Patents

Literature

996results about How to "Improve low temperature impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

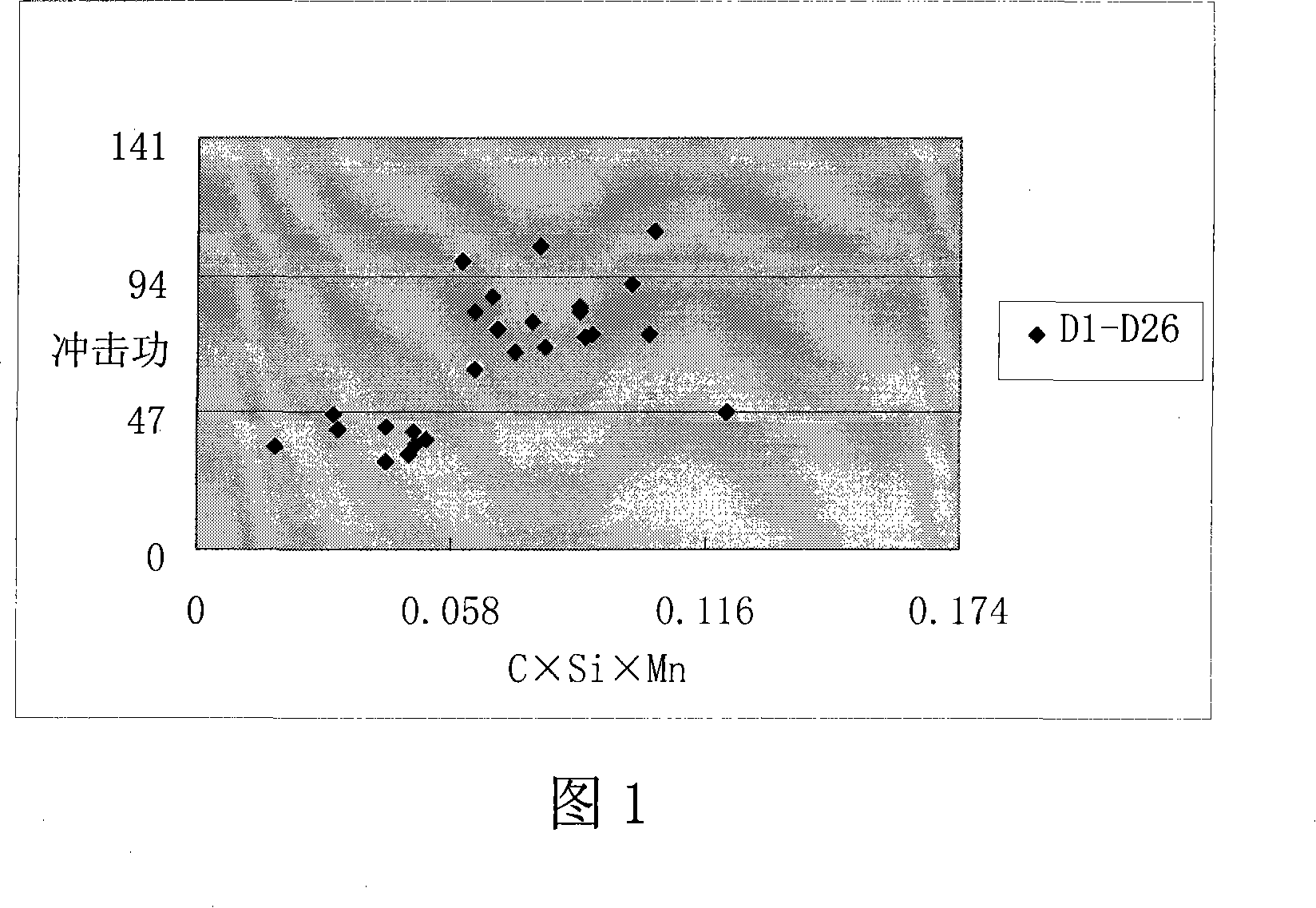

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

22Cr duplex phase stainless tube welding method

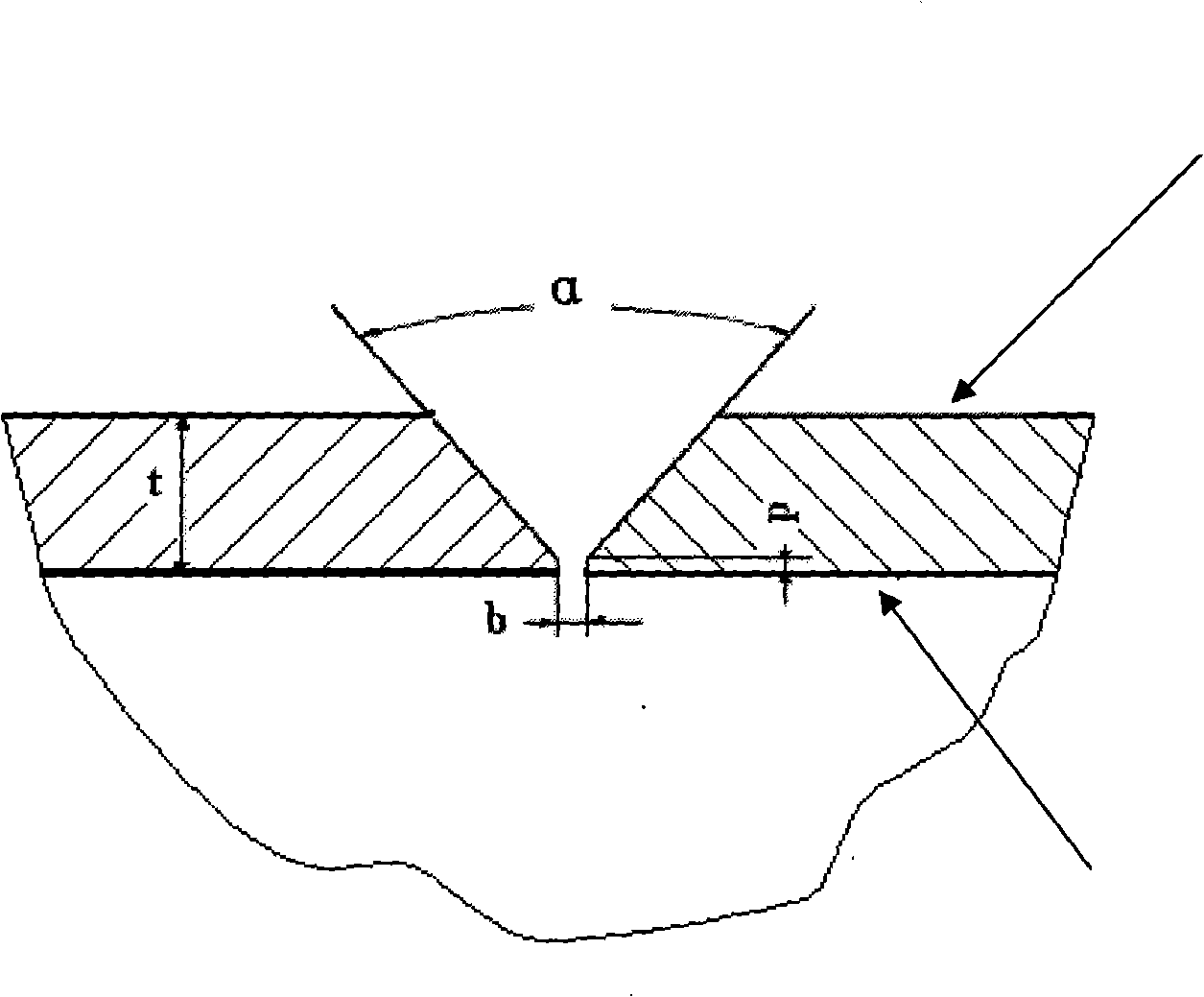

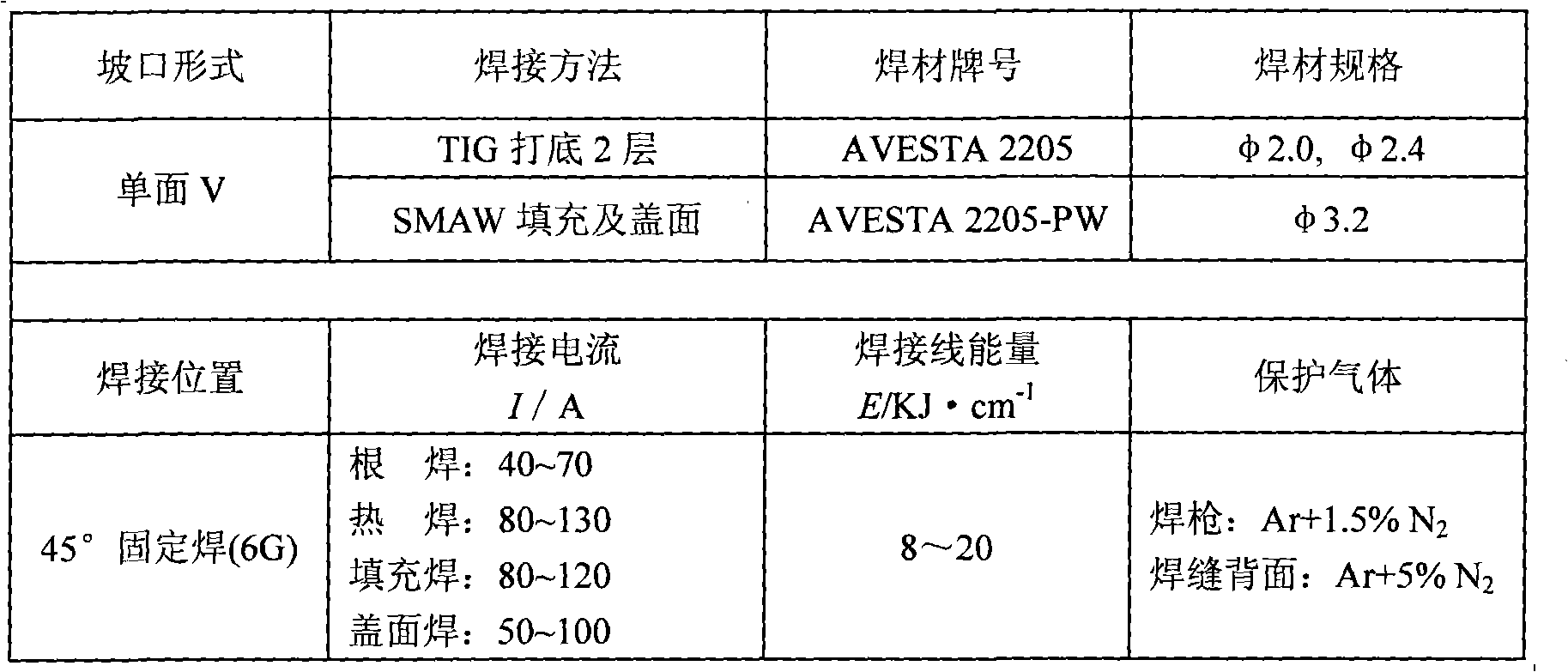

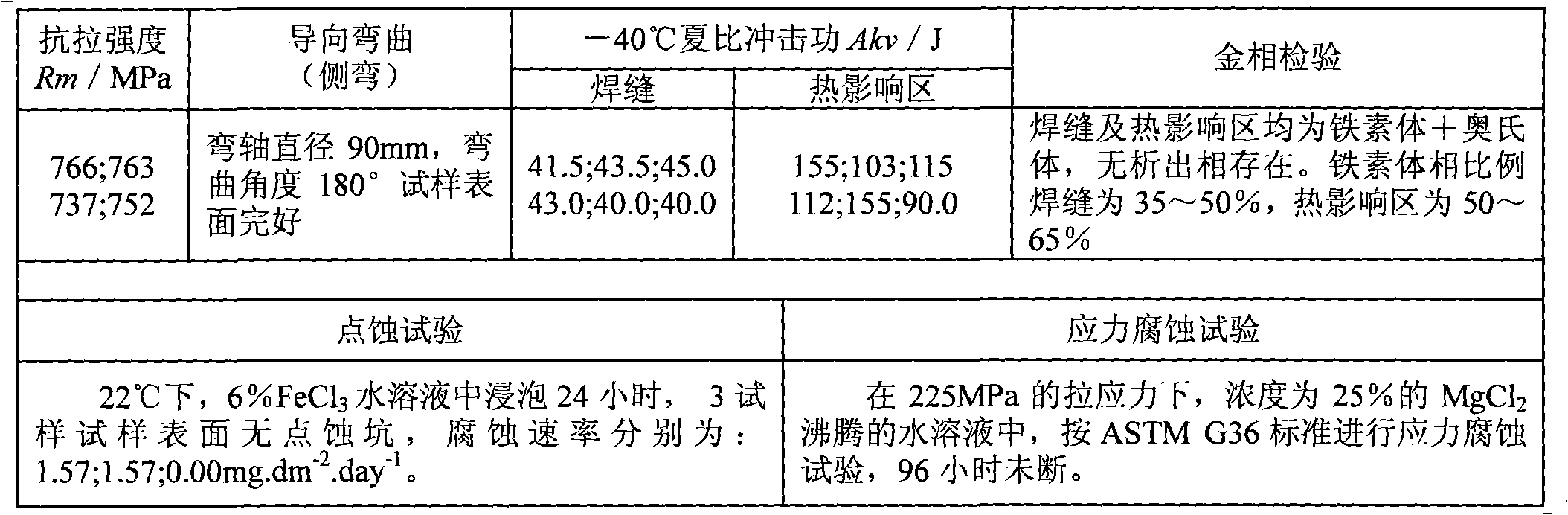

InactiveCN101288918AImprove tensile propertiesImprove low temperature impact toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesMicrostructurePitting corrosion

The invention relates to a welding method of 22Cr duplex stainless steel corrosion resistant alloy pipe, which adopts a gas mixture of 99.995 percent pure Ar and 98 to 99 percent Ar plus 2 percent N2 or a gas mixture of 90 to 95 percent of N2 plus 5 to 10 percent H2 to weld the two laterals within the range equal to or more than 100mm inside the pipe; back welding, fill welding and cap welding are implemented when the oxygen content is equal to or less than 50ppm; the welding and filling metal deposit includes the following components according to the weight percentage: C is equal to or less than 0.04, Cr is 22.0 to 23.5, Ni is 8.5 to 10.5, Mo is 3.0 to 3.5, Mn is 0.5 to 2.0, Si is equal to or less than 0.9, P is equal to or less than 0.04, S is equal to or less than 0.03, N is 0.15 to 0.20 and Cu is equal to or less than 0.75. A balanced austenitic-ferritic microstructure is obtained with good joint tensility and low-temperature shock toughness, as well as good corrosion performances of anti-pitting corrosion of chloride, stress corrosion and simulated environment medium corrosion resistance.

Owner:CNPC TUBULAR GOODS RES INST

High-strength high ductility gas protecting welding stick

InactiveCN101234457ASimple welding processStable welding wire qualityWelding/cutting media/materialsSoldering mediaChemical compositionUltra fine

The invention relates to a gas shielded welding wire with high strength and high toughness, which solves the defects that the existing strength grade in the technical field is unsuitable for market demand and is of high cost. The technical scheme of the invention is that the components of the welding wire (according to the weight percentage) are as follows: 0.04 to 0.10 of C, 0.30 to 0.80 of Si, 1.30 to 2.0 of Mn, 0.40 to 0.89 of Ni, 0.20 to 0.50 of Cr, 0.20 to 0.60 of Mo, 0.56 to 0.80 of Cu, 0.05 to 0.20 of Ti, 0.002 to 0.010 of B, less than 0.020 of P, less than 0.015 of S, less than 0.03 of Als and the rest of Fe and inevitable impurities. The welding wire of the invention has stable quality. The mechanical property of a deposited metal is that Rel is equal to 810MPa; Rm is equal to 840MPa; A is equal to 16 percent and Z is equal to 66 percent. The average impact power AKV in minus 20 DEG C is 141J; and the average impact power AKV in minus 40 DEG C is 128J; and the average impact power AKV in minus 60 DEG C is 70J. The welding wire is suitable for gas shielded welding of 800MPa grade of ultra-fine steel; as the content of Ni is reduced, the cost of the welding wire is reduced dramatically and the implementation is easy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

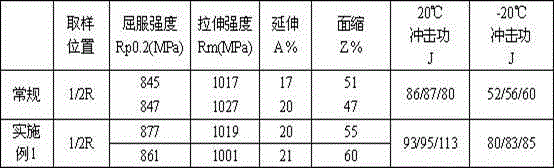

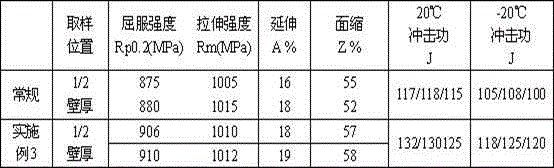

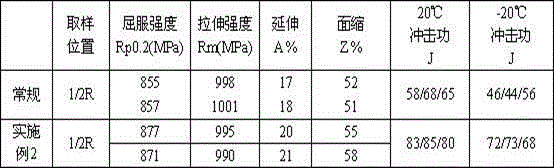

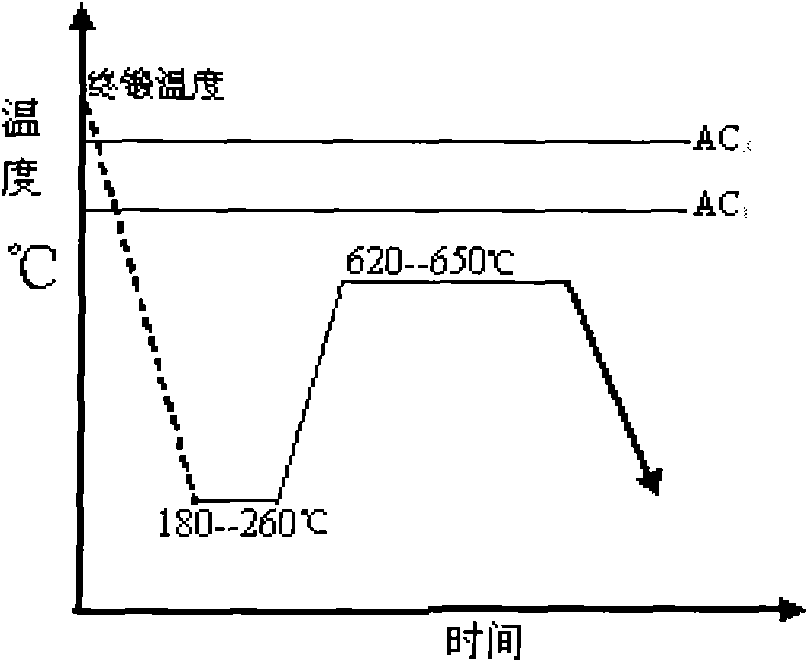

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

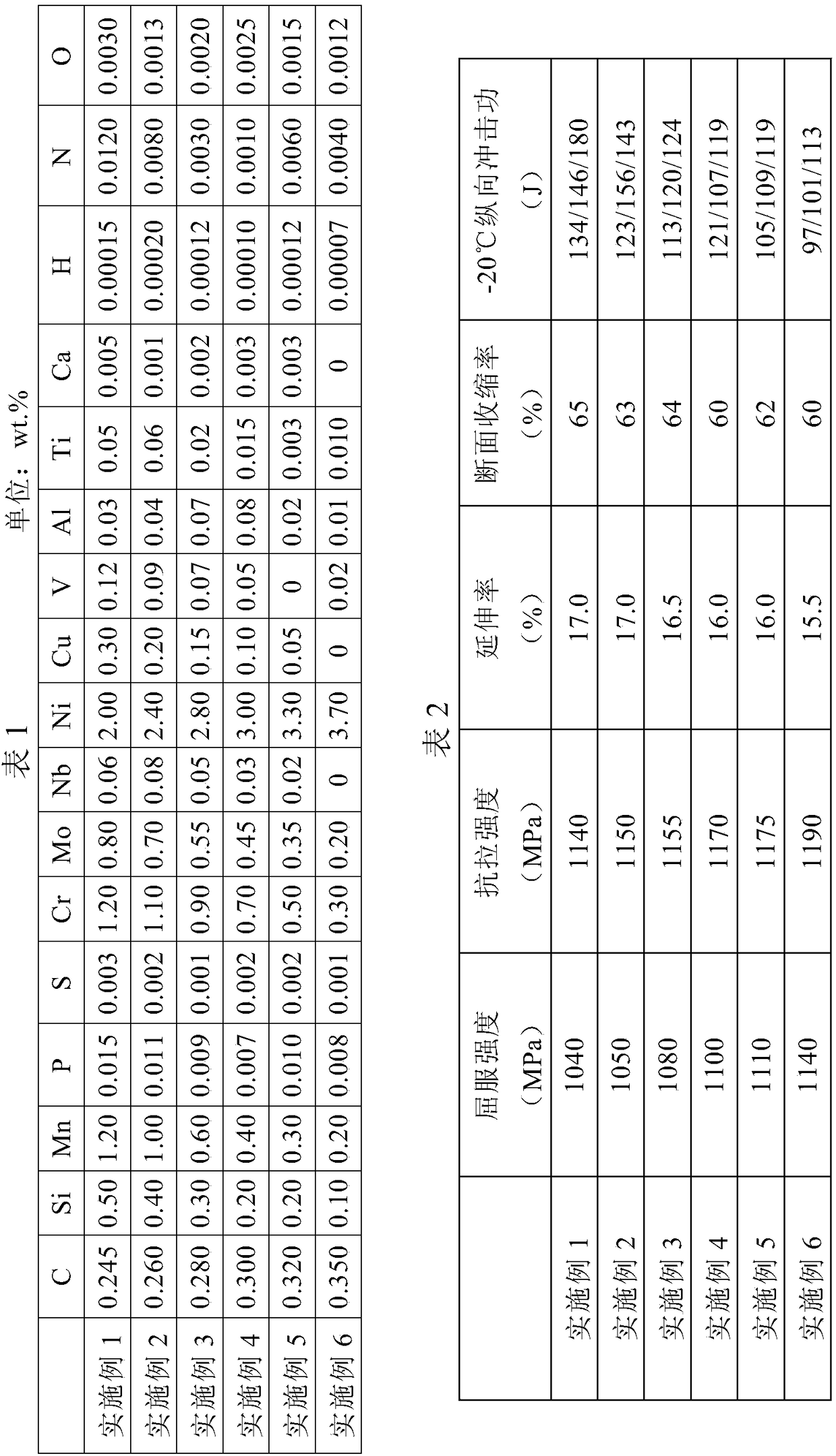

Wind power flange alloy steel and preparation technology of parts thereof

The invention discloses wind power flange alloy steel and a preparation technology of parts thereof. The alloy steel comprises the following chemical compositions: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, nickel, copper, nitrogen, oxygen, hydrogen, rare earth and the balance of iron and the inevitable impurities. The preparation technology of the alloy steel parts comprises the following steps: pretreating molten iron, smelting in a converter, performing external refining, casting steel ingots, performing flame cleaning, heating, forging, slowly cooling, performing heat treatment, machining, performing flaw detection, inspecting, packaging and warehousing. Compared with the existing alloy steel used in the wind power generation at home and aboard, the alloy steel disclosed by the invention has higher tensile strength, yield strength, elongation after fracture and reduction of area, particularly higher low-temperature impact toughness. The atmosphere corrosion resistance and the sea atmosphere corrosion resistance are increased by two levels.

Owner:江阴同庆机械制造有限公司

Easy cut by flame abrasion-resistant steel in high rigidity, in toughness and preparation method

A high-hardness and-toughness antiwear steel plate easy to be cut by flame proportionally contains Fe, C, Si, Mn, Nb, Ti, B, Cr and additive element chosen from Ni, Mo, 'Al, Cu, V, Ca, REM and Mg. Its preparing process includes rolling and quenching from the temp not lower than Ar3 conversion point to the temp lower than M2 conversion point. It has better weldability.

Owner:杨军

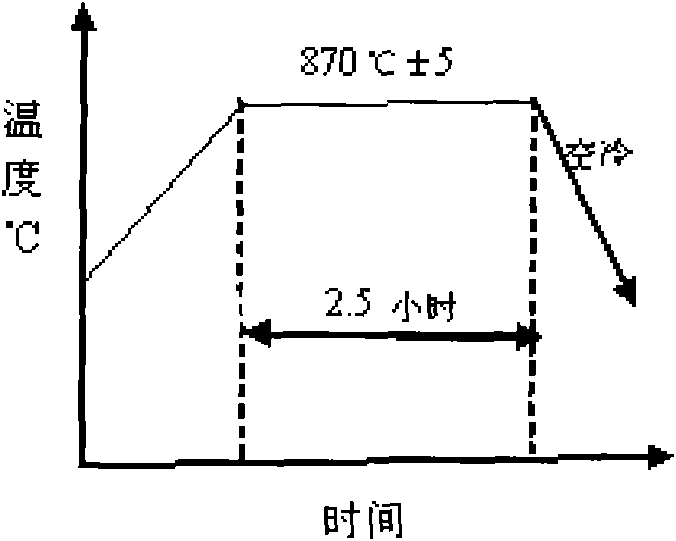

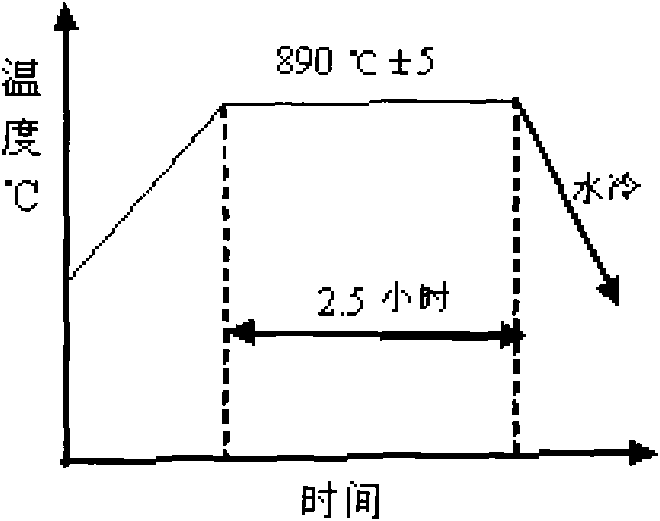

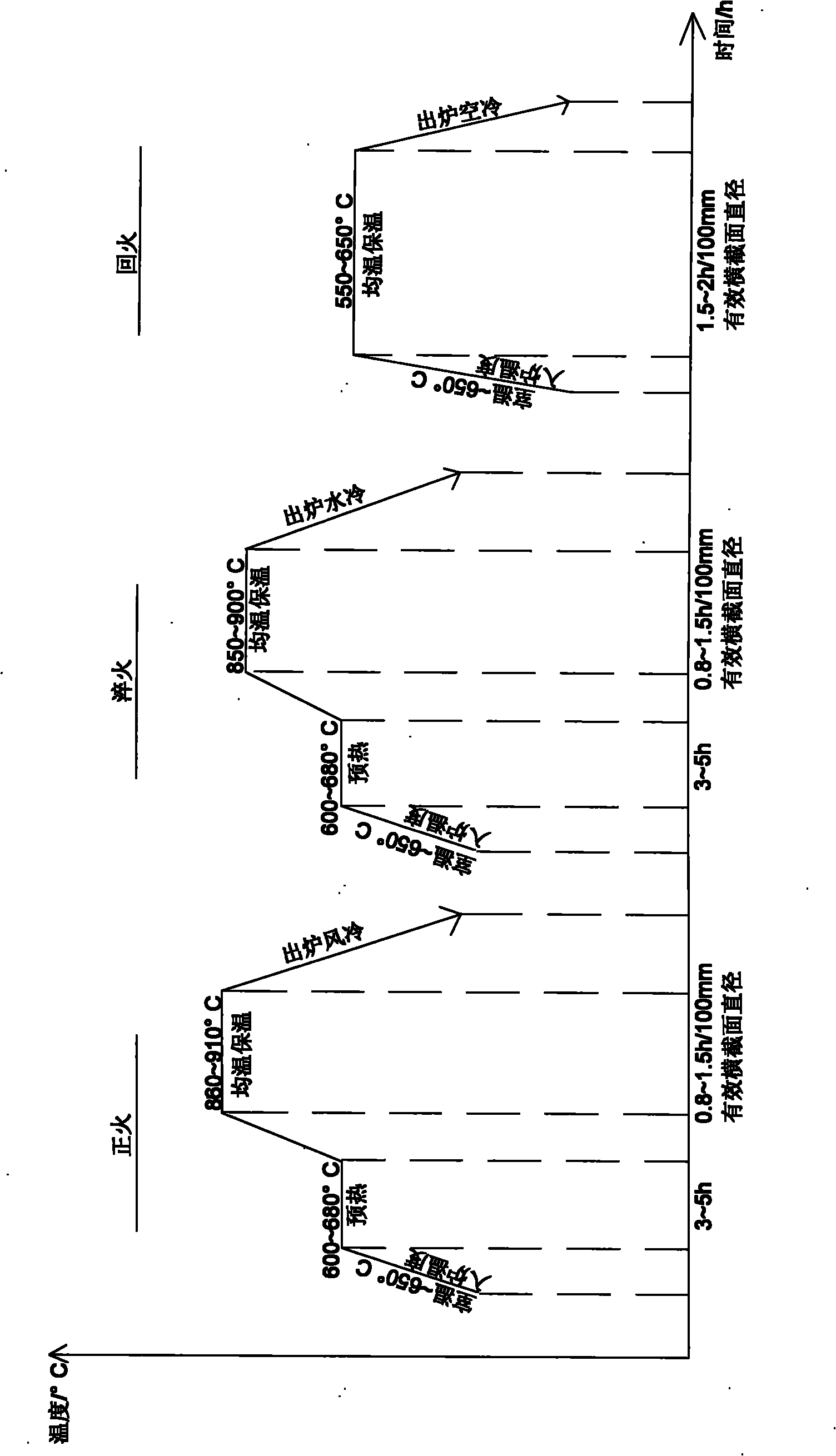

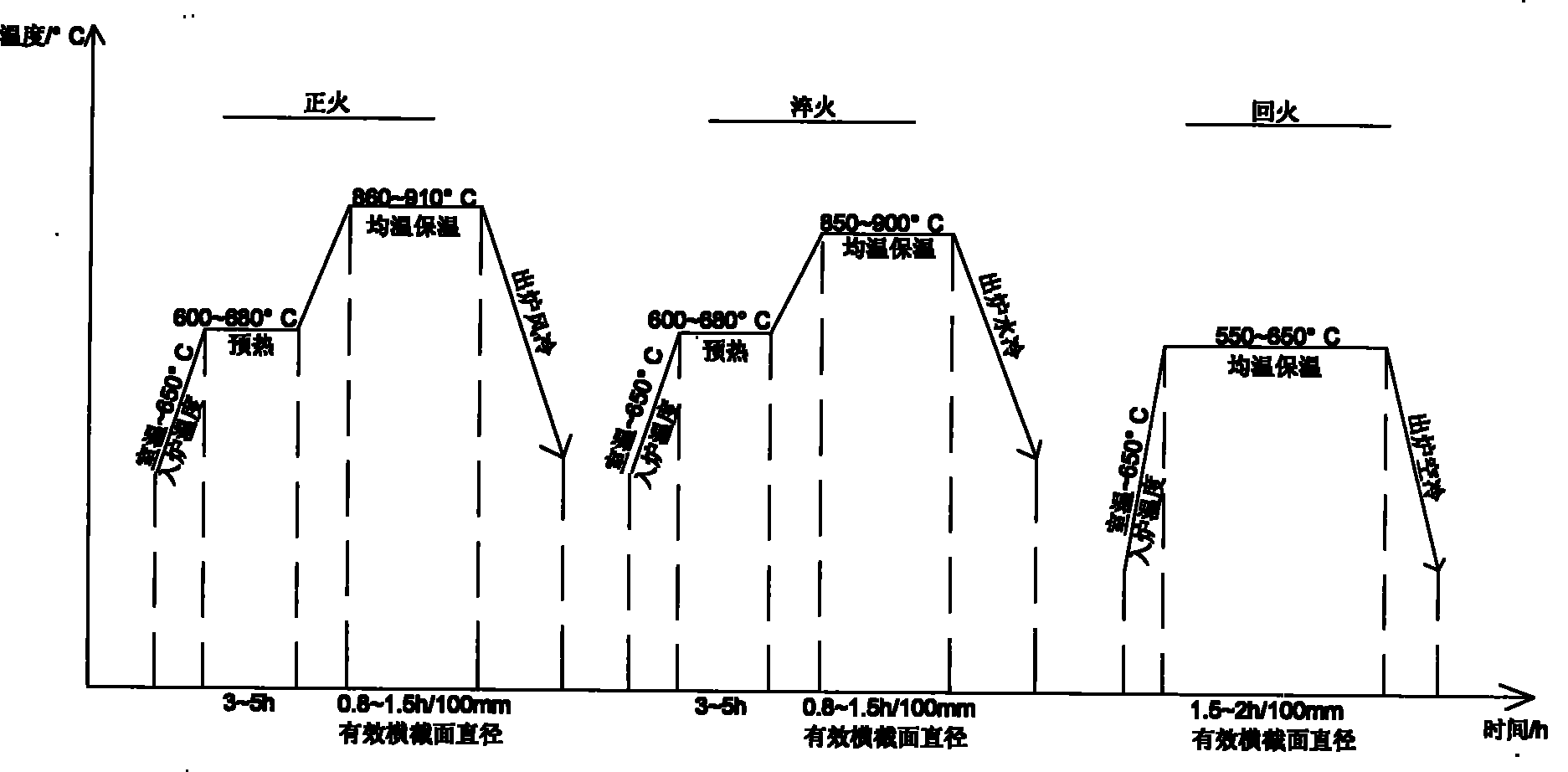

Heat treatment process of AISI4340 steel forgings

The invention belongs to the technical field of the production technology of steel forging products used in low temperature and discloses a heat treatment process of AISI4340 steel forgings. In the heat treatment process, air cooling is performed after normalization; the temperature of water-cooling after quenching is 10-20 DEG C, the dimension unit of the effective cross-section is millimeter, the unit of cooling time is second, and the cooling time is 2-3 times of the effective cross-section dimension of AISI4340 steel forgings. By using the heat treatment process of the invention, the strength of the AISI4340 steel forgings can be enabled and the low-temperature impact toughness is effectively improved, thus the service life of forgings is prolonged.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

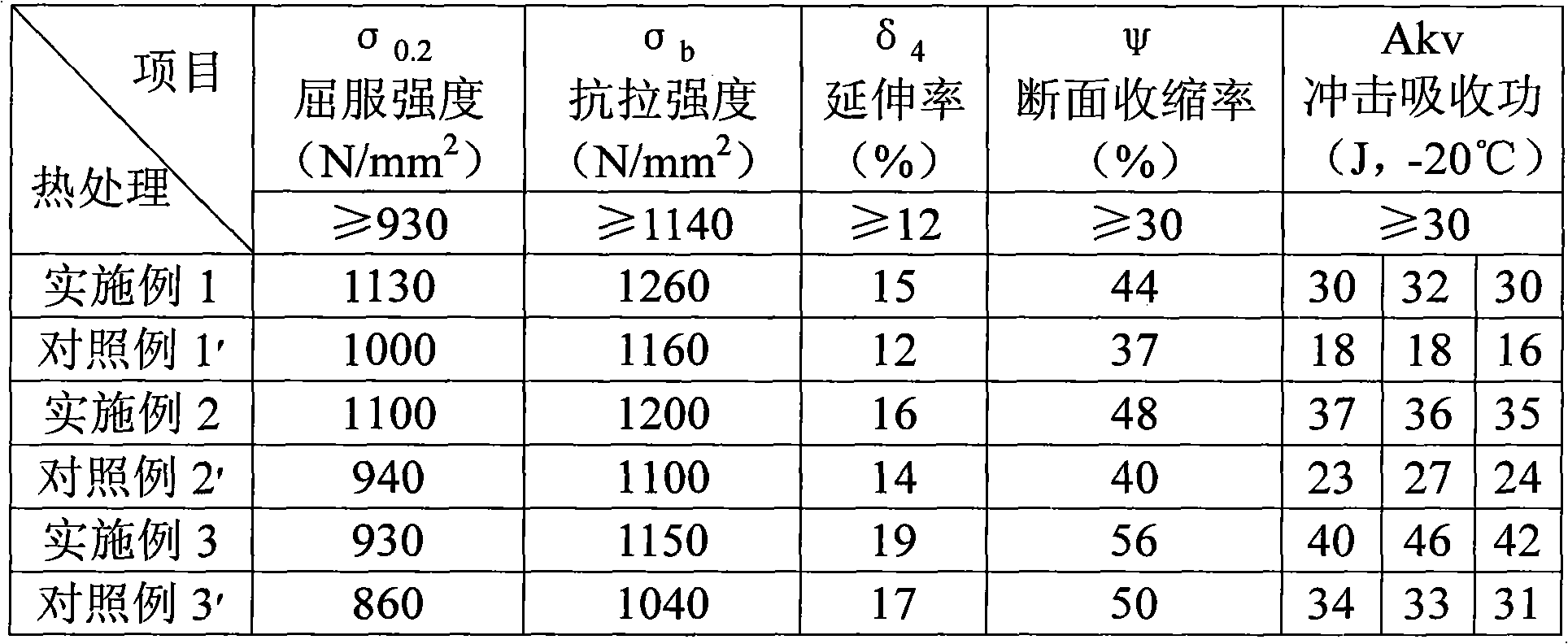

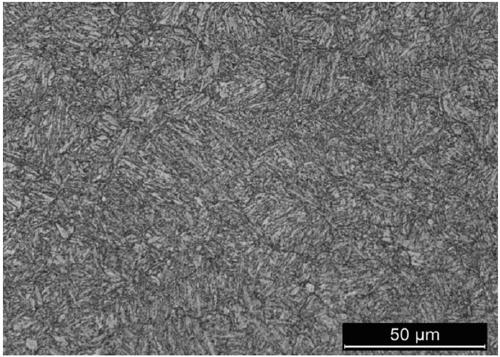

InactiveCN109136737AImprove low temperature impact toughnessImprove tensile propertiesShrinkage rateUltimate tensile strength

The invention discloses ultrahigh tough steel with tensile strength of 1100 Mpa and a manufacturing method thereof. Chemical components of the tough steel comprises, by weight, 0.245-0.350% of C, 0.10-0.50% of Si, 0.20-1.20% of Mn, P less than or equal to 0.015%, S less than or equal to 0.003%, 0.30-1.20% of Cr, 0.20-0.80% of Mo, 2.00-3.70% of Ni, 0-0.30% of Cu, 0-0.08% of Nb, 0-0.12% of V, 0.01-0.08% of Al, 0.003-0.06% of Ti, Ca less than or equal to 0.005%, H less than or equal to 0.002%, N less than or equal to 0.0120%, O less than or equal to 0.0030%, Fe and inevitable impurities. The preparation method adopts quenching plus tempering heat treatment, and tempered martensites plus tempered bainites and residual austenite tissue are obtained. The yield strength of steel is greater than or equal to 900 Mpa, the tensile strength is greater than or equal to 1100 Mpa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 70 J, the elongation rate is greater than or equal to 15%, the shrinkage rate of a fracture surface is greater than or equal to 50%, good strength, low-temperature toughness and plasticity are achieved, and the ultrahigh tough steel can be used for manufacturing high-performance ocean platform mooring cables of R6 grade and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

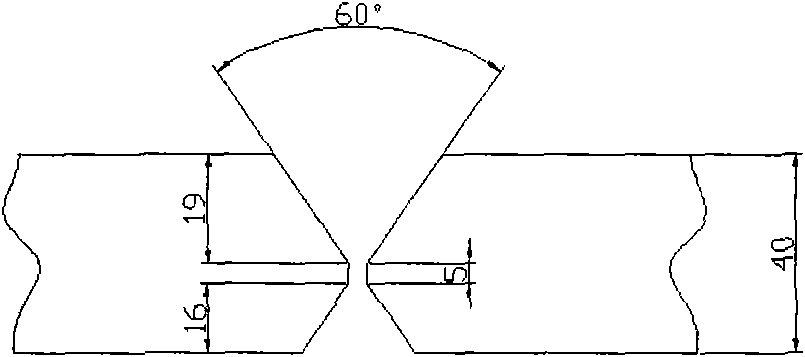

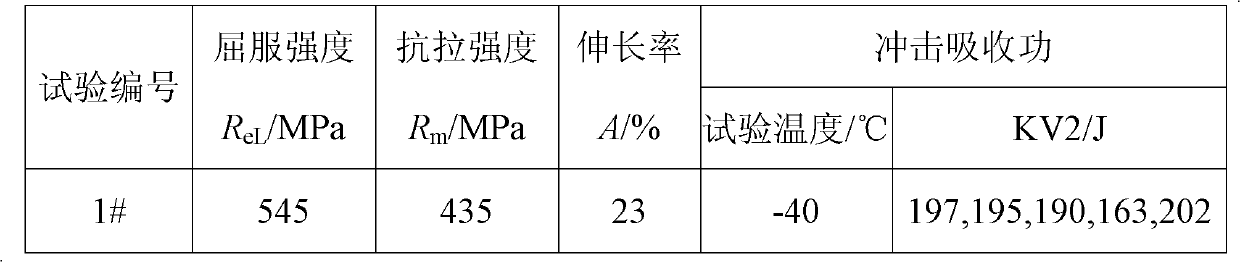

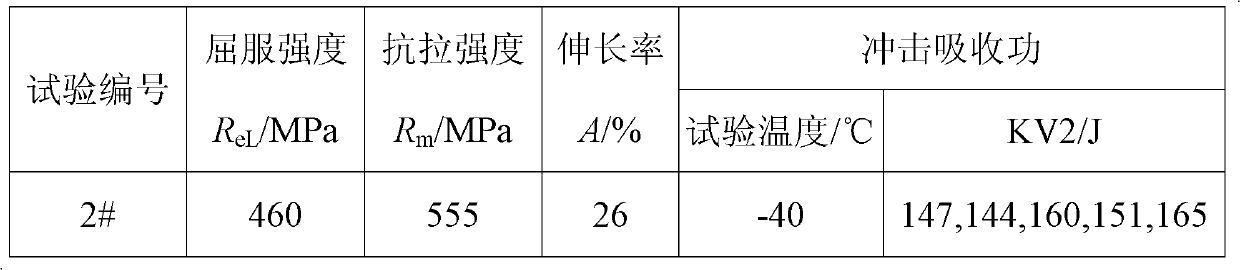

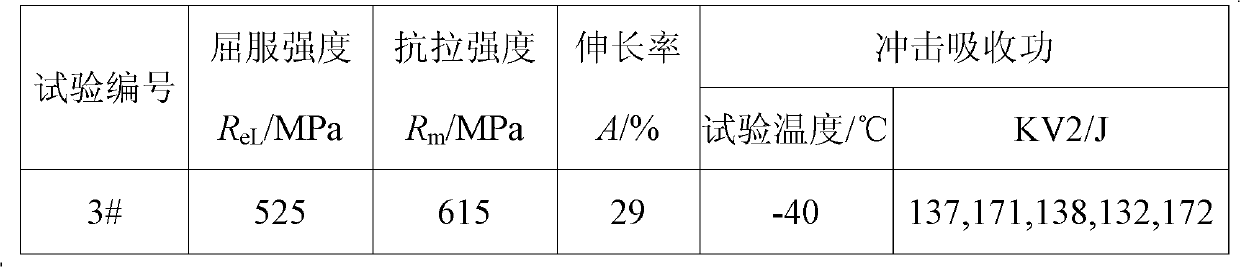

Butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade

InactiveCN101658970AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsButt jointWeld seam

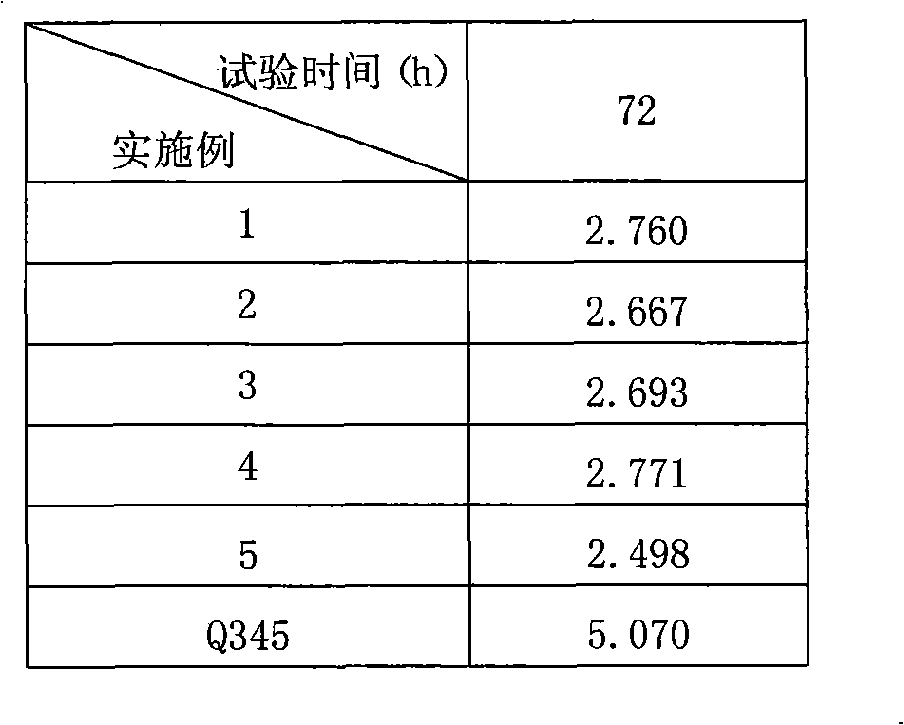

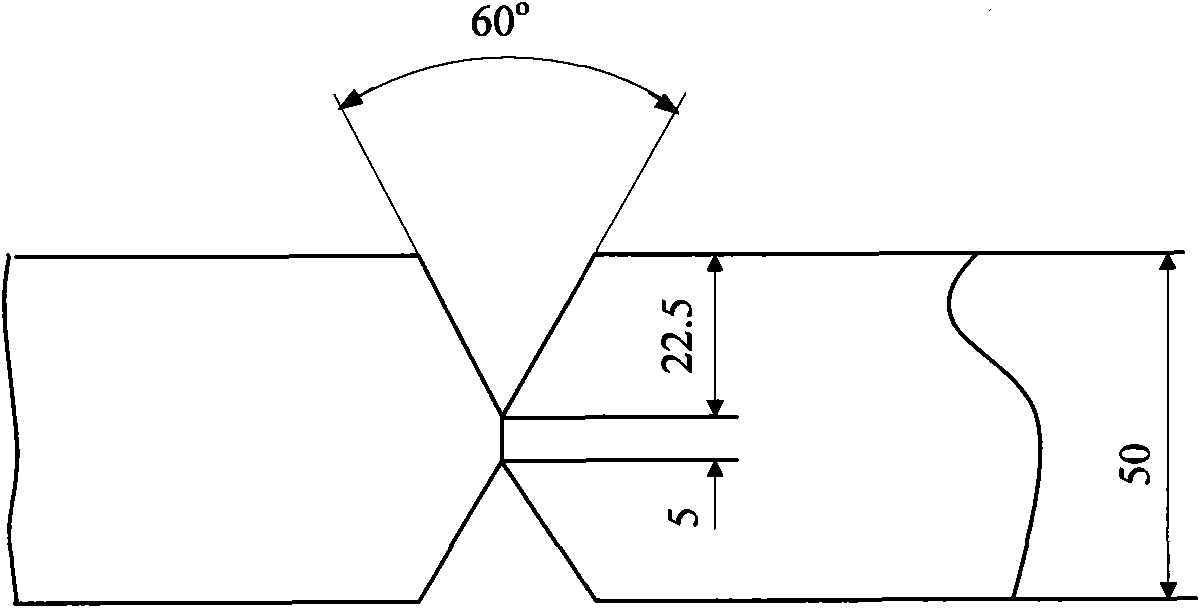

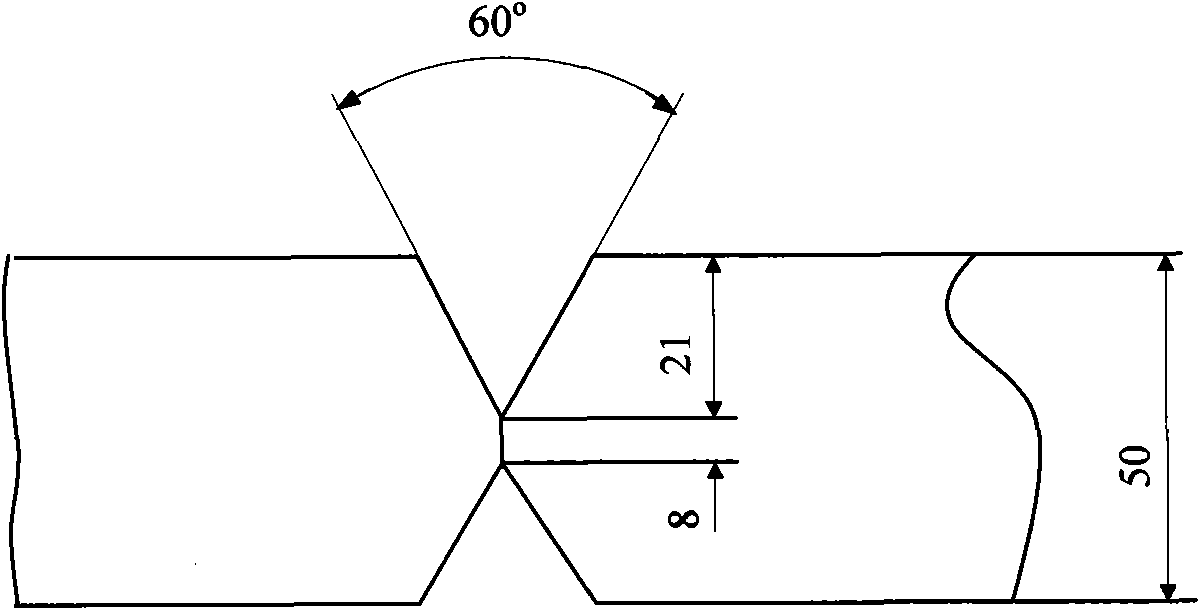

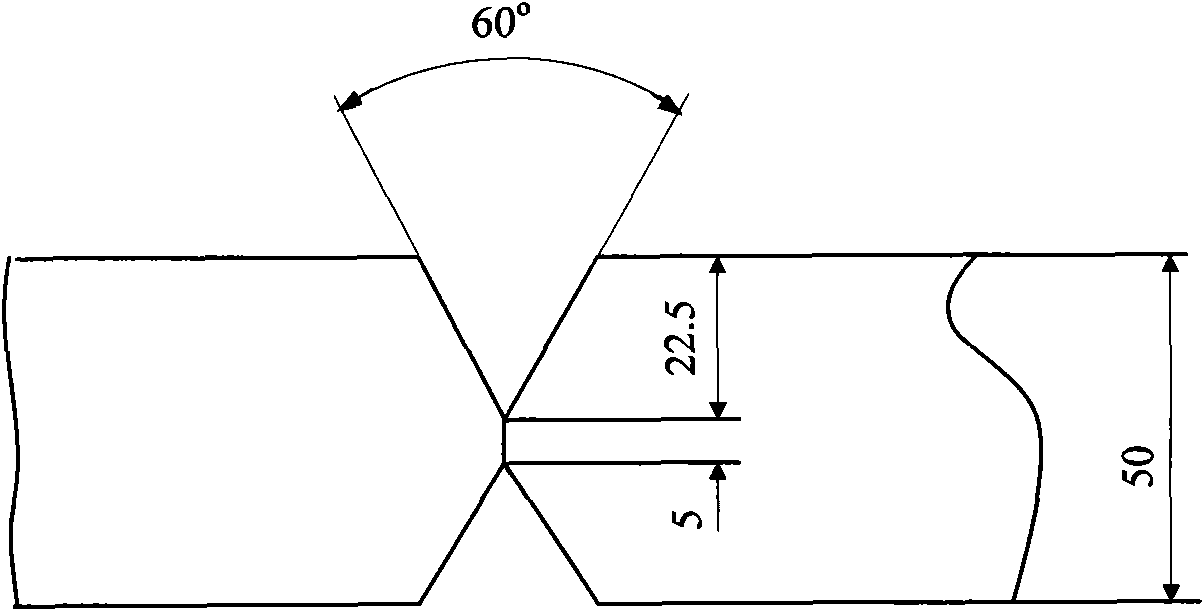

The invention relates to a butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade, overcoming the defects that at the present, bridge steel and other engineering structural steel which are in 690Mpa strength grade needs preheating before welding and heat treatment after welding and has severe welding environment and the like during manual and gas protective welding. The butt joint submerged-arc welding method comprises the following steps: adopting steel with tensile strength Rm of between 690Mpa and 745Mpa, the yield strength ReL of between 550 and 690Mpa, the extension rate A of between 19 percent and 21 percent, KV2 ballistic work of between 165J and 180J at 40 DEG C below zero and the thickness of 40mmm, and adopting same-thickness butting;adopting matched welding wires with the tensile strength more than 690Mpa and diameter phi of 4.0mm, and using CHF105 as a welding flux; adopting a double-sided X-type asymmetrical submerged-arc welding groove with the angle of 60 degrees and the truncated edge of 5mm; continuously welding until welding seams are full, and under the conditions that the welding current is 570A, the voltage is 31V,the speed is 35cm / min and the linear energy is 30kj / cm; baking the welding flux for 1 hour at 350DEG C and keeping the temperature of welding layers between 100 DEG C and 150DEG C.

Owner:武钢集团有限公司

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High strength high tenacity high weather resistant gas protecting welding wire

InactiveCN1593836AThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsChemical compositionLine tubing

The invention relates to a kind of high strength, high tenacity, high withering, and air protecting welding thread. It can avoid mismatching of present welding material, especially poor quality of prevent gas erode. The technique is flowing: first the chemical component is : C:0.04~0.12; Si:0.40~0.80; Mn:1.40~2.0;P<=0.020;S0.015;Ni:0.40~1.0;Cr:0.20~0.50;Ti:0.06~0.20;Cu:0.30~0.50;B:0.002~0.0079;Als<=0.02; a little Fe and other unavoidable impurities. The welding thread is protected by mix gas that is made of percent 80 Ar and percent 20 CO2. The thread head is better in gas eroding proof and mechanism. The tensile strength of the welding slot is as high as 735MPa. And AKv(-0.4 DEG C) of it is 182 J, AKv(-0.6 DEG C) of it is 173 DEG C. The thread is suited to gas protecting welding for important part of railroad, bridge, pipe and so on.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

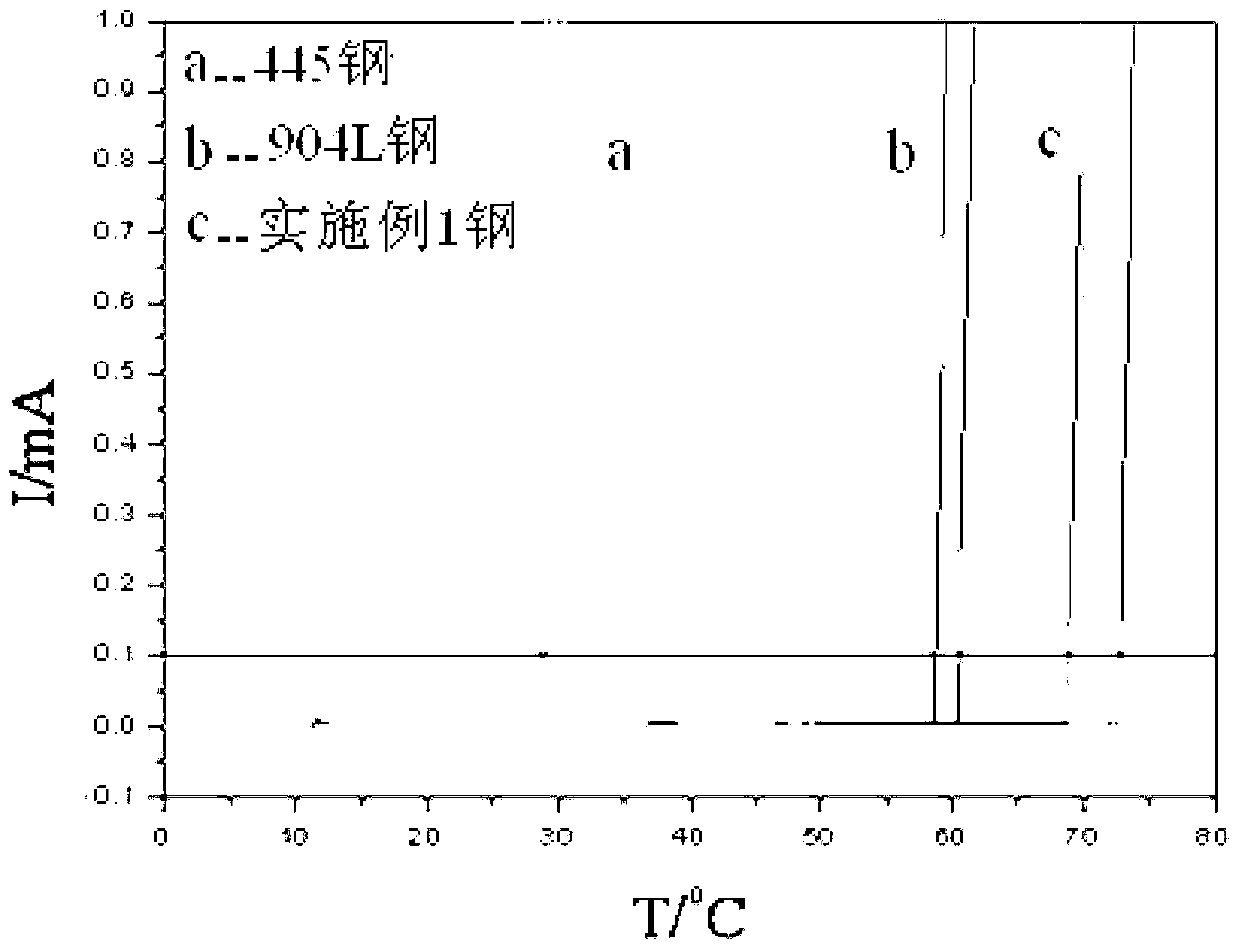

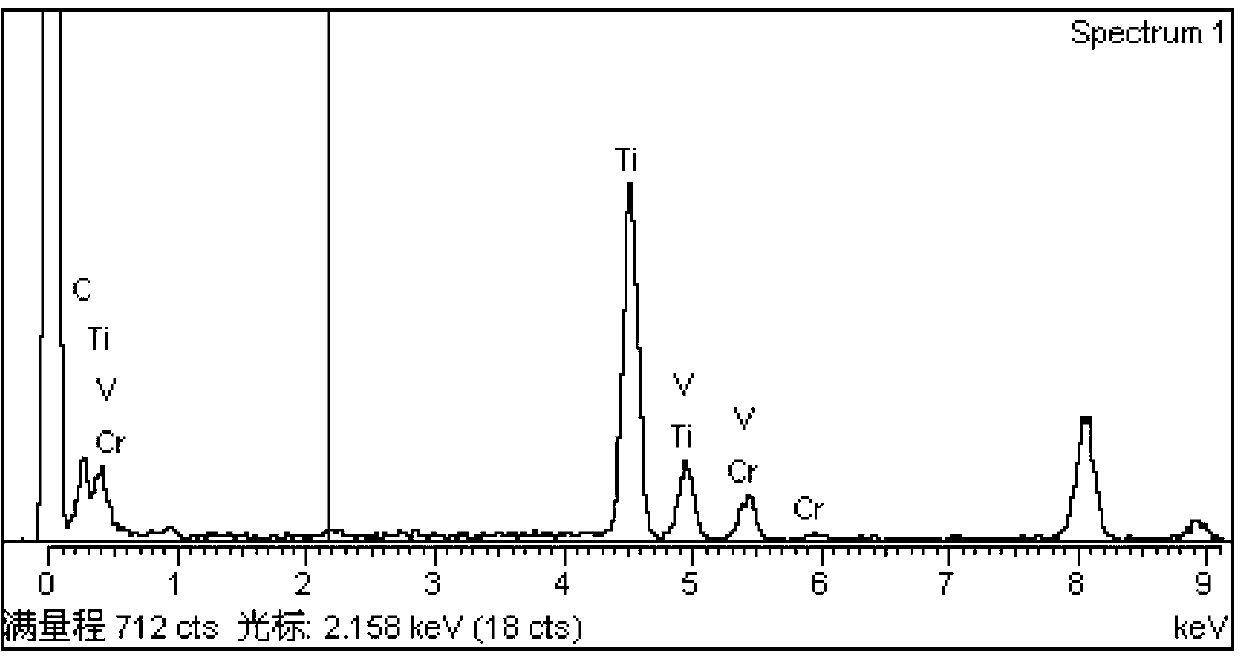

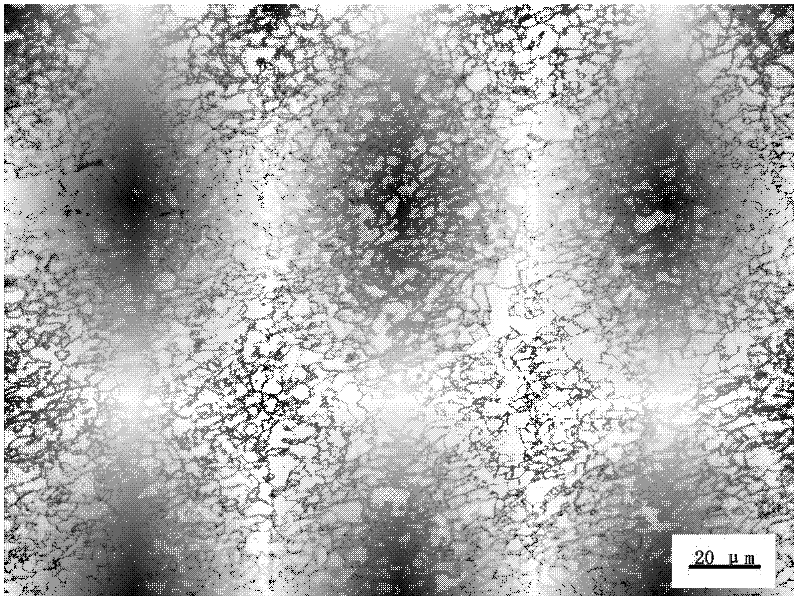

High-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and manufacturing method thereof

ActiveCN103276307AImprove corrosion resistanceImprove low temperature toughnessTransition temperatureImpurity

The invention discloses a high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and a manufacturing method thereof. The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate comprises, by weight, 0.005 to 0.015% of C, 0.005 to 0.020% of N, 0.2 to 0.5% of Si, 0.2 to 0.5% of Mn, less than or equal to 0.035% of P, less than or equal to 0.010% of S, 25 to 28% of Cr, less than or equal to 4.0% of Ni, 2.0 to 4.0% of Mo, 0.1 to 0.3% of V, 0.10 to 0.30% of Ti, 0.2 to 0.4% of Nb, less than or equal to 0.005% of Al, less than or equal to 0.005% of O, and the balance Fe and unavoidable impurities, wherein based on Cr content, Mo content, Ti content, Nb content, C content and N content respectively represented by Cr, Mo, Ti, Nb, C and N, Cr+3.3*Mo is greater than or equal to 35% and Ti+Nb is greater than or equal to 16(C+N). The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate has a ductile-brittle transition temperature below -40 DEG C, pitting potential above 1000mv, a critical pitting temperature above 70 DEG C, a corrosion rate below 0.2g / m<2>h in boiling hydrochloric acid having a concentration of 1wt%, yield strength above 380MPa, tensile strength above 520MPa, an elongation rate A50mm above 25% and Vickers hardness of 180 to 220, and can be used in various harsh environments.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High-strength steel for 750 to 880 MPa-level vehicles and production method thereof

The invention relates to high-strength steel for 750 to 880 MPa-level vehicles and a production method thereof. The high-strength steel comprises the following chemical ingredients in percentage by weight: 0.07 to 0.09 percent of C, 0.15 to 0.25 percent of Si, 1.4 to 1.9 percent of Mn, 0.04 to 0.06 percent of Nb, 0 to 0.15 percent of Mo, 0 to 0.04 percent of V, 0.07 to 0.14 percent of Ti, 0.01 to 0.06 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.008 percent of N and the balance of Fe and inevitable impurities. The production method comprises the following steps of: smelting; casting to form a casting blank; heating to the temperature of between 1,180 and 1,250 DEG C; performing final rolling at the temperature of between 820 and 850 DEG C; performing final cooling at the temperature of between 560 and 600 DEG C; and after a steel coil rolls off a production line, cooling slowly. By the production method, the strength of the material is between 750 and 880 MPa, and the steel has high low-temperature impact toughness and cold forming performance.

Owner:SHOUGANG CORPORATION

Steel for nuclear-island seamless steel tube and production method thereof

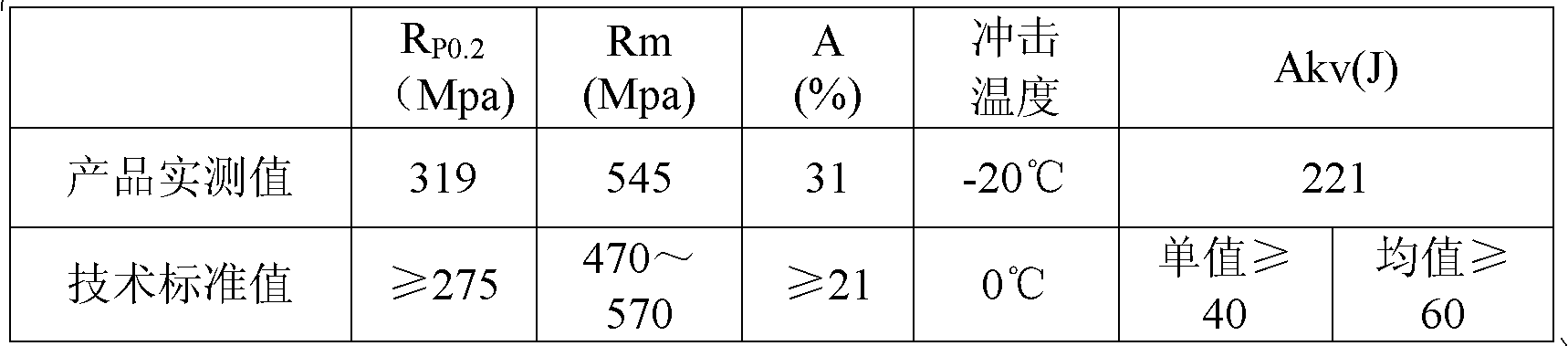

InactiveCN102021488AImprove low temperature impact toughnessAvoid internal cracksAlloy elementSteel tube

The invention belongs to the field of metallurgical technology, especially relating to steel for a nuclear-island seamless steel tube and a production method thereof. The steel in the invention comprises the following chemical components in percentage by weight: more than 0 and no more than 0.20 percent of C, no less than 0.10 and no more than 0.35 percent of Si, no less than 0.80 and no more than 1.60 percent of Mn, more than 0 and no more than 0.020 percent of P, more than 0 and no more than 0.015 percent of S, more than 0 and no more than 0.25 percent of Cr, more than 0 and no more than 0.50 percent of Ni, more than 0 and no more than 0.18 percent of Cu, more than 0 and no more than 0.10 percent of Mo, more than 0 and no more than 0.06 percent of V, no less than 0.020 and no more than 0.050 percent of Al, more than 0 and no more than 0.030 percent of Sn and the balance of Fe. The steel in the invention has the advantages of meeting the condition that the carbon equivalent is no more than 0.48 (Ceq = C + Mn / 6 + (Cr + Mo + V) / 5 + [(Ni +Cu)+ 15]<=0.48), controlling the contents of the main elements such as carbon and manganese in the steel, stabilizing the tensile property of the steel tube subjected to simulated destressing heat treatment, and simultaneously ensuring the tensile properties of the tube body and a sample subjected to the simulated destressing heat treatment to meet the technical standards. Because a residual element nickel as an alloy element is added, the low-temperature impact toughness of the steel in the invention is improved, and the impact toughness requirements for the steel at the temperatures of 0 DEG C and minus 20 DEG C are met.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

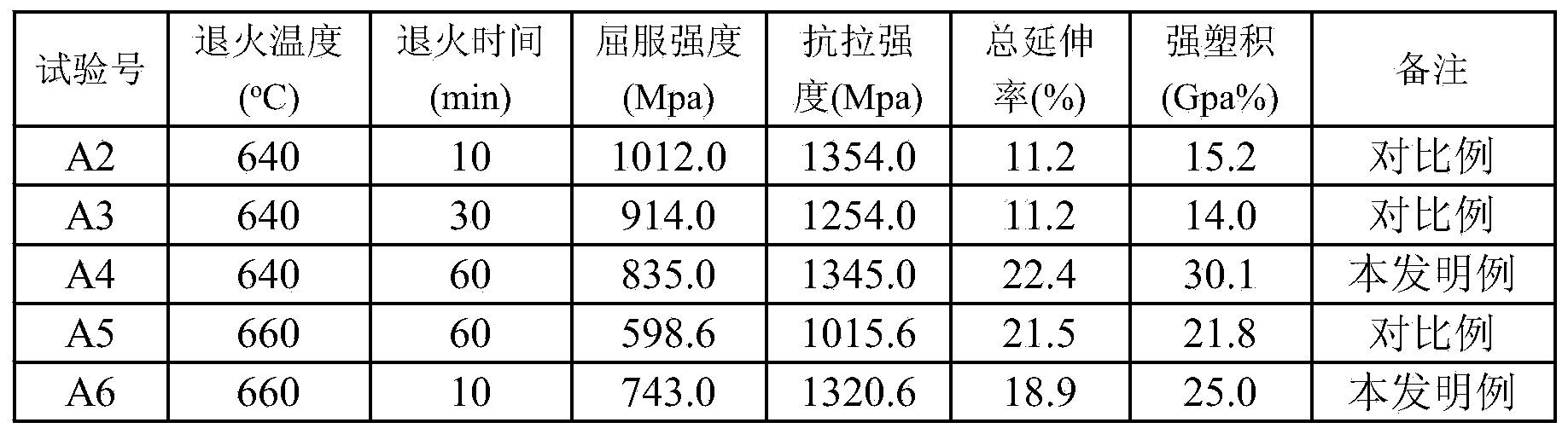

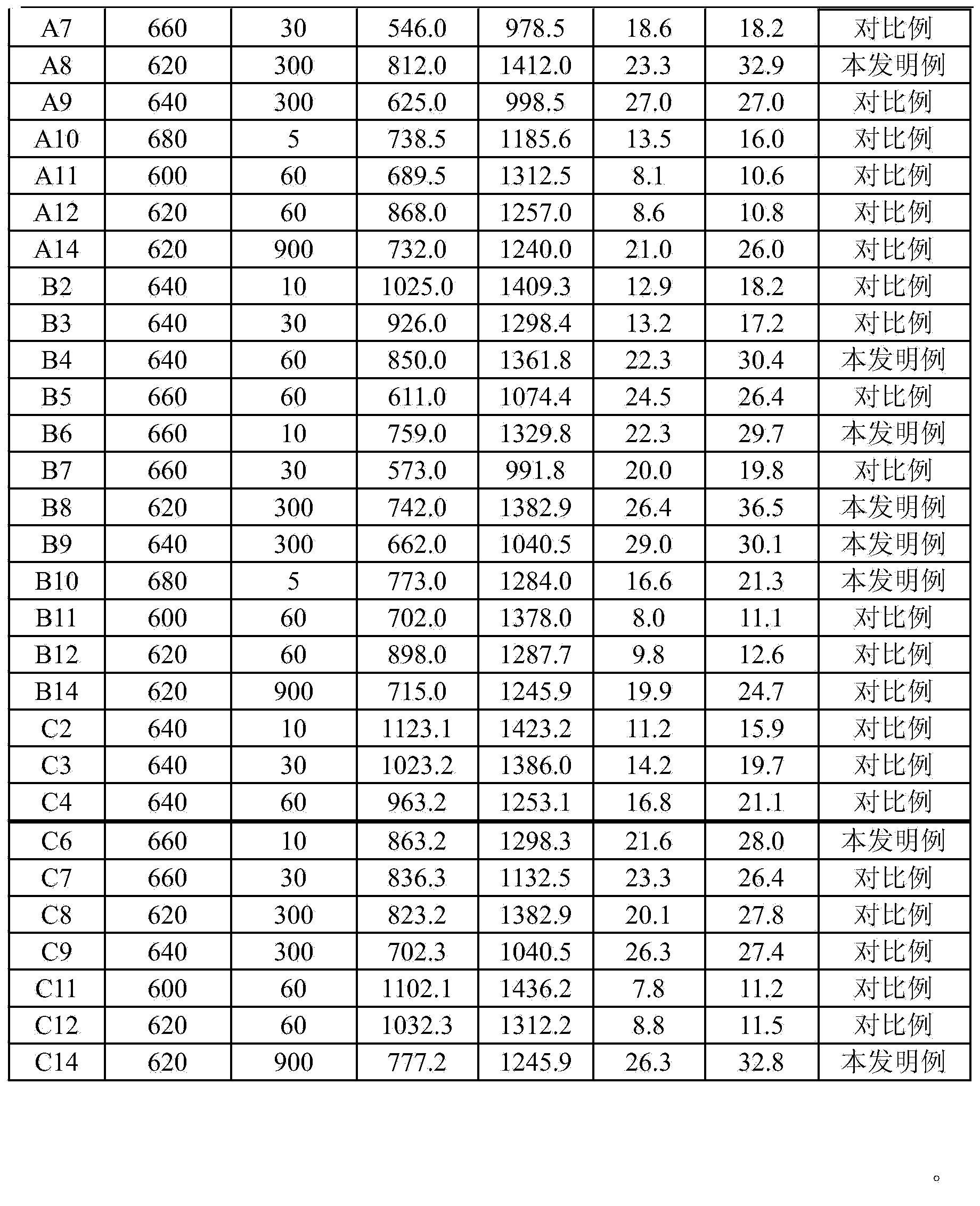

Double-phase twinborn induced plastic super-strength automobile steel plate and preparation method thereof

The invention belongs to the technical field of automobile steel, and in particular relates to a double-phase twinborn induced plastic super-strength automobile steel plate and a preparation method thereof. The steel plate comprises the following chemical elements in percentage by weight: 0.3-0.6% of C, 8-12.00% of Mn, 1.00-3.00% of Al, less than or equal to 0.020% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities. The steel plate can be selectively cold-rolled with 5-25% of rolling reduction after warm-rolling at 100-250 DEG C, or a hot continuous rolled plate coil is cold-rolled after being softened and annealed. The yield strength of the steel plate is greater than or equal to 650MPa, the tensile strength is 1000-1500MPa, the extension rate of short continuous annealing is 15-25%, the product of strength and elongation is 20-35GPa%, the extension rate obtained after cover-type prolonged annealing is 25-40%, and the product of strength and elongation is 30-40GPa%.

Owner:UNIV OF SCI & TECH BEIJING

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

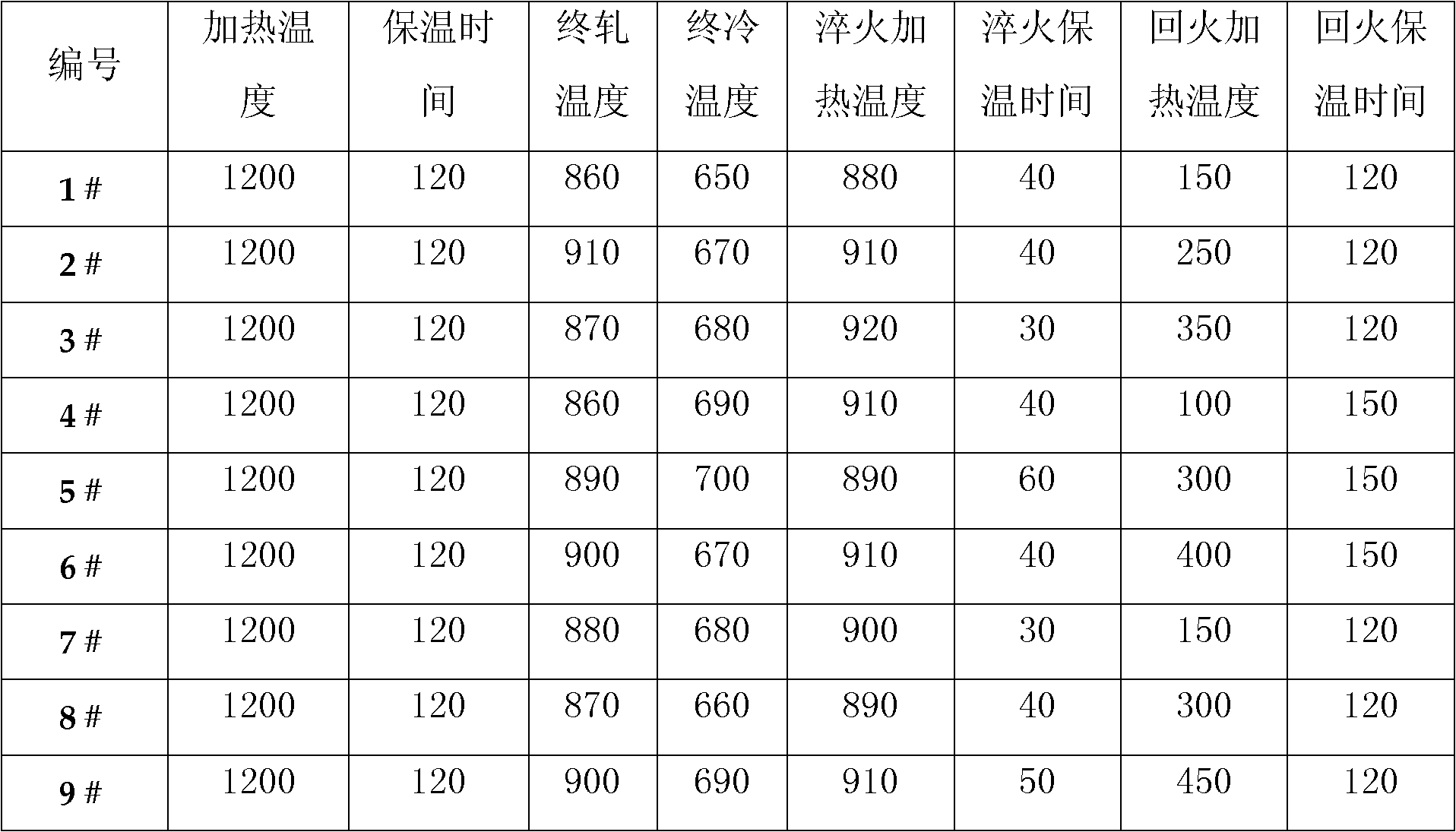

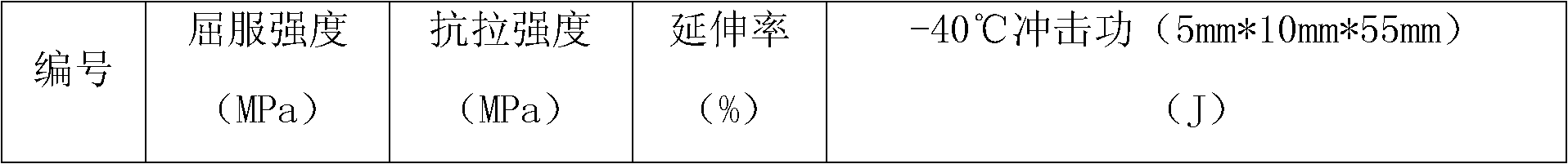

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

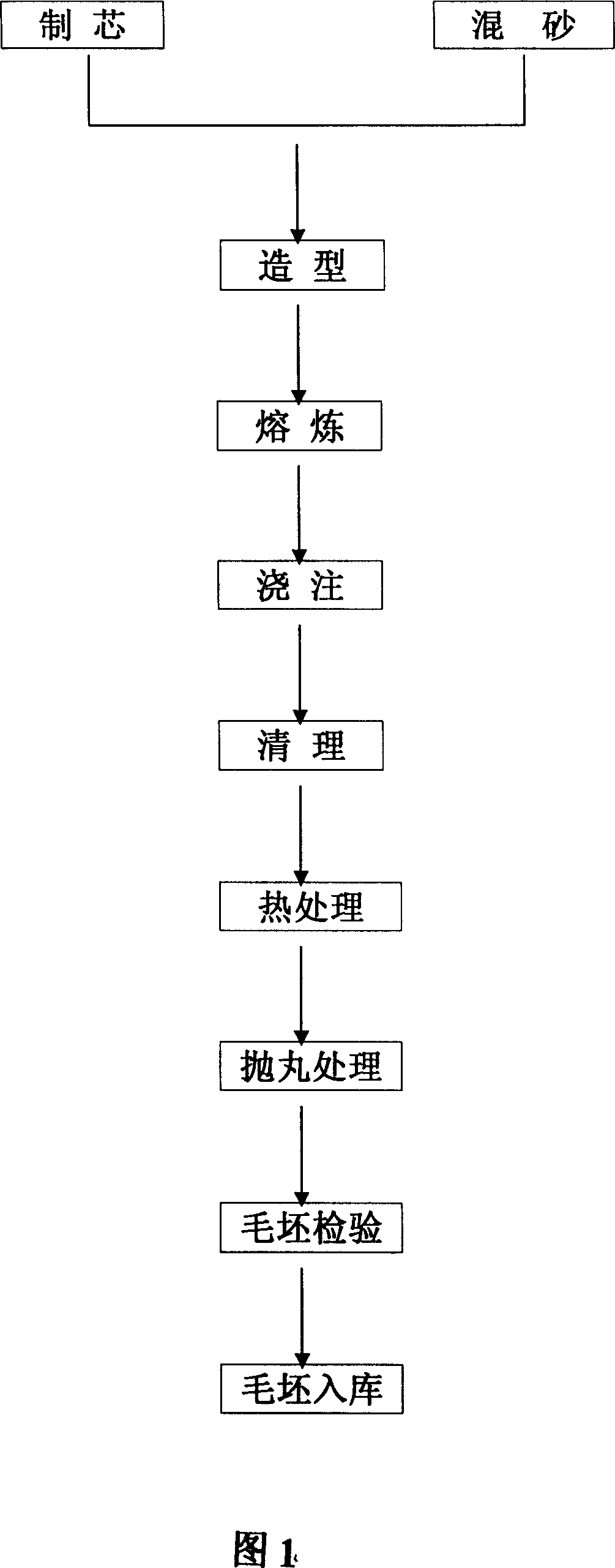

High nickel austenite spheroidal graphite cast-iron gas exhaust branch pipe casting technique

InactiveCN1923412AReduce burning lossImprove the mechanical properties at room temperatureMolten metal pouring equipmentsExhaust apparatusFerrosiliconDuctile iron

The invention relates to a method for casting high-nickel austenite nodular graphite cast iron discharge branch tube. Wherein, the invention comprises preparing core, mixing sand, shaping, smelting, irrigating, thermally processing, machining, dropping, checking, and packing; the smelting comprises mixing material, controlling smelting, balling, and breeding, and the nickel is added at later period; adding chromium at overheated period of iron water; the balling agent is nickel magnesium silicon iron balling agent; the breeding agent is 75 silicon iron; the iron water is irrigated quickly to charge section; the irrigating temperature is 1460-1530Deg. C; the thermally processing increases the casting to 870-1000Deg. C; keeping temperature for 3-6hours, cooling to 620Deg. C, and discharging. The invention has high impact-resistance and worm-anti property, better corrosion-resistance and oxidization resistance.

Owner:西峡县内燃机进排气管有限责任公司

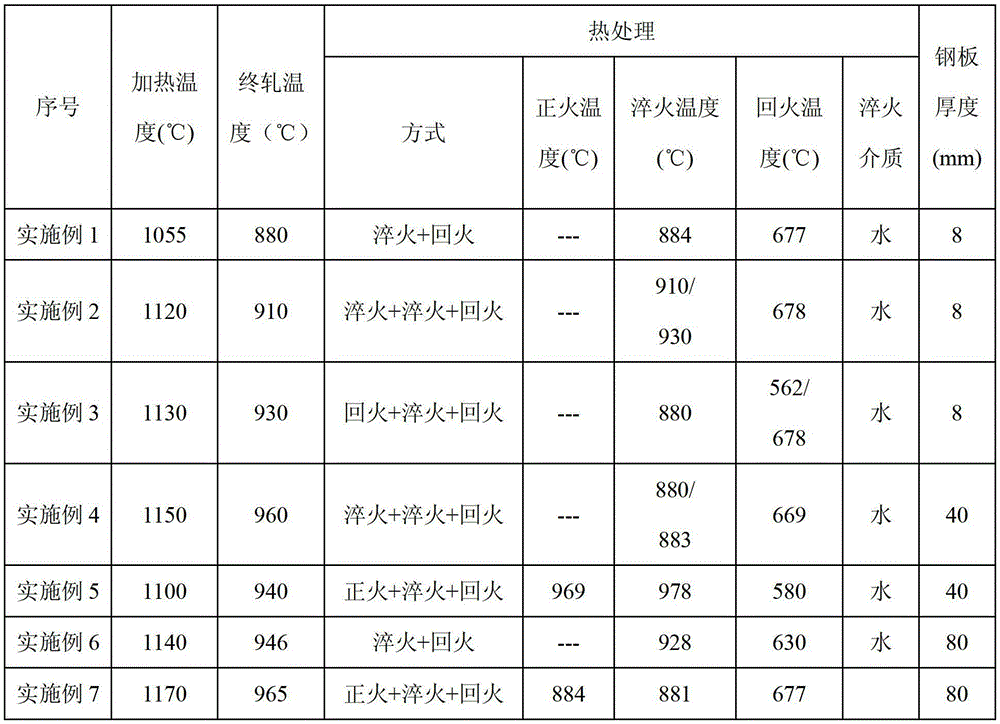

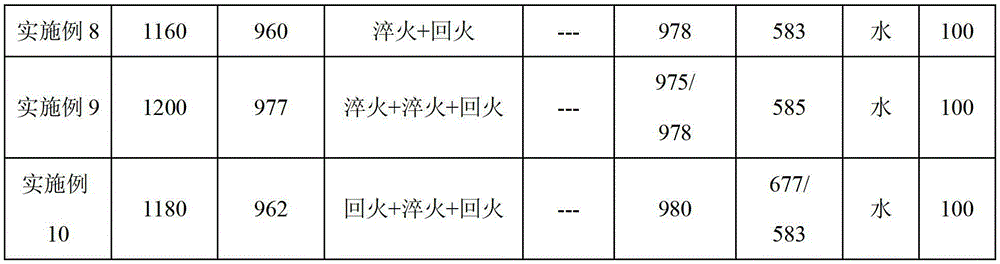

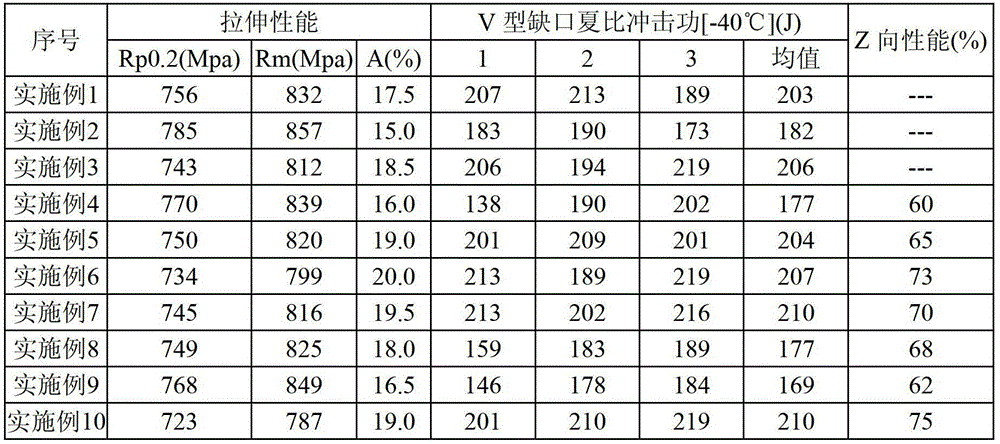

Steel plate with high strength and excellent low-temperature toughness and manufacturing method thereof

The invention discloses a steel plate with high strength and excellent low-temperature toughness, and the steel plate comprises the following chemical elements in percentage by weight: more than or equal to 0.03% and less than or equal to 0.18% of C, more than or equal to 0.20% and less than or equal to 0.30% of Si, more than or equal to 0.50% and less than or equal to 1.10% of Mn, more than or equal to 0.010% and less than or equal to 0.030% of Ti, more than or equal to 0.02% and less than or equal to 1.15% of Cr, more than or equal to 0.01% and less than or equal to 0.80% of Mo, more than or equal to 0.05% and less than or equal to 1.40% of Ni, more than or equal to 0.010% and less than or equal to 0.040% of Nb, more than or equal to 0.0001% and less than or equal to 0.0650% of V, more than or equal to 0.025% and less than or equal to 0.050% of Al, more than or equal to 0.001% and less than or equal to 0.004% of Ca, more than or equal to 0.0001% and less than or equal to 0.0025% of B, and the balance of Fe and other inevitable impurities. The invention also discloses a manufacturing method of the steel plate with high strength and excellent low-temperature toughness, and the manufacturing method comprises the following steps of: (1) smelting; (2) refining outside a furnace; (3) continuously casting; (4) heating a plate blank; (5) rolling; and (6) carrying out heat treatment.

Owner:BAOSHAN IRON & STEEL CO LTD

High-alkalinity high-tenacity low-hydrogen agglomerated flux and preparation method thereof

ActiveCN102601544AImprove weld metal toughnessImprove low temperature impact toughnessWelding/cutting media/materialsSoldering mediaSodium silicateHydrogen content

The invention discloses a high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the following components by weight: 18-21.5% of MgO, 33-35% of CaF2, 15-20% of Al2O3, 17-21% of SiO2, 3.5-8% of CaO, 1-5% of MnO, 2-5% of BaCO3, and less than or equal to 3% of FeO, wherein the total weight of the components is 100%. The invention further discloses a preparation method of the high-alkalinity high-tenacity low-hydrogen agglomerated flux, which comprises the steps of: mixing the raw materials and performing dry agitation, adding sodium silicate that accounts for 20wt% of the mixed powder, performing wet agitation, sending the materials to a pelletizer to pelletize, entering into a drying furnace after being dried by hot wind, drying at 180-230 DEG C, screening after discharge and then entering into a sintering furnace, sintering in the sintering furnace at 830-860 DEG C and discharging, and finally, screening and cooling to obtain the high-alkalinity high-tenacity low-hydrogen agglomerated flux. The flux provided by the invention solves the problems that a current flux is poor in toughness of weld metal and high in diffusible hydrogen content in deposited metal.

Owner:BAOJI YUSHENG WELDING MATERIAL

Large-thickness steel plate for oceaneering and production method thereof

The invention belongs to the technical field of steel and iron, and in particular discloses a large-thickness steel plate for oceaneering and a production method thereof. The large-thickness steel plate for oceaneering comprises the following components in percentage by weight: 0.07-0.09 percent of C, 0.15-0.40 percent of Si, 1.40-1.50 percent of Mn, not more than 0.012 percent of C, not more than 0.005 percent of S, 0.60-0.70 percent of Ni, 0.030-0.040 percent of Nb, 0.020-0.045 percent of Al, 0.13-0.17 percent of Mo, 0.04-0.05 percent of V, 0.012-0.020 percent of Ti and the balance of Fe and inevitable impurities. The large-thickness steel plate for oceaneering has the advantages of pure steel quality, good low-temperature impact toughness, high thickness (Z direction) tensile cross section contractibility rate, large thickness, high strength, good low-temperature aging impact toughness and low product cost. The large-thickness steel plate for oceaneering, provided by the invention,is suitable for use of large-thickness structures for oceaneering.

Owner:WUYANG IRON & STEEL +1

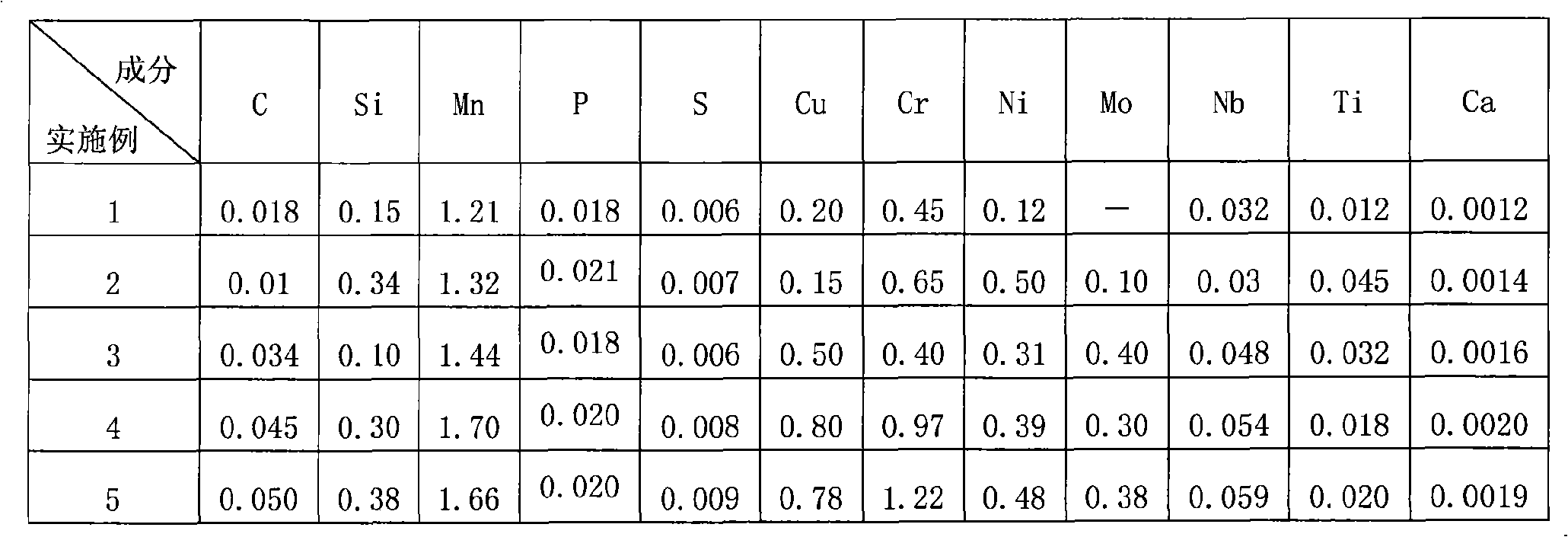

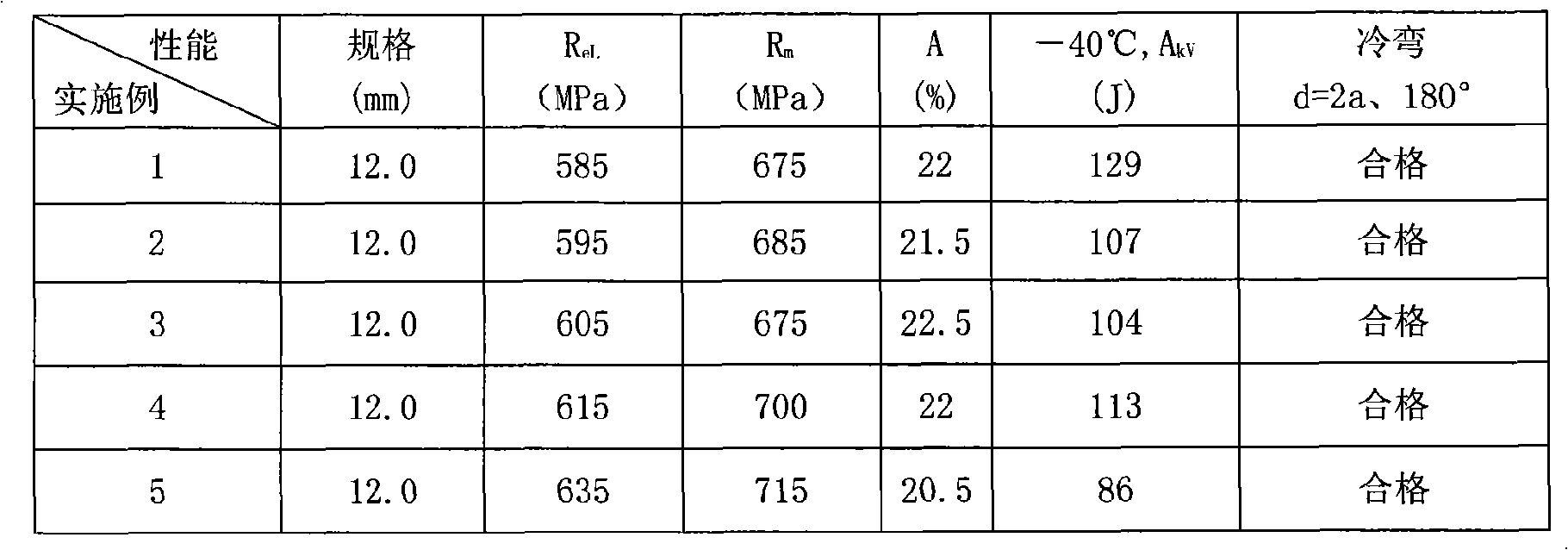

Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

InactiveCN101407892AGood mechanical propertiesSimple chemical compositionMechanical propertyWeathering steel

The invention discloses an ultra low carbon hot rolling weathering steel with the yield strength of more than the grade of 550MPa and belongs to the manufacturing field of low alloy steel. The steel consists of the compositions with the following weight percentages: 0.01 to 0.05 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, equal to or less than 0.02 percent of P, equal to or less than 0.010 percent of S, 0.15 to 0.80 percent of Cu, 0.40 to 1.25 percent of Cr, 0.10 to 0.50 percent of Ni, equal to or less than 0.40 percent of Mo, 0.03 to 0.06 percent of Nb, equal to or less than 0.050 percent of Ti, 0.0010 to 0.0020 percent of Ca and the residual quantity of Fe and unavoidable impurities. The steel has good mechanical properties, the yield strength of equal to or more than 550MPa and the tensile strength of equal to or more than 650MPa which are both higher than that of traditional weathering steel. Besides, Ti is included in the compositions of the steel.

Owner:武钢集团有限公司

Method of submerged-arc welding of thick sheet S355NL for low-temperature wind tower

InactiveCN101862887AImprove low temperature impact toughnessImprove securityArc welding apparatusWelding/cutting media/materialsMechanical propertyHeat treated

The invention discloses a method of submerged-arc welding of a thick sheet S355NL for a low-temperature wind tower, which comprises the following steps: adopting an S355NL thick sheet satisfying requirements for chemical composition, weight percentage and technical conditions, wherein the carbon equivalent Ceq of steel is less than or equal to 0.42 percent; using welding wires satisfying requirements for chemical composition and weight percentage; adopting symmetric double-sided X type grooves as submerged-arc welding groove, wherein the groove angle is 60 degrees, the groove gap is 0.5mm, and when the thickness of the sheet is less than or equal to 50mm and the ambient temperature is no lower than 10 DEG C, no preheating is needed for welding; and selecting welding parameters, wherein the welding heat input is less than or equal to 50kJ / cm. The invention realizes the welding process that no preheating is needed prior to welding and no heat treatment is needed after welding during manufacture of the thick sheet structure of the butt joint of the steel plate S355NL for the low-temperature wind tower in marine and cold regions. Due to the multi-layer multi-channel continuous welding, the welded joint has excellent comprehensive mechanical properties, and weld joints and weld heat-affected zones has large impact toughness reserves and safety margins. Therefore, the invention is suitable for promotion and application in the manufacture of the low-temperature wind tower in the factory.

Owner:NANJING IRON & STEEL CO LTD

800MPa grade low-welding crack sensitive tempering type hydroelectric steel plate

InactiveCN104532148AImprove low temperature impact toughnessMicroorganizedMaterials scienceImpact toughness

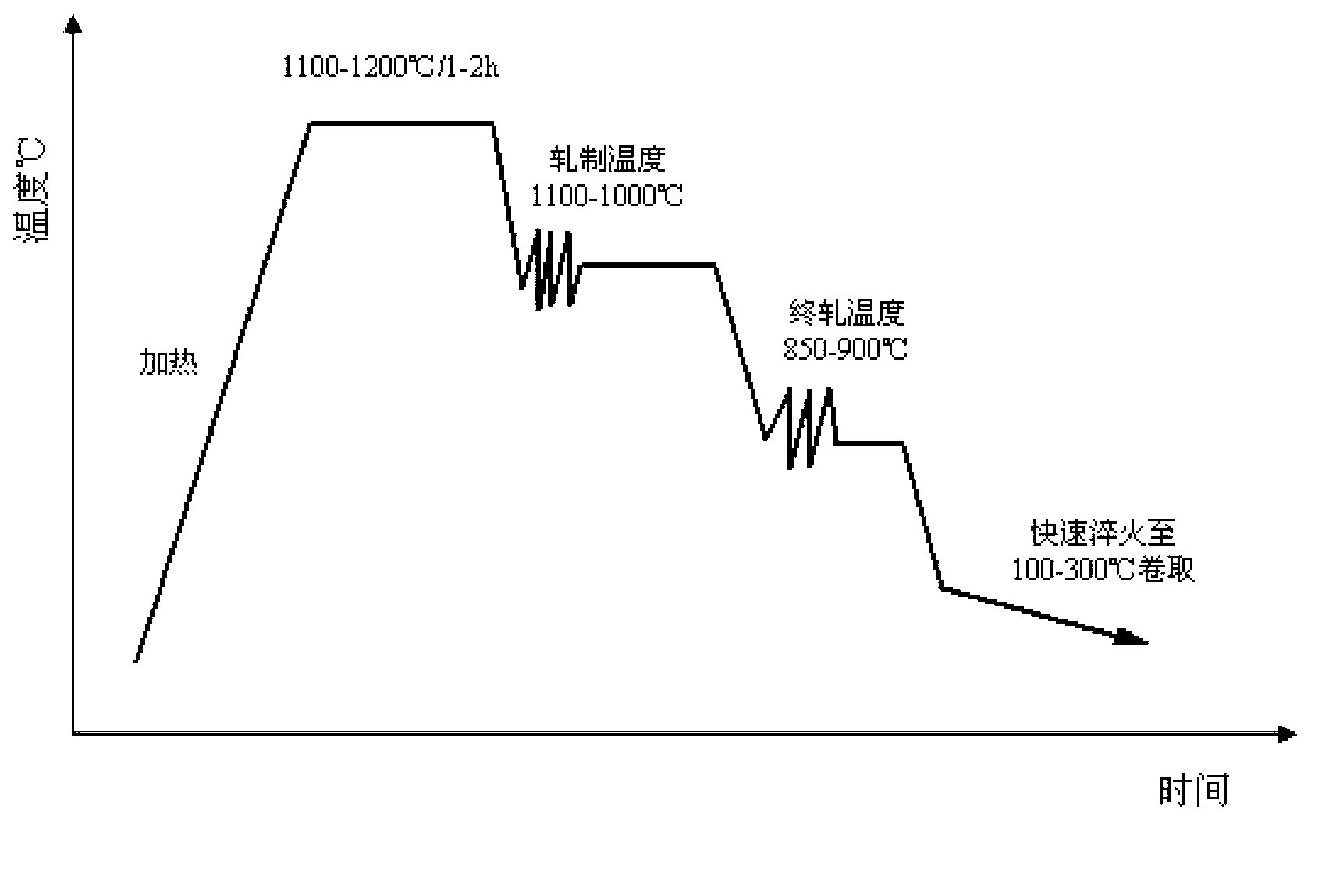

The invention relates to an 800MPa grade low-welding crack sensitive tempering type hydroelectric steel plate. The steel plate comprises the following components in percentage by weight: 0.09-0.14% of C, 0.24-0.35% of Si, 0.7-1.45% of Mn, less than or equal to 0.013%, less than or equal to 0.002% of S, less than or equal to 0.035% of Nb, 0.012-0.02% of Ti, 0.30-0.50% of Ni, 0.020-0.070% of Alt, 0.035-0.060% of V, 0.25-0.60% of Cr, 0.25-0.55% of Mo, 0.15-0.30% of Cu, less than or equal to 0.0060% of N, less than or equal to 0.00030% of H, 0.0008-0.002% of B and the balance of Fe. The preparation method comprises the following steps: smelting and casting to a cast blank according to set compositions; heating and rolling in two stages; and quickly cooling to temper and thermally treat to obtain excellent strength, plasticity and low-temperature impact toughness which are matched, so that the request on hydroelectric steel is satisfied.

Owner:NANJING IRON & STEEL CO LTD +1

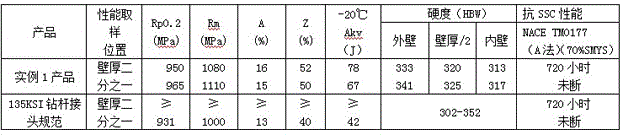

130KSI-grade and 135KSI-grade corrosion-resistant drill tool steel for oil and gas fields and manufacturing method thereof

ActiveCN107177797AImprove strength and toughnessMeet anti-H

<sub>2</sub>

S corrosion characteristics requirementsFurnace typesHeat treatment furnacesMechanical propertyContinuous rolling

The invention relates to high-toughness and hydrogen sulfide corrosion resistant round steel and a manufacturing method thereof. The round steel comprises, by mass, 0.25-0.40% of C, 0.20-0.45% of Si, 0.95-1.50% of Mn, 1.35-1.90% of Cr, less than or equal to 0.002% of S, less than or equal to 0.008% of P, 0.75-1.30% of Mo, 0.10-0.30% of Ni, 0.05-0.25% of V, 0.010-0.050% of Nb, 0.10-0.30% of Cu, less than or equal to 0.050% of Al, 0.0005-0.005% of Ca, and the balance Fe and unavoidable impurity elements. The hot-rolled round steel is produced through a process route of continuous casting-continuous rolling-annealing, the round steel is subjected to heat treatment directly, or a machined semi-finished drill tool is subjected to heat treatment. On the premise that related 130KSI and 135KSI synthesized mechanical properties are met correspondingly, according to an America NACE TM0177 standard hydrogen-sulfide-resistant stress corrosion test, a product is not broken for 720 hours under the condition that 70% of nominal yield stress is pre-loaded in a saturated H2S solution. The material is suitable for 130KSI-strength-grade and 135KSI-strength-grade drill tools under the mining environment of acidic oil and gas fields.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

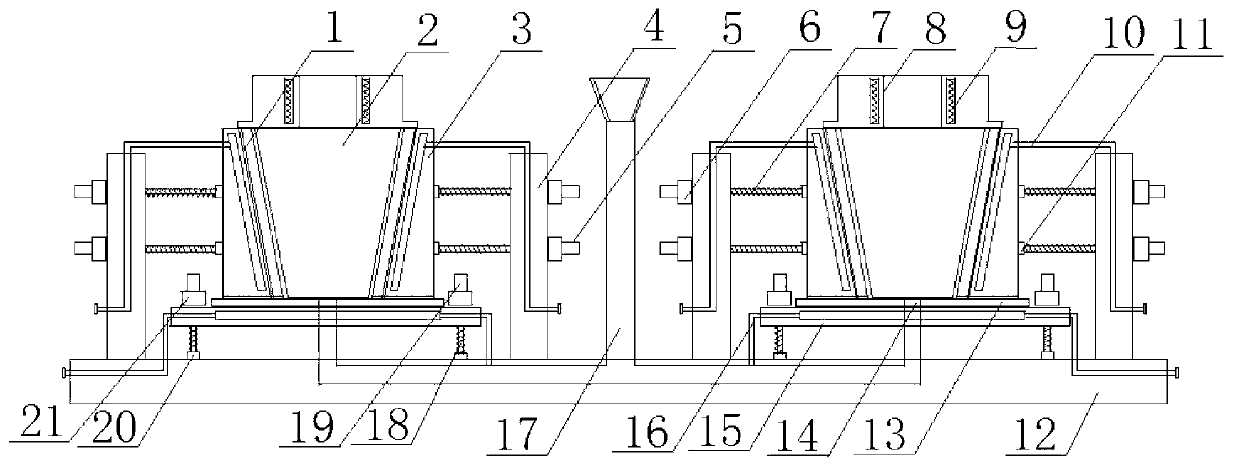

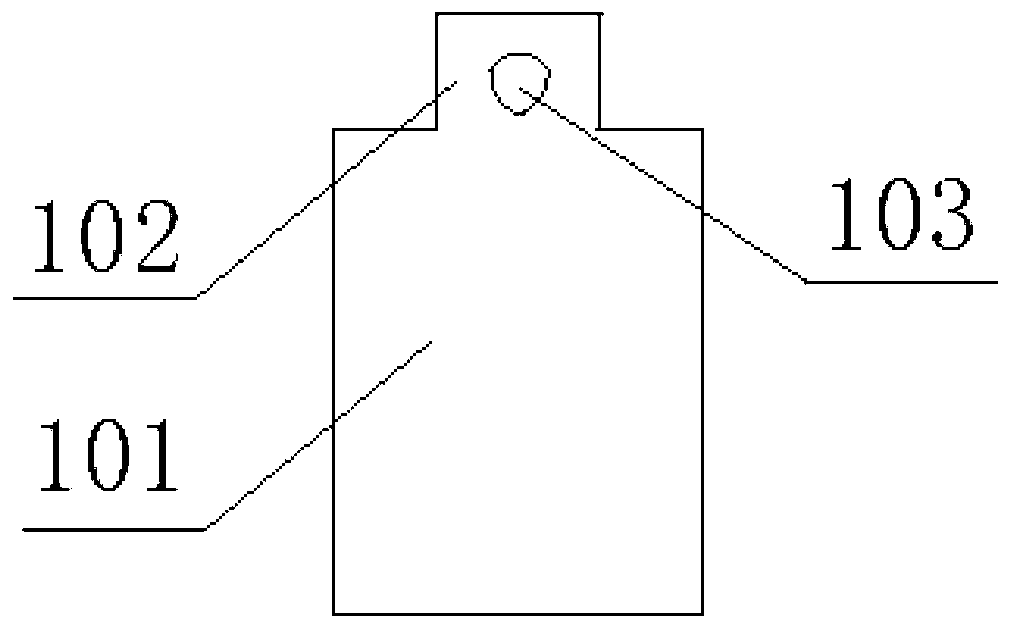

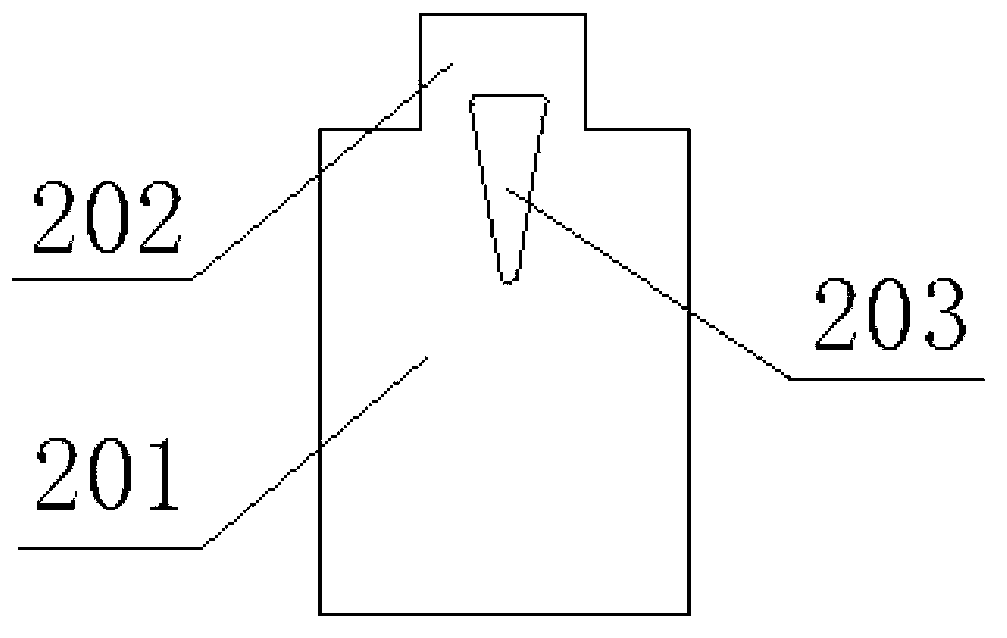

Steel plate ingot casting device and method for producing ultra-thick steel plate cast ingot with same

The invention discloses a steel plate ingot casting device, which comprises a pedestal, a fixed framework and an ingot mold, wherein the fixed framework is fixedly connected with the pedestal; the ingot mold is positioned in the fixed framework and consists of two pairs of side templates, i.e., front, rear, left and right side templates, and a bottom template; the outer sides of the side templates and the bottom template are respectively provided with a cooling water box; the side templates are provided with squeezing mechanisms; the bottom template is provided with a lifting mechanism; the side templates and the bottom template are all copper plate products; and the bottom template is provided with a runner port. According to the steel plate ingot casting device, deformation under cold and hot intensity stress can be avoided, and a shrinkage hole is avoided; since the solidification time is greatly shortened, the segregation in a steel ingot can be obviously relieved, thereby greatly improving the internal quality and the performance of a produced ultra-thick plate; and meanwhile, the steel plate ingot casting device has the advantages of freely adjustable ingot mold size, long service life of the ingot mold and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Manufacture method of extremely-thick steel plate for hydropower station through continuous-cast billet

ActiveCN103014283AUniform and stable impact toughnessMeet welding performance requirementsMetal rolling arrangementsDie castingQuenching

The invention provides a manufacture method of an extremely-stick steel plate for a hydropower station through a continuous-cast billet, and belongs to the technical field of production of continuous-cast steel plates. The manufacture method comprises the technological processes of continuous casting, rolling, cooling after rolling, austenite quenching, subcritical quenching and high-temperature tempering, thus a composite-phase structure of ferrite, acicular ferrite, small granular bainite and small residual bainite can be formed in the core part of the steel plate after the high-temperature tempering. The manufacture method has the advantages that the extremely-thick steel is given the same performance as the thin steel plate under the combination and organizational control of heat treatment process based on the smaller proportion; and compared with the methods of die casting and forging, the manufacture method provided by the invention is simple, convenient, easy to carry out and high in yield, and reduces the producing cost.

Owner:SHOUGANG CORPORATION

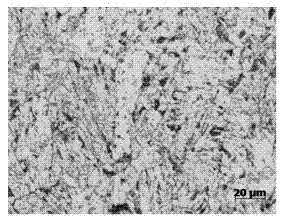

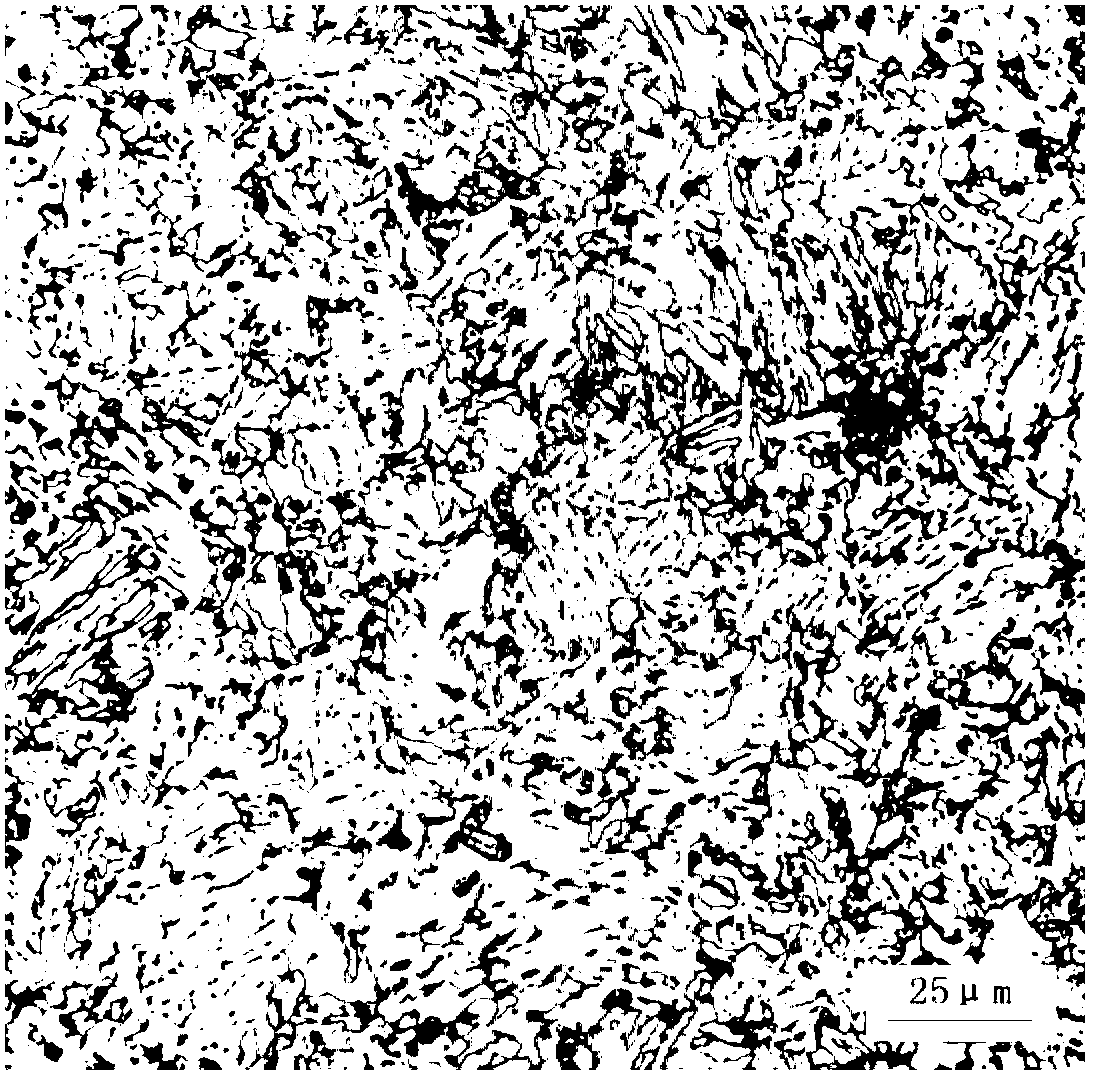

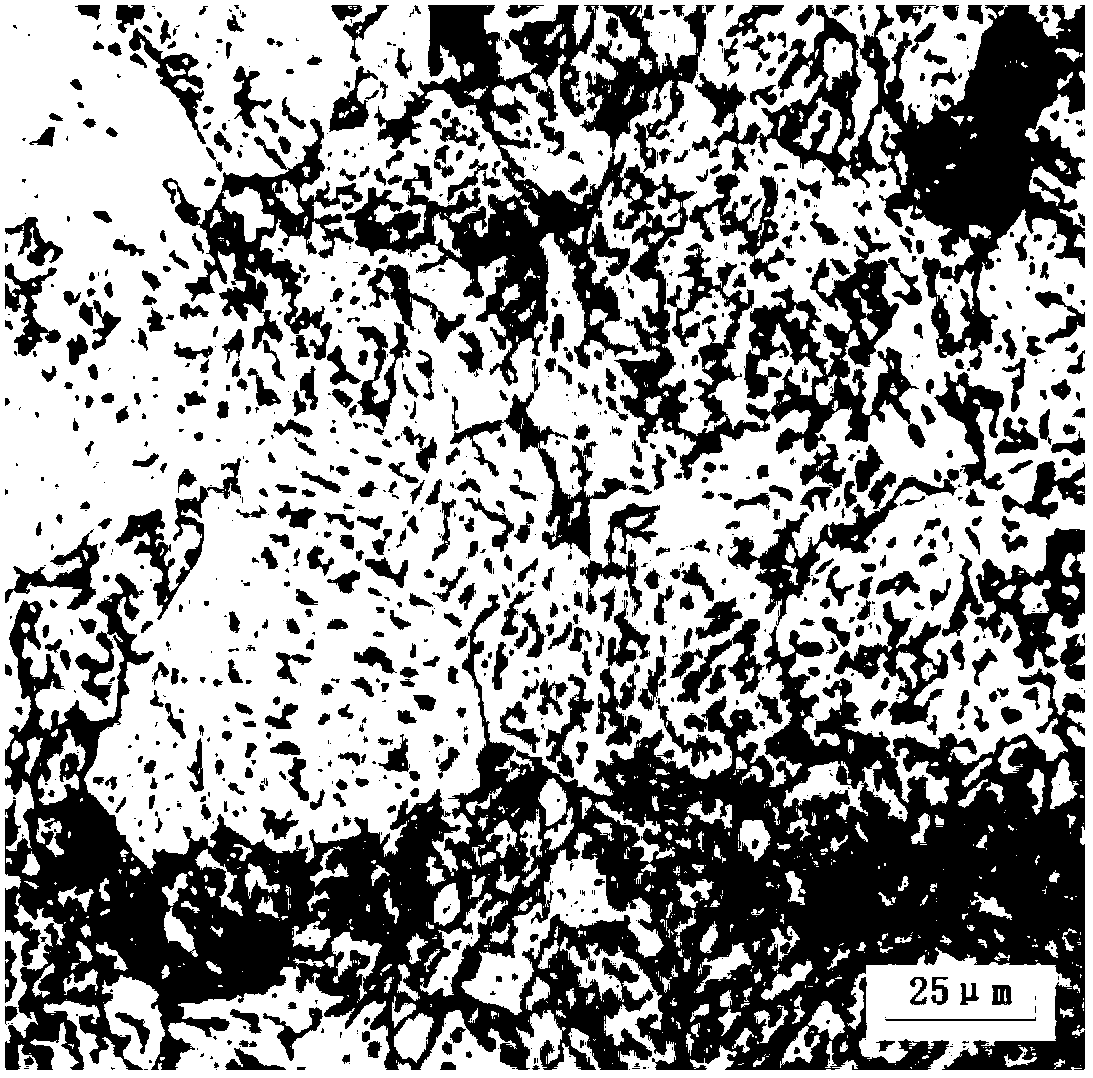

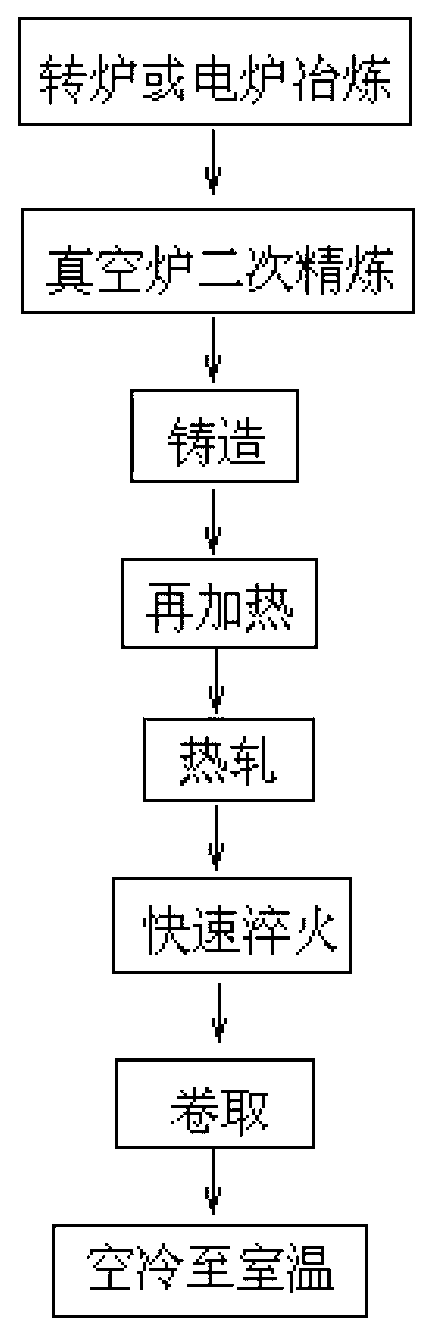

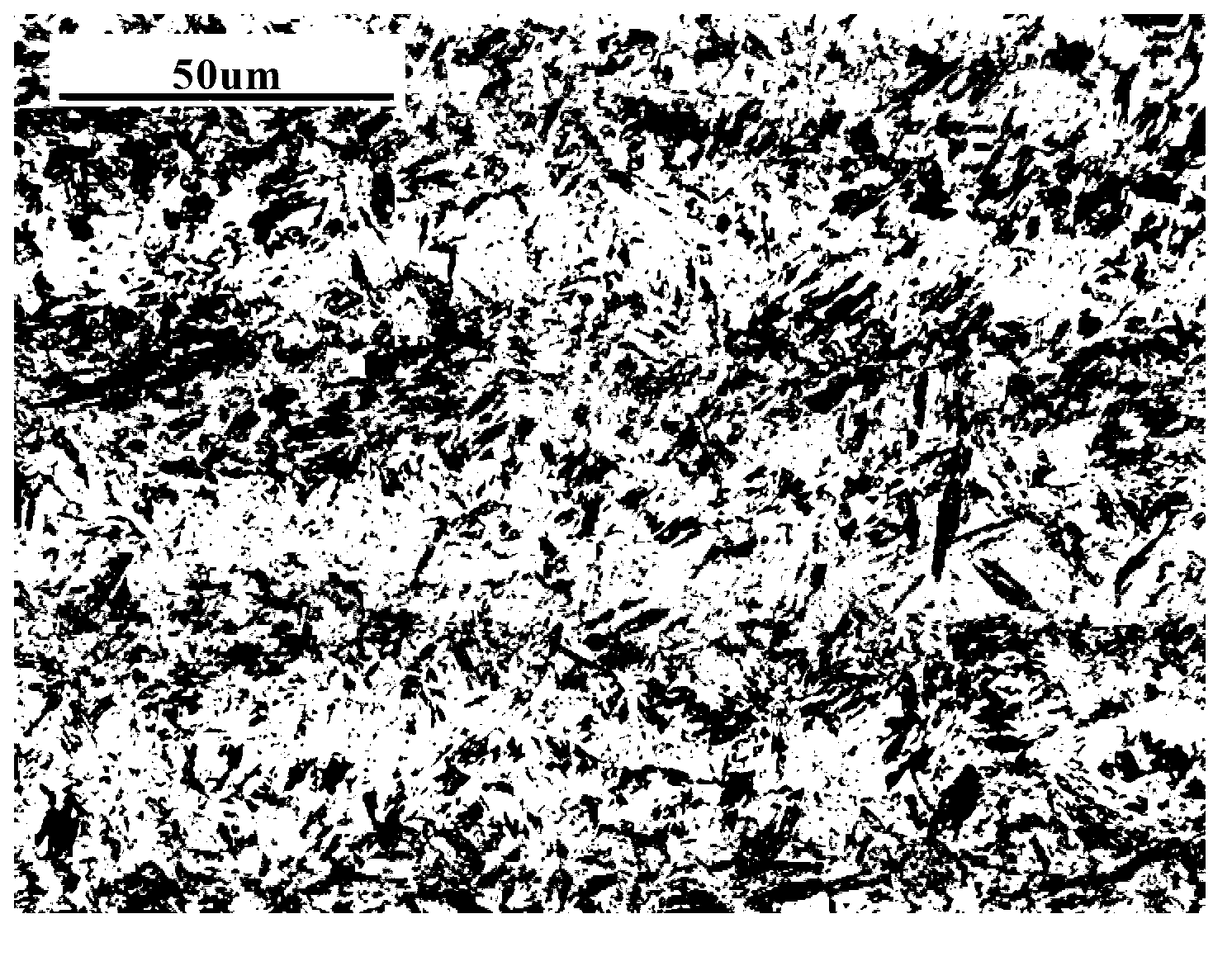

High-strength and high-toughness hot-rolled wear-resistant steel and preparation method thereof

The invention discloses high-strength and high-toughness hot-rolled wear-resistant steel and a preparation method thereof. The high-strength and high-toughness hot-rolled wear-resistant steel comprises the following chemical ingredients in percentage by weight: 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, not greater than 0.015% of P, not greater than 0.005% of S, 0.02-0.08% of Al, not greater than 0.006% of N, not greater than 30 ppm of O, 0.005-0.015% of Ti, 0.5-2.0% of Ni, and the balance of Fe and inevitable impurities, wherein the sum of Mn and Ni is 3.2-3.6%; the microscopic structure is composed of lath martensites and retained austenites, and the volume percentage content of the retained austenites is 5.0-15.0%; and the high-strength and high-toughness wear-resistant steel obtained by the processes of hot continuous rolling and rapid quenching has a tensile strength of greater than 1500 MPa, a yield strength of 1150-1400 MPa, a thickness of 3-12 mm, a good ductility (of greater than 10%), and a good low-temperature impact toughness (impact energy of 38-48 J at minus 20 DEG C), and shows excellent strong-plastic matching.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

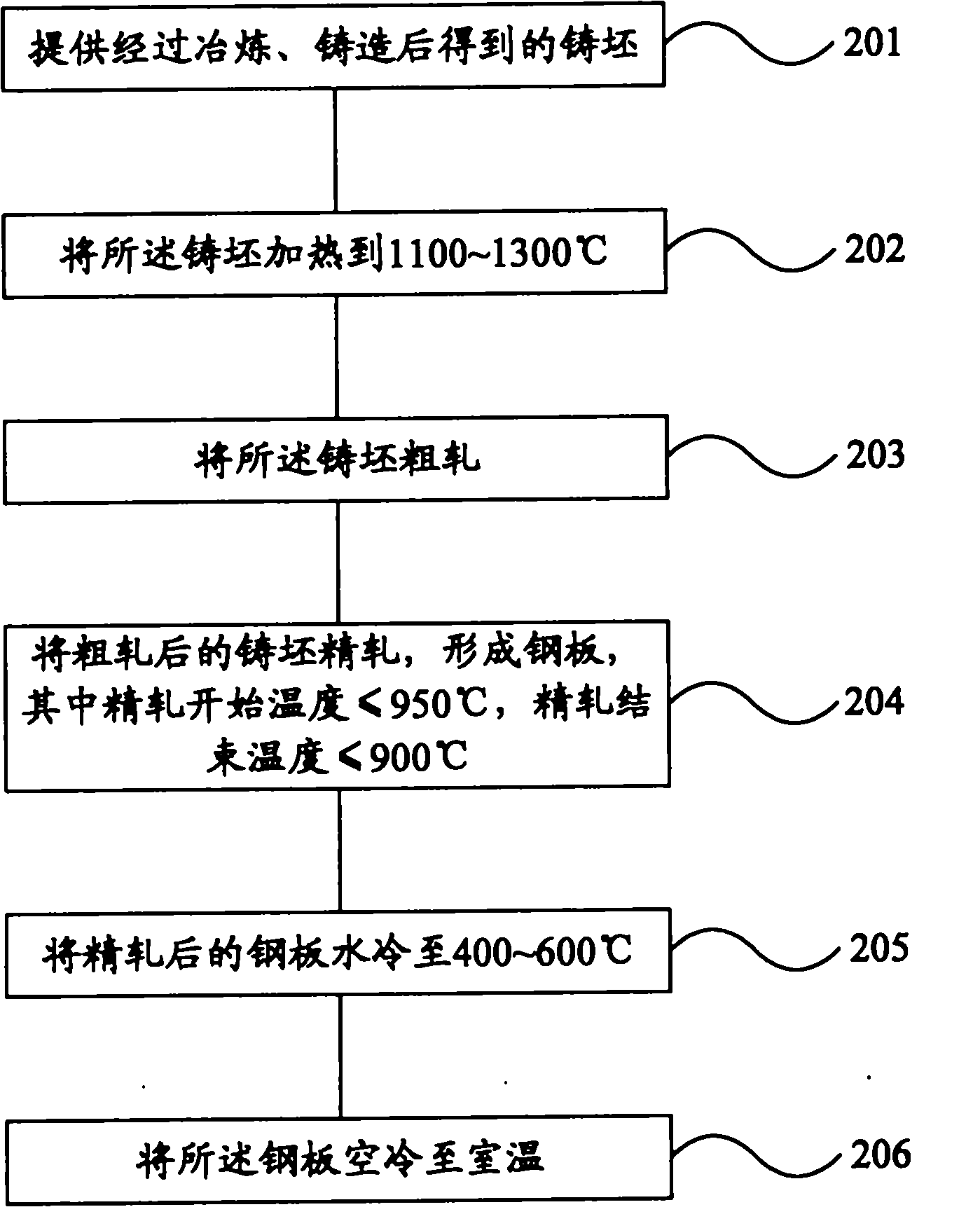

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com