Patents

Literature

229 results about "Cure time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

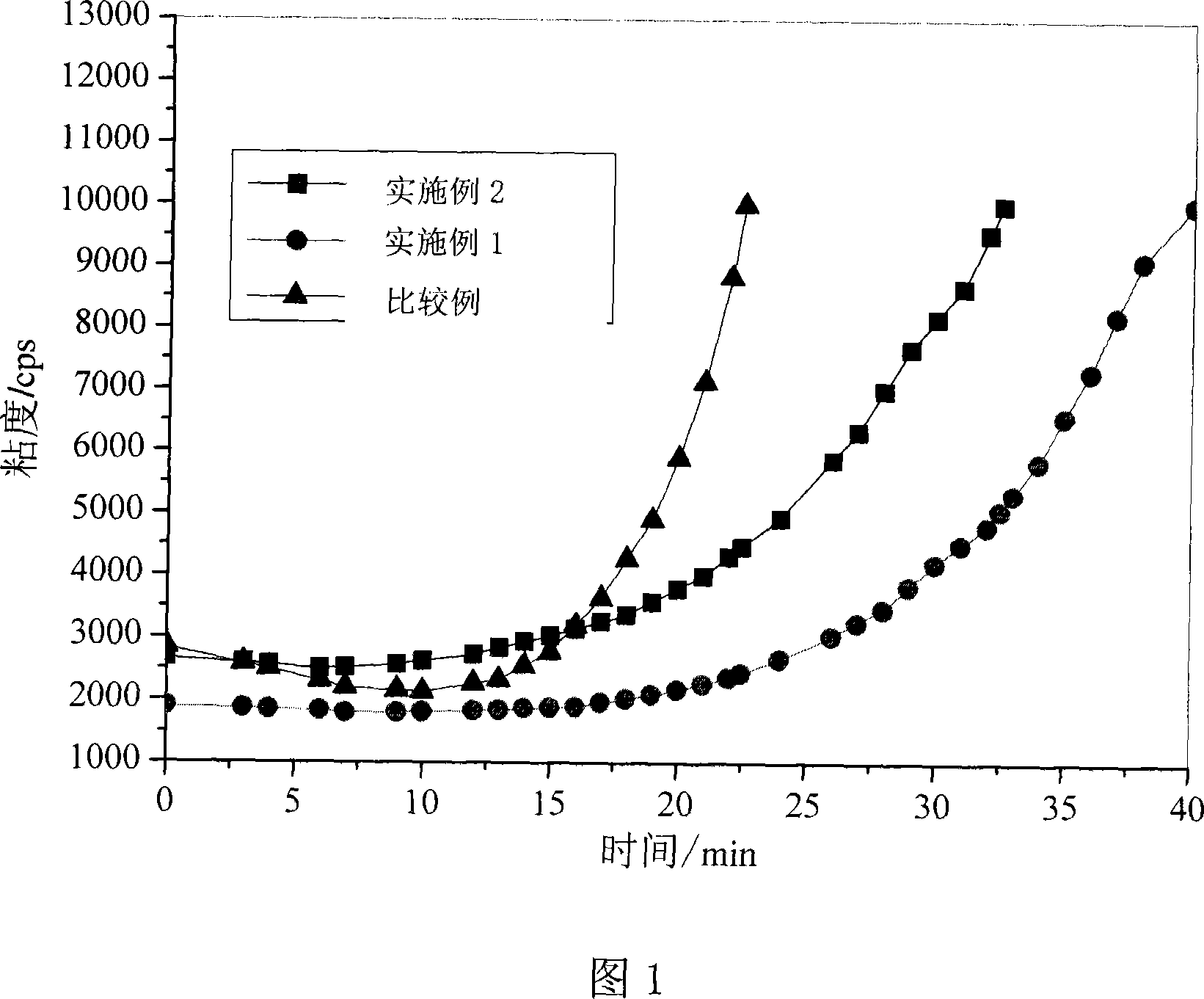

Cure time refers to the length of time needed for something to fully cure. Many substances need cure time to fully cure. Examples are: epoxies, glues, resins, concrete, etc. In a rubber compound, cure time is the length of time to reach optimum viscosity or modulus at a certain temperature.

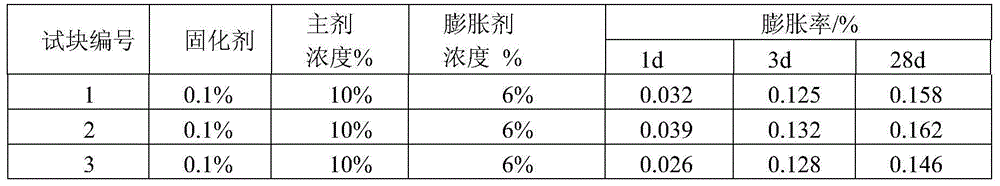

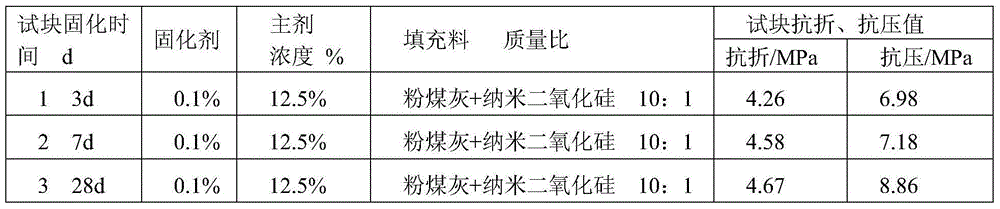

Curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof

The invention relates to the technical field of curing agents and particularly relates to a curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, comprises the following components in percentage by weight: 0.1-2% of fluorosilicate, 0.001-0.02% of surfactant, 5.0-30.0% of at least one of silica sol or silicate and the balance of water. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, has the advantages of short curing time, thick surface hardened layer and high surface hardness, and can be widely used for surface hardening and curing treatment of concrete buildings or structures of highways, squares, garages, supermarkets, factory buildings and the like.

Owner:DONGGUAN MERROCK IND

Coating compositions having extended pot life and shortened cure time and combination of chemicals used therein

InactiveUS6084026AExtension of timeRaise the ratioSynthetic resin layered productsPolyurea/polyurethane coatingsCarbamateDibutyl tin dilaurate

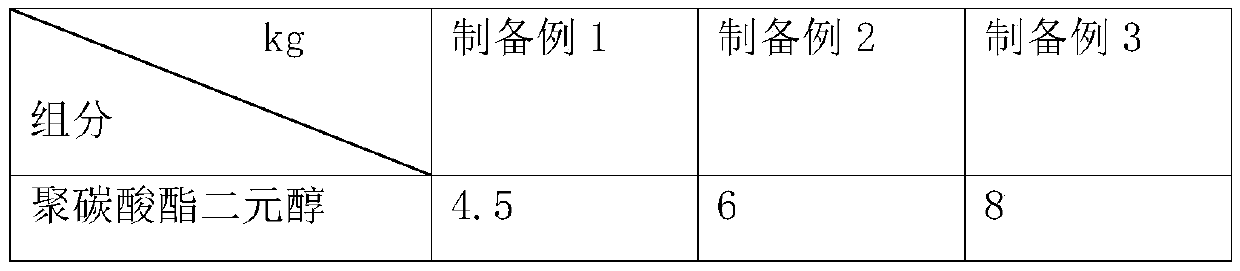

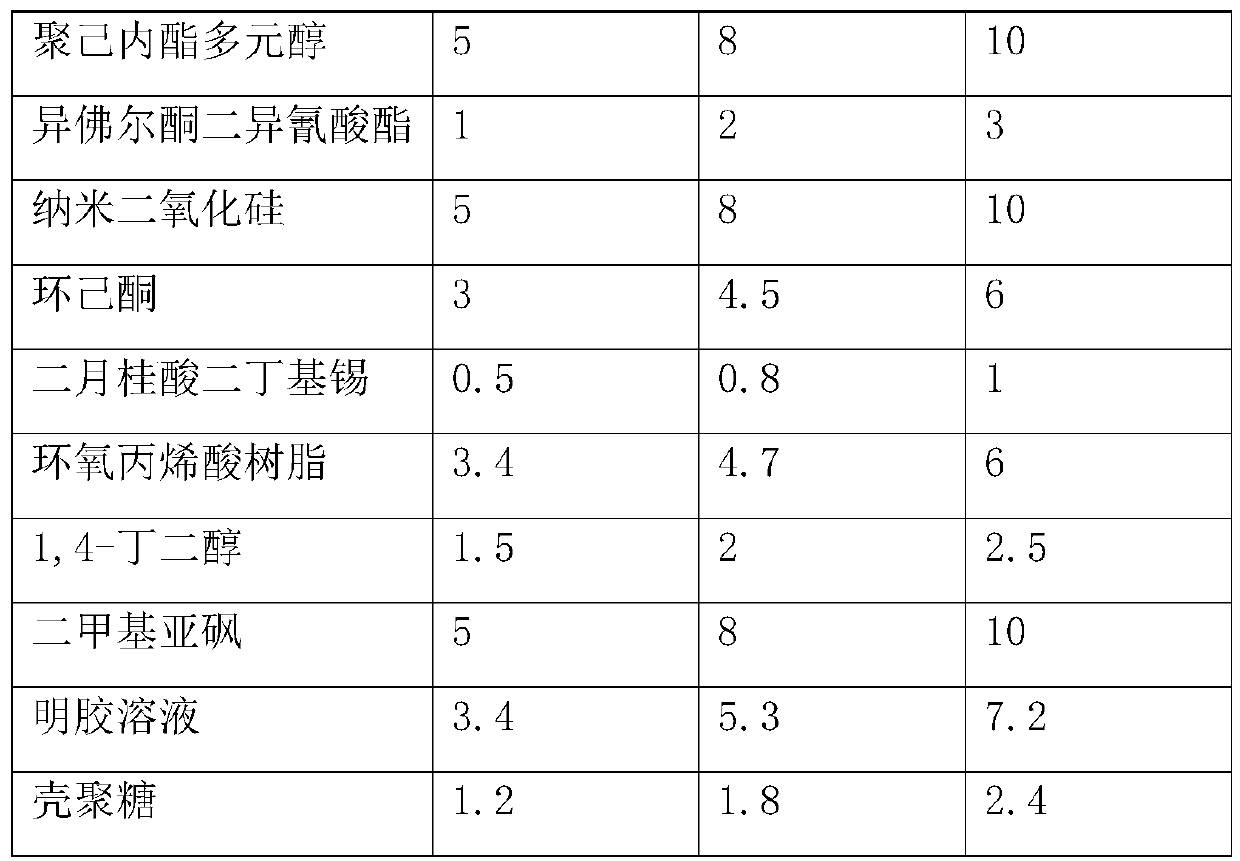

A combination of chemicals suitable for extending pot life and shortening cure time of a pot mix of a thermosetting composition is disclosed. The combination of chemicals includes a catalyst, such as, dibutyl tin dilaurate; carboxylic or sulfonic acid; and an extender compound, such as 2,4 pentanedione. The combination is generally included in a polymeric component of the urethane composition. The extended pot life provides the user with longer open time during which to efficiently apply a coating of the pot mix over a wide variety of substrate surfaces while still producing coatings that cure quickly upon application.

Owner:ROHM & HAAS CO

Double-component epoxy resin embedding adhesive and its preparation method and can sealing technique

ActiveCN101235269ALow viscositySave operating timeOther chemical processesEpoxy resin adhesivesEpoxyAlcohol

Bi-component epoxy resin pouring sealant and the preparation and the potting technology are disclosed, which comprises an epoxy resin A component and a cursing agent B component, wherein the curing agent B component at least comprises the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent. The potting technology comprises mixing and stirring evenly the epoxy resin A component and the curing agent B agent to conduct the potting, and spraying a layer of absolute alcohol on the surface of the pouring sealant after 10-15 minutes. The advantages are that gel time is prolonged through adopting the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent, the requirement of operation time is fulfilled, and the operation time can reach 20-30 minutes, thereby being beneficial for the encapsulation of housing with large capacity, and the pouring sealant of the invention has the effect of fast curing, wherein the curing time is 1-3 hours, and defoaming is accelerated through spraying a layer of absolute alcohol on the surface of colloid after pouring, thereby making the solid gel surface bright and flat after curing.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Method for modifying cyanate ester resin by hydroxyl-terminated polybutadiene

The invention relates to a method for modifying cyanate ester resin by hydroxyl-terminated polybutadiene, which comprises the following steps: adding hydroxyl-terminated polybutadiene rubber into the cyanate ester resin with the addition quantity of 5 to 30 weight percent; heating and melting the mixture to be uniformly mixed; heating the mixture to 120+ / -15DEG C for pre-polymerization for 10 to 60 min; carrying out casting and curing; uniformly heating at 130 to 200 DEG C for 7 to 10h for curing; and obtaining the modified cyanate ester resin with good performance. The modified system improves the curing process of the resin system, reduces the curing temperature of the resin system, shortens of the curing time, reduces the manufacture cost of the materials, the impact toughness of the cured modified cyanate ester resin is obviously improved, and the thermal stability is maintained. Because the modification system has good compatibility, the modification system does not need solvents, and the invention belongs to a direct method with the advantages of no pollution and simple operation.

Owner:NANJING UNIV

Primer with long cure time for polymeric substrates

InactiveUS20060167190A1Improve adhesionLong open timeSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceAdhesive

The invention relates to a primer composition, comprising at least one polyurethane prepolymer (A) with isocyanate terminal groups, at least one aliphatic polyisocyanate (B), at least one aromatic polyisocyanate (C) and at least one reaction product (D), which may be obtained from at least one epoxysilane and at least one aminosilane or from at least one epoxysilane and at least one mercaptosilane. The invention relates to the use of the primer composition as primer for adhesives, sealants and floor coatings.

Owner:SIKA TECH AG

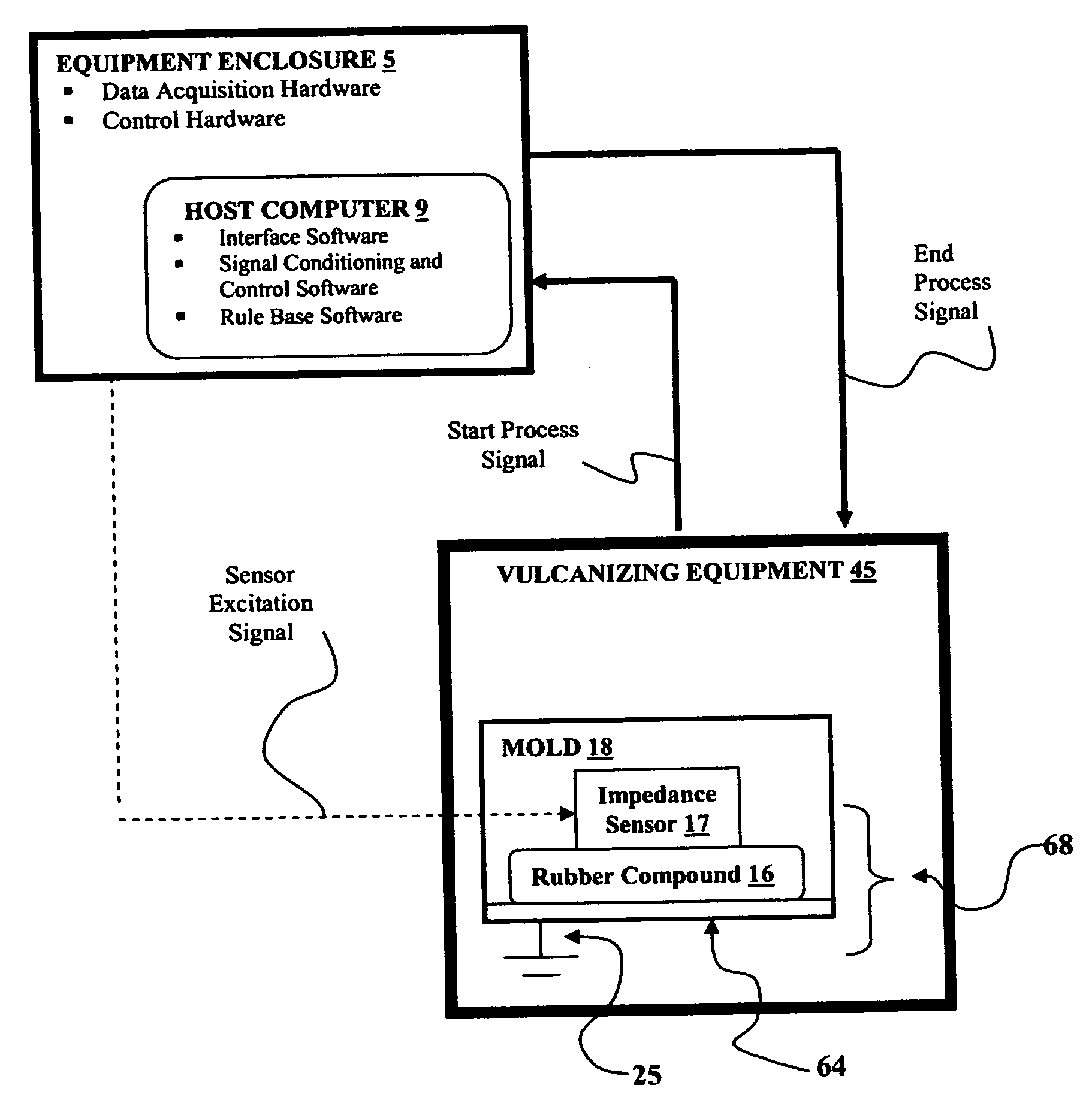

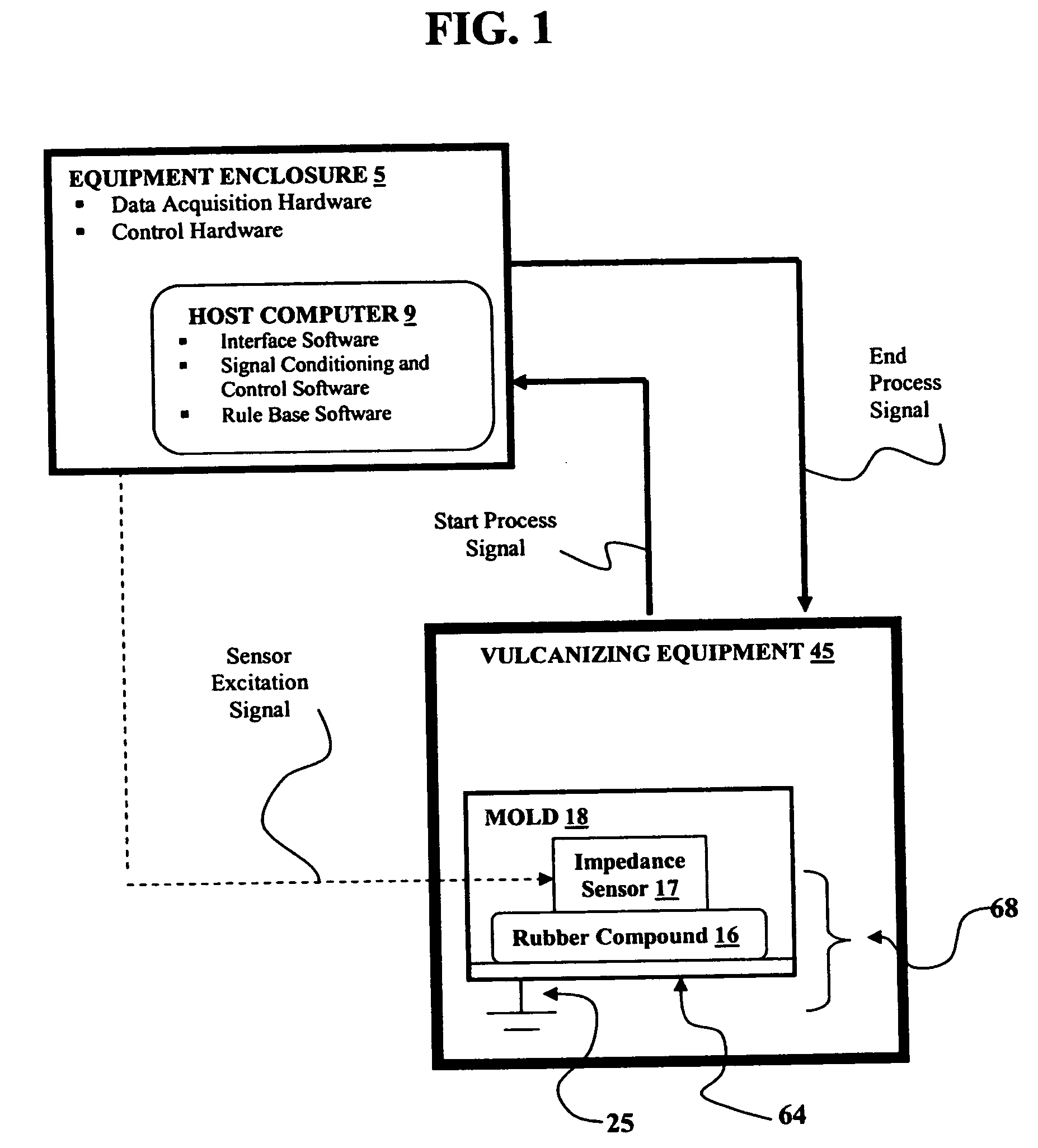

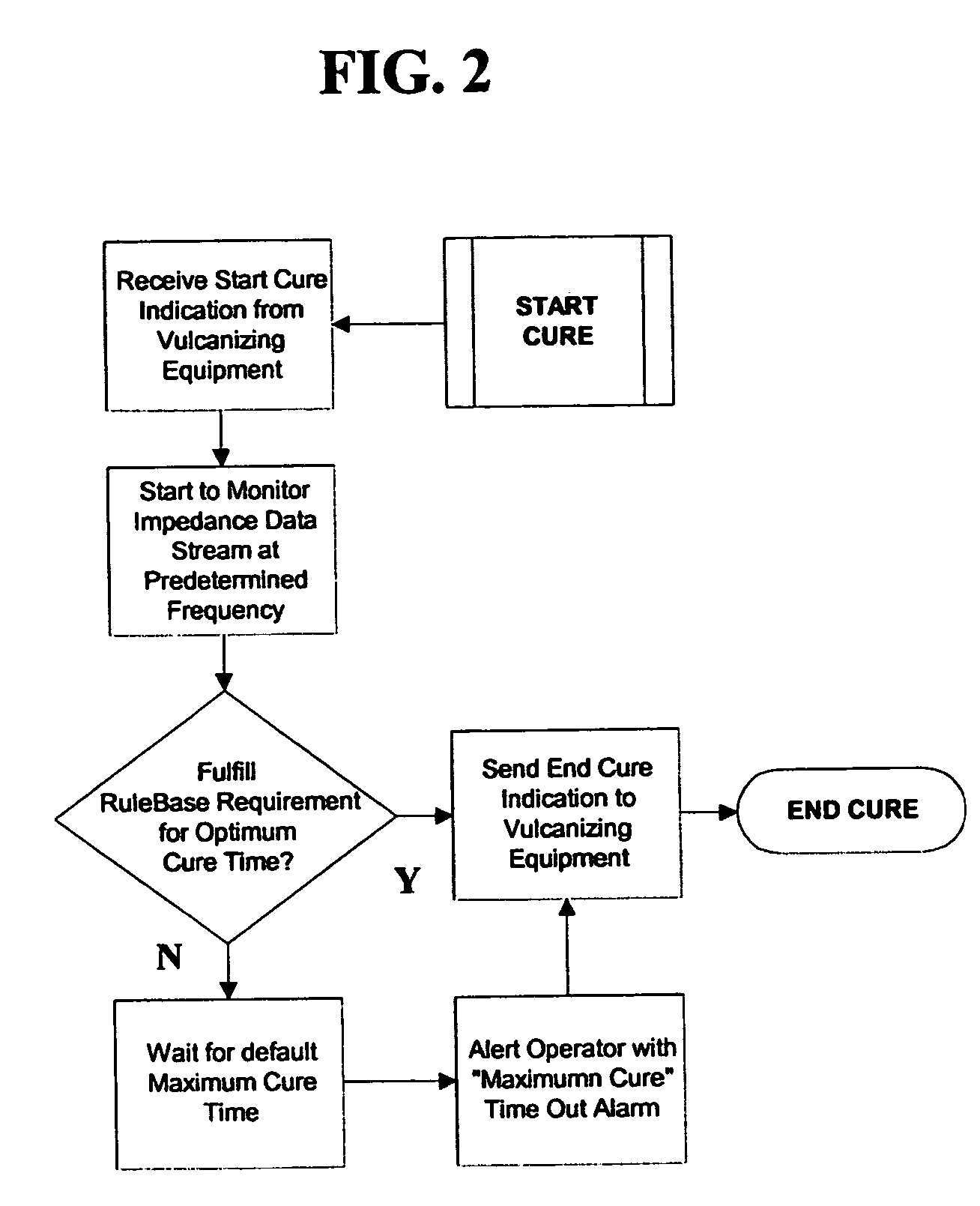

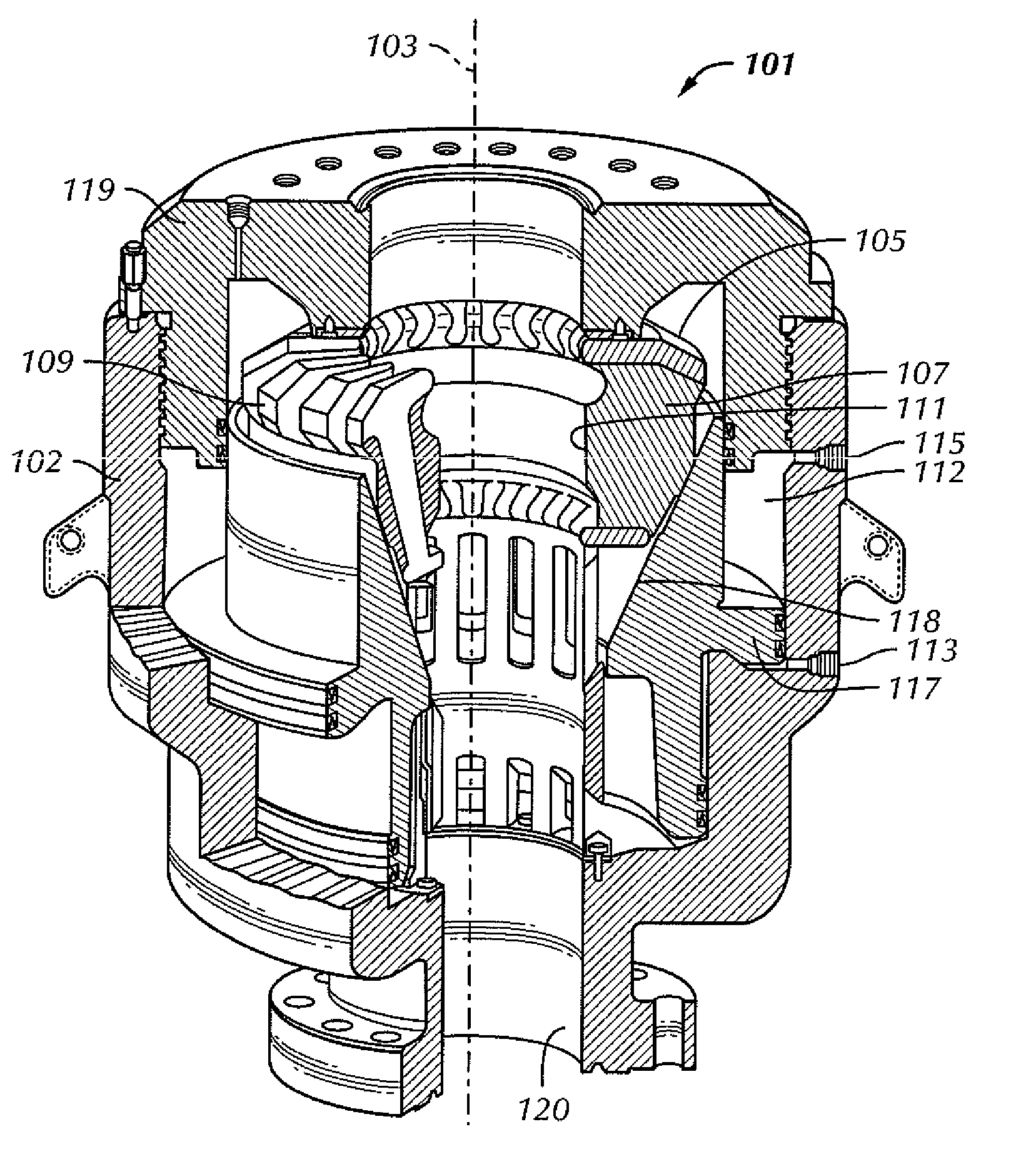

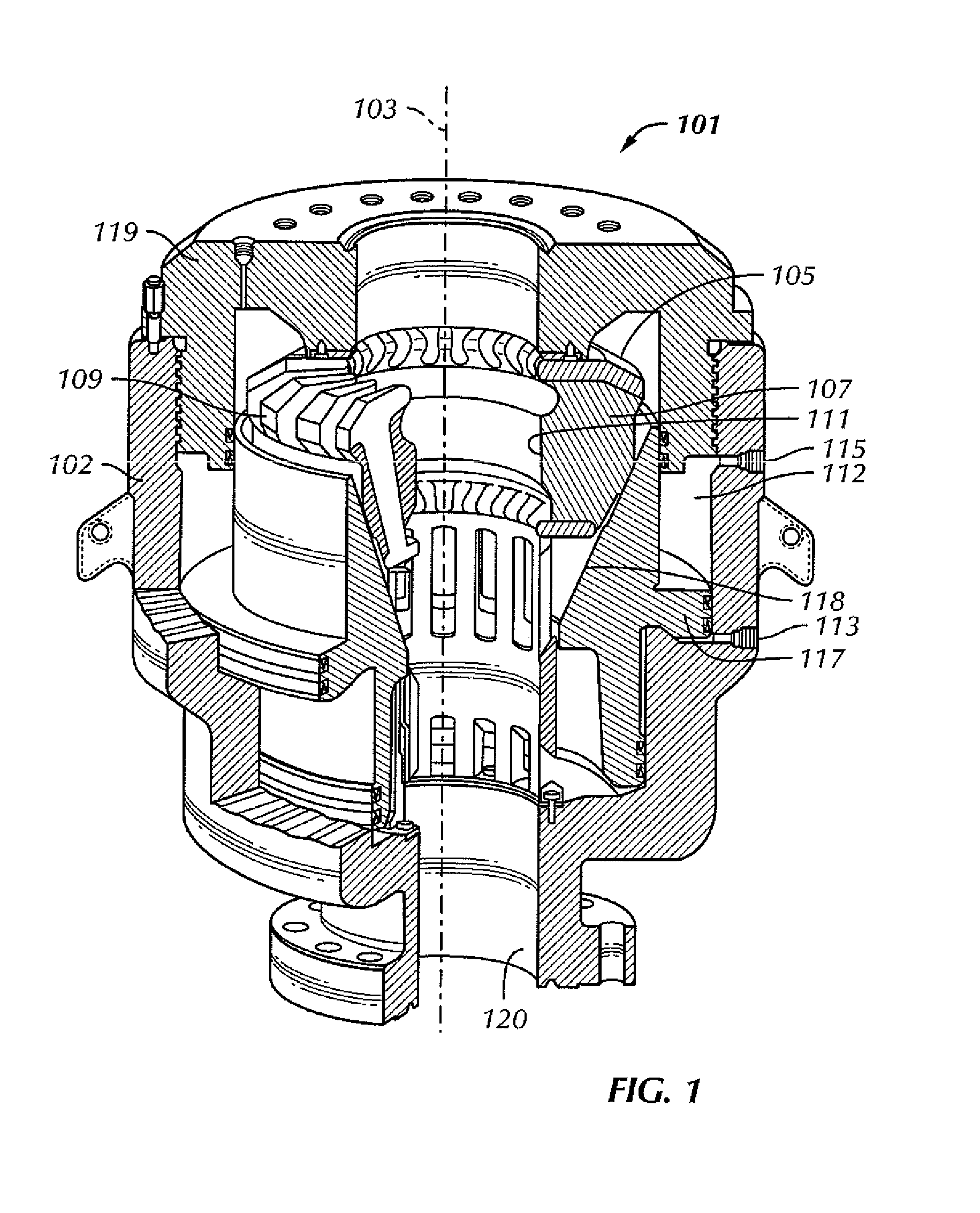

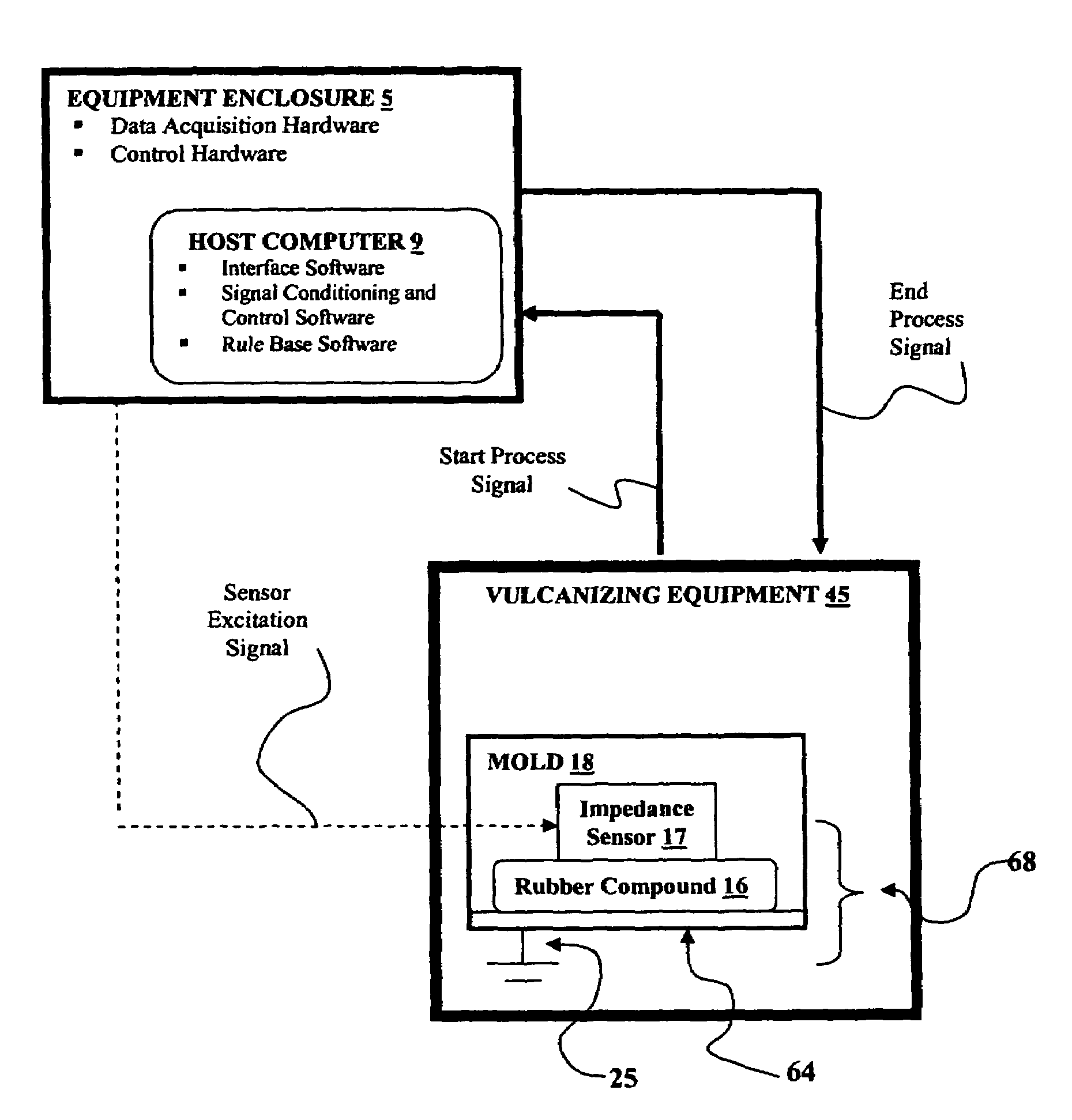

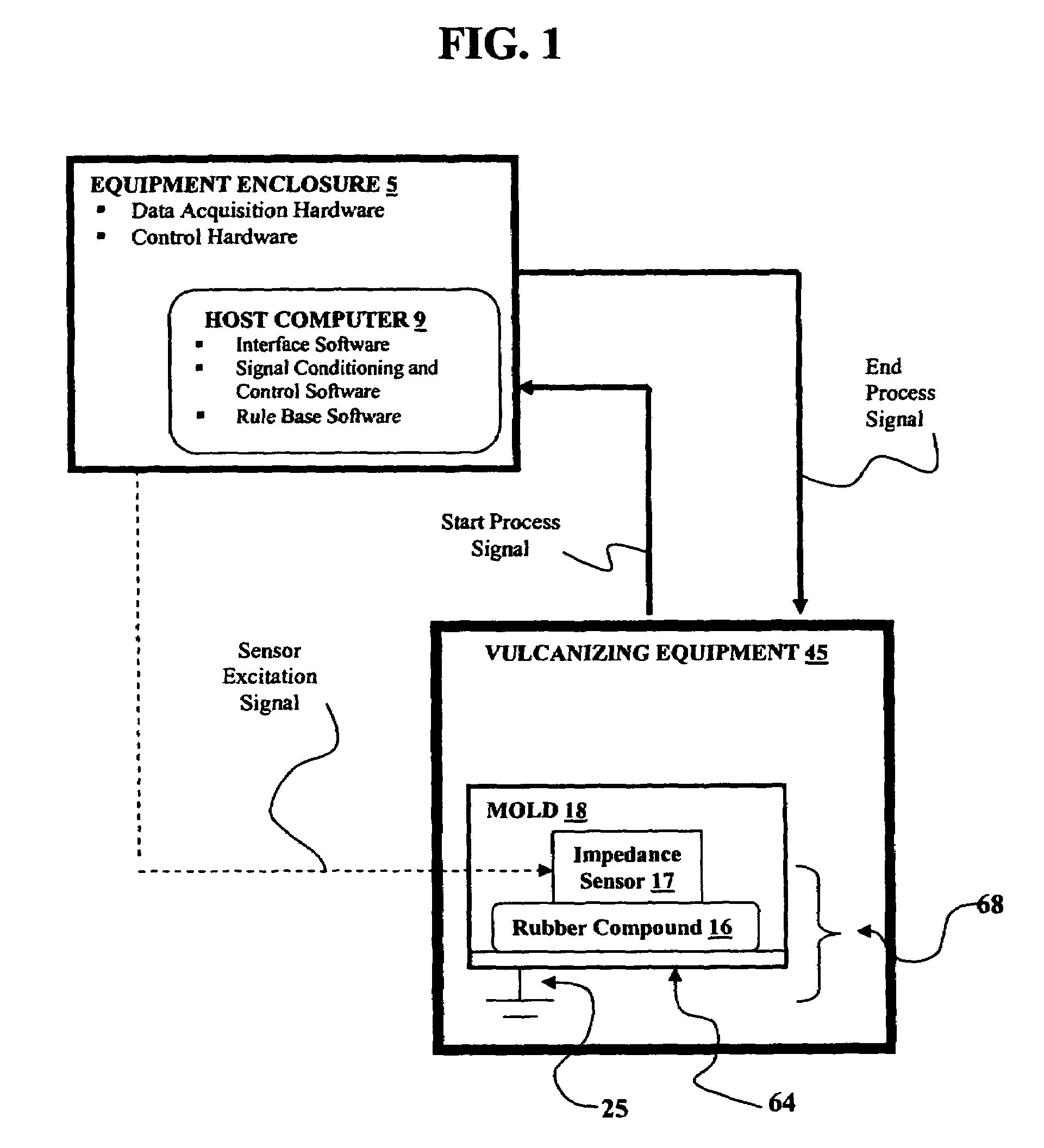

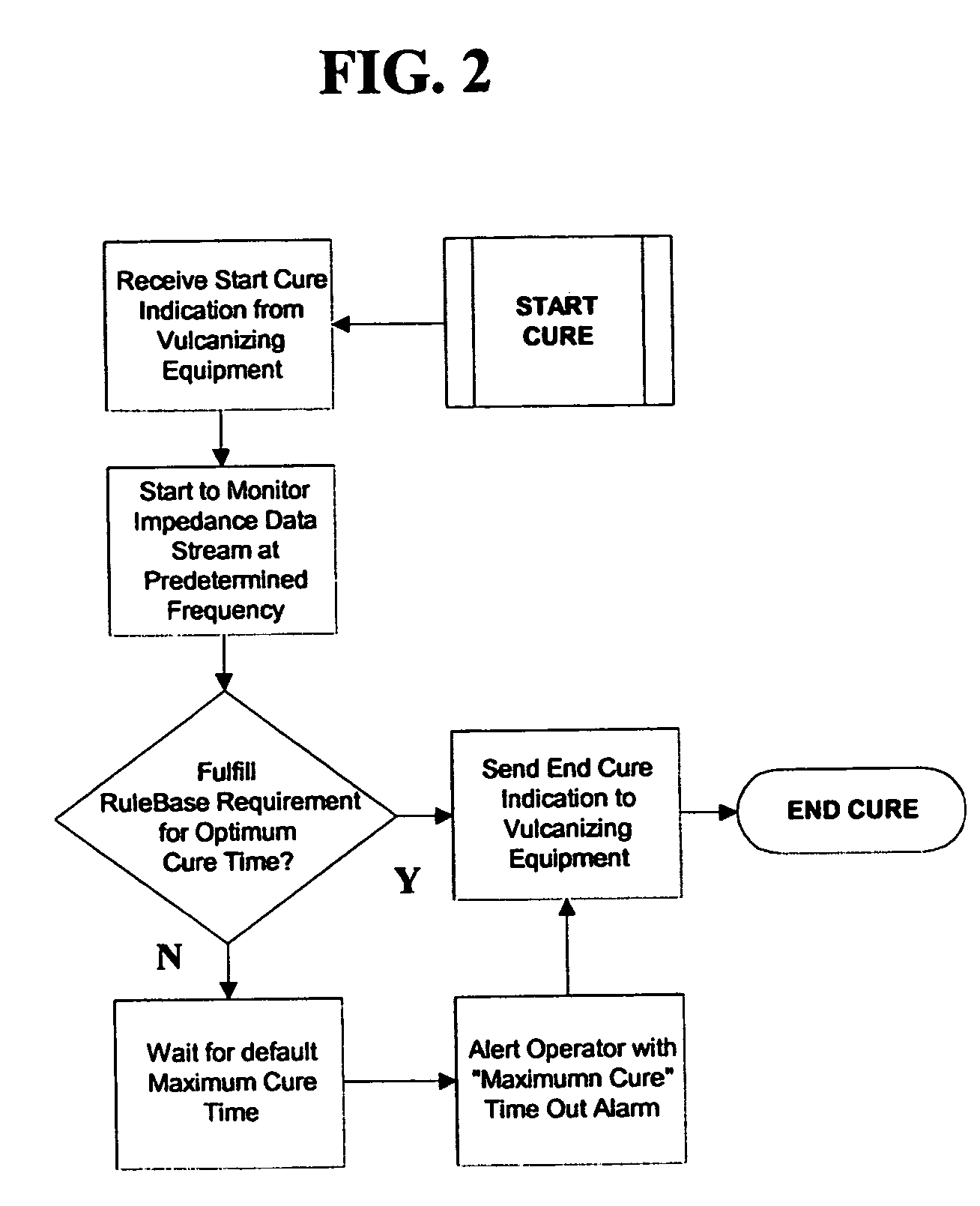

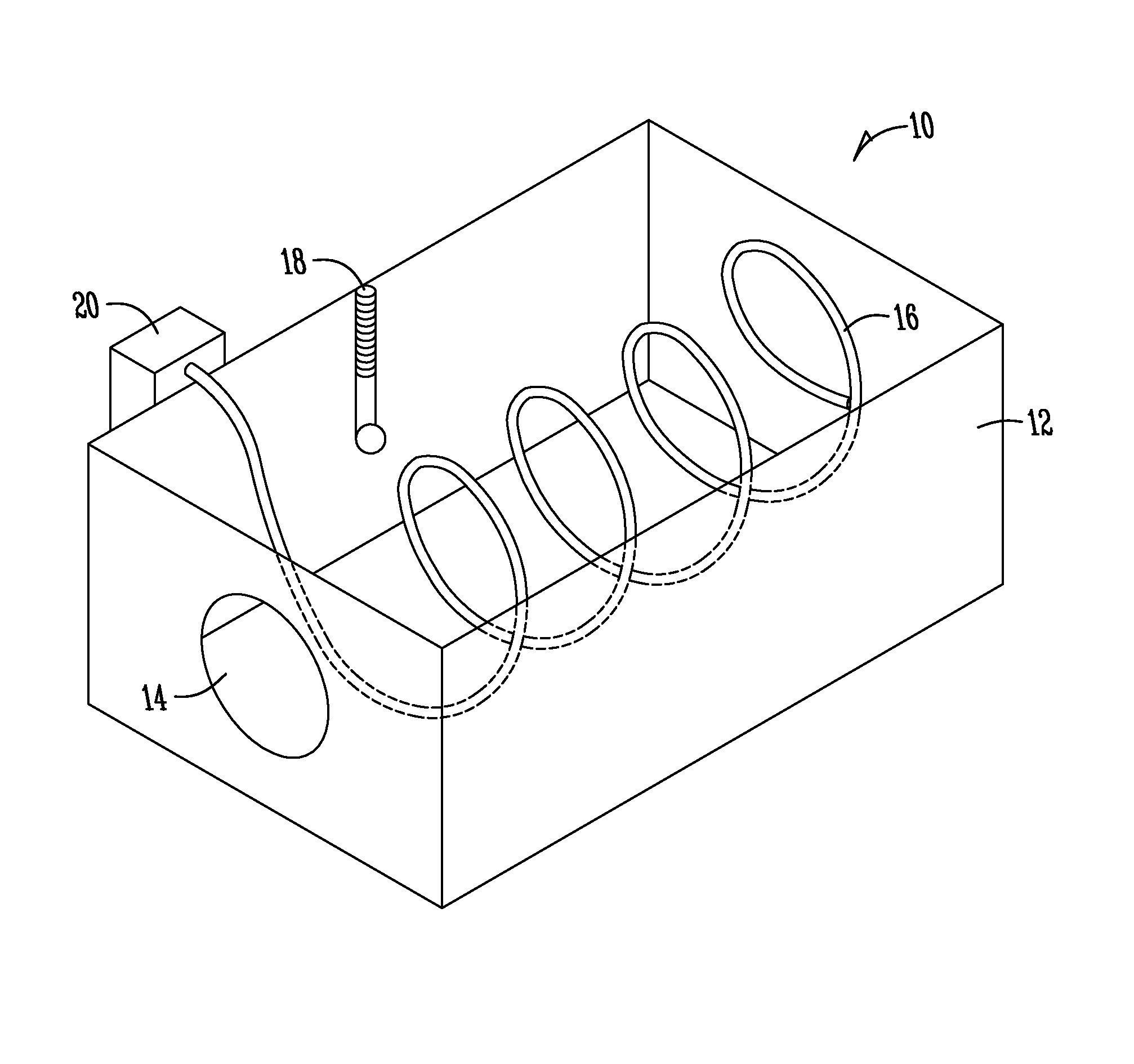

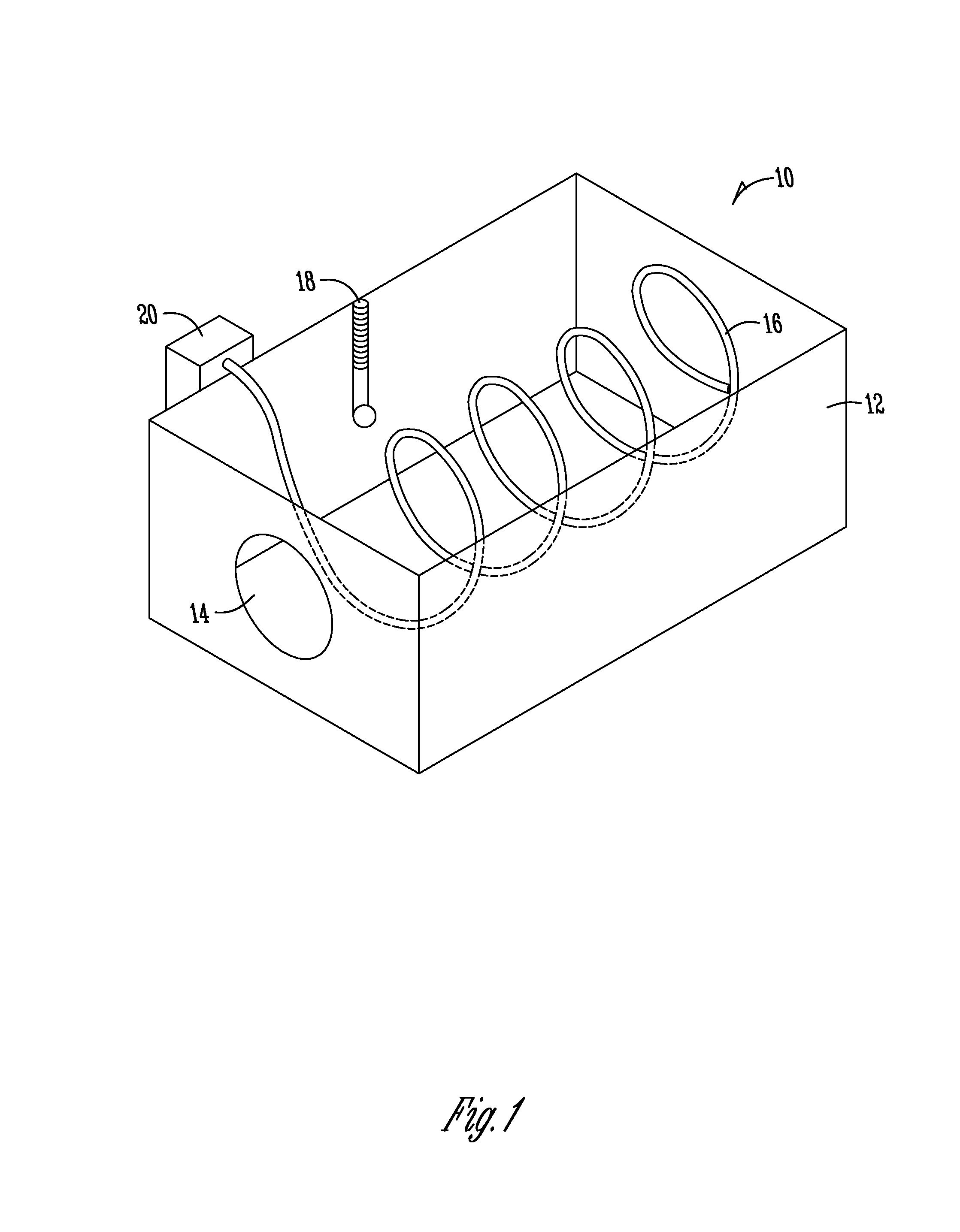

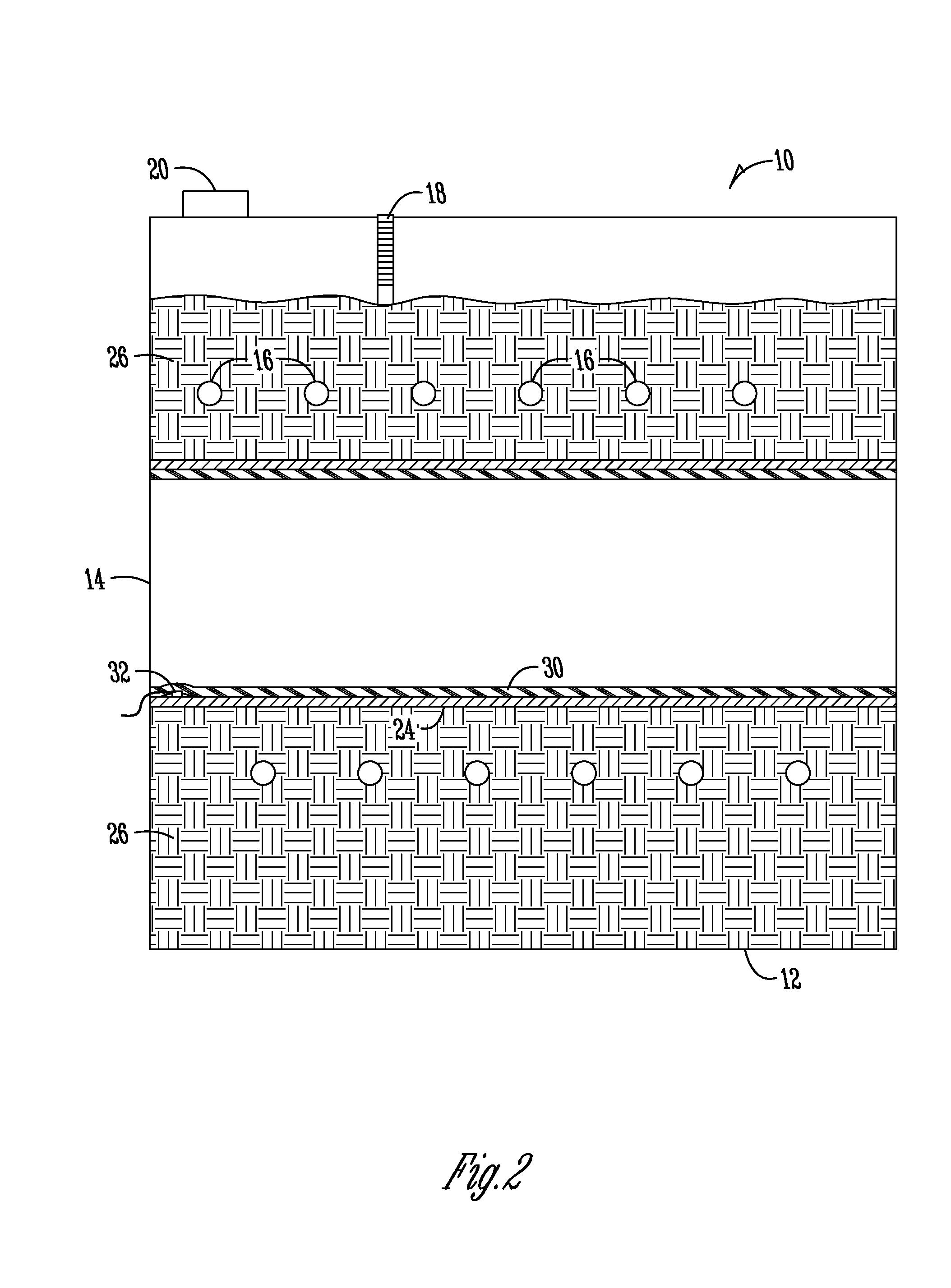

Process and apparatus for improving and controlling the vulcanization of natural and synthetic rubber compounds

InactiveUS20050119785A1Uniform qualityReduce process cycle timeResistance/reactance/impedenceDigital computer detailsChemistryChemical compound

A process for curing a natural or synthetic rubber compound under a plurality of curing conditions by: (1) obtaining time dependent data streams of dielectric or impedance values from a non-bridged impedance sensing circuit and a capacitor having the rubber compound being cured as a dialectric; (2) determining impedance related measurements from the obtained data streams; (3) determining a predictive curing equation by performing a multiple regression between: (a) reheometric data obtained from a plurality of different rubber compound samples cured in a rheometer at various environmental curing conditions, and (b) corresponding samples cured in a production mold at the same environmental conditions; (4) adjusting the curing equation to obtain cured parts having one or more desired properties; and (5) controlling the mass producing cured parts with a controller that uses the curing equation for predicting a cure time for each part, wherein the predictions are effective over variations in the rubber compound, and in the mold temperature.

Owner:SIGNATURE CONTROL SYST

Revised cure cycle for annular packing units

InactiveUS20080023865A1Analogue computers for chemical processesDesign optimisation/simulationElastomerBlowout preventer

A method to manufacture a blowout preventer seal including disposing at least one insert and at least one elastomeric material in a mold, heating the mold to a cure temperature, curing the at least one elastomeric material, measuring a temperature of the at least one elastomeric material during the curing, adjusting a cure time and the cure temperature based on the measured temperature of the elastomeric material, and removing the cured blowout preventer seal from the mold.

Owner:HYDRIL USA MANUFACTURING LLC

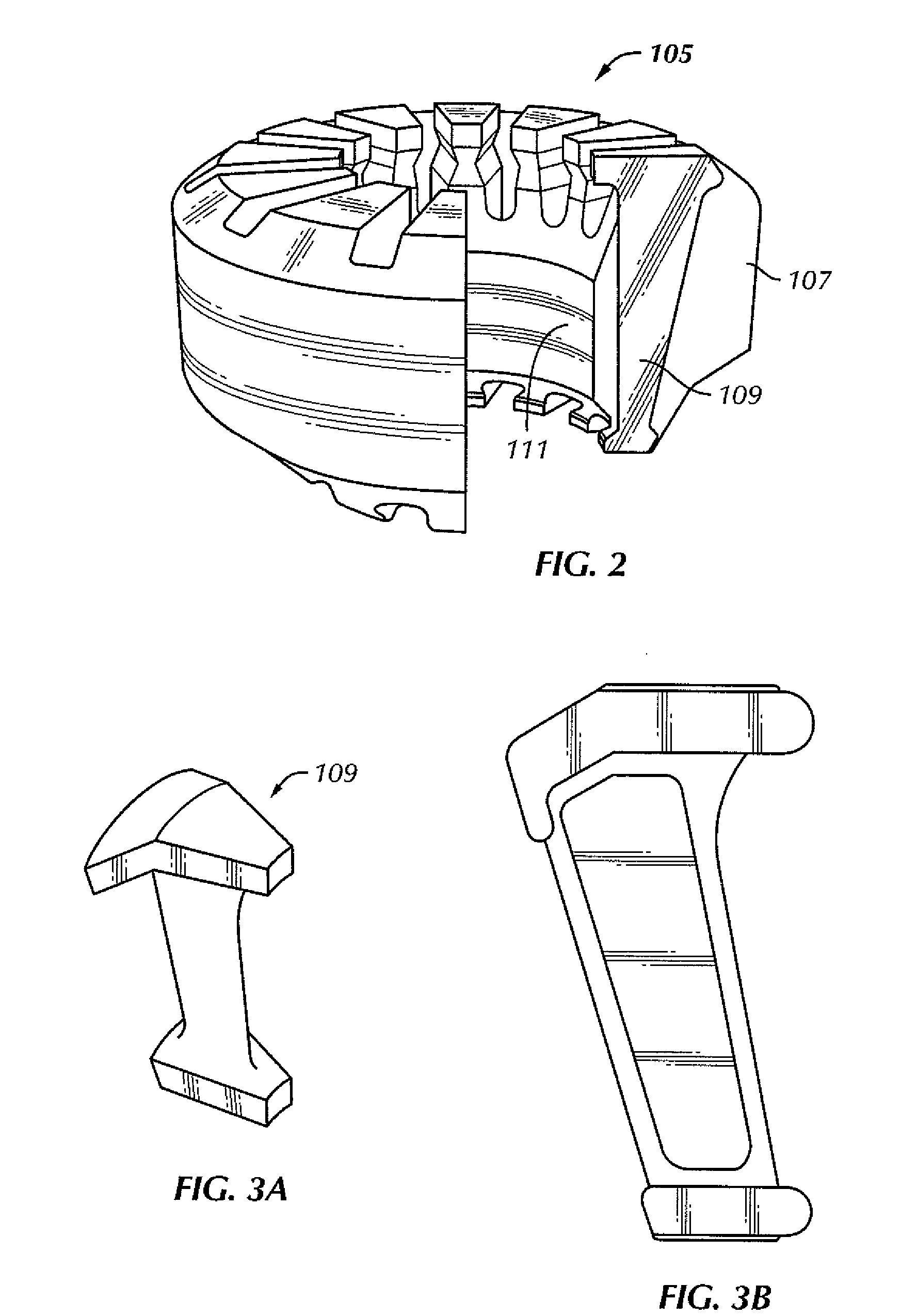

Process and apparatus for improving and controlling the vulcanization of natural and synthetic rubber compounds

InactiveUS7245985B2Unique shapeQuality improvementResistance/reactance/impedenceVoltage-current phase angleCompound aElectricity

A process for curing a natural or synthetic rubber compound under a plurality of curing conditions by: (1) obtaining time dependent data streams of dielectric or impedance values from a non-bridged impedance sensing circuit and a capacitor having the rubber compound being cured as a dialectric; (2) determining impedance related measurements from the obtained data streams; (3) determining a predictive curing equation by performing a multiple regression between: (a) reheometric data obtained from a plurality of different rubber compound samples cured in a rheometer at various environmental curing conditions, and (b) corresponding samples cured in a production mold at the same environmental conditions; (4) adjusting the curing equation to obtain cured parts having one or more desired properties; and (5) controlling the mass producing cured parts with a controller that uses the curing equation for predicting a cure time for each part, wherein the predictions are effective over variations in the rubber compound, and in the mold temperature.

Owner:SIGNATURE CONTROL SYST

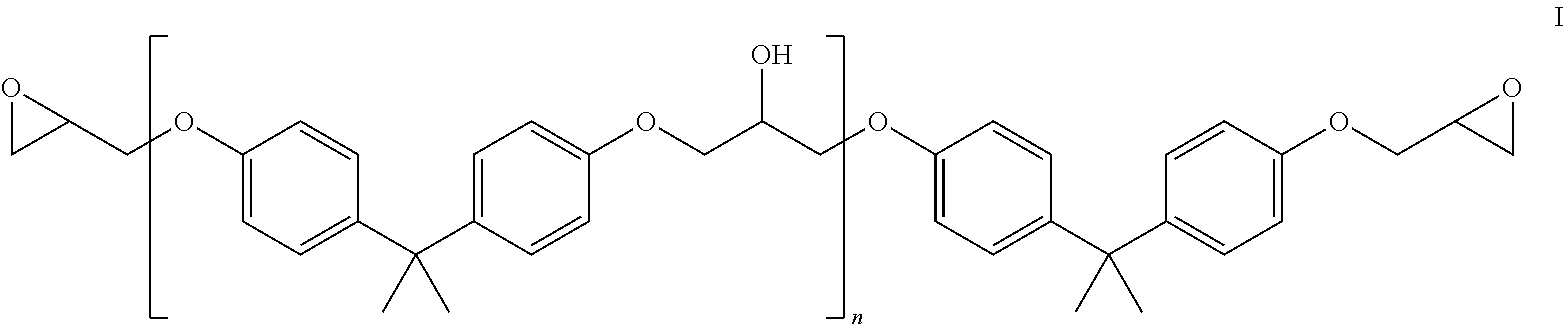

Water borne epoxy resin dispersions and epoxy hardener compositions

ActiveUS20140256852A1Reduce and eliminate solventReducing and eliminating amine blushNon-macromolecular organic additionPaper/cardboardPolymer scienceEnd-group

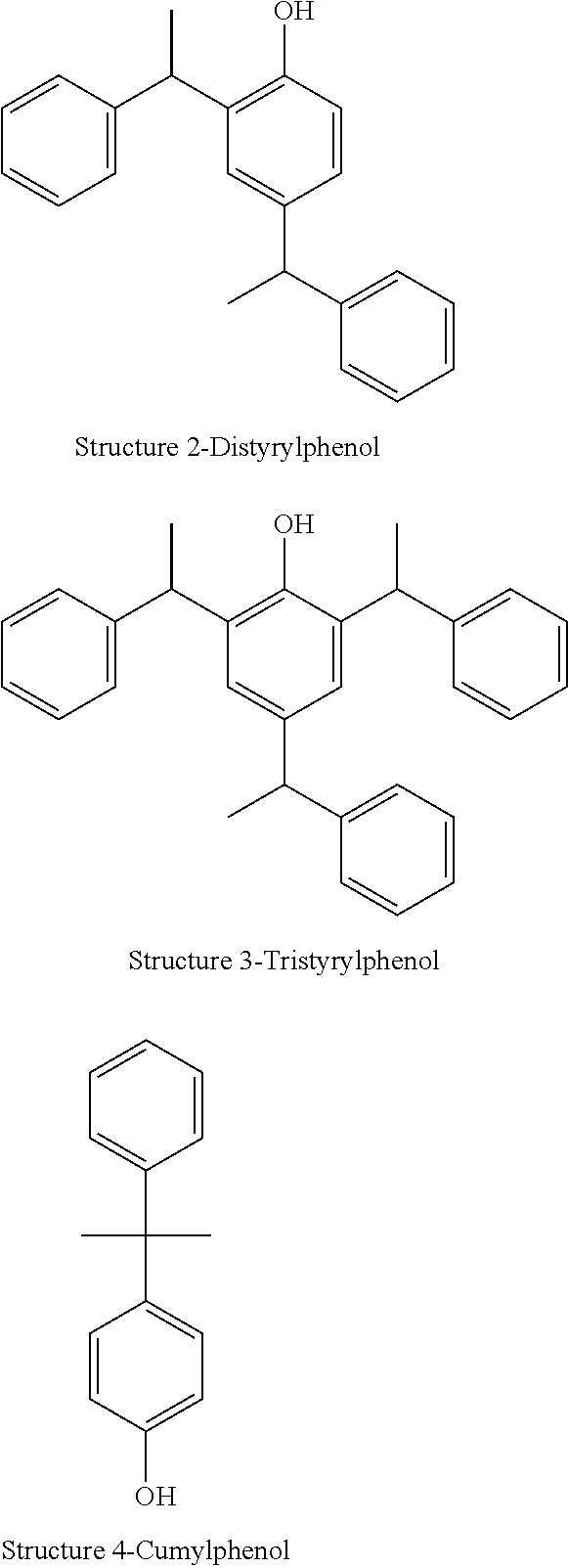

An epoxy or hardener mixture comprising (a) optionally water, (b) at least one hardener or epoxy resin, and (c) from 0.1 to 20 weight percent, based on epoxy resin of at least one distyryl phenol, tristyryl phenol or cumylphenol based additive surfactant with phosphate or sulfonate end groups having the structure R—OXn-W wherein R designates a polystyrylphenol or cumylphenol, preferentially chosen from among distyrylphenol, tristyrylphenol or cumylphenol, and mixtures thereof, and wherein OX designates ethylene oxide and / or propylene oxide. The number of groups “n” varies from 0 to 200, and W designates H, sulfate (—SO3−) or phosphate (—PO3H or —PO2—OXnR). Freeze thaw resistance and improved stability is obtained in epoxy mixtures used in dispersion form. Improved pot life and cure time is obtained using either the epoxy mixture, the hardener mixture or a combination of the two in epoxy hardener formulations.

Owner:ETHOX CHEM LLC

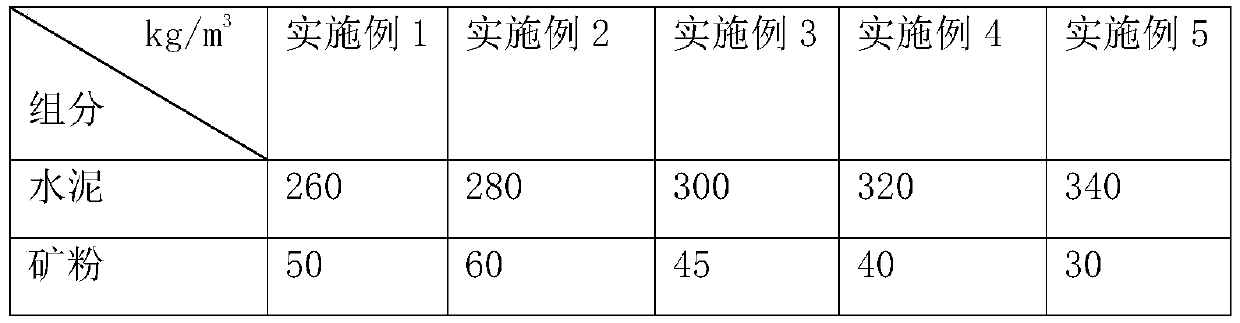

Colored pervious concrete and preparation process thereof

The invention discloses a colored pervious concrete and a preparation process thereof. The colored pervious concrete is prepared from the following raw materials in parts by weight: 260 to 340 parts of cement; 30 to 60 parts of mineral powder; 60 to 90 parts of fly ash, 20 to 45 parts of silica fume, 150 to 200 parts of water, 700 to 900 parts of a fine aggregate, 800 to 1200 parts of a coarse aggregate, 10 to 20 parts of a pigment, 8 to 16 parts of an early strength accelerator, 45 to 80 parts of bisphenol A epoxy resin, 35 to 55 parts of polyurethane modified gelatin and 60 to 90 parts of acuring accelerator; wherein the curing accelerator is prepared from 2-ethyl-4-methylimidazole, a modified anhydride curing agent and a cardanol modified polyamide in a mass ratio of 1 to (1.3 to 1.5)to (0.7 to 1). The colored pervious concrete has the advantages of being high in pervious coefficient, high in early compressive strength and breaking strength, short in curing time, capable of shortening open traffic time and good in thermal aging resistance and freezing and thawing resistance.

Owner:成都新豪鼎盛建材有限公司

Concrete adhesive

The invention discloses a concrete adhesive. The concrete adhesive comprises the following materials in parts by weight: 50-80 parts of epoxy resin, 10-20 parts of acetone, 5-8 parts of ethylenediamine, 10-20 parts of dibutyl phthalate, 50-80 parts of quartz sand, 40-60 parts of cement, 20-40 parts of imide and 100-200 parts of water. Compared with the prior art, the adhering strength of the concrete adhesive disclosed by the invention is 2-3Mpa, the curing water temperature is 10-20 DEG C after underwater construction and the curing time is 7days; and the concrete adhesive has the advantages that adhering strength is high, construction is convenient, curing time is short and the like.

Owner:WUJIANG QINGYI TEXTILE

Adhesive compositions and use thereof

The invention provides adhesives comprising at least one polymer component which contains at least 65 weight percent propylene, at least one nucleator and at least one functionalized wax. The inventive adhesives have increased heat resistance and decreased set-time, making them particularly well suited for assembly and packaging applications.

Owner:HENKEL KGAA

Red mud-based self-suspension flexible grouting material and preparation method thereof

The invention provides a red mud-based self-suspension flexible grouting material and a preparation method thereof, and mainly aims at solving the technical problems that an existing inorganic grouting material is poor in self-suspension performance and bad in flexibility. According to the red mud-based self-suspension flexible grouting material and the preparation method thereof, red mud, a suspending agent, a catalyst, a cross-linking agent and water are adopted to compose a component A, polyaryl polymethylene isocyanate serves as a component B, in the use process, the component A and the component B are mixed to be uniform according to a proportion, and the red mud-based self-suspension flexible grouting material is obtained. The red mud-based grouting material is good in self-suspension performance and easy to grout; the curing time is easy to control, the bonding strength is high after curing is achieved, and the flexibility is good. The red mud-based self-suspension flexible grouting material can be widely applied to repairing of road cracks.

Owner:HENAN POLYTECHNIC UNIV

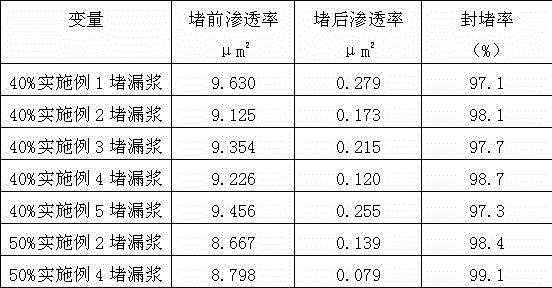

Curable leak-stopping agent

ActiveCN102191024BCuring time controllableImprove performanceDrilling compositionPhysical chemistryCotton fibre

The invention relates to a curable leak-stopping agent. The curable leak-stopping agent comprises the following components which are mixed by weight percentage: 30 to 50 percent of curable material blast furnace, 5 to 15 percent of high filtration material diatomite or fly ash, 15 to 25 percent of fibrous material asbestos fiber, cotton fiber or cob, 2 to 5 percent of soft elasticity expansion material elastic tyre rubber and 20 to 30 percent of acid-soluble material calcium carbonate. The leak-stopping agent provided in the invention can be used independently. The curing time is controllable; the leak-stopping efficiency is high and the leak-stopping agent does not discriminate leakage layer apertures or crack dimensions. The leak-stopping agent is an efficient and curable leak-stopping agent which can be used to stop crack leakage and cave nonreservoir and reservoir leakage.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Solvent-free single-component polyurethane adhesive and preparation method thereof

The invention relates to a solvent-free single-component polyurethane adhesive and a preparation method thereof. The adhesive comprises the following raw materials in percent by weight: 70-85% of isocyanate, 15-30% of polyhydric alcohols, and a catalyst of which the weight is 0.02%-0.06% of the total weight of the isocyanate and the polyhydric alcohols. The adhesive provided by the invention belongs to a wet-cured type polyurethane adhesive, the storage life is longer than 6 months, the opening time is longer than 24 hours, the curing time is short as the adhesive can be quickly cured within 30 seconds when encountering water at the temperature of 120-130 DEG C, and the bonding strength is high. The adhesive is used for hot-pressing adhesion among polyurethane foam, glass fiber cloth and non-woven fabric during the manufacture of automobile mould pressing roof, the hot-pressing temperature is 120-130 DEG C, the curing time is 20-30s and the bonding strength is 15-20N.

Owner:CHANGCHUN YINGLONG MATERIAL TECH CO LTD

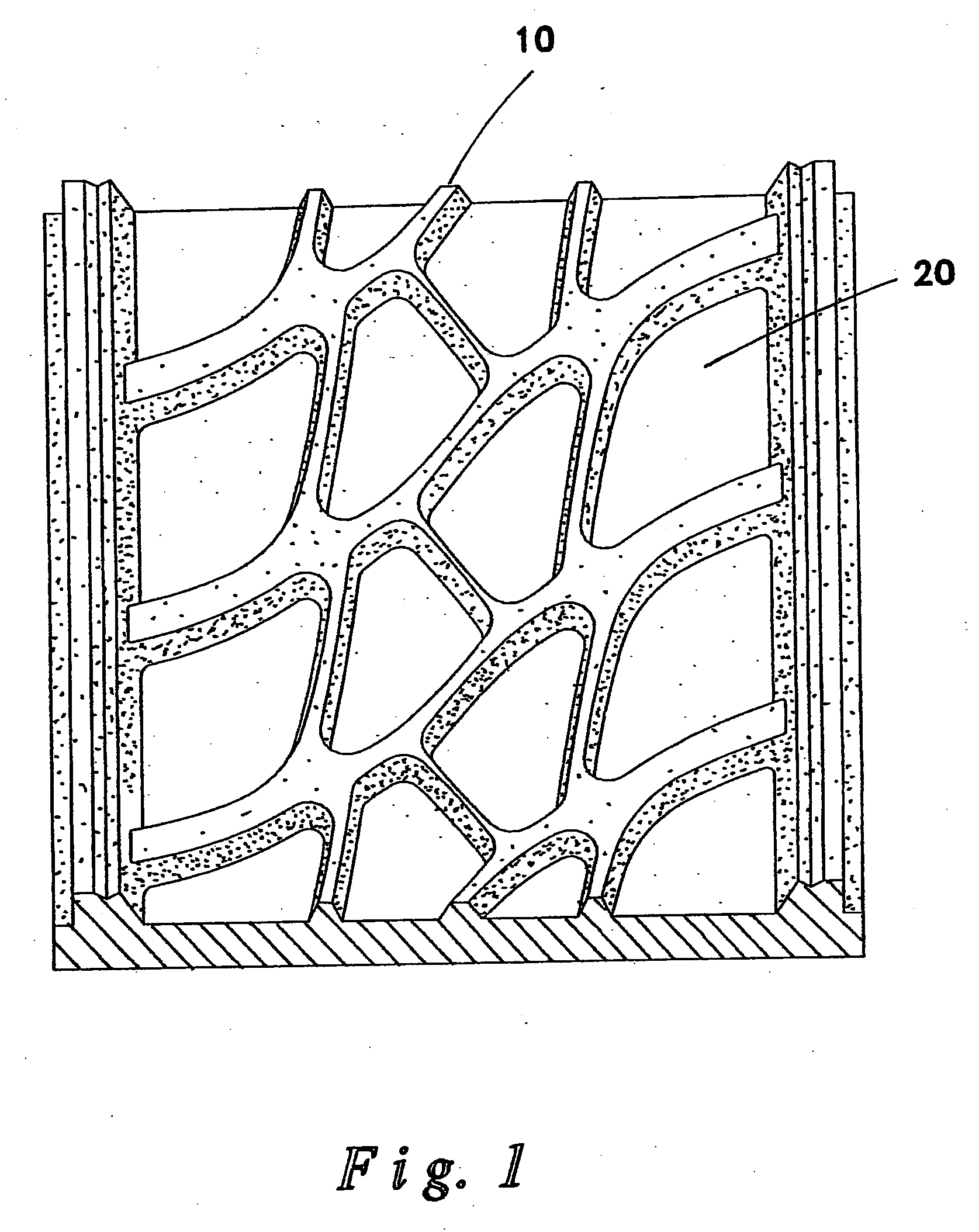

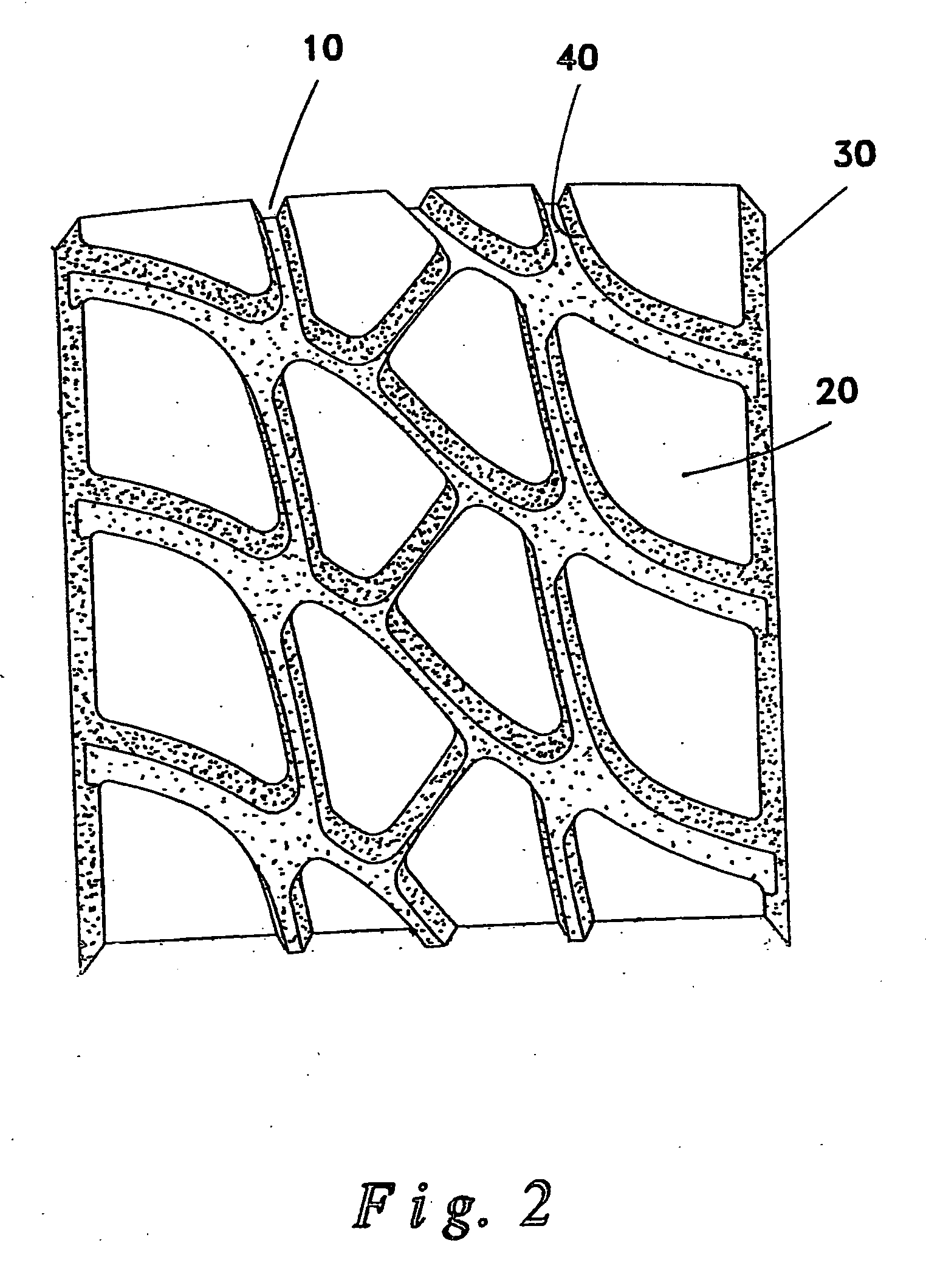

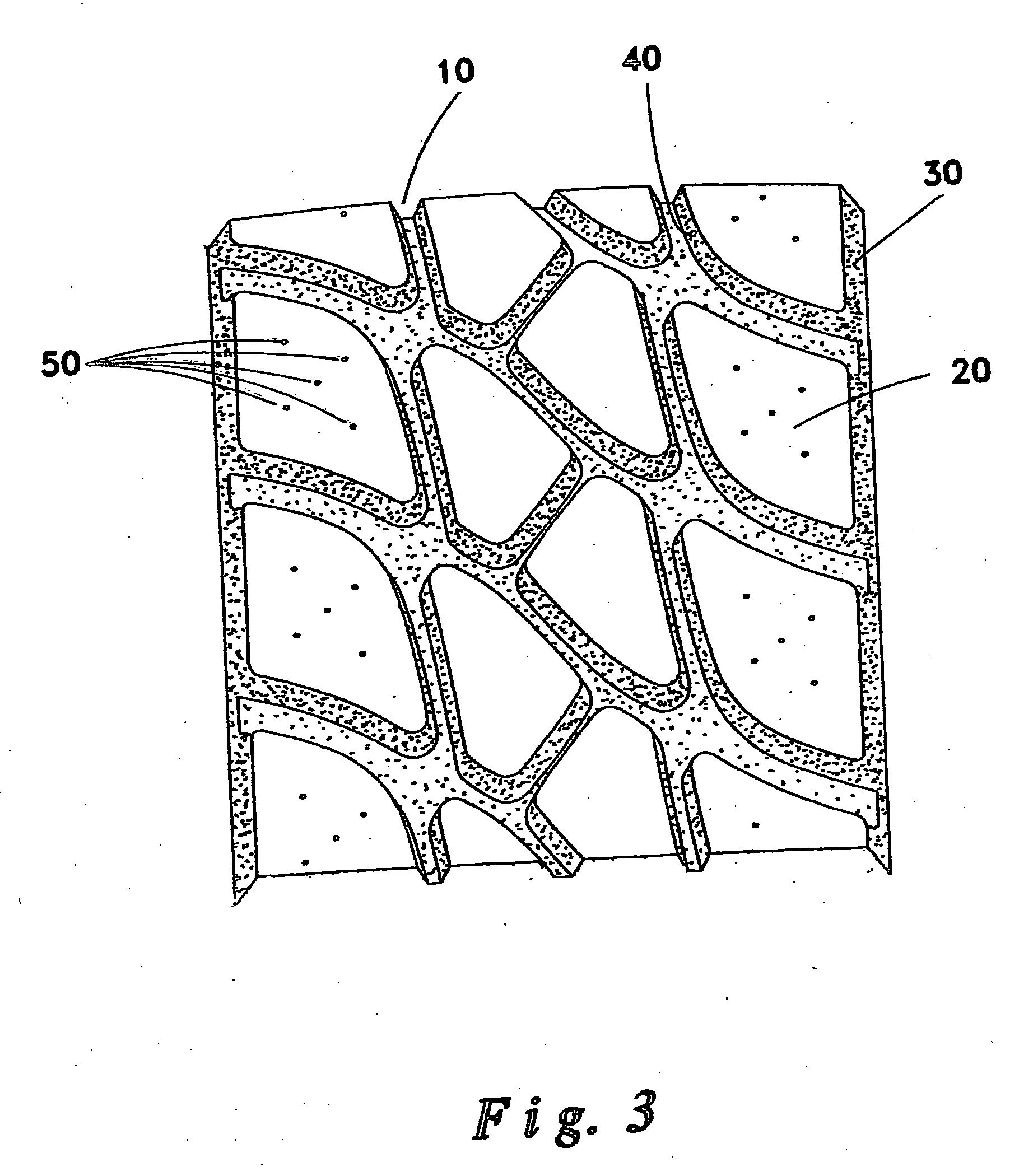

Method for curing a thick, non-uniform rubber article

Finite element analysis or thermocouple probes are used to determine the state of cure for each zone of a non-uniform, thick rubber article, such as a large tire or a tread for a tire. From this knowledge of those cure-limiting zones, heat transfer elements are added to the mold to enhance the transfer of heat into these cure-limiting zones and to provide a more optimum cure. The use of heat transfer pins and / or mini-sipes are an efficient and practical means of reducing total cure time in the press and optimizing cure state without substantially affecting the performance of the article such as the tire. Reductions in cure time of 10% or more are demonstrated.

Owner:MICHELIN RECH & TECH SA +1

Photopolymerizable coating composition

InactiveUS20120189779A1Convenient coatingSynthetic resin layered productsPretreated surfacesFunctional monomerPolyamide

A photopolymerizable coating composition and method for polyamide substrates, wherein the photopolymerizable coating composition consists of at least one acid-functional monomer with a molecular weight less than 240 g / m, at least one reactive crosslinking monomer and at least one photoinitiator. The coating compositions of the invention have improved adhesion to polyamide substrates, and also provide faster cure times and more effective protection from environmental insults as compared to prior art compositions.

Owner:BRIZON

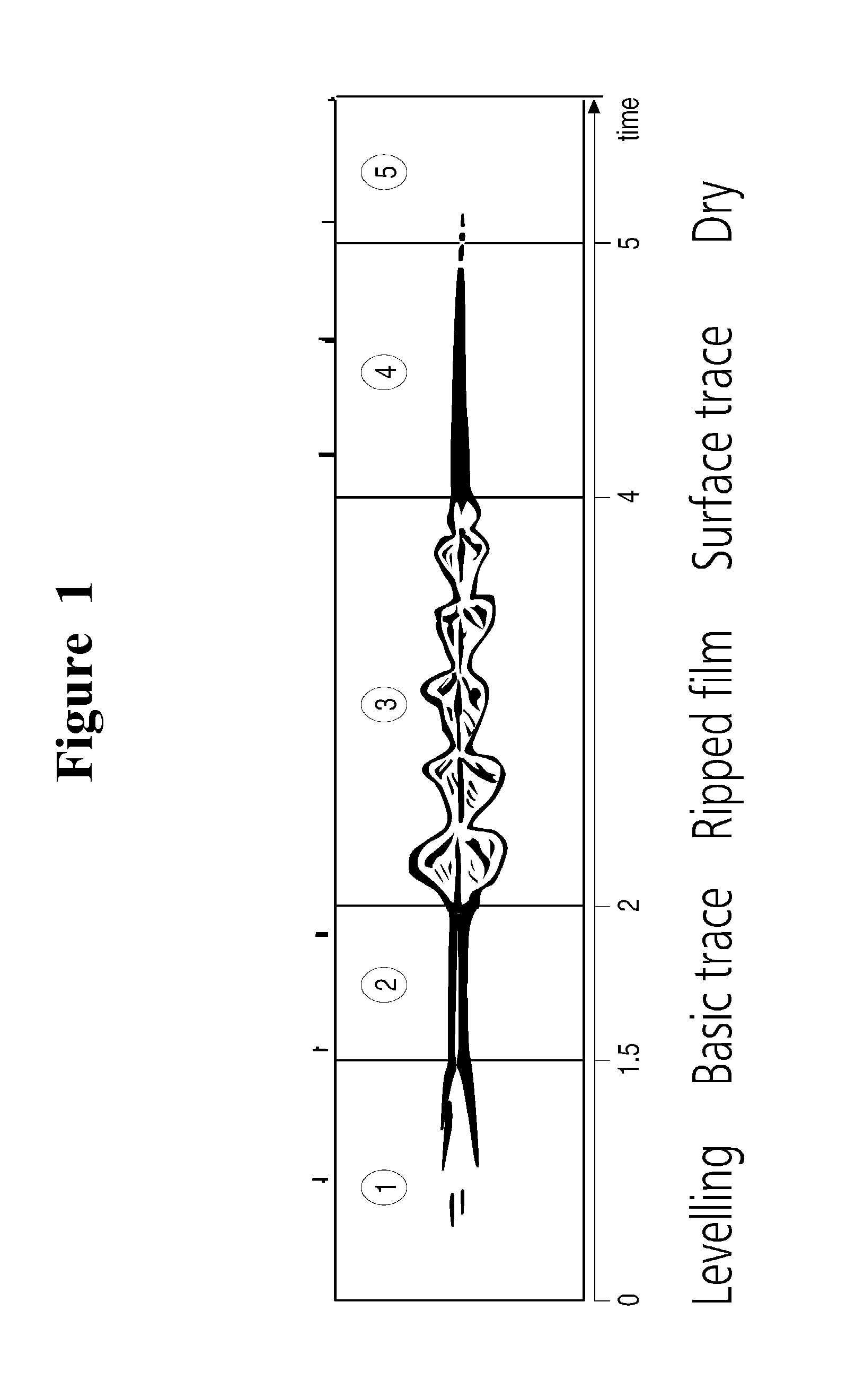

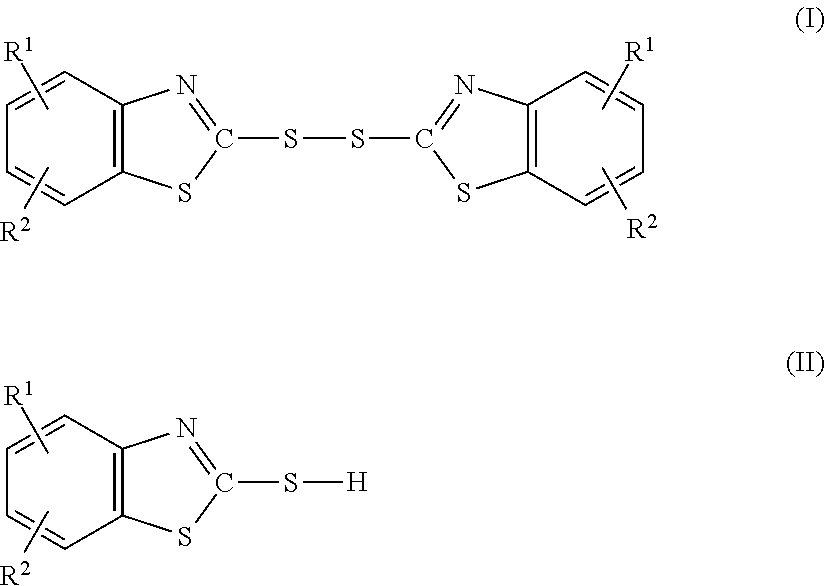

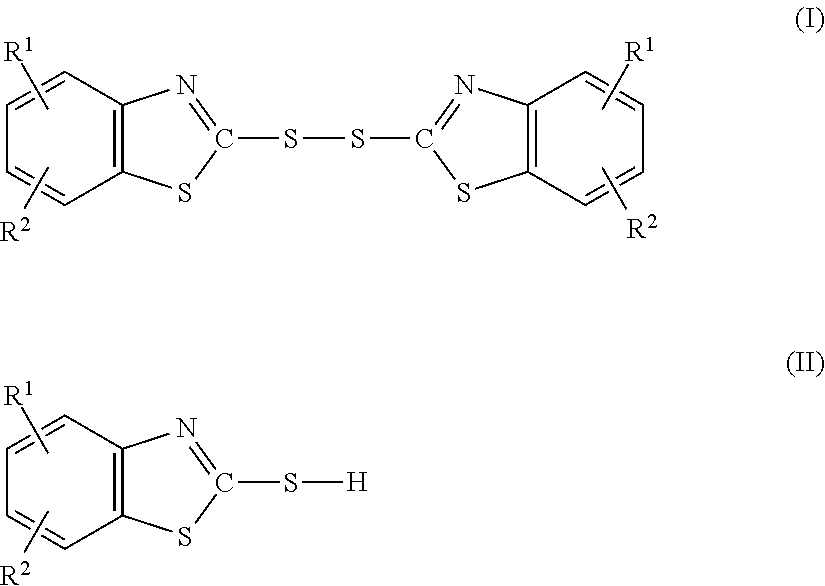

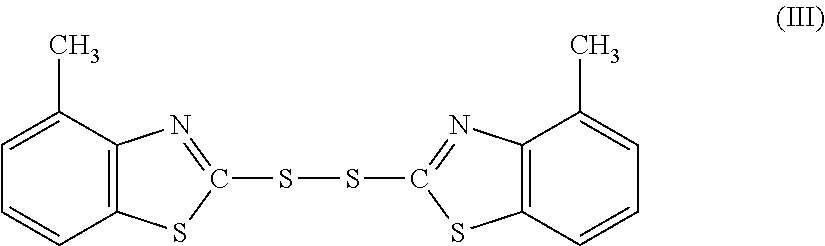

Rubber composition for cap tread and winter tire

InactiveUS20120259038A1Improve cross-linking efficiencyMaintain good performanceSpecial tyresVulcanizationHeat resistance

Provided are a rubber composition that makes it possible to improve heat resistance and particularly suppress changes in the properties (e.g. hardness) of the vulcanized rubber composition with long-term use (rubber hardening degradation) to suppress a reduction in performance on snow and ice to extend the life-span, without increase in the antioxidant amount, achieve good performance on snow and ice, wet-grip performance, and abrasion resistance, and reduce curing time and enhance cross-linking efficiency; and a winter tire including a cap tread produced from the composition. The rubber composition for a cap tread comprises a rubber component containing an isoprene-based rubber and butadiene rubber; silica; aromatic oil; a compound represented by formula (I) and / or formula (II); and a thiuram vulcanization accelerator, wherein the amount of silica is 15-80 parts by mass, and the amount of aromatic oil is 15-80 parts by mass, per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

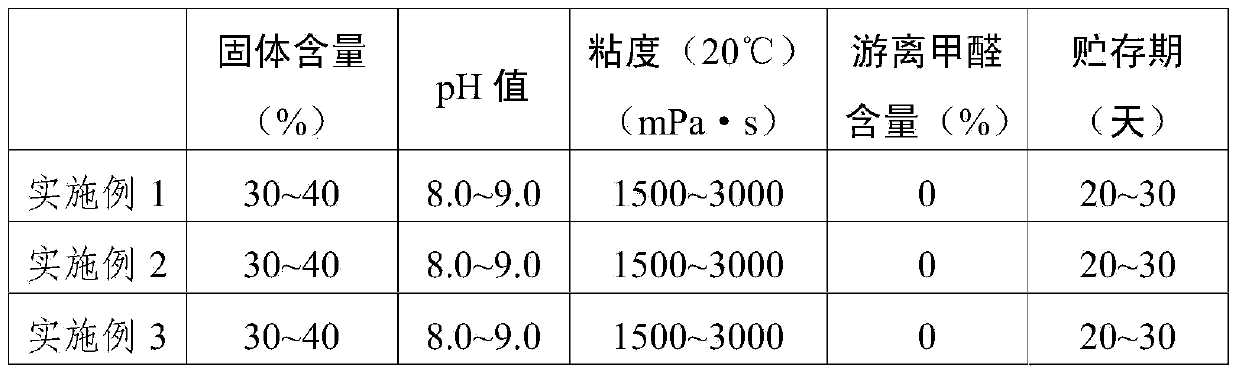

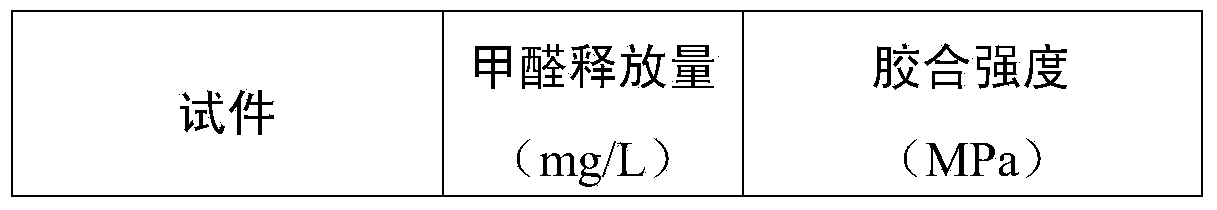

Adhesive for artificial boards and preparation method thereof, and plywood prepared from adhesive

ActiveCN103740325ASolve pollutionSolve Exhaust ProblemsNon-macromolecular adhesive additivesProtein adhesivesAdhesive cementFuran

The invention relates to an adhesive for artificial boards and a preparation method thereof, and a plywood prepared from the adhesive. The adhesive for artificial boards is prepared from a dispersion medium, a protein substance, an alkaline compound and a crosslinking reinforcer, wherein the crosslinking reinforcer is a furfuryl alcohol-furfural furan resin. The adhesive for artificial boards is free of formaldehyde, is mainly prepared from renewable substances, and thus, is an environment-friendly adhesive for artificial boards; the adhesive provided by the invention thoroughly solves the problem of formaldehyde pollution when in use, and ensures water resistance, adhesion strength and other practical properties of the adhesive; compared with the prior art, the components have favorable synergetic effects, so that the effect is enhanced; the preparation method is simple, does not need very long curing time, is convenient to operate and has high production efficiency; and generally, the method comprehensively utilizes the resources, saves the production cost, conforms to the principles of environmental protection and sustainable development, and has favorable application prospects.

Owner:SCHOLAR HOME SHANGHAI NEW MATERIAL CO LTD

Fast-drying, low-temperature type environmental-protection epoxy resin bicomponent dry coating and preparation method thereof

The invention discloses a fast-drying, low-temperature type environmental-protection epoxy resin bicomponent dry coating, which consists of two components, namely A and B, and is characterized by: 1. 10 to 15 minutes of initial curing time at the temperature of 25 DEG C and 1 hour of fully curing time; 2. good anti-seismic property, anti-shock property, anti-aging property, anti-compression property, and waterproof property, moisture-proof property, anti-acid property, and the like; 3. high bonding strength, less influence of seasonal climate on construction thereof, being capable of being prepared on the condition of low temperature of minus 20 to minus 80 DEG C, non-hardening property in winter and thus overcoming the difficulty of construction in winter; 4. 30 to 45 minutes of surface drying time, thereby providing a reasonable construction period for construction; and 5. good toughness, non-brittleness, and being capable of preventing deformation, distortion, and falling-off caused by various external factors. The invention can be widely applicable to industries such as construction and decoration, machinery, metal and ceramics, leather and wood, furniture and footwear, and the like.

Owner:成都市双流新达实业有限责任公司

Spraying rapid-condensed rubber asphalt waterproof coating material

InactiveCN103102809AEasy to operateShort construction periodUnspecified rubber coatingsBituminous coatingsForeign matterPolymer science

The invention relates to a spraying rapid-condensed rubber asphalt waterproof coating material which comprises the following formula by weight percent: 50% to 60% of asphalt, 2% to 3% of special emulsifiers, 10% to 20% of rubber emulsions, 0% to 2% of dispersing agents and 0% to 2% of stabilizers. Compared with the prior art, the coating material provided by the invention has the advantages that (1) the operation is simple, rapid and convenient, and the construction period is short; the efficiency is high, i.e., the spraying area of the coating material sprayed continuously for 8 hours by adopting one machine with two spraying guns (three-person group) is more than 1500 m<2>; and the coating material is free of being influenced by the complexity of a base surface structure; and (2) the coating material is formed by compounding a plurality of compound rubbers through a mutual network penetrating technology and a nanotechnology, wherein the coating material is rapidly condensed at the initial phase by utilizing the condensation-prompting catalysis principle, i.e., the film forming speed is rapid, and the initial condensation curing time is only from 3 to 5 seconds. In addition, the surface of a product on the construction site is prevented from being bonded with foreign matters or being damaged, and the defect such that the common paint flows easily is overcome.

Owner:王恒傲

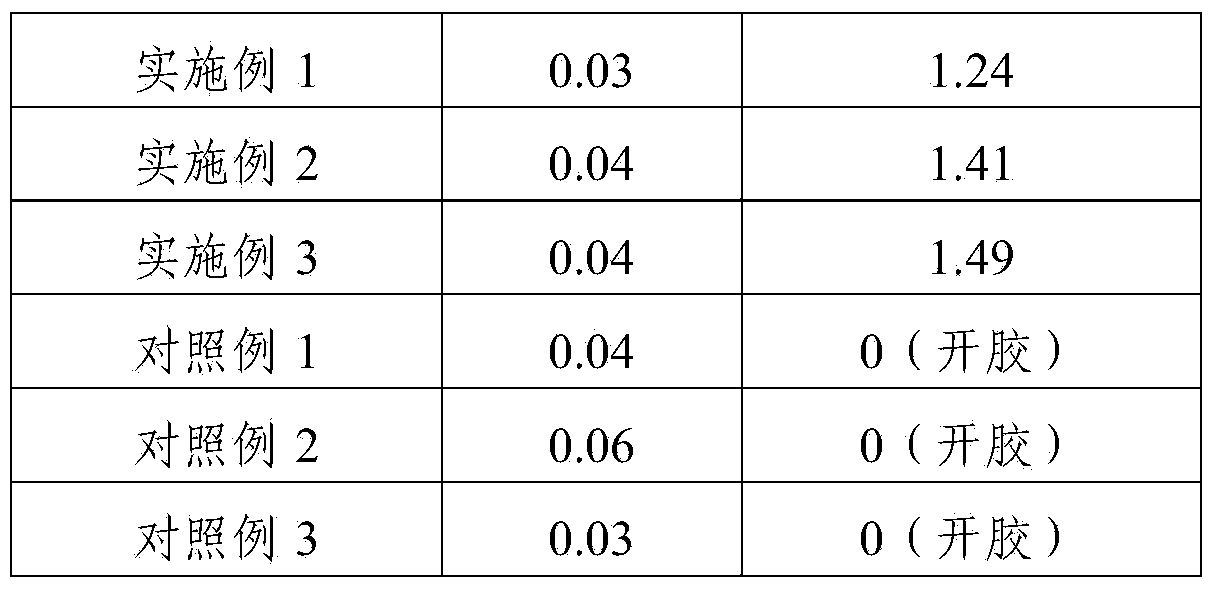

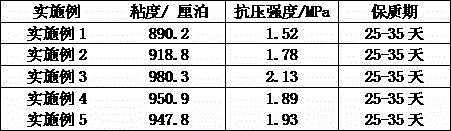

Quick-curing adhesive and preparation method thereof

InactiveCN102190996AReduce investmentShort curing timeAldehyde/ketone condensation polymer adhesivesElectricityAdhesive

The invention discloses a quick-curing adhesive and a preparation method thereof. The quick-curing adhesive is prepared from phenol, 37% formaldehyde, 86% polyformaldehyde, NaOH, H2O, silane coupling agent and phenolic resin curing agent. When the quick-curing adhesive disclosed by the invention is used for preparing an emery cloth grinding tool, the curing drying technique can be implemented after directly drying for 2 hours. Compared with the traditional technique, the invention greatly shortens the curing time, saves the investment into the curing oven, cancels the aging treatment, enhances the work efficiency in production and saves the manpower, thereby greatly shortening the production cycle of the product, achieving the goal of greatly lowering the product cost, enhancing the market competitiveness of the product and improving the economic benefit; and meanwhile, the invention can save electricity, steam, water, coal and the like, and make contributions in the aspects of energy conservation and emission reduction.

Owner:新沂市张氏磨具发展有限公司

Sealant for photovoltaic module and preparation method of sealant

ActiveCN104178040AStable chemical propertiesStable and water resistantOther chemical processesOrganic non-macromolecular adhesivePolymer scienceOctanoic Acids

The invention belongs to the technical field of sealants and relates to a sealant for a photovoltaic module. The sealant is characterized by comprising the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 15-25 parts of 201 polysulfide rubber, 10-15 parts of m-phenylenediamine, 10-20 parts of dibutyl phthalate, 1-3 parts of diethylenetriamine, 30-50 parts of talc power, 10-15 parts of maleic anhydride, 15-20 parts of 651 low-molecular-weight polyamide, 4-6 parts of stannous octoate and 20-30 parts of epoxypropane phenyl ether or diglycidyl resorcinol ether or ethylene glycol diglycidyl ether. The invention also discloses a preparation method of the sealant. The sealant disclosed by the invention has the beneficial effects of convenience in operation, short curing time, good adhesion, low water vapor and gas permeability, good sealing property / weather resistance and UV resistance and wide application temperature range and the long-term performance is maintained.

Owner:特瓦特能源科技有限公司

Vamp spray glue and preparation method thereof

ActiveCN103805115ALow viscosityGood yellowing resistanceMineral oil hydrocarbon copolymer adhesivesEpoxy resin adhesivesEpoxyElastomer

The invention provides vamp spray glue and a preparation method thereof. The vamp spray glue is characterized in that each 100 parts of vamp spray glue comprises the following components in parts by weight: 8-15 parts of an ethylene-segmented copolymer elastic body, 5-18 parts of water-white hydrogenated rosin, 5-12 parts of full-hydrogenated petroleum resin, 5-10 parts of 3# glycerinum resin, 2-8 parts of E-12 epoxy resin, 20-30 parts of aromatic environment-friendly solvent oil, 5-15 parts of cyclohexane, 5-15 parts of butanone, 10-20 parts of methyl acetate and 1-2 parts of xanthochromia-resisting auxiliary agent. The vamp spray glue prepared by utilizing the preparation method is non-toxic, environmentally friendly, is short in curing time, good in xanthochromia resistance and low in temperature and cost and is curable and novel.

Owner:GUANGDONG ORIENT RESIN

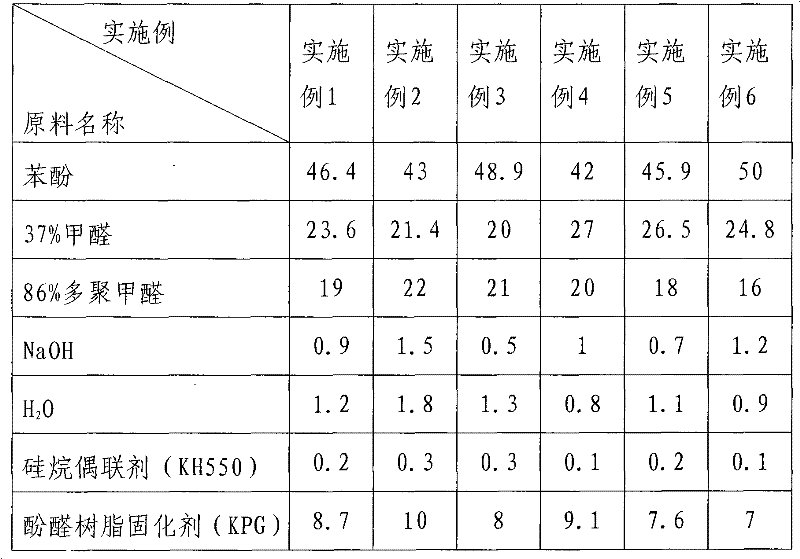

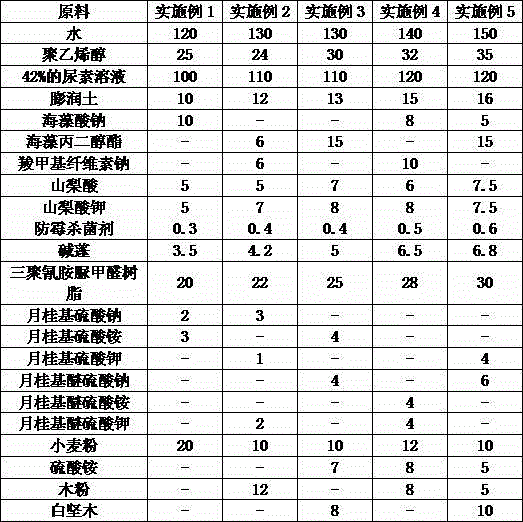

Adhesive composition for veneer sheets and preparation technique thereof

InactiveCN104592911ANo pollution in the processExtended service lifeNon-macromolecular adhesive additivesMacromolecular adhesive additivesFoaming agentAdhesive

The invention relates to the technical field of adhesives, particularly an adhesive composition for veneer sheets and a preparation technique thereof. The adhesive composition is composed of the following substances in parts by mass: 120-150 parts of water, 25-35 parts of polyvinyl alcohol, 100-120 parts of 42% urea solution, 10-16 parts of bentonite, 10-20 parts of thickener, 10-15 parts of preservative, 0.3-0.6 part of moldproof bactericide, 3.5-6.8 parts of iodine weed, 20-30 parts of melamine urea-formaldehyde resin, 5-10 parts of foaming agent and 20-30 parts of filler. The pH value of the adhesive composition is 3-5. The adhesive composition for veneer sheets avoids using formaldehyde, benzene, toluene and other toxic substances, can satisfy the demands of people for green construction materials and high-grade furniture in home decoration, and is suitable for demands of people. The artificial sheet produced by using the product can completely implement no toxicity, no harm and environment friendliness. The adhesive composition has the advantages of no environmental pollution in the production process, short curing time and long effective service life.

Owner:贵港领航木业有限公司

Temperature sensing within an underground structure to determine liner cure schedule

InactiveUS20140015155A1Pipe elementsAuxillary shaping apparatusTemperature measurementTemperature sense

The invention utilizes temperature sensing to measure the internal temperature of an underground structure, such as a pipe, for the purpose of determining a proper cure interval and / or mix ratio of a resin system during a lining operation. A temperature sensor is placed within a pipe or other underground structure to be rehabilitated and at least one temperature measurement is taken within the structure prior to or simultaneously with the installation of a liner. Once the temperature of an internal aspect of the structure is taken, a cure schedule is utilized to determine the appropriate curing time based on test data obtained from baseline tests performed under simulated conditions in a soil cell apparatus. A computer program may be utilized such that upon entering the type of resin, the lowest recorded temperature of the structure, and the initial resin temperature, a cure schedule is supplied.

Owner:LMK TECH LLC

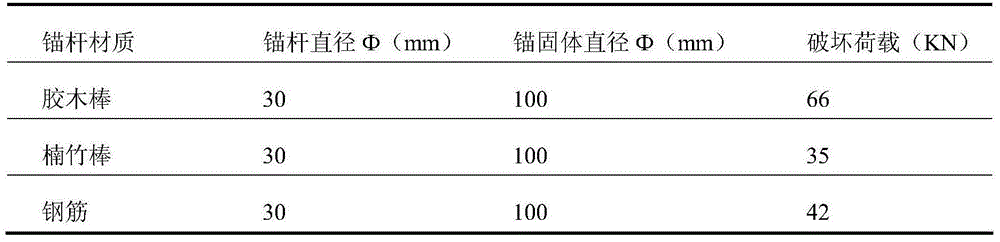

Earthen site grouting material of fiber bakelite rod grouted rock bolt based on water-based fluorine

The invention discloses an earthen site grouting material of a fiber bakelite rod grouted rock bolt based on water-based fluorine. The earthen site grouting material is prepared from the following raw materials at the ratio of (8-10) to (8-10) to (0.5-1.5) to (0.7-1) to (8-10) to (1.5-2.5) to (4-5), wherein the ratio is mass ratio. The earthen site grouting material has consistency with a surrounding soil material in ingredient, physical and chemical property and mechanical property, can be fused into a whole under the action of a curing agent water-based fluorine and inserted bar glue, and has compatibility with a surrounding rammed earth layer; meanwhile, the material contains the water-based fluorine, the inserted bar glue and the like, is close to cotton and bast fiber and phenolic resin in the bakelite rock bolt in property, and has relatively good compatibility; the curing time can be shortened; and filling and anchoring are facilitated.

Owner:SHAANXI NORMAL UNIV

Epoxy polyamide adhesive and preparation method thereof

InactiveCN104403619AImprove adhesionHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

An epoxy polyamide adhesive and its preparation method belong to the field of adhesives. The epoxy polyamide adhesive is an adhesive prepared by using epoxy resin and polyamide as main materials, has good caking property with materials such as a steel plate, a rubber plate and the like, and can be applied in bonding between a steel plate and a steel plate as well as between a steel plate and a rubber plate. By interaction between an inorganic filling material and organic main materials, adhesive force, strength and toughness of the adhesive are enhanced. The epoxy adhesive prepared by using polyamide as a curing agent has advantages of high peel strength and high strength. By using melamine and polyamide as a composite curing agent, the defect that curing time is long when polyamide is separately used as a curing agent is solved. The epoxy polyamide adhesive has low curing temperature, can be cured at room temperature, and has advantages of simple technology and convenient operation.

Owner:山东华亚环保科技有限公司

Epoxy resin structural adhesive with high binding force and preparation method thereof

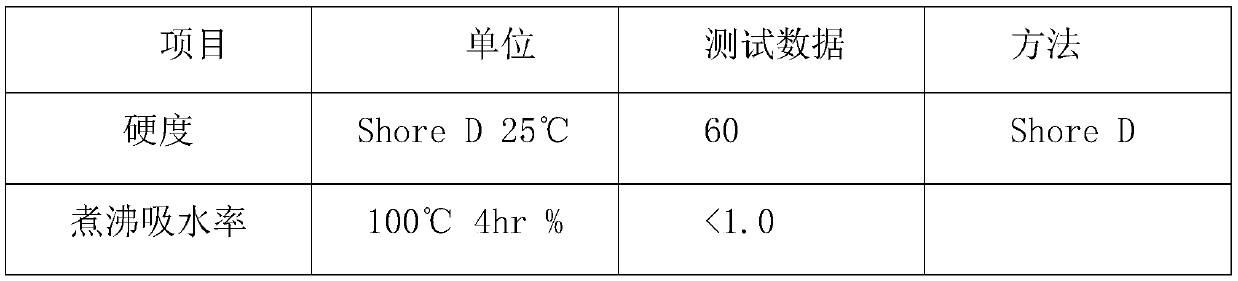

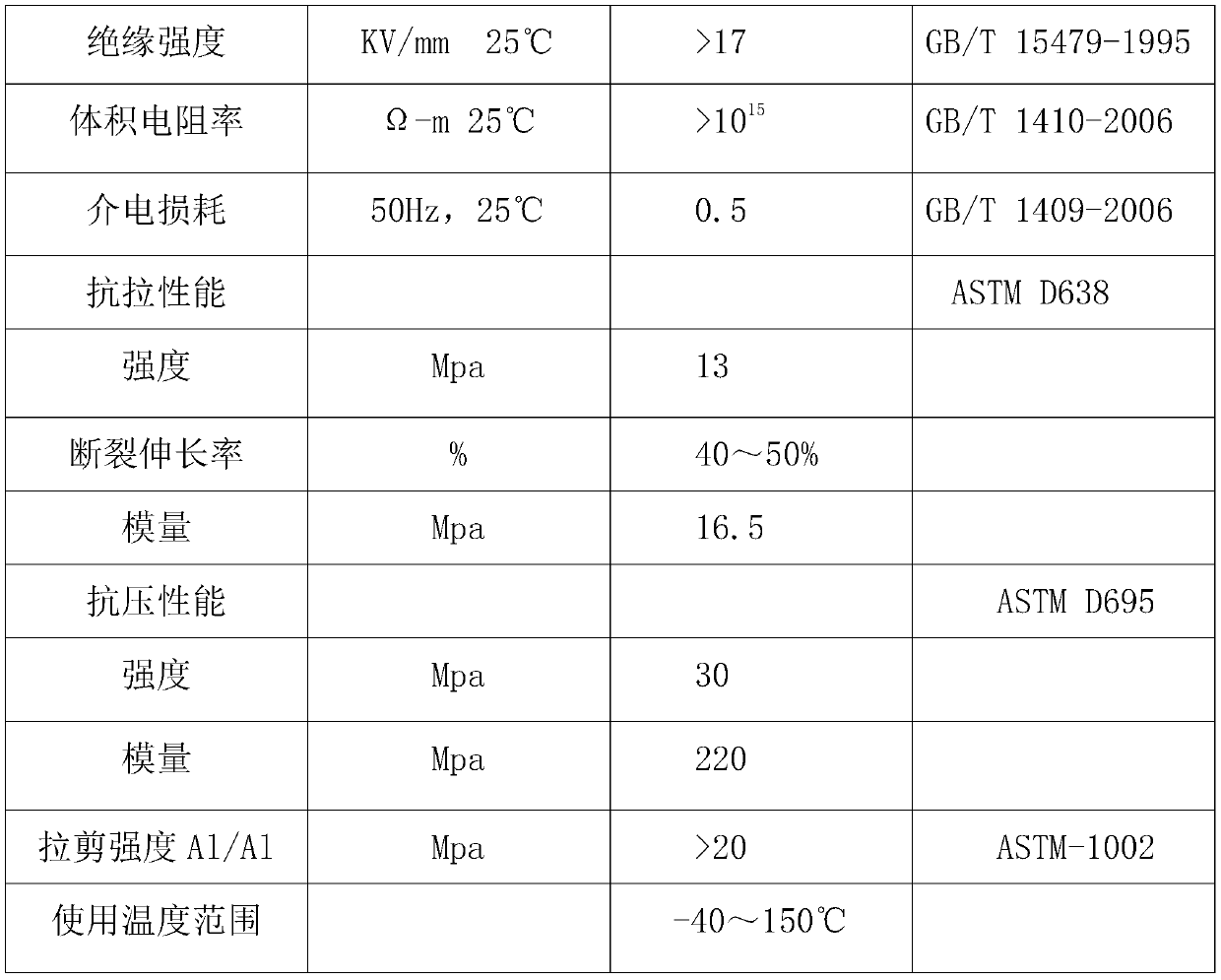

InactiveCN110511708AGuaranteed bonding performanceGuaranteed flexibilityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPolyamide

The invention relates to the technical field of adhesive materials, and discloses an epoxy resin structural adhesive with high binding force and a preparation method thereof, the epoxy resin structural adhesive is formed by curing a component A and a component B according to a weight ratio of 100 / 50; the component A comprises the following components: 95-100 parts by mass of special epoxy resin; 0.2 to 0.5 part by mass of a defoaming agent; 0.3 to 0.8 part by mass of a coupling agent and 0.5 to 2.0 parts by mass of a rheological assistant; the component B comprises the following components inparts by mass: 95-100 parts of polyamide; 0.2 to 5.0 parts of an accelerant and 0.2 to 0.5 part of a defoaming agent, and the epoxy resin structural adhesive solves the problems of long curing time and high curing temperature requirement of epoxy resin structural adhesives, has high bonding performance and flexibility, high and low temperature resistance, high elongation at break and excellent electrical insulation performance of cured products, and can better protect battery packs and reduce economic losses when accidents occur.

Owner:上海闰龙电子材料有限公司

Curing agent for casting furan resin

The invention discloses a curing agent for casting furan resin. The curing agent is prepared through mixing 13-15 parts by mass a mother liquor A with 1-2 parts by mass of a mother liquor B, wherein the mother liquor A comprises, by mass, 10-12 parts of xylene, 138-142 parts of sulfuric acid with the mass percentage concentration of 98%, 47-50 parts of methanol, 3-5 parts of urea and 1-3 parts of hydrogen peroxide; and the mother liquor B comprises, by mass, 50-57 parts of sulfuric acid with the mass percentage concentration of 98%, 10-14 parts of methanol, 30-35 parts of water and 3-8 parts of aluminum trichloride. The novel curing agent for casting furan resin has the advantages of no large influences in the use period, shortening of the curing time and improvement of the production efficiency of casting enterprises through adjusting resin and the curing agent.

Owner:黄石汇波材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com