Patents

Literature

588results about How to "Ensure quality stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen peroxide and peracetic acid mixed disinfectant and preparation method thereof

InactiveCN103843817AEasy to sterilizeImprove sterilization effectBiocidePeroxide active ingredientsAcetic acidDisinfectant

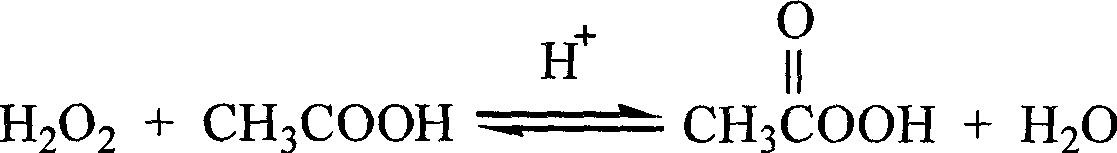

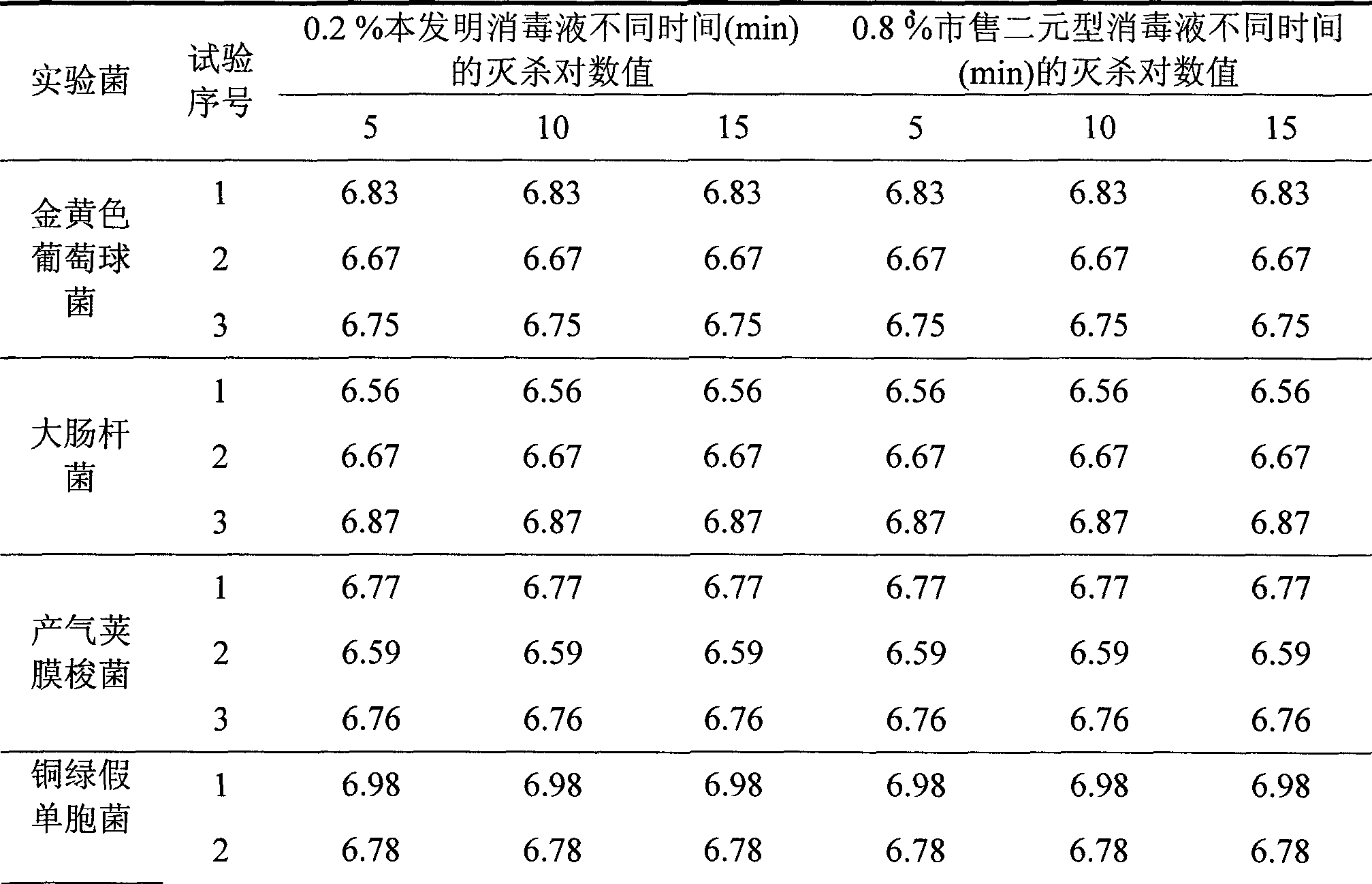

The invention relates to a hydrogen peroxide and peracetic acid mixed disinfectant and a preparation method of the disinfectant. The disinfectant is prepared by the steps of mixing hydrogen peroxide, acetic acid and sulfuric acid at the room temperature to prepare mixture containing peracetic acid and hydrogen peroxide, feeding a stabilizer and a surface active agent into the mixture containing the peracetic acid and the hydrogen peroxide, and mixing. The mixed disinfectant comprises 3-9g / 100g peracetic acid, 20-35g / 100g hydrogen peroxide, 5-12g / 100g acetic acid, 0.1-2g / 100g sulfuric acid, 0.05-2g / 100g stabilizer, 0.05-2g / 100g surface active agent and the balance of water. The hydrogen peroxide and peracetic acid mixed disinfectant is good in stability, is capable of rapidly killing various microorganisms such as bacteria, mould, yeast, spores and the like, and is safe, non-toxic and free from secondary pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for preparing tobacco herbal fragrant substance for cigarette solution of electronic cigarette

ActiveCN104450186ANo pollution in the processHigh yieldTobacco treatmentEssential-oils/perfumesLiquid smokeSolvent

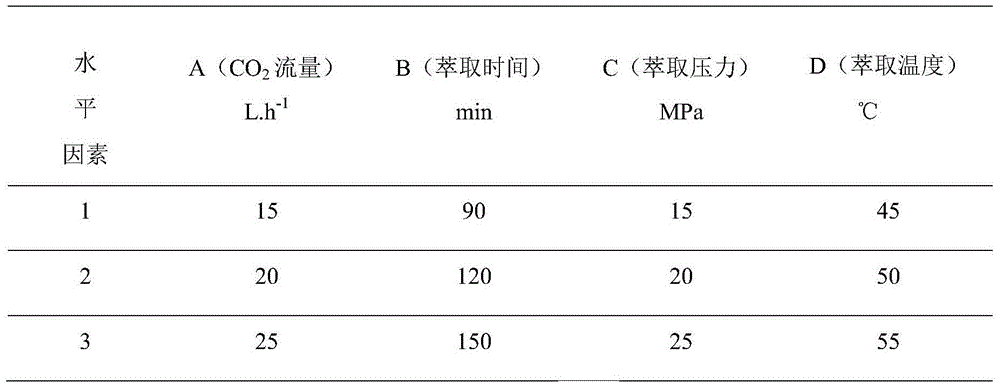

The invention discloses a method for preparing a tobacco herbal fragrant substance for cigarette solution of an electronic cigarette. The method comprises the steps that waste and inferior tobaccos are extracted in an ultrasound-enhanced supercritical extraction device for 1.5-2 hours at the temperature of 40-55 DEG C in the presence of an entrainer under the conditions that the ultrasonic frequency is 20KHz, the ultrasonic power is 100W, the flow rate of carbon dioxide of 10-20L / h and the extraction pressure is 15-25 MPa, so as to prepare a mixed solution of carbon dioxide and the tobacco herbal fragrant substance, wherein the entrainer is a mixed solvent of propylene glycol, ethanol and distilled water; the mixed solution is separated by virtue of a separation kettle at temperature of 45- 60 DEG C under the separation pressure of 7-12MPa to obtain the tobacco herbal fragrant substance. The tobacco herbal fragrant substance contains tobacco natural fragrant substance components, nicotine and the like and is applied to the cigarette solution of the electronic cigarette so that the cigarette solution of the electronic cigarette is endowed with the same sense organ characteristic and a satisfaction sense of smoking as common cigarettes. The extraction method is easy to carry out, low in cost, and stable and safe in product quality; the environment pollution is avoided; compared with the conventional supercritical extraction process, the method has the advantage that material consumption and energy consumption are reduced.

Owner:CHINA TOBACCO SHANDONG IND

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

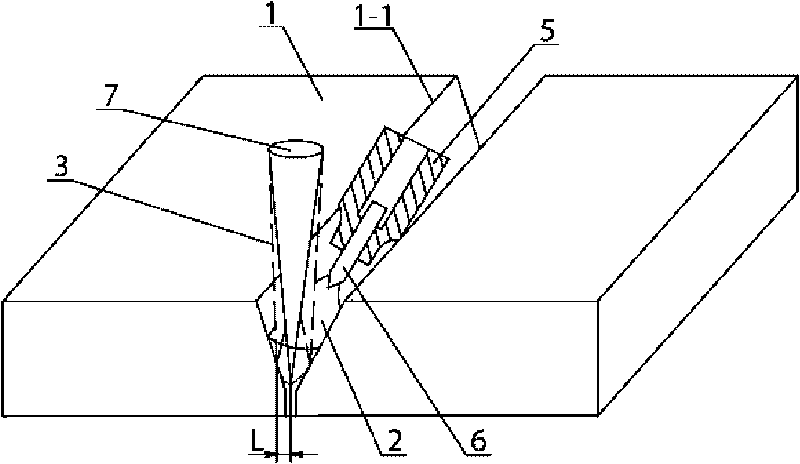

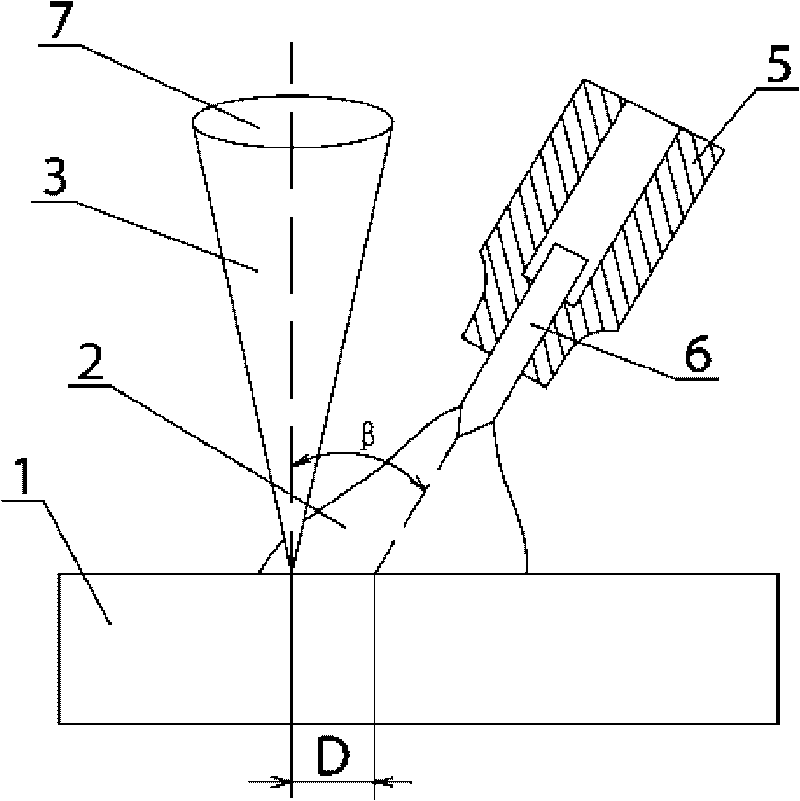

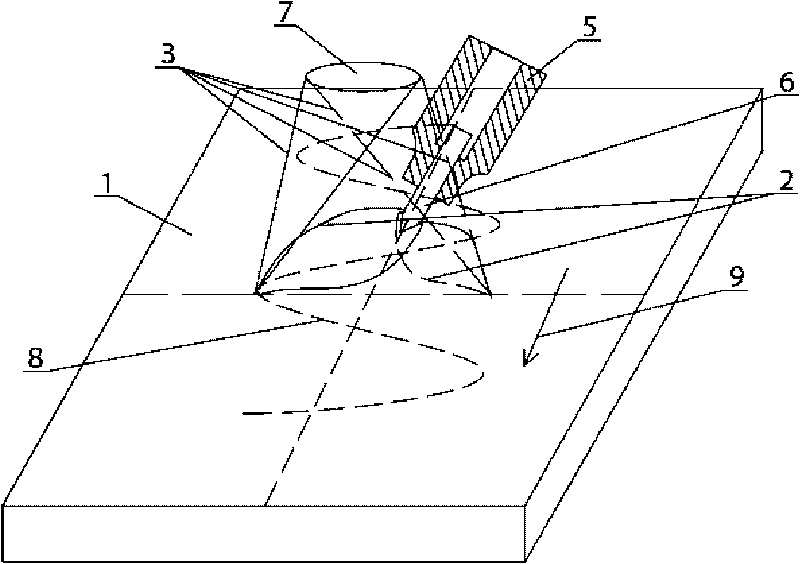

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

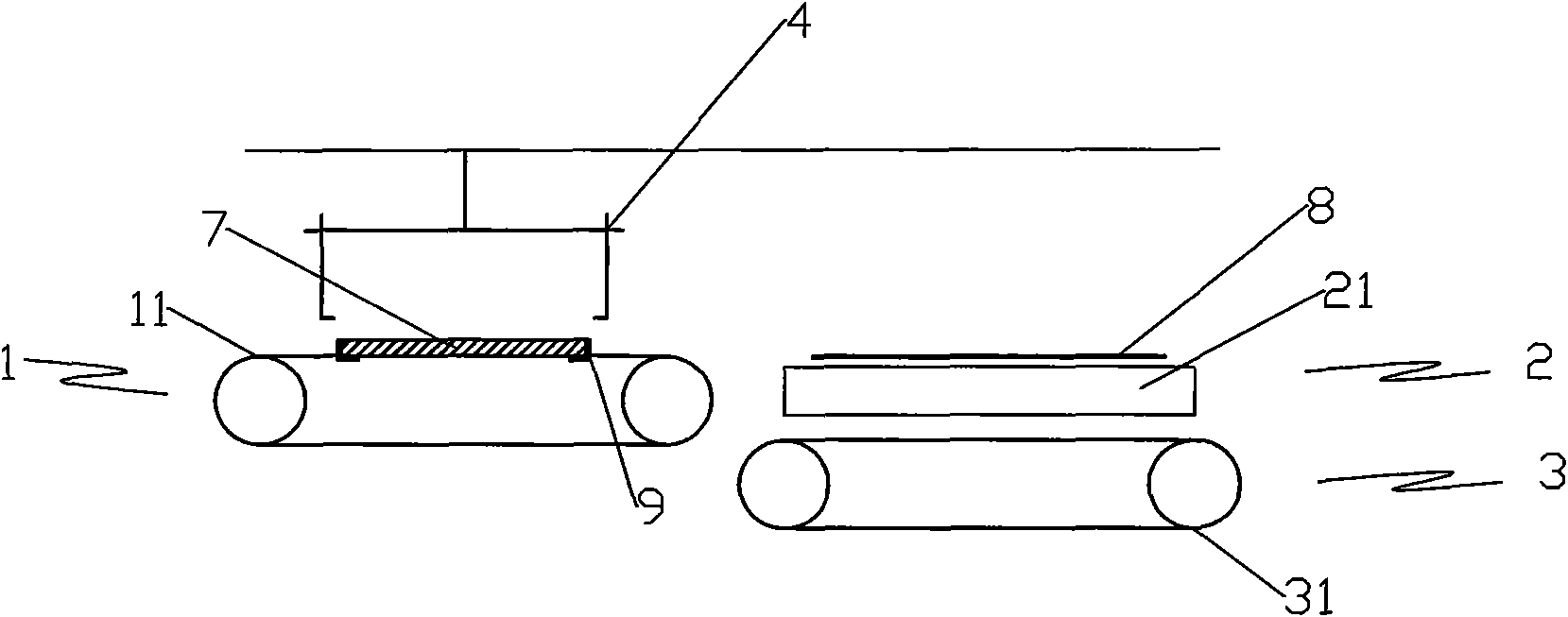

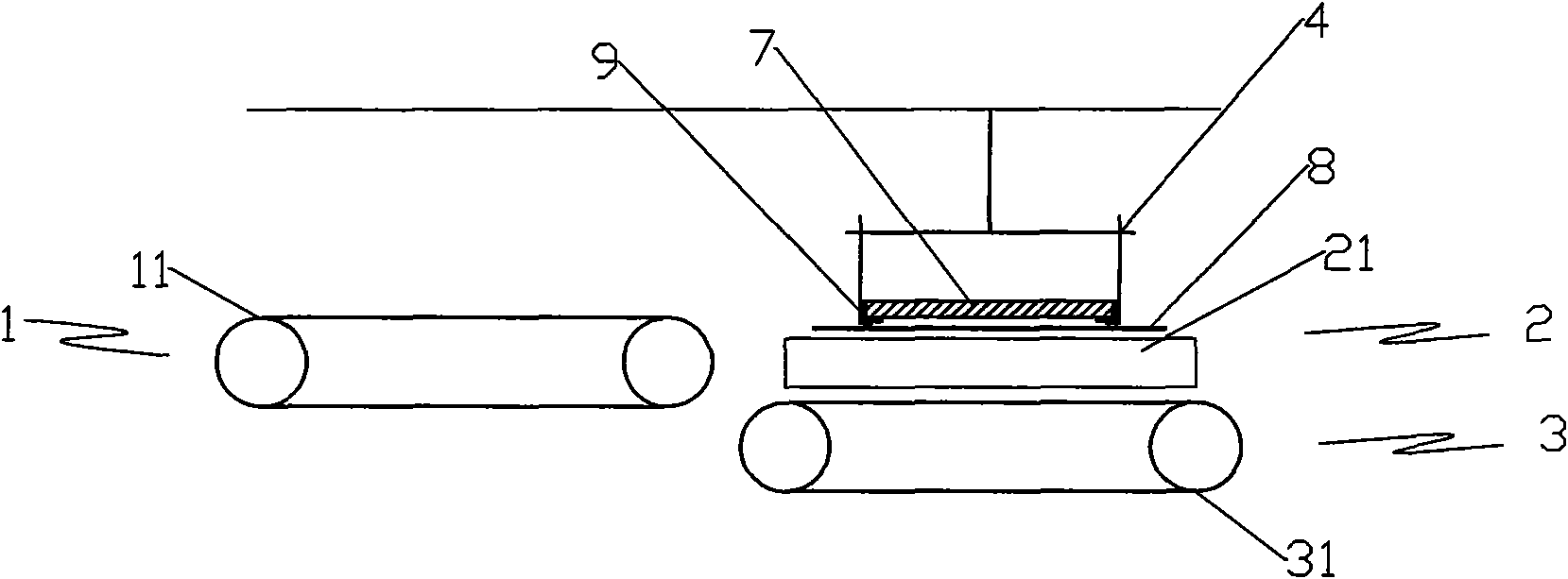

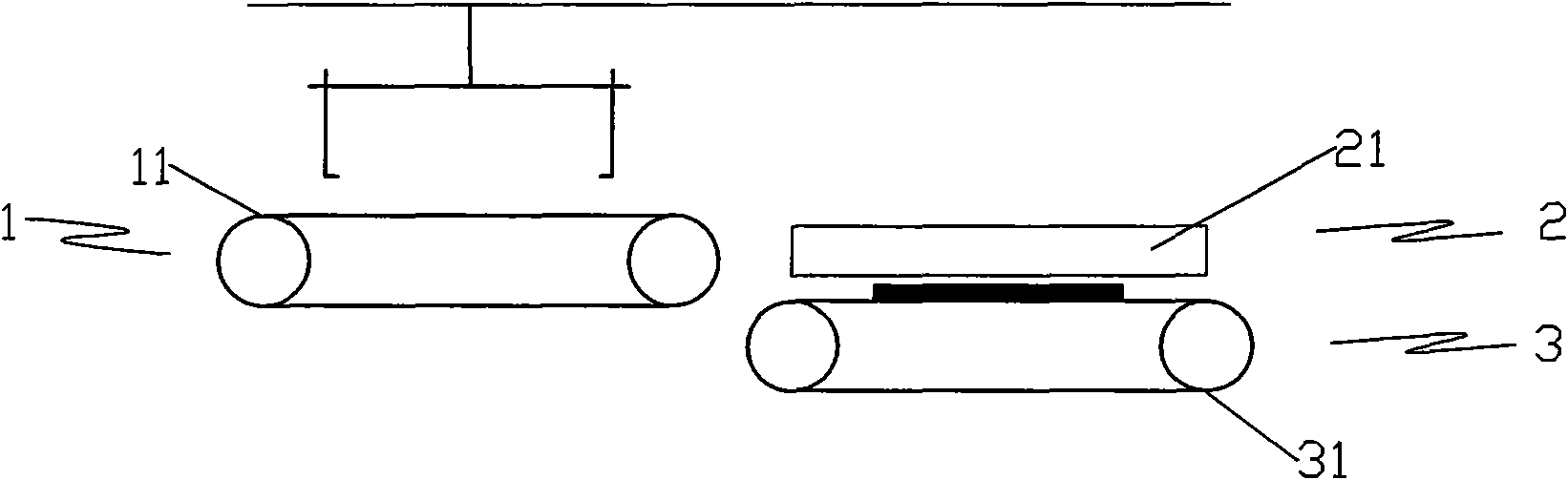

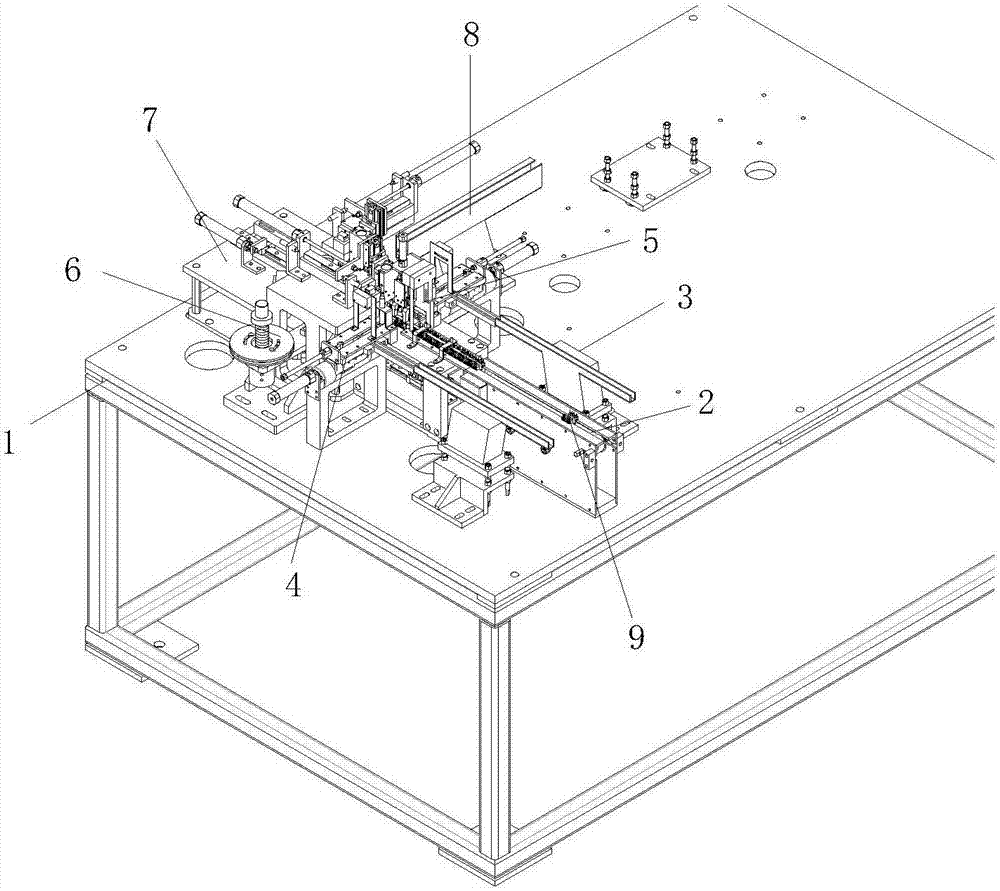

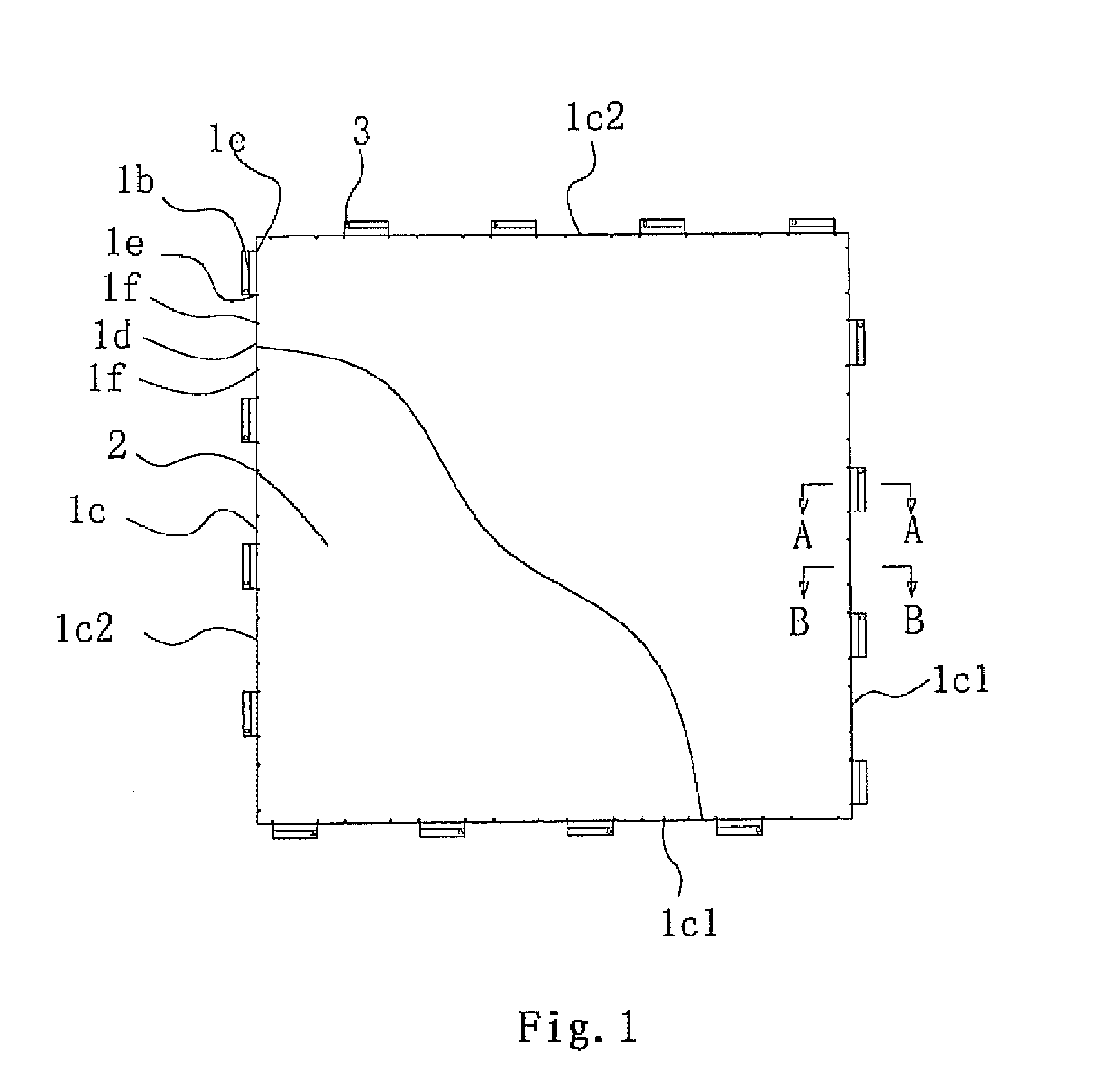

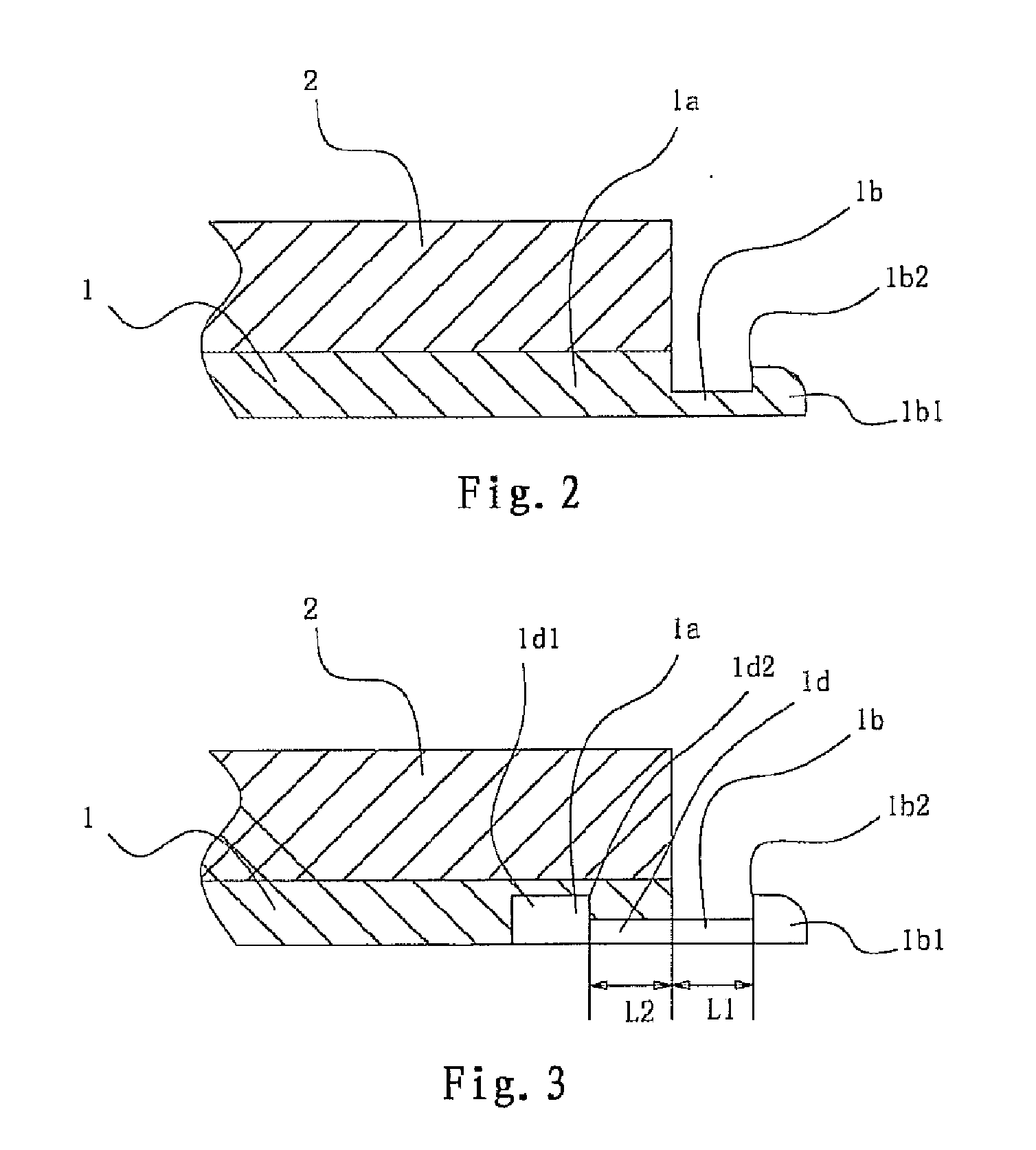

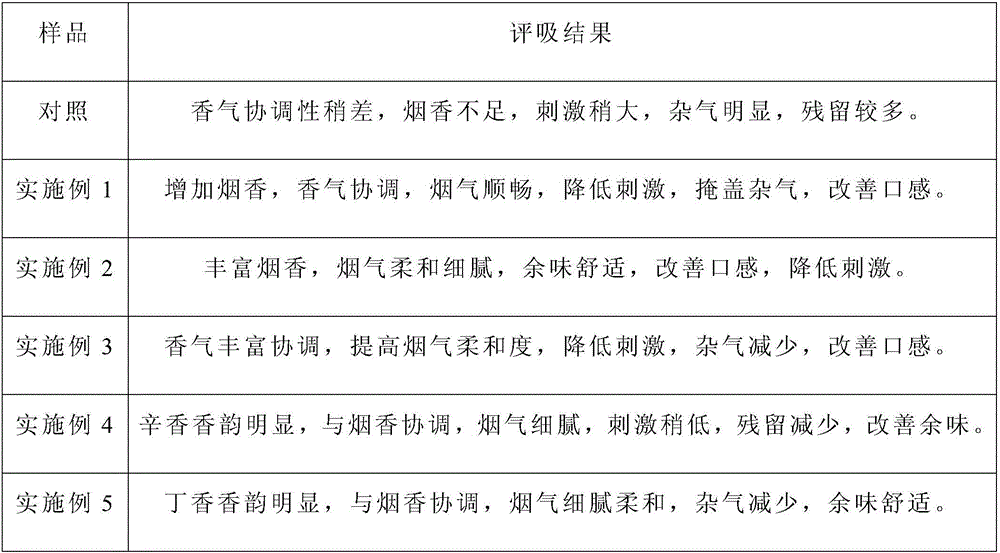

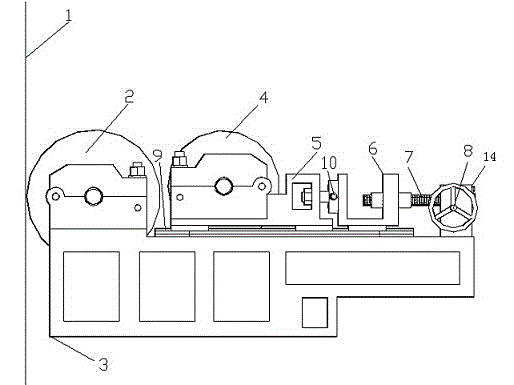

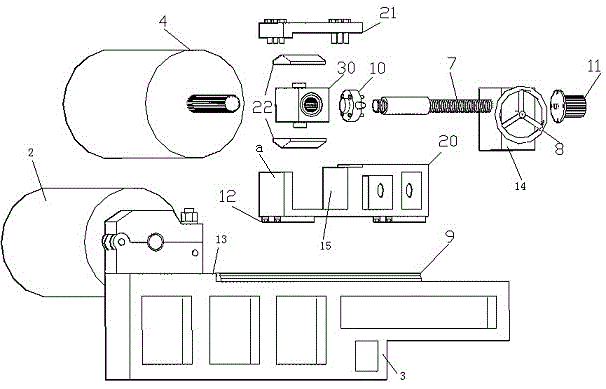

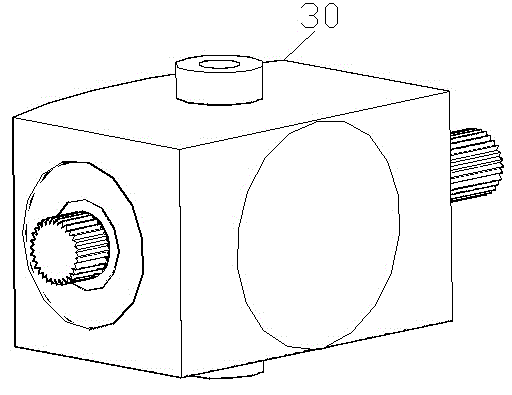

Packaging process and packaging equipment for large-specification ceramic tile

ActiveCN101992864AEnsure quality stabilityRealize automatic high speedWrapper folding/bending apparatusConveyor wrappingBrickEngineering

The invention discloses a packaging process and packaging equipment for a large-specification ceramic tile. Three independent working faces are included. The centering process, the alignment patting process and the corner wrapping process of a tile stack are finished on the first working face; the prepackaging location of the tile stack is finished on the second working face by using pre-placed box packaging paper; the tile pack packaging is finished in the process of the tile stack falling to the third working face; and finally, the outlet tiles of the tile pack are conveyed on the third working face. The packaging equipment comprises three working platforms, wherein the first working platform is provided with a centering mechanism, an alignment patting mechanism and a corner picking and placing mechanism; the second working platform is provided with a vertical packaging device; and the third working platform is arranged below the second working platform and is provided with an outlet tile conveying device. The invention adopts a brand-new packaging process flow and the packaging equipment with a brand-new layout to package the large-specification ceramic tile, makes the packaging speed greatly improved under the condition of ensuring the packaging quality stability and realizes automatic high-speed corner-wrapping packaging.

Owner:KEDA INDUSTRIAL GROUP CO LTD

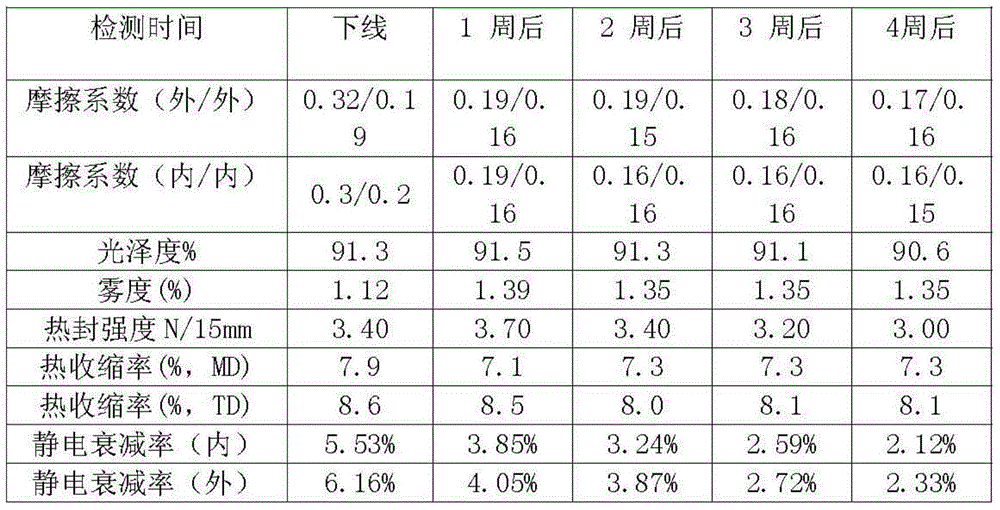

BOPP film with endurable and smoothness characteristics and preparation method therefor

InactiveCN105172284ALarge specific surface areaHigh activitySynthetic resin layered productsSurface layerAntistatic agent

The invention discloses a BOPP film with endurable and smoothness characteristics. The BOPP film is formed by a core layer, a surface layer and an inner layer through co-extrusion and combination. The surface layer comprises, by weight, 96.0%-96.8% of homo-polypropylene resins, 0.1%-2.0% of slipping agents and 0.1%-2.0% of antiblocking agents. The core layer comprises, by weight, 99.5%-99.7% of homo-polypropylene resins and 0.3%-0.5% of antistatic agents. The inner layer comprises, by weight, 84.1%-84.9% of homo-polypropylene resins, 14.0%-14.9% of slipping master batches and 0.1%-2.0% of antiblocking agents. The invention also discloses a preparation method for the BOPP film. The slipping master batches are prepared from homo-polypropylene resins, nano inorganic materials and slipping agents through the synergistic effect and are added in the inner layer components, the finally prepared BOPP film has various performances same as a common BOPP film, and can delay loss of the slipping agents in the product. Thus the slipping system plays a lasting and effective role, the packaging film has durable slipping characteristics in a certain time quantum, and the packaging speed is ensured.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

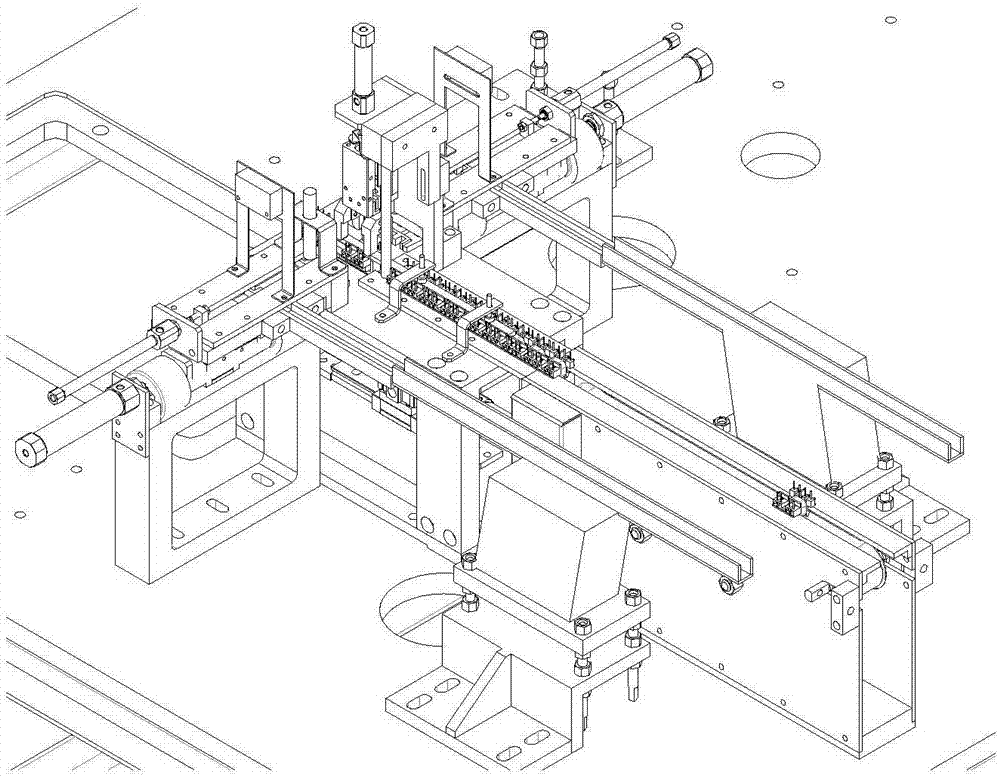

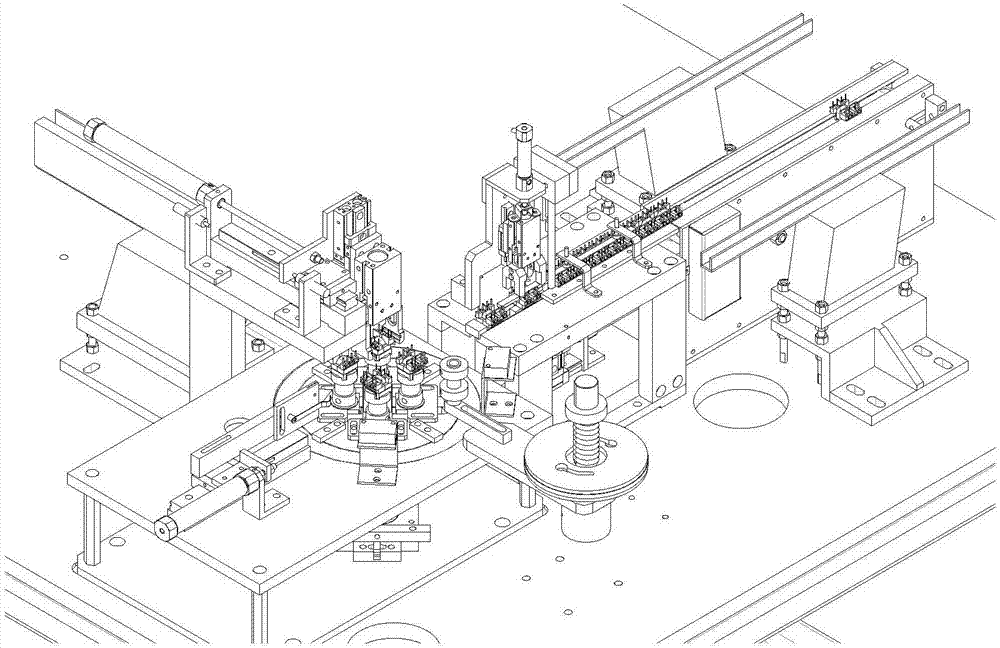

Household electrical appliance product transformer assembly assembling system

ActiveCN106876128AImprove assembly work efficiencyAchieve windingAssembly machinesInductances/transformers/magnets manufactureButt jointAdhesive

The invention discloses a household electrical appliance product transformer assembly assembling system. The household electrical appliance product transformer assembly assembling system includes a rack and a workbench arranged on the rack; a first conveying mechanism, a second conveying mechanism, a third conveying mechanism, an assembly magnetic core inserting positioning mechanism, magnetic core inserting mechanisms, a feeding and grabbing mechanism, an adhesive tape conveying mechanism, a rotation adhesive tape winding mechanism, and a discharging grabbing mechanism are arranged on the workbench, wherein the first conveying mechanism, the second conveying mechanism and the third conveying mechanism are used for conveying a transformer assembly to be assembled; a discharging end of the first conveying mechanism is in butt joint with a feeding end of the assembly magnetic core inserting positioning mechanism; the magnetic core inserting mechanisms are arranged on two sides of the assembly magnetic core inserting positioning mechanism; feeding ends of the magnetic core inserting mechanisms are in butt joint with a discharging end of the second conveying mechanism for conveying a magnetic core; and the feeding and grabbing mechanism is correspondingly arranged on a discharging end of the assembly magnetic core inserting positioning mechanism. The household electrical appliance product transformer assembly assembling system is reasonable in structural design, can achieve rapid inserting and rapid winding of the magnetic core, can achieve continuous assembly production, and can greatly improve the assembly working efficiency.

Owner:浙江预立兴川机器人技术股份有限公司

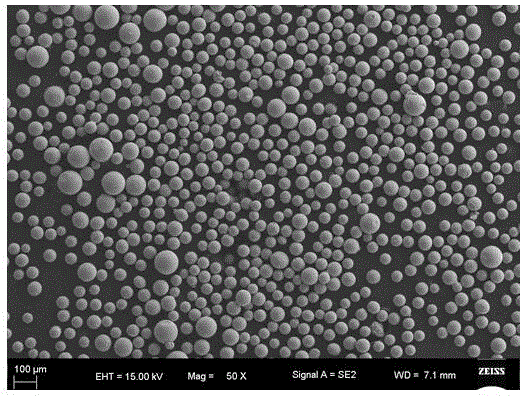

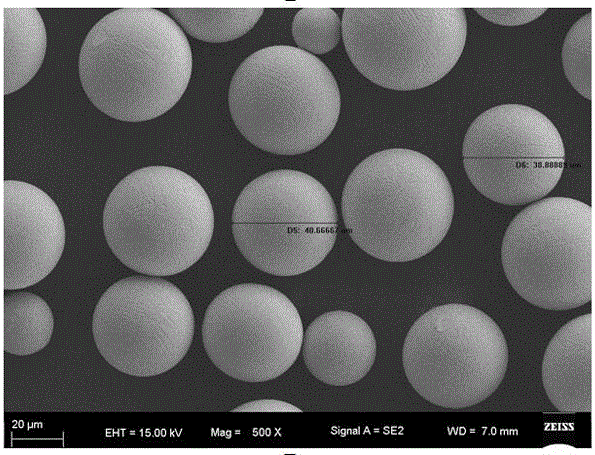

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Method for preparing ball shape mixed lithium cobaltate and it prepared ball shape mixed lithium cobaltate

InactiveCN1588675ALow purity requirementReduce manufacturing costElectrode manufacturing processesCobalt compoundsElectrolysisCobalt(II,III) oxide

The invention provides spheral doping lithium cobaltate prepn. method, high-activity doping colbalt hydroxide is prepared by electrolyzing metal cobalt, then to be fired in oxidating atmosphere to produce sphere cobalt orthoplumbate, finally, the spheral cobalt orthoplumbate and lithium carbonate are mixed first to produce high-activity doping lithium cobalate. By the invention, requirement of purity for raw material used to produce doping lithium cobalate is lower to reduce prodn. costs and increase electrochemistry performance of products.

Owner:BEIJING GREEN POWER TECH +1

Composite heat treatment method applicable to Cu-Cr-Zr alloy wire

ActiveCN103898425ASimple preparation and processing technologyEnsure quality stabilityNon-ferrous metalHeat treating

The invention relates to a composite heat treatment method applicable to a Cu-Cr-Zr alloy wire, and belongs to the field of non-ferrous metal heat treatment. Th e method is as below: using the Cu-Cr-Zr alloy wire rod as a raw material wire billet; conducting a solid solution treatment; conducting multi-path cold drawn to form a disc wire; conducting a single-stage or multi-stage aging treatment;and conducting one or more rounds of continuous cold processing and annealing. The method is applicable to preparation process of ultrafine wires of a variety of low alloyed Cu-Cr-Zr-X alloy containing 0.15-0.6 wt.% of Cr, 0.03-0.4 wt.% of Zr,0.01-0.1 wt.% of fourth and fifth group elements (Sn, Si, Ag and RE) and the balance of Cu. The invention simplifies preparation processing technology for of the aging strengthening type of alloy wire,saves material and energy, at the same time ensures the stability of quality of wire, and can satisfy the usage requirement of cables with different comprehensive performance in many fields.

Owner:GRIMAT ENG INST CO LTD

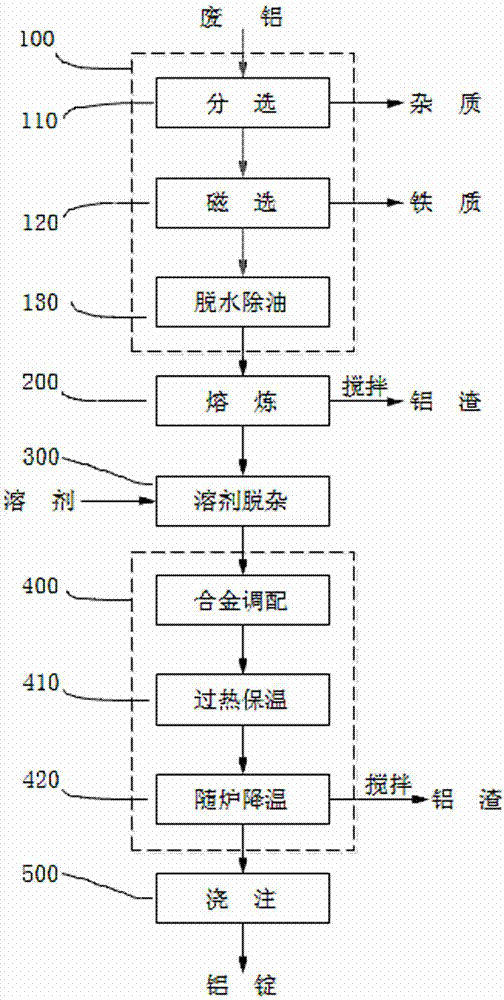

Method for efficiently regenerating cast aluminum alloy by aluminum scraps

The invention discloses a method for efficiently regenerating cast aluminum alloy by aluminum scraps. The method for efficiently regenerating cast aluminum alloy by aluminum scraps comprises the following processes of: screening, smelting, alloy-mixing and pouring, wherein the screening process specifically comprises the following step of: removing impurities and moisture in the aluminum scraps; the smelting process specifically comprises the step of melting and stirring the aluminum scraps after the screened aluminum scraps are charged, so that the slag is removed; the alloy-mixing process specifically comprises the following steps of: adding 9%-11% (in percentage by weight) of Si and 0.8%-1.1% of Fe when the temperature of the impurity-removed aluminum scrap solution reaches 680 DEG C to 740 DEG C, keeping the temperature after the components are uniformly stirred and removing the slag; and the casting process specifically comprises the following step of: pouring the slag-removed molten aluminum to the mould to obtain the cast aluminum alloy ingot or the aluminum alloy casting piece. According to the method for efficiently regenerating cast aluminum alloy by aluminum scraps, the aluminum scraps are enabled to reach the technical requirements of the cast aluminum alloy by aluminum scrap screening and alloy mixing, and therefore, the method has the advantages of being simple in process, strong in aluminum scrap adaptability, stable in aluminum alloy stability, low in cost, and high in aluminum recycling rate.

Owner:YUNNAN AOKAI TECH DEV

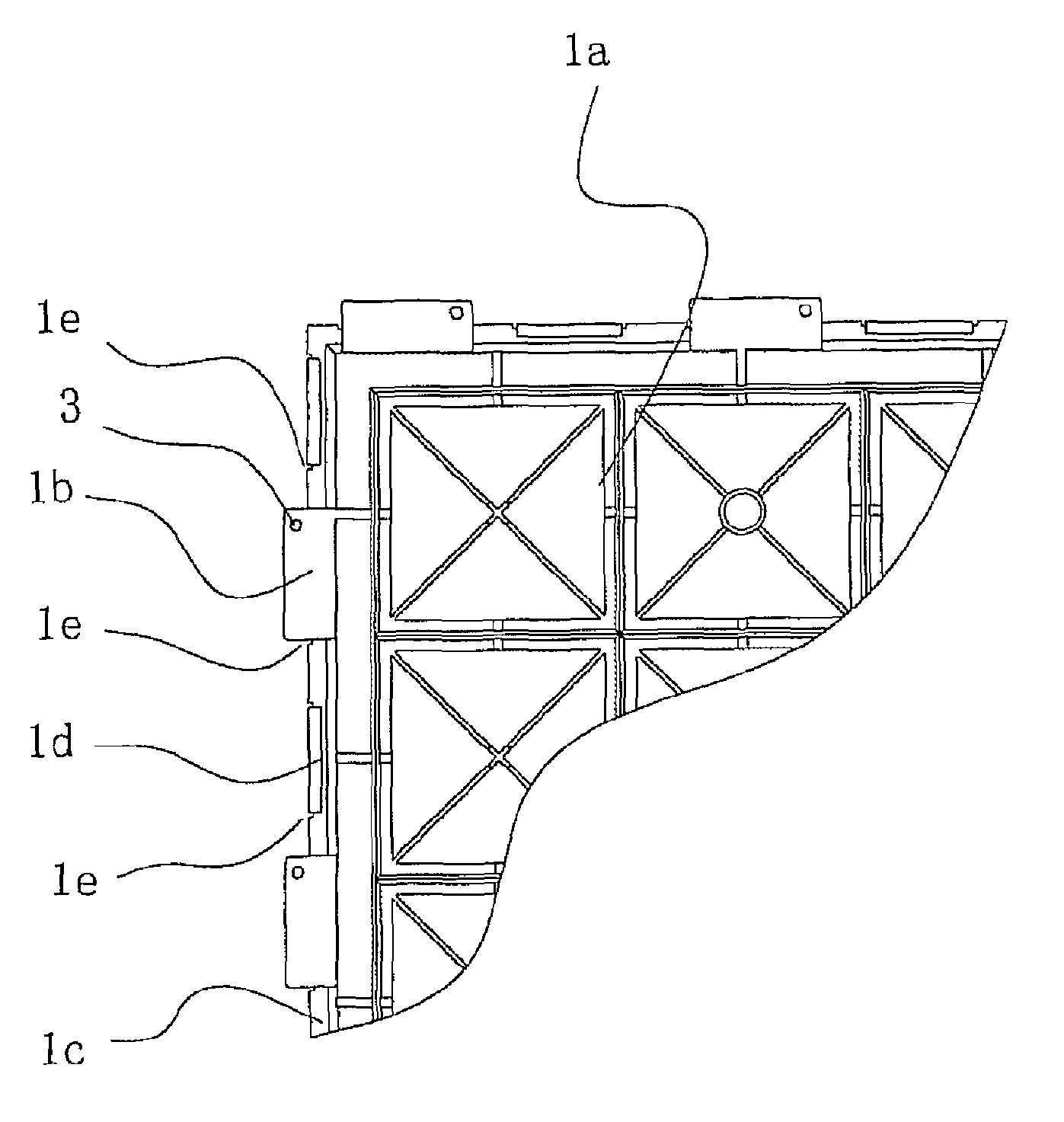

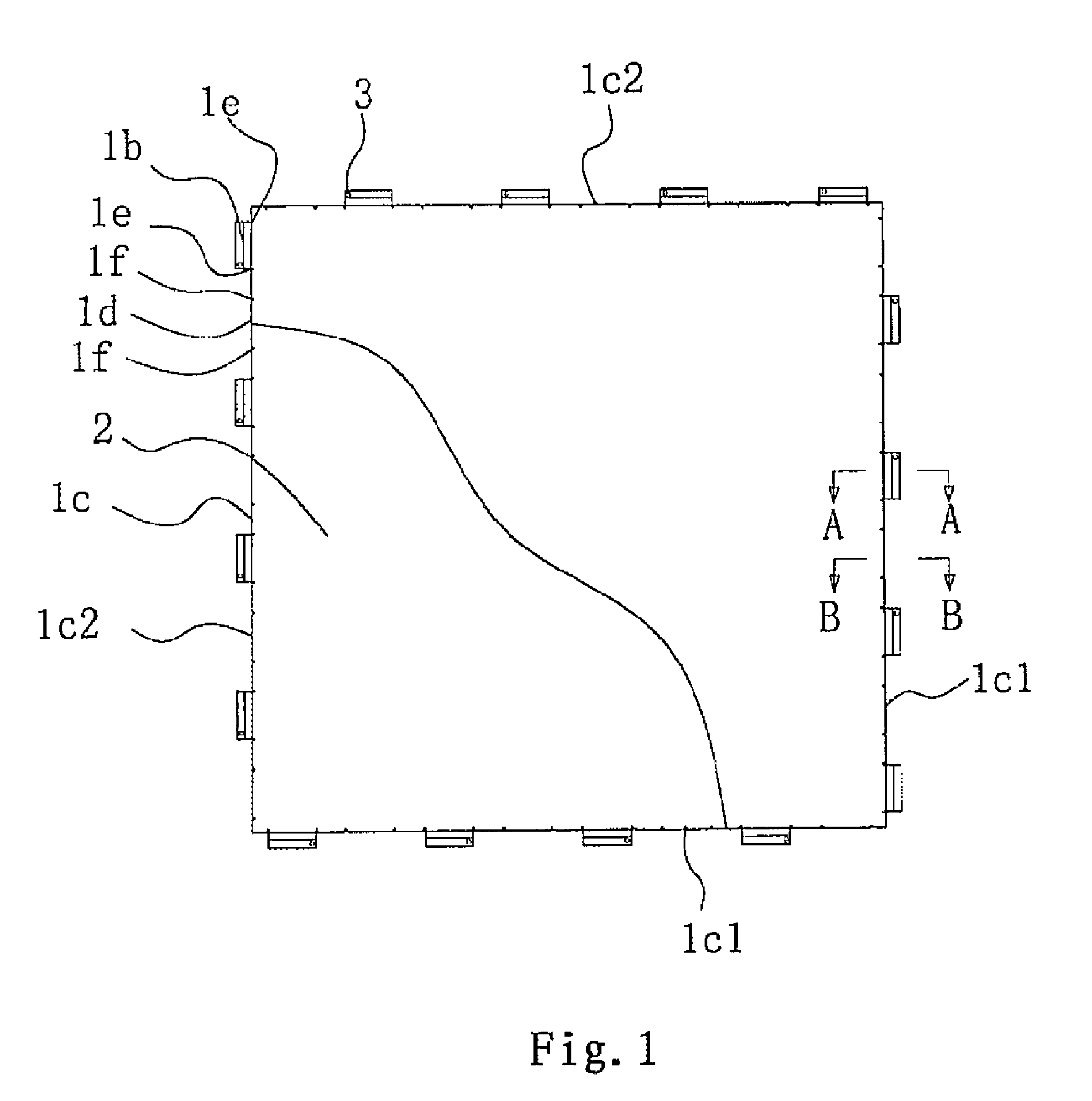

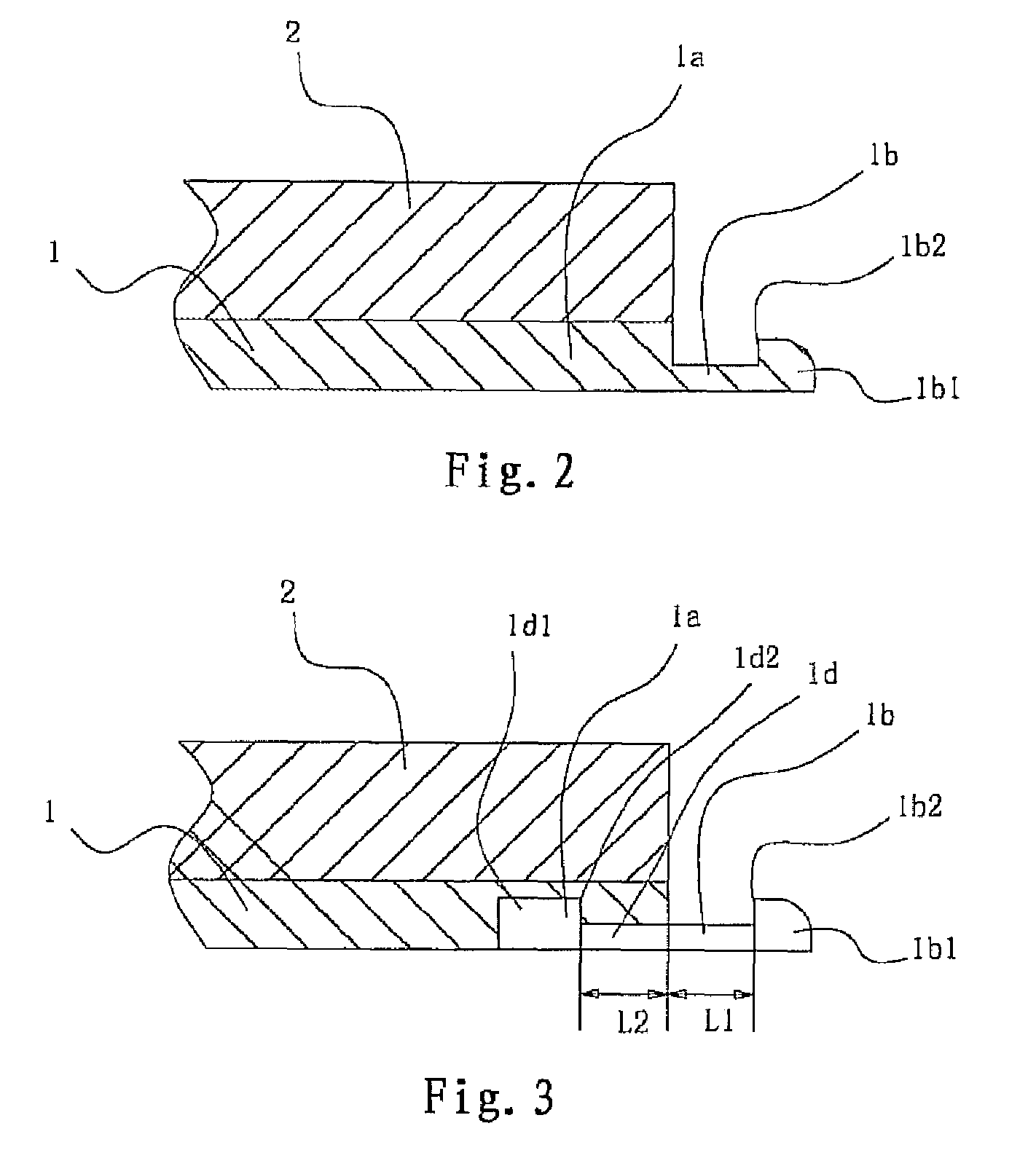

Easy-to-Lay Floor Board

Aspects relate to improved floor boards. Certain embodiments may be laid and fixed without the need for fixing with adhesive or nails. Example floor boards are convenient for use and simple in structure, and after a decorative strip is adopted, it further has the advantage of good decorative effects. In one embodiment, a floor board includes a four-sided surface board connected to a four-sided base board. In one embodiment, positions of board-shaped hooking tongues on two edges of the base board body and positions of board-shaping hooking tongues on two other edges of the base board body are arranged in a staggered manner, and the positions of buckles on two edges of the base board body and the positions of buckles on two other edges of the base board body are arranged in a staggered manner.

Owner:HONG KONG MEI LI SHENG FLOORING +1

Conjugated-diolefin (co)polymer rubber and process for producing the same

A conjugated diolefin (co)polymer rubber is provided which is small in variations in the Mooney viscosity of the resulting rubber, and in which later changes in the Mooney viscosity with the elapse of time can also be restrained. A conjugated diolefin (co)polymer rubber which is a conjugated diolefin (co)polymer rubber obtained from a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, having an alkoxysilyl group and desolvated under alkaline conditions.

Owner:JSR CORPORATIOON

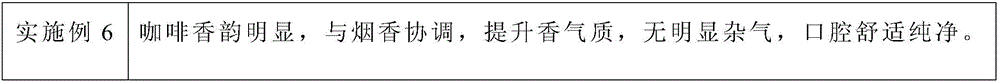

Preparation method of natural spice superfine powder and application of natural spice superfine powder in tobacco sheets

InactiveCN106174684AFine and uniform particlesGood dispersionTobacco preparationTobacco treatmentDispersityFlavor

The invention provides a preparation method of natural spice superfine powder and an application of natural spice superfine powder in tobacco sheets. The preparation method comprises the following steps: (1) preparing spice fine powder; (2) conducting low-temperature superfine grinding; and (3) adding spice superfine powder to a paper pulp making front tank, uniformly stirring the spice superfine powder, conducting paper making and drying processes on paper pulp, so that a fiber sheet base is formed, then directly dip-coating or spraying a concentrated solution on the sheet base, and conducting drying and slicing, so that the tobacco sheets are obtained. Special spice, which is prepared by virtue of a superfine grinding technology, has the characteristics of being intense and pure in aroma, tiny and uniform in particle, relatively good in dispersity and good in absorption ability, and meanwhile, the pure natural attribute of the finished product (the superfine powder) is guaranteed; the spice prepared by the invention, after applied to the tobacco sheets, can enrich aroma quantity and the spice can coordinate with cigarette flavor, so that smoke is soft and delicate, oral residue is relieved, irritation is reduced and offensive odor is masked, and the aroma can stably last for a long time; and the natural spice superfine powder, as a spice additive, is applicable to flavoring treatment of the sheets.

Owner:HUBEI CHINA TOBACCO IND

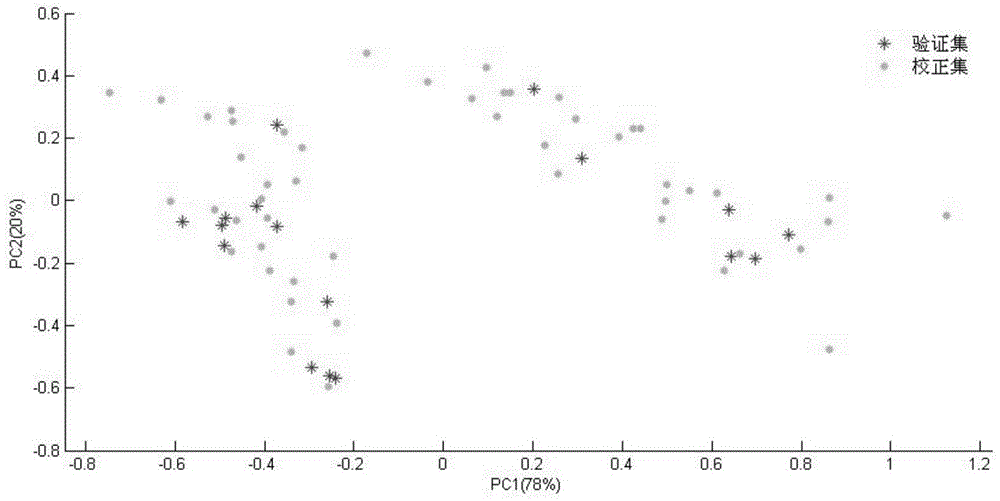

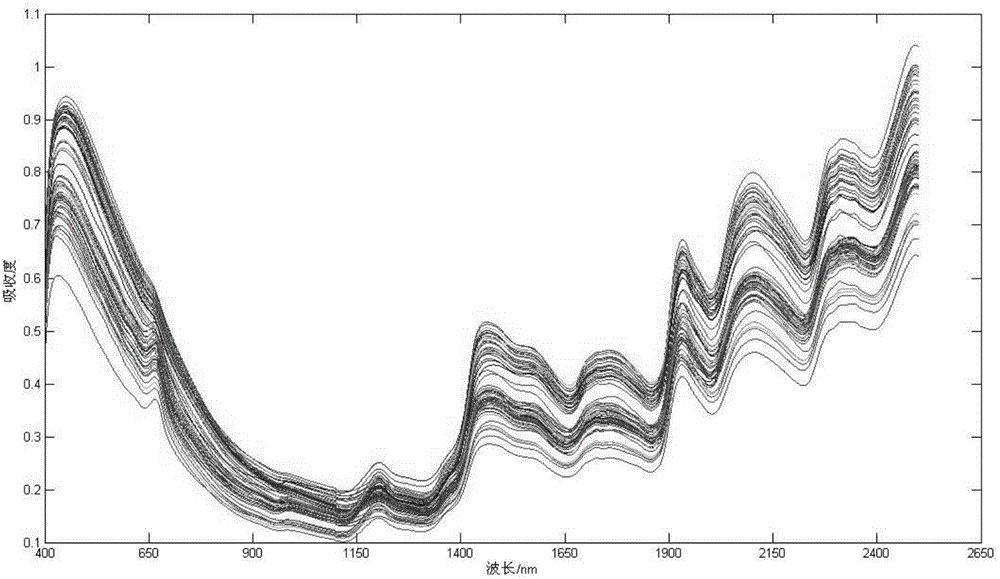

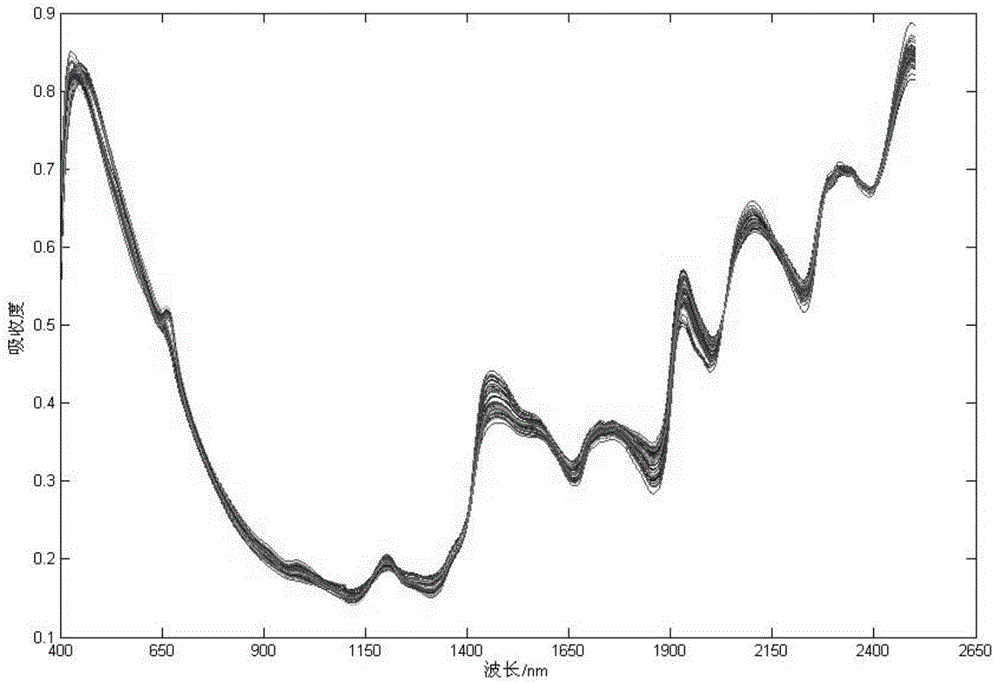

Method for detecting medicated leaven fermentation process quality on line by using near infrared spectrum

InactiveCN104596984AQuick calculation of enzyme activity valueGrasp the fermentation statusMaterial analysis by optical meansReflectivityLeast squares support vector machine

The invention discloses a method for detecting medicated leaven fermentation process quality indexes on line. The method comprises the following steps: (1) sampling at different medicated leaven fermentation time points; (2) obtaining the near infrared spectrum data of each sample by adopting a diffuse reflectance method, and measuring the protease activity and / or the amylase activity of each sample; (3) establishing the correlation between the near infrared spectrum data of each sample and the protease activity of each sample and / or the correlation between the near infrared spectrum data of each sample and the amylase activity of each sample by adopting a least square support vector machine method, a partial least square method or a neural network, preferentially adopting the least square support vector machine method to obtain an enzyme activity predication model based on a near infrared spectrum; and (4) detecting the medicated leaven fermentation process quality indexes on line by adopting the enzyme activity predication model. The method disclosed by the invention can be used for controlling the production process quality rapidly in real time and has the advantages of wide application range and good applicability.

Owner:BEIJING UNIV OF CHINESE MEDICINE

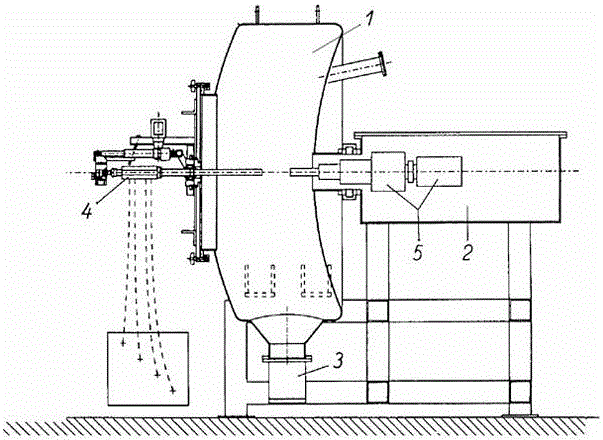

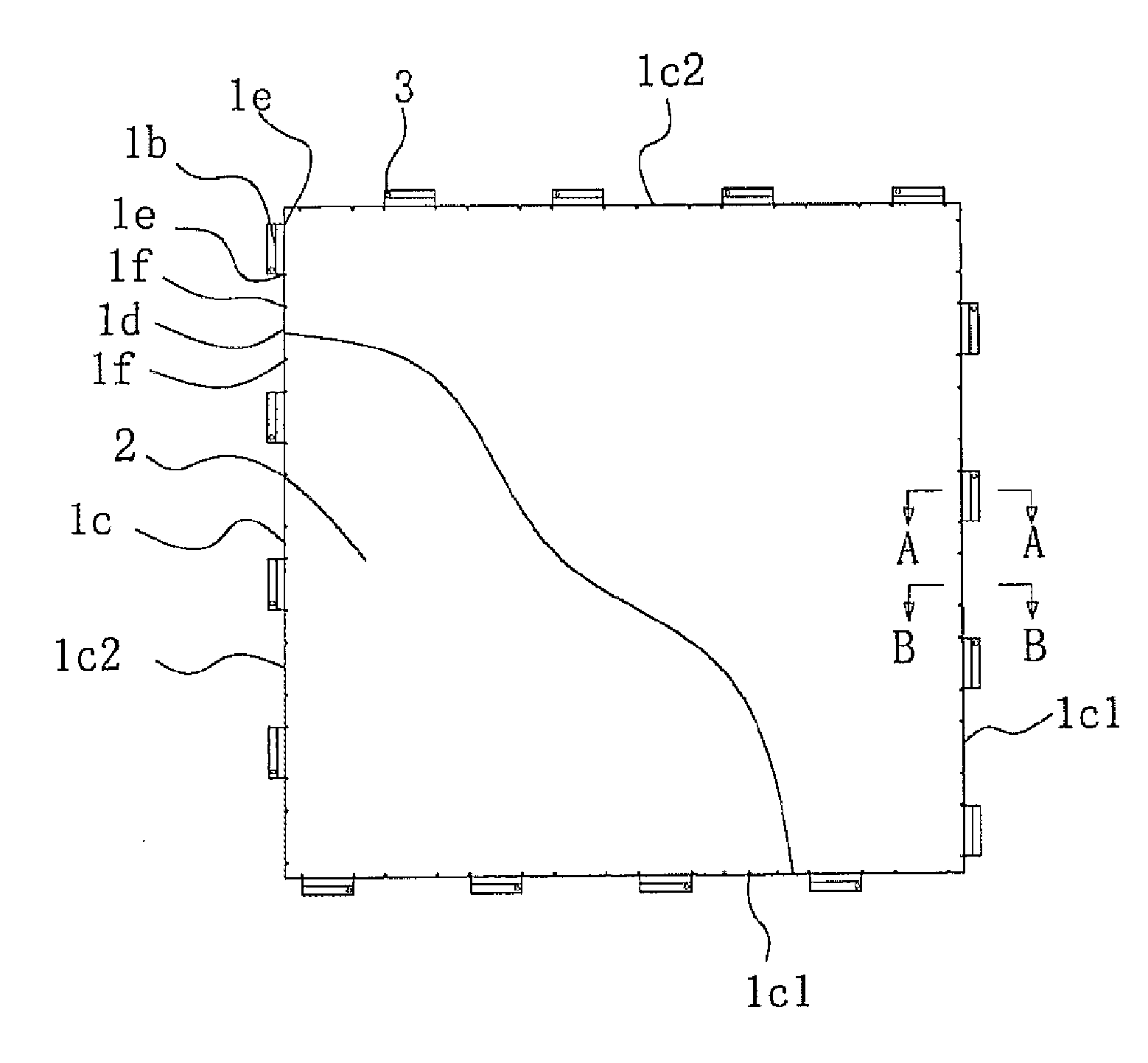

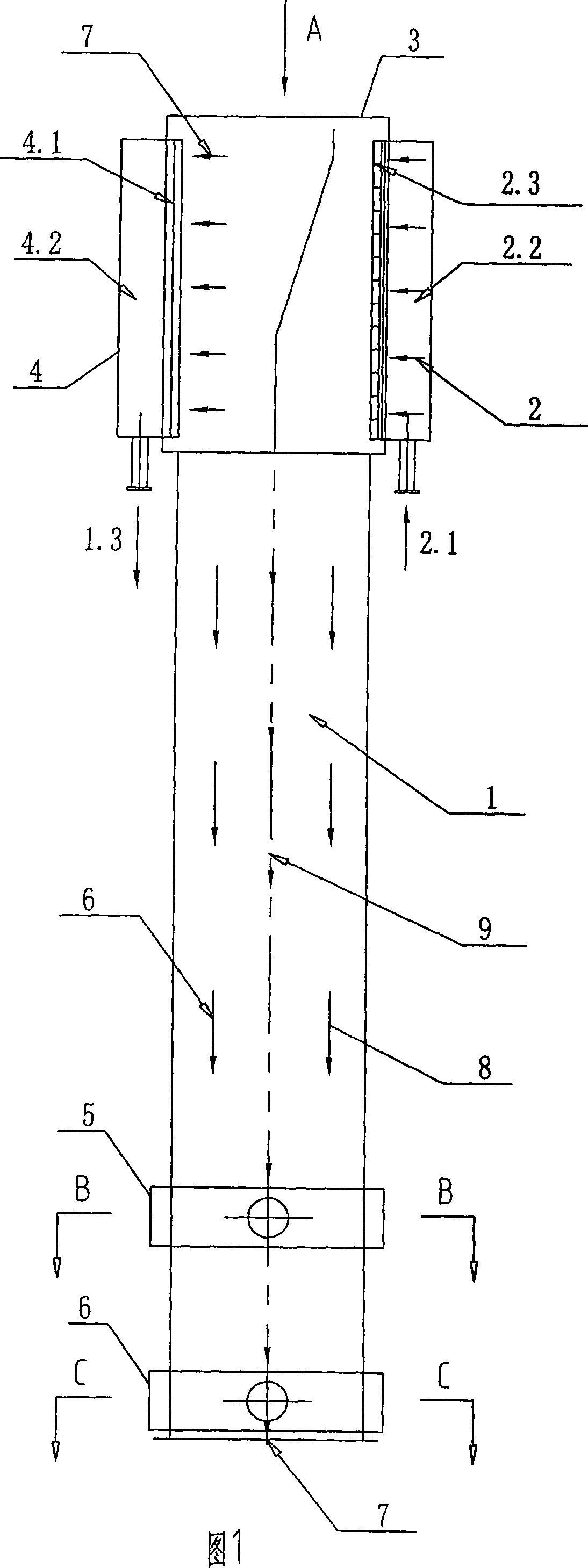

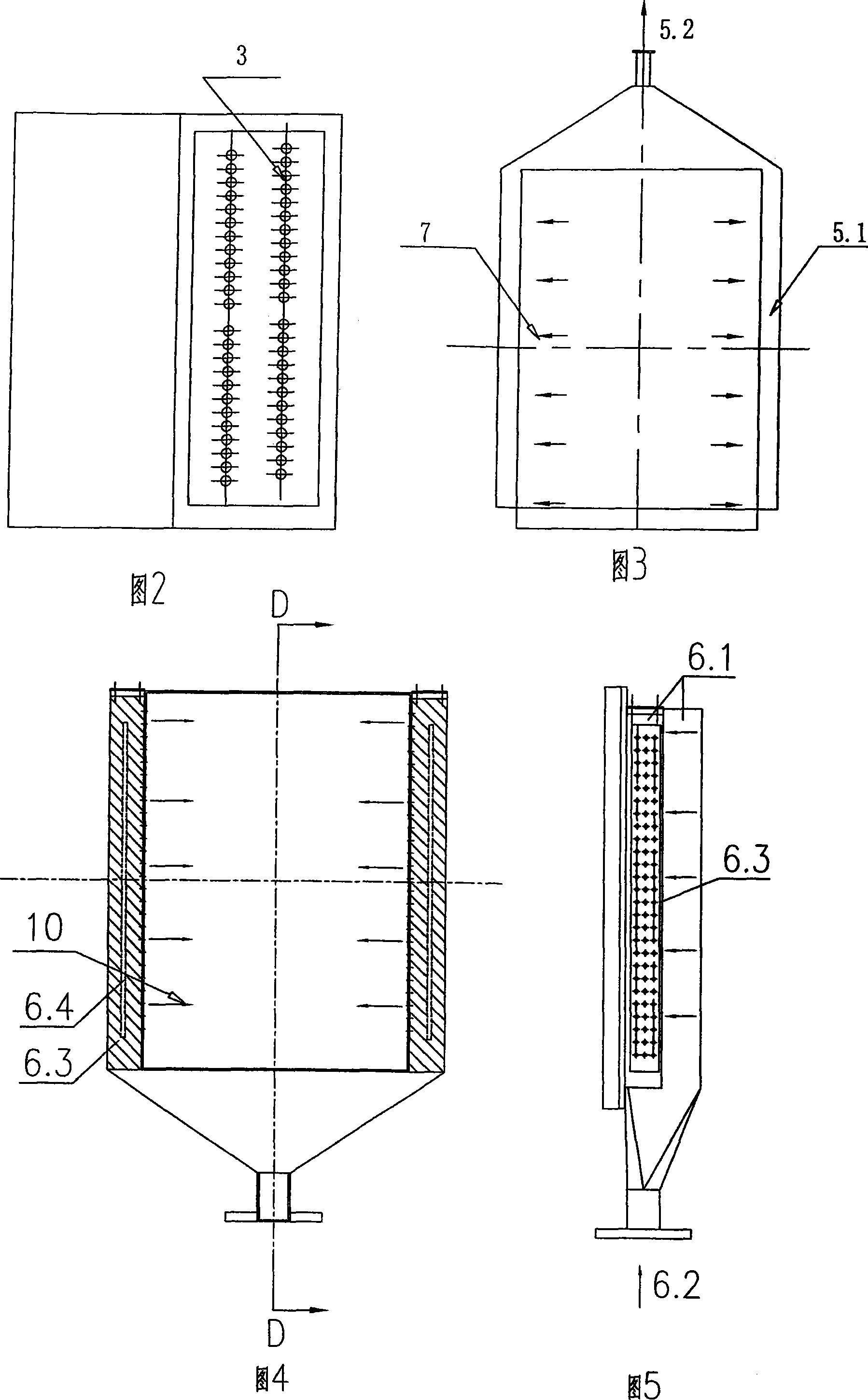

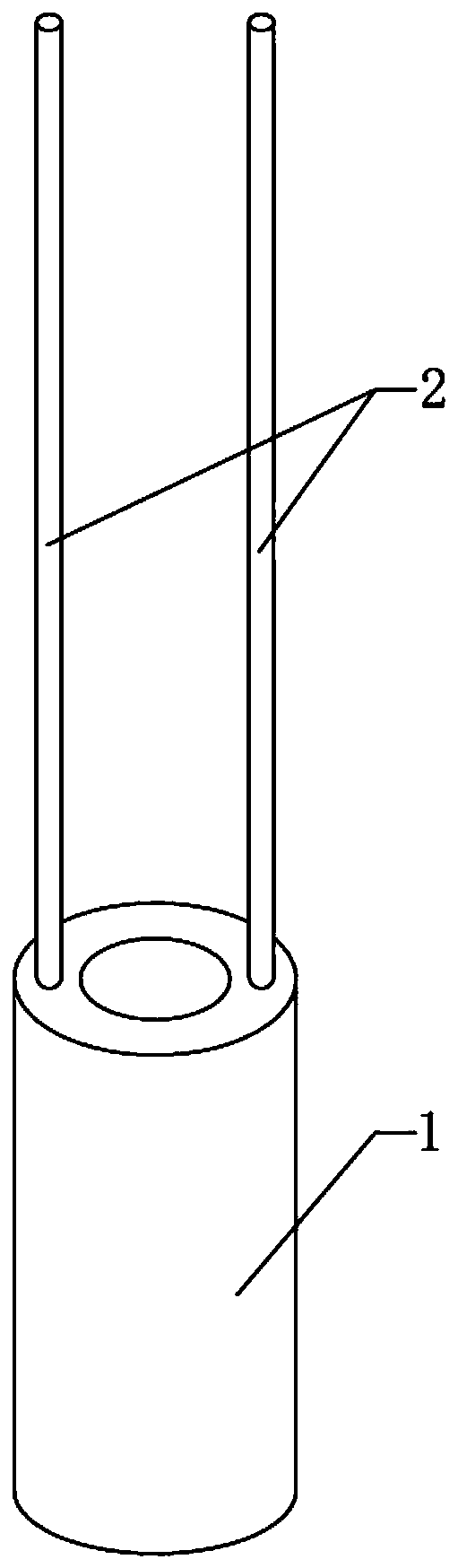

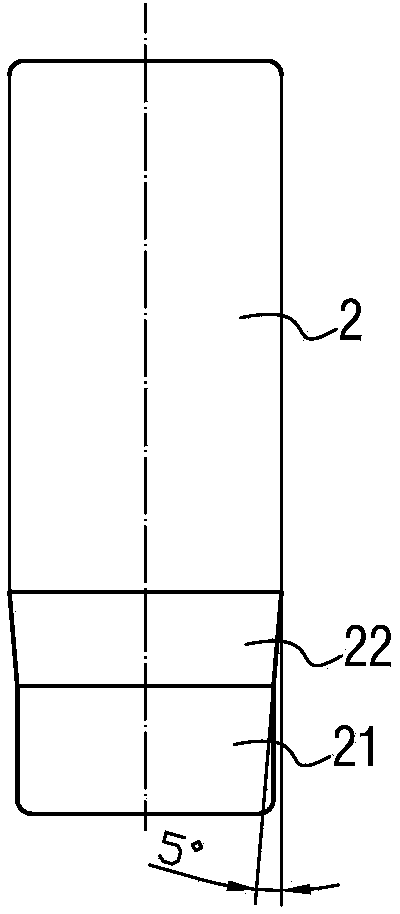

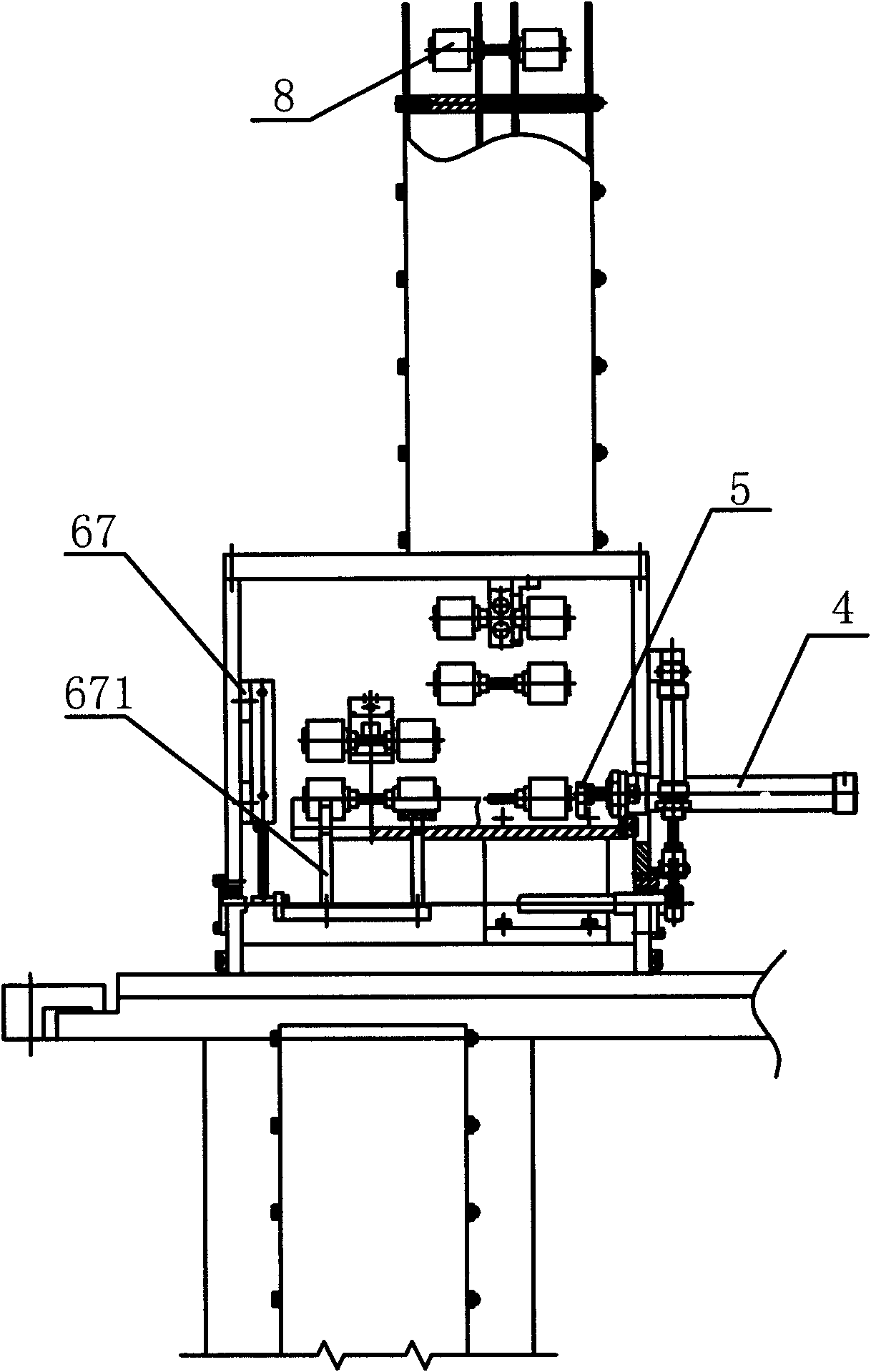

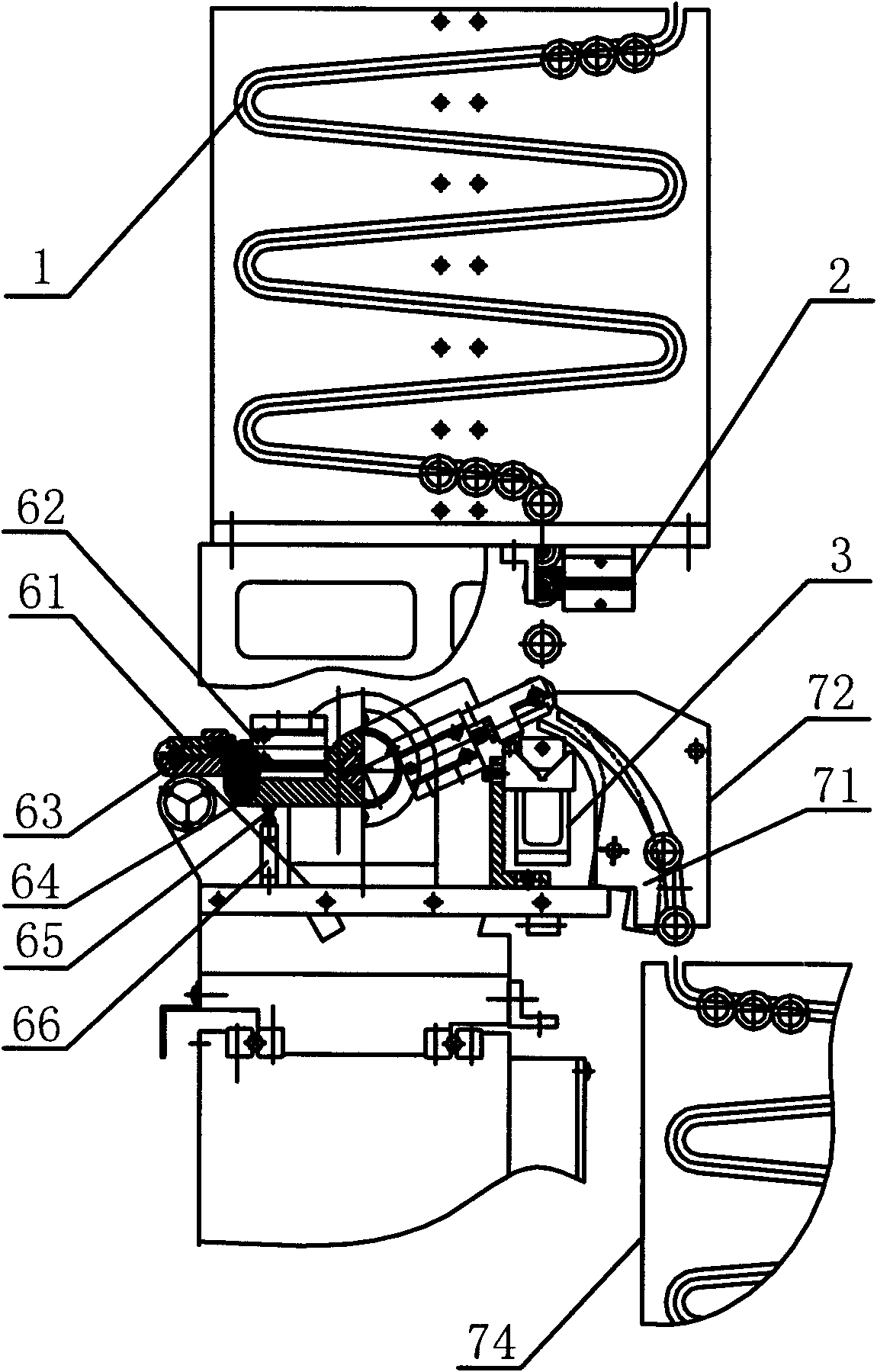

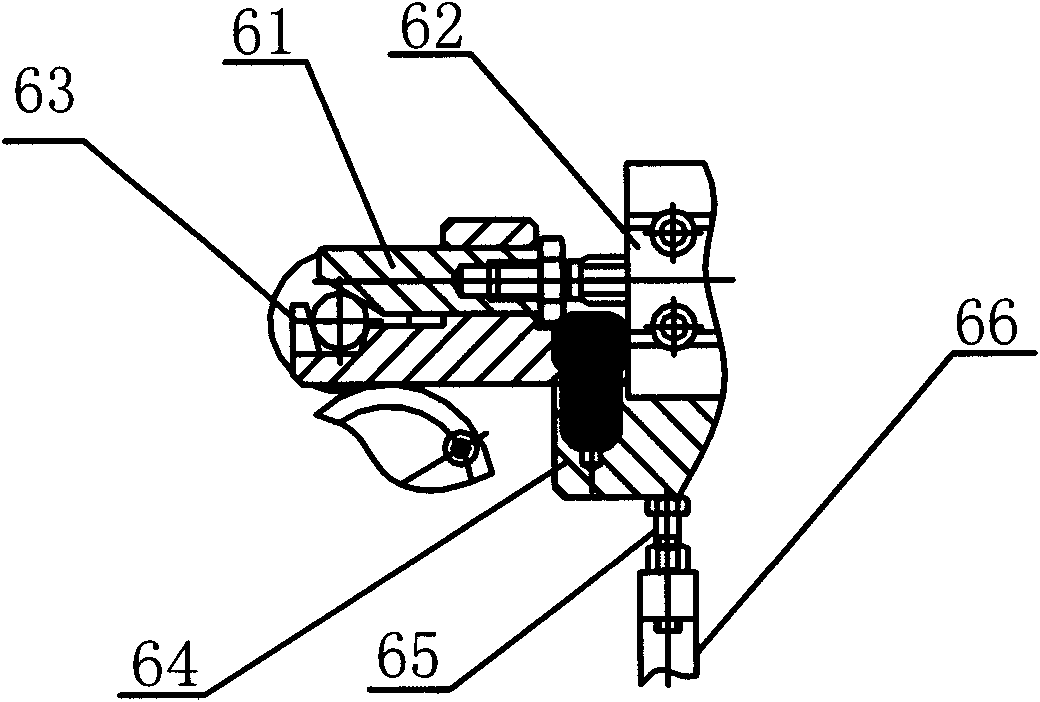

48 head square spinning path

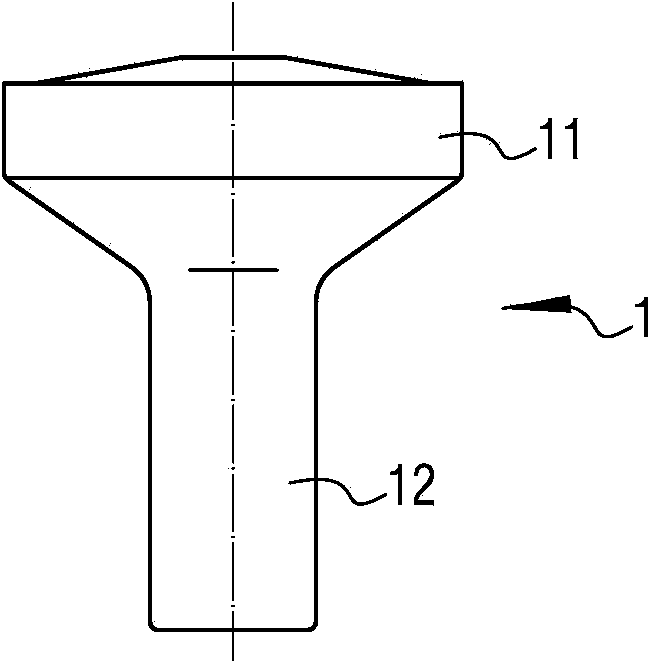

ActiveCN101235550AGuaranteed stabilityEnsure quality stabilityArtificial filament heat treatmentDry spinning methodsLow nitrogenEngineering

The invention relates to a square spinning channel with 48 joints, which comprises a square tube shaped spinning channel body (1), an upper side air inletting cabinet (2), a spinning component with 48 joints (3) and an upper side air returning cabinet (4), wherein the 48-joint spinning component (3) is mounted on the top of the square tube shaped spinning channel body (1), the upper side air inletting cabinet (2) and the upper side air returning cabinet are respectively mounted on the left side and the right side of the top of the square tube shaped spinning channel body (1). The square spinning channel with 48 joints is characterized in that a lower air returning device (5) and a lower nitrogen gas air curtain device (6) are mounted on the lower portion of the square tube shaped spinning channel body (1), wherein the lower air returning device (5) and the lower nitrogen gas air curtain device (6) are mounted up and down in interval, the square spinning channel with 48 joints can greatly improve the output of the spinning under the precondition of slightly increasing the number of the spinning channel and winder device and the like.

Owner:JIANGYIN L V CHEM FIBER PROCESS TECH

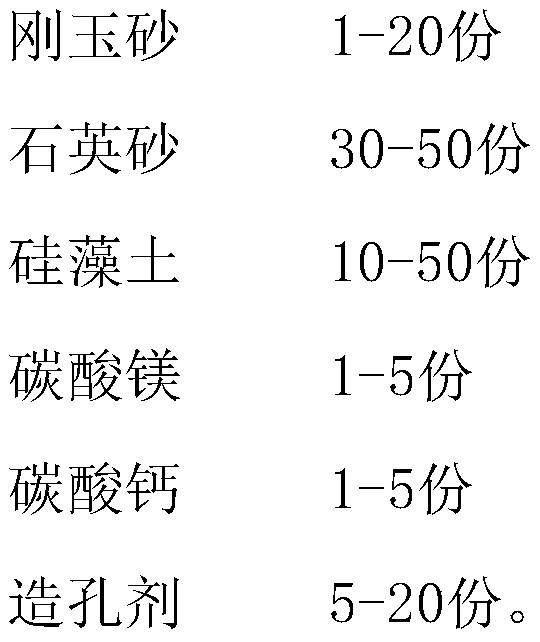

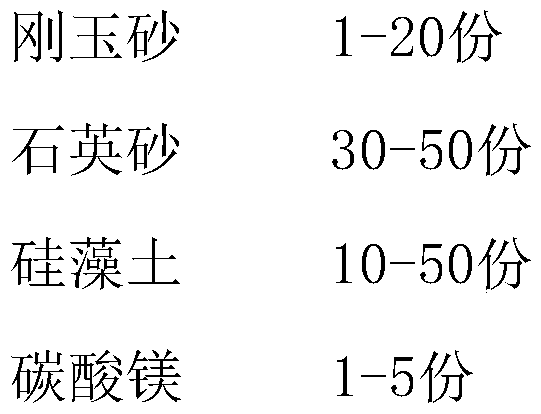

Porous ceramic heating body and preparation method thereof

InactiveCN110981454AHigh strengthImprove performanceTobaccoCeramicwareElectronic cigaretteSilicon dioxide

The invention relates to the technical field of electronic cigarettes, in particular to a porous ceramic heating body and a preparation method thereof. The porous ceramic heating body comprises a porous ceramic matrix and a metal heating element. The porous ceramic matrix comprises the following raw materials in parts by weight: 1-20 parts of emery, 30-50 parts of quartz sand, 10-50 parts of diatomite, 1-5 parts of magnesium carbonate, 1-5 parts of calcium carbonate and 5-20 parts of a pore forming agent. The porous ceramic heating body is novel in structure, high in product porosity and highin strength; the metal heating element is not oxidized; the diatomite forms gaps under the action of the pore forming agent, so the porosity of the produced porous ceramic heating body is guaranteed;magnesium carbonate and calcium carbonate can decompose a part of carbon dioxide gas under a high-temperature condition, so porosity is improved; and magnesium oxide and calcium oxide generated afterhigh-temperature decomposition form aluminosilicate together with silicon dioxide and aluminum oxide, so the inter-binding property of material particles is improved, and the structural stability andstrength of the porous ceramic matrix are improved.

Owner:KEY MATERIAL

Online intelligent monitoring method for working performance of concrete at construction site

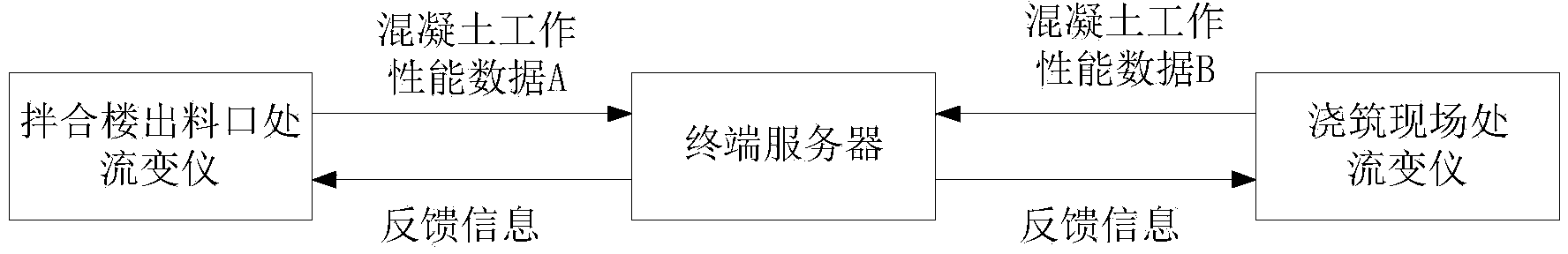

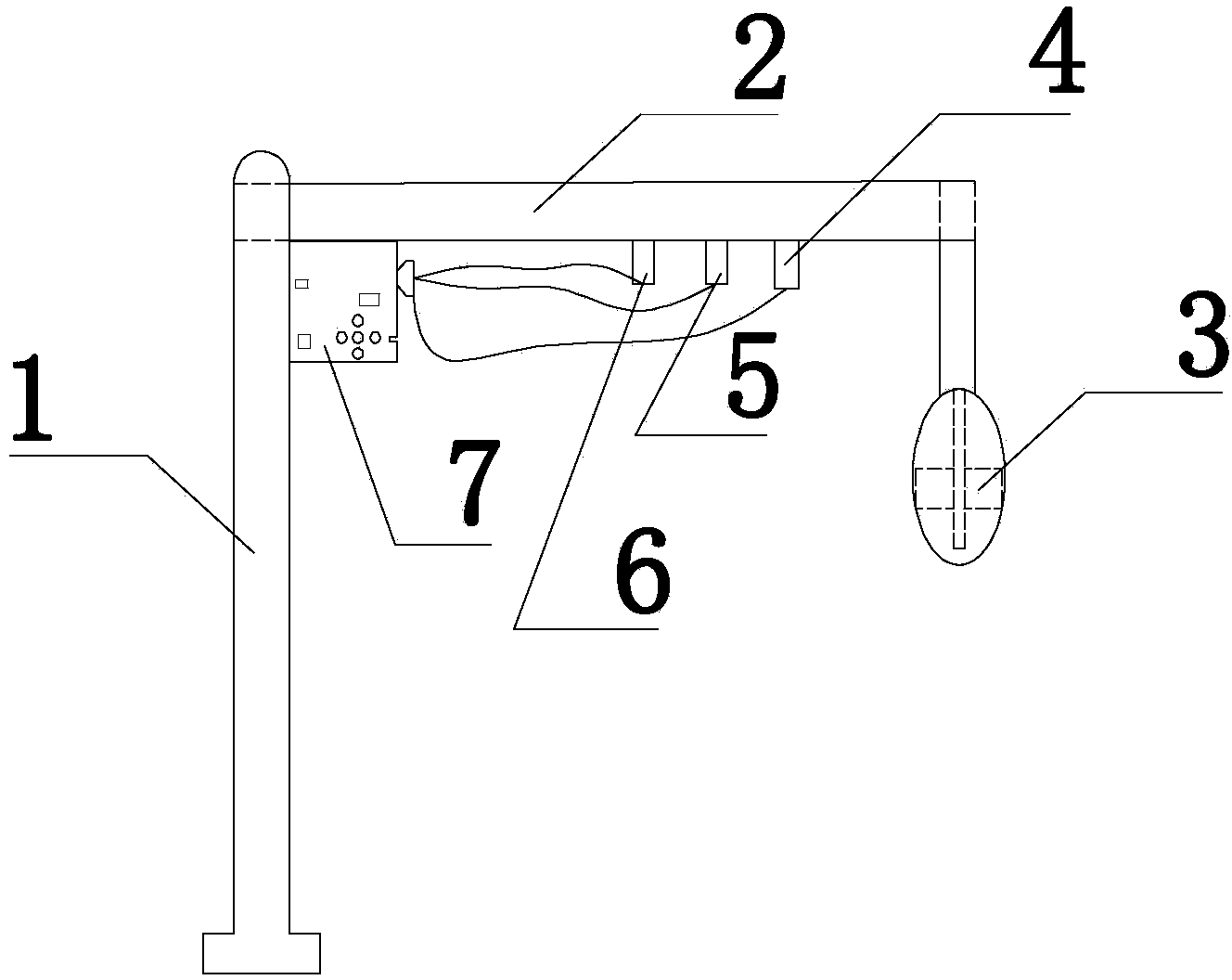

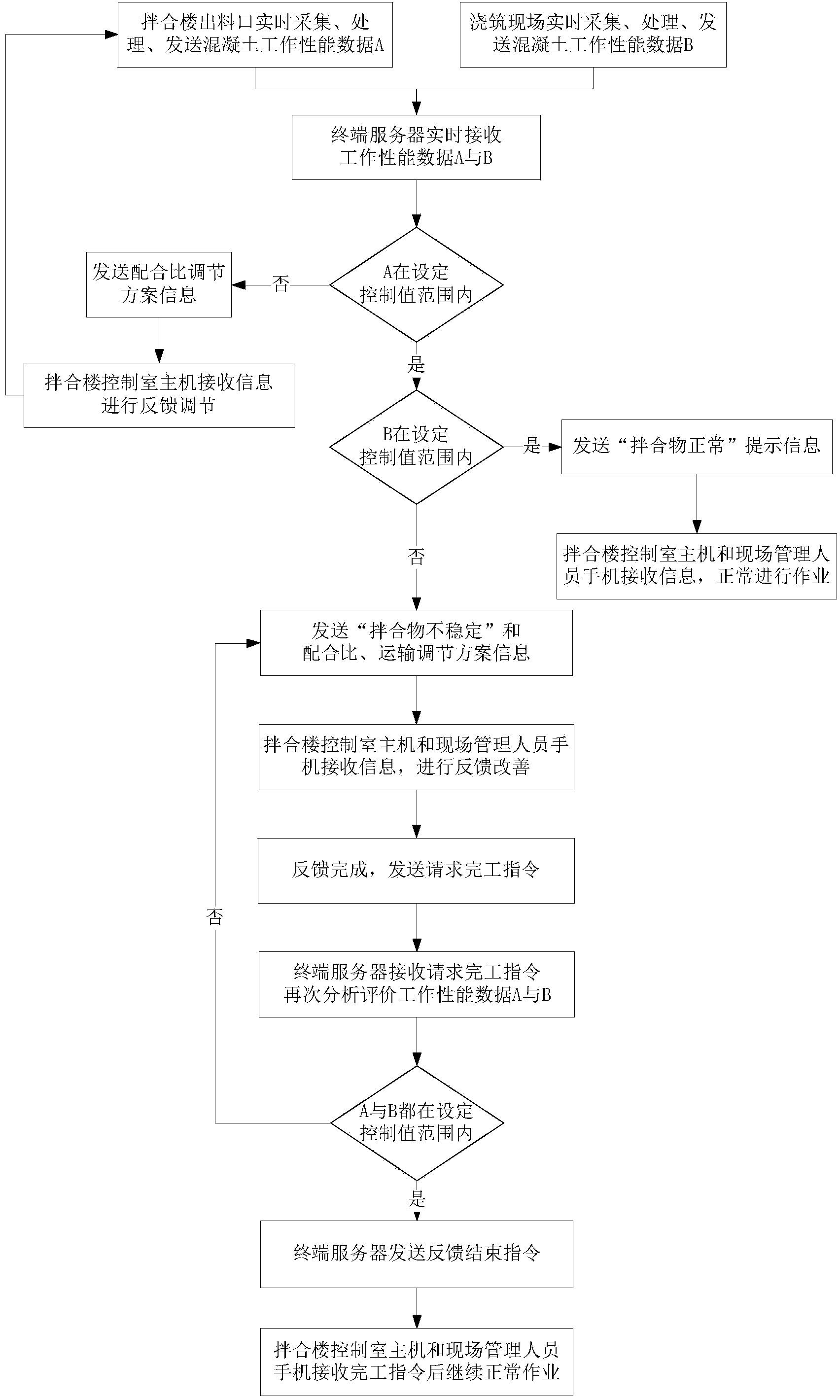

InactiveCN104345718AEnsure quality stabilityAvoid big differences in workabilityTotal factory controlProgramme total factory controlTerminal serverWork performance

The invention discloses an online intelligent monitoring method for working performance of concrete at a construction site. Through real-time collection and detection of an ageing change rule of rheological parameters of mixtures in the same mixing batch at a mixing floor discharge hole and the construction site, and the methods of analyzing, evaluating and feeding back by a terminal server, the working performance of the concrete in construction and transportation processes is monitored in real time. According to the online intelligent monitoring method, automatic intelligence of the detection process is achieved, overlarge deviation in difference of the working performance of the concrete at the construction site can be avoided, and the quality stability of the concrete mixture is ensured.

Owner:HOHAI UNIV +1

Forging method of disc-shaped integrated part and die used for forging method

ActiveCN104108012AImprove mechanical propertiesEnsure quality stabilityForging/hammering/pressing machinesEngineeringTurbine

The invention provides a forging method of a disc-shaped integrated part. The forging method comprises the steps of blanking by use of a sawing machine and processing by use of a lathe, applying a lubricant and heating for pre-forging, next, carrying out shot blasting and applying the lubricant after removing burrs by turning, heating for die forging, and then checking the quality of die forging at the junction of the turned disc and the rod, and if the quality is satisfied, drawing the rod to the final dimension by use of twice firing. The forging method is characterized in that the composite forging method of combined die forming and free forging is adopted for processing, in other words, the disc is formed by virtue of die forming, while the rod is drawn out by virtue of free forging, the targeting die for die forging is designed so that the deformation degree of the material can be effectively controlled and the deformation dead region can be avoided, the targeting spraying lubrication method is adopted so that the surface quality and the internal structure of a forged piece can be effectively controlled and the forged piece having excellent comprehensive mechanical properties can be obtained, and the quality stability of the forged piece produced by use of the disc-shaped integrated part such as a free turbine disc is guaranteed. The invention also provides a die for the method.

Owner:CHINA HANGFA SOUTH IND CO LTD

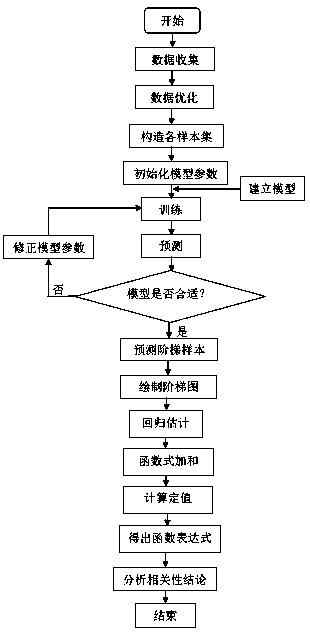

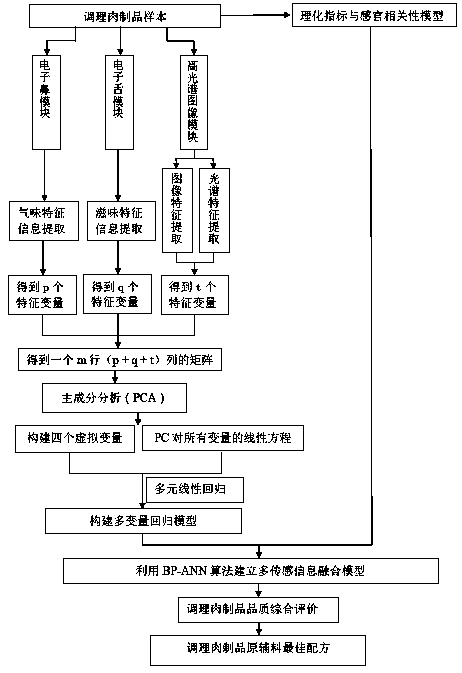

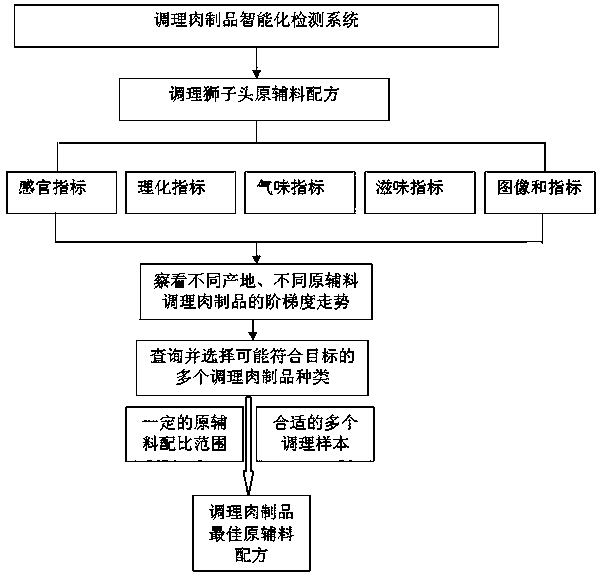

Prepared meat product quality intelligent evaluation system and method

ActiveCN108960315AQuick forecastAdjust in timeCharacter and pattern recognitionMicrocontrollerSensor array

The invention discloses a prepared meat product quality intelligent evaluation system and method. The multi-sensor information fusion technology is used, and the intelligent electronic nose module, the intelligent electronic tongue module, the hyperspectral image acquisition module, the data analysis system, the computer and the friendly man-machine management interface in the evaluation system are utilized to perform evaluation. The intelligent electronic nose module is connected with the computer through a data line and comprises a gas sensitive sensor array, an airtight chamber, a samplingpump, a discharge pump and a single-chip microcomputer device. The gas sensitive sensor array is connected with the single-chip microcomputer device. The gas to be measured is pumped out by the sampling pump and then enters the reaction chamber of the sensor array to have adsorption reaction with the sensors so that the resistance of the sensors changes. The resistance signal is converted into thevoltage signal according to the converter and then transmitted to the computer through serial port communication. The problems of high subjectivity of artificial sensory evaluation, poor consistencyand unstable product quality can be overcome and the intelligent solution can be provided for enterprises on complex raw material and auxiliary material proportioning.

Owner:HENAN AGRICULTURAL UNIVERSITY

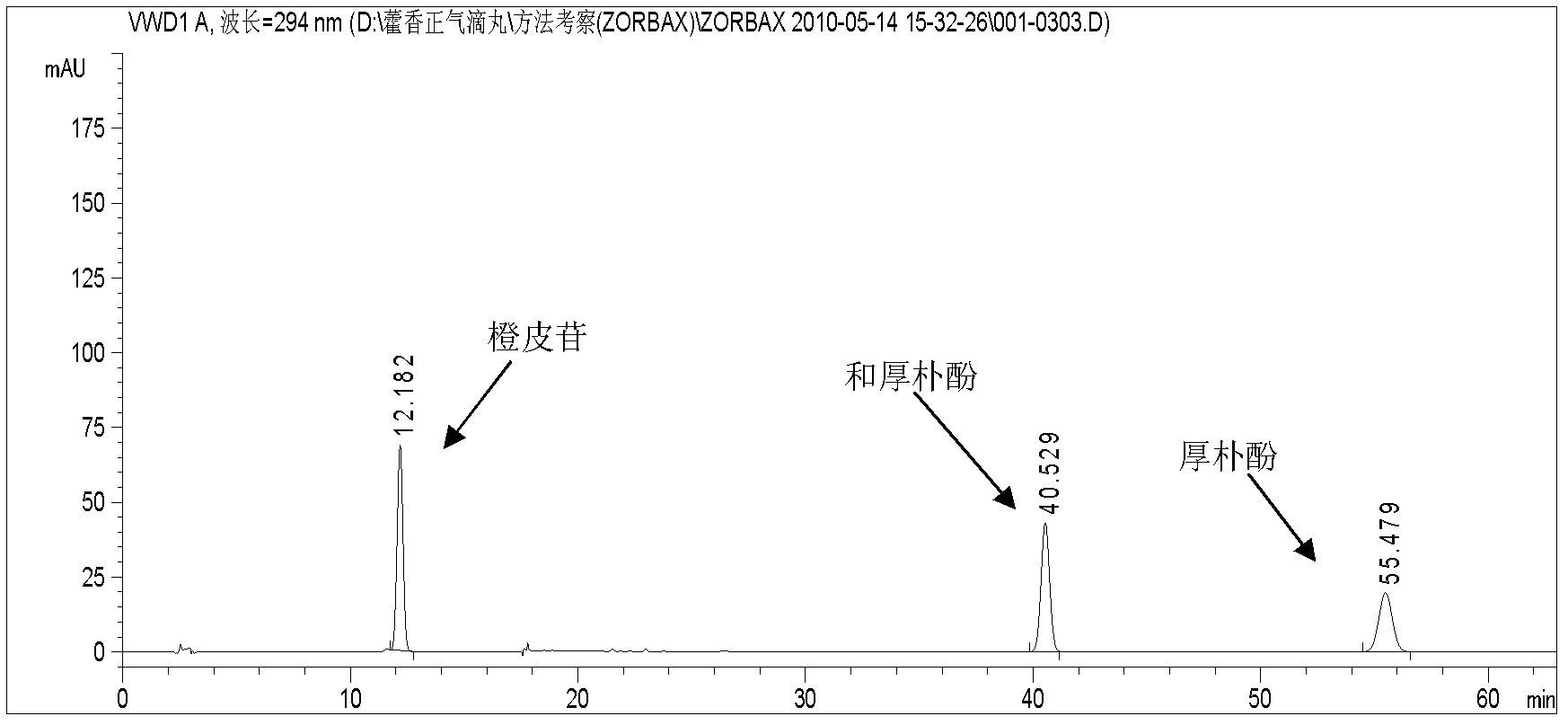

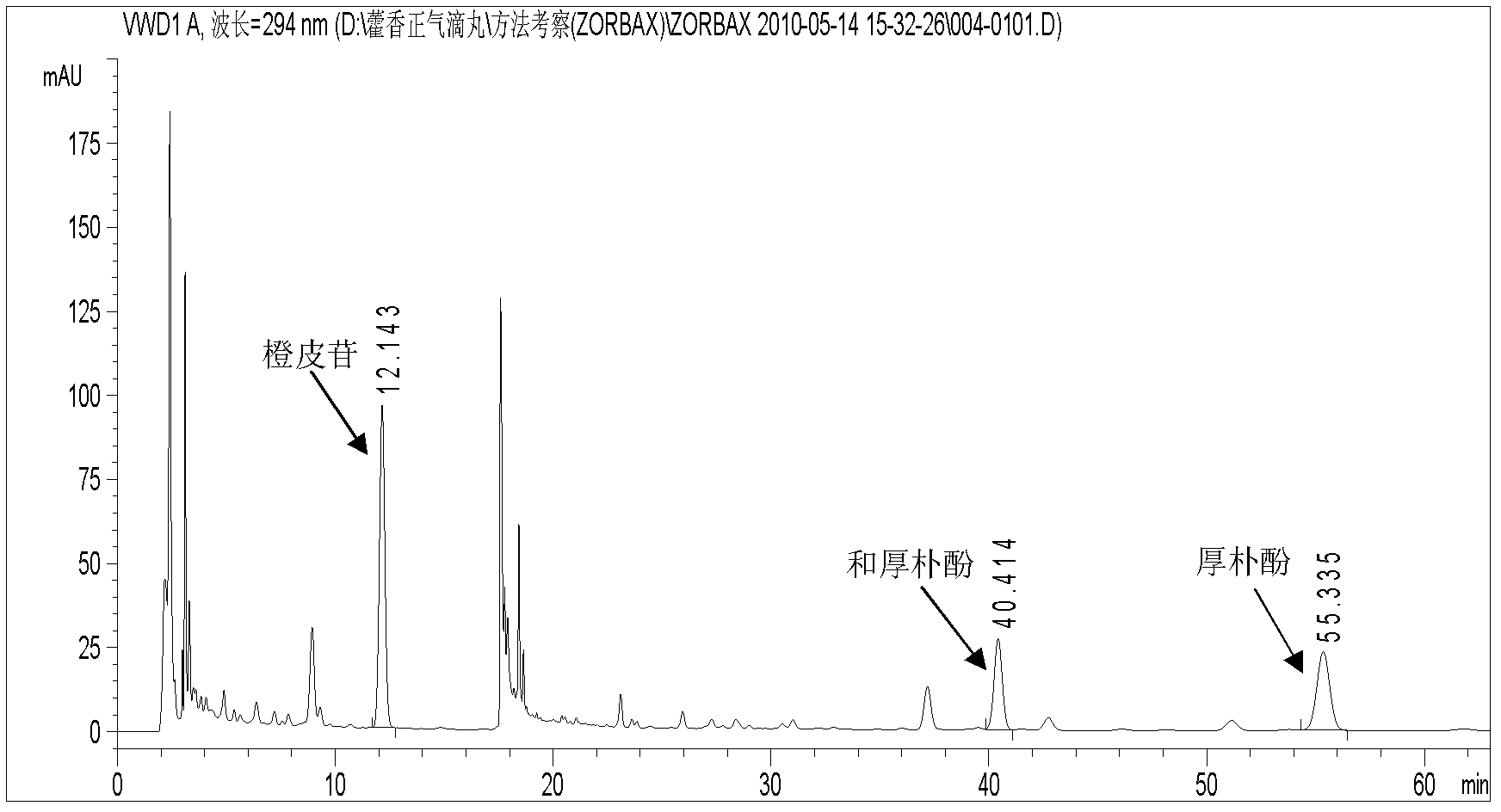

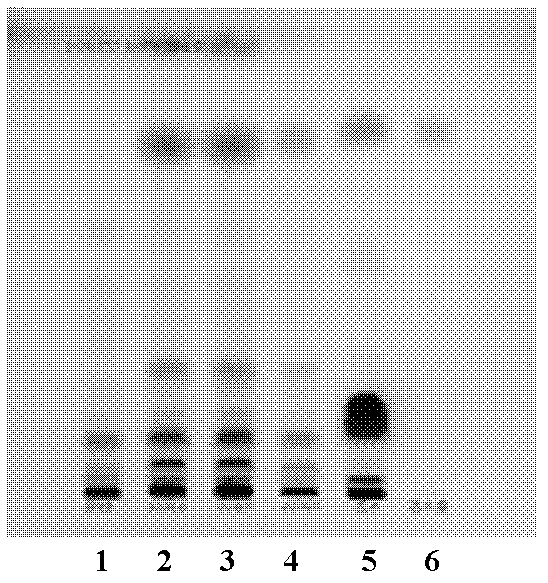

Quality detection method for Huoxiang Zhengqi dripping pills

ActiveCN102998411ASmall amount of sampleGood identification specificityComponent separationThin-layer chromatographyMagnolol

The invention relates to the medicinal field, and concretely relates to a quality detection method for Huoxiang Zhengqi dripping pills. The quality detection method comprises an identification method and a content determination method, and the identification method comprises the steps of Atractylodes lancea identification, dahurian angelica root identification, cortex magnoliae officinalis and Pogostemon cablin oil thin-layer identification, Perilla frutescens leaf oil identification, dried orange peel identification, licorice identification and Pinellia Tuber idenfication and is carried out through using thin layer chromatography. The quality detection method also comprises the determination of the contents of effective components in the Huoxiang Zhengqi dripping pills, the effective components comprise hesperidins, magnolols and honokiols, and the content determination method is carried out through adopting high performance liquid chromatography.

Owner:TIANJIN TASLY PHARMA CO LTD

Special primer for heavy-duty machinery

InactiveCN102618144AAvoid interferenceEnsure quality stabilityAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistanceEpoxy

The invention relates to a special primer for heavy-duty machinery, which consists of A components and B components, wherein the A components include, by weight percentage (amount to 100%), 40-50% of epoxy resin, 8-12% of diluents, 1-5% of auxiliary, 7-15% of paint and 28-37% of fillers, and the B components include modified polyamide curing agent. The primer made by resin with proper epoxy equivalent, functional paint and fillers and high-performance curing agent is stable in quality, dry, quick, excellent in corrosion resistance, applicable to various coating manners, excellent in construction compatibility, low in price, non-toxic and environment-friendly and can be applied to the heavy-duty machinery having high requirement for corrosion resistance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

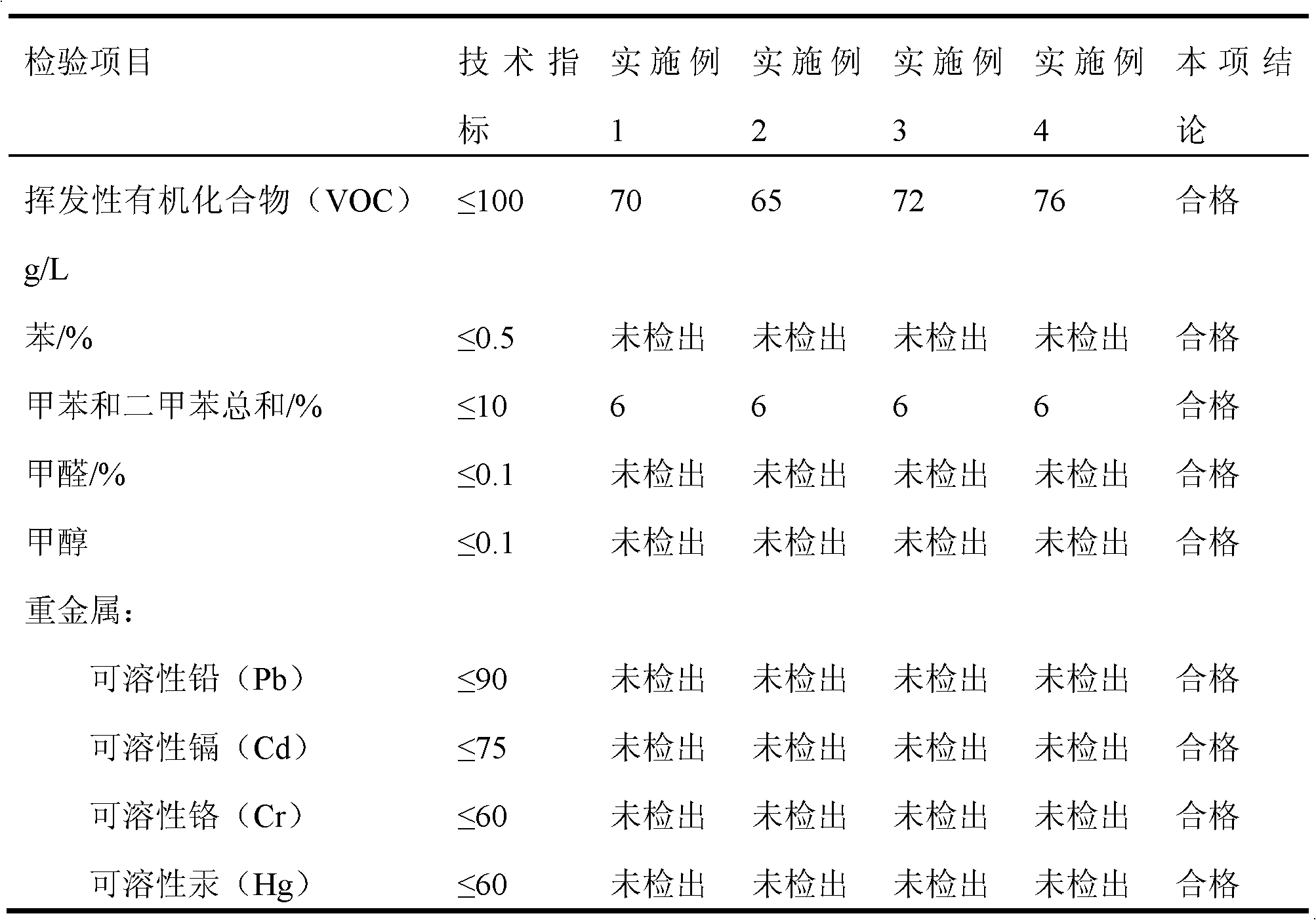

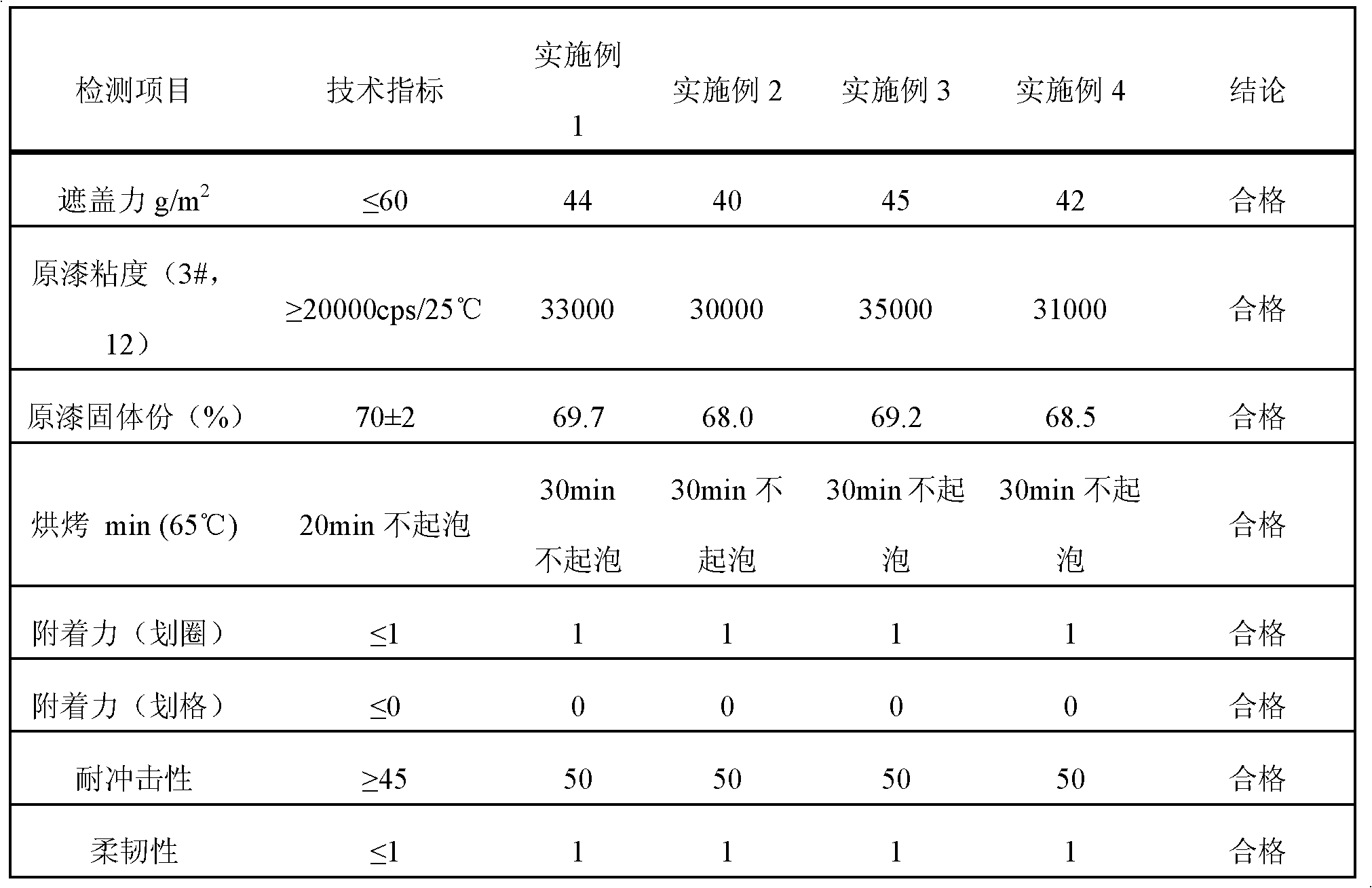

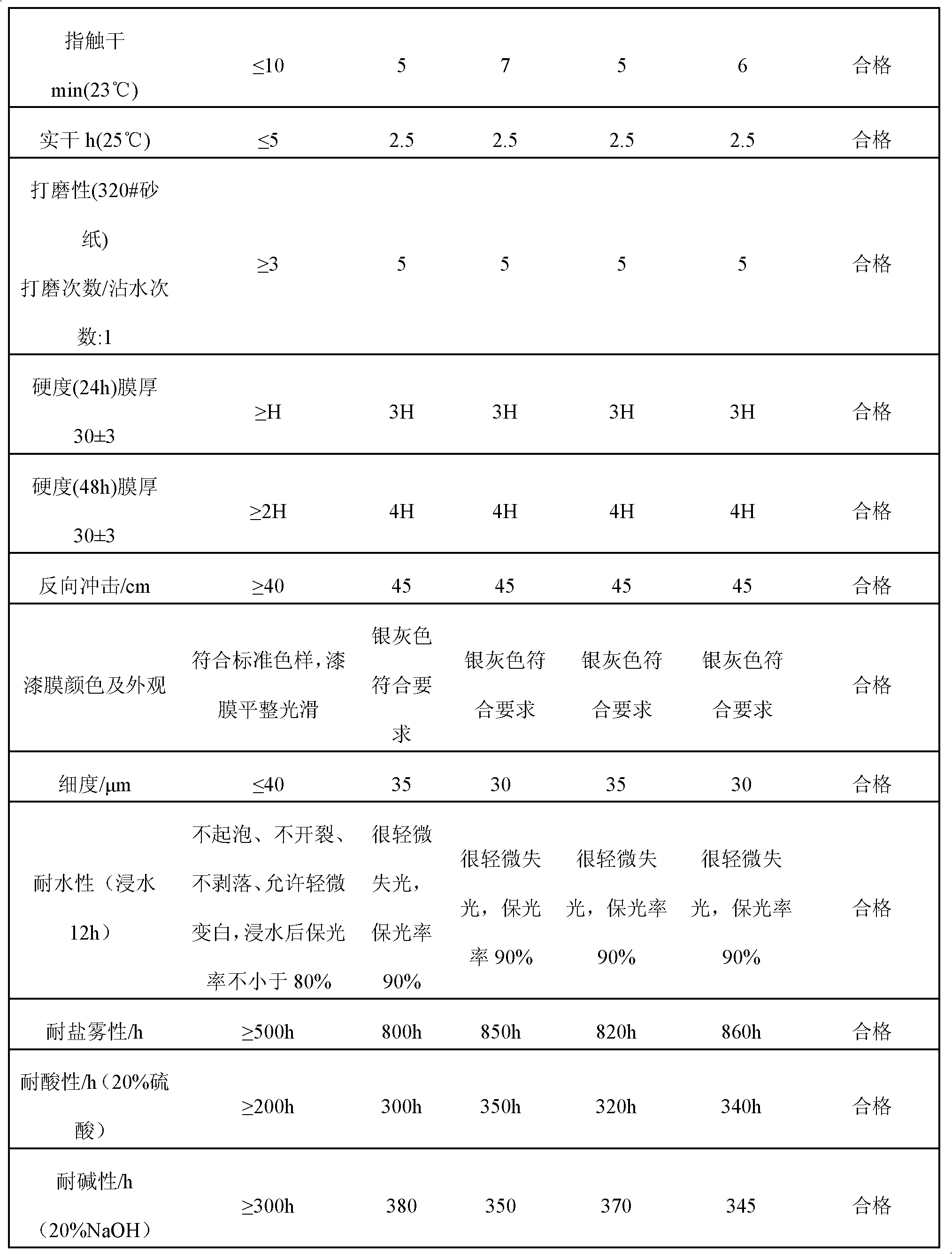

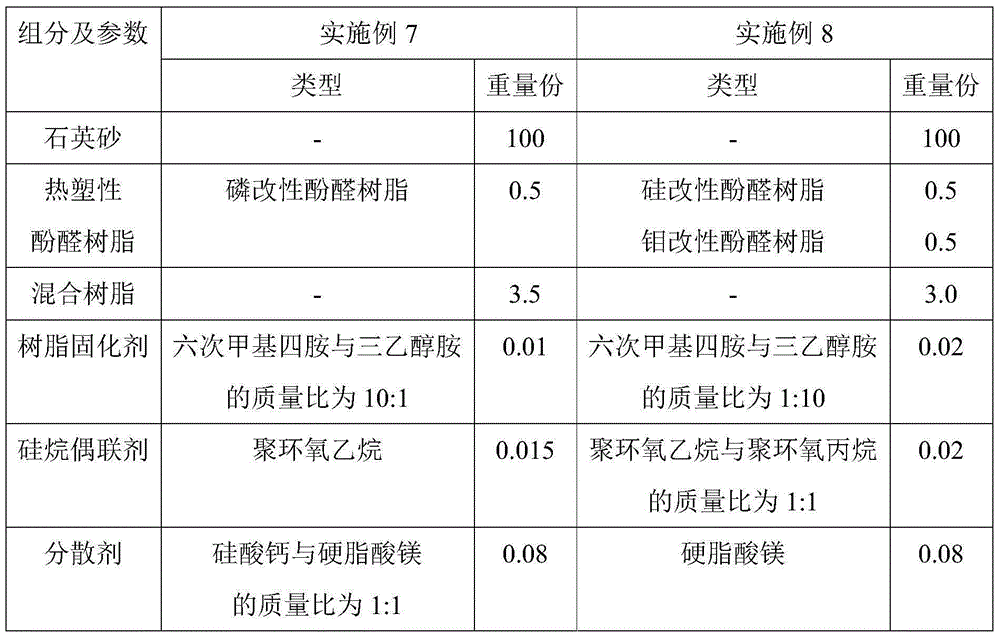

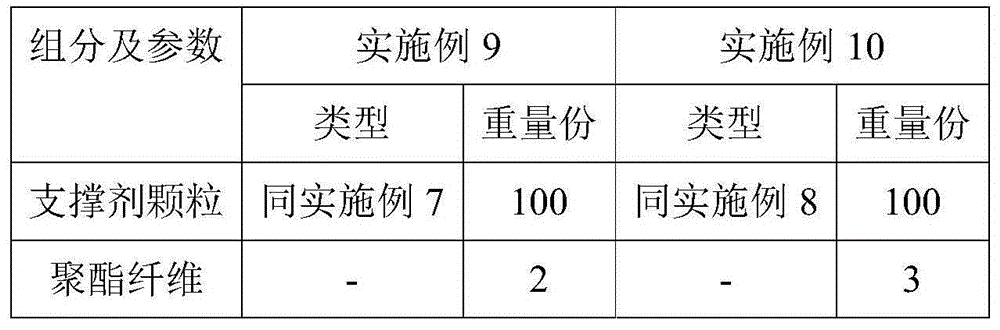

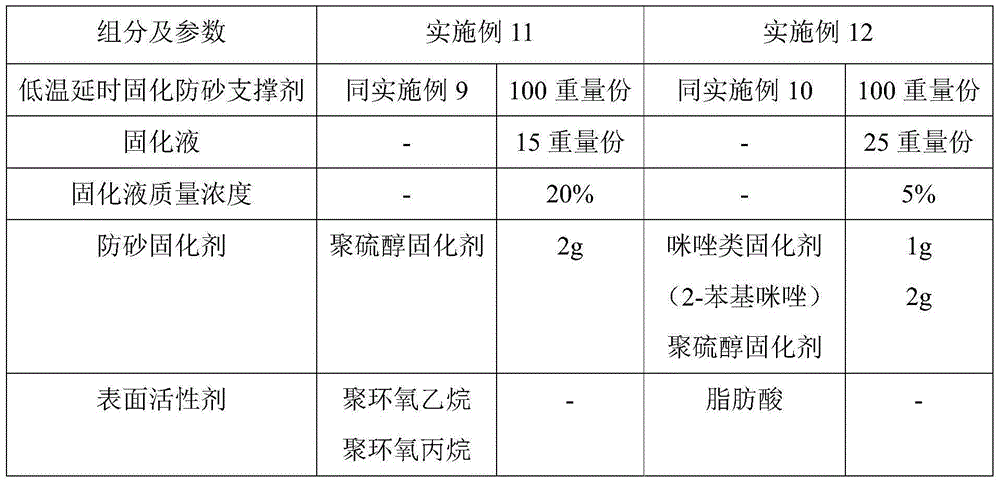

Low-temperature delayed-curing sand-control proppant, preparation method of proppant as well as low-temperature delayed-curing sand-control system

ActiveCN105112043AHigh compressive strengthEnsure quality stabilityFluid removalDrilling compositionTemperature resistanceSilane coupling

The invention discloses a low-temperature delayed-curing sand-control proppant, a preparation method of the proppant as well as a low-temperature delayed-curing sand-control system. The sand-control proppant comprises proppant particles, wherein proppant particles comprise quartz sand and composite resin layers, and the composite resin layers comprise inner resin layers and outer resin layers; the inner resin layers are thermoplastic phenolic resin layers; the outer resin layers comprise components in parts by weight as follows: 1.0-3.5 parts of mixed resin, 0.01-0.02 parts of a resin curing agent, 0.005-0.02 parts of a silane coupling agent and 0.05-0.1 parts of a dispersant; the mixed resin is a mixture of thermoplastic phenolic resin and epoxy resin; the mass ratio of the quartz sand to the inner resin layers to the mixed resin of the outer resin layers is 100:(0.5-2.0):(1.0-3.5). The temperature resistance and the compressive strength of the sand-control proppant are improved by the aid of the composite resin layer, and the sand-control proppant can be cured at the low temperature and even the normal temperature and can be adapted to stratums at different temperatures.

Owner:HENAN TIANXIANG NEW MATERIALS

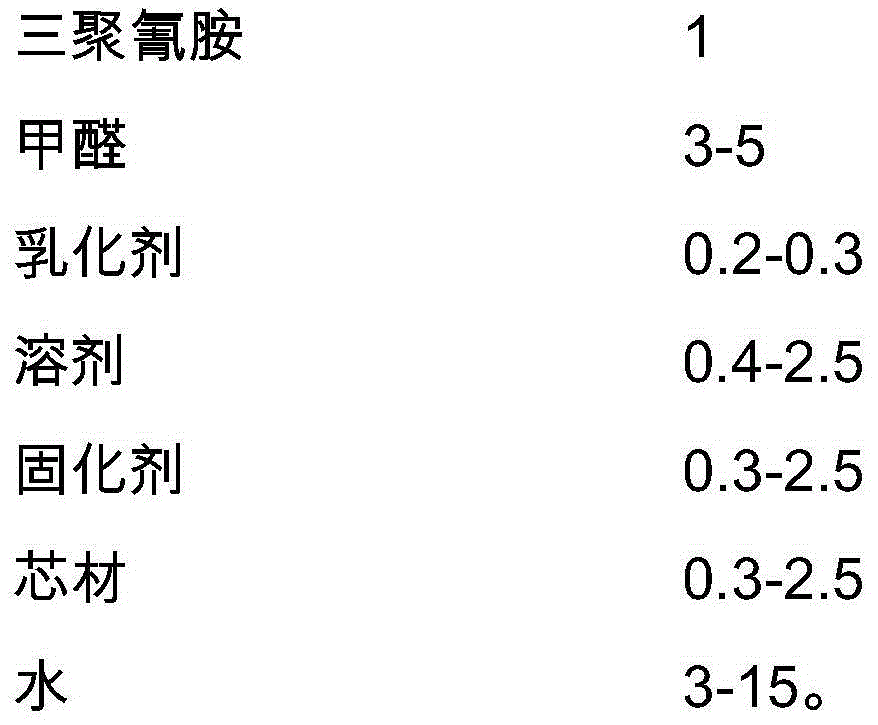

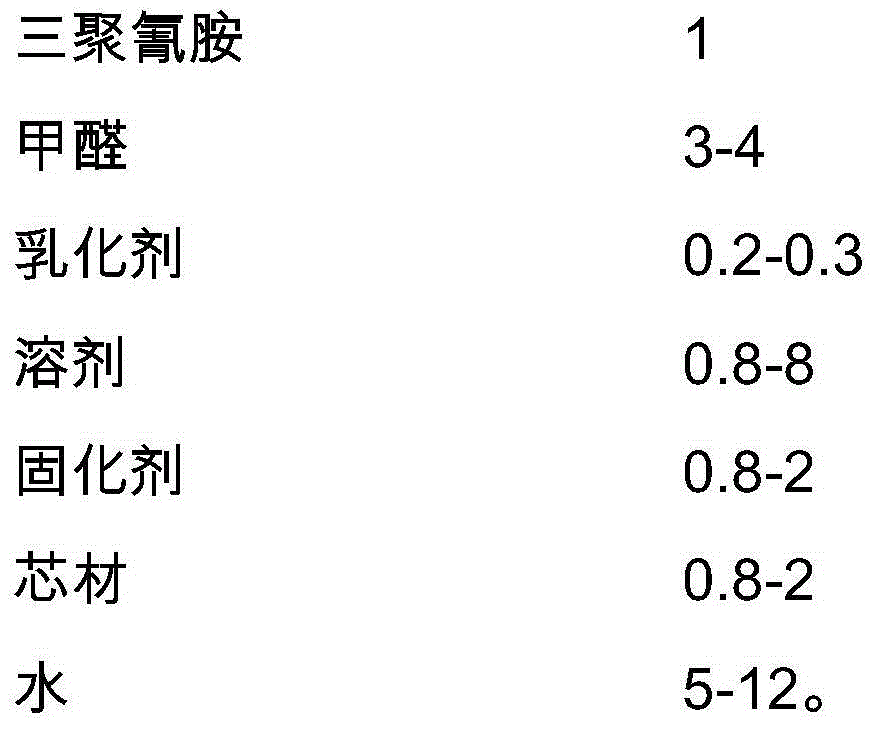

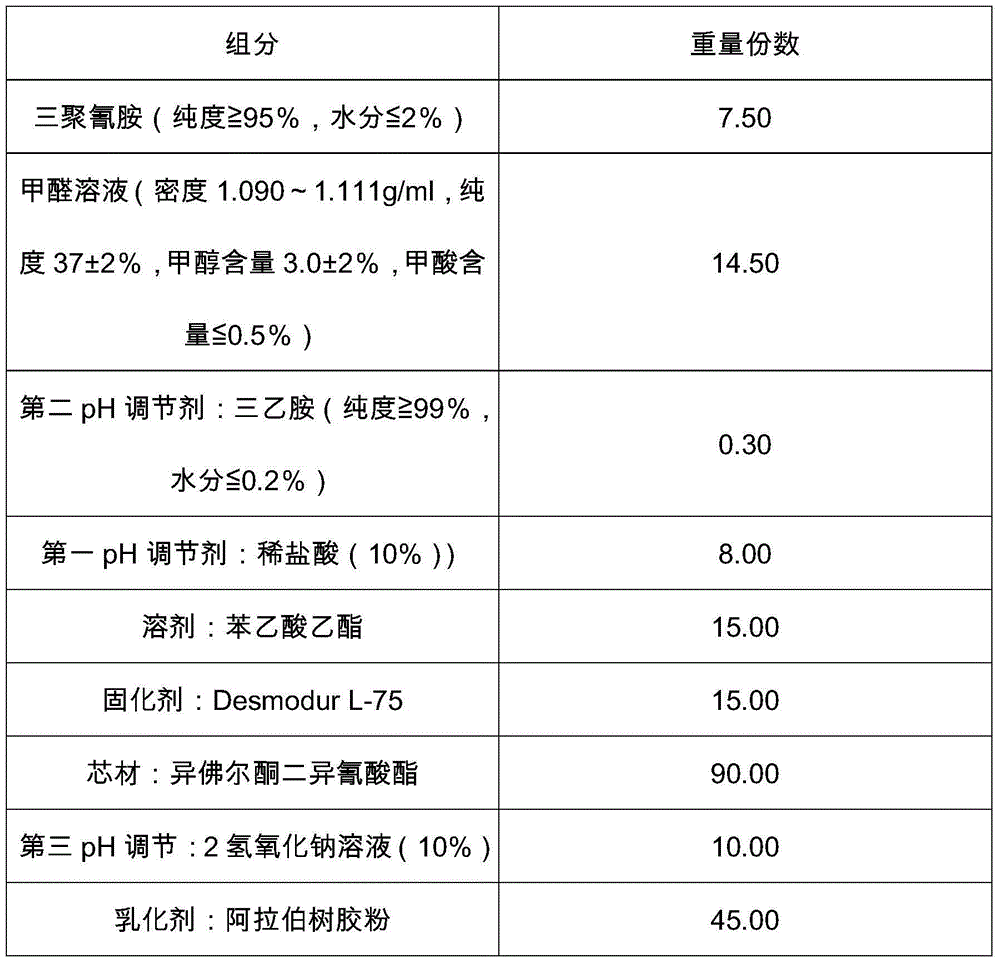

Double-shell microcapsule and its preparation method and use

ActiveCN104888671AImprove mechanical propertiesImprove impact resistanceMacromolecular adhesive additivesCoatingsEmulsionMelamine formaldehyde

The invention discloses a double-shell microcapsule and its preparation method and use. The preparation method comprises orderly adding and mixing melamine and a formaldehyde solution according to a mole ratio of 1: 3-5, adding distilled water into the mixed solution to obtain a melamine-formaldehyde performed polymer, wherein the mass of the distilled water is 1-3 times that of the formaldehyde solution, adding the melamine-formaldehyde performed polymer and an emulsifier into a reactor according to a ratio of 100: 20-30, adjusting pH to 1-6, adding a solvent-curing agent-core material homogeneous mixture with a mass ratio of 1: 1: 3 to 1: 2: 12 into the reactor, wherein the total mass of the homogeneous mixture is 1-2.5 times that of the melamine-formaldehyde performed polymer, carrying out emulsification for 20-50min, heating the emulsion to more than 40 DEG C, carrying out a reaction process for 3-5h and adjusting pH to greater than or equal to 6. The double-shell microcapsule has good mechanical properties, guarantees product quality stability and storage stability and has a wide raw material source and a low shell raw material price. The preparation method has simple processes, can be used in the fields of foods, drugs and cosmetics, can be widely used in the field of functional materials and widens a microcapsule usage scope.

Owner:南雄市星隆化工有限公司

Interlocking modular floor tile

Owner:HONG KONG MEI LI SHENG FLOORING +1

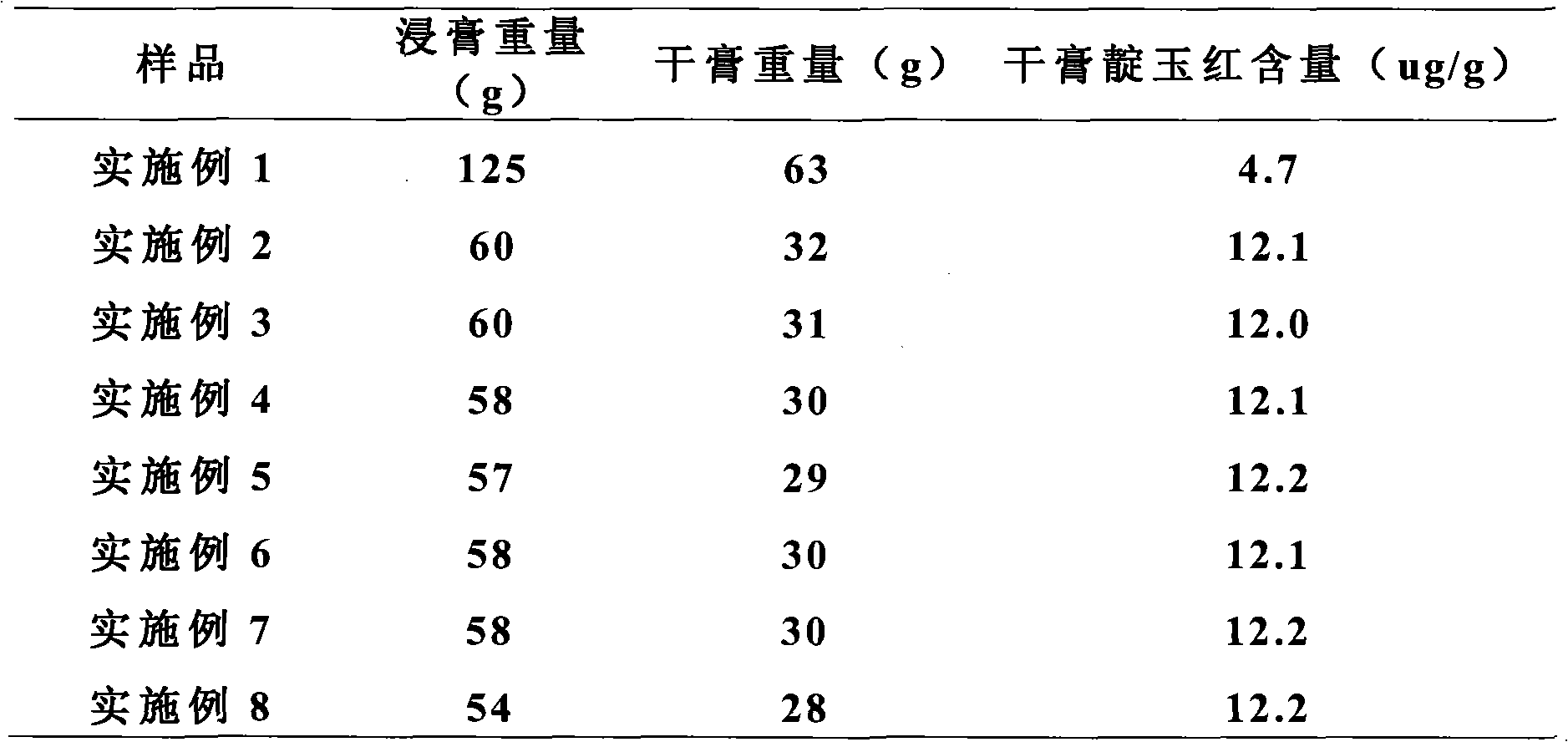

Process for refining isatis root extract by applying membrane separation technique

ActiveCN101564407AGuaranteed contentShorten the production cycleRespiratory disorderMagnoliophyta medical ingredientsAlcohol freeUltrafiltration

The invention discloses a process for refining isatis root extracted liquid by applying membrane separation technique. The isatis root extracted liquid is obtained by extracting isatis root by water. The process includes centrifugating the isatis root extracted liquid, taking centrifugal clear liquid, ultrafiltrating the centrifugal clear liquid, obtaining penetrating liquid, nanofiltrating the penetrating liquid, then the residual being isatis root extract. By adopting ultrafiltration membrane to effectively filtering the isatis root extracted liquid and concentrating the isatis root liquid by concentration technique, the isatis root extract is produced. The process realizes alcohol-free production, shortens production period, reduces energy consumption, lowers production cost, ensures content of effective content, enhances quality of product, and ensures quality stability of product.

Owner:苏州华辰净化股份有限公司

Bacteriostatic and mildewproof agent for smokeless tobacco and production method of bacteriostatic and mildewproof agent

InactiveCN103704879AImprove high moisture contentGuarantee quality safety and stabilityTobacco treatmentSmokeless tobaccoNicotiana tabacum

The invention belongs to the field of smokeless tobacco, and particularly relates to a bacteriostatic and mildewproof agent for smokeless tobacco and a production method of the bacteriostatic and mildewproof agent. The bacteriostatic and mildewproof agent is extracted from plants with bacteriostatic and mildewproof functions; an extract is directly produced via a steam distillation method, ethanol reflux extraction method or ethanol extraction method, or produced by refining after concentration, separation and chemical treatment. By the bacteriostatic and mildewproof agent, quality safety and stability of smokeless tobacco products during storage can be effectively guaranteed, greenness and long-term effective bacteriostasis are realized in the true sense, and the bacteriostatic and mildewproof agent tastes good.

Owner:HONGTA TOBACCO GRP

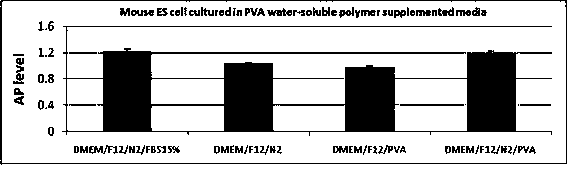

Stem cell culture medium

ActiveCN104357379AInhibition of differentiationEfficient in vitro expansionArtificially induced pluripotent cellsNon-embryonic pluripotent stem cellsWhole blood productTotipotential stem cell

The invention relates to a stem cell culture medium which contains certain chemical components as follows: water-soluble non-polyelectrolyte polymers, inorganic salts, vitamins, amino acids, glucose, transferrin, insulin or a substitute with the same functions as the insulin (the IGF-1 / 2), and a fibroblast growth factor. The stem cell culture medium containing the certain chemical components is free of additives from an animal source, namely various animal products, trophoblast cells and conditioned mediums, and has the advantages that cell differentiation resulted from non-absolute purification of the traditional culture medium blood products can be avoided; a totipotential stem cell culture medium can be provided to effectively increase human totipotential stem cells (including the hESC and the hiPSC) in vitro, achieve a remarkable effect, and substitute for the traditional culture mediums from an animal source; due to the adoption of the stem cell culture medium stem cell culture medium, the quality stability of each product batch can be ensured effectively to facilitate the product standardization.

Owner:刘兴宇

Roller coater

ActiveCN103056063AEliminate the effects ofImprove pressure detection accuracyLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention discloses a roller coater which comprises a painting roller, a roller coater rack, a solution-taking roller, a solution-taking roller rack and a roller rest pressure adjustment device, wherein the roller rest pressure adjustment device comprises an operating side bearing base, a driving side bearing base, a sliding block, a turbine worm, a pressure detection element, a handwheel, a servo motor, linearity guide rails and linearity rails. The roller coater provided by the invention achieves the technical purposes that the automatization feedback and adjustment of the roller coater are realized, and the reaction accuracy is improved. Through the roller coater disclosed by the invention, the pressure detection element contacting the spherical surface of the operating side bearing base and the spherical surface of the driving side bearing base is adopted, a signal is provided for the operation of the servo motor, the regulation and control of a roller interval are beneficial, the accuracy and consistency of the thickness of a painting film are improved, and the quality of the painting film of the surface of a steel band and quality stability are guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

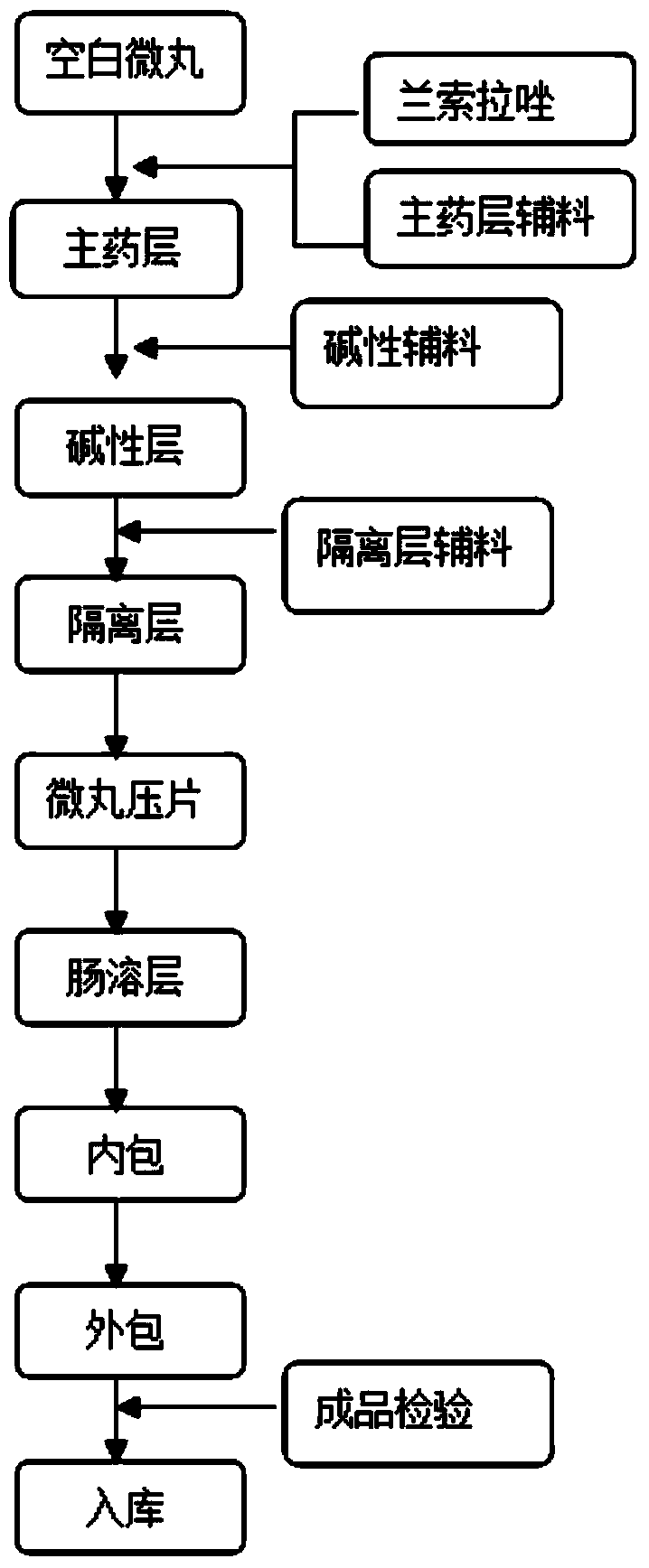

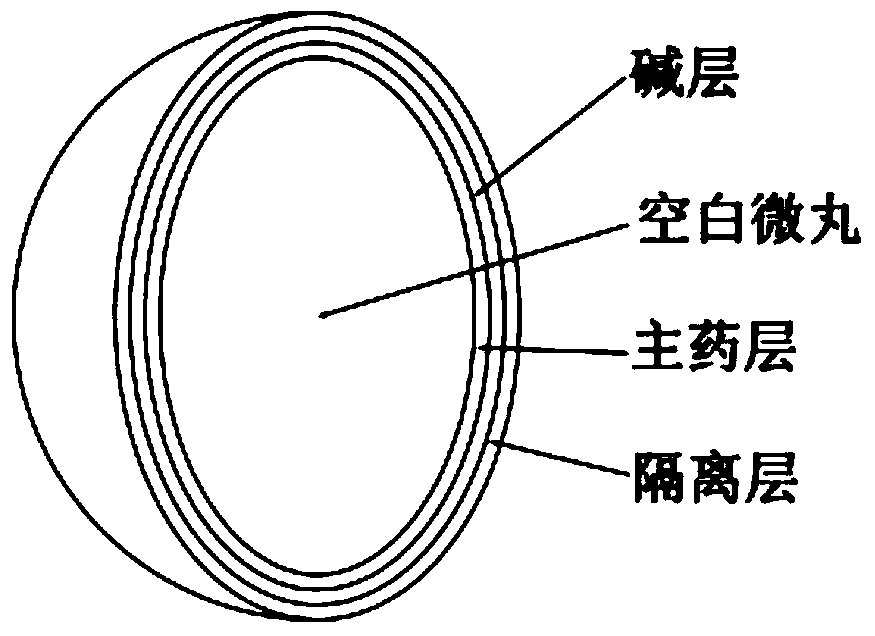

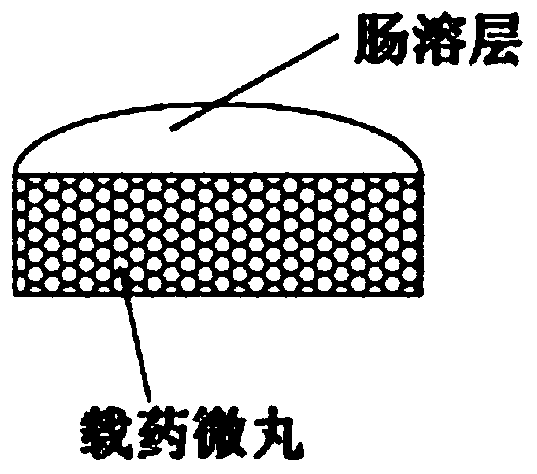

Stable, uniform and efficient lansoprazole enteric-coated tablets and preparation method thereof

ActiveCN103705483AGood content uniformityEasy to operateAntibacterial agentsOrganic active ingredientsMedicineIsolation layer

The invention discloses stable, uniform and efficient lansoprazole enteric-coated tablets and a preparation method thereof. Each enteric-coated tablet comprises a main medicament layer, an alkaline layer, an isolation layer and an enteric coated layer from inside to outside. The enteric-coated tablets are characterized in that a pellet drug loading and pellet tabletting coating technology is adopted to perform coated pellet tabletting so as to ensure that each pellet forms an integral drug release unit. The lansoprazole enteric-coated tablets disclosed by the invention are simple in preparation process, large in production volume, good in quality controllability, stable in product quality, high in release speed, good in homogeneity and high in bioavailability, and are suitable for industrial mass production.

Owner:湖北潜龙药业有限公司

Full-automatic charging-discharging system for spinning roller grinding machine

InactiveCN101612714ASmooth slidingImprove stabilityRevolution surface grinding machinesGripping headsEngineeringManipulator

The invention discloses a full-automatic charging-discharging system for a spinning roller grinding machine. The full-automatic charging-discharging system comprises a charging device, a feeding device, a gripping device, a grinding device, a discharging device and a storing device, wherein the charging device comprises an S-shaped slide way and an order blanking mechanism which is arranged on the lower end of the S-shaped slide way; the feeding device comprises a supporting platform provided with a chute, and a horizontal feeding cylinder; and the gripping device comprises a manipulator. Compared with the prior art, the full-automatic charging-discharging system has the advantages that: because the charging device is provided with the S-shaped slide way, the smooth slide-down of a rubber roller is ensured, the storing capacity is increased and reaches 80, and the one-time storing time is 1.5h; when the rubber roller is moved from the charging device to the gripping device, by changing the moving direction, the rubber roller is changed from slide-down to transverse movement, so that the moving stability of a workpiece is improved; the strong manipulator is used for gripping the rubber roller, and the precision of the repeated positioning is high, and the acted grinding force is big; and the system and the grinding machine can be assembled and disassembled conveniently.

Owner:安徽尚美电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com