Patents

Literature

1078results about How to "Achieve uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food preparation

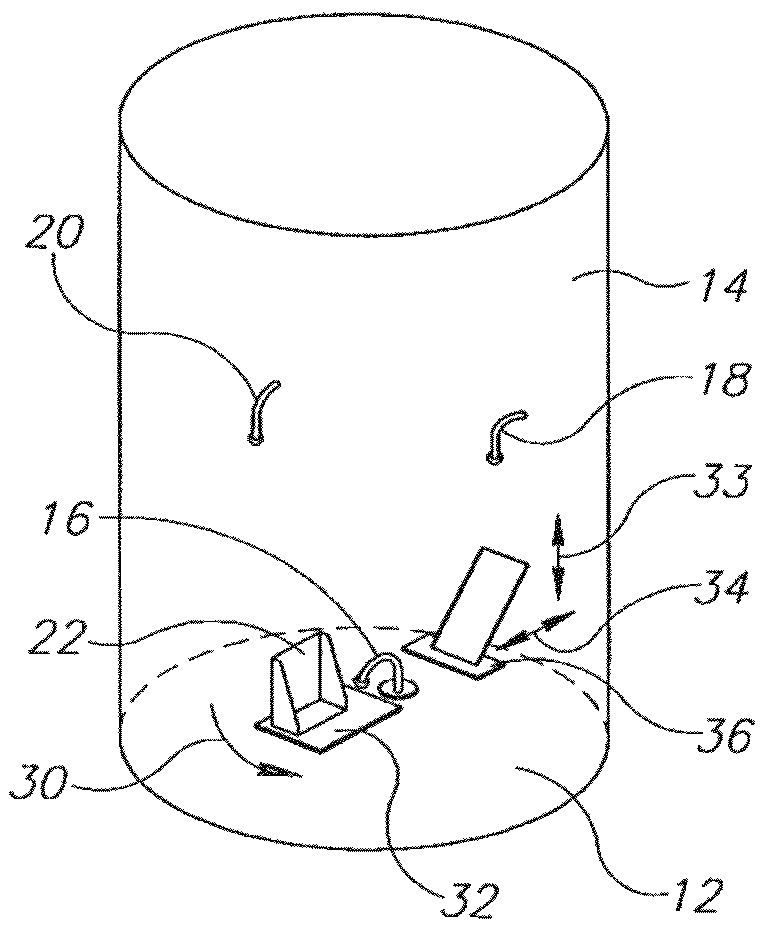

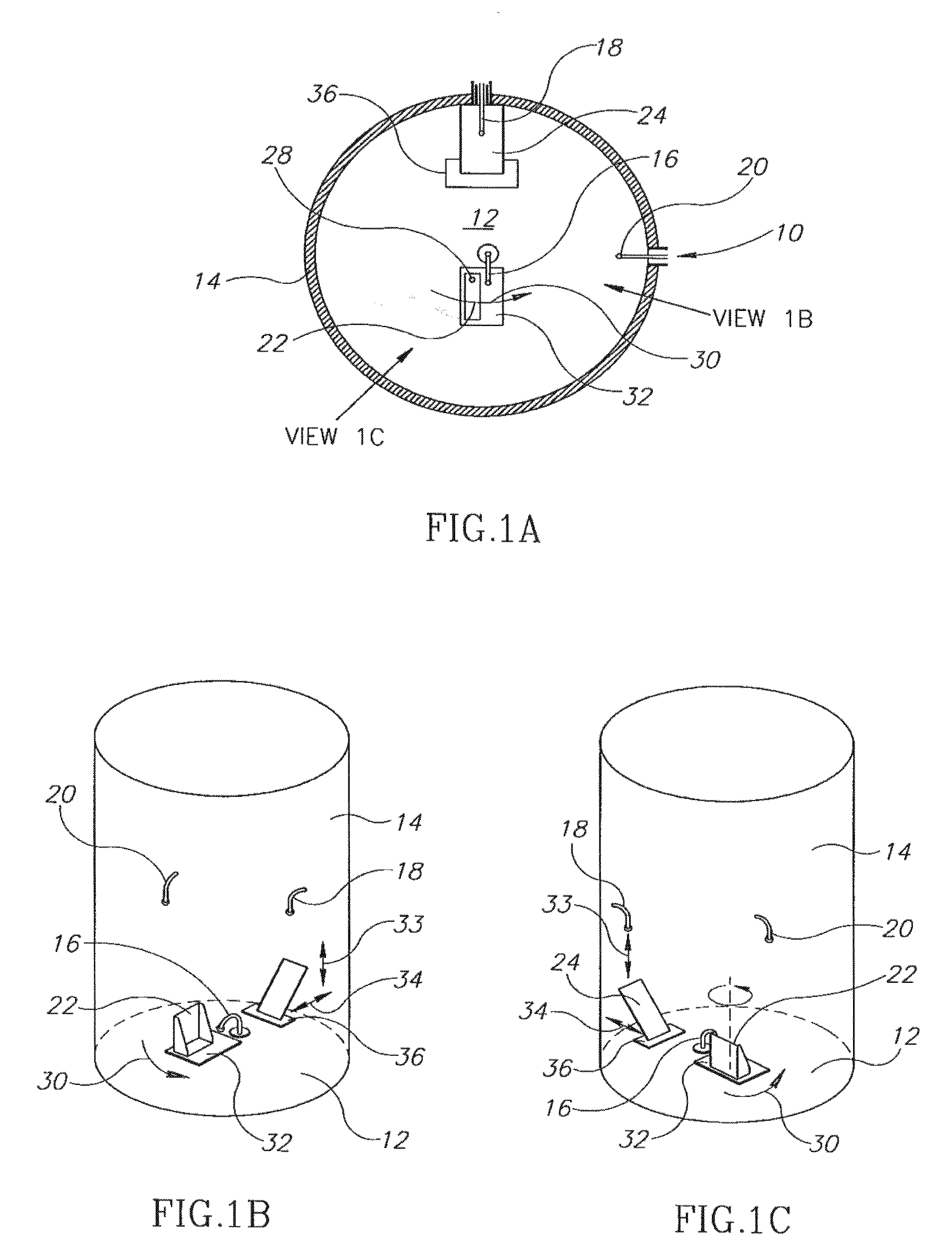

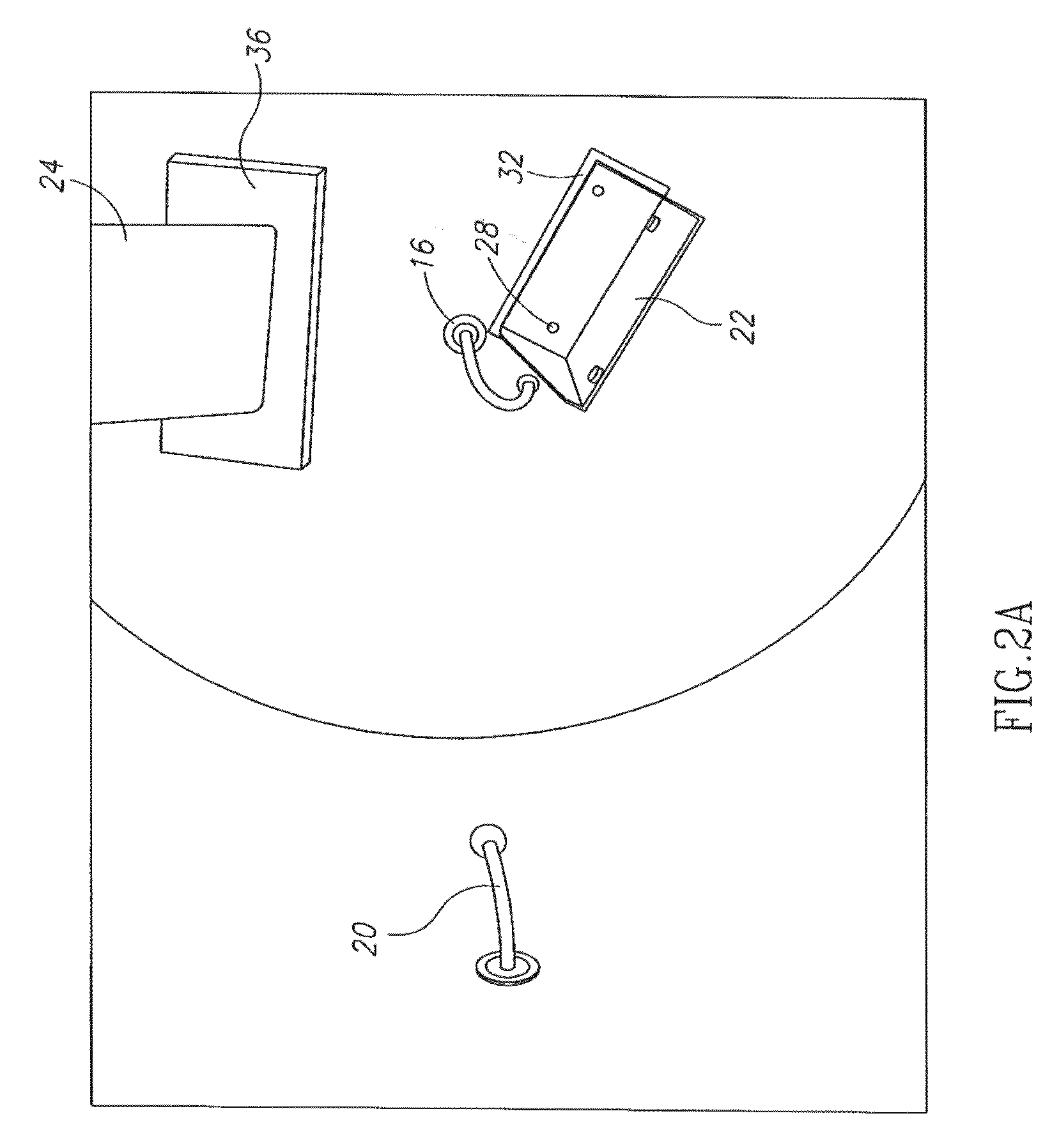

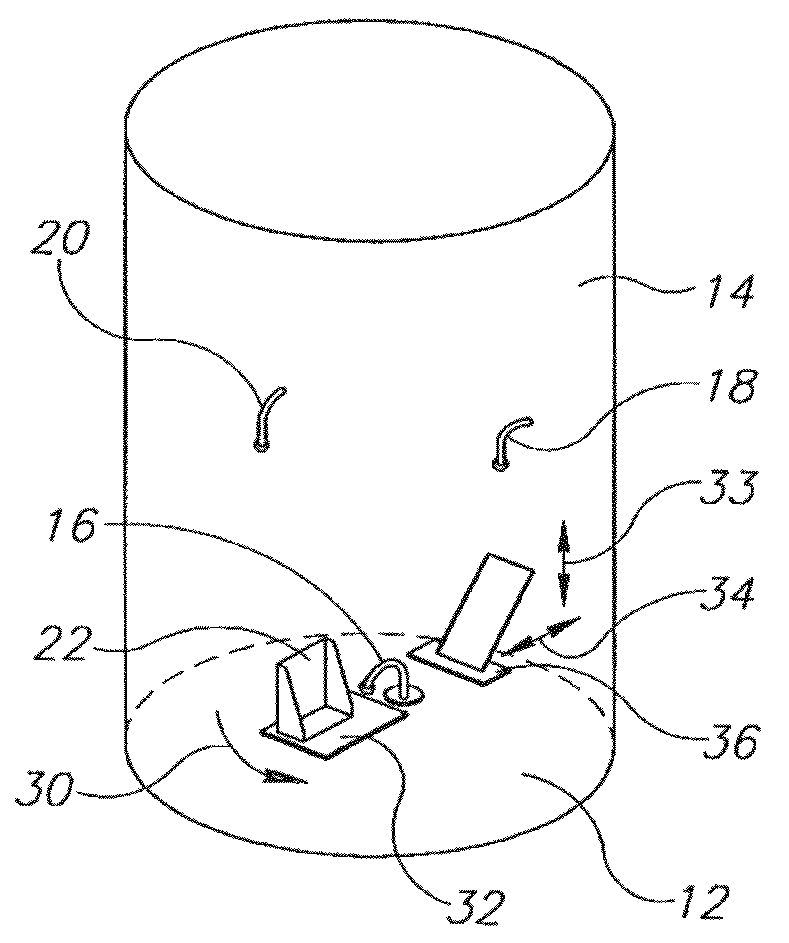

ActiveUS20090236335A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

Food preparation

ActiveUS20090236333A1Improve efficiencyIncrease net powerContainer decorationsLevel indicationsEngineeringIngested food

Owner:JOLIET 2010 LTD

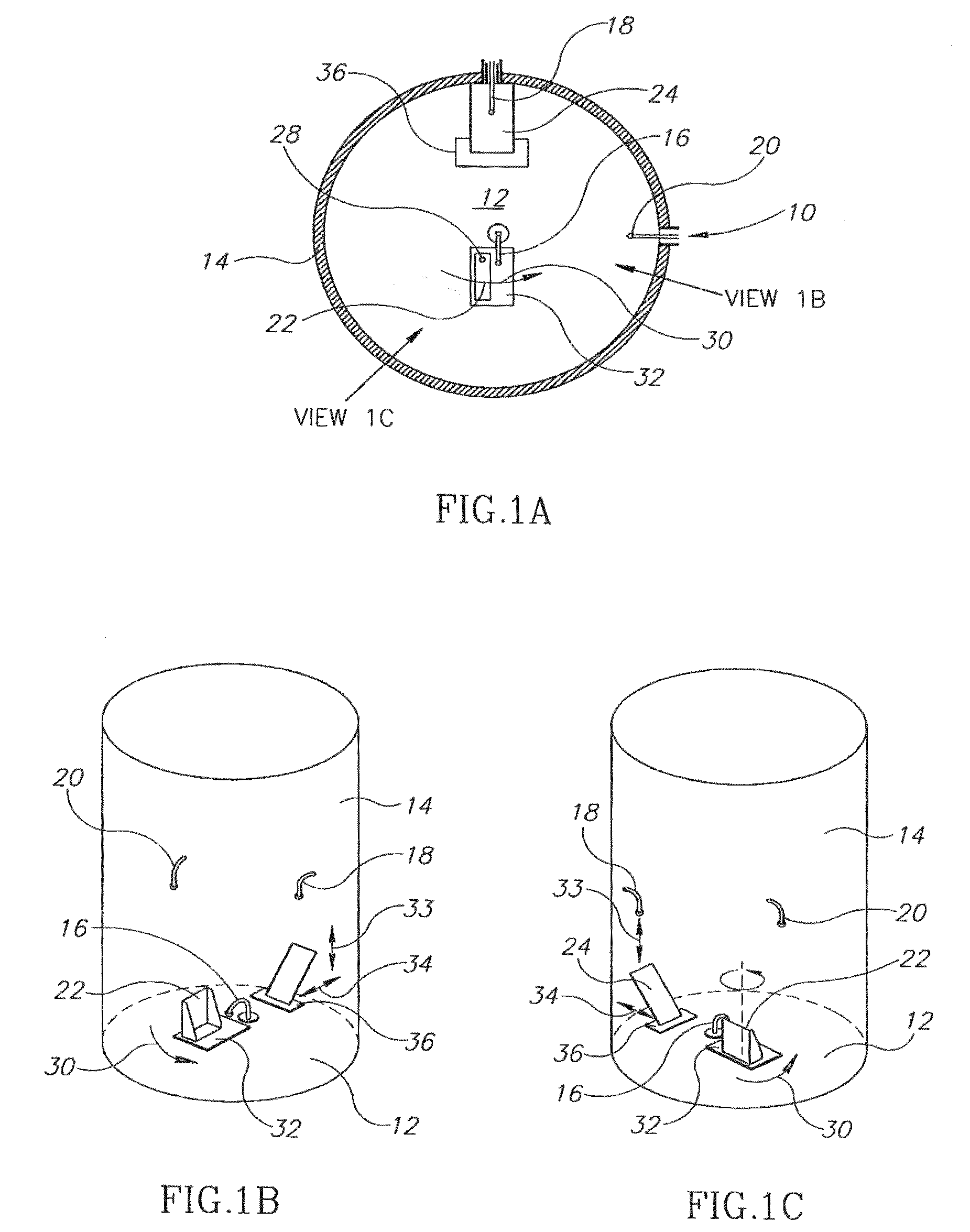

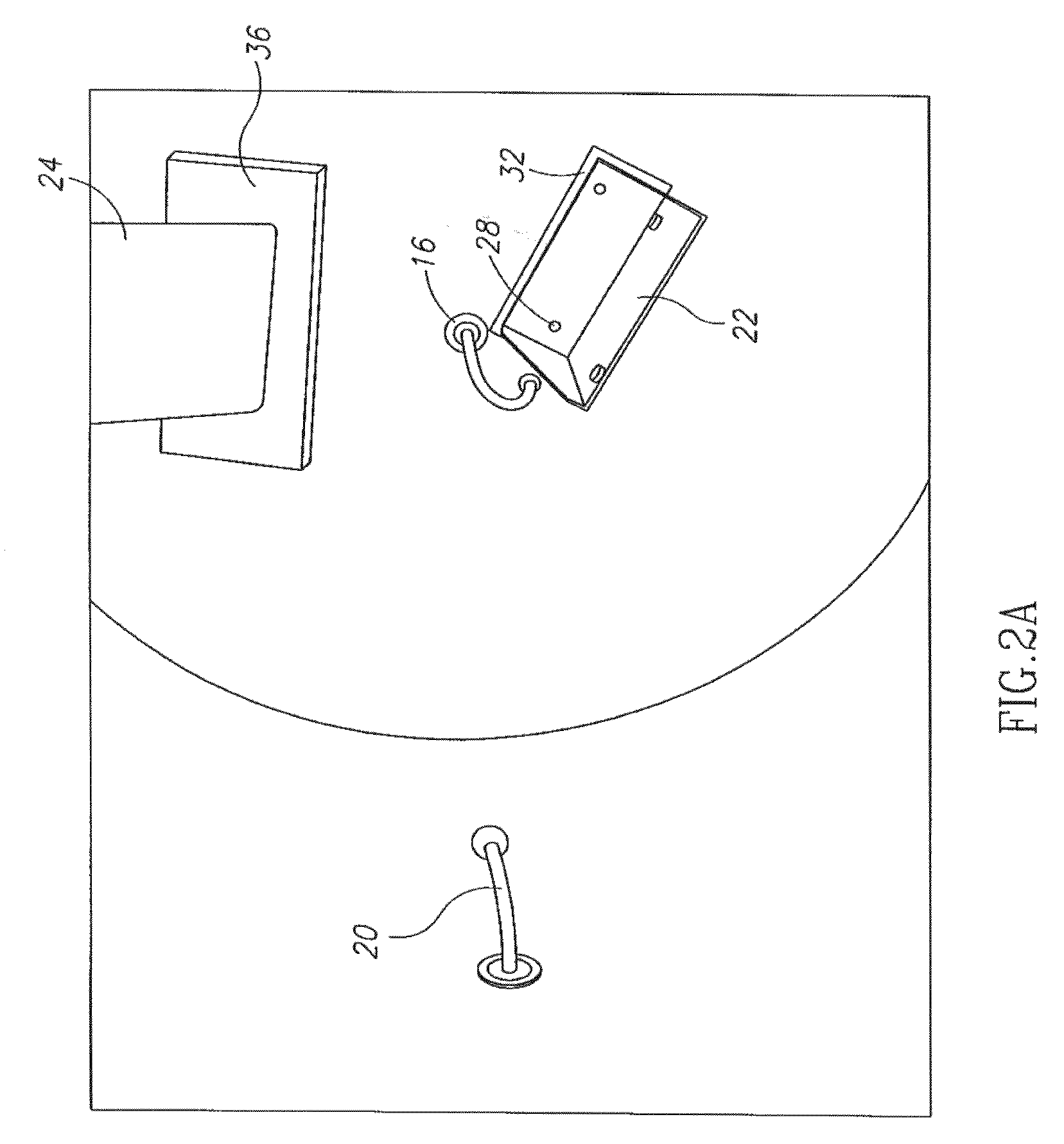

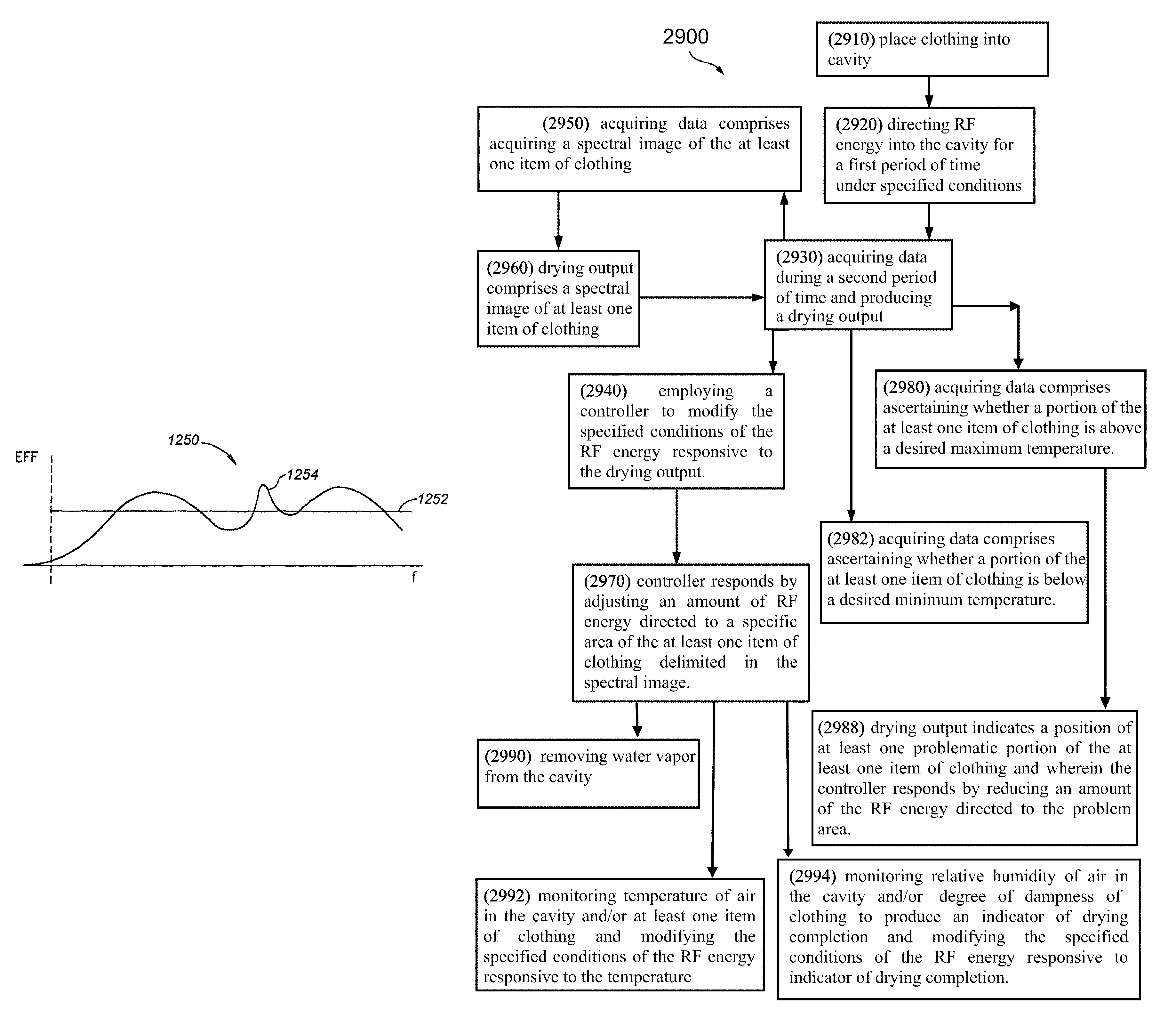

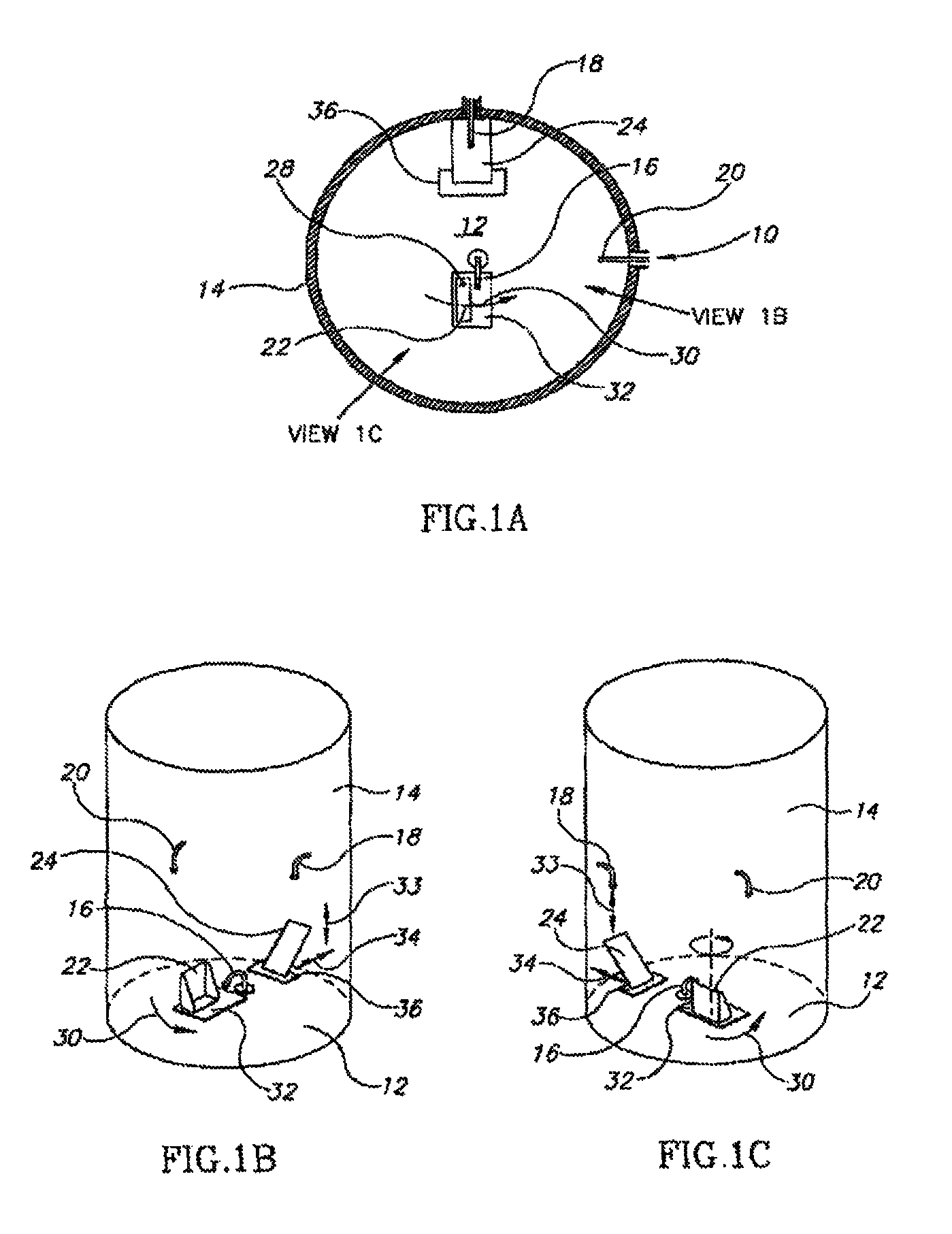

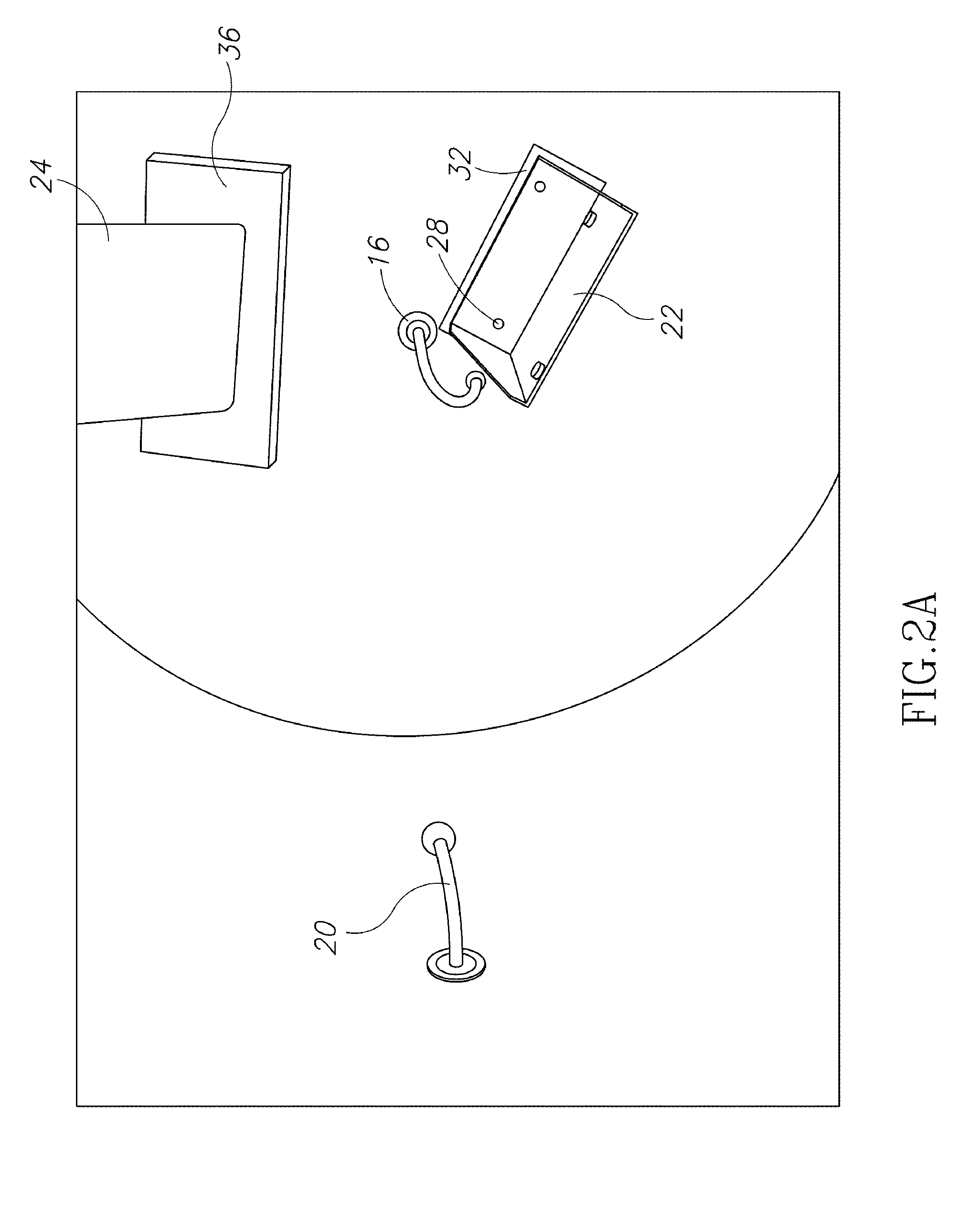

Drying apparatus and methods and accessories for use therewith

ActiveUS8839527B2Improve efficiencyIncrease net powerDrying solid materials with heatOhmic-resistance heatingControl mannerBroadband

A method of drying an object comprising, providing an object into an RF cavity; applying broadband RF energy to the object in controlled manner which keeps the object within a desired temporal temperature schedule and within a desired spatial profile; and terminating the drying when it is at least estimated that a desired drying level is achieved.

Owner:BORA APPLIANCES +1

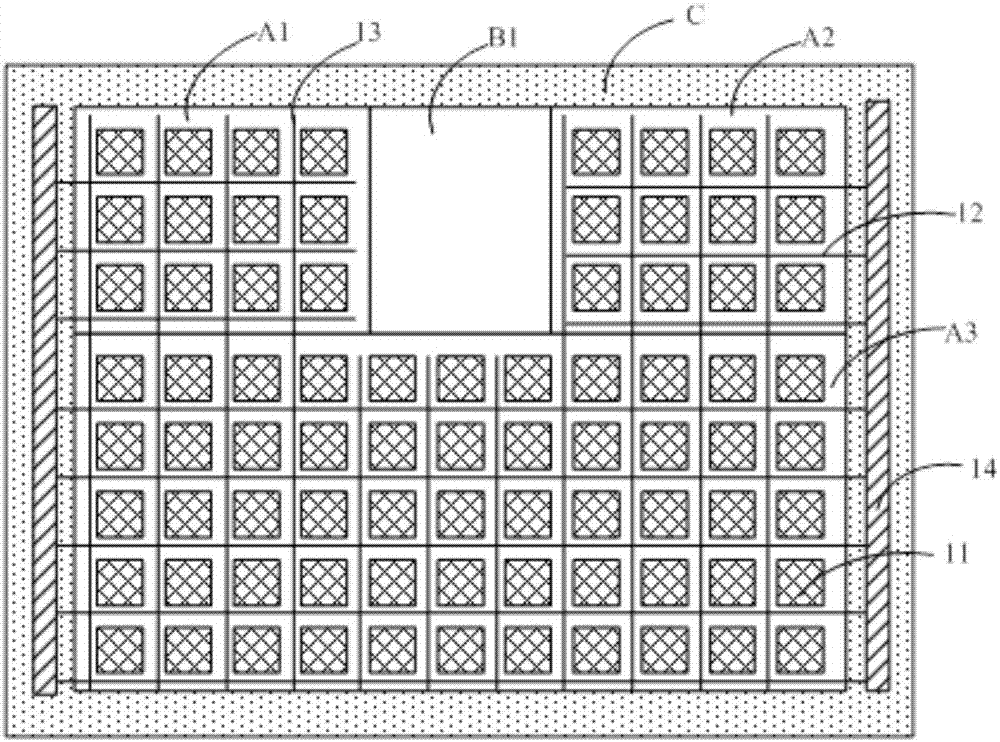

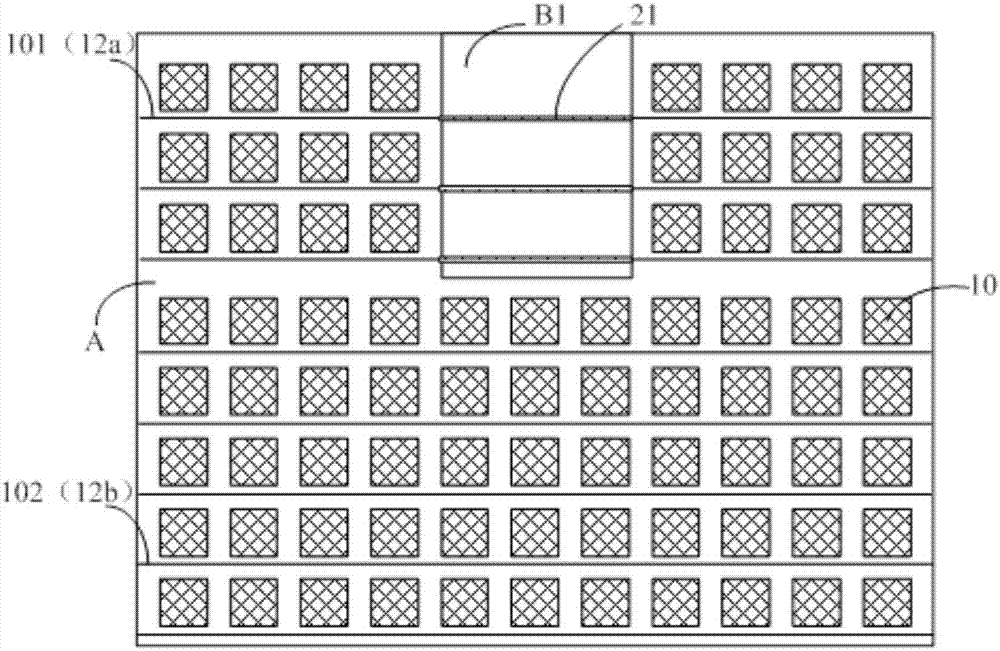

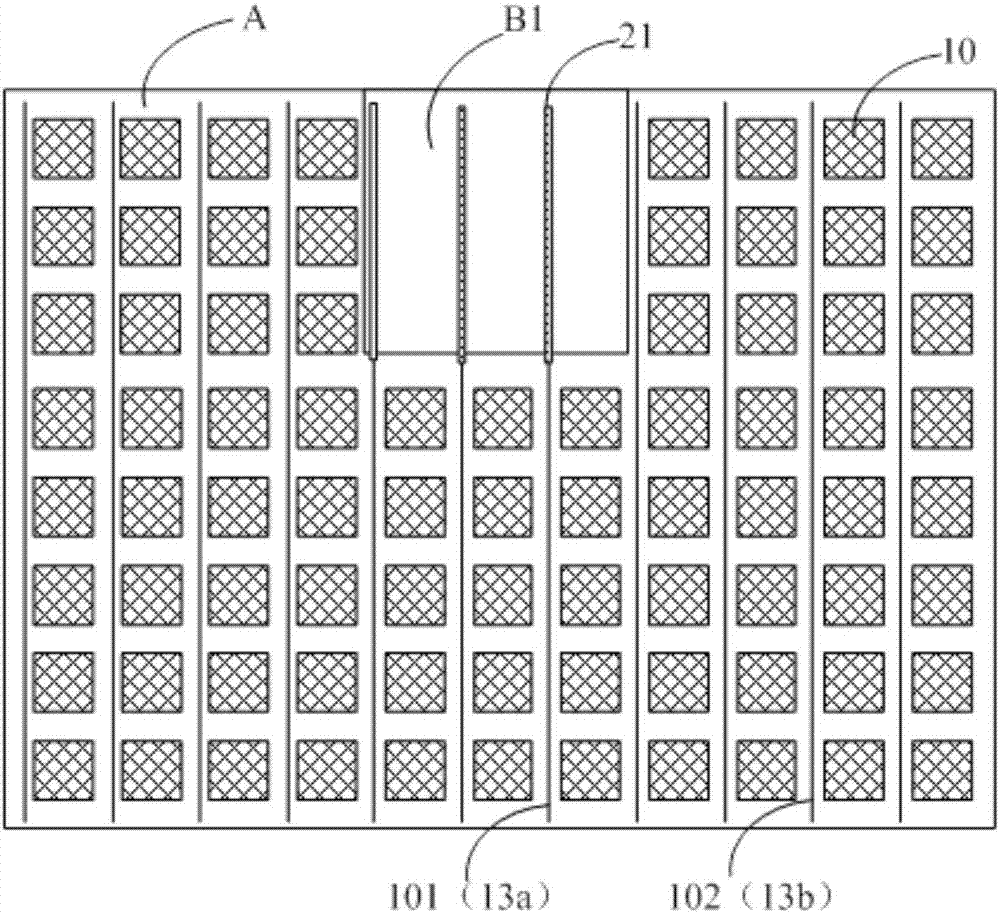

Organic light-emitting display panel and organic light-emitting display device

ActiveCN108010947AAvoid the problem of uneven display or even split screen phenomenonImprove the display effectSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The present invention discloses an organic light-emitting display panel and an organic light-emitting display device. The display panel and the display device are used for avoiding the phenomena of uneven display and even split screen because of different loads of signal lines, and thus the display effect of the display panel is improved. The organic light-emitting display panel has a display areaand a middle area. The display panel comprises an array substrate, multiple pixels located at the display area of the array substrate, and a first signal line and a second signal line extending alonga first direction, wherein the multiple pixels are arranged in an array, and the first signal line and a second signal line can provide signals for the pixels. The pixel number corresponding to the first signal line is less than the pixel number corresponding to the second signal line. The middle area comprises a first transparent wire electrically connected with the first signal wire.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

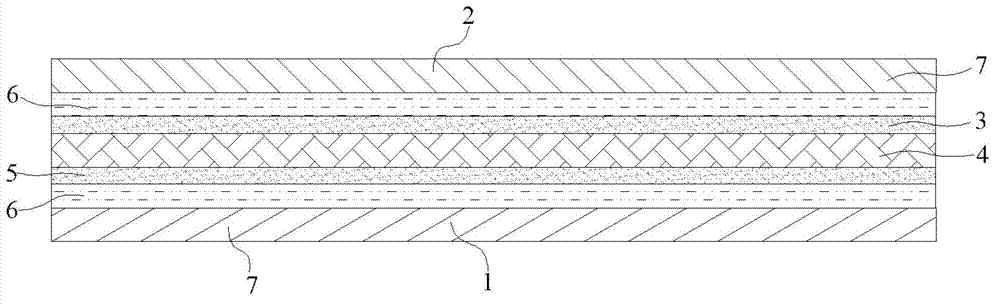

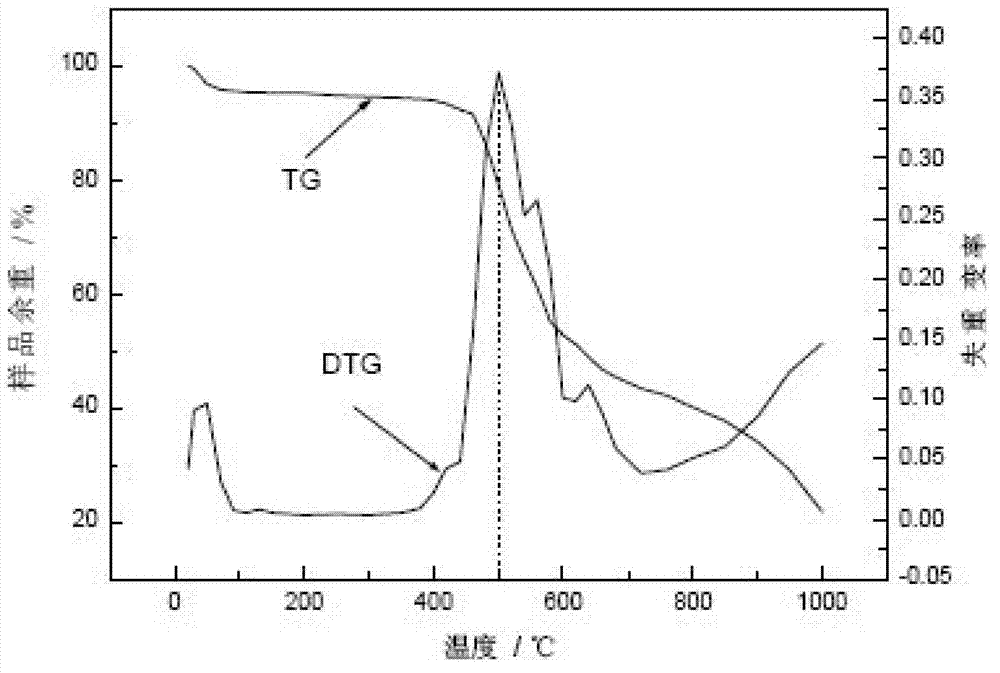

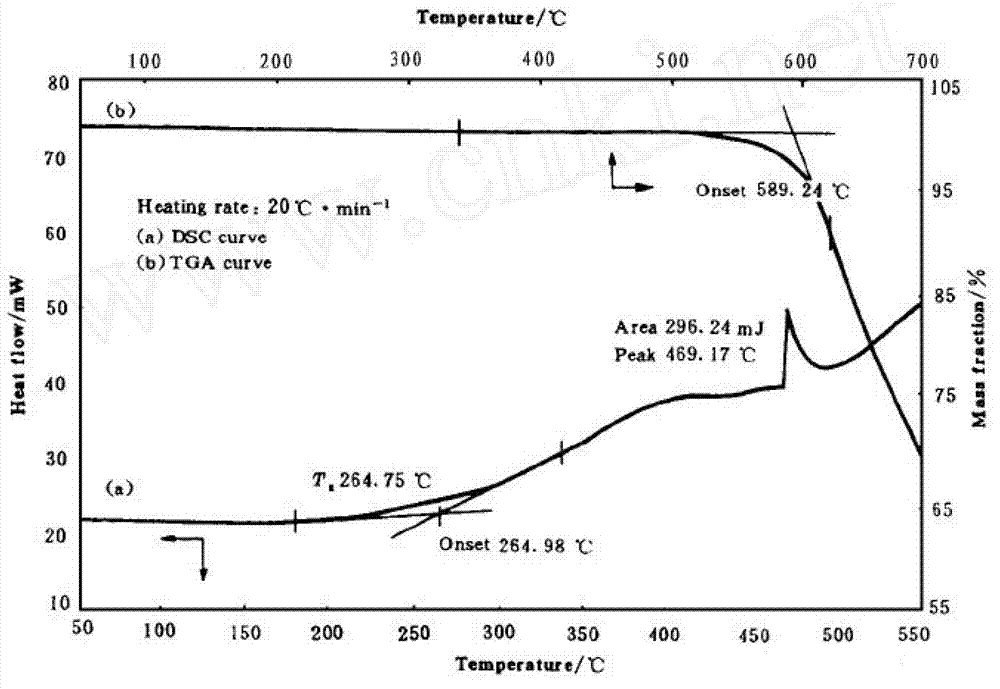

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

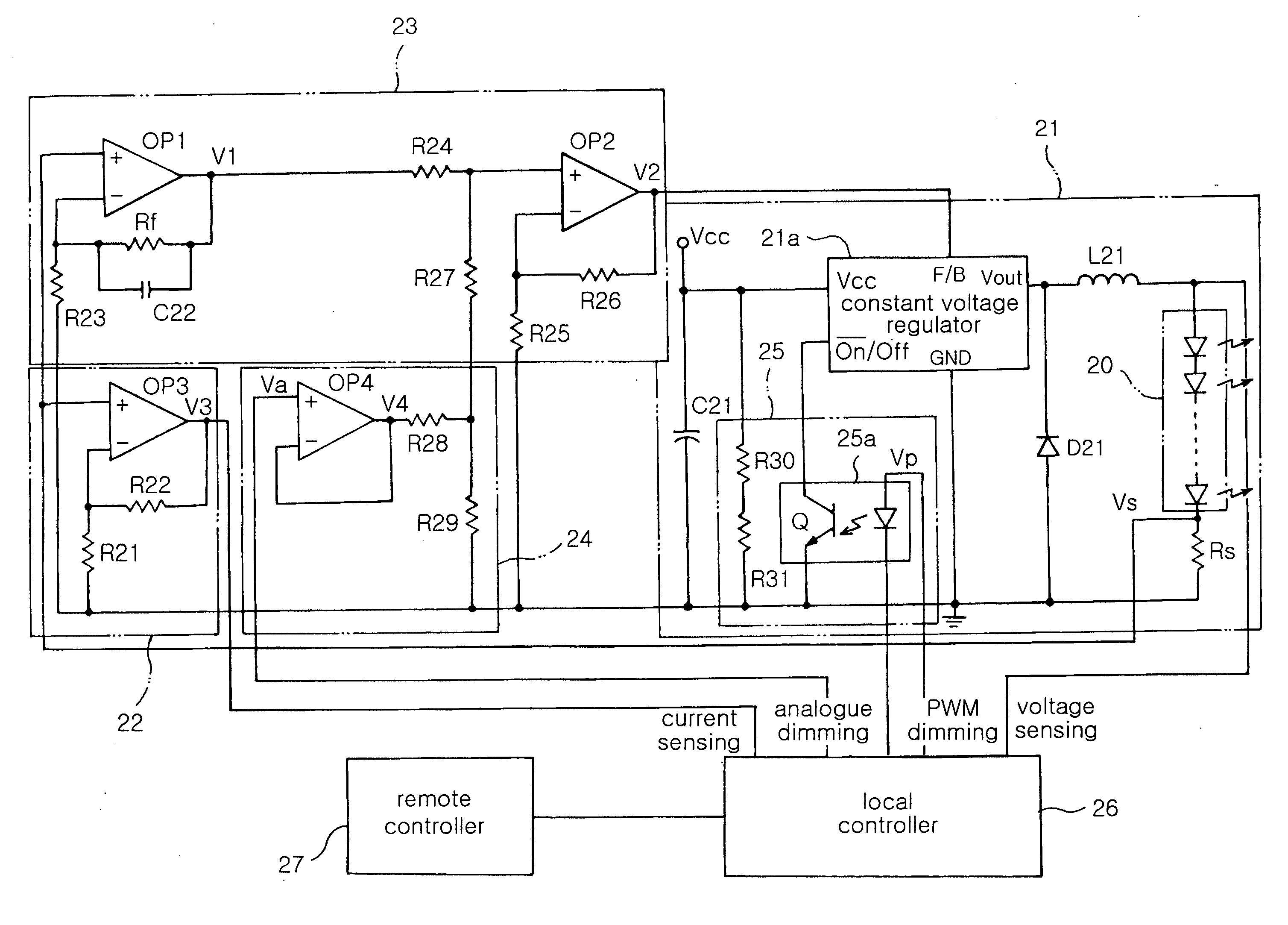

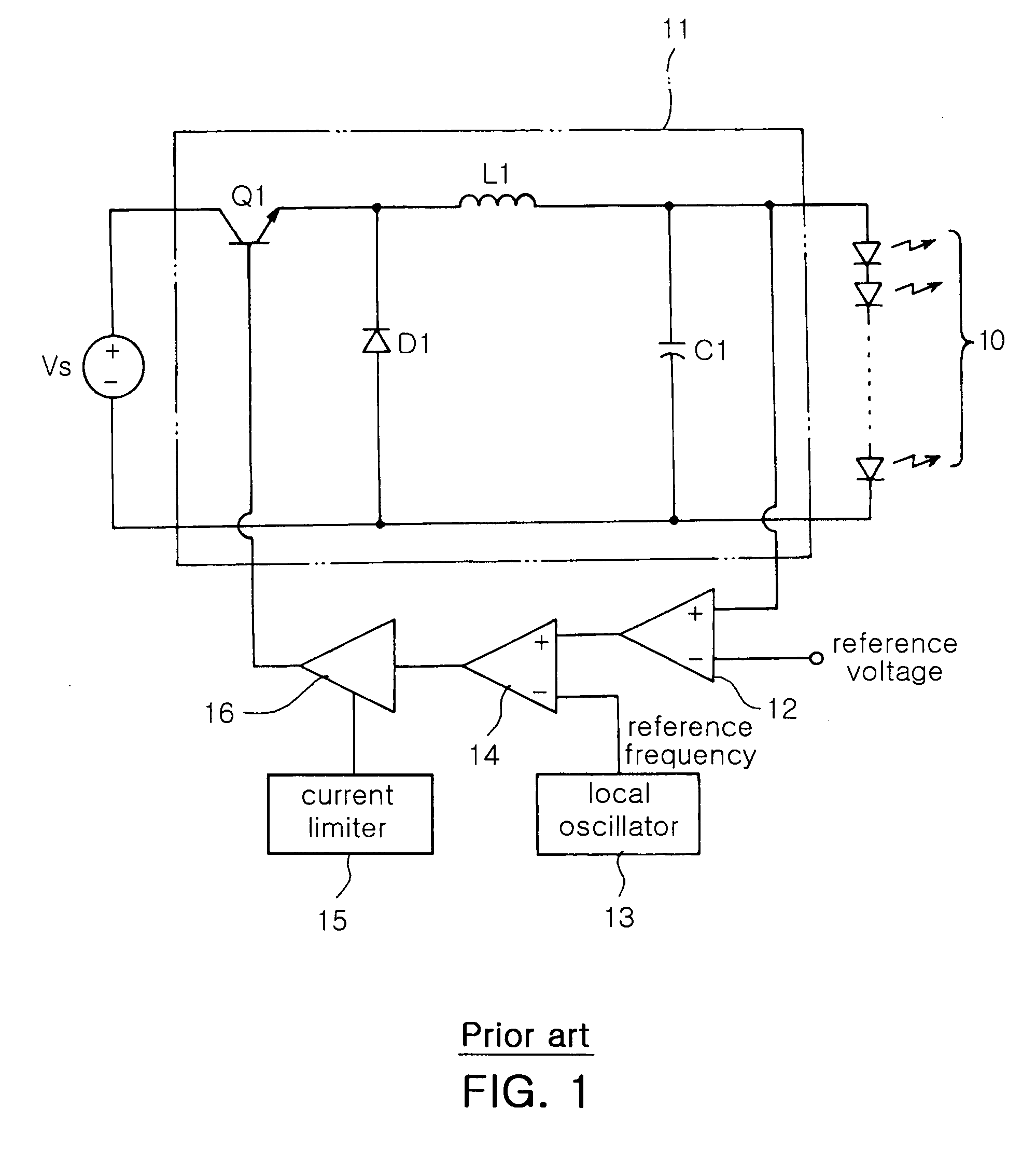

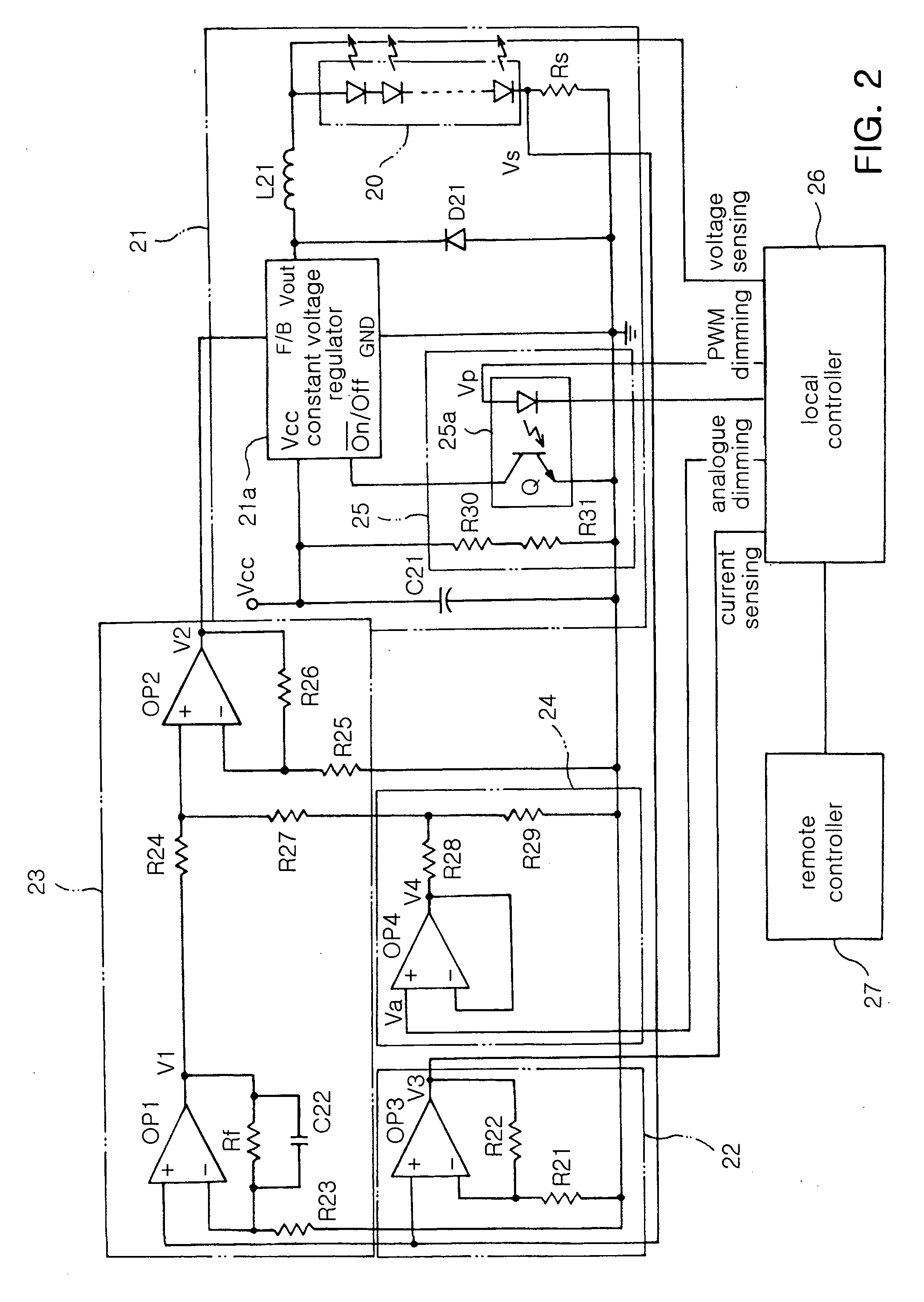

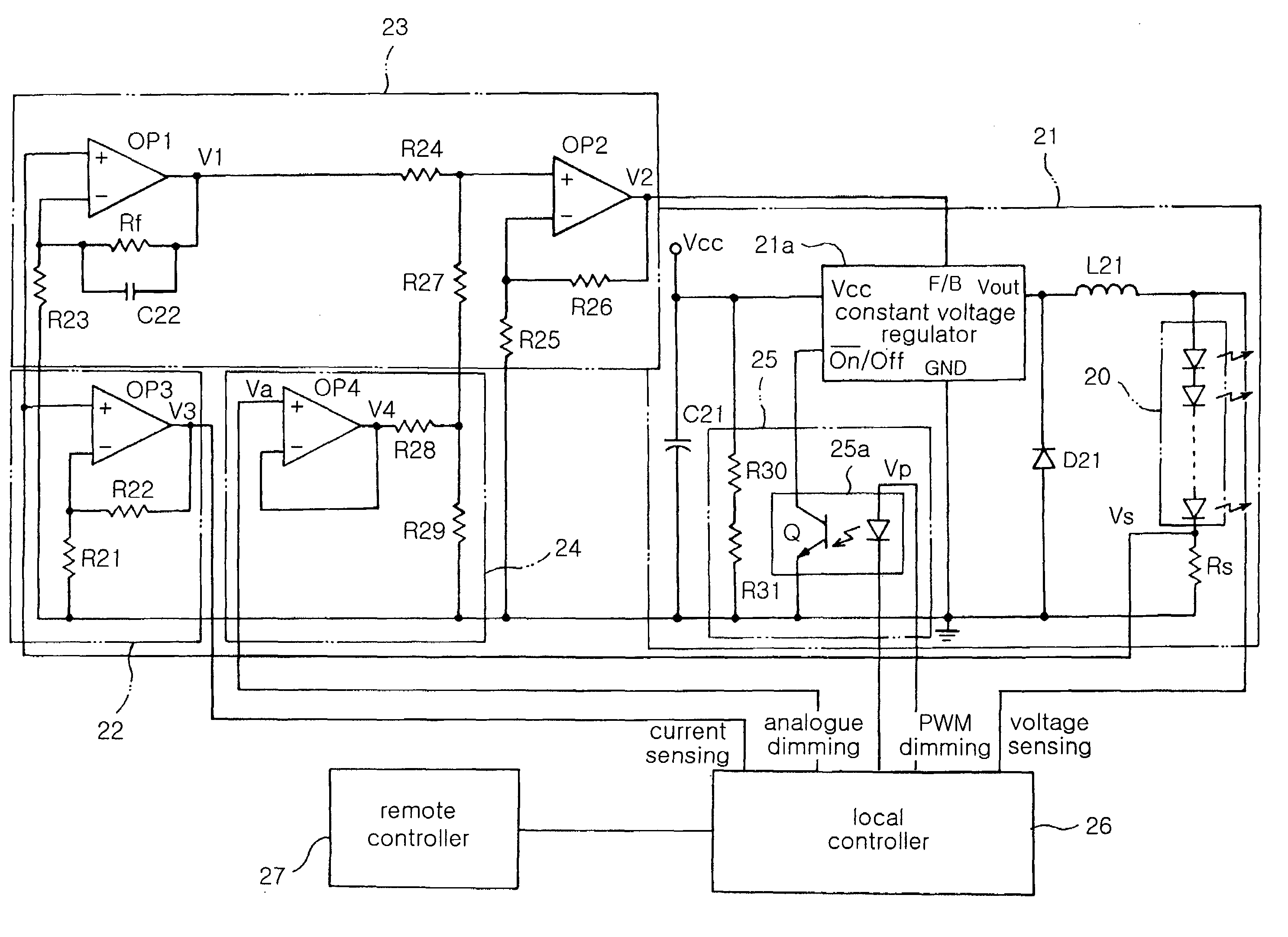

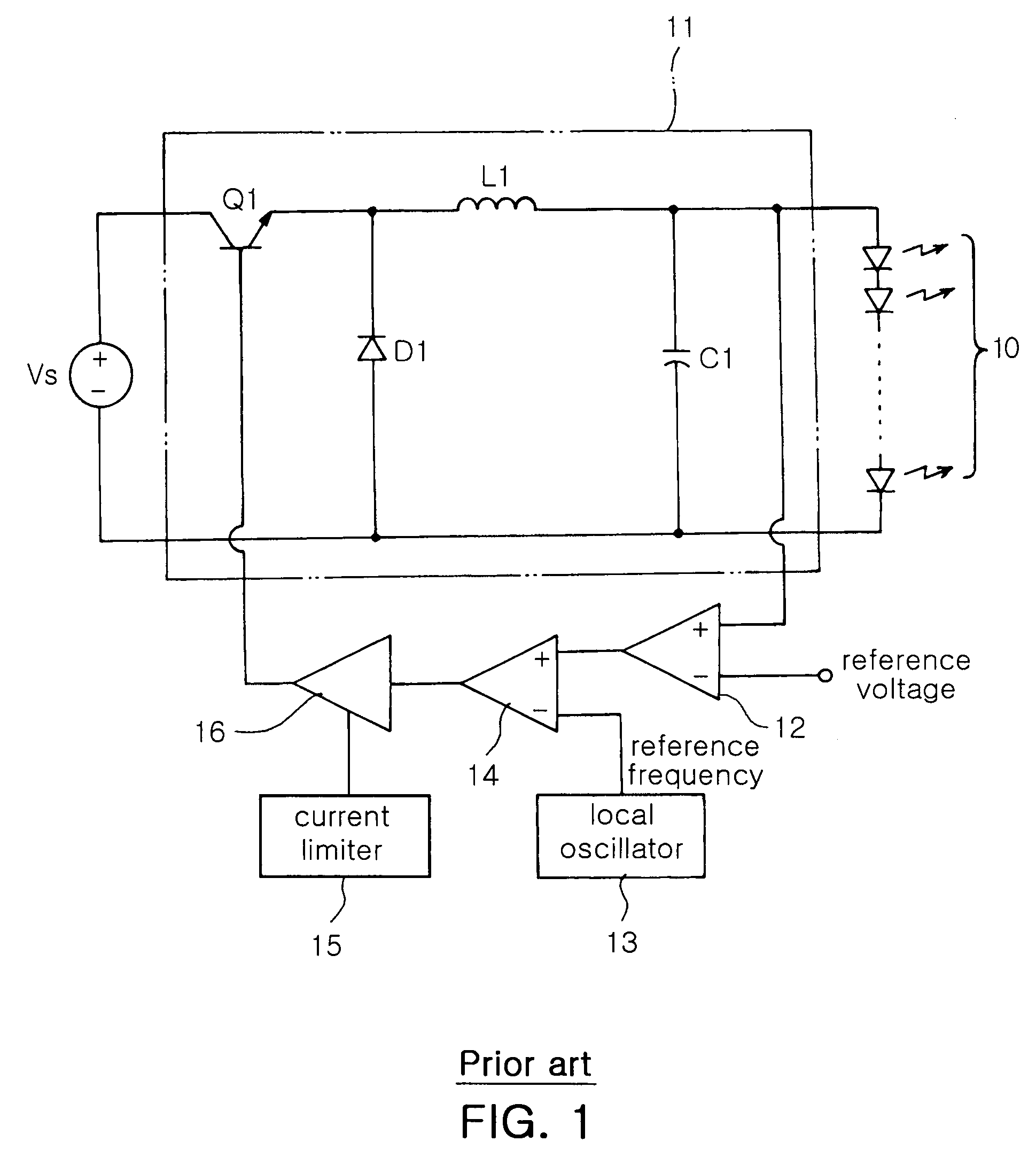

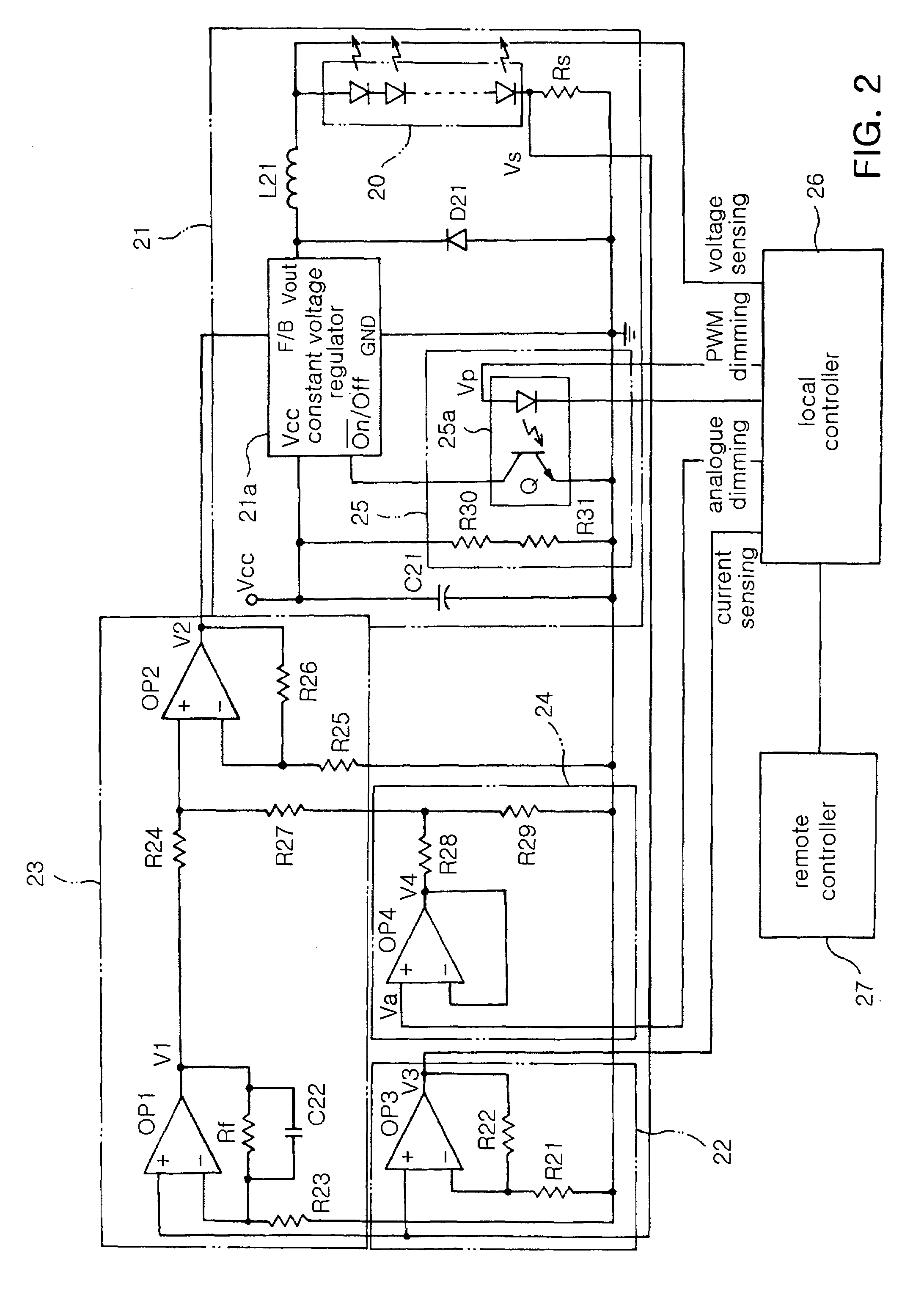

LED array driving apparatus and backlight driving apparatus using the same

InactiveUS20060175986A1Uniform color and luminanceUniform colorStatic indicating devicesElectroluminescent light sourcesVoltage regulationFeedback controller

The present invention relates to an LED array driving apparatus and a backlight driving apparatus using the same which enables regulation of analogue and PWM dimming for each channel and LED of a backlight, thereby allowing uniform luminance and color in all regions of backlight. The invention converts power with a constant voltage regulator to provide PWM pulse type power to the LED array having a plurality of LEDs connected in series. It regulates the on / off interval of the constant voltage regulator via a PWM dimmer to adjust the duty ratio of the PWM pulse. Further, it regulates the level of the driving current detected at the LED array via the feedback controller and analogue dimmer to apply to the constant voltage regulator by feedback process, thus regulating the amplitude of the PWM pulse.

Owner:SAMSUNG ELECTRONICS CO LTD

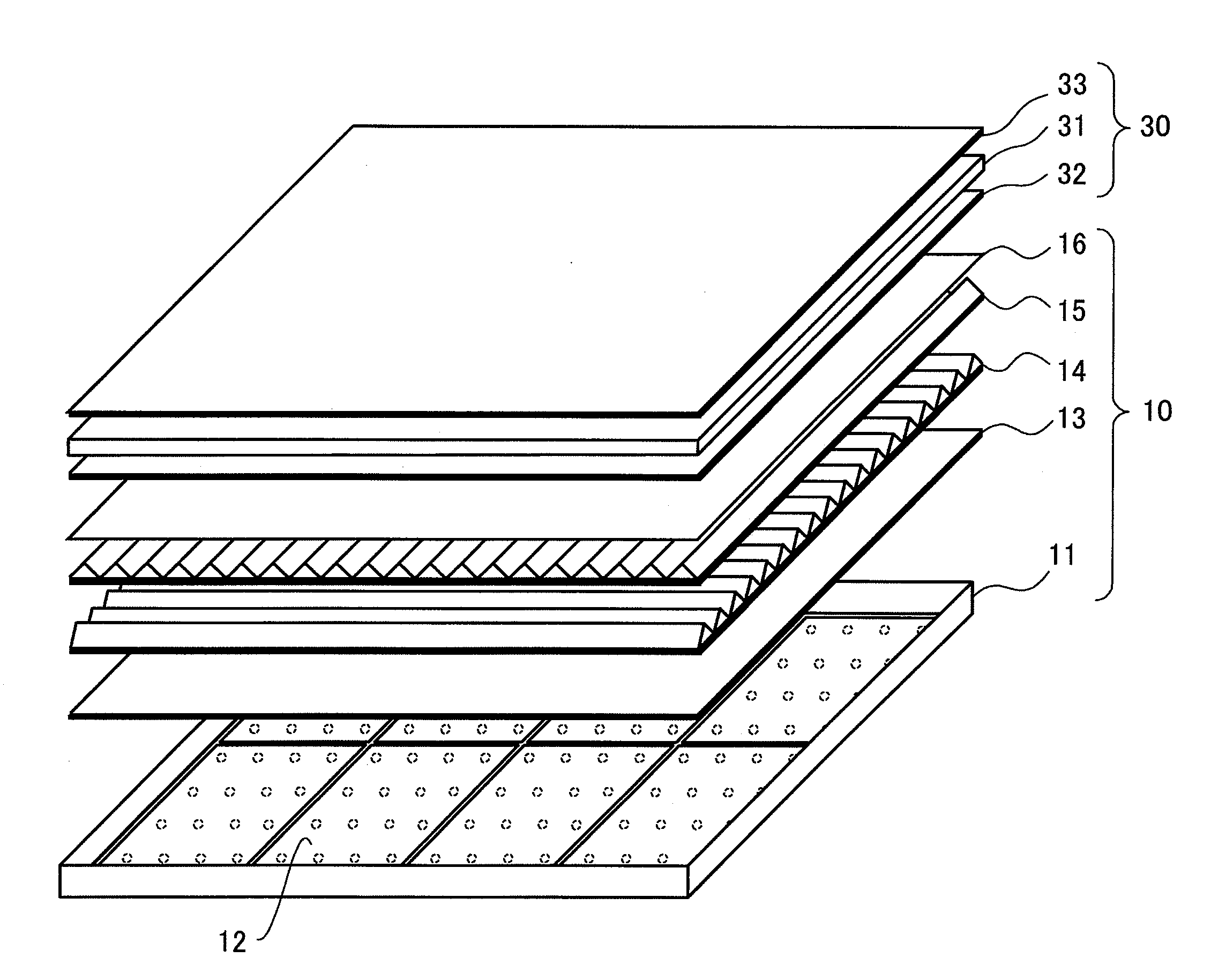

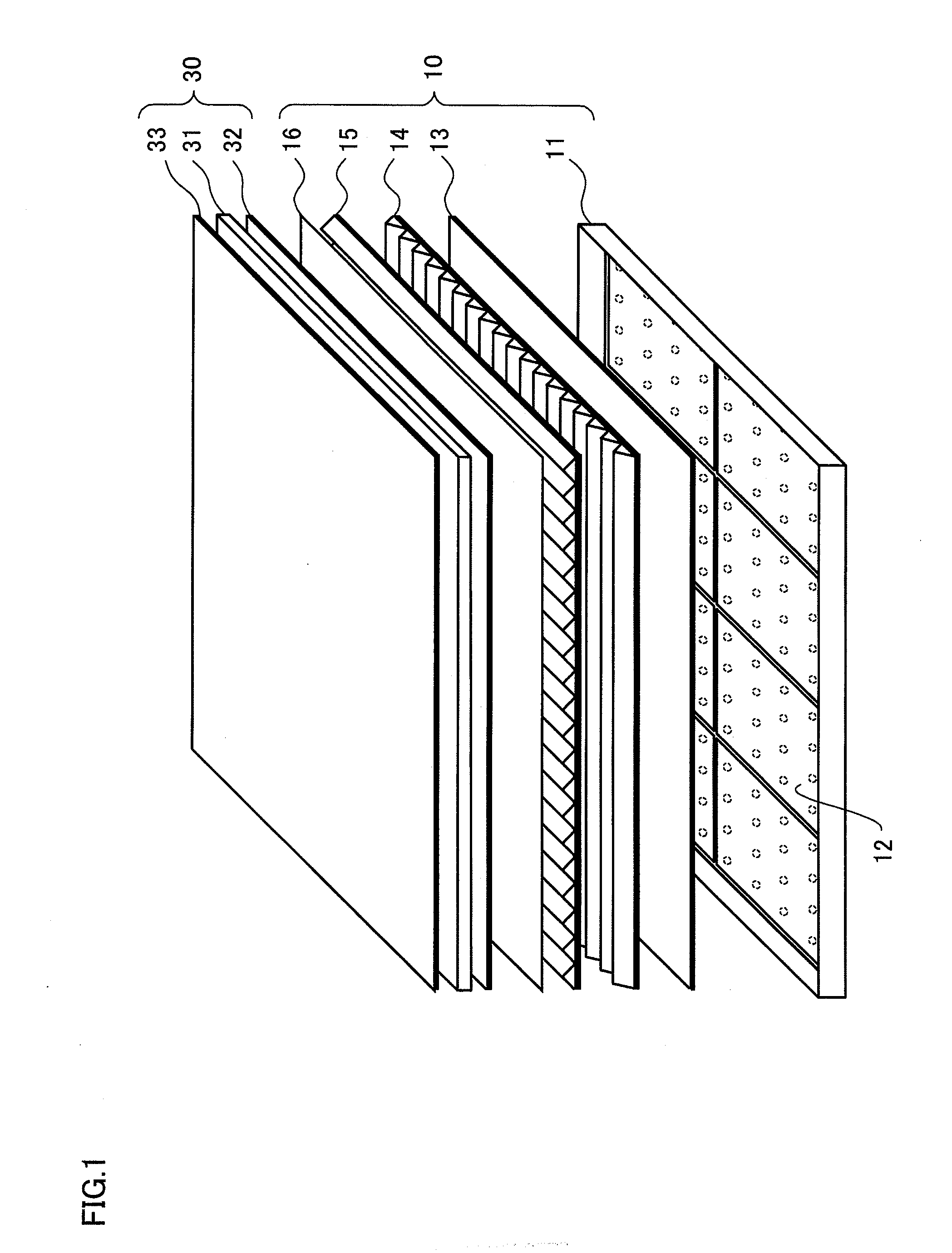

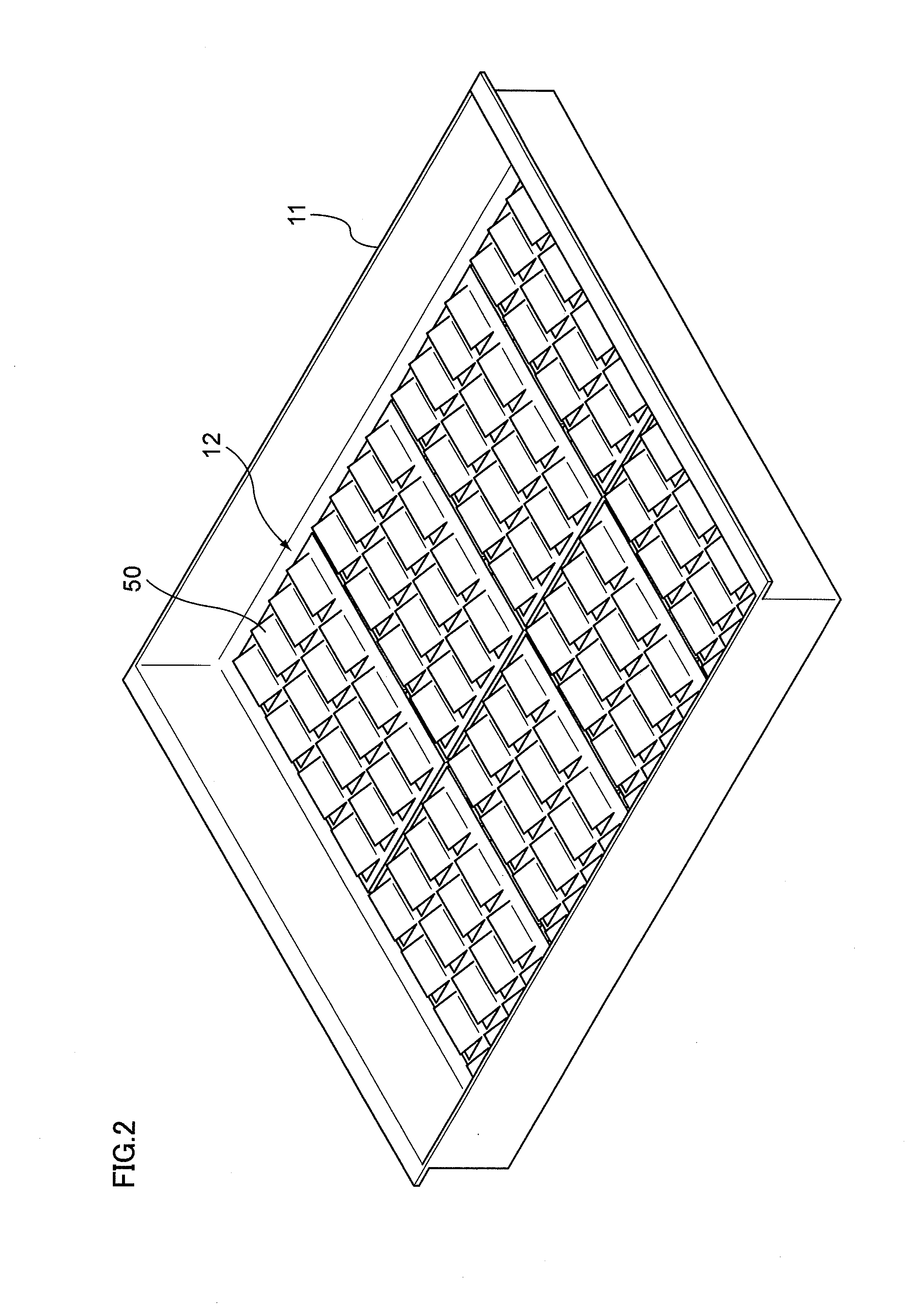

Light emitting device and display device using same

InactiveUS20090257215A1Reduction and non-uniformity in luminanceAchieve uniformitySolid-state devicesIlluminated signsSolid-stateDisplay device

A light emitting device is provided with an LED substrate (mounting substrate) (12); a plurality of light-emitting diodes (LEDs) (21) mounted on the LED substrate (12); and a reflector (50), which is mounted on the LED substrate (12), has a first surface (52a), and a second surface (52b) having a front-rear relationship with the first surface (52a), reflects light emitted from one light-emitting diode (LED) (21) of the light-emitting diodes (LEDs) (21) by the first surface (52a), and reflects light from the light-emitting diode (LED) (21) adjacent to the one light-emitting diode (LED) (21) by the second surface (52b). Thus, in a backlight device using a solid-state light emitting element, such as a LED, luminance is made uniform by reducing luminance nonuniformity.

Owner:SHOWA DENKO KK

LED array driving apparatus and backlight driving apparatus using the same

InactiveUS7276863B2Uniform colorUniform luminanceStatic indicating devicesElectroluminescent light sourcesDriving currentLed array

The present invention relates to an LED array driving apparatus and a backlight driving apparatus using the same which enables regulation of analogue and PWM dimming for each channel and LED of a backlight, thereby allowing uniform luminance and color in all regions of backlight. The invention converts power with a constant voltage regulator to provide PWM pulse type power to the LED array having a plurality of LEDs connected in series. It regulates the on / off interval of the constant voltage regulator via a PWM dimmer to adjust the duty ratio of the PWM pulse. Further, it regulates the level of the driving current detected at the LED array via the feedback controller and analogue dimmer to apply to the constant voltage regulator by feedback process, thus regulating the amplitude of the PWM pulse.

Owner:SAMSUNG ELECTRONICS CO LTD

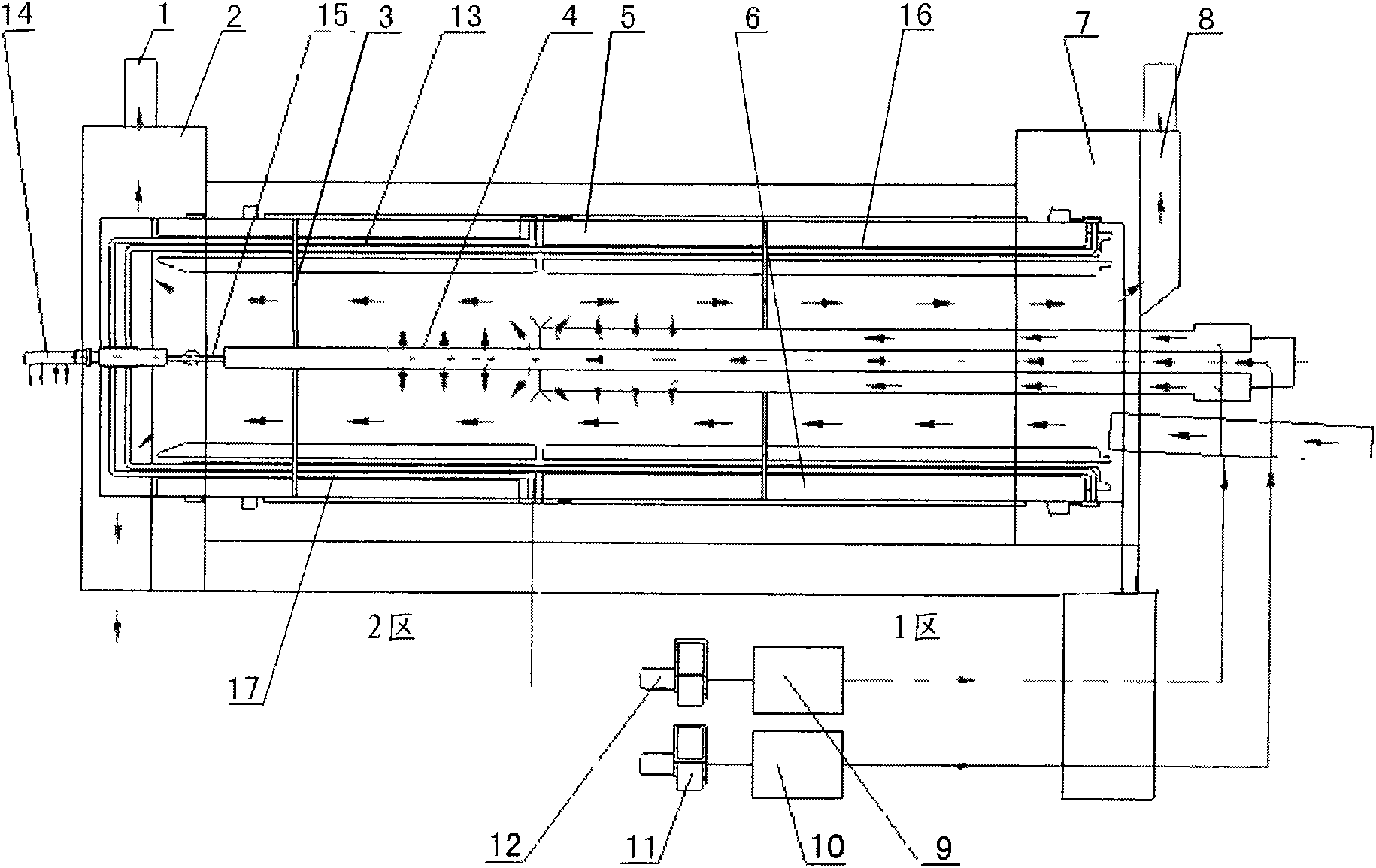

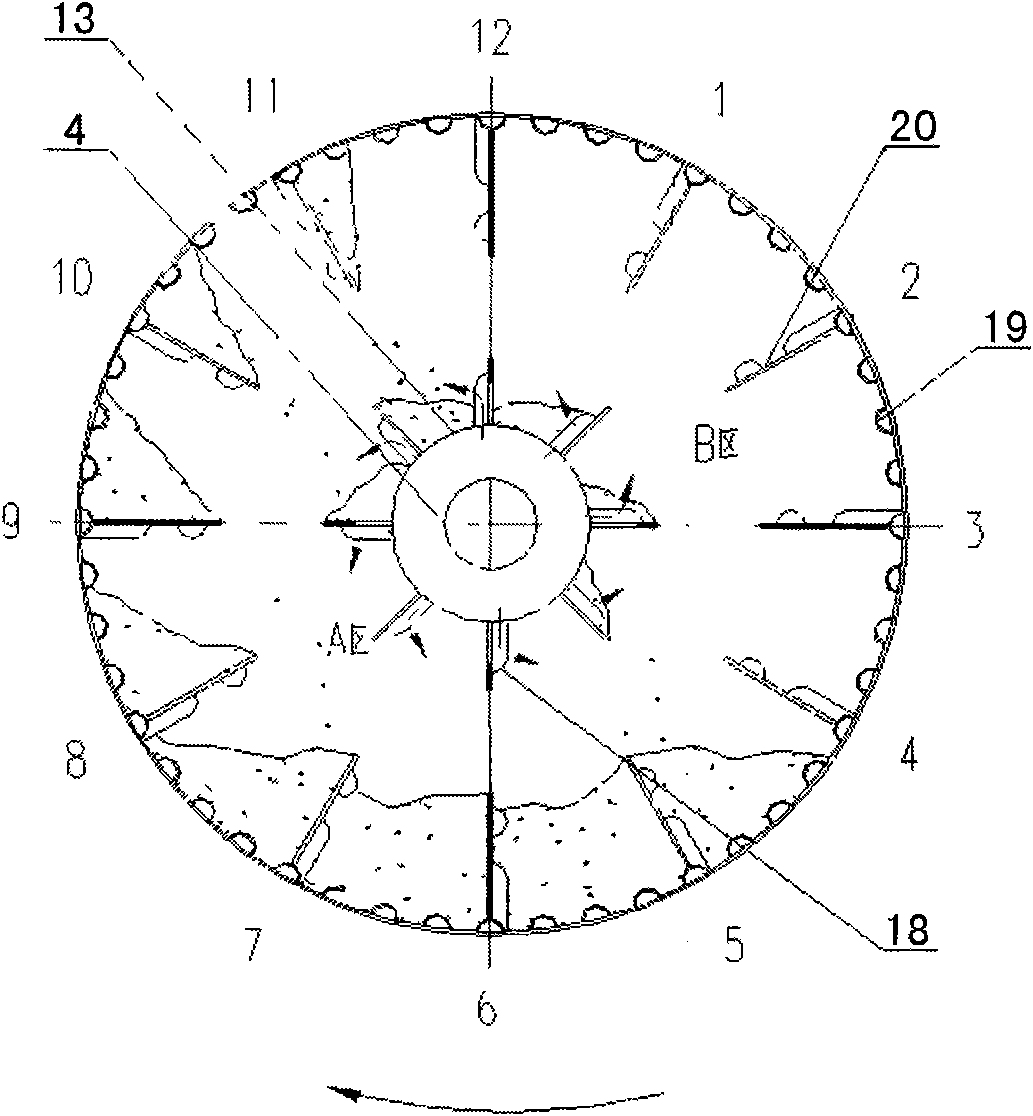

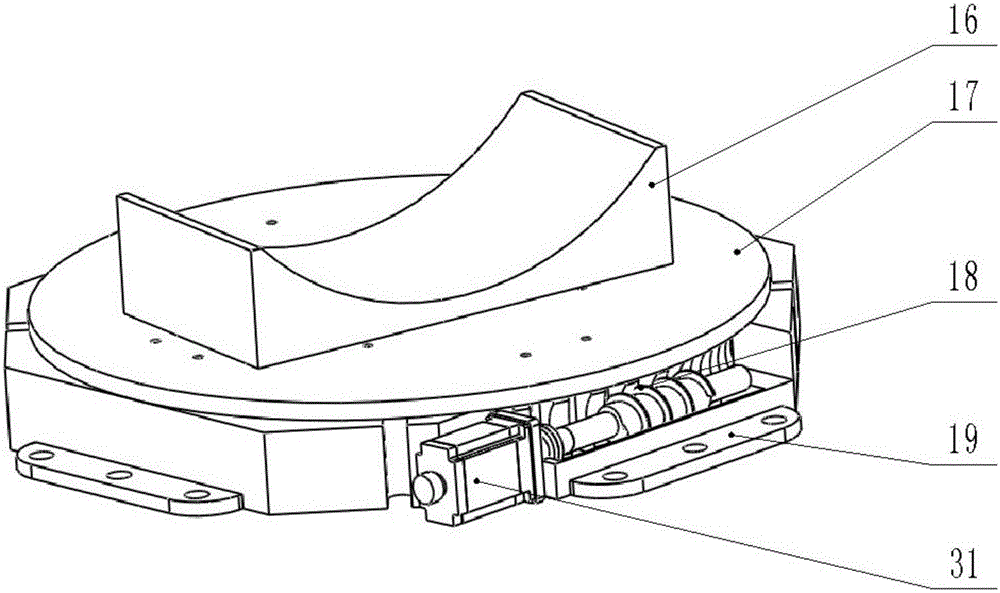

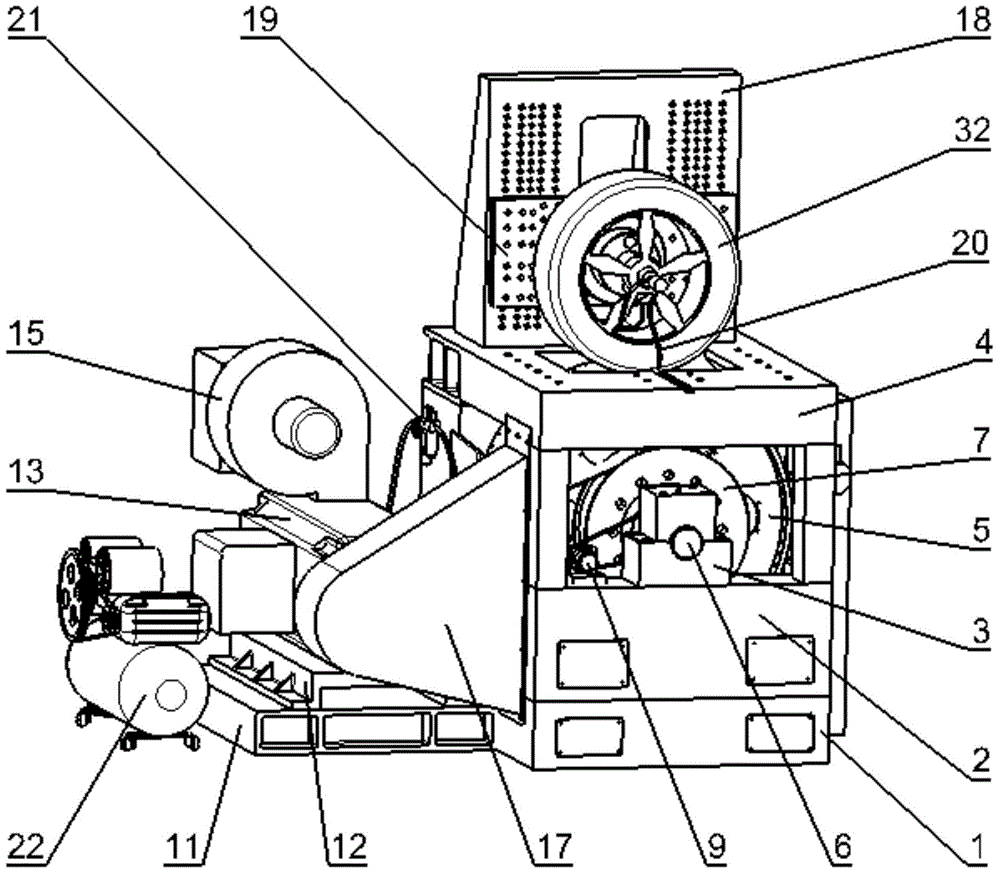

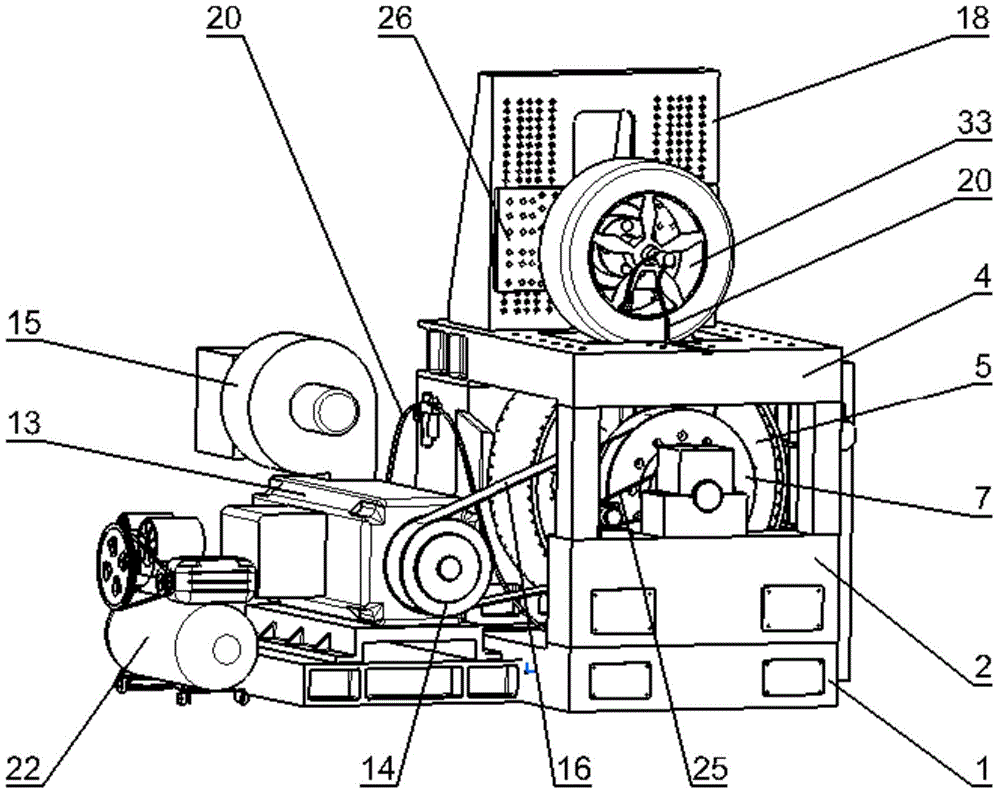

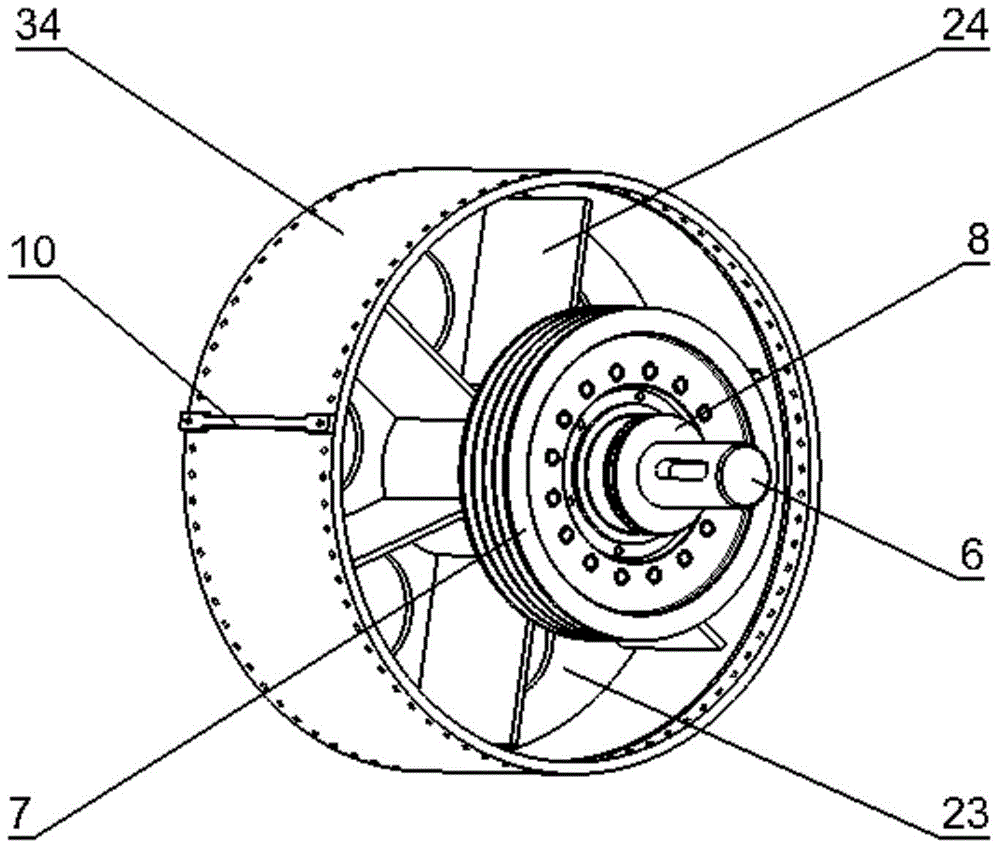

Sectional type low temperature roller cut tobacco drying equipment

ActiveCN101611921AAchieve processing strengthAchieve uniformityTobacco preparationEngineeringSEMI-CIRCLE

The invention discloses a sectional type low temperature roller cut tobacco drying equipment, comprising a barrel body, a feeding cover, a discharging cover and moisture exhaust pipelines, wherein, the feeding cover and the discharging cover are arranged on the two ends of the equipment and are respectively connected with a moisture exhaust pipeline on the equipment; the inner barrel wall of the barrel is uniformly distributed with semi-circle pipes and hot wind introducing pipelines; the barrel is internally provided with a cooking plate; wherein, the barrel is a sectional barrel with at least a high temperature zone and a low temperature zone; the barrel body is internally installed with a low hot wind pipeline and a high hot wind pipeline which is contained on the low hot wind pipeline; the two pipes and the barrel body are connected to form a wire spoke which can revolve synchronously; the inlets of the low hot wind pipeline and the high hot wind pipeline are respectively connected with a hot wind heater and an air blower which are externally corresponded to the inlets; the cooking plate is arranged in radial direction in the high hot wind pipeline. As the barrel temperature and the hot wind temperature can be respectively adjusted and controlled sectionally, the adjustment of height difference of the temperature of two-section barrel body and hot wind temperature and the cross current between hot wind and materials can achieve different processing strength and uniformity of cut tobacco drying, and can improve entirely comprehensive aesthetic quality and processabilityresistance of tobacco.

Owner:QINHUANGDAO TOBACCO MACHINERY

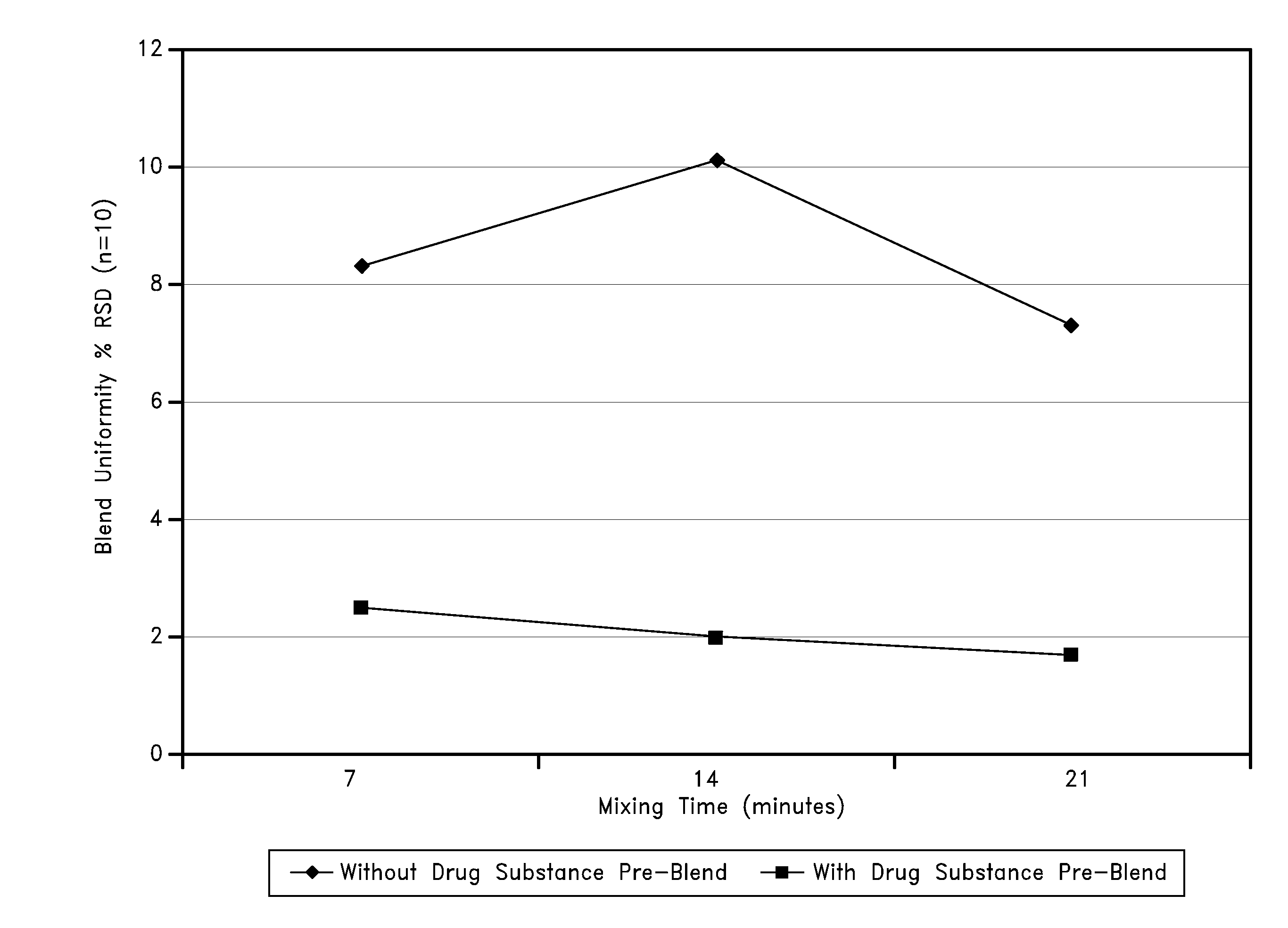

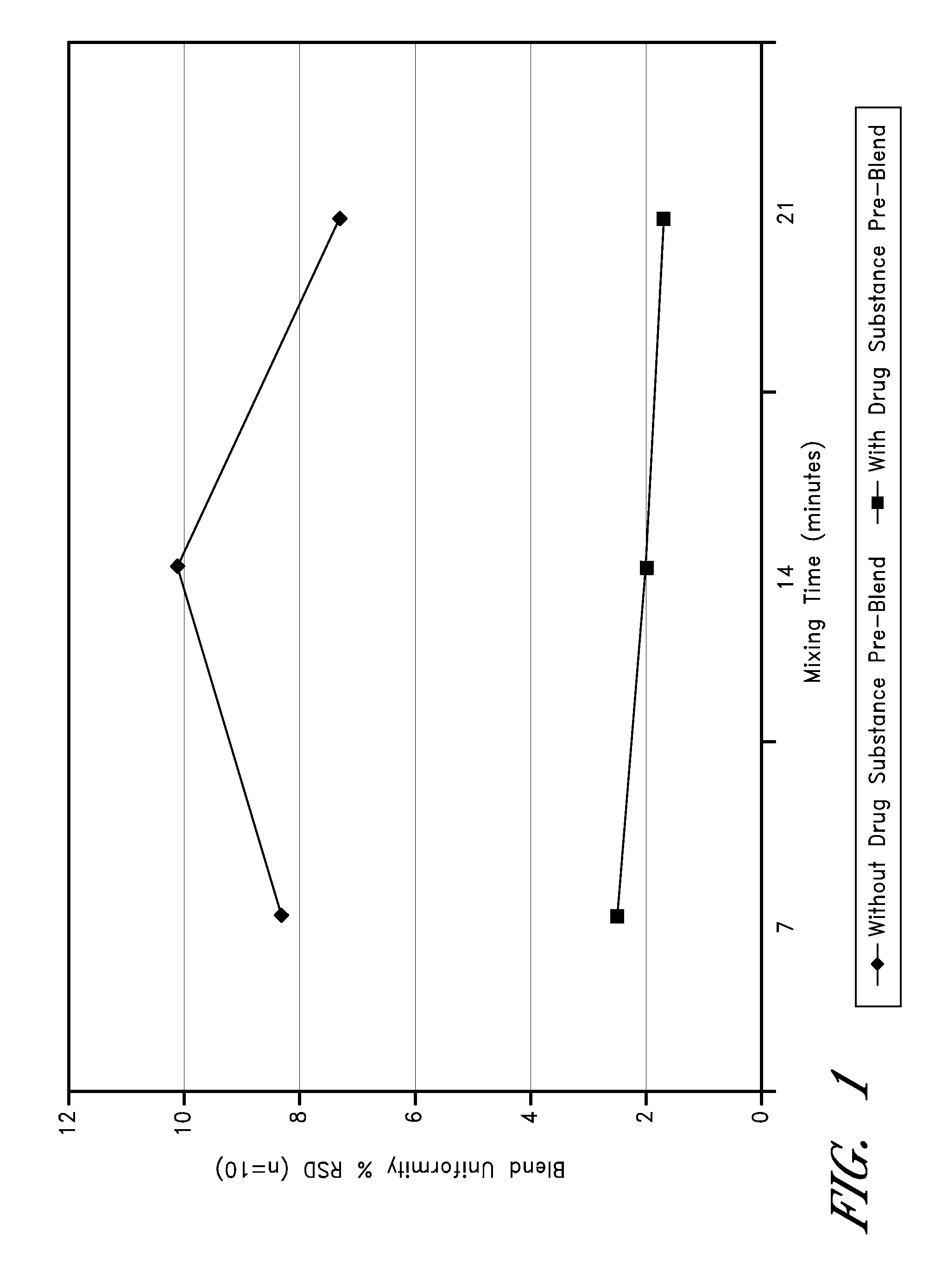

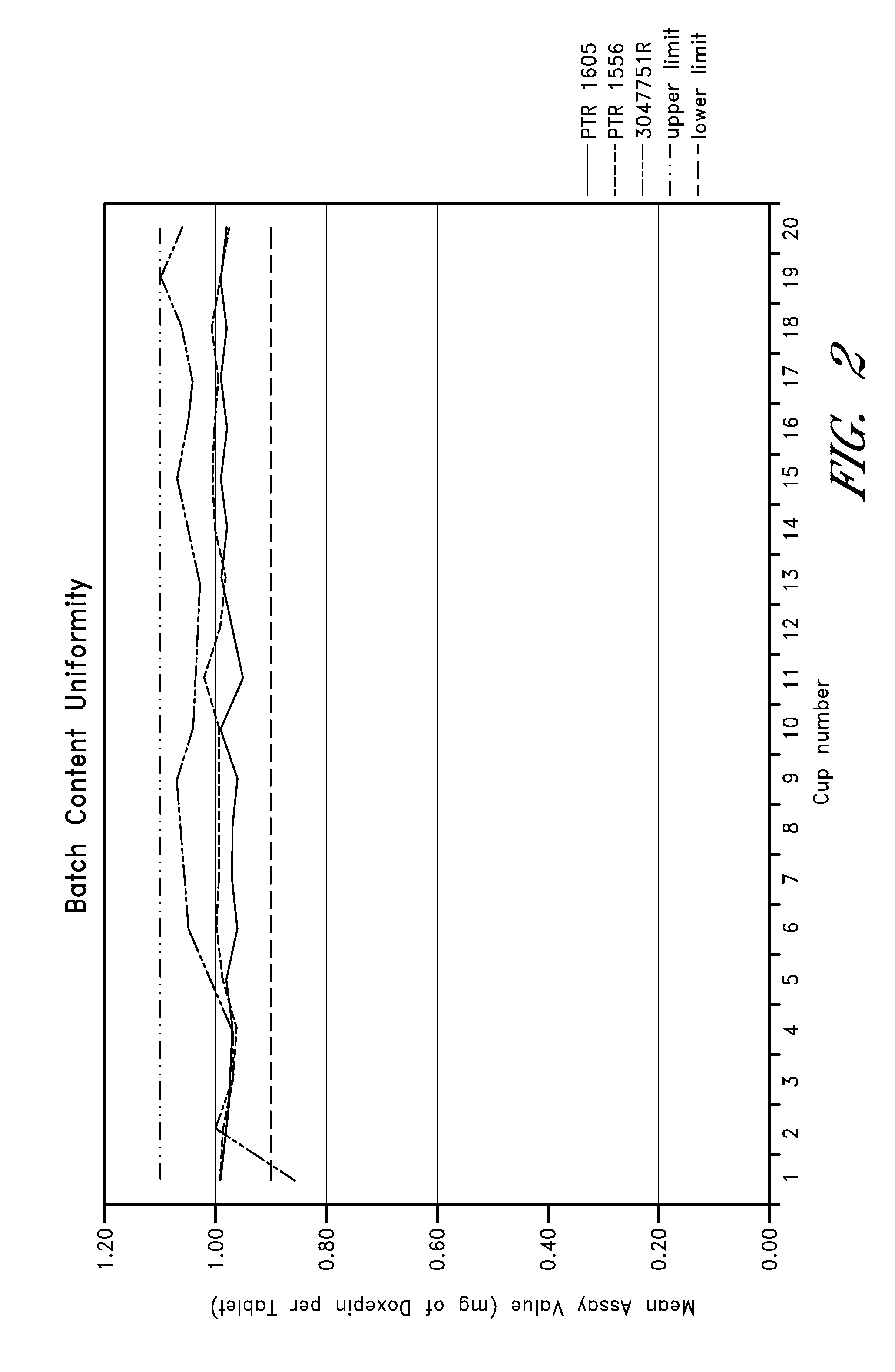

Low-dose doxepin formulations and methods of making and using the same

InactiveUS20090074862A1Dissolve fastEasy to swallowOrganic active ingredientsBiocideMedicinePharmaceutical formulation

The invention disclosed herein generally relates to low-dose oral doxepin pharmaceutical formulations and the use of these formulations to promote sleep.

Owner:SOMAXON PHARMA

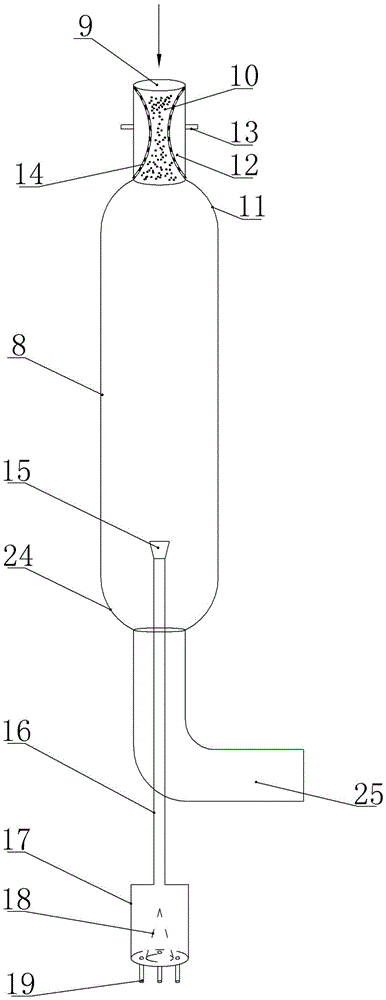

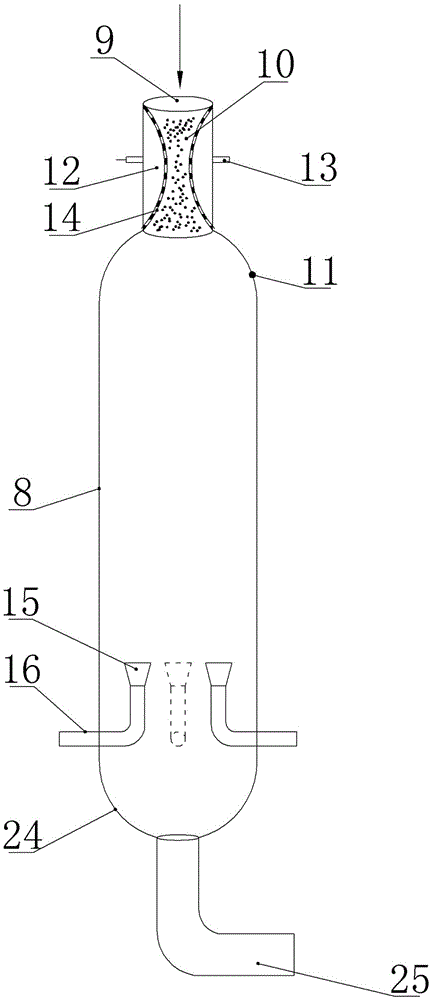

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

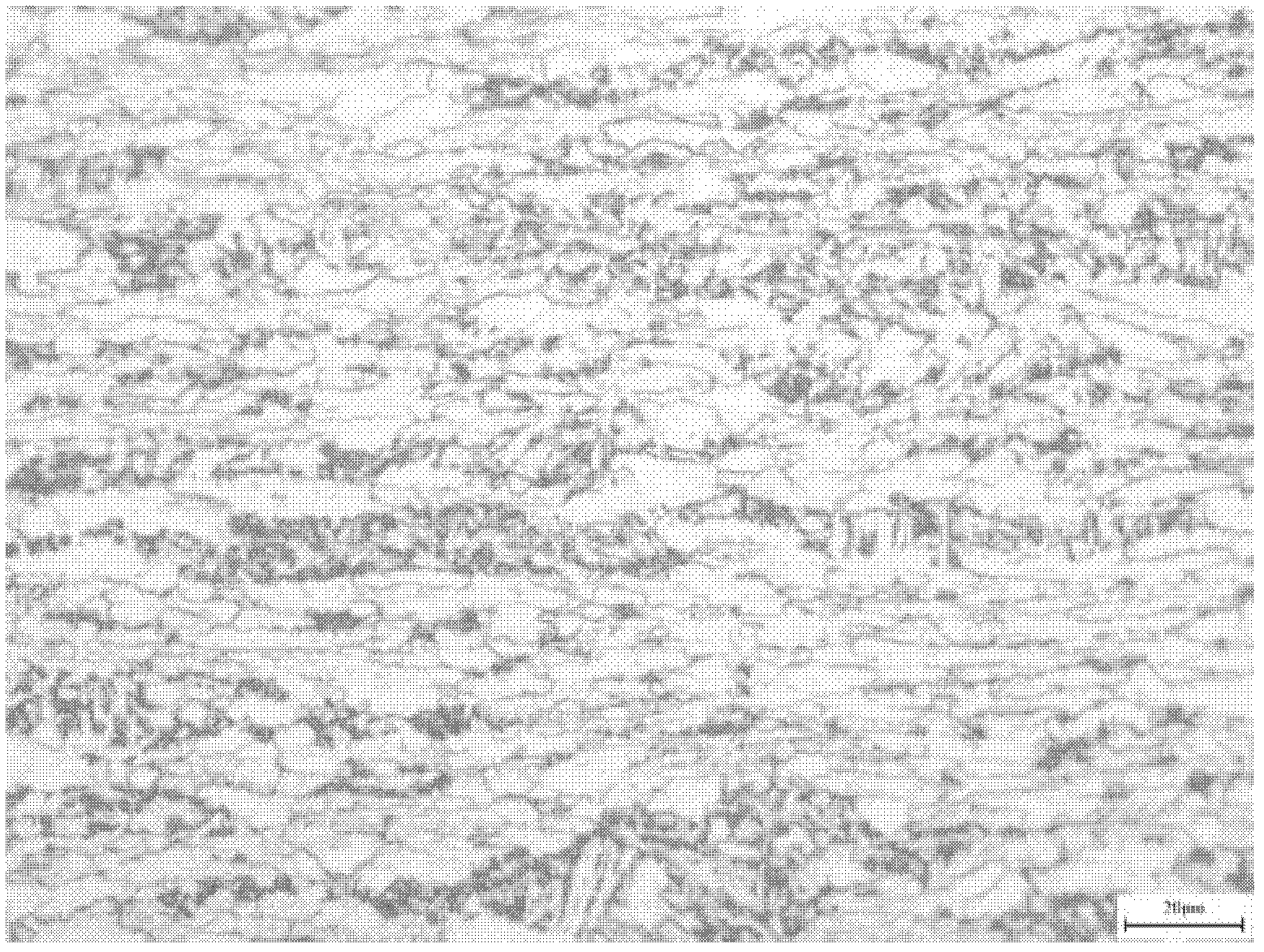

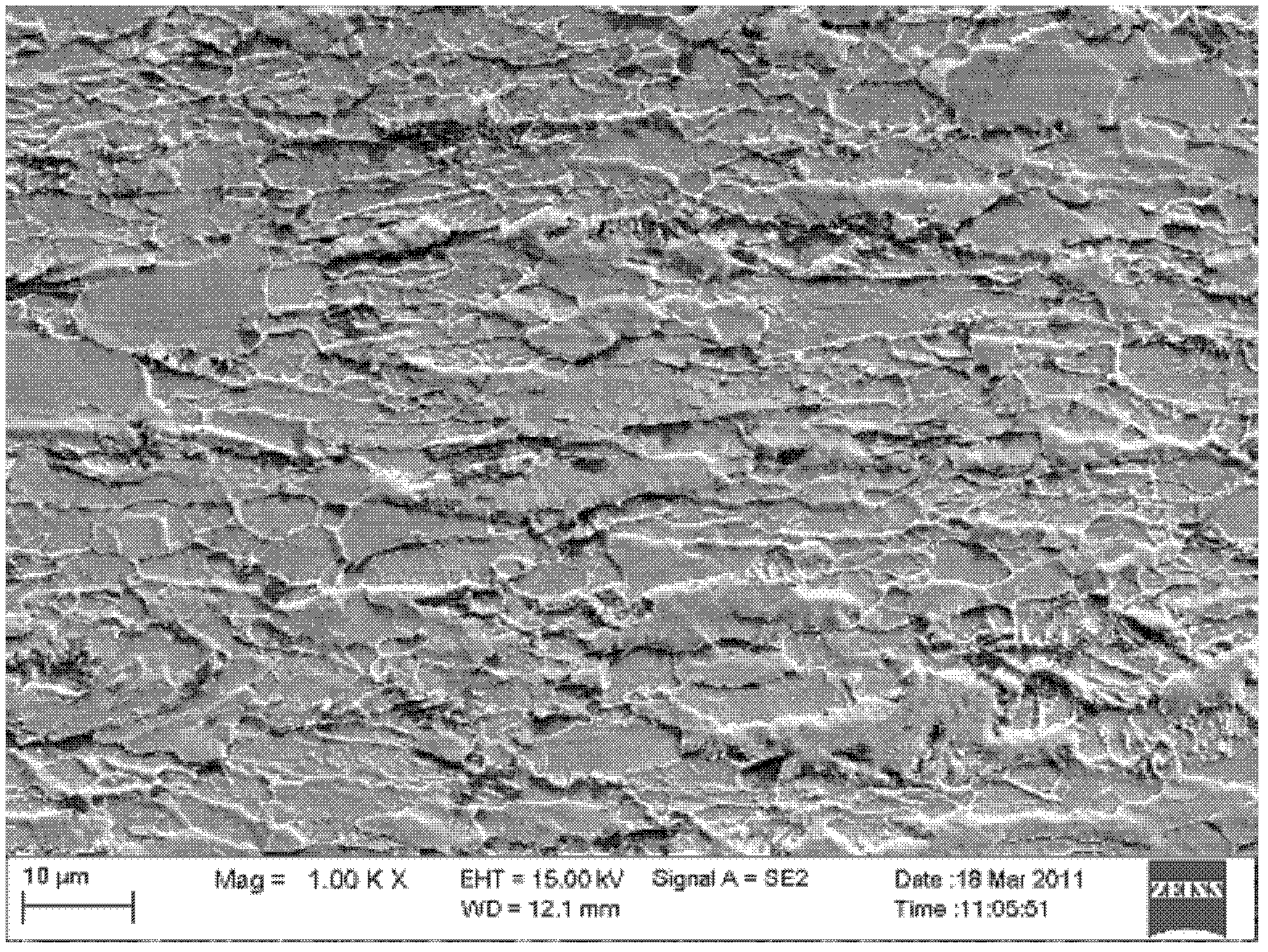

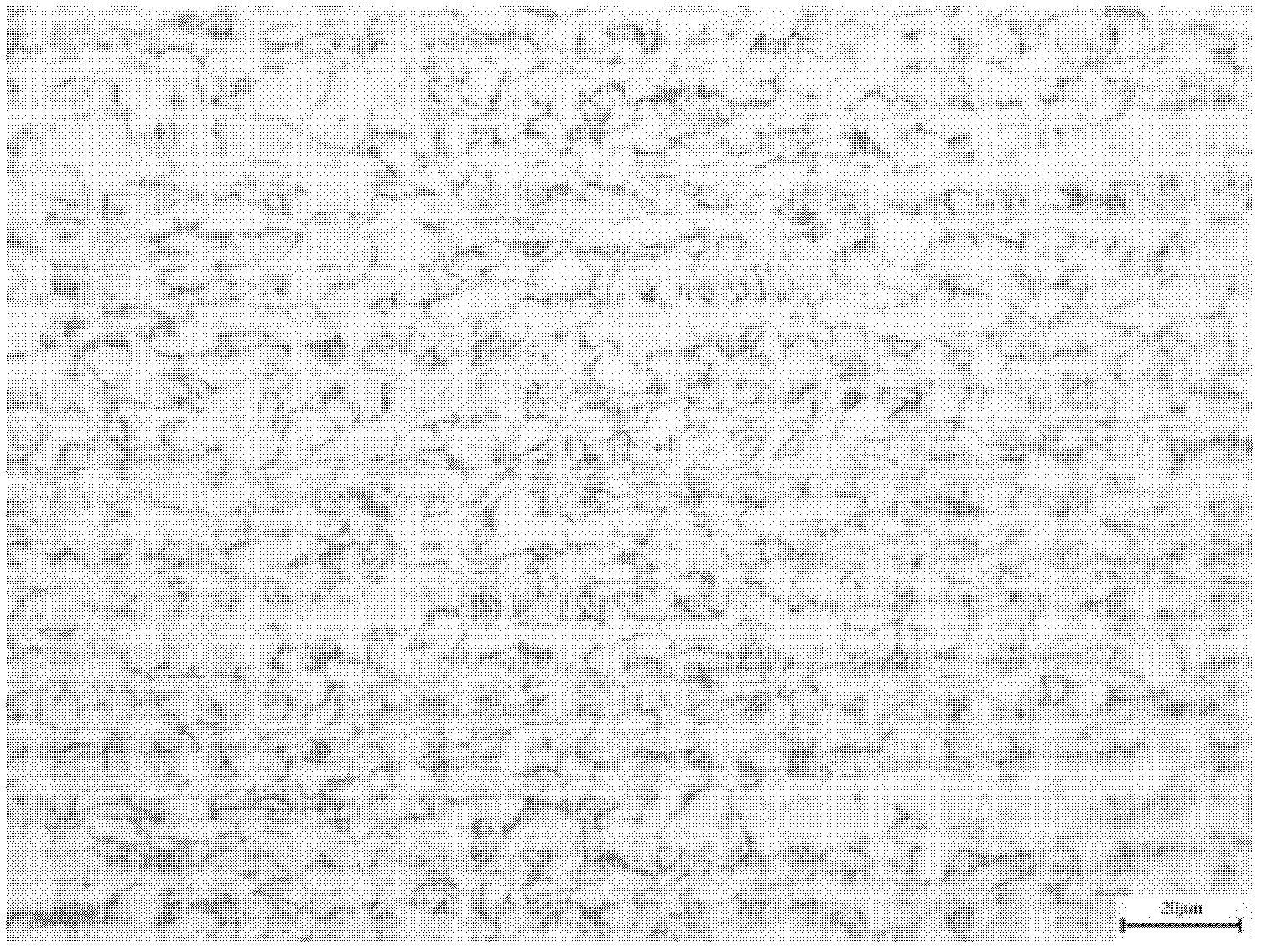

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

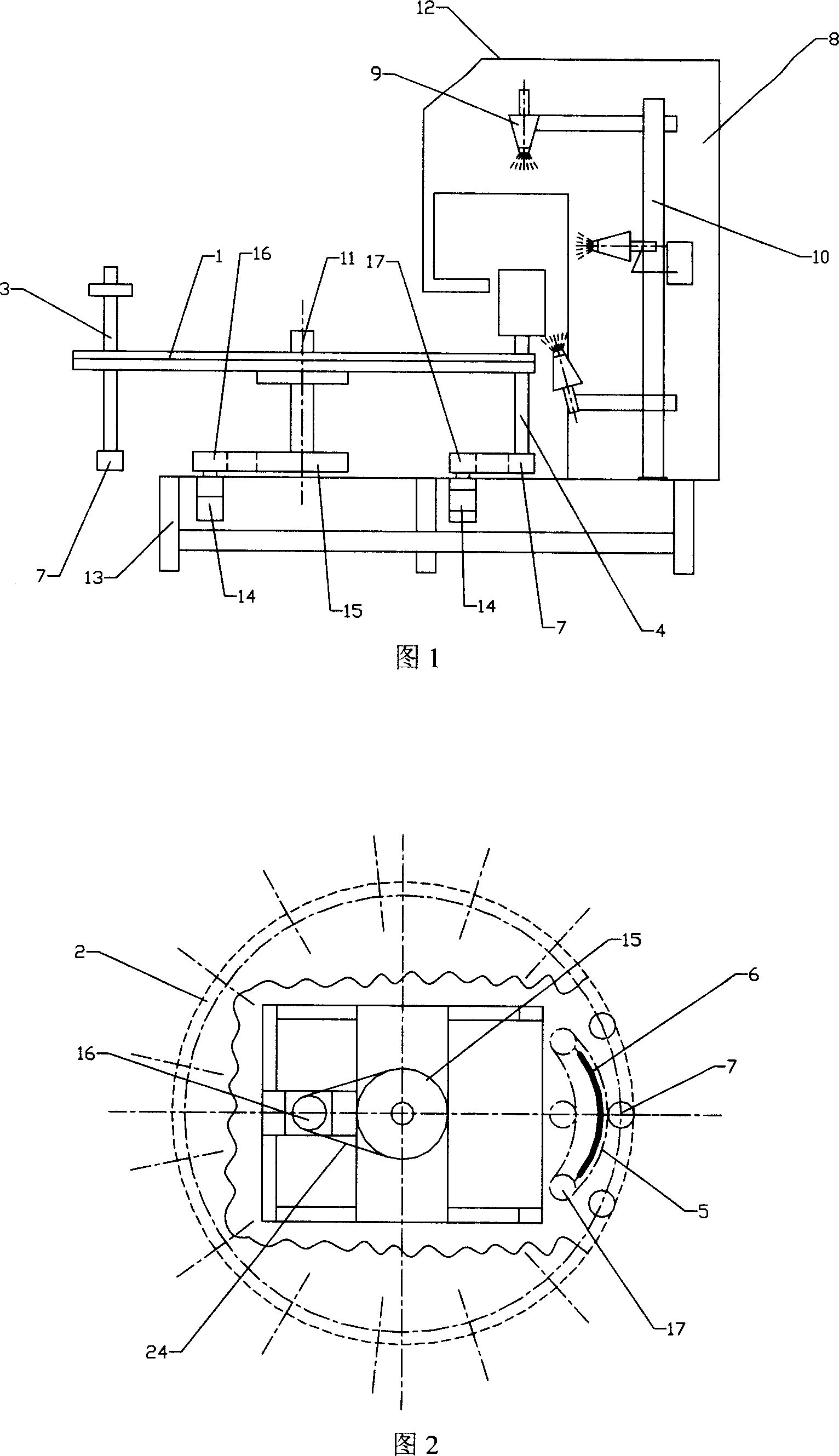

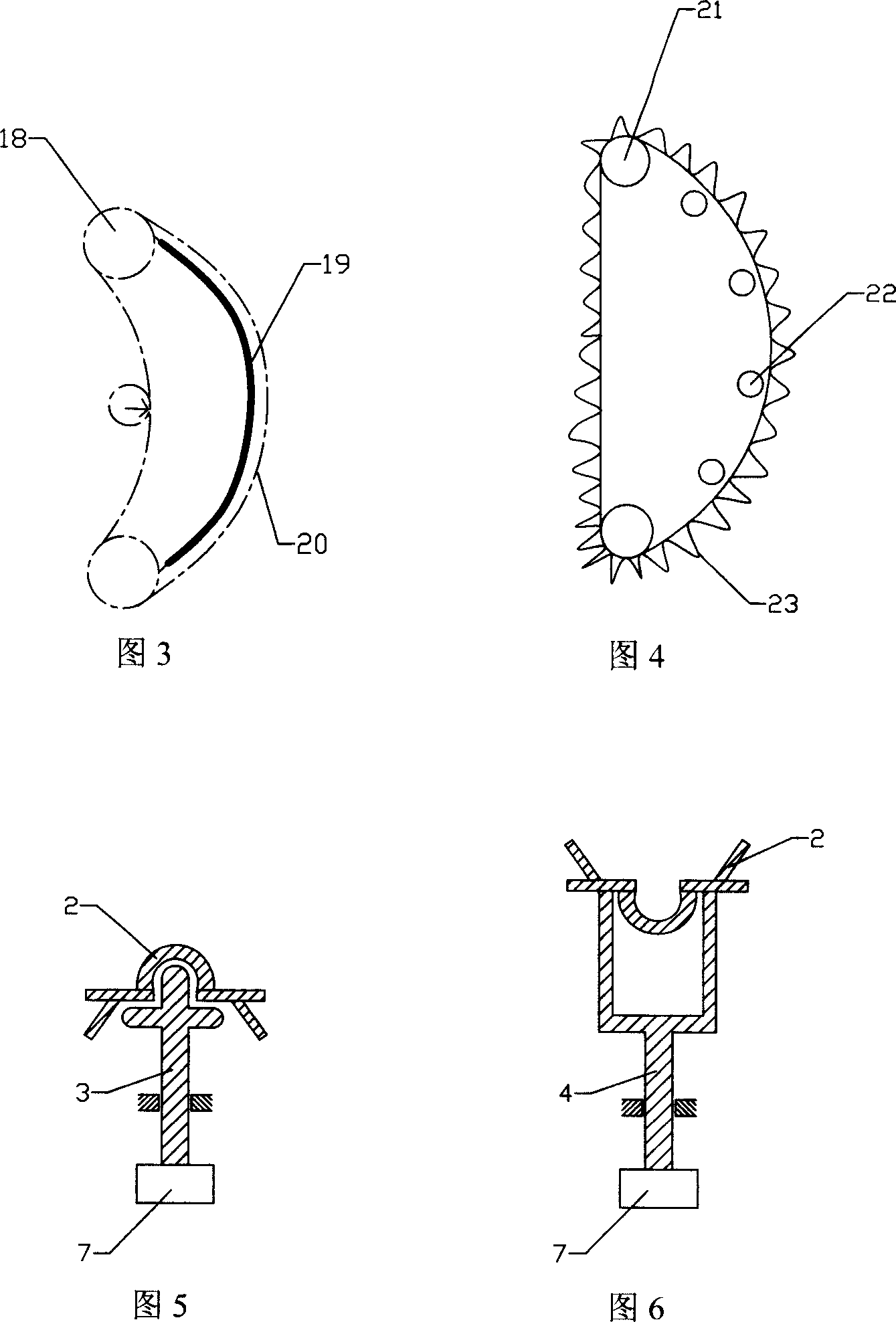

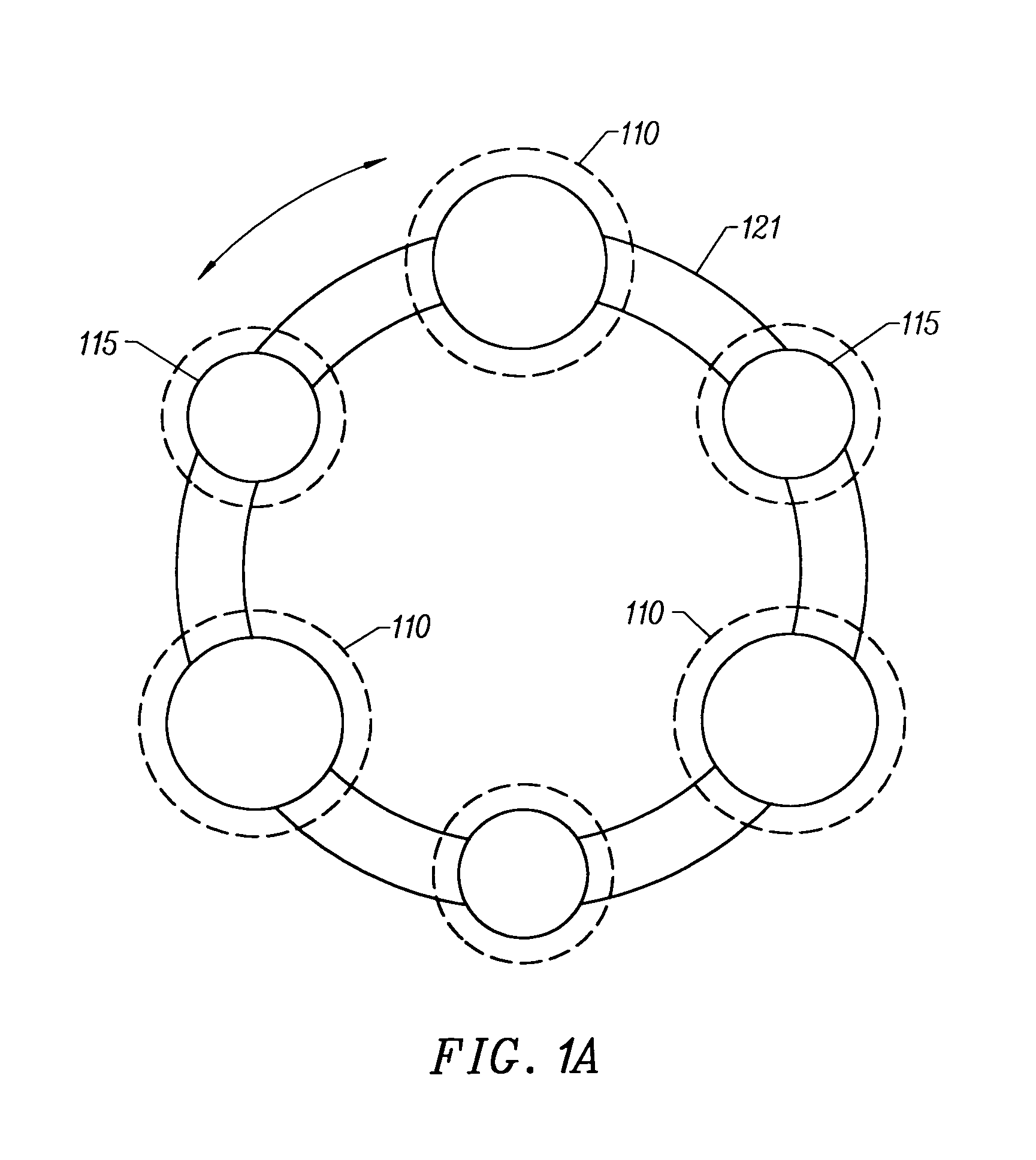

Spray technology of high voltage insulator surface coating and its spray device

ActiveCN100998974AAchieve uniformitySimple structureLiquid surface applicatorsSpraying apparatusEngineeringHigh pressure

A technology for spraying a dirt sparkle-resistant film layer on the surface of high-voltage insulator includes such steps as fixing several rotary supporters on the edge of a rotary disc, fixing an insulator to one rotary supporter, and driving said supporter to rotate by drive mechanism when the high-voltage insulator comes in a spraying room while spraying paint from high-pressure spray gun onto the surface of the insulator. Its apparatus is also disclosed.

Owner:FUZHOU UNIV +2

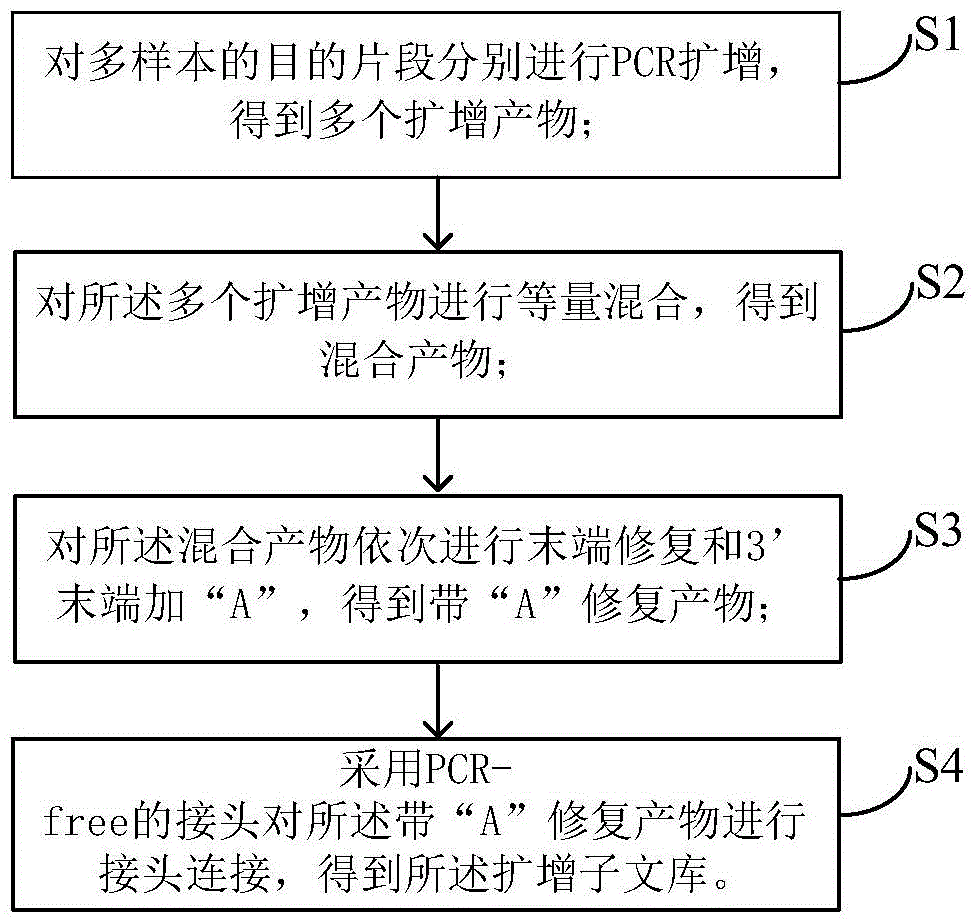

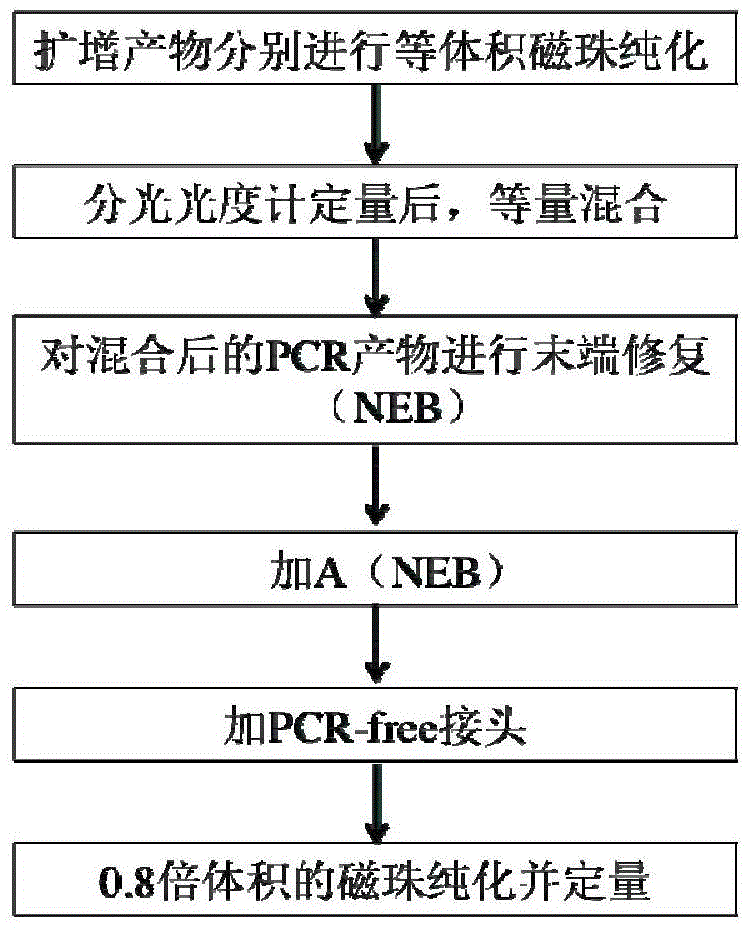

Amplification sublibrary and construction method thereof

InactiveCN104562213AAvoid preferenceAchieve uniformityNucleotide librariesMicrobiological testing/measurementRepeatabilityBiology

The invention provides an amplification sublibrary and a construction method thereof. The construction method comprises the following steps: S1, performing PCR amplification on target fragments of multiple samples to obtain a plurality of amplification products; S2, performing balanced mixing on the amplification products to obtain a mixed product; S3, sequentially performing fragmentation and terminal repairing on the mixed product, and adding A at a terminal 3' of the mixed product to obtain an A-repaired product; S4, jointing the A-repaired product by using a joint of PCR-free to obtain the amplification sublibrary. Through balanced mixing of the amplification products and through joint connection by using the optimized PCR-free, by the construction method, preference generated by PCR as well as chimeras in environmental samples is avoided, so that sequencing data between different samples have good consistency, subsequent clustering analysis and technical repeatability are more reasonable and more accurate, and can more really reflect evolutional relationship between the environmental samples.

Owner:BEIJING NOVOGENE TECH CO LTD

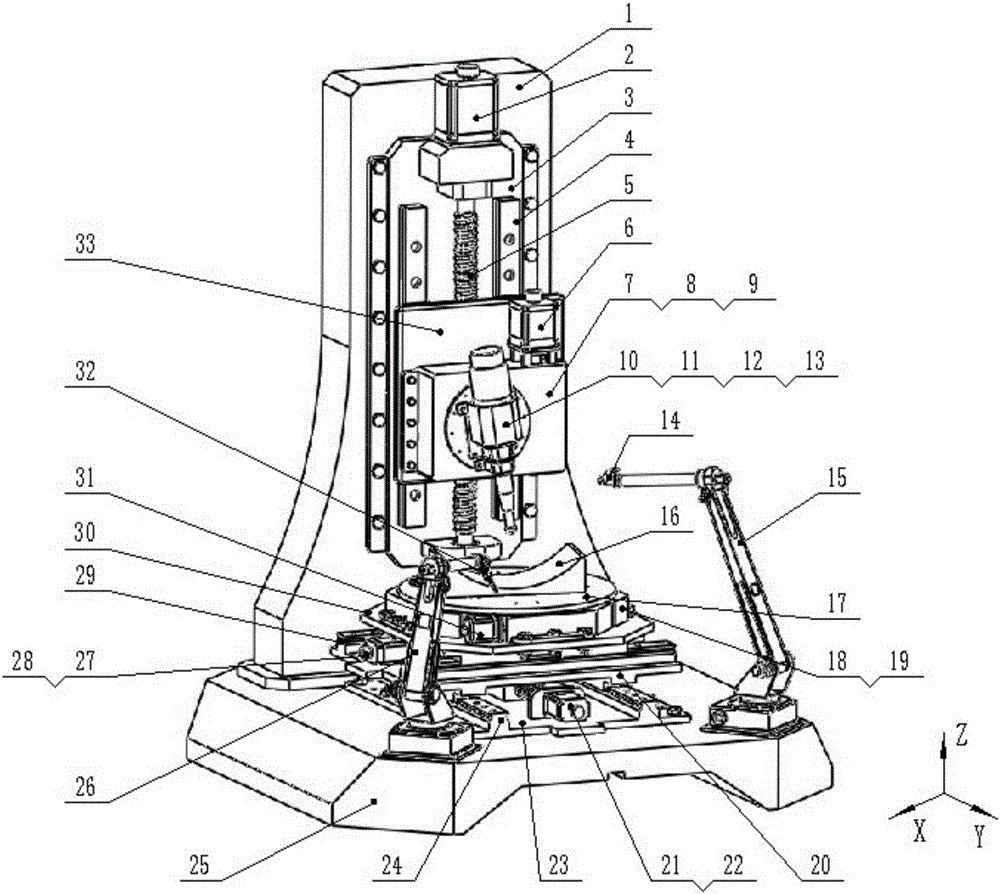

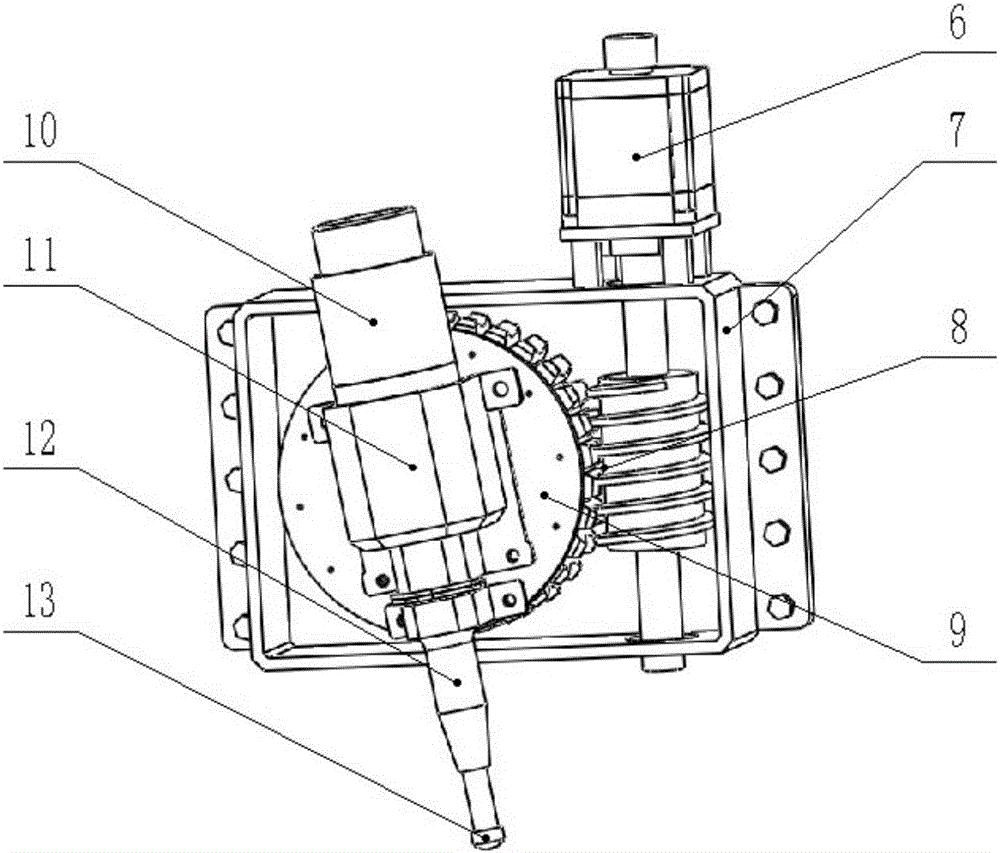

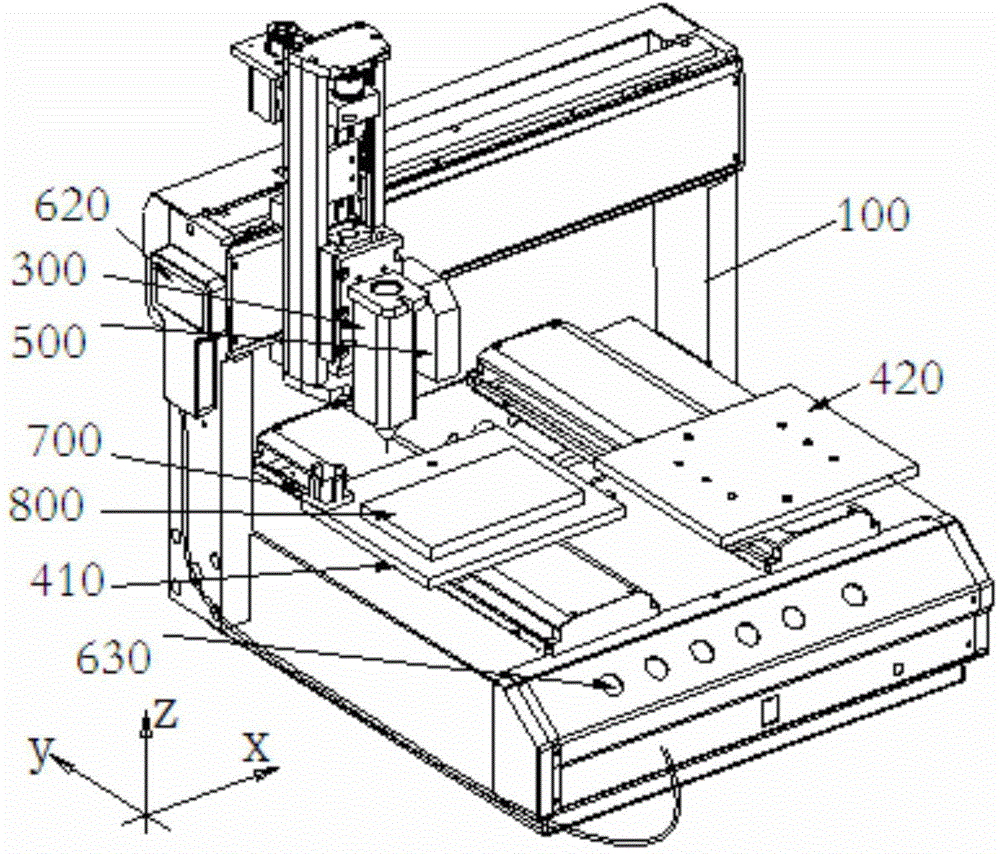

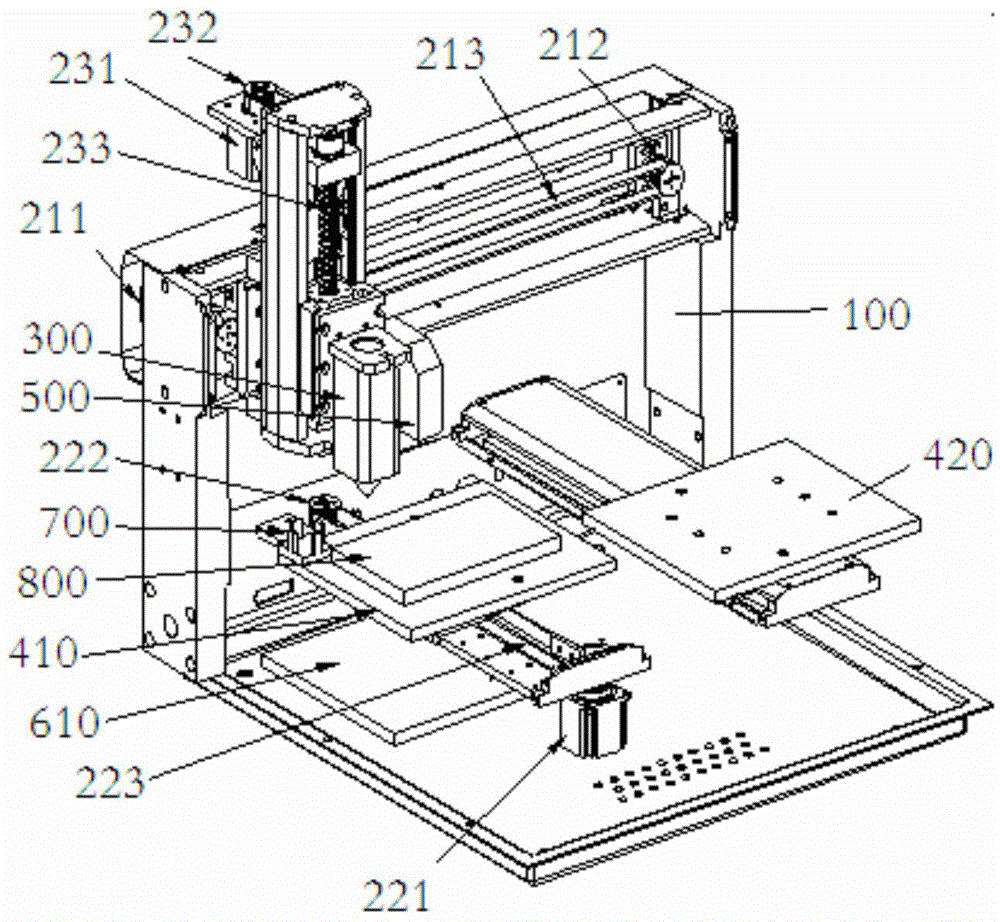

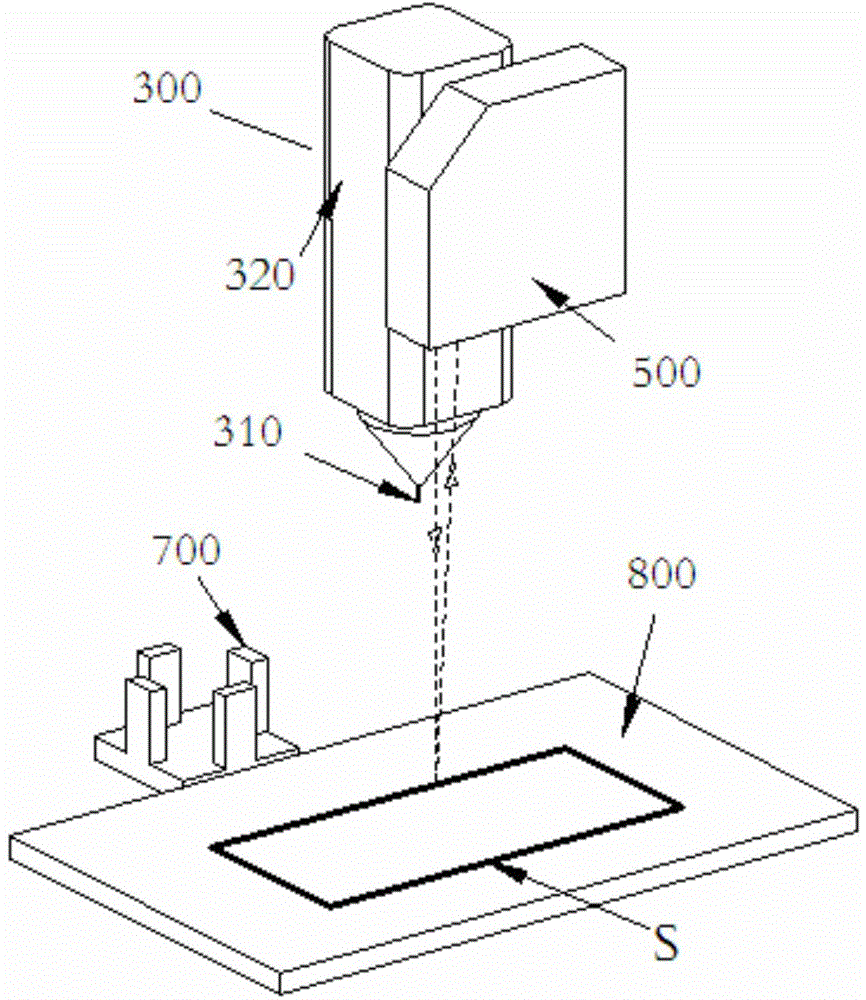

Five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining and using method thereof

ActiveCN106475868AUniform contact stressHigh polishing precisionGrinding carriagesOptical surface grinding machinesUltrasonic vibrationEngineering

The invention discloses a five-axis two-dimensional ultrasonic polishing machine tool for optical curved face machining. The machine tool is composed of a rack, a three-dimensional moving device, a rotary ultrasonic vibration polishing device, a rotary workbench, a polishing liquid ultrasonic atomizing and applying device and an on-line workpiece detection device. When the machine tool is used, the amplitude of the ultrasonic vibration polishing device is obtained according to the calculation formula (please see the formula in the description); five-axis linkage is achieved through a program control system, and the axis of a polishing head is made to always coincide with the normal line of a workpiece polishing point; a 45-degree included angle is kept between the jetting direction of polishing liquid and the normal line of the polishing point. The polishing machine tool has the advantages that ultrasonic energy transmission is concentrated, the contact stress between the surface of the polishing head and the surface of a workpiece is uniform, the polishing precision is high, the removal rate in the polishing process is high, the utilization rate of the polishing liquid is high, and the polishing precision of the workpiece can be detected on line.

Owner:NORTHEASTERN UNIV

Functional diatomite putty powder and preparation method thereof

InactiveCN105949863AImprove efficiencyShorten the timeFilling pastesInorganic pigmentsMaterials science

The invention relates to putty powder, in particular to functional diatomite putty powder and a preparation method thereof, wherein the putty powder includes in percent by weight: 10-50% of high-temperature activated diatomite, 5-30% of an inorganic binder, 30-70% of an inorganic filler, 0.01-2% of a functional aid, 0.1-5% of an inorganic pigment, 0.5-5% of an organic binder, and 0.5-5% of an organic aid. The functional diatomite putty powder meets the related standard requirements of putty powder and diatomite, and has qualified constructability and functionality, namely having standard-meeting properties such as humidity regulation, formaldehyde clarifying performance, long duration of formaldehyde purifying performance, mold-proof performance, and mold durability.

Owner:CENT SOUTH UNIV +1

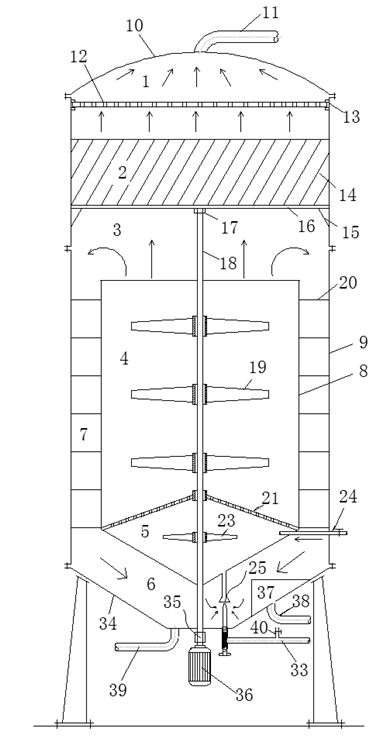

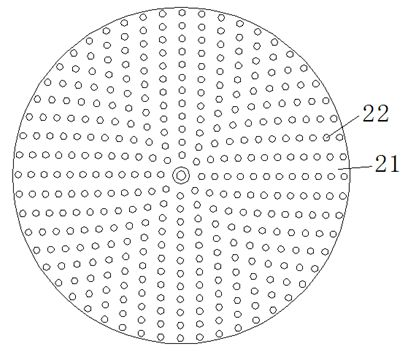

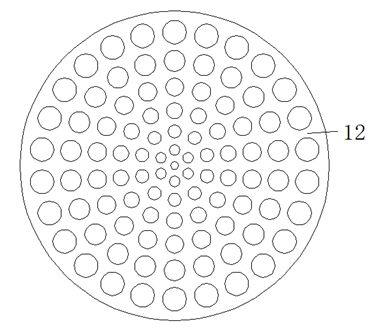

Integrated water purifying and processing equipment

ActiveCN102001769AGuaranteed concentrationReduce dosageMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSludge

The invention discloses integrated water purifying and processing equipment. The equipment comprises an external barrel and an internal barrel, wherein a convex head is arranged at the top of the external barrel; a water outlet is formed in the center of the convex head; a conical bottom plate is arranged at the bottom of the external barrel; a mixer motor and a speed reducer are arranged in the center of the bottom of the conical bottom plate; the speed reducer is provided with a stirring shaft; the side wall of the conical bottom plate is provided with a dredge pipe; an escape pipe is arranged at the bottom of the conical bottom plate; the inner side of the external barrel is divided into a clean water zone, an inclined tube settling zone, a mud and water separating zone, a secondary cluster flocculation zone, a primary flocculation reaction zone and a mud collection zone in turn from top down; a sludge concentrating zone is arranged between the internal barrel and the external barrel; the equipment is provided with a coagulant quick coagulation device and a sludge hydraulic automatic backflow device to keep the concentration of the sludge in the reaction zone stable; the sludge concentrating zone is provided with a spiral bevel plate to efficiently concentrate the sludge; and the clean water zone is provided with a water collecting plate to realize pressure effluent. The equipment has a simple structure, compact layout and high space utilization rate, is convenient to operate, and is suitable for clarifying tap water in middle-sized and small cities and purifying industrial water by primarily removing turbidity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

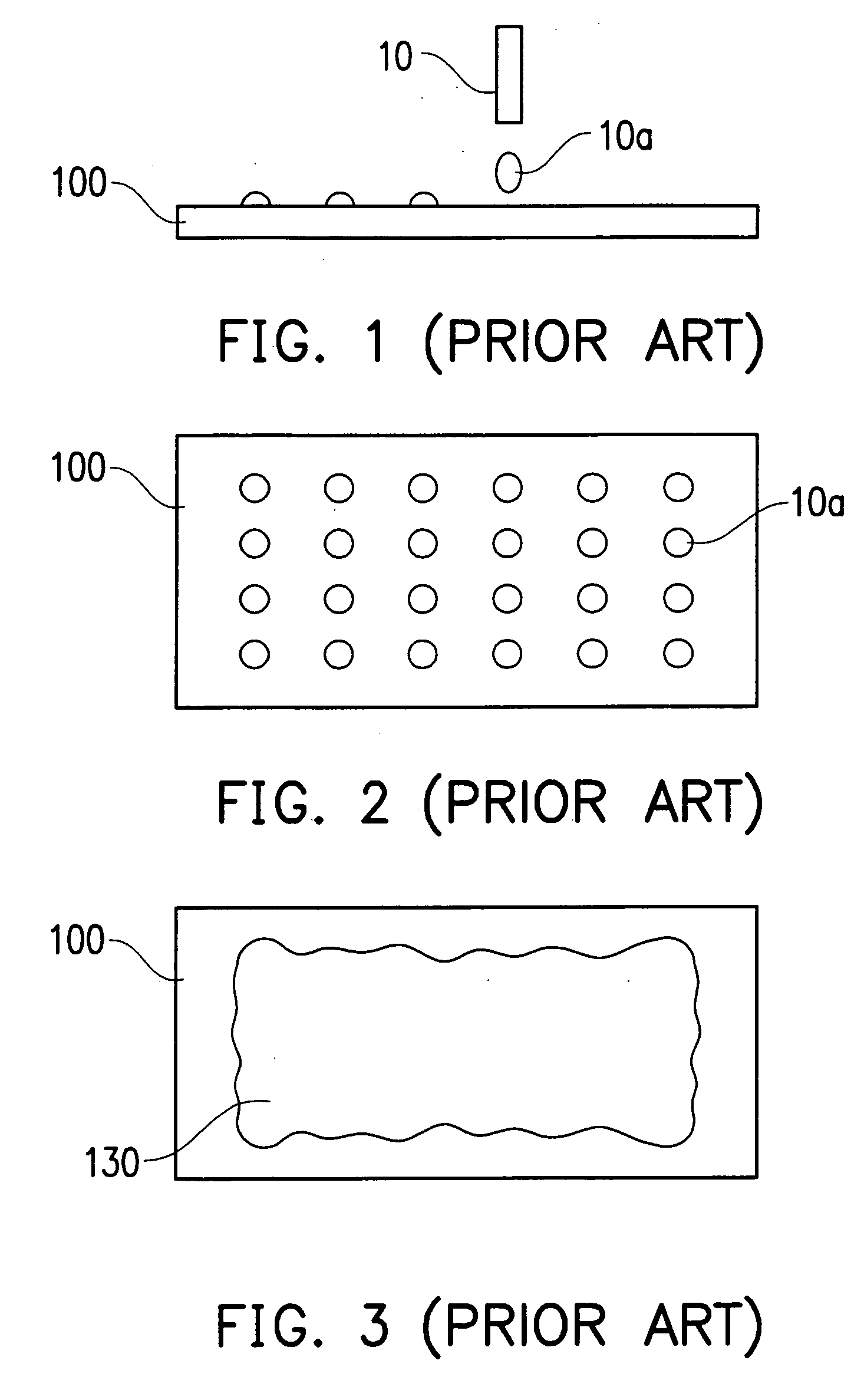

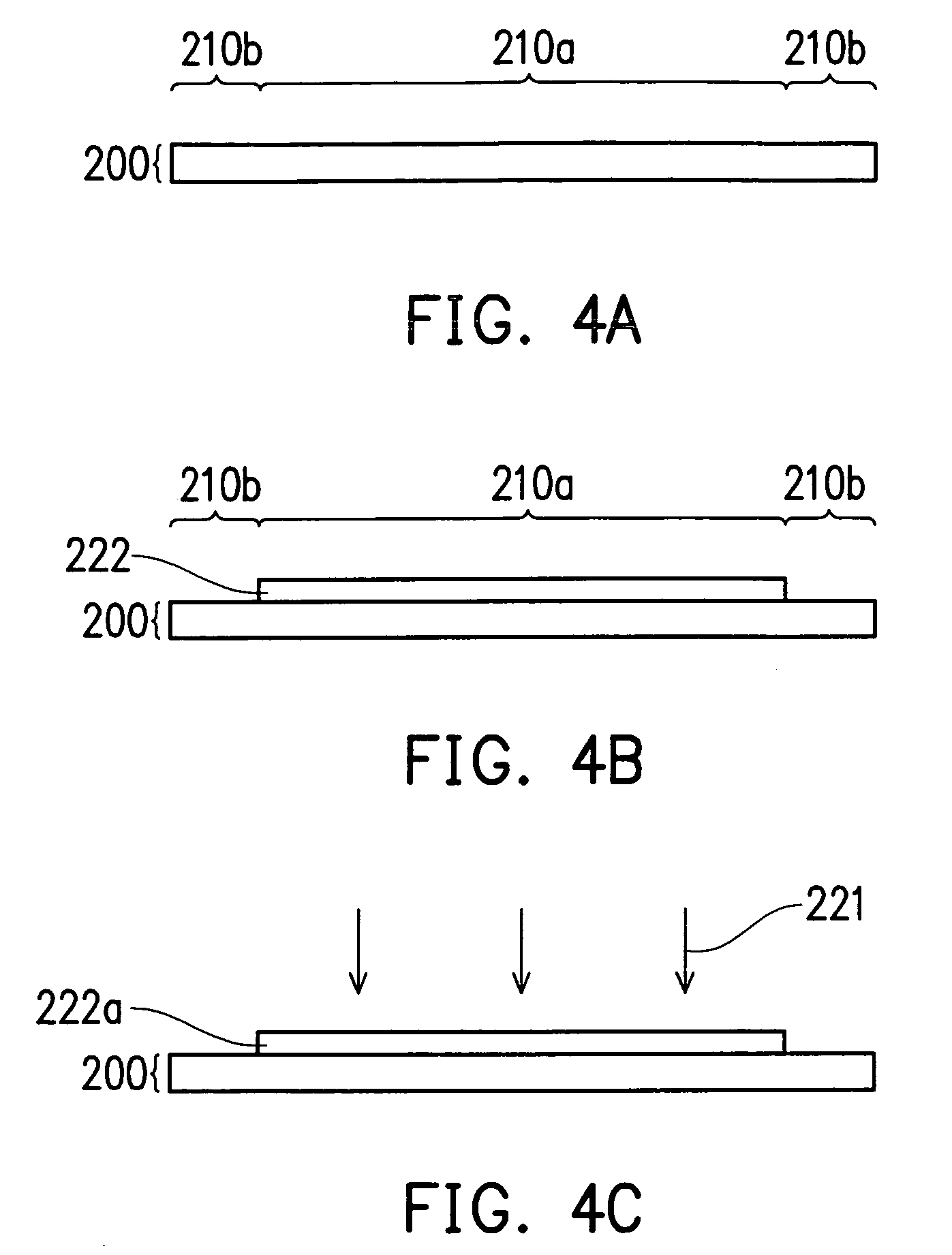

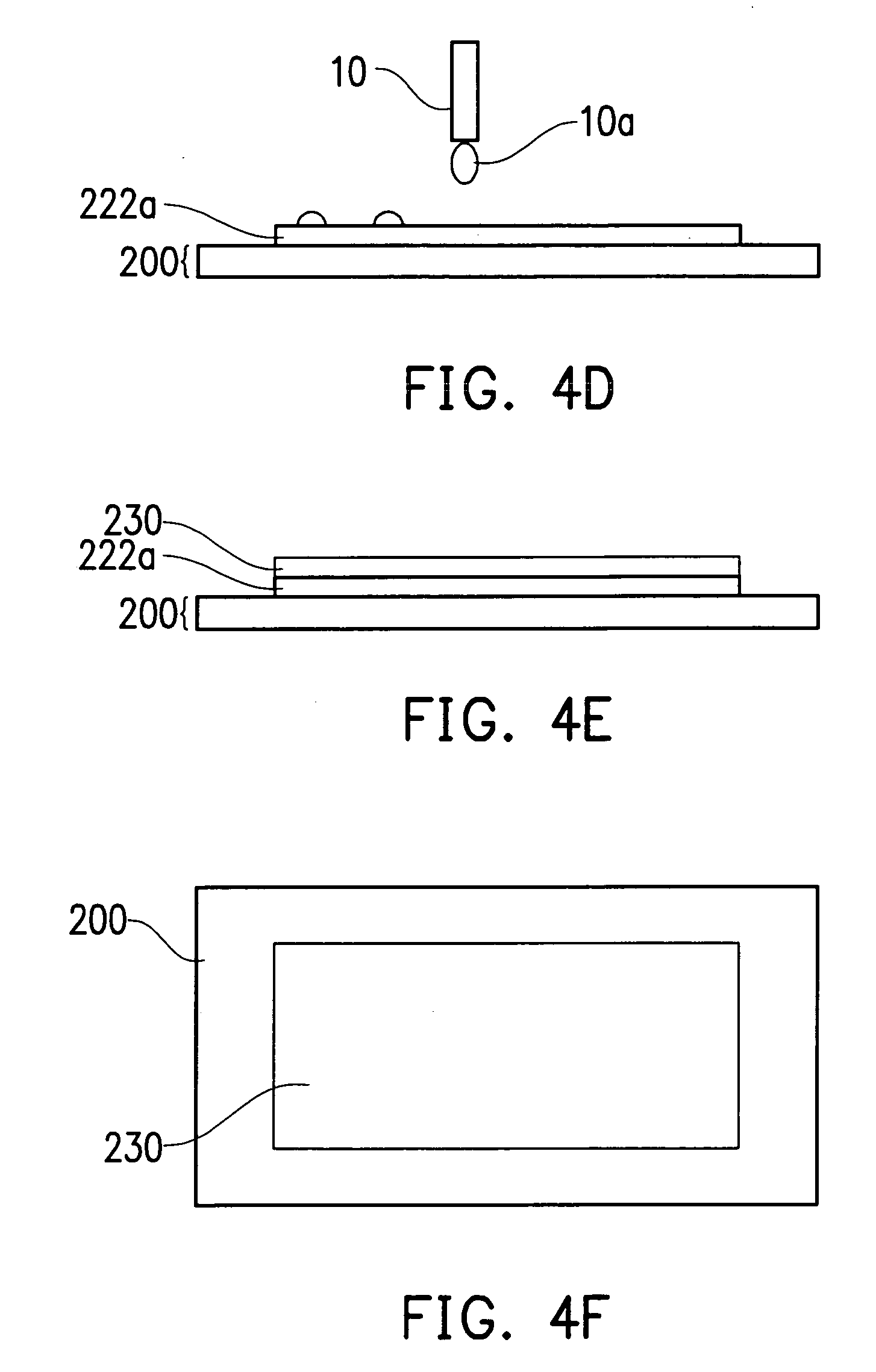

Substrate structure of liquid crystal display and method of forming alignment layer

InactiveUS20060172091A1Uniform layersImprove film propertiesLiquid crystal compositionsRadiation applicationsLiquid-crystal displayWater layer

Owner:AU OPTRONICS CORP

Glue dispensing machine and glue dispensing position measuring method

InactiveCN104874522AResolve discontinuityAchieve uniformityLiquid surface applicatorsMeasurement devicesEngineeringMechanical engineering

The invention discloses a glue dispensing machine and a glue dispensing position measuring method. A height measuring mechanism is mounted on a glue dispensing mechanism of the glue dispensing machine and is used for measuring workpiece thickness, and an operator can set a point Z according to height data measured by the height measuring mechanism without moving the height of a needle manually, so that the problem of discontinuous glue dispensing caused by deformation degree of a to-be-glued workpiece can be solved, and uniformity and continuity in glue dispensing are achieved.

Owner:SHENZHEN TINNO WIRELESS TECH

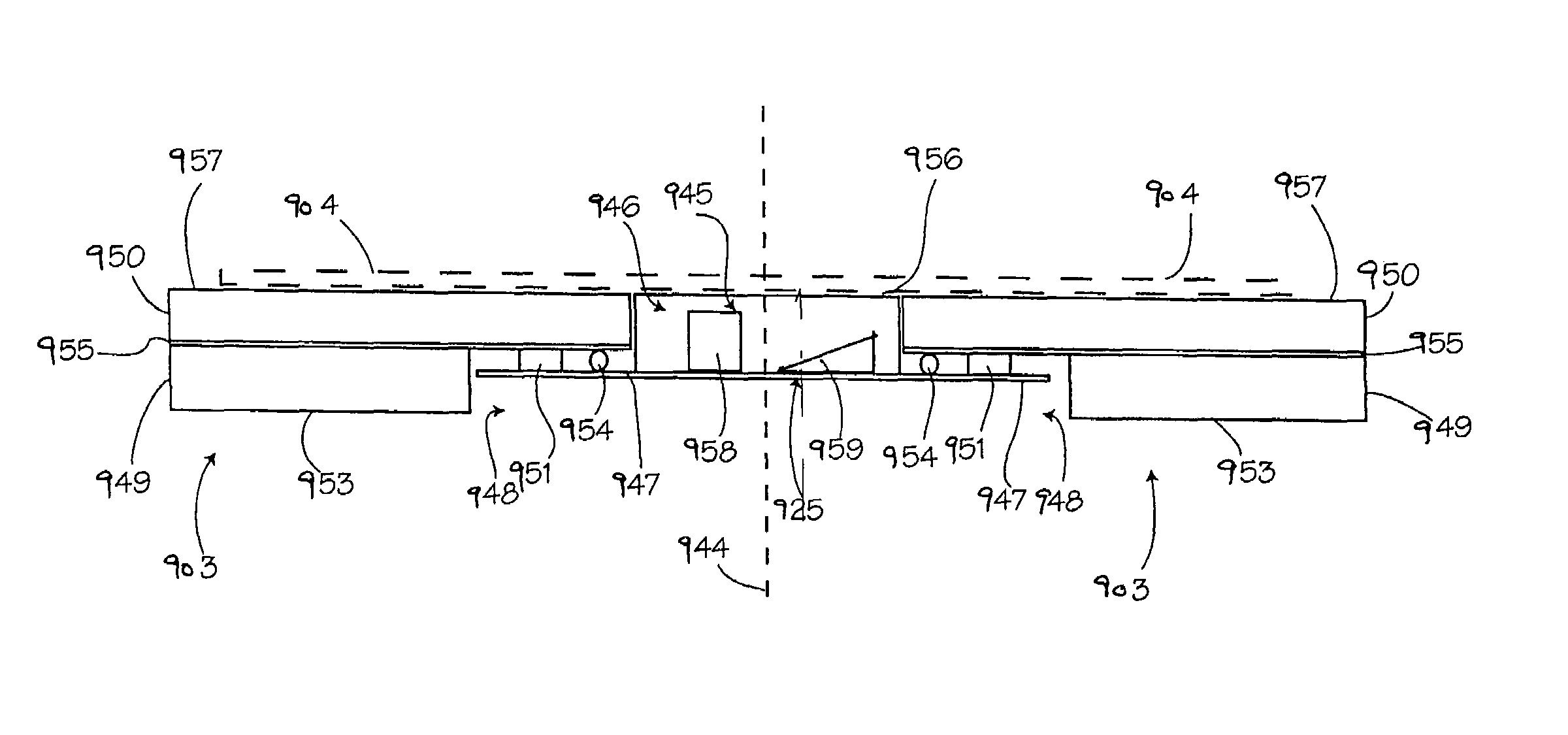

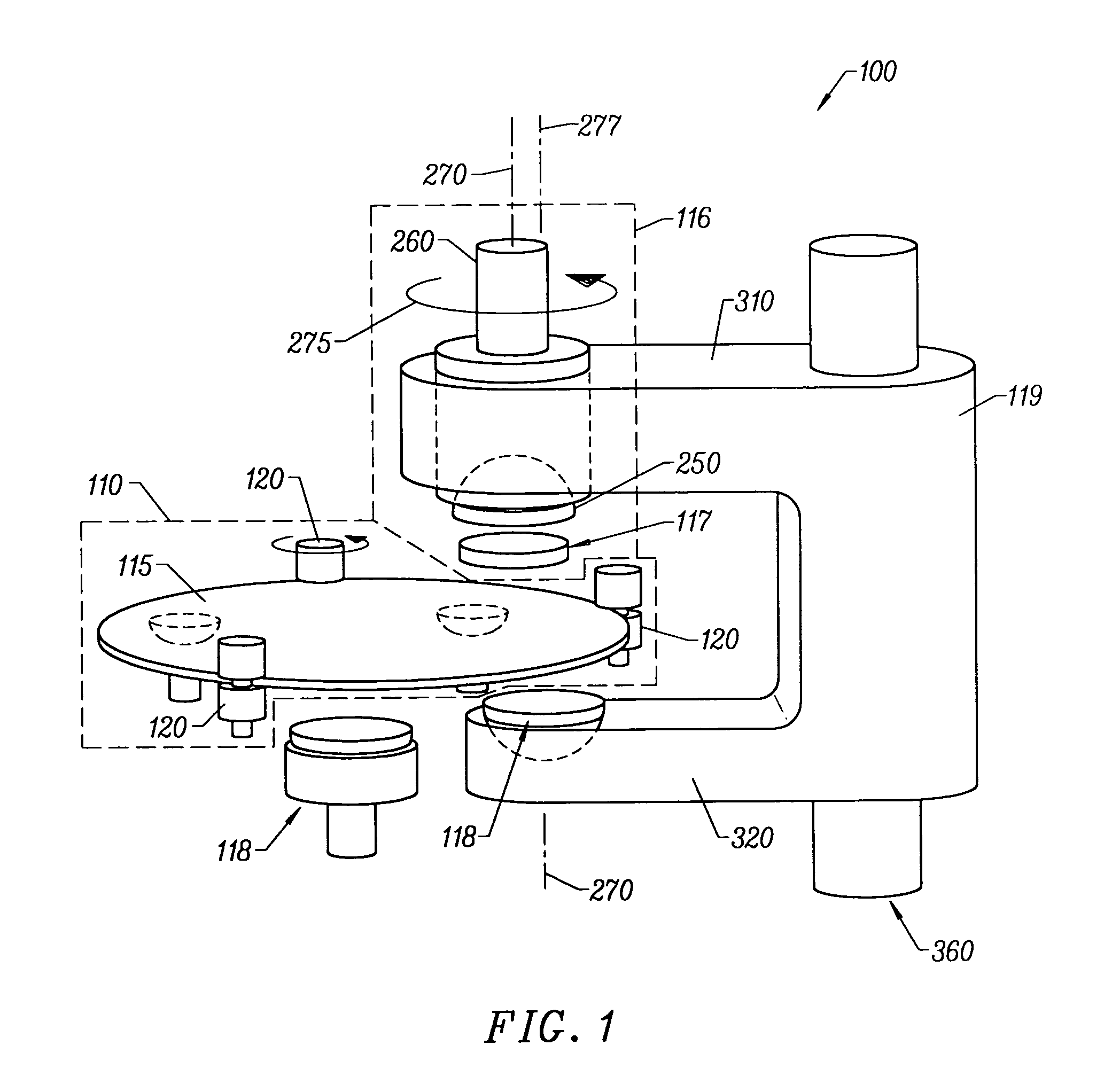

In situ feature height measurement

InactiveUS6976901B1Achieve uniformityPolishing machinesRevolution surface grinding machinesHeight differenceLight intensity

Embodiments of the invention provide methods and apparatus for in situ feature height measurement of an object being planarized. In one embodiment, a method of planarizing an object comprises polishing a surface of the object to be planarized using a polishing pad having a cavity; and directing an incident light from the cavity of the polishing pad to optically measure feature heights of surface features on the surface of the object to obtain measurement data during the polishing of the surface using the polishing pad. The feature heights are relative height differences of the features measured by directing the incident light at the surface of the object from the cavity and observing a reflected light intensity of a reflected light from the features on the surface to the cavity.

Owner:REVASUM INC +1

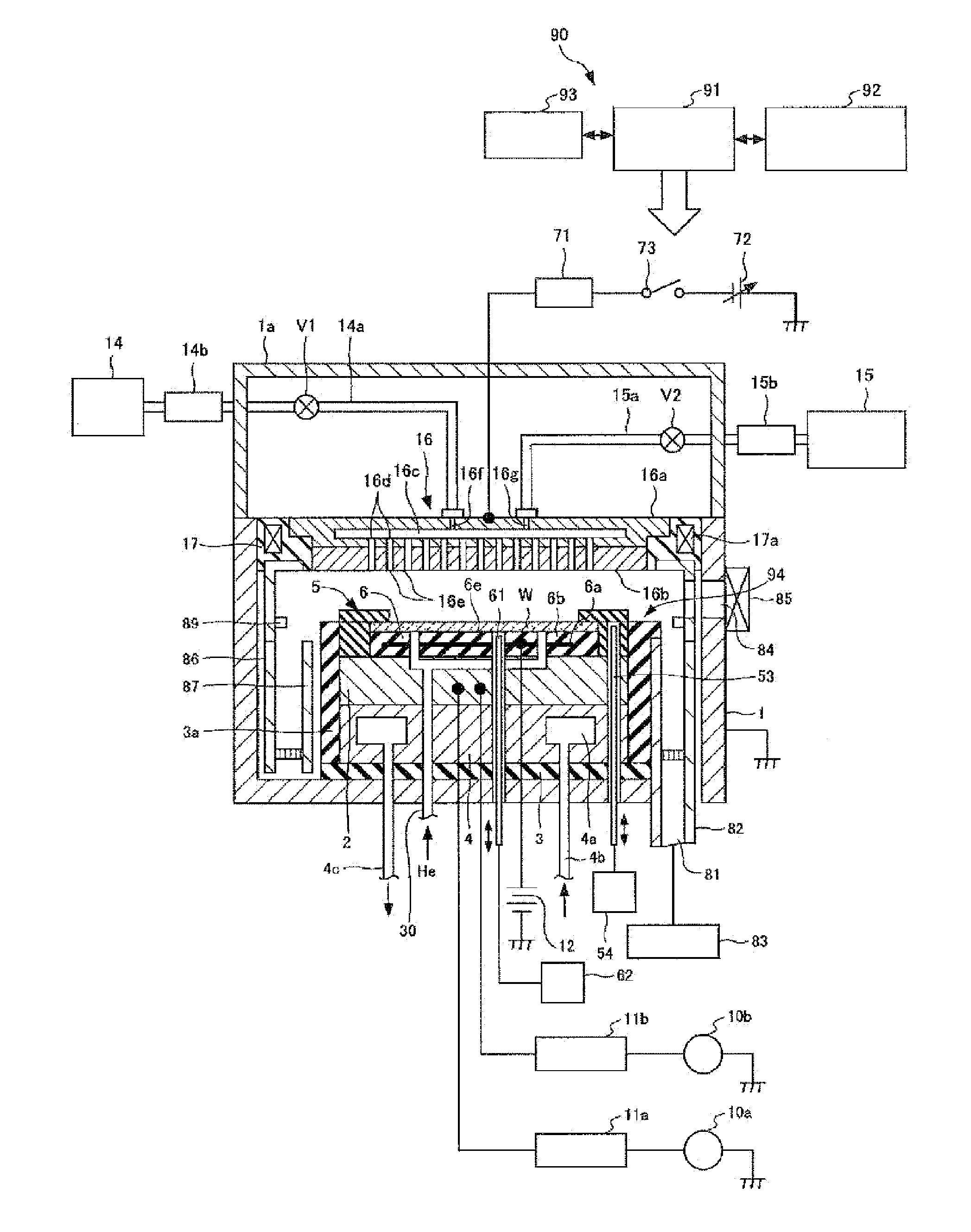

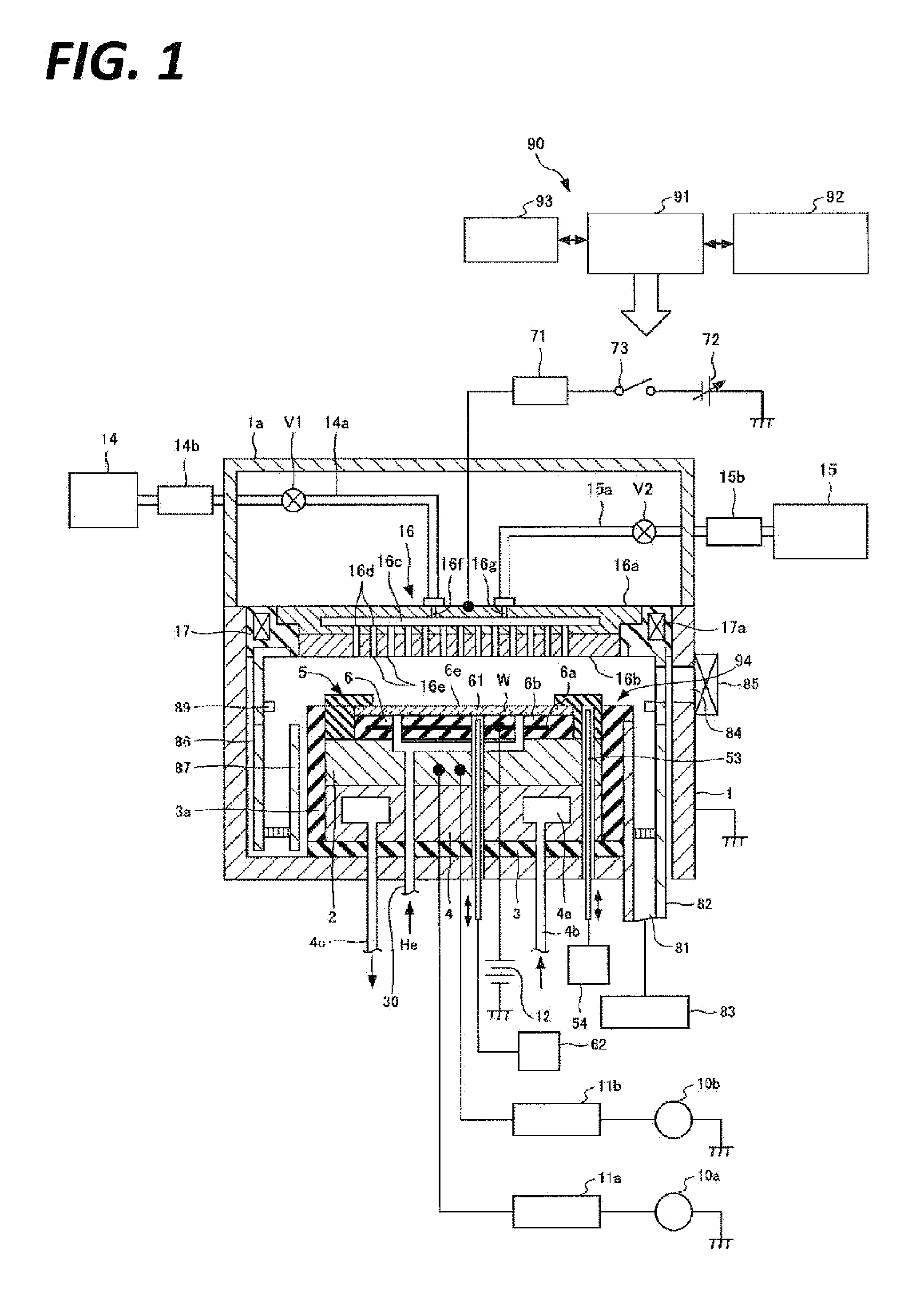

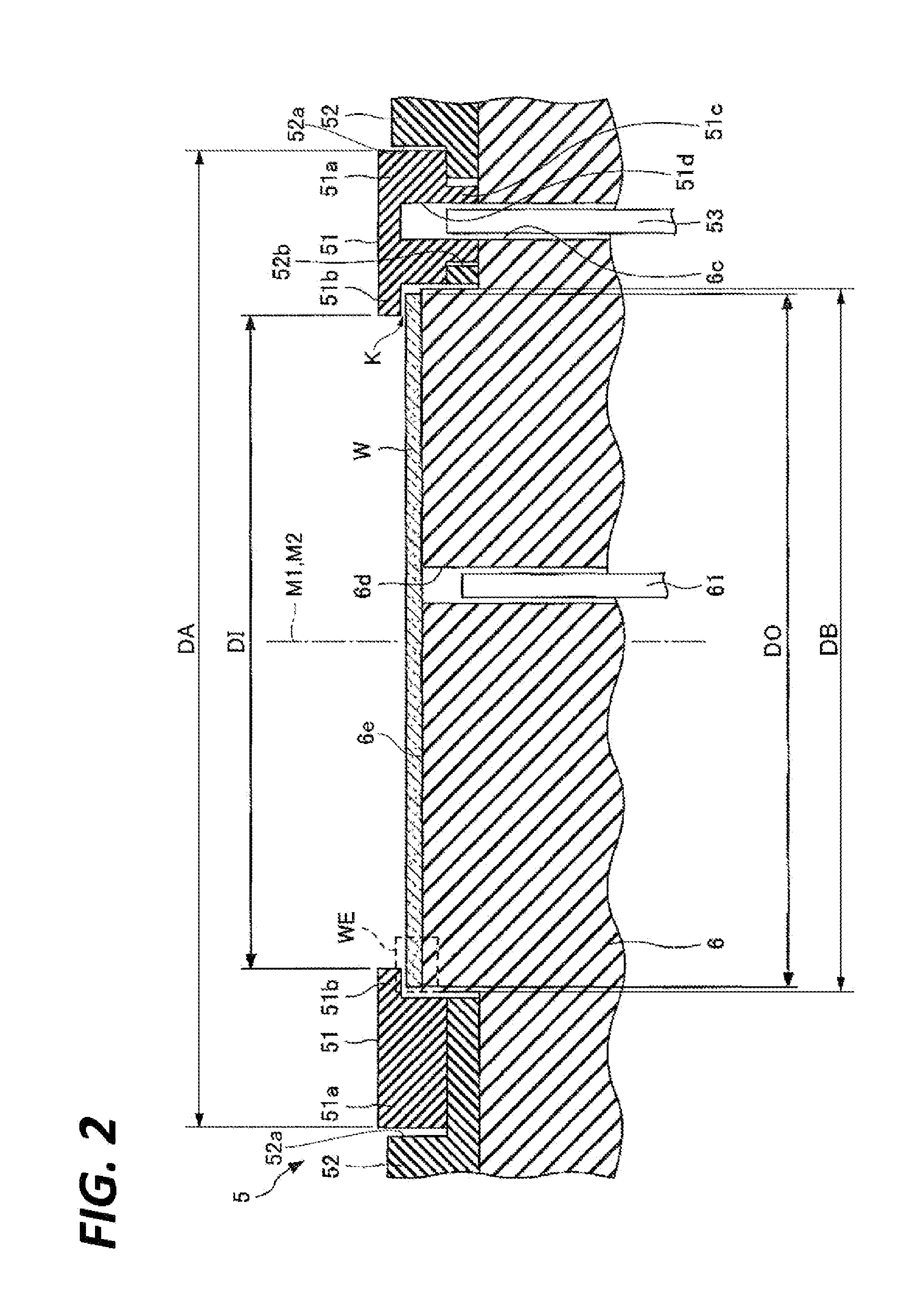

Substrate mounting table and plasma treatment device

InactiveUS20140311676A1Achieve uniformityElectric discharge tubesSolid-state devicesPlasma treatmentEngineering

A substrate mounting table (94) is equipped with a mounting table (2), an electrostatic chuck (6), and a bevel covering (5). The electrostatic chuck (6) has a supporting surface (6e) which is in contact with the whole of the rear surface of a wafer (W). The annular bevel covering (5) has an outer diameter (DA) which is greater than that of the supporting surface (6e), and an inner diameter (DI) which is smaller than that of the wafer (W). The bevel covering (5) is disposed such that, when viewed from the direction orthogonal to the supporting surface (6e), the bevel covering (5) surrounds the periphery of the wafer (W) supported on the supporting surface (6e).

Owner:TOKYO ELECTRON LTD

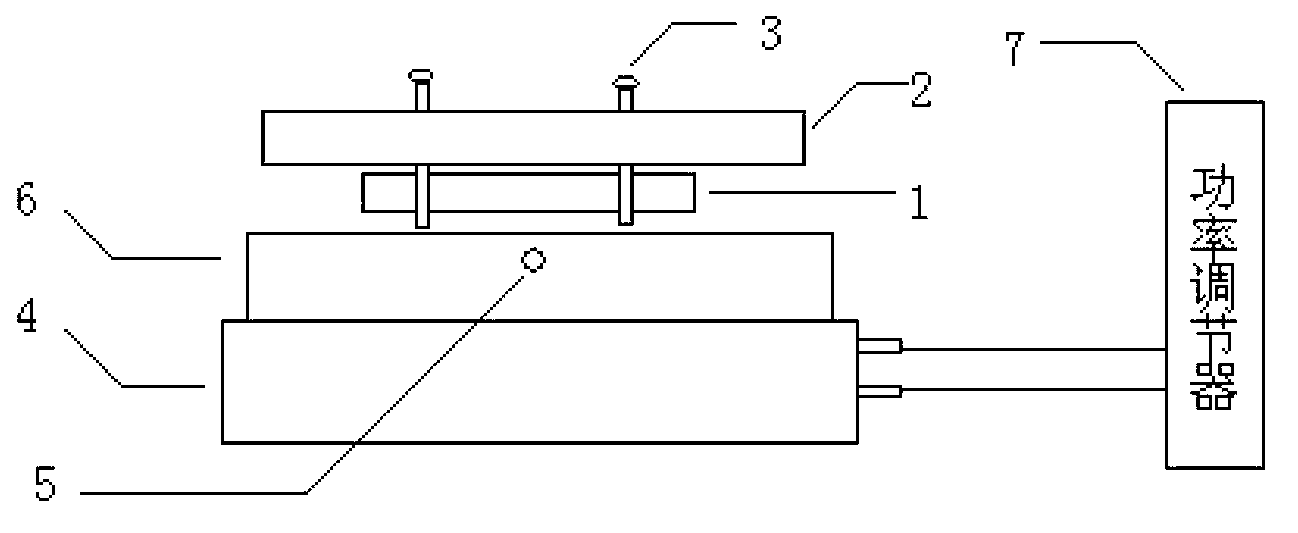

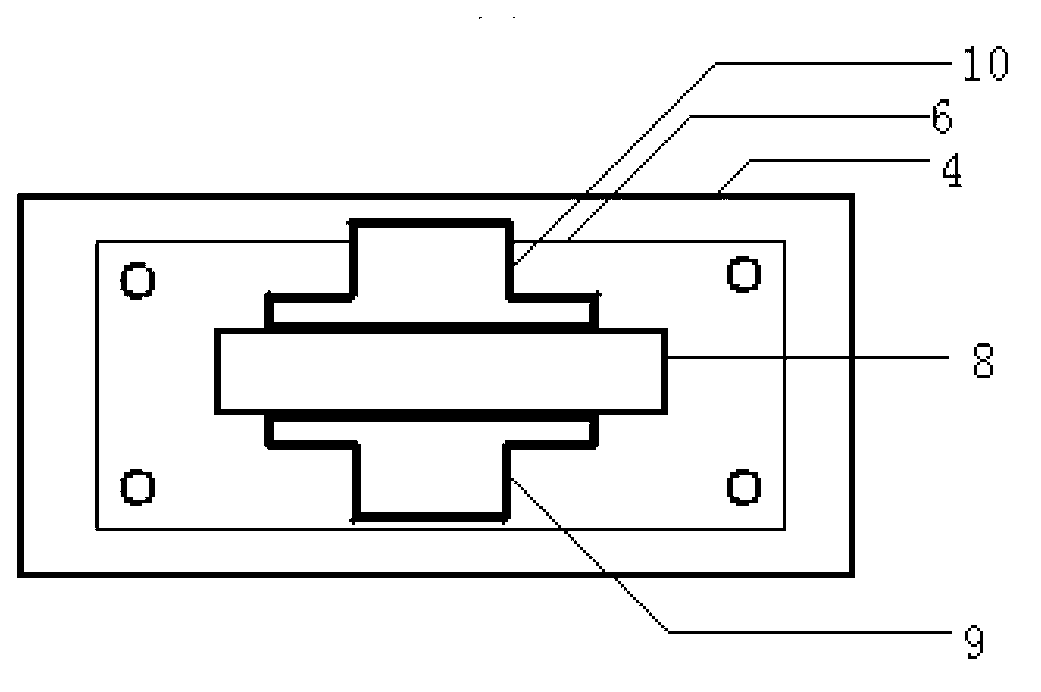

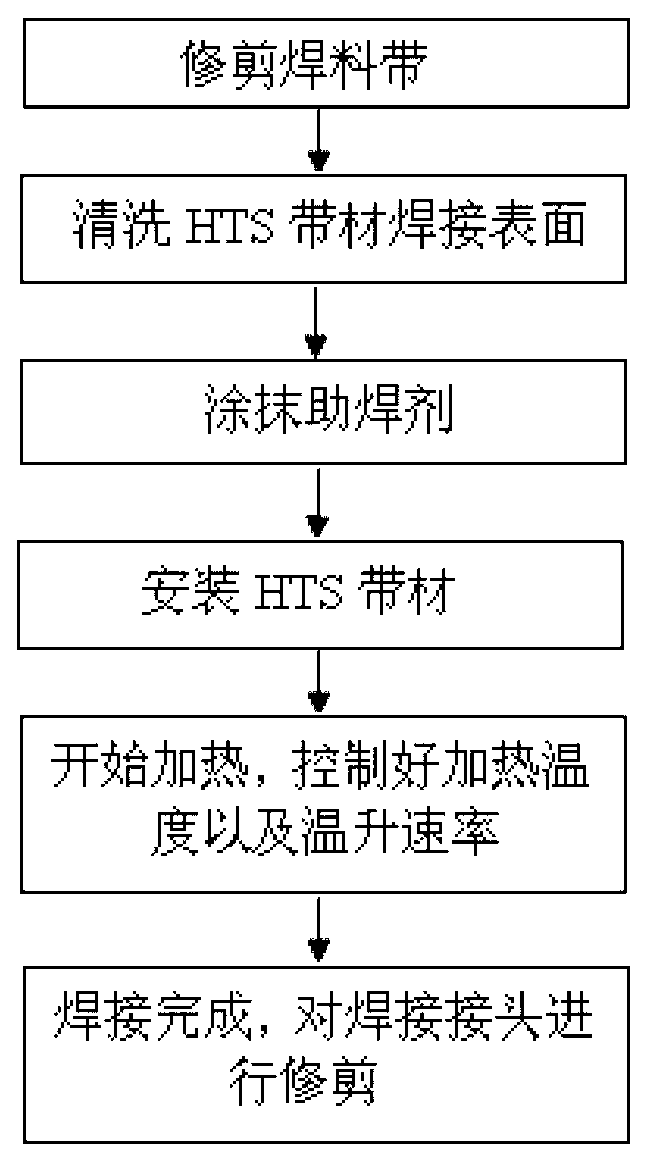

Welding device and welding method for high temperature superconducting strip

InactiveCN103170699APrevent affecting the solder effectEasy to operateHeating appliancesMetal working apparatusHigh temperature superconductingEngineering

The invention discloses a welding device and a welding method for a high temperature superconductive strip. The device comprises a heating plate, a heat conduction temperature equilibrium welding substrate, a silicon rubber pressing piece, a welding pressing plate, a power regulator and bolts. The welding method based on the welding device comprises the following steps: a welding strip is trimmed, welding surface of the high temperature superconducting (HTS) strip is cleaned, scaling powder is coated, the HTS strip is installed, heating temperature and temperature rising speed are controlled when heating starts, welding joints are trimmed after welding is finished and the like. The device is simple in operation, easy to fix and capable of achieving efficient speedability of welding, ensuring evenness of pressure at the positions of the joints, controlling the heating temperature and the temperature rising speed effectively, ensuring evenness of temperature at the positions of the welding joints and preventing excursion of the HTS strip and welding materials at the lap joint position effectively, and therefore effects of the welding materials can not be influenced.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

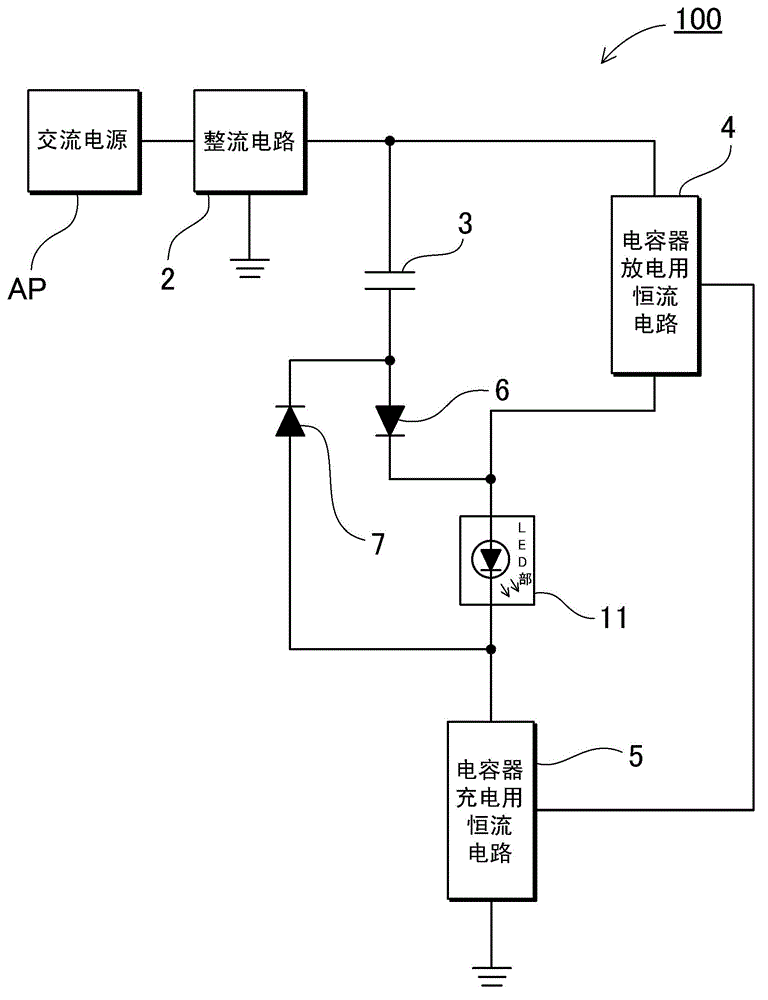

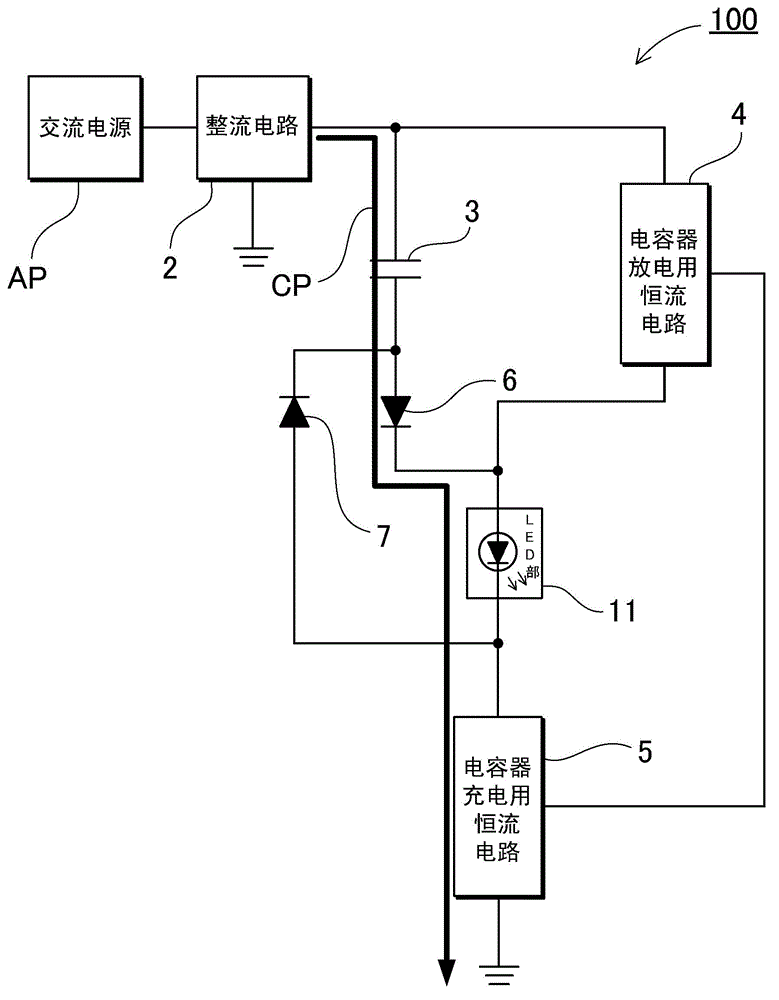

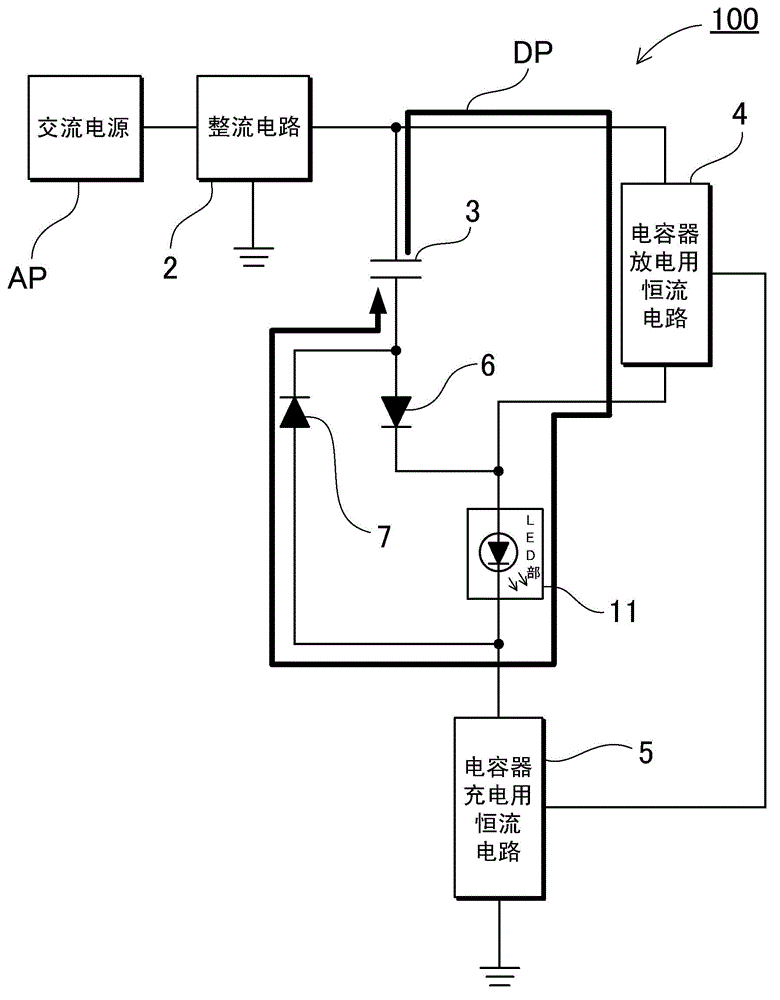

Light-emitting diode driving apparatus including charging/discharging capacitor

ActiveCN102802303AIncrease the number ofImprove efficiencyElectrical apparatusElectroluminescent light sourcesCharge currentPower flow

A charging diode 6 is connected to the capacitor 3 and the anode of a first LED 11, and limits the direction of the charging current. A discharging diode 7 is connected to the capacitor 3 and the cathode of the first LED 11, and limits the direction of the discharging current. A charging path CP is provided which includes the capacitor 3, the charging diode 6, and the charger 5. The capacitor 3 is charged through the charging path CP. A discharging path DP is provided which includes the capacitor 3, the discharging diode 7 and a discharger 4. The capacitor 3 is discharged through the discharging path DP. A transient path TP is provided which does not include the capacitor 3 but includes the first LED 11, the charger 5 and the discharger 4.

Owner:NICHIA CORP

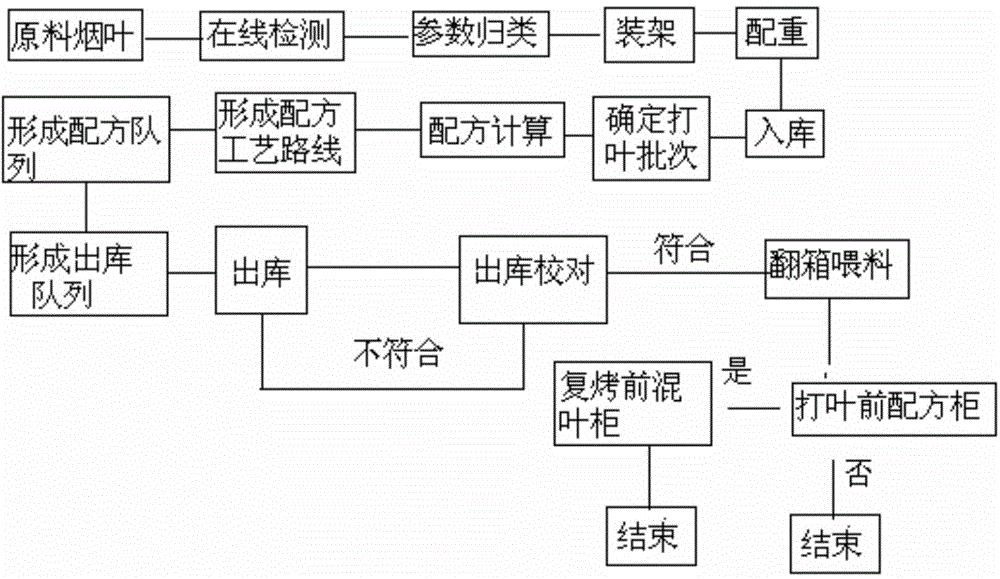

Tobacco formula uniformity regulating and controlling method

InactiveCN104432474AImprove uniformityOptimizing the mixing processTobacco preparationCo-operative working arrangementsInformatizationAutomatic control

The invention discloses a tobacco formula uniformity regulating and controlling method. The tobacco formula uniformity regulating and controlling method sequentially comprises the following steps of scanning and detecting raw material tobaccos by using a detection device to obtain detection parameters; dividing values of the detection parameters into a plurality of intervals, wherein the raw material tobaccos with the values of the detection parameters in the same interval are at the same grade; racking the raw material tobaccos at the same grade according to the set weight to obtain tobacco boxes, wherein RFID labels recording corresponding grades are posted on the tobacco boxes,; arranging the tobacco boxes on goods allocations of high racks in a high-bay depot, wherein the tobacco boxes at the same grade are evenly distributed on the different high racks; exporting corresponding tobacco boxes according to a formula process route and conveying the tobacco boxes to a feeding bin so as to perform feeding and cabinet distribution. The industrial and large-scale tobacco formula uniformity regulating and controlling method can basically achieve informatization and automatic control in the whole course, manpower and material resources are saved, and further the tobacco lamina quality uniformity is improved.

Owner:HUAHUAN INT TOBACCO +1

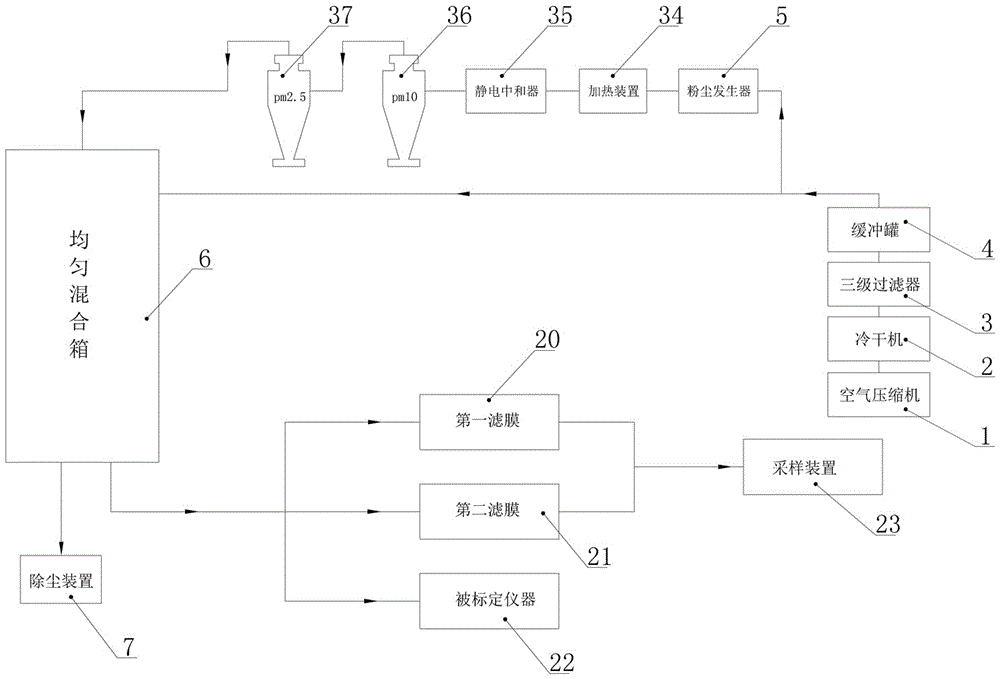

System for calibrating particulate matter measuring instruments and calibrating method of system

ActiveCN105486619AAchieve uniformityAchieve stabilityParticle suspension analysisParticulatesDust detection

The invention belongs to the technical field of dust detection, and discloses a system for calibrating particulate matter measuring instruments and a calibrating method of the system. The system comprises a compressed air processing device, a dust generator and an evenly-mixing box, wherein the compressed air processing device, the dust generator and the evenly-mixing box are sequentially communicated. A dust sample collector and a dust removal device are communicated with the lower portion of the evenly-mixing box. The evenly-mixing box comprises a sedimentation mixing chamber, a mixing section and a sample discharging section. The mixing section comprises a dust feeding pipe, a mixer and an upper transition cavity, an air diluting bin is formed between the dust feeding pipe and the mixer, a plurality of compressed air inlets are evenly formed in the portion, corresponding to the air diluting bin, of the dust feeding pipe in a communicated mode, and mixing through holes for diluting air in a non-directional mode are evenly formed in the pipe wall of the mixer. By means of the system and the calibrating method, the dust generation amount, the dilution air flow, the dust dilution concentration, the sample flow and the evenness of mixing of dust and dilution air are all effectively controlled, and therefore measuring instruments within different dust mass concentration ranges can be calibrated.

Owner:HENAN PROVINCE INST OF METROLOGY

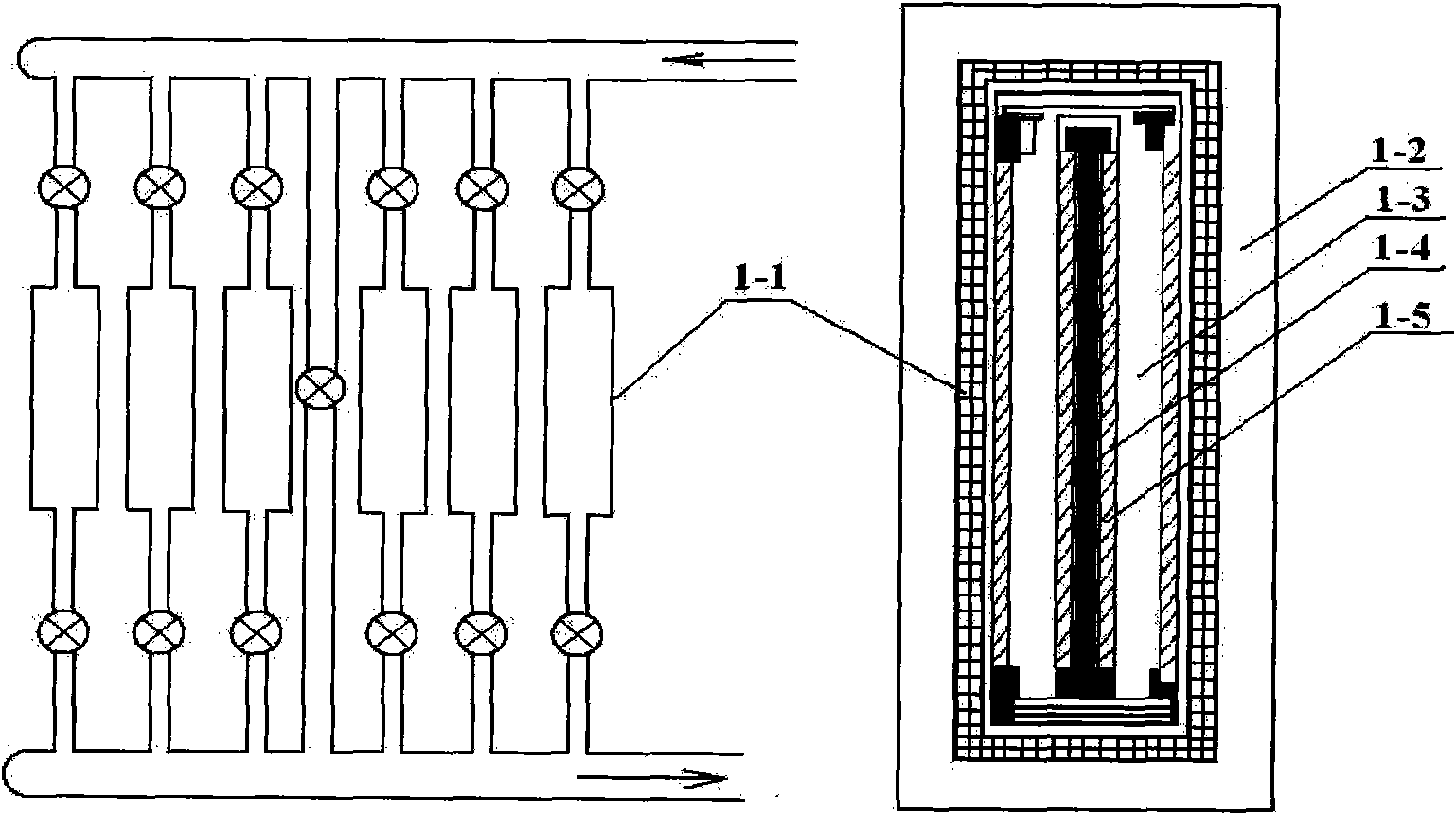

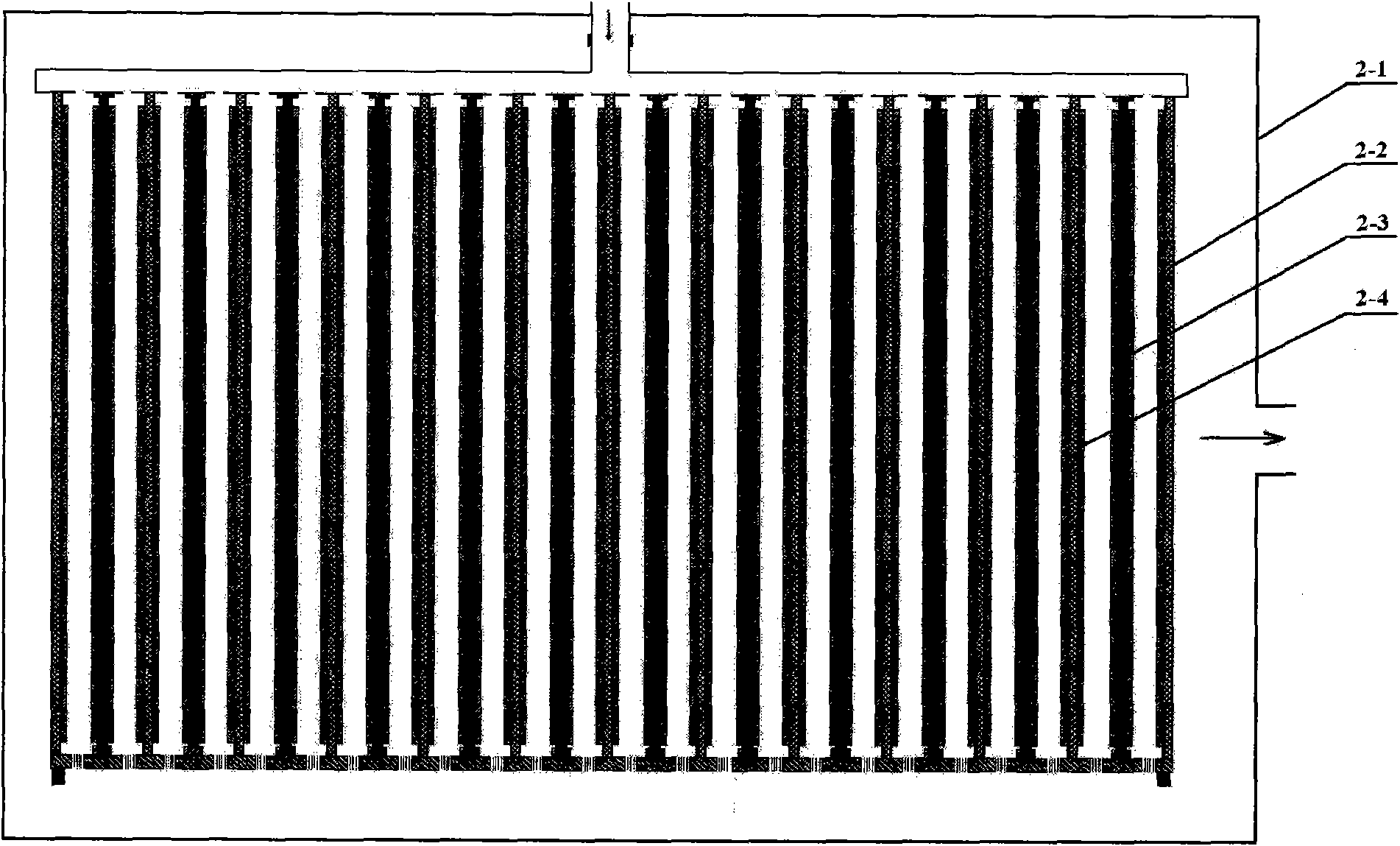

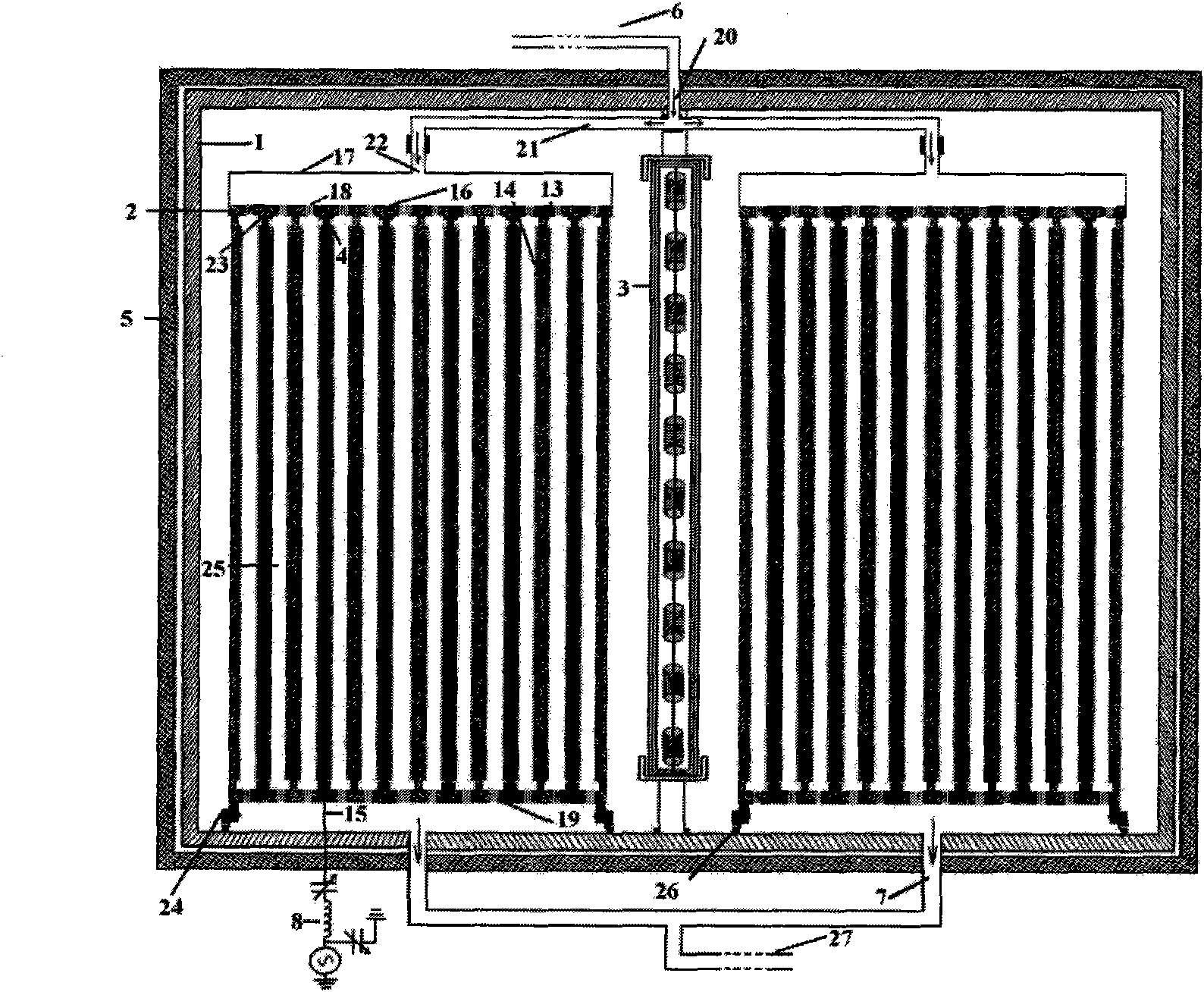

PECVD system with internal heater

InactiveCN101962759ACompact structureEasy to operateChemical vapor deposition coatingEngineeringSingle chamber

The invention discloses a PECVD system with an internal heater, comprising a vacuum chamber and movable plasma boxes arranged in the vacuum chamber. The four peripheral walls of the vacuum chamber are provided with heating panels, and at least two movable plasma boxes exist. Each of the movable plasma boxes is arranged in the vacuum chamber in parallel, and the internal heater for heating the vacuum chamber uniformly is arranged between the movable plasma boxes. The internal heater can greatly enhance the output of the single-chamber deposition system, and avoid the problem of unbalanced temperature distribution caused by the traditional heating ways. The PECVD system of the invention effectively solves the non-uniform thickness of silicon-based thin film deposited on the glass substrate with TCO, enhances the performance of the large-area silicon-based thin film solar cell, lays the foundation of the development of the large-area PECVD thin film deposition system, and effectively promotes the industrialization of the silicon-based thin film cell technology.

Owner:SHENZHEN GLOBAL SOLAR ENERGY TECH

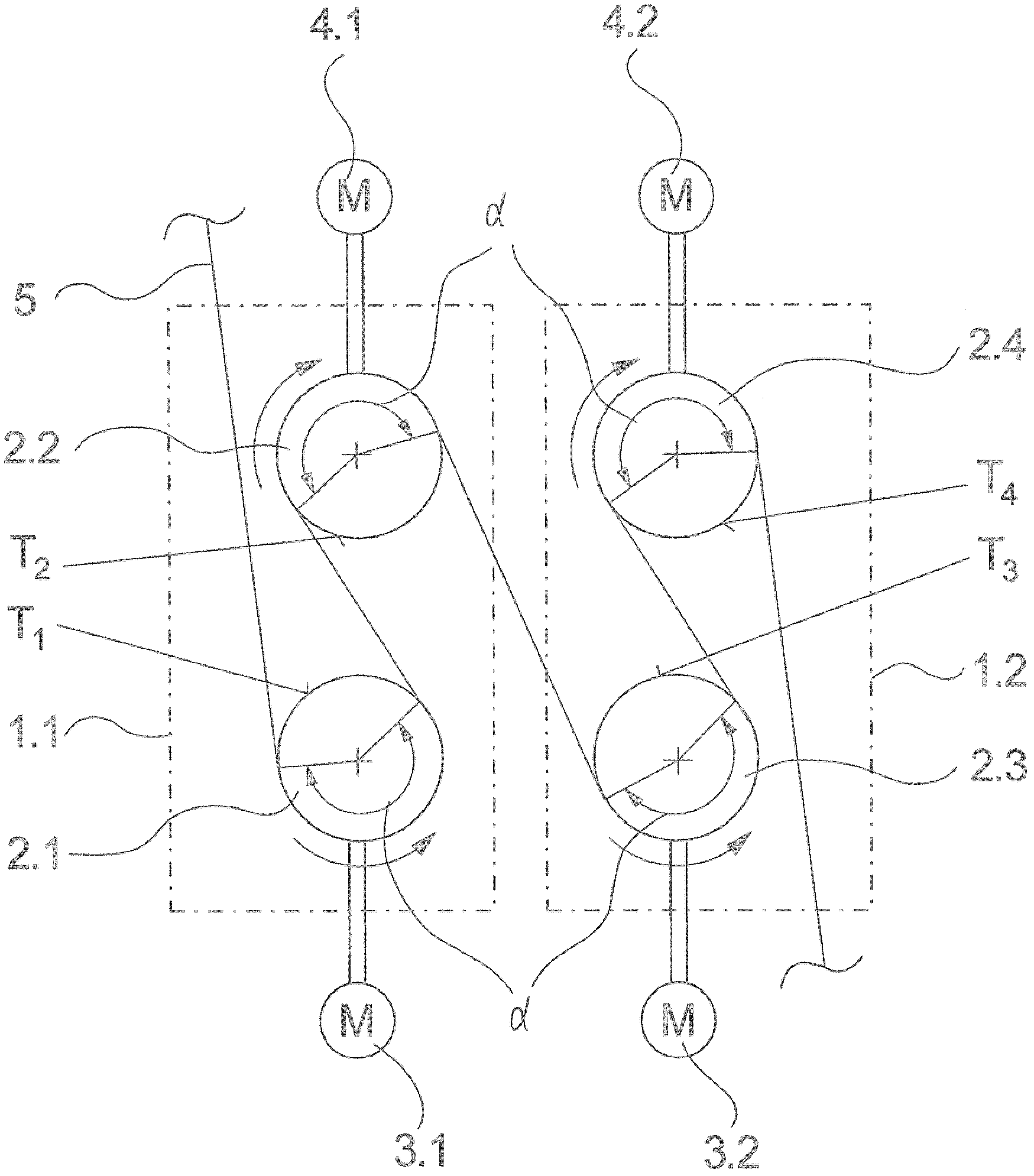

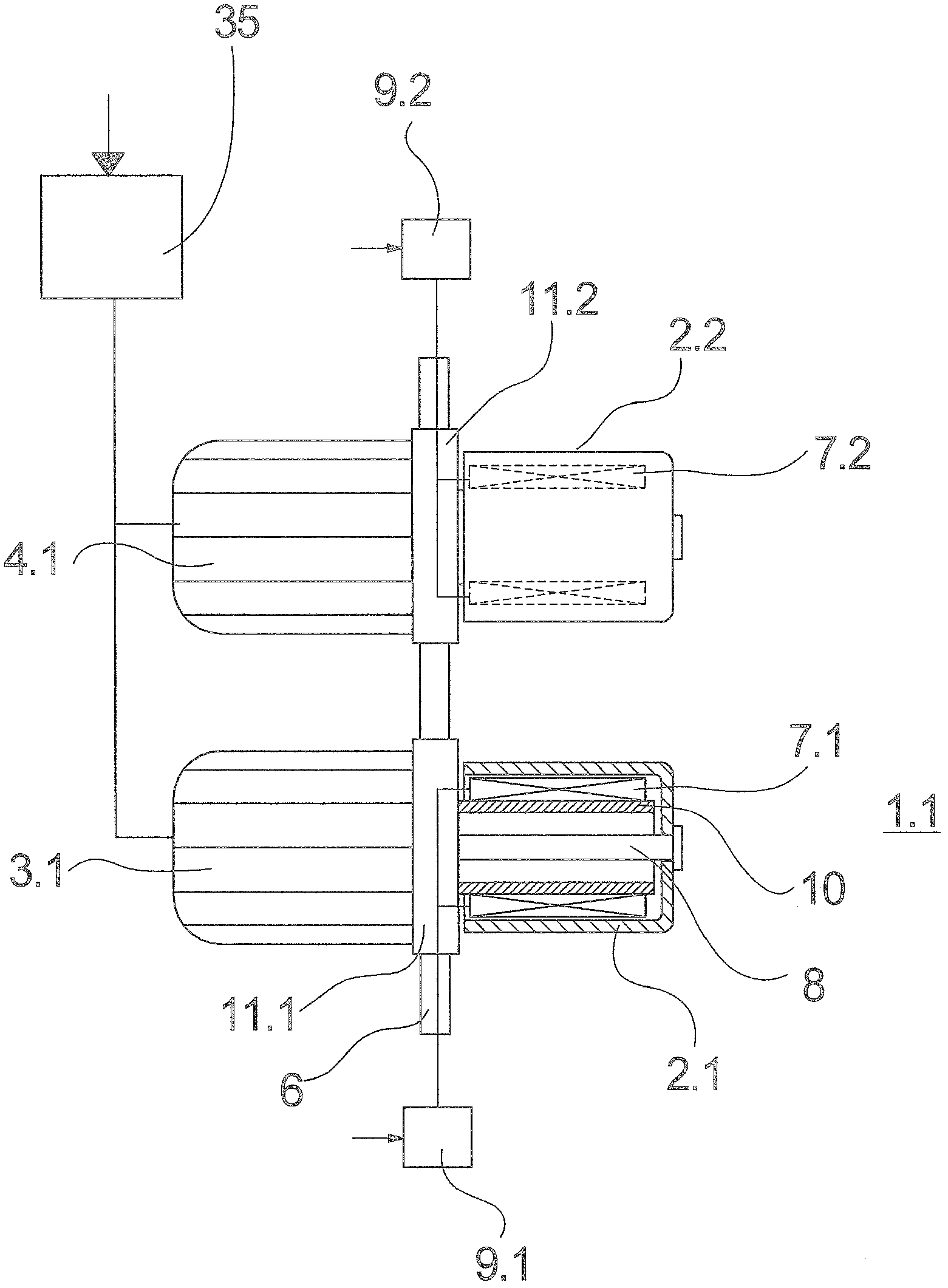

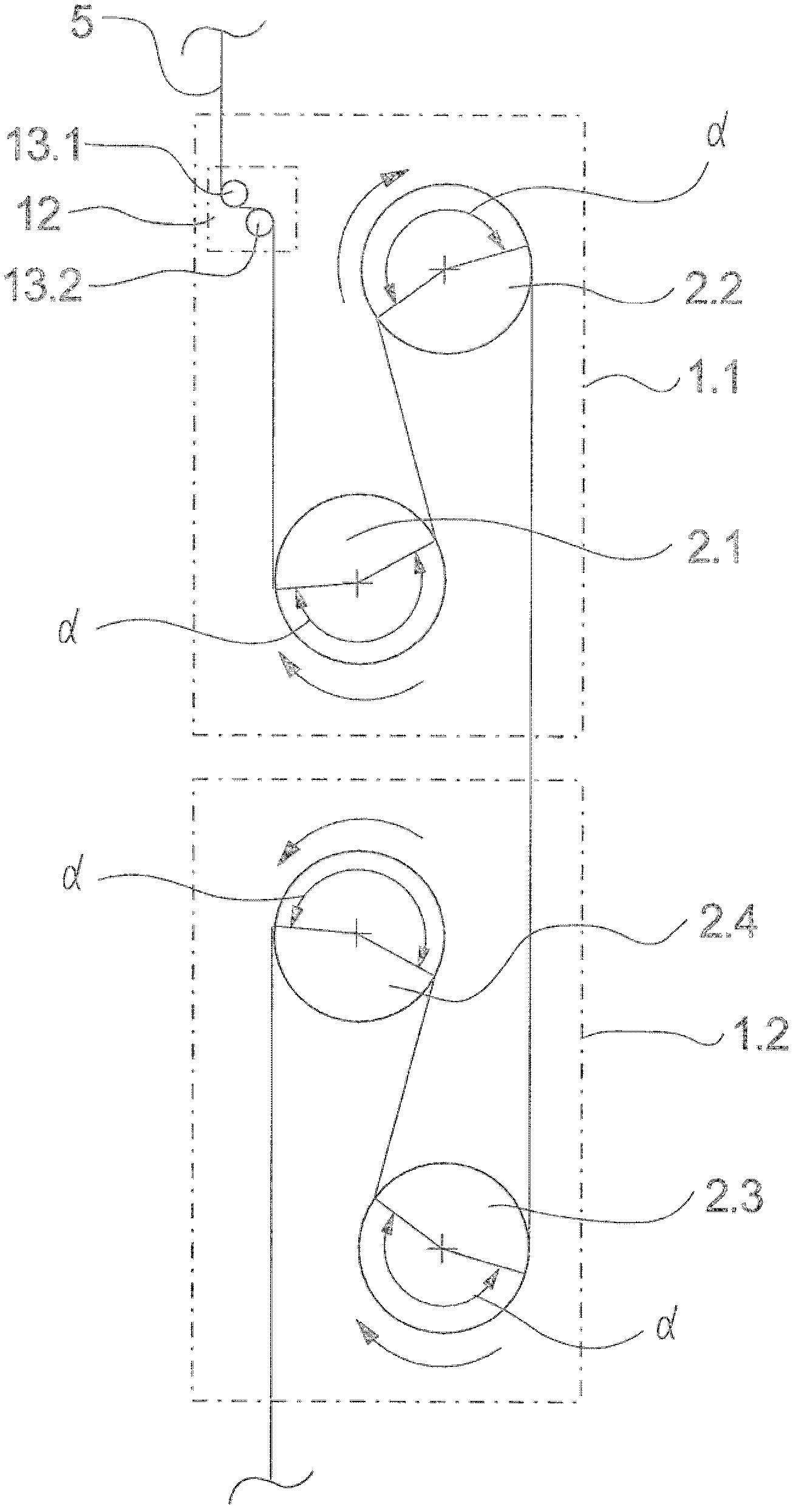

Method for removing and drawing a synthetic thread and a device for performing the method

ActiveCN102471935AHeating evenlyAchieve uniformityArtificial filament heat treatmentStretch-spinning methodsSpinningSingle filament

The invention relates to a method and a device for removing and drawing a synthetic thread to form a fully drawn yarn. The thread is formed by joining a plurality of extruded filaments and is guided by contact on the circumference of heated guide jackets of several driven galette pairs. In order to obtain a gentle and highly homogenized treatment of the filaments, the thread is guided in an S-shaped or Z-shaped thread course by a first galette pair having two guide jackets driven in opposite directions during the removal from a spinning zone and before the drawing. Thus, both sides of the thread can be brought directly into circumferential contact with the guide jackets for in order to heat the thread.

Owner:OERLIKON TEXTILE GMBH & CO KG

Test bed and method for testing high-frequency mechanical characteristic of tire

InactiveCN104458286AAchieve stiffnessAchieve uniformityVehicle tyre testingRoad surfaceControl valves

The invention relates to a test bed and a method for testing the high-frequency mechanical characteristic of a tire. The test bed comprises a simulation road surface rack assembly composed of a bottom plate, a lower box body, a shaft base and an upper box body, a simulation road surface assembly composed of a high-rigidity drum, a main shaft, a driven belt pulley, a synchronous belt pulley, a speed measuring assembly and road surface protruding blocks, a drive mechanism assembly composed of a motor base, a motor plate, a servo motor, a drive belt pulley and an air blower, a transmission toothed belt, a wheel cover, a tire positioning assembly composed of a positioning support and an installing plate assembly, and a tire inflating and deflating mechanism assembly composed of an air pipe, a tire pressure control valve and an air pump, and the transmission toothed belt and the wheel cover are arranged between the drive belt pulley and the driven belt pulley. The test method comprises the steps that a deflated tire is installed on the positioning support and pressed on the outer surface of the high-rigidity drum, the tire is inflated to be vertically loaded, and the different road surface protruding blocks are installed on the high-rigidity drum to carry out the test and collect data. The test bed and the method are suitable for testing and modeling of the high-frequency mechanical characteristic of the tire.

Owner:JILIN UNIV

Unleaded Cu-based sliding bearing material and preparation method thereof

InactiveCN101576118AAchieve lead-freeImprove mechanical propertiesLiquid/solution decomposition chemical coatingSliding contact bearingsGraphiteHigh intensity

The invention relates to an unleaded Cu-based sliding bearing material and a preparation method thereof and the invention has the characteristics that: the material is composed of nickel, tin, zinc, iron, graphite, bismuth, copper and assistants, the substrate of the material is unleaded copper alloy, and the antifriction and antisticking constituent element is bismuth and graphite. The Cu-based bearing material features high intensity, and good antifriction and antisticking, thus realizing an unleaded Cu-based bearing material. The lead is cancelled in an original bearing material with lead and copper, and a synergistic effect of bismuth and graphite can replace the use of lead, thus completely overcoming the defect of lead pollution; moreover, the service performance of the bearing remains nearly the same, therefore the unleaded Cu-based sliding bearing material can completely replace the bearing material with lead and copper. The material of the invention can be applied in food machinery, drugs machinery, construction machinery, automobile and other products, and has advantages of good antifriction and antisticking, good heat dissipation effect, oxidation resistance and corrosive resistance.

Owner:HEFEI UNIV OF TECH

A kind of high-strength high-toughness ship plate steel and its TMCP production method

InactiveCN102277529AEasy to shapeQuality improvementTemperature control deviceMaterials scienceSteel plates

The invention provides a high-strength and high-toughness ship plate steel and its TMCP production process, which comprises the following components by weight percentage: C: 0.04-0.08%; Si: 0.15-0.40%; Mn: 1.30-1.55%; P : ≤0.012%; S: ≤0.005%; Nb: 0.025~0.045%; Ti: 0.010~0.020%; Ni: 0.015~0.025%; Als: 0.020~0.050%; N: ≤0.007%; Impurities. The invention also provides a ship plate steel plate and a preparation method thereof. The ship plate steel and the ship plate steel plate provided by the invention have low production cost, high production efficiency, stable product performance and small quality fluctuation.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com