Patents

Literature

4623 results about "Unsaturated polyester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unsaturated polyester. Unsaturated polyester, any of a group of thermosetting resins produced by dissolving a low-molecular-weight unsaturated polyester in a vinyl monomer and then copolymerizing the two to form a hard, durable plastic material.

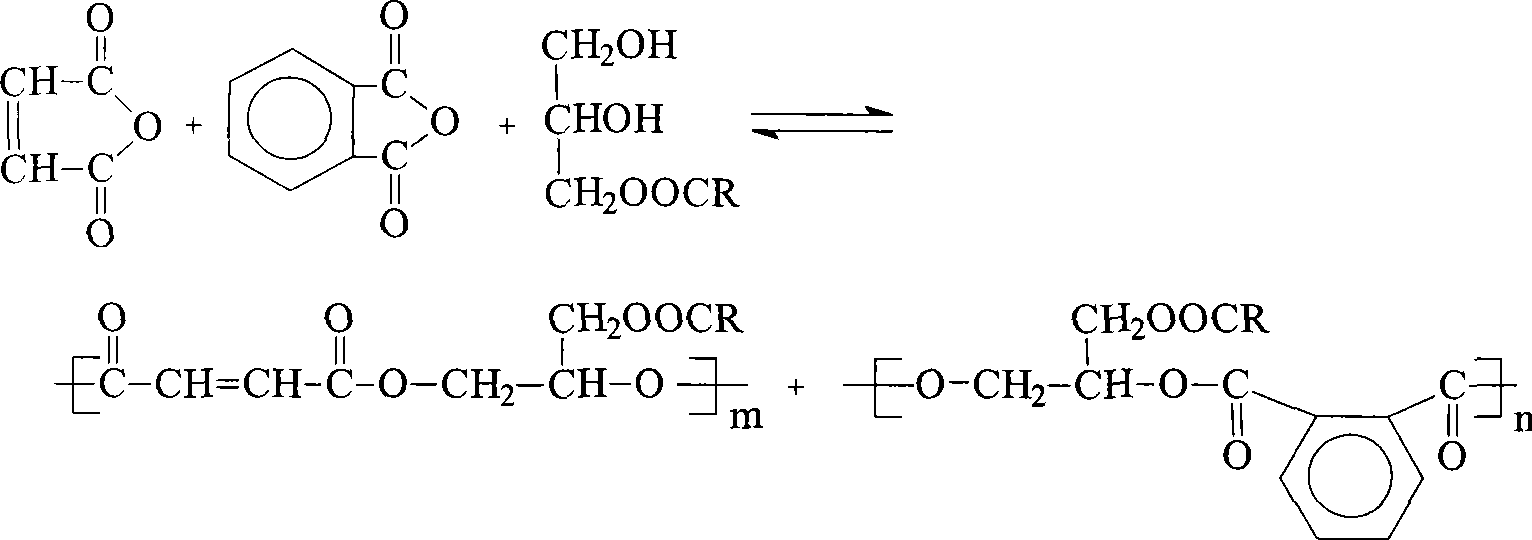

Polyester process

A process for the preparation of an unsaturated polyester which comprises (i) reacting an organic diol with a cyclic akylene carbonate in the presence of a first catalyst to thereby form a polyalkoxy diol, and (ii) optionally adding thereto a further amount of cyclic alkylene carbonate in the presence of a second catalyst, and (iii) subsequently polycondensing the resulting mixture with a dicarboxylic acid.

Owner:XEROX CORP

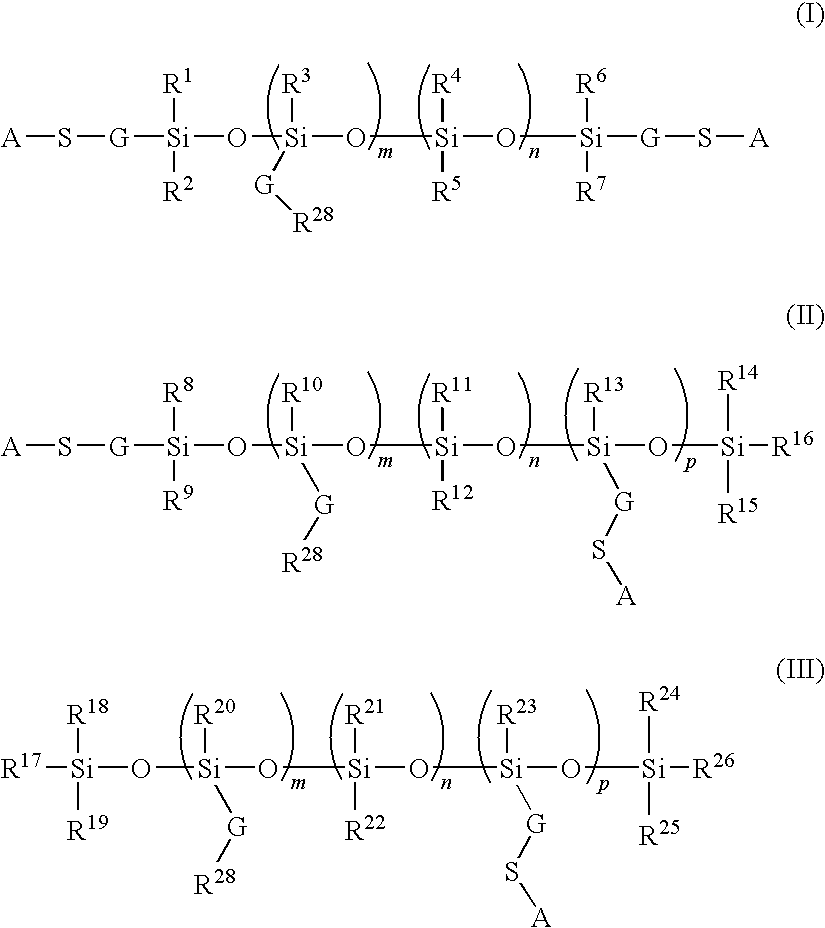

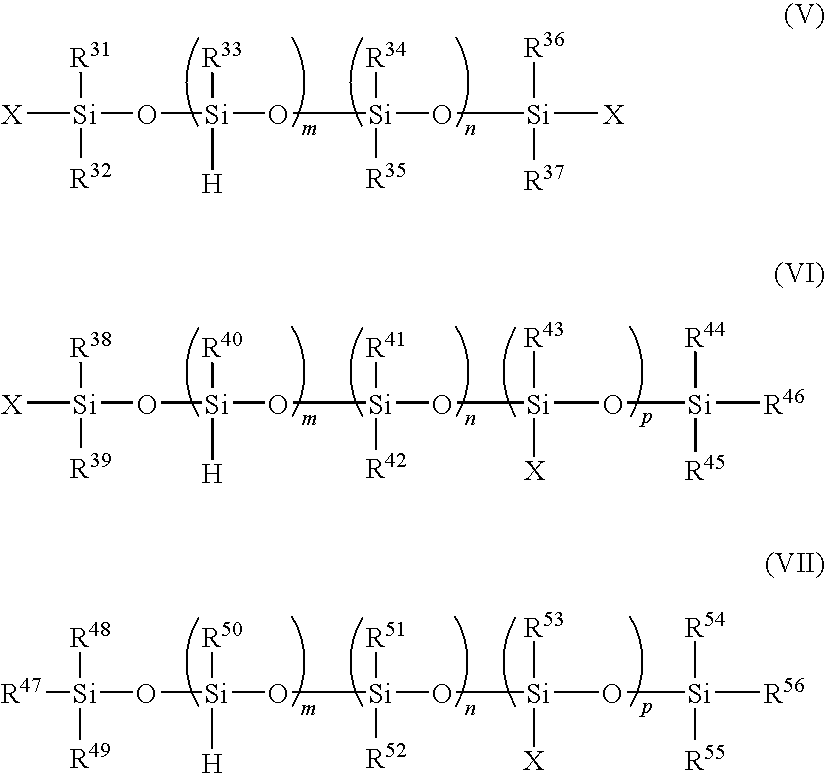

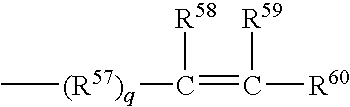

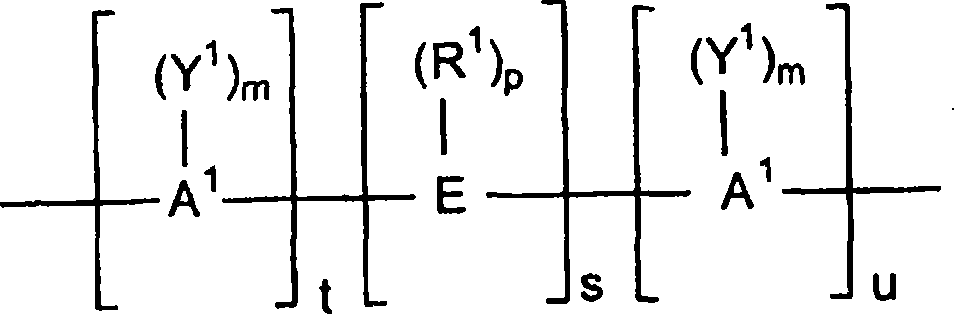

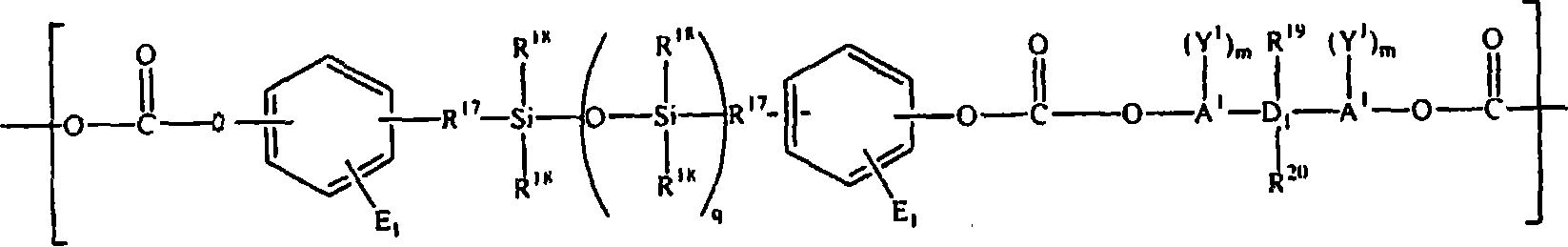

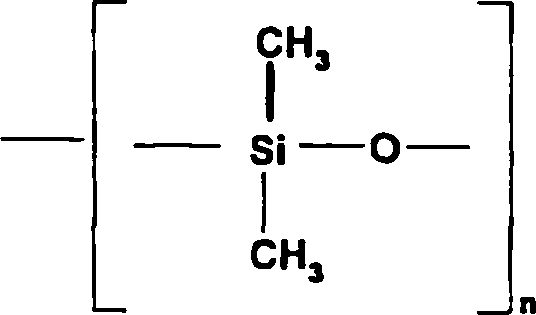

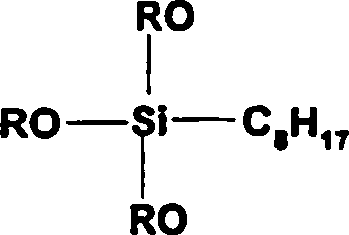

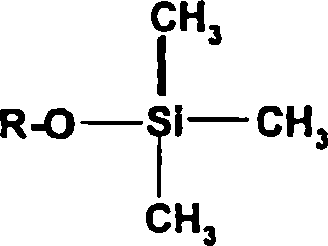

Polyorganosiloxane composition for use in unsaturated elastomer, article made therefrom, and associated method

A tire composition is provided that may include a sulfur-functional linear polyorganosiloxane and an unsaturated elastomer. The sulfur-functional linear polyorganosiloxane may include a chemically protected sulfur group, which includes a thiocarbamate, a dithiocarbamate, or a derivative or analog of thiocarbamate or dithiocarbamate. Under certain conditions, the sulfur group may react with the unsaturated elastomer. The invention includes embodiments that may relate to methods of making and using the sulfur-functional linear polyorganosiloxane in tire compositions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

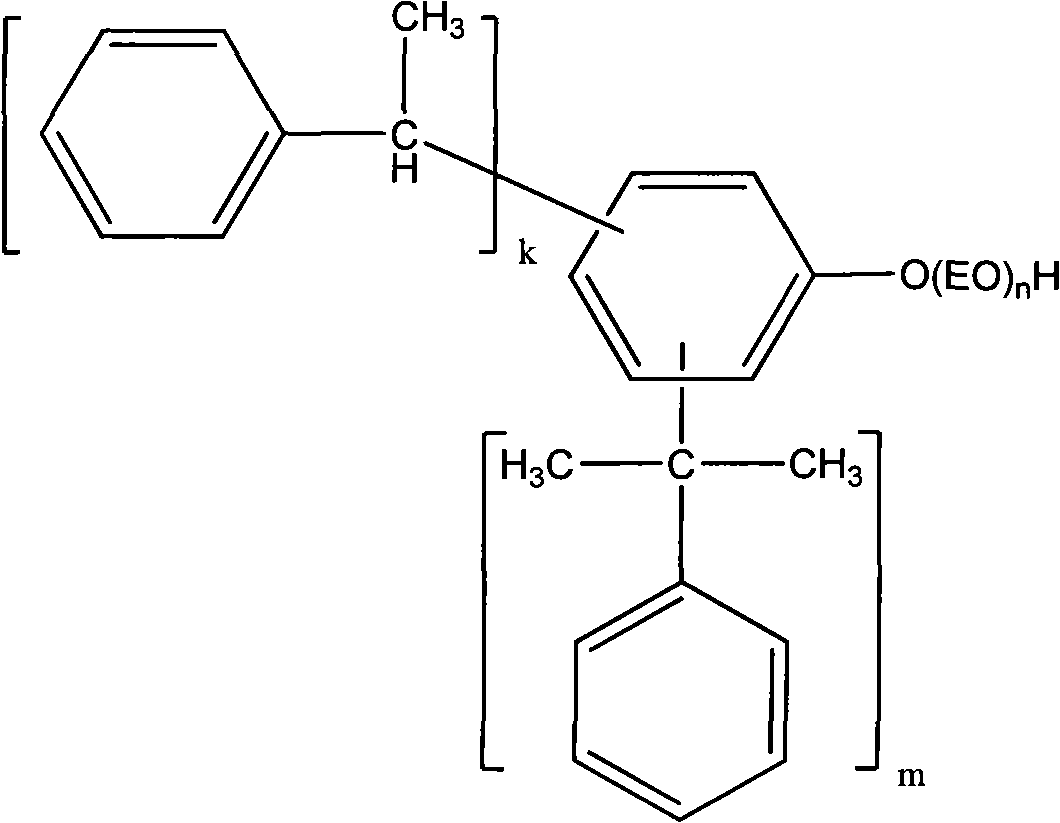

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

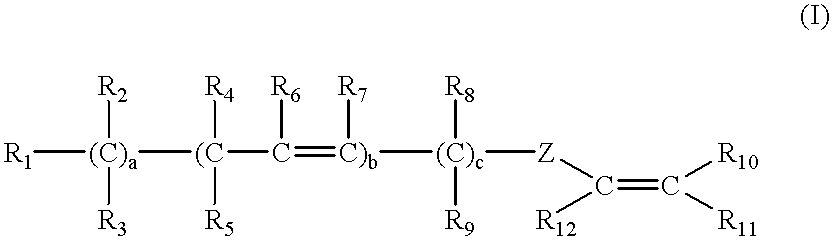

Latex compositions containing ethylenically unsaturated esters of fatty compounds and applications thereof

Novel latex or emulsion compositions containing internally plasticizing and crosslinkable monomers derived from traditional semi-drying or non-drying oils are disclosed and claimed. The monomers are ethylenically unsaturated derivatives of long-chain olefinic compounds. Preferred embodiments include latex formed from acrylate or methacrylate esters of fatty alcohols. A process for the synthesis of the latex composition is also disclosed, which involves (a) polymerization of the ethylenically unsaturated derivatives of a long-chain olefinic compound in an aqueous phase with at least one other copolymerizable monomer; and (b) blending of so formed polymer with at least one drier and a surfactant to form the novel latex or emulsion compositions. These compositions form films at low minimum film forming temperatures (MFT) ranging from -5 to 10° C. and cure to above ambient glass transition (Tg) polymers without the use of traditional organic cosolvents which contribute to environmental pollution via volatile organic compounds (VOCs) emissions. These compositions are therefore useful in waterborne coatings, contact and pressure sensitive adhesives, and inks.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI +1

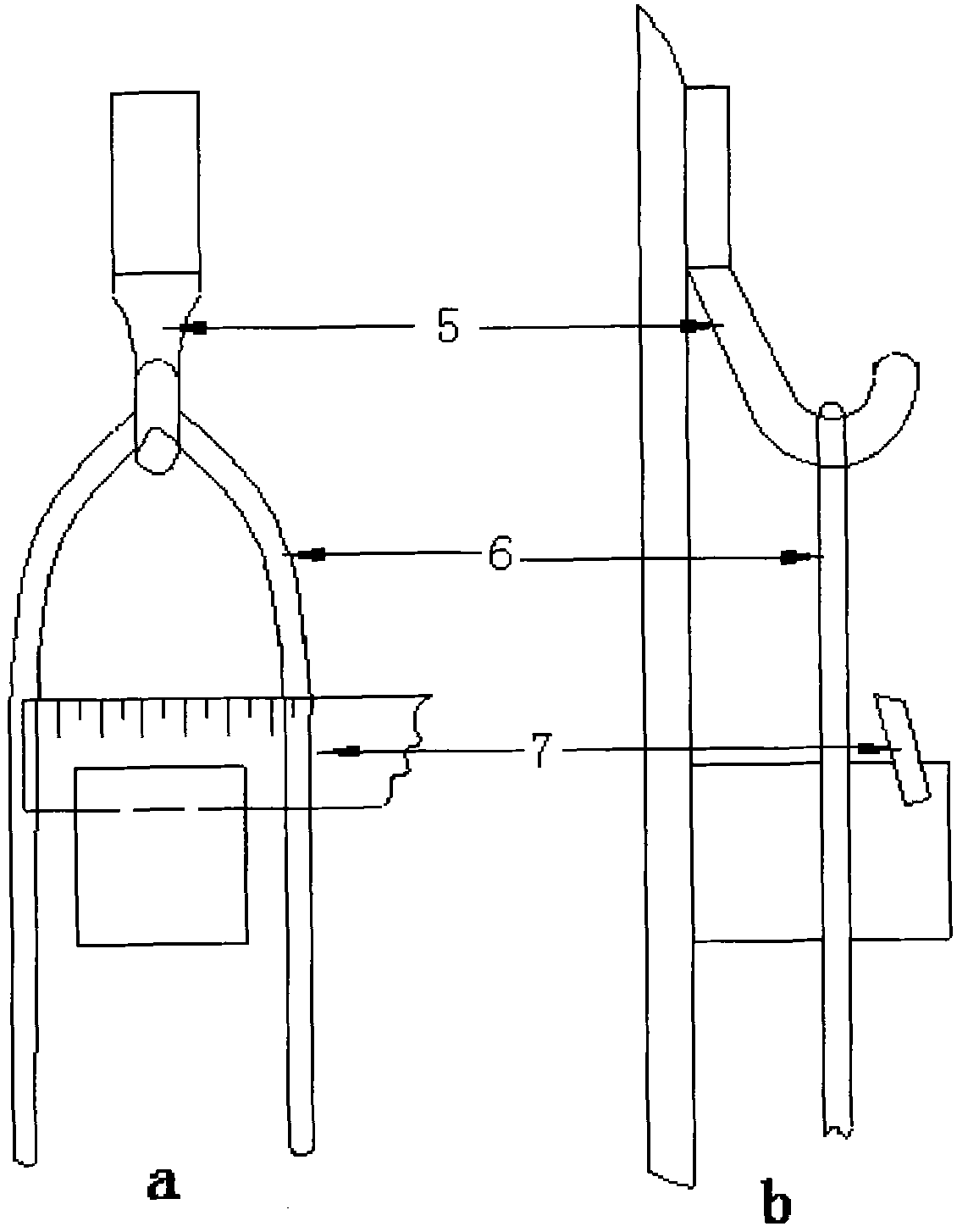

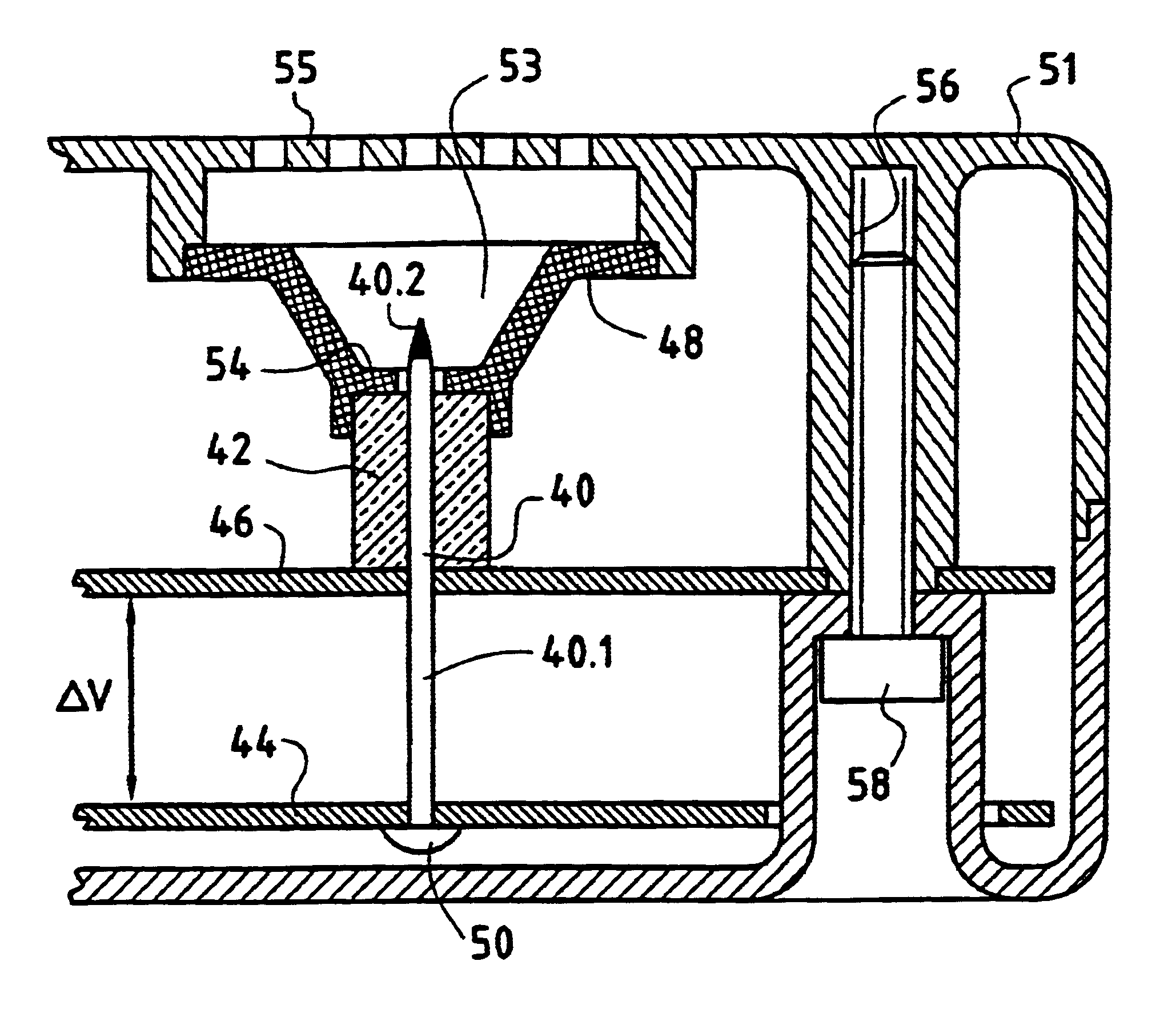

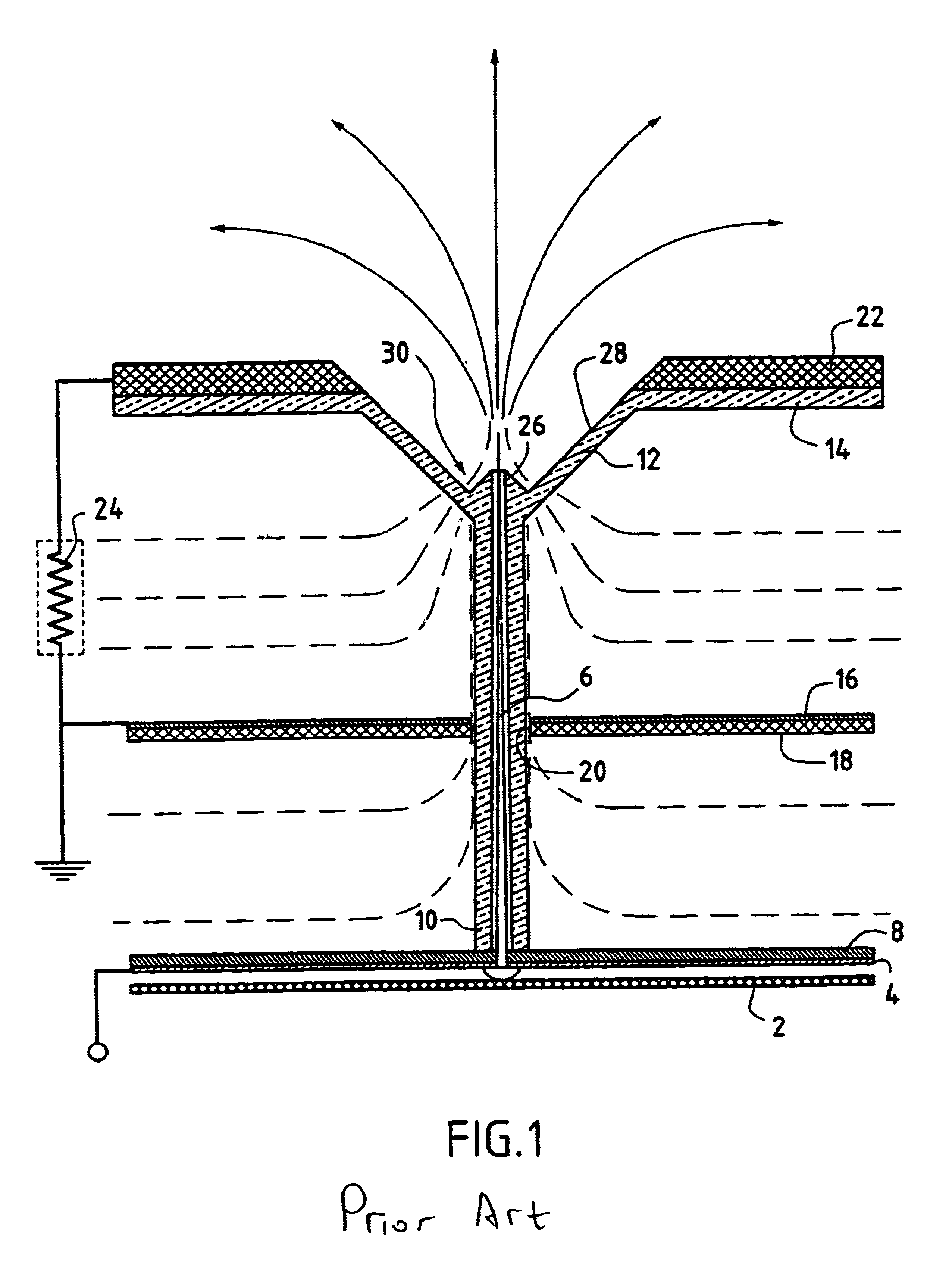

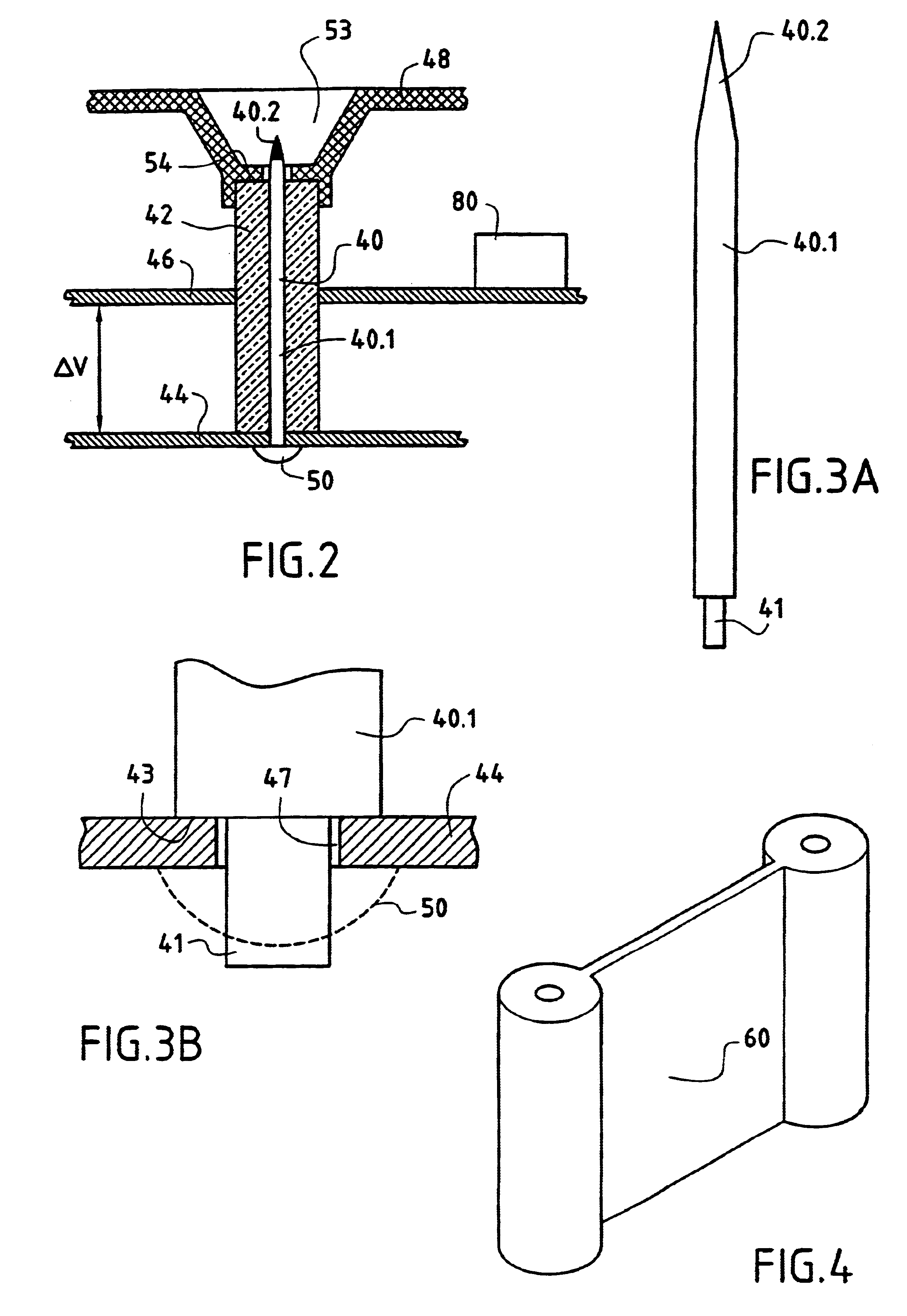

Ion generating device

InactiveUS6735830B1Material analysis by optical meansVessels or leading-in conductors manufacturePolyesterGlass fiber

The invention relates to apparatus for generating ions in a gaseous medium, the apparatus comprising one or more needles (40) each presenting a shank (40.1) and an emitter end (40.2), a sheath (42) of composite material comprising glass fiber reinforced unsaturated polyester surrounding the shank (40.1) of each needle, and means (44, 46, 80) for applying a voltage between two portions of the shank of each needle.

Owner:GENIE & ENVIRONNEMENT

Toner, method for preparing the toner, and developer including the toner

A toner including a binder resin comprising a polyester resin in an amount of from 50 to 100% by weight, wherein the polyester resin includes an unsaturated polyester resin which is preferably a crystalline polyester resin; a colorant; and a fatty acid metal salt which is preferably microencapsulated. A method for preparing a toner including forming particles of a toner composition including at least a binder resin including a polyester resin in an amount of from 50 to 100% by weight and a colorant, in an aqueous medium to prepare a dispersion of a particulate material, wherein the polyester resin includes an unsaturated polyester resin; drying the particulate material; and mixing a fatty acid metal salt with the particulate material to subject double bonds of the unsaturated polyester resin to oxidation polymerization.

Owner:RICOH KK

Raw material of artificial quartzite plate and method for preparing artificial quartzite by using the same

The invention discloses a raw material of an artificial quartzite plate and a method for preparing artificial quartzite by using the same. The raw material of the artificial quartzite plate comprises a substrate material and additives, wherein the substrate material comprises 20-70 wt% of quartz sand, 20-70 wt% of quartz powder, 8-12 wt% of unsaturated polyester resin, and 0.3-0.7 wt% of color paste; the additives comprise a composite curing agent and a coupling agent, the weight of the composite curing agent is 0.8-2.0 % of the weight of the unsaturated polyester resin, and the weight of the coupling agent is 0.5-1.5 % of the weight of the unsaturated polyester resin; the composite curing agent is prepared by mixing a middle-temperature curing agent and a high-emperature curing agent, and the weight ratio of the middle-temperature curing agent to the high-temperature curing agent is 1 / 9-3 / 7. Practices show that by using the raw material to prepare artificial quartzite, the cost is low, the efficiency is high, and the comprehensive properties of the product are excellent.

Owner:WUHAN SHARESUN HI TECH BUILDING MATERIAL

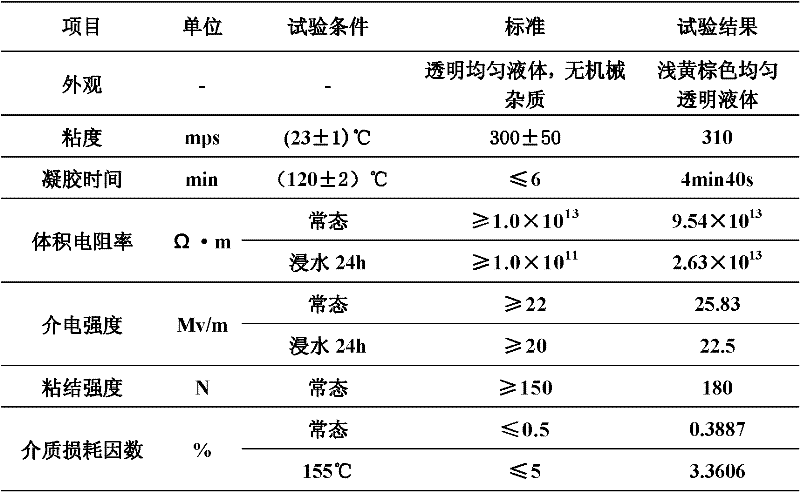

Environmentally-friendly type solvent-free impregnating resin and preparation method thereof

InactiveCN102225986AConservation TrendsPromote safe productionApplying solid insulationCoils manufactureLow voltageTransformer

The invention discloses an environmentally-friendly type solvent-free impregnating resin and a preparation method thereof. The impregnating resin comprises: 100 parts by weight of one or more high heat-resistant unsaturated polyester resins, 0 to 100 parts by weight of one or more modified epoxy resins, 50 to 200 parts by weight of one or more novel reactive diluents, 0.1 to 1 parts by weight of one or more polymerization inhibitors, 1.5 to 3.8 parts by weight of one or more initiators and 0 to 2 parts by weight of one or more auxiliary agents. Under the same work conditions, a baking time of the solvent-free impregnating resin is less than about one third of a baking time of the existing conventional solvent-free type impregnating resin utilized for middle and low voltage motors and transformers, and an energy consumption of the solvent-free impregnating resin is lower than about 25% of an energy consumption of the existing conventional solvent-free type impregnating resin middle and low voltage motors and transformers.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

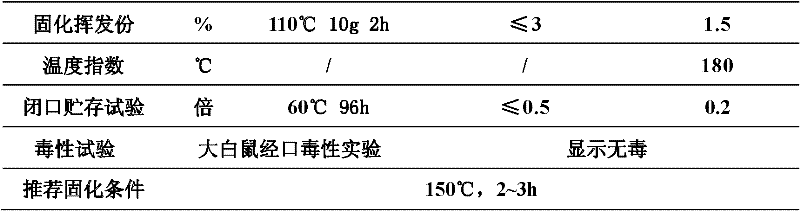

Method for producing metal composite, and chassis for electronic equipment

ActiveUS20130242487A1Excellent amenability to thin-walling and lightweightingHigh degree of designMagnetic/electric field screeningDigital data processing detailsEpoxyShell molding

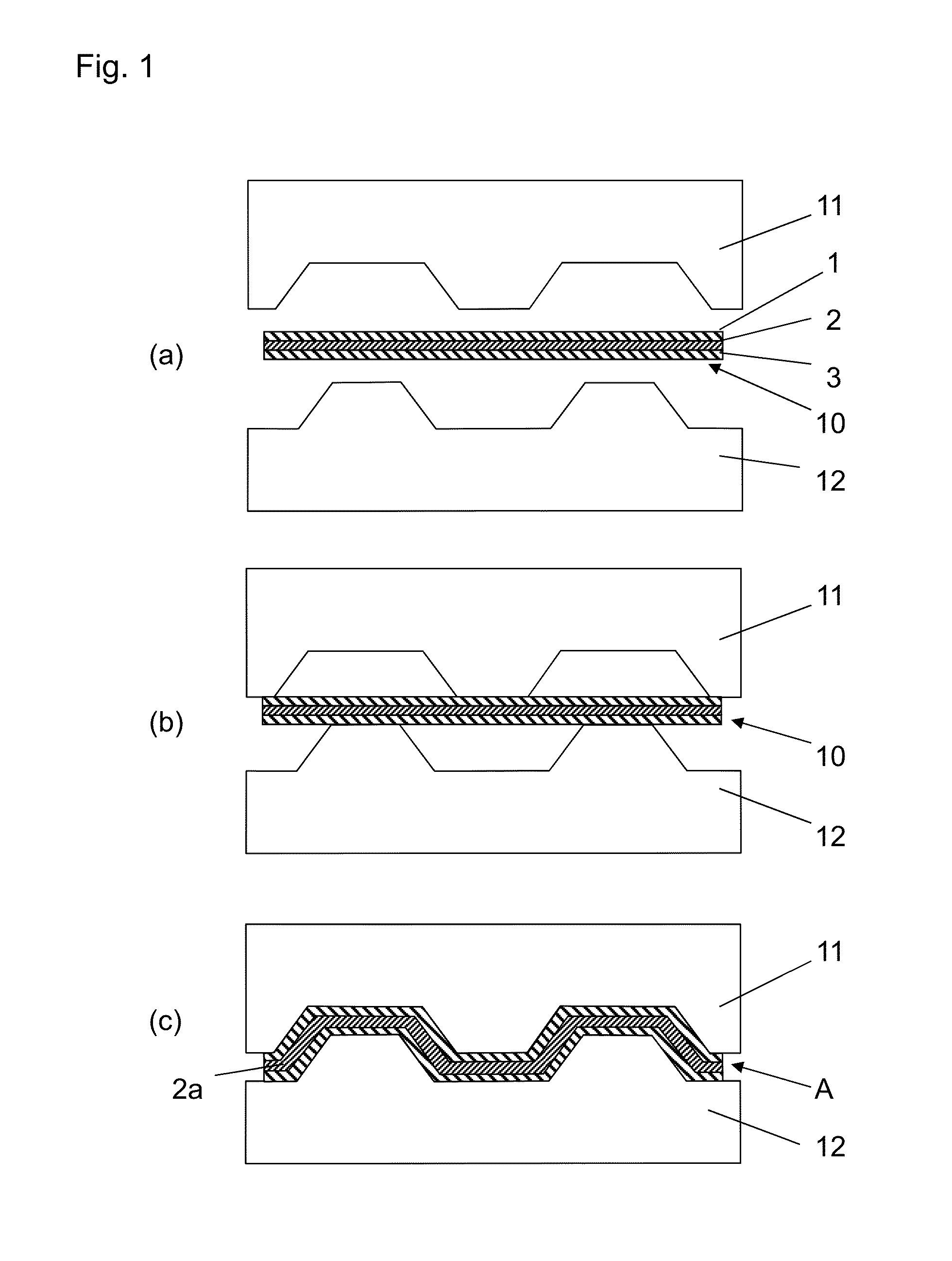

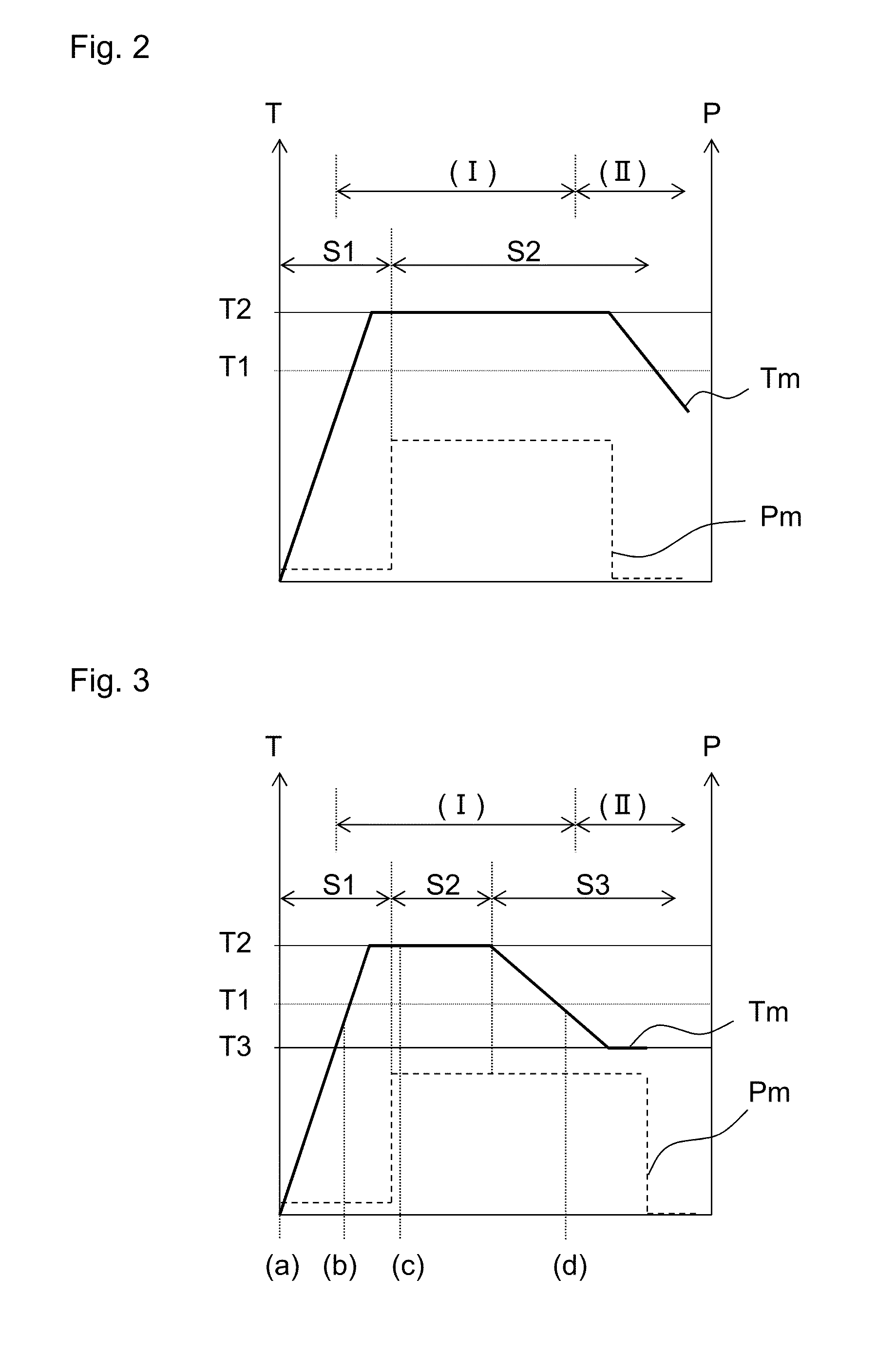

A method is provided for producing a metal composite. The composite includes a metal material and a resin curing layer provided along the metal material, and is obtained by using heat and pressure to mold a preform. The preform includes a sheet-shaped base material containing a thermosetting resin, and a metal material arranged or layered so as to contact the sheet-shaped base material. The method for producing a metal composite includes heating the sheet-shaped base material and semi-curing the thermosetting resin while the metal material in the preform arranged inside a mold is heated to a temperature exceeding 180° C., and molding the preform into a composite using pressure, wherein the thermosetting resin is at least one type selected from the group consisting of epoxy resins, phenol resins, benzoxazine resins, and unsaturated polyester resins.

Owner:TORAY IND INC

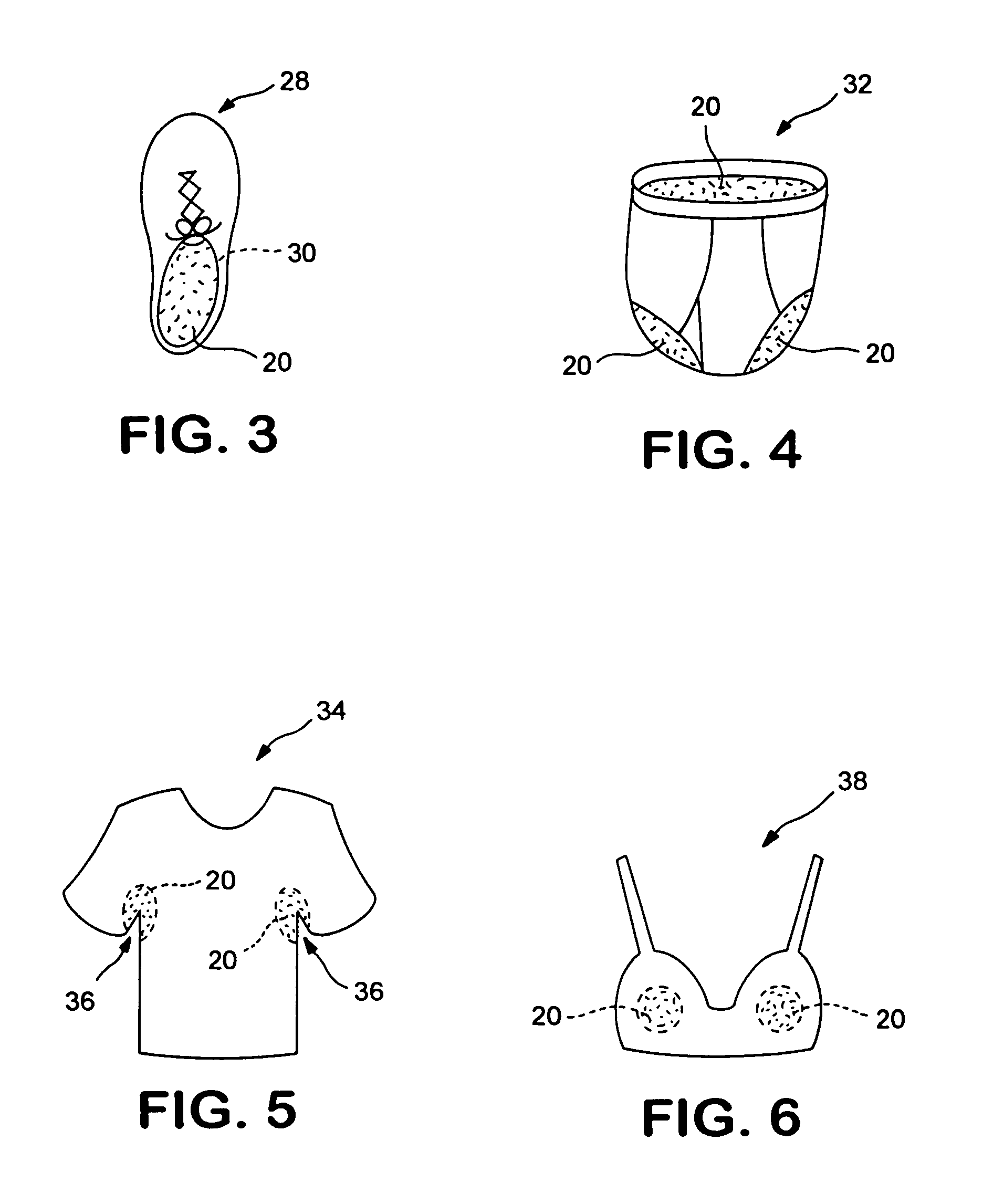

Absorbent binder coating

InactiveUS7115321B2Latent moisture-induced crosslinking capabilityMedical devicesBaby linensWound dressingMoisture

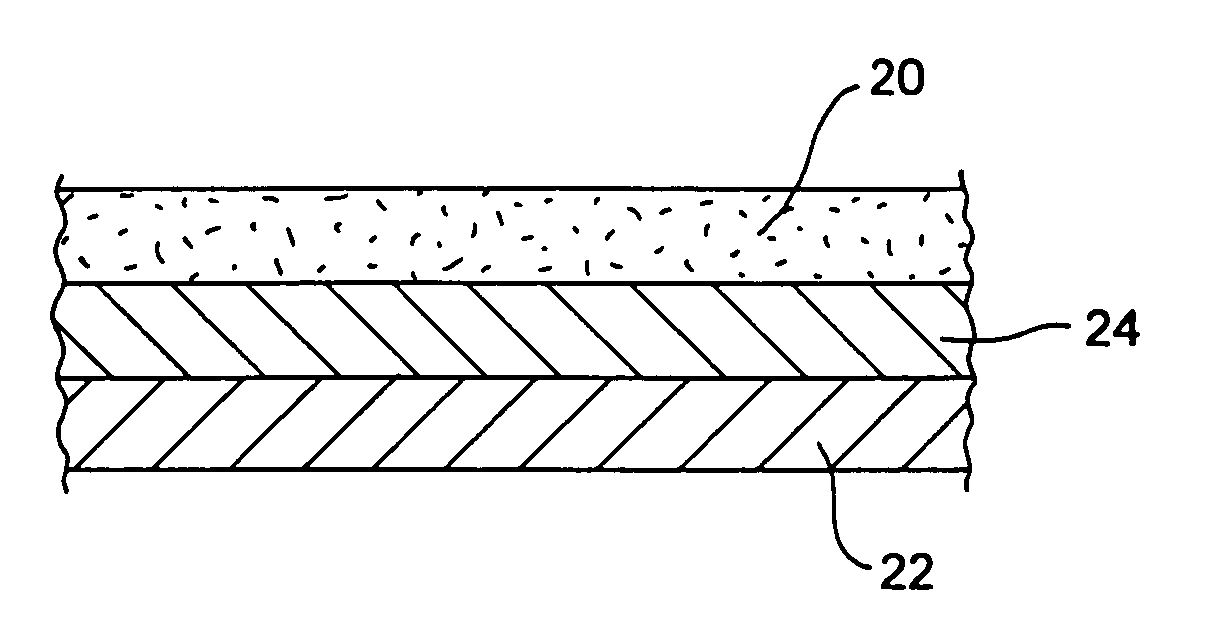

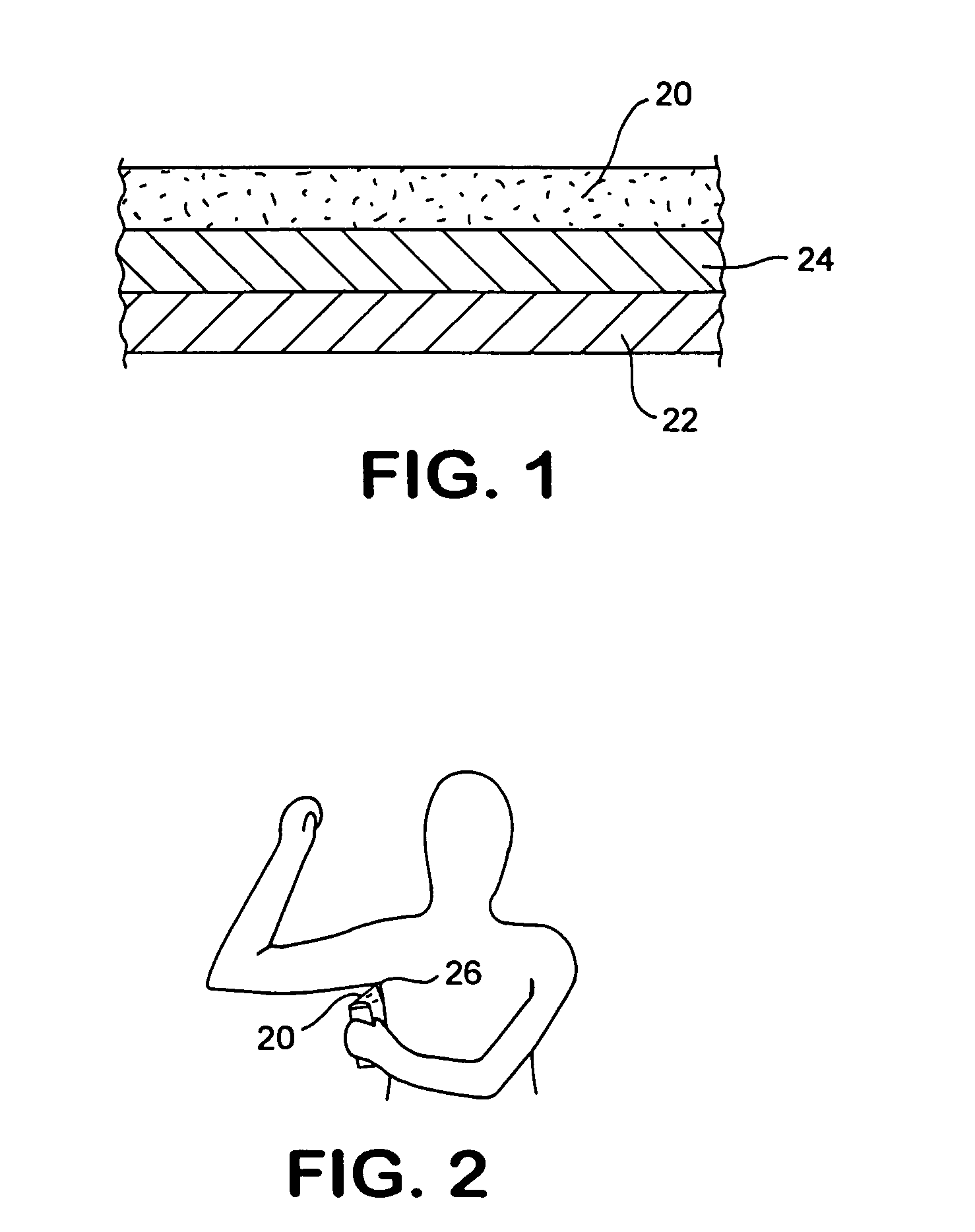

An absorbent binder coating including monoethylenically unsaturated polymer units, polyacrylate ester units that include an alkoxysilane functionality, and polyolefin glycol units and / or polyolefin oxide units, can be applied to various substrates. For example, the coating can be self-applied to an article of clothing or to a person's skin to provide absorbency. Alternatively, the coating can provide moisture absorbency, as well as adhesive properties, when incorporated into various articles including medical devices, wound dressings, laminates, absorbent garments, packaging materials, and horticultural products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

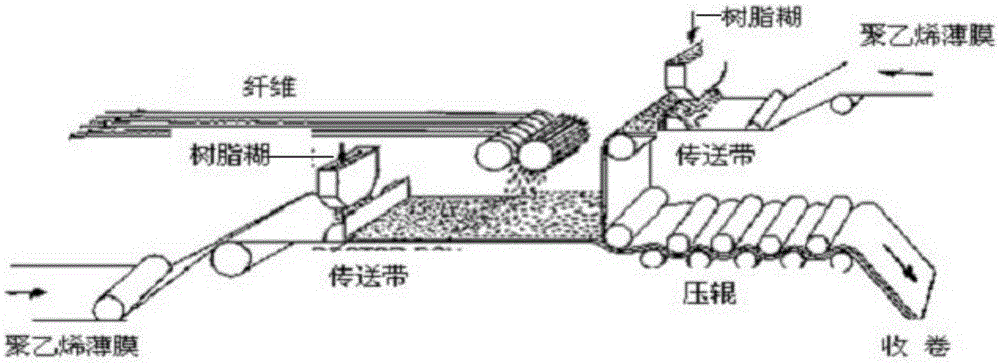

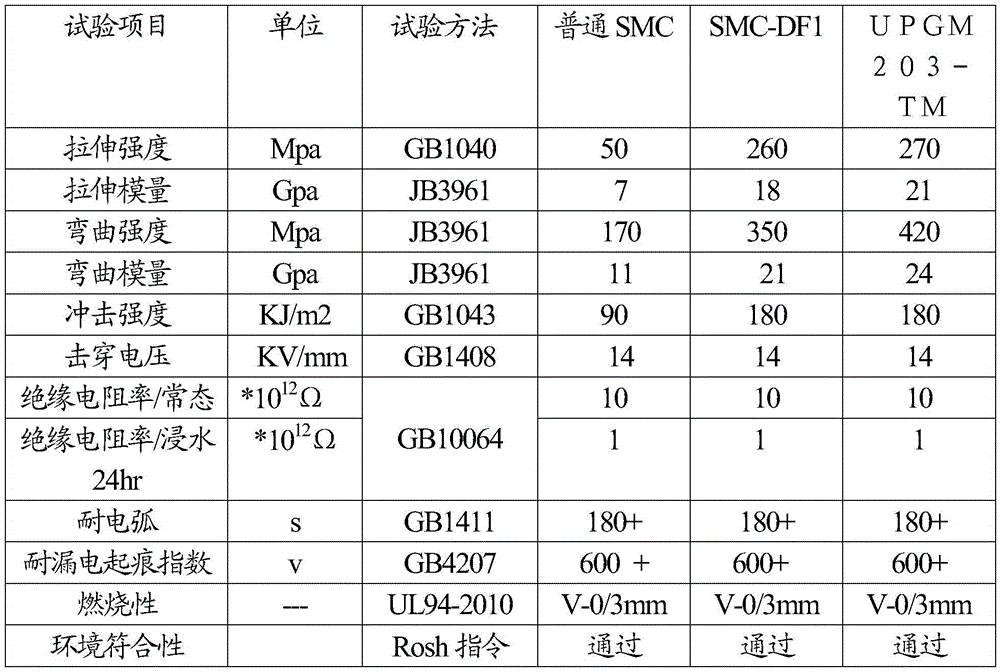

Continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound

The invention relates to the field of composite materials, in particular to a continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound. The continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound comprises the following components in part by weight: 15 to 50 parts of unsaturated polyester resin, 5 to 12 parts of low astringent, 8 to 20 parts of chopped glass fibers of 12 to 26 millimeters, 1.5 to 8 parts of directional continuous glass fibers, 10 to 50 parts of calcium carbonate, 10 to 50 parts of aluminum hydroxide, 0.2 to 1 part of organic peroxide, 1 to 4 parts of styrene, 0.2 to 1 part of thickening agent, and 1 to 3 parts of mold discharging agent. The continuously-directional glass fiber reinforcement unsaturated polyester sheet molding compound has the advantages of reasonable formula design, good flame retardance, high strength, low manufacturing cost and stable quality.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

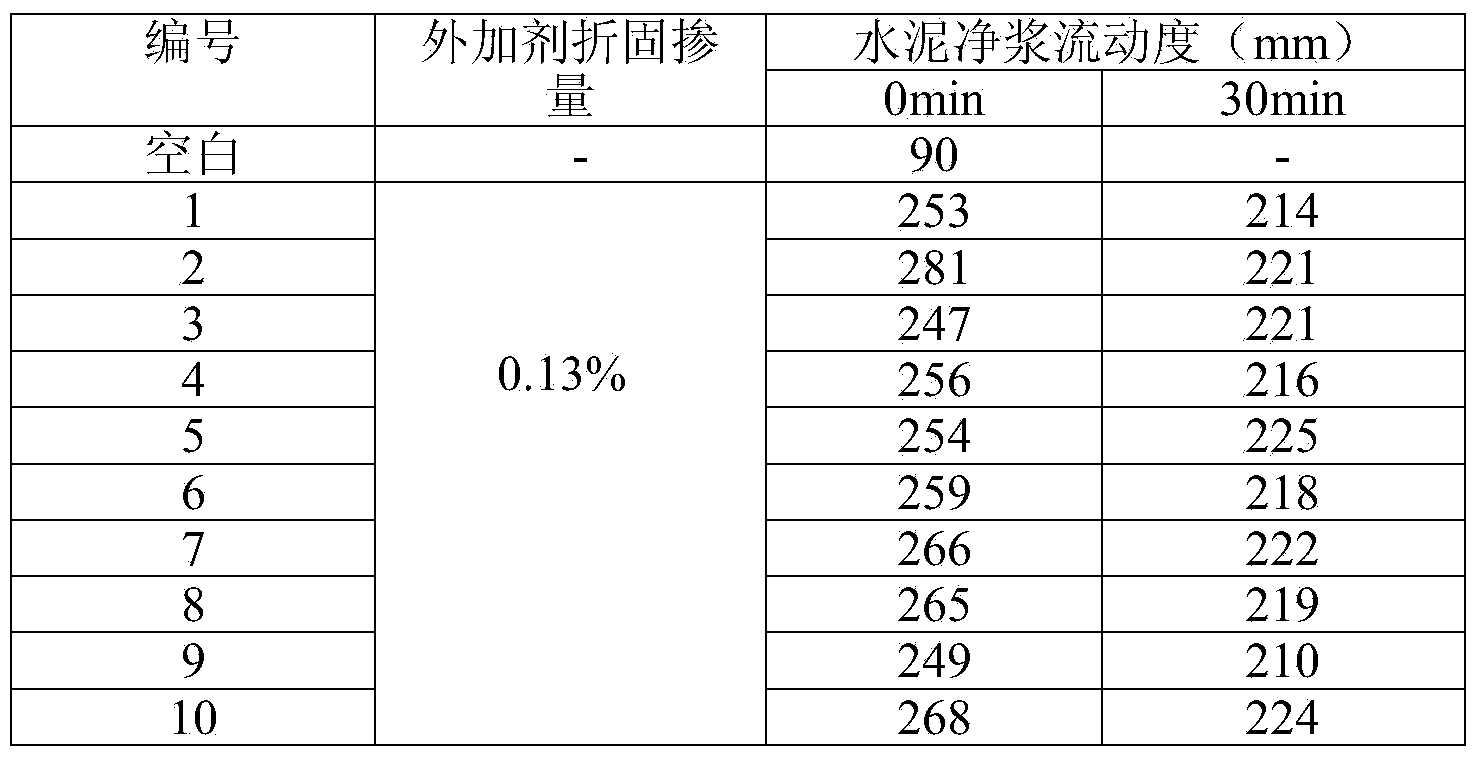

Preparation method and application of unsaturated polyether

The invention relates to a preparation method and application of unsaturated polyether. The preparation method comprises the following steps: (1) adding unsaturated alcohol and a catalyst into a first reactor, replacing with nitrogen, continuously adding epoxide with short branches and reacting to obtain an intermediate product A, wherein the unsaturated alcohol is one or a mixture of more than two of methyl allyl alcohol and isoamyl alcohol at any proportion and the mass ratio of the unsaturated alcohol to epoxide is 1.0:(0.1-5.0); and (2) putting the intermediate product A obtained in the step (1) and the catalyst into a second reactor, replacing with nitrogen, continuously introducing ethylene oxide and reacting to obtain polyether B, and neutralizing the pH value of the polyether B product to be 5-7 with a neutralizing reagent, wherein the mass ratio of the intermediate product A to ethylene oxide is 1.0:(15.0-51.0). The invention also provides the unsaturated polyether prepared by the preparation method, which is disclosed by the invention and application of unsaturated polyether in synthesis of polycarboxylic water reducer and the water reducer prepared from the unsaturated polyether synthesized by the method has the advantages of low doping amount, high water reduction rate, good slump-retaining agent and like.

Owner:HONGBAOLI GRP CO LTD

Graphene oxide/unsaturated polyester composite material and preparation method thereof

The invention discloses a graphene oxide / unsaturated polyester composite material and a preparation method of the composite material. The composite material comprises the raw materials: dihydric alcohol, graphene oxide, saturated binary acid or acid anhydride, unsaturated binary acid or acid anhydride, vinyl monomer, and normal polymerization inhibitor, initiator and accelerant, wherein the content of the graphene oxide is 0.06-0.5wt%. The preparation method of the graphene oxide / unsaturated polyester composite material comprises the following steps of: adding the graphene oxide into the dihydric alcohol to directly and ultrasonically disperse, or adding the dihydric alcohol into graphene oxide water solution to ultrasonically disperse and remove water in a fractional distillation way so as to obtain graphene oxide / dihydric alcohol solution which is evenly dispersed; performing polycondensation between the obtained graphene oxide / dihydric alcohol solution and the saturated binary acidor acid anhydride, unsaturated binary acid or acid anhydride and polymerization inhibitor with metering ratio, and diluting by adding the vinyl monomer after the polymerization so as to prepare graphene oxide / unsaturated polyester resin; and adding the initiator and the accelerant, and curing and crosslinking to prepare the graphene oxide / unsaturated polyester composite material.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

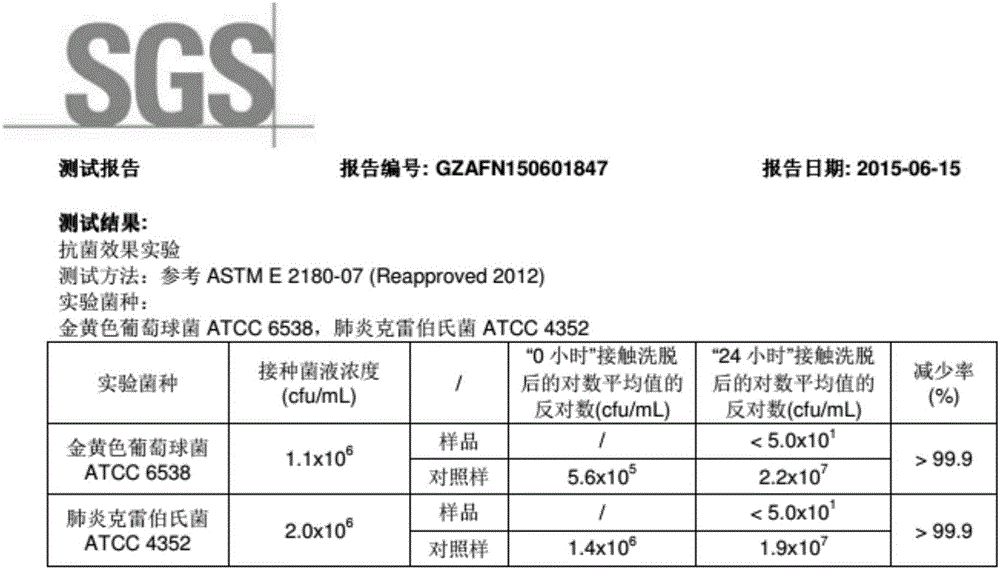

Anti-bacterial artificial quartzite board and preparation method thereof

The invention discloses an anti-bacterial artificial quartzite board. The anti-bacterial artificial quartzite board is prepared from 55-65% of particulate raw materials with the diameter ranging from 0.075 mm to 5 mm, 20-30% of quartz powder with the diameter ranging from 0.005 mm to 0.045 mm, 0.01-10% of colored pigment, 0.1-1% of a silane coupling agent, 8-14% of unsaturated polyester resin, 0.8-1.4% of a curing agent and 0.01-0.1% of an anti-bacterial agent, wherein the particulate raw materials are quartz particles or glass particles or a mixture of quartz particles and glass particles. Anti-bacterial performance of the anti-bacterial artificial quartzite board reaches 99.9% or above, and basically no bacterium exists.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Heat curable thermosetting luminescent resins

InactiveUS6905634B2Improve luminous performanceImprove propertiesLuminescent paintsElectroluminescent light sourcesSodium BentoniteAlkaline earth metal

Luminescent polymers are prepared from thermosetting unsaturated polyesters, suspending fillers and phosphorescent pigments and utilized to make gel coated articles and molded, cast and fiberglass reinforced plastic (FRP) articles. The luminescent polymers show bright and long-lasting photoluminescent afterglow, strong thermostimulation of afterglow by heat and electroluminescent properties. The preferred thermosetting unsaturated polyester resins are prepared by condensing mixtures of ethylenically unsaturated and aromatic dicarboxylic acids and anhydrides with dihydric alcohols and a polymerizable vinylidene monomer. Preferred suspending fillers and thixotropic modifiers include silica, microspheres, glass fibers and other short fibers, nepheline syenite, feldspar, mica, pumice, magnesium sulfate, calcium carbonate, bentonite and the various clays and thixotropic modifiers and mixtures thereof. Preferred phosphorescent pigments include alkaline earth aluminate phosphors, zinc sulfide phosphors and mixtures of these phosphors.

Owner:BURNELL JONES PETER

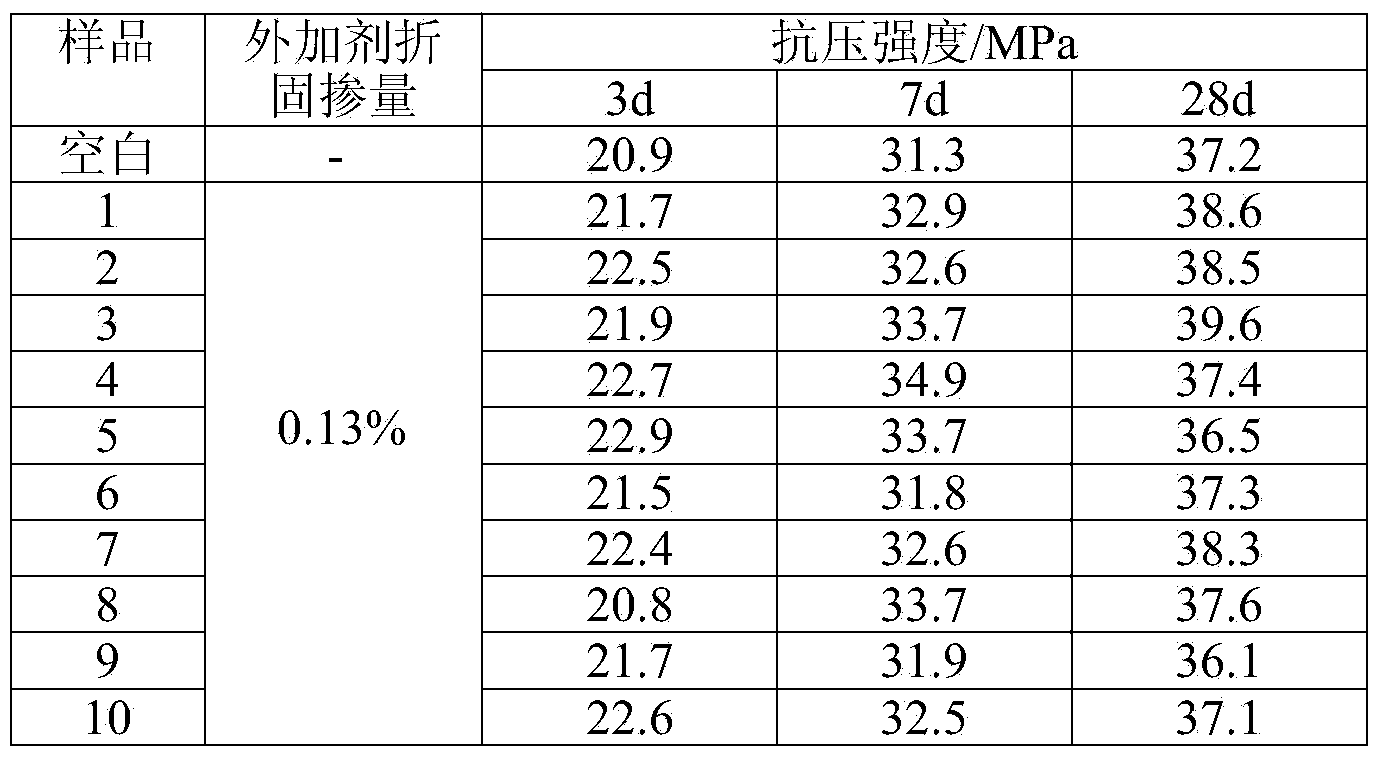

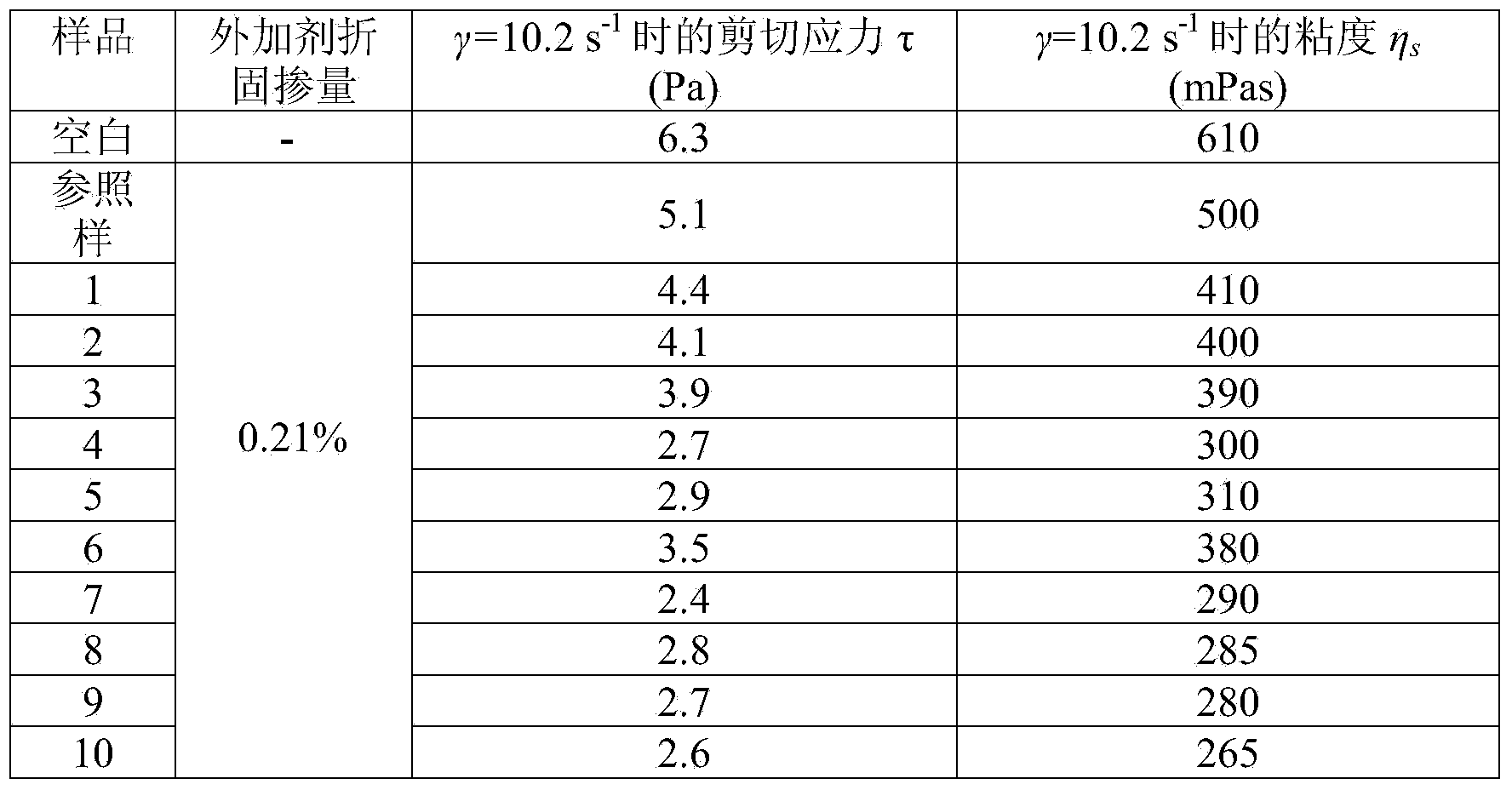

Preparation method of viscosity-reducing type polycarboxylate superplasticizer

The invention relates to a preparation method of a viscosity-reducing type polycarboxylate superplasticizer. The preparation method comprises the following specific steps: firstly stirring acid anhydride small monomers containing unsaturated double bonds and binary primary amine type organic small molecules at a certain temperature to generate unsaturated primary amine type small monomers; then adding organic small molecules containing epoxy groups and the organic small molecules containing halogen groups into a generated reaction system of the unsaturated primary amine type small monomers and continuously stirring for 5-72h to obtain products, namely quaternary ammonium salt type unsaturated small monomers; and further performing water-phase free radical polymerization reaction on the quaternary ammonium salt type unsaturated small monomers, unsaturated ester type small monomers, unsaturated acid type small monomers and unsaturated polyester large monomers under the action of an initiator and a chain transfer agent, adjusting the pH value after the reaction and adding water to obtain the viscosity-reducing type polycarboxylate superplasticizer. The viscosity-reducing type polycarboxylate superplasticizer prepared by the method provided by the invention has the advantages of simple reaction, easiness in control, low cost and the like. Furthermore, the viscosity of concrete can be reduced, the slump retention can be improved.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

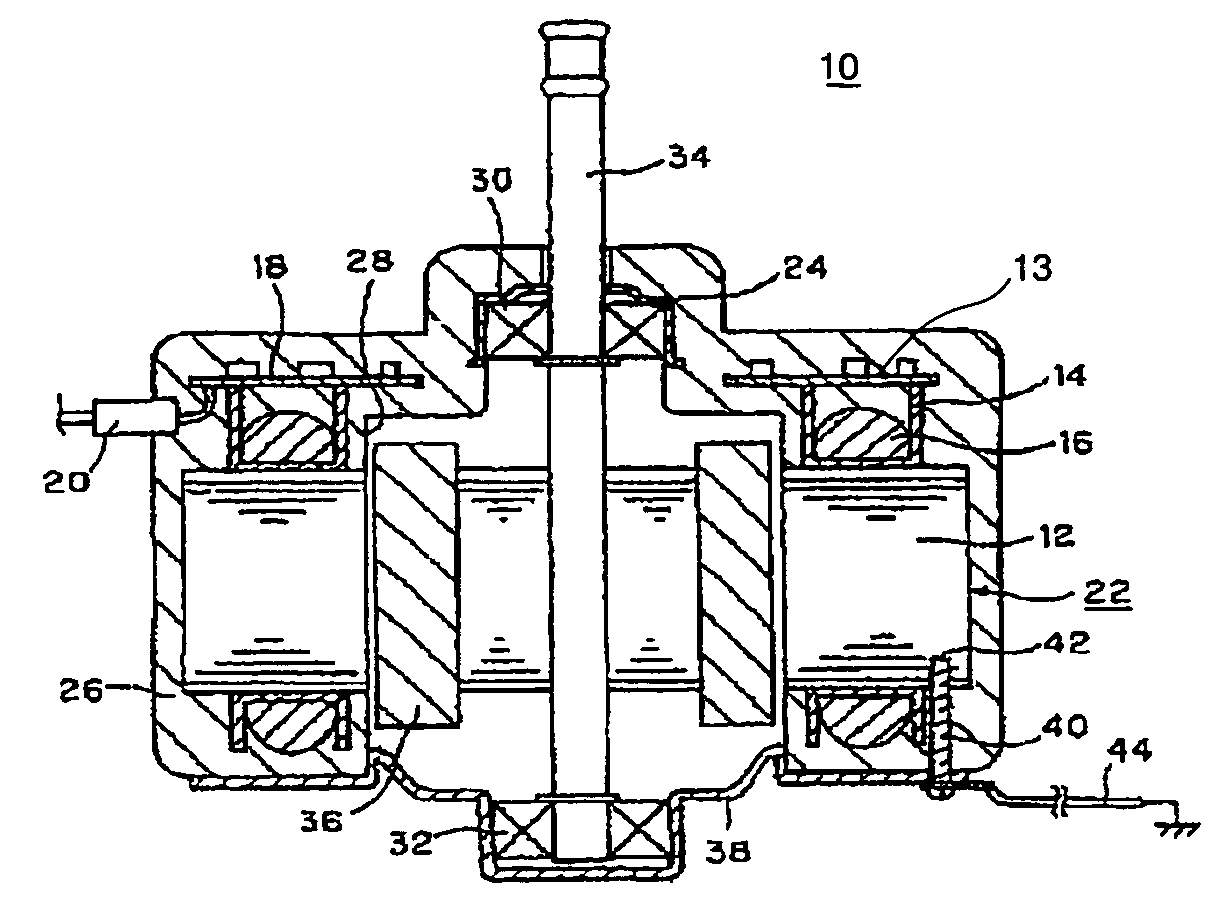

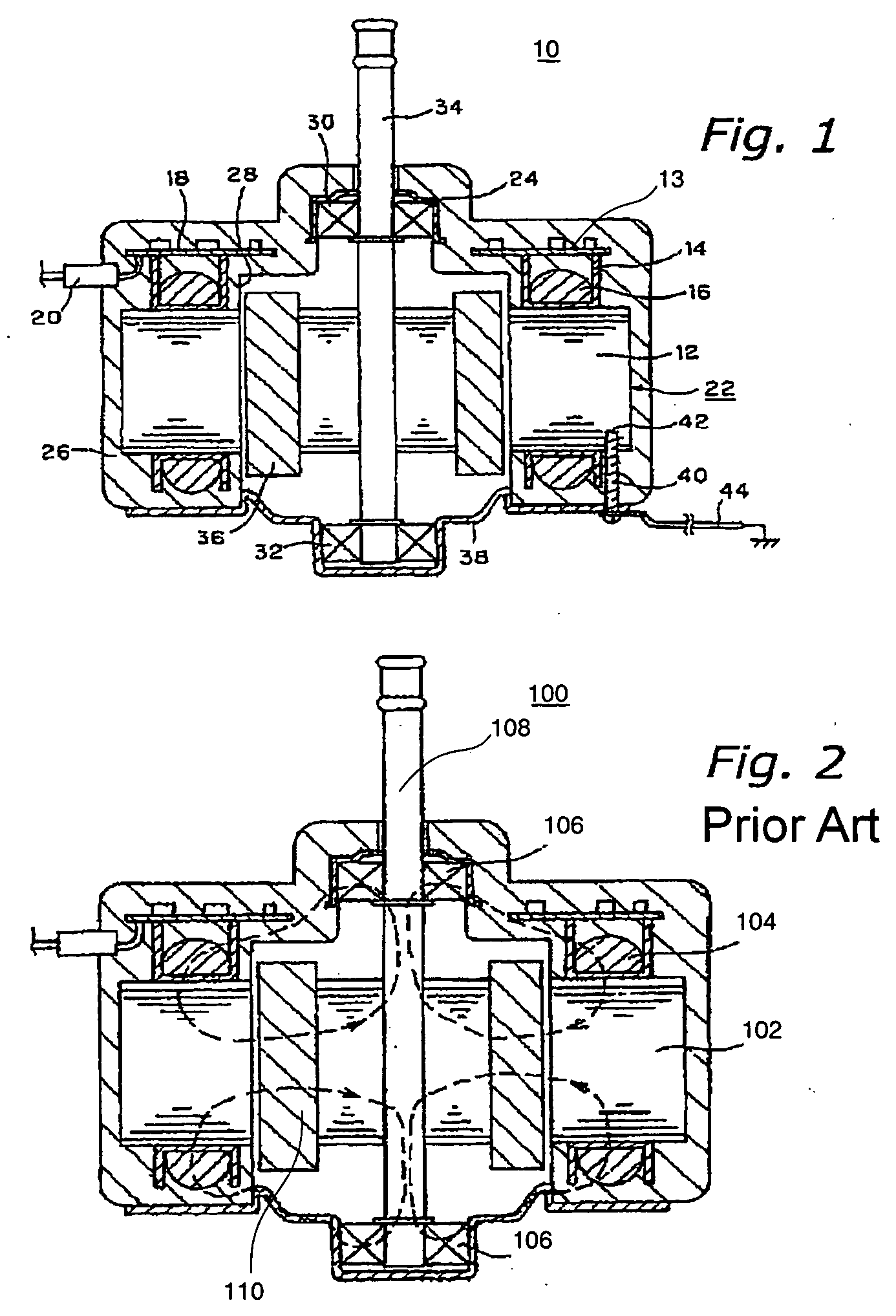

Brushless DC motor with molded resin housing

InactiveUS20060220474A1Avoid flowAssociation with grounding devicesMagnetic circuit characterised by insulating materialsEngineeringElectric current flow

An invention is provided wherein the bearings of a molded motor do not become electro-eroded. An inner rotor type, brushless DC motor 10 is provided having a stator 22 which has a stator core 12 wound with a coil 16, a housing 26 formed by covering the outside surfaces of the motor 10 with an unsaturated polyester, molding resin having electrical insulating properties, and an earth electrode 40 made of metal, installed to go through a metal bracket 38 and the housing 26 to reach the stator core 12, such that electric current flows from the stator core 12 and the bracket 38 to the exterior, preventing electro-erosion and resulting deterioration of bearings 30, 32.

Owner:NIDEC SHIBAURA CORP

Method for producing modified unsaturated polyester resins by low purity technical grade dicyclopentadiene

The present invention relates to a novel method of using industrial dicyclopentadiene of purity of 75 percent to 85 percent to prepare modified unsaturated polyester resin. In the preparation of the resin, the industrial dicyclopentadiene separated from the saturated or unsaturated dicarbonic acid or acidic anhydride and the distilled part of mixed C5 is used as the raw material. After hydrolysis and addition reaction, the diol or polyol of appropriate amount is added. The polymerization and dehydration reaction is done with the influence of acidic catalyst. When the mixture is condensed to the designated acid value, the inhibitor and cross-linking monomer of appropriate amount are added and then stirred to prepare the product. The present invention has the advantage that the cost of resin is lower than the common type unsaturated resin. At the same time, the air-drying performance, heat resistance, volumetric shrinkage rate and other performances are all superior to the common type unsaturated polyester resin. The product can be widely used in the fields of glass steel, mold, plastic clothing, sealing, and adhesive and so on.

Owner:泉州永悦新材料有限公司

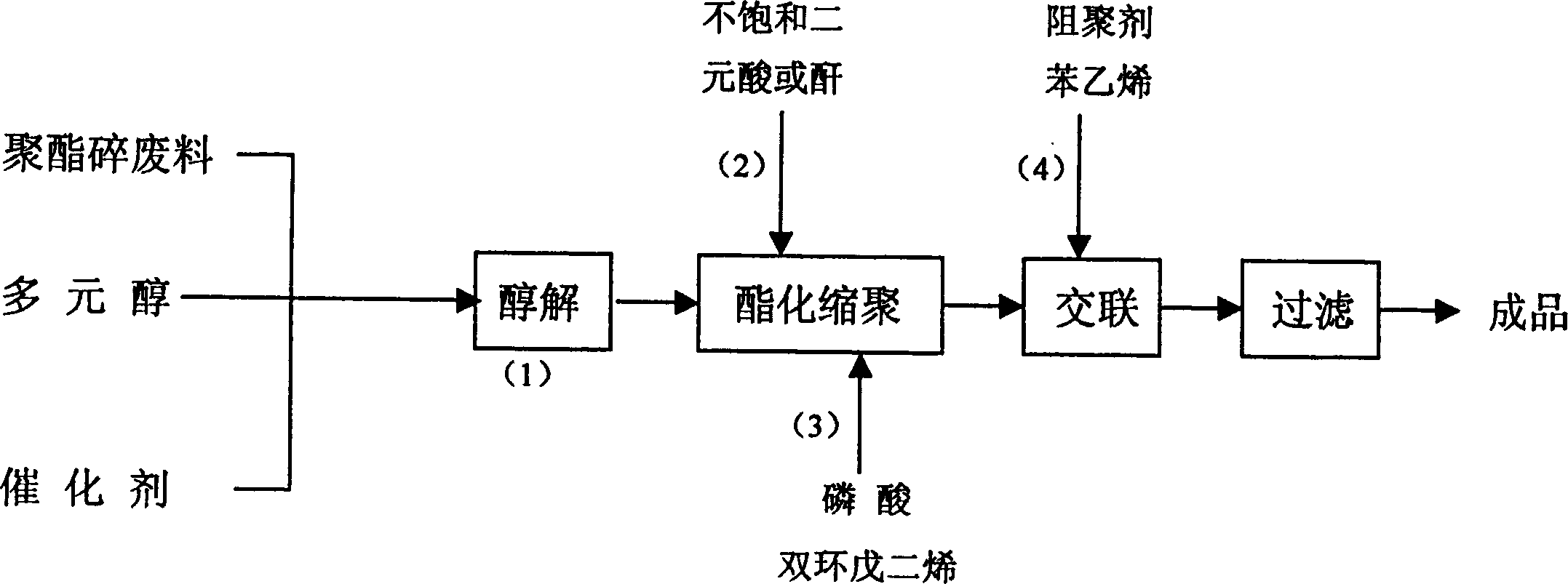

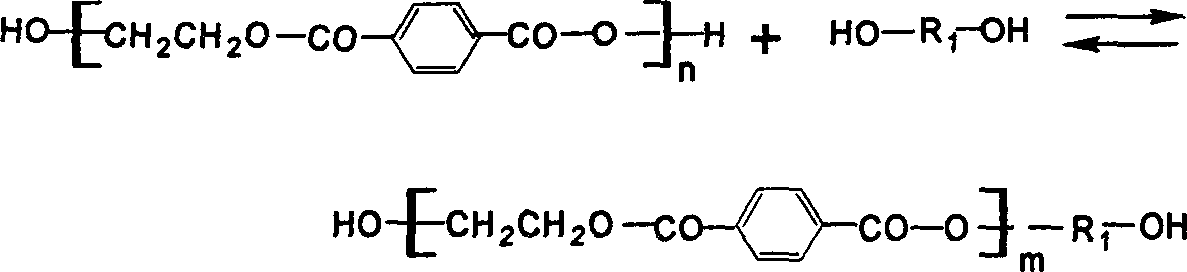

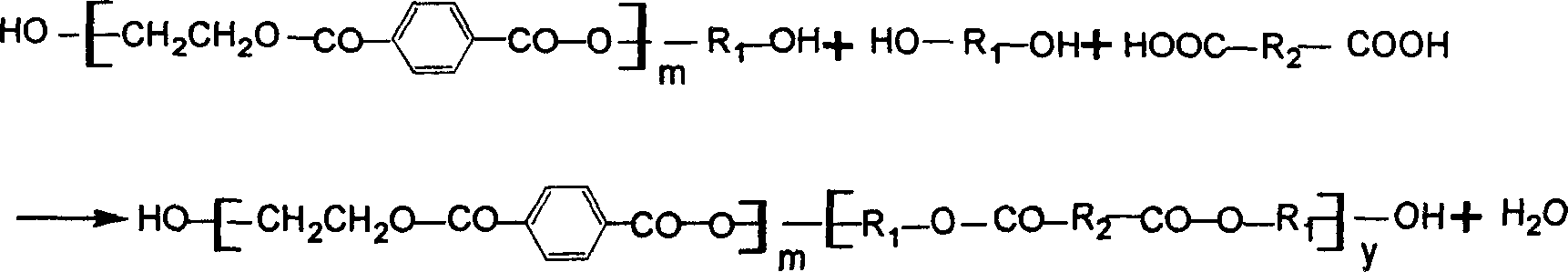

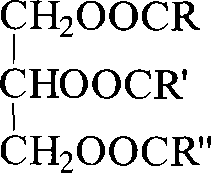

Synthesis of p-phenyl unsaturated polyester resin by using waste polyester material

The invention relates to a method for synthesizing unsaturated phenolic resin with various etherification waste, which includes the four steps: (1) etherification waste and polyhydric alcohol have alcohol sis and ester interchange with catalyst existing; (2)alcohol zed product and unsaturated binary acid or have etherification polycondensation; (3) use dicyclopentadiene (DCPD) to blocking modify in the later period of etherification polycondensation; (4) add into styrene solution for cross linking. The invention has plentiful sources of raw material, low price, decreased pollution and productive cost and energy saving, as well as eliminates the disadvantage of bad dissolubility in styrene .

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

High-strength man-made quartz plate and preparation method thereof

The invention discloses a high-strength man-made quartz plate and a preparation method thereof. The plate comprises the following raw materials: unsaturated polyester resin, an inorganic material, a pigment, a coupling agent, a strength increasing material, a promoter and a curing agent. The preparation method includes: weighing all the raw materials according to a weight ratio, mixing uniformly, filling a mould with the material mixture, vibrating under vacuum, degassing by vacuum pressing, curing and forming at a medium temperature, and performing surface sanding processing to obtain a finished product. Beneficial effects of the man-made quartz plate and the preparation method thereof are that: the man-made quartz plate has increased plate density, increased rupture strength, increased compressive strength, increased falling-ball impact strength, reduced water adsorption rate, improved comprehensive performance indexes, and prolonged service lifetime; the application fields of finished products of the man-made quartz plate are largely increased; and the strength increasing material is added, thus largely increasing the strength of the man-made quartz plate.

Owner:中山市华纳装饰材料有限公司

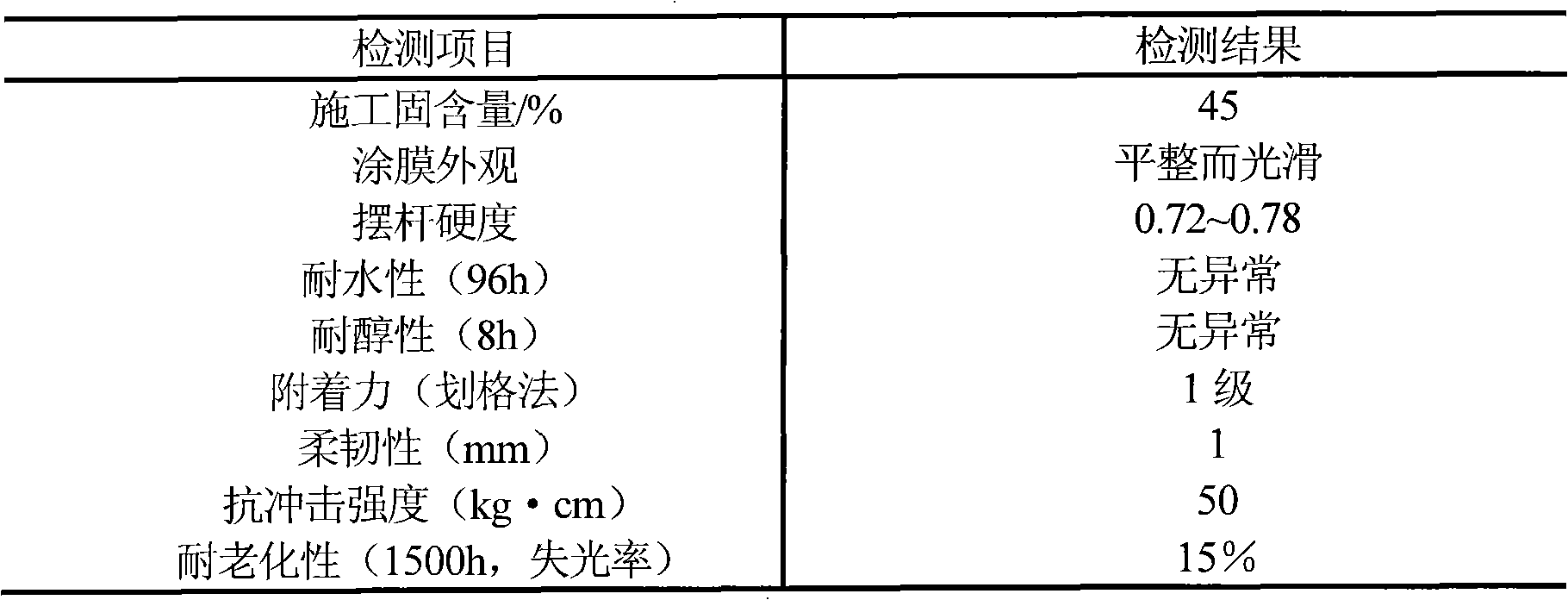

Preparation method of hydroxy fluorine-containing water-based acrylic resin-polyurethane hybrid

ActiveCN101845118AGood weather resistanceImprove low temperature impact resistanceCoatingsWater basedPolyester

The invention relates to a preparation method of hydroxy fluorine-containing water-based acrylic ester-polyurethane. The preparation process is as follows: (1) carrying out condensation polymerization on dihydric alcohol containing double bonds and binary acid at different proportions to synthesize unsaturated hydroxyl-terminated polyester; (2) taking unsaturated polyester as the talleta of polyurethane, adding a certain amount of dihydric alcohol chain extender so as to enable hydrophilic monomer, catalyst and diisocyanate to react, neutralizing and adding water for chain extension to prepare water-based polyurethane containing unsaturated double bonds; and (3) taking the macro-monomer of the water-based polyurethane as a surfactant, and utilizing acrylic ester- ethylene monomers, fluorine-containing acrylic ester monomers and hydroxyl acrylic ester monomers to synthesize the hydroxy fluorine-containing water-based acrylic resin-polyurethane hybrid by a nonsoap emulsion polymerization method. The invention can regulate the structure and performances of resin by regulating the use amount of fluorine monomers and hydroxyl monomers. The invention introduces hydroxyl into a water-based fluorine-containing acrylic ester polyurethane macromolecule chain so as to prepare room temperature-dried or baking-type thermoset water-based paint together with water-based polyisocyanates and water-based amino plastic, thus greatly improving the performance of the water-based paint; and the prepared paint can be used in various basal materials such as wooden wares, metal, plastics, concretes and the like.

Owner:广东天银实业有限公司 +1

Optically clear polycarbonate polyester compositions

An optically clear thermoplastic resin composition consisting essentially of: structural units derived at least one substituted or unsubstituted polycarbonate, at least greater than 30 weight percent of a substituted or unsubstituted polyester, a modified polycarbonate, an impact modifier having a refractive index in the range between about 1.51 and about 1.56 and an additive is disclosed. The composition possess good optical properties, flow, stability and mechanical property. Also disclosed is a process to prepare these compositions and articles therefrom.

Owner:SHPP GLOBAL TECH BV

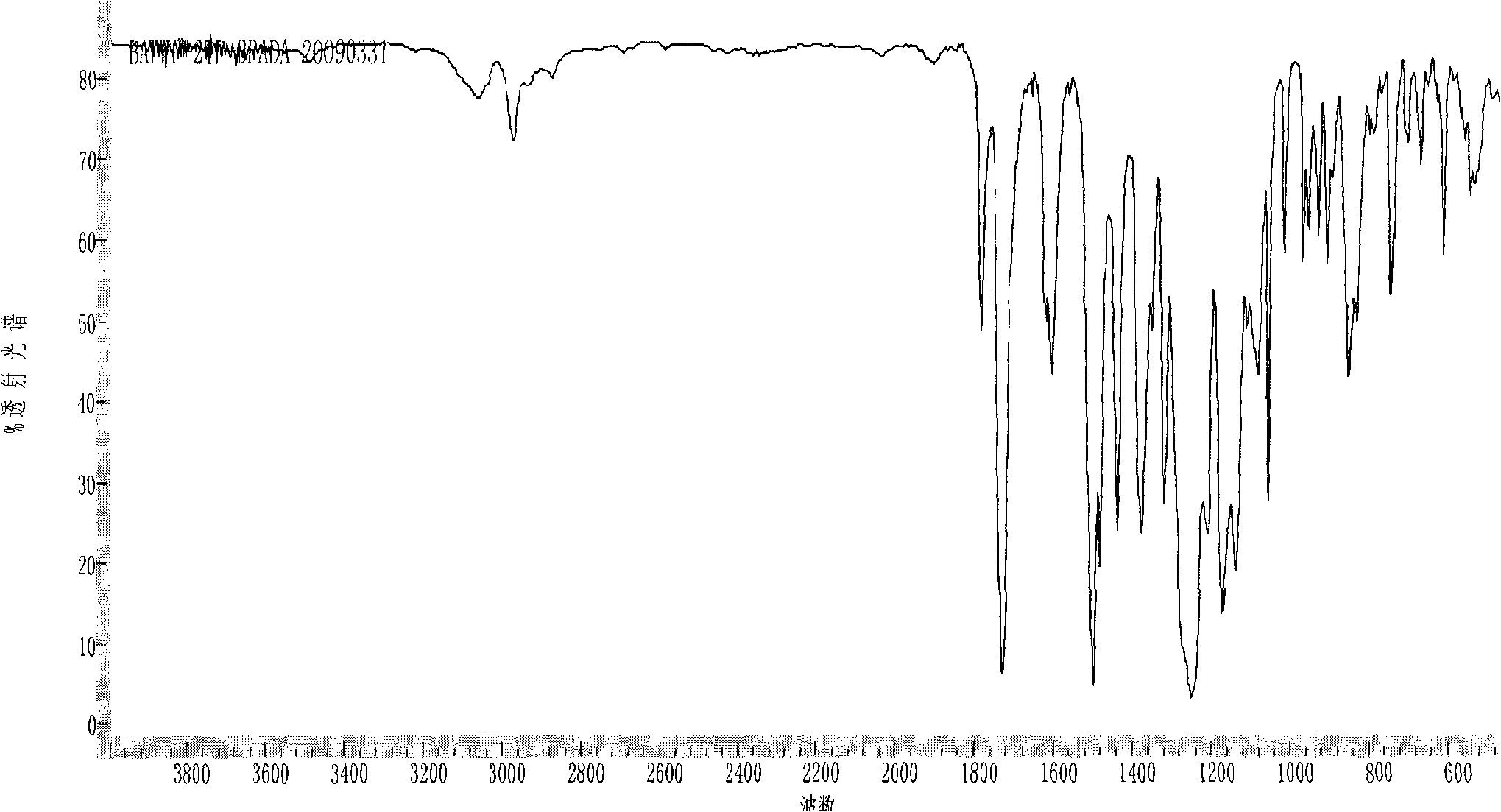

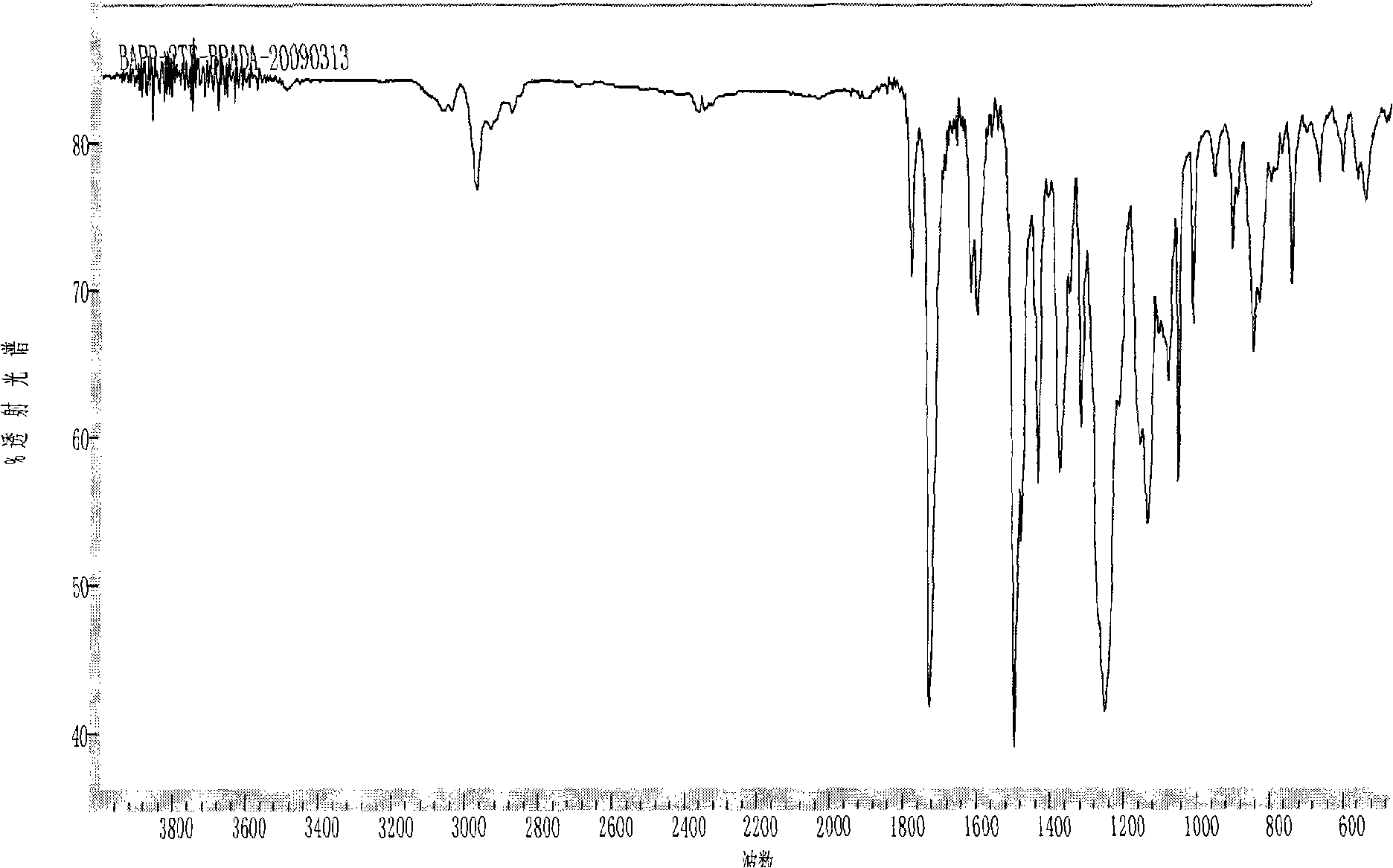

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

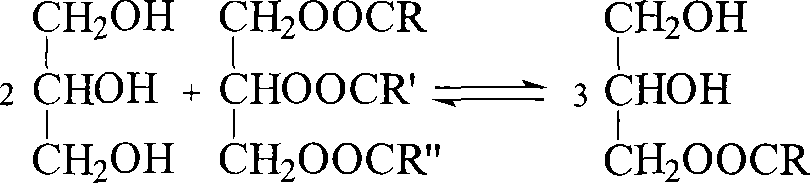

Method for synthesizing unsaturated polyester resin

The invention relates to a process for synthesizing unsaturated polyester resin with renewable vegetable fat, which comprises generating acid ester through conducting alcoholysis reaction for vegetable oil and organic polyatomic alcohol, using as modified dihydric alcohol and being leading to the typical synthesis formulation of unsaturated polyester resin, completely replacing conventional dihydric alcohol, using for synthesizing unsaturated polyester, and then mixing with cross-linking monomer. The resin which is synthesized has excellent hue, appropriate viscosity, excellent heat stability, favorable alkali resistivity, wonderful flexible property and low shrinking rate, which is suitable for various composite material shaping technology such as hand lay-up, winding and spraying and the like. Renewable raw material of vegetable oil with cheap price is applied in the synthesis process of the invention, and the stability of product is excellent.

Owner:江苏大力士云石护理材料有限公司

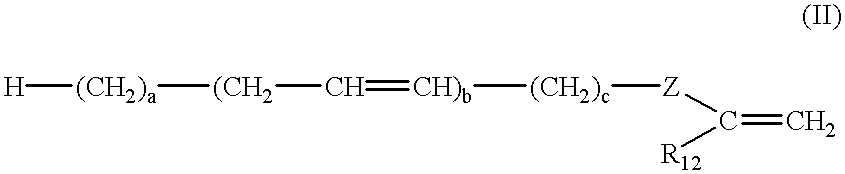

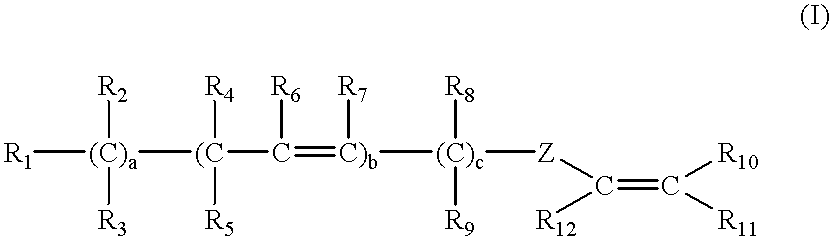

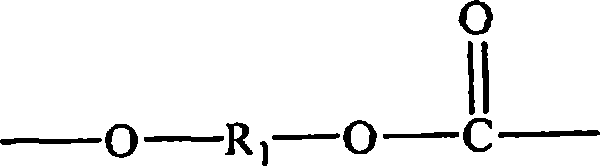

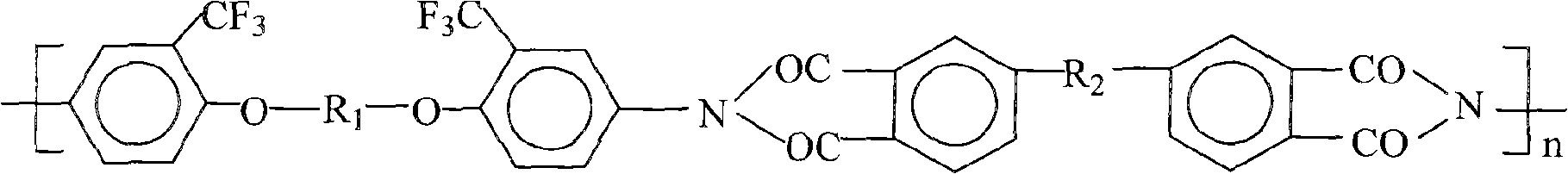

Thermoplastic fluorine-containing fully aromatic polyimide powder and preparation method thereof

The invention relates to thermoplastic fluorine-containing fully aromatic polyimide powder, which has a general molecular structural formula shown above, wherein -R1 is a divalent linking group of fluorine-containing aromatic primary diamine; and -R2 is a divalent linking group of a molecule of aromatic acid dianhydride. The method comprises the following steps: reacting the fluorine-containing aromatic primary diamine with the aromatic acid dianhydride in a phenol solvent in the presence of a catalyst for 5 to 10 hours; pouring the hot solution in a precipitator with high-speed stirring to precipitate solid powder; and obtaining the thermoplastic fluorine-containing fully aromatic polyimide powder after filtration, washing, soaking, filtration and drying. The thermoplastic fluorine-containing fully aromatic polyimide powder has good solubility, is a high-performance heat-resistance toughness modifier for epoxy resin, unsaturated polyimide resin, unsaturated polyester resin and other thermosetting resins, and is good in application prospect, simple in operation, low in cost, environmentally-friendly, and suitable for industrial production.

Owner:DONGHUA UNIV

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

Unsaturated polyester resin fiber reinforced sheet-shape molding compound and preparation method thereof

The invention discloses an unsaturated polyester resin fiber reinforced sheet-shape molding compound, comprising unsaturated polyester resin, a low shrinkage agent, a filler, a curing agent, a thickener, a mold release agent, a reinforcing material, a colorant and an additive. The unsaturated polyester resin is characterized by comprising one or more of o-phenylene resin, m-phenylene resin and vinyl ester resin in mixing; the filler is modified aluminium hydroxide; the reinforcing material is made of one or more selected from the group containing alkali-free chopped glass fiber, alkali-free untwisted continuous glass fiber rove, high silica glass fiber and Kevlar fiber. The molding compound combines light weight, high strength, retardance, corrosion resistance and insulation, has the advantages of high weight percentage of reinforced material, good electrical properties, significantly improved mechanical properties, tensile strength of not less than 100Mpa, bending strength of not less than 300Mpa, impact strength not less than 260 KJ / m<2>, dielectric strength of not less than 12KV / mm, flame retardance of UL94V-0 and product thickness of up to 60mm, and can be used for compression molding of electrical insulation structural parts.

Owner:SICHUAN D&F ELECTRICAL TECH

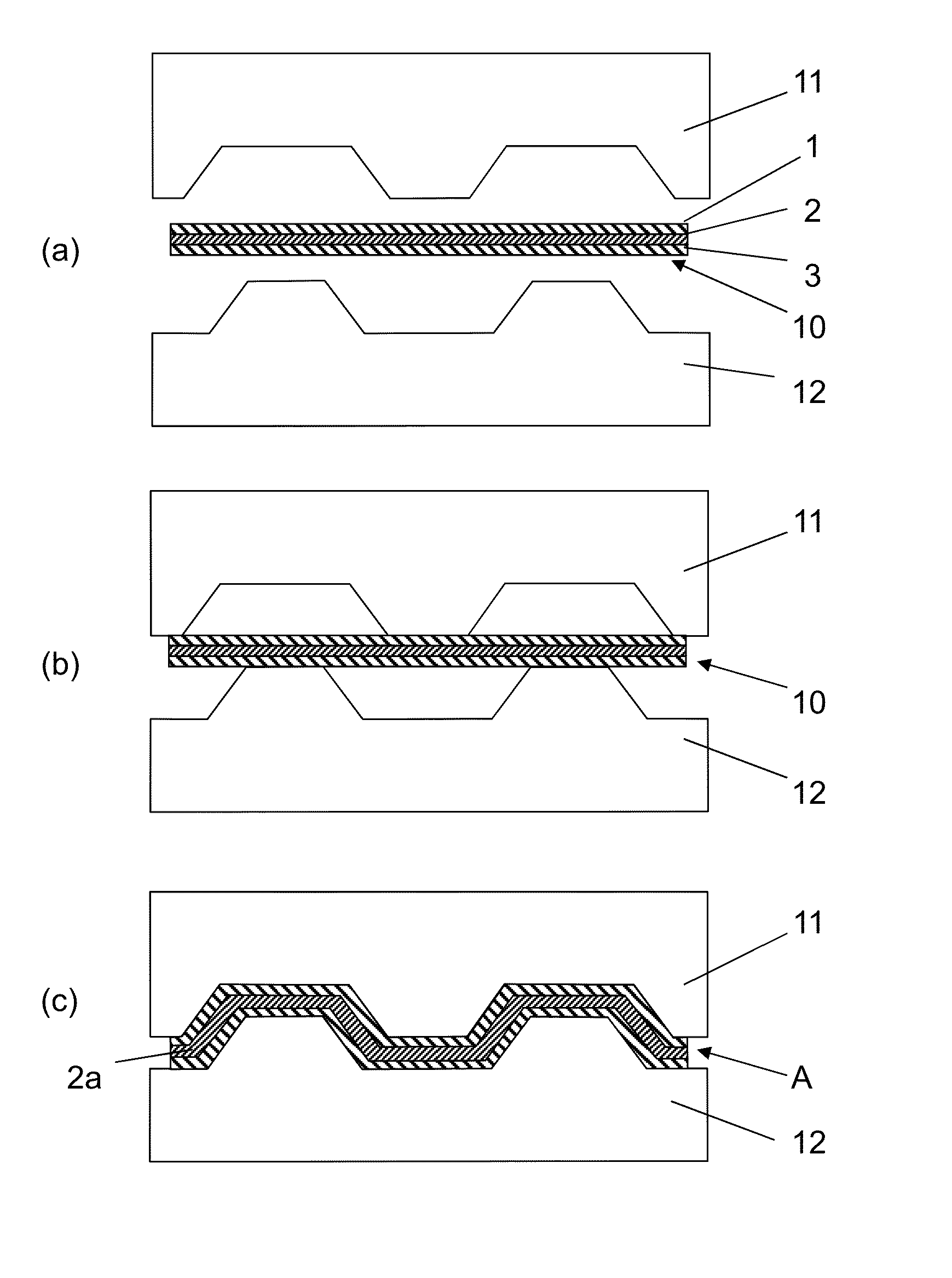

Molding material containing unsaturated polyester resin and microfibrillated plant fiber

ActiveUS20110263756A1High mechanical strengthGood effectCeramic shaping apparatusVegetable fibersHemicellulose

The present invention relates to a molding material comprising an unsaturated polyester resin and microfibrillated plant fibers, the microfibrillated plant fibers comprising cellulose and hemicellulose, and having a specific surface area of 5 to 20 m2 / g; a method of producing the molding material; a molded article obtained by curing the molding material; and a method of producing an unsaturated polyester resin molded article comprising microfibrillated plant fibers.

Owner:DAINIPPON INK & CHEM INC +1

Fiberglass radome modified by glass beads and preparation method thereof

The invention discloses a fiberglass radome modified by glass beads, which reduces the DK value thereof, and improves the wave penetration performance of the products. The fiberglass radome modified by glass beads is prepared by the following raw materials in weight portion: 100 portions of unsaturated polyester, 2-10 portions of glass beads, 0.5-2 portions of mold release agent, 0.5-2 portions of curing agent and 0.5-2 portions of accelerator.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

Branched polyester polymers and coatings comprising the same

A polyester prepared by free radical polymerization of an unsaturated polyester prepolymer, wherein the polymerization occurs primarily by reaction of the unsaturation is disclosed. Coatings comprising the same are also disclosed, as are substrates coated at least in part with such coatings.

Owner:PPG IND OHIO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com