Double-shell microcapsule and its preparation method and use

A microcapsule and double-shell technology, which is applied in the field of double-shell microcapsules and its preparation, can solve the problems of unsatisfactory mechanical properties and tolerance of microcapsules, difficult step release, unfavorable long-term storage, etc., to achieve sustained and stable slow release Good effect, good mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

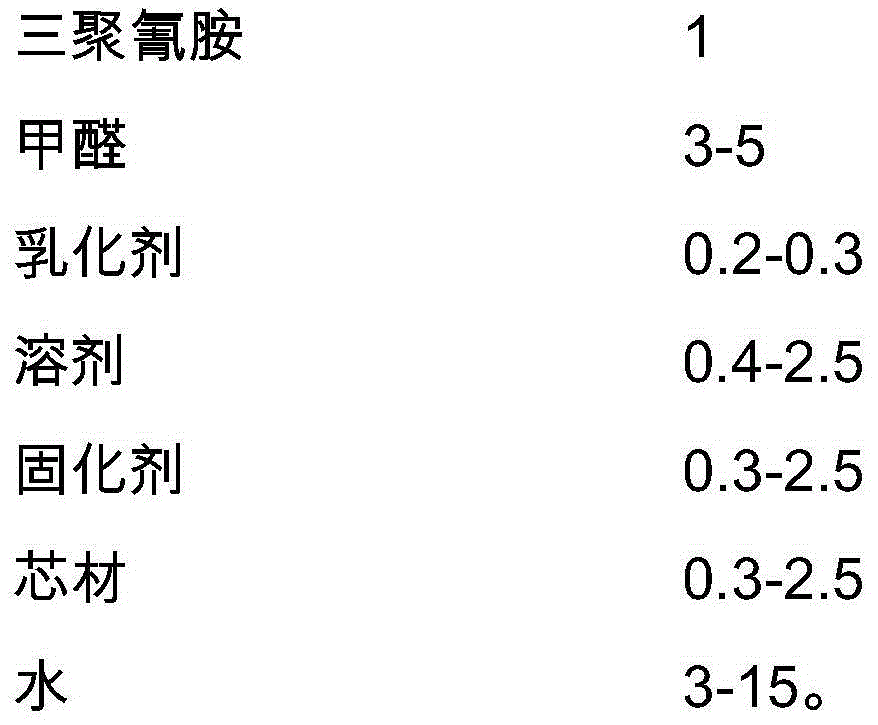

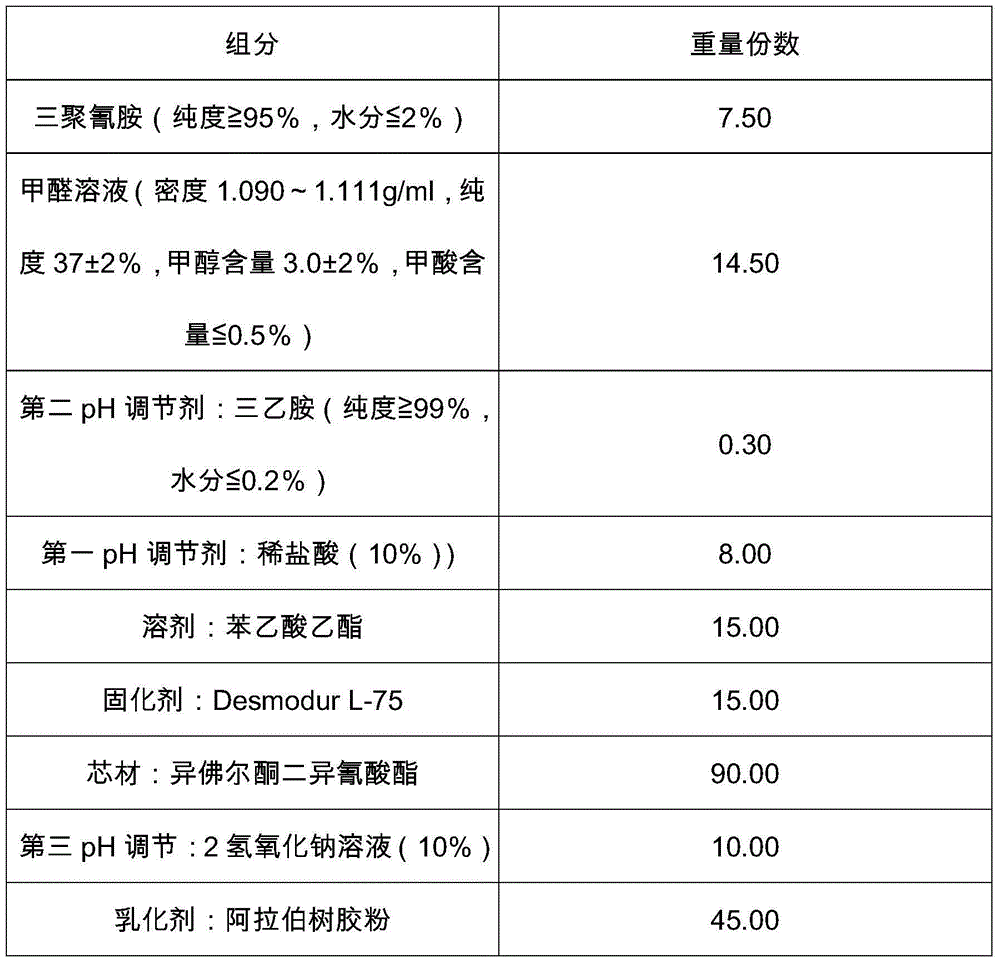

[0038] The raw material formulation of the double-shell microcapsules used in the self-healing adhesive is shown in the table below.

[0039]

[0040] The preparation method of double-shell microcapsules is made by the following steps:

[0041] (1) Preparation of melamine-formaldehyde prepolymer

[0042] Weigh melamine and formaldehyde solution according to the formula, (add melamine first and then add formaldehyde) in a three-necked flask and stir and mix, add an appropriate amount of the second pH regulator triethylamine to adjust the pH of the system to 8-9, and mix the melamine-formaldehyde solution at 65 Heat and stir in a water bath at ℃, the system becomes transparent after about 10 minutes, add distilled water of the same quality as the formaldehyde solution, and continue the reaction for 50 minutes to obtain a transparent low molecular weight water-soluble melamine-formaldehyde prepolymer;

[0043] (2) Preparation of melamine-formaldehyde polyurea resin double-shell...

Embodiment 2

[0046] A self-repairing epoxy adhesive, which is made of the following components in parts by weight,

[0047] components

parts by weight

E-44 epoxy resin

100

9

11

double shell microcapsules

4.8-10

[0048] Wherein, the E-44 epoxy resin is a product produced by Jinan Resin Chemical Co., Ltd.

[0049] The preparation method of the self-repairing epoxy adhesive is to mix and disperse the components according to the above formula. After testing (detection method and standard according to national regulations), it can be seen that adding double-shell microcapsules by 4.8 parts by weight can improve the tensile strength of the cured product by 40% after slight damage; adding double-shell microcapsules by 8 parts by weight Capsules can increase the tensile strength of cured products by 80% after slight damage.

Embodiment 3

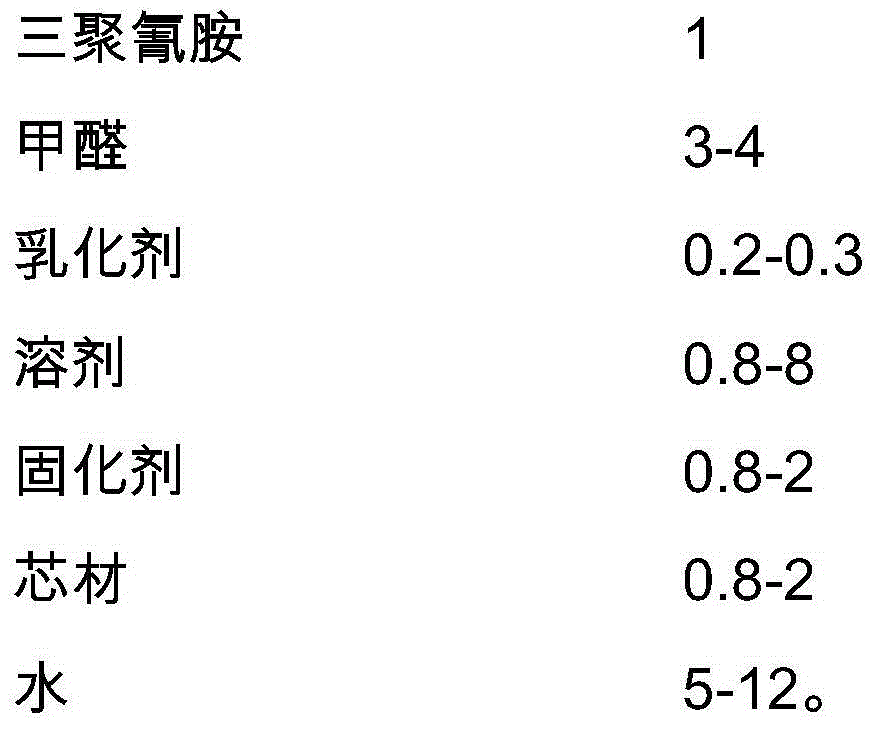

[0051] The formula of double-shell microcapsules for food or cosmetic additives is as follows:

[0052]

[0053] The preparation method of double-shell microcapsules is made by the following steps:

[0054] (1) Preparation of melamine-formaldehyde prepolymer

[0055] Weigh melamine and formaldehyde solution according to the formula, (add melamine first and then add formaldehyde) in a three-necked flask and stir and mix, add an appropriate amount of the second pH regulator triethylamine to adjust the pH of the system to 8-9, and mix the melamine-formaldehyde solution at 65 Heat and stir in a water bath at ~70°C. After about 10 minutes, the system becomes transparent. Add distilled water of the same quality as the formaldehyde solution and continue the reaction for 50 minutes to obtain a transparent and low-molecular-weight water-soluble melamine-formaldehyde prepolymer;

[0056] (2) The preparation process of melamine-formaldehyde polyurea resin double-shell microcapsules: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com