Patents

Literature

310results about How to "Solve recycling difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

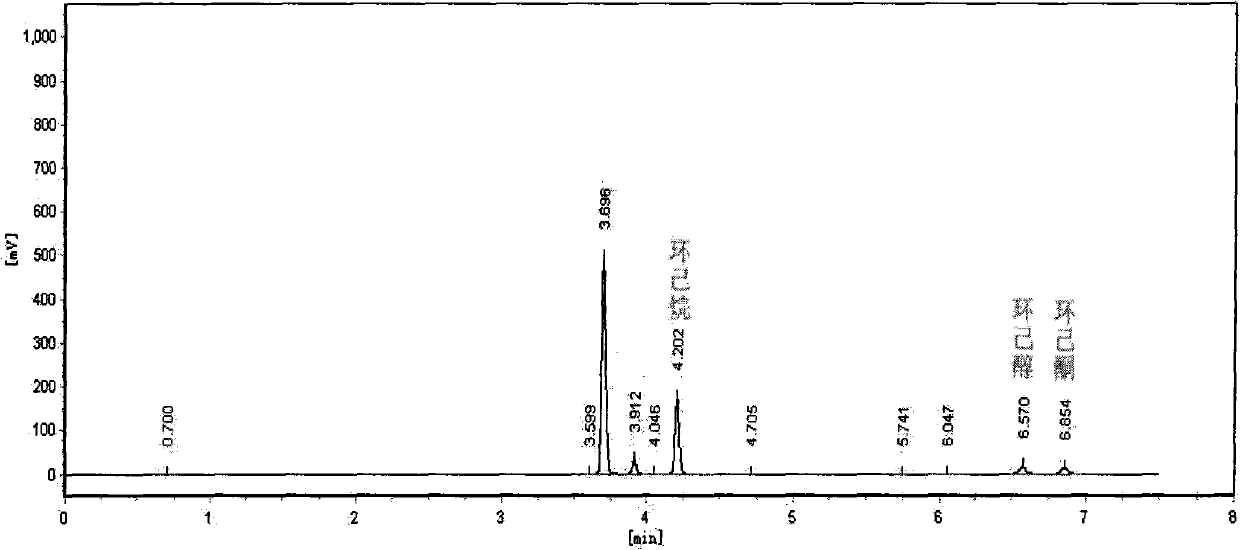

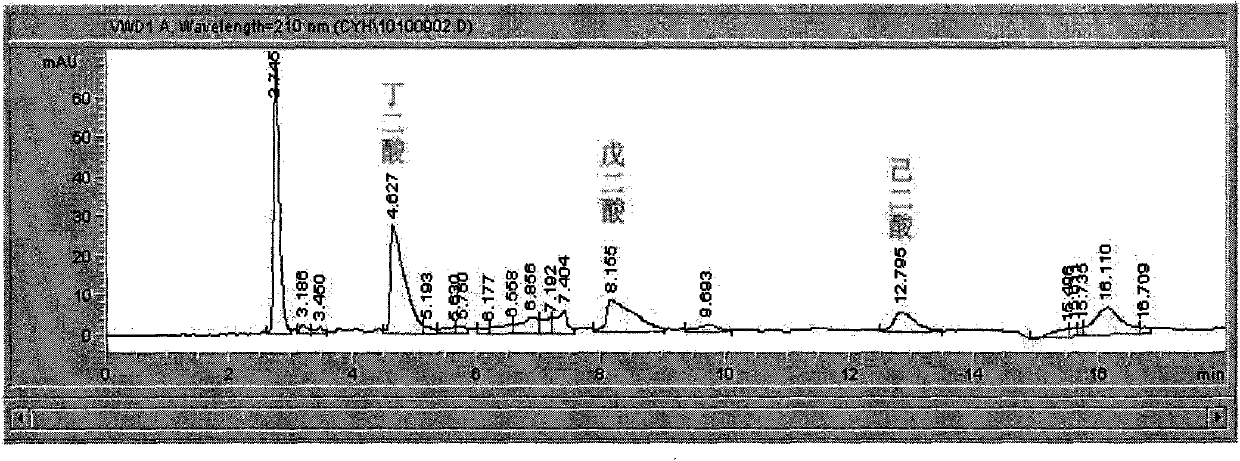

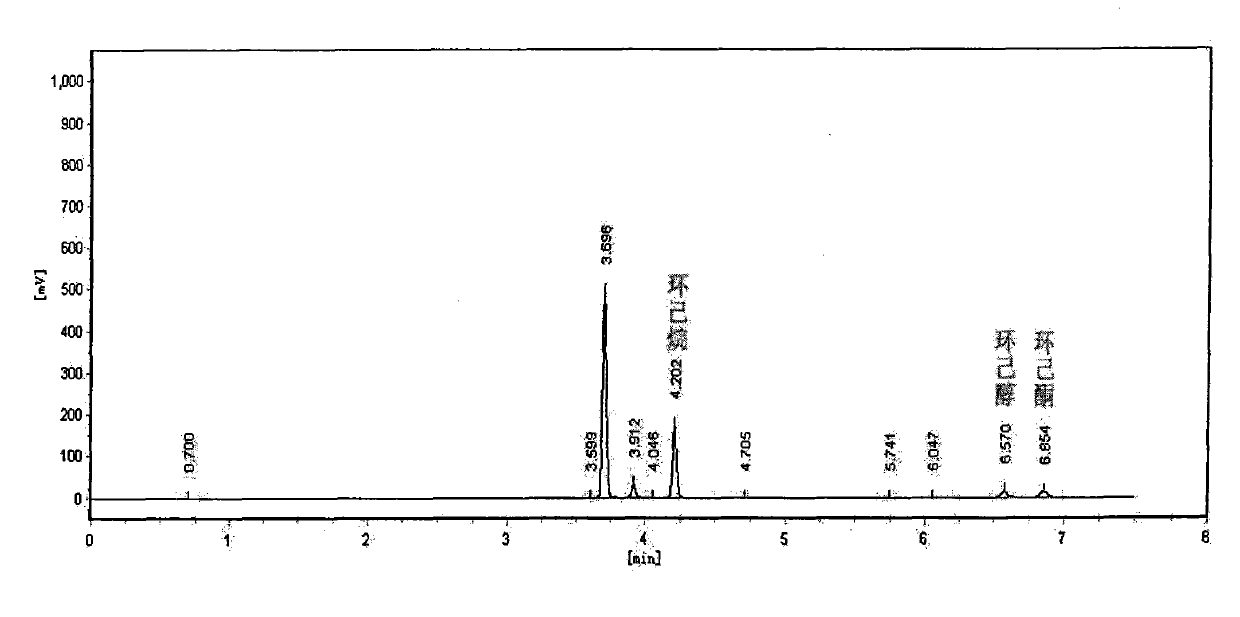

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

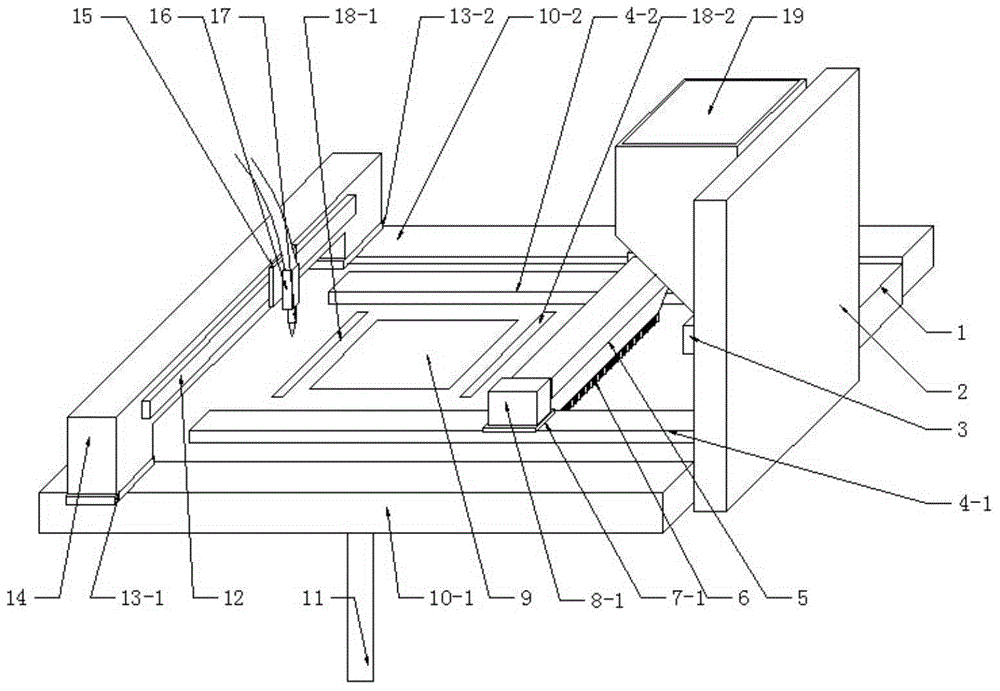

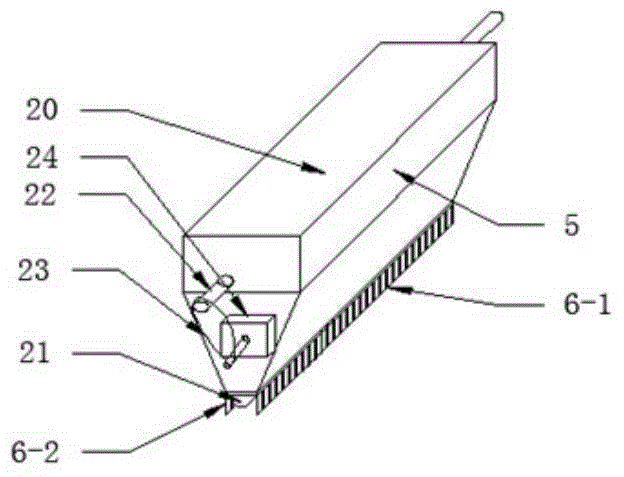

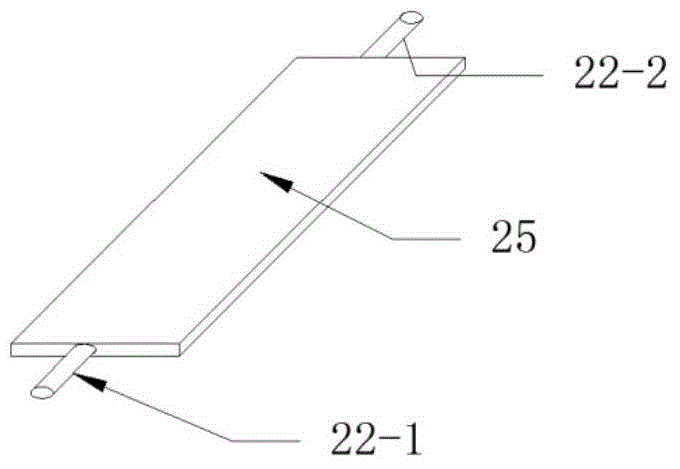

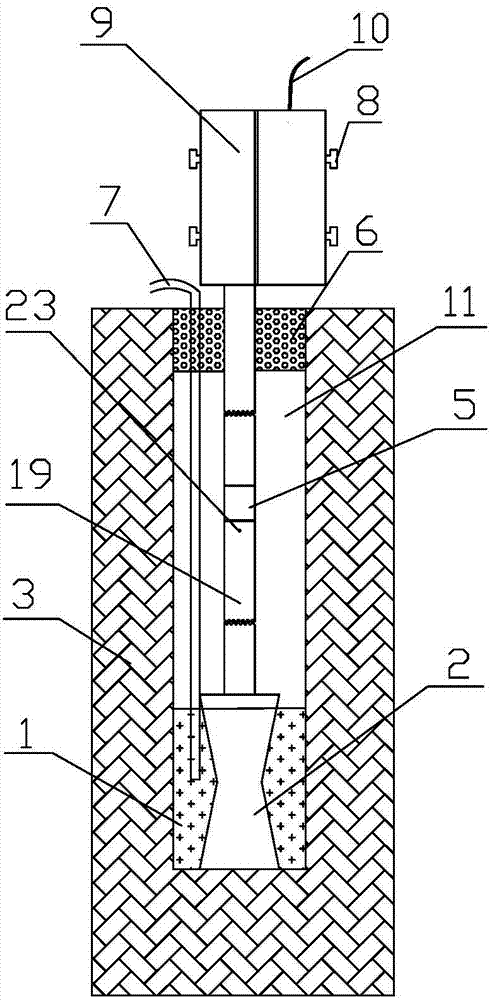

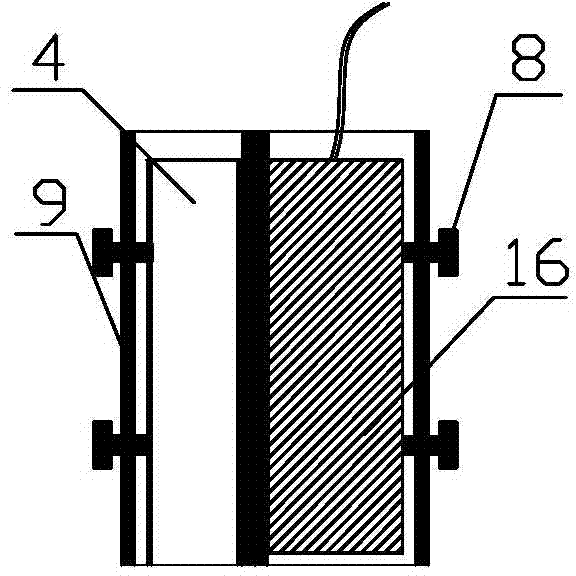

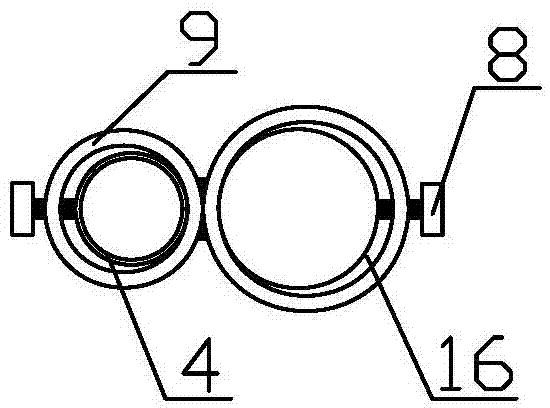

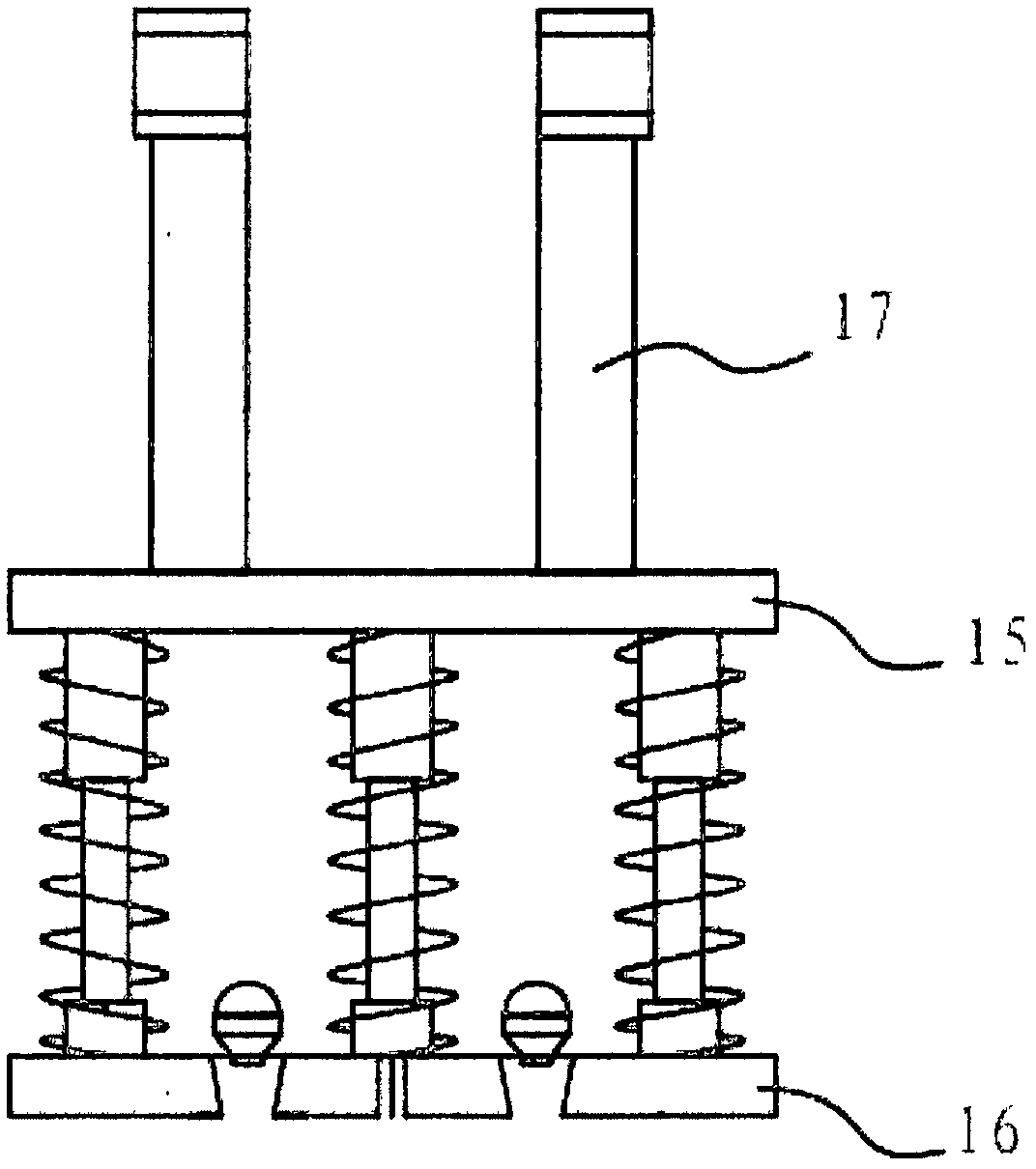

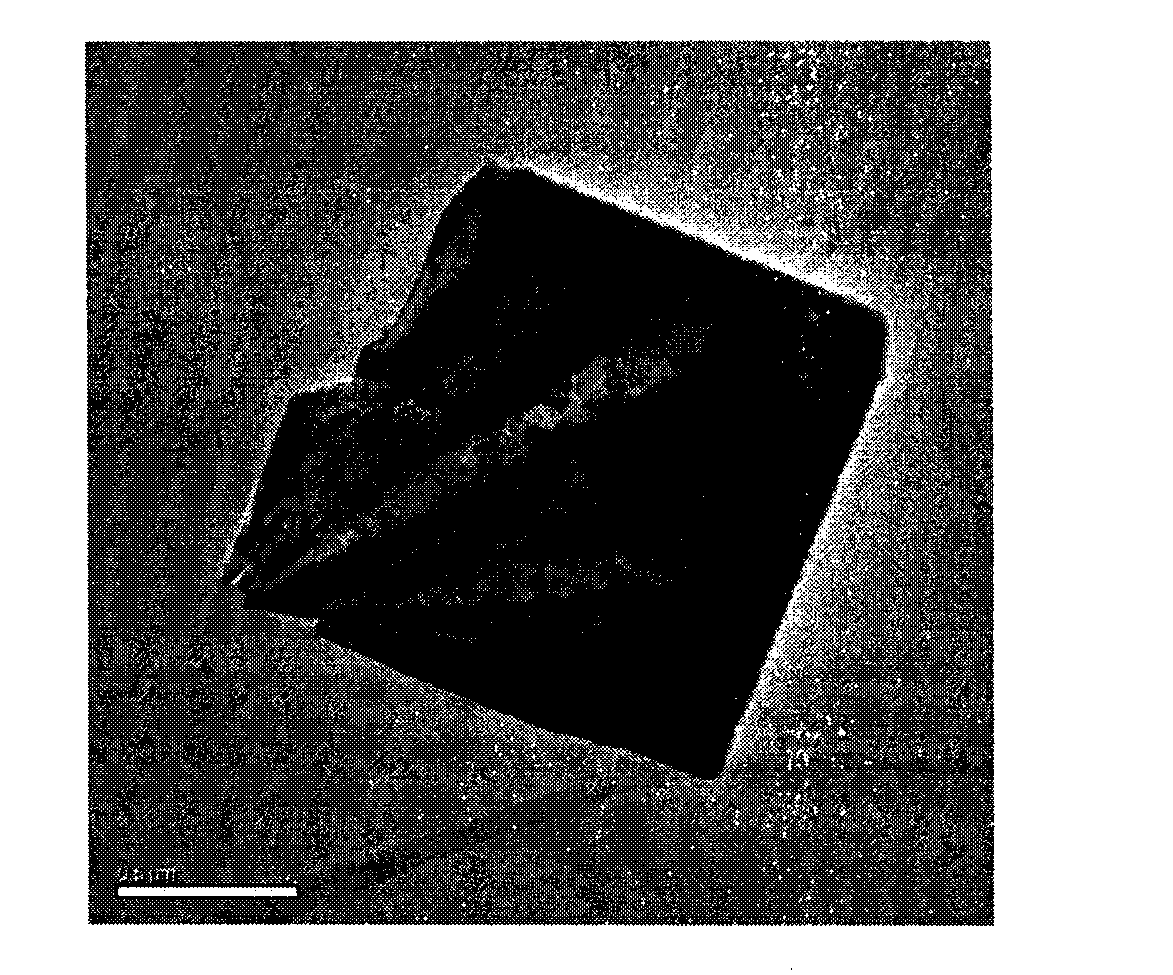

Selective laser melting powder sending and laying device used for compounding of different types of powder

ActiveCN105562687ASolve recycling difficultiesReduce consumptionIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting powder sending and laying device used for compounding of different types of powder. The selective laser melting powder sending and laying device comprises a worktable, a forming cylinder, a powder spraying device and a powder laying device. The upper surface of the forming cylinder is arranged on the worktable. The powder spraying device and the powder laying device are arranged on the two sides of the forming cylinder. The powder spraying device is characterized in that powder spraying electric guide rails, a support, a nozzle electric guide rail and a nozzle are included; the nozzle is arranged on the nozzle electric guide rail; the nozzle electric guide rail is arranged on the powder spraying electric guide rails through the support; and the powder spraying electric guide rails are fixed to the worktable. The powder laying device comprises a powder hopper, a powder scraping electric guide rail and a supporting frame; the powder hopper is arranged on the powder scraping electric guide rail through the supporting frame; and the powder scraping electric guide rail is fixed to the worktable. According to the selective laser melting powder sending and laying device used for compounding of different types of powder, the selective laser melting technology and the laser cladding coaxial powder sending technology are combined, and the purposes of effectively recovering powder during compound additive manufacturing of gradient materials and forming parts with complex gradients in any direction are achieved.

Owner:NANJING UNIV OF SCI & TECH

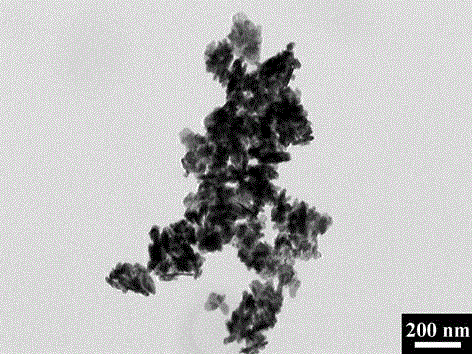

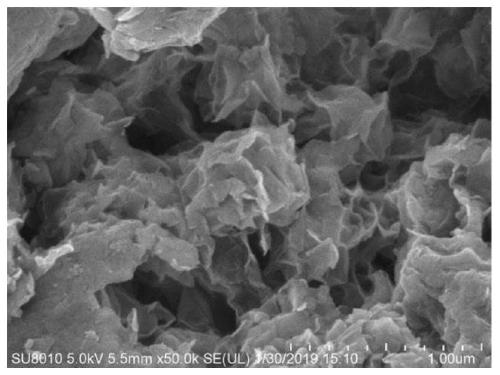

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

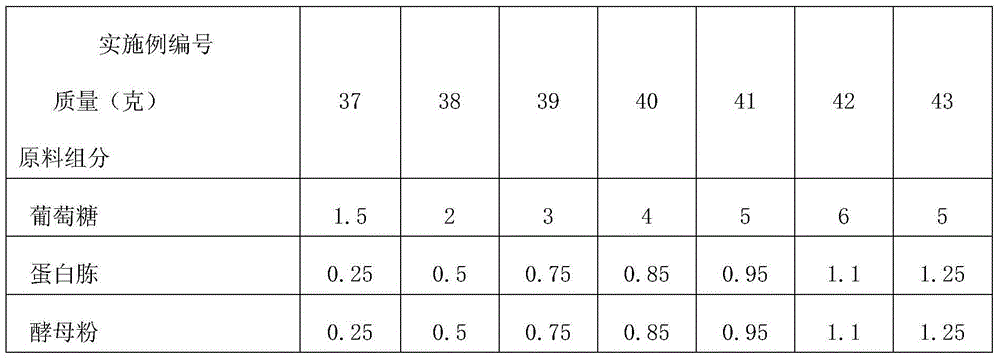

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

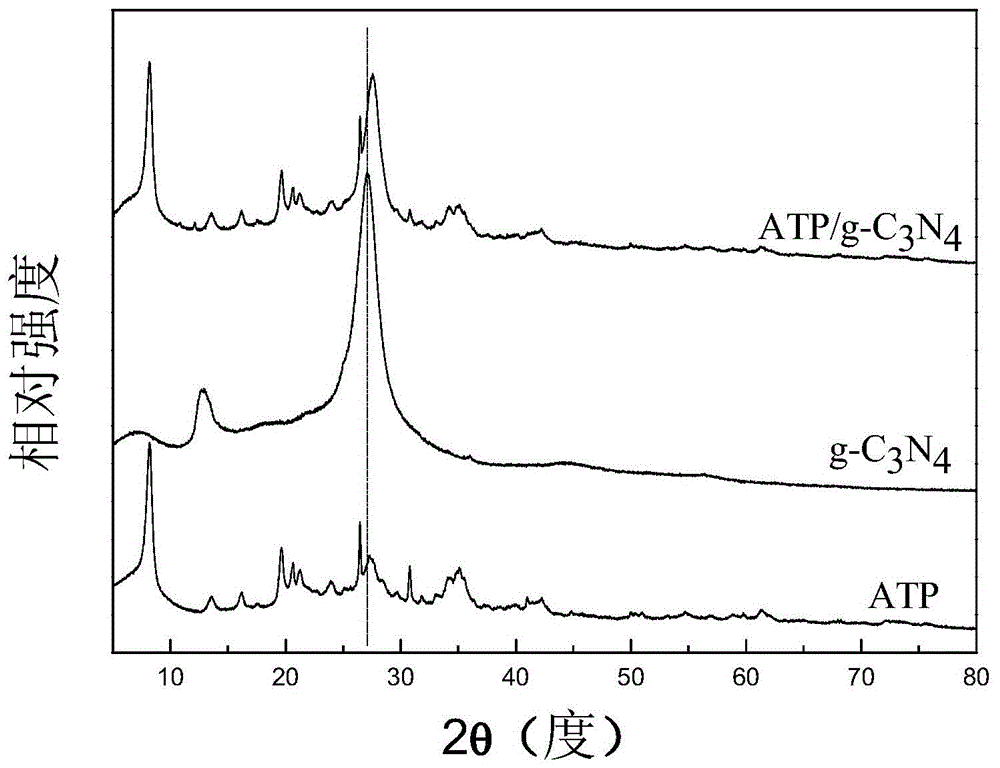

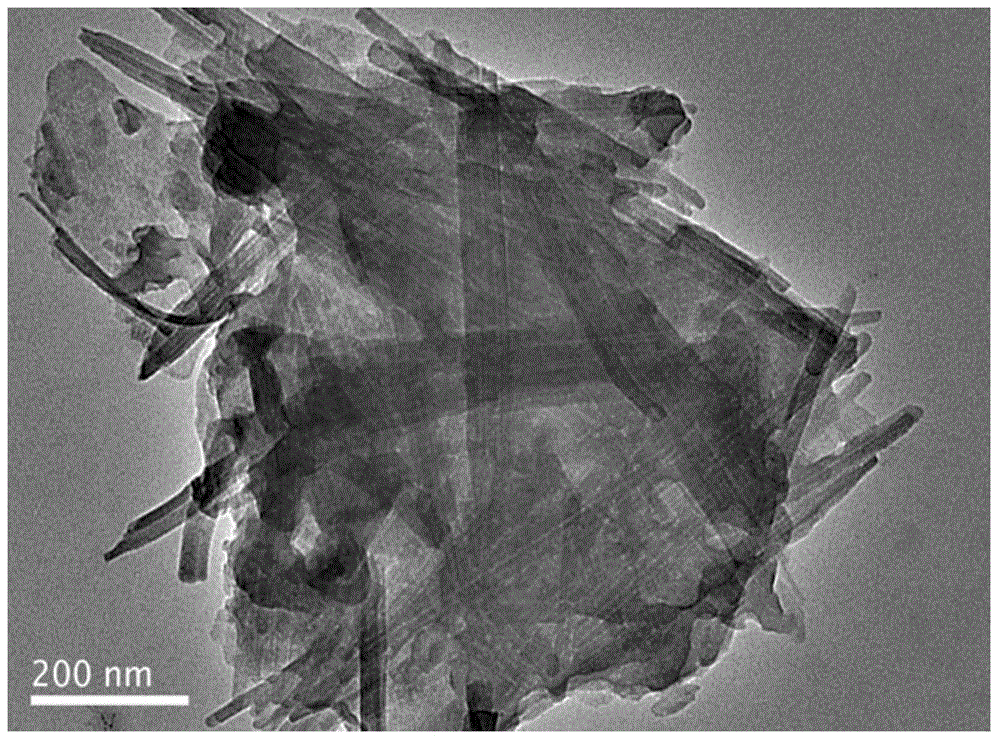

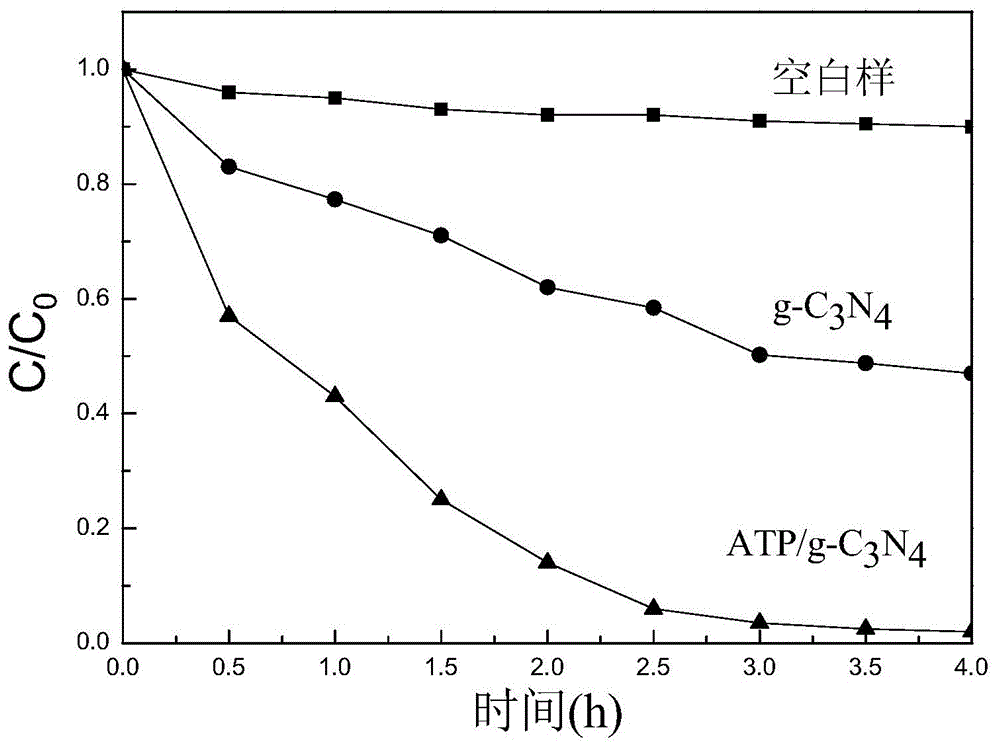

Attapulgite/graphite phase carbon nitride composite material and preparation method thereof

ActiveCN104588063AAvoid uneven loadGood dispersionPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionCarbon composites

The invention relates to the technical field of nonmetallic mineral finish machining and inorganic processing, in particular to an attapulgite / graphite phase carbon nitride composite material. The attapulgite / graphite phase carbon nitride composite material takes attapulgite as a carrier and takes graphite phase carbon nitride as an active ingredient; the mass ratio of the attapulgite to the graphite phase carbon nitride is 1: 1 to 1: 10. By compounding the graphite phase carbon nitride with the attapulgite, the foreign ions in the attapulgite enter the crystal lattices of the graphite phase carbon nitride to increase the defects and change the energy level; the silicon oxide in the attapulgite can possibly form a heterojunction structure with the graphite phase carbon nitride so as to promote the transfer of photo-generated electrons and avoid the self-compounding of the photo-generated electrons; through the concerted catalysis action between the carrier and the active ingredient, the catalytic activity of the composite material is strengthened to a great extent.

Owner:山东一开电气设备有限公司

Method of decomposing thermoset epoxy resin and its composite material

InactiveCN1974641ASolve recycling difficultiesLow monofilament tensile forcePlastic recyclingEpoxyFiber

The method of decomposing thermoset epoxy resin and its composite material is for recovering and reusing thermoset epoxy resin and its composite material. The method of decomposing thermoset epoxy resin includes the steps of adding thermoset epoxy resin and decomposing liquid into reaction kettle; and decomposing. The method of decomposing thermoset epoxy resin composite material includes the steps of adding thermoset epoxy resin composite material and decomposing liquid into reaction kettle; decomposing; solid-liquid separating; and washing and stoving solid matter to obtain decomposed thermoset epoxy resin and reinforcing fiber. The present invention has thermoset epoxy resin decomposing rate of 90-100 % and reinforcing fiber recovering rate of 100 %, and the decomposed product is separated and reused as chemical material.

Owner:HARBIN INST OF TECH

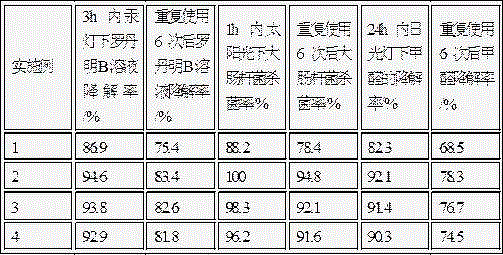

Preparation method of TiO2 photocatalyst by loading TiO2 to diatomite formed in advance and doping rare earth

InactiveCN105080528AIncrease chance of contactImprove photodegradation efficiencyBiocideWater/sewage treatment by irradiationSol-gelMercury vapors

The invention relates to a preparation method of TiO2 photocatalyst by loading TiO2 to diatomite formed in advance and doping rare earth, and belongs to the technical field of photocatalysis. The preparation method comprises the steps of: pickling original diatomite, roasting the pickled diatomite, and uniformly mixing the roasted diatomite, a binder, a fluxing agent and the like so as to obtain molded diatomite; and using tetrabutyl orthotitanate and dehydrated alcohol as raw materials, preparing TiO2 and rare earth doped TiO2 sol by a sol-gel method, macerating the preformed diatomite in the sol, drying the macerated diatomite, and calcining the dried diatomite so as to obtain the load type photocatalyst. The photocatalyst can prevent the TiO2 from running off; besides, the rare earth is doped, so that the utilization rate of visible light by the TiO2 is increased; when a mercury-vapor lamp is used for 3 hours, 95% of a rhodamine b solution can be degraded; when the photocatalyst is illuminated for an hour under sunlight, escherichia coli can be thoroughly killed; when the photocatalyst is illuminated for 24 hours by common daylight lamps, 92% of methanal can be degraded; the photocatalyst is excellent in photocatalytic property and stability, which indicates that the photocatalyst has favorable application prospects in the respects of waste water treatment, sanitation and sterilization, air purification and the like.

Owner:NORTHEASTERN UNIV

Recyclable installation device of microseism sensor and installation method

The invention discloses a recyclable installation device of a microseism sensor and an installation method. The installation device includes a base, installation rods, an injection pipe, a rubber ring and a double sleeve. During installation, the microseism sensor is placed outside an installation hole. The microseism sensor is connected and fixed with the steel base through the installation rods and the double sleeve. The base is coupled with a rock body through cement mortar. Microseism signals are spread to the microseism sensor by the steel base through the installation rods. During recycling, screws on the double sleeve are screwed outside the installation hole so that the microseism sensor is recycled and the installation rods are rotated and pulled out outside the installation hole for recycling. The recyclable installation device of the microseism sensor and the installation method solve a problem that a microseism sensor is difficult to fix, maintain, protect and retract and are capable of receiving and acquiring vibration signals near any position and at the same time, positioning precision of a microseism source is ensured and the cost of microseism monitoring is saved. The recyclable installation device of the microseism sensor and the installation method are widely applicable to microseism monitoring of projects such as underground workshops, tunnels, slopes and roadways and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Preparation method of supported photocatalyst Bi2WO6-TiO2/foam metal

InactiveCN104383915AEvenly dispersedAvoid reunionMetal/metal-oxides/metal-hydroxide catalystsAlcoholPhysical chemistry

The invention relates to a preparation method of supported photocatalyst Bi2WO6-TiO2 / foam metal. Bi(NO3)3.5H2O and Na2WO4.2H2O are used as a Bi source and a W source, ethylene glycol and absolute ethyl alcohol are used as a mixed solvent, TiO2 powder is added and mixed uniformly, the mixture reacts for 15h at 180 DEG C and then is washed and dried; Bi2WO6-TiO2 precursors are dispersed in an absolute ethyl alcohol solution, a foam metal carrier is soaked and washed with acetone, diluted hydrochloric acid and deionized water, then a silica gel layer with the solid content of 25% is coated on the surface of the foam metal carrier and is dried in the air for 20min in a leveling manner for standby use; dispersion liquid is uniformly sprayed to the foam metal carrier coated with the silica gel, and the foam metal carrier is dried in the air for 20min in a leveling manner and is roasted for 2h at 400 DEG C to obtain the supported photocatalyst Bi2WO6-TiO2 / foam metal. The preparation process is simple, can be amplified easily, and is suitable for large-scale practical application.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

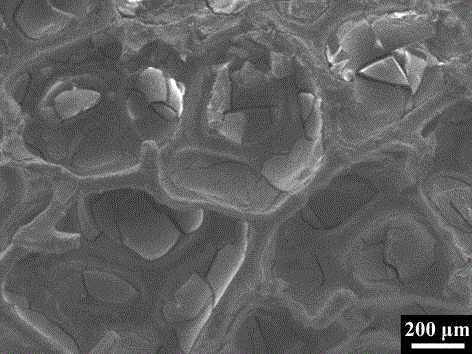

Waste carbon fiber reinforced nylon 6 composite material and preparation method thereof

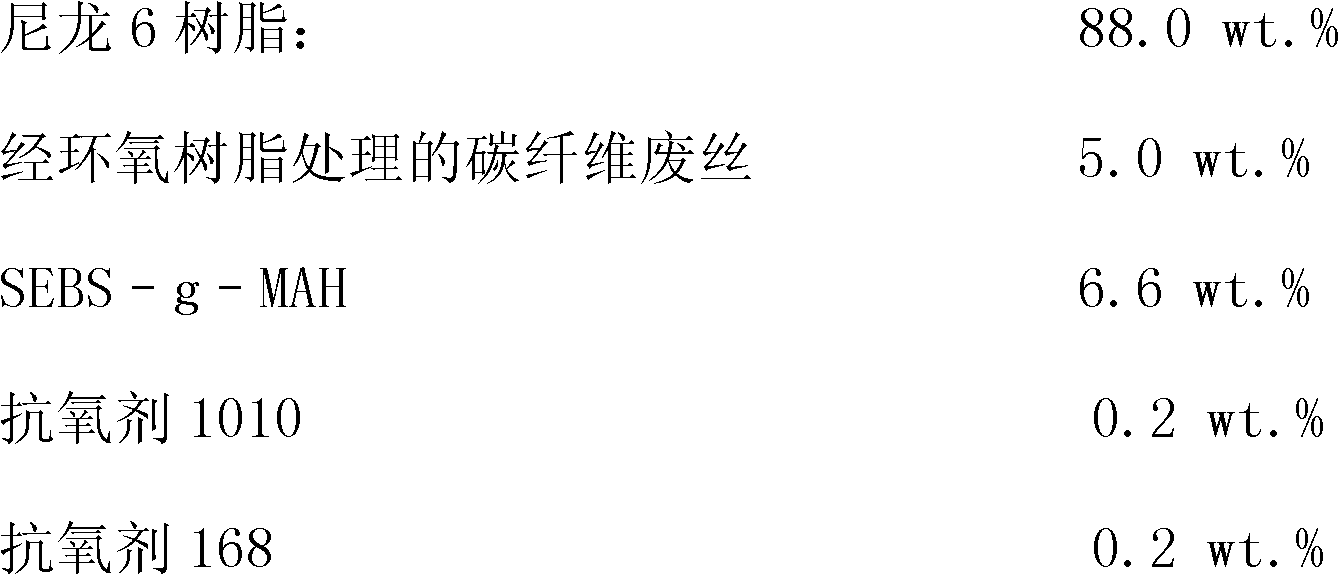

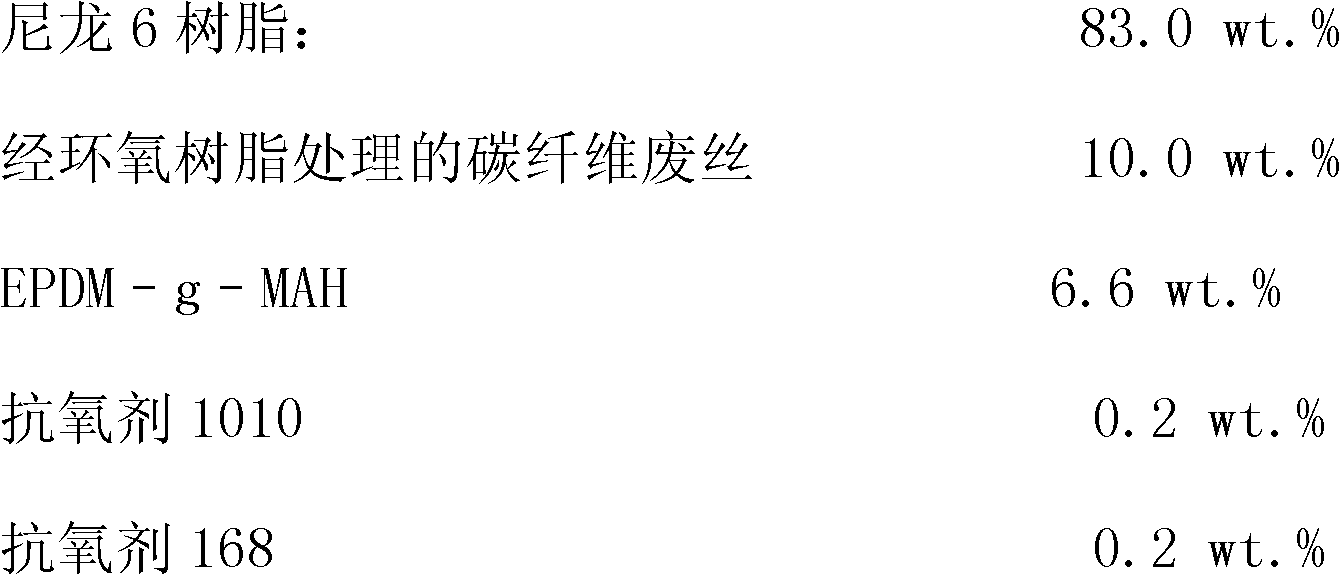

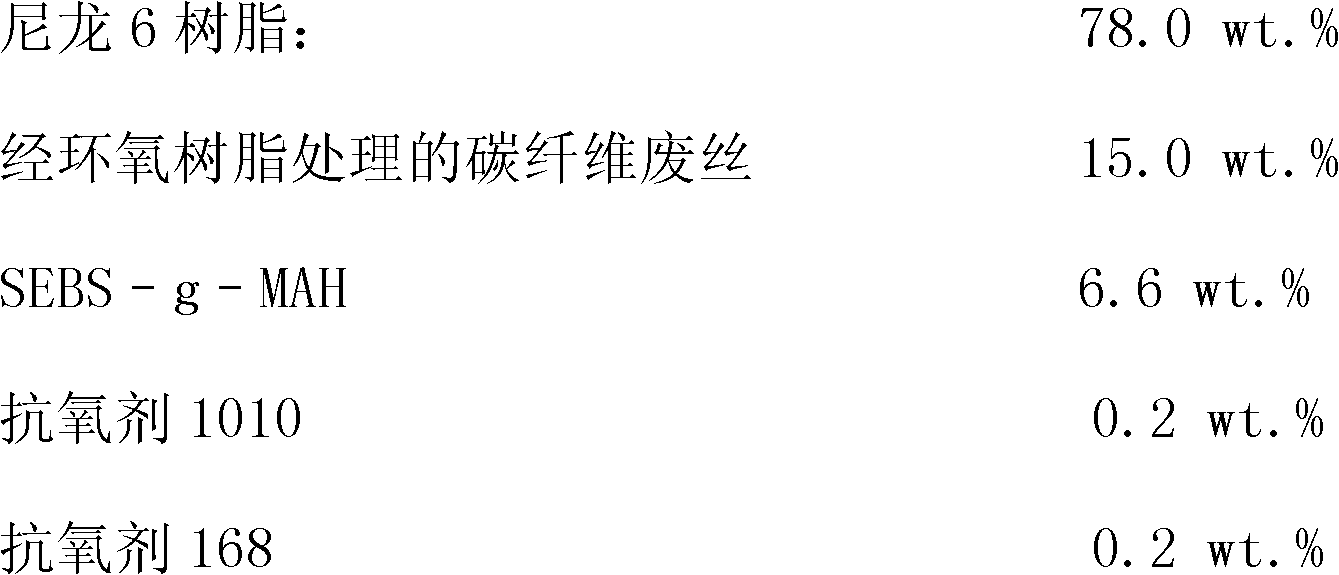

The invention discloses a waste carbon fiber reinforced nylon 6 composite material and a preparation method thereof, and belongs to the technical field of macromolecular materials. The composite material comprises the following components in percentage by weight: 70 to 90 weight percent of nylon 6 resin, 5 to 20 weight percent of waste carbon fiber subjected to surface modification treatment of epoxy resin or concentrated nitric acid and silane coupling agent, 0 to 10 weight percent of toughening agent, and 0.2 to 0.5 weight percent of antioxidant. The preparation method comprises the following steps of: performing modification by using the bisphenol A epoxy resin or sequentially using the concentrated nitric acid and the silane coupling agent, and drying; adding the mixed materials into a double-screw extruder in a ratio, performing melt blending extrusion, controlling each section of a charging barrel to the temperature of between 240 and 260 DEG C, and controlling a head outlet to the temperature of between 250 and 260 DEG C; and staying the melt, performing water cooling, granulating, sieving and drying. The composite material prepared by the method has high strength, modulus and antistatic performance; and the impact resistance of the composite material is improved by adding the toughening agent.

Owner:BEIJING UNIV OF CHEM TECH

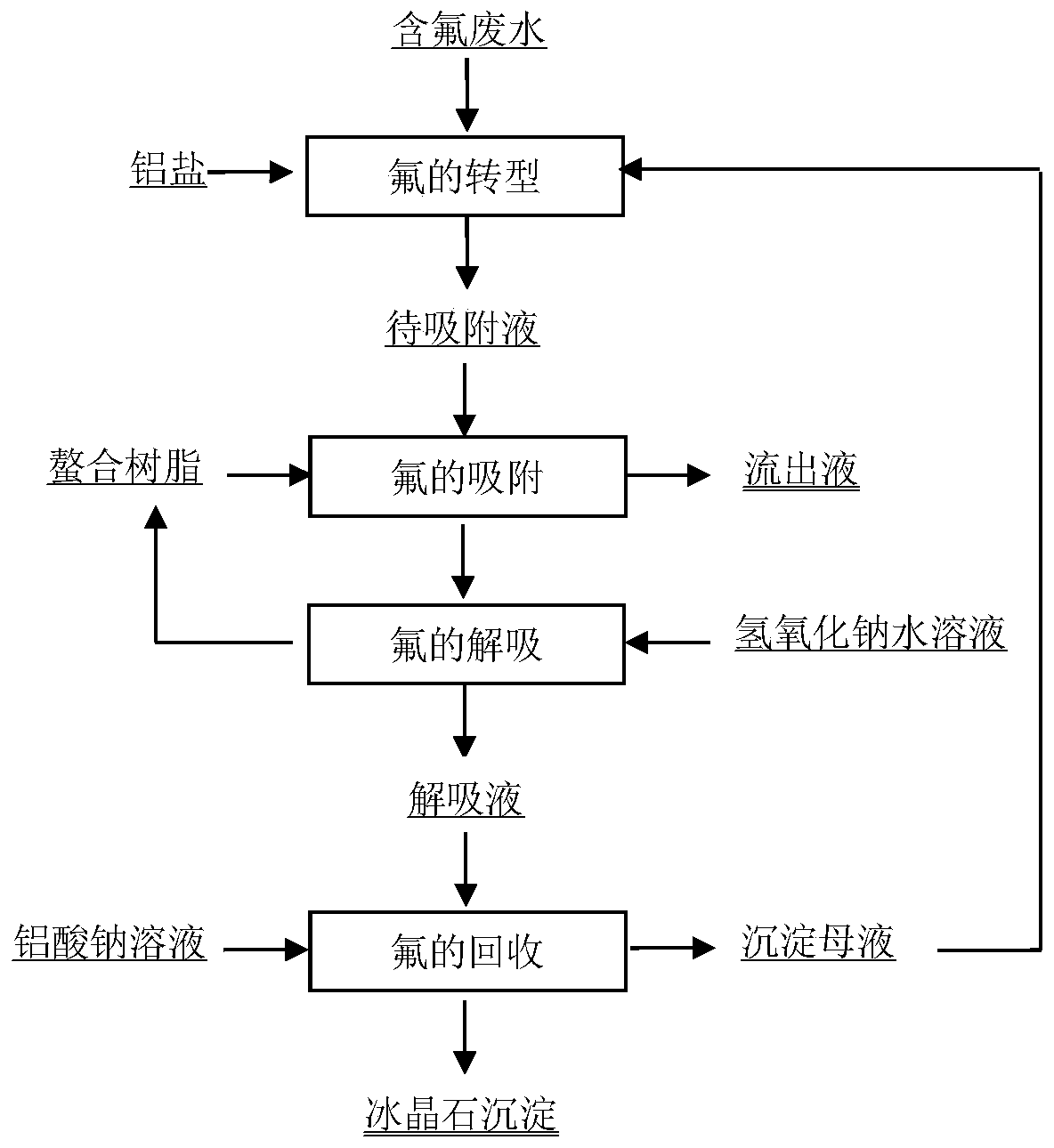

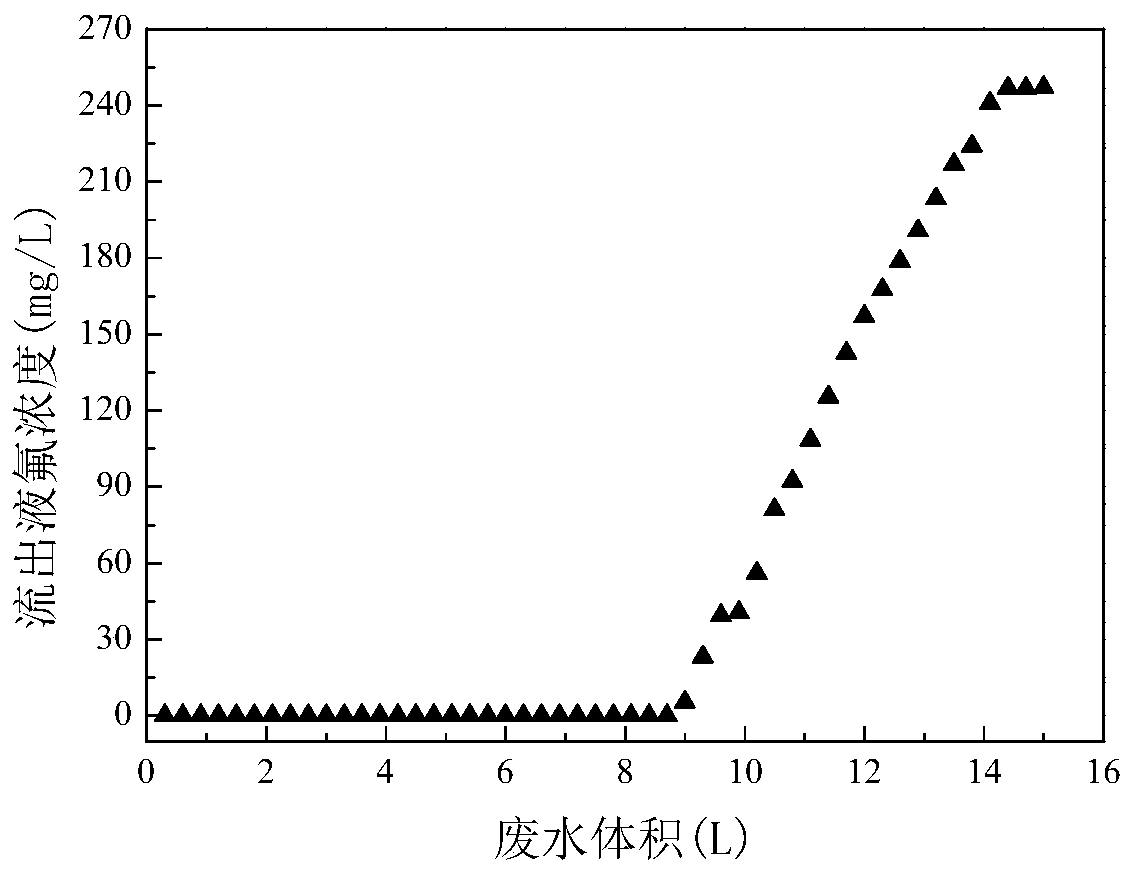

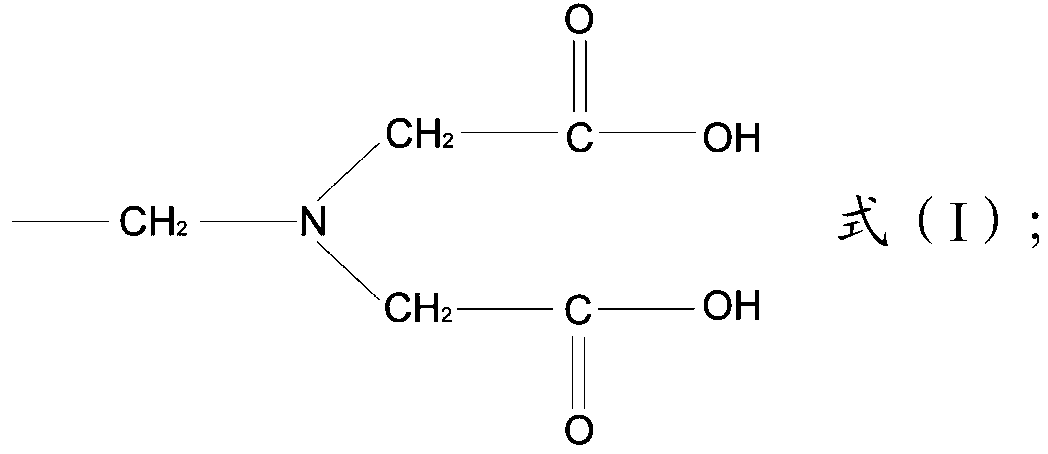

Treatment method for waste water containing fluorine

ActiveCN110104733AReduce dosageEasy to operateSpecific water treatment objectivesWater contaminantsIon exchangeIon

The invention belongs to the field of treatment of waste water, and particularly relates to a treatment method for waste water containing fluorine. The treatment method comprises the following steps that a) the waste water containing the fluorine is mixed with aluminium salt to obtain to-be-adsorbed liquid; b) the to-be-adsorbed liquid flows through an ion exchange column filled with chelate resinfor adsorption exchange to obtain effluent, wherein the chelate resin is iminodiacetic acid resin and / or phosphoramidic acid resin. According to the method, by adding the aluminium salt, F- in the aqueous solution is transformed into an aluminum fluoride complex, then the selectivity of the chelate resin is utilized for adsorption to efficiently remove the fluorine, and the concentration of fluorine ions in the adsorption effluent can be lower than 6 mg / L. According to the method, it is not necessary to load metal ions such as aluminum on the chelate resin in advance, the problems are solvedthat a traditional resin loading modification process is complex, the consumption amount of aluminium salt is large, and the cost is high, and the method has the advantages that there is a small application amount of the agent (the aluminium salt), the operation is simple, the cost is low, and the adsorption effect is good.

Owner:湖南中金岭南康盟环保科技有限公司

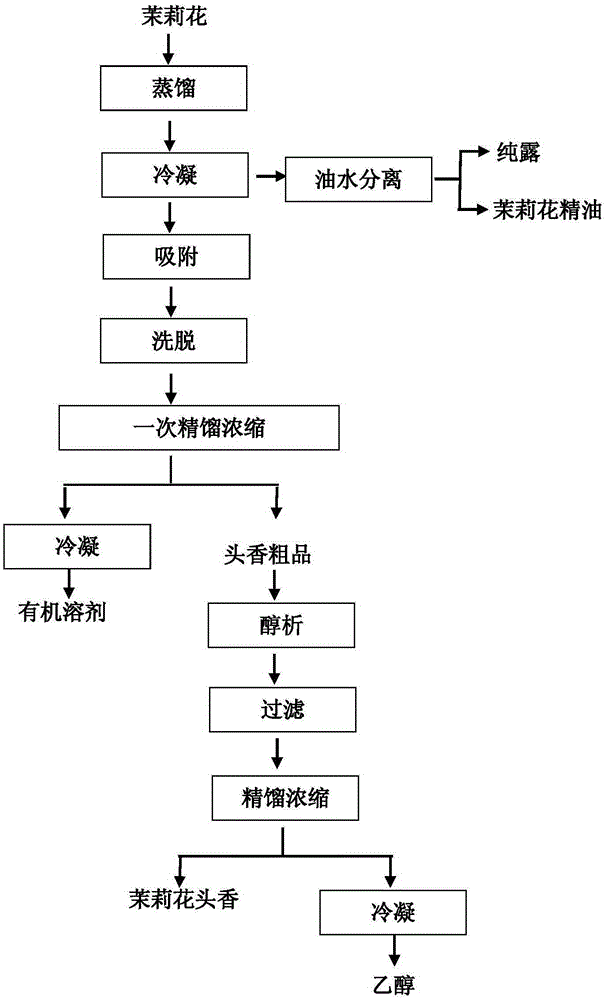

Method for extracting essential oil and headspace volatile of arabian jasmine flower

InactiveCN105296162AOvercome technical problemsLower distillation temperatureEssential-oils/perfumesOrganic chemistryHorticulture

The invention discloses a method for extracting essential oil and headspace volatile of arabian jasmine flowers. The method comprises the steps of distilling, condensing, oil water separating, adsorbing, primary rectifying concentrating, alcohol precipitating, secondary rectifying concentrating and the like. According to the method, in a vacuum state, vapor is adopted to distill the essential oil of the arabian jasmine flowers, distilling temperature is reduced, distilling time is shortened, the use rate of equipment is improved, the quality and yield of the essential oil of a product are improved, the production cost is reduced, and the technical problems of the existing traditional solvent method and supercritical carbon dioxide method are overcome. The headspace volatile of the arabian jasmine flowers is obtained by concentrating of a rectifying tower, and compared with the existing reduced pressure distillation, the method has the advantages that the loss of easy-to-volatile headspace volatile component is reduced, and the purity of the headspace volatile can be improved. By using the method in the invention to extract the essential oil and headspace volatile of the arabian jasmine flowers, the yields are respectively 0.23-0.28% and 5.5-6.0% and the yields of the respective components are obviously improved.

Owner:GUANGXI FORESTRY RES INST

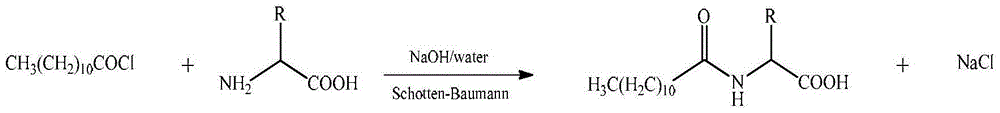

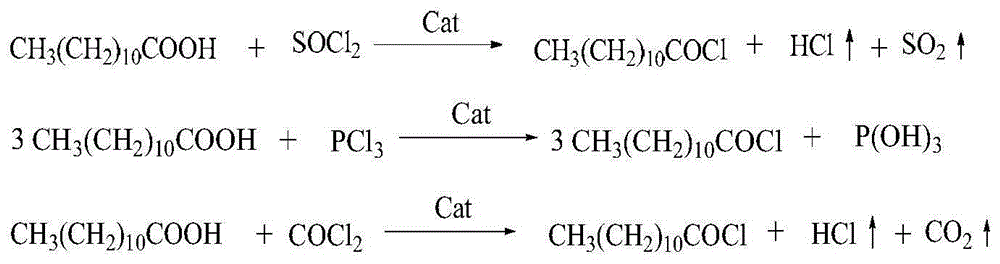

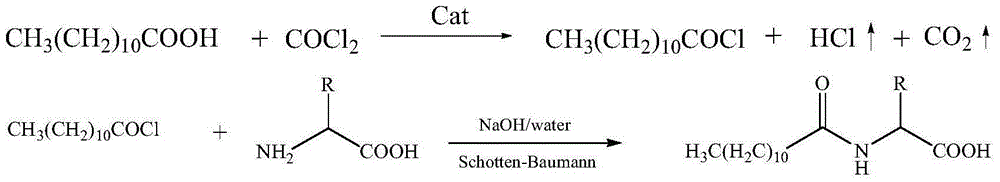

Method for synthesizing laurel acyl amino acid sodium

ActiveCN105152957AHigh catalytic activityReduce solubilityOrganic compound preparationCarboxylic acid amides preparationAmino acid synthesisFatty amine

The invention discloses a method for synthesizing laurel acyl amino acid sodium. The method comprises the steps that lauric acid and phosgene react by being catalyzed by organic aryl amide, and lauroyl chloride is prepared; lauroyl chloride and amino acid react in an alkaline solution, and lauroyl amino acid salt is prepared; extraction separation is carried out, a catalyst is recycled from an organic phase, a water phase is sequentially subjected to acidification, filter separation, sodium hydroxide neutralizing and cooling crystallization, and laurel acyl amino acid sodium is obtained. According to the method, organic aryl amide is mainly adopted as the catalyst for the reaction of lauric acid and phosgene, the lauric acid acylation reaction is thorough, no residue exists, acyl chloride products do not need layering, distilling and other purifying processes can be directly used for synthesizing laurel acyl amino acid sodium, and especially the catalyst can be recycled and cyclically utilized through a simple method. Compared with use of existing DMF and other fatty amine catalysts, the process steps are greatly simplified, the yield and quality of the product are improved, production cost is reduced, environmental protection is facilitated, and the requirements of industrial production are met.

Owner:CHANGSHA PUJI BIOTECH

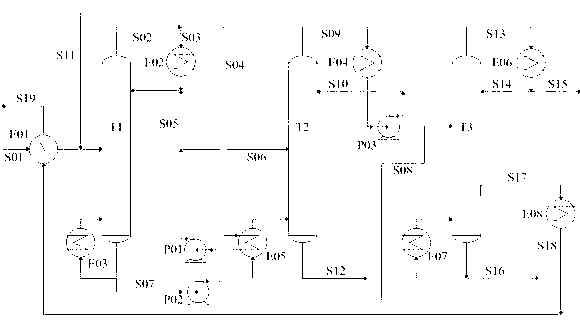

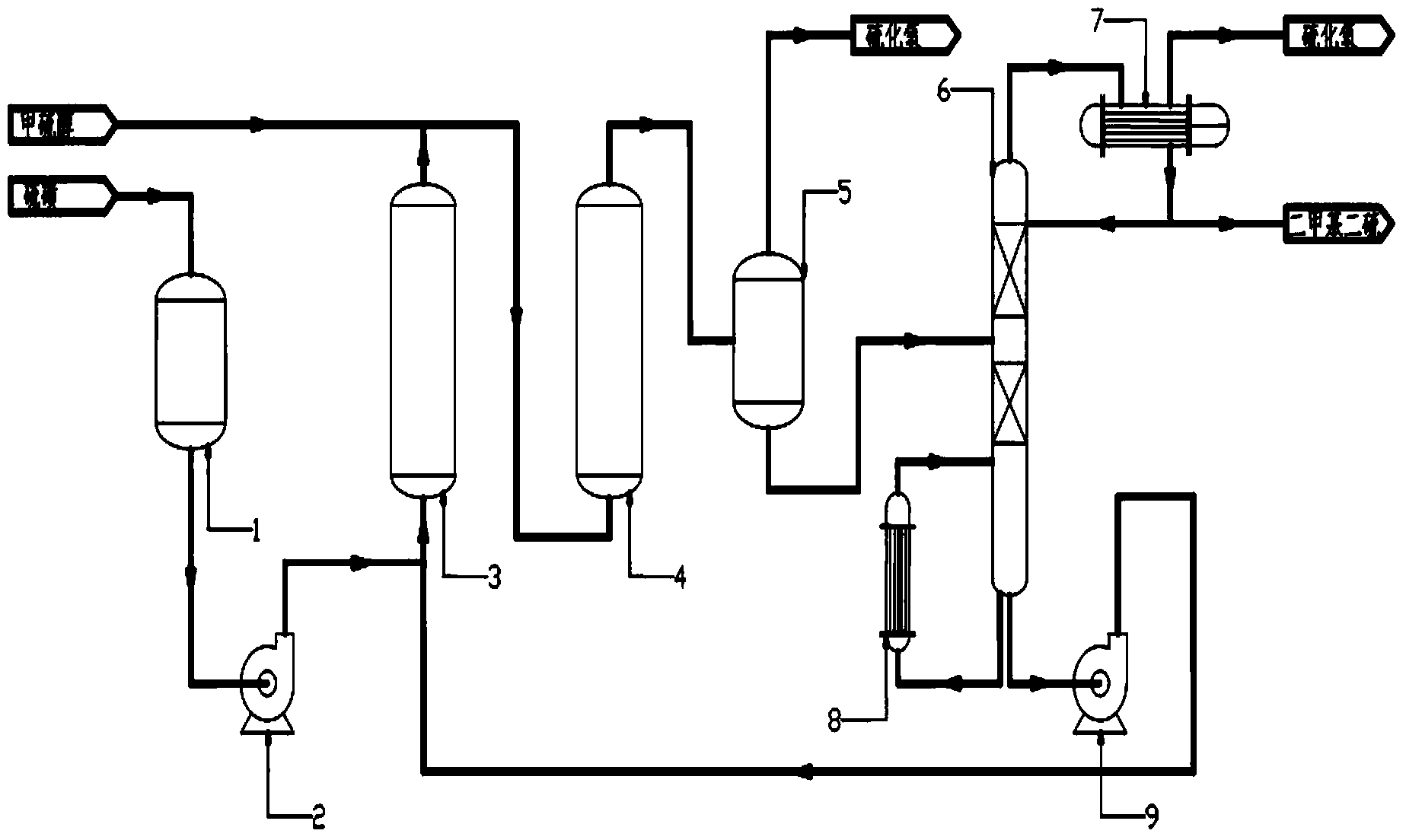

Method and production equipment for variable-pressure distillation and purification of methyl acetate

InactiveCN103102265ALow purityHigh purityOrganic compound preparationCarboxylic acid esters preparationExtractive distillationEthylic acid

The invention relates to a method and production equipment for variable-pressure distillation and purification of methyl acetate. The method mainly comprises the following step of: carrying out variable-pressure distillation and separation on a mixed solution of methyl acetate, methanol and water through a pressurized distillation column, an atmospheric distillation column and a methyl acetate refining column. The fundamental principle is as follows: by utilizing the characteristic that the sensitivity of azeotropic compositions of methyl acetate-methanol and methyl acetate-water is changed along with the pressure variation, the separation and purification of the mixed solution of the methyl acetate, the methanol and the water are realized by adopting the distillation columns with different operating pressures and the purposes of energy conservation and consumption reduction are realized through heat integration, so that the problems that conventional processes of salt extraction, extractive distillation and the like are low in product purity, difficult in solvent recovery and higher in energy consumption and have need for introducing the third component and the like are solved. Therefore, the method disclosed by the invention has the advantages of high methyl acetate yield, high product purity, simple process, low energy consumption and the like.

Owner:FUZHOU UNIV

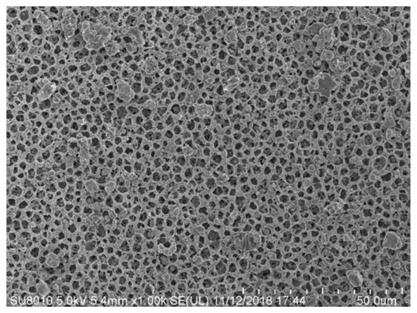

Photocatalytic membrane, preparation method thereof and degradation application of photocatalytic membrane on disinfection by-product precursor

ActiveCN109772454AAvoid churnNot easy to loseWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsUltrafiltrationFiltration

The invention discloses a photocatalytic membrane, a preparation method thereof and degradation application of the photocatalytic membrane on a disinfection by-product precursor. The preparation method of the photocatalytic membrane comprises the following steps that molybdenum disulfide (MoS2) and graphene oxide (GO) are compounded to prepare a MoS2 / RGO (reduced graphene oxide) compound; a polyvinylidene fluoride ultrafiltration membrane is provided and immersed in a Tris-dopamine hydrochloride solution to obtain a polydopamine loaded polyvinylidene fluoride ultrafiltration membrane; then theMoS2 / RGO compound is dissolved in water and subjected to ultrasonic treatment, an aqueous solution of the MoS2 / RGO compound is subjected to vacuum suction filtration on the polydopamine loaded polyvinylidene fluoride ultrafiltration membrane, and then vacuum drying is carried out to prepare the photocatalytic membrane. The preparation method of the photocatalytic membrane and the prepared photocatalytic membrane can be used for efficiently degrading the disinfection by-product precursor in a visible light area.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

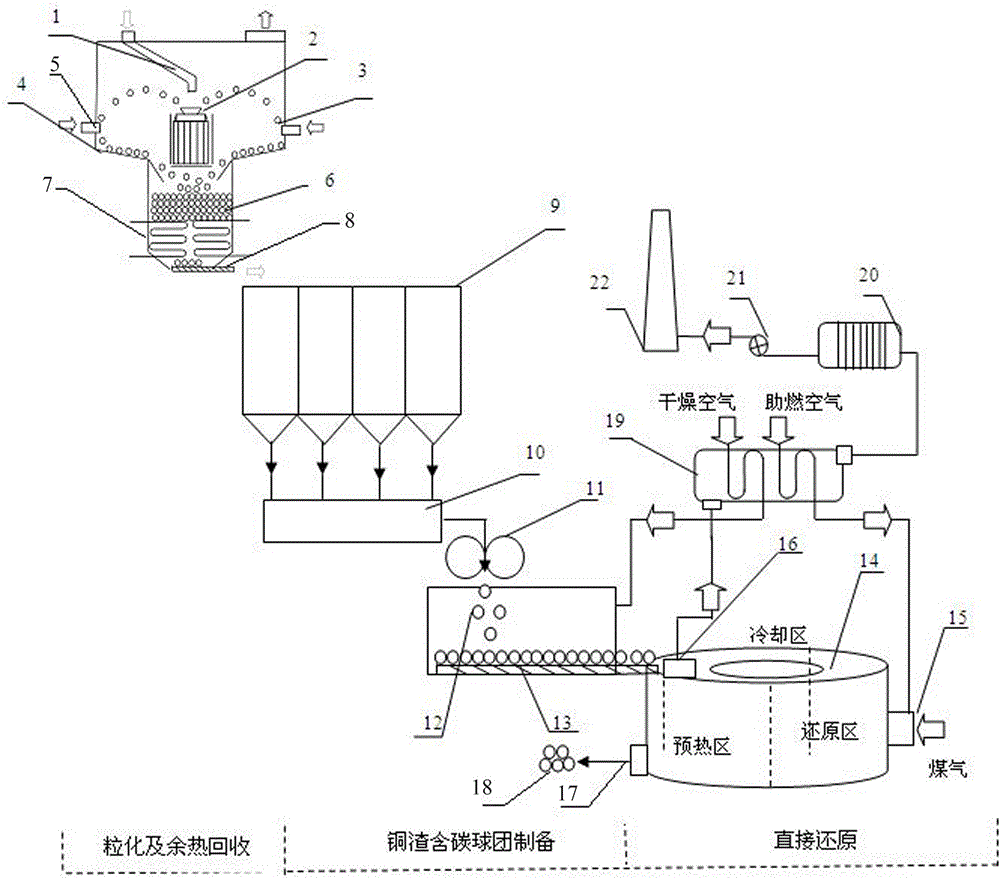

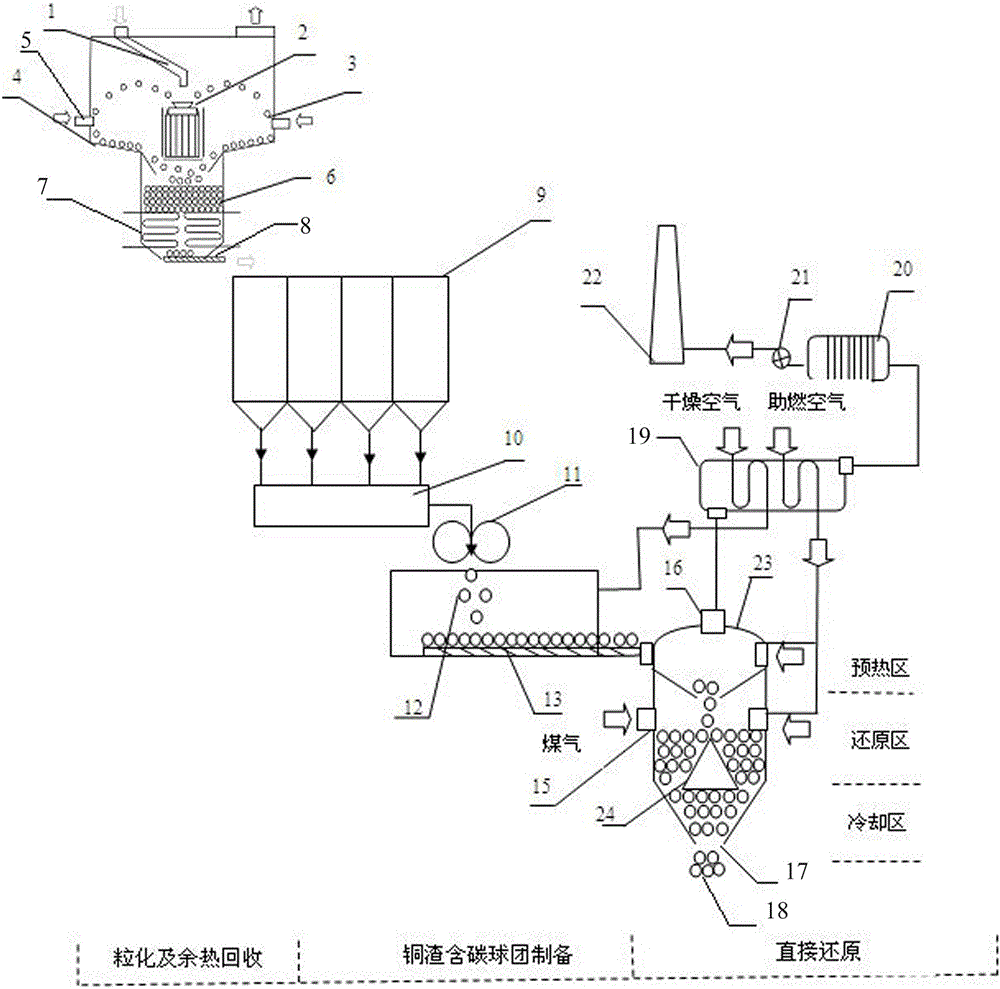

System and method for recycling copper slag waste heat and directly reducing and extracting iron

ActiveCN106086276AEliminate the grinding processReduce energy consumptionShaft furnaceHearth type furnacesFerrous metallurgyFlue gas

The invention belongs to the technical field of non-ferrous metallurgy and particularly relates to a system and method for recycling copper slag waste heat and directly reducing and extracting iron. According to the system and method for recycling the copper slag waste heat and directly reducing and extracting the iron, granulated copper slag particles are directly prepared into copper slag carbon-containing particles, the ore grinding procedure is omitted, and the energy consumption in the pelleting process of pellets in the prior art is reduced; in a drying furnace, the compressive strength of dried copper slag carbon-containing pellets is improved, and a guarantee is provided for direct reducing; according to the system and method for recycling the copper slag waste heat and directly reducing and extracting the iron, by controlling the temperature of a reducing furnace, the reducing rate of the iron in copper slag is increased; and by recycling flue gas waste heat in the furnace, the waste heat recycling rate is increased, the production cost is reduced, the energy conservation and emission reduction purposes are achieved, and the problem that copper slag waste heat recycling and iron recycling are different at current is solved.

Owner:NORTHEASTERN UNIV

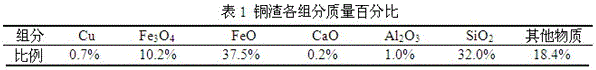

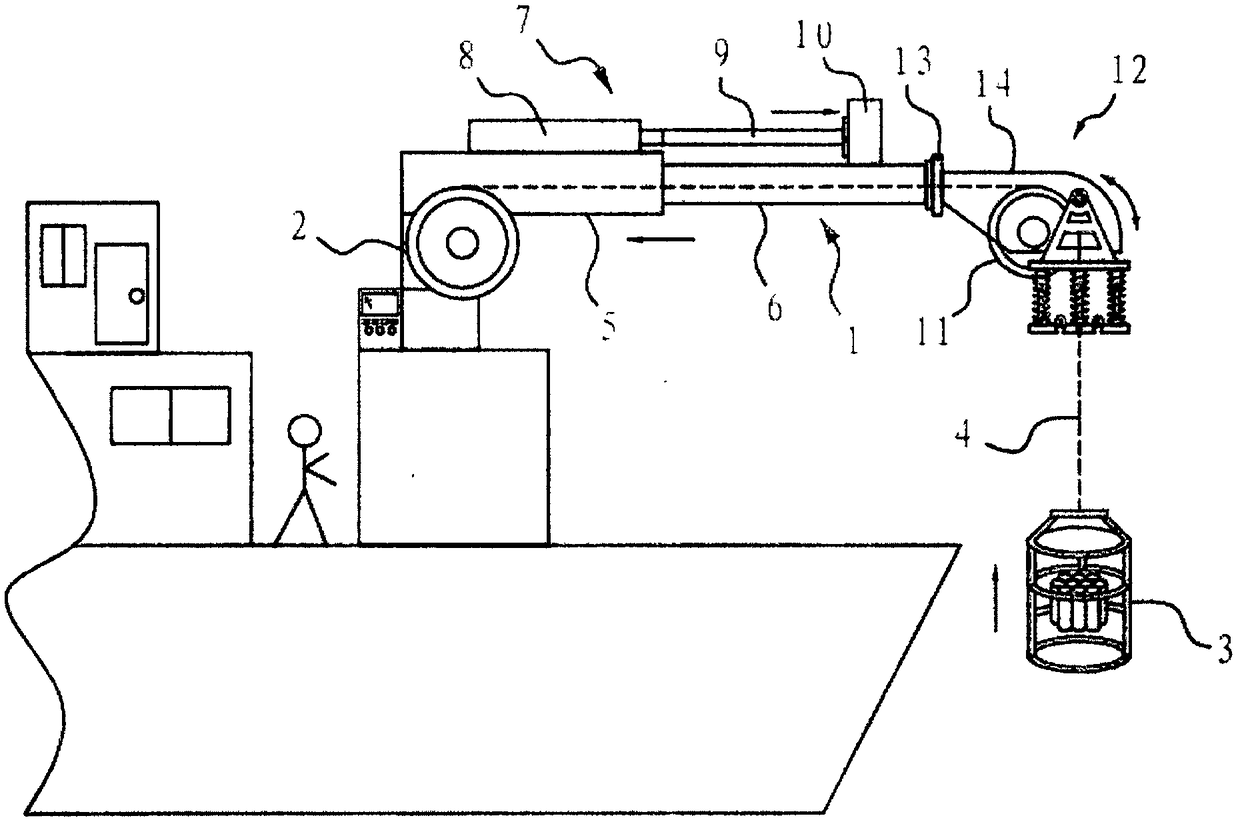

Throwing and recycling protection device for CTD seawater sampling equipment

ActiveCN108190759AAvoid damageSolve storage problemsWithdrawing sample devicesCranesLocking mechanismEngineering

The invention discloses a throwing and recycling protection device for CTD seawater sampling equipment. The throwing and recycling protection device comprises a winch provided with a hoisting beam. The hoisting beam comprises a fixed beam and a movable beam. A steel wire rope is released through the winch and penetrates the fixed beam and the movable beam. The steel wire rope further comprises a drive mechanism for driving the movable beam to telescopically move along the fixed beam. The tail end of the movable beam is provided with a rotation wheel for supporting the steel wire rope and a locking mechanism. The locking mechanism comprises a protection head connected to the tail end of the movable beam, an upper locking plate and a lower locking plate, wherein a damping component is arranged between the upper locking plate and the lower locking plate. The lower locking plate is provided with an electromagnet used for fixing the hoisted and recycled CTD seawater sampling equipment to the lower locking plate. After recycling, the problems that traditionally, the CTD seawater sampling equipment is placed on a ship, slides and suffers from collisions, and consequently the CTD seawatersampling equipment is damaged is solved, and the problem about storage of the CTD seawater sampling equipment in the field is solved.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

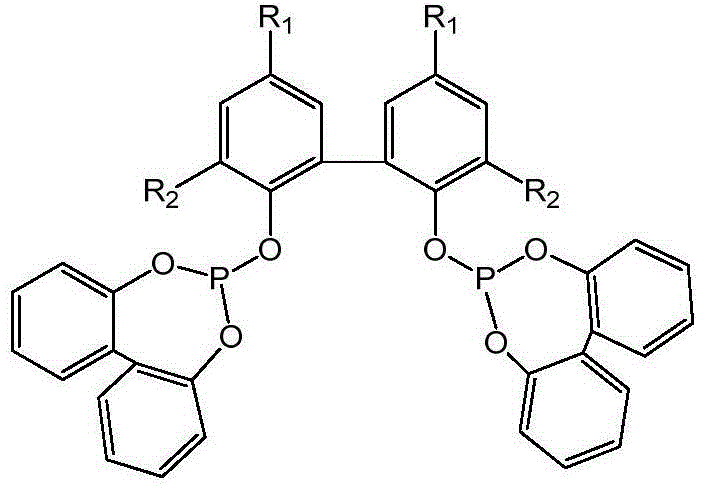

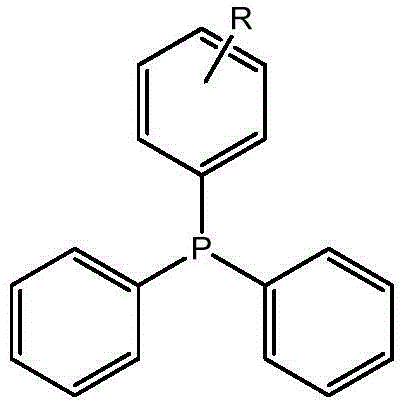

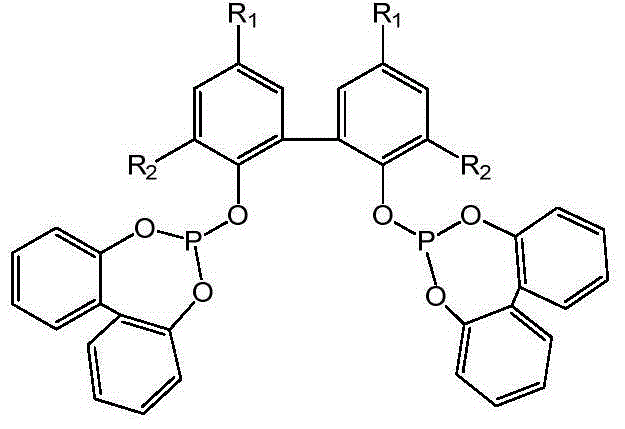

Preparation method of ferromagnetic nanoparticle supported rhodium complex hydroformylation catalyst

ActiveCN104475161AHigh activityEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionHomogeneous catalysisNanometre

The invention provides a preparation method of a ferromagnetic nanoparticle supported rhodium complex hydroformylation catalyst. The method comprises the following step: bonding a rhodium complex to the surface of the superparamagnetic Fe3O4 nanoparticles by a bridging ligand to obtain the ferromagnetic nanoparticle supported rhodium complex hydroformylation catalyst. The invention provides a catalyst prepared by the method and application of the catalyst in hydroformylation reaction. According to the SPION-Rh catalyst, the nanoparticles with huge surface area are combined with rhodium to construct the nano catalytic cluster, thereby being beneficial to enhancing the catalytic efficiency. The catalyst has favorable activity in hydroformylation reaction. After introducing the magnetic particles, the metal rhodium can be simply recovered by applying an external magnetic field, thereby easily solving the problem of difficulty in recovery of rhodium in the homogeneous catalysis in industry.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method for continuously producing dimethyl disulfide

ActiveCN103864650ASolve recycling difficultiesGuaranteed conversionOrganic compound preparationHydropoly/poly sulfide preparationDiallyl disulfideMethyl disulfide

The invention discloses a method for continuously producing dimethyl disulfide. The method is characterized in that after being molten, a material sulfur is fed into a dimethyl trisulfide reactor by virtue of a feeding pump so as to react with recycled dimethyl disulfide to generate dimethyl trisulfide; dimethyl trisulfide and methyl mercaptan are feed into a dimethyl disulfide reactor so as to react to generate dimethyl disulfide; a dimethyl disulfide crude product is fed into a separating tank, so that most of hydrogen sulfide is separated out, a liquid-phase product is fed into a rectifying tower, a dimethyl disulfide product is condensed and recycled at a tower top, hydrogen sulfide is exhausted as a non-condensable gas, and the dimethyl disulfide and dimethyl trisulfide in a tower kettle are returned and recycled. A method of enabling dimethyl trisulfide to be excessive is adopted, so that methyl mercaptan is completely converted, separating requirements are lowered and a separating process is simplified, and therefore, not only can the dimethyl disulfide yield be improved to 90%, but also the product purity is up to 99wt%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Man-made lawn and preparation method therefor

ActiveCN105568498AIncrease binding forceImprove pullout forceGround pavingsGeotextilesEngineeringLawn

The invention relates to a preparation method for a man-made lawn. The preparation method comprises the following steps: arranging warp yarns on a warp beam of a braiding machine, arranging weft yarns on the braiding machine in a direction perpendicular to the warp yarns, arranging man-made grass silk yarns on a yarn creel at the back part of the braiding machine, enabling the man-made grass silk yarns to participate in braiding of bottom cloth in a direction parallel to the warp yarns, and performing grass jacquard weaving treatment on the man-made grass silk yarns by utilizing jacquard equipment of the braiding machine; bypassing the bottom cloth for 2-10 circles by each man-made grass silk yarn to form a cluster of grass silk, setting the height of the grass silk cluster to be 10-70mm, and arranging 6-12 warp yarns between any two adjacent grass silk clusters; and arranging 3-8 weft yarns between any two adjacent grass silk clusters in the grass silk clusters arranged vertically. The preparation method is simple, easy to operate and convenient for industrial production, and pullout force of the grass silk can be increased; and the man-made lawn prepared with the method has the advantages of environmental protection, wide application range and high stability.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

Process for producing adipic acid and hexanediamine by depolymerization of nylon-66

InactiveCN1611477ASolve the problem of high operating costsHigh purityOrganic compound preparationCarboxylic compound preparationSocial benefitsDepolymerization

The invention relates to a kind of technology for manufacturing adipic acid and hexane diamine by depolymerization with nylon-66 (hexamethylene diammonium adipate), which composed with acidolysis section, cooling and crystallization section, virgin acid separation section, recrystallization section, neutralization section, and refining section. Firstly, take acidolysis to get adipic acid; after, add alkali, take neutralization reaction to get hexane diamine. The acid used in acidolysis section is sulfuric acid, and the alkali used in neutralization reaction is lime cream. This technology adapts to industrialized grest production, can solve problem of high operating cost in industrial production of waste nylon-66 depolymerization production enterprise, and can get adipic acid and hexane diamine with higher purity. And also it has no new pollution and higher economic effect and social benefit.

Owner:宁波敏特尼龙工业有限公司

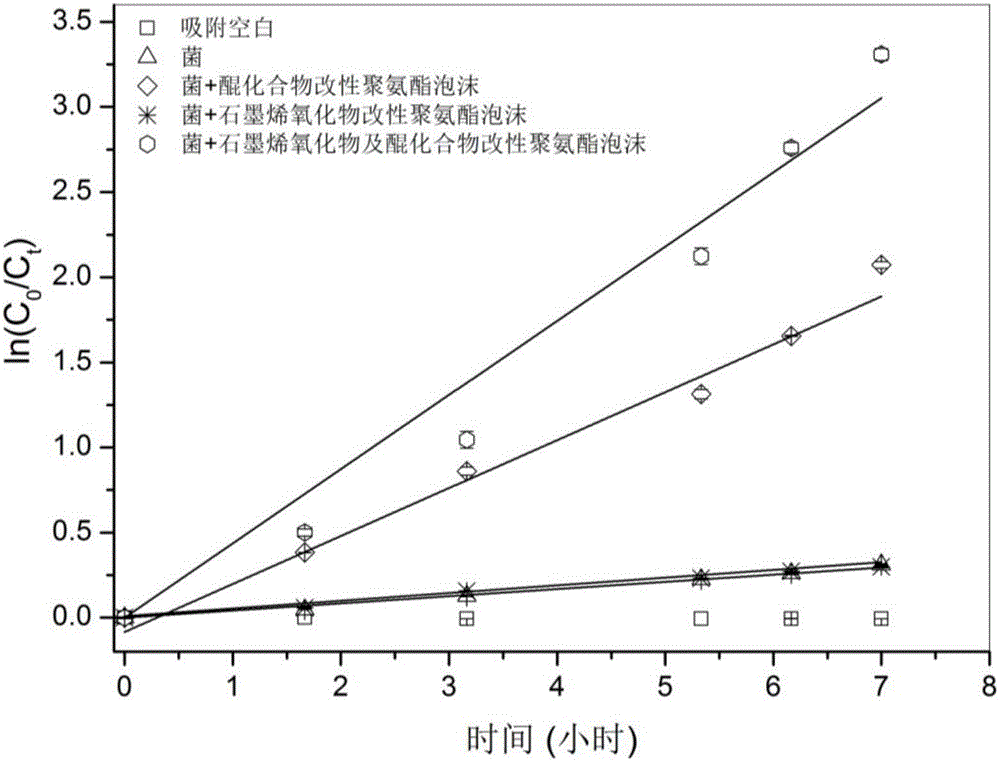

Preparation method of graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier

InactiveCN106830311AStable decompositionPromote conversionWater contaminantsTreatment with anaerobic digestion processesSulfonyl chloridePollution

The invention relates to a preparation method of a graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier and belongs to the technical field of water treatment in environmental engineering. The preparation method comprises the following steps: preparing a graphene oxide modified polyurethane foam composite material from a hydroxyl-containing macroporous foam material at the room temperature by virtue of a physical adsorption method, and aminating the composite material until graphene oxide and polyurethane foam contain a certain amount of primary amine; and reacting by virtue of an anthraquinone compound containing sulfonyl chloride groups with primary amine, so as to fix a quinone compound, wherein the hydroxyl-containing macroporous foam material can be polyvinyl alcohol foam or polyvinyl alcohol doped polyurethane foam and the like. According to the preparation method, the quinone compound and graphene oxide are simultaneously fixed to the surface of the macroporous foam material, so that the contact among a redox mediator, graphene and microorganisms is facilitated; and the technical bottlenecks that graphene and the water soluble quinone compound in a water treatment system are difficult to be recycled and flow out along with water to cause secondary pollution are solved.

Owner:DALIAN UNIV OF TECH

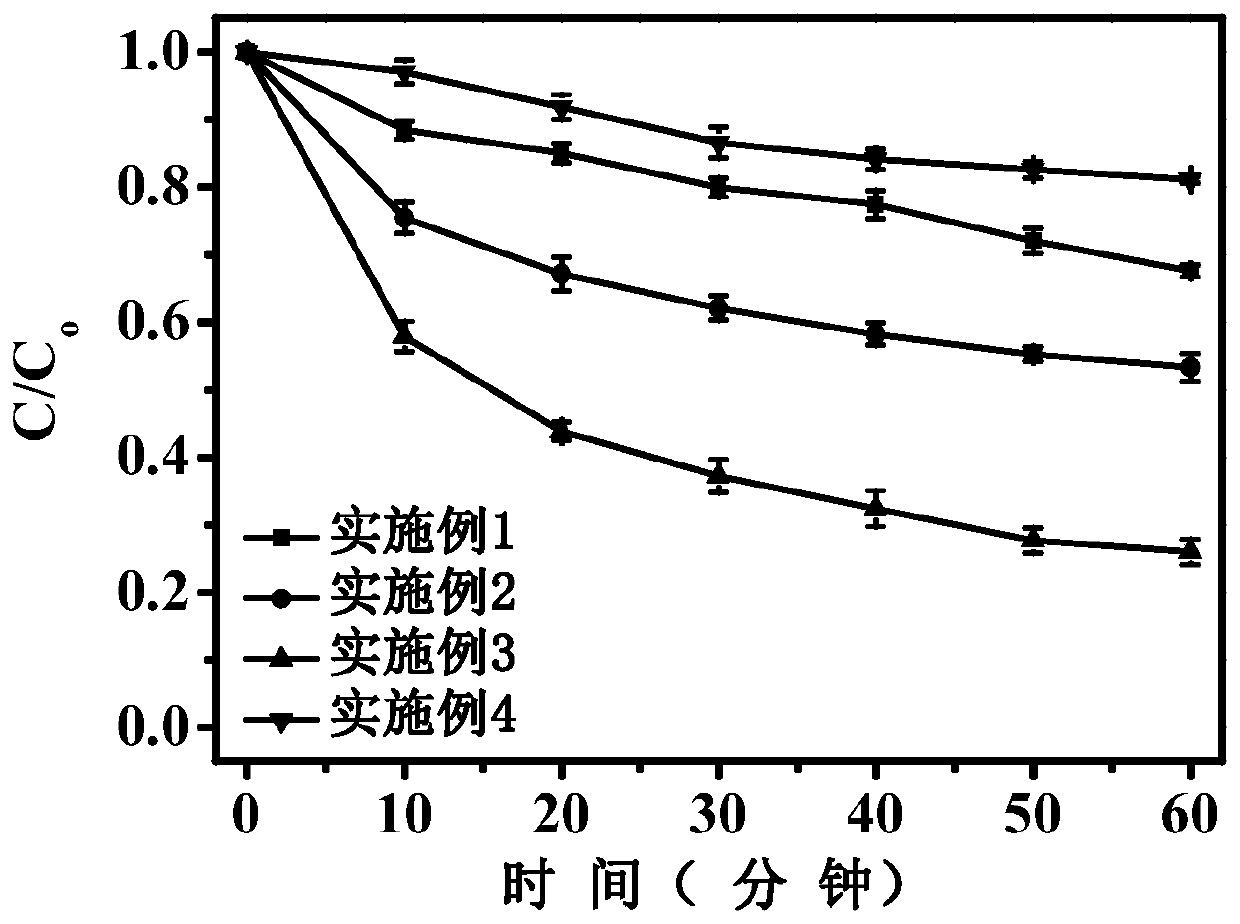

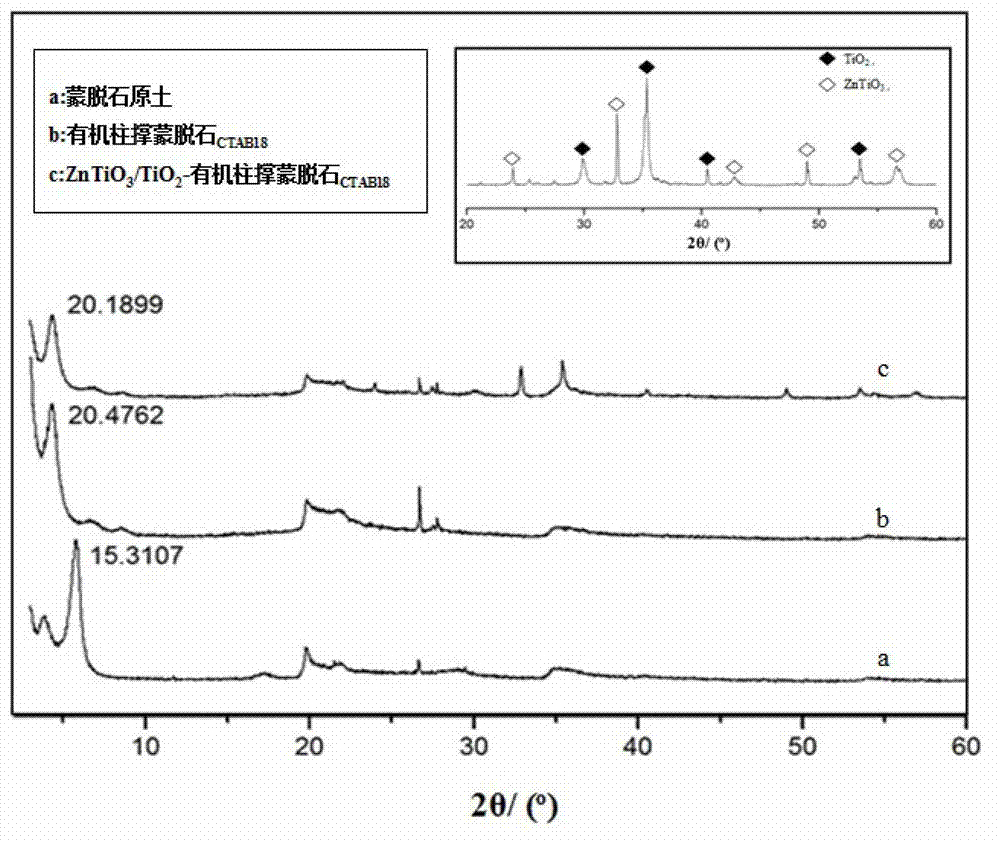

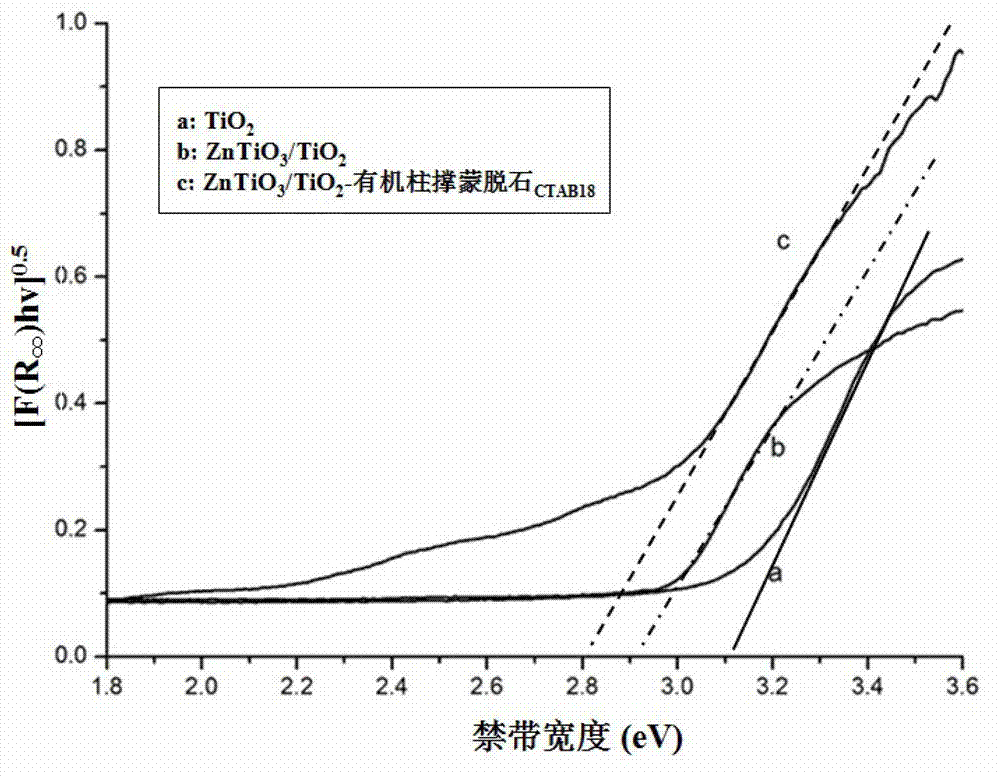

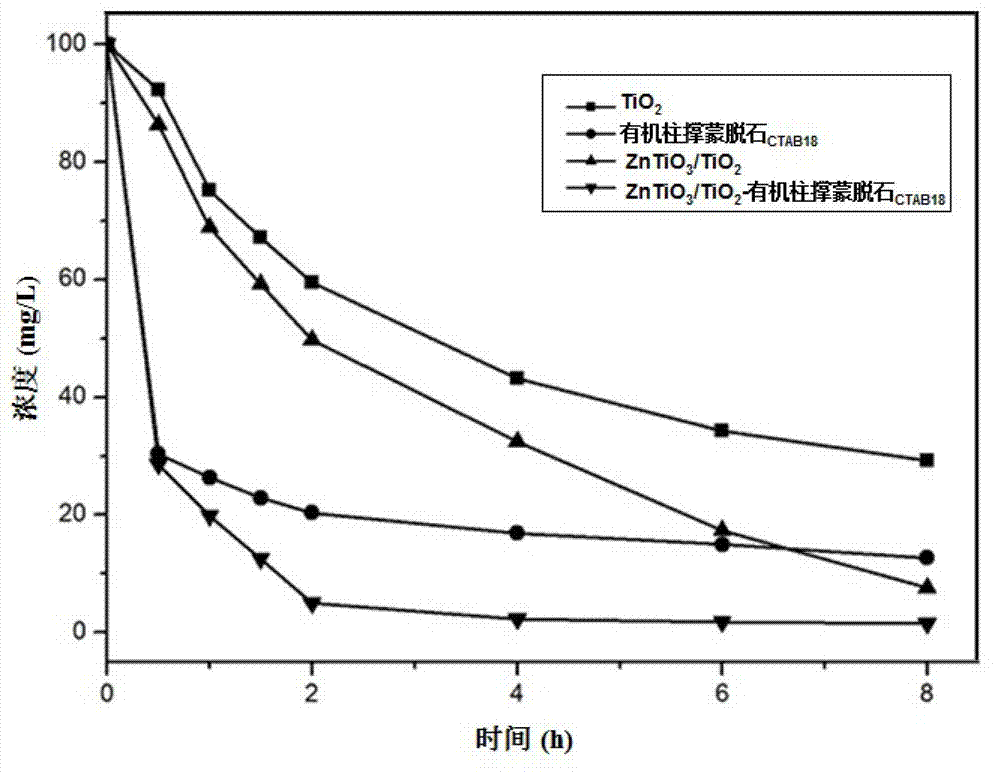

Composite material having visible-light catalytic activity and preparation method thereof

ActiveCN103071477APracticalEasy to operateMetal/metal-oxides/metal-hydroxide catalystsIntercalation reactionSol-gel

The invention discloses a composite material having a visible-light catalytic activity and a preparation method thereof. The composite material having a visible-light catalytic activity is prepared by compounding organic pillared clay and a modified ZnTiO3 / TiO2 material. The organic pillared clay is prepared by an intercalation reaction between an organic pillaring agent and raw clay. The ZnTiO3 / TiO2 material is prepared by a sol-gel method. The ZnTiO3 / TiO2 material and the organic pillared clay are compounded into the ZnTiO3 / TiO2-organic pillared clay composite material having a visible-light catalytic activity. Compared with single TiO2, the ZnTiO3 / TiO2-organic pillared clay composite material has good responsibility in a visible wavelength range. Through utilization of the organic pillared clay as a carrier, adsorption performances of the ZnTiO3 / TiO2-organic pillared clay composite material are improved. The preparation method has the advantages of simple processes, no special equipment, low investment, low cost and popularization convenience.

Owner:SOUTH CHINA UNIV OF TECH

Active-carbon-loaded manganese dioxide and titanium dioxide ozone catalyst for advanced treatment and preparation method

ActiveCN106540686AHigh catalytic activityEasy to handleWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsFiltrationDissolution

The invention relates to an active-carbon-loaded manganese dioxide and titanium dioxide ozone catalyst for advanced treatment and a preparation method. The preparation method comprises: dissolving KMnO4 and an oxidant in deionized water, respectively; till the complete dissolution is completed, adding a MnSO4 solution to the KMnO4 solution drop by drop; adding TiO2 powder, performing a reaction at 180 DEG C for 12 h, and performing washing, filtration and drying to obtain MnO2-TiO2 composite particles; dispersing the composite particles in the deionized water; adding active carbon; performing soaking in a MnO2-TiO2 suspending liquid; and after the soaking is finished, putting the obtained product in a muffle furnace for roasting to obtain active-carbon-loaded manganese dioxide and titanium dioxide ozone catalyst particles. The reaction time can be effectively reduced, the removal efficiency of COD is improved, and the catalyst can be used to the field of water pollution treatment.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

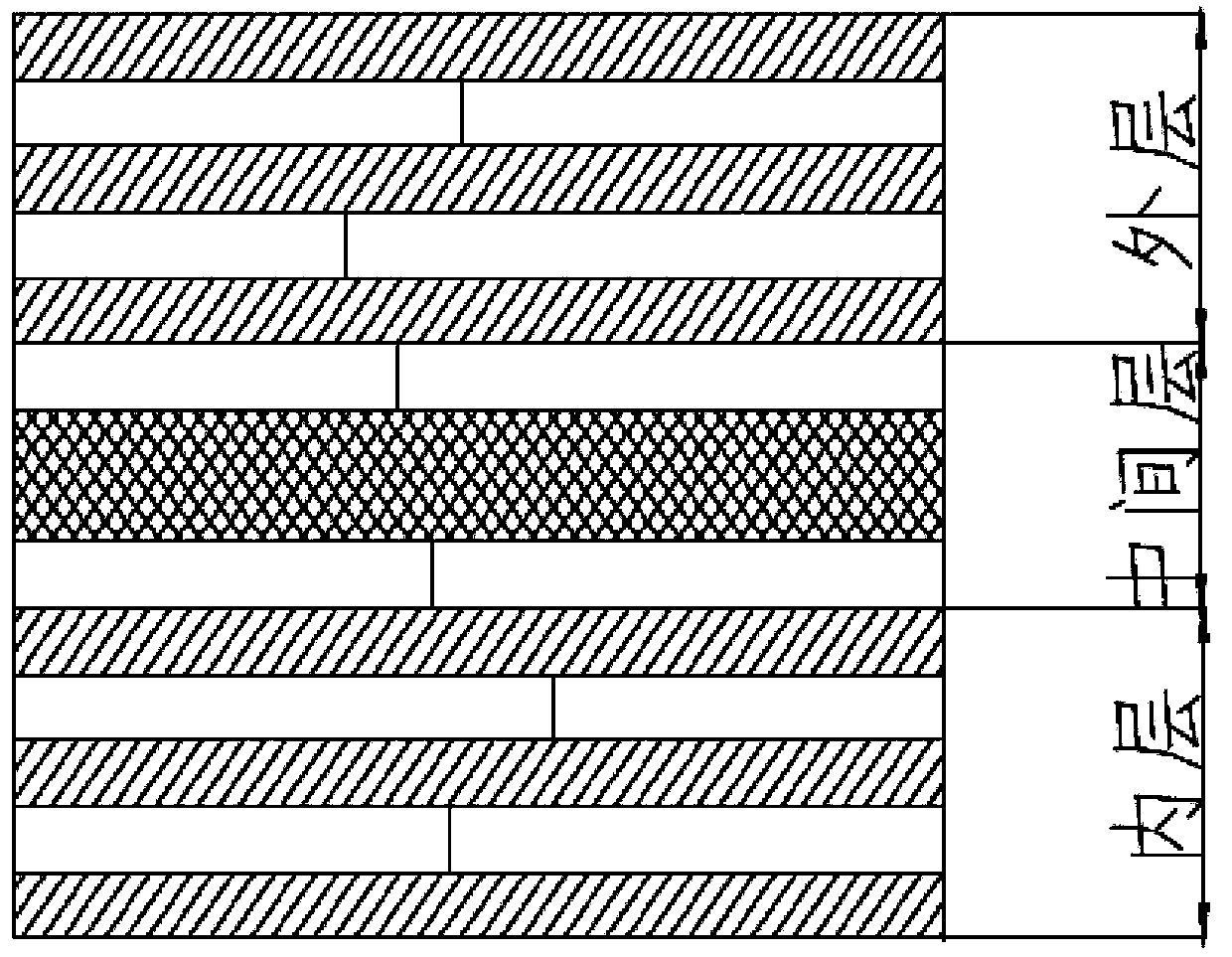

High-temperature resistant oil well rubber sealing ring material and preparation method thereof

ActiveCN103496229AGood high temperature resistanceReduce raw material costsEngine sealsLaminationFilling materialsCarbon black

The invention provides a high-temperature resistant oil well rubber sealing ring material and a preparation method thereof. The rubber sealing ring material is composed of three parts: the inner layer and the outer layer are both composed of high-strength knitted cloth added with inorganic materials such as carbon black, nano zirconia, and the like; the middle layer is prepared through following steps: compounding rubber powder, which has been desulfurated through thermal mechanical shearing, with fluoro-rubber, adding a compatilizer to increase the compatibility between the rubber powder and the fluoro-rubber; then adopting high-strength knitted cloth, which has been subjected to a surface treatment, as the support body, adding inorganic filling materials such as carbon black, nano zirconia, and the like, and subjecting the knitted cloth added with inorganic filling materials to a high-temperature sulfide cross-linked forming so as to obtain the middle layer. The sealing ring knitted cloth and the rubber base material are subjected to processes of multi-layer compounding and sulfide forming. The sealing ring prepared by the invention has a good high-temperature resistant performance, and is capable of being used in areas with a large temperature difference for a long period.

Owner:CHANGZHOU UNIV

Method for preparing adipate

ActiveCN102001931ALow costHigh reactivityChemical recyclingCarboxylic preparation by oxidationAdipic acidSolvent

The invention discloses a method for preparing adipate, comprising the following steps of: (1) adding cyclohexane, solvent, an initiator and a solid catalyst into a reactor and mixing to form a mixed suspension; (2) introducing enough amount of oxygen into the mixed suspension to be used as an oxidant; and reacting under the conditions that the pressure is 0.5-5MPa and the temperature is 100-200DEG C for 1-20h; (3) separating the reaction mixture in the step (2) to obtain the solid catalyst and a liquid phase mixture; and (4) separating the adipate from the liquid phase mixture in the step (3). The invention prevents nitric acid from corroding the environment and the equipment, can solve the problems that a homogeneous catalyst is difficult to recover and is deactivated in the oxidation process of the cyclohexane, is free from using noble metals and has high reaction selectivity and favorable activity. The used catalyst can be recycled.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving lignocellulose raw material enzymolysis efficiency and lignose recovery rate

ActiveCN105755883AHigh economic feasibilitySolve recycling difficultiesLignin derivativesPaper material treatmentFiberEnvironmental resistance

The invention provides a method for improving lignocellulose raw material (especially bamboo reed fiber raw material) enzymolysis efficiency and lignose recovery rate. According to the method provided by the invention, through methods of ionic liquid dissolving, solid acid catalyzing and raw material regenerating by an acetone water solvent, compact cell wall structures of bamboo reeds are broken, and regenerative raw materials with rough fiber surface and II crystal form cellulose are obtained, so that the problem that liquid acid catalytic-ion liquid is difficult to recycle is solved, and the bamboo reeds can be utilized for high value; lignose powder is recycled with higher yield through heating, decompressing and distilling, so that the problem that ionic liquid lignose is difficult to recycle is solved, and the time for lignose recycle is shortened; a pre-processing and seperation method is simple and convenient to operate; the used reagents can be recycled and reused so as to be green and environmentally friendly; the recycle of acetone is favorable to environment protection and health of operators; the economic feasibility of ionic liquid pre-processing is improved.

Owner:山东银鹰化纤有限公司

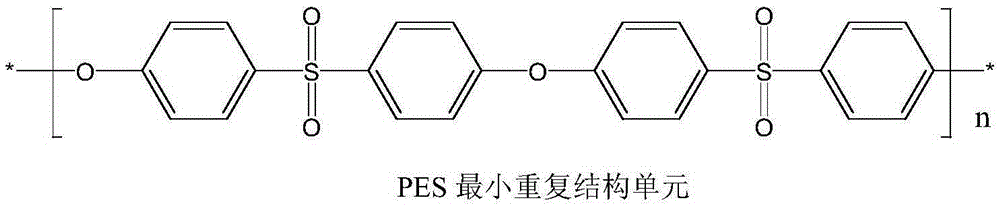

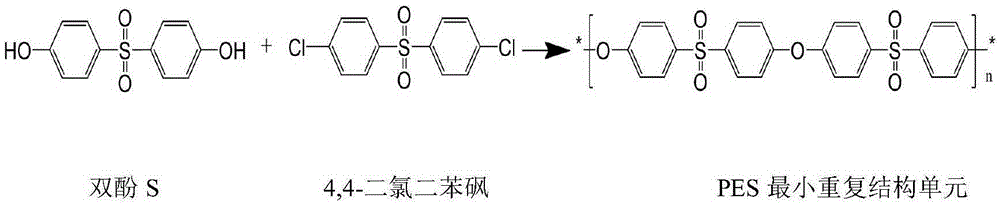

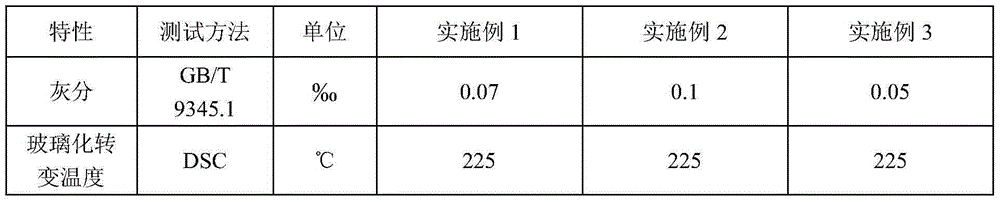

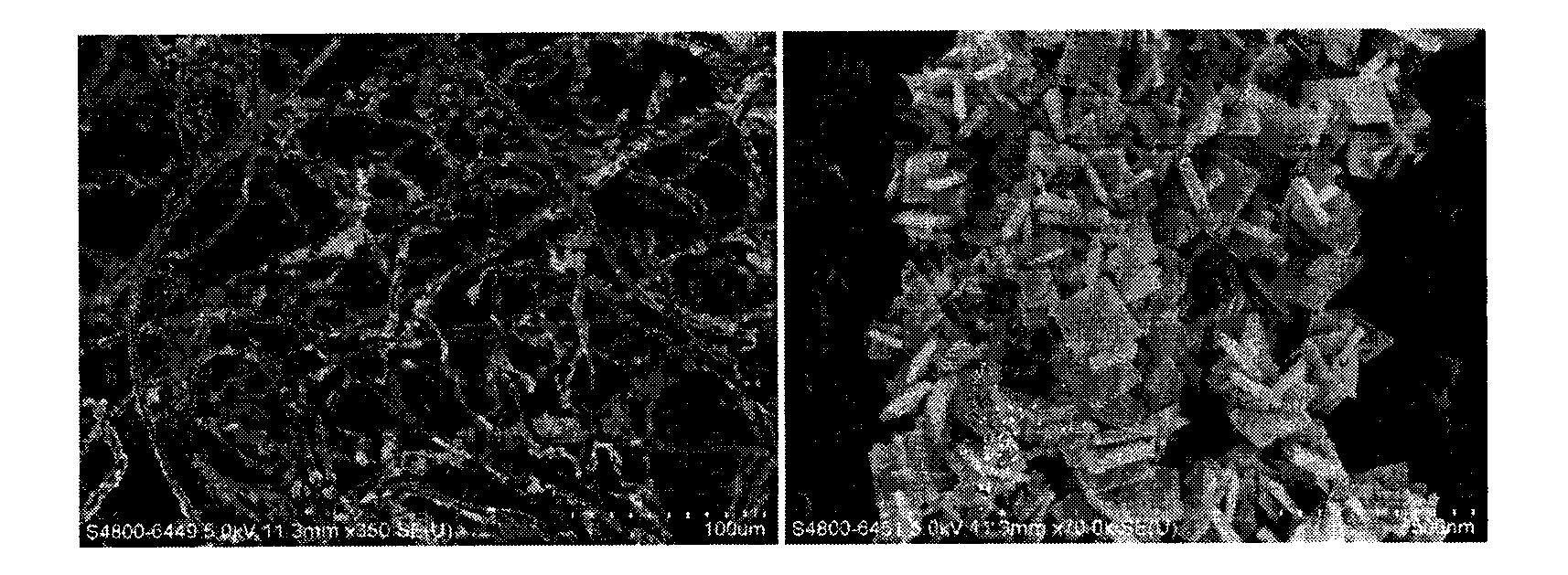

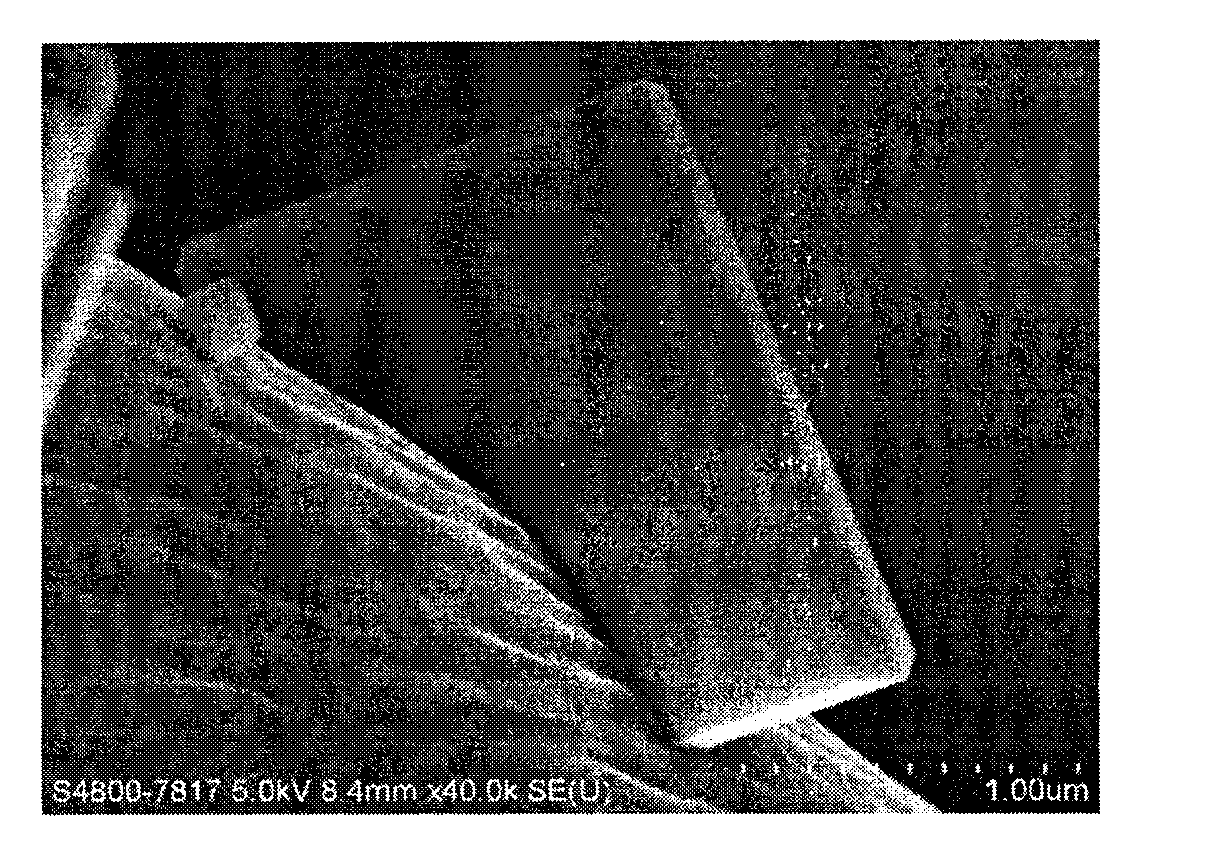

Preparation method of polyethersulfone resin

InactiveCN105254890AGuaranteed Purity and PerformanceOvercoming Process DiscontinuitiesBisphenol SPrecipitation

The invention relates to a preparation method of polyethersulfone resin. The method comprises the steps of polymer synthesis, precipitation and purification, bisphenol S and 4,4-dichlorodiphenylsulfone are adopted as raw materials, sulfolane is adopted as a solvent, trimethylbenzene is adopted as a desiccant, K2CO3 is adopted as a catalyst, and the whole reaction process is carried out under the protection of an inert gas. The polyethersulfone resin naturally precipitates in a precipitation solution to make a material become a powdery slurry, so the material conveying and next step purification treatment are facilitated, thereby the problems of difficult product purification and difficult solvent recovery are solved, high molecular chains of the polyethersulfone resin are not destroyed, and the purity and the performances of the above product are guaranteed. The polyethersulfone resin prepared by adopting the preparation method has high purity and stable performances, can be applied in fields of foods, electrons, machines, medical treatment and chemical engineering, and solves the problem of low quality of the product due to high content and difficult removal of impurities in products prepared through traditional methods.

Owner:中昊黑元化工研究设计院有限公司

Preparation method of carbon fiber loaded titanium dioxide nanometer sheet

InactiveCN103055835AEasy to prepareImprove securityPhysical/chemical process catalystsFiberCarbon fibers

The invention relates to a preparation method of a carbon fiber loaded titanium dioxide nanometer sheet. The method comprises the following steps: uniformly stirring carbon fibers and a titanium source under an acidic condition; using fluoborate as a morphology control preparation, wherein the mol ratio of the carbon fibers, the titanium source, the fluoborate, hydrochloric acid and deionized water is 1:(1-5):(1-10):(10-100):(100-1000); placing a reaction kettle in a thermostat at the temperature of 150-200 DEG C; and reacting for 4-24 hours so as to obtain the carbon fiber loaded titanium dioxide nanometer sheet. Through adoption of the loaded photocatalyst, the recycling problem of the catalyst can be solved and the secondary pollution problem caused by nanoparticles can be effectively avoided. The preparation method of the carbon fiber loaded titanium dioxide nanometer sheet, provided by the invention, has the advantages of simplicity, good safety and good operability. The prepared carbon fiber loaded titanium dioxide nanometer sheet has a broad application prospect in the field of photocatalytic degradation of organic pollutants, dye sensitized solar cells and the like.

Owner:吕晓莹 +1

Method for dephosphorization treatment on molten iron by using stainless steel self-produced dedusting ash ball

ActiveCN103215405AGood dephosphorization effectSolve recycling difficultiesRecycling and recovery technologiesProcess efficiency improvementSteelmakingDust control

The invention provides a method for dephosphorization treatment on molten iron by using stainless steel self-produced dedusting ash ball, so as to solve the problems in the prior art that dedusting ash produced from stainless steel production cannot be effectively resolved and that self-produced waste cannot be utilized. The method comprises the steps of desilication and dephosphorization. The main raw materials for the dephosphorization treatment of dedusting ash ball comprise passivation lime powder, dedusting ash ball and fluorite. The invention effectively solves the problem of difficult recycling of dedusting ash ball from steelmaking and reduces the smelting cost, so as to advocate green, environmental protection and recycling.

Owner:JIUQUAN IRON & STEEL GRP

Method for sorting gold from gold-bearing high-arsenic tailings

InactiveCN101709385ASolve recycling difficultiesNo pollution in the processProcess efficiency improvementSulfiteGold deposit

The invention relates to a method for sorting gold from gold tailings in gold mines, in particular to a method for sorting gold from gold-bearing high-arsenic tailings. The method comprises the following steps of: grounding gold-bearing high-arsenic tailings into be smaller than or equal to 200 meshes after sieving, mixing into ore pulp of a certain concentration, adding sulphite, H2SO4 and sulphate in sequence, presoaking, mixing and activating for a certain time, adding CaO, butyl xanthic acid and Dithiophosphate BA in sequence, sending to a flotation cell, adding No.2 oil and obtaining golden concentrates after rough sorting and selection. The invention solves the problem of hard recovery of gold and other useful minerals in the gold-bearing high-arsenic tailings, and has the gold recovery rate of over 85 percent, no secondary pollution to environment, simple technology and low recovery cost.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com