Patents

Literature

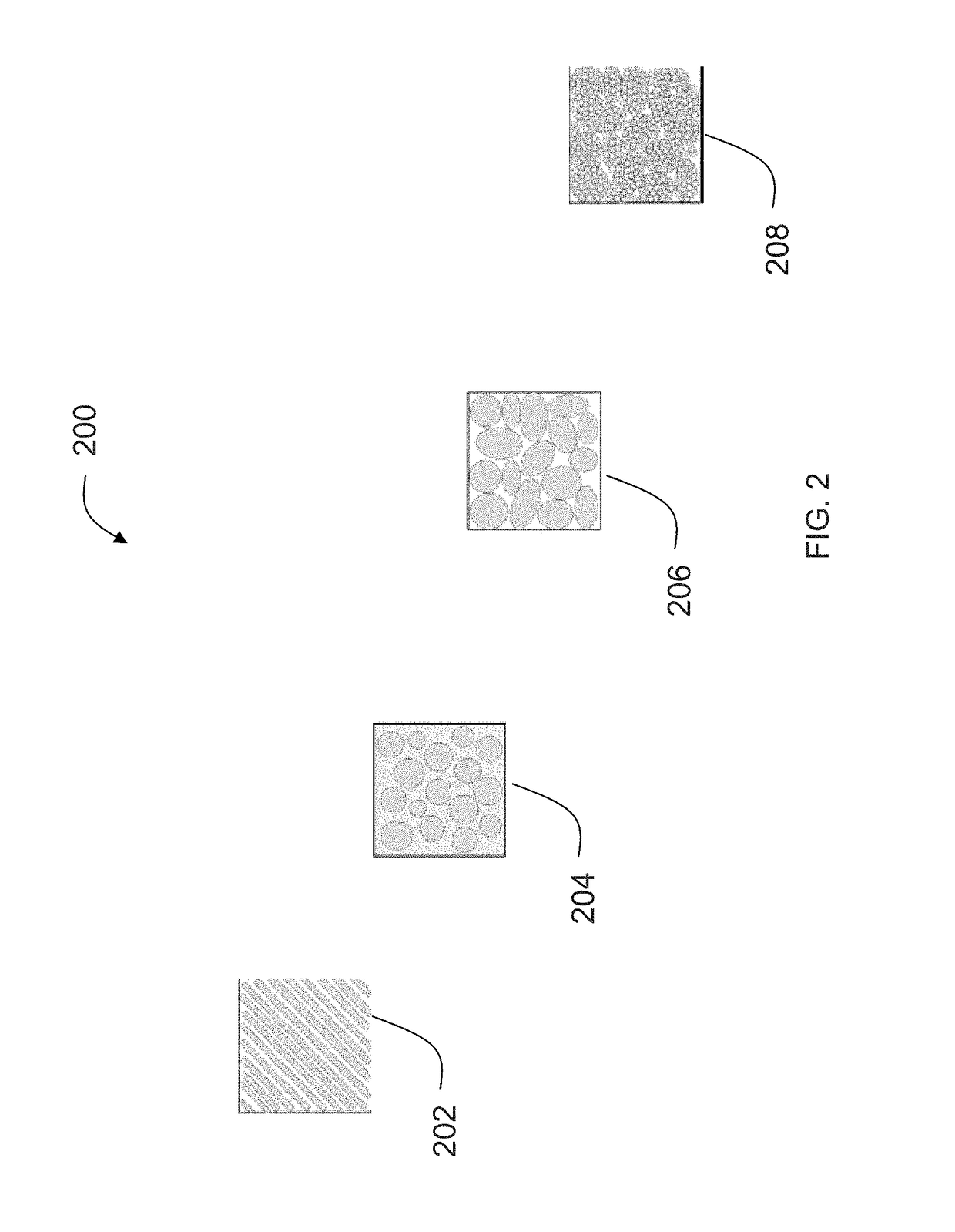

81 results about "Thermomechanical processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermomechanical processing, is a metallurgical process that combines mechanical or plastic deformation process like compression or forging, rolling etc. with thermal processes like heat-treatment, water quenching, heating and cooling at various rates into a single process.

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

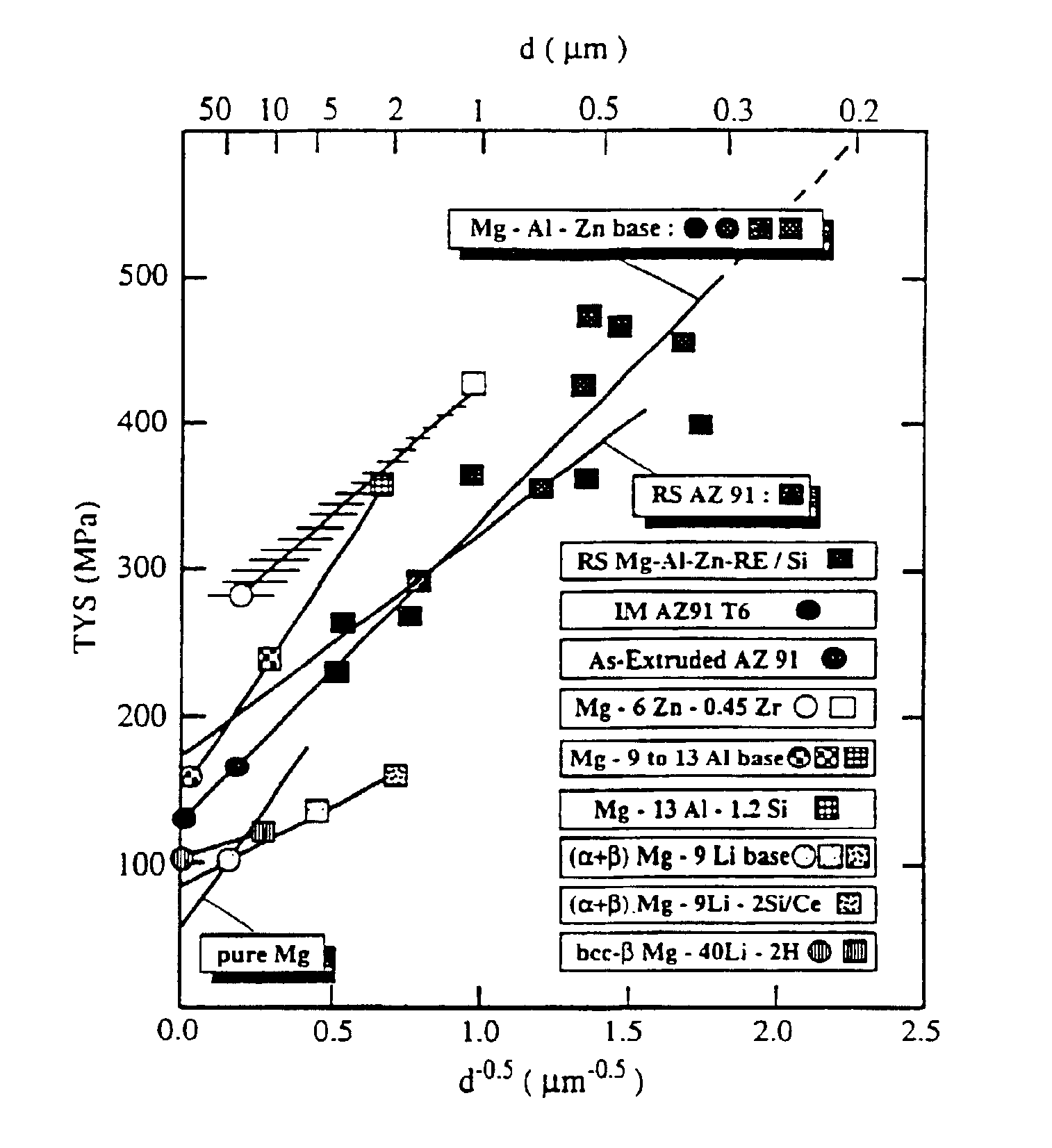

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

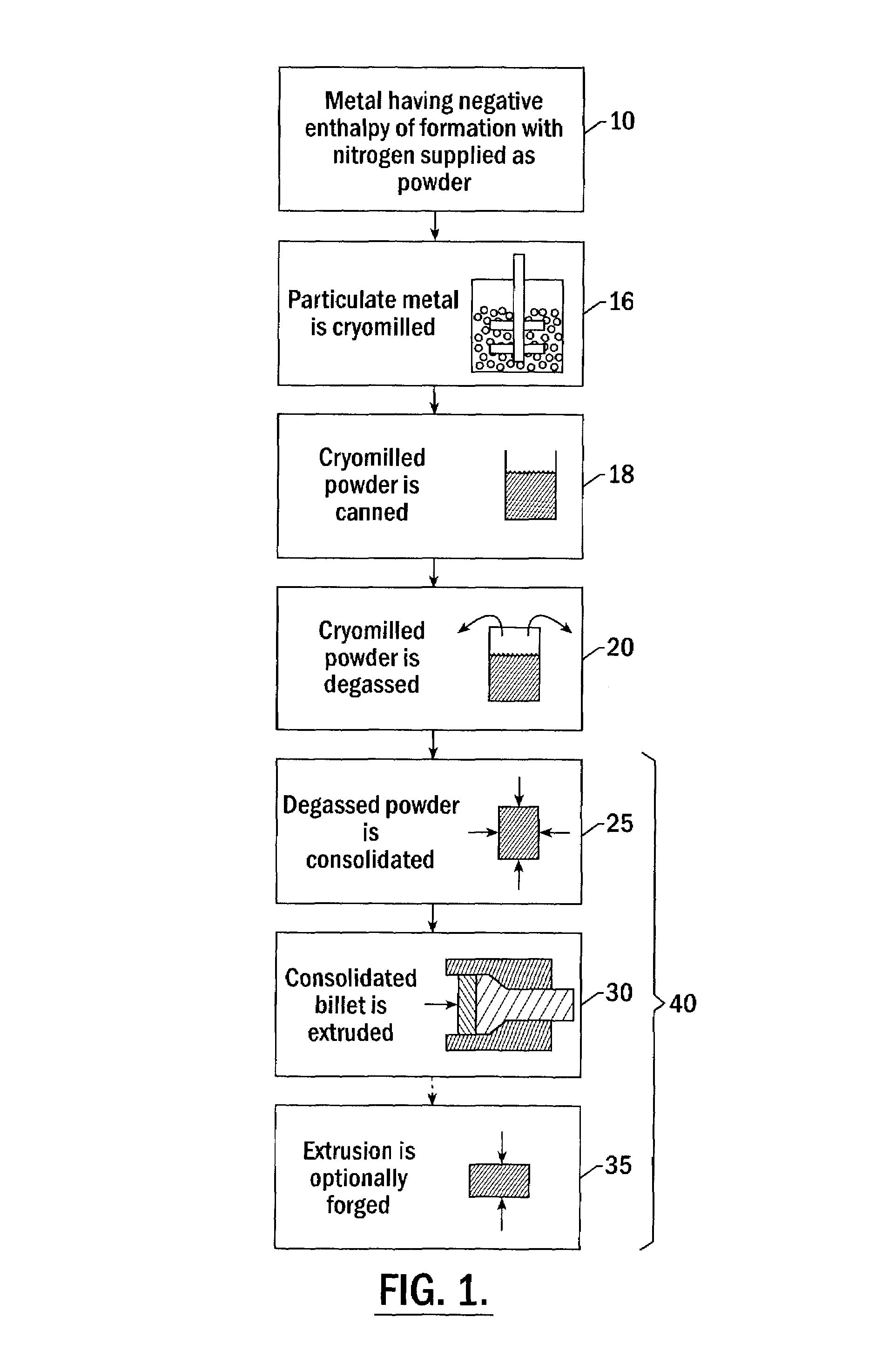

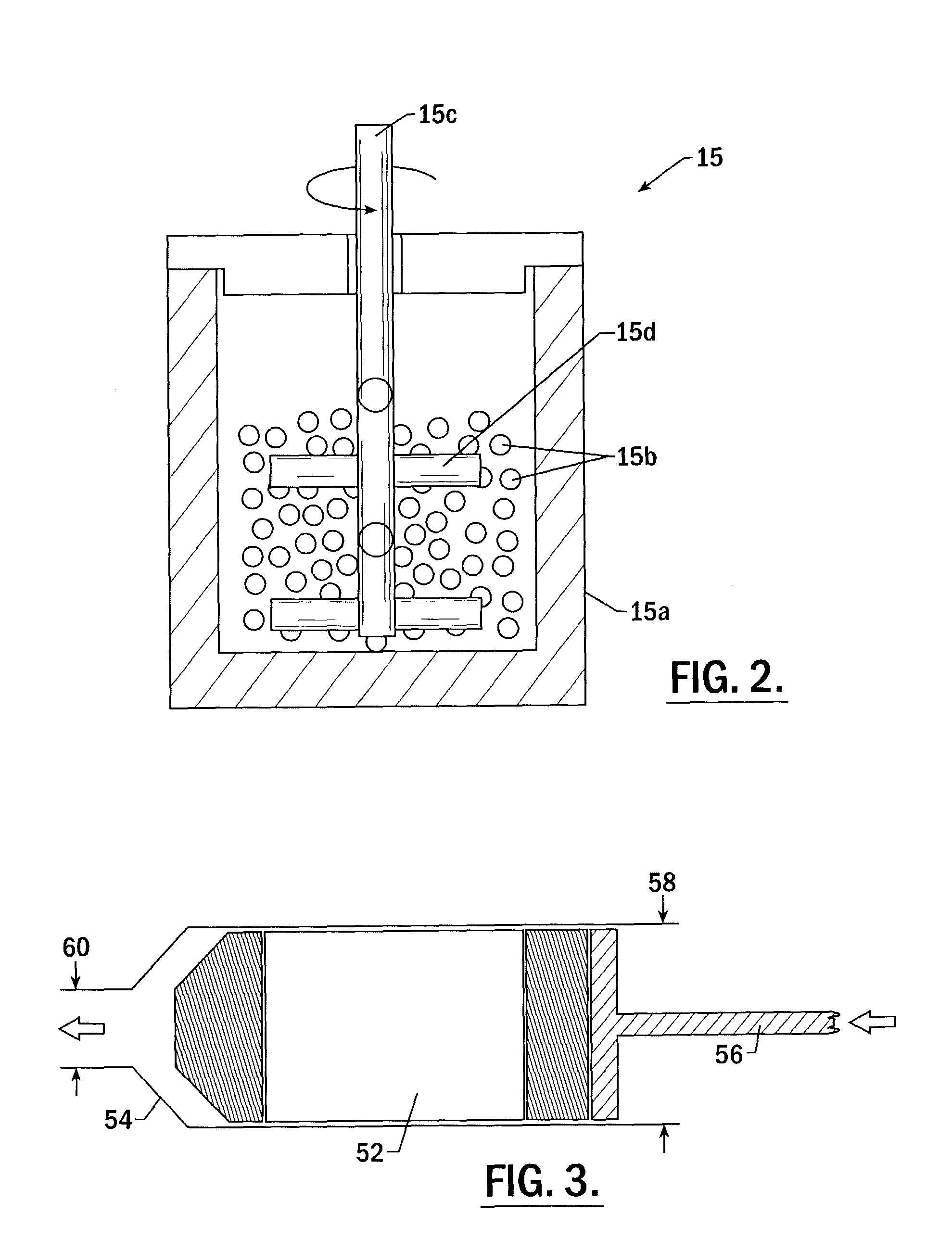

Method for preparing nanostructured metal alloys having increased nitride content

InactiveUS7344675B2Reduce grain growthHigh strengthTransportation and packagingMetal-working apparatusMetal alloyHigh intensity

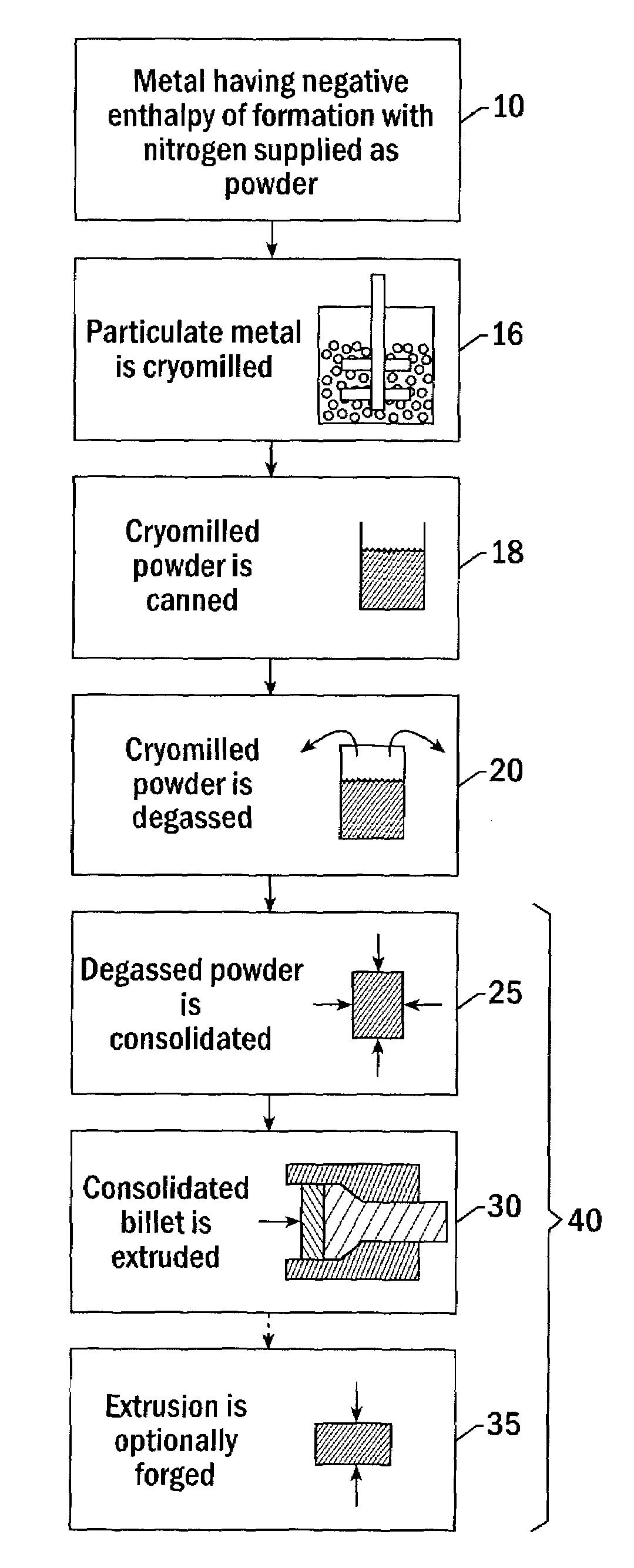

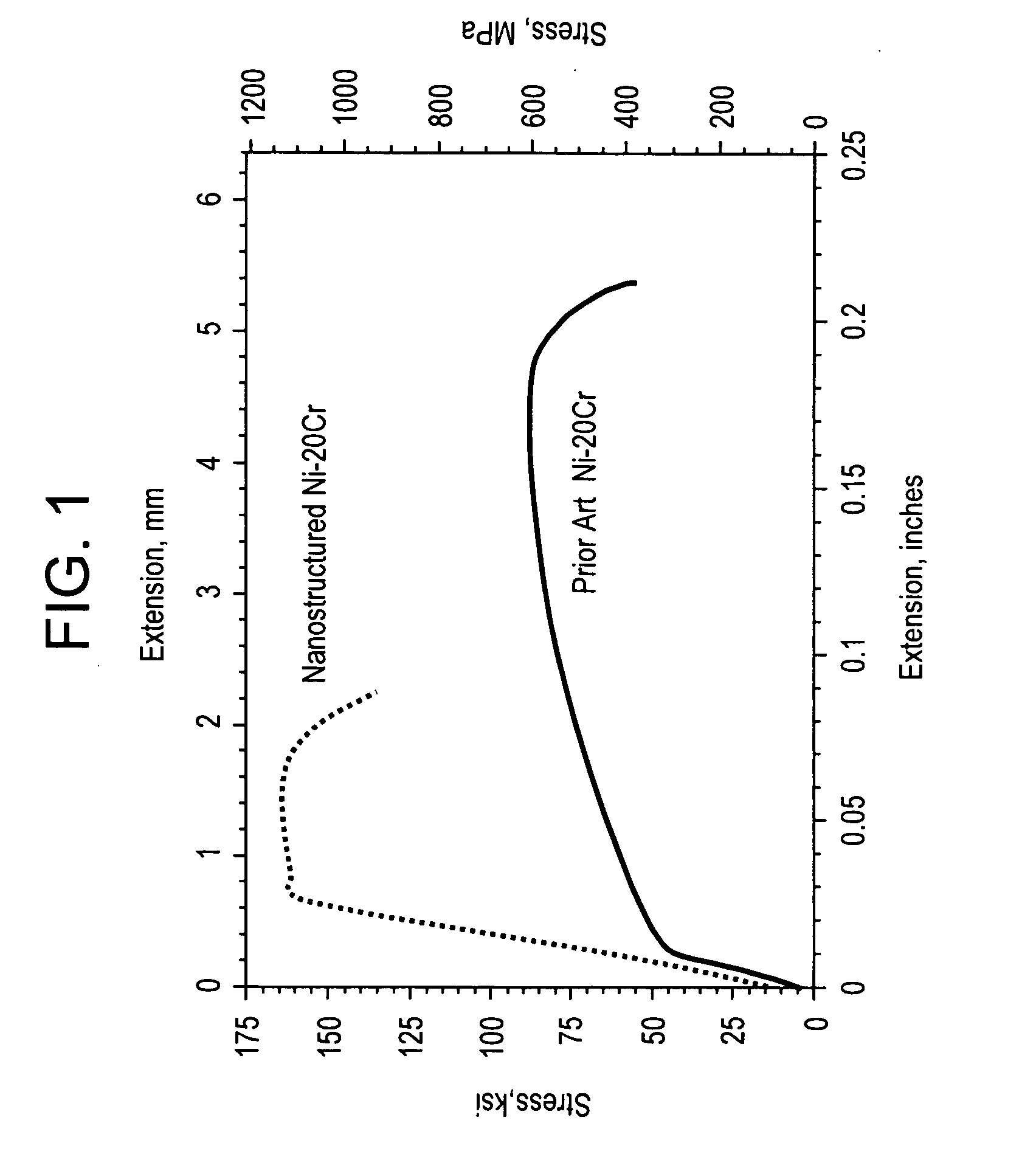

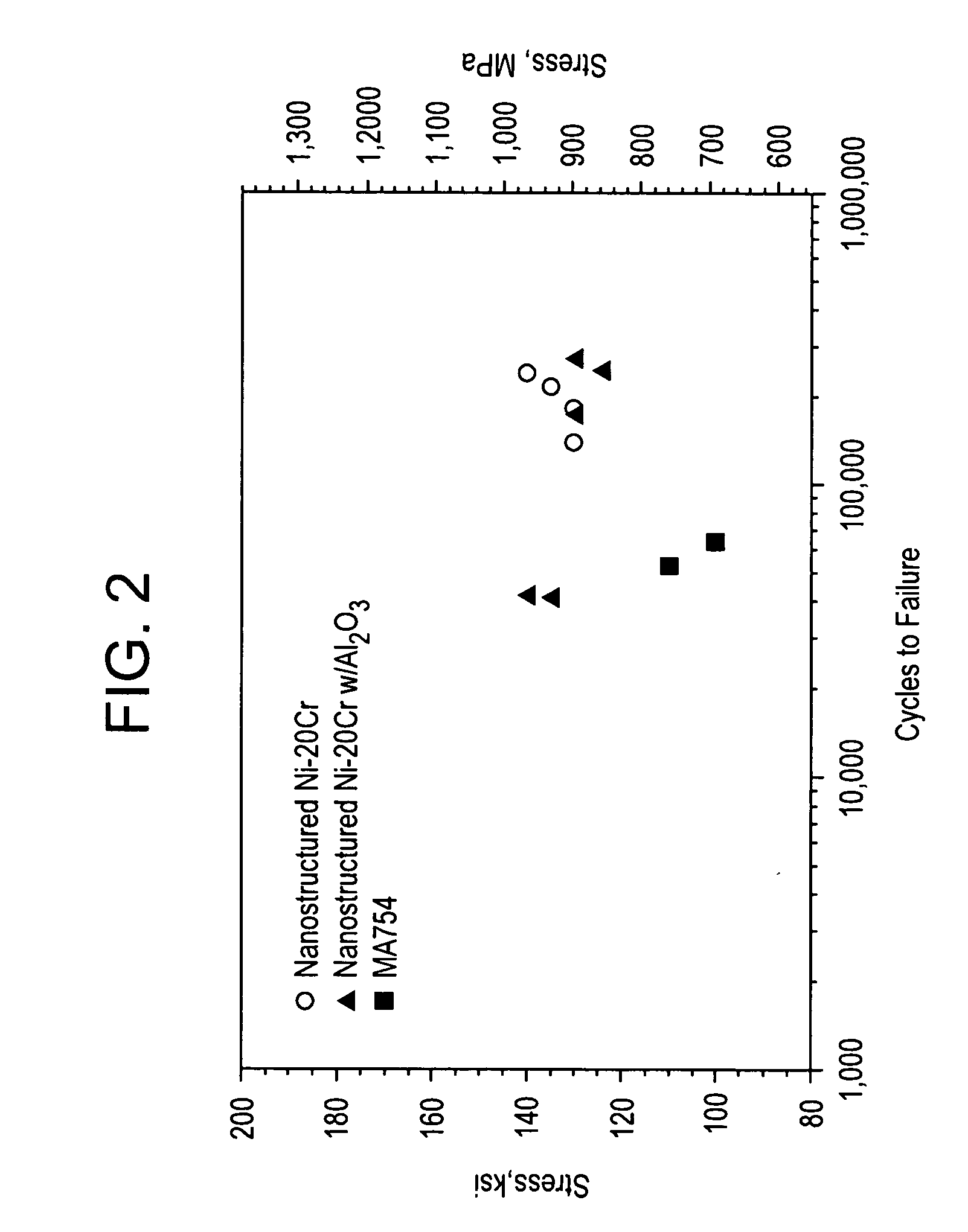

A method of producing high strength nanophase metal alloy powder by cryomilling metal powder under conditions which cause the formation of intrinsic nitrides, and of producing high strength metal articles by subjecting the nitrided cryomilled powder to thermo-mechanical processing. The intrinsic nitrides present within the alloy significantly reduce grain growth during thermo-mechanical processing, resulting in formed metal products of high strength and improved ductility.

Owner:THE BOEING CO

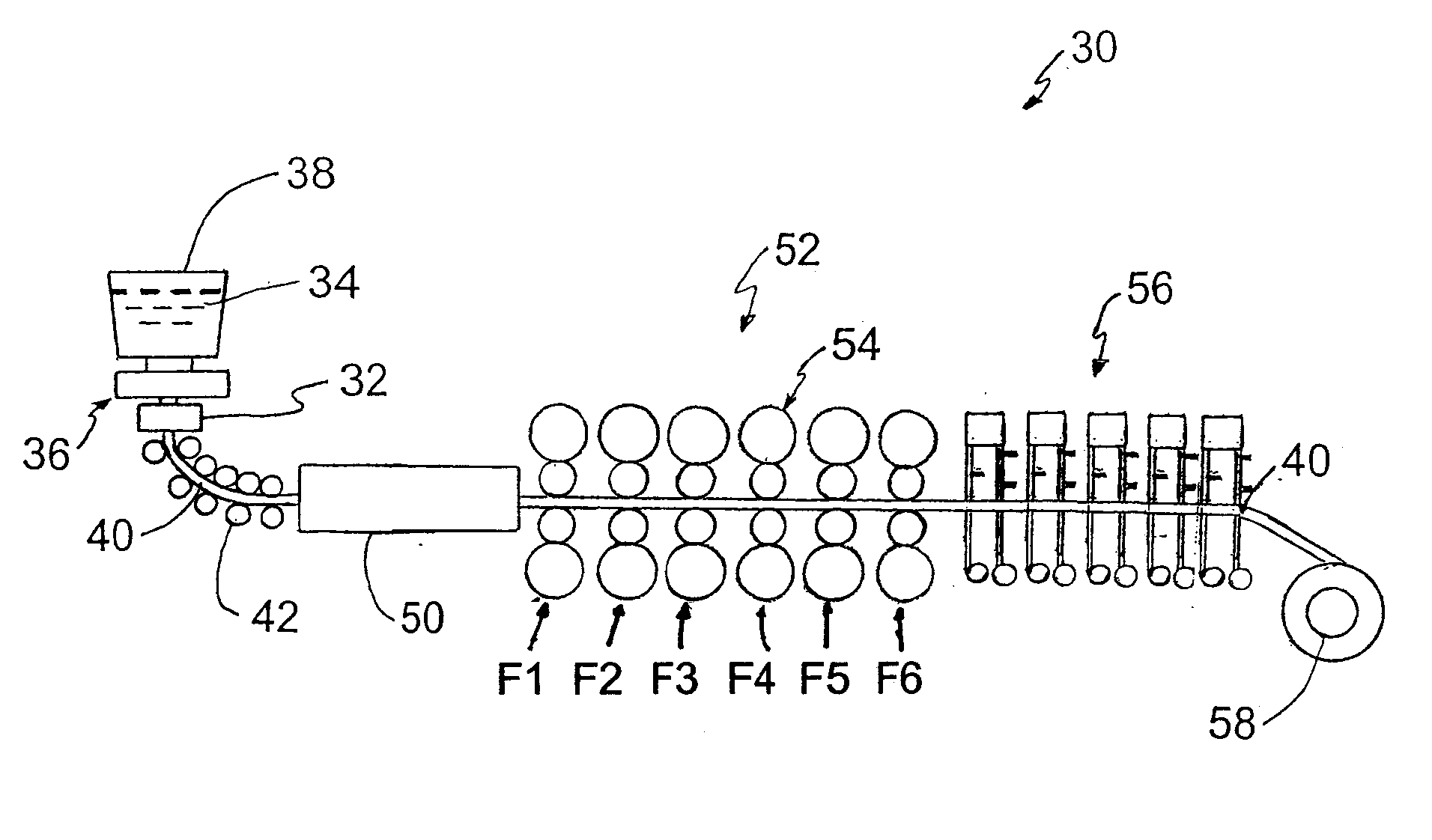

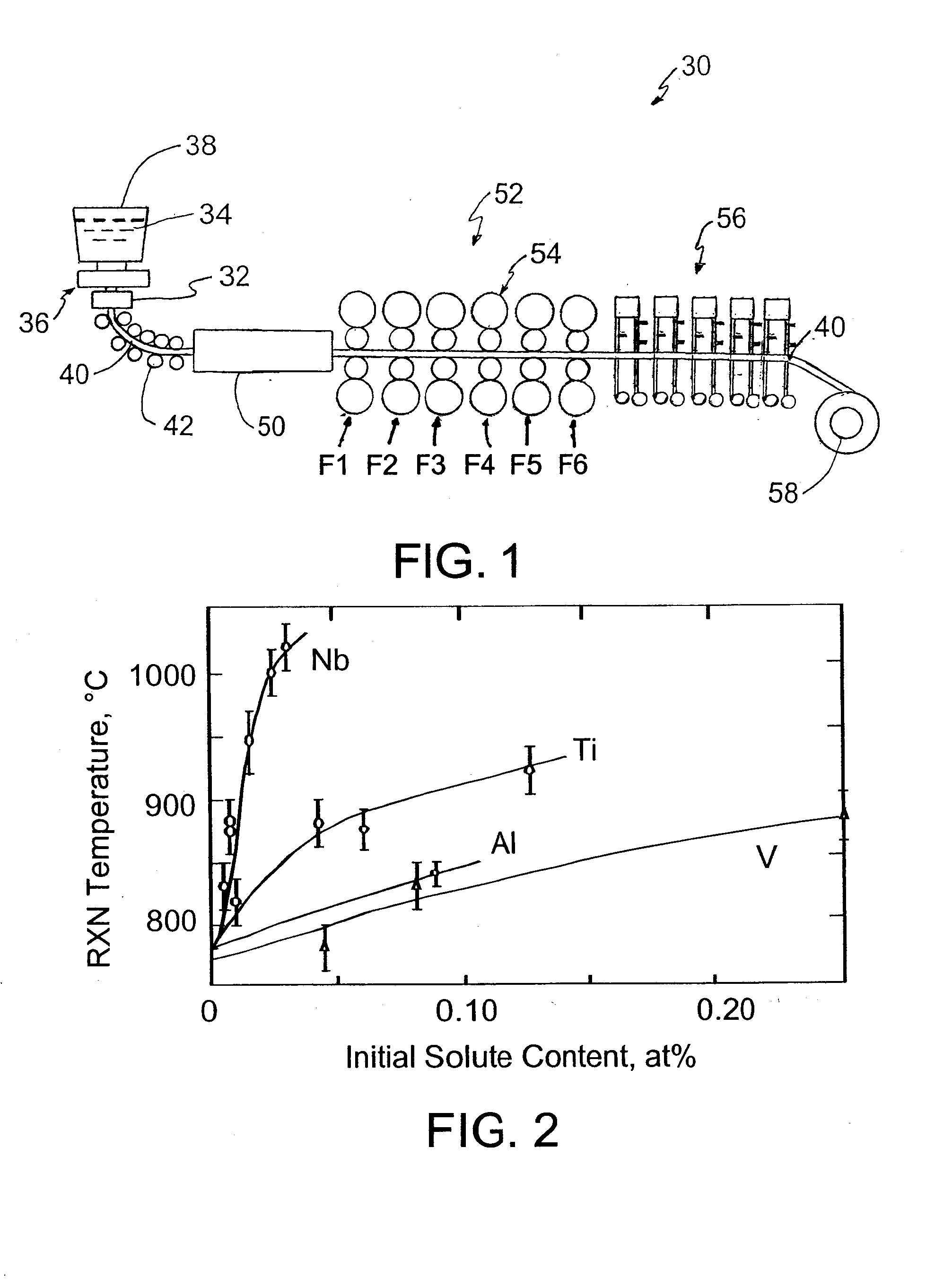

Thermomechanical processing routes in compact strip production of high-strength low-alloy steel

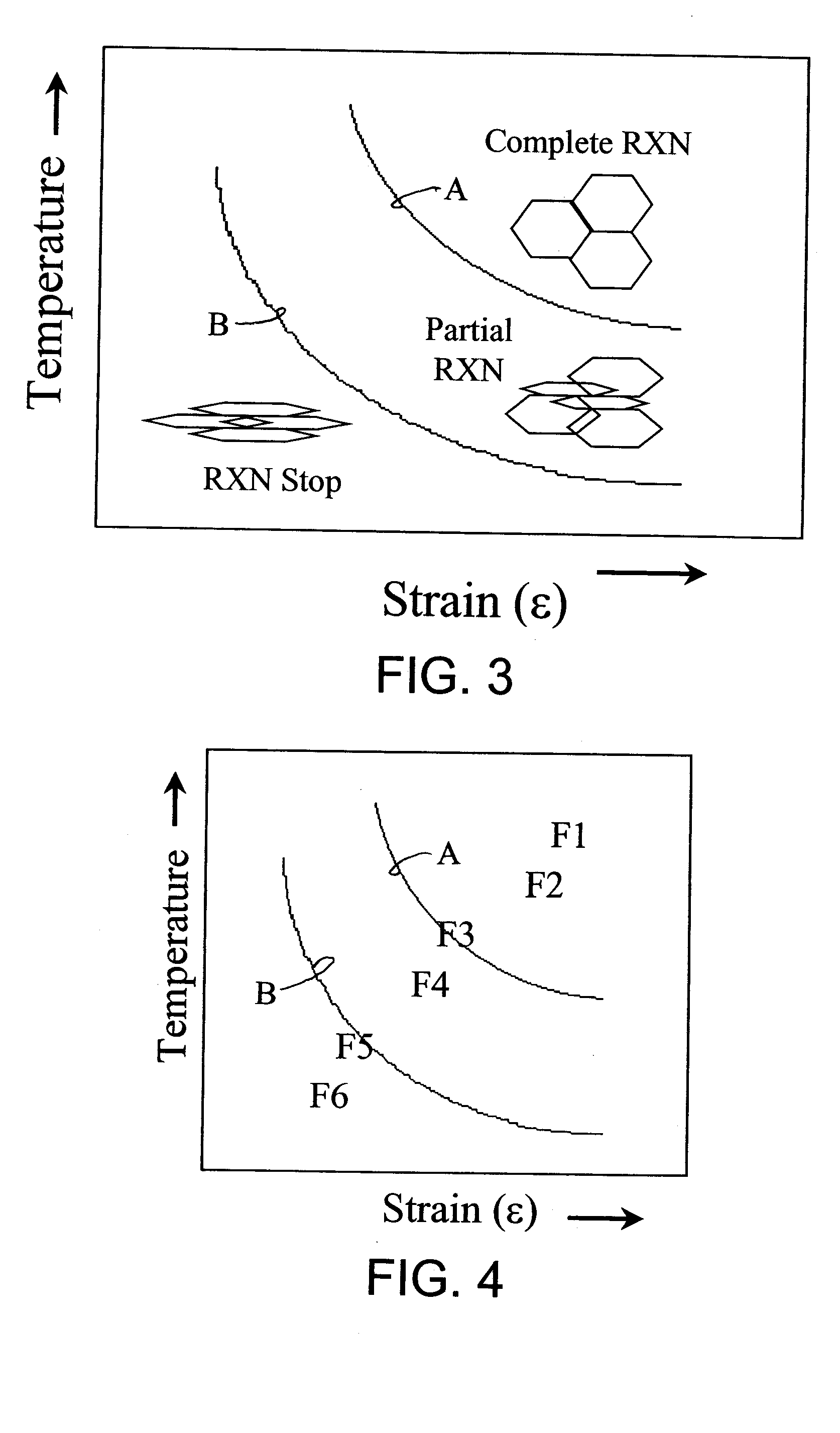

InactiveUS20050115649A1Accurate ultrasonic testingTime allowedMetal rolling arrangementsAustenite grainThin slab

Process for hot rolling of high-strength low-alloy steel cast in Compact Strip Production as a thin slab. The strain and temperature at initial roll stands where deformation occurs allows full recrystallization, and at latest roll stands where deformation occurs there is no recrystallization. Deformation is absent at strains and temperatures where partial recrystallization would occur, allowing increased recrystallization over conventional CSP rolling. The result may be beneficial for microalloyed high-strength low-alloy steel in permitting accurate ultrasonic testing of welds. The time allowed between deformation at passes through roll stands may be increased by eliminating deformation at one or more central roll stands. Combined with increased strain at the initial roll stands where the temperature of the steel is in the full recrystallization region, the process may result in a relatively fine and uniform austenite grain size.

Owner:NUCOR CORP

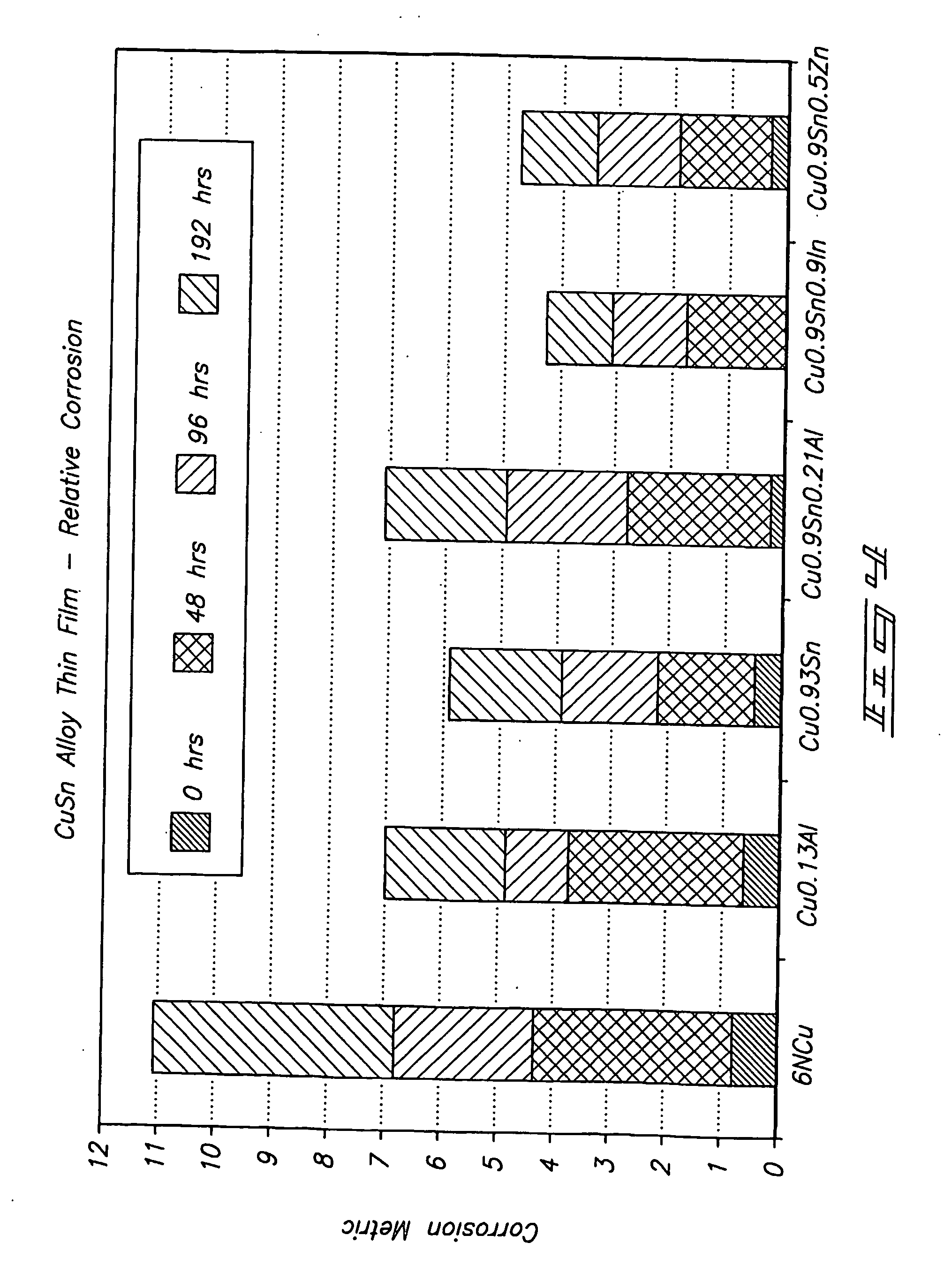

Copper-containing pvd targets and methods for their manufacture

InactiveUS20070039817A1CellsSemiconductor/solid-state device detailsGas phaseEqual channel angular extrusion

The invention includes a physical vapor deposition target containing copper and at least two additional elements selected from Ag, Al, As, Au, B, Be, Ca, Cd, Co, Cr, Fe, Ga, Ge, Hf, Hg, In, Ir, Li, Mg, Mn, Nb, Ni, Pb, Pd, Pt, Sb, Sc, Si, Sn, Ta, Te, Ti, V, W, Zn and Zr, a total amount of the at least two additional elements being from 100 ppm to 10 atomic %. The invention additionally includes thin films and interconnects which contain the mixture of copper and at least two added elements. The invention also includes forming a copper-containing target. A mixture of copper and two or more elements is formed. The mixture is cast by melting and is subsequently cooled to form a billet which is worked utilizing one or both of equal channel angular extrusion and thermomechanical processing to form a target.

Owner:HONEYWELL INT INC

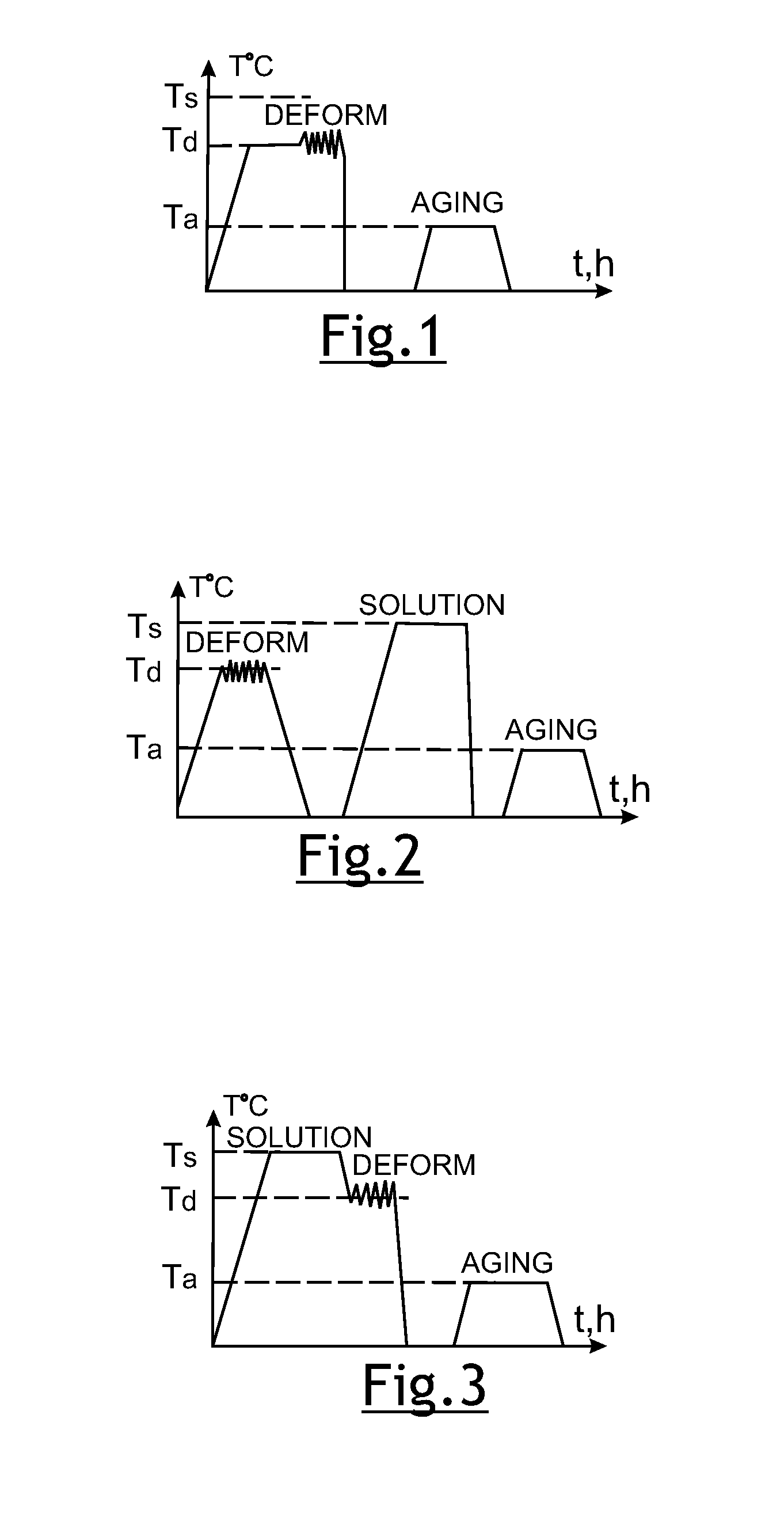

Hot thermo-mechanical processing of heat-treatable aluminum alloys

The invention includes the hot thermo-mechanical processing of heat-treatable aluminum alloys comprising preparation of the billet material, heating the billet to obtain the temperature for solution treatment, holding the billet at this temperature a sufficient amount of time required for the dissolution of soluble elements, cooling the billet to the temperature necessary for plastic deformation with essential preservation of the solid solution, plastic deformation, immediate quenching of the billet after plastic deformation, and then billet aging at the corresponding temperature and time. Additional plastic deformation may be used between stages of quenching and aging. An embodiment specifies cooling rate, forging temperature and strain rate.

Owner:ENGINEERED PERFORMANCE MATERIALS

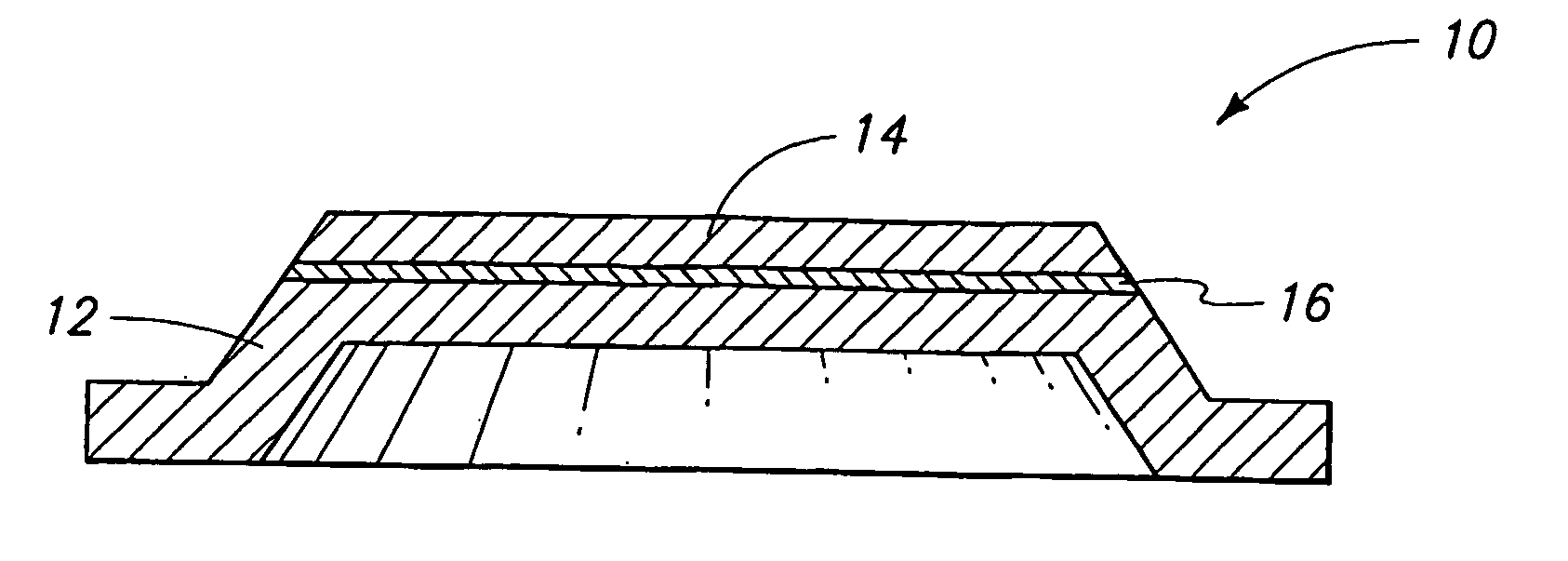

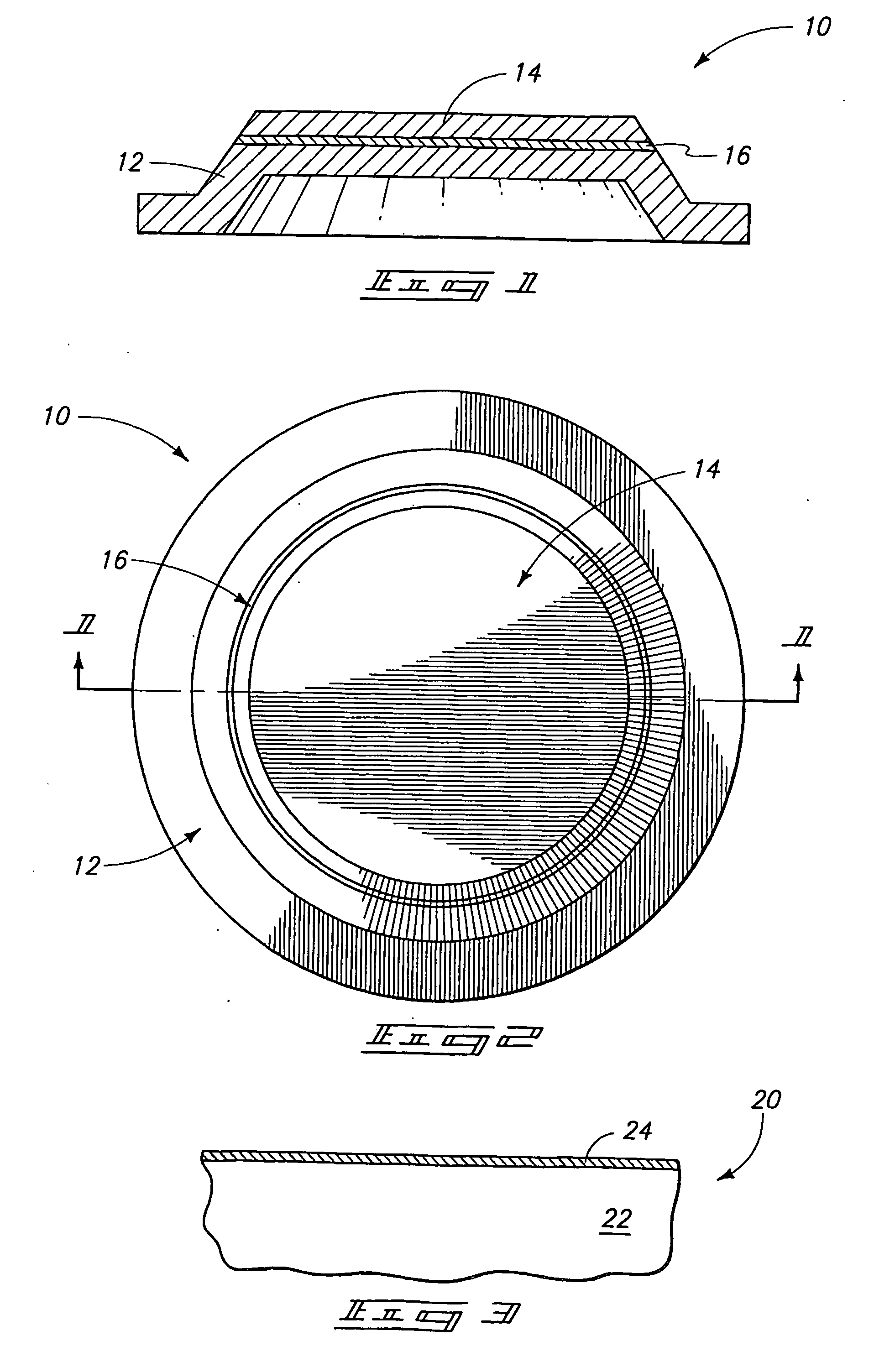

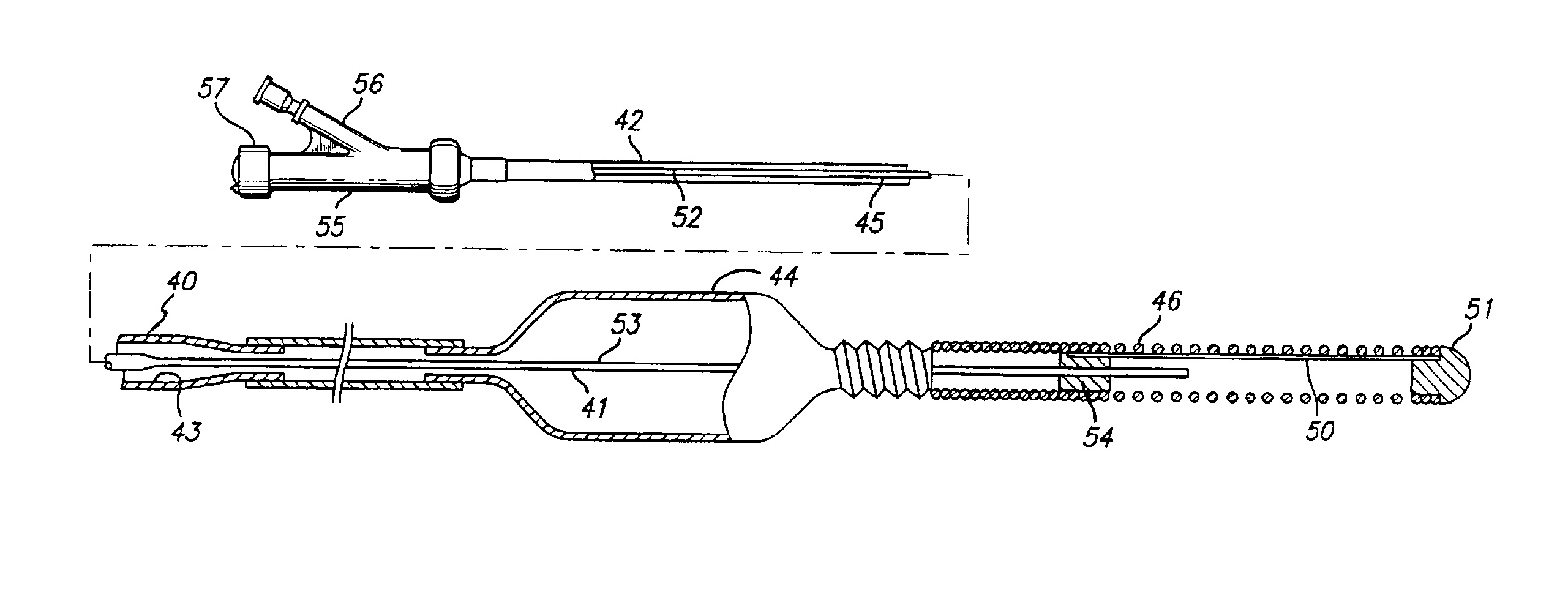

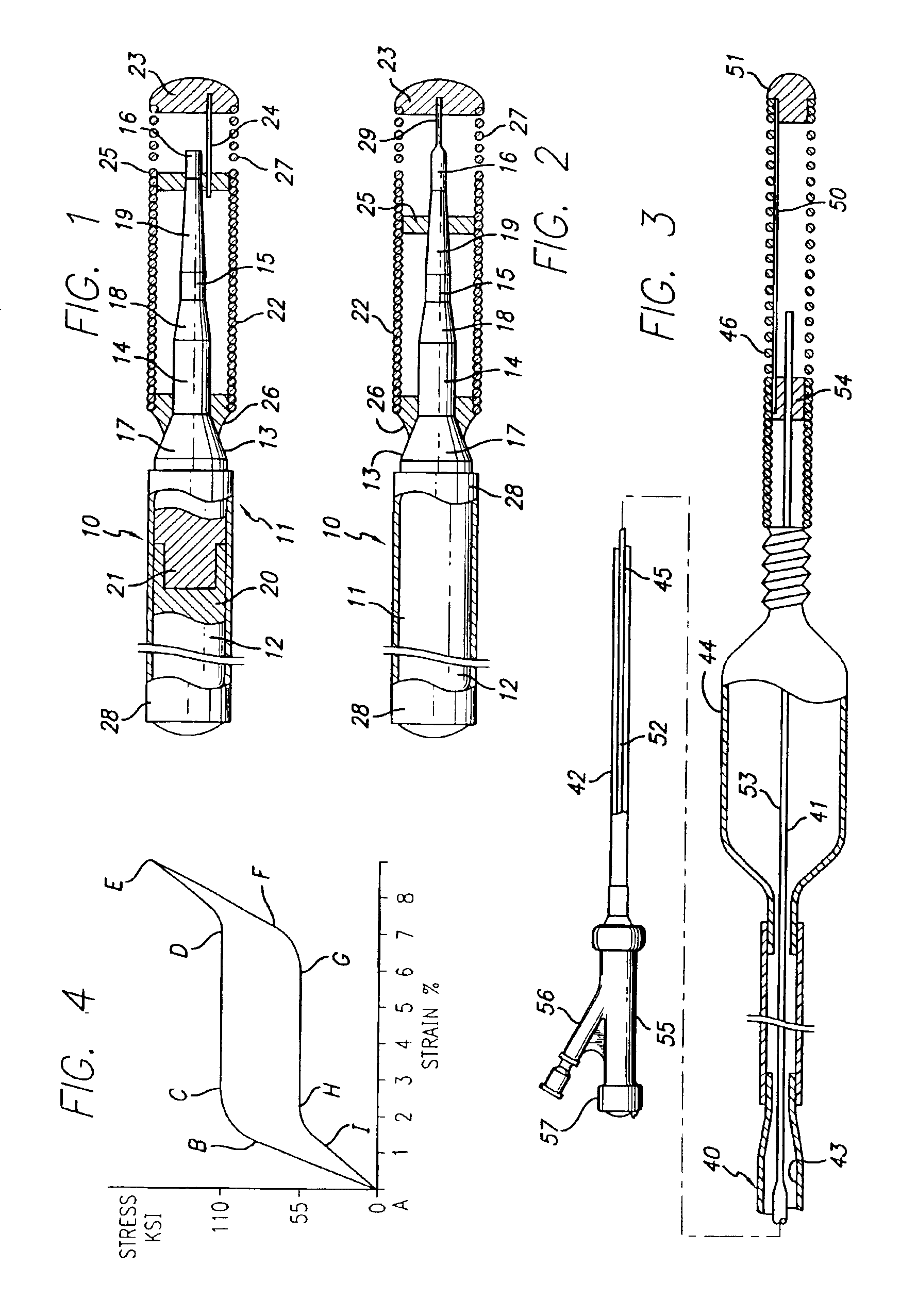

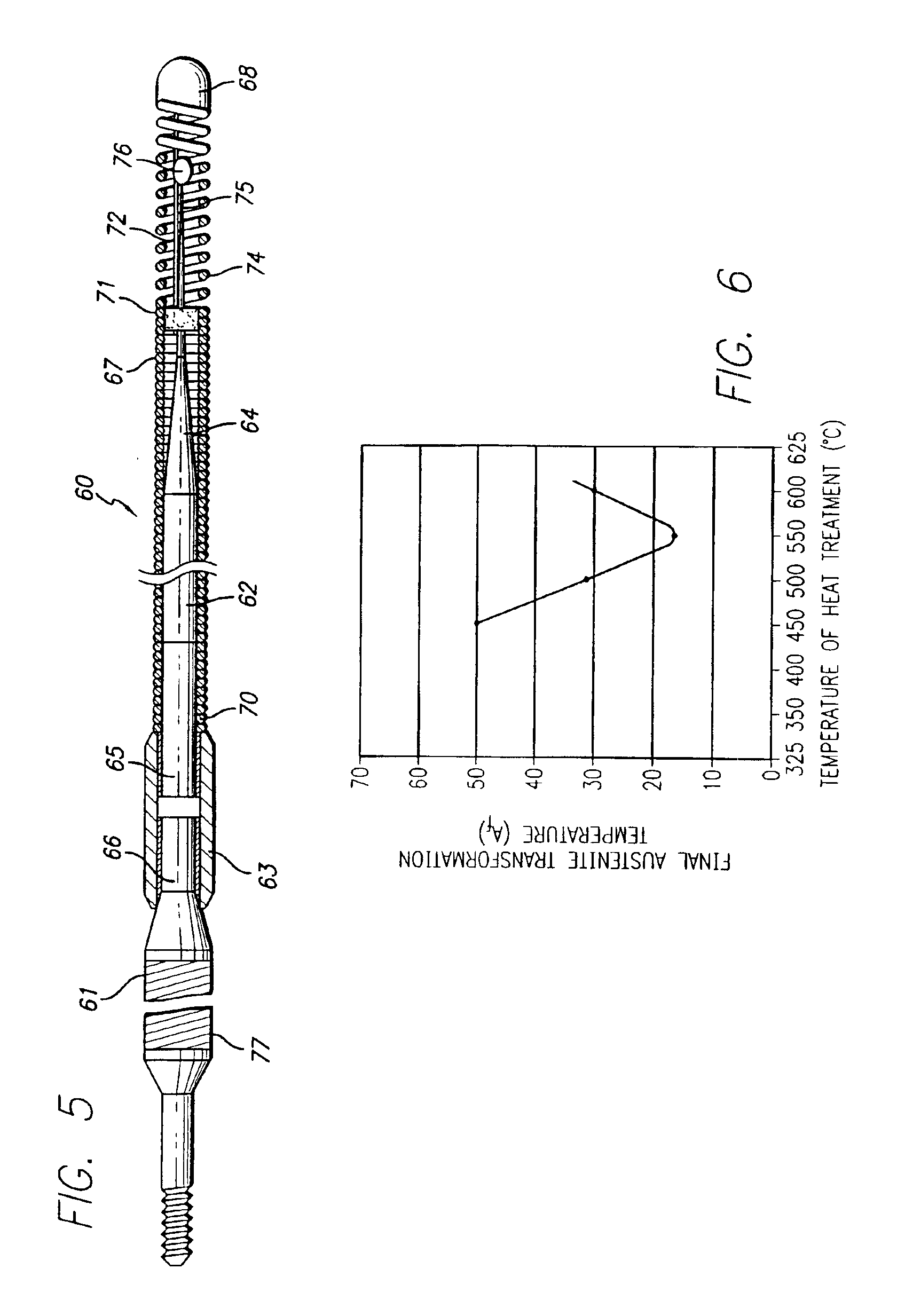

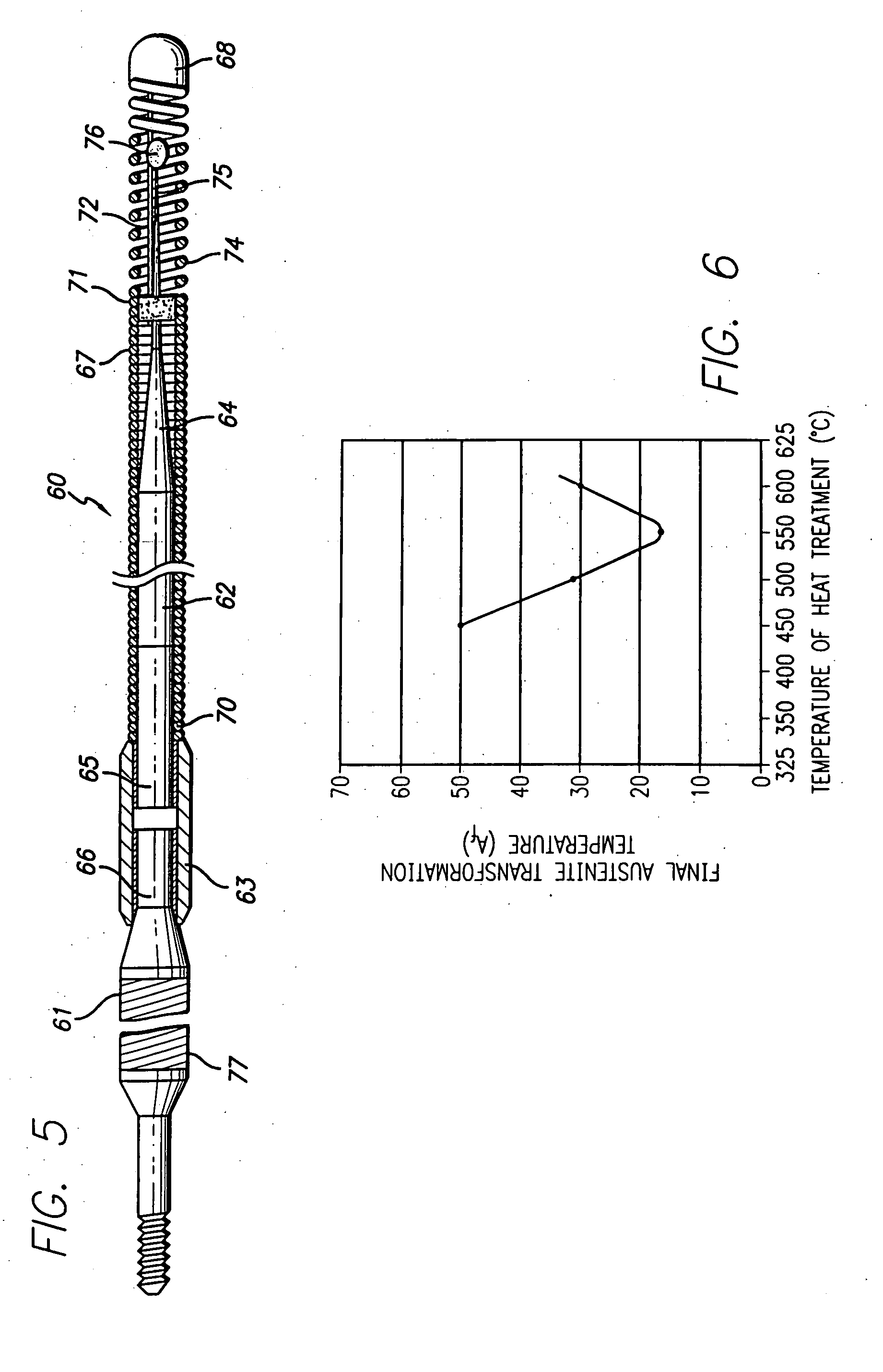

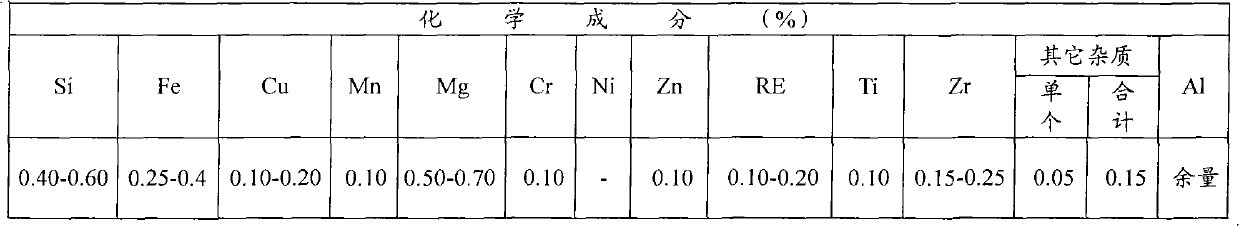

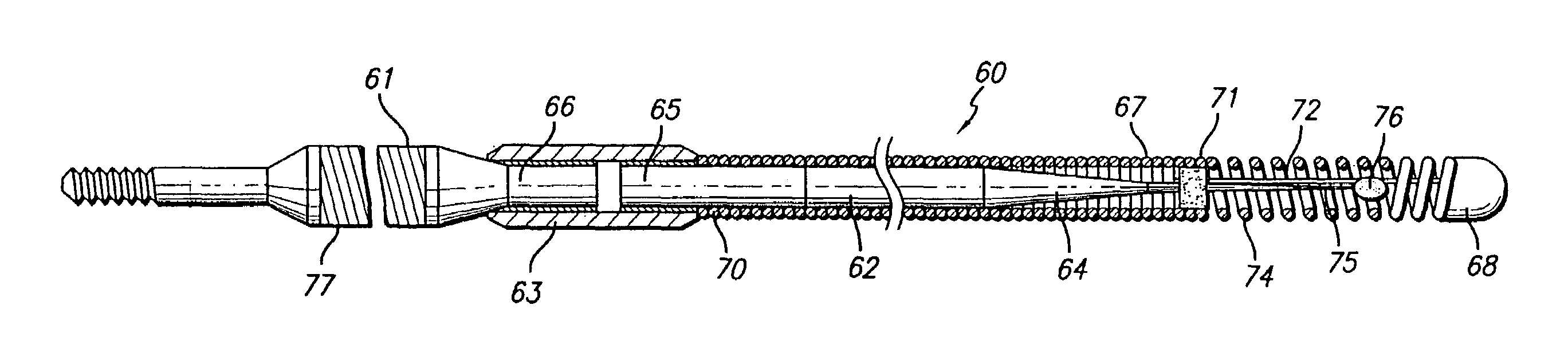

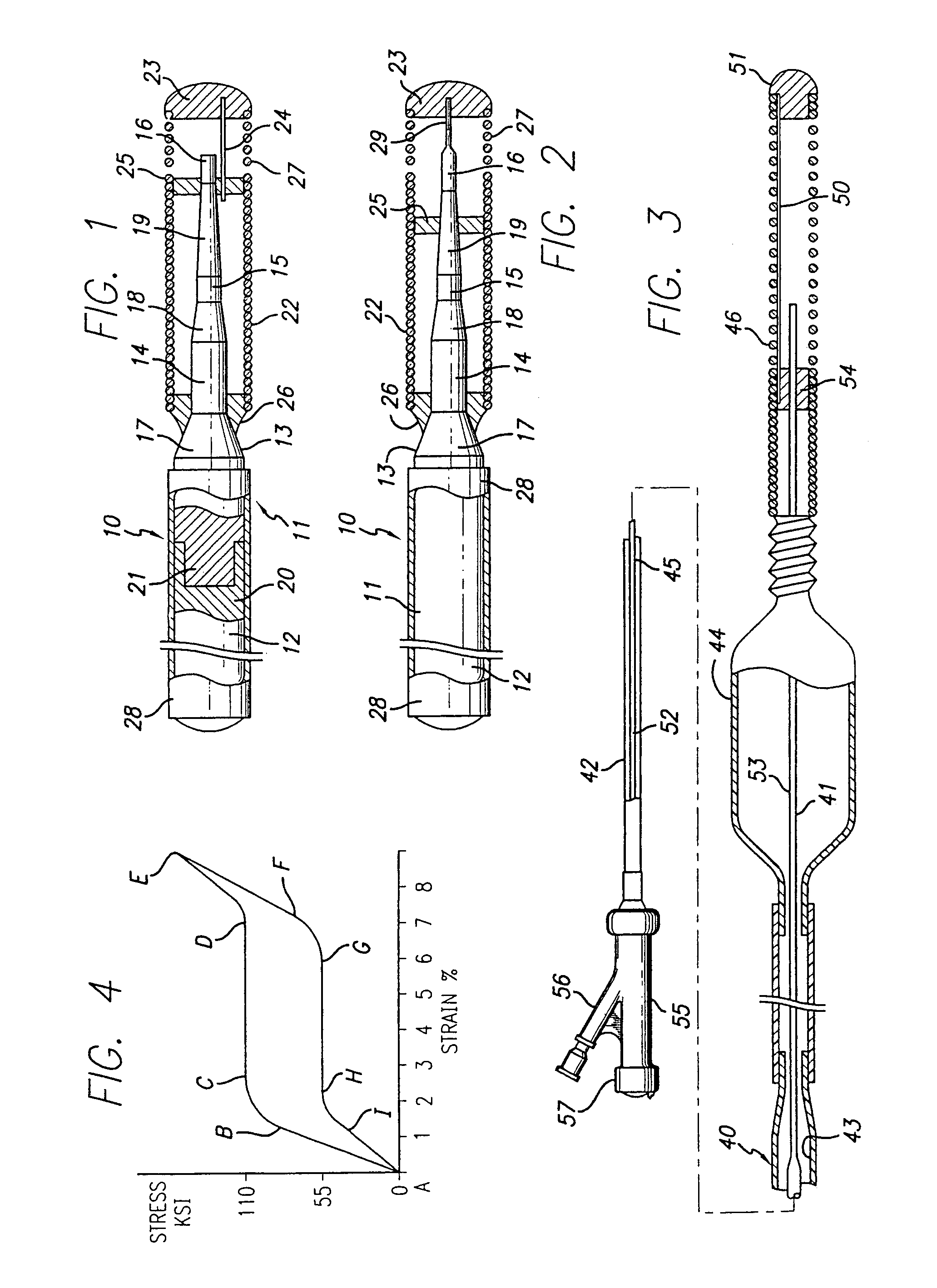

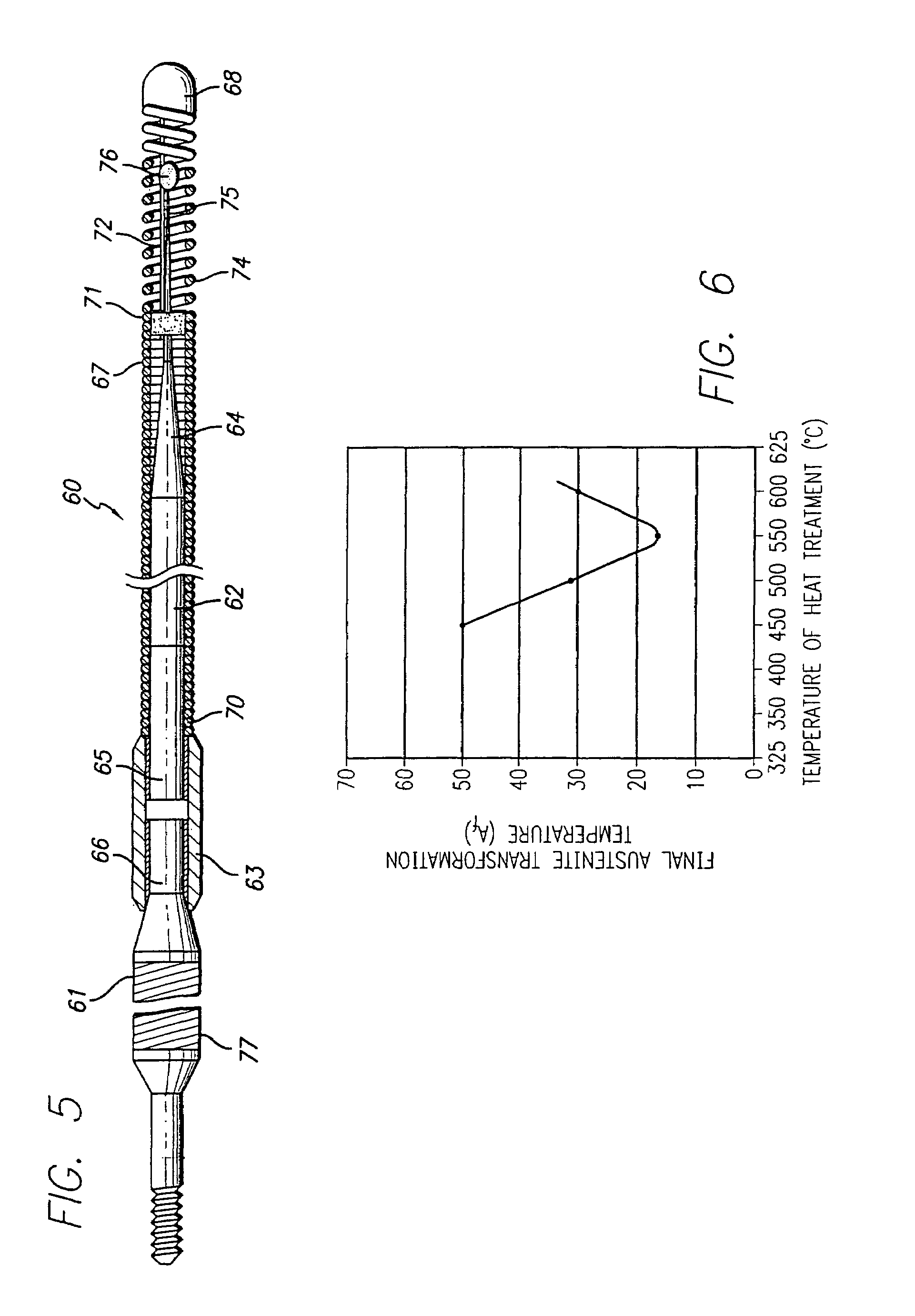

Superelastic guiding member

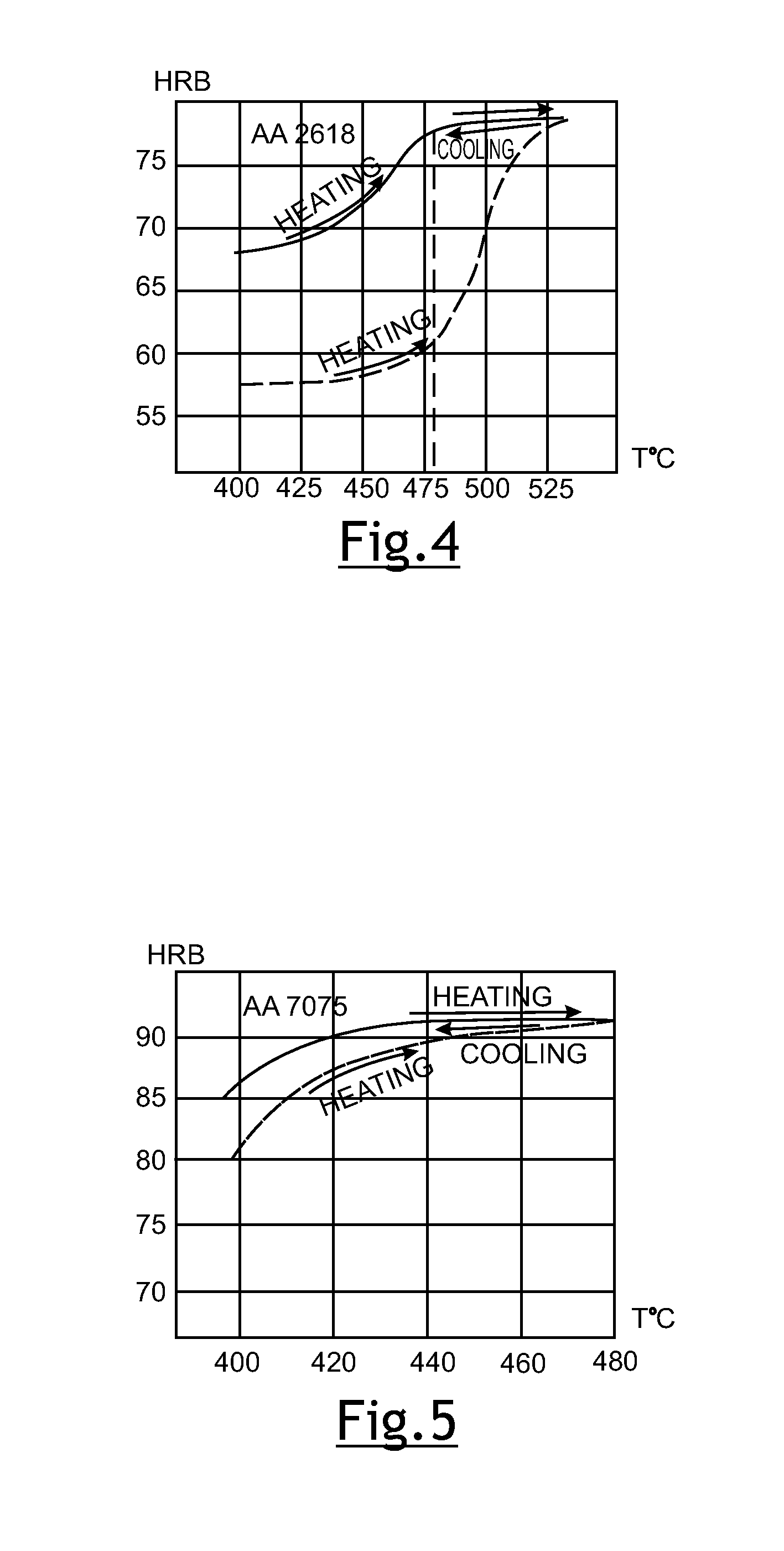

InactiveUS7244319B2Uniform residual stressImproved torque responseStentsGuide wiresStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

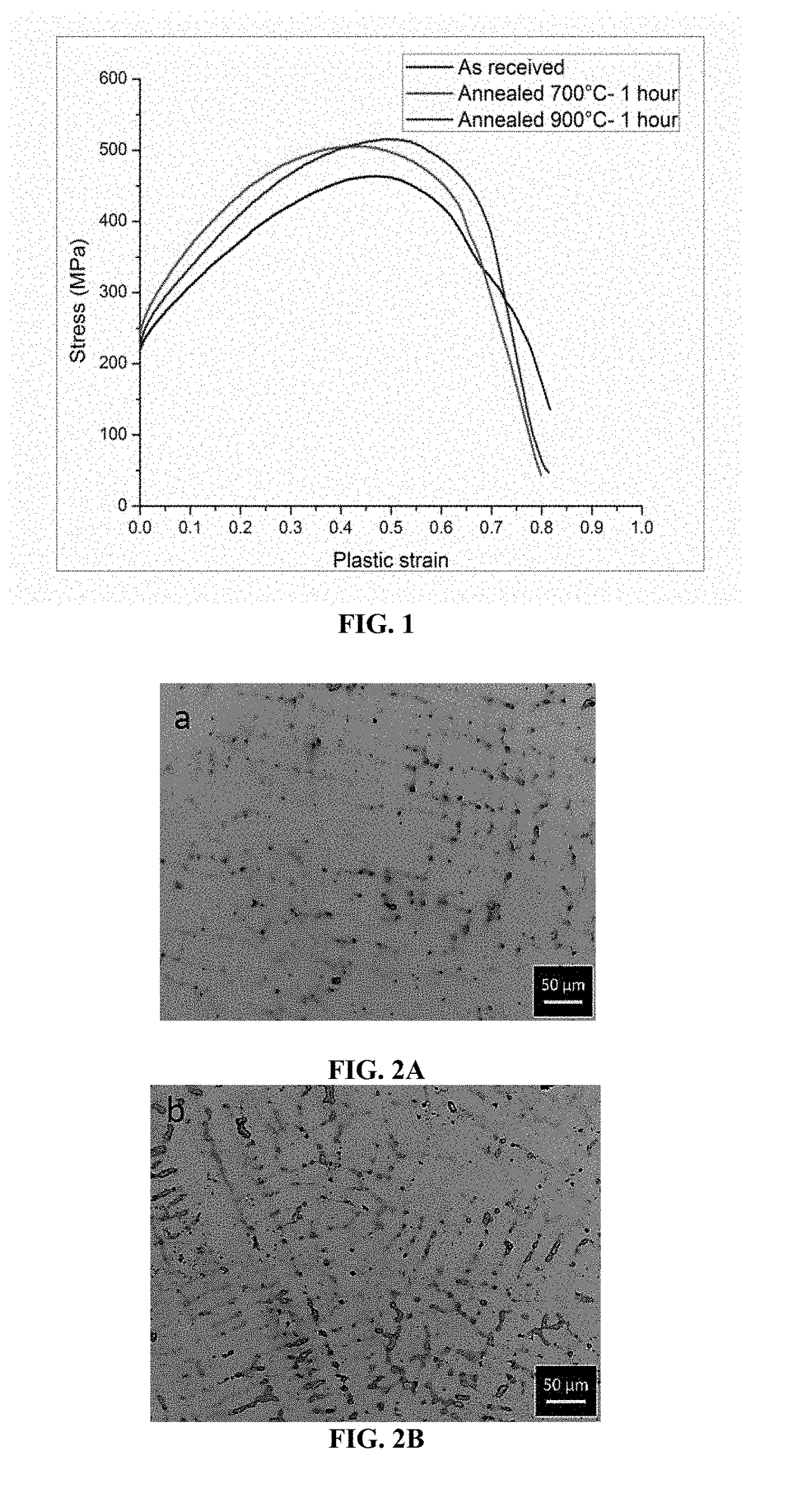

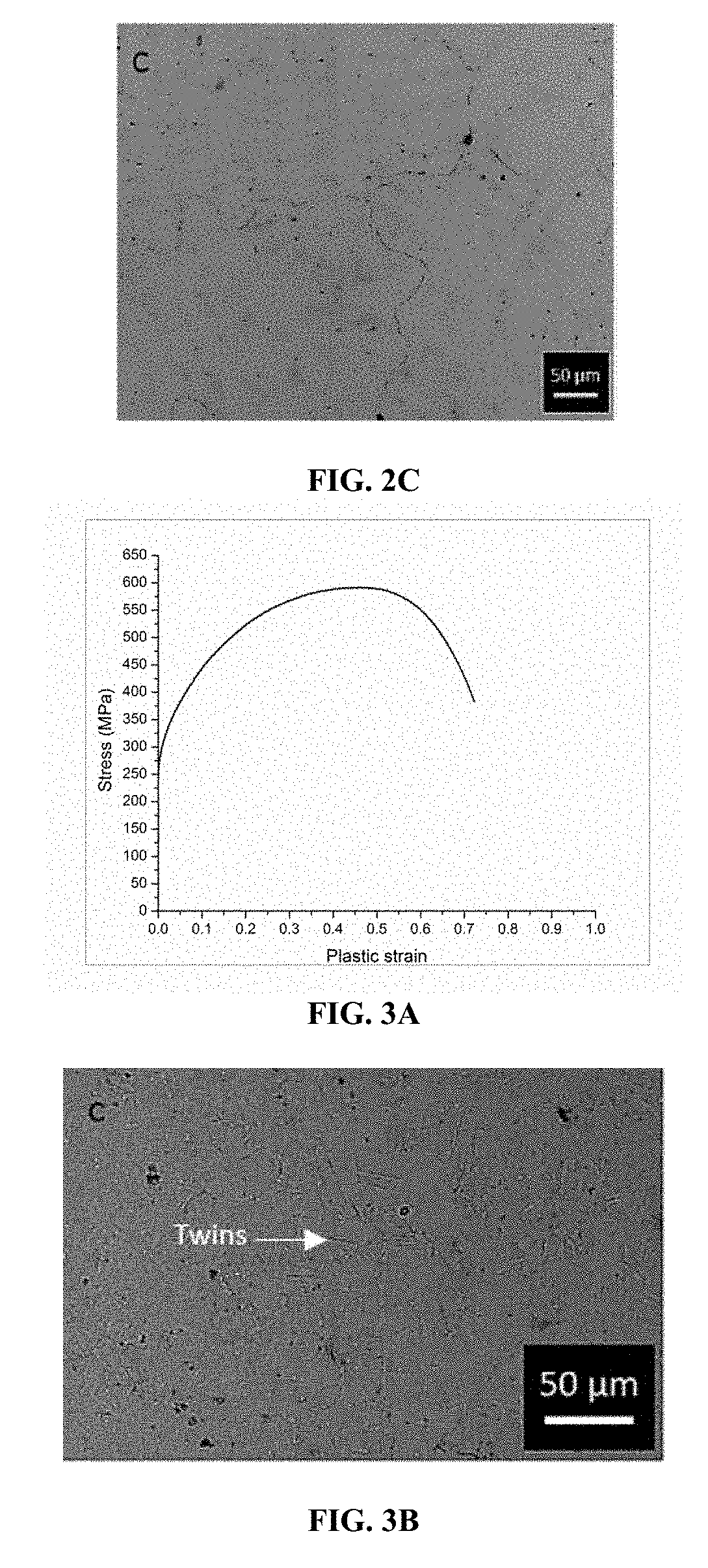

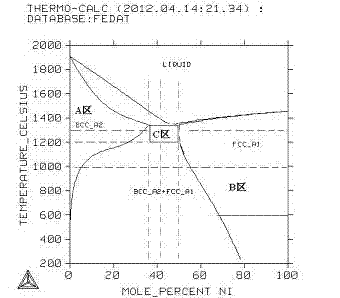

Thermo-mechanical processing of high entropy alloys for biomedical applications

InactiveUS20170232155A1High strengthAverage distributionSurgeryFurnace typesHigh entropy alloysBiomedical equipment

The present invention includes an apparatus and method of making the apparatus that biomedical apparatus comprises a device adapted for use in a biomedical application that comprises a high entropy alloy comprising at least 5 elements.

Owner:UNIVERSITY OF NORTH TEXAS

Titanium alloy microstructural refinement method and high temperature, high strain rate superplastic forming of titanium alloys

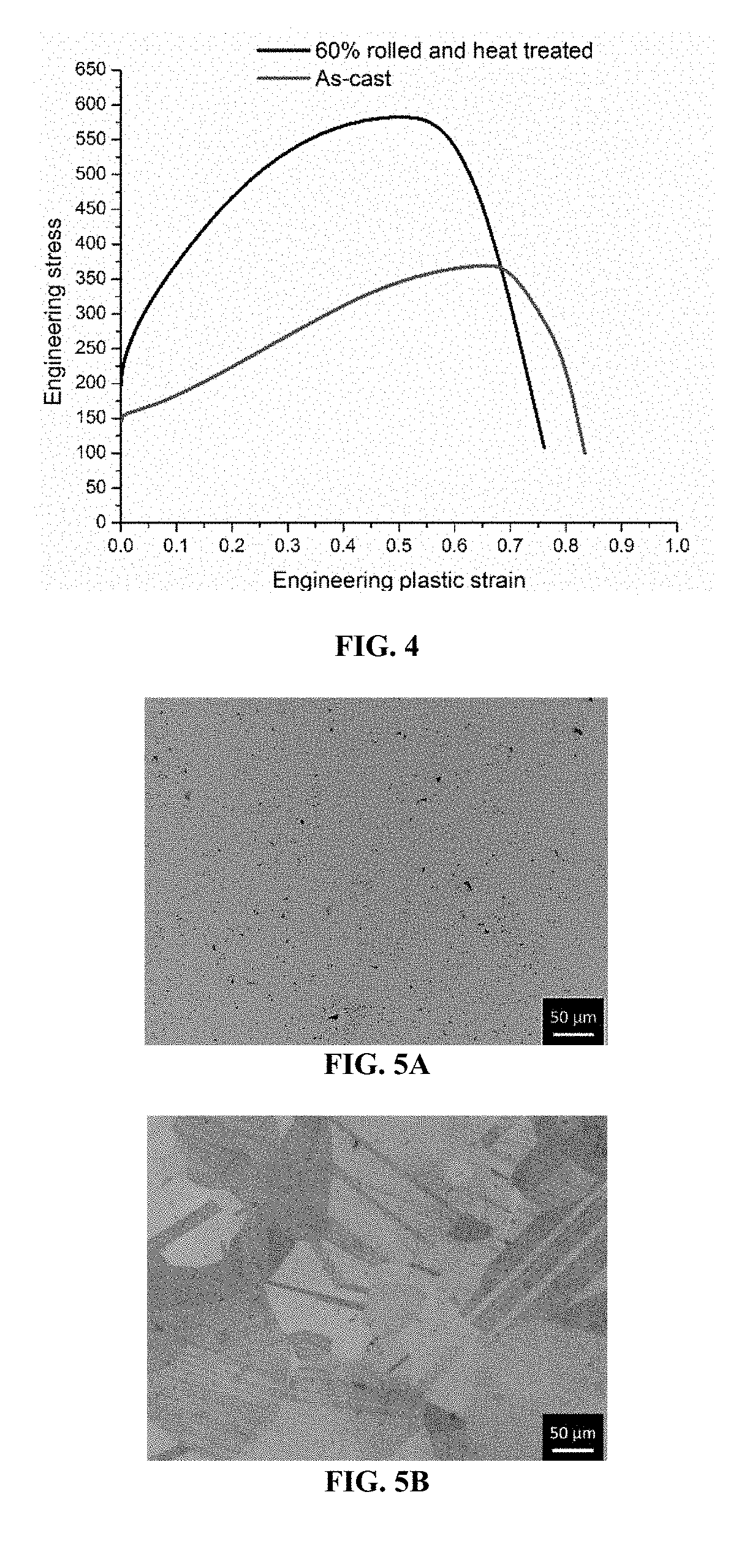

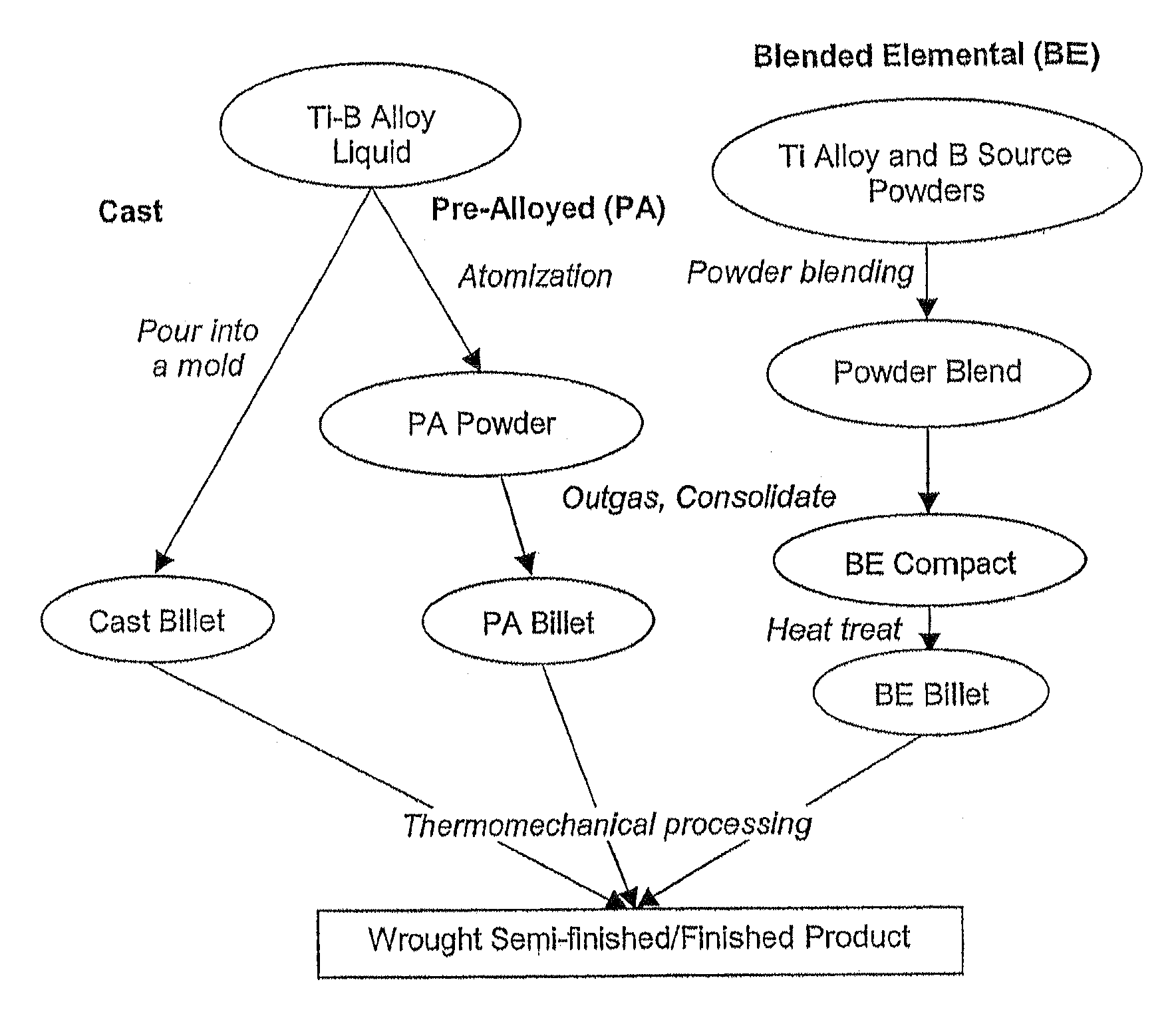

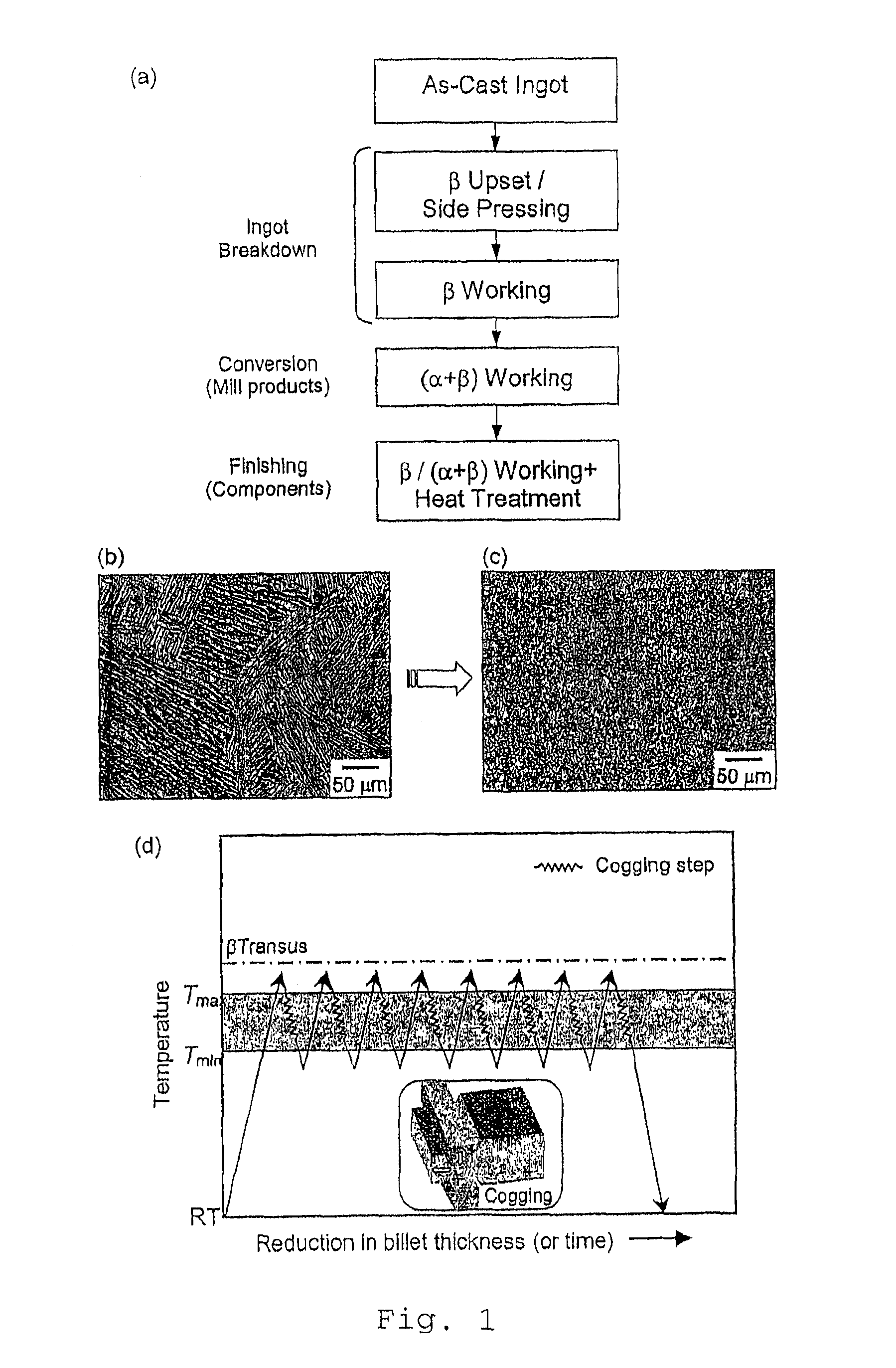

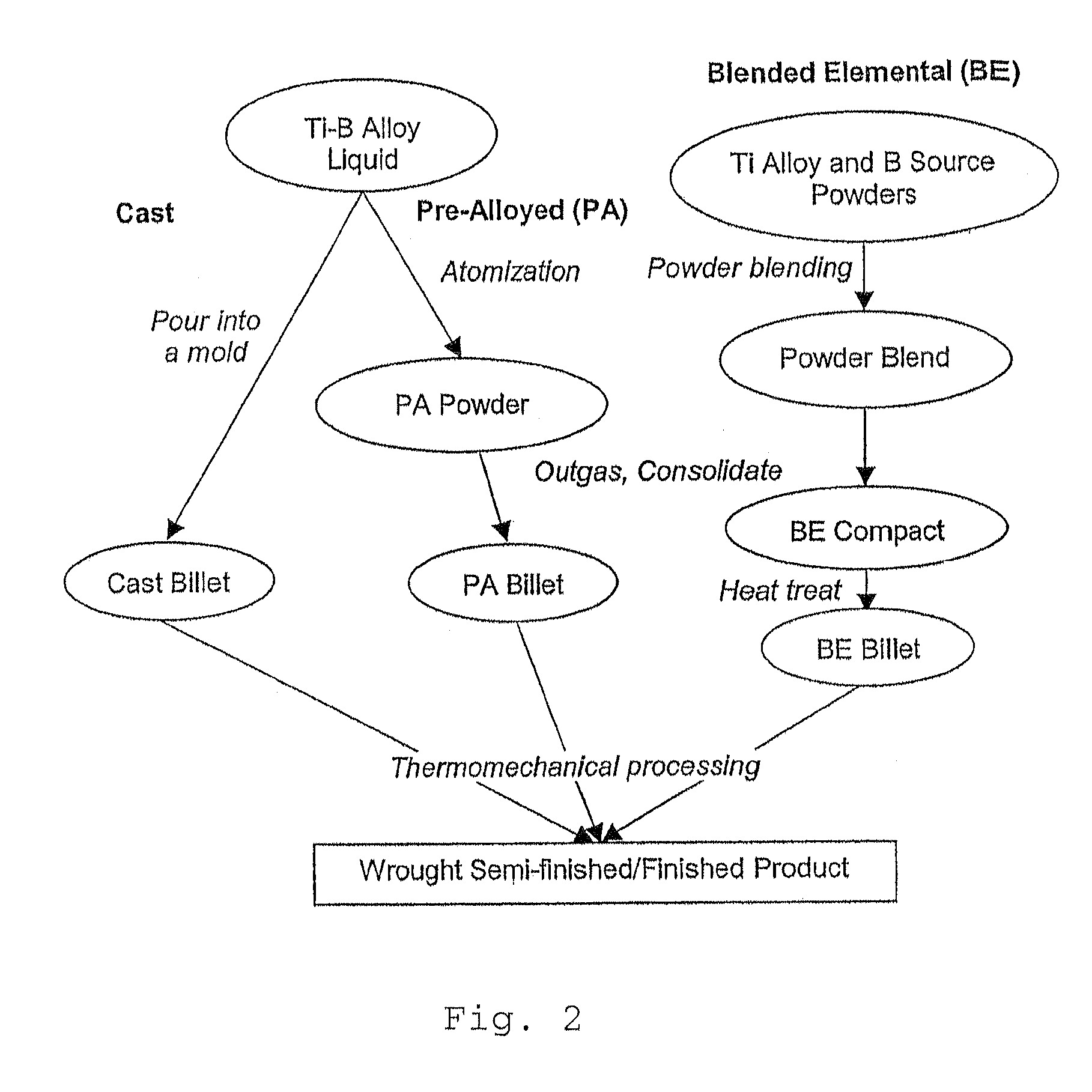

A method for refining the microstructure of titanium alloys in a single thermomechanical processing step, wherein the titanium alloy comprises boron. In some embodiments, the method comprises the steps of first adding boron to the titanium alloy then subjecting the boron-containing titanium alloy to a thermomechanical processing step. Also provided is a method for achieving superplasticity in titanium alloys comprising the steps of selecting a boron-containing titanium alloy, determining the temperature and strain rate necessary to achieve beta superplasticity, and applying sufficient temperature and strain rate to the boron-containing titanium alloy to deform the alloy to the desired shape. Also provided methods of forming titanium alloy parts and the parts prepared by these methods.

Owner:OHIO UNIV

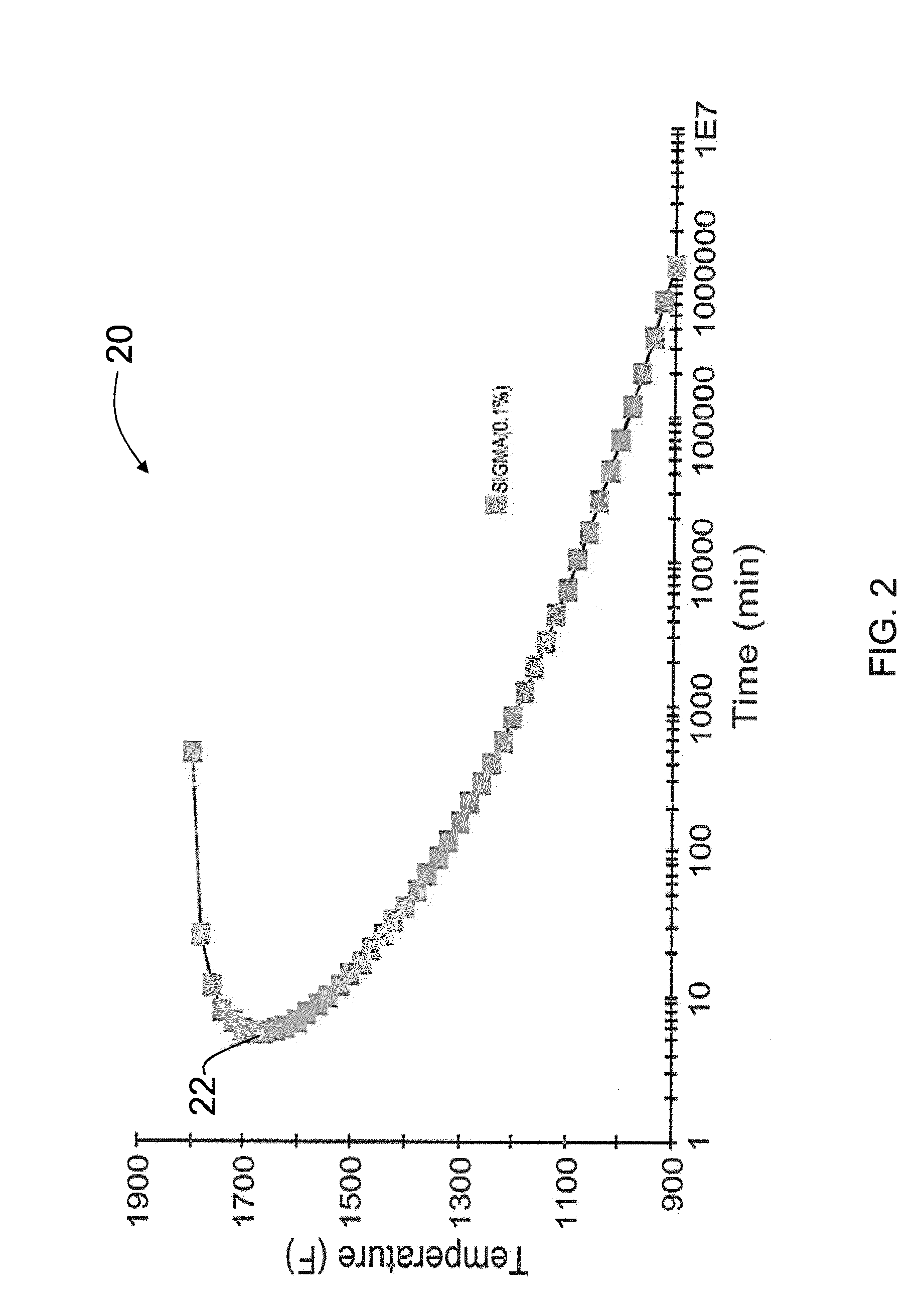

Methods for processing alloys

A method of processing a workpiece to inhibit precipitation of intermetallic compounds includes at least one of thermomechanically processing and cooling a workpiece including an austenitic alloy. During the at least one of thermomechanically working and cooling the workpiece, the austenitic alloy is at temperatures in a temperature range spanning a temperature just less than a calculated sigma solvus temperature of the austenitic alloy down to a cooling temperature for a time no greater than a critical cooling time.

Owner:ATI PROPERTIES LLC

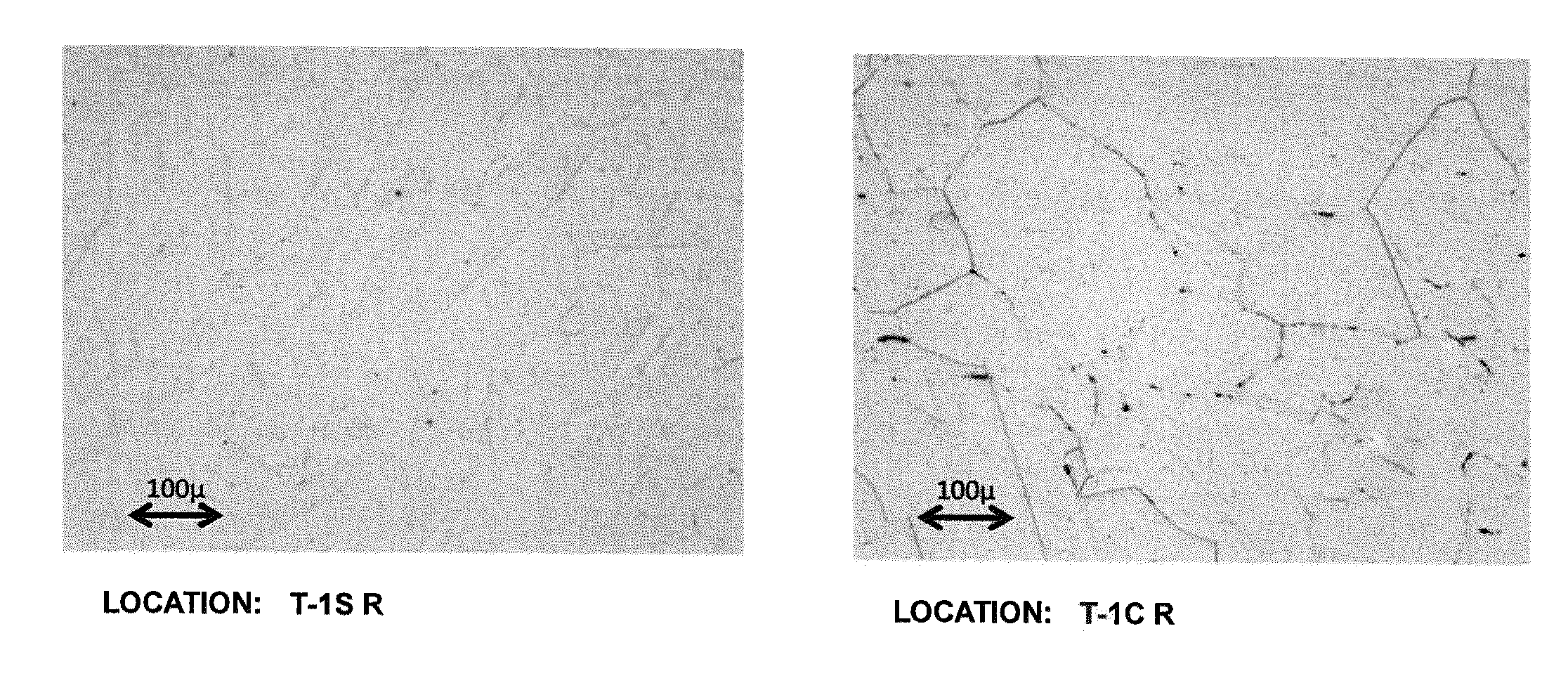

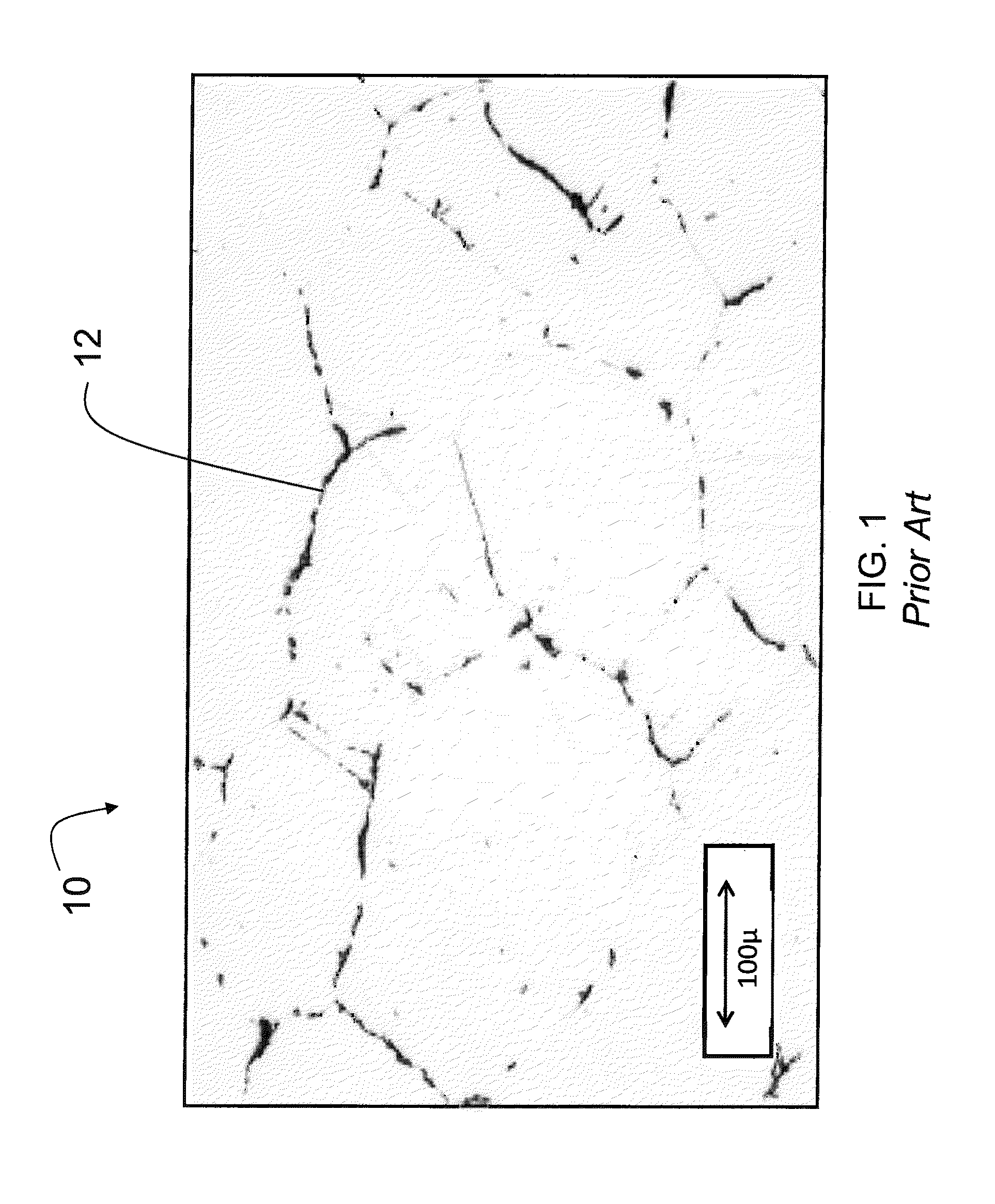

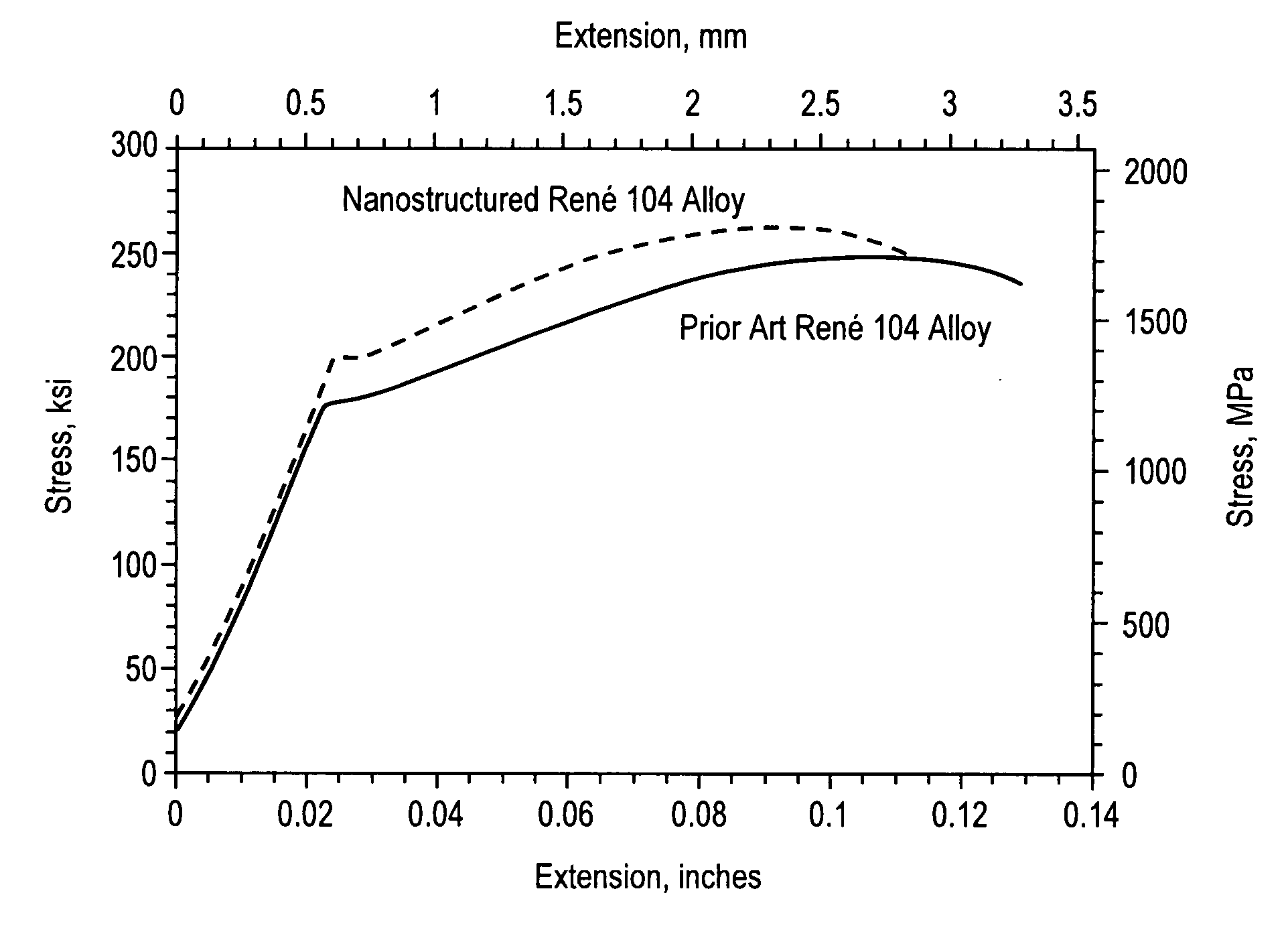

Nanostructured superalloy structural components and methods of making

A superalloy-containing structural component includes a superalloy matrix, and a plurality of hard phase nanoparticles dispersed at grain boundaries within the superalloy matrix, wherein the plurality of hard phase nanoparticles dispersed at the grain boundaries comprise about 1 volume percent to about 30 volume percent of the structural component, and wherein the superalloy matrix and the plurality of hard phase nanoparticles dispersed at the grain boundaries within the base superalloy matrix have been thermo-mechanically processed to form the structural component. A method for making a structural component includes introducing dislocations into a superalloy particle matrix effective to form new grain boundaries within a plurality of superalloy particles, introducing hard phase dispersoid nanoparticles at a plurality of grain boundaries of the superalloy particles effective to pin the grain boundaries, and thermo-mechanically processing the superalloy particles and hard phase dispersoid nanoparticles to form the superalloy-containing structural component.

Owner:GENERAL ELECTRIC CO

Superelastic guiding member

InactiveUS20070249965A1Guaranteed normal transmissionConstant stress levelGuide wiresSurgeryStress inducedNiobium

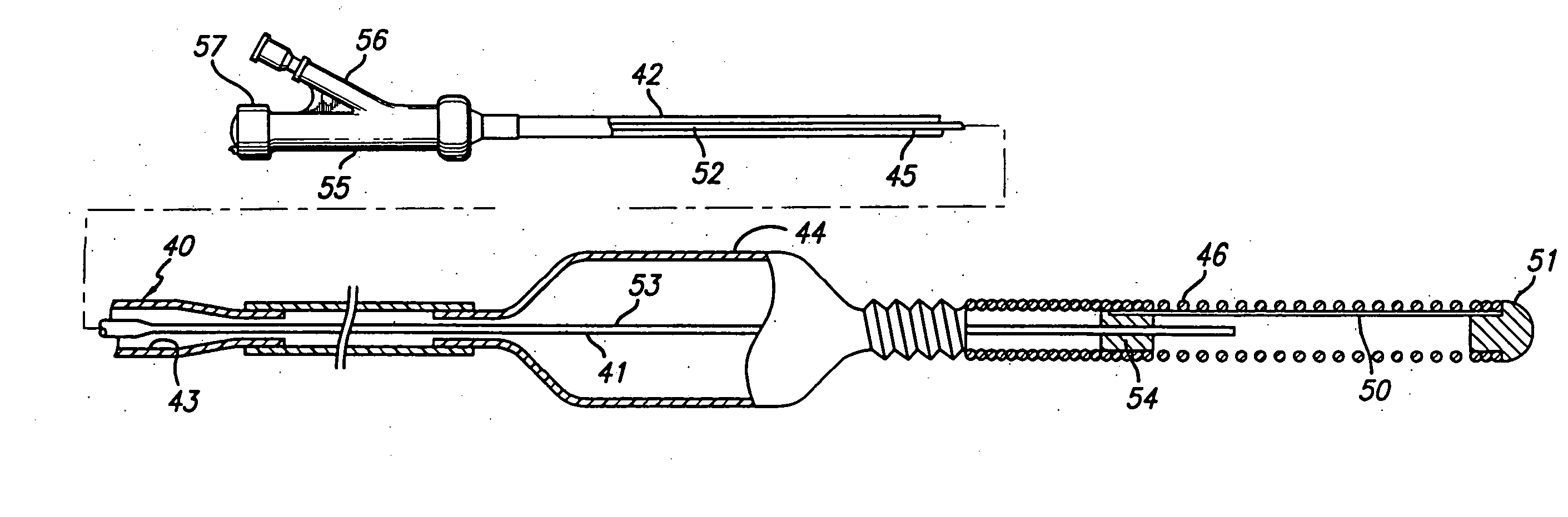

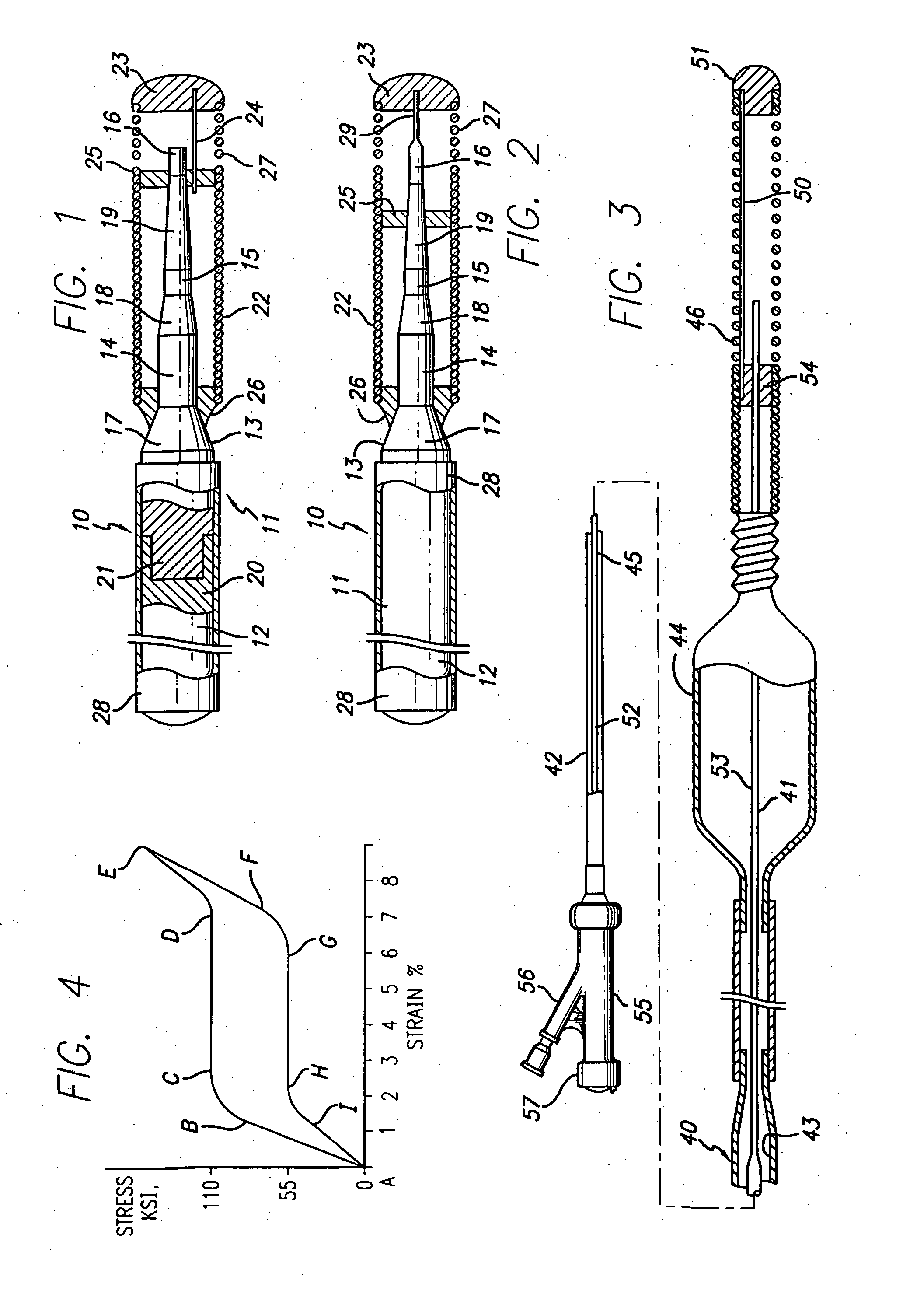

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

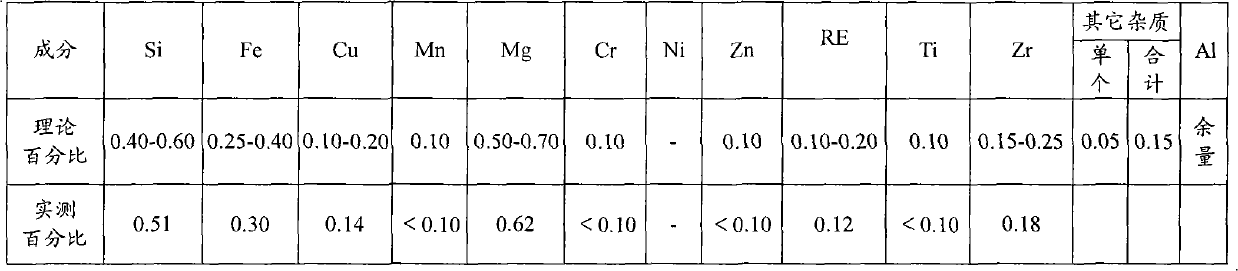

Aluminum alloy tubular conductor and production process thereof

InactiveCN101768688AHigh tensile strengthRaise the operating temperatureSingle tube conductorsMetal/alloy conductorsElectrical conductorHeat treated

The invention provides an aluminum alloy tubular conductor and a production process thereof. The aluminum alloy tubular conductor is prepared with Al-Mg-Si-Fe-Cu-Zr-RE alloy. The aluminum alloy tubular conductor adopts the Al-Mg-Si-Fe-Cu-Zr-RE alloy, the tensile strength and the use temperature of the aluminum alloy after being added with Cu, Fe, Zr and RE are increased, thereby the performance of the aluminum alloy tubular conductor is greatly improved. The production process of the aluminum alloy tubular conductor adopts a thermomechanical processing process, controls the cold processing rate after quenching within a certain range, thereby not only greatly improving the tensile strength of the product, but also facilitating the improvement of the recrystallization temperature of the alloy, so as to improve the heat resistant performance of the alloy.

Owner:湖北兴和电力新材料股份有限公司

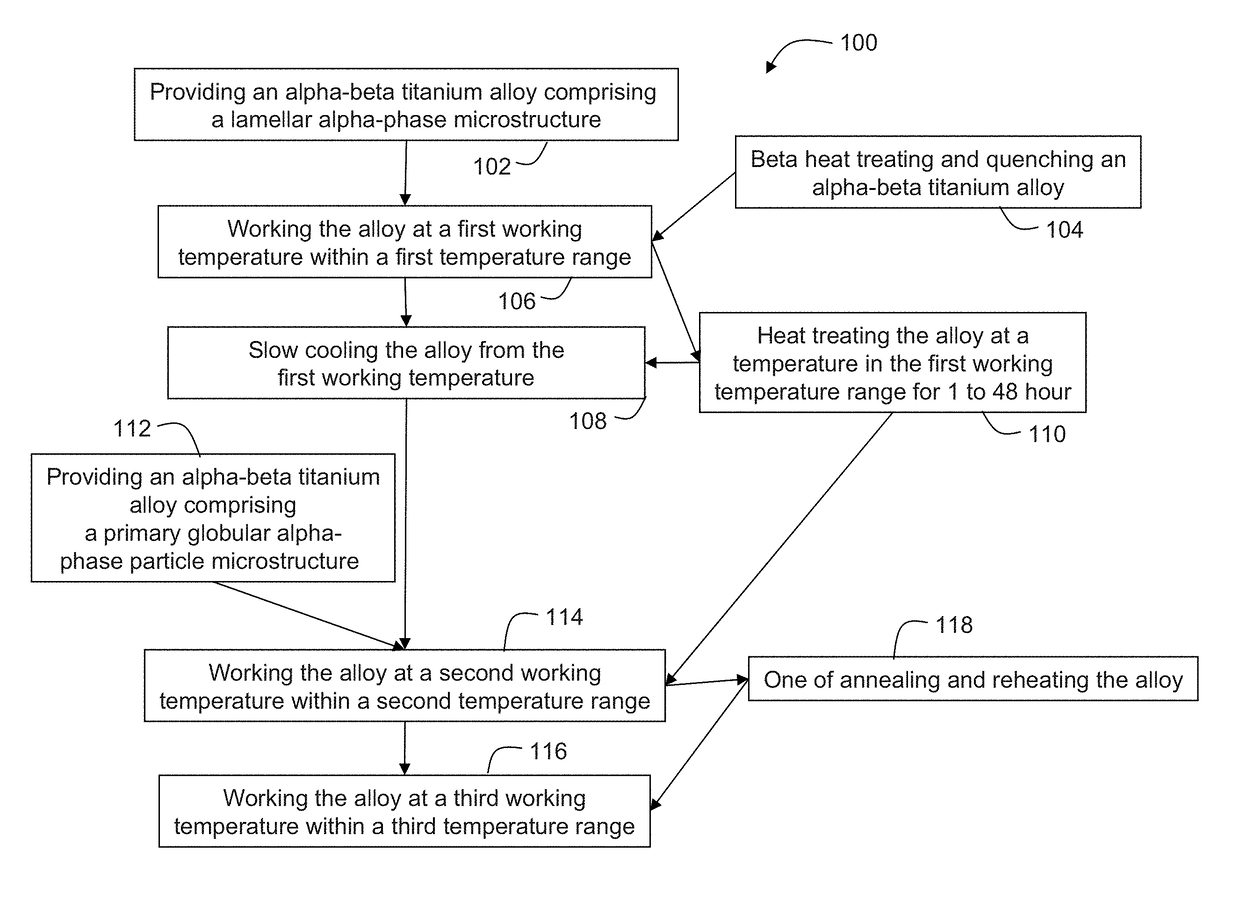

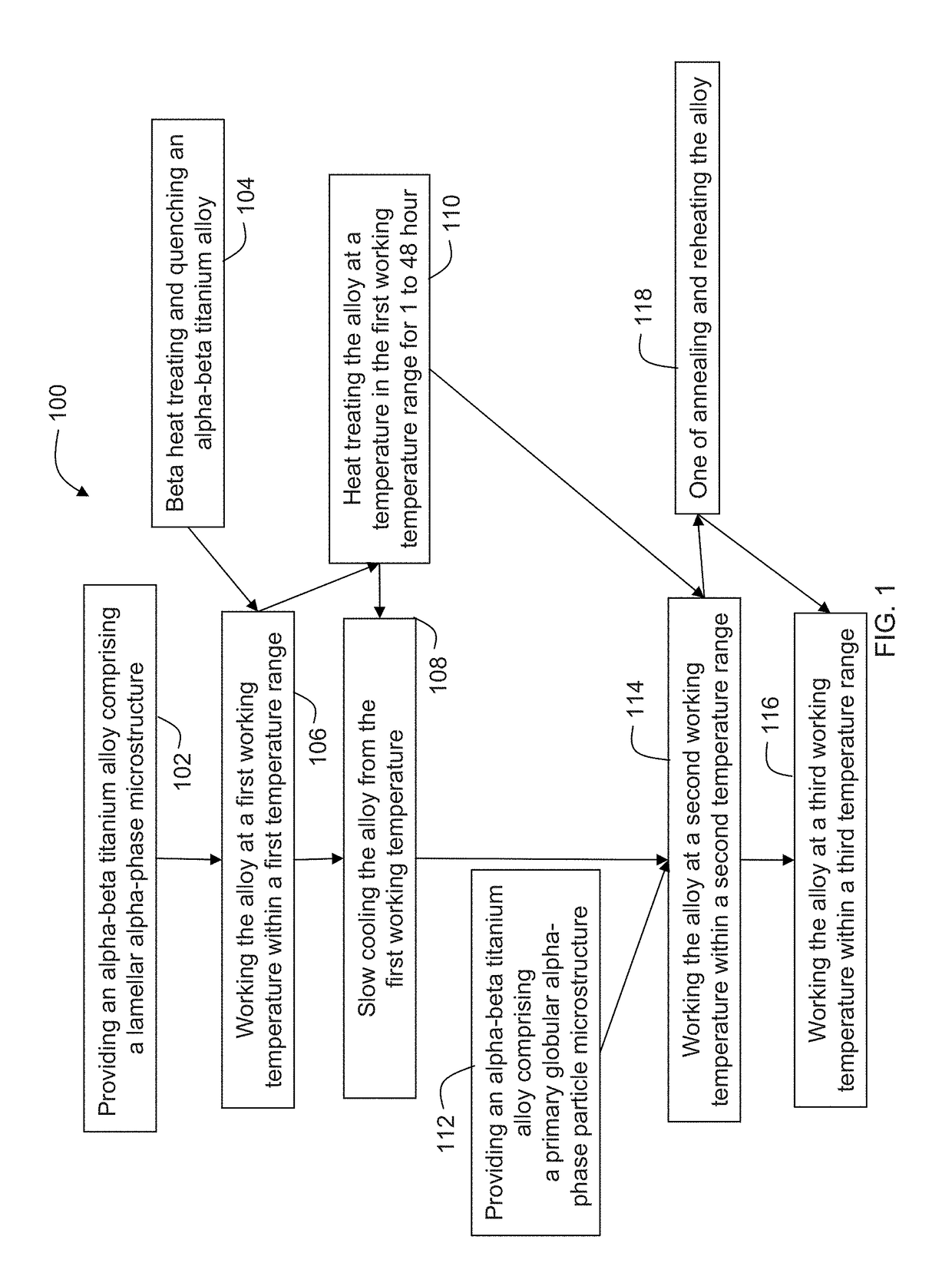

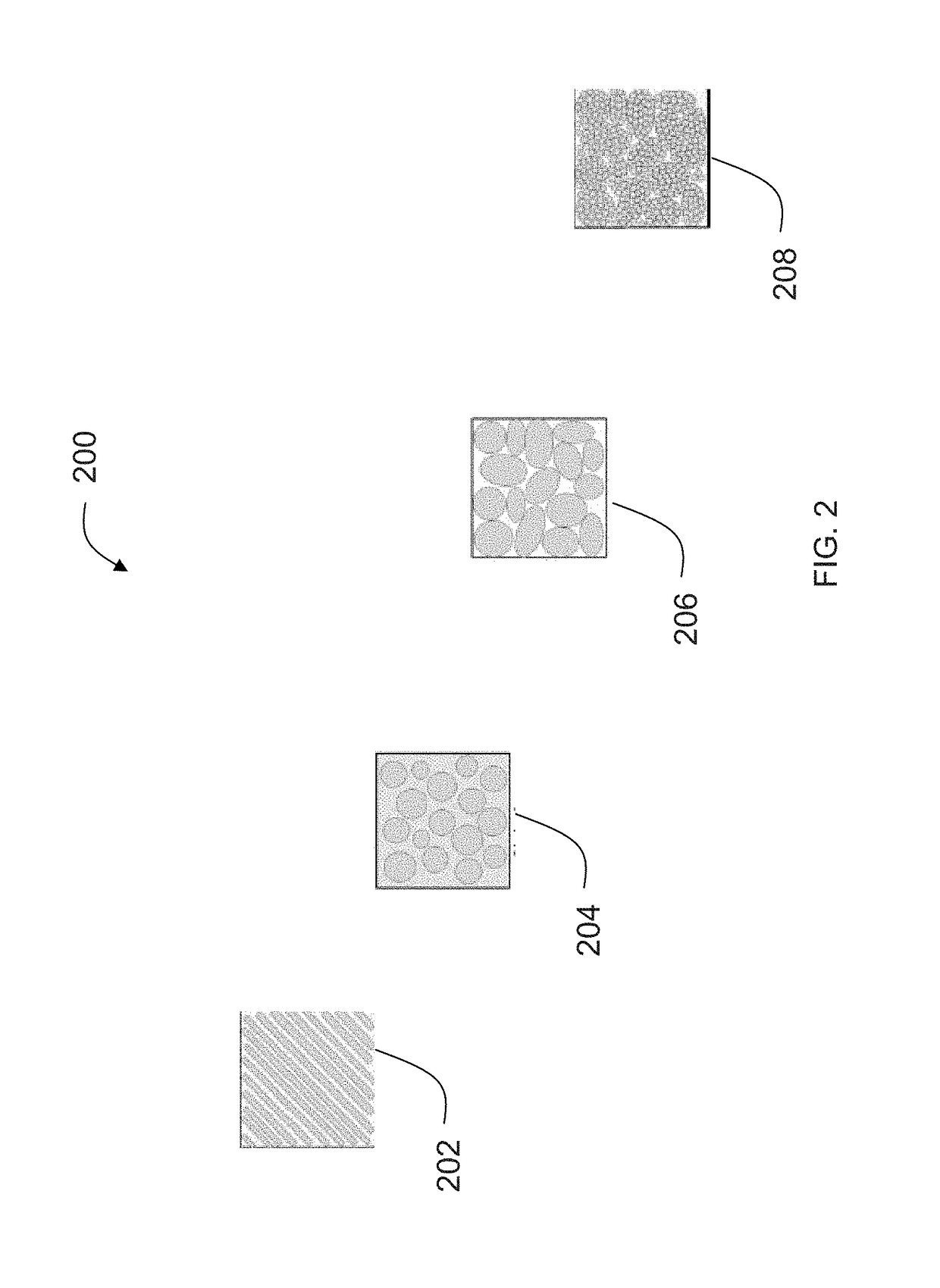

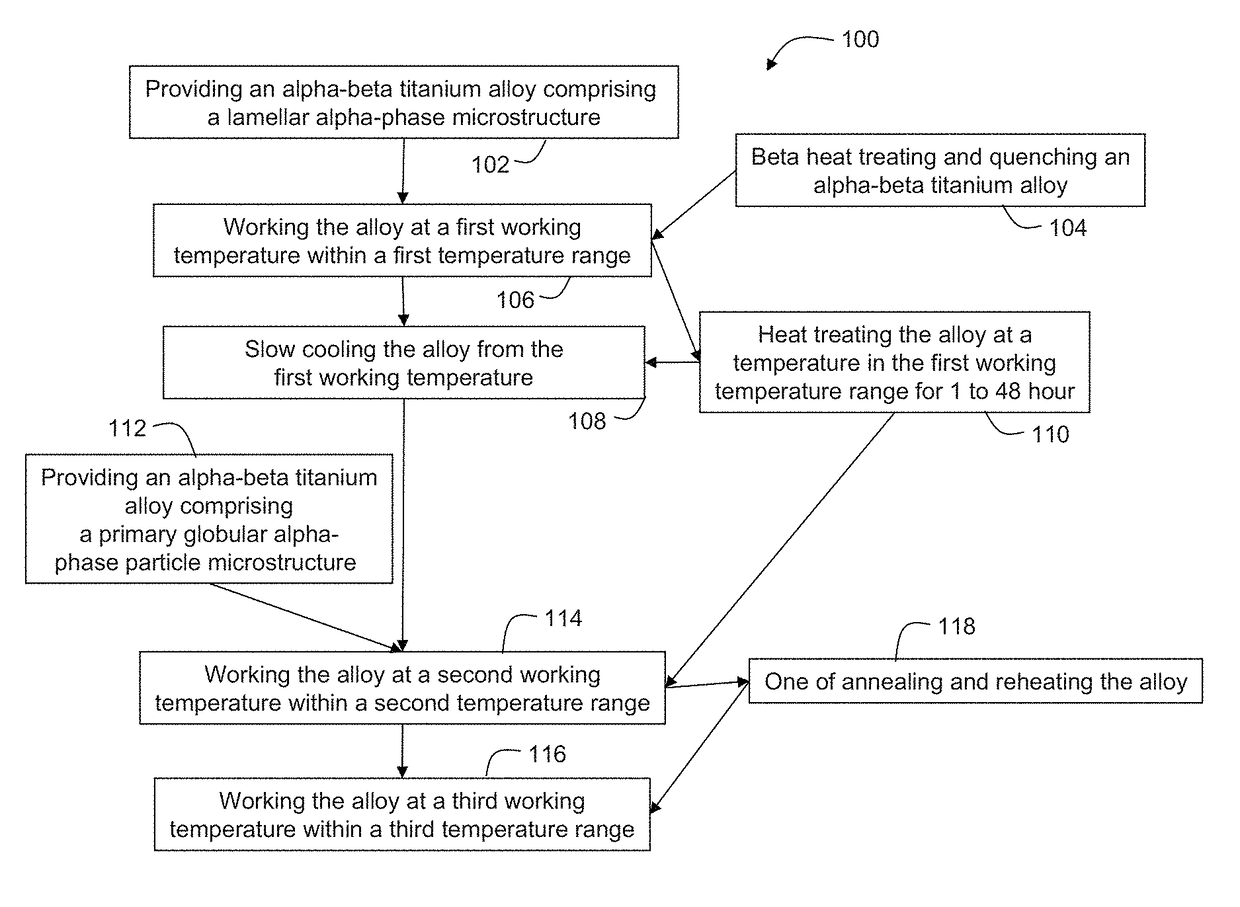

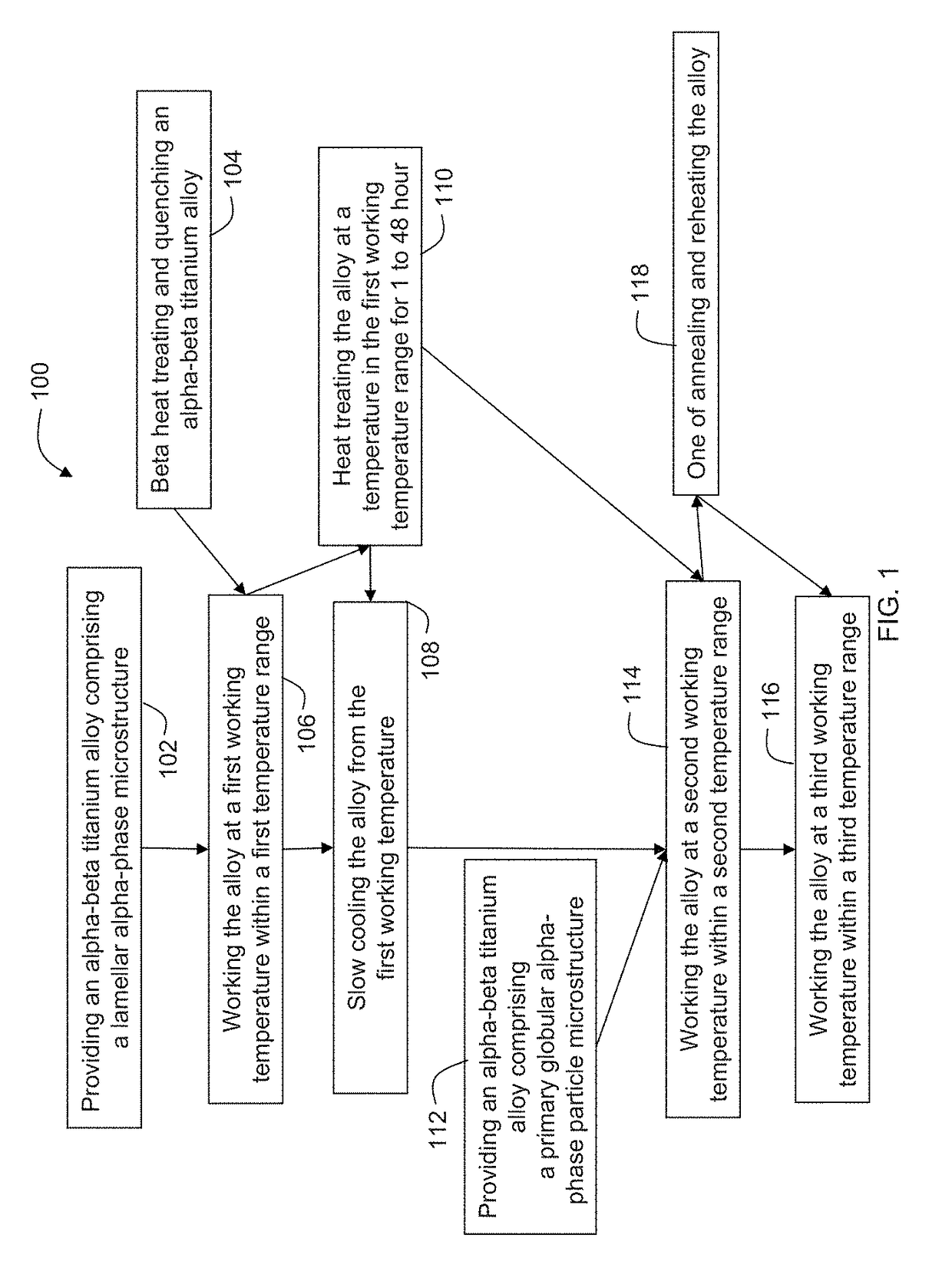

Thermomechanical processing of alpha-beta titanium alloys

One embodiment of a method of refining alpha-phase grain size in an alpha-beta titanium alloy comprises working an alpha-beta titanium alloy at a first working temperature within a first temperature range in the alpha-beta phase field of the alpha-beta titanium alloy. The alloy is slow cooled from the first working temperature. On completion of working at and slow cooling from the first working temperature, the alloy comprises a primary globularized alpha-phase particle microstructure. The alloy is worked at a second working temperature within a second temperature range in the alpha-beta phase field. The second working temperature is lower than the first working temperature. The is worked at a third working temperature in a third temperature range in the alpha-beta phase field. The third working temperature is lower than the second working temperature. After working at the third working temperature, the titanium alloy comprises a desired refined alpha-phase grain size.

Owner:ATI PROPERTIES LLC

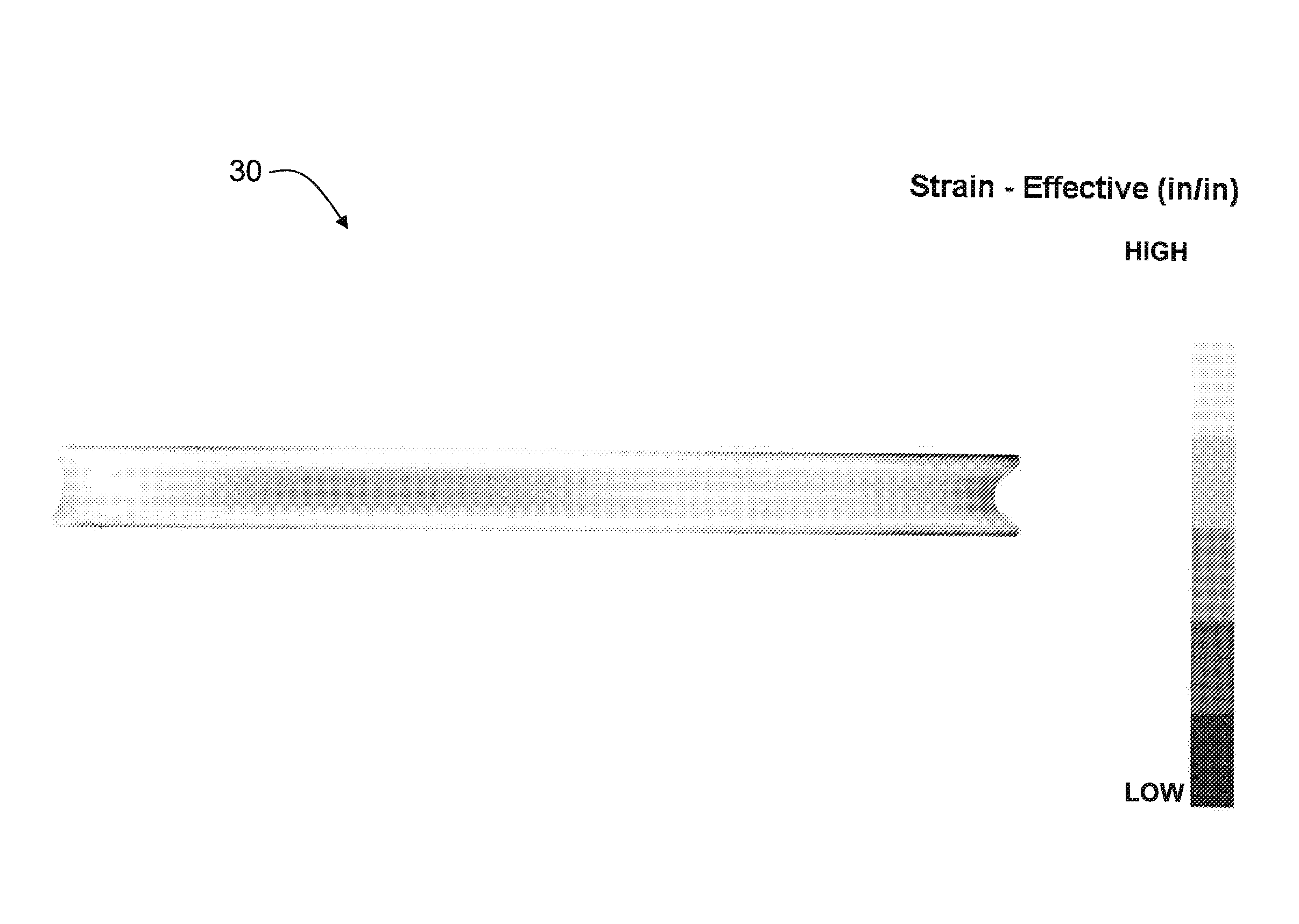

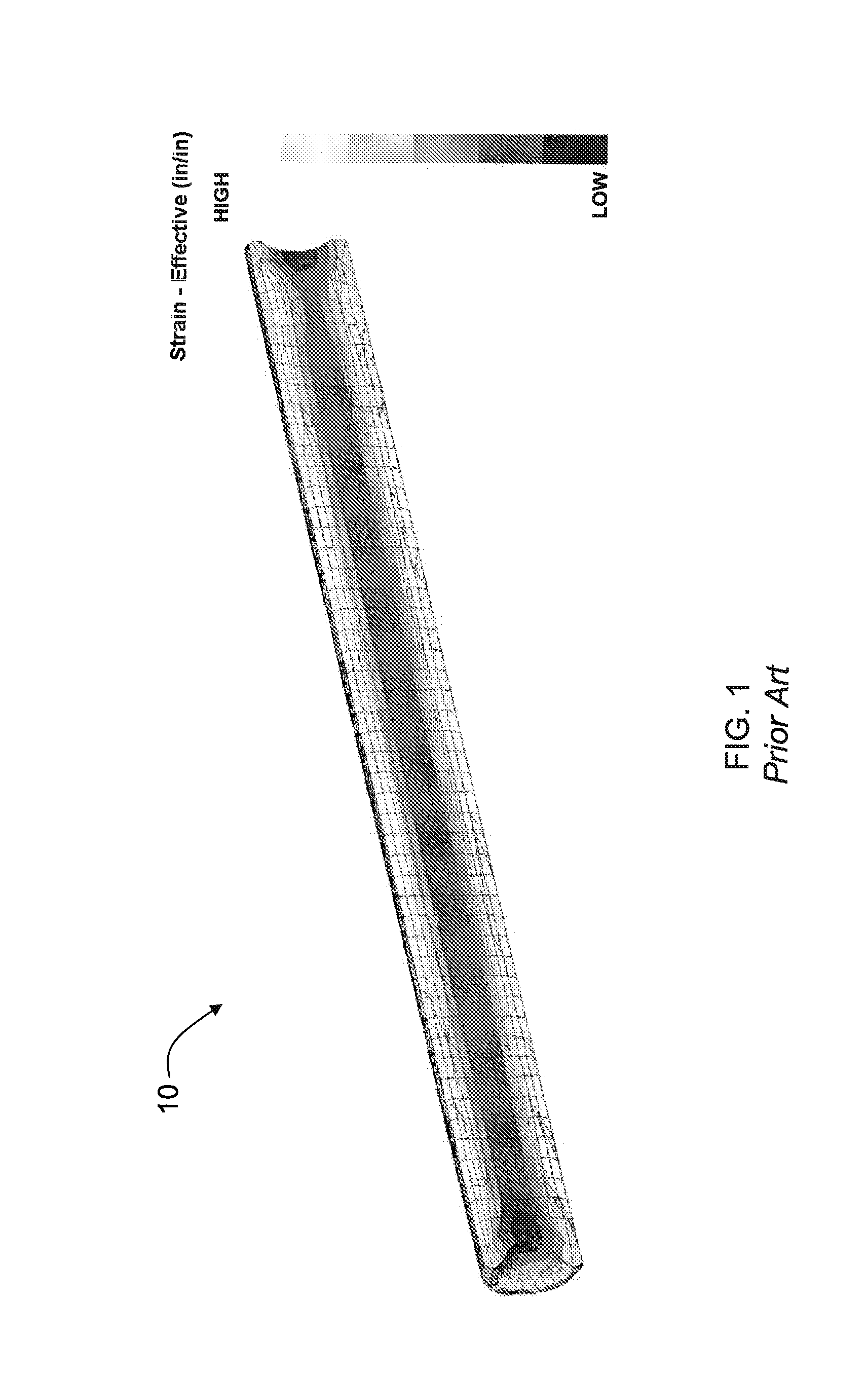

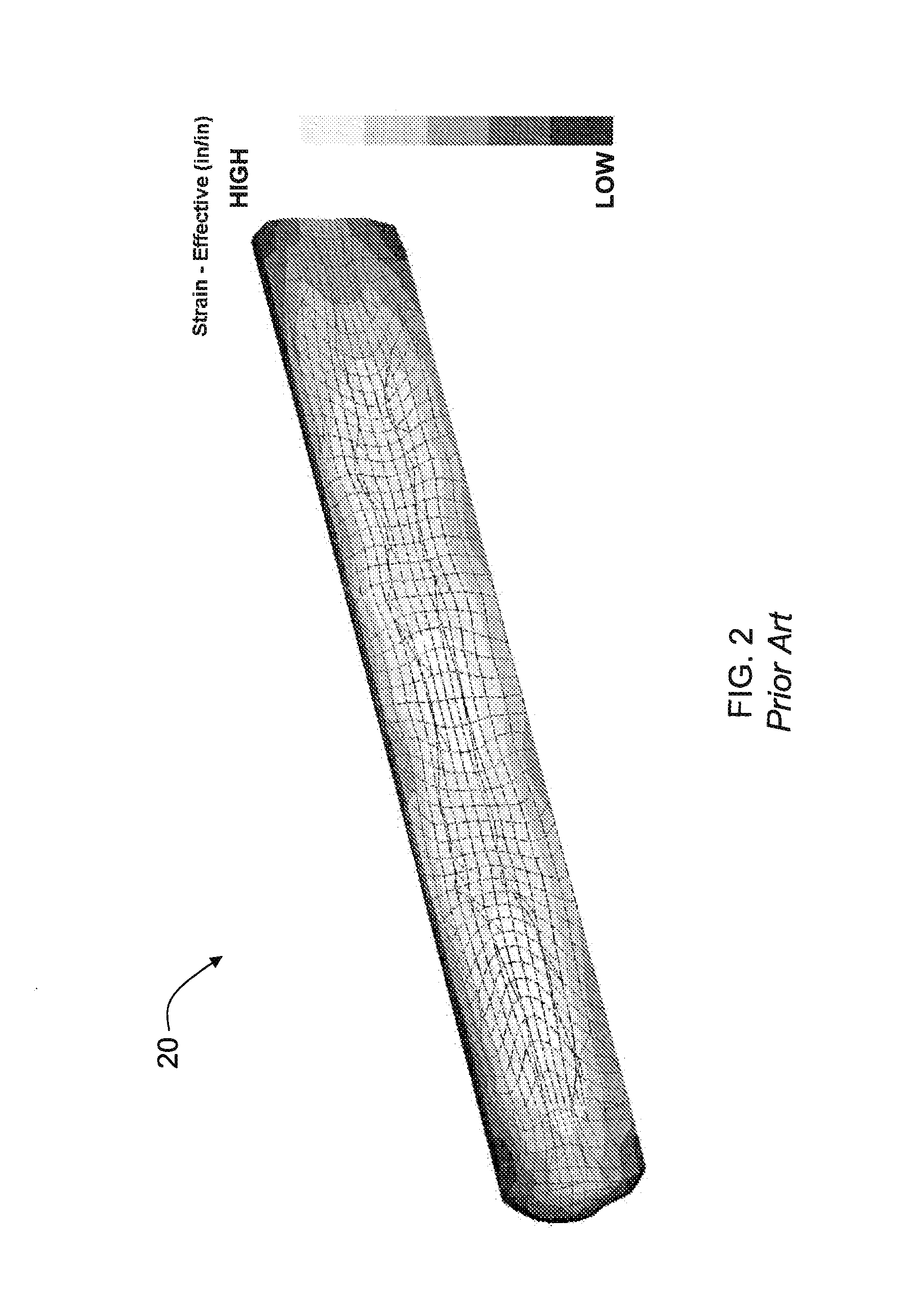

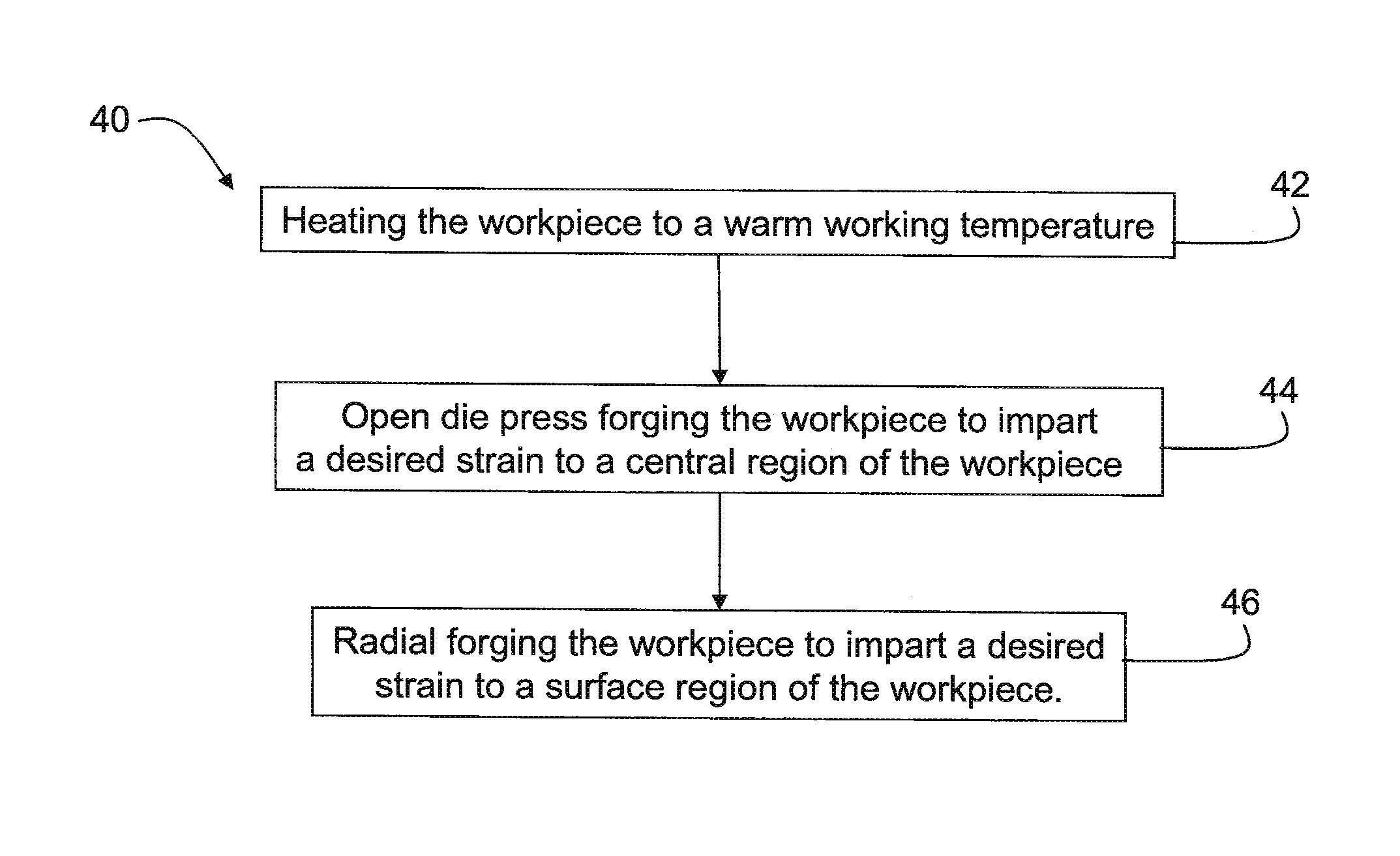

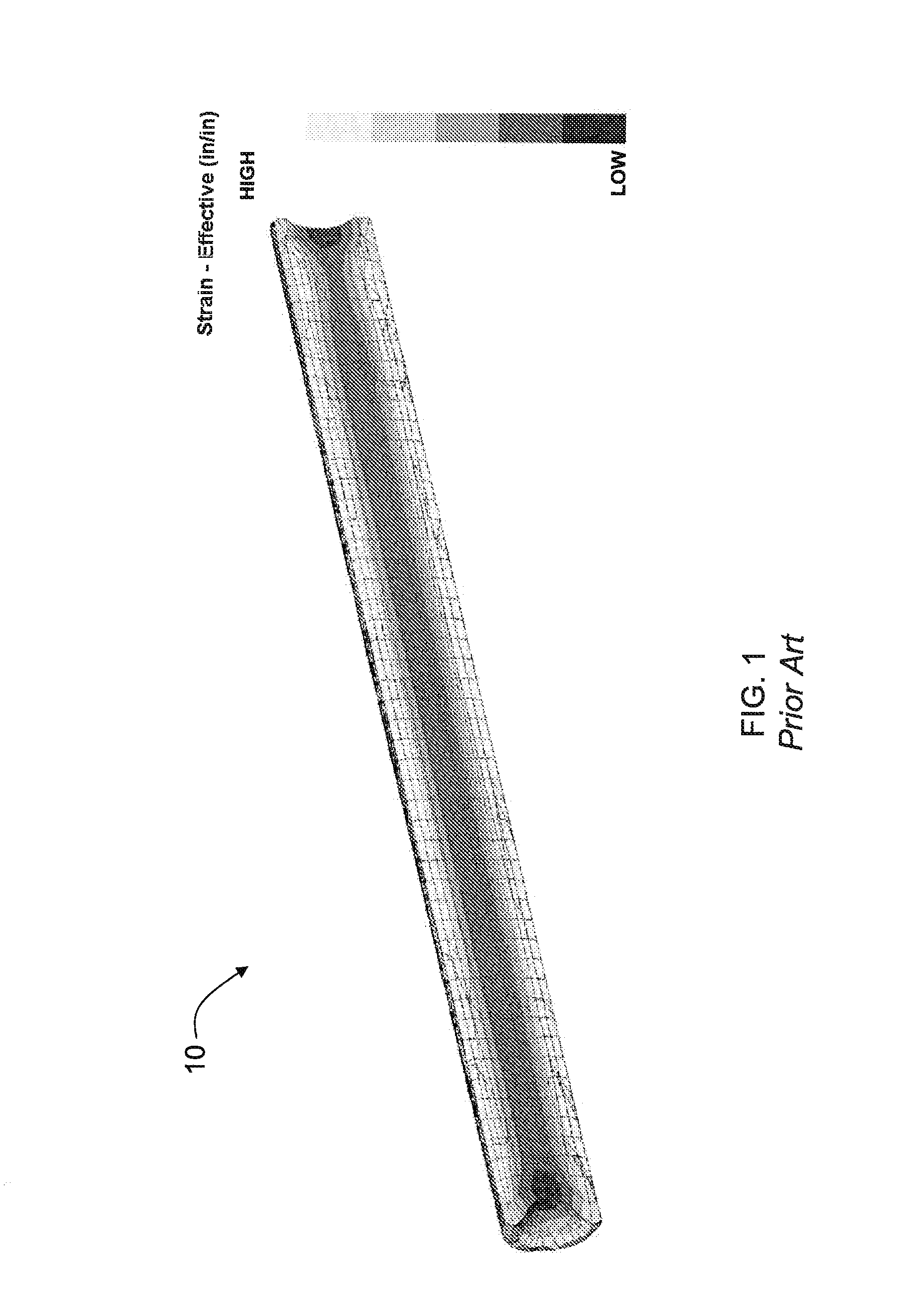

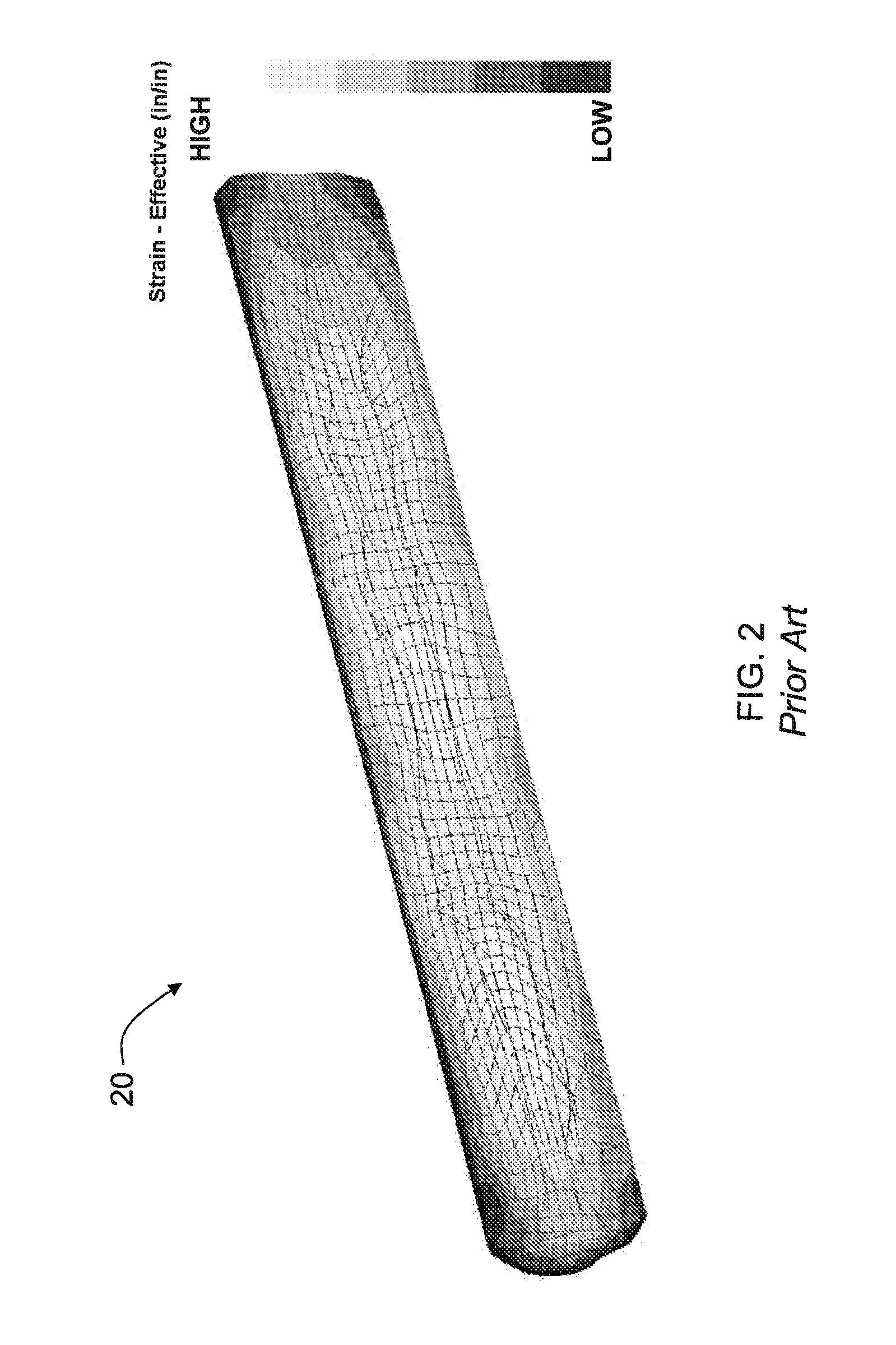

Thermomechanical processing of high strength non-magnetic corrosion resistant material

A method of processing a non-magnetic alloy workpiece comprises heating the workpiece to a warm working temperature, open die press forging the workpiece to impart a desired strain in a central region of the workpiece, and radial forging the workpiece to impart a desired strain in a surface region of the workpiece. In a non-limiting embodiment, after the steps of open die press forging and radial forging, the strain imparted in the surface region is substantially equivalent to the strain imparted in the central region. In another non-limiting embodiment, the strain imparted in the central and surface regions are in a range from 0.3 inch / inch to 1 inch / inch, and there exists no more than a 0.5 inch / inch difference in strain of the central region compared with the strain of the surface region of the workpiece. An alloy forging processed according to methods described herein also is disclosed.

Owner:ATI PROPERTIES LLC

Superelastic guiding member

InactiveUS7258753B2Guaranteed normal transmissionConstant stress levelStentsGuide wiresStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

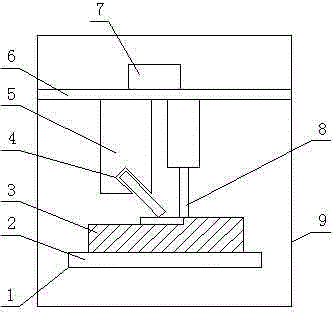

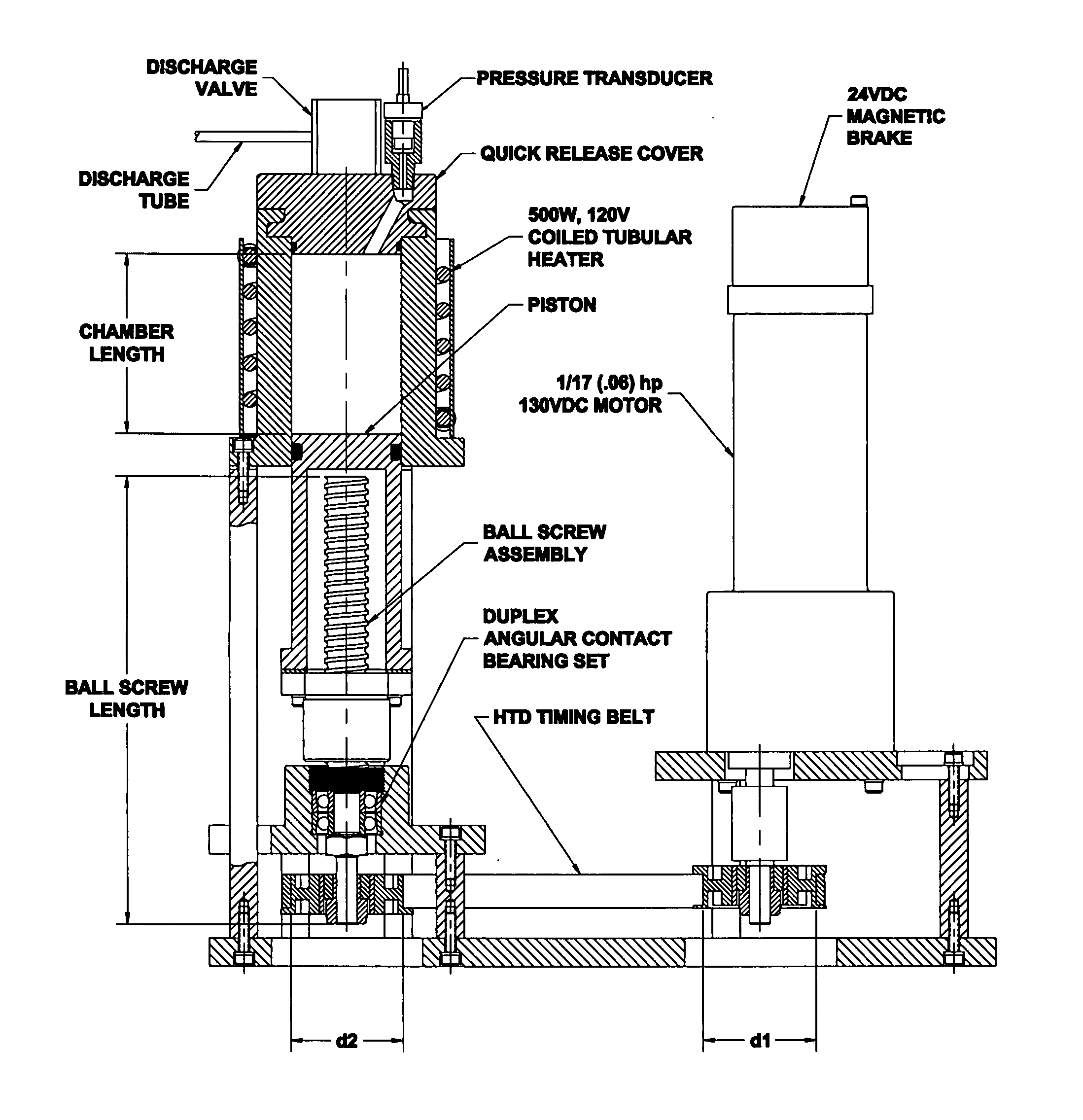

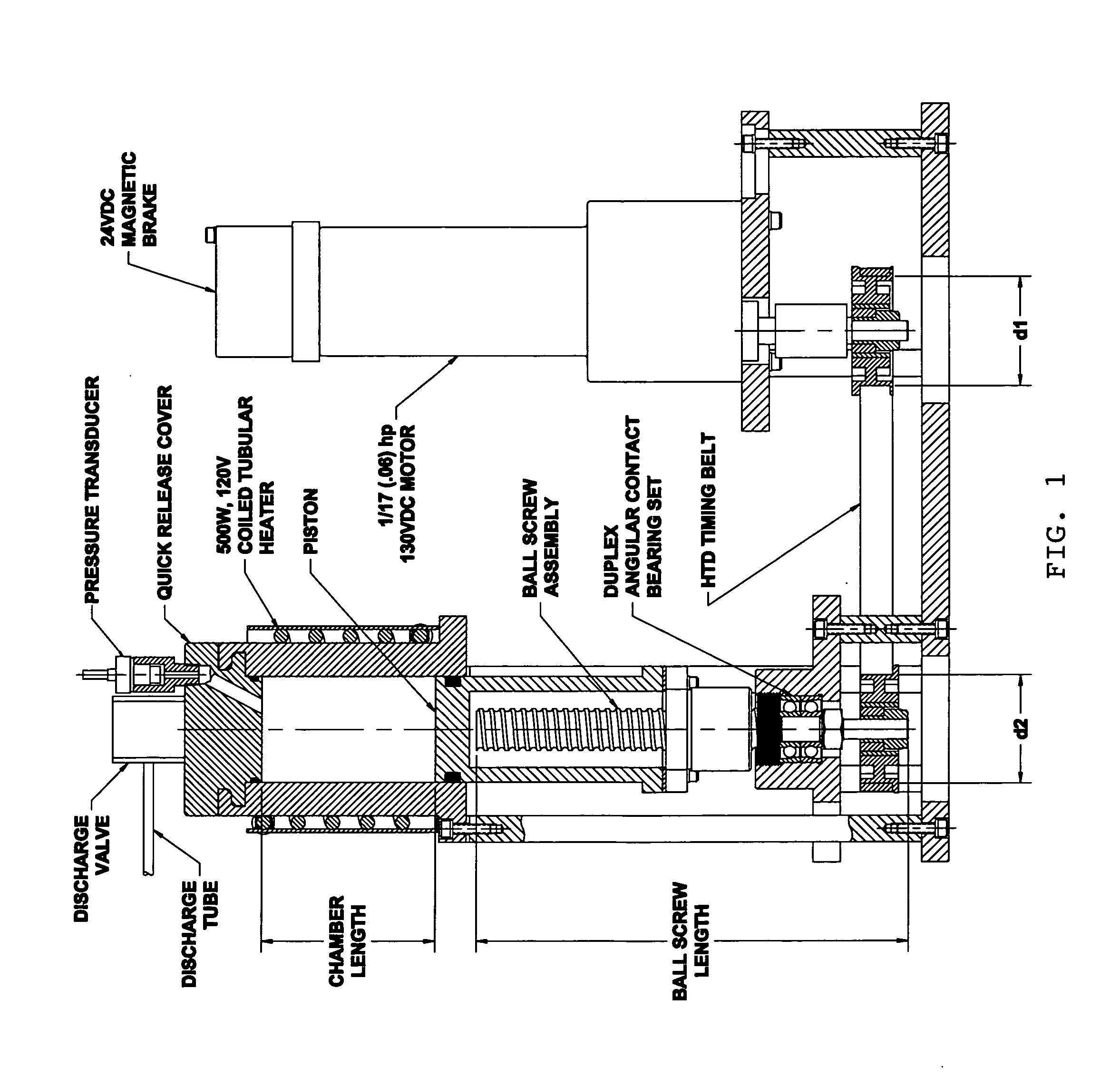

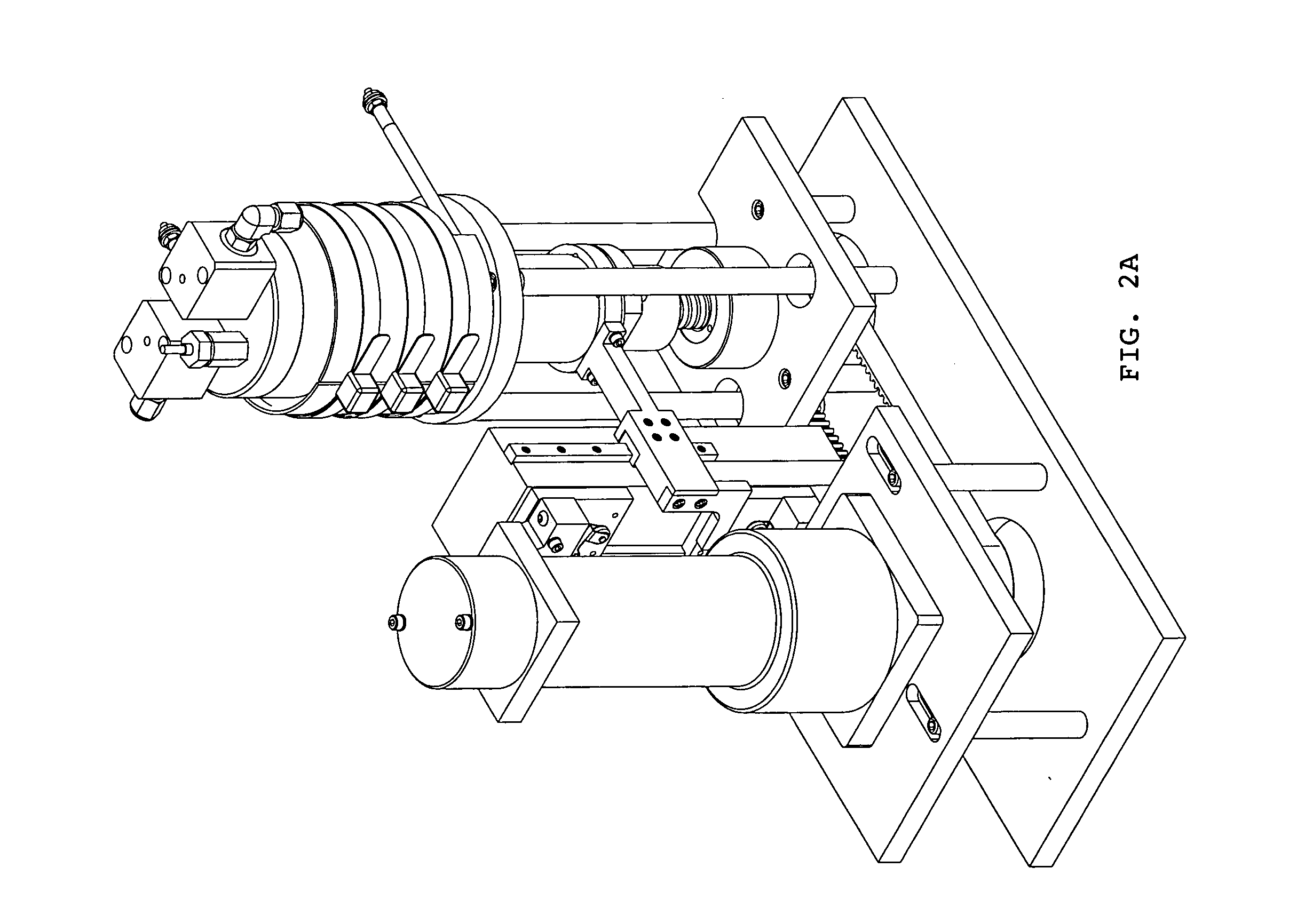

Manufacturing machine and method of titanium alloy parts

ActiveCN106591824AImprove performanceTight bonding between layersMetallic material coating processesTitanium alloyDirect current

The invention provides a manufacturing machine and method of titanium alloy parts. The manufacturing machine is characterized by comprising a machine body; a movable platform is arranged on the lower portion of the machine body; a preformed billet is arranged on the movable platform; a thermomechanical processing head is arranged above the preformed billet; a titanium alloy bar hopper is arranged on one side of the thermomechanical processing head; a movable guide rail is connected with the upper portion of the titanium alloy bar hopper and the upper portion of the thermomechanical processing head; and a driver used for driving the titanium alloy bar hopper and the thermomechanical processing head is arranged on the movable guide rail. The manufacturing method of the titanium alloy parts comprises the steps that titanium alloy bars are put into the titanium alloy bar hopper, the preformed billet is installed on the movable platform, direct-current voltage is applied to the other ends, not in contact with one another, of the titanium alloy bars, thermomechanical processing is conducted on metal molten drops spread on the preformed billet through the thermomechanical processing head, the titanium alloy bars are melted and form the molten drops, then thermomechanical processing is conducted immediately for forming after the molten drops drop on the preformed billet, and the titanium alloy parts can be formed in line-by-line and layer-by-layer modes. By the adoption of the technical scheme, the performance of the manufactured parts is remarkably improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Thermomechanical processing of high strength non-magnetic corrosion resistant material

A method of processing a non-magnetic alloy workpiece comprises heating the workpiece to a warm working temperature, open die press forging the workpiece to impart a desired strain in a central region of the workpiece, and radial forging the workpiece to impart a desired strain in a surface region of the workpiece. In a non-limiting embodiment, after the steps of open die press forging and radial forging, the strain imparted in the surface region is substantially equivalent to the strain imparted in the central region. In another non-limiting embodiment, the strain imparted in the central and surface regions are in a range from 0.3 inch / inch to 1 inch / inch, and there exists no more than a 0.5 inch / inch difference in strain of the central region compared with the strain of the surface region of the workpiece. An alloy forging processed according to methods described herein also is disclosed.

Owner:ATI PROPERTIES LLC

Apparatus, pods and methods for processing expandable food materials

InactiveUS20100143549A1Improve output qualityMinimized starch damageCooking vesselsFood shapingCombined useComputer module

The present invention relates in general to methods and apparatus for processing expandable food materials, and more particularly to methods and apparatus for low shear thermo-mechanical processing of food materials and unique pods for use in connection with such methods and apparatus. The invention can include cooker and extruder apparatus for the customized production of food products, including a compression module, a dryer module, and a control unit, that interact with the pods to produce desired food product.

Owner:SHEAR GOODNESS

Nickel-chromium alloy target with high purity and high compositional uniformity and method for preparing same

InactiveCN102732845AGuaranteed uniformitySuperheat is easy to controlVacuum evaporation coatingSputtering coatingOptical communicationImpurity

The invention relates to a nickel-chromium alloy target with high purity and high compositional uniformity and a method for preparing the same. According to the technical scheme of the invention, the parameter of processes including smelting, solidifying, thermal-mechanical processing and annealing heat treatment of the nickel-chromium series alloy target are controlled accurately according to the material science and the process calculation and simulation results. The nickel-chromium series alloy target prepared by adopting the method has a wide component range, comprises 5-95% of nickel, less than or equal to 0.0005% of impurities and the balance of chromium, and can be widely applied to the optoelectronic industry, the data storage industry, the integrated-circuit industry, the optical communication industry and other sophisticated industry.

Owner:FUZHOU UNIV

Thermomechanical processing of aluminum alloys

ActiveUS8163113B2Good molding effectNot adversely affect formabilitySolid solutionUltimate tensile strength

A cast aluminum alloy containing up to about 0.35% by weight chromium is heated to a first elevated temperature to homogenize the casting and dissolve the chromium content in an aluminum-based matrix phase. The alloy is then heated at a lower elevated temperature to cause the precipitation of a portion of the chromium as an aluminum-containing and chromium-containing intermetallic compound. A suitable amount of chromium is retained in solid solution in aluminum. Thus, the concentration of dissolved chromium in an aluminum alloy may be controlled to fall within specified ranges which result in improvements in both the strength and ductility of the alloy. Impurity amounts of iron may also be precipitated as intermetallic particles from the aluminum matrix to enhance the ductility of the aluminum-based alloy.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Shaping method of irregular steel component

The invention relates to a shaping method of an irregular steel component, which belongs to the technical field of machining. The shaping method comprises the following steps of: processing blanks by adopting a casting method; processing the blanks into blank materials respectively by adopting a thermal machining method; putting the blank materials into a hot isostatic pressing canning by adopting arranging, overlaying and stacking methods; performing edge sealing welding and vacuum packaging and supporting prefabricated blanks; putting the prefabricated blanks into a hot isostatic pressing furnace for performing diffused connection; and removing the canning to prepare an irregular steel component. The method can be used for preparing high-performance structural pieces of various alloy components and various shapes without using any large-sized thermal machining equipment, has the advantages of high efficiency and low cost, and is suitable for preparing various high-strength steel structures.

Owner:赵冰

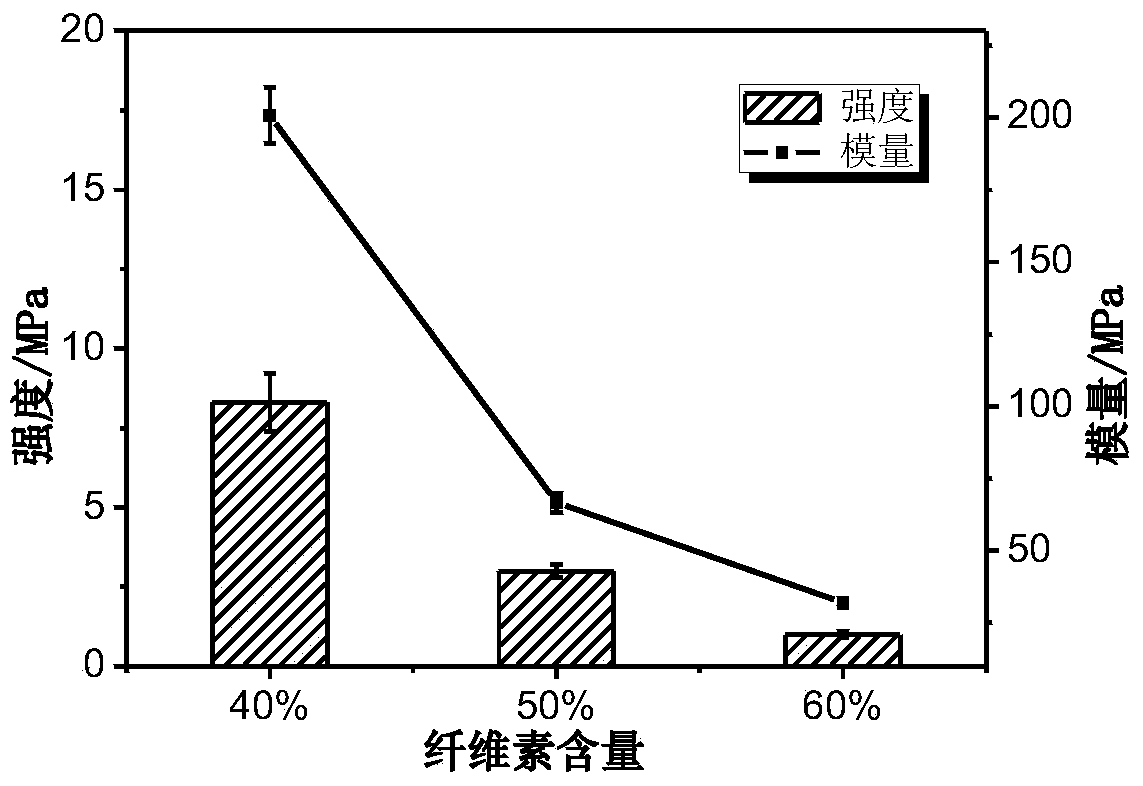

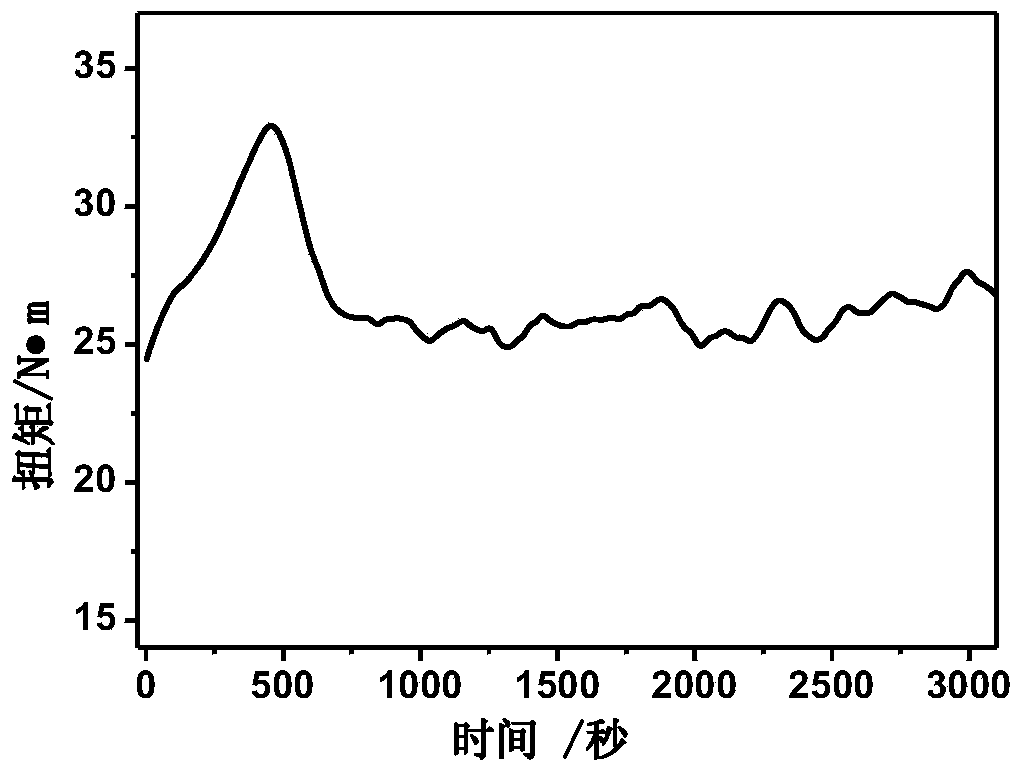

Cellulose thermoplastic material and preparation method thereof

The invention discloses a cellulose thermoplastic material and a preparation method thereof. The thermoplastic material consists of ionic liquid and cellulose, wherein a mass ratio of the ionic liquid to cellulose is 20 / 80-50 / 50, and the ionic liquid serves as a plasticizer and can break hydrogen bonds among cellulose molecules and increase the free volume, so that cellulose plasticization is realized. The preparation method comprises the following steps: premixing, mixing, performing thermal machining and molding, impregnating and roasting. The cellulose thermoplastic material can be repeatedly molded and processed and is resistant to plasticizer migration and stable in structure. Compared with the prior art, the method for preparing the cellulose thermoplastic material, provided by the invention, has the characteristics of simple process and high production efficiency; the product can be subjected to secondary processing, the defect that the conventional cellulose material is single in form is overcome, and the application field of the cellulose material is widened.

Owner:ZONYA PRINTING & PACKAGING CO LTD

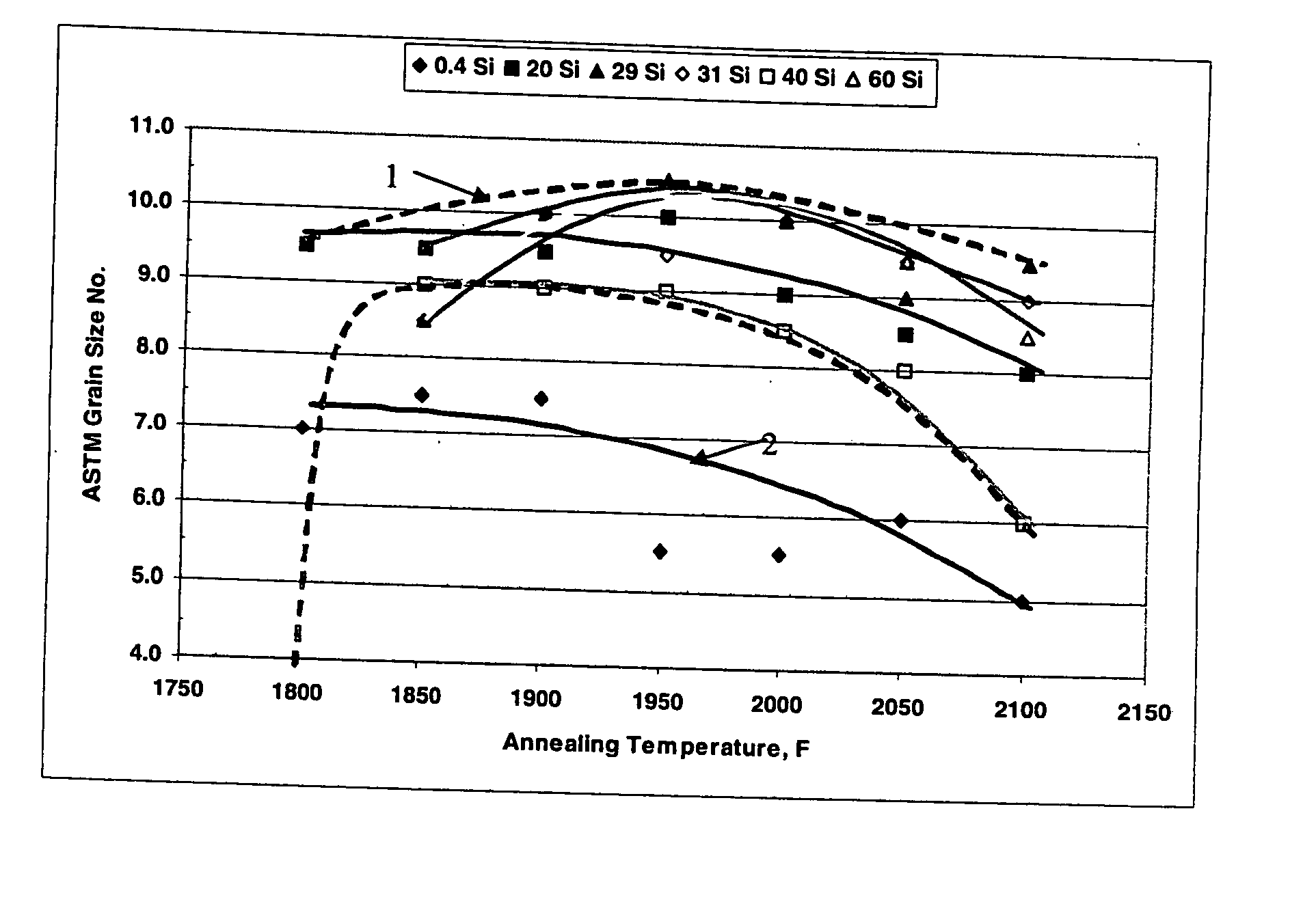

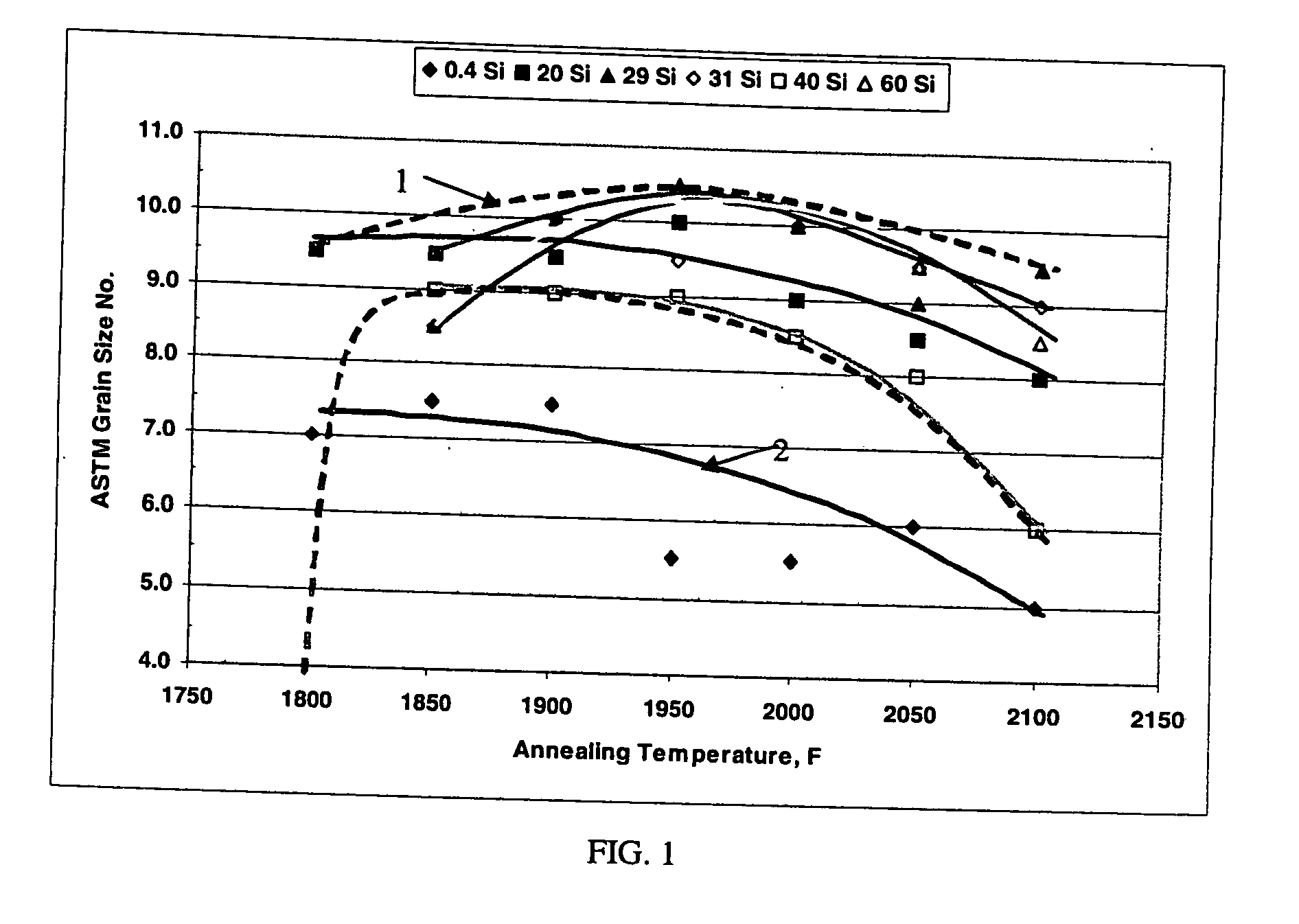

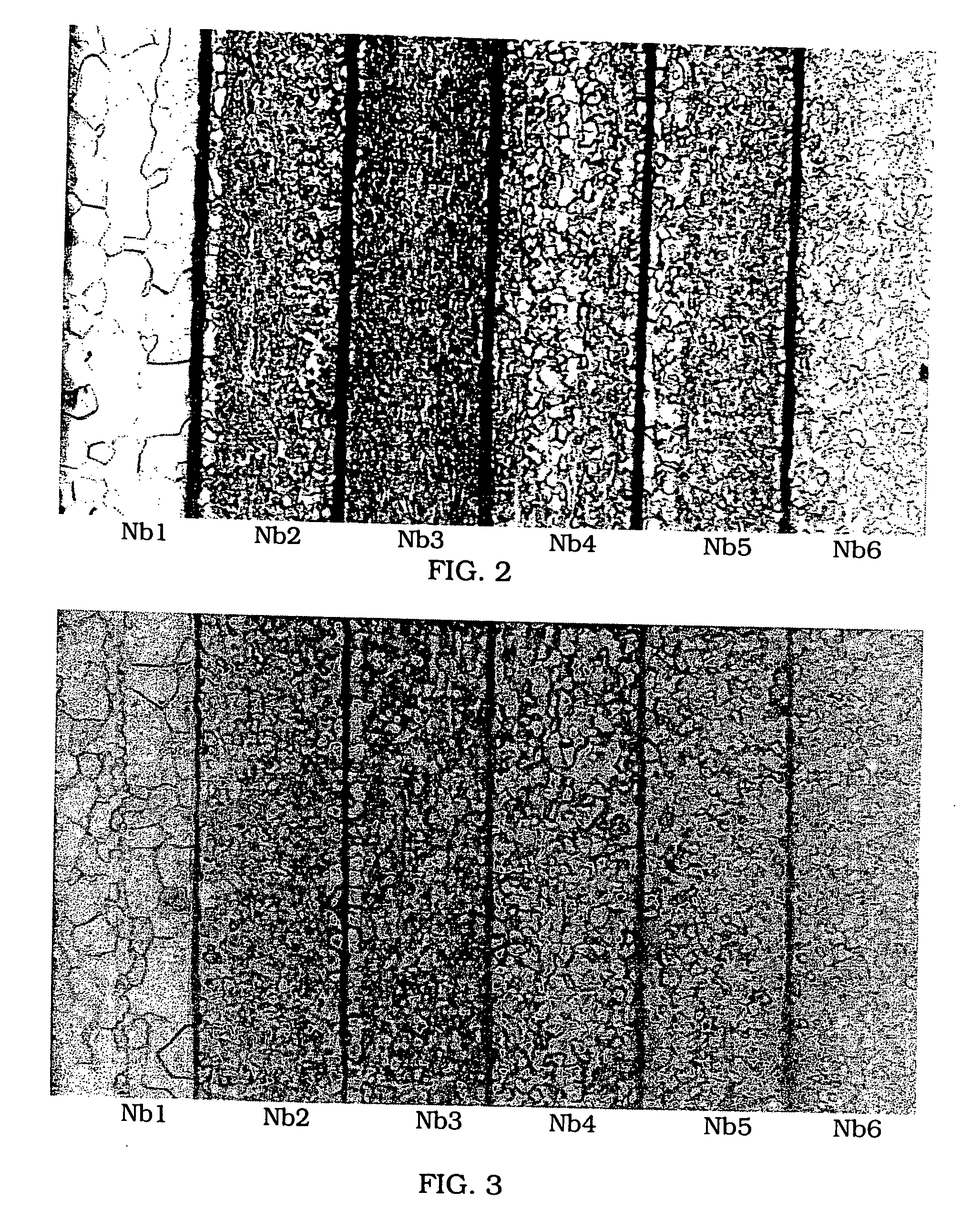

Fine grain niobium sheet via ingot metallurgy

A method of making a silicon-containing alloy of niobium or tantalum that includes: A) forming a blend comprising niobium or tantalum powder and silicon powder and pressing the blend to form pressed blend; B) attaching the pressed blend to an electrode comprising niobium or tantalum; C) melting the electrode and pressed blend under vacuum arc remelting conditions, such that the blend mixes with the melted electrode; D) cooling the melted electrode to form an alloy ingot; and E) applying thermo-mechanical processing steps to the alloy ingot to form a wrought product. The method provides a fully recrystalized niobium or tantalum wrought product with a grain size finer that ASTM 5, that can be used to make deep drawn cups and sputtering targets.

Owner:MATERION NEWTON INC

Precipitation-strengthened nickel-iron-chromium alloy

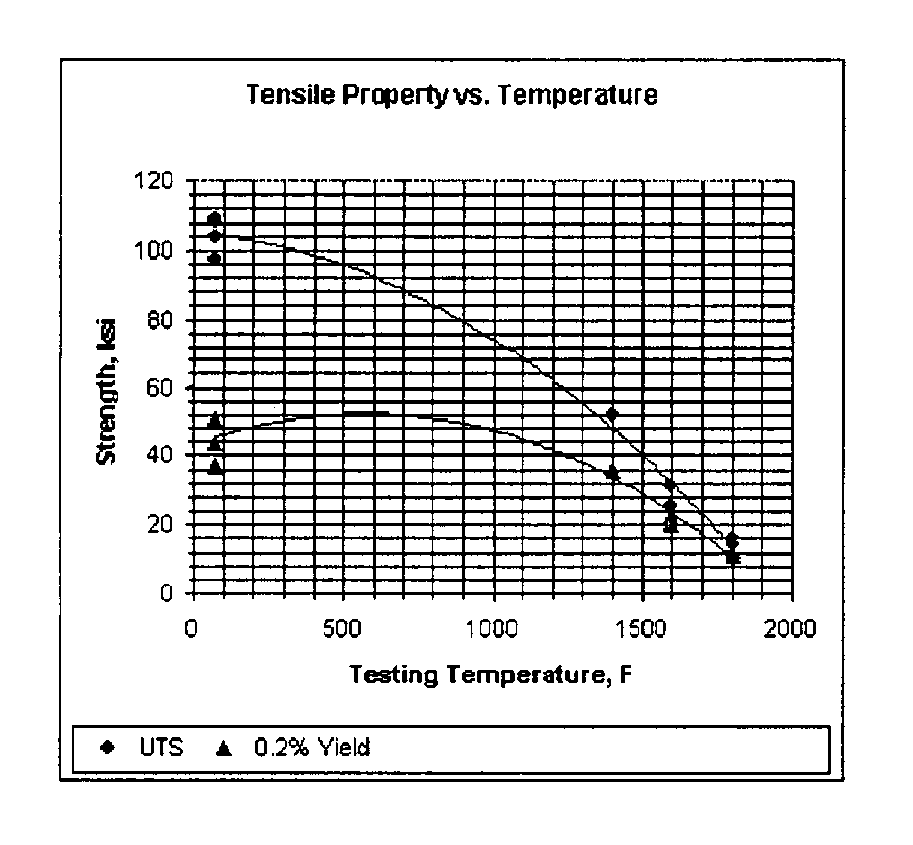

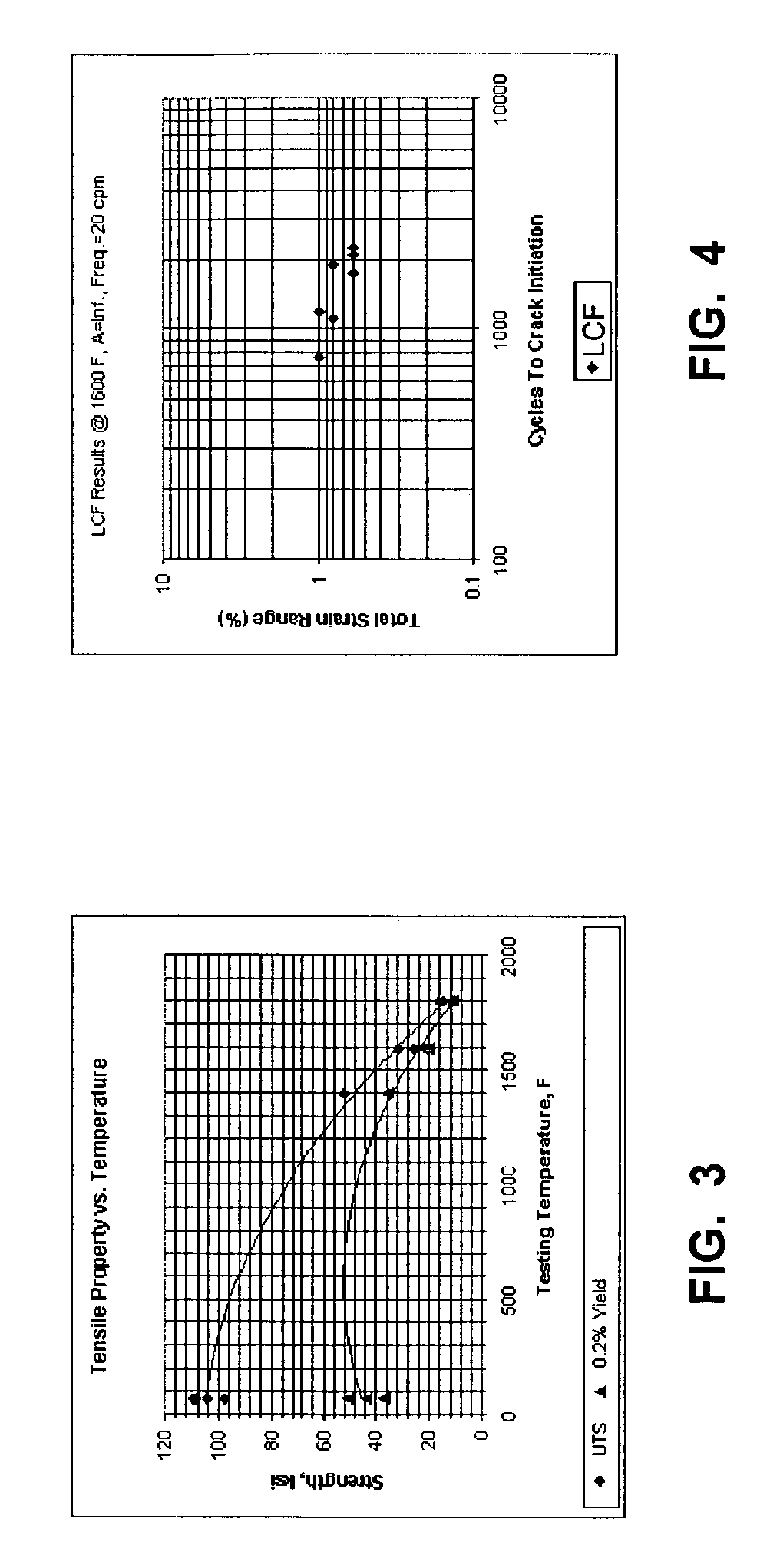

InactiveUS7118636B2Improved low cycle fatigue resistanceFine grain structureBlade accessoriesGas turbine plantsSolubilityAustenite grain

An Fe—Ni—Cr alloy formulated to contain a strengthening phase that is able to maintain a fine grain structure during forging and high temperature processing of the alloy. The alloy contains a sufficient amount of titanium, zirconium, carbon and nitrogen so that fine titanium and zirconium carbonitride precipitates formed thereby are near their solubility limit in the alloy when molten. In the production of an article from such an alloy by thermomechanical processing, a dispersion of the fine titanium and zirconium carbonitride precipitates form during solidification of the melt and remain present during subsequent elevated processing steps to prohibit austenitic grain growth.

Owner:GENERAL ELECTRIC CO

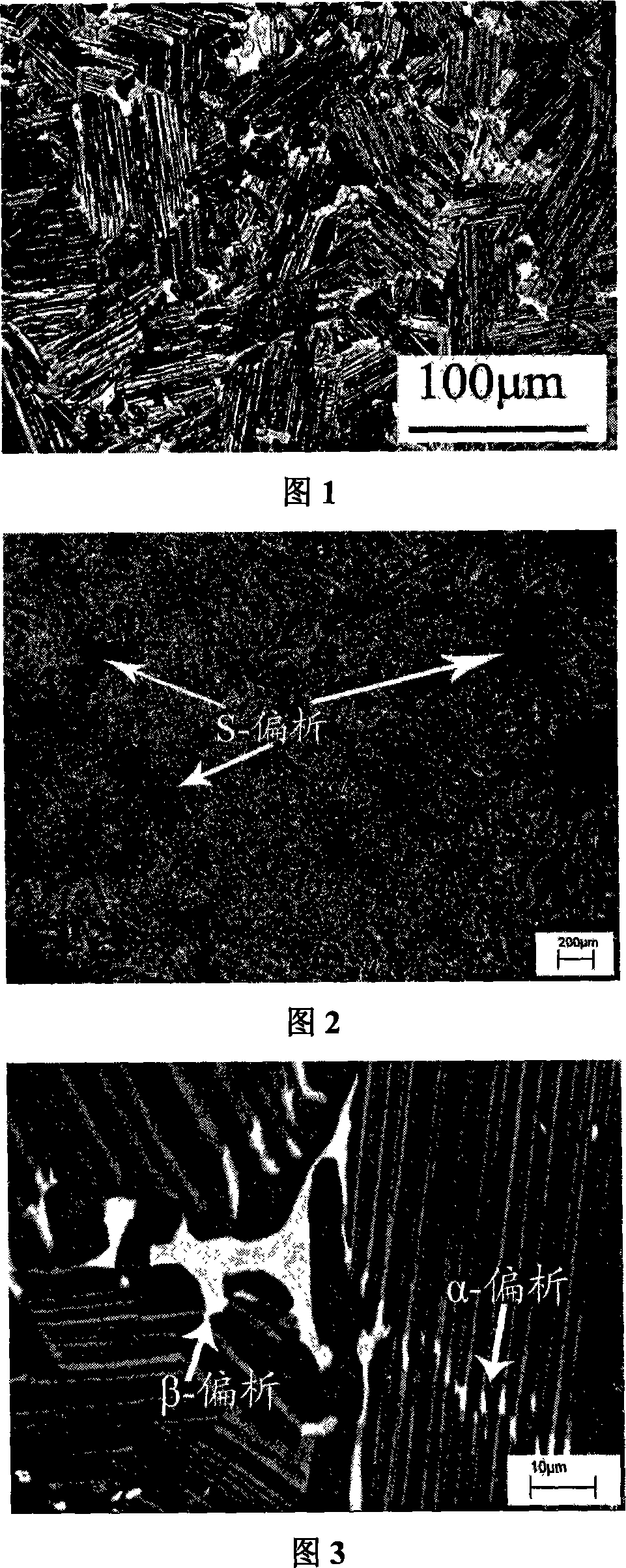

Heat treatment process for large size as-cast high-Nb TiAl-base alloy to obtain complete lamellar structure

The present invention belongs to the field of intermetallic compound technology and is especially heat treatment process for optimizing the structure of large size as-cast high-Nb TiAl-base alloy to obtain fine and homogeneous complete lamellar structure. The present invention features that alloy samples of sizes 10x10x10 mm to 60x60x60 mm are cut off from as-cast high-Nb TiAl-base alloy ingot, set into crucible, maintained inside a heat treatment furnace at 1350-1400 deg.c for 6-36 hr, maintained inside one other heat treatment furnace at 900-1050 deg.c for 30-60 min, and finally air cooled outside the furnace to room temperature. Thus treated alloy has fine and homogeneous complete lamellar structure, greatly increased available sizes and low treating cost.

Owner:UNIV OF SCI & TECH BEIJING

Thermomechanical processing of alpha-beta titanium alloys

Owner:ATI PROPERTIES LLC

Method for controlling structure refinement of cast TiAl-based alloy and form of boride

The invention discloses a method for controlling the structure refinement of a cast TiAl-based alloy and the form of boride. The method can effectively control the form and size of boride while uniformly refining the TiAl-based alloy cast structure. The method comprises the following steps: performing the semisolid isothermic thermal insulation treatment, wherein the temperature is 5-20 DEG C lower than the temperature of the alloy liquidus; and performing the solid aging thermal treatment to further refine the alloy structure and obtain the near lamellar structure with tiny lamella groups. The process provided by the invention needs no hot mechanical treatment of canned-forging in multiple steps, thereby greatly increasing the available size of the alloy material and reducing the processing cost of the unused casting alloy.

Owner:BEIHANG UNIV

Fine grain niobium sheet via ingot metallurgy

A method of making an alloy of niobium that includes: A) forming a blend comprising niobium powder and a powder of a metal selected from the group consisting of yttrium, aluminum, hafnium, titanium, zirconium, thorium, lanthanum and cerium and pressing the blend to form pressed blend; B) attaching the pressed blend to an electrode comprising niobium; C) melting the electrode and pressed blend under vacuum arc remelting conditions, such that the blend mixes with the melted electrode; D) cooling the melted electrode to form an alloy ingot; and E) applying thermo-mechanical processing steps to the alloy ingot to form a wrought product. The method provides a fully recrystallized niobium wrought product with a grain size finer that ASTM 5, that can be used to make deep drawn cups and sputtering targets.

Owner:H C STARCK INC

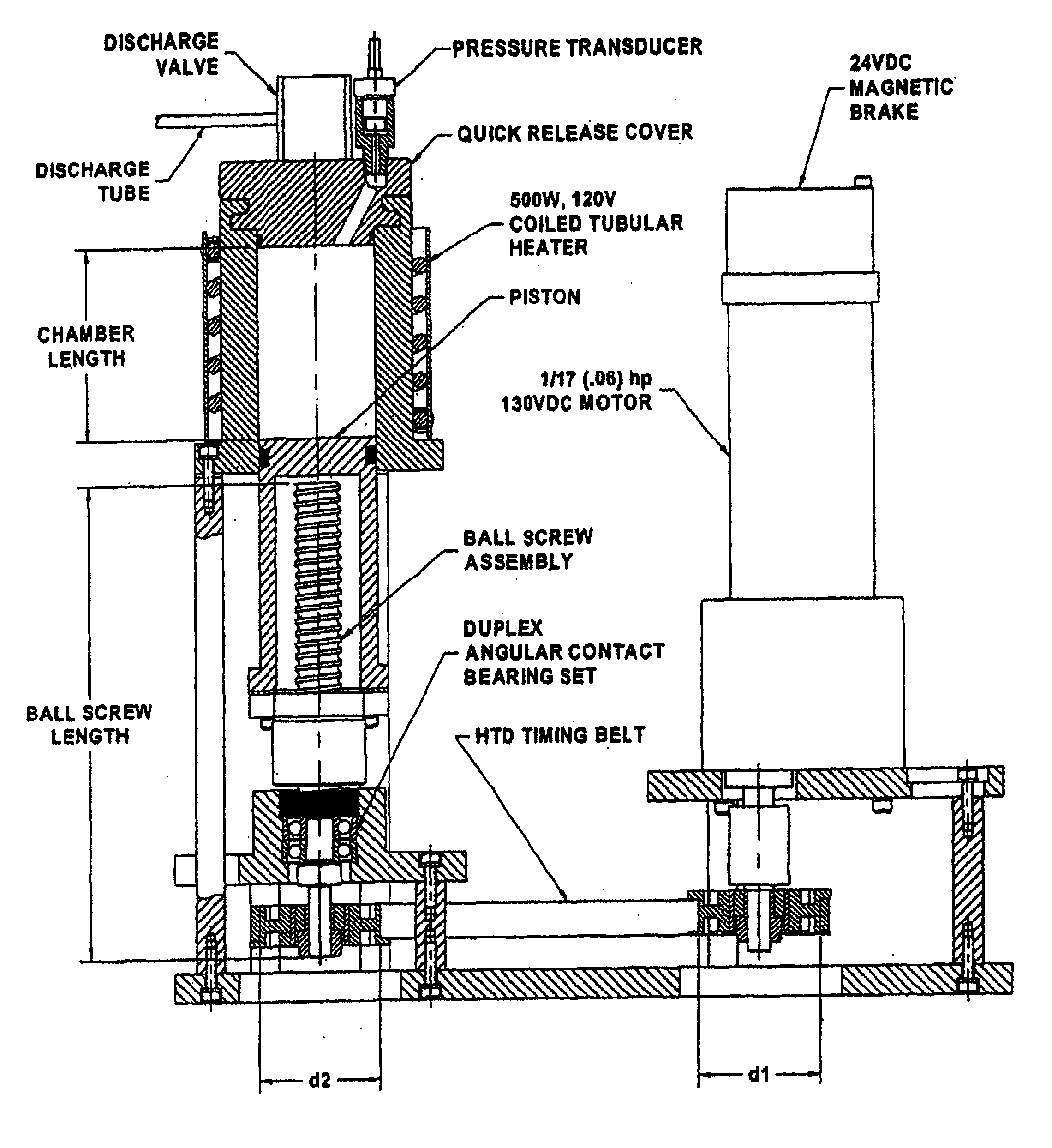

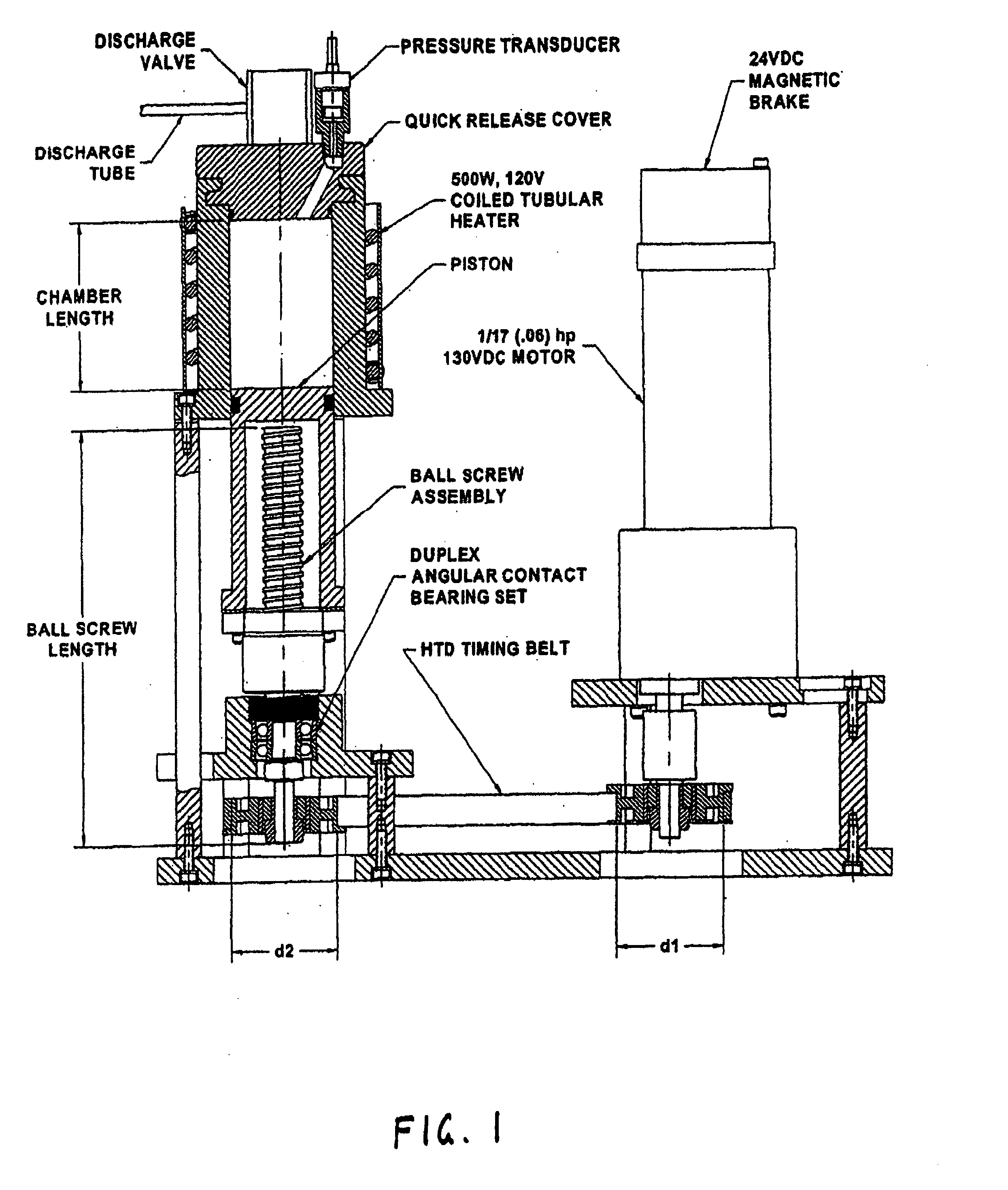

Methods and apparatus for processing expandable food materials

InactiveUS20070075154A1Improve output qualityMinimized starch damageAir heatersDough extruding machinesFood materialEngineering

The present invention relates in general to methods and apparatus for processing expandable food materials, and more particularly to methods and apparatus for low shear thermo-mechanical processing of food materials. The invention can include cooker and extruder apparatus for the customized production of food products, including a compression module, a dryer module, and a control unit.

Owner:SHEAR GOODNESS

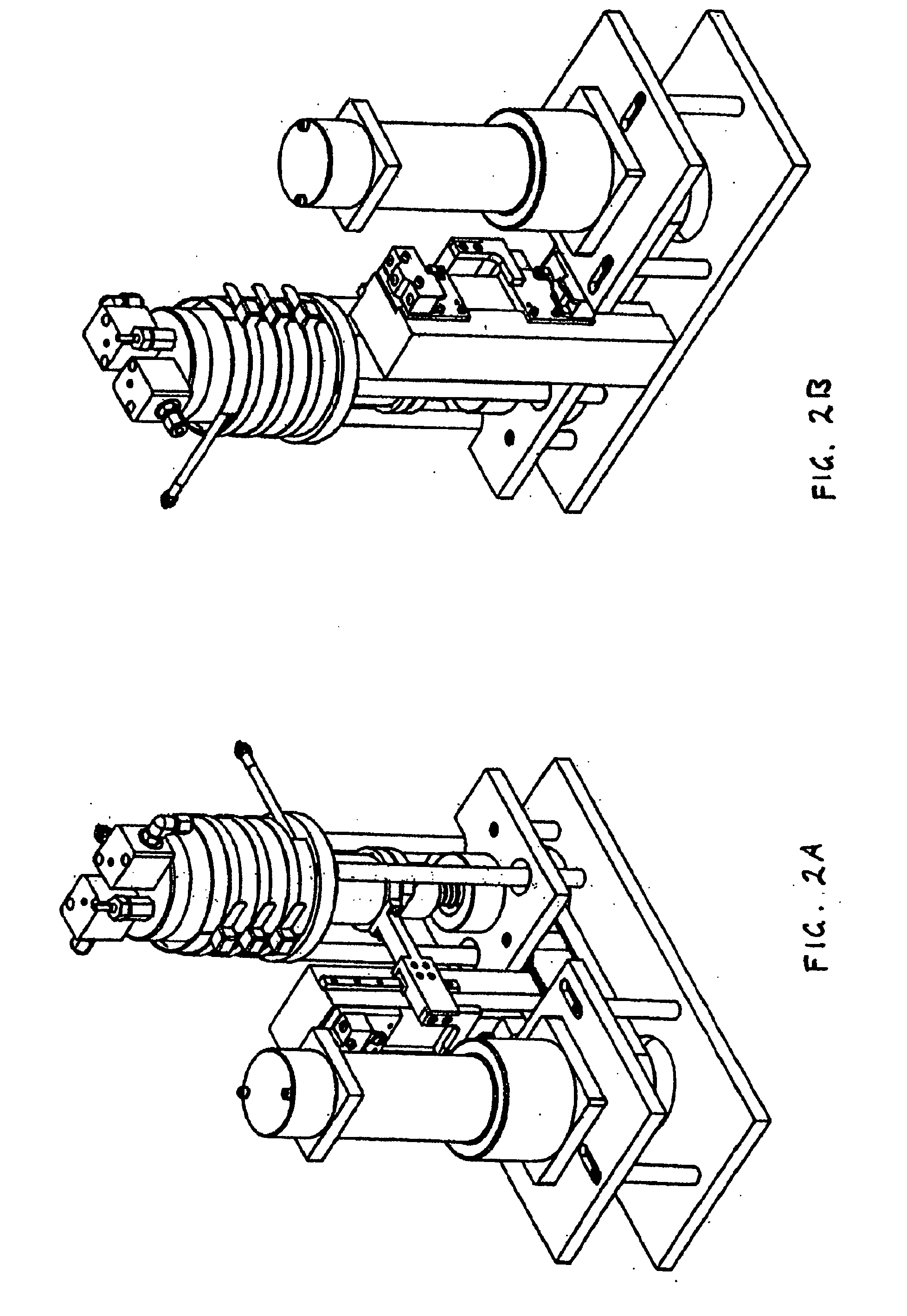

Powder extrusion of shaped sections

InactiveUS20100178194A1Cost effectiveLow costTransportation and packagingMetal-working apparatusMaterials scienceMetal

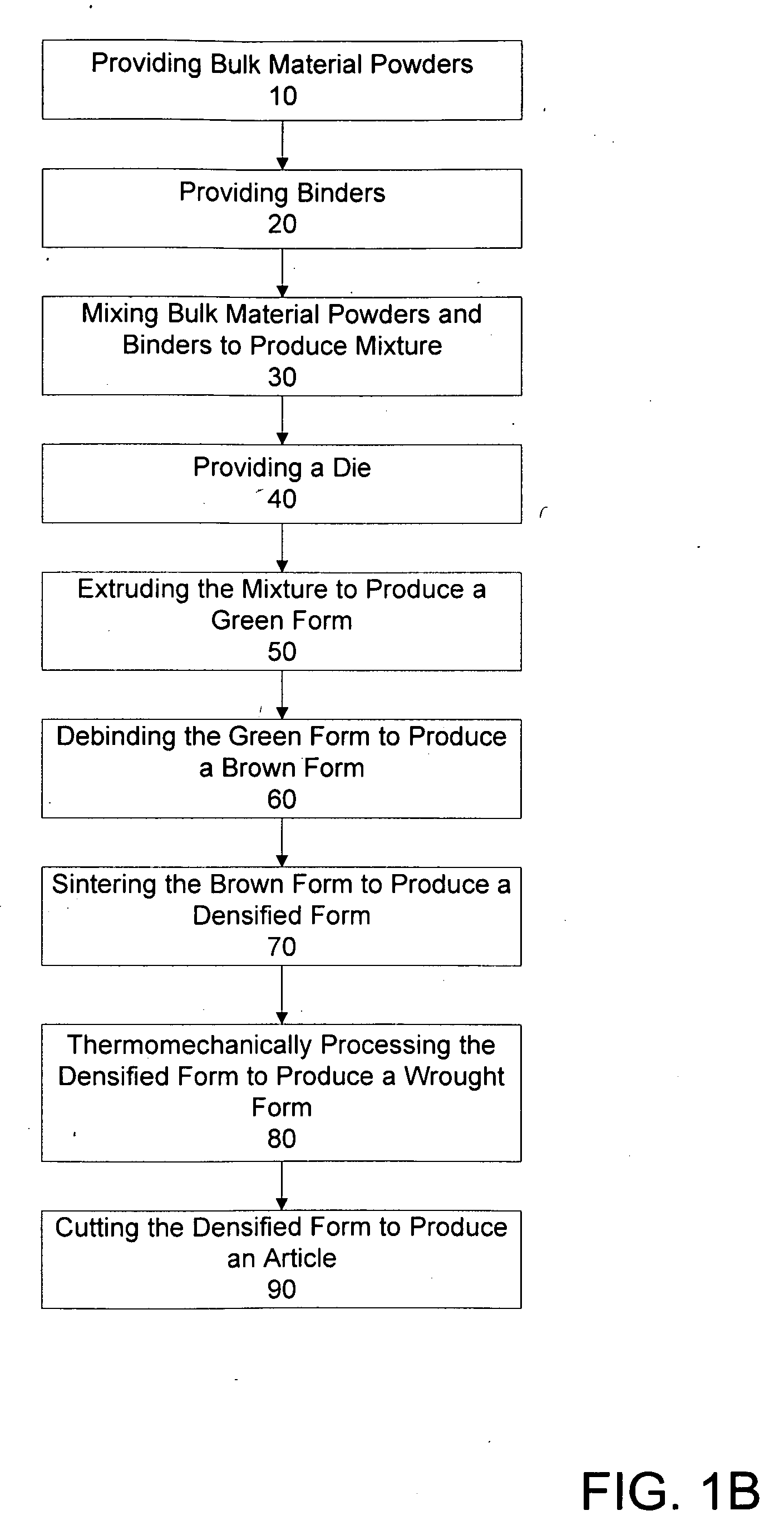

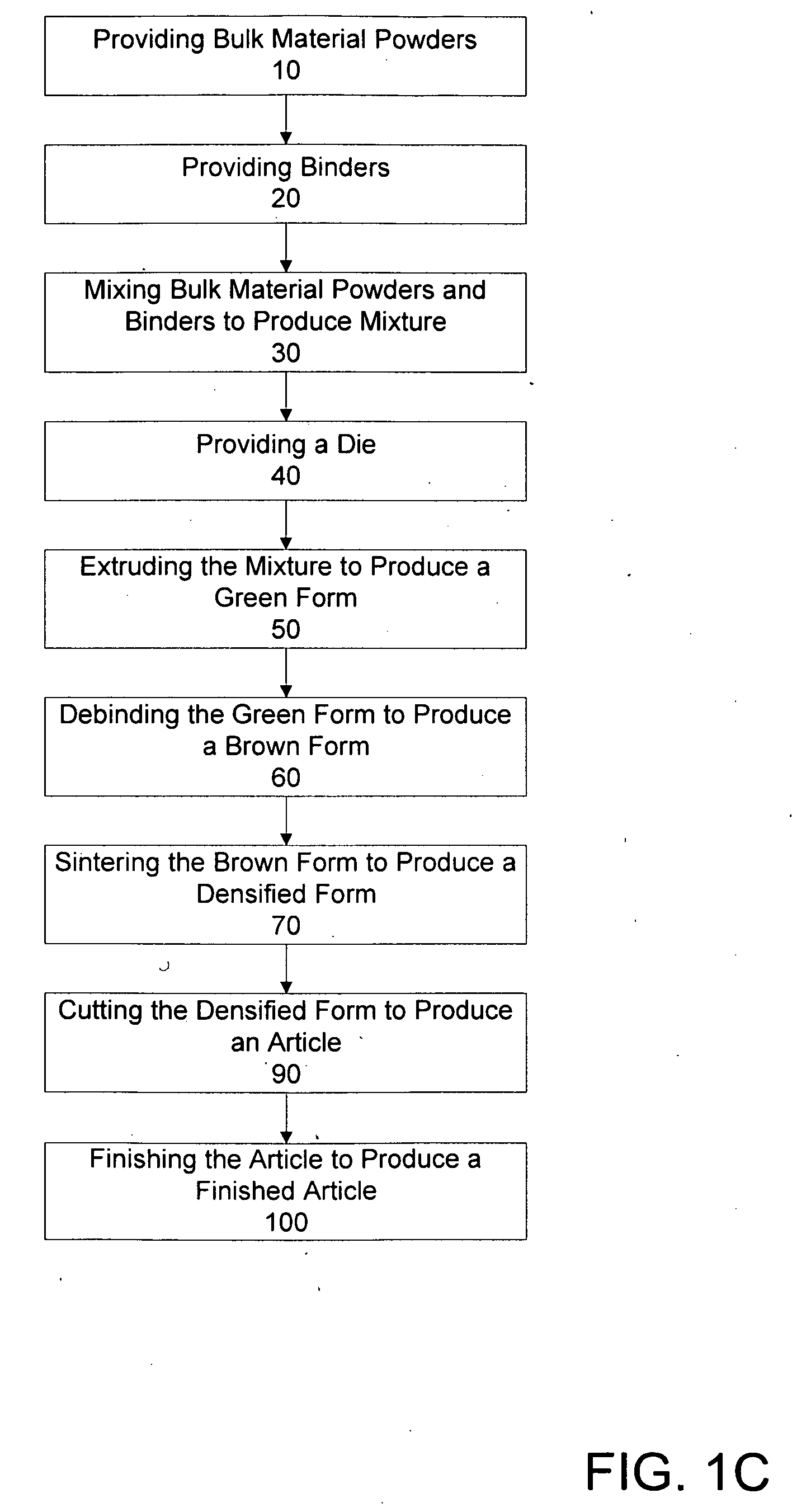

The present invention provides a continuous powder extrusion method for making an article having a profile including an outer shape and optionally including one or more inner hollows. One or more bulk material powders and one or more binders are provided, and the bulk material powders and the binders are mixed to form a mixture. A die is provided, the die optionally including a mandrel having one or more shapes. The mixture is extruded through the die and the optional mandrel to produce a green form. The green form is debound to produce a brown form and the brown form is sintered to produce a densified form. The densified form is optionally processed using thermal, mechanical, and / or thermomechanical processing to produce a wrought form. The densified or wrought form is optionally cut to a length and / or finished using traditional metal finishing processes.

Owner:ACCELLENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com