Unsaturated polyester resin button and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of unsaturated polyester resin buttons and its preparation, to achieve the effect of reduced dosage, excellent mechanical properties, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

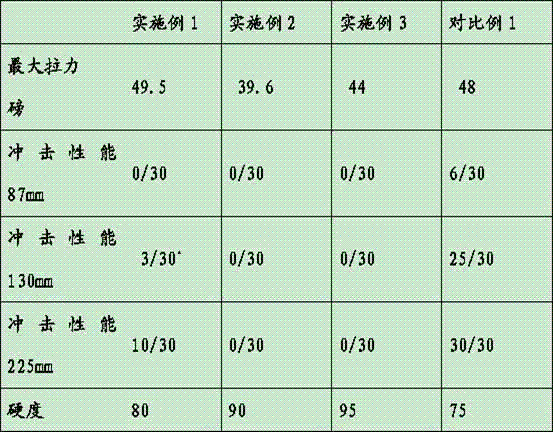

Examples

Embodiment 1

[0018] Add 100 parts of o-phthalic unsaturated polyester resin, 2 parts of styrene, 2 parts of wax water, 1 part of blue color paste, and 1.2 parts of cobalt cyclooctanoate accelerator in the material barrel, stir for 3 minutes, and then add 20 parts of 200-mesh calcium carbonate, continue to stir for 10 minutes, finally add 1.2 parts of methyl ethyl ketone peroxide as a curing agent, stir for 1 minute, pour it into a centrifugal tablet machine (machine speed 20-30r / min), centrifuge and solidify for 50 minutes, take the tablet, and then punch the blank , dipping, button turning, polishing and other processes to obtain button products. The diameter of this button is 18L (1L=0.635mm), and the style is A8603. Air bubbles and shrinkage were not observed during button preparation.

[0019]

Embodiment 2

[0021] With embodiment 1, difference is to select at least one in 100 parts of 200 mesh calcium carbonate, calcium silicate, magnesium carbonate, talcum powder, silicon dioxide, aluminum hydroxide, hollow glass microsphere, cobalt naphthenate accelerator is 1.6 parts, styrene is 6 parts. After adding 1.6 parts of methyl ethyl ketone peroxide as a curing agent, stir for 1 minute, pour it into a centrifugal tablet machine (machine speed 20-30r / min), centrifuge and solidify for 30 minutes, take a tablet, and then go through the processes of punching, soaking, turning, and polishing to obtain buttons. Button products, the diameter of this button is 18L, and the style is A8603.

[0022]

Embodiment 3

[0024] With embodiment 1, the difference is to select at least one of 300 parts of 200 mesh calcium carbonate, calcium silicate, magnesium carbonate, talcum powder, silicon dioxide, aluminum hydroxide, hollow glass microspheres, 1.5 parts of white color paste, 10 Parts of styrene, 4 parts of cobalt naphthenate accelerator, 100 parts of isophthalic unsaturated polyester resin, 4 parts of methyl ethyl ketone peroxide. Add the curing agent methyl ethyl ketone peroxide, stir for 1 minute, then pour it into a centrifugal tablet machine (machine speed 20-30r / min), centrifuge and solidify for 40 minutes, take the tablet, and then go through the processes of punching, soaking, turning buttons, polishing and other processes to obtain button products , the diameter of this button is 18L, and the style is A8603.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com