Patents

Literature

1161results about How to "Prevent static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

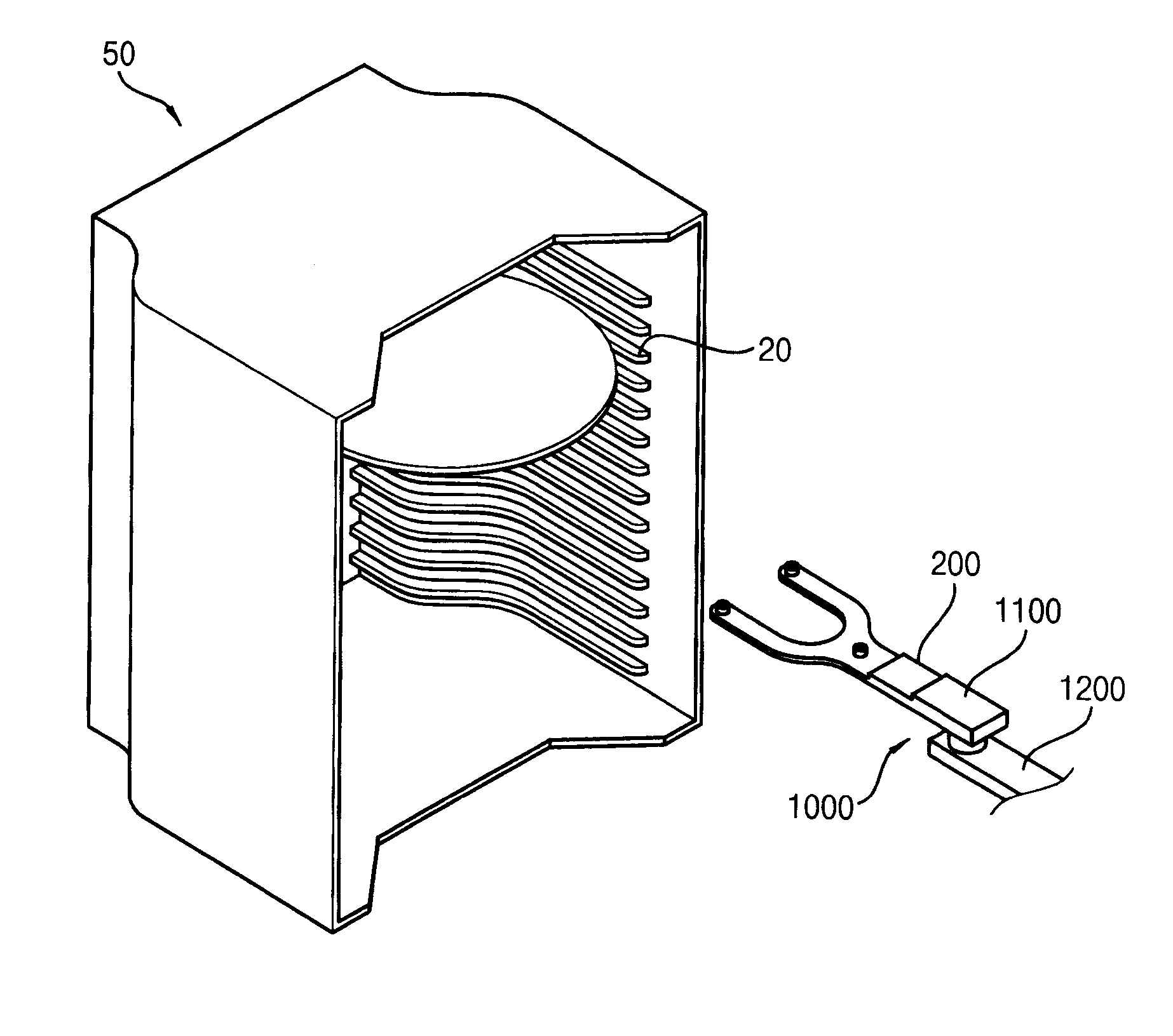

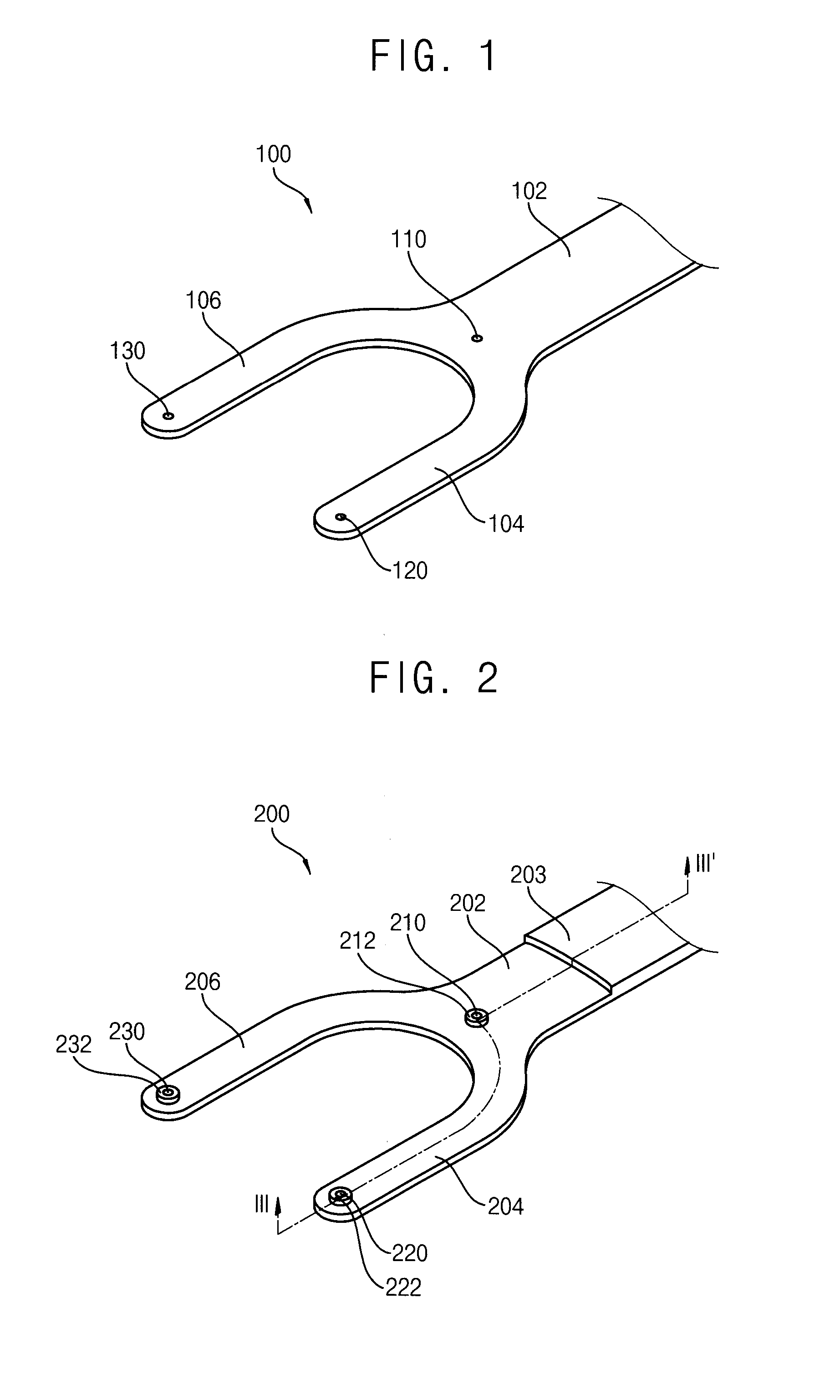

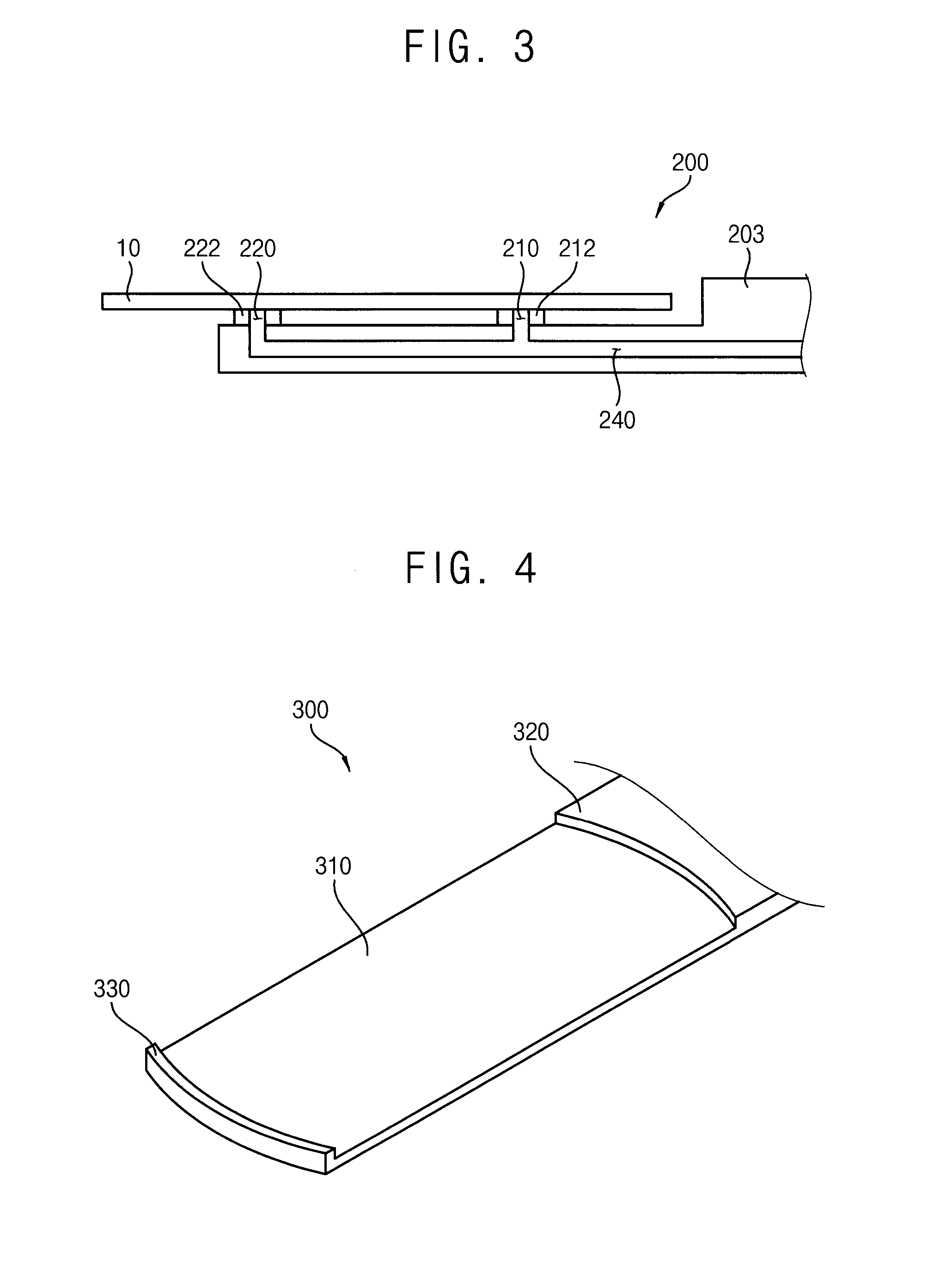

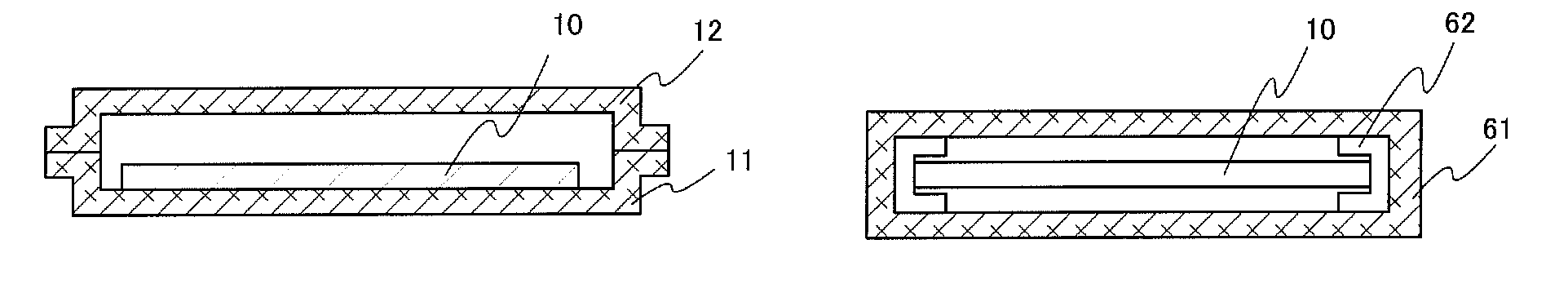

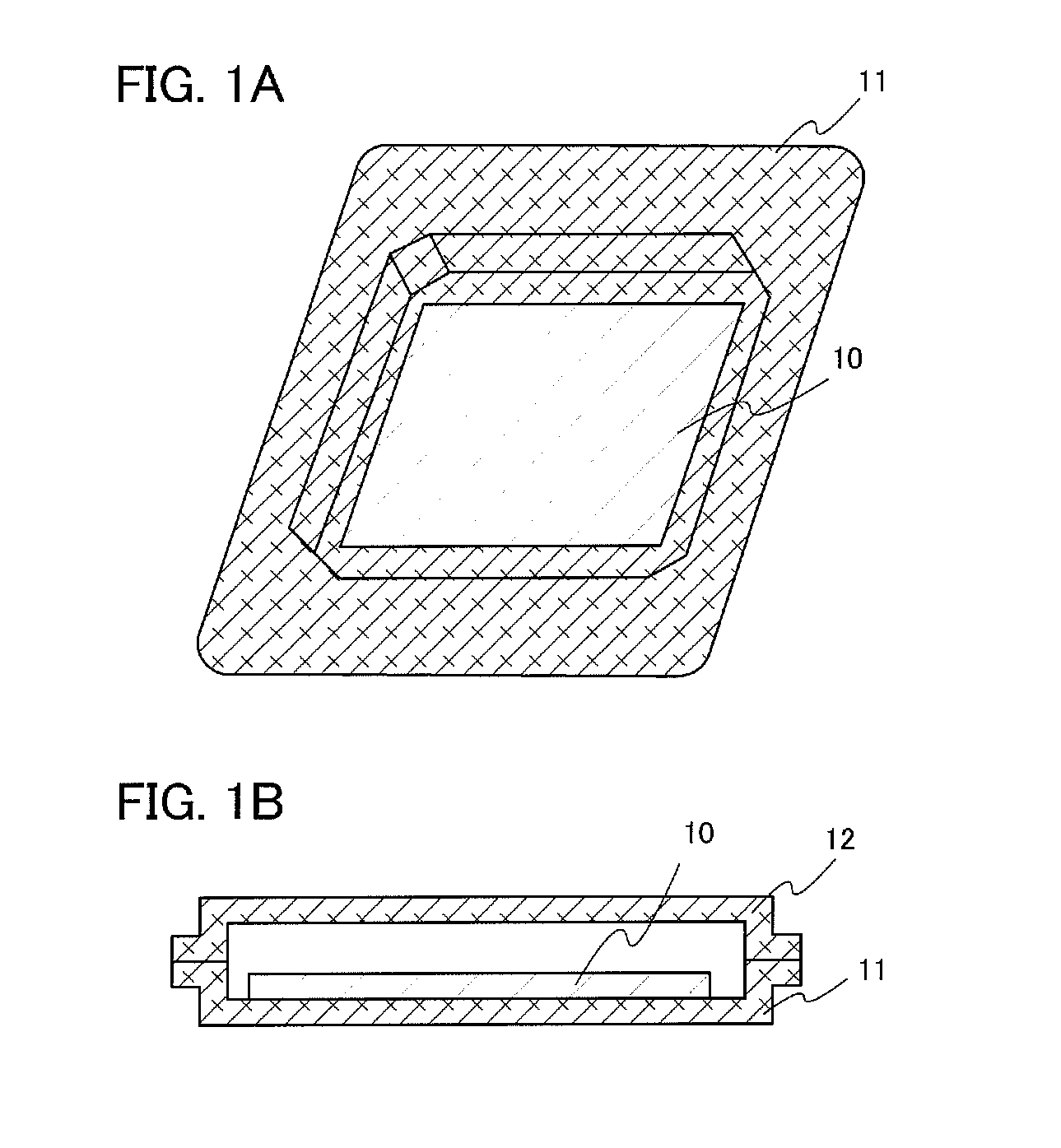

Wafer transfer blade and wafer transfer apparatus having the same

InactiveUS20140227072A1Damage is prevented and mitigatedDamage can be prevented and mitigatedGripping headsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

A wafer transfer blade including a body including metal oxide and configured to support a wafer, and an adsorbing part on the body, the adsorbing part having at least one therein and configured to apply vacuum pressure to attach the wafer on the body may be provided. The body may include metal oxide to prevent static electricity.

Owner:SAMSUNG ELECTRONICS CO LTD

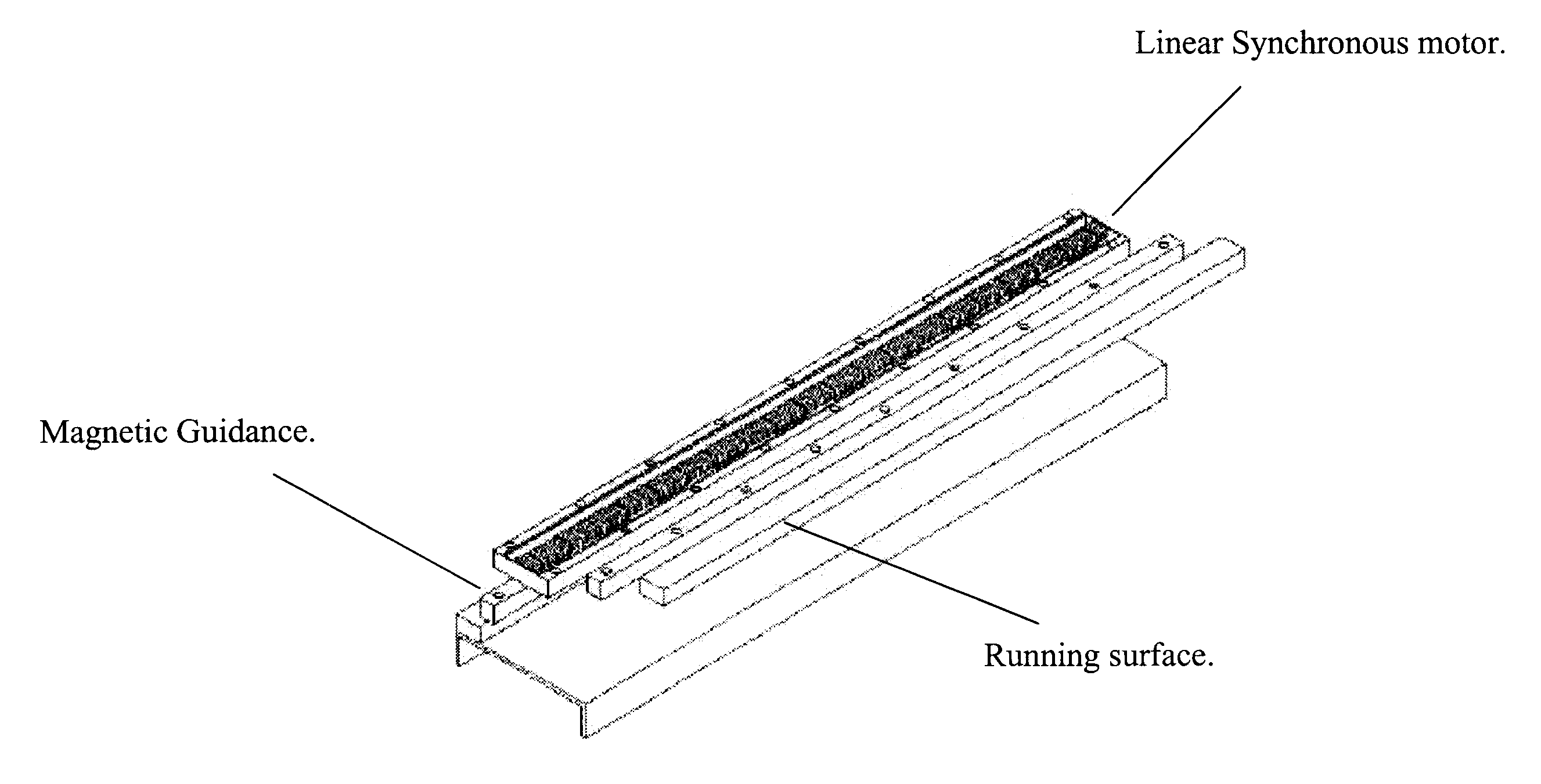

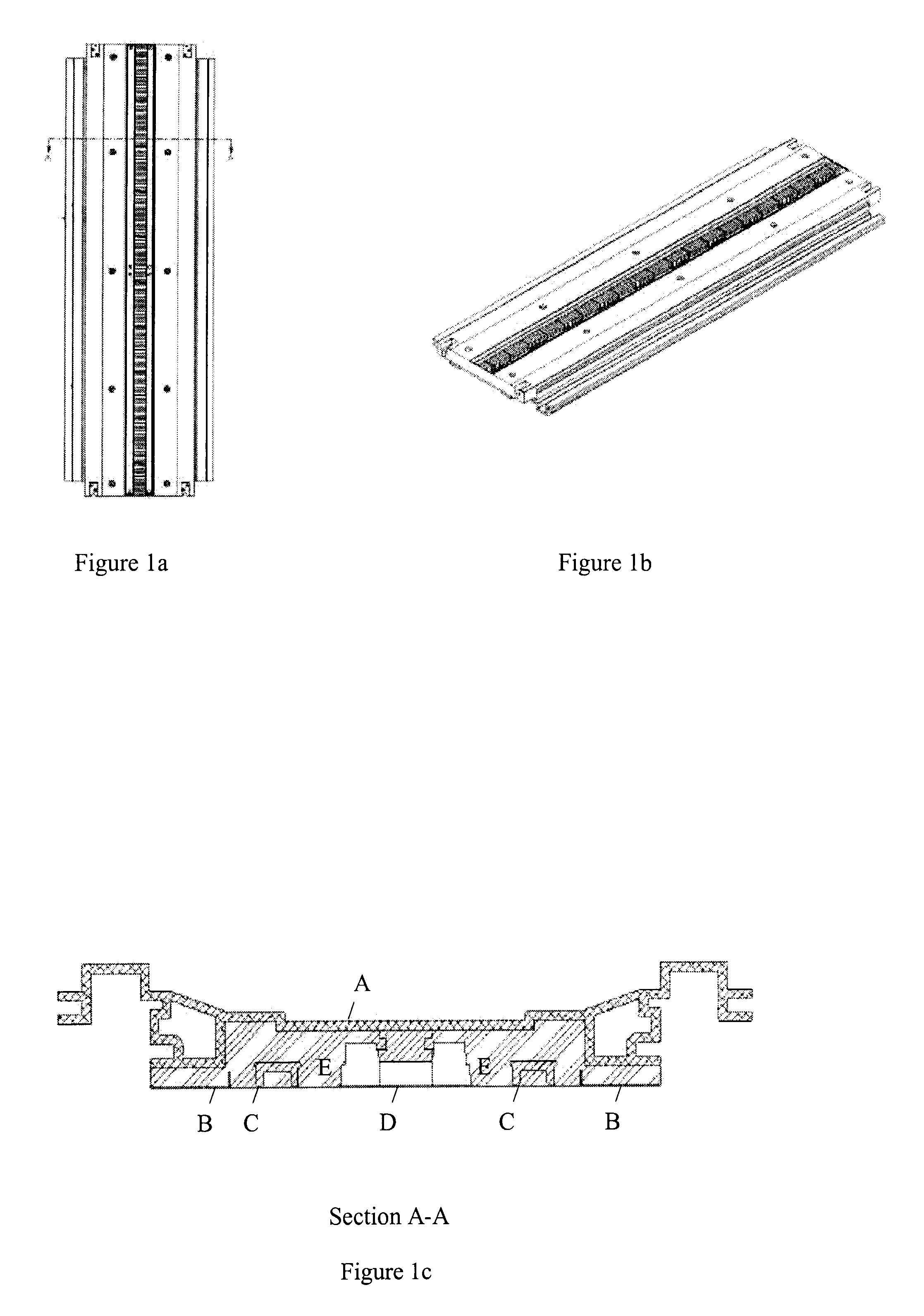

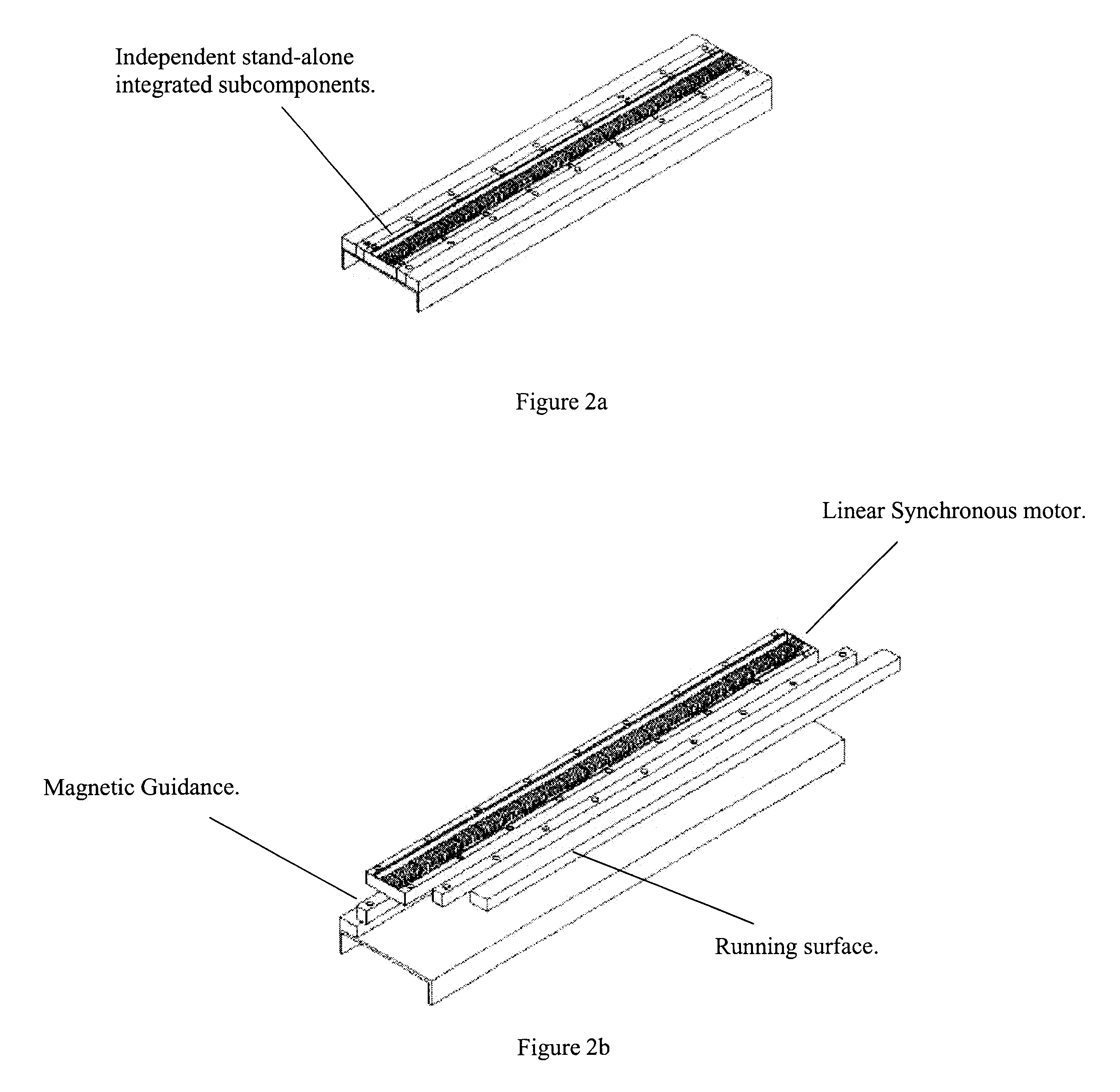

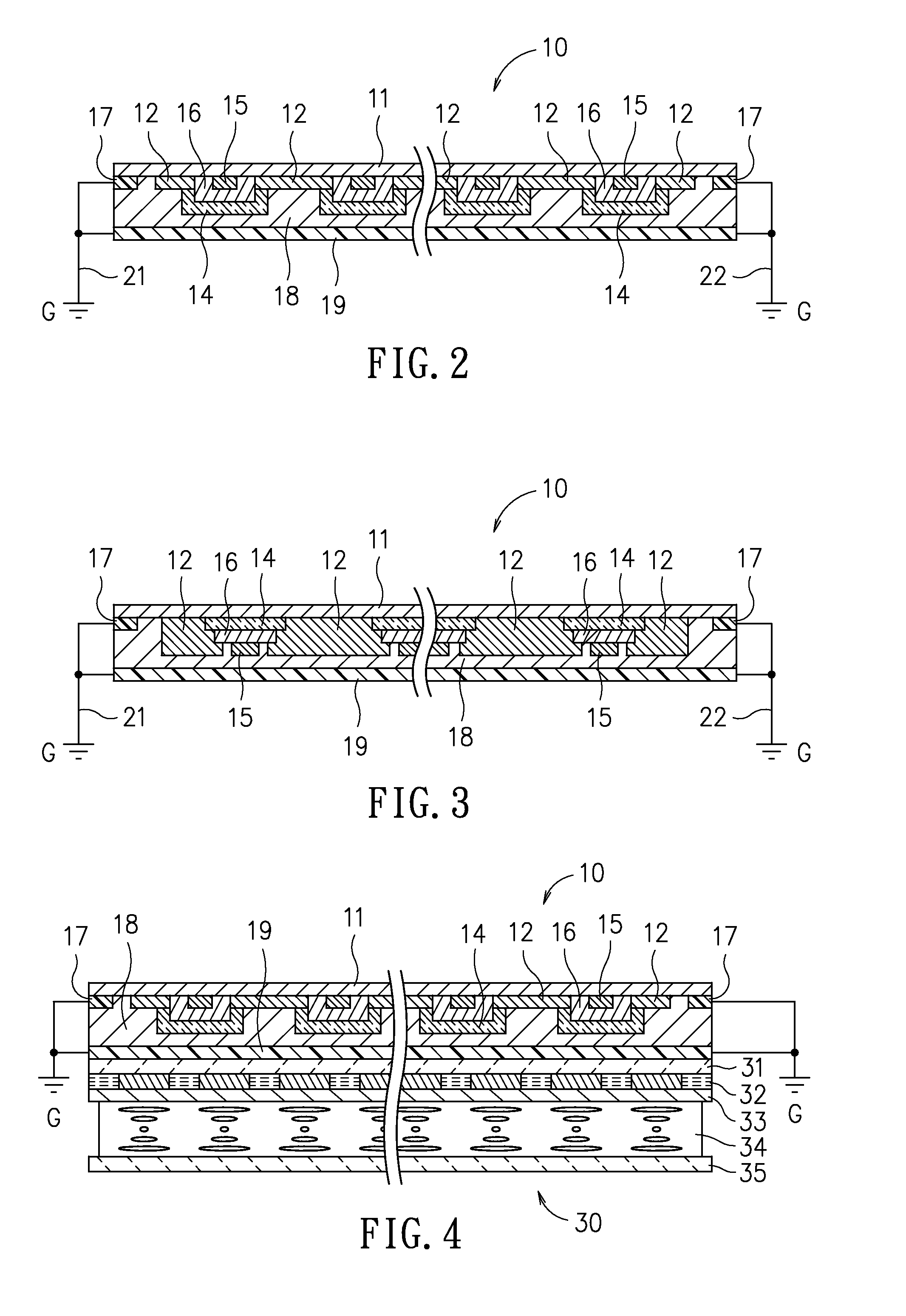

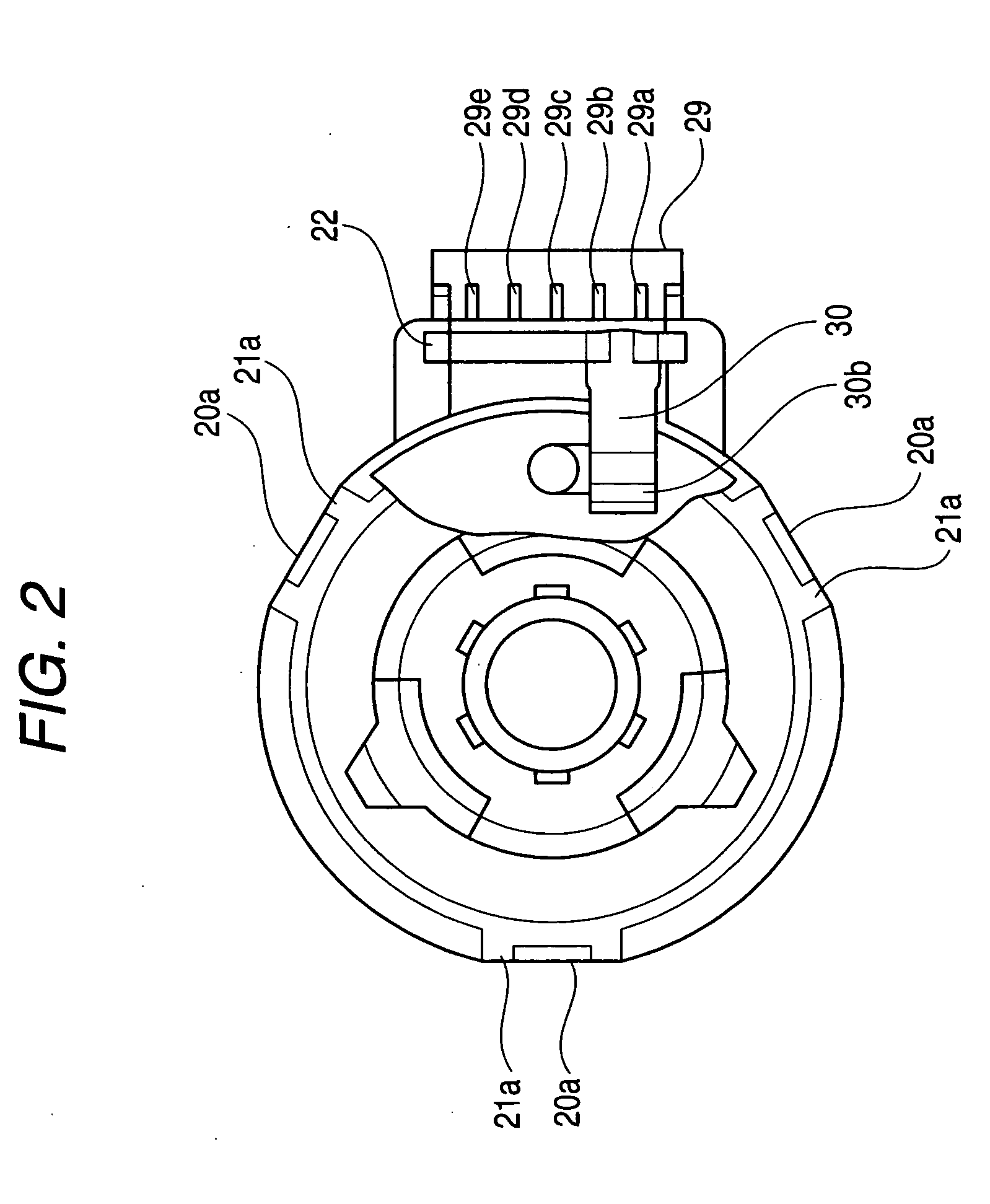

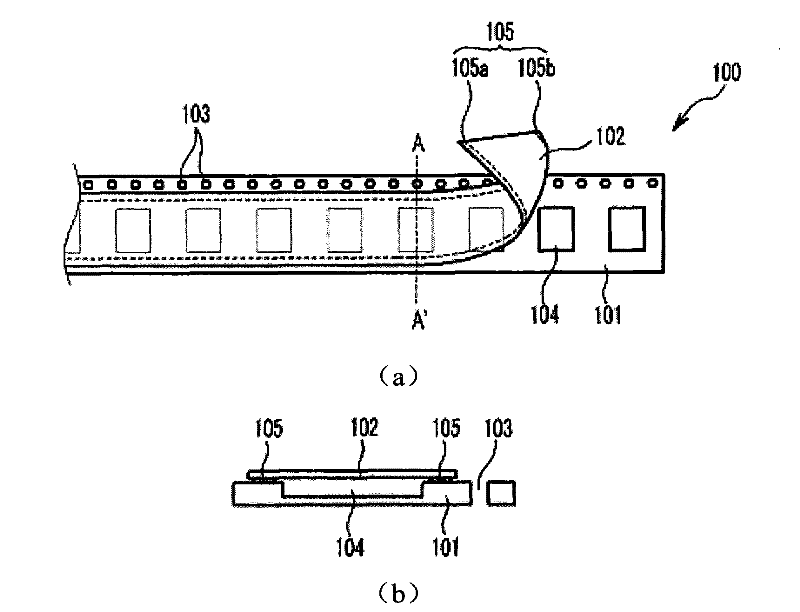

Modular linear motor tracks and methods of fabricating same

InactiveUS6578495B1Low costMaintain positioning accuracyRailway vehiclesElectric vehicle charging technologyModularityComputer module

A module for a linear motor propulsion guideway contains a combination of linear motor propulsion, vehicle guidance, position sensing, communication, and vehicle or pallet running surface subcomponents. These are integrated during the manufacturing into a single component or module for ease of shipping and precision of installation at a site where the guideway is to be installed. A single manufacturing operation is used to position, affix, and encapsulate the selected subcomponent(s) in a module or modules. For example, the component(s) can be designed to be located in a plastic injection mold, typically, a reaction injection mold (RIM), which allows the subcomponent(s) to be positioned, aligned, and encapsulated in a single manufacturing step that has only a several minute cycle time. In this manner positional accuracy among the relationship of the subcomponent(s) can be maintained within a small tolerance (on the order of 0.25 mm) while costs remain very low.

Owner:MAGNEMOTION INC

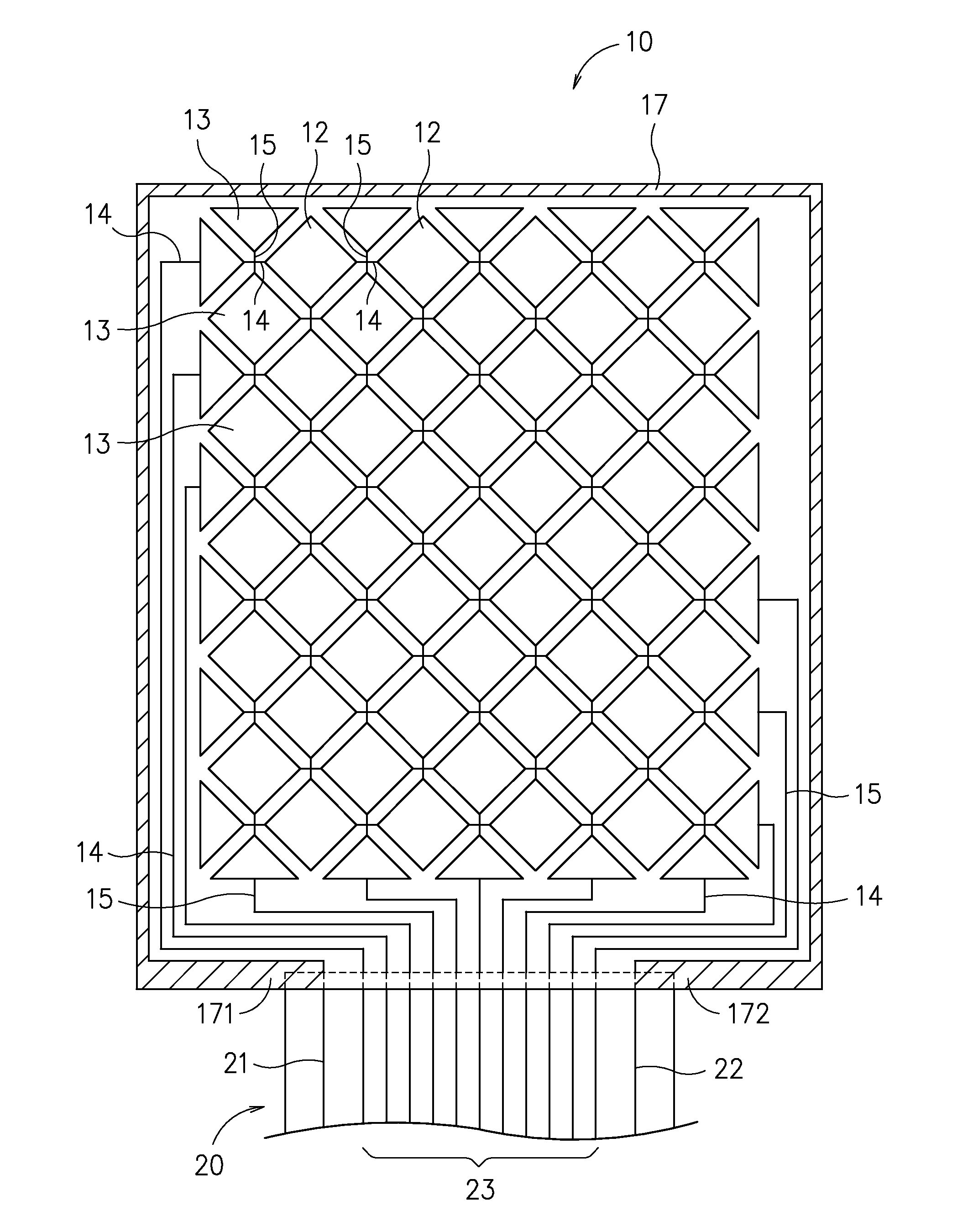

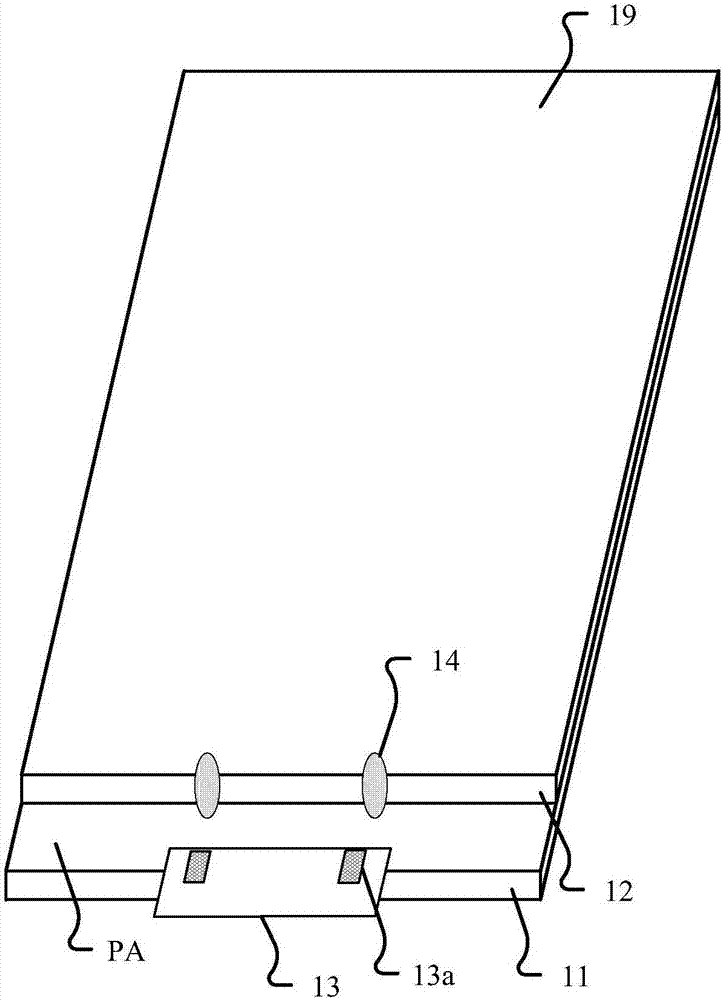

Touch panel and touch display device using the same

InactiveUS20120075218A1Prevent be damagePrevent static electricityInput/output processes for data processingTouch panelEngineering

A touch panel comprising a substrate, a touch element, a first grounding electrode, an insulation layer and a second grounding electrode is disclosed. The touch element is disposed on a first surface of the substrate. The first grounding electrode is disposed on the first surface to surround the touch element. The insulation layer is disposed on the first surface to cover the touch element and the first grounding electrode. The second grounding electrode is disposed on the first insulation layer or on a second surface of the substrate opposite to the first surface. Therefore, the ESD can be conducted to the grounding end G of the circuit component through the enclosed first grounding electrode, and the signal interference between the touch panel and display can be shielded by the second grounding electrode to enhance anti-ESD and anti-noise abilities of the touch panel.

Owner:WINTEK TECH DONGGUAN +1

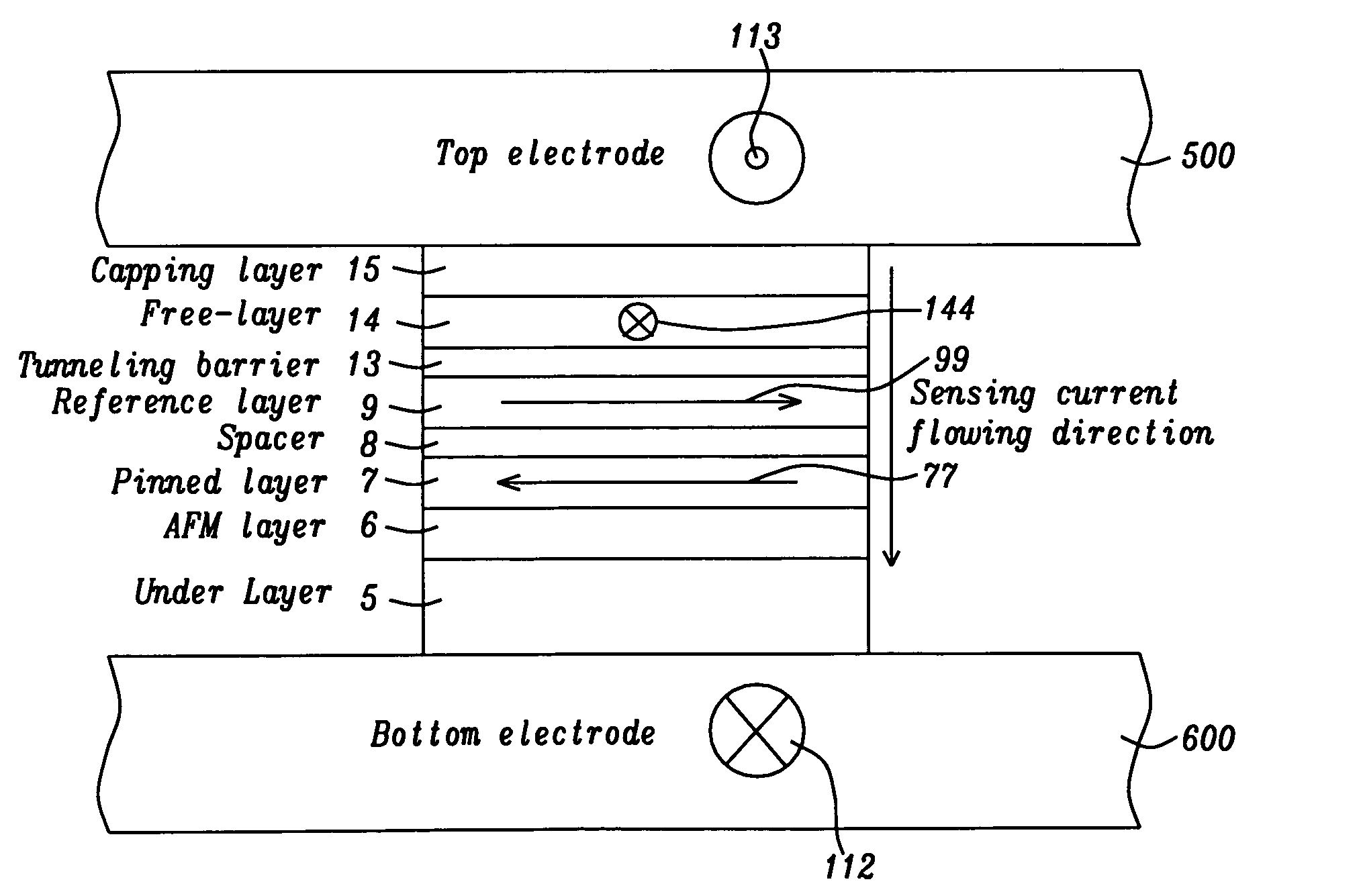

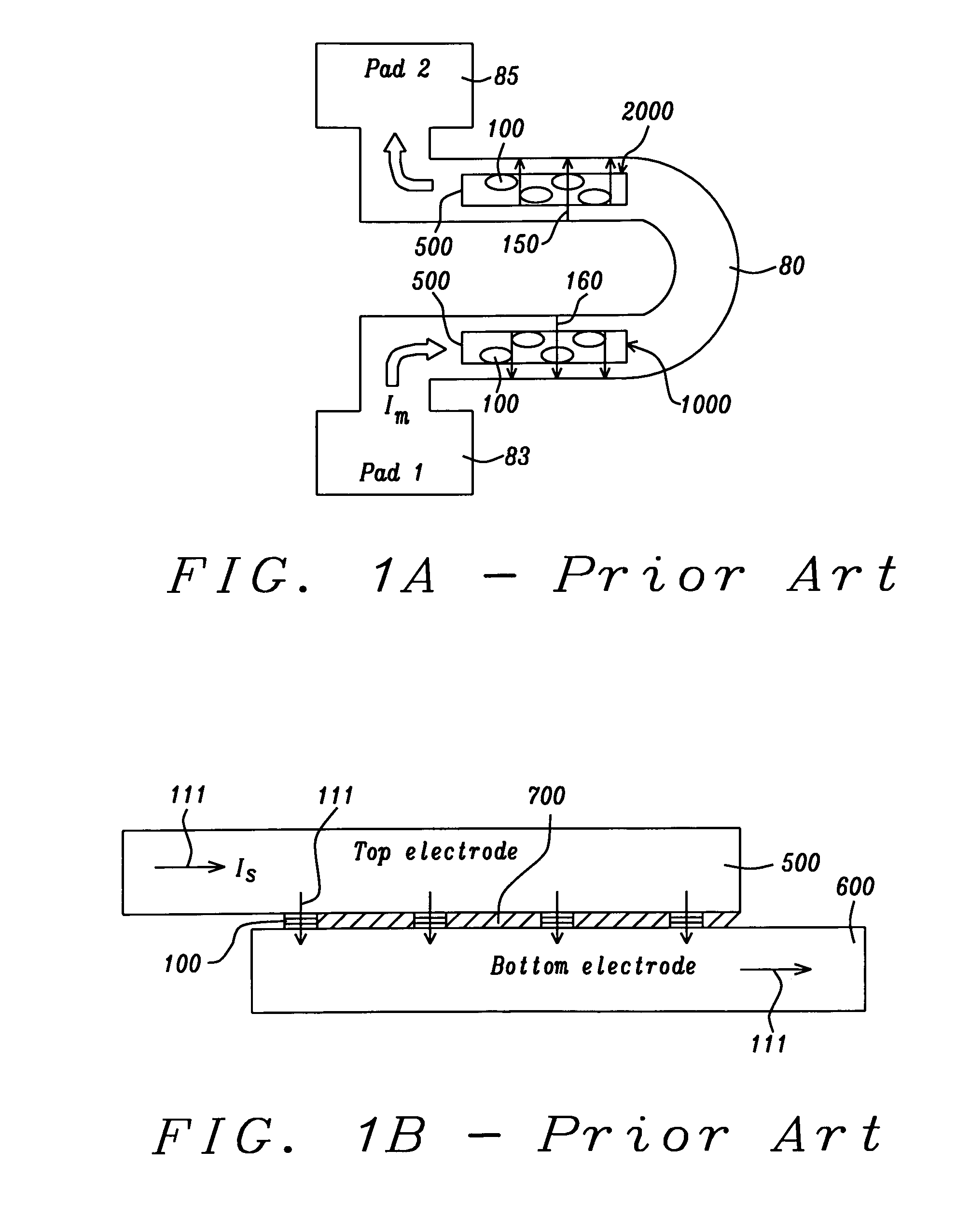

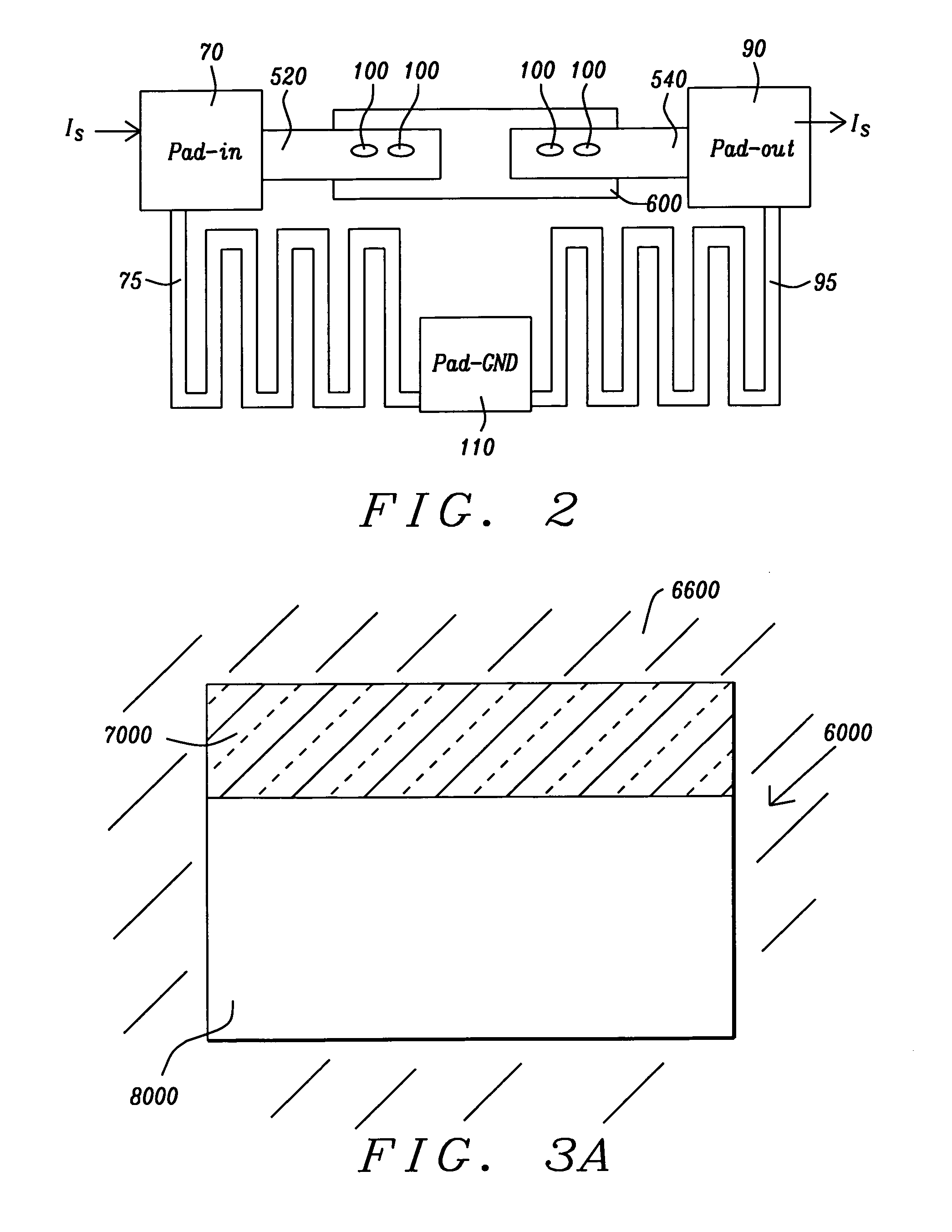

MTJ based magnetic field sensor with ESD shunt trace

ActiveUS20100007344A1Prevent static buildupEliminate non-reproducibilityCurrent/voltage measurementManufacture of electrical instrumentsHigh resistanceElectrical resistance and conductance

Presented herein is a shunted MTJ sensor formed of a plurality of electrically connected MTJ cells for measuring magnetic fields and currents and its method of fabrication. To provide stable single domain magnetic moments of the MTJ cells and to ensure that the magnetic moments return to a fixed bias point in the absence of external magnetic fields, the cells are formed of sufficiently small size and with elliptical cross-section of aspect ratio greater than 1.2. To eliminate the possibility of ESD damage to the cells, they are protected by a parallel shunt, formed as a trace of sufficiently high resistance that directs accumulated charges harmlessly to ground while bypassing the cells.

Owner:HEADWAY TECH INC

Chemical etching, cleaning and drying method of single-crystal silicon solar battery and integrated processing machine

InactiveCN101087007AImprove reflective effectAvoid secondary pollutionFinal product manufactureSemiconductor devicesEtchingWater source

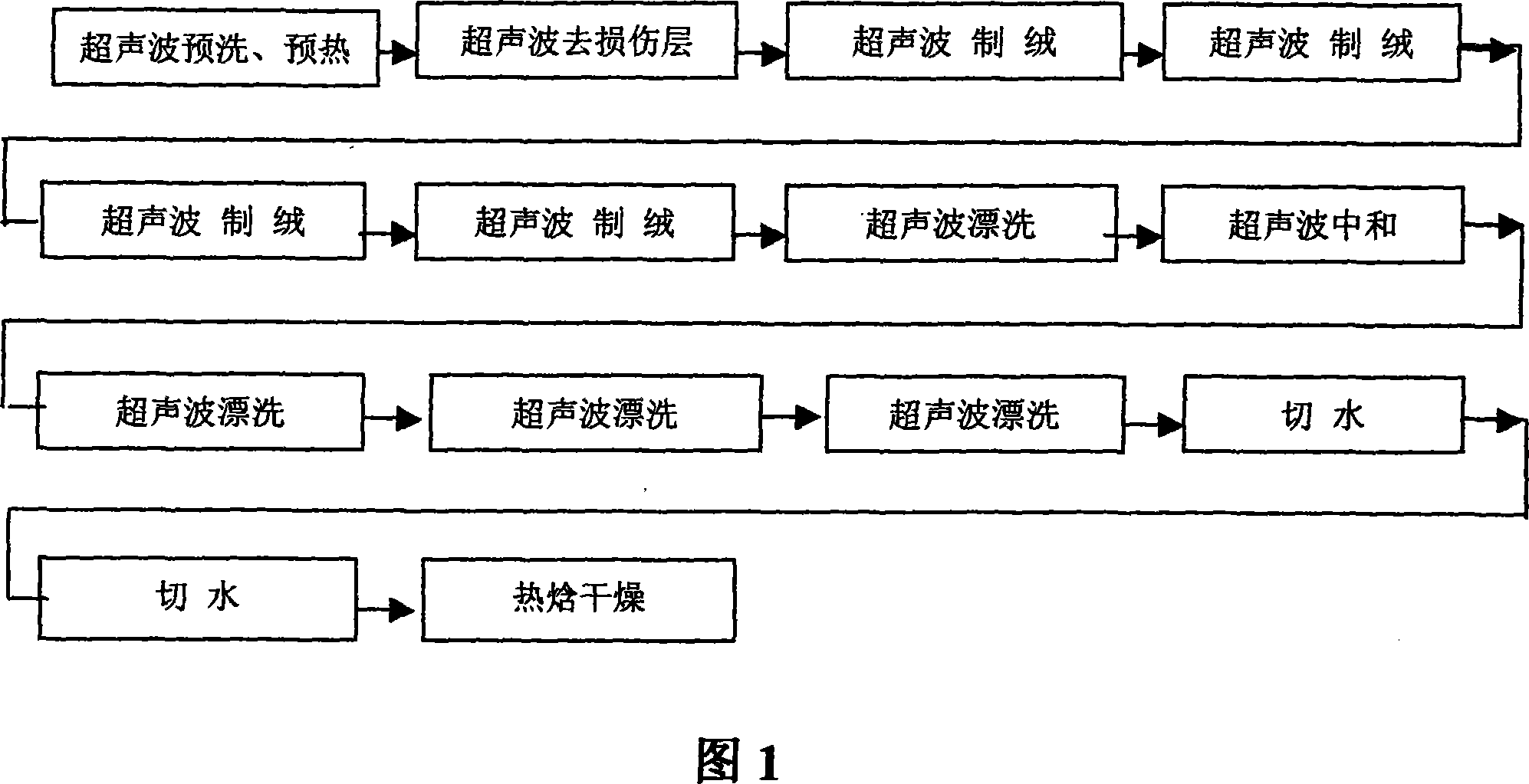

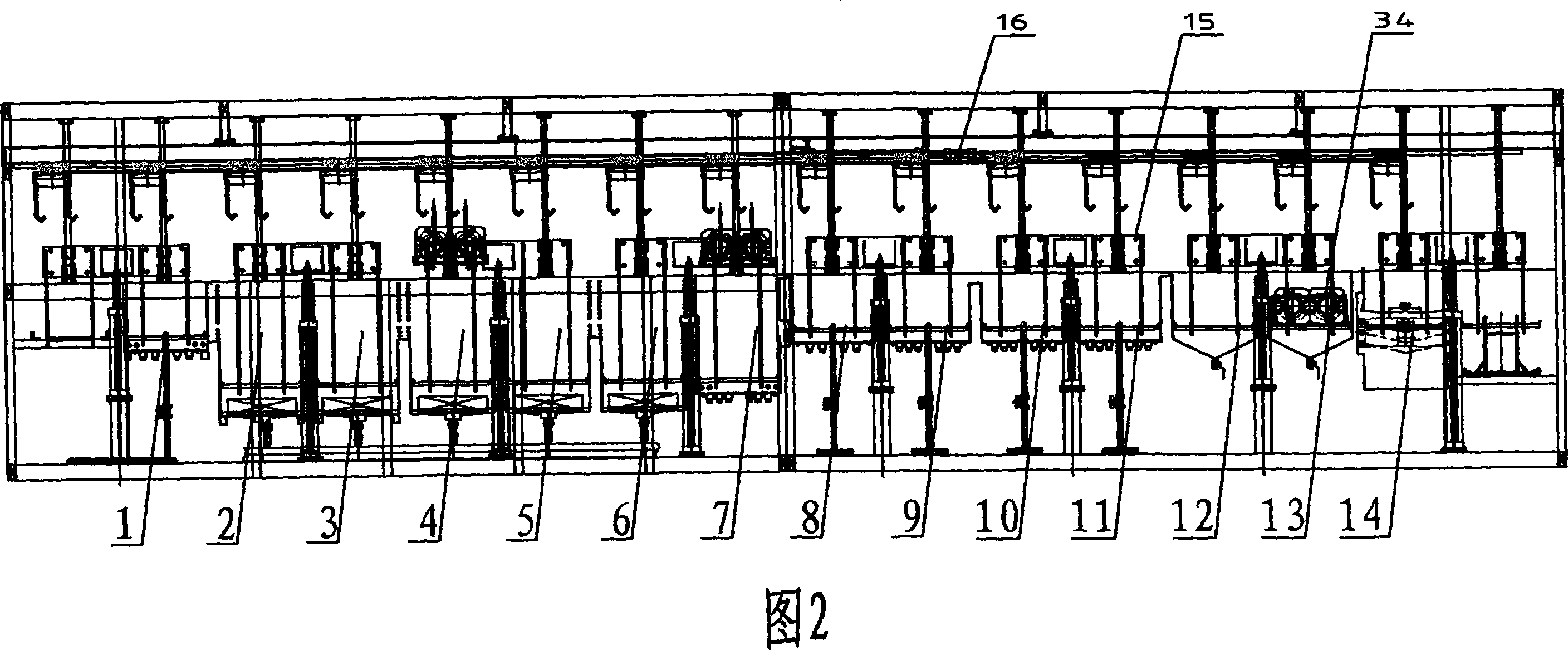

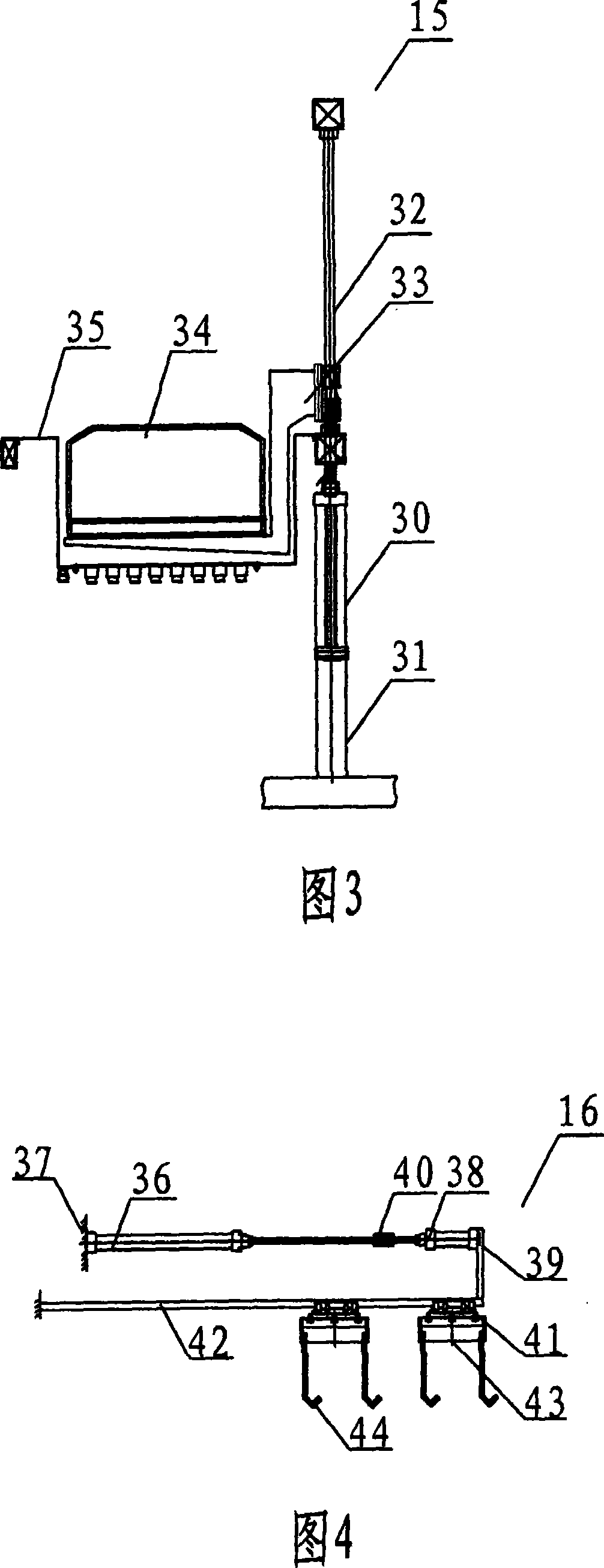

Monocrystalline silicon solaode chemical etching, washing, drying method and integral processor belong to technique field of chemical etching technique and washing. It characterized in that it not only includes water, acid, alkali, but also ultrasonic participates in etching and washing course: it includes following steps: (1) ultrasonic washes and heats in advance, (2) ultrasonic removes damnification layer, (3) ultrasonic makes herbs into wool, (4) ultrasonic rinses, (5) washing with acid to counteract, (6) ultrasonic rinses, (7) cutting water, (8) hot enthalpy to dry. Positive effects of the invention are: adopting ultrasonic to etch and wash, liquid of making wool can be acted with silicon piece, similar coarseness degree can be generated on surface, perfect pyramid pattern can be obtained; it also eliminates kalium, natrium ion from alkalescent solution, and extends service life of silicon piece; pollution can be decreased, energy consumption and water source can be saved greatly, it is a practical invention.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH +2

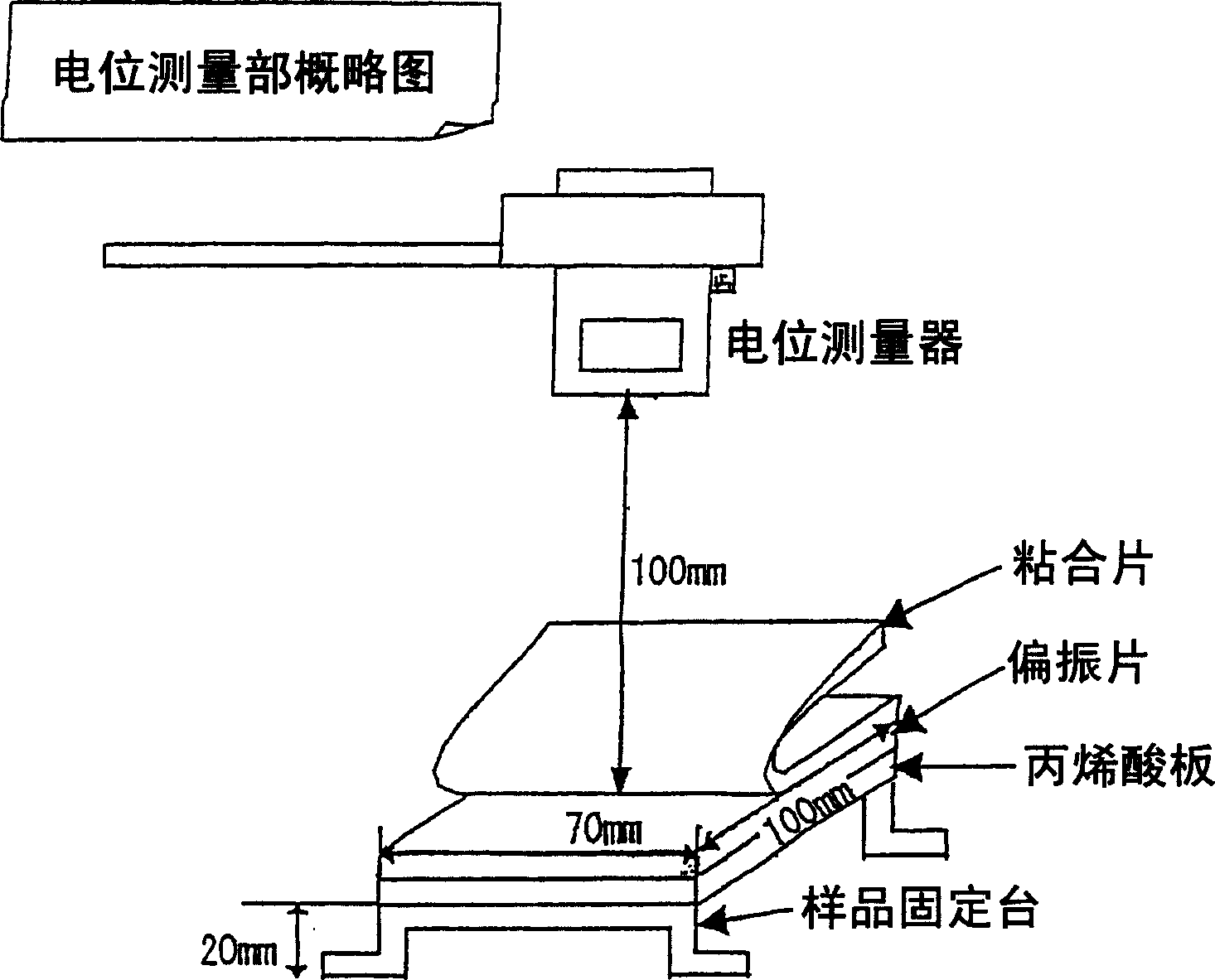

Adhesive film and image display device

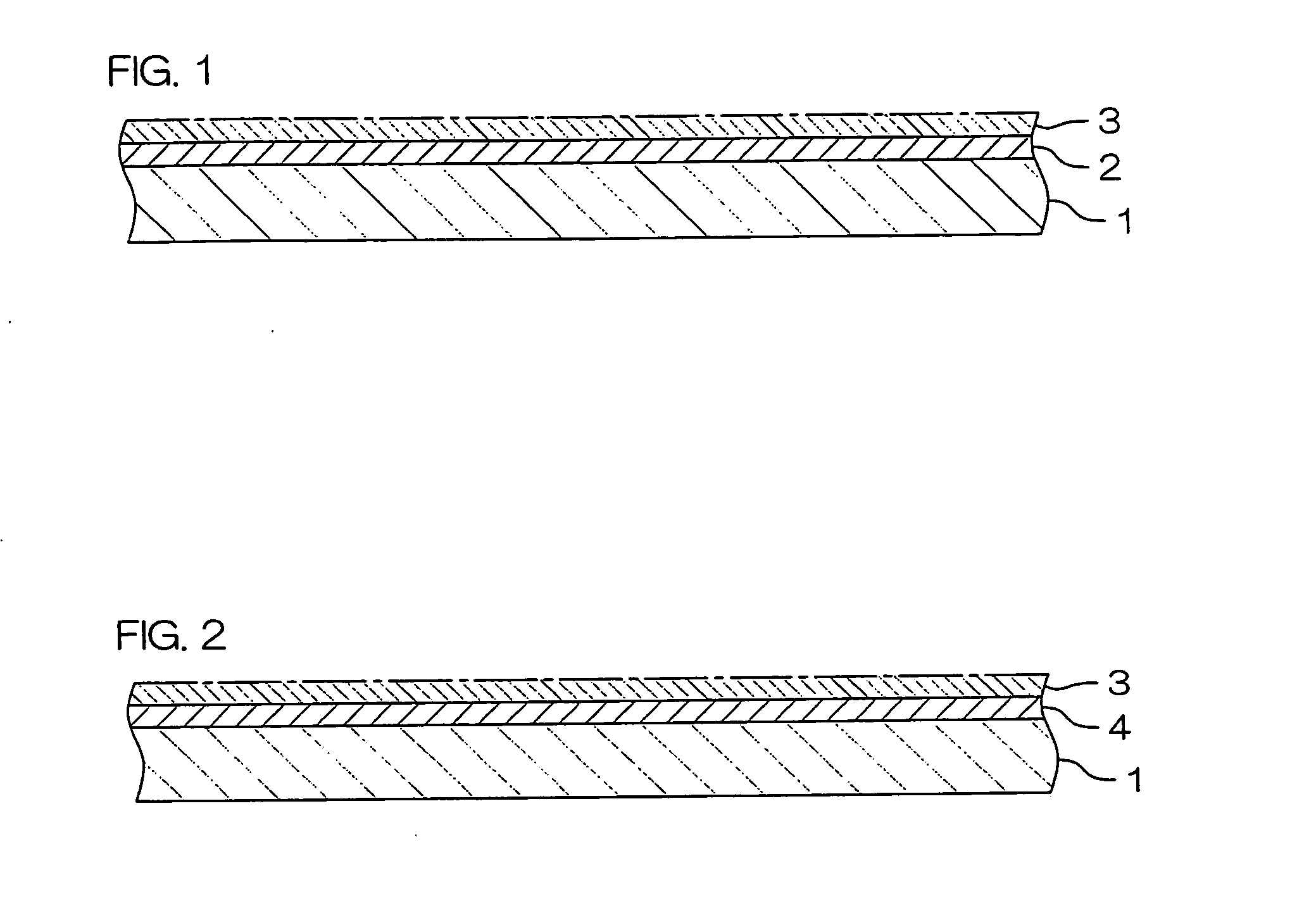

InactiveUS20070031660A1Improve bindingImprove adhesionSynthetic resin layered productsLaminationAntistatic agentWater dispersible

An adhesive film prevents static charge on peeling generated when removed from an adherend and also improves adhesion between a base material and an adhesive layer, where an under coat layer containing an organometallic is formed on the base material and then an adhesive layer is formed on the base material. Alternatively, an adhesive film showing high adhesion with a glass substrate, and including an antistatic layer, which prevents static charge on peeling generated when the surface protective film is removed, and improves adhesion between a base material and an adhesive layer, where the adhesive film includes a base material, an adhesive layer made of a water dispersible adhesive including, and an antistatic layer, containing a water soluble or water dispersible conductive material, interposed between them, and the adhesive film is stuck onto an image display device.

Owner:NITTO DENKO CORP

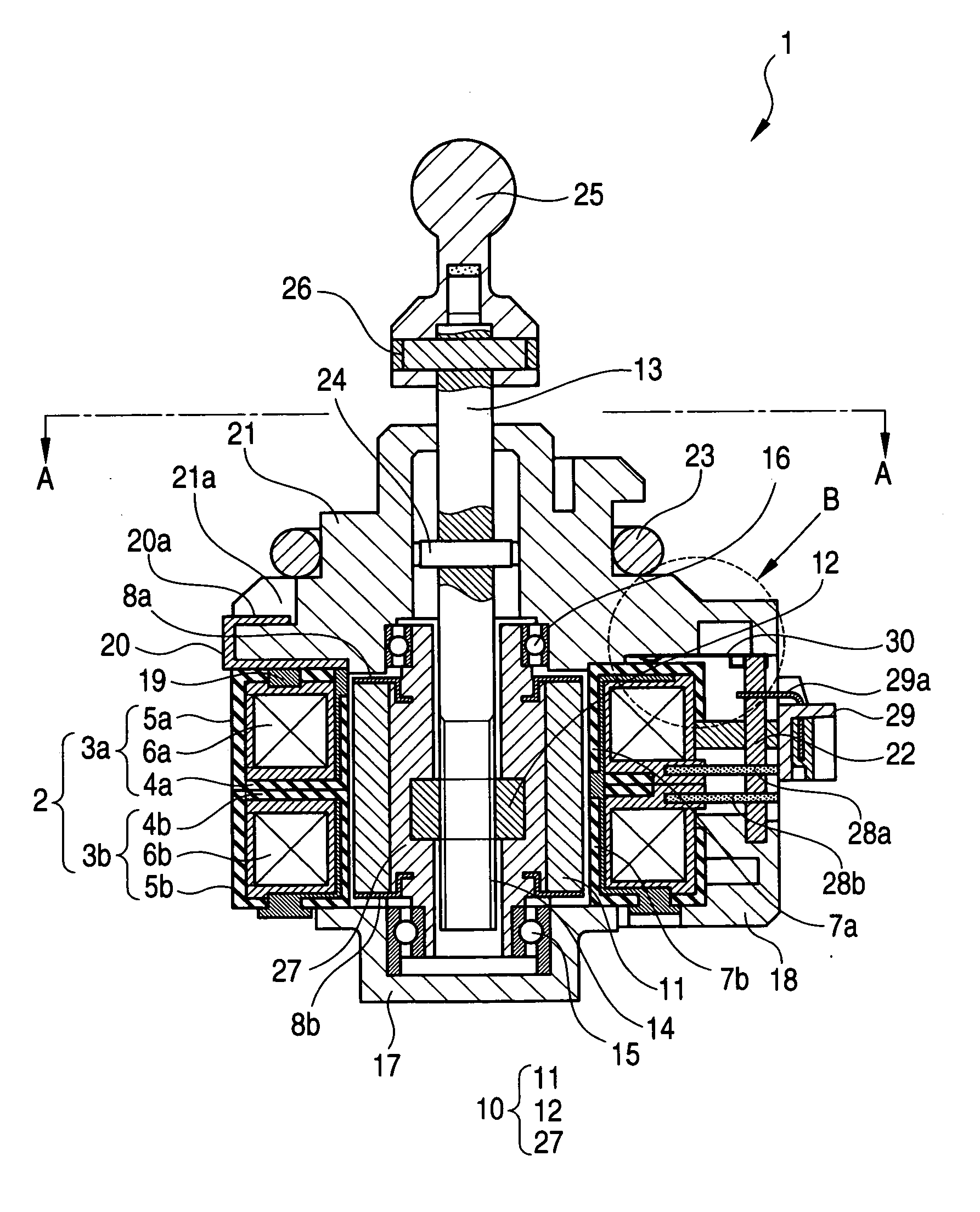

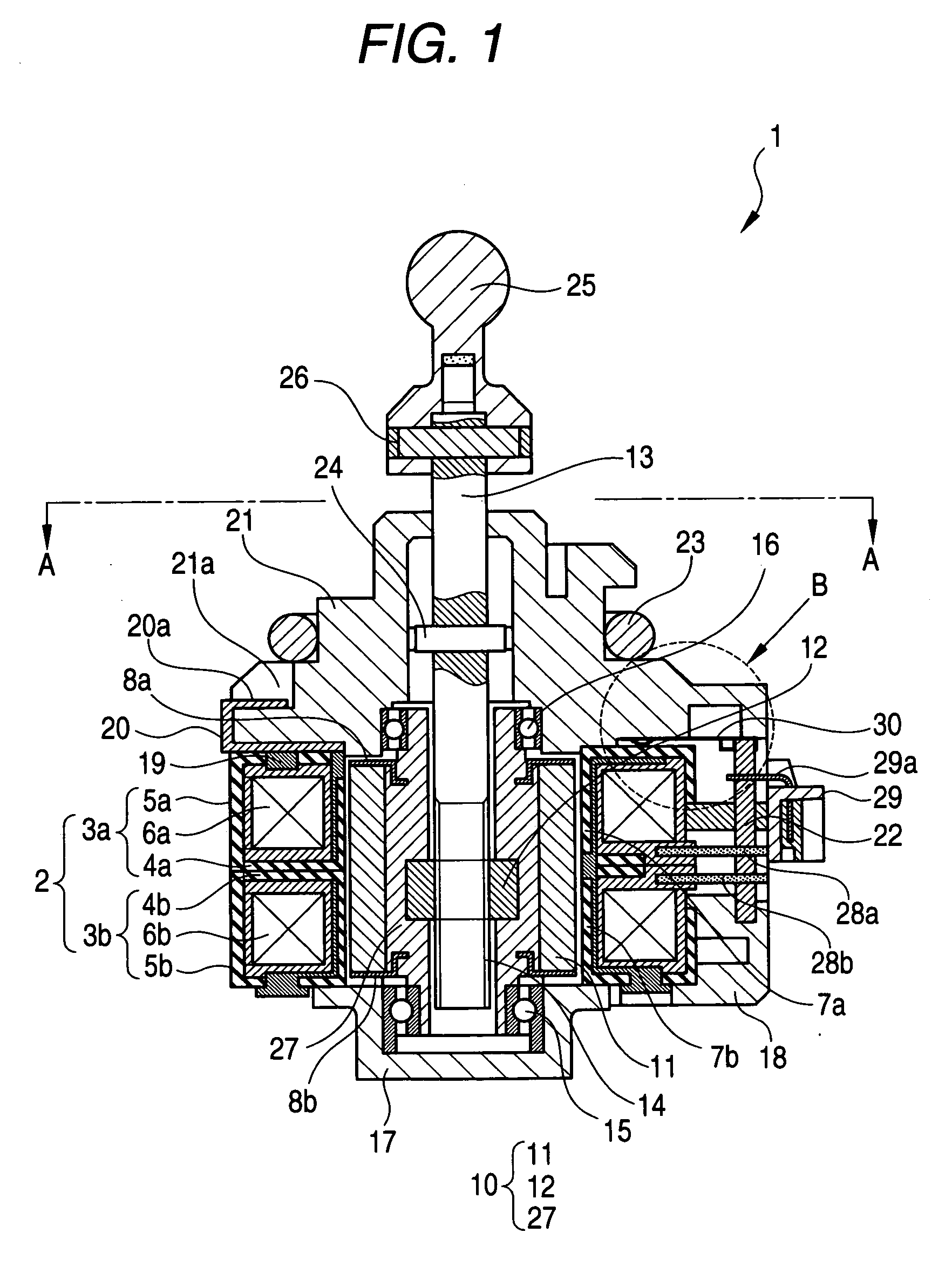

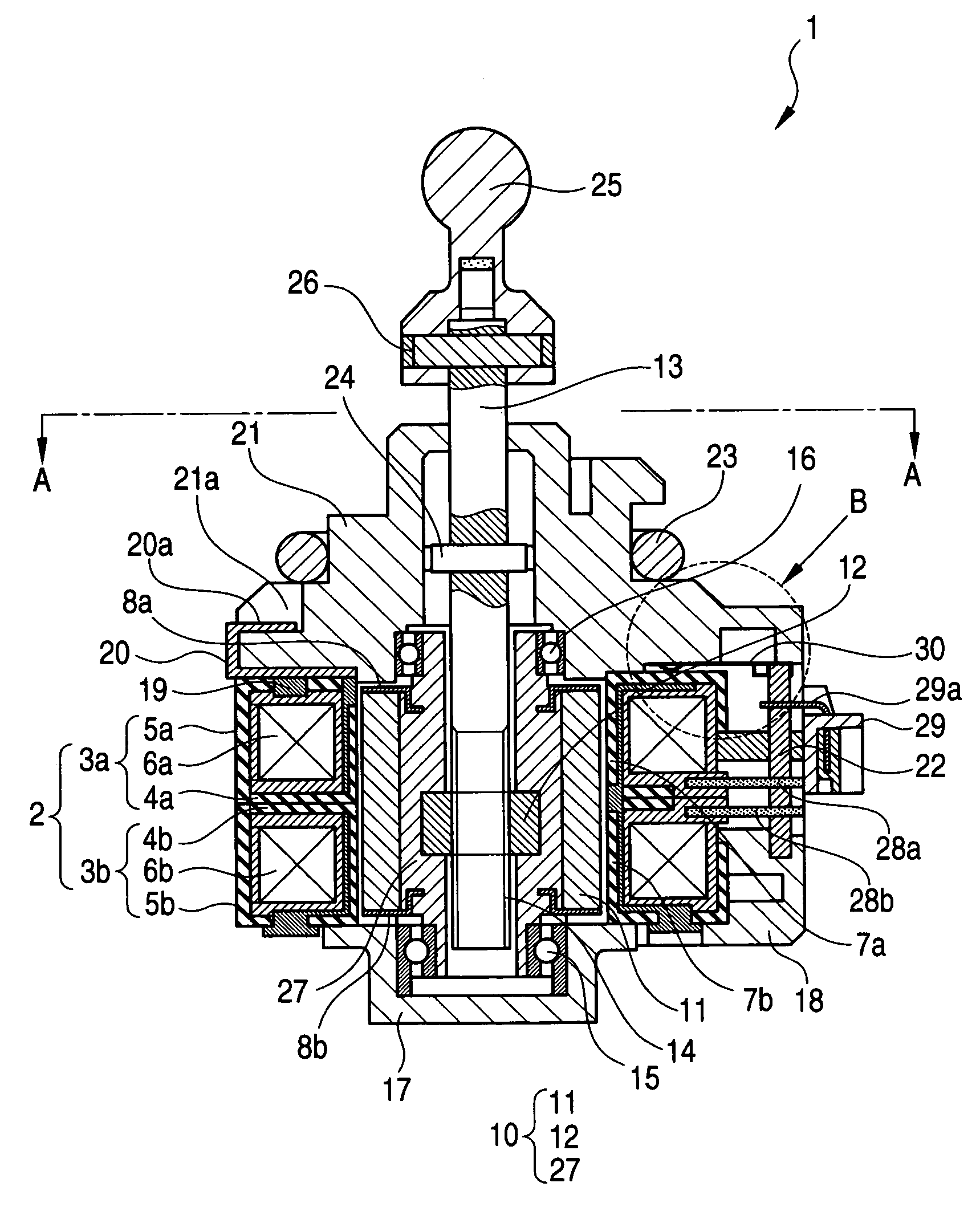

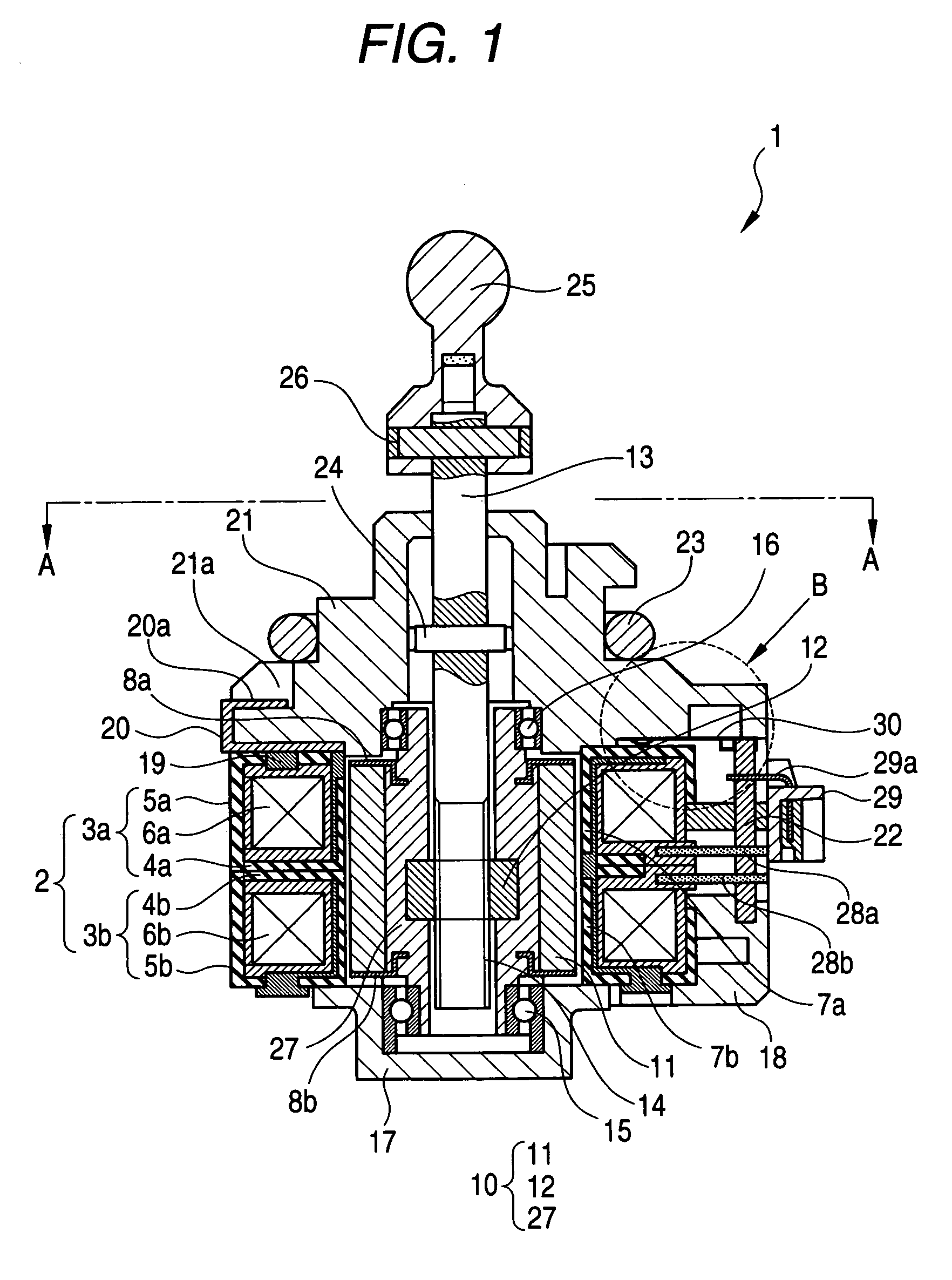

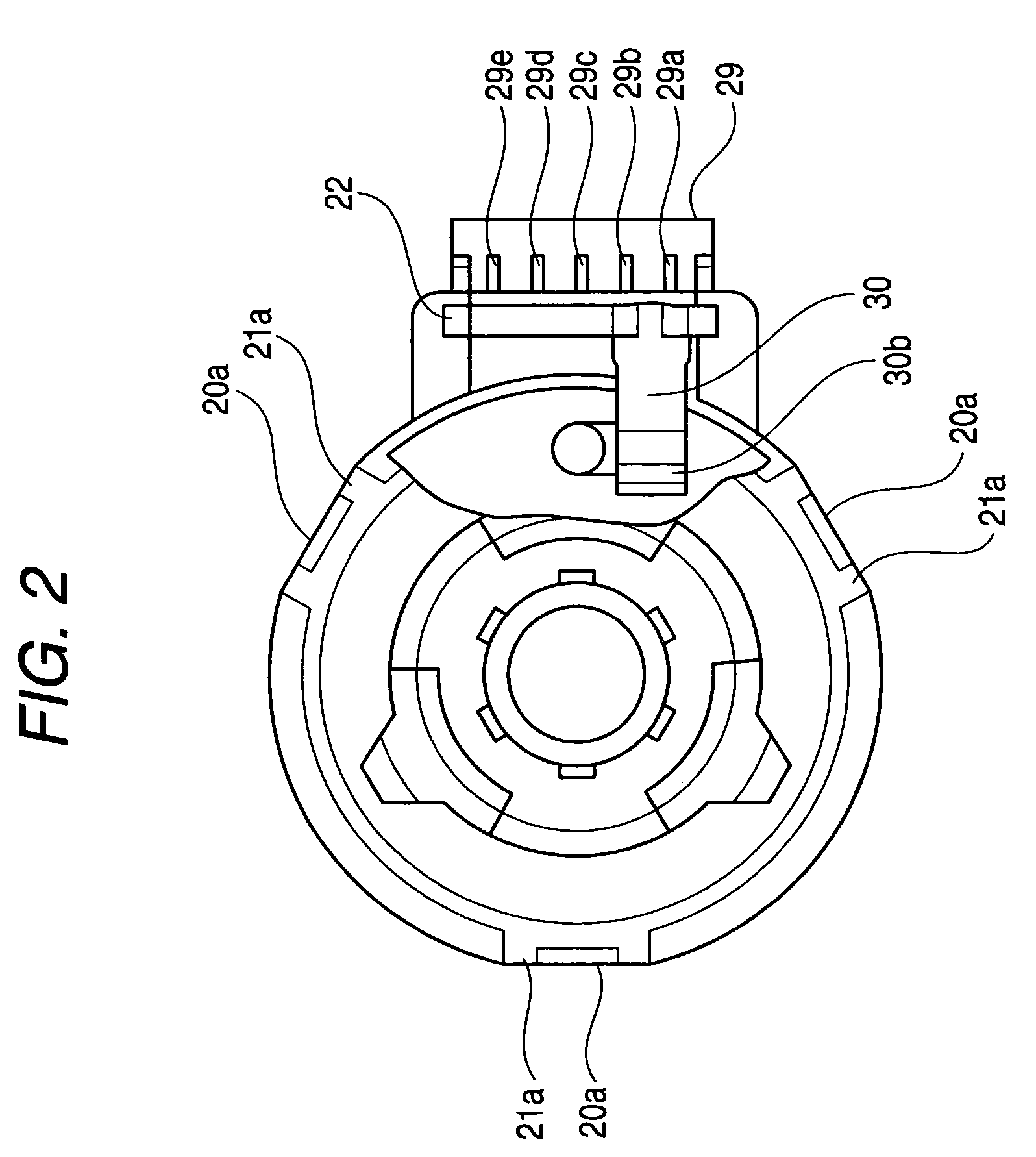

Actuator provided with grounding terminal

ActiveUS20050275297A1Noise effectPrevent static electricityAssociation with grounding devicesSupports/enclosures/casingsStatorMagnet

There is provided an actuator which includes: a stator assembly including a pair of stator yokes, and a coil disposed between the pair of stator yokes; a rotor unit including a magnet at its outer circumference and disposed inside the stator assembly; an output shaft disposed inside the rotor unit; a housing; a front plate disposed between the stator assembly and the housing; a printed board having a land portion leading to a grounding wire; and a grounding terminal having electrical conductivity and elasticity and disposed between the stator assembly and the housing. One end portion of the grounding terminal makes contact with one of the pair of stator yokes, and the other end portion thereof makes connection to the land portion of the printed board, whereby static electricity and electromagnetic noises generated in the stator assembly are conducted to the grounding wire.

Owner:MINEBEAMITSUMI INC

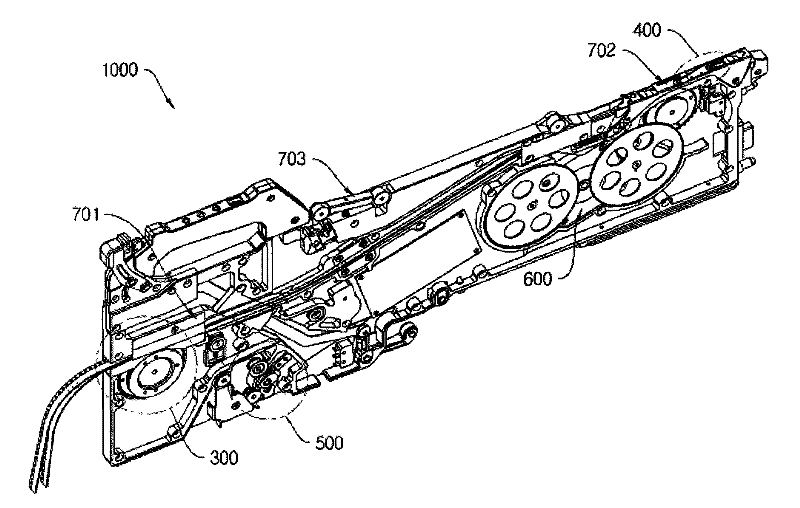

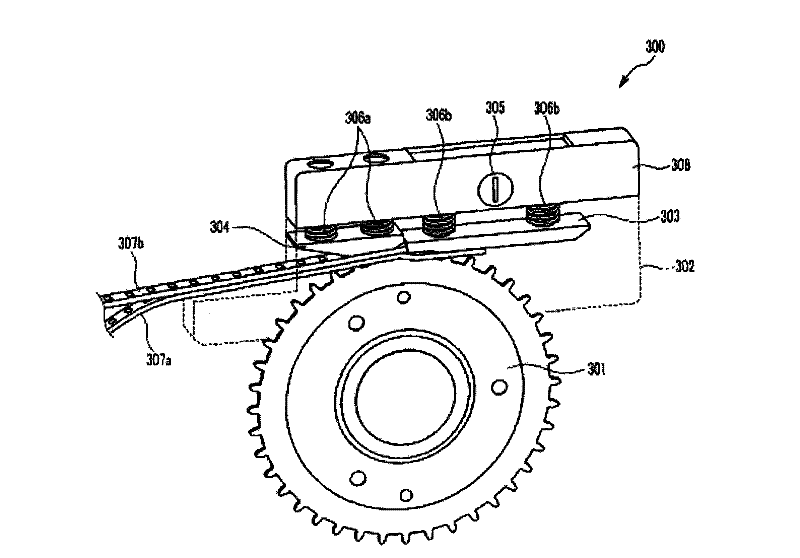

Carrier tape feeder

InactiveCN102209462AEasy replacement workShorten the timeMetal-working apparatusAdhesivesMechanical engineering

A carrier tape feeder is provided. The carrier tape feeder includes a unit for loading a carrier tape, a picking-up unit and a driving unit. The pick-up unit includes a knife portion, a folding-guiding portion, and an inversion-guiding portion. The knife portion separates a cover tape from a base tape in a first adhesive portion. The folding-guiding portion is spaced from one lateral side of the knife portion to induce folding of the cover tape separated by the knife portion in the lengthwise direction in a state in which the cover tape is partially attached to the base tape in a second adhesive portion. The inversion-guiding portion extends in an oblique direction from the knife portion and the folding-guiding portion toward the outside of the carrier tape to induce inversion of the upper and lower surfaces of the cover tape folded in the folding-guiding portion so as to be superimposed on the base tape. The distal end of the lateral side of the folding-guiding portion opposed to the knife portion extends above the second adhesive portion.

Owner:STS

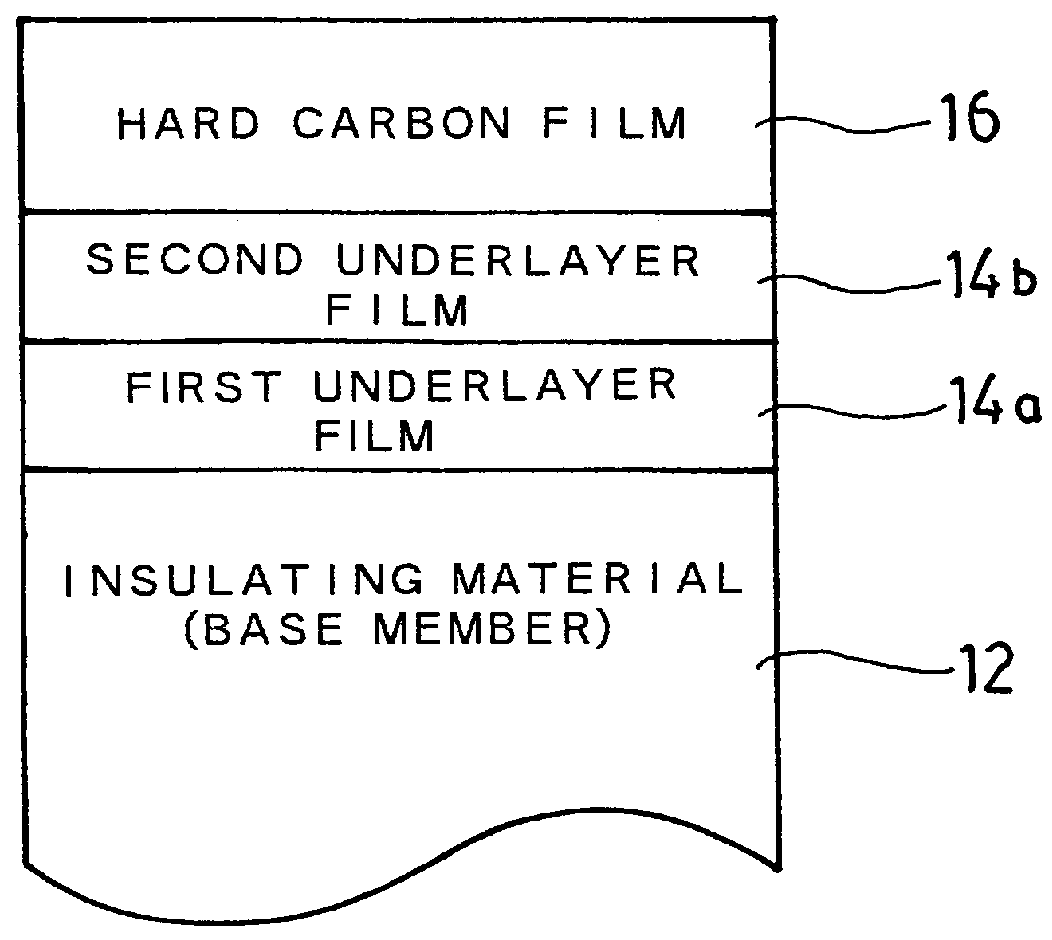

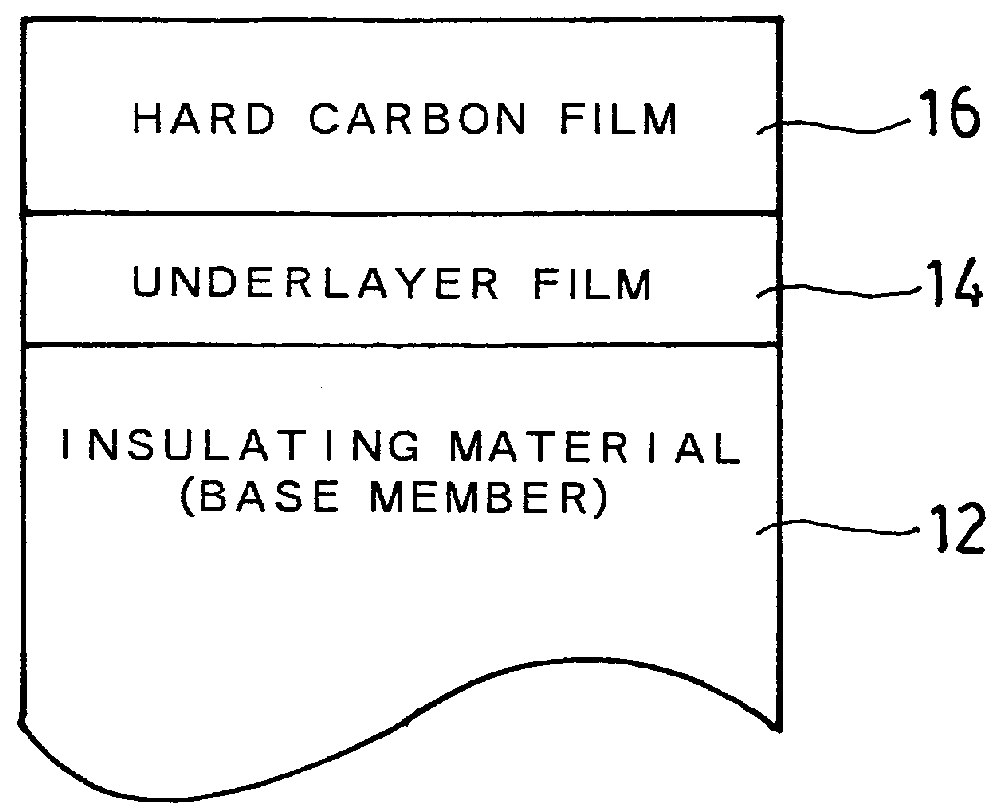

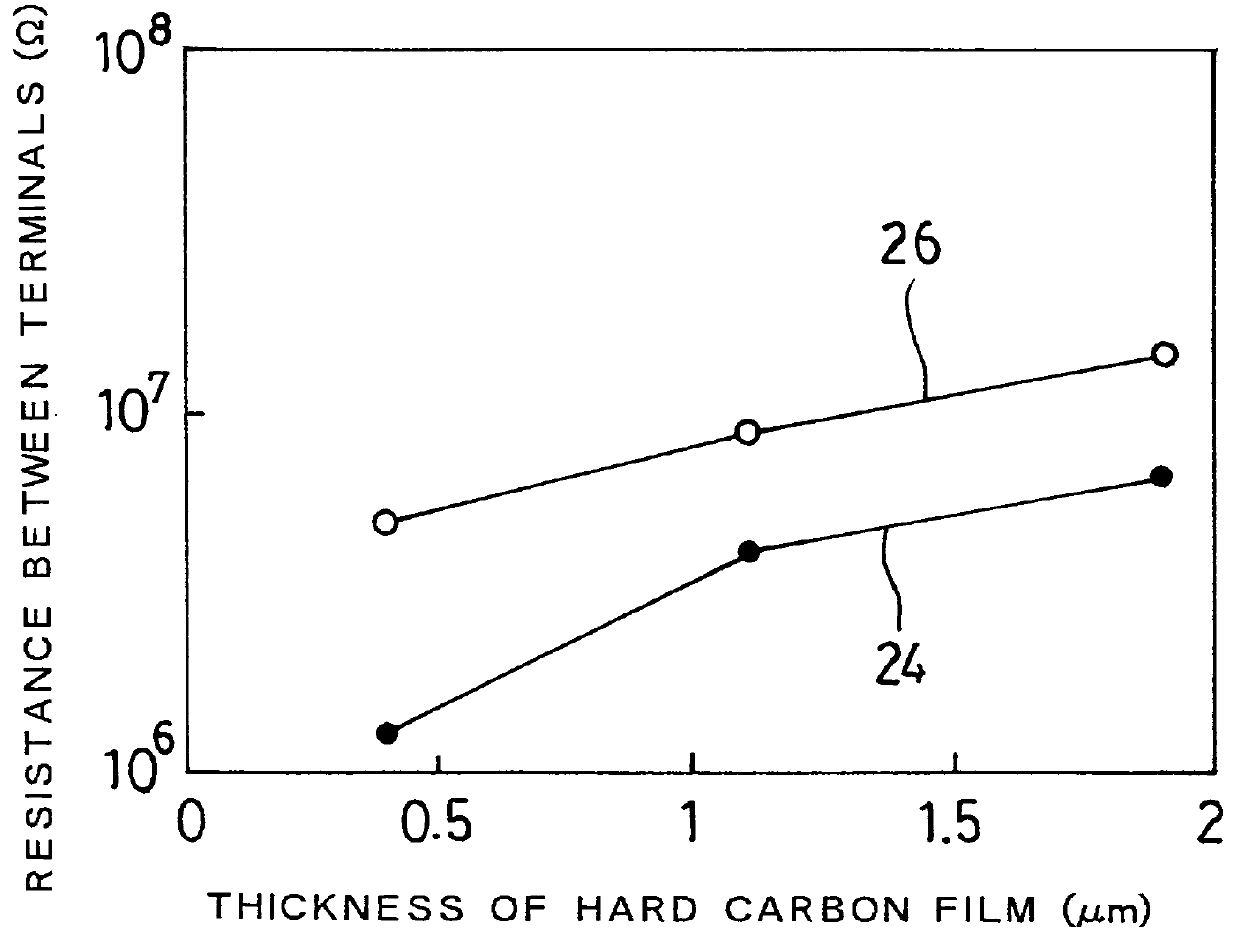

Method of forming films over insulating material

InactiveUS6080445AHigh surface hardnessImprove wear resistanceSpecial surfacesChemical vapor deposition coatingElectrical resistance and conductanceCarbon film

A method of forming films over an insulating material is provided whereby an underlayer film having electric conductivity is formed on the surface of the insulating material constituting a base member, and a hard carbon film is formed over the underlayer film so that the surface electrical resistance value of the hard carbon film can be controlled so as not to cause the surface thereof to be charged with static electricity by varying an electrical resistance value of the underlayer film. In the case where the underlayer film is formed of a metal film composed of titanium, chromium, tungsten, or the like, the resistance value thereof can be changed by varying the thickness of the metal film. In the case where the underlayer film is formed of a semiconductor film composed of silicon, germanium, or the like, the resistance value thereof can be changed by varying the thickness of the semiconductor film, or the concentration of an impurity added thereto.

Owner:CITIZEN WATCH CO LTD

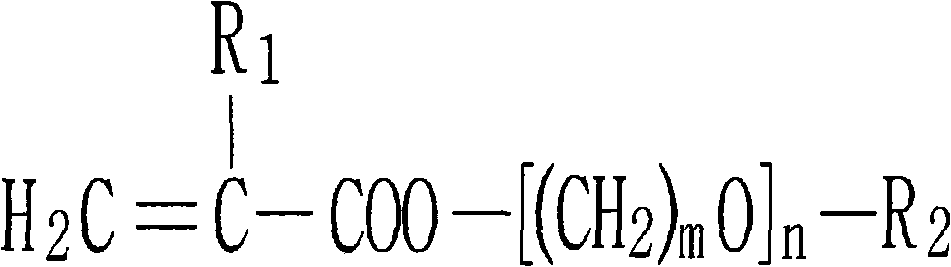

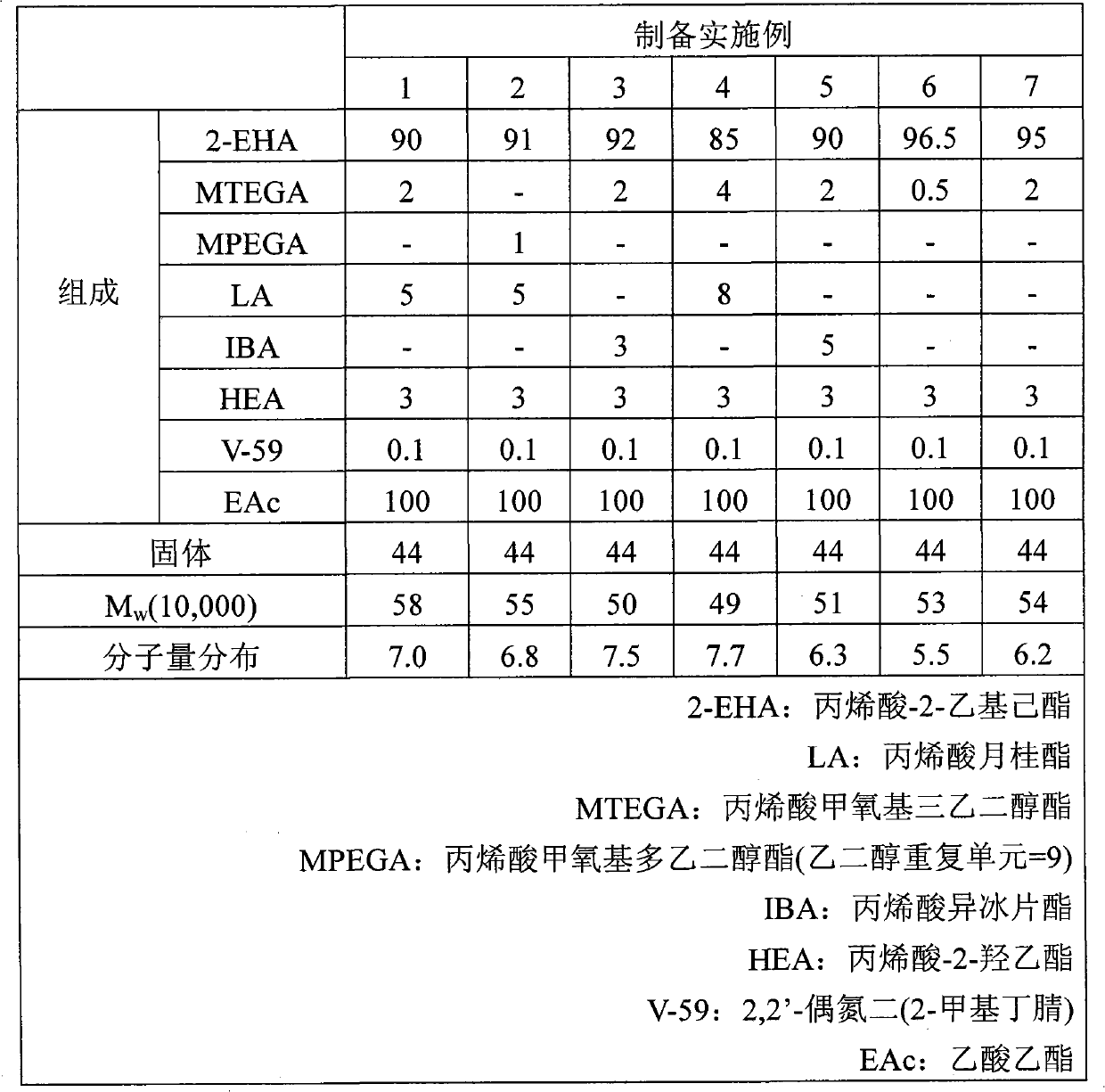

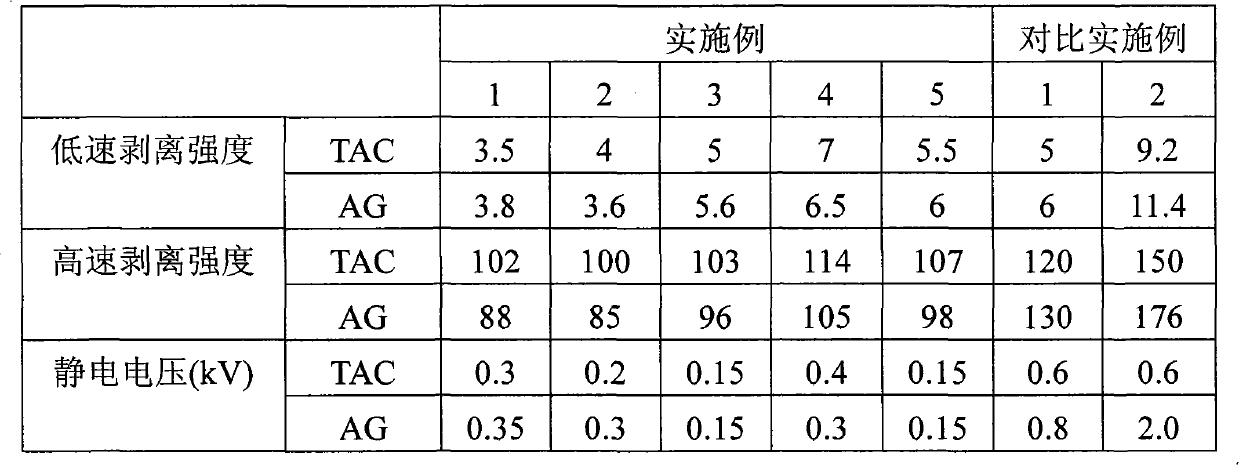

Pressure-sensitive adhesive compositions, pressure-sensitive adhesive sheets and surface protecting films

ActiveCN1749344AReduce pollutionPrevent static electricityFilm/foil adhesivesEster polymer adhesivesMonomer compositionAcid value

An adhesive combination comprises (methyl) acrylic acid series polymer and alkali metal salt, wherein the (methyl) acrylic acid series polymer takes the following compositions as monomer composition: 5 to 100 weight percent (methyl) acrylic acid alkylene oxide addition compound, 0 to 95 weight percent (methyl) acrylic acid series monomer of alkyl with one to fourteen carbon atoms except the addition compound and 0 to 95 weight percent other polymerizing monomer; moreover, the acid value of the (methyl) acrylic acid series polymer is less than ten. Therefore, the invention can provide an anti-static adhesive combination which can prevent an adherend receiving no destaticization from carrying static electricity during stripping, thereby reducing the pollution on the adherend and having high adhesion reliability; moreover, the invention also provides an anti-static adhesion slice class and surface protective film formed by the combination.

Owner:NITTO DENKO CORP

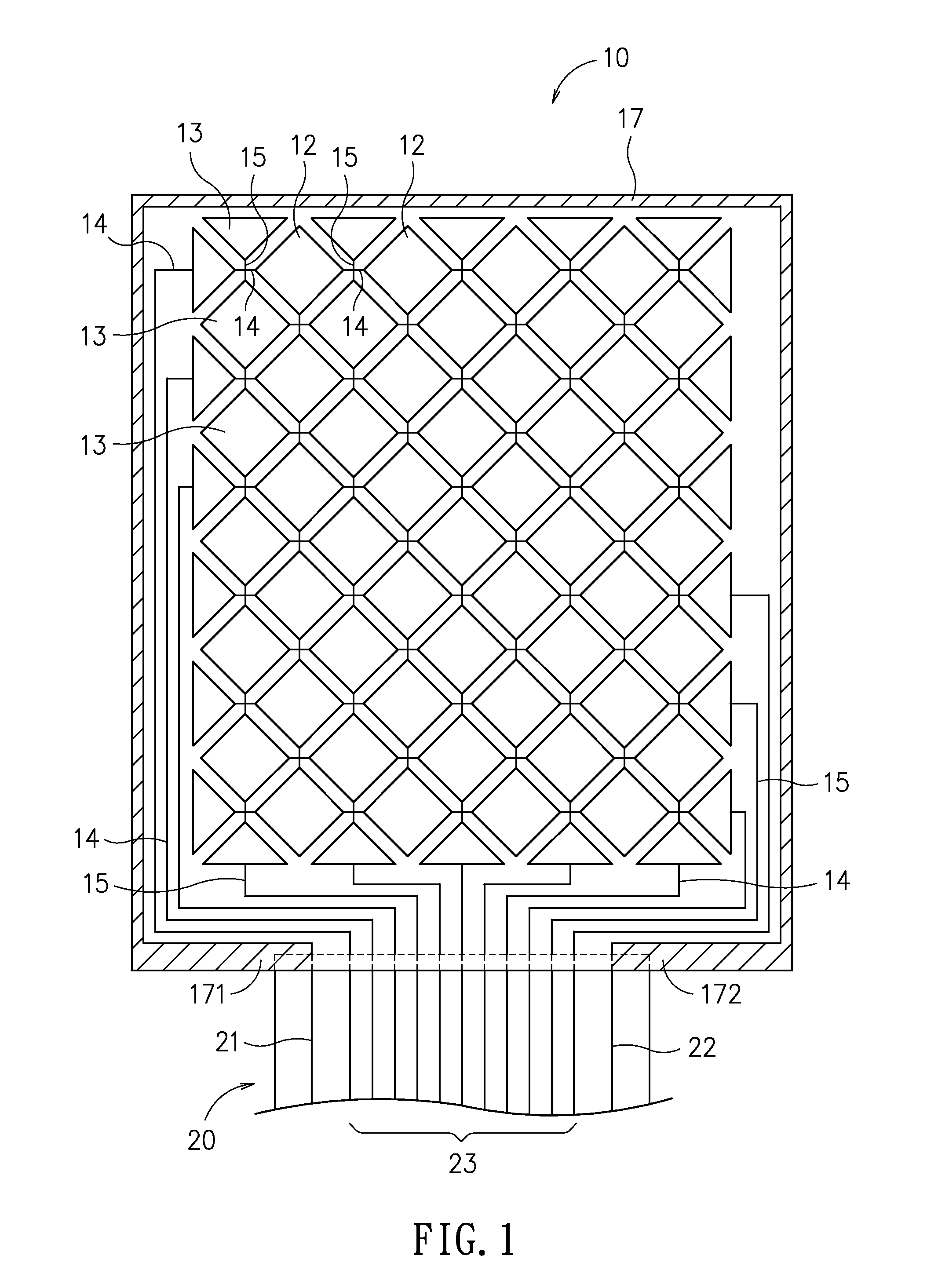

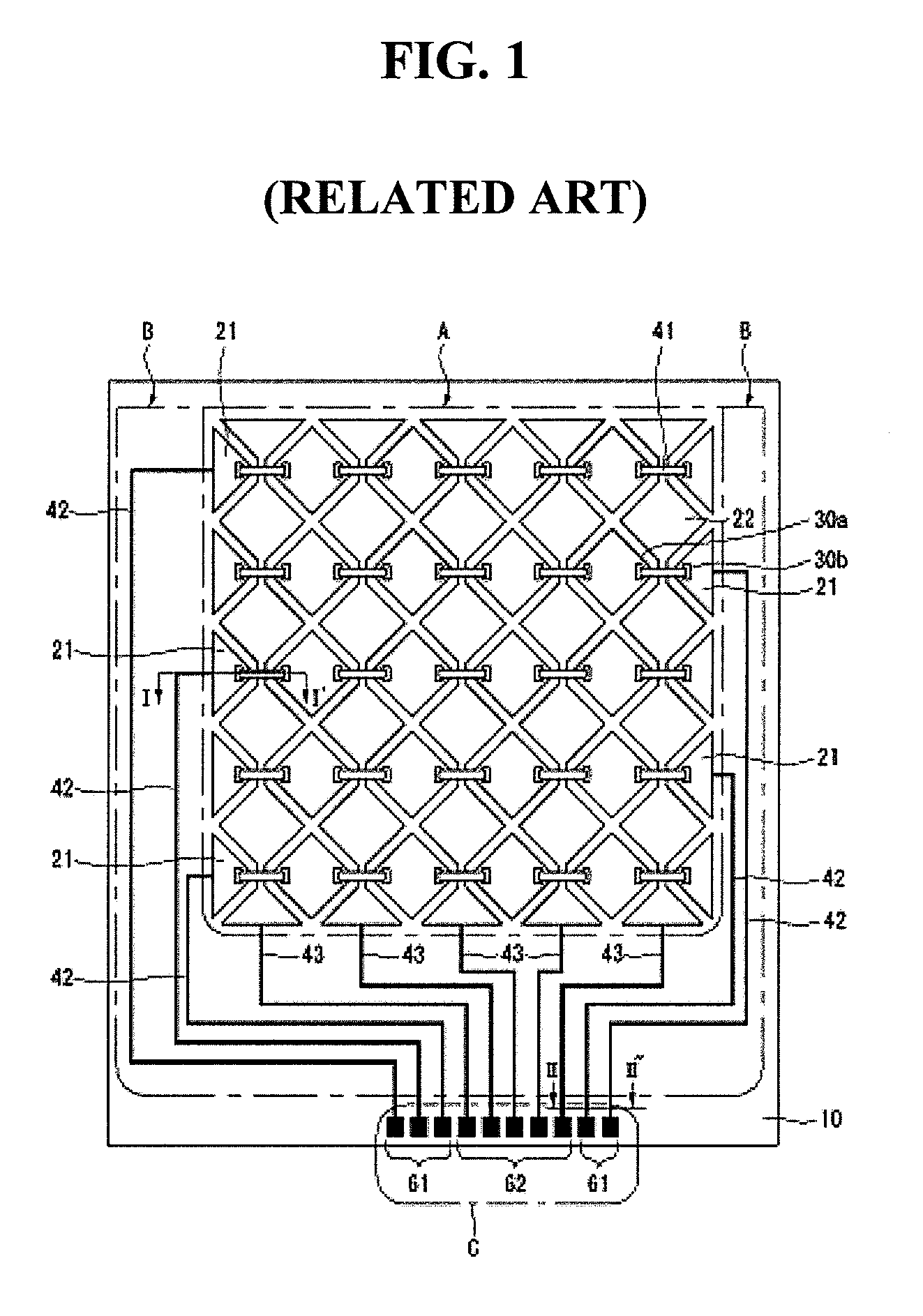

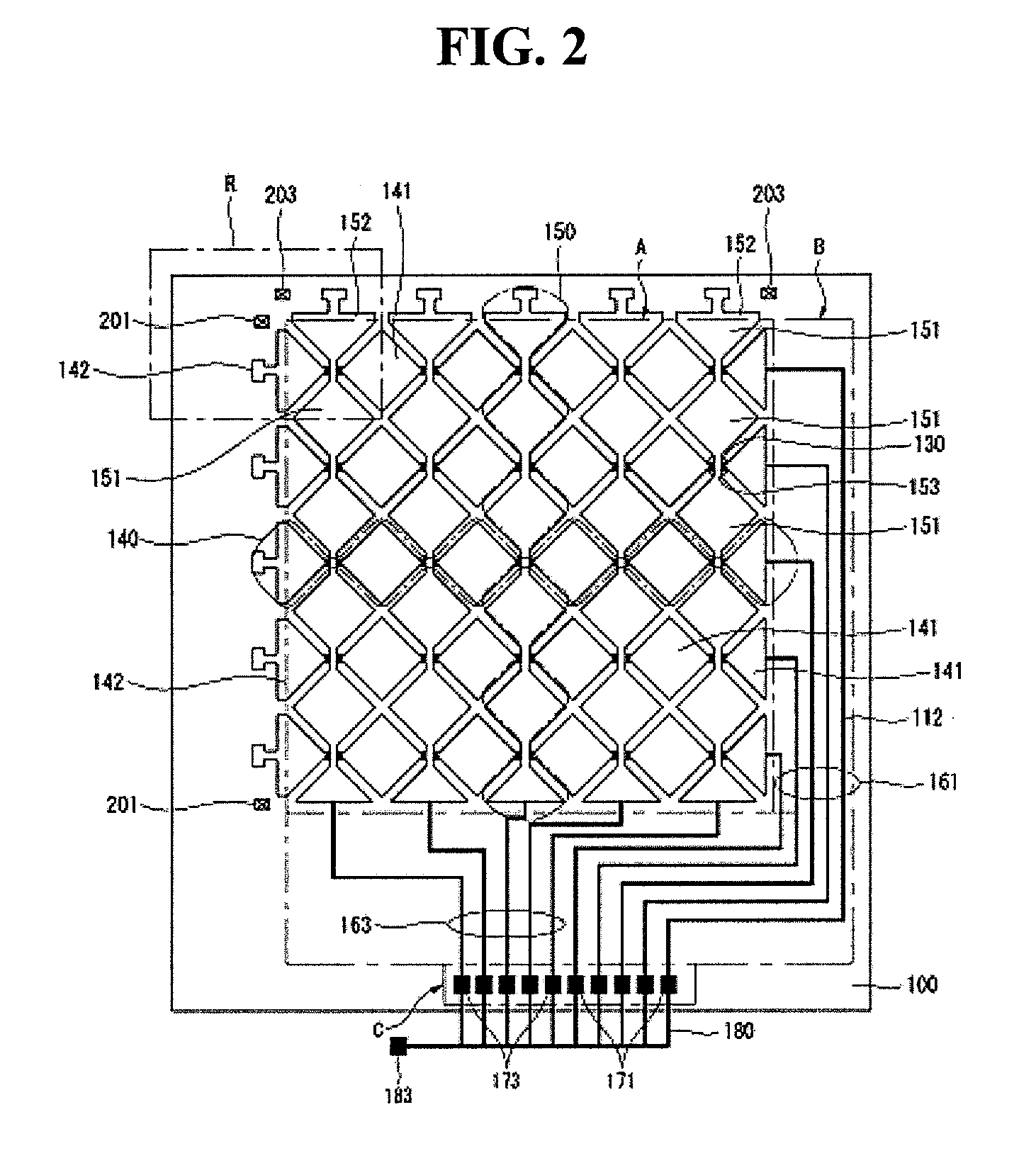

Touch screen panel

ActiveUS20120080302A1Prevent static electricityTact time be reduceElectronic switchingInput/output processes for data processingCross overElectrical and Electronics engineering

A touch screen panel according to an embodiment includes a substrate; an electrode forming part formed on the substrate, the electrode forming part including a plurality of first electrode serials arranged in parallel in a first direction and a plurality of second electrode serials arranged in parallel in a second direction to cross over the plurality of first electrode serials; a routing wire forming part formed on the substrate outside the electrode forming part, the routing wire forming part including a plurality of first routing wires respectively connected to the plurality of first electrode serials and a plurality of second routing wires respectively connected to the plurality of second electrode serials; and an insulation layer configured to insulate the first electrode serial from the second electrode serial at each of intersections of the first electrode serials and the second electrode serials.

Owner:LG DISPLAY CO LTD

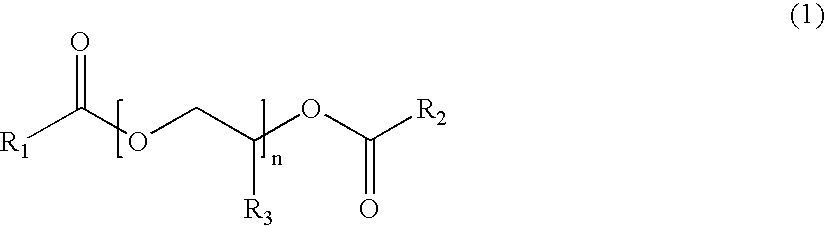

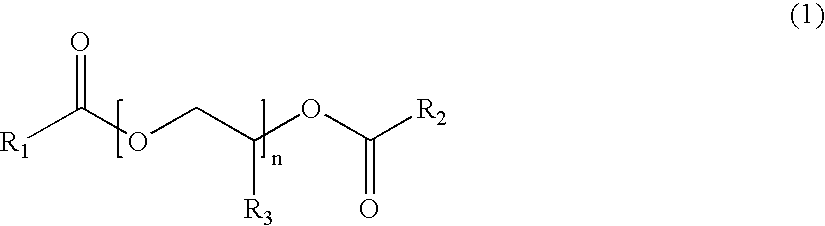

Acrylic pressure sensitive adhesive compositions

ActiveUS20060279923A1Improve antistatic performanceWithout whitening appearanceNon-macromolecular adhesive additivesDigital data processing detailsStrong acidsNuclear chemistry

The present invention relates to an acrylic pressure sensitive adhesive composition, specifically, an acrylic pressure sensitive adhesive composition having improved anti-static properties, comprising 100 part by weight of acrylic copolymers, 0.01 to 20 part by weight of ester plasticizer having at least one ether linkage in the molecular structure, and 0.001 to 25 part by weight of metal salts consisting of alkali metal cation, and anion which is counter-ion of super strong acid and has perfluoro alkyl group, and prevent whitening of appearance under high temperature and humidity condition as well as static electricity without change of the durability, transparency, and adhesion.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

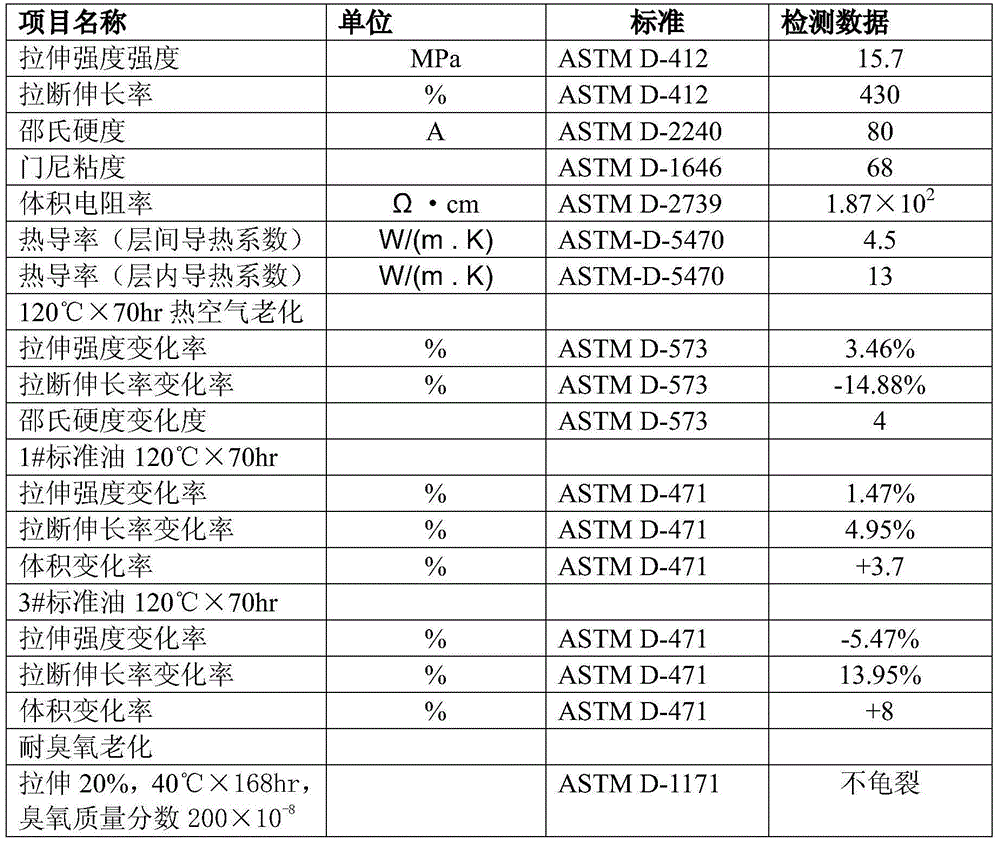

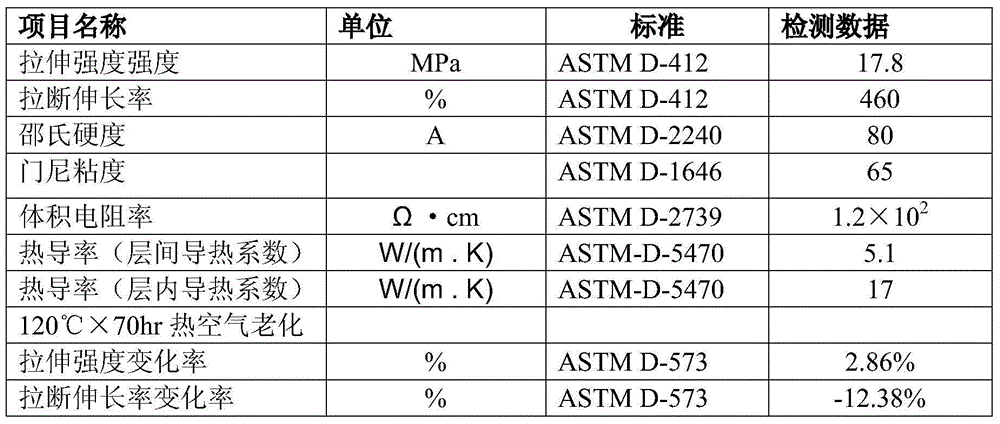

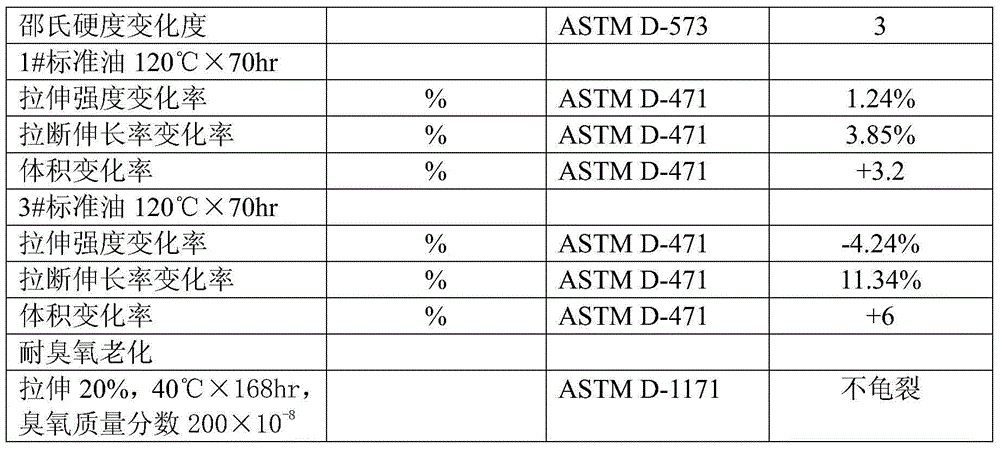

High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

ActiveCN104961983AExcellent electrical and thermal conductivityExcellent mechanical properties and oil resistancePetroleumConductive rubber

The invention relates to a high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material is prepared from following ingredients, by weight, 50 to 100 parts of an electroconductive thermal conductive rubber master batch, 40 to 60 parts of an auxiliary rubber material, 30 to 50 parts of a reinforced material, 30 to 50 parts of a flexibilizer, 30 to 50 parts of a filling material, 8 to 10 parts of a stabilizing agent, 10 to 15 parts of a tackifier, 3 to 5 parts of a vulcanizing agent, and 2 to 3 parts of a vulcanizing assistant agent. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent electrical conductivity and thermal conductivity; volume resistivity is as high as 102 omega.cm; heat conductivity coefficient is higher than 4W / (m.K); the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material can be applied to special fields such as petroleum, coal mine, and spaceflight; the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent mechanical properties, oil resistance, and air aging resistance, and can be used in oil medium or in outdoor environment.

Owner:青岛科凯达橡塑有限公司

Pressure-sensitive adhesive composition, protective film, polarizer and liquid crystal display comprising the same

ActiveCN101910346AEasy to processIncreased durabilityLayered productsPolarising elementsLiquid-crystal displayStatic performance

The present invention relates to an acrylic pressure-sensitive adhesive composition, and more particularly, to an acrylic pressure-sensitive adhesive composition capable of showing an excellent anti-static performance, and solving a transferring problem of additives and a problem concerning a balance of low-rate and high-rate peel strength, by comprising a) an acrylic copolymer including a monomer having a functional group capable of chelating with a metal salt, and a hydrophobic monomer and b) a metal salt.

Owner:LG CHEM LTD

Actuator provided with grounding terminal

ActiveUS7151333B2Prevent static electricitySimple working processAssociation with grounding devicesSupports/enclosures/casingsEngineeringActuator

There is provided an actuator which includes: a stator assembly including a pair of stator yokes, and a coil disposed between the pair of stator yokes; a rotor unit including a magnet at its outer circumference and disposed inside the stator assembly; an output shaft disposed inside the rotor unit; a housing; a front plate disposed between the stator assembly and the housing; a printed board having a land portion leading to a grounding wire; and a grounding terminal having electrical conductivity and elasticity and disposed between the stator assembly and the housing. One end portion of the grounding terminal makes contact with one of the pair of stator yokes, and the other end portion thereof makes connection to the land portion of the printed board, whereby static electricity and electromagnetic noises generated in the stator assembly are conducted to the grounding wire.

Owner:MINEBEAMITSUMI INC

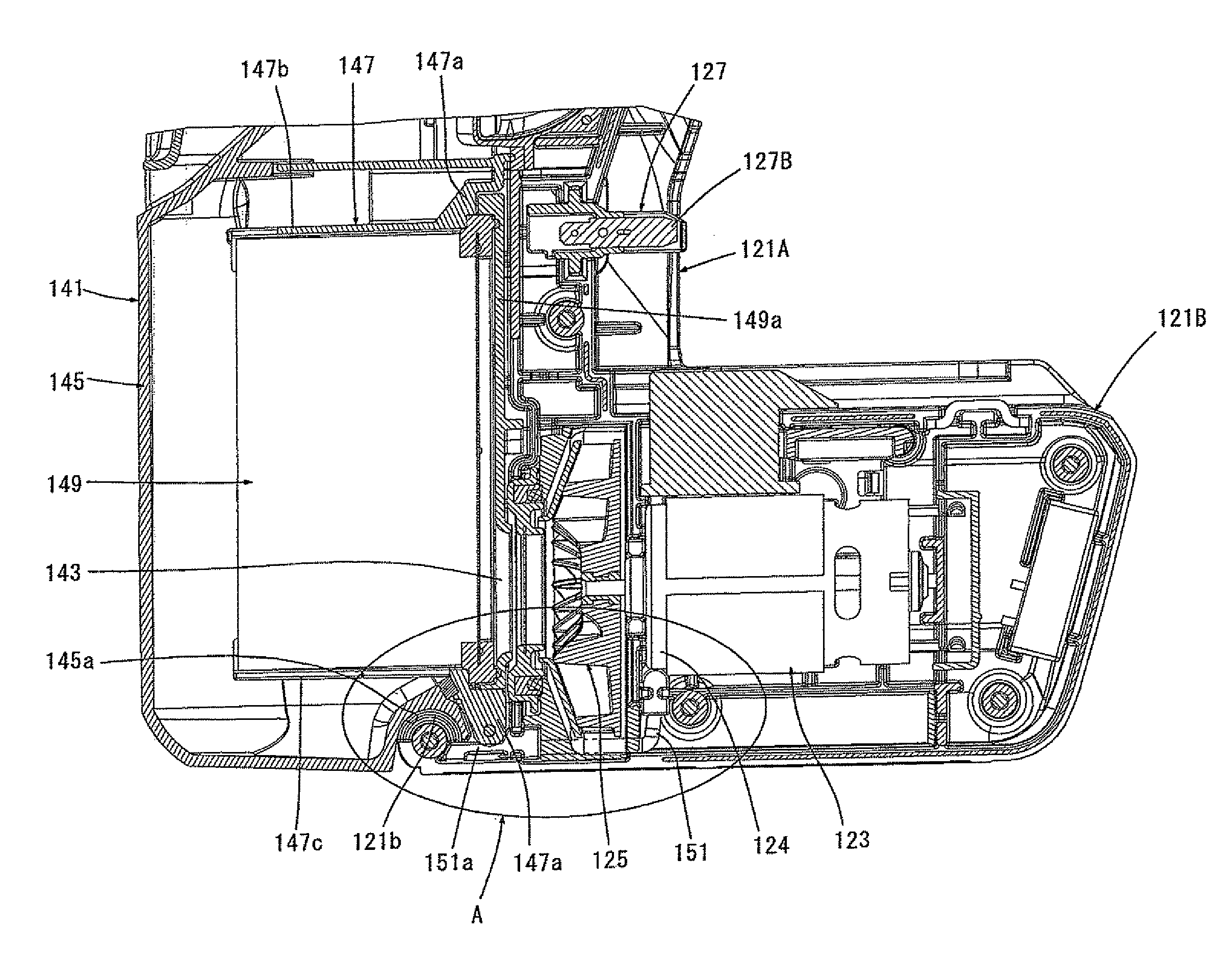

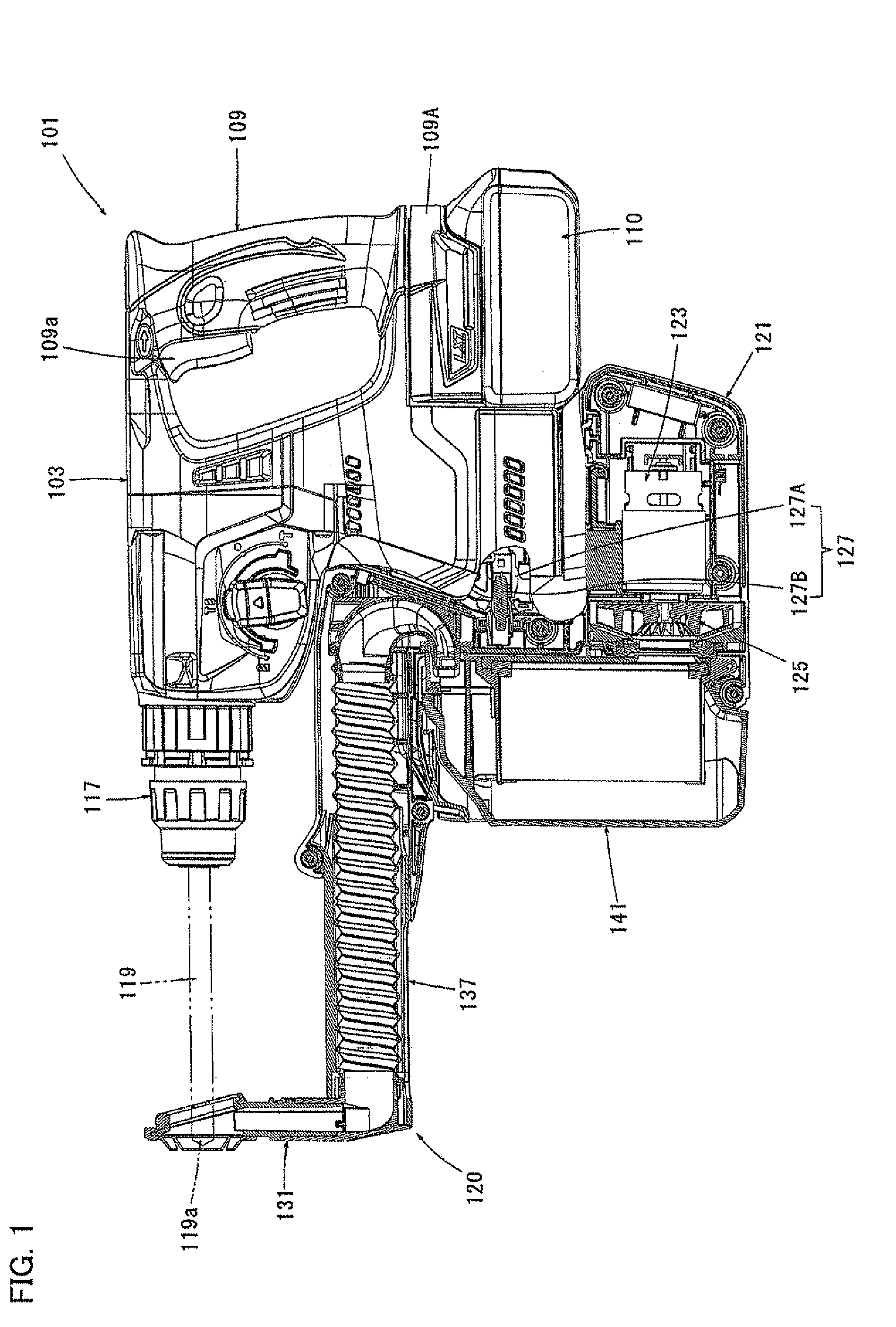

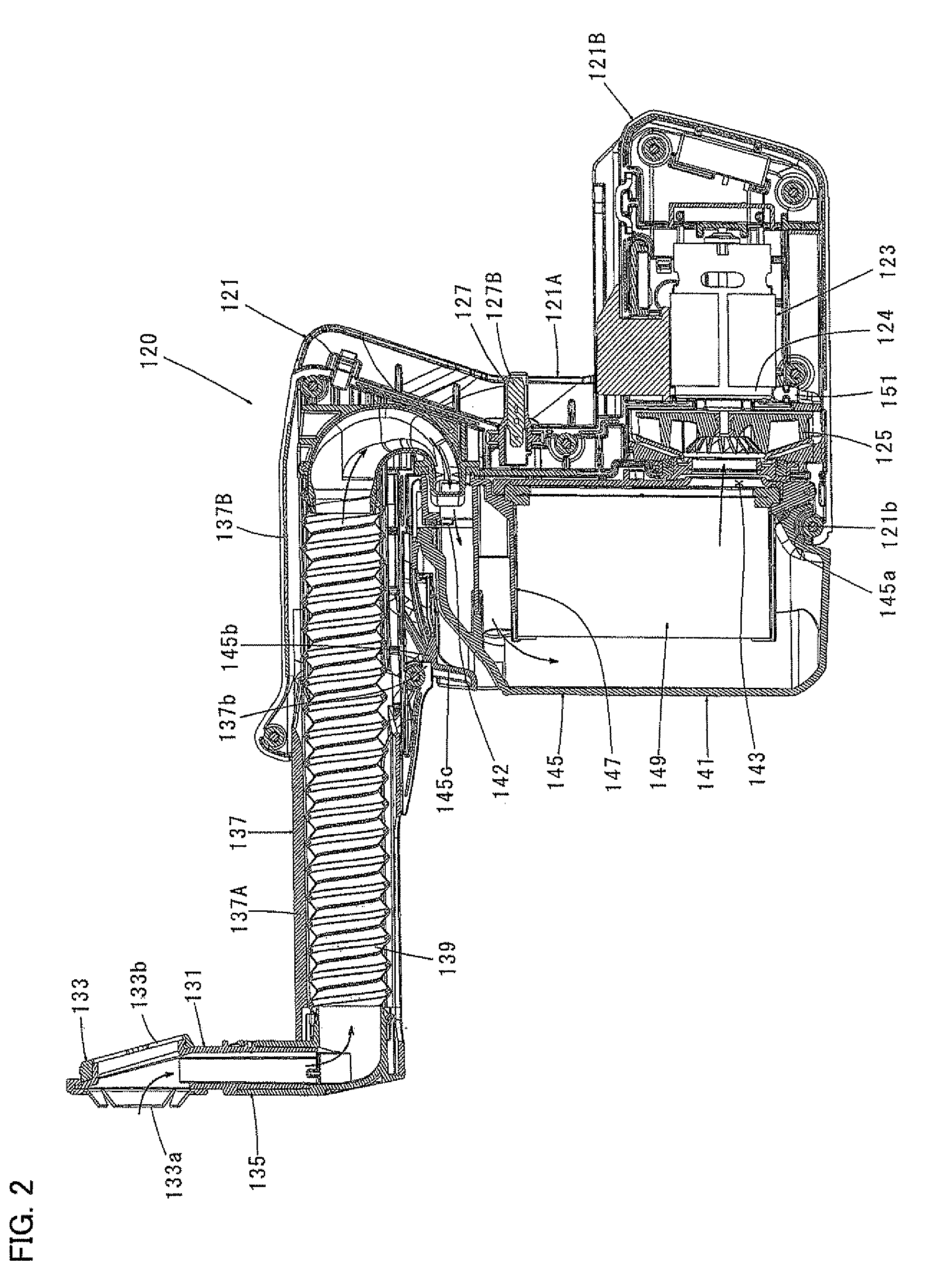

Dust collecting device

ActiveUS20130031879A1Prevention of static chargeSimple structureCombination devicesAuxillary pretreatmentElectrical and Electronics engineeringStatic Charges

A dust collecting device is provided which is capable of preventing static charge while rationally collecting dust generated during operation.A dust collecting device 120 is removably attached to a power tool 101 and can be carried together with the power tool 101, and collects dust generated when a predetermined operation is performed on a workpiece by driving a tool bit 119 coupled to the power tool 101. Further, the dust collecting device 120 has a dust suction region 131 that sucks dust generated during operation in response to the operation of the tool bit 119, a dust transfer region 137 that transfers the dust sucked in the dust suction region 131, and a dust storage region 141 that communicates with the dust transfer region 137 and stores the dust. Furthermore, the dust collecting device 120 has a grounding member 147 through which static charge on the dust is dissipated.

Owner:MAKITA CORP

Display panel and display device

ActiveCN107247373AConducive to narrow borderReduce areaPrinted circuit groundingSemiconductor/solid-state device detailsChip on filmDisplay device

The invention discloses a display panel and a display device, and belongs to the field of display technologies. The display panel comprises electrically conductive adhesion bodies, a chip on film, an electrically conductive layer, a first substrate and a second substrate. The first substrate is opposite to the second substrate, the chip on film is adhered at a step region of the first substrate, and the electrically conductive layer is positioned on the side, which is far away from the first substrate, of the second substrate; the chip on film comprises a grounding bonding pad, and the grounding bonding pad is arranged on the side, which is far away from the first substrate, of the chip on film; the electrically conductive adhesion bodies are electrically connected with the electrically conductive layer and are electrically connected with the grounding bonding pad. According to the technical scheme, the display panel and the display device have the advantages that the grounding bonding pad is arranged on the side, which is far away from the first substrate, of the chip on film, accordingly, the occupied area of the step regions can be reduced while static electricity is prevented, and frames of the display panel can be advantageously narrowed.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

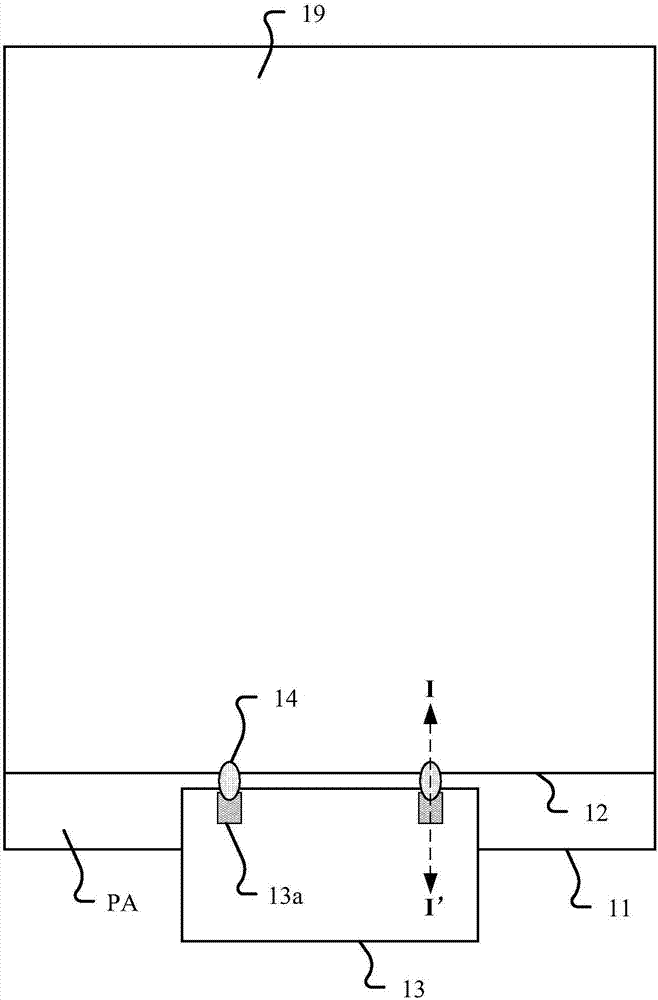

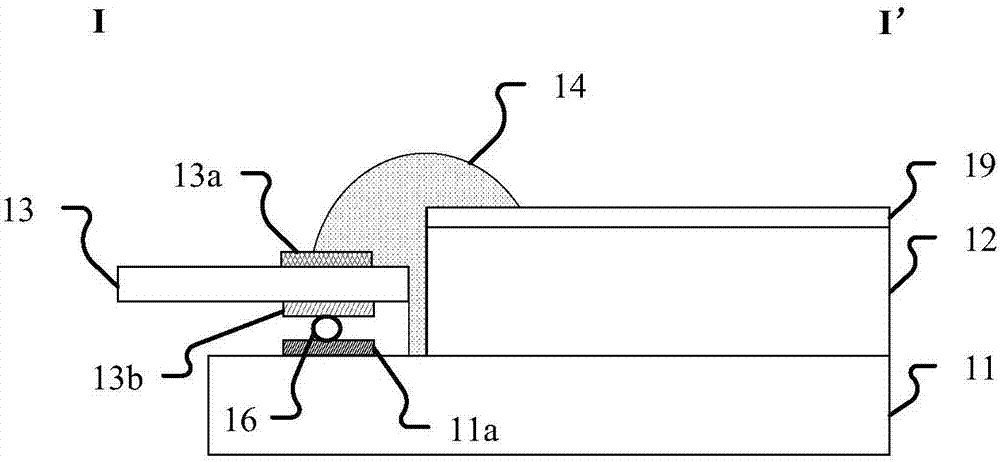

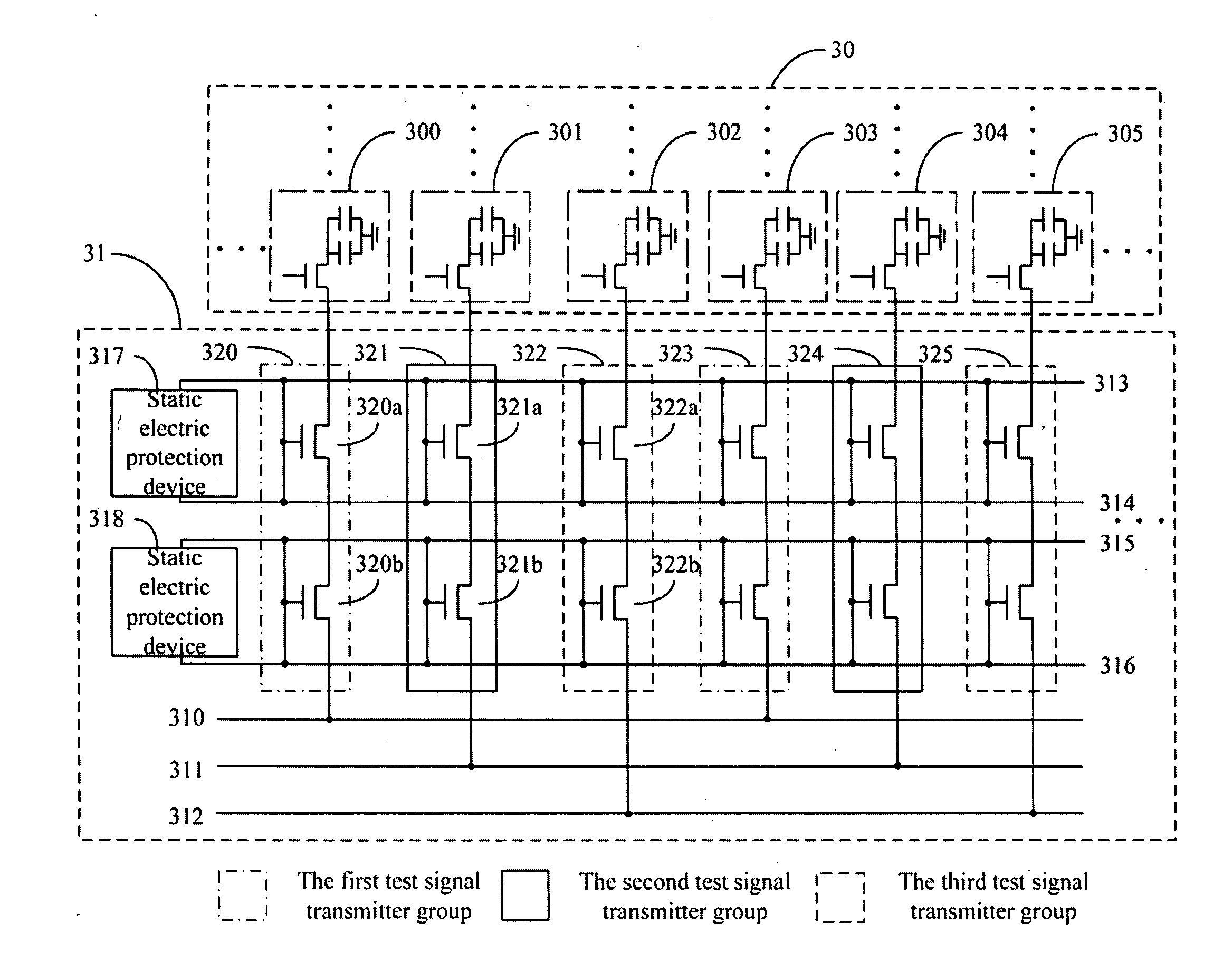

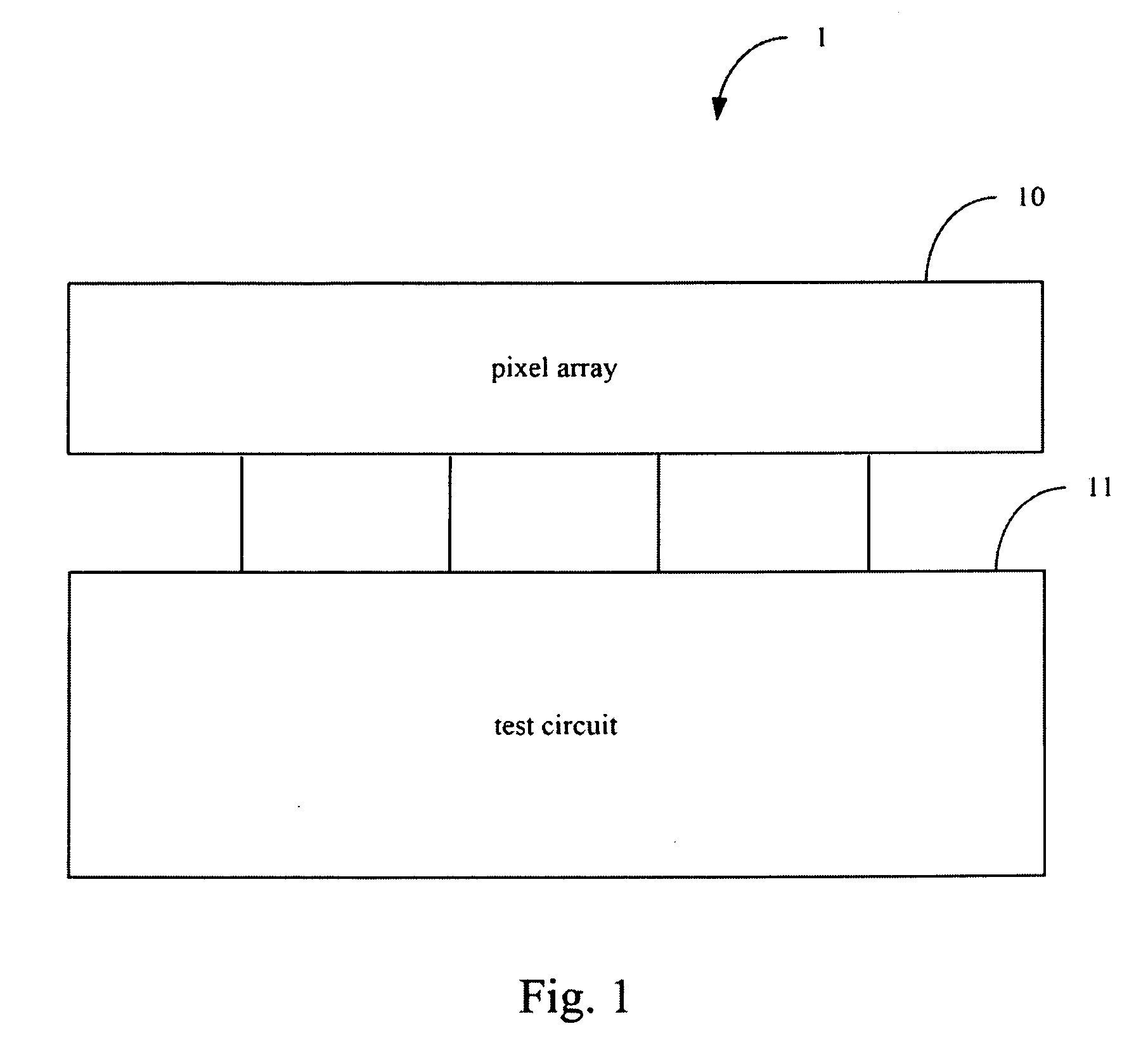

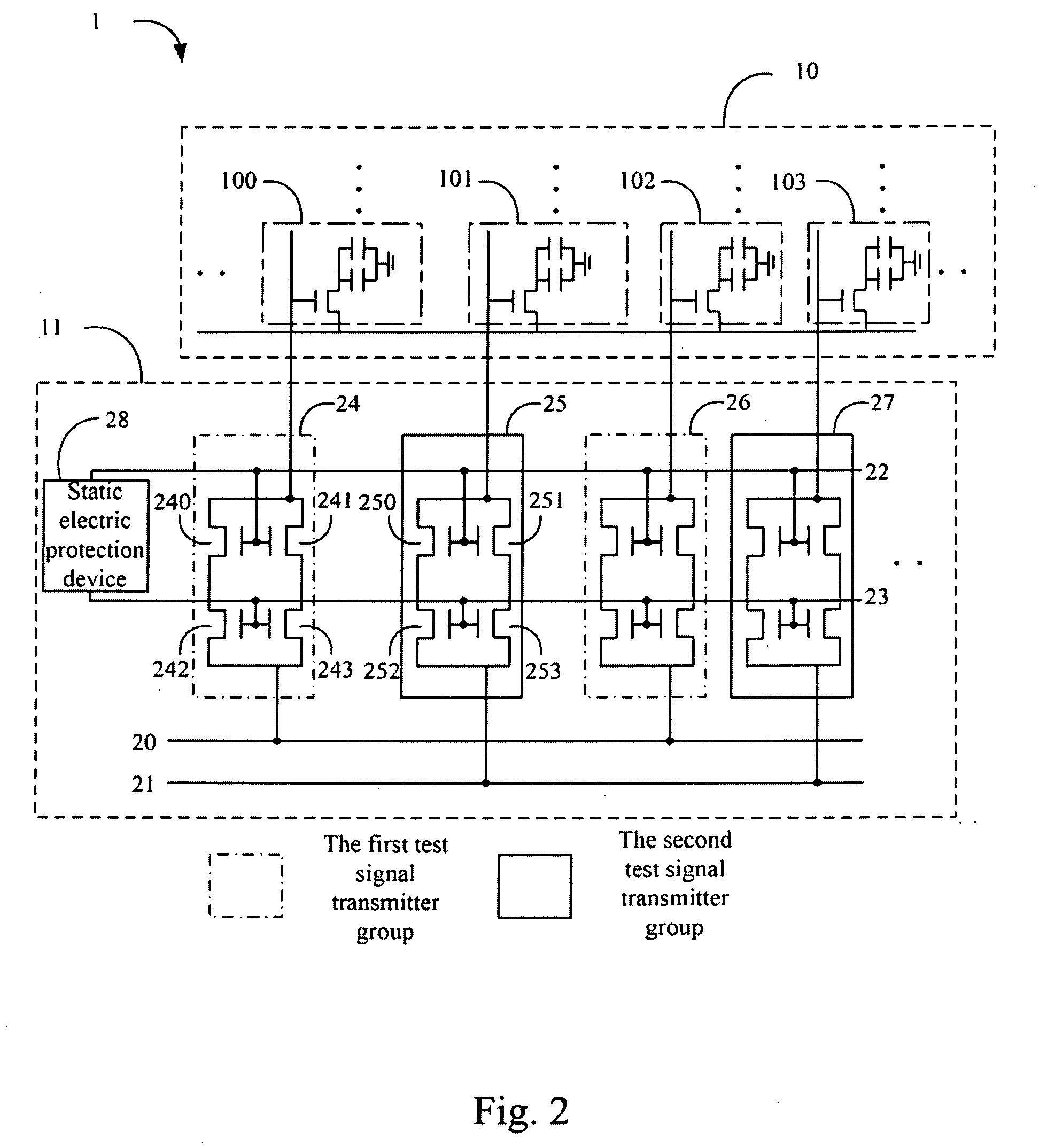

Test circuit adapted in a display panel of an electronic device

ActiveUS20100073009A1Highly preventive effectPrevent static electricityStatic indicating devicesElectrical testingEngineeringSignal lines

A test circuit adapted in a display panel of an electronic device is provided. The test circuit is to test the pixel array function of the display panel, wherein the test circuit comprises: a plurality of test signal lines, a plurality of test signal transmitters, a plurality of gate lines and at least one static electricity protection device. The test signal lines receive a plurality of corresponding test signals respectively. The test signal transmitters comprises a plurality test signal transmitter groups comprising at least one transmitter, wherein each transmitter group corresponds to a test signal line and connects the test signal line and the pixel array. Each gate line connects to the gate of the at least one transmitter. The static electricity protection device is placed between two of the gate lines.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

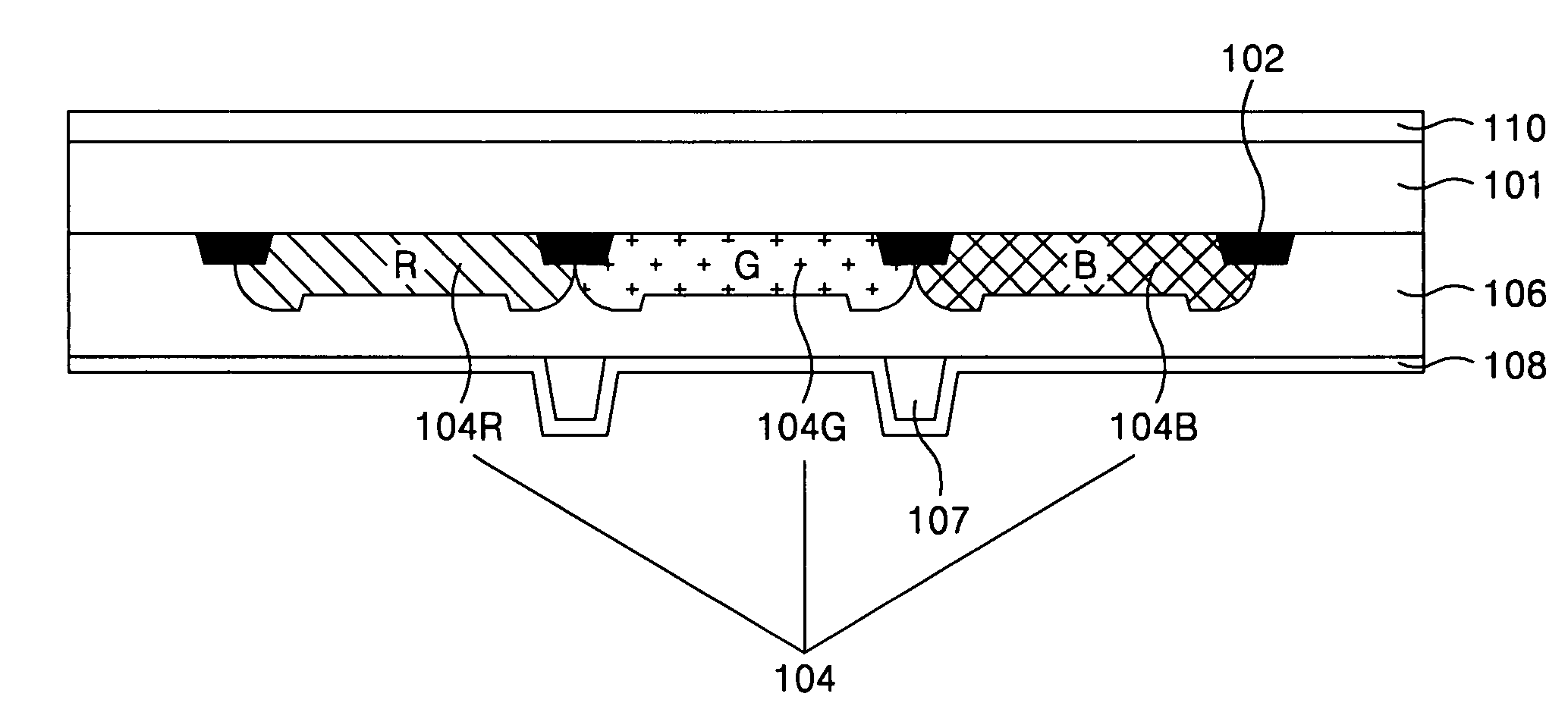

Color filter substrate and fabricating method thereof

ActiveUS20070132921A1Avoid it happening againPrevent buildupLiquid crystal compositionsPhotosensitive materialsResistConductive materials

A color filter substrate includes a substrate, a black matrix that defines cell areas on a substrate and prevents light leakage, a color filter formed in the cell areas defined by the black matrix, and a conductive thin film formed on the rear surface of the substrate for preventing the generation of static electricity, wherein the conductive thin film is formed of a photo-resist containing a conductive material.

Owner:LG DISPLAY CO LTD

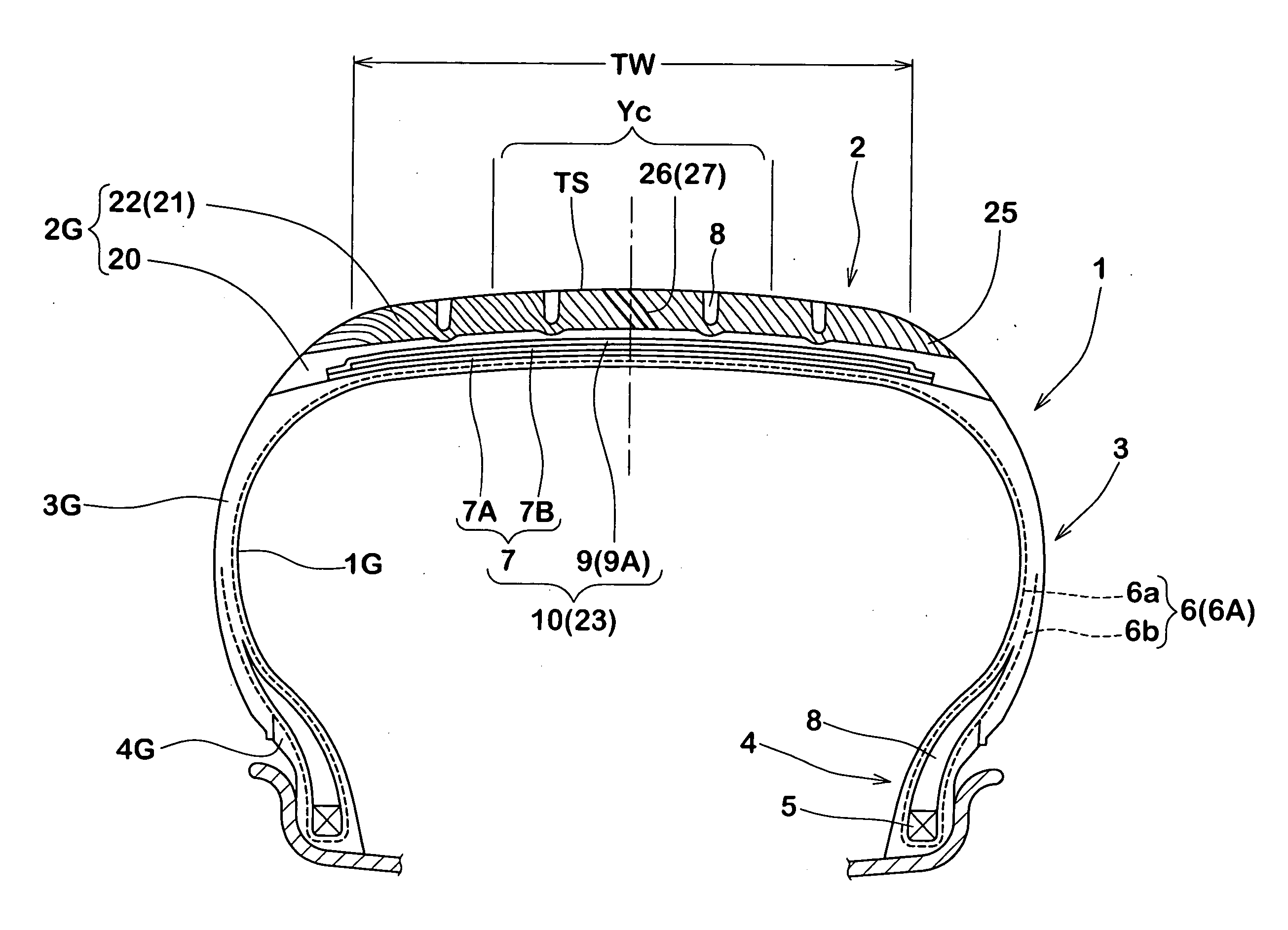

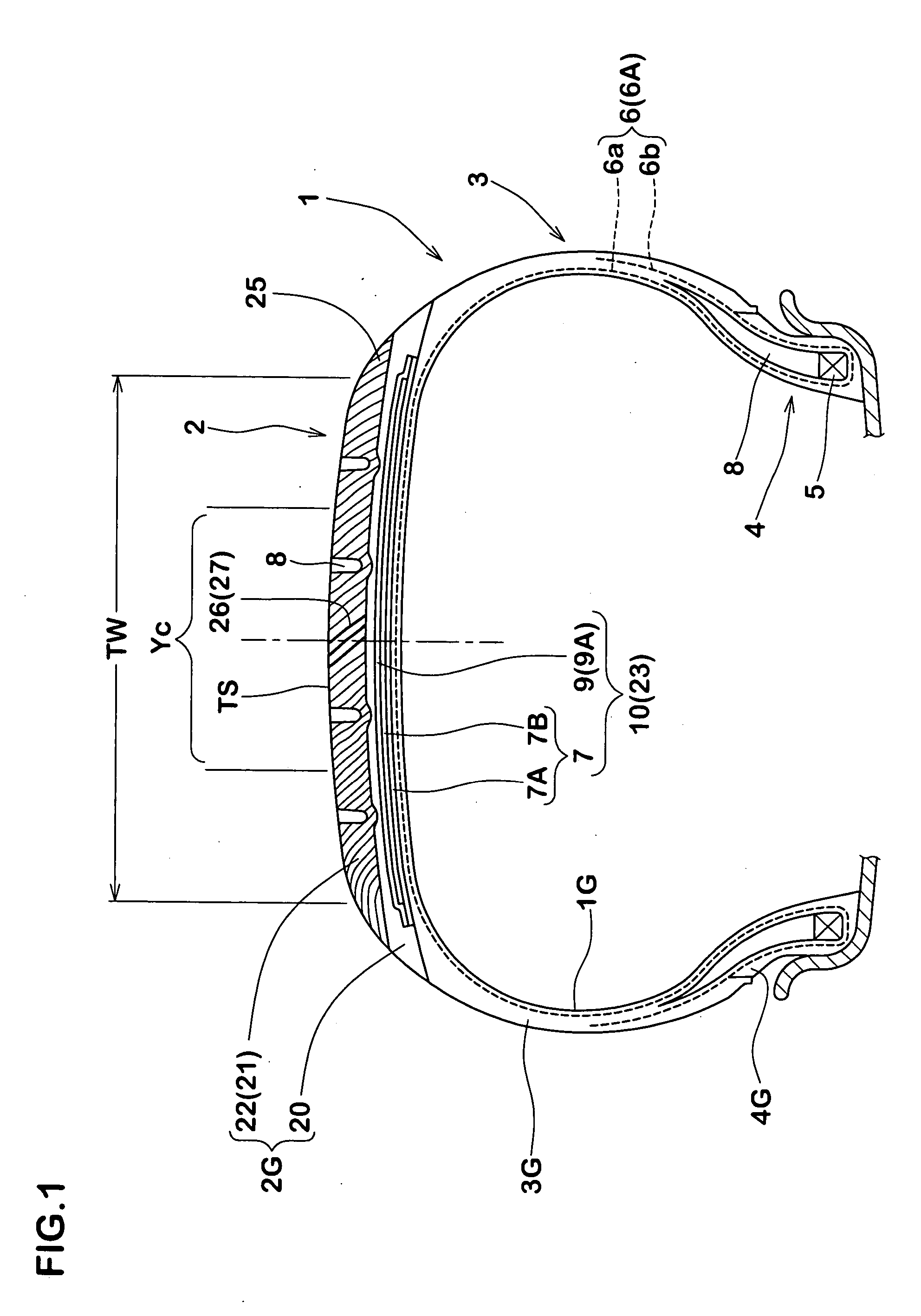

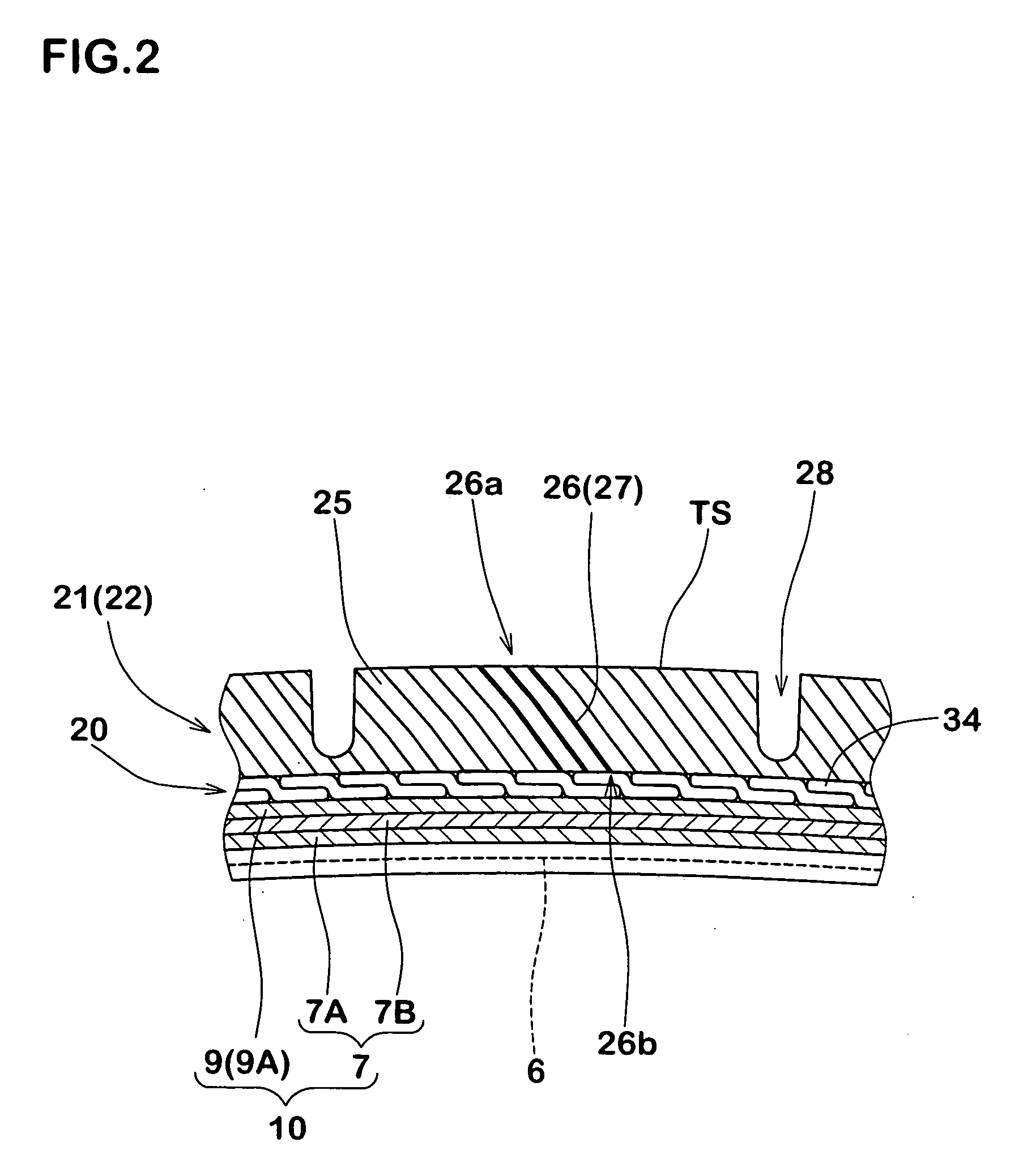

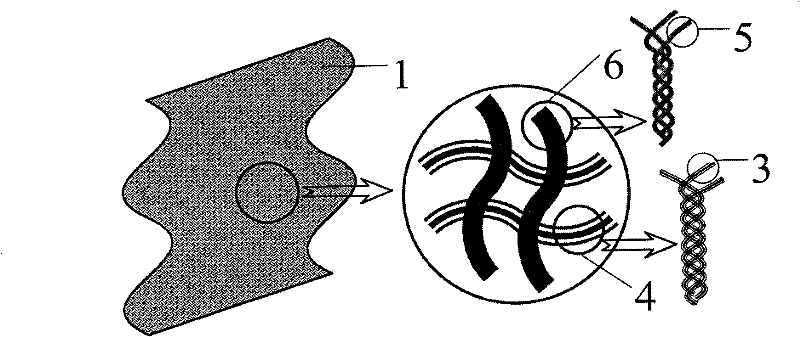

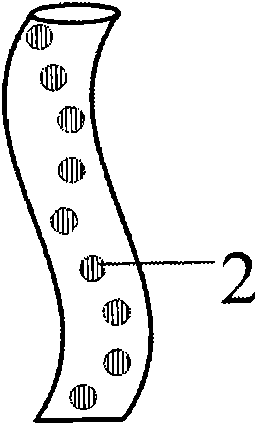

Pneumatic tire, producing method of pneumatic tire, and forming apparatus of rubber strip winding body

InactiveUS20060042733A1Efficiently producing tireExcellently satisfying both low rolling resistanceSpecial tyresTyresGround contactConductive materials

A pneumatic tire comprises a conductive tread conductive part which is disposed on an inner side of a tread portion, and a tread rubber portion comprising a rubber strip winding body in which a rubber strip is spirally wound and superposed in a circumferential direction. A radially outer surface of the tread rubber portion forms a tread-ground contact surface, and a radially inner surface of the tread rubber portion is in contact with the tread conductive part. At least one surface of the rubber strip is formed with a conductive film made of conductive material. An outer edge of the conductive film appears on the tread-ground contact surface, and an inner edge of the conductive film is in contact with the tread conductive part so that the conductive film forms a conductive path.

Owner:SUMITOMO RUBBER IND LTD

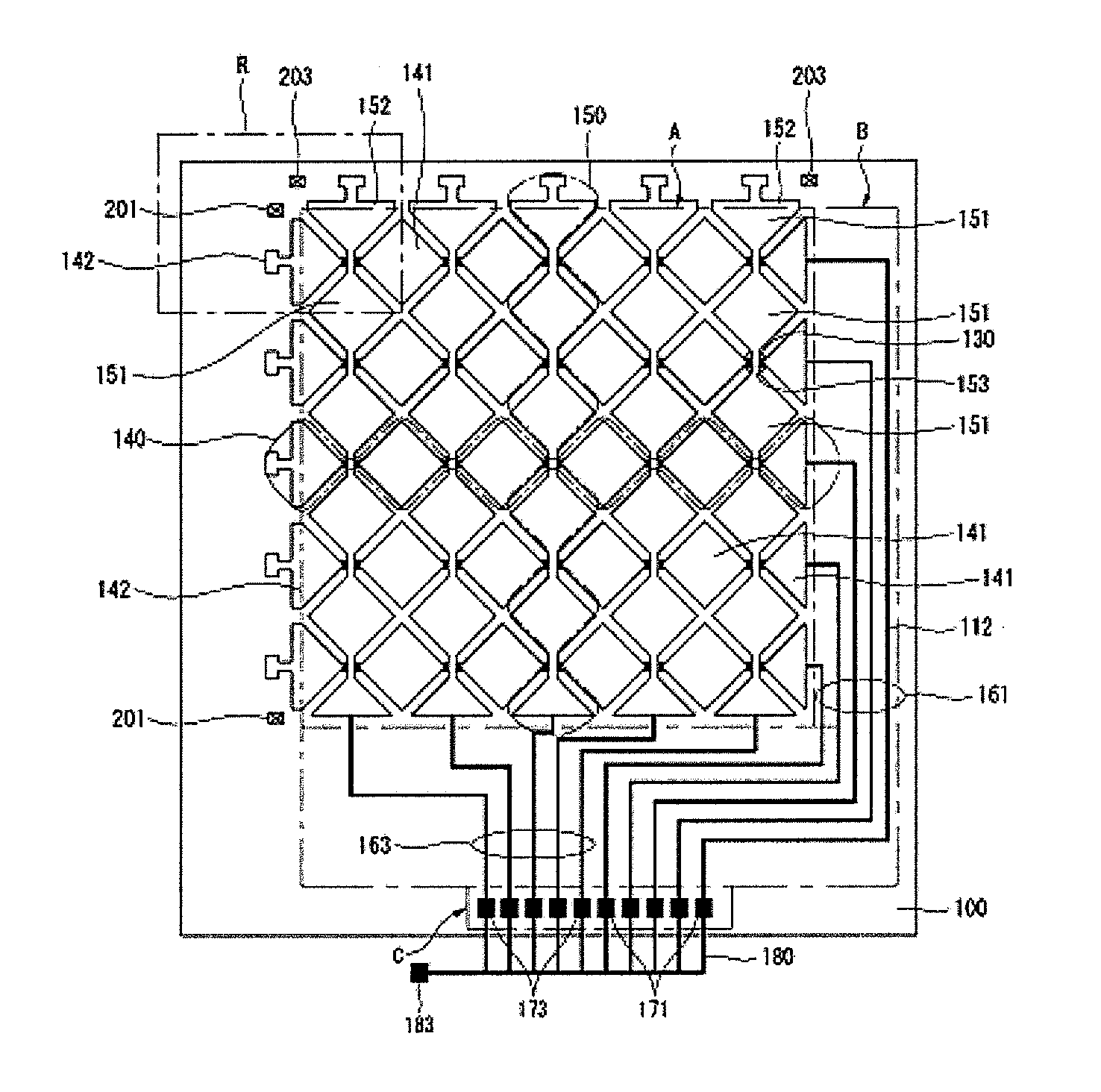

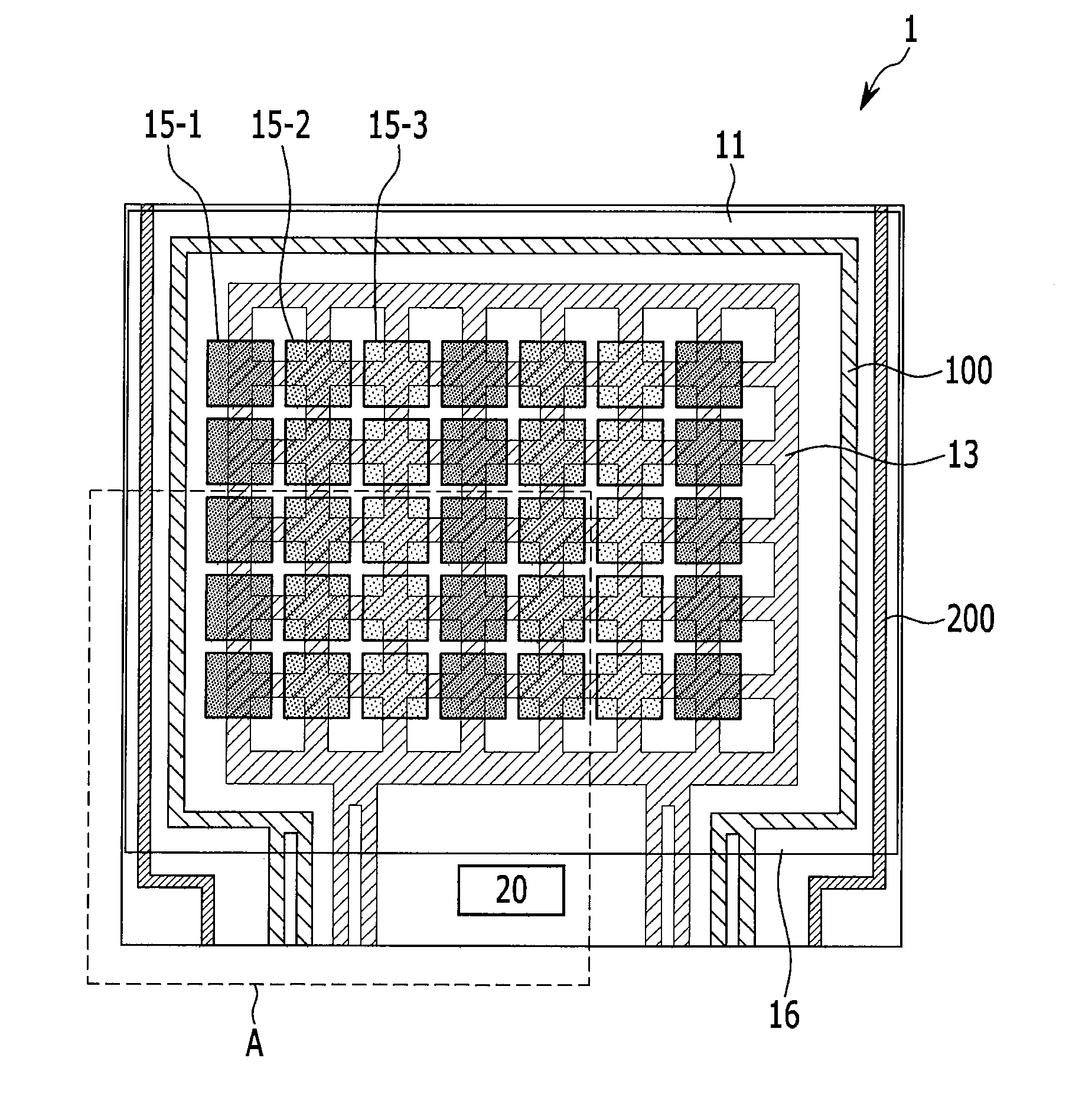

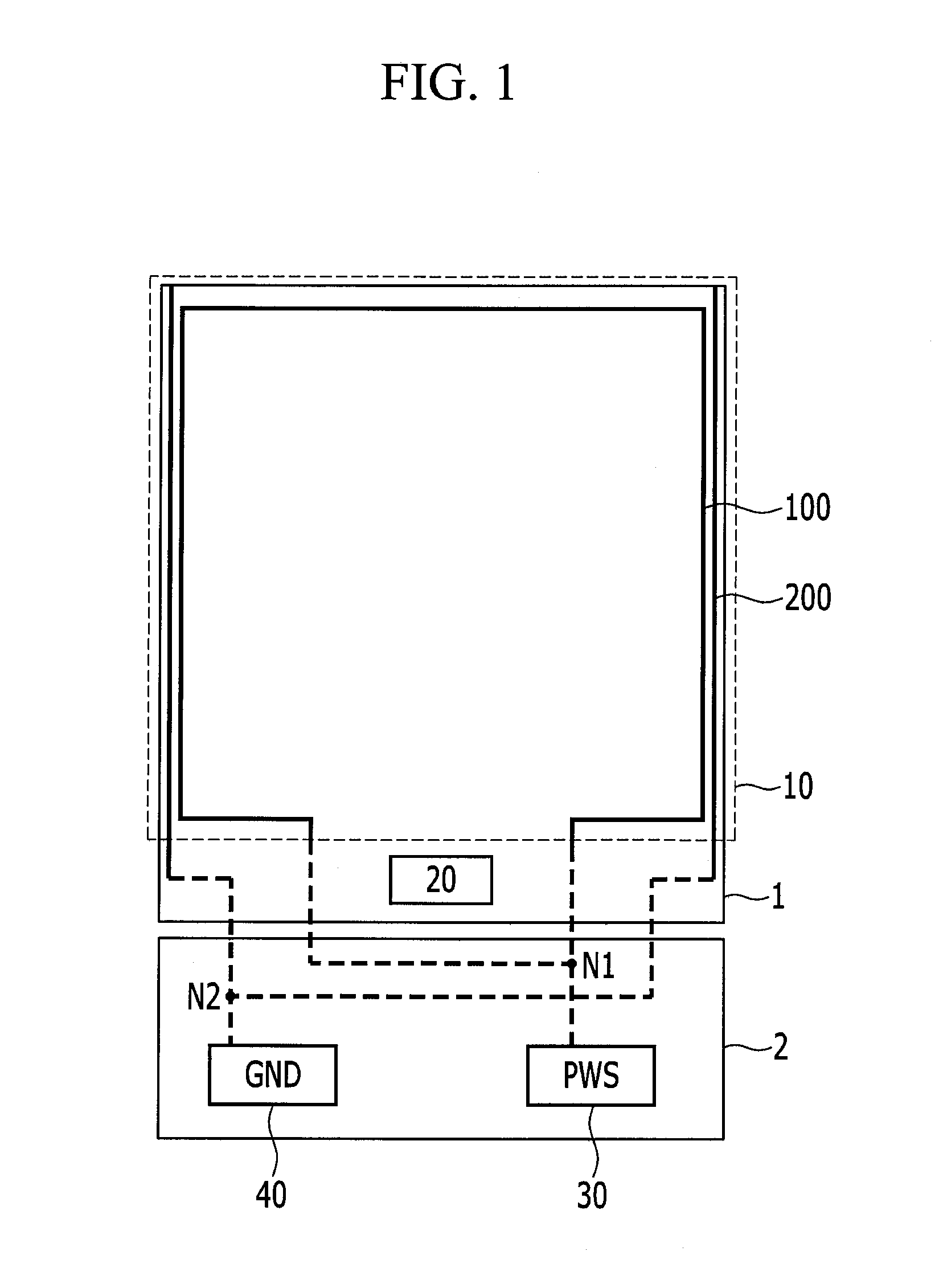

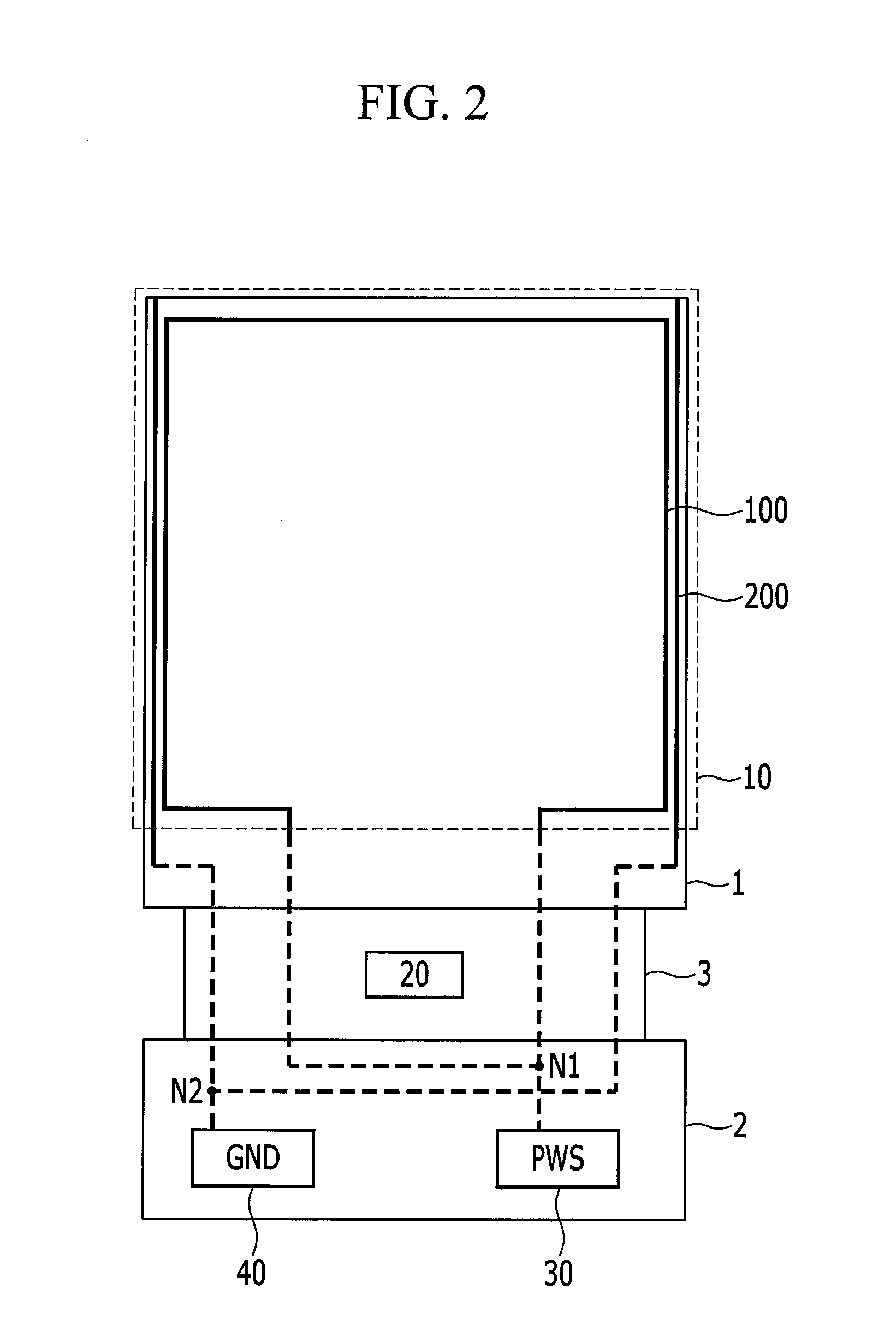

Display panel for preventing static electricity, method for manufacturing the same, and display device including the display panel for preventing static electricity

InactiveUS20140001966A1Efficiency reduce and eliminateExcellent qualitySparking plugsStatic indicating devicesEngineeringDisplay device

A display panel, a manufacturing method of the display panel, and a display device including the display panel are provided. The display panel includes: a substrate; a display unit on the substrate and including a plurality of pixels for displaying an image according to a video signal; a power supply wire on the substrate, coupled to the plurality of pixels, and configured to transmit a driving voltage for driving the plurality of pixels; and a dummy wire on the substrate, separated from the display unit and the power supply wire, and coupled to a ground electrode or a power supply unit for supplying the driving voltage.

Owner:SAMSUNG DISPLAY CO LTD

Manufacture method of conductive fire-retardant acrylic fiber

InactiveCN104805684AMake up for the shortcomings of flammabilityPrevent static electricityFibre typesPolymer scienceFire retardant

The invention discloses a manufacture method of conductive fire-retardant acrylic fiber. The manufacture method comprises the following steps: (1) preparing a spinning solution; (2) performing spinning formation; (3) performing copper salt treatment; (4) adding acrylic fiber containing copper ions obtained in the step (3) into a mixed aqueous solution, and reacting in an airtight high-temperature reaction kettle at 120-140 DEG C for 4-5 hours to prepare the fire-retardant acrylic fiber; (5) taking out and cleaning the acrylic fiber obtained in the step (4), and putting the acrylic fiber at 70-90 DEG C for 2-3 hours in a constant-temperature manner. Through the manner and with the adoption of the manufacture method of conductive fire-retardant acrylic fiber, the acrylic fiber subjected to the antistatic treatment can prevent static electricity during application, ensures normal application of a user, has a fire-retardant function, and overcomes the flammable defect of cloth.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

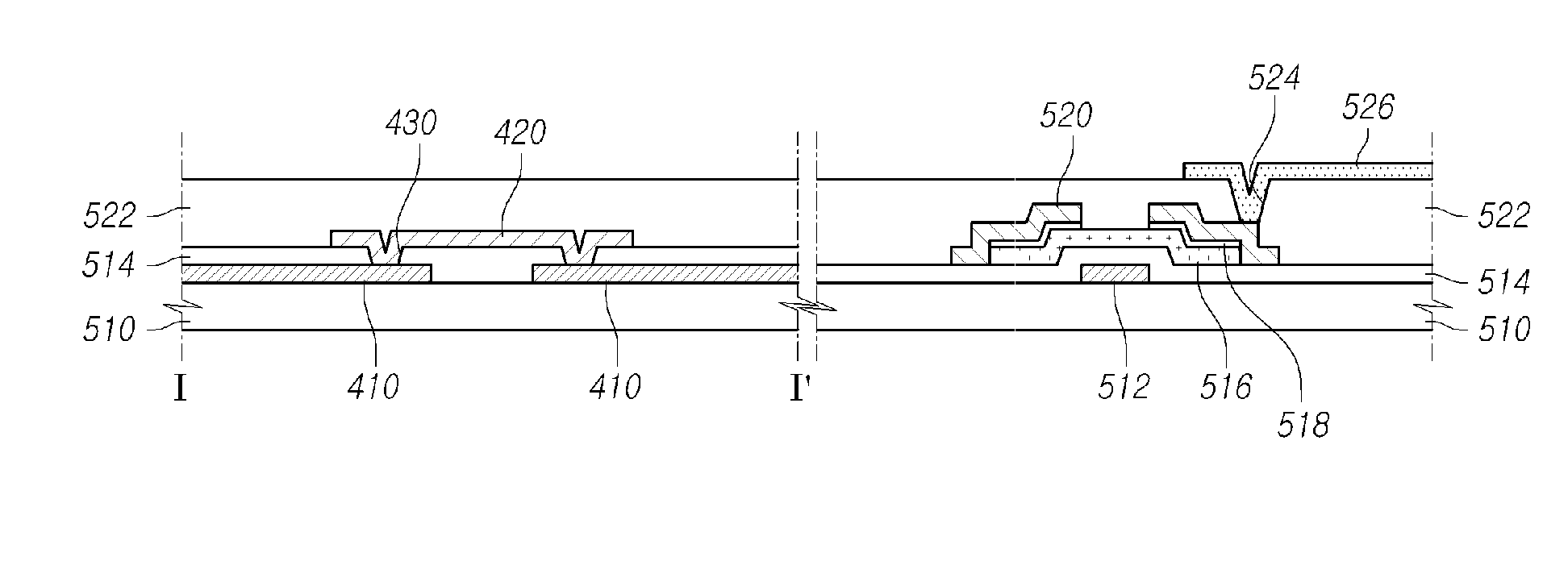

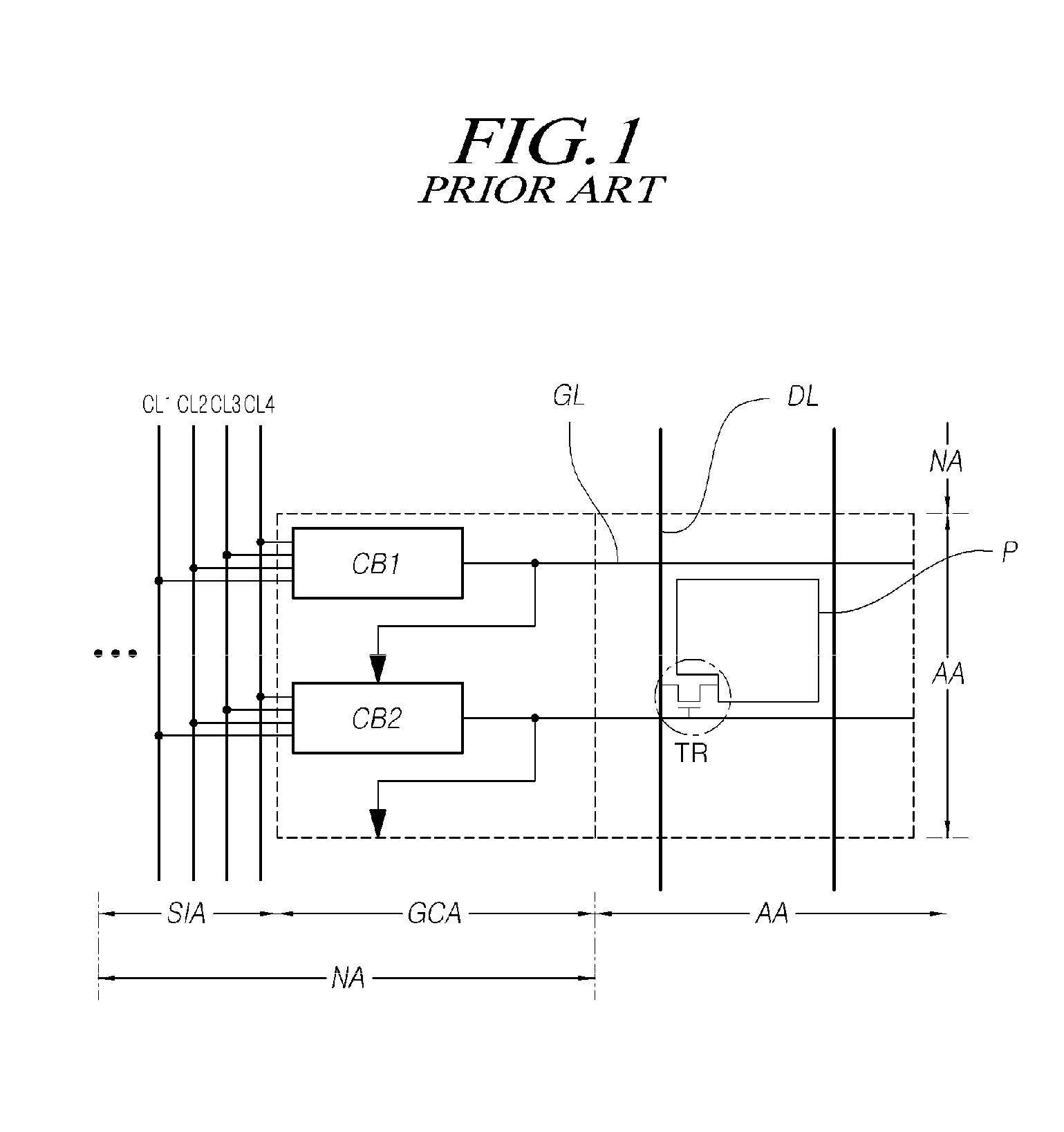

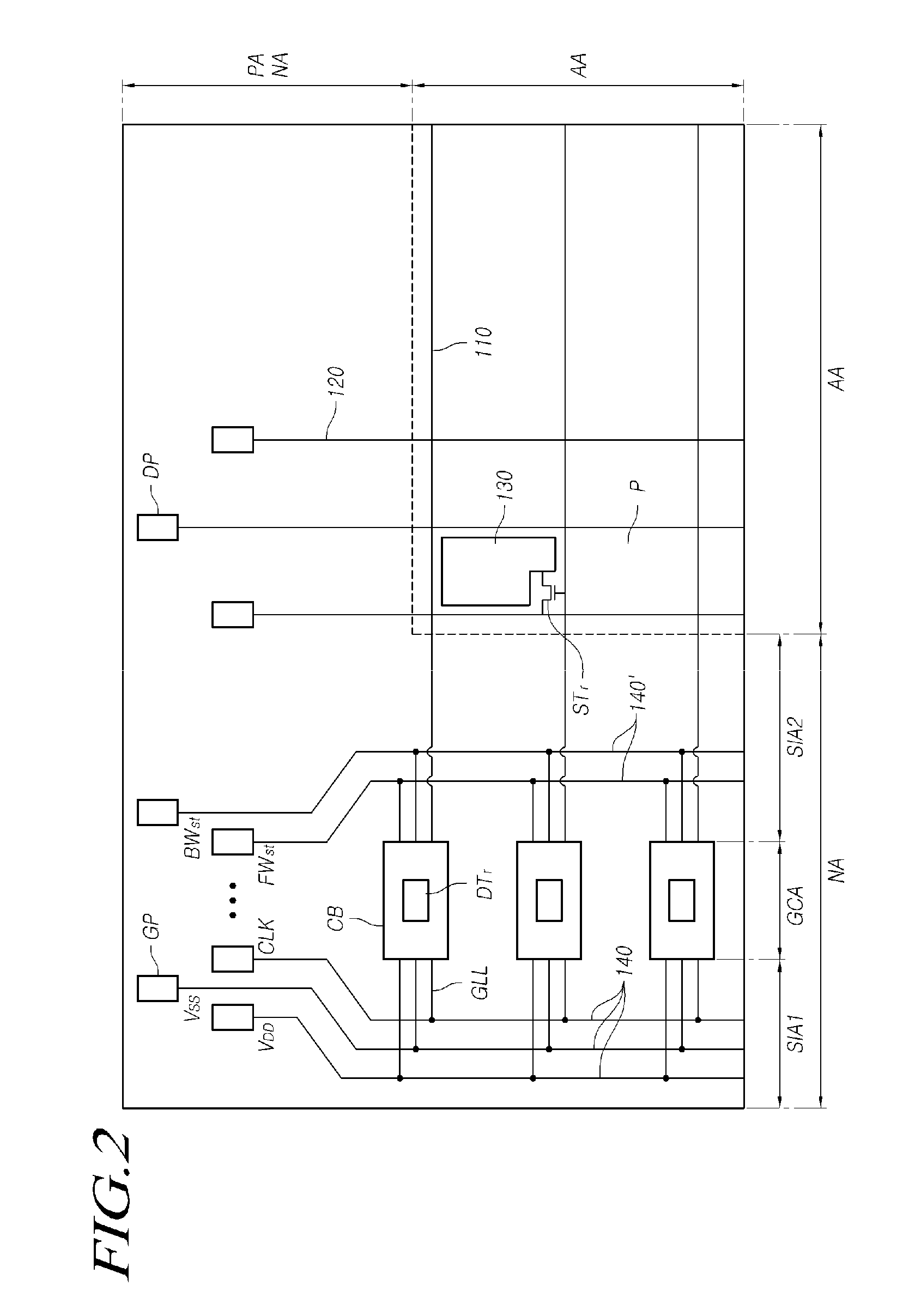

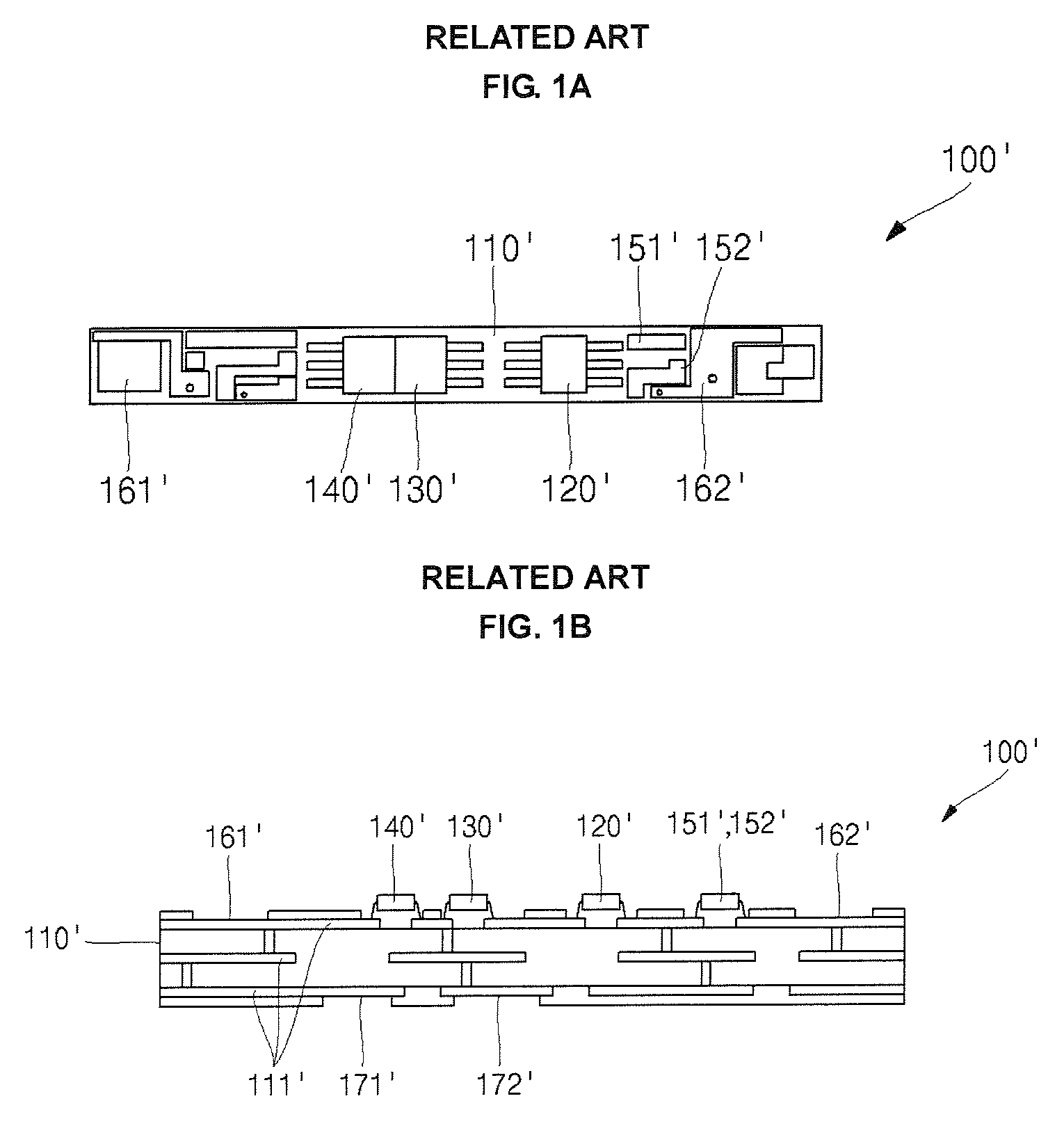

Array Substrate For Display Panel And Method For Manufacturing Thereof

ActiveUS20150123136A1Avoid it happening againPrevent static electricityStatic indicating devicesSolid-state devicesHemt circuitsMaterials science

Disclosed are an array substrate and a method of fabricating the same. The array substrate includes an active area including a plurality of pixels defined at an intersection area of a gate line and a data line, a gate driving circuit formed at one side of a non-active area and a signal line extending in parallel with the data line in the non-active area to transfer a signal to the gate driving circuit. The signal line includes a first line with a plurality of segmental lines, and at least one additional line formed of a different material and formed at a different layer than the first line. The at least one additional line electrically connects two segmental lines of the first line adjacent to each other.

Owner:LG DISPLAY CO LTD

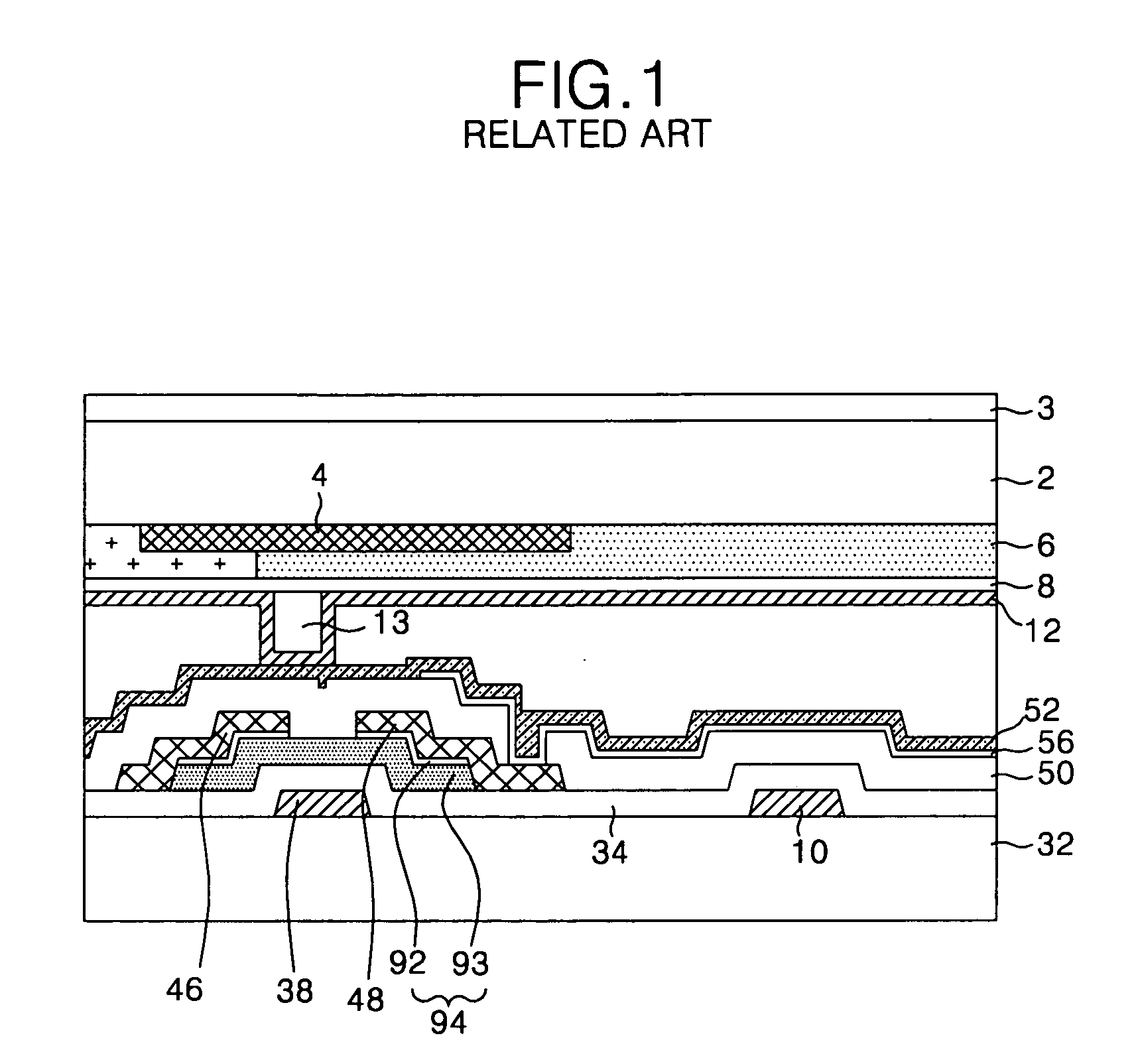

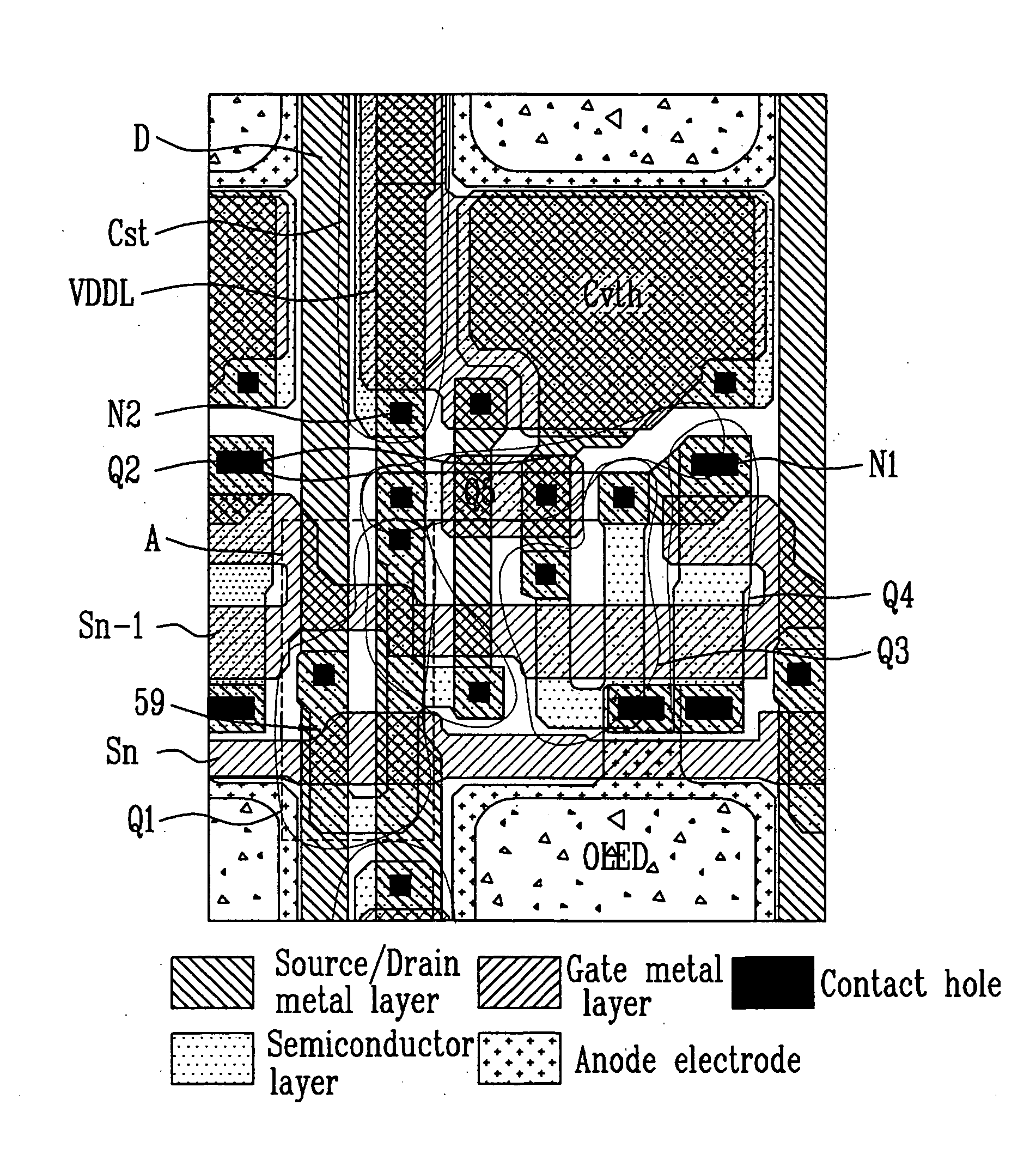

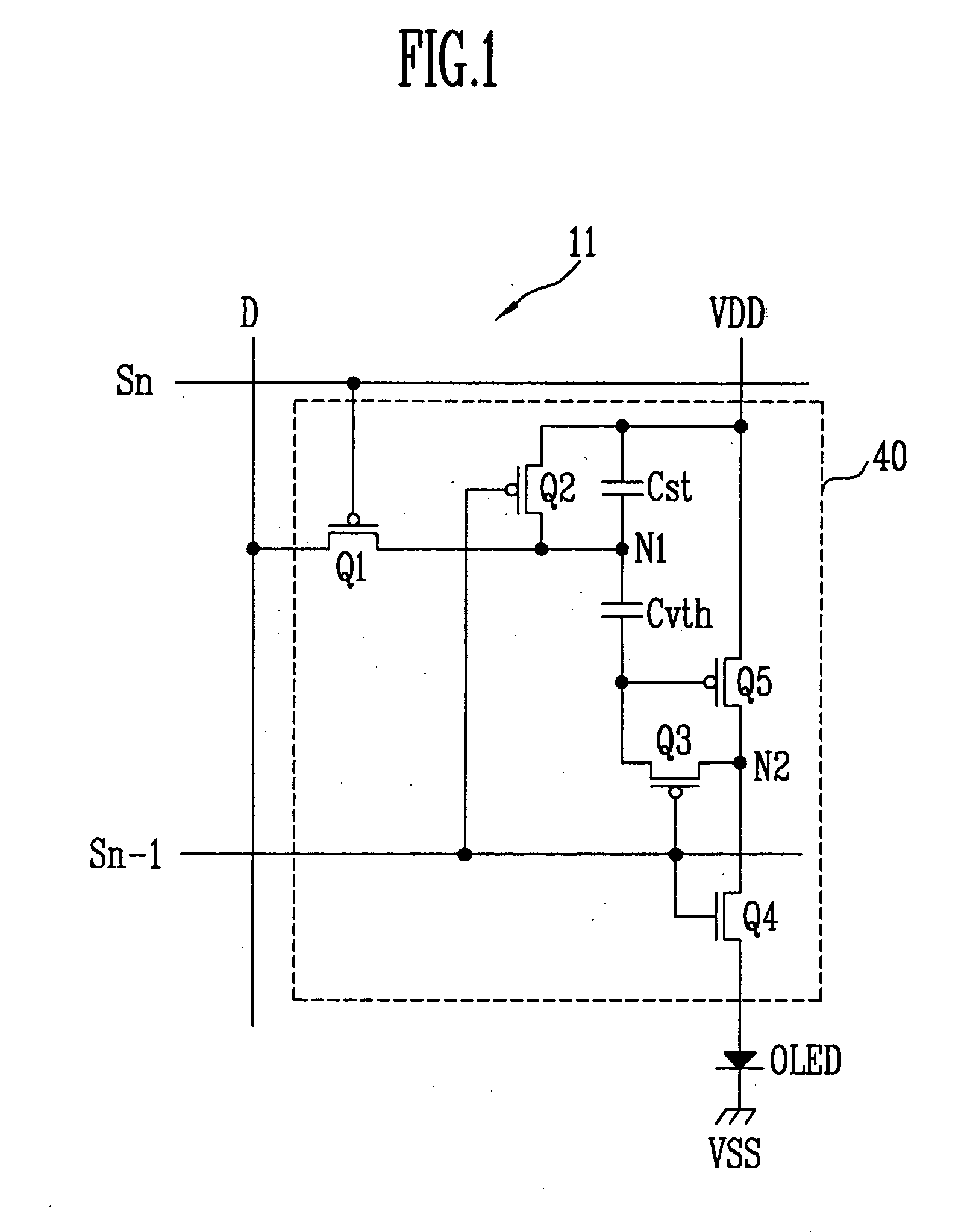

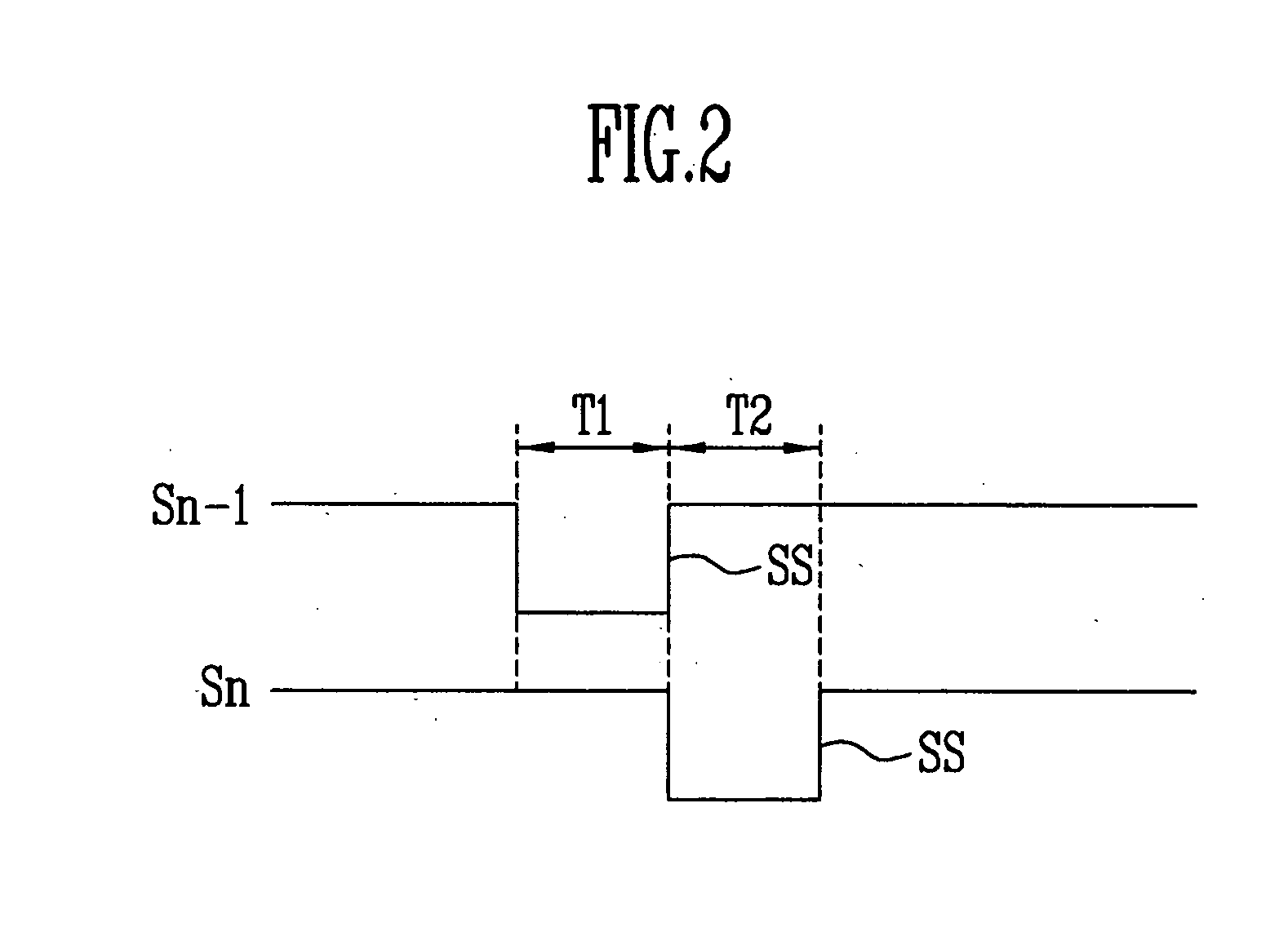

Transistor, method of fabricating the same, and light emitting display comprising the same

ActiveUS20050287750A1Prevent static electricityTransistorStatic indicating devicesDevice formDisplay device

A light emitting display comprises: at least one first metal layer; a second metal layer crossing the first metal layer and having a first width; a light emitting device formed adjacent to a region where the first metal layer and the second metal layer cross each other; and a pixel circuit including at least one transistor which causes the light emitting device to emit light. The transistor comprises a semiconductor layer having a second width greater than the first width. With this configuration, in the light emitting display of the present invention, the semiconductor layer of the transistor is formed in a region where the source / drain metal layer and the gate metal layer cross each other, and has a width greater than that of the source / drain metal layer, so that the source / drain metal layer is disposed within the width of the semiconductor layer. Thus, a tip of the gate metal layer, formed in the grain and the pattern edge of the semiconductor layer, is not disposed within the region overlapping the source / drain metal layer so that generation of static electricity between the gate metal layer and the source / drain metal layer is prevented.

Owner:SAMSUNG DISPLAY CO LTD

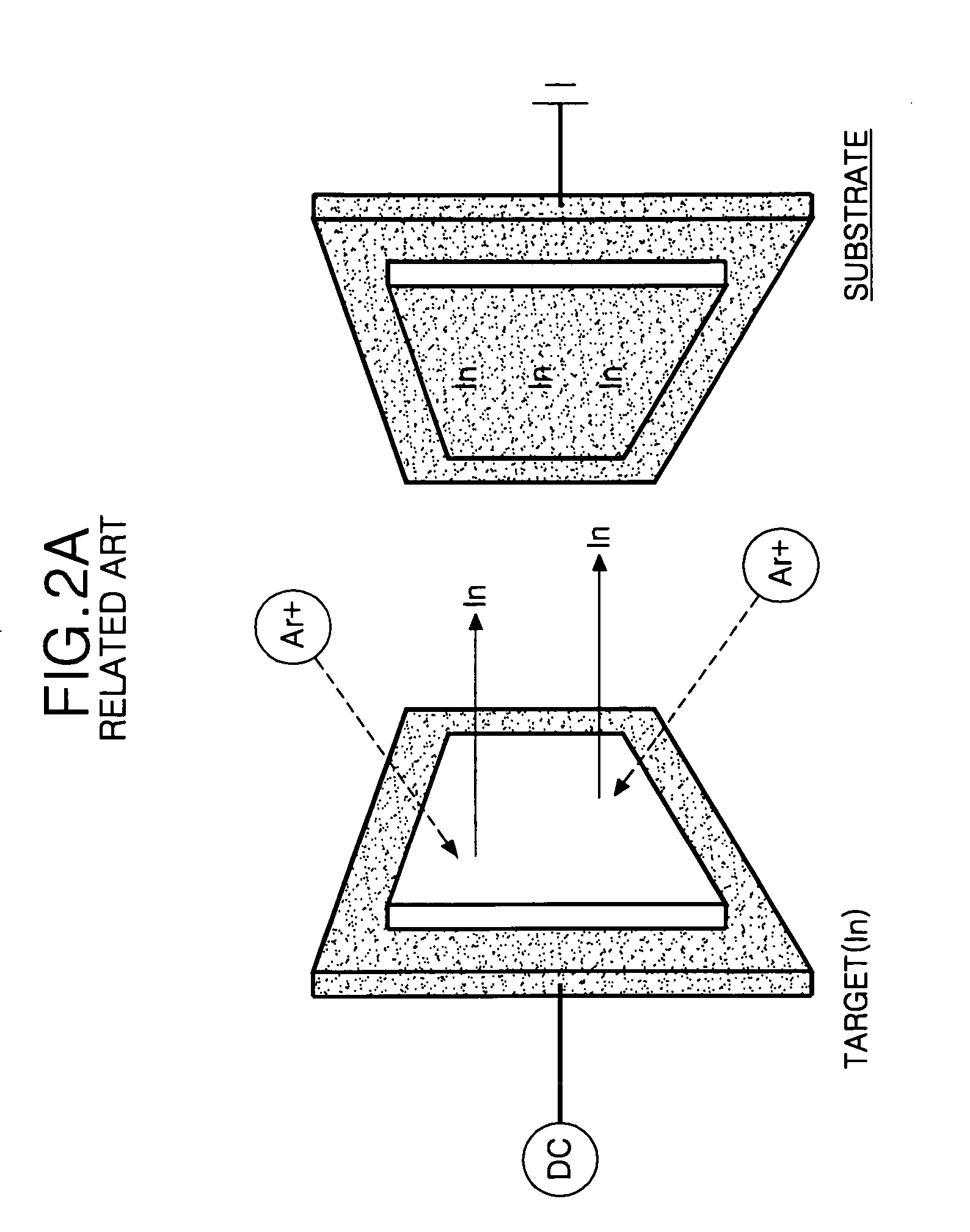

A composite fabric containing liquid metal

ActiveCN102296405AQuick exportImprove thermal conductivityFibre treatmentWoven fabricsTextile fiberYarn

The invention relates to a compound-type fabric containing liquid metal. The fabric can be completely woven by blended fiber yarn of a liquid-metal-containing fiber, and can also be woven by mixing a natural fiber yarn and blended fiber yarn of the liquid-metal-containing fiber, wherein the liquid-metal-containing fiber is a textile fiber the surface of which is adhered with liquid metal nanoparticles, a tubular textile fiber the pipe of which is filled with liquid metal, or a reticular casing-pipe-type textile fiber which is woven by nanowires and the reticular casing pipe of which is filledwith liquid metal; and the liquid metal is gallium metal, gallium-based alloy, Na-K alloy or wood metal containing indium. The compound-type fabric can be made into a single layer, two layers or three layers according to requirements, can be used as a basic fabric for manufacturing articles such as clothes, trousers, shoes and hats, gloves, stockings, bedclothes and pillowcases and the like, can endow clothing and household articles with temperature adjusting, radiation proofing, electrostatic resisting and sterilizing and antimicrobial functions, has stable performance and high reliability, needs not to be added with other organic components, and can be used for making up the defect of the property singleness of the traditional fabric.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

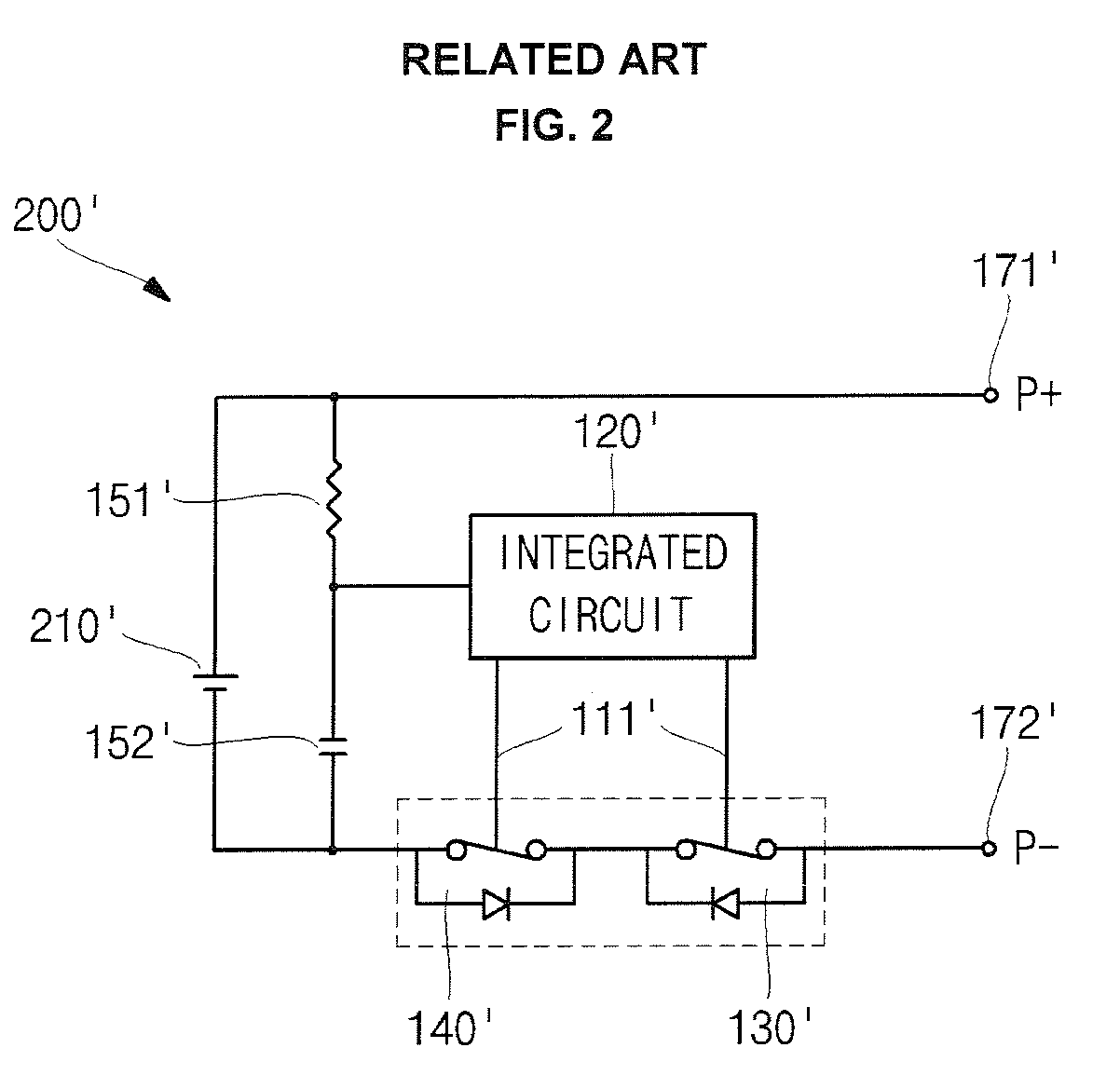

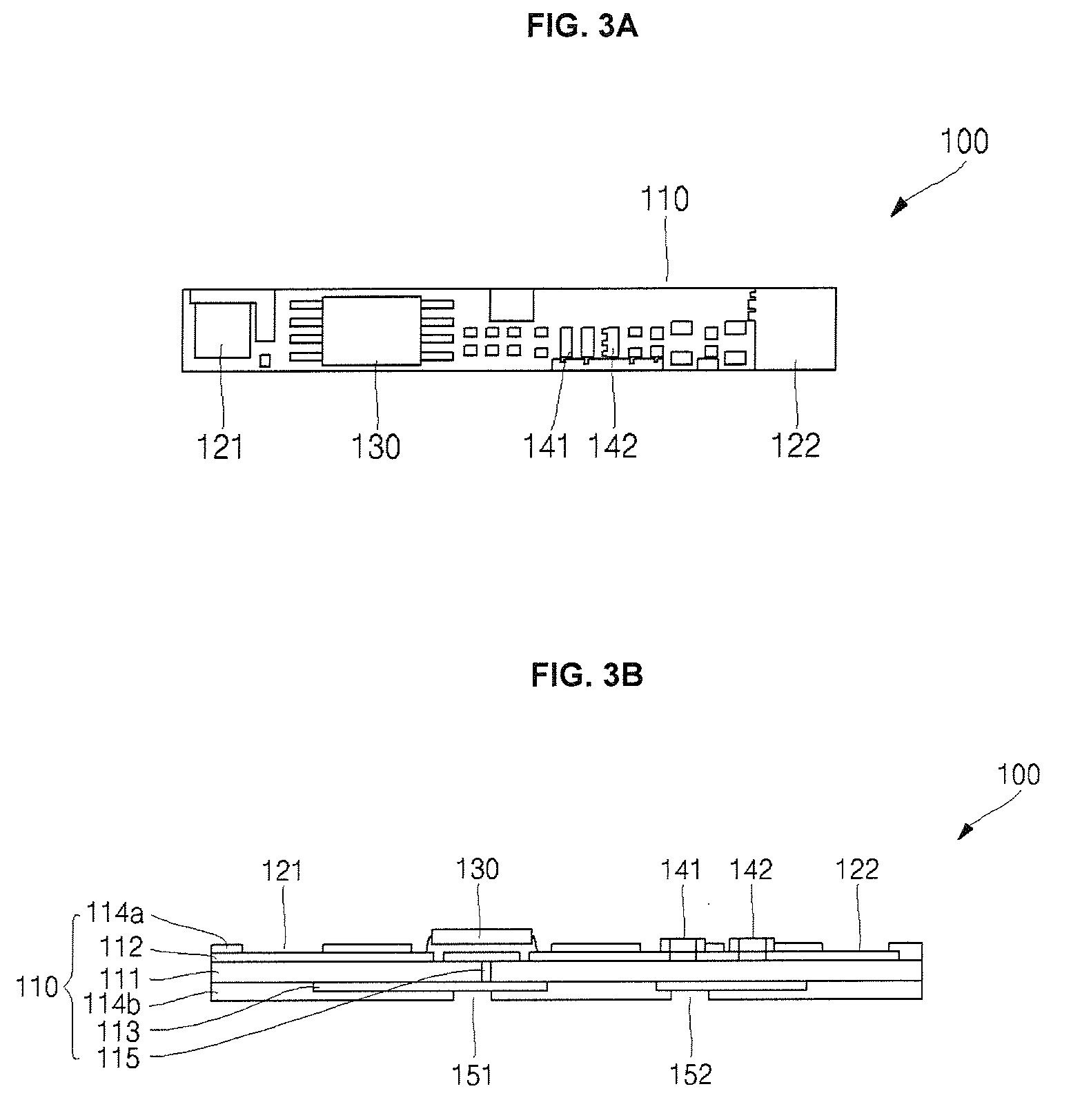

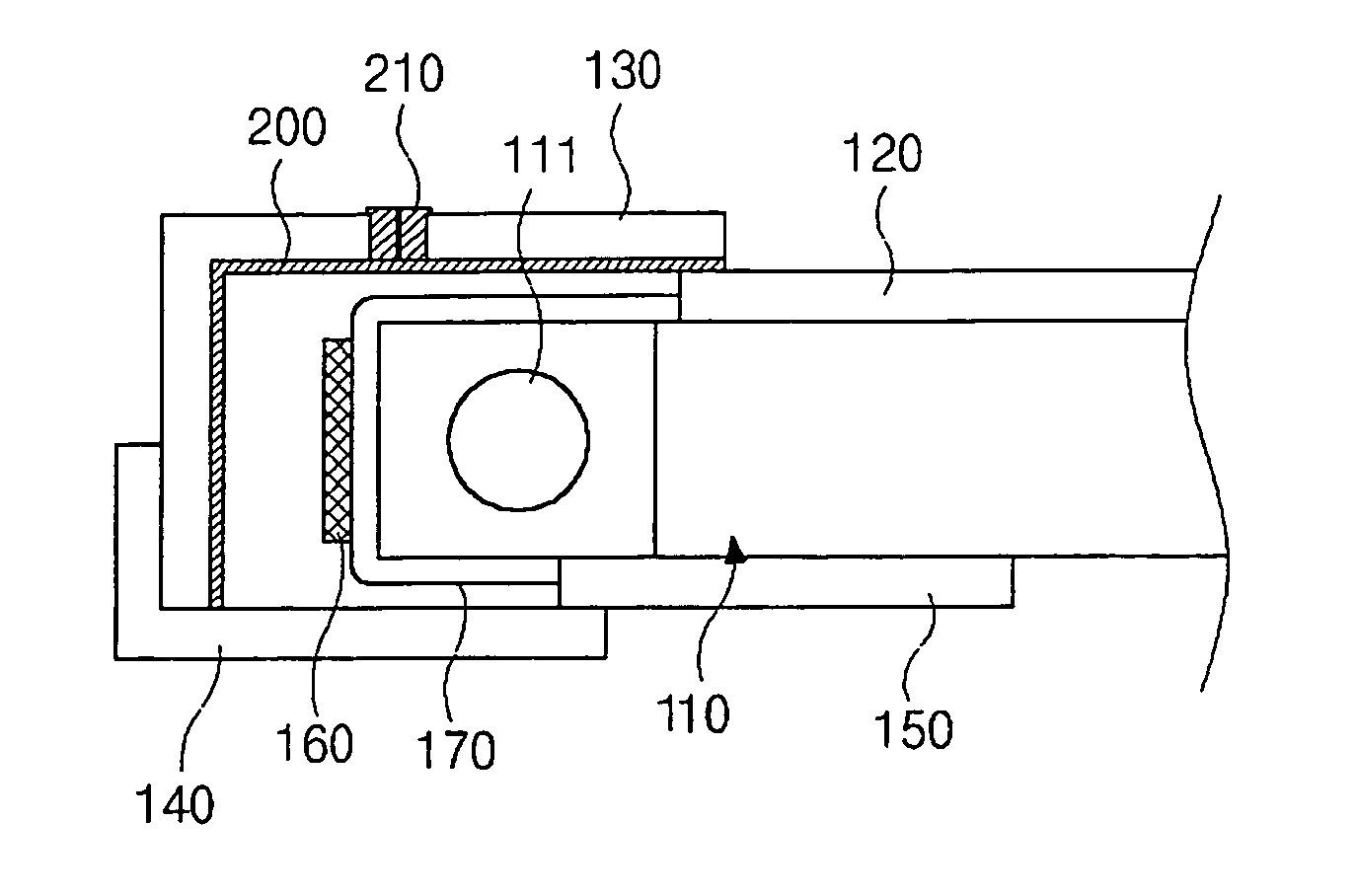

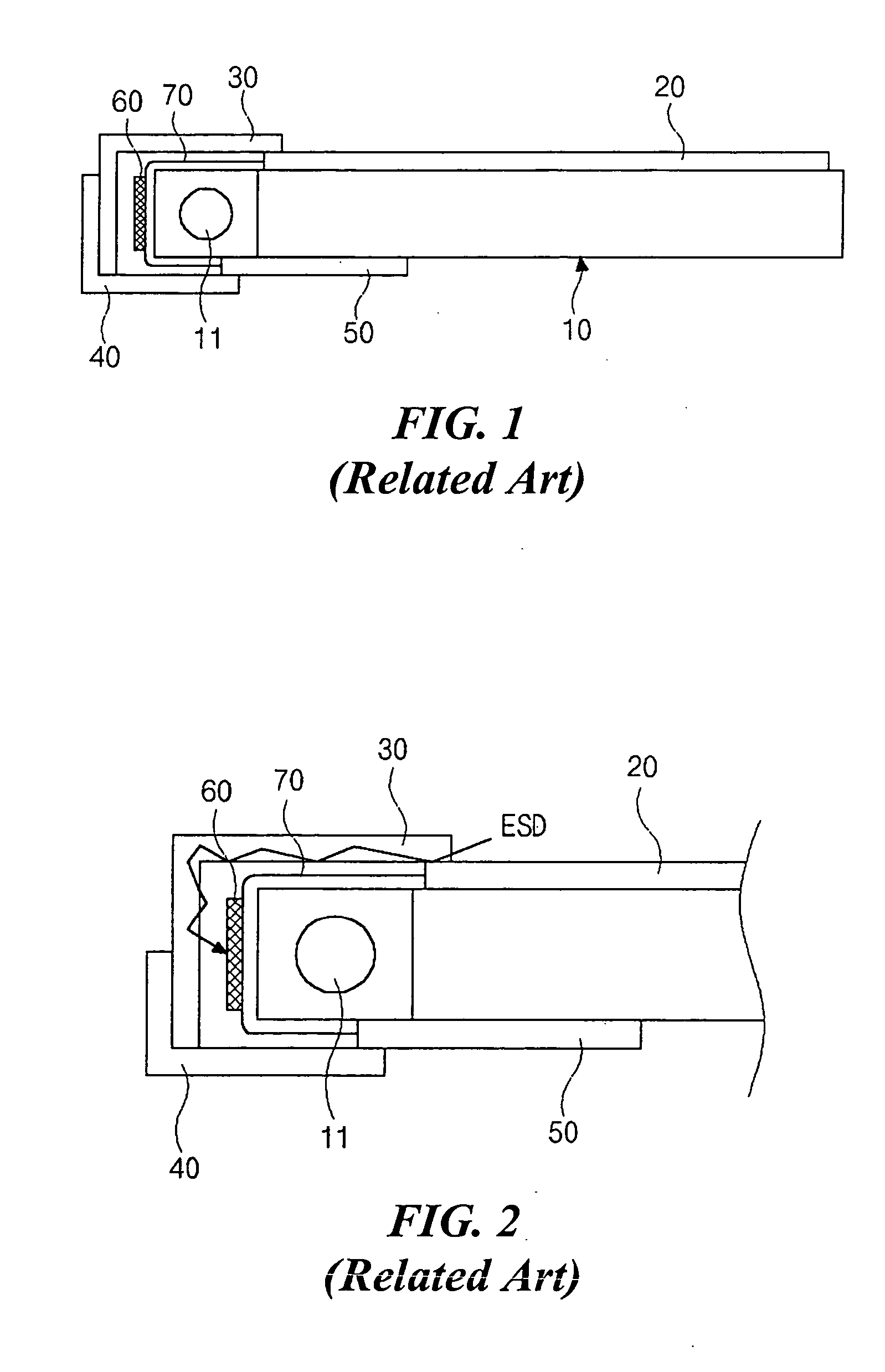

Single unit protection circuit module and battery pack using the same

ActiveUS20070222417A1Increase probabilityPrevent static electricityPrinted circuit aspectsSolid-state devicesRechargeable cellSemiconductor package

A protection circuit module includes a printed circuit board in which at least one wiring pattern is formed, a conductive pad that is coupled to a wiring pattern of the printed circuit board, and is electrically coupled to a rechargeable battery, and a semiconductor package that is soldered on the wiring pattern of the printed circuit board, so that if the voltage of the rechargeable battery is in the overcharged or over-discharged state, the semiconductor package selectively blocks a charging path or a discharging path of the rechargeable battery.

Owner:SAMSUNG SDI CO LTD

Underground gas plugging coating in coal mine

This invention provides an underground gas plugging coating in coal mine, consisting of an individually packaged liquid material and a powder material in the weight ratio of 0.3 to 0.45: 1; wherein the powder material comprises the following components by weight percentage: 30% to 45% of concrete, 30% to 40% of quartz powder, 5% to 10% of talcum powder, 5% to 10% of flyash, 7% to 13% of aluminium hydroxide, 0% to 4% of magnesium hydroxide, 2% to 4% of ammonium polyphosphate, 1% to 2% of melamine, 1% to 2% of pentaerythritol and 1% to 1.5% of carbon fiber; the liquid material is flexible styrene-acrylate emulsion or flexible pure acrylic emulsion. The coating is characterized by flame retardancy, antistatic property, watertightness, tight bonding with the coal wall and elasticity, further more, can prevent the gas from leaking after being sprayed on the coal wall, and reduce the gas concentration in the laneway.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Liquid crystal display module

ActiveUS20050094053A1Prevent static electricityLow costNon-linear opticsIdentification meansLiquid-crystal displayEngineering

A liquid crystal display module includes a backlight assembly, a liquid crystal panel on the backlight assembly, a printed circuit board under the backlight assembly, a top case covering a peripheral portion of the backlight assembly and a peripheral portion of the liquid crystal panel, a driving IC between the backlight assembly and the top case, and an insulating member between the top case and the driving IC.

Owner:LG DISPLAY CO LTD

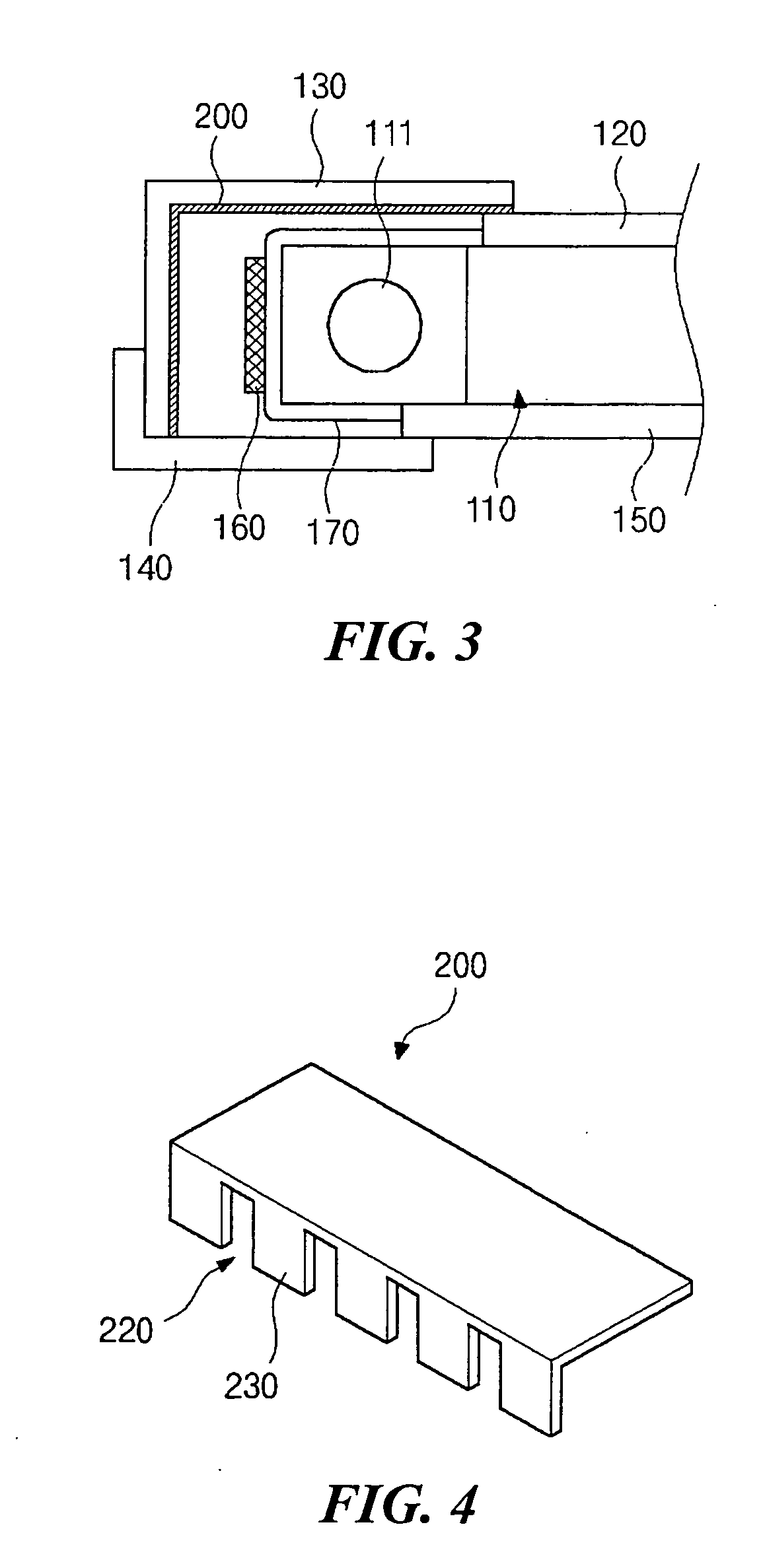

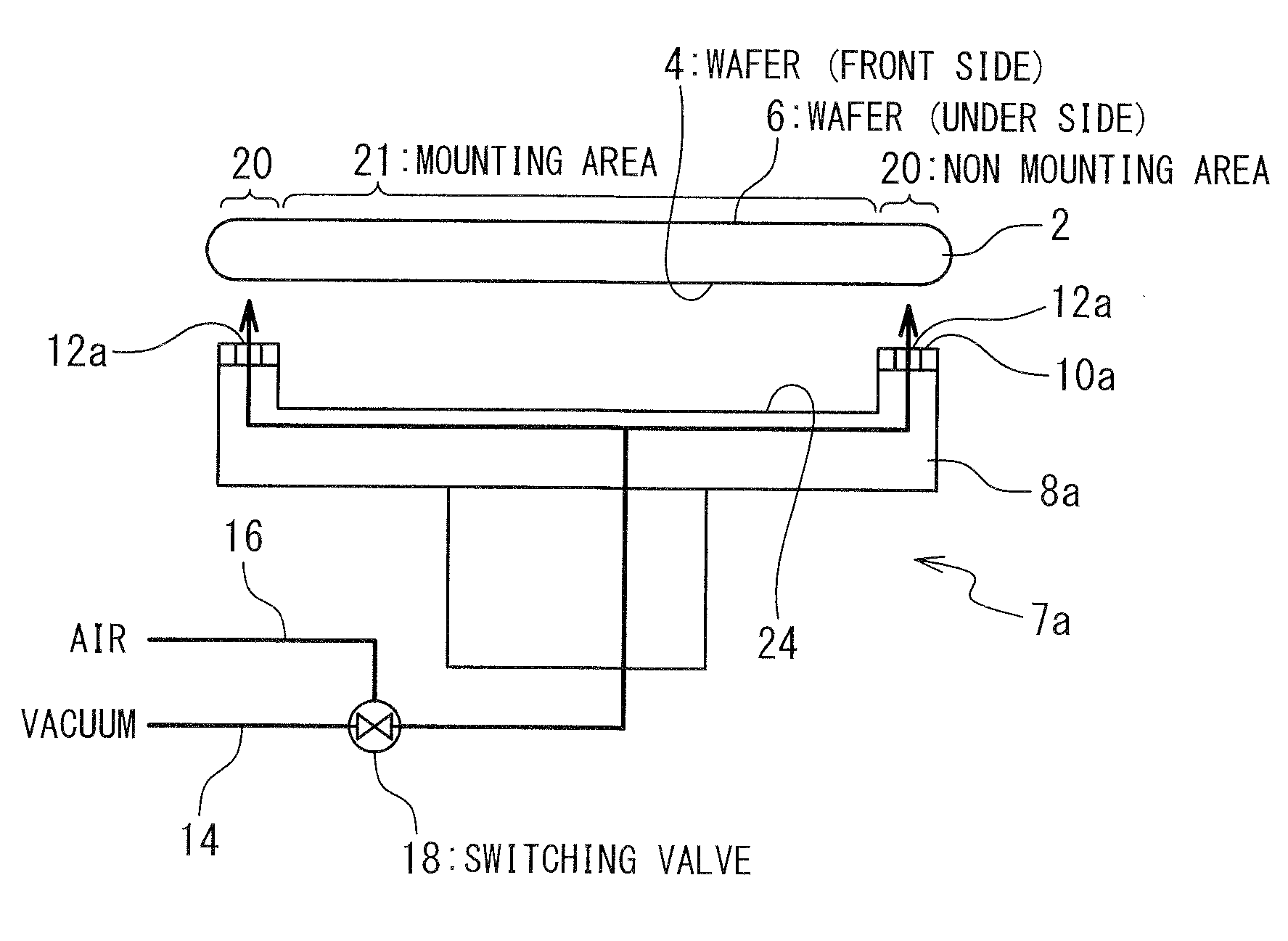

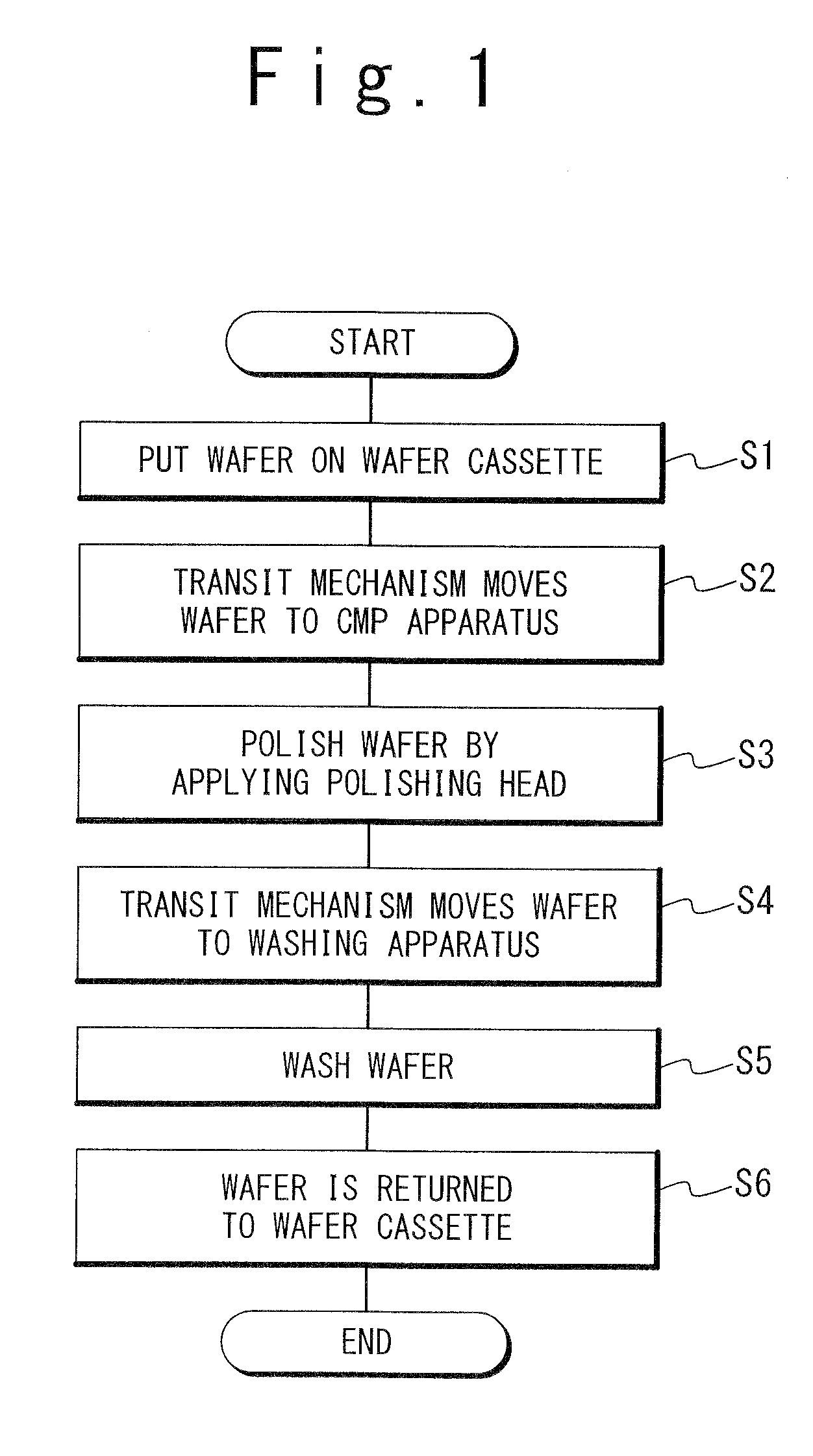

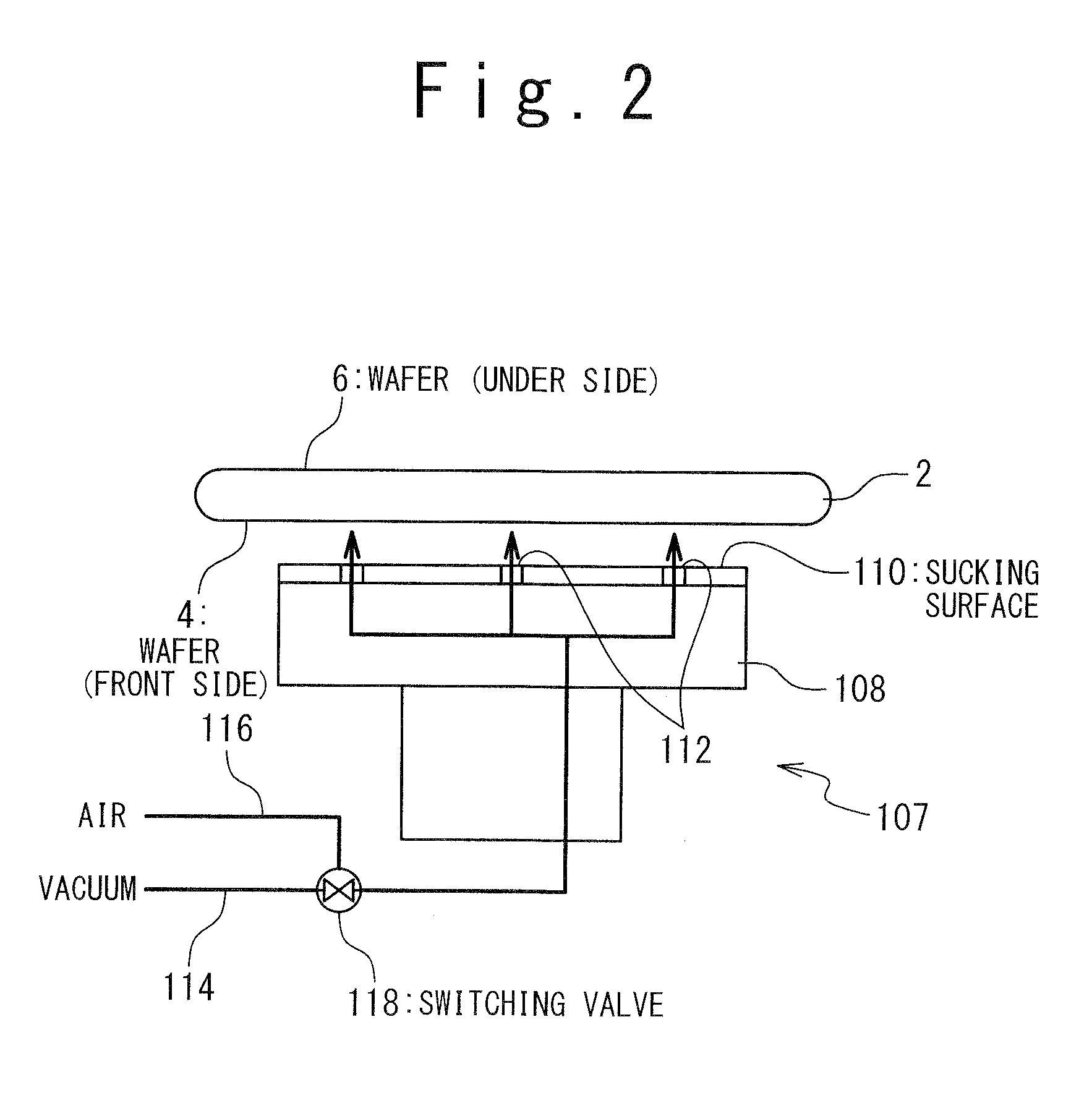

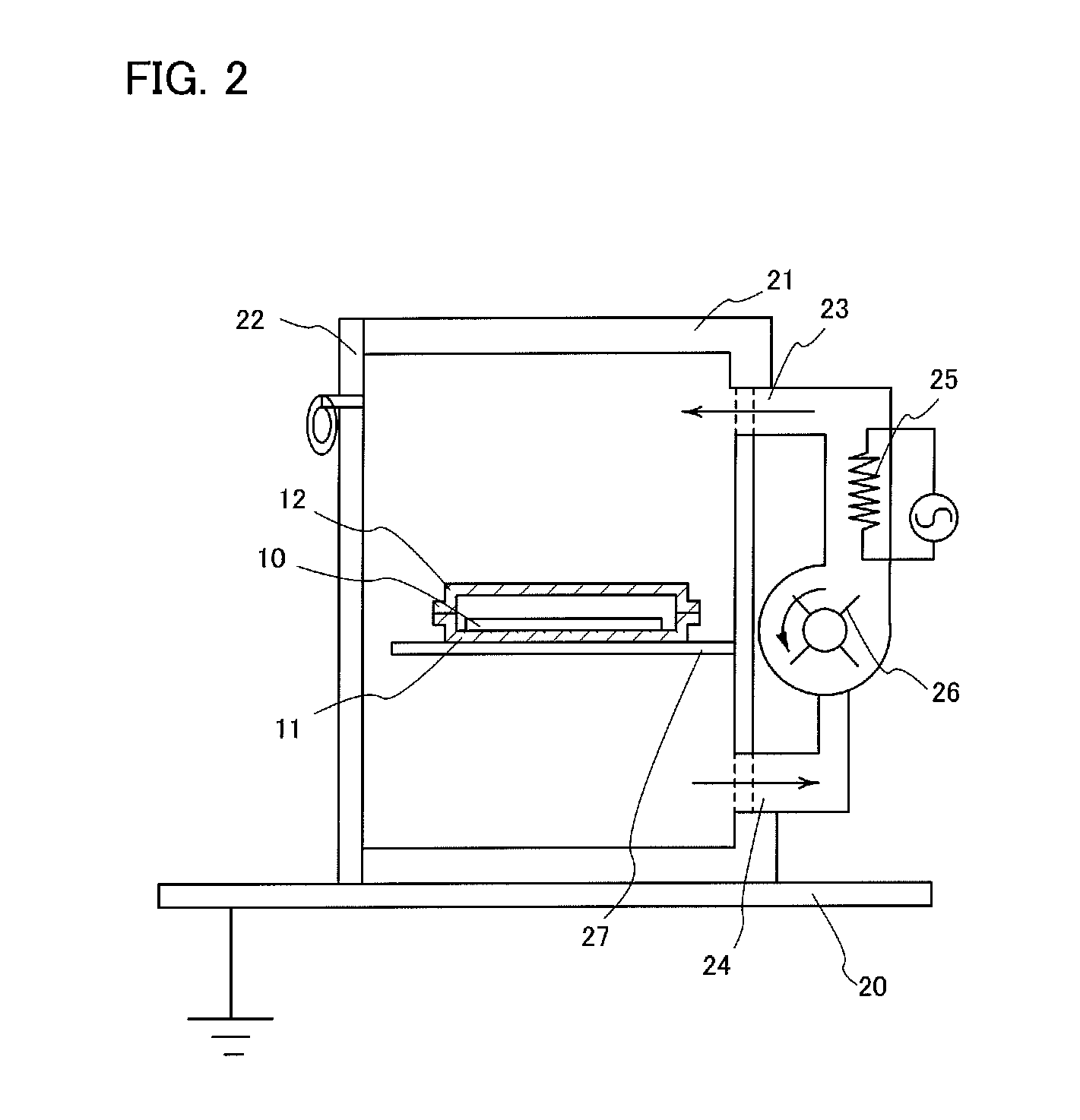

Semiconductor manufacturing apparatus and semiconductor manufacturing method

ActiveUS20080146124A1Prevent static electricitySleeve/socket jointsPolishing machinesManufactured apparatusEngineering

A semiconductor manufacturing apparatus includes a supporting unit for supporting a semiconductor wafer received from a CMP apparatus and a vacuuming system for holding the wafer on the supporting unit. The vacuuming is applied only in a peripheral area of the wafer. In the peripheral area of the wafer, any circuit such as interconnections and devices are not manufactured. When the wafer is released by supplying gas to the vacuumed space, even if static electricity occurs, the electronic circuit to be manufactured on the wafer does not harmed, because the static electricity occurs only in the peripheral area where any circuit does not exist.

Owner:RENESAS ELECTRONICS CORP

Method for removing electricity and method for manufacturing semiconductor device

ActiveUS8268642B2High yieldIncrease productionSemiconductor/solid-state device testing/measurementSolid-state devicesElectricityPower semiconductor device

An object is to suppress a significant change in electrical characteristics of thin film transistors and a deviation thereof from the designed range due to static electricity, and to improve the yield in manufacturing semiconductor devices. In order to prevent a substrate from being charged with static electricity by heat treatment or to favorably reduce static electricity with which a substrate is charged in a manufacturing process of a semiconductor device, heat treatment is performed with a substrate provided with a thin film transistor stored in a conductive container. In addition, a heating apparatus for performing the heat treatment is electrically connected to a ground potential, and the container and the substrate are also electrically connected to the ground potential.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com