Method for removing and drawing a synthetic thread and a device for performing the method

A technique for drawing filaments and threads, applied in the field of devices implementing the method, can solve the problems of non-slip transmission, difficulty in drawing force, etc., and achieve the effects of relaxation, short contact length, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

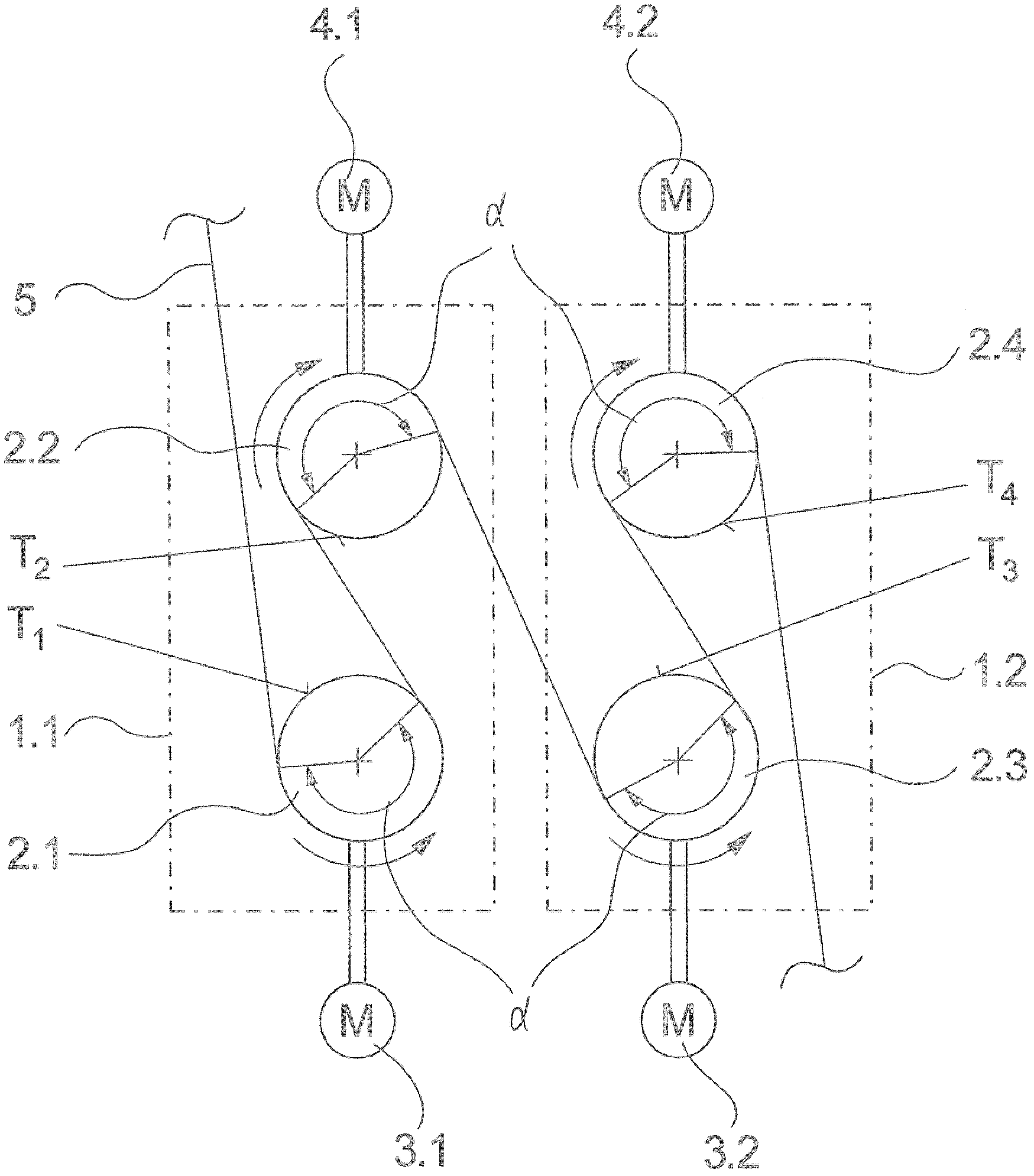

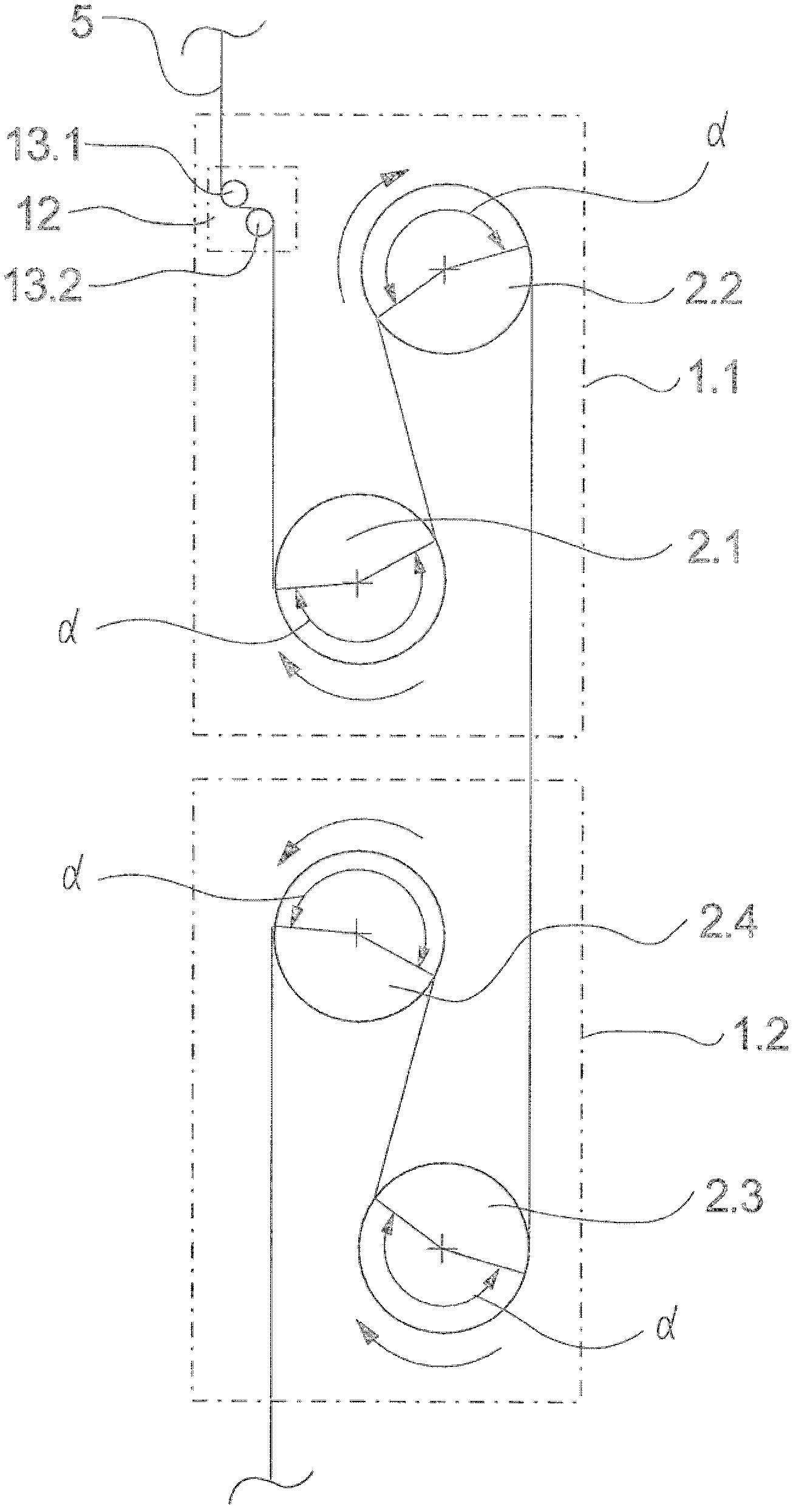

[0034] figure 1 A godet system of a first embodiment of the device according to the invention for carrying out the method according to the invention is shown.

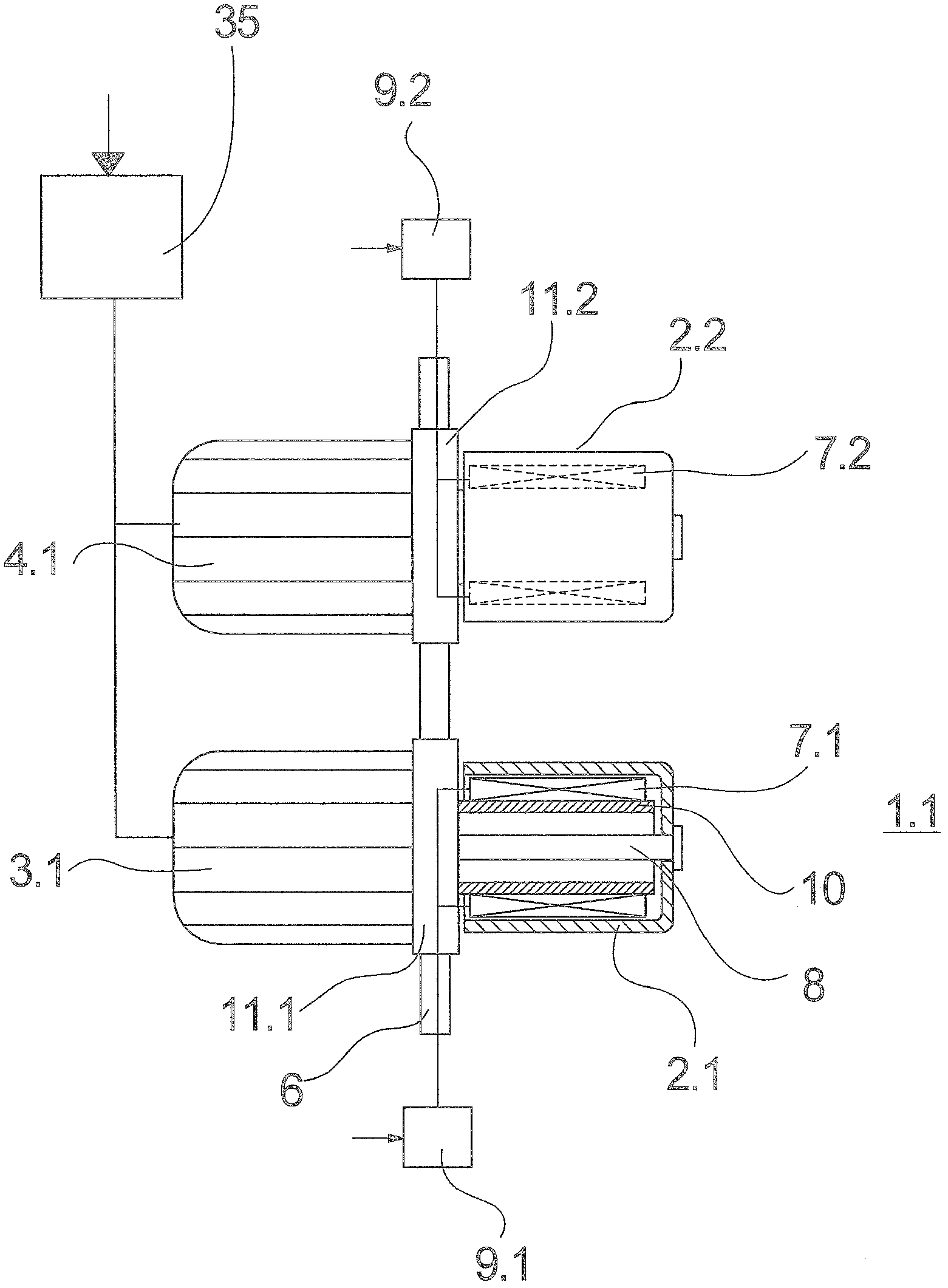

[0035] This embodiment comprises two godet pairs 1.1 and 1.2, which are arranged side by side. The first godet pair 1.1 has two guide sleeves 2.1 and 2.2 driven at the same peripheral speed. The guide sleeves 2.1 and 2.2 of the godet pair 1.1 are arranged one above the other and are driven by separate electric motors 3.1 and 4.1. The electric motor 3.1 of the guide sleeve 2.1 is designed to be left-handed and drives the guide sleeve 2.1 in a counterclockwise rotation. The electric motor 4.1 is designed to be clockwise and drives the guide sleeve 2.2 to rotate clockwise. Therefore, the guide sleeves 2.1 and 2.2 rotate in opposite directions. Electric motors 3.1 and 4.1 are preferably operated via a common motor controller.

[0036] Each guide sleeve 2.1, 2.2 here has a heating device (not shown) in order to heat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com