Patents

Literature

107 results about "High-strength low-alloy steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength low-alloy steel (HSLA) is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. HSLA steels vary from other steels in that they are not made to meet a specific chemical composition but rather to specific mechanical properties. They have a carbon content between 0.05–0.25% to retain formability and weldability. Other alloying elements include up to 2.0% manganese and small quantities of copper, nickel, niobium, nitrogen, vanadium, chromium, molybdenum, titanium, calcium, rare earth elements, or zirconium. Copper, titanium, vanadium, and niobium are added for strengthening purposes. These elements are intended to alter the microstructure of carbon steels, which is usually a ferrite-pearlite aggregate, to produce a very fine dispersion of alloy carbides in an almost pure ferrite matrix. This eliminates the toughness-reducing effect of a pearlitic volume fraction yet maintains and increases the material's strength by refining the grain size, which in the case of ferrite increases yield strength by 50% for every halving of the mean grain diameter. Precipitation strengthening plays a minor role, too. Their yield strengths can be anywhere between 250–590 megapascals (36,000–86,000 psi). Because of their higher strength and toughness HSLA steels usually require 25 to 30% more power to form, as compared to carbon steels.

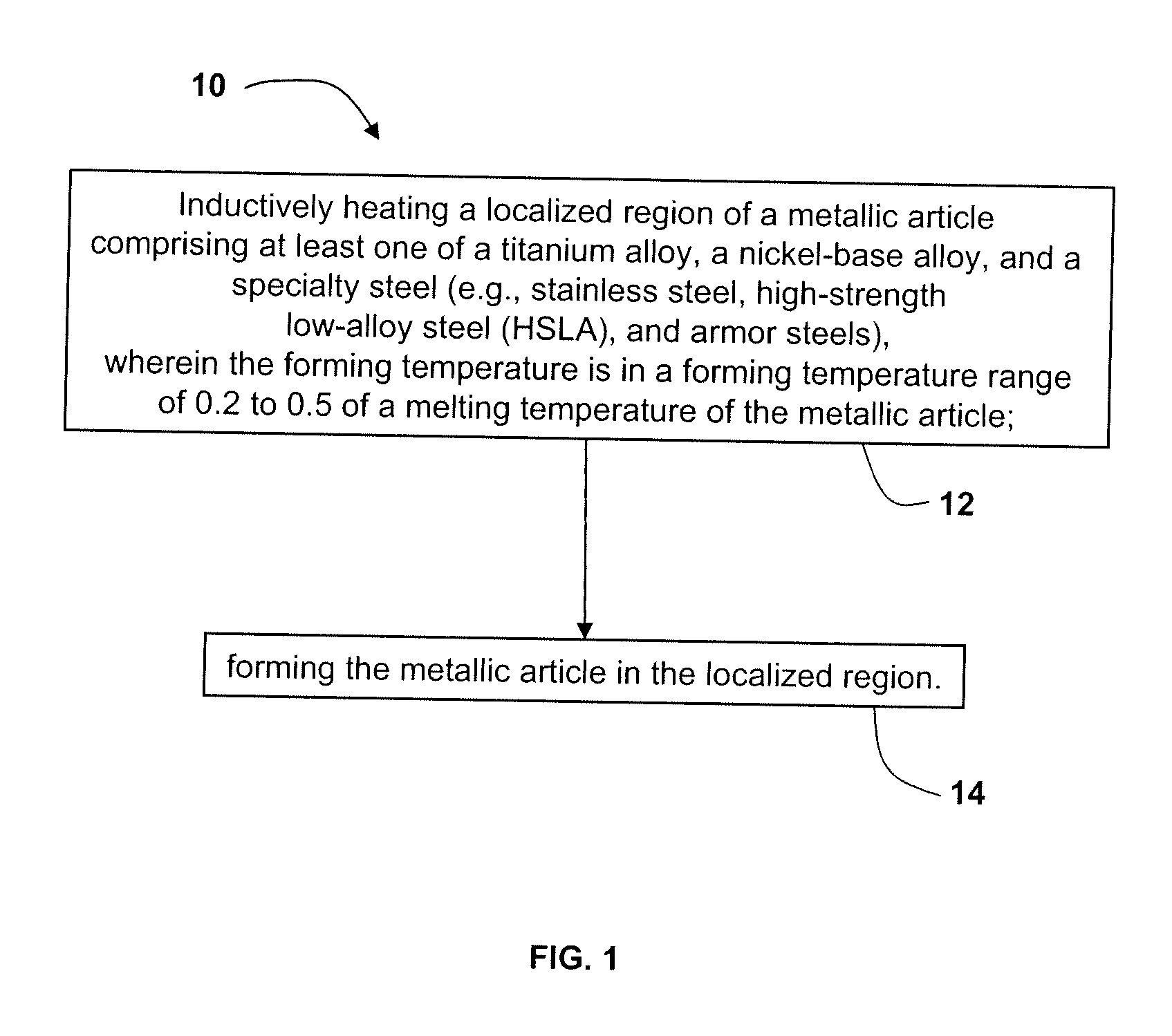

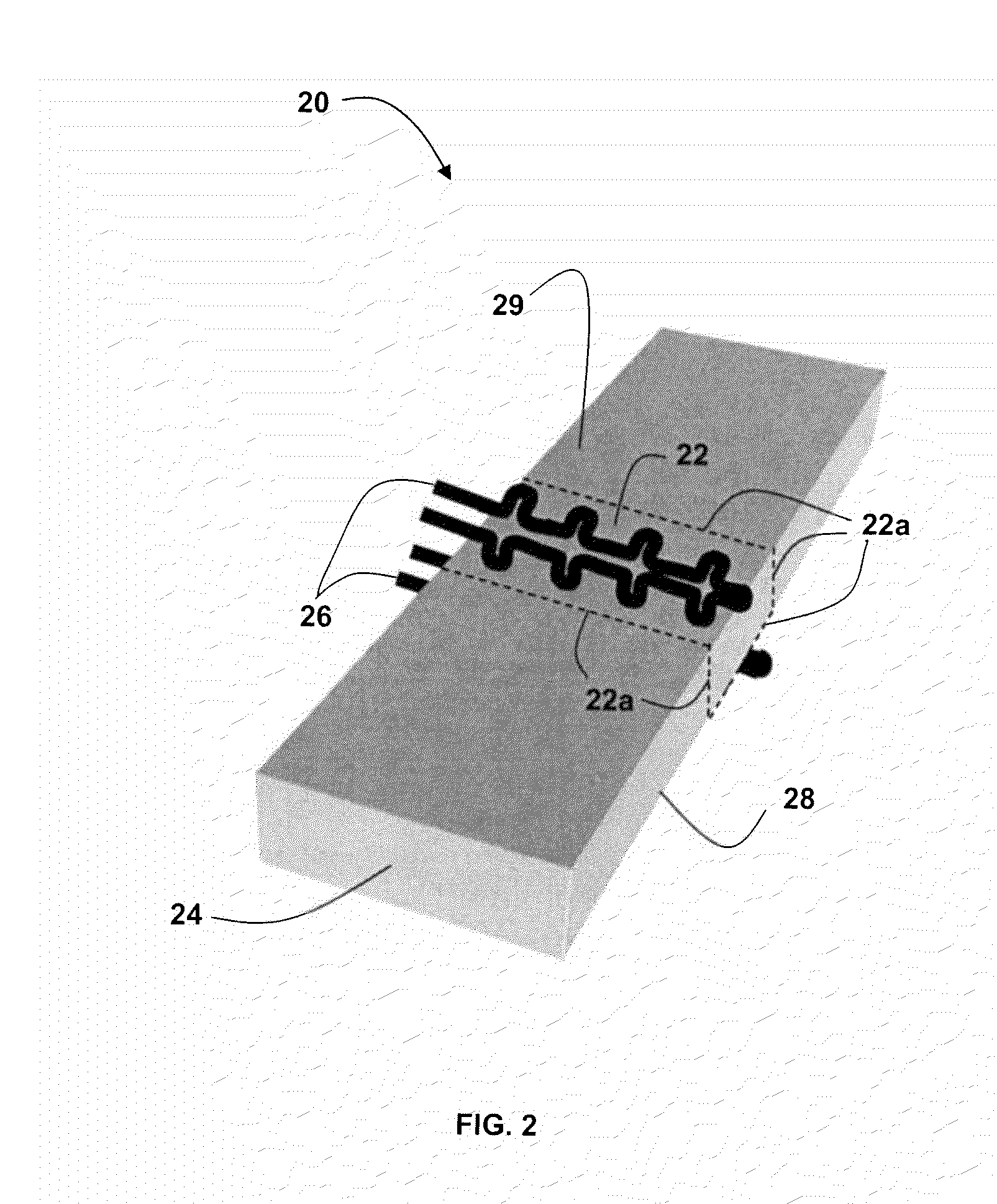

Elevated Temperature Forming Methods for Metallic Materials

A method of forming a metallic article includes directly and / or indirectly inductively heating a localized region of a metallic article to a forming temperature. The metallic article may comprise materials selected from titanium alloys, nickel-base alloys, and specialty steels, e.g., stainless steel, high-strength low-alloy steel, armor steel alloys, and the like. The forming temperature may be in a forming temperature range of 0.2 to 0.5 of a melting temperature of a metallic material comprising the article. The metallic article is formed in the localized region. Devices for indirectly and directly inductively heating a localized region of a metallic article are disclosed. Articles including metallic articles processed according to the methods and / or devices taught herein also are disclosed.

Owner:ATI PROPERTIES

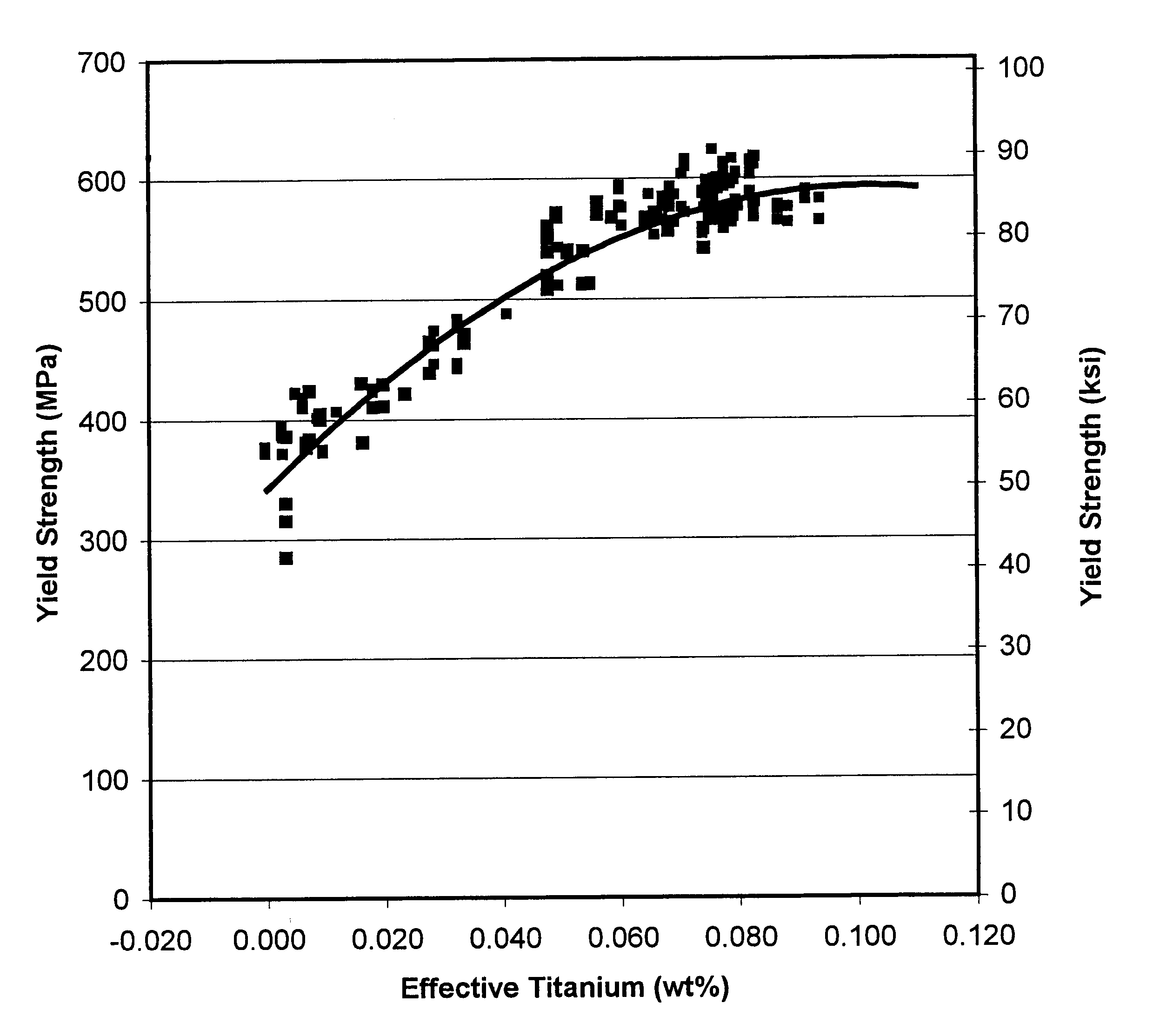

Method for producing titanium-bearing microalloyed high-strength low-alloy steel

A composition and method of making a high-strength low-alloy hot-rolled steel sheet, strip, or plate bearing titanium as the principal or only microalloy strengthening element. The steel is substantially ferritic and has a microstructure that is at least 20% acicular ferrite. The steel has a minimum yield strength of at least 345 MPa (50 ksi) and even over 621 MPa (90 ksi) adding titanium as the lone microalloy element for strengthening, with elongation of 15% and more. Addition of vanadium, niobium, or a combination thereof can result in yield strengths exceeding 621 MPa (90 ksi). Effective titanium content, being the content of titanium in the steel not in the form of nitrides, oxides, or sulfides, is in the range of 0.01 to 0.12% by weight. The manufacturing process includes continuously casting a thin slab and reducing the slab thickness using thermomechanical controlled processing, including dynamic recrystallization controlled rolling.

Owner:NUCOR CORP

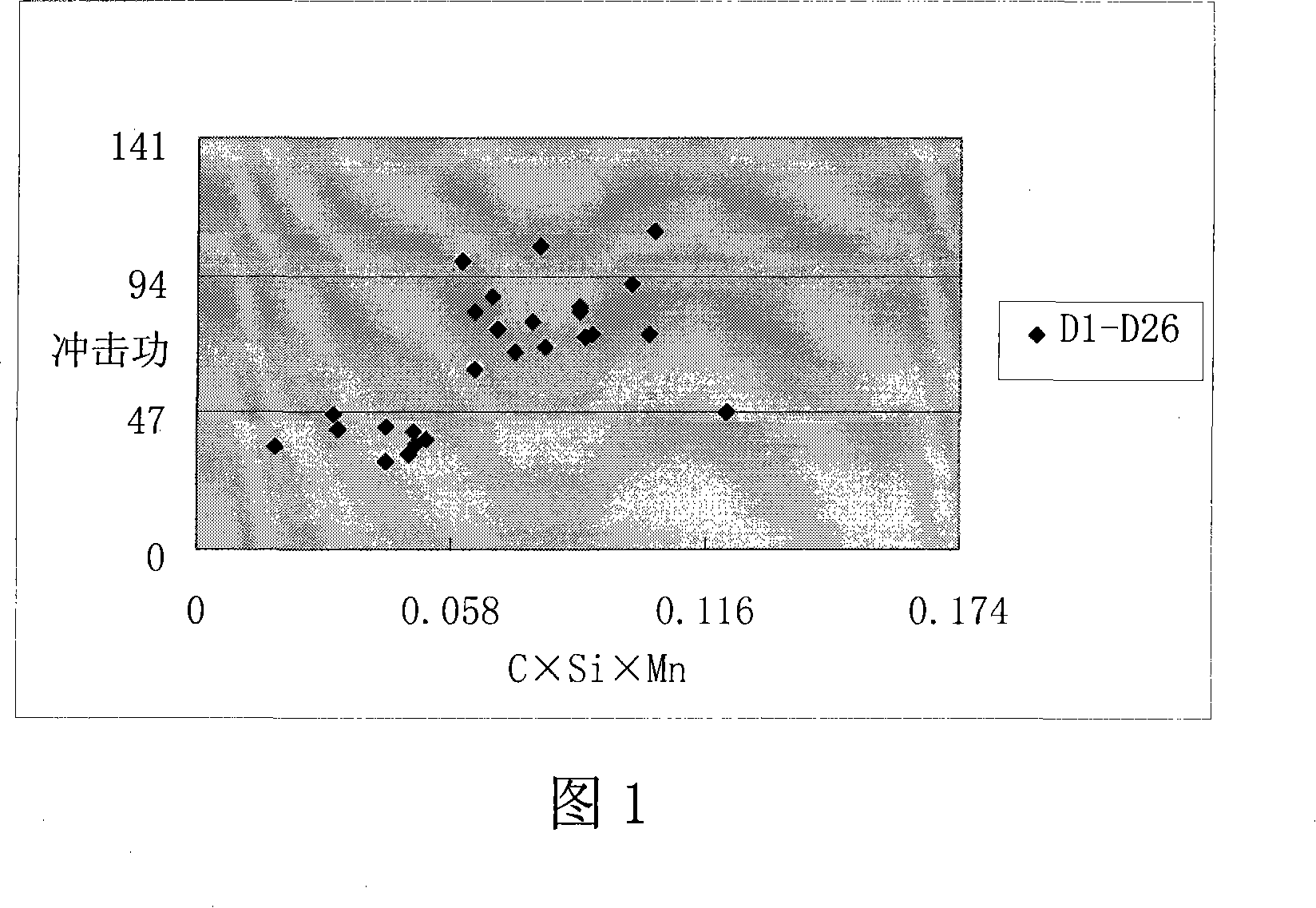

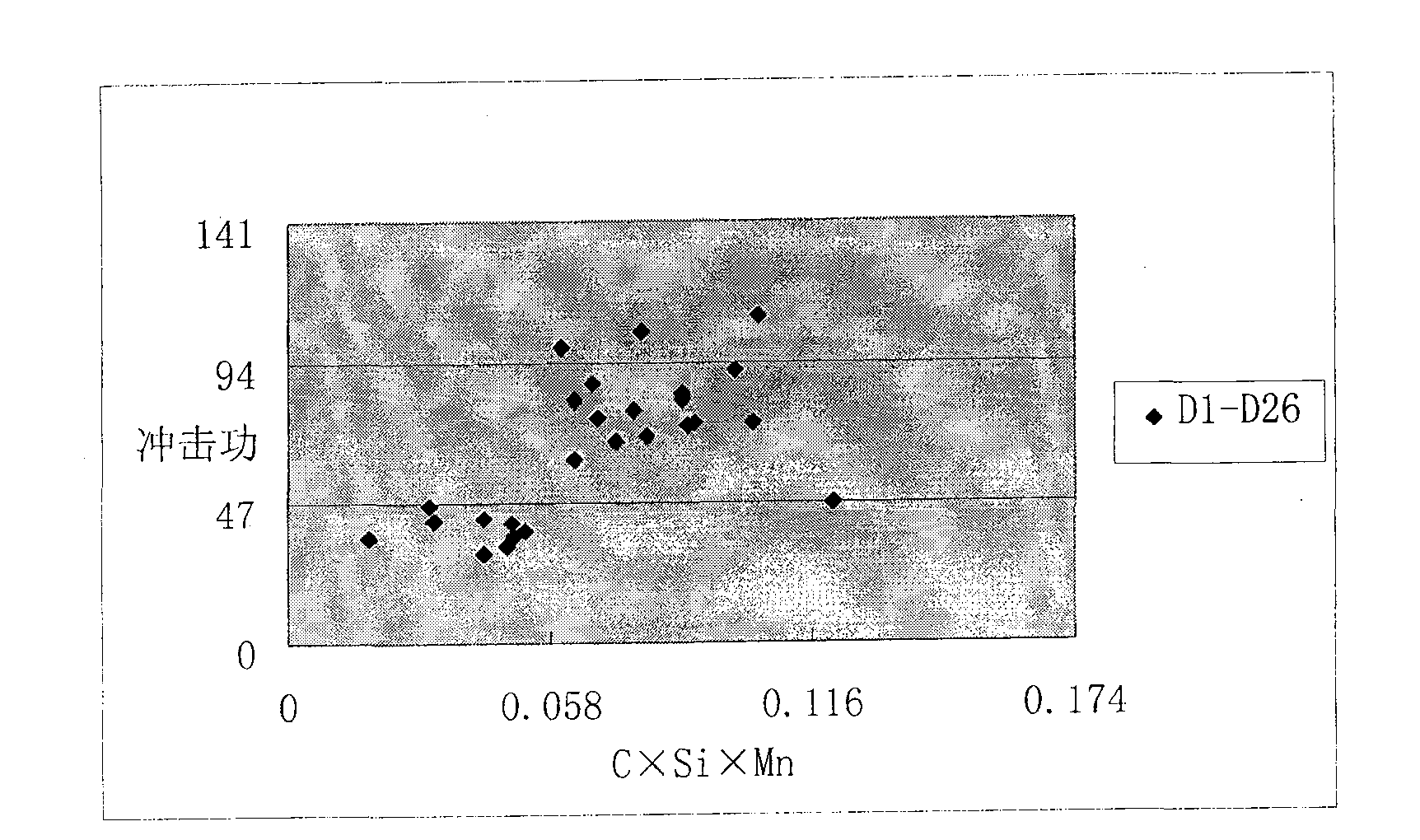

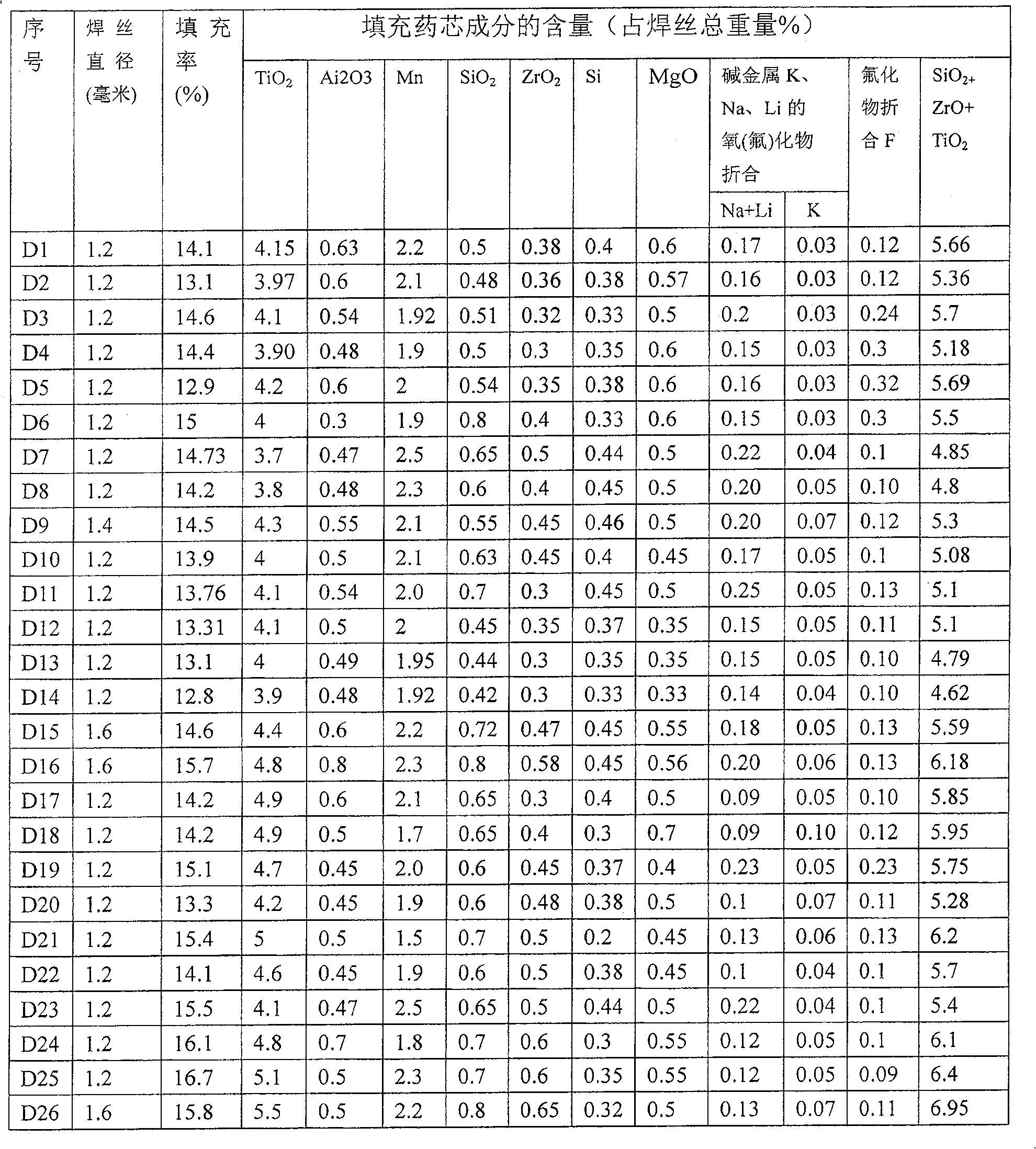

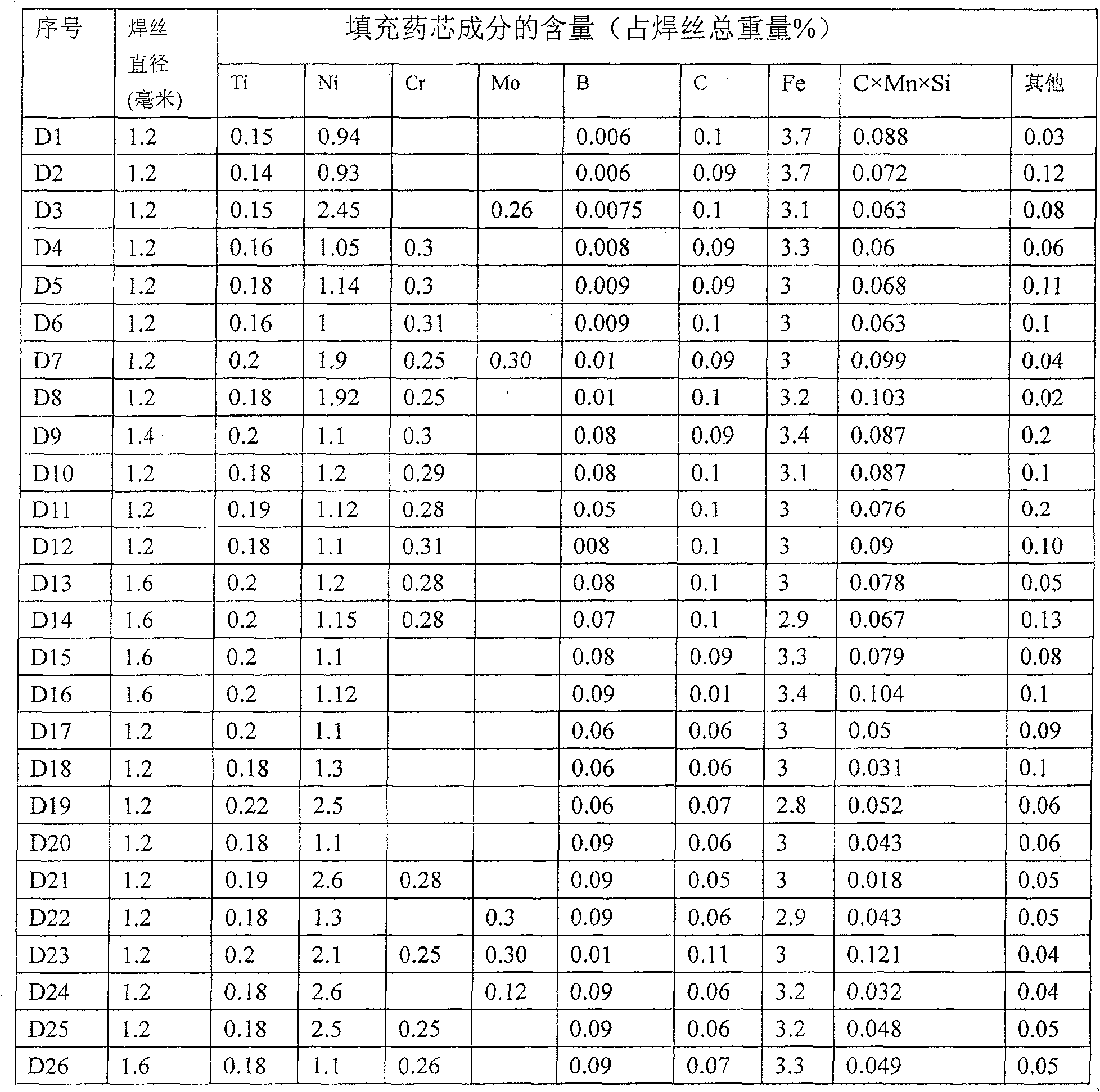

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Low alloy high-strength steel plate capable of being welded in large energy input and method of producing the same

ActiveCN101153370AImprove toughnessSimple designRoll mill control devicesHeat treatment process controlHeat-affected zoneSheet steel

The invention provides a high strength low alloy steel plate suitable for high heat input welding and is characterized in that the chemical composition (wt percent) of steel comprises 0.04 percent to 0.16 percent of C, 0.10 percent to 0.50 percent of Si, 0.40 percent to 1.8 percent of Mn, 0.020 percent to 0.050 percent of Nb, 0.006 percent to 0.030 percent of Ti, 0.0030 percent to 0.010 percent of N, 0.015 percent to 0.060 percent of Al and the rest, Fe and other inevitable impurities; meanwhile, C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4+V / 14 is less than or equal to 0.45 percent and the total amount of Ti and the total amount of N are that [Ti percent]T is more than or equal to 2.667[N percent]T-0.004667 percent; moreover, Ti microalloying is adopted to ensure that the Ti / N ratio in the second sort of particle generated ranges between 2.4 and 3.2. The manufacture method of the steel plate adopts austenite recrystallization zone and austenite non-recrystallization zone rolling and forced water cooling after rolling; moreover, when the steel plate is under 50 KJ / cm to 150 KJ / cm high heat input welding, the welding heat affected zone has excellent toughness. The invention has the advantages of simple production process, low cost and wide applicability.

Owner:ANGANG STEEL CO LTD

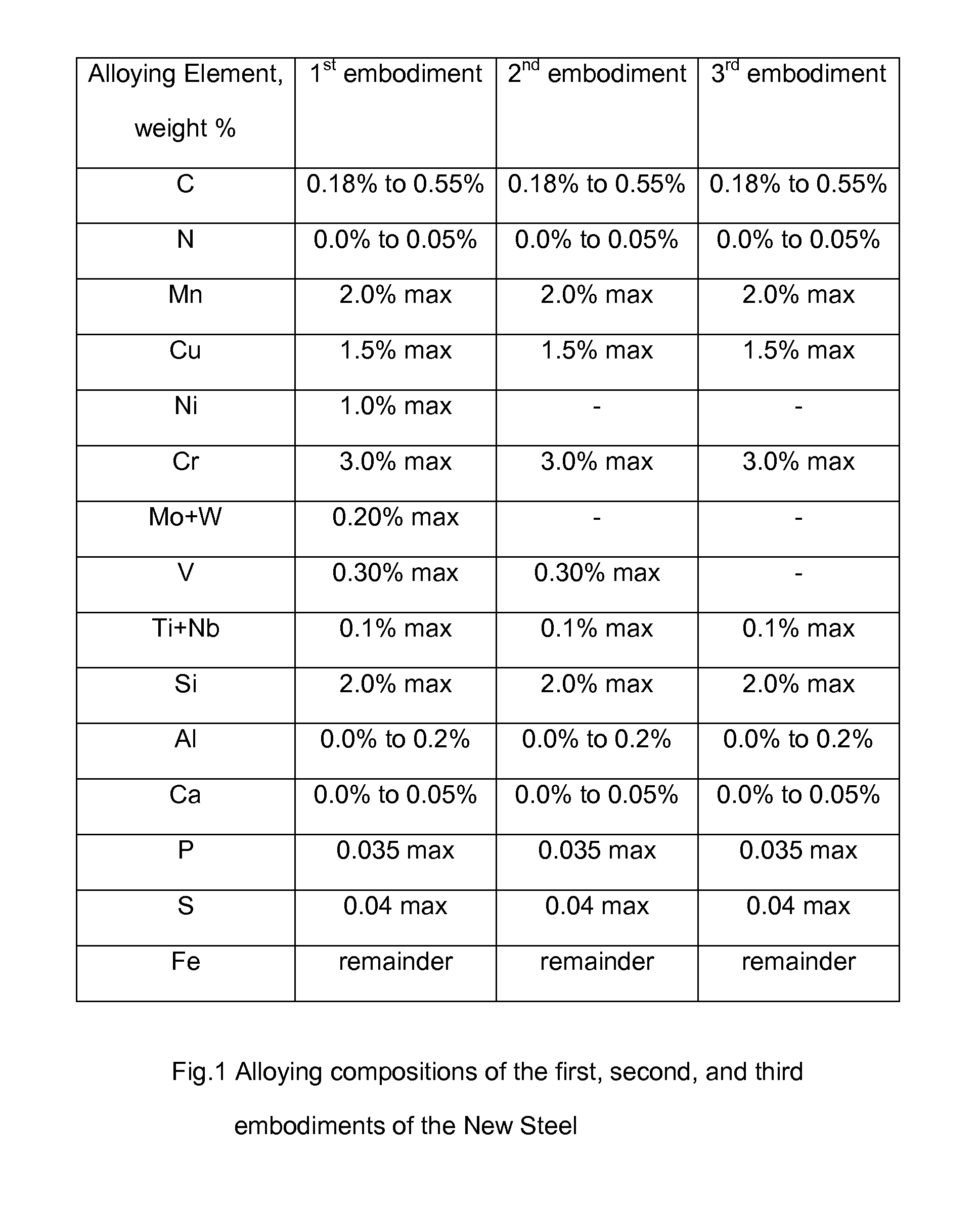

High Strength Low Alloy Steel and Method of Manufacturing

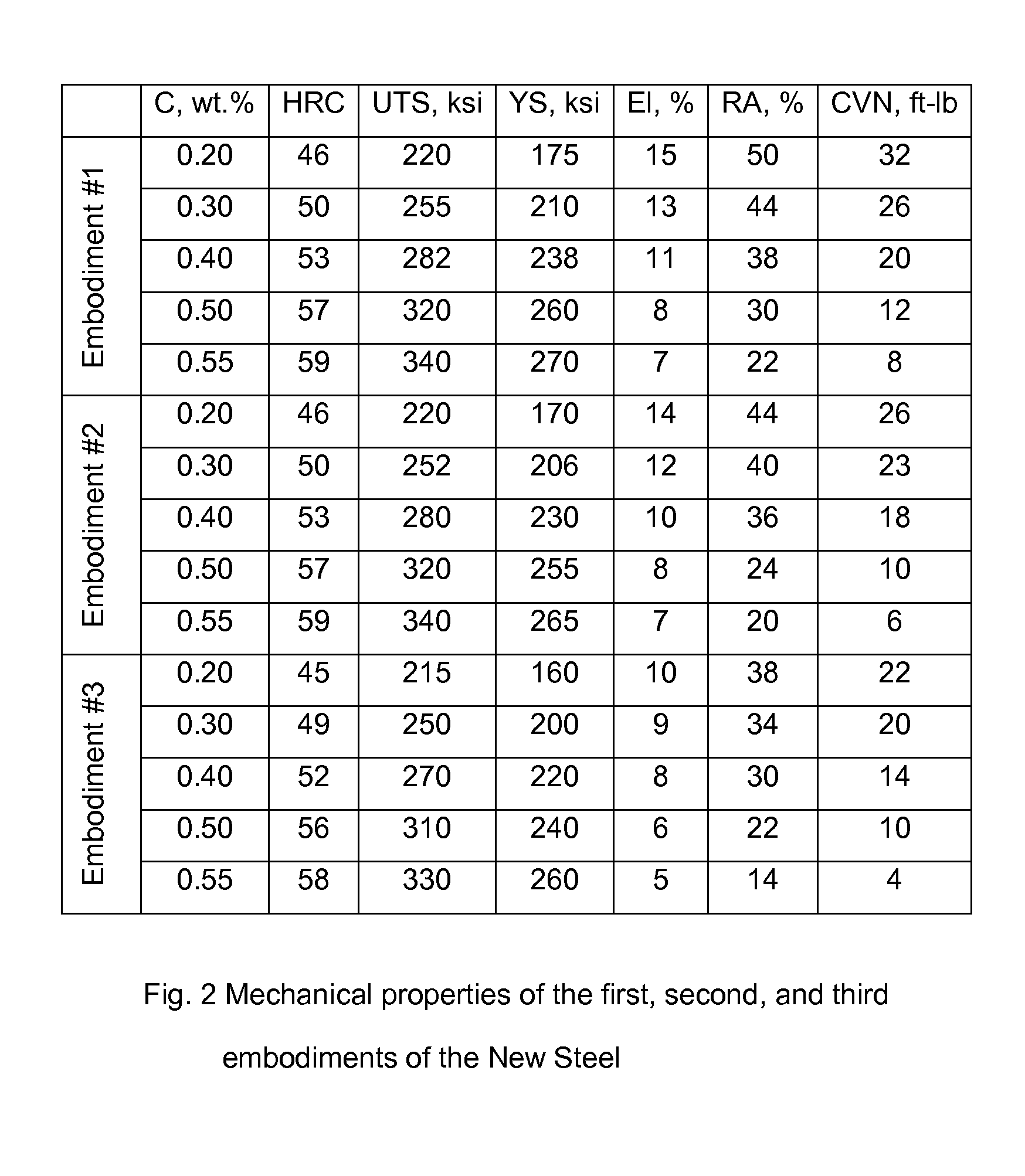

The present invention relates to a wrought, quenched and tempered, fine-grained, with deep hardenability, high strength and low alloy steel having a sum of the alloying elements: nickel, molybdenum, tungsten, vanadium, titanium, and niobium in weight percentage of 1.60% maximum in the first embodiment; vanadium, titanium, and niobium in weight percentage of 0.40% maximum in the second embodiment; titanium and niobium in weight percentage of 0.10% in the third embodiment. The air melted and hot forged steel of the first embodiment has hardness of HRC 55, an ultimate tensile strength of 300 ksi, a yield strength of 257 ksi, a total elongation of 9%, a reduction of area of 32%, and Charpy v-notch impact toughness energy of 15 ft-lb after normalizing, gas quenching, and tempering at 450° F.

Owner:VARTANOV GREGORY

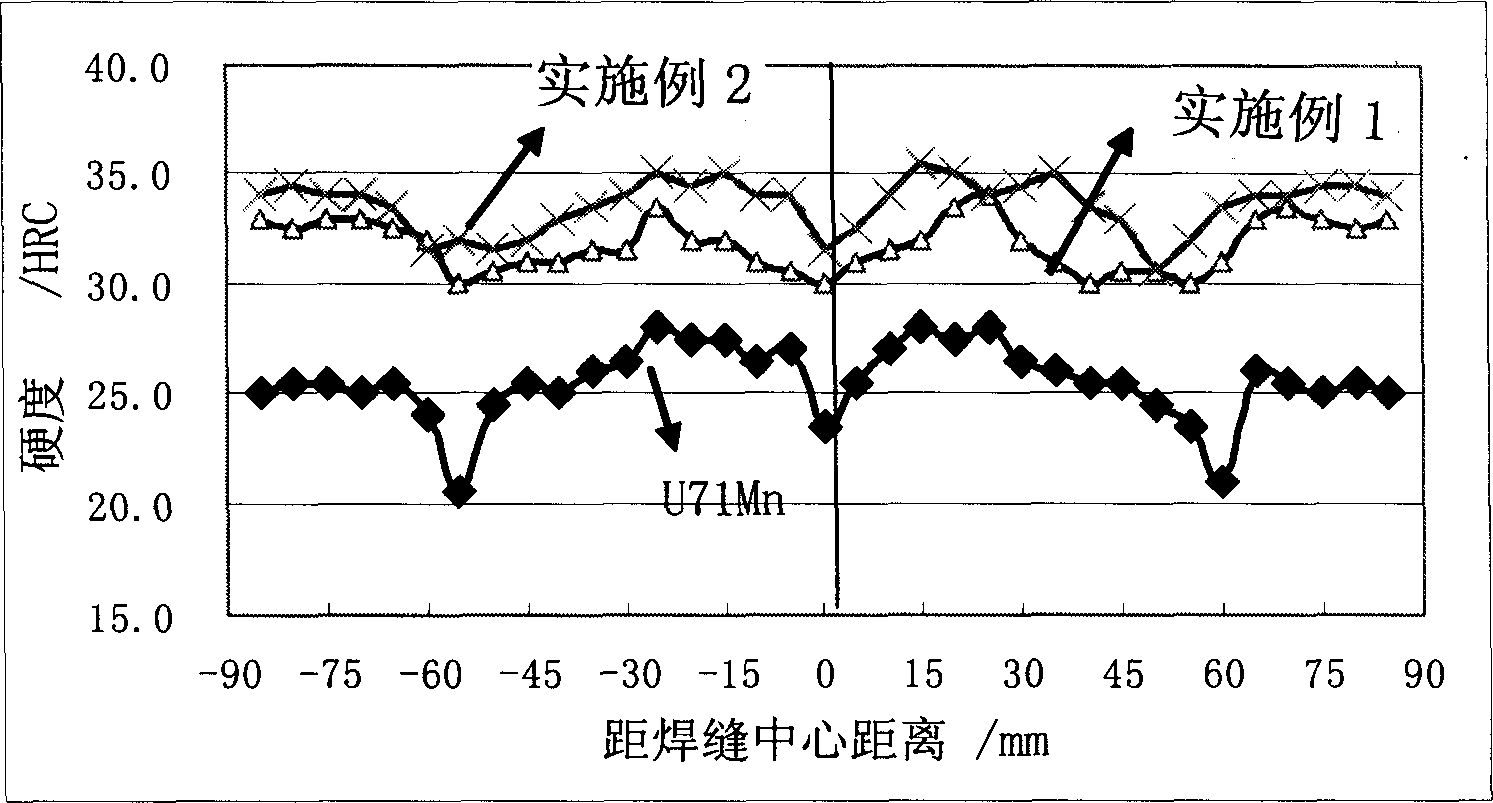

Pearlite like high strength low alloy rail steel and producing method thereof

ActiveCN1793402AImprove wear resistanceHigh strengthTemperature control deviceFurnace typesChemical compositionHigh intensity

The invention relates to a pearly high-strength low-alloy steel rail iron and manufacturing method. Its chemical composition percentage by weight includes: C:0.70-0.95%, Si:0.20-1.10%, Mn:0.50-1.50%, V:0.01-0.20%, Cr:0.15-1.20%, P: not less than 0.035%, S:not less than 0.035%, and Al: not less than 0.005%. The method includes the following steps: smelting; adding carburant and alloy; vacuum processing; billet heating; rolling; and cooling. The cooling speed is not more than 4.0 centigrade degree per second. The formed steel rail has good ware resistance and welding property. The method has simple technology and convenient operation.

Owner:PANZHIHUA IRON AND STEEL

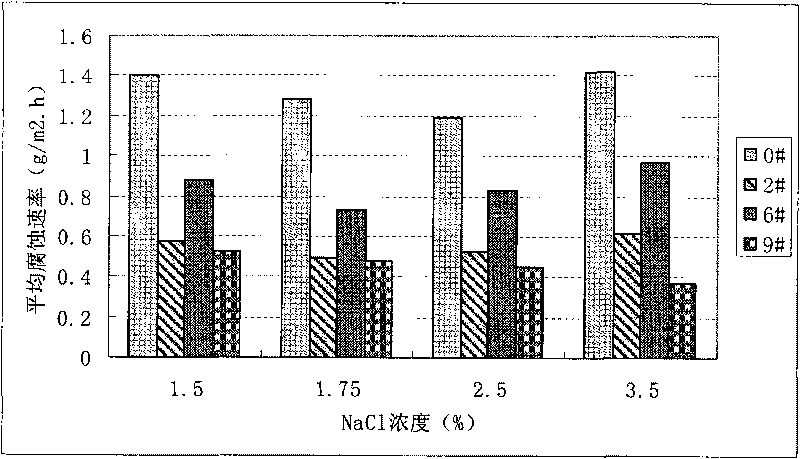

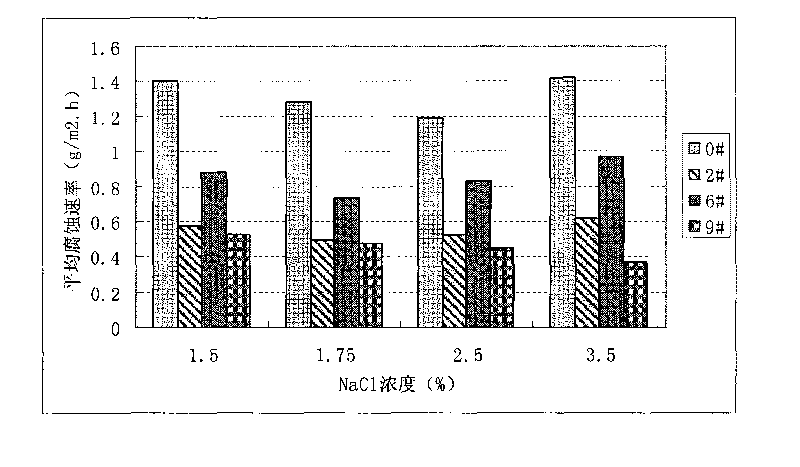

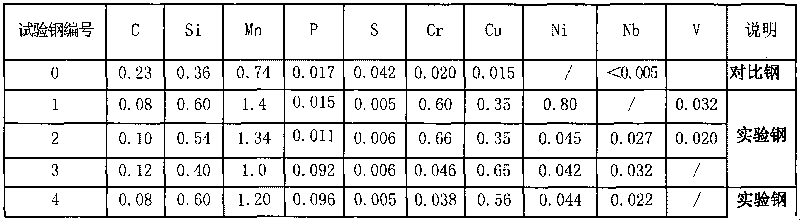

Cl- corrosion resistant high-strength low-alloy steel bar and production method thereof

InactiveCN101709434AAccelerated corrosionWith durability design requirementsTemperature control deviceSteel barPerformance index

The invention discloses a Cl- corrosion resistant high-strength low-alloy steel bar and a production method thereof, and belongs to the technical field of steel bars. The alloy in a basic alloy system comprises the following elements in percentage by weight: 0.08 to 0.25 percent of C, 0.35 to 1.1 percent of Si, 0.7 to 2.0 percent of Mn, 0.05 to 0.10 percent of P, 0.010 percent of S, 0.30 to 1.60 percent of Cr, 0.2 to 0.80 percent of Cu, 0.2 to 1.0 percent of Ni, and the balance of Fe and inevitable impurity elements; and one or more of micro alloy elements comprising V, Nb, Ti, B and the like can be added with trace according to the performance requirement of the steel bar, and the total amount of the micro alloy elements is controlled in a range of 0.01 to 0.5 percent. The steel bar has the advantage of economic and reasonable cost, and the Cl- corrosion resistance of the steel bar is obviously superior to that of carbon steel. The performance index of the steel bar meets the requirement of 400MPa-grade steel bars in GB1499-2007; and the steel bar has good welding performance and mechanical connection performance, and is applied to a concrete structure with durability design requirement under the marine environment condition.

Owner:CENT IRON & STEEL RES INST

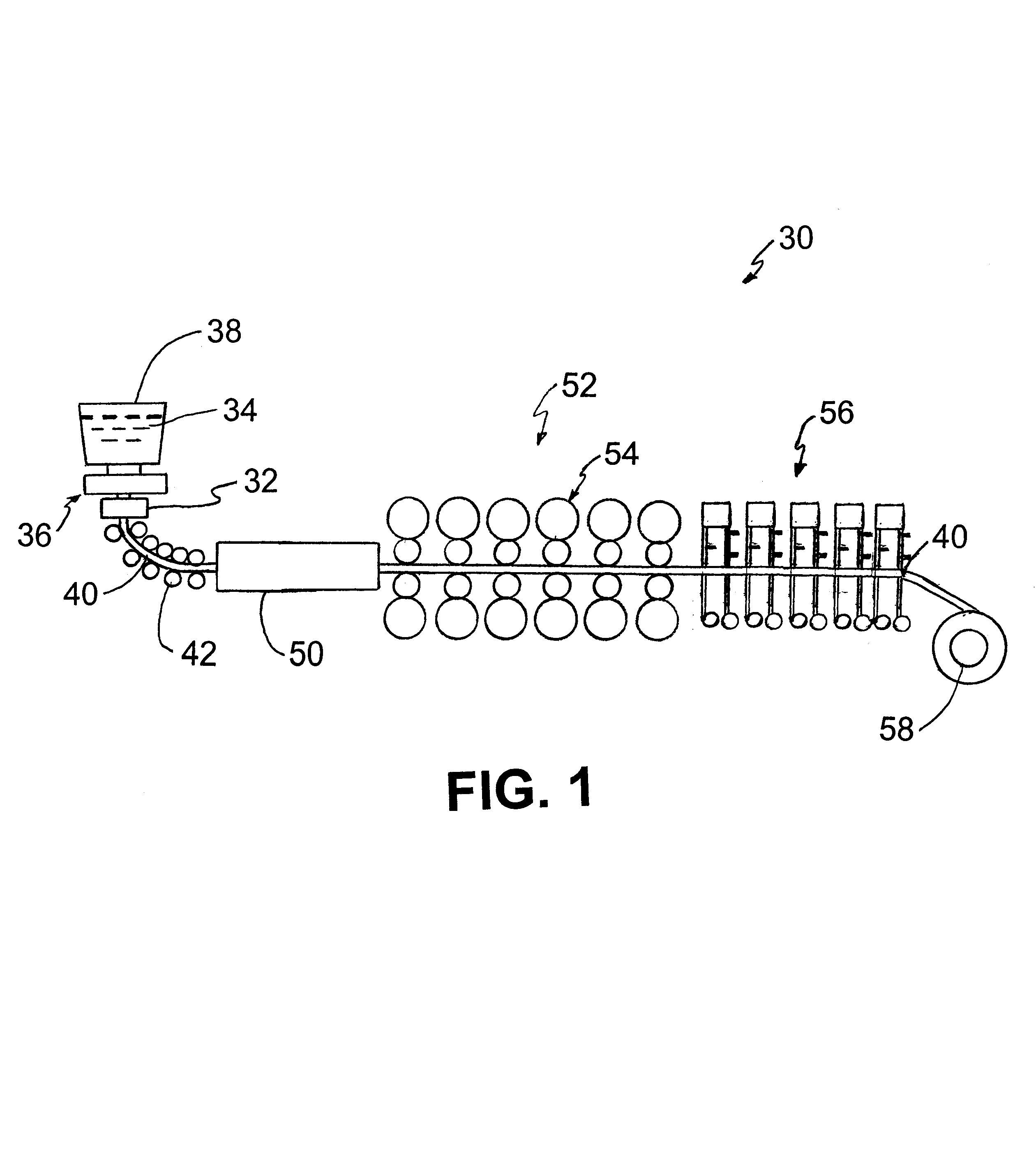

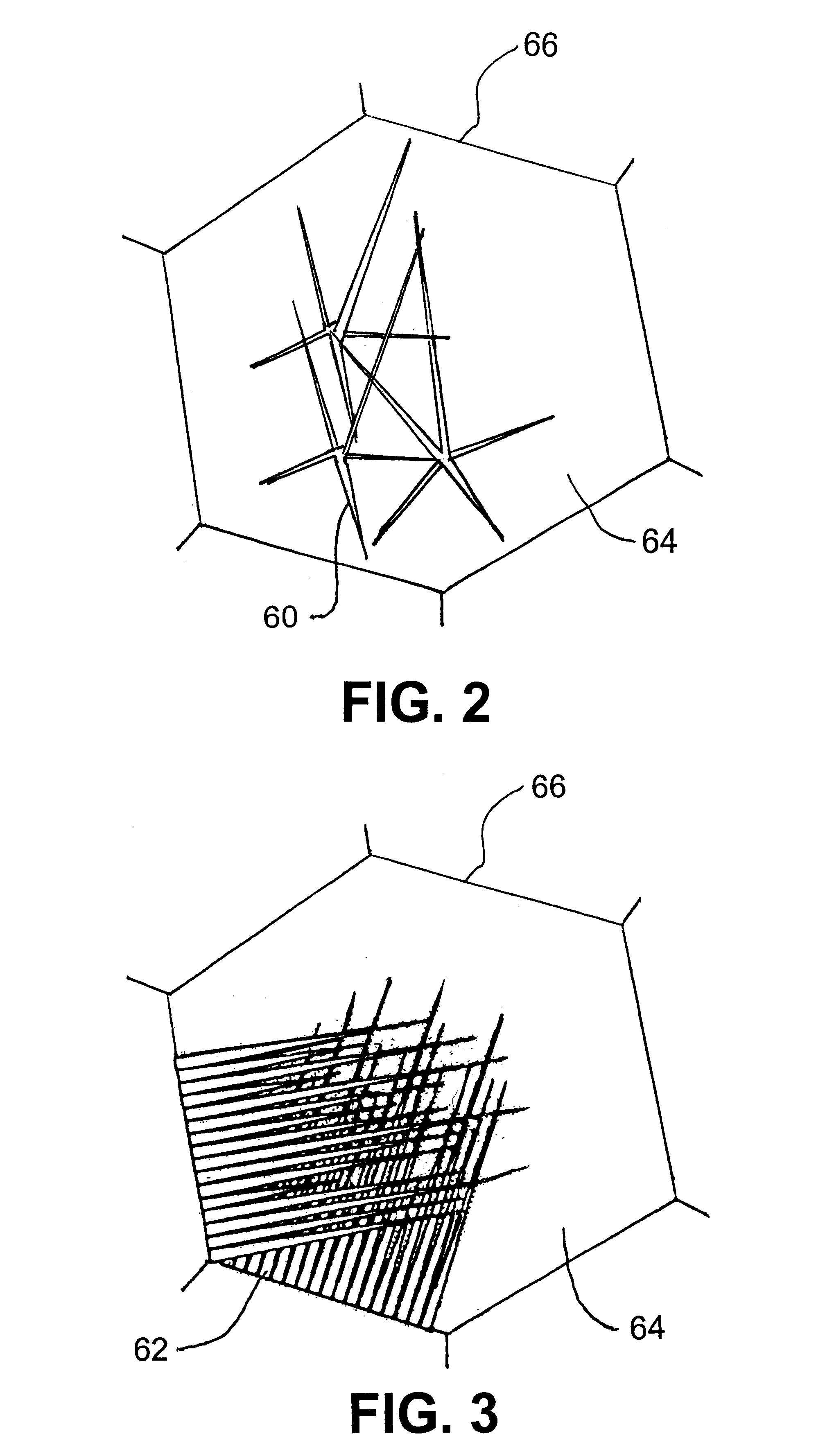

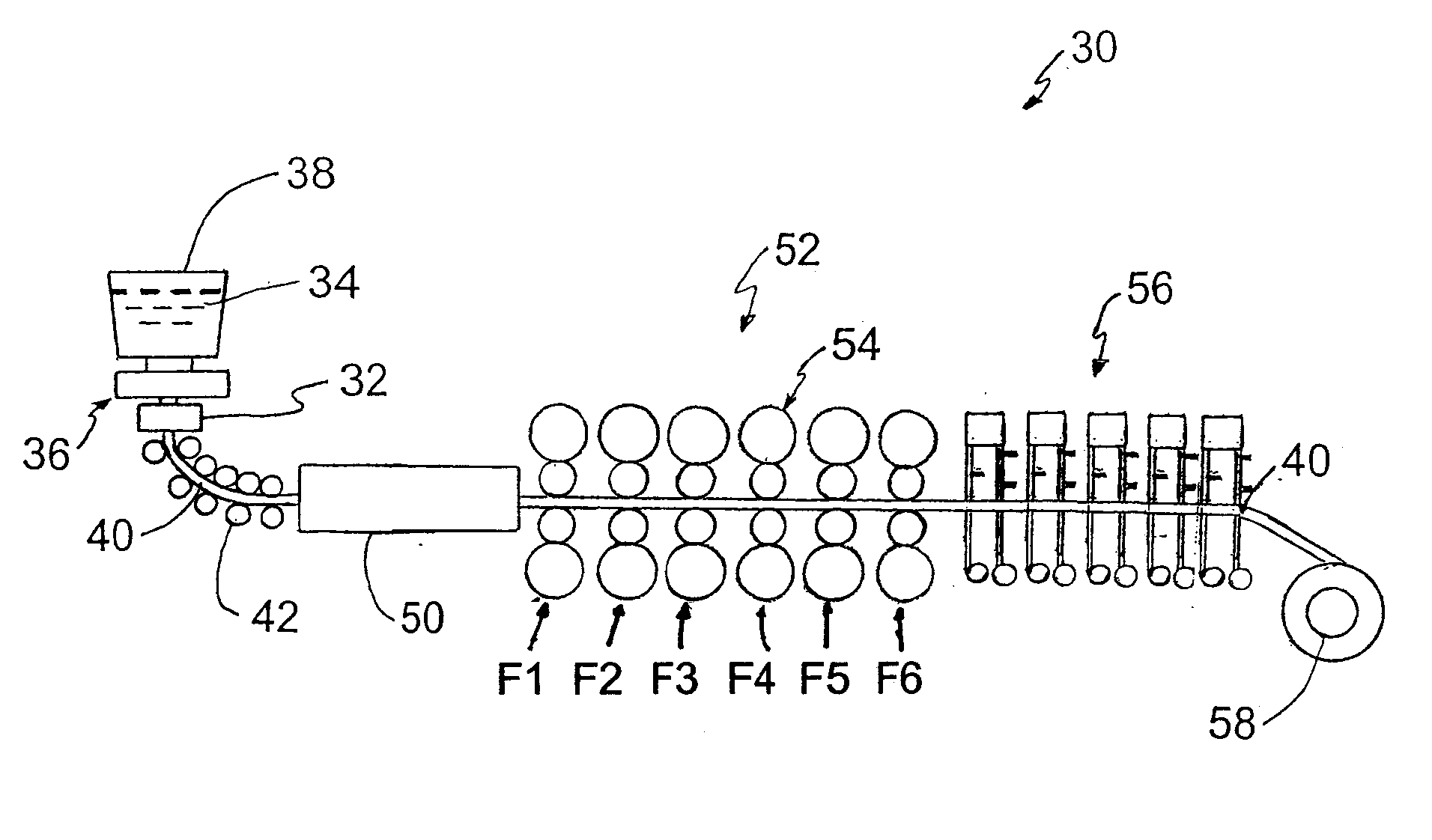

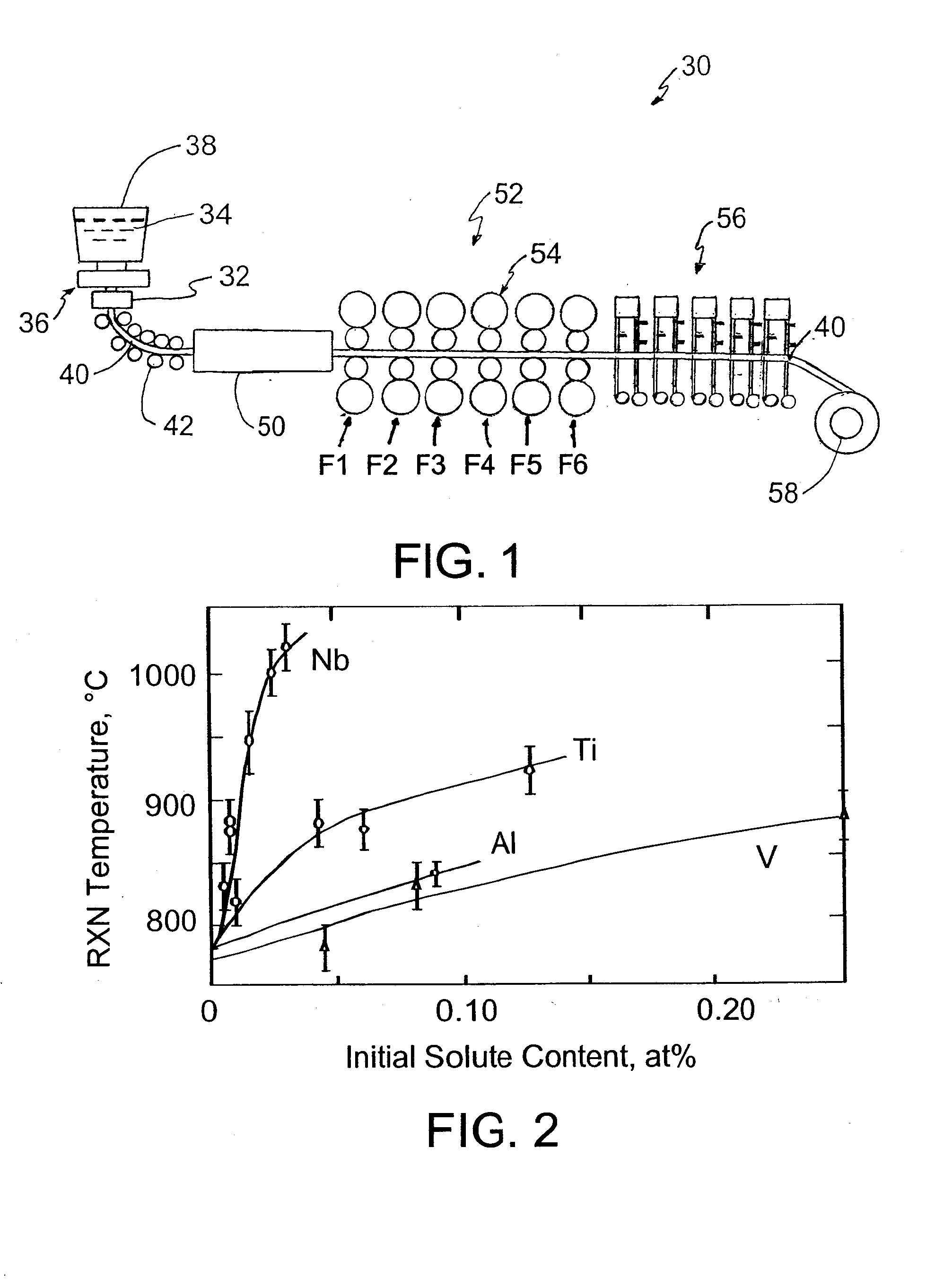

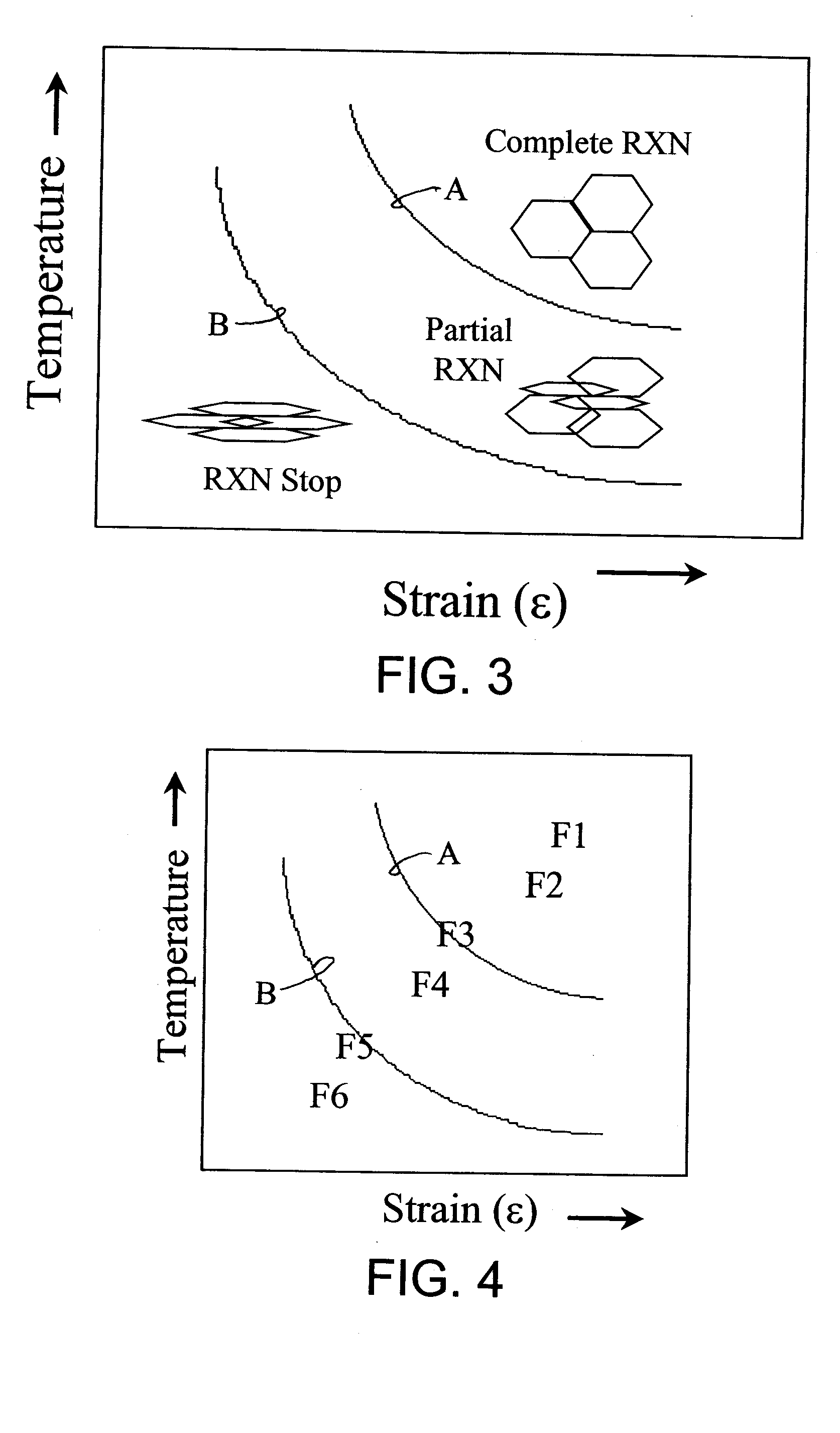

Thermomechanical processing routes in compact strip production of high-strength low-alloy steel

InactiveUS20050115649A1Accurate ultrasonic testingTime allowedMetal rolling arrangementsAustenite grainThin slab

Process for hot rolling of high-strength low-alloy steel cast in Compact Strip Production as a thin slab. The strain and temperature at initial roll stands where deformation occurs allows full recrystallization, and at latest roll stands where deformation occurs there is no recrystallization. Deformation is absent at strains and temperatures where partial recrystallization would occur, allowing increased recrystallization over conventional CSP rolling. The result may be beneficial for microalloyed high-strength low-alloy steel in permitting accurate ultrasonic testing of welds. The time allowed between deformation at passes through roll stands may be increased by eliminating deformation at one or more central roll stands. Combined with increased strain at the initial roll stands where the temperature of the steel is in the full recrystallization region, the process may result in a relatively fine and uniform austenite grain size.

Owner:NUCOR CORP

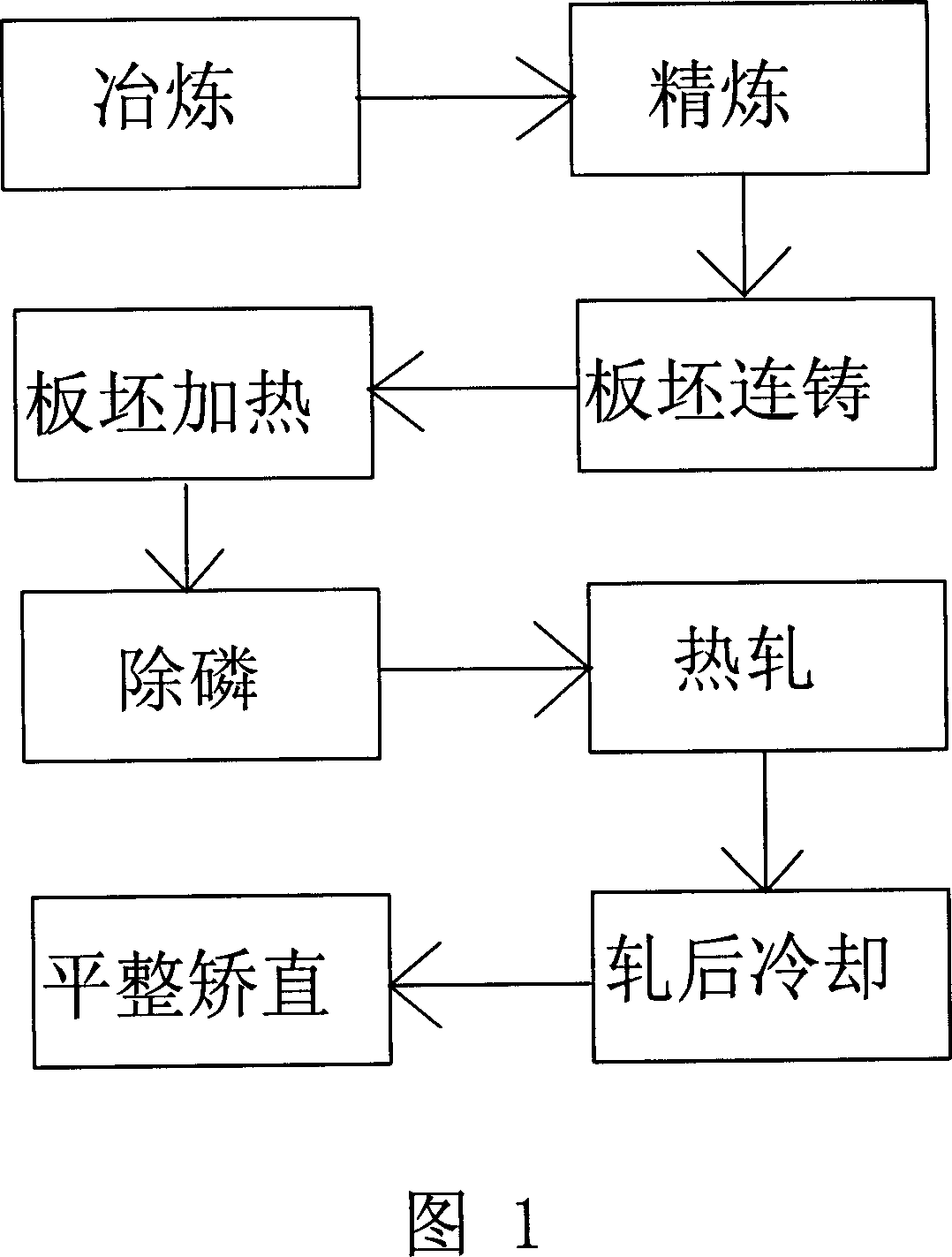

Manufacturing technique of low compression ratio high grade pipe line steel

InactiveCN1927486AImprove performanceRoll force/gap control deviceTemperature control deviceNiobiumHeating temperature

The invention relates to a method for producing high-strength low-alloy steel. Wherein, it comprises smelting, refining, casting sheet blank, heating blank, removing phosphor, cooling and flattening; the smelting step uses pure steel, low phosphor, and low sulfur; in the casting step, the loose of blank and the aliquation are lower than B0.5level; in the heating step, vanadium+niobium+ titanium0.15%, nickel+chromium+copper<=0.50%, and the heating temperature is 1180-1220Deg. C; in the thermal rolling step, in the crystallize process, the deformation temperature is 1070-1000Deg. C, the deformation amount is 40-60%, and the rolling speed is 1.5-2.5m / s, and in the second step that rolling the non-crystallized area, the pressure is 200-400MPa, the rolling speed is 5-1.5m / s, and the deformation amount is 60-75%; and the interlayer cooling speed in the cooling step is 15Deg. C / s-25Deg. C / s.

Owner:NANJING IRON & STEEL CO LTD +1

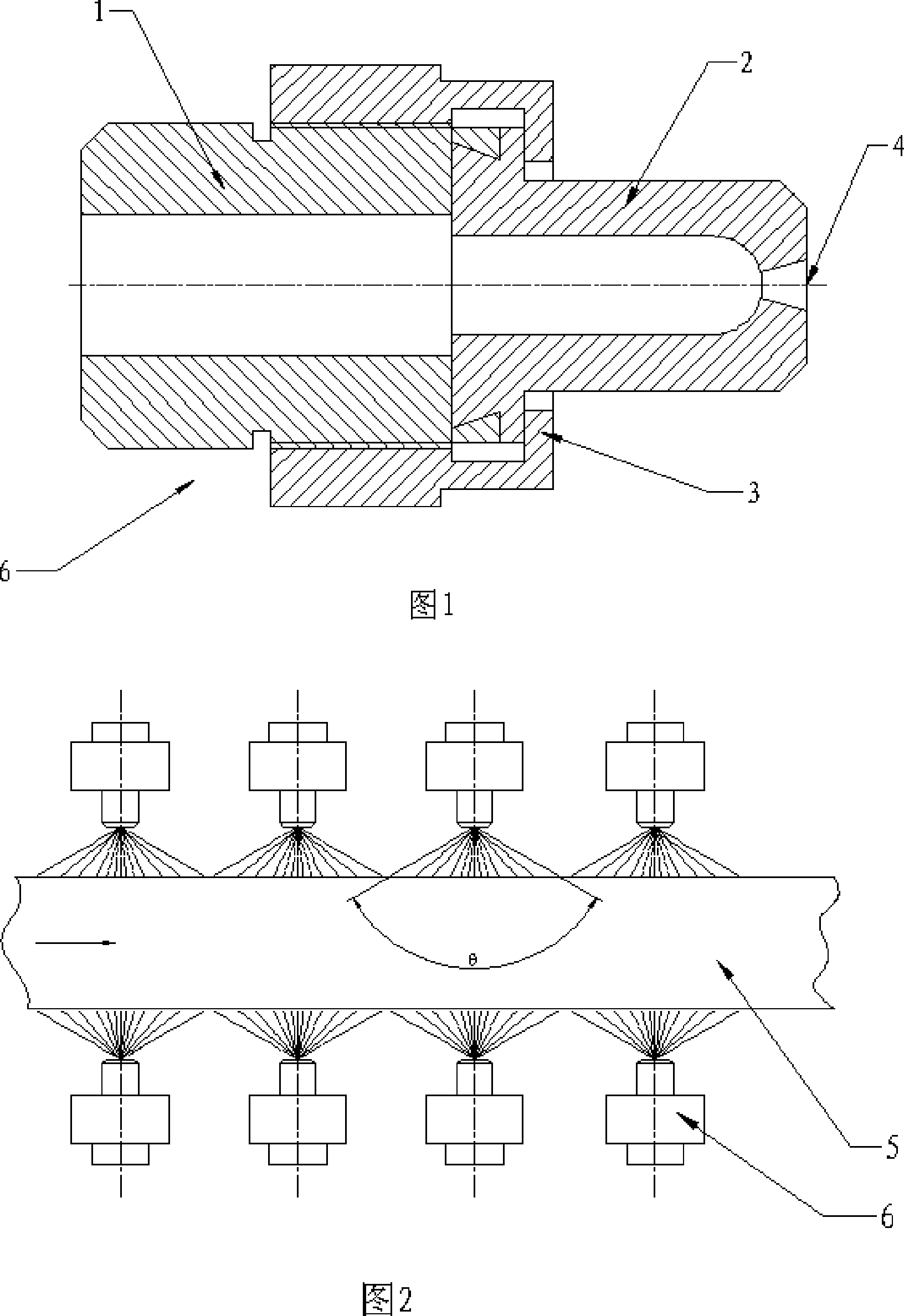

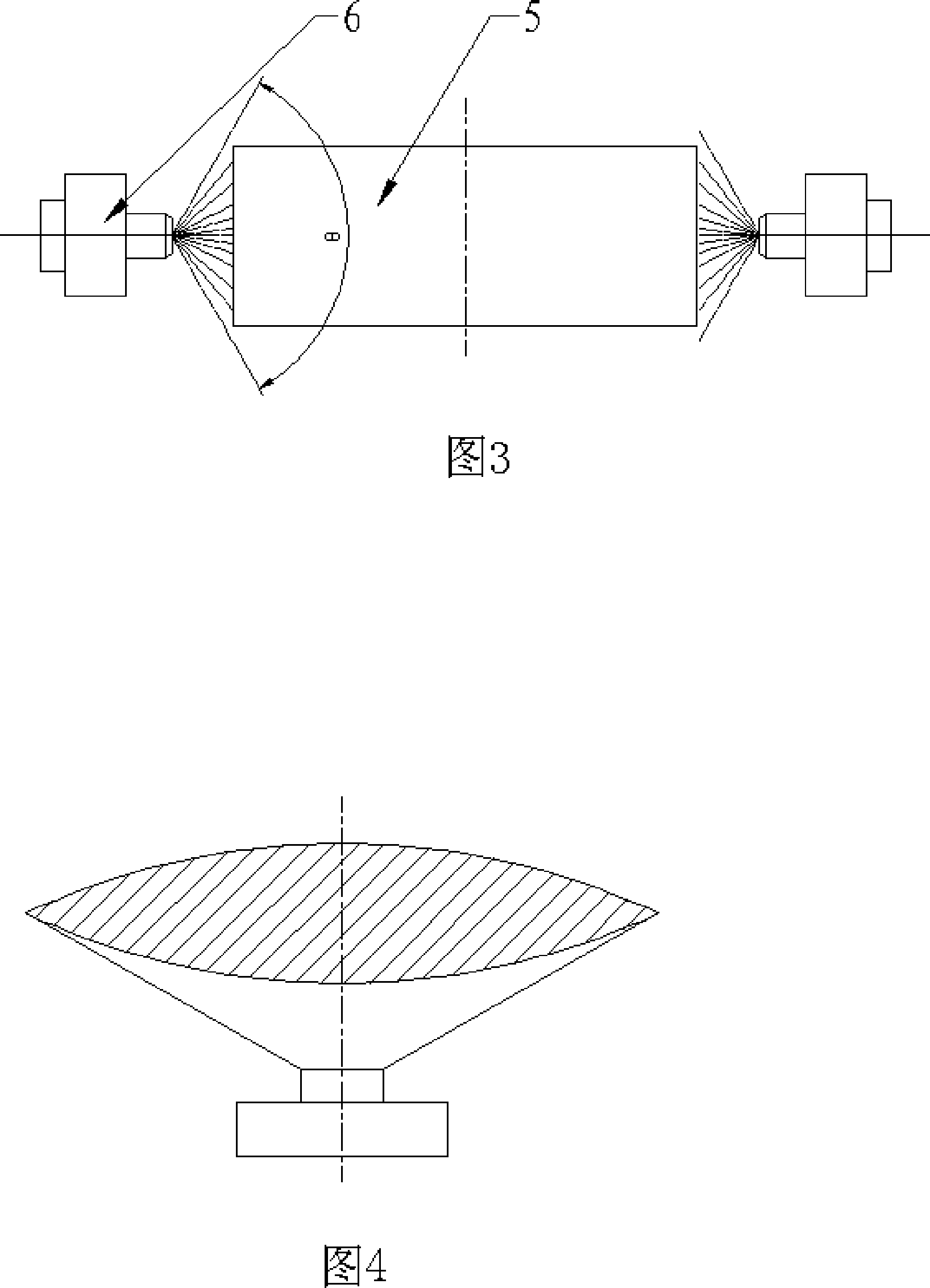

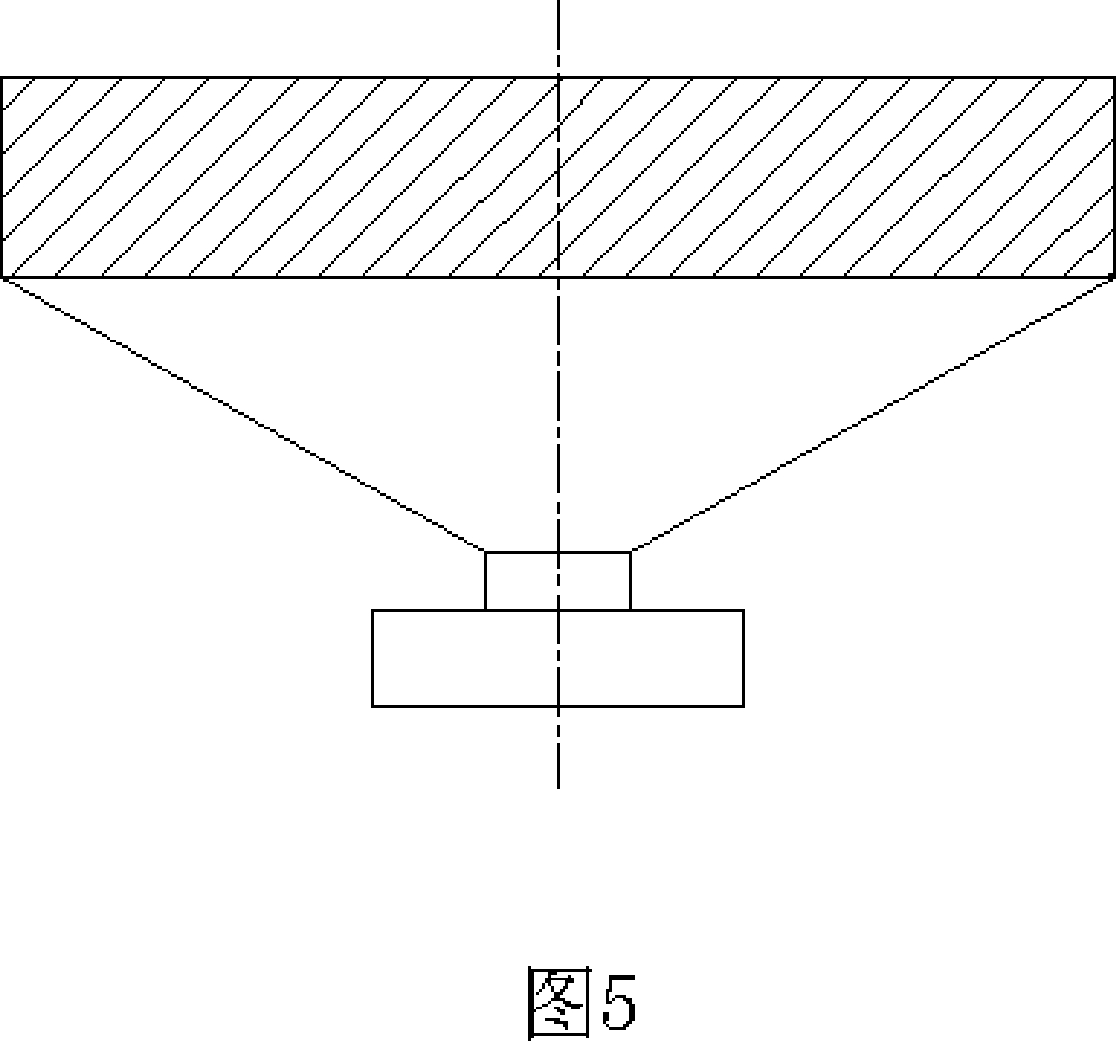

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

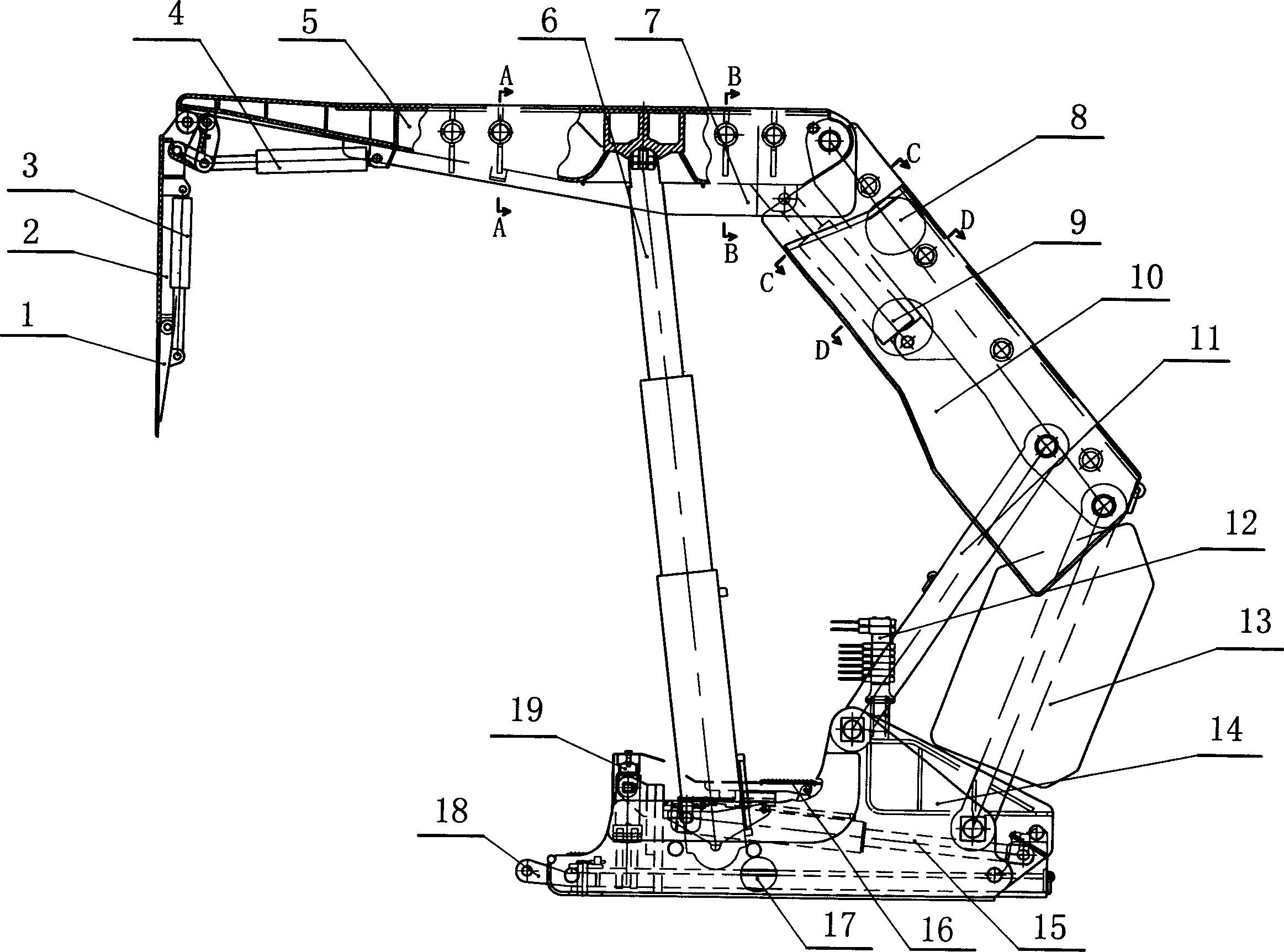

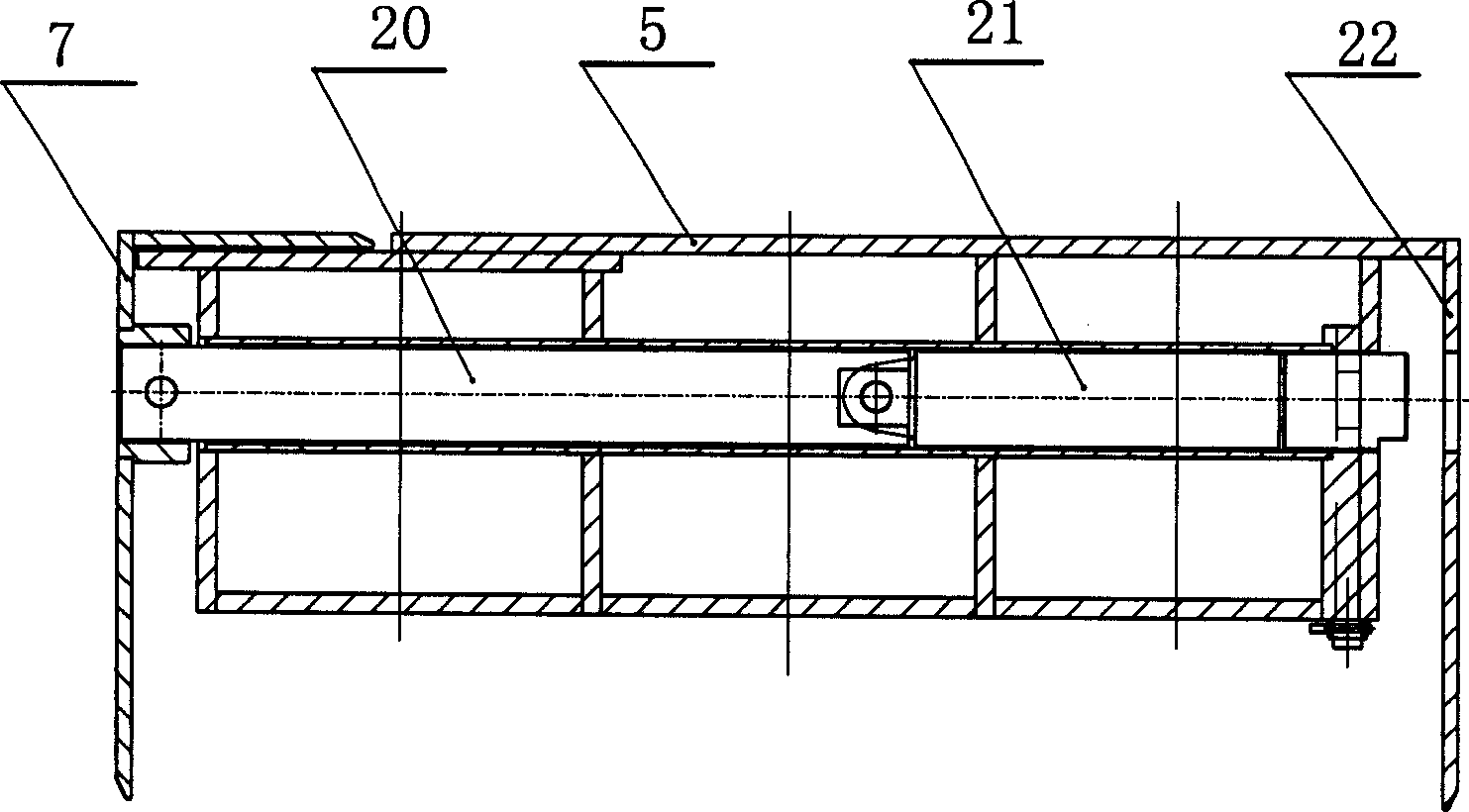

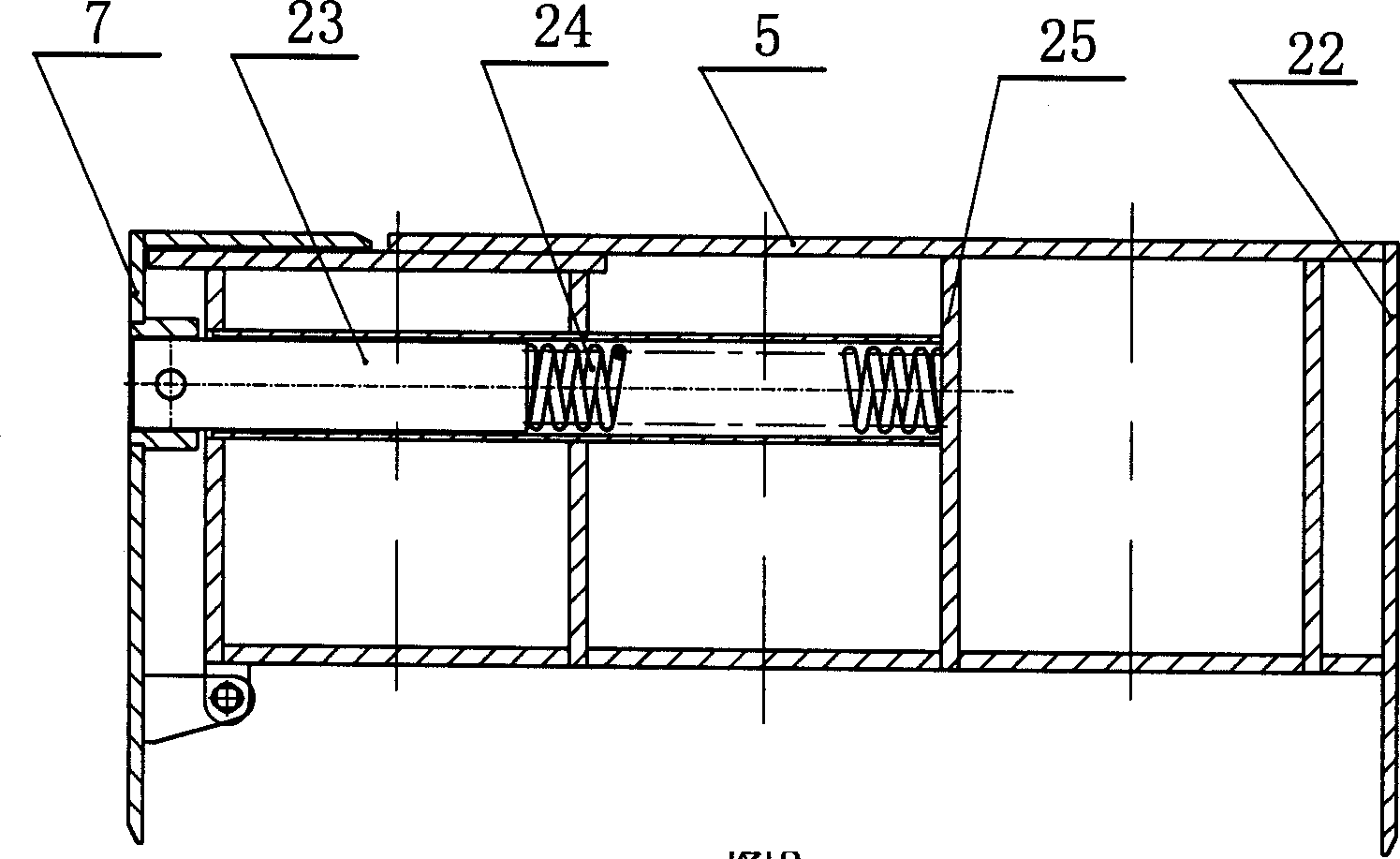

Thick coal-bed shield hydraulic support

InactiveCN1851235AImprove stress conditionExtended service lifeMine roof supportsEngineeringHigh intensity

The invention is a thick coal bed hydraulic shield support, able to implement synthetic mechanized mining of thick coal beds, comprising top beam, shield beam, seat, column, balancing jack, front link rod, rear link rod, displacive jack and operating valve set, where the top beam and shield beam are equipped with side push jacks, and long and short guide rods inside and equipped with side backplates and hinged mutually; the top and bottom ends of the balancing jack are equipped on the top beam and shield beam, respectively; the top and bottom ends of the column are arranged on the lower part of the top beam and the seat, respectively; the upper ends of the front and rear link rods are hinged at the rear end of the shield beam and the lower ends of them are hinged on the seat; the displacive jack is equipped on the seat; the operating valve set is equipped on the bottom surface of the top beam. And it has large height regulating range and high moving speed, and improves force bearing conditions of the support and prolongs the service life of the support. And the support is made of high-intensity low-alloy steel sheet, small- bulk and lightweight.

Owner:ZAOZHUANG MINING GRP CO LTD

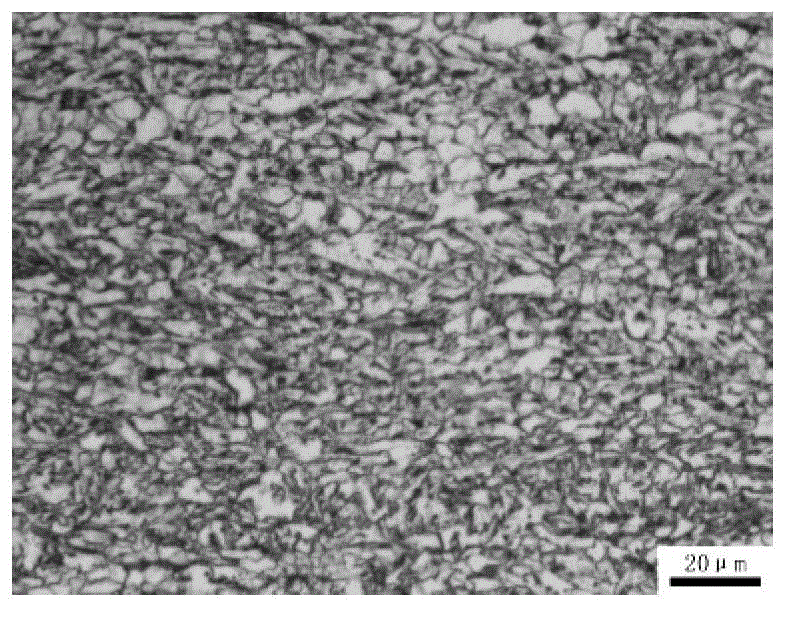

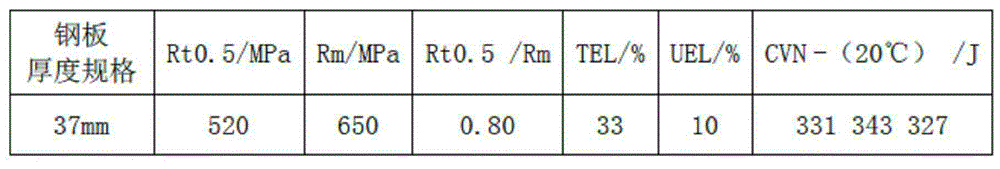

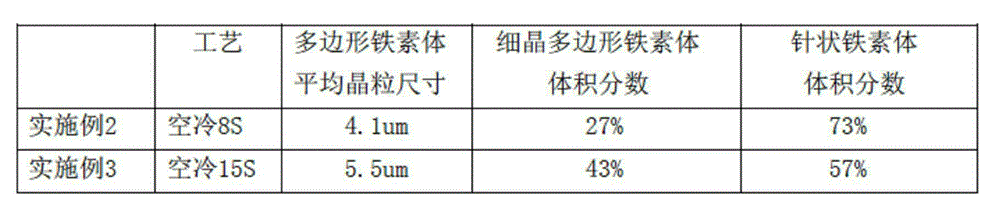

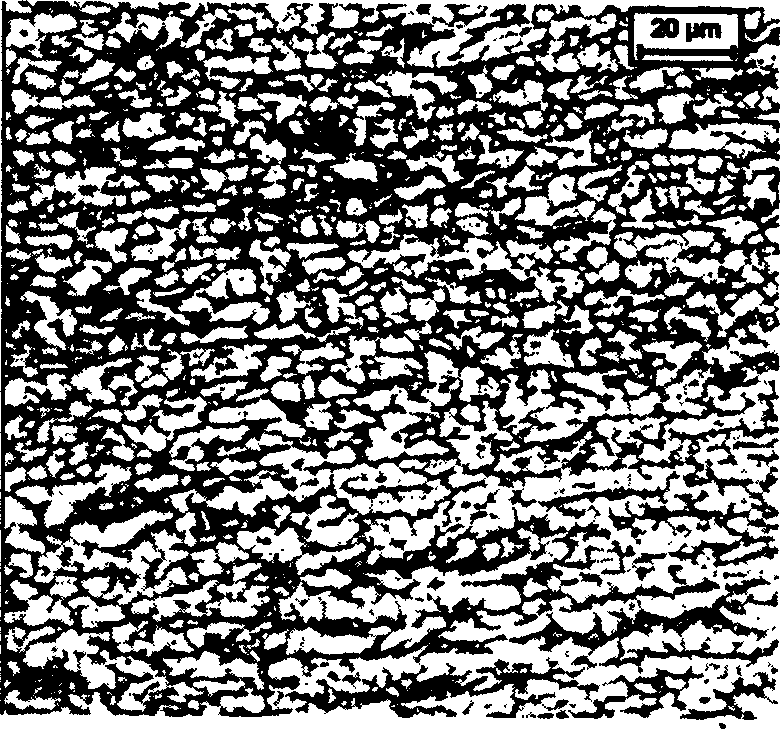

Polygonal ferrite-acicular ferrite two-phase steel plate/belt and production method thereof

ActiveCN103147000ARaise the ratioLow costTemperature control deviceChemical compositionHigh intensity

The invention discloses a polygonal ferrite-acicular ferrite two-phase steel plate / belt and a production method thereof and belongs to the technical field of high-strength low-alloy steel. The low-alloy steel comprises the following chemical components in percentage by weight: 0.03%-0.12wt% of C, 0.10wt%-1.5wt% of Si, 0.5wt%-2.1wt% of Mn, not more than 0.02wt% of P, not more than 0.01wt% of S, 0.02wt%-0.1wt% of Nb, 0.05wt%-0.45wt% of Mo, the balance being Fe and inevitable impurities. A few alloy elements including 0-0.4wt% of Cu, 0-0.5wt% of Ni, 0-0.5wt% of Cr and the like are added in the low-alloy steel. The production process comprises the following steps of: steel-making, continuous-casting, re-heating, rough-rolling, finish-rolling, cooling, relaxing and preserving the heat and quickly cooling. The polygonal ferrite-acicular ferrite two-phase steel plate / belt has the advantages of high toughness and plasticity in addition to high strength level, and is applicable to the vehicle plate filed and the pipeline steel filed with high requirements on strength, plasticity and toughness.

Owner:CENT IRON & STEEL RES INST

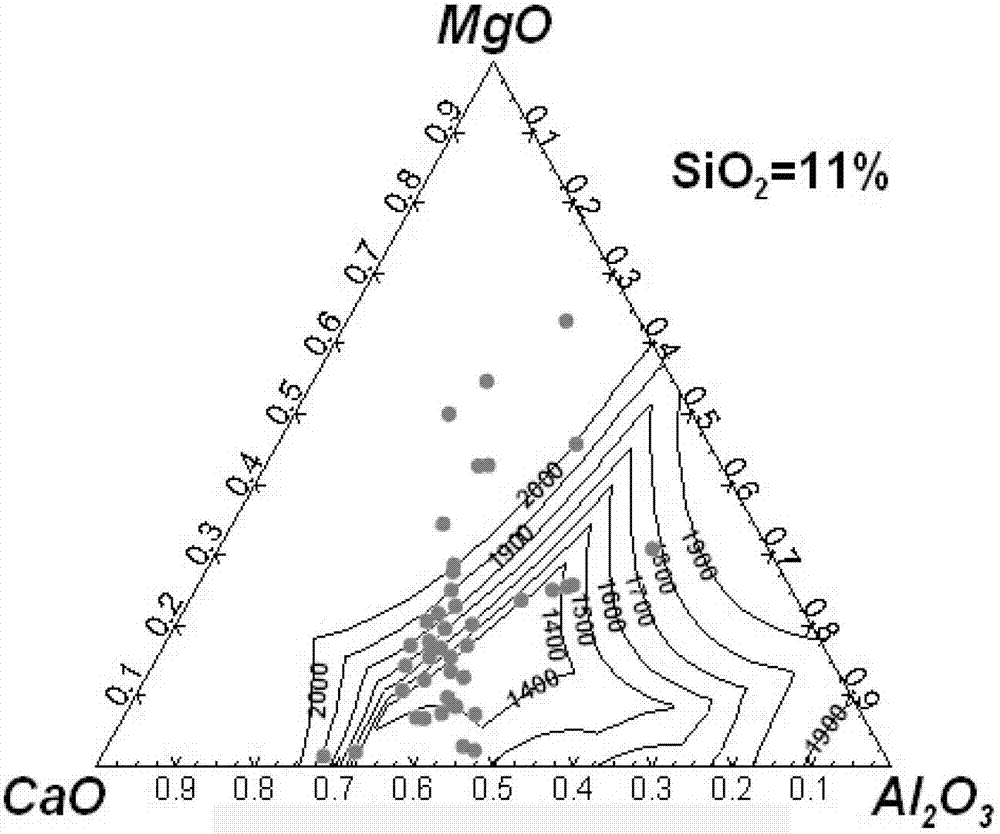

Method for controlling low-melting-point inclusion in high-strength low-alloy steel

InactiveCN103045806ANot easy to polymerizeReduce distortionProcess efficiency improvementNon-metallic inclusionsMaterials science

The invention provides a method for controlling a low-melting-point inclusion in high-strength low-alloy steel, which comprises the following steps: 1, tapping into a ladle, and adding additives into molten steel in the ladle after the start of tapping, wherein the additives include an iron alloy, aluminum deoxidizer, slow release deoxidizer and lime; 2, performing LF (ladle furnace) refinement in the ladle, wherein the basicity range of slag in the refinement process is 3-6; the refining slag subjected to LF slagging comprises the following components in percentage by mass: 50-65% of CaO, 6-12% of MgO, 13-26% of Al2O3, 9-19% of SiO2 and less than 0.5% of (FeO+MnO); 3, after slagging, blowing Ar gas from the bottom of the ladle, and desulfurizing while strongly stirring; and 4, in the strongly stirring process and the subsequent process, reacting the slag, the molten steel and an inclusion. The invention has the following advantages: favorable deoxidization and desulfurization effect is achieved, and simultaneously, the composition of the non-metallic inclusion in the steel is controlled to be in a high-melting-point region of a CaO-MgO-Al2O3(-SiO2) phase diagram, so that the inclusion is less prone to polymerization, and less deformation is caused in the subsequent rolling process, thereby achieving the purpose of controlling the large strip-shaped inclusion in a high-strength low-alloy steel plate.

Owner:UNIV OF SCI & TECH BEIJING

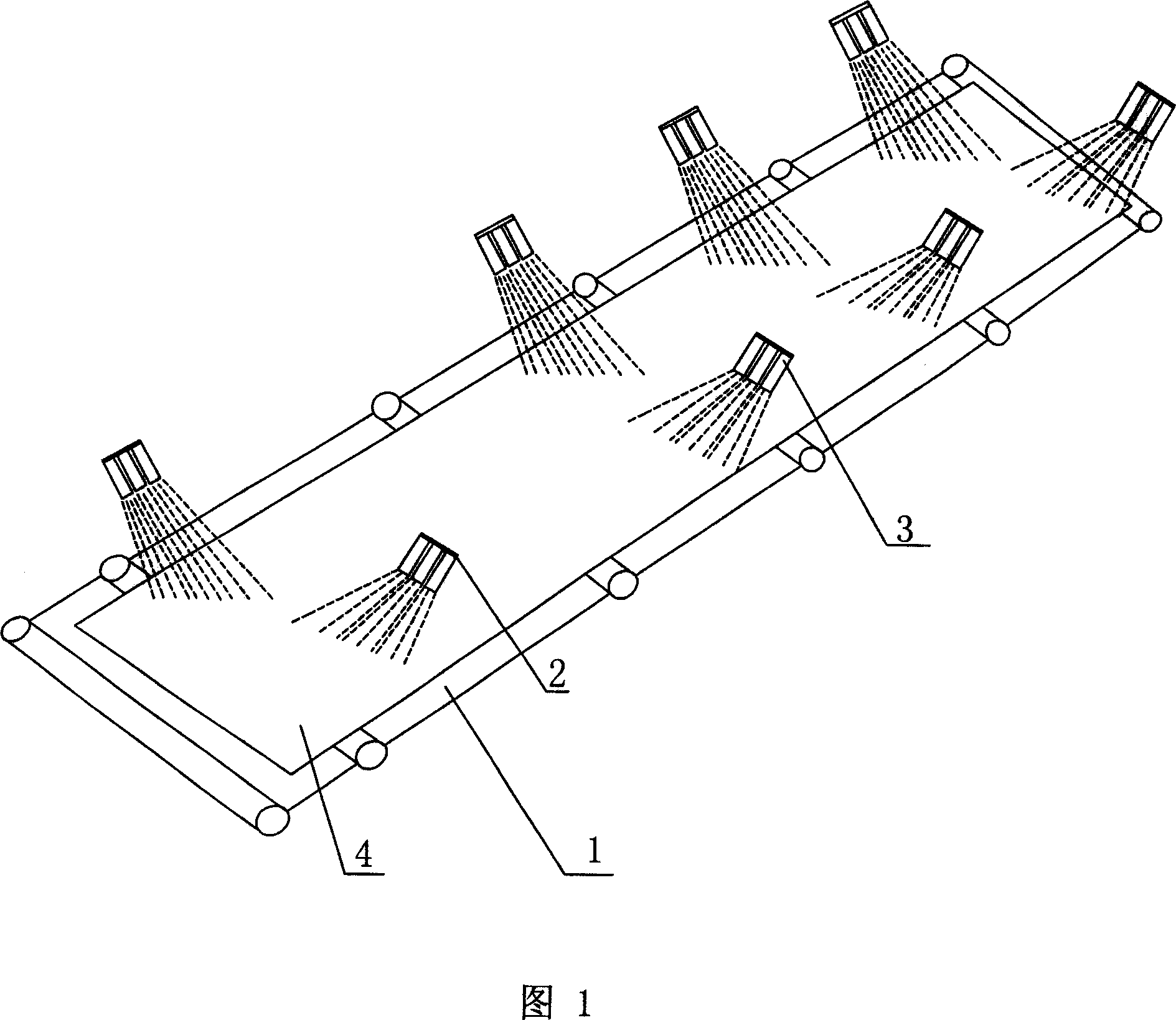

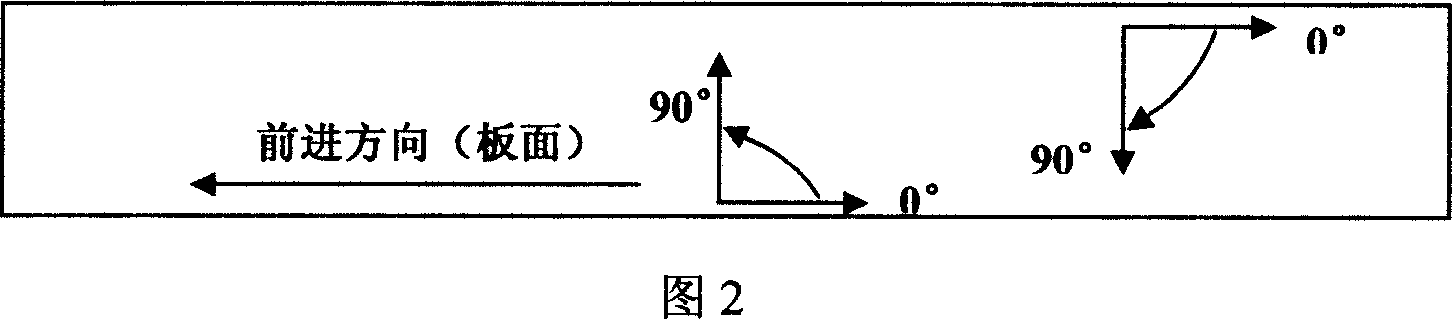

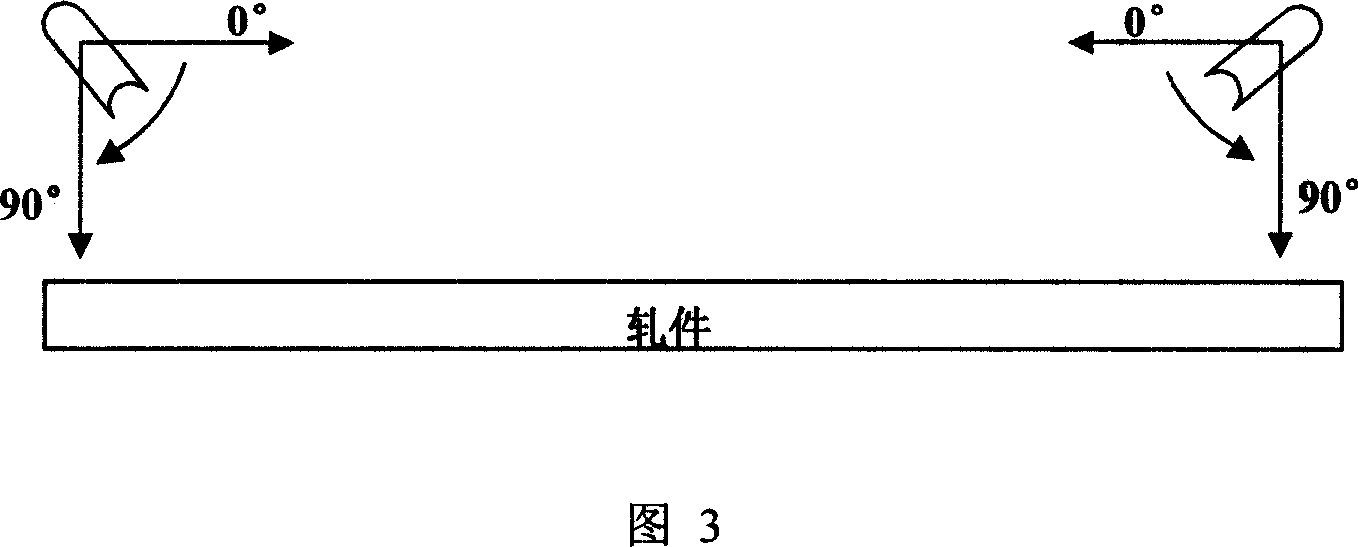

Laminated flowing cooling water side-jetting sweeping system after high-strength low-alloy steel being rolled

InactiveCN1947876AAvoid defects such as bucklingImprove mechanical propertiesWork treatment devicesCooling bedsSheet steelSprayer

A side-spray scavenge system for the laminar-flow cooling water on the rolled high-strength low-alloy steel is composed of a conveying roller way for conveying the rolled steel on it, and a laminar-flow cooling unit with at least a group of side sprayers arranged at both sides of said roller way, connected to water inlet tube, and with at least one nozzle.

Owner:NANJING IRON & STEEL CO LTD +1

Low-alloy high-strength steel and its manufacturing method

The high strength low alloy steel comprises: C 0.06-0.09 wt%, Mn 1.30-1.40 wt%, Si 0.195-0.305 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, V 0.025-0.035 wt%, Nb 0.015-0.025 wt%, Ti 0.010-0.020 wt%, Al 0.020-0.035 wt%, and Ca 0.0015-0.0045 wt%, except Fe and inevitable impurity. The making process includes: a. smelting in converter with C content in blowoff not less than 0.04 wt% and free oxygen controlled in 550-650 ppm; b. RH vacuum deairing for over 6 min; c. calcifying treatment at the overheat temperature controlled in 10-20 deg.c higher than liquid phase line temperature; and d. casting at temperature of 10-20 deg.c higher than liquid phase line and casting speed of 1.1-1.3 m / min. The present invention has lowered Nb content for avoiding edge crack, reasonable V content for required strength, and calcification for pure steel content and stable quality.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of low carbon 42MPa grade composite fortified ultrafine crystal grain band steel

A 420 MPa-class low-carbon band steel with superfine crystal grains contains C (0.1-0.14 wt.%), Si (0.18-0.40), Mn (0.85-1.10), P (0-0.01), S (0-0.01) and Fe (rest). Its preparing process includes such steps as smelting, conticasting, coarse rolling, fine rolling, cooling, and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (420-450 MPa), high tension strength (530-550 MKPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Ultralow-hydrogen type high efficiency iron powder welding rod for low alloy high streagth steel

InactiveCN1657224AImprove low temperature toughnessGood pressure coating processWelding/cutting media/materialsSoldering mediaIron powderHydrogen

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Coated welding wire for welding low-alloy high-strength steel and manufacturing method

InactiveCN106736013AMeet welding requirementsHigh strengthWelding/cutting media/materialsSoldering mediaHigh intensityImpurity

The invention discloses a coated welding wire for welding low-alloy high-strength steel. The coated welding wire comprises a welding wire substrate and a coating which coats the surface of the welding wire substrate, wherein the welding wire substrate is made from the following components in percentage by weight: 0.029 to 0.041 percent of Ti, 0.01 to 0.015 percent of Al, 0.083 to 0.11 percent of Nb, 0.1 to 0.15 percent of C, 0.2 to 0.3 percent of Cr, 0.3 to 0.5 percent of Si, 0.01 to 0.03 percent of N, 1.4 to 1.7 percent of Ni, 0.1 to 0.6 percent of Mo, less than or equal to 0.002 percent of P, less than or equal to 0.002 percent of S, and the balance of iron and unavoidable impurities, wherein as specified by the following formula, K is between 0.013 and 0.032, K=29[Ti]+52[Al]+27[Nb]-100[N]; [Al], [Ti], [Nb] and [N] represent the weight percentage contents of Al, Ti, Nb and N in the welding wire substrate respectively. The invention further discloses a manufacturing method of the coated welding wire for welding the low-alloy high-strength steel. By adopting the coated welding wire, high strength of welding metal is ensured, the welding performance of the low-alloy high-strength welding wire is improved finitely, the occurrence of cold cracks is controlled, a low splashing rate is achieved, and the welding requirement of the high-strength low-alloy steel is met.

Owner:安徽飞弧焊业股份有限公司

Universal gondola car

ActiveCN101434242ASafe and fast loading and unloadingMeet the use requirementsUnderframesAxle-box lubricationBogieGeneral purpose

The invention belongs to general-purpose open wagons, belonging to the transportation vehicles, in particular to the rail conveying vehicles. The invention comprises a body, a braking device, a bogie and a coupler and draft gear device. The body comprises a chassis and a side wall and an end wall which are arranged to be vertical to the chassis; and doors are arranged on the side wall. The body forms a proper integral stressing frame structure to reduce the self-weight of the body steel structure without reducing the rigid so as to lead the wagon to get higher bearing capability. Two couples of split folding doors are arranged on each side of the body and the door is provided with better closing performance and higher reliability and safety. The side wall appears as a split-style side wall and the discharging can be simultaneously carried out on two sides of the body so as to enhance the loading and discharging speed. The body is provided with a full-steel welded structure and the main beam parts and plates adopt the 09CuPTiRE-A atmospheric corrosion-resistant high-strength low-alloy steel so as to enhance the anti-corrosion performance and prolong the service-life and maintenance cycle of the wagon and also to reduce the maintenance work and conveying cost.

Owner:CRRC MEISHAN

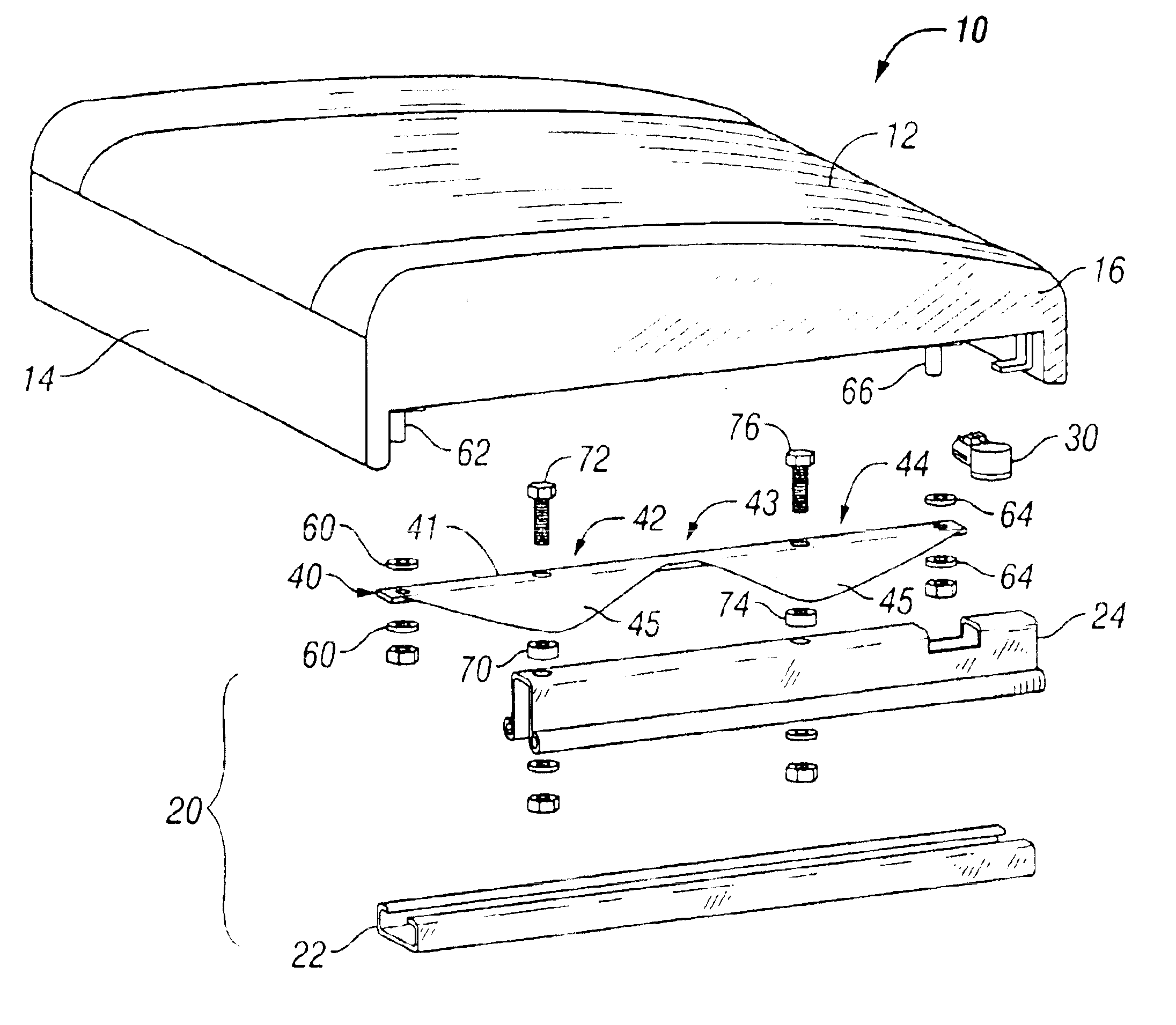

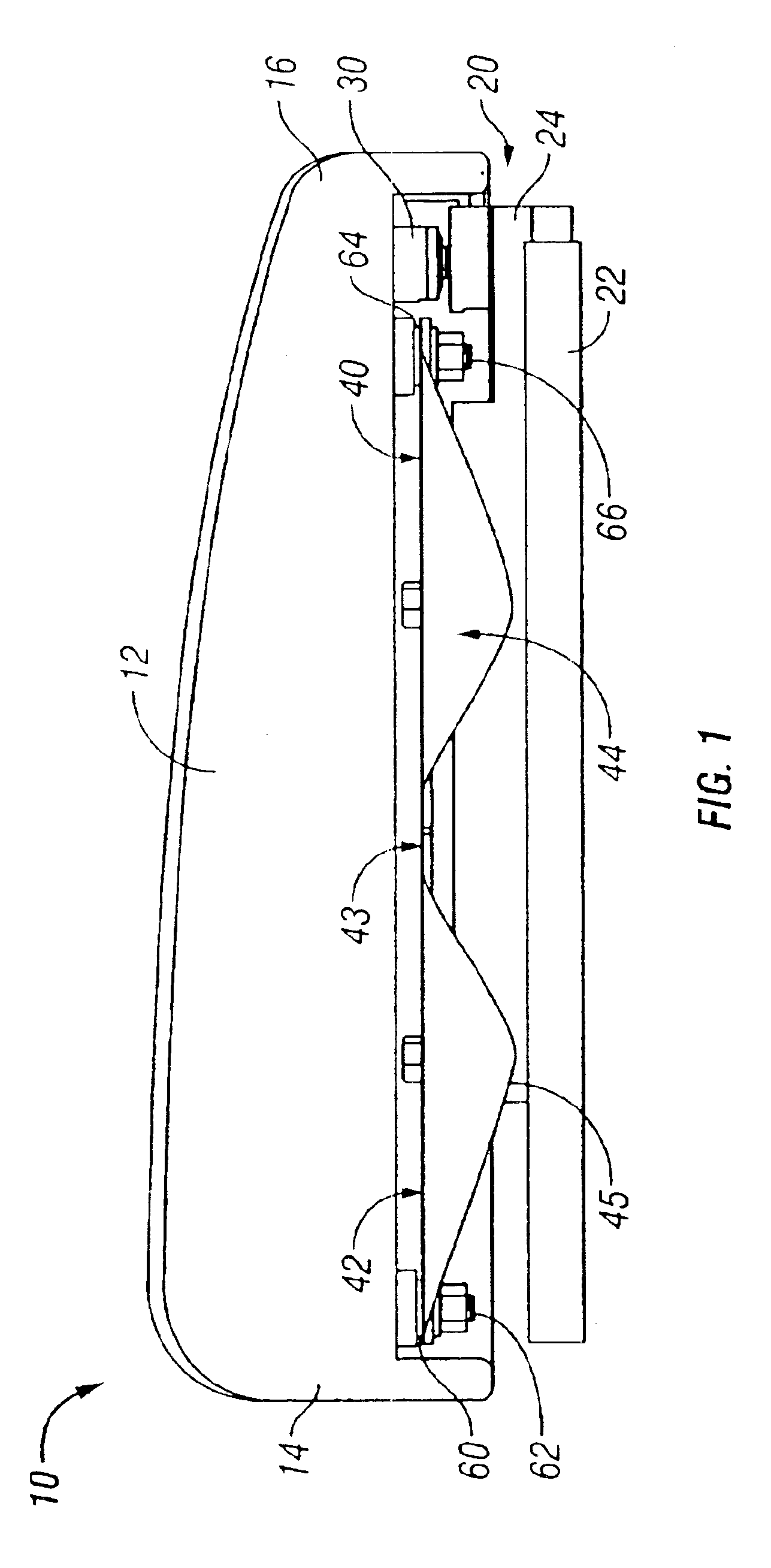

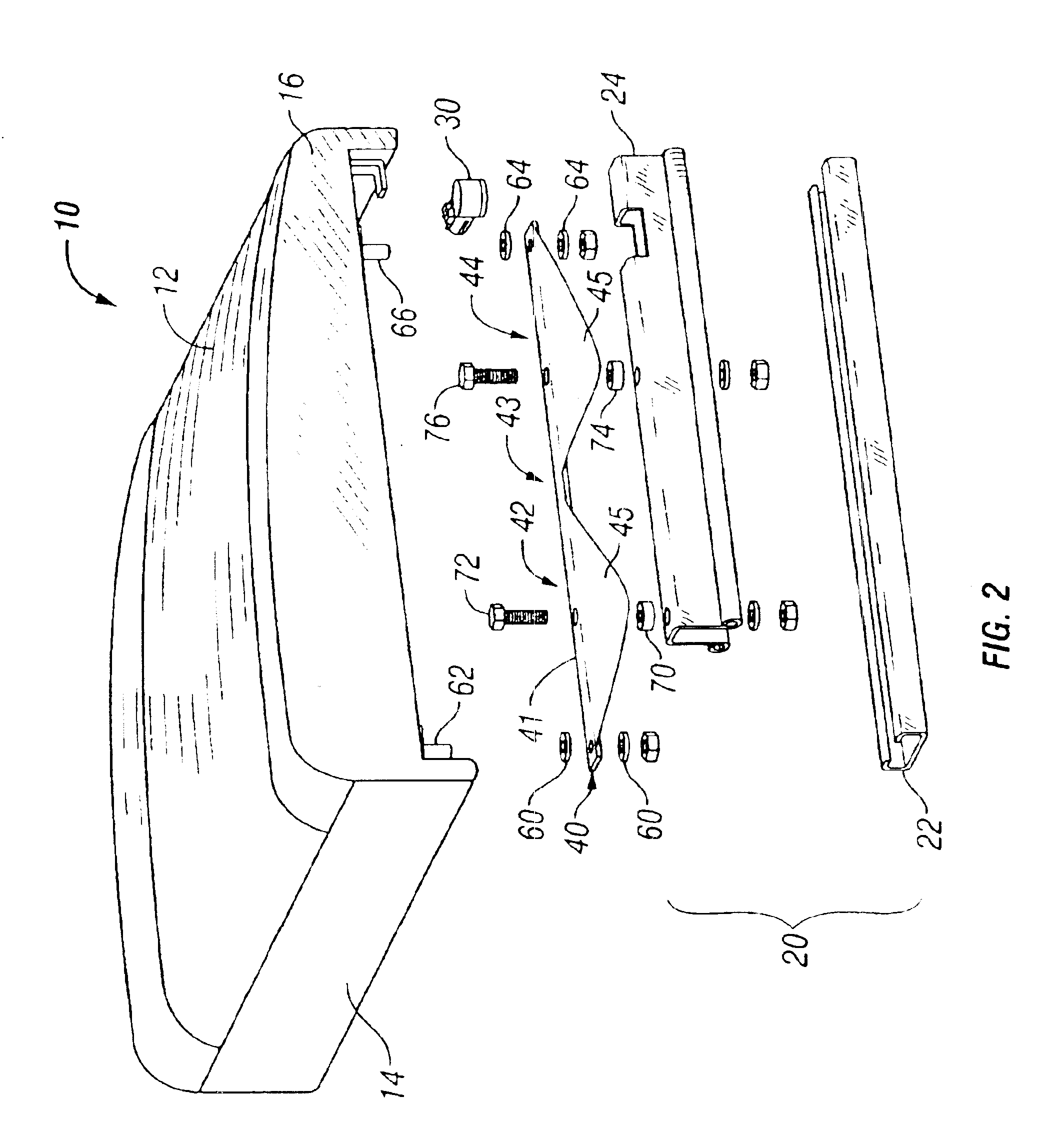

Seat weight measurement system

InactiveUS6849807B2Improve rigidityAdd flexiblyElectric devicesBelt retractorsHigh intensityAlloy steel

A weight measurement system is disclosed for measuring the weight of an occupant in a vehicle seat. In a preferred embodiment, a sensor is positioned at the rear portion of the vehicle seat and a load transfer link is used to transfer the weight from the front portion of the vehicle seat to the rear portion, to be measured by the sensor. The transfer link is a selectively compliant beam having a first rigid section and a second rigid section connected to each other via a flexible area. The first and second rigid sections preferably include wing portions for increasing the rigidity of the sections. The flexible area is more compliant than the rigid sections. The load transfer link is configured to transition a load placed on the front portion of the link to the rear portion. In a more preferred embodiment of the invention, the load transfer link is made of a high strength, low alloy steel.

Owner:KAVLICO CORP

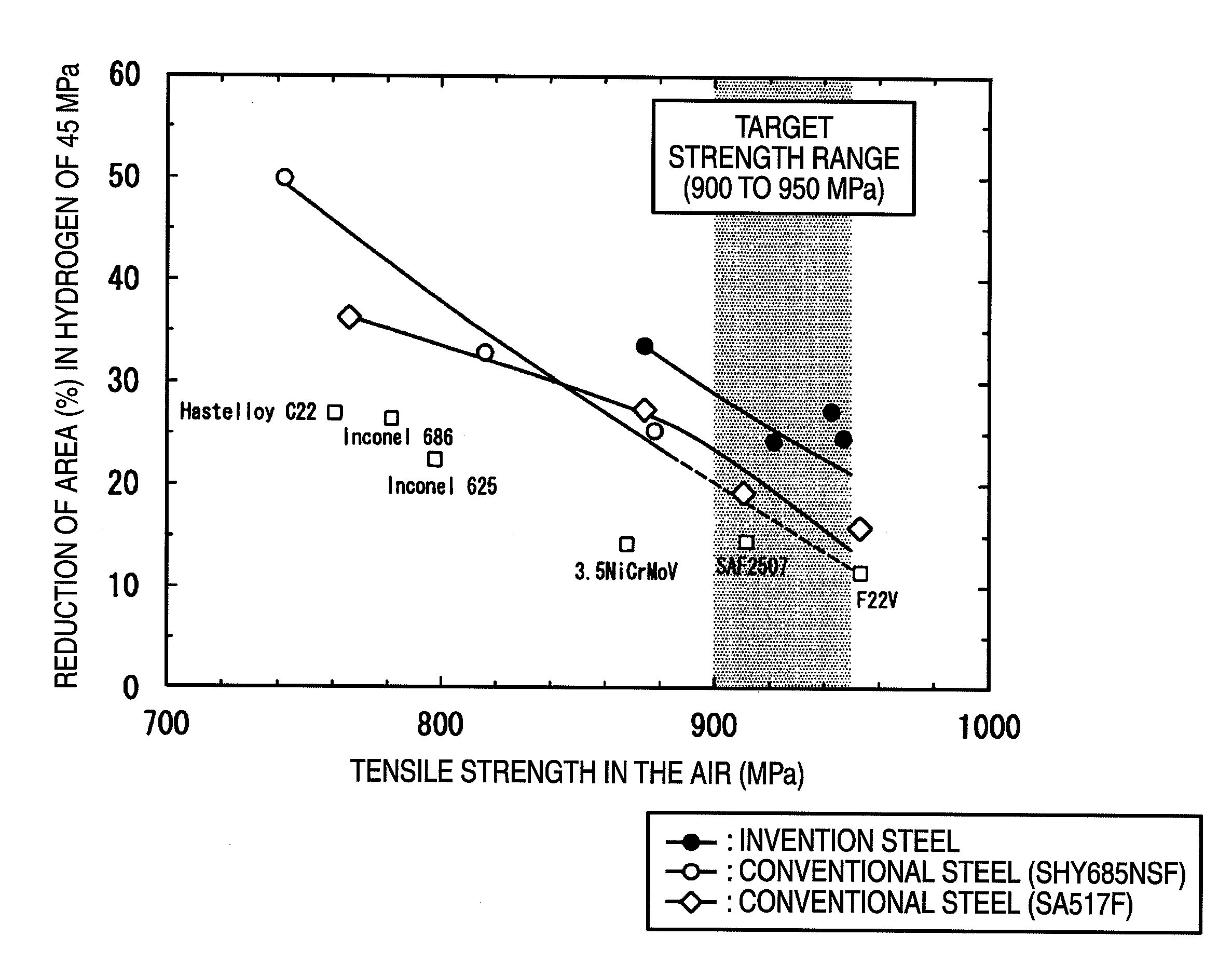

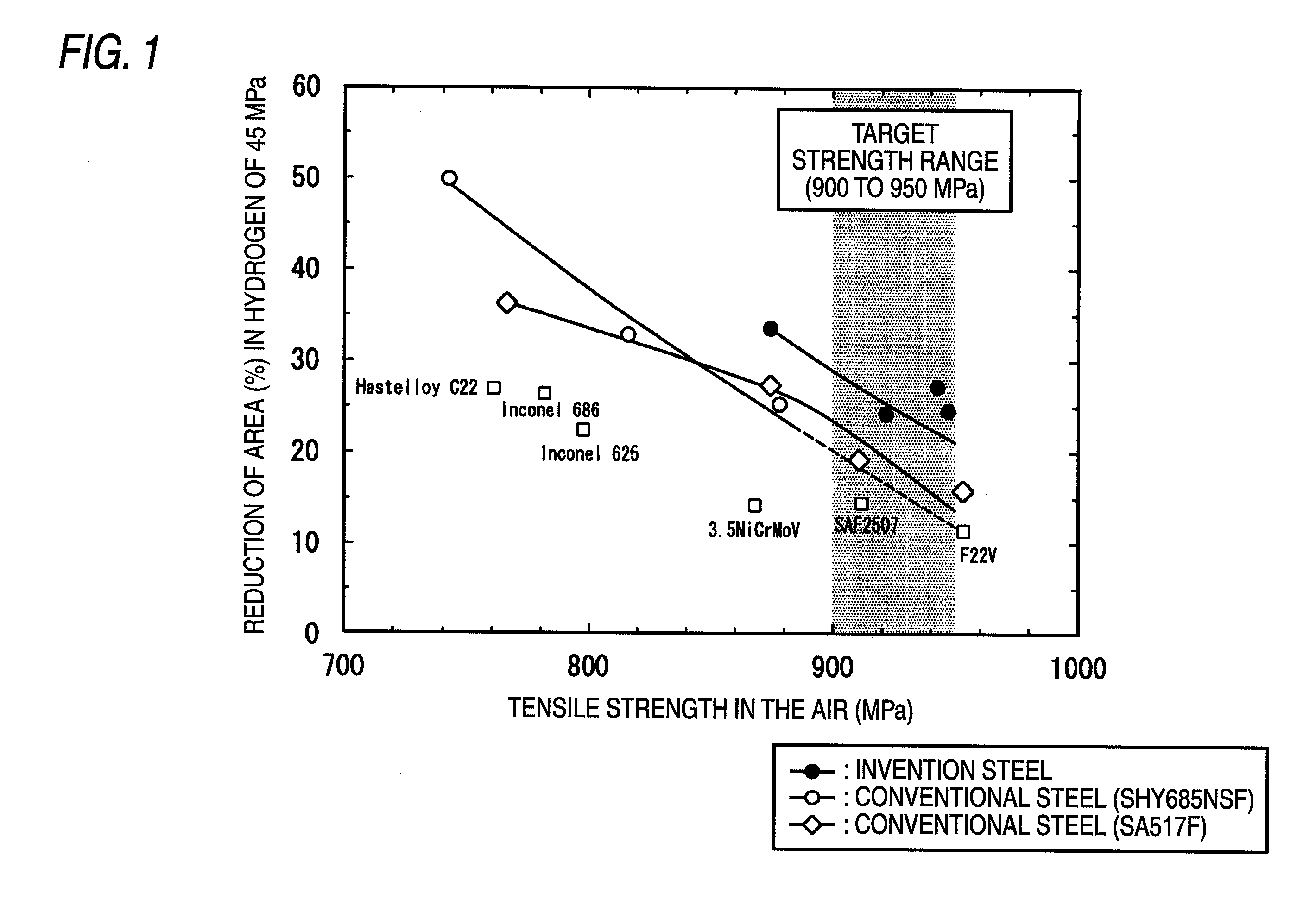

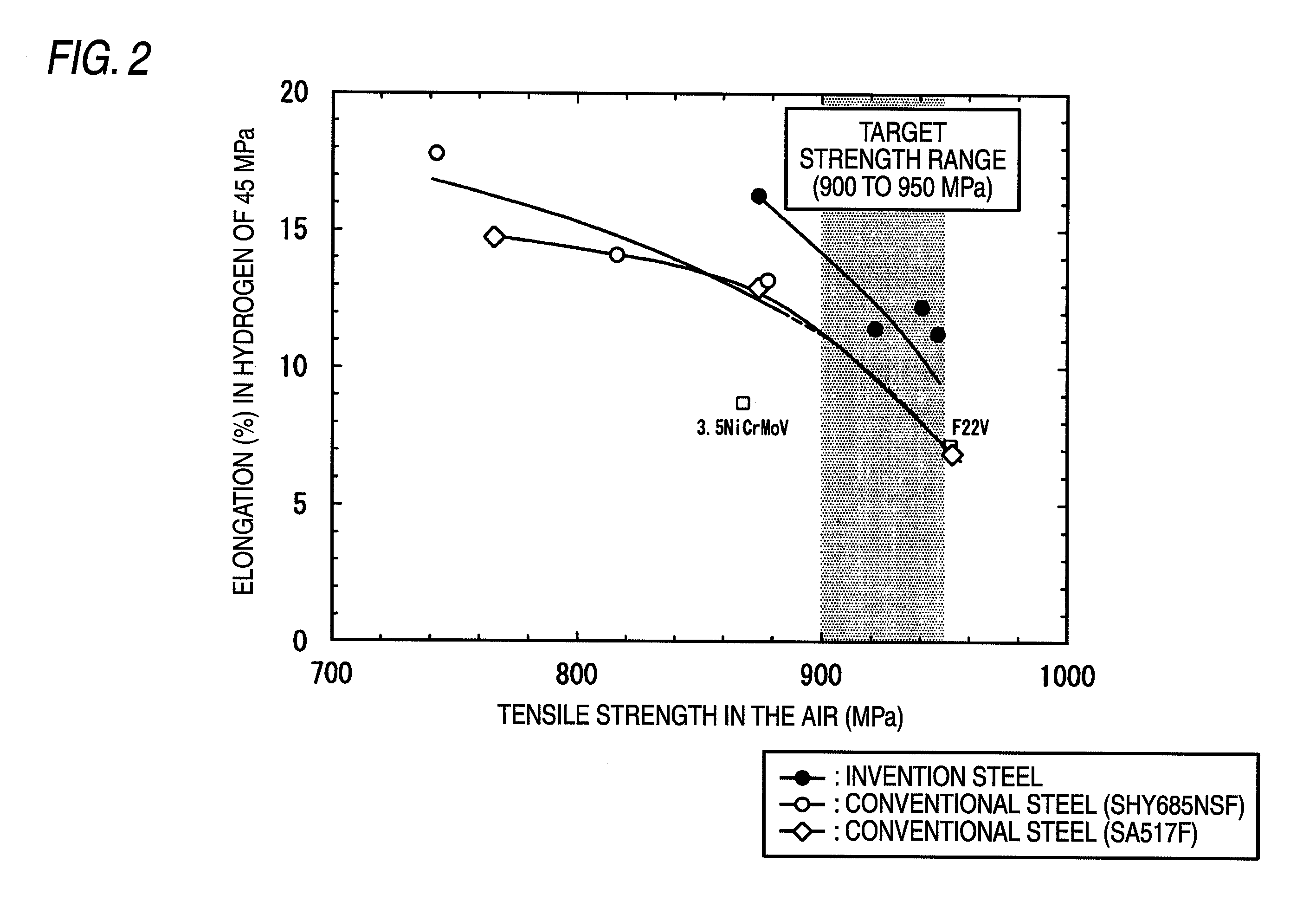

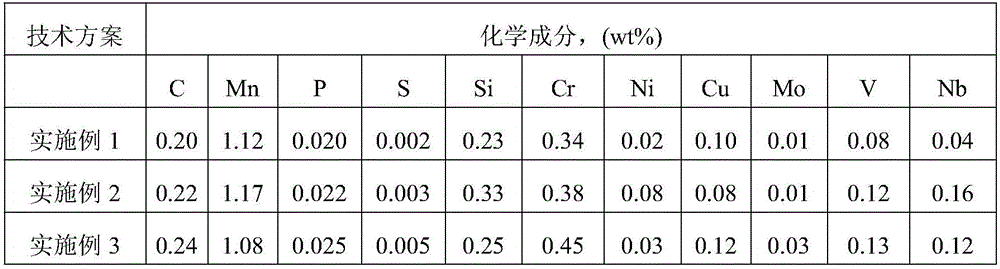

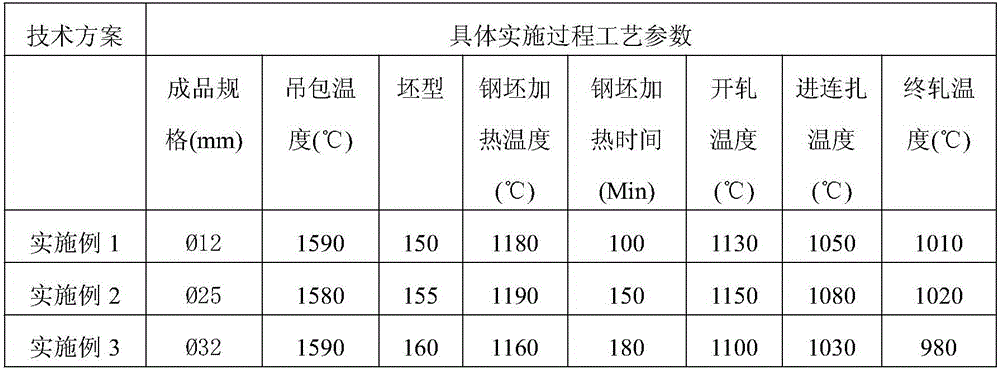

High-strength low-alloy steel excellent in high-pressure hydrogen environment embrittlement resistance characteristics and method for producing the same

Owner:JAPAN STEEL WORKS LTD

High-strength low alloy steel force transfer rod and manufacturing method thereof

The invention discloses a high-strength low alloy steel force transfer rod. The force transfer rod comprises the following chemical elements in percentage by weight: 0.20-0.24% of carbon, silicon not more than 0.35%, 1.00-1.50% of manganese, nickel not more than 0.35%, 0.35-0.50% of chromium, molybdenum not more than 0.35%, 0.10-0.15% of vanadium, 0.05-0.20% of niobium, copper not more than 0.35%, sulfur not more than 0.035%, phosphorus not more than 0.035%, 0.018-0.025% of nitrogen, and the balance of iron. A coating force transfer rod is adopted; the data under general conditioners shows the initial cost is increased by 25-50% compared with general carbon steel; if accounted by the total project investment, the cost is increased only by 0.49-2.16%; but in consideration of long-time service life, the corrosion-resistant service life can reach 75 years or more; and if the saved maintenance cost at this time is calculated, the economical value is higher, and the force transfer rod is suitable for the national demands of sustainable development.

Owner:浙江富钢集团有限公司

Ultrahigh-strength low-alloy steel and manufacturing method thereof

InactiveCN104726782AGood mechanical propertiesSimple processUltimate tensile strengthMechanical property

The invention relates to ultrahigh-strength low-alloy steel and a manufacturing method thereof. The alloy steel comprises the following components in percentage by weight: 0.40-0.42% of C, 0.20-0.30% of Si, 0.65-0.75% of Mn, not more than 0.002% of S, not more than 0.005% of P, 0.75-0.85% of Cr, 0.25-0.28% of Mo, 1.85-1.95% of Ni and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: smelting raw materials by an electric furnace, refining outside the furnace, performing vacuum degassing, re-melting electroslag, forging and performing heat treatment to obtain the ultrahigh-strength low-alloy steel. Compared with the prior art, the ultrahigh-strength low-alloy steel manufactured by the manufacturing method provided by the invention has good mechanical properties, wherein the tensile strength Rm is not less than 1800MPa, the yield strength Rp 0.2 is not less than 1400Mpa, and the elongation rate A5 is not less than 10%; and the process for manufacturing the ultrahigh-strength low-alloy steel is simple and easy to operate.

Owner:SHANGHAI SHENJIANG FORGING

Low carbon 520MPa grade composite fortified ultra fine crystal grain band steel

A 520 MPa-class low-carbon band steel with superfine crystal grains contains C (0.12-0.15 wt.%), Si (0.15-0.40), Mn (1.10-1.30), Nb (0.007-0.015), P (0-0.01), S (0-0.001 and Fe (rest), and is prepared through smelting, conticasting, heating, rolling twice, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (520-570 MPa), high tension strength (620-690 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Production method of electrogalvanized high-strength low-alloy steel plate HC340LA+ZE for automobile

The invention discloses a production method of an electrogalvanized high-strength low-alloy steel plate HC340LA+ZE for an automobile, and belongs to the technical field of steel smelting. The technological process included by the production method comprises the steps of molten steel smelting and plate blank forming through casting, hot continuous rolling, cold continuous rolling, continuous annealing, leveling and electrogalvanizing. Components of molten steel smelting comprise, by mass percent, 0.04%-0.09% of C, 0.10%-0.25% of Mn, 0.02%-0.06% of Al, 0.010%-0.019% of Nb, 0.031%-0.039% of Ti, 0.010%-0.030% of P, not larger than 0.05% of Si, not larger than 0.025% of S, 0.02%-0.09% of Cr, 0.01%-0.08% of Ni and the balance Fe and inevitable impurities. The requirement of HC340LA+ZE steel prepared through the production method for the technology is loose, a product has good impact performance at normal temperature, automobile body deformation during colliding can be reduced, and passengersafety can be ensured.

Owner:武汉钢铁有限公司

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN100515655CImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsCrack resistanceArc stability

A low-alloy steel flux-cored welding wire for carbon dioxide gas shielded welding, the composition and content of the flux core in % of the total weight of the welding wire are as follows: TiO2: 3-6, Si: 0.3-0.5, Mn: 1.5-3.2, SiO2: 0.1 -0.8, ZrO2: 0.1-0.5, Fe: 2-7, Al+Mg: 0.5-1.2, Ni: 0.5-5, B: 0.002-0.015, Ti: 0.1-0.3, oxidation of alkali metal K, Na, Li The content of fluoride or fluoride equivalent to K, Na, and Li is 0.1-0.35, the content of fluoride F is 0.05-0.2, the fluoride or oxide of rare earth metal is equivalent to 0.005-0.2 of rare earth metal, and the content of C, Si, and Mn in the welding wire The product of the contents is 0.058-0.11. For high-strength low-alloy steel all-position welding process performance is good, it can maintain good arc stability and welding operation performance under the condition of high current and fast welding, the weld seam is smooth, the connection strength is high and it has a good -40 ℃ low temperature Impact toughness and excellent crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

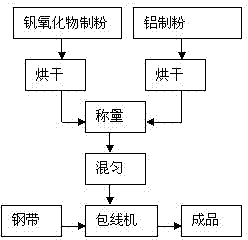

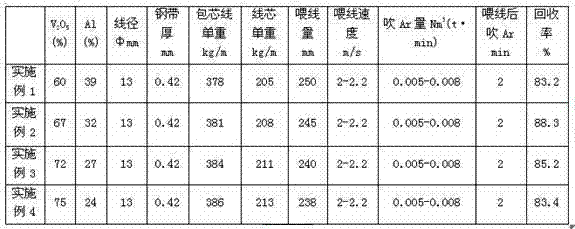

Vanadium oxide core-spun yarn for smelting vanadium microalloyed steel to increase vanadium content

The invention relates to a vanadium oxide core-spun yarn for smelting vanadium microalloyed steel to increase the vanadium content, belongs to high-strength low-alloy steel, and particularly relates to a vanadium-content-increasing additive for external vanadium microalloyed steel refining. The vanadium oxide core-spun yarn comprises a yarn core and an outer cover, wherein the outer cover is tightly clad on the yarn core. The vanadium oxide core-spun yarn is characterized in that the yarn core is formed by fully mixing 60-75% of powdered vanadium oxide V2O5, 39-24% of a powdered reducing agent (aluminum powder), and the balance being impuritiesby weight percentage; the outer cover is a low-carbon steel strip, and the thickness is 0.32-0.45mm; the core-spun yarn is circular strip-shaped, and the diameter is phi 9-13mm; the weight ratio of the yarn core and the outer cover per meter is 1.16-1.22. The vanadium oxide core-spun yarn is prepared according to the steps of powder preparation, drying, batching, powder stirring, finished product packaging and checking. The vanadium oxide core-spun yarn has the advantages that the design is novel and the technical process of melting ferrovanadium is simplified; energy is saved, the consumption is reduced, and the production cost is reduced; the vanadium recovery rate is obviously improved, the defects of a large amount dust and the environmental pollution are further prevented, and the vanadium oxide core-spun yarn is beneficial to safe production.

Owner:马鞍山中冶钢铁冶金高新技术有限公司 +1

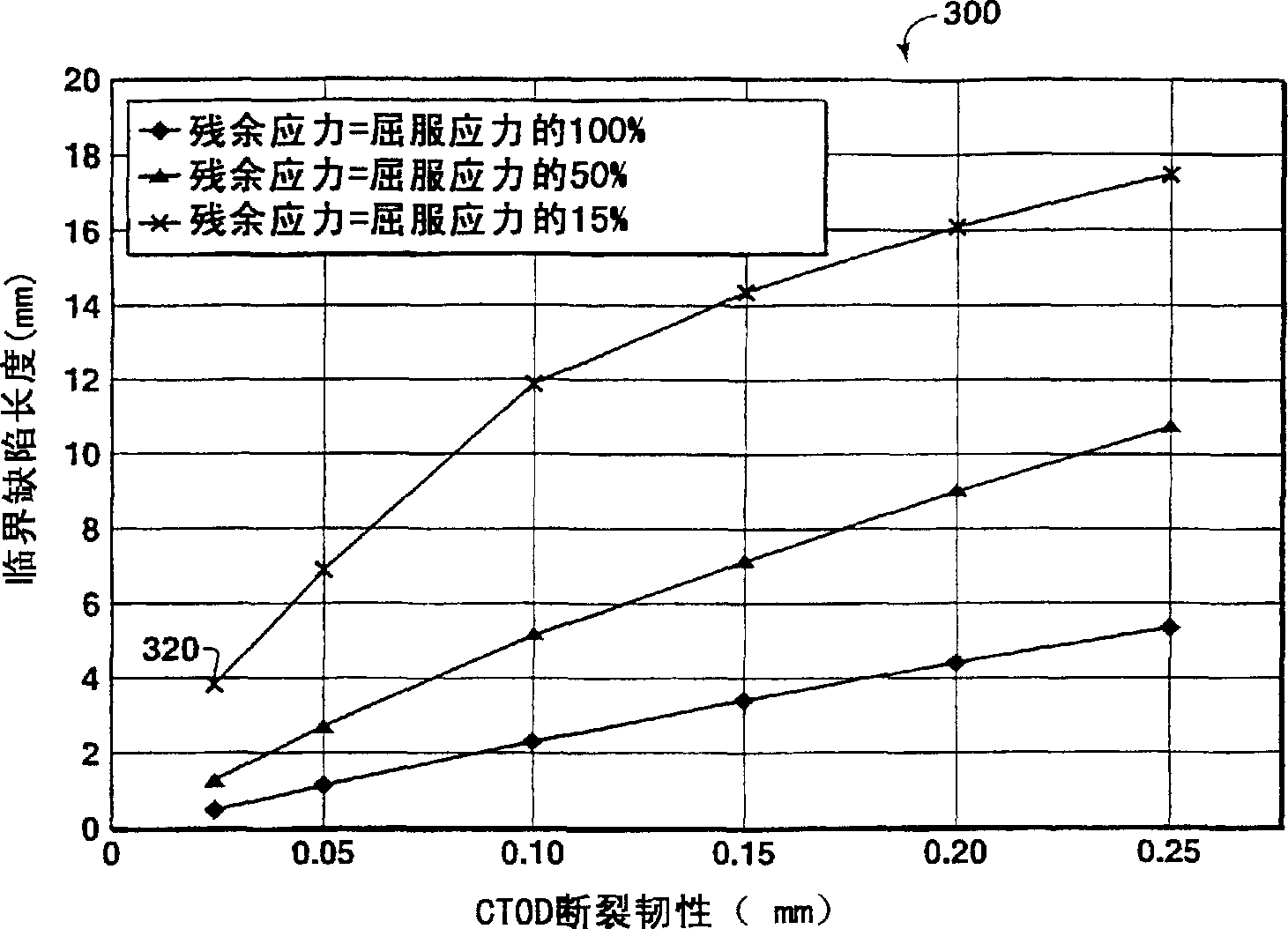

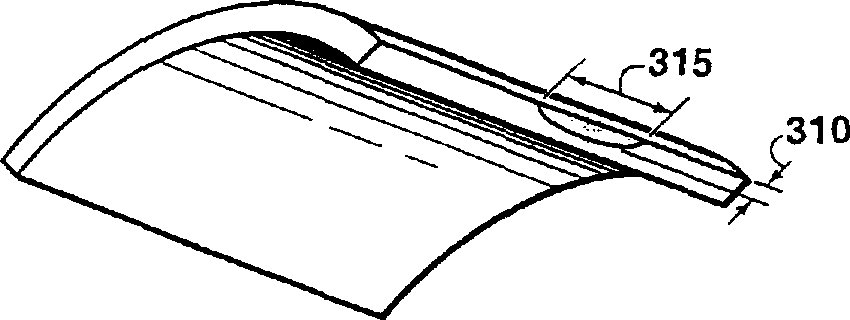

Ultra-high strength cryogenic weldments

Provided is a welding method for connecting the ultra-high strength low alloy steels, in order to obtain weldments with a tensile strength greater than about 900 MPa (130ksi). The welding line metal on the said weldments has a fracture toughness suited to low-temperature applications based on the known the fracture mechanics principle.

Owner:EXXON PROD RES CO

Low carbon 420 MPa grade composite fortified ultr-fine crystal grain band steel

A 420 MPa-class low-carbon band steel with superfine crystal grains contains C (0.10-0.14 wt.%), Si (0.18-0.40), Mn (0.85-1.10), P (0-0.01), S (0-0.01) and Fe (rest), and is prepared through smelting, conticasting, heating, rolling twice, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (420-450 MPa), high tension strength (530-550 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Preparaton method of low carbon 520 MPa grade composite fortified ultra fine crystal grain band steel

A 520 MPa-class low-carbon band steel with superfine crystal grains contains C (0.12-0.15 wt.%), Si (0.5-0.40), Mn (1.10-1.30), Nb (0.007-0.015), P (0-0.01), S (0-0.01) and Fe (rest), and is prepared through smelting, conticasting, coarse rolling, fine rolling, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (520-270 MPa), high tension strength (630-690 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com