Thermomechanical processing routes in compact strip production of high-strength low-alloy steel

a technology of low-alloy steel and compact strip, applied in the direction of metal rolling arrangement, etc., can solve the problem of not allowing recrystallization, and achieve the effect of increasing the time allowed between deformation passes through roll stands, accurate ultrasonic welding test, and increasing recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is directed to a process for manufacturing high-strength low-alloy steel that is substantially ferritic, has a relatively uniform and fine ferrite grain size, has relatively high toughness, and has relatively low ultrasonic test background levels. The steel is generally appropriate for use as line pipe to the extent that is satisfies certain industry standards, such as, for example, American Petroleum Institute Standards for linepipe and other high performance steel grades. The steel includes one or more microalloying elements, such as niobium, vanadium, titanium, or a combination thereof.

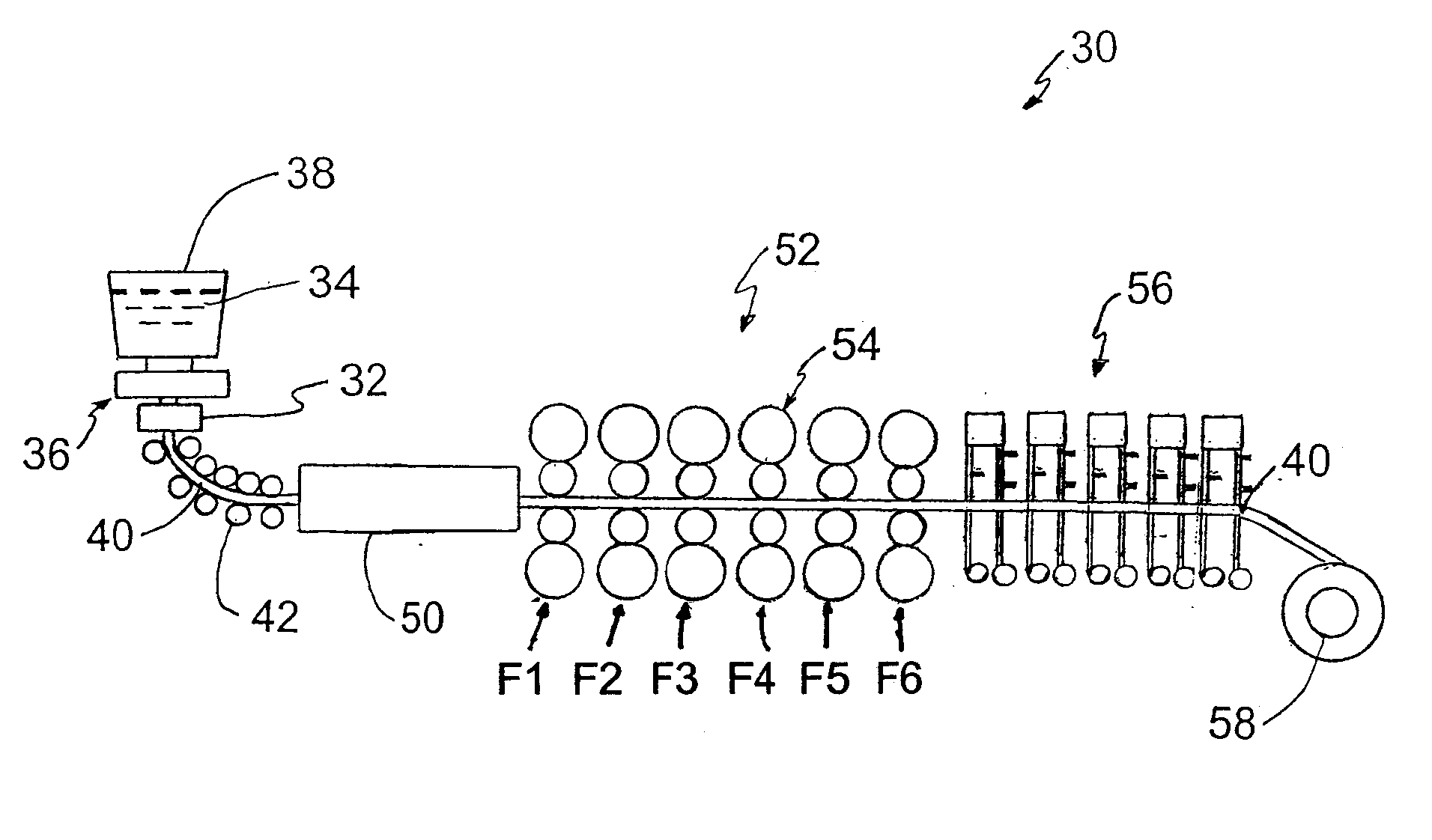

[0028] The metallurgical situation is very different in a CSP plant than in an integrated mill. Referring now to the drawings, FIG. 1 shows a thin-slab casting line 30 used in the present invention. The casting apparatus includes a mold 32 that receives molten steel 34 from a delivery system 36 filled by a ladle 38. The molten steel 34 passes through the mold 32, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com