Patents

Literature

124results about How to "Stable decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

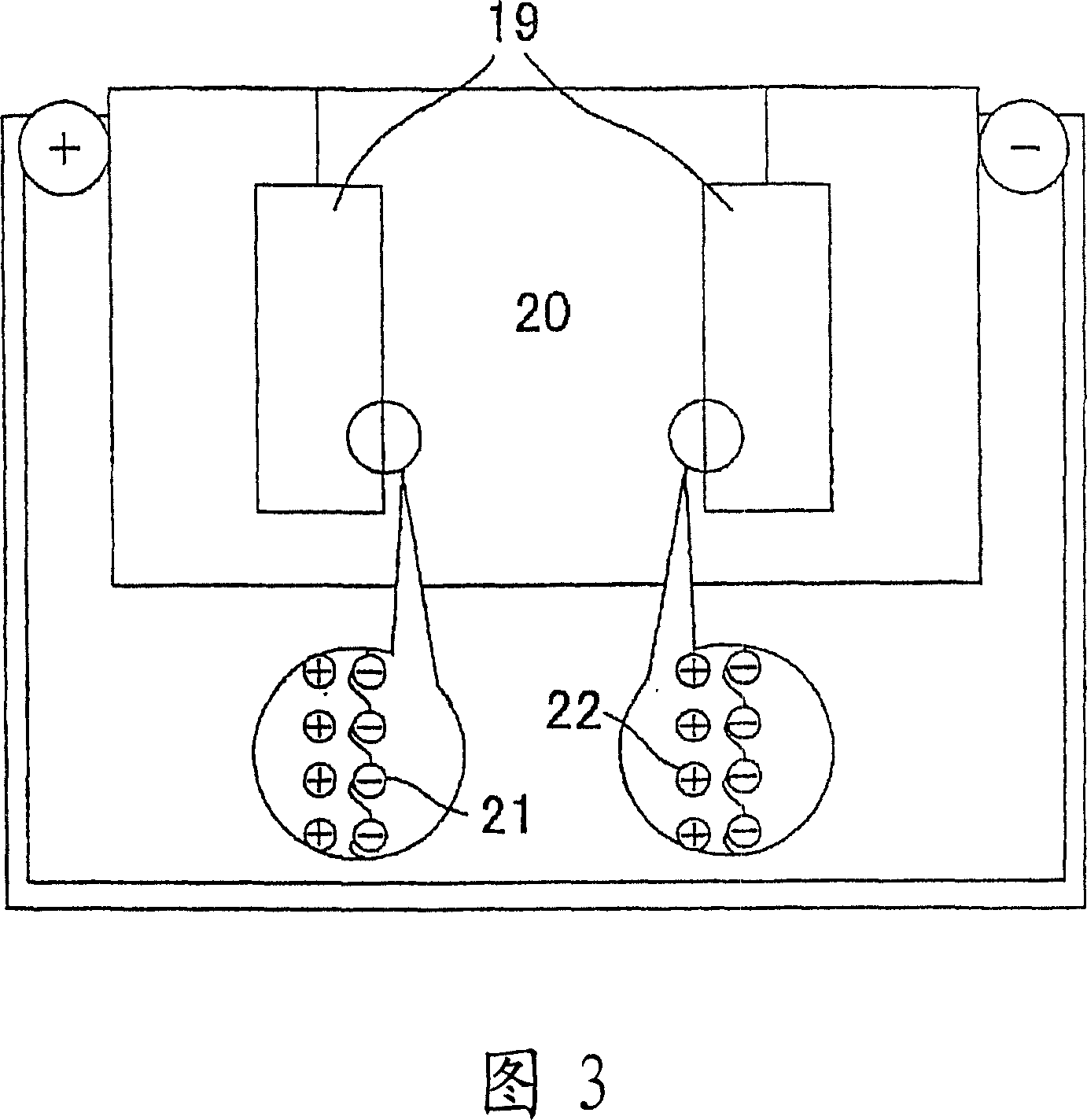

Material for electrolytic solution, ionic material-containing composition and use thereof

InactiveCN1950970AStable decompositionNo corrosionHybrid capacitor electrolytesOrganic chemistryIonSolvent

An object of the present invention is to provide a material for an electrolytic solution having improved ionic conductivity and, showing excellent in low temperature property, being stable with time,and being electrochemically stable at a high potential, and an ionic material-containing composition exhibiting excellent fundamental performance such as electrochemical stability, and preferably usedin a variety of utilities. Another object of the present invention is to provide utilities thereof. The material for an electrolytic solution is the material containing an ionic compound, and the material comprises a cyano group-containing anion represented by the formula (1) and 1 to 99% by mass of a solvent in 100% by mass of the material for an electrolytic solution.

Owner:NIPPON SHOKUBAI CO LTD

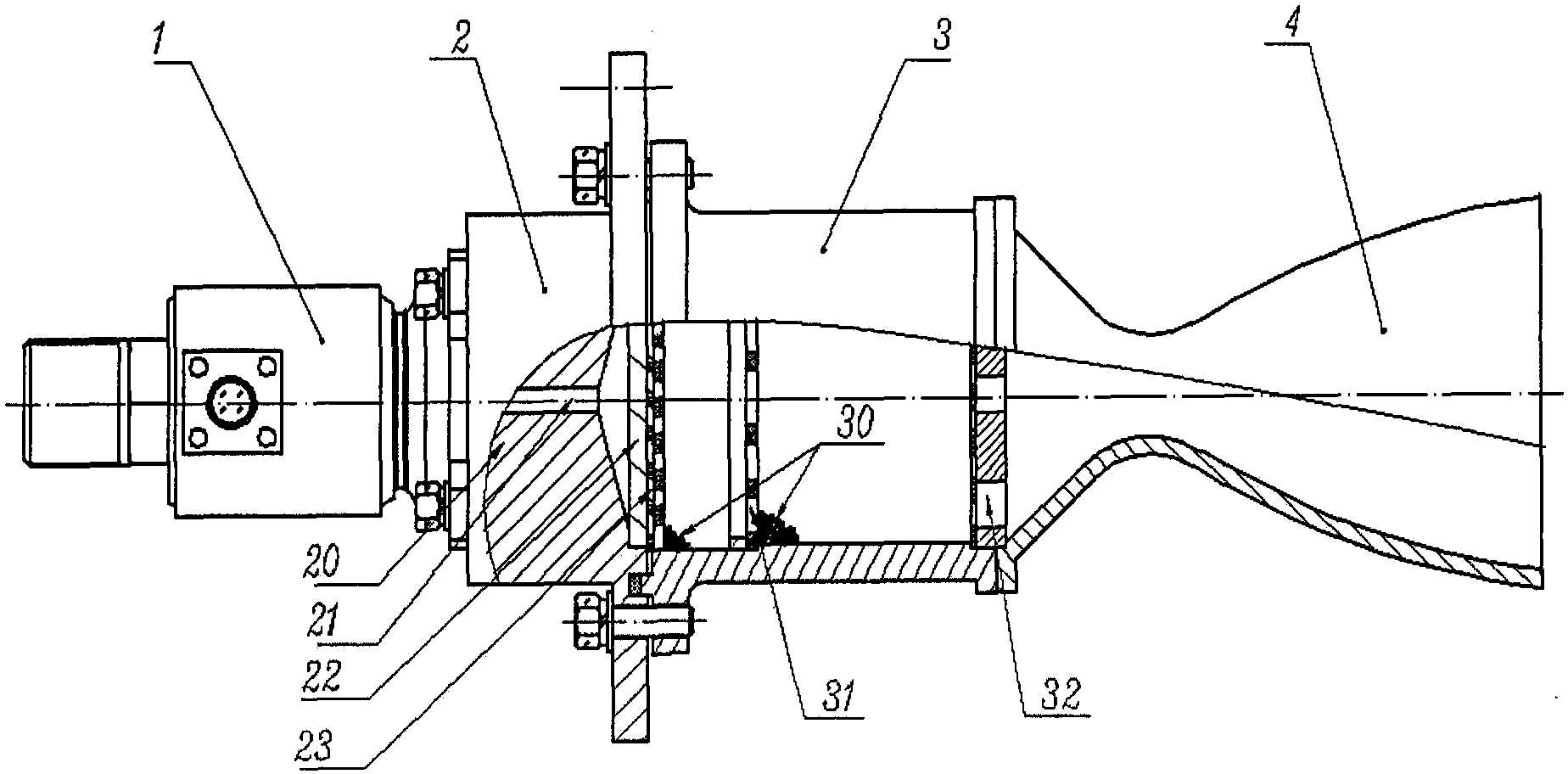

Low-thrust single-component hydrogen peroxide rocket engine

InactiveCN106134393BStable decompositionEfficient decompositionRocket engine plantsHigh concentrationHydrazine compound

The invention discloses a small-thrust single-component hydrogen peroxide rocket engine applied to space vehicles and aircrafts, which comprises a solenoid valve, an injector, a catalytic decomposition chamber and a nozzle connected in sequence. The solenoid valve delivers hydrogen peroxide to the injector. The hydrogen peroxide is transported through the injector and injected into the catalytic decomposition chamber. Under the action of the catalyst, it is decomposed into high-temperature and high-pressure gas, and then discharged from the nozzle to generate thrust. The invention uses high-concentration hydrogen peroxide as the propellant of the single-component attitude control rocket engine, which can replace the existing conventional toxic hydrazine single-component propellant, and achieves the beneficial effect of making the single-component attitude control engine non-toxic.

Owner:SHANGHAI INST OF SPACE PROPULSION

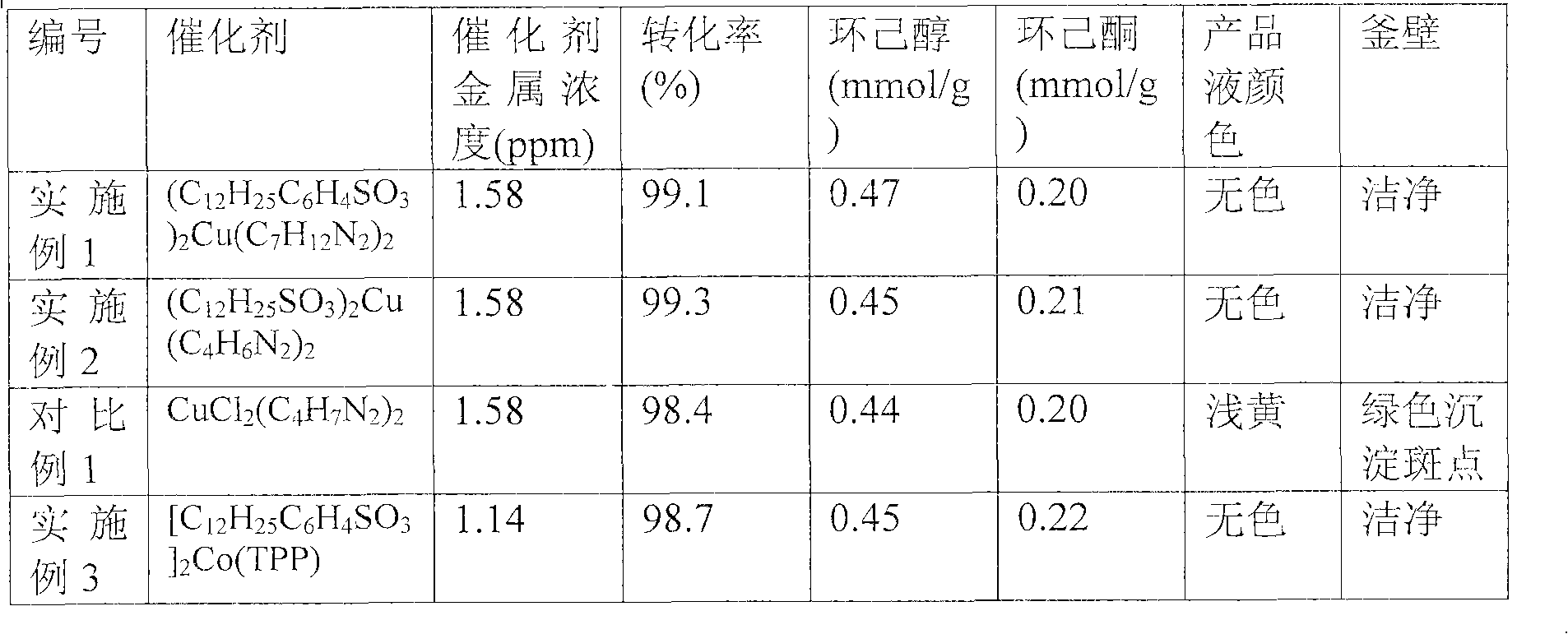

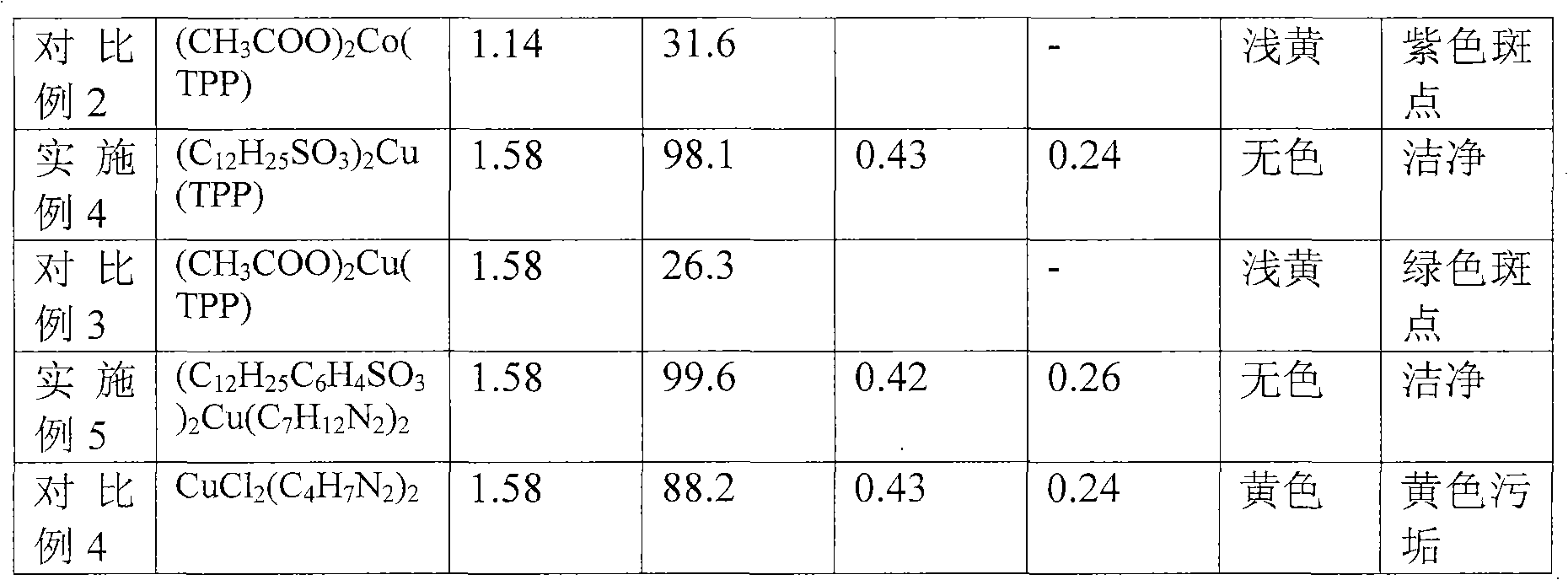

Complex catalyst system and application thereof to decomposition of naphthene hydrogen peroxide

ActiveCN102397794AStable decompositionPrevent precipitationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionStrong acids

The invention discloses a complex catalyst system and application thereof to decomposition of naphthene hydrogen peroxide. The catalyst system is AxMFn, wherein A is a strong acid anion, M is an active center transition metal cation, and F is an organic ligand of a nitrogen-containing heteroatom; the strong acid anion A is a strong acid radical anion containing lipophilic C4-C30 long-chain alkyl;x represents an anion mole number corresponding to every mole of transition metal cation M; and n represents the mole number of the ligand F contained in every mole of transition metal M anion. Due to the adoption of the complex catalyst system, naphthene hydrogen peroxide can be decomposed stably into naphthene alcohol and naphthene ketone under the liquid phase condition of 80-150 DEG C, and catalyst metal is prevented from precipitating and scaling.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements and application method thereof

The invention relates to the technical field of pickling agents, and particularly relates to an environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements and an application method thereof. The environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements is prepared from the following components by weight content in each liter of water: 5-60g of sulfuric acid, 5-10g of sulfamic acid, 20-100g of strong oxidant, 50-140g of fluoride, 20-70g of chloride, 3-8g of corrosion inhibitor, 10-20g of ethanol and 1L of water. The environment-friendly stainless steel pickling agent free of nitrogen and phosphorus elements disclosed by the invention is short in cleaning time, and good in cleaning effect, and can be used for cleaning at normal temperature, a cleaned stainless steel welding spot part is bright in color and luster, and the environment-friendly stainless steel pickling agent is convenient to use, and can be recycled, so that the cost is reduced, and pollution to the environment is reduced.

Owner:Dongguan Kaimeng Chemical Co Ltd

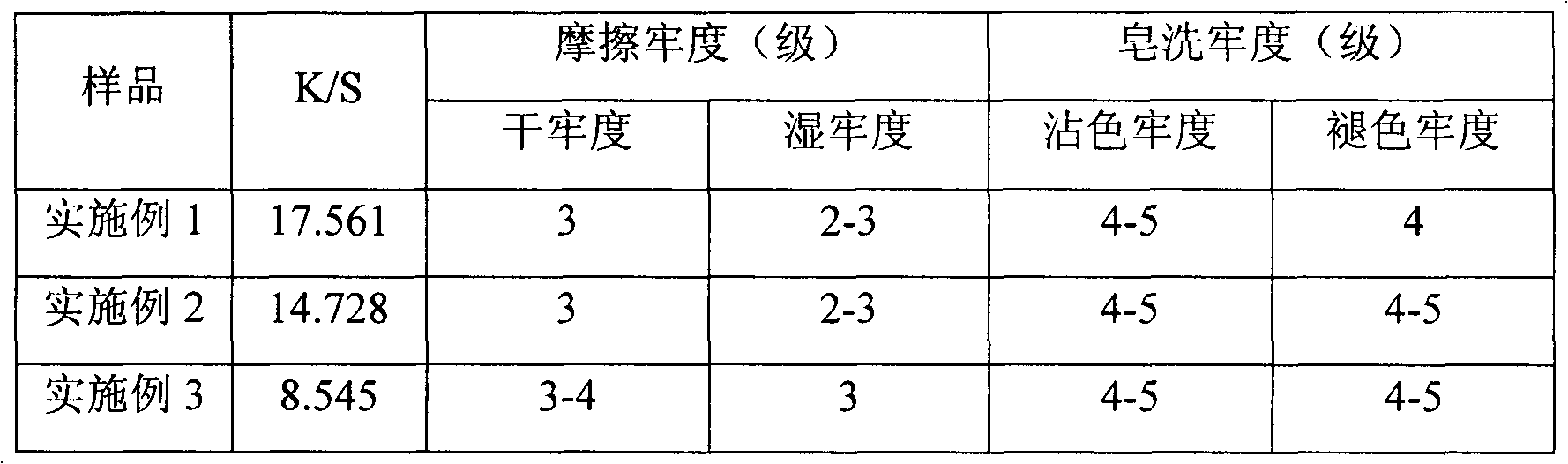

One-bath processing method for pure-cotton knitted fabric scouring and bleaching and pigment dyeing

InactiveCN102605653AStable decompositionEfficient decompositionBiochemical fibre treatmentBleaching apparatusWater savingTextile dyeing

The invention relates to a one-bath processing method for pure-cotton knitted fabric scouring and bleaching and pigment dyeing, belonging to the technical field of textile dyeing and finishing. The process adopted in the invention comprises the following steps: (1) carrying out scouring and bleaching treatment on pure-cotton knitted fabric, wherein waste liquid discharge is not needed after the treatment is completed; (2) after the scouring and bleaching treatment is completed, adjusting the treating fluid to a certain condition, and then adding catalase, so that residual hydrogen peroxide is sufficiently decomposed; and (3) preparing a pigment dyeing solution by utilizing the residual fluid and dyeing the pure-cotton knitted fabric, adding a binding agent to the residual fluid after the dyeing is completed for fixation, and finally taking out the knitted fabric and carrying out dehydration, drying and curing treatment. According to the invention, two processes, namely pure-cotton knitted fabric scouring and bleaching and pigment dyeing, are combined and carried out in a same treatment bath, thereby not only ensuring the dyeing effect, but also repeatedly utilizing the scouring and bleaching residual fluid, and being remarkable in water-saving and energy-saving effects.

Owner:QINGDAO UNIV

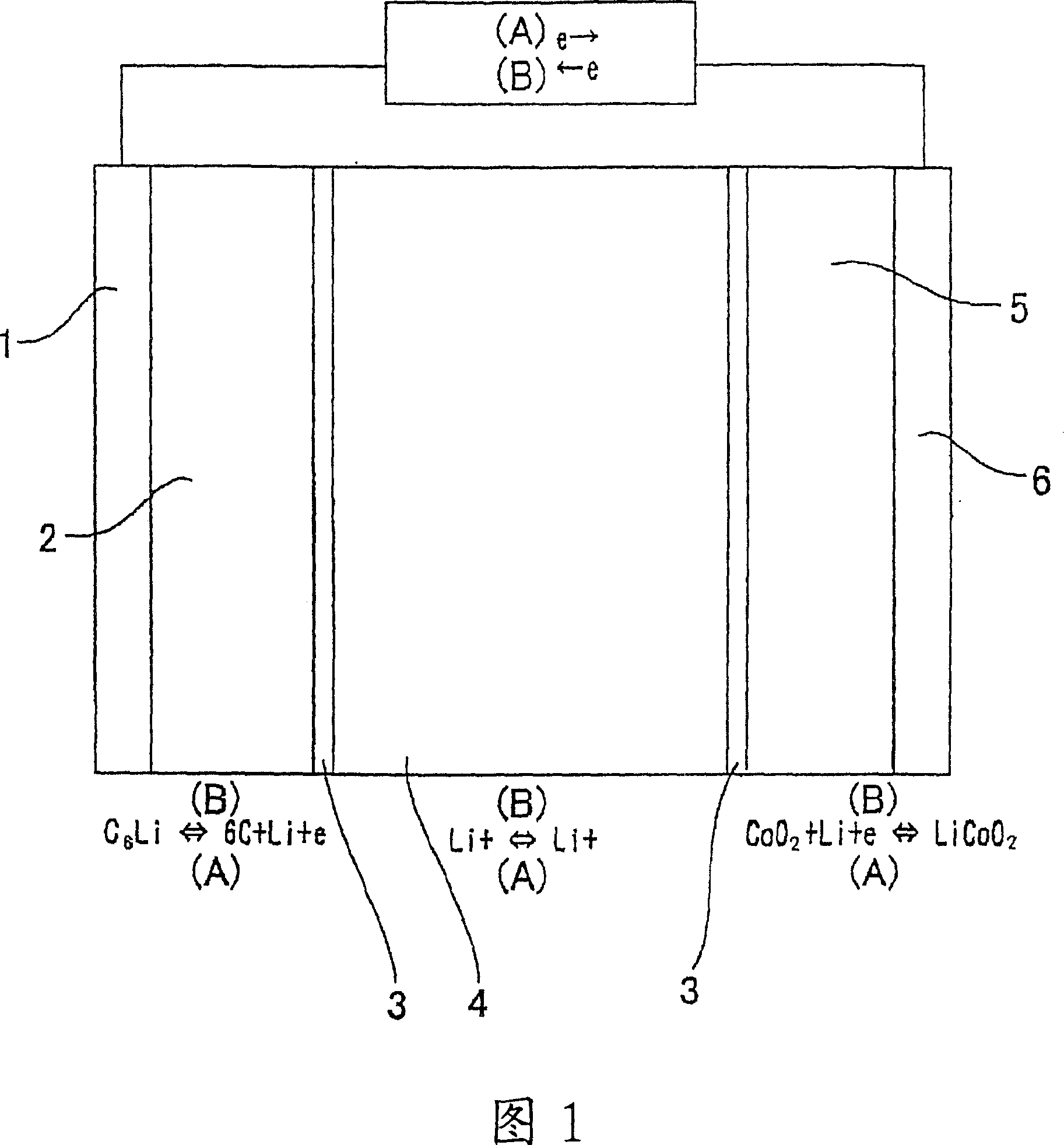

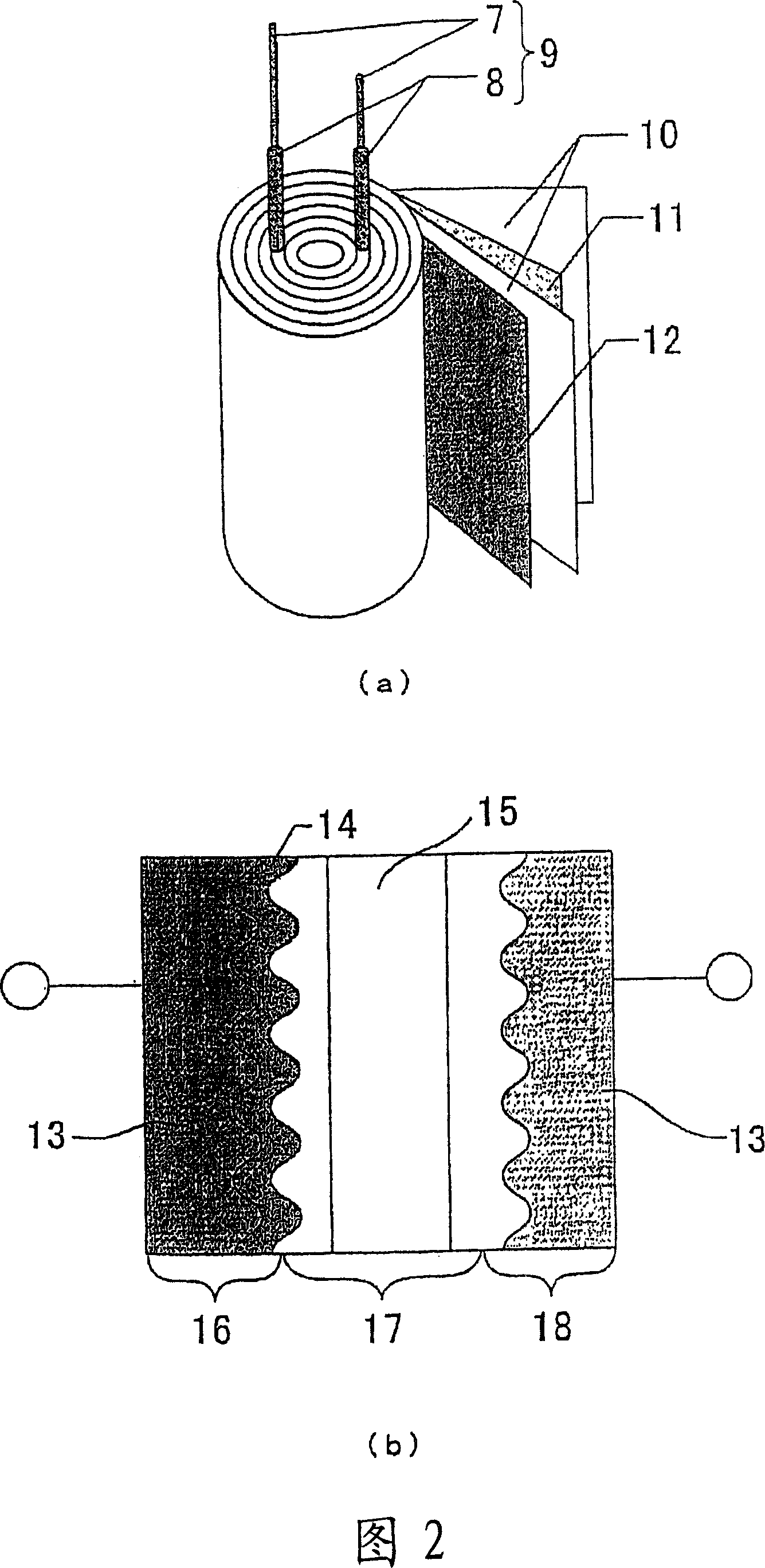

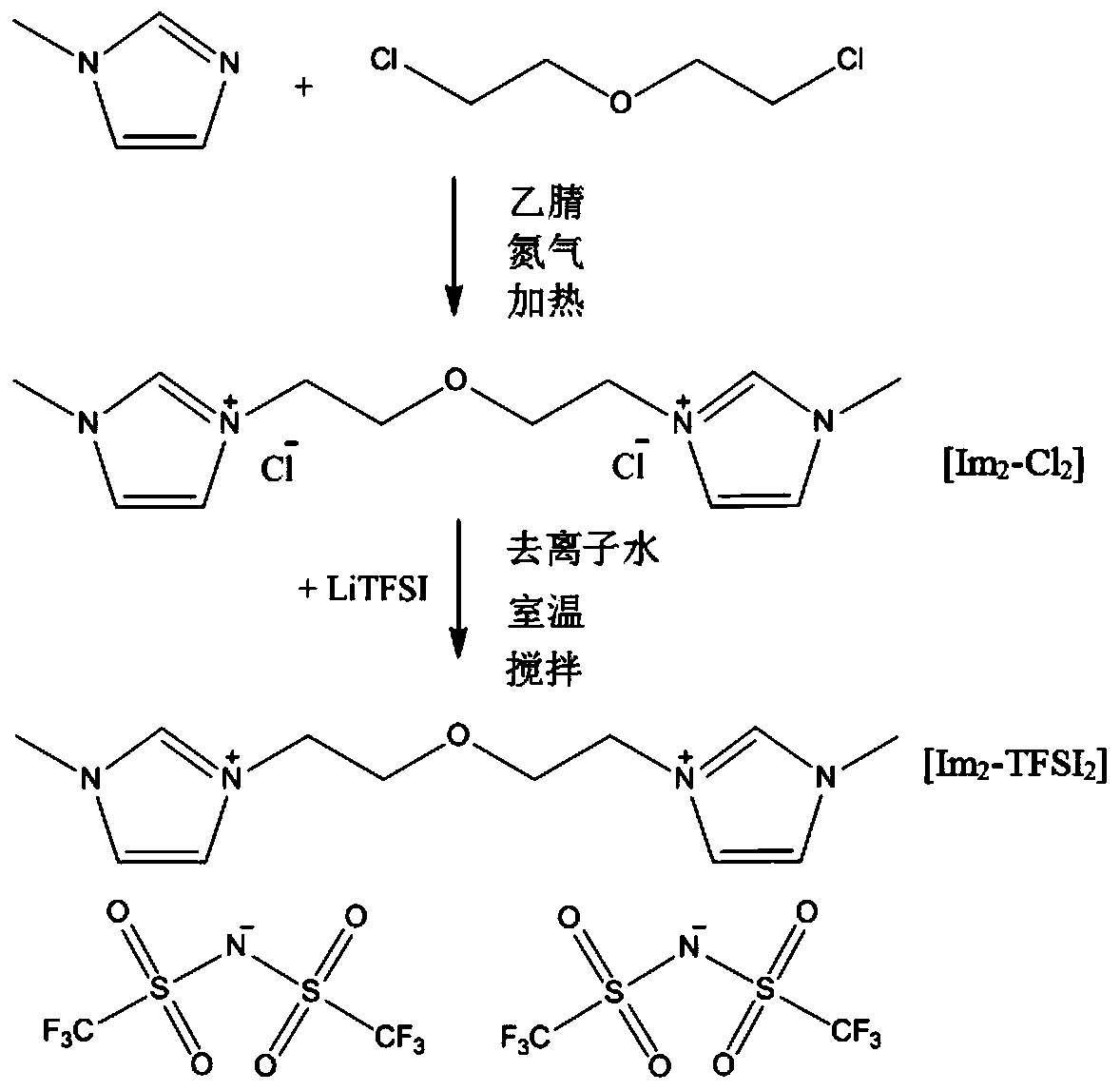

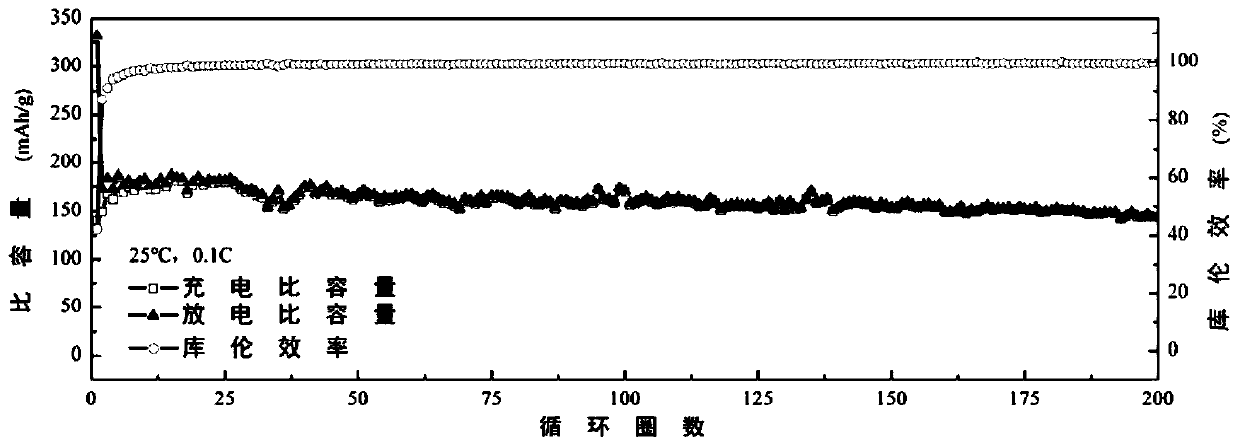

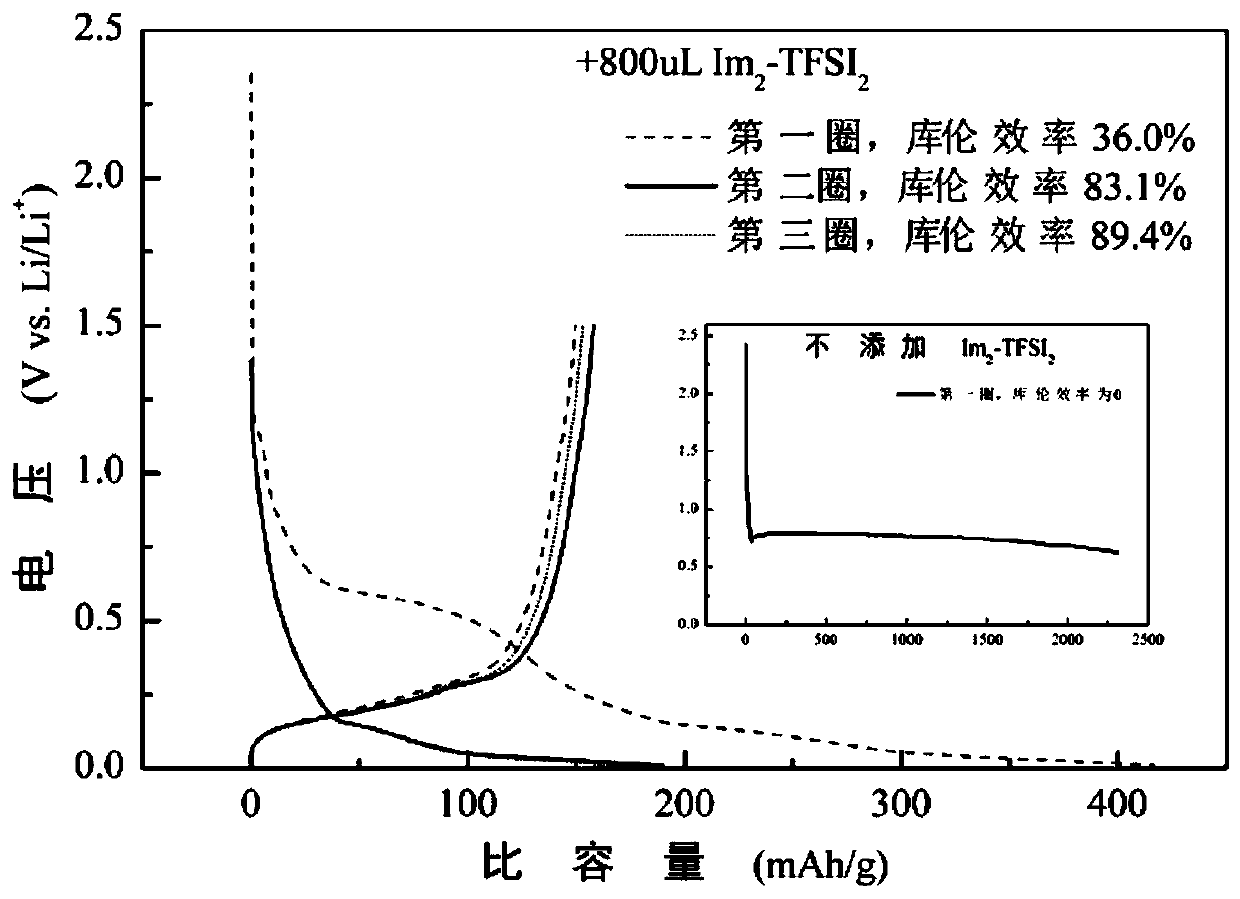

Bi-imidazole ring functional ionic liquid, preparing method thereof, electrolyte and lithium secondary battery

ActiveCN109776423AHigh thermodynamic stabilityImprove electrochemical stabilityGroup 5/15 element organic compoundsGroup 3/13 element organic compoundsReductive decompositionElectrochemical window

The invention belongs to the field of batteries, and discloses a bi-imidazole ring functional ionic liquid, a preparing method thereof, an electrolyte and a lithium secondary battery. The di-imidazolering functional ionic liquid comprises divalent cations with bi-imidazole rings and ether group functional groups and two anions. The bi-imidazole ring functional ionic liquid has higher thermodynamic stability, electrochemical stability and positive and negative electrode compatibility. Moreover, the preparing method is simple, the product is high in purity and good in hydrophobicity, the thermal decomposition temperature can reach 430 DEG C, the room-temperature conductivity can reach 10<-4>S / cm, the electrochemical window can reach 5.6V vs.Li / Li+, and the safety of the lithium secondary battery can be improved. A bi-imidazole ring ionic liquid electrolyte can effectively inhibit reductive decomposition of imidazolium cations on a graphite negative electrode specially in a graphite negative electrode system, a stable SEI membrane can be formed without addition of any low-boiling-point film-forming additive, so that the battery can be stably circulated under the conditions of normaltemperature and high temperature, and has very high practical application value.

Owner:XIAMEN UNIV

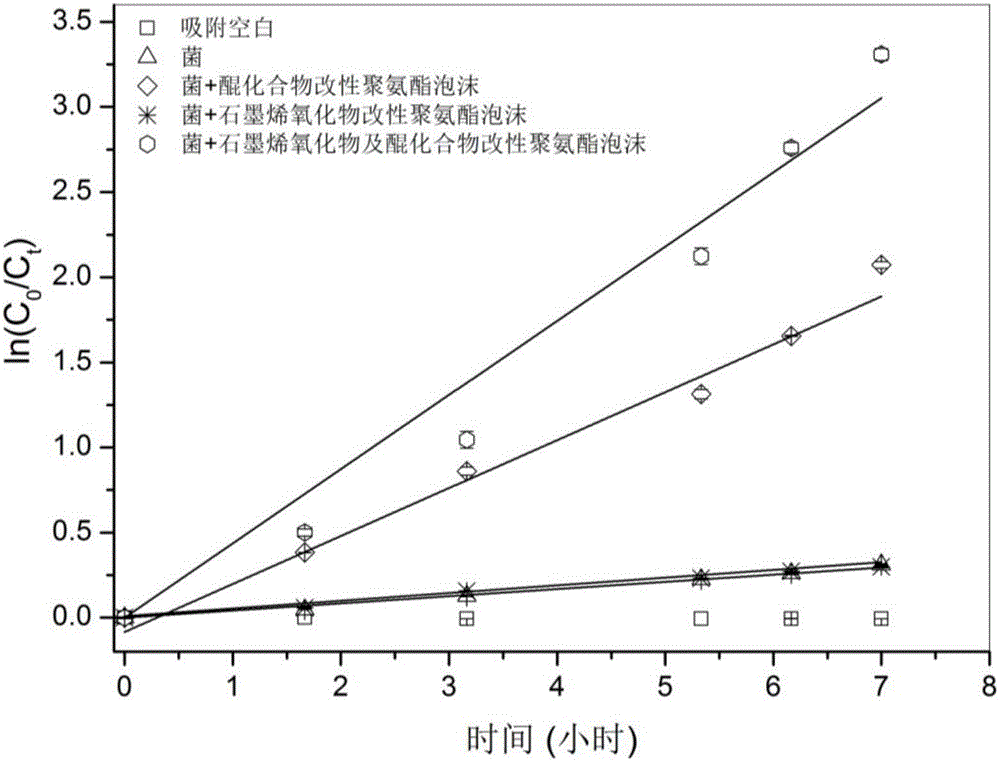

Preparation method of graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier

InactiveCN106830311AStable decompositionPromote conversionWater contaminantsTreatment with anaerobic digestion processesSulfonyl chloridePollution

The invention relates to a preparation method of a graphene oxide and quinone compound co-modified hydroxyl-containing macroporous foam carrier and belongs to the technical field of water treatment in environmental engineering. The preparation method comprises the following steps: preparing a graphene oxide modified polyurethane foam composite material from a hydroxyl-containing macroporous foam material at the room temperature by virtue of a physical adsorption method, and aminating the composite material until graphene oxide and polyurethane foam contain a certain amount of primary amine; and reacting by virtue of an anthraquinone compound containing sulfonyl chloride groups with primary amine, so as to fix a quinone compound, wherein the hydroxyl-containing macroporous foam material can be polyvinyl alcohol foam or polyvinyl alcohol doped polyurethane foam and the like. According to the preparation method, the quinone compound and graphene oxide are simultaneously fixed to the surface of the macroporous foam material, so that the contact among a redox mediator, graphene and microorganisms is facilitated; and the technical bottlenecks that graphene and the water soluble quinone compound in a water treatment system are difficult to be recycled and flow out along with water to cause secondary pollution are solved.

Owner:DALIAN UNIV OF TECH

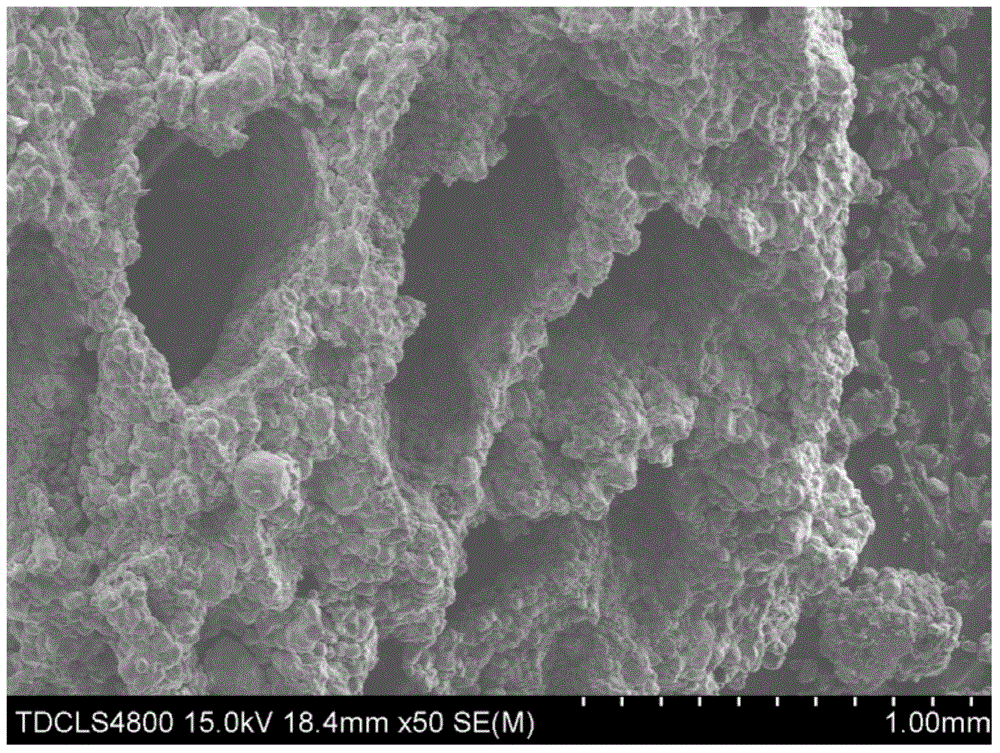

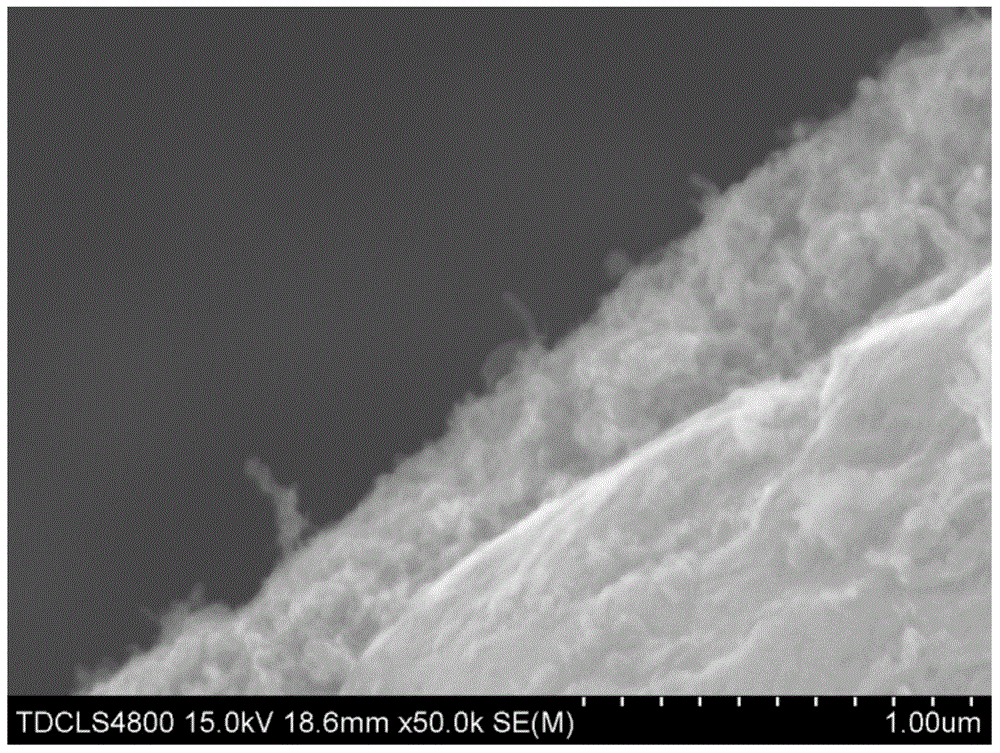

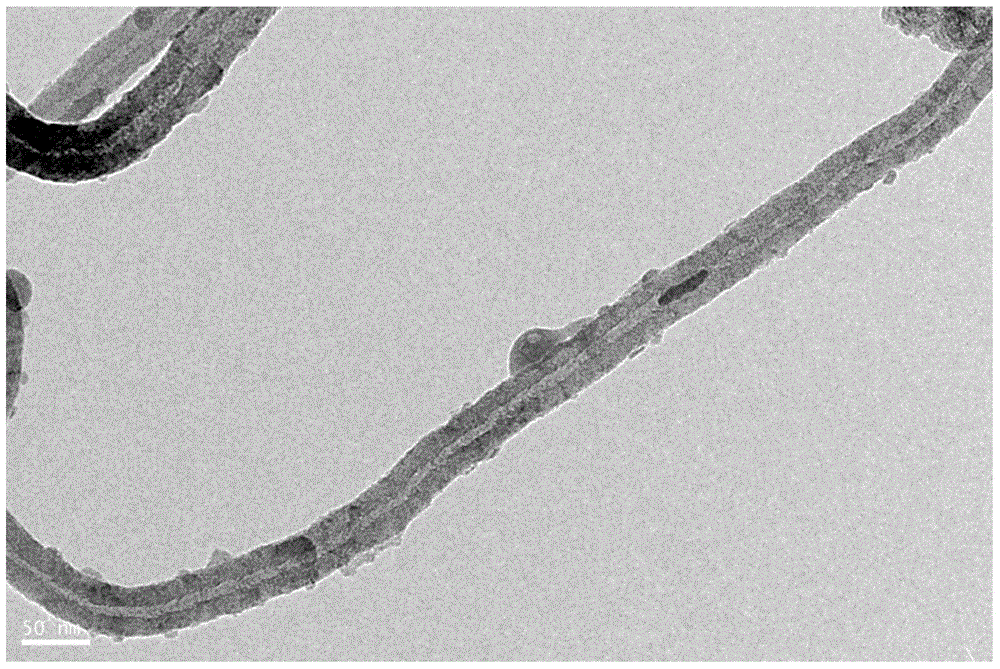

Preparation method of carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption

ActiveCN104911388AHighlight substantiveGood deformabilityChemical vapor deposition coatingVibration attenuationNitrate

The invention provides a preparation method of a carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption, relates to the manufacturing of an alloy with open or closed pores, and specifically relates to the preparation method of the carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption with urea as a pore-forming agent and nickel as a carbon nanotube synthesis catalyst; the preparation method comprises the following steps: preparing the mixed powder of nickel nitrate, urea and aluminum powder; preparing a foamed aluminum blank; and preparing the carbon nanotube reinforced foamed aluminum composite material. The method is used for overcoming the defects of structural defect, low mechanical properties and low buffer energy-absorption property, large density and no lightweight property of the foamed aluminum materials prepared in the prior art, complex preparation process, relatively high cost and difficult realization of functional structure integration of the foamed aluminum serving as an energy-absorption material.

Owner:HEBEI UNIV OF TECH

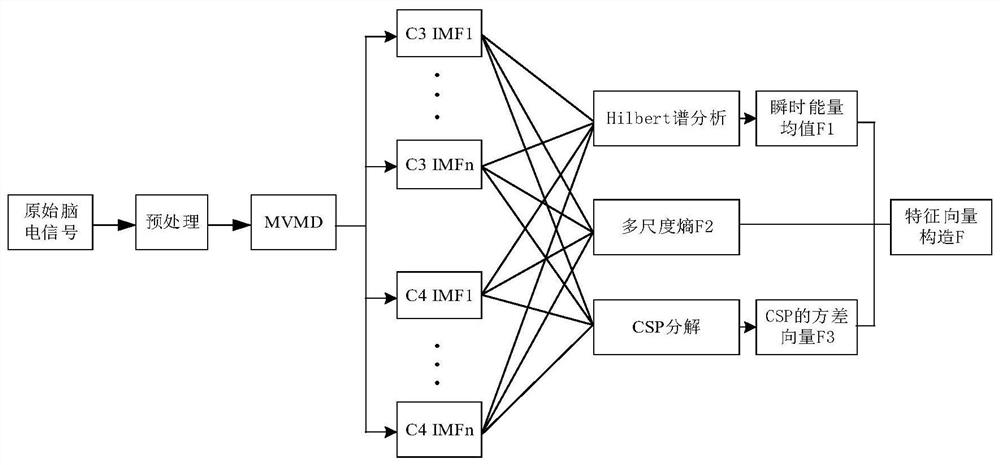

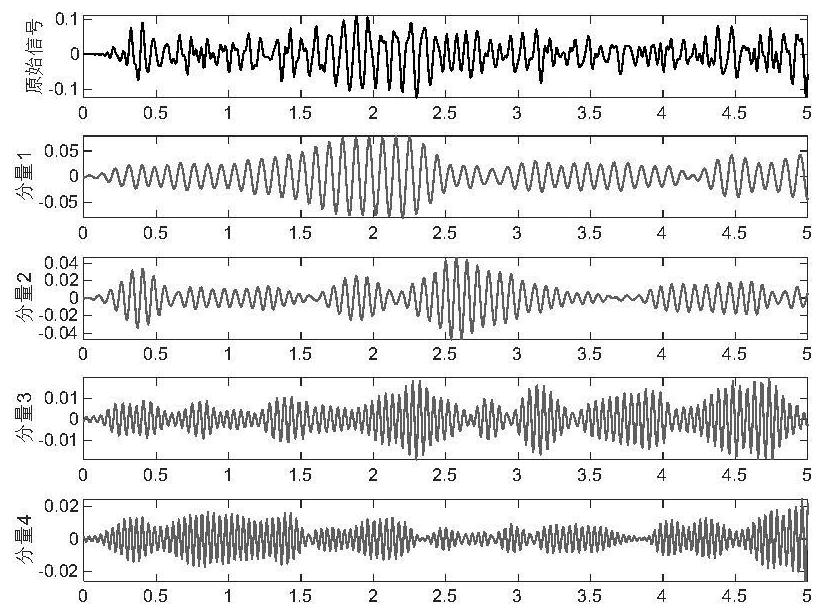

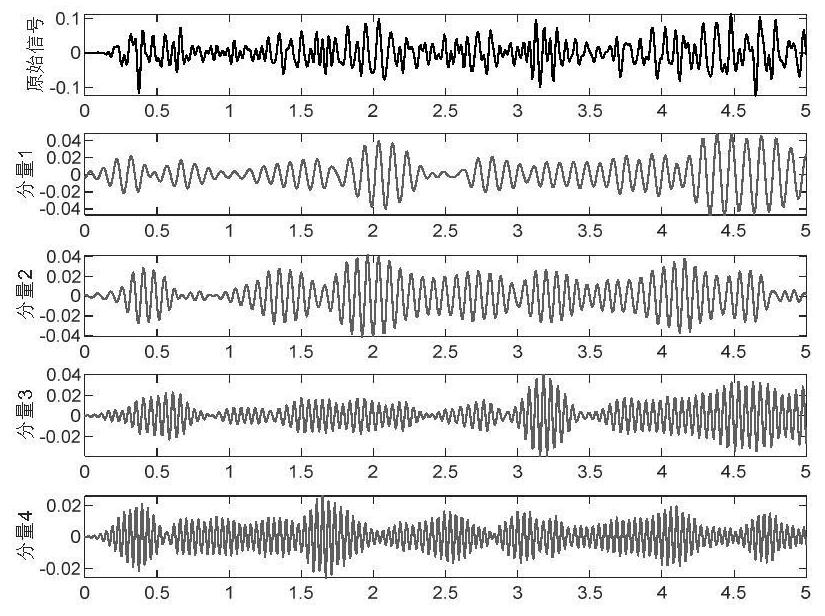

Electroencephalogram multi-domain feature extraction method based on multivariate variational mode decomposition

The invention discloses an electroencephalogram multi-domain feature extraction method based on multivariate variational mode decomposition. The method comprises the following steps: firstly, carryingout adaptive decomposition on original electroencephalogram multi-channel data by using multivariate variational mode decomposition (MVMD), and then extracting time domain features and nonlinear dynamics features of signals from intrinsic mode function (IMF) components obtained by decomposition; meanwhile, combining the IMF components to construct a new signal matrix, extracting spatial featuresof the reconstructed signals by adopting a common spatial pattern (CSP) method, and combining the time domain, nonlinear dynamics and spatial domain features; and finally classifying the feature set through a support vector machine (SVM). According to the method, important information components related to a specific task can be effectively distinguished, and a new idea is provided for feature extraction of the electroencephalogram signals.

Owner:HANGZHOU DIANZI UNIV

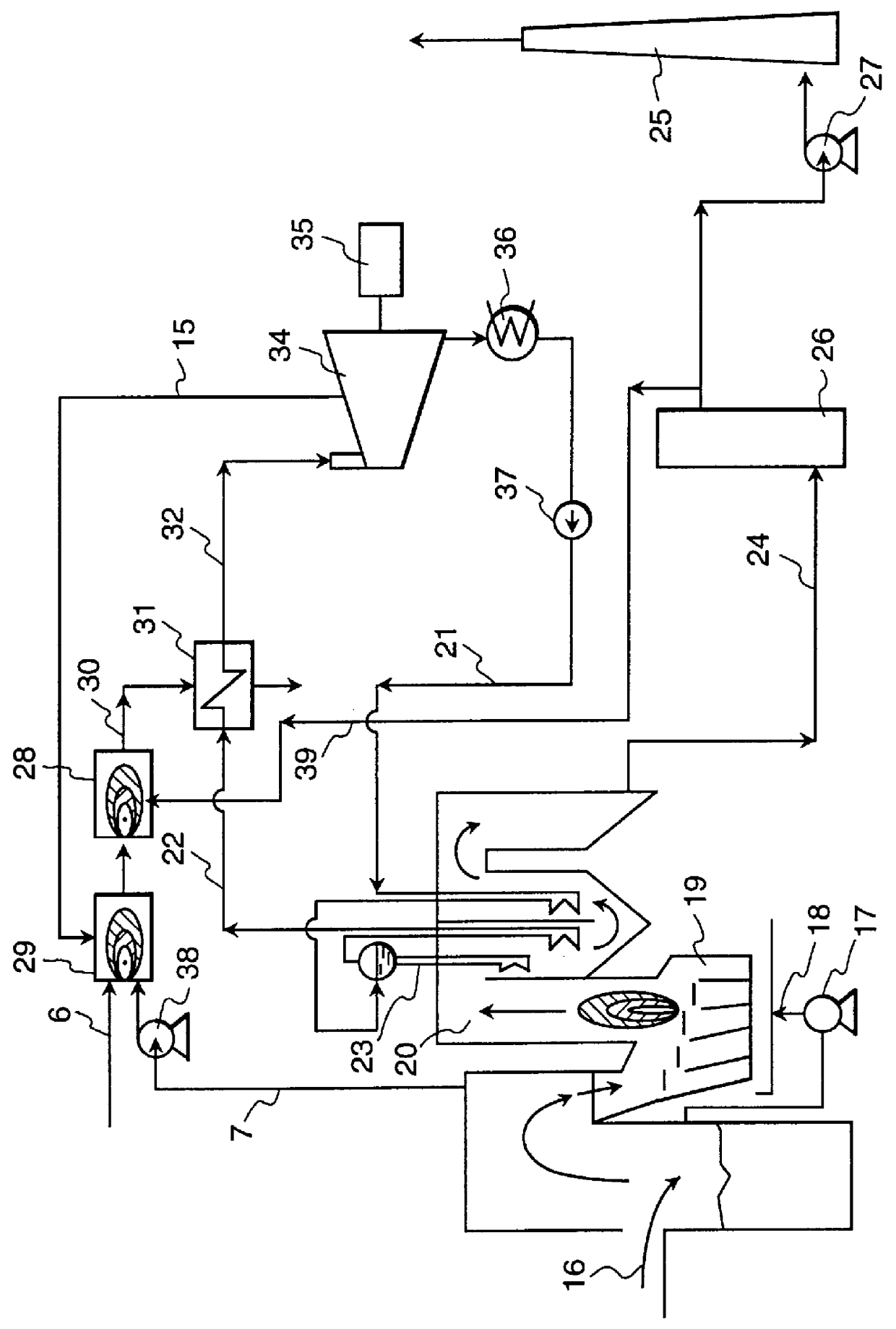

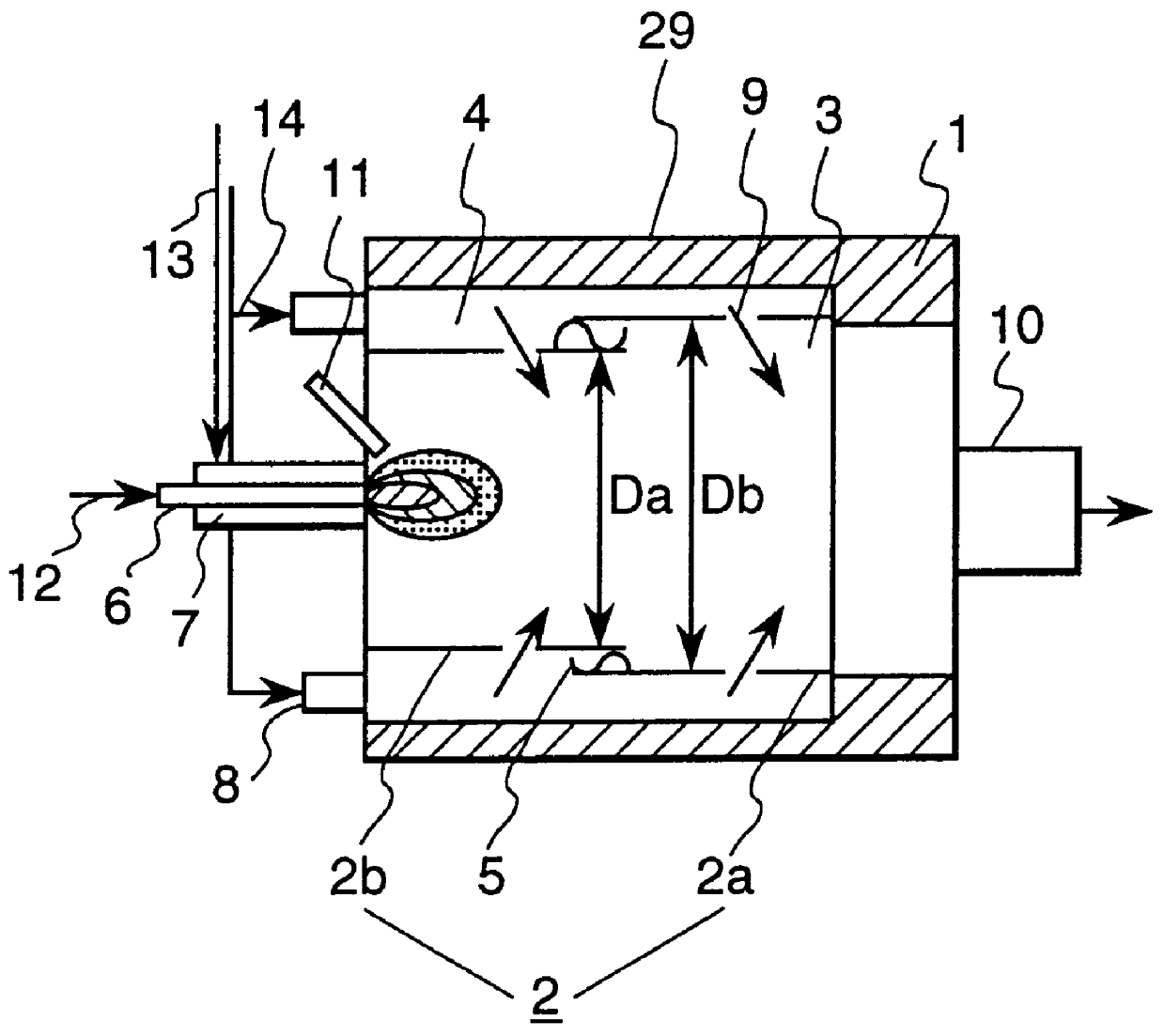

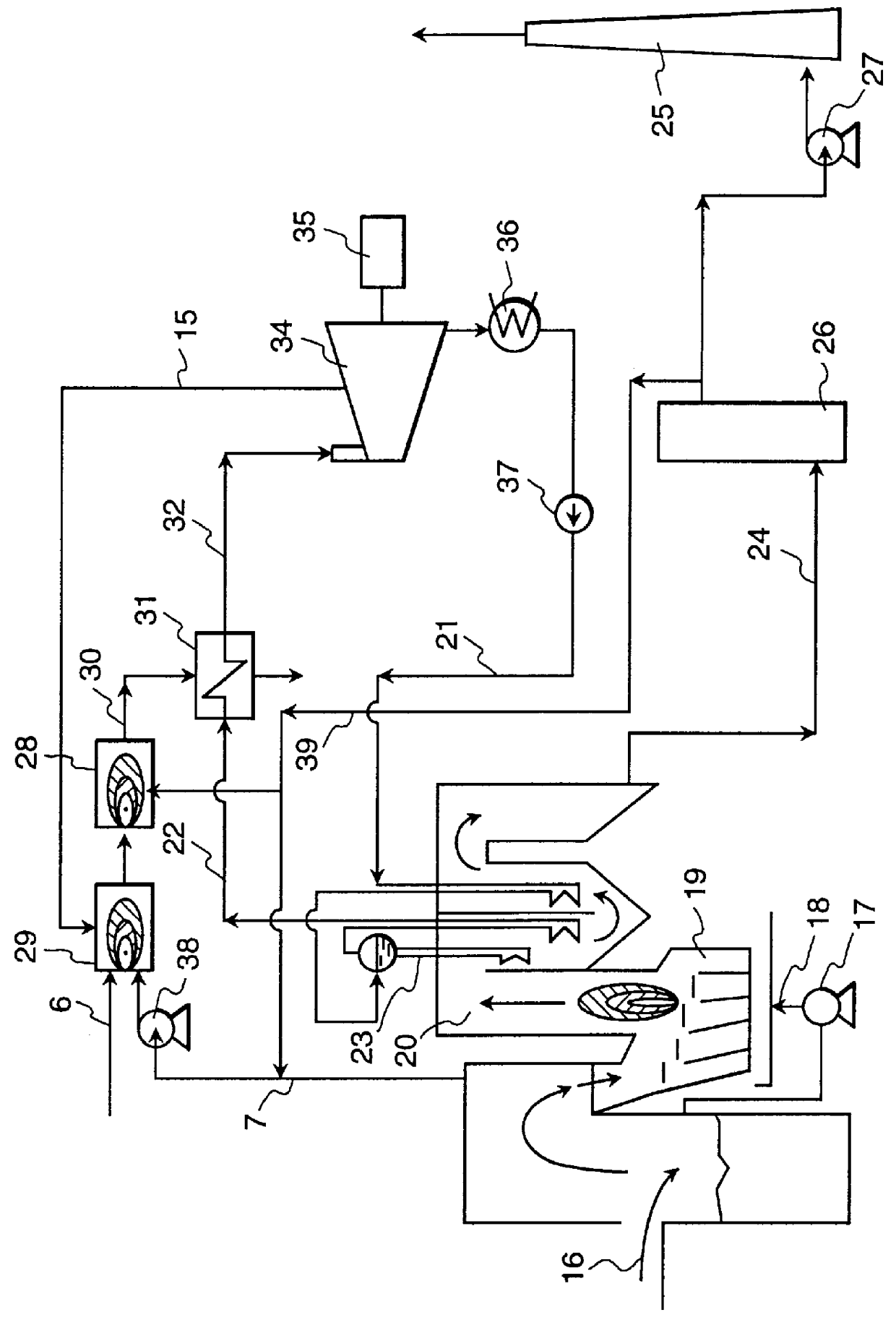

Waste processing system and fuel reformer used in the waste processing system

InactiveUS6014863AStable decompositionSuppresses the production of nitrogen oxidesHydrogenTurbine/propulsion fuel supply systemsSuperheaterAutomotive engineering

A waste-to-energy incineration system, in which the amount and heat value of exhaust gas largely changes in long and short periods, comprises an incinerator for burning waste, a boiler in the incinerator for generating steam with exhaust heat generated by the incinerator, a superheater for superheating steam generated in the boiler, a steam turbine driven by steam superheated by the superheater, a generator driven by the steam turbine, a fuel reformer for reforming source fuel, and a combustor burning fuel gas reformed by the fuel reformer and at least a part of exhaust gas led from the incinerator which is able to stably decompose generated dioxin in waste incineration exhaust gas.

Owner:HITACHI LTD

Method for simultaneously preparing pyromellitic acid and terephthalic acid with coal serving as raw material

InactiveCN102816061AStable decompositionSimple componentsOrganic compound preparationCarboxylic preparation by ozone oxidationIsomerizationPotassium

Disclosed is a method for simultaneously preparing a pyromellitic acid and a terephthalic acid with coal serving as a raw material. The method includes firstly, adding potassium hydroxide, a coal sample and distilled water in a high pressure kettle to perform a reaction, cooling after the reaction to obtain an oxidation product, filtering and removing insoluble residues to obtain a filter liquor, acidizing the filter liquor by a concentrated sulfuric acid to enable a water soluble acid to be completely free, extracting a processed solution by butanone to obtain an extract liquor, subjecting the extract liquor to a vacuum evaporation to obtain a concentrate, recycling the butanone, subjecting the concentrate to a vacuum drying to obtain the water soluble acid, subjecting the water soluble acid to a selective decarboxylation in a mixed medium of an sulfuric acid, potassium acid sulfate and the distilled water to obtain the pyromellitic acid, adding coal acids and catalysts which remain after the preparation of the pyromellitic acid in a reacting kettle to perform a constant temperature isomerization reaction of the coal acids to obtain a filter liquor, cooling the filter liquor after the reaction, adjusting potential of hydrogen (pH) of the filter liquor by an diluted hydrochloric acid, precipitating the terephthalic acid in a sedimentation mode, filtering, washing and drying to obtain the refined terephthalic acid. By means of the method, the pyromellitic acid and the terephthalic acid can be simultaneously prepared, the reaction conditions are mild, conditions for devices are low, the terephthalic acid is a main product due to a high yield, and the pyromellitic acid is an auxiliary product.

Owner:LIUPANSHUI NORMAL UNIV

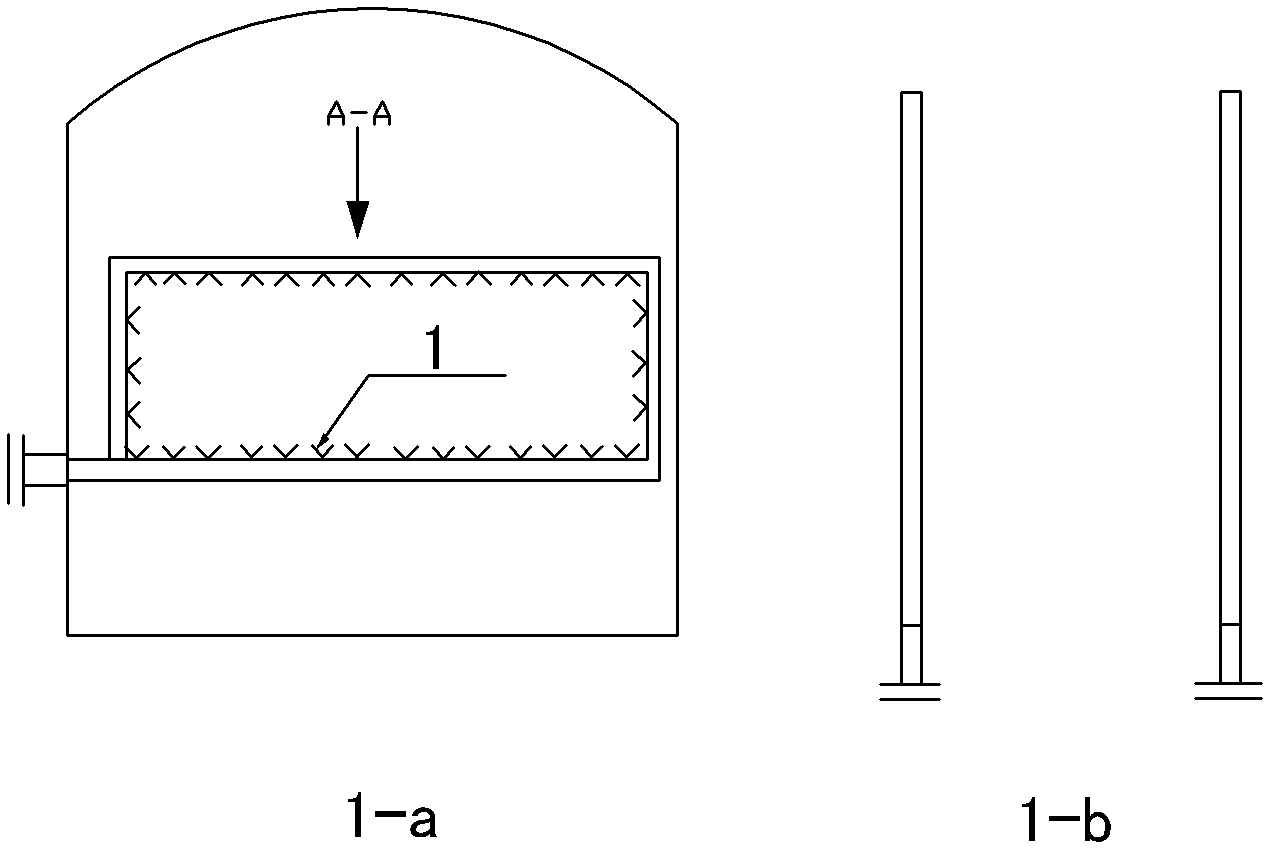

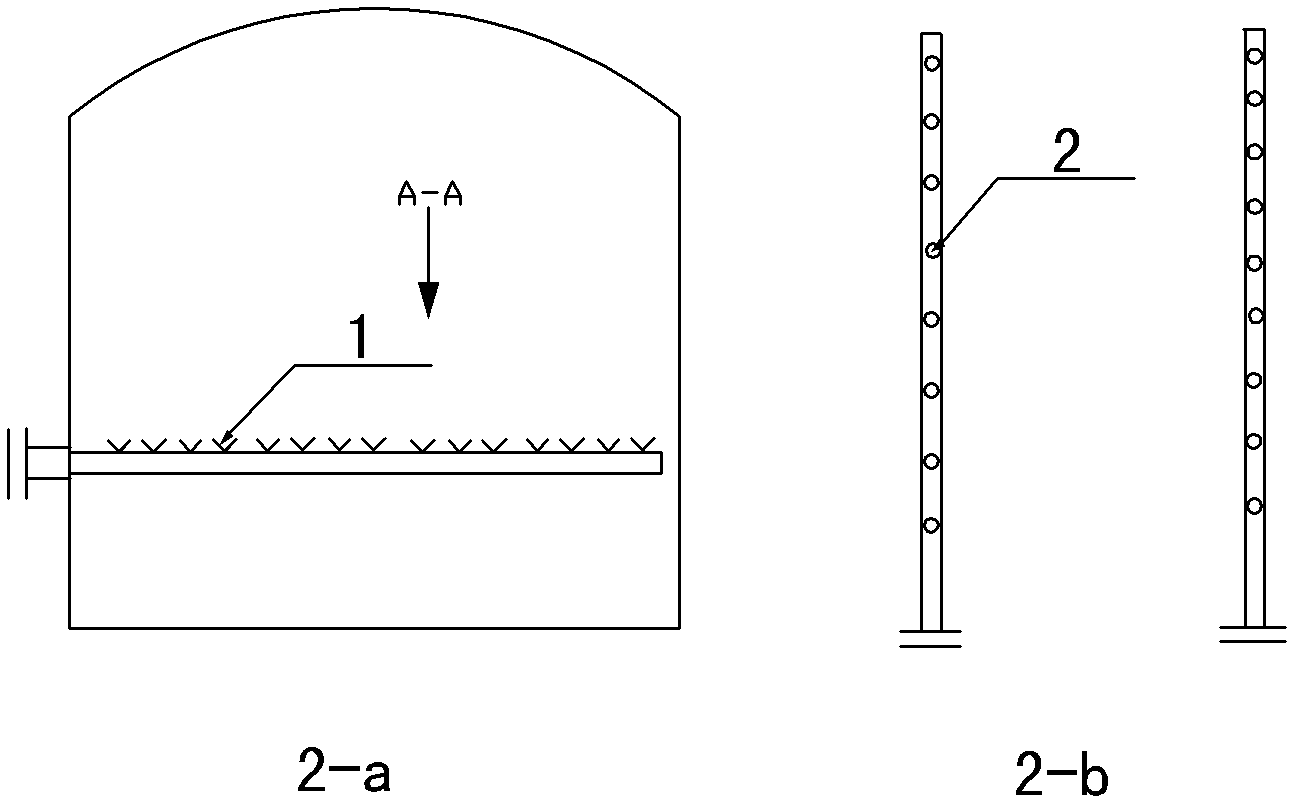

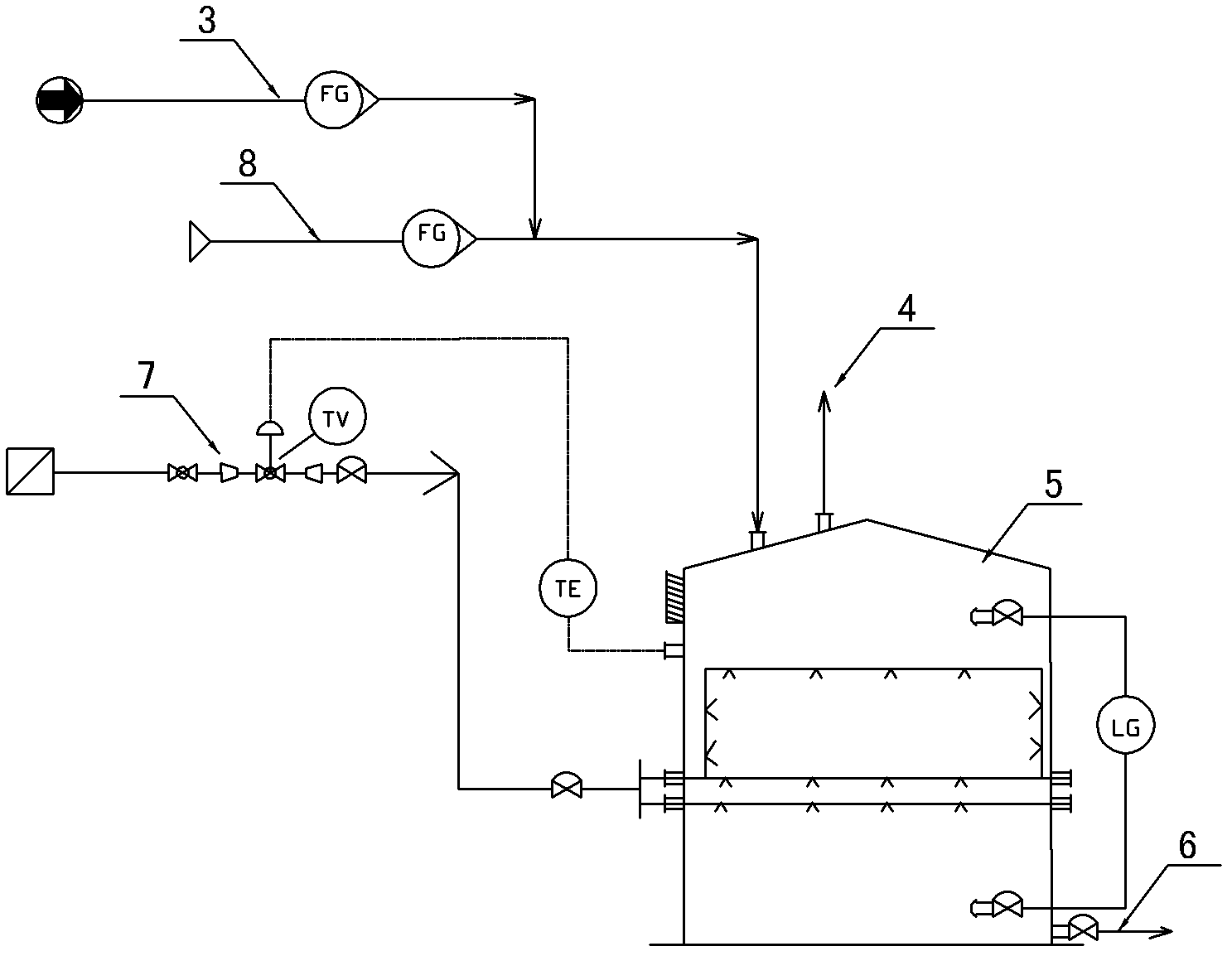

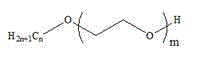

Method for increasing chlorate decomposition efficiency

ActiveCN102634813AHeating evenlyImprove chlorate decomposition abilityElectrolysis componentsSaline waterDecomposition

The invention relates to a method for increasing chlorate decomposition efficiency, which belongs to the technical field of preparation of ion film caustic soda. The method is realized by means of improving the structures of steam heating tubes in a chlorate decomposition tank and adjusting parameters of a decomposition process. The steam heating tubes are arranged in double layers, the steam heating tubes on the lower layer upwards spray gas, the steam heating tubes on the upper layer downwards spray gas, and steam nozzles are uniformly arranged on the steam heating tubes. The process parameters include that the mass ratio of light salt brine for decomposing chlorate to outflow light salt brine of an electrolyzer is 1:1.4-1.6; preacid of the light salt brine after the light salt brine decomposes the chlorate is controlled in a range from 25g / l to 32g / l; and the temperature of the light salt brine in the chlorate decomposition tank ranges from 94 DEG C to 97 DEG C. Uniformity of the temperature in the chlorate decomposition tank is improved, decomposition stability is ensured, chlorate decomposition rate reaches 82-95%, and the content of the chlorate in the salt brine of a device is ensured to be qualified and stable.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

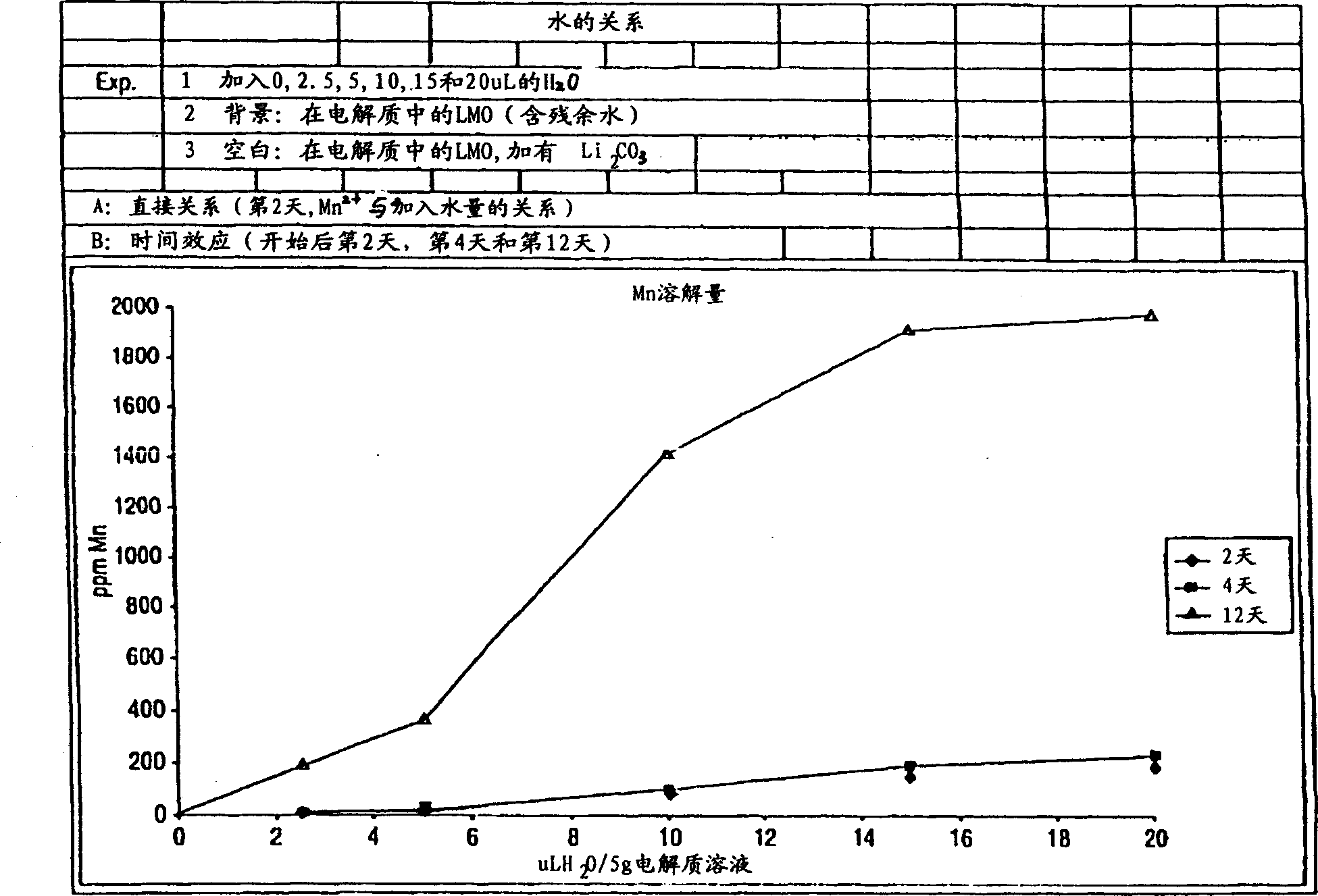

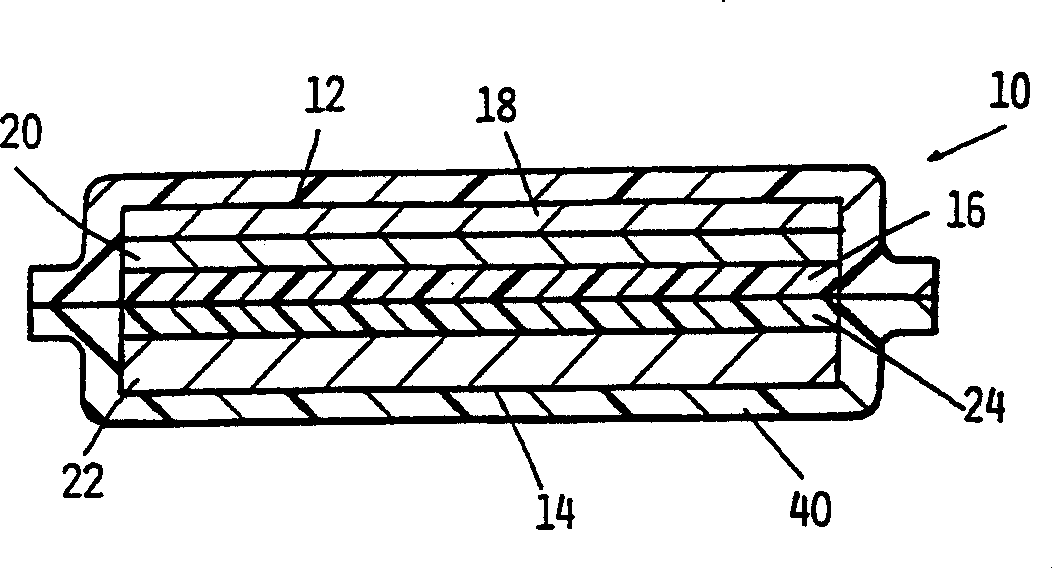

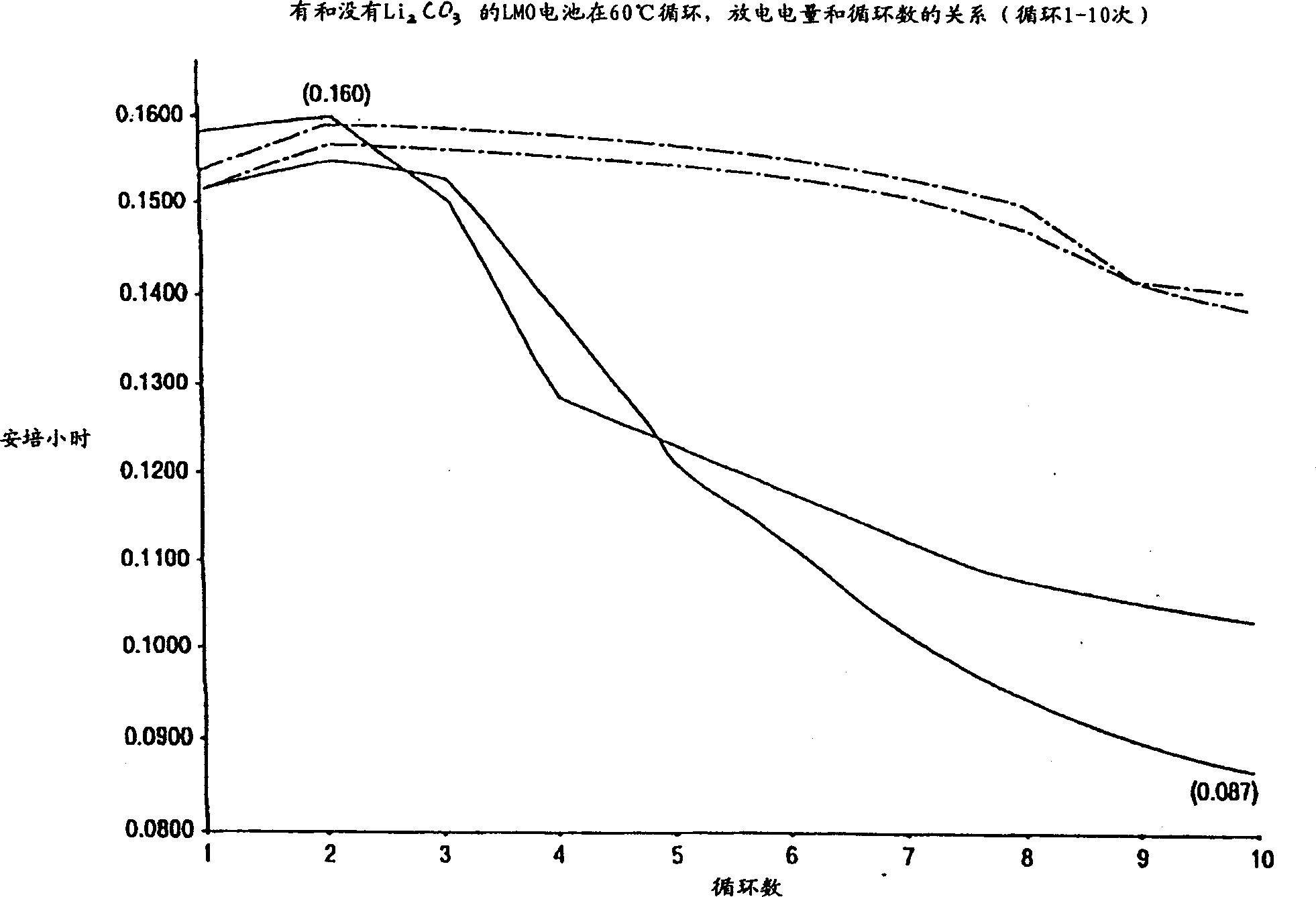

Stabilized electrochemical cell active material

InactiveCN1351767AEasy to chargeImprove discharge performanceCell electrodesSecondary cellsElectricityDecomposition

A method for forming the composition stabilized against capacity degradation comprises particles of spinel lithium manganese oxide (LMO) enriched with lithium by a decomposition product of lithium carbonate forming a part of each said particle and characterized by a reduced surface area and increased capacity expressed in milliamp hours per gram as compared to non-enriched spinel.

Owner:VALENCE TECH INC

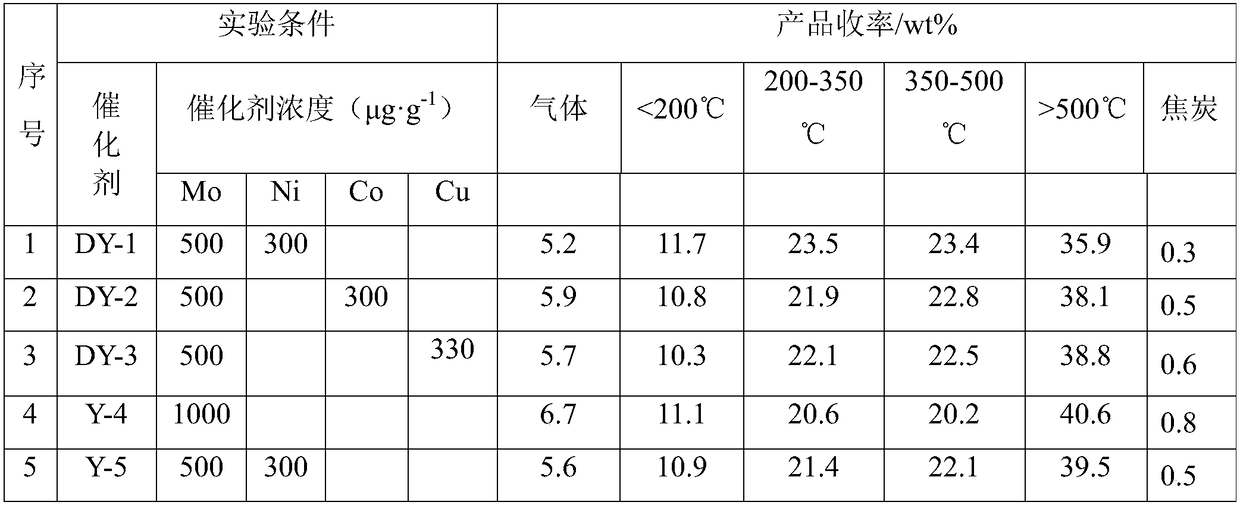

Self-vulcanization oil-soluble molybdenum based bimetallic catalyst and preparation method and applications thereof

ActiveCN108745385AReduce usageReduce use costPhysical/chemical process catalystsHydrocarbon oils treatmentVulcanizationSlurry reactor

The invention relates to the field of hydrogen cracking of heavy oil, and specifically relates to a self-vulcanization oil-soluble molybdenum based bimetallic catalyst and a preparation method and applications thereof. The preparation method comprises following steps: mixing a molybdenum source compound with a second metal salt to generate a molybdenum based bimetallic compound through a chemicalprecipitation method; processing the molybdenum based bimetallic compound by a vulcanizing agent to obtain bimetallic sulfo-molybdate; reacting organic amines with bimetallic sulfo-molybdate to prepare an oil-soluble molybdenum based bimetallic catalyst precursor; and adding a dispersant into the precursor to obtain the self-vulcanization oil-soluble molybdenum based bimetallic catalyst. The prepared catalyst has an excellent hydrogenation activity and a good coke inhibiting performance; furthermore, the preparation technology is simple, the addition amount of catalyst is little, the application is convenient, and the catalyst is suitable for a low cost slurry reactor hydrogen cracking technology, which uses inferior heavy oil rich in metals, coal residues, sulfur, and solids, and has a potential market value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Preparation method for anticorrosion steel used for water-cooling spray nozzle

ActiveCN106119724AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingMolten stateBoriding

The invention discloses a preparation method for anticorrosion steel used for a water-cooling spray nozzle. The method comprises the following steps that raw materials are heated into a molten state to obtain a liquid alloy, wherein the liquid alloy comprises, by weight, 0.1-0.25% of C, 1.2-1.5% of Cr, 0.3-0.6% of Al, 1.2-1.6% of Mg, 0.2-0.3% of Zr, 0.4-0.6% of Ni, 1.2-1.3% of Mn, 0.08-0.12% of Mo, 0.1-0.13% of V, 0.03-0.06% of Co, 0.02-0.05% of Ga, 1.5-1.6% of T, 0.6-0.8% of Si and the balance Fe; a steel billet is obtained through casting; heat treatment is conducted; boriding is conducted; and the steel billet subjected to heat treatment and boriding is coated with a conversion film.

Owner:滁州帝邦科技股份有限公司

Preparation method of negative ion antibacterial adsorption material composition

The invention provides a preparation method of a negative ion antibacterial adsorption material composition. The method is characterized in that (a) 13X molecular sieve raw powder accounting for 60 to75 percent of the total mass of the composition, alkali metal oxides accounting for 10 to 20 percent of the total mass of the composition, tourmaline powder accounting for 10 to 20 percent of the total mass of the composition, and the balance of bonding agents and hole expansion agents are proportionally mixed to form mixed powder of a uniform system; (b) the mixed powder is soaked into a water solution of AgNO3, then, ultrasonic concussion is performed to form suspension; next, a NaOH solution is added for regulating pH to 10; a mixed solution is formed. (c) the mixed solution is sealed andheated under the hydrothermal condition; after the separation, sintering is performed at high temperature; crushing is performed to obtain the composition. Compared with the prior art, the preparationmethod provided by the invention has the advantages that the cost is low; for indoor pollution gas, the adsorption capability is realized; the decomposition and desorption prevention performance is also realized; a certain number of negative ions can also be released; the adsorption effect is promoted; beneficial effects are achieved on the human body.

Owner:慕林健康负氧离子医用建材(深圳)集团有限公司

Hydrogen peroxide bleaching stabilizer for cotton fabrics

The invention relates to an environment-friendly stabilizer for hydrogen peroxide bleaching of cotton fabrics. The stabilizer is formed by compounding 10%-15% of EthyDiaminedhephen Acetic-Na, 0.1%-0.5% of polyacrylamide, 5%-10% of alcohol amine, 5%-10% of boric acid, 2%-10% of sodium citrate, 2%-5% of magnesium inorganic salt, 3%-5% of a dispersant, 3%-10% of fatty alcohol-polyoxyethylene ether and distilled water. According to the invention, O atoms and N atoms with strong negativity in alcohol amine and [HO2.] free radicals formed during decomposition of hydrogen peroxide form hydrogen bonds, the decomposition of hydrogen peroxide is effectively controlled, and holes generated by local brittle damage of fibers are eliminated. According to the invention, no silica scale is generated during application of the stabilizer without silicate, and thus a bleached fabric is good in hand feeling; as the stabilizer is free of phosphorous substances, environment pollution is avoided, and the stabilizer has environment-friendly effect.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Prep. of alumina---monox composite oxides film

InactiveCN1448534AStable decompositionComponent adjustableChemical vapor deposition coatingNon oxide ceramicsHydrogen

The present invention is the preparation process of composite alumina-silica film. The composite alumina-silica film with adjustable alumina / silica ratio is prepared in chemical vapor deposition furnace as the composite oxide film producing apparatus with only inert gas argon as carrier gas and diluent gas at the temperature of 500-800 deg.c. The said preparation process may be used in preparing film with strong hydrogen permeability, antiwear coating on the surface of metal and non-oxide ceramic-base composite material as antioxidant coating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for removing nitric acid and nitrates from high-level radioactive liquid waste

InactiveCN104517663AThe denitrification process is gentleImprove stability and securityRadioactive decontaminationRadiochemistryAmmonium

The present invention discloses a method for removing nitric acid and nitrates from a high-level radioactive liquid waste. Nitric acid and nitrates are converted to ammonium nitrate; with urea formaldehyde resin as a reducing agent, as NH4NO3 can be easily decomposed into N2, H2O and O2 under the catalysis of H+ and Cl-, the nitric acid and nitrates in the high-level radioactive liquid waste are removed through oxidation-reduction reactions. The method mainly comprises the following steps: (1) UF resins are prepared using a certain ratio of urea and formaldehyde as raw materials and an alkali-acid-alkali process; (2) with ammonia and ammonium salts added, the nitric acid in the high-level radioactive liquid waste can be neutralized and the produced nitrates can be converted into ammonium nitrate which can be easily decomposed by a metathetical reaction; (3) the UF resins are added into the high-level radioactive liquid waste and conduct a denitration reaction under the catalysis of H+ and Cl-. Compared with traditional denitration of high-level radioactive liquid waste, the method in the present invention has a more stable reaction and a lower explosion risk, produces a small amount of NO2, and at the same time the denitrated objects can be both nitric acid and nitrates in the high-level radioactive liquid waste.

Owner:NANJING UNIV OF SCI & TECH

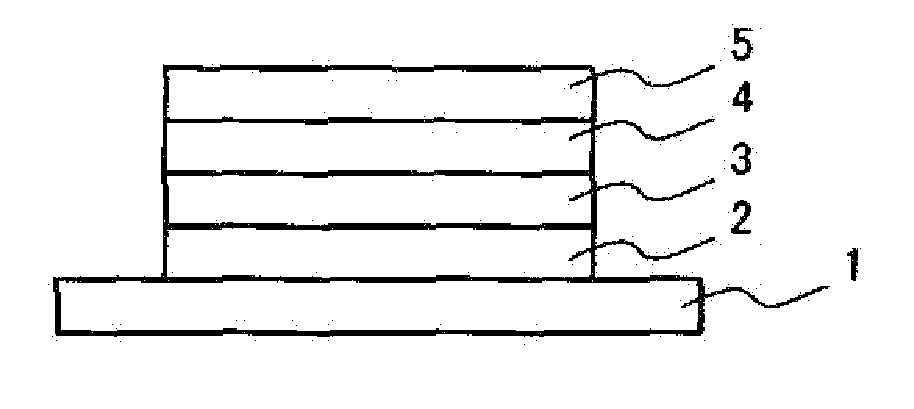

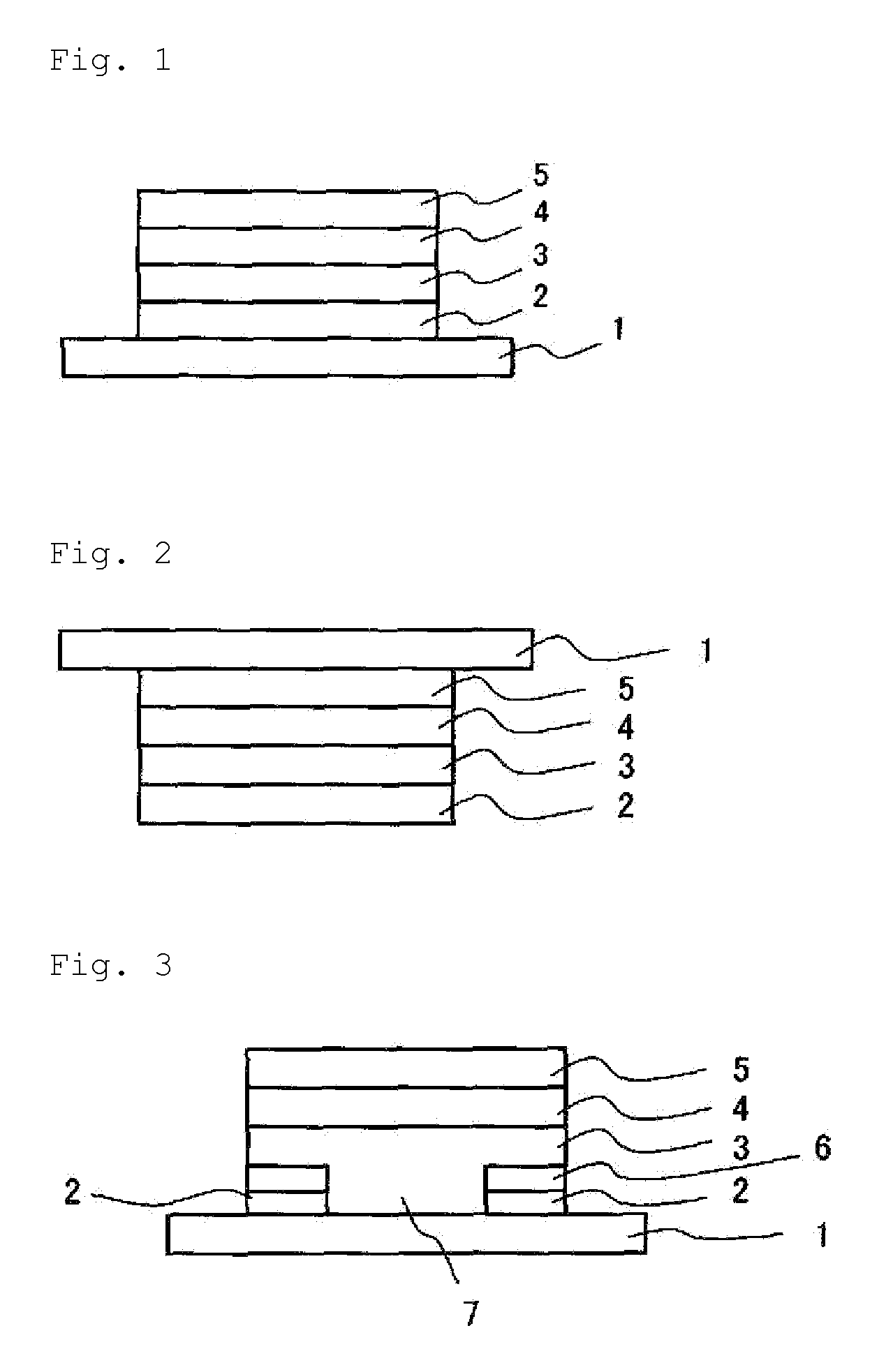

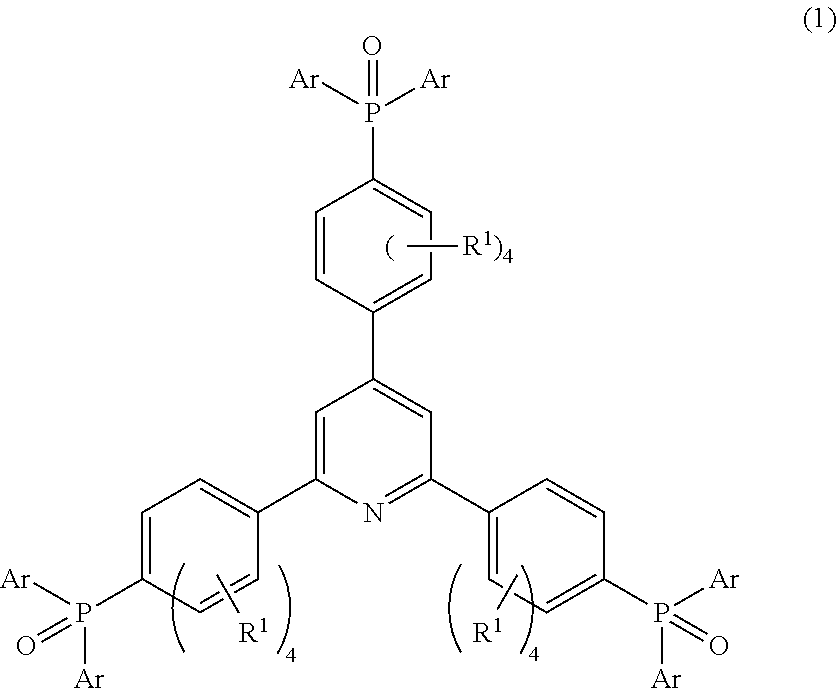

Phosphine oxide compound, organic electroluminescence element, production method and uses thereof

InactiveUS20120256171A1Stable decomposition rateStable productionSolid-state devicesSemiconductor/solid-state device manufacturingHalogenHydrogen atom

A compound having a stable deposition rate suitable for forming an electron-transporting layer of an organic El element. The compound is represented by the following formula (1):wherein in the formula (1), plural R1 are each an alkyl group having 1 to 10 carbon atoms, an alkoxy group having 1 to 10 carbon atoms, a halogen atom, or a hydrogen atom, and may be the same as or different from one another; and plural Ar are each a monovalent substituted or unsubstituted aromatic group optionally containing a hetero atom, and may be the same as or different from one another.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparing method for wear-resisting steel used for water-cooling nozzle

InactiveCN106048514AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingSodium bicarbonateBoron carbide

The invention discloses a preparing method for wear-resisting steel used for a water-cooling nozzle. The preparing method includes the following steps that smelting and pouring are conducted; heat treatment is conducted; a steel billet obtained after heat treatment is subjected to pretreatment and then put into a boriding agent, the temperature is increased to 910 DEG C to 930 DEG C, heat insulation is conducted for 6 h to 7 h, and then a steel billet generated after boriding is obtained; and covering of a conversion film is conducted. The use amount of the boriding agent ranges from 1.3 g / cm<2> to 1.6 g / cm<2>, and the boriding agent includes, by weight, 4-6 parts of boron carbide, 10-15 parts of borax, 3-4 parts of potassium fluoborate, 0.5-1 part of sodium fluosilicate, 5-7 parts of sodium bicarbonate, 40-50 parts of silicon carbide and 30-35 parts of activated carbon. Covering of the conversion film includes the specific steps that the steel billet generated after boriding is cleaned and then put into a conversion solution, the temperature is increased to 40 DEG C to 50 DEG C, heat insulation is conducted for 18 min to 22 min, and the wear-resisting steel used for the water-cooling nozzle is obtained through drying. The wear-resisting steel has good wear-resisting performance and is good in corrosion resistance performance and high temperature resistance performance.

Owner:CHUZHOU DIBANG TECH

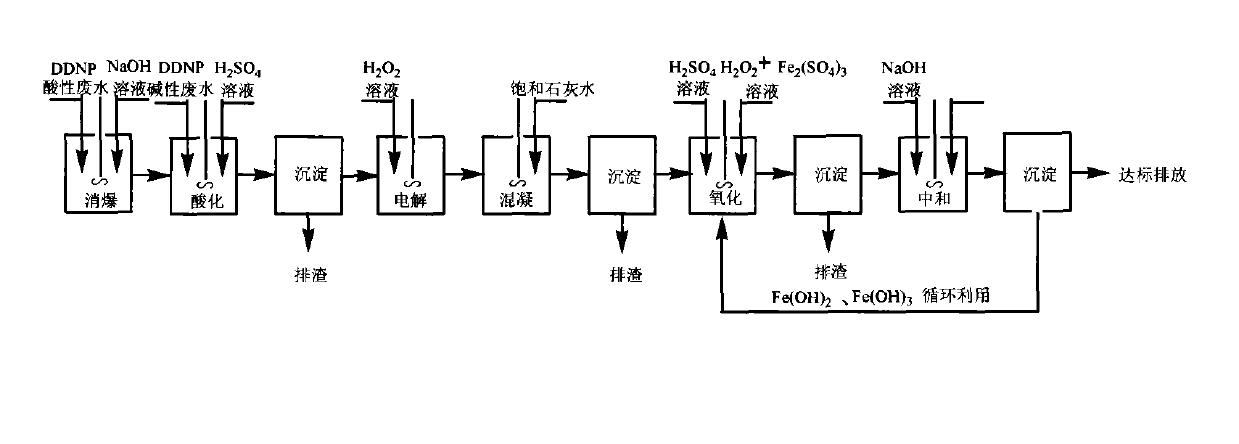

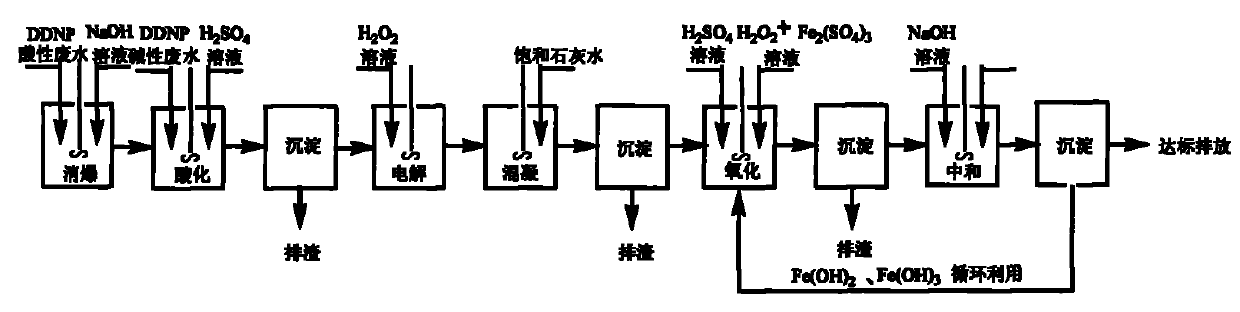

Treatment method of industrial waste water containing diazodinitrophenol

InactiveCN102020382AEffective destructionPromote oxidationMultistage water/sewage treatmentNature of treatment waterElectrolysisIndustrial waste water

The present invention provides a novel treatment method of industrial waste water containing diazodinitrophenol, which comprises the main steps of: explosion elimination, acidification, electrolysis, coagulation, oxidization and neutralization. Firstly DDNP acid waste water is subjected to explosion elimination and mixed with DDNP alkaline waste water, most nitrophenol compounds are precipitated under certain acidic condition, residual organic compounds are eliminated totally by electrolysis, coagulation and oxidizing degradation, after neutralization, the waste water can meet national emission standards without secondary pollution to environment.

Owner:SHANGRAO NORMAL UNIV

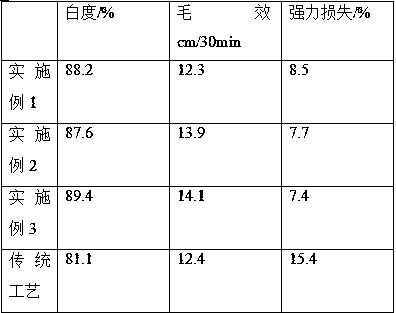

Pre-treatment process for textile fabric

ActiveCN108252000AEasy to useEasy to operateTextile storage in superimposed formSingeingPolyesterEngineering

The invention belongs to the technical field of the dyeing pre-treatment of textile fabric, and particularly relates to a pre-treatment process for the textile fabric. The pre-treatment process for the textile fabric specifically comprises the following steps: singeing; rolling cold-batch working solution; piling; washing in 7-10 grids by hot water, wherein the temperature is 98 DEG C; washing bycold water; and drying. The pre-treatment process is capable of, through a DF-boiling and bleaching agent and other assistants, preparing the continuous, rapid, low-temperature, and low-alkaline efficient pre-treatment working solution, the working solution is extensively applied to a pre-treatment processing technology of textiles, such as pure cotton, polyester cotton, brocade cotton, rayon, non-woven fabric, dacron, and tencel, so the piling time can be reduced from 20-24 hours of a traditional cold-batch process to 2-6 hours, and the refining effect of cotton fabrics and the uniformity ofdyeing are greatly improved. The dye-uptake of the dyeing effect is improved by 10%-20%, and the hand feeling is softer.

Owner:石狮市鼎盛漂染织造有限公司

Cordyceps and sea cucumber polypeptide tableted candy with effects of tonifying kidney and producing germs

The invention discloses a cordyceps and sea cucumber polypeptide tableted candy with effects of tonifying the kidney and producing germs. The cordyceps and sea cucumber polypeptide tableted candy is prepared from the following components in percentage by weight: 35 to 50% of cordyceps polypeptide compound, 10 to 15% of sea cucumber polypeptide, 15 to 20% of rhizoma polygonati, 10 to 16% of oysterpeptide, 10 to 16% of fructus lycii, and the balance of medical or food health-care auxiliary materials. The cordyceps and sea cucumber polypeptide tableted candy has the advantages that by utilizingthe specialty of the cordyceps polypeptide compound, the effects of the sea cucumber polypeptide, the rhizoma polygonati, the oyster peptide and the fructus lycii can be further enhanced; by reasonably compounding the components, the functions of nourishing Yin and tonifying the kidney, and producing germs are realized, and the purpose of enhancing the kidney function of the human body is realized; by adopting the raw materials with homology of medicine and food, the safety level is highest, namely that the food raw materials can be reasonably compounded without limiting the usage amounts; theeffects and safety are simultaneously realized, any side effect is avoided, and the dose extreme is avoided.

Owner:佗鹊堂国投生物科技股份有限公司

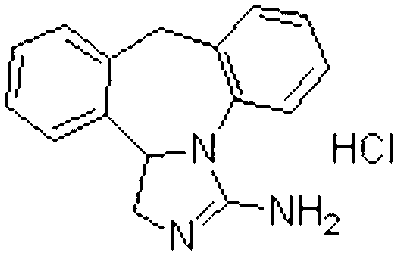

Stable granular medicine composition containing epinastine or hydrochloride thereof

InactiveCN103251563AStable decompositionPharmaceutical non-active ingredientsGranular deliveryDrug productAllergic reaction

The invention discloses a stable granular medicine composition containing epinastine or hydrochloride thereof. The stable granular medicine composition also comprises a binding agent which has a stabilizing effect on the epinastine or the hydrochloride thereof. Meanwhile, the invention also discloses a preparation method of the stable granular medicine composition. The granular medicine composition disclosed by the invention can also be used as a medicament which urgently needs to be developed in clinic and has an excellent effect on allergic reaction diseases of children.

Owner:BEIJING KEYUAN CHUANGXIN TECH

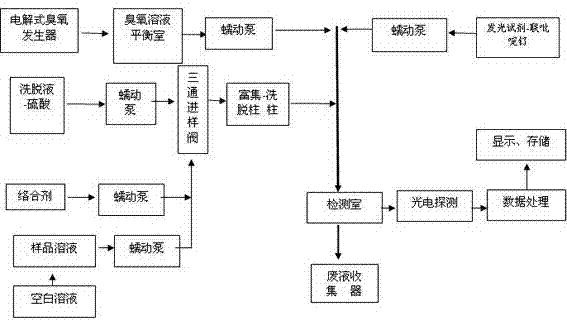

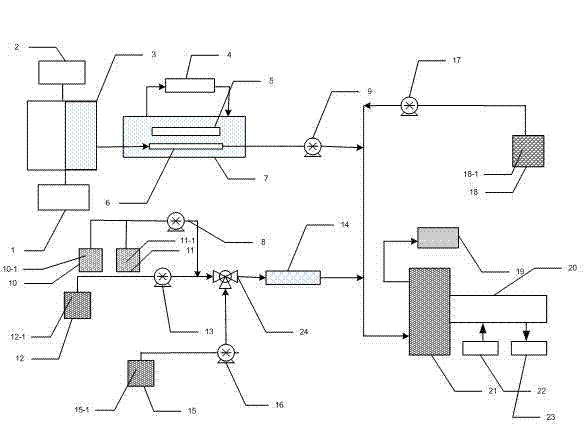

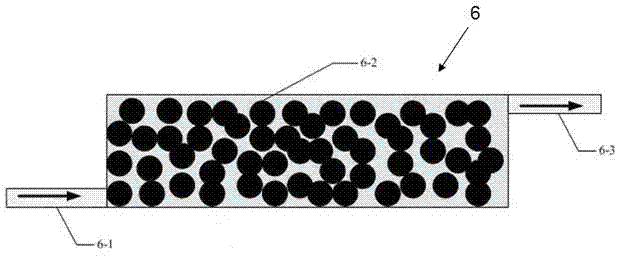

Detecting device and method for detecting flow injection chemiluminescence water inorganic mercury

ActiveCN103499570AStable decompositionImprove stabilityChemiluminescene/bioluminescenceFluorescent lightPollution

The invention provides a detecting device and method for detecting flow injection chemiluminescence water inorganic mercury, aims to solve the problems that in the prior art, an ozone solution is easy to decompose, on-site operation cannot be performed, analyzing time is long, analyzing process is complicated, conditions are rigorous, energy consumption is high, secondary pollution can be produced and the like. A catalyst of ruthenium trichloride is filled into a dynamic ozone solution balancing pipe; when the ozone solution flows into the dynamic ozone solution balancing pipe, the catalyst of the ruthenium trichloride is irradiated by a fluorescent light, the ozone in the ozone solution is inhibited from generating hydroxyl radicals, the ozone solution is stable and decompose rarely, and stability of the ozone solution is improved. The detecting device used for detecting the inorganic mercury in water has the advantages of scene, rapidness, convenience and flexibility.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Nanometer antibacterial water-based ink and preparation method thereof

InactiveCN105153795AImprove antibacterial detoxificationGood antibacterial detoxificationInksWater basedEpoxy

The invention provides a nanometer antibacterial water-based ink and a preparation method thereof, and relates to the technical field of ink preparation. The ink is prepared from the following raw materials: aqueous acrylic acid color paste, a wetting agent, an aqueous organic pigment, a defoaming agent, melamine, titanium dioxide, nanometer silica, nanometer titanium dioxide, nanometer zinc oxide, an aqueous levelling agent, an epoxy resin, isopropanol, ethanol, calcium stearate, alkyl sodium sulfonate, and magnesium palmitate. According to the invention, by adding nanometer silica, nanometer titanium dioxide, and nanometer zinc oxide into the ink, the property, of decomposing harmful microbe and harmful gases, of the ink is improved, and the comprehensive properties of the ink are improved. The nanometer components can be preferably compatible with the ink, so that the prepared ink is stable in performance. Furthermore, the water-based ink has advantages of good antibacterial and detoxifying properties, strong adhesive force, short drying time, and good rubbing resistance. The preparation method is simple in process and easy to operate, and the ink is energy-saving and environment-friendly, and is easy to popularize and use.

Owner:ANHUI ZHONGCAI PRINTING

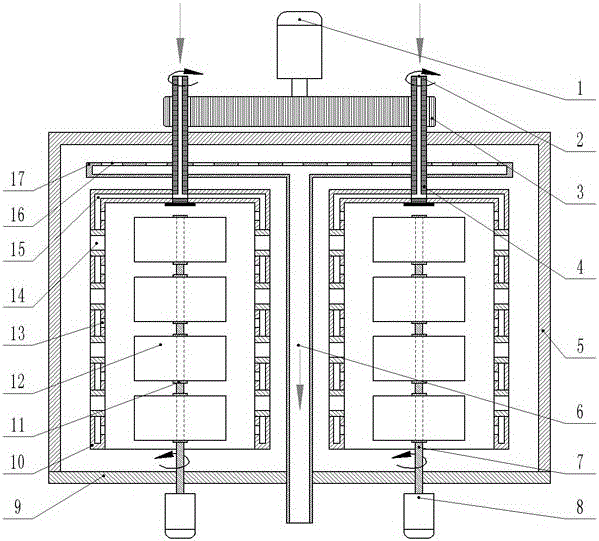

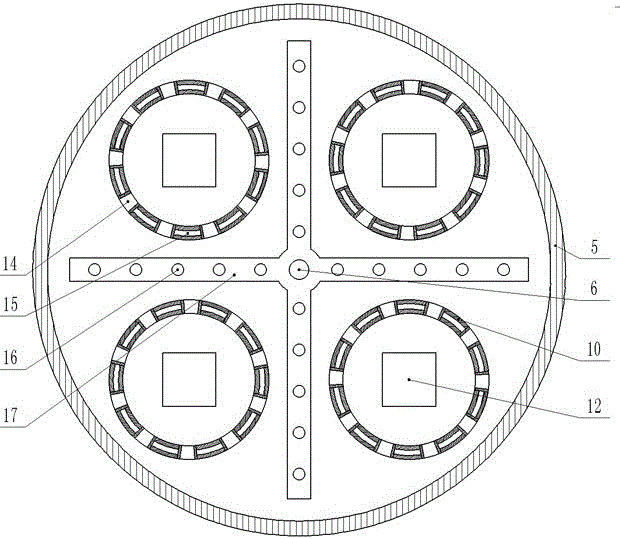

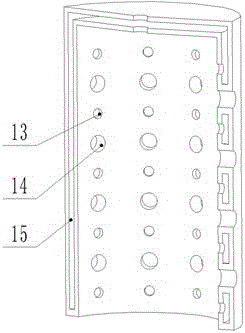

Ion nitriding device for realizing workpiece nitriding temperature equalization

ActiveCN107177816AImprove uniformityImprove decomposition rateSolid state diffusion coatingIonDecomposition

The invention relates to an ion nitriding device, in particular to an ion nitriding device for realizing workpiece nitriding temperature equalization. The device comprises a furnace body, a furnace chassis, a multifunctional active screen, an upper transmission system, a lower transmission system, an intake system and an exhaust system. The device is characterized in that the furnace body is cylindrical; the furnace chassis is disc-shaped; the furnace body is put rightly above the furnace chassis to form a furnace cavity; the multifunctional active screen is vertically suspended in the furnace cavity; the upper transmission system is fixed at the top of the furnace body; the upper transmission system drives the multifunctional active screen to rotate clockwise; the lower transmission system is fixed on the furnace chassis, and drives workpieces to anticlockwise rotate; the intake system consists of an intake part of the upper transmission system, and an intake part of the multifunctional active screen; and the exhaust system consists of a main exhaust pipe and a branch exhaust pipe. The ion nitriding device effectively improves the intake and exhaust uniformity, increases the gas decomposition rate and stabilizes the cathode and anode distance to realize the workpiece nitriding temperature uniformity and to guarantee consistence of nitriding layer thicknesses and performances. The related device is also suitable for physical vapor deposition and chemical vapor deposition of material surfaces.

Owner:XIHUA UNIV

Method for fire protection and modification of properties of expanded polyesters

ActiveUS20110171446A1Easy to handleEfficient use ofManual label dispensersCeramic shaping apparatusPolyesterFire protection

The present invention relates to an easy-to-apply, but versatile method for modifying the physical and chemical resistance properties of expanded polyester products, such as fire retardancy and hydrolysis resistance, by melt-modification of the surface layer(s) of said foams and sponges, the manufacturing of such products and the use of such products.

Owner:ARMACELL ENTERPRISE GMBH & CO KG

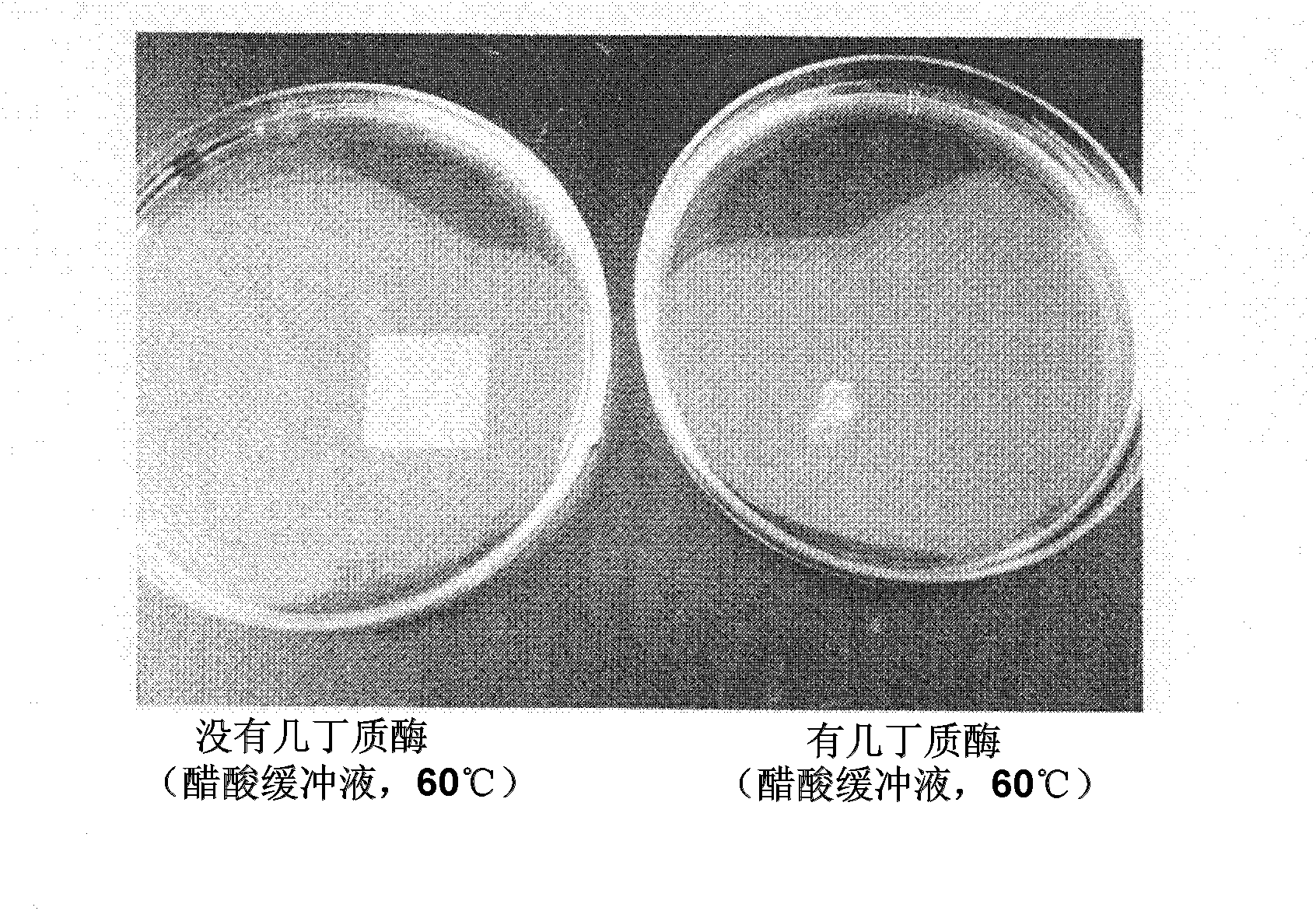

Degradable composite material containing chitin or chitosan

InactiveCN102573937AReduce the burden onWide range of usesAbsorbent padsDermatological disorderChitin formationPolysaccharide

Disclosed is a degradable composite material which has autolytic ability and contains at least one polysaccharide selected from among chitins and chitosans. By having a molded article, which contains at least one polysaccharide selected from among chitins and chitosans, support a degrading enzyme that is capable of hydrolyzing the polysaccharide, it becomes possible to gradually degrade the polysaccharide in an environment where moisture is present, such as a living organism.

Owner:THERMOSTABLE ENZYME LAB +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com