Patents

Literature

2720results about How to "Short curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-solid-content UV (Ultraviolet)-curing aqueous urethane acrylate dispersion liquid and preparation method thereof

InactiveCN102030884AImprove curing efficiencyReduce consumptionPolyurea/polyurethane coatingsDistillationAdhesive

The invention discloses a high-solid-content UV-curing aqueous urethane acrylate dispersion liquid and a preparation method thereof, wherein the method comprises the following steps of: firstly carrying out the monoesterfication reaction on the partial hydroxide group at the tail end of hyperbranched polyester and the anhydride group of dicarboxylic anhydride to obtain an intermediate I; carrying out the end capping reaction on an isocyanate group in diisocyanate and the hydroxide group in a hydroxyalkyl methacrylate monomer to obtain a reaction intermediate II; carrying out the reaction on the residual hydroxide group of the intermediate I and the residual isocyanate group of the reaction intermediate II to obtain a reaction intermediate III; and carrying out alkali neutralization, aqueous dispersion and reduced-pressure distillation on the reaction intermediate III to remove an organic solvent to obtain the UV-curing urethane acrylate aqueous dispersion liquid. The dispersion liquid has the characteristics of high solid content, relatively low viscosity, UV curability, good mechanical performance of a paint film and the like, conforms to the concept of environmental protection, can be applied to the fields of environment-friendly coatings, aqueous ink, aqueous adhesives, fabric coating agents and the like and has broad prospect.

Owner:SOUTH CHINA UNIV OF TECH

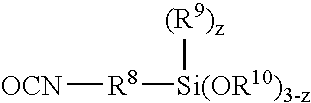

Two-part moisture-curable resin composition and adhesive, sealant and coating compositions based thereon

ActiveUS20090124751A1Improve stabilityIncrease line speedPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsScavengerAntioxidant

A two-part moisture-curable resin composition comprises:a) a first part substantially free of moisture comprising:(1) moisture-curable silylated resin and,(2) optionally, one or more additional components selected from the group consisting of plasticizer, solvent, thixotropic agent, particulate material, moisture scavenger, isocyanate scavenger, crosslinker, adhesion promoter, U.V. stabilizer and antioxidant; and,b) a second part comprising:(1) water in an amount sufficient to cure moisture-curable silylated resin (a)(1);(2) at least one plasticizer and / or particulate material,(3) nonionic surfactant in an amount sufficient to provide a stable emulsion of plasticizer (b)(2), if present, and a stable suspension of particulate material (b)(2), if present,(4) optionally, one or more additional components selected from the group consisting of solvent, thixotropic agent, pH adjuster, U.V. stabilizer and antioxidant,provided, the first part and / or the second part further comprises catalyst (c) for the condensation reaction of hydrolyzed moisture-curable silylated resin (a)(1).

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Reactive polyurethane hot-melt adhesive for edge sealing in wood industry and preparation method thereof

InactiveCN103031100AHigh strengthLower melting temperaturePolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a reactive polyurethane hot-melt adhesive for edge sealing in wood industry, which is prepared from the following raw materials in percentage by weight: 10-30% of crystalline polyester polyol, 10-30% of amorphous polyester polyol, 8-15% of high-molecular-weight thermoplastic resin, 10-25% of diisocyanate, 1-8% of plasticizer, 10-30% of inorganic filler, 0.05-0.5% of antioxidant and 0.05-0.5% of ultraviolet absorbent. In addition, the invention also discloses a preparation method of the reactive polyurethane hot-melt adhesive. The adhesive disclosed by the invention has the advantages of extremely high drying speed, excellent initial bonding strength and final strength, high heat resistance, high storage stability, excellent environment friendliness, simple preparation technique, low cost and the like. The invention can well satisfy the requirements for edge sealing in wood industry, and is beneficial to industrialization of edge sealing production in wood industry.

Owner:嘉兴市恒泰化工科技有限公司

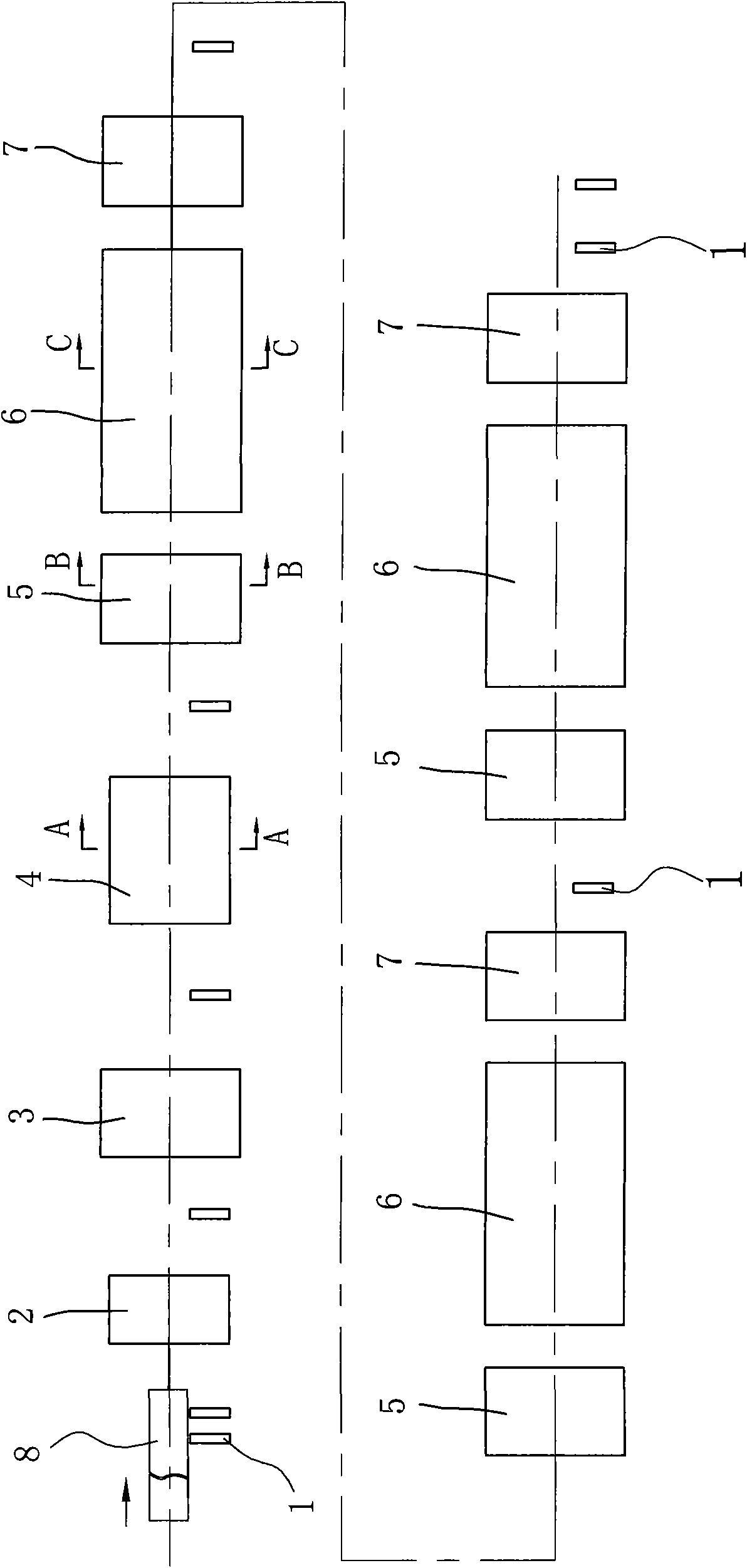

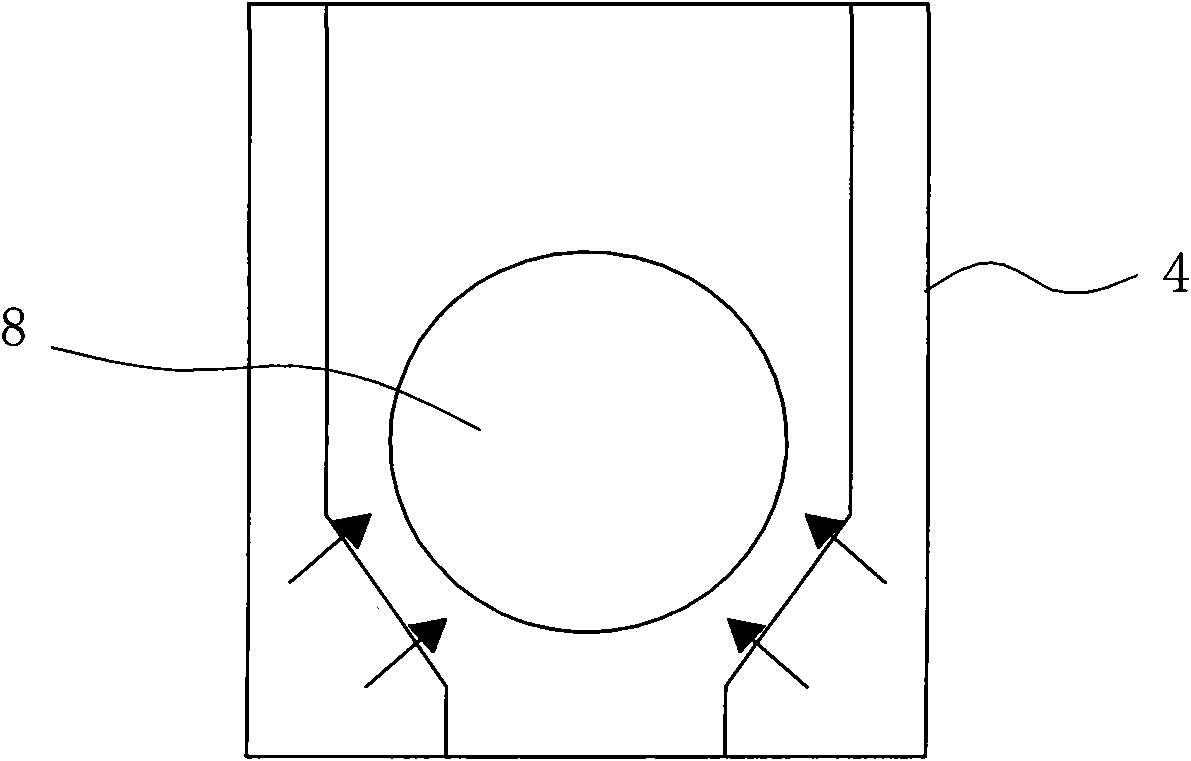

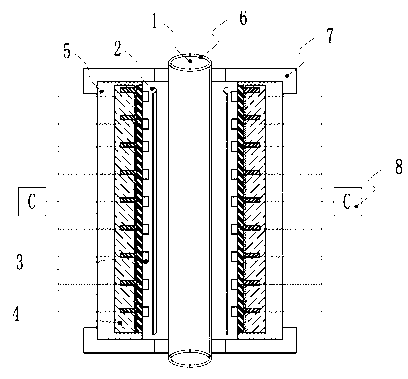

Automatic coating technology of large-scale steel pipe anticorrosion coating and production line thereof

ActiveCN101607247AHigh painting efficiencyShort curing timePretreated surfacesCorrosion preventionSteel tubeSurface finishing

The invention relates to an automatic coating technology of large-scale steel pipe anticorrosion coating and a production line thereof. The coating technology adopts the steps that steel pipes enter into a dehumidification cleaner, an automatic shot blasting machine, a preheating drying chamber, a spray chamber, a paint film solidifying chamber and a cooling chamber under the conveying of a steel pipe conveying mechanism, and after decontamination, dehumidification, surface treatment and preheating, the steel pipes enter into paint spraying, paint film solidifying and cooling processes; the production line comprises a steel pipe conveying mechanism, a dehumidification cleaner, an automatic shot blasting machine and a preheating drying chamber, wherein, the automatic shot blasting machine is arranged between the dehumidification cleaner and the preheating drying chamber; the automatic coating technology and the production line are characterized in that a paint spraying and solidifying unit is also arranged at the rear part of the preheating drying chamber; the paint spraying and solidifying unit comprises a spray chamber, a paint film solidifying chamber and a cooling chamber which are arranged in a line from the front part to the rear part in sequence, wherein, a coating machine for coating anticorrosion coat to the surfaces of the steel pipes is arranged in the spray chamber, and a hot air circulating system is arranged in the paint film solidifying chamber. The invention has the advantages that continuous and automated operation can be performed on a production line, the production efficiency is high, the coating quality is good, and environmental pollution is avoided.

Owner:宁波华恒防腐工程有限公司

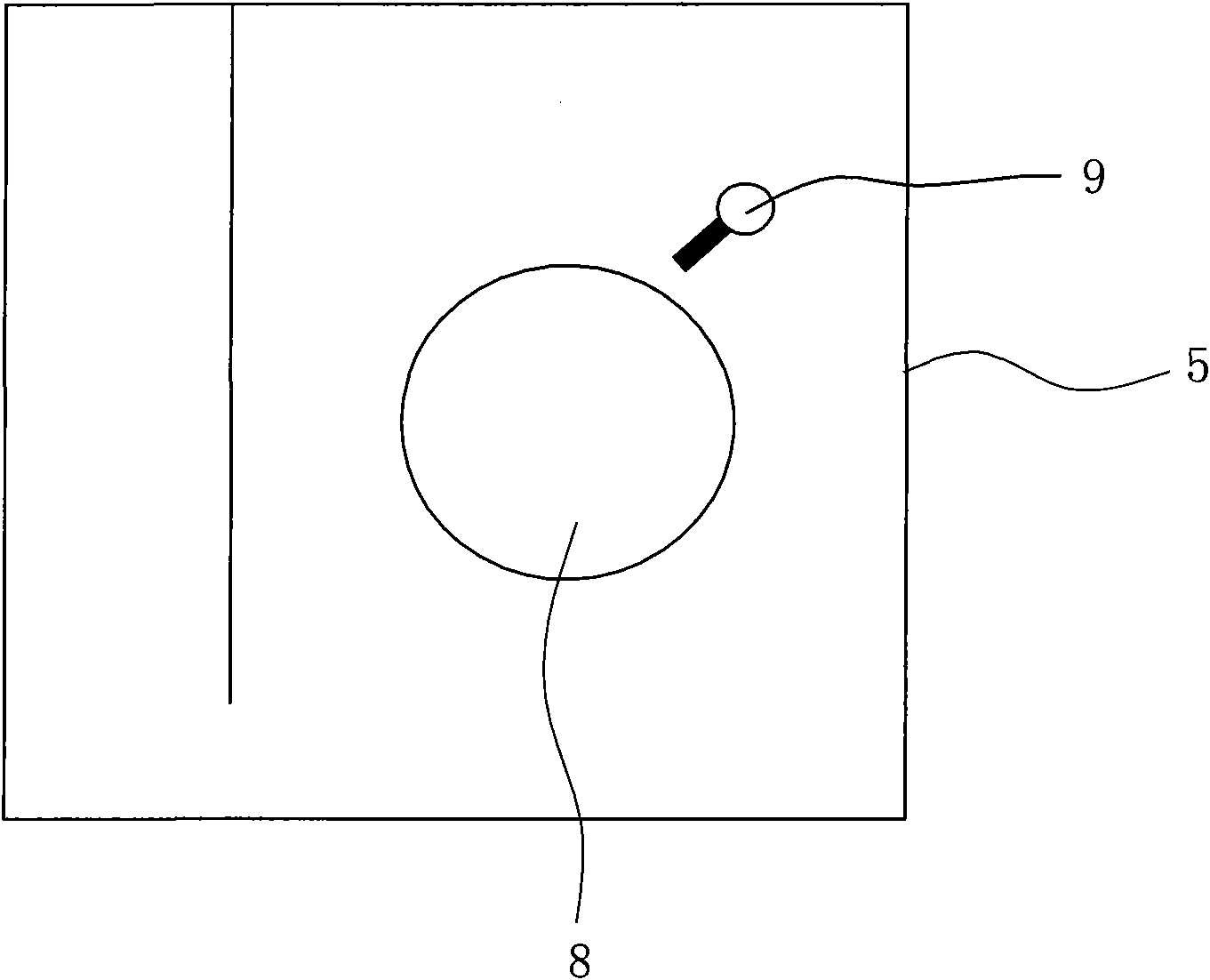

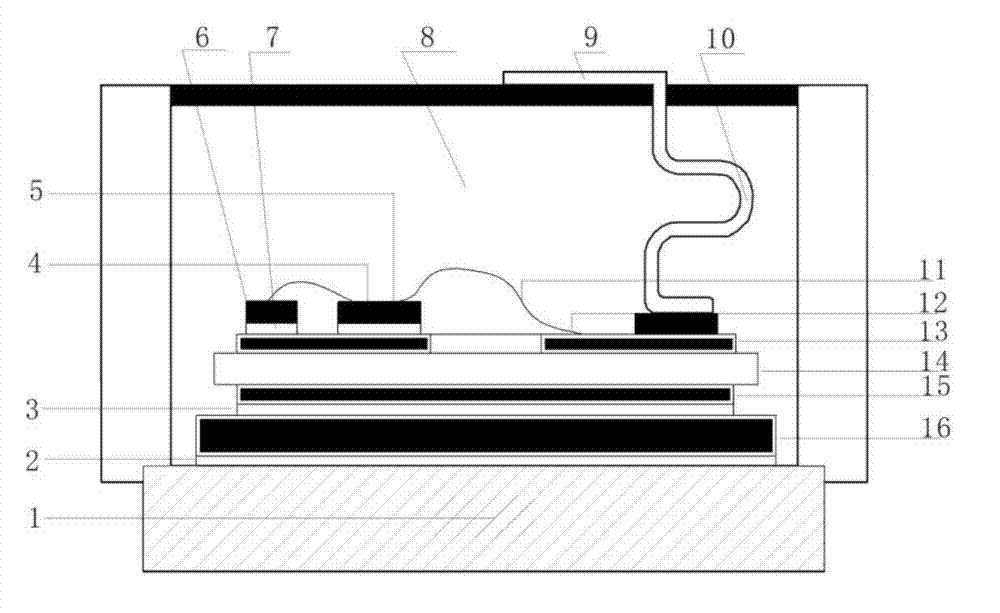

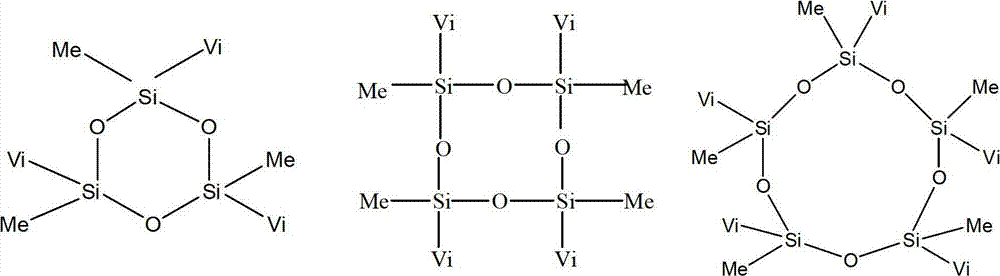

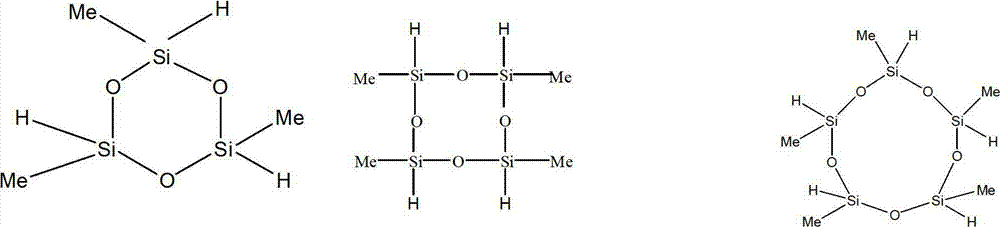

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Ultraviolet light cured paint for leather or leatherette

InactiveCN1436825AHigh glossGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyWear resistant

The present invention is ultraviolet light cured paint for leather and leatherette. The ultraviolet light cured paint consists of: aliphatic polyuretheane acrylic ester 25-50 wt%, acrylic acid modified epoxy resin 0-20 wt%, reactive acrylic ester monomer 10-50 wt%, light initiator 5 wt%, leveling agent 0.3-1 wt%, defoaming agent 0.1-0.5 wt%, wetting agent 0.5-1.5 wt%, wear-resistant agent 0.5-3 wt% and solvent 2-20 wt%. The ultraviolet light cured paint for leather and leatherette of the present invention is white or milk white colloid liquid, has solid content of 80-98%, may be stored at room temperature and lightproof condition for one year, and has the features of curing at normal temperature, high production efficiency, forming film with excellent flexibility, high luster degree, high wear resistance, high corrosion resistance and high durability, etc.

Owner:湖南亚大新材料科技股份有限公司

Special primer paint for medium and high grade automobile aluminum hubs and preparation method of primer paint

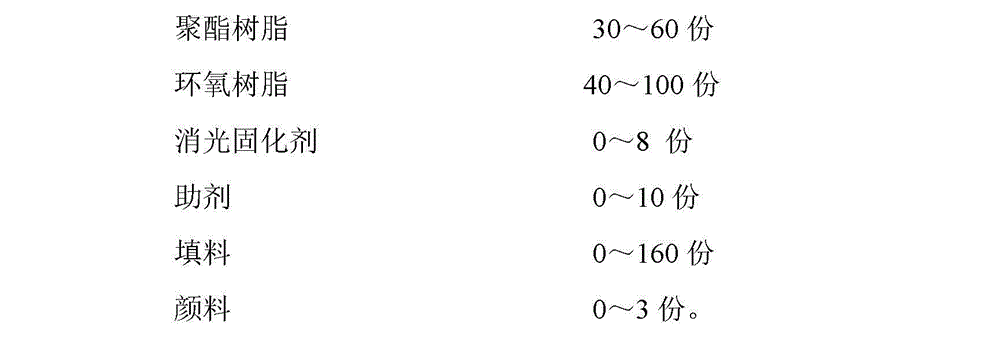

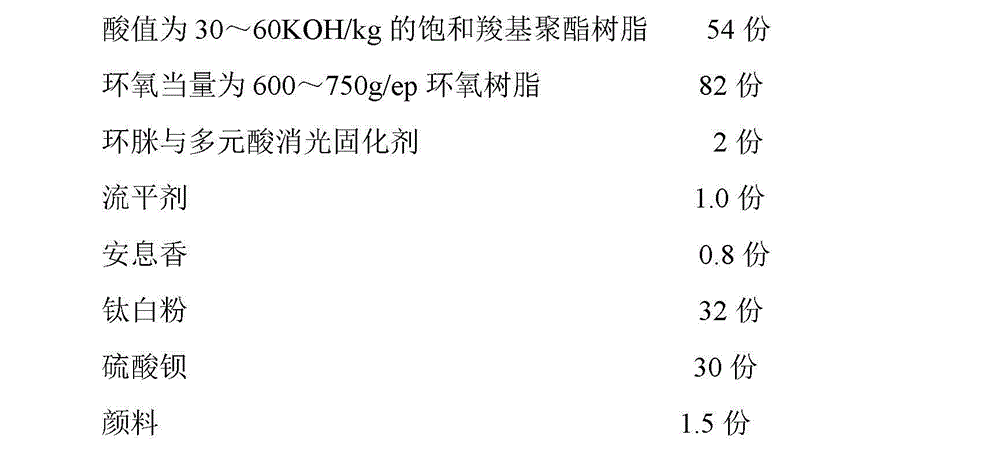

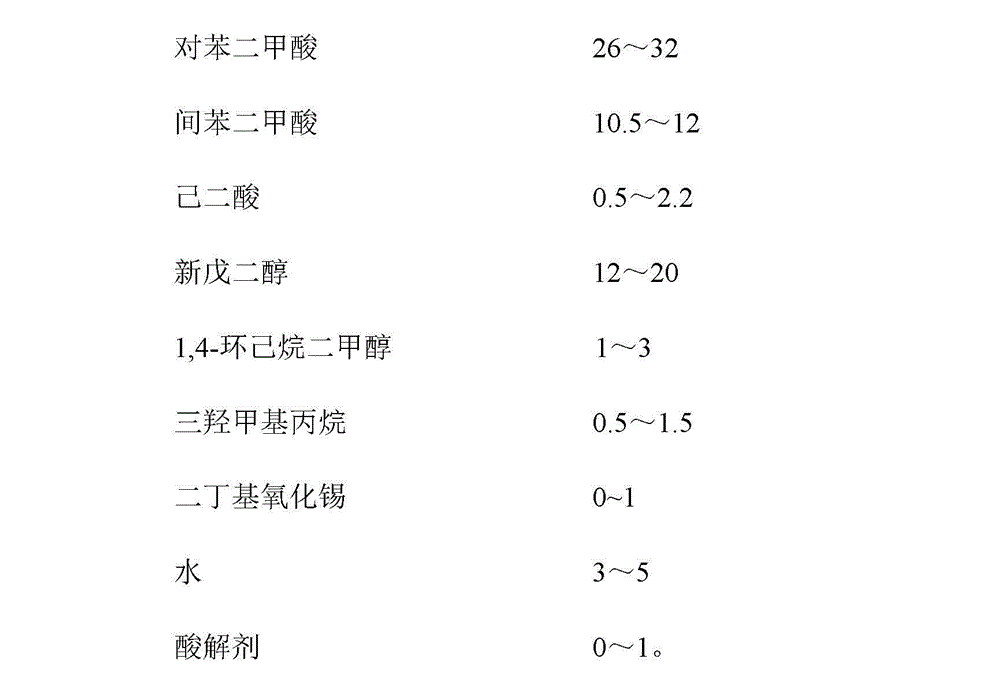

ActiveCN102911585ANon-toxic and environmentally friendlyImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyPolyester resin

The invention discloses special primer paint for medium and high grade automobile aluminum hubs. The primer paint comprises, by weight, 30-60 parts of polyester resin, 40-100 parts of epoxy resin, 0-8 parts of matting and curing agents, 0-10 parts of additives, 0-160 parts of packing and 0-3 parts of pigment. The invention further discloses a preparation method of the paint. Once a coating of the paint is solidified, the paint has good leveling property, breathability and chemical resistance.

Owner:GUANGZHOU KINTE IND

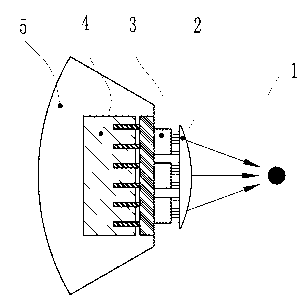

Ultraviolet curing equipment and method for optical fiber coating

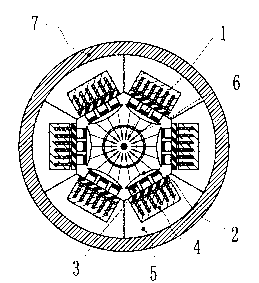

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

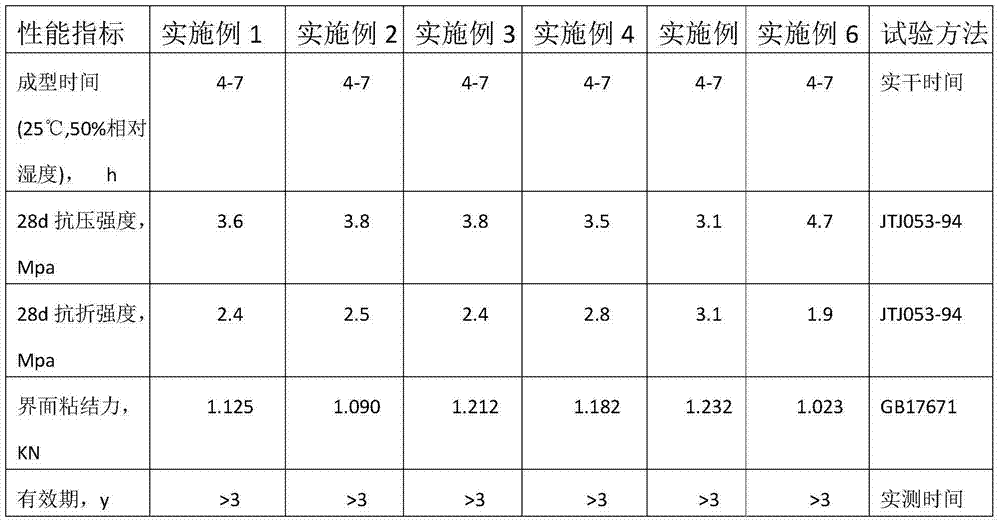

Asphalt base composite material for pavement crack repair

The invention discloses an asphalt base composite material for pavement crack repair. The asphalt base composite material for pavement crack repair is prepared from a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 120-150 parts of anionic emulsified asphalt, 1-3 parts of water reducing agent, 1-3 parts of defoaming agent, 3-8 parts of binder and 0-10 parts of water, and the component B comprises the following raw materials in parts by weight: 100 parts of cement, 70-110 parts of sand and 0.01-0.06 part of expanding agent. The asphalt base composite material for pavement crack repair has the flexibility of asphalt, the rigidity of cement and certain strength, is used for crack pouring and can bear and transfer loading force; the binder is added to the material so as to play a role of reinforcing the binding force between the material and crack walls, so that the service life of a pavement is prolonged, and the re-cracking phenomenon is difficult to occur. The asphalt base composite material for pavement crack repair has the advantages of low cost price, simple construction, low requirements on constructors, low energy consumption, low cost, strong binding power and long useful life and can be widely applied to the pavement crack repair.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

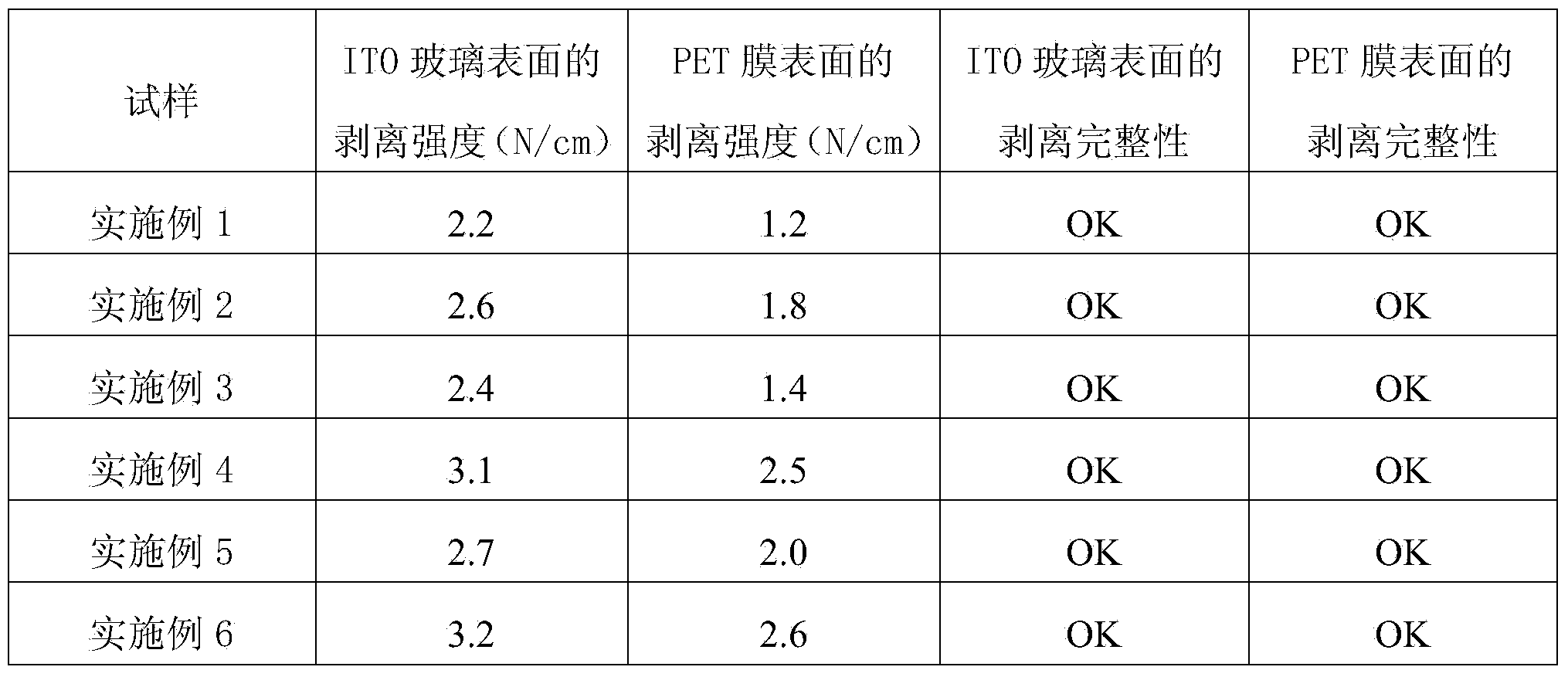

Ultraviolet-cured stripping protective material and preparation method and application thereof

ActiveCN103627313AHigh elongationEasy to dryPolyurea/polyurethane coatingsPolyethylene terephthalate glycolUltraviolet lights

The invention belongs to the technical field of surface protective materials, and discloses an ultraviolet-cured stripping protective material and a preparation method and application thereof. The stripping protective material comprises the following components in parts by weight: 50-90% of polyurethane modified acrylic ester, 5-35% of acrylics reactive diluent, 1-8% of photoinitiator, 1-15% of filler, and 0-10% of additive. According to the ultraviolet-cured stripping protective material, the ultraviolet light is used for triggering a chained polymerization, the time for curing is short, generally 1-5 seconds, and the production efficiency is high; not any organic gas is released, so that the preparation method is more environment-friendly; the use and operation process is simple and convenient, the surface of the material is not affected due to overheating curing, mist is generated after stripping; the integral protective material can be better stripped, is not sticky, has no mist, and is applicable to protecting surfaces of ITO (indium tin oxide) glass, ITO membranes and PET (polyethylene terephthalate) membranes.

Owner:GUANGZHOU MECHANICAL ENG RES INST

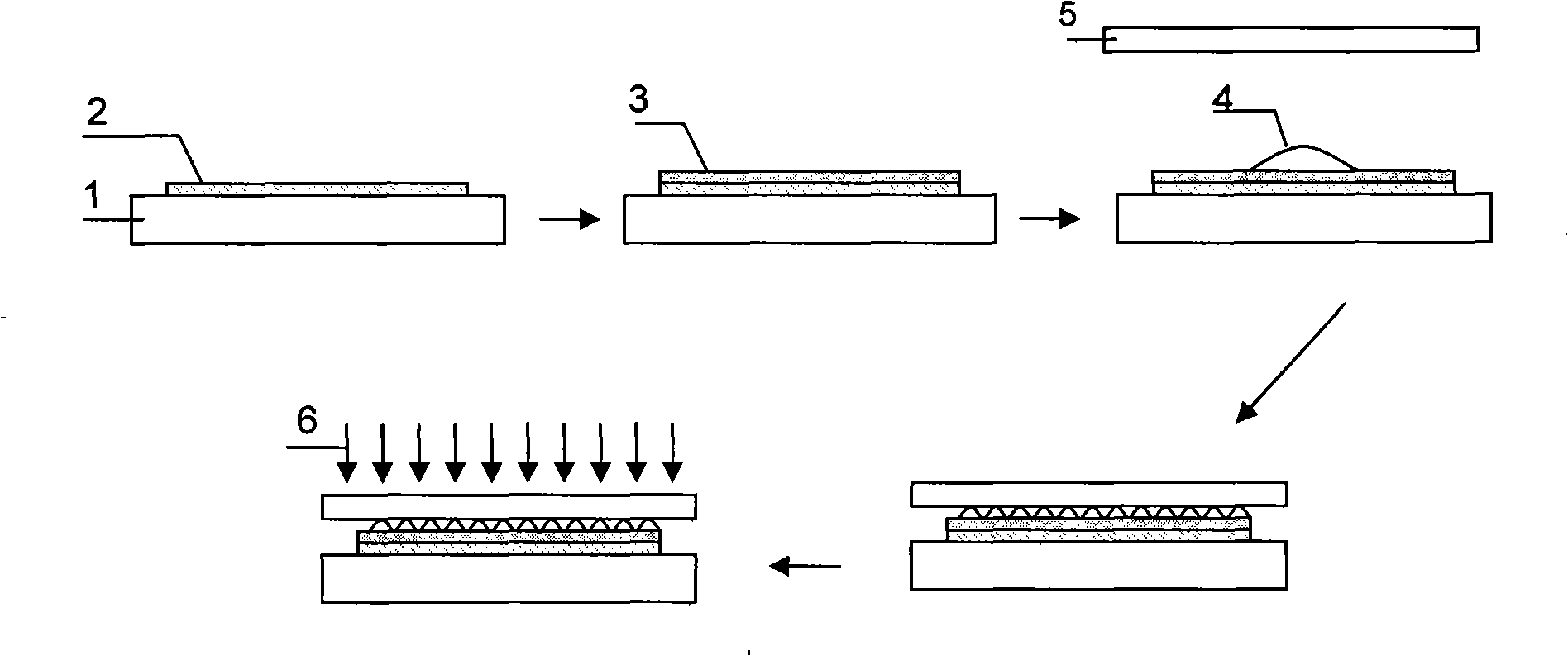

Encapsulation method for top radiation organic EL part

InactiveCN101359722AOvercome operabilityOvercome timeSolid-state devicesSemiconductor/solid-state device manufacturingElectrical devicesOrganic electroluminescence

The invention belongs to the organic electroluminescence field, in particular to a packaging method for a top-emitting organic electroluminescent device, comprising the packaging to the top-emitting organic electroluminescent device having an upright structure and an inverted structure. A layer of organic or inorganic material which has a thickness of 10nm to 100nm and has high transmittance in a visible light region and is also easy of thermal evaporation deposition is coated on a top electrode of the top-emitting organic electroluminescent device to serve as a protective layer of the device, then a luminous zone of the device is coated with package resin, and finally a transparent packaging cover plate is pressed thereon. The method improves the packaging tightness of the device, avoids the damage to the device caused by friction, and overcomes the disadvantages of complicated operational procedures, long solidification time and high costs of the previous packaging process, and the method has advantages of simple process, short solidification time, low costs and good barrier property of oxygen and vapor, and is widely applied in the aspect of packaging to electronic and electrical devices such as organic electroluminescent devices (OLED).

Owner:JILIN UNIV

High-adhesion ultraviolet radiation polyurethane double-solidifying carpentry paint and preparation method thereof

InactiveCN101100583AImproves toughness and tensile strengthPrevent cracking of paint filmLiquid surface applicatorsPolyurea/polyurethane coatingsChemistryMagnesium silicate

A high-adhesive ultraviolet polyurethane dual curing woodenware coating consists of dual-component priming paint and finish; Priming paint A consists of polyurethane acrylic ester with -NCO group 30-50 proportion, modified nanometer silicon dioxide 10-20 proportion, superfine hydrated magnesium silicate 10-20 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion; Priming paint B consists of polyurethane acrylic ester with hydroxy-group 20-30 proportion, modified nanometer silicon dioxide 10-20 proportion, superfine hydrated magnesium silicate 10-20 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion; Finish consists of polyurethane acrylic ester 10-30 proportion, epoxy-acrylic ester 10-30 proportion, modified nanometer silicon dioxide 10-30 proportion, active diluting agent 20-40 proportion and light evocating agent 1-5 proportion. It has better coating adhesion, mechanical strength and abrasive resistance. It can be used to coat large-area oily woods.

Owner:CHANGZHOU GUANGHUI CHEM +2

Room temperature super-fast curing double-component solvent-free polyurethane structural adhesive and preparation method and use method thereof

The invention discloses a room temperature super-fast curing double-component solvent-free polyurethane structural adhesive including A and B components; the A component comprises the following components in parts by weight: 50-90 parts of polyols, 0-50 parts of a chain extender, 0.5-15 parts of a catalyst, 0-30 parts of a filler and 5-10 parts of a stabilizer; the B component includes the following two parts: 50-100 parts of polyaryl polymethylene isocyanate and 0-50 parts of hexamethylene diisocyanate. The structural adhesive prepared by the method can be rapidly cured at room temperature.

Owner:WENZHOU INST OF BIOMATERIALS & ENG

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS20080242764A1Improve adhesionImprove propertiesSynthetic resin layered productsOrganic non-macromolecular adhesiveCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerization in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

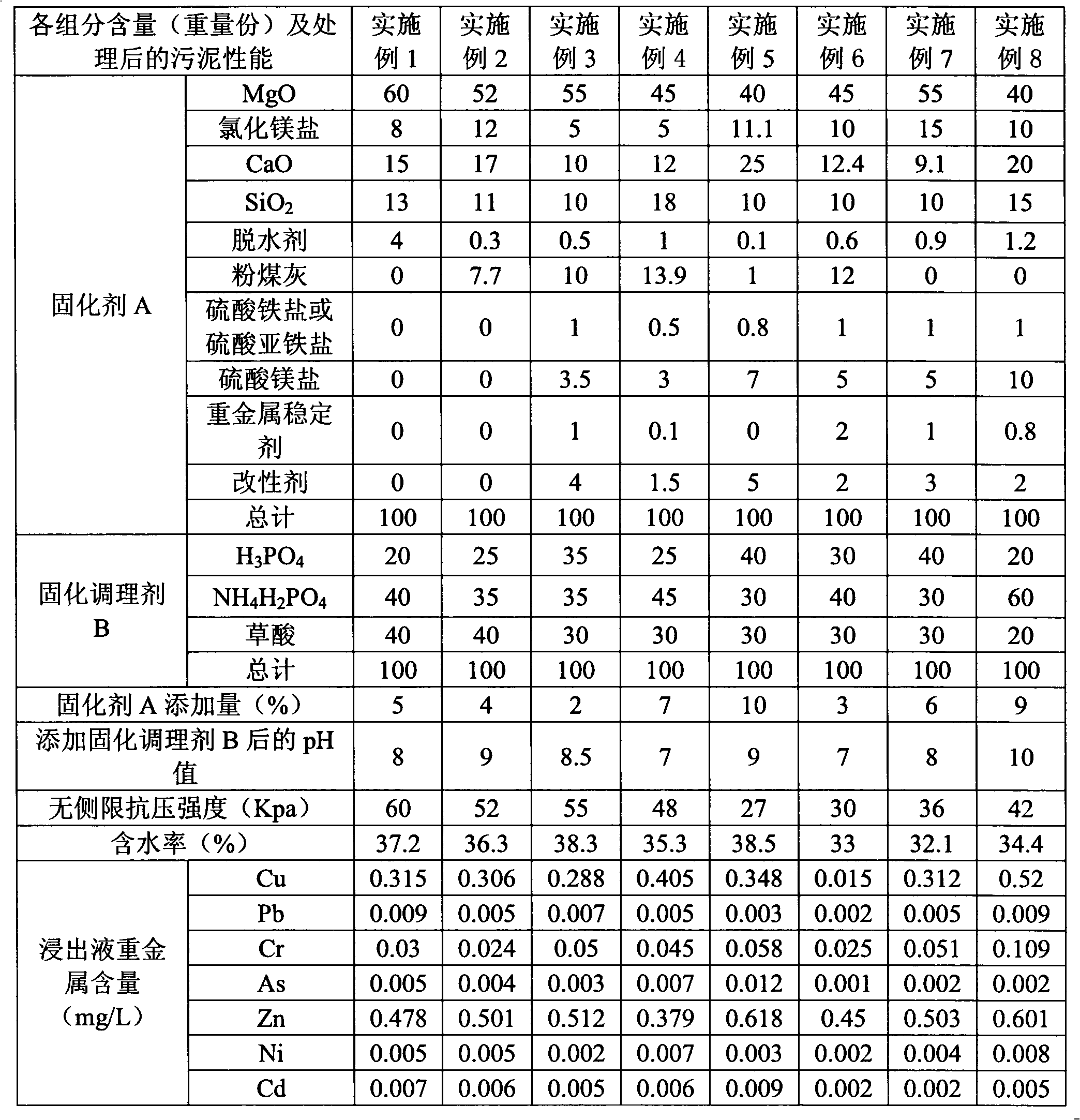

Sludge curing treatment agent and method for treating sludge by use of curing treatment agent

InactiveCN103664126AReduce moisture contentCause secondary pollutionSludge treatment by de-watering/drying/thickeningOXALIC ACID DIHYDRATEChloride salt

The invention provides a novel sludge curing treatment agent. The curing treatment agent comprises a curing agent A and a curing conditioner B, wherein the curing agent A comprises the following components in percentage by weight: 40-60% of MgO, 5-20% of magnesium chloride salt, 10-20% of SiO2, 10-30% of CaO, 0.1-4% of dehydrating agent and 0-20% of fly ash; the curing conditioner B comprises the following components in percentage by weight: 20-40% of H3PO4, 30-50% of NH4H2PO4 and 20-40% of oxalic acid; the curing agent A accounts for 0.5-10% of the total amount of sludge in treatment by mass; and the curing conditioner B accounts for 0-5% of the total amount of sludge in treatment by mass. By adopting the sludge curing treatment agent provided by the invention to treat the sludge with relatively high water content and particularly water content over 80%, the sludge can be cured generally in 1-2 days, the curing time is short, and the water content is reduced to about 30% 7 days later; after the curing, the water content of the sludge is low; and the sludge after the curing treatment can be subjected to landfill on site or applied to roadbed, greening, earthing, ecological restoration and the like, thereby avoiding secondary pollution to environment.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

Hot-pressed veneer adhesive and preparation method thereof

ActiveCN102585736ALow costShort curing timeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveCarvacryl acetate

The invention discloses a hot-pressed veneer adhesive and a preparation method thereof. The hot-pressed veneer adhesive mainly comprises the following components: deionized water, polyvinyl alcohol, an emulsifier, an initiator, methacrylic acid, N-methylol acrylamide, vinyl acetate, a plasticizer, a buffering agent, cassava starch, borax, a dispersing agent, aqueous rosin, a defoaming agent and a corrosion inhibitor. When the hot-pressed veneer adhesive is prepared, the preparation method comprises the following steps of: firstly synthesizing a self-crosslinked polyvinyl acetate copolymerization modified emulsion, then adding 20-35% of raw cassava starch, a crosslinking agent, waterborne tackifying resin and other auxiliaries for mixing and finally preparing the hot-pressed veneer adhesive with excellent performances. Compared with a traditional urea resin veneer adhesive, the adhesive prepared by the invention has the advantages of convenience in use, low curing temperature, short curing time and no harm to an environment and a human body.

Owner:顶立新材料科技股份有限公司

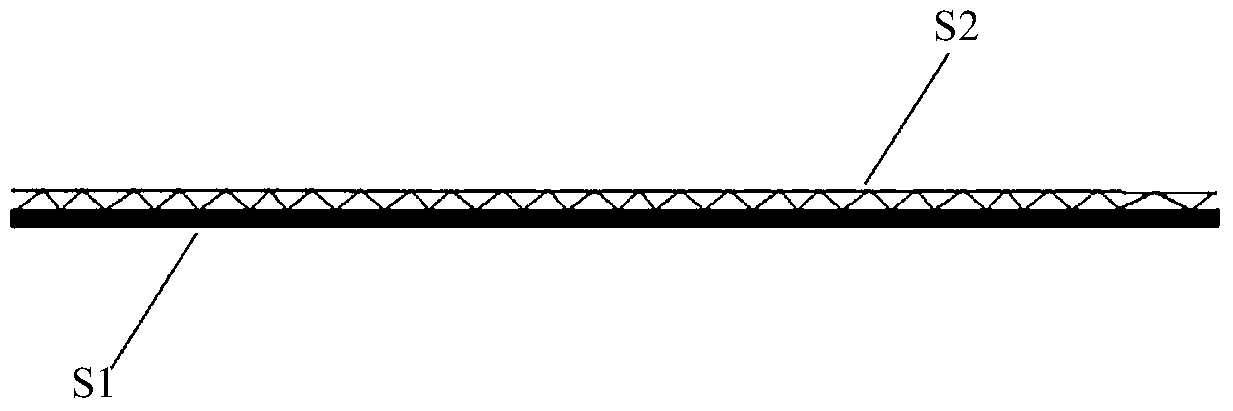

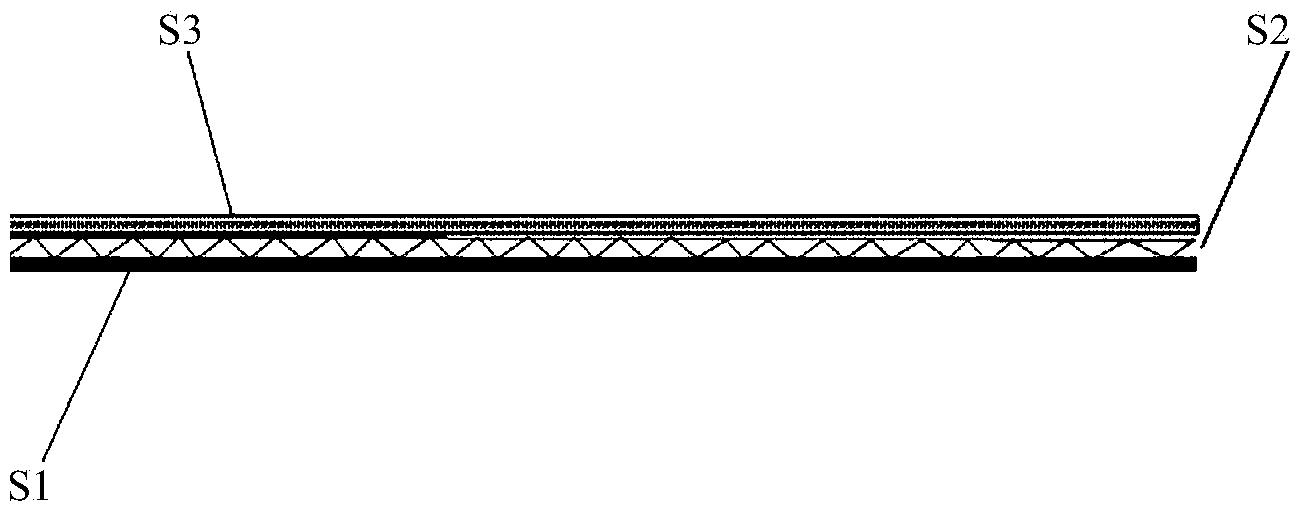

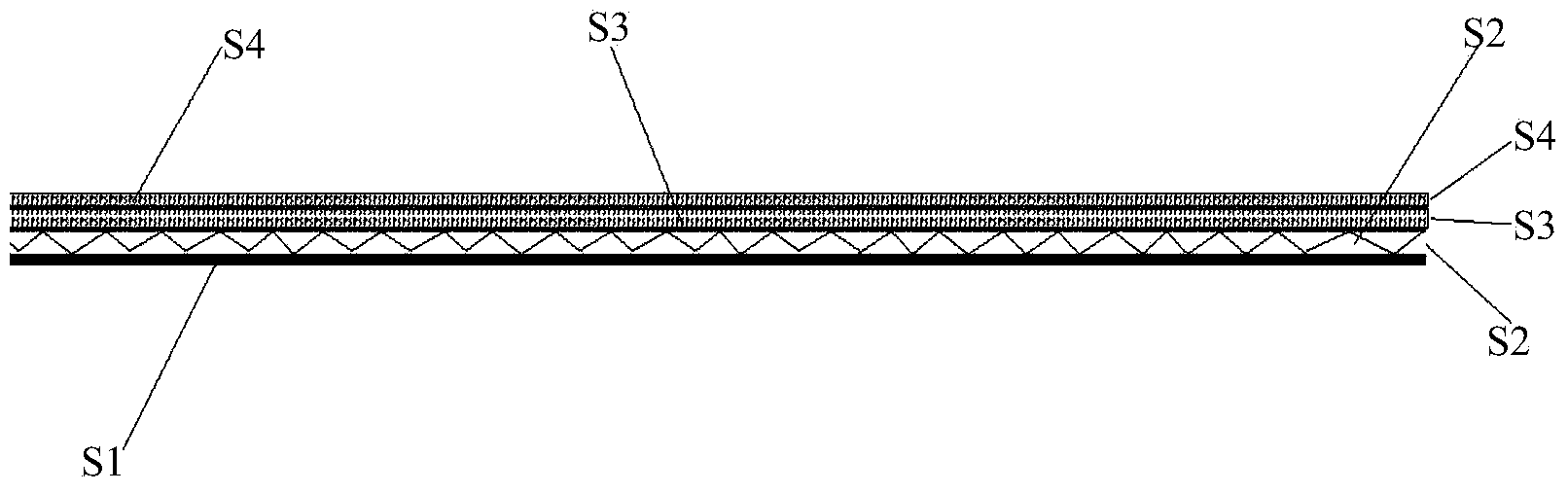

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Environment-friendly fire-resistant insulating material and manufacturing method thereof

InactiveCN102627833AReduce consumptionShort curing timeSynthetic resin layered productsHeat-exchange elementsComposite materialEnergy source

The invention discloses an environment-friendly fire-resistant insulating material and a manufacturing method thereof. The insulating material is formed by sizing and curing a resin rubber, wherein the resin rubber is prepared from the following components in parts by weight: 100 parts of resin, 1 to 8 parts of curing agent, 100 to 300 parts of high-heat conductivity powder, 1 to 5 parts of coupling agent, 1 to 30 parts of auxiliary agent, 30 to 200 parts of diluent and 1 to 4 parts of releasing agent. By the manufacturing method of the environment-friendly fire-resistant insulating material, the heat conductivity of a product is improved, the heat conduction efficiency is also improved at the same time, the curing time in a production process is reduced, the production efficiency is improved, the consumption of an energy source is reduced, the energy is saved, and the environment is protected.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

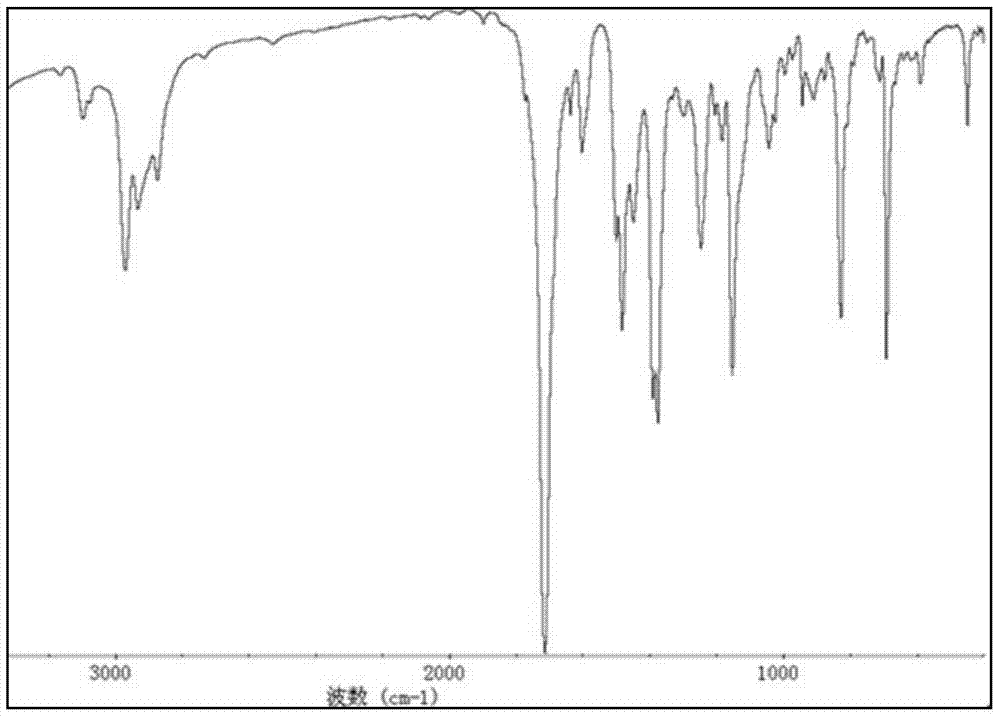

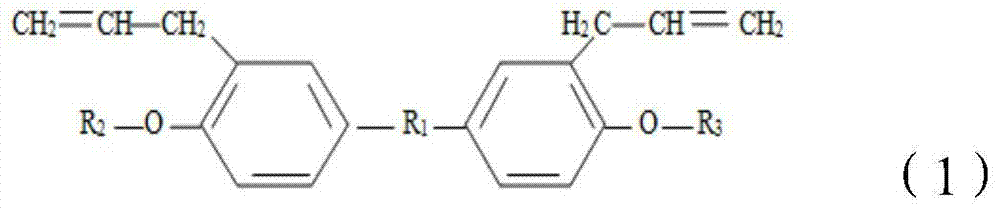

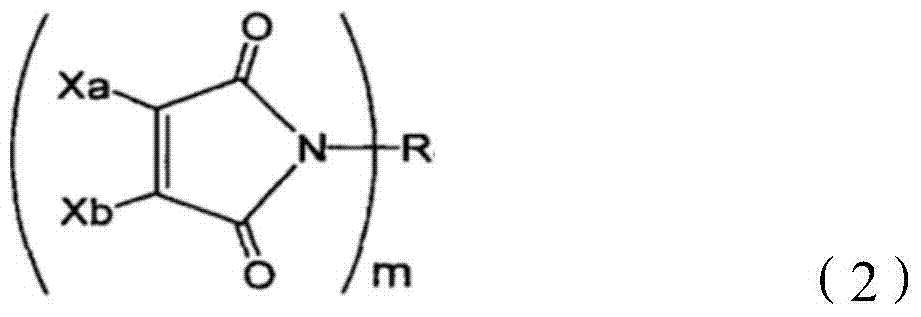

Thermosetting resin composition and applications thereof

ActiveCN103756315AGood thermal stability and heat and humidity resistanceGood toughnessSynthetic resin layered productsElectrical equipmentPrepolymerOxygen atom

The invention provides a thermosetting resin composition comprising a prepolymer of a diallyl compound and a maleimide compound, wherein the structural formula of the diallyl compound is shown as a formula (1) described in the specification; R1 is -C (CH3)2, -C (CF3)2, -SO2, -CH (CH3), -CH2 or an oxygen atom; R2 and R3 are same or different aliphatic hydrocarbon with the carbon number below 10 or aromatic hydrocarbon with the carbon number below 30; the R2 and the R3 contain no allyl group. The thermosetting resin composition has the advantages of good heat stability and heat and humidity resistance, low dielectric constant and dielectric loss angle tangent and excellent process machinability. The embodiment of the invention further provides applications of the thermosetting resin composition to resin sheets, resin composite metal foils, prepregs, laminated boards, metal foil clad laminates and printed circuit boards.

Owner:HONOR DEVICE CO LTD

Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

ActiveCN101812280AImprove cooling effectImprove work efficiencyNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to an environment-friendly heat conduction insulating glue used by high-power LEDs, which is characterized by being prepared from the following raw materials in percentage by weight: 50-68 percent of micro-grade high-thermal conductive powder, 18-30 percent of epoxy resin, 4-10 percent of curing agent, 7-15 percent of solvent, 0.6-1.5 percent of accelerator and 1-2 percent of additive; and the micro-grade high-thermal conductive powder is selected from a mixture formed by one or more of micro-grade aluminum powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder. The invention also relates to a preparation method of the heat conduction insulating glue. The environment-friendly heat conduction insulating glue used by high-power LEDsis obtained by optimizing the matching ratio and the modification of the raw materials and improving and simplifying the preparation process. Besides high resistivity, the heat conduction insulating glue also has high thermal conductivity, higher working temperature, strong viscosity, high cutting strength and fine performance index.

Owner:连云港市昭华光电科技有限公司

Curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof

The invention relates to the technical field of curing agents and particularly relates to a curing agent for sealing and hardening surface of concrete, as well as preparation and construction methods thereof. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, comprises the following components in percentage by weight: 0.1-2% of fluorosilicate, 0.001-0.02% of surfactant, 5.0-30.0% of at least one of silica sol or silicate and the balance of water. The curing agent for sealing and hardening the surface of the concrete, provided by the invention, has the advantages of short curing time, thick surface hardened layer and high surface hardness, and can be widely used for surface hardening and curing treatment of concrete buildings or structures of highways, squares, garages, supermarkets, factory buildings and the like.

Owner:DONGGUAN MERROCK IND

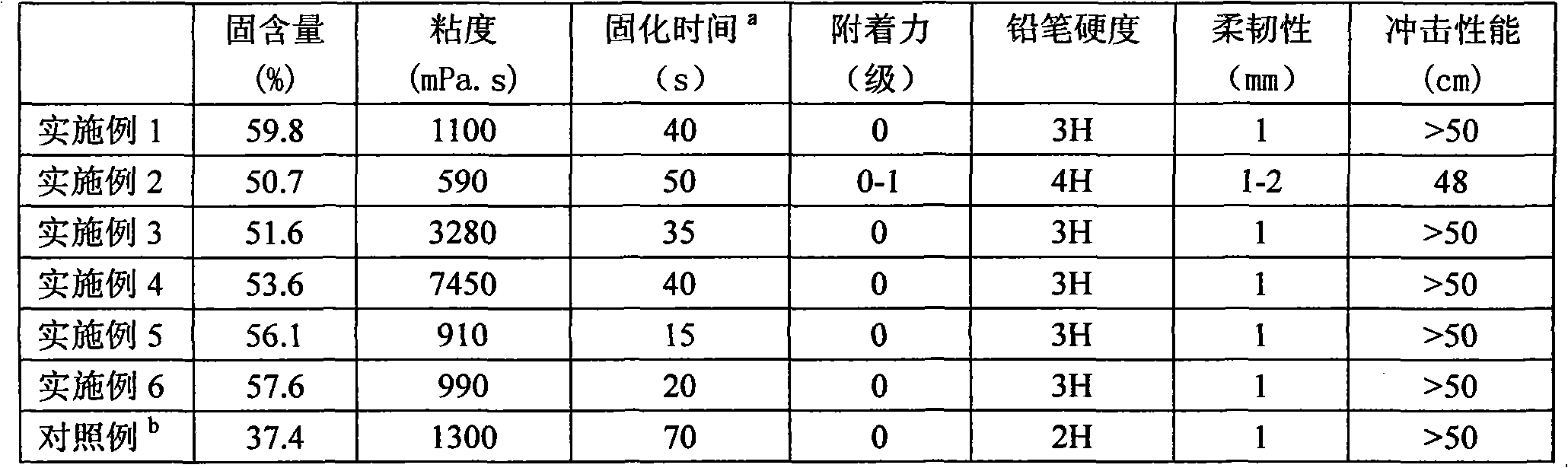

Normal-temperature multiple curing organic-inorganic hybridized aqueous nano polyurethane woodware coating and preparation method thereof

InactiveCN101798483ANo pollution in the processNon-flammablePolyurea/polyurethane coatingsIn situ polymerizationDouble bond

The invention discloses a normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating and a preparation method thereof. The coating mainly contains organic-inorganic hybridized aqueous nano polyurethane latex, a film-forming assistant, a defoaming and foam inhibitor, a flatting agent, a base material wetting agent, a stable dispersing agent, a thickening agent and an aqueous photo initiator, wherein the organic-inorganic hybridized aqueous nano polyurethane latex is prepared by firstly obtaining a polyurethane prepolymer by pre-polymerizing, and then adding an inorganic nano material in an organic-inorganic hybridization way by an in-situ polymerization technology, and finally grafting a photo-curing end-capping agent containing active functional groups and C-C double bonds. The normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating is obtained by adding and dispersing pigment fillings and an assistant evenly in the organic-inorganic hybridized aqueous nano polyurethane latex. The invention not only solves the pollution problem of a solvent-type VOC (Volatile Organic Compound) coating, but also solves the problem of aqueous coatings which have the defects of poor toughness and poor performances in weather resistance, aging resistance, acid resistance, alkaline resistance and solvent resistance.

Owner:SICHUAN UNIV +1

Hydrophilic super-lubricating coating applied to surfaces of medical apparatuses and preparation method of hydrophilic super-lubricating coating

The invention provides a hydrophilic super-lubricating coating applied to surfaces of medical apparatuses and a preparation method of the hydrophilic super-lubricating coating. The hydrophilic super-lubricating coating comprises a bottom layer and a surface layer, wherein on the basis of the principle of dissolution in similar material structures, the bottom layer and the base material (the surface layer) are firmly bonded; and the surface layer and the bottom layer are firmly connected by virtue of chemical bonds which are formed from ultraviolet grafting and inter-molecular forces. By virtue of a dipping-coating technology, the surfaces of the medical apparatuses are dipped in a bottom layer solution and are subjected to partial curing in ultraviolet radiation; and then, the medical apparatuses that the bottom layer is partially cured are dipped in a surface layer paint and are subjected to complete curing under ultraviolet rays, so that the surface layer is uniformly and stably distributed on the bottom layer. According to the hydrophilic super-lubricating coating and the preparation method provided by the invention, the hydrophilic super-lubricating paint can get rapidly cured under the ultraviolet rays, and the obtained hydrophilic coating is excellent in lubricating performance and durability, and friction and tissue injuries, which are caused in an inserting process, can be effectively relieved; and moreover, the hydrophilic super-lubricating coating is easily available in raw materials and low in cost.

Owner:DALIAN UNIV OF TECH

Single-component skin similar texture paint

ActiveCN101240145AShort curing timeShorten the production cyclePolyurea/polyurethane coatingsPre conditioningChemistry

The invention belongs to the solvent paint field, especially relates to a single component skill-similar texture paint, raw materials of which comprising elastic resin 35wt%to 65wt%, handle filler 20wt% to 40wt%, solvent 5wt% to 30wt%. Said components further comprise dispersing auxiliary 0wt% to 5wt%, which is respectively one or more mixtures of leveling agent, dispersant, anti-settling agent and antifoaming agent; further comprising matt laminated powder 0wt% to 2wt%, further handle filler 0wt% to 2wt%,which are one or more mixtures of constant slipping agent, anti-scratching agent for industrial paint; preferably, the elastic resin is thermoplastic polyurethane elastic resin modified by perchloro-ethylene resin. The invention provides a new prescription of single component skill-similar texture paint, applying skill-similar texture paint creatively in decorative coat on surface of pencil under the pre-condition of not changing decorative coat craft on surface of the pencil and excellent contact of skill-similar texture paint coat, which greatly reduces solidifying time of texture coat and reduces manufacturing cost of relevant products.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

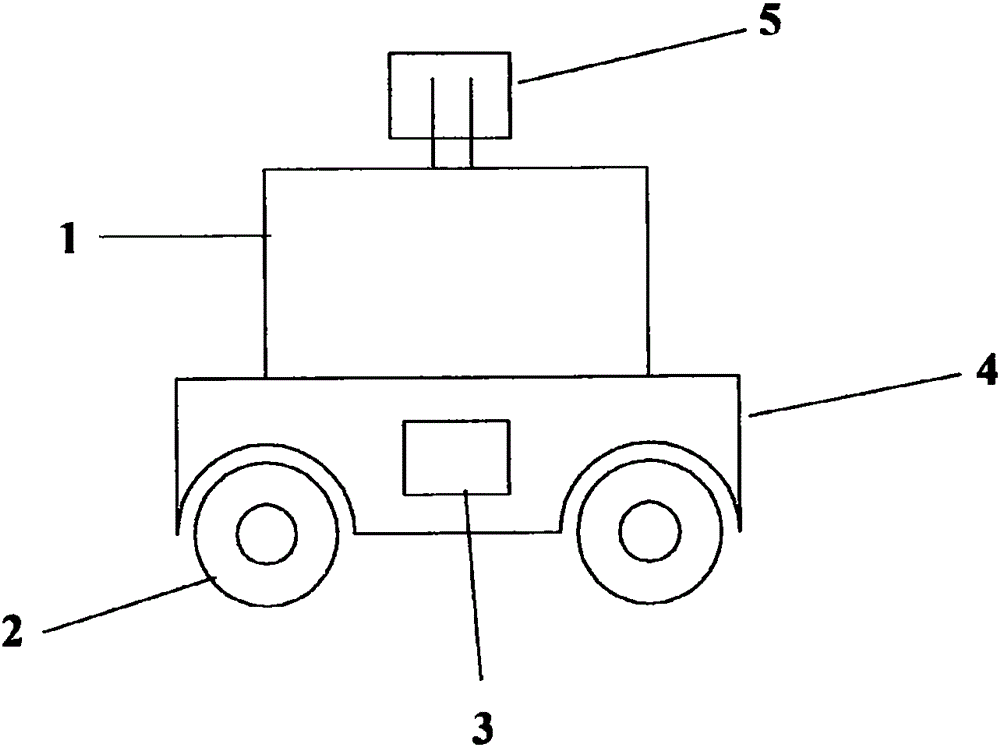

Unmanned express delivery conveying system and conveying method

InactiveCN105279625AEasy to operateConvenient automatic sortingInksCo-operative working arrangementsEngineeringHigh security

The invention discloses a new unmanned express delivery conveying system and conveying method. Detailed plans are made from goods departure, to transportation paths, and finally to clients, so that the goods are safely, accurately and fast to be delivered to the clients. In addition the invention carries out further optimization on RF labels. The cost is reduced so as to make the system and conveying method of the invention to have stronger market competitiveness. The operation is simple and unattended. The unmanned express delivery conveying system runs 24 hours a day. RFID labels are automatically added to express delivery articles. It is helpful to automatic sorting. A large number of time and manpower are saved. After express items are in place, confirmation information is sent to recipients in real time, and the safety is improved. The unmanned express delivery conveying system and conveying method can be widely used in various communities where express delivery is frequently needed, and are safe and fast, low in cost and convenient in maintenance.

Owner:CIXI DAFEIMIAO ELECTRONICS TECH CO LTD

Unsaturated polyester resin button and preparation method thereof

The invention discloses a preparation method of an unsaturated polyester resin button, comprising the following steps: adding 100 parts of the unsaturated polyester resin, 1-4 parts of inhibitors and 2-10 parts of monomer diluent to a material barrel; adding 20-300 parts of non-organic powder under the stirring state; stirring uniformly; adding 1-4 parts of curing agents; continuously stirring, and pouring on a centrifugal flaker or a roller producing machine; curing at indoor temperature for 20 to 60 min to obtain the blank sheets or rods; flushing the blanks, cutting and dipping the blanks, mechanically twisting and polishing to obtain the button product. The invention reduces the use quantity of the unsaturated polyester resin, indirectly reduces the use of petroleum-based materials, and has simple process and low cost. The prepared product has excellent mechanical property.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

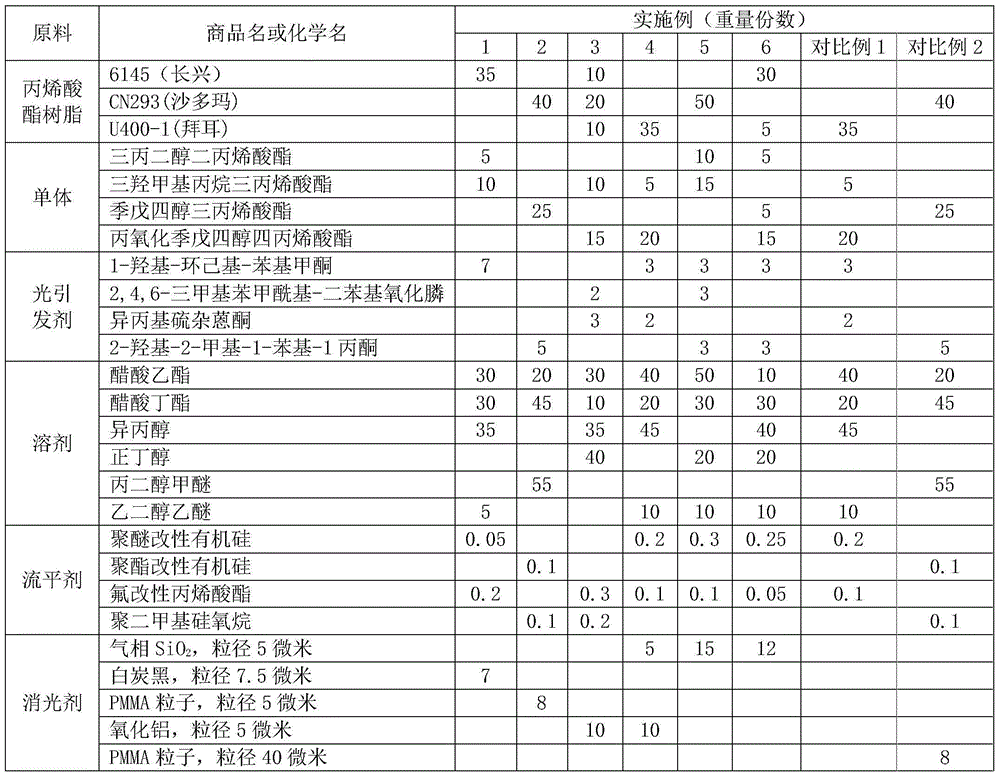

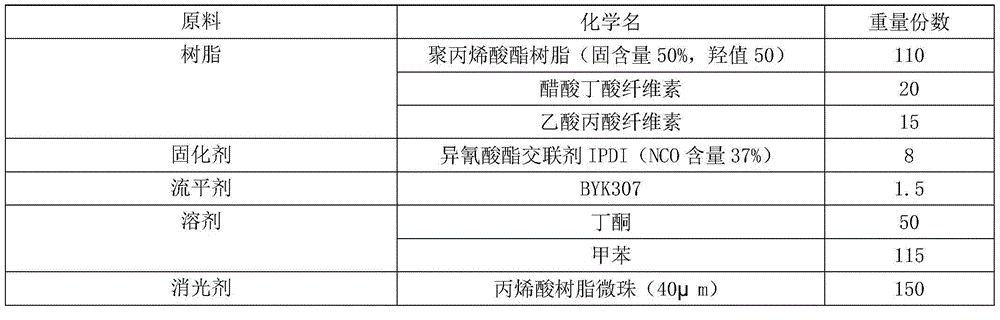

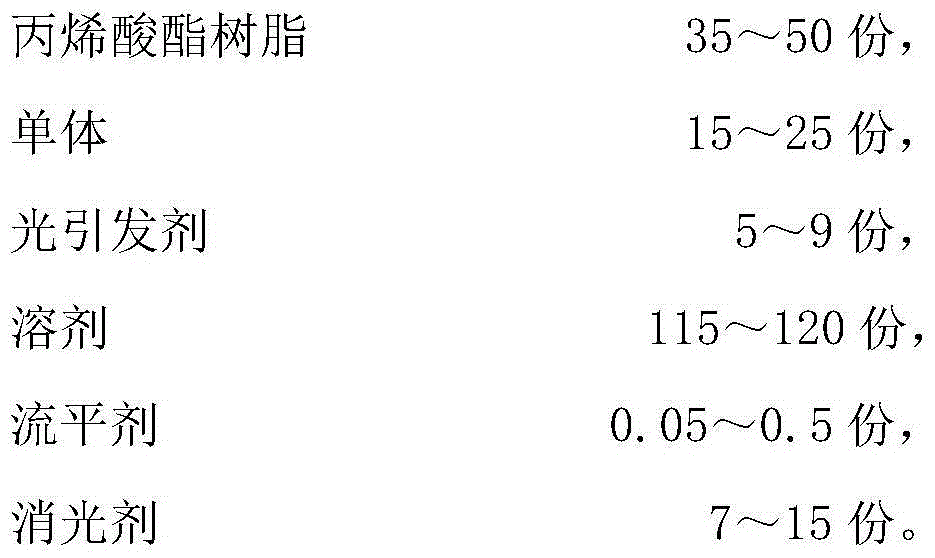

High wear-resistant ultraviolet curing diffusion film coating composition for PET (polyethylene terephthalate)

InactiveCN104312415AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsPolyester coatingsPolyesterPolyethylene terephthalate glycol

The invention discloses a high wear-resistant ultraviolet curing diffusion film coating composition for PET (polyethylene terephthalate). The composition comprises the following components in parts by weight: 35-50 parts of acrylate resin, 15-25 parts of a monomer, 5-9 parts of a photoinitiator, 115-120 parts of a solvent, 0.05-0.5 part of a leveling agent and 7-15 parts of a matting agent. The acrylate resin is one or more of highly functional aliphatic urethane acrylate resin, aliphatic polyester acrylate resin, aliphatic urethane methacrylate resin and aliphatic polyester methacrylate resin; and the matting agent is one or more of pure polyester matting particles, gas-phase silicon dioxide micro-powder, wax powder, polymethylurea resin micropowder, aluminum oxide, polymethyl methacrylate and white carbon black, wherein the particle size is micron grade. Compared with the prior art, the high wear-resistant ultraviolet curing diffusion film coating composition for PET is energy-saving, efficient and high in haze adjustability, the wear resistance can be improved to 10 times / 1000g and the practicality is higher.

Owner:SHANGHAI WEIKAI CHEM +1

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

Sand texture type polyester/epoxy powder coating and preparation method thereof

InactiveCN103160192AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyPollution

The invention discloses a sand texture type polyester / epoxy powder coating and a preparation method thereof. The sand texture type polyester / epoxy powder coating comprises the following raw materials, by weight, 350-400 parts of polyester resin (P5040), 240-280 parts of epoxy resin (E-12), 100-150 parts of extinction barium sulfate, 40-60 parts of spherical silica powder, 8-12 parts of modified polyethylene wax powder, 10-15 parts of organic coated titanium dioxide, 5-10 parts of sand texture agent (SWMBX-30), 4-6 parts of benzoin, 5-8 parts of 2-phenyl imidazoline, 4-6 parts of 2-methylimidazole, 5-10 parts of ferrite yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The prepared powder coating has the advantages of being high in hardness, high in intensity, high in abrasion resistance, good in heat resistance, good in ageing resistance, short in solidifying time, environment-friendly, free of pollution and the like. The solidified coating produces a texture effect of the sand texture, the sand texture is meticulous and clear, distribution is even, visual comfort is provided for people, and combination properties of the coating are good.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com