Nickel-chromium alloy target with high purity and high compositional uniformity and method for preparing same

A nickel-chromium alloy, high-purity technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of uneven microscopic distribution of finished components, low product consistency and yield, and process parameter dependence. Experience and other issues to achieve the effect of easy control of superheat, fast heating speed, uniform distribution of alloy composition and temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

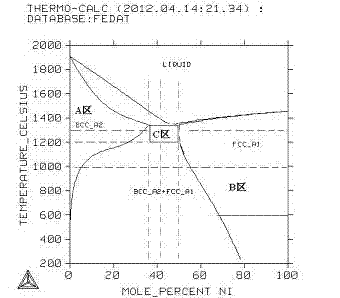

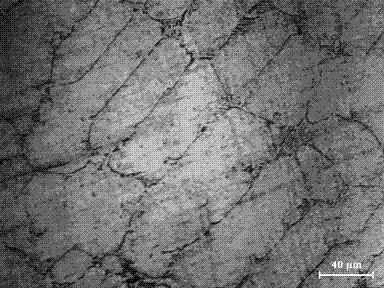

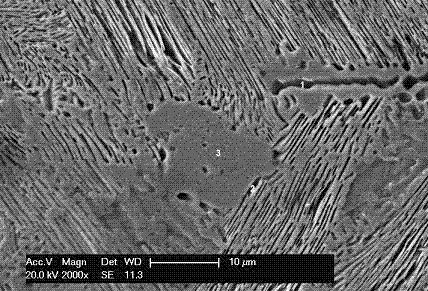

[0040] Design and prepare a nickel-chromium atomic percentage of 50%:50% alloy target,

[0041] a) Composition design and batching, select 159.1g of Jinchuan nickel block with a purity of 99.96% and 140.9g of 1# chromium block with a purity of 99.99% that meet the national standard, so that the total weight of the alloy raw material is 300 g, and the atomic percentage of nickel and chromium is 50 %:50%;

[0042]b) For the production of alloy ingots, put the above ingredients into the crucible of the water-cooled copper crucible vacuum induction suspension melting furnace, and vacuumize the melting chamber to (1.0±0.2)×10 -3 After Pa, use the inert gas argon to wash the furnace, and then vacuumize it again, then backfill the inert gas with argon protection, the furnace pressure is 100±10Pa, and carry out melting and alloying under the protection of inert gas argon;

[0043] c) After turning off the induction melting power supply, the alloy liquid is directly cooled into the wa...

Embodiment 2

[0054] To design and prepare a nickel-chromium alloy target with an atomic percentage of 20%:80%, the specific steps are the same as in Example 1, the difference is that:

[0055] 1) Adjust the composition percentage of Ni atoms and Cr atoms in the nickel-chromium alloy described in step a) to 20%:80%, and the impurity content is ≤0.0005%;

[0056] 2) Set the annealing temperature of the final annealing (solution aging) homogenization treatment in step g) at 1200°C, and the annealing time is 3 hours; after mechanical finishing, a nickel with a diameter of 60mm and a thickness of 6mm is obtained Chromium sputtering target, in which the composition ratio of Ni atoms to Cr atoms is 20.0870%:79.9125%, and the impurity is ≤0.0005%.

Embodiment 3

[0058] Design and preparation of a nickel-chromium alloy target with an atomic percentage of 80%:20%

[0059] Concrete steps are identical with embodiment one, difference is:

[0060] 1) Adjust the composition percentage of Ni atoms and Cr atoms in the nickel-chromium alloy described in step a) to 80%:20%, and the impurity content is ≤0.0005%;

[0061] 2) Set the annealing temperature of the final annealing (solution aging) homogenization treatment in step g) at 1000°C, and the annealing time is 8 hours; after mechanical finishing, a nickel with a diameter of 60mm and a thickness of 6mm is obtained Chromium sputtering target, in which the ratio of Ni atoms to Cr atoms is 79.8870%:20.1125%, and the impurity is ≤0.0005%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com