Quick-curing adhesive and preparation method thereof

A rapid curing and production method technology, applied in adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve waste of funds, energy and manpower, high manufacturing costs, long process routes, etc. problems, to achieve the effect of improving work efficiency, enhancing market competitiveness, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

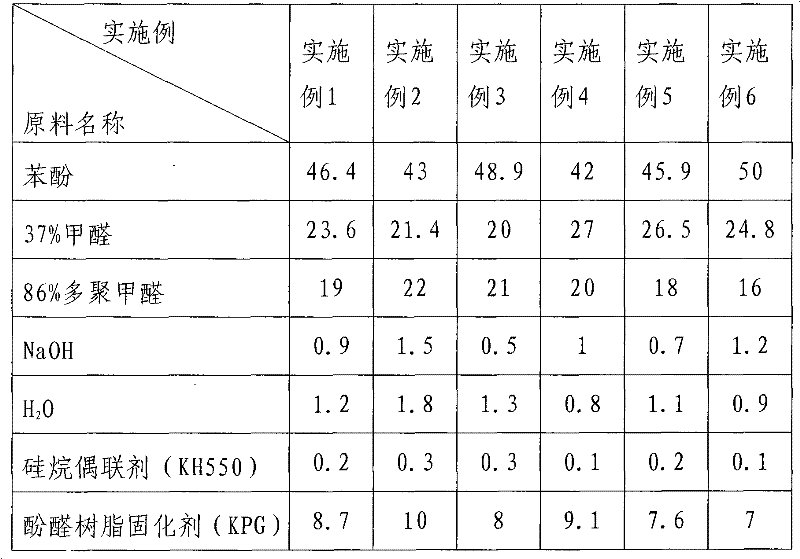

[0027] Embodiment: the raw material formula of the embodiment of the present invention is referring to table 1:

[0028] Table 1: (unit: weight percentage)

[0029]

[0030] According to above-mentioned raw material formula, preparation method is carried out according to the following steps:

[0031] ①. First add phenol into the reactor, then add 37% formaldehyde into the reactor and stir for 20 minutes;

[0032] ②. Add NaOH to the reaction kettle and stir it. After stirring for 20 minutes, heat it. NaOH is a catalyst, which can speed up the reaction rate;

[0033] ③. When the temperature reaches 60°C, add cooling water to the reaction kettle, the temperature rises sharply during the reaction, and add cooling water to lower the temperature;

[0034] ④. When the temperature reaches 78°C, keep the constant temperature for 60 minutes, then divide the water and paraformaldehyde into 6 equal parts, add one part of water and one part of paraformaldehyde to the reaction kettle e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com