Magnesium alloy sheet forming property improving method based on twinning deformation

A technology of twin deformation and formability, which is applied in the field of improving the formability of magnesium alloy thin plates, can solve the problems of complex large deformation and limited improvement of formability, and achieve the effect of improving formability and improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for improving the formability of a magnesium alloy sheet based on twin deformation, characterized in that it comprises the following steps:

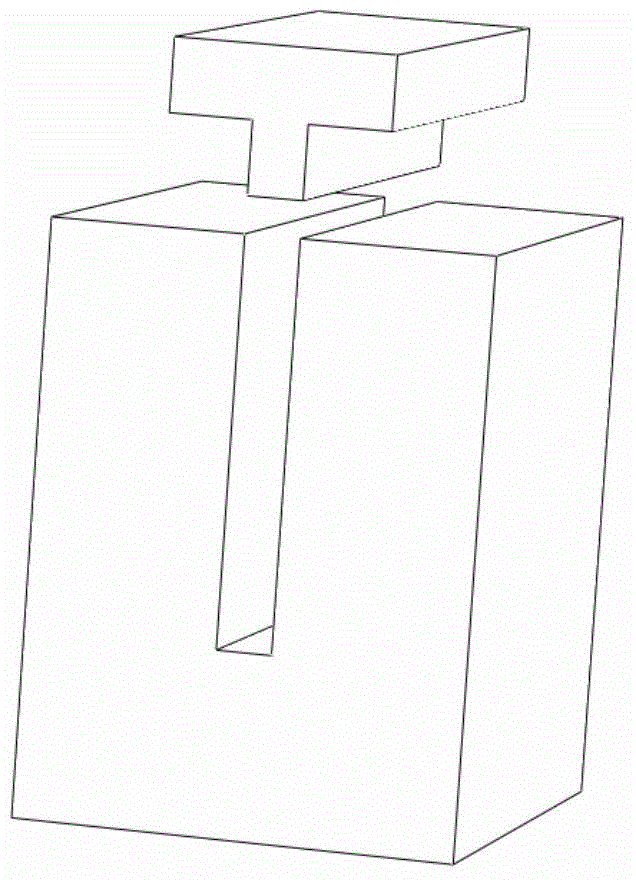

[0032] 1) Collect or process a set of plane strain compression molds suitable for the plate to be processed or a set of molds that can prevent in-plane compression instability of the thin plate, such as figure 1 shown.

[0033] It is worth noting that, figure 1 A mold for realizing the purpose of the present invention is provided, and the mold includes an upper mold and a lower mold. The upper mold is composed of horizontal plates and vertical plates perpendicular to each other; the vertical section of the upper mold is a "T-shaped" plane; the upper end of the lower mold is provided with a rectangular groove; the rectangular groove along the horizontal direction Both ends pass through the side of the lower mold; the vertical plate of the upper mold fits the rectangular groove of the lower mold; the rectangular groove ca...

Embodiment 2

[0040] The basic steps of this embodiment are the same as those of Embodiment 1, except that compression is performed from two directions, including the following steps:

[0041] 1) Select a set of plane strain molds; figure 1 As shown, the plane strain compression mold includes an upper mold and a lower mold. The upper mold is composed of horizontal plates and vertical plates perpendicular to each other; the vertical section of the upper mold is a "T-shaped" plane; the upper end of the lower mold is provided with a rectangular groove; the rectangular groove along the horizontal direction The two ends pass through the side of the lower mold; the vertical plate of the upper mold fits with the rectangular groove of the lower mold.

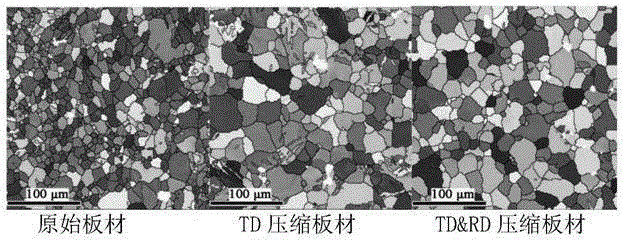

[0042] 2) from the magnesium alloy thin plate to be processed (thickness 2.2mm identical with embodiment 1), block sample is taken; figure 2 As shown, the block sample cut in this embodiment is a rectangular sample, and its four sides are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com