High-strength hot-dip galvanized steel sheet having excellent moldability and shape fixability, and method for manufacturing same

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in the direction of hot-dip galvanizing process, manufacturing tools, chemical instruments and methods, etc., which can solve the problems of reduced formability, not necessarily high absolute value of tensile flanging performance, and variable springback. Achieve the effect of excellent formability and shapeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

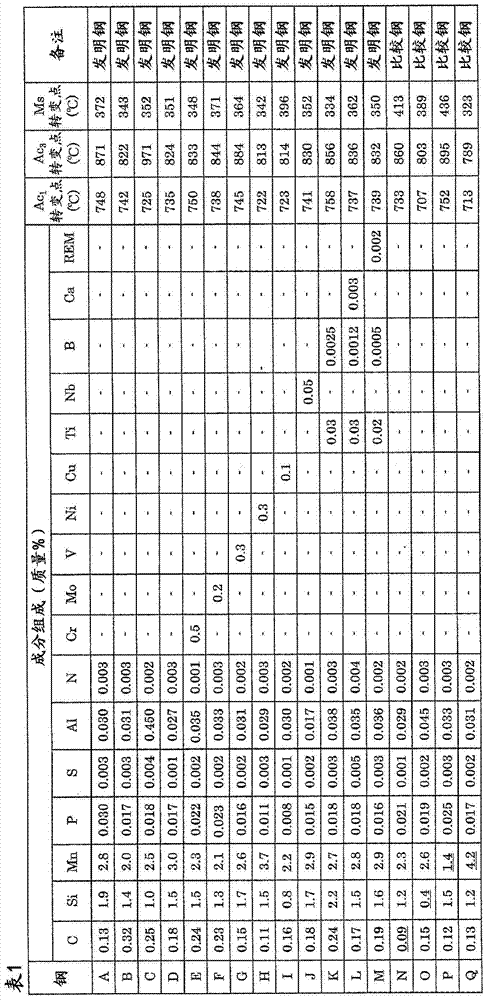

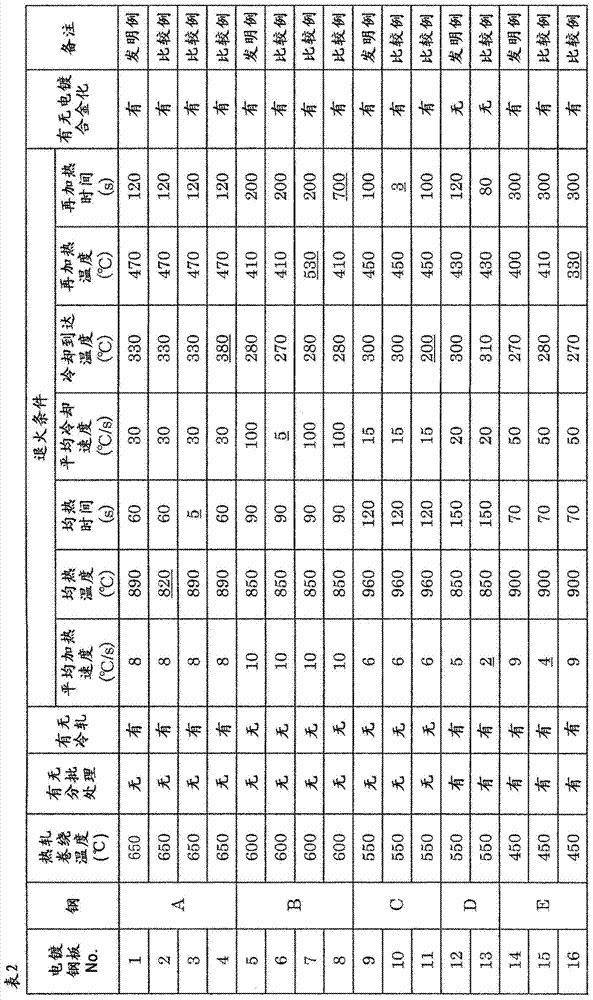

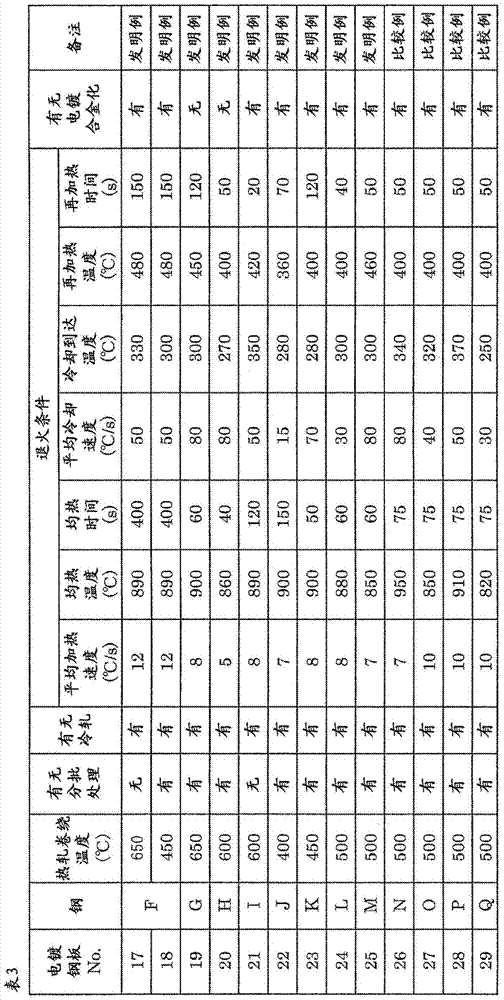

[0087] Steels having the composition shown in Table 1 were smelted in a converter and continuously cast to produce steel slabs (in Table 1, N is an unavoidable impurity). These steel slabs were heated to 1200° C., rough-rolled and finish-rolled, and coiled at a coiling temperature of 400 to 650° C. to obtain hot-rolled sheets with a thickness of 2.3 mm. Next, a portion was softened at a temperature of 600° C. and a heat treatment time of 5 hours by batch processing, and after pickling, it was cold-rolled to a thickness of 1.4 mm to produce a cold-rolled steel sheet for annealing. Another part of the steel plate which was hot-rolled to a plate thickness of 2.3 mm was pickled and then directly used for annealing. Annealing is carried out through the continuous hot-dip galvanizing production line under the conditions shown in Table 2 and 3, immersed in a 460°C plating bath, and the adhesion amount is 35-45g / m 2 The coated layer was cooled at a cooling rate of 10°C / s to make hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com