Patents

Literature

705results about "Association with grounding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

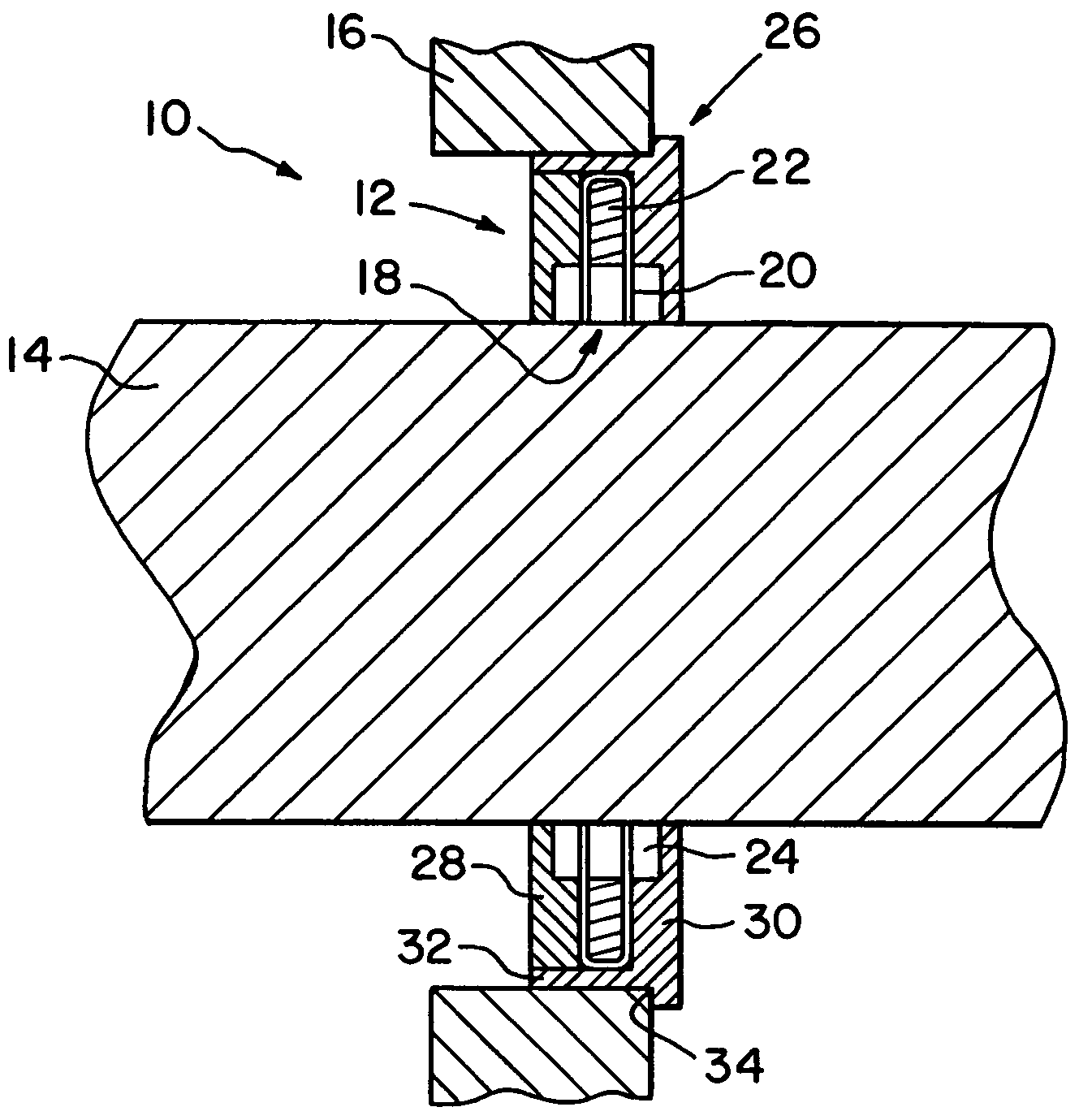

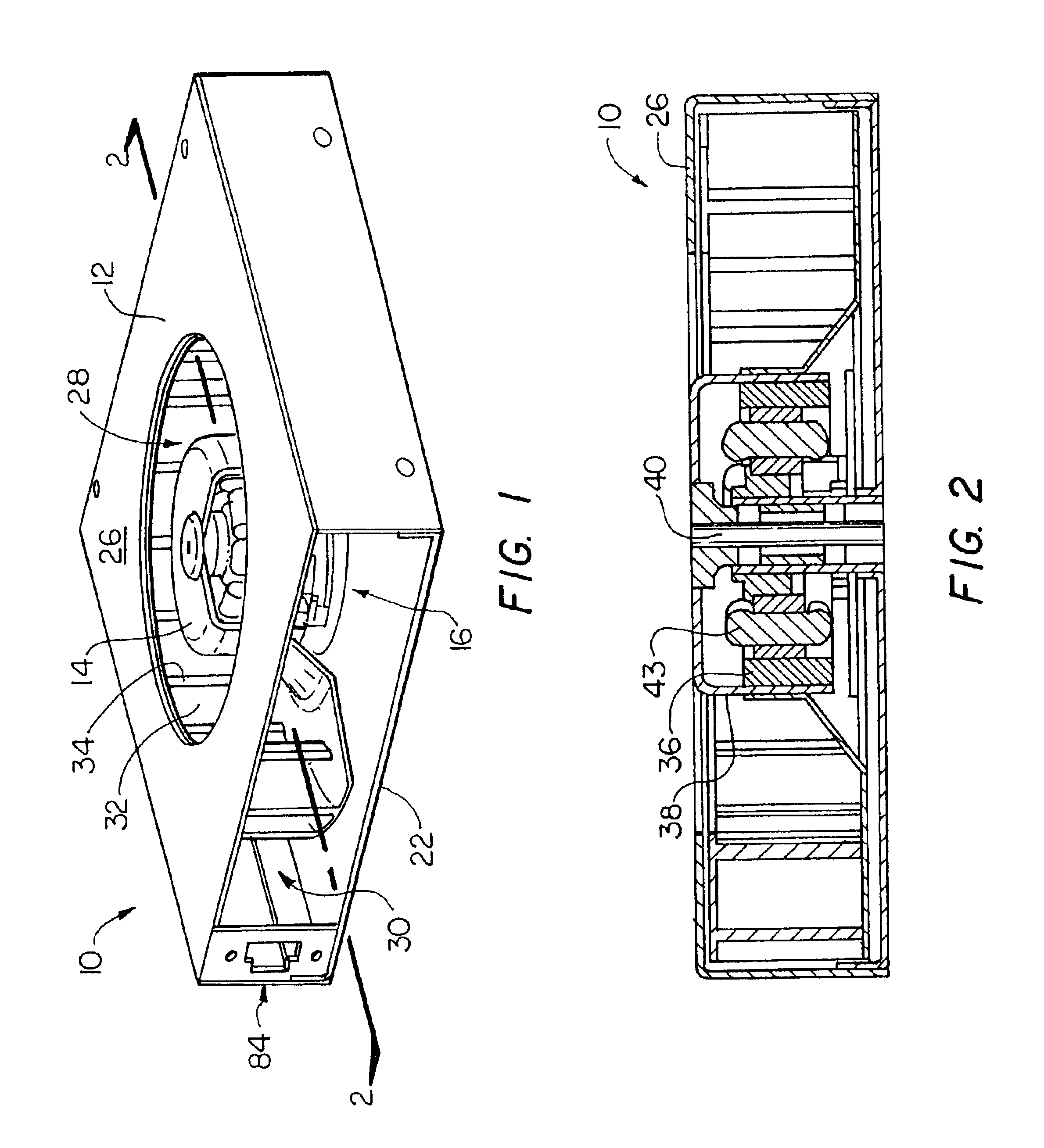

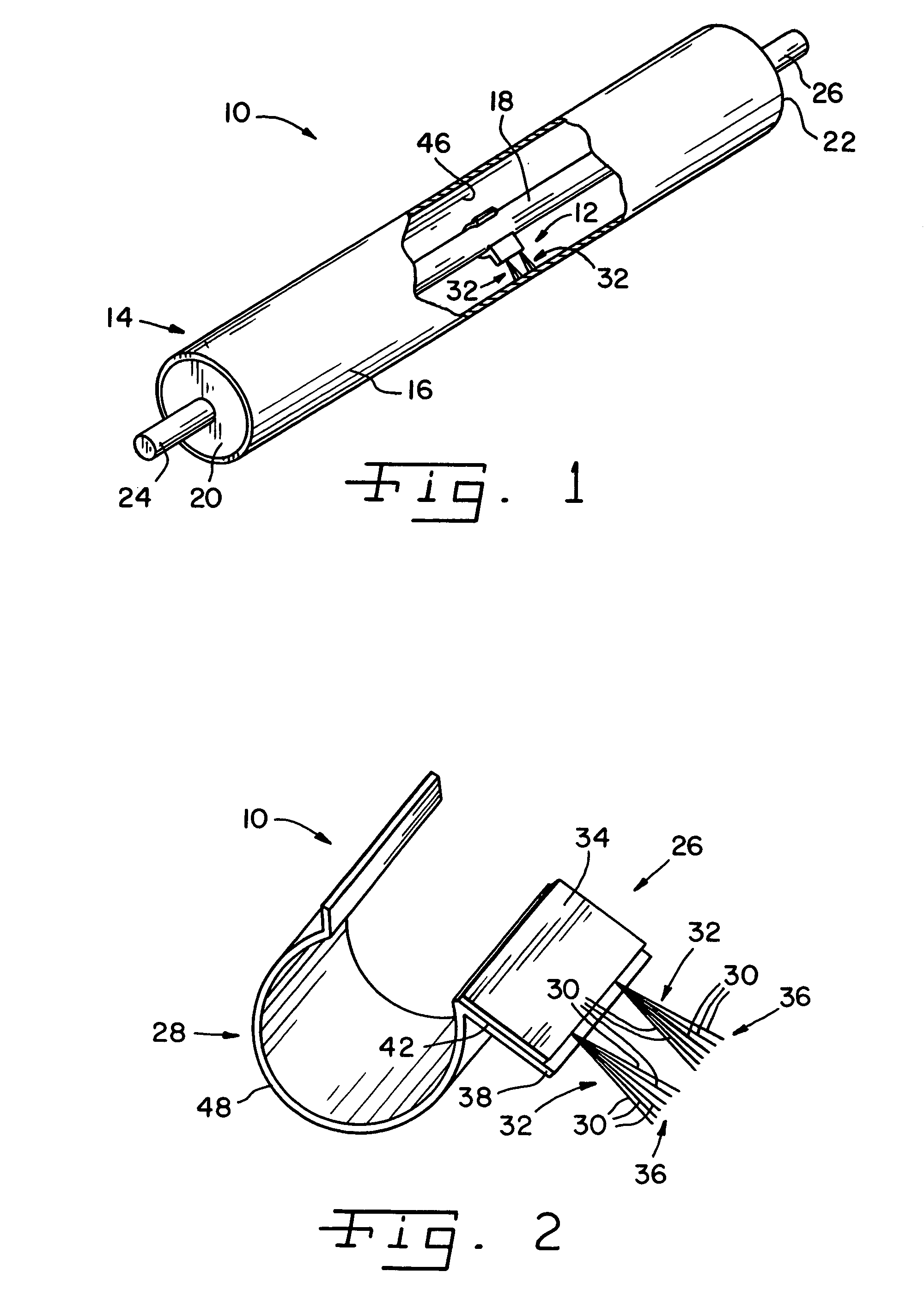

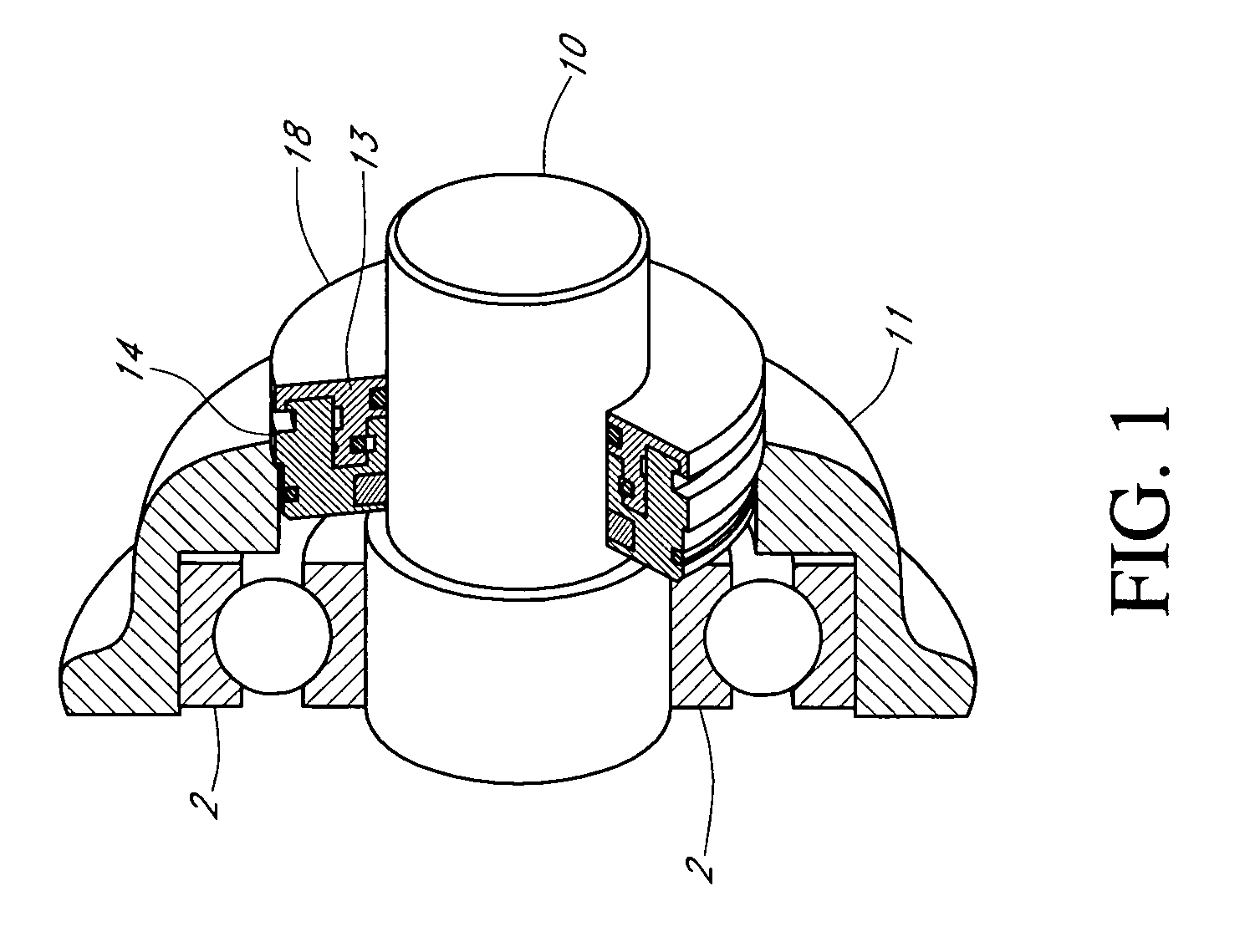

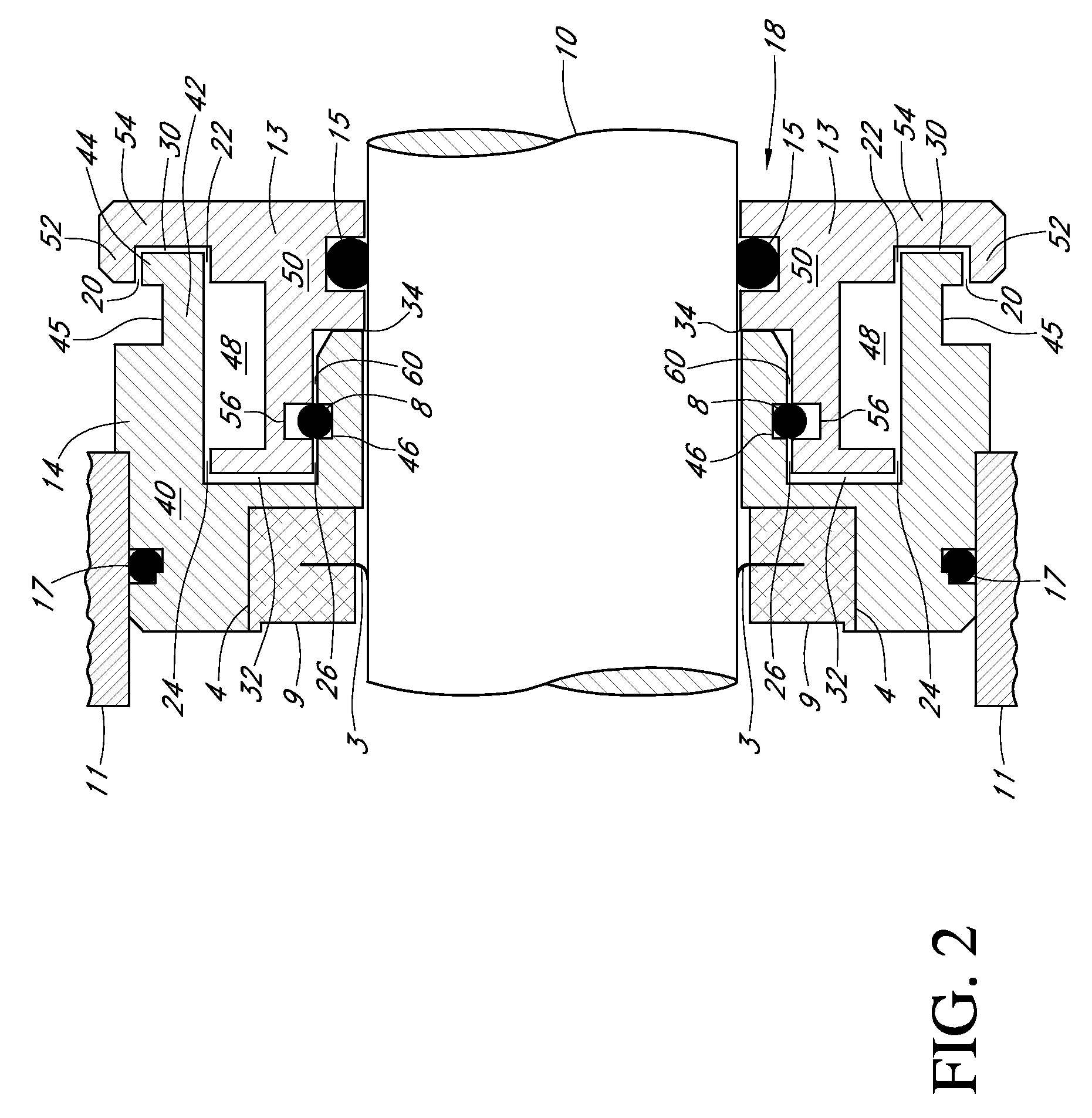

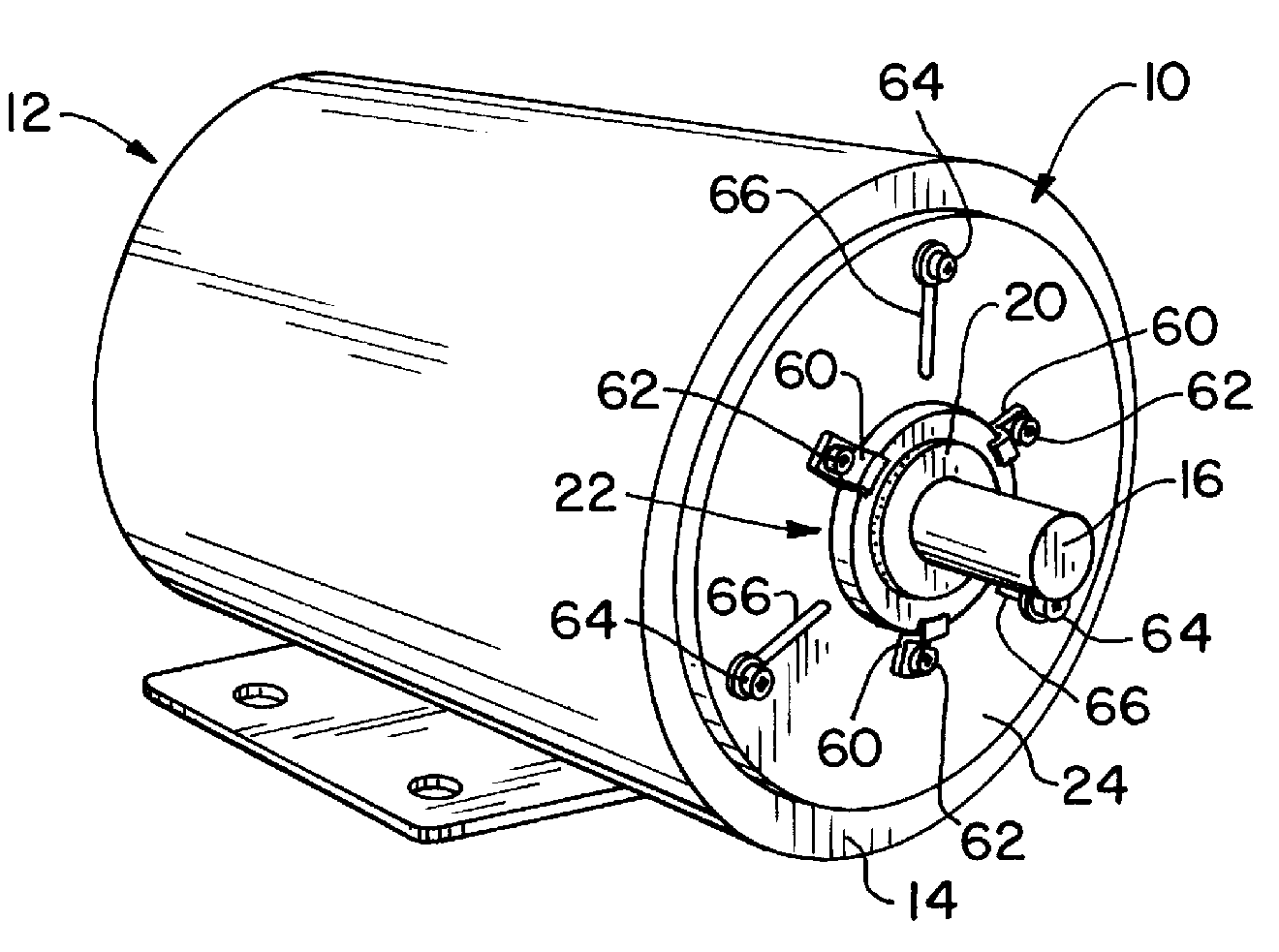

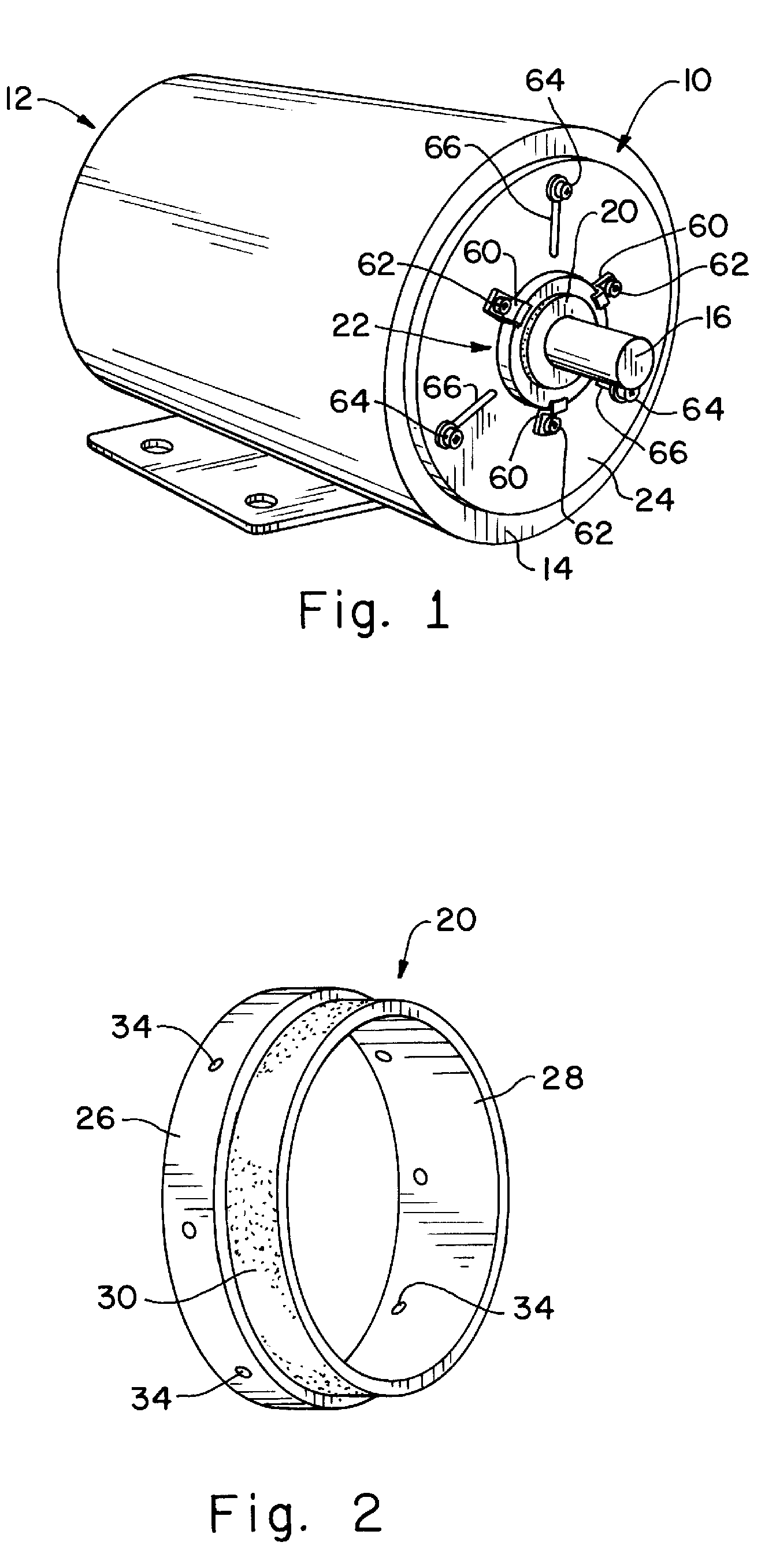

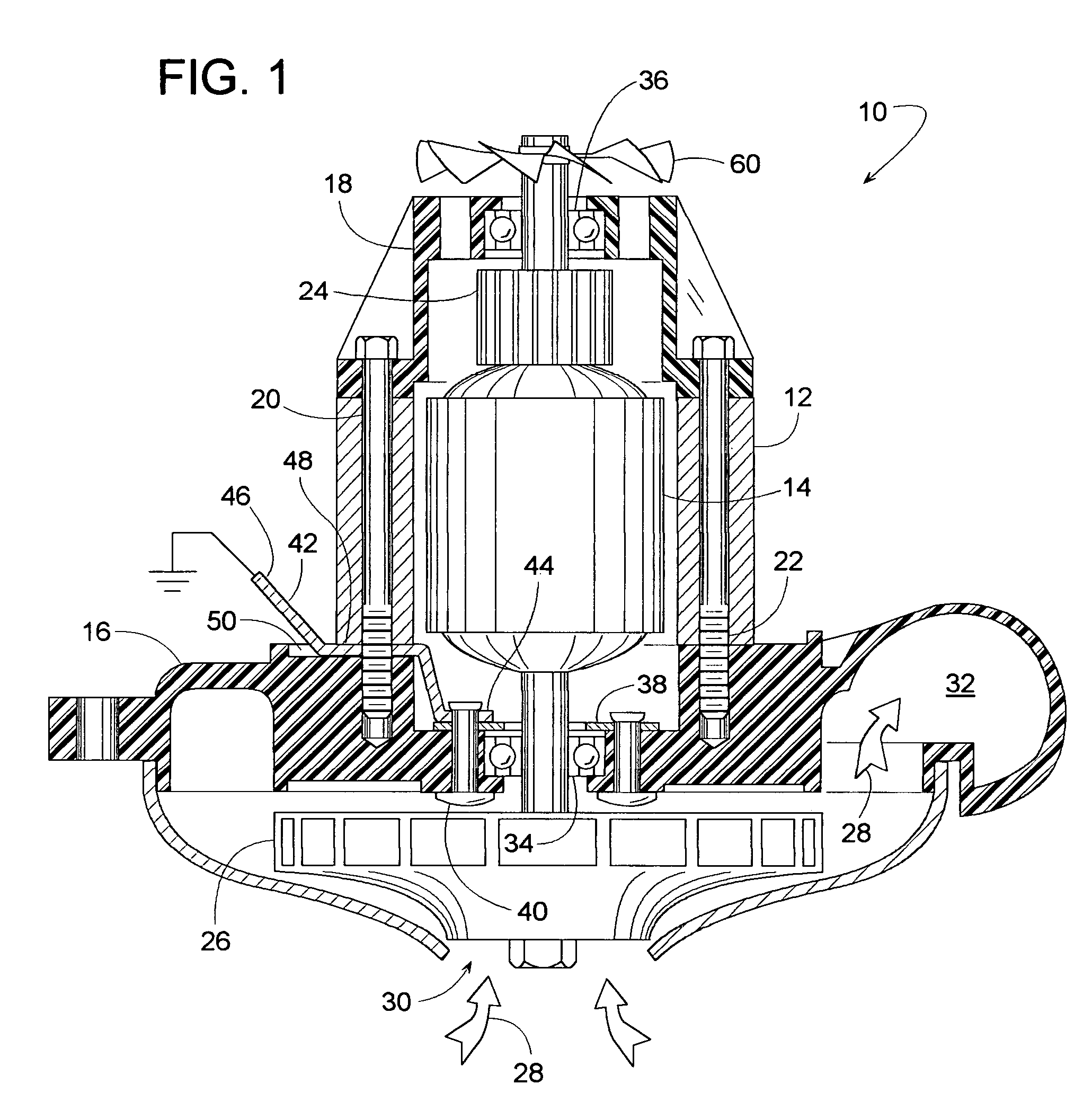

Grounding brush for mitigating electrical current on motor shafts

ActiveUS7193836B2Reduce shaft currentEfficient assemblyAssociation with grounding devicesEmergency protective arrangement detailsElectric machineClassical mechanics

A grounding brush for mitigating static electric charge on a motor shaft includes a plurality of filaments secured to an annular frame around the shaft, with tips of the filaments disposed in a channel defined by the frame. Conductive powder can be provided in the channel to improve current flow from the shaft to the filaments.

Owner:ILLINOIS TOOL WORKS INC

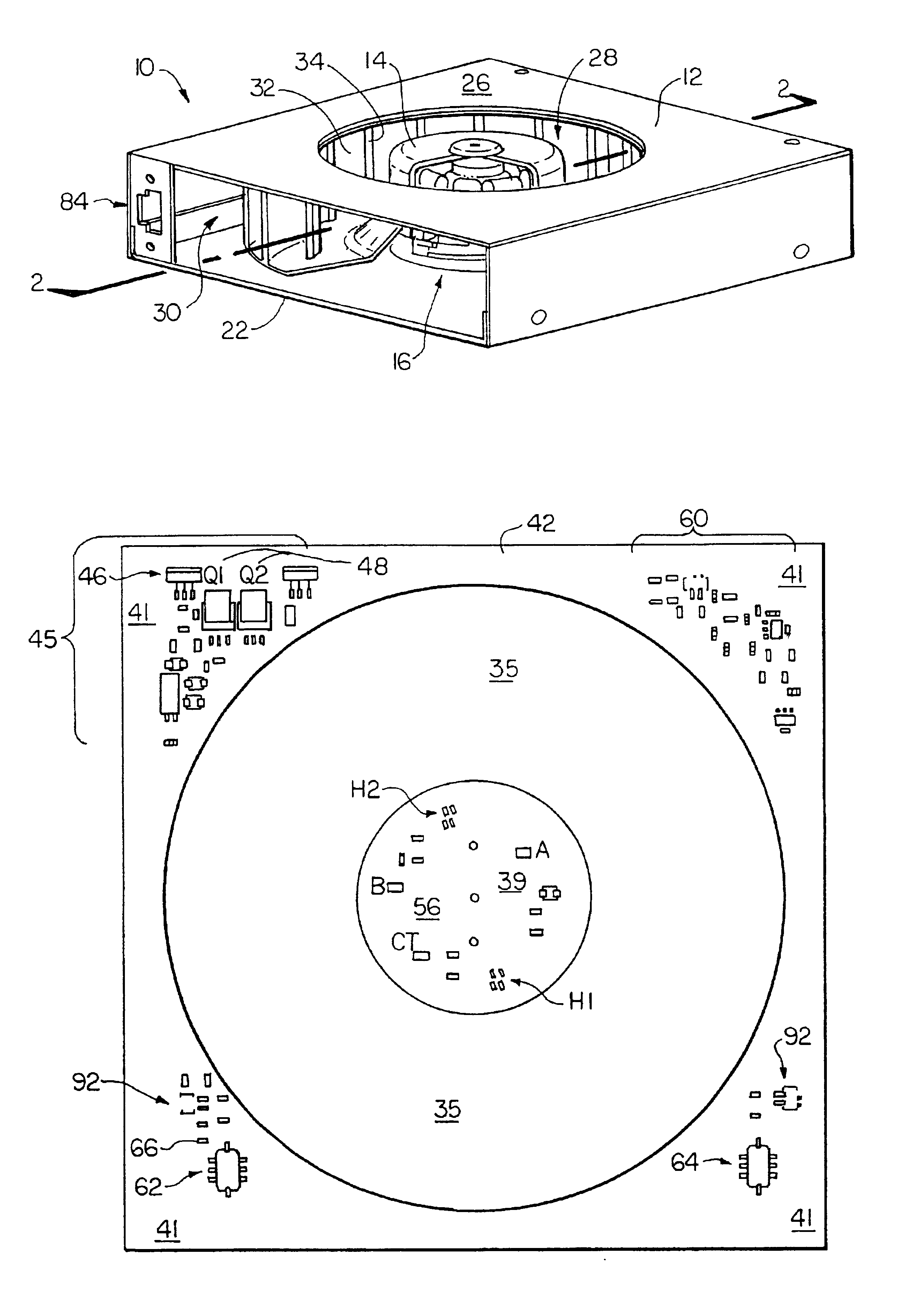

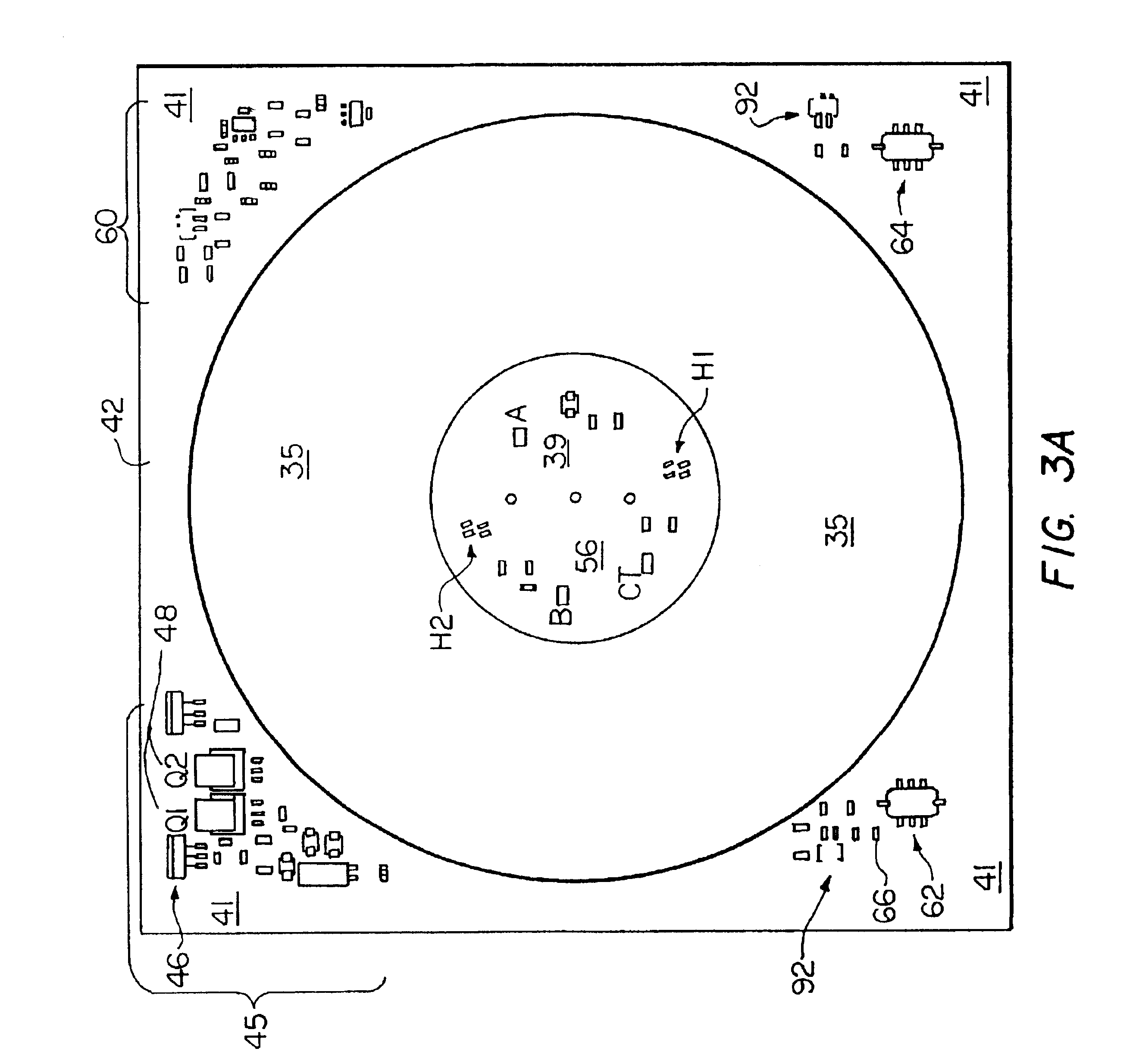

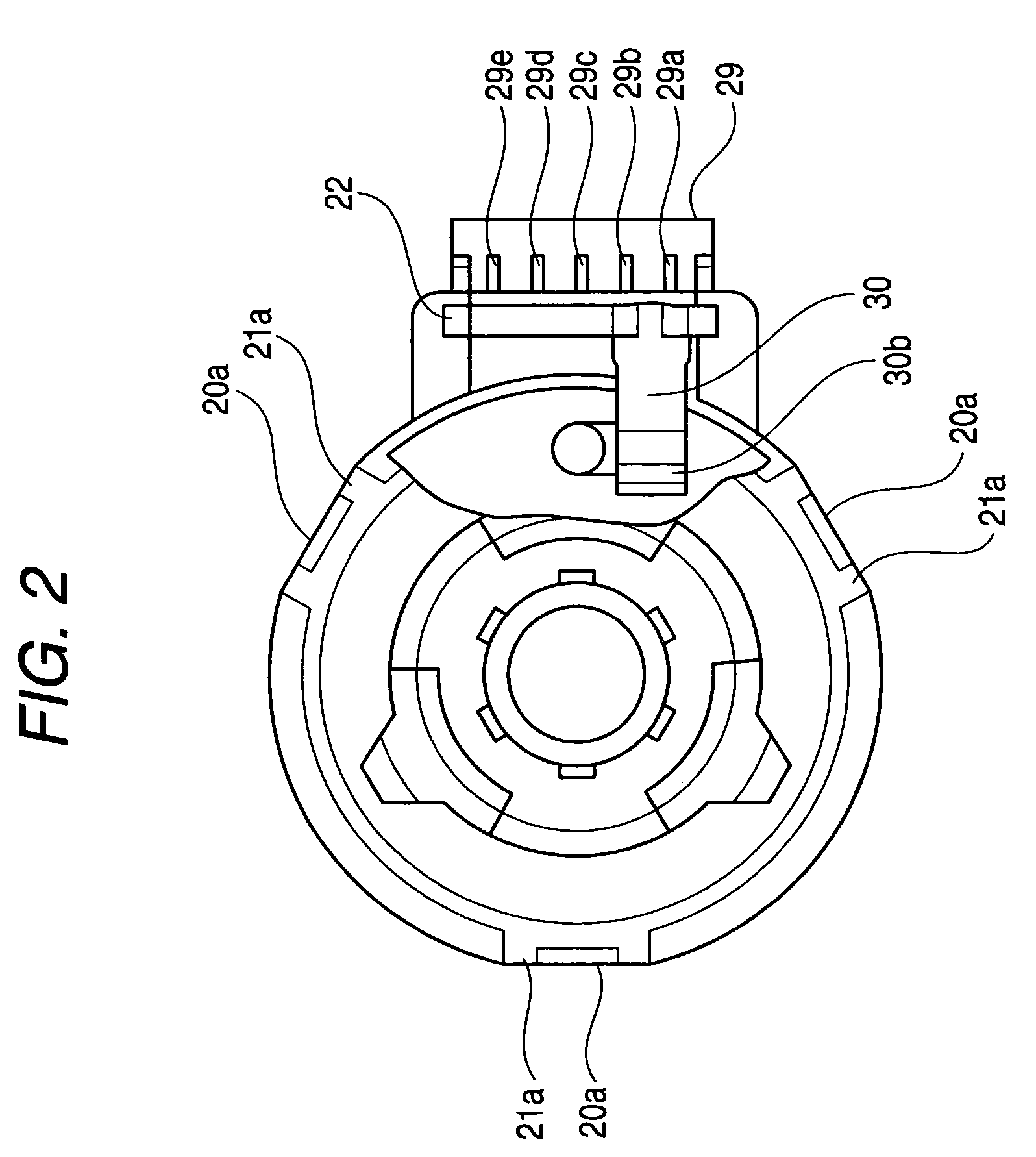

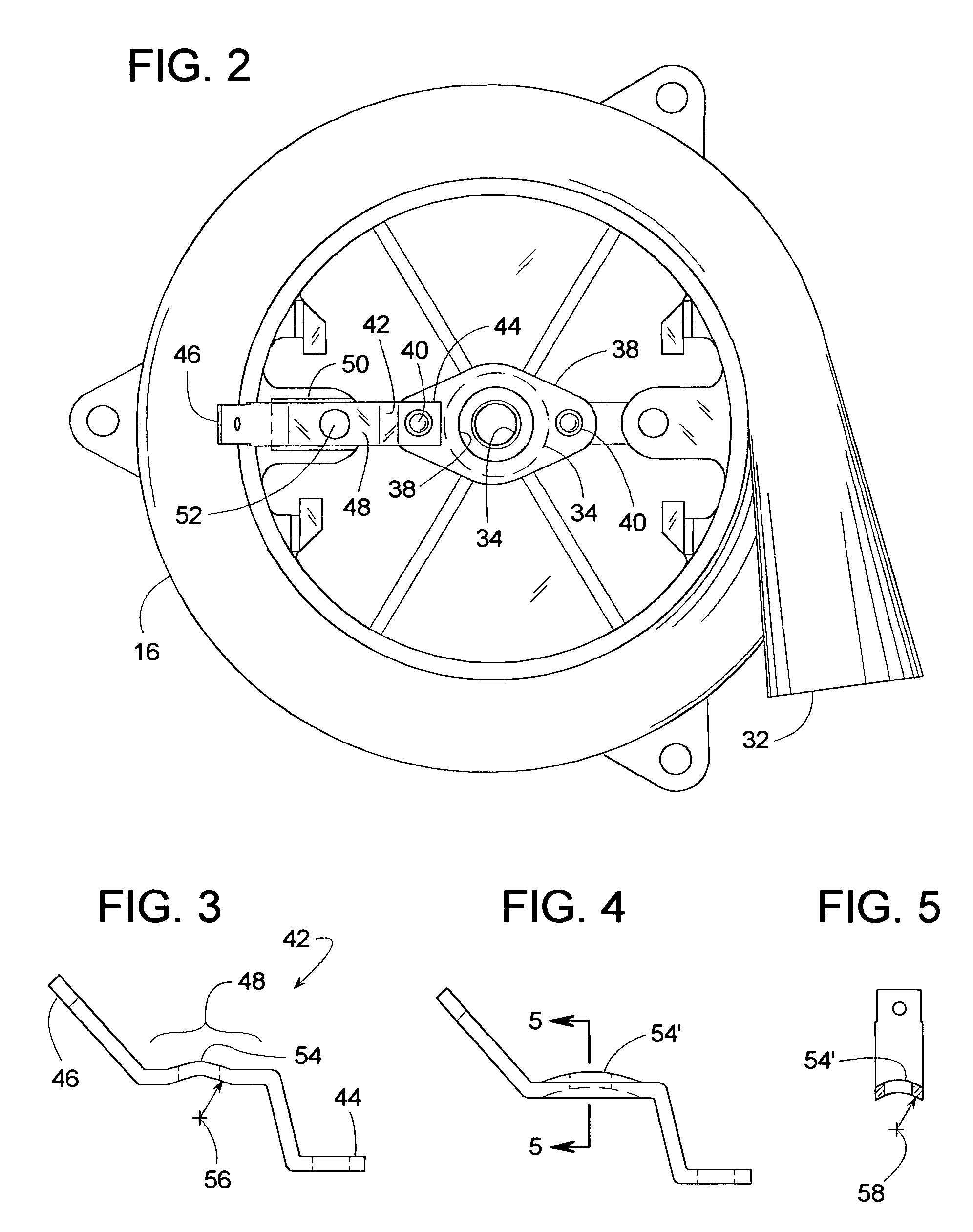

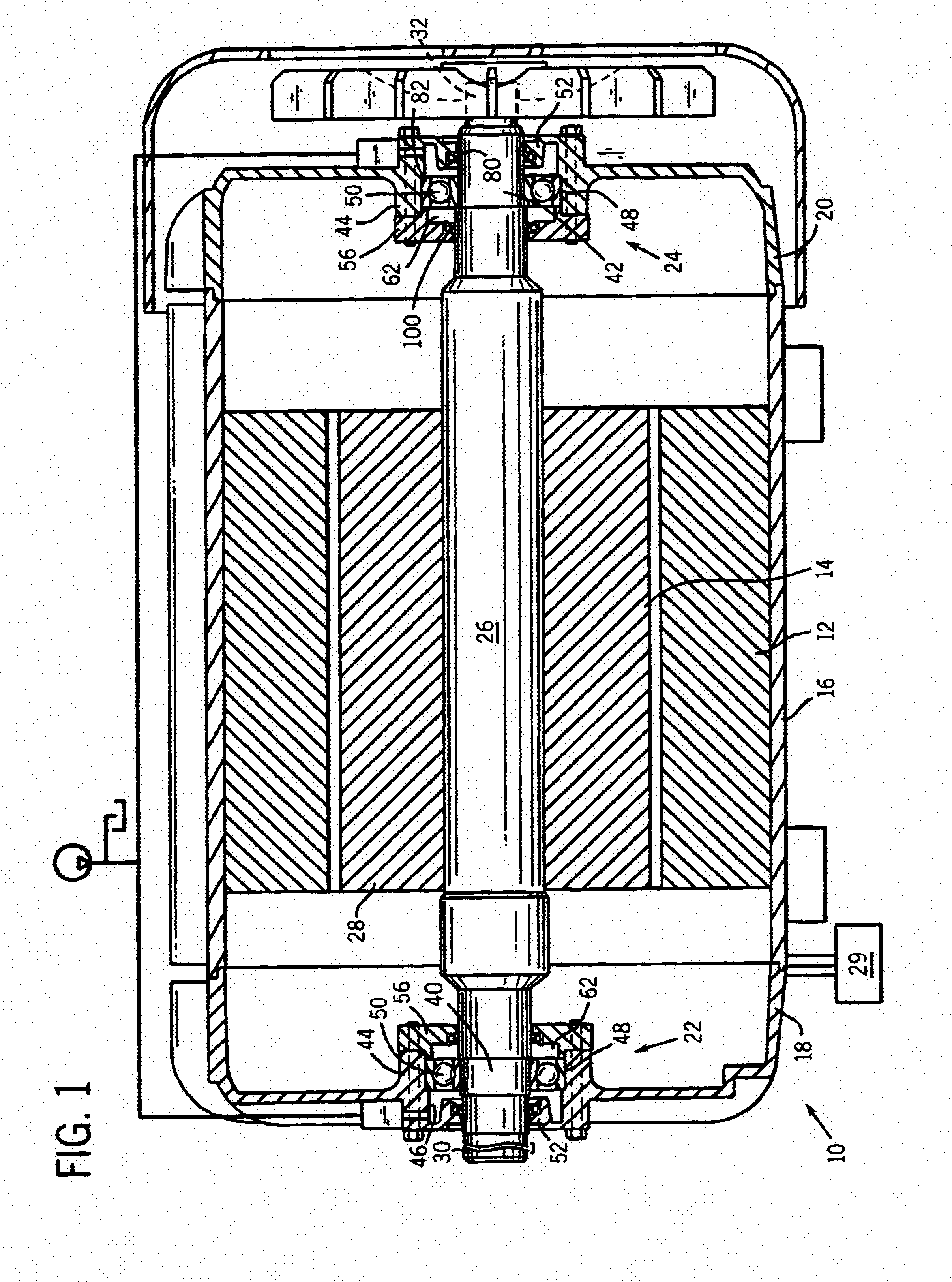

Low profile motor

InactiveUS6841957B2Monitor performanceAC motor controlSynchronous motors startersSurface mountingElectronic component

A flat pack blower utilizes surface mounting techniques for mounting the blower electronics on a thin laminated circuit board to reduce the blower profile. To that end, the blower includes a stator, and a rotor rotatably coupled to the stator. The stator includes a coil, a pole coupled with the coil, and a laminated circuit board having blower control circuitry and pads for electrically connecting the blower control circuitry to the coil. Use of surface mounting techniques on the laminated circuit board thus eliminates the discrete electronic components and the wires connecting such components.

Owner:MOTION HLDG

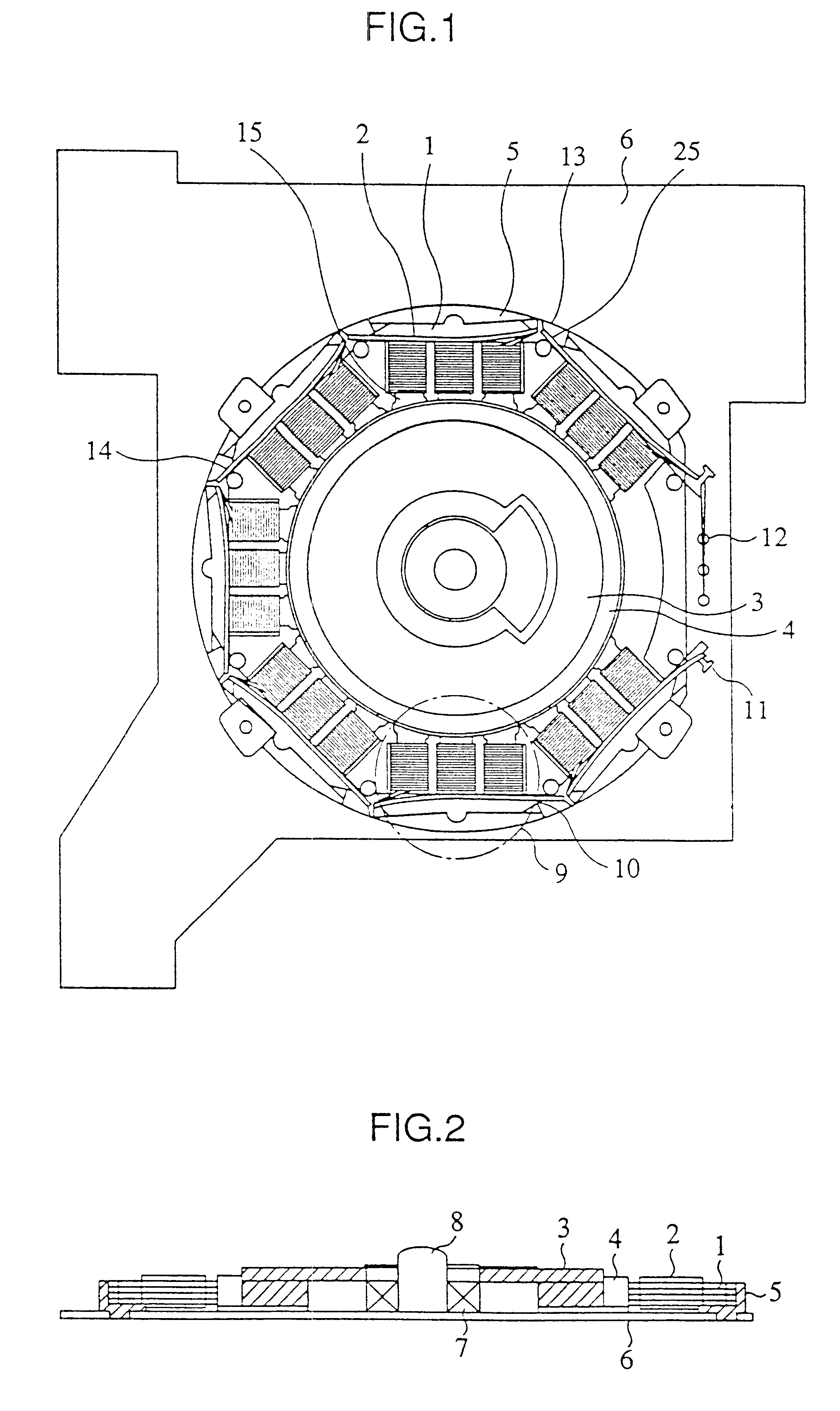

Molded motor

ActiveUS20080042499A1Hold steadyHigh strengthAssociation with grounding devicesMagnetic circuit characterised by insulating materialsEngineeringElectrically conductive

An inner rotor type molded motor controlled by pulse width modulation using an inverter circuit includes a pair of electrically conductive brackets attached to a load-side portion and an anti-load-side portion of a motor frame. An electrically conductive tape is attached on the outside of the motor frame to extend between the brackets, thereby short-circuiting the brackets to each other. In this manner, electrical erosion in the molded motor can be prevented.

Owner:NIDEC SHIBAURA CORP

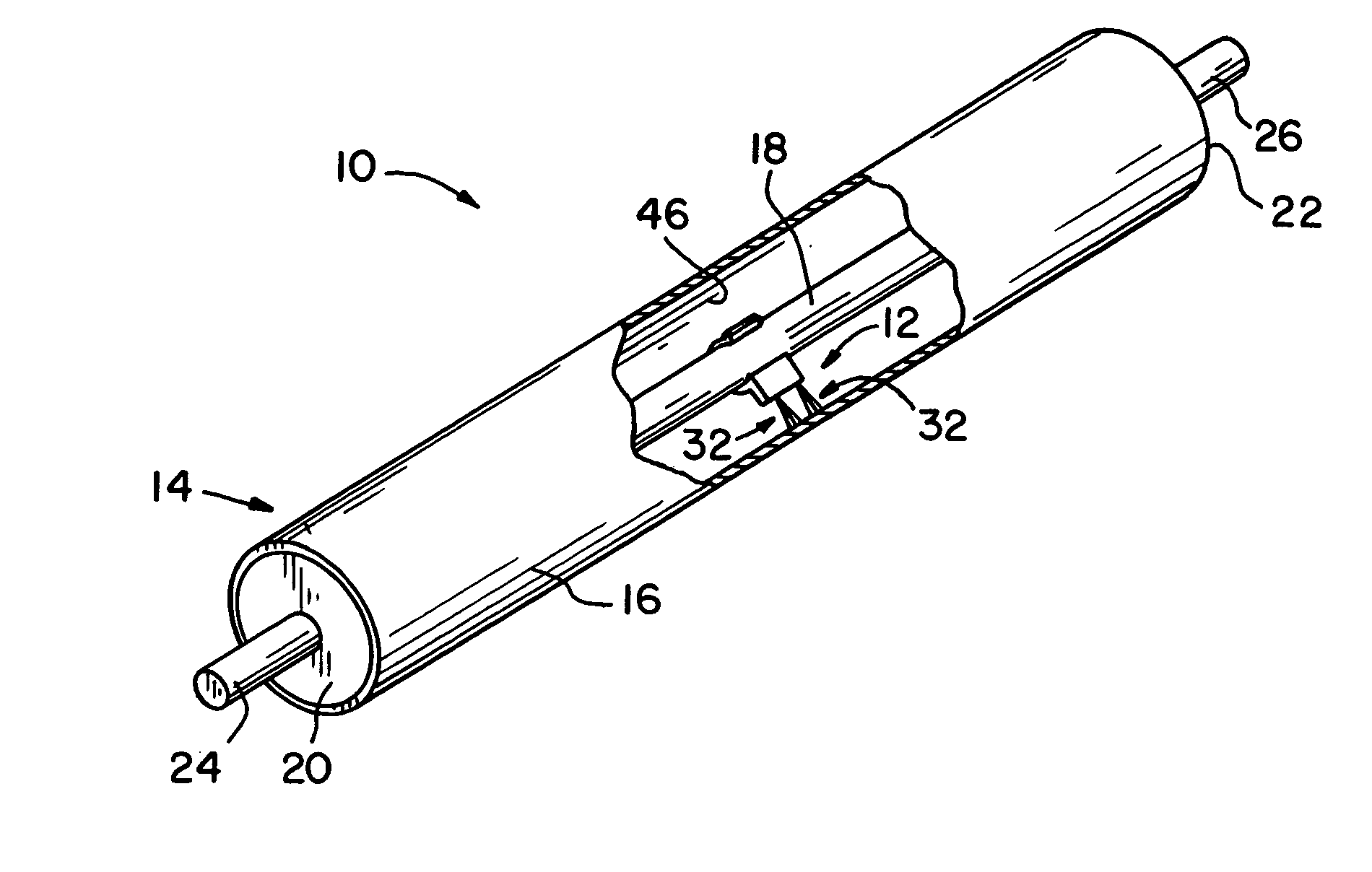

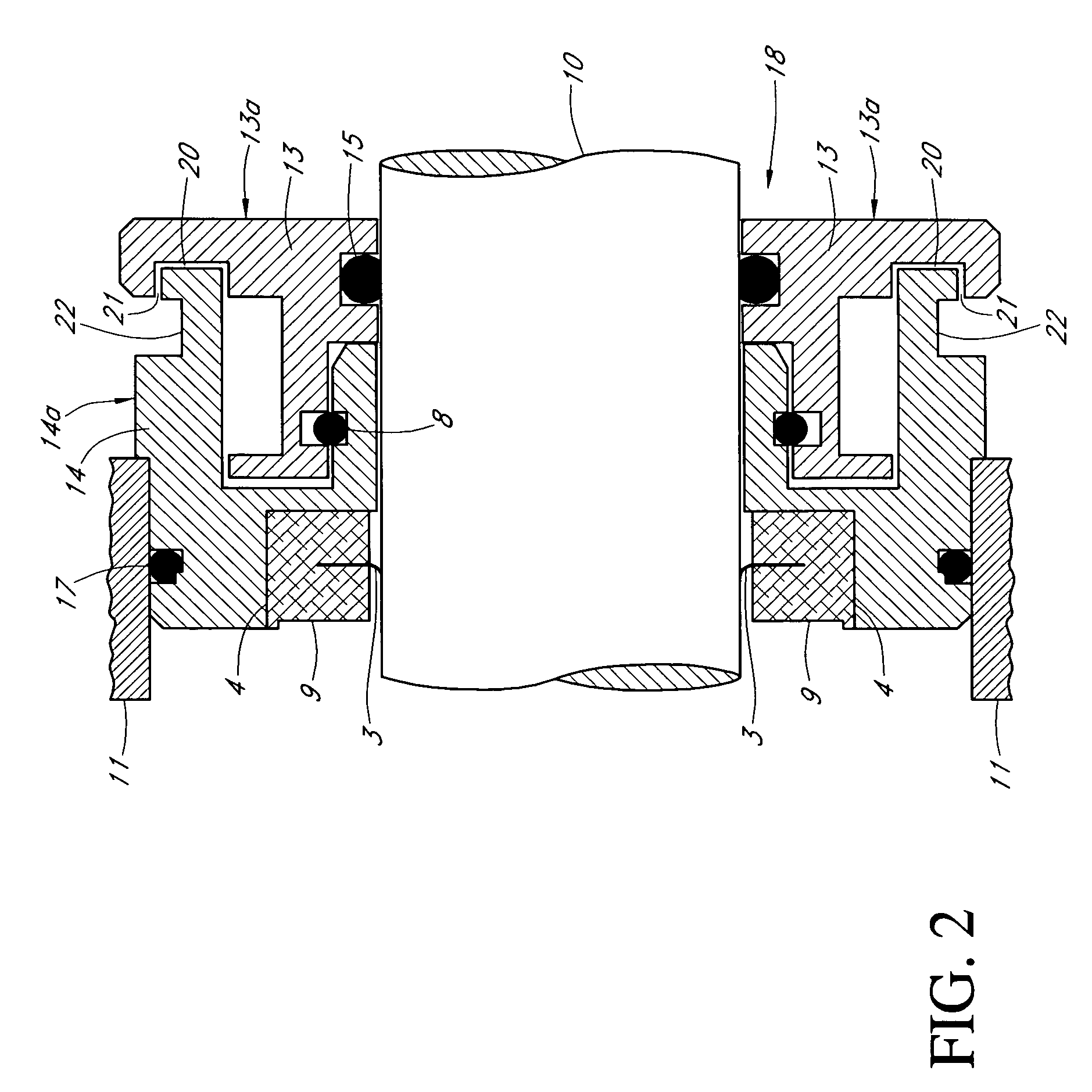

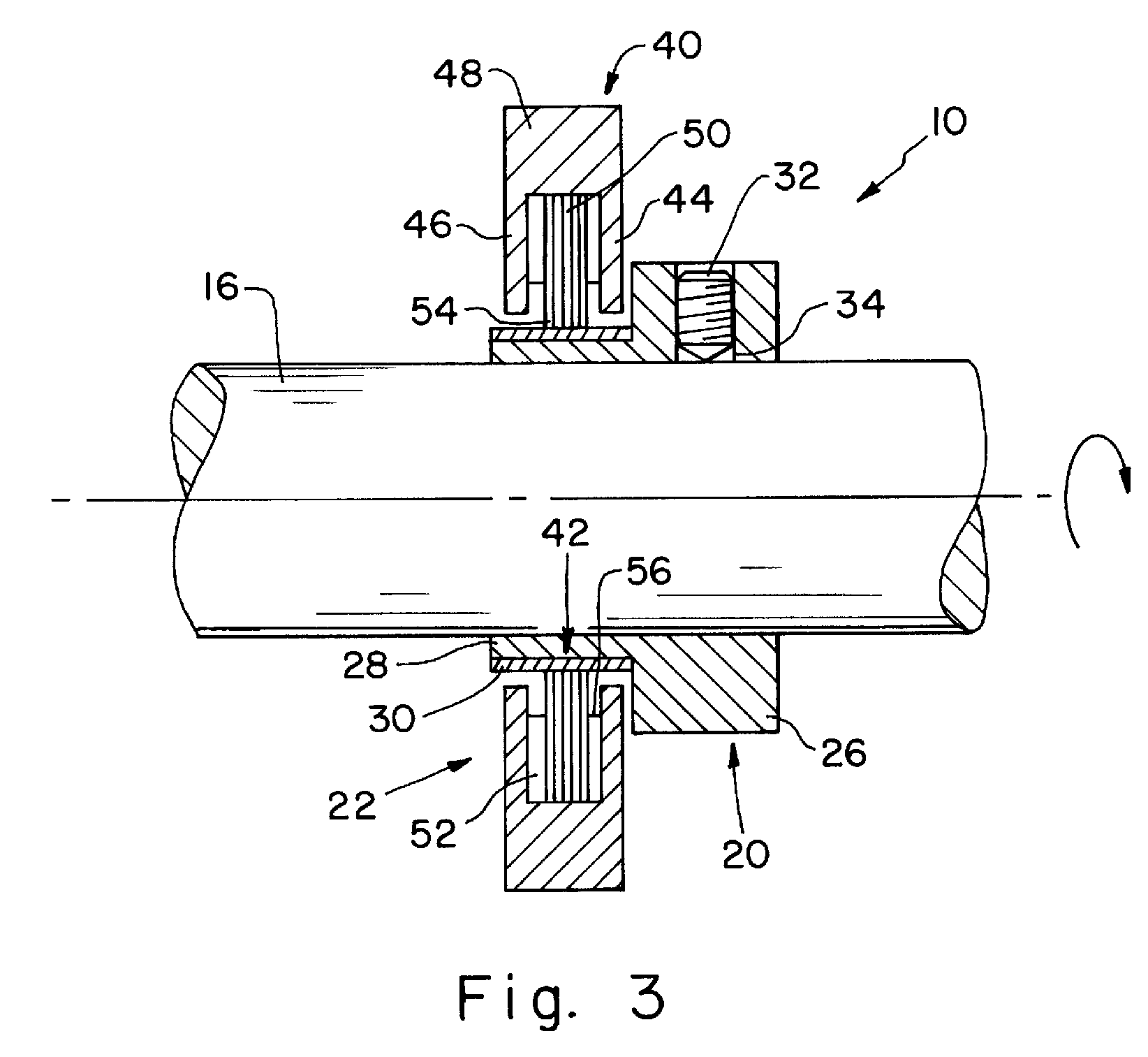

Static charge neutralizing assembly for use on rollers and shafts

ActiveUS7136271B2Not easy to wearNot easy to failAssociation with grounding devicesRelaysIonizationElectric field

A static charge neutralizer for a moving component of an apparatus includes a plurality of filaments on a conductive strip, with tips of the filaments disposed adjacent but spaced from the moving component. The filaments induce ionization in the presence of an electrical field from the statically charged surface of the moving component.

Owner:ILLINOIS TOOL WORKS INC

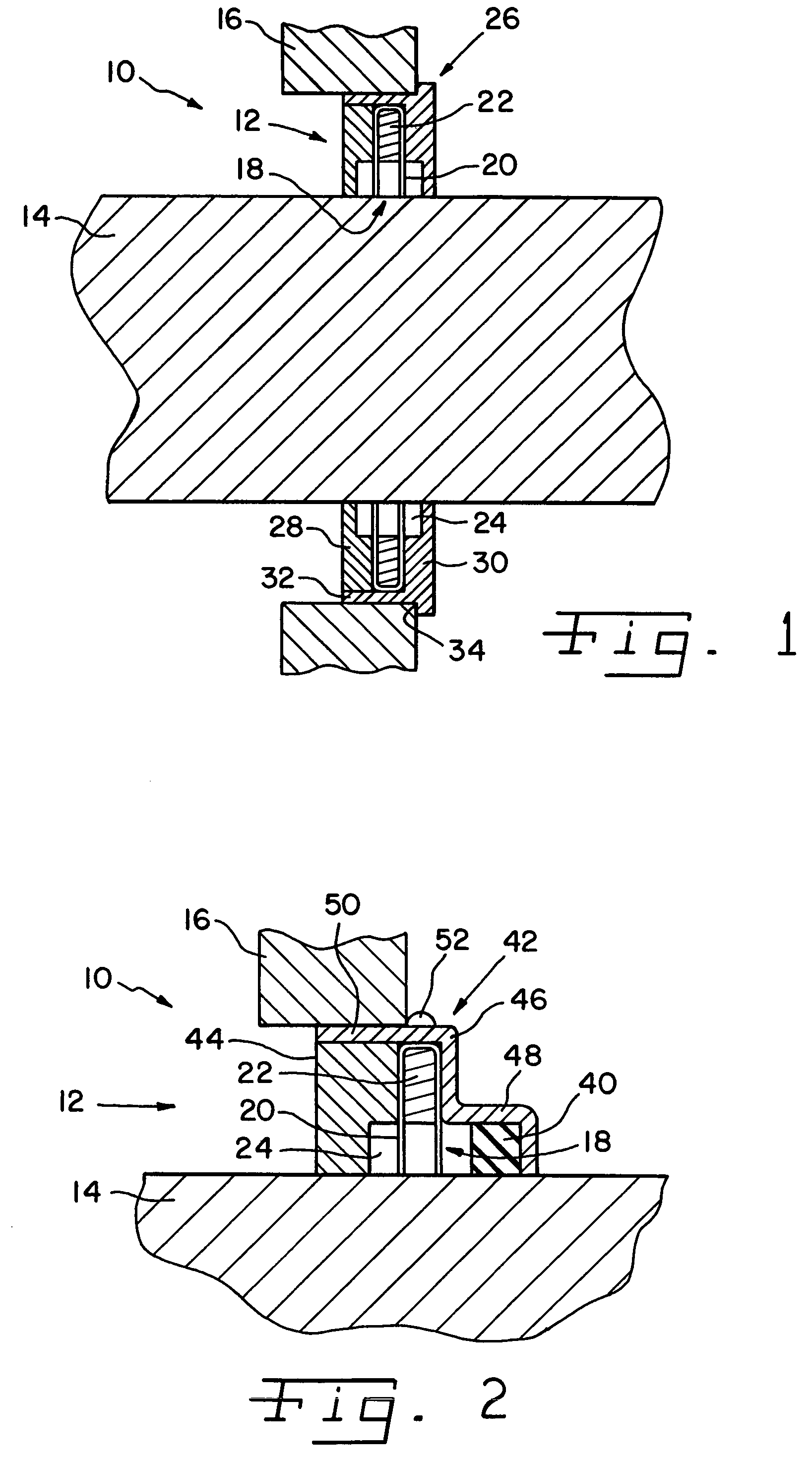

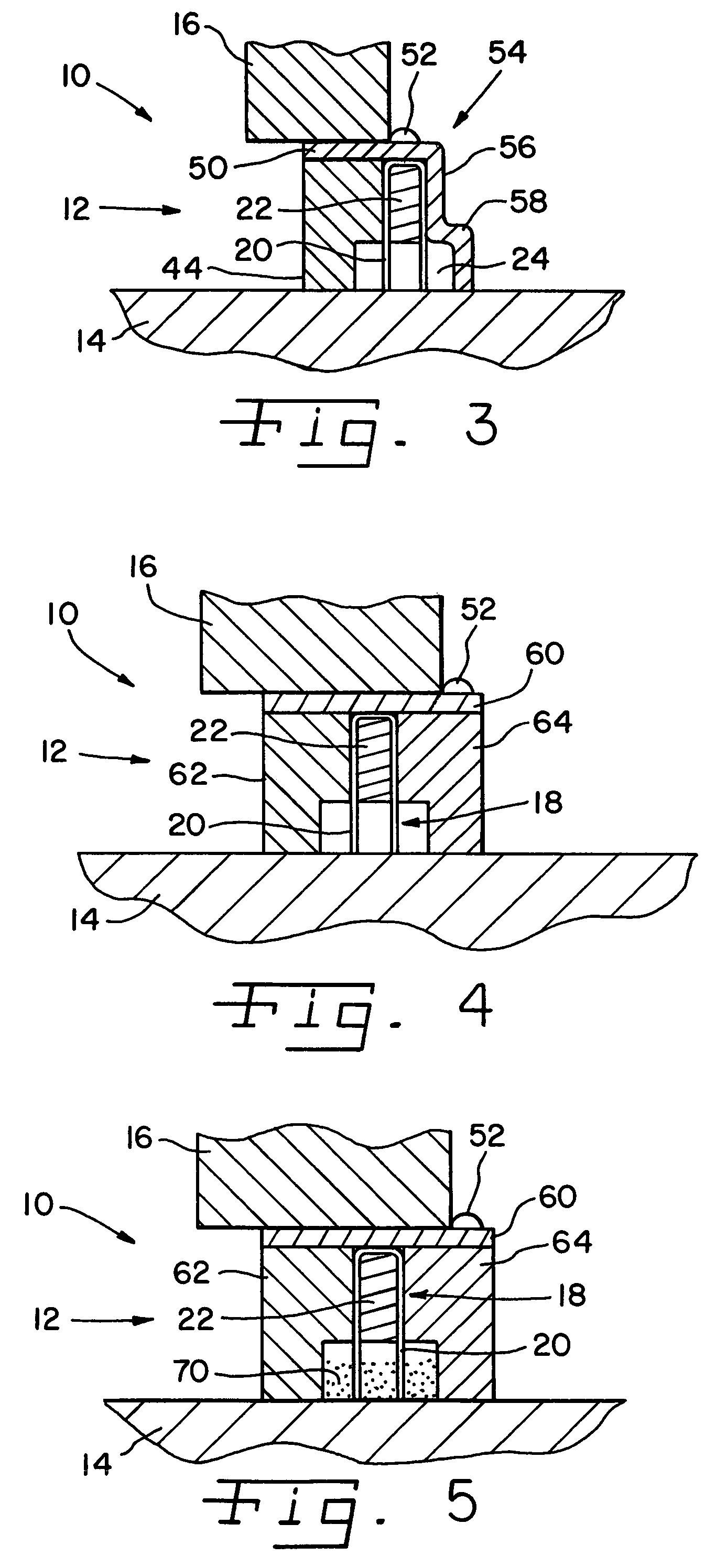

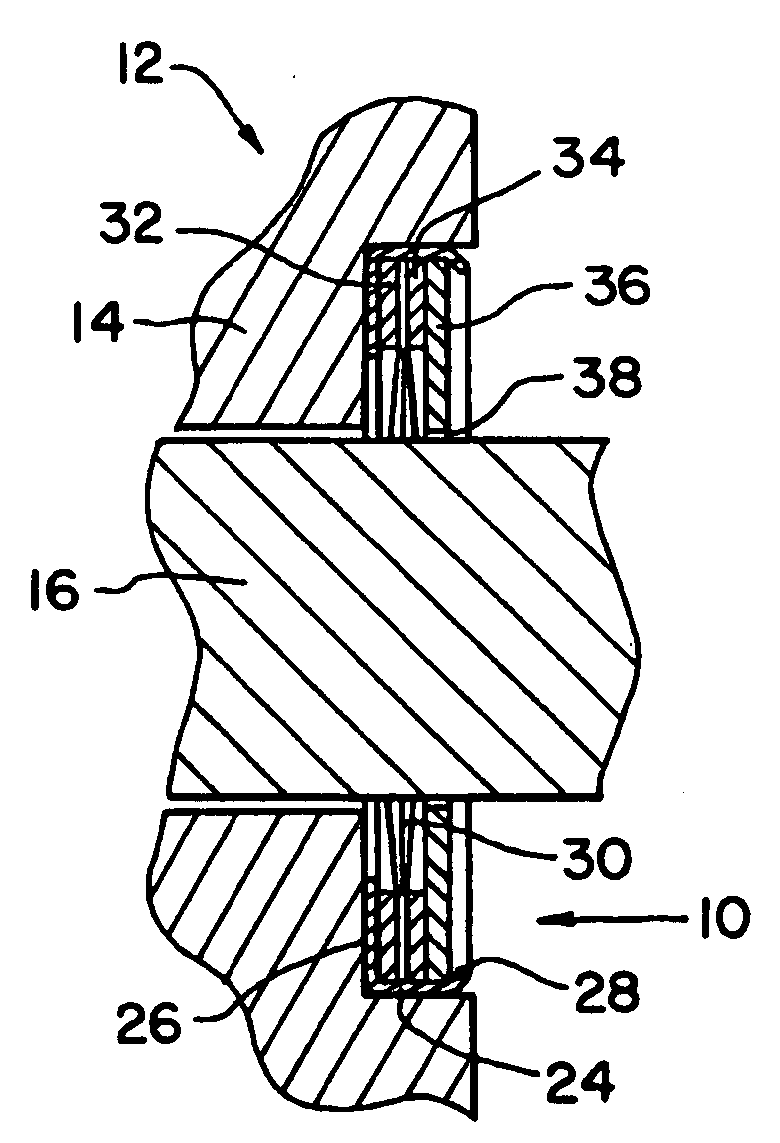

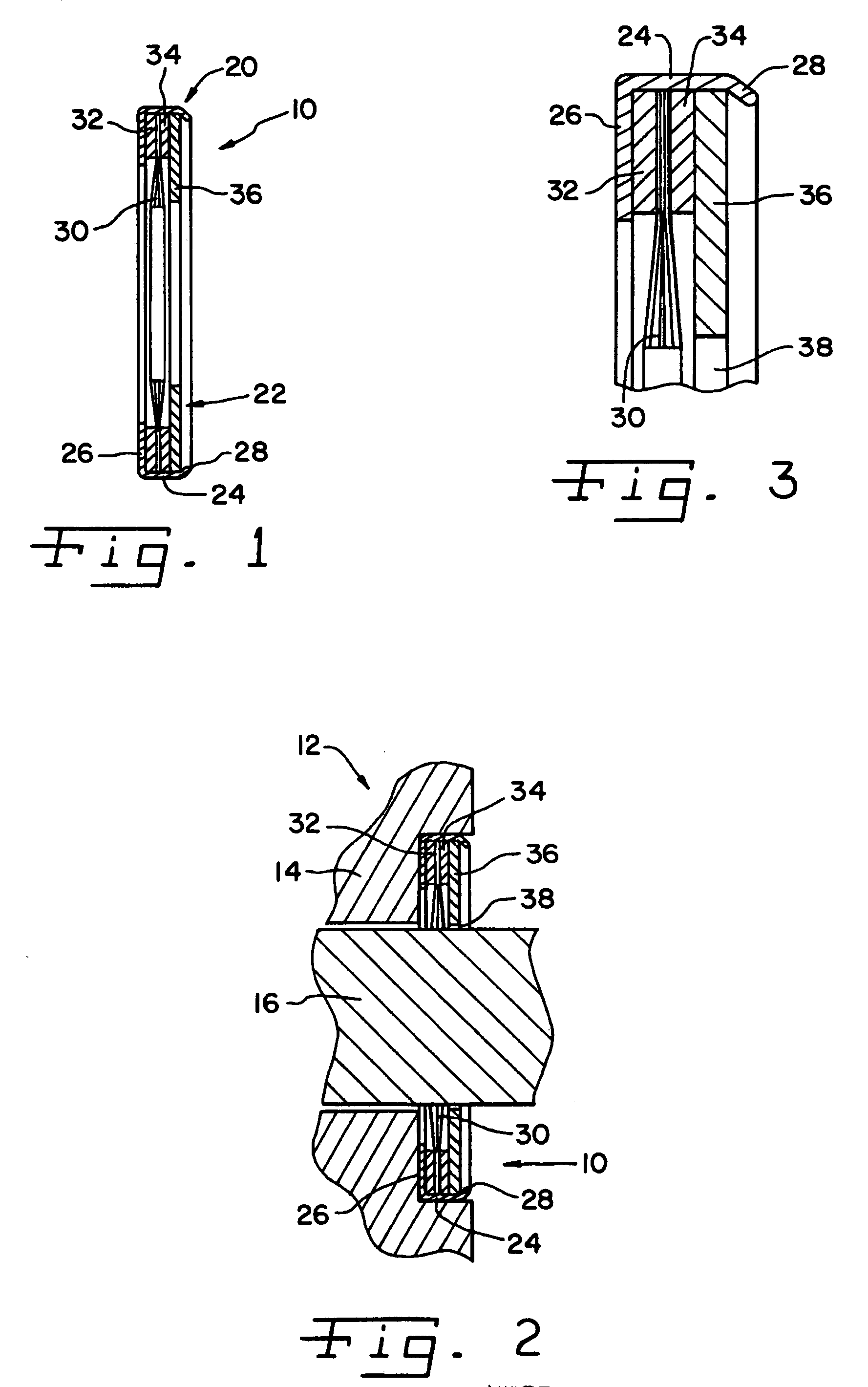

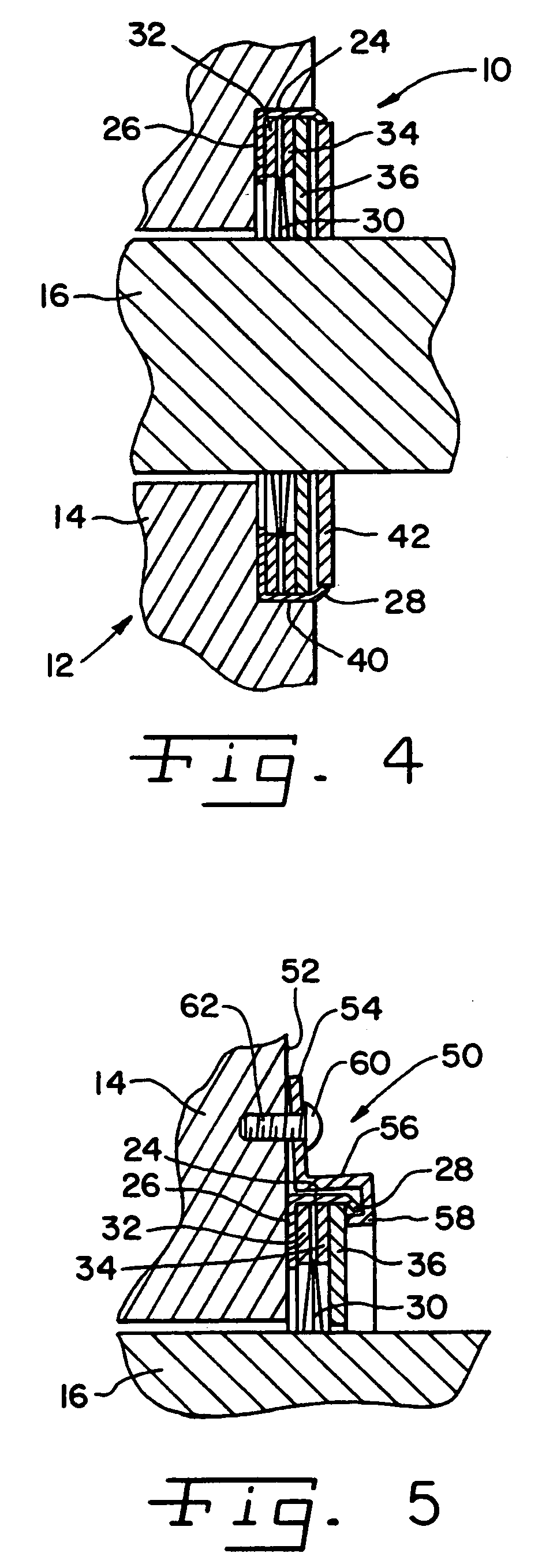

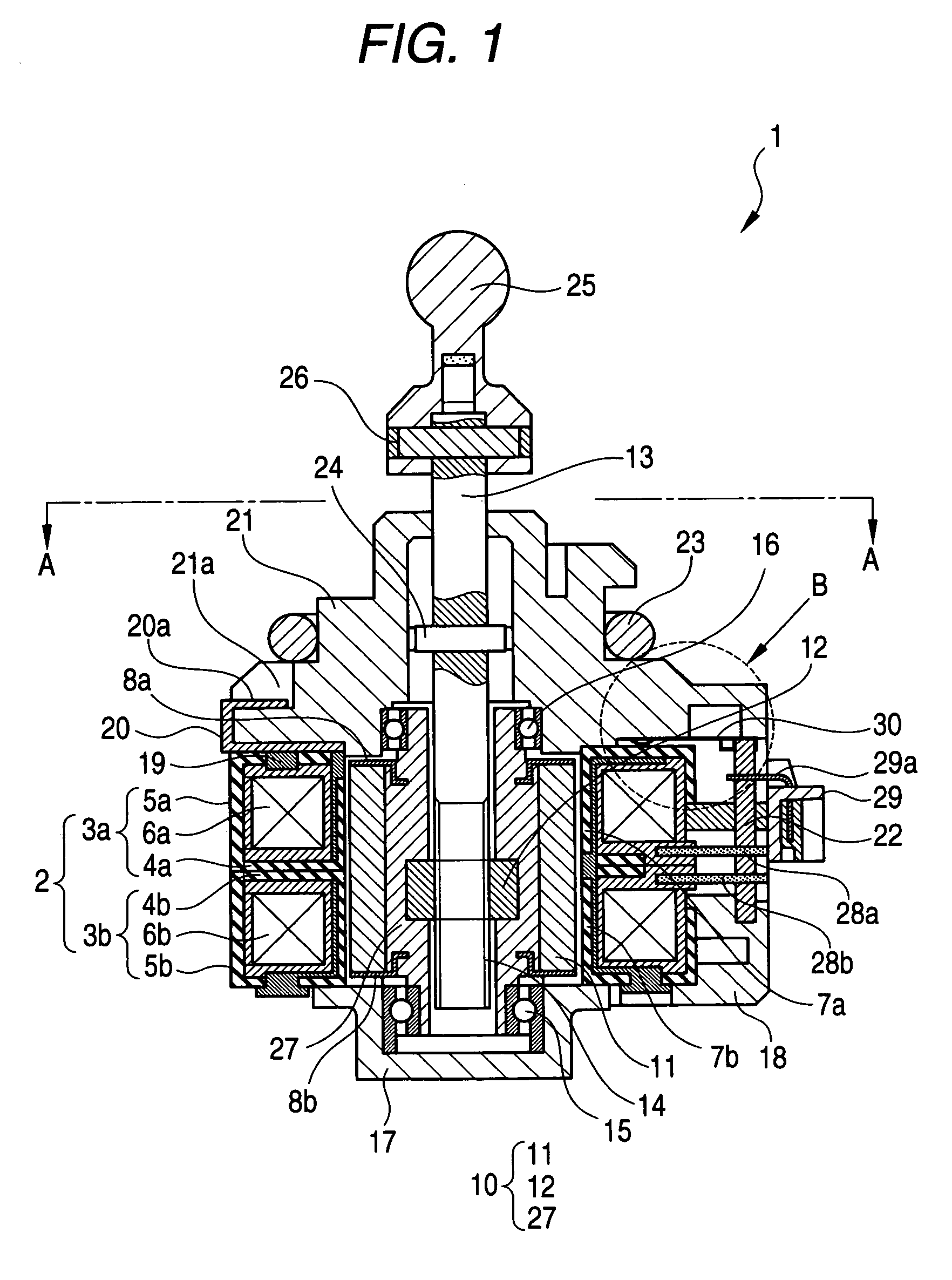

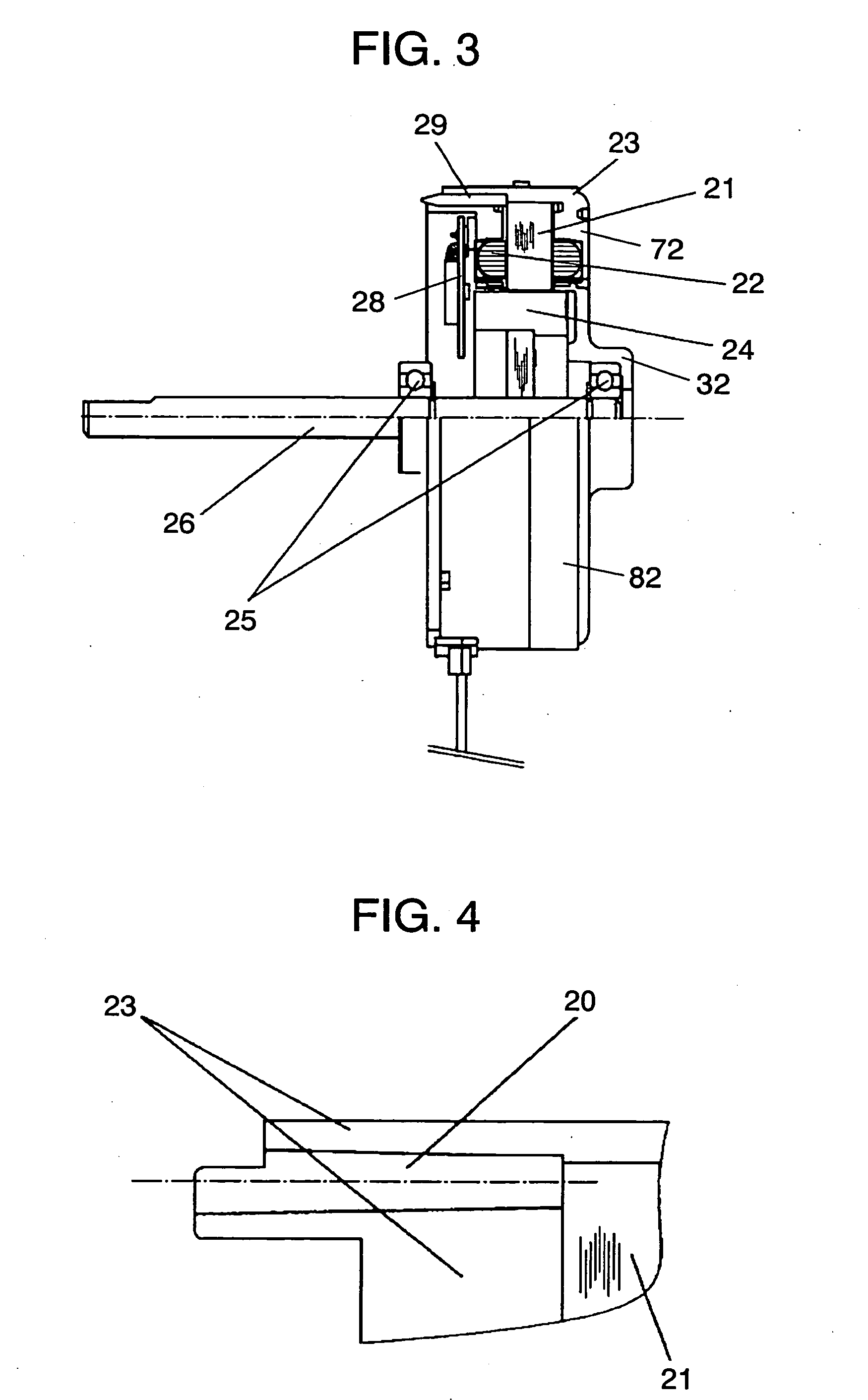

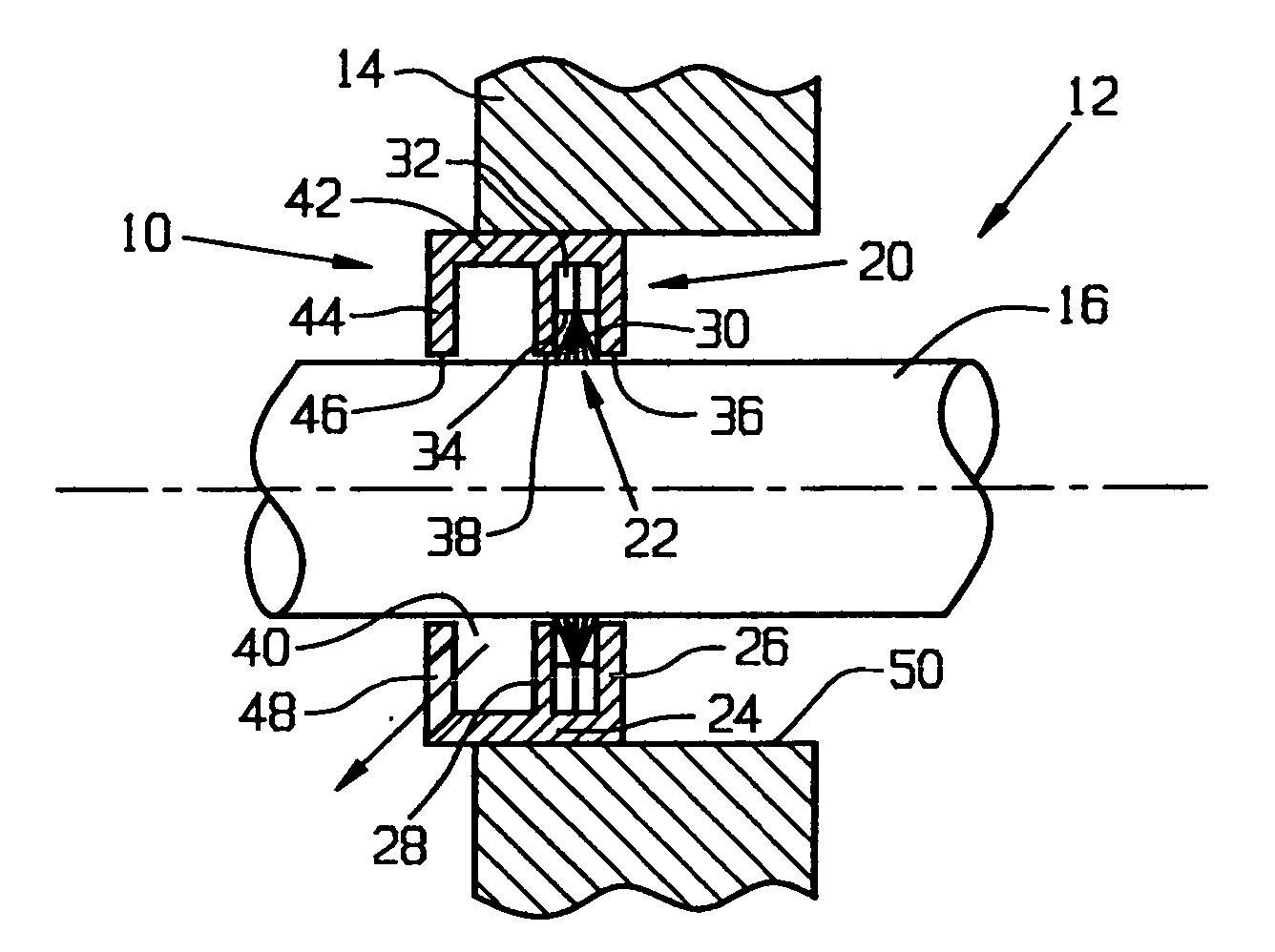

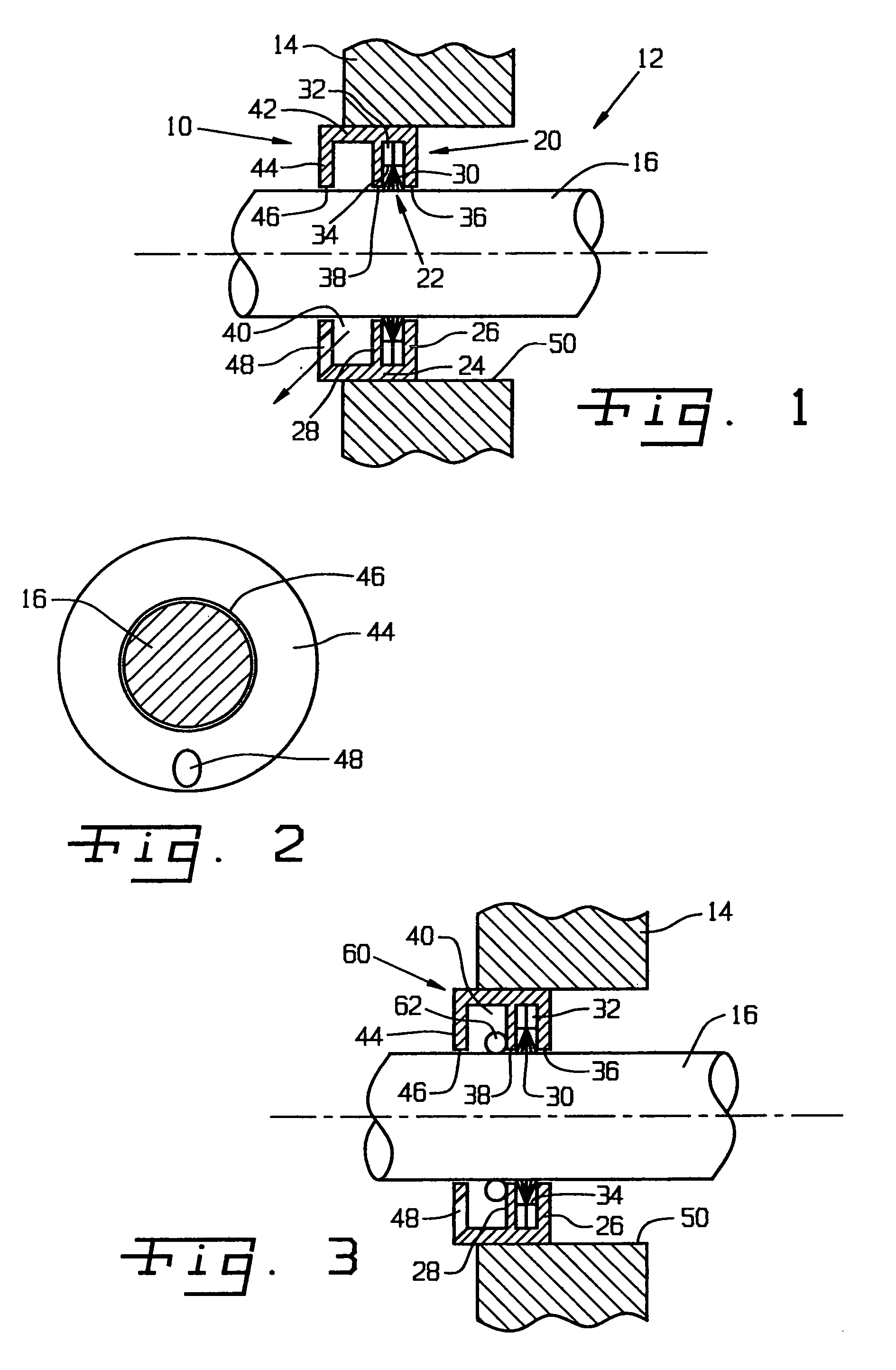

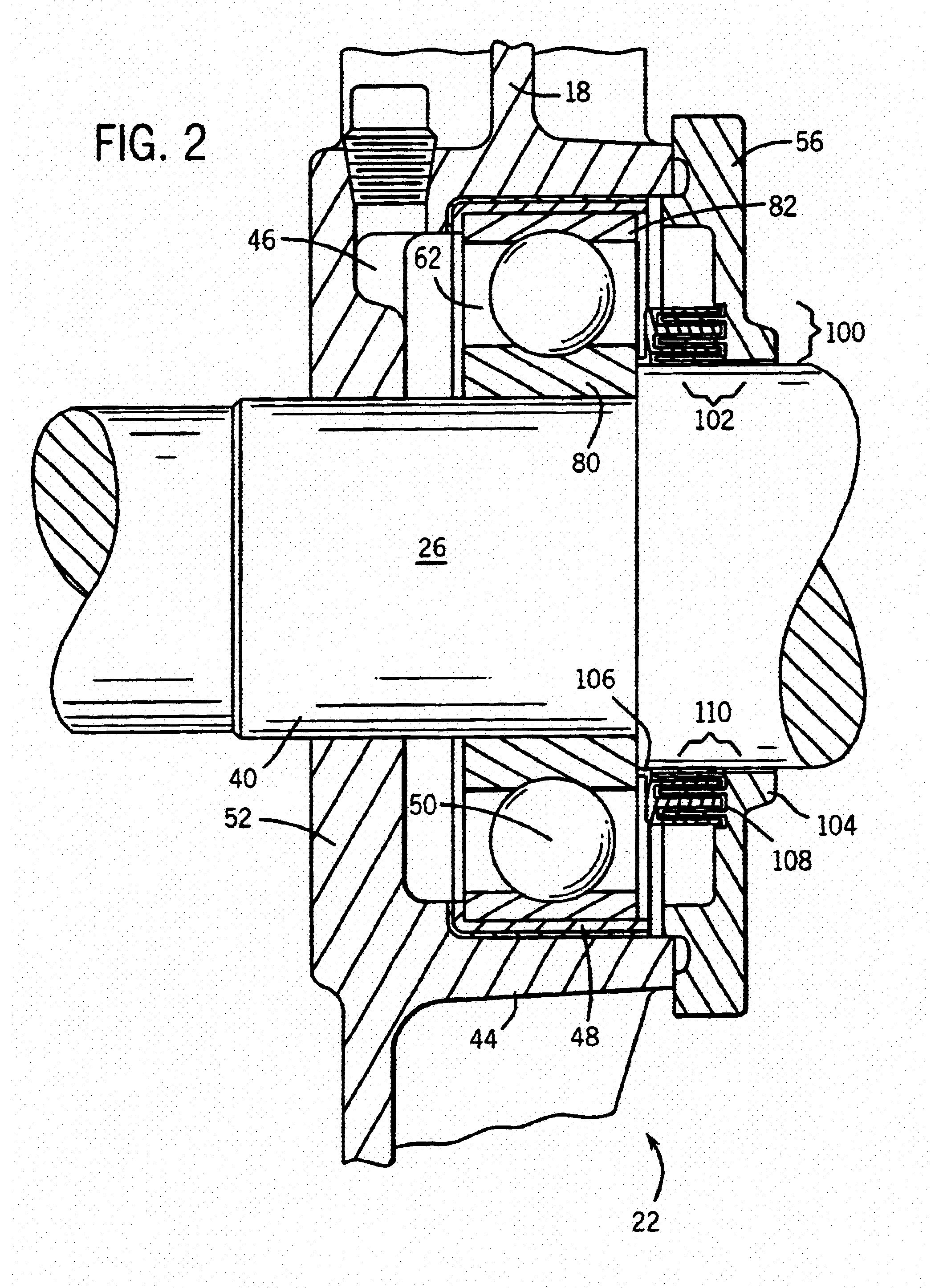

Shaft current control brush ring assembly

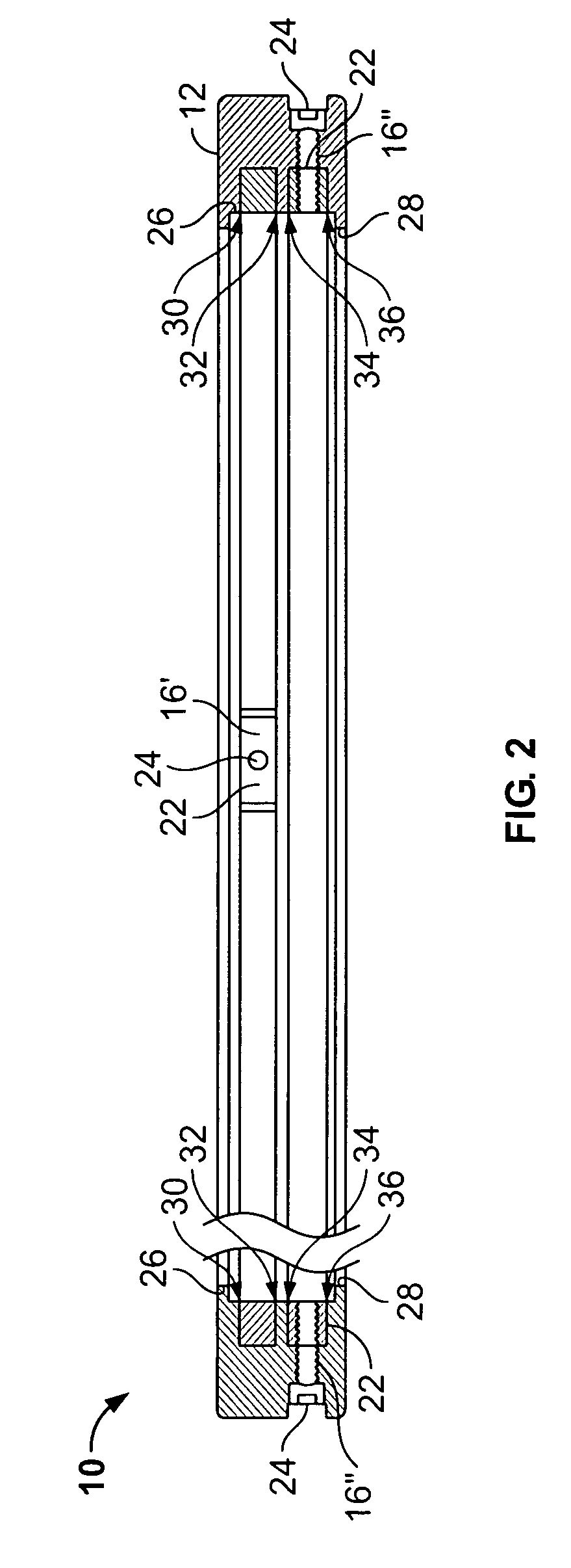

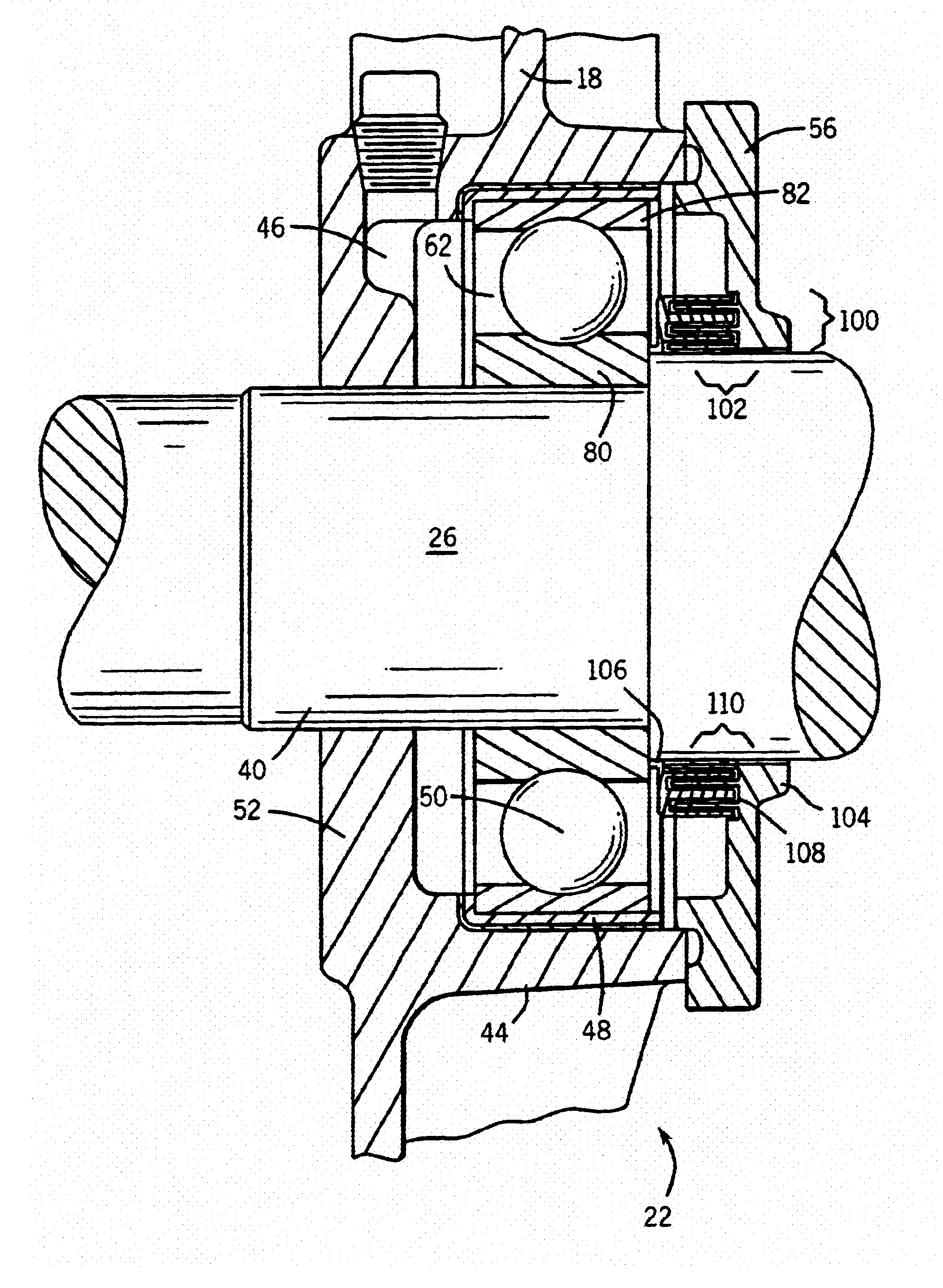

ActiveUS20060007609A1Reduce shaft currentEfficient assemblyAssociation with grounding devicesEmergency protective arrangement detailsInterference fitTroffer

A shaft current control brush ring assembly includes a cup and a brush ring assembly secured within the cup. The cup is secured to a motor faceplate, within a recess formed in the faceplate by interference fit, or by means of a clamp attached to the faceplate. A slinger can be associated with the brush ring assembly.

Owner:ILLINOIS TOOL WORKS INC

Motor ground seal

InactiveUS7521827B2Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesShock coolingRadial projection

Owner:INPRO INC

Lubricant for oil retaining bearing

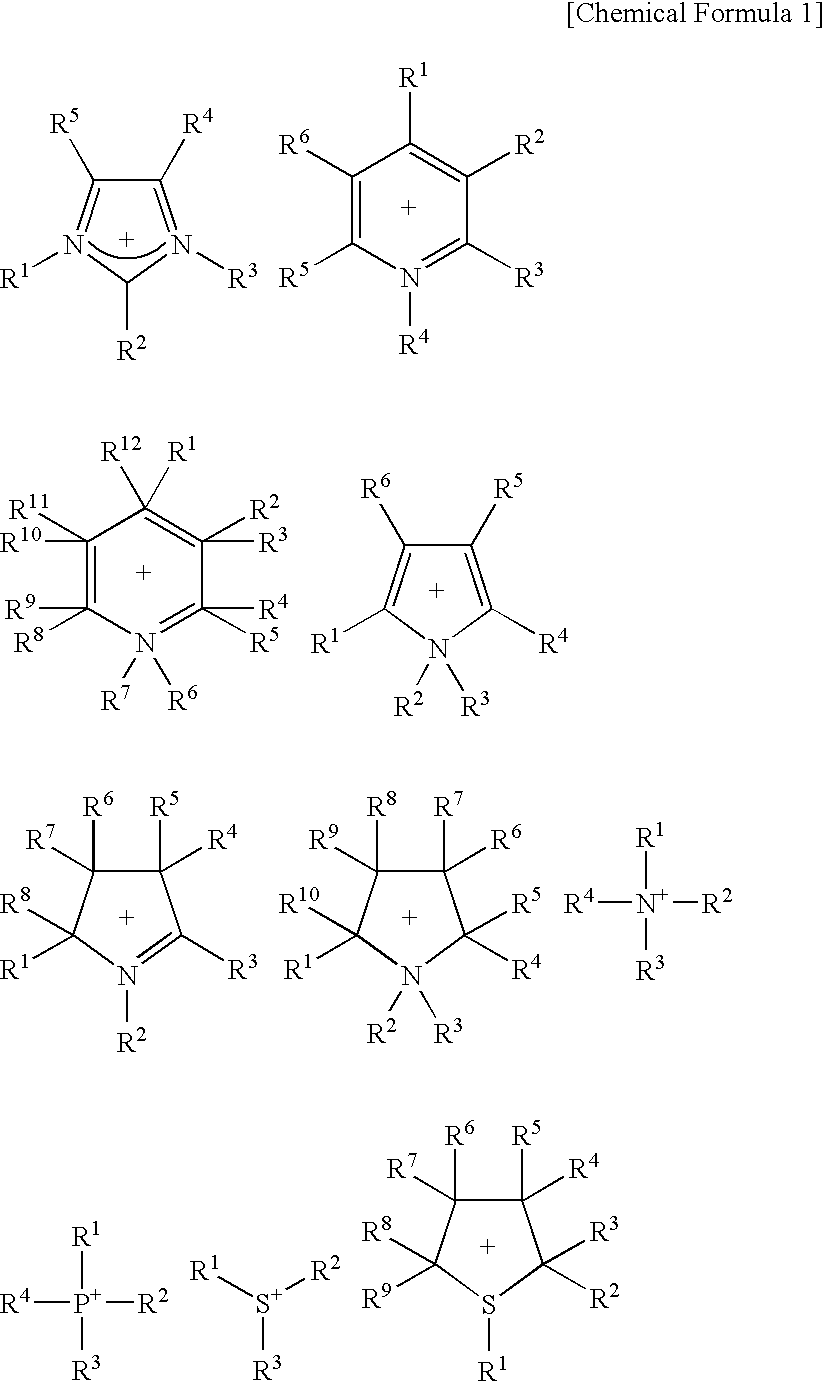

InactiveUS20090069204A1Low vapor pressureImprove heat resistanceAssociation with grounding devicesShaftsHeat resistanceEngineering

A lubricant for an oil retaining bearing containing 1 to 100% by mass of an ionic liquid. The lubricant has a low vapor pressure, low flammability, excellent heat resistance and ability to suppress the emanation of low volatile components and decomposed gases during use, or a lubricant for an oil retaining bearing which has antistatic property and is capable of grounding the static electricity generated by flow charging of the lubricant.

Owner:IDEMITSU KOSAN CO LTD

System and method of reducing bearing voltage

InactiveUS20030057783A1Association with grounding devicesEmergency protective arrangement detailsCapacitanceMechanical engineering

Technique for reducing bearing current discharges in a system by increasing the surface area between the shaft and the frame of the system and thereby increasing the rotor to frame capacitance.

Owner:BALDOR ELECTRIC COMPANY

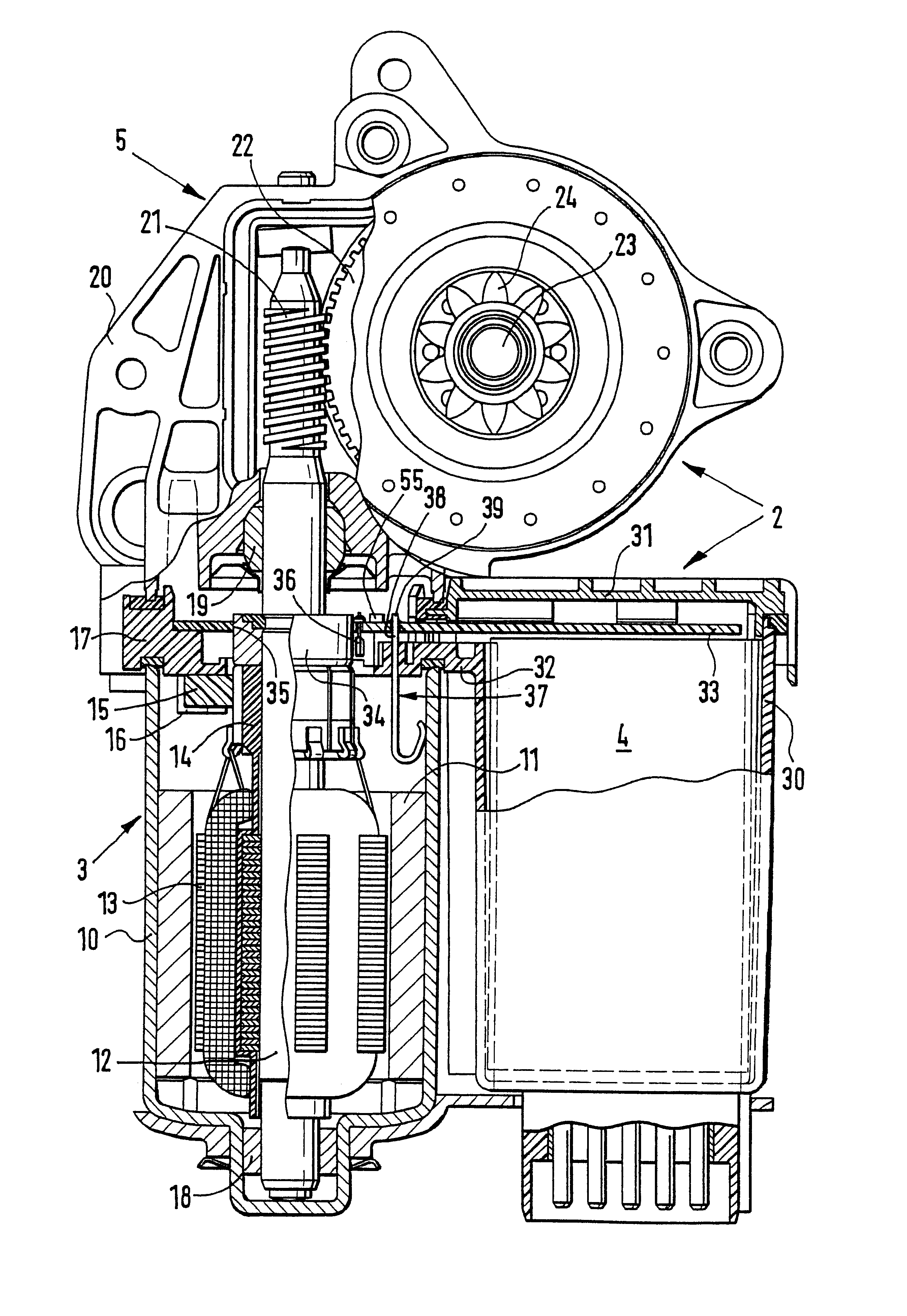

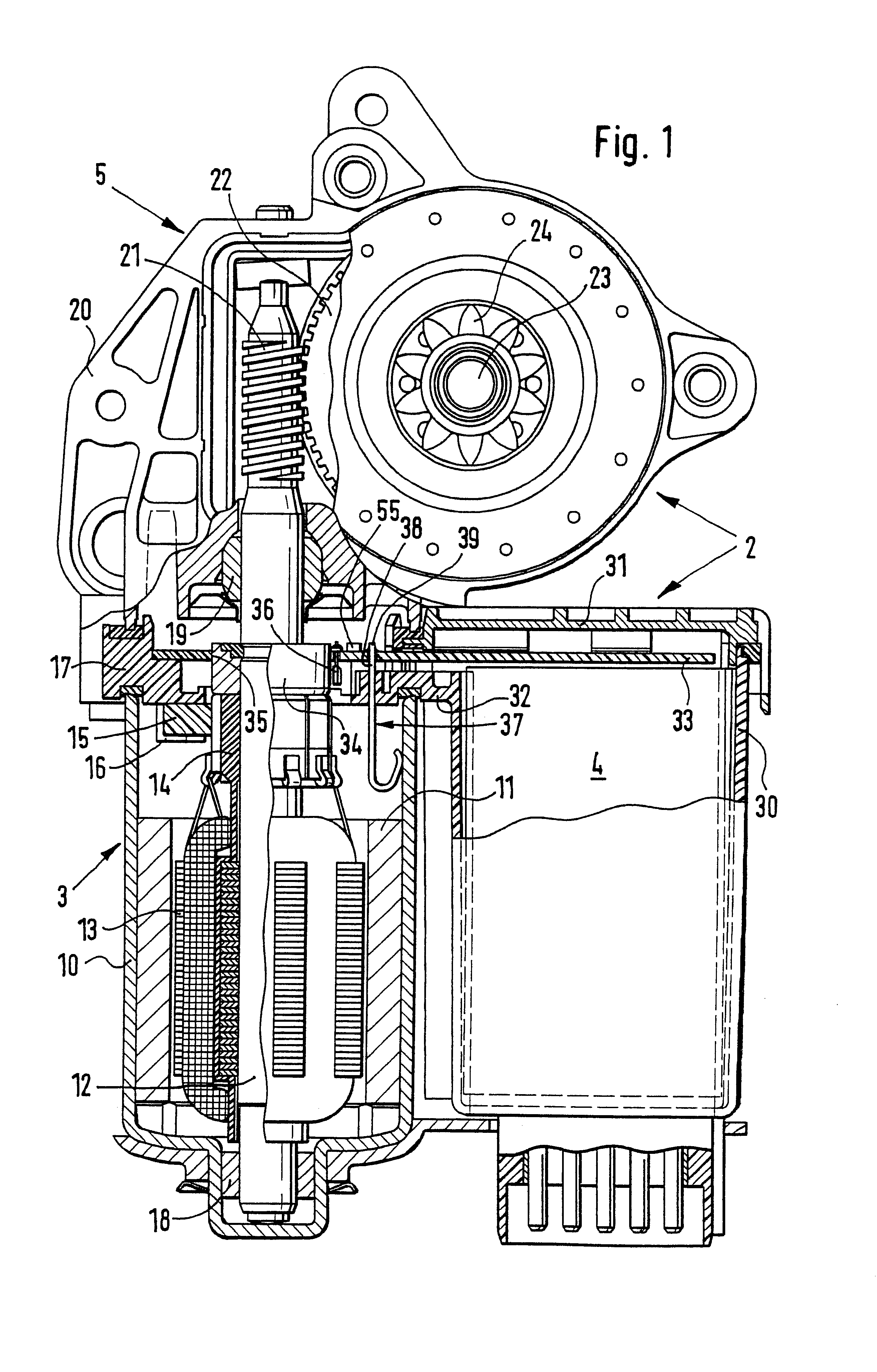

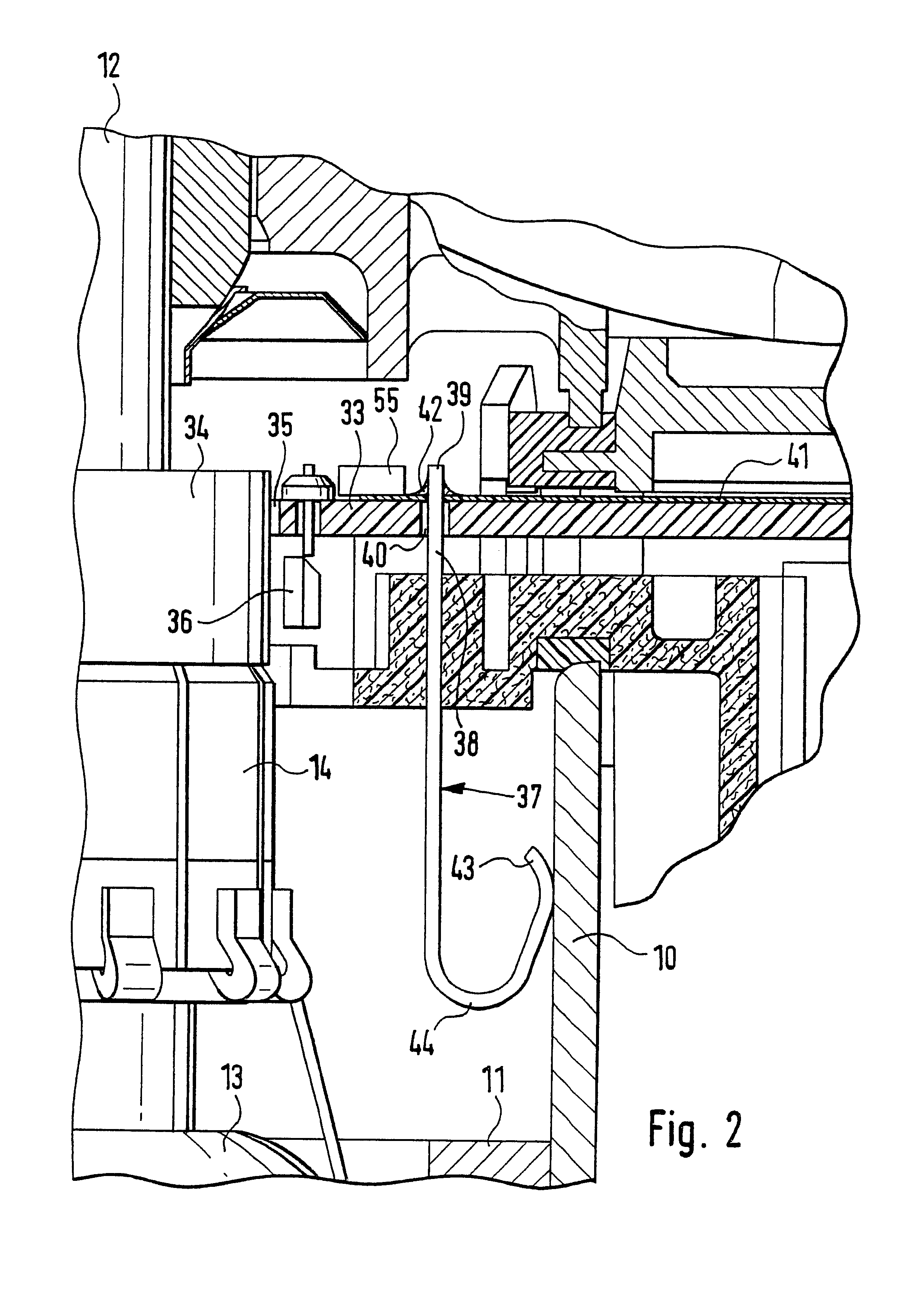

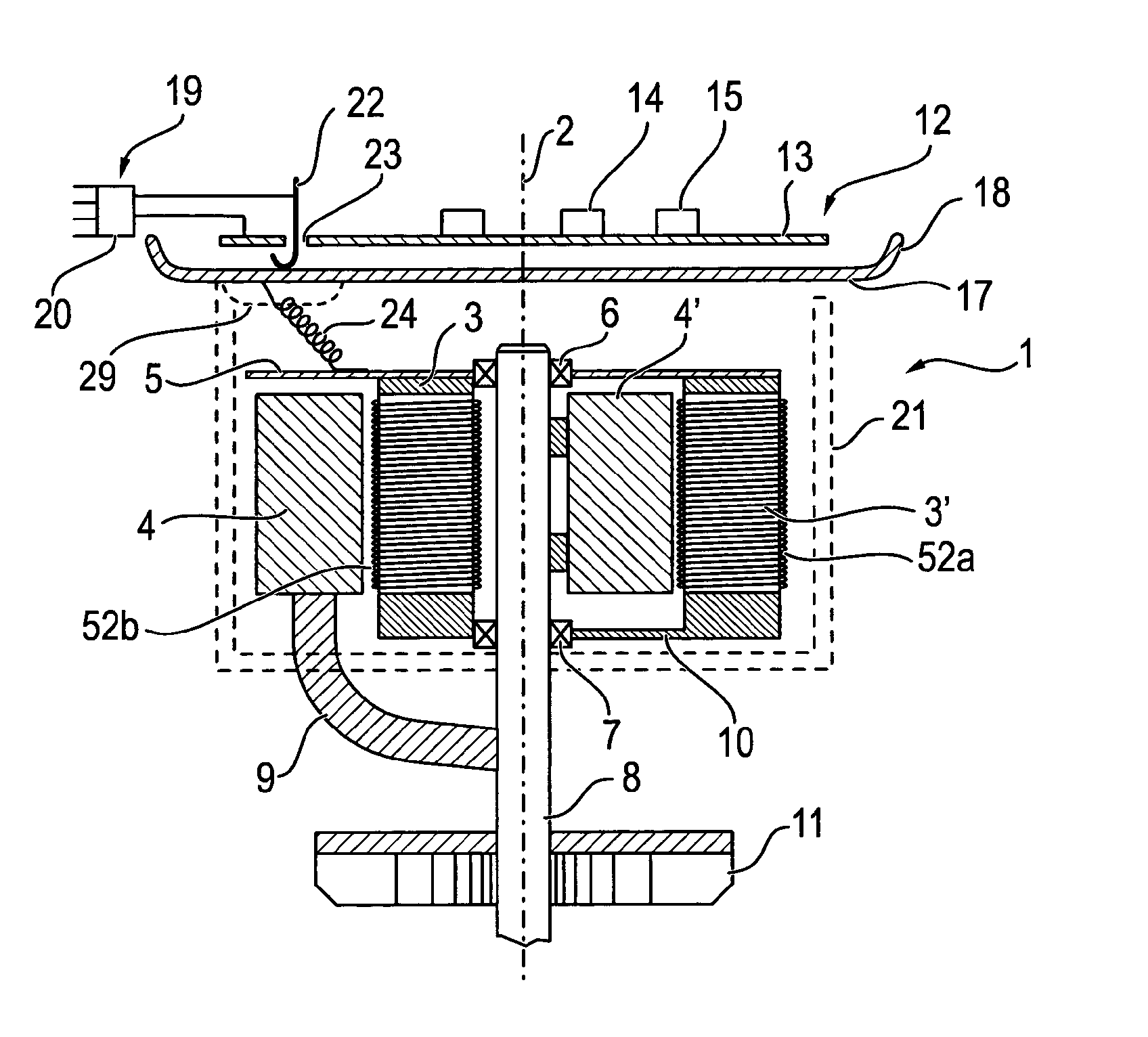

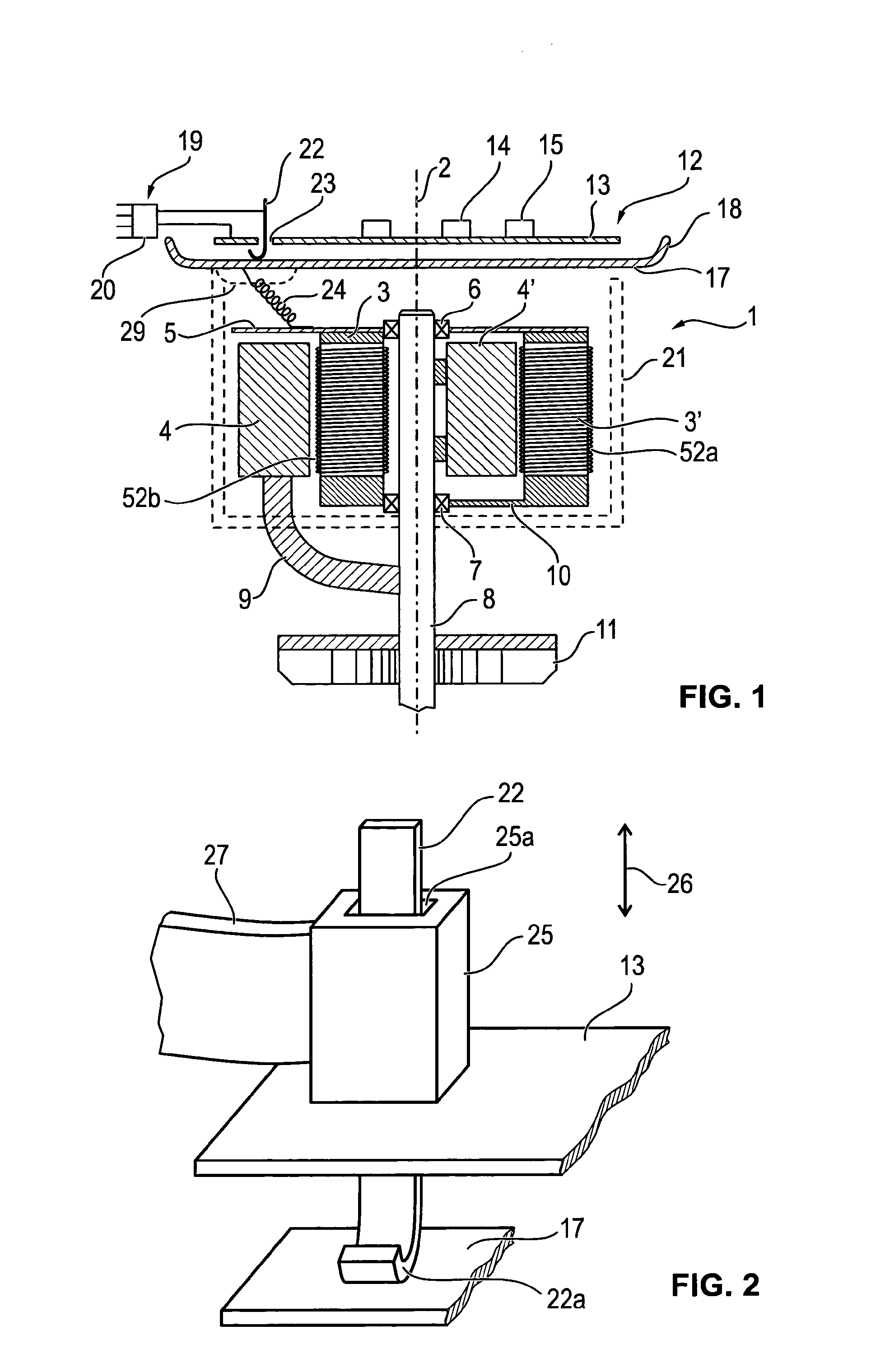

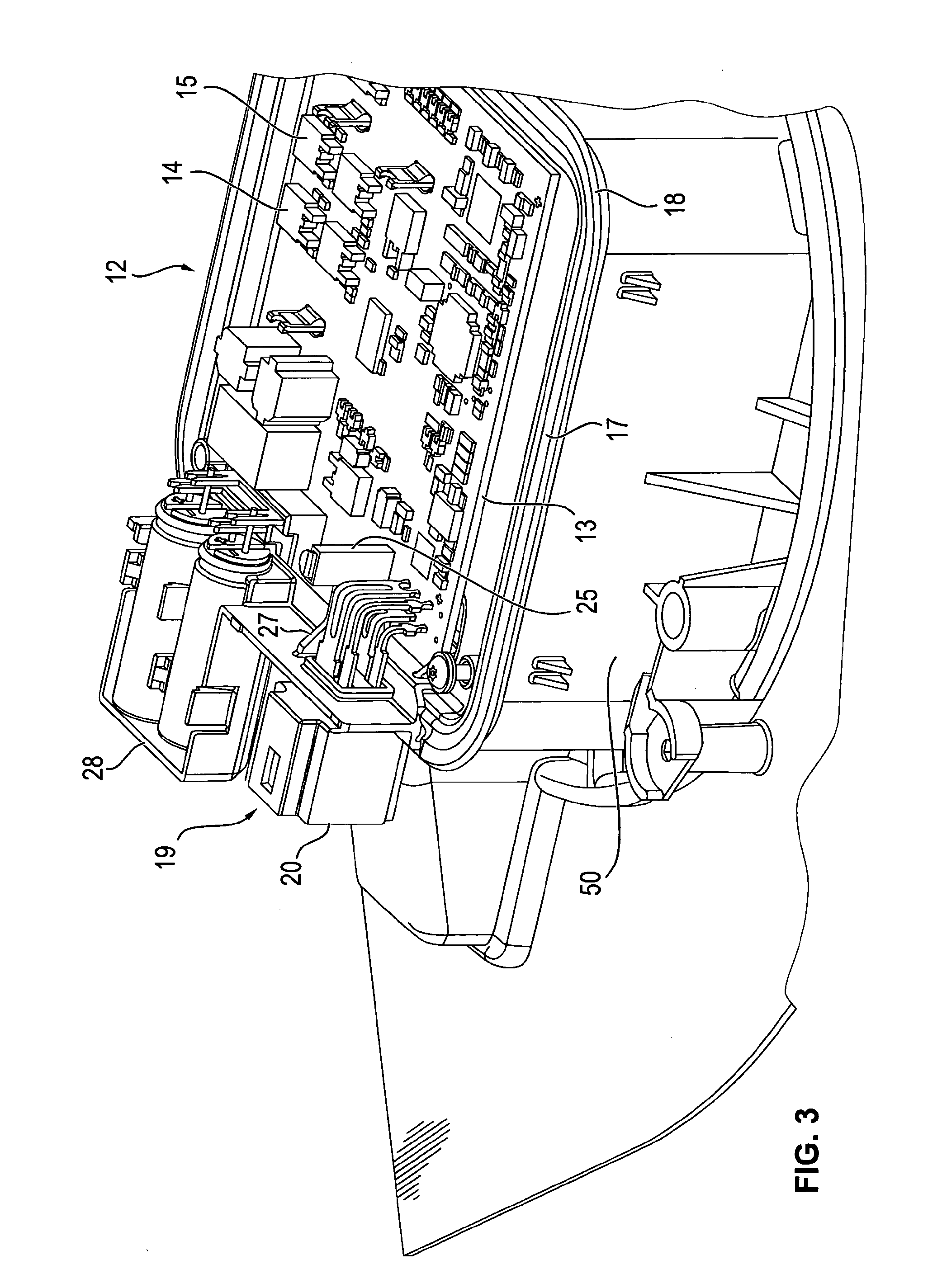

Actuating drive with an electric motor and control electronics

InactiveUS6528915B1Association with grounding devicesMechanical energy handlingElectrical conductorControl electronics

An actuating drive with an electric motor that has a metallic electric motor housing, a shaft, an armature, collector, brushes, and a brush holder plate, and control electronics. Electronic and electric components are connected to a printed circuit board and the printed circuit board protrudes at right angles to the shaft and into a cross section of the electric motor housing. Outside the electric motor housing, the electronic and electric components are protected by a control electronics housing. Radio interference suppression means, for example, can be disposed inside the actuating drive. The system includes a printed circuit board with a strip conductor and a contact spring that leads from the strip conductor and this contact spring protrudes into the electric motor housing, wherein a resilient free end of the spring rests against the electric motor housing producing an electrical contact.

Owner:ROBERT BOSCH GMBH

Rotary motor and production method thereof, and laminated core and production method thereof

InactiveUS6323571B1Association with grounding devicesMagnetic circuit rotating partsProduction rateMagnetic poles

An object of the present invention is to provide a low cost, high performance, thin structure rotary motor for driving medium used in magnetic disk drive unit, optical disk drive unit or the like, in order to improve the productivity of terminating processing and the reliability of the coils. Magnetic materials which are divided to a plurality of blocks or divided corresponding to respective magnetic pole teeth are connected by means of thin portions. The respective magnetic pole teeth are wound continuously with wire without cutting the wire at the positions in which the thin portions are connected. When a stator is assembled, a plurality of blocks or magnetic pole teeth are disposed on a substrate by separating or bending the thin portions.

Owner:MITSUBISHI ELECTRIC CORP

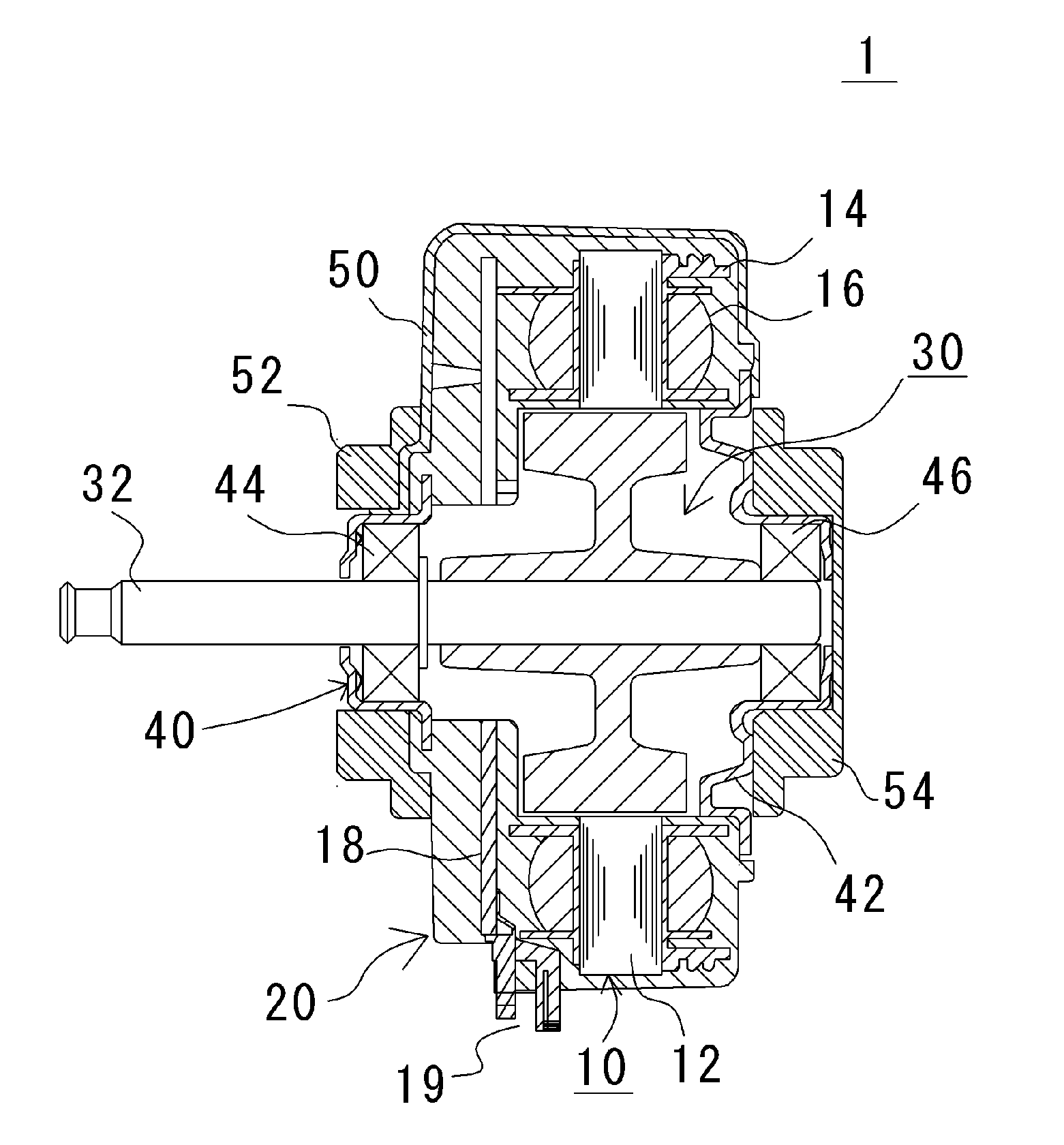

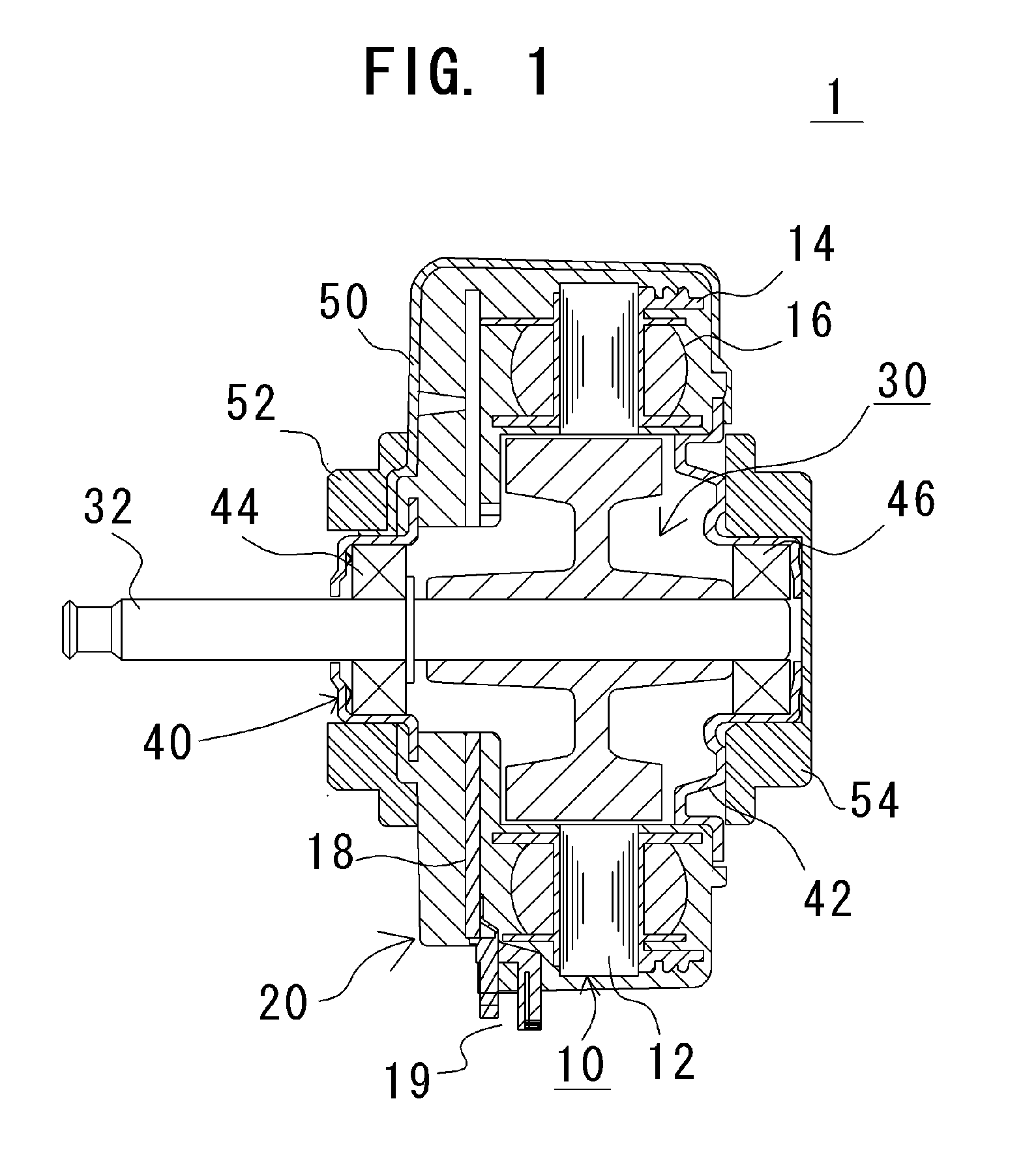

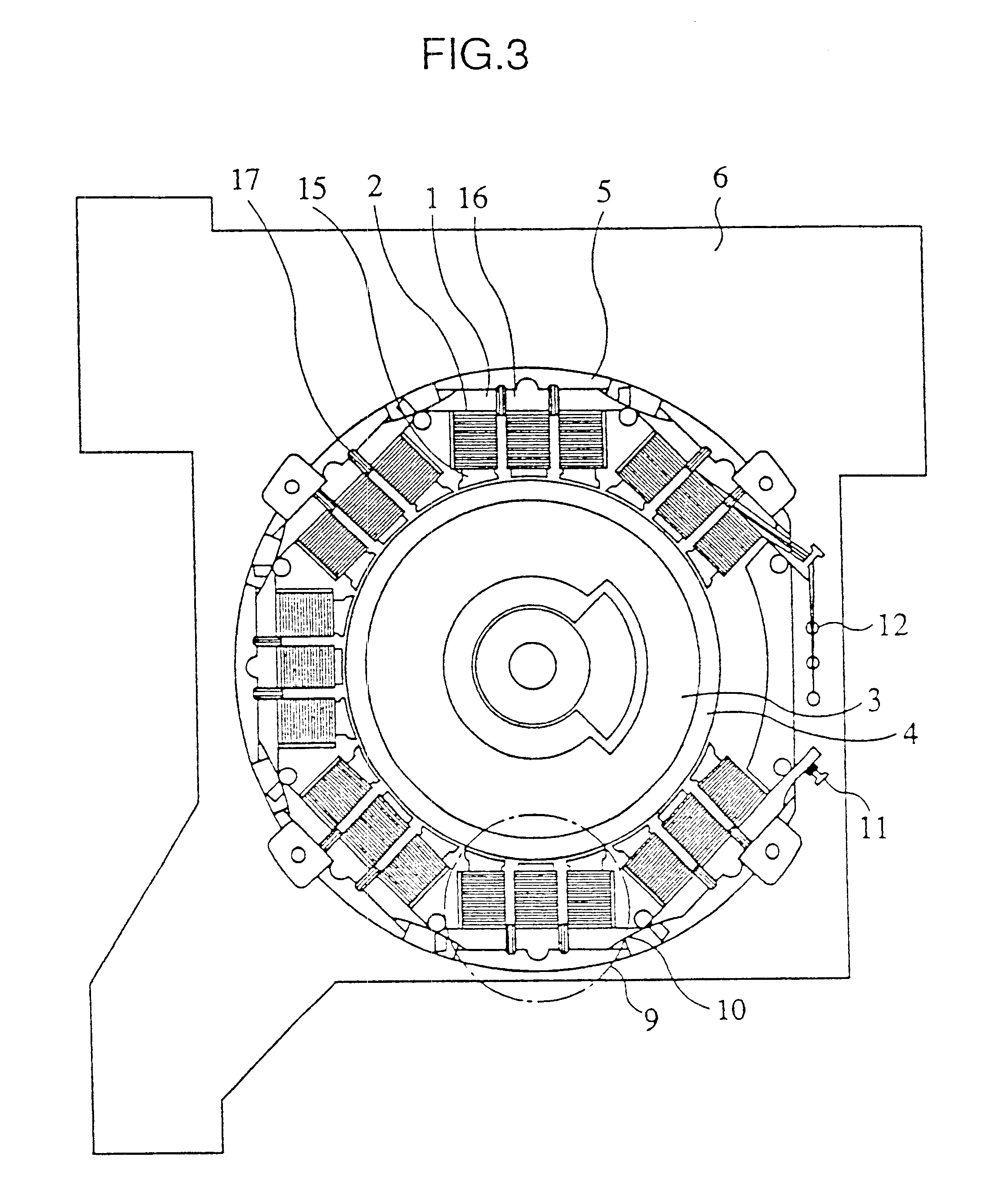

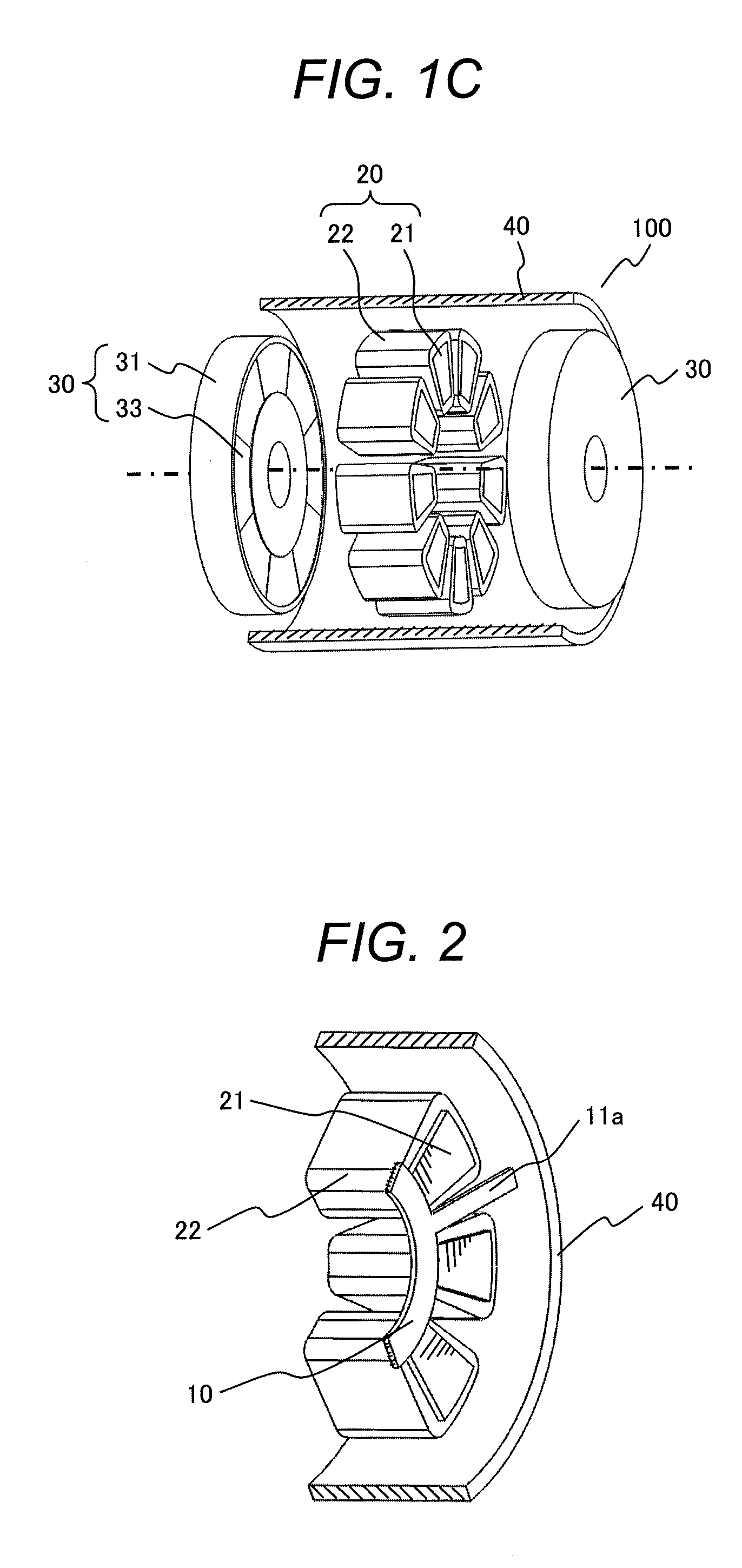

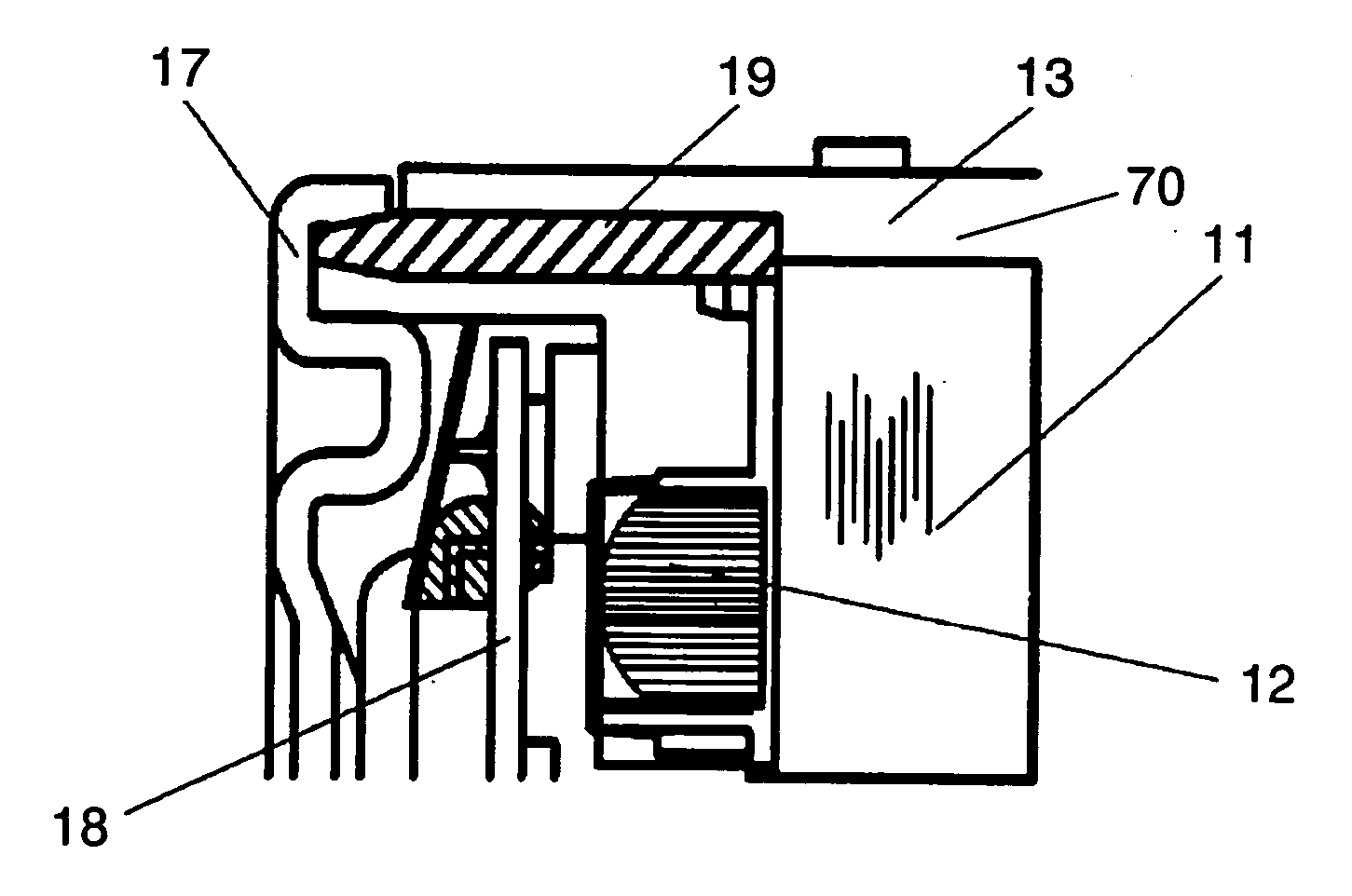

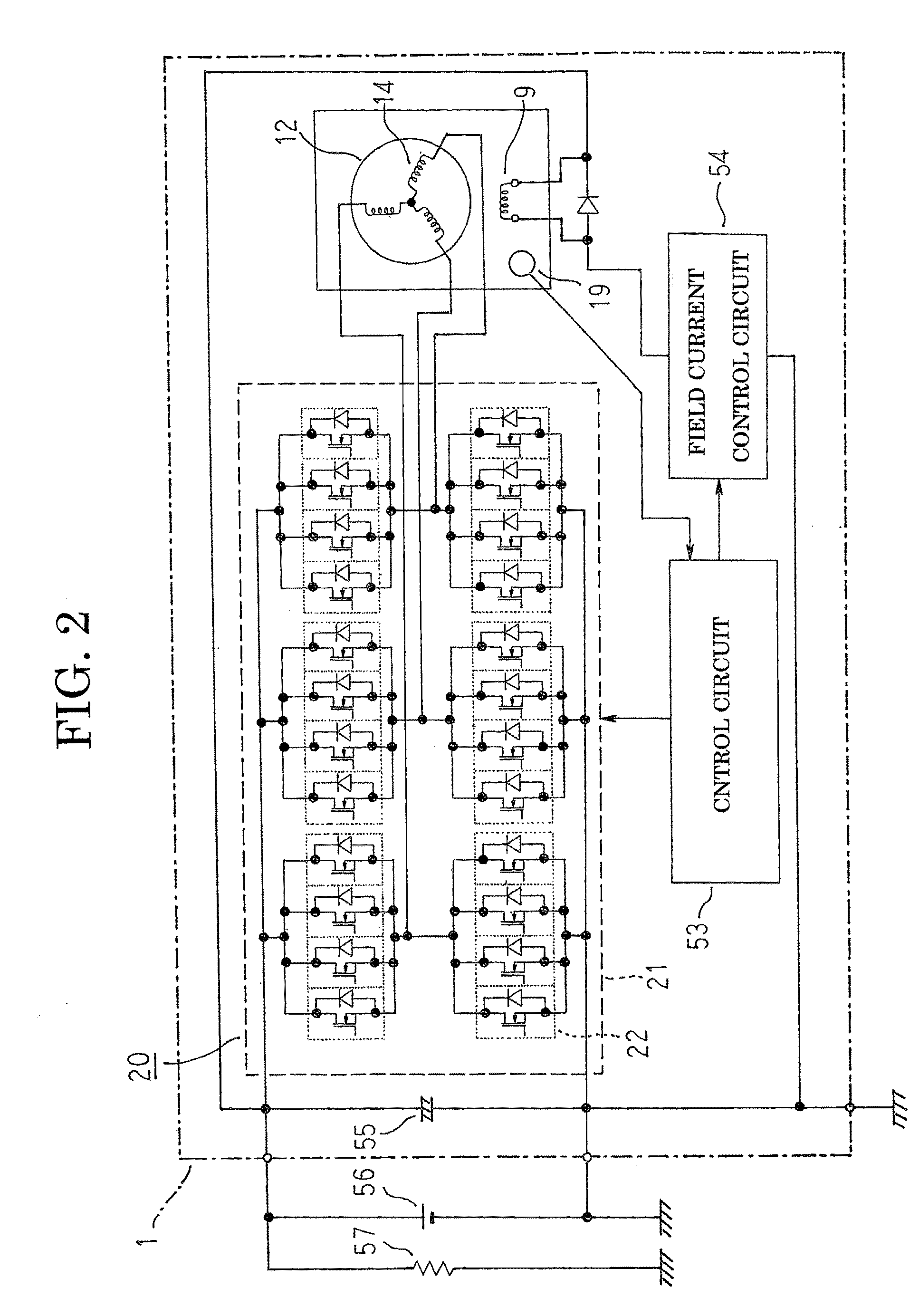

Brushless DC motor with molded resin housing

InactiveUS20060220474A1Avoid flowAssociation with grounding devicesMagnetic circuit characterised by insulating materialsEngineeringElectric current flow

An invention is provided wherein the bearings of a molded motor do not become electro-eroded. An inner rotor type, brushless DC motor 10 is provided having a stator 22 which has a stator core 12 wound with a coil 16, a housing 26 formed by covering the outside surfaces of the motor 10 with an unsaturated polyester, molding resin having electrical insulating properties, and an earth electrode 40 made of metal, installed to go through a metal bracket 38 and the housing 26 to reach the stator core 12, such that electric current flows from the stator core 12 and the bracket 38 to the exterior, preventing electro-erosion and resulting deterioration of bearings 30, 32.

Owner:NIDEC SHIBAURA CORP

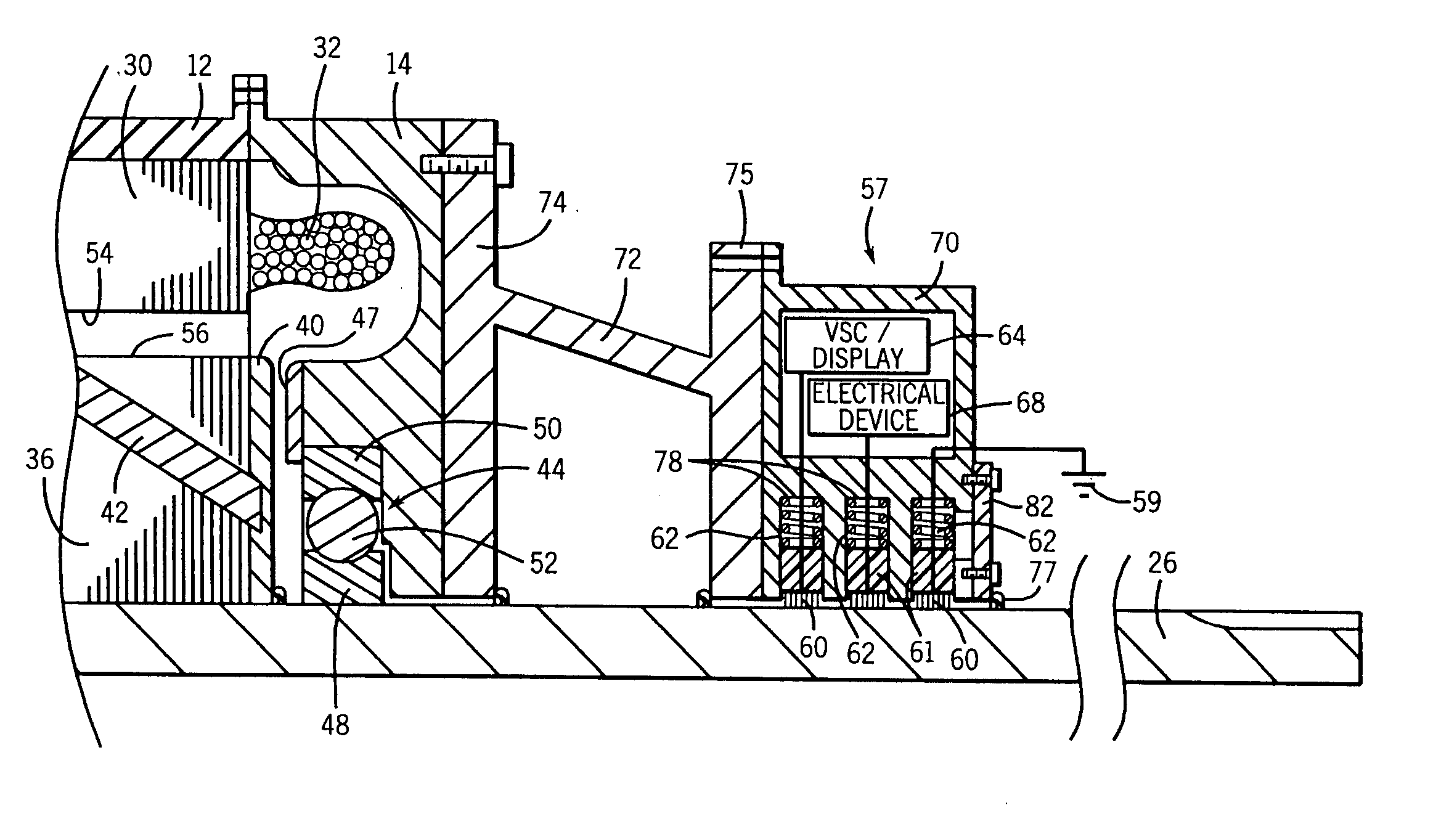

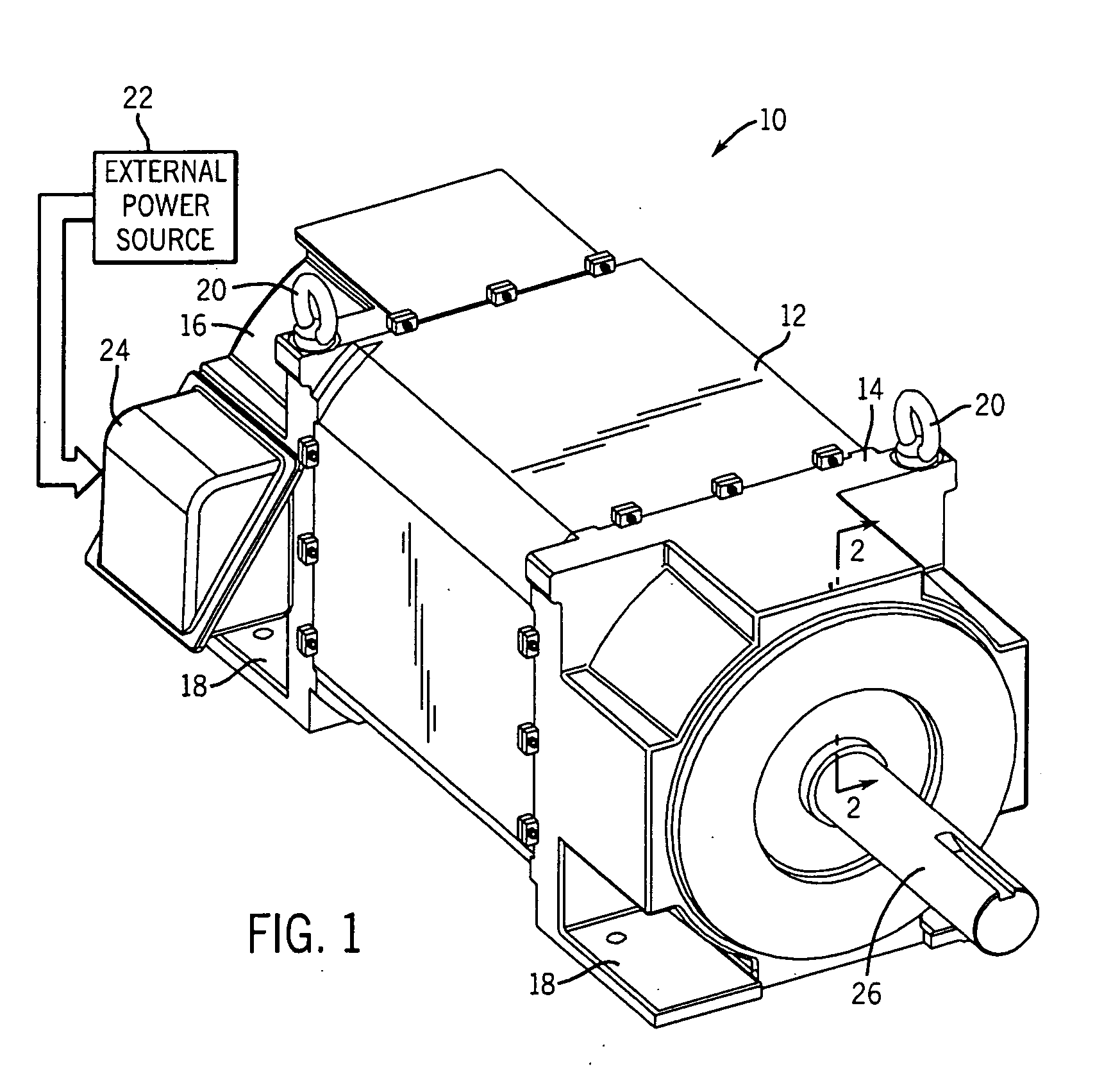

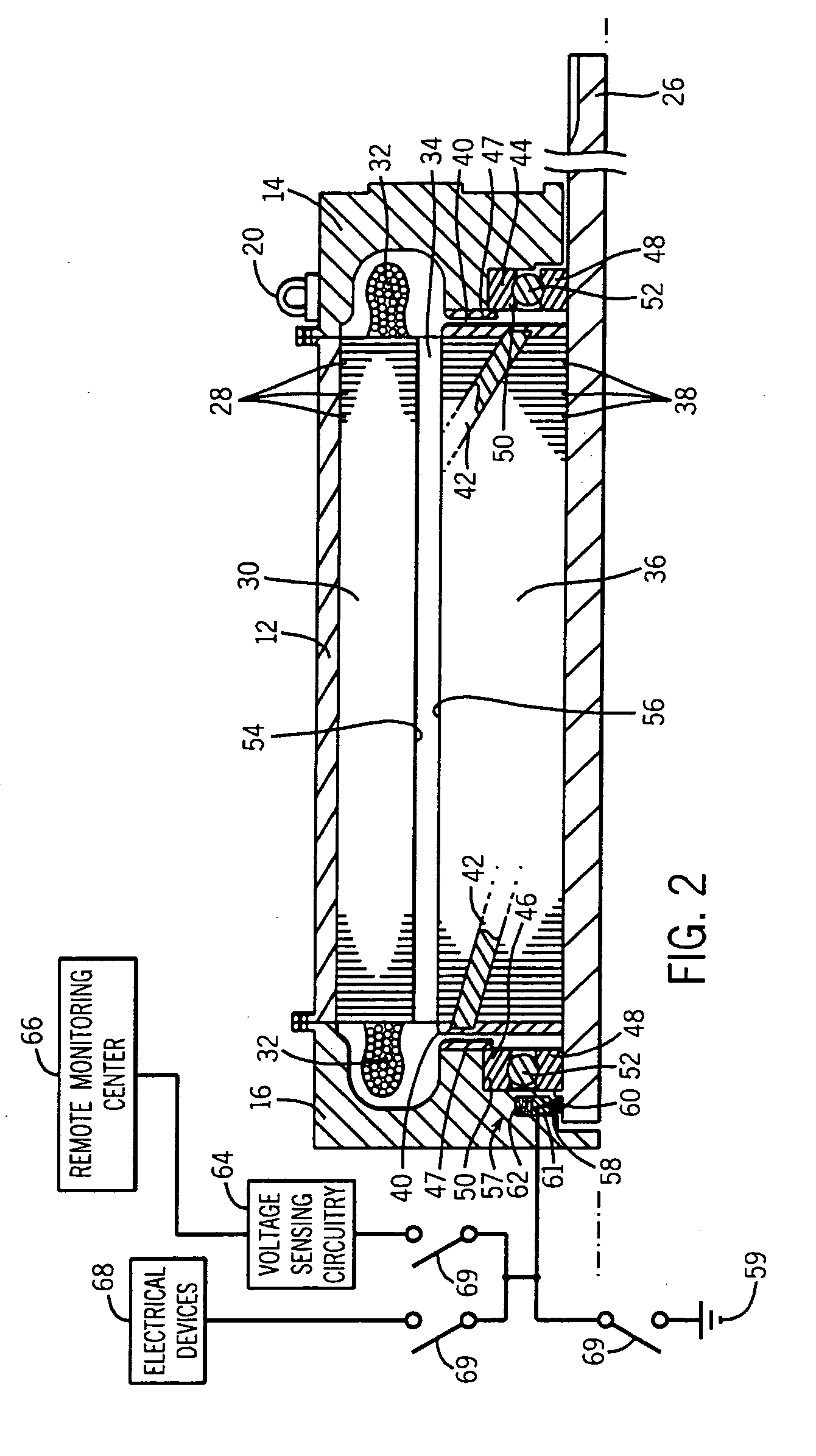

Method and apparatus for dissipating shaft charge

InactiveUS20050285464A1Accelerated dissipationReduce harmAssociation with grounding devicesRotary current collectorEngineeringVoltage

The present invention relates generally to dissipation of shaft charge. According to an exemplary embodiment, the present invention provides a charge-dissipating device that includes a dissipation member disposed in an explosion-proof enclosure. When mounted to a rotatable shaft of an electric motor, for example, the dissipation member is configured to generally abut against the rotatable shaft. The dissipation member dissipates shaft-charge developed in the rotatable shaft during operation of the motor. By dissipating shaft charge, the likelihood of arcing and / or bearing current (Ib) occurrences are reduced or eliminated. In accordance with another exemplary embodiment, a transmission member is configured to impart a voltage signal onto the shaft.

Owner:RELIANCE ELECTRIC TECH

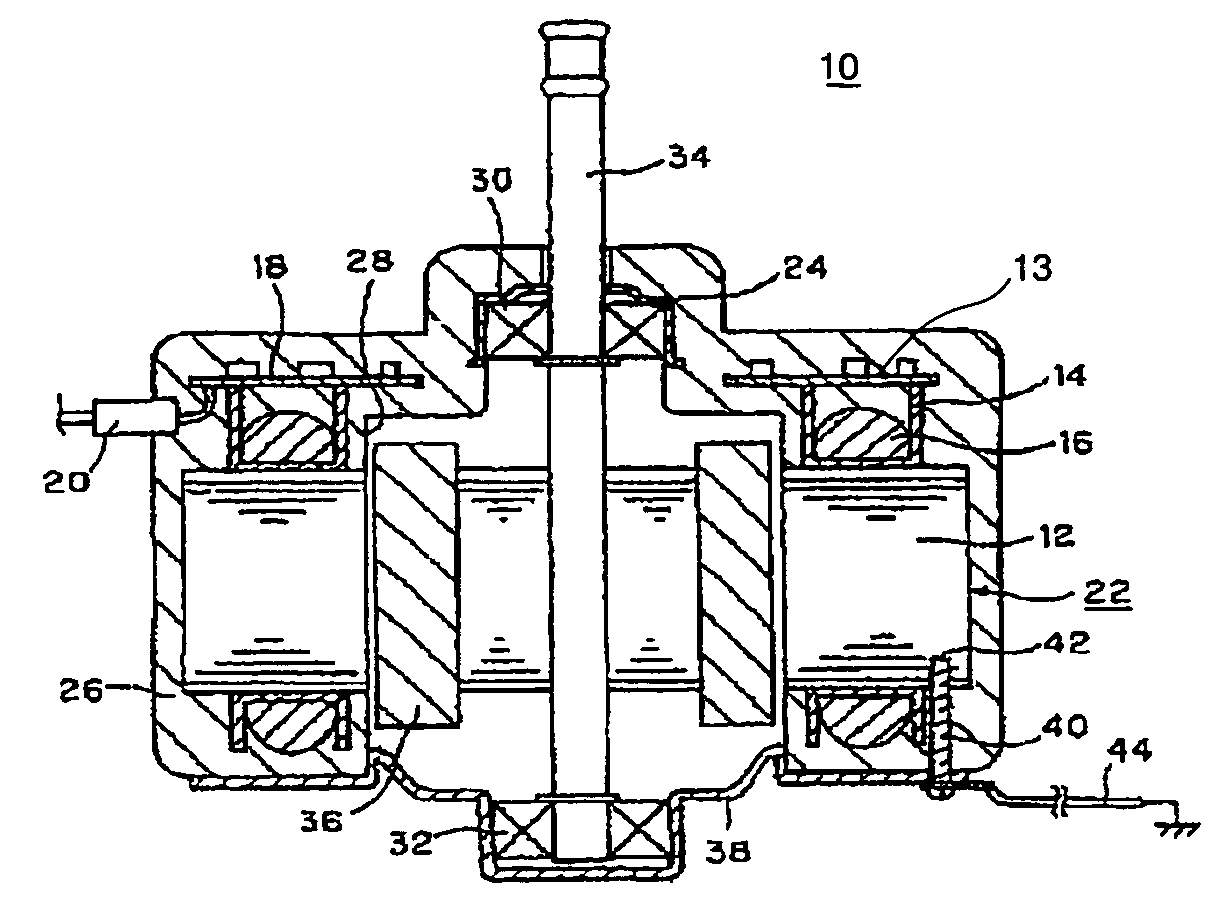

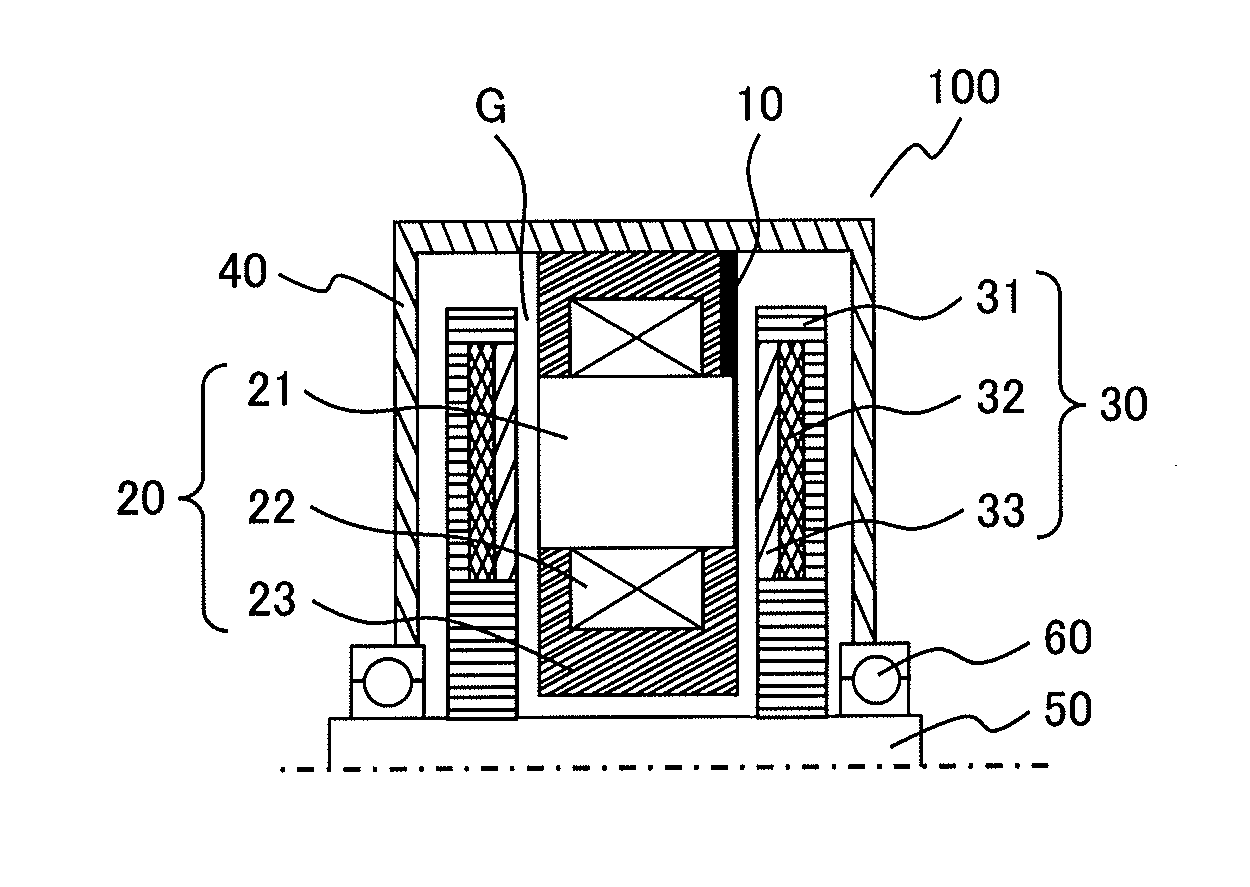

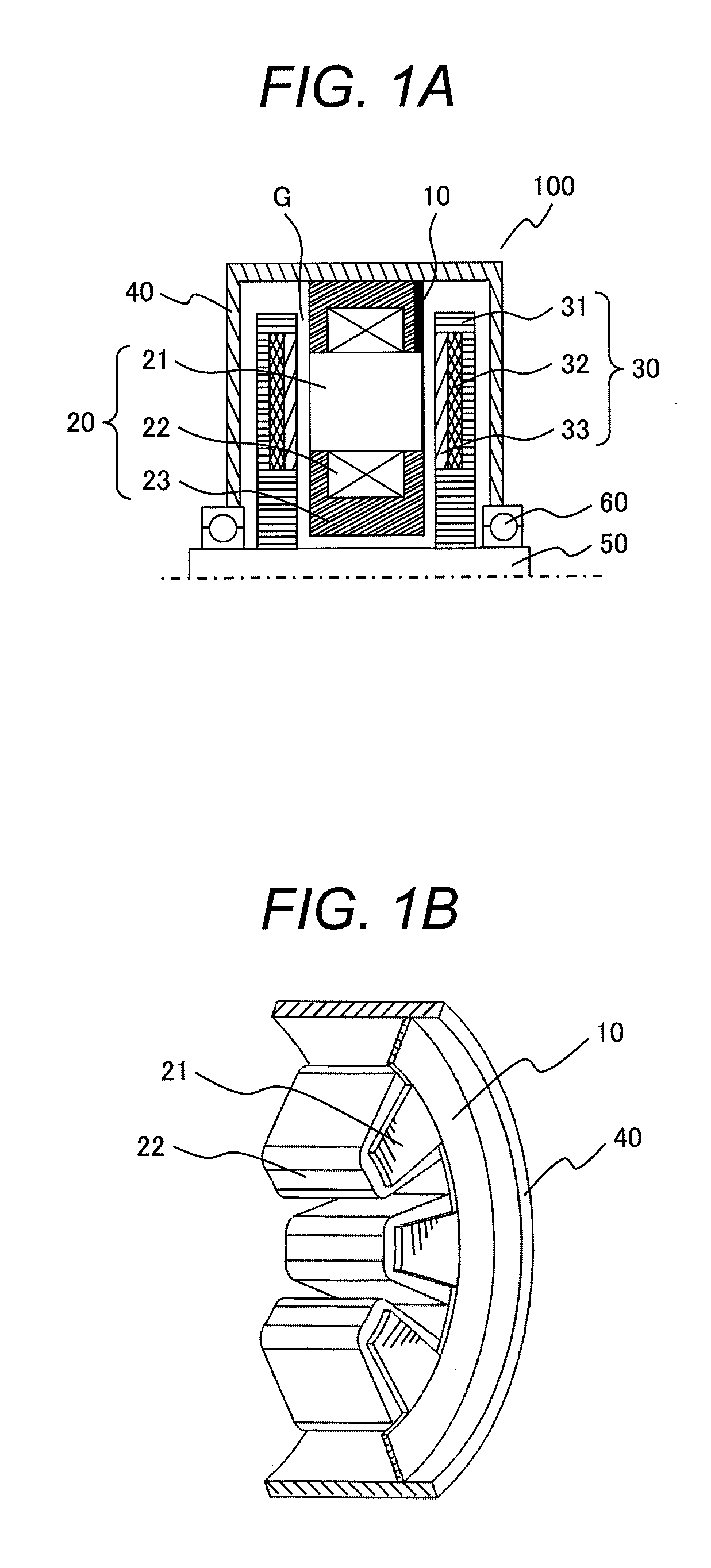

Axial Gap Rotating-Electric Machine

ActiveUS20140009009A1Association with grounding devicesMagnetic circuit characterised by insulating materialsElectric machineElectrical and Electronics engineering

An axial gap rotating-electric machine includes a stator, a rotor arranged via an air gap in the direction of an axis of rotation of a rotating-electric machine with respect to the stator, and a housing configured to accommodate the stator and the rotor, and the stator includes a plurality of stator cores arranged in the circumferential direction, coils configured to wind the peripheries of the respective stator cores, and a resin for molding the plurality of stator cores wound with the coils, and the stator cores each include a protruding portion protruding partly from the coil in the direction of axis of rotation, and a conductive member is provided so as to come into contact with peripheral surfaces of the protruding portions of the stator cores, and grounding is achieved by the conductive member.

Owner:HITACHI LTD

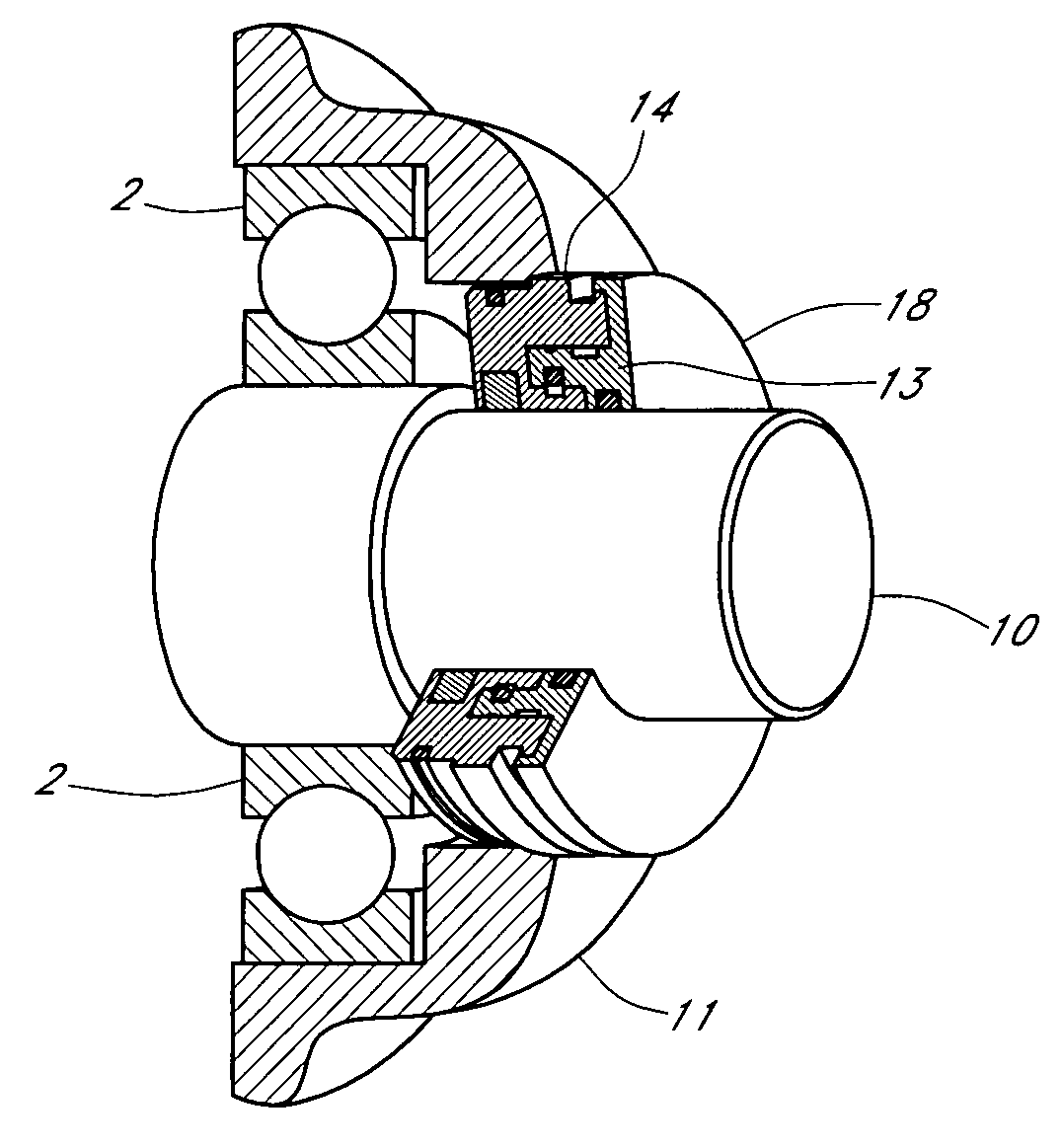

Motor ground seal

InactiveUS20070138748A1Prevent oil leakageImprove sealingEngine sealsAssociation with grounding devicesEngineeringRelative motion

A shaft seal assembly is disclosed having a stator including a main body and axial and radial projections therefrom. The rotor is radially extended and encompasses the axial and radial projections from said stator. A passageway formed between the radial projection of stator and rotor results in an axial passageway having its opening facing rearwardly from the rotor and away from the source of impinging coolant and / or contaminant. A concentric circumferential receptor groove in the stator facing the housing allows insertion of conductive means for transmission of electrostatic charge away from the shaft through the shaft seal assembly to the housing and ground. The receptor groove is opposite the axial passageway and provides for both a substantially lower contaminant environment and improved engagement with conductive means. The dimension of interface gap between the rotor and the radial projection from the stator, which the access to the shaft of any impinging material is fixed at a predetermined value and does not vary with the relative movement between the rotor and the stator. The shaft seal assembly provides improved rejection or warding off of contaminants from ingress into the labyrinths and ultimately restrains attack of the bearing environment as well as substantial elimination of bearing current and attendant bearing fluting or frosting.

Owner:INPRO INC

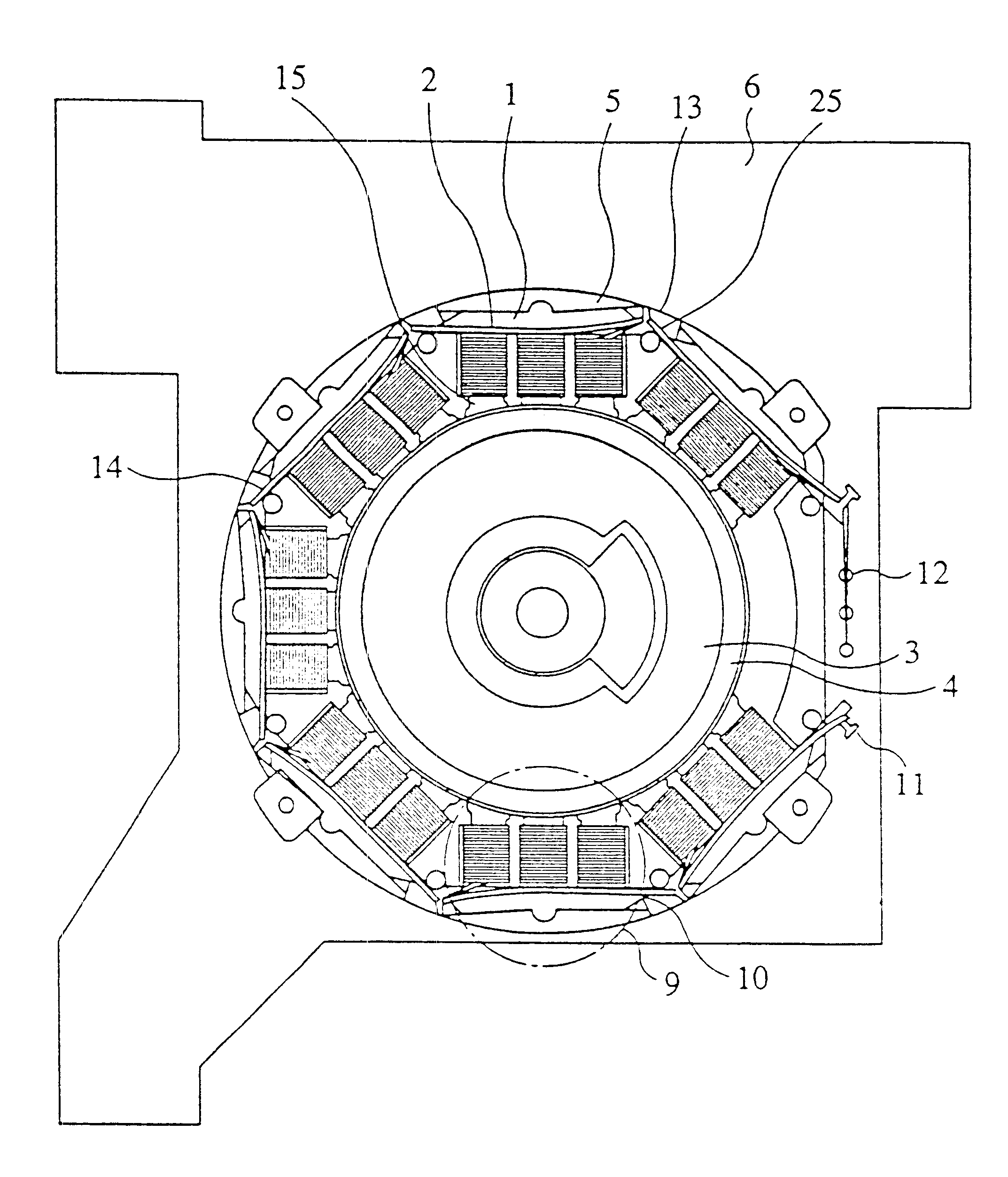

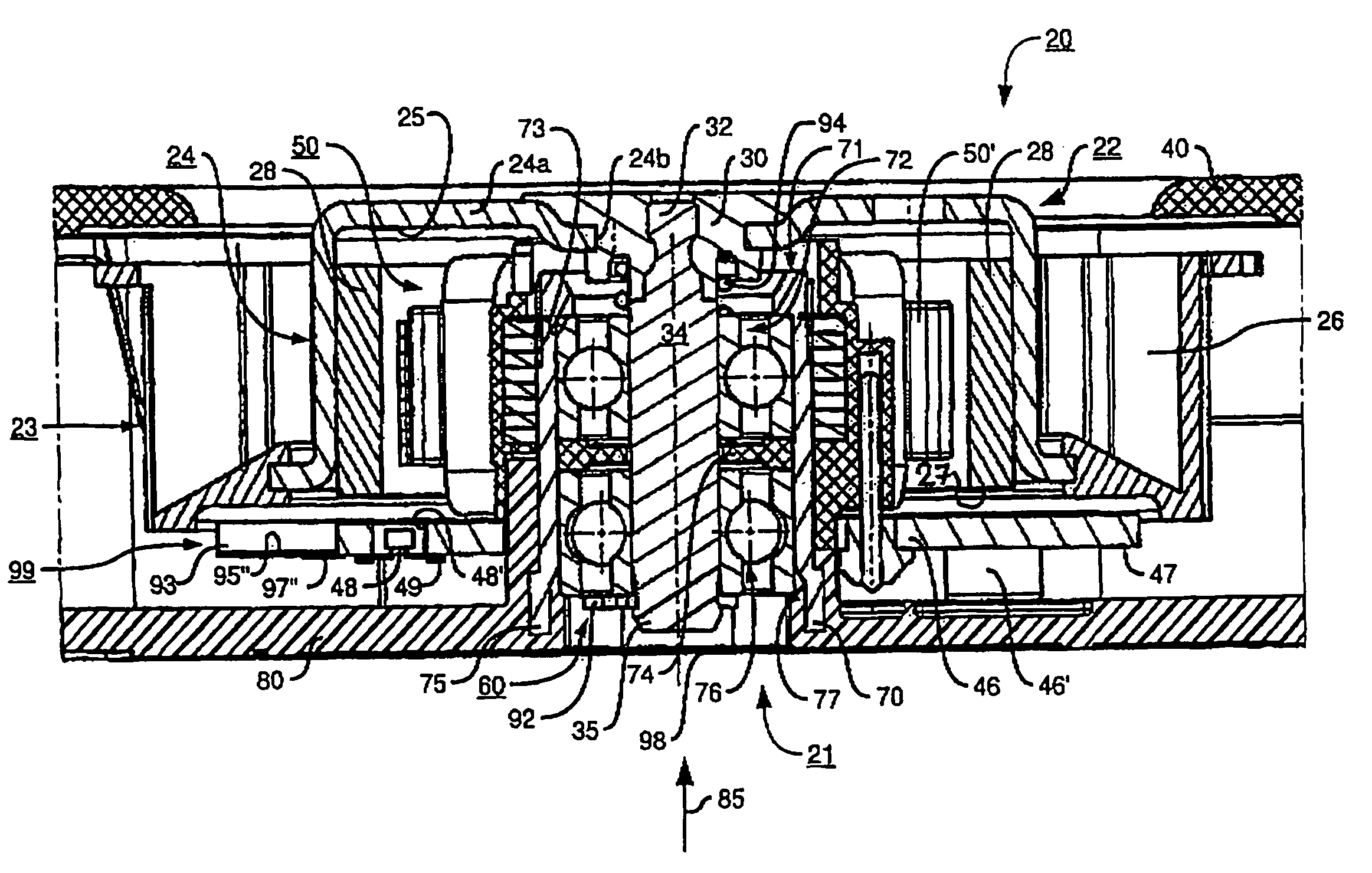

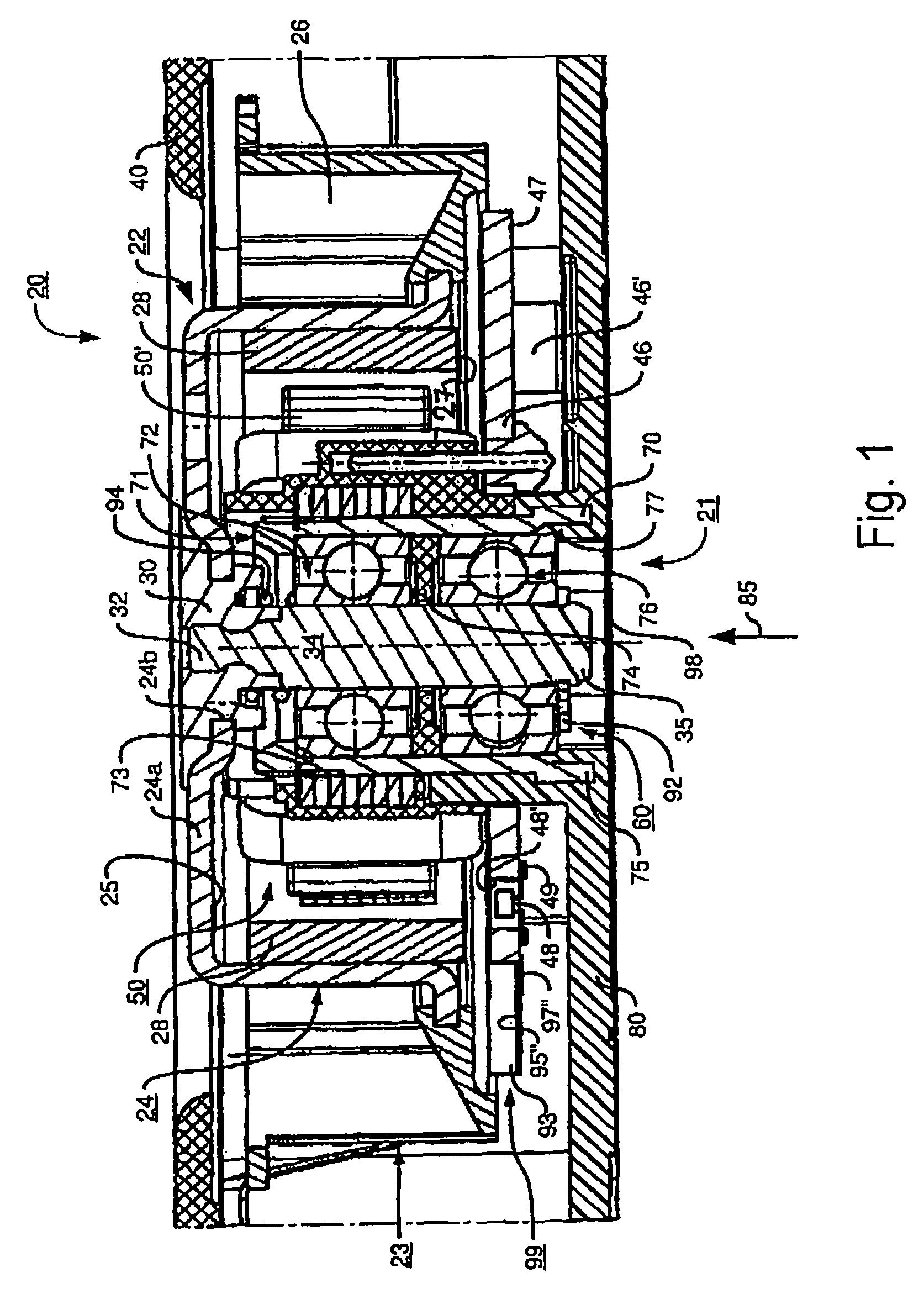

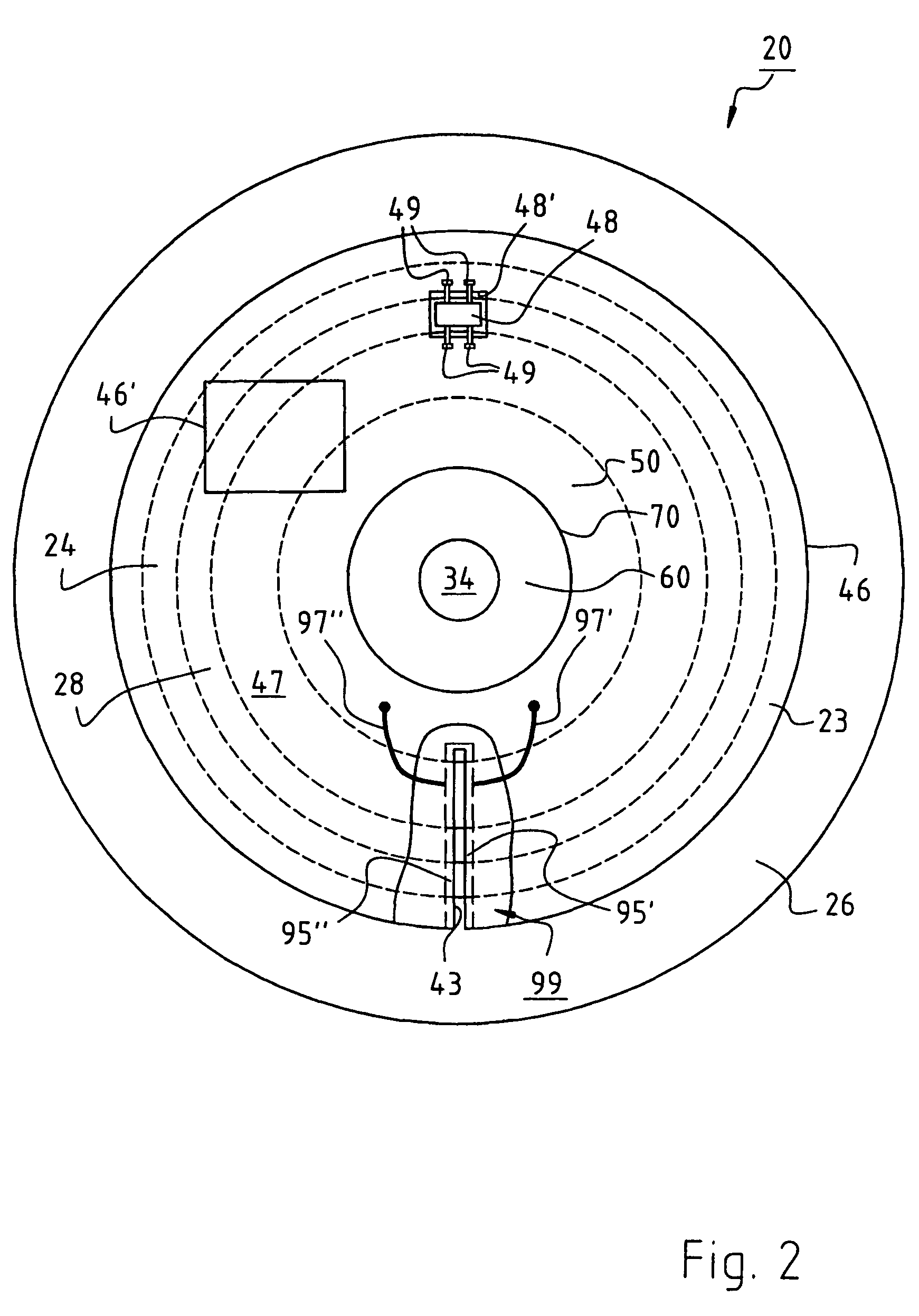

Electronically commutated external rotor motor with a circuit board

An electronically commutated motor (ECM 21) has reduced vulnerability to Electro-Static Discharge (ESD). The motor has an internal stator (50) and an external rotor (22) equipped with a permanent magnet (28), which rotor is separated by an air gap from the internal stator (50). The rotor has a shaft (34) on which a magnetic yoke element (24) is mounted. A leakage flux region on an end face (27) of the magnet (28) actuates a Hall sensor (48) located adjacent a first aperture (48′) in a circuit board (46) supporting electronic control components. In order to prevent static discharges from passing through the first aperture (48′) and endangering the electronic components, the circuit board (46) is formed with a second aperture (43) on whose edge is provided at least one electrical conductor (95′, 95″), connected to ground (112), to which any charge that builds up during operation can harmlessly discharge.

Owner:EBM PAPST ST GEORGEN & -

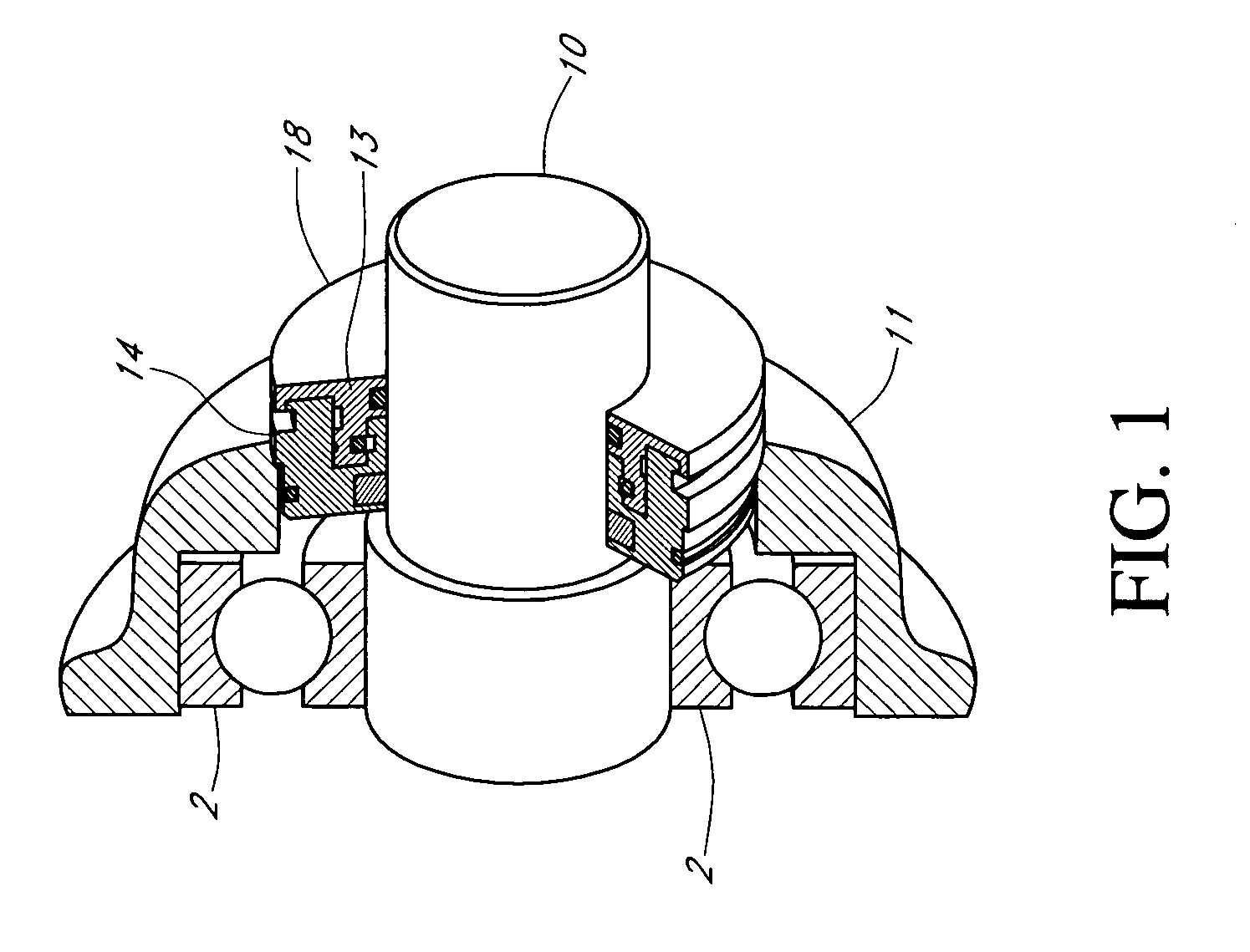

Motor Grounding Seal

InactiveUS20110204734A1Prevent oil leakageAvoid pollutionEngine sealsAssociation with grounding devicesCoolantRadial projection

A shaft seal assembly is disclosed having a stator including a main body and axial and radial projections therefrom. The rotor may be radially extended to encompass the axial and radial projections from said stator. A passageway formed between the radial projection of stator and rotor results in an axial passageway having its opening facing rearwardly from the rotor and away from the source of impinging coolant and / or contaminant. A concentric circumferential receptor groove in the stator facing the housing allows insertion of a conductive insert for transmission of electrostatic charge away from the shaft through the shaft seal assembly to the housing and ground. The receptor groove is opposite the axial passageway and provides for both a substantially lower contaminant environment and improved engagement with the conductive insert.

Owner:ORLOWSKI DAVID C +1

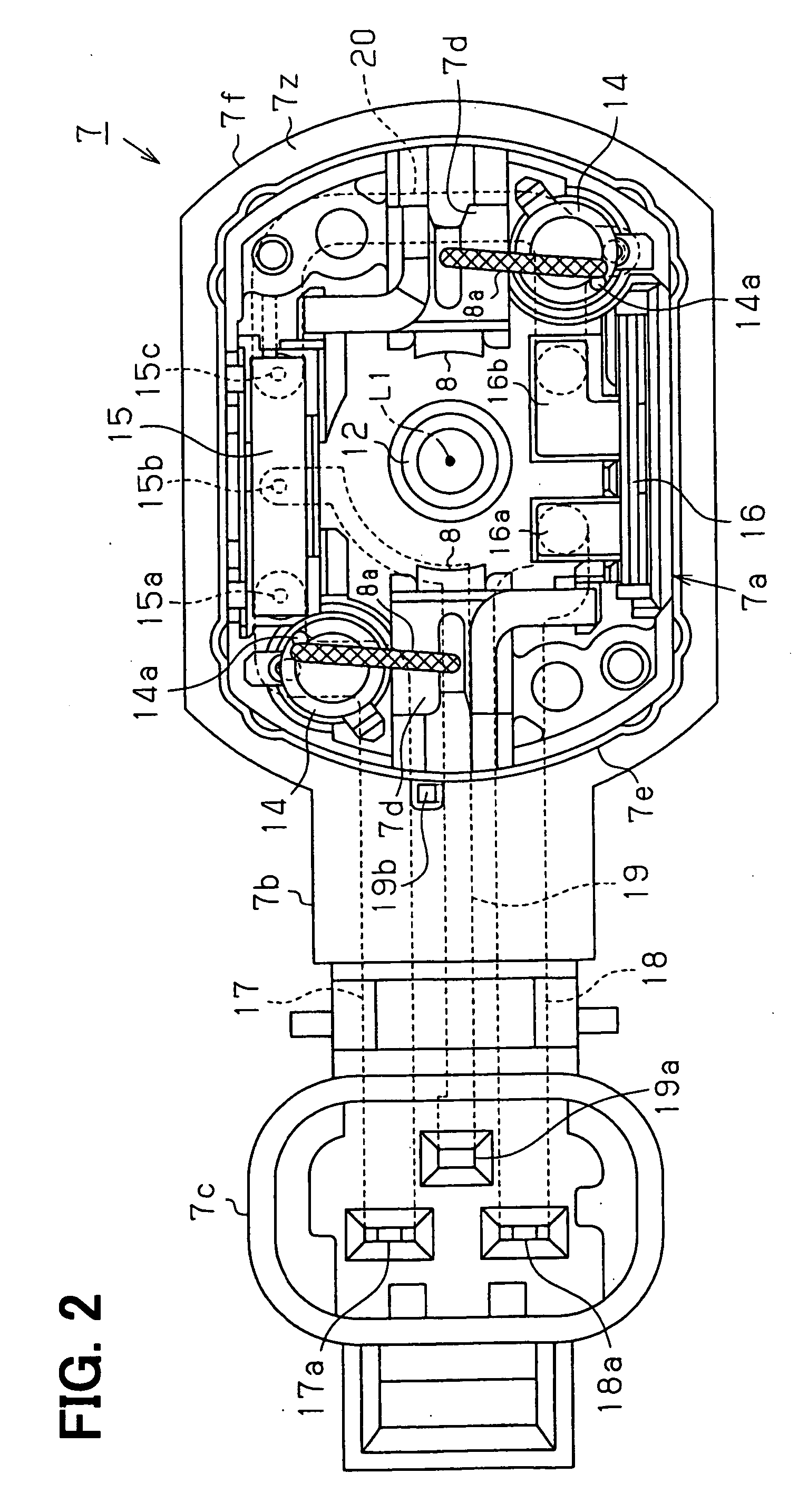

Actuator provided with grounding terminal

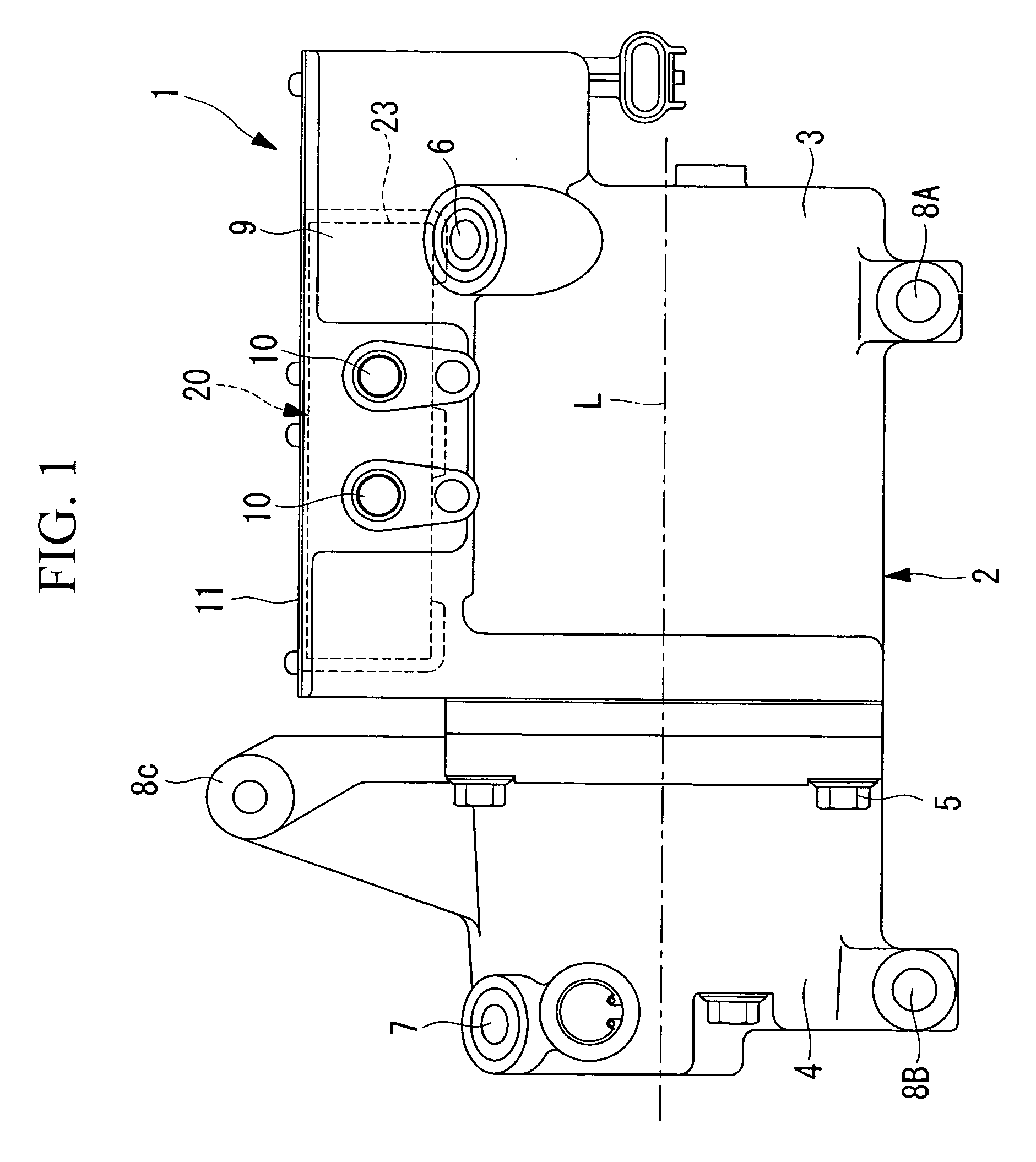

ActiveUS7151333B2Prevent static electricitySimple working processAssociation with grounding devicesSupports/enclosures/casingsEngineeringActuator

There is provided an actuator which includes: a stator assembly including a pair of stator yokes, and a coil disposed between the pair of stator yokes; a rotor unit including a magnet at its outer circumference and disposed inside the stator assembly; an output shaft disposed inside the rotor unit; a housing; a front plate disposed between the stator assembly and the housing; a printed board having a land portion leading to a grounding wire; and a grounding terminal having electrical conductivity and elasticity and disposed between the stator assembly and the housing. One end portion of the grounding terminal makes contact with one of the pair of stator yokes, and the other end portion thereof makes connection to the land portion of the printed board, whereby static electricity and electromagnetic noises generated in the stator assembly are conducted to the grounding wire.

Owner:MINEBEAMITSUMI INC

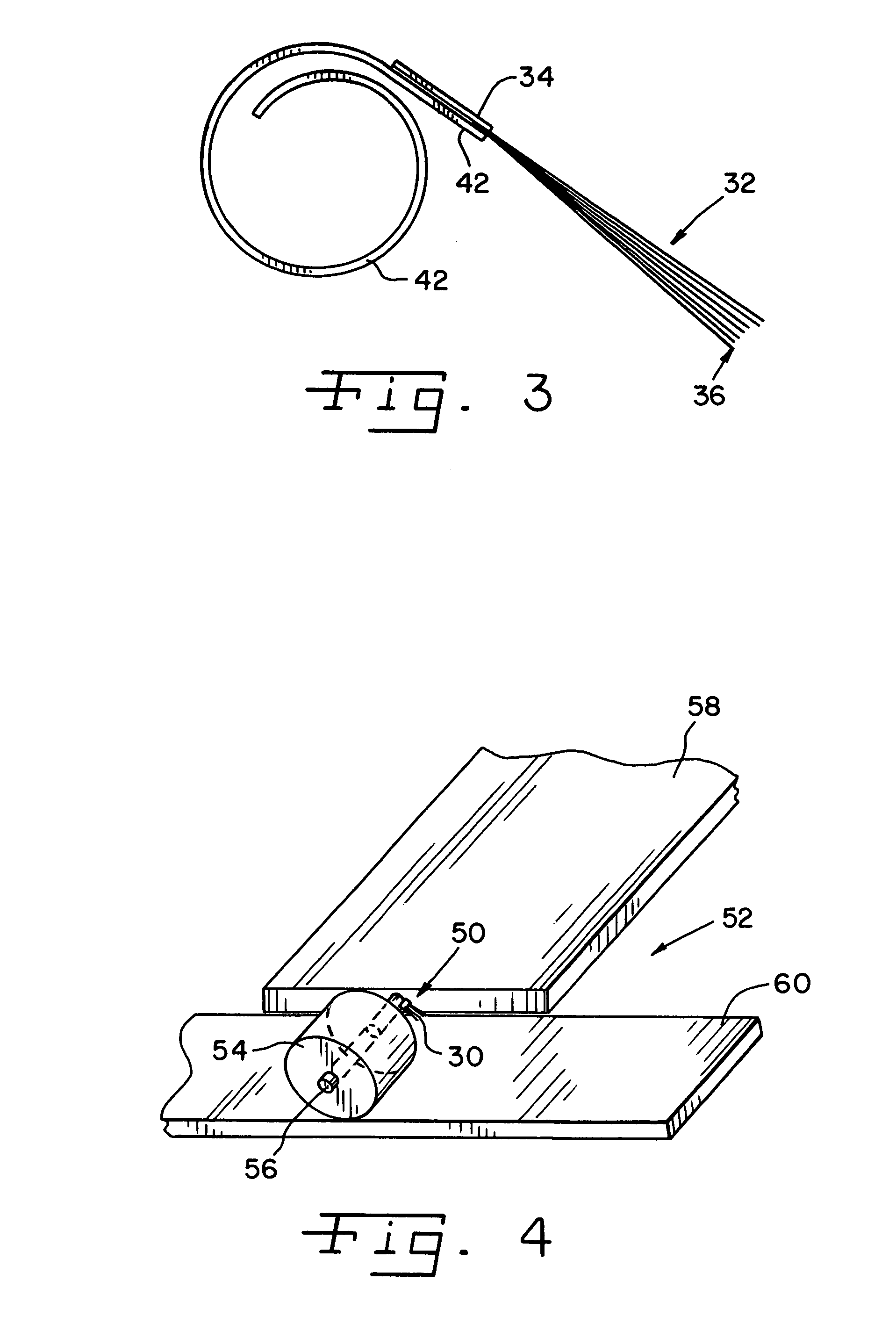

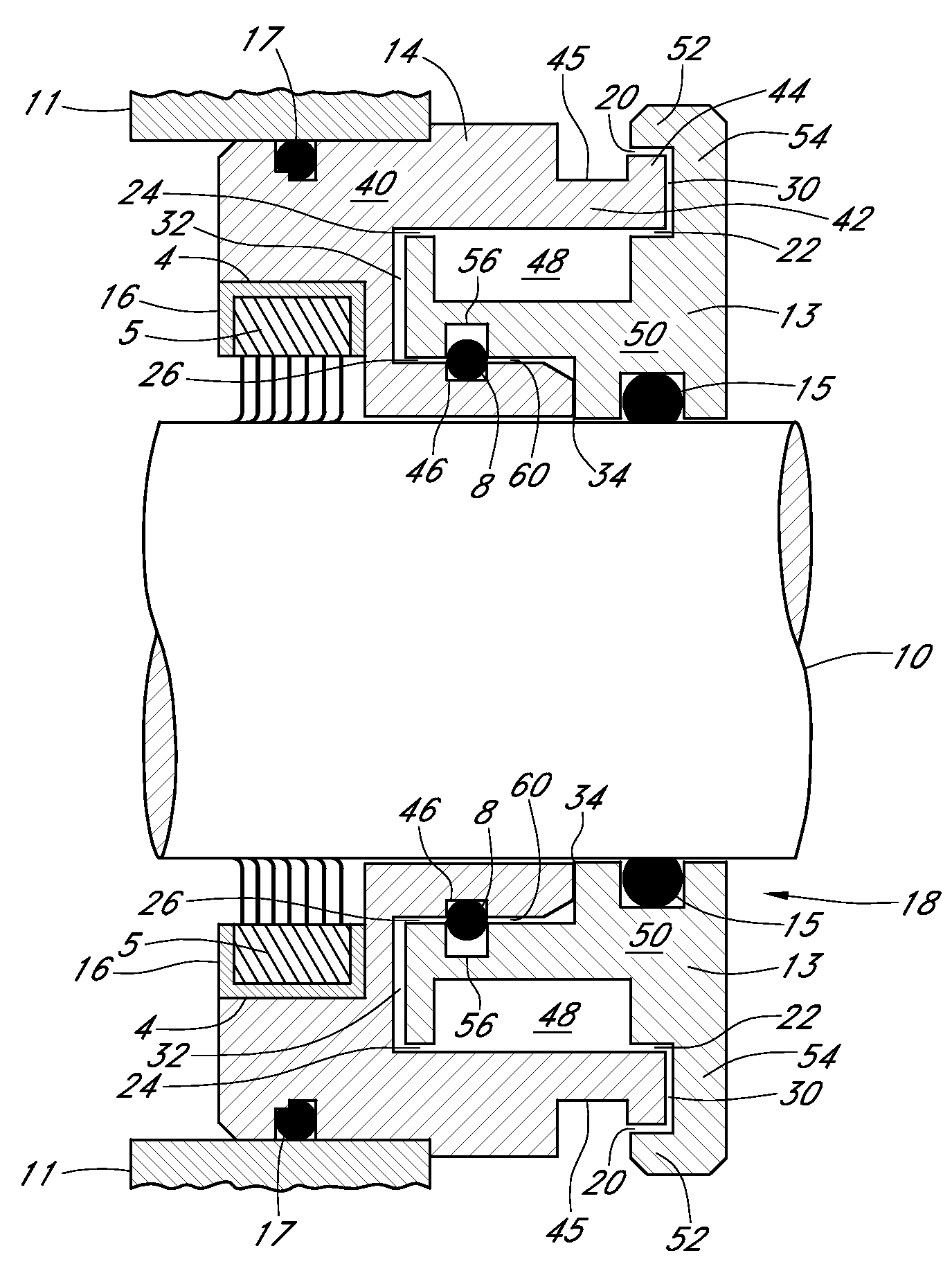

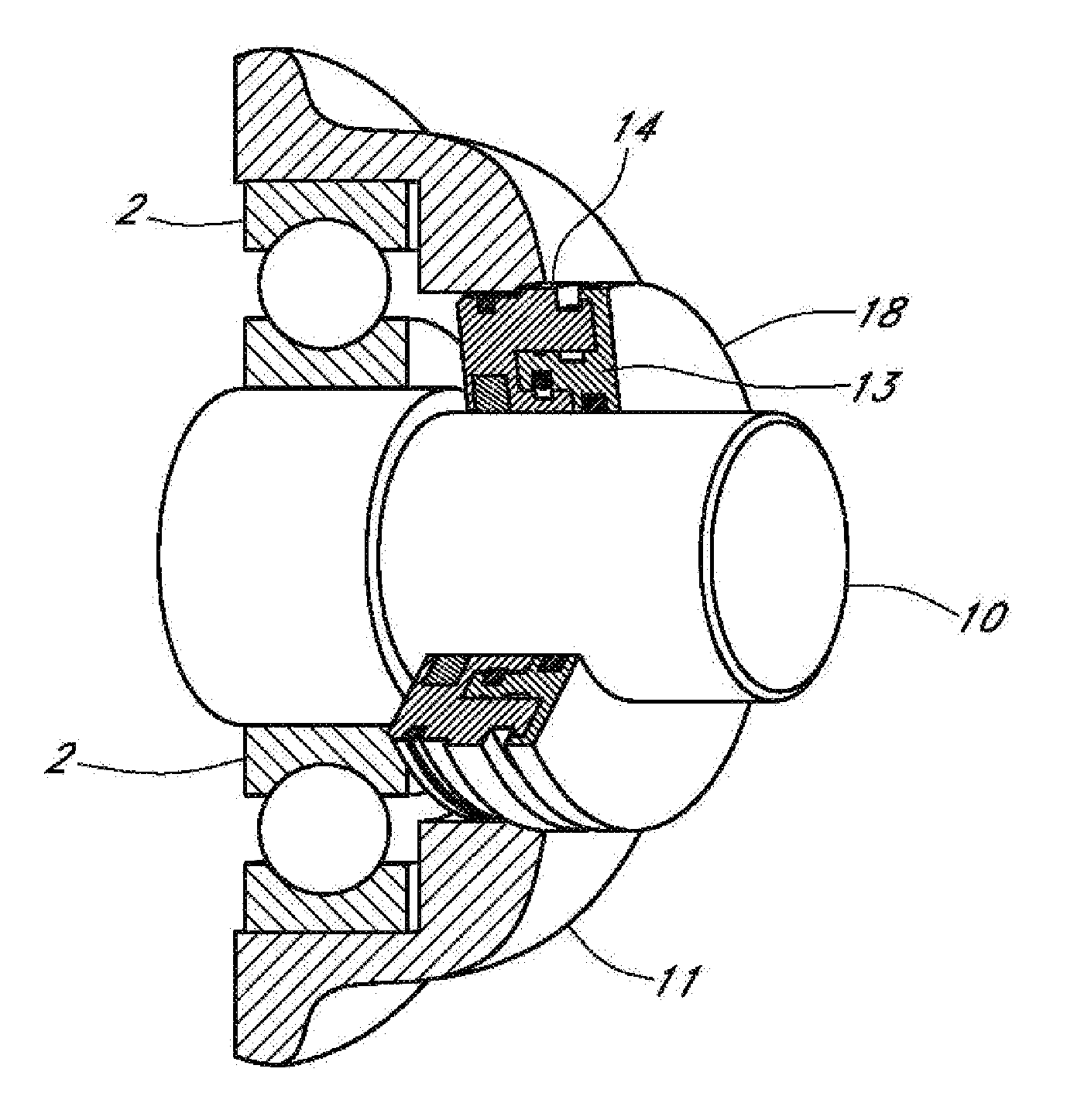

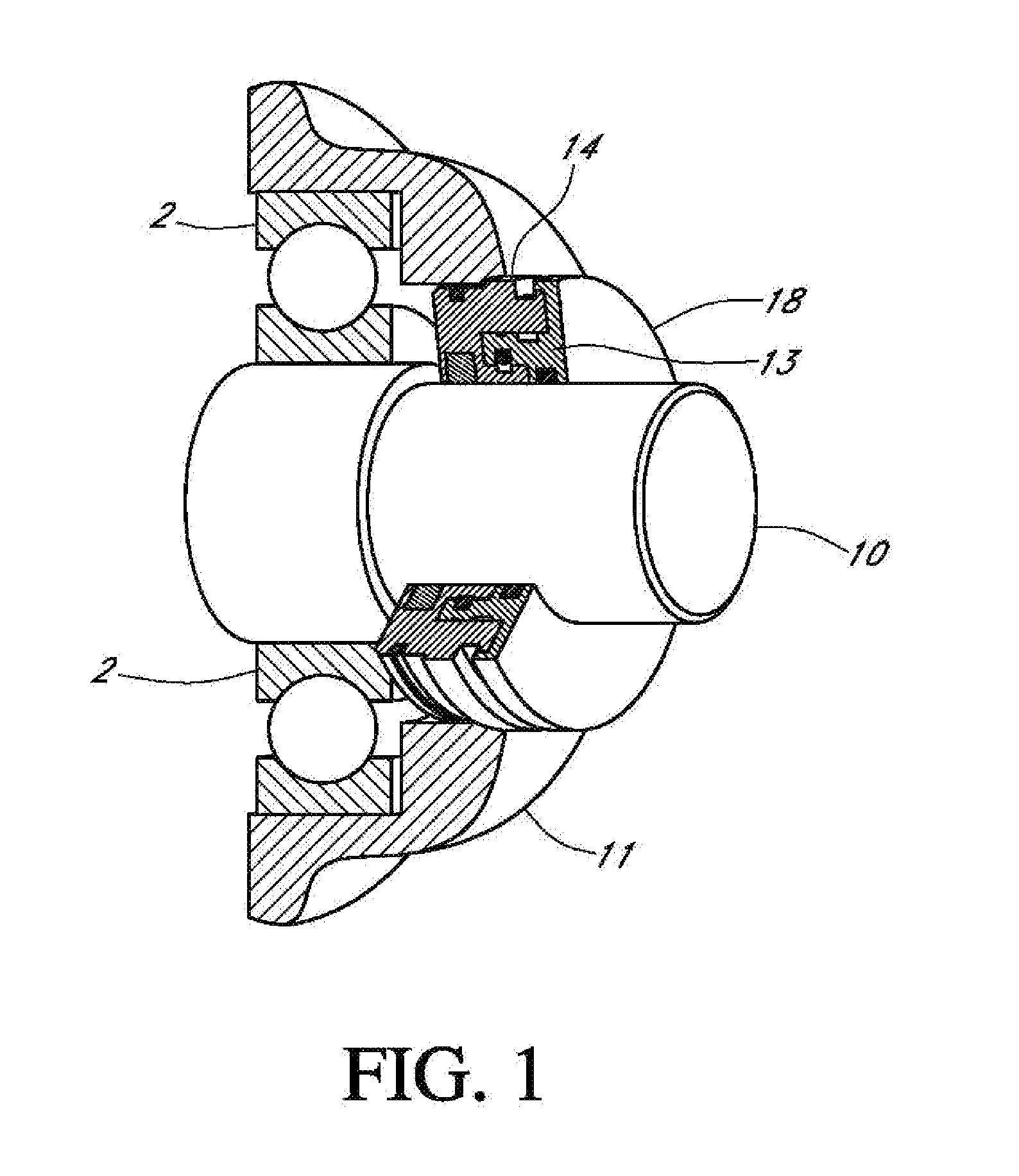

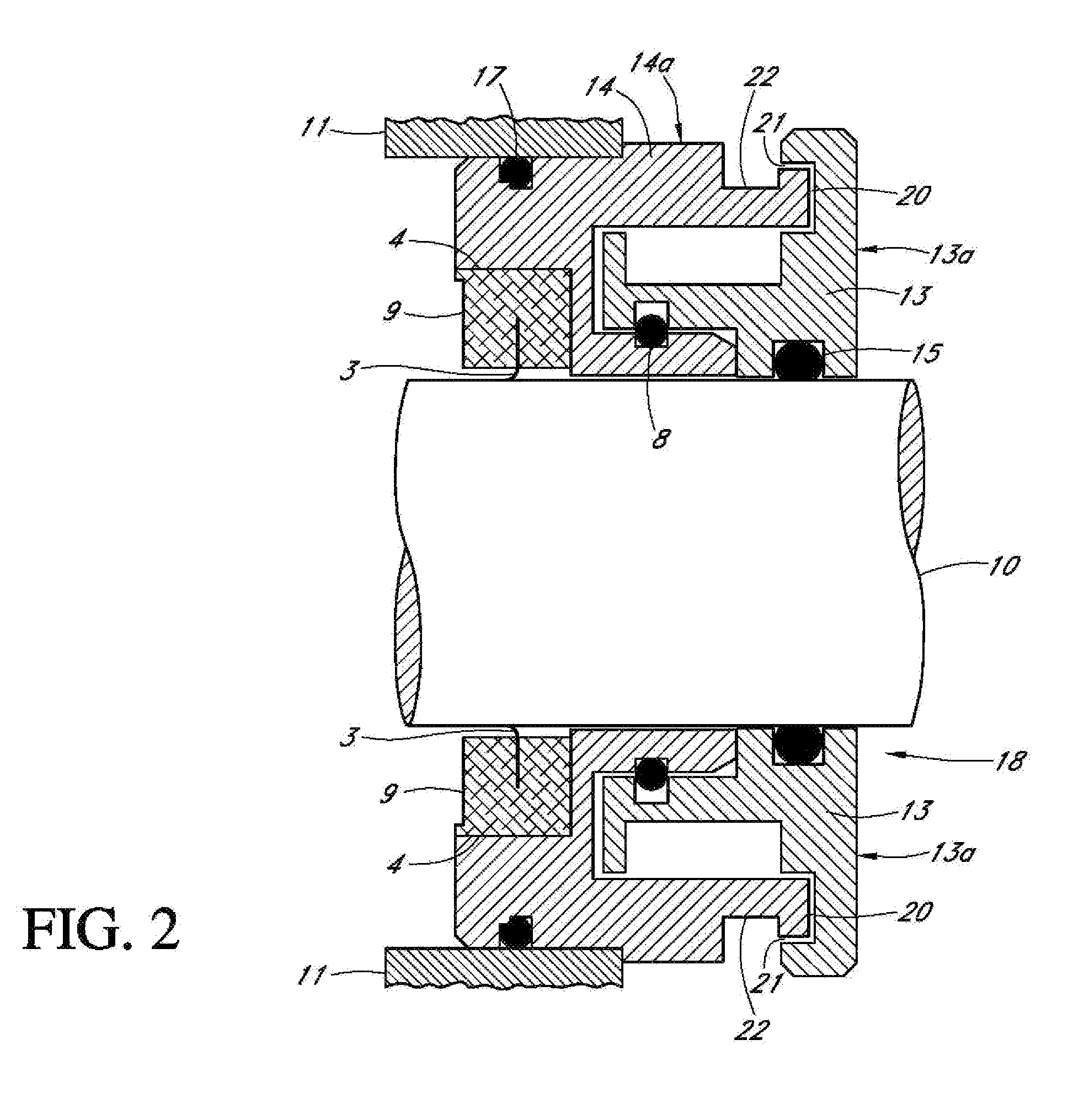

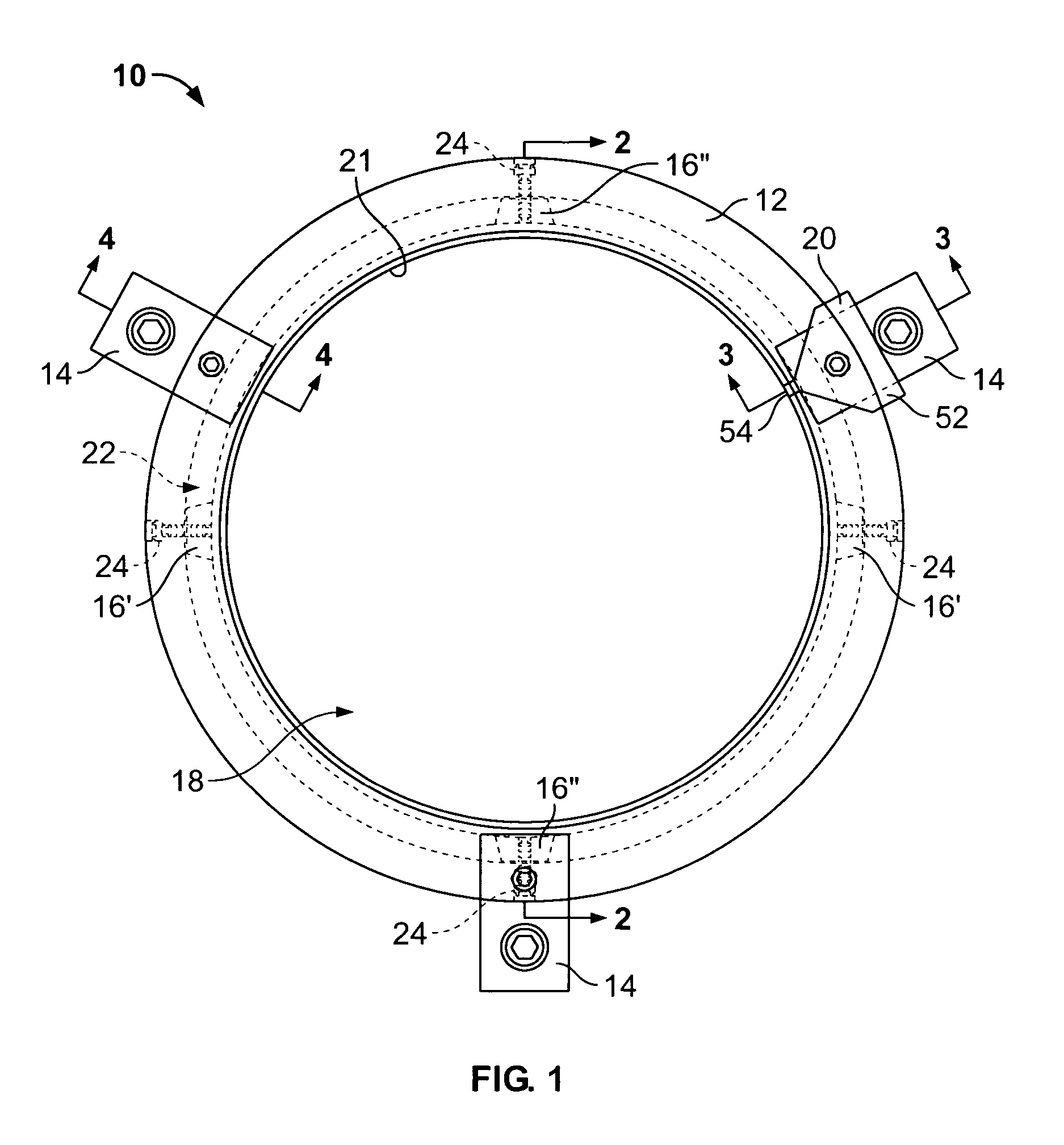

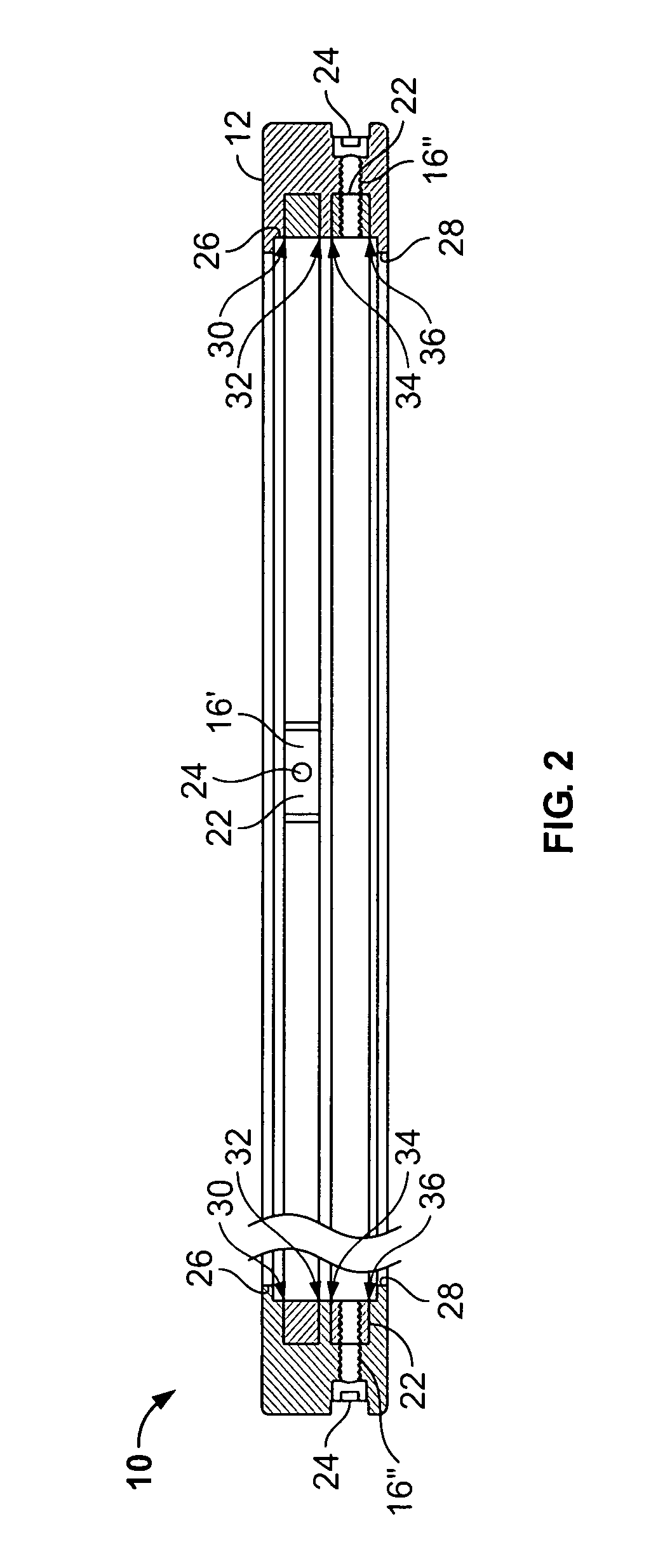

Grounding brush system for mitigating electrical current on rotating shafts

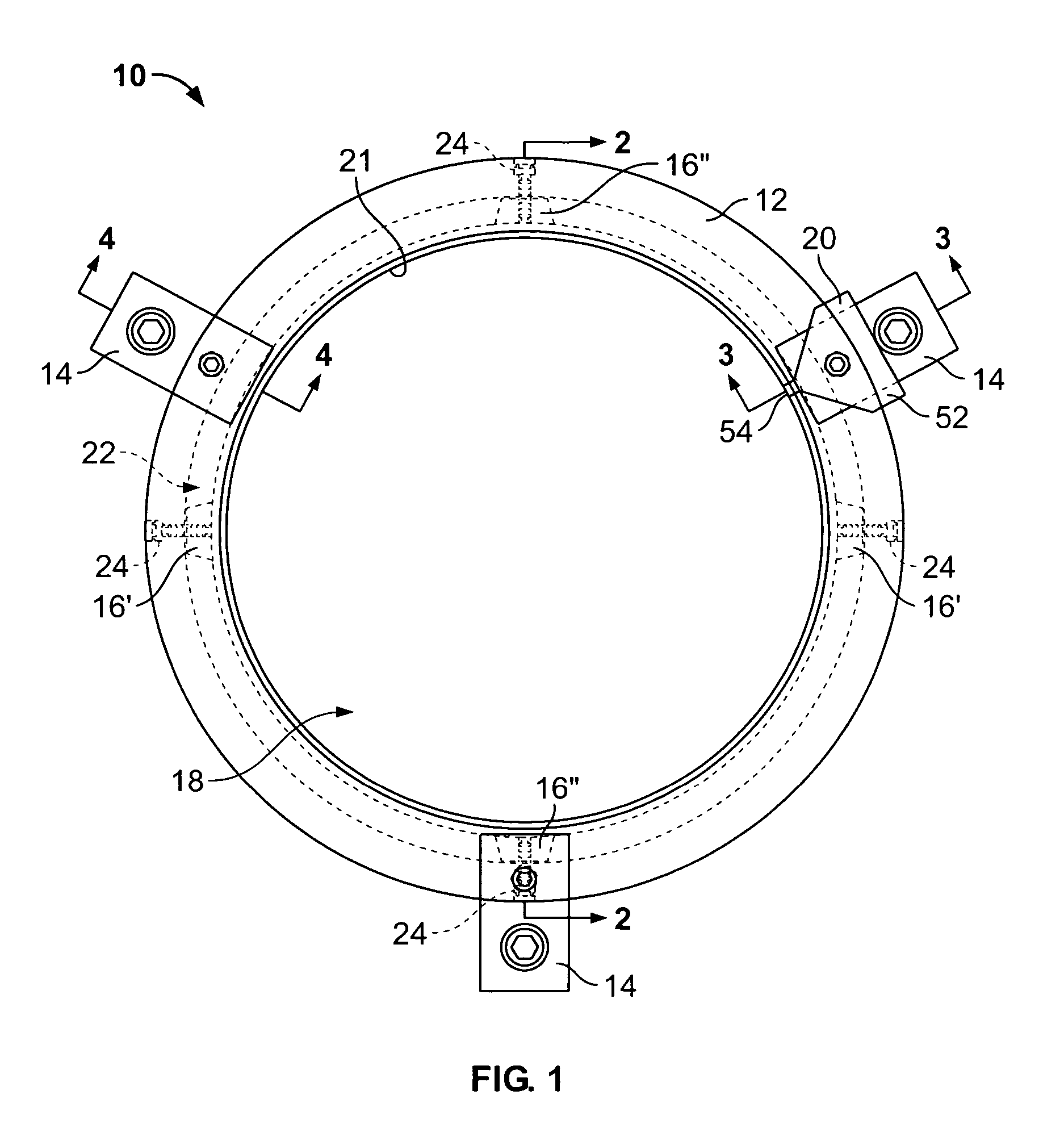

ActiveUS20080258576A1Rotary current collectorAssociation with grounding devicesEngineeringElectrical current

An improved grounding brush system for mitigating electrical current on a moving object such as a rotating shaft includes an electrically conductive layer applied to the object and associated with a brush assembly for conducting electrical current from the moving object to ground.

Owner:ILLINOIS TOOL WORKS INC

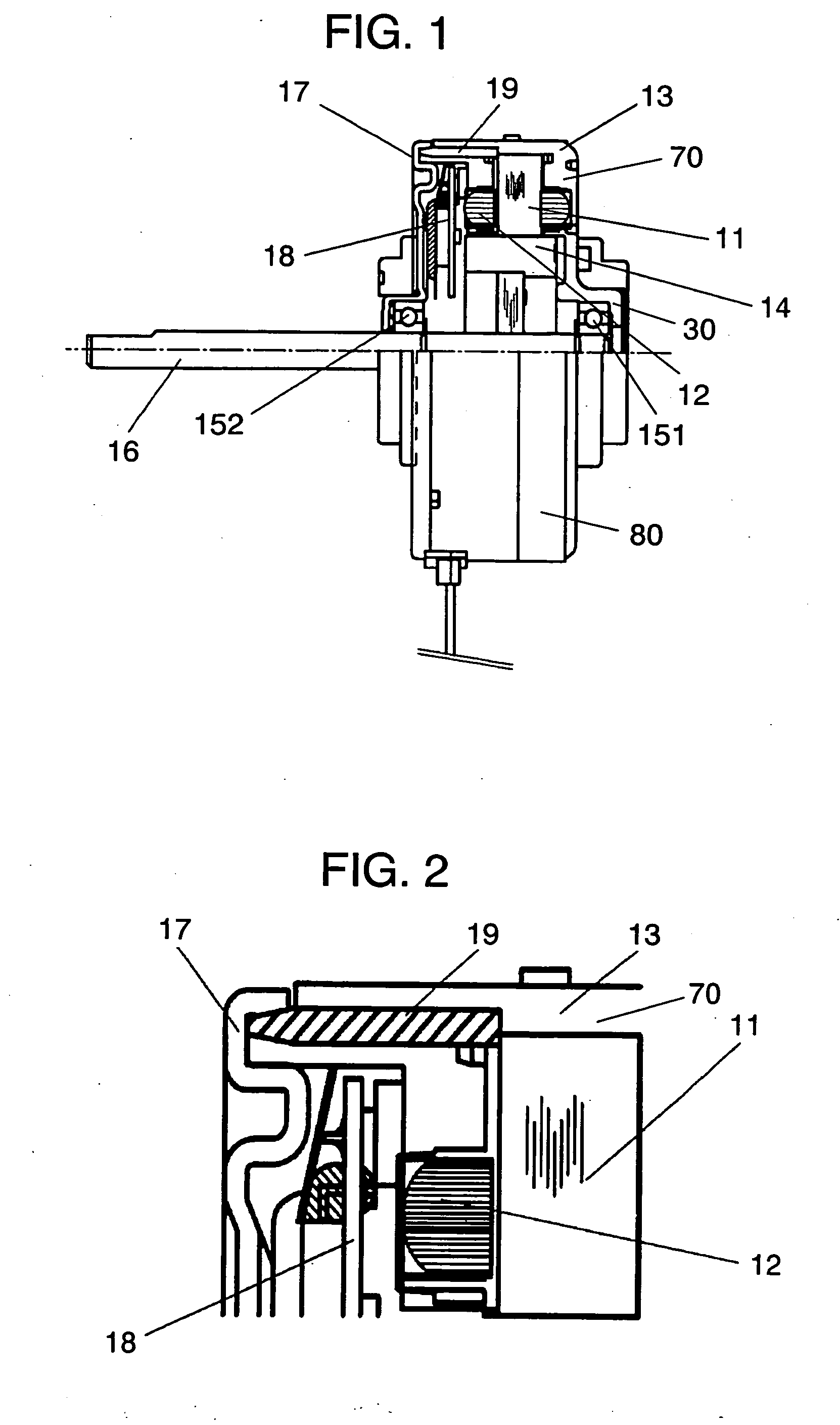

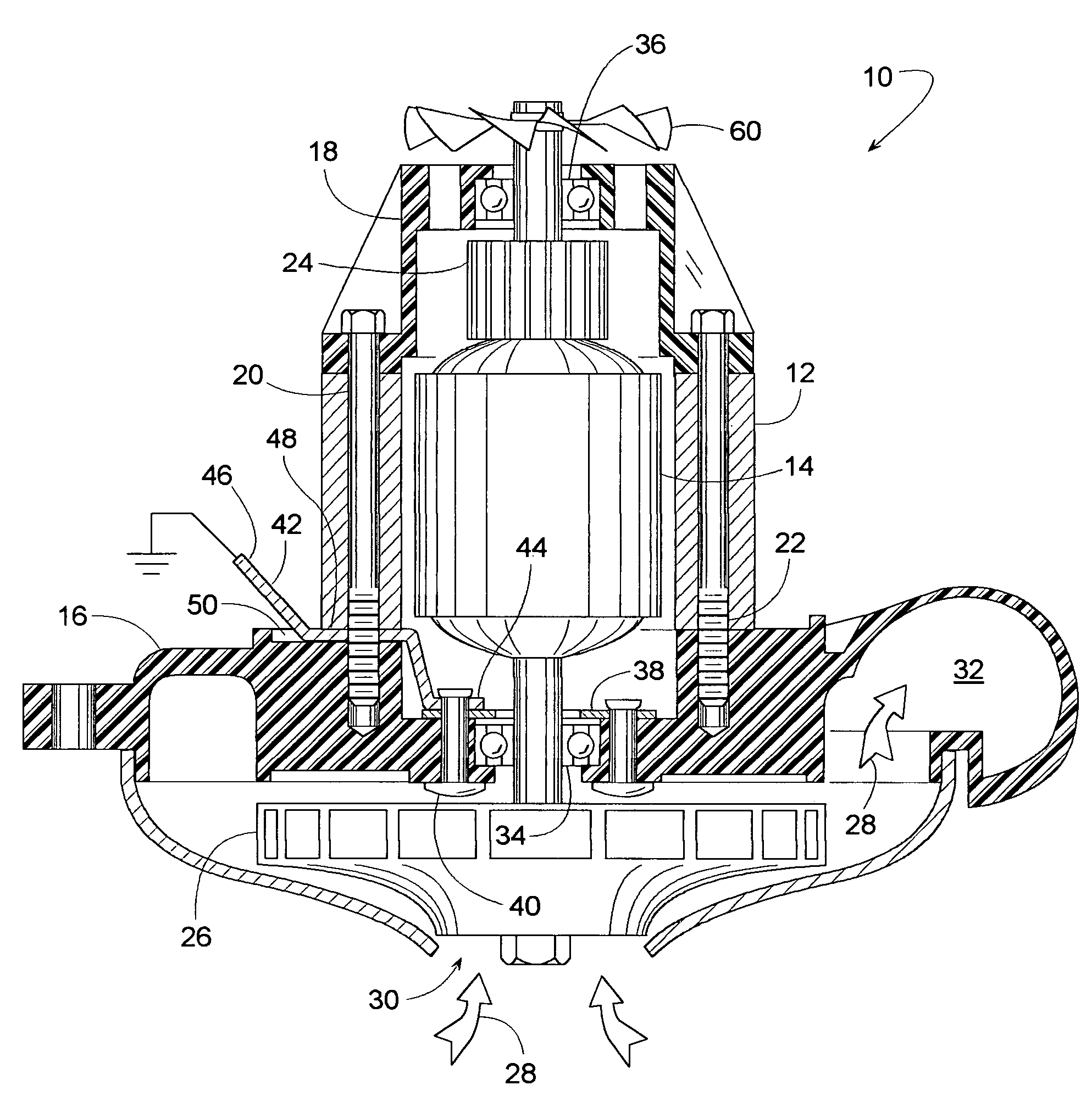

Motor and electric apparatus equipped with same

ActiveUS20060186746A1Reduce voltageAvoiding the electrolytic corrosionAssociation with grounding devicesMagnetic circuit characterised by insulating materialsEngineeringElectric motor

A motor comprises a stator having a stator core and a stator winding wound on the stator core and integrally molded with insulation resin, a rotor provided with a shaft, a first bearing and a second bearing for supporting the shaft, a bracket connected to the stator and retaining at least one of the first bearing and the second bearing, and a conductive member short-circuiting between the stator core and the bracket.

Owner:PANASONIC CORP

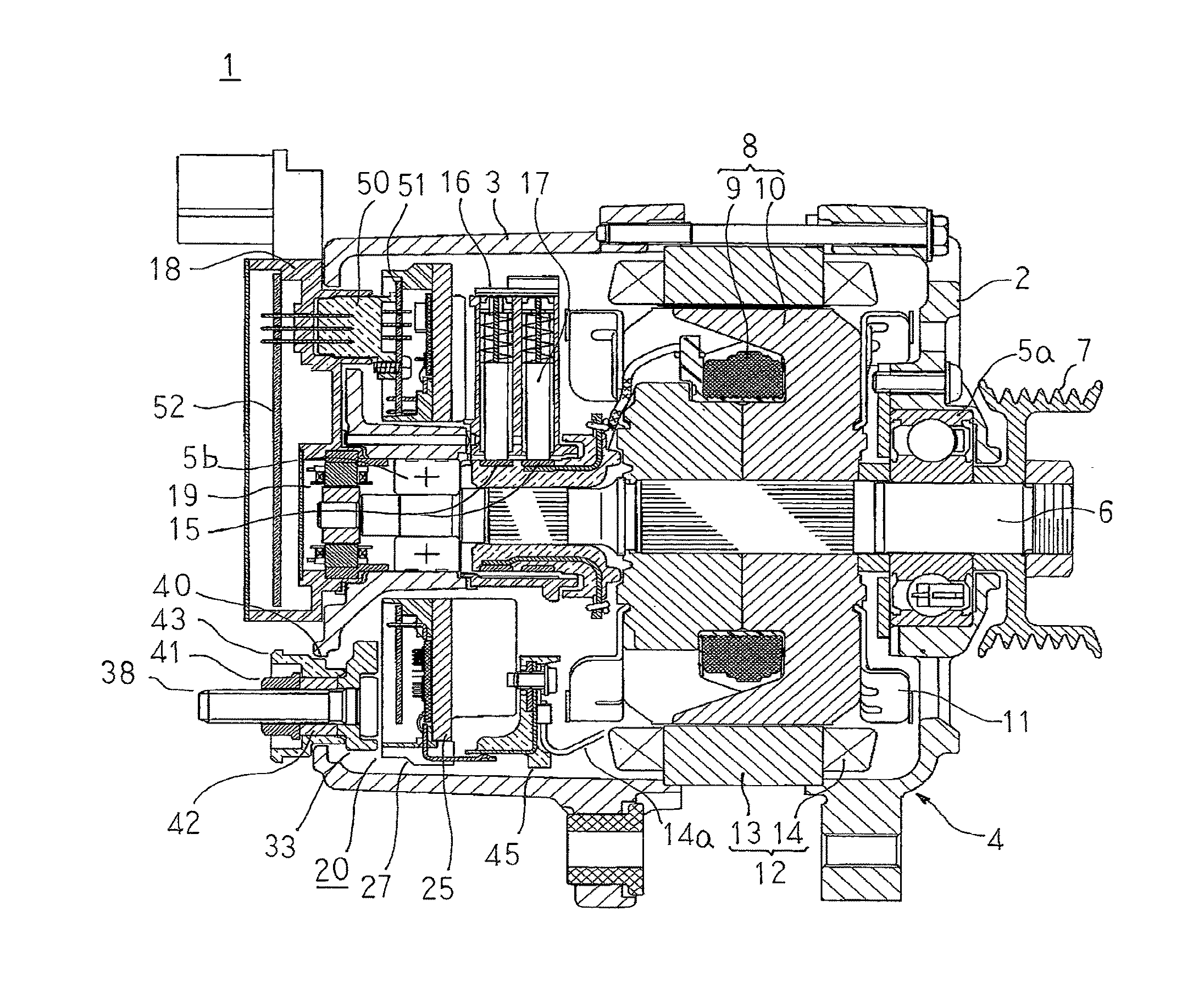

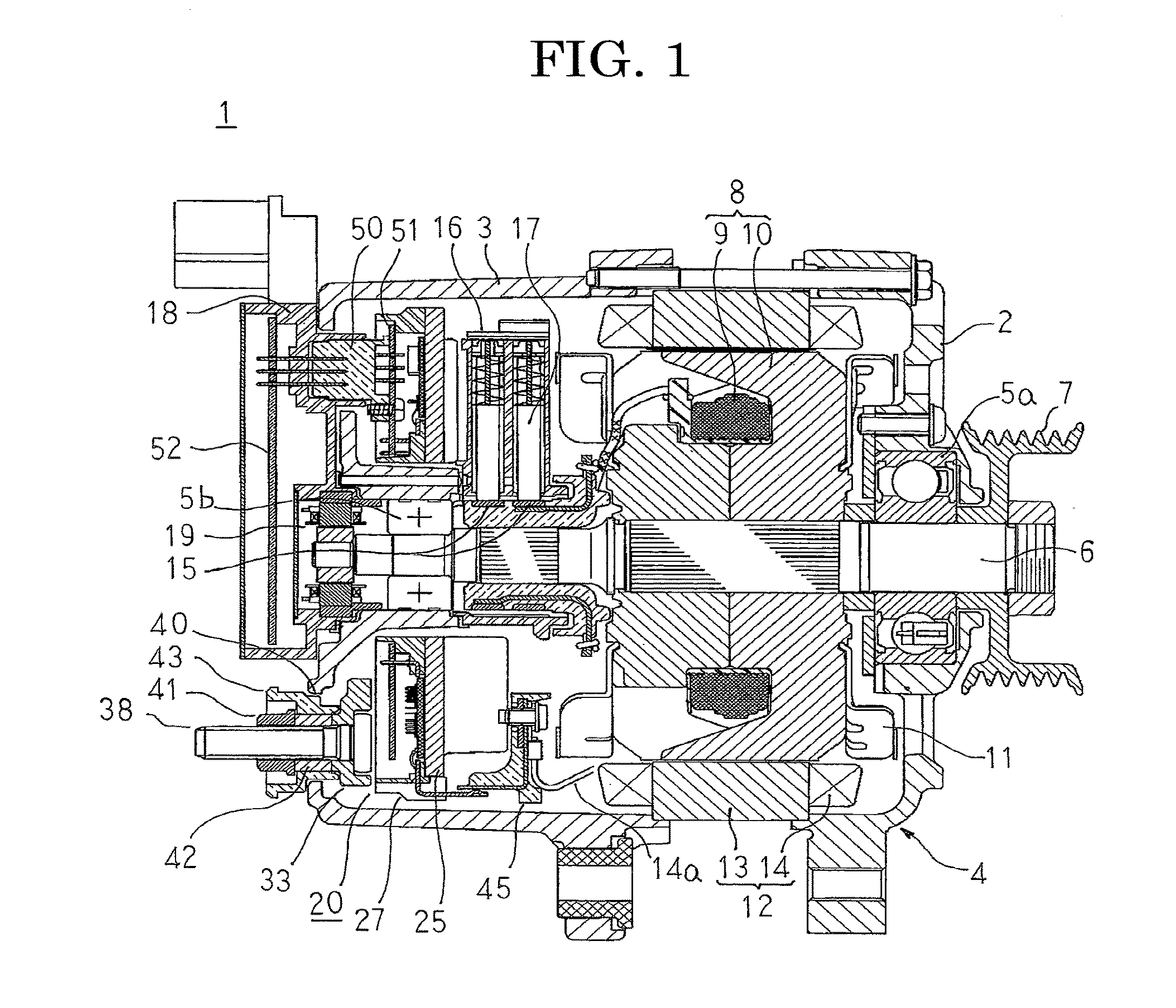

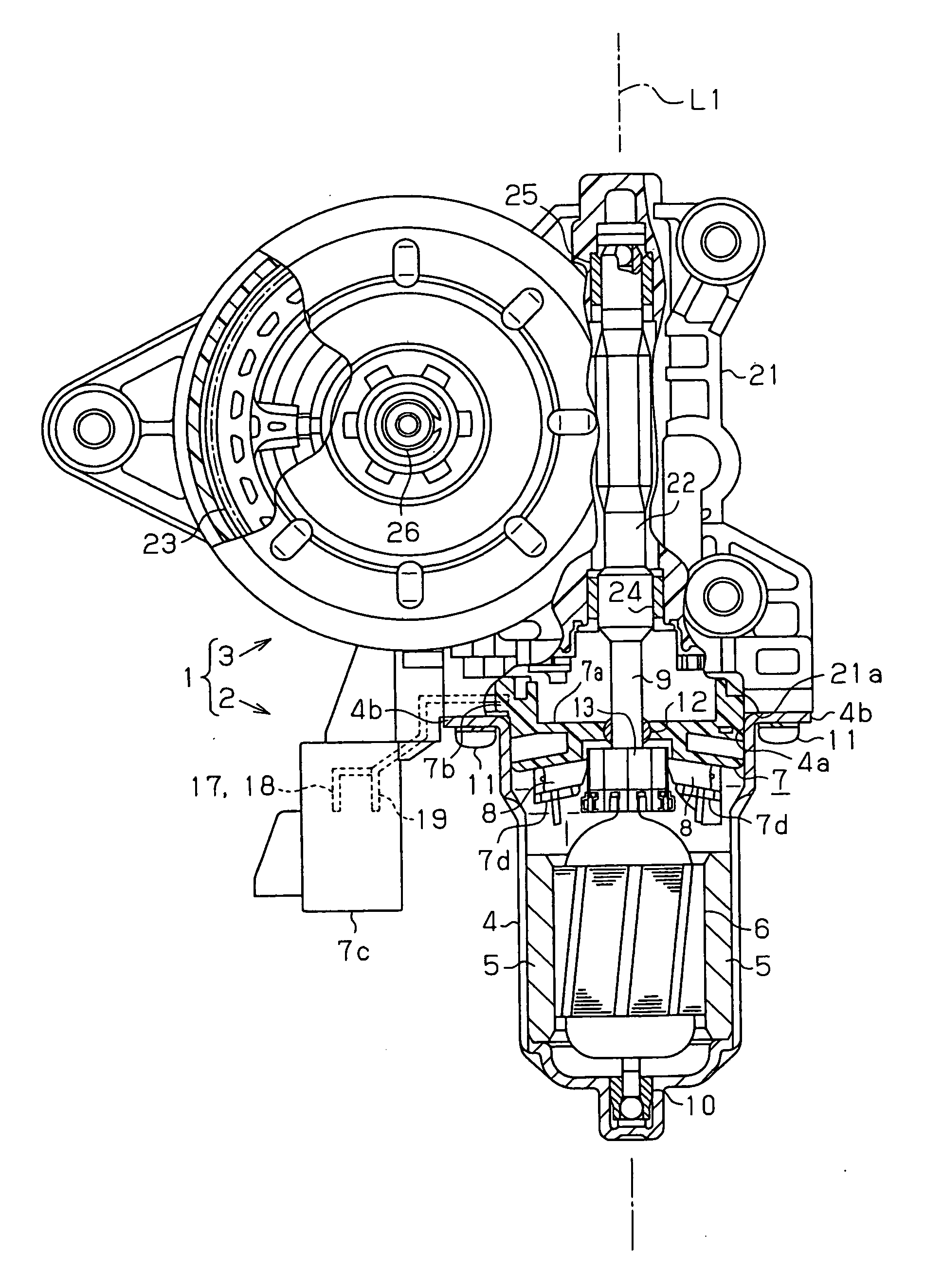

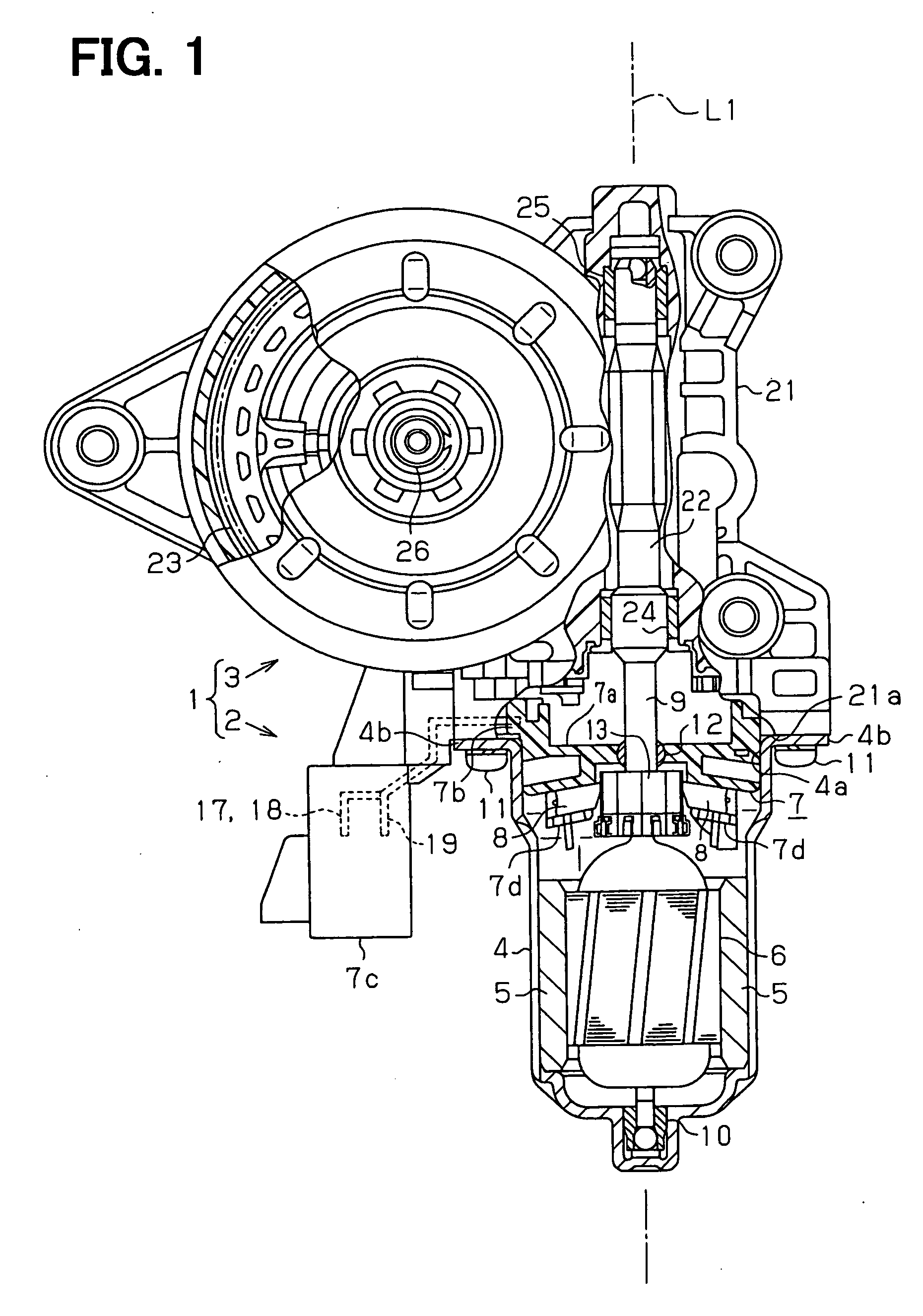

Automotive dynamoelectric machine

ActiveUS20100308700A1Suppressing deterioration of cooling performanceSuppressing excessive temperature increaseSynchronous generatorsAssociation with grounding devicesElectrical conductorEngineering

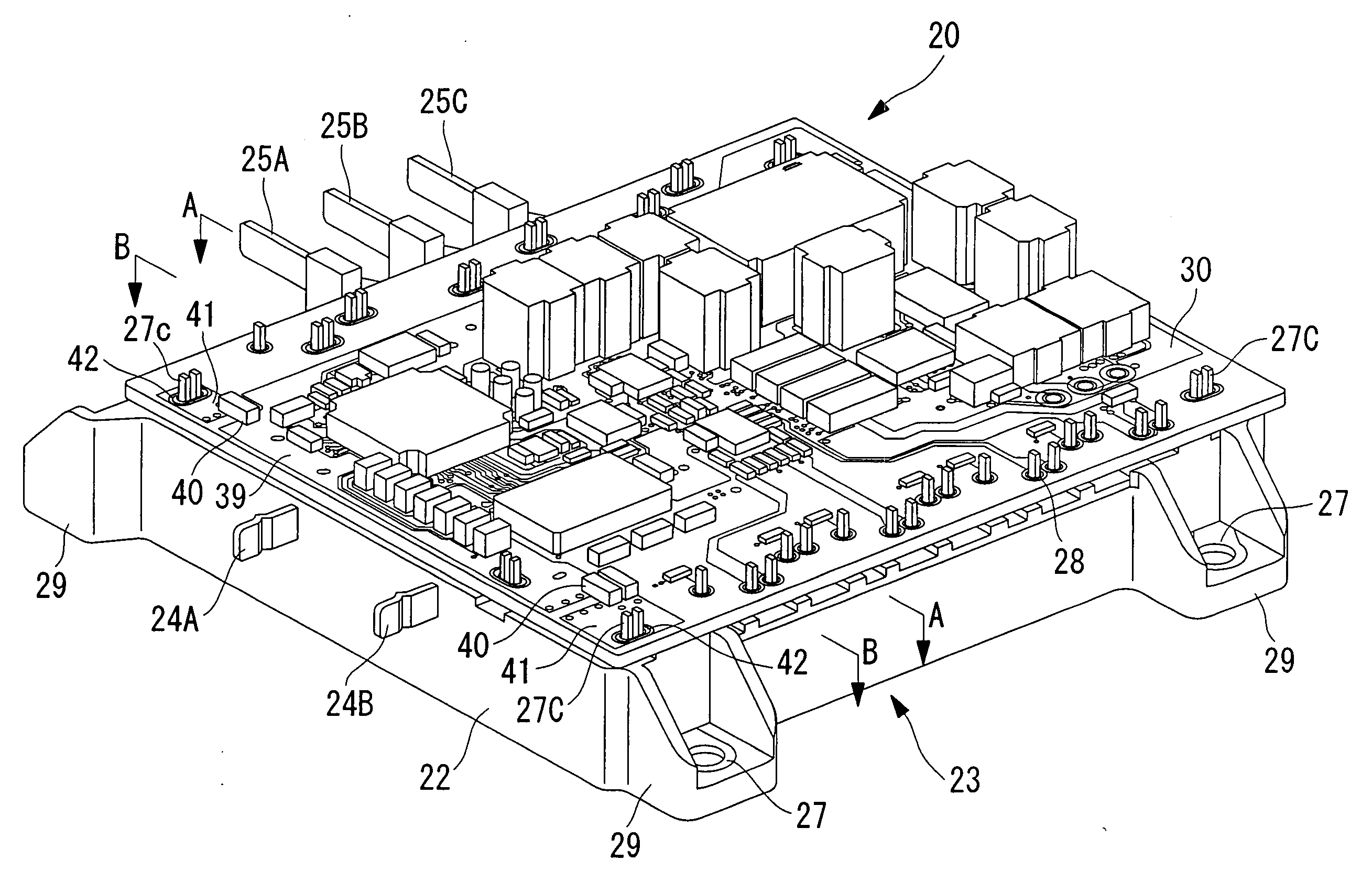

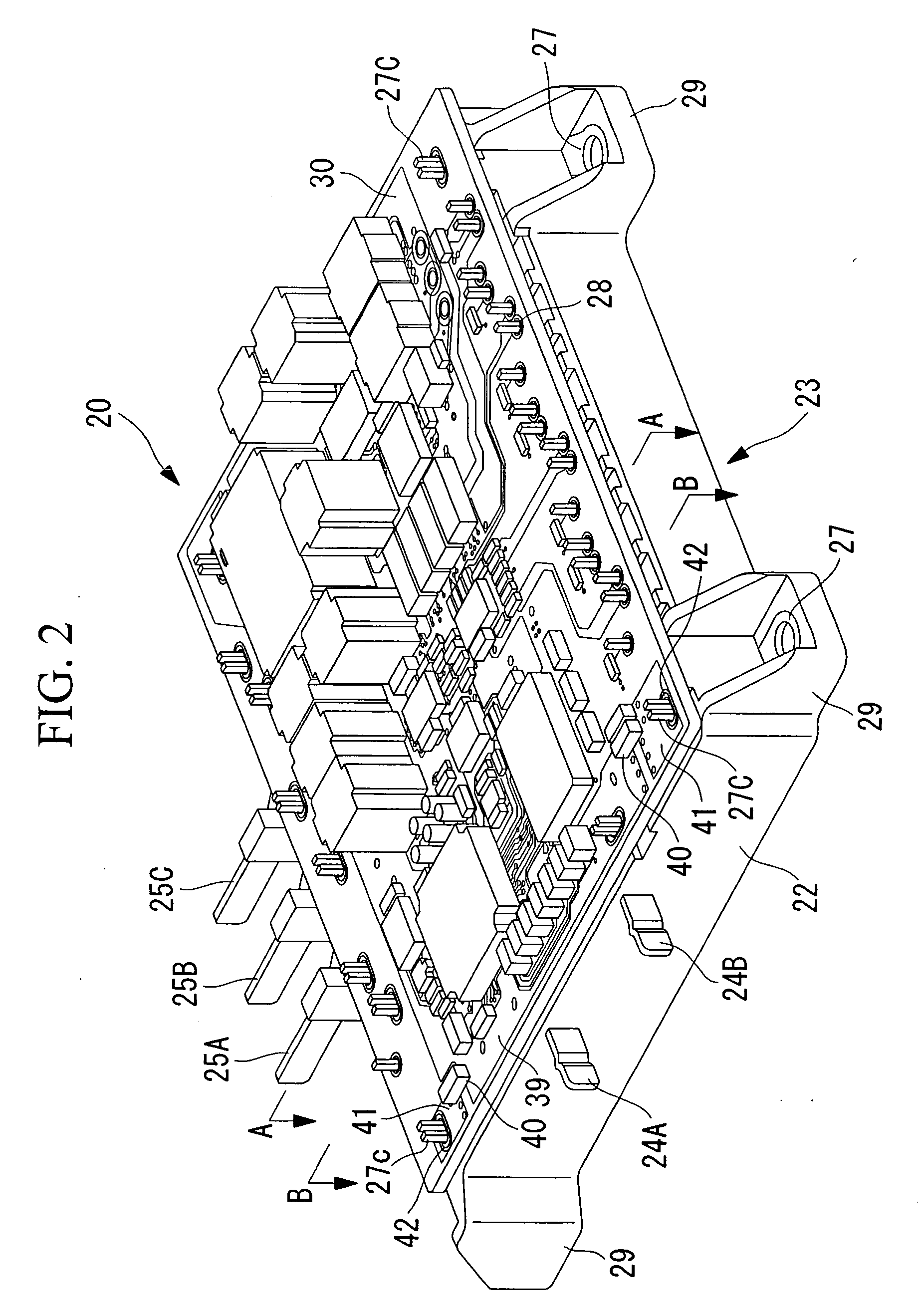

An inverter power module includes: a heatsink that is shaped into a ring-shaped flat plate; a plurality of power MOSFETs that are mounted onto substrates, and mounted to a front surface of the heatsink; a circuit board that is a resin-molded body into which a plurality of inserted conductors are insert molded; and a bus bar that is fixed to the heatsink so as to be disposed on an opposite side of the circuit board facing the heatsink, and that is connected to a power source line of an inverter power circuit by means of a battery electric potential connecting terminal, the heatsink is electrically connected to the rear bracket by being fixed to the rear bracket, and the rear bracket is connected to a ground line of the inverter power circuit by means of the ground electric potential connecting terminal.

Owner:MITSUBISHI ELECTRIC CORP

Ground strap for a motor having a plastic housing

ActiveUS6987338B1Easy alignmentLow costBowling gamesAssociation with grounding devicesFastenerAerospace engineering

For a motor having a plastic bracket, a single-piece ground strap grounds both the motor's stator and rotor. The ground strap has one end fastened to a bearing retainer of the motor, an opposite end connected to a ground wire, and an intermediate section that is compressed between the stator and the housing. The end connected to the bearing retainer grounds the rotor, and the intermediate section grounds the stator. The ground strap is fastened to the motor using fasteners that already exist in an otherwise identical but ungrounded motor. In some cases, a combination bearing retainer and ground strap is blanked and formed as a unitary piece.

Owner:ELECTRO MOTOR

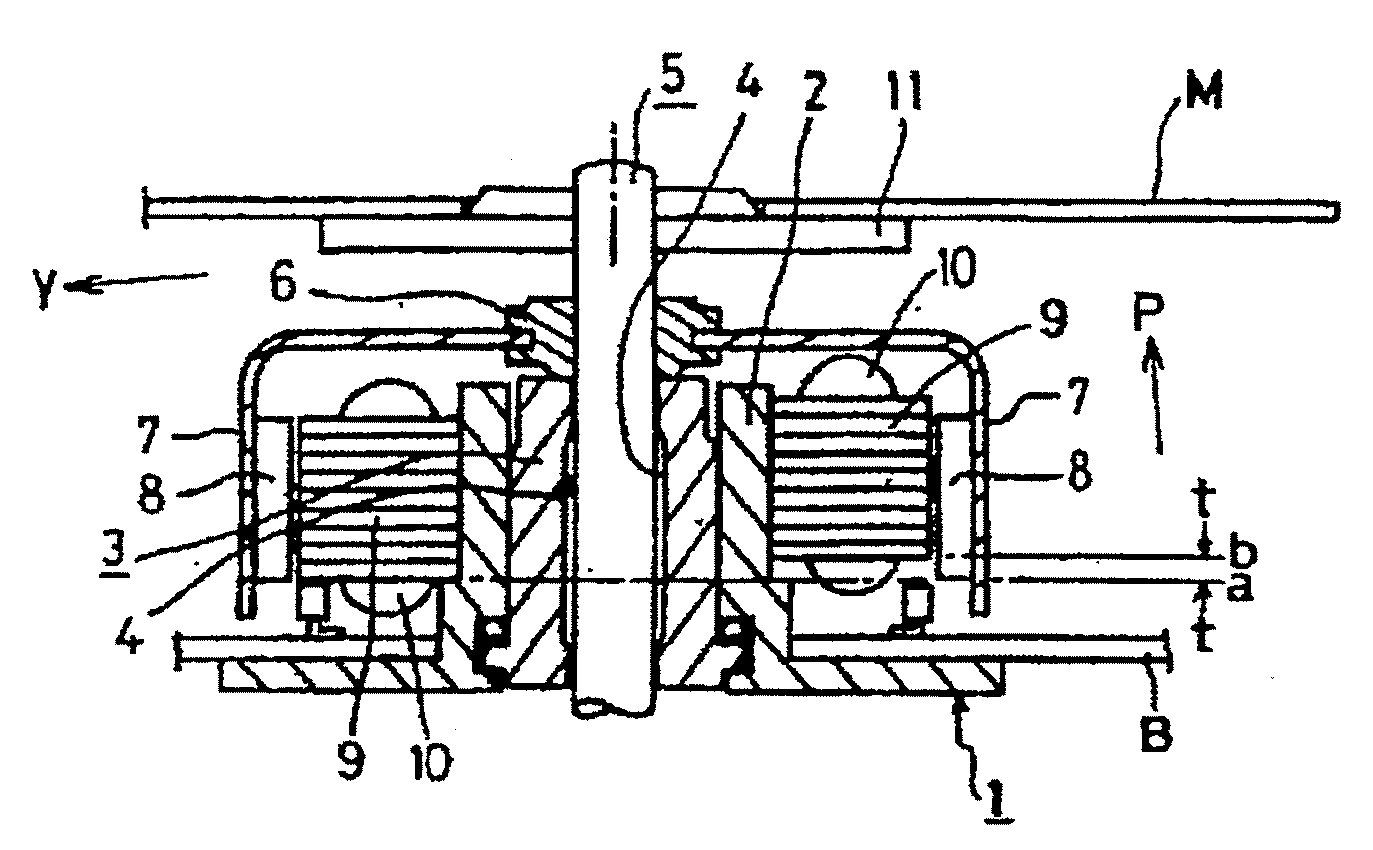

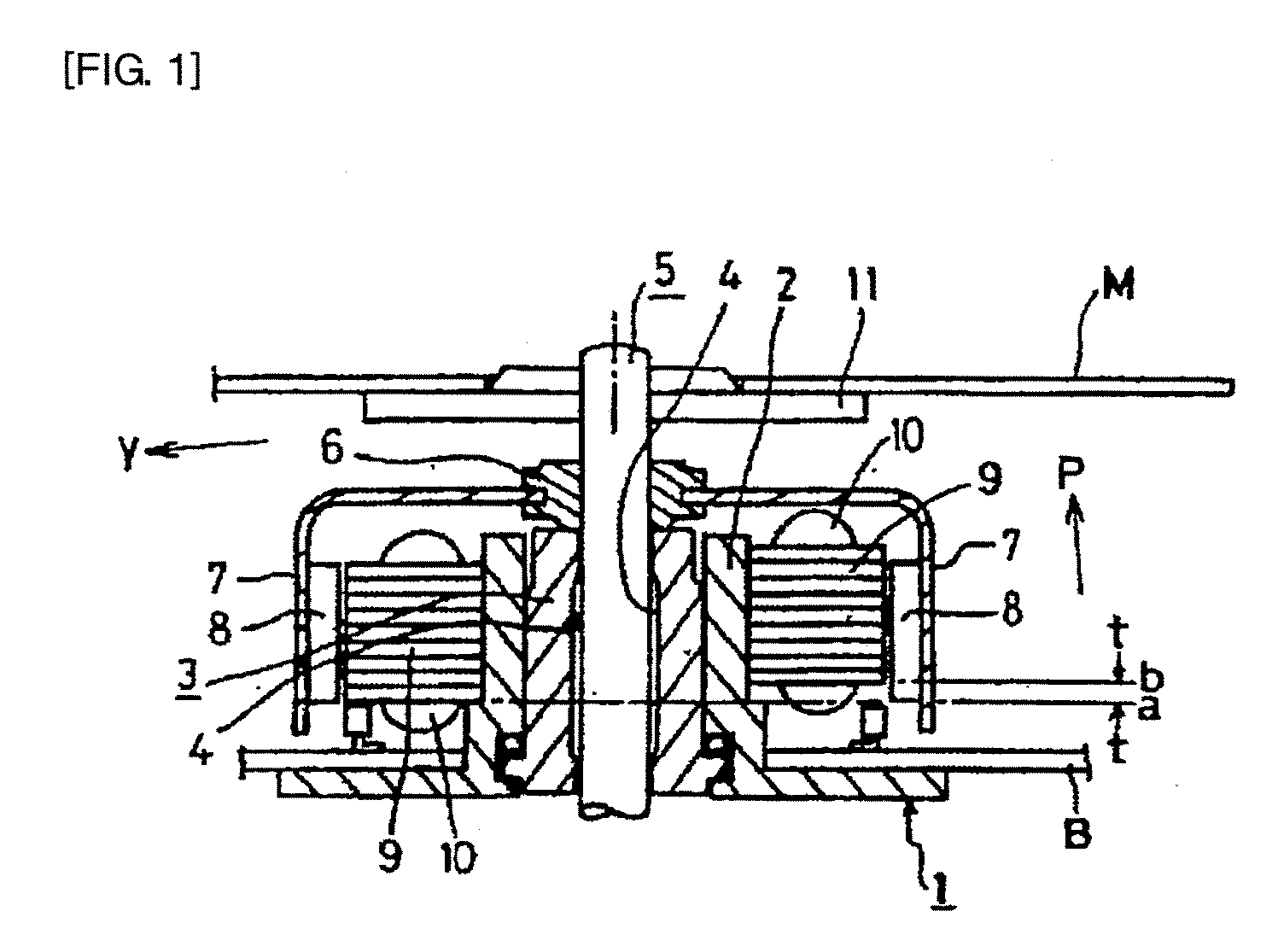

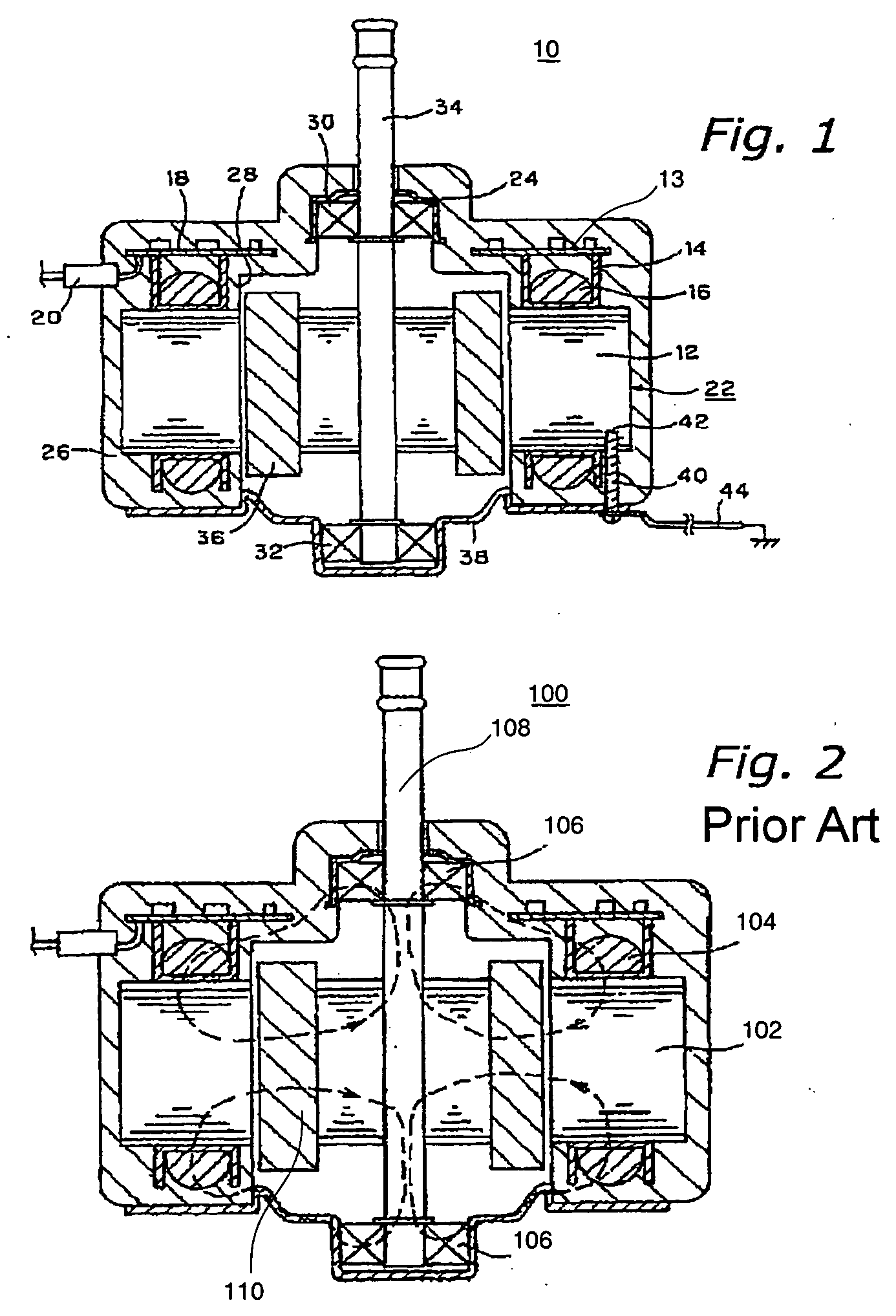

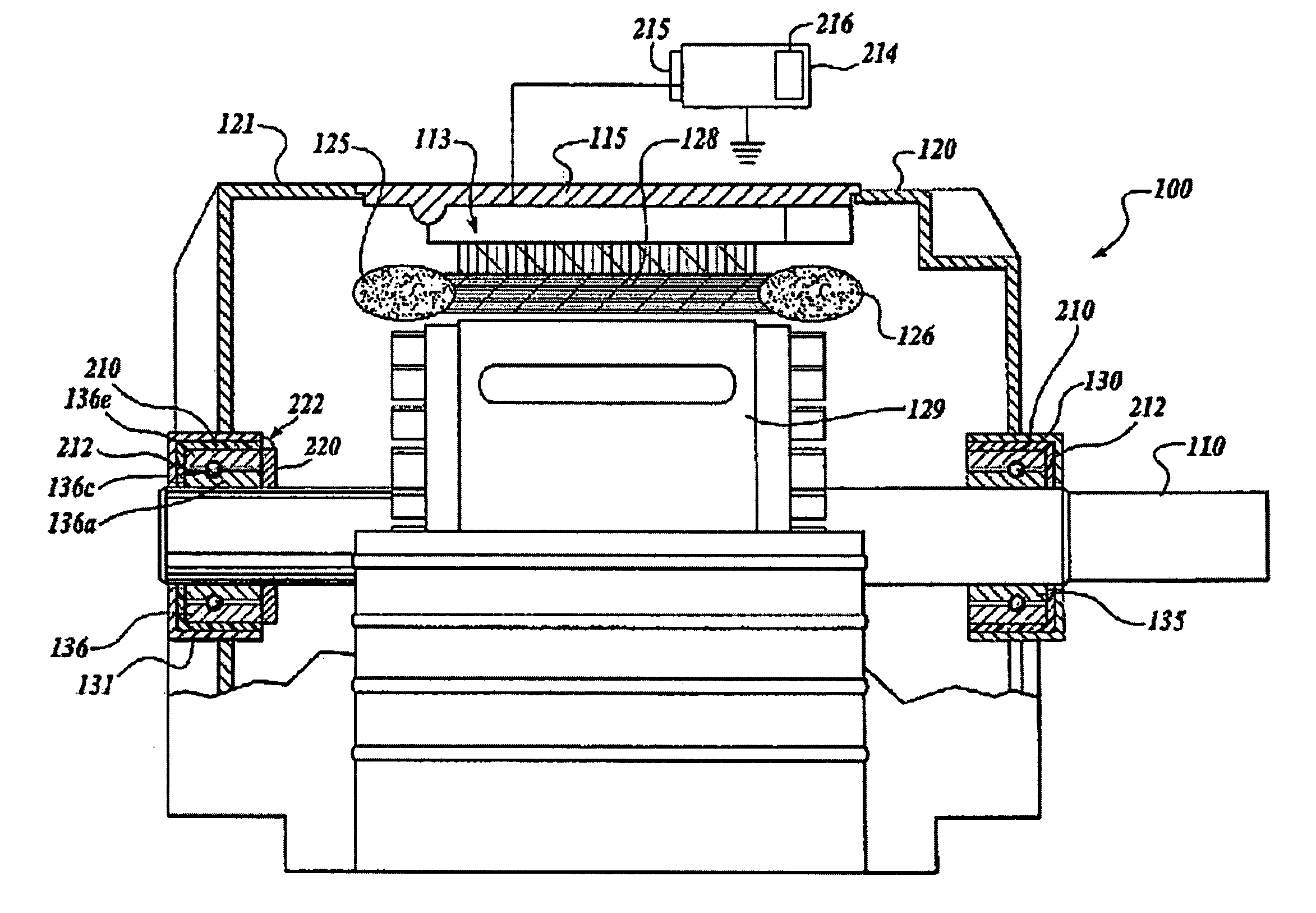

Method and system for reducing bearing fluting in electromechanical machine

InactiveUS7071589B2Reduce the amount requiredReduce chanceAssociation with grounding devicesConveyorsFrequency changerElectric machine

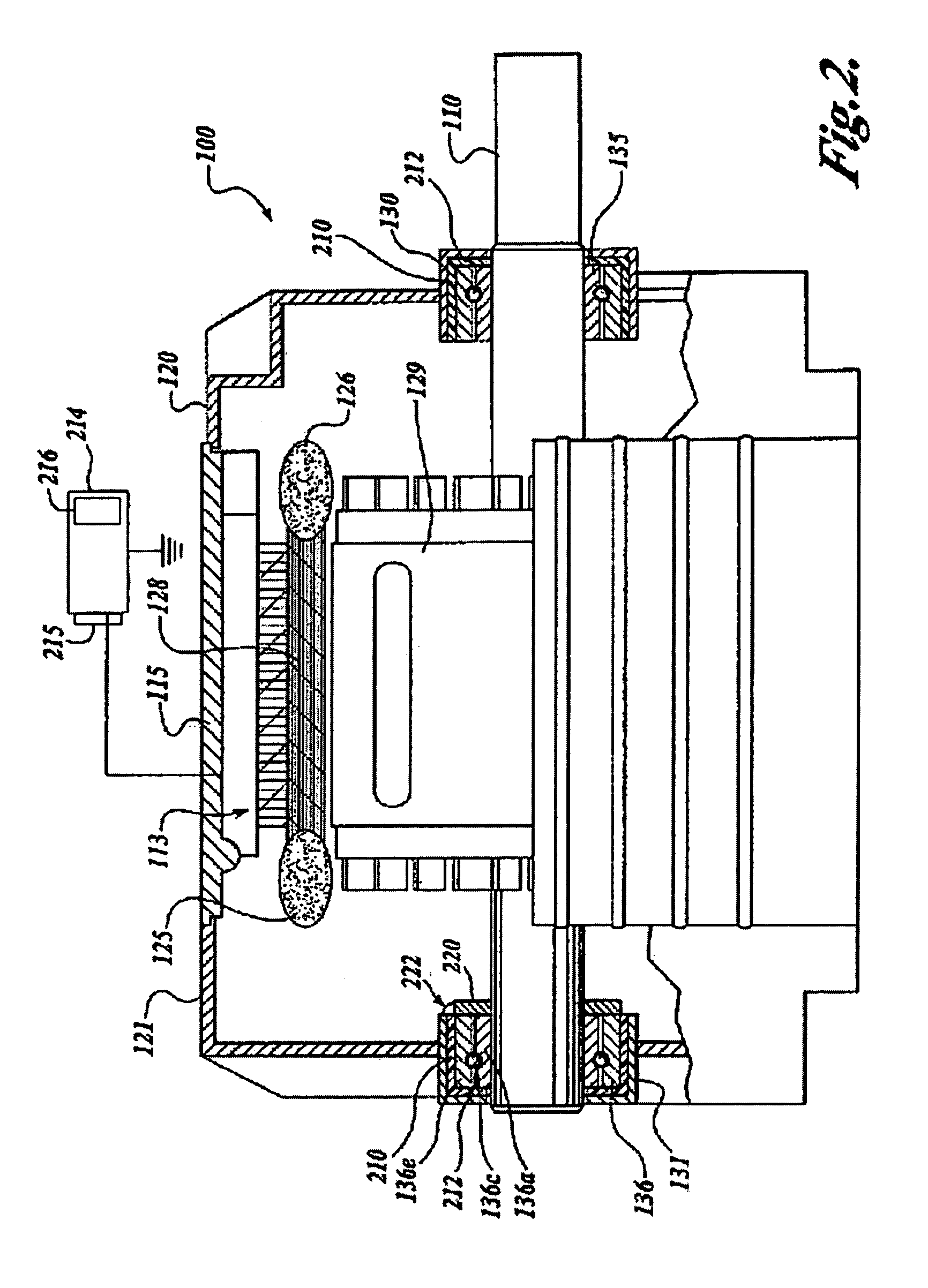

A non-conductive insulating ring (210) is inserted between a motor bell (130) and a motor bearing (135) that supports a motor shaft (110). Stray currents that normally discharge thorough the motor shaft and the motor bearing to the motor bell are prevented due to the non-conductive nature of the insulating ring. Additionally, the motor shaft is grounded to provide a low-impedance alternative path to stray shaft currents. When a fast-switching frequency converter is used to drive the motor shaft, additional arrangements such as a common mode choke, reduction of the switching frequency of the converter, and reduction of the turn-of / off rate of a semiconductor device used in the converter, may be provided to further reduce the stray currents flowing thorough the motor bearings.

Owner:PRECOR

Integrated-inverter electric compressor

ActiveUS20090246047A1Good effectImprove reliabilityAssociation with control/drive circuitsAssociation with grounding devicesComputer moduleMetal substrate

An integrated-inverter electric compressor whose grounding effect and grounding reliability are increased by reliably grounding an inverter device to a housing and in which the size the inverter device are reduced by simplifying the grounding structure is provided. The integrated-inverter electric compressor includes an inverter device provided in an inverter container on the outer circumference of a housing. The inverter device includes an inverter module formed by integrating a power-related metal substrate and a resin case and is provided with a control-related substrate on the upper surface of the inverter module; the resin case is integrated with mounting legs provided at a plurality of locations on the circumference; the mounting legs are grounded to the power-related metal substrate and the control-related substrate; and grounding terminals, which frame-ground the substrates to the housing, are insert-molded in such a manner that the grounding terminals are securable to the inverter container with screws.

Owner:MITSUBISHI HEAVY IND LTD

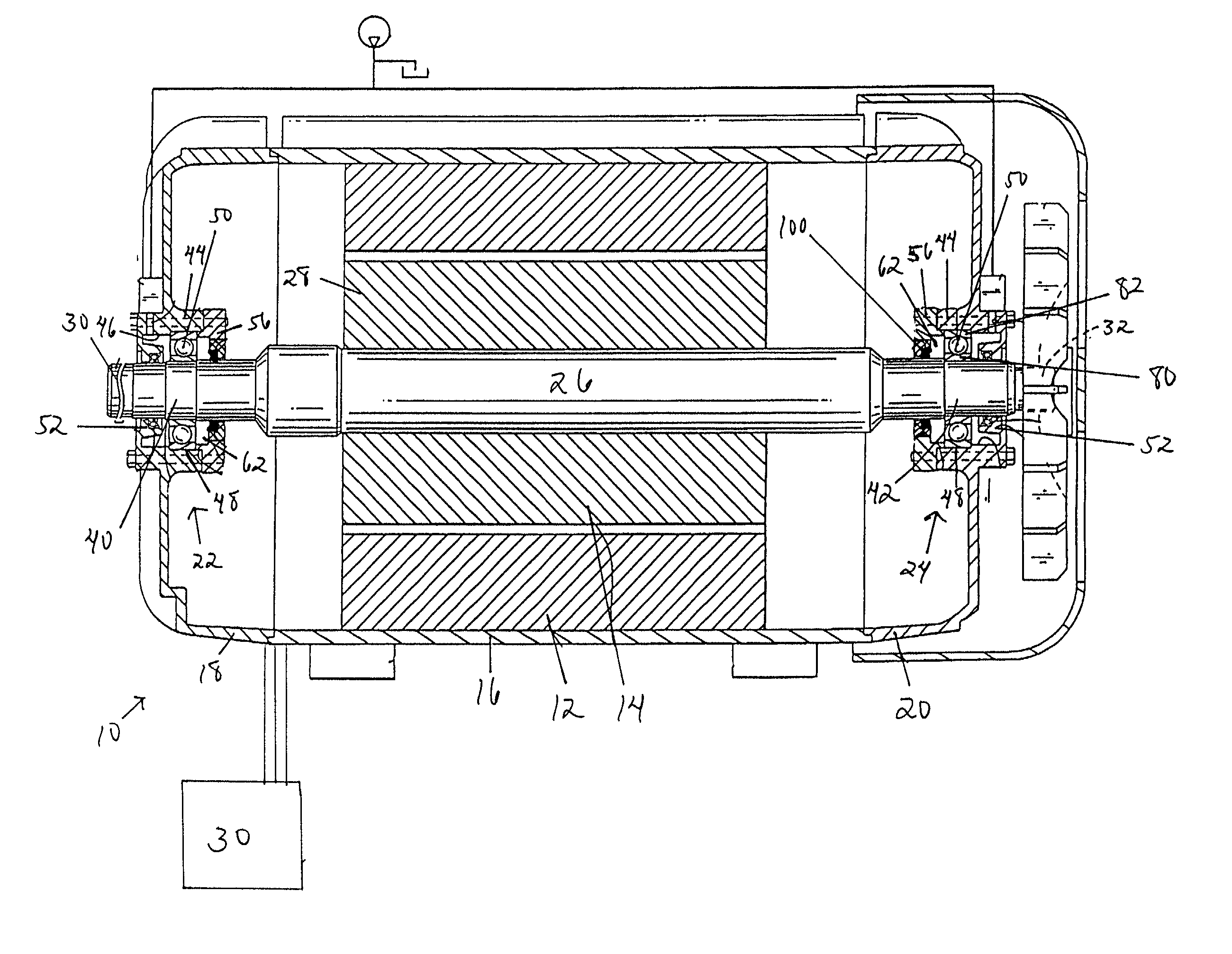

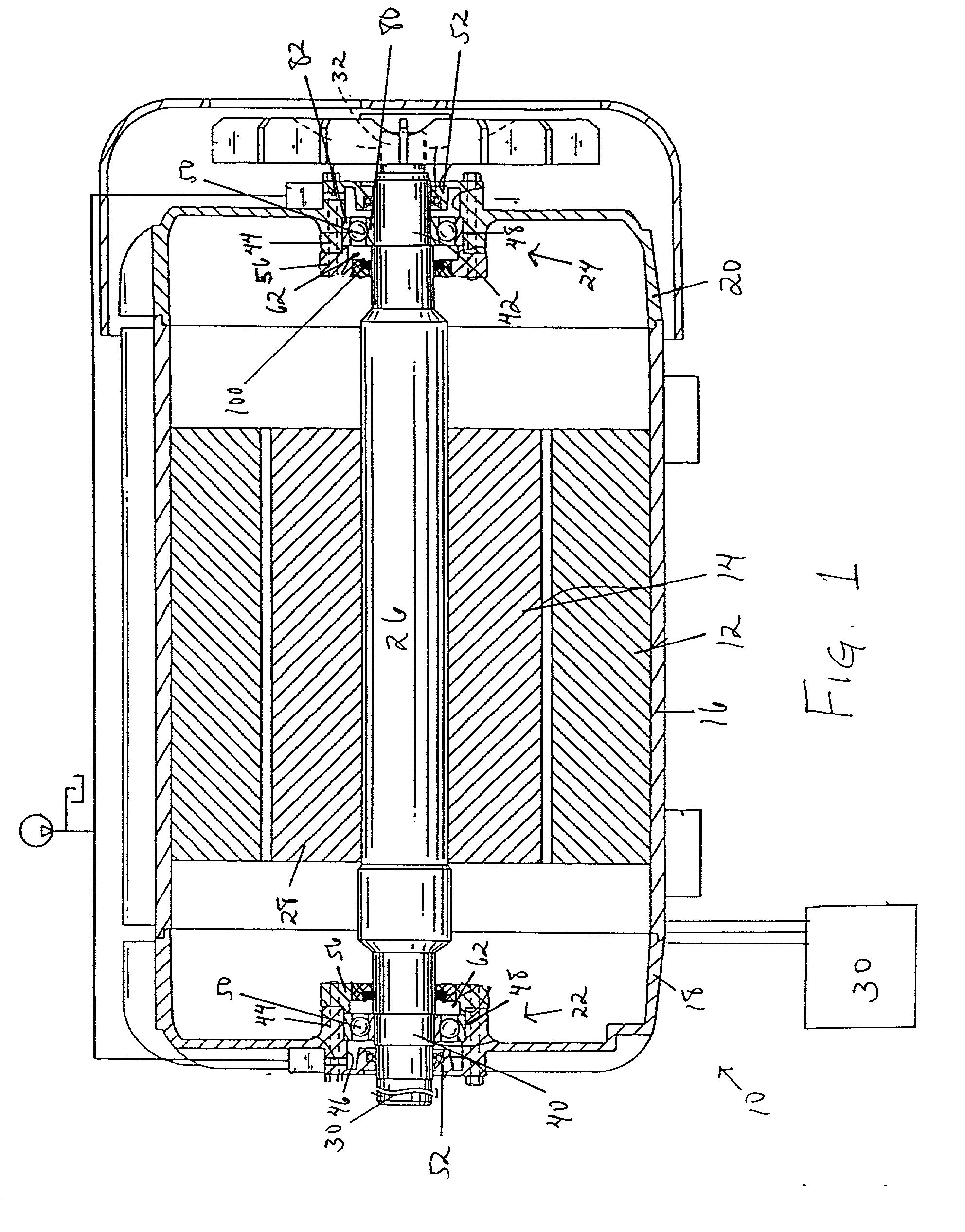

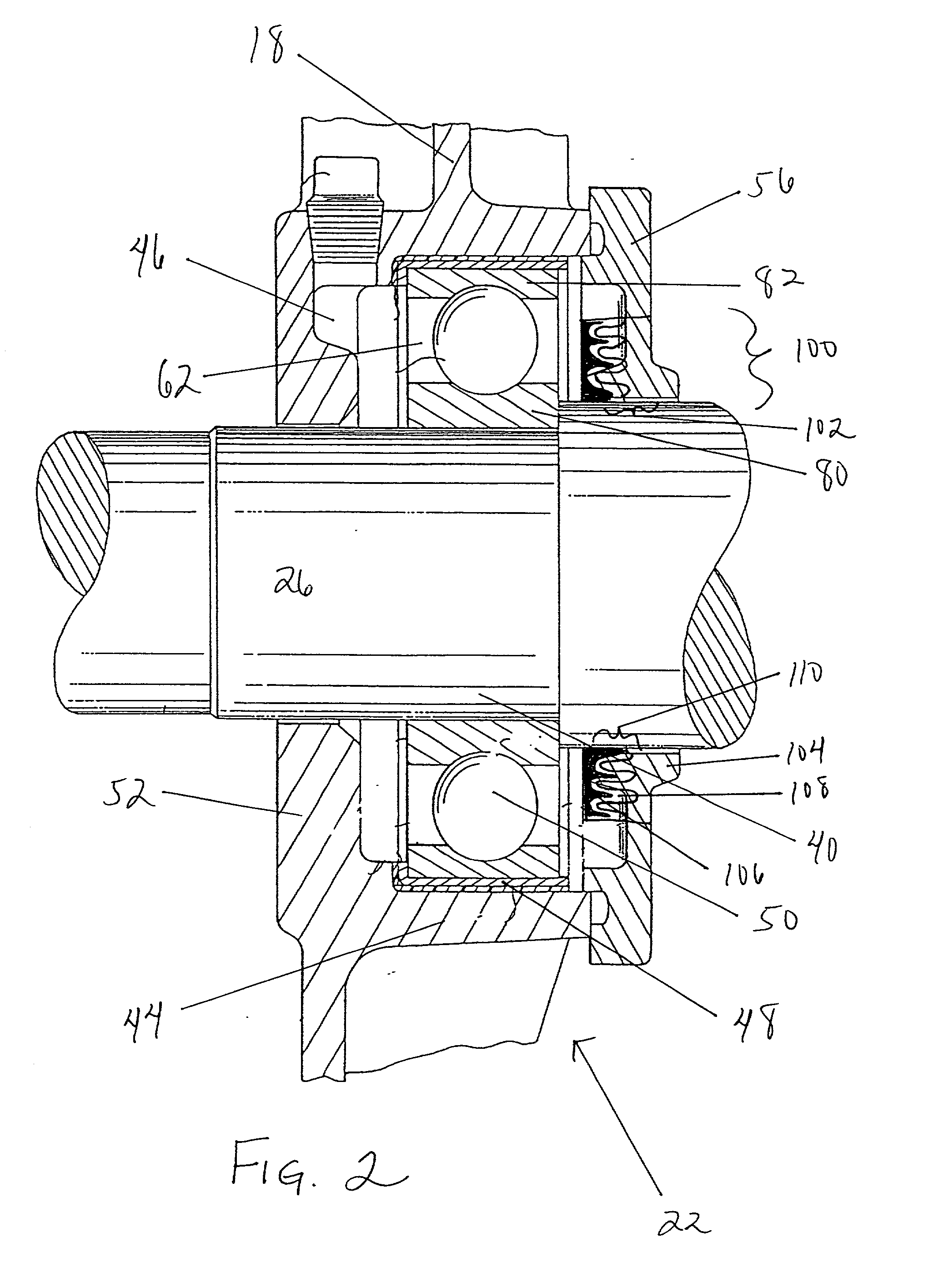

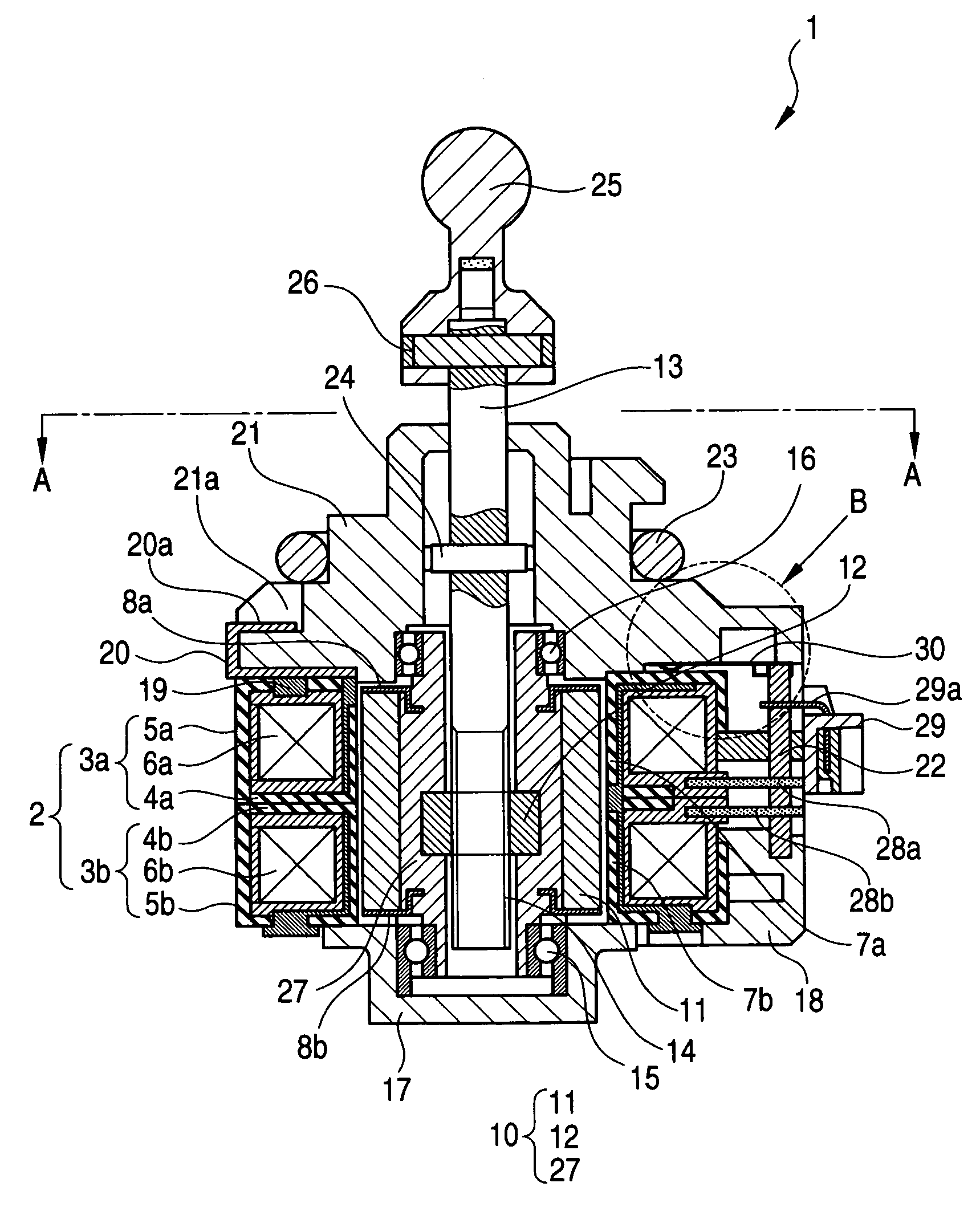

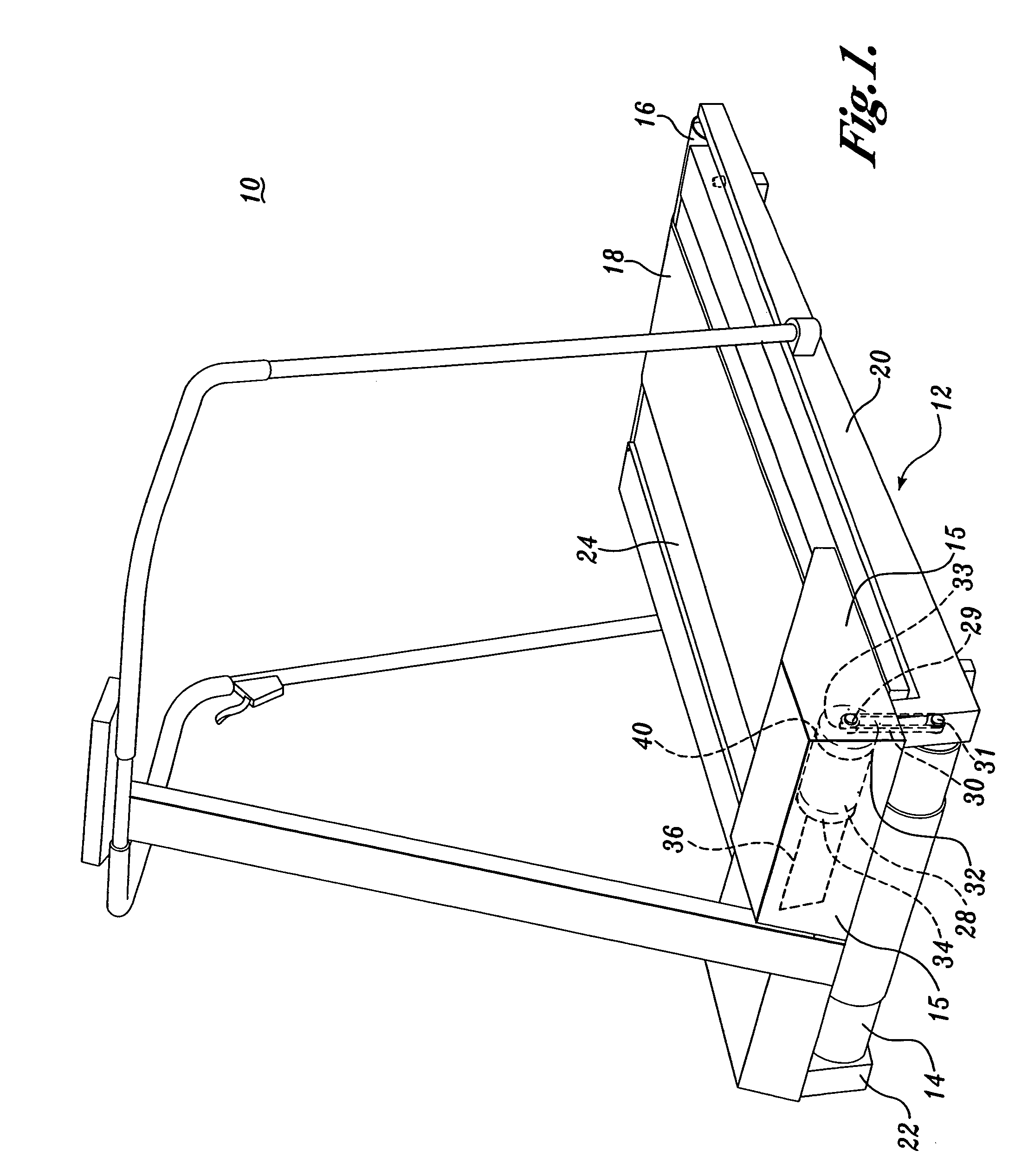

Shaft current control brush assembly with drainage

ActiveUS20070040459A1Reduce shaft currentEfficient assemblyRotary current collectorAssociation with grounding devicesElectrical and Electronics engineeringEngineering

Owner:ILLINOIS TOOL WORKS INC

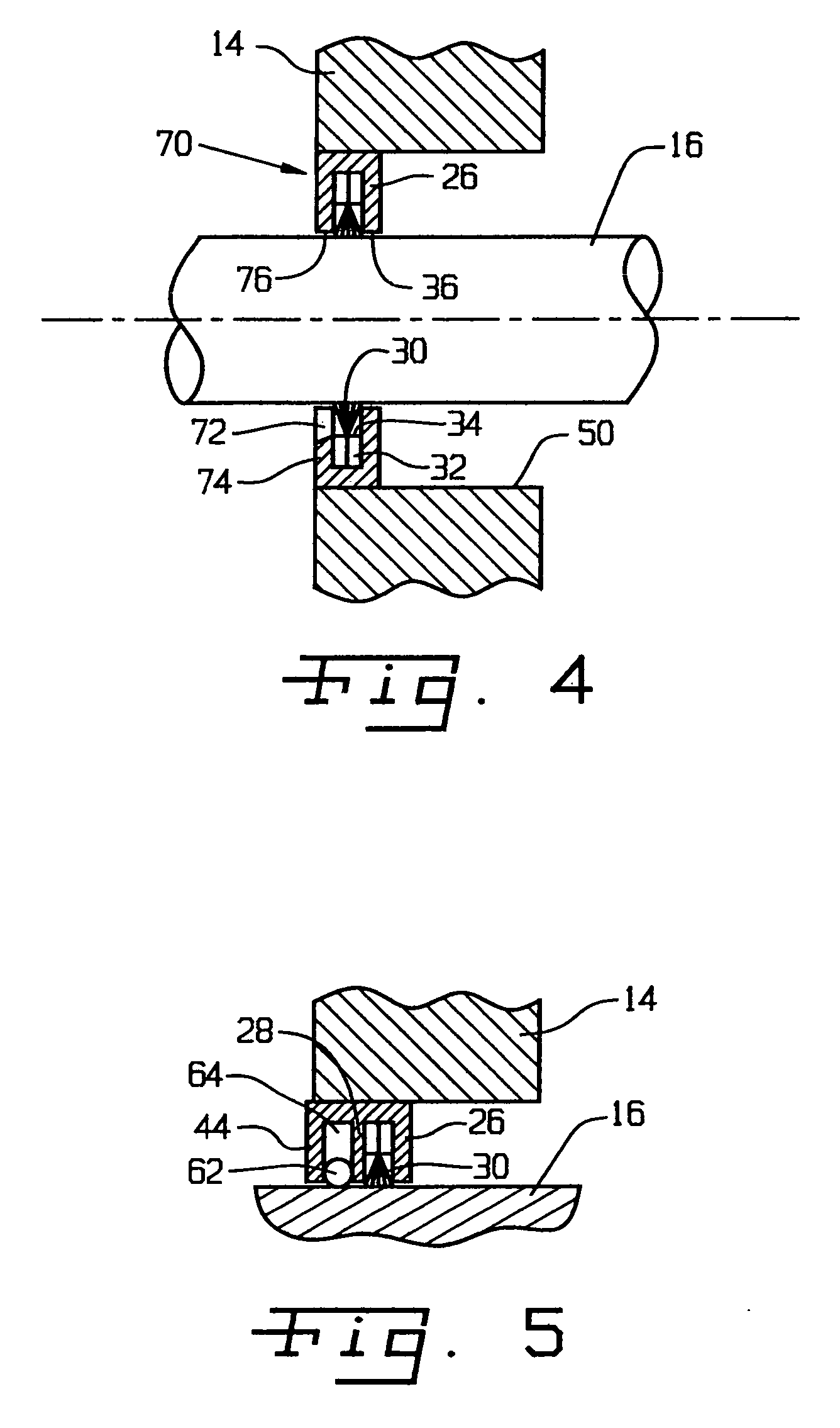

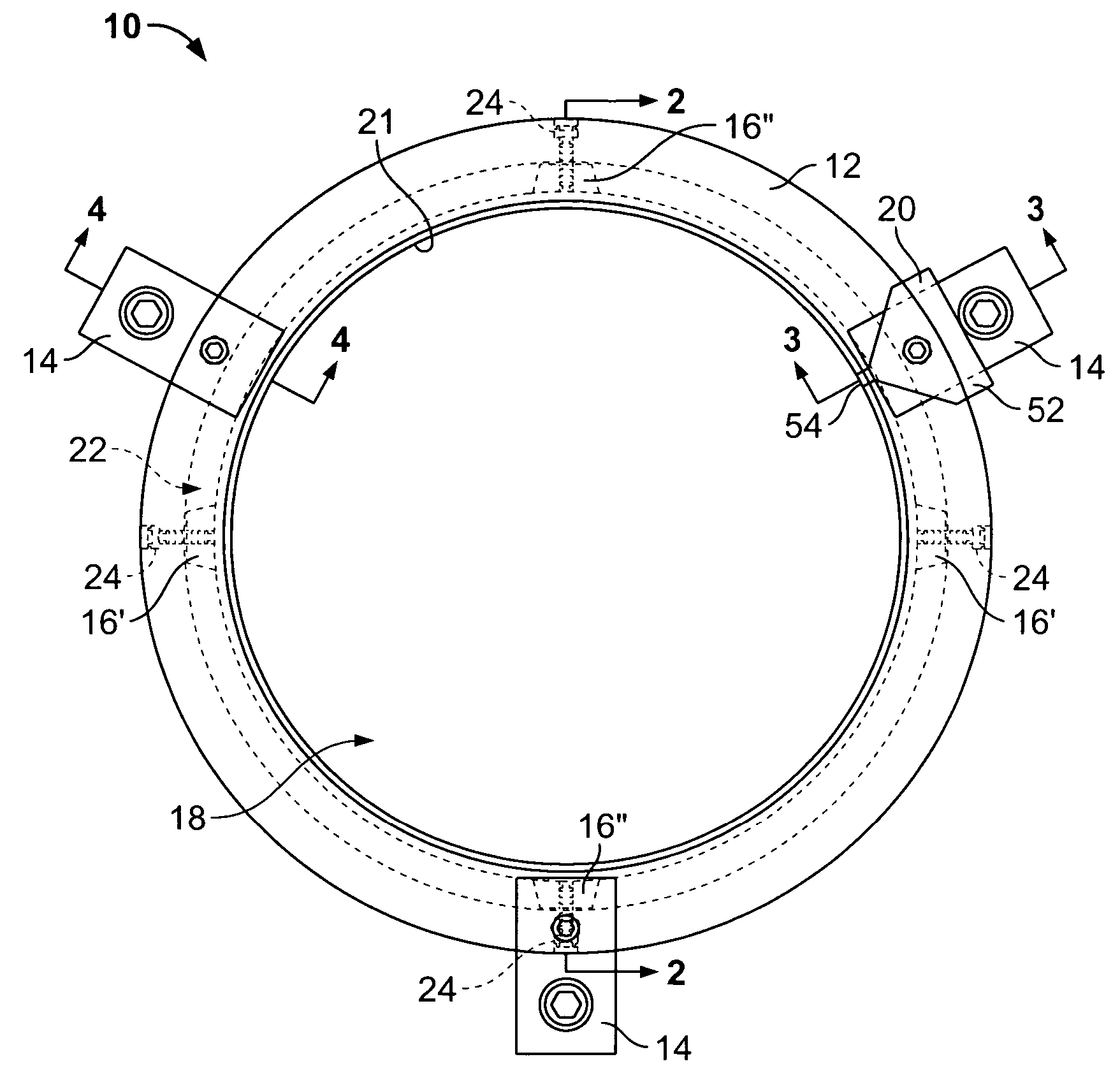

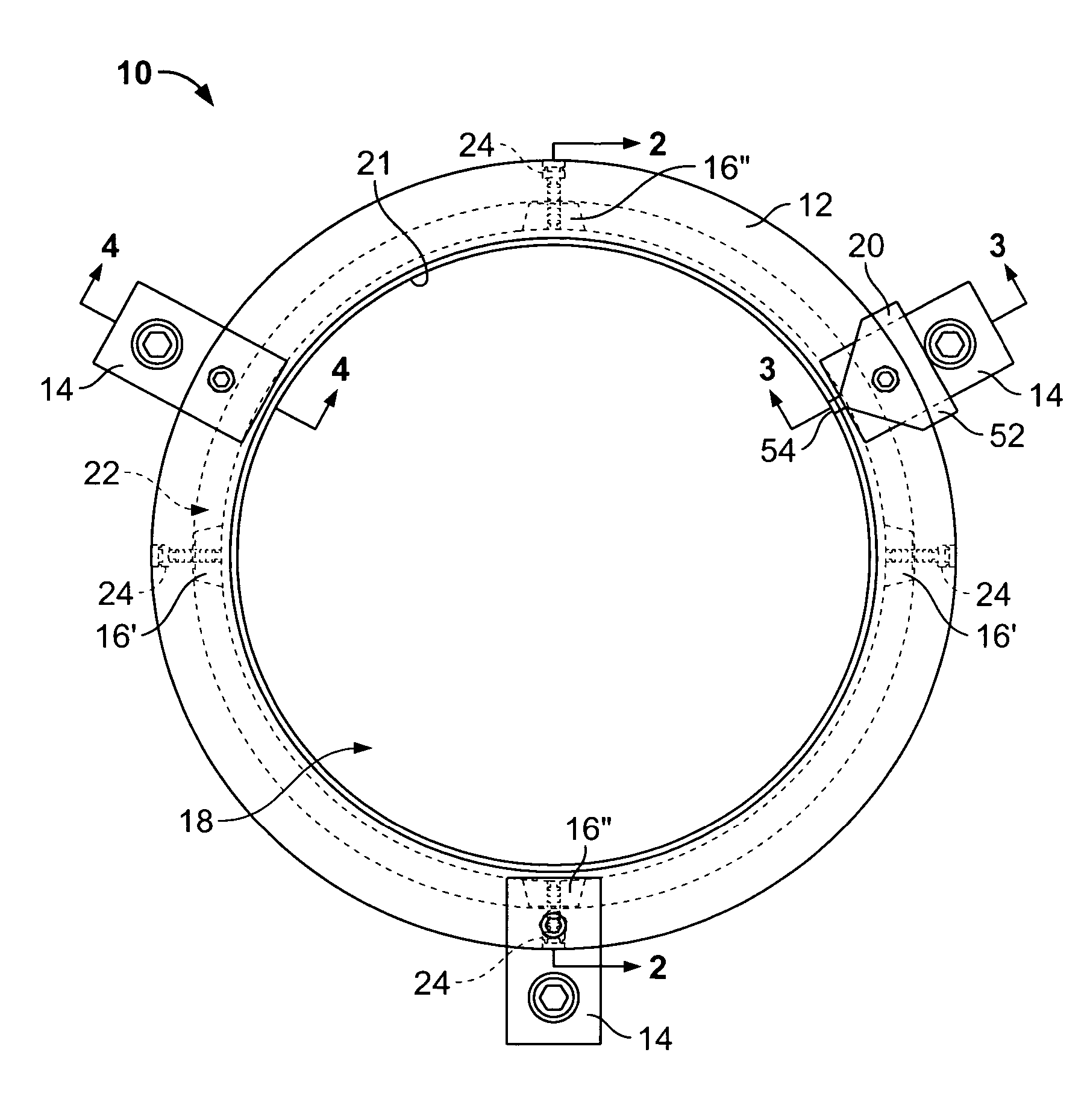

Grounding system for a rotating shaft

A system is provided for dissipating electrical charges that build on a rotatable shaft extending from an electrically-grounded motor housing or rotating shafts conductively linked to components that create and electrical charge, such as wind turbine blades, power generator turbines, and the like. The system includes a frame defining a central opening wherein the rotatable shaft is positioned with the central opening, a first grounding fiber secured within the frame, and a fiber clamp positioned with the frame. The fiber clamp acts to urge the first grounding fiber toward the central opening. The system may also include a mounting bracket having a frame mounting channel, wherein a portion of the frame is securely retained within the frame mounting channel, and an installation guide positioned on the mounting bracket. The installation guide may be configured to properly align the frame and the first grounding fiber relative to the rotatable motor shaft.

Owner:ILLINOIS TOOL WORKS INC

System and method of reducing bearing voltage

InactiveUS6670733B2Association with grounding devicesEmergency protective arrangement detailsCapacitanceEngineering

Technique for reducing bearing current discharges in a system by increasing the surface area between the shaft and the frame of the system and thereby increasing the rotor to frame capacitance.

Owner:BALDOR ELECTRIC COMPANY

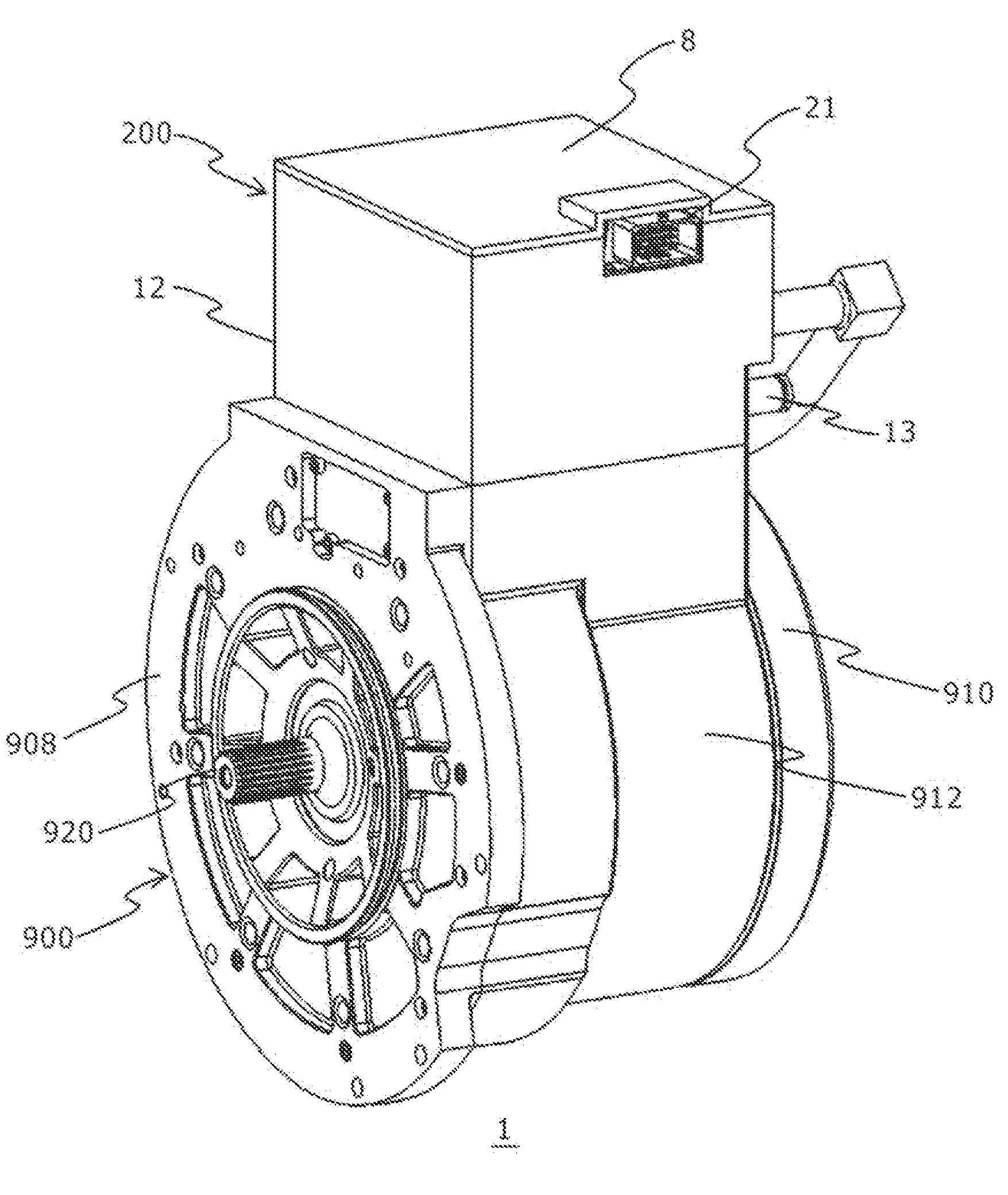

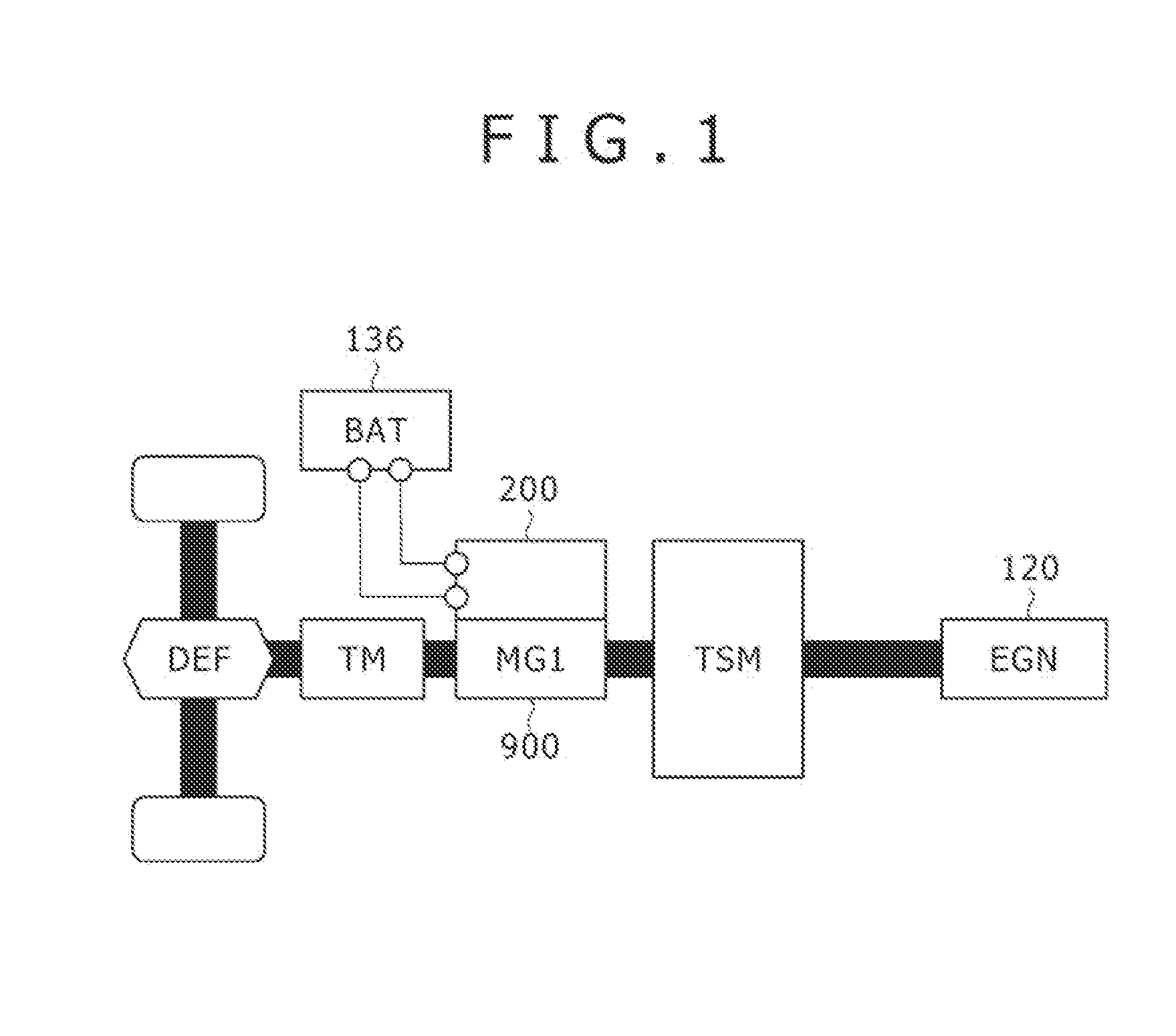

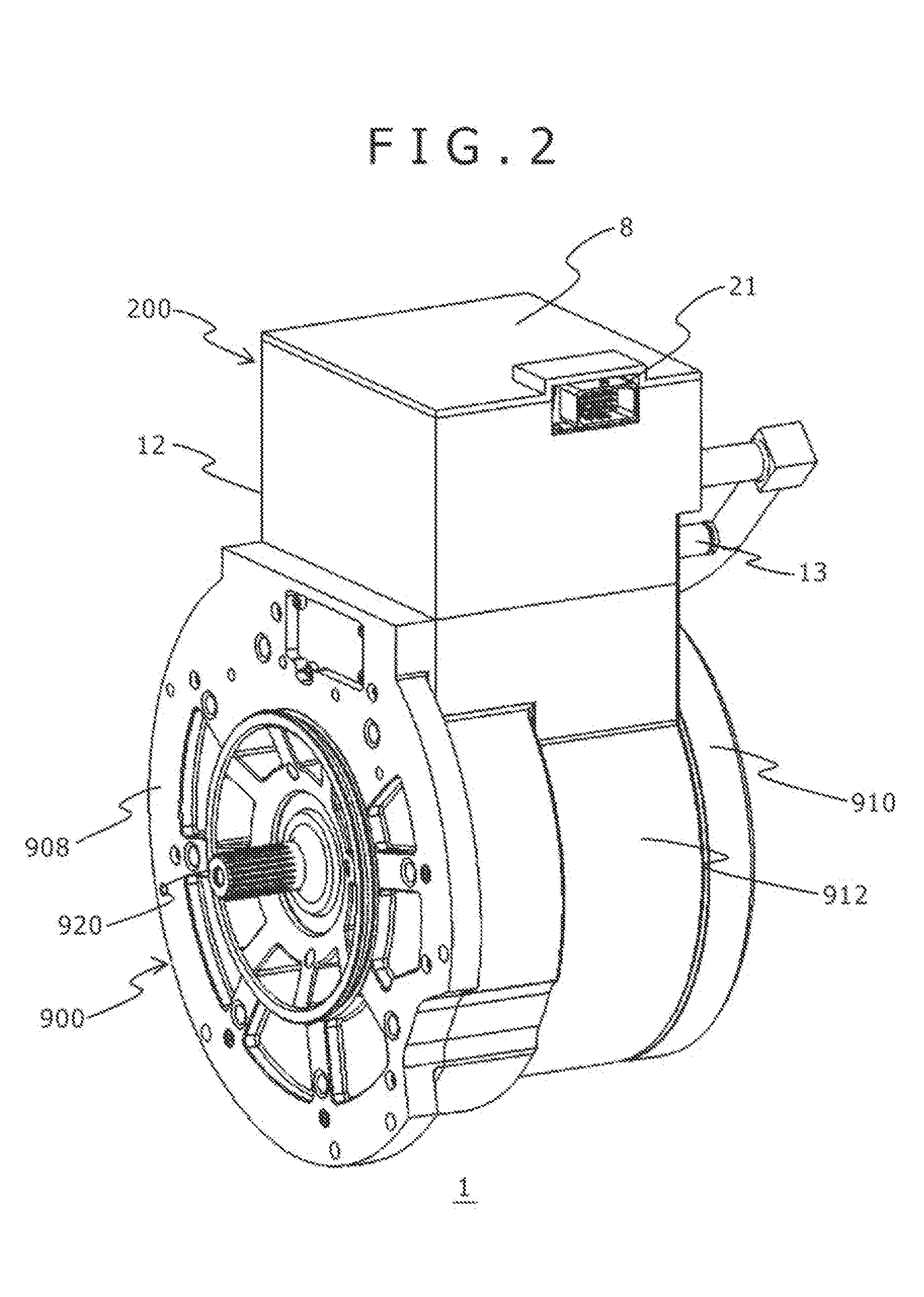

Mechanical-Electrical Integrated Electric Drive System

InactiveUS20140306563A1Inhibit bad effectsAssociation with control/drive circuitsAssociation with grounding devicesCapacitanceElectricity

Disclosed is a mechanical-electrical integrated electric drive system capable of returning common mode current from a rotary electric machine's side to a virtual neutral point of a power-conversion device inside the electric drive system, where the system comprises a rotary electric machine that includes a rotor, a stator having a stator core including armature windings, and a housing holding the stator and having AC terminals of the armature windings arranged thereon; a power conversion device that is fixed to the periphery of the housing and includes an inverter circuit and AC bus bars connecting the inverter circuit with the AC terminals; conductor rings that are arranged in contact with the stator core to collect common mode current deriving from stray capacitance of the stator; and a connection wire that connects the conductor bar to a virtual neutral point on the DC input side of the inverter circuit.

Owner:HITACHI AUTOMOTIVE SYST LTD

Rotary electric machine

ActiveUS20150333596A1Emission reductionEffective and efficient mannerAssociation with control/drive circuitsAssociation with grounding devicesElectricityElectric machine

A rotary electric machine, in particular an electric motor, has a winding, an electronic control device, and an electrically conductive shielding plate arranged between the control device and the winding. A connection device which includes at least one coupling element for electrically connecting the control device to one or more lines and a mass element provided for connecting to an electric mass potential. In order to improve the machine with respect to electromagnetic interference, the shielding plate is electrically conductively connected to the mass element by way of a sheet metal tongue via a first electric pressure-contact.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Grounding system for a rotating shaft

A system is provided for dissipating electrical charges that build on a rotatable shaft extending from an electrically-grounded motor housing or rotating shafts conductively linked to components that create and electrical charge, such as wind turbine blades, power generator turbines, and the like. The system includes a frame defining a central opening wherein the rotatable shaft is positioned with the central opening, a first grounding fiber secured within the frame, and a fiber clamp positioned with the frame. The fiber clamp acts to urge the first grounding fiber toward the central opening. The system may also include a mounting bracket having a frame mounting channel, wherein a portion of the frame is securely retained within the frame mounting channel, and an installation guide positioned on the mounting bracket. The installation guide may be configured to properly align the frame and the first grounding fiber relative to the rotatable motor shaft.

Owner:ILLINOIS TOOL WORKS INC

Motor and brush holder thereof

ActiveUS20060244321A1Suppress electromagnetic noiseRotary current collectorAssociation with grounding devicesSliding contactCapacitor

A brush holder of a motor is provided with a holder body portion and a connector portion, which are integrally formed from a resin. The holder body portion is installed in a yoke housing of the motor to hold a brush to be in slide contact with a commutator. The connector portion is connected with an external connector to energize an armature. A grounding terminal is embedded in brush holder to extend from the holder body portion to the connector portion to be connected to a grounding line of the external connector. A capacitor is installed on the holder body portion to connect a point on a power supply terminal between the connector portion and the brush to the grounding terminal.

Owner:DENSO CORP

Popular searches

Record information storage Recording on magnetic disks Electrostatic charges Arrangements responsive to excess voltage Multiple motor speed/torque control Generators/motors Modifications using gaseous coolants Association for rectification Motor/generator/converter stoppers Dynamo-electric converter control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com