Patents

Literature

1341 results about "Chemical element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A chemical element is a species of atom having the same number of protons in their atomic nuclei (that is, the same atomic number, or Z). For example, the atomic number of oxygen is 8, so the element oxygen consists of all atoms which have 8 protons.

Functionally graded cemented tungsten carbide

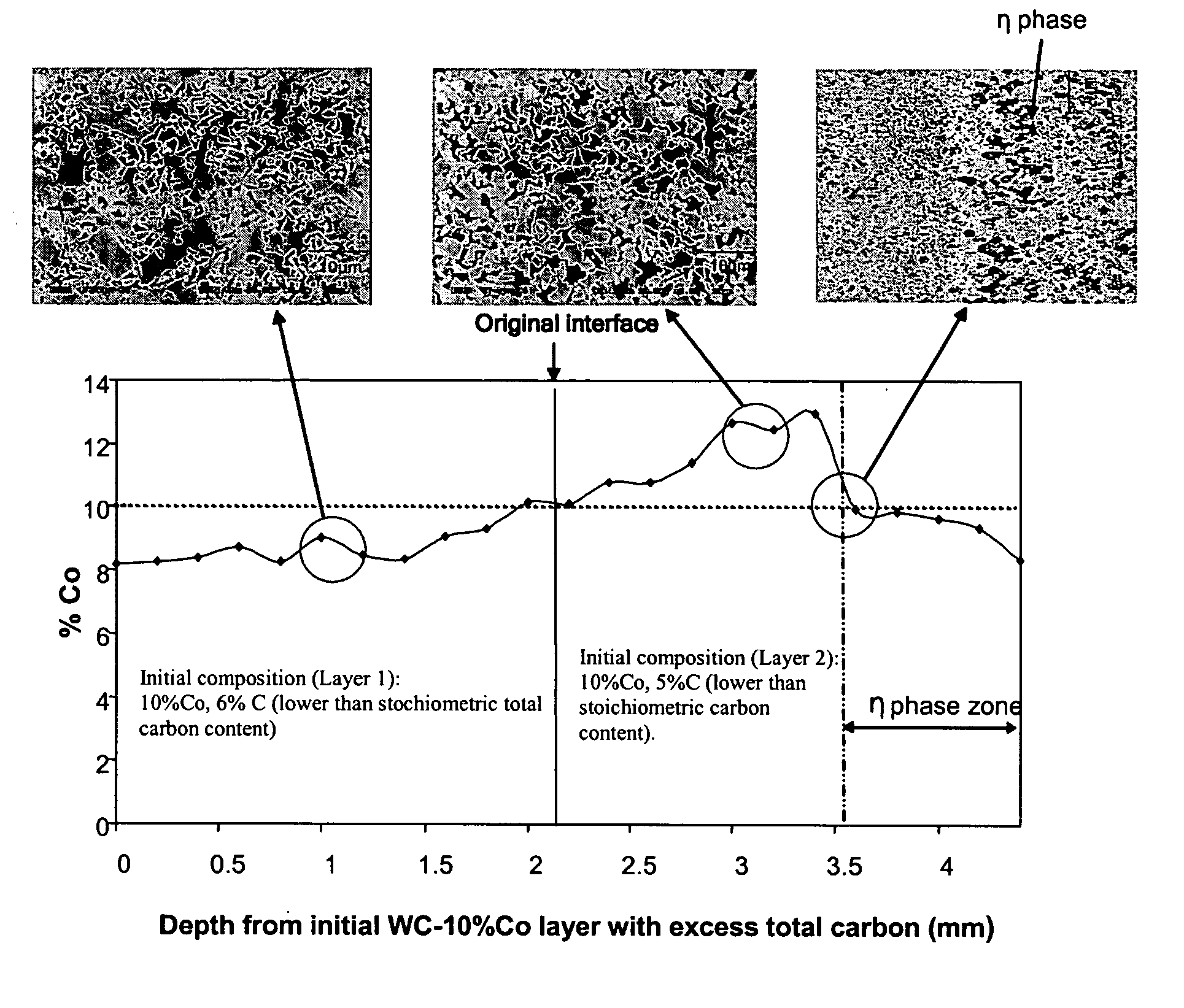

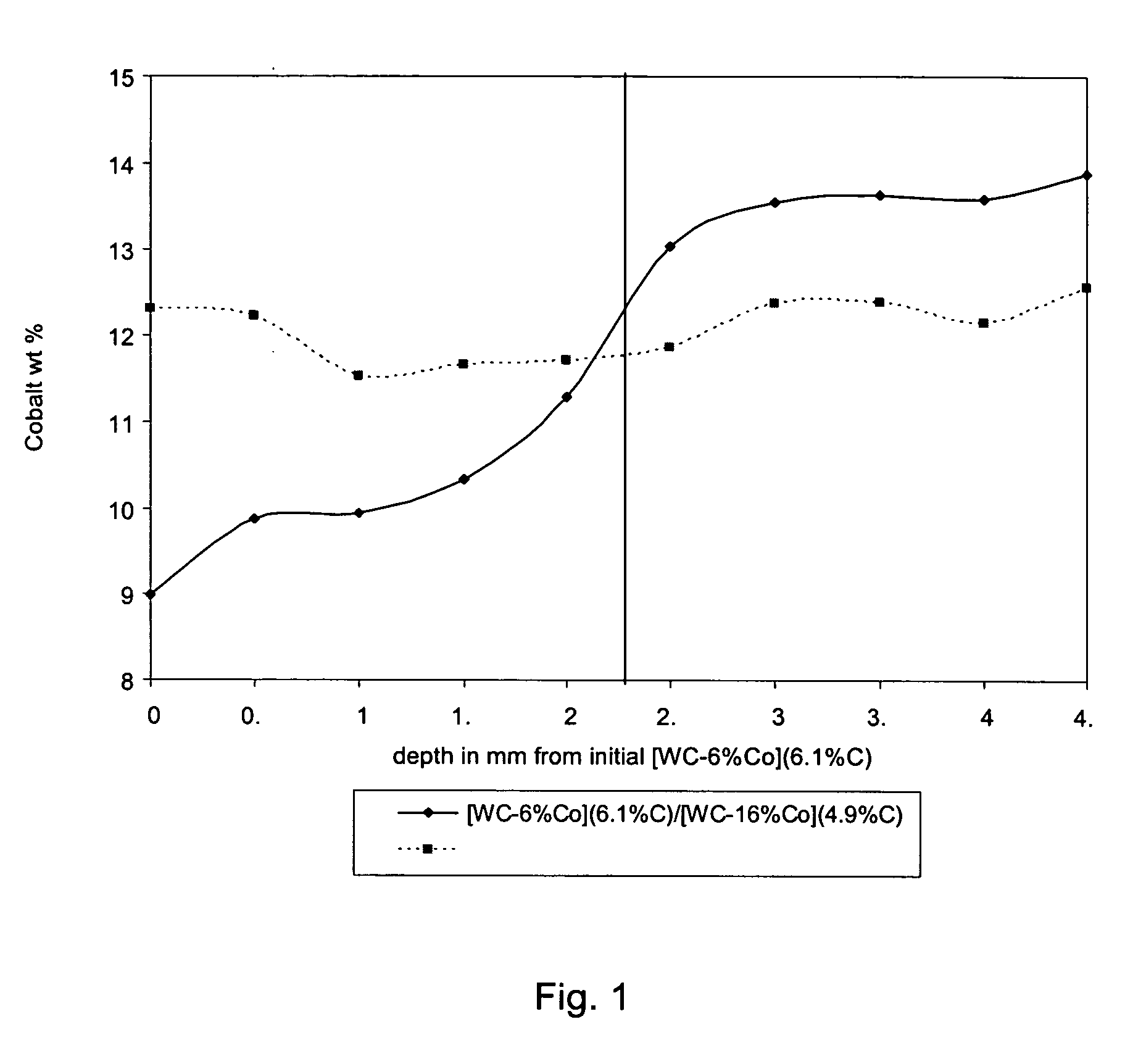

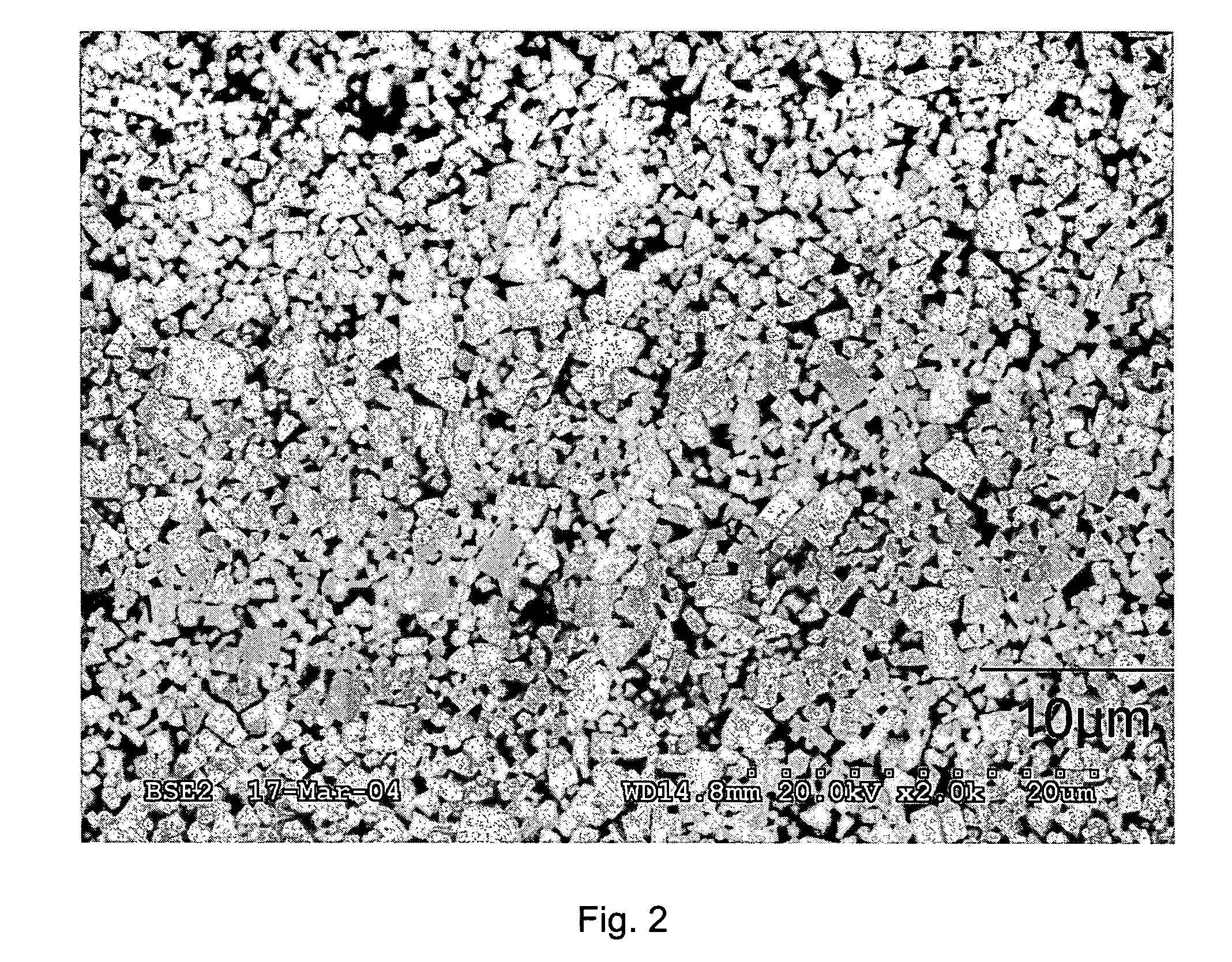

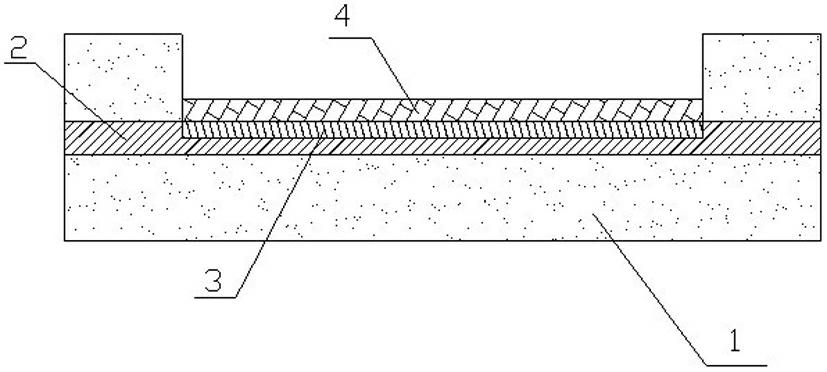

The present invention is a method for producing functionally graded materials that contain a hard phase that is embedded in a metal matrix phase. The material have a continuous gradient of a matrix metal phase. An example of these types of materials include functionally graded cemented tungsten carbide (the hard phase) that has a continuous gradient of cobalt (the matrix metal) from one reference position, for example, one surface of a part, to another reference position, for example, the opposite surface of the part or within the part. The functionally graded materials are sintered via a liquid phase sintering (LPS) technique. In order to achieve the desired continuous gradient of the matrix metal, an initial gradient of one of the chemical elements of the hard phase is designed and built into the part prior to liquid phase sintering. The exact gradient of the composition material elements that will be required depends on factors such as the desired final matrix metal gradient, the dimension of the part to be made, and the sintering time and temperature.

Owner:UNIV OF UTAH RES FOUND

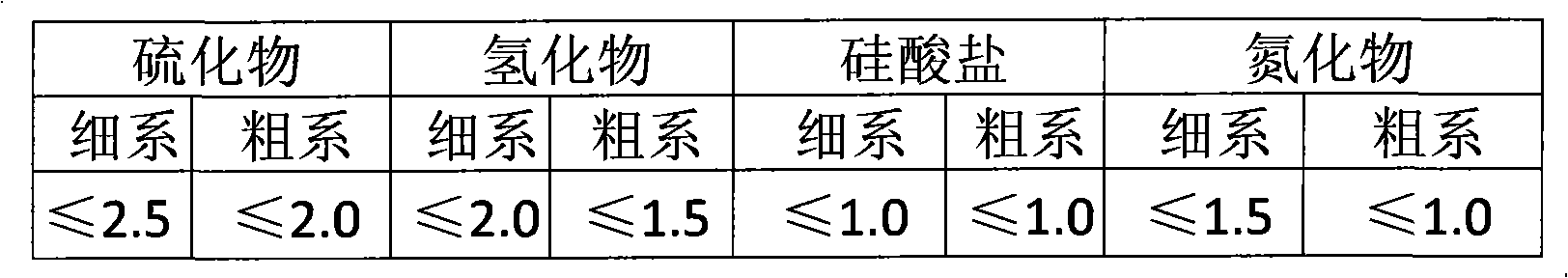

High-strength high-toughness anticorrosion high-temperature bearing/pinion steel and preparation method thereof

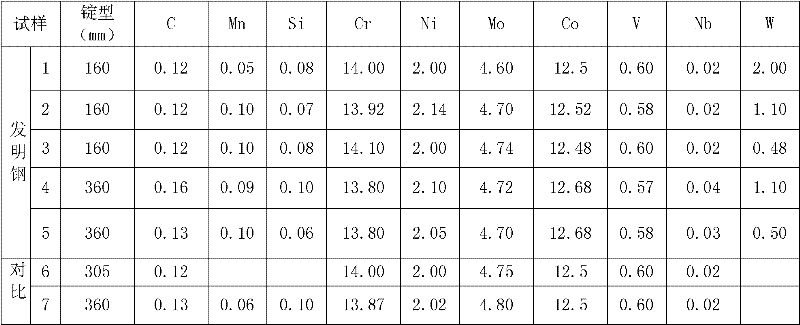

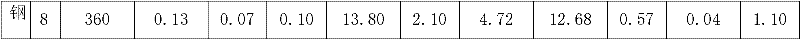

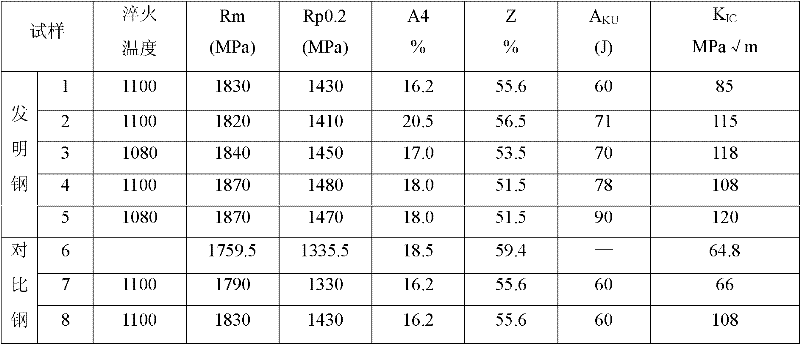

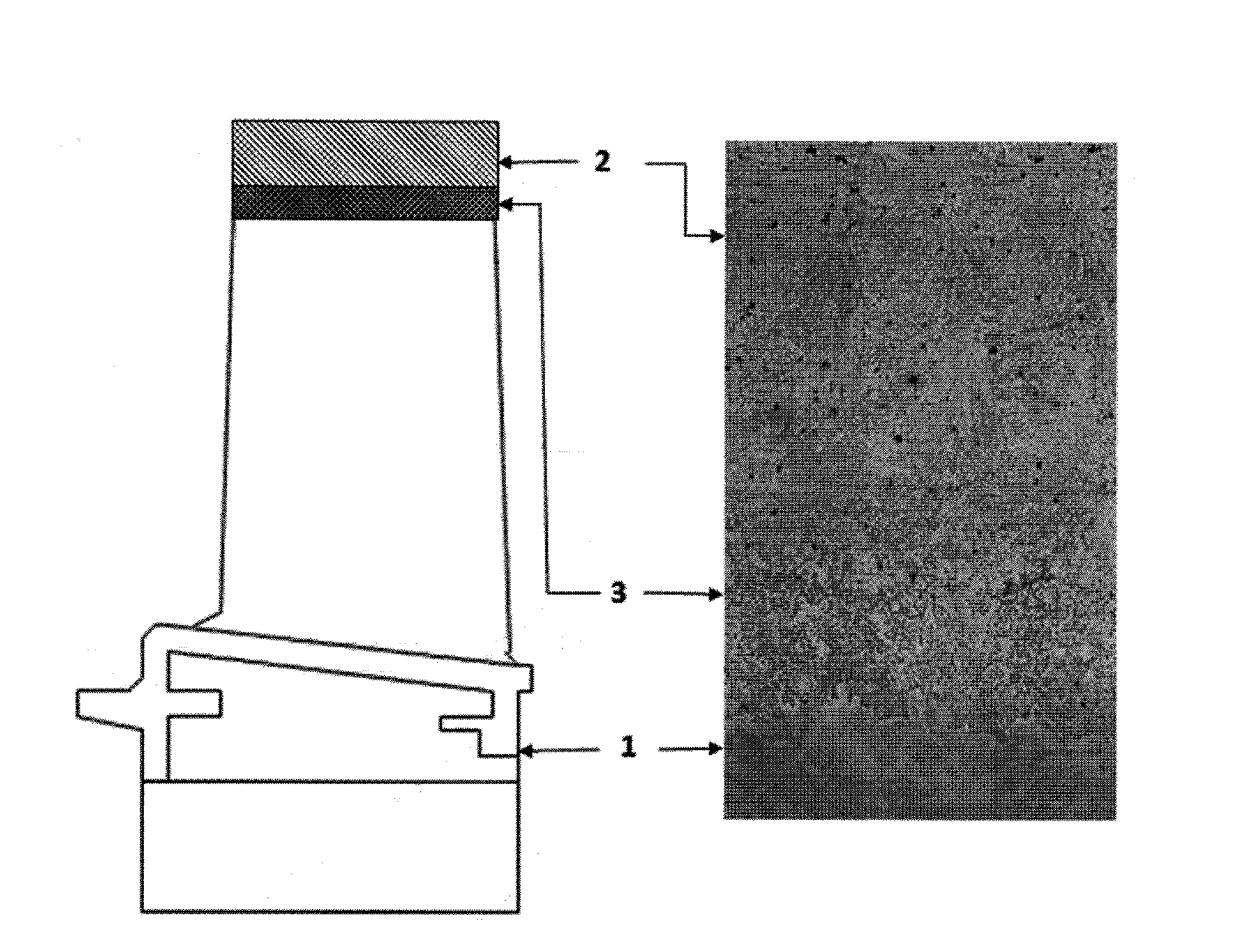

The invention relates to a high-strength high-toughness anticorrosion high-temperature bearing / pinion steel and a preparation method thereof, belonging to the technical field of bearing / pinion steel. The bearing / pinion steel comprises the following chemical elements in percentage by weight: 0.10-0.22% of C, at most 0.5% of Mn, at most 0.5% of Si, 12.0-15.0% of Cr, 1.50-3.00% of Ni, 4.00-6.00% of Mo, 0.50-0.90% of V, 12.0-15.0% of Co, 0.30-2.00% of W, 0.02-0.08% of Nb and the balance of Fe and inevitable impurities, wherein the V / Nb ratio is 25-35, the Mo / W ratio is 6-12, the Co / Mo ratio is 2-3, Cr+6Si+4Mo+1.5W+11V+5Nb<=52%, 40C+2Mn+4Ni+30N+2Co>=42%, and [O]+[N]+[H]<=0.0040%. The preparation method comprises the following steps: proportioning and controlling the components; carrying out vacuum smelting; carrying out hot working on a steel ingot to obtain a steel product; carrying out surface carburized hardening treatment on the steel product; and carrying out heat treatment on the steel product. The invention can satisfy the requirements of new-generation bearing / pinion steel for bearing the actions of high temperature and corrosive environment in the service process, and implements good cooperation of high strength, high hardness, high toughness, high temperature properties and anticorrosion property.

Owner:CENT IRON & STEEL RES INST

Method of cladding, additive manufacturing and fusion welding of superalloys and materialf or the same

The present concept is a method of substantially crack-free cladding, fusion welding and additive manufacturing of superalloys. The method involves the application of a high temperature pre-alloyed filler powder that includes melting point depressants, to a superalloy base material. The base material and pre-alloyed filler powder are heated to a temperature that will fully melt the pre-alloyed filler powder and also melt a surface layer of the base material, thereby forming a weld pool. Upon solidification and cooling of the weld pool, there is coalescence between a weld bead and the base material thereby forming the weld bead which is substantially crack-free. The high temperature pre-alloyed filler powder consists in wt % of the following chemical elements: Co 9-15%; Al 3-6.5%; C 0.1-0.2%; Ti, Zr and Hf with a total content from 1 to 8.5%; Ta and Nb with a total content from 0.5 to 8.5%; W and Mo with a total content from 7 to 20%; Cr and Re with a total content from 6.5 to 18.5%; Fe and Mn with a total content from 0.1 to 1%; B 0.1-0.6% with Ni and impurities to balance.

Owner:LIBURDI ENG

High-strength and high-toughness spring steel and manufacturing method thereof

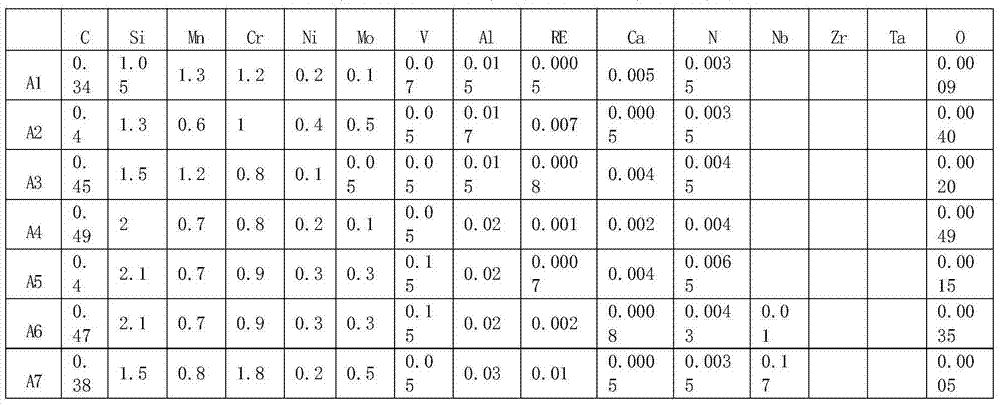

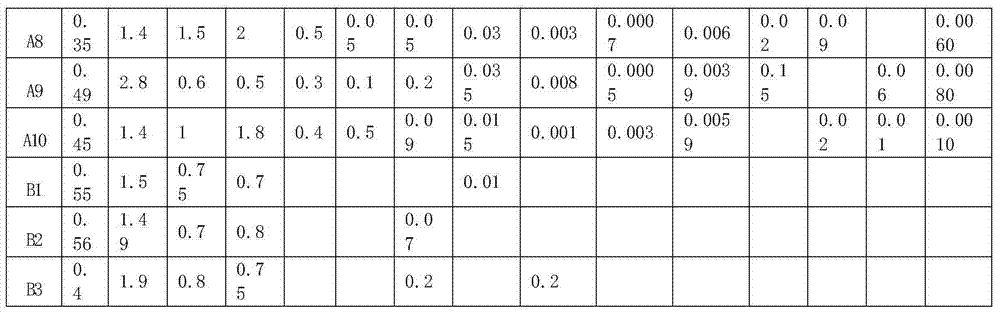

ActiveCN103484781ASufficiently ductileSufficient resistance to elastic reductionChemical elementSpring steel

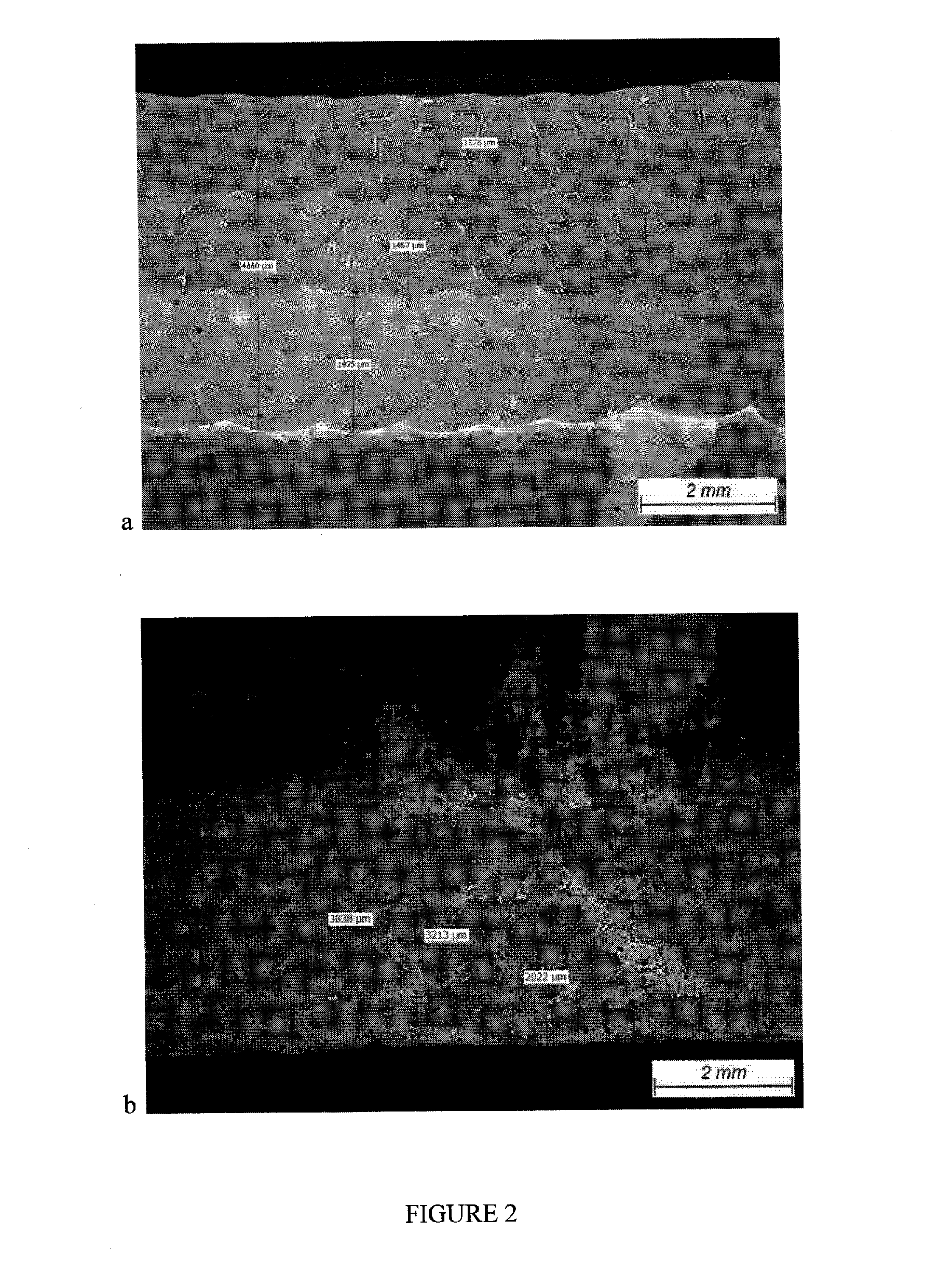

The invention discloses a high-strength and a high-toughness spring steel. The spring steel comprises the following chemical elements in percentage by mass: 0.34-0.49% of C, 1.00-2.80% of Si, 0.60-1.50% of Mn, 0.50-2.0% of Cr, 0.1-0.5% of Ni, 0.05-0.5% of Mo, 0.05-0.20% V, 0.0035-0.0065% of N, 0.0015-0.035% of Al, 0.0005-0.01 % of RE, 0.0005-0.005% of Ca, 0.005-0.0080% of O, and the balance of Fe and inevitable impurity wherein the following formulas are satisfied, Si+0.75*(Mn+Cr)+0.6*(Ni+Mo) is larger than or equal to 3.0%, Al / O is larger than or equal to 4.0, and RE+0.75*Ca is larger than or equal to 0.002%. Correspondingly, the invention further discloses a manufacturing method of the high-strength and high-toughness spring steel.

Owner:BAOSHAN IRON & STEEL CO LTD

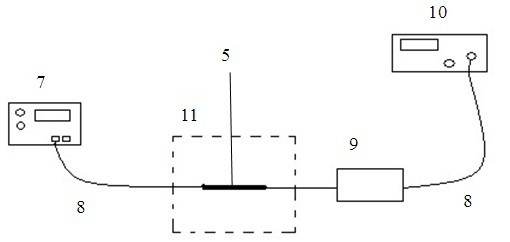

Graphene film sensitized D-shaped optical fiber surface plasmon resonance (SPR) sensor and preparation method thereof

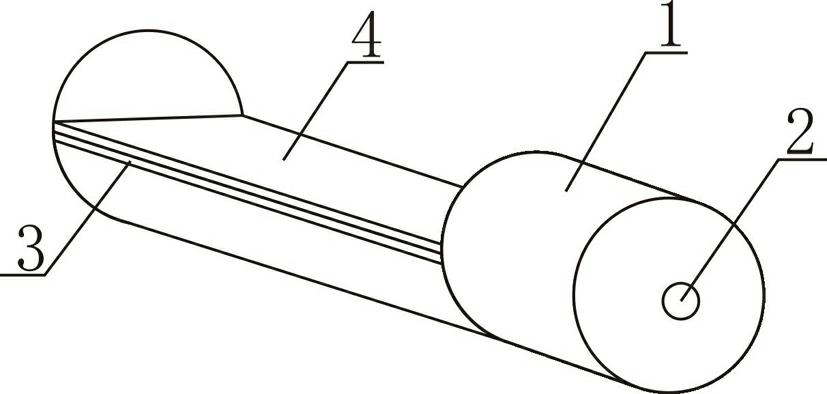

InactiveCN102621104AImprove sensitivityHigh strengthScattering properties measurementsChemical elementCvd graphene

The invention discloses a graphene film sensitized D-shaped optical fiber surface plasmon resonance (SPR) sensor. The sensor comprises a D-shaped optical fiber, wherein a silver film layer is arranged on the polished surface of the D-shaped optical fiber; and a graphene film layer is arranged on the surface of the silver film layer. A preparation method comprises the following steps of: (1) preparing the D-shaped optical fiber, and preparing the silver film layer on the polished surface of the D-shaped optical fiber; and (2) preparing the graphene film layer on the surface of the silver film layer. The D-shaped optical fiber is used as a light transmission medium, an SPR structure is formed by plating a silver film on the surface of the D-shaped optical fiber, the sensitivity of the SPR sensing structure is increased by depositing or growing a graphene film material on the surface of the silver film, and the sensor has the prominent advantages of small volume, light weight, high sensitivity, quick response and the like, and has wide application prospects in the aspect of detecting trace gas, liquid, chemical elements, deoxyribonucleic acid (DNA) and the like in the fields of biology, chemistry, medicine and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Conductive thickener, electronic device and solar battery comprising electrodes formed by conductive thickener

ActiveCN102376379ANon-conductive material with dispersed conductive materialSemiconductor devicesGibbs free energyOptoelectronics

The invention relates to a conductive thickener and an electronic device and a solar battery comprising electrodes formed by the conductive thickener. The conductive thickener comprises conductive powder, a metal glass and an organic carrier, wherein, the metal glass comprises an alloy comprising at least two chemical elements selected from a chemical element having a low resistivity, a chemical element formed a solid solution with the conductive powder or a chemical element having a high oxidation potential, and wherein, the chemical element having the low resistivity has a resistivity about 100 micro-ohmmeter-cm, and the chemical element having the high oxidation potential has a Gibbs free energy absolute value about 100 kilojoule / moore or more.

Owner:SAMSUNG ELECTRONICS CO LTD

Alloy vermicular cast iron glass mold material and preparation method thereof

The invention relates to an alloy vermicular cast iron glass mold material and a preparation method thereof, and belongs to the field of glass mold manufacturing. The alloy vermicular cast iron glass mold material comprises the following chemical elements in percentage by mass: 3.5-3.6% of carbon, 2.9-3.0% of silicon, 0.4-0.5% of manganese, 0.4-0.5% of molybdenum, less than 0.15% of vanadium, less than 0.10% of titanium, 0.3-0.4% of chromium, 0.4-0.5% of nickel, less than 0.05% of phosphorus, less than 0.03% of sulfur and the balance of iron. The invention has the following advantages: the reasonable selection of the metal elements and the mass percents thereof is beneficial to saving noble metal materials and reducing the variety of the used noble metal elements; the selected alloy elements have a favorable solution strengthening effect, thereby being beneficial to enhancing the strength of the iron element under a high-temperature environment and then prolonging the service life of the glass mold; and the preparation method provided by the invention is beneficial to the dispersion and distribution of second-phase carbides in grain boundaries, so that the grain boundaries can be strengthened, and the creep strength can be improved.

Owner:ORI MOLD TECH SUZHOU

Gas sensor and method of making

A gas sensor is disclosed. The gas sensor includes a gas sensing layer including at least one chemical compound with the general chemical formula MαO62Nγ, wherein M is at least one chemical element selected from the group consisting of W, Ti, Ta, Sr, Mo, and combinations thereof, and α, β, γ are self-consistent, said gas sensing layer being capable of detecting at least one gas selected from the group consisting of NO, NO2, SO2, O2, H2O, CO, H2, and NH3, at least one electrode positioned within a adhesion layer composed of a material selected from the group consisting of Ti, Cr, and combinations thereof, and a response modification layer composed of a material selected from the group consisting of Mg, Ti, V, Cr, Mn, Co, Ni, Zn, Nb, Ru, Rh, Pd, Ta, W, Re, Pt, and combinations thereof. The at least one electrode is in communication with the sensing layer. A method of fabricating the gas sensor is also disclosed.

Owner:AMPHENOL THERMOMETRICS

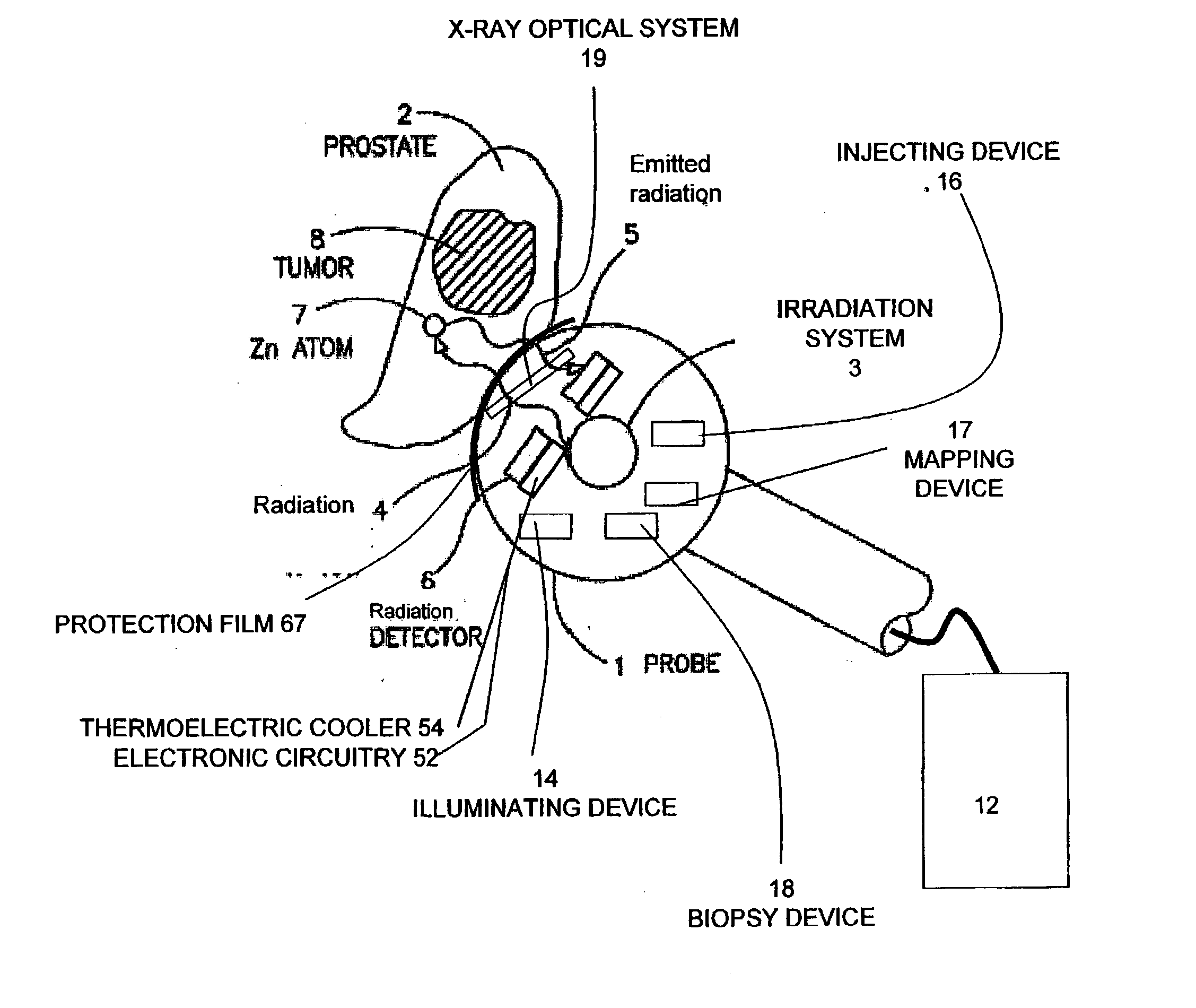

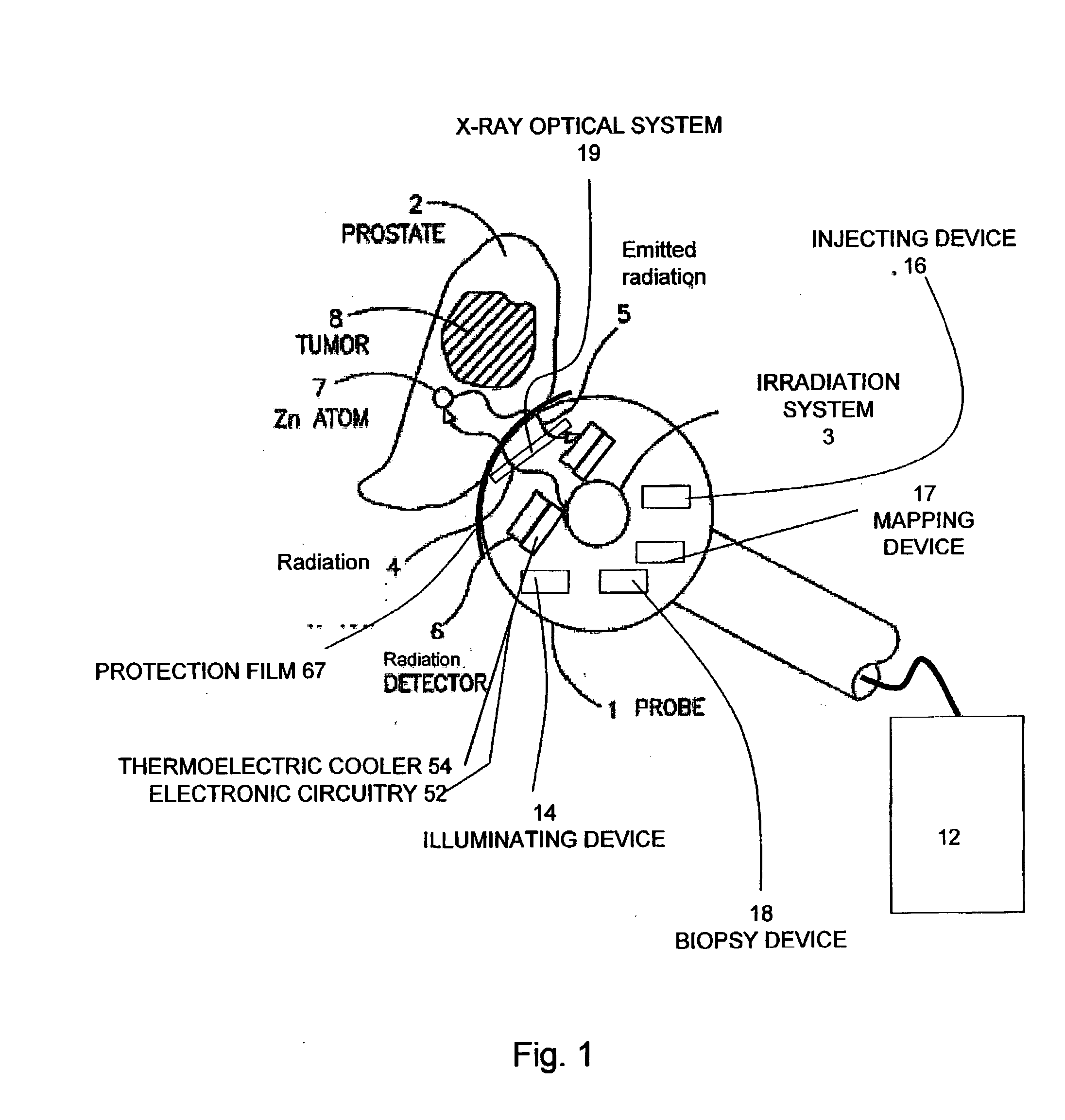

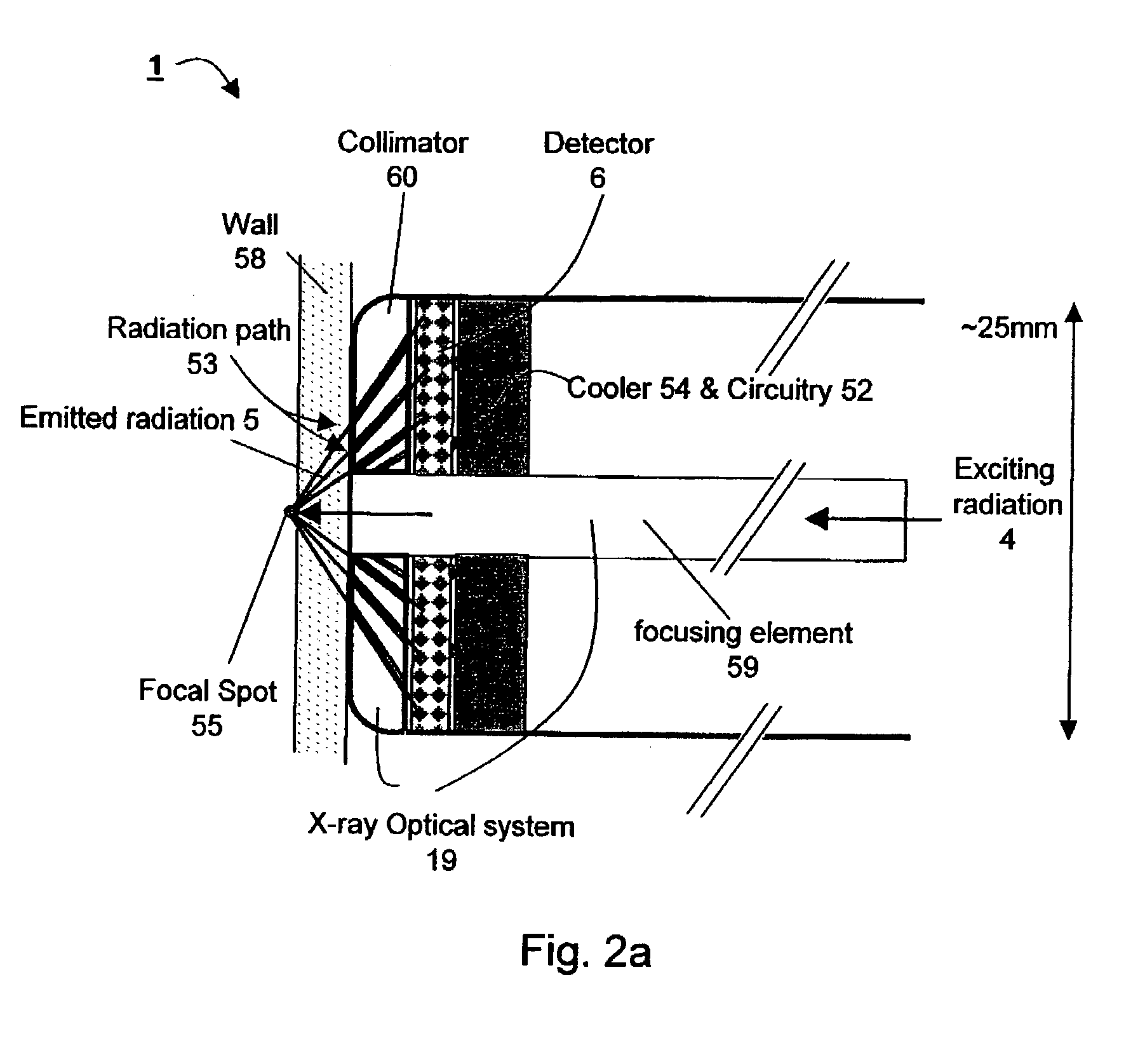

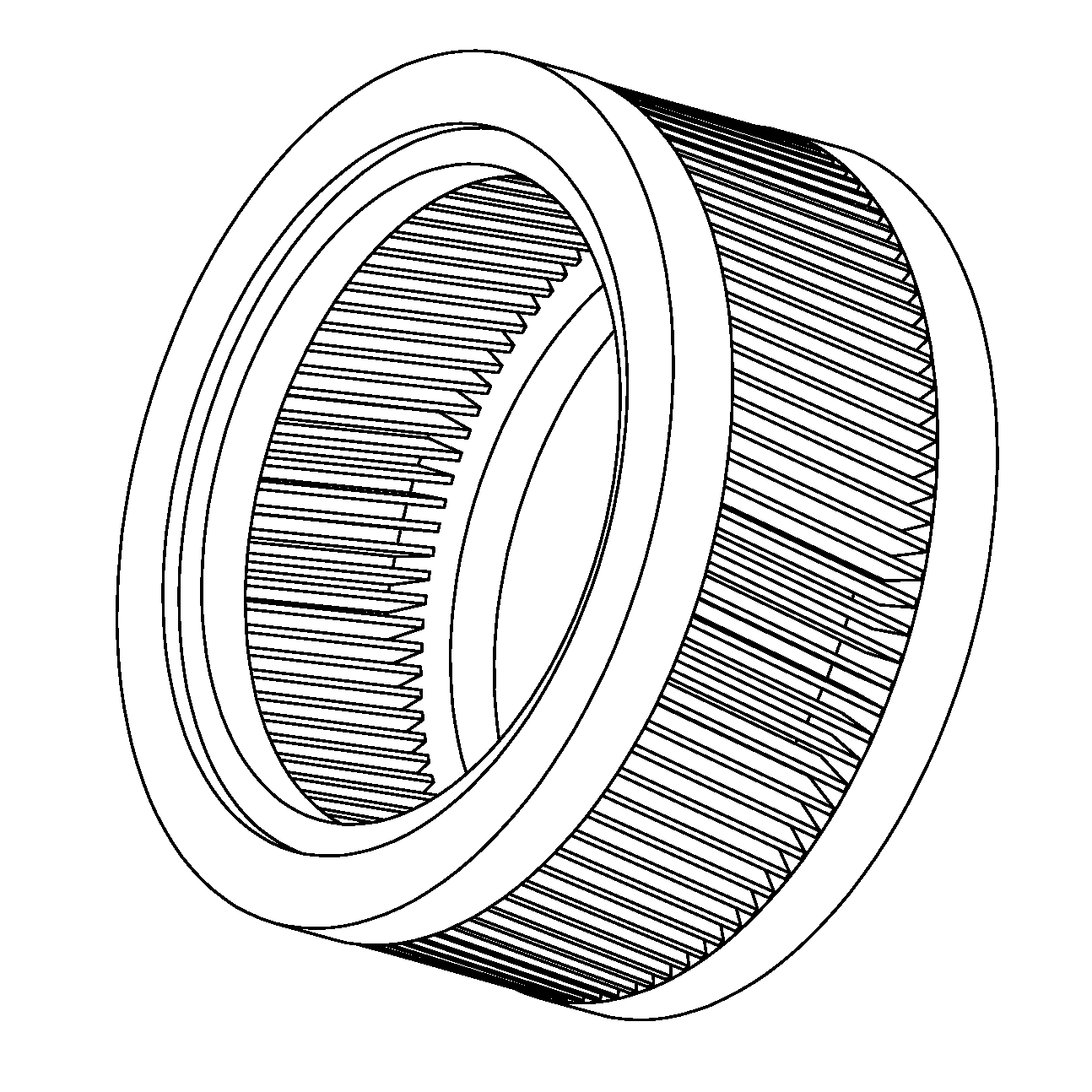

System and method for cancer detection

Apparatus for non-invasive in vivo detection of a chemical element in the prostate of a subject, comprising: (a) a probe adapted for being inserted into at least one of the rectum or the urethra of the subject; (b) an irradiation system capable of exciting the chemical element to emit radiation to form emitted radiation; (c) a radiation detector located within the probe, wherein the radiation detector is capable of detecting the emitted radiation and wherein the radiation detector is suitable for mapping the emitted radiation; and (d) a signal recording, processing and displaying system for mapping the level of tie chemical element in the prostate of the subject at a plurality of different points in the prostate according to the mapping of the emitted radiation. In one embodiment, the irradiation system is capable of delivering exciting radiation through the probe to the prostate; in another embodiment the emitted radiation comprises fluorescent X-ray radiation.

Owner:SOREQ NUCLEAR RES CENT ISRAEL ATOMIC ENERGY COMMISSION +1

High silicon cast aluminium spectrum standard sample and its preparation method

InactiveCN1410572AUniform chemical compositionDense tissuePreparing sample for investigationAnalysis by material excitationChemical compositionStandard samples

The standard specimen contains chemical elements with following weight ratios in pure aluminium Si: 1.03-13.70, Fe: 0.147-1.50, Cu: 0.125-7.44, Mn: 0.090-1.05, Mg: 0.049-1.53, Zn: 0.052-1.05, Ti: 0.034-0.274 etc. Since the Al-Sr modification is adopted, thus the specimen provides the features of even chemical elements, compact structure, free of bulky initializing coarse grains as well as raised processability. The long-playing diffusion fusion technique adopted makes silicon diffuse to aluminium adequetely so as to increase uniformity of chemical elements in the specimen evidently.

Owner:SOUTHWEST ALUMINUM GRP

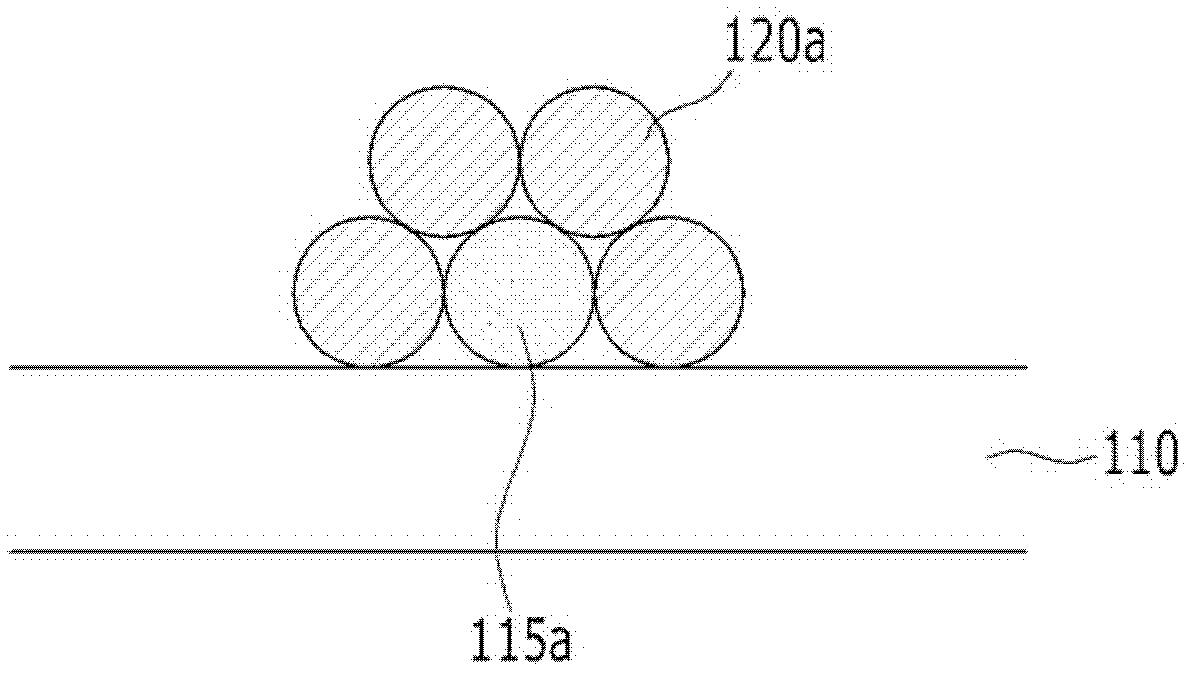

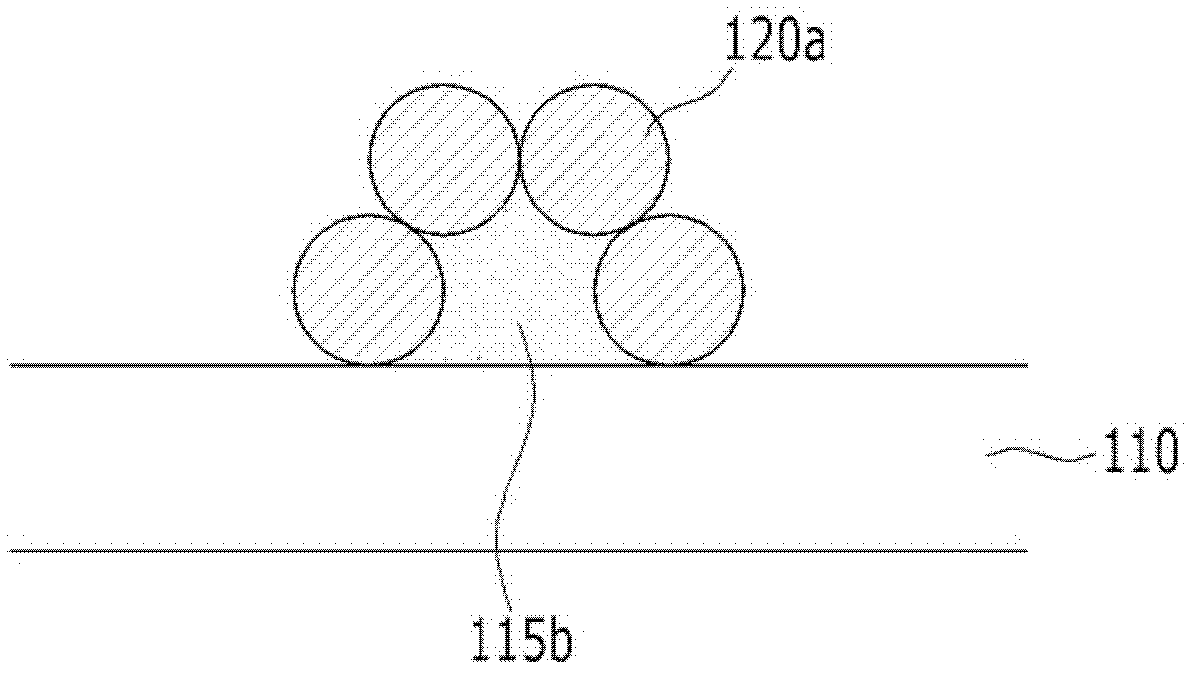

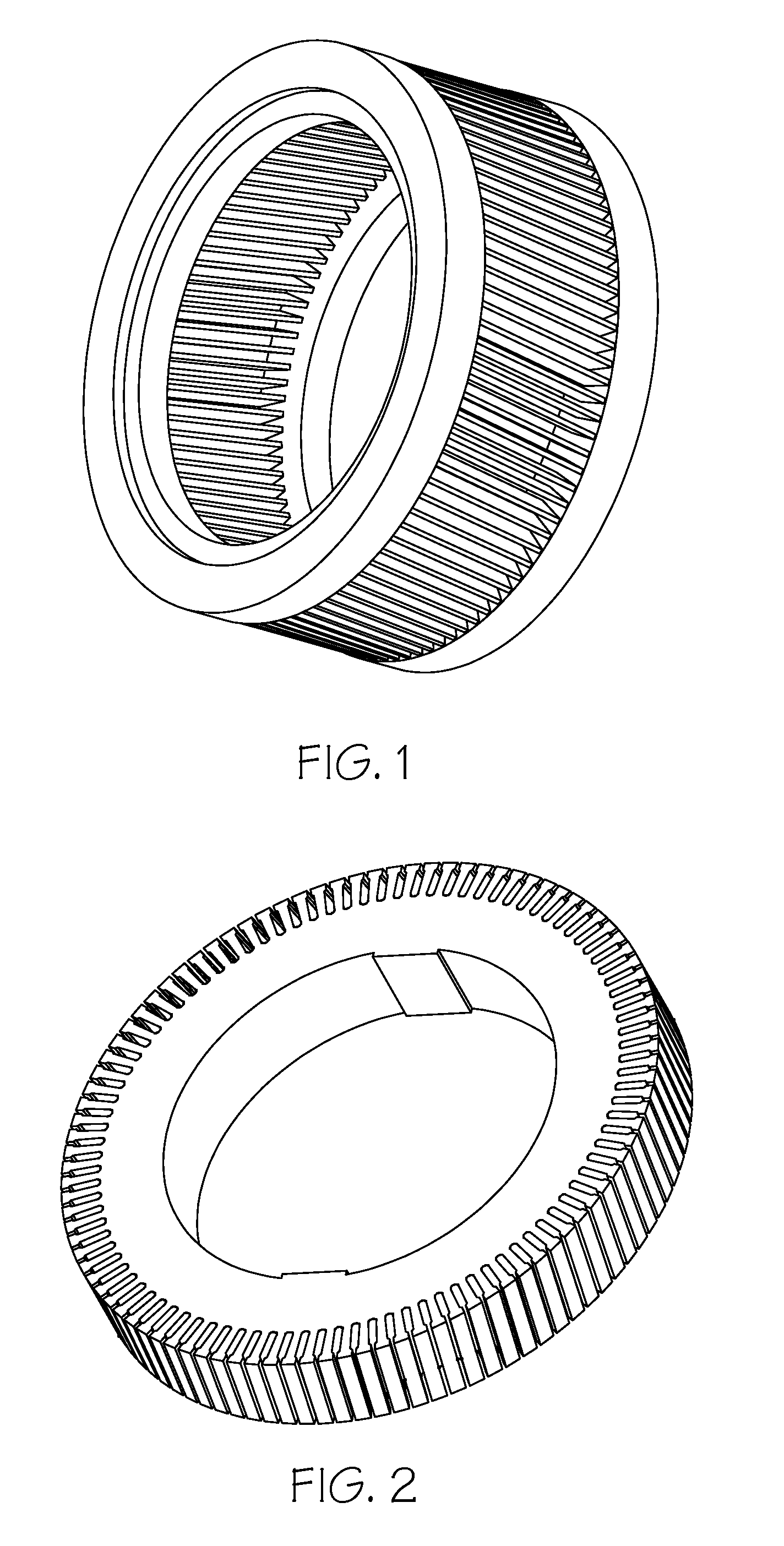

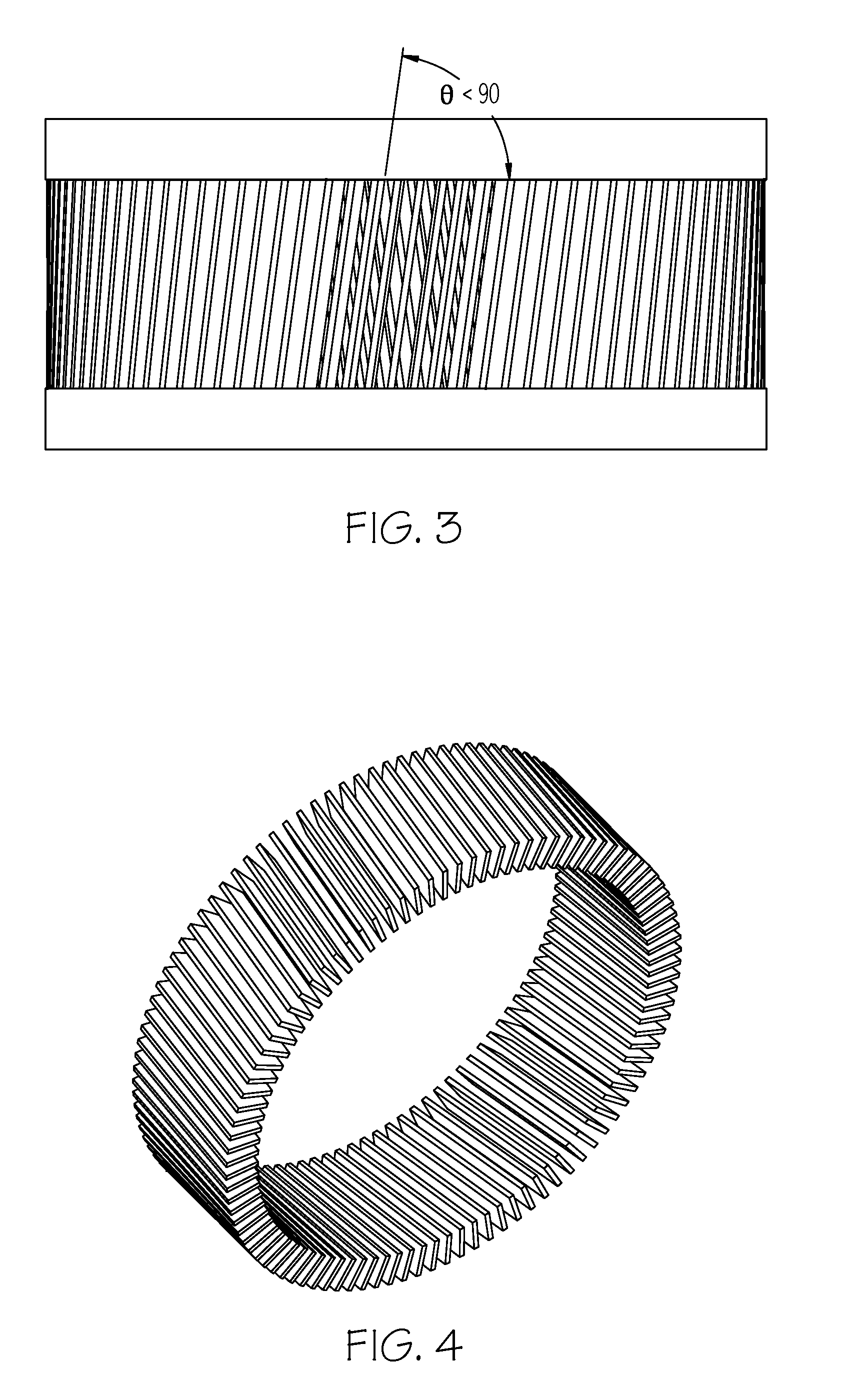

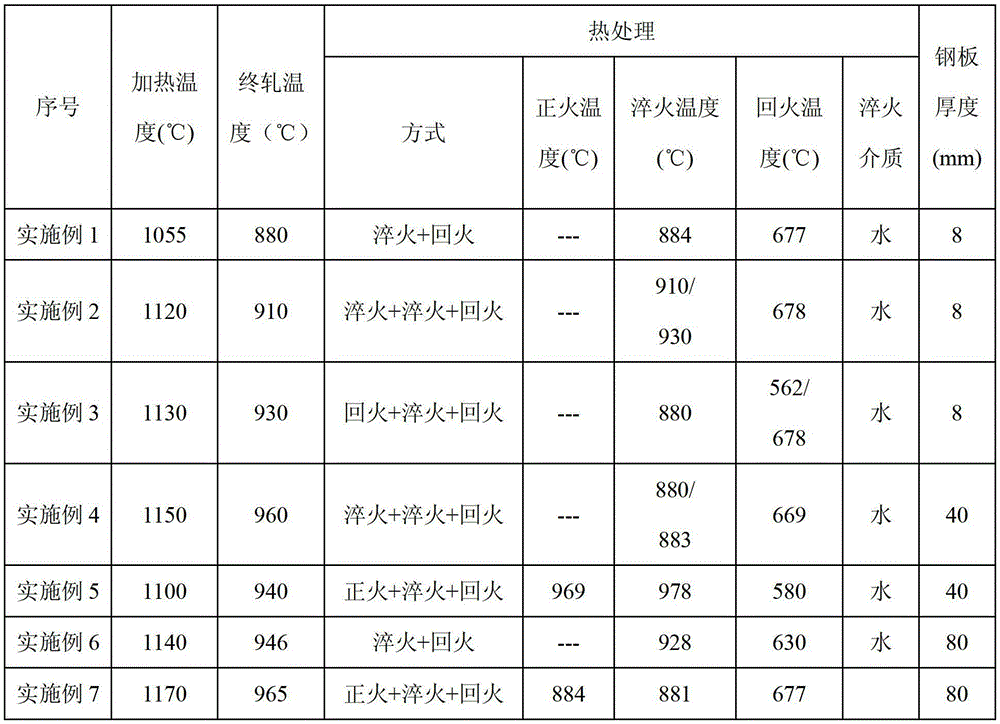

Methods of manufacturing induction rotors with conductor bars having high conductivity and rotors made thereby

Squirrel cage rotors of aluminum based material end rings joined with high conductive and durable material (such as copper) conductor bars for use in electric motors and methods of making them are described. The methods include forming conductor bars by casting or other metal forming methods in the slots of laminate steel stack, or positioning the preformed or premade solid conductor bars in the longitudinal slots of the stacked laminated steel, with bar ends extending out of the laminated steel stack ends, optionally coating the extended part of the conductors (bars) with a latent exoergic coating containing Al and one or more conductor bar chemical elements, positioning the laminated steel stack having conductors (bars) in a casting mold that forms the cavity of both end rings of the rotor, filling the end ring cavities with aluminum melt, and allowing the end rings to solidify under pressure. Alternatively, the conductor bars and end rings can be made separately and mechanically joined together.

Owner:GM GLOBAL TECH OPERATIONS LLC

Catalyst for o-Fluoro nitrobenzene hydrogenation and its preparation and application

InactiveCN1631524AHigh yieldLower ground contentOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementBenzene

The invention concerns the reaction of benzene catalyst adding hydrogen, specific speaking, it's a kind of catalyst to produce 4-ammonia base-3-F benzene fen and its application. The catalyst is made of carrier, active parts and helping dose. The main active parts are: dear metal Pt, Pd or Rh, whose weight is of catalyst 0.1%--20%. Help doses are IA, ó�A, ó¾B, ó° or Sparse soil chemical element. The catalyst has the feature of high active in reactivation, good choosing ability and many reuses. The catalyst can also be used in other replacing nitric unit benzene adding hydrogen and catalyst process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nickel catalyst for selective hydrogenation

ActiveCN101147871AGood activity at low temperatureGood choiceHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementNickel catalyst

The present invention relates to a nickel catalyst for selective hydrogenation. The catalyst composition includes the following components: (by wt%) (a), 5.0-40.0% of metal nickel or its oxide; (b), 0.01-20.0% of at least one element selected from molybdenum or tungsten or its oxide; (c), 0.01-10.0% of at least one element selected from rare earth elements or its oxide; (d), 0.01-2.0% of at least one element selected from IA or IIA of periodic table of chemical elements or its oxide; (e), 0-15.0% of at least one element selected from Si, P, B or F or its oxide; (f), 0-10.0% of at least one element selected from IVB of periodic table of chemical elements or its oxide; and (g), the rest is aluminium oxide. Said catalyst can be used for pyrolysis gasoline hydrotreating production.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

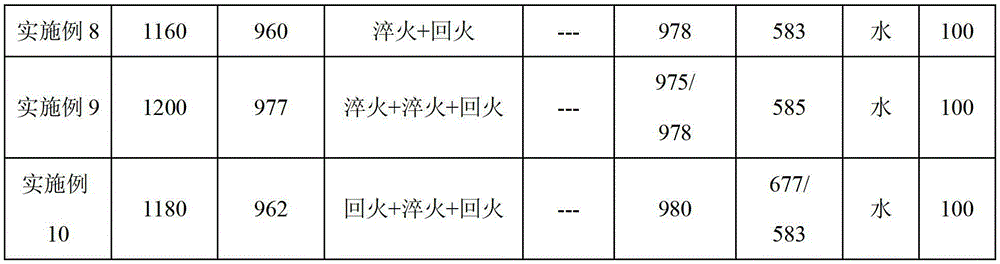

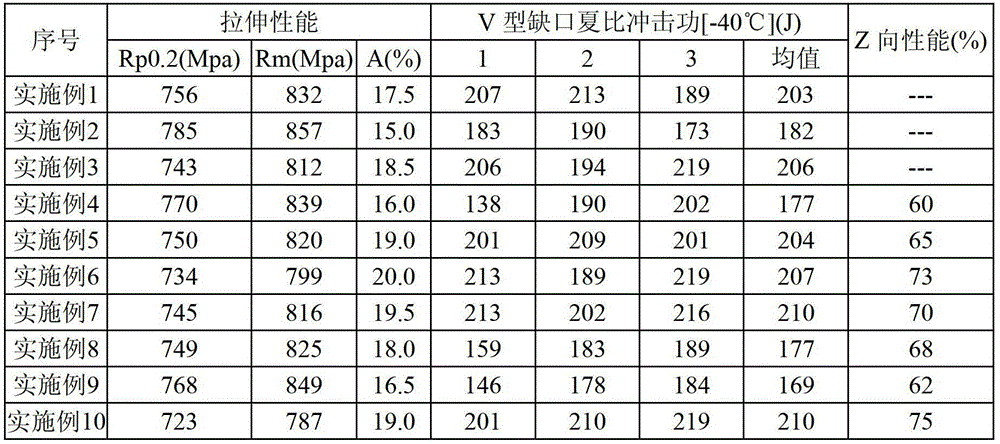

Steel plate with high strength and excellent low-temperature toughness and manufacturing method thereof

The invention discloses a steel plate with high strength and excellent low-temperature toughness, and the steel plate comprises the following chemical elements in percentage by weight: more than or equal to 0.03% and less than or equal to 0.18% of C, more than or equal to 0.20% and less than or equal to 0.30% of Si, more than or equal to 0.50% and less than or equal to 1.10% of Mn, more than or equal to 0.010% and less than or equal to 0.030% of Ti, more than or equal to 0.02% and less than or equal to 1.15% of Cr, more than or equal to 0.01% and less than or equal to 0.80% of Mo, more than or equal to 0.05% and less than or equal to 1.40% of Ni, more than or equal to 0.010% and less than or equal to 0.040% of Nb, more than or equal to 0.0001% and less than or equal to 0.0650% of V, more than or equal to 0.025% and less than or equal to 0.050% of Al, more than or equal to 0.001% and less than or equal to 0.004% of Ca, more than or equal to 0.0001% and less than or equal to 0.0025% of B, and the balance of Fe and other inevitable impurities. The invention also discloses a manufacturing method of the steel plate with high strength and excellent low-temperature toughness, and the manufacturing method comprises the following steps of: (1) smelting; (2) refining outside a furnace; (3) continuously casting; (4) heating a plate blank; (5) rolling; and (6) carrying out heat treatment.

Owner:BAOSHAN IRON & STEEL CO LTD

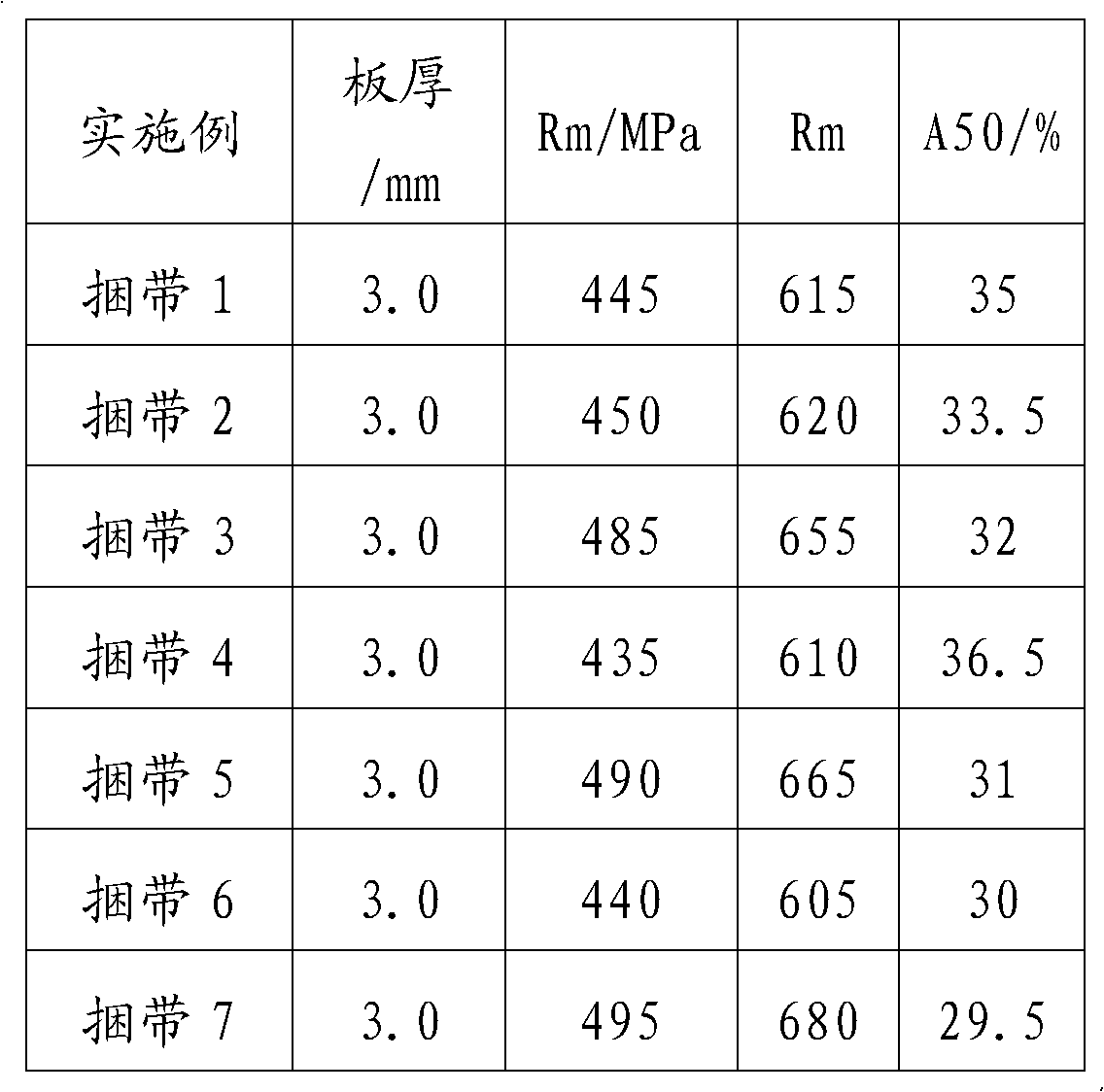

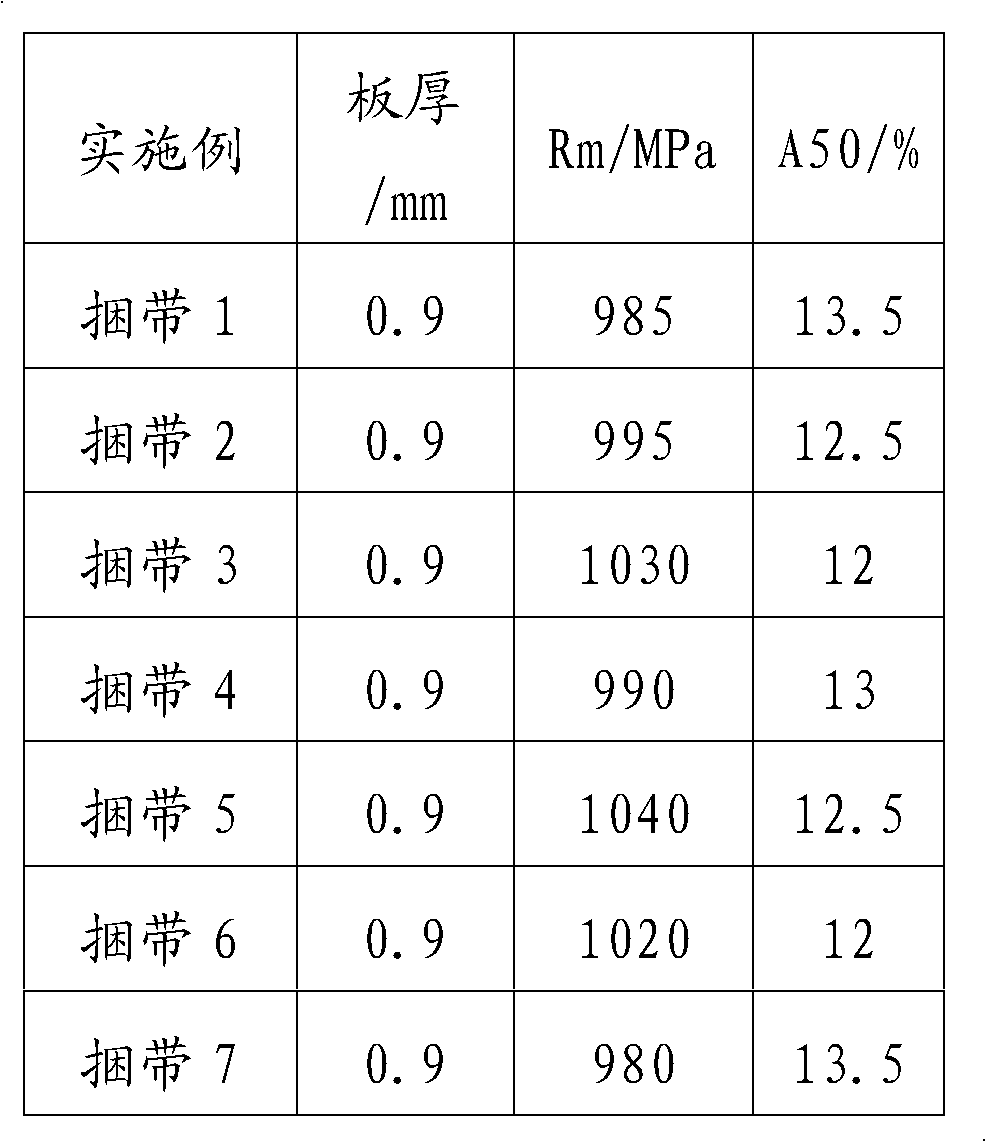

High-strength binding band and production method thereof

The invention relates to a high-strength binding band and a production method thereof, solving the problems that the existing high-strength steel bands are complex in production method and process, high in control difficulty, high in equipment investment and high in product cost and are not environment-friendly. In the process, the weight percentage of chemical elements of steel is as follows: 0.03-0.25 percent of C, 0.50-2.00 percent of Si, 0.50-2.50 percent of Mn, 0.10-0.20 percent of P, 0-0.015 percent of S, 0.01-0.20 percent of Als, and the balance of Fe and other unavoidable impurities; and the high-strength binding band is obtained by molten iron steelmaking, hot rolling, cold rolling and blue annealing, wherein in the blue annealing process, the annealing temperature is controlled to be 450-600 DEG C, the temperature of a lead bath furnace is controlled to be 400-550 DEG C, and the band speed is controlled to be 5-7m / min. In the invention, the process control is simple, the cost is low, environmental pollution is less, the performances are better, the process is simple and convenient as well as feasible, the production efficiency is high, and the tensile strength reaches 980MP.

Owner:武钢集团有限公司

Fiber reinforced composite material

The present disclosure relates to a fiber reinforced composite material. In an embodiment, the composite material includes a PLLA fiber material and a matrix material that does not have the same chemical element composition as the fiber material. Other fiber reinforced composite materials are also disclosed.

Owner:SMITH & NEPHEW INC

Multi-element perovskite material, as well as preparation and application thereof

ActiveCN107299393ABroaden applicationReduce pollutionPolycrystalline material growthFrom normal temperature solutionsHalogenChemical element

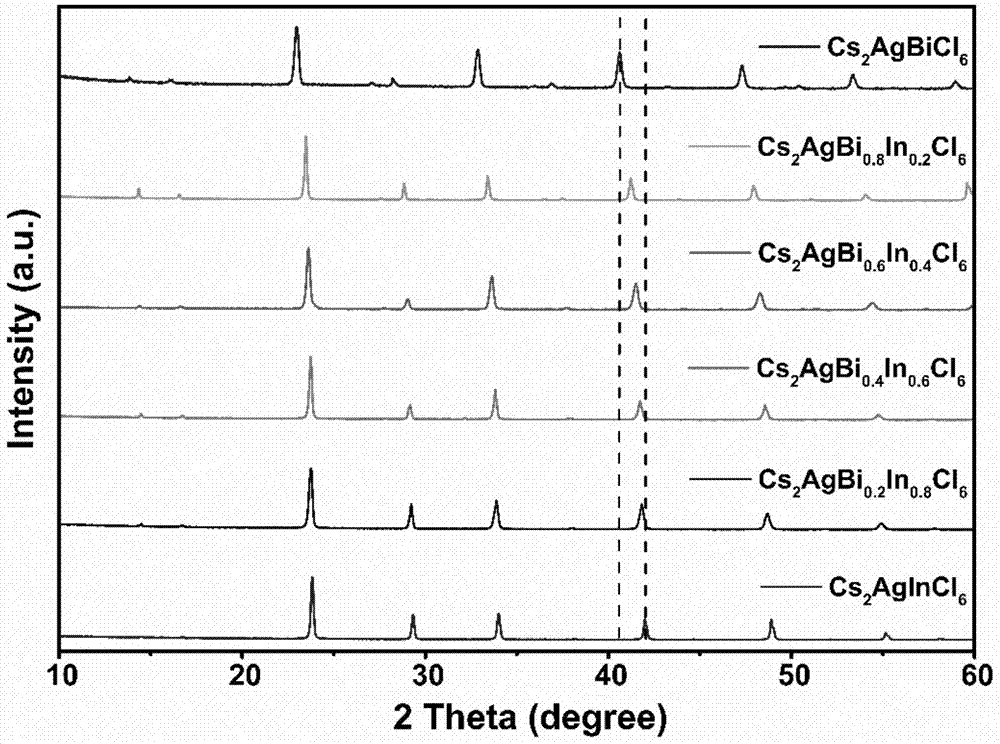

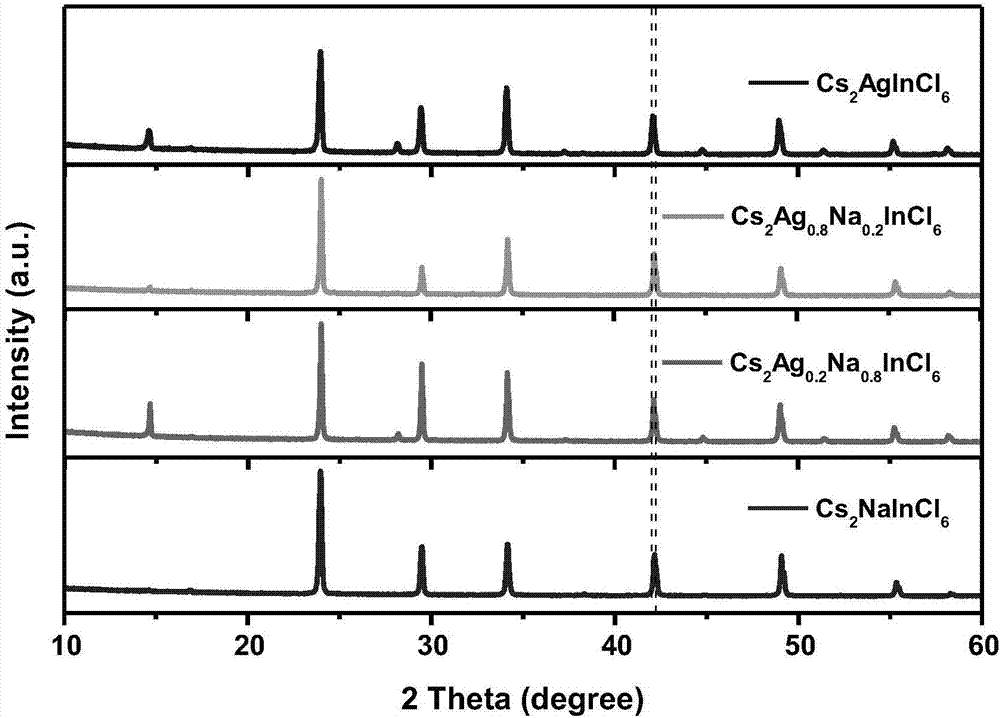

The invention discloses a multi-element perovskite material, as well as preparation and application thereof. The multi-element perovskite material is multi-element fully-inorganic metal non-lead halide salt and has a perovskite structure; the chemical formula of the multi-element perovskite meets: (the formula is shown in the description), wherein x is greater than or equal to 0 and less than or equal to 1, y is greater than or equal to 0 and less than or equal to 1, A is Cs<+>, B1, B2, B3 and B4 are Na<+>, Ag<+>, In<3+> and Bi<3+> respectively, and X is a halogen element. Through improvement on the varieties and proportion of the key chemical elements of the perovskite material, being compared with the prior art, the multi-element perovskite material can effectively solve the problems that the conventional multi-element perovskite material has few varieties, and is difficult to regulate and control, and high in environmental pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of 500hb wear-resistant steel plate and its manufacturing method

ActiveCN102260829ASolderableStrong construction machinery applicabilityWear resistantChemical element

The invention discloses a 500 HB wear resistant steel plate, whose chemical elements contain, by weight, 0.23-0.33% of C, 0.10-0.50% of Si, 0.50-1.50% of Mn, Cr being less than or equal to 1.50%, Mo being less than or equal to 0.80%, 0.01-0.10% of Al, 0.01-0.10% of Ti, 0.0005-0.0040% of B, 0.01-0.08% of RE, 0.002-0.010% of Ca, Ni being less than or equal to 2.50%, P being less than or equal to 0.050%, S being less than or equal to 0.030%, and the balance being Fe and other unavoidable impurities. In addition, the mass percentages of the above chemical elements satisfy the following conditions: (Si+Mn) is less than or equal to1.50% and greater than or equal to 0.50%; (Al+Ti) is less than or equal to 0.15% and greater than or equal to 0.03%. Correspondingly, the invention also provides a manufacturing method of the 500 HB wear resistant steel plate. The steel plate prepared by the method has good mechanical processing property and its rigidity can reach over 500 HB.

Owner:BAOSHAN IRON & STEEL CO LTD

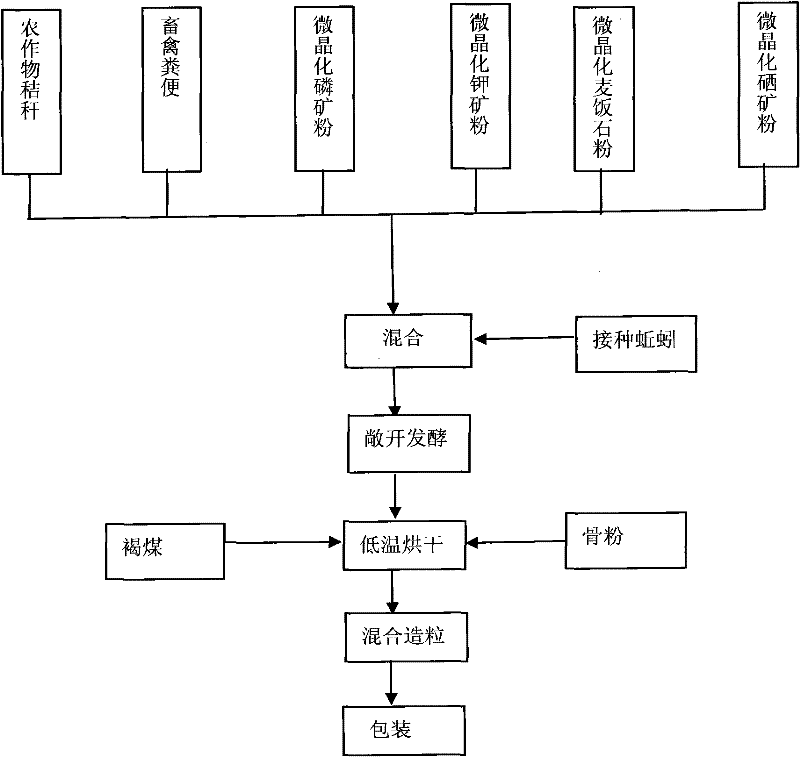

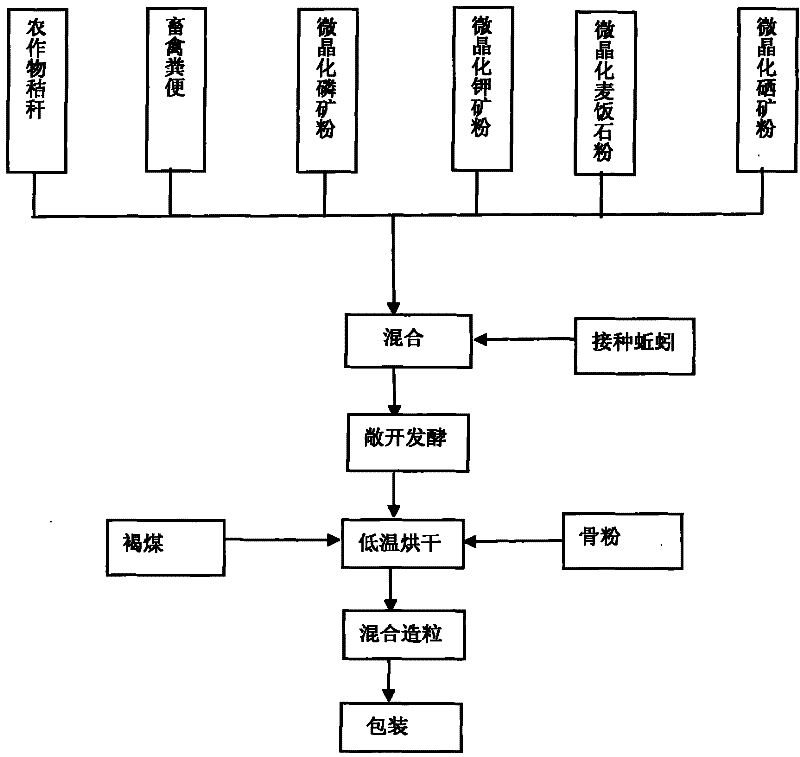

Efficient green micro-crystallized mineral-biological compound fertilizer and production method thereof

ActiveCN102408279AIncrease commodity rateNo pollution in the processFertilizer mixturesPhosphatePotassium

The invention discloses an efficient green micro-crystallized mineral-biological compound fertilizer and a production method thereof. The compound fertilizer comprises the following components in parts by mass: 7-9 parts of N, 7-9 parts of P2O5, 7-9 parts of K2O, 25-30 parts of organic matters, 8-12 parts of humic acid, 3-6 parts of amino acid and 15-20 parts of chemical elements such as calcium,silicon, magnesium, selenium, molybdenum, boron and zinc, as well as not less than 0.02 billion / kg of available active bacteria. The efficient green micro-crystallized mineral-biological compound fertilizer has the beneficial effects of being capable of adapting to acidic-alkaline soil and neutral soil in various regions, improving the soil, enhancing the adsorption ability of the soil on nutrients, preventing nitrogen and potassium from being washed away by water due to a large amount of rainfall, reducing formation of insoluble phosphate and improving fertility of the soil; and in addition,nitrogen, phosphorus and potassium in the original soil can be activated to be absorbed by crops by virtue of microelements contained in the fertilizer, and the supply capability of the deep soil nutrients can be enhanced, thus the physiochemical indexes and biological environment of the soil can be improved in case of long-term application, hardened soil can be reduced, and the quality of crops can be obviously improved.

Owner:山东清大生态科技有限公司

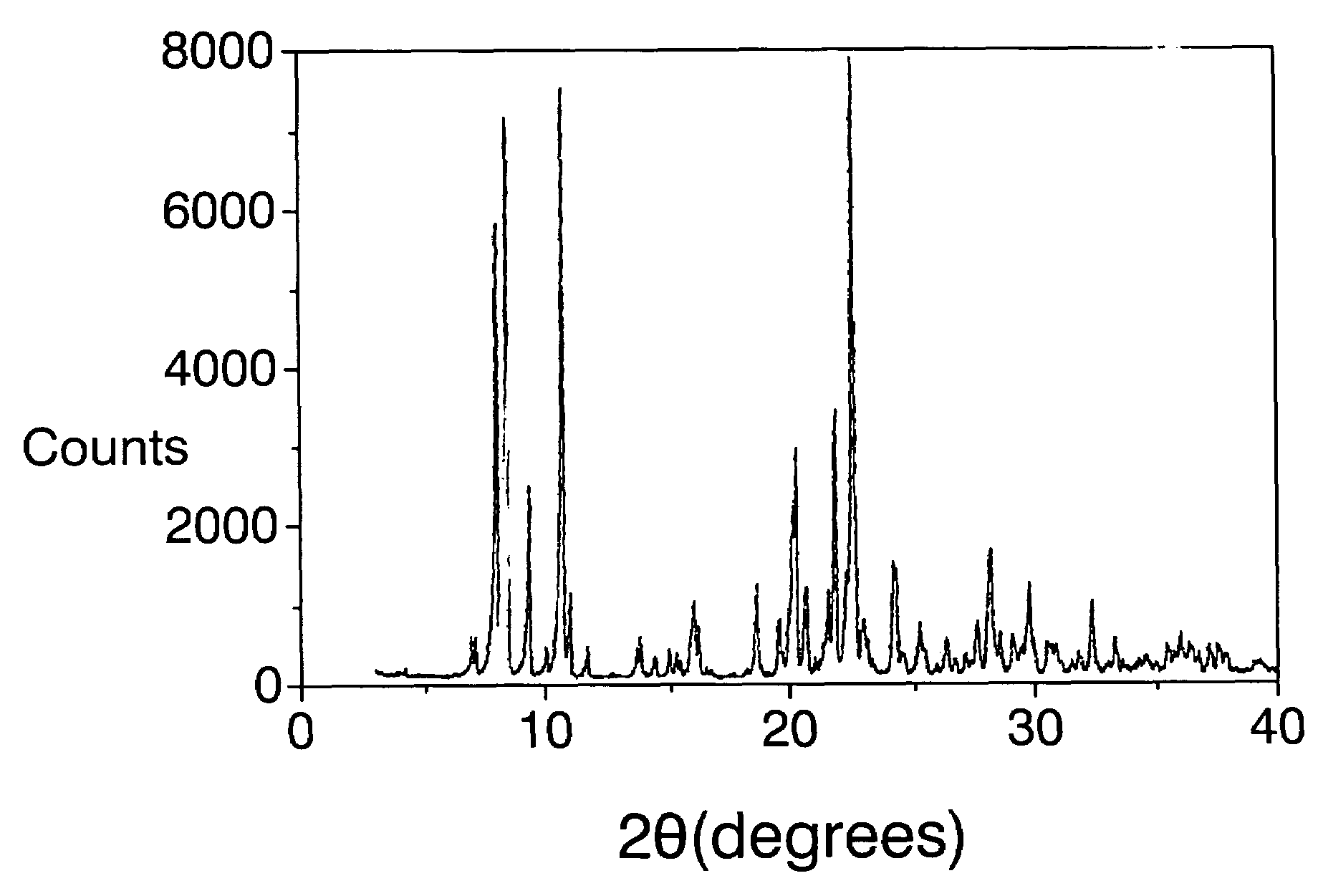

Microporous crystalline zeolite material (zeolite ITQ-22), synthesis method thereof and use of same as a catalyst

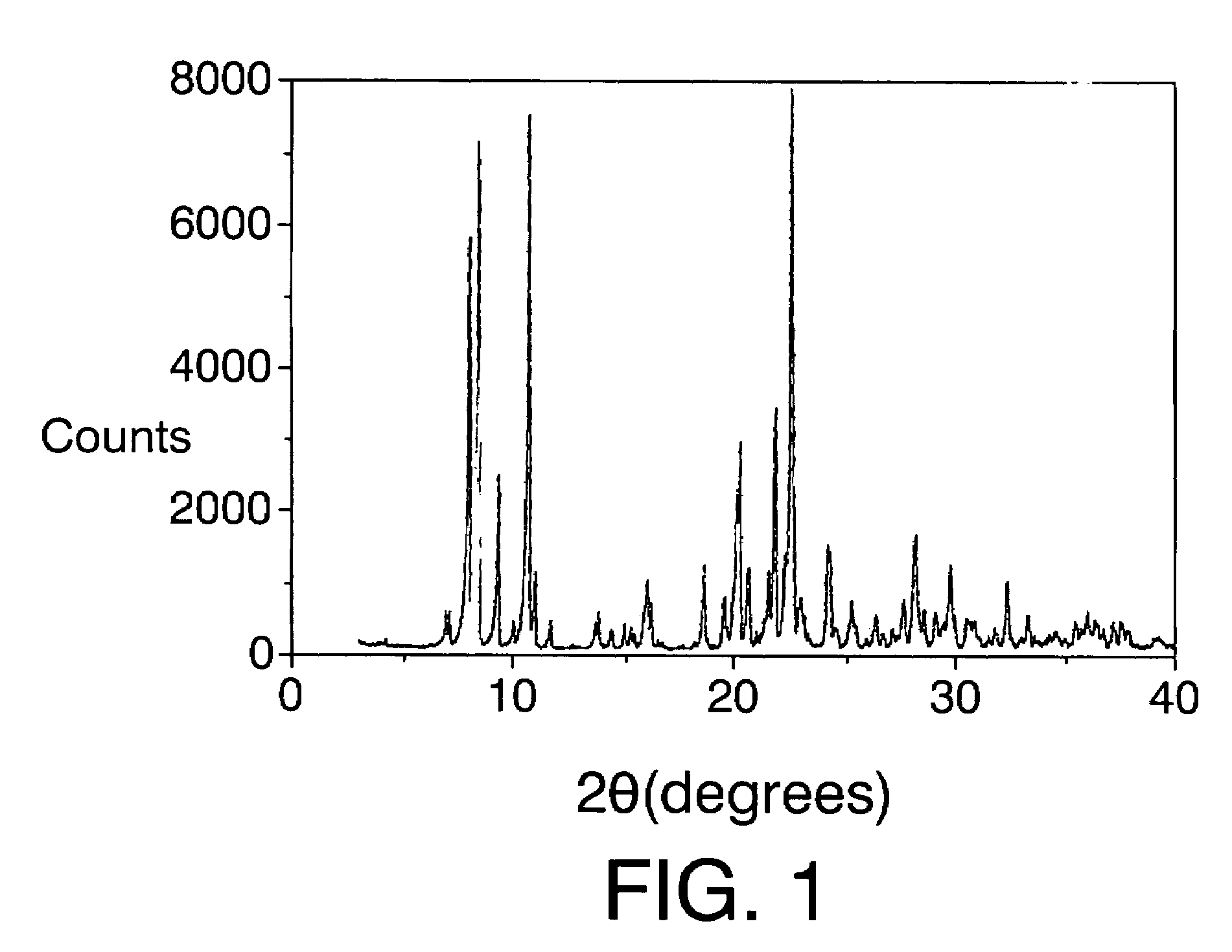

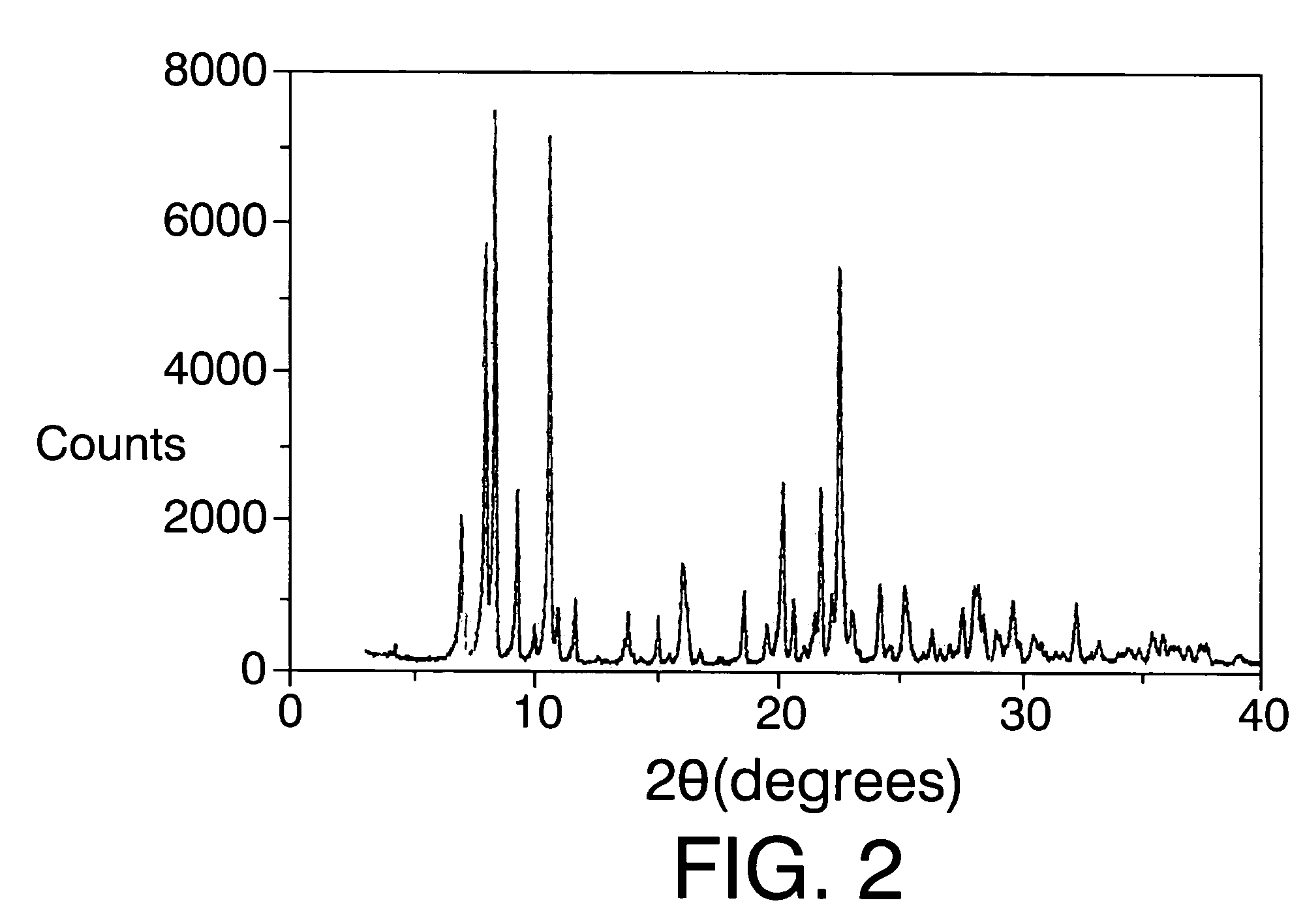

InactiveUS7449169B2Eliminate occlusionIncrease contentOxygen-containing compound preparationAluminium compoundsSynthesis methodsOxidation state

The present invention refers to a microporous crystalline material of zeolitic nature (ITQ-22) which, in the calcined state, has the empirical formula x(M1 / nX02):yYO2:zR:wH20whereinM is H+ or at least one inorganic cation of charge +n;X is at least one chemical element of oxidation state +3, preferably selected from the group consisting of Al, Ga, B, Fe and Cr;Y is at least one chemical element with oxidation state +4 other than Si and Ge, preferably selected from the group consisting of Ti, Sn and V;x has a value less than 0.2, preferably less than 0.1 and can take the value zero,y has a value less than 0.1, preferably less than 0.05 and can take the value zero,z has a value less than 0.8, preferably between 0.005 and 0.5 and can take the value zero,with a characteristic X-ray diffraction pattern, to the method of preparation and to the use of the material in separation and transformation processes of organic compounds.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

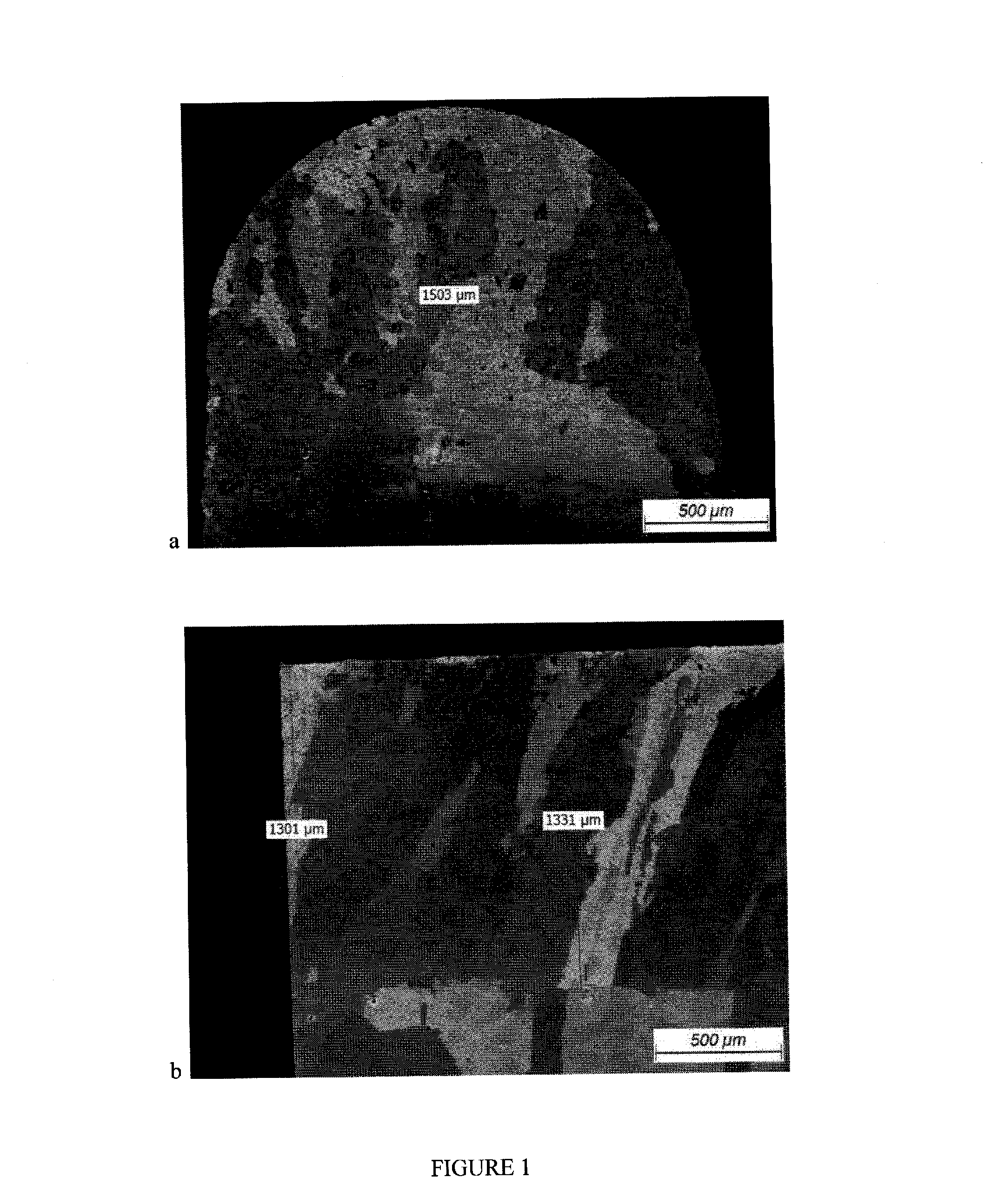

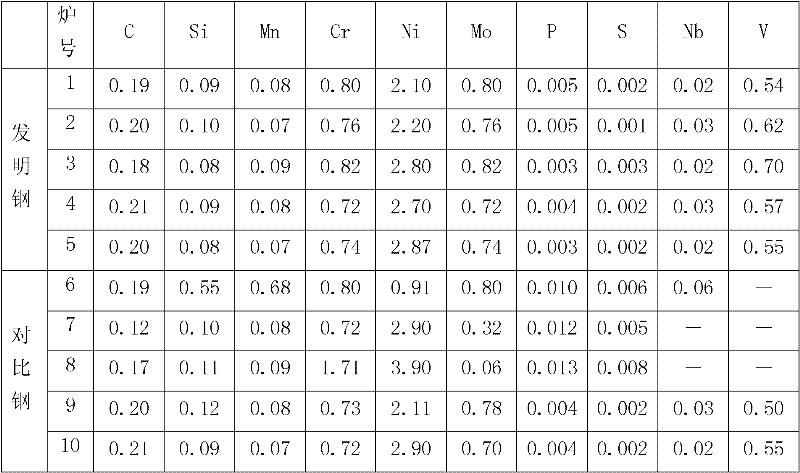

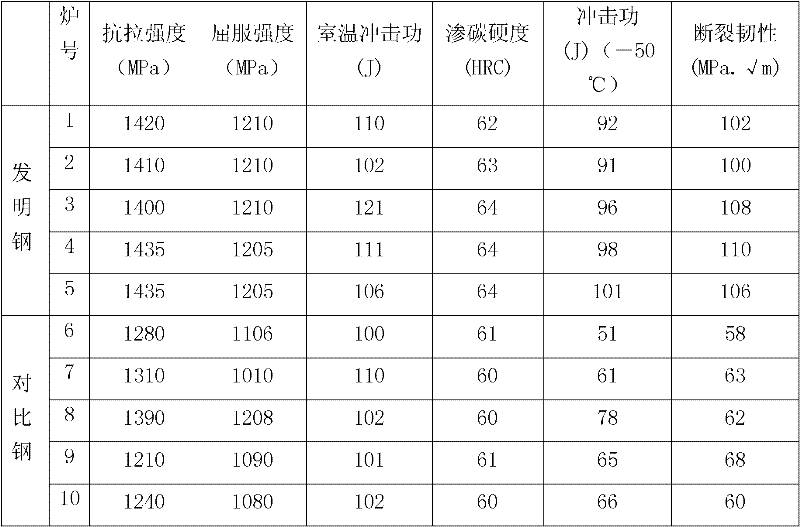

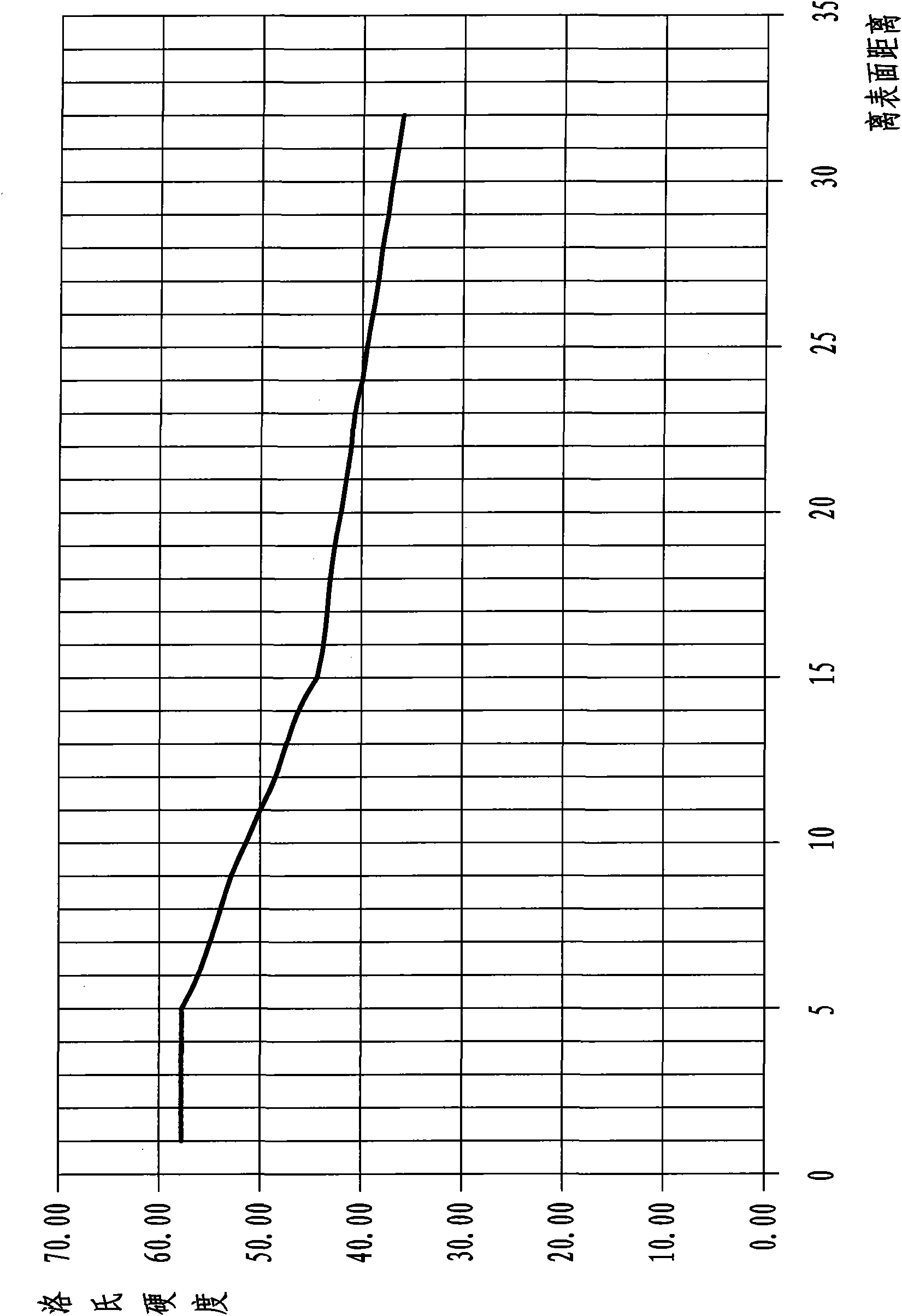

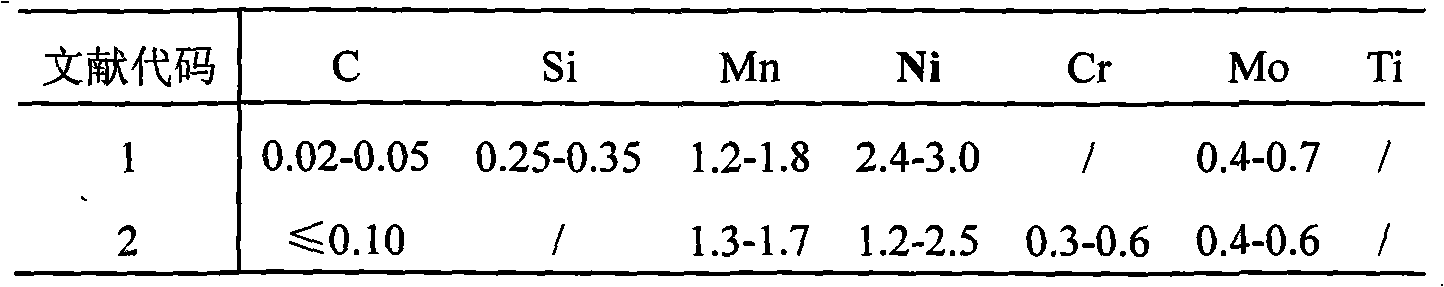

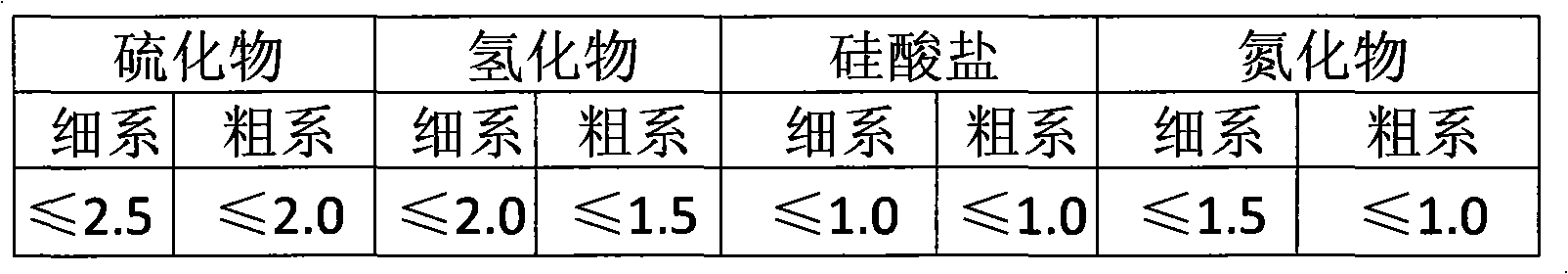

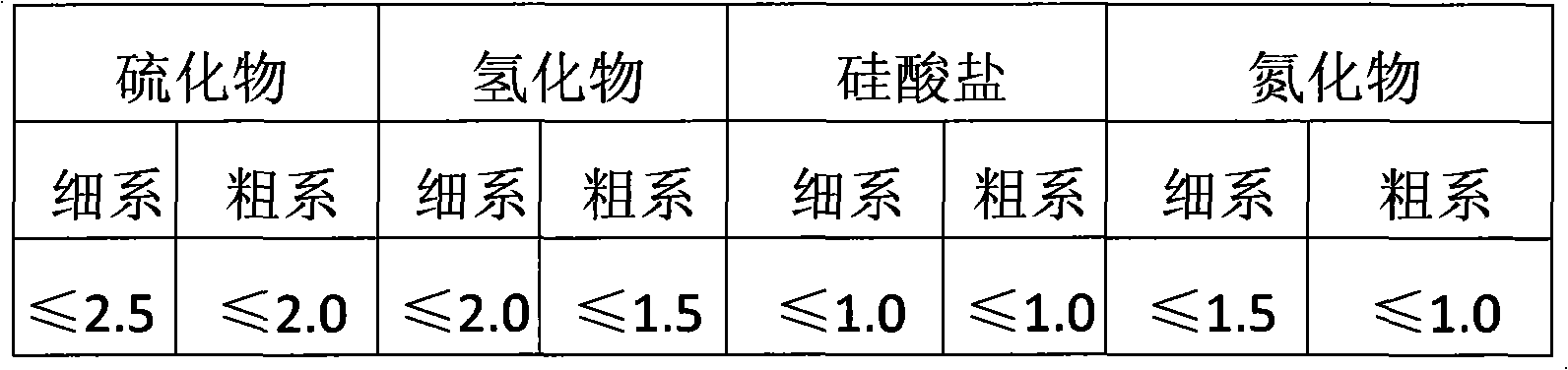

Carburized bearing steel for high-speed railways and preparation method thereof

The invention relates to a carburized bearing steel for high-speed railways and a preparation method thereof, belonging to the technical field of steel for railways. The bearing steel comprises the following chemical elements in percentage by weight: 0.18-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, at most 0.01% of P, at most 0.005% of S, 0.5-2.0% of Cr, 1.5-4.5% of Ni, 0.3-1.5% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: proportioning and controlling the components; carrying out vacuum smelting; carrying out hot working on a steel ingot to obtain a steel product; carrying out surface carburized hardening treatment on the steel product; and carrying out heat treatment on the steel product. The invention satisfies the requirements in the service process of the bearing steel for high-speed trains, and implements good cooperation of high surface hardness and high core strength / toughness.

Owner:CENT IRON & STEEL RES INST

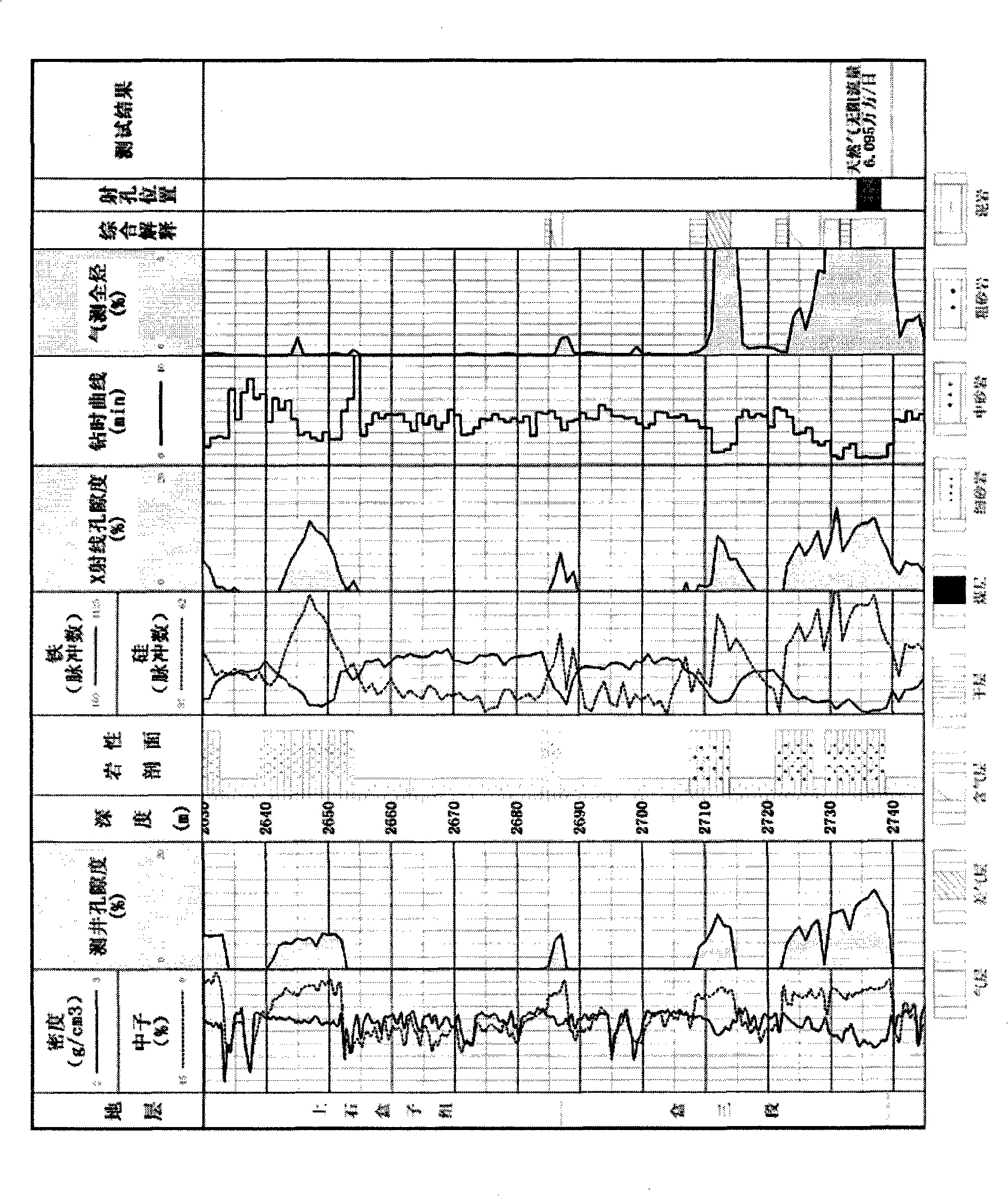

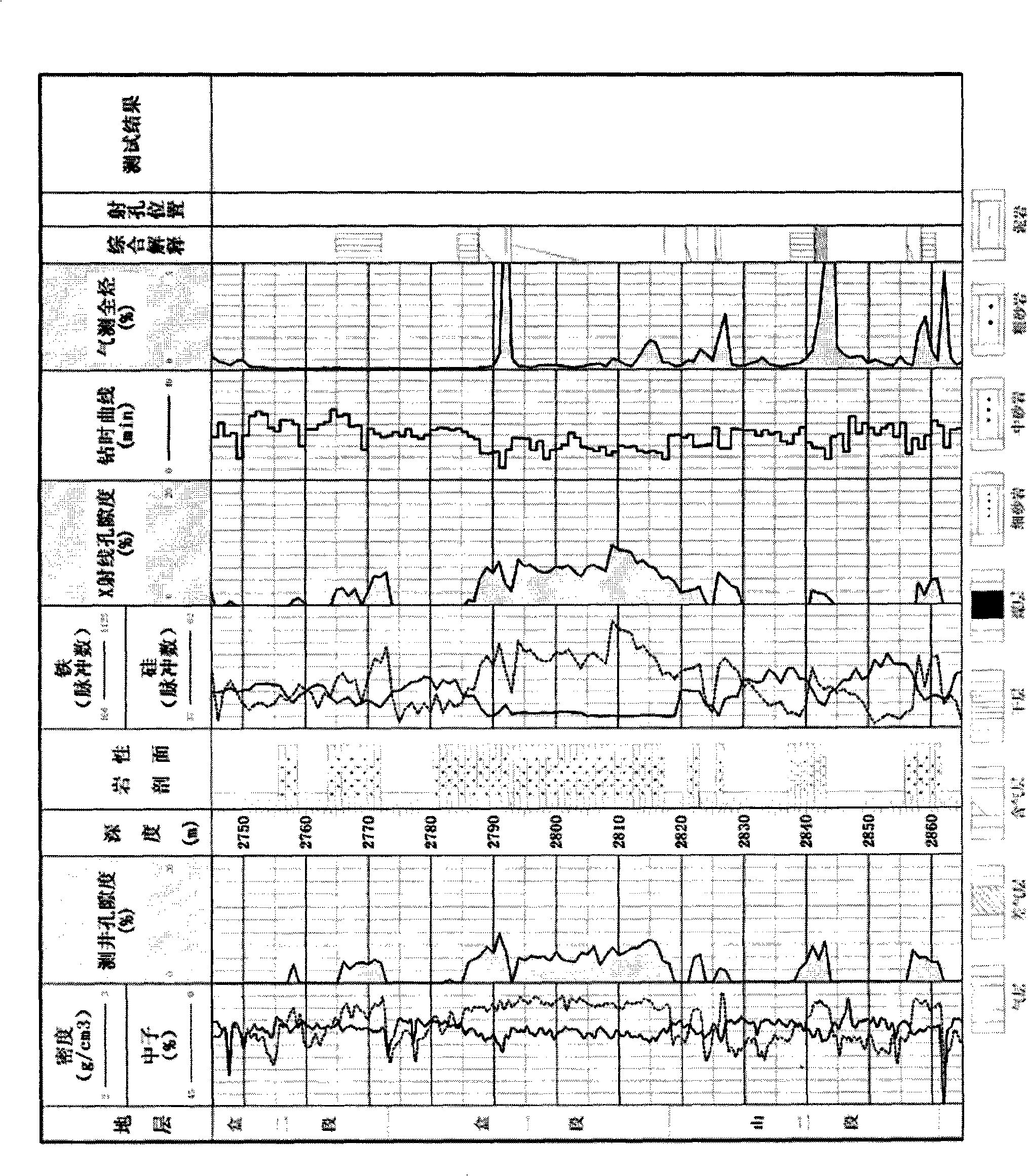

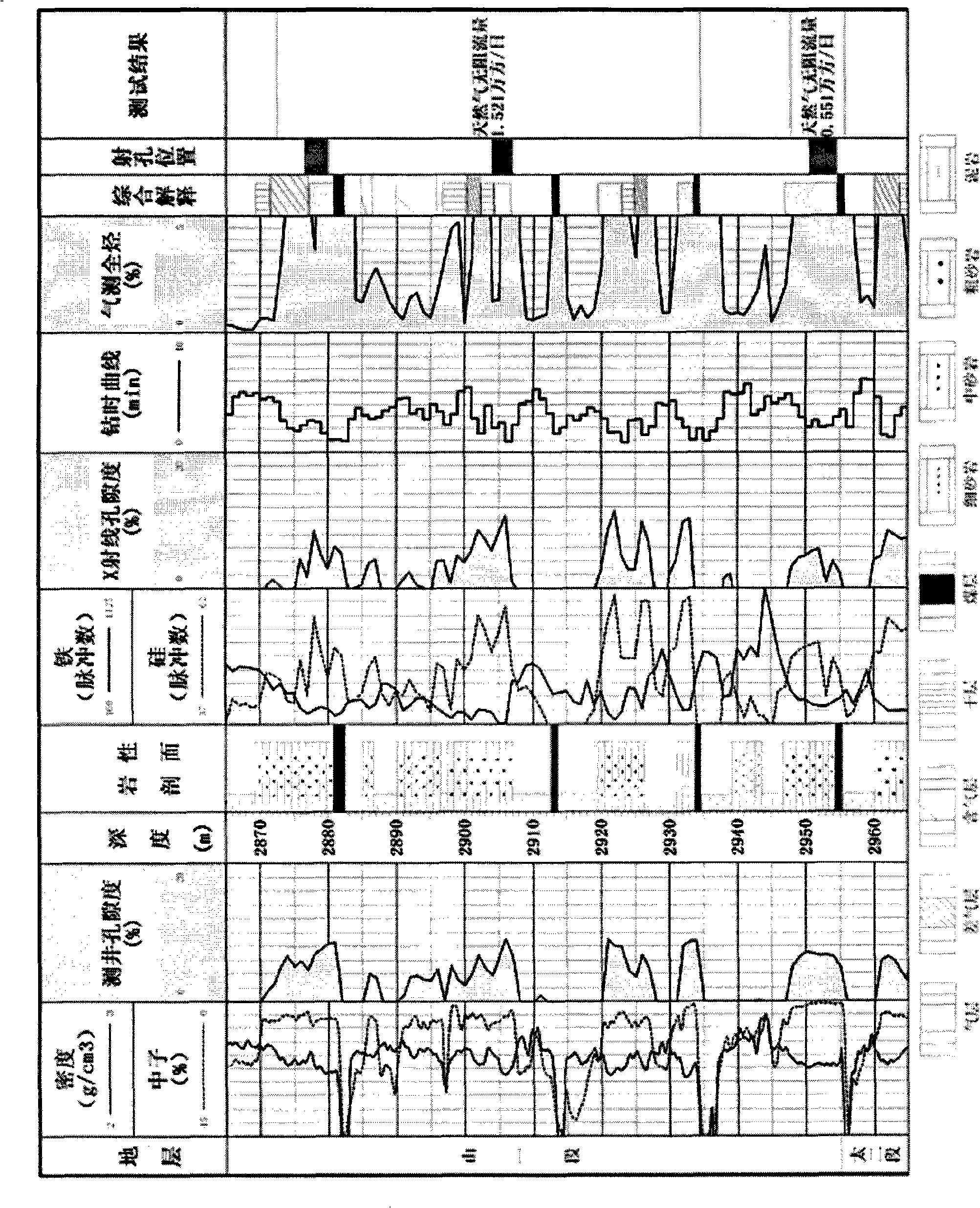

Analytical method of X-ray fluorescence terrigenous clastic rock porosity in petroleum well drilling

ActiveCN101344001ACorrect and effective guidanceCorrect and Effective Exploration and Development PracticeBorehole/well accessoriesPorosityAnalysis data

The invention relates to a method for using X-ray fluorescence to analyze the extent of porosity of terrigenous clasolite in oil drilling; the method comprises the following steps of: adopting an energy dispersion-typed X-ray fluorescence analyzer to carry out continuous analysis to the chemical elements in the rock core and rock debris in the oil drilling field with the drilling depth; obtaining the analysis data of the X-ray fluorescence changing with the depth; selecting silicon and ferrum elements which have obvious positive and negative relationship with the reservoir property of the rock; using the data of the silicon and ferrum elements to carry out 0-1 normalization data calculation; then calculating the extent of porosity; finally mapping the curve of the extent of porosity; and evaluating the reservoir property according to the curve of the extent of porosity and the value of the extent of porosity. The method of the invention can carry out X-ray fluorescence analysis and the analysis of the extent of porosity of the terrigenous clasolite in real time, use the data of the extent of porosity in real time to carry out quantitative evaluation to the reservoir property of the rock, form a geology explanation and evaluation method with the drilling based on the analysis of the X-ray fluorescence and guide exploration and development practice of oil and natural gas accurately and effectively.

Owner:中石化石油工程技术服务有限公司 +3

Method for preparing lithium ion battery anode material spherical LiFePO4

InactiveCN101746742AImprove conductivitySmall particle sizeCell electrodesPhosphorus compoundsChemical elementSolvent

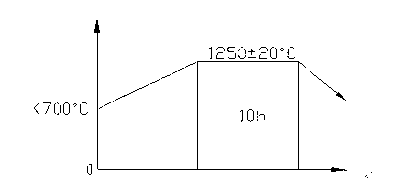

The invention relates to a method for preparing lithium ion batter anode material spherical LiFePO4. The method is characterized in that: lithium source, iron source, phosphorous source, doped chemical element compound and carbon precursor are mixed, liquid phase stirring ball milling is carried out in solvent for 1-20h, then spray drying is carried out, thus obtaining spherical precursor with uniform particle size distribution, the precursor is placed into a high temperature furnace and heated to 500-1000DEG C at 1-6 DEG C / min under inert atmosphere, high temperature sintering is carried out for 5-24h, and temperature reduction is carried out, thus obtaining the spherical LiFePO4 powder. Available ferric iron is selected as iron source, thus reducing product cost; regular carbon bed structure is constructed in the interior of the main body of the material and on the surface of the main body of the material, thus improving conductivity of the material; liquid phase ball milling and spray drying are combined, and sintered precursor with small particle size and narrow particle size distribution is obtained, thus improving batch reproducibility of product.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

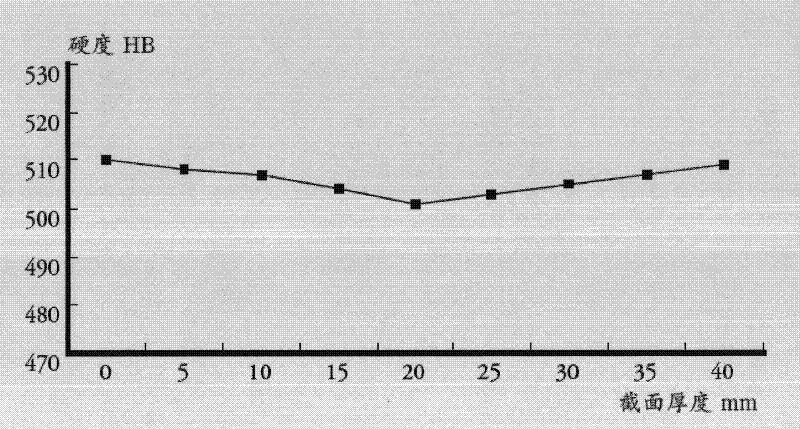

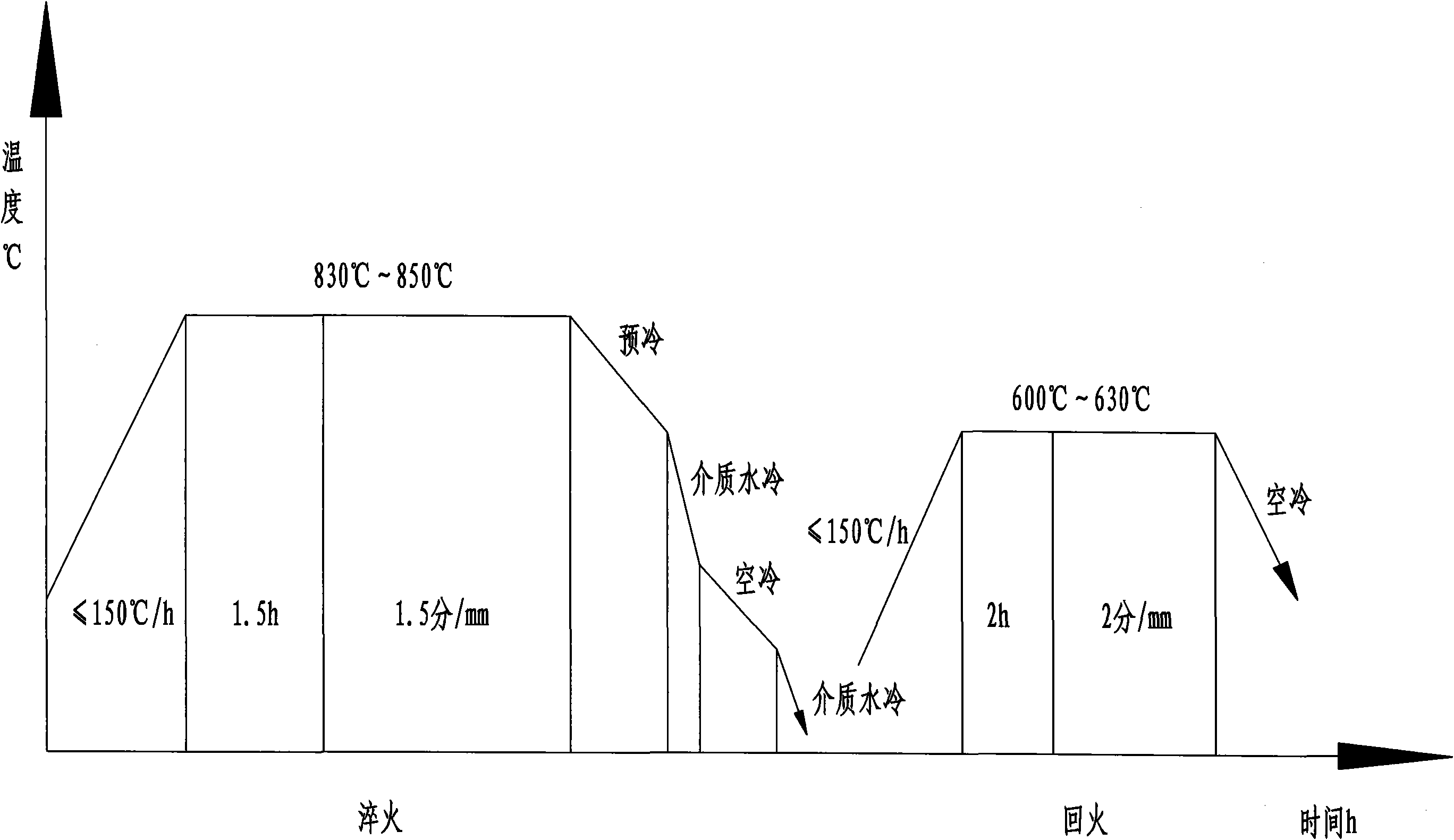

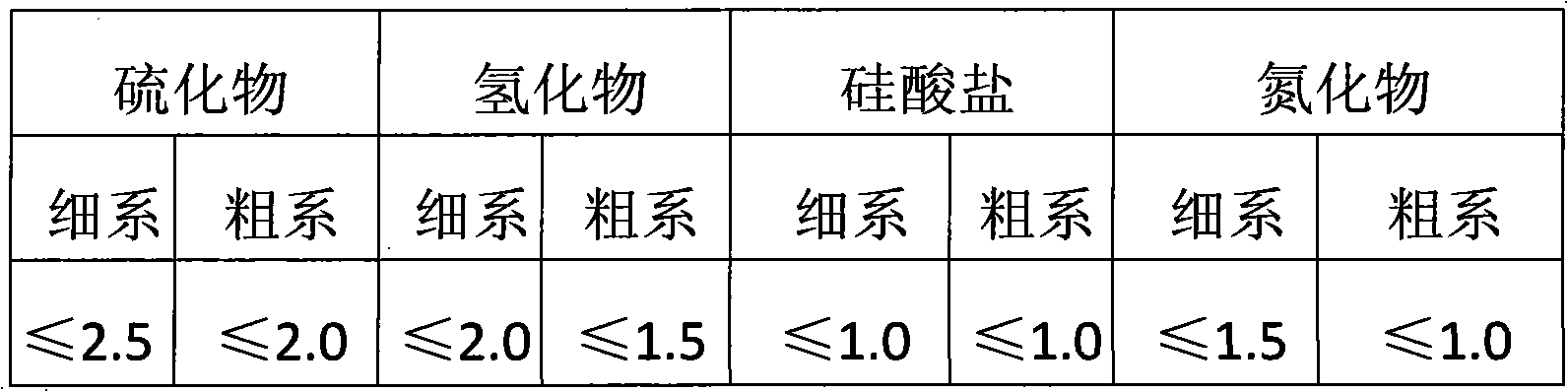

Material for overweight ring forging and manufacturing process for ring forging

The invention discloses a material for an overweight ring forging. The material comprises the following chemical elements in percentage by weight: 0.41 to 0.45 percent of C, 0.17 to 0.37 percent of Si, 0.80 to 1.00 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 1.05 to 1.20 percent of Cr, less than or equal to 0.30 percent of Ni, 0.20 to 0.25 percent of Mo, less than or equal to 0.20 percent of Cu, 0.02 to 0.04 percent of Al and the balance of Fe, wherein the content of oxygen and hydrogen elements meets the following requirements: [O] is less than or equal to 20ppm, and [H] is less than or equal to 2.0ppm. A manufacturing method for the ring forging comprises the following steps of: blanking a steel ingot which comprises the components and is taken as a raw material, forging and preparing a blank, performing ring rolling, performing heat treatment, and machining to obtain the wind tower flange ring forging. The method is characterized in that a workpiece obtained after forging, blank preparation and ring rolling is roughly turned and then is subjected to heat treatment; and the heat treatment process comprises heat treatment after forging and hardening and tempering. The method is applicable to the manufacture of 28 tons of overweight ring forgings.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

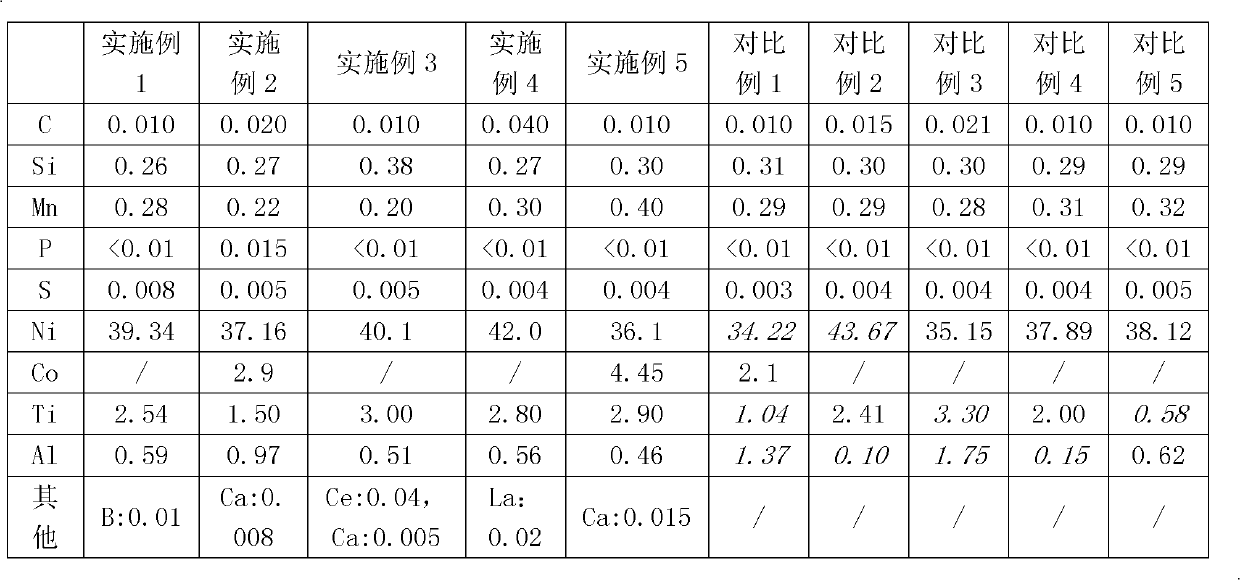

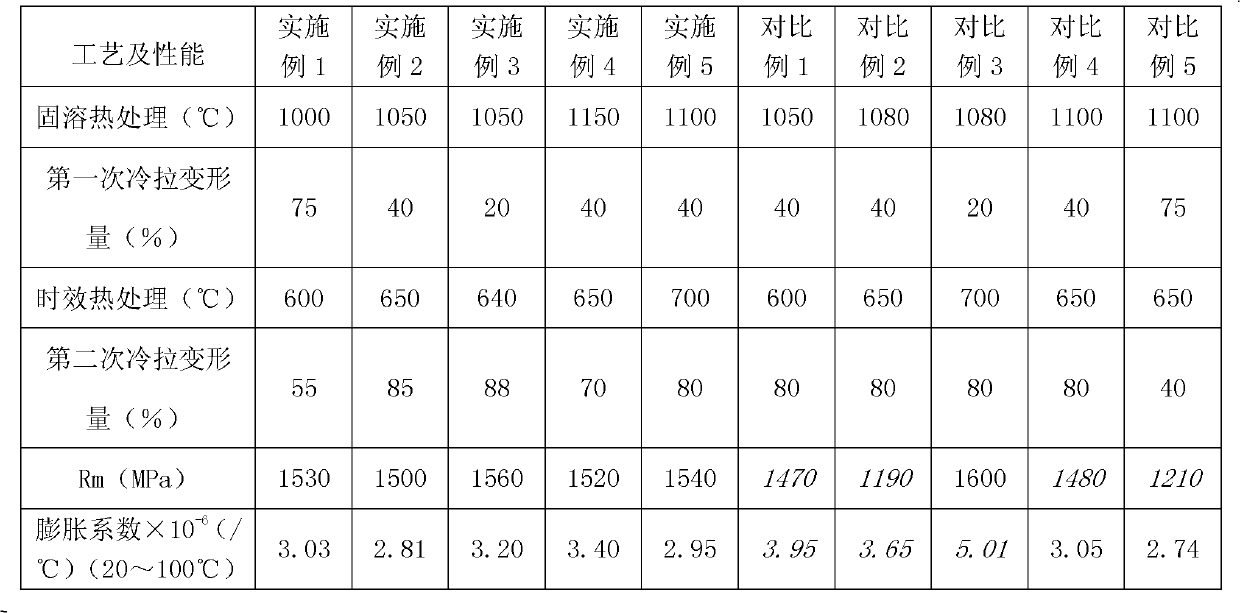

High-strength and low-expansion coefficient alloy wire and manufacturing method thereof

The invention discloses a high-strength and low-expansion coefficient alloy wire. The matrix is of austenite. The austenitic matrix is dispersedly distributed with Ni3(Ti, Al). The chemical elements of the high-strength low-expansion coefficient alloy wire includes by mass percent: no more than 0.05% of C; no more than 0.50% of Si; no more than 0.60% of Mn; 36.0-42.0% of Ni; 1.5-3.0% of Ti; 0.3-1.0% of Al; the balance being Fe and other unavoidable impurities. Accordingly, the present invention also discloses a manufacturing method of the high-strength and low-expansion coefficient alloy wire. The tensile strength of the high-strength and low-expansion coefficient alloy wire described by the invention is greater than or equal to 1500 Mpa, and the average linear expansion coefficient is less than or equal to 3.5*10-6 / DEG C in the range of 20-100 DEG C temperature.

Owner:宝武特种冶金有限公司

Ring forge piece material of wind power rotary supporting ring and ring forge piece manufacturing technology thereof

InactiveCN101812645AIncrease MnIncrease Mo contentFurnace typesHeat treatment furnacesManufacturing technologyChemical element

The invention discloses a ring forge piece material of a wind power rotary supporting ring, comprising the following chemical elements in weight percentage: 0.41-0.45 percent of C, 0.17-0.37 percent of Si, 0.80-1.00 percent of Mn, at most 0.020 percent of P, at most 0.020 percent of S, 1.05-1.20 percent of Cr, at most 0.30 percent of Ni, 0.20-0.25 percent of Mo, at most 0.20 percent of Cu, 0.02-0.04 percent of Al, at most 20ppm of O, at most 2.0ppm of H and Fe as the rest. A wind power rotary supporting ring forge piece manufactured by the material comprises the following technical steps: blanking, forging to manufacture a blank, rolling a ring, hot treating and accurately turning, wherein the hot treating step comprises the steps of hot treatment normalization and hot treatment hardening and tempering. The ring forge piece material is suitable for the ring forge piece of the wind power rotary supporting ring.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

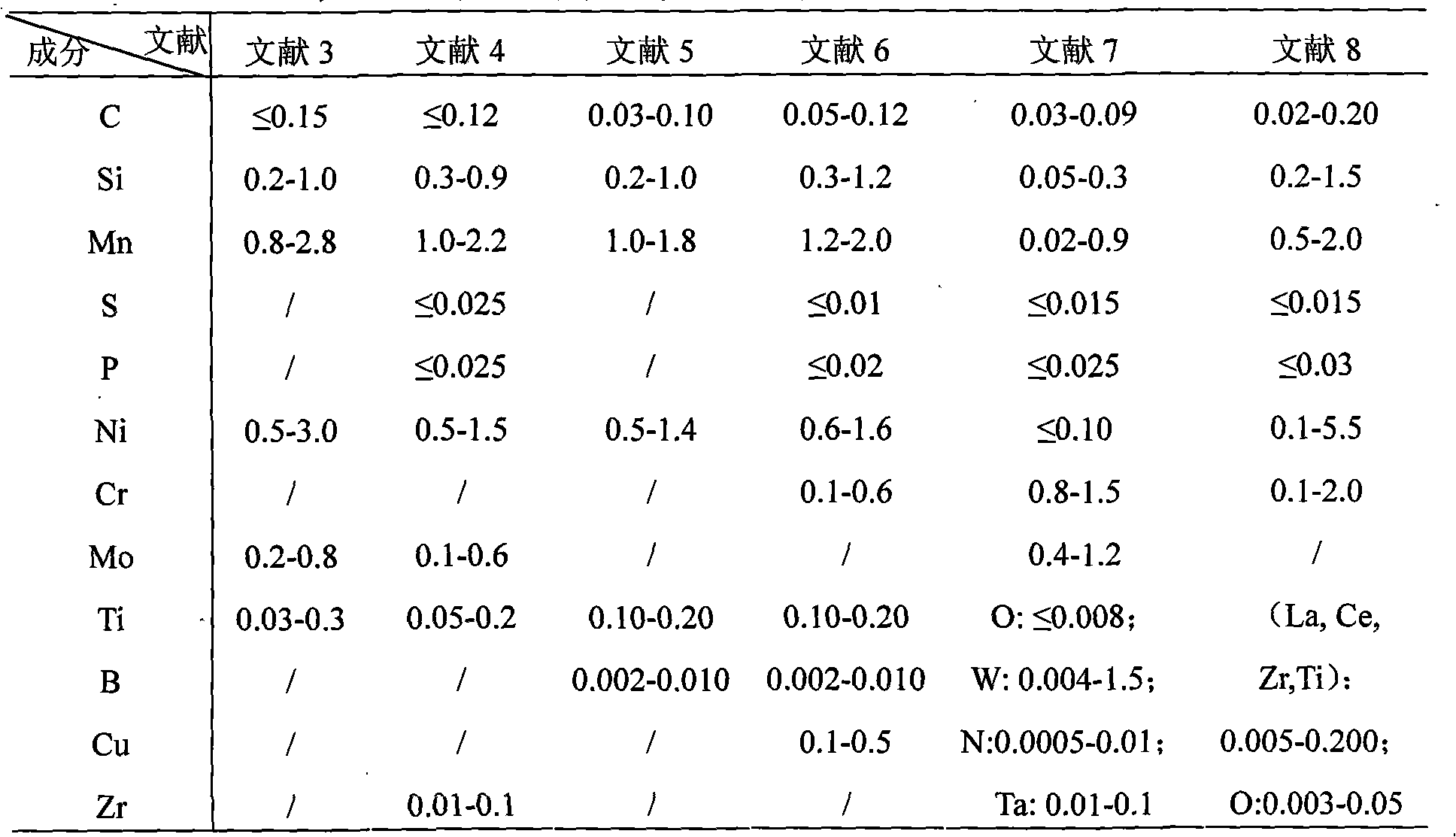

High intensity gas shielded welding wire, wire rod and application thereof

ActiveCN101288925ASimple designReduce dosageArc welding apparatusWelding/cutting media/materialsCrack resistanceChemical element

The invention provides a gas protection welding wire rod and a welding wire thereof. Both the wire rod and the welding wire comprises the following elements (according to the weight percent): C is 0.03 to 0.12, Si is 0.30 to 0.80, Mn is 1.2 to 2.2, S is equal to or less than 0.015, P is equal to or less than 0.020, Ni is 0.4 to 1.0, Cr is 0.1 to 0.5, Mo is 0.2 to 0.6, Ti is 0.06 to 0.2, and the rest is Fe and inevitable impurity elements. The welding wire provided by the invention has the advantages of simple chemical element design, small content of the precious alloy elements and low crack sensitivity coefficient, and the deposited metal has the advantages of high intensity, excellent crack resistance and low-temperature shock toughness and excellent dynamic performance. The welding wire of the invention is suitable for the welding of low alloy structure steel with 600 to 800MPa tensile strength, which is applicable to engineering mechanics, heavy trucks, hydraulic power, coal power and other industries.

Owner:BAOSHAN IRON & STEEL CO LTD

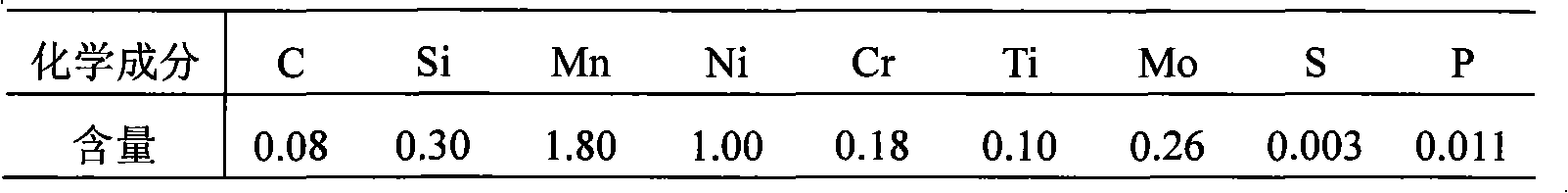

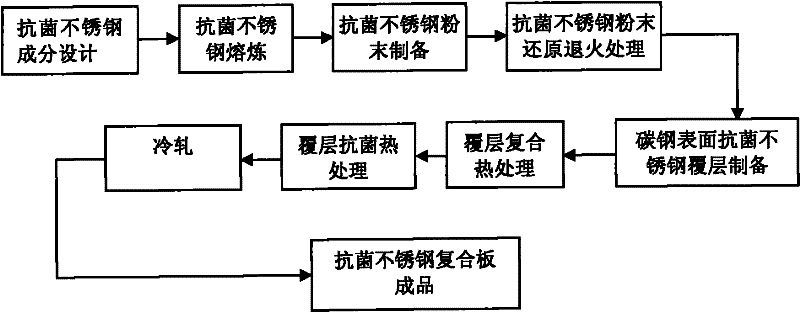

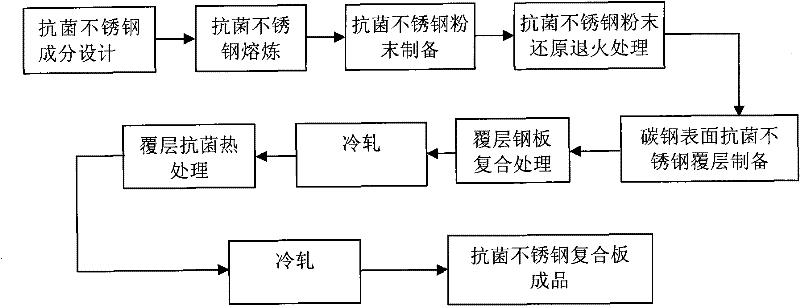

Antibacterial stainless steel clad steel plate and manufacturing method thereof

ActiveCN102260832ATaking into account corrosion resistanceAntibacterialMolten spray coatingSheet steelChemical element

The invention discloses an antibacterial stainless steel composite steel plate, which comprises a carbon steel substrate and a surface antibacterial stainless steel layer. The surface antibacterial stainless steel layer comprises the following chemical elements of: by weight, 0-10% of Cu, 0-1.0% of Ag, 13-28% of Cr, 0-18% of Mn, 0-0.4% of N, 0-3% of Mo, 0-6% of Al, 0-2% of V, 0-1.0% of Zn, 0-15% of Ni, C being less than or equal to 0.08%, Si being less than or equal to 0.15%, P being less than or equal to 0.03%, S being less than or equal to 0.01%, Ti being less than or equal to 1%, and the balance being Fe and other inevitable impurities. Correspondingly, the inventor also discloses a manufacturing method of the antibacterial stainless steel composite steel plate. According to the method, the antibacterial stainless steel layer is prepared on the surface of the carbon steel substrate with good processability by a specific technology, and then a composite treatment is carried out by aspecial processing technology to form the antibacterial stainless steel composite steel plate which has corrosion resistance, antibacterial property and cold workability at the same time.

Owner:BAOSHAN IRON & STEEL CO LTD

Multi-component multifunction health-care yarn with kender, negative and medical stone and its health-care textile

This invention belongs to the fiber field. It relates to a kindo f blended yarn, especially a kind of blended health protection yarn and its health protection textile. It can penetrate scores of natural chemical elements and health elements to our body, and can permanently release negative ion, can penetrate scores of natural chemical elements and health elements to our body, and can permanently release negative ion, eradiate far infrared lfie light wave and so as to improve blood mcirocirculation. This invention contains kendir short fiber, negative ion viscose short fiber, medical stone viscose short fiber, they are the functional fiber. The mass percent is: kendir short fiber 10-17%, negative ion viscose short fiber 5-50%, medical stone viscose short fiber 5-60%. Others must be grouped as color cotton, milk fiber, and soybean short fiber and other natural fiber or one or two kinds of modification chemical fiber. We use these to spin the multi-group, multi-functional health protection yarn of 6-120 branches, the yarn are weaved to health protection textile of 80g / m2-500g / m2, then we put into 10-200 dan Leica yarn or urethane elastic fiber to weave the resilience health protection textile.

Owner:天津百益尔康科技发展有限公司

Ring forging of rotary support ring for wind power equipment and method for manufacturing same

ActiveCN101592131AHigh mechanical strengthHigh hardnessFinal product manufactureWind motor supports/mountsElectricityHydrogen

The invention discloses a ring forging of a rotary support ring for wind power equipment, which is stable and reliable in quality and meets the use requirements in a severe environment. The ring forging comprises the following chemical elements by weight: 0.41 to 0.45 percent of C, 0.17 to 0.37 percent of Si, 0.60 to 0.80 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 1.0 to 1.20 percent of Cr, less than or equal to 0.30 percent of Ni, 0.15 to 0.25 percent of Mo, less than or equal to 0.025 percent of Cu, 0.01 to 0.04 percent of Al, and the balance of Fe; moreover, the contents of hydrogen and oxygen elements meet the following requirements that: [O] is less than or equal to 20 ppm, and [H] is less than or equal to 2.0 ppm. The manufacturing method comprises the following steps of: selecting billet steel prepared by the components as a raw material; and performing blending, forging, blanking, ring rolling, thermal treatment and finishing turning machining on the billet steel to obtain the ring forging of the rotary support ring. The method is characterized in that: a workpiece obtained after the forging, blanking and ring rolling is subjected to rough turning machining, and then subjected to the thermal treatment including thermal treatment normalizing and thermal treatment tempering. The product manufactured by the method can meet the requirements of the large-sized wind power equipment.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com