Thick coal-bed shield hydraulic support

A technology of hydraulic support and thick coal seam, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of small lifting space of roof beam, deep burial of mining coal seam, poor use effect, etc. The effect of high working face output and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

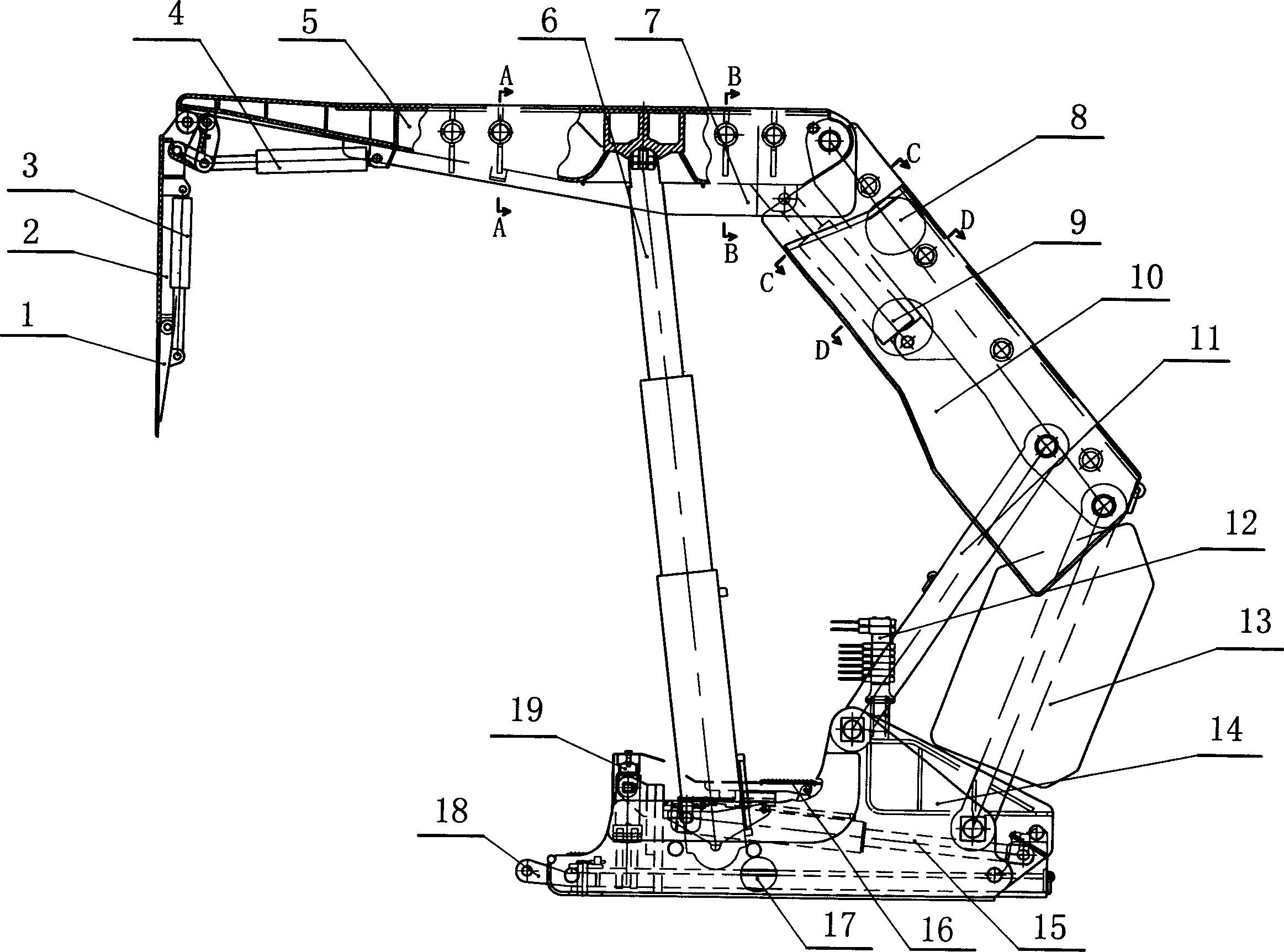

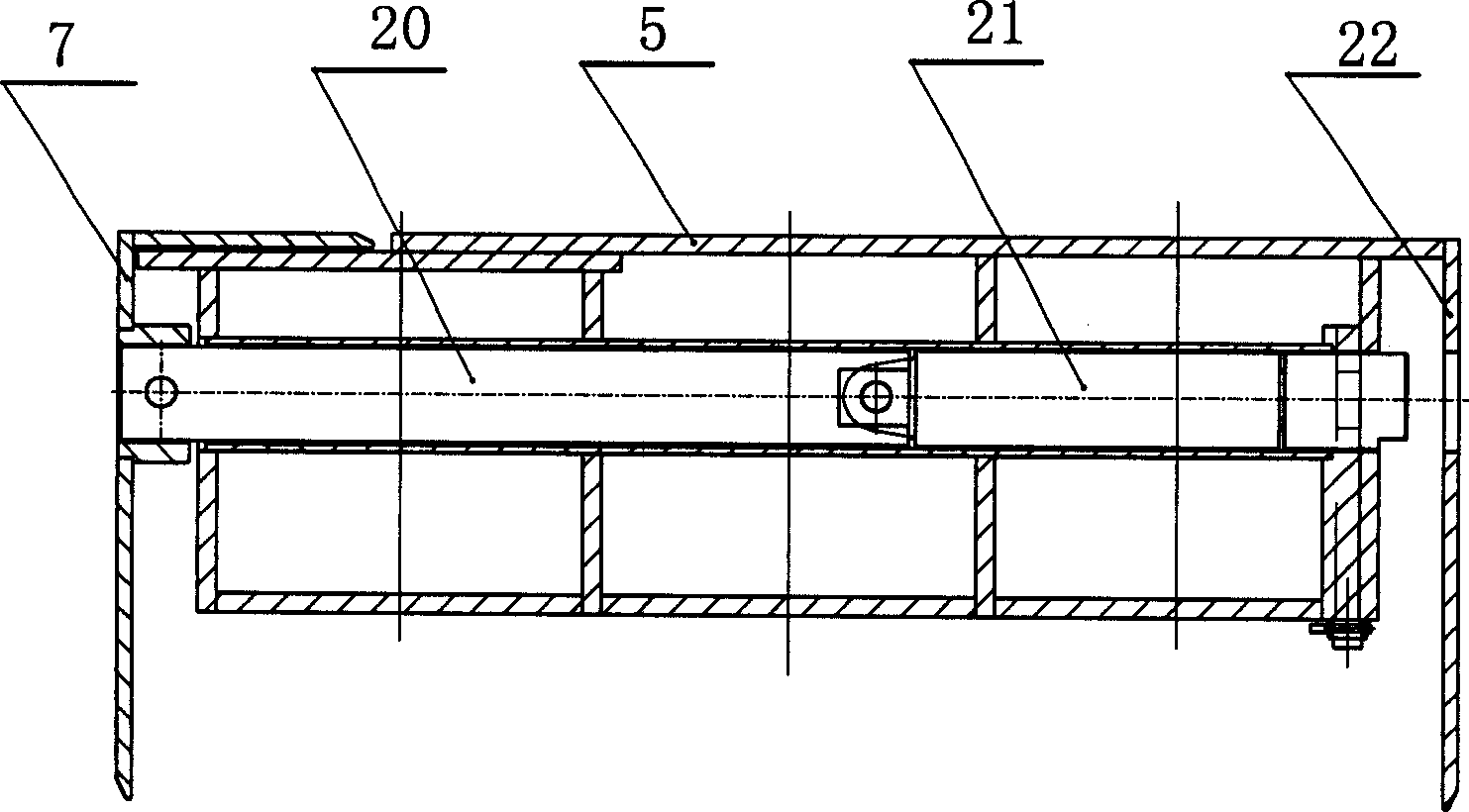

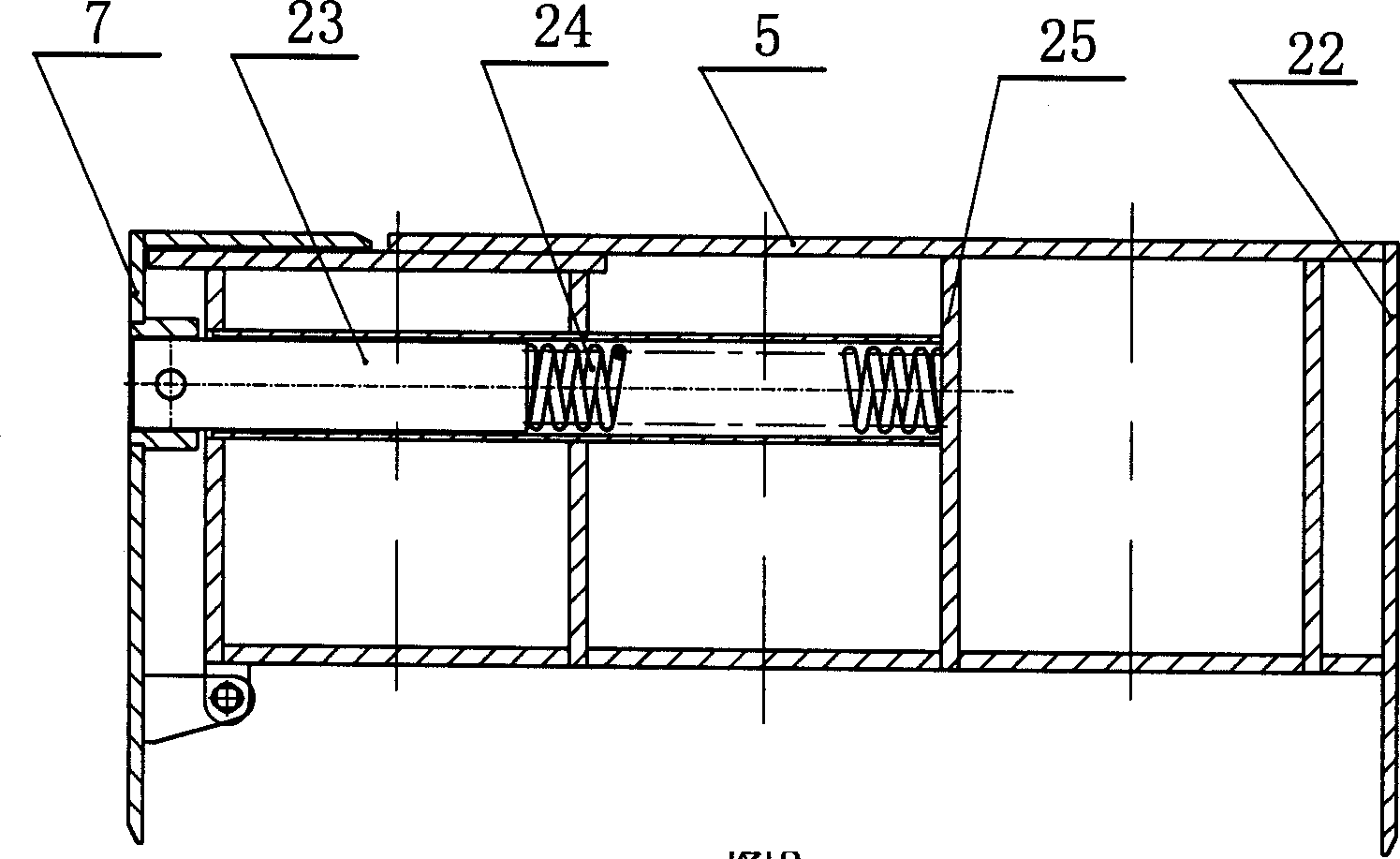

[0019] A thick coal seam cover type hydraulic support, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6Shown, wherein comprise top beam 5, cover beam 8, base 14, column 6, front link 11, rear link 13, push jack 15 and control valve group 12; The rear end of top beam 5 and the front end of cover beam 8 The upper end of the column 6 is installed on the shaft seat on the bottom surface of the top beam 5 through the pin shaft, and is connected with it in relative rotation, and the lower end of the column 6 is installed on the base 14 through the pin shaft, and forms with it Relatively rotating connection; the upper end of the front link 11 is installed on the rear end of the shield beam 8 through the hinge shaft, and the lower end of the front link 11 is installed on the base 14 through the hinge shaft; the rear link ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com