Patents

Literature

1303 results about "Epoxy adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for applying a streamable epoxy adhesive

InactiveUS20050070634A1Low viscosityHigh strength bondAdhesive processes with adhesive heatingEpoxy resin adhesivesBENZYL ALCOHOL/WATERViscosity

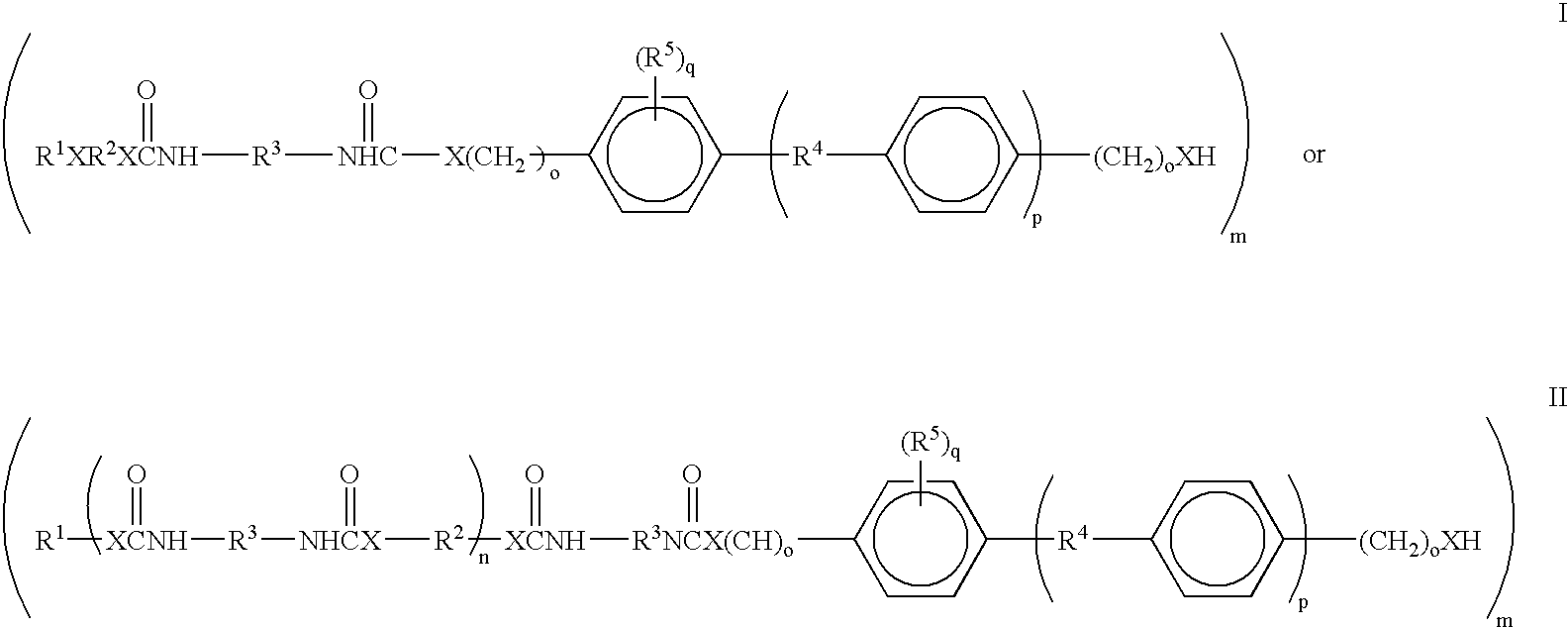

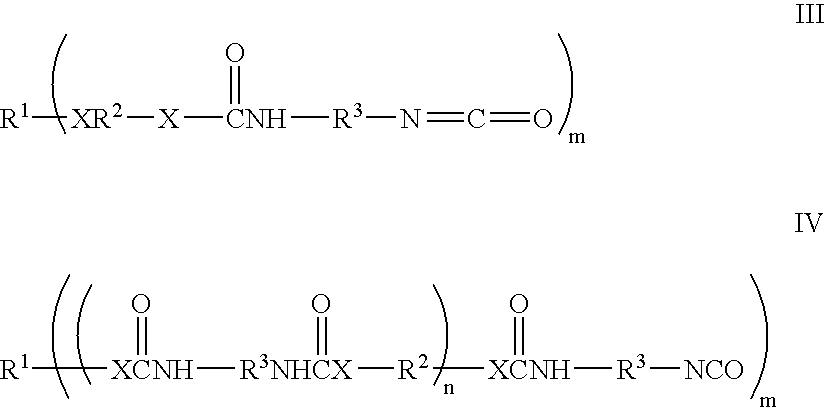

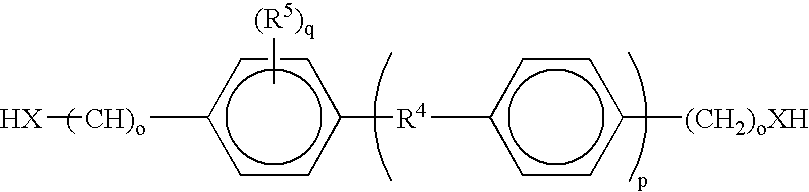

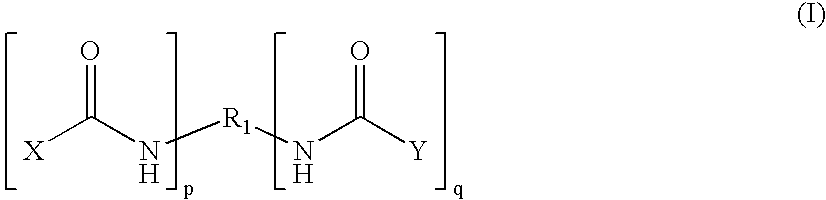

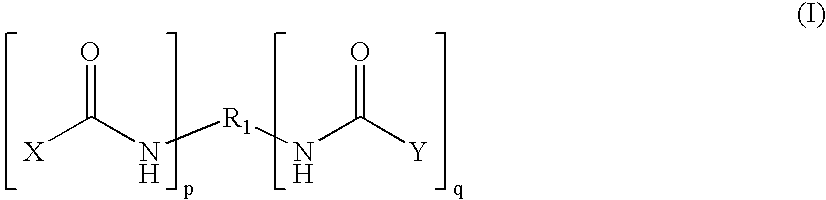

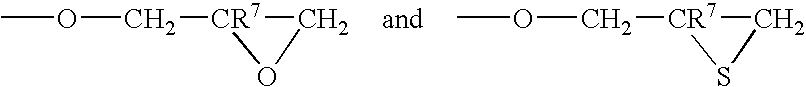

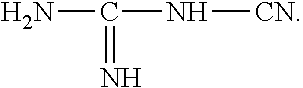

The invention is a composition comprising applying to a substrate a stream of an adhesive comprising: one or more epoxy resins; one or more rubber modified epoxy resins; one or more toughening compositions comprising the reaction product of one or more isocyanate terminated prepolymers and one or more capping compounds having one or more phenolic, benzyl alcohol, aminophenyl, or, benzylamino groups wherein the reaction product is terminated with the capping compounds; one or more curing agents for epoxy resins and one or more catalysts which initiate cure at a temperature of about 100° C. or greater; and optionally; fillers adhesion promoters, wetting agents or rheological additives useful in epoxy adhesive compositions; wherein the adhesive composition has a viscosity at 45° C. of about 20 Pa.s to about 400 Pa.s. The composition can be used as an adhesive and applied as a stream using a high speed streaming process.

Owner:DOW GLOBAL TECH LLC

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Toughened epoxy adhesive composition

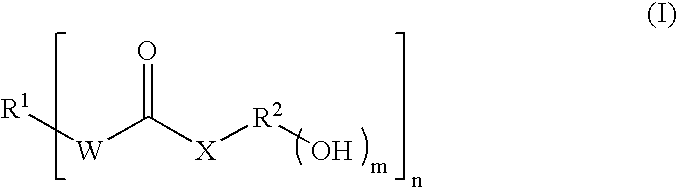

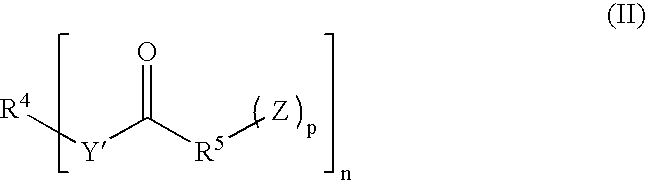

ActiveUS20060276601A1Improved lap shear and impact peel strengthGood storage stabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsElastomerEnd-group

The invention is an epoxy resin based adhesive composition comprising an epoxy resin and a compound comprising an elastomeric prepolymer residue selected from the group of a polyurethane, a polyurea and a polyurea polyurethane having isocyanate end groups, the isocyanate end groups of said prepolymer residue being capped by a capping compound selected from the group consisting of a primary aliphatic, cycloaliphatic, heteroaromatic and araliphatic amine, a secondary aliphatic, cycloaliphatic, aromatic, heteroaromatic and araliphatic amine, a thiol and an alkyl amide, said capping compound being bound to the end of the polymer chain of the elastomeric prepolymer in a manner such that the end to which it is bonded no longer has a reactive group. In addition to the capping compound defined above above, a capping compound selected from the group consisting of a phenol and a polyphenol can be used for capping the isocyanate end groups of the prepolymer residue

Owner:DOW GLOBAL TECH LLC

Toughened epoxy adhesive composition

ActiveUS20050209401A1High impact strengthImprove crash resistanceMacromolecular adhesive additivesEpoxy resin adhesivesAcrylonitrileEpoxy adhesive

The invention relates to an epoxy adhesive composition comprising a) a first epoxy resin, b) a second epoxy resin modified with an acrylonitrile-butadiene rubber, the latter comprising on average less than about 25 weight percent acrylonitrile, and c) a toughener. The total amount of component b) and component c) is higher than about 30 percent based on the total weight of the composition, and the weight ratio of component c) to component b) is greater than about 1:1. The invention further relates to the use of said epoxy adhesive composition for the assembly of parts of a vehicle. It also relates to a vehicle, parts of which are assembled by said epoxy adhesive composition.

Owner:DOW GLOBAL TECH LLC

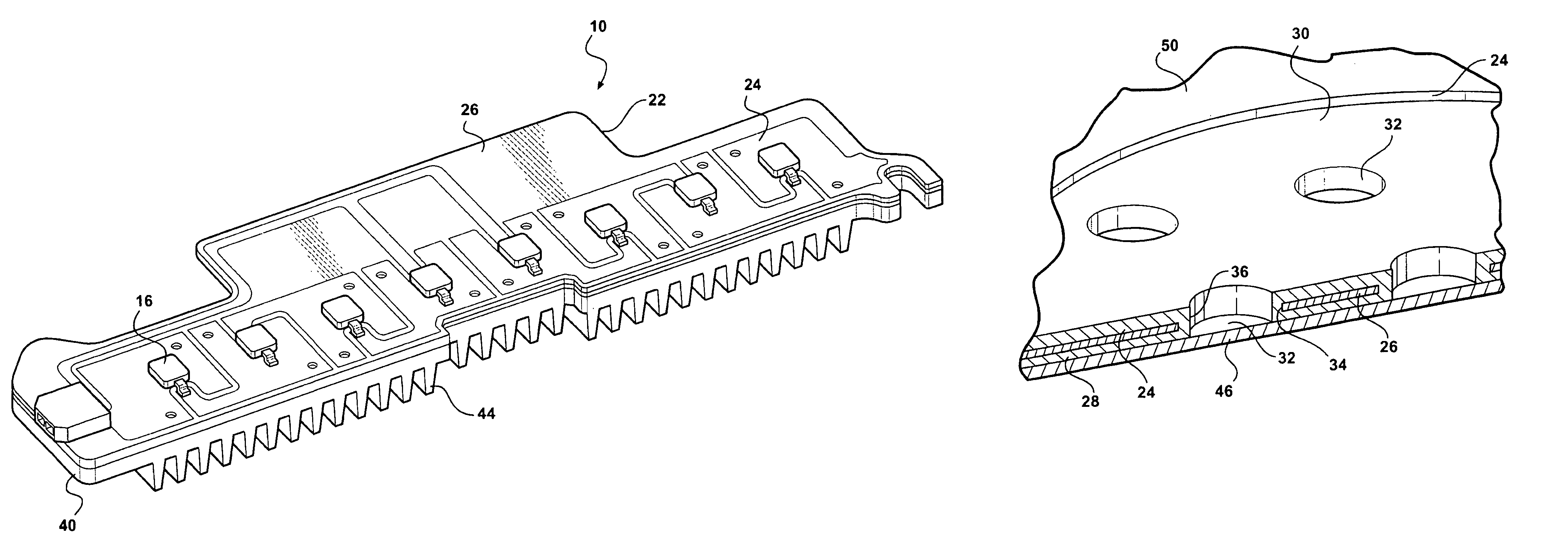

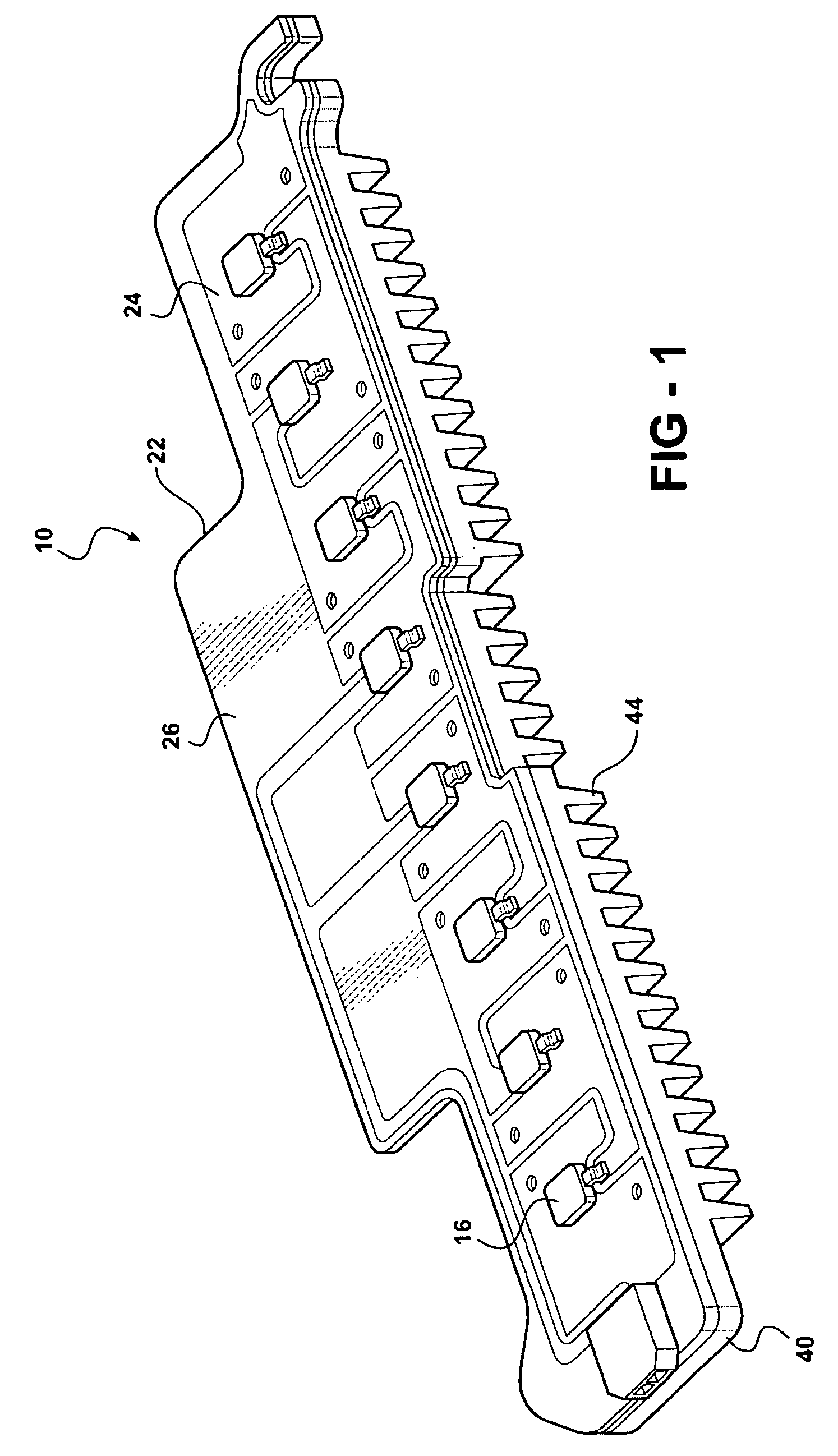

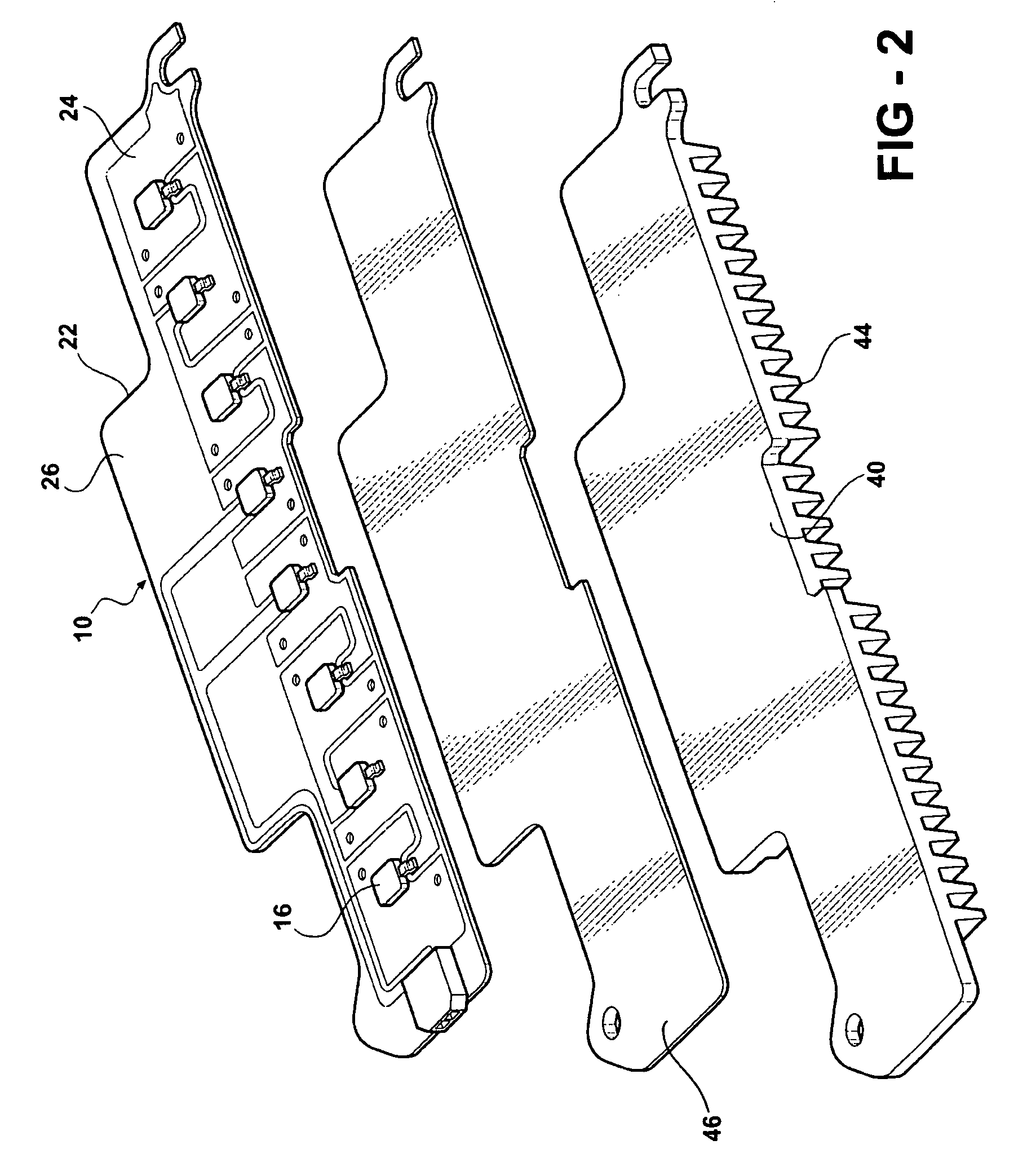

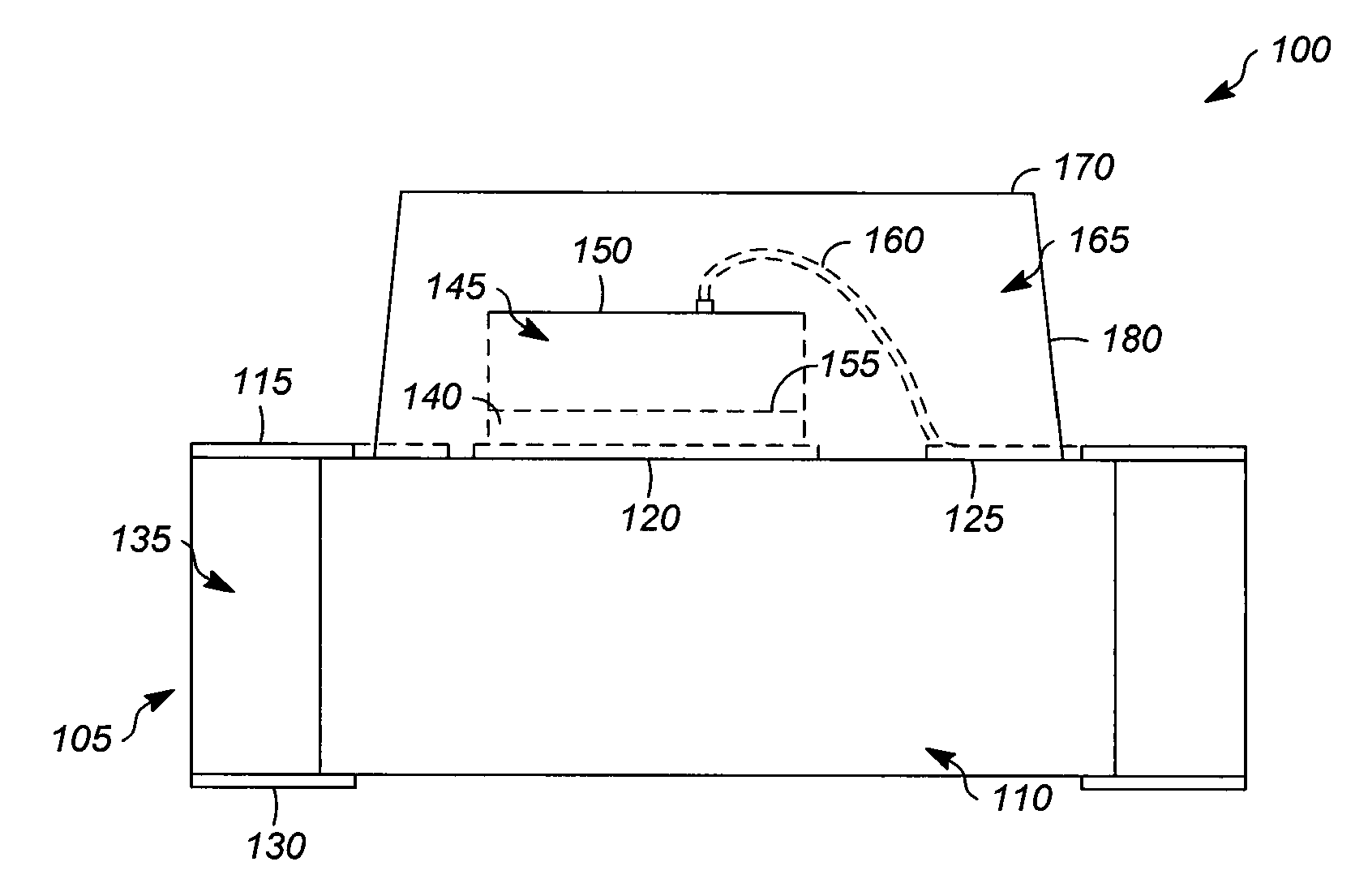

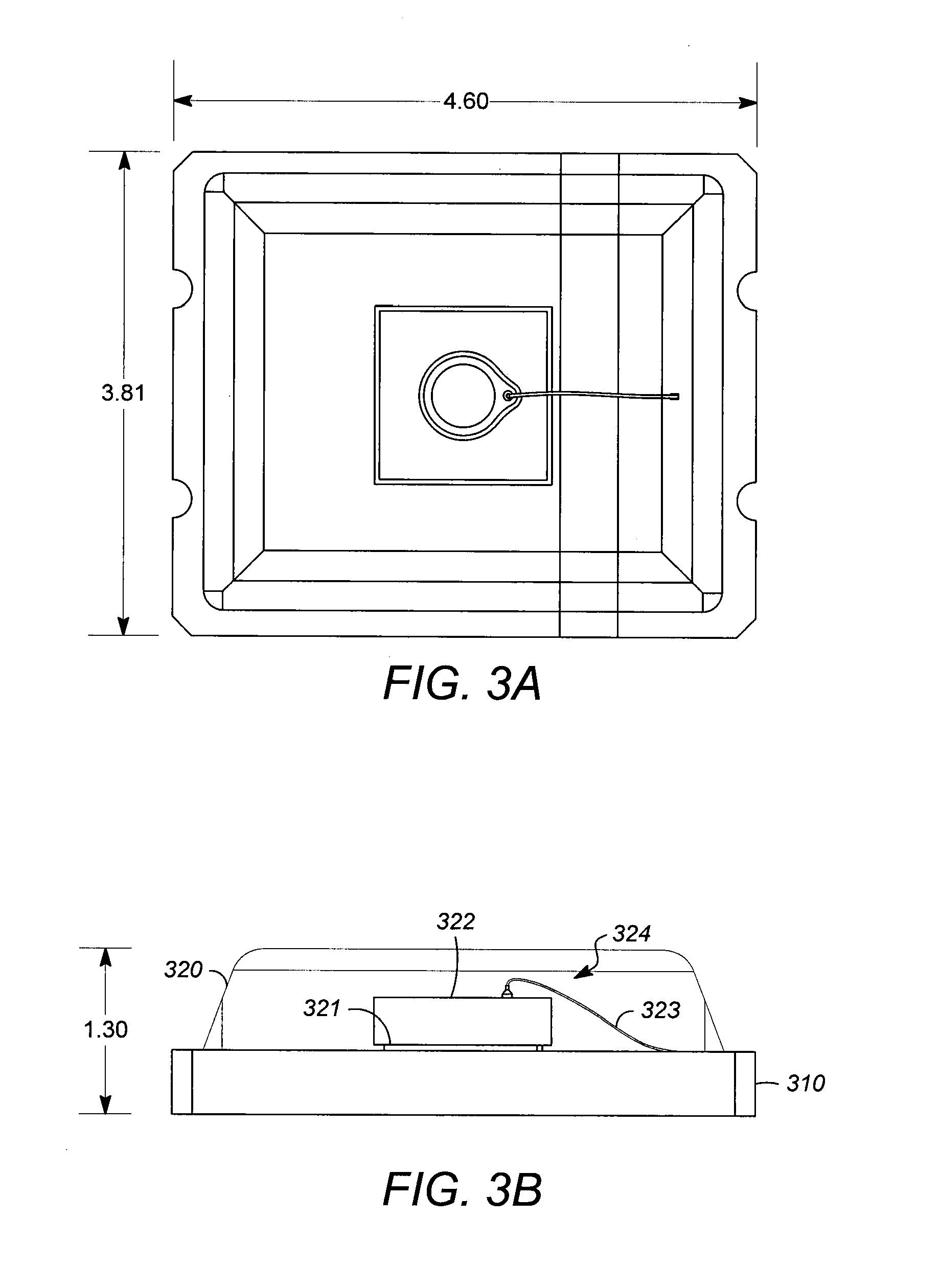

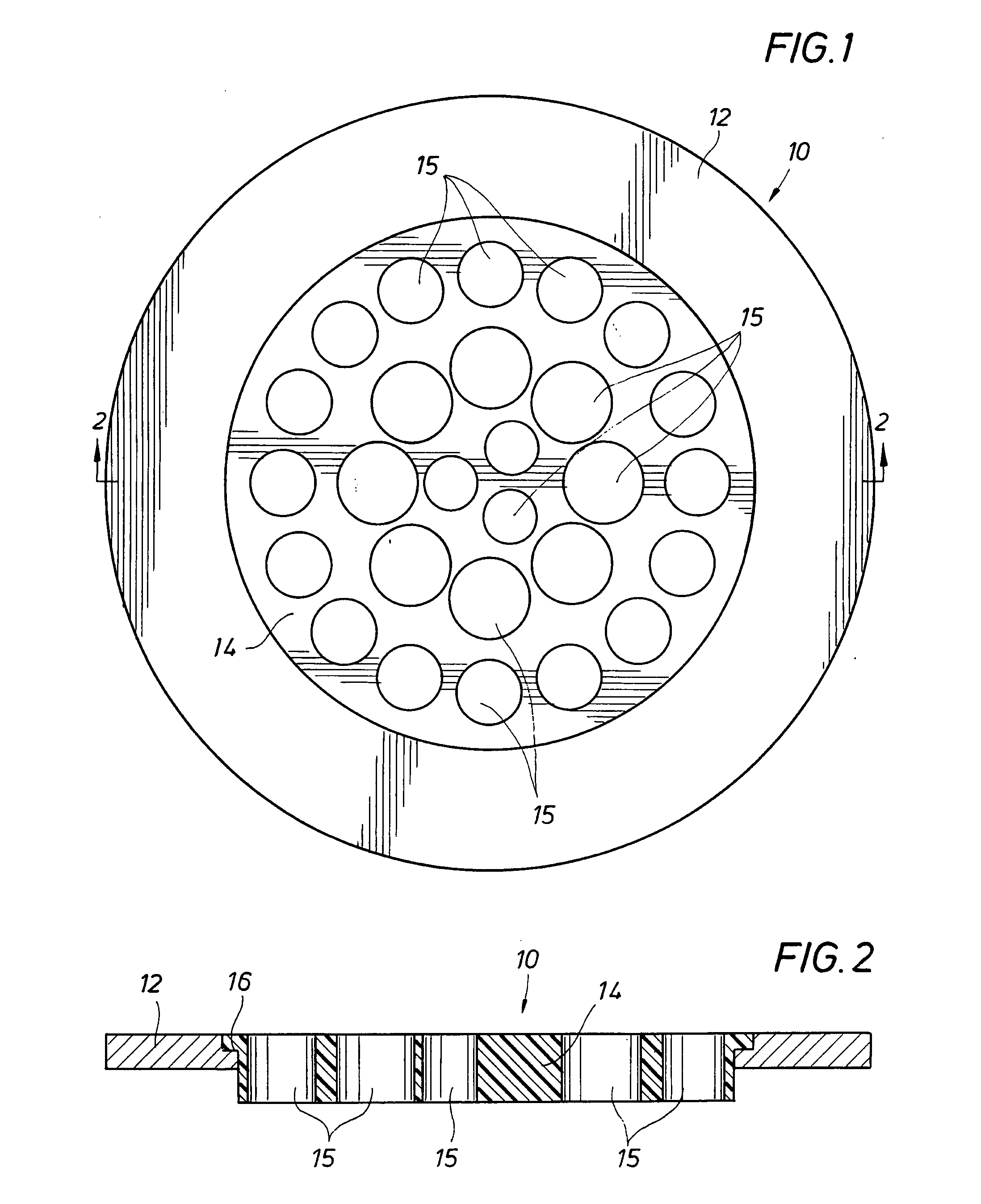

LED light module assembly

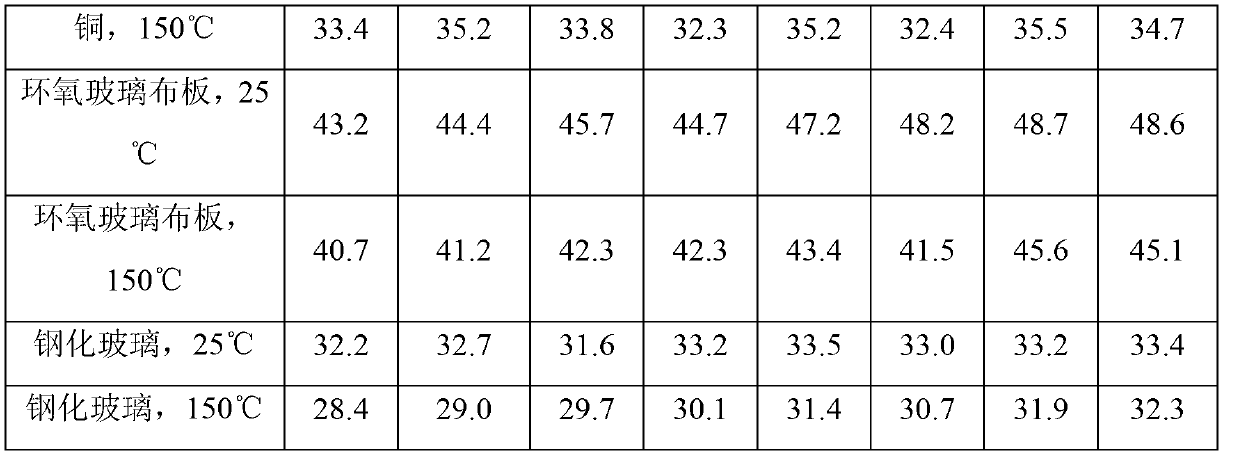

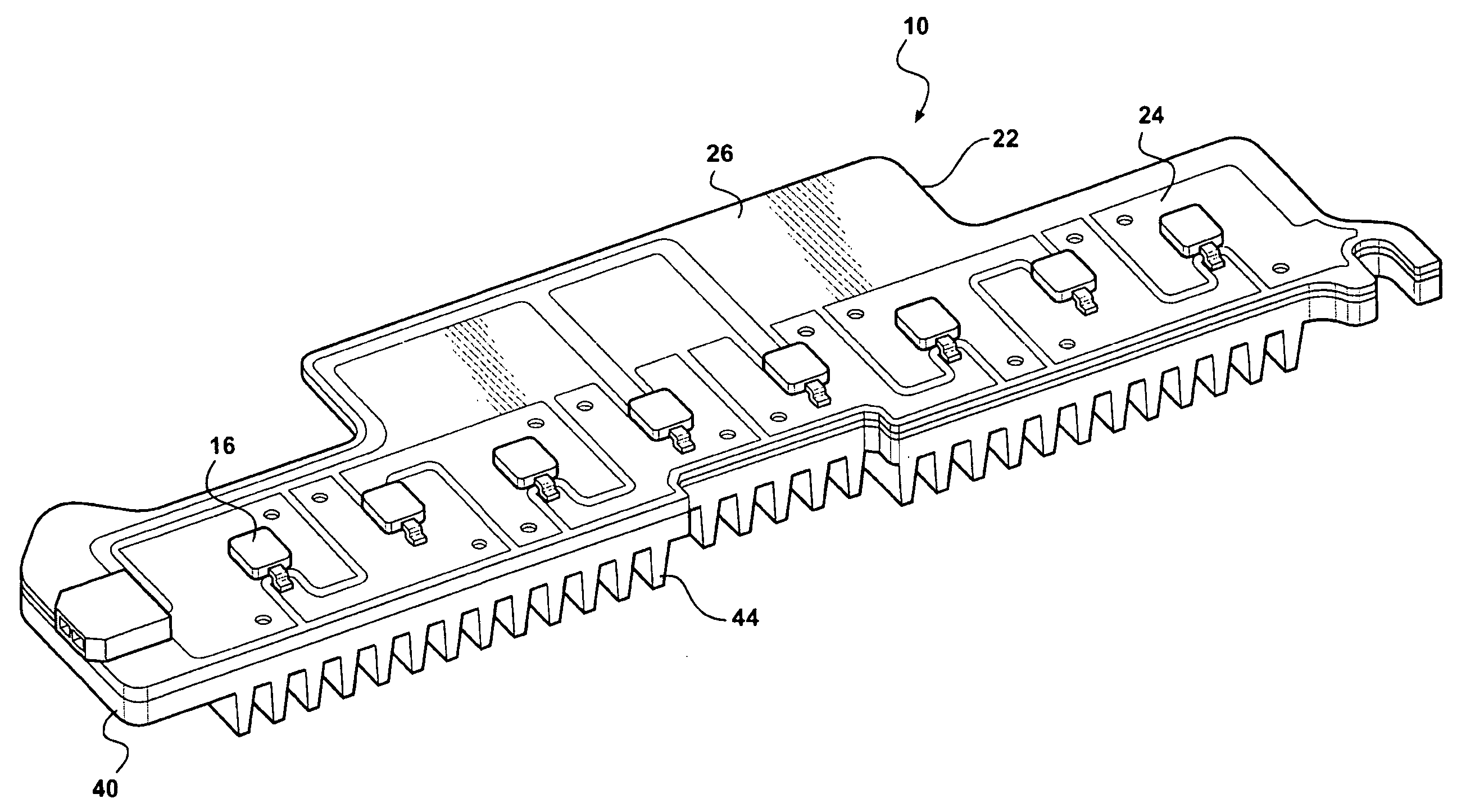

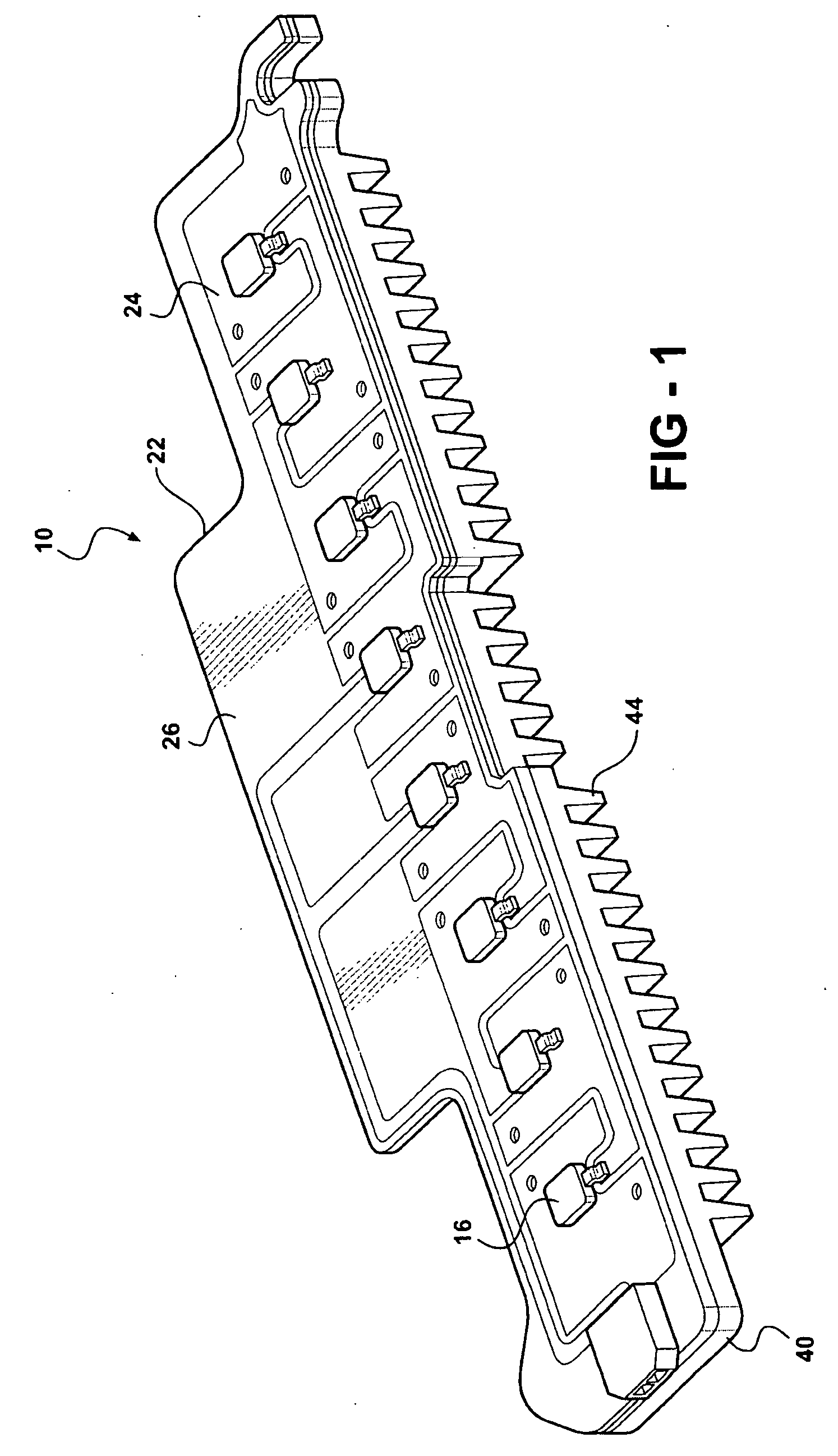

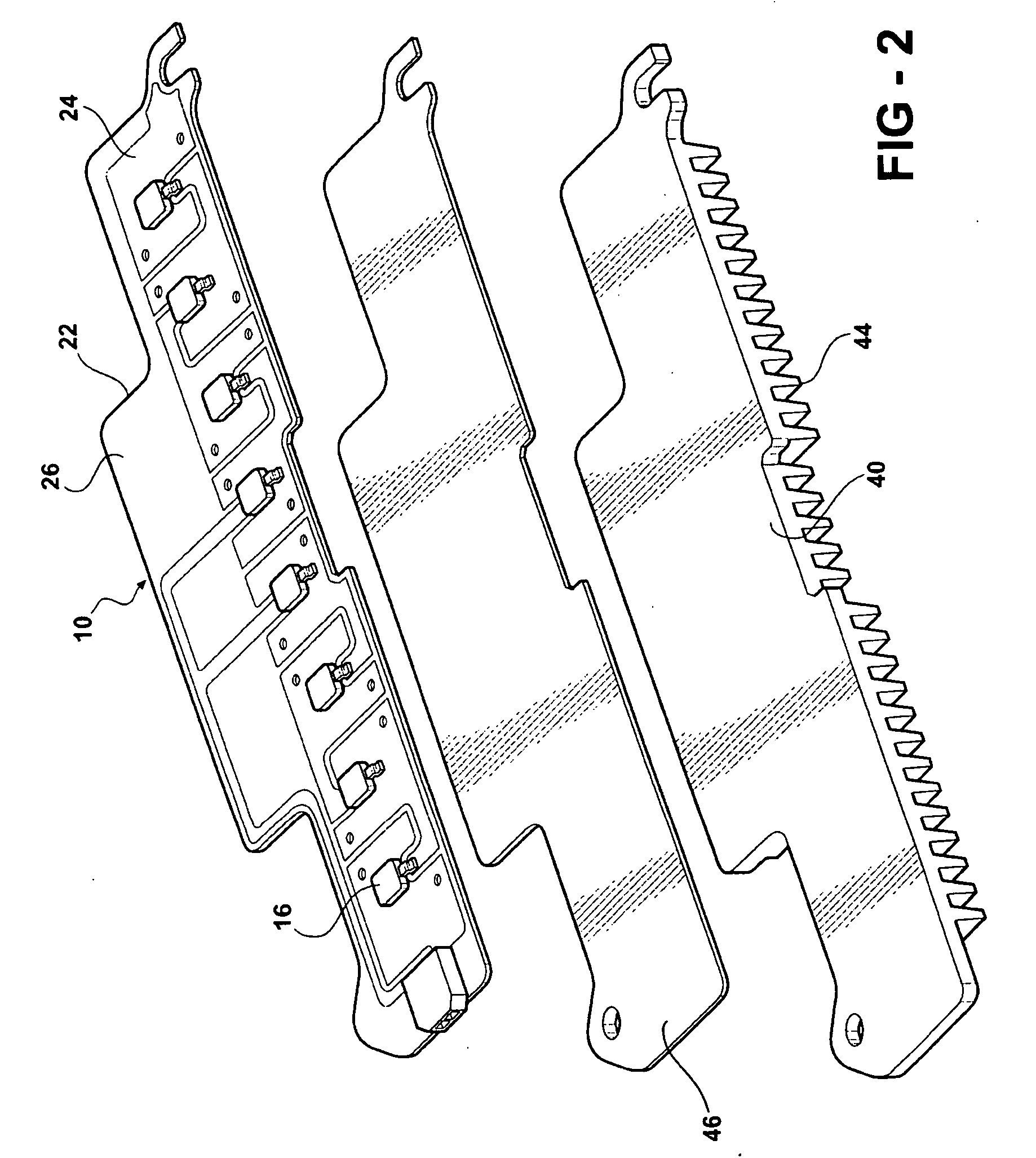

ActiveUS20060181878A1Point-like light sourceLighting heating/cooling arrangementsSurface mountingFlexible circuits

An LED light module assembly for use with high power, high light output LED's includes a thin flexible circuit board with surface mounted LED's and other electronic components which is attached to a metal heat sink using a layer of a thermally conductive adhesive, such as a thermally conductive epoxy adhesive. A conduction path is provided from the LED carrier through the flexible circuit board by the incorporation of one or more thermally conductive vias in the region of the attachment pad used to bond the LED to the flexible circuit board. These vias provide a conduction path from the back side of the LED carrier through the circuit board to the thermally conductive adhesive and heat sink. The LED light module assembly has the capacity to dissipate between about 10-14 W of power without exceeding a maximum LED junction temperature of about 125° C.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Manufacturing method for semiconductor device

InactiveUS20050009313A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

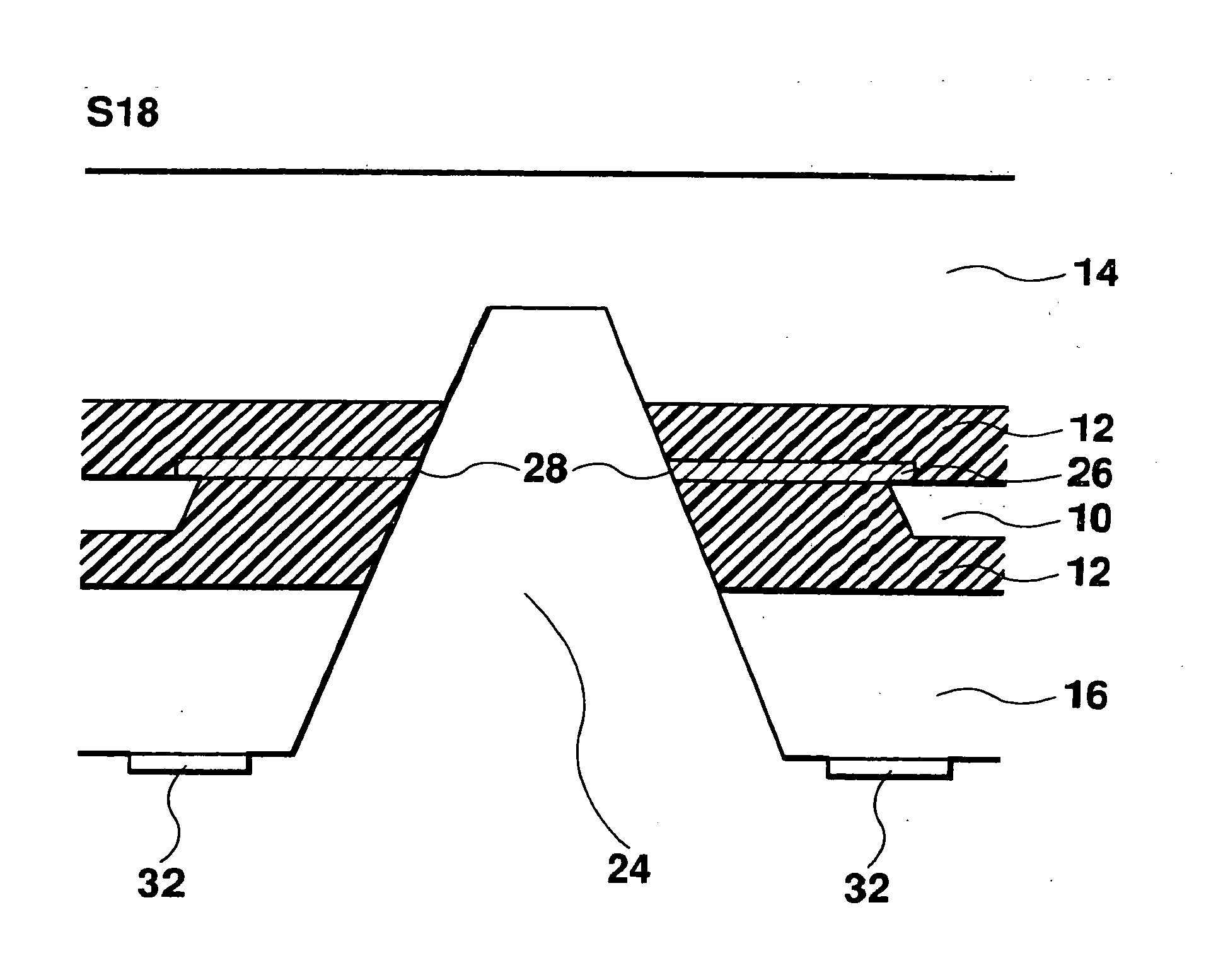

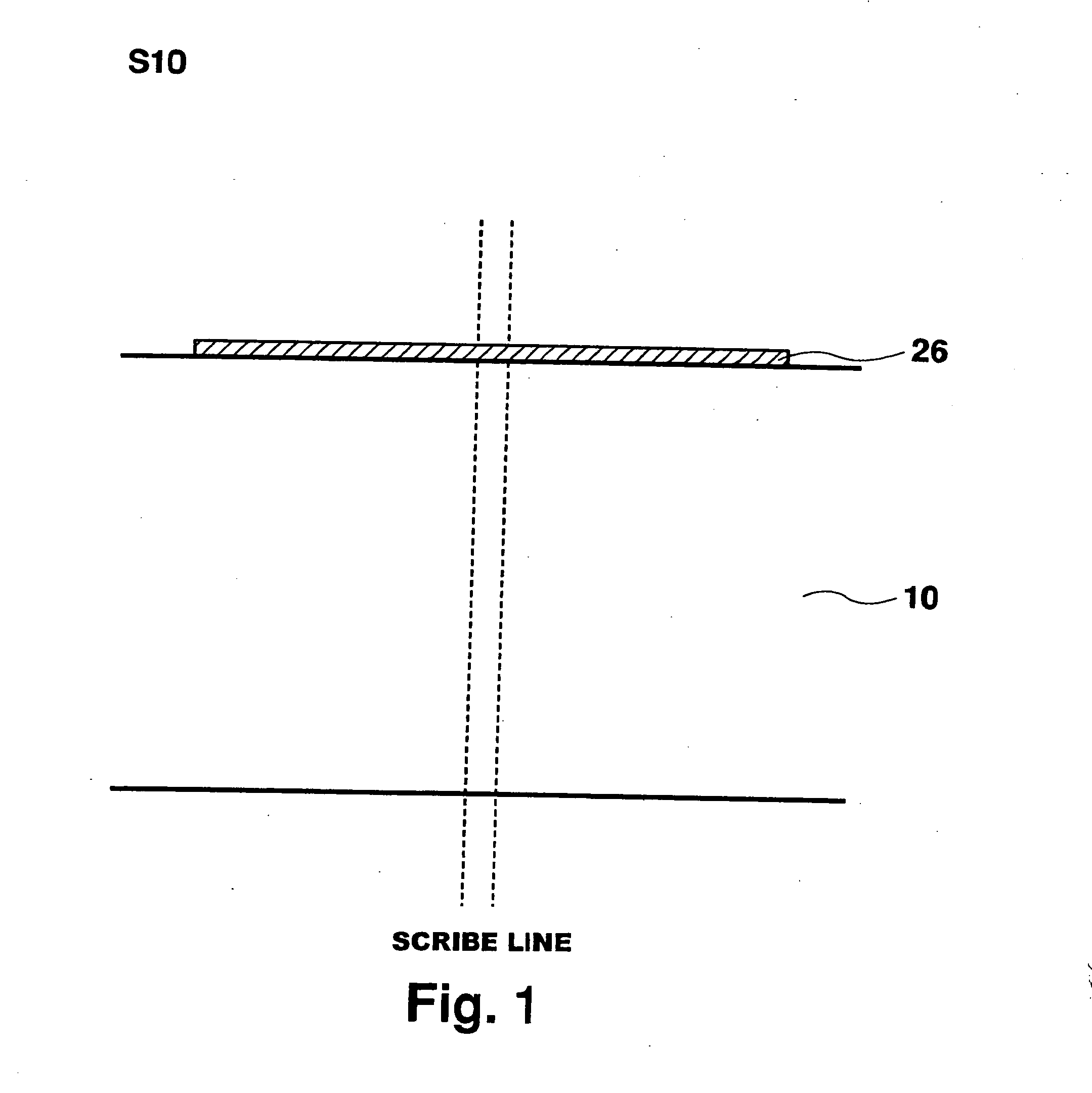

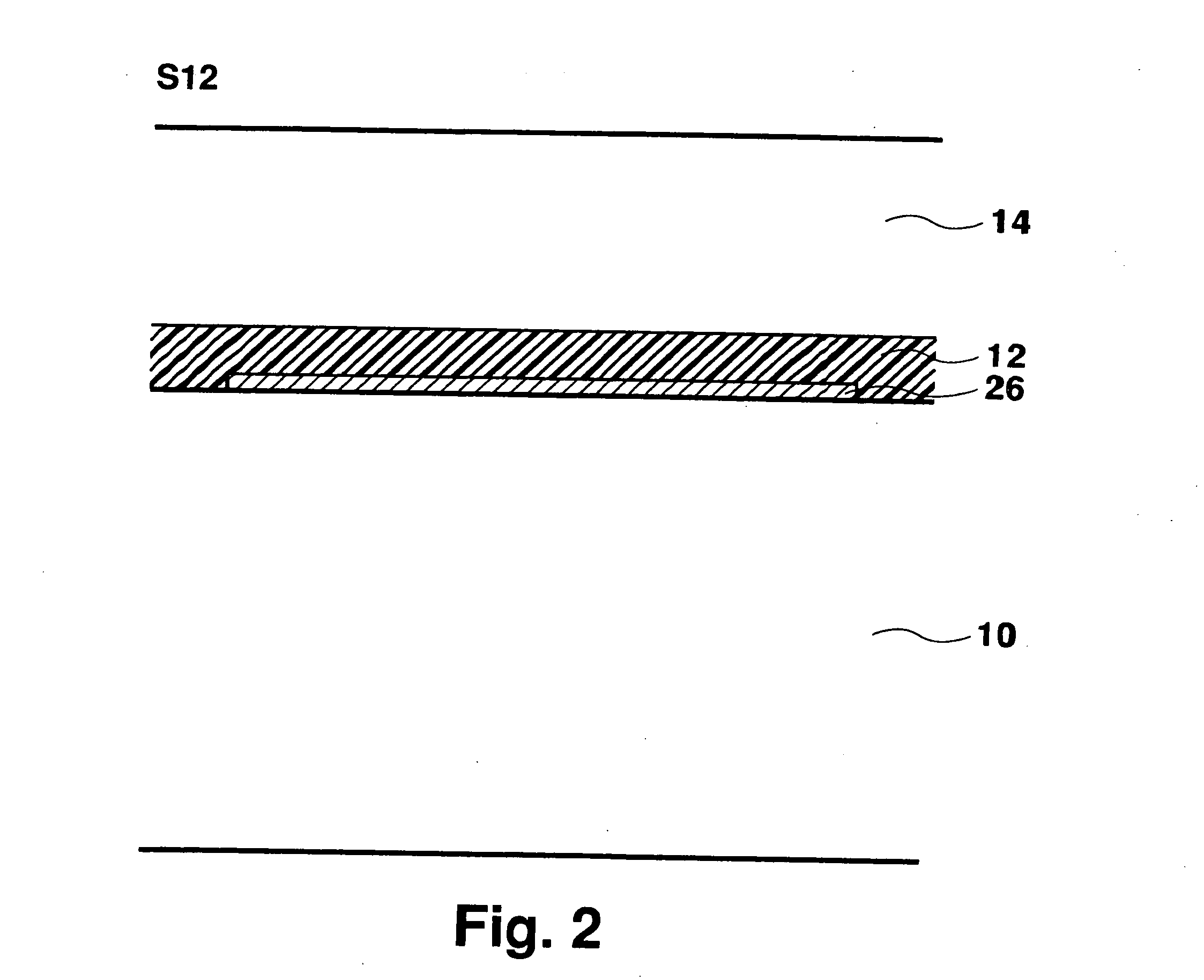

An internal wire is formed via an oxide film on the front surface of a semiconductor substrate so as to extend toward the boundary relative to an adjacent integrated circuit region. An upper supporting base is fixedly formed on the front surface of the semiconductor substrate by means of a resin layer of epoxy adhesive or the like, and a lower supporting base is fixedly formed on the back surface of the semiconductor substrate by means of a resin layer of epoxy adhesive or the like, whereby a laminated body is formed. The resin layer and the internal wire are partially removed, leaving a portion of the laminated body, to thereby form an inverted-V shaped groove (a cut-off groove) where a part of the internal wire is exposed to the outside. Thereafter, the resulting cut-off groove is exposed to plasma atmosphere to thereby dissolve, and thus remove, any remaining resin fragments attached to the exposed end portion of the internal wire.

Owner:SANYO ELECTRIC CO LTD

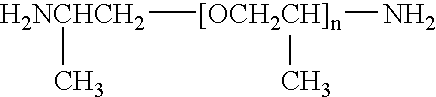

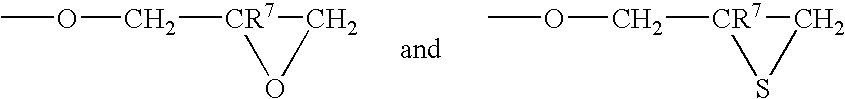

Epoxy adhesive having improved impact resistance

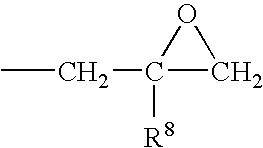

InactiveUS20030196753A1Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyphenolExpandable microsphere

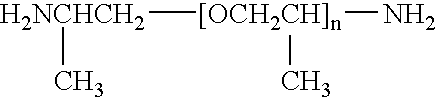

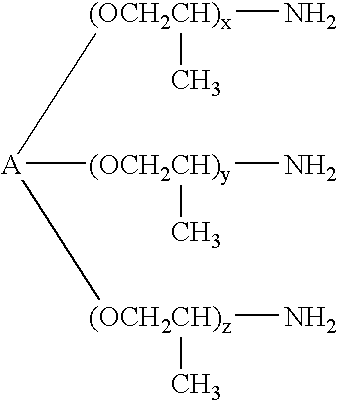

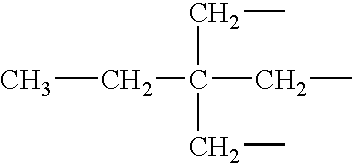

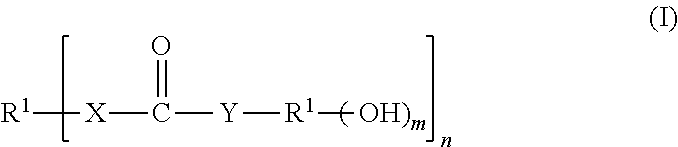

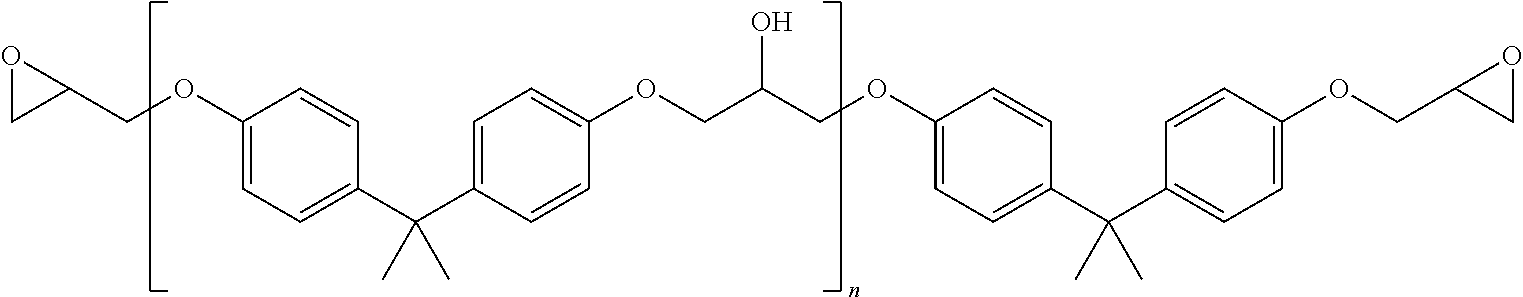

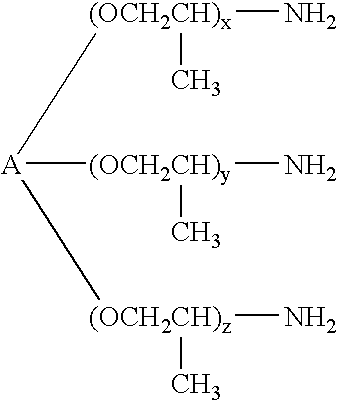

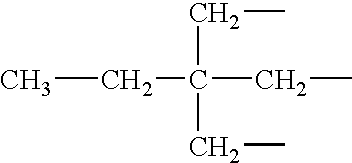

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Accelerated and toughened two part epoxy adhesives

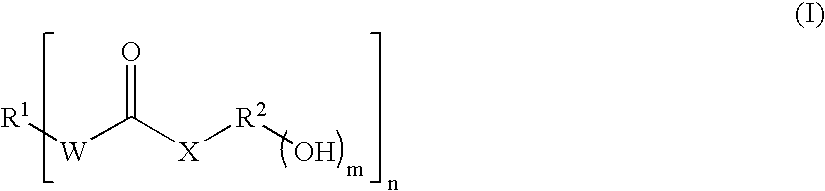

InactiveUS20150184039A1High dynamic impact peel strengthFast curing timeMacromolecular adhesive additivesEpoxy resin adhesivesFiberGlass fiber

A 2K epoxy adhesive is provided that has rapid cure time and good strength characteristics. Both the epoxy resin composition and the hardener composition of the 2K epoxy comprise a reactive toughener. Such adhesives are useful in the manufacture and / or repair of large machinery (e.g., automobiles), and are useful for bonding like or unlike materials, such as metal and composites (e.g., carbon fiber or glass fiber composites).

Owner:DOW GLOBAL TECH LLC

Structural modified epoxy adhesive compositions

InactiveUS20020164485A1Reduce opening timeGood substrate adhesionSynthetic resin layered productsThin material handlingSilanesFirming agent

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

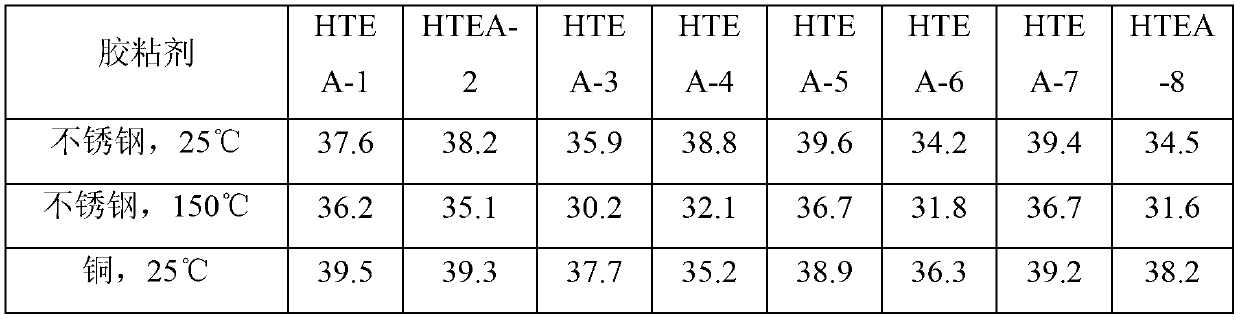

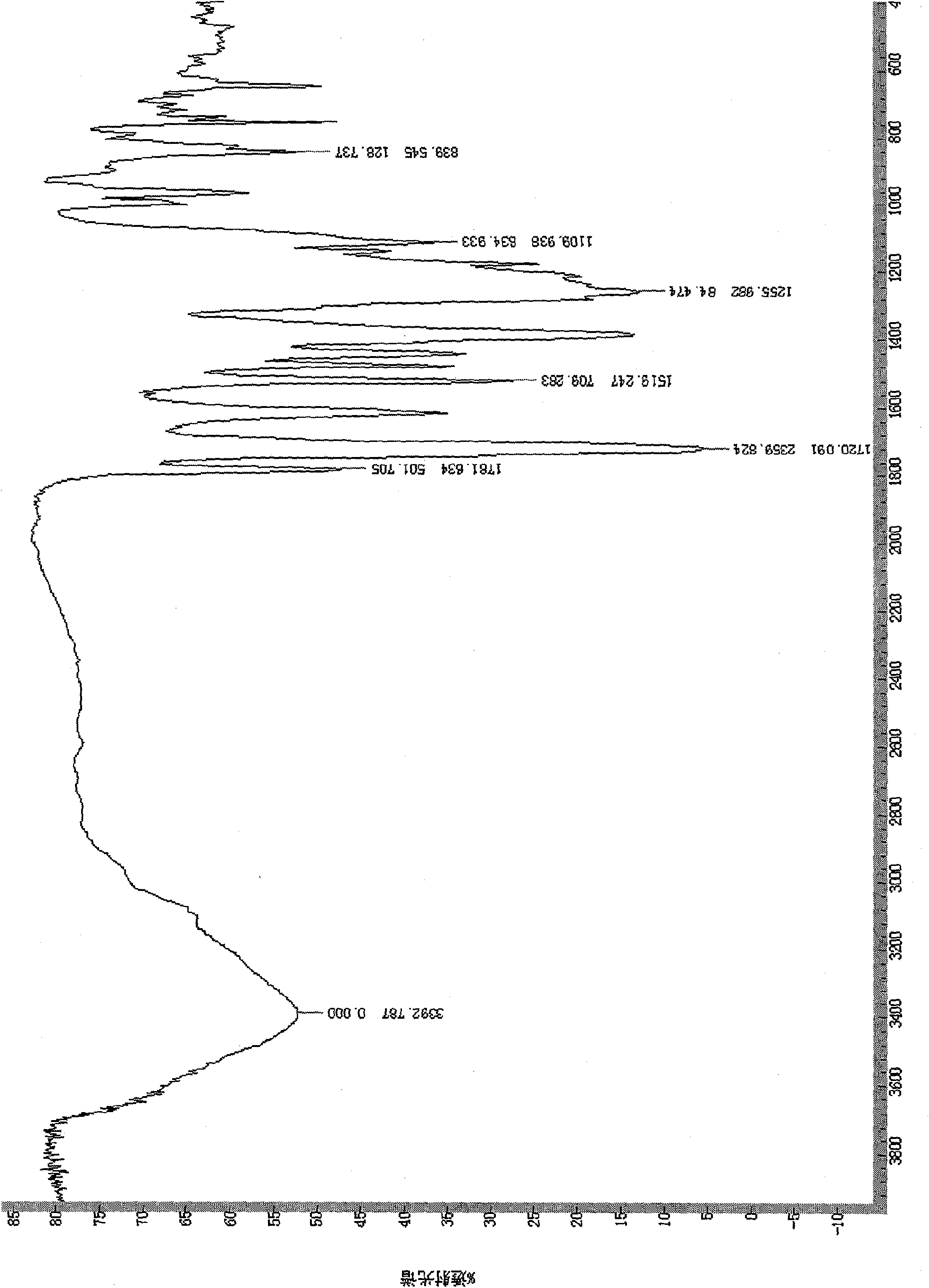

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

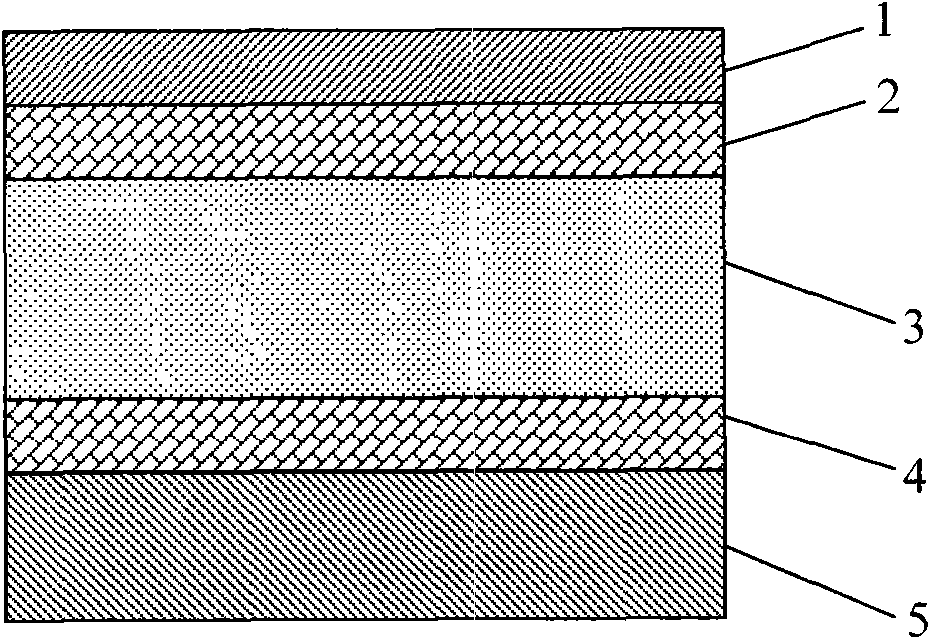

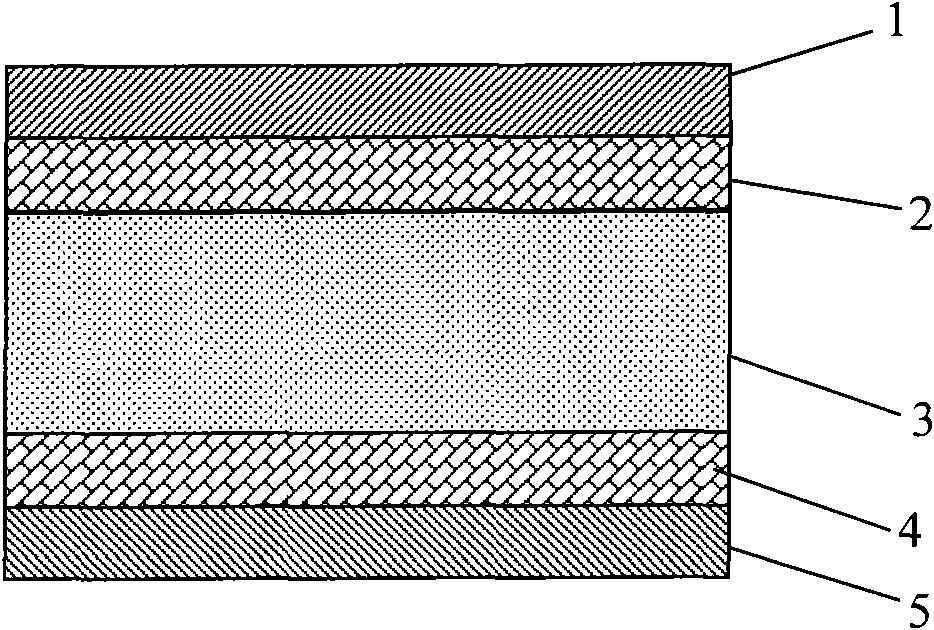

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

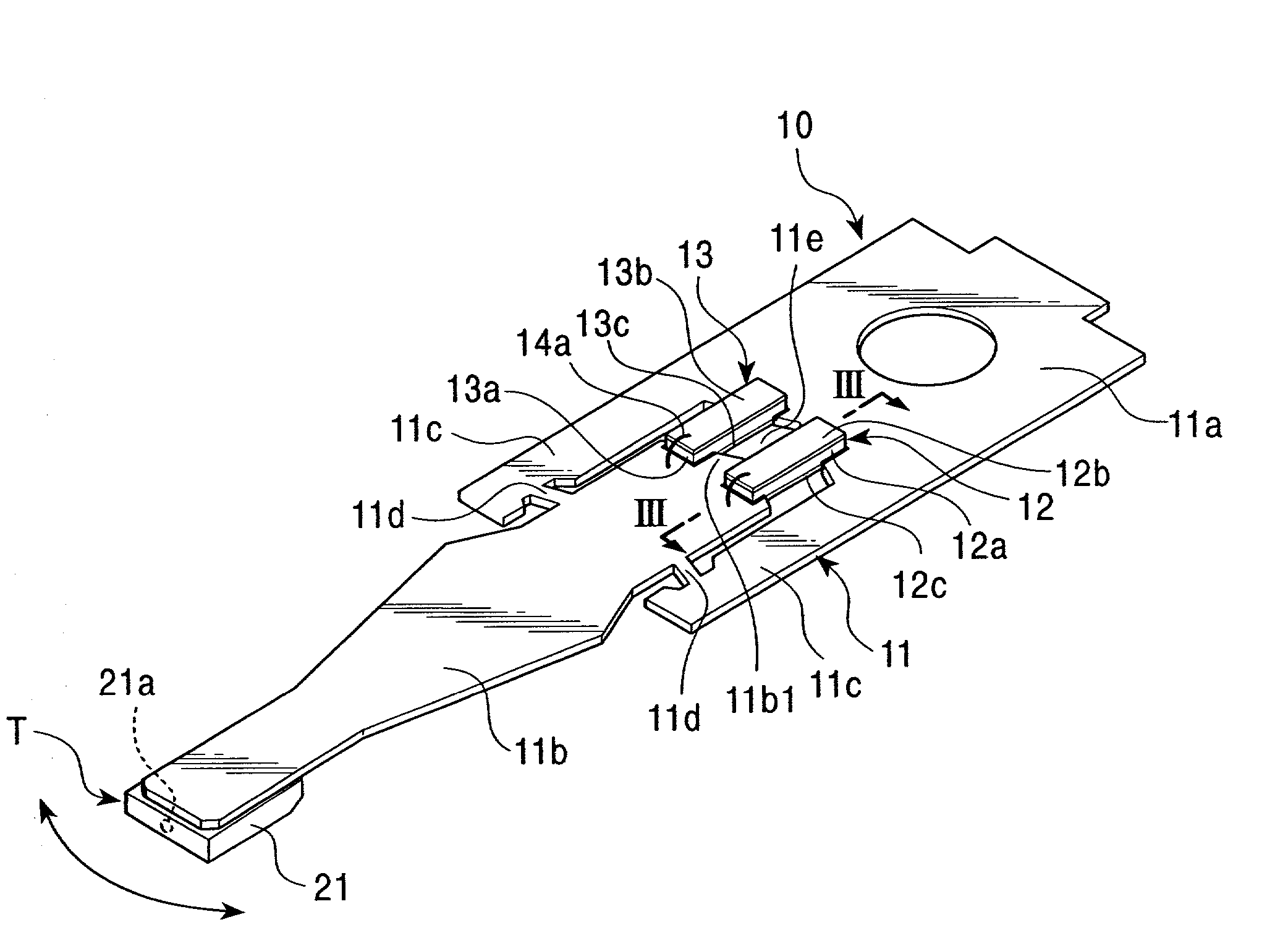

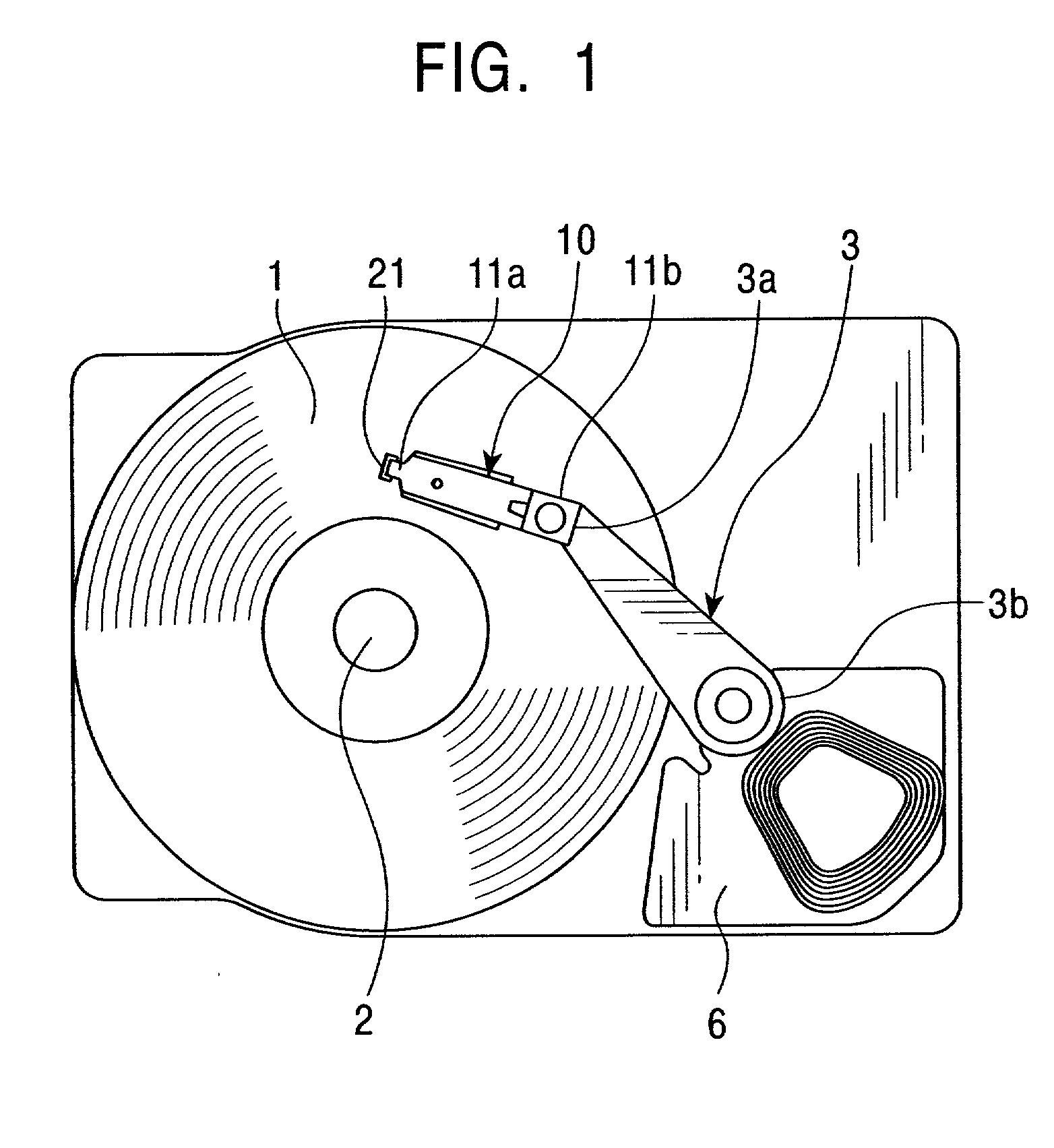

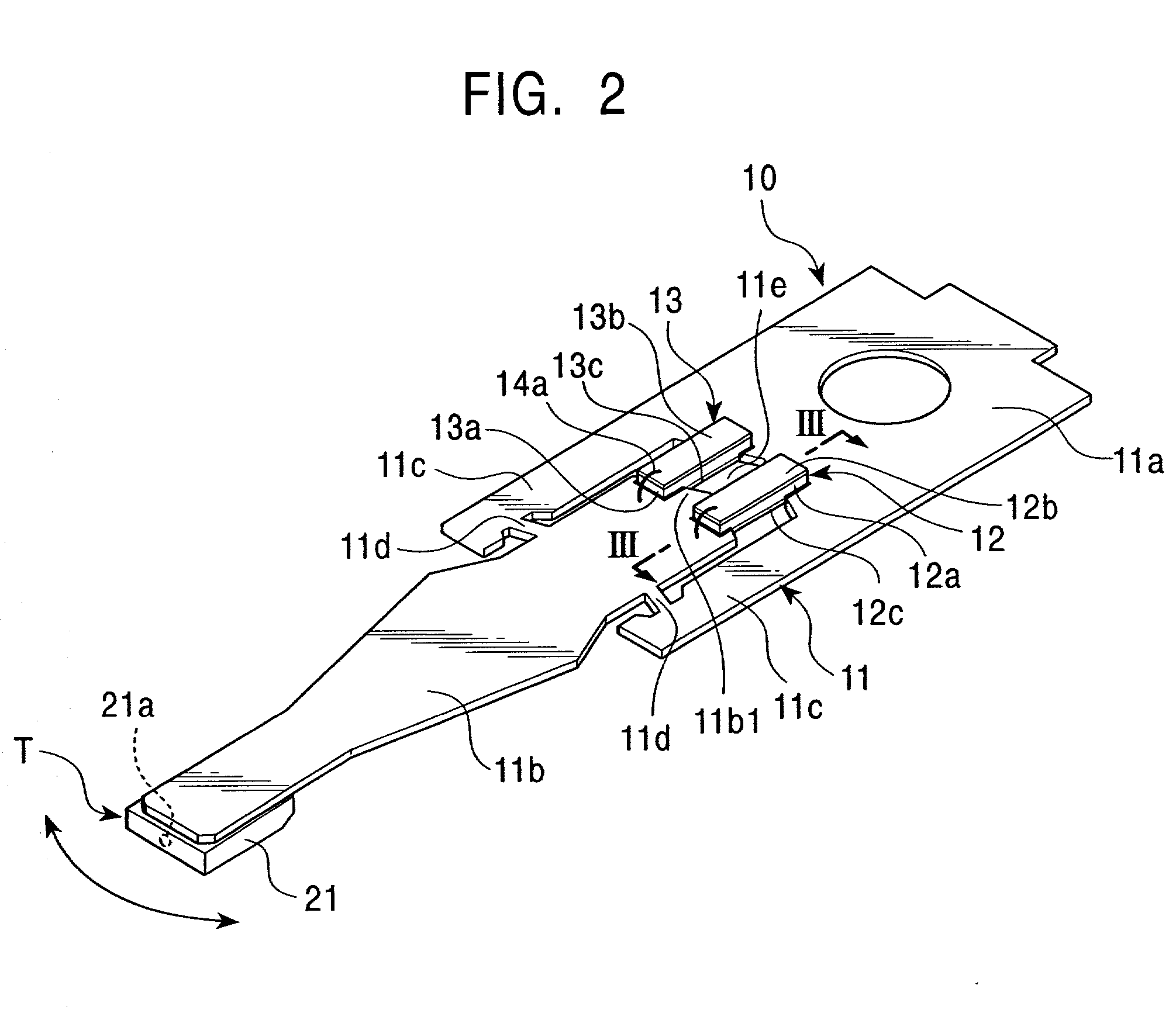

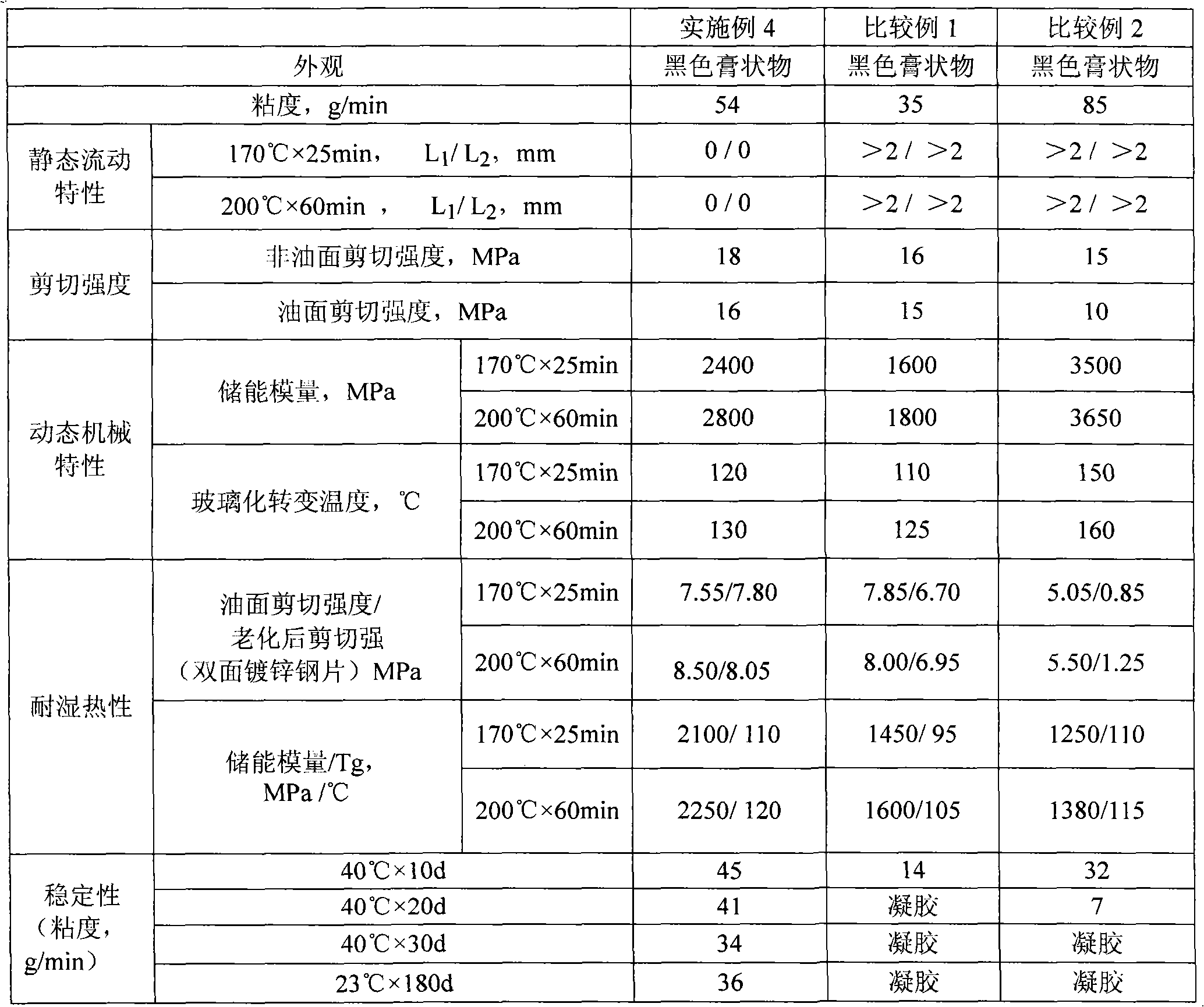

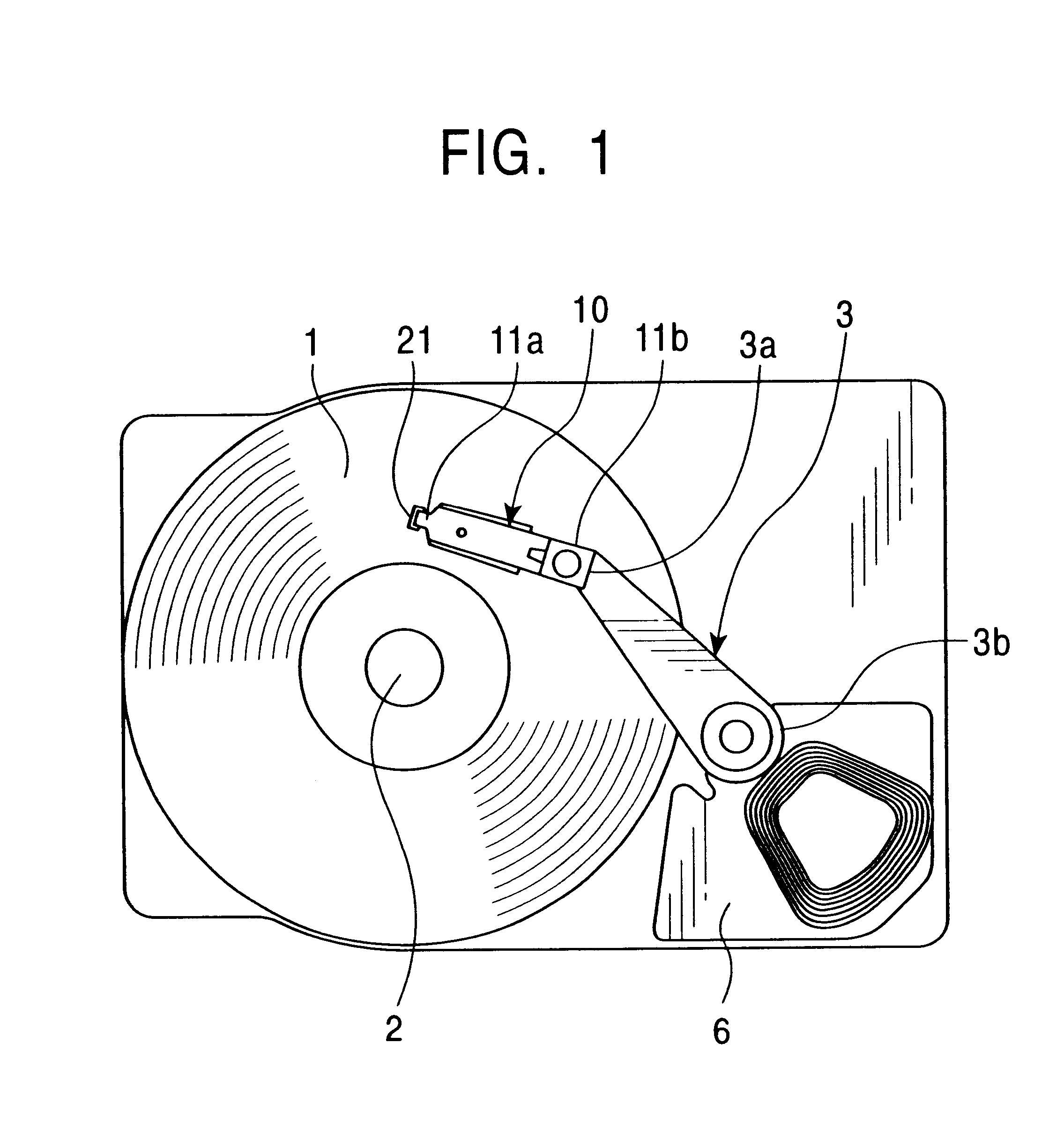

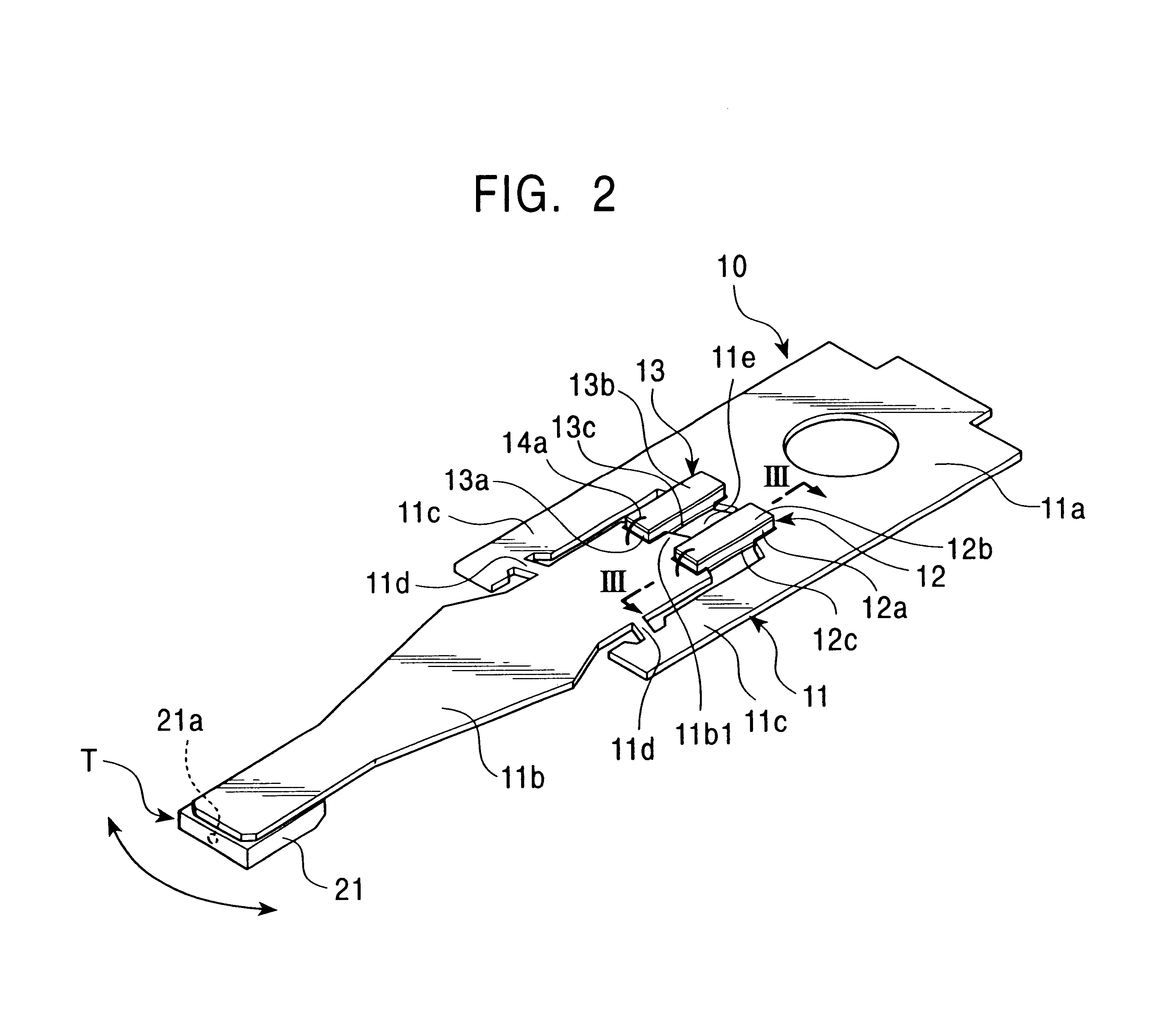

Magnetic head device having suspension with microactuator bonded thereto

The present invention provides a magnetic head device exhibiting a good bonded state of a piezoelectric element and a load beam, and excellent reliability. The magnetic head device includes a slider provided with a reproducing element for detecting a magnetic signal recorded on a recording medium, and a recording element for recording a magnetic signal on the recording medium, an elastic supporting member for supporting the slider, and piezoelectric elements mounted on the elastic supporting member, for distorting the elastic supporting member to change the position of the slider. The piezoelectric element and the elastic supporting member are bonded together with a photo-curing and thermosetting epoxy adhesive resin having a Young's modulus of 1 GPa or more at 25° C., and a glass transition temperature of 90° C. or more.

Owner:TDK CORPARATION

LED light module assembly

ActiveUS7284882B2Point-like light sourceSemiconductor/solid-state device detailsFlexible circuitsSurface mounting

An LED light module assembly for use with high power, high light output LED's includes a thin flexible circuit board with surface mounted LED's and other electronic components which is attached to a metal heat sink using a layer of a thermally conductive adhesive, such as a thermally conductive epoxy adhesive. A conduction path is provided from the LED carrier through the flexible circuit board by the incorporation of one or more thermally conductive vias in the region of the attachment pad used to bond the LED to the flexible circuit board. These vias provide a conduction path from the back side of the LED carrier through the circuit board to the thermally conductive adhesive and heat sink. The LED light module assembly has the capacity to dissipate between about 10-14 W of power without exceeding a maximum LED junction temperature of about 125° C.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Epoxy adhesive having improved impact resistance

InactiveUS6998011B2Increase resistanceImprove toughnessPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyolNitrile rubber

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

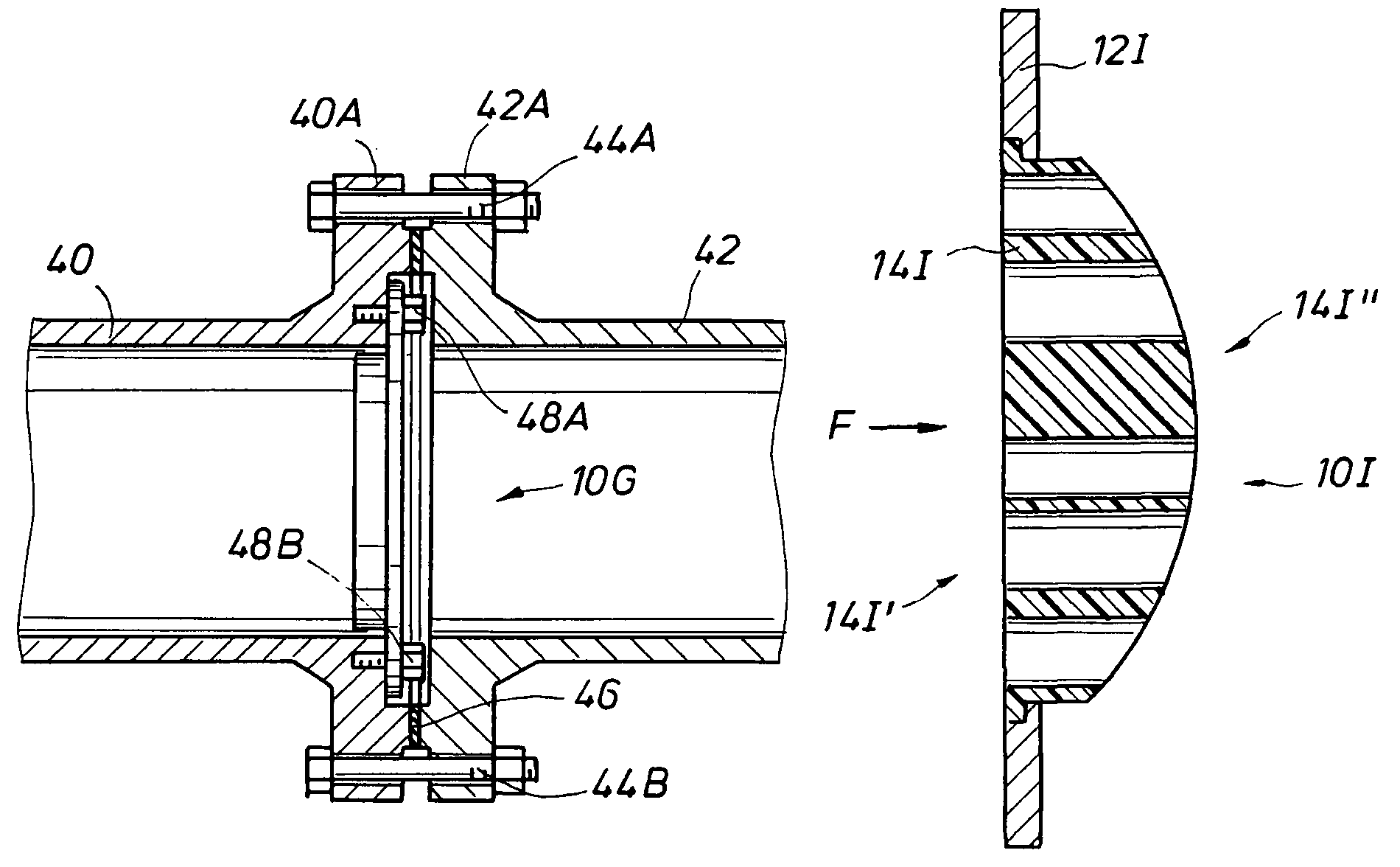

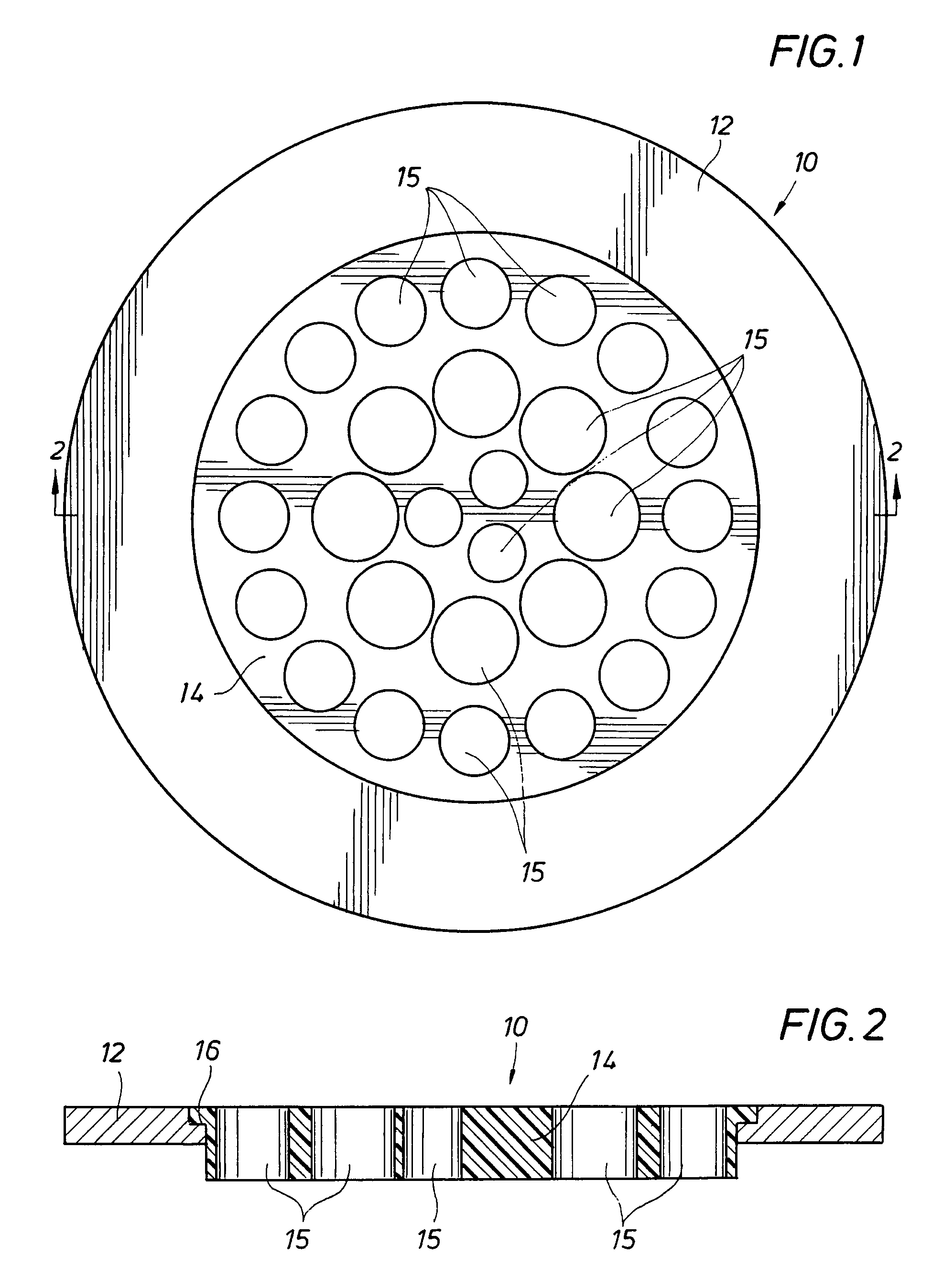

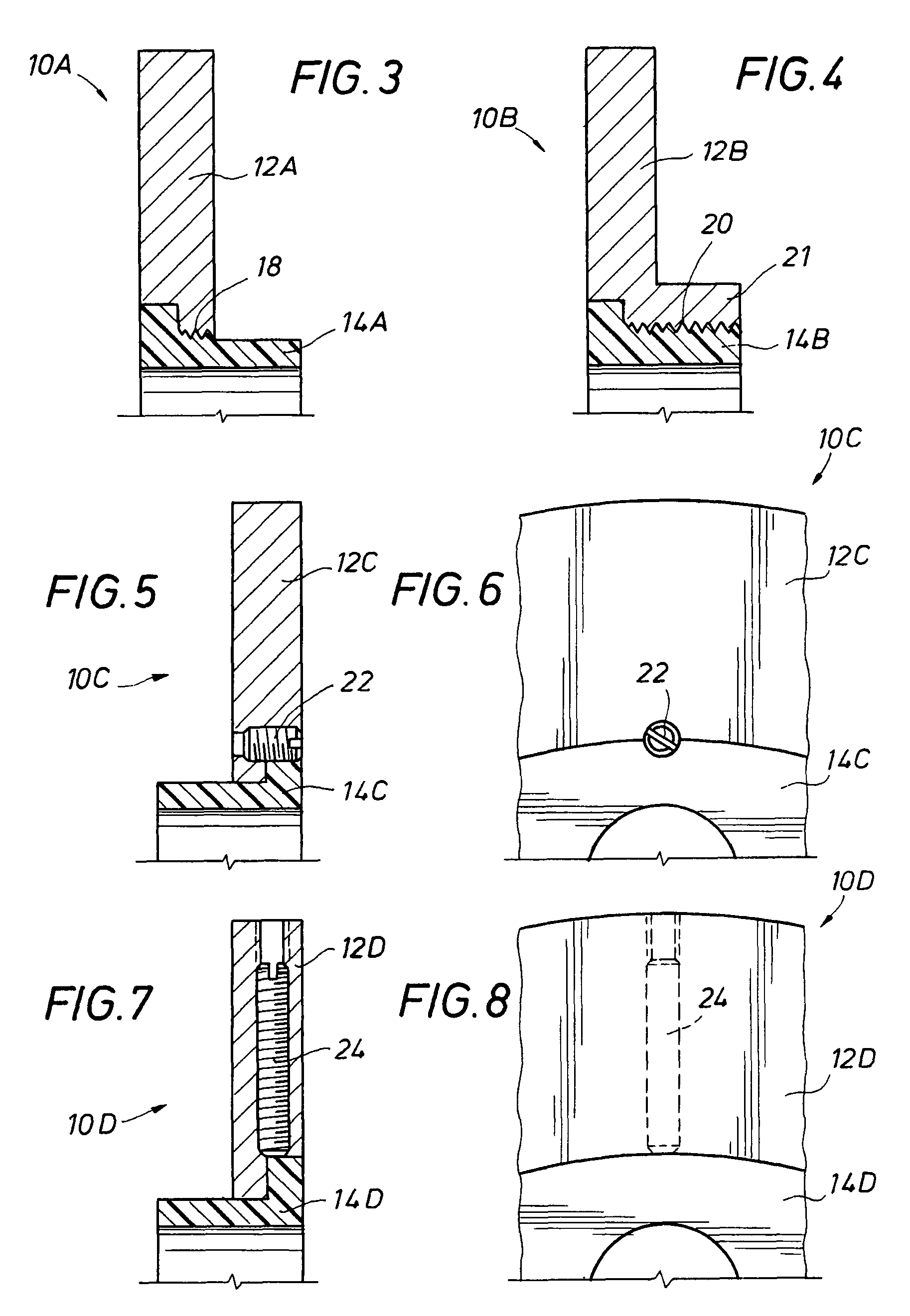

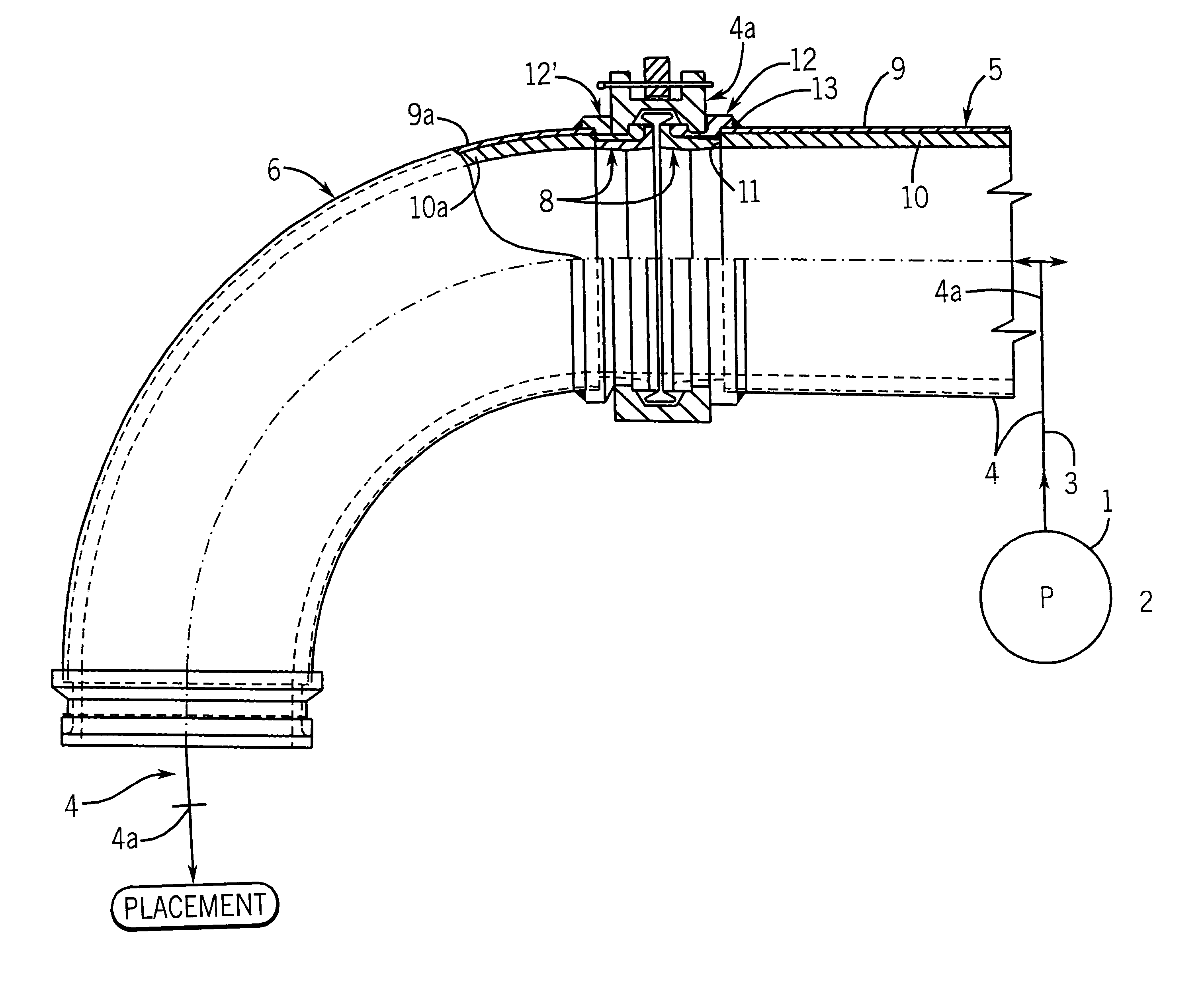

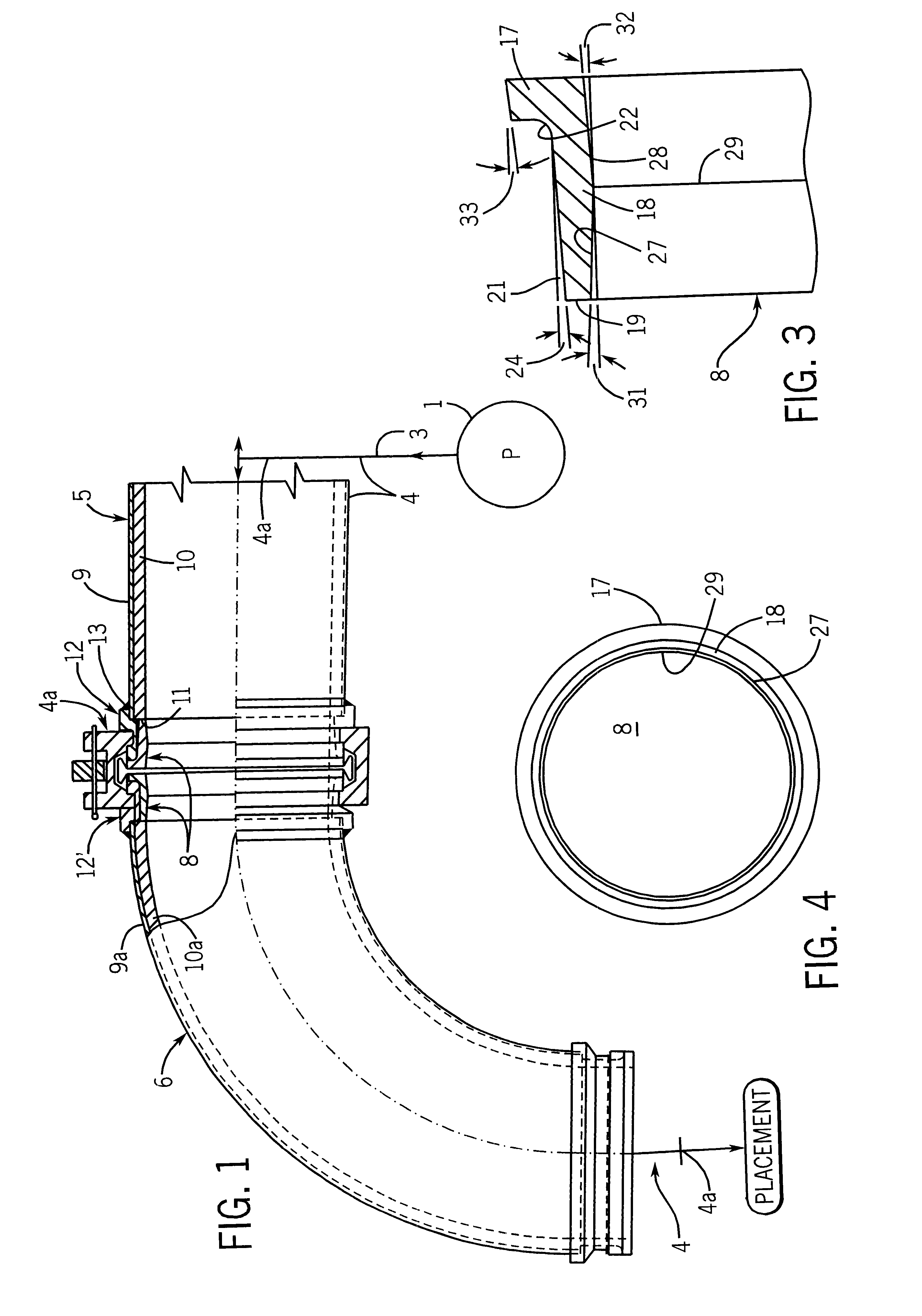

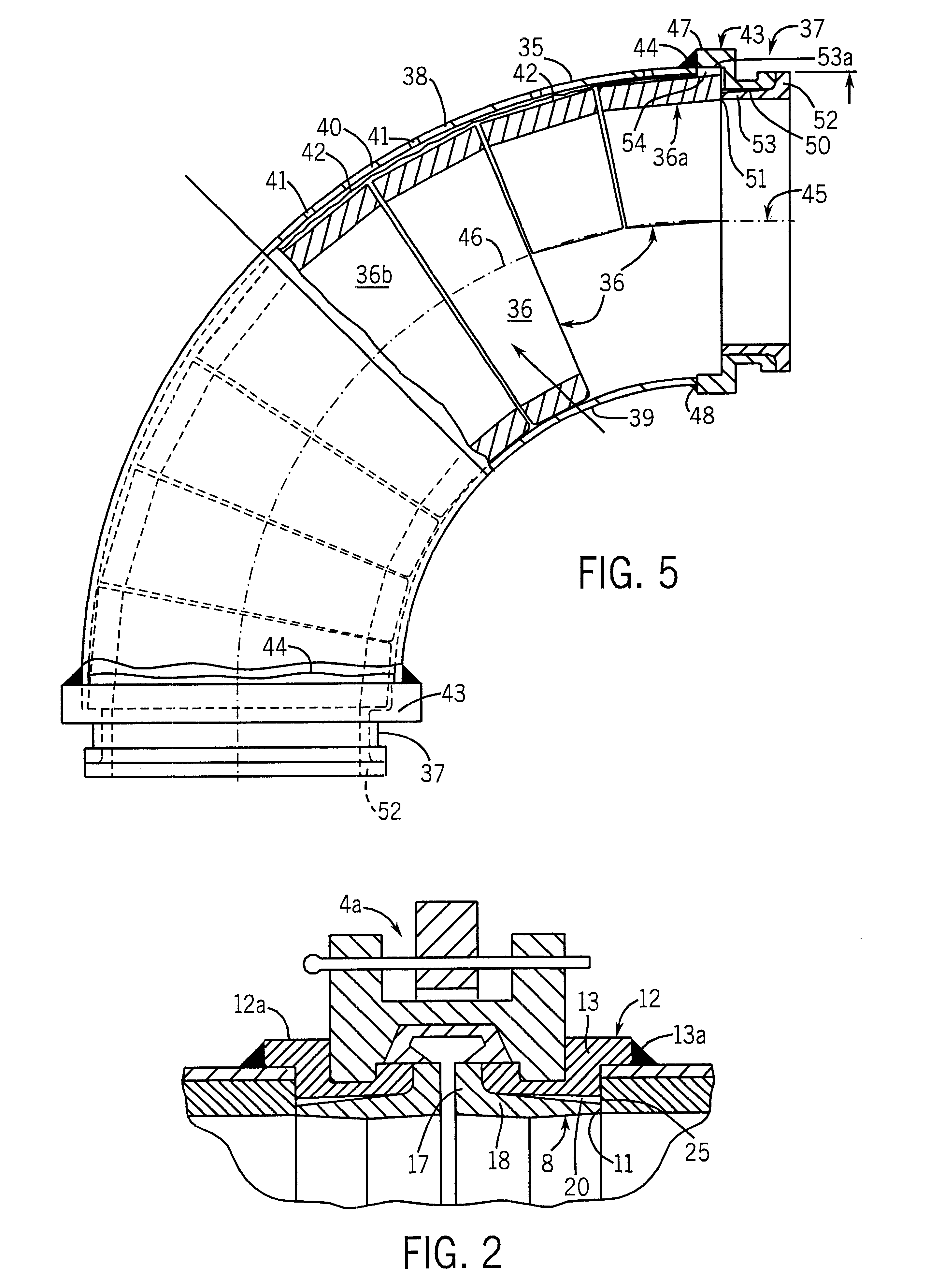

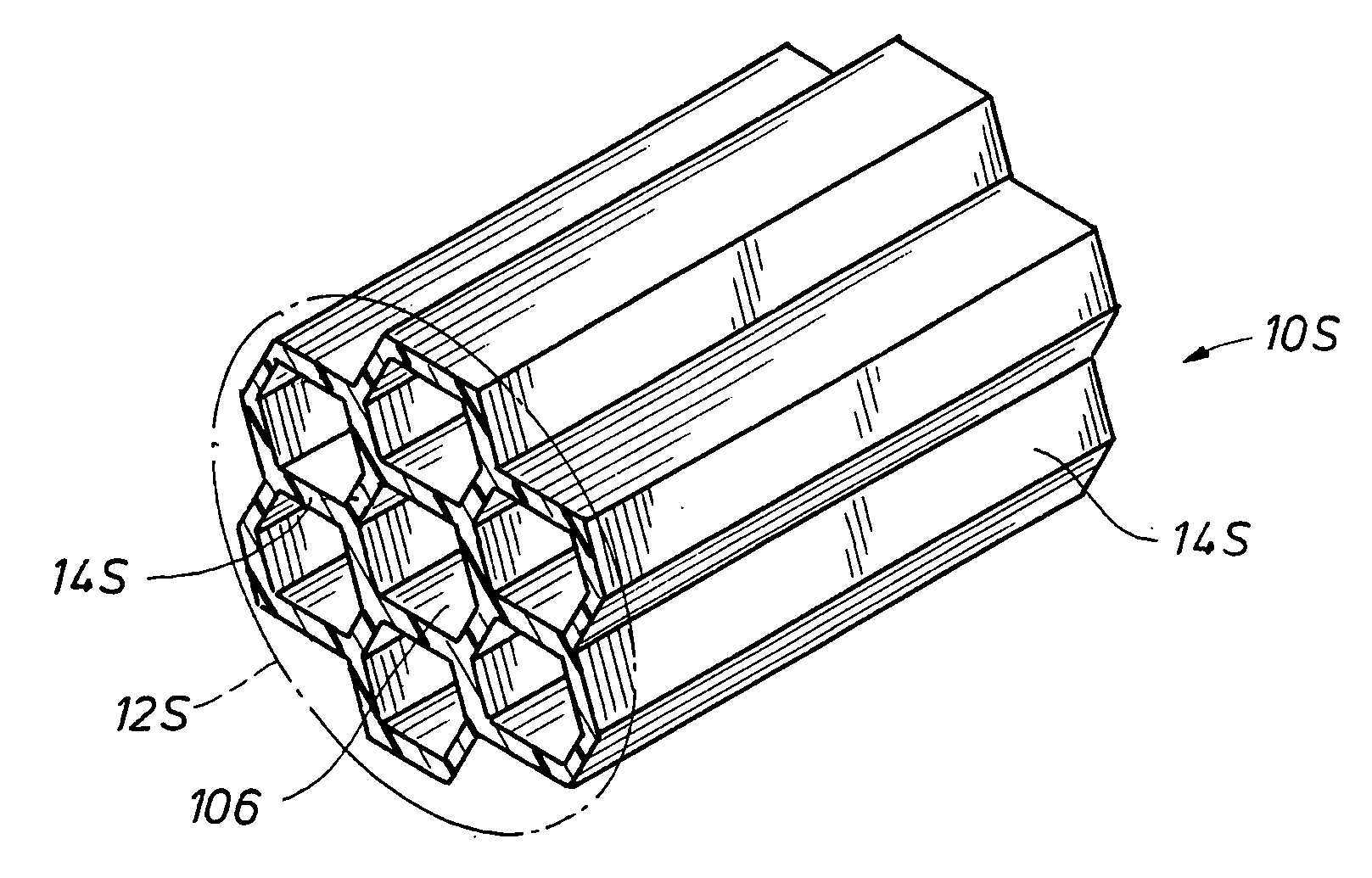

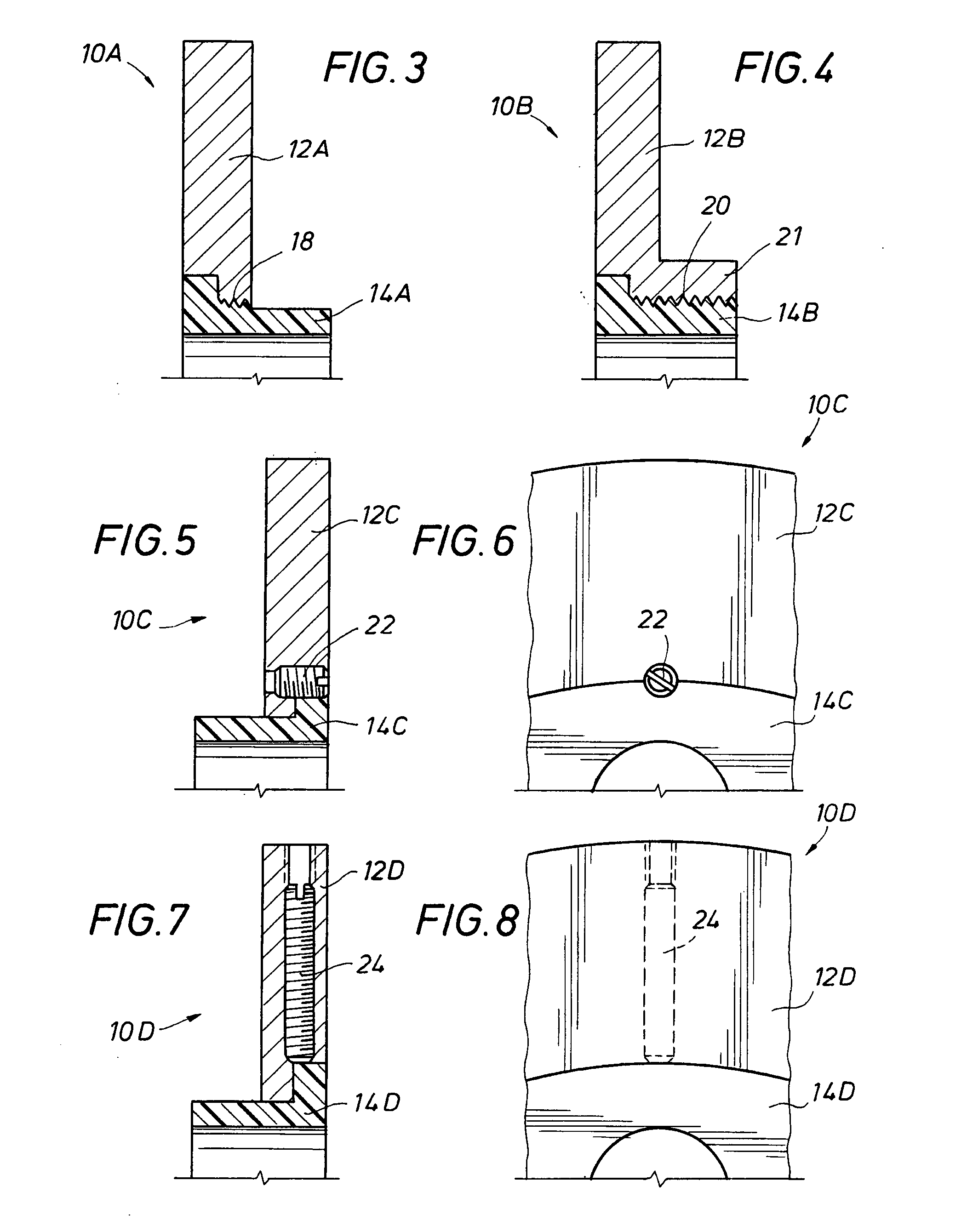

Multiple material piping component

The piping component is comprised in part of a metal housing that is positionable with a metal pipe. The metal housing forms an opening in which a piping component body is inserted. The body of the piping component can be fastened to the metal housing using an epoxy adhesive, a set screw connection, a threaded connection, press fit connection, a key connection or a pin connection or a combination of these connections. The body is comprised of plastic, which is less expensive than metal and facilitates forming, including machining or molding, while maintaining its structural integrity in a hostile fluid environment, such as in oil or gas. Piping components such as flowmeters, flow conditioners, small volume provers, static mixers, samplers, and valves are contemplated for use with these multiple materials.

Owner:SAVANT MEASUREMENT CORP

Heat-resistant structural epoxy resins

ActiveUS20080251202A1Improve suppression propertiesAvoid excessive adhesionLaminationLamination apparatusMicrosphereEpoxy adhesive

Epoxy adhesive compositions containing a rubber-modified epoxy resin contain a bisphenol. The bisphenol can be pre-reacted with the rubber-modified epoxy resin to advance the resin. The adhesives are resistant to thermal degradation as can occur in so-called “overbake” conditions, in which the adhesive is heated to high temperatures for prolonged periods of time. In addition, expanded microballoons are included in epoxy structural adhesives to promote a desired fracture mode.

Owner:DOW GLOBAL TECH LLC

Optoelectronic devices with laminate leadless carrier packaging in side-looker or top-looker device orientation

ActiveUS20110079801A1Low ion contentImprove moisture resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLead bondingEngineering

A laminate leadless carrier package comprising an optoelectronic chip, a substrate supporting the chip, the substrate comprising a plurality of conductive and dielectric layers; a wire bond coupled to the optoelectronic chip and a wire bond pad positioned on the top surface of the substrate; an encapsulation covering the optoelectronic chip, the wire bond, and at least a portion of the top surface of the substrate, wherein the encapsulation is a molding compound; and wherein the package is arranged to be mounted as a side-looker. A process for manufacturing laminate leadless carrier packages, comprising preparing a substrate; applying epoxy adhesive to a die attach pad; mounting an optoelectronic chip on the die attach pad; wire-bonding the optoelectronic chip; molding a molding compound to form an encapsulation covering the optoelectronic chip, a wire bond, and the top surface of the substrate; and dicing the substrate into individual packages.

Owner:EXCELITAS CANADA

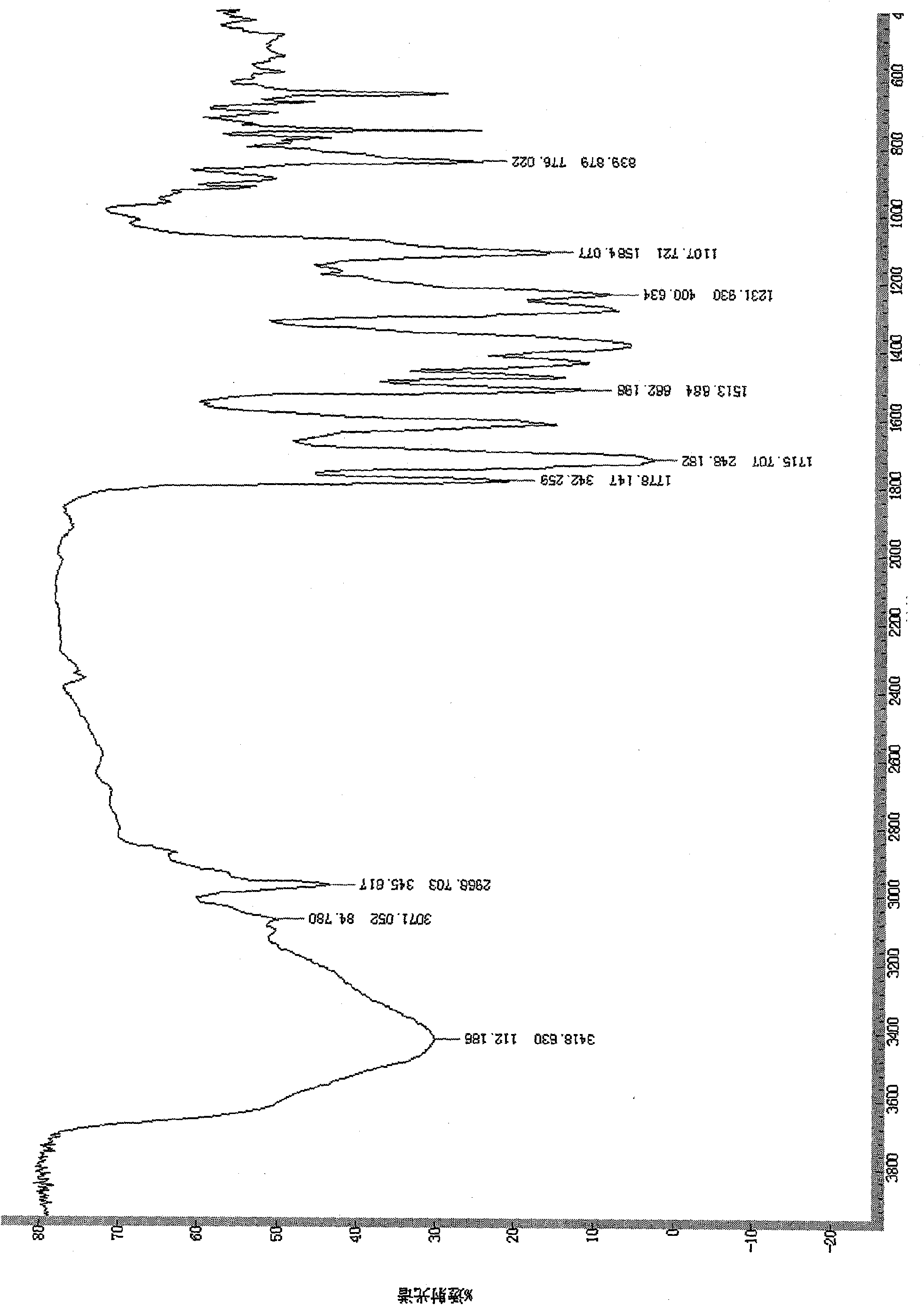

Preparation method for high strength solventless epoxy adhesive

InactiveCN101544879AConvenient sourceSimple preparation processModified epoxy resin adhesivesDiluentHigh intensity

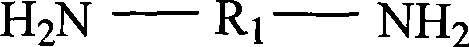

The invention relates to a preparation method for a high strength solventless epoxy adhesive. The preparation method comprises the following steps: carrying out reaction on an aromatic primary diamine and an epoxy resin for 0.5 to 2 hours at 60 to 100 DEG C, adding an active flexibilizer, and carrying out reaction for 1 to 3 hours at 80 to 110 DEG C to obtain a modified sticky epoxy resin system; and adding an active diluent and a curing agent in the modified epoxy resin system, and stirring the mixture evenly to obtain the high strength solventless epoxy adhesive. The preparation method has a simple process, low cost, convenient operation and convenient reaction raw material sources, and is capable of completing the preparation process in a general device and facilitates realization of the industrialized production. In addition, the viscosity of the high strength solventless epoxy adhesive reaches 15 to 1,000 Pa.s at 25 DEG C; the bond strength maximally reaches 35 MPa; and the high strength solventless epoxy adhesive has bright application prospect.

Owner:DONGHUA UNIV

Pipe having replaceable wear resistant lined coupler

InactiveUS6467812B1Rapid and cost-effective formationQuick inexpensive replacementFlanged jointsThermal insulationWear resistantEngineering

A pipe section for concrete includes an end coupler interconnecting to another pipe section in a flow line. The coupler has an outer clamp secured extended from the pipe end with a coupling groove. An encircling clamp has sides located in the grooves of adjacent pipe sections to lock the pipe section together. The body and pipe end form an inner recess extending from the pipe end. An insert liner has a tubular portion matching the recess, with the outer surface of the tubular portion tapered to form a gap within the recess. The insert liner has an outer flange matching the outer diameter of the body and abuts the body. The inner wall of the liner has a central transition point from which the wall tapers inwardly in opposite directions to the outer end. The body member is formed of a high strength ductile steel. The insert liner is formed of a wear resistant material having a Rockwell hardness of 80 to 90. A carbide alloy consisting essentially of carbides, martensite, bainite and austenite, and 12-15% chromium, 2-3% carbon and traces nickel, molybdenum and austenite. A toughened ceramic is disclosed. The liner is adhesively bonded to the body using an epoxy adhesive which is responsive to heat for release of the liner. The liner is inserted by applying adhesive on the tubular portion and then pushing the liner into the recess.

Owner:CONSTR FORMS

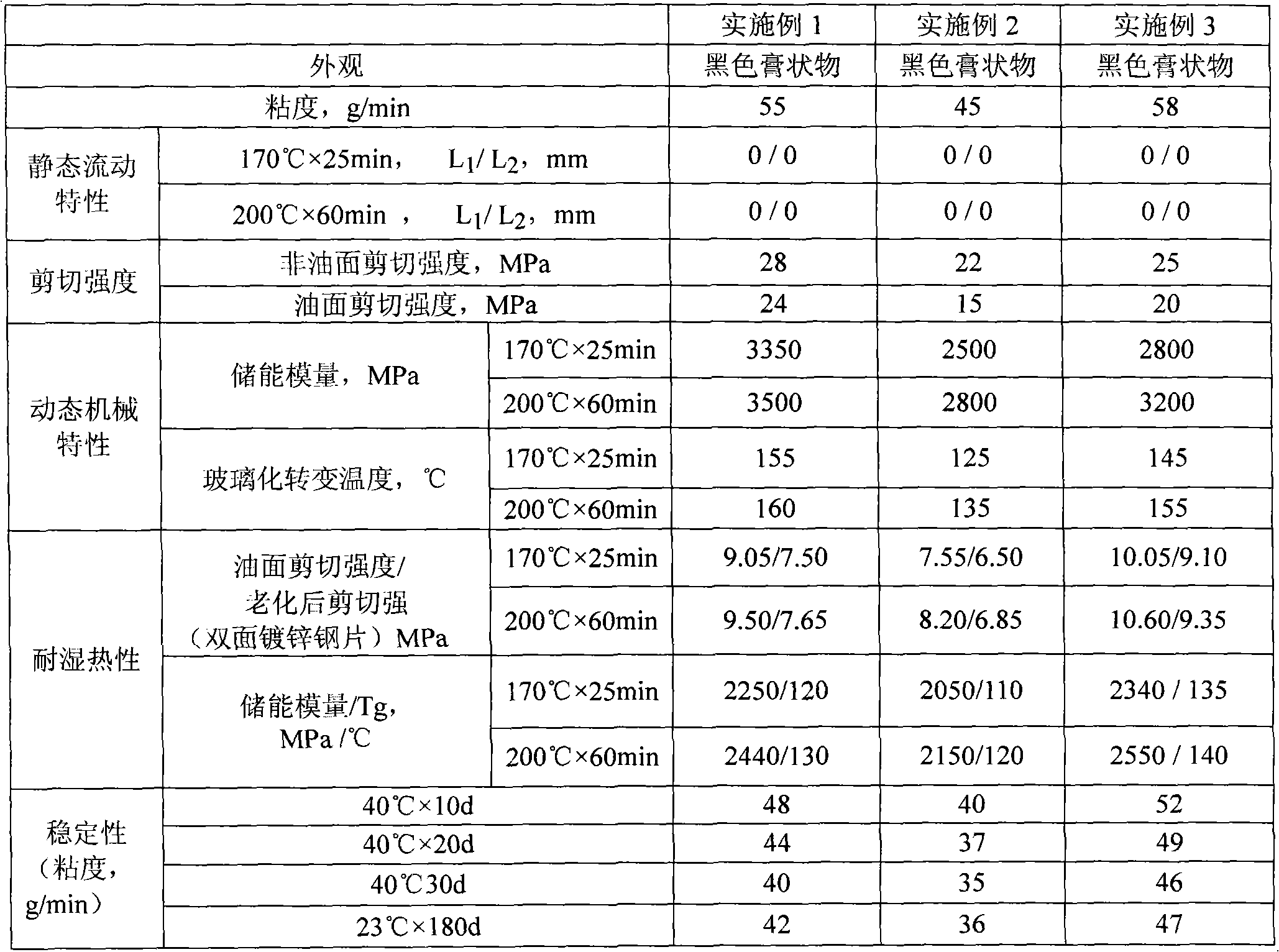

Automobile hemming adhesive and preparation method thereof

ActiveCN102115654AGood workmanshipImprove thixotropyNon-macromolecular adhesive additivesEpoxy resin adhesivesPlasticizerHeat resistance

The invention relates to an automobile hemming adhesive and a preparation method thereof, belonging to the technical field of single-component epoxy adhesives. The automobile hemming adhesive is mainly used for bonding an automobile hemming part. The automobile hemming adhesive is mainly characterized by comprising (A) epoxy resin, (B) modified epoxy resin, (C) toughener, (D) epoxy diluter, (E) thermoplastic resin, (F) plasticizer, (G) thermal stabilizer, (H) latent curing agent, (I) coupling agent, (J) filler and (K) pigment. The preparation method comprises the following steps: (1) evenly stirring (E) and (F) at 5-35 DEG C; (2) adding the mixed liquid composition in the step (1), and (A), (B), (C), (D), (G), (H), (I), (J) and (K) into a movable mixer, and evenly stirring at 5-35 DEG C; (3) passing the mixture in the step (2) through a three-roller machine once or twice; and (4) vacuumizing the movable mixer, stirring, defoaming, and discharging for later use. The invention mainly solves the problems of low environmental-protection index, poor technical properties of sizing, short storage period, low modulus, poor moisture and heat resistance and the like in the existing hemming adhesive.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Magnetic head device having suspension with microactuator bonded thereto

The present invention provides a magnetic head device exhibiting a good bonded state of a piezoelectric element and a load beam, and excellent reliability. The magnetic head device includes a slider provided with a reproducing element for detecting a magnetic signal recorded on a recording medium, and a recording element for recording a magnetic signal on the recording medium, an elastic supporting member for supporting the slider, and piezoelectric elements mounted on the elastic supporting member, for distorting the elastic supporting member to change the position of the slider. The piezoelectric element and the elastic supporting member are bonded together with a photo-curing and thermosetting epoxy adhesive resin having a Young's modulus of 1 GPa or more at 25° C., and a glass transition temperature of 90° C. or more.

Owner:TDK CORPARATION

Low temperature curing high temperature resistant inorganic / organic hybridization epoxy adhesive and preparation thereof

InactiveCN101440268AImprove brittlenessImprove high temperature heat aging resistanceInorganic adhesivesEpoxy resin adhesivesCouplingLow temperature curing

The invention discloses a low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive and a preparation method thereof, which relate to an inorganic / organic hybrid epoxy adhesive and a preparation method thereof. The invention solves the problems that inorganic / organic hybrid epoxy adhesive prepared by the prior art has poor high-temperature thermal aging resistance and needs high curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive is prepared by an epoxy resin, an epoxy resin low-temperature curing agent, a coupling agent, an inorganic active hybrid material and a dispersant. The preparation method comprises the following steps: the epoxy resin, the epoxy resin low-temperature curing agent and the coupling agent are mixed and stirred evenly, and then the inorganic active hybrid material and the dispersant are added into the mixture to be stirred evenly to obtain the low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has high high-temperature bonding strength, good high-temperature thermal aging performance and low curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has the advantages of simple production technology, convenient operation and broad application.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

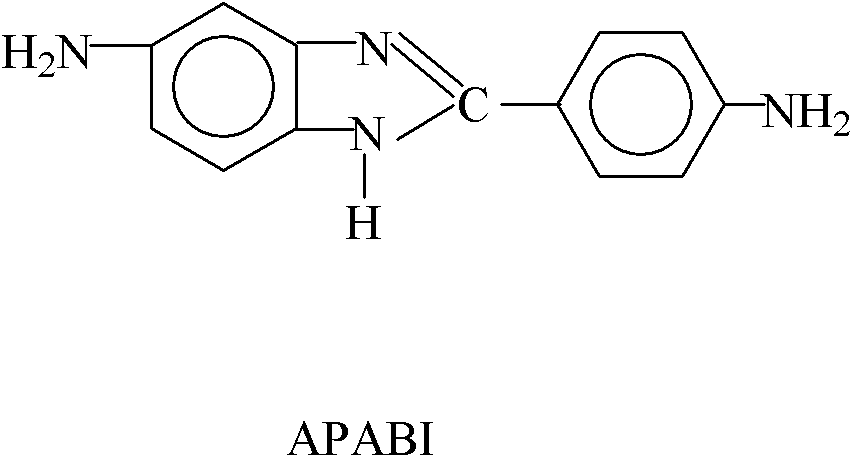

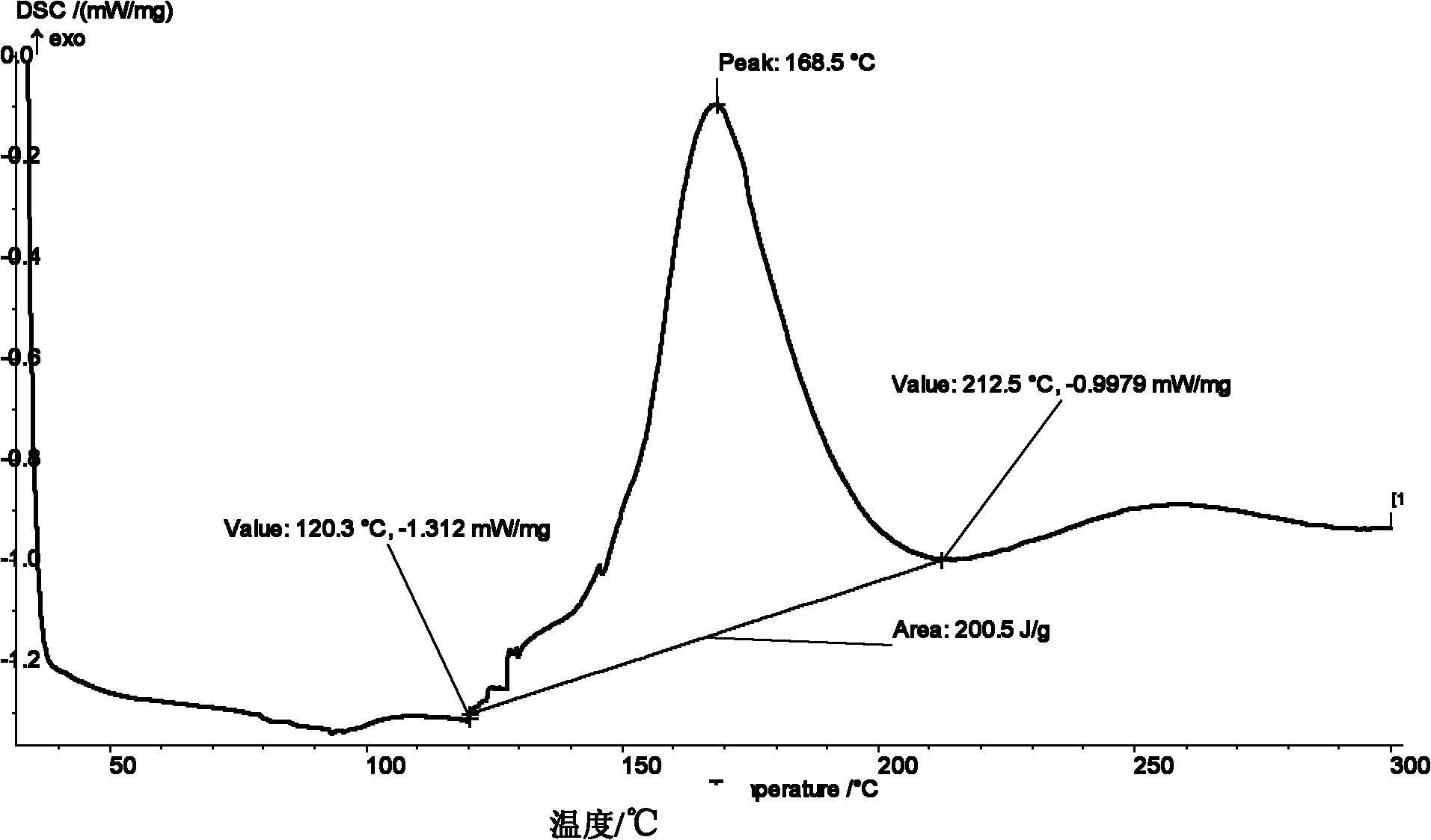

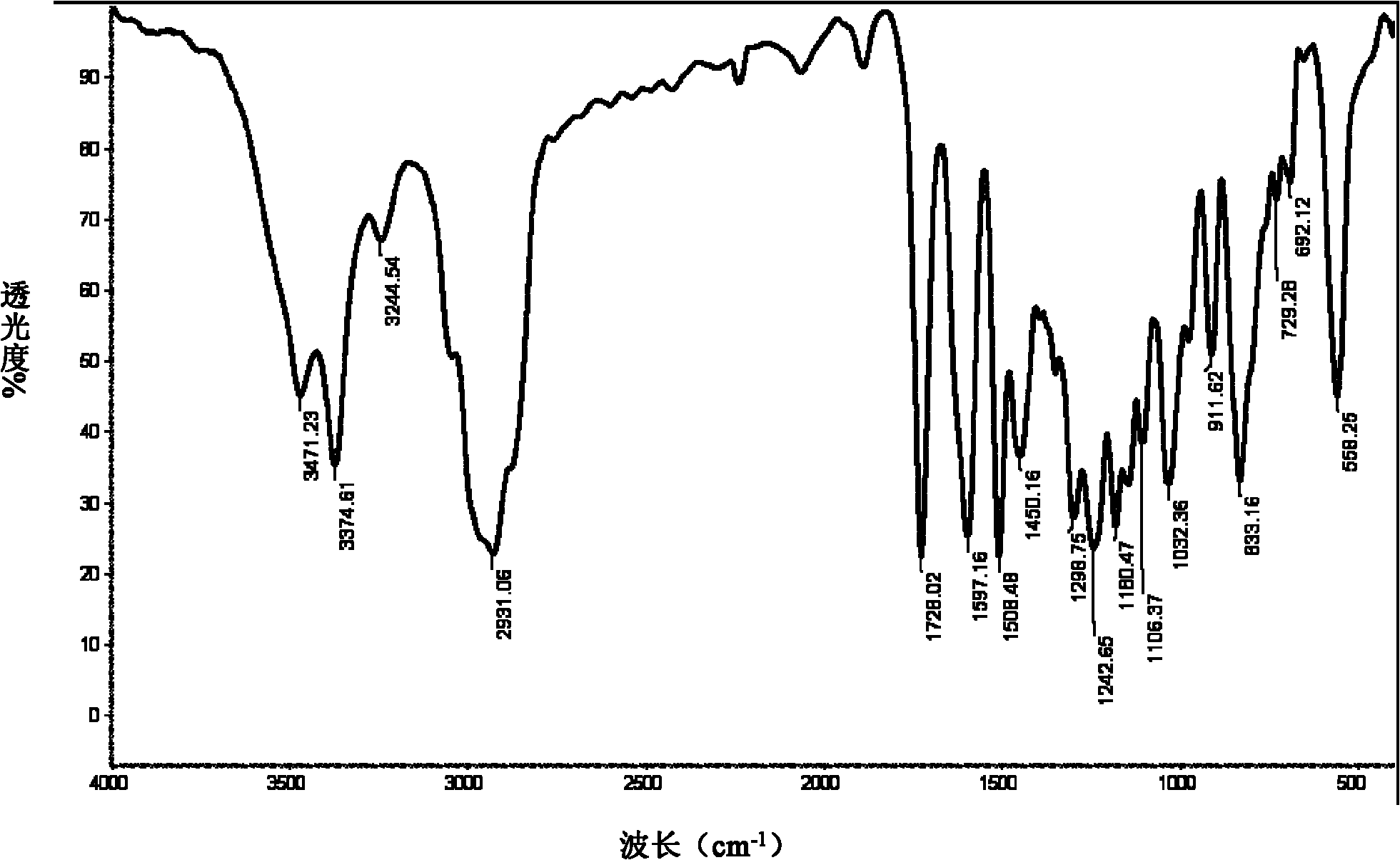

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

Solar battery backboard taking modified polyvinylidene fluoride alloy layer as weathering protective layer

ActiveCN101582459ANovel structureMaterials are readily availableSynthetic resin layered productsElectrical equipmentPolyurethane adhesiveAlloy

The invention relates to a solar battery backboard which takes a modified polyvinylidene fluoride alloy layer as a weathering protective layer. The backboard comprises the following components according to the adhesion in turn: a weathering layer, an adhesive layer, a structure-enhancing layer, a second adhesive layer and a second weathering layer; wherein, the first weathering layer and the second weathering layer are the polyvinylidene fluoride alloy layers modified by inorganic materials; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and fine performance, conforms to the requirement of backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

Multiple material piping component

The piping component is comprised in part of a metal housing that is positionable with a metal pipe. The metal housing forms an opening in which a piping component body is inserted. The body of the piping component can be fastened to the metal housing using an epoxy adhesive, a set screw connection, a threaded connection, press fit connection, a key connection or a pin connection or a combination of these connections. The body is comprised of plastic, which is less expensive than metal and facilitates forming, including machining or molding, while maintaining its structural integrity in a hostile fluid environment, such as in oil or gas. Piping components such as flowmeters, flow conditioners, small volume provers, static mixers, samplers, and valves are contemplated for use with these multiple materials.

Owner:SAVANT MEASUREMENT CORP

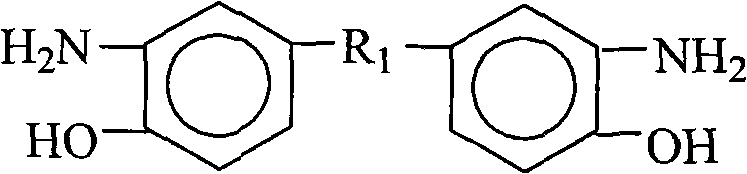

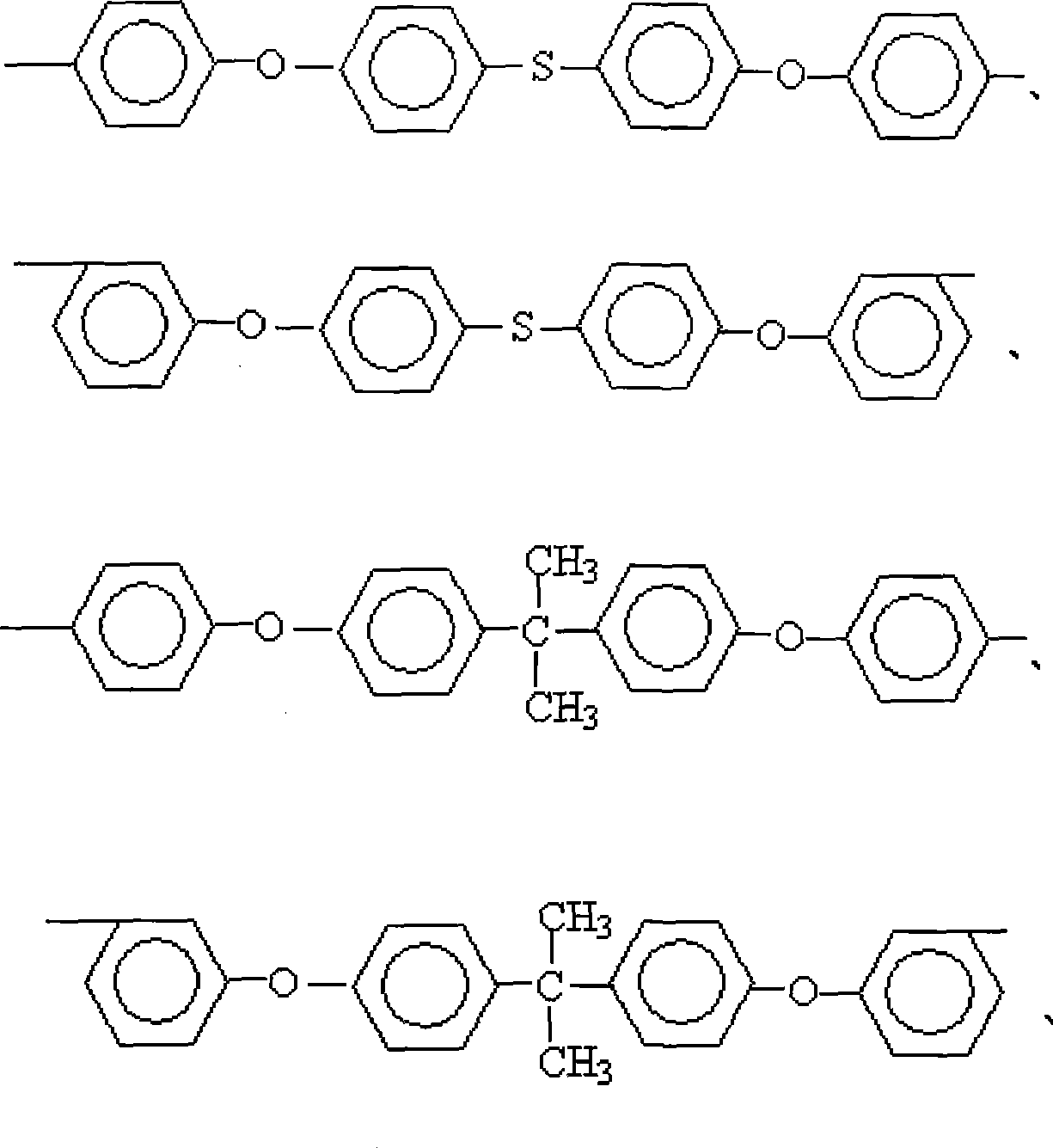

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Releasable microcapsule and adhesive curing system using the same

InactiveUS6936644B2Easy curingFinal product manufactureSolid-state devicesEpoxy adhesivePolymerization

An uncured epoxy adhesive comprising a resin component, a hardener component, and a microencapsulated accelerator component. The microencapsulated accelerator component comprises an infrared absorber, an accelerator and a wall that covers substantially the entire surface of the accelerator. The epoxy adhesive is cured by exposing it to infrared energy. The infrared energy is absorbed by the infrared absorber which disintegrates the wall and allows the accelerator to come into contact with the other adhesive components and initiate the curing polymerization reaction.

Owner:ALENT INC

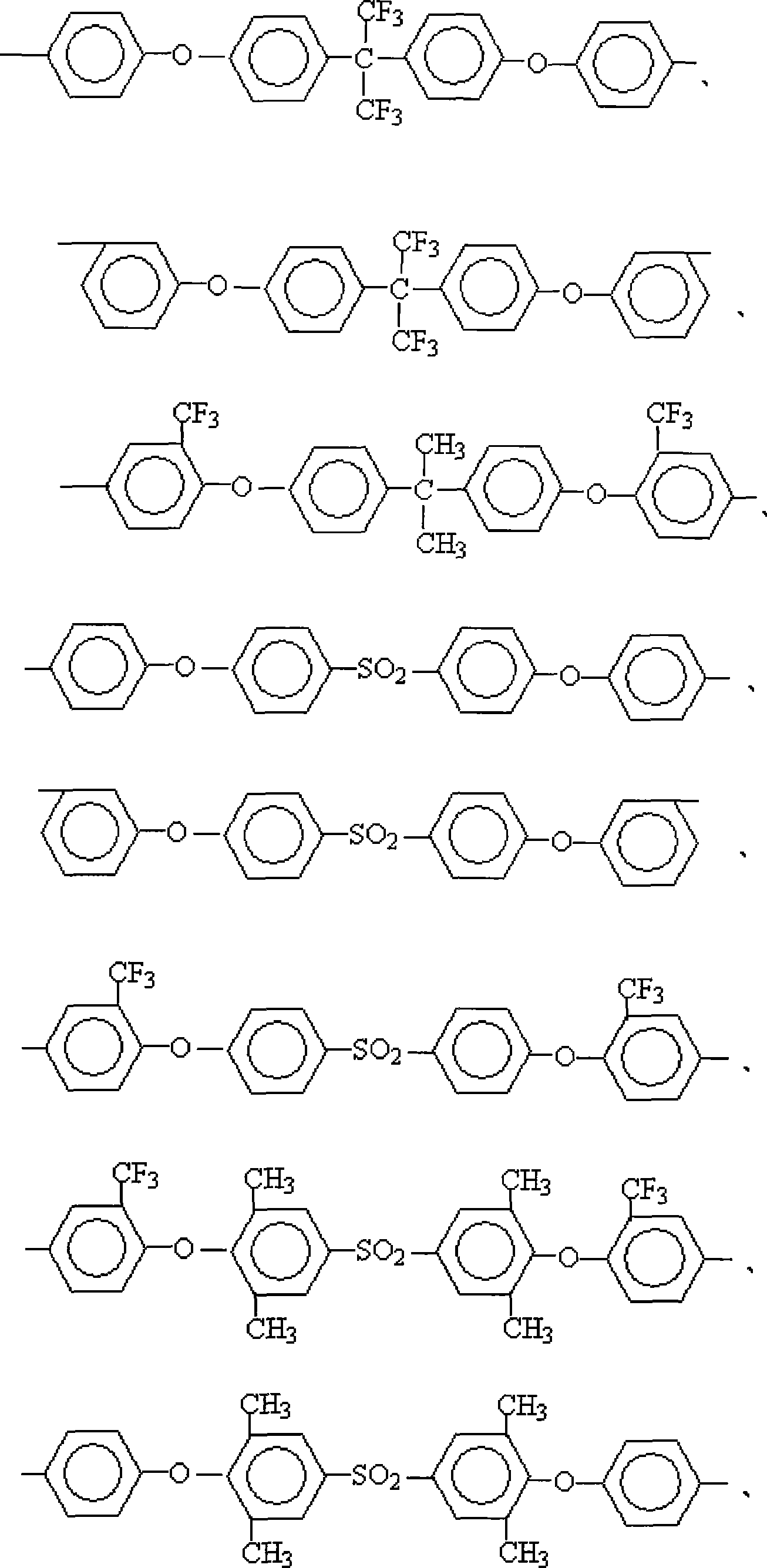

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

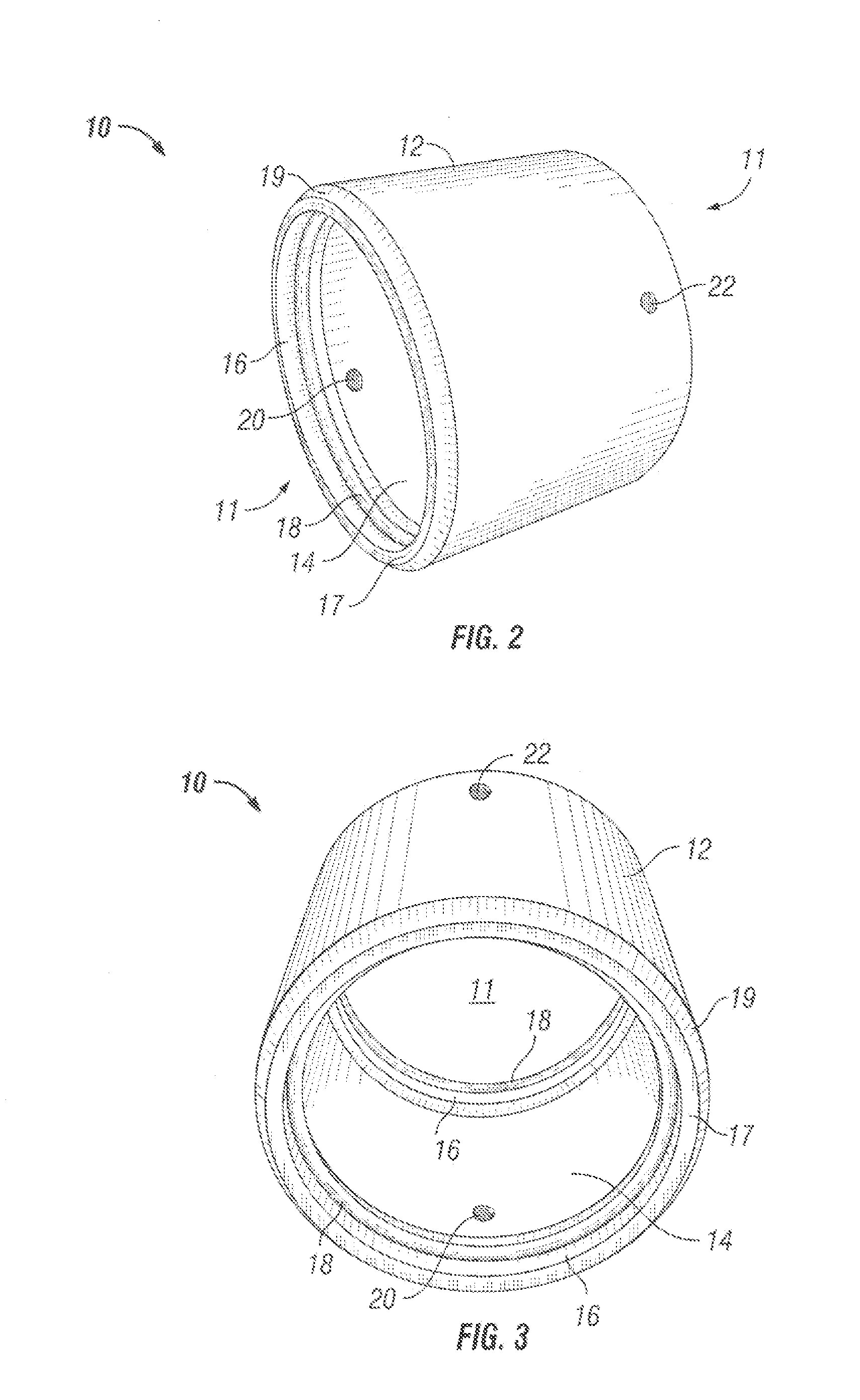

Epoxy secured stop collar for centralizer

InactiveUS20070284037A1Better securingImprove securitySleeve/socket jointsDrilling rodsEngineeringEpoxy adhesive

A stop collar for securing a centralizer in place on a large diameter easing segment comprises a collar adapted for forming an annular chamber when received onto a casing segment. The stop collar is adapted for receiving and retaining a liquid gel epoxy adhesive in the annular chamber until the epoxy sets or cures to secure the stop collar in place on the casing.

Owner:FRANKS INT

Preparation method of room temperature cured high temperature tolerant flexible epoxy adhesive

InactiveCN1546590AImprove temperature resistanceGood flexibilityEpoxy resin adhesivesPliabilityRoom temperature

The invention discloses a preparation method of room temperature cured high temperature tolerant flexible epoxy adhesive, wherein the adhesive comprises a binding component and a hardening component, wherein the binding component includes flexibilizing constituent, heatproof constituent and plasticity agent, the hardening constituent comprises main hardening agent and hardening accelerating agent. The epoxy adhesive provided by the present invention has good tenacity and high binding strength.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)