Sectional type low temperature roller cut tobacco drying equipment

A drying equipment and segmented technology, which is applied in the field of segmented low-temperature drum leaf silk drying equipment, can solve problems such as inability to meet process requirements and use requirements, improve comprehensive sensory quality and process resistance, reduce moisture deviation, The effect of removing internal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

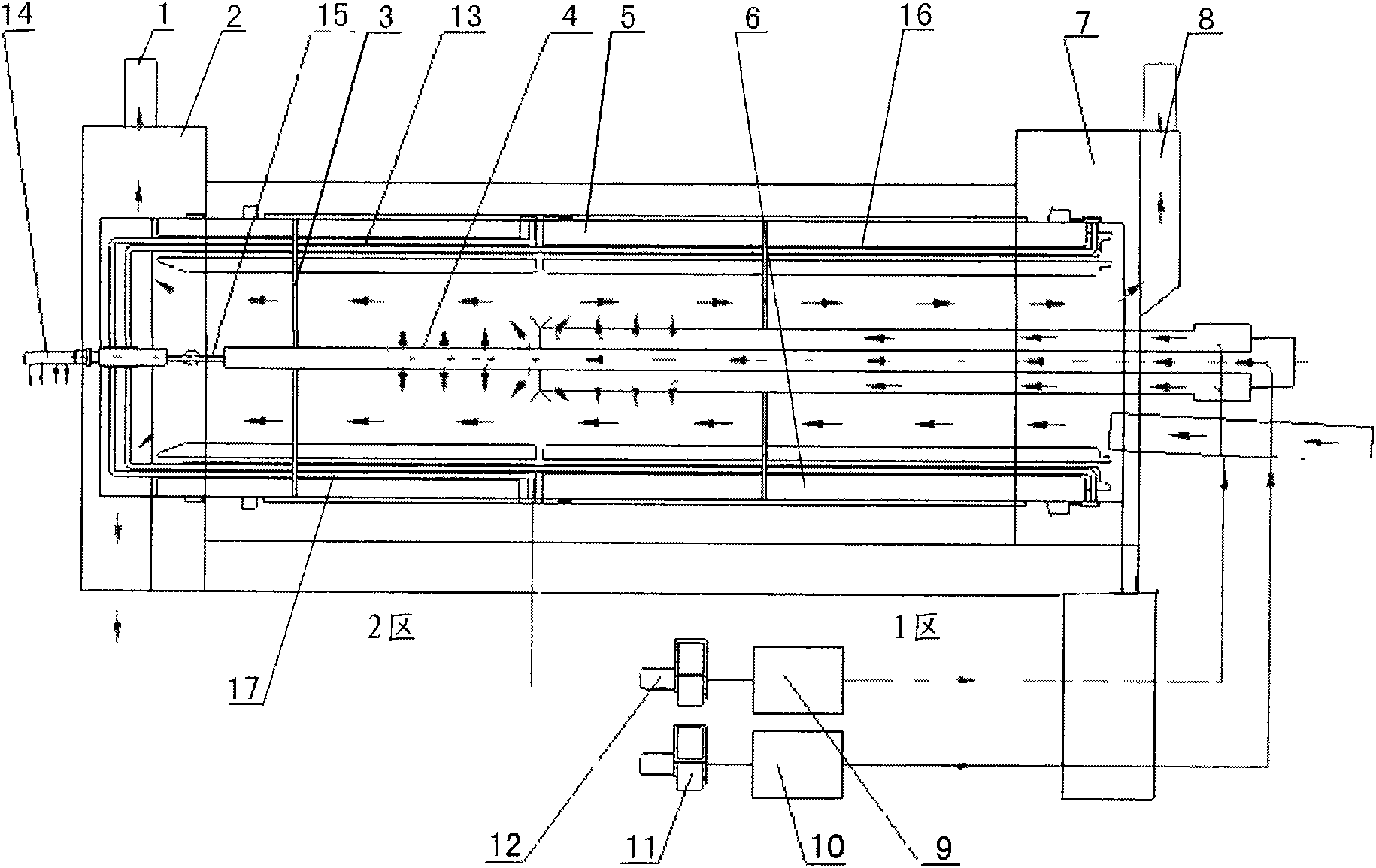

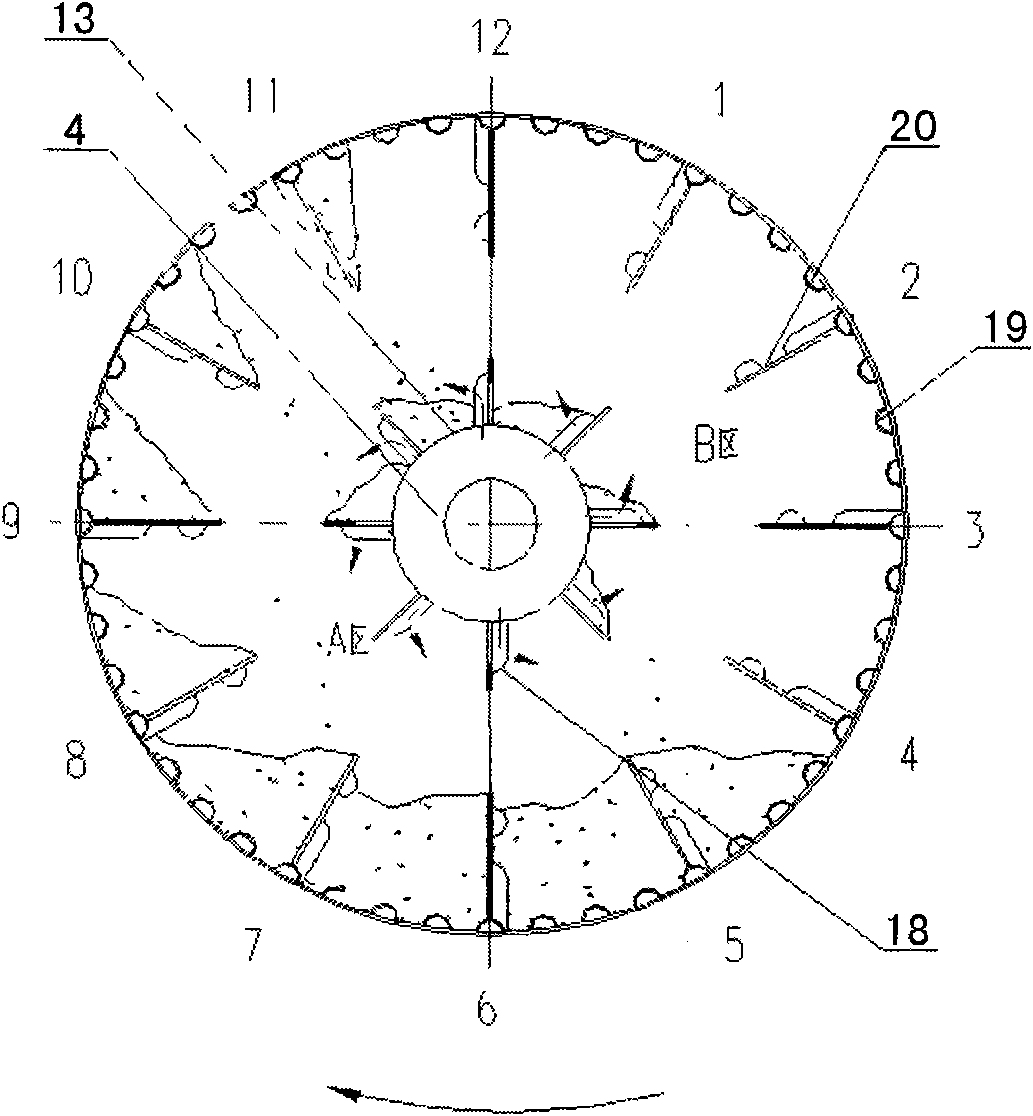

[0015] See figure 1 The segmented low-temperature drum leaf silk drying equipment shown includes a cylinder body 5 installed on a frame 6; at both ends of the cylinder body 5, a feed cover 7, a discharge cover 2, and a feed cover 7 are arranged. 1. The discharge cover 2 is connected with a moisture discharge pipe 8 which is respectively connected with a respective moisture discharge system for automatic control and adjustment of the moisture discharge. A semicircular pipe 19 and a cylinder frying plate 20 are evenly distributed along the axial direction of the inner cylinder wall of the cylinder body 5 . In this embodiment, the cylinder body 5 is a two-section cylinder body with a high-temperature zone and a low-temperature zone, and an independent functional control unit is formed between each section. A low hot air duct 4 and a high hot air duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com