Ion nitriding device for realizing workpiece nitriding temperature equalization

A technology of ion nitriding and workpiece, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of uneven nitriding temperature, achieve uniform temperature, improve uniformity, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

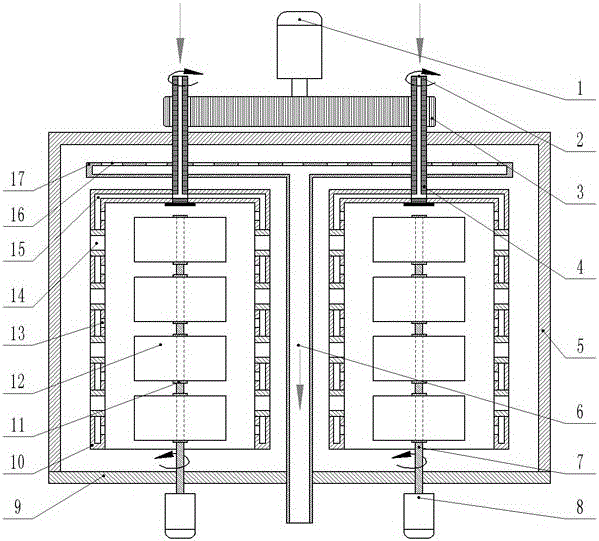

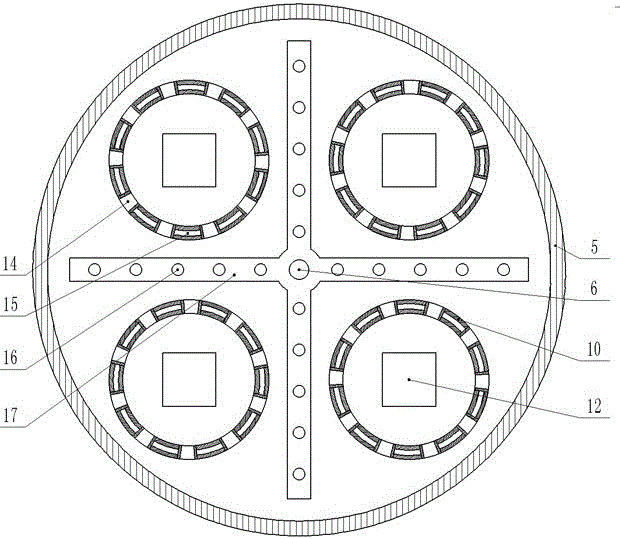

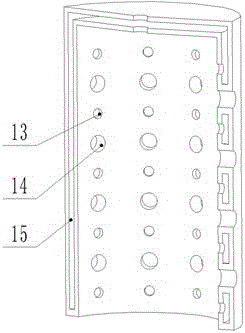

[0017] Such as figure 1 with figure 2 As shown, a kind of ion nitriding device that realizes uniform nitriding temperature of the workpiece comprises a furnace body 5, a furnace chassis 9, and a multifunctional active screen 10, the furnace body 5 is cylindrical, the furnace chassis 9 is disc-shaped, and the furnace body 5 is placed directly above the furnace chassis 9 to form a furnace chamber; the multifunctional active screen 10 is vertically suspended in the furnace chamber, and the upper transmission system is fixed on the top of the furnace body 5, and the upper transmission system drives the multifunctional active screen 10 to rotate clockwise; the lower transmission system Fixed on the furnace chassis 9, the lower transmission system drives the workpiece 12 to rotate counterclockwise, and the workpiece is fixed on the tooling 11; the air intake system is composed of the air intake part of the upper transmission system and the air intake part of the multifunctional act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com