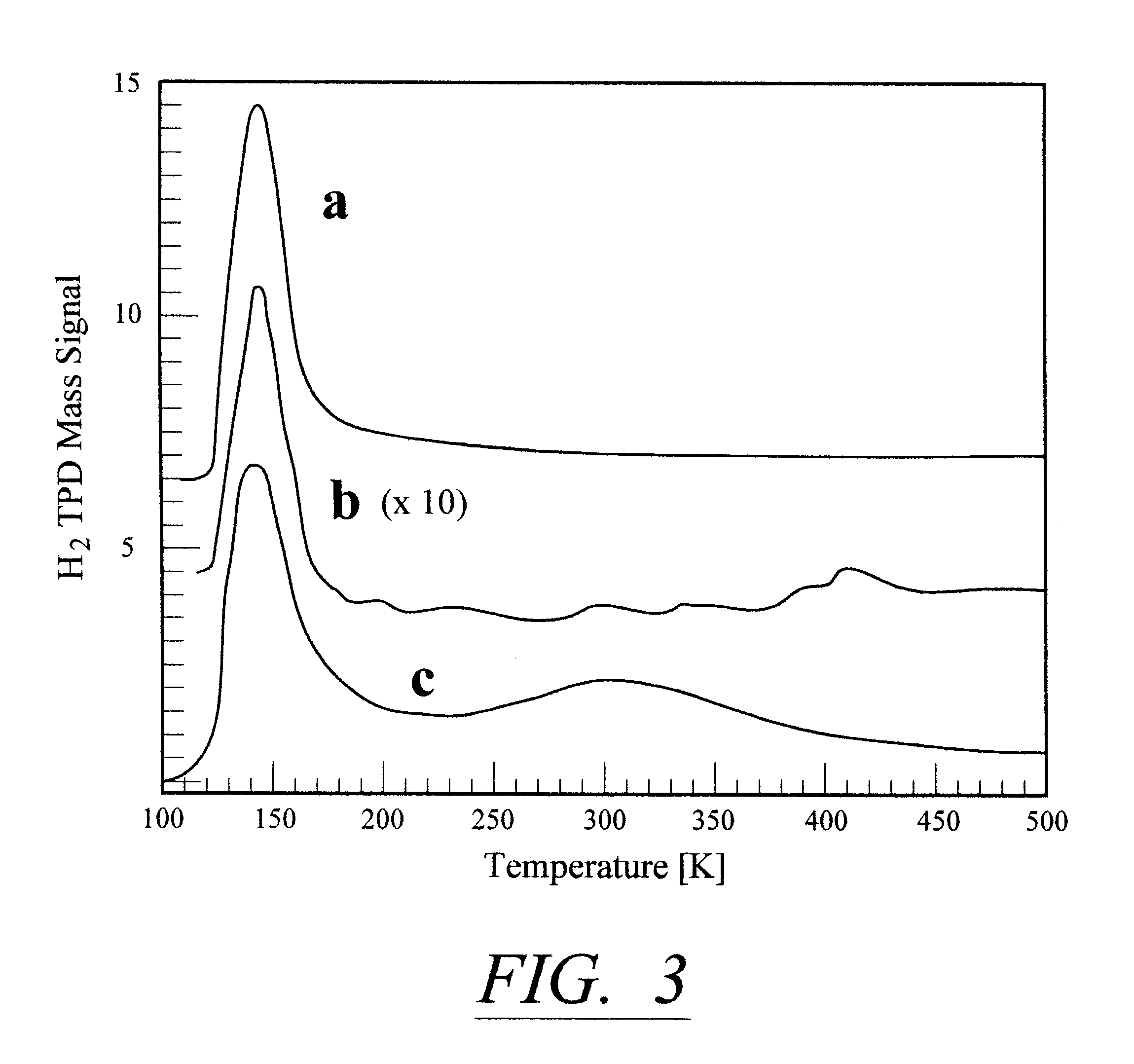

In a method for storing hydrogen in a carbon material containing microstructures in the form of cones with cone angles being multiples of 60°, the carbon material is introduced in a reaction vessel which is evacuated while the carbon material is kept at a temperature of 295-800 K, after which pure hydrogen gas is introduced in the reaction vessel, the carbon material being exposed to a hydrogen gas pressure in the range of 300-7600 torr such that the hydrogen gas is absorbed in the carbon material, and after which the reaction vessel is left at the ambient temperature with the carbon material under a fixed hydrogen gas pressure. For use the hydrogen is released in the form of a gas from the carbon material either at ambient temperature or by heating the carbon material in the reaction vessel. In a method for refining a carbon material of this kind for hydrogen storage, the carbon material is produced in a reaction chamber with the use of a catalyst for adjusting the cone angle distribution of the microstructures. Use for storing of hydrogen as fuel for powering transport means, including vehicles.

Owner:INSTITUTT FOR ENERGITEKNIKK

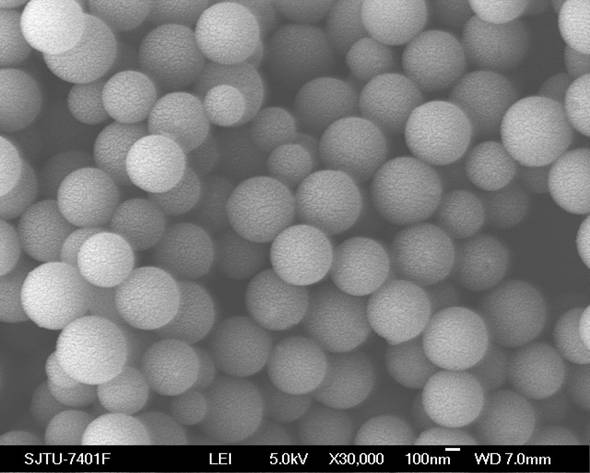

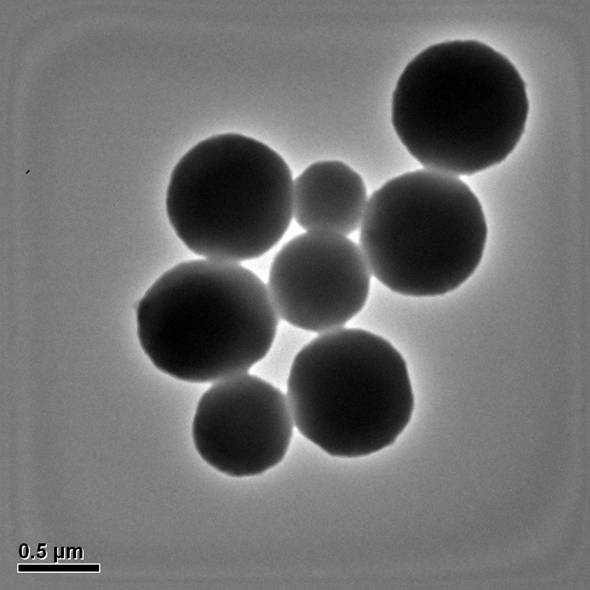

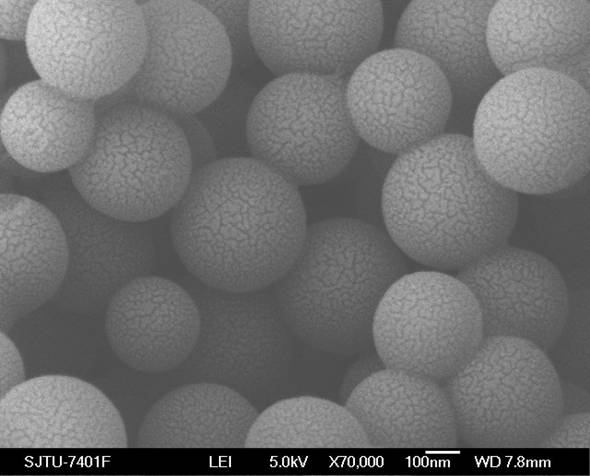

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

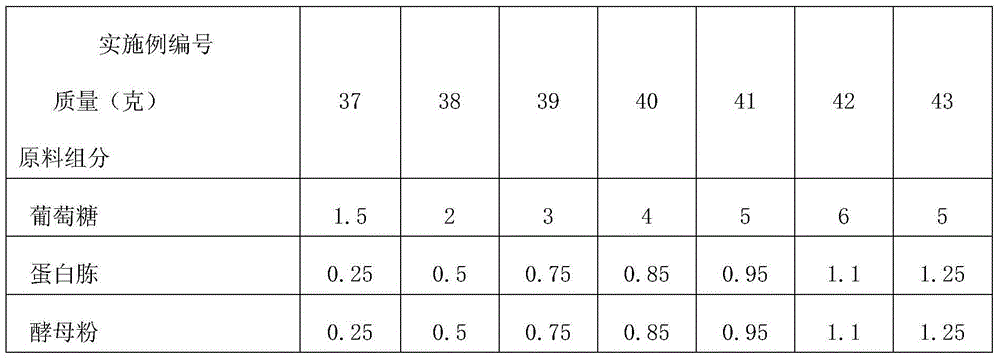

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

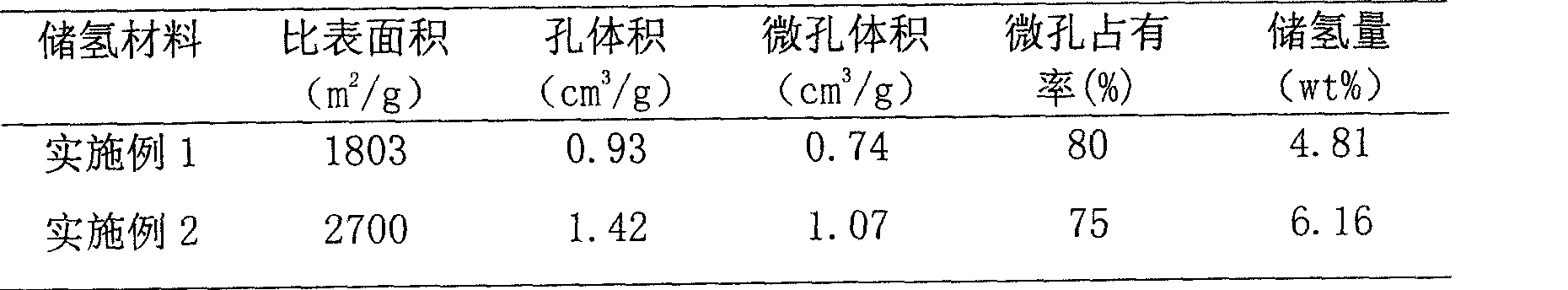

Method for preparing porous carbon spheres doped with nitrogen and phosphorus and application

The invention belongs to the technical fields of inorganic material chemistry and new energy, and discloses a method for preparing porous carbon spheres doped with nitrogen and phosphorus and an application. Water serves as a solvent, polyphosphazenes microspheres and activating agents are mixed in a mass ratio of (0.2-2):1, concentration of the polyphosphazenes microspheres is maintained at a level of 10-30wt%, stirring is performed completely, the mixture of the polyphosphazenes microspheres and the activating agents is obtained through centrifugal separation, the mixture of the polyphosphazenes microspheres and the activating agents is subjected to carbonization, and finally the porous carbon spheres doped with the nitrogen and the phosphorus are obtained. The activating agents are potassium hydroxide, sodium hydroxide, calcium chloride or zinc chloride. The polyphosphazenes microspheres serve as a carbon precursor in the method, are synthesized directly under the room temperature condition, and has a simple art process and high productivity. Simultaneously, the activating agents are used for processing polyphosphazenes so as to improve specific surface areas and pore structures of the porous carbon spheres greatly and be beneficial to improve hydrogen storage capacity.

Owner:ZHENGZHOU UNIV

Metal cation-doped covalent organic framework derivatives for hydrogen storage and method of using the same

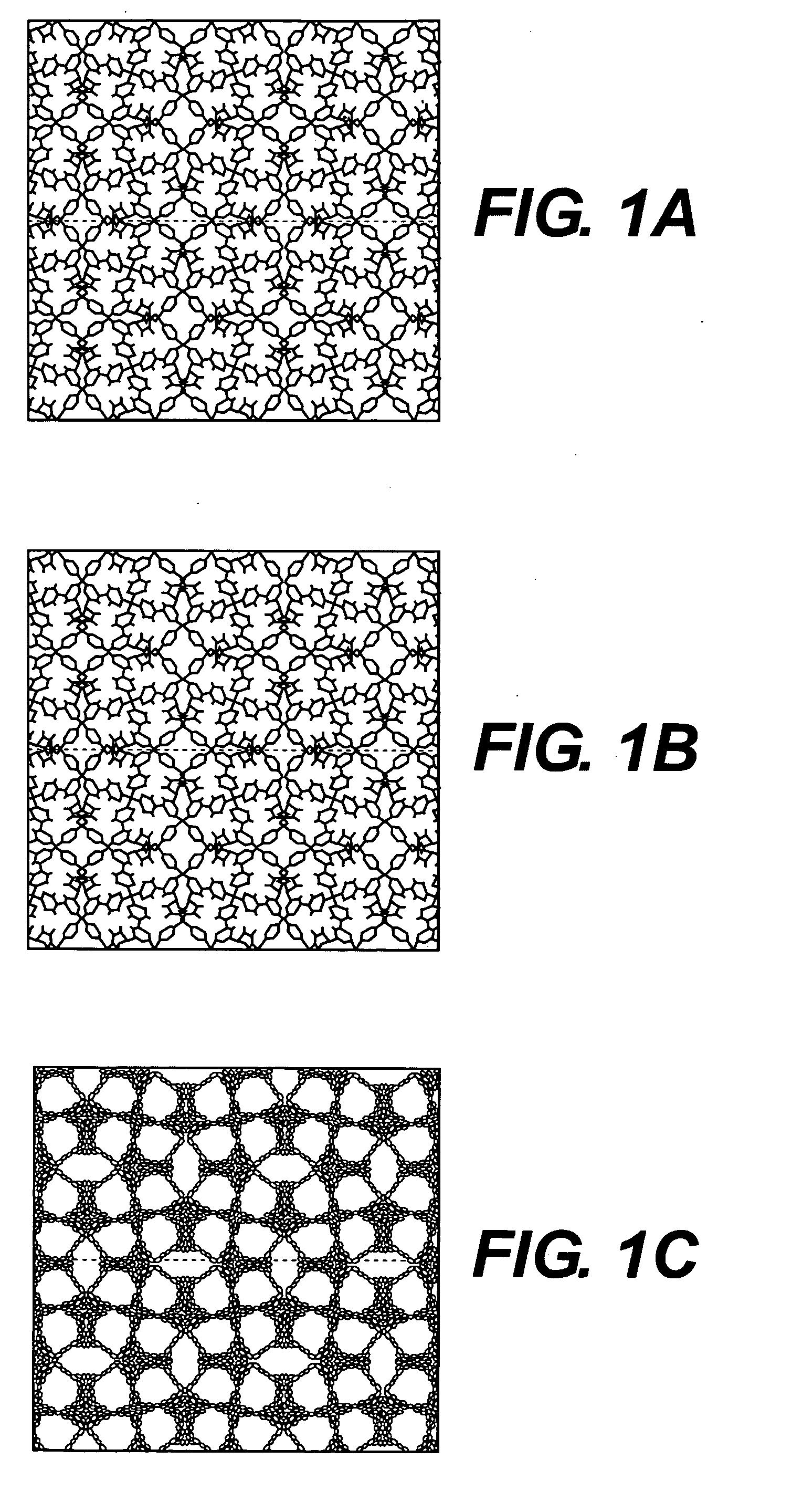

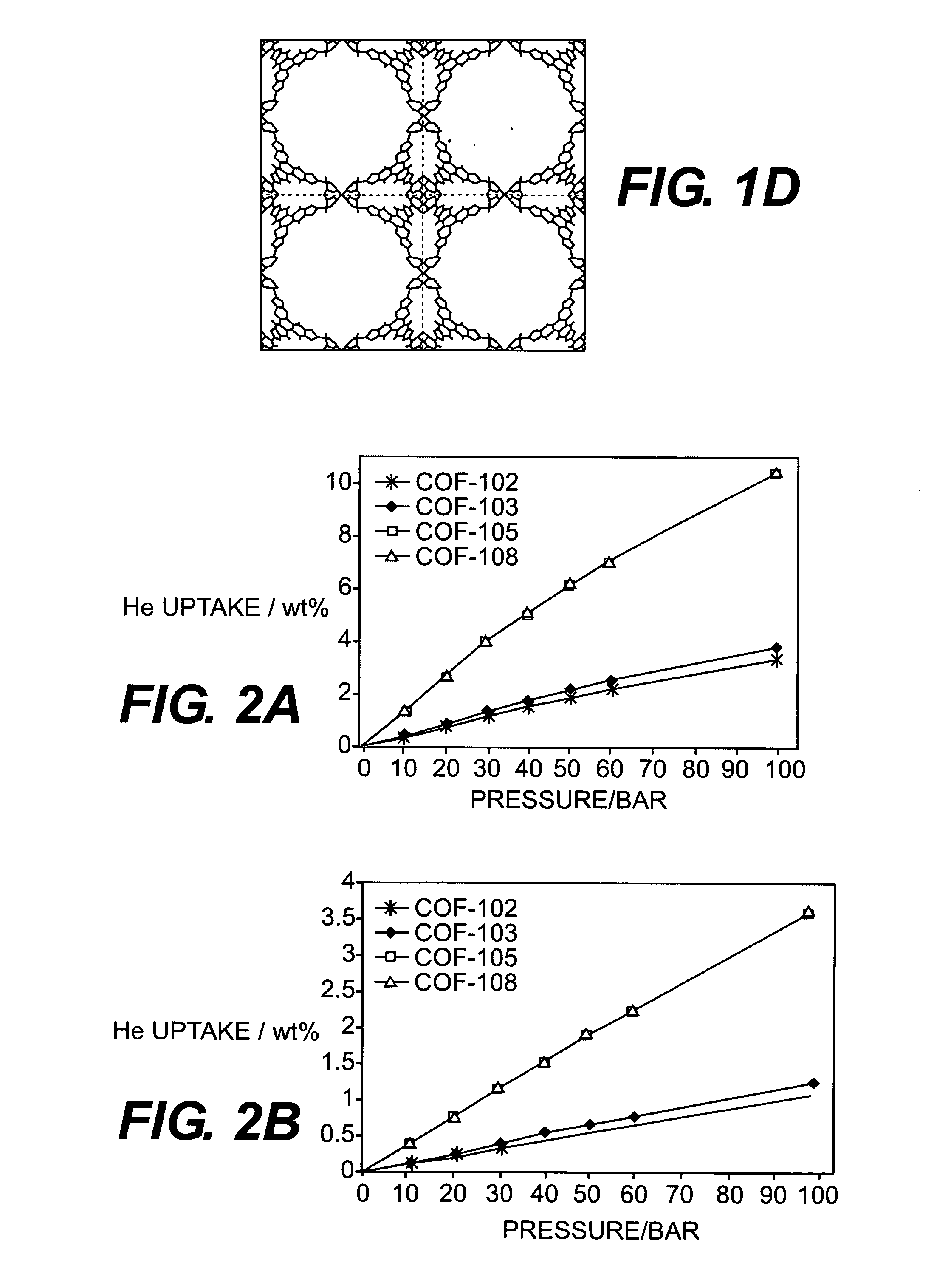

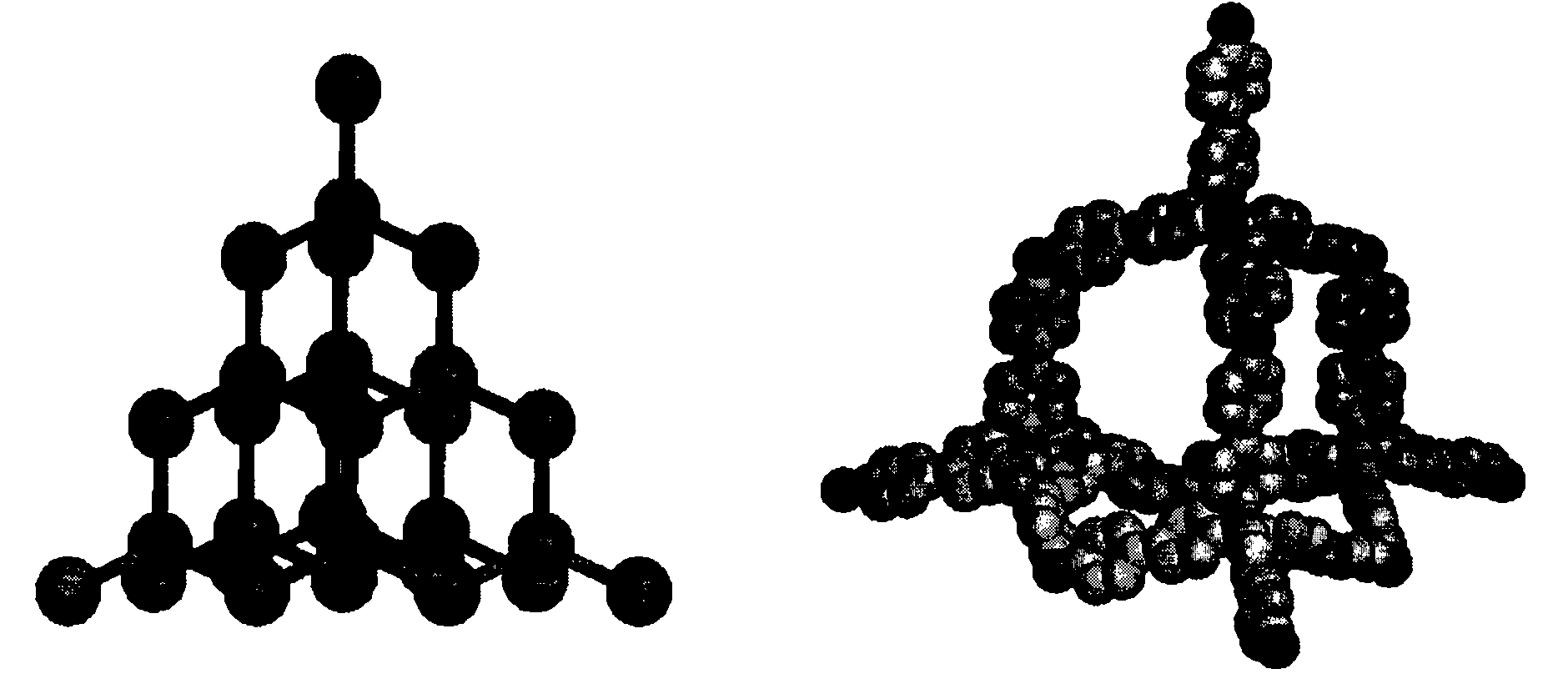

ActiveUS20110236301A1Massive absorption and desorptionImprove hydrogen storage performanceSilicon organic compoundsOther chemical processesPhenyl groupCovalent organic framework

Disclosed are a novel hydrogen storage material with enhanced hydrogen storage capacity prepared by doping an organic framework material with light metal cations, and a method of using the same for hydrogen storage. The present inventive material has at least one phenyl group at each face of a triangular building unit, which is doped with metal cations such as alkali metal cations, alkali-earth metal cations, etc., so that the material exhibits greatly improved capacity of hydrogen absorption and desorption at room temperature and can provide hydrogen storage materials practically adapted for fuel batteries useable even at room temperature.

Owner:KOREA ADVANCED INST OF SCI & TECH

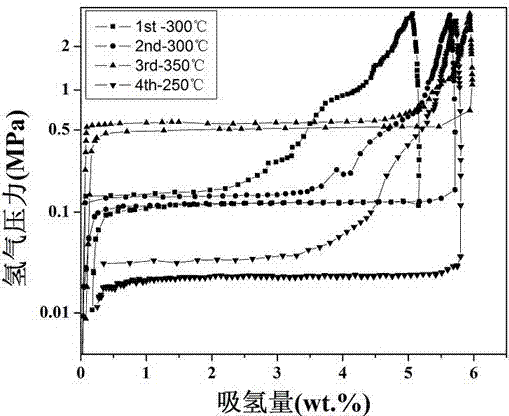

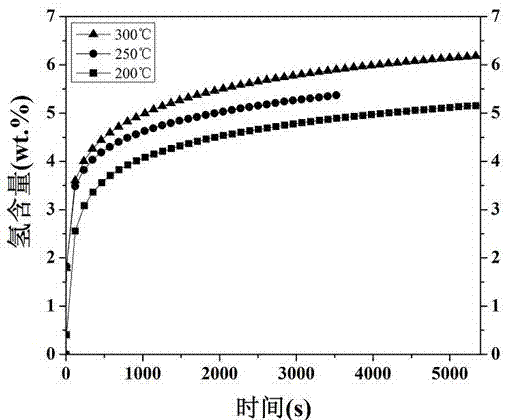

Magnesium-based hydrogen storage alloy with long period structure and preparation method thereof

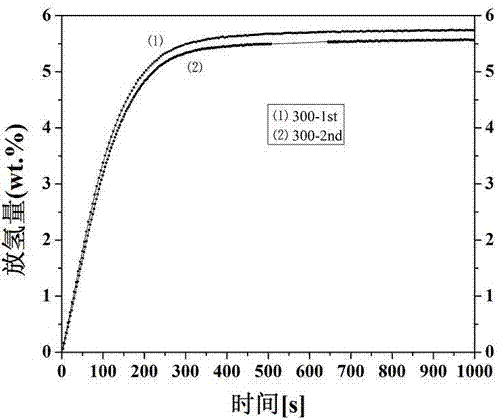

ActiveCN102337438AHigh activityAbsorption and desorption of hydrogen are normalChemical compositionMechanical milling

The invention provides a magnesium-based hydrogen storage alloy with a long period structure and a preparation method thereof. The magnesium-based hydrogen storage alloy has the chemical composition of Mg100-(2x-4x)Nix-3xYx (x is not less than 2 and not more than 6), and has a 18R and 14H long period stacking ordered structure. The preparation method comprises the following steps of: taking pure magnesium and Ni-Y intermediate alloys according to the chemical composition, carrying out induction smelting to obtain magnesium-based alloy cast ingots, mechanically crushing, and then carrying out high-energy mechanical milling to finally obtain the magnesium-based hydrogen storage alloy. The magnesium-based hydrogen storage alloy provided by the invention has good activation property and hydriding / dehydriding kinetics property; Ni atoms and Y atoms in the long period structure form Mg2NiHx and YH2-3 in the hydriding process and are evenly distributed among Mg particles in nanoscale, therefore, the hydrogen storage property of the Mg-based hydrogen storage alloy is greatly improved. The preparation method provided by the invention is simple and applicable to industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

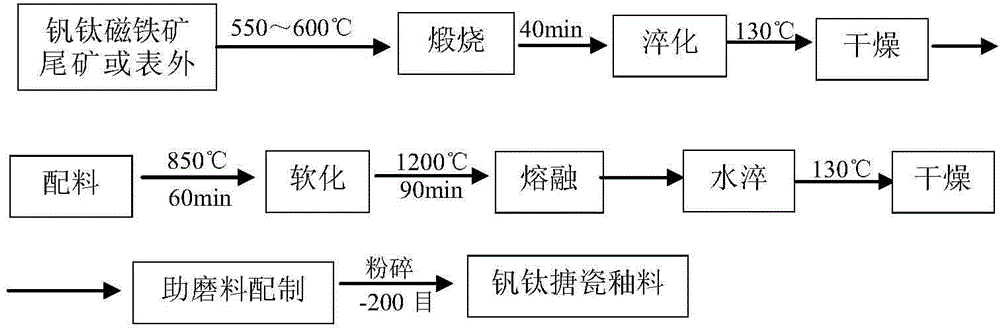

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

Preparation method for MOF-5 metal-organic frameworks

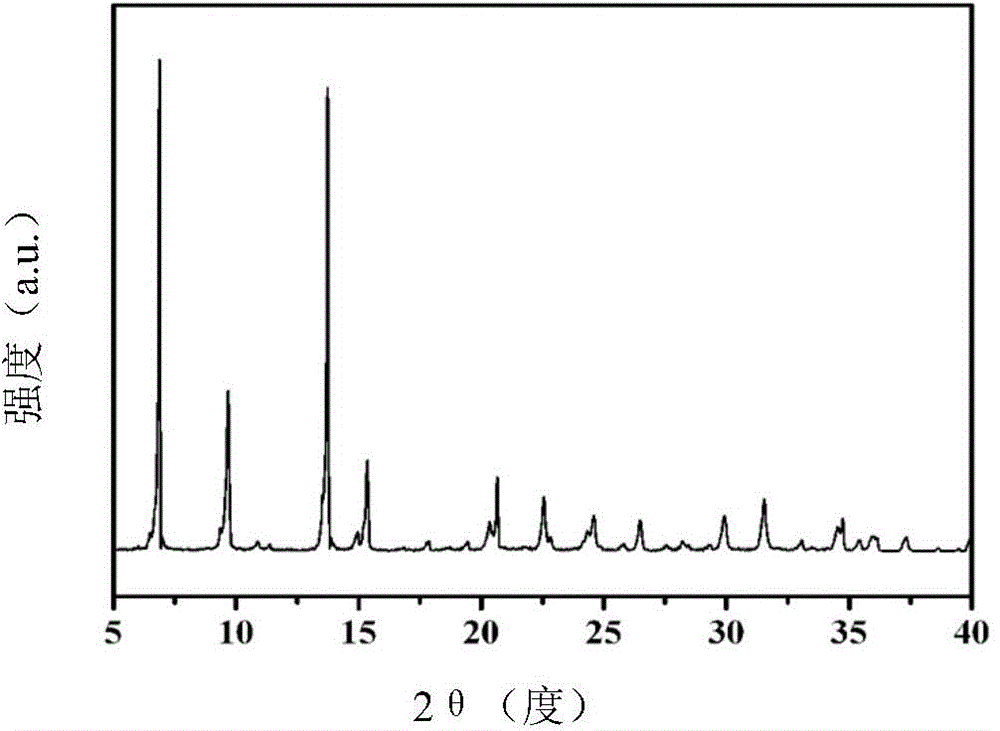

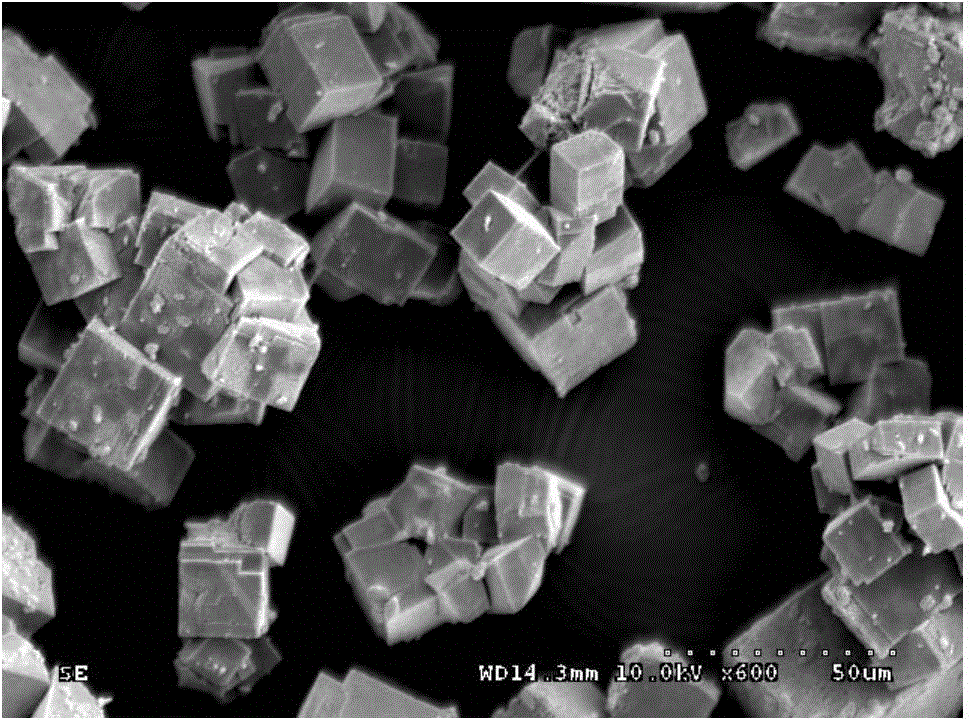

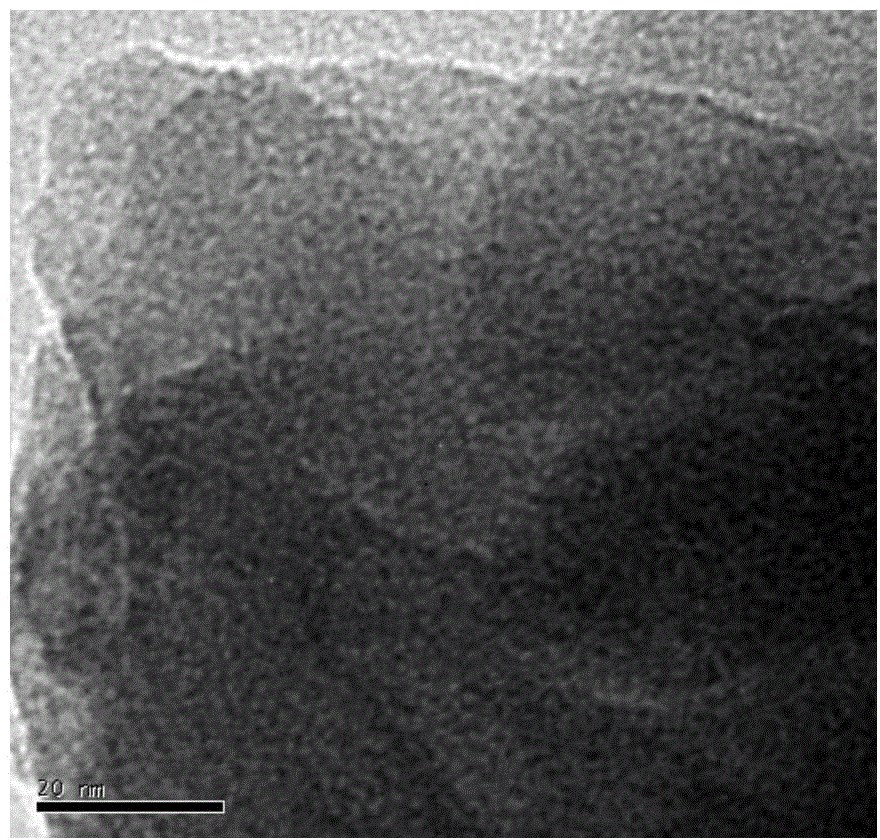

InactiveCN104148019AAvoid destructionImprove hydrogen storage performanceOther chemical processesHydrogen separation using solid contactHigh concentrationMetal-organic framework

The invention discloses a preparation method for MOF-5 metal-organic frameworks of interpenetrating structures. The preparation method comprises the following steps: (1) dissolving Zn(NO3)2.6H2O and H2BDC into a DMF solvent; adding TEA (triethylamine) to produce white precipitate and then filtering, wherein a filtrate is a precursor solution; and (2) heating for 24 to 48 hours at 90 to 110 DEG C to obtain MOF-5 crystals. The preparation method integrates the advantages of a TEA direct mixing method and a solvothermal method. Firstly, a reaction solution with the relatively high concentration is required for preparing the interpenetrating structures, while the reaction solution with the relatively high concentration can damage the MOF-5 seed crystals, and the damage can be avoided by adding the TEA; secondly, the white precipitate produced after the TEA is added is removed, and a remained clarified liquor is reserved for performing reaction, so that the high crystallinity of the MOF-5 crystals is guaranteed; in addition, the TEA is also introduced into intergranular mesoporous, so that the hydrogen storage capacity of interpenetrated MOF-5 is improved. The preparation method disclosed by the invention can also be used for preparing the carbon-material-doped interpenetrated MOF-5. The MOF-5 metal-organic frameworks of the interpenetrating structures, which are prepared by the preparation method, have the high hydrogen storage capacity and the high thermal stability.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Mesopore carbon load nickel hydrogenation catalyst and preparation method thereof

InactiveCN101693201AOvercoming the problem of low activityHigh activityOrganic compound preparationCatalyst activation/preparationDispersityNickel salt

The invention provides a mesopore carbon load nickel hydrogenation catalyst and a preparation method thereof. For the load type catalyst, a carrier is mesopore carbon, an active component is metal nickel, and the mass of the nickel is 5-50 percent of that of the carrier. The preparation method comprises the following steps: soaking the mesopore carbon carrier in an organic soaking liquid containing nickel salt precursor under the action of ultrasonic, standing at room temperature, drying, and activating the precursor containing a metal component through the reducibility of the carrier, i.e. by a thermal reduction mode. The invention has the advantages of high dispersity of the active component, excellent performance of the catalyst, simple preparation process and low cost and can be used for preparing p-aminophenol by carrying out liquid-phase hydrogenation on p-nitrophenol.

Owner:NANJING UNIV OF TECH

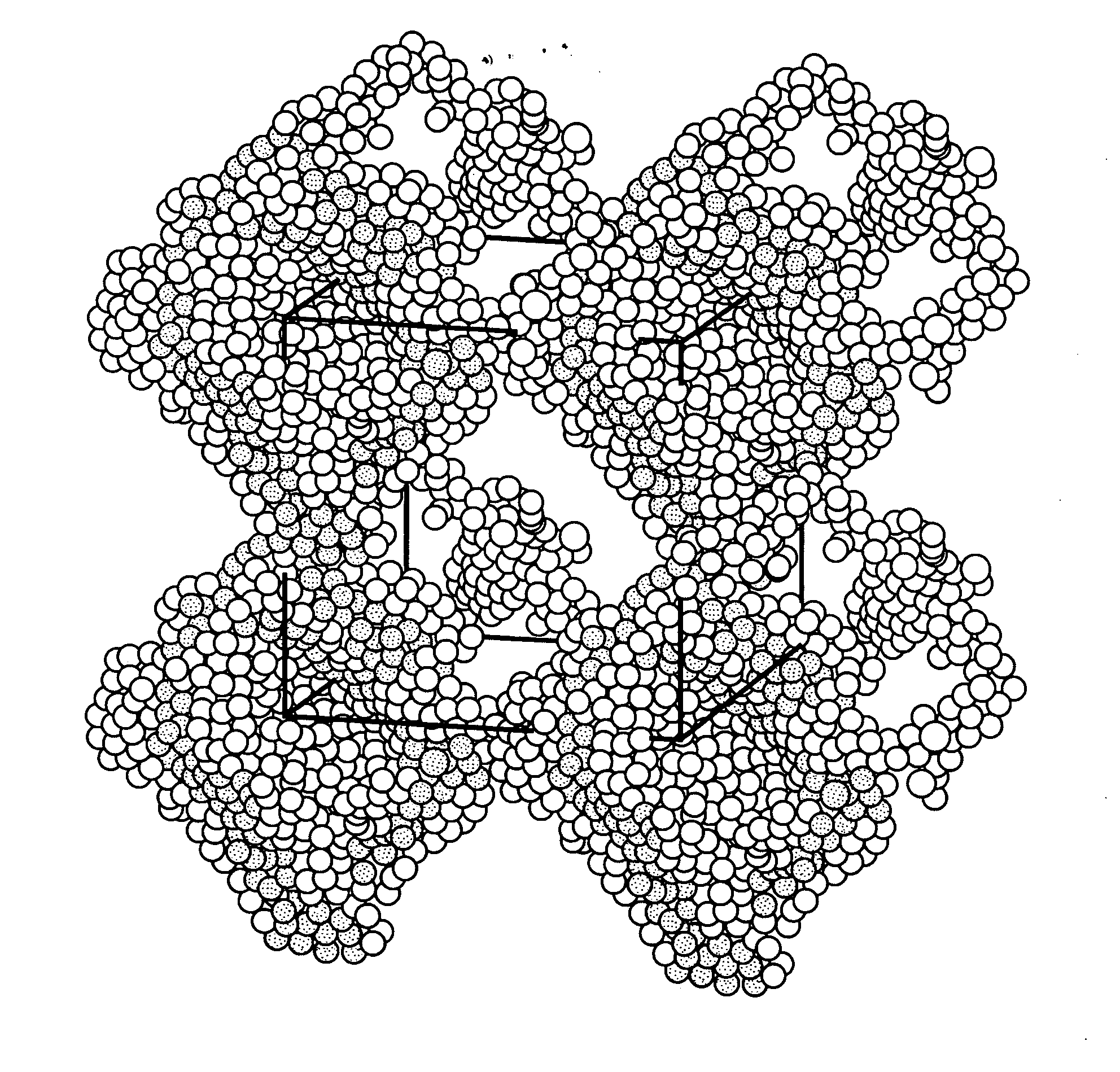

Porous polymer material with ultra-high specific surface area, preparation method thereof and use thereof in gas storage or liquid adsorption

ActiveCN101934222AImprove thermal stabilityGood hydrothermal stabilityOther chemical processesTetraphenylmethanePolymer

The invention relates to the field of functional materials, in particular to a porous polymer material with an ultra-high specific surface area, a preparation method thereof and use thereof in gas storage or liquid adsorption. The porous polymer material with an ultra-high specific surface area is poly(tetraphenylmethane) of which the molecular formula is (C(Ph)4)n and the structure is shown below.

Owner:深圳市普迈达科技有限公司

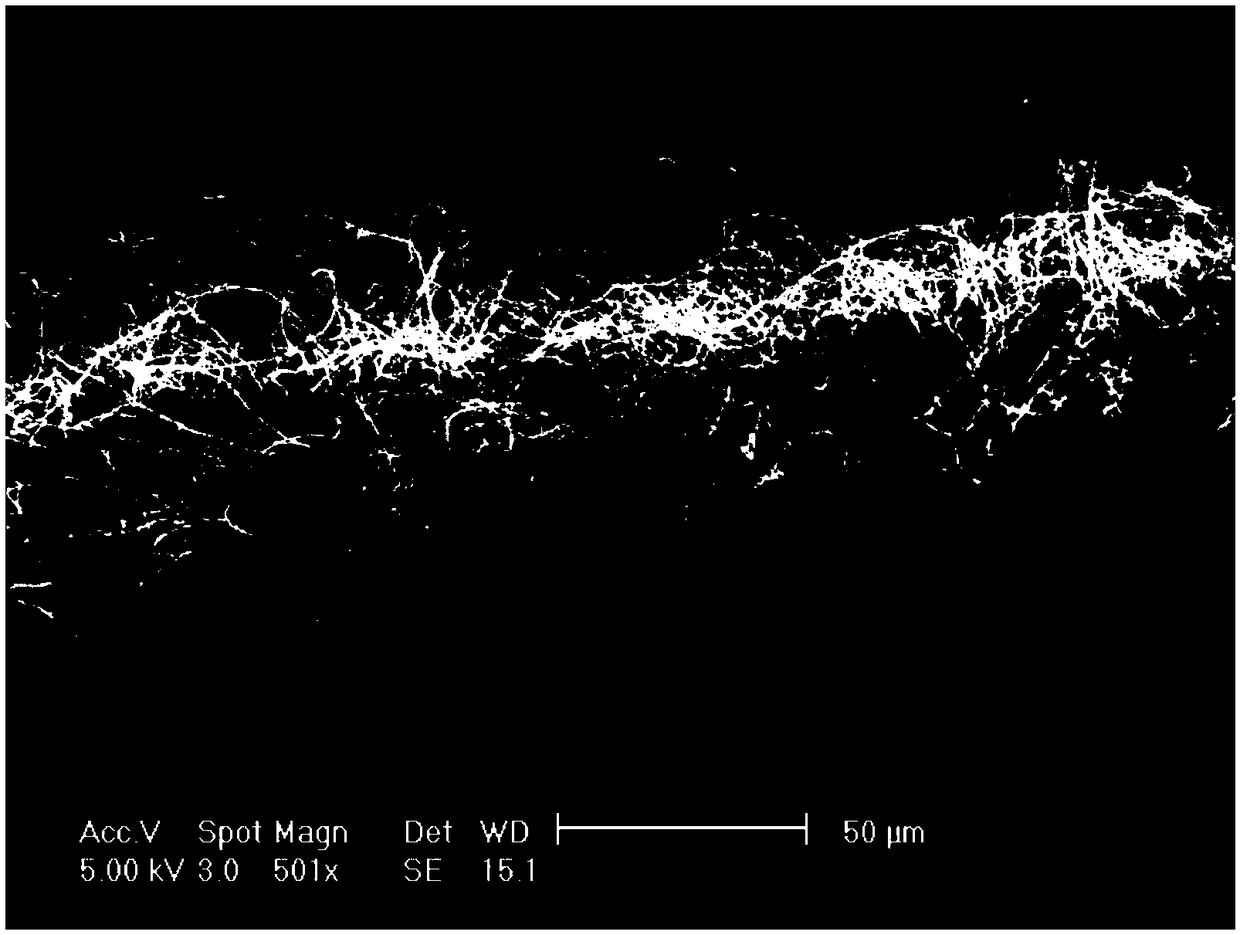

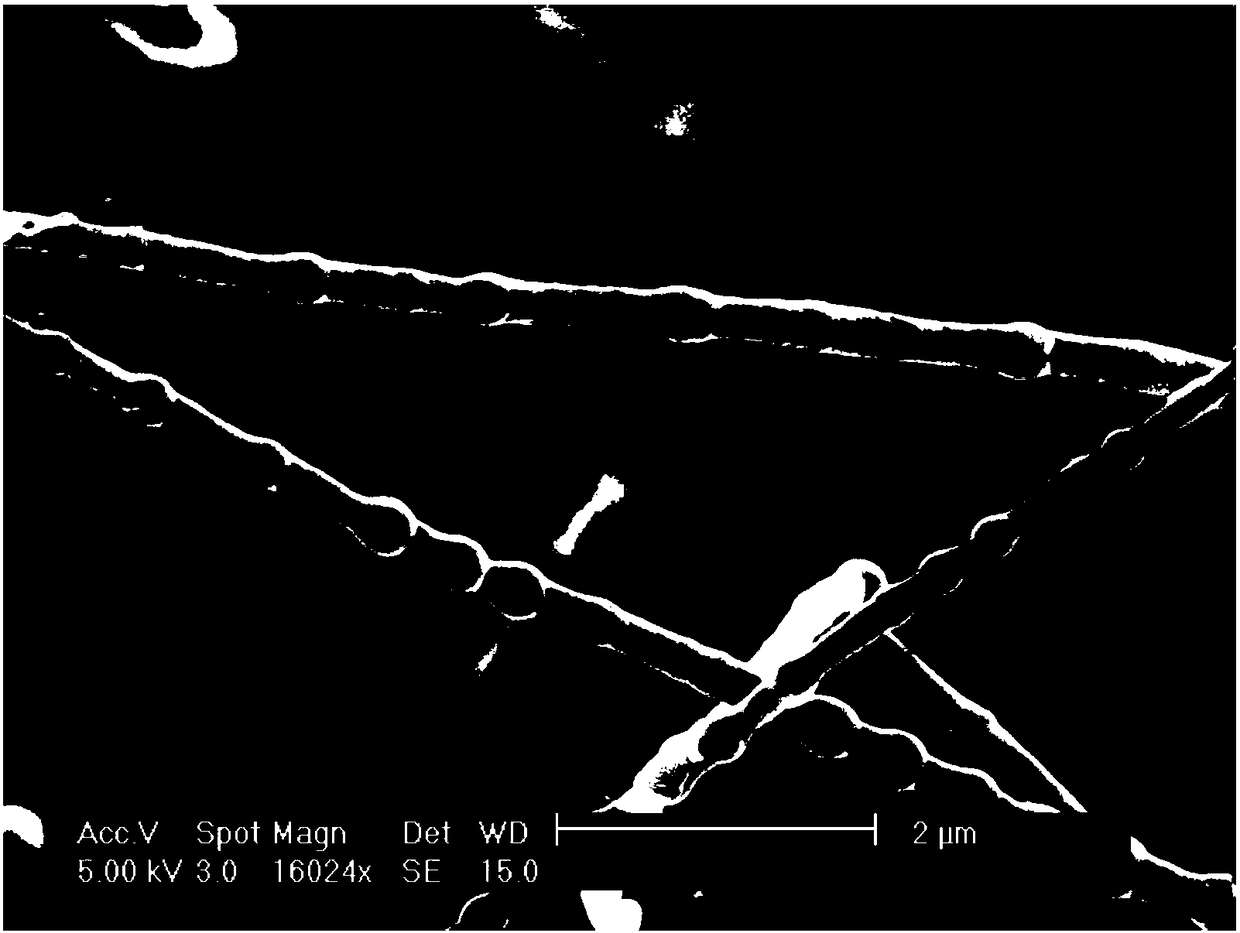

Method for preparing lignin-based carbon fiber hydrogen storage material by electrostatic spinning process

ActiveCN104947246AWide variety of sourcesLow priceFilament/thread formingFibre chemical featuresAir atmosphereMicro nano

The invention relates to a method for preparing a hydrogen storage material, and particularly relates to a method for preparing a lignin-based carbon fiber hydrogen storage material by electrostatic spinning. The method comprises the following steps: preparing a sodium lignin sulfonate / polyacrylonitrile / nickel acetate / boric acid spinning solution; preparing sodium lignin sulfonate / polyacrylonitrile composite micro-nano fiber through electrostatic spinning; drying in a vacuum drying oven and pre-oxidizing in an air atmosphere in a muffle furnace; and gradually heating and calcining in a condition of continuously introducing an inert gas into the tubular furnace to obtain sodium lignin sulfonate / polyacrylonitrile composite carbon fiber containing a Ni-B catalyst, wherein Ni-B realizes an effect of catalytic graphitization. The prepared sodium lignin sulfonate / polyacrylonitrile composite carbon fiber has relatively high graphitization degree, and the hydrogen absorption capacity under the conditions of 298K and 95bar reaches 0.92wt% within 60s.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

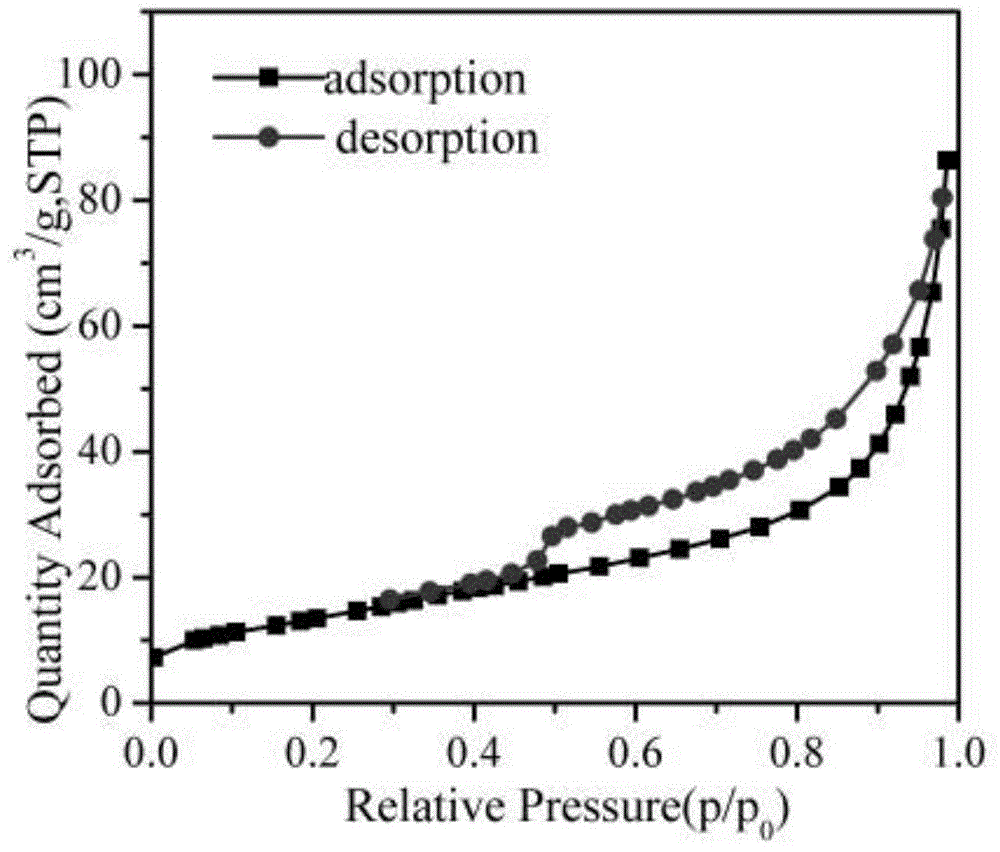

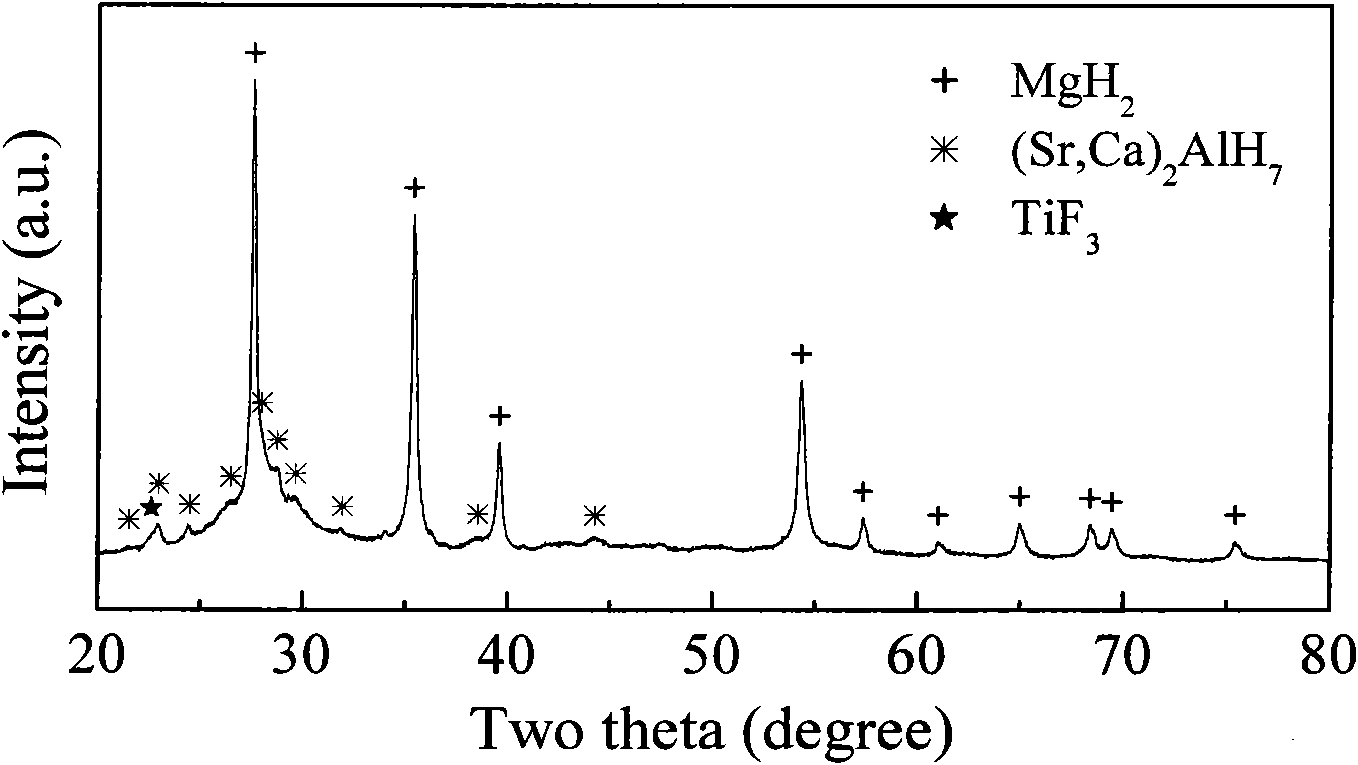

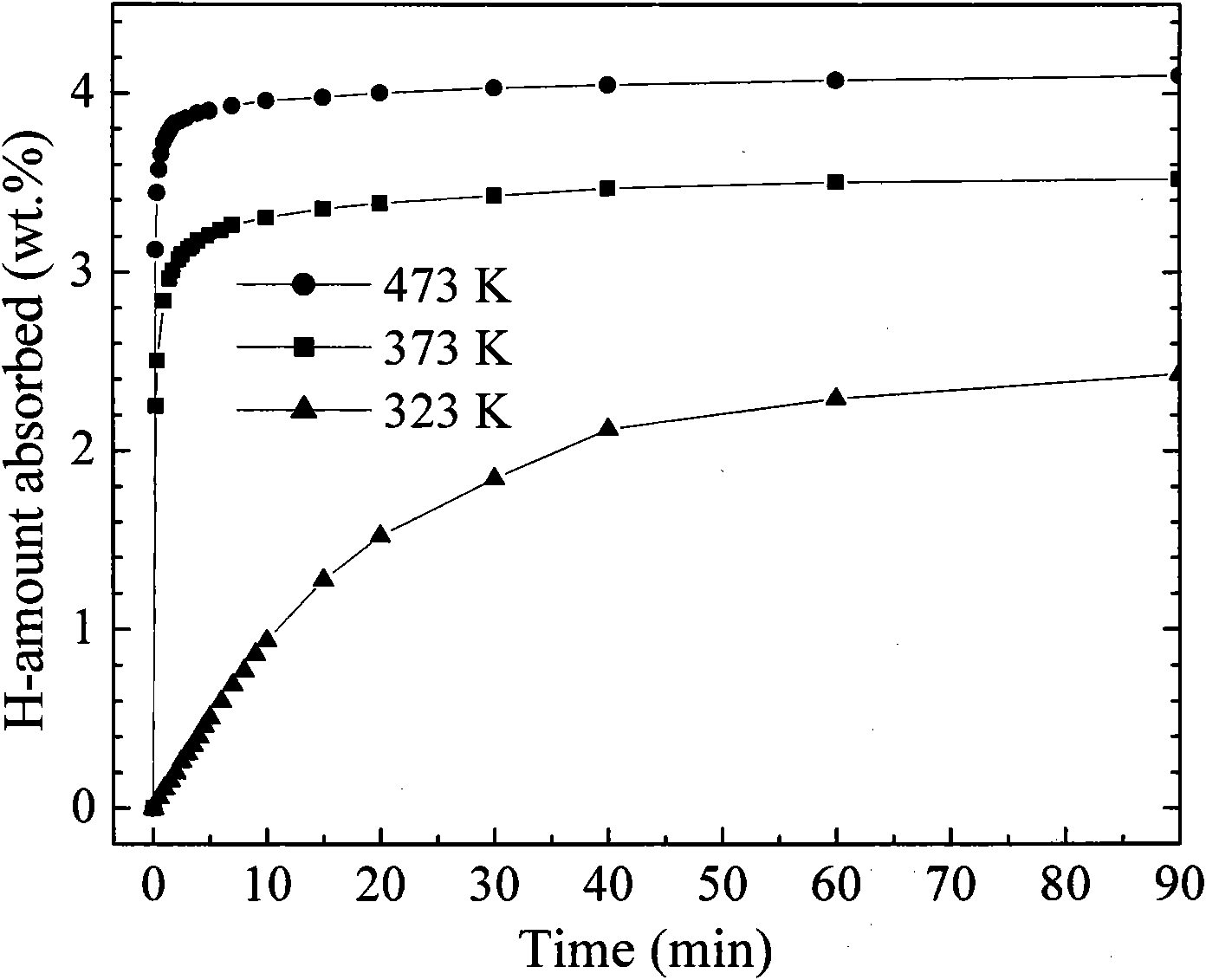

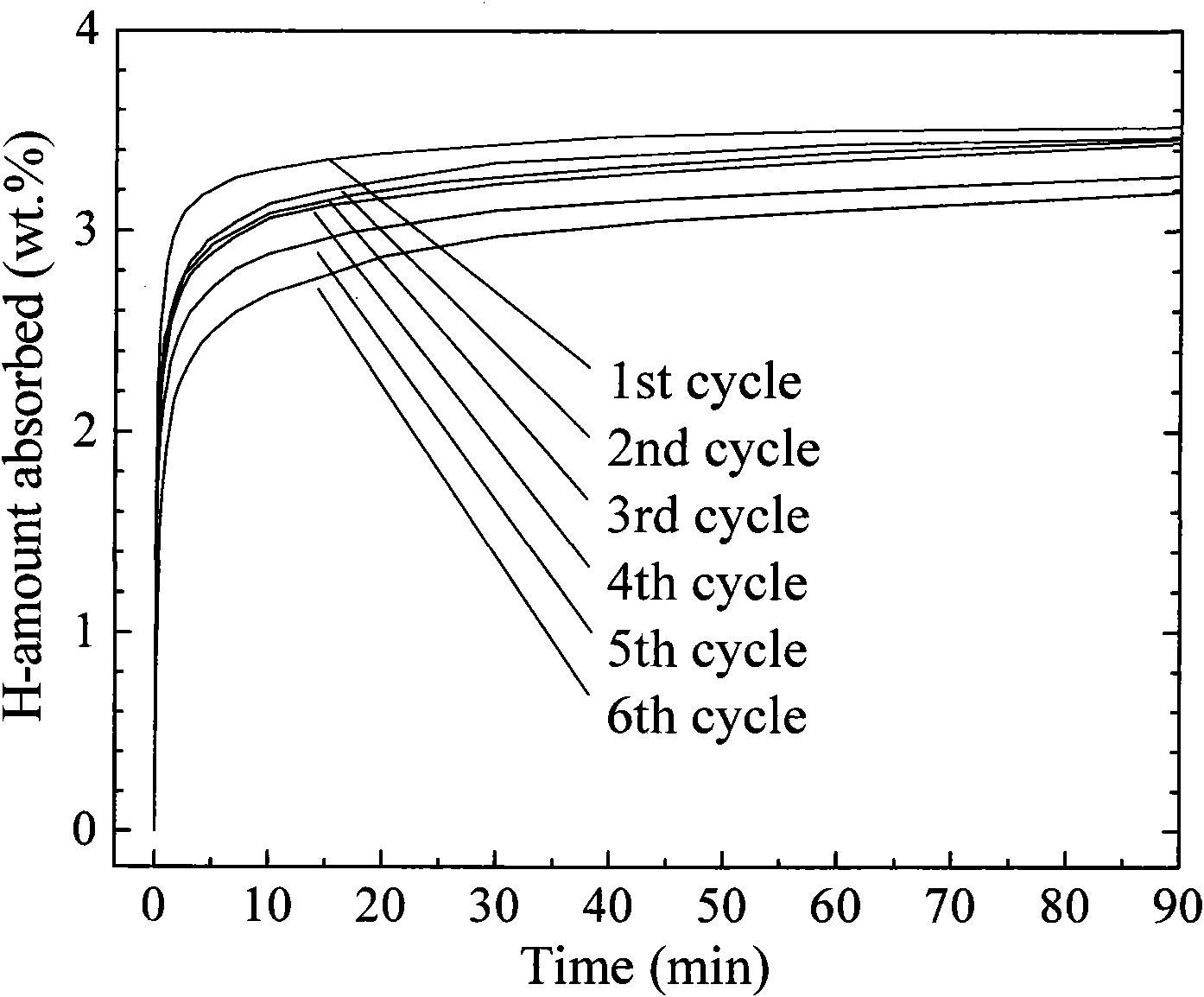

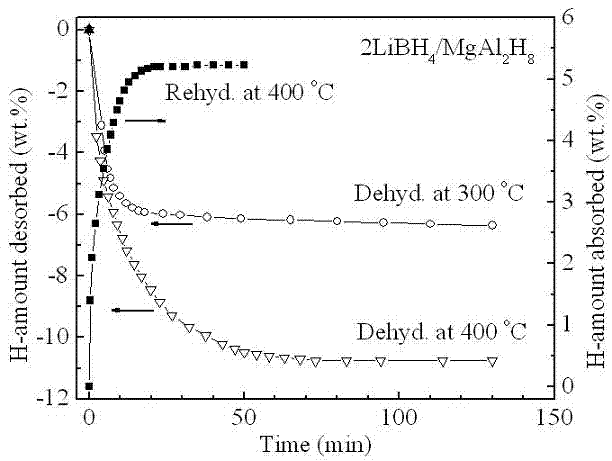

Mg-based composite hydrogen storage material containing alkaline earth metals-aluminum hydride and preparation method thereof

InactiveCN101549854AImprove hydrogen storage performanceHigh hydrogen storage capacityHydrogen productionAlkaline earth metalHydrogen fuel cell

The invention provides an Mg-based composite hydrogen storage material containing alkaline earth metals-aluminum hydride and a preparation method thereof, which belongs to the technical field of hydrogen storage material. The chemical general formula of the hydrogen storage material is MgH2+x wt.%(Sr1-yCay)2AlH7+z wt.%TiF3, wherein x is more than or equal to 30 and less than or equal to 50, y is more than or equal to 0 and less than or equal to 0.5, and z is more than or equal to 2 and less than or equal to 10. The hydrogen storage material is gained by mechanically ball milling three materials powder of MgH2, (Sr, Ca)2AlH7 and TiF3, a planetary ball mill is adopted when ball milling, the ball material ratio is 15:1 to 20:1, the rotational speed is 350 to 400rpm, the ball milling time is 10 to 20h, the ball milling protecting atmosphere is argon gas or hydrogen gas, and the atmosphere pressure is 1 to 5atm. The invention has the advantages that: the preparation technique is simple, the provided composite hydrogen storage materials do not need to be activated, and have high hydrogen storage capacity, simultaneously have good low temperature hydrogen absorption dynamic performance and high hydrogen absorption and desorption cycling stability. The invention is applicable to the safe and efficient storage and transportation of the hydrogen, especially the hydrogen fuel cells and other fields.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

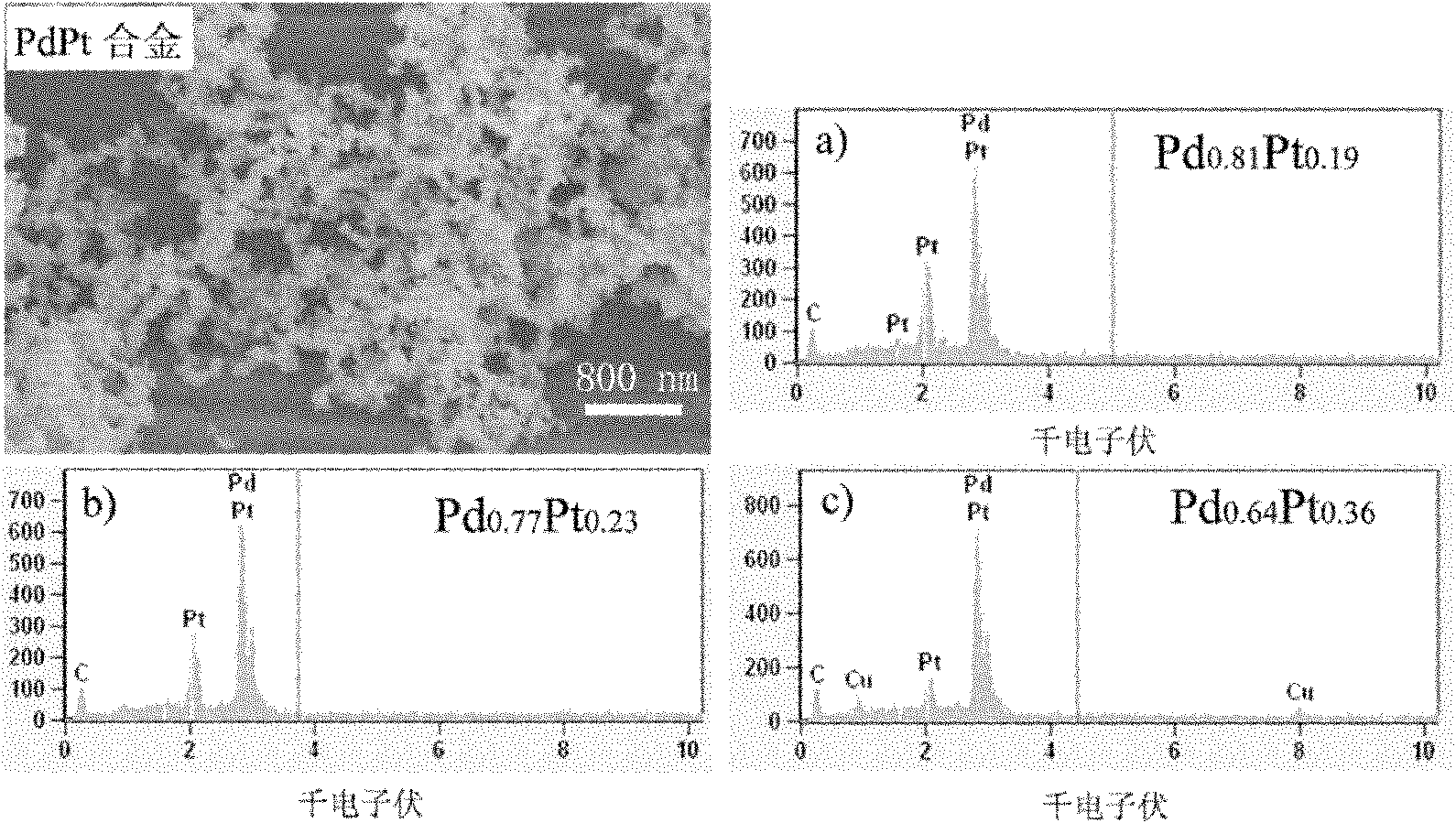

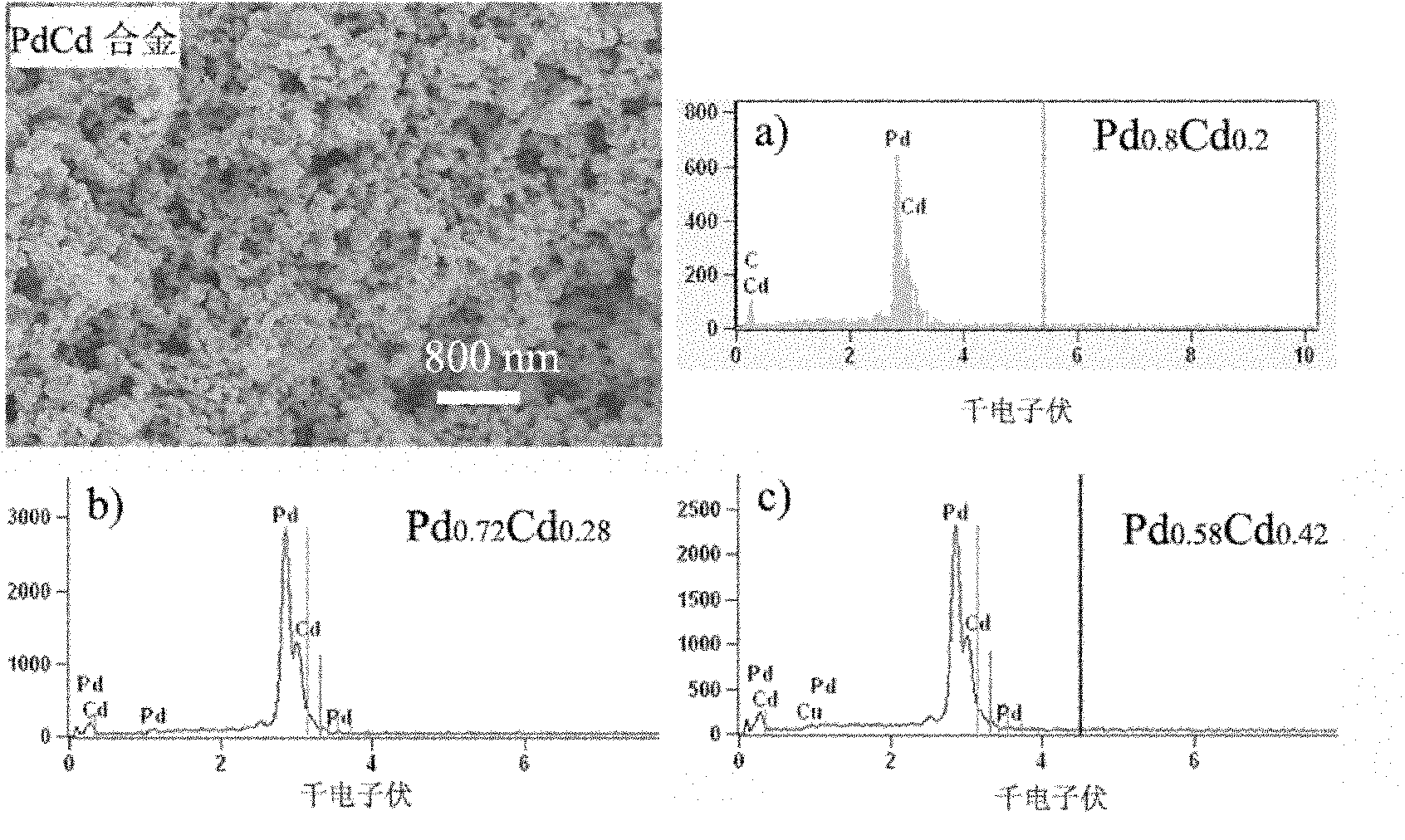

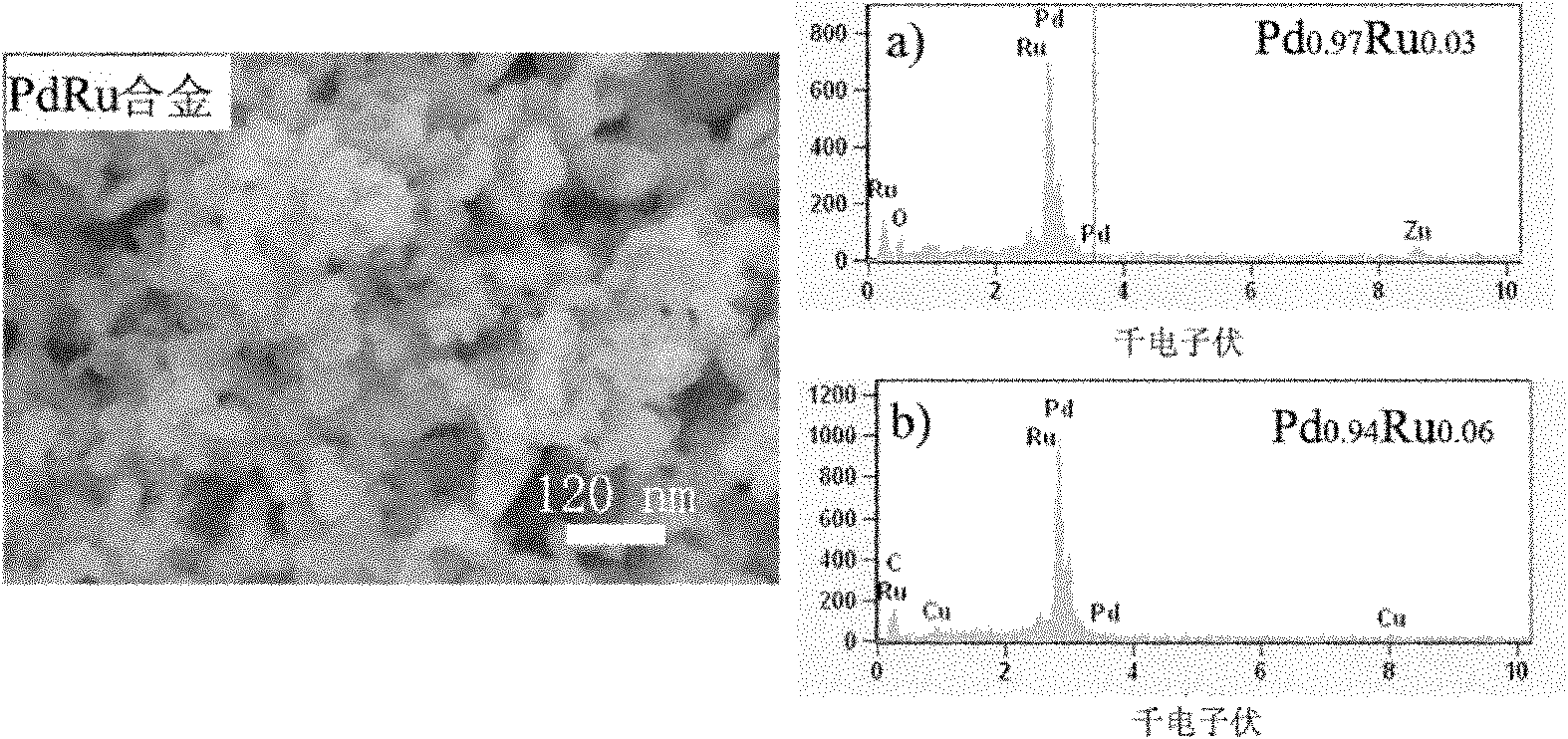

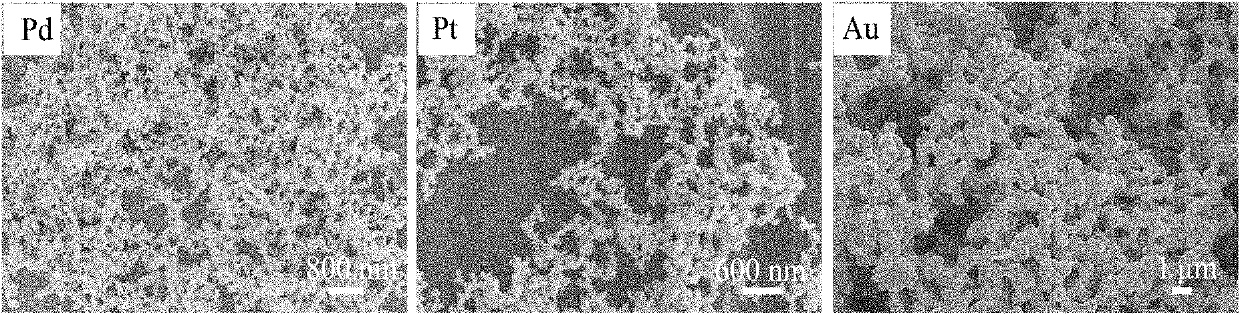

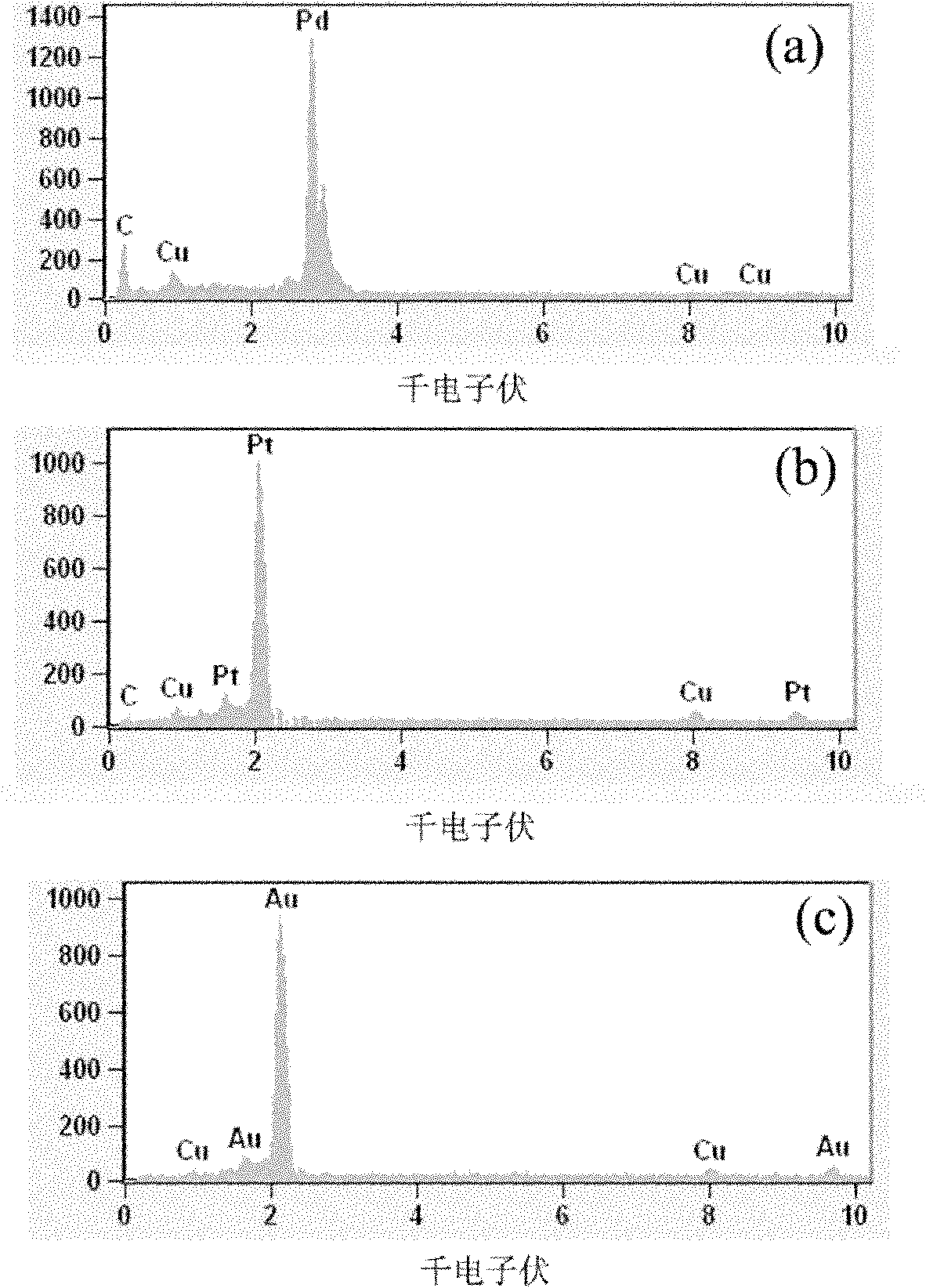

Method for preparing noble metal alloy nano material with three-dimensional porous network structure

The invention discloses a method for preparing a noble metal alloy nano material with a three-dimensional porous network structure. By adopting a one-step hydrothermal method, the method comprises the following steps of: firstly adding glycol, a metal precursor and a surfactant into a reaction kettle, stirring uniformly, then adding formaldehyde into the reaction kettle and stirring uniformly; sealing the reaction kettle, and then putting the reaction kettle in an oven with the temperature of 130-200 DEG C, and reacting for 6-10 hours; and finally, cooling the reaction kettle to room temperature naturally, cleaning centrifugally to finally obtain the noble metal alloy nano material with the three-dimensional porous network structure. In the method, the attributive advantages of noble metal and the three-dimensional porous network structure are combined, and the one-step hydrothermal method is adopted. Compared with the traditional methods, the method has the characteristics of simple operation method, strong universality, high yield and high repeatability and the like, and the prepared noble metal alloy has uniform appearance, strong stability, high purity and is adjustable in size and component.

Owner:苏州科昂泰材料科技有限公司

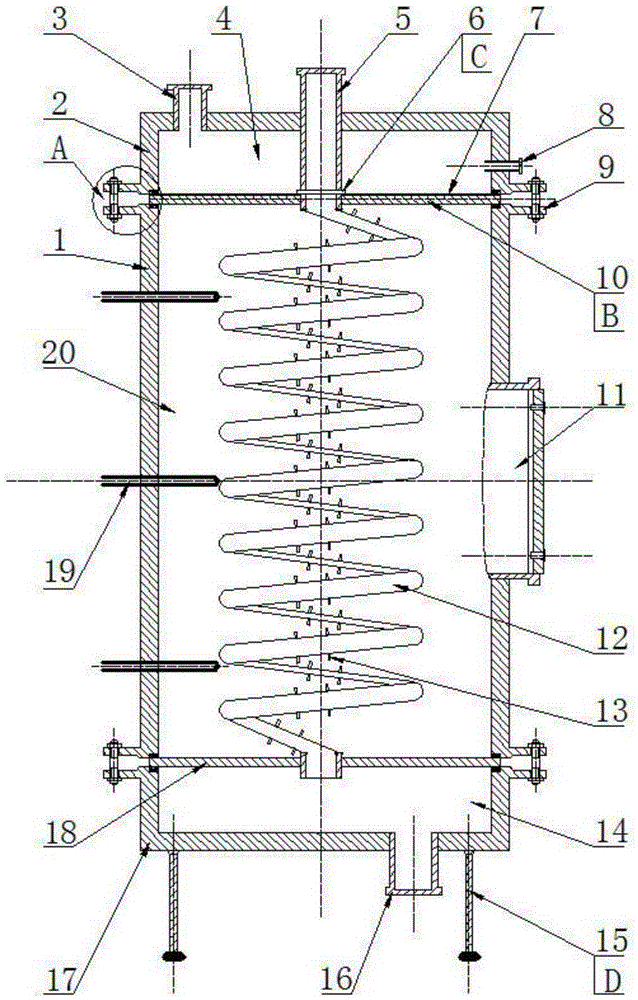

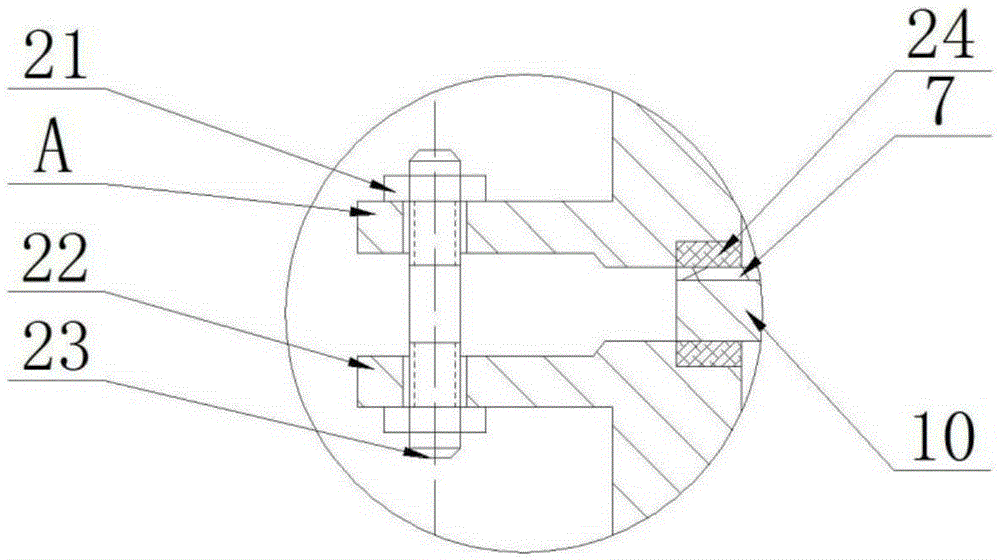

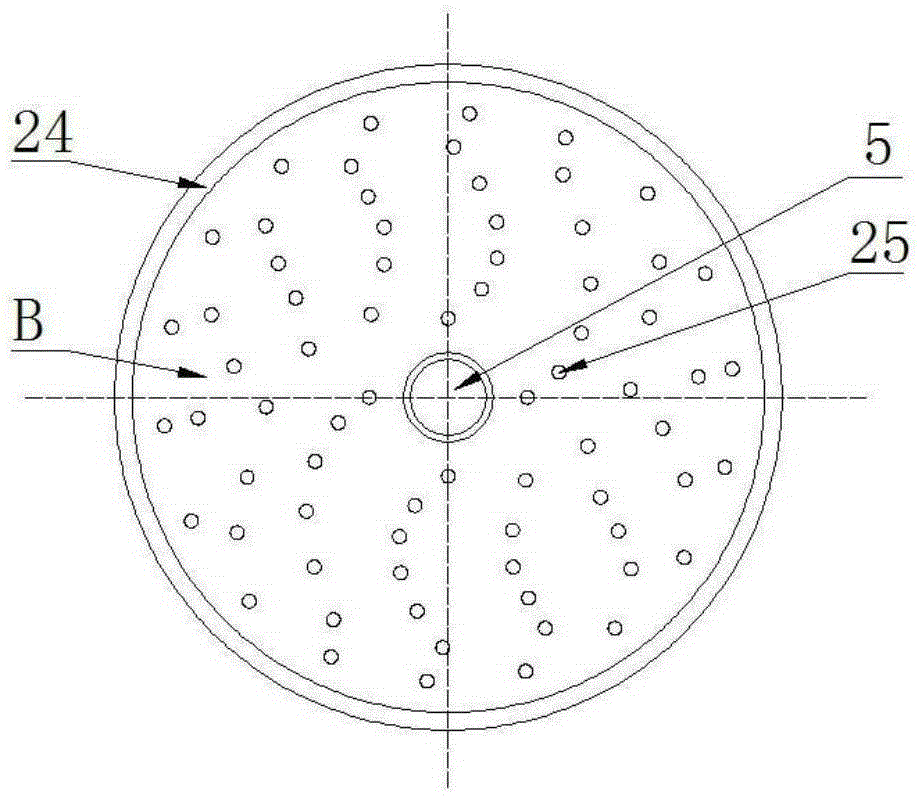

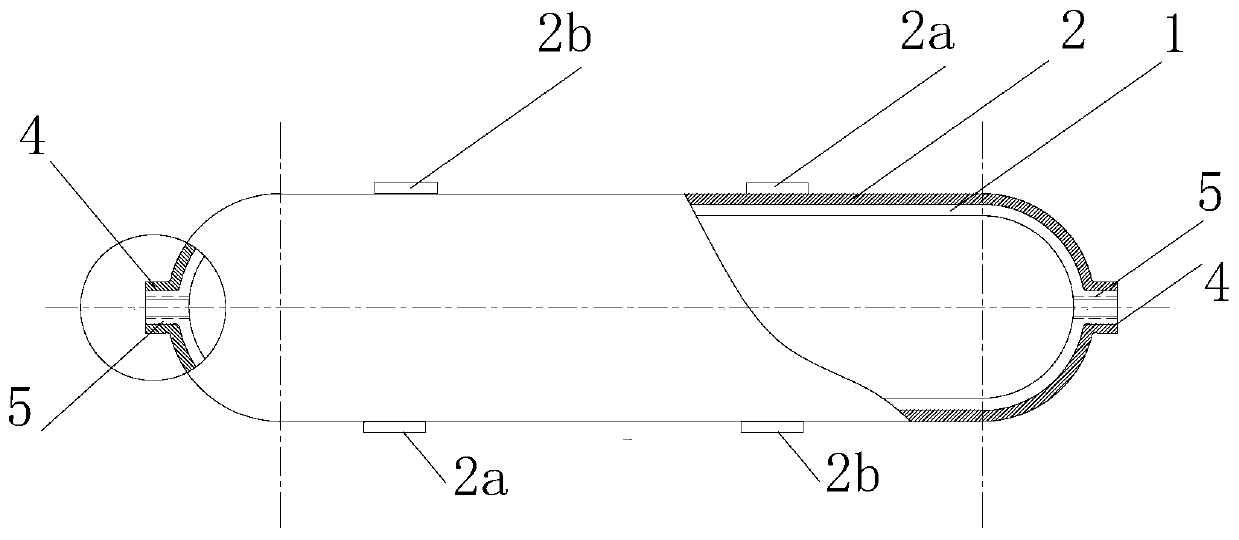

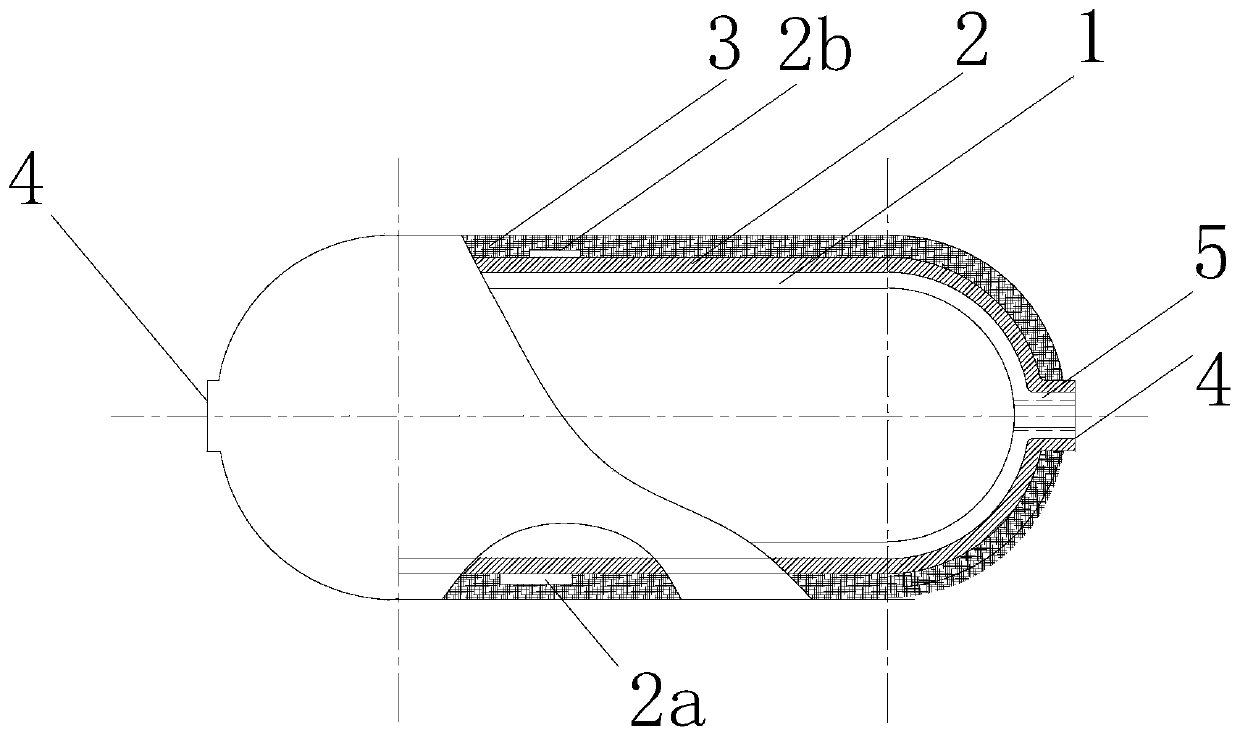

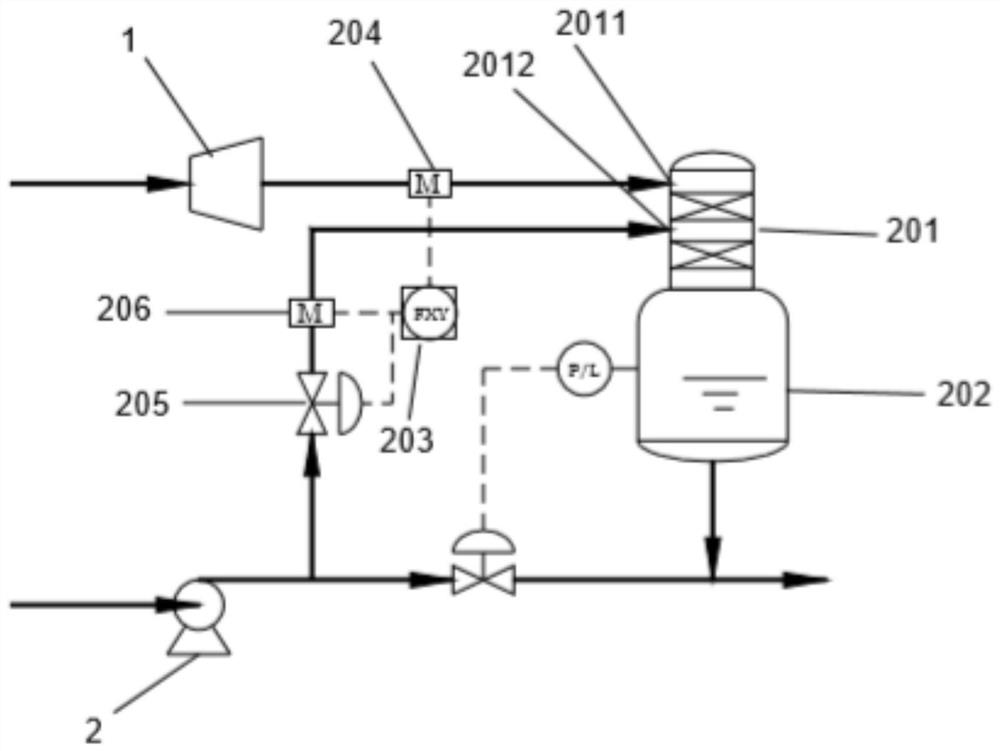

Hydrogen storage reactor and system with fin and spiral coil type heat exchanger coupled

ActiveCN105289440AImprove heat transfer performanceImprove hydrogen storage performanceHeat exchanger casingsChemical/physical/physico-chemical processesChemical reactorDehydrogenation

The invention discloses a hydrogen storage reactor and system with a fin and a spiral coil type heat exchanger coupled, and belongs to the technical field of chemical reactor design. The overall structure of the reactor is a cylindrical shell, and the fin and the spiral coil type heat exchanger subjected to geometric structure optimization are coupled in the shell in an integrated mode, and a heat exchange fluid inlet and outlet pipeline and a hydrogen inlet and outlet pipeline are fixed to the top end and bottom end of the shell respectively. Heat exchange fluid enters the spiral coil type heat exchanger from the center of the top end of the shell, and flows out of the center of the bottom end of the shell, and hydrogen enters the shell through multiple holes channels evenly distributed in the top end of the shell, and reacts with metal hydride. The hydrogen storage reactor and system have the advantages that operation is easy, the structure is compact, hydrogen can be fast dispersed into a bed layer, the heat and mass transfer effect is good, and the hydrogen storage reactor and system are suitable for hydrogen occasions with the large heat effect in the hydrogenation / dehydrogenation reaction process.

Owner:XI AN JIAOTONG UNIV

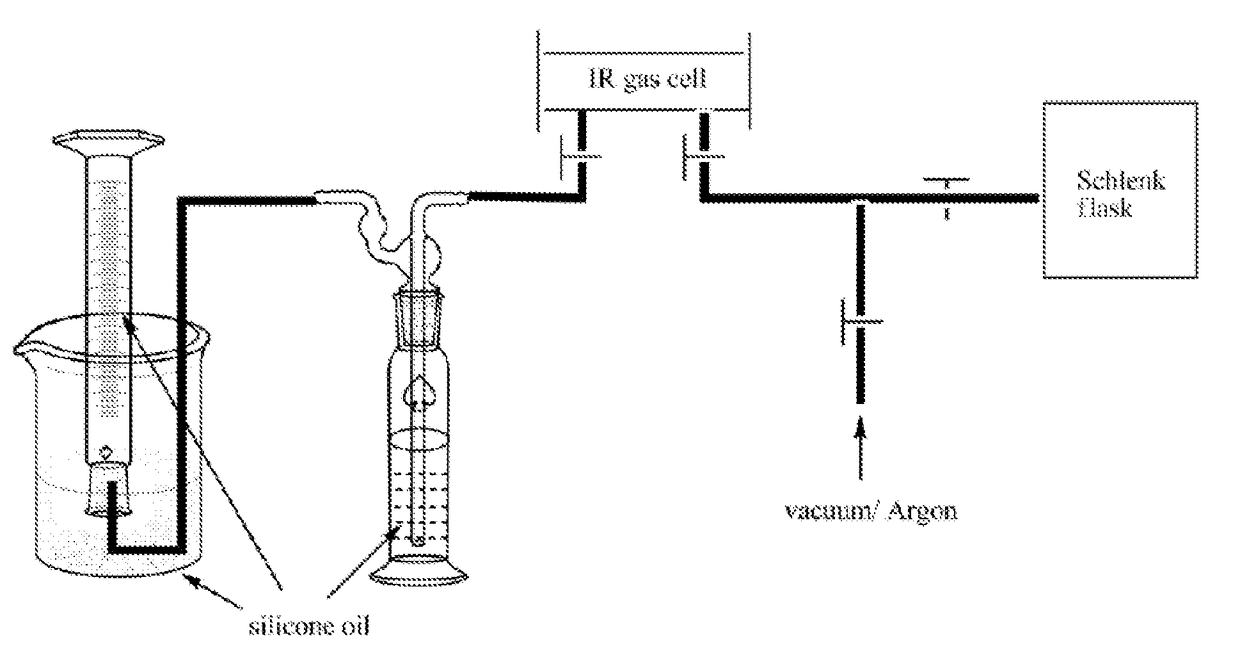

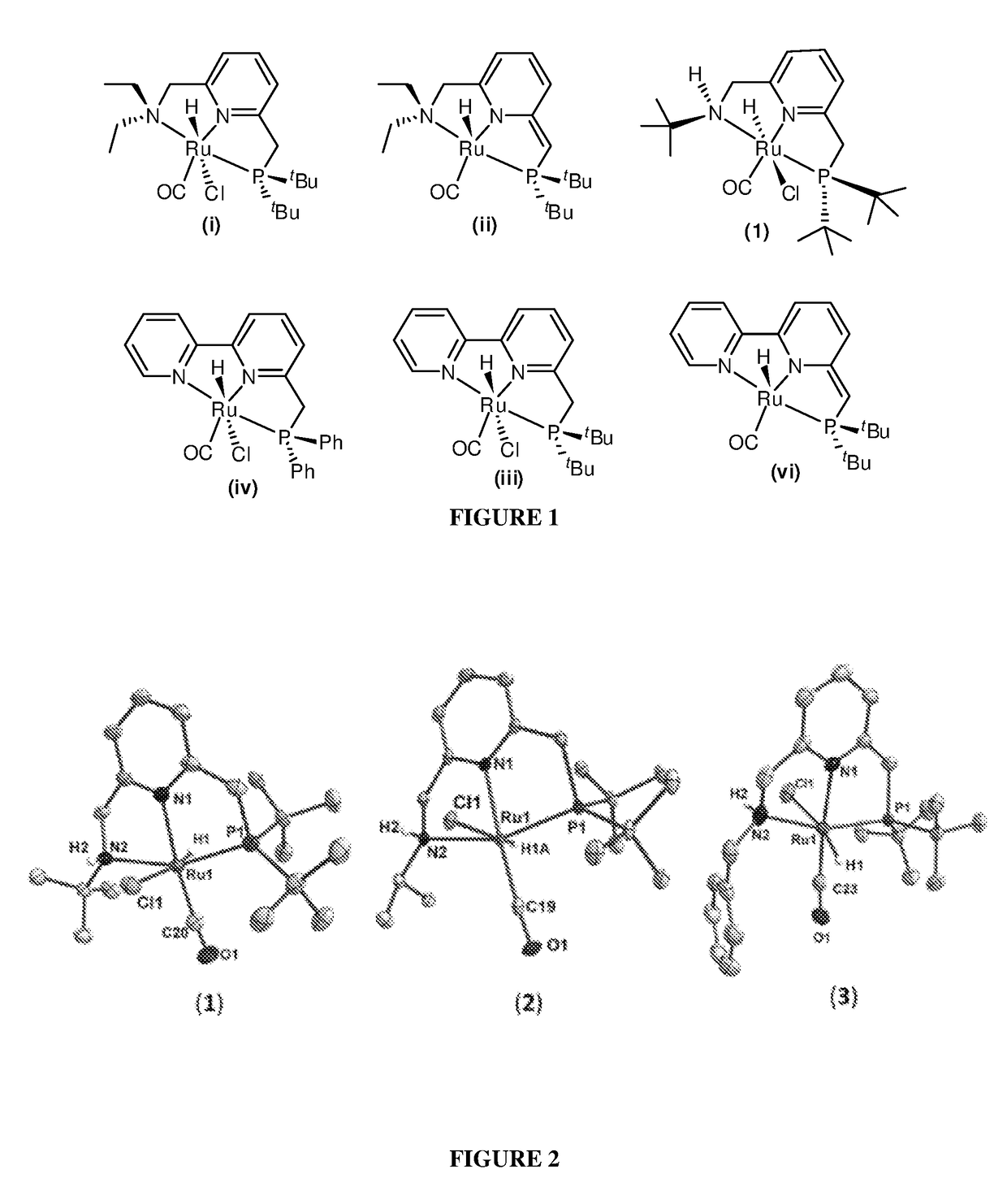

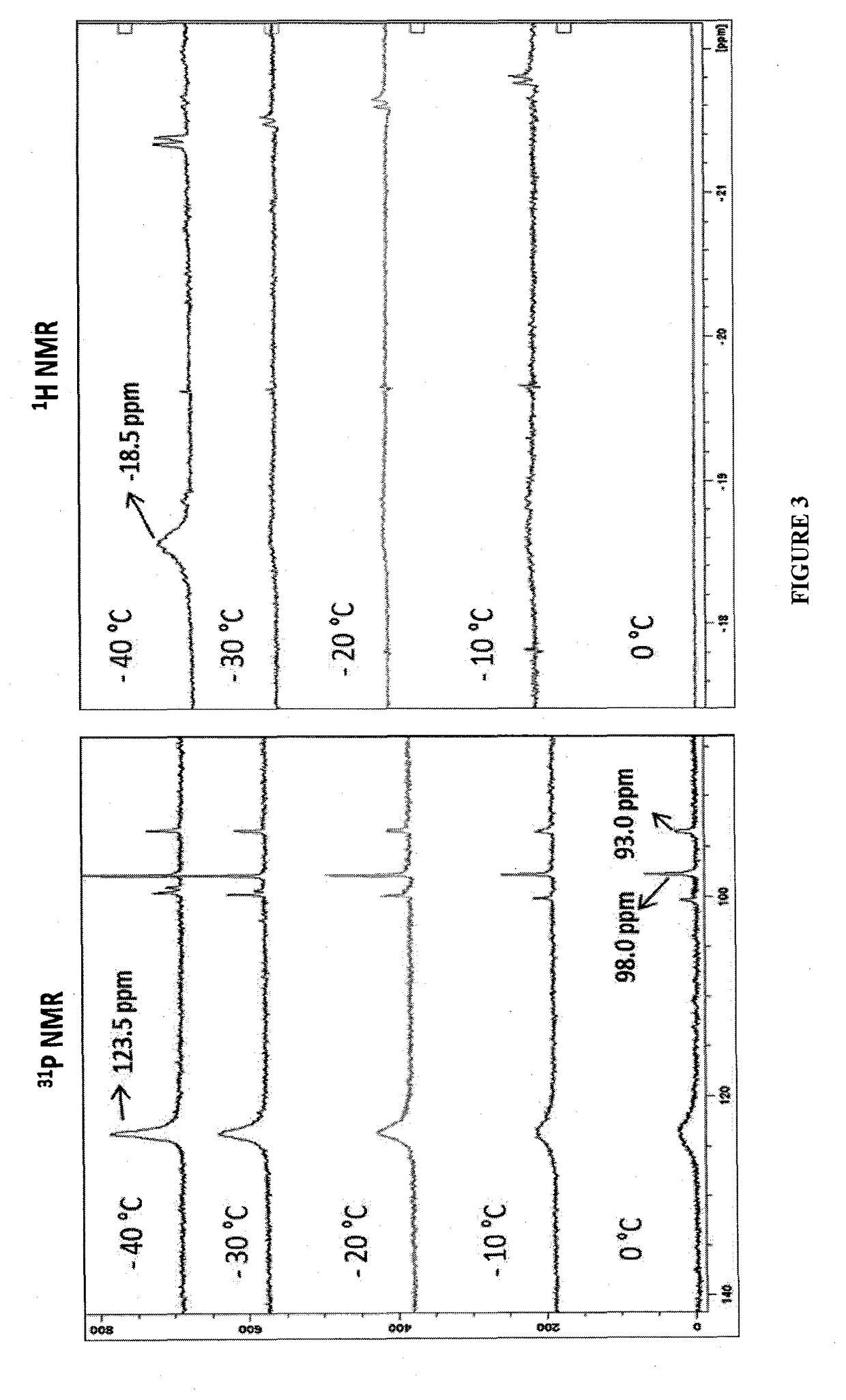

Liquid-organic hydrogen carrier systems based on catalytic peptide formation and hydrogenation

ActiveUS20170283257A1Low-cost and efficientLow-costAmino compound purification/separationOrganic compound preparationMethyl groupDehydrogenation

The present invention provides a system and method of storing hydrogen (H2) and releasing it on demand, comprising and making use of diaminoalkanes and alcohols, or aminoalcohols as liquid-organic hydrogen carrier systems (LOHC). 2-amino-ethanol (AE) or its N-methyl derivative 2-(methylamino)ethanol undergo catalytic dehydrogenation to form a cyclic dipeptide (glycine anhydride—GA) or its N,N-dimethyl derivative (N,N-dimethyl GA) with release of hydrogen. Similarly, ethylenediamine (ED) and ethanol undergo catalytic dehydrogenation to form N,N′-diacetylethylenediamine (DAE) with release of hydrogen. Glycine anhydride (GA) or N,N-dimethyl-GA may be hydrogenated back to 2-aminoethanol (AE) or 2-(methylamino)ethanol, respectively, each of which functions as a hydrogen storage system. N,N′-diacetylethylenediamine (DAE) may be hydrogenated back to ED and ethanol, which functions as a hydrogen storage system. These reactions may be catalyzed by a variety of compounds or complexes, including Ruthenium complexes as described herein.

Owner:YEDA RES & DEV CO LTD

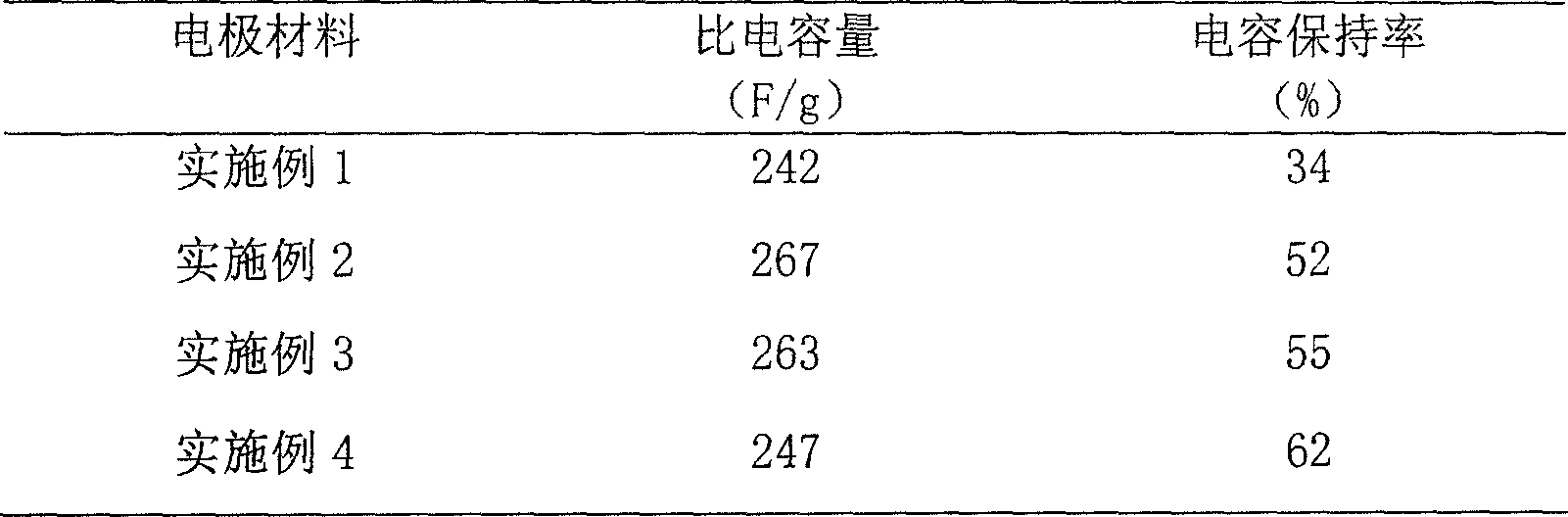

Method for preparing nitrogen-doped porous carbon material by two-step method and application thereof

InactiveCN101531357AExcellent electrochemical performanceIncreased hydrogen storage at low temperatureFurfuryl alcoholCarbon nitrogen

The invention relates to a method for preparing a nitrogen-doped porous carbon material by a two-step method and application thereof, and belongs to the field of hydrogen storage materials and new energy materials. The nitrogen-doped porous carbon material is prepared by adopting a template carbonization method, which comprises that: firstly, a microporous molecular sieve such as ZSM-5, 3A, 5A, 13X, Y, beta and the like is used as a template, and then nitrogen-doped porous carbon material is prepared by adopting the two-step method combining liquid-phase impregnation and chemical precipitation. The liquid-phase impregnation uses sucrose, furfuryl alcohol, polyacrylonitrile and the like as a carbon or carbon-nitrogen precursor which is impregnated in the template, and the chemical precipitation comprises that propylene, acetonitrile, phenyl ethylene, methylbenzene and the like are precipitated on the template by a CVD method in turn. And then, nitrogen-doped porous carbon is further obtained through the process steps such as high temperature carbonization, template removal and the like. The nitrogen-doped porous carbon material with different structures can be obtained by controlling process conditions. The nitrogen-doped porous carbon material prepared by the method has the advantages of high specific surface area, large pore volume, narrow aperture distribution and adjustable pore structure, and can be used for the hydrogen storage materials and super-capacitor electrode materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Aluminum and steel composite layer hydrogen storage tank and filament winding reinforced hydrogen storage bottle with aluminum and steel composite layer hydrogen storage tank as core

InactiveCN110173619AImprove hydrogen storage performanceVessel geometry/arrangement/sizeVessel wallsHigh volume manufacturingFiber-reinforced composite

The invention discloses an aluminum and steel composite layer hydrogen storage tank and a filament winding reinforced hydrogen storage bottle with the aluminum and steel composite layer hydrogen storage tank as a core. A barrel-shaped aluminum alloy with a certain wall thickness is adopted to form the inner layer of the hydrogen storage tank, the two ends of the hydrogen storage tank are semi-spherical shells which are continuously connected, cylindrical pipe joints are arranged at the two ends, making contact with the spherical surface, of the central axis of the cylinder and are smoothly transitioned to and integrated with the spherical surface, a standard internal thread is machined in the inner hole of each pipe joint, the outer surface of the aluminum alloy inner layer is tightly andcontinuously coated with a layer of steel with a certain thickness, the steel layer is a main pressure-bearing layer of the hydrogen storage tank, an aluminum liner can prevent the steel hydrogen embrittlement produced during hydrogen storage of the container, furthermore, the aluminum and steel composite layer hydrogen storage tank is adopted as the core, filament reinforced composite material winds around the outer surface, and therefore the pressure-bearing upper limit of the hydrogen storage tank can be larger than 1000 MPa, and the aluminum and steel composite layer hydrogen storage tankand the filament winding reinhanced hydrogen storage bottle with the aluminum and steel composite layer hydrogen storage tank as the core are easy to process, are suitable for large-scale production,and realizes an effect of promoting the arrival of hydrogen energy economy undoubtedly.

Owner:杨清萍

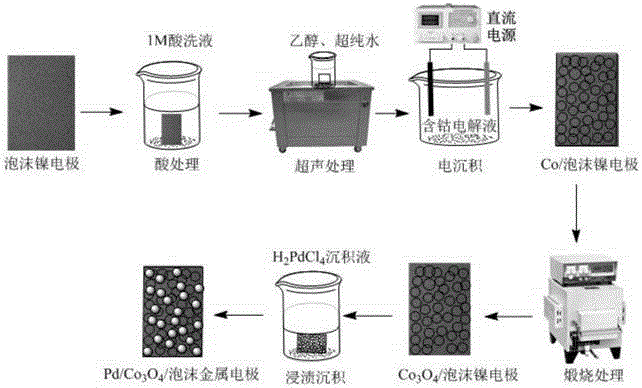

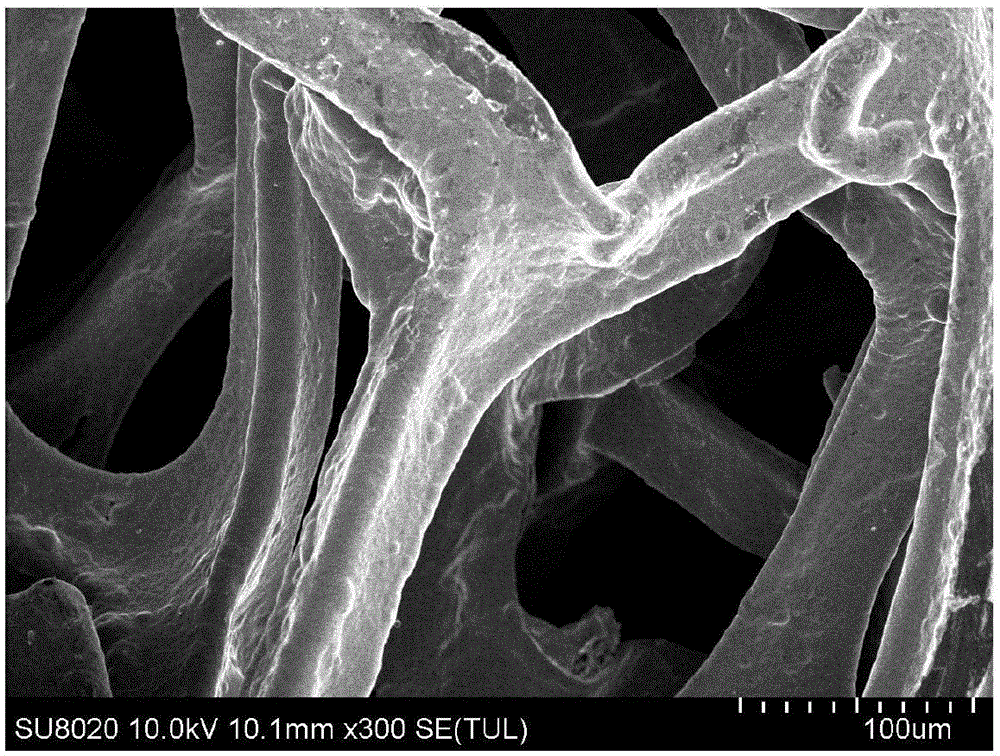

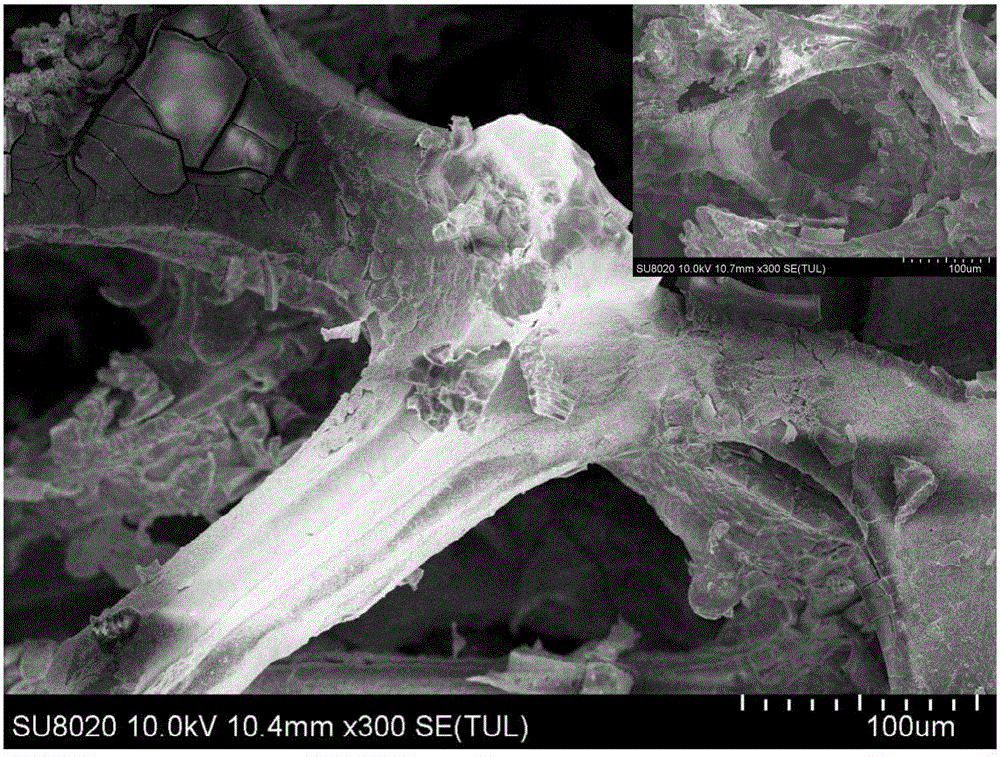

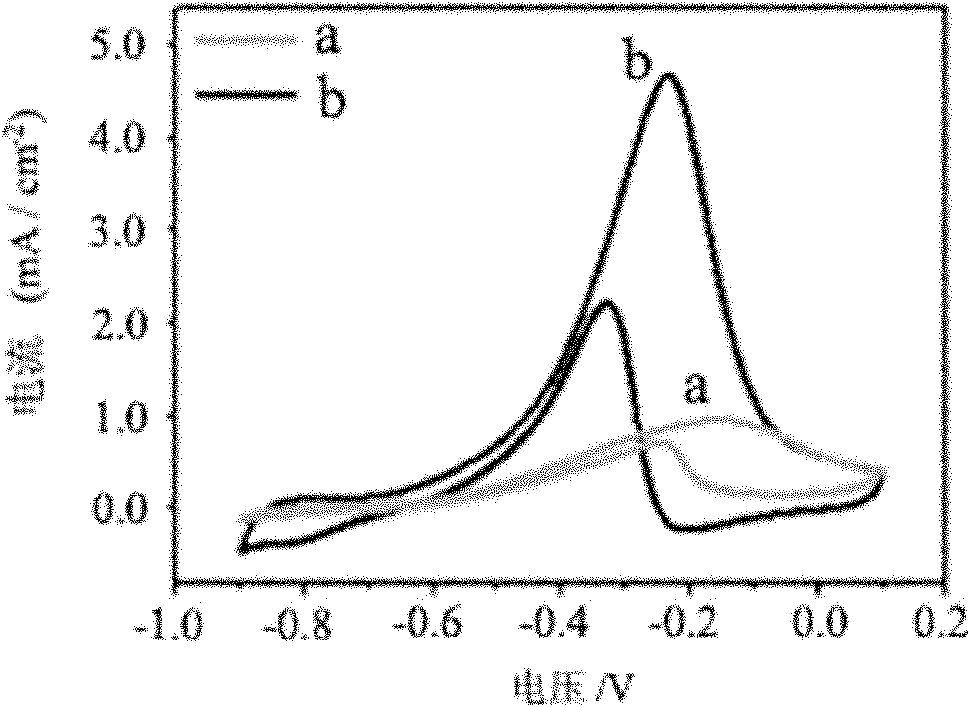

Preparation method of Pd/Co3O4/foamed nickel electrode materials

ActiveCN105040041AResolve difficult to recoverSolve pollutionWater/sewage treatmentNickel electrodeMetal electrodes

The invention relates to a method applicable to a palladium-modified metal electrode with foamed nickel materials as bases. The method comprises the steps that an oxidation layer and oil fouling on the surface of the foamed nickel base materials are removed; bivalent cobalt salt and sodium salt are used for preparing electro-deposition liquid, an inert graphite electrode is used a positive electrode, the foamed nickel base materials are used as a negative electrode, electro-deposition is performed with constant temperature and constant current for preparing a Co / foamed nickel electrode, and drying is performed; the Co / foamed nickel electrode is placed in a tube type resistance furnace, the temperature is increased at a constant speed till reaching the preset value, constant-temperature calcination is performed, and then the Co3O4 / foamed nickel electrode can be obtained; and H2PdC14 impregnation-deposition liquid is prepared, the Co3O4 / foamed nickel electrode is placed in the impregnation-deposition liquid, the impregnation-deposition liquid is shaked in a table concentrator till the impregnation-deposition liquid becomes colorless, and therefore a Pd / Co3O4 / foamed nickel electrode is obtained. The hydrogen-evolution potential of the electrode can be lowered, the hydrogen production and storage capability of the system are improved, and it is ensued that electrocatalytic reduction and degradation are rapidly and efficiently performed on halogenated organic matter.

Owner:GUANGXI UNIV

Method for improving hydrogen storing property of AB2 type hydrogen storing alloy

The invention discloses a modifying method of AB2-typed hydrogen-reserving property of hydrogen-reserving alloy in the alloy making technical domain, which is characterized by the following: designing each component of AB2-typed hydrogen-reserving alloy with purity over 99.9%; adding Nb element to allocate into new alloy; adopting non-consumable (tungsten electrode) vacuum arc furnace to fuse alloy; guaranteeing the casting component and tissue uniformity; inhibiting gravity segregation; adopting Zr and Ti as atom A and Cu, Fe, Ni, Mn, Cr, Co, V, Pd and Nd as atom B; adding Nb element to change microscopic structure and tissue shape of hydrogen-reserving alloy; improving the stability of hydrogen-reserving property effectively.

Owner:TSINGHUA UNIV

Magnesium-base hydrogen storage material having added transition metal oxide

A Mg-base hydrogen-bearing material containing oxide of transition metal is prepared from pure Mg, powdered transition metal, and the oxide of transmition metal, such as Cr2O3, MnO2, Fe2O5, V2O5, TiO2, Fe3O4, NiO, MnO, or V2O3. Its advantages are high kinetic and thermodynamic performance of filling and releasing hydrogen, high hydrogen filling speed, and high hydrogen-bearing capacity.

Owner:HARBIN INST OF TECH

Hydrogen Absorbing Alloy, Hydrogen Absorbing Alloy Electrode, Secondary Battery and Production Method of Hydrogen Absorbing Alloy

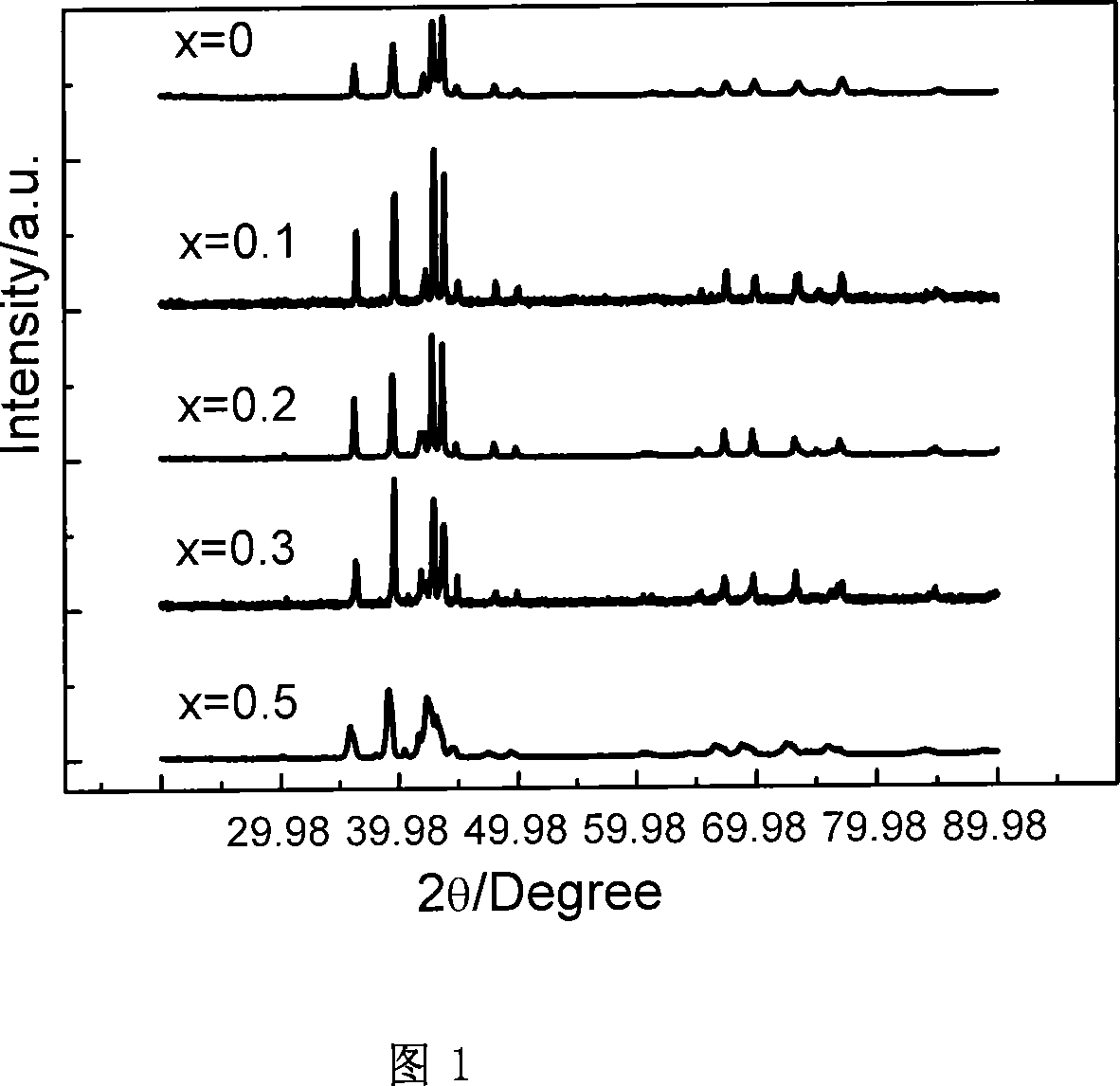

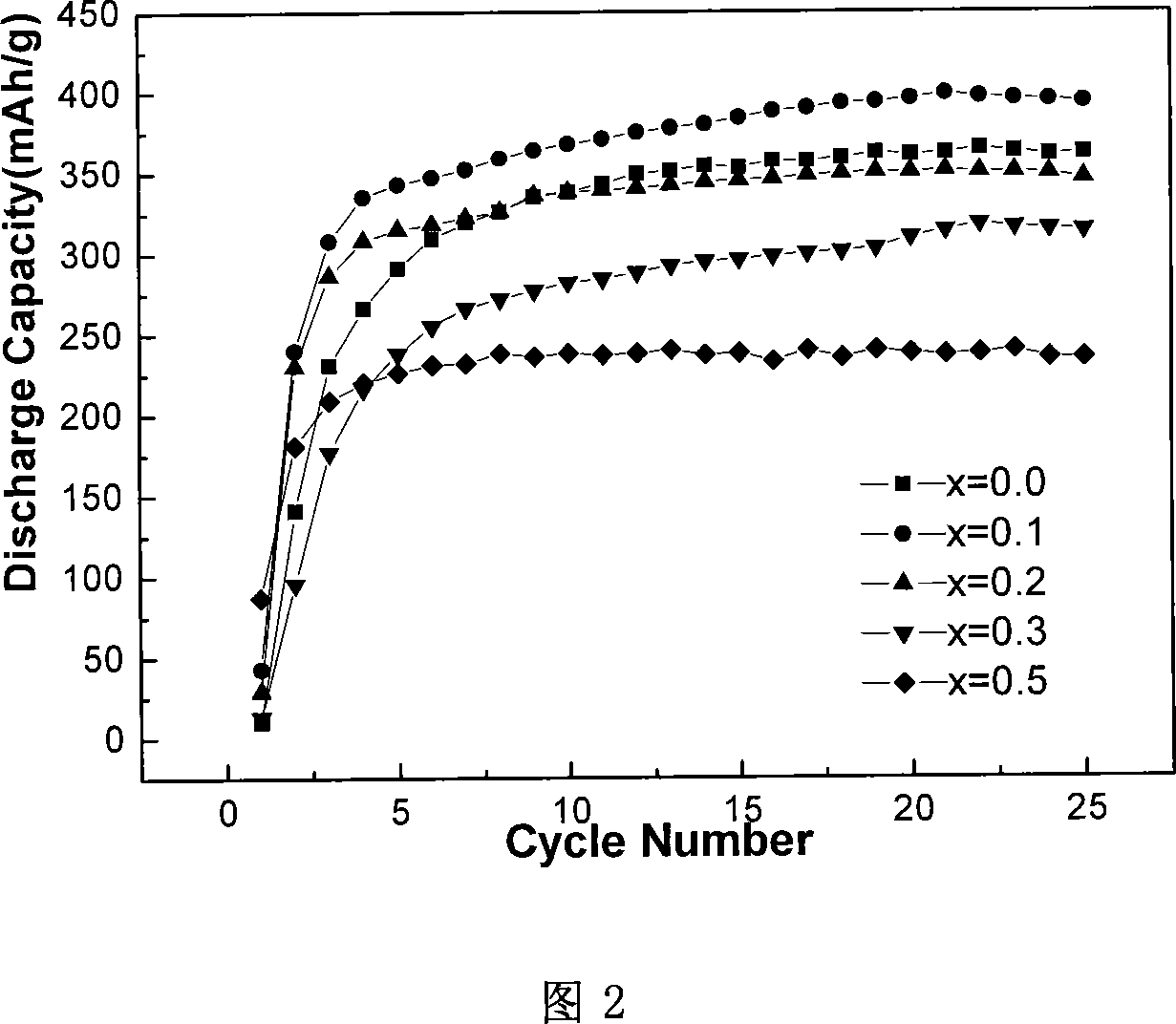

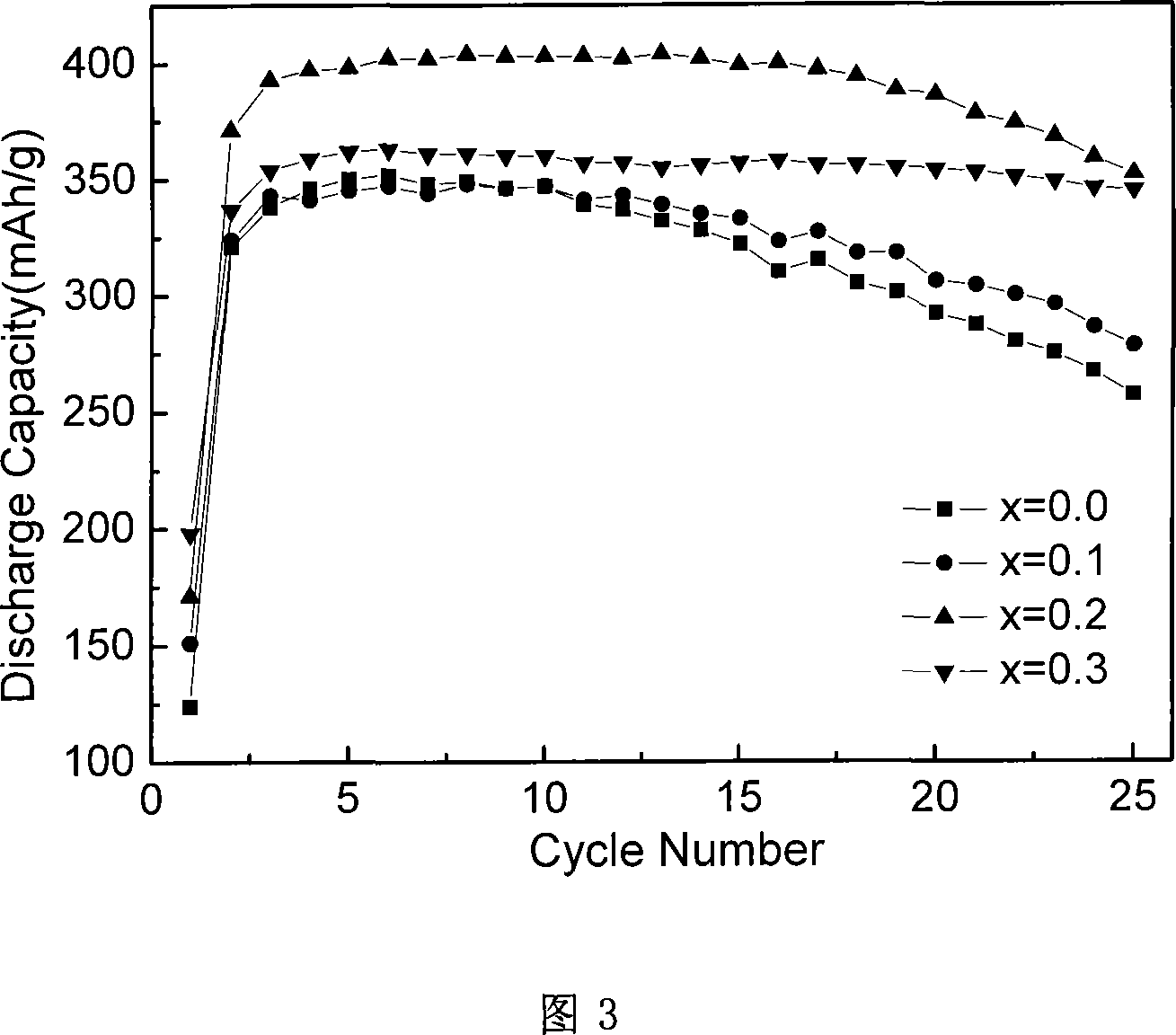

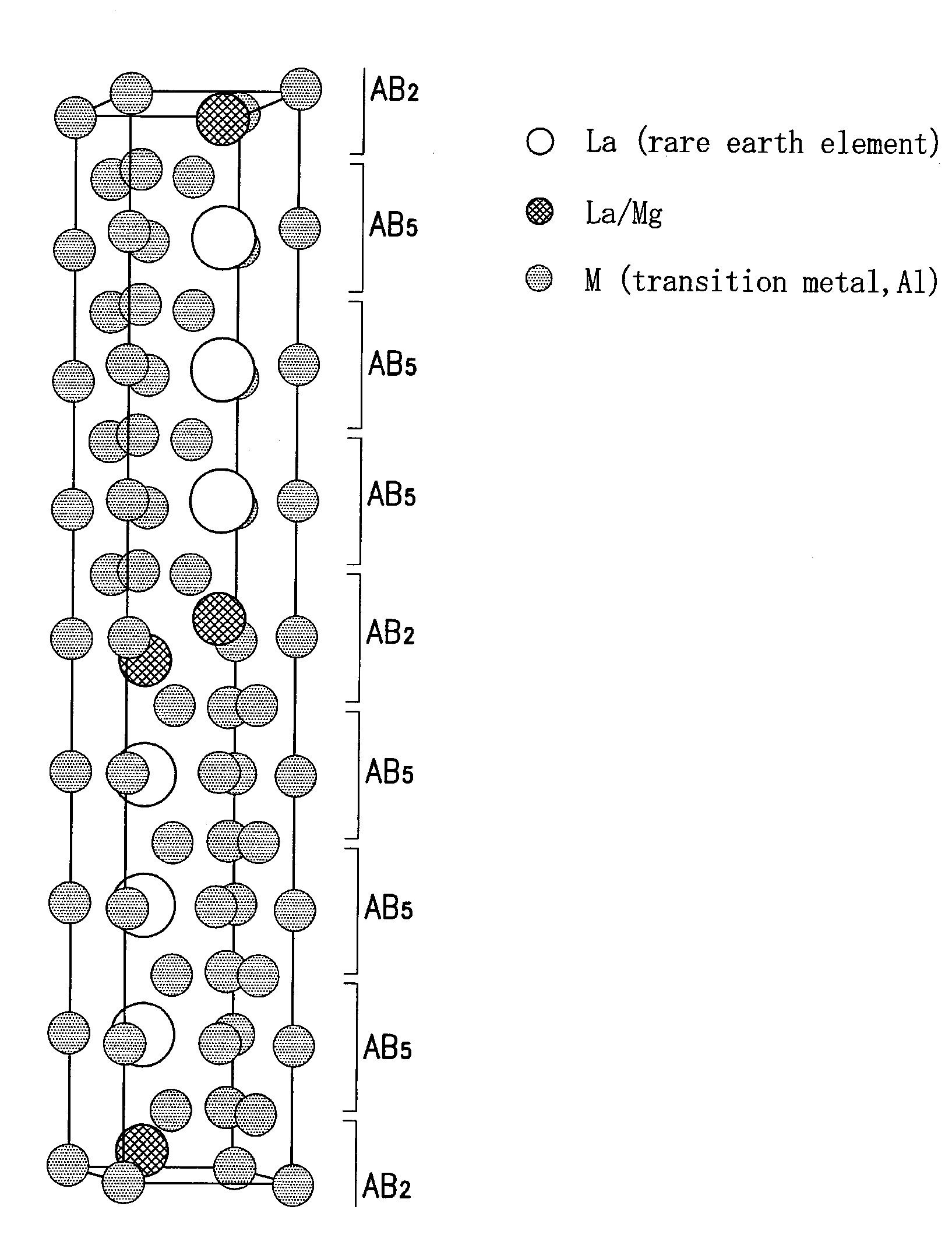

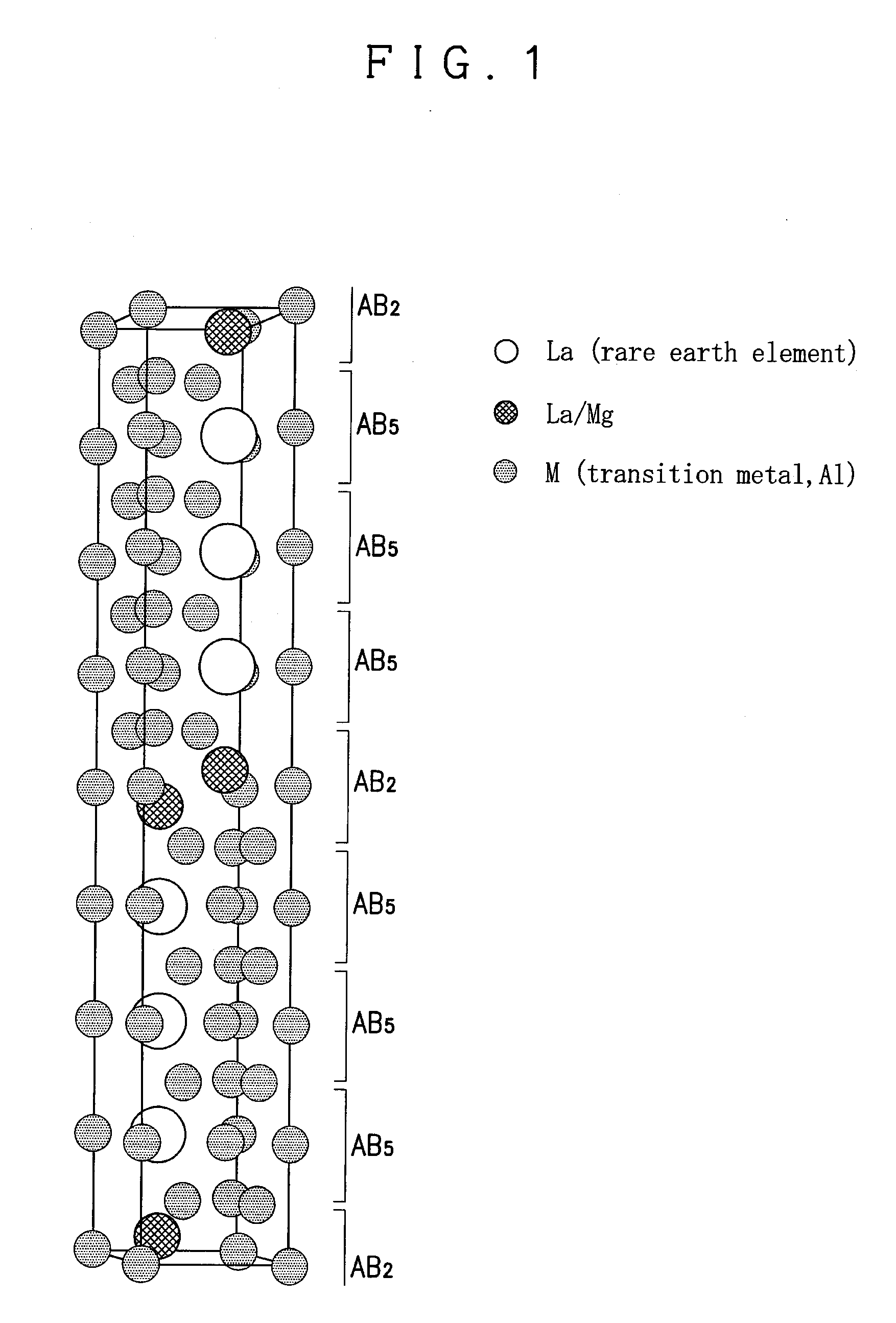

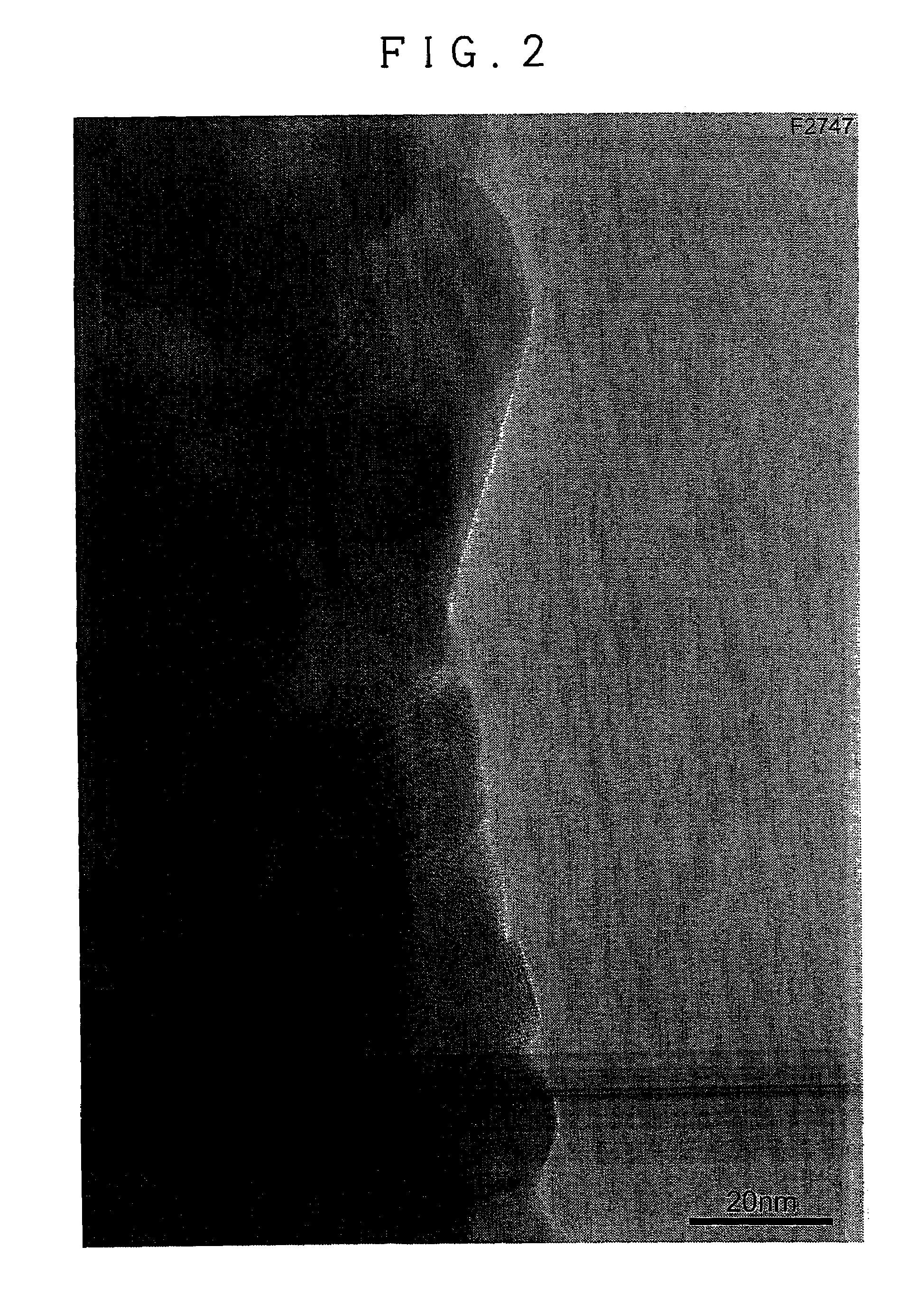

ActiveUS20090226342A1Improve hydrogen storage performanceIncreased durabilityReactant parameters controlCell electrodesRare-earth elementCrystal structure

The present invention provides a hydrogen absorbing alloy containing a phase of a Pr5Co19 type crystal structure having a composition defined by a general formula A(4−w)B(1+w)C19 (A denotes one or more element(s) selected from rare earth elements including Y (yttrium); B denotes an Mg element; C denotes one or more element(s) selected from a group consisting of Ni, Co, Mn, and Al; and w denotes a numeral in a range from −0.1 to 0.8) and having a composition as a whole defined by a general formula R1xR2yR3z (15.8≦x≦17.8, 3.4≦y≦5.0, 78.8≦z≦79.6, and x+y+z=100; R1 denotes one or more element(s) selected from rare earth elements including Y (yttrium); R2 denotes an Mg element, R3 denotes one or more element(s) selected from a group consisting of Ni, Co, Mn, and Al; the numeral of Mn+Al in the z is 0.5 or higher; and the numeral of Al in the z is 4.1 or lower).

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

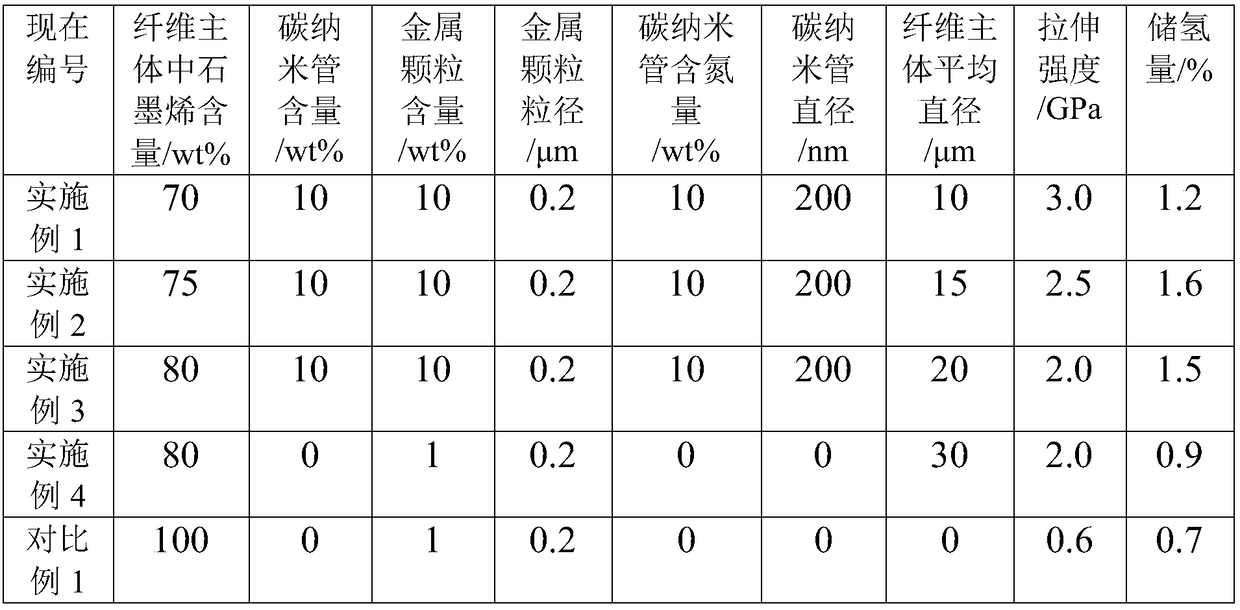

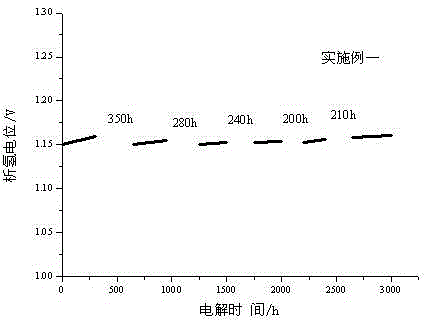

Graphene-based carbon fiber high in strength and hydrogen storage capacity, and preparation method thereof

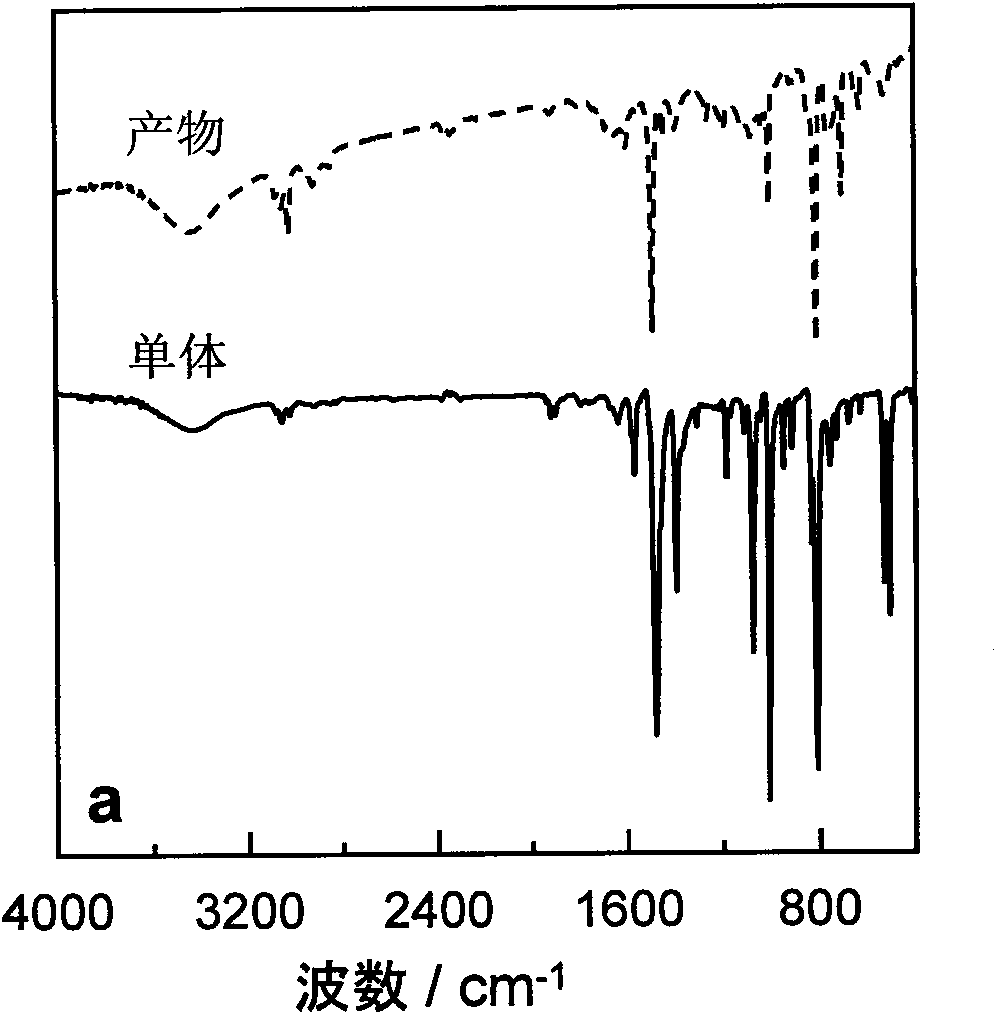

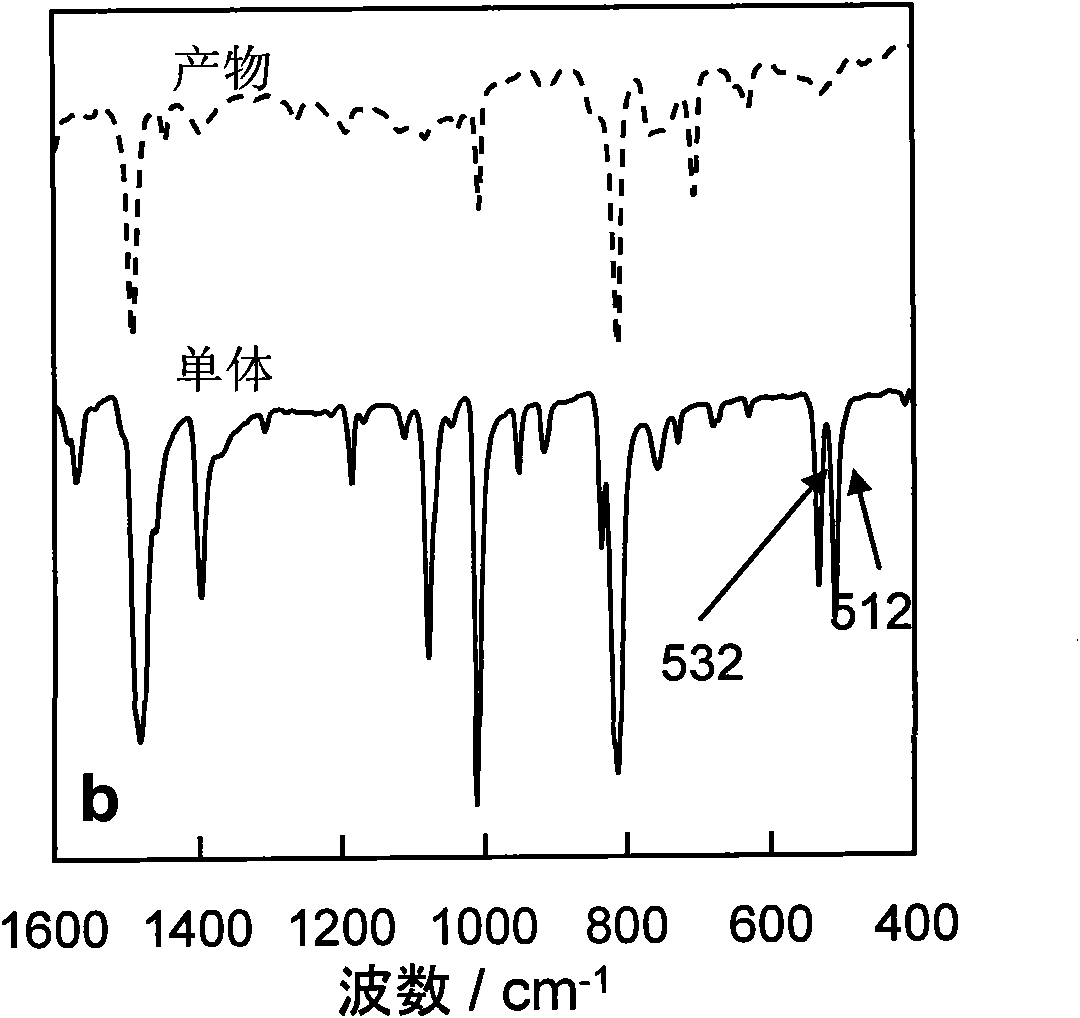

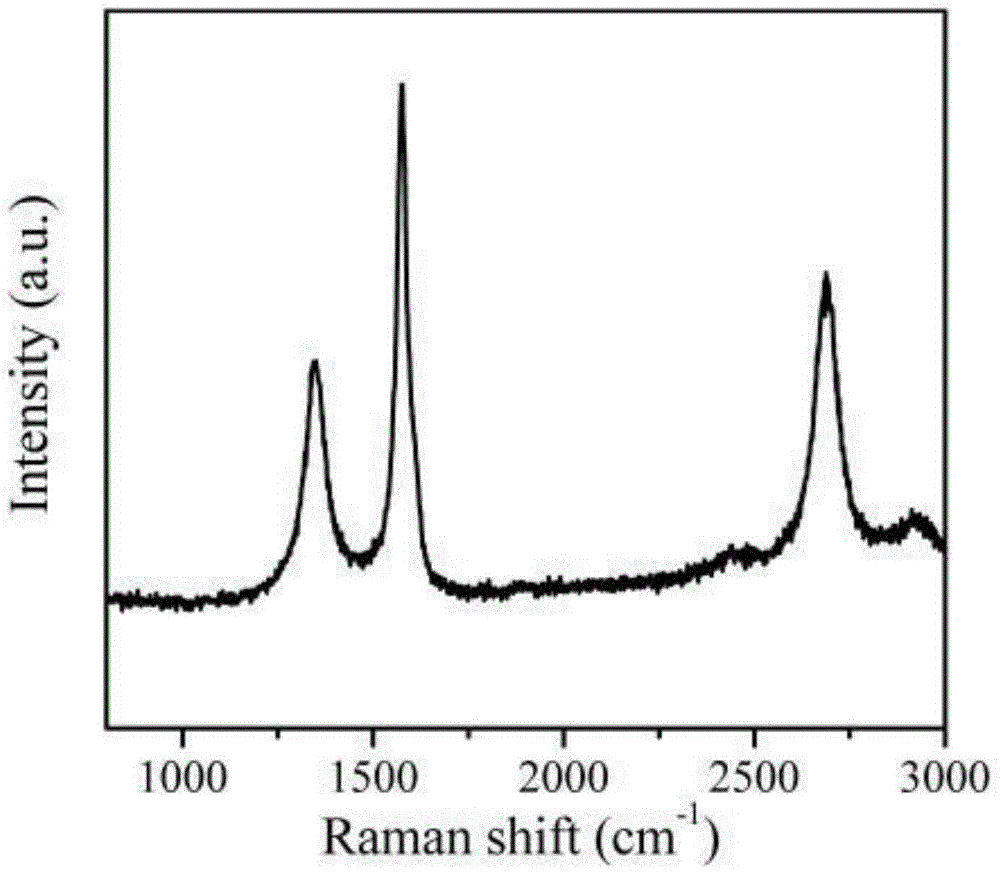

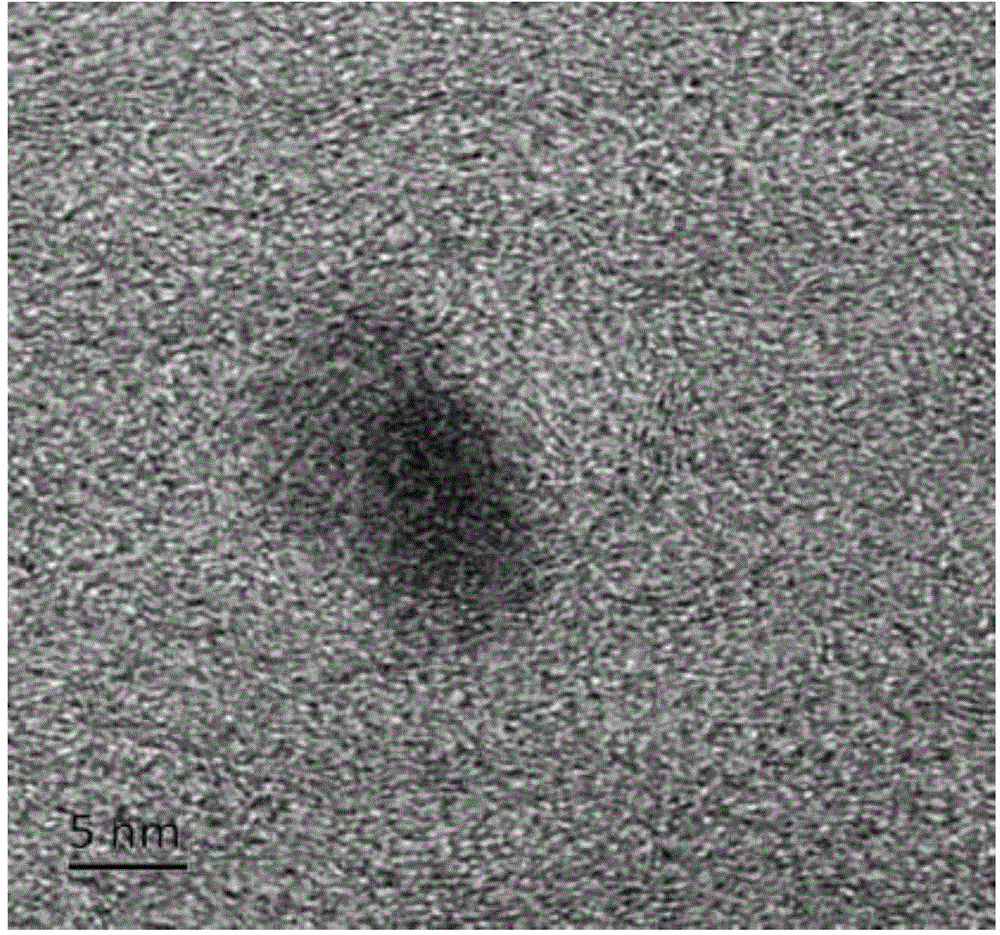

ActiveCN109423702AHigh strengthHigh hydrogen storage capacityArtificial filament chemical after-treatmentArtifical filament manufactureFiberNew energy

The invention belongs to the field of carbon material, and relates to a graphene-based carbon fiber high in strength and hydrogen storage capacity, and a preparation method thereof. The fiber main body of the graphene-based carbon fiber high in strength and hydrogen storage capacity is composed of graphene and amorphous carbon, wherein the weight amount of graphene accounts for 60 to 100% of the weight amount of the fiber main body; the fiber main body may also be loaded with carbon nanotube, the fiber main body, or the fiber main body and the carbon nanotube grows on the fiber main body are modified with metal particles; when the total weight amount of the graphene-based carbon fiber is taken as 100wt%, the content of the metal particles ranges from 0 to 30wt%, and the content of carbon nanotube ranges from 0 to 300wt%. The graphene-based carbon fiber is prepared through following steps: oxidized graphene based initial fiber is prepared through spinning of a spinning solution preparedthrough mixing of an oxidized graphene aqueous solution and a polymer solution based on solution spinning method, and the initial fiber is subjected to carbonization so as to obtain a finished product. The preparation method is simple; the performance is excellent; and the graphene-based carbon fiber can be taken as a hydrogen storage material, and can be used in the fields such as new energy automobile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite hydrogen evolution negative pole with micropore hydrogen storage layer and preparing method for composite hydrogen evolution negative pole

InactiveCN105350015ALarge specific surface areaImprove bindingMolten spray coatingElectrodesElectrolysisThermal spraying

The invention discloses a composite hydrogen evolution negative pole with a micropore hydrogen storage layer and a preparing method for the composite hydrogen evolution negative pole. The method includes the steps that (1) base body pretreatment, wherein a base body is subject to alkali soaking and washing, and then sand blasting is carried out; (2) a hydrogen storage middle layer is prepared, wherein the step includes the steps: (2.1) plasma thermal spraying treatment is carried out, a Ni50A150 alloy and hydrogen storage alloy powder are evenly mixed according to the weight ratio being (0.95-0.8): (0.05-0.2), and a plasma spraying device is used for spraying; and (2.2) activating treatment is carried out, the base body treated in the step (2.1) is placed into a first alkaline solution to be soaked, excitation is carried out, and the micropore middle layer with the high specific surface area and the high hydrogen storage performance is obtained; and (3) a thermal decomposition method is adopted for preparing a catalyst layer on the hydrogen storage middle layer. The preparing method is simple and reliable in preparation process, the commercial process is easily achieved; and the prepared composite hydrogen evolution pole has the beneficial effects that the hydrogen evolution catalytic activity is high; during continuous electrolysis, the countercurrent resisting capacity is high, and the service life of the pole is long.

Owner:派新(上海)能源技术有限公司

Hydrogen-storing hydride complexes

ActiveUS8153020B1Increase ratingsLower decomposition temperatureHydrogenOther chemical processesActivation energyBiological activation

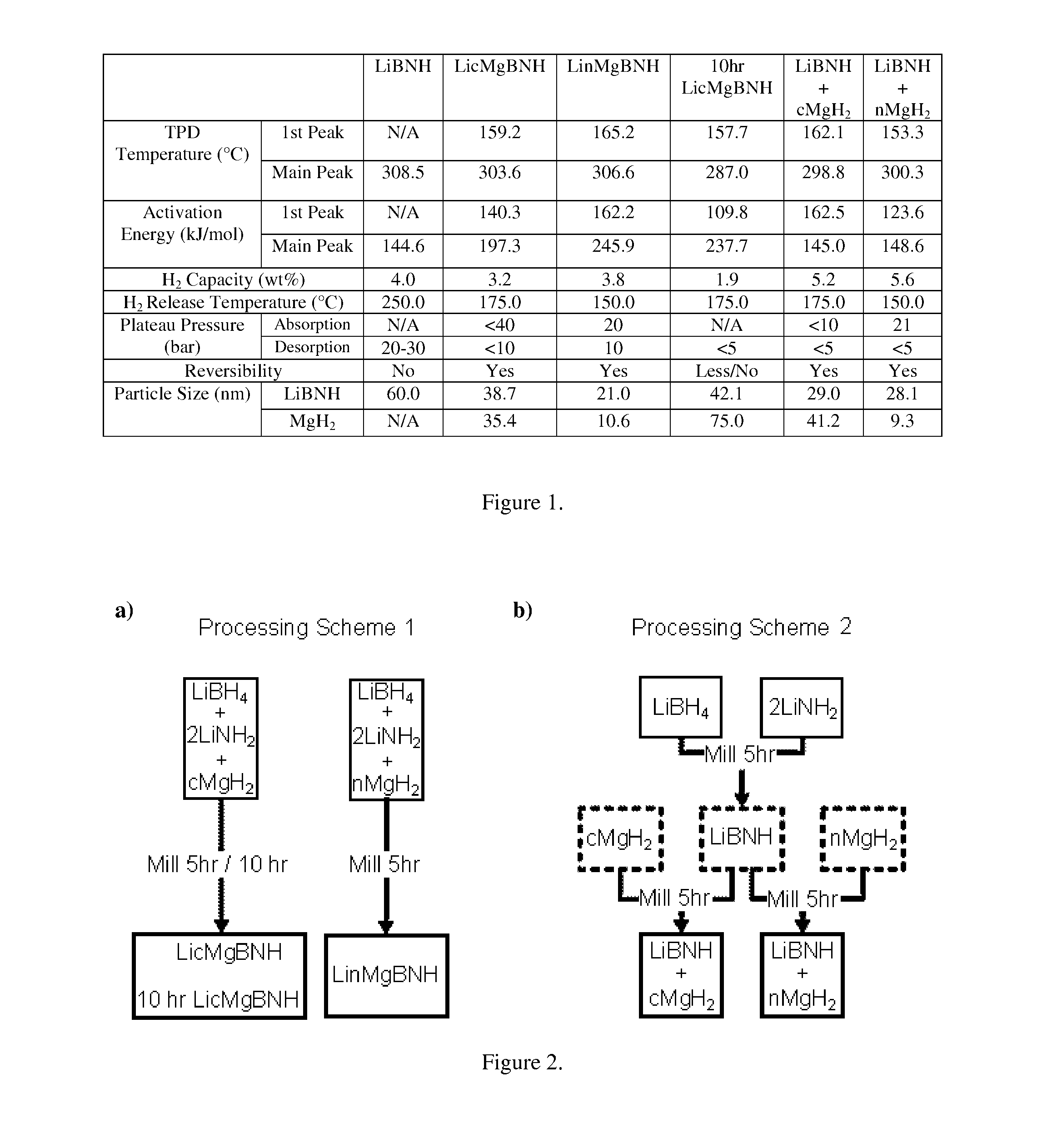

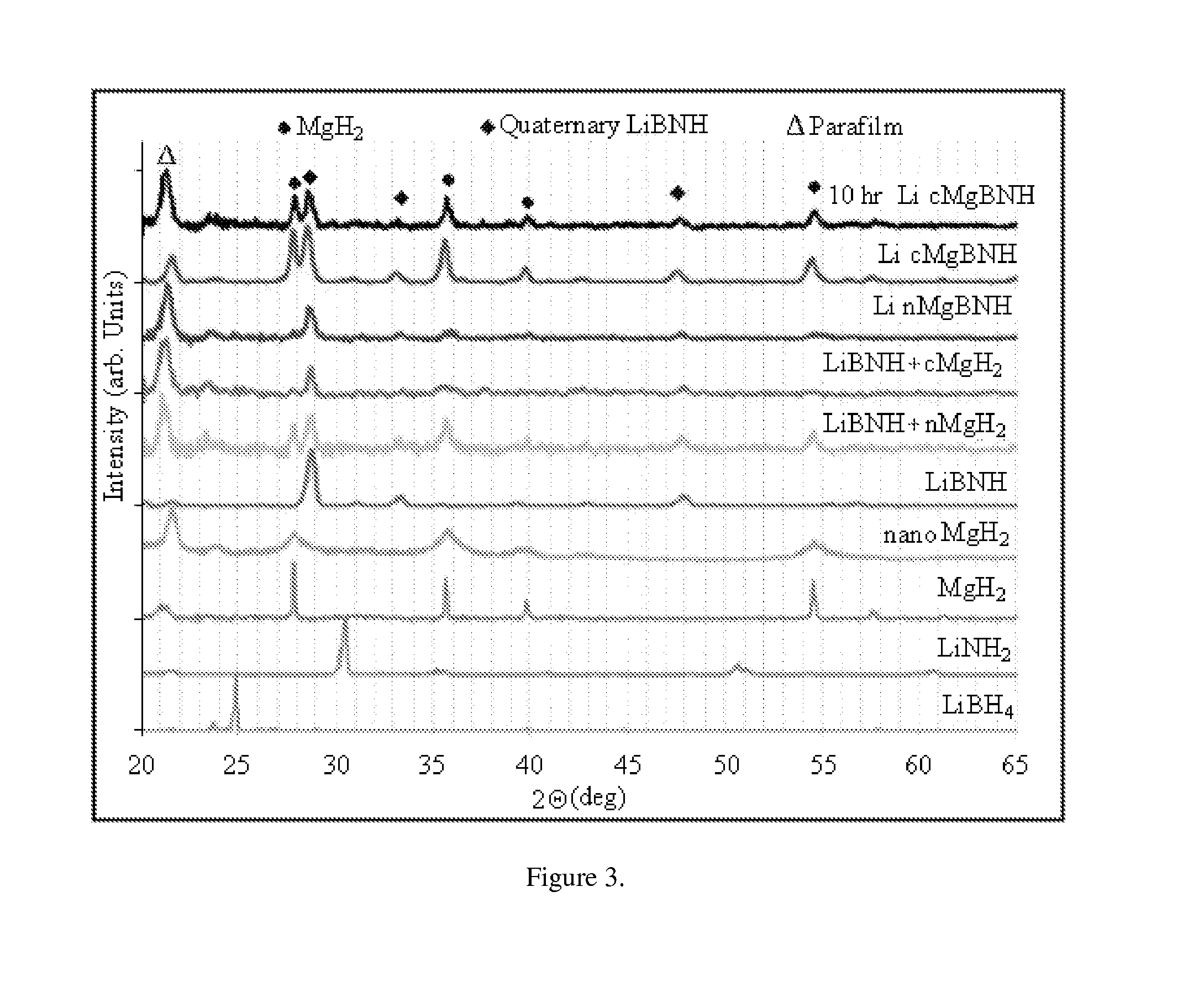

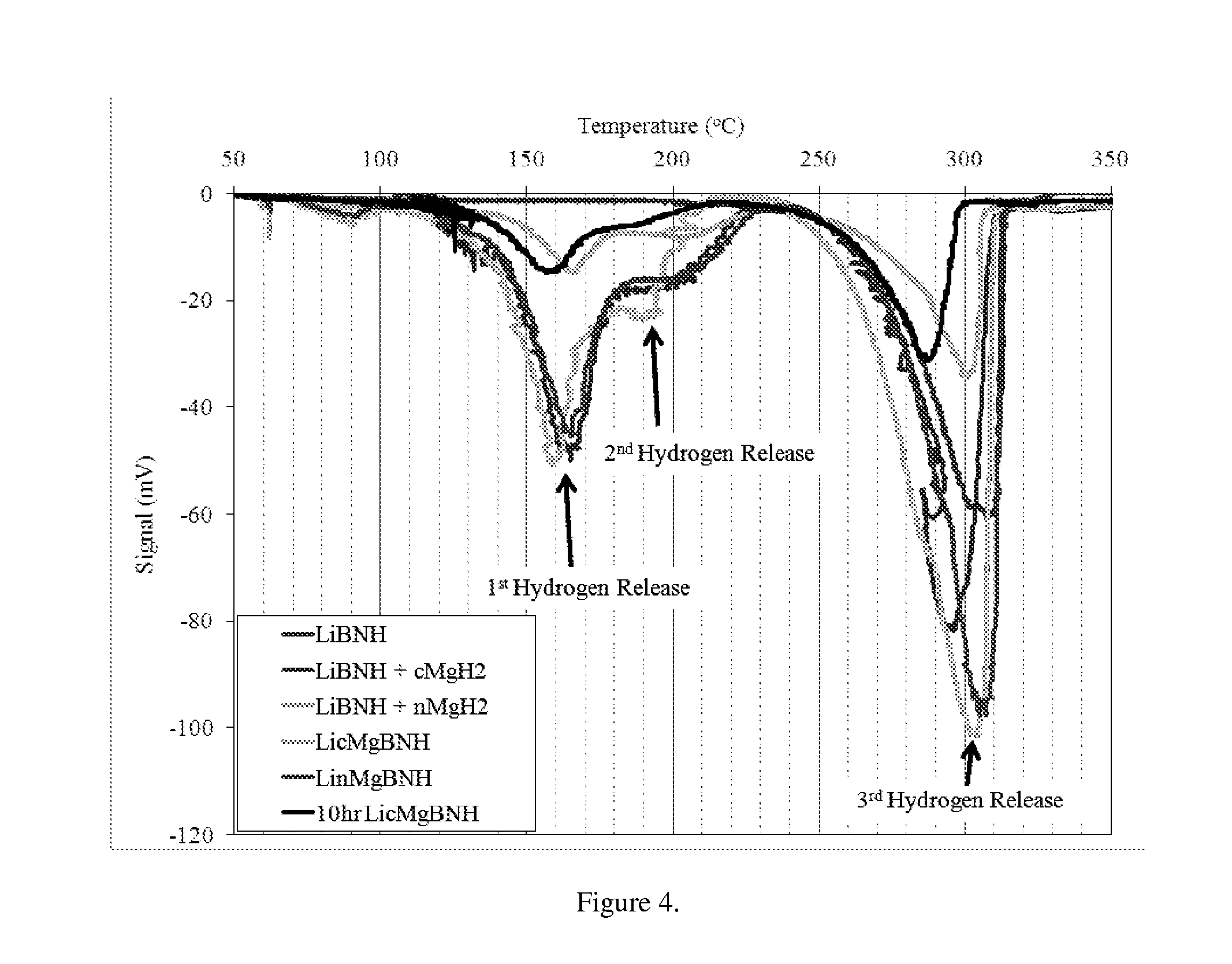

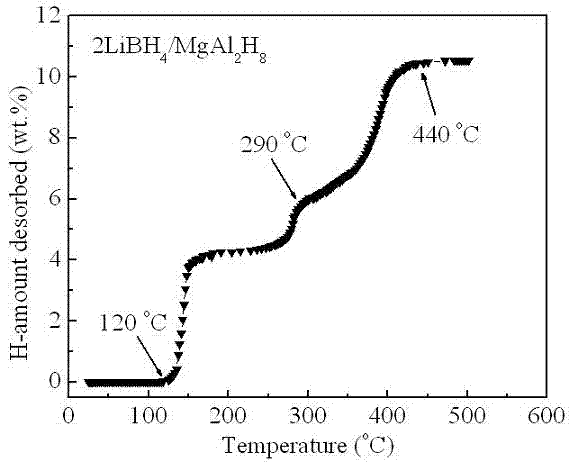

A ternary hydrogen storage system having a constant stoichiometric molar ratio of LiNH2:MgH2:LiBH4 of 2:1:1. It was found that the incorporation of MgH2 particles of approximately 10 nm to 20 nm exhibit a lower initial hydrogen release temperature of 150° C. Furthermore, it is observed that the particle size of LiBNH quaternary hydride has a significant effect on the hydrogen sorption concentration with an optimum size of 28 nm. The as-synthesized hydrides exhibit two main hydrogen release temperatures, one around 160° C. and the other around 300° C., with the main hydrogen release temperature reduced from 310° C. to 270° C., while hydrogen is first reversibly released at temperatures as low as 150° C. with a total hydrogen capacity of 6 wt. % to 8 wt. %. Detailed thermal, capacity, structural and microstructural properties have been demonstrated and correlated with the activation energies of these materials.

Owner:UNIV OF SOUTH FLORIDA

Method for improving hydrogen storage property of lithium borohydride

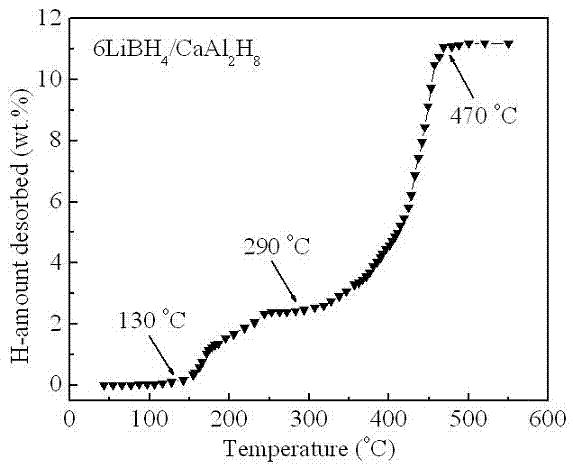

InactiveCN102502488AImprove hydrogen storage performanceImproved hydrogen releaseHydrogen productionAlkaline earth metalHydrogen fuel cell

The invention provides a method for improving a hydrogen storage property of lithium borohydride, and belongs to the technical field of hydrogen storage materials. The method comprises the following steps of: mixing the lithium borohydride and alkaline-earth metal alanate according to the molar ratio of 2:1-10:1 under the protection of vacuum or inert gases, and heating mixed powder of the lithium borohydride and the alkaline-earth metal alanate to a certain temperature to ensure that the alkaline-earth metal alanate is decomposed into alkaline-earth metal hydride, aluminum or aluminum alloy in advance. By the method, double effects of in situ and concerted catalysis in the process of discharging and absorbing hydrogen of the lithium borohydride by using the alkaline-earth metal alanate are achieved, so that a hydrogen discharging temperature of the lithium borohydride is greatly reduced, and the hydrogen absorbing and discharging dynamic properties of the lithium borohydride are improved. The method is suitable for storing the hydrogen safely and efficiently and is particularly applied in fields of hydrogen fuel cells and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Fullerene hydrogen storage material modified by hydrogen storage alloy or metal nano-particle

InactiveCN1557701AReduced Diffusion ResistanceReduce manufacturing costMaterial nanotechnologyRare earthFullerene

The hydrogen storing material is fullerene material with hydrogen storing metal or alloy compounded to the surface. Fullerene is spherical carbon molecule or carbon cage comprising several decades or several thousands of even number of carbon atoms and in the chemical expression of Cn, with n is 60 or other even number greater than 60. Fullerene as hydrogen storing material may be also mixture of tow or more spherical carbon molecule or carbon cage in any ratio. The hydrogen storing metals includes IA to IVB heat releasing soluble metals and VB to VIII heat absorbing soluble metals except Pd. The hydrogen storing alloy may be crystalline RE-Ni alloy in AB5 form, Zr-base or Ti-base Laves line AB2 form alloy, FeNi and Ti line AB form alloy, etc. The hydrogen storing material of the present invention has hydrogen storing capacity of 2.0-4.0 wt%.

Owner:WUHAN UNIV OF TECH

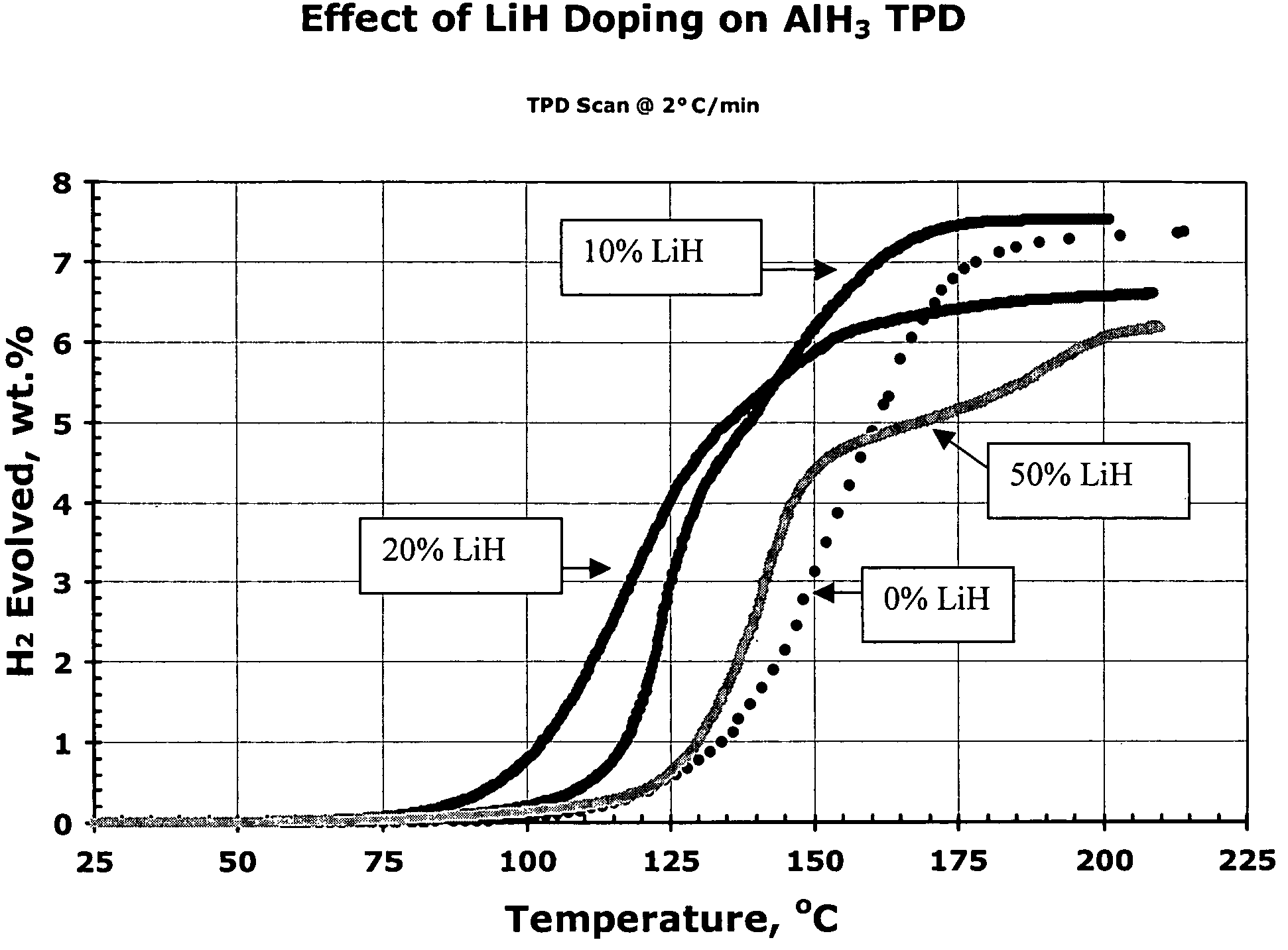

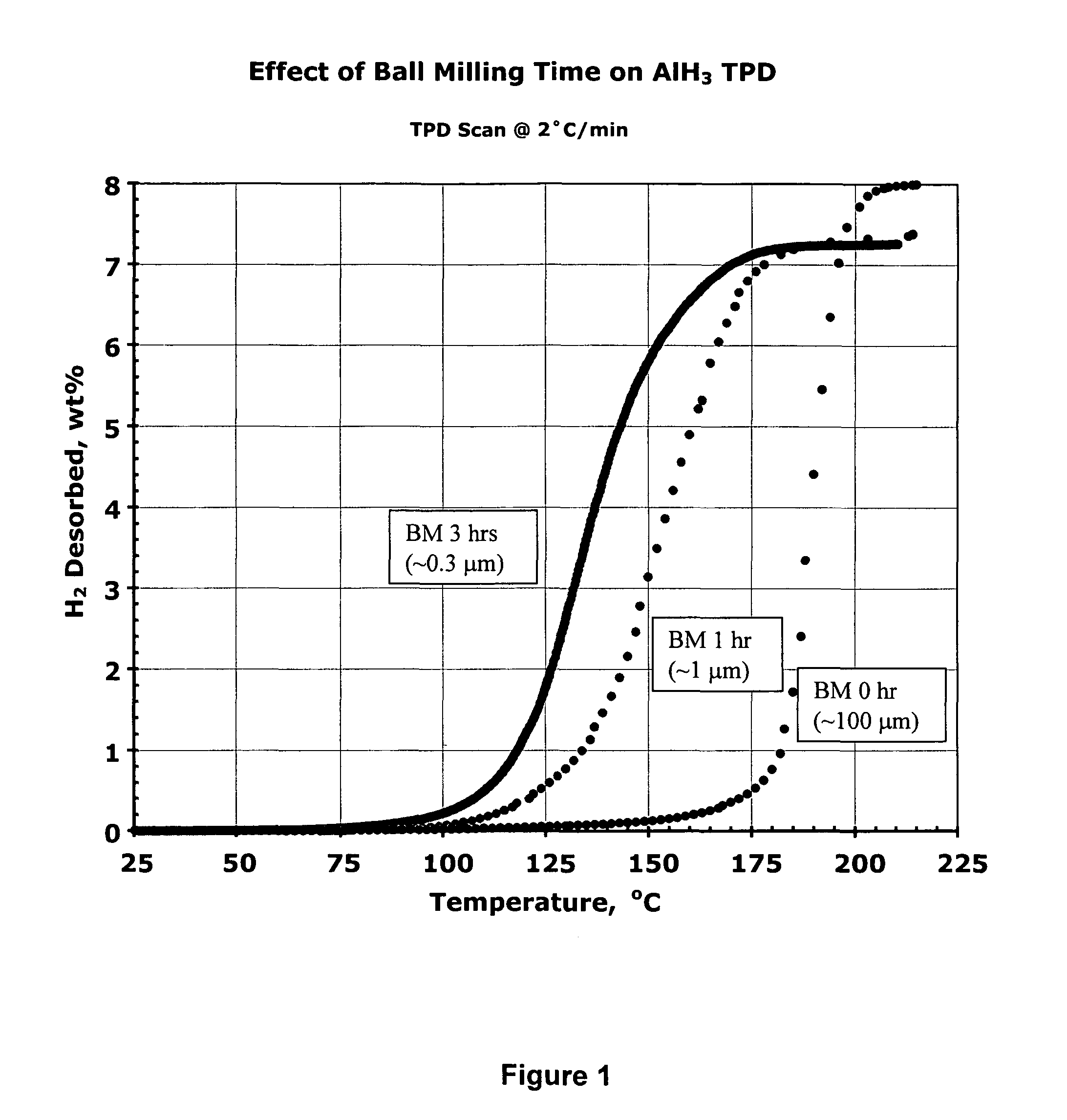

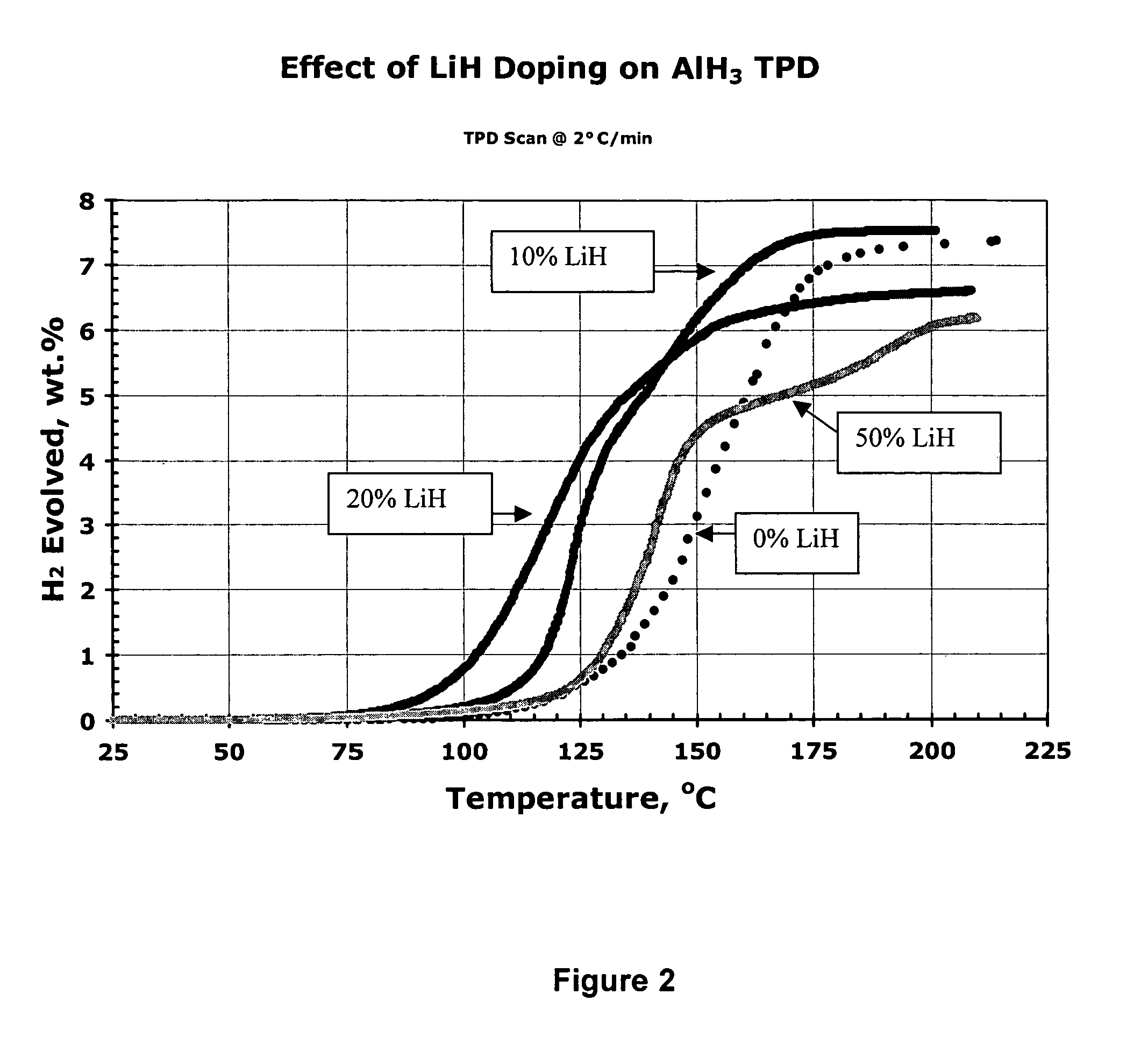

Activated aluminum hydride hydrogen storage compositions and uses thereof

InactiveUS7837976B2Improve hydrogen storage performanceImproved desorption kineticsAlkali/alkaline-earth/beryllium/magnesium hydridesMultiple metal hydridesHydrogen desorptionALUMINUM HYDRIDE

In one aspect, the invention relates to activated aluminum hydride hydrogen storage compositions containing aluminum hydride in the presence of, or absence of, hydrogen desorption stimulants. The invention particularly relates to such compositions having one or more hydrogen desorption stimulants selected from metal hydrides and metal aluminum hydrides. In another aspect, the invention relates to methods for generating hydrogen from such hydrogen storage compositions.

Owner:BROOKHAVEN SCI ASSOCS

Method for preparing electrocatalytic noble metal nanomaterial with three-dimensional network structure

ActiveCN102166518AAdjustable sizeHigh purityNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingNanomaterials

The invention discloses a method for preparing an electrocatalytic noble metal nanomaterial with a three-dimensional network structure, and the method is implemented by using a one-step hydrothermal process. The method comprises the following steps: firstly, adding ethanediol, noble metal precursors and surfactants into a reaction kettle, and uniformly stirring the obtained mixture in the reaction kettle; then, adding formaldehyde into the reaction kettle, and evenly stirring the mixture in the reaction kettle; sealing the reaction kettle, putting the reaction kettle into a baking oven to react for 6-10 hours at a temperature of 130-200 DEG C; and finally, naturally cooling the reaction kettle to room temperature, then carrying out centrifugal washing on the reaction kettle. By using the method disclosed by the invention, the preparation of electrocatalytic noble metal nanomaterials with a three-dimensional network structure can be realized; in a porous network structure formed by themutual fusion of noble metal particles with a particle diameter of dozens of nanometers, the hole size is several nanometers to hundreds of nanometers, the attribute advantages of noble metals and the porous network structure are combined, and the one-step hydrothermal process is adopted; and compared with other existing methods, the method disclosed by the invention has the characteristics of simplicity, strong universality, simple instrument, high repeatability, and the like.

Owner:太仓佳诚半导体设备有限公司

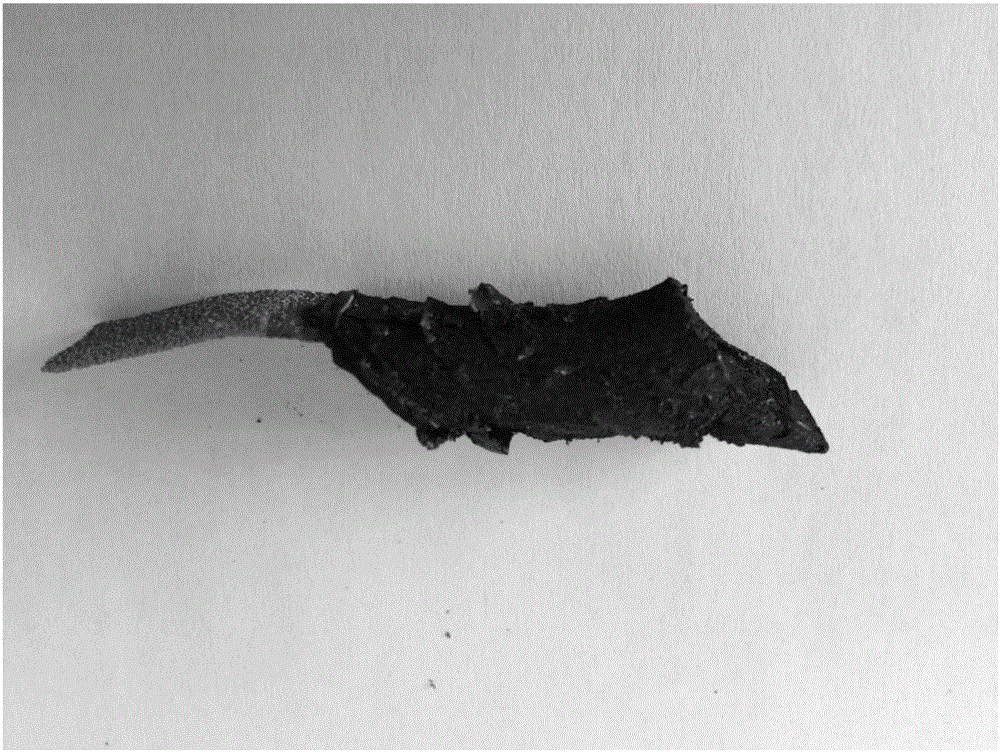

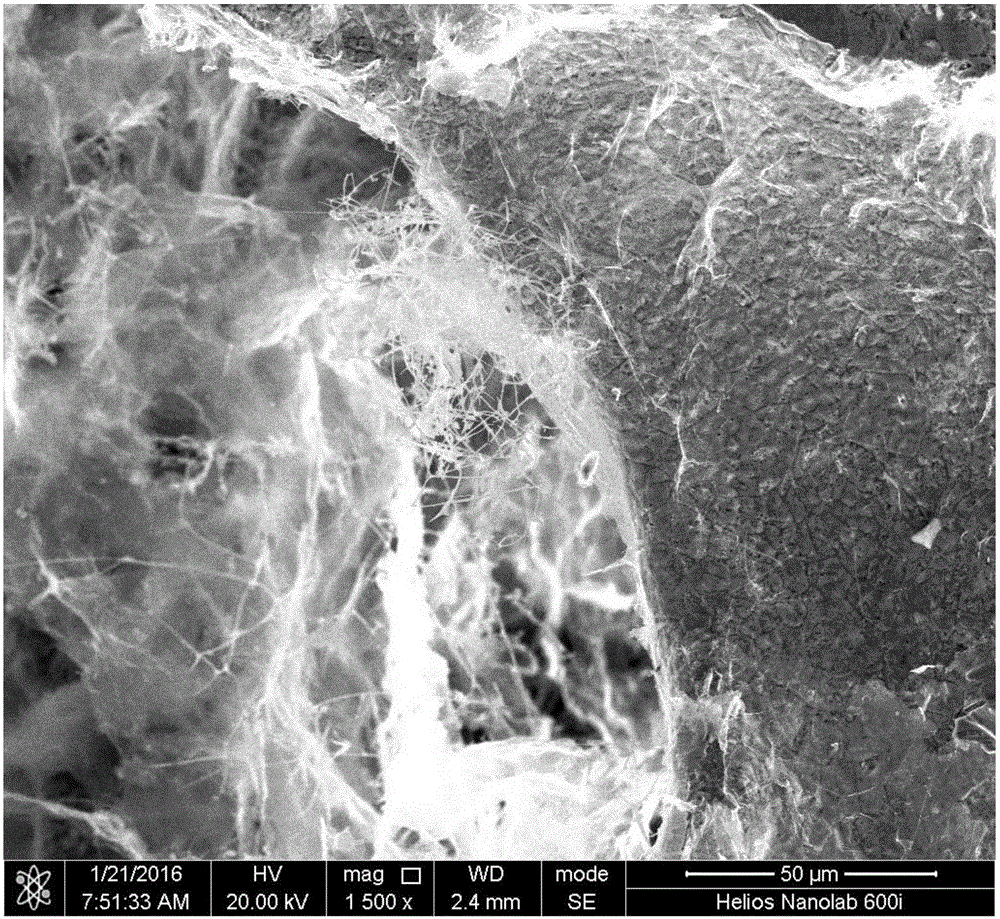

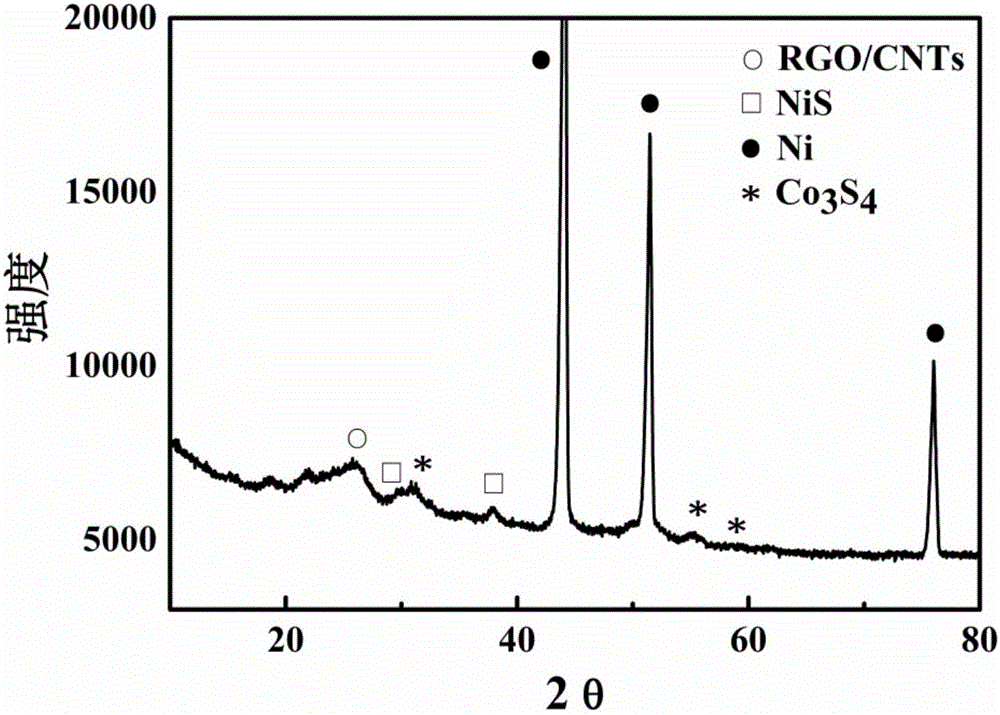

Preparation method for nickel sulfide/graphene/carbon nano tube/cobalt sulfide three-dimensional composite hydrogen storage material

ActiveCN105883939AHigh hydrogen storage activityLarge specific surface areaNickel sulfidesFreeze-dryingCarbon nanotube

The invention provides a preparation method for a nickel sulfide / graphene / carbon nano tube / cobalt sulfide three-dimensional composite hydrogen storage material and relates to a method for preparing the composite hydrogen storage material. The method aims at solving the technical problem that an existing cobalt sulfide composite material cannot be used as an electrochemical hydrogen storage electrode. The preparation method includes the steps that 1, oxidized graphene / carbon nano tube dispersion liquid is prepared; 2, cobaltous acetate and sulfur are added into the oxidized graphene / carbon nano tube dispersion liquid, the mixture is stirred to be uniform, and mixed liquid is obtained; 3, the mixed liquid is ball-milled; 4, foamed nickel is washed; 5, the mixed dispersion liquid is added into a hydrothermal kettle, glucose is added, foamed nickel is soaked in the mixed dispersion liquid, and a hydrothermal reaction is conducted for 48-60 h at the temperature of 180-220 DEG C; after the reaction is over, leaching and freeze drying are conducted, and the nickel sulfide / graphene / carbon nano tube / cobalt sulfide three-dimensional composite hydrogen storage material is obtained. The specific area of the composite hydrogen storage material ranges from 70 m<2> / g to 81 m<2> / g, and the composite hydrogen storage material can be used as the hydrogen storage electrode.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

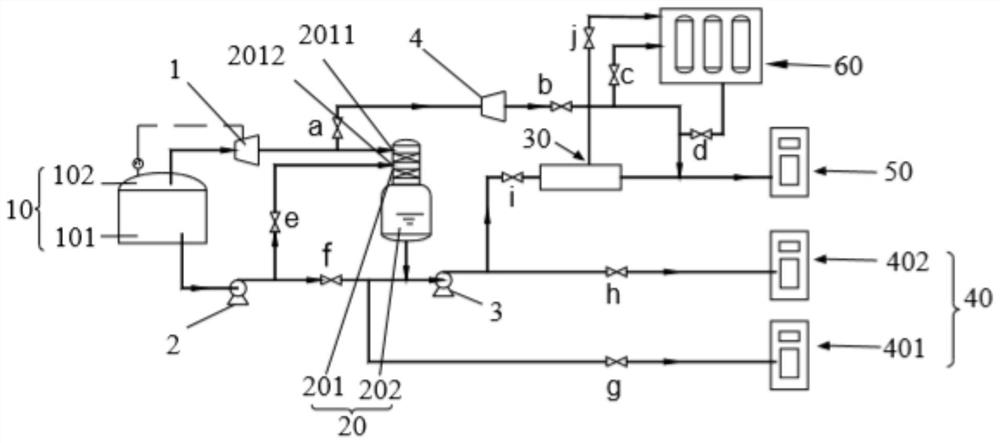

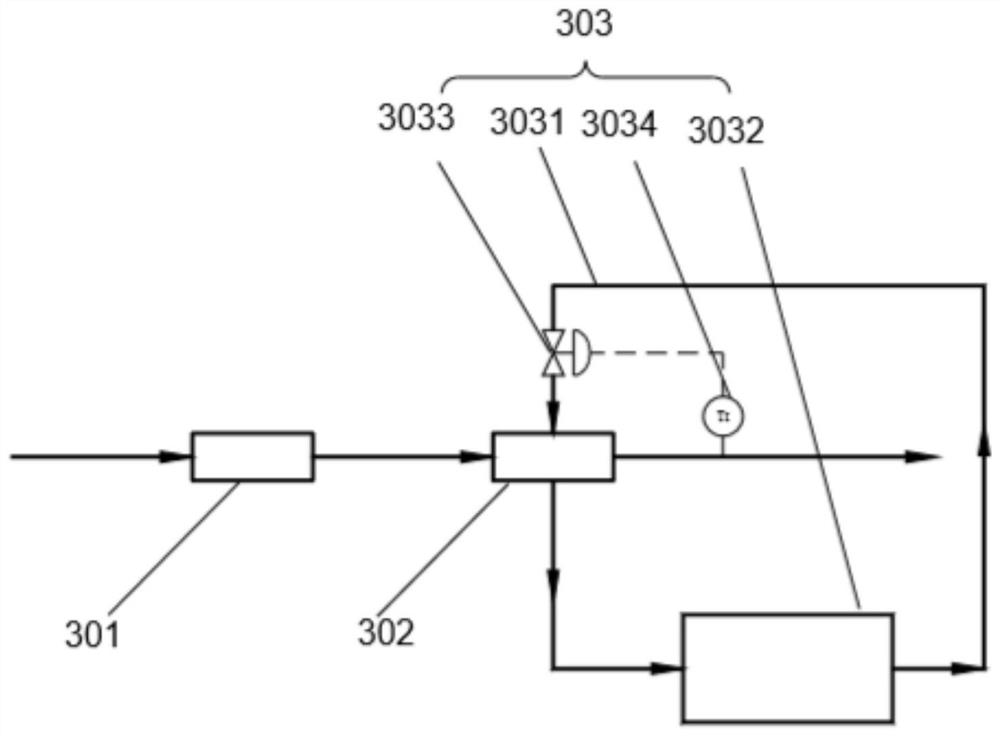

Evaporation gas recovery system of hydrogenation station

PendingCN111928109AImprove hydrogen storage performanceVessel geometry/arrangement/sizeGas handling/storage effectsThermodynamicsGas phase

The invention relates to the technical field of hydrogenation stations, and discloses an evaporation gas recovery system of a hydrogenation station. The evaporation gas recovery system of the hydrogenation station comprises a hydrogen storage tank, a hydrogen liquefaction system, a liquid hydrogen gasification system, a liquid hydrogen filling system, a hydrogen filling system and a hydrogen buffering system, wherein the hydrogen storage tank comprises a liquid hydrogen storage space and a low-temperature gas phase space; the inlet end of the hydrogen liquefaction system respectively communicates with the liquid hydrogen storage space and the low-temperature gas phase space; the outlet end of the hydrogen liquefaction system respectively communicates with the liquid hydrogen filling systemand the liquid hydrogen gasification system; the outlet end of the liquid hydrogen gasification system communicates with the hydrogen filling system; the hydrogen filling system communicates with thelow-temperature gas phase space; the hydrogen buffering system is connected in parallel on a pipeline communicating the hydrogen filling system with the low-temperature gas phase space; and the hydrogen buffering system communicates with the liquid hydrogen gasification system. The evaporation gas recovery system of the hydrogenation station can achieve mixed filling, and can fully recycle hydrogen evaporation gas in the station to achieve energy conservation and emission reduction.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Carbon nanometer pipe high energy storage battery negative pole material and is preparation method

InactiveCN1538543AImprove hydrogen storage performanceHigh hydrogen storage specific capacityElectrode manufacturing processesCapacitanceHigh energy

The invented material contains wt ratio 2-5:1 of nano-carbon tube modified by copper and agglomerant of teflon, and conduction agent, which is 1% of total weight. Preparing method includes following steps: after dipping in HF solution, nano-carbon tube in concentrated H2SO4 and HNO3 is boiled; rinsing tube till neutrality by using deionized water; even mixing CuSO4 solution, nano-carbon tube and complexing agent, adjusting pH of solution by sodium hydroxide; titration is carried out by using formalin till Cu2+ is deoxidized from copper complexation solution; mixing nano-carbon tube of deposited metal granules, Teflon and acetylene black fabricates slurry; coating slurry on foam nickel, drying and chill pressing produces electrode material. Performances of the material are high capability of storing hydrogen, specific capacitance 1200-1710mAh / g and stable charging and discharging capability.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com