Patents

Literature

11200results about How to "Good synergy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Golf ball

InactiveUS6921345B2Solid comfortable feelGood rebound characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes a hot-molded product of a rubber composition comprising a base rubber composed of (a) 20-100 wt % of a polybutadiene having a high cis-1,4 content, a minimal 1,2 vinyl content, and a viscosity η of up to 600 mPa·s at 25° C. as a 5 wt % toluene solution, and satisfying a certain relationship between Mooney viscosity and polydispersity index Mw / Mn, in combination with (b) 0-80 wt % of another diene rubber, (c) an unsaturated carboxylic acid, (d) an organosulfur compound, (e) an inorganic filler, (f) an organic peroxide, and optionally, (g) an antioxidant. The hot-molded product has a difference in JIS-C hardness between the center and surface thereof of up to 15 units. The composition and hardness characteristics of the hot-molded product provide the golf ball with a solid comfortable feel upon impact and an excellent rebound.

Owner:BRIDGESTONE SPORTS

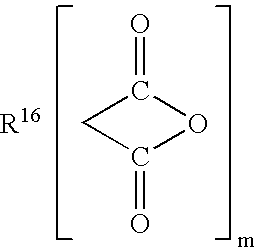

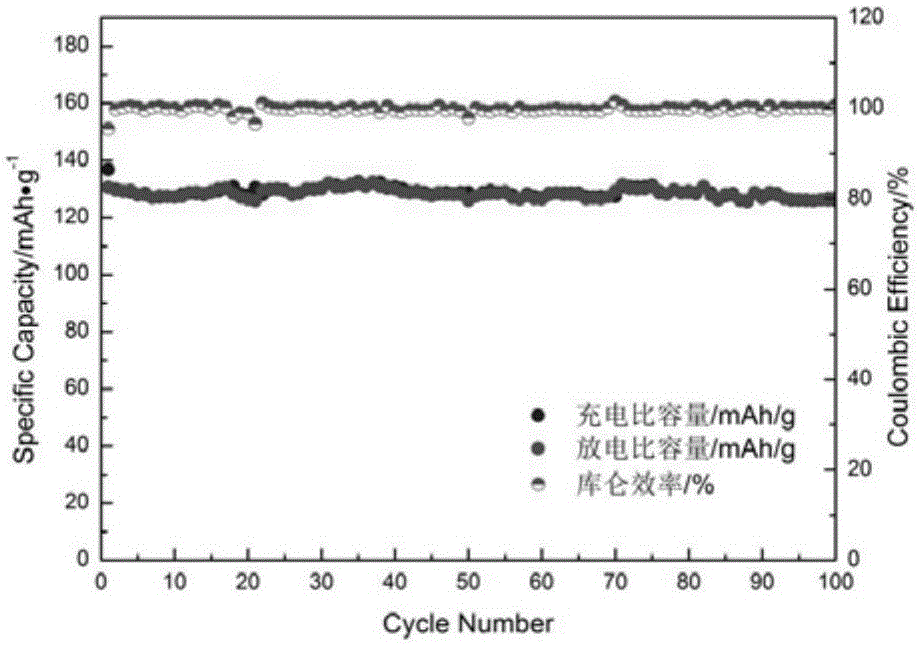

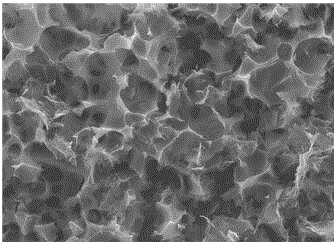

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

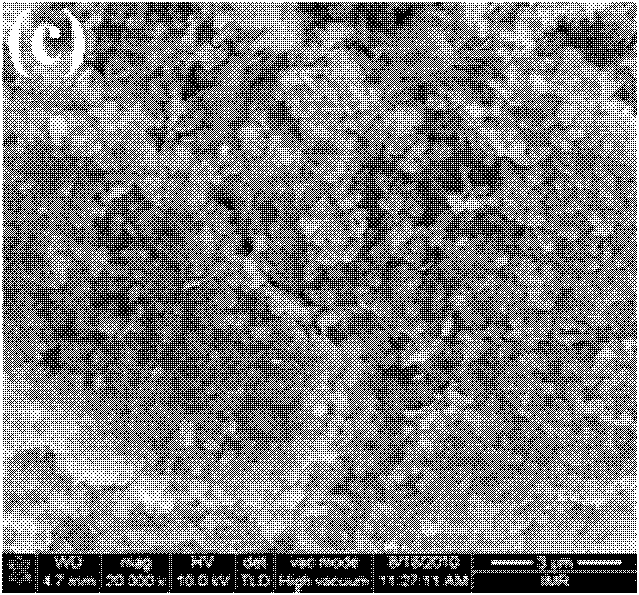

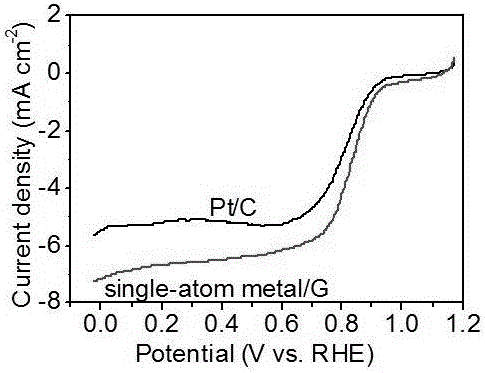

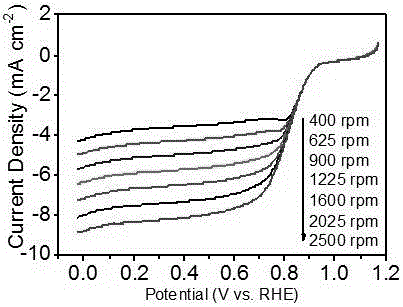

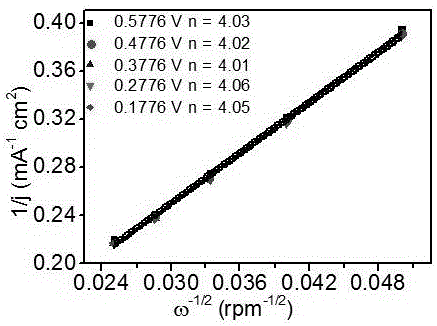

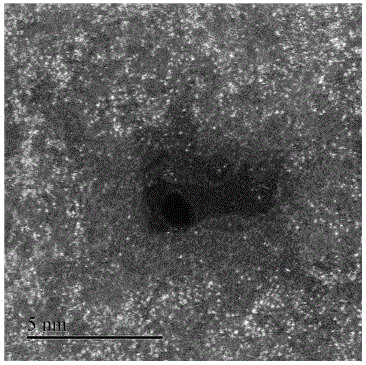

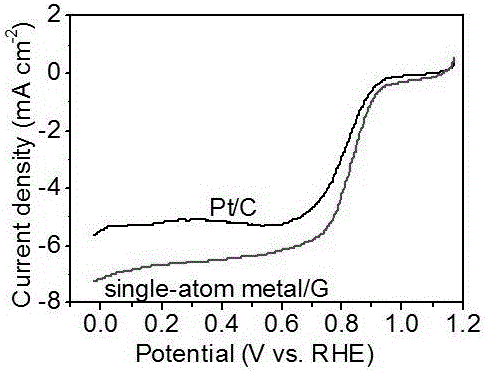

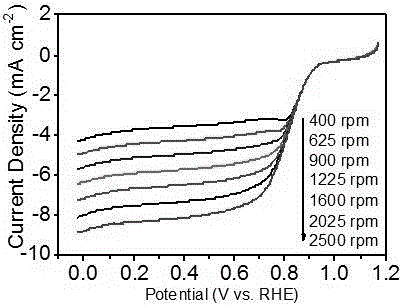

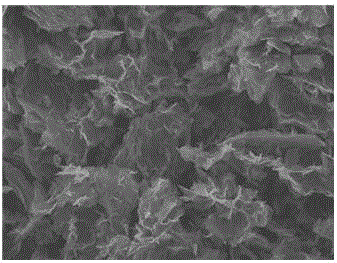

Monodisperse metal atom/graphene composite catalyst and preparation method and application thereof

ActiveCN106694007ALow costSimple stepsCell electrodesCatalyst activation/preparationCvd grapheneChemistry

The invention discloses a monodisperse metal atom / graphene composite catalyst and a preparation method and application thereof. The catalyst is formed by loading monodisperse metal atoms on / in graphene, wherein the content of the monodisperse metal atoms is 0.0001wt%-5.0wt%; the content of heteroatom doped graphene is 95wt%-99.9999wt%; and the content of heteroatom in graphene is 0wt%-90wt%. The monodisperse metal atom / graphene composite catalyst is obtained through an electrochemical method, and the preparation method is simple, easy to operate and control, low in cost, high in efficiency, good in quality, high in security and favorable for industrial production. The composite catalyst has the characteristics of high activity and good stability when being applied to electro-catalytic oxygen reduction, and has better comprehensive performance and good application prospects relative to commercial 20wt% of Pt / C.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

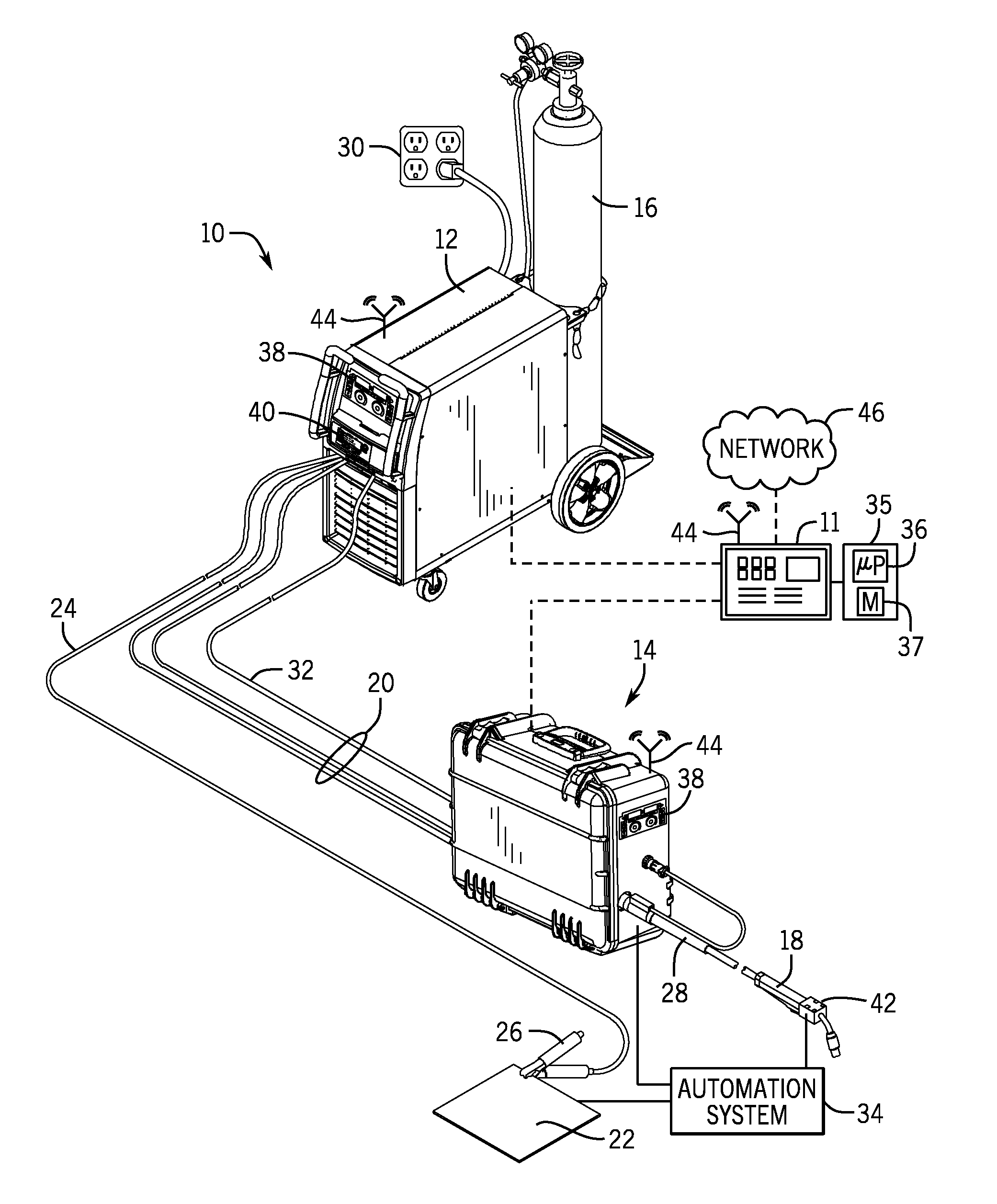

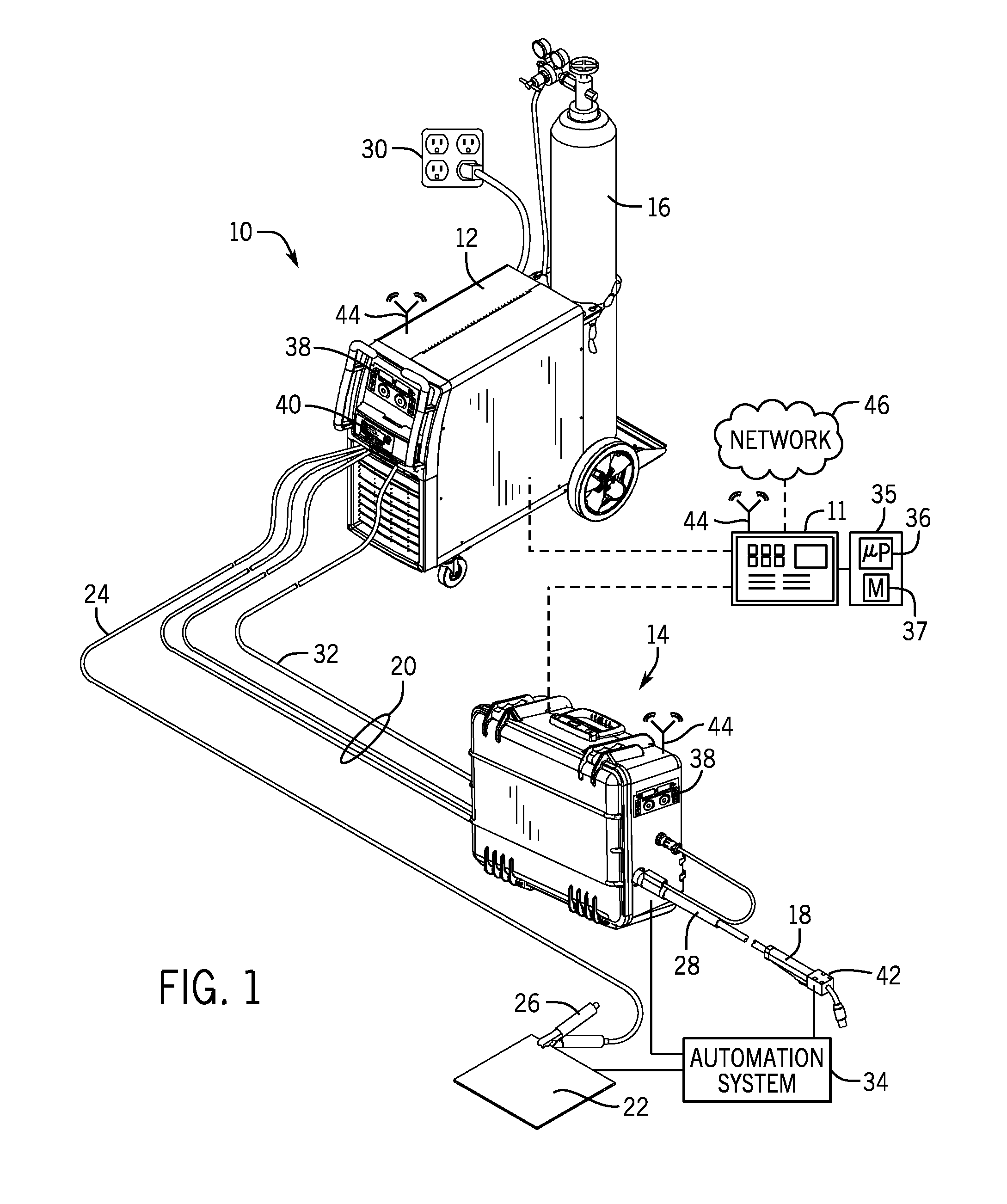

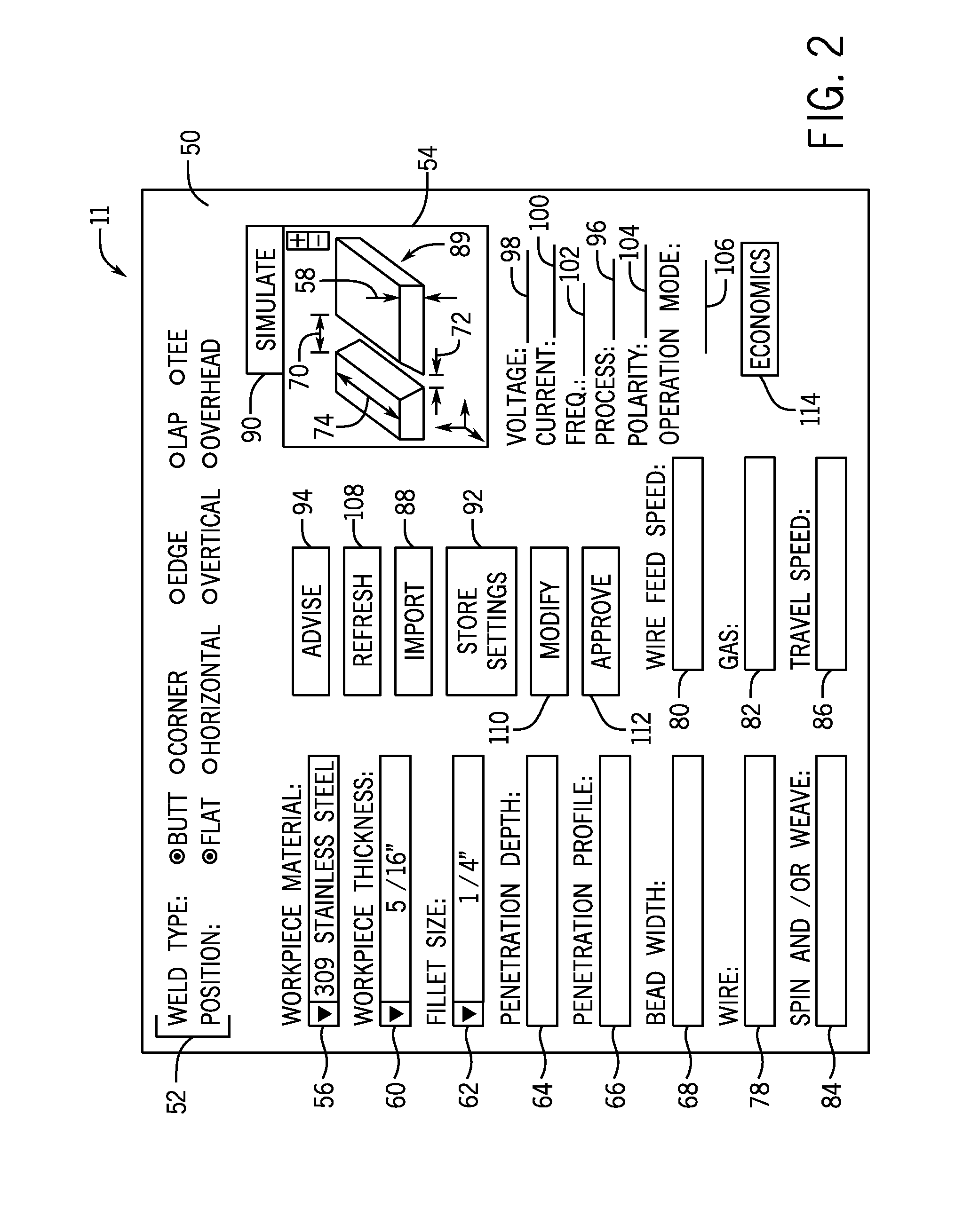

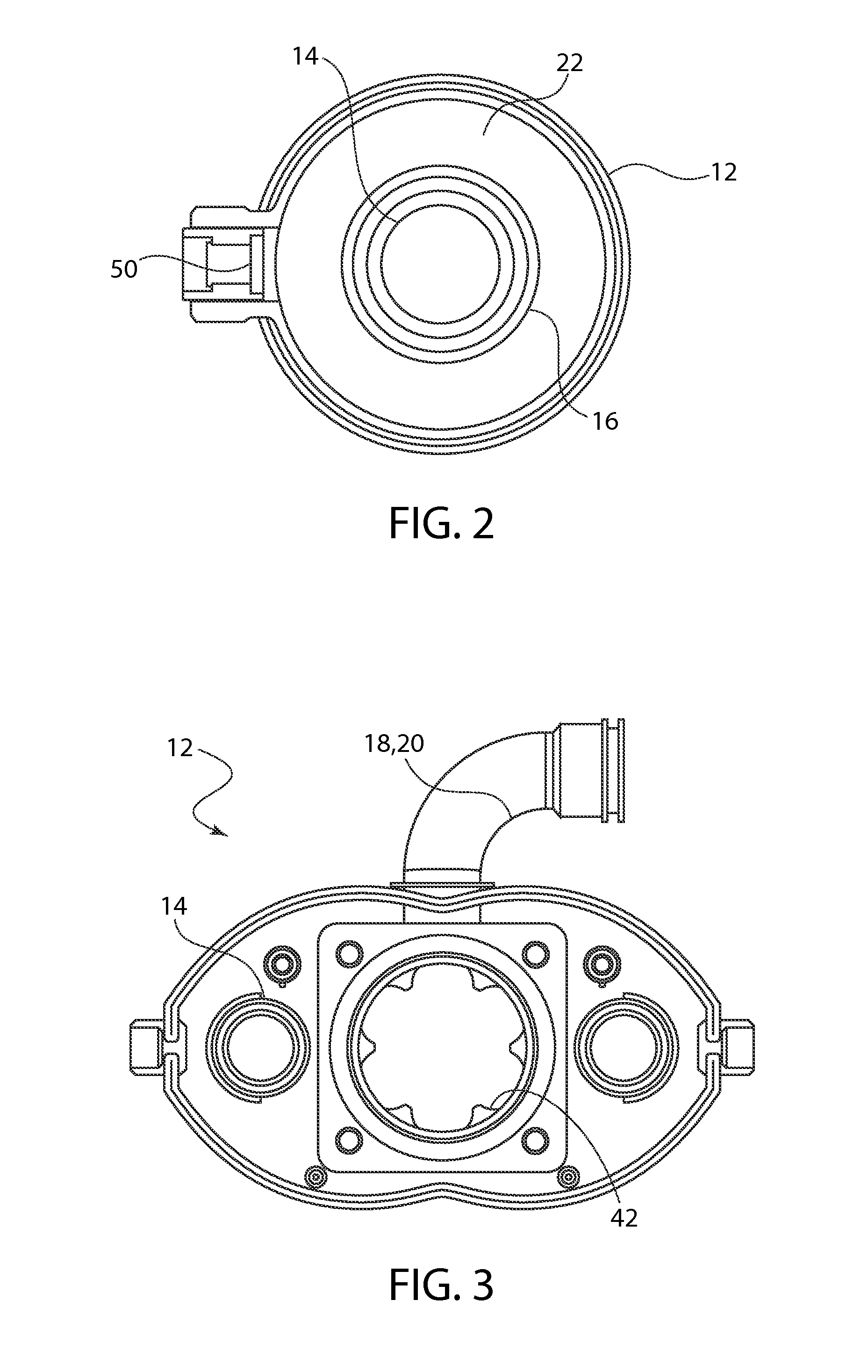

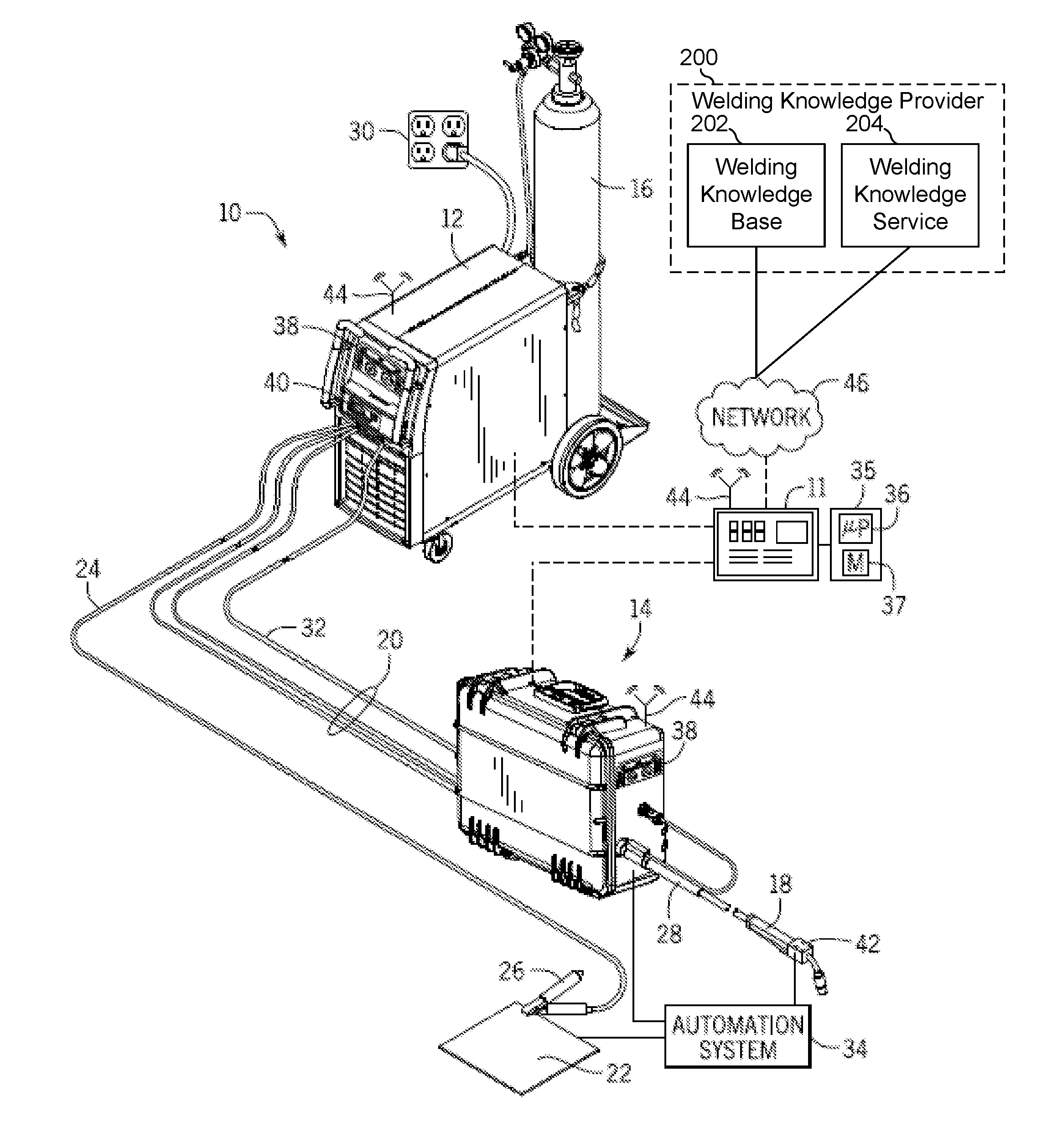

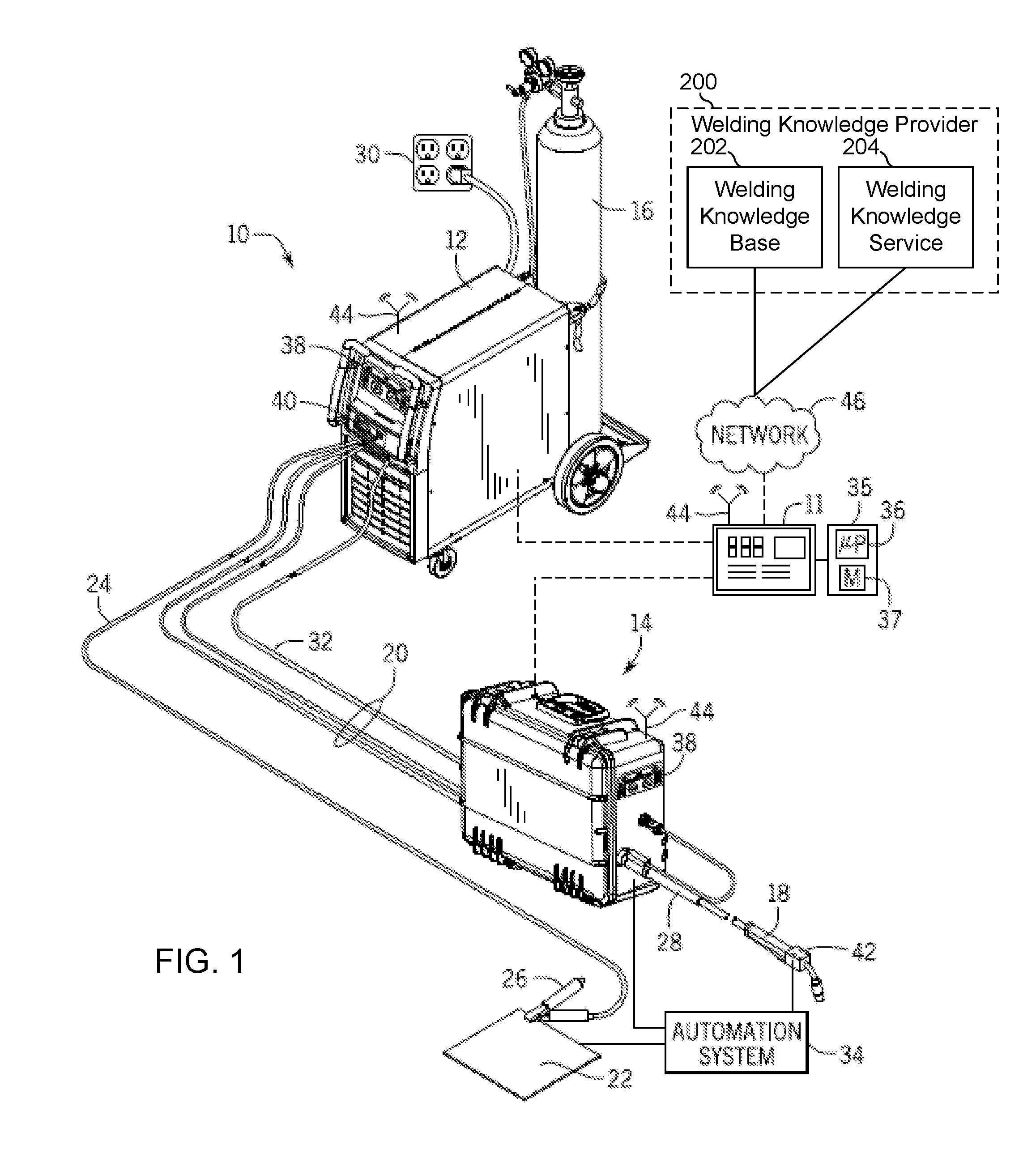

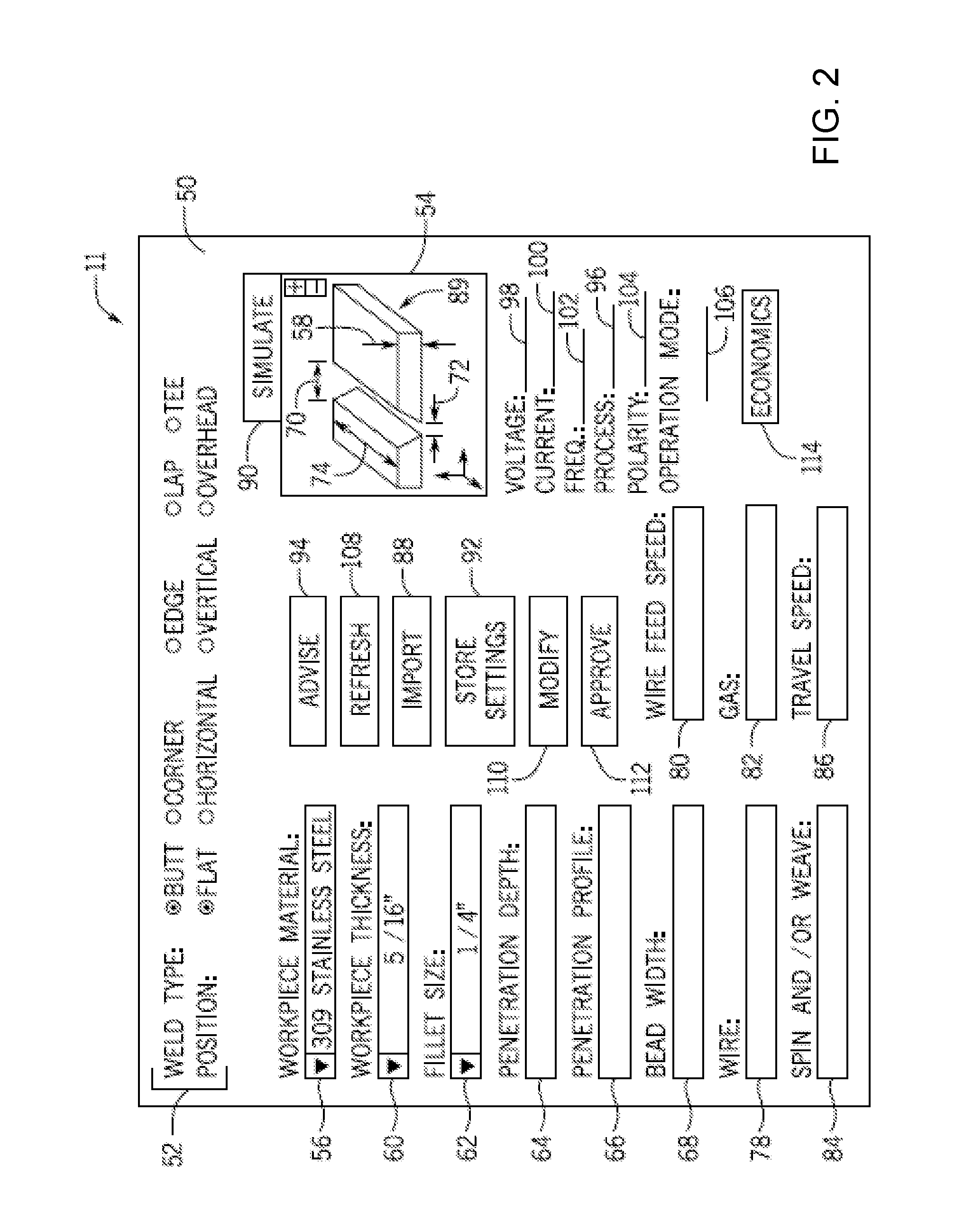

System and method for selecting weld parameters

InactiveUS20150122781A1Good synergyProgramme controlWelding/cutting media/materialsEngineeringWelding process

The welder interface described above may increase synergy with the welding system for the user. The welder interface receives input parameters of a desired weld from a user and advises a weld process and weld variables for producing the desired weld. The welder interface may be integral with a component of the welding system, or a separate component that may be coupled with the welding system. The welder interface may utilize data from a look-up table, neural network, welding procedure system, or database to advise the weld process and weld variables. The user may utilize the welder interface to simulate the weld process and the effect of the weld variables on a simulated weld. The user may modify the input parameters prior to producing a weld, and the user may modify the weld variables after reviewing the results of the produced weld for subsequent welding applications.

Owner:ILLINOIS TOOL WORKS INC

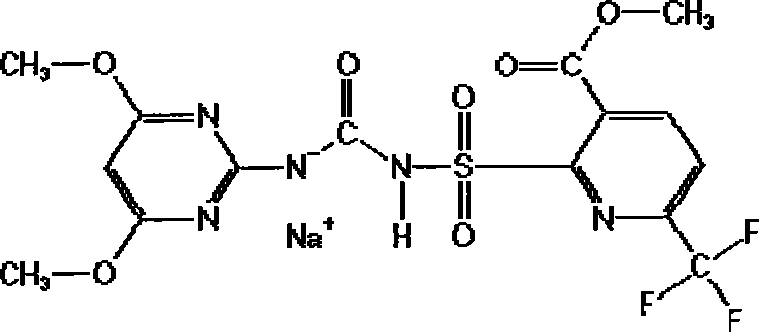

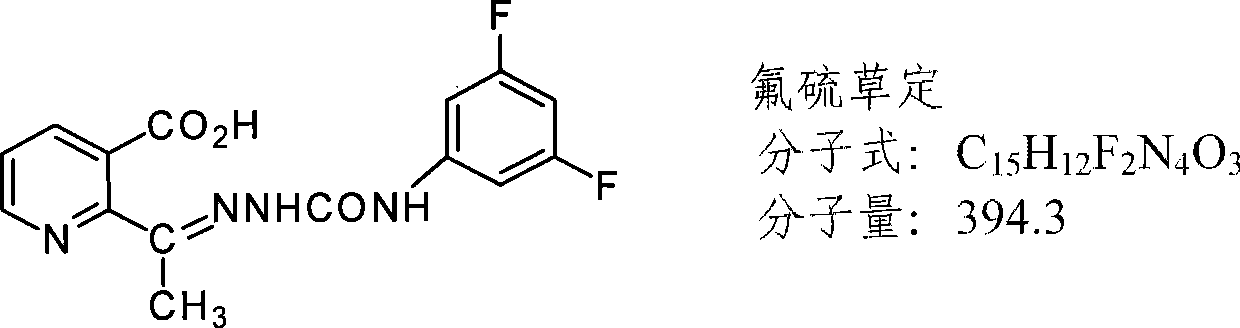

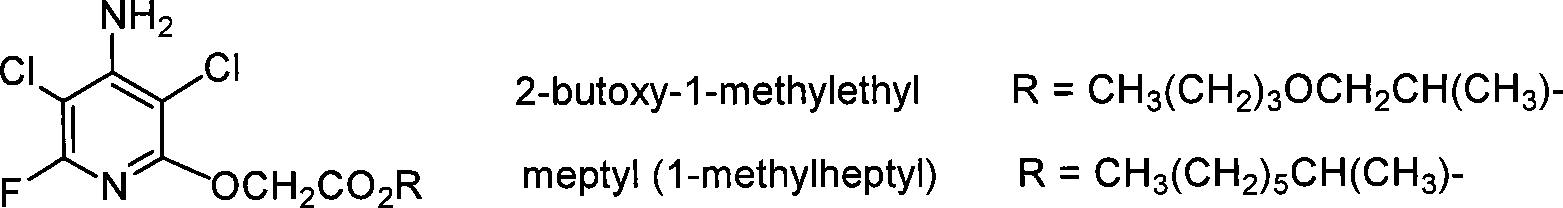

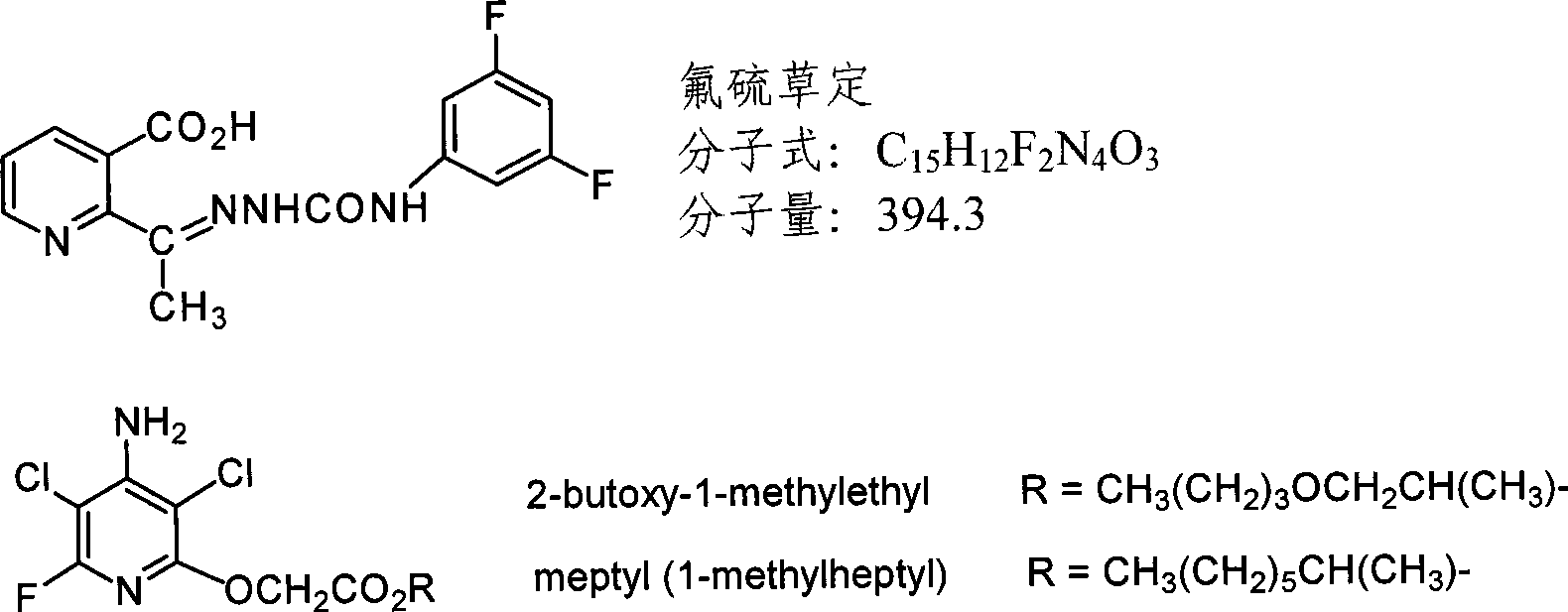

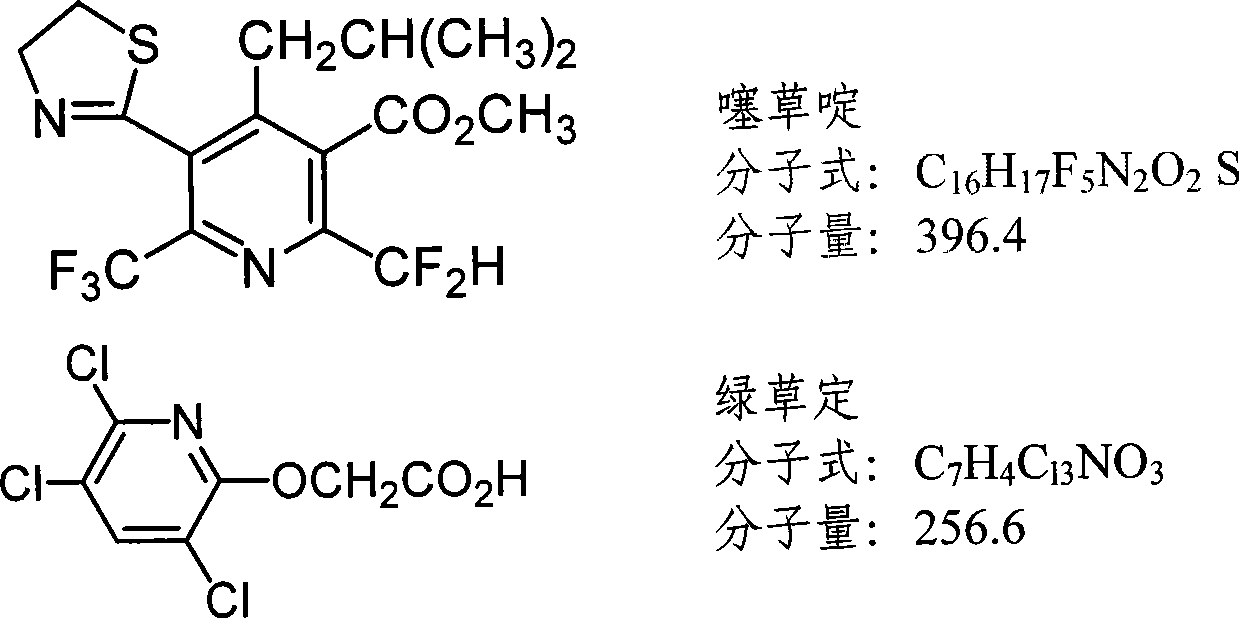

Herbicide composition containing sulfonylurea, pyridine and cyhalofop-butyl and use thereof

ActiveCN101530104AGood synergyImprove weed control effectBiocideAnimal repellantsSulfonylureaBULK ACTIVE INGREDIENT

The invention relates to a herbicide composition, containing sulfonylurea or salt thereof, pyridine and cyhalofop-butyl as active ingredients with the weight ratio of 0.1 to 5: 0.1 to 10: 0.1 to 10. Compared with herbicides with single dose, the weed control effect of the herbicide composition of the invention is obviously improved, thereby reducing the using dosage, reducing the influence degreefor the environment while reducing the pesticide cost, simultaneously enlarging weed control spectrum, and having good control efficiency for Gramineae and broadleaf weeds in rice paddy fields.

Owner:SHANGYU NUTRICHEM

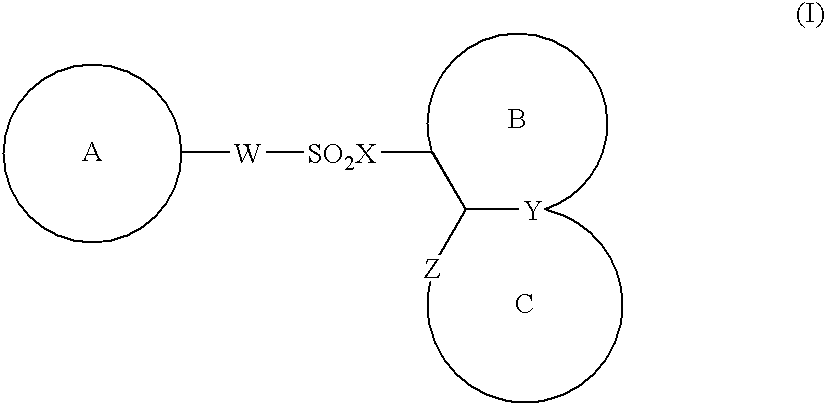

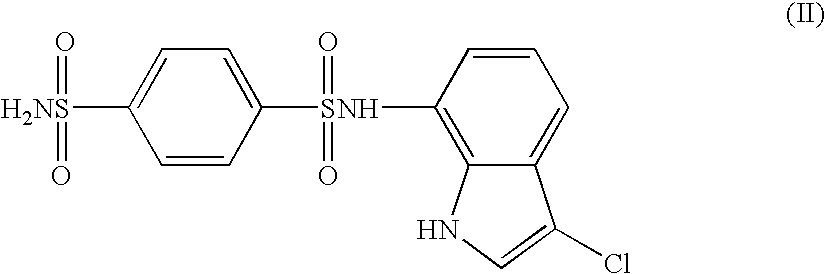

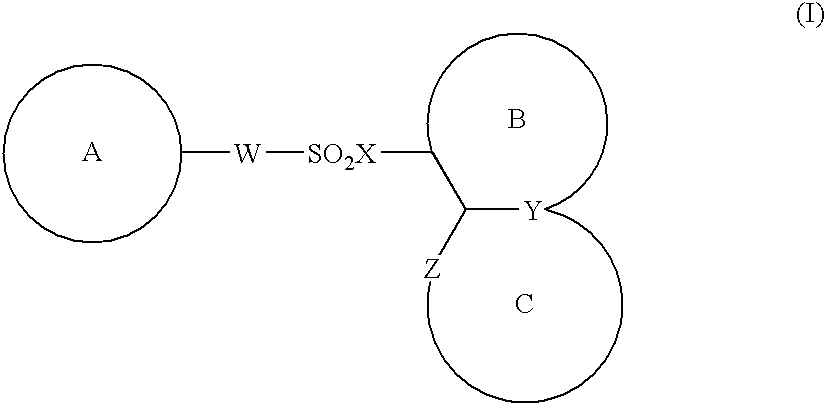

Medicinal compositions for concomitant use as anticancer agent

InactiveUS20030215523A1Good synergyEliminate side effectsHeavy metal active ingredientsBiocideCarboplatinAnticarcinogen

The present invention provides a medicinal composition having an excellent antitumor activity. That is, it provides a medicinal composition comprising a sulfonamide compound, a sulfonate compound or a salt of them, which is represented by the following formula: (wherein ring A represents an aromatic ring which may have a substituent group; ring B represents a 6-membered unsaturated hydrocarbon ring which may have a substituent group etc.; ring C represents a 5-membered hetero-ring containing one or two nitrogen atoms, and the ring C may have a substituent group; W represents a single bond or -CH=CH-; X represents -NH- etc.; and Y represents a carbon atom or a nitrogen atom; and Z represents -NH- etc.), particularly N-(3-chloro-1H-indol-7-yl)-4-sulfamoylbenzenesulfonamide or a salt thereof, combined with at least one substance selected from (1) irinotecan hydrochloride trihydrate; (2) mitomycin C; (3) 5-fluorouracil; (4) cisplatin; (5) gemcitabine hydrochloride; (6) doxorubicin; (7) taxol; (8) carboplatin; (9) oxaliplatin; (10) capecitabine; and (11) a salt of the above-mentioned (1) to (10).

Owner:EISIA R&D MANAGEMENT CO LTD

Herbicide composition containing sulfonylurea, pyridine and penoxsulam and use thereof

InactiveCN101530105AGood synergyImprove weed control effectBiocideAnimal repellantsEnvironment effectSulfonylurea

The invention relates to a herbicide composition, containing sulfonylurea or salt thereof, pyridine and penoxsulam as active ingredients with the weight ratio of 0.1 to 5: 0.1 to 10: 0.1 to 10. Compared with herbicides with single dose, the weed control effect of the herbicide composition of the invention is obviously improved, thereby reducing the using dosage, reducing the influence degree for the environment while reducing the pesticide cost, simultaneously enlarging weed control spectrum, and having good control efficiency for Gramineae and broadleaf weeds in rice paddy fields.

Owner:NUTRICHEM LAB CO LTD

Hydro-isomerization catalyst for paraffine, and its preparing method and application

InactiveCN1792451ASuitable for acidityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveAlkane

A catalyst for the hydroisomerizing reaction of paraffin is composed of the active component (0.05-5.0 Wt%) chosen from Pt, Pd and Ir, and the composite molecular sieve ZSM-22 / ZSM-23 (or ZSM-23 / ZSM-22). It has high catalytic activity and selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

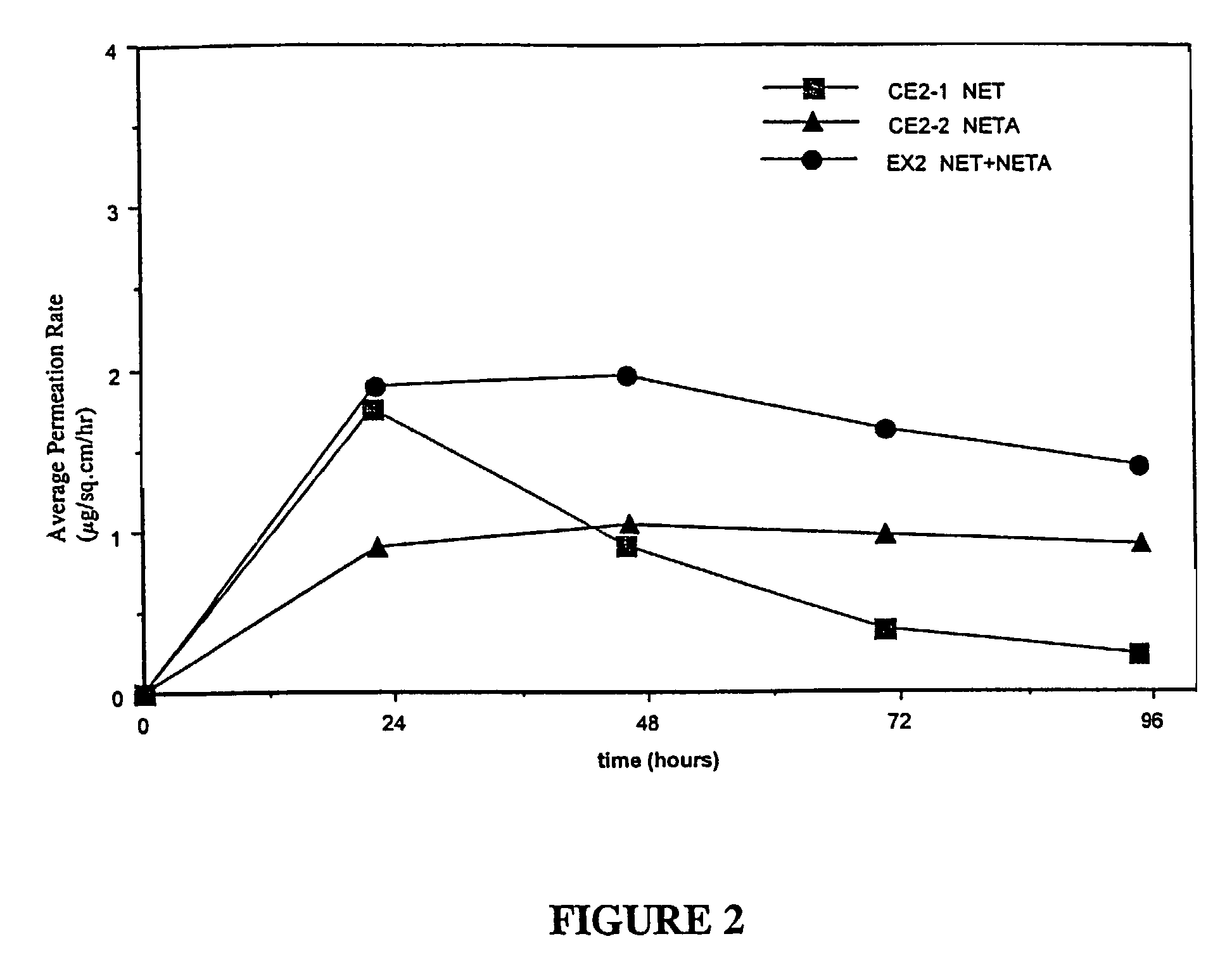

Enhanced drug delivery in transdermal systems

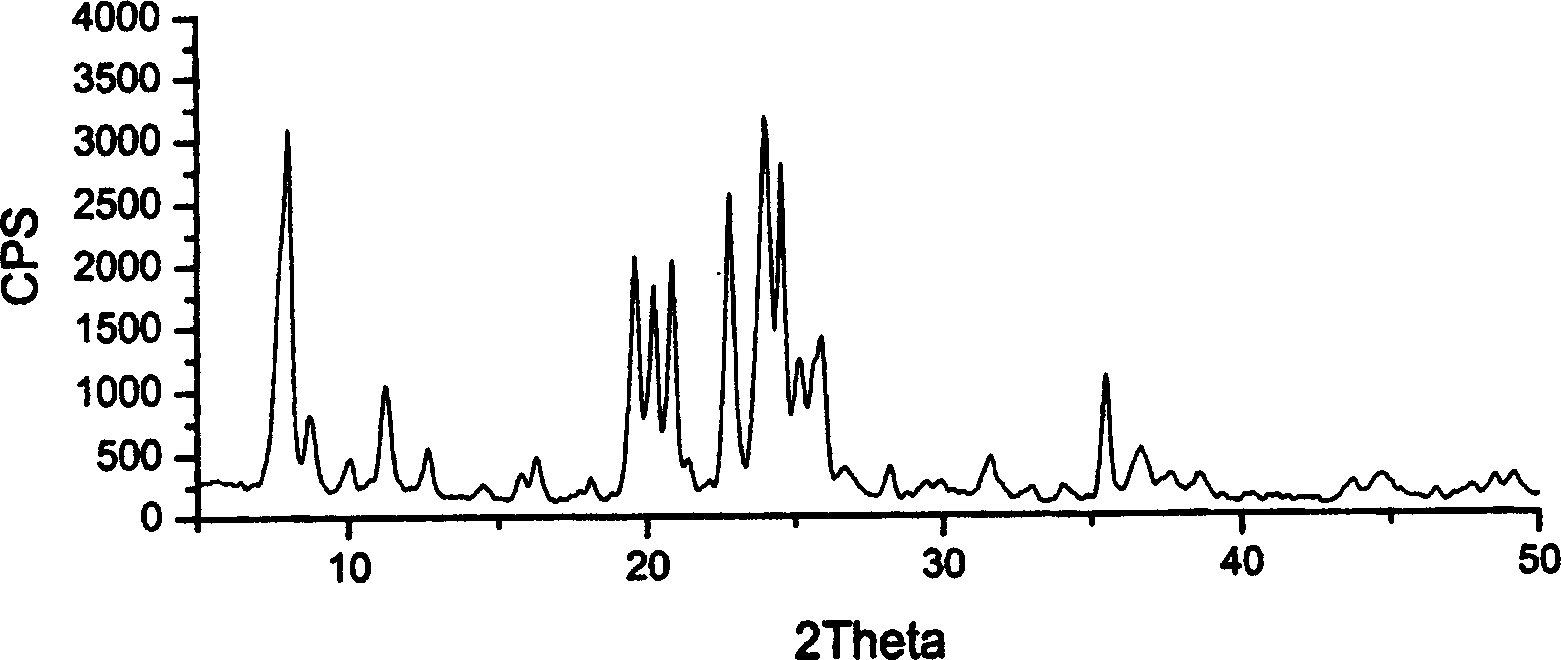

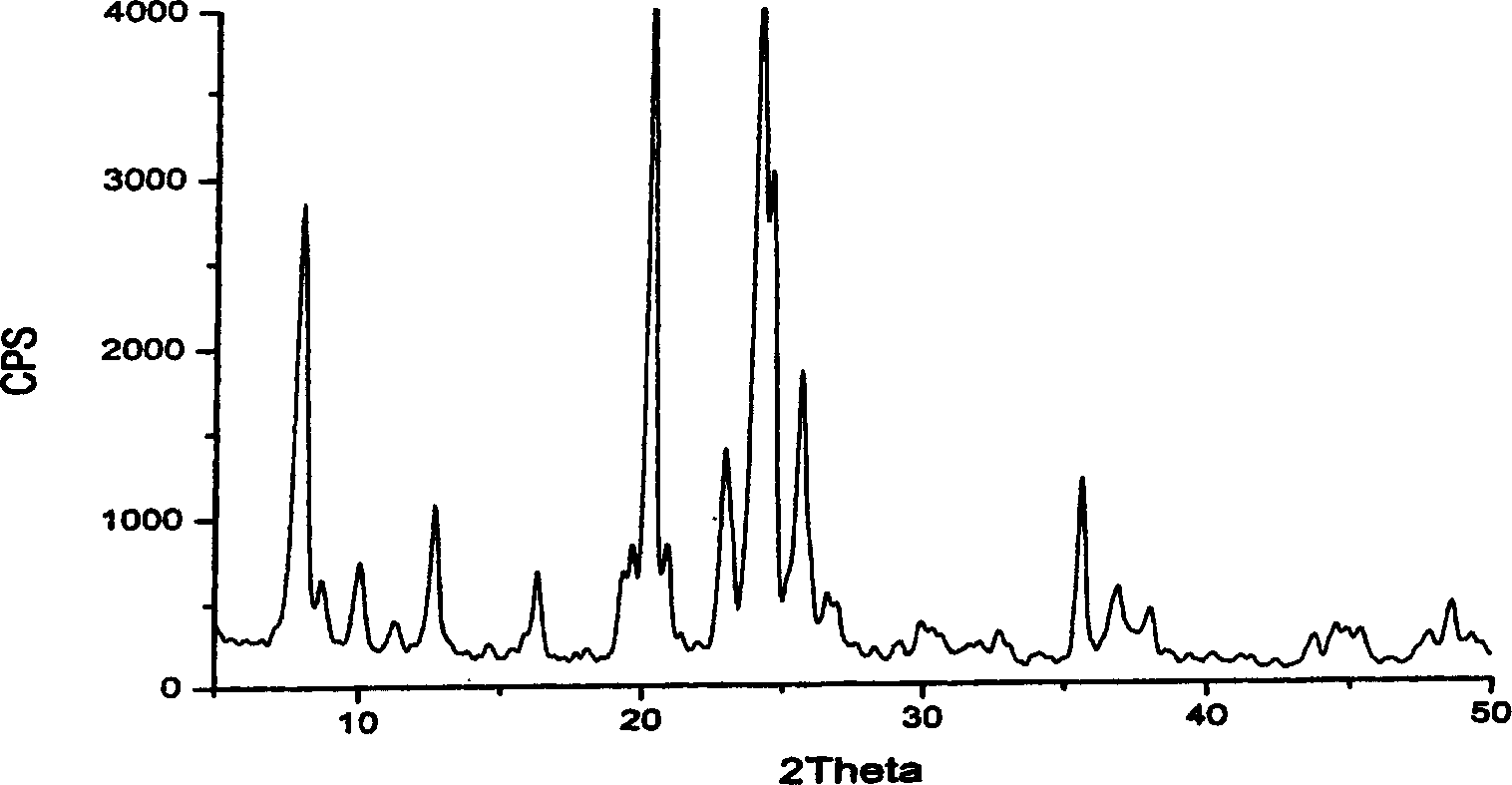

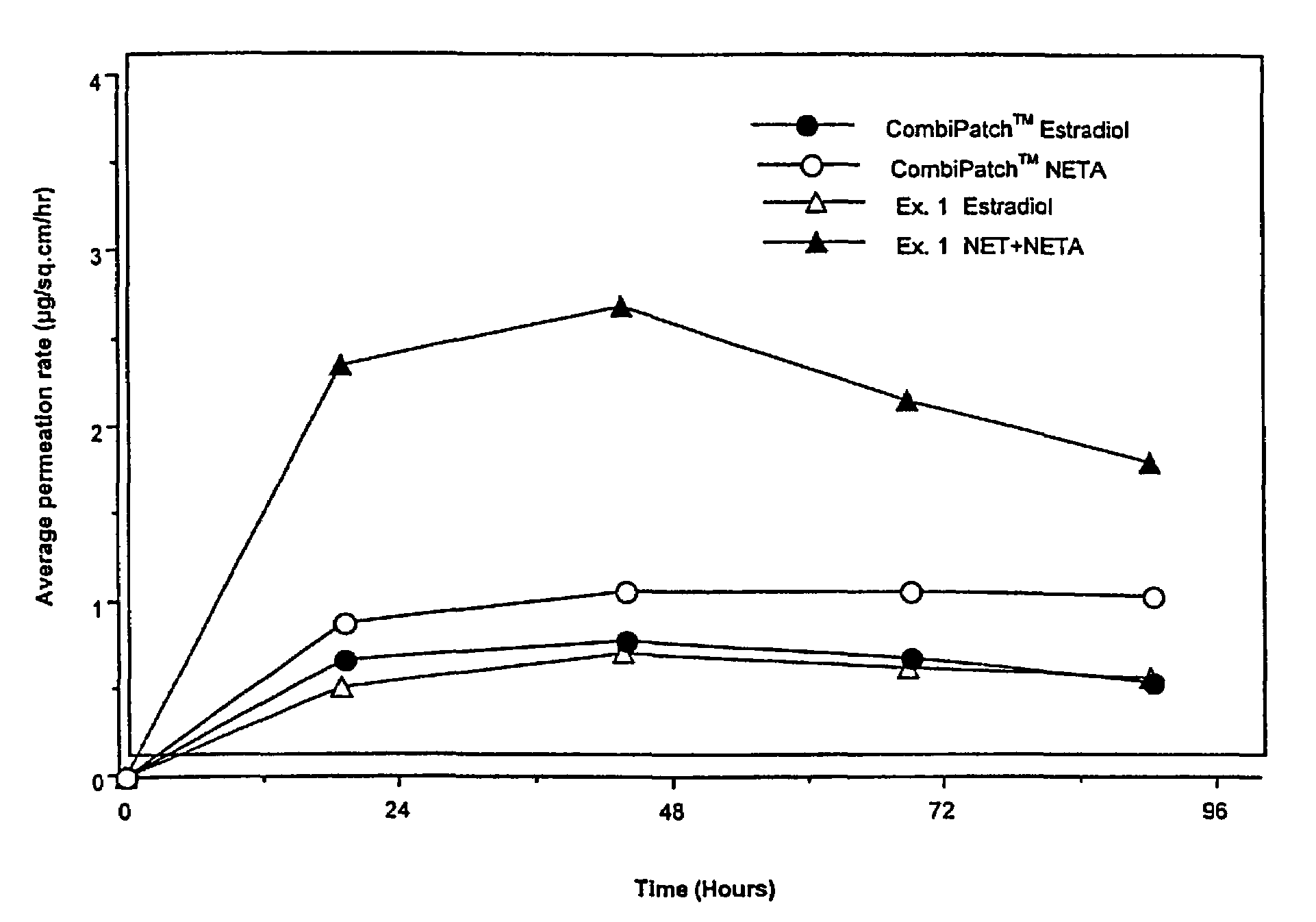

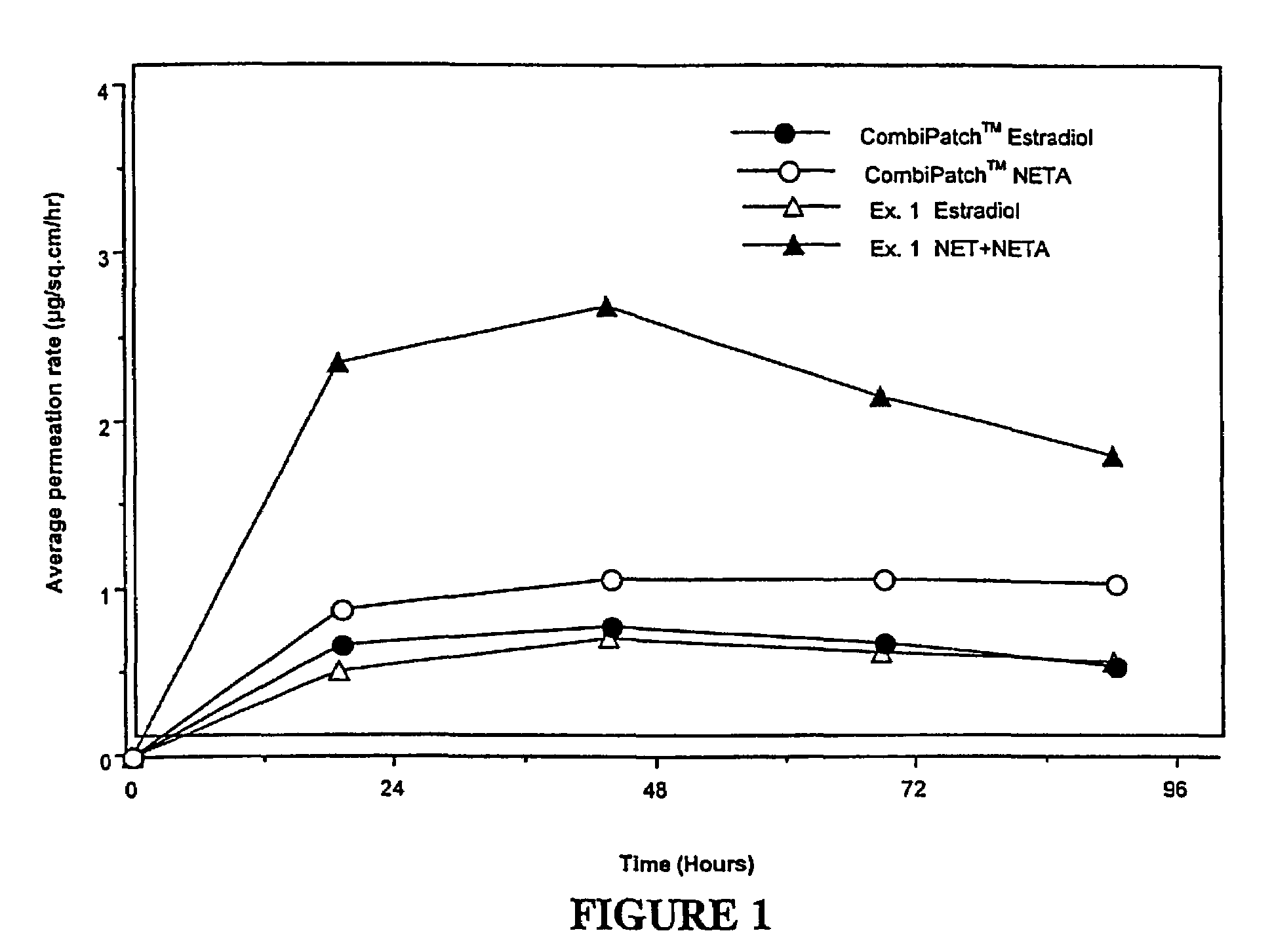

InactiveUS7456159B2Convenient amountGood synergyOrganic active ingredientsBiocideActive agentEthyl ester

A composition for transdermal administration resulting from an admixture includes: a therapeutically effective amount of a drug that includes a parent drug and a prodrug; and and a pharmaceutically acceptable carrier, wherein the parent drug and prodrug are individually present in an amount sufficient for a pharmacological effect. In a preferred embodiment, the admixture includes: a therapeutically effective amount of a pharmaceutically active agent that includes a corresponding steroid and a steroid derivative; and a carrier for the pharmaceutically active agent. The steroid and the corresponding steroid derivative are present in a weight ratio of 10:1 to 1:10 steroid: corresponding steroid derivative. In a preferred embodiment ratio is 6:1 to 1:6. In a preferred embodiment, the corresponding steroid derivative is a steroid ester. In another preferred embodiment, the carrier is a polymer that includes a pressure-sensitive adhesive. In another preferred embodiment, the parent drug is an ACE inhibitor such as ramipril and the prodrug is an ACE inhibitor prodrug such as ramipril ethyl and / or methyl ester.

Owner:NOVEN PHARMA

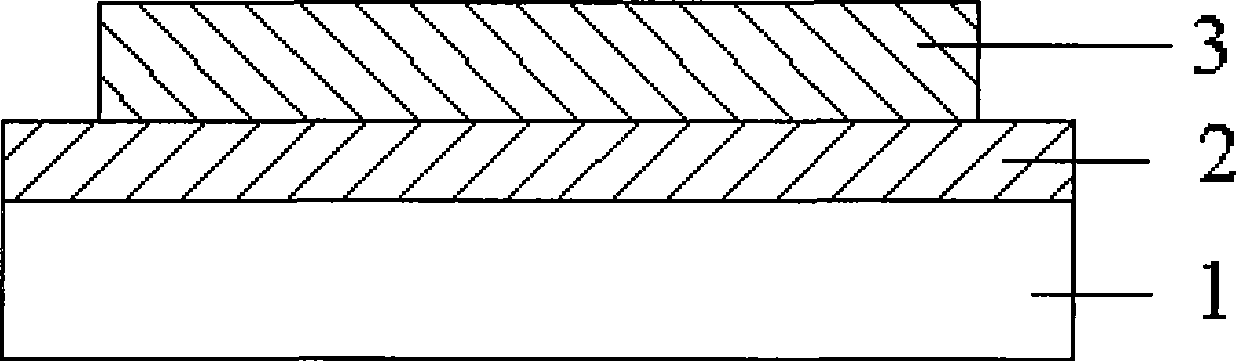

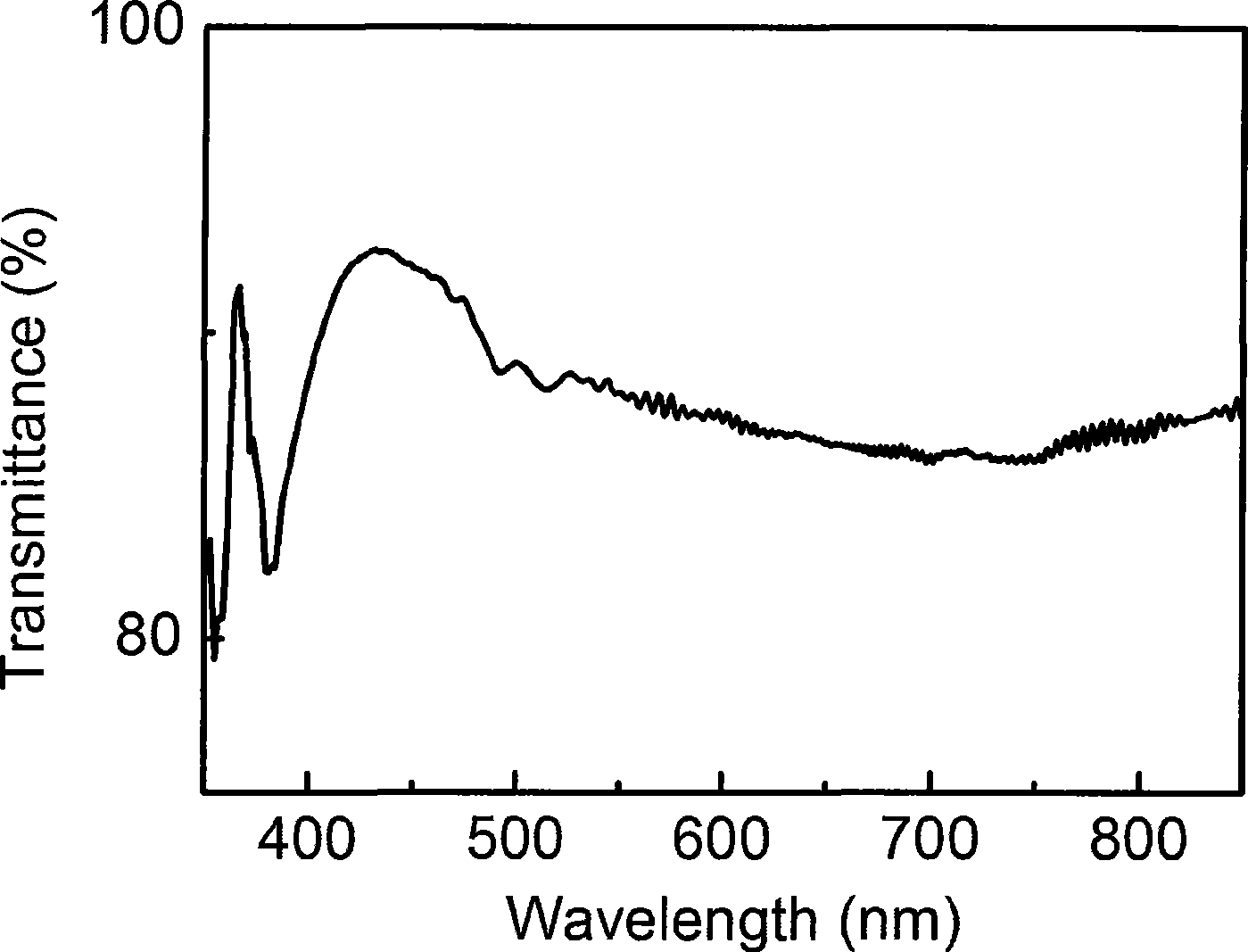

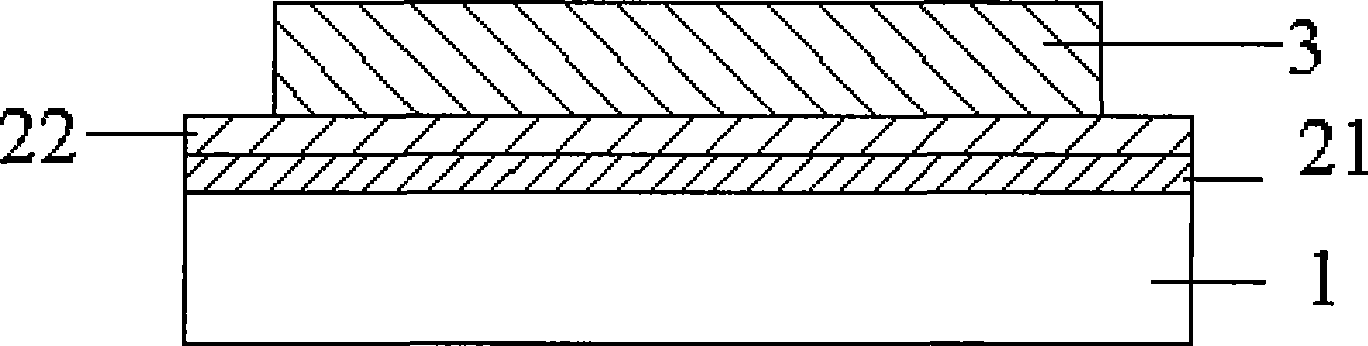

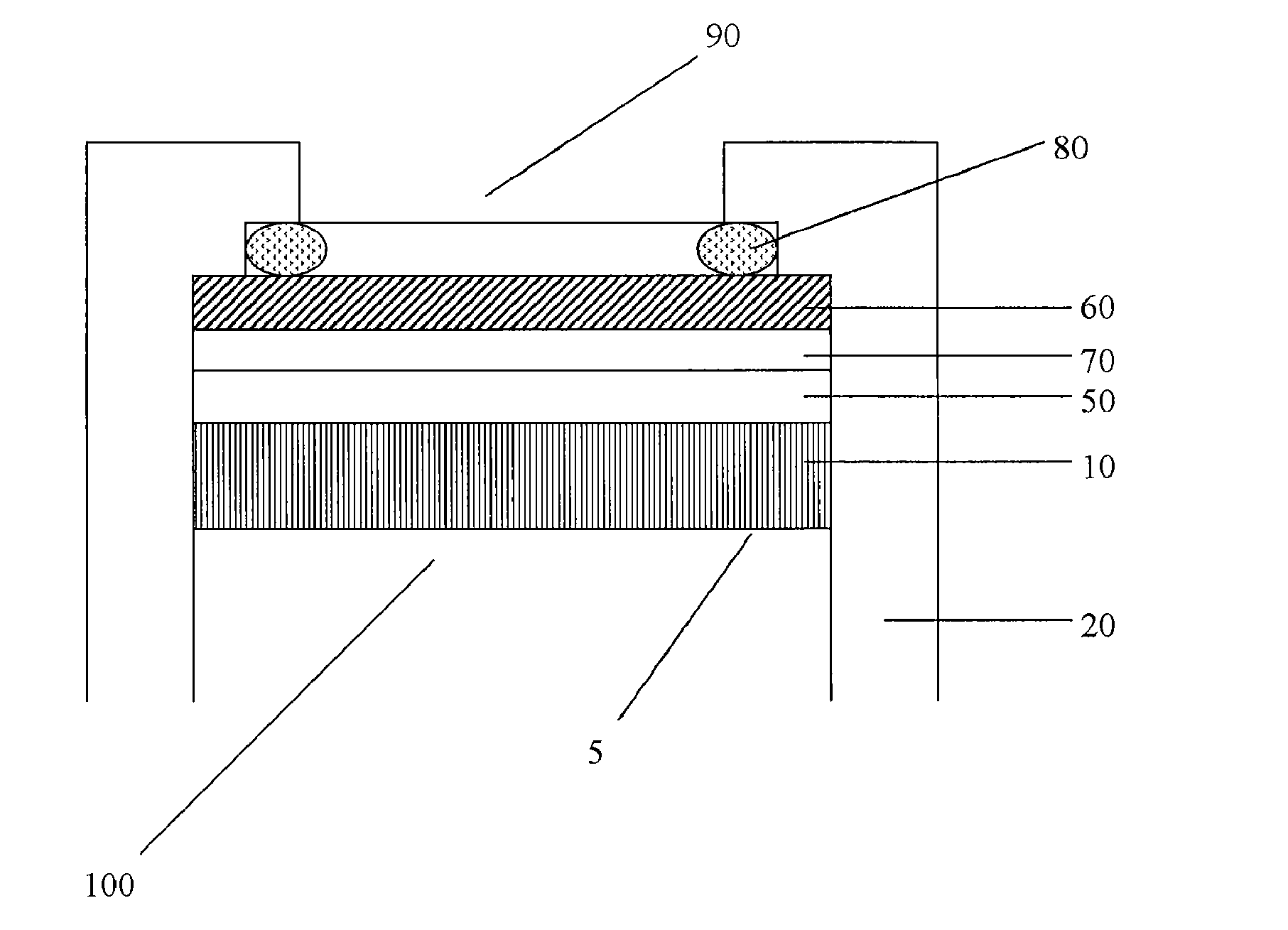

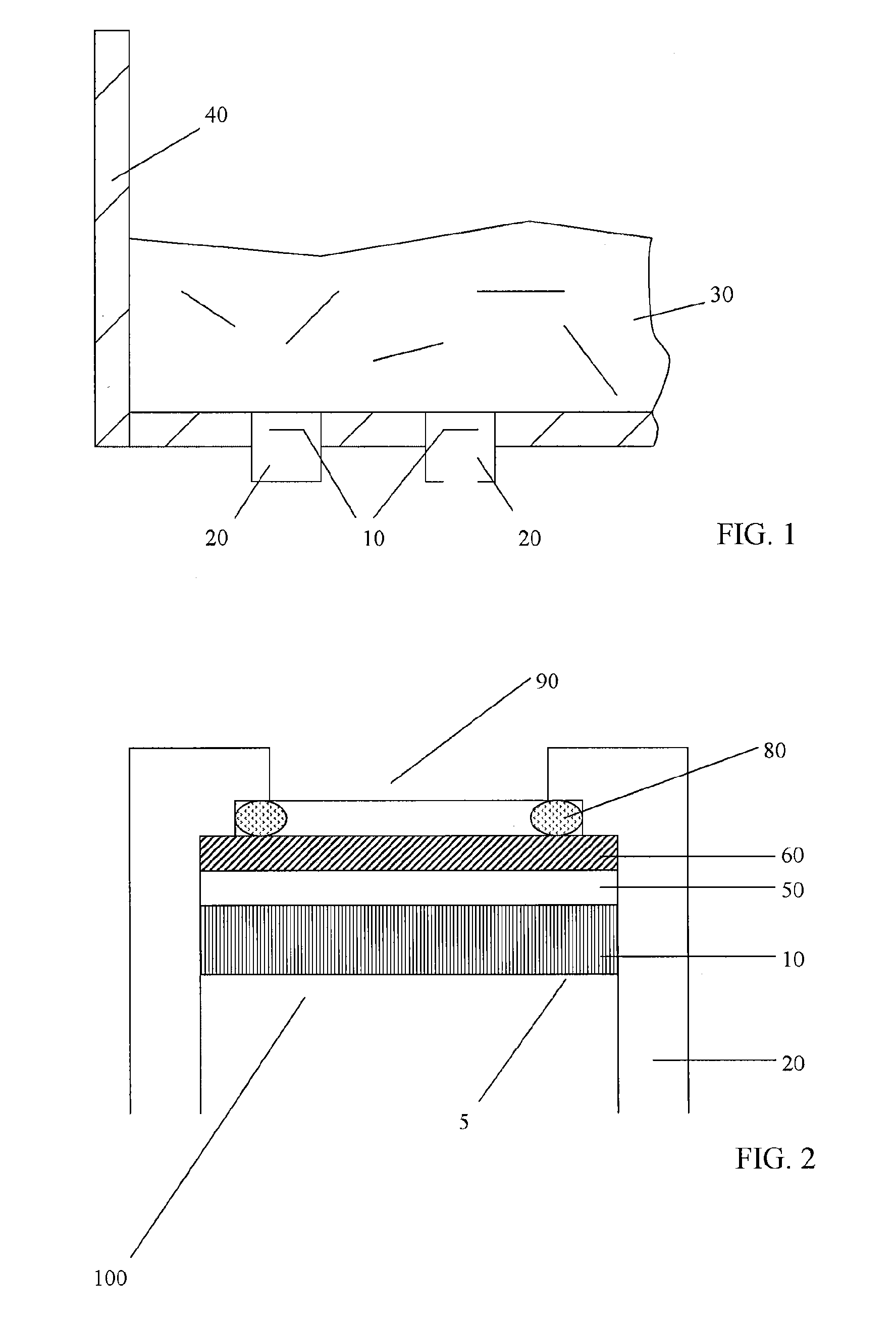

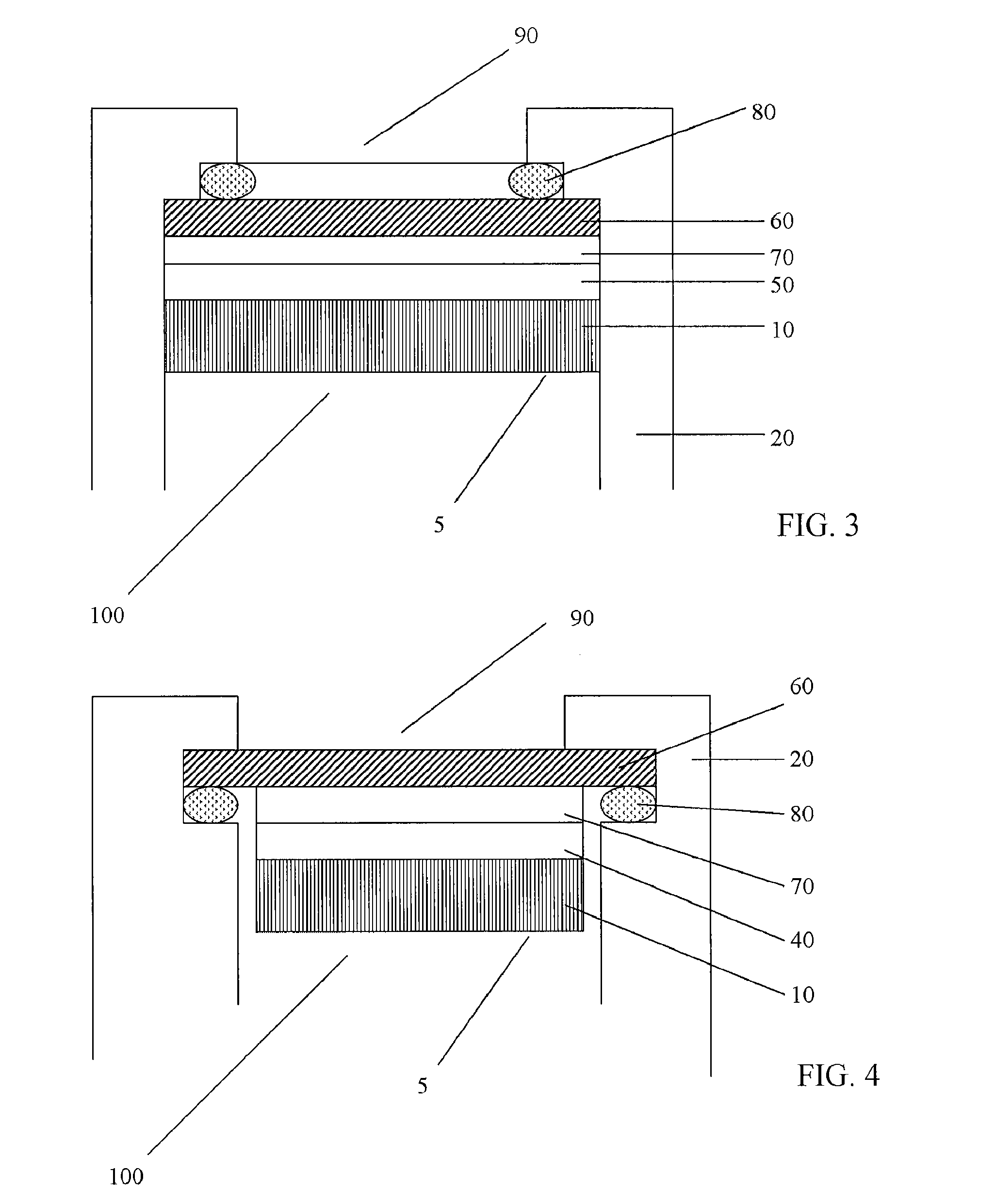

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

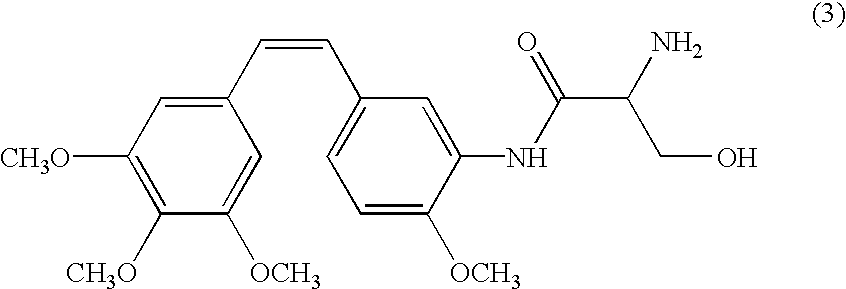

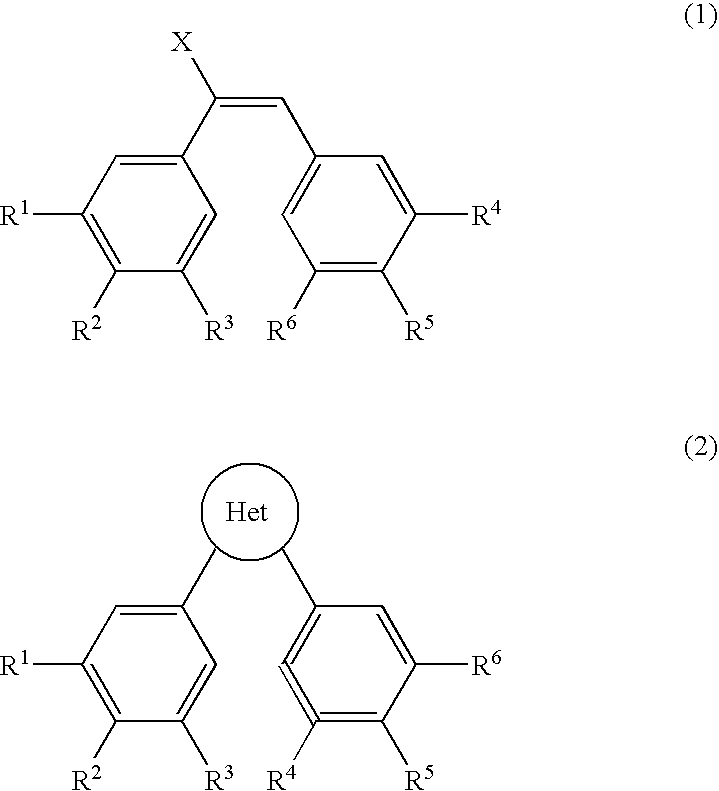

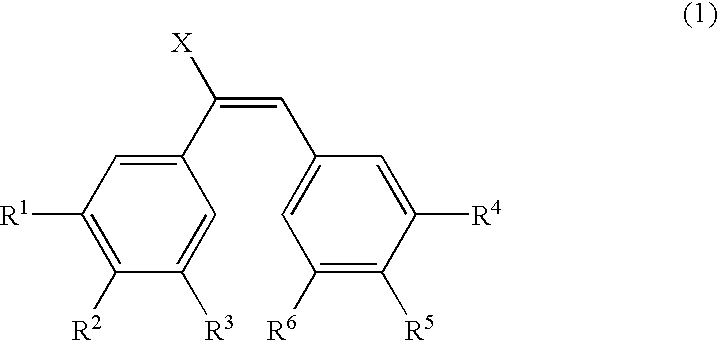

Anti-tumor composition

InactiveUS6992106B2Good curative effectEasy to optimizeBiocideHalogenated hydrocarbon active ingredientsPlatinumMedicine

The present invention provides composition having as active ingredients a stilbene derivative and a platinum coordination compound which is highly efficacious and highly safe for treating tumors, particularly for the treatment of solid or malignant tumors and thus methods of cancer and tumor treatment using the composition are also provided.

Owner:AJINOMOTO CO INC

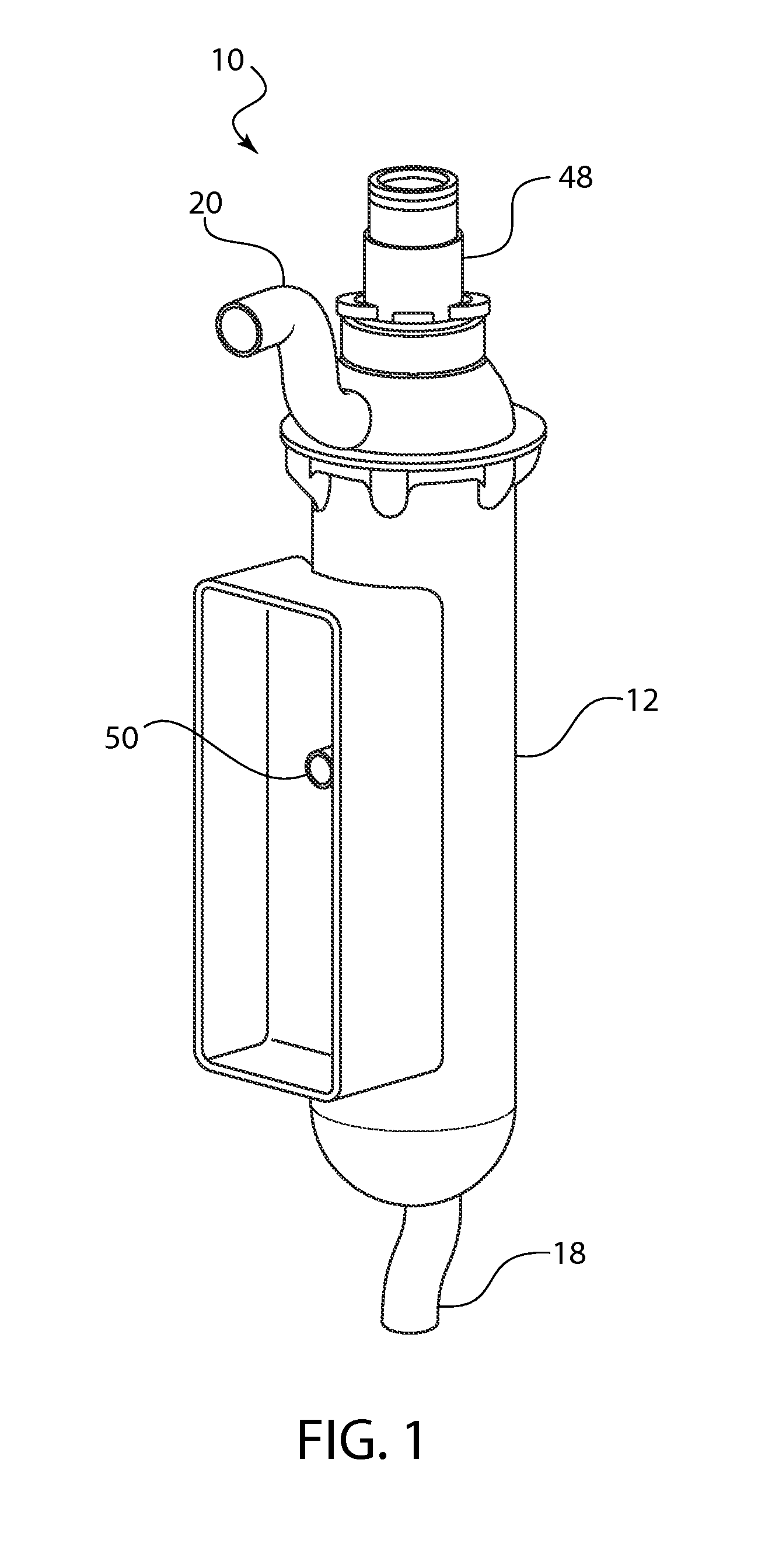

Systems and methods for disinfecting water

ActiveUS20120051977A1Reduce power consumptionLow costWrappers shrinkageScattering properties measurementsPotable waterOn board

Embodiments of the present invention provide systems and methods for point of use location treatment of potable water supplies on demand on board passenger vehicles, such as aircraft. The systems described generally provide increased safety features, alternate ultraviolet light sources, and reduced power consumption.

Owner:MAG AEROSPACE IND INC

Composite molecular sieve in ten-element cyclic structure and its synthesis process

InactiveCN1772611AGood synergyHigh yieldMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesPhosphoric acidChemistry

The composite molecular sieve in ten-element cyclic structure has ten-element cyclic Si-Al structure and ten-element cyclic aluminum silicon phosphate structure. It is prepared through adding ZSM-22, ZSM-23, ZSM-5, EU-1, NU-87 or other ten-element cyclic structure Si-Al molecular sieve into aluminum silicon phosphate sol obtained via mixing Si source, Al source, P source, water and template agent to obtain primary sol; and subsequent hydrothermal crystallization to obtain the compound molecular sieve. The synthesis conditions may be altered based on the requirement to change the two phase ratio and the Si / Al ratio. Normally, the added amount of ten-element cyclic Si-Al molecular sieve is 0.01-0.6 time the total oxide weight in the aluminum silicon phosphate sol. The composite molecular sieve in ten-element cyclic structure may be used in the isometric dewaxing of lubricant oil and the isometric pour point depression of diesel oil and exhibits excellent catalytic performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

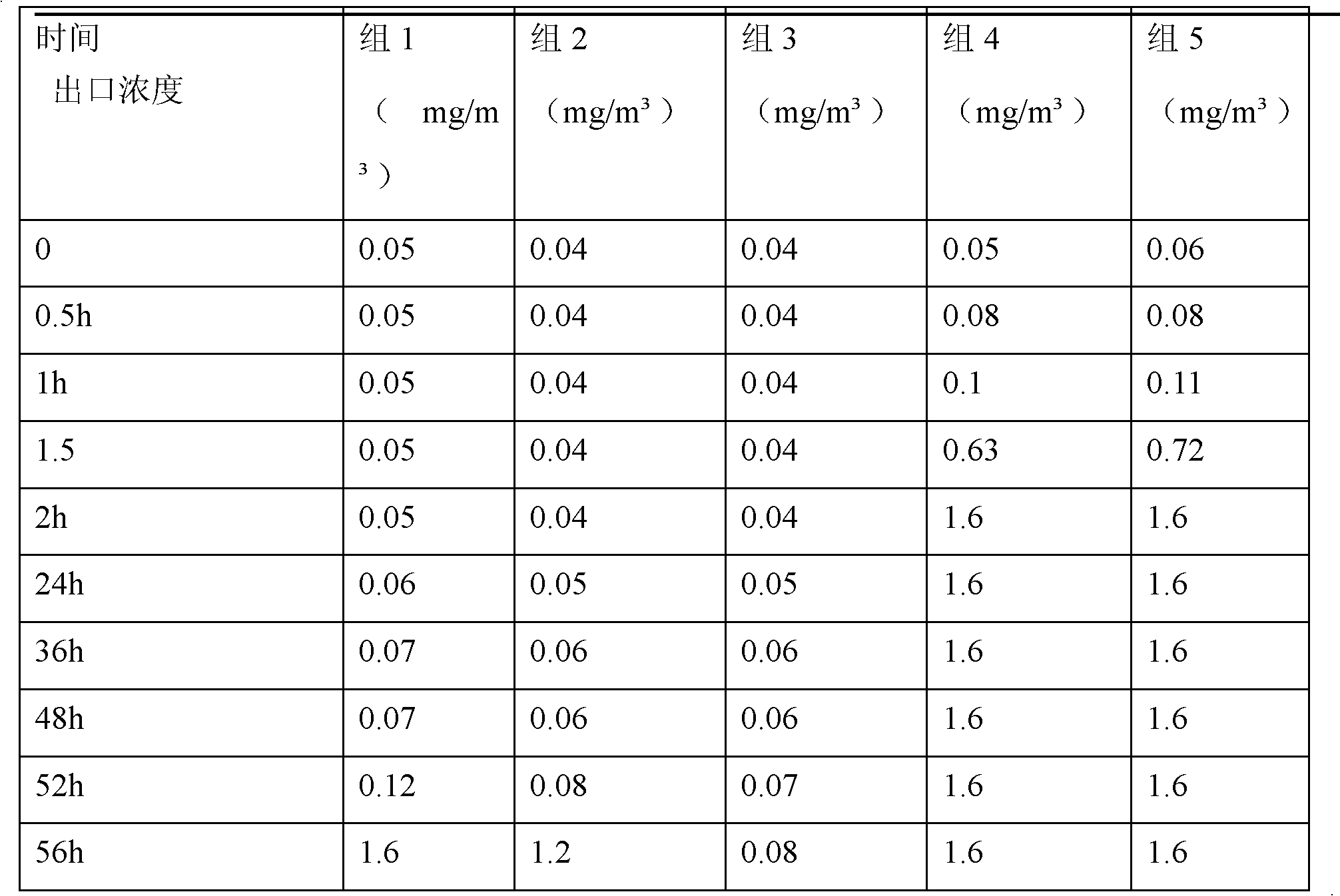

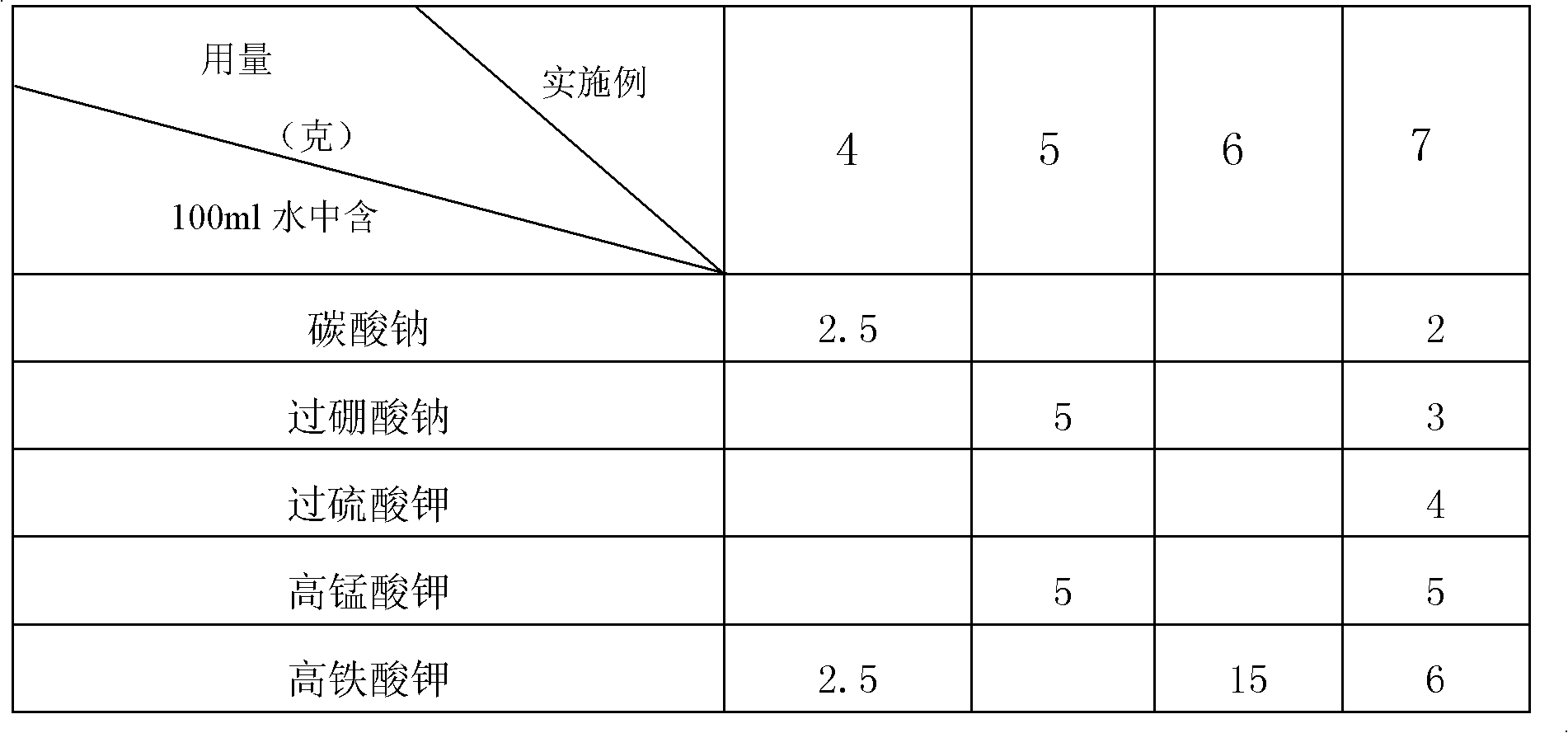

Oxidation type air purifying material and preparation method thereof

InactiveCN102101008ASolve the secondary release of harmful gasesSolve the purificationDispersed particle separationAir cleaningAqueous solution

The invention discloses an oxidation type air purifying material which has low cost and good air purifying effect and does not have secondary pollution. The oxidation type air purifying material is formed by loading an inorganic oxidant on an inorganic adsorbing material. The invention provides a method for preparing the material simultaneously, which comprises the following steps of: drying the inorganic adsorbing material till the moisture of the inorganic adsorbing material is less than 4 percent; preparing aqueous solution, which is at the concentration of between 5 and 20 percent (g / ml), of the inorganic oxidant; and immersing the aqueous solution of the inorganic oxidant in the inorganic adsorbing material for 18 to 36 hours, draining redundant liquid, and drying in a drying oven at the temperature of between 50 and 130 DEG C.

Owner:河北亚太环境科技发展股份有限公司

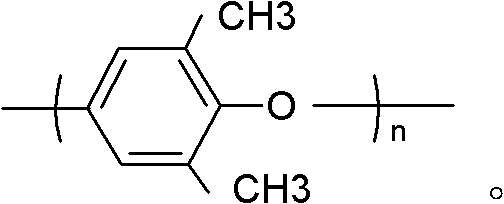

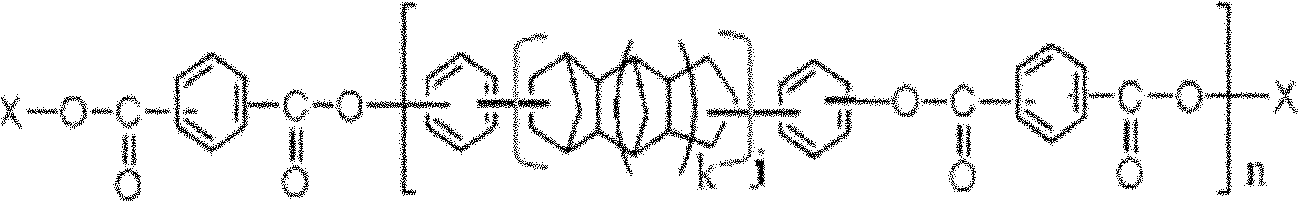

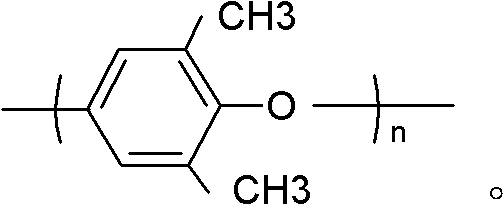

Epoxy resin composition as well as prepreg and laminated board made of same

InactiveCN102051022AGood heat resistanceLow water absorptionSynthetic resin layered productsCircuit susbtrate materialsDielectric lossChemistry

The invention relates to an epoxy resin composition as well as a prepreg and a laminated board made of the same. The epoxy resin composition comprises the following components in parts by weight: 1-50 parts of modified polyphenylene oxide resin, 30-80 parts of epoxy resin, 20-60 parts of active ester curing agent, 0-50 parts of filler and 1-20 parts of assistant. The prepreg made of the epoxy resin composition comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The laminated board made of the epoxy resin composition comprises a plurality of laminated prepregs, wherein each prepreg comprises a base material and the epoxy resin composition which is attached to the base material through soaking and drying. The invention has the advantages of high heat resistance, high fire retardancy, low dielectric constant, low dielectric loss, excellent high-frequency dielectric properties and the like, and is suitable to be used as a high frequency circuit substrate material.

Owner:GUANGDONG SHENGYI SCI TECH

Method and Apparatus for an Improved Aerosol Generator and Associated Uses and Equipment

ActiveUS20110114744A1Reduce probabilityLow temperature of insideMovable spraying apparatusSpray nozzlesChemical reactionTransducer

The invention is an apparatus and methods for optimizing the performance and protecting one or more aerosol generating transducers from deterioration while operating in a chemically reactive aqueous solution by utilizing one or more protective barrier techniques to eliminate chemical interaction between the aqueous solution and the transducers, among other features of the generator including these transducers. The method of the present invention produces an aerosol producing transducer with the transducer housing and assembly to be constructed in such a way as to assure its efficient and effective long-term and problem free operation in an aqueous solution that is chemically reactive.

Owner:ALTAPURE

Impregnating solution of hydrogenation catalyst, its preparation method, hydrogenation catalyst and preparation method thereof

ActiveCN103055956AImprove hydrodesulfurization activityHigh activityMolecular sieve catalystsCatalyst activation/preparationHydrodesulfurizationDecane

The invention provides an impregnating solution of a hydrogenation catalyst and its preparation method. The method includes: preparing a VIII-th group metal compound and a first organic complexing agent into an aqueous solution A; preparing a VIB-th group metal compound into an aqueous solution B; and mixing the aqueous solution A and the aqueous solution B. Specifically, the ligand of the first organic complexing agent at least contains the coordination atom N. The invention also provides a hydrogenation catalyst and a preparation method thereof. Compared with current catalysts, the hydrogenation catalyst provided in the invention has high hydrodesulfurization activity. For example, a mixed solution of n-decane with a 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) content of 0.59wt% is adopted as the raw material, and hydrodesulfurization activity contrast evaluation is performed on the catalyst provided in the invention and a contrast catalyst. In terms of a contrast catalyst activity of 100, the hydrodesulfurization activity of the catalyst provided in the invention can reach 120.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing preserved kiwi fruit by vacuum freeze drying

InactiveCN102742711AAdjust acidity properlyGood hardening effectConfectionerySweetmeatsLiquid glucoseActinidia

A method for preparing preserved kiwi fruit by vacuum freeze drying. The method comprises steps of: peeling and slicing kiwi fruit, immersing the kiwi fruit in color protecting liquid, and then placing the kiwi fruit in a hardening liquid for hardening; after hardening, conducting an ultrasonic pretreatment in liquid glucose; and then successively carrying out vacuum sugar permeability, prefreezing, vacuum freeze drying, and packing to obtain the preserved kiwi fruit. According to the present invention, glucose lactone is added into a calcium chloride hardening liquid to coagulate protein in the fruit pieces and significantly improve hardening effect. The ultrasonic pretreatment and vacuum sugar permeability avoid a heat treatment process of rapid heating for a long time or short time, so that the kiwi fruit slices are still bright green (quite similar with an original fruit color). Vacuum freeze drying on the kiwi fruit realizes a high nutrient conservation rate.

Owner:NORTHWEST UNIV(CN)

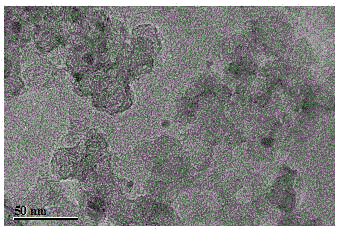

Method for preparing monodisperse metal atom/graphene composite material employing electrochemical dissolved graphite

ActiveCN106654300ALow costSimple stepsCell electrodesMetal/metal-oxides/metal-hydroxide catalystsGraphiteElectrochemistry

The invention discloses a method for preparing a monodisperse metal atom / graphene composite material employing electrochemical dissolved graphite. The method comprises the steps of (1) preparing an electrode from a graphite-based material; (2) electrolyzing the prepared electrode in an electrolytic cell, carrying out solid-liquid separation and recycling an electrolyte; (3) further stripping the solid obtained by separation and carrying out solid-liquid separation to obtain a crude monodisperse metal atom / graphene composite material; (4) separating and purifying the crude monodisperse metal atom / graphene composite material; and (5) carrying out thermal treatment on the composite material obtained in the step (4) under inert atmosphere protection and cooling and drying the material to obtain a monodisperse metal atom / graphene composite catalyst. The preparation method is simple in process steps, high in efficiency and low in energy consumption, and massive production can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

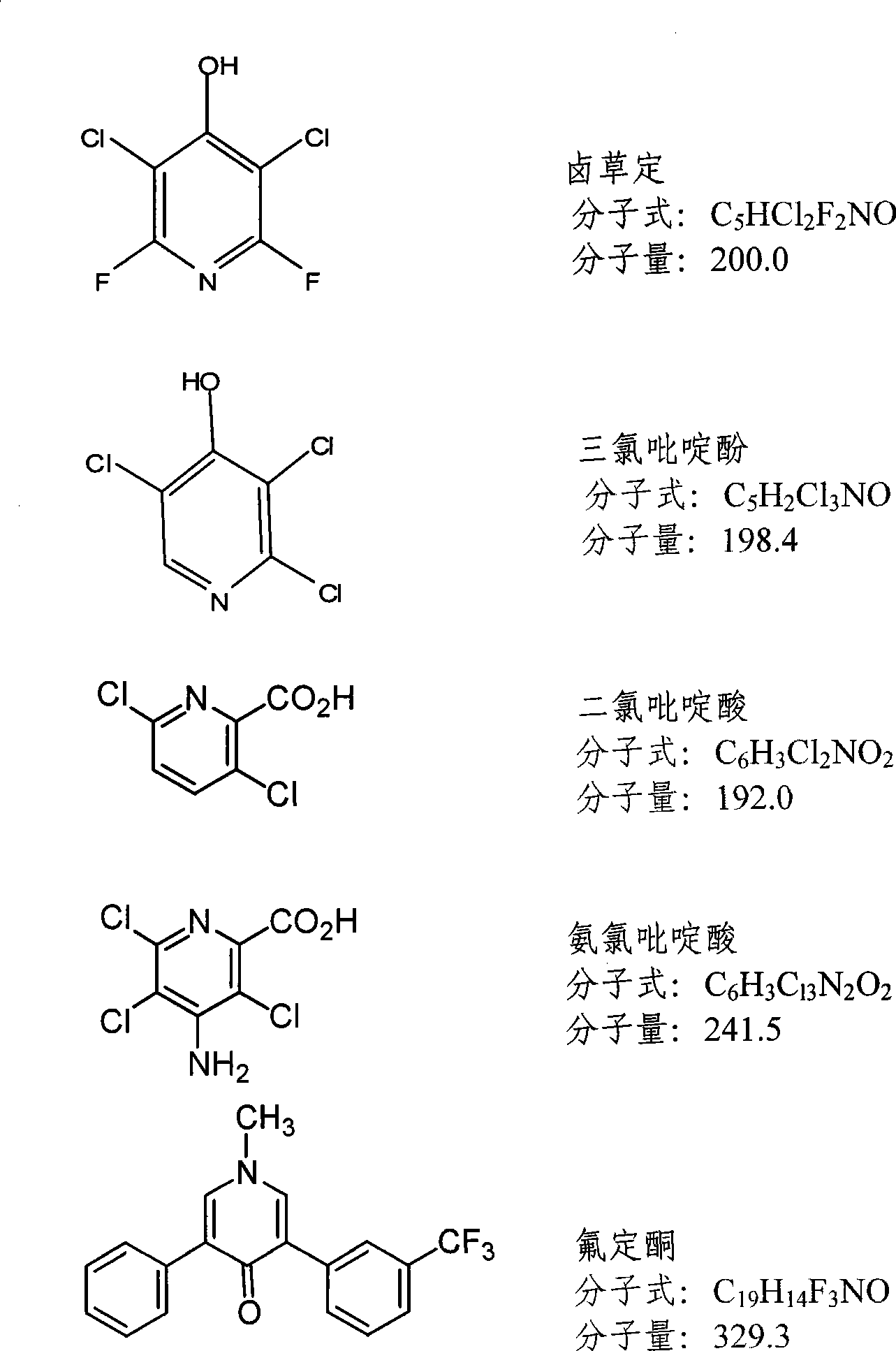

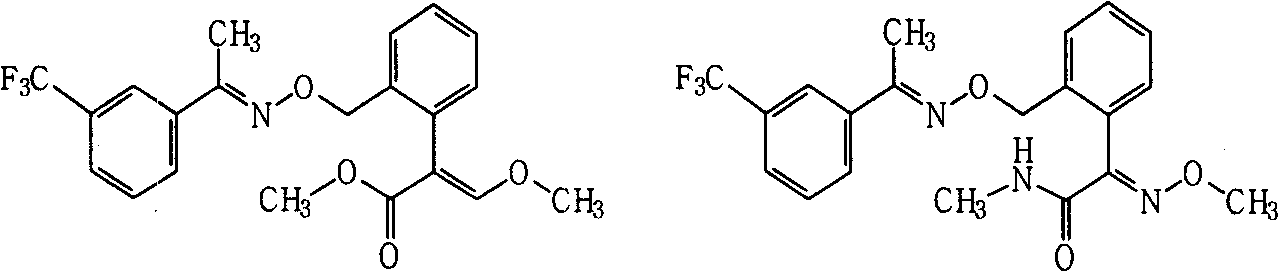

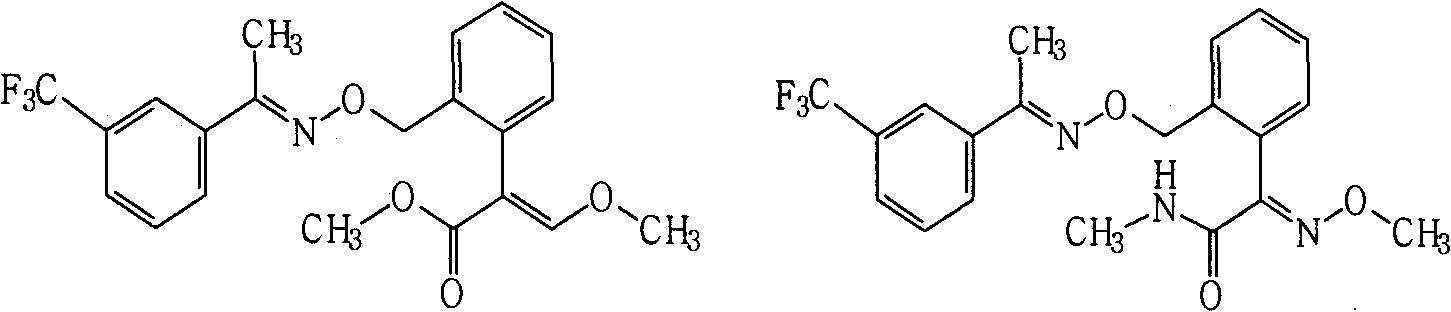

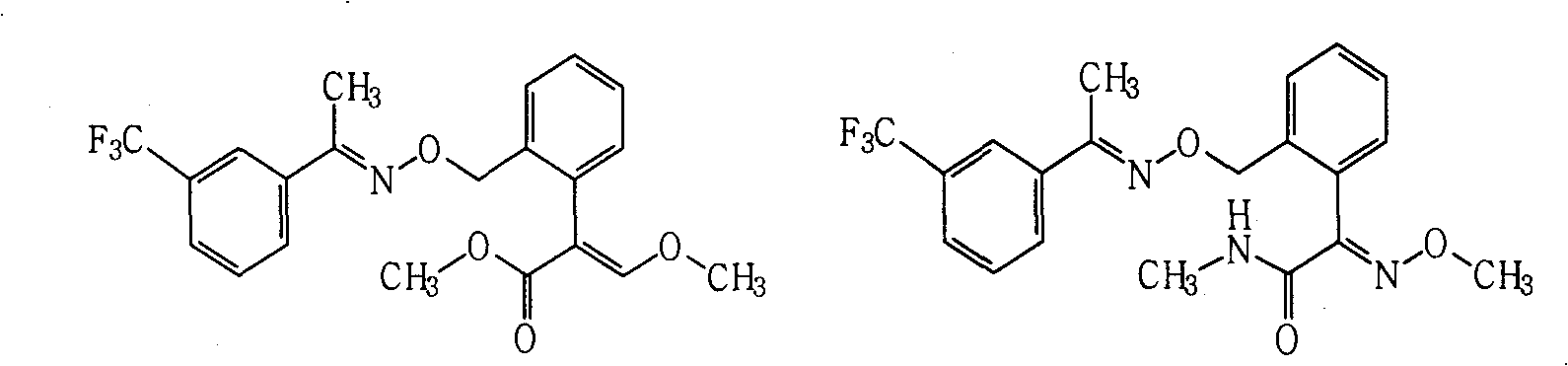

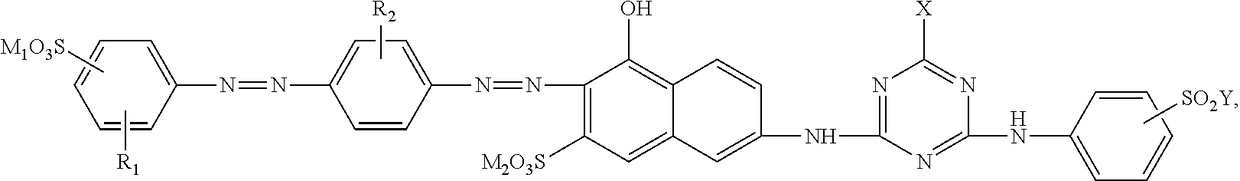

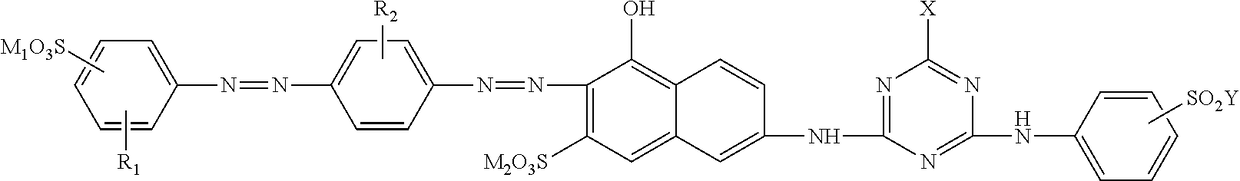

Fungicide composition

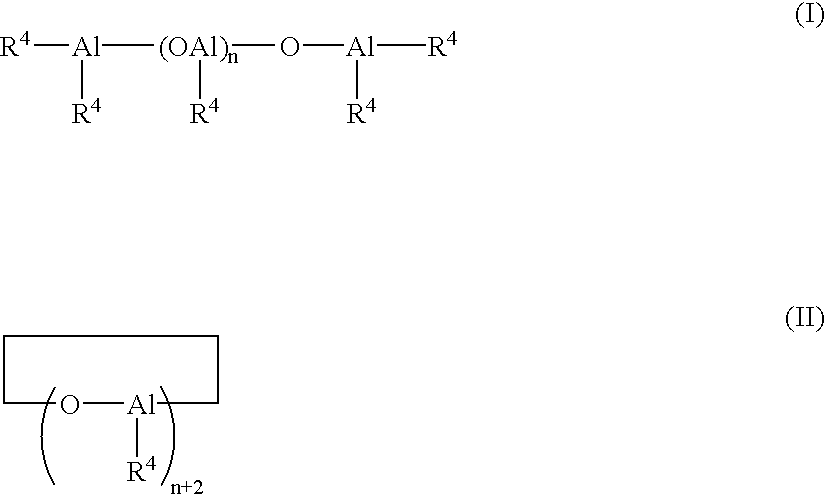

ActiveCN101637157AGood synergyImprove the effect of disease preventionBiocideFungicidesThiocarbamateCarbamate

The invention provides a fungicide composition containing an active component A and an active component B, and application thereof in preventing and controlling various agricultural fungal diseases. The active component A in the composition is one of two methoxyl acrylic ester compounds; and as shown above, the active component B of the compound A1 and the compound A2 is one of the following fungicide varieties: thiocarbamate compounds or salt thereof, aliphatic compounds or salt thereof, carbamate compounds or salt thereof, oxazole compounds or salt thereof, thiazole compounds or salt thereof, amide compounds or salt thereof, organophosphorus compounds or salt thereof, imidazole compounds or salt thereof, antibiotic compounds or salt thereof, pyridine compounds or salt thereof and triazole compounds or salt thereof.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

Nanostructured quasi-solid electrolyte applied to lithium ion batteries or lithium sulfur batteries and preparation method and application thereof

ActiveCN105070946AImprove conductivityImprove stabilitySolid electrolytesCell seperators/membranes/diaphragms/spacersSolid state electrolyteLithium sulfur

The invention discloses a nanostructured quasi-solid electrolyte applied to lithium ion batteries or lithium sulfur batteries and a preparation method and application thereof. The nanostructured quasi-solid electrolyte is a macro solid-state electrolyte material which is formed by an inorganic-organic hybrid framework material adsorbing ion conductive agent. The preparation method of the nanostructured quasi-solid electrolyte is as follows: in protective atmosphere, the inorganic-organic hybrid framework material is soaked in the ion conductive agent and sufficiently mixed, and redundant solvent is then volatilized. The prepared nanostructured quasi-solid electrolyte with high lithium ion conductivity can be substituted for both organic electrolyte and diaphragms in conventional lithium ion batteries, and thereby safety problems caused by the leakage of the organic electrolyte can be effectively prevented; a lithium battery assembled from the electrolyte can use a metal lithium plate as a cathode.

Owner:CENT SOUTH UNIV

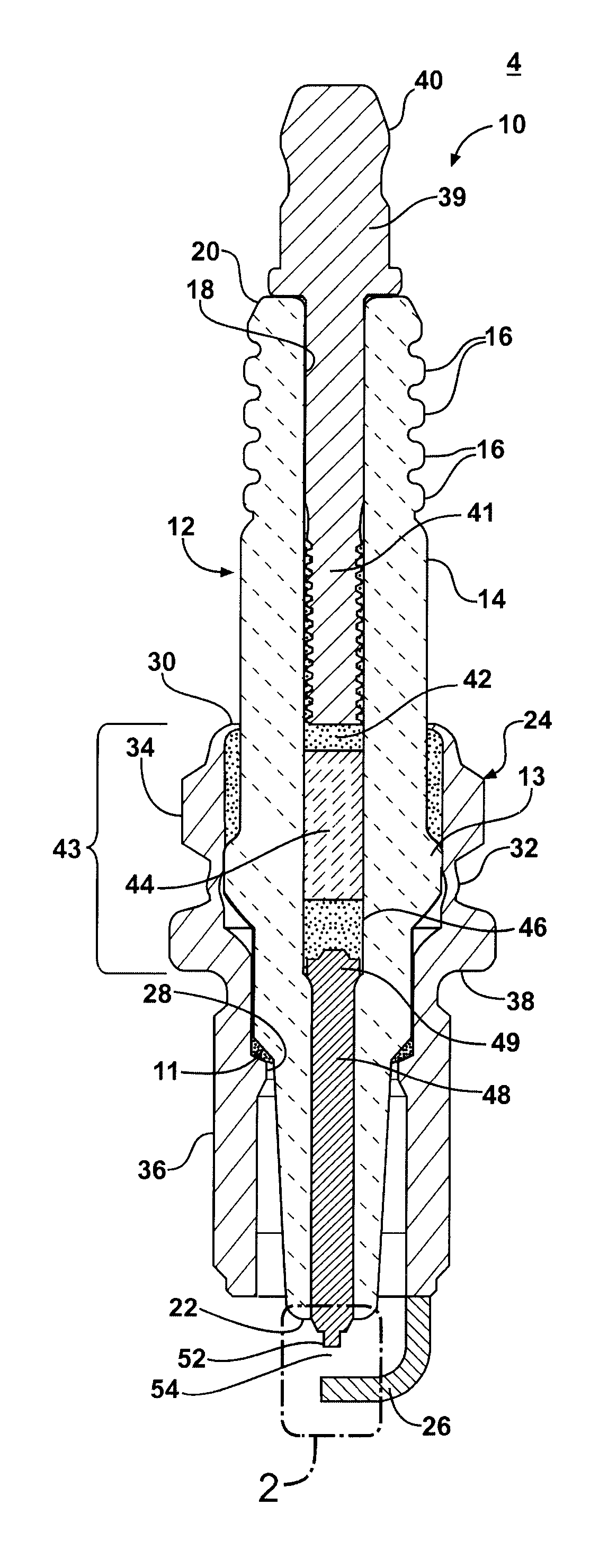

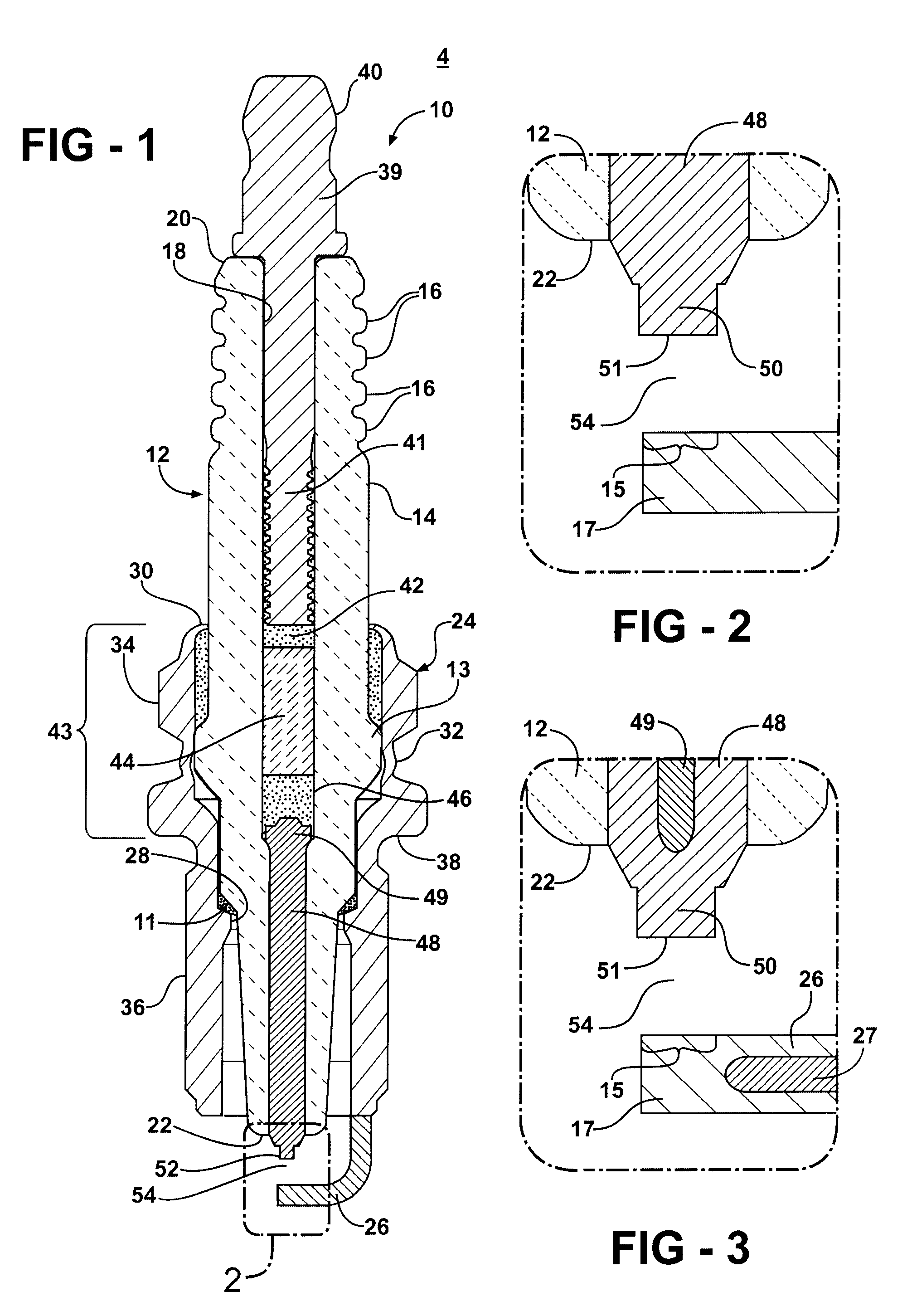

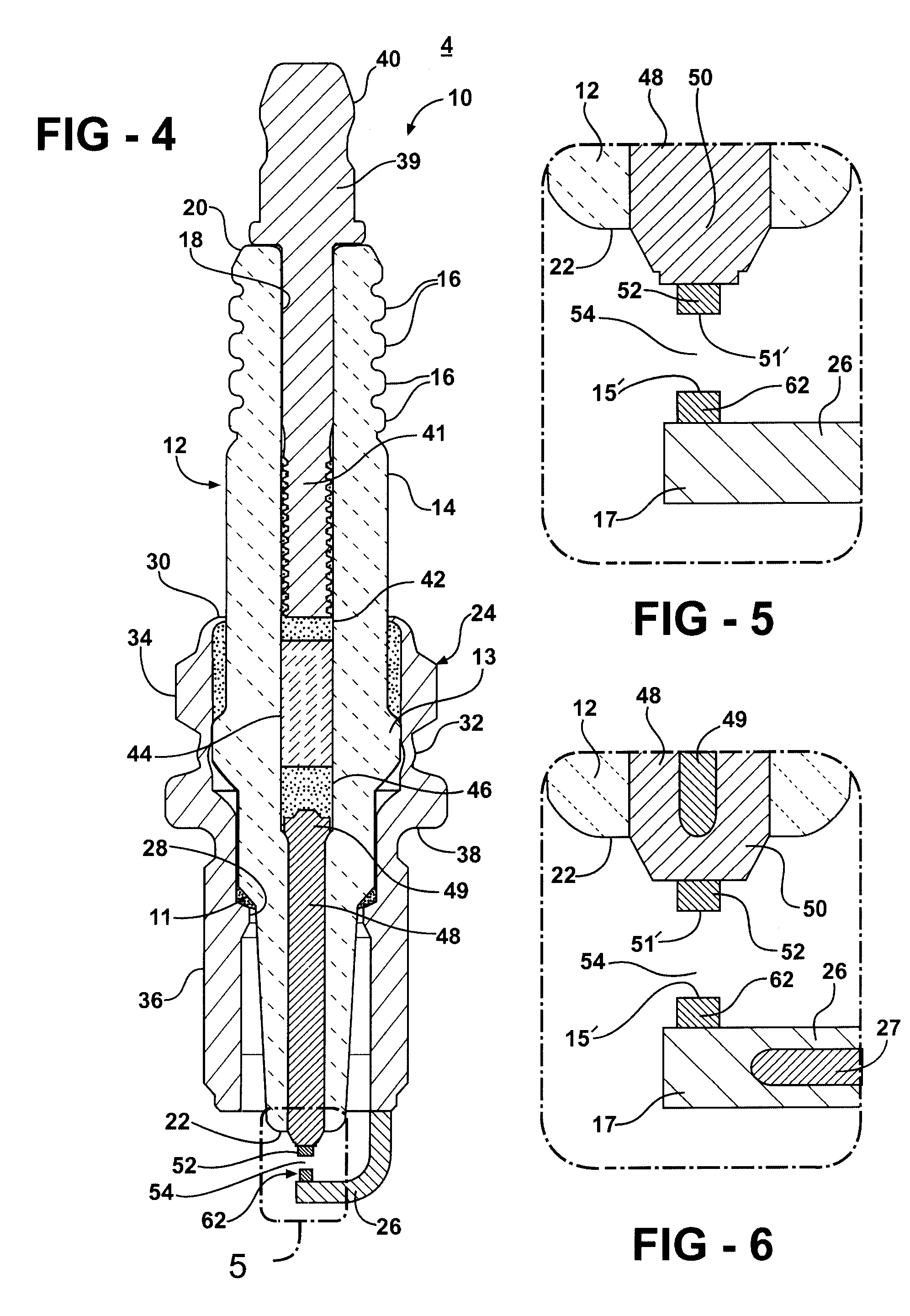

Electrode for an Ignition Device

An electrode for an ignition device is made from a Ni-based nickel-chromium-iron alloy which has improved resistance to high temperature oxidation, sulfidation, corrosive wear, deformation and fracture includes, by weight of the alloy: 14.5-25% chromium; 7-22% iron; 0.2-0.5% manganese; 0.2-0.5% silicon; 0.1-2.5% aluminum; 0.05-0.15% titanium; 0.01-0.1% total of calcium and magnesium; 0.005-0.5% zirconium; 0.001-0.01% boron, and the balance substantially Ni. It may also include at least one rare earth element selected from the group consisting of: yttrium, hafnium, lanthanum, cerium and neodymium in amounts ranging from 0.01-0.15% by weight, and incidental impurities, including cobalt, niobium, molybdenum, copper, carbon, lead, phosphorus or sulfur. These total of these impurities will typically be controlled to limits of 0.1% cobalt, 0.05% niobium, 0.05% molybdenum, 0.01% copper, 0.01% carbon, 0.005% lead, 0.005% phosphorus and 0.005% sulfur. The ignition device may be a spark plug which includes a ceramic insulator, a conductive shell, a center electrode disposed in the ceramic insulator having a terminal end and a sparking end with a center electrode sparking surface, and a ground electrode operatively attached to said shell having a ground electrode sparking surface, the center electrode sparking surface and the ground electrode sparking surface defining a spark gap therebetween. At least one of the center electrode or the ground electrode includes the solution-strengthened Ni-based nickel-chromium-iron alloy. The Ni-based nickel-chromium-iron alloy electrodes of the invention may also include a core with thermal conductivity greater than that of the Ni-based nickel-chromium-iron alloy, such as copper or silver or their alloys.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Preparation method of sulfur-active carbon/graphene composite material

ActiveCN106602013AWide variety of sourcesEasy to prepareCell electrodesLi-accumulatorsActivated carbonSulfur

The invention discloses a preparation method of a sulfur-active carbon / graphene composite material. The preparation method comprises the following steps of (1) pre-processing a biomass raw material; (2) mixing the pre-processed biomass raw material, graphene and an activating agent to form a solid mixed material; (3) performing activation, washing, solid-liquid separation and drying on the solid mixed material to obtain an active carbon / graphene composite material; and (4) combining the active carbon / graphene composite material with sulfur to obtain the sulfur-active carbon / graphene composite material. The composite material provided by the invention has the advantages of simple preparation process step, high efficiency and low energy consumption, and production on a large scale can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Compositions for improving mental performance

ActiveUS20050244510A1Improved mental performanceElimination of mental fatigueHeavy metal active ingredientsBiocidePoor focusAntioxidant

The present invention provides formulas for producing compositions for the structural / functional nutritional support for those who struggle with poor focus, concentration and / or memory. In addition, the present invention provides compositions comprising nutritional / botanical factors helpful to those who subjectively experience transient mental fatigue or poor cognitive function. The compositions of this invention consist primarily of the following ingredients B-complex vitamins, antioxidants, minerals, phosphatidyl serine (PS), choline, dimenthyl-aminoethanol (DMAE), docosahexaenoic acid (DHA), L-pyroglutamic acid, as well as herbal extracts from Bacopa monniera, Vinca minor, and Huperzia serrata. The present invention also relates to the administration of these compounds to alleviate mental fatigue or poor cognitive function.

Owner:SYNERGY STRIPS CORP

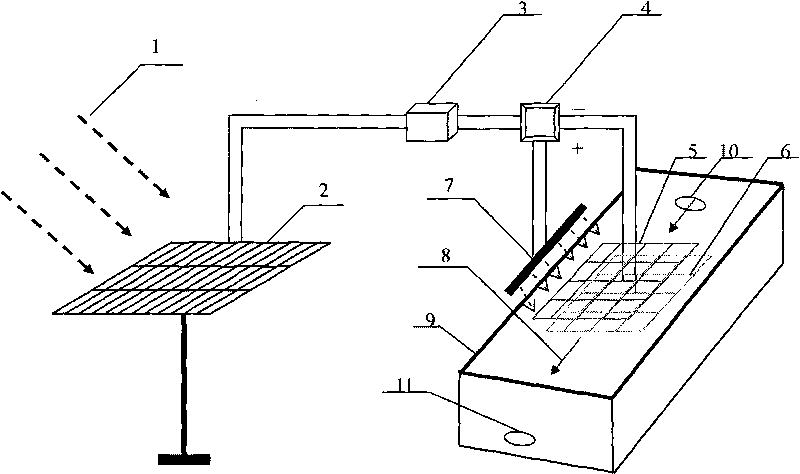

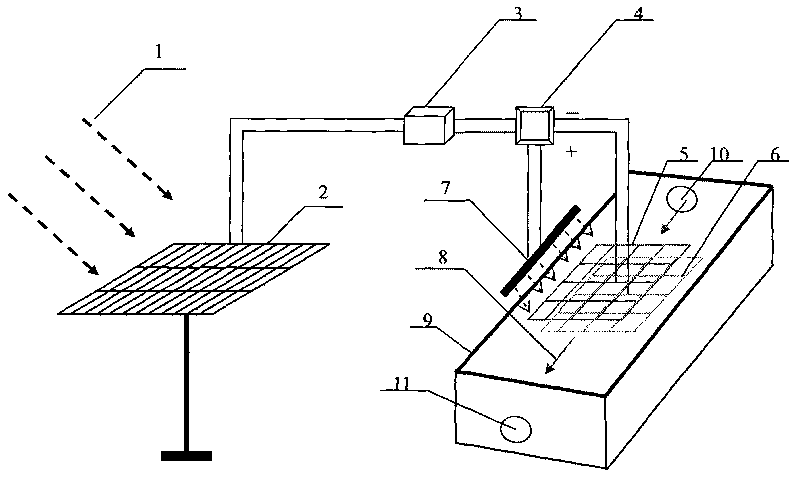

Integral solar energy photoelectricity water-treatment device

InactiveCN101693560AImprove processing efficiencyAdjustable processing efficiencyBatteries circuit arrangementsWater/sewage treatment by irradiationSolar lightElectrical battery

The invention relates to an integral solar energy photoelectricity water-treatment device comprising an electrode couple or an three-dimensional electrode as well as an electrolytic bath, a storage battery, solar energy battery components and corresponding controllers and an ultraviolet lamp, wherein the electrode couple or the three-dimensional electrode is loaded with photocatalytic materials; the ultraviolet lamp is used for illuminating a photoelectrode; the solar energy battery components convert the received solar light energy to electric energy which is then transmitted and stored in the storage battery so as to supply power for the ultraviolet lamp and / or the electrode couple intermittently or continuously. The invention integrates an optical chemical oxidation process and an electric chemical oxidation process which both generate enhancement and synergetic effects for improving the water treatment efficiency, or the functions of the optical chemical oxidation process and the electric chemical oxidation process can be independently exerted to realize water purification; the invention has the advantages of simple structure, low manufacturing cost, safe and simple operation, easy realization of automation and safe maintenance, driving the entire water treatment process by wholly or partly utilizing the electric energy converted from the solar energy, solving the problem of high dependence on energy sources in a photoelectrocatalytic water treatment process and being capable of not depending on the traditional power grid in service.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

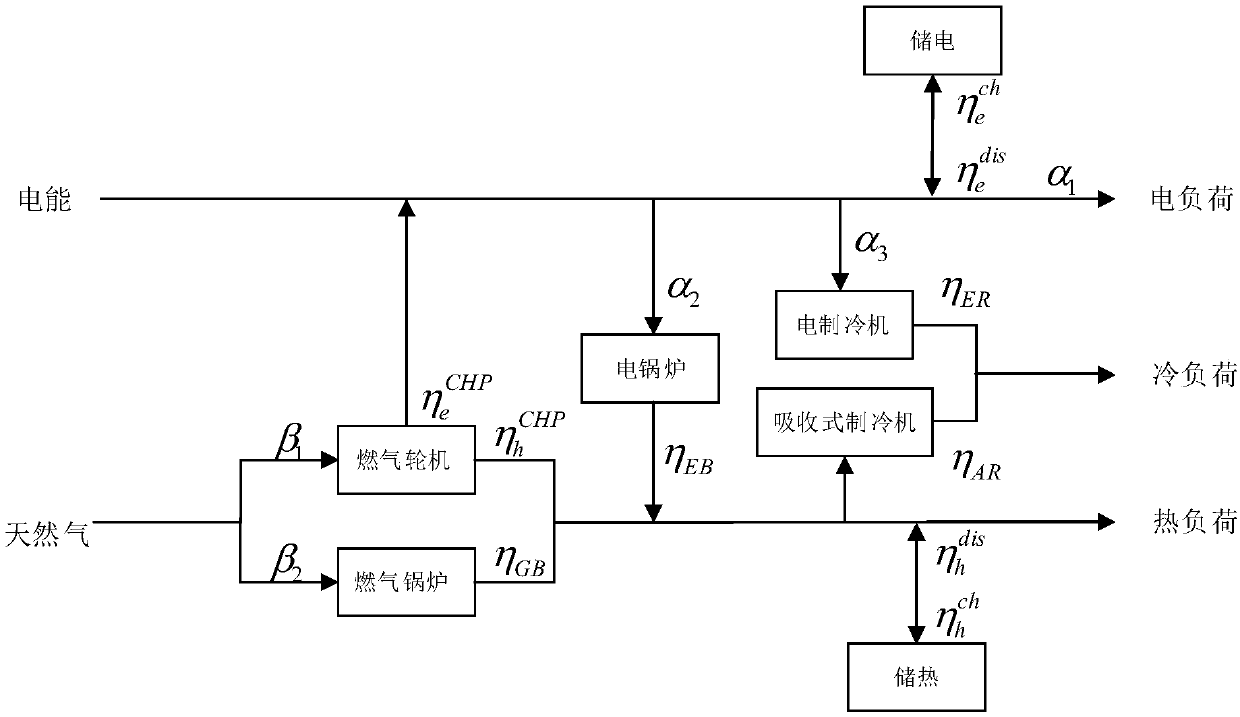

Method for optimizing operation of regional integrated energy system taking into account load aggregator

ActiveCN109063925AImprove economyReduce energy costsForecastingResourcesEnergy system optimizationIntegrated energy system

The invention discloses a method for optimizing the operation of a regional integrated energy system considering a load aggregator, First, the day-ahead forecasting data of electric load and day-aheadforecasting data of cold and heat load of the regional integrated energy system are obtained, Load aggregators obtain their respective regional integrated energy system heating and cooling loads taking into account the demand side response according to the specified different demand side response plans, In order to minimize the total operating cost of the regional integrated energy system, network constraint, energy production and conversion equipment constraints, As that constraint of the energy storage equipment and the cold-thermoelectric power balance of the regional integrated energy system are the constraint condition, an optimization model is established to obtain the operation power planning of each energy supply equipment and energy storage equipment, and the operation planning cost under each demand side response plan is compared to determine the optimal load aggregator demand side response plan and the optimal operation planning of each energy supply equipment and energy storage equipment. The method of the invention can effectively improve the economy of the operation of the regional integrated energy system.

Owner:HEFEI UNIV OF TECH

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Microbial fermentation antibiotic-free feed and preparing method thereof

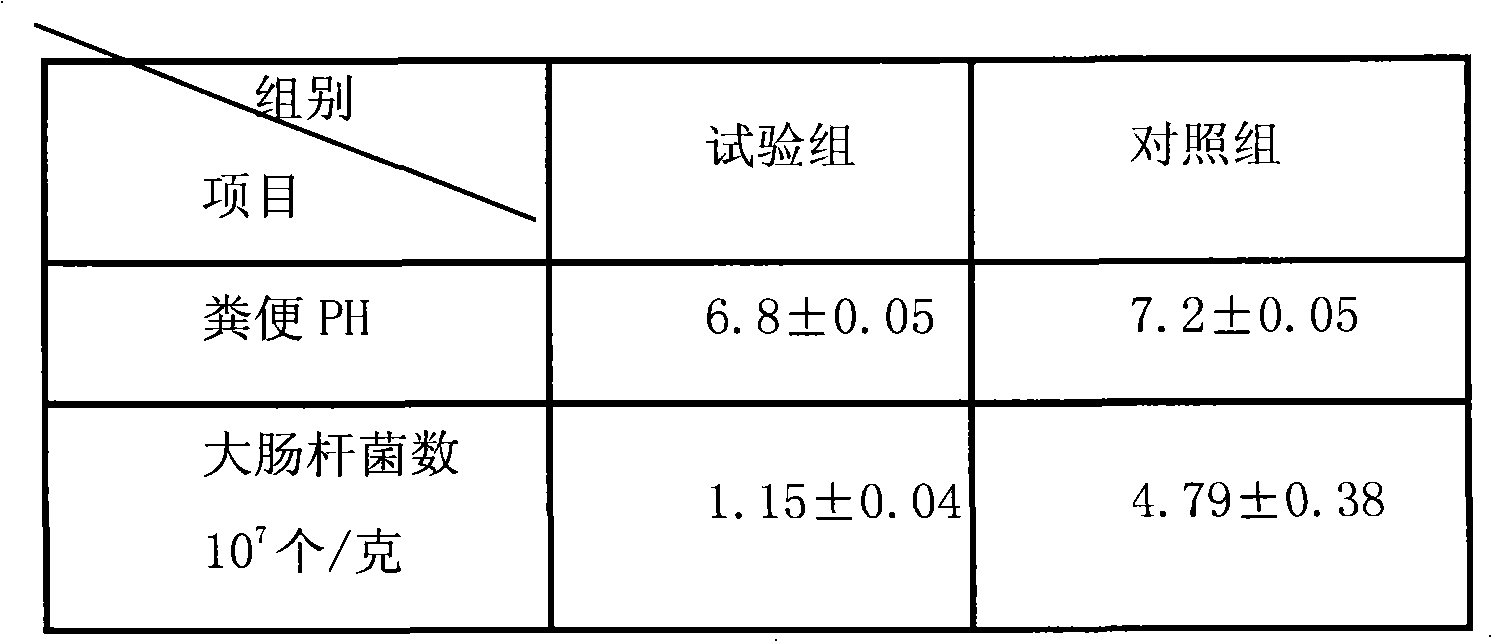

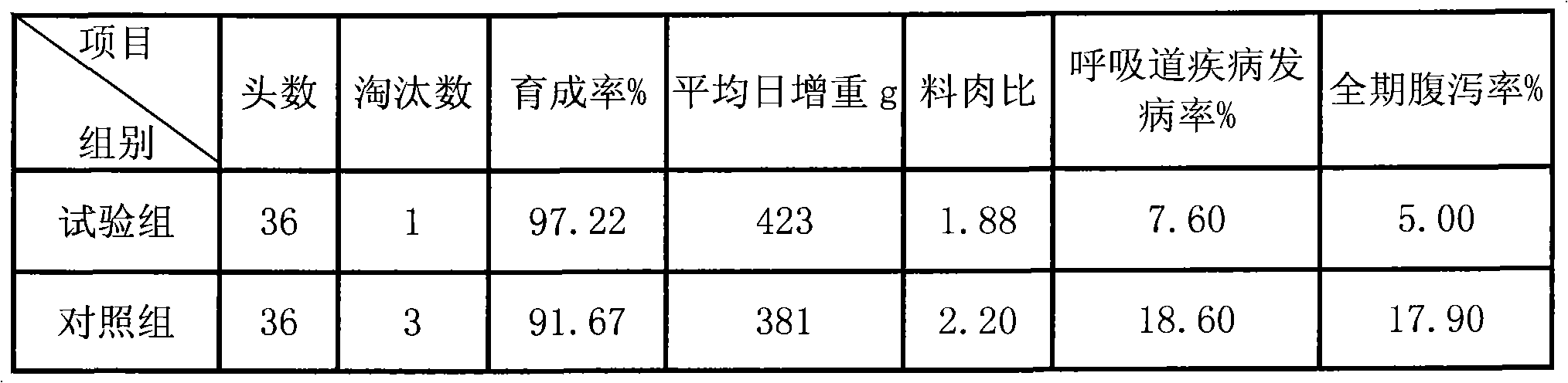

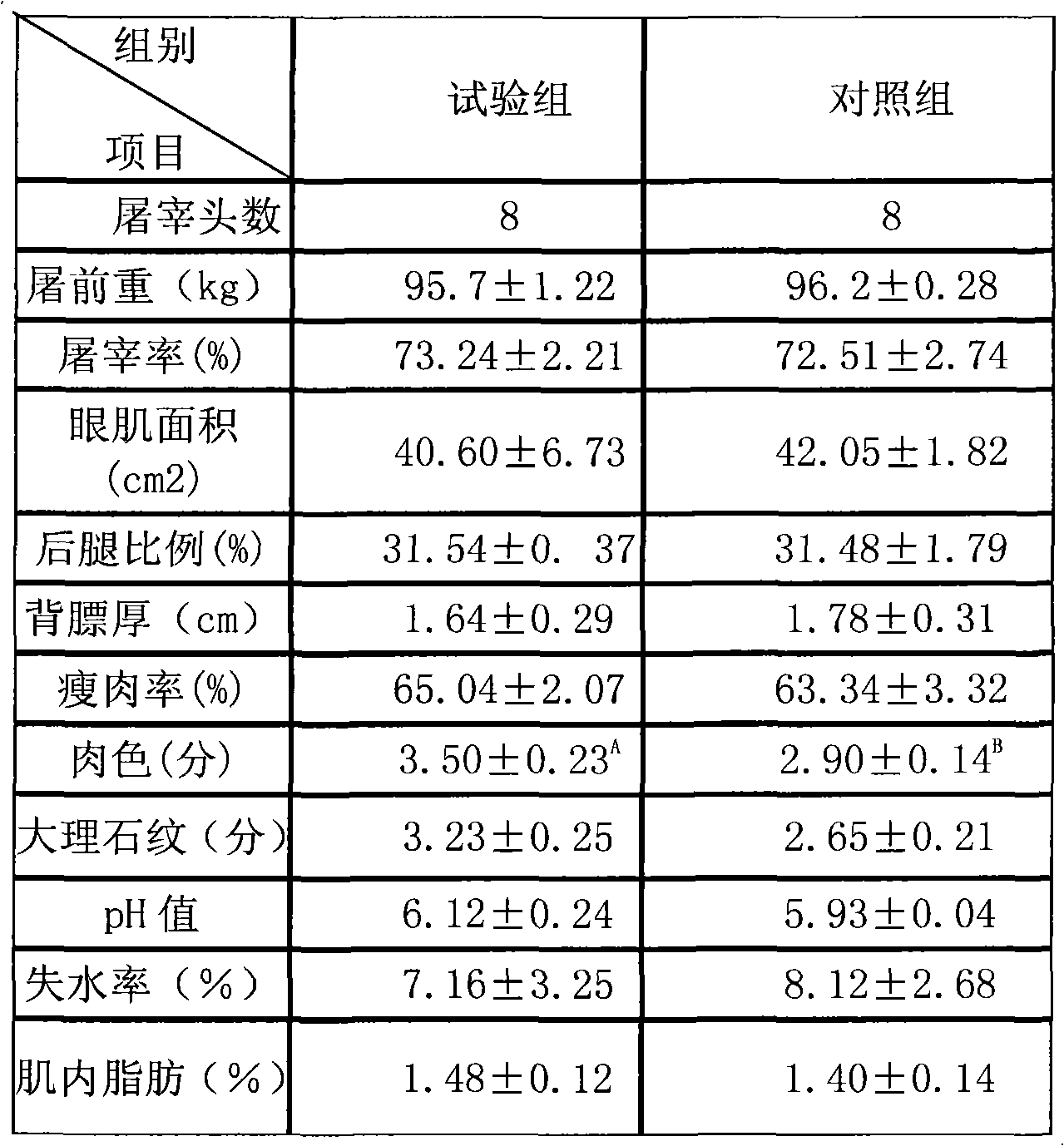

InactiveCN101828634AImprove immunityGood for healthFungiBacteriaLactobacillus acidophilusAspergillus niger

The invention discloses a microbial fermentation antibiotic-free feed, which comprises a batch and a composite fermentation material. The batch consists of the following raw materials in part by weight: 30 to 50 parts of corn, 20 to 40 parts of bean pulp, 5 to 20 parts of cotton seed meal, 2 to 5 parts of calcium hydrophosphate, 0.2 to 0.4 part of salt, 0.1 to 0.2 part of composite trace element, and 0.2 to 0.4 part of composite vitamin; and the composite fermentation material consists of the following fermentation materials in part by weight: 30 to 70 parts of lactobacillus acidophilus fermentation material, 10 to 20 parts of bacillus subtilis fermentation material, 20 to 35 parts of saccharomyces cerevisiae fermentation material, 1 to 3 parts of trichoderma longbrachiatum fermentation material, 1 to 3 parts of aspergillus niger fermentation material, and 1 to 3 parts of aspergillus oryzae fermentation material, wherein the weight ratio of the batch to the composite fermentation material is 96-92:4-8.

Owner:湖南创新生物科技有限公司

Systems and methods for selecting weld parameters

InactiveUS20170036288A1Good synergyProgramme controlArc welding apparatusProgram planningWelding power supply

Systems and methods for selecting weld parameters are disclosed. An example machine readable storage medium includes machine readable instructions which, when executed, cause a processor to: present a user interface; identify, for a weld based on input received via the interface, user-defined weld information including at least one of a material to be welded, an expected result of the weld, an on-hand material, or weld equipment available to be used for the weld; transmit the user-defined weld information to a welding knowledge provider; present one or more welding plans via the interface based on a response from the welding knowledge provider, the one or more welding plans including at least one of a welding device configuration, welding supplies information, or welding operator instructions; and automatically configure a welding power supply using one of the welding plans based on a selection of the one of the welding plans via the interface.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com