Patents

Literature

253 results about "Hardening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardening is caused by precipitation of the constituent in some form other than that of atomic dispersion, and probably in fine molecular, colloidal or crystalline form, and. the hardening effect of CuAl 2 in aluminum was deemed to be related to its particle size.

Method for preparing preserved kiwi fruit by vacuum freeze drying

InactiveCN102742711AAdjust acidity properlyGood hardening effectConfectionerySweetmeatsLiquid glucoseActinidia

A method for preparing preserved kiwi fruit by vacuum freeze drying. The method comprises steps of: peeling and slicing kiwi fruit, immersing the kiwi fruit in color protecting liquid, and then placing the kiwi fruit in a hardening liquid for hardening; after hardening, conducting an ultrasonic pretreatment in liquid glucose; and then successively carrying out vacuum sugar permeability, prefreezing, vacuum freeze drying, and packing to obtain the preserved kiwi fruit. According to the present invention, glucose lactone is added into a calcium chloride hardening liquid to coagulate protein in the fruit pieces and significantly improve hardening effect. The ultrasonic pretreatment and vacuum sugar permeability avoid a heat treatment process of rapid heating for a long time or short time, so that the kiwi fruit slices are still bright green (quite similar with an original fruit color). Vacuum freeze drying on the kiwi fruit realizes a high nutrient conservation rate.

Owner:NORTHWEST UNIV(CN)

Cu-Cr-Zr alloy preparation technology for contact wire

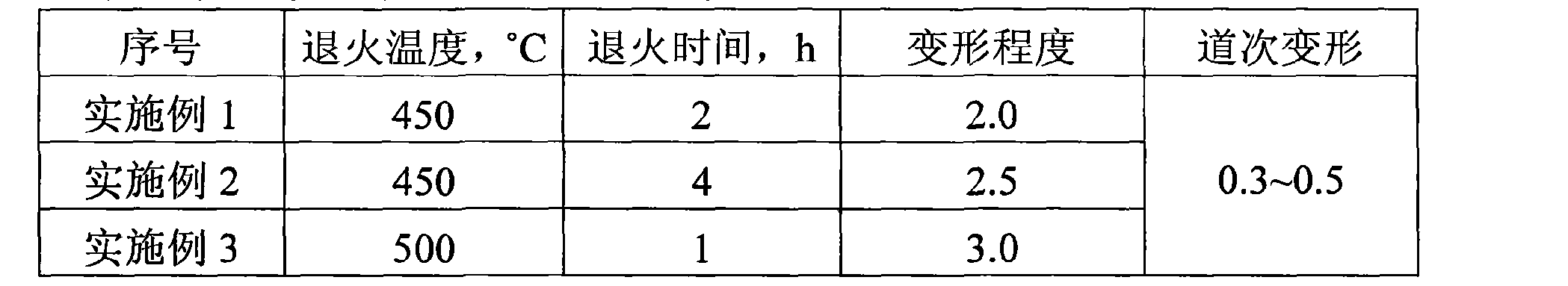

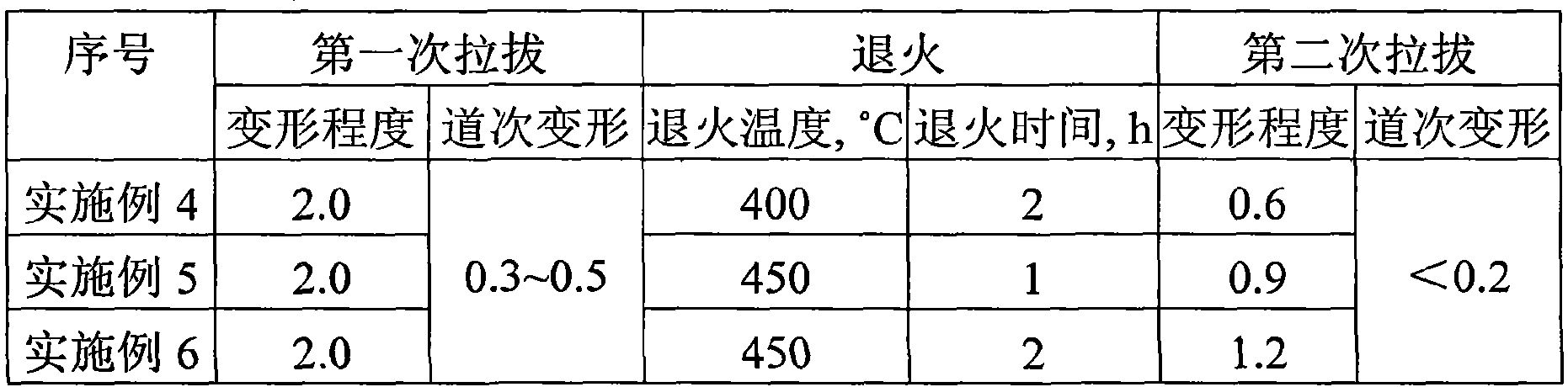

The invention discloses a process for preparing Cu-Cr-Zr alloys applicable to contact lines. The process comprises the following steps that alloys comprising 0.30 to 0.50 percent of Cu, 0.10 to 0.15 percent of Cr, 0.01 to 0.02 percent of Zr and Si are melt in a vacuum induction furnace, wherein alloy elements, namely Cr, Zr and Si, are added by master alloys; fine casting-state crystal grains and oversaturated matrix tissues having secondary dendritic crystal spaces are obtained by controlling solidification velocity and cooling velocity; rolling in fit, drawing deformation and annealing thermal treatment to the fine casting-state crystal grains and oversaturated matrix tissues are carried out so as to control deformation degrees and parameters for the thermal treatment; and the strain-hardening effect and the precipitation strengthening effect are organically combined. Therefore, the alloys have the advantages of excellent tensile strength, electrical conductivity and high-temperature resistant softening capacity and lower cost under the conditions of simplified process and the simpler apparatus and components, and are applicable to industrial production.

Owner:邢台鑫晖铜业特种线材有限公司 +3

Heat treatment technology for pearlite steel rail hardening

InactiveCN105483347AAchieve a hardening effectEasy to operateFurnace typesHeat treatment furnacesPearliteHardening effect

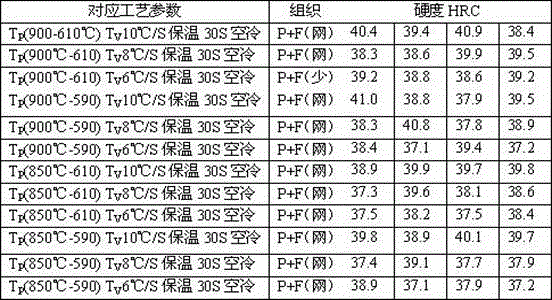

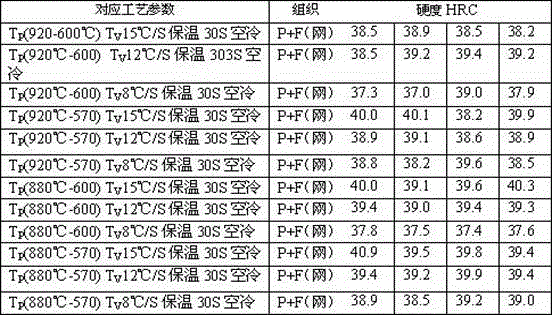

The invention relates to a heat treatment technology for pearlite steel rail hardening. The heat treatment technology for pearlite steel rail hardening is characterized in that a steel rail is heated to 880 DEG C to 920 DEG C, the temperature is kept for 10 minutes to 15 minutes, according to the different types of steel, the temperature is decreased to be within the specific temperature interval according to the specific cooling speed range and is kept for 30 seconds, and air cooling is conducted; the air cooling includes the specific steps that according to the pearlite steel rail hardening process system adopting a U75 V material, the temperature ranging from 880 DEG C to 920 DEG C is kept for 10 minutes to 15 minutes, the temperature is decreased to 570 DEG C to 600 DEG C with the cooling speed being 8 DEG C / s to 15 DEG C / s, and then the temperature is decreased to 20 DEG C to 25 DEG C with the cooling speed being 0.2 DEG C / s to 0.5 DEG C / s in an air cooling manner; and according to the pearlite steel rail hardening process system adopting a U76 CrRE material, the temperature ranging from 850 DEG C to 900 DEG C is kept for 10 minutes to 15 minutes, the temperature is decreased to 590 DEG C to 610 DEG C with the cooling speed being 6 DEG C / s to 10 DEG C / s, and then the temperature is decreased to 20 DEG C to 25 DEG C with the cooling speed being 0.2 DEG C / s to 0.5 DEG C / s in an air cooling manner. The heat treatment technology has the advantages that the specific hardening heat treatment technology of steel rails made of certain specific components is standardized, operability is high, optimum matching of the hardening heat treatment technology and the components of the steel rails is achieved, and the hardening effect of the steel rails is achieved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

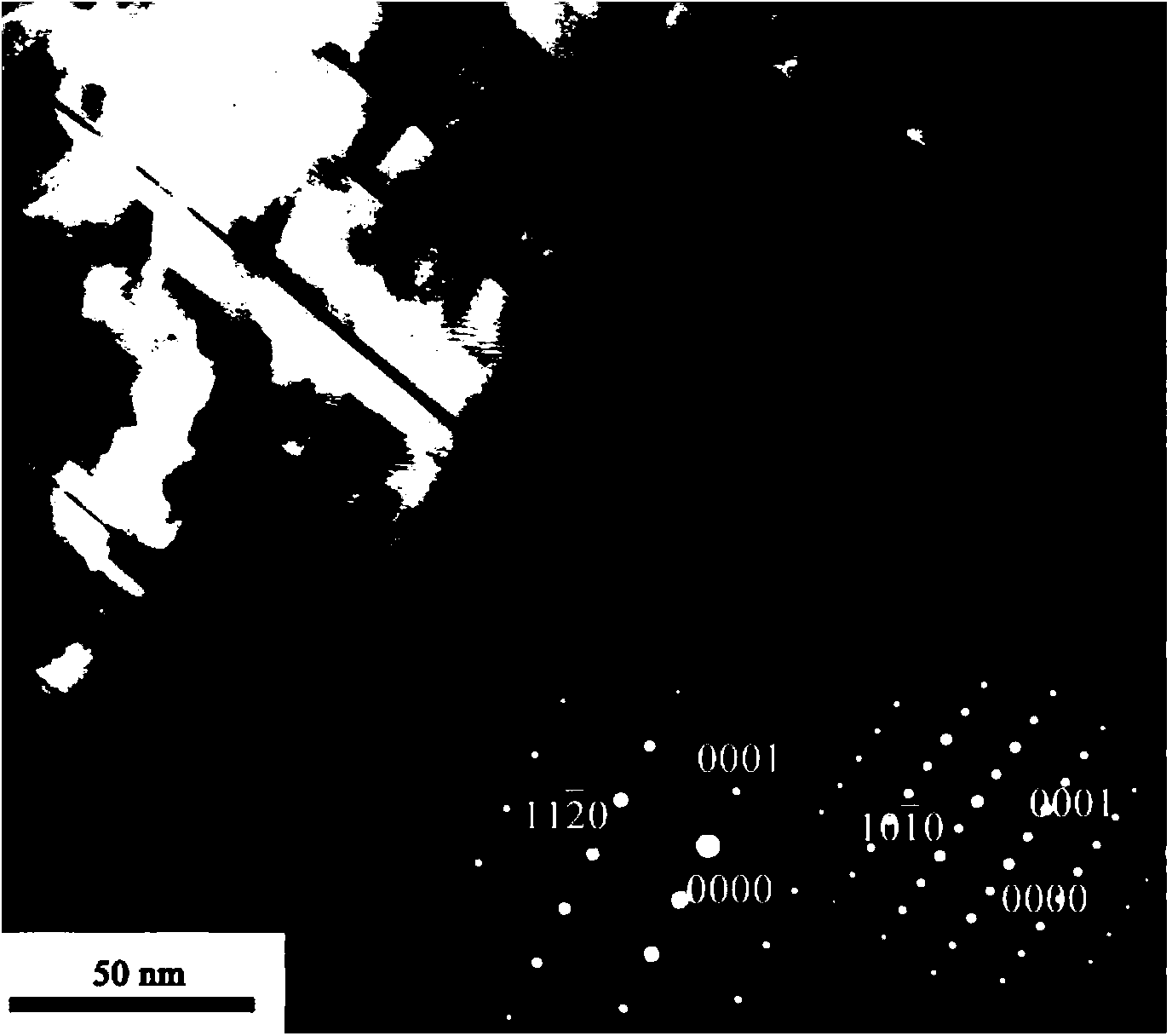

Preparation method for rear-earth magnesium alloy

The invention provides a preparation method for a rear-earth magnesium alloy. The preparation method comprises the following steps of: casting a magnesium melt, extruding and forming after solution treatment, then carrying out cold-rolling and ageing treatment to obtain the rear-earth magnesium alloy, wherein the rear-earth magnesium alloy comprises Mg, Nd, Gd, Y, Zn and Zr. Compared with the prior art, cold-rolling and ageing treatment is carried out after carrying out solution treatment, extruding and forming, so that a great number of beta phases and LPSO phases exist on a crystal boundary, the crystal boundary is pinned to prevent crystalline grains from growing in a transformation process, crystalline grains in the alloy are refined, and therefore, yield strength of the rear-earth magnesium alloy is improved; the rear-earth magnesium alloy has the LPSO phases with 14H structures, and is regularly distributed along extruding direction; stability of the boundary improves strength and toughness of the rear-earth magnesium alloy; moreover, high-density dislocation is introduced in cold-rolling, and nucleation of beta' phases in an ageing process is promoted, so that ageing hardening effect of the alloy is improved; meanwhile, the beta' phases can be more refined by the cold-rolling.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

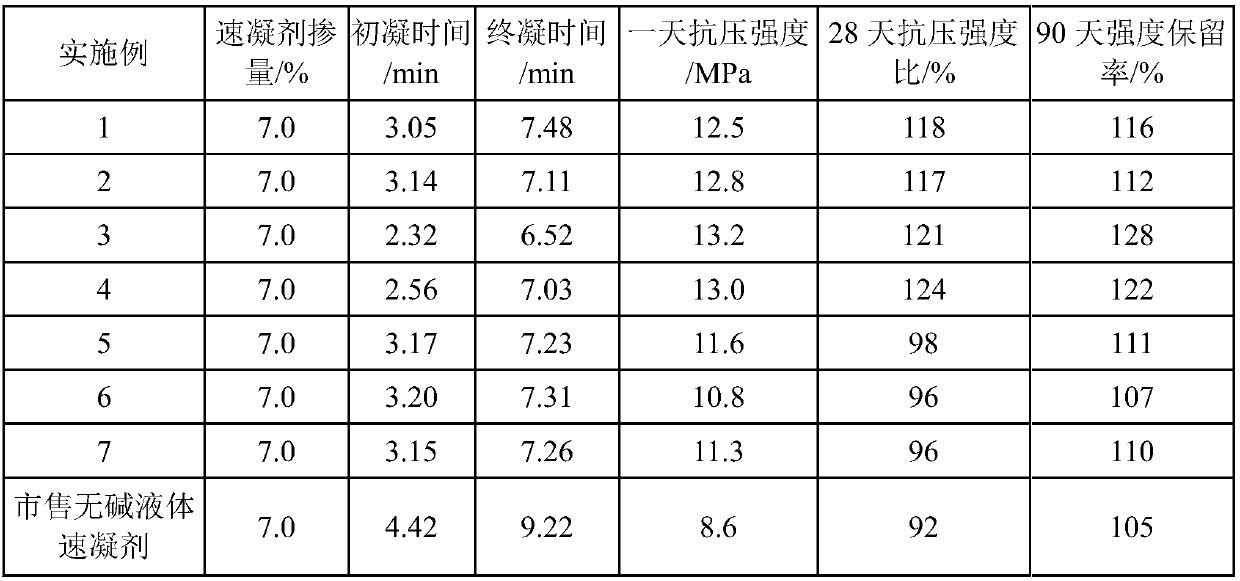

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

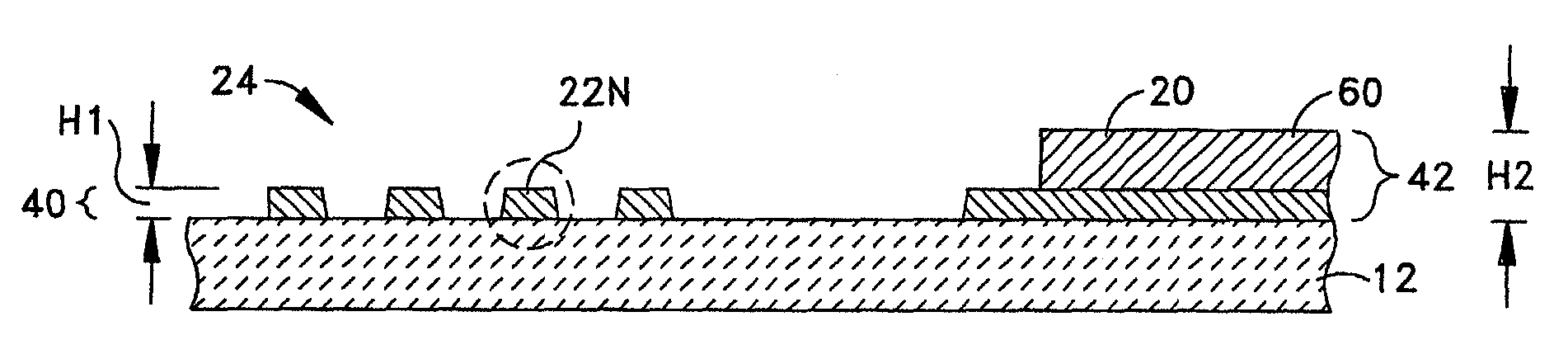

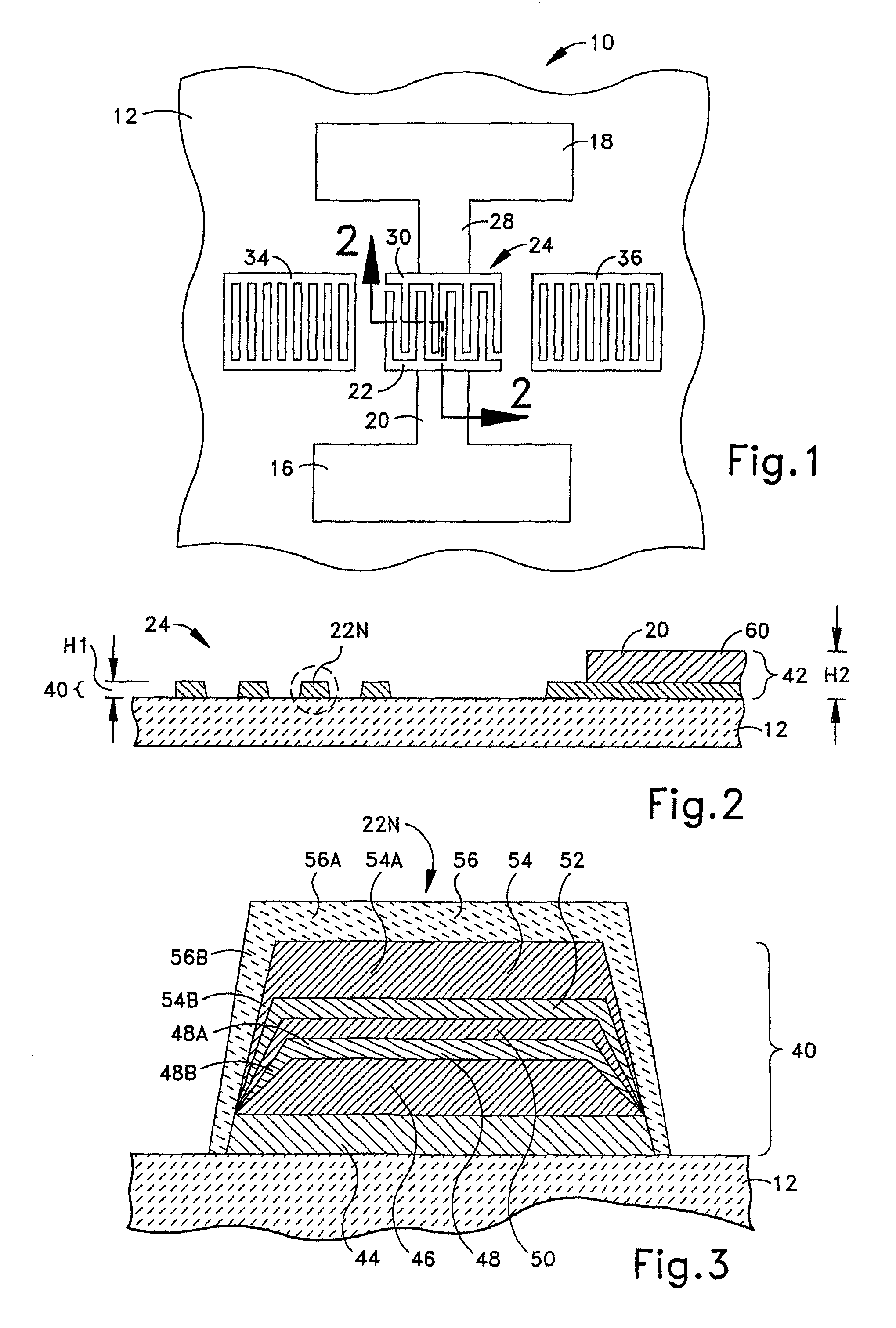

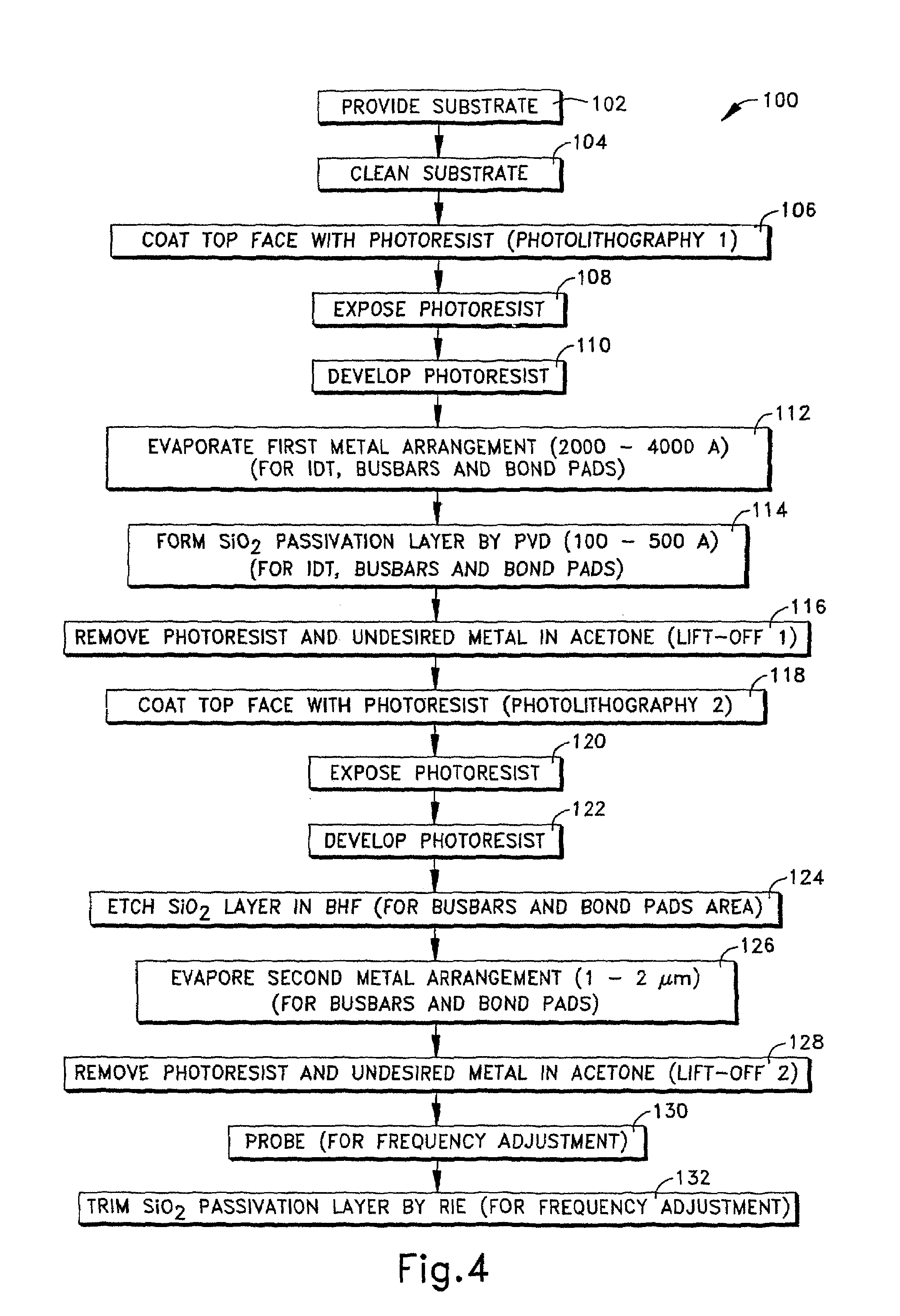

Surface acoustic wave device having improved performance and method of making the device

InactiveUS7148610B2Hardening effectPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical connectionTransducer

Owner:OC OERLLIKON BALZERS AG

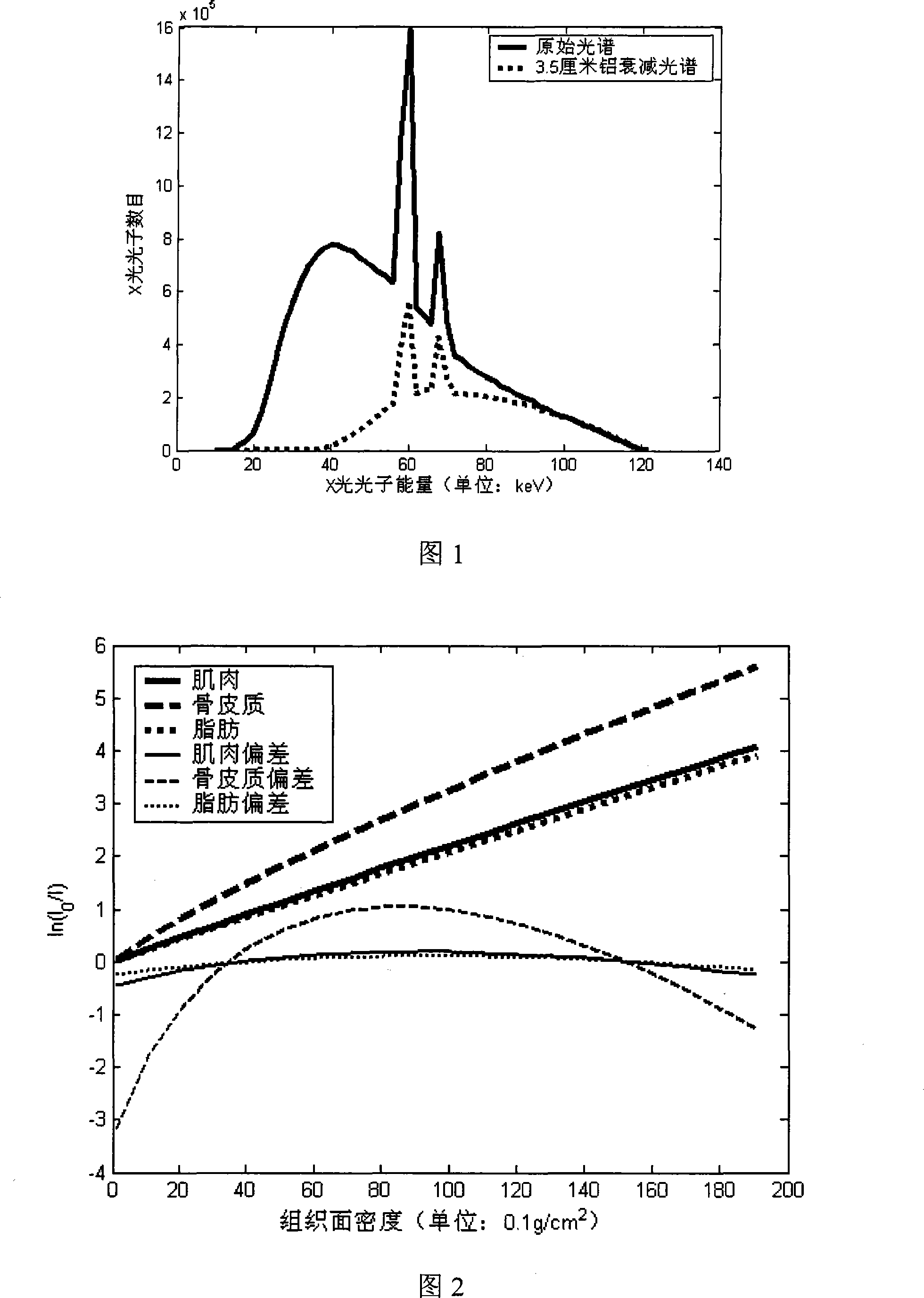

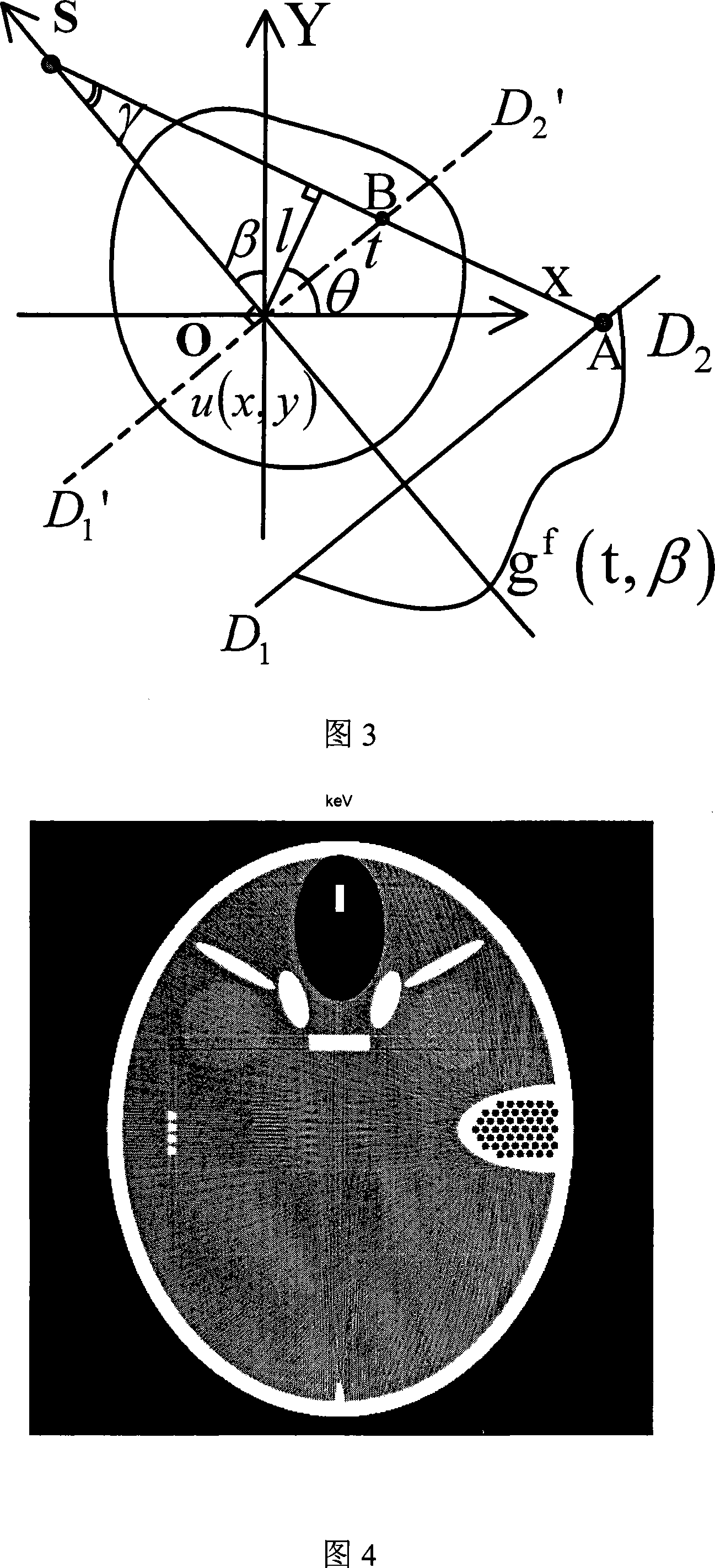

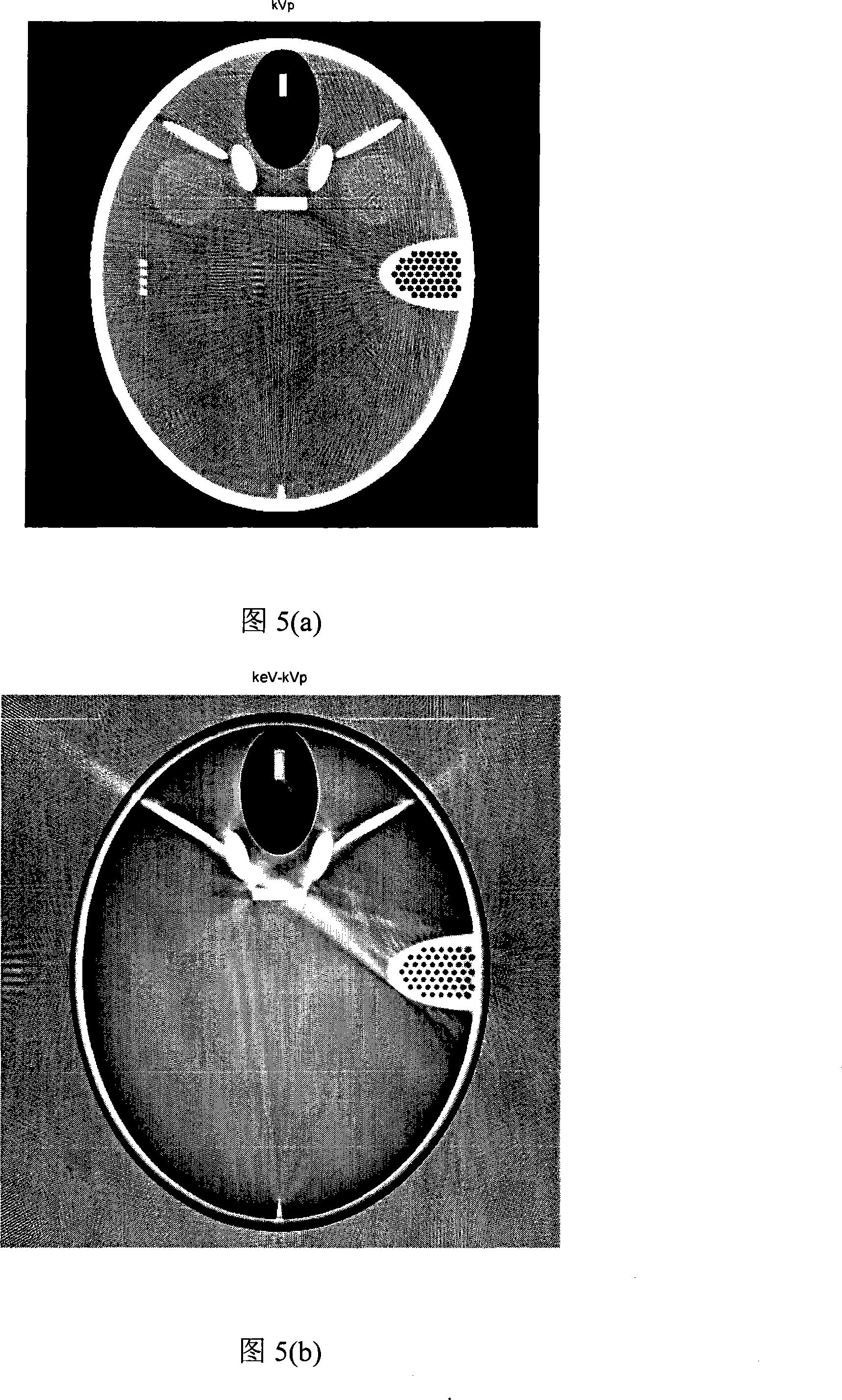

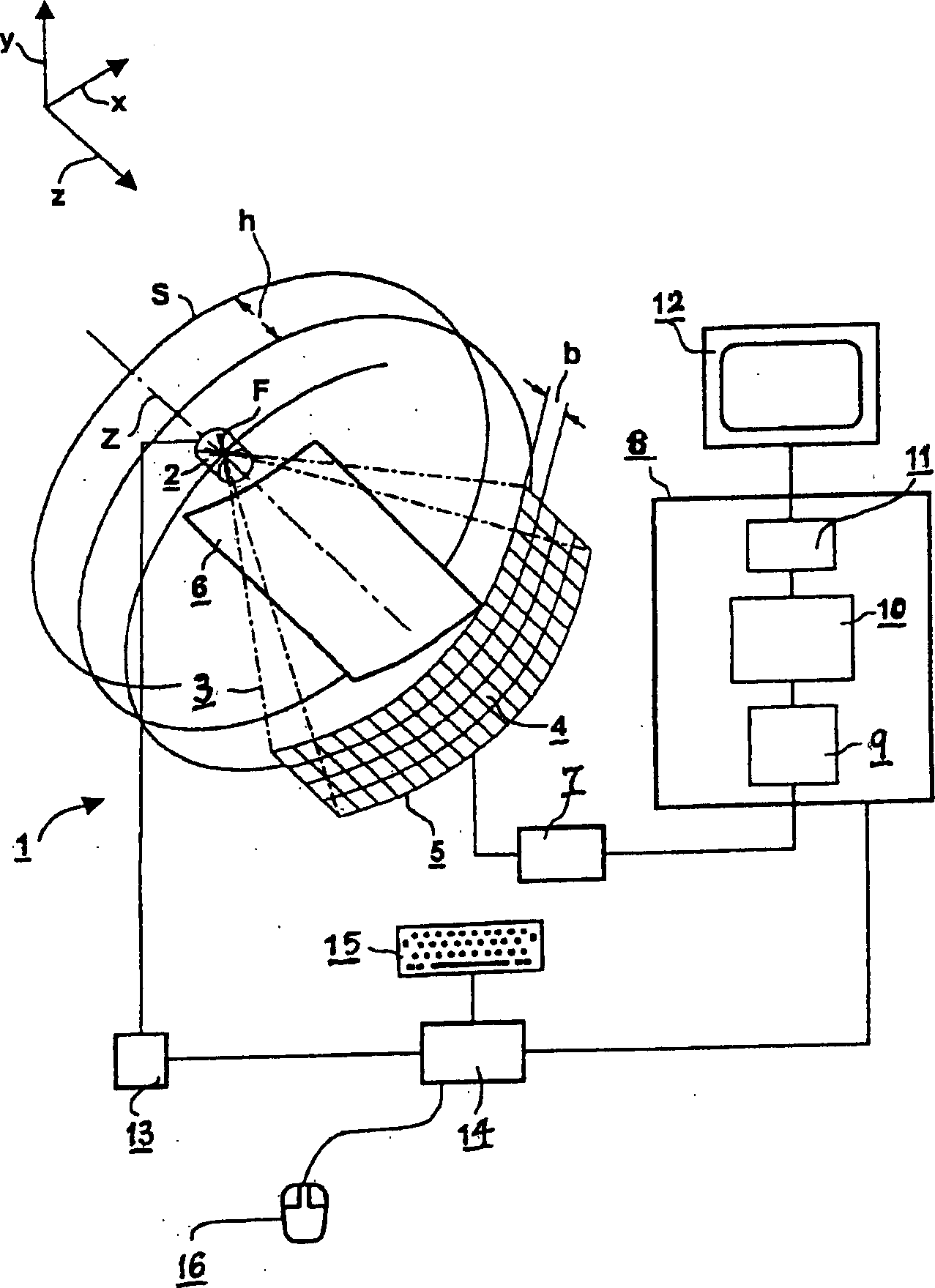

Method for correcting projection pencil sclerosis based on CT data consistency

InactiveCN101226642AImprove the correction effect2D-image generationComputerised tomographsHigh densityX-ray

The invention discloses a beam hardening correction method of CT projection data based on data dependency. The method is based on physics imaging model of medical X-ray, constructs a minimization solution problem between CT projection data, combines the minimization problem and obtains solution of intermediate parameter. For realizing more precise correction result, the method estimates reducing proportion of substance with high density in projection data according to primary correction construction result and CT reprojection. The invention is adaptable for realizing beam hardening correction function of various X-ray CT devices. Compared with the existing method only with water modeling correction, the method of the invention respectively considers differences of beam hardening effect of tissues with different density. Compared with the existing method of bone correction, the method of the invention can automatically adapted to different imaging subjects more flexibly and has better correction precision.

Owner:XI AN JIAOTONG UNIV

Surface metallurgy technique for cobalt-containing super-hard high-speed steel

The invention relates to a surface metallurgy process of cobalt containing super-hard high-speed steel, which pertains to the surface metallurgical field. The invention is characterized in that: first, a double-layer glow discharging ion metallic cementation technique is used for filtering an alloying element on the surface of Fe-based material with lower cost so as to form a surface alloying layer; then, a carburizing treatment is carried out to form a surface high-speed steel alloying layer; thereafter, a thermal treatment is carried out to lead the surface high-speed steel alloying layer to have the excellent properties of the super-hard high-speed steel. The hardening characteristics of the super-hard high-speed steel is that fine and dispersed alloy carbide and intermetallic compound are precipitated to generate hardening, the surface hardness of the filtered workpiece reaches at 1000-1150HV after quenching and tempering treatment. The invention has the advantages that: since coarse primary carbide is not formed during the crystallizing process, formidable inhomogeneous carbide in the traditional production of smelting, forging-rolling high-speed steel is solved. Fine and dispersed carbide on the surface metallurgical high-speed greatly improves the hardening effect, saves a great deal of alloying elements, reduces the cost and is capable of being widely used for manufacturing cutting tools of various machine tools.

Owner:TAIYUAN UNIV OF TECH

Phenolic resin self-hardening sand and preparation method thereof

ActiveCN104139154AImprove moisture resistanceHigh compressive strengthFoundry mouldsFoundry coresPolyamideHardening effect

The invention discloses phenolic resin self-hardening sand and a preparation method thereof. The self-hardening sand is made of roughing sand, phenolic resin, a silane coupling agent, methyl formate, calcium carbonate, aluminic acid ester, ethylene glycol, bentonite and polyamides. The rough sand passing through a 250-mesh screen and the bentonite passing through a 300-mesh screen are mixed, then the phenolic resin, the silane coupling agent, the polyamide, the calcium carbonate, the aluminic acid ester, the ethylene glycol and the methyl formate are added in sequence, rapid stirring is carried out until the materials are mixed fully, and the stirring speed is 129 r / min. The preparation method is simple, the prepared phenolic resin self-hardening sand is small in gas generating amount and does not contain harmful elements of nitrogen, phosphorus, sulphur or the like, the hardening effect is good, and under the condition that the roughing sand is at ambient temperature, the hardening time is 15 to 20 min; the intensity is high, after hardening is conducted for 24 hours, the compressive strength is 7.4 to 8.5 MPa, compared with the self-hardening sand in the prior art, the occurrence rate of the heat crack phenomenon is reduced by 18 percent, and the phenolic resin self-hardening sand is especially suitable for casting of steel castings.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

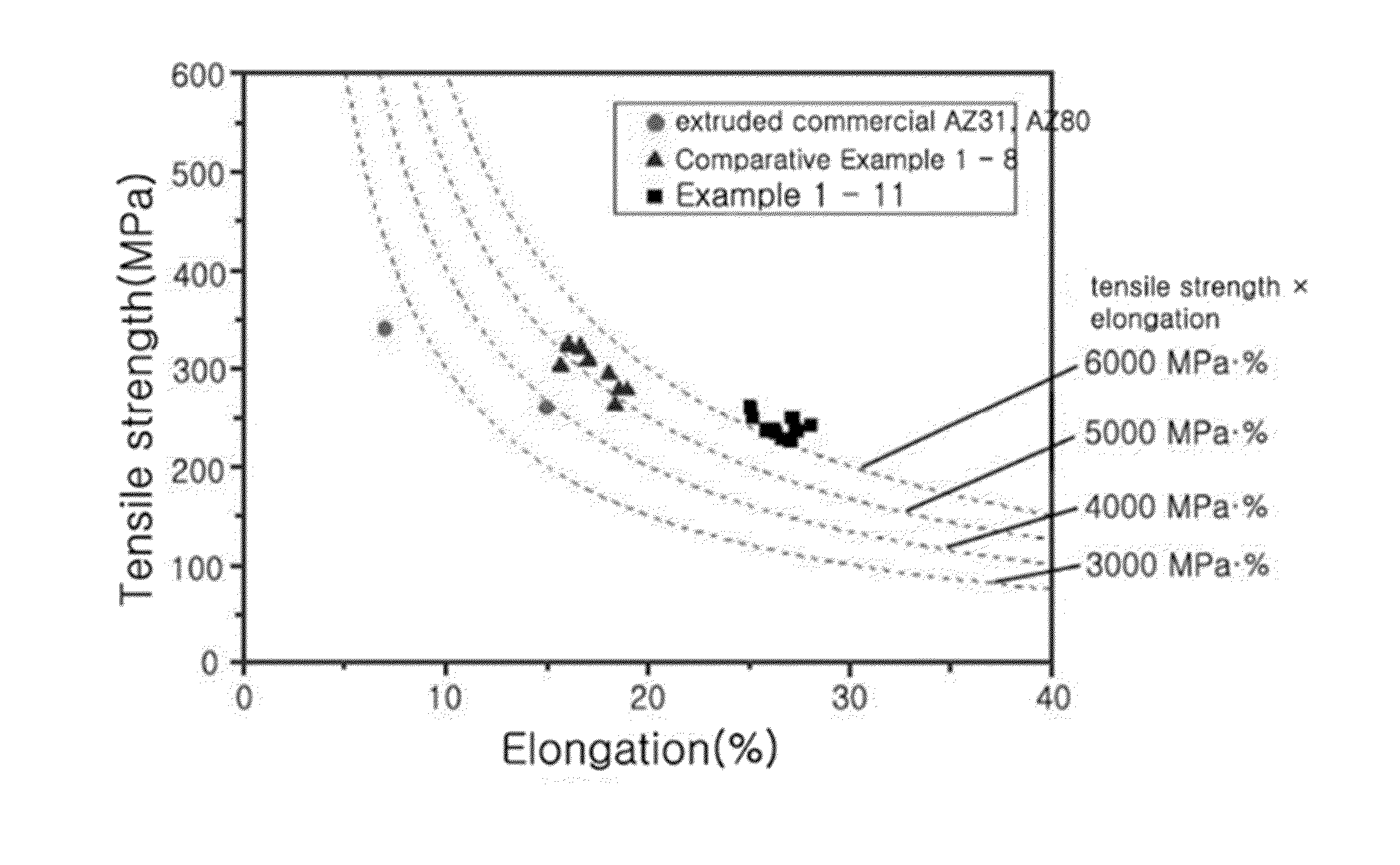

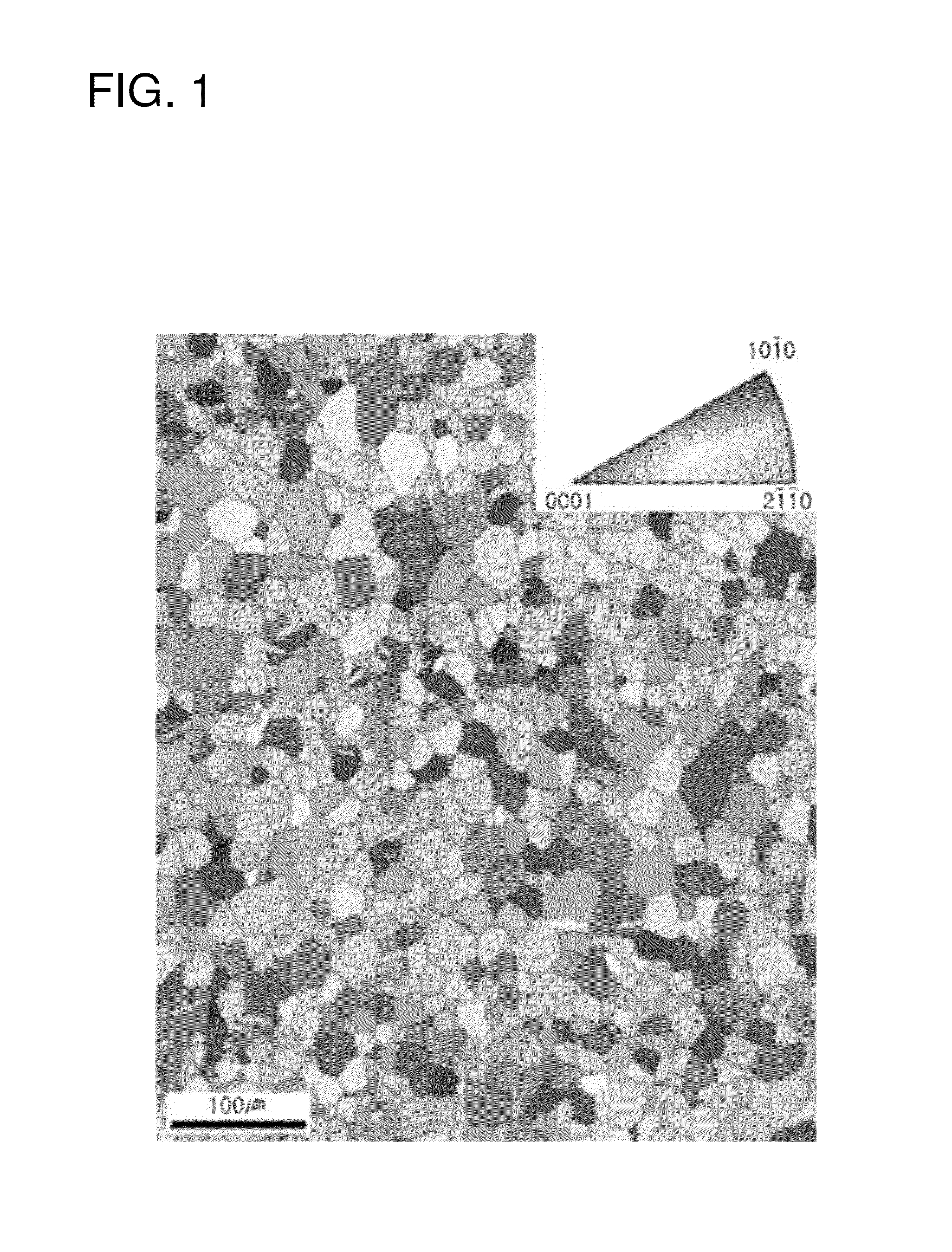

Magnesium alloy having high ductility and high toughness, and preparation method thereof

InactiveUS20140332121A1Improve ductilityImprove toughnessFoundry mouldsFoundry coresManganeseRare earth

A magnesium alloy having high ductility and high toughness, and a preparation method thereof are provided, in which the magnesium alloy includes 1.0-3.5 wt % of tin, 0.05-3.0 wt % of zinc, and the balance of magnesium and inevitable impurities, and a preparation method thereof. Magnesium alloy with a relatively small tin content is added with zinc, and optionally, with one or more alloy elements selected from aluminum, manganese and rare earth metal, at a predetermined content ratio. As a result, the alloy exhibits superior ductility and moderate strength due to the suppression of excessive formation of precipitates and some precipitates hardening effect, respectively. Accordingly, compared to extruded material prepared from conventional commercial magnesium alloys, higher ductility and toughness are provided, so that the alloy can be widely applied over the entire industries including automotive and aerospace industries.

Owner:KOREA INST OF MASCH & MATERIALS

Methods and systems using a numerical model to describe polymeric material properties

InactiveCN102254060ADesign optimisation/simulationSpecial data processing applicationsMathematical modelNumerical models

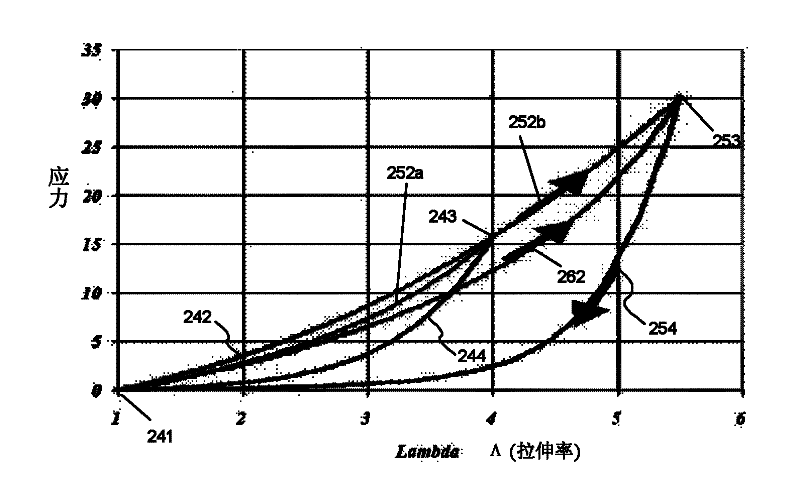

Methods and systems using a numerical model to describe polymeric material properties are disclosed. FEM model of a product is defined. FEM model includes one or more solid elements of polymeric material. In a time-marching simulation of the product under loads, stress state of the solid elements is calculated from deformation gradient tensors. Stress state incorporates the Mullins effect and strain hardening effect, also includes elastic stress, viscoelastic stress and back stress. A yield surface is defined to determine whether the elements are under plastic deformation. Plastic strain is obtained to update the deformation gradient tensor, which is then used to recalculate the stress state. Calculations continue until updated stress state is within a tolerance of the yield surface, at which time the results of polymeric material elements are obtained. The numerical model takes into account all characteristics of a polymeric material.

Owner:LIVERMORE SOFTWARE TECH

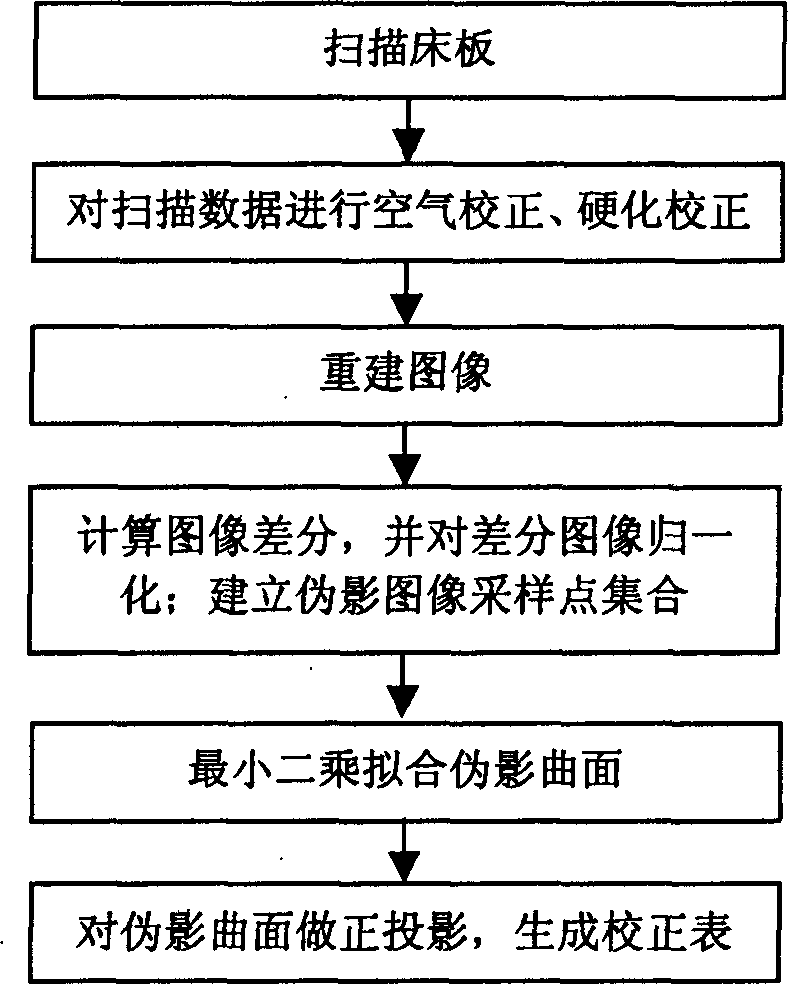

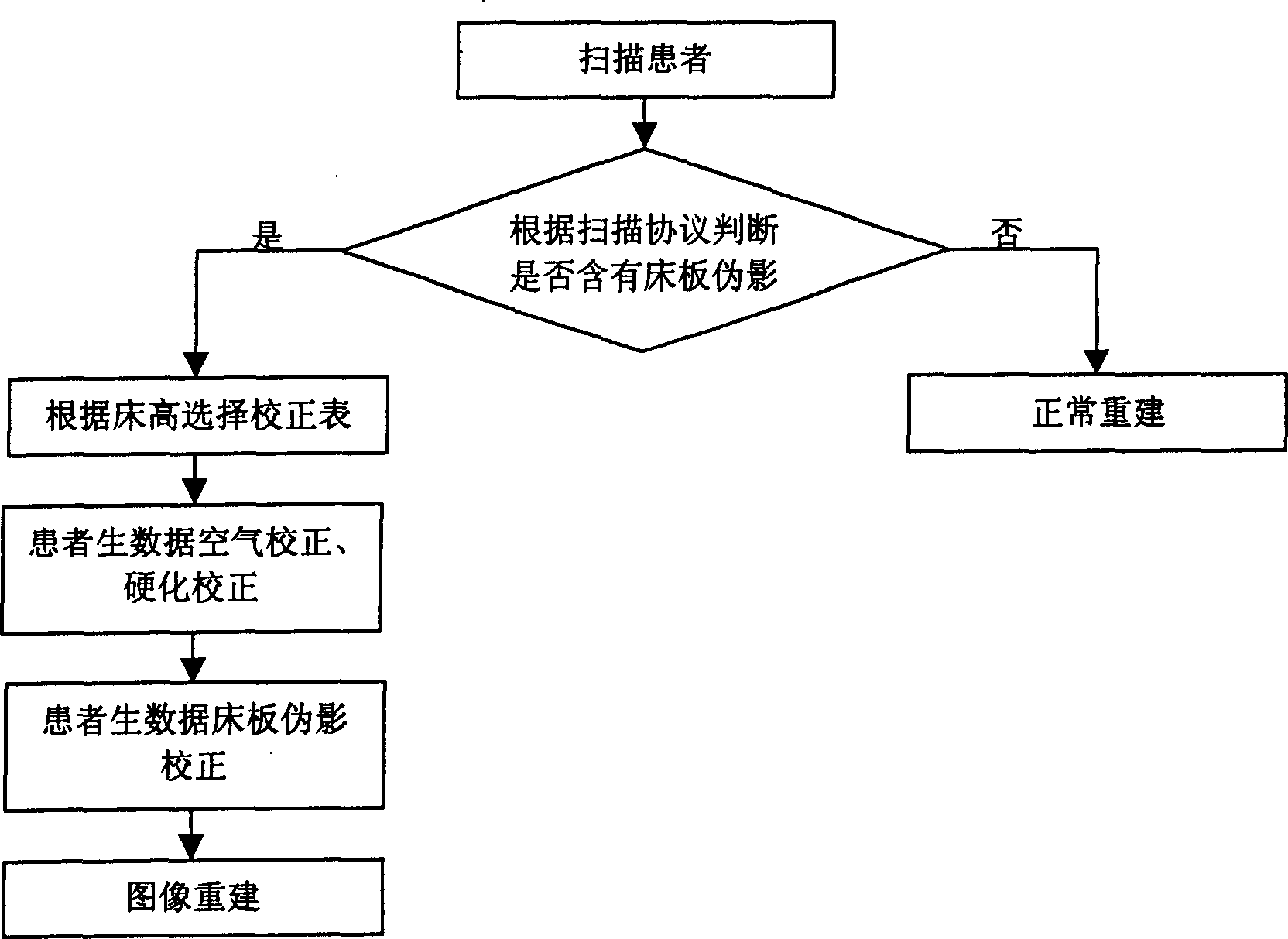

X-ray computerised tomograph capable of automatic eliminating black false image

A CT machine able to automatically eliminate the false black image features that the hardening effect of ray beam and the scatter effect of bed plate are integrally processed to obtain a calibration table, and the calibration table is input to its computer for eliminating the false black image. Said processing procedure is also disclosed.

Owner:SHENYANG NEUSOFT MEDICAL SYST CO LTD +1

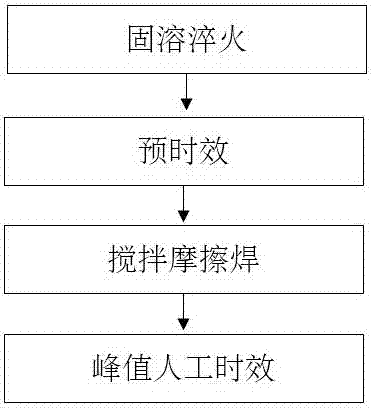

Preparation technology of 6-series aluminum alloy friction stir welding member

ActiveCN107570862AReduce manufacturing costLittle loss of strengthNon-electric welding apparatusFriction weldingPeak value

The invention discloses a preparation technology of a 6-series aluminum alloy friction stir welding member. The preparation technology mainly comprises the steps of on-line or off-line solution hardening, preageing, friction stir welding, peak-value artificial ageing and the like. According to the preparation technology of the 6-series aluminum alloy friction stir welding member, a 6-series aluminum alloy material is subjected to low-temperature preageing treatment after being subjected to solution hardening to enable the strength of aluminum alloy to keep low in a certain time, then frictionstir welding is conducted, forced cooling is conducted in a welded high-temperature area while welding is conducted to enable a solution hardening effect to be achieved, and peak-value artificial ageing is conducted on the overall member after welding is completed, so that it is guaranteed that the strength loss at the welded portion is low, and the ratio of the tensile strength of a weld joint tothe tensile strength of a base material is larger than or equal to 0.85.

Owner:广西南南铝加工有限公司

Machining process of large duplex stainless steel impeller

ActiveCN103418991APrevent thermal deformation during hoistingUniform outlet widthStructural engineeringSS - Stainless steel

The invention relates to a machining process of a large duplex stainless steel impeller. The machining process comprises the steps of casting, thermal treatment of a front deformation protector, solutionizing treatment, finishing and rough polishing, component re-inspection, mechanical property inspection, RT radiographic inspection, defect treatment, repair welding and rough polishing, rough machining, trimming, stress relief thermal treatment, semi-finish machining, fine polishing, finish machining, balance test duplicate removal and the like. The machining process is small in hardening effect, small in dimension deformation, good in impeller machining dimension accuracy and high in surface smoothness. The work completion size inspection is controlled at the temperature lower than 40 DEG C. In addition, the processing efficiency is high, the quality is good, the dimensional accuracy and the position dimension tolerance deformation of the impeller can be ensured to be small, and the graph dimension requirement and the technical requirements can be met.

Owner:SHENYANG SANKE VALVES IND CO LTD

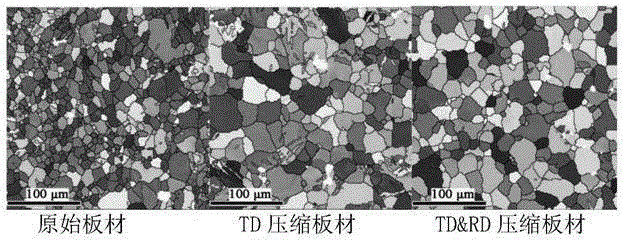

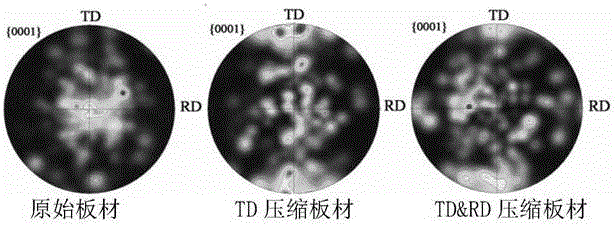

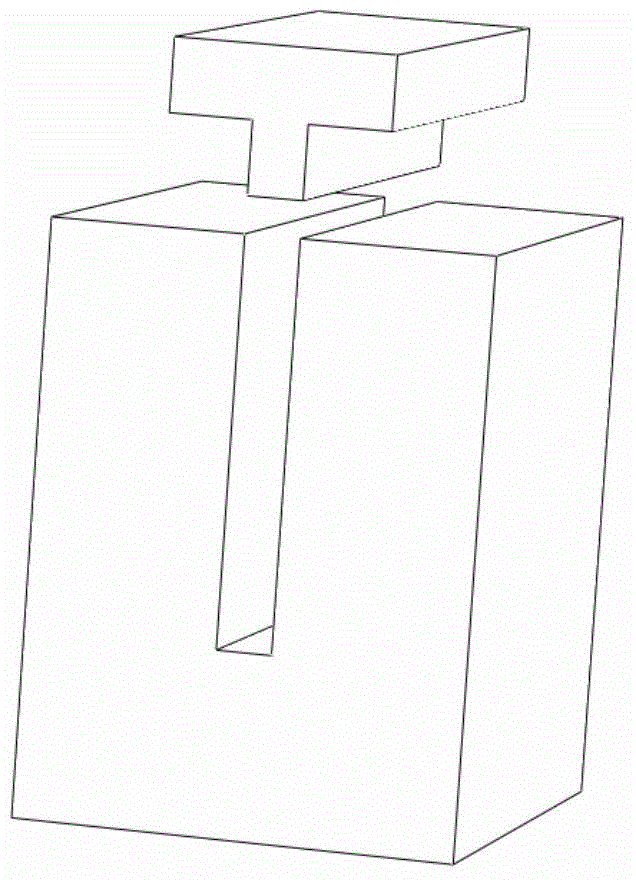

Magnesium alloy sheet forming property improving method based on twinning deformation

The invention provides a magnesium alloy sheet forming property improving method based on twinning deformation, and belongs to the field of nonferrous metal plastic working. By means of the magnesium alloy sheet forming property improving method based on twinning deformation, compression deforming in a plane is conducted on a magnesium alloy sheet, a stretching twinning deformation mechanism is activated, the basal texture of the sheet is changed, and the forming property of the sheet is improved. The method comprises the following steps that 1, a plane strain mold or a mold preventing instability of compression in the plane is prepared; 2, compression deforming in the plane is conducted on the magnesium alloy sheet through the mold; 3, a pre-deformed sheet material is subjected to annealing treatment, a strain hardening effect is eliminated, and therefore a magnesium alloy sheet with improved forming property is obtained. The basal texture of the magnesium alloy sheet which is processed through the method is remarkably changed, the forming property is substantially improved, and reliable guarantee is provided for subsequent deep processing of magnesium alloy sheets.

Owner:CHONGQING UNIV

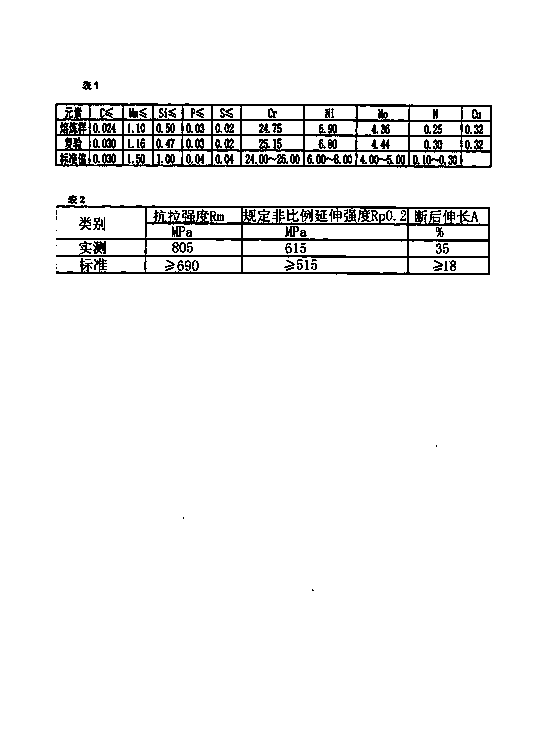

High-toughness and high-wear-resistant cold-work die steel

The invention discloses a high-toughness and high-wear-resistant cold-work die steel, belonging to the field of tool and die steels. The steel comprises the following chemical components in percentage by weight: 0.8-1.5% of C, 0.5-1.5% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 1.5% of Mn, 0.8-2.5% of Mo, 8.0-11.0% of Cr, 0.1-1.0% of V, less than or equal to 1.0% of N, and the balance of Fe and inevitable impurities. Compared with the prior art, the high-toughness and high-wear-resistant cold-work die steel disclosed by the invention keeps high wear resistance, and has higher toughness and bending strength and good comprehensive performances at the same time. Compared with a Cr12 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel reduces the Cr content, and ensures that a material has higher toughness. Compared with a Cr8 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel increases the Cr content, increases the wear resistance, and reasonably controls the C / Cr ratio, thus achieving the purposes of obtaining a better carbide distribution state than the Cr8 type cold-work die steel, and ensuring that the material has better toughness. The content of elements Mn and Si is increased so as to improve the hardness and enhance the wear resistance. By adopting relatively high Nb<+>V composite alloying, the effects of V in the steel are increased, and the secondary hardening effect is improved.

Owner:CENT IRON & STEEL RES INST

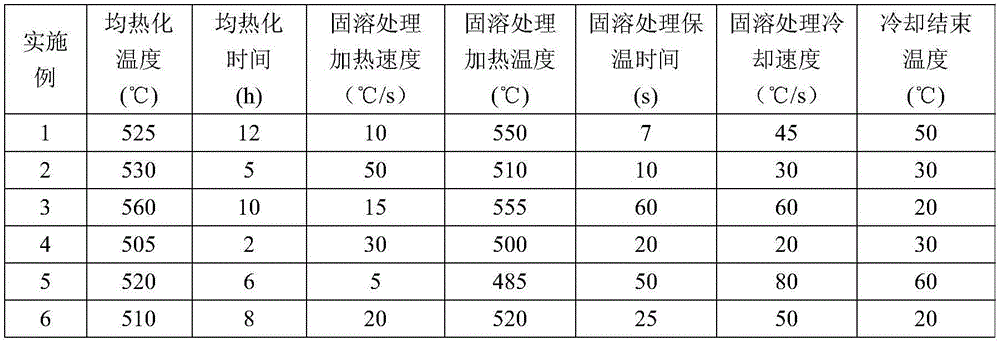

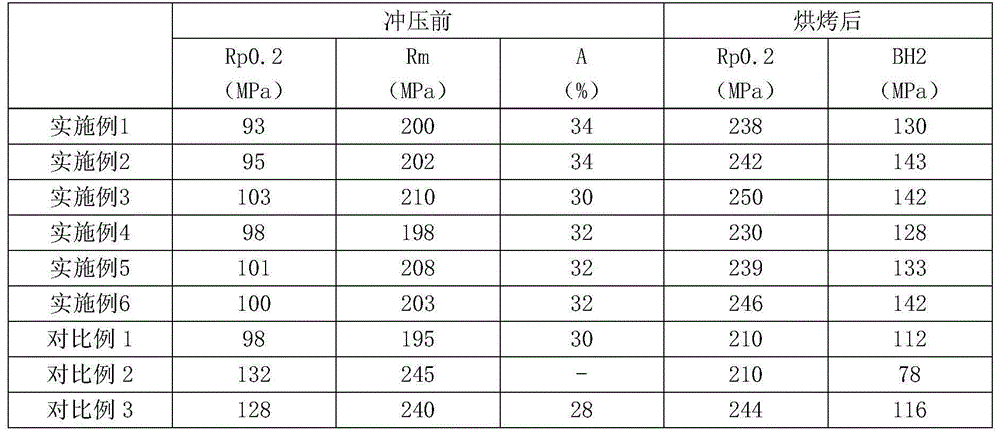

Al-Mg-Si aluminum alloy material, aluminum alloy plate, and preparation methods of Al-Mg-Si aluminum alloy material and aluminum alloy plate

The invention discloses an Al-Mg-Si aluminum alloy material. The Al-Mg-Si aluminum alloy material comprises the following chemical elements in mass percentage: Mg of which the mass percentage is equal to or larger than 0.5% and equal to or smaller than 1.0%, Si of which the mass percentage is equal to or larger than 0.6% and equal to or smaller than 1.5%, Sn of which the mass percentage is equal to or larger than 0.02% and equal to or smaller than 0.2%, Mn of which the mass percentage is equal to or larger than 0.1% and equal to or smaller than 0.45%, Fe of which the mass percentage is larger than 0 and equal to or smaller than 0.4%, Ti of which the mass percentage is equal to or larger than 0.02% and equal to or smaller than 0.1%, Zn of which the mass percentage is equal to or smaller than 0.15%, Cr of which the mass percentage is equal to or smaller than 0.1%, and the balance of Al and other inevitable impurities; in addition, the requirement that the total mass percentage of the Mg and the Si is equal to or smaller than 2.0% is met. In addition, the invention further discloses an aluminum alloy plate made from the Al-Mg-Si aluminum alloy material, and a preparation method of the aluminum alloy plate. The aluminum alloy material disclosed by the invention not only has an excellent forming property, but also has a preferable bake hardening effect.

Owner:BAOSHAN IRON & STEEL CO LTD

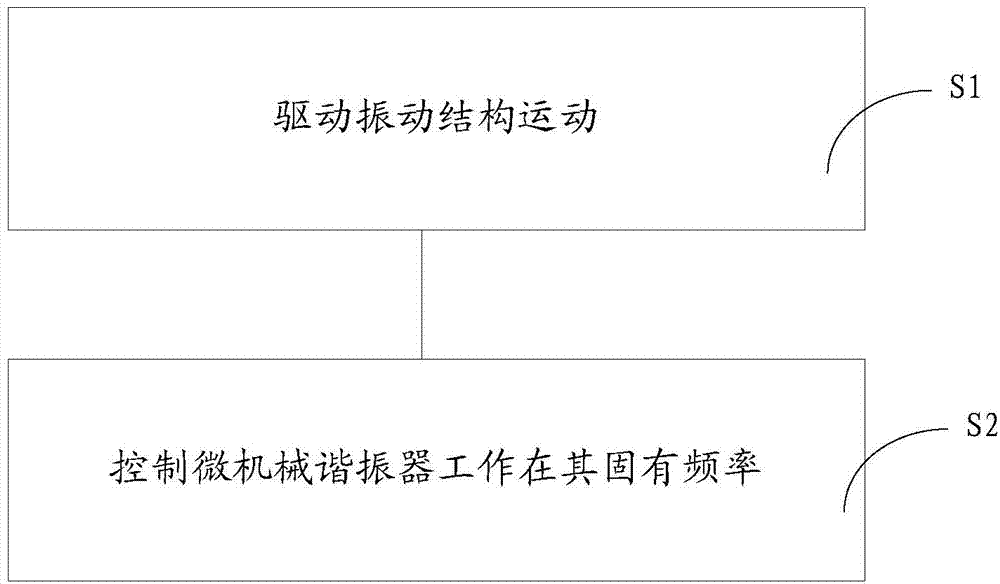

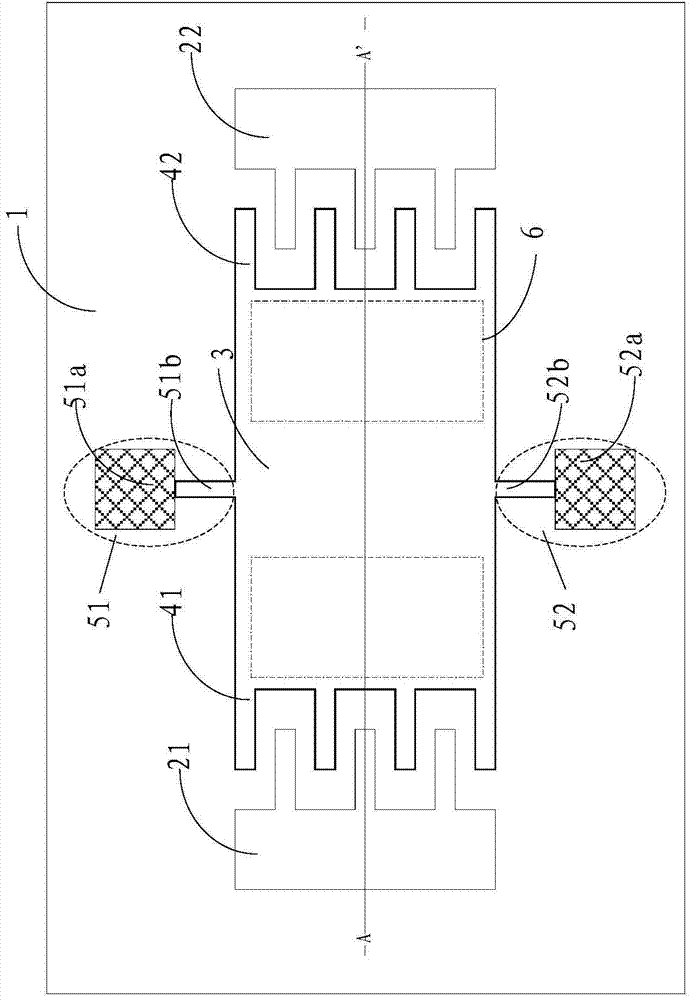

Oscillation control method for micromechanical resonator and micromechanical resonator

ActiveCN104333344AImprove stabilityControl natural frequencyImpedence networksVibration controlReciprocating motion

The invention discloses an oscillation control method for a micromechanical resonator and the micromechanical resonator. The micromechanical resonator comprises a substrate, and an oscillation structure and a driving structure which are arranged on the substrate. The driving structure is used for driving the oscillation structure of the micromechanical resonator to move in a reciprocating way, generating facilitating electrostatic force which is applied to the oscillation structure and facilitates reciprocating movement of the oscillation structure when the oscillation structure moves in the reciprocating way, and generating restricting electrostatic force which is applied to the oscillation structure and restricts reciprocating movement of the oscillation structure so that frequency deviation generated by the softening effect of an electrostatic spring and frequency deviation generated by the hardening effect of the electrostatic spring in reciprocating movement of the oscillation structure can be mutually cancelled, and thus the micromechanical resonator is controlled to work at the inherent frequency and work stability of the micromechanical resonator is enhanced.

Owner:SENODIA TECH (SHANGHAI) CO LTD

Preparation method of silicon dioxide modified polyether polyol

The invention belongs to the technical field of chemical synthesis, and in particular discloses a preparation method of silicon dioxide modified polyether polyol. The preparation method comprises the steps of diluting water glass, adjusting pH to be 4-7, and adding a compound S and polyether polyol for reacting, thus obtaining the silicon dioxide modified polyether polyol, wherein a chemical formula of the compound S is (R-O)n-SiXm, R is the alkyl of C1-C20, X is any substituent group, n is 1, 2 or 3, and n plus m is equal to 4. An inorganic matter silicon dioxide is introduced into the polyether polyol, the prepared silicon dioxide modified polyether polyol has a reinforcing and hardening effect on a polyurethane material, and the use amount of isocyanate in the polyurethane material can be reduced; the size of particles in the silicon dioxide modified polyether polyol is 10 nanometers to 10 micrometers, so that the possibility that the local performance defect of a polyurethane product occurs due to uneven filler distribution is reduced.

Owner:SHANDONG BLUSR DONGDA CHEM

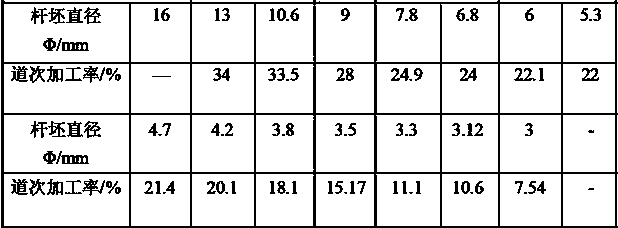

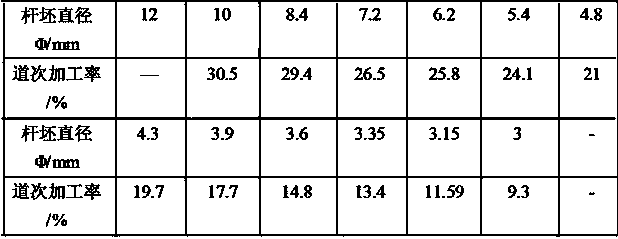

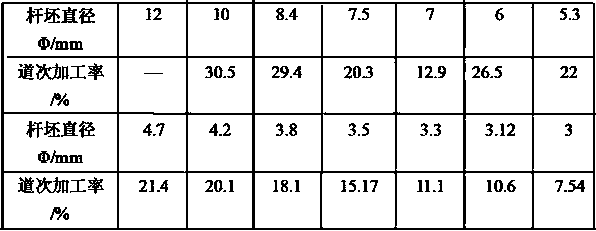

Short-process preparing method for high-strength and high-conduction Cu-Cr-Ag alloy

ActiveCN108277378AThe degree of recrystallization is controllableComposition is stableSolution treatmentStrength of materials

The invention provides a non-solid-solution treatment short-process preparing method for a high-performance Cu-Cr-Ag alloy. A Cu-Cr-Ag alloy rod billet is prepared and obtained through up-drawing continuous casting, and the up-drawing temperature is 1200-1250 DEG C; multi-pass drawing is conducted; aging is conducted; and final drawing is conducted. The supersaturated solute atomic concentration is obtained through the fast-cooling process of up-drawing continuous casting, solid solution treatment is not conducted, solute atoms are promoted to precipitate directly through matching of subsequent drawing and the aging technology, the recrystallization degree is controlled synchronously to retain a certain machining hardening effect, and through strengthening mechanisms of solid-solution strengthening, aging precipitation phase strengthening and cold work hardening, and the purpose of preparing the high-strength and high-conduction softening-resisting Cu-Cr-Ag alloy can be achieved without solid solution treatment. The tensile strength of materials can reach 500-755 MPa, the conductivity is 70-85% IACS, the elongation is 1-14%, and the softening temperature can reach 550-600 DEG C. The short-process preparing method has the characteristics of the short process, high efficiency and low energy consumption, and the prepared Cu-Cr-Ag alloy can meet the practical application demand ofthe fields such as semiconductors and rail traffic.

Owner:JIANGXI UNIV OF SCI & TECH

Rubber explosive for explosion hardening

ActiveCN104370668AUniform compositionImprove consistencyExplosive working-up apparatusPolymer scienceAdhesive

The invention relates to the field of explosives and in particular relates to a rubber explosive for explosion hardening. The technical problems that the consistency is low, the low-temperature resistance is low, the explosive is difficult to form, the adhesiveness with the metal surface is low, the manufacturing process is toxic, large-scale production cannot be realized and the like existing in metal surface hardening at present are solved. The rubber explosive for explosion hardening is prepared by the following steps: (a) placing rubber in gasoline, and standing for 24 hours; (b) fully dissolving an adhesive in the gasoline; (c) preparing an additive mixing system, namely mixing the rubber, the adhesive, a plasticizer, a rubber accelerator and an oxidizing agent uniformly; (d) uniformly kneading the additive mixing system and the explosive into paste; (e) repeatedly pressing the explosive paste into sheets of the needed thickness; (f) naturally airing; and (g) cutting the explosive sheets into specific shapes, thereby obtaining the rubber explosive for explosion hardening. According to the formula, the low-temperature resistance and processibility of the explosive can be improved, and the explosion hardening effect of the explosive is guaranteed.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

Soil stabilizer and preparation method thereof

ActiveCN105505400AAbundant raw materialsLow costBuilding constructionsOrganic fertilisersCalcium biphosphateBrick

The invention belongs to the technical field of stabilizers and particularly relates to a soil stabilizer and a preparation method thereof. The soil stabilizer mainly comprises 2-acrylamido-2-methylpropane sulfonic acid, polyacrylamide, sodium sulfate, calcium phosphate, a polysaccharide, sodium lignosulfonate, sodium silicate, sodium hydroxide and water. The formulation of the soil stabilizer provided by the invention is reasonable and scientific in matching and may effectively shorten stabilizing time of soil and enhance soil stabilizing and hardening effects, and experiments show that a solid brick obtained by stabilizing may be as hard as and even harder than a red brick, has waterproof performance also meeting the waterproof standards of red bricks and is an ideal soil stabilizer.

Owner:刘静沂

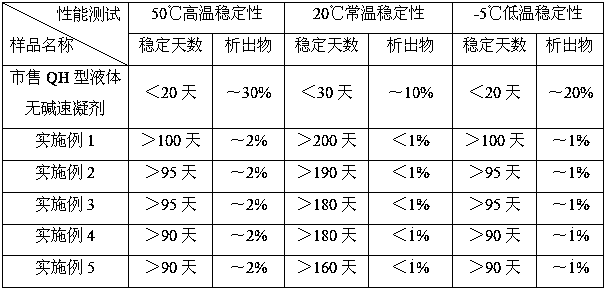

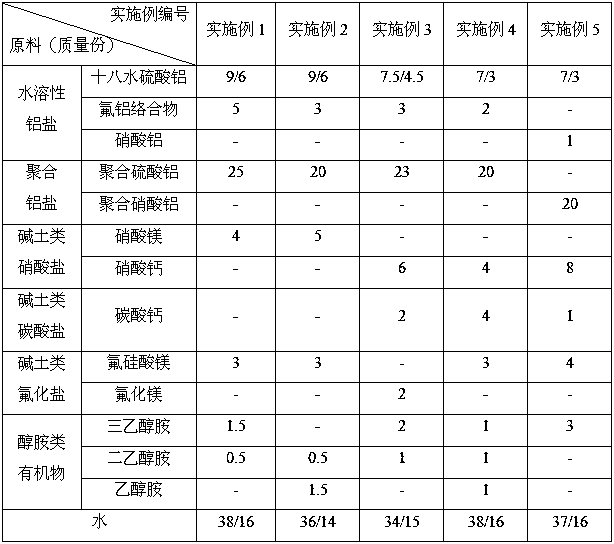

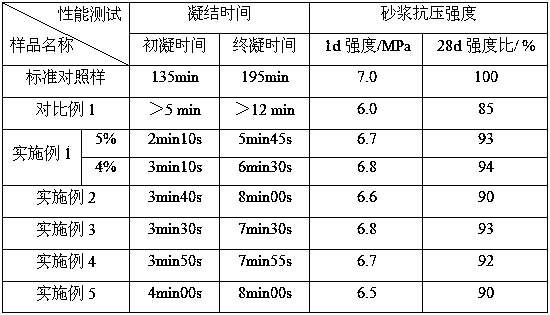

Anti-freezing alkali-free liquid accelerator and preparation method thereof

An anti-freezing alkali-free liquid accelerator and a preparation method thereof are disclosed. The accelerator is mainly prepared from water-soluble aluminium salt, polyaluminium salt, alkaline earthnitrate and / or carbonate, alkaline earth fluoride salt, alcamines organic matter and water. The preparation method comprises the following steps: firstly dissolving a part of water-soluble aluminiumsalt by the use of a part of water, heating and stirring, adding polyaluminium salt and alkaline earth nitrate and / or carbonate, heating and reacting, cooling, successively adding alkaline earth fluoride salt, alcamines organic matter and the rest of water-soluble aluminium salt, adding the rest of water, and filtering. After the accelerator with the dosage of 4% is added into cement, initial setting time of cement paste is less than or equal to 4 min, and final setting time is less than or equal to 8 min; and early strength and long-term strength are both high. The accelerator of the invention has good storage stability at room temperature, low temperature and high temperature. In the case of redissolving after freezing, almost no precipitate is precipitated out, and the rapid hardening effect is not attenuated. The method of the invention has advantages of simple process, low cost and zero emission, and is suitable for industrial production.

Owner:湖南同远新材料科技有限公司

Preparation method of high-melt strength polypropylene resin with long-chain branched structure characteristic

The invention relates to a preparation method of high-melt strength polypropylene resin with long-chain branched structure characteristic. According to the preparation method, polymerization reactions are carried out section by section based on MgCl2 / TiCl4 type high-efficiency Ziegler-Natta catalysts. The preparation method comprises the following steps of carrying out propylene homo-polymerization, generating a homo-polypropylene matrix framework-linear polypropylene resin matrix, introducing alpha, omega-alkadiene monomer to carry out copolymerization, generating co-polypropylene in which the long chain is branched and some parts are interlinked, and evenly dispersing the co-polypropylene in which the long chain is branched and some parts are interlinked into a linear polypropylene resin-based polypropylene resin body to obtain the high-melt strength polypropylene resin with the long-chain branched structure characteristic. The preparation method is simple in polymerization technique, the high-melt strength polypropylene resin with the long-chain branched structure characteristic has good particle morphology, and the polymer melt has relatively strong strain hardening effect once being stretched.

Owner:INST OF CHEM CHINESE ACAD OF SCI

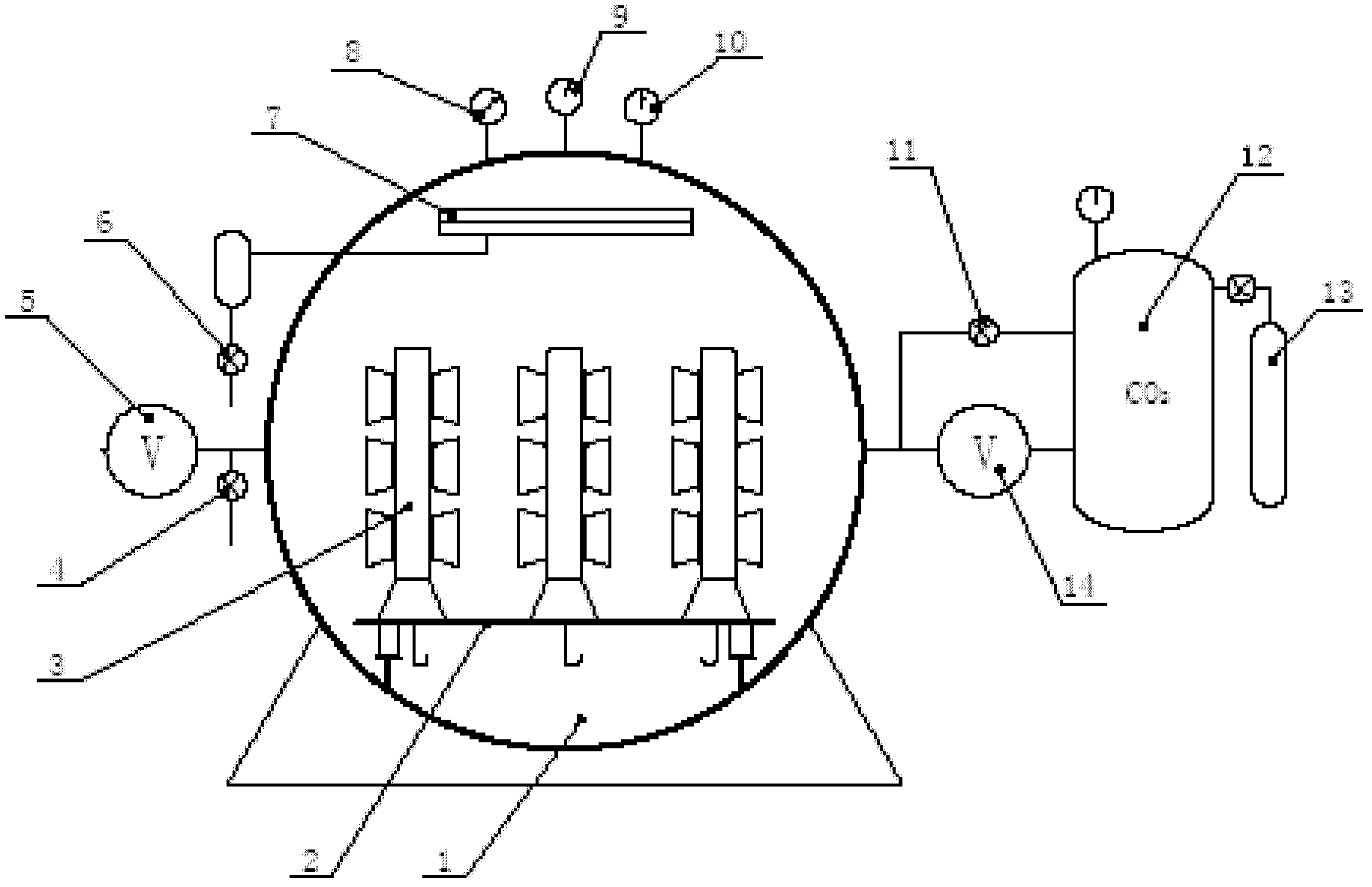

Precision investment casting water glass binder shell CO2 gas hardening technology

InactiveCN102632201ANo emissionsHardened operating environment is goodFoundry mouldsFoundry coresChemical reactionInlet valve

The invention relates to a precision investment casting water glass binder shell CO2 gas hardening technology which comprises the following steps of: (1) placing a shell to be hardened in a fully-sealed hardening chamber; (2) starting a vacuum pump to keep the sealed chamber in a vacuum state; (3) introducing CO2 gas into the hardening chamber and starting a fast dehumidifying system so that a coating layer on the shell surface is subjected to chemical reaction and physical dehydration effect together with the CO2 gas to finish the hardening of the shell; and (4) closing a CO2 gas inlet valve and starting a sucking pump to suck the CO2 in the hardening chamber back to a storage tank for circular use. Compared with the traditional technology, the technology provided by the invention has the advantages: 1, the hardening operation environment is good, harmful substances are not discharged in roasting, and thus the technology is an environmentally-friendly production technology; 2, the hardening effect is good, and the phenomenon of halfway hardening of the shell is avoided; and 3, the consumption of CO2 gas is low, and the material cost of the shell hardening agent is reduced.

Owner:WUHAN ZONKING METAL PRODS

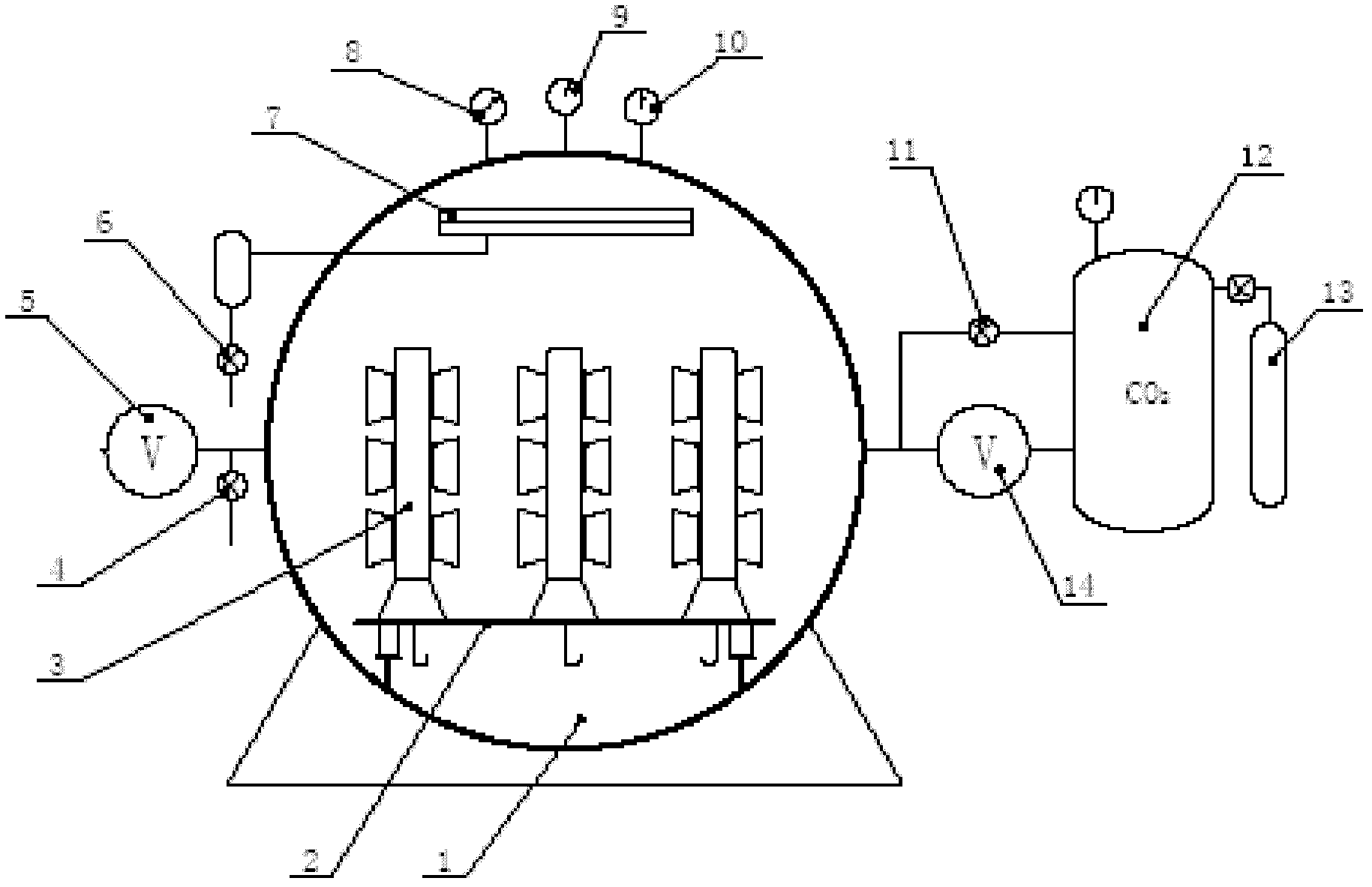

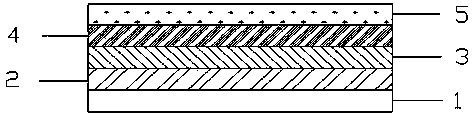

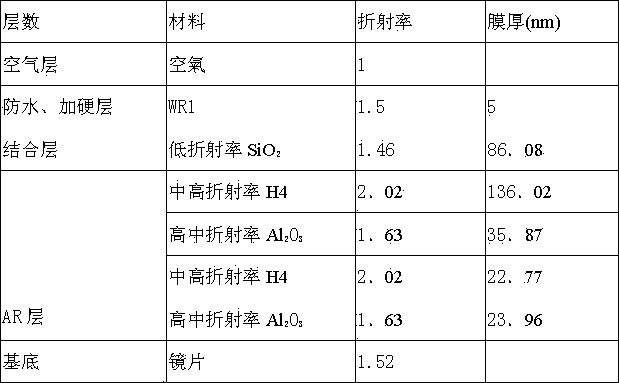

Ultrahard waterproof membrane and processing technology of ultrahard waterproof membrane

ActiveCN104090313AReduce reflectivityWaterproof lowCoatingsOptical elementsSystems designEvaporation

The invention relates to an ultrahard waterproof membrane and a processing technology of the ultrahard waterproof membrane. The ultrahard waterproof membrane sequentially comprises an optical glass lens (1), an antireflection membrane layer (2), a combination layer (3), a waterproof hardening layer (4) and an air layer (5) from bottom to top. The ultrahard waterproof membrane is characterized in that the antireflection membrane layer (2) is sequentially composed of first-layer high-medium refractive index membrane materials, second-layer medium-high refractive index membrane materials, third-layer high-medium refractive index membrane materials and fourth-layer medium-high refractive index membrane materials. According to the ultrahard waterproof membrane and the processing technology, mixed design of the multiple kinds of the membrane materials is adopted in membrane system design, the waterproof membrane materials and the antireflection membrane layer are well combined, and plated curves have the ultralow reflectivity; meanwhile, an electronic beam evaporation waterproof drug device is adopted in the evaporation technology, the membrane layer is firm and even, the produced ultrahard waterproof membrane has the waterproof, dustproof and hardening effect, and the low reflectivity is achieved.

Owner:DANYANG DANYAO OPTICS CO LTD

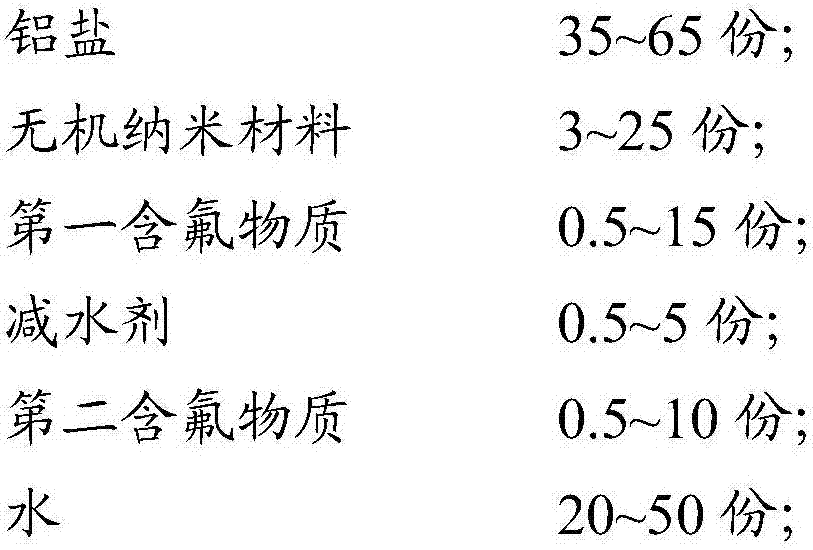

Alkali-free liquid concrete accelerator and preparation method and application of alkali-free liquid concrete accelerator

The invention provides an alkali-free liquid concrete accelerator. The alkali-free liquid concrete accelerator comprises the following components by mass: 35-65 parts of aluminum salt, 3-25 parts of inorganic nano material, 0.5-15 parts of first fluorine substance, 0.5-5 parts of water reducer, 0.5-10 parts of second fluorine substance, and 20-50 parts of water; the first fluorine substance comprises one or a mixture of more of fluoride, fluosilicate and borofluoride; the second fluorine substance is fluosilicate. The provided alkali-free liquid concrete accelerator has a good fast hardening effect, the conservation rate of long-term strength of the concrete is high, and the alkali-free liquid concrete accelerator is suitable for spraying the concrete.

Owner:WUJIAQU GEHUI CHEM ENG

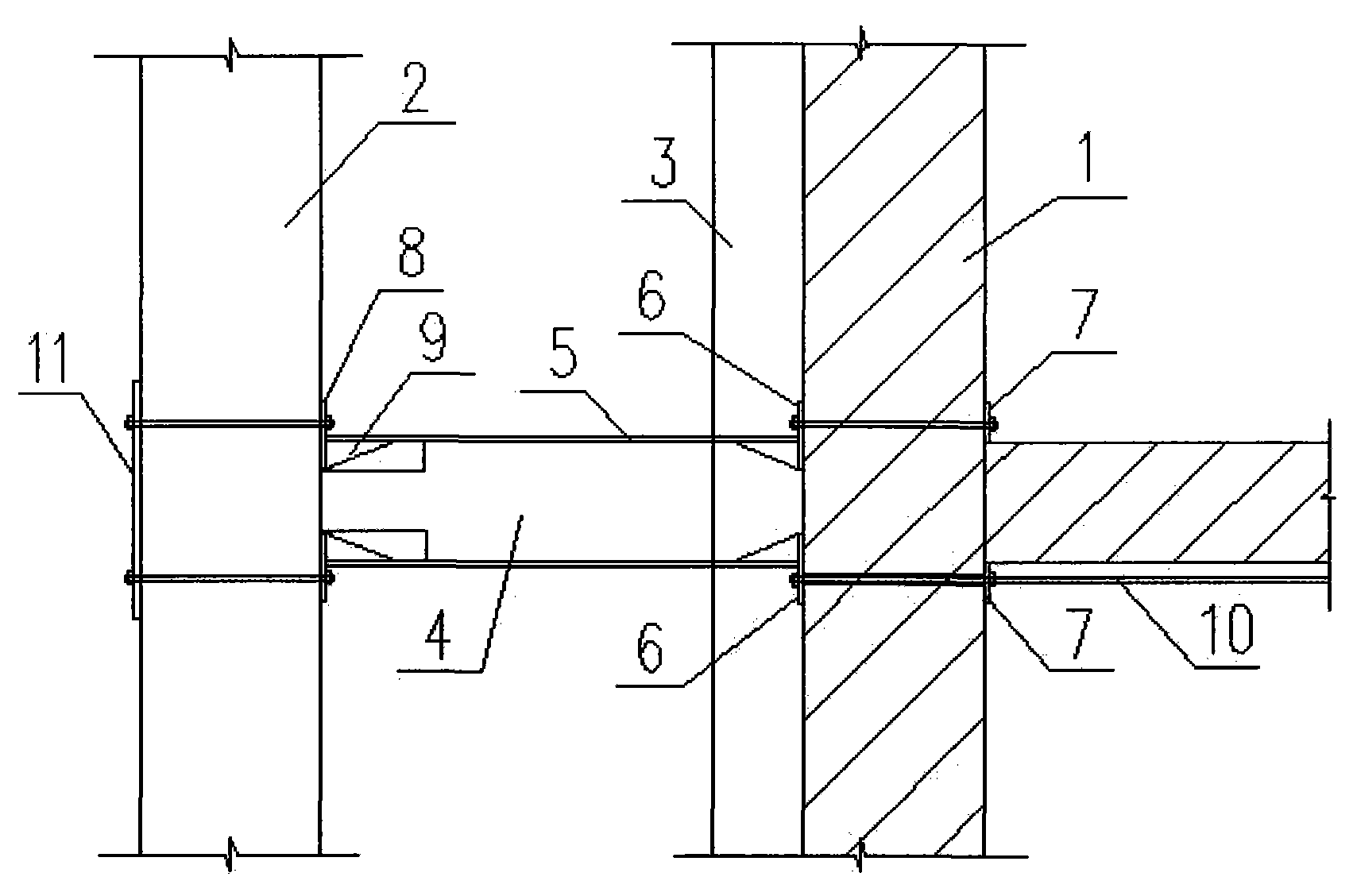

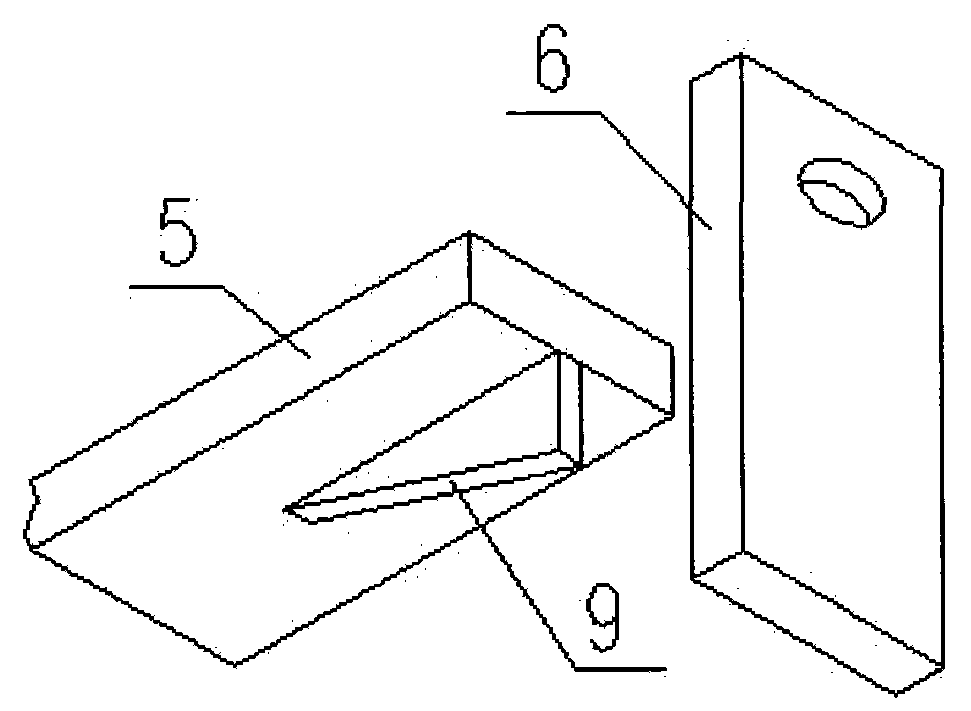

Enhanced cover-type story-adding structure and hardening method thereof

InactiveCN103362316AFix stability issuesClosely connectedBuilding repairsSheet steelStructural stability

The invention relates to an enhanced cover-type story-adding structure and a hardening method thereof and belongs to the seismic hardening field. A newly-added cover-type story-adding framework is adopted and comprises a cover framework inner column and a cover framework outer column, as well as a cover framework bream arranged therebetween; strip-shaped steel plates are arranged on the upper surface and the lower surface of the cover framework beam; the newly-added cover-type story-adding framework and an original structure are connected through adding the strip-shaped steel plates and end anchoring, so that the novel and new structures are connected more closely and the structural stability is enhanced. Meanwhile, the part of the original structure transverse wall, not meeting the shock-resistant requirement, is hardened through steel pull rods at firstly, and anchor plates at the two ends are connected with the newly-added cover-type story-adding framework in an anchoring manner. By adopting the structure and the method which are provided by the invention, the hardening effect is enhanced, the two structural systems are adopted for bearing together, so that the anti-seismic property is improved on the whole.

Owner:福建省中马建设工程有限公司

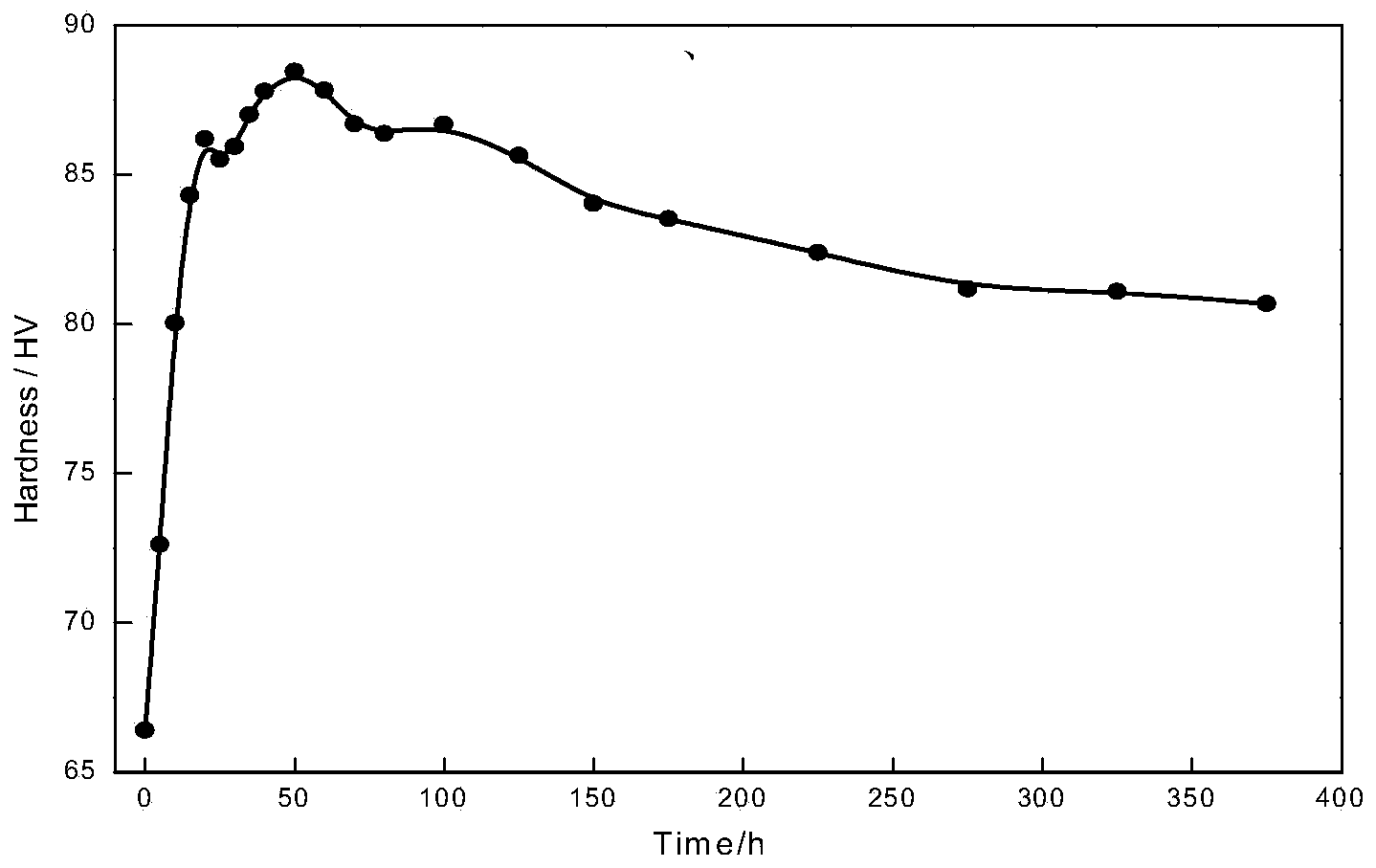

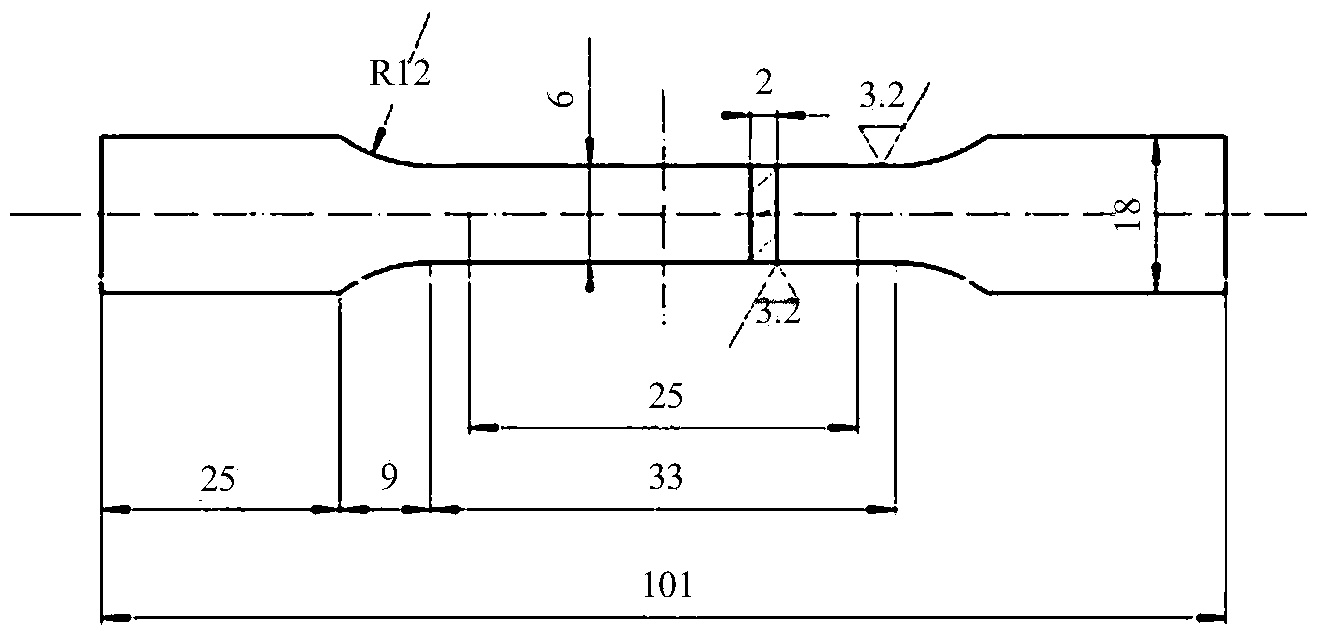

Age hardenable Mg-Zn-Cr-Bi-Zr alloy and preparation method thereof

The invention discloses an age hardenable Mg-Zn-Cr-Bi-Zr alloy and a preparation method thereof. The alloy comprises the following components in percentage by mass: 4-10% of Zn, 0.1-0.5% of Cr, 0.1-1.0% of Bi, 0.3-0.5% of Zr, and the balance of Mg. The preparation method of the alloy comprises the following steps: preheating a prepared alloy burden, feeding CO2 / SF6 mixed gas as a shielding gas for smelting, and carrying out diffusion annealing on the obtained Mg-Zn-Cr-Bi-Zr as-cast alloy material for 48 h at a temperature of 380 DEG C; carrying out wire cutting on the obtained object, so that a sample for aging heat treatment and a platy tensile sample are obtained; carrying out solid dissolving on the samples; and aging the obtained product for 0-400 hours at a temperature of 160 DEG C, so that the age hardenable Mg-Zn-Cr-Bi-Zr alloy is obtained. According to the invention, a Mg-Zn-Cr-Bi-Zr alloy which has a relatively thin as-cast structure and is good in age hardening effect, thermal stability and mechanical properties and low in cost can be prepared.

Owner:NORTHEASTERN UNIV

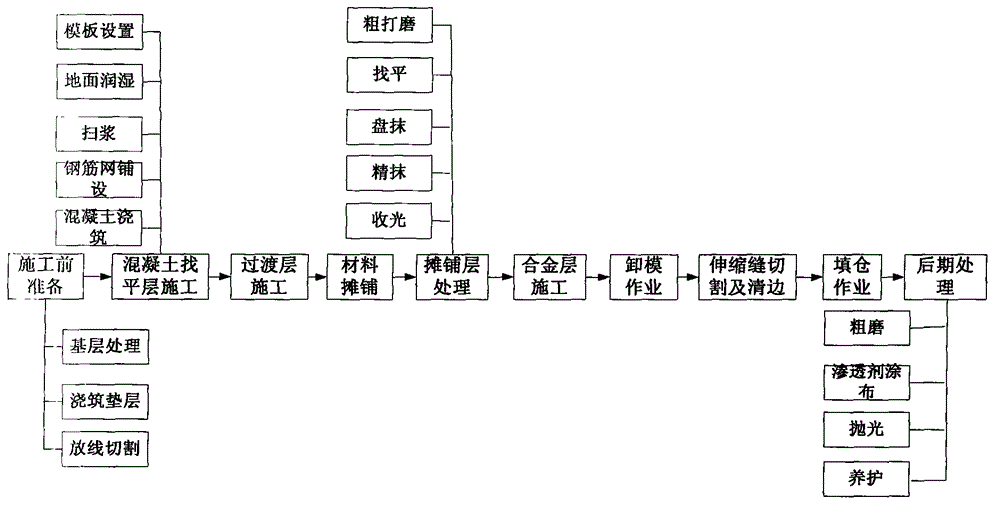

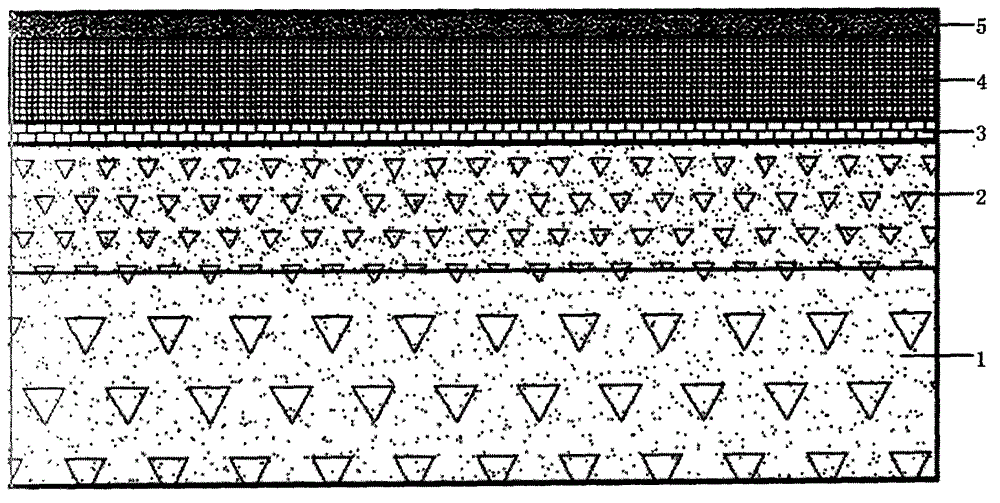

Construction method for paving-type high-abrasion-resistance alloy terrace

The invention provides a construction method of a paving type high wear-resistant alloy floor. The invention improves the construction technology of the original alloy floor. The finished floor not only ensures the overall aesthetics and applicability, but also has the effects of hardening, compacting, sealing, and dustproof, achieving high wear resistance and high durability. Scratch resistance, high impact resistance, high cleanliness and other properties.

Owner:薛家珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com