Preparation method of hypha/nanoparticle composite sphere material

A technology of nanoparticles and composite balls, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, hydrogen production, etc., can solve the problems of difficult recycling of nanoparticles and achieve good photocatalytic performance , The effect of solving difficult recycling, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

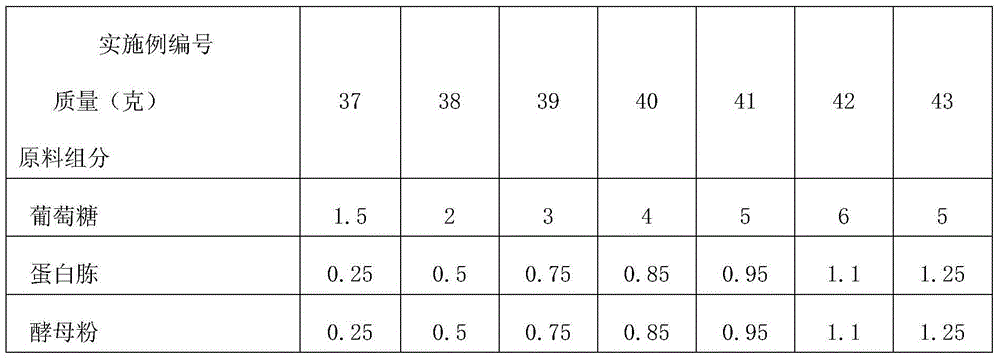

[0027] A preparation method of mycelium / nano carbon nitride composite ball material, comprising the following steps:

[0028] a. Preparation of medium: According to the raw material components and proportions containing 2 grams of glucose, 0.25 grams of peptone, 0.25 grams of yeast powder, and the balance of water in every 100 ml of liquid culture solution, take the raw materials of each component, mix them evenly, and make them Dissolve the solids, keep the pH value unchanged, and sterilize them for 15 minutes under the conditions of a pressure of 103.4 kPa vapor pressure and a temperature of 120 °C to obtain a liquid culture medium; Add 125 ml of liquid culture medium to the conical flask;

[0029] b. Preparation of composite ball material: add 10 ml of nano-carbon nitride aqueous solution with a concentration of 2 mg of nano-carbon nitride per ml of solution to the sterilized liquid medium in the conical flask, mix well, and then insert the fungus 0.1 g of strain, cultivat...

Embodiment 2

[0032] A preparation method of mycelium / nano carbon nitride composite ball material, comprising the following steps:

[0033] a. Preparation of medium: According to the raw material components and proportions containing 3 grams of glucose, 0.5 grams of peptone, 0.3 grams of yeast powder, and the balance of water in every 100 ml of liquid culture solution, take the raw materials of each component, mix them evenly, and make them Dissolve the solids, keep the pH value unchanged, and sterilize them for 15 minutes under the conditions of a pressure of 103.4 kPa vapor pressure and a temperature of 120 °C to obtain a liquid culture medium; Add 125 ml of liquid culture medium to the conical flask;

[0034] b. Preparation of composite ball material: Add 6 ml of nano-carbon nitride aqueous solution with a concentration of 4 mg of nano-carbon nitride per ml of solution to the sterilized liquid medium in the conical flask, mix well, and then insert the fungus 0,1 g of strain, cultivated ...

Embodiment 3

[0037] A preparation method of mycelium / nano carbon nitride composite ball material, comprising the following steps:

[0038] a. Preparation of medium: According to the raw material components and ratios containing 6 grams of glucose, 0.6 grams of peptone, 0.8 grams of yeast powder, and the balance of water in every 100 ml of liquid culture solution, take the raw materials of each component, mix them evenly, and make them Dissolve the solids, keep the pH value unchanged, and sterilize them for 15 minutes under the conditions of a pressure of 103.4 kPa vapor pressure and a temperature of 120 °C to obtain a liquid culture medium; Add 125 ml of liquid culture medium to the conical flask;

[0039] b. Preparation of composite ball material: add 15 ml of nano-carbon nitride aqueous solution with a concentration of 5 mg of nano-carbon nitride per ml of solution to the sterilized liquid medium in the conical flask, mix well, and then insert the fungus 0,15 grams of strain, cultivated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com